Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1397 results about "Hydrophily" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrophily is a fairly uncommon form of pollination whereby pollen is distributed by the flow of waters, particularly in rivers and streams. Hydrophilous species fall into two categories: (i) Those that distribute their pollen to the surface of water. e.g. Vallisneria's male flower or pollen grain are released on the surface of water, which are passively carried away by water currents; some of them eventually reach the female flower (ii) Those that distribute it beneath the surface. e.g. seagrasses in which female flower remain submergered in water and pollen grains are released inside the water.

Selective membrane having a high fouling resistance

InactiveUS6913694B2Improve antifouling performanceImprove the immunitySemi-permeable membranesSynthetic resin layered productsEpoxyCross-link

Owner:SAEHAN INDS CO LTD

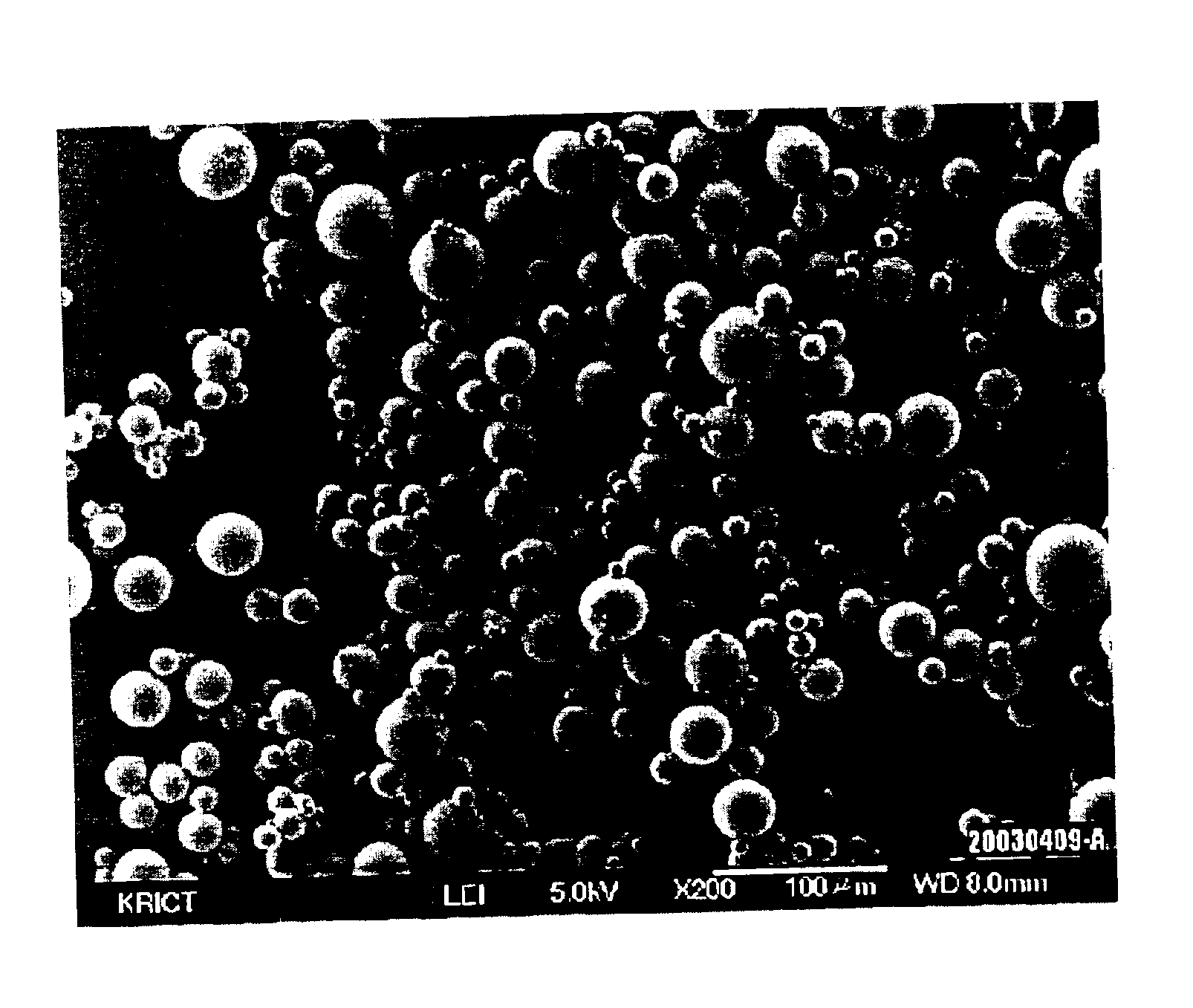

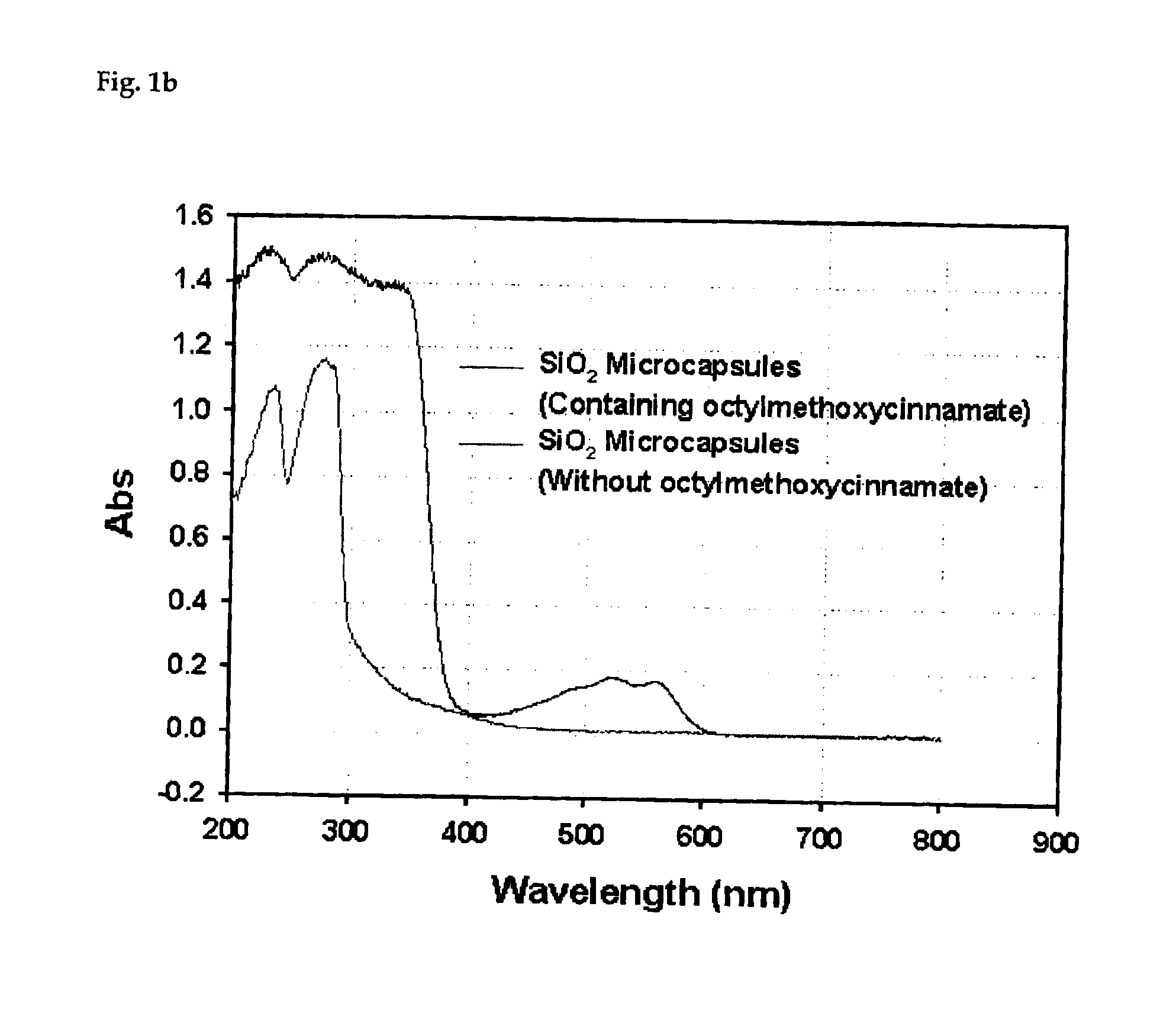

Process for preparing silica microcapsules

InactiveUS6855335B2Reduce environmental pollutionPowder deliveryGlass/slag layered productsAmmonium hydroxideSilica gel

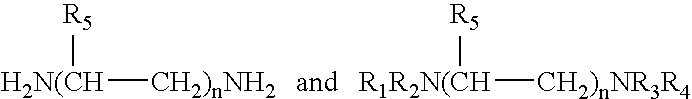

The present invention relates to a process for preparing silica microcapsules and more particularly, to a process for preparing silica microcapsules comprising the steps of dissolving tetraethyl orthosilicate (TEOS) into an aqueous solution containing a hydrolysis catalyst to control a degree of hydrolysis and contribute hydrophilicity or lipophilicity, adding a core material and an appropriate amount of aminopropyltrialkoxysilane(APS) as a gelling agent into the solution, and emulsifying and dispersing the resulting solution to a solution having a polarity opposite to that of the core material to microcapsulate by coating the core material with silica shell via a sol-gel reaction. The process for preparing microcapsules of the present invention reduces environmental pollution compared to conventional processes using an alkali gelling agent such as an ammonia solution, and are suitable for both organic or inorganic core materials having hydrophilic or lipophilic property.

Owner:UNITECH CO LTD (JP)

Mitigation of Biomolecular Adsorption with Hydrophilic Polymer Additives

ActiveUS20090280251A1Reduce surface tensionInhibit bindingSludge treatmentVolume/mass flow measurementHydrophilic polymersPhenyl Ethers

Molecular adsorption to the microfluidic device surfaces can be passively and actively mitigated by mixing certain hydrophilic polymers (organic polymers with repeating hydrophilic groups—the preferred polymers being amphipathic surfactants—with the sample liquid during or prior to relevant microfluidic operations. Nonionic surfactants such as polyoxyethylene sorbitan monooleate and polyoxyethylene octyl phenyl ether are especially effective. High molecular weight polyethylene polymers are also effective. The hydrophilic polymers appear to prevent binding of the fouling molecules to the microfluidic by occupying the surface sites in place of the fouling molecules or by interacting with the fouling molecules to prevent binding of the fouling molecules the surface. When surface adsorption is thus mitigated, microfluidic devices can readily handle samples containing biomolecules to enable active sample concentration, filtering, washing, transport, mixing and other sample handling operations.

Owner:ADVANCED LIQUID LOGIC

Modified membranes

InactiveUS20050029186A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Modified membranes

InactiveUS6884350B2Reduce dirtEssential mechanical properties of the membranesMembranesSemi-permeable membranesVinyl etherPolyamide

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Mixed hydrophilic/hydrophobic fiber media for liquid-liquid coalescence

ActiveUS20100200512A1Liquid suspension thickening by filtrationWater/sewage treatmentWashburn's equationFiber

An immiscible lipophilic or hydrophilic liquid phase separated respectively from a continuous hydrophilic phase or a lipophilic phase liquid. Fibers having hydrophilic and hydrophobic properties are mixed, layered, etc., and formed into a filter. The separation mechanism involves capture of small droplets of the immiscible phase, coalescence of the small droplets into larger droplets as the immiscible liquid flows through the fiber filter, and release of the large immiscible droplets from the filter. With respect to separation of a hydrophilic immiscible fluid such as water in a lipophilic continuous fluid such as oil, the hydrophobic fibers will cause small water droplets to migrate towards the hydrophilic fibers whereby large droplets are formed on hydrophilic surface. The large droplets stay on hydrophilic fiber surface for extended periods of time and continue to coalescence until they are so large that they can no longer be maintained by the hydrophilic fibers and are released and drained off of the filter. In designing such filter, wettability of the filter media is an important parameter. The filter media can be designed by mixing hydrophilic and hydrophobic fibers in various proportions to achieve an optimum wettability range for separation of the immiscible liquid from the continuous phase liquid. The wettability of filter media can be characterized by a modified Washburn Equation.

Owner:THE UNIVERSITY OF AKRON

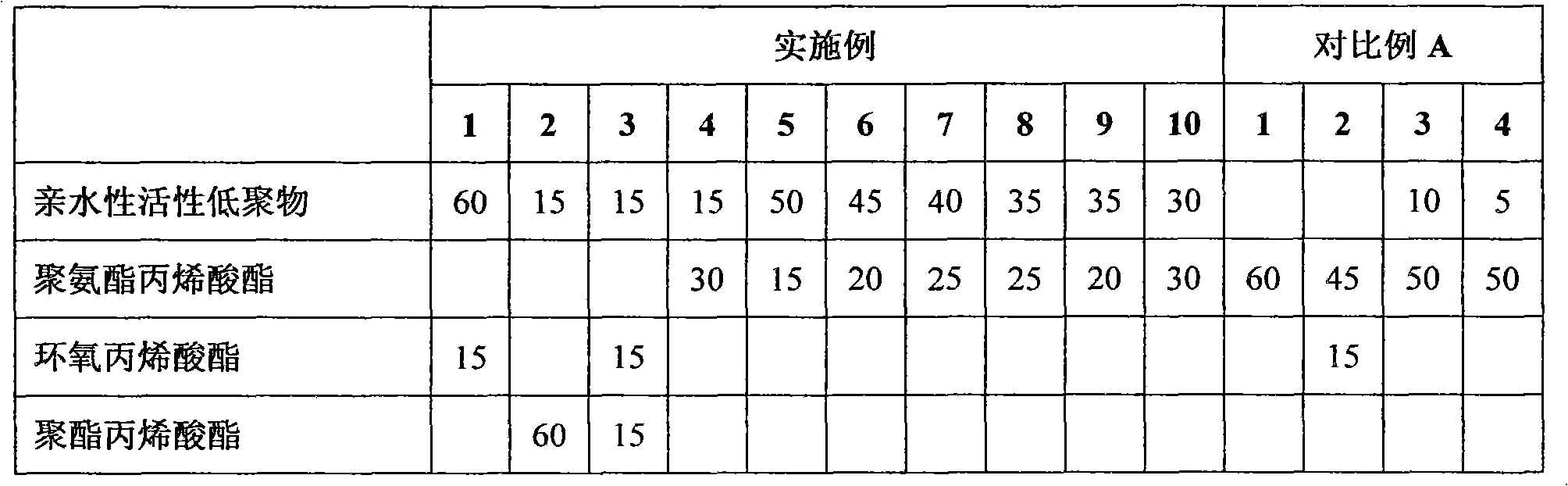

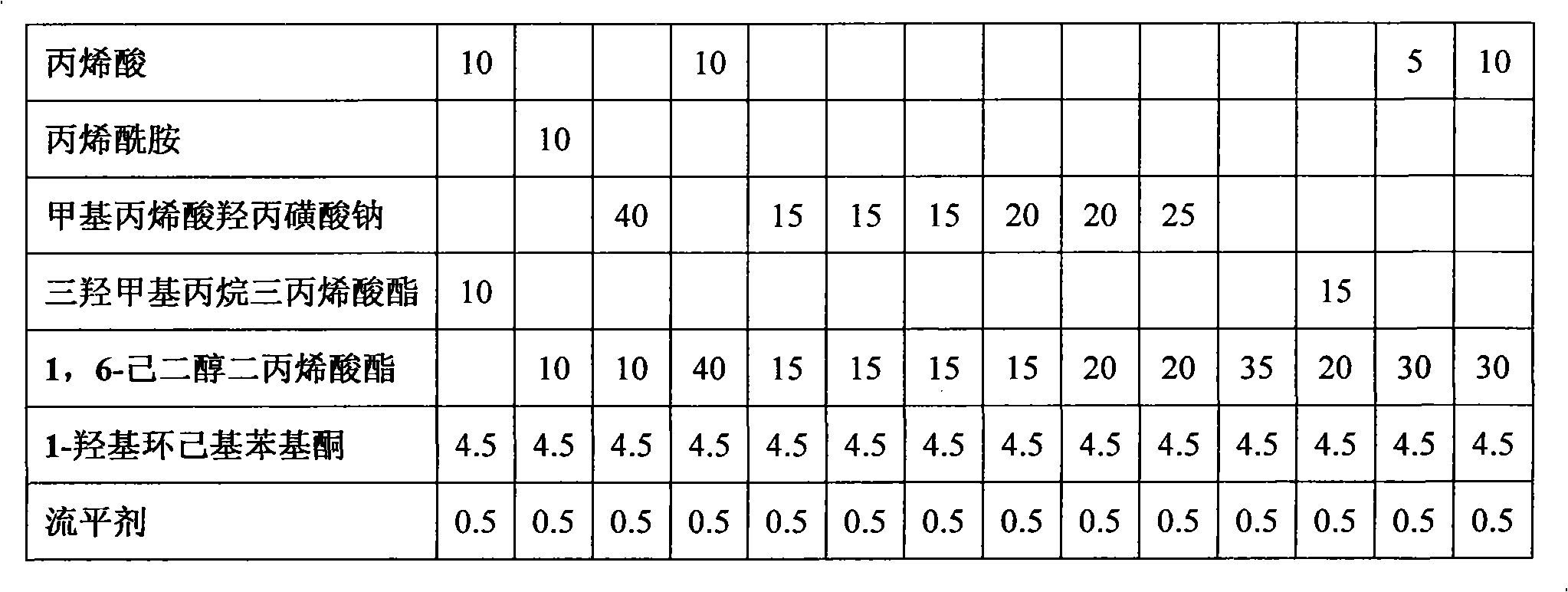

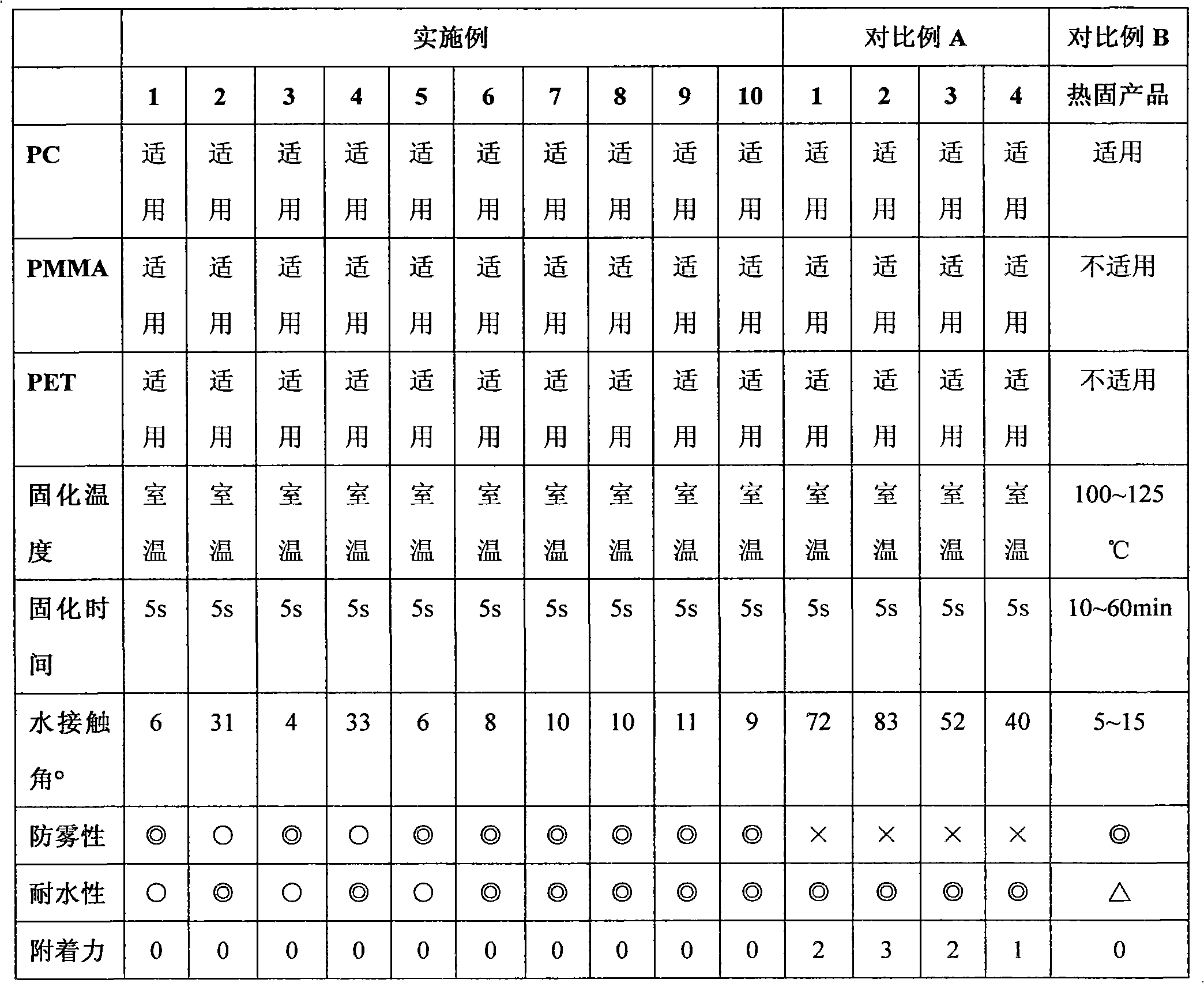

Ultraviolet light curing anti fogging coating composite and preparing method thereof

InactiveCN101602913ASimple production processIncrease productivityPolyurea/polyurethane coatingsPolyether coatingsOligomerUltraviolet lights

The invention relates to an ultraviolet light curing anti fogging coating composite with fine anti fogging effect and a preparing method thereof. The ultraviolet light curing coating composite comprises hydrophilic activated oligomer, hydrophobic light curing resin, hydrophilic polymeric monomers, hydrophobic activated diluent, photoinitiator and additive. The method comprises the following steps: accurately weighting and placing the hydrophilic activated oligomer and the hydrophobic light curing resin into a container, adding the hydrophilic polymeric monomers, the activated diluent and the additive in turn to mix for 10min, and then adding the photoinitiator, mixing for 5min to obtain the composite in the invention which is preserved in dark place. The ultraviolet light curing anti fogging coating composite provided by the invention can be coated on thermal sensitivity plastic base material such as PC, PMMA, PET and the like; the coating after the ultraviolet light curing has fine hydrophily and physical performance. The invention has fine anti fogging and fog inhibiting effect, and the coating has good adhesive force and water resistance which can ensure the durability of the anti fogging performance.

Owner:GUANGZHOU HUMAN CHEM

Modified membranes

InactiveUS20050032982A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:MULLER HEINZ JOACHIM

Modified membranes

InactiveUS20050029185A1Reduce dirtEssential mechanical properties of the membranesSemi-permeable membranesMembranesVinyl etherReverse osmosis

A porous polymeric membrane formed from a blend of a polymeric membrane forming material, such as polyvinylidene fluoride or polysulfone and a polymeric reactivity modifying agent adapted to modify the surface active properties of the porous polymeric membrane. The reactivity modifying agent is preferably a linear polymeric anhydride, such as poly(alkyl vinyl ether / maleic anhydride). The surface activity modifications include modification of the hydrophilicity / hydrophobicity balance of the membrane, or hydrolysis followed by reaction with a polyamine to form a crosslinked polyamide layer. Such modified membranes have use as reverse osmosis membranes.

Owner:EVOQUA WATER TECH LLC

Porous polyvinylidene blending porous membrane and process for producing same

InactiveCN101015773AAchieve hydrophilicImprove throughputSemi-permeable membranesSolventWater treatment

The invention discloses a plate-tubular porous membrane based on polyvinylidene fluoride mixture, and relative production. The membrane substantially comprises polyvinylidene fluoride, dual-block amphipathic epoxyethane, and inorganic particles. And the preparation comprises that mixing polyvinylidene fluoride, dual-block amphipathic epoxyethane, inorganic particles, aperture adjusting agent and polarity solvent to obtain the membrane preparing liquid, using said membrane preparing liquid into plate or tubular liquid membrane, immerging the liquid membrane into solidifying bath mainly comprising water to be solidified into plate or tubular membrane. And the apertures of plate membrane and tubular membrane are 0.01-5.0 and 0.01-0.2 micrometers. The hydrophilic chain section of amphipathic epoxyethane is abundant at the face or aperture walls of the membrane, while said two membranes are both better in hydrophilic property and permeable property, with significant resistance on organic adsorption, to be used as ultra-filter membrane and micro-filter membrane in membrane water treatment.

Owner:ZHEJIANG UNIV

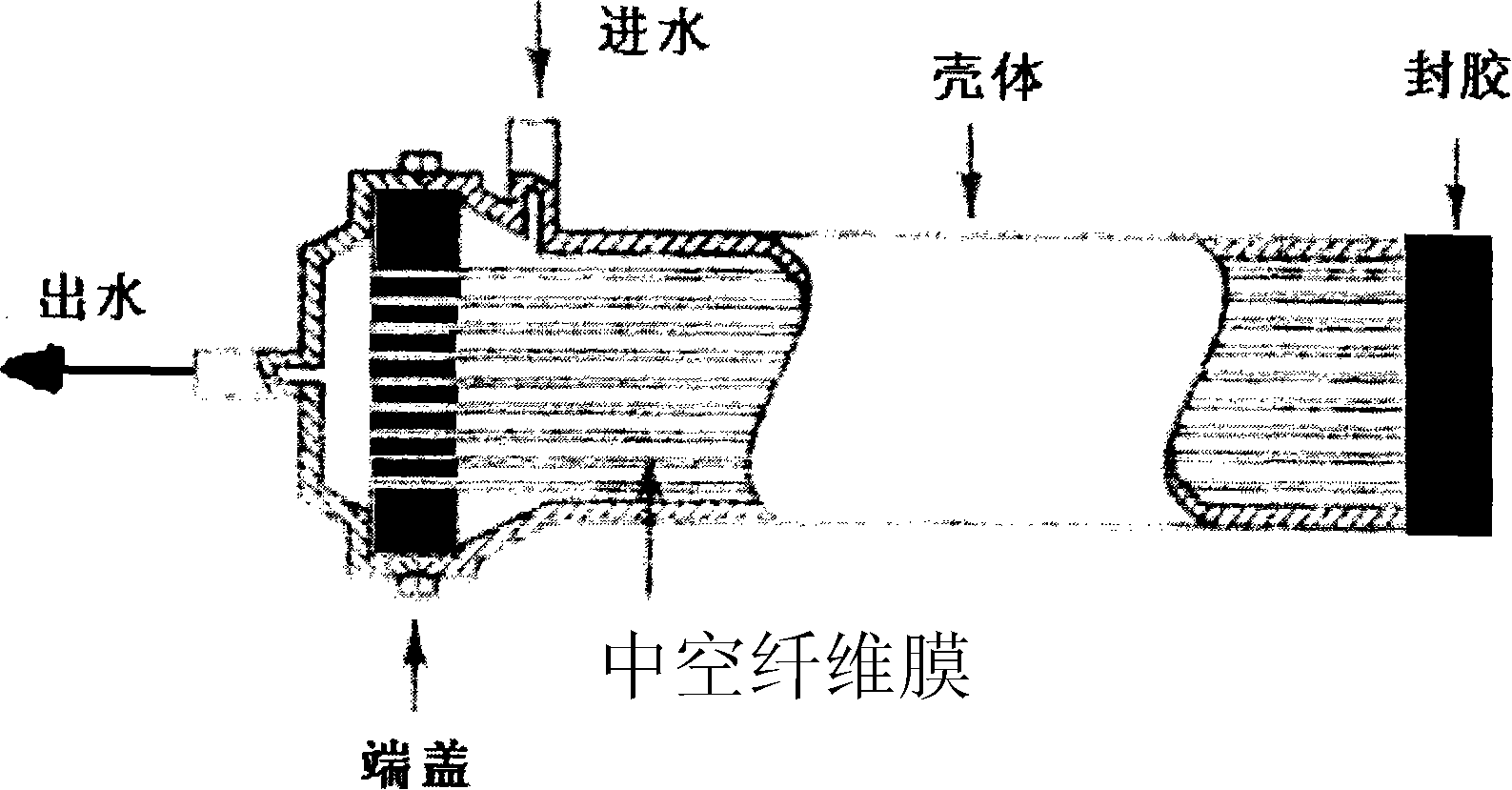

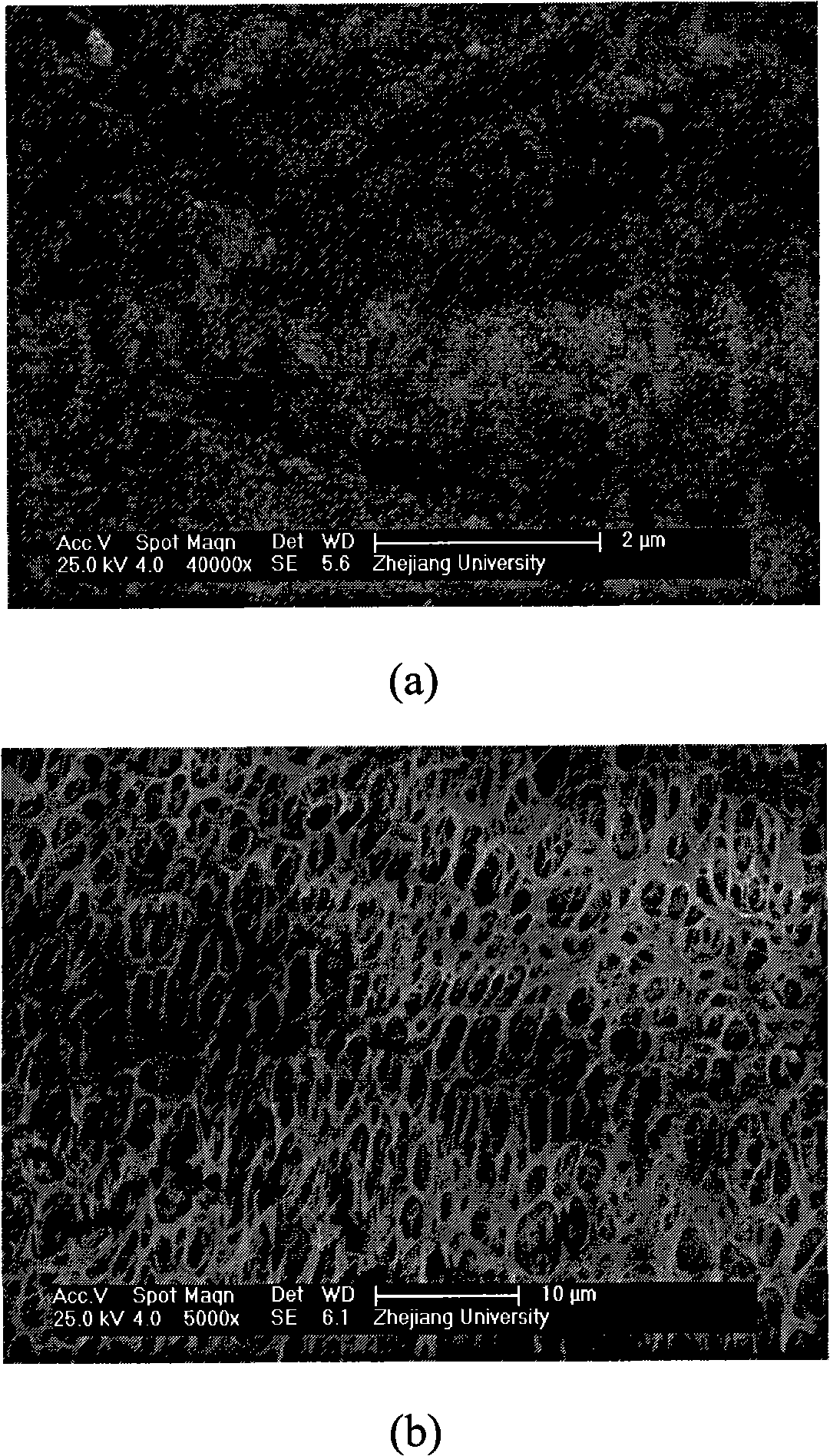

Hydrophilicity kynoar hollow fiber microporous membrane and preparation method thereof

ActiveCN101190401AImprove anti-pollution performanceAvoid adsorptionSemi-permeable membranesHollow fibrePorosity

The invention discloses a hydrophilic polyvinylidene fluoride hollow fiber microporous membrane and the preparation method thereof. The main composition and the mass content of the membrane are 70% to 90% of polyvinylidene fluoride, amphiphilic poly-(propylene oxide-oxirane), 5% to 29% of poly-(methacrylic acid- acrylic acid) or poly-(methacrylic acid methyl ester-vinyl alcohol) copolymer and 1% to 5% of nano-silicon dioxide. The membrane preparation method is that all the components are mixed and dissolved with aperture regulator, thickener and solvent to obtain the membrane preparation liquid; after that, the hollow fiber forming is carried out through a dry-wet spinning technique, and finally cleaning and drying are implemented. The obtained membrane has adjustable internal diameter and external diameter, 60% to 80% of porosity and the aperture ranging from 0.01micron to 0.2micron. As a water disposal separating membrane material with excellent performance, the invention has the advantages of being able to be fully humid, organic adsorption resistance and great water flux, etc.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

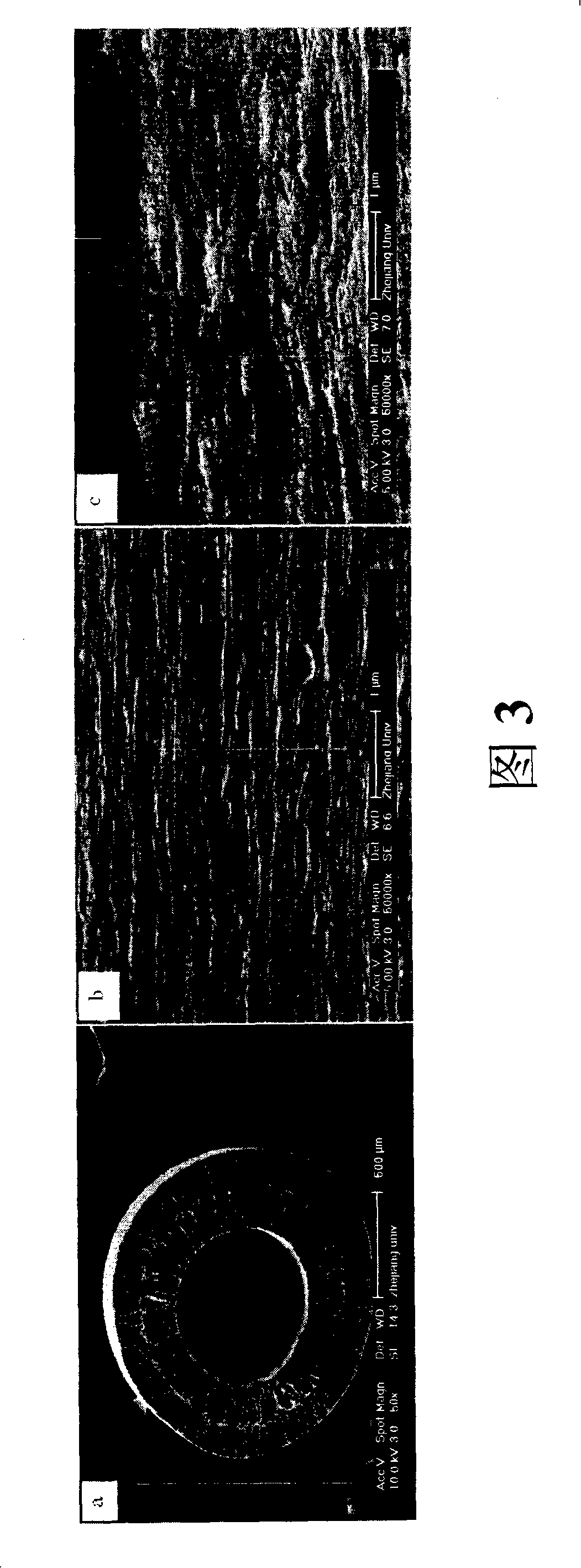

Preparation of hydrophilic polyvinylidene fluoride microporous membrane

InactiveCN1704152AImprove hydrophilicitySimple processSemi-permeable membranesPhysical chemistryFiber type

The invention relates to a method for preparing hydrophilic PVDF microporous barrier. The principal raw material is polyvinylidene fluoride with the range of molecular weight: 5000 to 50000. It prepares hydrophilic PVDF microporous barrier by the method of separating solution and compounding dip-coating modification. It especially suits the occasion of effluent treatment, medicine separation and biochemy. The technology can prepare microporous barriers with plate type and hollow fiber type.

Owner:杨虎

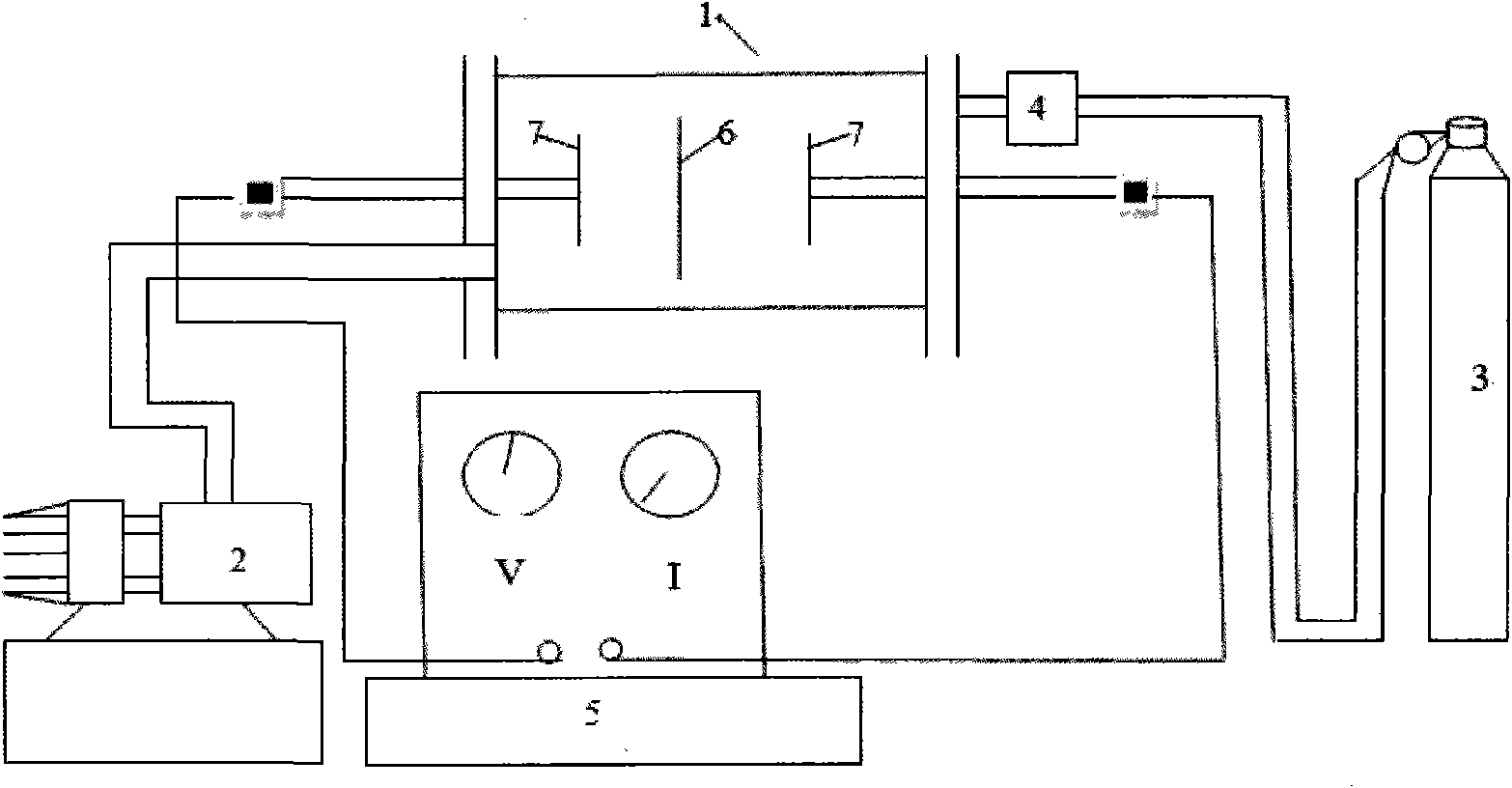

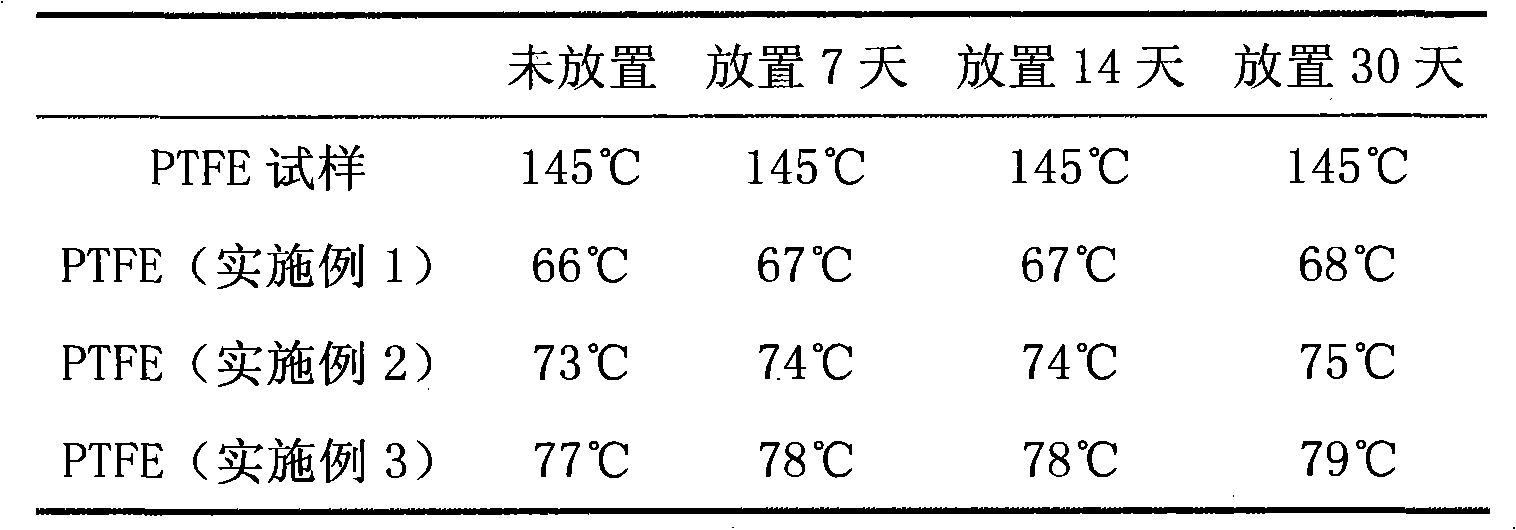

Surface hydrophilic modification method for polytetrafluoroethylene bulked membrane

InactiveCN101890314ASimple processEfficient treatment processSemi-permeable membranesWater layerLow pressure plasma

The invention relates to a surface hydrophilic modification method for a polytetrafluoroethylene bulked membrane, which is characterized by comprising the steps of: pretreating a polytetrafluoroethylene membrane by adopting low-pressure glow discharge plasma to make the surface of the polytetrafluoroethylene membrane generate active groups, and grafting acrylic acid to form a relatively stable hydrophilic layer. The method has the advantages that: the active groups are generated on the surface of the polytetrafluoroethylene membrane by low-pressure plasma treatment, and the relatively stable hydrophilic layer can be formed on the surface of the membrane by acrylic acid grafting treatment, so that the hydrophilicity of the polytetrafluoroethylene membrane is effectively improved, and the effect is lasting; and the polytetrafluoroethylene membrane is treated by the low-pressure plasma induction and acrylic acid grafting, so the treatment method is simple, high-efficiency, water and energy-saving, and suitable for industrialized production.

Owner:DONGHUA UNIV

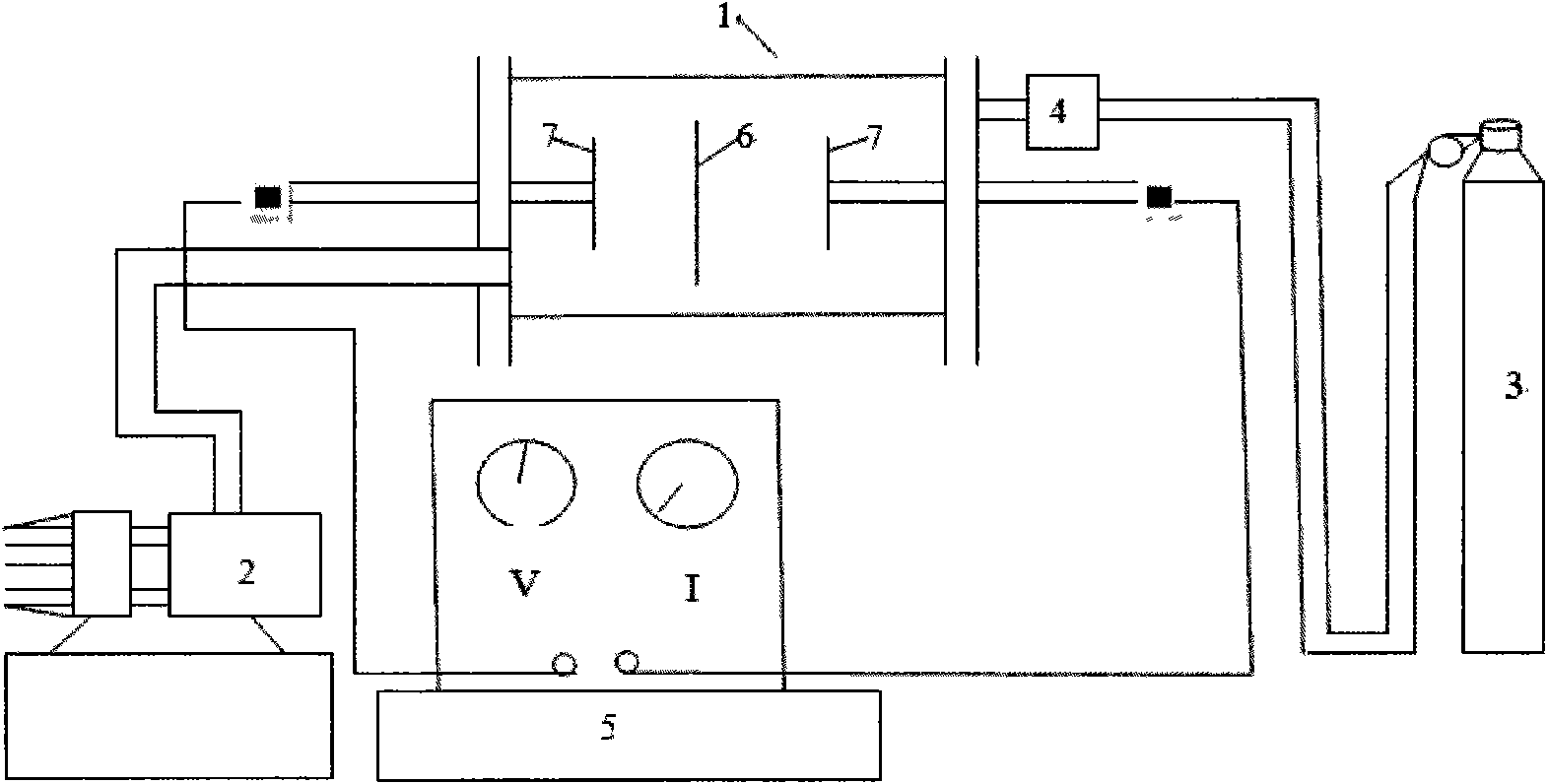

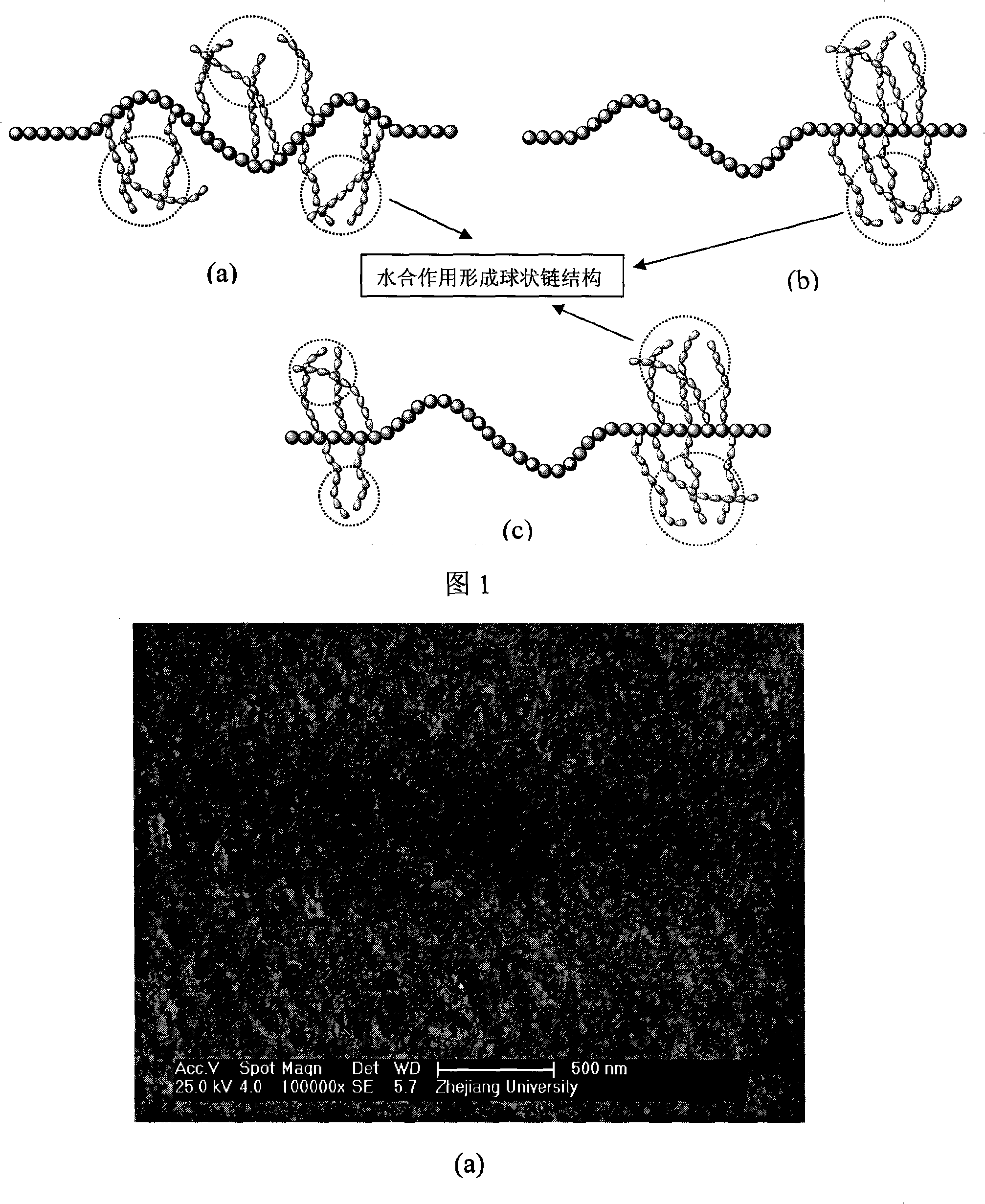

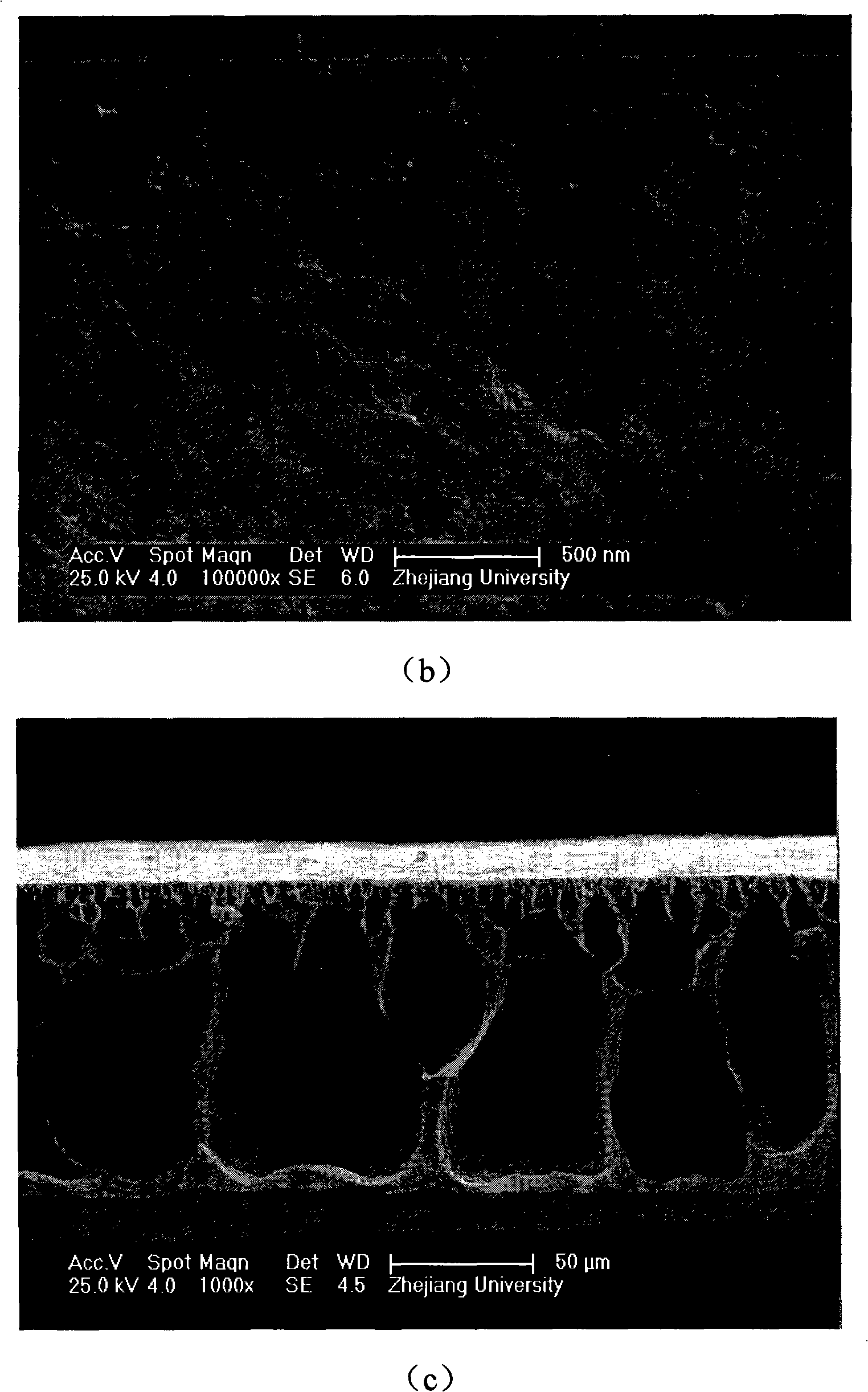

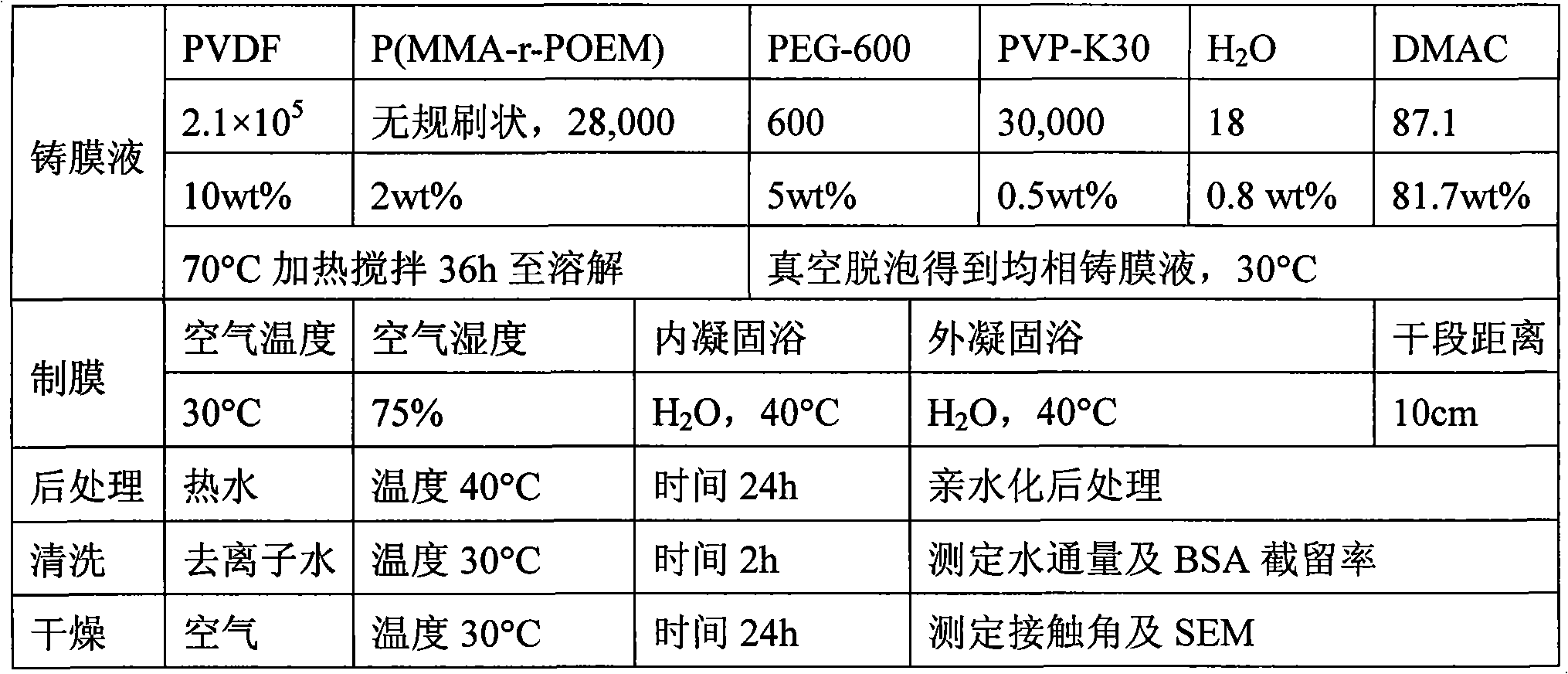

Method for modifying polyvinylidene fluoride ultrafiltration membrane by amphiphilic co-polymer

InactiveCN101264428AImprove hydrophilicityReduce energy consumptionSemi-permeable membranesUltrafiltrationDumbbell shaped

The invention discloses a method of producing the hyperfiltration membrane of amphiphilic copolymer modified polyvinylidene fluoride, comprising the following steps: 1) mixing polyvinylidene fluoride, poly (methyl methacrylate - monomethyl ether polyoxyethylene methyl methacrylate), additives, non-solvent and solvent to form the casting film solution; 2) making the casting film solution into the polyvinylidene fluoride membrane by using the film forming machine and then soaking in the coagulation bath; 3) conducting the posttreatment of hydrophilicity; 4)obtaining the hydrophilic polyvinylidene fluoride ultrafiltration membrane after cleaning and drying. The method is characterized in that the brush shape, chain ball shape or dumbbell shape amphiphilic copolymer are mixed with the polyvinylidene fluoride to produce the polyvinylidene fluoride hyperfiltration membrane with hydrophilicity, anti-pollution, large flux and high retention rate by adopting the solution phase conversion method. The method has the advantages that the obtained membrane is provided with dozens to hundreds nanometer of particular densified hydrogel surface layers, the contact angle of the membrane surface can be reduced below 60 degrees and can be lowered to 0 degree within tens of seconds, the water flux can reach 1000L / m<2> / h (0.1Mpa) or above, the retention rate of BSA can reach 90% or more and the recovery rate of water cleaning flux can reach 90% or higher.

Owner:ZHEJIANG UNIV

Selective membrane having a high fouling resistance

ActiveUS20070175821A1Improve antifouling performanceMembranesSemi-permeable membranesHydrophilic coatingChemical compound

A selective membrane having a high fouling resistance. In one embodiment, the selective membrane is a composite polyamide reverse osmosis membrane in which a hydrophilic coating is applied to the polyamide layer of the membrane, the hydrophilic coating being made by covalently bonding a hydrophilic compound to residual acid chlorides of the polyamide membrane, the hydrophilic compound including (i) at least one reactive group that is adapted to covalently bond directly to the polyamide membrane, the at least one reactive group being at least one of a primary amine and a secondary amine; and (ii) at least one non-terminal hydroxyl group.

Owner:TORAY ADVANCED MATERIALS KOREA

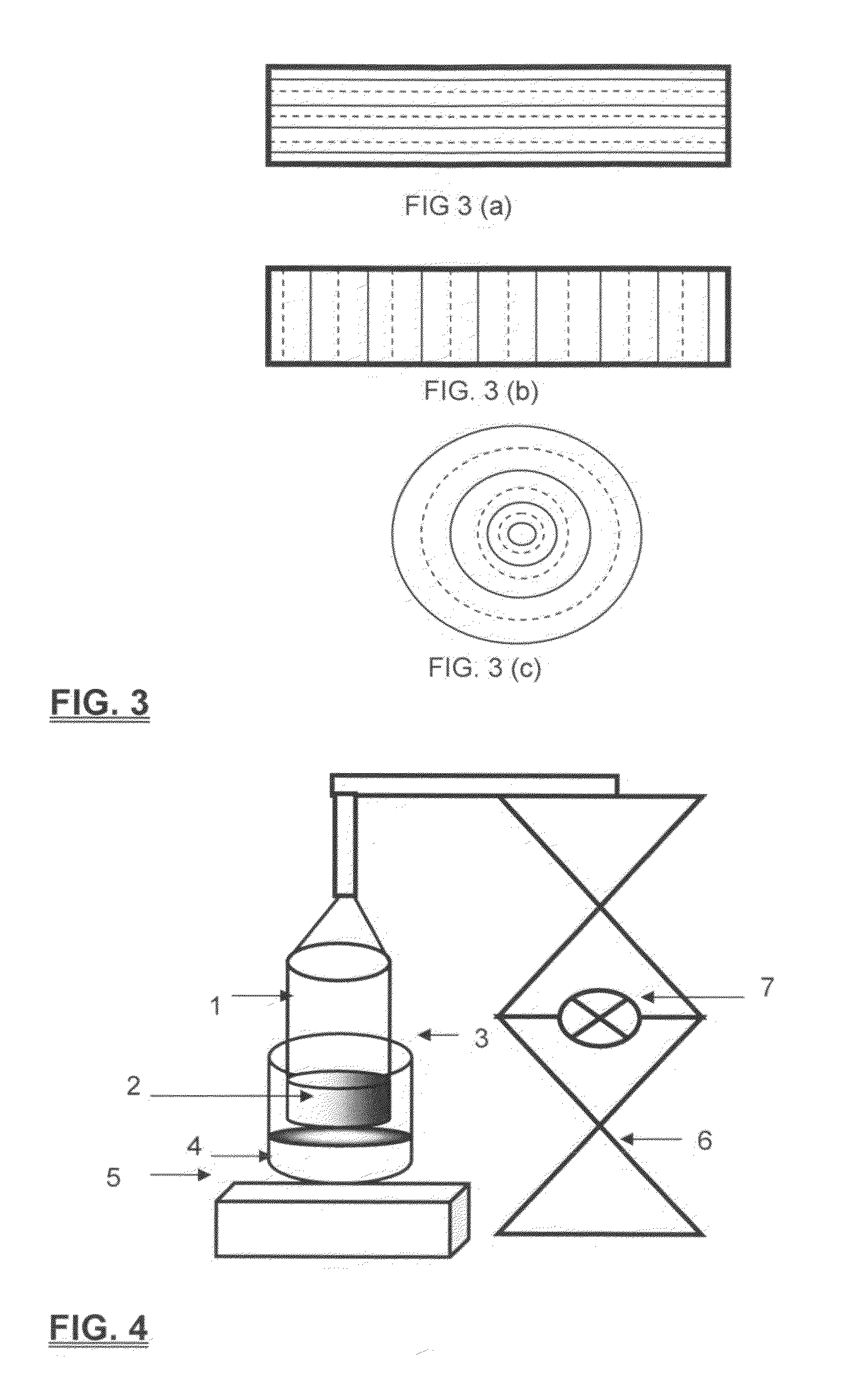

Comfortable and quick-drying type fabric with difference between inner layer and outer-layer of hydrophily and hydrophobicity and production method thereof

ActiveCN1831233AImprove hydrophobicityImprove hydrophilicityFibre treatmentDyeing processEngineeringMoisture

The invention discloses a comfortable, quick drying fabric whose inner and outer layers have hydrophilic and hydrophobic properties, respectively, and the producing method thereof, characterized by that: one side of the fabric is hydrophobic and made by applying water repellent assistant onto the fabric using coating or printing technique, where the region with the water repellent assistant is a water repellent region accounting for 50%-99% of the total area of the hydrophobic side, and the rest of the hydrophobic side is a hydrophilic region accounting for 1%-50% of the total area of the hydrophobic side; and the other side of the fabric is hydrophilic without the water repellent assistant. And water and sweat can be quickly transmitted to the hydrophilic side, so as to have an one-way water transmitting effect, and the clothing made of the fabric is comfortable to wear and quick to dry when absorbing moisture.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

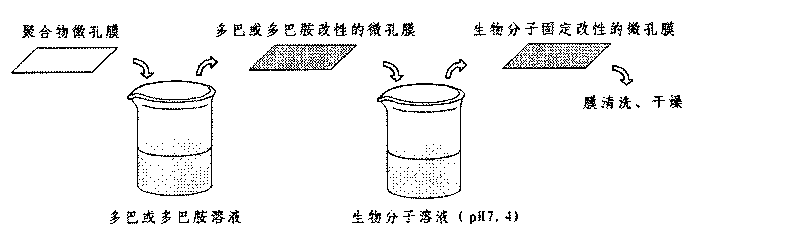

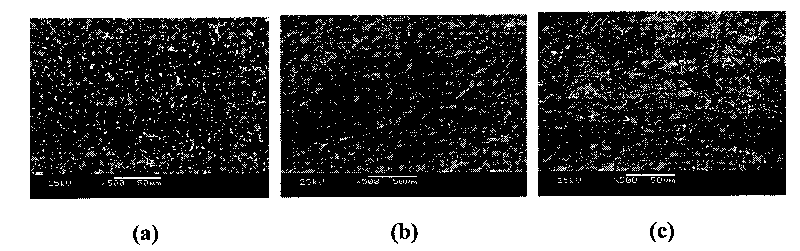

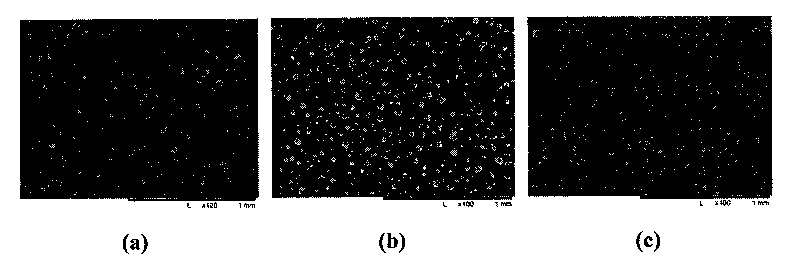

Method for fixing biological molecules on polymer microporous membrane surface

ActiveCN101745327ALow costEase of mass industrial productionSemi-permeable membranesBiocompatibility TestingPhosphoric acid

The invention discloses a method for fixing biological molecules on a polymer microporous membrane surface, comprising the following steps: (1) respectively dissolving DOPA compounds and the biological molecules in a trihydroxymethyl aminomethane - muriatic acid buffer solution and a phosphoric acid buffer solution to prepare solutions; (2) immersing a polymer microporous membrane in a DOPA compound solution and oscillating to cause the DOPA compounds to be auto-polymerized-compounded on the membrane surface and to be closely attached to the membrane surface and a membrane pore wall; (3) immersing the polymer microporous membrane modified by the DOPA compounds in a biological molecule solution, and fixing the biological molecules on the polymer microporous membrane surface by the addition reaction between catechol groups of the membrane surface and amidogen in the biological molecules. The method for fixing biological molecules on the polymer microporous membrane surface has simple process, the prepared polymer microporous membrane has good hydrophilic property and biocompatibility, and the method has important meaning for improving the permeability and the biocompatibility of the polymer microporous membrane.

Owner:ZHEJIANG UNIV

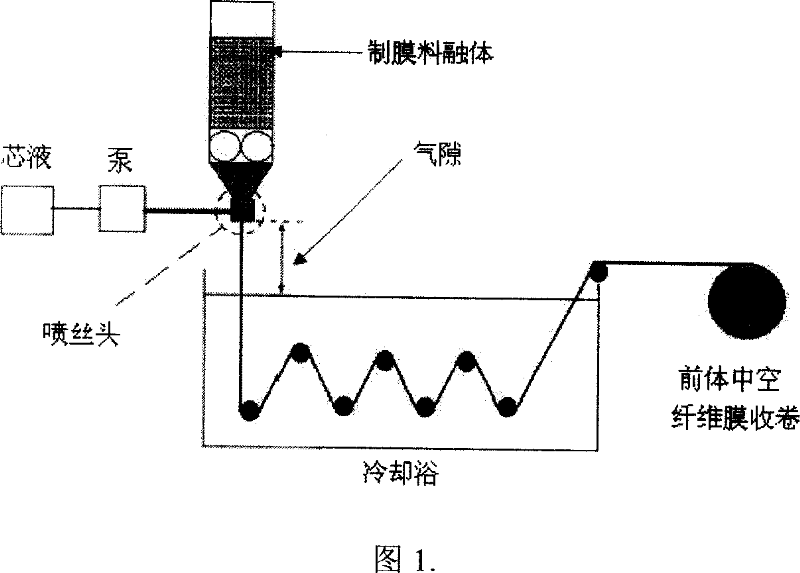

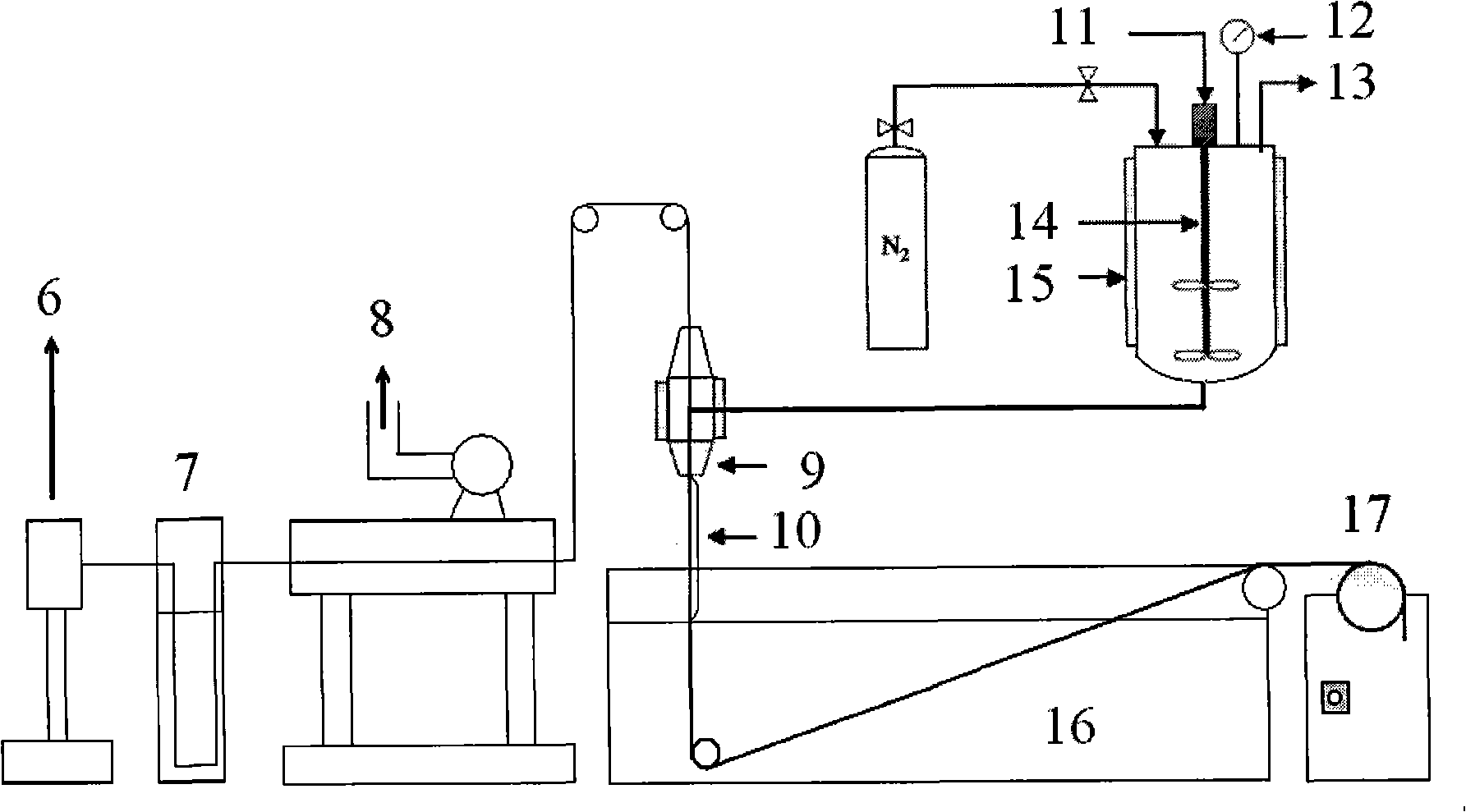

Hydrophilicity polyethylene hollow fiber micro-hole film and the preparation method

InactiveCN101036861AExtended cleaning cycleHydrophilic realizationSemi-permeable membranesFiberMolten state

The invention discloses hydrophilic polyethylene hollow fiber microporous membrane and preparation process thereof. Said membrane is characterized in that it mainly comprises polyethylene, amphoteric copolymer containing polyethylene oxide, and inorganic nano particles. The membrane preparing process is carried out based on thermally induced phpase separation and surface segregation principles, comprising the steps of (1) preparing membrane blank by fusion and blending of amphoteric copolymer containing polyethylene oxide, diluent, and inorganic nano particles; (2) preparing hollow fiber membrane precursor by hollow process spinning of membrane blank in molten state; (3) extracting diluent in hollow fiber membrane precursor by using organic solvent to obtain said hydrophilic polyethylene hollow fiber microporous membrane, wherein the porosity of said membrane is between 40% and 80%, and average pore diameter is between 0.1mum and 5.0mum. The microporous membrane in the invention has the characteristics of high hydrophilicity, narrow pore size distribution, high strength, and good chemical stability, and serves as micro-filtration and ultra-filtration membrane material with high performance, low cost, pollution resistance, and long serve life for water treatment.

Owner:ZHEJIANG UNIV

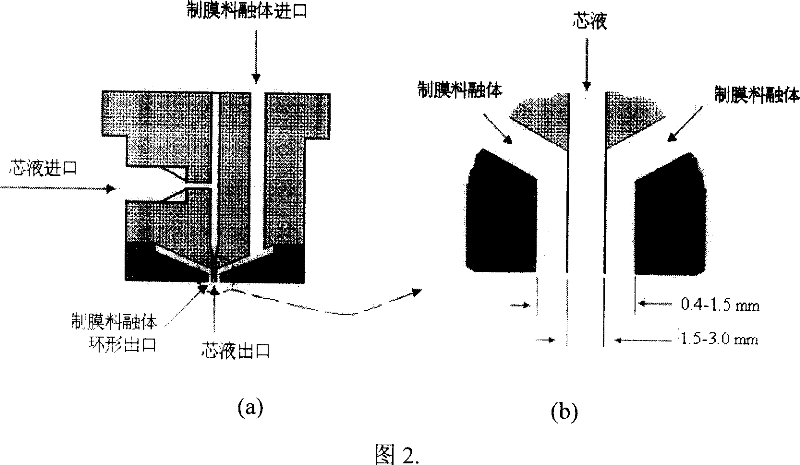

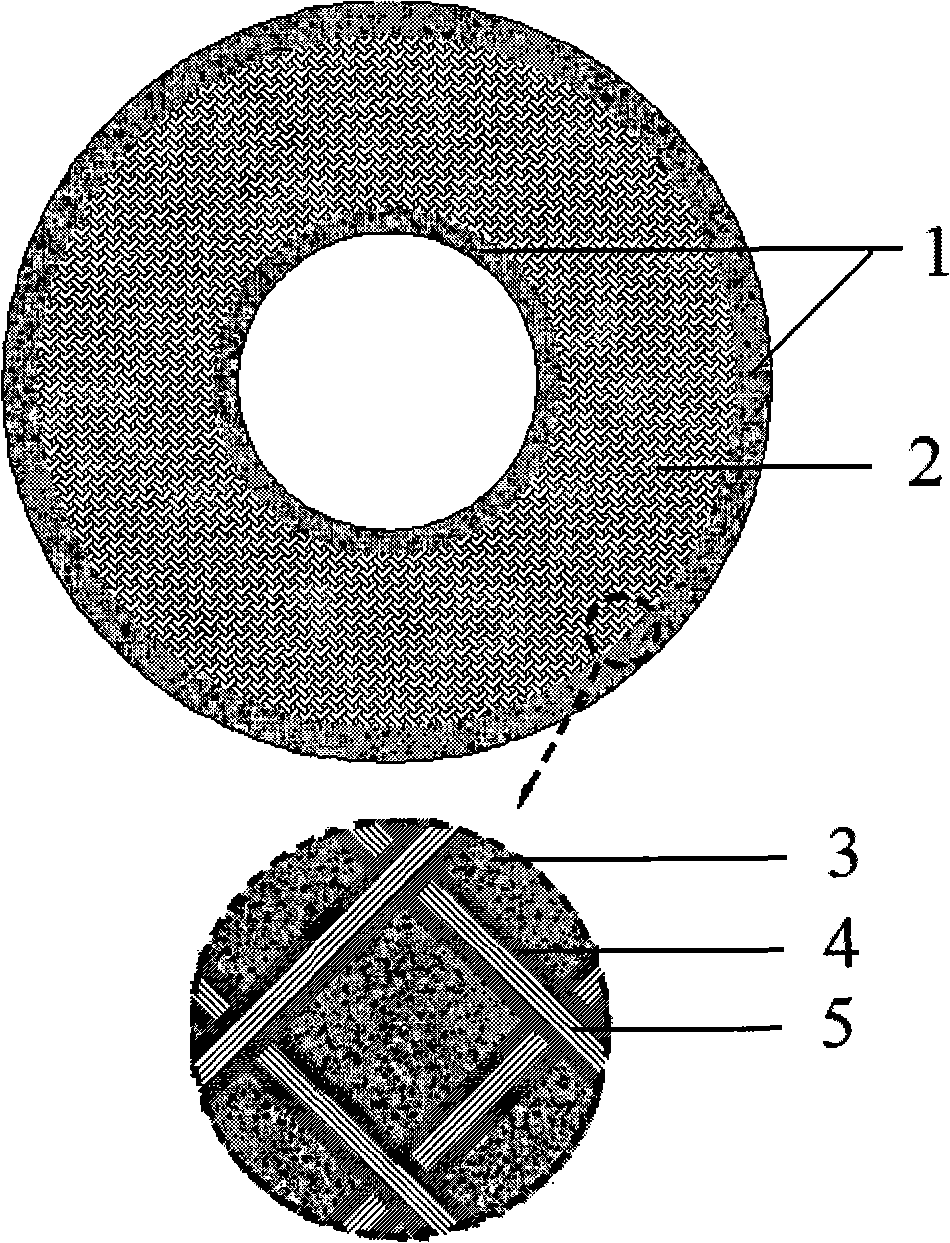

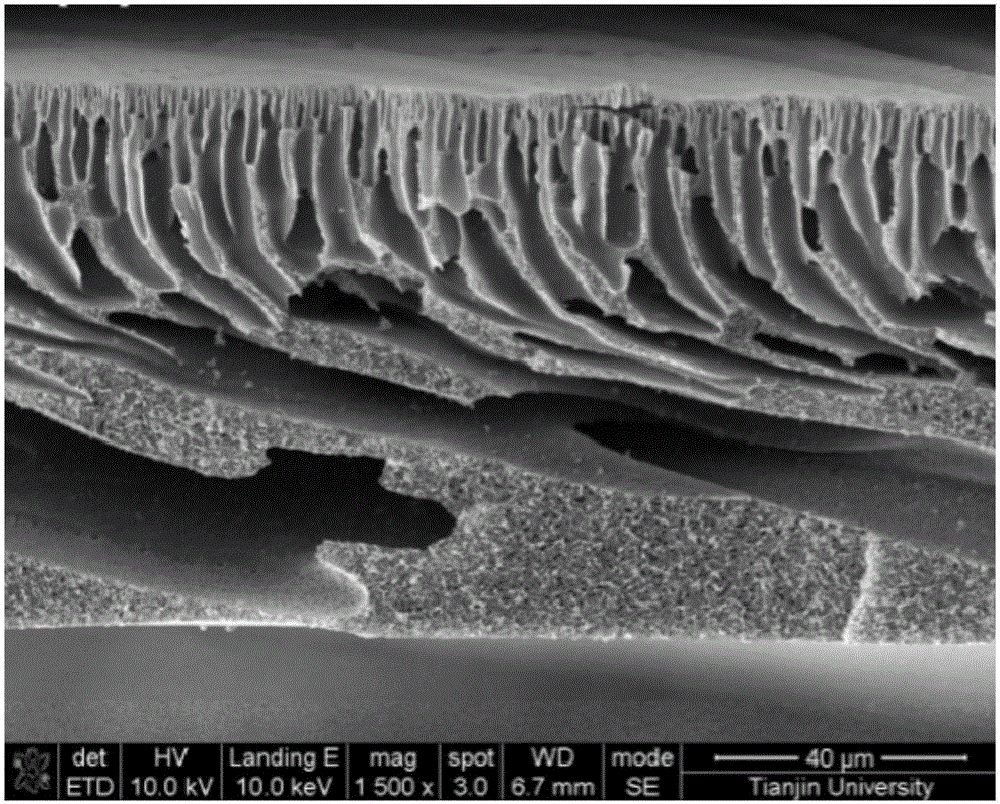

Preparation method of polyvinylidene fluoride hollow fiber composite microporous film with strong interface binding power

InactiveCN101357303AHigh mechanical strengthIncrease backwash pressureSemi-permeable membranesFiberInterfacial bonding

The invention discloses a preparation method of a polyvinylidene fluoride hollow fiber composite microporous membrane which has strong interfacial bonding force. The preparation method comprises the following steps: 1) neutral or amphiphilic substances which have good bonding force with braided fiber tubes and the polyvinylidene fluoride are prepared into dilute solution; 2) the dilute solution of the neutral or amphiphilic substances is coated once on the braided fiber tubes; 3) casting membrane liquid is used for secondary coating on the coated braided fiber tubes, and the polyvinylidene fluoride hollow fiber composite membrane is obtained by a solution phase transition method; 4) post-hydrophilization treatment is carried out; 5) the polyvinylidene fluoride hollow fiber composite membrane is cleaned and dried to obtain the hydrophilic polyvinylidene fluoride hollow fiber composite microporous membrane. The preparation method takes the braided fiber tubes as supporting tubes, uses an amphiphilic copolymer and the polyvinylidene fluoride to be blended, and prepares the polyvinylidene fluoride hollow fiber composite microporous membrane which has strong interfacial bonding force, hydrophilicity, pollution resistance, large flux, high interception rate and high mechanical strength by the solution phase transition method.

Owner:TONGXIANG JIANMIN FILTER MATERIALS

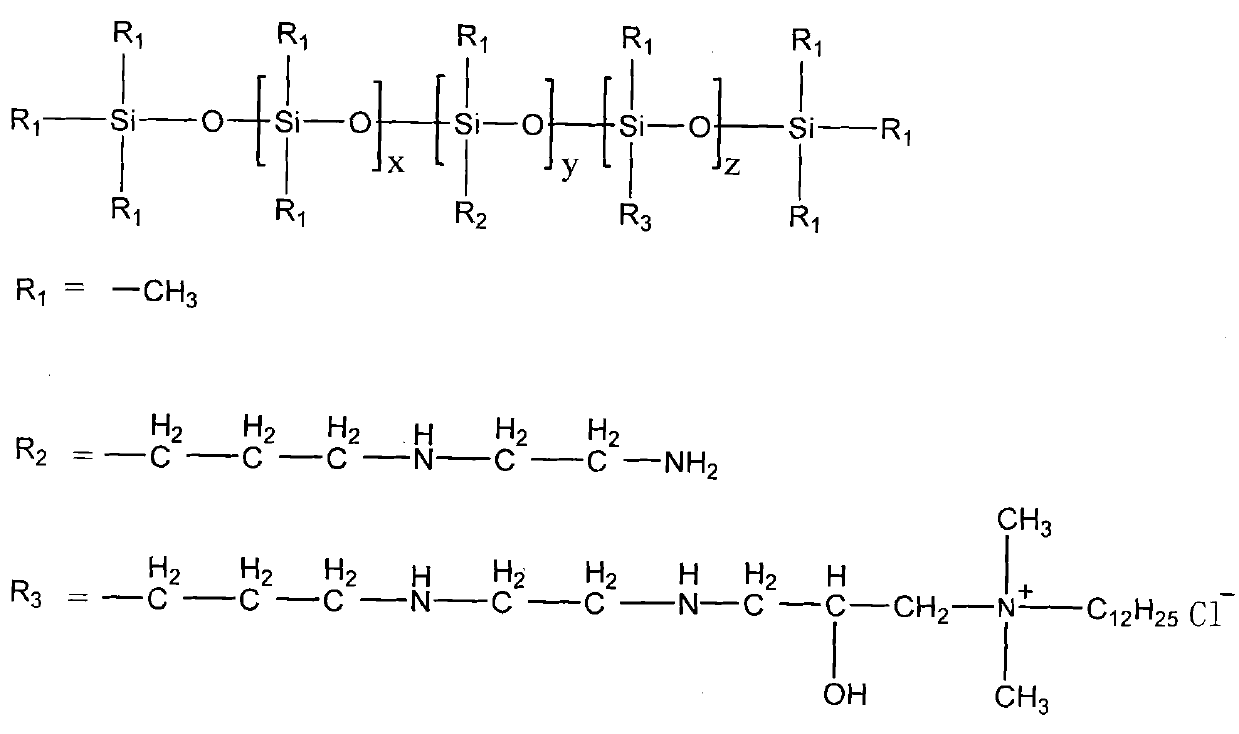

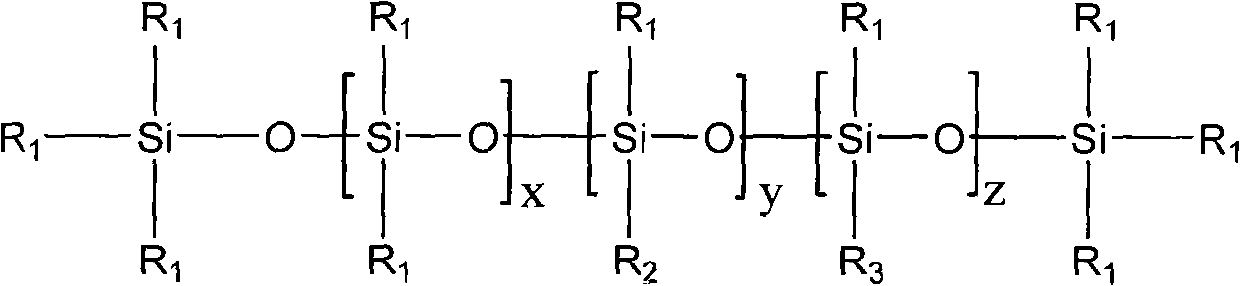

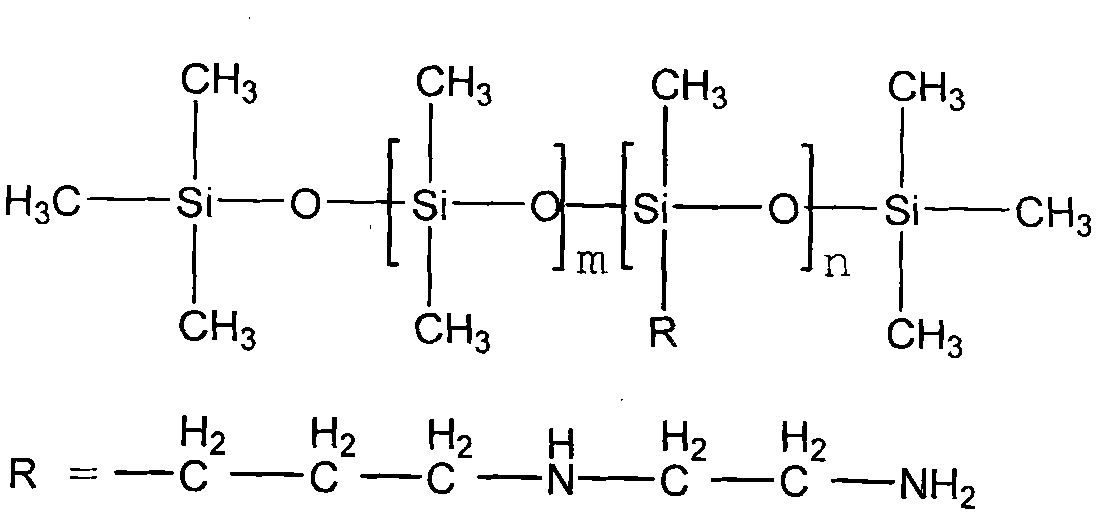

Quaternized modified amino silicone oil softener and preparation and application thereof

InactiveCN101914206AAvoid yellowingImprove hydrophilicityVegetal fibresTetramethylammonium hydroxideDisiloxane

The invention relates to a quaternized modified amino silicone oil softener and preparation and application thereof. The softener comprises the following general formula in the specification. The preparation comprises the following steps of: (1) adding octamethylcy-clotetrasiloxane into a container, adding a coupling agent N-beta-(aminoethyl)-gamma-aminopropyl methyl dimethoxysilane into the container dropwise, adding a tetramethyl ammonium hydroxide catalyst and subsequently a capping agent hexamethyl disiloxane into the container, and then performing reduced pressure distillation to obtain amino silicon oil; (2) dissolving the amino silicon oil into a solvent, adding the mixture into epichlorohydrin, stirring and heating to react under the protection of nitrogen, and removing the solvent by steaming to obtain an intermediate product; and (3) uniformly mixing N,N-dimethyl-decanamide and the solvent to obtain a mixture, stirring with heating, adding the intermediate product dropwise into the mixture under the protection of nitrogen, performing a thermostatic reaction, and removing the solvent by steaming to obtain the product. The softener of the invention has high hydrophilicity and high stability; fabric processed by the softener has excellent soft handfeel, high hydrophilicity, low yellowing, antibacterial property and the like; and the softener is simple to prepare and is suitable for industrial production.

Owner:DONGHUA UNIV

Ternary composite microsphere formulation and its preparation method

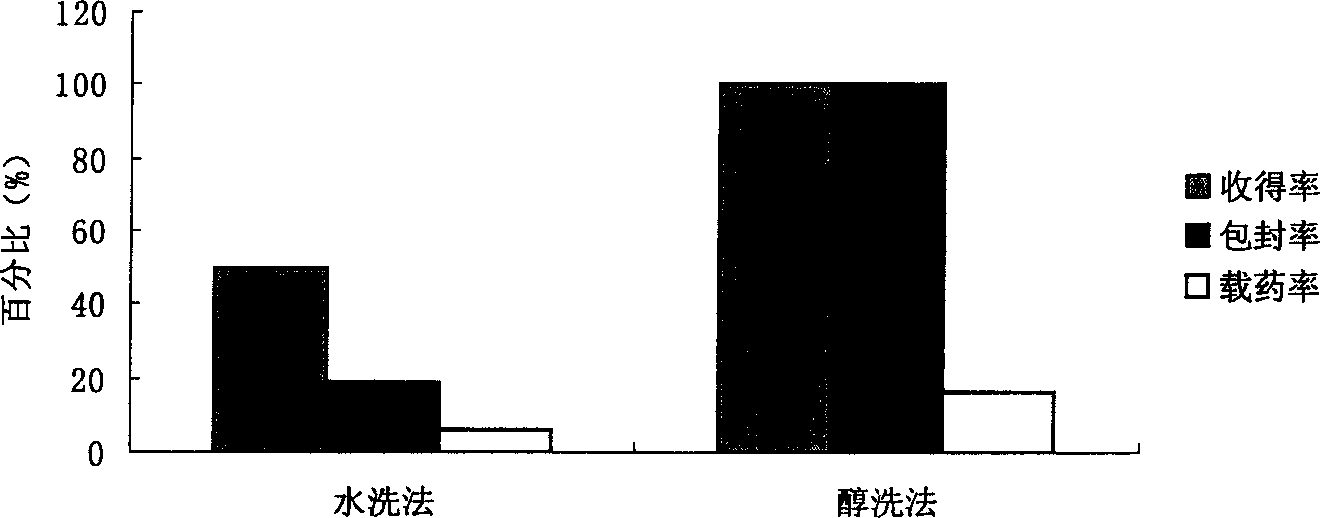

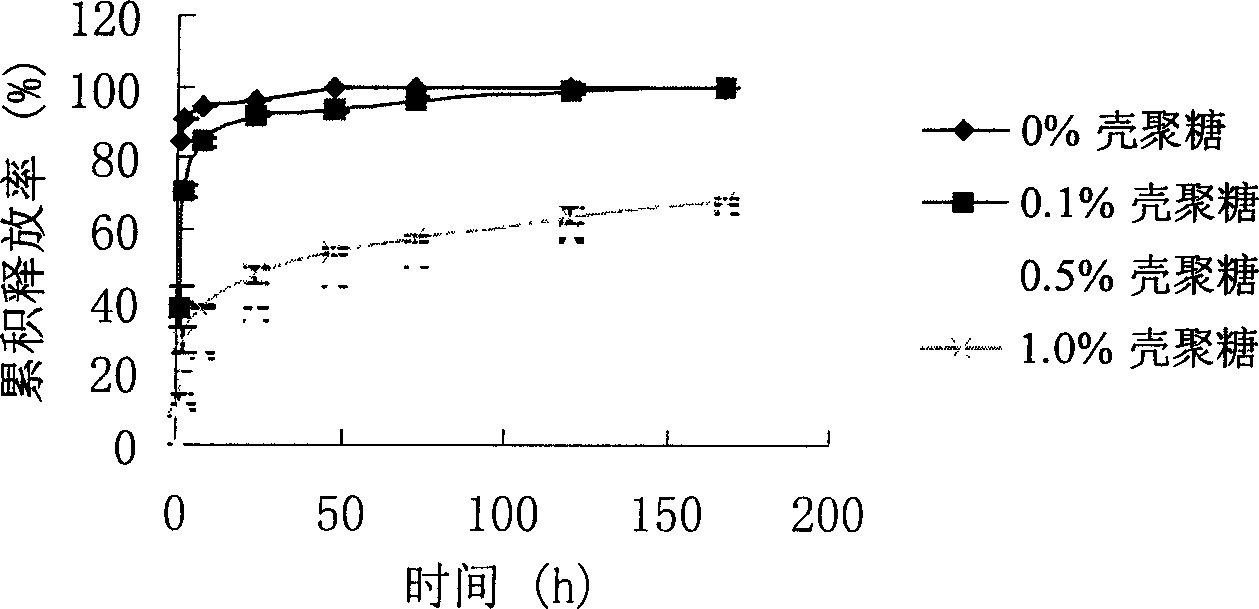

InactiveCN1557283AReduce incomplete releaseImprove protectionPharmaceutical delivery mechanismMicroballoon preparationLactideMicrosphere

The triple composite microsphere preparation consists of mainly model medicine, calcium alginate, chitosan, and diglycolide-lactide copolymer. The preparation process includes W / O emulsification, washing with isopropanol to prepare small calcium alginate microcapsule, coating with chitosan to form compact double-layered alginic acid-chitonsan microcapsule, the subsequent emulsifying and solvent volatilization step to coat the double-layered alginic acid-chitonsan microcapsule into diglycolide-lactide copolymer to form the three-layered composite microsphere. The present invention can protect protein and polypeptide medicine in hydrophilic sodium alginate-chitonsan microcapsule environment to reduce abrupt release and incomplete release, prolong the medicine release time, and regulate the medicine releasing mode via altering PLGA composition.

Owner:ZHEJIANG UNIV

Hybridization hydrogel flat membrane for water filtration and preparation method thereof

InactiveCN103170250ANothing producedHigh strengthSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisCross-linkSolubility

The invention discloses a hybridization hydrogel flat membrane for water filtration and a preparation method thereof. Irreversible deposition of macromolecules, colloids, electrolytes and the like is easy to occur on the surface of the membrane or inside the membrane because of hydrophobicity of a membrane filtration material, and thus causes membrane pollution, resulting in that the membrane flux is reduced continuously and the membrane separation process can not be normally implemented. The invention discloses the hybridization hydrogel flat membrane for water filtration. The flat membrane takes sodium alga acid as a macromolecule skeleton, acrylamide and a ramification of the acrylamide as a polymerization monomer to be added with a chemical crosslinking agent and an ionic crosslinked agent, and a water-solubility compound as a pore-foaming agent, and then a high-strength high-tenacity double cross-linked network hydrogel is formed in a polymerization manner, the pore-foaming agent is eluted so as to obtain the flat membrane which is used for water filtration, and the hybridization hydrogel flat membrane high hydrophily and good anti-fouling performance. The preparation method provided by the invention has the advantages that the process is simple, the cost is low, a waste solvent is not generated, and the obtained hydrogel flat membrane has good application prospect in easily-polluted membrane separation fields such as oil-water separation, protein separation and microorganism filtration.

Owner:TIANJIN POLYTECHNIC UNIV

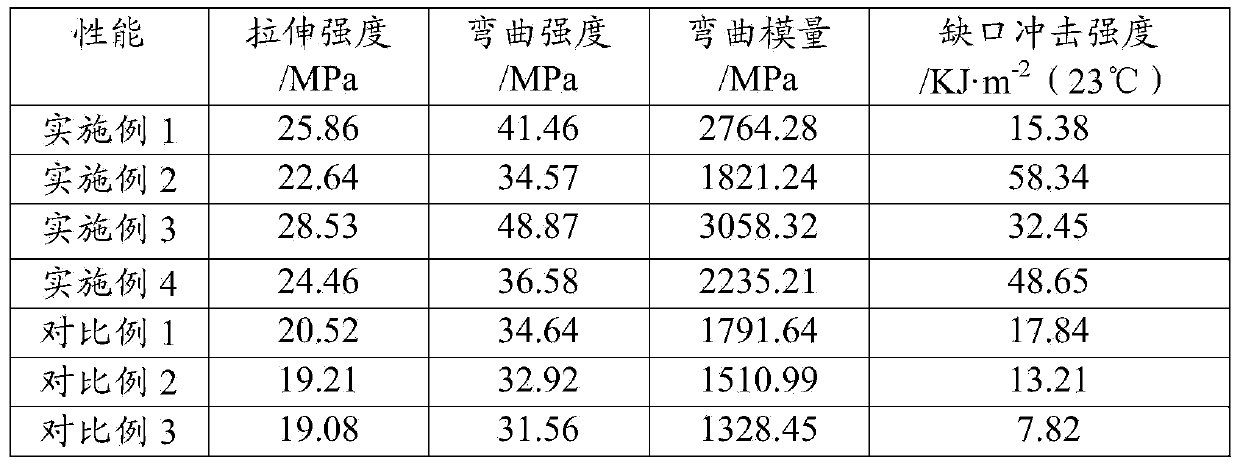

Polypropylene composition and preparation method thereof

The invention provides a polypropylene composition. The polypropylene composition consists of the following components in parts by mass: 10-90 parts of first polypropylene, 3-20 parts of a flexibilizer and 10-80 parts of nano filler master batch, so that the nano-scale polypropylene composition with excellent dispersion and high stiffness-toughness balance is obtained. The invention further provides a preparation method for the polypropylene composition. According to the preparation method provided by the embodiment of the invention, the nano filler is treated by virtue of a modifier, so that the surface polarity of the nano filler is changed into lipophilicity from hydrophily, the compatibility between the nano filler and polypropylene is improved, excellent dispersion of a nano material in polypropylene is realized by virtue of a phase interface transfer process, and thus, the comprehensive performances of the nano polypropylene composition are improved.

Owner:惠州市沃特新材料有限公司

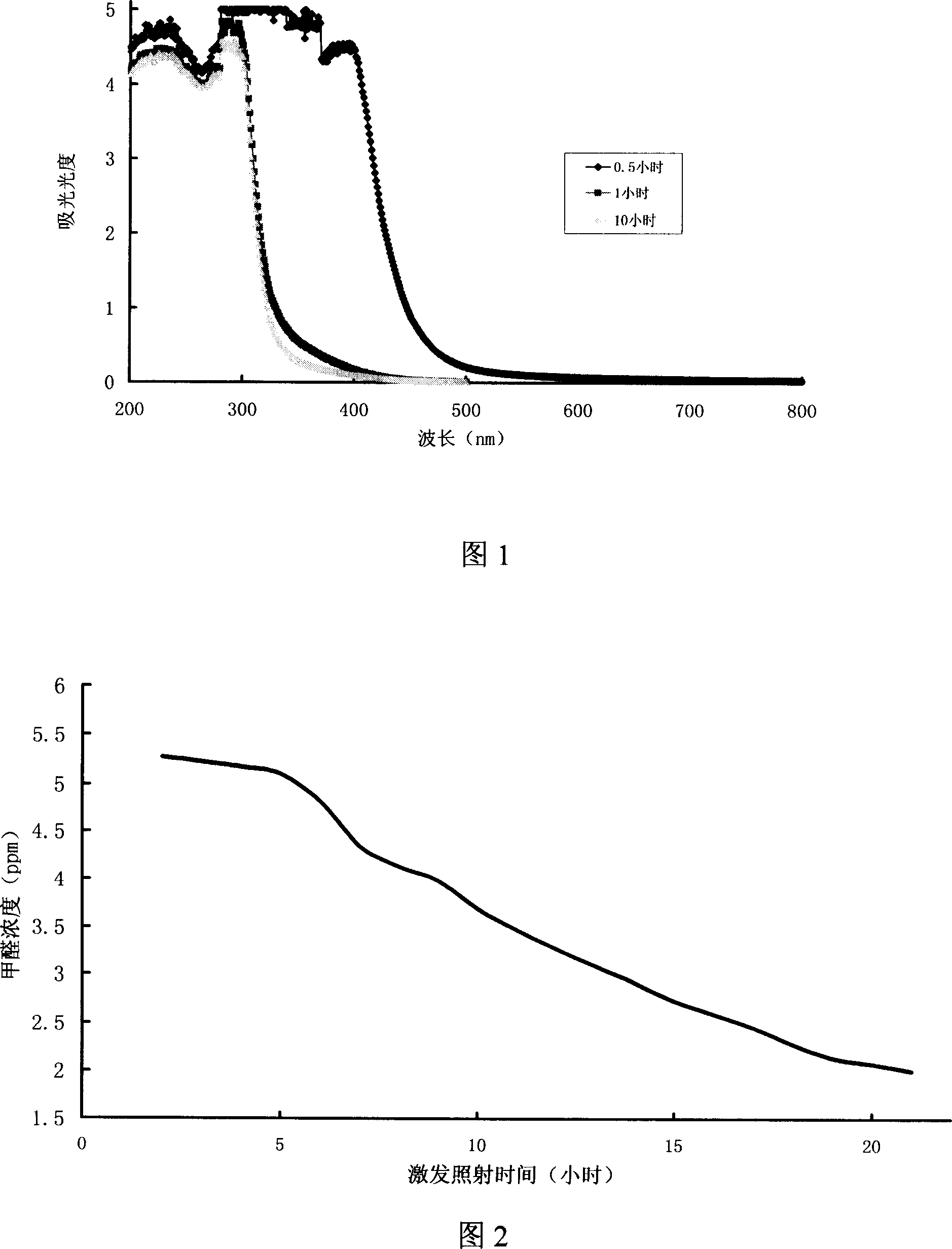

Prepn process of nanometer composite titania/silica photocatalyst sol and transparent photocatalyzing film

InactiveCN101088606AWide variety of sourcesLow pricePhysical/chemical process catalystsDispersed particle separationTitaniumHardness

The present invention belongs to the field of inorganic metal oxide, and is especially process of preparing nanometer titania / silica photocatalyst sol and transparent photocatalyzing film. The anatase type nanometer titania / silica photocatalyst sol is prepared with inorganic low concentration titanium compound solution as material at normal pressure and 40-100 deg.c. The sol has high hydrophilicity, high photocatalyzing activity, high transparency and particle size of 15-30 nm. The sol may be painted onto substrate of different properties to form self-cleaning transparent photocatalyzing film with high hardness and high antifouling and antiseptic performance. The sol has high stability, small and homogeneous size and high performance; and the preparation process has low cost and simple operation and is suitable for large scale production and application.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Preparation method of hydrophilic separation membrane

ActiveCN103861466AImprove hydrophilicityIncreased pure water fluxSemi-permeable membranesChemical reactionMembrane surface

The invention discloses a preparation method of a hydrophilic separation membrane. The separation membrane comprises a basement membrane support layer and a hydrophilic separation membrane layer. According to the method, by membrane surface chemical reaction, a hydrophilic substance is introduced into hydroxylated-treated basement membrane support layer surface to form the hydrophilic separation membrane layer. The separation membrane has a good hydrophilic property and high pure water flux. The preparation method of the hydrophilic separation membrane is a simple, effective and practical membrane preparation method. The separation membrane can be used in water treatment, food, pharmaceuticals, petrochemical industry and other fields.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

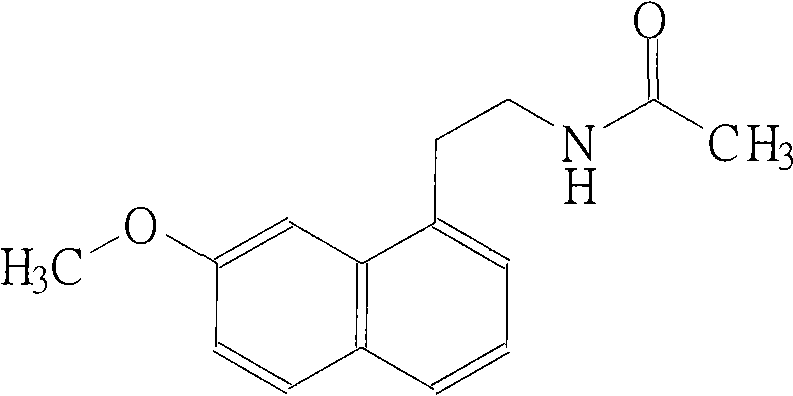

Preparation method of agomelatine I type crystal

The invention discloses a preparation method of an agomelatine I type crystal which is an anti-depressant. The preparation method comprises the following steps of: dissolving crude agomelatine in a hydrophily organic solvent, filtering, dropping the filtrate into water under stirring, separating out solids and drying; wherein the weight part ratio of the hydrophily organic solvent to the water is 1:2-50. The agomelatine I type crystal prepared by the invention has excellent quality, good reproducibility, and high purity of HPLC normalization method to be above 99 percent, and is more suitable for large-scale industrialization production.

Owner:TIANJIN TAIPU PHARMA SCI & TECH DEV

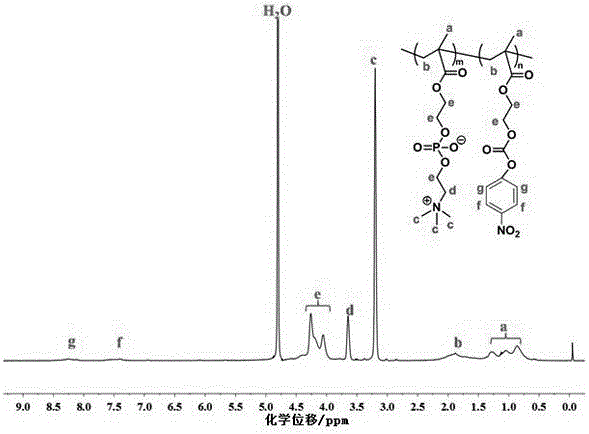

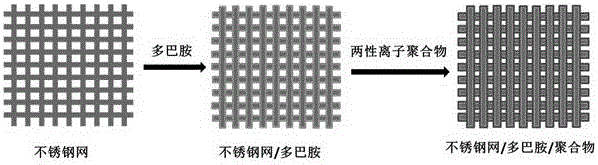

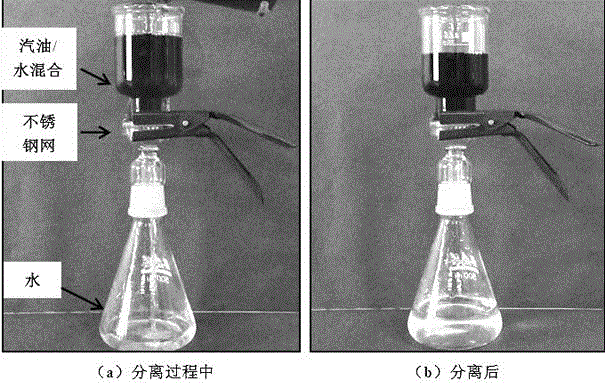

Method for preparing hydrophilic/oleophobic oil-water separation stainless steel net films

ActiveCN105964014AHigh strengthCorrosion resistantMembranesSemi-permeable membranesDip-coatingPollution

The invention relates to a method for preparing hydrophilic / oleophobic oil-water separation stainless steel net films. Stainless steel nets are used as bases. The method includes constructing a poly-dopamine medium layer on the surface of each stainless steel net in dip-coating or spraying modes; dipping the stainless steel nets with the poly-dopamine medium layers in zwitter-ionic polymers with active ester groups; or spraying the zwitter-ionic polymers with the active ester groups on the surfaces and meshes of the stainless steel nets with the poly-dopamine medium layers; carrying out amidation coupling reaction on the zwitter-ionic polymers and each poly-dopamine medium layer to form a stable hydrophilic polymer film on the surface and the meshes of the corresponding stainless steel net. The method has the advantages that the hydrophilic / oleophobic oil-water separation stainless steel net films prepared by the aid of the method are super-hydrophilic and are high in water flux, stable in structural performance and high in anti-pollution capacity; the method has a broad application prospect in the aspects of recycling marine oil slick, removing water from crude oil, treating oily sewage and the like.

Owner:NORTHWEST UNIV

Hydrophilic modification method of polytetrafluorethylene separation membrane surface

InactiveCN101301591ASimple production processSuitable for industrial productionSemi-permeable membranesCross-linkHydrophilization

The present invention discloses a hydrophilization modification method of polytetrafluoroethylene membrane surface, comprising the following course: pretreating the polytetrafluoroethylene membrane by lycine surfactant, evenly coating a layer of hydrophilic polymer on the surface, placing the membrane material coated with hydrophilic polymer into the quaternized cross linker solution for in-situ quaternized cross linking reaction, finally getting the lasting hydrophilic modified polytetrafluoroethylene separation membrane. The present invention has abundant modifier source, simple method and low cost, and is suitable for industrial production; the cross-linked hydrophilic layer on the membrane surface is not liable to drain away; the modified polytetrafluoroethylene membrane has good hydrophilicity and persistence.

Owner:ZHEJIANG UNIV

Charged membrane

InactiveUS6849185B1Ion-exchanger regenerationSolid sorbent liquid separationBacterial contaminantsMicroporous membranes

The present invention provides a hydrophilic charged microporous membrane comprising a porous hydrophobic substrate and a coating comprising a charge-providing agent. The present invention further provides a hydrophilic charged membrane comprising a porous hydrophobic substrate and a hydrophilic charge-providing agent distributed within the substrate. The present invention further provides a filter as well as a filter device comprising the inventive hydrophilic charged membrane. The present invention further provides a process for treating a fluid containing bacterial contaminants such as endotoxins comprising contacting the membrane with the fluid to provide a bacterial contaminant depleted fluid.

Owner:PALL CORP

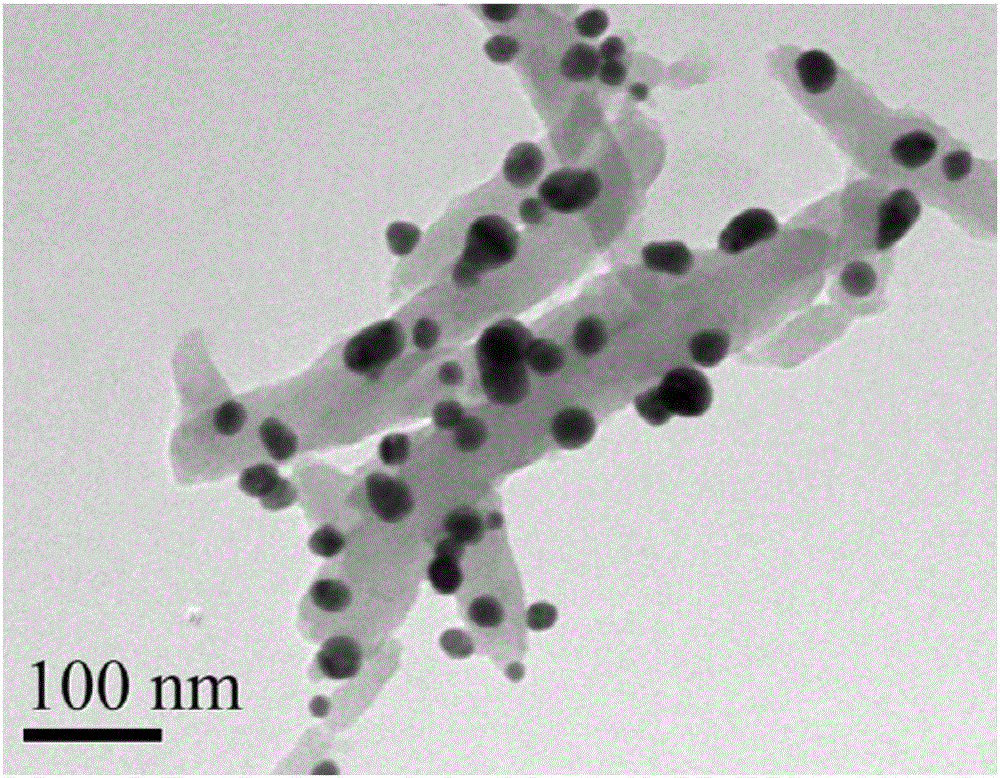

Method of preparing antibacterial anti-pollution ultrafiltration membrane by adopting silver-loaded nano composite material

ActiveCN105195025AImprove hydrophilicityImprove antibacterial propertiesBiocideSemi-permeable membranesUltrafiltrationPollution

The invention discloses a method of preparing an antibacterial anti-pollution ultrafiltration membrane by adopting a silver-loaded nano composite material. The method comprises the following steps: preparing a nano material water dispersion solution, adding trihydroxymethyl aminomethane and dopamine hydrochloride, stirring and reacting for 2 to 12 hours, centrifugally washing, then drying to obtain a polydopamine-modified nano material; preparing a mixed solution containing the polydopamine-modified nano material, a silver-ammonium solution, a stabilizer and water, stirring for 2 to 12 hours, centrifugally washing, and then drying to obtain the silver-loaded nano composite material; dispersing the silver-loaded nano composite material in an organic solvent, adding a membrane material, stirring, completely dissolving the membrane material, and standing to obtain a membrane casting solution; and scraping the membrane casting solution into a flat membrane by utilizing a flat membrane scraping machine, immersing in a coagulating bath, and carrying out a phase conversion to obtain the antibacterial anti-pollution ultrafiltration membrane. The ultrafiltration membrane has good hydrophilia, durable antibacterial performance and excellent anti-pollution performance, has good antibacterial and sterilization effect for colibacillus, bacillus subtilis and the like; moreover, the silver nano particles stably exist in the antibacterial anti-pollution ultrafiltration membrane.

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com