Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

174 results about "Decrepitation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Decrepitation is the noise produced when certain chemical compounds are heated, or it refers to the cracking, or breaking-up of lumps of limestone during heating. Such compounds include lead nitrate and calcine.

Method for preparing heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet

ActiveCN101521069AImprove coercive forceNot easily oxidizedInorganic material magnetismRare-earth elementDehydrogenation

The invention discloses a method for preparing a heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet, which belongs to the technical field of magnetic materials. The prior preparation method improves the coercive force and the temperature stability of magnets by adding heavy rare earth elements, namely terbium or dysprosium into master alloy, but the method can cause the residual magnetism of the magnets, the reduction of magnetic energy product and the increase of manufacturing cost. The method adopts heavy rare earth terbium hydride and dysprosium hydride nano-powder doping technology to prepare the sintered NdFeB permanent magnet with high coercive force and excellent magnetic property. The method comprises the following steps: preparing NdFeB powder by a rapidly solidified flake process and a hydrogen decrepitation process; preparing the terbium hydride or the dysprosium hydride nano-powder by physical vapor deposition technology; mixing the two powders, and performing magnetic field orientation and press forming; and performing dehydrogenation treatment, sintering and heat treatment on a green compact at different temperatures, and obtaining the sintered magnet. The coercive force of the magnet prepared by the method is higher than that of the prior sintered magnet with the same ingredients; and compared with the sintered magnet with the equivalent coercive force, the proportion of the terbium and dysprosium needed by the magnet prepared by the method is remarkably reduced.

Owner:BEIJING UNIV OF TECH

Method for preparing rare-earth permanent magnets by infiltration process and graphite box utilized in method

InactiveCN102568806AReduce manufacturing costReduce usagePermanent magnetsSolid state diffusion coatingRare earthMaterials science

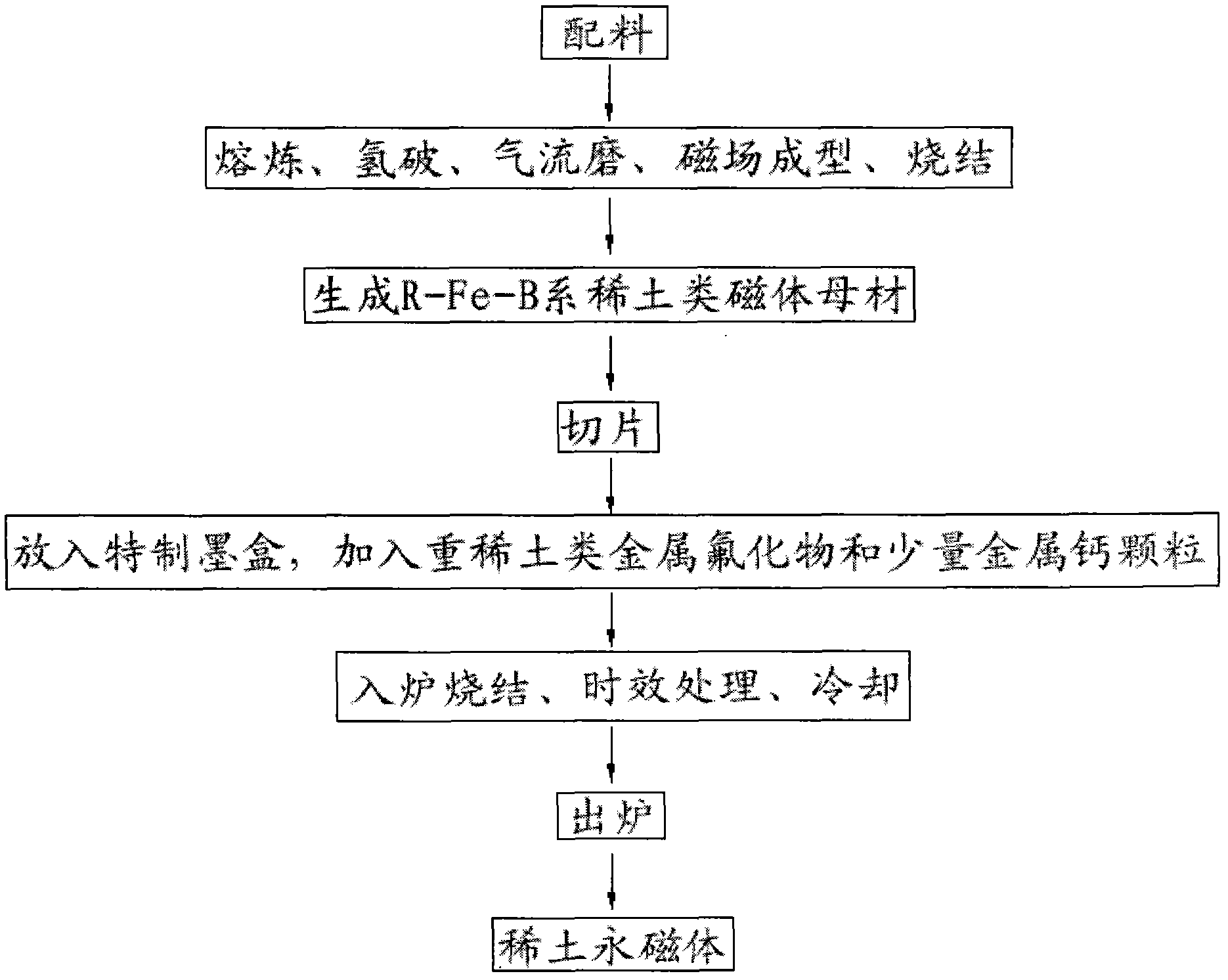

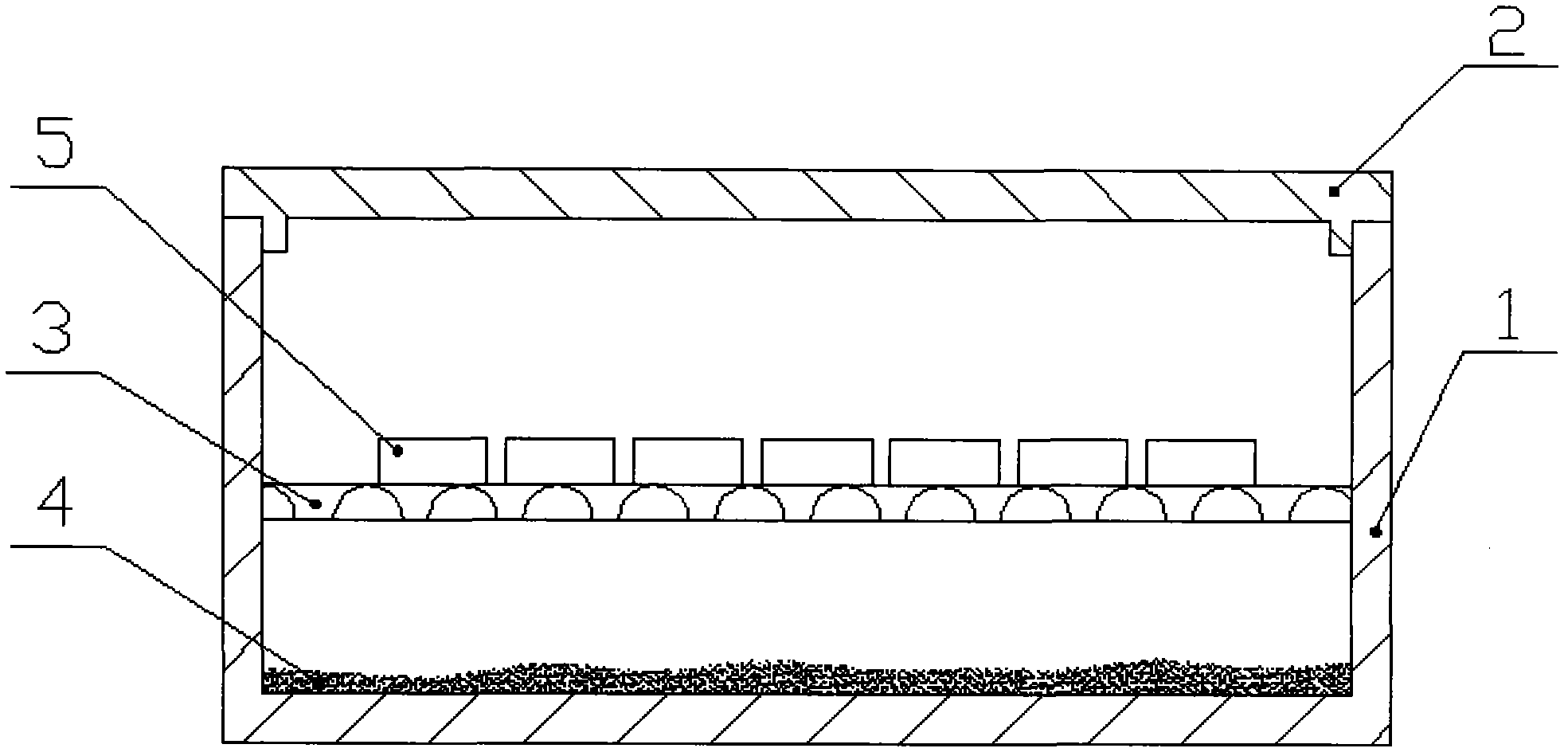

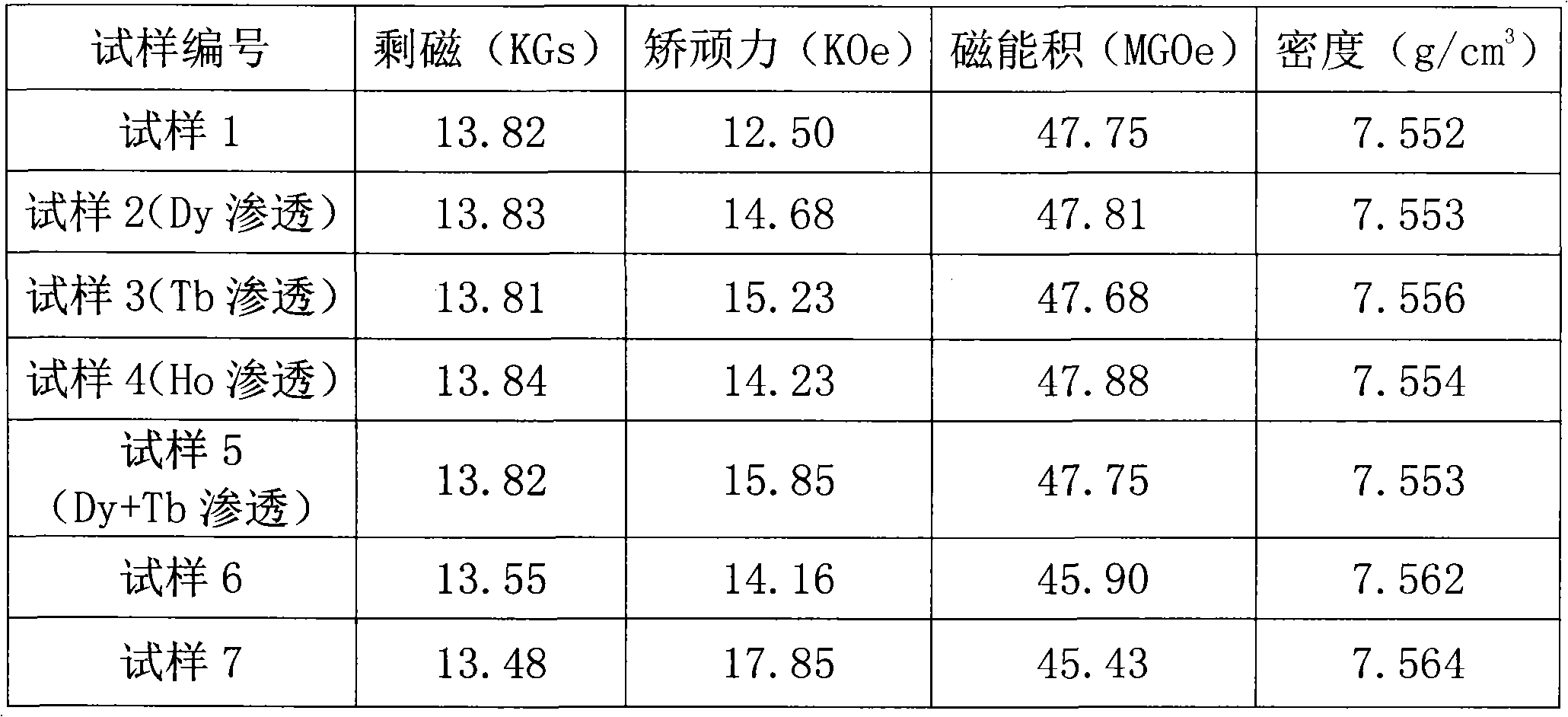

Disclosed are a method for preparing rare-earth permanent magnets by the infiltration process and a graphite box utilized in the method. The method includes: preparing base materials of R (rare earth)-Fe (ferrum)-B (boron) rear earth magnets by prepared raw materials which are subjected to smelting, hydrogen decrepitation, magnetic field forming, sintering and the like; cutting the base material into slices with the thickness ranging from 2mm to 10mm; placing the slices into a specially-made graphite box and placing heavy rare earth type metal fluoride and a few of metal calcium particles into the bottom of the graphite box; sintering the graphite box in a sintering furnace, inflating air into the sintering furnace to cool the temperature to be lower than 60 DEG C, finally ageing magnets, then inflating Ar gas into the sintering furnace to cool the temperature to be lower than 60 DEG C after ageing, and finally obtaining the rare-earth permanent magnets. Elements including Dy (dysprosium), Tb (terbium), Ho (holmium) and the like are infiltrated into the crystal boundary of the R-Fe-B to prepare high-coercivity rare-earth permanent magnets by means of infiltration process, usage of heavy rare earth metal can be greatly reduced, and production cost of magnets can be effectively reduced. Additionally, the method for preparing rare-earth permanent magnets by the infiltration process is simple in operation and suitable for batch production.

Owner:BAOTOU TIANHE MAGNETICS TECH CO LTD

Method for recycling sintered neodymium-iron-boron waste materials

ActiveCN104190943ANo pollution in the processSave resourcesRecycling and recovery technologiesHazardous substanceAlloy

The invention discloses a method for recycling sintered neodymium-iron-boron waste materials. The method is characterized by including the following steps that the neodymium-iron-boron waste materials are classified and collected according to performance trade marks; the classified and collected waste materials and abrasive materials are mixed and then placed in a vibration polisher machine, and a cleaning agent is added for vibration finishing cleaning; the waste materials obtained after vibration finishing cleaning are ultrasonically cleaned and dried for standby; according to the standard identical to the performance trade marks of the waste materials obtained through the steps, alloy cast slices are prepared through batching, smelting and casting; the cleaned waste materials and the prepared alloy cast slices with the same trade marks are mixed, and hydrogen decrepitation processing is conducted on the mixture; the materials obtained after hydrogen decrepitation processing are ground into powder, pressed, formed, and sintered into a neodymium-iron-boron magnet. According to the method, no harmful matter is generated in the production process, the production process is environmentally friendly and free of pollution, resources can be effectively saved, the recovery rate is high, cost is reduced, and procedures are simple, easy and convenient to implement and feasible.

Owner:SINO MAGNETICS TECH

High-performance rare earth permanent magnet sintered magnet and manufacturing method thereof

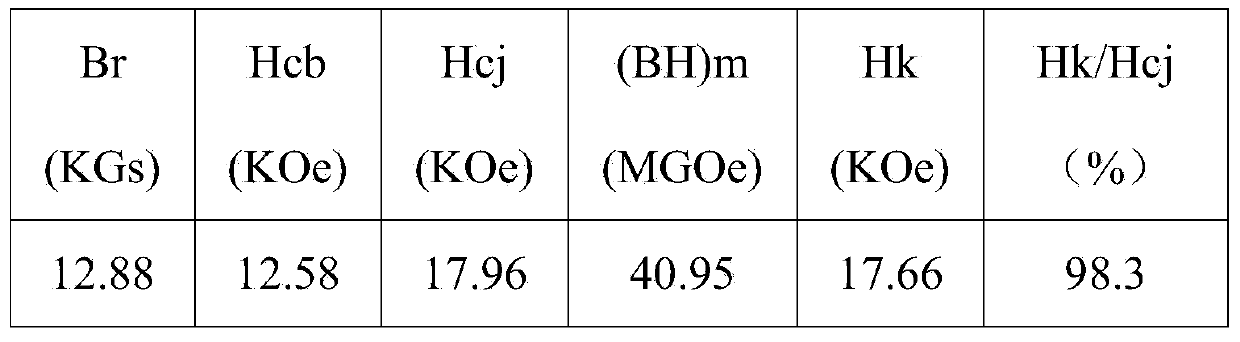

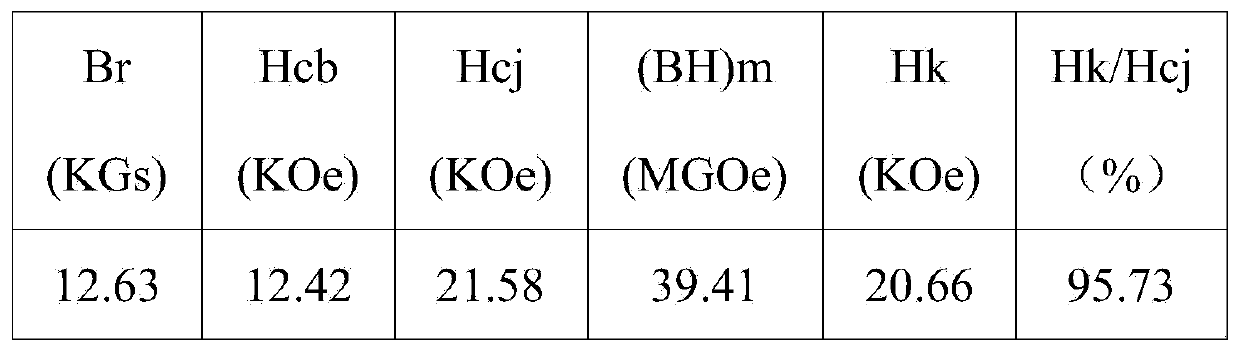

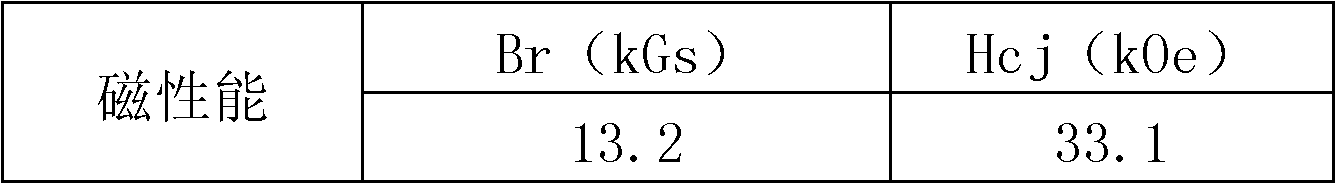

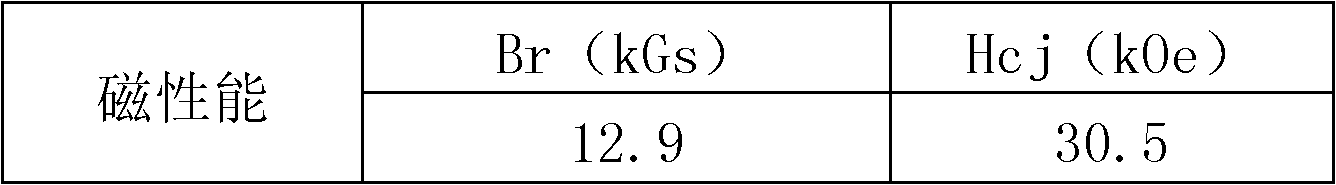

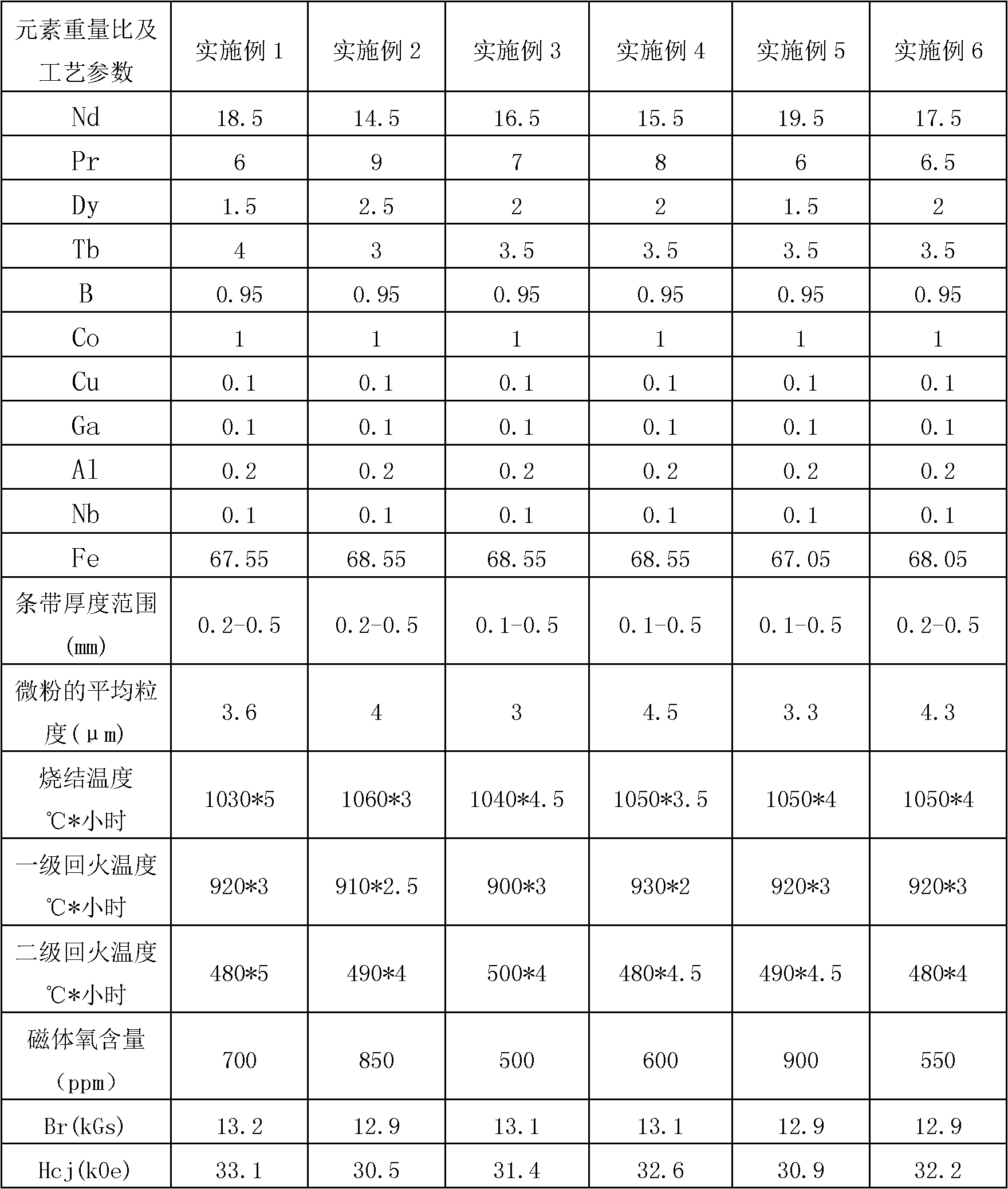

The invention provides a rare earth sintered magnet and a manufacturing method thereof. The magnetic property residual magnetism Br of the magnet is between 12.8 and 13.3 kGs, the intrinsic coercivity Hcj is more than or equal to 30 kOe, and the content of oxygen in the magnet is between 500 and 900 ppm. The rare earth sintered magnet is prepared by the manufacturing process that: a smelting procedure is a vacuum quick-setting process, and the thickness of produced sheet alloys is between 0.1 and 0.5mm; a hydrogen decrepitation process is used for production in an intermediate crushing procedure; a jet mill is used for production in a micro powder manufacturing procedure, and the average particle size of micro powder is between 3.0 and 4.5 mu m; a compression procedure is used for compression molding under the environment of anaerobic inert gas; and a sintering procedure is used for sintering and aging by means of a vacuum sintering furnace.

Owner:SANVAC BEIJING MAGNETICS +1

Manufacturing method of high-coercivity R-Fe-B sintered permanent magnet material

ActiveCN102534358ASimple preparation processImprove coercive forceInorganic material magnetismInductances/transformers/magnets manufactureHydrogen pressureDysprosium

The invention discloses a manufacturing method of a high-coercivity R-Fe-B sintered permanent magnet material, which specifically comprises the following steps: blending raw materials according to a certain proportion and casting into an alloy plate with a thickness of 0.1-0.4mm; performing hydrogen decrepitation of the alloy plate and dehydrogenizing to a hydrogen pressure less than 10Pa at a temperature of 400-600 DEG C; sending the alloy plate after hydrogen decrepitation into a mill under the anaerobic environment protected by inert gas, grinding to a grain size less than 0.5mm, micro-grinding with an airflow mill and preparing R-Fe-B alloy powder with a grain size d being equal to 2-4 mum in a classification manner; adding at least one of nano dysprosium oxide, nano terbium oxide andnano holimium oxide with a grain size being less than 100nm into the prepared R-Fe-B alloy powder under the anaerobic environment protected by the inert gas, uniformly mixing, carrying out orientation in a magnetic field of 1.5-3T and pressing into a pressed blank; and carrying out high-temperature sintering for three times and aging treatment for two times in a vacuum sintering furnace under theanaerobic environment protected by the inert gas to prepare a high-coercivity R-Fe-B sintered permanent magnet without size limitation. The manufacturing method has the advantages of simple process and low cost.

Owner:YANTAI ZHENGHAI MAGNETIC MATERIAL CO LTD

Low-cost sintered neodymium iron boron magnet and production method thereof

ActiveCN102592777AInhibition appearsImprove performancePermanent magnetsInductances/transformers/magnets manufactureNiobiumMaterials science

The invention discloses a low-cost sintered neodymium boron magnet, which comprises components including, by weight percentage, 5.0-6.5% of Pr (praseodymium), 20-28% of Nd (neodymium), 3-5% of Ho (holmium), 1.0-1.1% of boron, 0.4-0.8% of Al (aluminum), 0.1-0.2 % of Zr (zirconium), 0.4-0.6% of Nb (niobium), 0.12-0.17% of Cu (copper), 0.03-0.08% of Ga (gallium), 0.4-1.0% of Co (carbon monoxide) andthe balance iron. The production method includes: pretreatment of raw materials, ingot casting and smelting, hydrogen decrepitation and pulverization, magnetic field orienting and forming, isostatic processing, sintering, ageing and detecting. In the low-cost sintered neodymium boron magnet, high-cost dysprosium of rare metal is substituted by low-cost holmium of rare metal, so that production cost of products is reduced without affecting magnetic performances of the sintered neodymium boron magnet. Furthermore, the production method is simple in operation, excellent ingot casting structure can be obtained by ingot casting and smelting process, and the high-performance sintered neodymium iron boron magnet can be obtained.

Owner:宁德市星宇科技有限公司

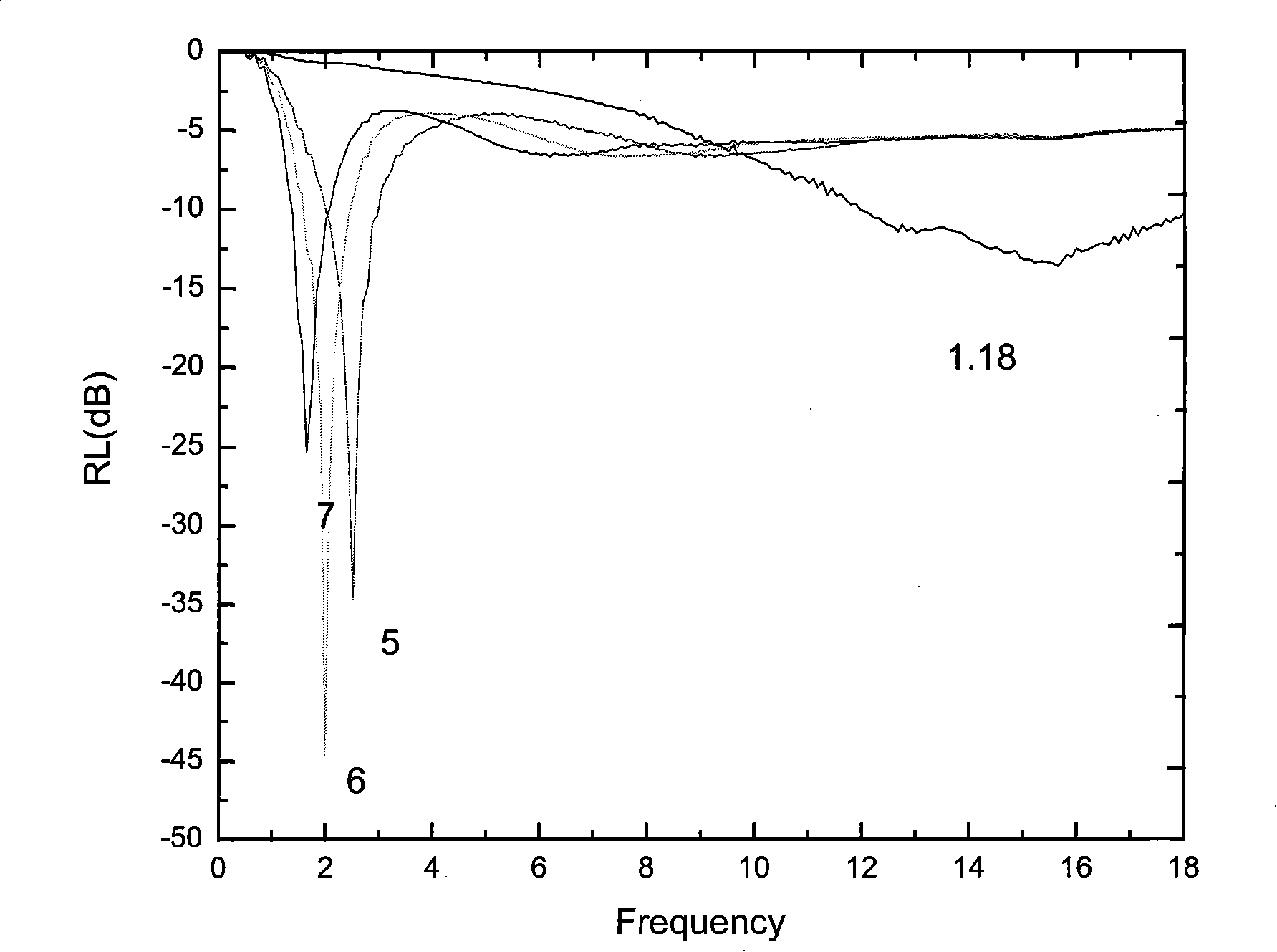

Rare earth Fe basis suction wave material and method for making the same

InactiveCN101203127AImprove absorbing performanceWide shielding bandMagnetic/electric field screeningRare earthOxidation resistant

The invention discloses a nano-crystal tombar thite ferrous absorbing material with good absorbing property and a preparation method thereof. The material is characterized in that the lanthanon with the weight percentage of 2% and 70%, the iron with the weight percentage of 5% and 98% and the little amount of doping element are smelted into tombar thite-ferrous alloy; the tombar thite-ferrous alloy is reacted with hydrogen by hydrogen decrepitation method under the temperature range from 0 to 700 DEG C, is broken into fine powder or be ball grinded into fine powder, and then is reacted with hydrogen to generate composite material of rare earths hydride (RHx) and Alpha-Fe under the temperature range from 100 DEG C to 1000 DEG C; finally, the composite material is oxidized, nitridized or oxidized and nitridized under low temperature to produce the composite material mainly being rare earth oxide or nitride / Alpha-Fe composite material. The material of the invention has the advantages of high absorbing capability, wide shield wave band, good anti-corrosion property, anti-oxidation property and low price, and can be used in the fields of electro-magnetic shielding in building, information and communication technical secrecy and military cloaking technique, and so on.

Owner:SICHUAN UNIV

Method for manufacturing La-and-Ce-contained neodymium iron boron rare earth permanent magnet

ActiveCN103996524AImprove antioxidant capacityReduce dosageInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementHydrogen

The invention discloses a method for manufacturing a La-and-Ce-contained neodymium iron boron rare earth permanent magnet. Raw materials are formed by LR-Fe-B-Ma alloy, HR-Fe-B-Mb alloy and metallic oxide micro powder, wherein the LR represents four rare earth elements which include La, Ce, Nd and Pr, the HR represents one or more rare earth elements which include Dy or Tb, the Ma represents one or more of Al, Co, Nb, Ga, Zr and Cu, and the Mb represents one or more of Al, Co, Nb, Ga, Zr, Cu and Mo. The manufacturing method includes the following working procedures: LR-Fe-B-Ma alloy smelting, HR-Fe-B-Mb alloy smelting, alloy hydrogen decrepitation, metallic oxide micro powder surface adsorbing and making, magnetic field forming, sintering and aging, and the neodymium iron boron rare earth permanent magnet is manufactured.

Owner:SHENYANG GENERAL MAGNETIC

Preparation method of trace nitrogen-containing Re-Fe-B permanent magnetic material

ActiveCN101615462AReduce dosageReduce the total amount of rare earthMagnetic materialsHydrogenRare earth

The invention relates to a preparation method of trace nitrogen-containing permanent magnetic material. The method comprises the following steps: (1) mixing raw materials according to designed formula requirements, (2) quickly hardening flakes, (3) performing hydrogen decrepitation, (4) crushing in low-temperature nitrogen protection or argon protection, (5) jet milling in low-temperature nitrogen protection or argon protection, (6) mixing, (7) shaping, (8) sintering, (9) aging and (10) processing and detection; all material conversion processes are controlled by full sealing. The rare earth permanent magnet prepared by the method only contains trace nitrogen, and anticorrosion property of the magnet is greatly enhanced.

Owner:EARTH PANDA ADVANCE MAGNETIC MATERIAL

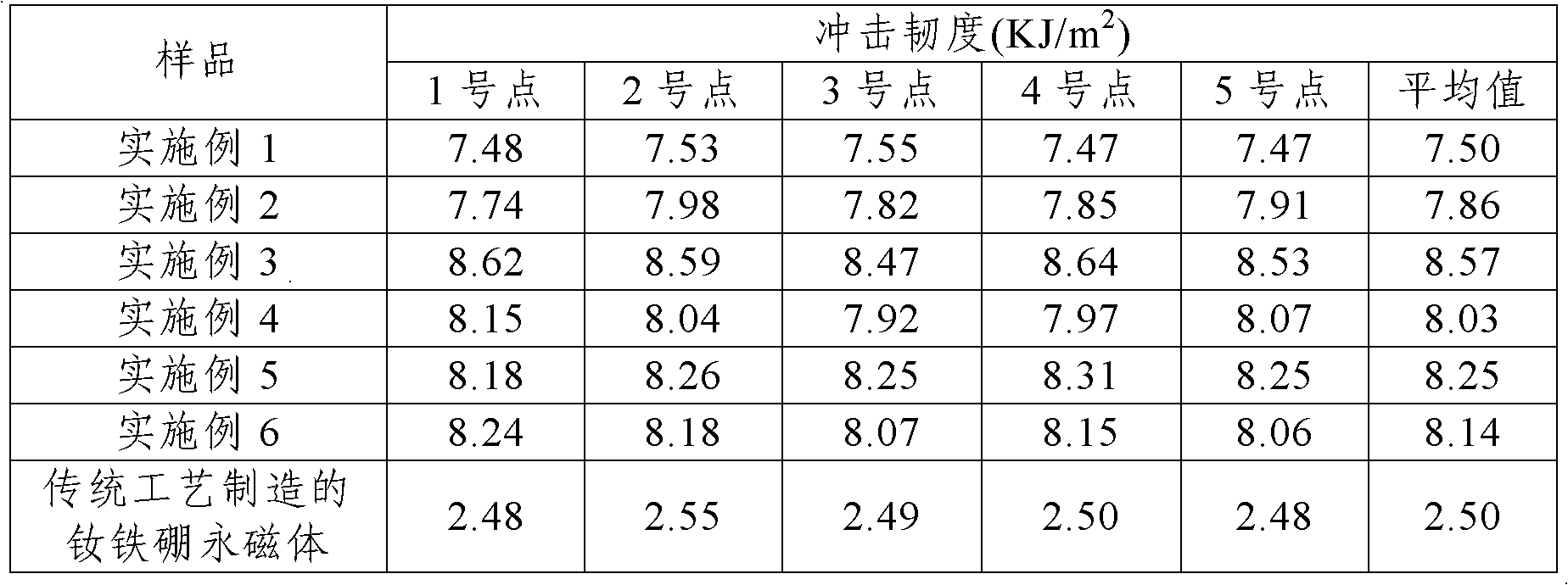

Manufacturing method of high-mechanical-strength sintered neodymium iron boron permanent magnets

ActiveCN102568738AAvoid coarseningHigh strengthPermanent magnetsInductances/transformers/magnets manufactureRare-earth elementCobalt

The invention discloses a manufacturing method of high-mechanical-strength sintered neodymium iron boron permanent magnets, which includes: firstly, utilizing rare-earth elements, iron, titanium, cobalt and boron iron alloy as raw materials and weighing the raw materials; secondly, mixing the weighed raw materials and disposing the same in a vacuum melting induction furnace, and preparing quick-hardened tablets by means of quick hardening process; thirdly, saturating the quick-hardened tablets to absorb hydrogen at the room temperature and dehydrogenating the same to prepare hydrogen decrepitation powder, then preparing magnetic powder by the hydrogen decrepitation powder through jet mill process; fourthly, molding the magnetic powder in an oriented manner, pressing to form magnets, disposing the magnets into a vacuum sintering furnace to be sintered in a vacuum environment, and performing tempering heat treatment to obtain blanks; and fifthly, machining the blanks, cleaning and removing oil, scouring to obtain high-mechanical-strength sintered neodymium iron boron permanent magnets with bending resistance strength not lower than 500MPa and impact toughness not lower than 7.5KJ / m2. By the manufacturing method, processing difficulty of the sintered neodymium iron boron permanent magnets is reduced greatly, application range of the sintered neodymium iron boron permanent magnets is broadened and economic potential thereof is high.

Owner:西安西工大思强科技股份有限公司

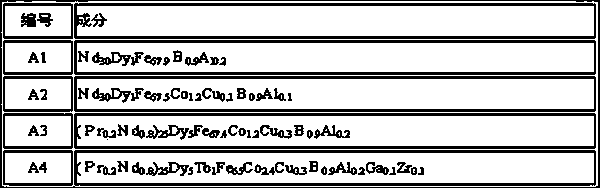

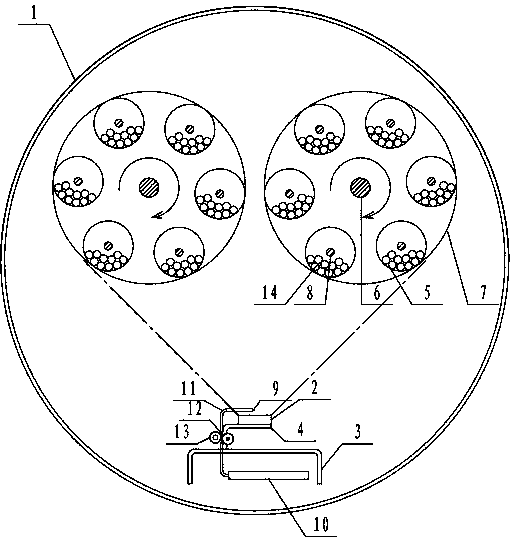

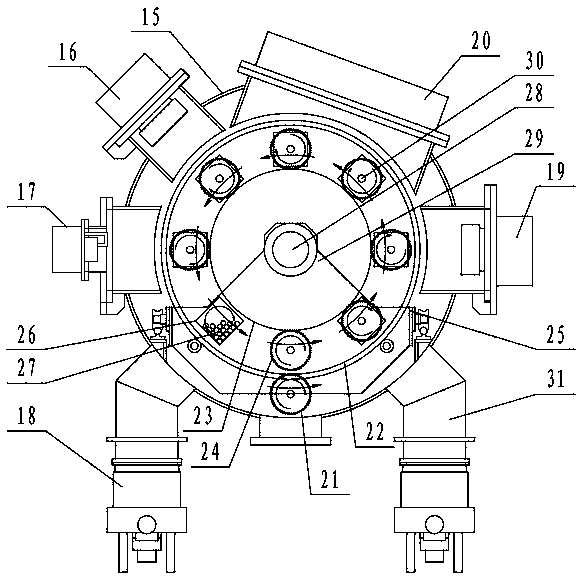

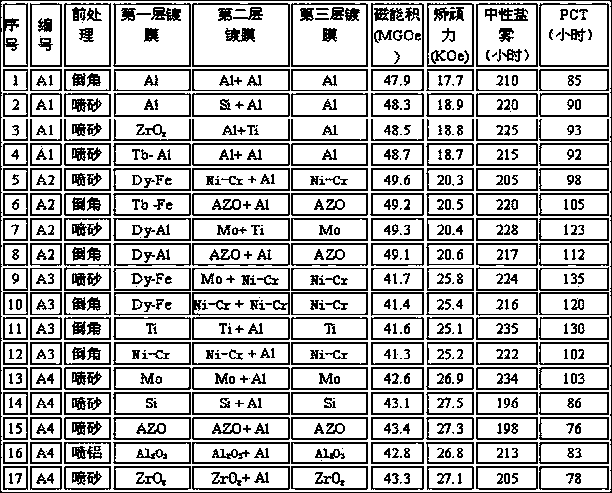

Hybrid film coating method of neodymium iron boron rare earth permanent magnet device

ActiveCN103854819AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingMolten stateRare earth

The invention discloses a hybrid film coating method of a neodymium iron boron rare earth permanent magnet device. According to the method, firstly, alloy smelting is carried out, alloy in a molten state is cast onto a rotary copper roller with a water cooling effect for being cooled to be manufactured into an alloy sheet, then, the alloy sheet is subjected to hydrogen decrepitation, material mixing and airflow powder grinding, next, materials are mixed by a material mixing machine and are then sent to a nitrogen gas protection magnetic field orientation pressing machine to be formed, the mixed materials are subjected to isostatic pressing after being encapsulated in a protection box, then, the sintering and the aging are carried out, a neodymium iron boron rare earth permanent magnet blank is prepared, the blank is subjected to machining, a neodymium iron boron rare earth permanent magnet is prepared, next, the neodymium iron boron rare earth permanent magnet is subjected to film coating, the neodymium iron boron rare earth permanent magnet device is formed, the film coating comprises three layers, the first layer and the second layer are magnetron sputtering coatings, and the second layer is a magnetron sputtering and multi-arc ion plating hybrid coating. The hybrid film coating is adopted as a surface treatment work procedure of the rare earth permanent magnet device, the anti-corrosion capability of the rare earth permanent magnet device is improved, and meanwhile, the magnetic performance of the rare earth permanent magnet device is also improved.

Owner:SHENYANG GENERAL MAGNETIC

Method for preparing heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet

ActiveCN101521069BImprove coercive forceNot easily oxidizedInorganic material magnetismRare-earth elementDehydrogenation

The invention discloses a method for preparing a heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet, which belongs to the technical field of magnetic materials. The prior preThe invention discloses a method for preparing a heavy rare earth hydride nano-particle doped sintered NdFeB permanent magnet, which belongs to the technical field of magnetic materials. The prior preparation method improves the coercive force and the temperature stability of magnets by adding heavy rare earth elements, namely terbium or dysprosium into master alloy, but the method can cause the rparation method improves the coercive force and the temperature stability of magnets by adding heavy rare earth elements, namely terbium or dysprosium into master alloy, but the method can cause the residual magnetism of the magnets, the reduction of magnetic energy product and the increase of manufacturing cost. The method adopts heavy rare earth terbium hydride and dysprosium hydride nano-powderesidual magnetism of the magnets, the reduction of magnetic energy product and the increase of manufacturing cost. The method adopts heavy rare earth terbium hydride and dysprosium hydride nano-powder doping technology to prepare the sintered NdFeB permanent magnet with high coercive force and excellent magnetic property. The method comprises the following steps: preparing NdFeB powder by a rapidldoping technology to prepare the sintered NdFeB permanent magnet with high coercive force and excellent magnetic property. The method comprises the following steps: preparing NdFeB powder by a rapidly solidified flake process and a hydrogen decrepitation process; preparing the terbium hydride or the dysprosium hydride nano-powder by physical vapor deposition technology; mixing the two powders, any solidified flake process and a hydrogen decrepitation process; preparing the terbium hydride or the dysprosium hydride nano-powder by physical vapor deposition technology; mixing the two powders, and performing magnetic field orientation and press forming; and performing dehydrogenation treatment, sintering and heat treatment on a green compact at different temperatures, and obtaining the sinterd performing magnetic field orientation and press forming; and performing dehydrogenation treatment, sintering and heat treatment on a green compact at different temperatures, and obtaining the sintered magnet. The coercive force of the magnet prepared by the method is higher than that of the prior sintered magnet with the same ingredients; and compared with the sintered magnet with the equivalented magnet. The coercive force of the magnet prepared by the method is higher than that of the prior sintered magnet with the same ingredients; and compared with the sintered magnet with the equivalent coercive force, the proportion of the terbium and dysprosium needed by the magnet prepared by the method is remarkably reduced.coercive force, the proportion of the terbium and dysprosium needed by the magnet prepared by the method is remarkably reduced.

Owner:BEIJING UNIV OF TECH

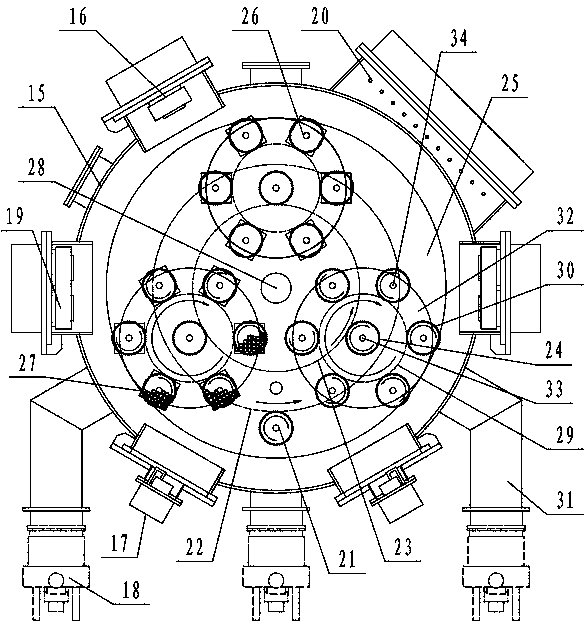

Method for preparing radiation oriental magnetic ring and radiation multipolar magnetic ring

ActiveCN101770862AGood orientationImprove magnetismInorganic material magnetismInductances/transformers/magnets manufactureAlicyclic HydrocarbonsNitrogen gas

The invention provides a method for preparing a radiation oriental magnetic ring and a radiation multipolar magnetic ring. The method comprises the following steps of: melting and casting raw material of alloy in a vacuum furnace; carrying out coarse / hydrogen decrepitation on the ingots in the inert atmosphere; adding matters into the powder subject to coarse / hydrogen decrepitation to mix; carrying out micro crushing on the alloy coarse powder by an airflow mill in the nitrogen atmosphere; annealing the alloy powder in the inert gas, vacuum or reduction atmospheres; adding carbonyl iron powder and at least one type of alicyclic hydrocarbon into the annealed alloy powder to mix; carrying out preorientation operation on the mixing powder; enabling the mixing powder to form a circular former in the magnetic field; carrying out integral grinding treatment on the inner wall of the circular former; and sintering the circular former in the vacuum or inert gas atmosphere. The invention has the advantages of effectively decreasing the oriental field required in forming, enhancing the oriental degree of the magnetic rings and improving the property of the magnetic rings.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH

Manufacturing method for neodymium iron boron lanthanon permanent magnet device with composite plated film

ActiveCN103824693AIncrease useImprove corrosion resistanceVacuum evaporation coatingSputtering coatingMolten stateRare earth

Owner:SHENYANG GENERAL MAGNETIC

Sintered neodymium iron boron permanent magnet based on crystal grain recombination and manufacturing method

ActiveCN104240888ACorrosion resistanceImprove performancePermanent magnetsInductances/transformers/magnets manufactureRare-earth elementHydrogen

The invention discloses a sintered neodymium iron boron permanent magnet based on crystal grain recombination and a manufacturing method. The permanent magnet has composite main phases that main phases with high heavy rare earth RH content are distributed around main phases with lower heavy rare earth RH content, and no continuous grain boundary phase exists in the composite main phases; average content of heavy rare earth RH on the periphery of the composite main phases is higher than content of heavy rare earth RH in the core part of the composite main phase, and the average crystal grain size of the composite main phases is 6-14mu m; heavy rare earth RH comprises more than one of Dy, Tb, Ho, Gd and Y elements. The manufacturing method comprises steps of first alloy smelting, second alloy smelting, hydrogen decrepitation, alloy plate mixing, jet mill powdering, magnetic field formation, vacuum sintering and aging; the step of first alloy smelting comprises a process of preparing first alloy plates containing Pr and Nd elements; the step of second alloy smelting comprises a process of preparing second alloy plates containing heavy rare earth RH elements.

Owner:SHENYANG GENERAL MAGNETIC

Method and device for measuring decrepitation, expansion and shrinkage performance of lump coal

ActiveCN102156149AImprove featuresImprove understanding of coal coke morphology changesMaterial thermal coefficient of expansionMaterial exposibilityExpansion rateCoal

The invention provides a method and a device for measuring decrepitation, expansion and shrinkage performance of a lump coal. The device comprises a heating system, a camera, a computer, a light source adjustment system and an atmosphere system, wherein the heating system comprises a furnace tube, a quartz window, a sample substrate, a sample and a temperature measuring thermocouple, wherein the top of the thermocouple contacts the sample substrate closely; the lens of the camera is a long-focus charge coupled device (CCD) lens; and the heating system is arranged right ahead of the CCD lens. The method comprises the following steps: heating a lump coal sample in the device; selecting a proper temperature point to collect an image when the image is clear; calculating the expansion rate and shrinkage rate of the volume. The pyrolyzation and degassing processes of the lump coal can be visually observed at different temperatures through providing a visual device and the measurement method; the expansion and shrinkage behavior and the decrepitation of the lump coal can be indirectly measured through image collecting, thus providing guidance basis for the use of the lump coal in a melting gasification furnace.

Owner:XINJIANG BAYI IRON & STEEL

Novel permanent magnet alloy with composite low-price rare earth added and preparation method thereof

ActiveCN104900360AImprove performanceImprove and increase the coercive forceInorganic material magnetismRare-earth elementAlloy

The invention belongs to the technical field of rare earth permanent magnetic materials, and relates to novel permanent magnet alloy with composite low-price rare earth added and a preparation method thereof. The chemical formula of the alloy is as follows, by weight, (GdxCeyRE1-x-y) a (Fe and TM)100-a-bBb, wherein x is larger than or equal to 0.01 and is smaller than or equal to 0.4, y is larger than or equal to 0. 1 and is smaller than or equal to 0.9, a is larger than or equal to 28 and is smaller than or equal to 35, b is larger than or equal to 0.9 and is smaller than or equal to 1.2, Re is one or more rare earth elements besides Ce and Gd, and TM refers to one or more of Ga, Co, Al, Cu, Nb, Zr, Ti and V. The preparation method of the rare earth permanent magnet alloy includes the steps of raw material preparation, strip-casting flake preparation, hydrogen decrepitation, orientation forming and pressing, sintering and heat treatment. A novel low-cost rare earth permanent magnetic material is obtained, efficient utilization of low-price Ce rare earth elements can be achieved, in particular, when the content of Ce in total rare earth reaches 50%, good coercivity and comprehensive magnetic performance can still be achieved, good corrosion resistance and machinability are kept, and obvious cost and price advantages can be achieved.

Owner:CENT IRON & STEEL RES INST

Multi-main phase Ho-containing NdFeB (neodymium iron boron) permanent magnet and manufacturing method thereof

ActiveCN104252938ACorrosion resistantImprove performanceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementLa element

The invention discloses a multi-main phase Ho-containing NdFeB (neodymium iron boron) permanent magnet and a manufacturing method thereof. The permanent magnet contains multiple main phases with different rare earth element contents. Oxide phases exist among the main phases. Oxygen contents of the oxide phases are higher than those of the main phases. The main phases with the high Ho content exist. Crystal grains composed of the main phases are isolated by grain boundaries. Average grain size is 6-14 um. The manufacturing method includes smelting a first alloy, smelting a second alloy, smelting a third alloy, performing hydrogen decrepitation, mixing the alloys, performing grinding powder, pressing under magnetic field, performing vacuum sintering, performing aging and the like. The method smelting the first alloy includes preparing the first alloy containing La element, Ce element, Pr element and Nd element. The method smelting the second alloy includes preparing the second alloy containing the element Pr, the element Nd, the element Dy and the element Ho. The method smelting the third alloy includes preparing the third alloy containing the element Pr, the element Nd, the element Dy and the element Gd.

Owner:SHENYANG GENERAL MAGNETIC

Manufacturing method for high-performance NdFeB rare earth permanent magnet devices

ActiveCN103996519AImprove magnetic propertiesAccelerated corrosionTransportation and packagingMetal-working apparatusFiberHydrogen

The invention discloses a manufacturing method for high-performance NdFeB rare earth permanent magnet devices. The high-performance NdFeB rare earth permanent magnet devices are made of R-Fe-Co-B-M rapid-hardening alloy, microcrystal HR-Fe alloy fibers and TmGn compound micro-powder. The manufacturing method comprises the steps of manufacturing the R-Fe-Co-B-M rapid-hardening alloy, manufacturing the microcrystal HR-Fe alloy fibers, performing hydrogen decrepitation on the alloy, performing mixing before pulverization, performing pulverization in a grinding mode through air flow, performing mixing after pulverization, forming a magnetic field, performing sintering and performing aging. In this way, a sintered NdFeB permanent magnet is manufactured, and machining and surface treatment are performed on the sintered NdFeB permanent magnet to manufacture various rare earth permanent magnet devices.

Owner:SHENYANG GENERAL MAGNETIC

Hybrid preparation method of high-performance sintered NdFeB permanent magnet

ActiveCN102218531AImprove remanenceHigh energy productInductances/transformers/magnets manufactureHydrogenIngot casting

The invention relates to a preparation method of sintered NdFeB, in particular to a hybrid preparation method of a high-performance sintered NdFeB permanent magnet. By means of the method, the problems that magnet performance indexes are relatively lower as the generation of alpha-Fe is difficult to overcome in the conventional process for ingot casting after smelting, and the main phase composition segregation is brought on by a metastable crystallization in a strip casting process for cooling are solved. The hybrid preparation method provided by the invention comprises the steps of separately designing a main phase and Nd-rich phase, wherein the main phase is prepared through smelting the raw materials in percentage by weight: 28-30% of Nd, 0.95-1.2% of B and the balance of Fe and adopting the strip casting process for cooling, hydrogen decrepitation and jet milling, and the Nd-rich phase is prepared through smelting the raw materials in percentage by weight: 46-54.5% of R, 0.95-1.2% of B. 7.5-20% of M and the balance of Fe and adopting an ingot casting process for cooling, hydrogen decrepitation and jet milling; mixing the main phase and Nd-rich phase powders according to a proportion of (92-98%):(2-8%); and finally, carrying out magnetic field orientation, compression moulding, sintering and tempering on the mixed magnetic powders.

Owner:内蒙古北方众恒磁谷新材料有限公司

Core-shell structure NdFeB magnetic powder high in electrical resistivity and magnetic performance and application

ActiveCN104959618ACoated evenlyThickness is easy to controlMagnetic materialsNitrationDehydrogenation

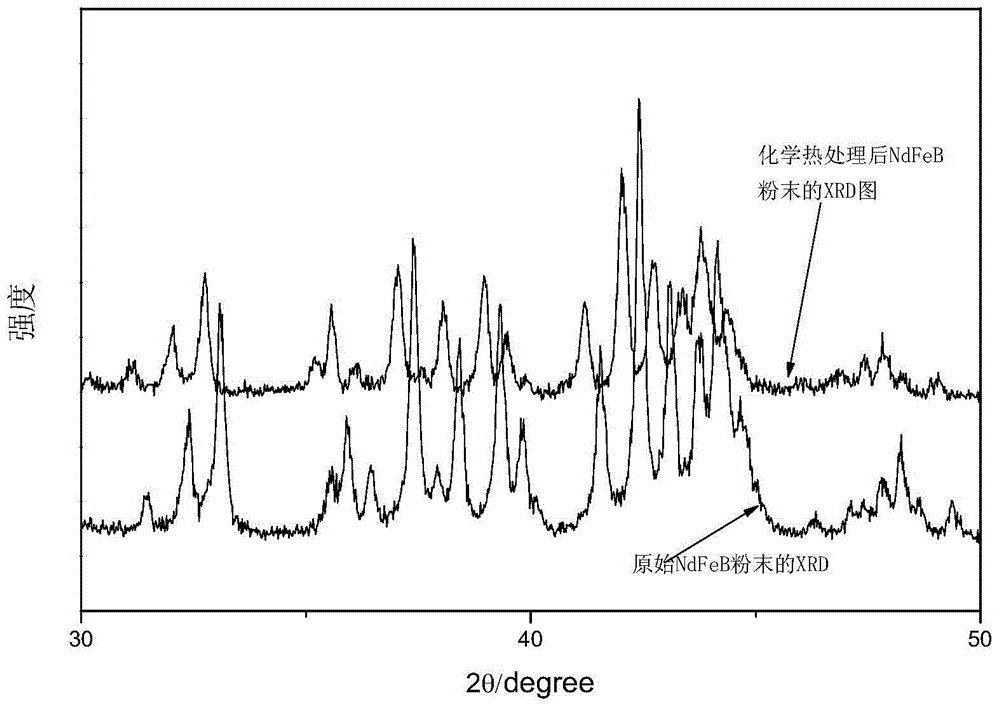

The invention discloses core-shell structure NdFeB magnetic powder high in electrical resistivity and magnetic performance. Firstly, a prepared raw material is subjected to induction melting to form Nd2Fe14B strip-casting flakes, wherein the average thickness of the strip-casting flakes is 0.1-0.5 mm; the strip-casting flakes are subjected to formed hydrogen decrepitation, and coarsely crushed magnetic powder is obtained after dehydrogenation; secondly, air flow grinding is performed under the inert gas protection atmosphere to obtain magnetic powder with approximate particle size of 1-6 micron; finally, the magnetic powder is put into a tube furnace, ammonia gas is led into the tube furnace at the flowing speed of 50-300 mL / min, the magnetic powder is heated to be at the temperature of 300-400 DEG C, is subjected to heat preservation for 5-30 minutes and then is cooled with cooling of the furnace, and the core-shell structure NdFeB magnetic powder can be obtained by continuously leading the ammonia gas during heat preservation and cooling performed with cooling of the furnace. Due to the insulation effect of a nitration layer, the core-shell structure NdFeB magnetic powder has the advantages of being high in electrical resistivity, high in corrosion resistance, good in demagnetizing-coupling effect, high in magnetic performance, controllable in nitration layer thickness, even in nitration layer coating and the like.

Owner:ZHEJIANG UNIV

Recycling technique for galvanized sintered NdFeB wastes

ActiveCN104801717AReduce pollutionReduce manufacturing costInorganic material magnetismRecycling and recovery technologiesRare earthImpurity

The invention discloses a recycling technique for galvanized sintered NdFeB wastes. The recycling technique comprises the following steps: performing multi-level breaking, hydrogen decrepitation, screening and airflow grinding on the sintered NdFeB wastes with a galvanized layer in turn, thereby acquiring the fine grains with few impurities and particle size being 3-5 microns; uniformly mixing the prepared auxiliary alloy with the fine grains made from the galvanized wastes at a certain ratio, wherein the auxiliary alloy can be the alloy powder containing one or more of praseodymium neodymium, holmium iron, gadolinium iron and dysprosium iron, and the proportion of the auxiliary alloy is 10-50%; performing the processes of forming, sintering, and the like, on the magnetic powder, thereby acquiring the required magnet. According to the recycling technique, the galvanized sintered NdFeB wastes are directly utilized to prepare the NdFeB products, and the rare earth separation is no longer performed, so that the environmental pollution is reduced and the manufacturing cost is lowered. According to the recycling technique, the galvanized sintered NdFeB wastes are subjected to multi-level breaking and hydrogen decrepitation and then screening and impurity-cleaning, so that the galvanized coating tablets and impurities in the electroplated wastes are extremely removed, and the basis for manufacturing the products at different grades is established.

Owner:安徽万磁电子股份有限公司

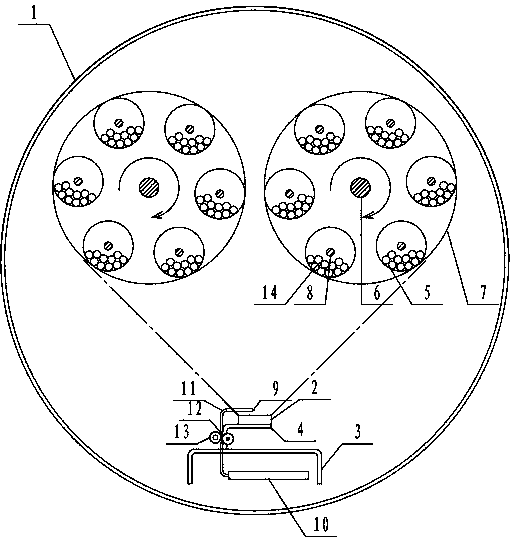

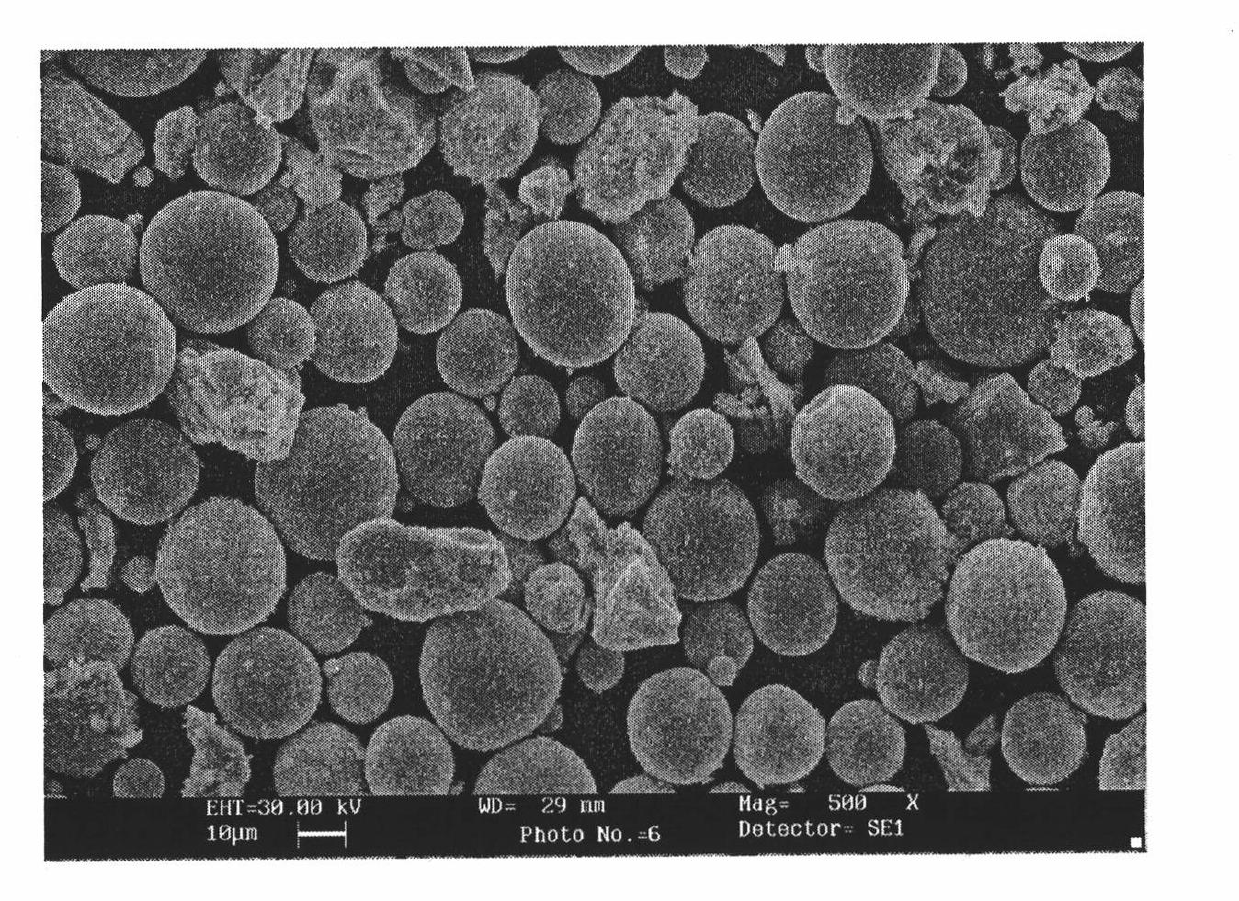

Minute spherical Nd-Fe-B powder preparation method

InactiveCN101767200ASmall granularityUniform compositionTransportation and packagingMetal-working apparatusHydrogenMetallurgy

The invention provides a minute spherical Nd-Fe-B powder preparation method, belonging to the powder preparation technical field. The method combines the hydrogen decrepitation (HD) technology with the radio frequency (RF) plasma melting and spheroidizing technology, selects hydrogen absorbing Nd-Fe-B powder as the raw material, completes the steps of hydrogen decrepitation, dehydrogenization and titanium powder spheroidization of the hydrogen absorbing Nd-Fe-B powder simultaneously by plasma treatment and prepares minute spherical Nd-Fe-B powder. The invention has the advantages that the method combines the hydrogen decrepitation (HD) technology with the radio frequency (RF) plasma melting and spheroidizing technology, shortening the technological process of production, improving the production efficiency, reducing the production cost, and guaranteeing that the prepared spherical Nd-Fe-B powder has minute granularity, even ingredient, good fluidity, high sphericity and low oxygen content and meets the demand for bonding Nd-Fe-B permanent magnet in industrial production.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of super-strong corrosion resisting neodymium-iron-boron magnet

ActiveCN103187168APromote sinteringImprove coercive forceInductances/transformers/magnets manufactureMagnetic materialsHydrogenIngot casting

The invention discloses a preparation method of a super-strong corrosion resisting neodymium-iron-boron magnet. The preparation method comprises the following steps: 1) preparing a master alloy into a neodymium-iron-boron ingot alloy through an ingot casting process or preparing the master alloy into a neodymium-iron-boron rapid-hardening slice through a rapid-hardening slice manufacturing process; 2) implementing hydrogen decrepitation or mechanical disruption on the master alloy, and then preparing powder through airflow milling or ball milling; 3) carrying out oil removal on the master alloy powder through an oil removal liquid, and activating through an activating liquid; 4) adding the activated master alloy powder into a plating solution, electroplating copper, and drying through a vacuum drying machine; 5) compressing and moulding the dried powder in a magnetic field; 6) sintering in a high-vacuum sintering furnace to obtain a sintered magnet; and 7) carrying out oil removal on the surface of the magnet and activating, and then electroplating copper. The prepared neodymium-iron-boron magnet disclosed by the invention is remarkably high in corrosion resistance and strong in binding force between plating layer and substrate; and the process is simple and applicable to mass production.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High temperature resistant samarium cobalt permanent magnet and preparation method thereof

InactiveCN105427988AExtended service lifeImprove toughnessInductances/transformers/magnets manufactureMagnetic materialsFiberHydrogen

The present invention relates to a high temperature resistant samarium cobalt permanent magnet and a preparation method thereof. The high temperature resistant samarium cobalt permanent magnet comprises a samarium cobalt permanent magnet material core layer and a ceramic protective layer, wherein the samarium cobalt permanent magnet material is externally coated with the ceramic protective layer, and the samarium cobalt permanent magnet material comprises a reinforcing fiber of 10-20% volume percent and a samarium cobalt permanent magnet powder of 80-90% volume percent. The samarium cobalt permanent magnet is prepared by using the following preparation method: performing batching according to components and mass percentages thereof of the samarium cobalt permanent magnet powder, and performing melting and quick solidification to obtain an alloy sheet; performing hydrogen decrepitation on the alloy sheet to obtain a powder; grinding the powder into a powder material by means of a jet mill directly; performing press forming on the reinforcing fiber and the powder material to obtain a green body; and subjecting the green body to high temperature sintering and heat treatment, and forming the ceramic protective layer on the surface, thereby obtaining the high temperature resistant samarium cobalt permanent magnet. The samarium cobalt permanent magnet obtained by using the method provided by the present invention has both a high magnetic property and a high mechanical property, also has good high temperature resistance, and is applicable in a high temperature environment of 500 DEG.C or above.

Owner:NINGBO STAR MATERIALS HI TECH

Low-weight loss neodymium-iron-boron magnet and preparation method thereof

InactiveCN105427993AImprove corrosion resistanceCorrosion resistanceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementHydrogen

The present invention relates to a low-weight loss neodymium-iron-boron magnet and a preparation method thereof. The low-weight loss neodymium-iron-boron magnet mainly consists of the following components in percentage by mass: 27%-32.5% of Nd, 1%-1.2% of B, 2%-3% of Co, 0.15%-2.75% of alloy element M1, 0.05%-1.1% of alloy element M2, 0.7%-1.3% of rare-earth elements (excluding rare-earth element Nd), and the balance Fe. The preparation method comprises the following steps: preparing raw materials according to components of the neodymium-iron-boron magnet and mass percentages of the components; performing smelting and casting to obtain a throwing band; performing hydrogen decrepitation and jet milling to form a powder material; pressing and shaping the powder material; performing high temperature sintering and surface treatment to obtain the low-weight loss neodymium-iron-boron magnet. According to the low-weight loss neodymium-iron-boron magnet and the preparation method thereof provided by the present invention, corrosion resistance of the magnet is improved, and moreover, the protective layer formed by the metal coating and the organic coating is applied to the surface of the magnet, thereby effectively alleviating the problem of corrosion weight loss of the neodymium-iron-boron magnet.

Owner:NINGBO STAR MATERIALS HI TECH

Preparation method of low-heavy-rare-earth and high-coercivity neodymium iron boron magnet

InactiveCN107546027AImprove coercive forceGrain refinementInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementDisproportionation

The invention discloses a preparation method of a low-heavy-rare-earth and high-coercivity neodymium iron boron magnet. The preparation method comprises the steps of performing material mixing based on designed components, smelting, quick hardening and piece casting; performing hydrogen decrepitation, a disproportionation reaction and air flow grinding on a neodymium iron boron cast piece to obtain neodymium iron boron fine powder; adopting a thermal resistance evaporation deposition method, depositing heavy rare earth element particles or high smelting quality element particles on the neodymium iron boron fine powder; and performing orientation pressing and shaping, vacuum sintering and thermal treatment on the obtained neodymium iron boron fine powder to obtain the final neodymium iron boron magnet. By virtue of the preparation method, the magnet coercivity of the obtained magnet material can be obviously improved, the magnet crystal particle can be thinned, the dosage of the heavy rare earth elements can be lowered, and the magnet manufacturing cost is lowered.

Owner:BAOTOU RES INST OF RARE EARTHS +1

Preparation method for boron-magnesium composite additive for pellets and product

InactiveCN102676799AGuaranteed gradeReduction expansion rate improvementChemical compositionBoron containing

The invention discloses a preparation method for a boron-magnesium composite additive for preparing pellets and a product. The method is characterized by comprising the following steps: crushing and drying magnesium ore serving as a raw material; roasting at the temperature of between 750 and 900DEG C for 30 to 120 minutes, taking out of a furnace, cooling, and grinding to obtain magnesium ore powder; grinding a boron-containing material of which the B2O3 grade is 5to 15 percent to obtain boron powder, mixing the two kinds of powder in a ratio to obtain the boron-magnesium composite additive comprising the following chemical compositions in percentage by weight: more than or equal to 58 and less than or equal to 70 percent of MgO, more than or equal to 11 and less than or equal to 23 percent of SiO2, more than or equal to 3 and less than or equal to 6 percent of B2O3, less than 1 percent of Al2O3 and more than or equal to 14 and less than or equal to 18 percent of burning loss; and adding the composite additive in an amount which is 1 to 2 percent of pellet raw material into the pellet raw material for pelletizing, and roasting at the temperature of between 1,200 and 1,300DEG C for 20 to 60 minutes to obtain the pellets. By the additive, the metallurgical properties of the pellets, such as decrepitation temperature, compressive strength, drop strength, low temperature reduction degradation index, medium temperature reducibility and reduction swellability can be obviously improved.

Owner:NORTHEASTERN UNIV

Preparation process for sintering 1kg-5.5kg of neodymium iron boron permanent magnetic material

ActiveCN103060658AImprove magnetic propertiesImprove magnetismInorganic material magnetismFurnace typesHydrogenOrganic glass

The invention discloses a preparation process for sintering 1kg-5.5kg of neodymium iron boron permanent magnetic materials, which belongs to the technical field of neodymium iron boron materials. The preparation process comprises the following steps of firstly, preparing materials; secondly, smelting, namely smelting the materials into cast pieces by using a rapid condensing melt-spinning furnace; thirdly, making powder, including hydrogen decrepitation and airflow milling; fourthly, shaping, namely, firstly magnetizing, secondly demagnetizing, compressing and shaping, pushing the compressed magnet pieces to an organic glass board, packaging in vacuum, carrying out equal static pressure treatment and eliminating the oil; and fifthly sintering, namely, putting the shaped blanks into a vacuum sintering furnace, heating and sintering, and carrying out sintering and tampering treatment in a primary tempering mode, a secondary tempering mode and an in-furnace insert gas cooling mode. The preparation process has the beneficial effects that by adopting appropriate magnetizing and demagnetizing, the material is easy to shape in compression; by adopting twice tempering and fan cooling, the magnetism of the magnet is improved, and crack and layering of a large piece of neodymium iron boron material are reduced, so that the size of the prepared neodymium iron boron material is enlarged.

Owner:JIANGSU JINSHI RARE EARTH CO LTD

Tb-containing multi-main-phase neodymium iron boron permanent magnet and manufacturing method

ActiveCN104240886ACorrosion resistantImprove performanceInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementGrain boundary

The invention discloses a Tb-containing multi-main-phase neodymium iron boron permanent magnet and a manufacturing method. The permanent magnet contains a plurality of main phases with different contents of rare earth elements, an oxide phase exists among the main phases, and the oxygen content of the oxide phase is higher than the oxygen content of the main phases; a high Tb-content main phase exists in the plurality of main phases, crystal grains formed by the plurality of main phases are isolated by a grain boundary phase, and the average crystal grain size is 6-14mum; heavy rare earth RH comprises more than one of the Dy, Tb, Ho, Gd and Y elements. The manufacturing method comprises the steps of first alloy smelting, second alloy smelting, third alloy smelting, hydrogen decrepitation, alloy mixing, powdering through a jet mill, magnetic field formation, vacuum sintering, aging and the like; the step of first alloy smelting comprises a process of preparing first alloy containing the Nd element; the step of second alloy smelting comprises a process of preparing second alloy containing the Pr, Nd and Dy elements; the step of third alloy smelting comprises a process of preparing third alloy containing the Pr, Nd and Tb elements.

Owner:SHENYANG GENERAL MAGNETIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com