Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2813 results about "Shrinkage rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low temperature co-fired ceramic with improved registration

InactiveUS6205032B1Semiconductor/solid-state device detailsSolid-state devicesHigh densityMetallurgy

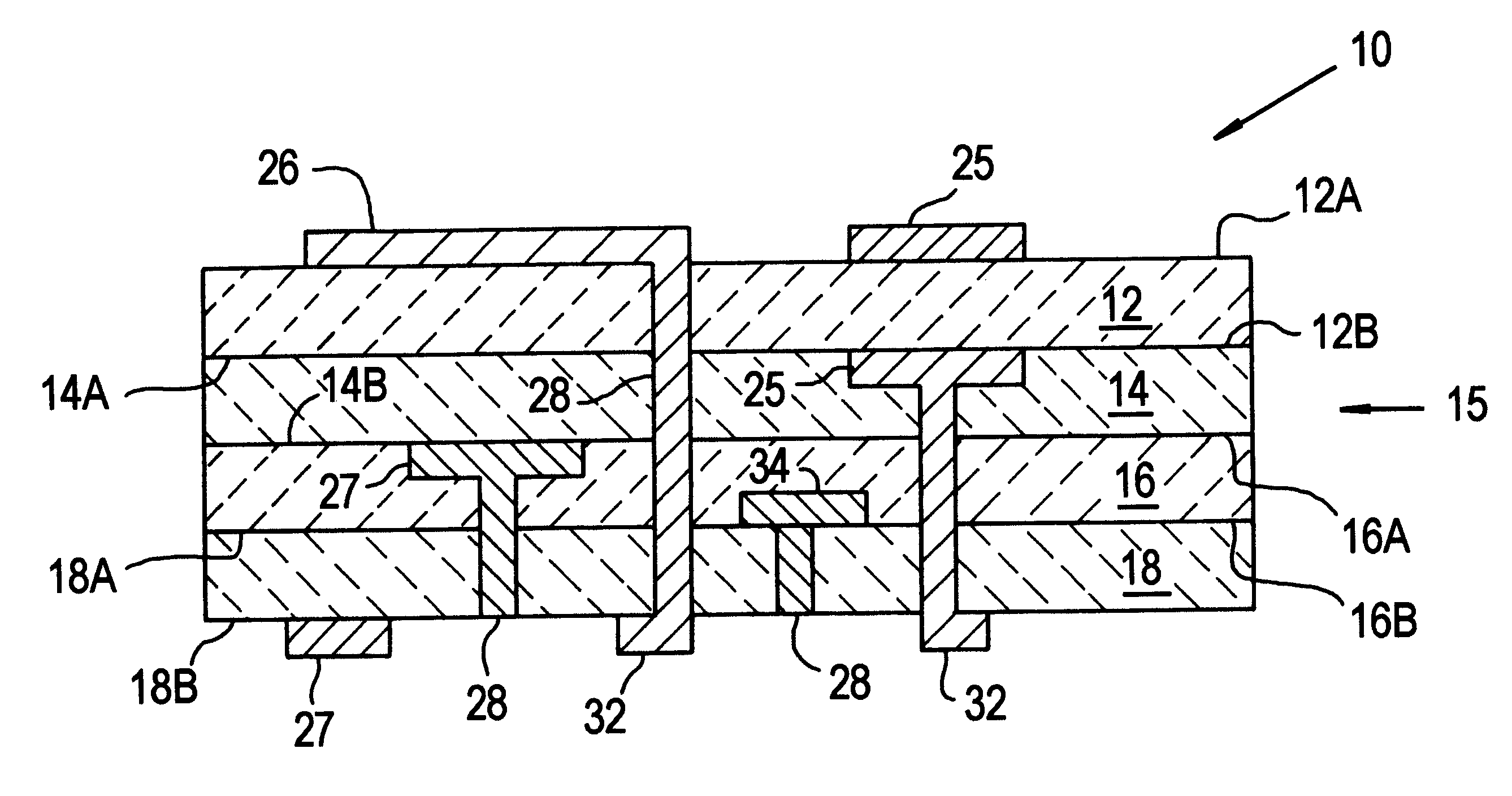

A low temperature co-fired ceramic assembly (LTCC) with a constraining core to minimize shrinkage of outer ceramic layers during firing. The outer ceramic layers have high density circuit features. A ceramic core includes several ceramic layers. Several via holes are located in the first and second ceramic layers. Several low density circuit features are located on the ceramic layers that make up the core. Outer ceramic layers are placed top and bottom of the ceramic core. The outer ceramic layers have via holes and high density circuit features. The circuit features patterned on the ceramic layers include resistors, capacitors, circuit lines, vias, inductors, or bond pads. The ceramic core is fired first in a furnace. The outer layers are then laminated to the ceramic core and fired. The ceramic core controls the shrinkage rate of the outer ceramic layers during firing allowing higher density circuit features on the outer layers.

Owner:CTS CORP ELKHART

Method and apparatus for providing an advantage to a player in a bonus game

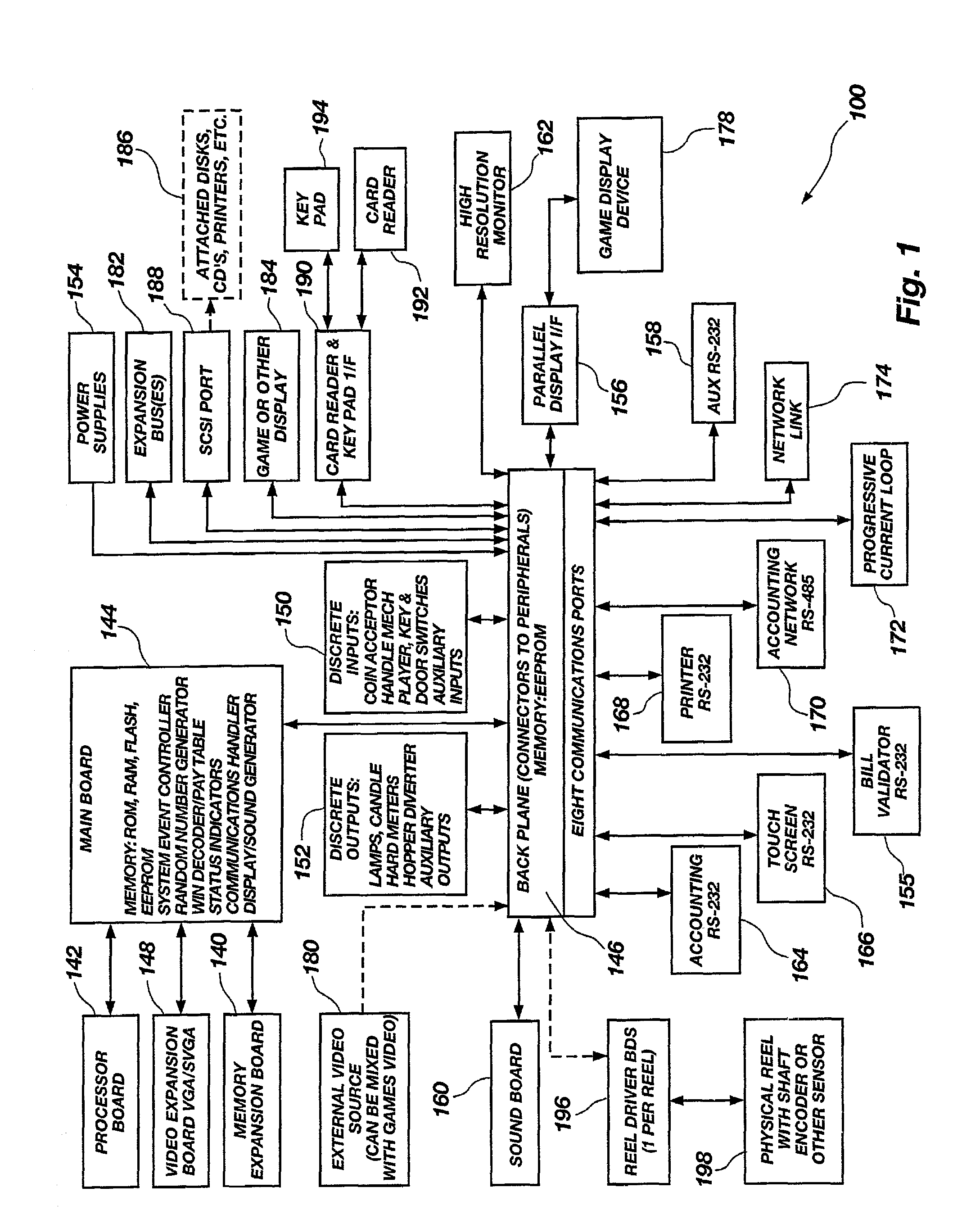

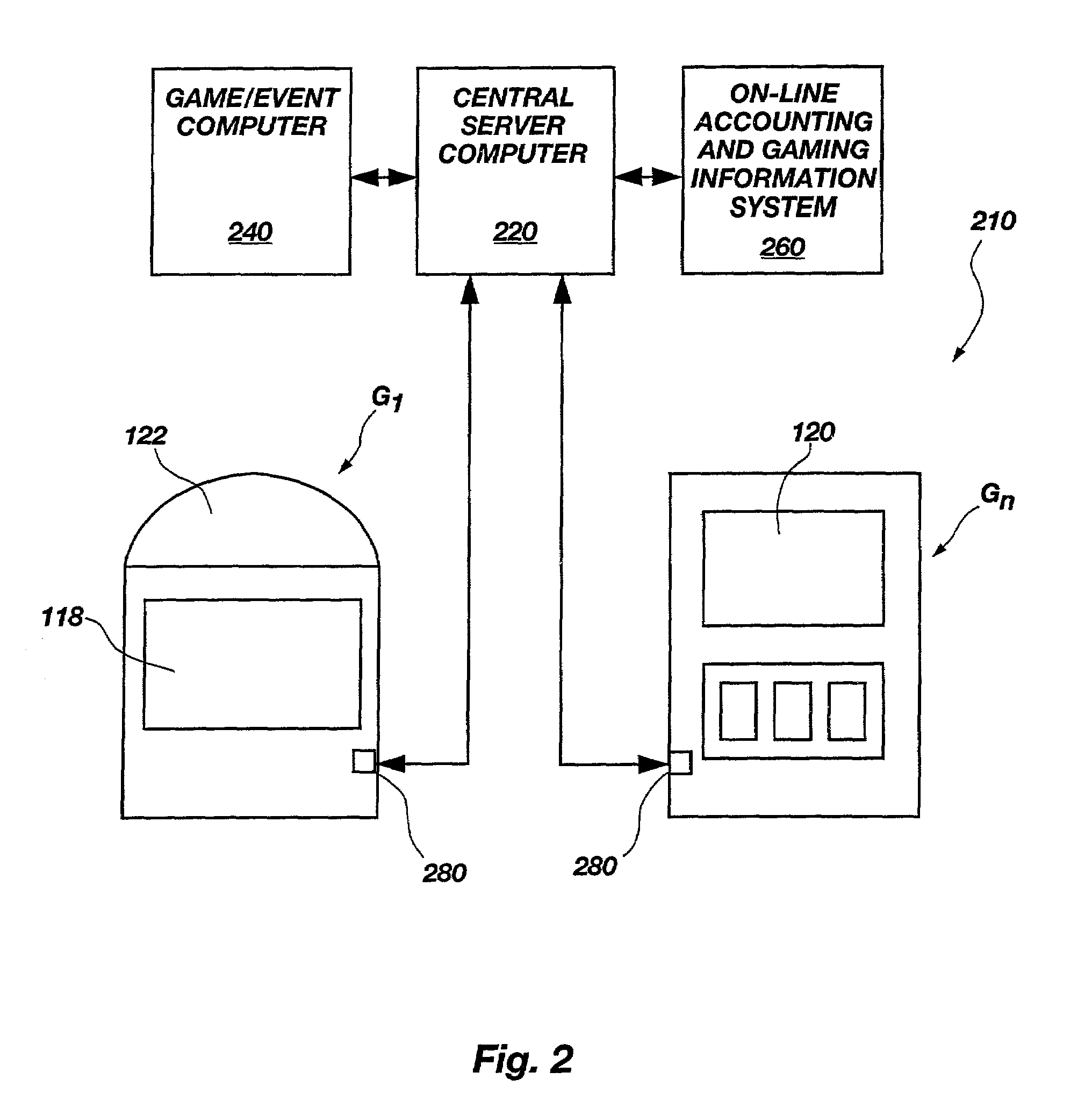

InactiveUS7052392B2Improve the odds of successLengthen his paddleApparatus for meter-controlled dispensingVideo gamesPaymentShrinkage rate

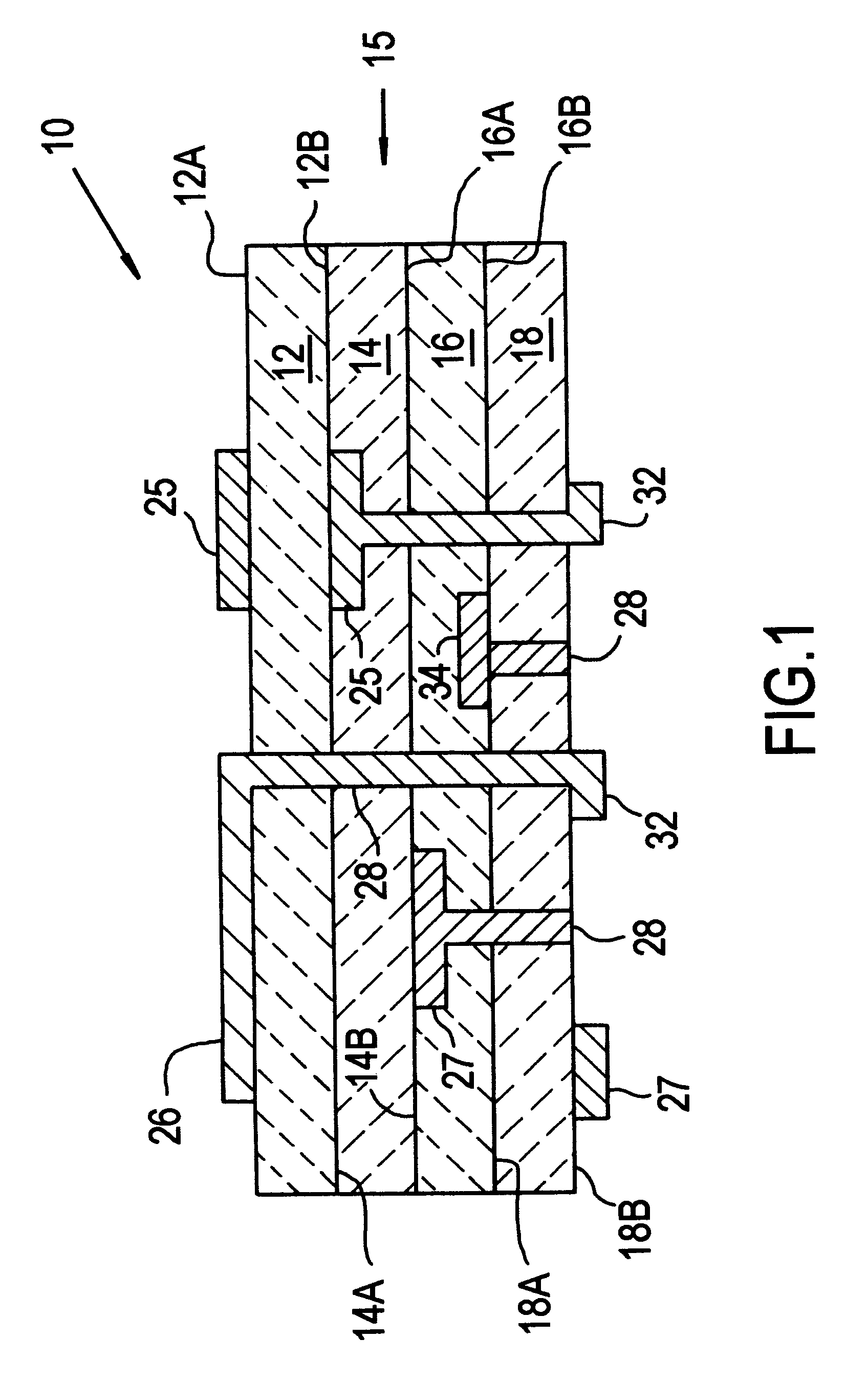

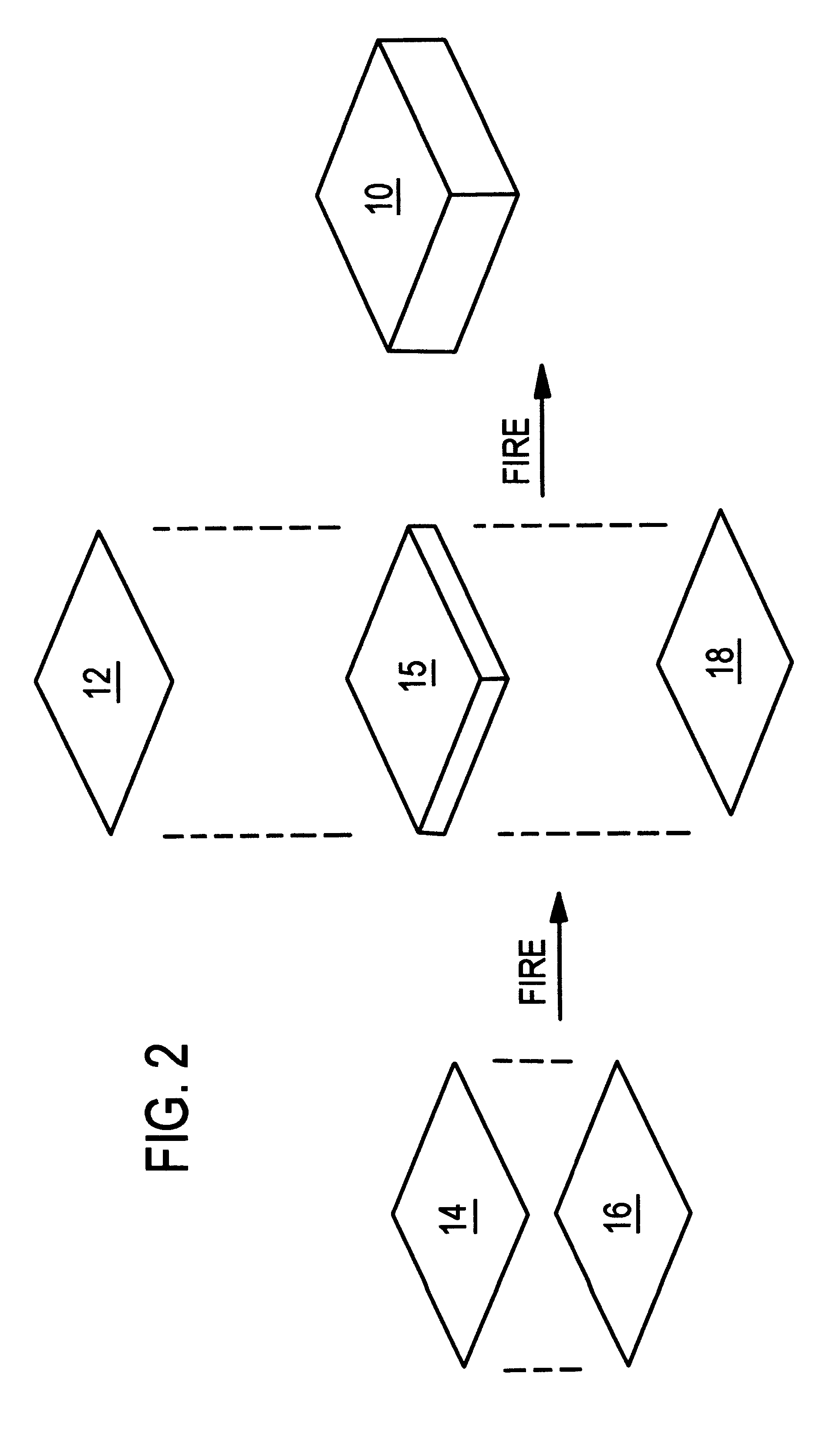

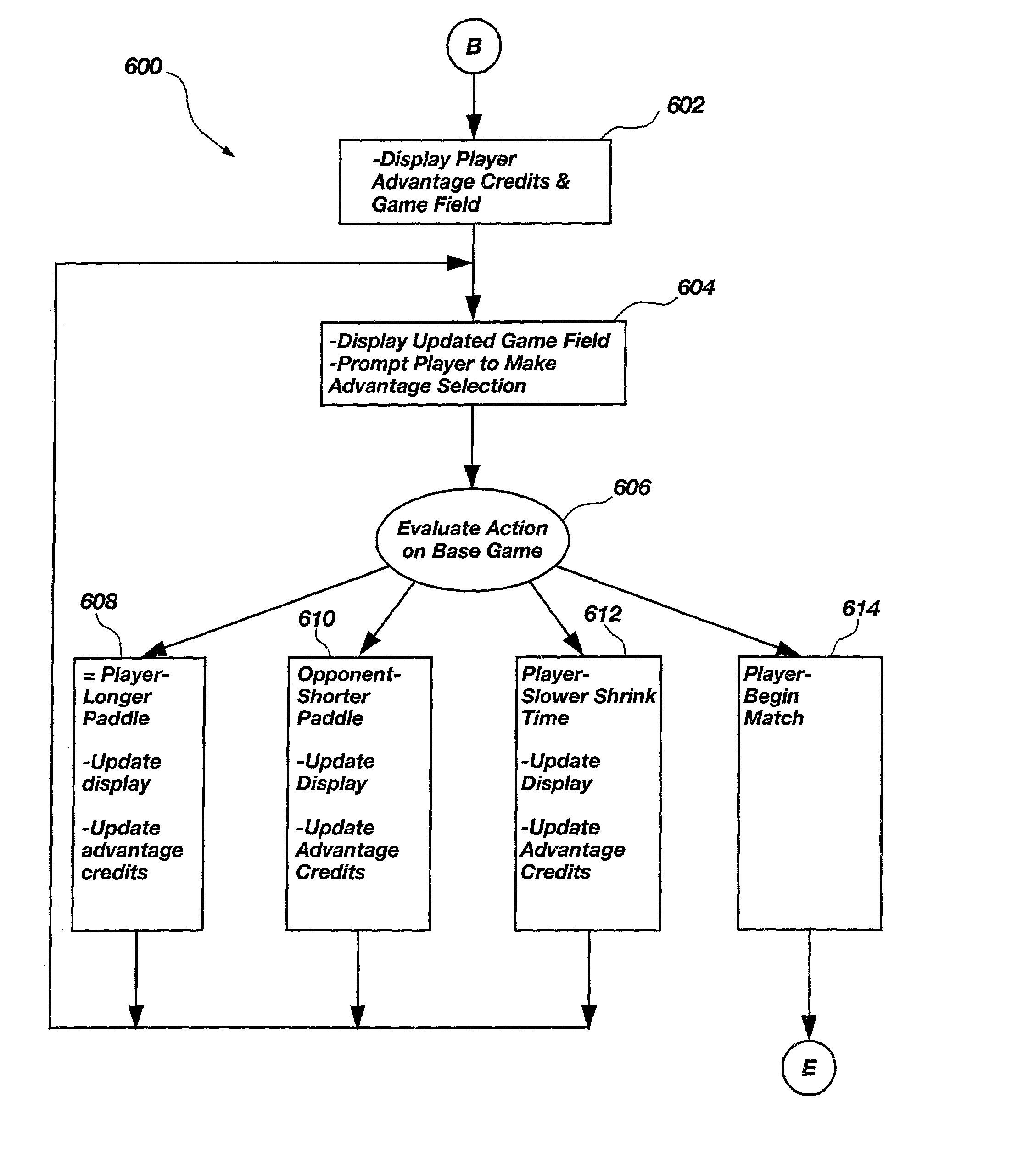

A video game allows a player to improve odds of success in a bonus game by winning an advantage outcome in association with play of a primary or base game. An exemplary bonus game is the game of Pong where the player can use advantage credits won in play of the primary or base game to provide himself with an advantage such as lengthening his paddle, shortening his opponent's paddle, or slowing the shrinkage rate of his paddle during the course of the bonus game. Alternatively, he may also purchase one or more advantages for use in the bonus game through monetary payment.

Owner:IGT

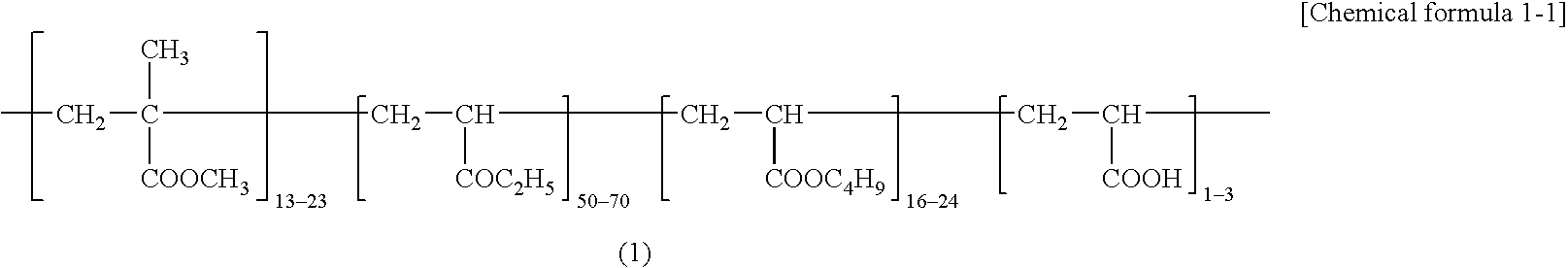

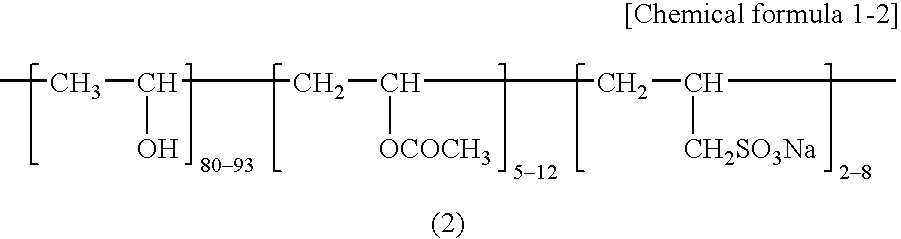

Skin preparations for external use for wrinkle reduction

InactiveUS20070148120A1Long durationImprove anti-wrinkle effectCosmetic preparationsHair cosmeticsCross-linkAdditive ingredient

To provide a skin treatment composition for wrinkle reduction that is superior in terms of the wrinkle reduction effect, usability, and the sensation during use. A skin treatment composition having a water dispersion of a polymer in which a non-water soluble film-forming polymer is dispersed in water wherein the main ingredients of said film-forming polymer are polyurethane having a film shrinkage rate of 20% or less and an acrylic type polymer having a film shrinkage rate of 20% or less. Also, a skin treatment composition for wrinkle reduction comprising (a) a non-emulsification type cross-linked silicone, (b) a film forming polymer having a film shrinkage rate of 20% or less containing as a main ingredient a polyurethane having a film shrinkage rate of 20%, (c) a liquid oil component, and (d) water.

Owner:SHISEIDO CO LTD

Acrylic Resin Films and Process for Producing the Same

InactiveUS20070243364A1Increase resistanceHigh transparencySynthetic resin layered productsOptical elementsGlutaric anhydrideFolding endurance

An acrylic resin film, in which acrylic elastic particles are mixed with an acrylic resin containing glutaric anhydride units, has a total light transmittance of 91% or more, a haze value of 1.5% or less, a folding endurance value (times) of 20 or more, and a heat shrinkage rate of less than 5% at least in either the machine direction or the transverse direction in a heat shrinkage test.

Owner:TORAY IND INC

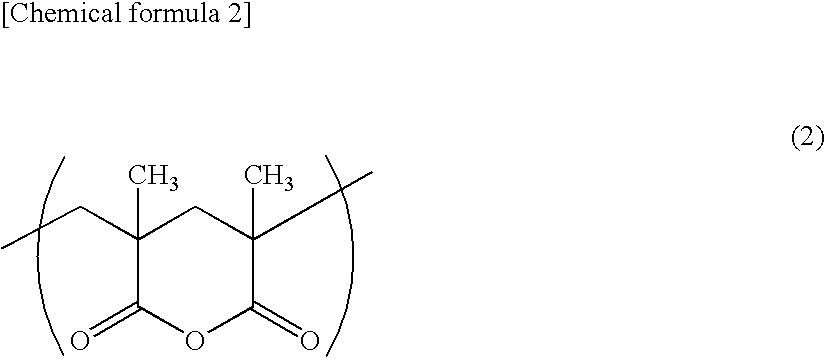

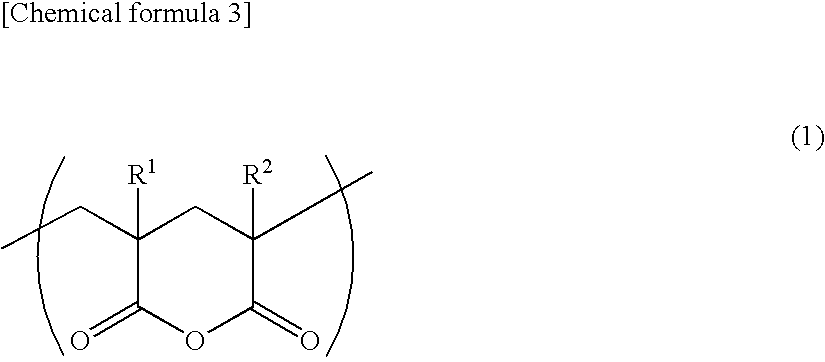

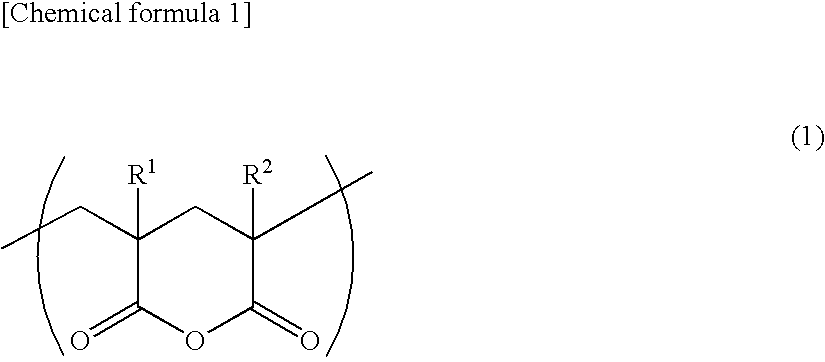

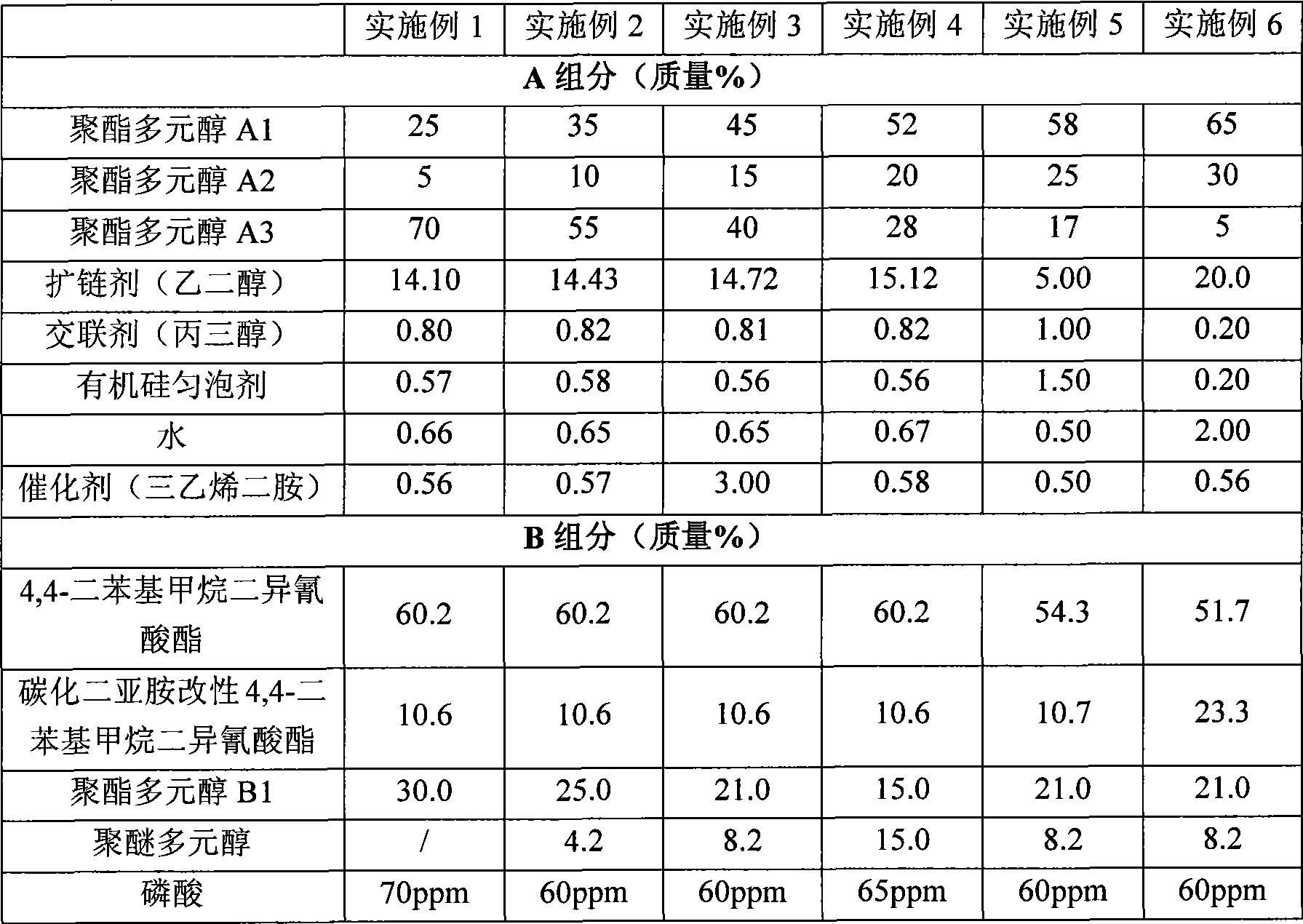

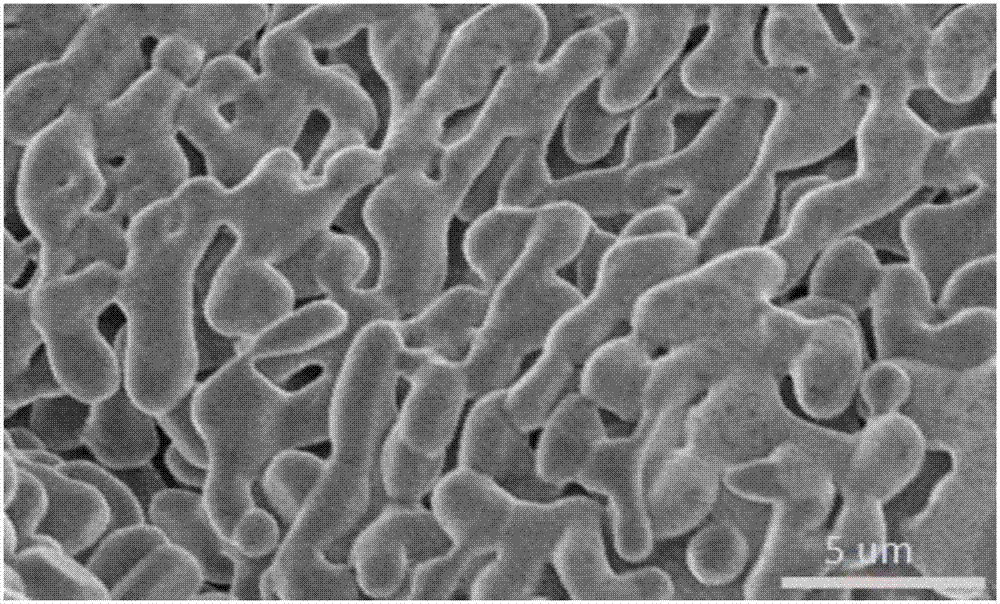

Low density high hardness polyurethane micropore elastomer and preparation thereof

The invention discloses a low-density high-hardness microporous polyurethane elastomer and a preparation method thereof; polyester polyol A1, polyester polyol A2, polyester polyol A3, Diol chain extender, crosslinking agent, tertiary amine or organic metal catalysts, organosilicone foam homogenizing agent and water foaming agent are placed in a reactor and then mixed for obtaining a component A; isocyanate, polyester polyol B1, polyether polyol, and side effect inhibitor are placed in the reactor and then reacted for preparing a component B; later, the two components are completely mixed and injected into a mold for being reacted and molded so as to obtain the microporous polyurethane elastomer. The microporous polyurethane elastomer which is produced by the method has the advantages of low density, high hardness, low product shrinkage rate and the like, and can be widely used in production of sole materials such as middle sole, large sole, and the like.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

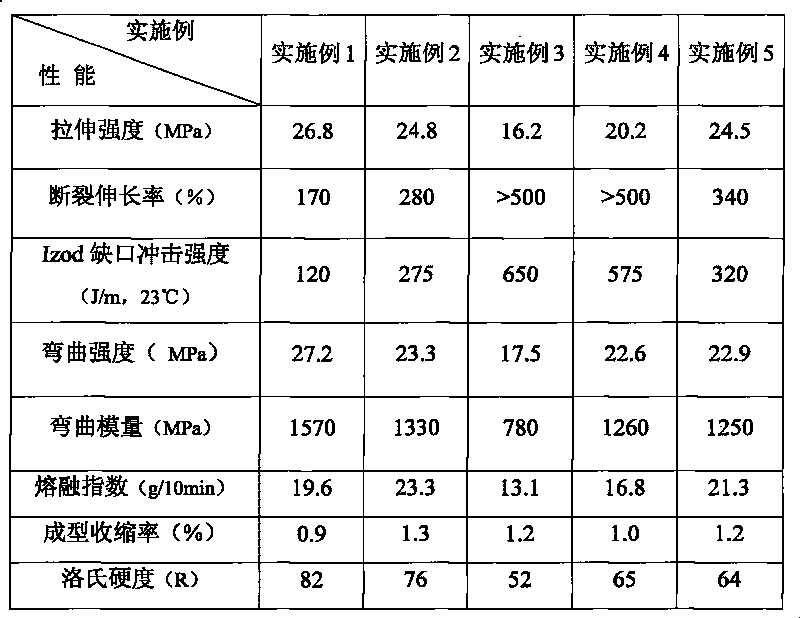

Modified polypropylene material for thin-wall bumper and preparation method thereof

The invention discloses a modified polypropylene material applicable for a thin-wall bumper and a preparation method thereof. The material comprises the following components in parts by weight: 50 to 90 parts of polypropylene, 5 to 20 parts of toughening agent, 10 to 15 parts of inorganic mineral, 5 to 15 parts of mineral fiber, 1 to 5 parts of compatibilizer and 1 to 5 parts of processing aid. The product of the invention has the characteristics of high fluidity, high toughness and high rigidity, simultaneously has the characteristics of high surface activity, low shrinkage, low linear thermal expansion and shrinkage rate, heat resistance and low temperature resistance and efficiently satisfies the requirement of a vehicle bumper material.

Owner:NANJING JULONG SCI&TECH CO LTD

Trilaminar co-extrusion thermal contraction resin film, manufacturing method and application method thereof

InactiveCN101318392AReduce pollutionReduce packaging costsWrappers shrinkageSynthetic resin layered productsThermal contractionPuncturing

The invention discloses a three-layer coextrusion heat shrinkage resin film, a production method and an application method. The-three layer coextrusion heat shrinkage resin film is produced by taking PE(LDPE, HPPE, LLDPE, mPE), EVA, PP, PA and EVOH resins as the main materials which are matched with a functional master batch and adopting a production method of one-step huffing. The largest transverse and longitudinal shrinking rates of the product can reach 60 percent and 85 percent; the largest shrinking force of the product can reach 2.0N / cm. The shrinking rate and the shrinking force of the product can be controlled and adjusted by controlling various technical parameters to lead a package to be firm and endurable. The packaged objects are pertinently led to reach the anti-rust, anti static, illumination-resistance, anti-aging, anti-puncturing, anti-low-temperature, anti-isolation, anti-bacteria and anti-degradation effects and the like by adjusting the material composition and mixture ratio of each layer. The three-layer coextrusion heat shrinkage resin film is used for replacing the traditional paper box wrappage to reduce the packaging cost. The mechanical properties are good, the pertinence is strong, the materials are saved; when the three-layer coextrusion heat shrinkage resin film is used, the shrinking temperature is low, the power is saved and the packaging cost is saved, thus effectively reducing the production cost and having extremely high application value.

Owner:大连华诺塑胶科技有限公司

Three-dimensional printing molding preparation method for porous ceramic for filtration

InactiveCN107098717ALoose connectionHigh precisionAdditive manufacturing apparatusDispersed particle filtrationShrinkage rateFiltration

The invention discloses a three-dimensional printing molding preparation method for a porous ceramic for filtration. The method comprises the following steps: S1 preparing a ceramic material for printing in a three-dimensional printer; S2 printing a porous ceramic green body through the three-dimensional printer by using the prepared printing ceramic material; and S3; conducting drying, rubber discharging and sintering on the printed porous ceramic green body to obtain a porous ceramic with a specific shape structure. The three-dimensional printing molding preparation method has the beneficial effects that ceramic particles are loose in connection, the density of the ceramic green body is low, the shrinkage rate after sintering is large, and the defects such as deformation and cracking are easy to occur, and the mechanical properties of the prepared products are lower; and a generated loose porous structure has larger pore size in pores, and the pore size and porosity are difficult to control through a molding process parameter. The ceramic material for printing according to the invention fully mixes solid powder with liquid additive, the ceramic particles are connected closely and the components are uniform, and the printed ceramic green body has high precision and good mechanical performance.

Owner:WUHAN UNIV OF TECH

Manufacturing method of high-strength, high-modulus and low-shrinkage polyester industrial yarn

ActiveCN102797054AGuaranteed positionAvoid stretching unevenlyFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses a manufacturing method of a high-strength, high-modulus and low-shrinkage polyester industrial yarn. The manufacturing method comprises the processes of preparation of a highly viscous melt polyester raw material, metering, spinning, cooling, oil applying, drawing, heat shaping and winding formation; the cooling comprises slow cooling, precooling, cooling in an air free zone and air blast cooling in sequence; the precooling part uses a driven hollow-out successive annular strip. Through the introduction of a precooling device, irregularity caused by tow shaking due to move-down of a curing point of a fiber is reduced, the linear density deviation is controlled within a lower range, and orientation and crystallization of an as-spun fiber are reduced, so that the high-strength, high-modulus and low-shrinkage polyester industrial yarn is obtained; and the high-strength, high-modulus and low-shrinkage polyester industrial yarn has the advantages of high breaking tenacity, high initial modulus, low linear density deviation, low breaking elongation and lower dry-heat shrinkage rate and can be used for preferably satisfying requirements on application.

Owner:JIANGSU HENGLI CHEM FIBER

Polypropylene composite material for 3D (Three Dimensional) printing and preparation method thereof

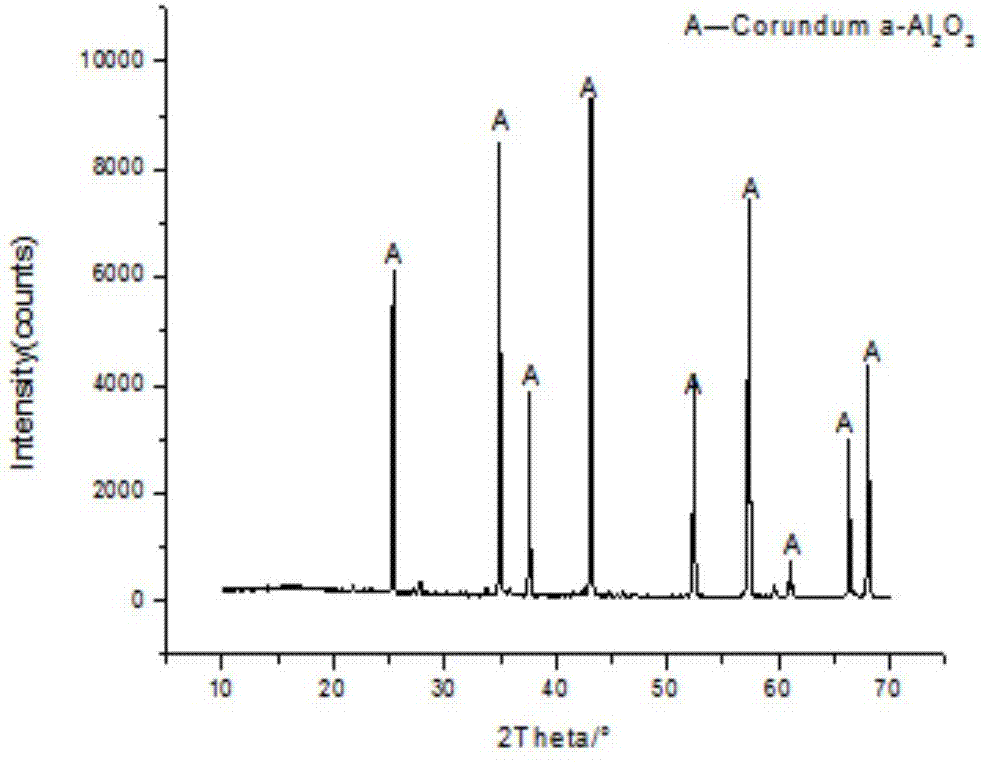

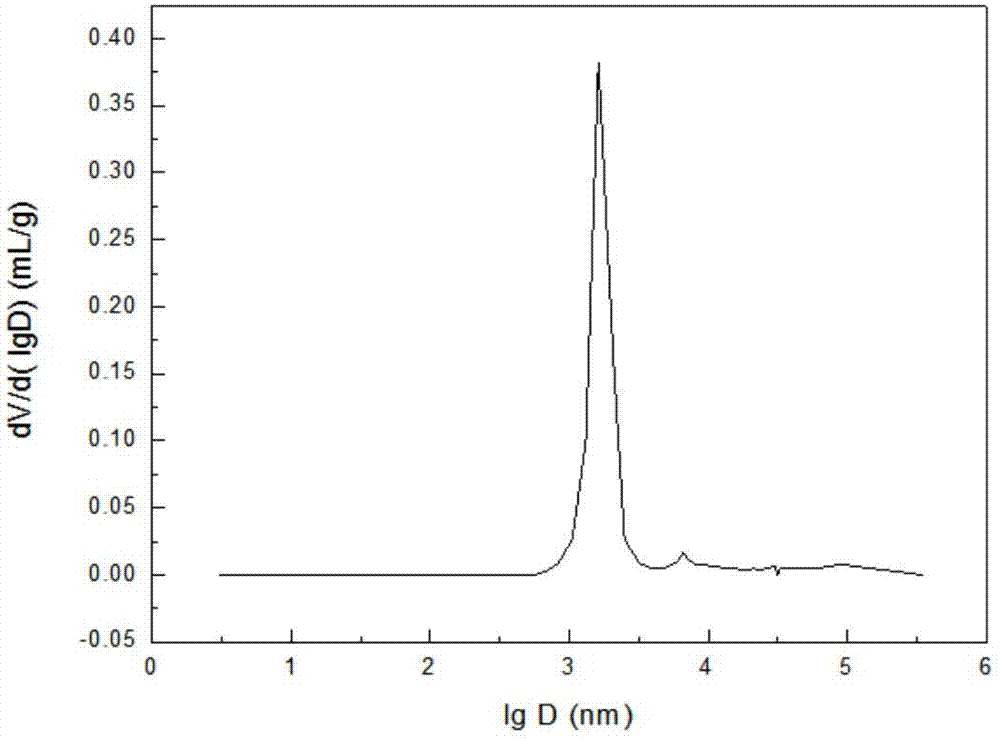

The invention discloses a polypropylene composite material for 3D (Three Dimensional) printing and a preparation method thereof. The polypropylene composite material is composed of following raw materials in percentage by weight: 70%-98% of polypropylene, 1%-20% of a transparent toughening agent, 0-10% of inorganic fillers, 0.1%-0.5% of a nucleating agent, 0.2%-2% of a stabilizing agent and 0-5% of other additives. The polypropylene composite material has the advantages that 1 a propylene-based elastic body is used as the toughening agent for processing polypropylene so that the roughness of materials can be improved and the shrinkage rate of the materials is reduced; the transparency is not greatly influenced; a beta nucleating agent is used for accelerating a crystallization speed; the molding speed is improved, the size of a spherical crystal is thinned and the transparency is improved; the density of a crystal region is reduced and the shrinkage rate is reduced; super-pure and superfine talcum powder or calcium sulfate crystal whiskers with a high mesh number and the like are adopted so that the shrinkage rate is reduced and the good transparency is kept. The polypropylene composite material for the 3D printing has the advantages that 1 the comprehensive performance is good; 2 a manner of wholly feeding from a main feeding opening is adopted so that the dispersion effects of the toughening agent, the talcum powder and the like are improved, and the performance of the composite material is further improved.

Owner:CHONGQNG PRET NEW MATERIAL +2

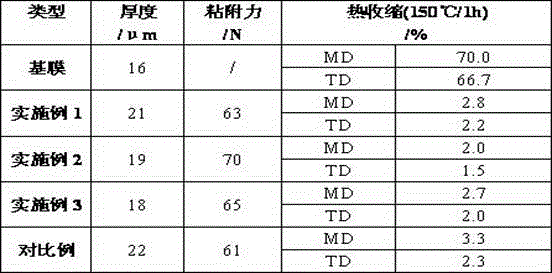

High-temperature resistant multi-layer separator composite lithium ion battery separator and preparation method thereof

The invention relates to a high-temperature resistant multi-layer separator composite lithium ion battery separator, and belongs to the technical field of a battery separator. The high-temperature resistant multi-layer separator composite lithium ion battery separator comprises the battery separator, the composite lithium ion battery separator is of a lamination structure comprising at least two layers of battery separators, adjacent battery separator layers are pasted and fixed by coating paste, and the coating paste comprises based on weight by mass: 20-40% of coating layer paste, 3-6% of adhesive, 0.2-0.5% of dispersing agent, 0.2-0.5% of gelatinzing agent, 0.05-0.2% of plasticizer, 0.05-0.2% of aging resistant agent, 0.05-0.2% of cross-linking agent, 0.1-0.5% of thickening agent and 0.3-1% of photoinitiator with the balancing being deionized water. The invention provides a preparation method of the high-temperature resistant multi-layer separator composite lithium ion battery separator. The battery separator has relatively high safety of the coating layer separator on a current and can also be resistant to high temperature, the shrinkage rate of the separator under a high-temperature condition is reduced, and the integral lifetime of the battery is prolonged; and moreover, the affinity of the separator and an electrolyte can be improved, the separator can be fully swelled by the electrolyte, and the cycle lifetime of the battery is favorably prolonged.

Owner:HEBEI GELLEC NEW ENERGY MATERIAL SCI&TECHNOLOY CO LTD

A method for manufacturing high-strength, high-modulus, low-shrinkage polyester industrial yarn

ActiveCN102797054BReduce disturbanceReduce the temperatureFilament/thread formingMonocomponent polyesters artificial filamentYarnFiber

The invention discloses a manufacturing method of a high-strength, high-modulus and low-shrinkage polyester industrial yarn. The manufacturing method comprises the processes of preparation of a highly viscous melt polyester raw material, metering, spinning, cooling, oil applying, drawing, heat shaping and winding formation; the cooling comprises slow cooling, precooling, cooling in an air free zone and air blast cooling in sequence; the precooling part uses a driven hollow-out successive annular strip. Through the introduction of a precooling device, irregularity caused by tow shaking due to move-down of a curing point of a fiber is reduced, the linear density deviation is controlled within a lower range, and orientation and crystallization of an as-spun fiber are reduced, so that the high-strength, high-modulus and low-shrinkage polyester industrial yarn is obtained; and the high-strength, high-modulus and low-shrinkage polyester industrial yarn has the advantages of high breaking tenacity, high initial modulus, low linear density deviation, low breaking elongation and lower dry-heat shrinkage rate and can be used for preferably satisfying requirements on application.

Owner:JIANGSU HENGLI CHEM FIBER

High temperature-resistant cellulose fiber base material-containing lithium ion battery diaphragm and preparation method of the same

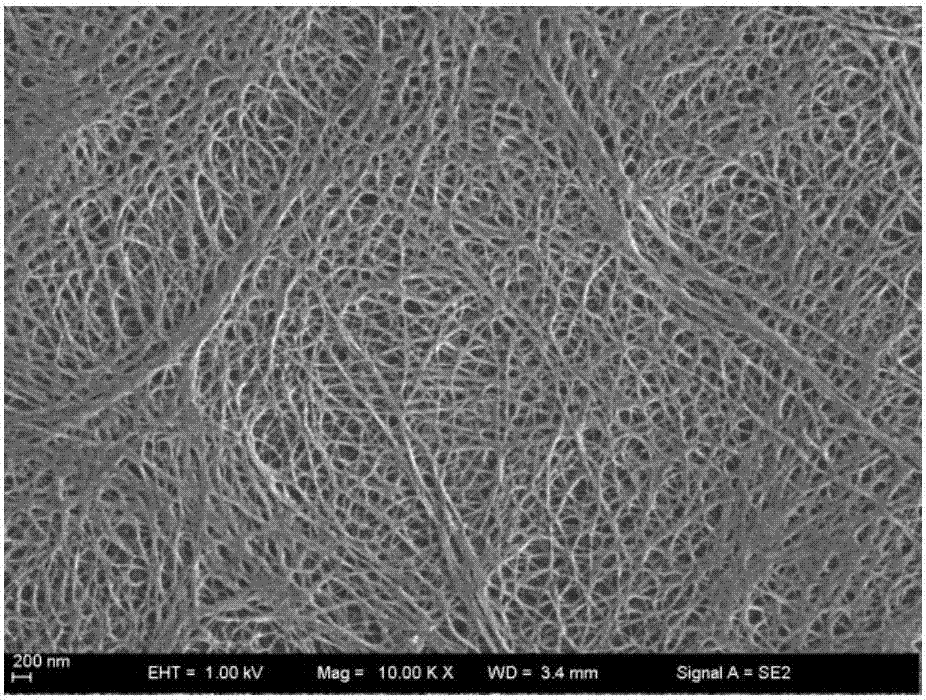

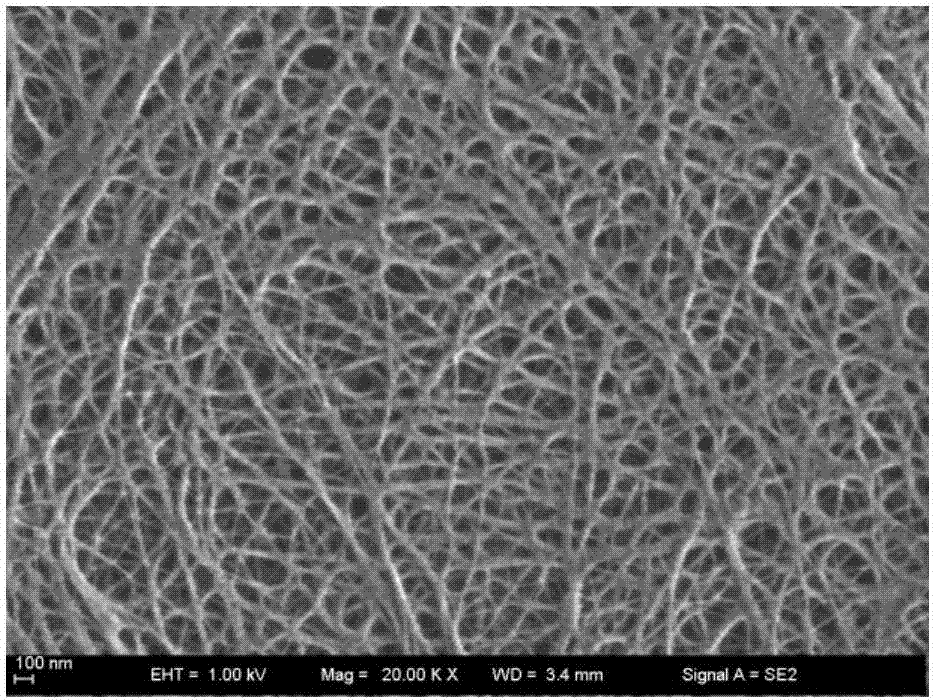

ActiveCN102856522AImprove wettabilityGreat suctionCellulosic plastic layered productsCell component detailsEmulsionMicrometer

The invention discloses a high temperature-resistant cellulose fiber base material-containing lithium ion battery diaphragm and a preparation method of the same. The battery diaphragm is characterized in that the thickness is 20-40 micrometers, the poriness is 40-60%, the gas permeability is 15-30sec / 100cc; and the diaphragm comprises the cellulose fiber base material, a porous bonding layer and an inorganic coating layer. The preparation method comprises the following steps of: mechanically foaming the waterborne polyurethane emulsion, conveying the foam glue to a foam bath device, dragging and immersing the cellulose fiber base material in the foam bath for gluing, and forming the porous bonding layer on the surface of the base material by the foam glue; spreading an inorganic coating on the surfaces of the cellulose fiber base material and the porous bonding layer to form the inorganic coating layer compositely; and drying. The battery diaphragm provided by the invention has better solution absorption and solution preserving capability to the electrolyte; the battery diaphragm cannot shrink, and the hot-shrinkage rates in longitudinal direction and transverse direction both are less than 2%; and the battery diaphragm is relatively high in ion penetrability, relatively lower in resistance, excellent in mechanical performance and steady in electrochemical performance, and can prevent battery short circuit and dendritic crystal diapirism.

Owner:CHINA HAISUM ENG

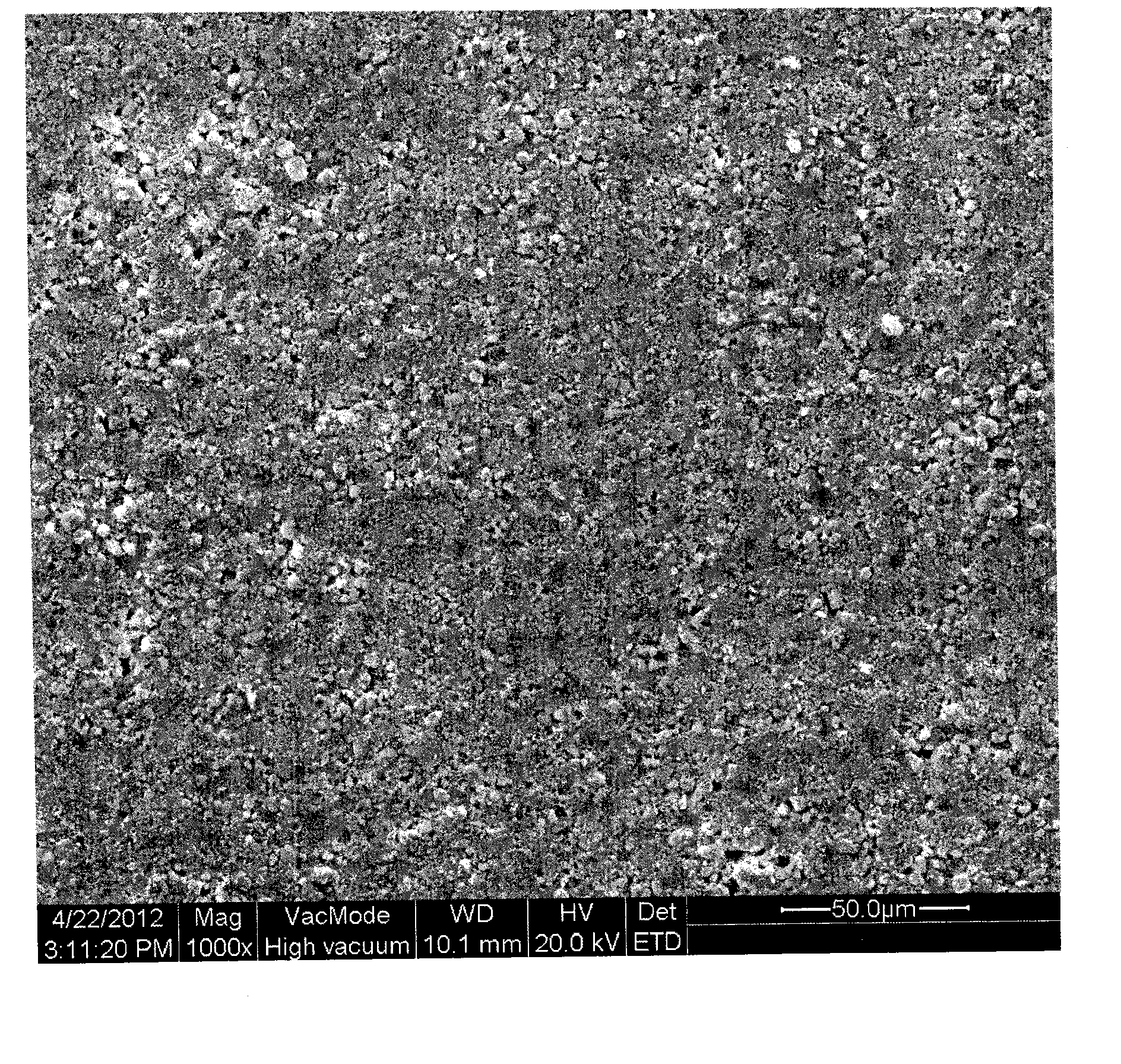

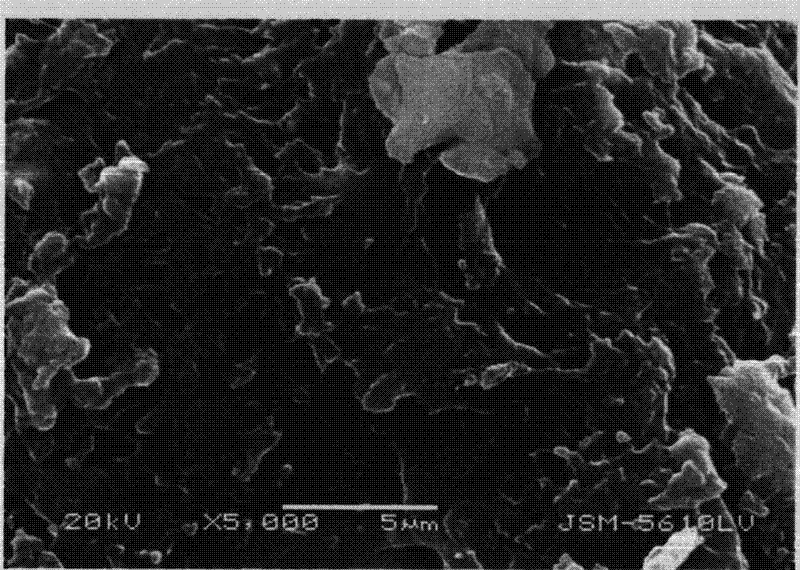

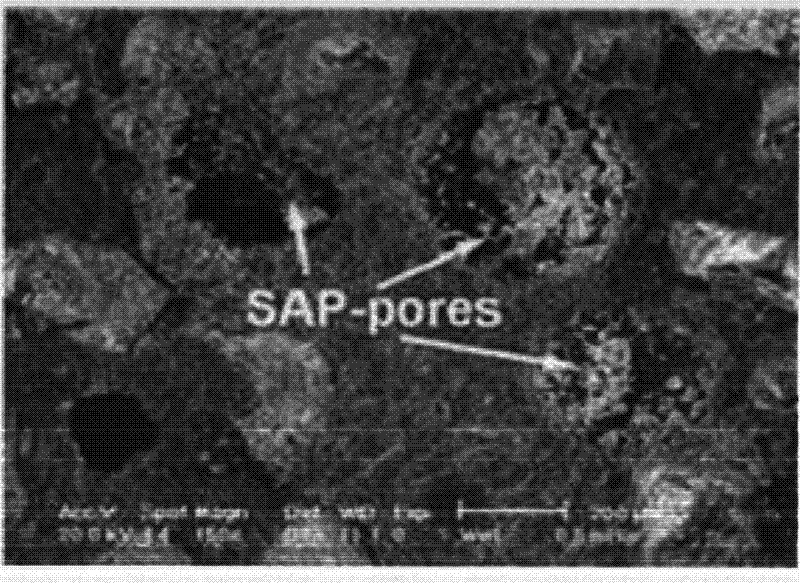

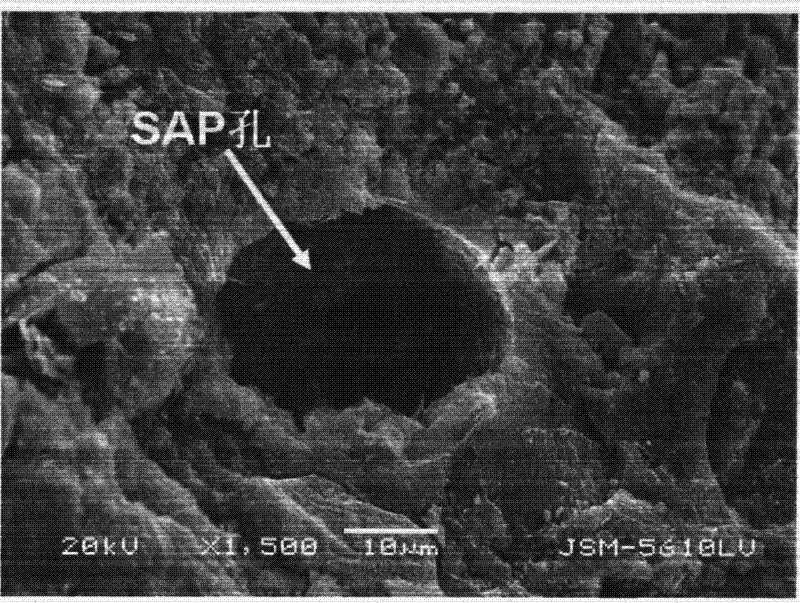

Preparation method for water-preserving and salt-tolerant alkaline concrete internal curing agent

The present invention discloses a preparation method for a water-preserving and salt-tolerant alkaline concrete internal curing agent. According to the method, plant starch, inorganic powder with a layered structure, an anionic monomer, a non-ionic monomer and water are adopted as main raw materials; under effects of an initiator, a cross-linking agent and a certain temperature, treatments of dissolving, reacting, filtering, washing, drying and crushing are performed to obtain the internal curing agent. The internal curing agent of the present invention has the following advantages that: the internal curing agent of the present invention provides the stronger deionized water absorbency than the existing internal curing agent, wherein the deionized water absorbency is increased by 200-500 times; the saline solution absorbency and the alkaline solution absorbency are 35-55% of the deionized water absorbency; the water-preserving rate of the internal curing agent of the present invention is 55-65% after the internal curing agent absorbs the alkaline solution; with adopting the low mixing amount of 0.05-0.5% of the internal curing agent, the strength of the silica fume-doped C60-C100 high-performance concretes is not reduced while the 7-day autogenous shrinkage rates of the concretes are reduced by 65-85%; the internal curing agent of the present invention is applicable for the high strength and early strength concrete pavement, steel pipe concrete under the closed environment, self-compacting concrete and other engineering fields, wherein the fields adopt the design with a low water-cement ratio and a high cementing material content, and adopt a large amount of high activity mineral admixtures.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

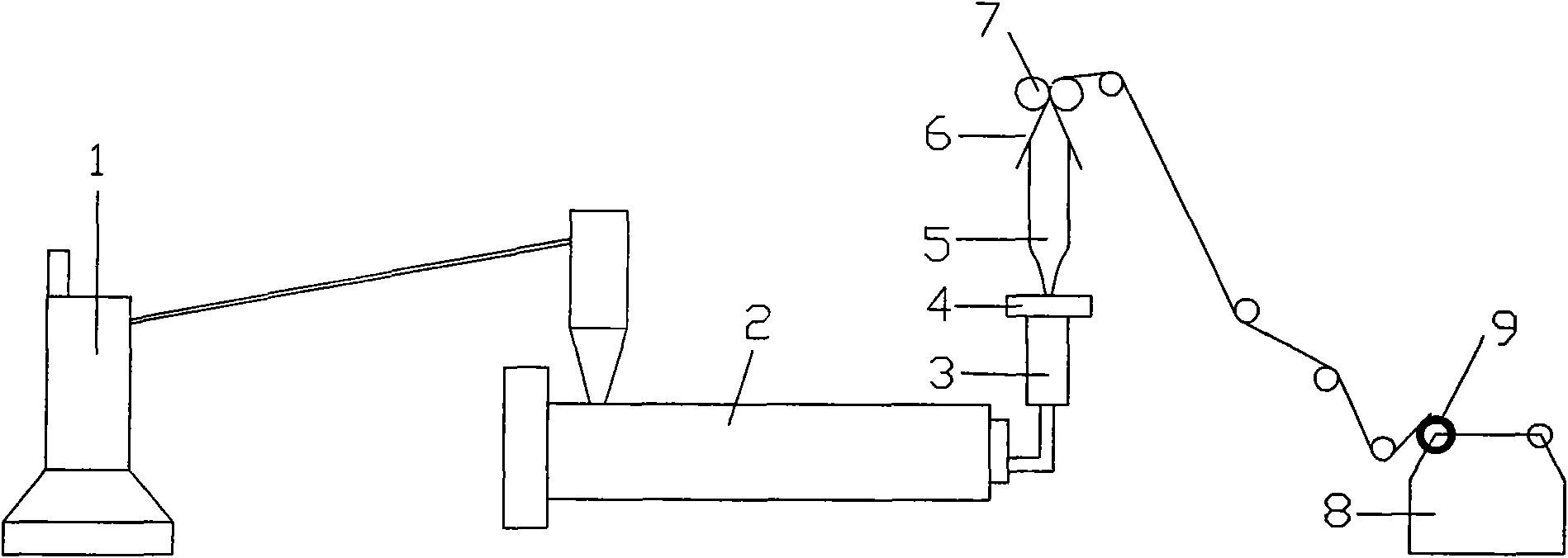

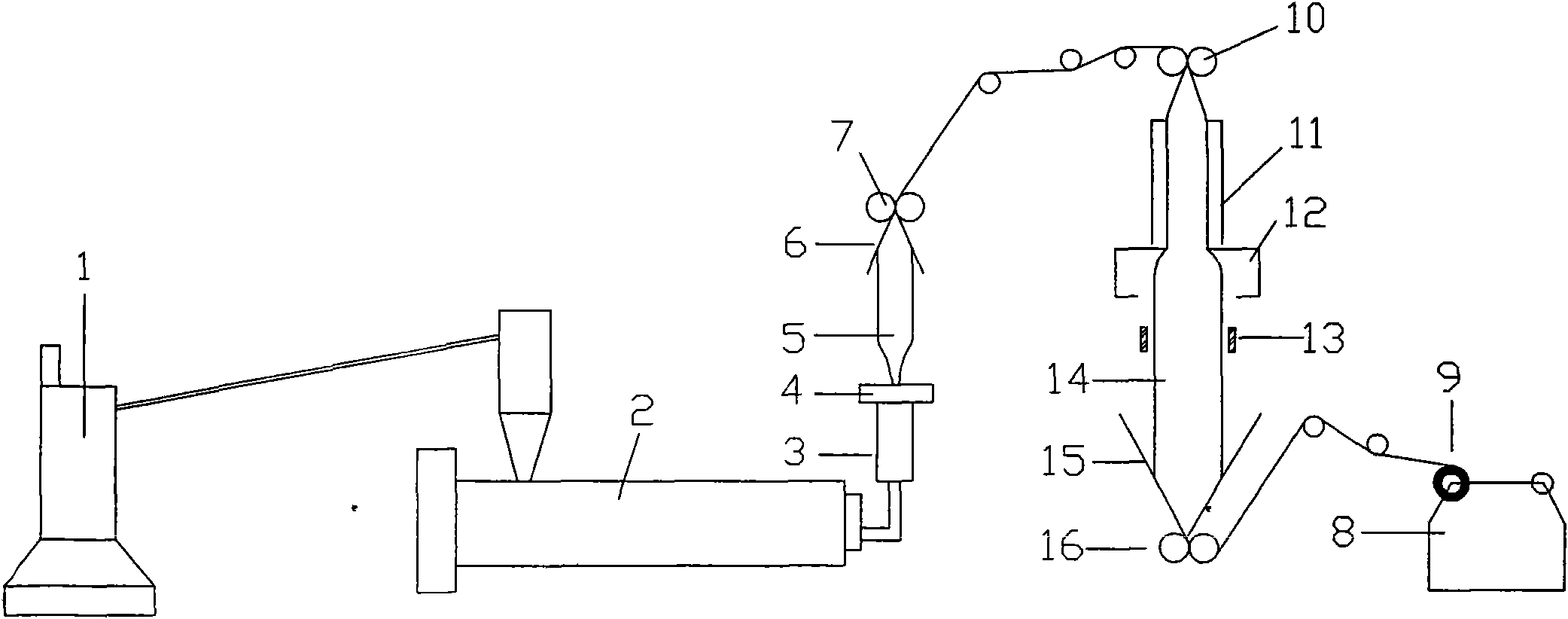

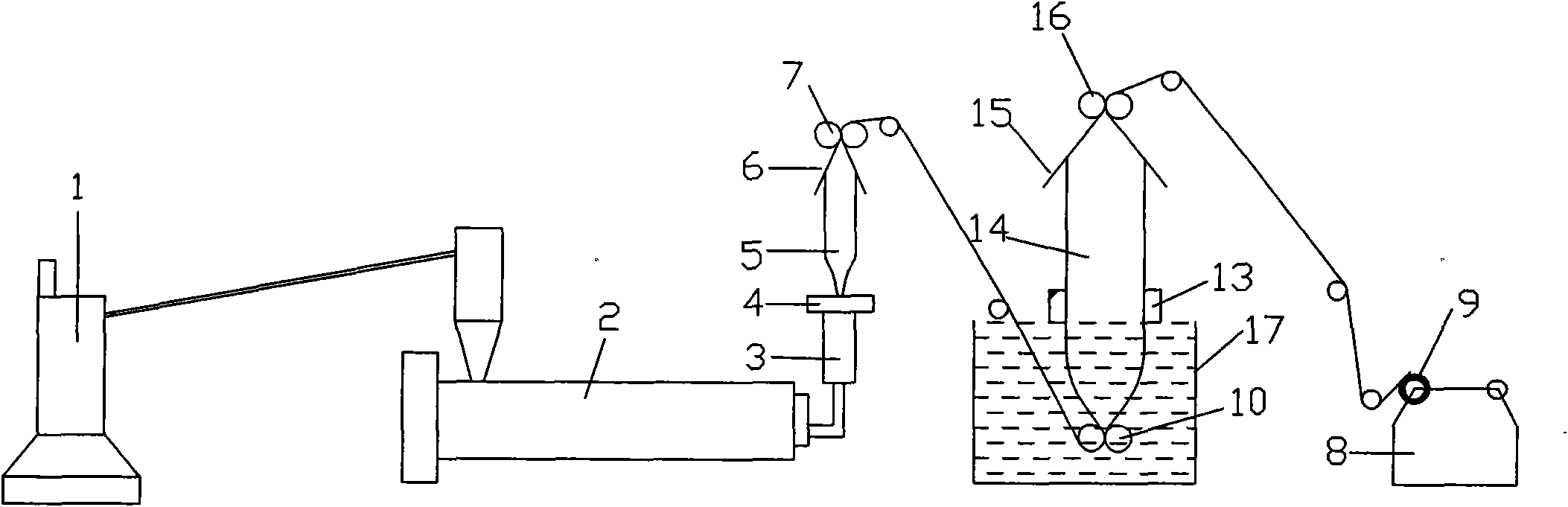

Terylene half speed blended spinning-type ammonia-substituted fiber blended spinning method and its apparatus

InactiveCN101265627AMeet the target requirementsStable Intrinsic IndexFilament/thread formingHeating/cooling textile fabricsYarnSingle stage

The invention designs a blending method and a device for terylene medium-speed blended ammoniac fibers, and includes section transporting and screening, section drying, screw extrusion, melting and spinning, and air blast cooling. The invention is characterized by the following steps: respectively enter POY spinning and FDY spinning after cooling, entering a nozzle for oiling after POY spinning, and then entering a pre-network; entering a tanker for oiling after FDY spinning, entering the pre-network, entering hot-rolling and drafting, enabling POY filaments and FDY filaments to enter into a guiding flute-type draw-off godet for combining and compounding, entering a go-between after compounding, hot-rolling and sizing, and winding and forming after entering a primary network. The blending method for the terylene medium-speed blended ammoniac fibers can produce FDY and POY composite network yarn by the single-stage process, the combined network yarn ITY product produced by the method has stable inner index and quality, little influencing factor, uniform waster-water shrinkage rate, stable chromaticity, and great economic benefit.

Owner:TONGKUN GRP

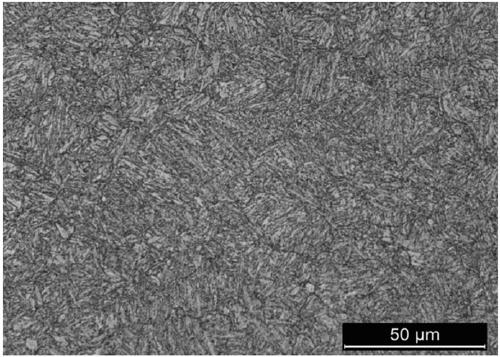

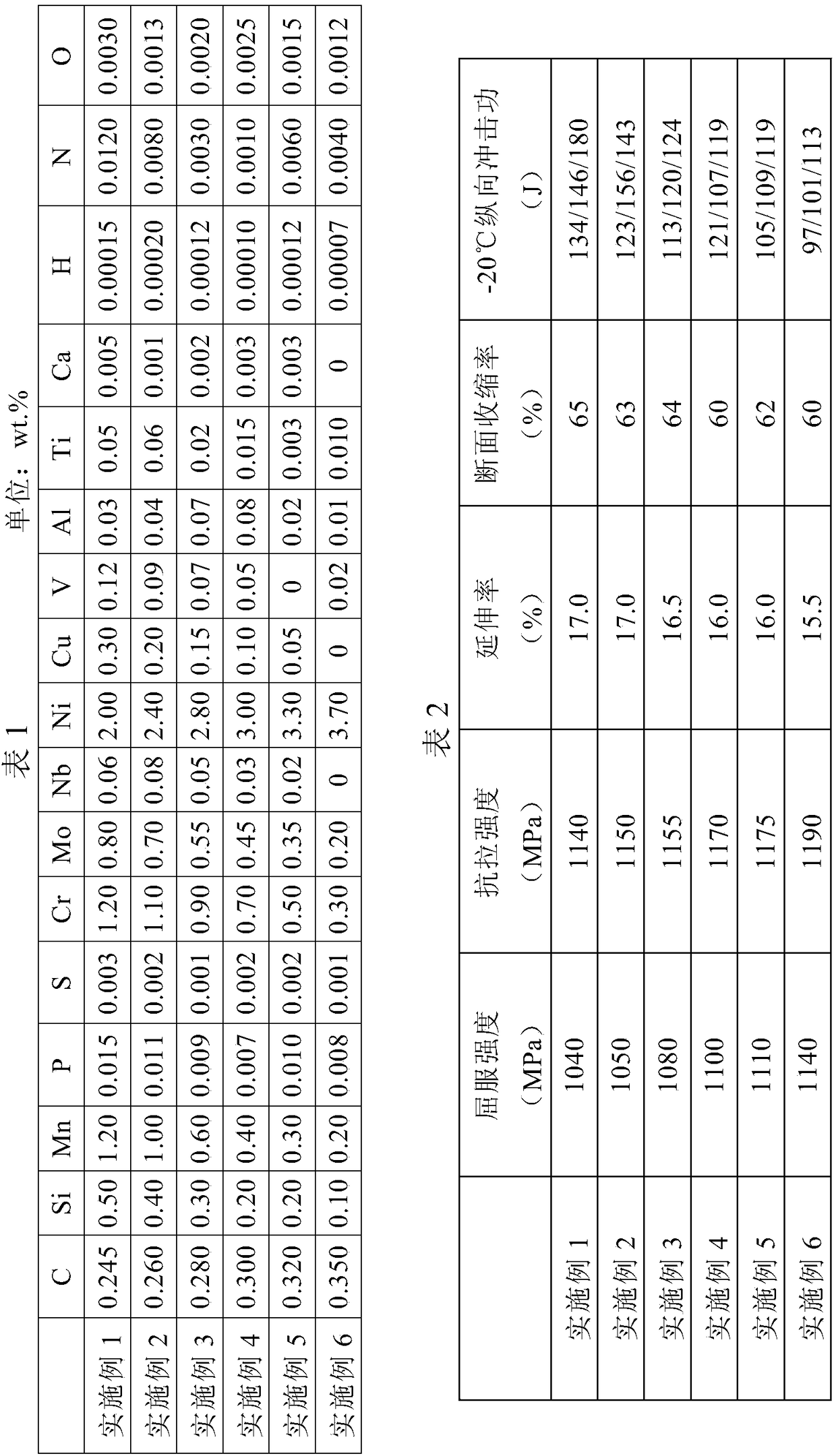

Ultrahigh tough steel with tensile strength of 1100 Mpa and manufacturing method thereof

InactiveCN109136737AImprove low temperature impact toughnessImprove tensile propertiesShrinkage rateUltimate tensile strength

The invention discloses ultrahigh tough steel with tensile strength of 1100 Mpa and a manufacturing method thereof. Chemical components of the tough steel comprises, by weight, 0.245-0.350% of C, 0.10-0.50% of Si, 0.20-1.20% of Mn, P less than or equal to 0.015%, S less than or equal to 0.003%, 0.30-1.20% of Cr, 0.20-0.80% of Mo, 2.00-3.70% of Ni, 0-0.30% of Cu, 0-0.08% of Nb, 0-0.12% of V, 0.01-0.08% of Al, 0.003-0.06% of Ti, Ca less than or equal to 0.005%, H less than or equal to 0.002%, N less than or equal to 0.0120%, O less than or equal to 0.0030%, Fe and inevitable impurities. The preparation method adopts quenching plus tempering heat treatment, and tempered martensites plus tempered bainites and residual austenite tissue are obtained. The yield strength of steel is greater than or equal to 900 Mpa, the tensile strength is greater than or equal to 1100 Mpa, the charpy impact energy Akv (-20 DEG C) is greater than or equal to 70 J, the elongation rate is greater than or equal to 15%, the shrinkage rate of a fracture surface is greater than or equal to 50%, good strength, low-temperature toughness and plasticity are achieved, and the ultrahigh tough steel can be used for manufacturing high-performance ocean platform mooring cables of R6 grade and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

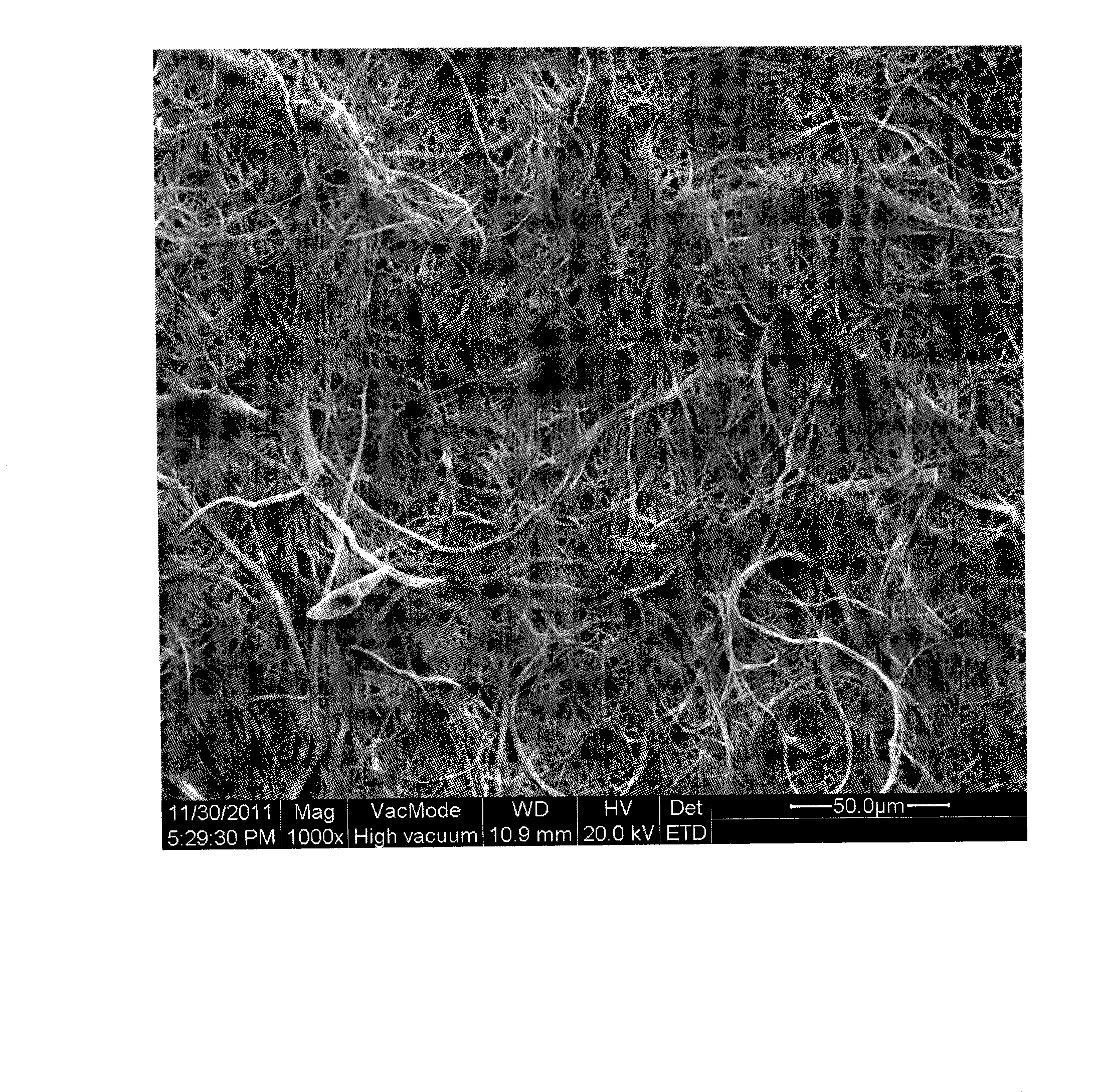

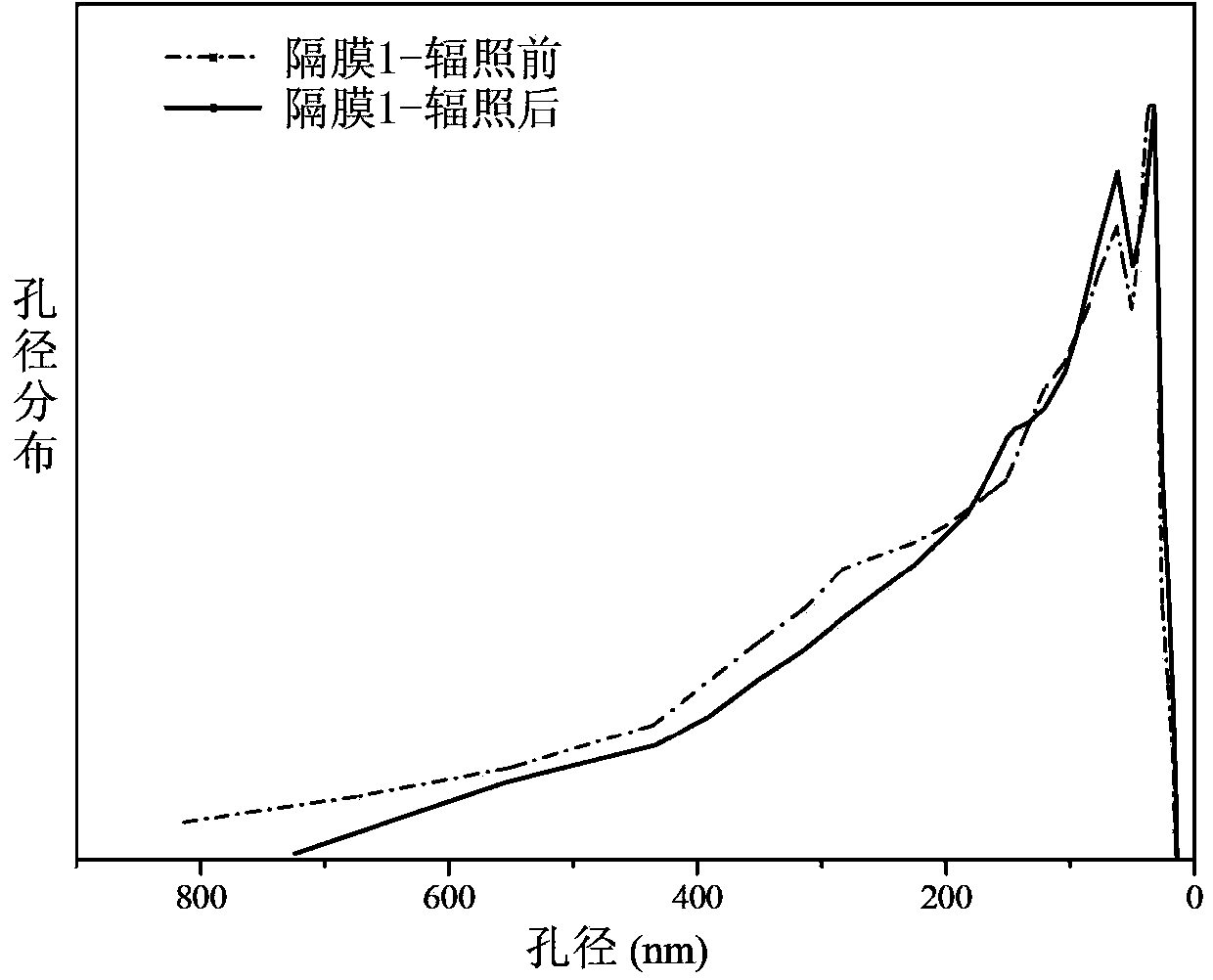

Irradiation cross-linking lithium-ion battery diaphragm and preparation method thereof

ActiveCN103421208AImprove securityLow closed cell temperatureCell component detailsCross-linkPolymer science

The invention discloses a preparation method of an irradiation cross-linking polyethylene porous diaphragm. According to the method, the polyethylene porous diaphragm is soaked in and adsorbs a volatile solvent containing initiator and cross-linking agent to lead initiator and cross-linking agent into the surface and the interior of the polyethylene porous diaphragm, and is then treated with irradiation cross-linking underwater or under the protection of inert gas, and a locally cross-linked diaphragm is obtained by controlling the cross-linking condition. The irradiation cross-linking lithium-ion battery diaphragm has the advantages that the tensile strength and the hydrophily are greatly improved; the high-temperature hot-shrinkage rate is greatly reduced; the defect of low membrane rupture temperature is overcome; the membrane rupture temperature is greatly raised while the normal hole closing of the diaphragm is guaranteed; the hole closing temperature of the diaphragm is 120 to 140 DEG C; the membrane rupture temperature is raised to be higher than 160 DEG C.

Owner:ZHEJIANG UNIV +2

Multi-hole polyester fiber DTY (draw textured yarn) and preparation method thereof

ActiveCN106283253AIncreased access to polyester interiorImprove cooling effectSpinnerette packsMonocomponent copolyesters artificial filamentFiberYarn

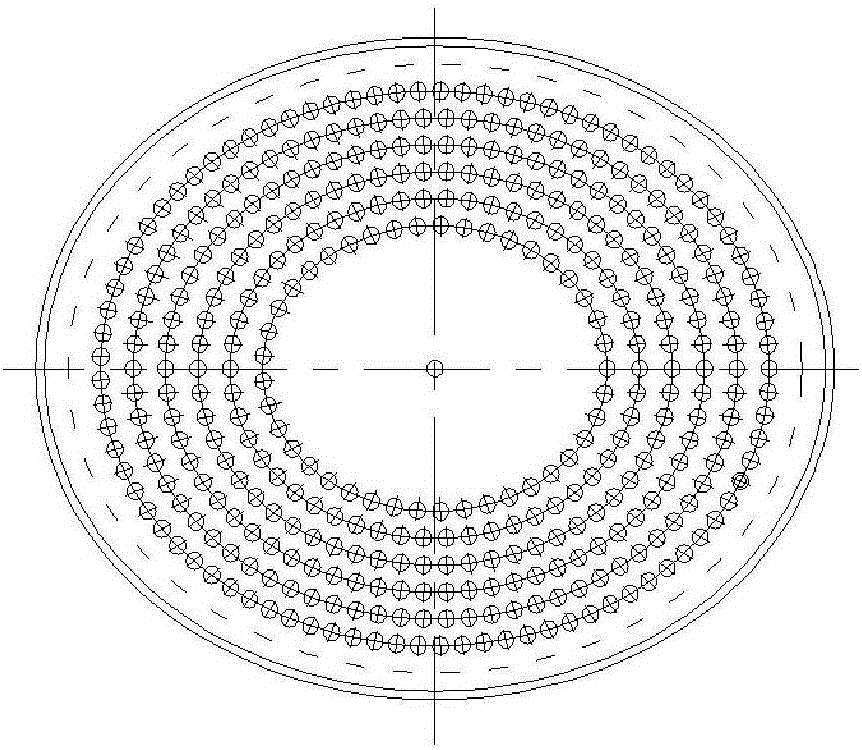

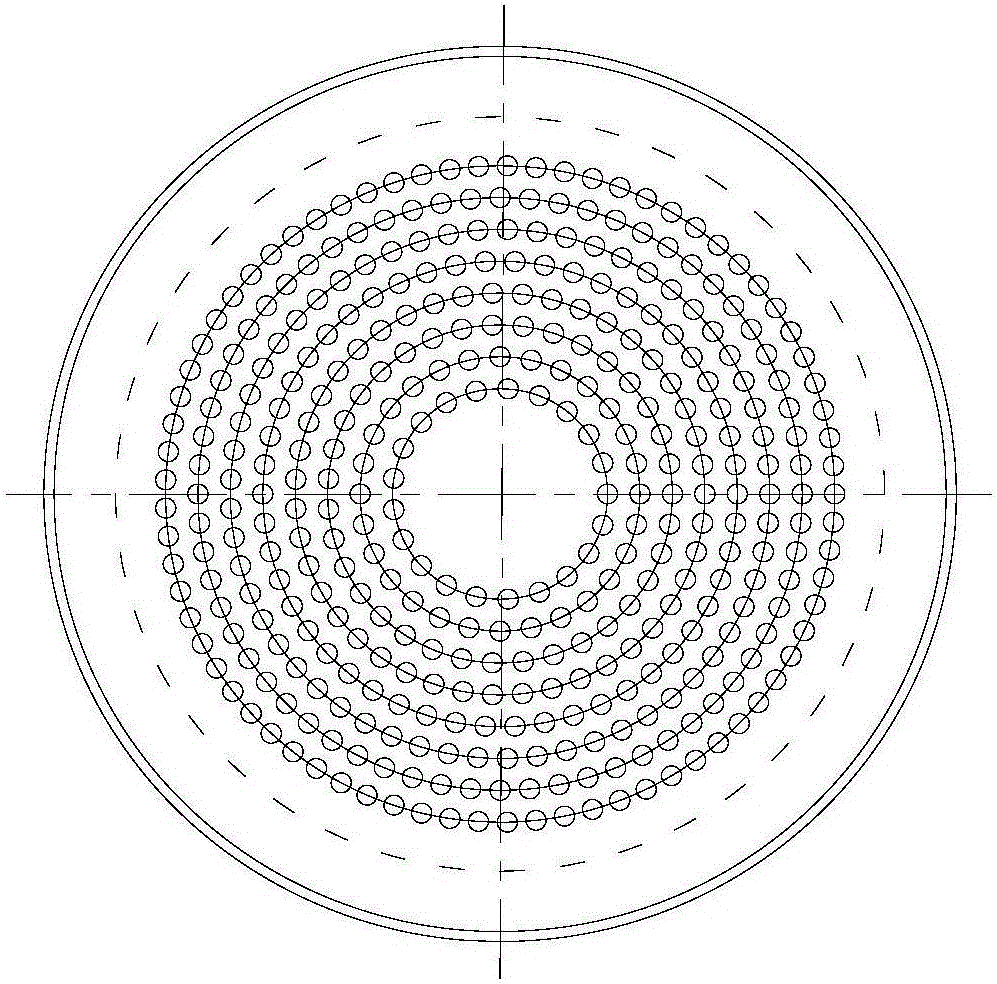

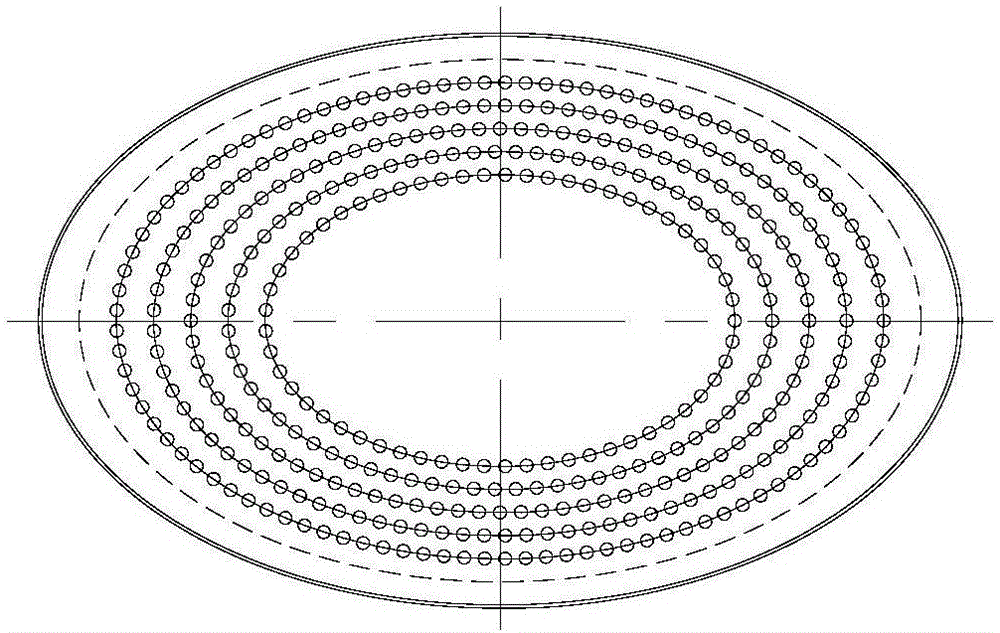

The invention relates to a multi-hole polyester fiber DTY (draw textured yarn) and a preparation method thereof. According to the preparation method, modified polyester is spun to prepare the multi-hole polyester fiber DTY by the aid of a multi-hole spinneret plate; spinneret holes in the multi-hole spinneret plate are elliptically arrayed, namely, the hole centers of the spinneret holes are positioned on concentric ellipses, the concentric ellipses are series ellipses, long axes of the all ellipses are collinear, short axes of the all ellipses are collinear, the modified polyester is used for preparing a POY (polyester pre-oriented yarn) and then further processed to obtain the multi-hole polyester fiber DTY. A preparation method of the modified polyester includes the steps: performing reaction for terephthalic acid and ethylene glycol to prepare terephthalic acid ethylene glycol ester; adding the terephthalic acid and dihydric alcohol with branching chains, and performing reaction for mixture to prepare terephthalic acid dihydric alcohol ester; continuing to react to obtain the modified polyester. According to the method, prepared fibers are excellent in performance, the deviation ratio of linear density of the DTY is smaller than or equal to 2.0%, a breaking strength CV (variation coefficient) value is smaller than or equal to 4.0%, a breaking elongation CV value is smaller than or equal to 8.0%, and a CV value of crimping shrinkage rate is smaller than or equal to 8.0%.

Owner:JIANGSU HENGLI CHEM FIBER

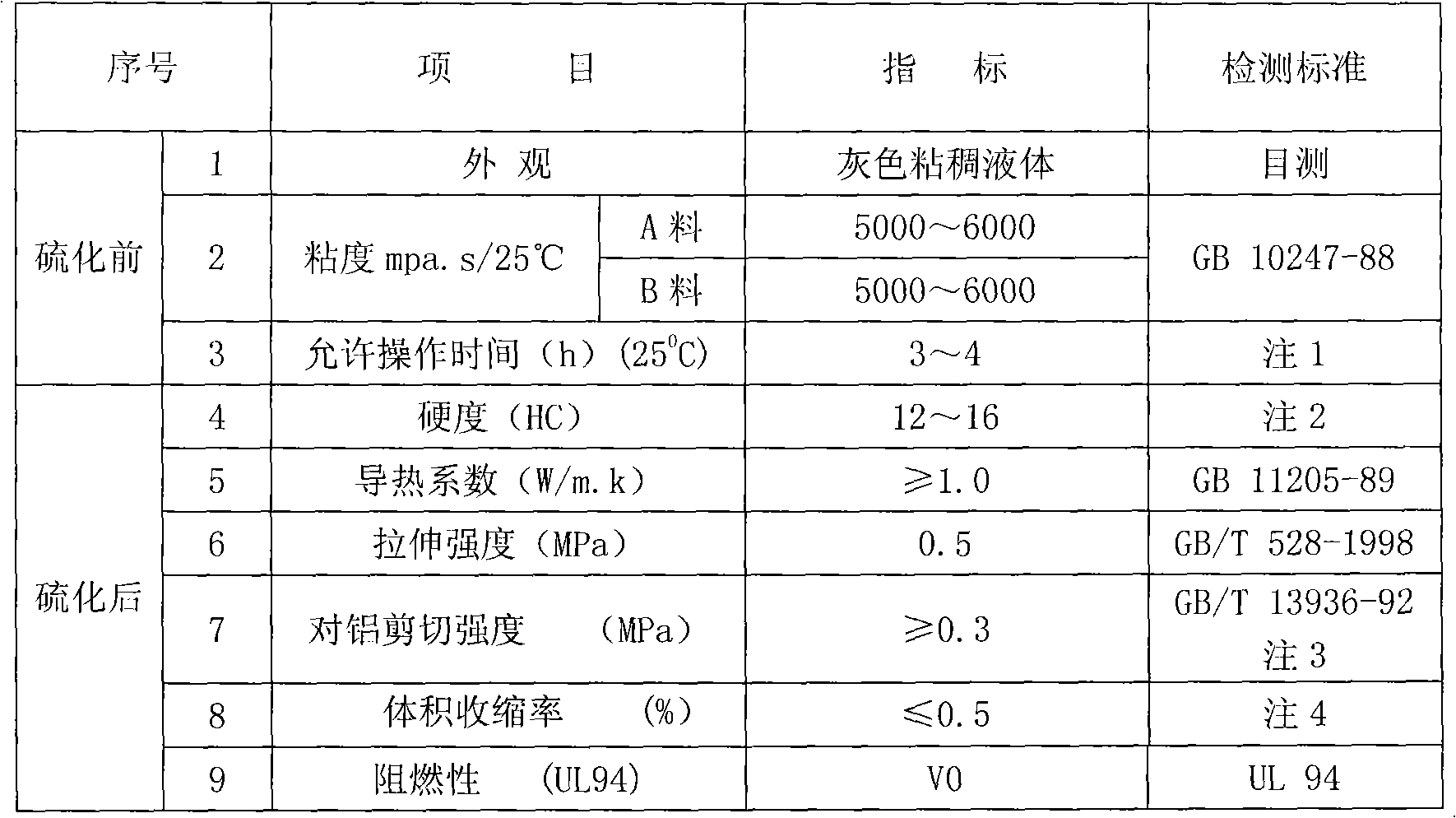

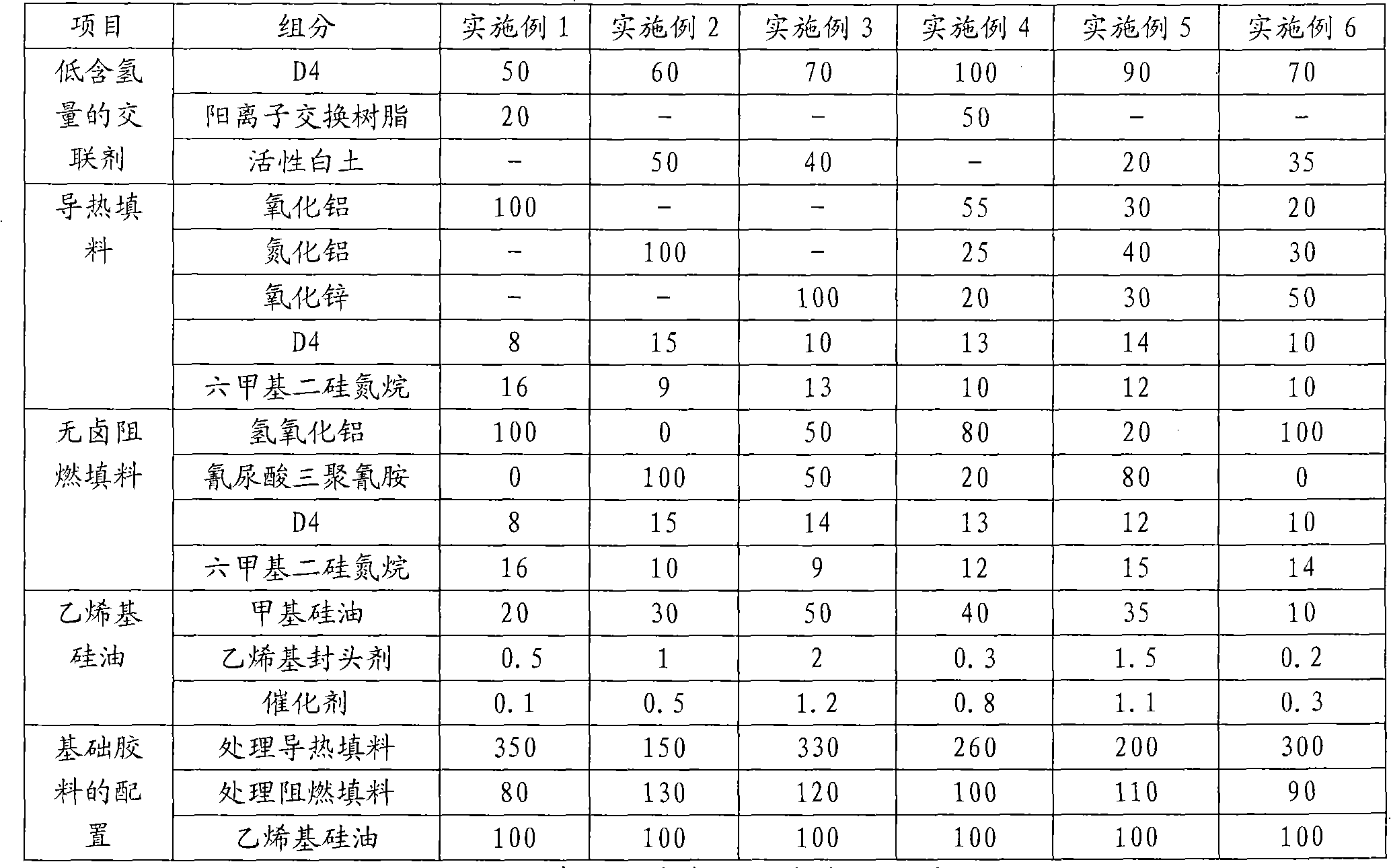

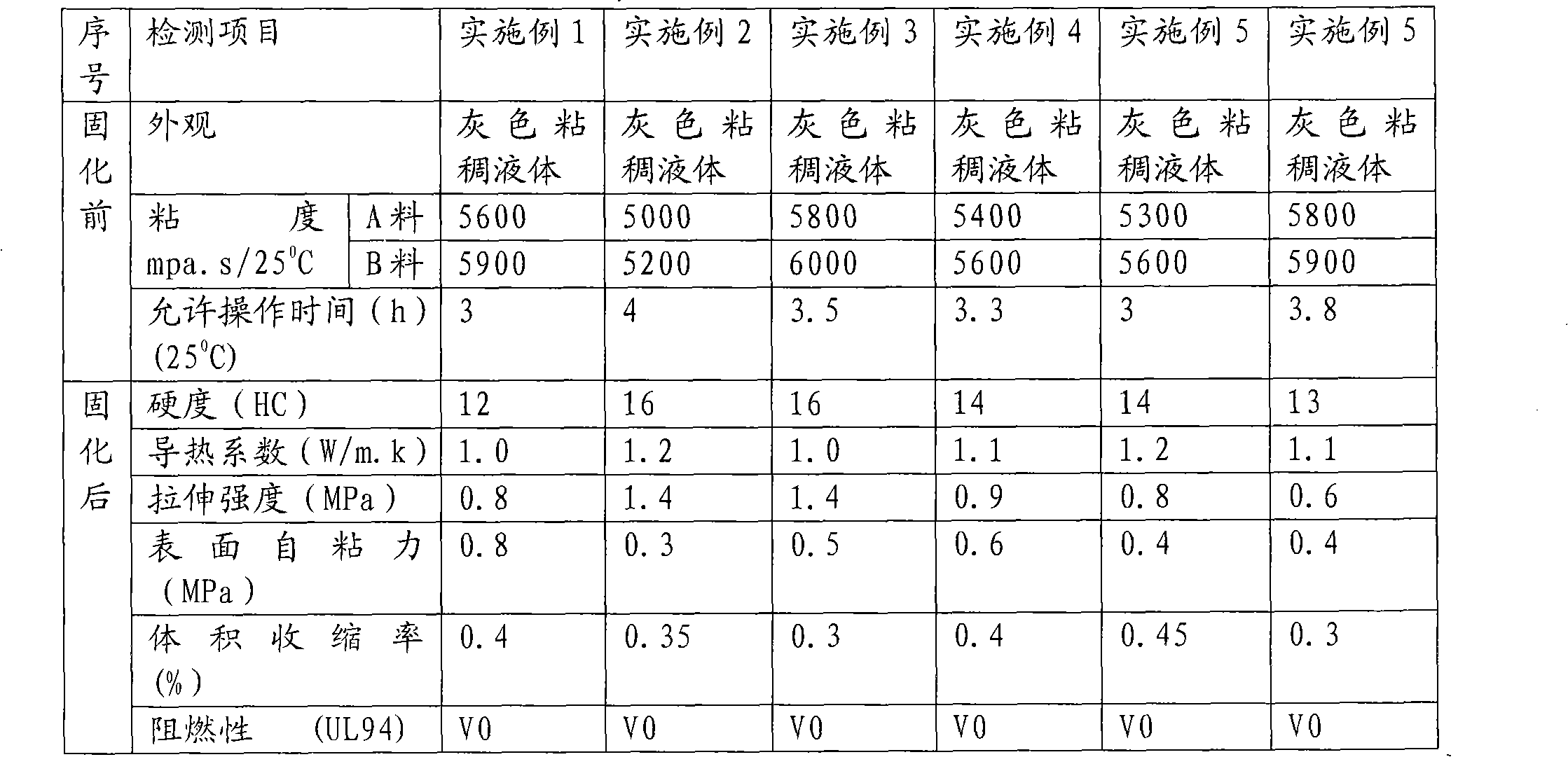

Double-component addition self-adhesive silicon rubber

The invention relates to a silicon rubber used for insulation protection of electronic products, in particular to a double-component addition self-adhesive silicon rubber. The double-component addition self-adhesive silicon rubber of the invention comprises material A and material B, and the mass ratio of the material A to the material B is 1:1, wherein material A is composed of 100 parts of basicrubber and 2-2.8 parts of cross linking agent containing low content of hydrogen; and material B is composed of 100 parts of basic rubber and 0.12 to 0.18 part of chloroplatinic acid complex. In theinvention, the raw material ratio of material A and material B of the silicon rubber is strictly controlled, each material is treated by a special process, therefore, the silicon rubber of the invention has good mobility, flame resistance, thermal conductivity and flexibility simultaneously, and have a certain degree of self-adhesion property. To the silicon rubber of the invention, the thermal conductivity is not less than 1.0w / m.k, the flame resistance is up to UL94V0 grade, the hardness is 12 to 16HC, and the shrinkage rate is less than 0.5%.

Owner:CHENGDU TALY TECH CO LTD

Halogen-free flame retardant polyamide 6 composition

The invention discloses a halogen-free flame-retardant polyamide 6 composition with high toughness and antistatic property. The composition comprises active magnesium hydrate, organic phosphate oligomer, zinc oxide crystal whisker, a macromolecular compatilizer, a plasticizer and an additive. The active magnesium hydrate and the organic phosphate oligomer are used to improve flame retardance; organic anlistatig and the zinc oxide crystal whisker are used to improve the antistatic property; and the macromolecular compatilizer is used to improve interaction among polyamide, the inorganic magnesium hydrate and the zinc oxide crystal whisker. The flame-retardant polyamide 6 composition has the advantages that compared with a sole magnesium hydrate flame-retardant polyamide 6, the use amount of the magnesium hydrate is reduced to below 50 mass percent; the impact strength of a gap is increased by over 80 percent; the breaking elongation rate is improved by approximately 20 times; the resistivity is reduced by 4 orders of magnitude; the flame retardant performance reaches UL94V-0 level; simultaneously, the toughness is basically maintained at the level of pure polyamide 6; the temperature for thermal deformation is much higher than 65 DEG C of the pure polyamide 6; and the molding shrinkage rate is reduced to 0.6 percent from 1.78 percent of the pure polyamide 6.

Owner:GUANGDONG XINHUI MEIDA NYLON

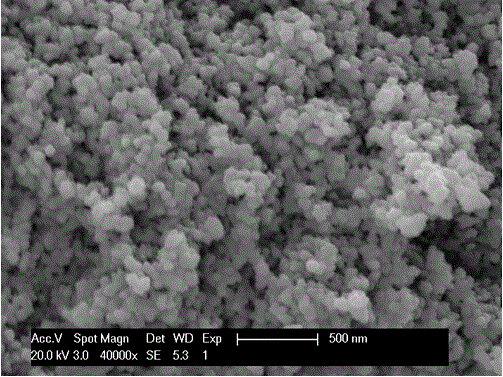

Method of taking micro-emulsion as precursor to rapidly prepare aerogel

ActiveCN106185959AReduce the impactHas the prospect of large-scale productionSilicaAerogel preparationFiberSupercritical drying

The invention relates to a method of taking micro-emulsion as the precursor to rapidly prepare aerogel. The method comprises the following steps: step one, measuring a special water soluble silicon source to prepare a quantitative water solution, adding a certain amount of surfactant and co-surfactant, and fully dissolving the surfactant and co-surfactant; step two, measuring a special active organic silicon compound and an auxiliary oil phase, adding the active organic silicon compound and the oil phase into the water solution, and stirring the solution at a high speed for a while so as to form a semi-transparent, uniform, and stable mixed solution, namely micro-emulsion; step three, compounding the micro-emulsion with inorganic additives and fiber felts for a while so as to form a solid phase, and carrying out aging and normal pressure (or supercritical) drying to obtain a fiber felt compounded aerogel material. The preparation technology is novel, the raw material cost is low, the application range is wide, a normal pressure drying method can be used, a supercritical drying technology can also be used, the obtained material has an excellent thermal insulation performance, the structural strength is high, and the long-term shrinkage rate is small.

Owner:纳诺科技有限公司

Material for vehicle bumper and preparation method thereof

The invention provides a material for a vehicle bumper and a preparation method thereof. The material comprises the following components in proportion: 49-69 percent of polypropylene, 5-25 percent of saturated ethylene-octene copolymers, 10-30 percent of calcium sulphate whiskers, 5-15 percent of maleic anhydride grafted polypropylene copolymers, 0.1-0.2 percent of nucleating agents, 0.3-0.6 percent of antioxygen and 0.2-0.5 percent of lubricating agents. The preparation method comprises the following steps: firstly uniformly mixing all the components except the calcium sulphate whiskers in a mixer according to the proportion; adding the calcium sulphate whiskers from a side feeding hole; and mixing the mixture in a double-screw extruder, extruding, cooling and pelletizing. Through modifying the polypropylene, the intensity and the tenacity thereof can be enhanced and the molding shrinkage rate of the polypropylene can be reduced; the prepared modified polypropylene material is applied on the vehicle bumper and has excellent product performance.

Owner:SUZHOU HESHENG NEW MATERIALS

PETG blow molding film and preparation method thereof

The invention relates to improvement of a PETG (polyethylene glycol terephthalate-1, 4-cyclohexanedimethanol ester) thin film and a preparation method. The PETG thin film is prepared by mixing 85-92 wt. % of PETG, 2.0-4.0 wt. % of opening agent, 0.5-1.5 wt. % of slipping agent, 0.2-1.0 wt. % of antistatic agent, 0.005-0.01 wt. % of chain extender and 5.0-10.0 wt. % of toughening agent blow molding, making film and shaping. Compared with casting and stretching, the invention has the advantages of short flow, convenient processing, no generation of scrap edge, high film-forming rate which can be increased by 8-10% than a stretching method, equipment investment saving, low operating cost, low production cost which can be reduced by about 20% or more and strong adaptability, adoption of various blowing measures for making the blown film, flexible and convenient product replacement and the like. Different blowing processes can be employed to obtain a non-shrinkage polyester film, and a unidirectional heat-shrinkable PETG film having approximate shrinkage rates lengthways and breadthways and giving priority to the lateral shrinkage rate. The resulting PETG thin film can be applied to a packaging film, a preservative film, a shed film, a label film and a tangle film.

Owner:YIXING GUANGHUI PACKAGE

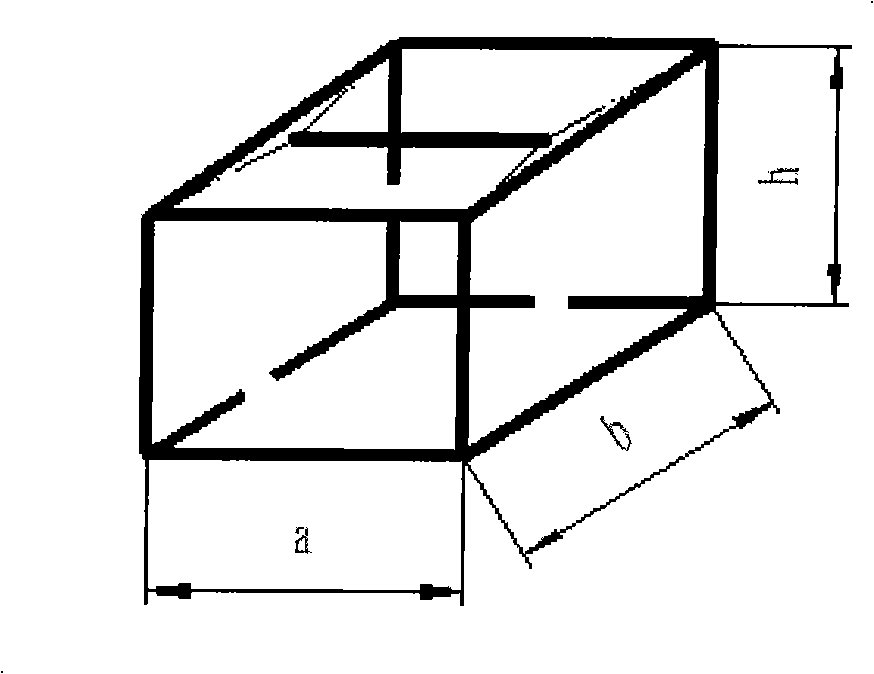

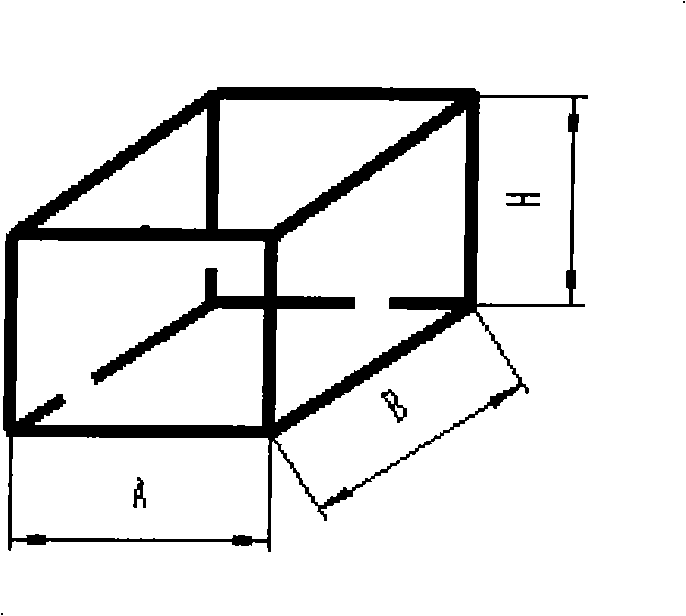

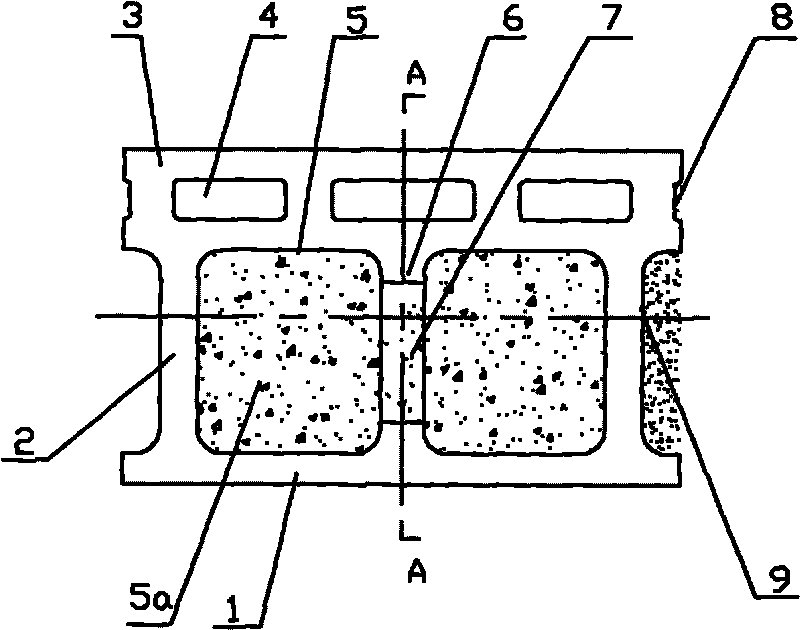

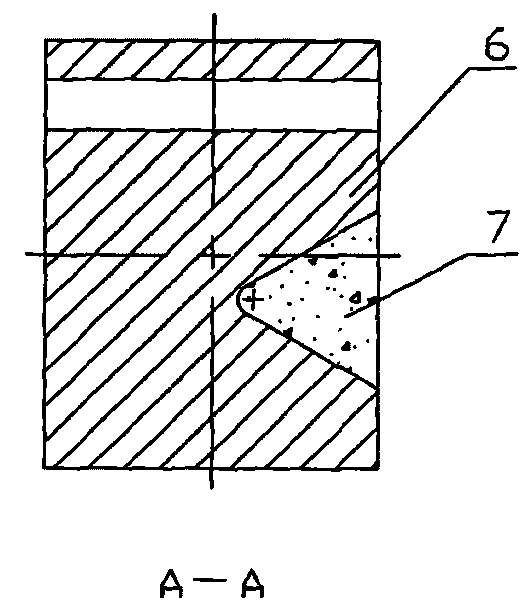

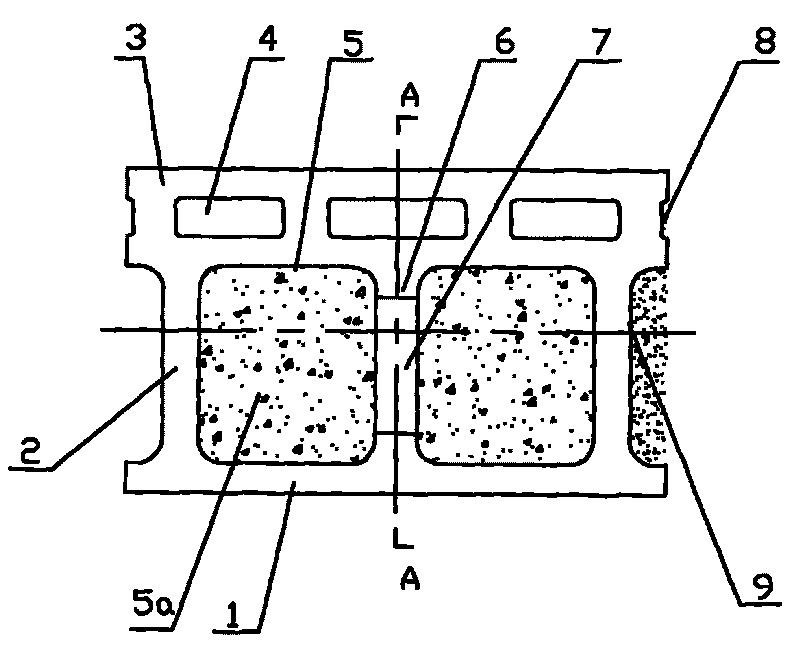

Non-homogeneous concrete composite automatic heat insulation building block

InactiveCN101694117AImprove insulation effectHigh void rateConstruction materialThermal engineeringBrick

The invention relates to a composite heat insulation building block which comprises a rectangular building block body, and is characterized in that one side of the rectangular building block body is provided with a group of parallel thermal insulation water-proof chamber (4); the middle part of the rectangular building block is provided with at least one heat insulation chamber (5) which is internally provided with heat insulation fillers (5a); the middle part of the rectangular building block is provided with two parallel heat insulation chambers (5); a leveling groove (7) used for leveling the heat insulation fillers are arranged on a rib plate (6) formed between the heat insulation chambers (5); and the connecting ends at two sides of the rectangular building block are respectively provided with an opening slit building groove (9) and an opening slit building groove (8). The composite heat insulation building block has the advantages of high void content (more than 60%), good heat insulation effect and high strength, and the produced composite heat insulation building brick has light weight, high strength, low water absorption rate, small air shrinkage rate, and good thermal engineering performance, and can meet the design requirement that building energy conservation rate can reach 65%.

Owner:金波

Photocuring adhesive used for adhering optic glass lenses and preparation method thereof

ActiveCN102167962AHigh refractive indexCuring shrinkage is smallModified epoxy resin adhesivesVinyl etherAdhesive

The invention discloses a photocuring adhesive used for adhering optic glass lenses, which consists of the following components in percentages by weight: 50-80% of main resin, 10-40% of auxiliary resin, 5-20% of active monomer, 4-4.5% of photo initiator and 0.5-1% of auxiliary. The main resin is alicyclic epoxy resin. The auxiliary resin is modified epoxy acrylate resin. The active monomer is oneor a mixture of vinyl ether monomers and acrylate monomers. The photo initiator is a radical photo initiator and a cation photo initiator. The auxiliary is a coupling agent. The photocuring optic adhesive has the characteristics of high curing speed, high refraction rate, high light transmittance, low curing shrinkage rate, small thermal deformation, strong adhesion force, small smell, yellowing resistance and the like.

Owner:SHENZHEN FISHER NEW MATERIALS CO LTD

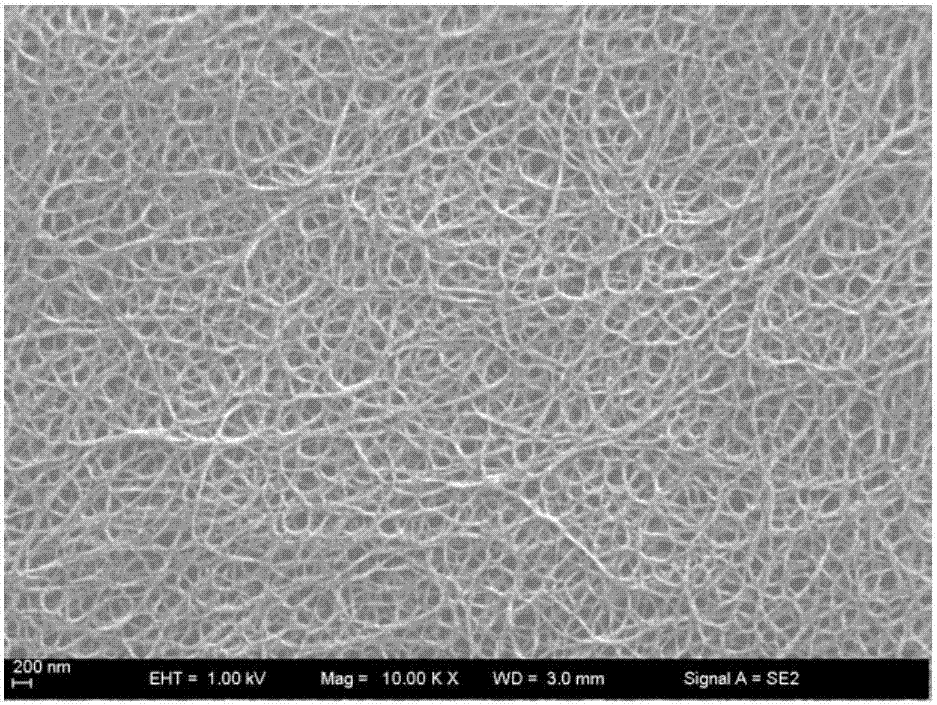

Lithium ion battery ceramic diaphragm paste

InactiveCN105489819ALow costAdjustable viscosityCell seperators/membranes/diaphragms/spacersInorganic particleShrinkage rate

The invention discloses paste for a lithium ion battery ceramic diaphragm. The lithium ion battery ceramic diaphragm comprises a basic membrane and a coating coated on a single side or double sides of the basic membrane. Paste adopted for the coating is paste which is formed in the mode that inorganic nanoparticles and whiskers are composited with a basic material and water. The inorganic nanoparticles are prepared from one of alumina, boehmite, silicon dioxide and barium sulfate, the whiskers are prepared from one of alumina and boehmite, and the basic material is prepared from a thickening agent, a dispersing agent and an adhering agent. The paste can continuously form a uniform inorganic nanometer and whisker coating on PE / PP in a roller painting mode, and the composite diaphragm with the ultra-thin coating and high adhesive force is obtained through drying. The composite diaphragm can effectively reduce the heat-shrinkage rate of the lithium ion battery ceramic diaphragm, and compared with a traditional composite diaphragm prepared from single inorganic particle paste, the ultrathin coating is favorable for increase of air permeability and ionic conductivity, and space in a battery and paste cost are saved.

Owner:EAST CHINA UNIV OF SCI & TECH

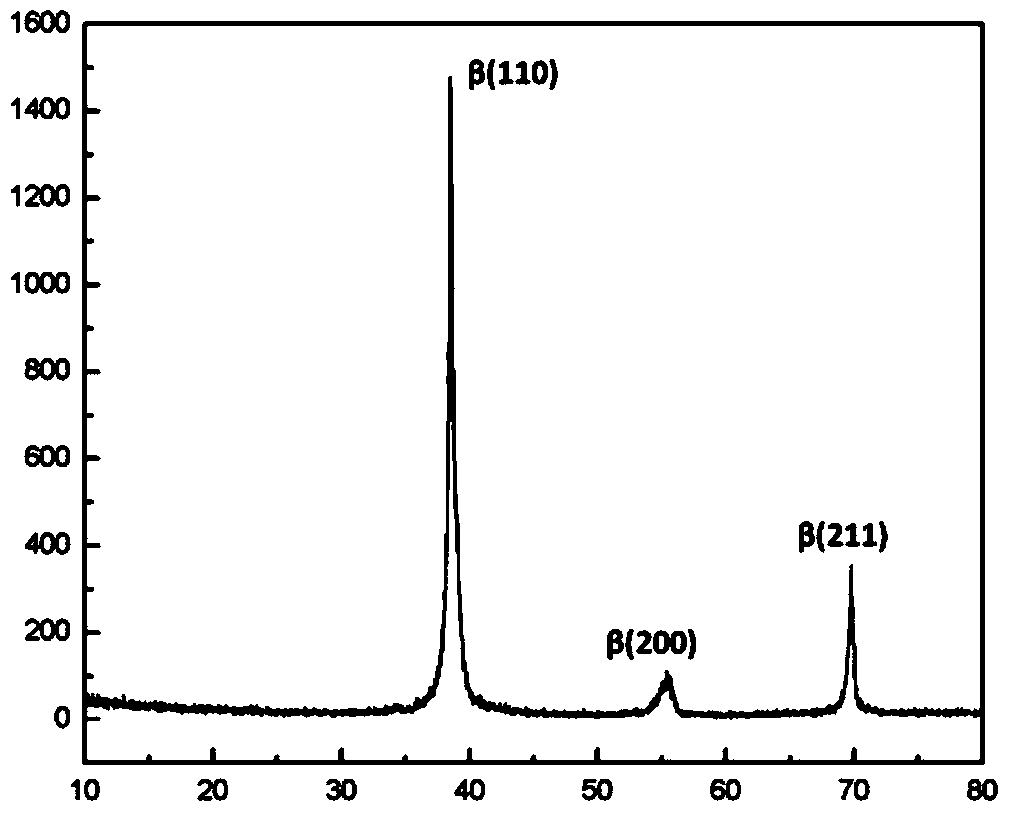

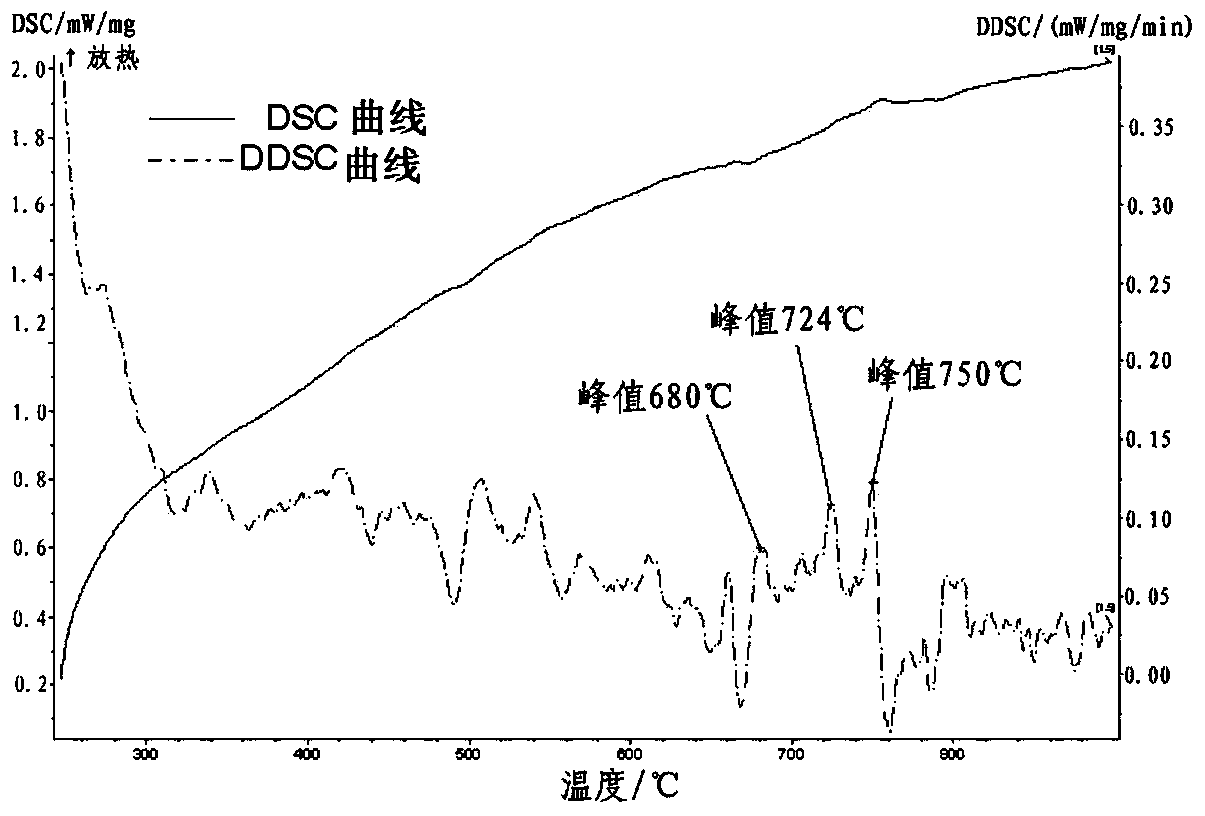

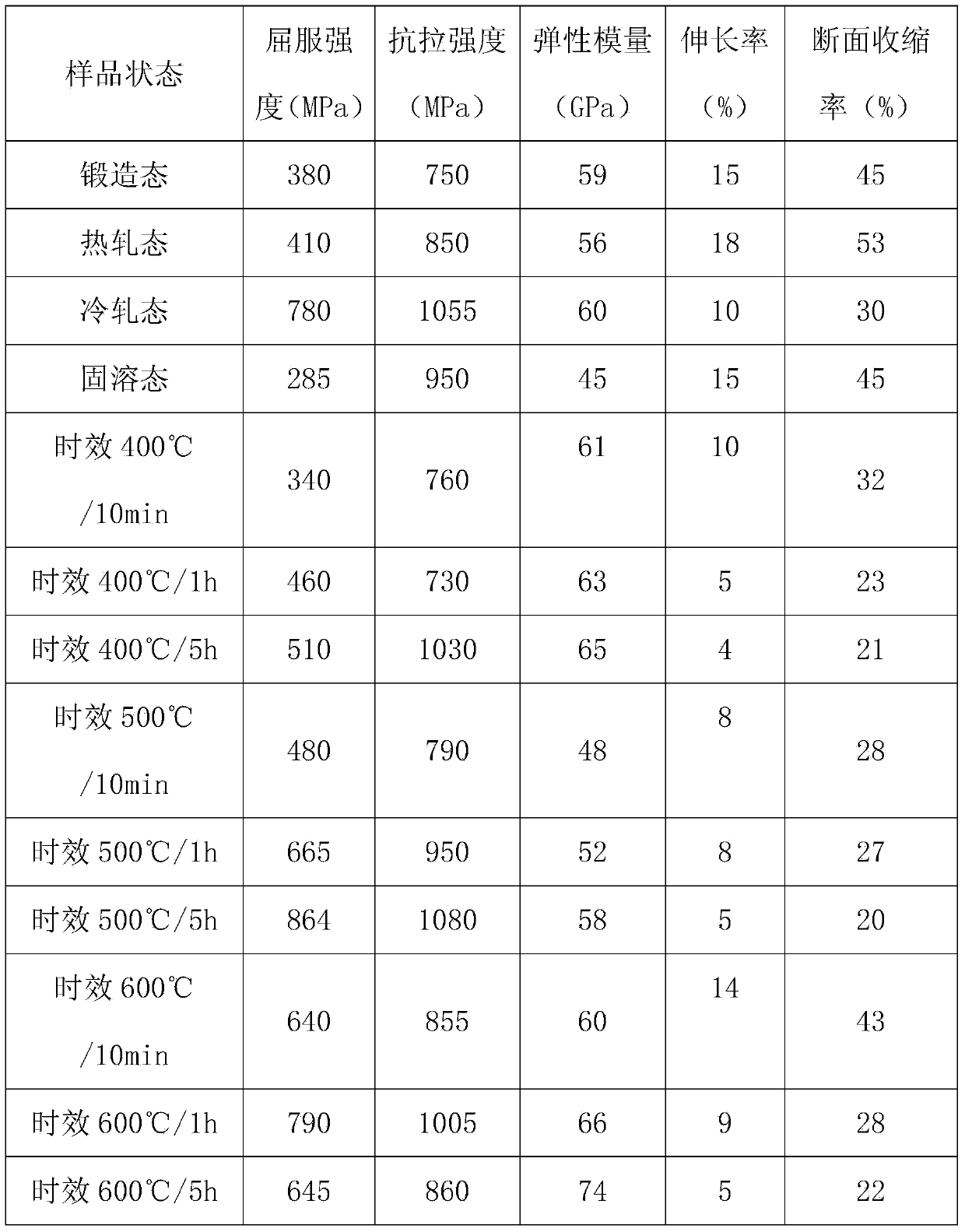

Metastable beta titanium alloy with low elastic modulus and preparing method thereof

The invention relates to a titanium alloy material, in particular to a multi-functional biomedical metastable beta titanium alloy material with excellent processing performance, and belongs to the technical field of titanium alloy material preparation. The alloy contains the following ingredients by mass: 18-27% of Nb, 0.5-2% of Mo, 3-5% of Zr, 7-9% of Sn, 0.1-0.3% of O and the balance of Ti. The titanium alloy has excellent comprehensive performance, and the strength and the elastic modulus of the alloy can be regulated through different thermal treatments. The elastic modulus E of the alloy is 40-7 3GPa, the yield strength sigma 0.2 is 260-864 MPa, the tensile strength sigma b is 686-1094 MPa, the elongation rate epsilon = 4-20%, and the facture surface shrinkage rate is 20-52%. The titanium alloy does not contain toxic elements, such as Al and V, and has excellent corrosion resistance, biocompatibility and cold processing performance. The titanium alloy can be used for manufacturing tissue repairing or substituting materials, such as artificial bones, artificial joints and bone plates.

Owner:BAOJI TITANIUM IND +1

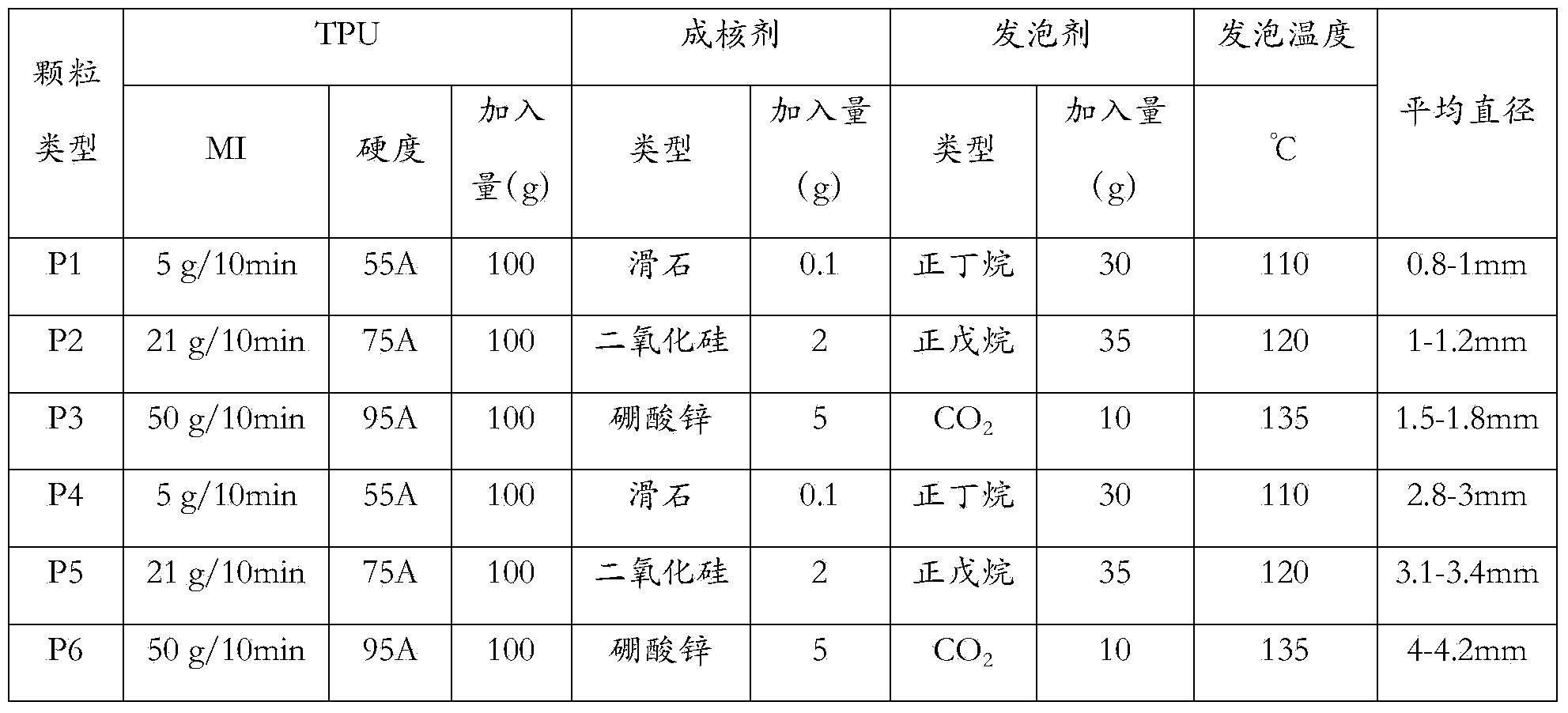

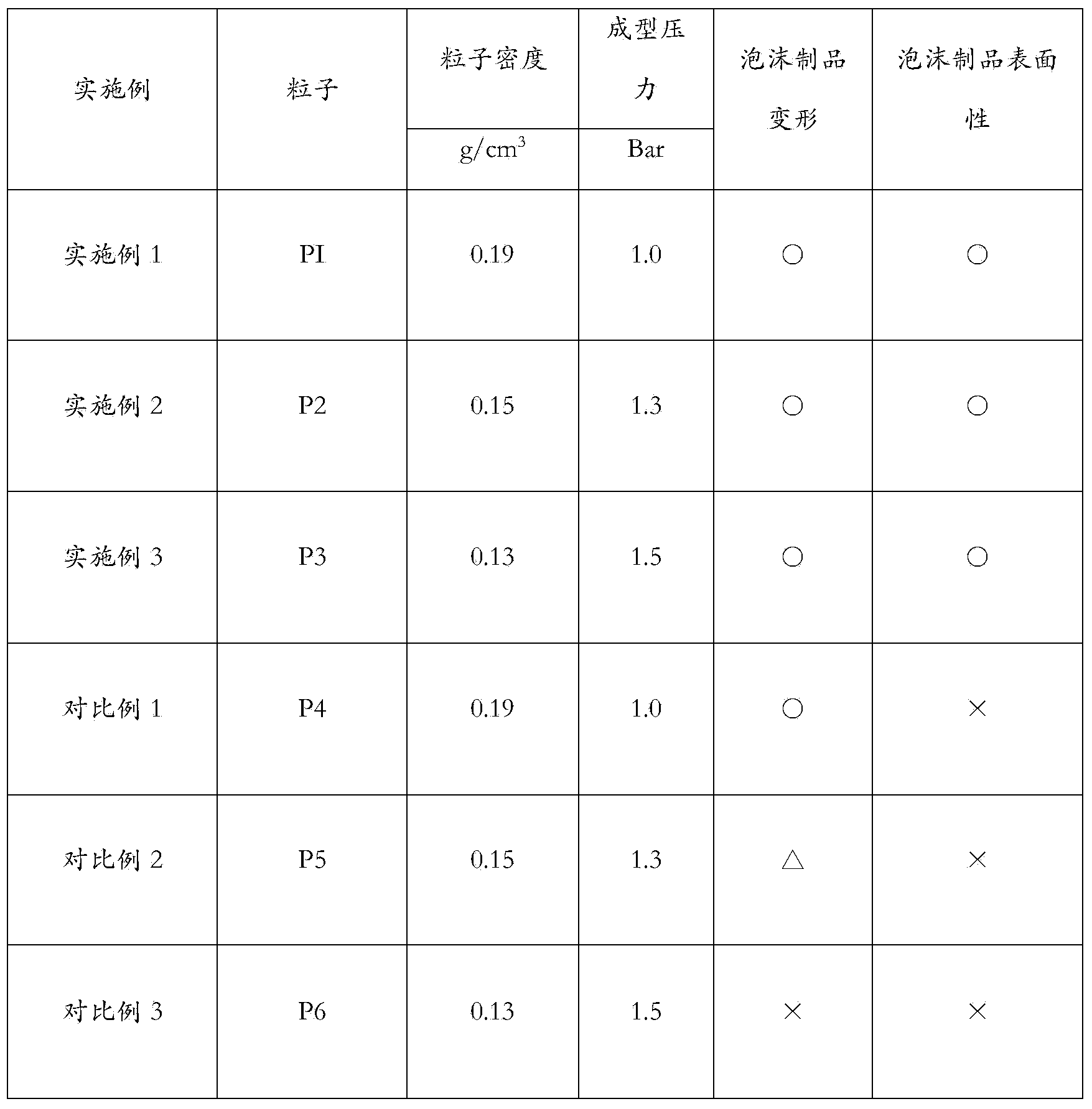

Foaming type thermoplastic polyurethane particles and preparation method thereof

The invention relates to foaming type thermoplastic polyurethane particles and a preparation method thereof. The particles are prepared from the following components in parts by weight: 100 parts of thermoplastic polyurethane elastomer particles, 0.1-5 parts of a pore nucleating agent and 1-40 parts of a foaming agent. The average diameter of the foaming type thermoplastic polyurethane particles which is prepared by mixing the thermoplastic polyurethane elastomer particles and the pore nucleating agent in a certain ratio is 1-4mm, so that the particles can be easily charged, and can be fused and molded at a relatively low water vapor pressure during a moulding process; and a molded foam product prepared from the foaming type thermoplastic polyurethane particles has the advantages of small deformation, low size shrinkage rate relative to the die, excellent size stability and attractive appearance.

Owner:MIRACLL CHEM

Method for making novel ferrite/iron-base composite material soft magnetic-powder core

ActiveCN1979698ALow shrinkageHigh bonding rateInorganic material magnetismInductances/transformers/magnets manufactureIron powderAdhesive

A preparation method for soft magnetic powder cores, a kind of new ferrite / ferreous-base compound material. Its power cores comprises the following materials with the given mass percentage: the 70~90% powder under 160 meshes, adhesive 1~30%; the powder materials comprises 10~100% ferreous powder and 0~90% MnZn ferrite powder, the adhesive is water glass adhesive and tetraethyl(ortho)silicate, which is made through mixing, molding, heat treatment, glue immersing, paint immersing and wrapping. The advantages of the invention are : (1) advanced formula design; (2) insulation adhesive is no toxin, no taste, less shrinkage rate, high bonding rate with powder; after immersing treatment, the quality coefficient value of powder cores is increased; (3) improves the integrated performance index parameter of magnetic powder cores, and the consistency of the performance parameter of product is guaranteed, the quality's conformity rate is improved too.

Owner:安徽众恒复合材料科技有限公司

Light-weight autoclaved aerated concrete and preparation process thereof

ActiveCN104557107AImprove shrinkageImprovement in compressive strengthCeramicwareFiberShrinkage rate

The invention relates to a novel building material, and particularly relates to a light-weight autoclaved aerated concrete and a preparation process thereof. The autoclaved aerated concrete is prepared by adding a certain proportion of inorganic fiber into quartz sand, lime, cement, gypsum and aluminum powder paste as the main materials. Through adjusting the corresponding preparation process, not only is the low density of the product ensured, but also the material shrinkage rate and compressive strength are greatly improved, the defects of low strength, large shrinkage and easy cracking of the autoclaved aerated concrete are solved, and the light-weight autoclaved aerated concrete and the preparation process thereof can be widely popularized and used.

Owner:山东京博环保材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com