Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

548 results about "Interfacial bonding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

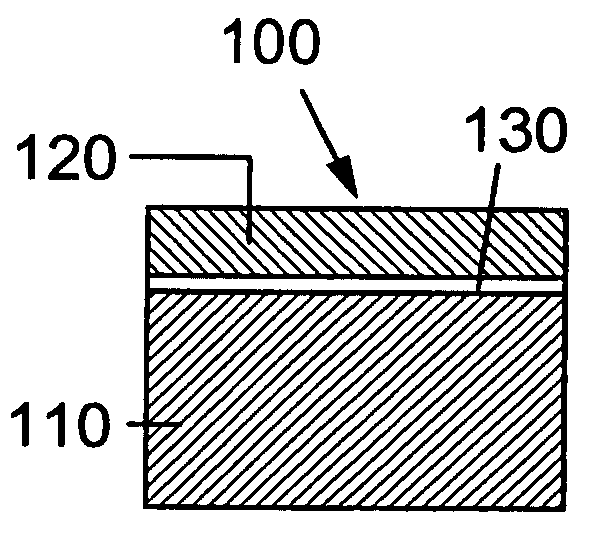

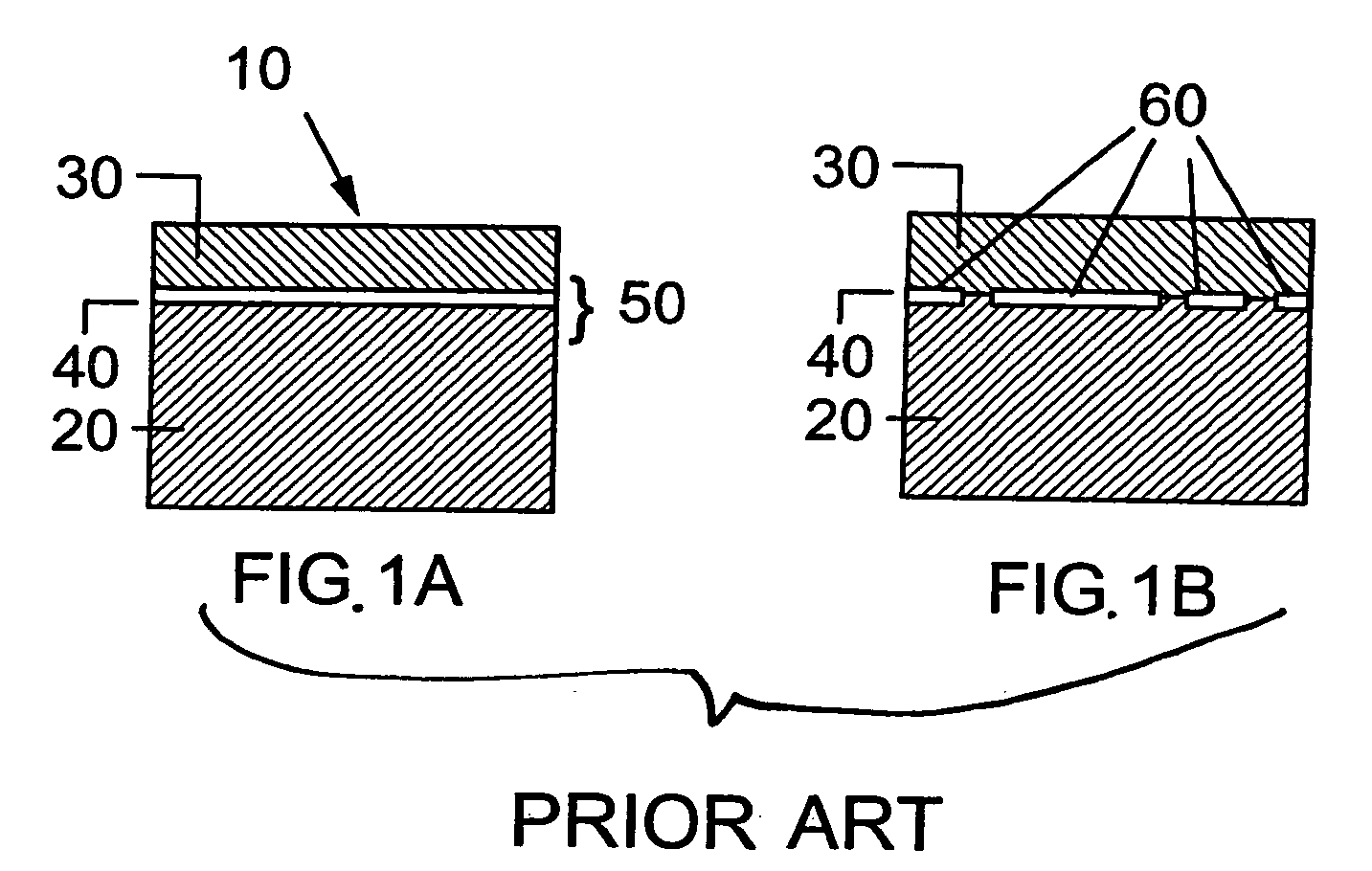

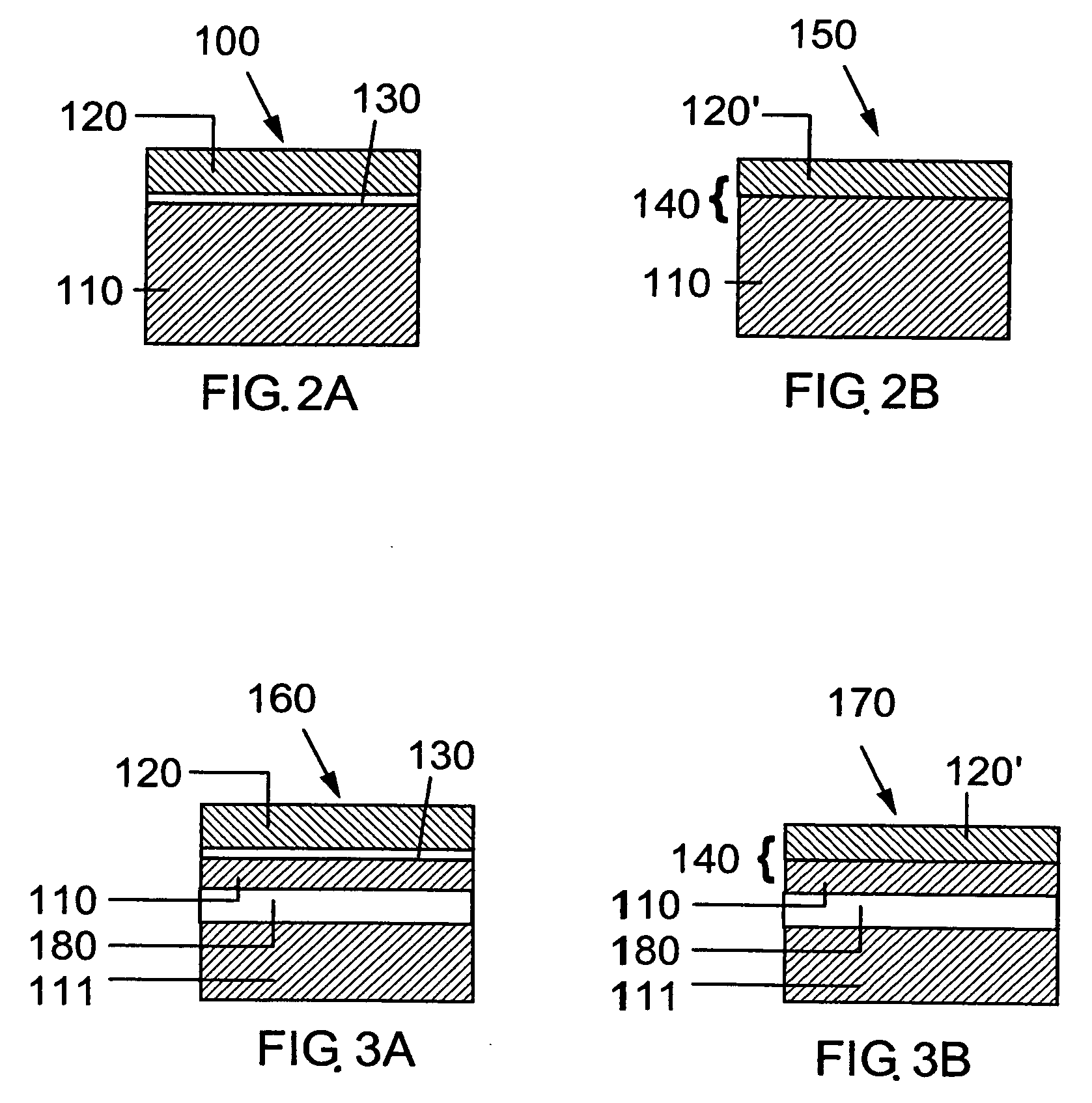

Quasi-hydrophobic Si-Si wafer bonding using hydrophilic Si surfaces and dissolution of interfacial bonding oxide

InactiveUS20060154442A1Thinning and removing materialSemiconductor/solid-state device manufacturingInterfacial oxideSemiconductor materials

The present invention provides a method for removing or reducing the thickness of ultrathin interfacial oxides remaining at Si—Si interfaces after silicon wafer bonding. In particular, the invention provides a method for removing ultrathin interfacial oxides remaining after hydrophilic Si—Si wafer bonding to create bonded Si—Si interfaces having properties comparable to those achieved with hydrophobic bonding. Interfacial oxide layers of order of about 2 to about 3 nm are dissolved away by high temperature annealing, for example, an anneal at 1300°-1330° C. for 1-5 hours. The inventive method is used to best advantage when the Si surfaces at the bonded interface have different surface orientations, for example, when a Si surface having a (100) orientation is bonded to a Si surface having a (110) orientation. In a more general aspect of the invention, the similar annealing processes may be used to remove undesired material disposed at a bonded interface of two silicon-containing semiconductor materials. The two silicon-containing semiconductor materials may be the same or different in surface crystal orientation, microstructure (single-crystal, polycrystalline, or amorphous), and composition.

Owner:GLOBALFOUNDRIES INC

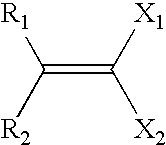

Surgical adhesive compostion and process for enhanced tissue closure and healing

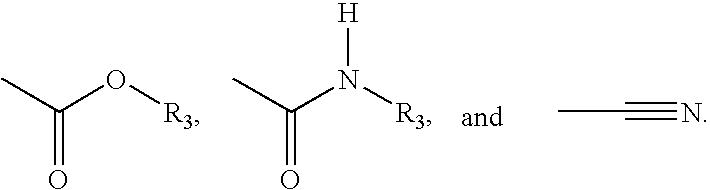

InactiveUS20070092483A1Promotes cellPromotes tissue in-growthPharmaceutical non-active ingredientsSynthetic polymeric active ingredientsPorositySide chain

A surgical tissue adhesive composition contains at least one 1,1-disubstituted electron-deficient olefin macromer. The adhesive composition of the invention has improved biocompatibility as well as controlled biodegradation characteristics and bioactivity. Adhesive co-monomer compositions contain at least one macromer with a pendant oligomer, polymer, or peptide chain as an acrylic ester of the reactive olefin. The polymers formed therefrom have a grafted brush-like nature. The composition is particularly useful for creating an adhesive bond at the junction of living tissue in surgical applications. The adhesive composition may further comprise co-monomer, co-macromer, cross-linker, or inter-penetrating polymer compounds containing peptide sequences that are bioactive or enzyme responsive. The peptide sequences are selected to promote tissue infiltration and healing in a particular biological tissue. The sequences may contain specific cell-adhesion, cell-signaling, and enzyme-cleavable domains. Furthermore, a degradable filler material may be included in the composition to create a reinforced composite. The filler preferably has a higher degradation rate than the polymer matrix, generating porosity upon degradation. The adhesive may further contain entrapped or incorporated drugs or biologics, including antibiotics or growth factors. The adhesive can be used to bind together the edges of living tissues during surgical procedures. The cured composition provides interfacial bonding and mechanical fixation while promoting tissue infiltration and replacement of the adhesive polymer.

Owner:POLLOCK POLYMER GROUP

Silicon-dioxide aerogel heat insulation composite material and preparation method thereof

InactiveCN103011745AImprove mechanical propertiesChange the chemical state of the surfaceFiberSupercritical drying

The invention provides a fiber-reinforced silicon-dioxide aerogel heat insulation composite material and a preparation method thereof. According to the preparation method, mineral fibers with high mechanical strength, low heat conductivity and good heat stability serve as a reinforcing phase, silicon alcoholate serves as a precursor, fiber-composite silicon-dioxide wet gel is prepared by adopting an acid-base two-step catalysis method, and the block-shaped fiber-reinforced silicon-dioxide aerogel heat insulation composite material is then obtained through aging, modification, solvent displacement and supercritical drying. The prepared aerogel heat insulation composite material has the advantages of excellent mechanical property, good heat-insulating property and higher heat resistance. The aerogel composite material has a three-dimensional porous network-like structure, the compatibility between fibers and an aerogel matrix is good, the interfacial bonding is firm, and no obvious interfaces exist; and according to the block-shaped aerogel composite material, the density is 0.15-0.25 g / cm<3>, the compressive strength is 10%, the strain energy reaches 0.4-2.0MPa, and the coefficient of heat conductivity is 0.016-0.027 W / mK.

Owner:TIANJIN UNIV

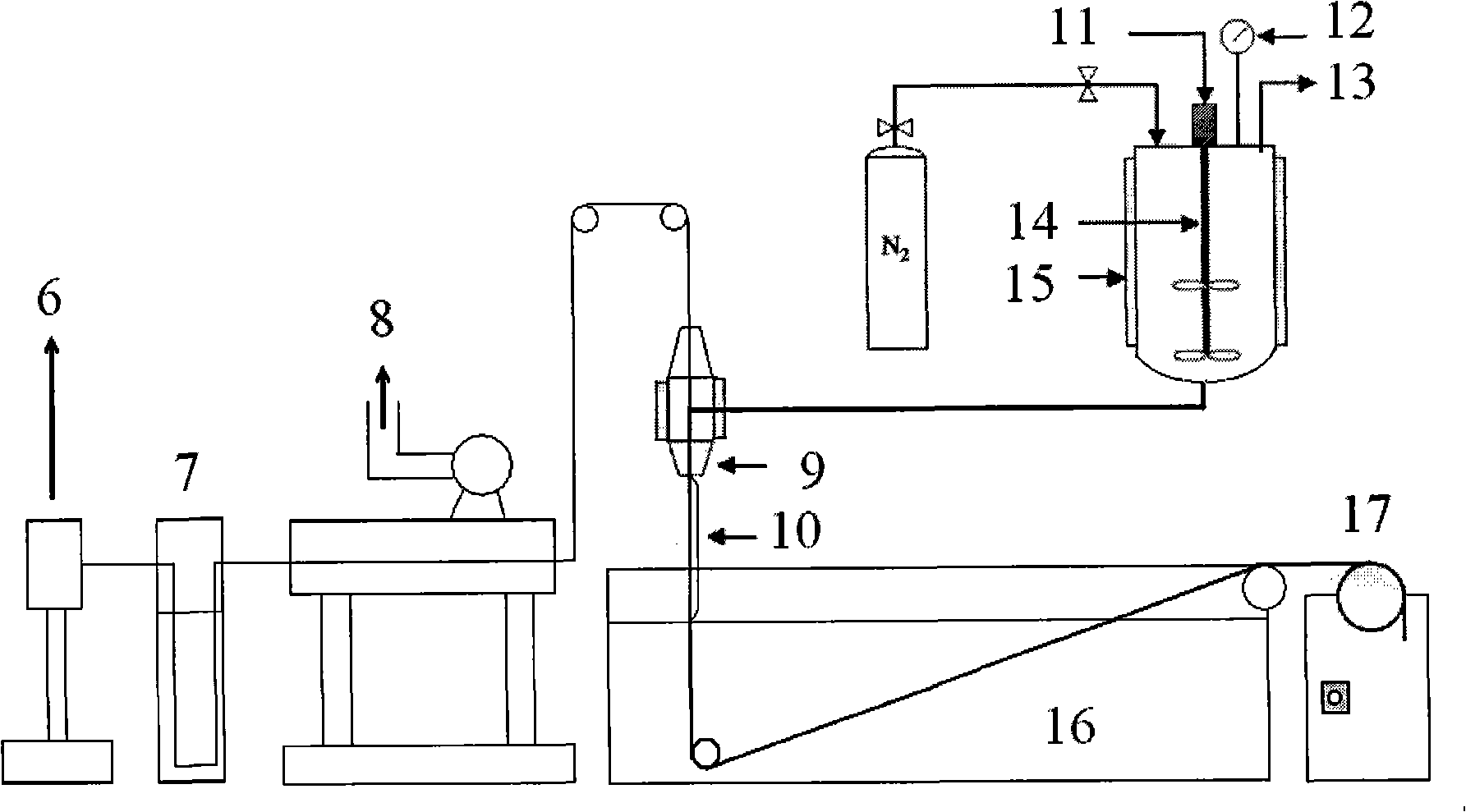

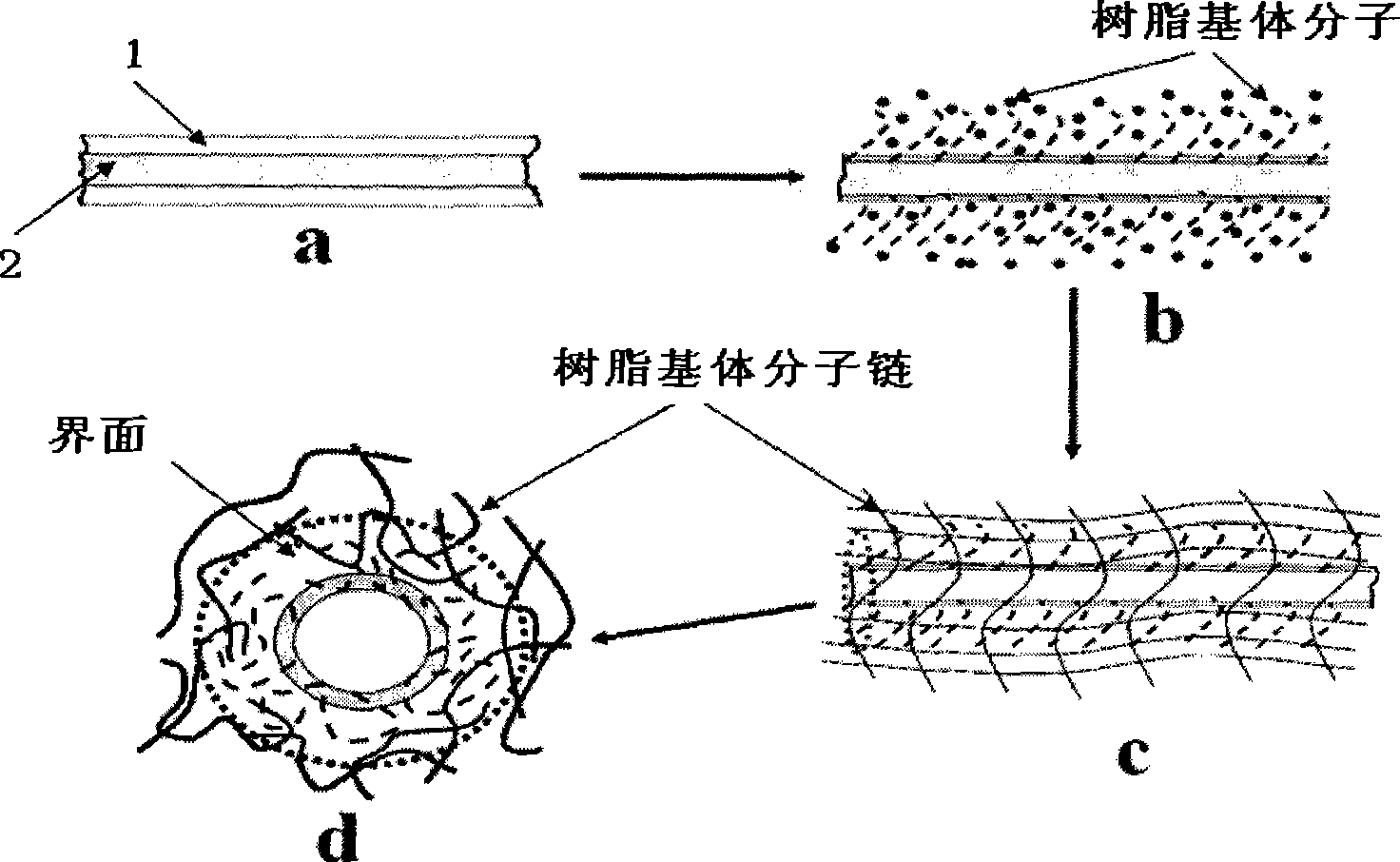

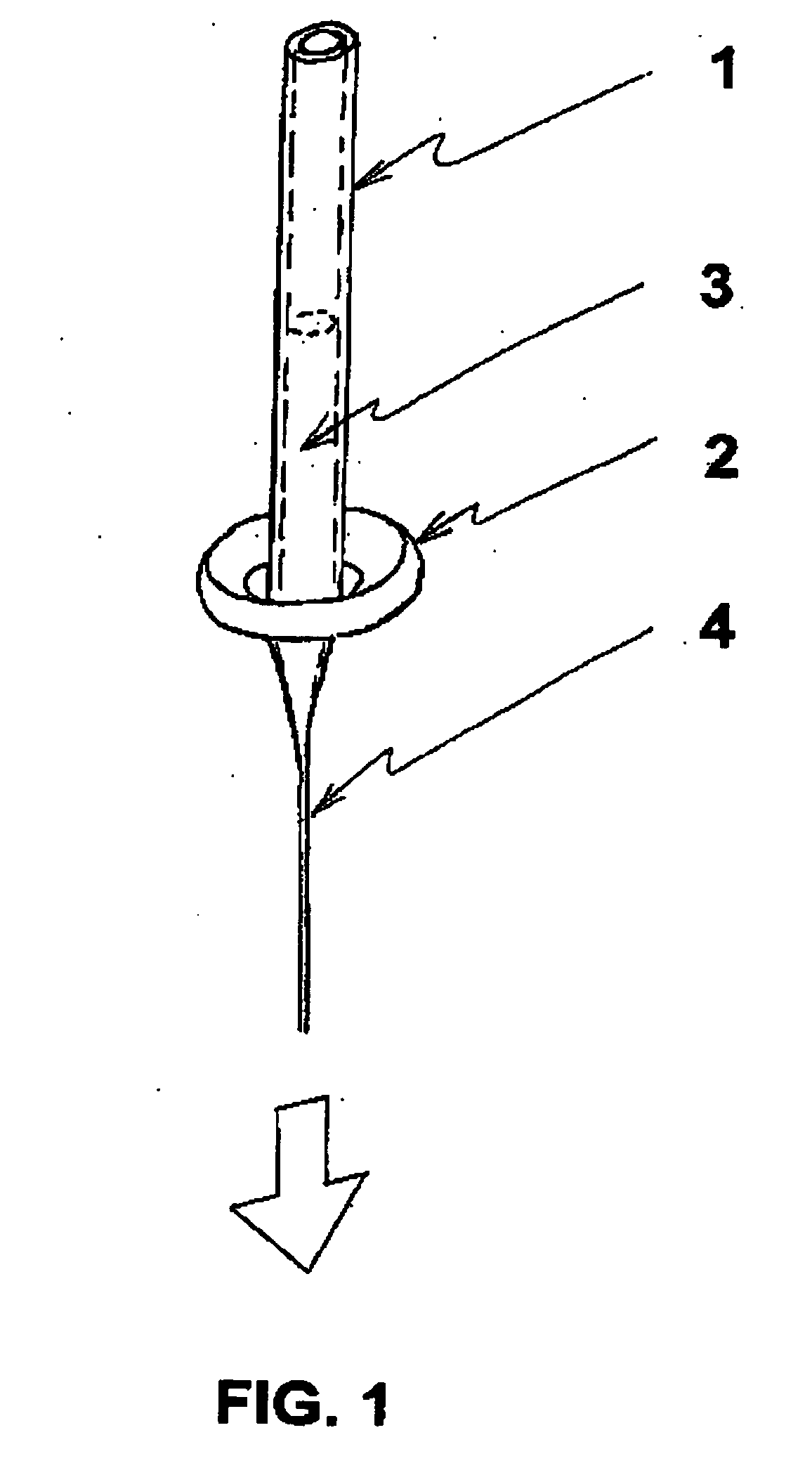

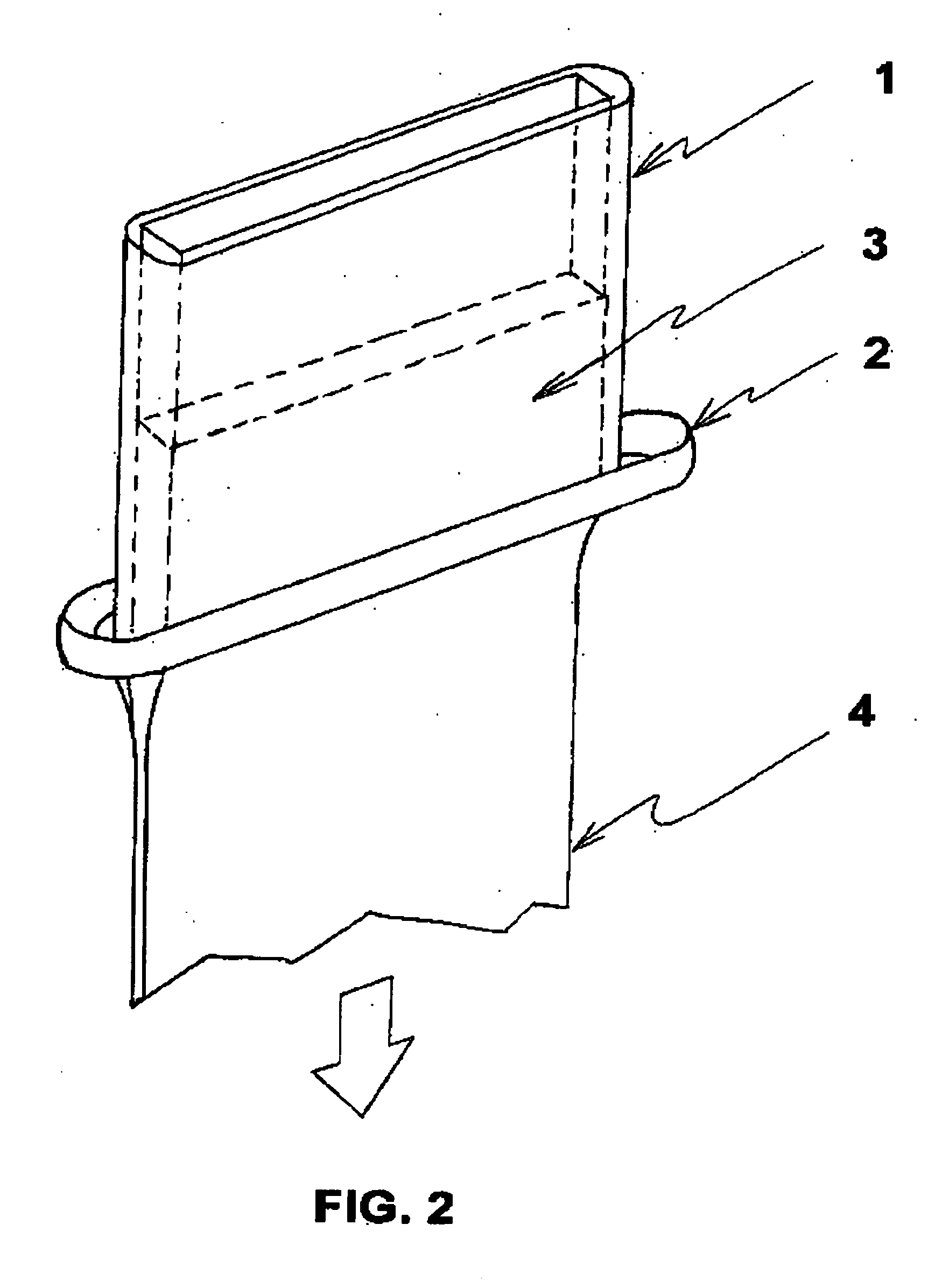

Preparation method of polyvinylidene fluoride hollow fiber composite microporous film with strong interface binding power

InactiveCN101357303AHigh mechanical strengthIncrease backwash pressureSemi-permeable membranesFiberInterfacial bonding

The invention discloses a preparation method of a polyvinylidene fluoride hollow fiber composite microporous membrane which has strong interfacial bonding force. The preparation method comprises the following steps: 1) neutral or amphiphilic substances which have good bonding force with braided fiber tubes and the polyvinylidene fluoride are prepared into dilute solution; 2) the dilute solution of the neutral or amphiphilic substances is coated once on the braided fiber tubes; 3) casting membrane liquid is used for secondary coating on the coated braided fiber tubes, and the polyvinylidene fluoride hollow fiber composite membrane is obtained by a solution phase transition method; 4) post-hydrophilization treatment is carried out; 5) the polyvinylidene fluoride hollow fiber composite membrane is cleaned and dried to obtain the hydrophilic polyvinylidene fluoride hollow fiber composite microporous membrane. The preparation method takes the braided fiber tubes as supporting tubes, uses an amphiphilic copolymer and the polyvinylidene fluoride to be blended, and prepares the polyvinylidene fluoride hollow fiber composite microporous membrane which has strong interfacial bonding force, hydrophilicity, pollution resistance, large flux, high interception rate and high mechanical strength by the solution phase transition method.

Owner:TONGXIANG JIANMIN FILTER MATERIALS

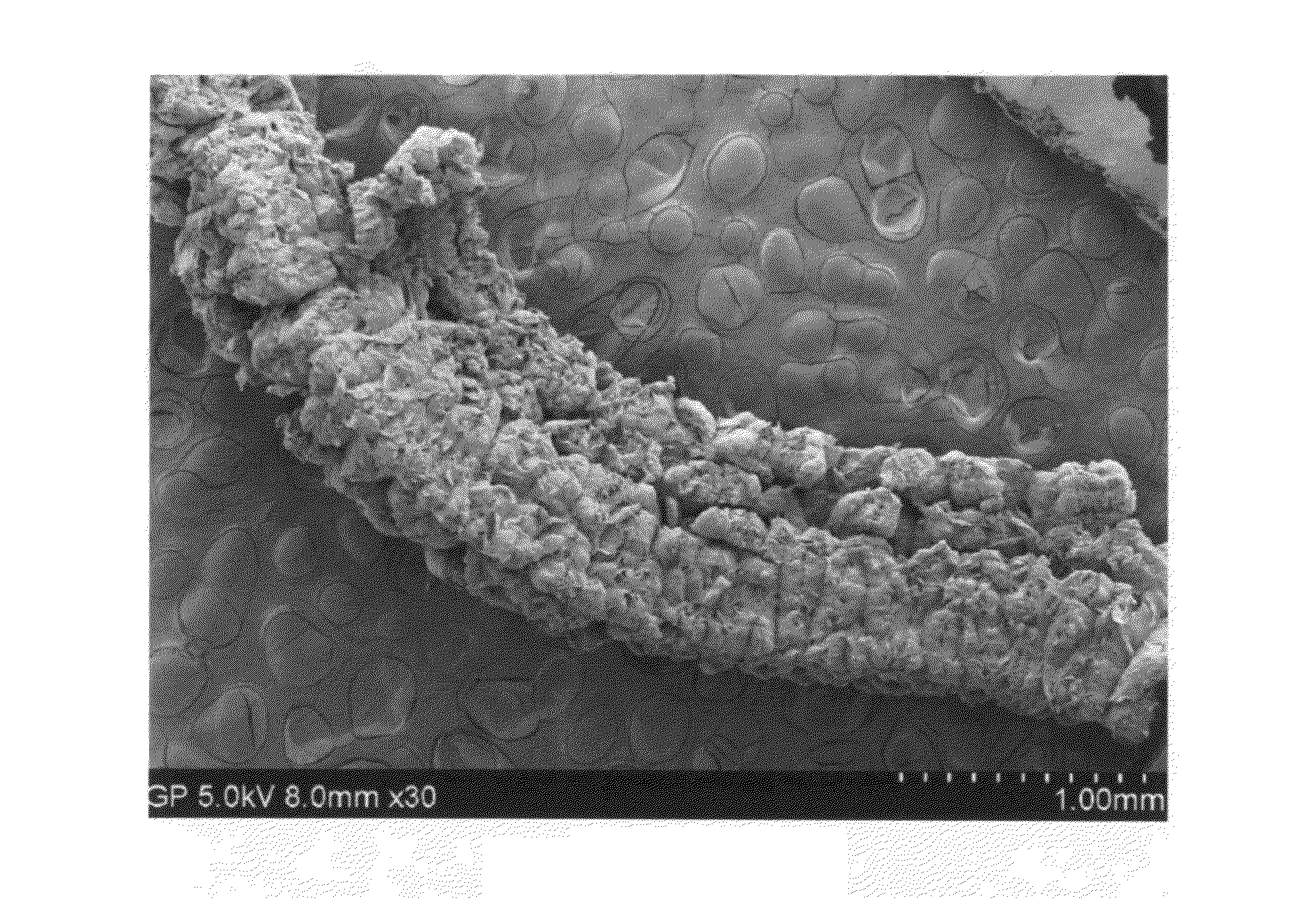

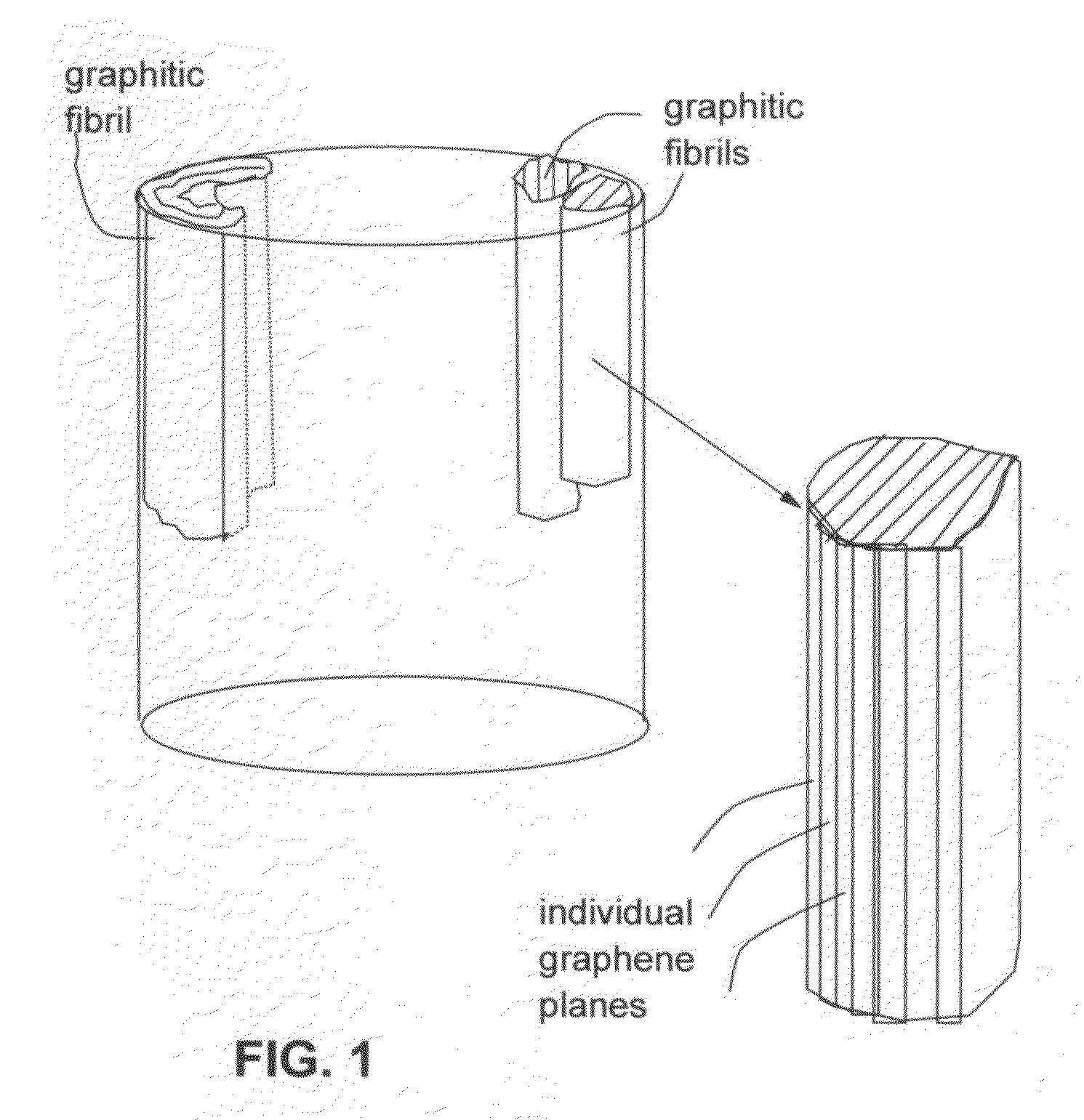

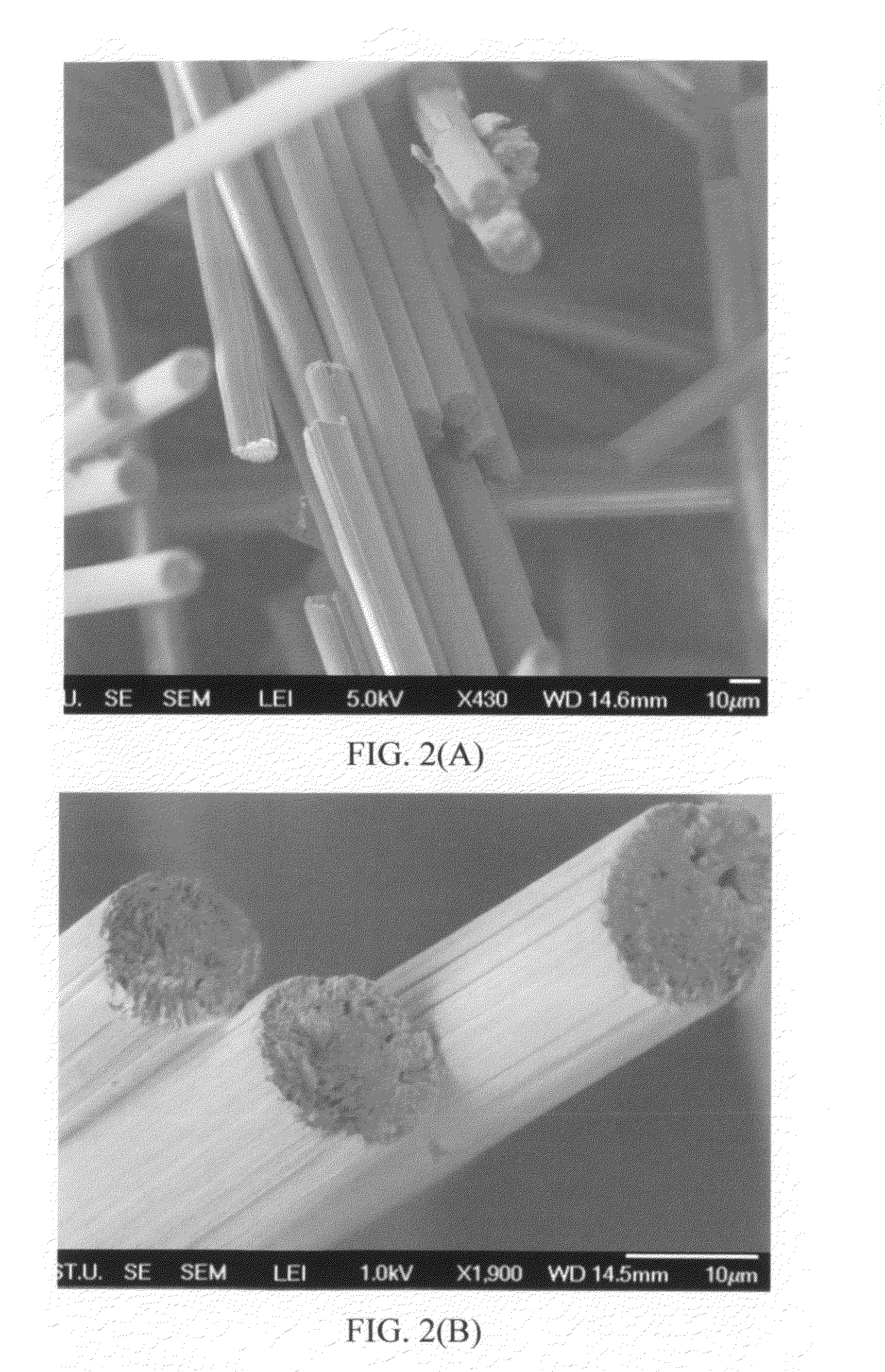

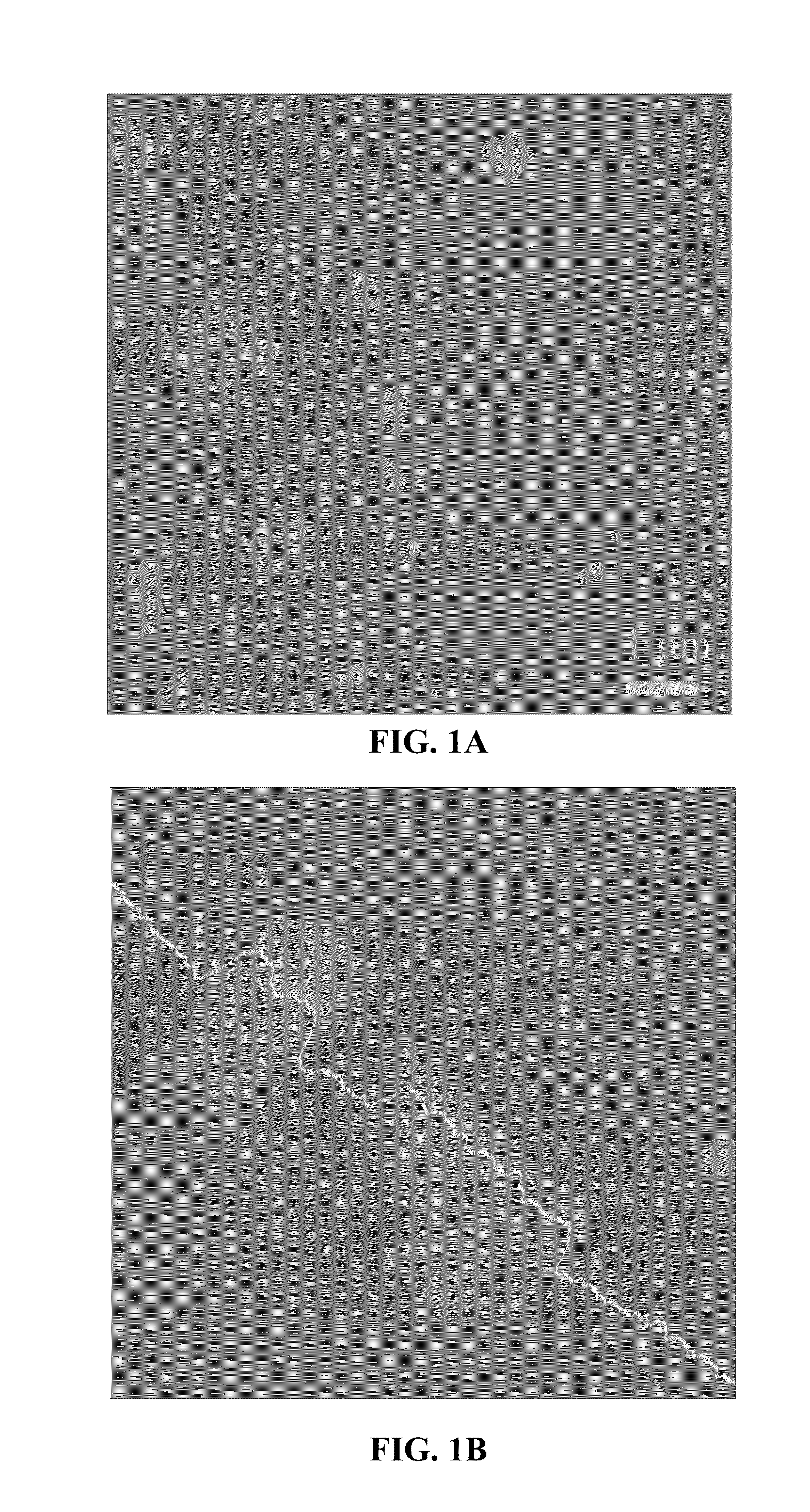

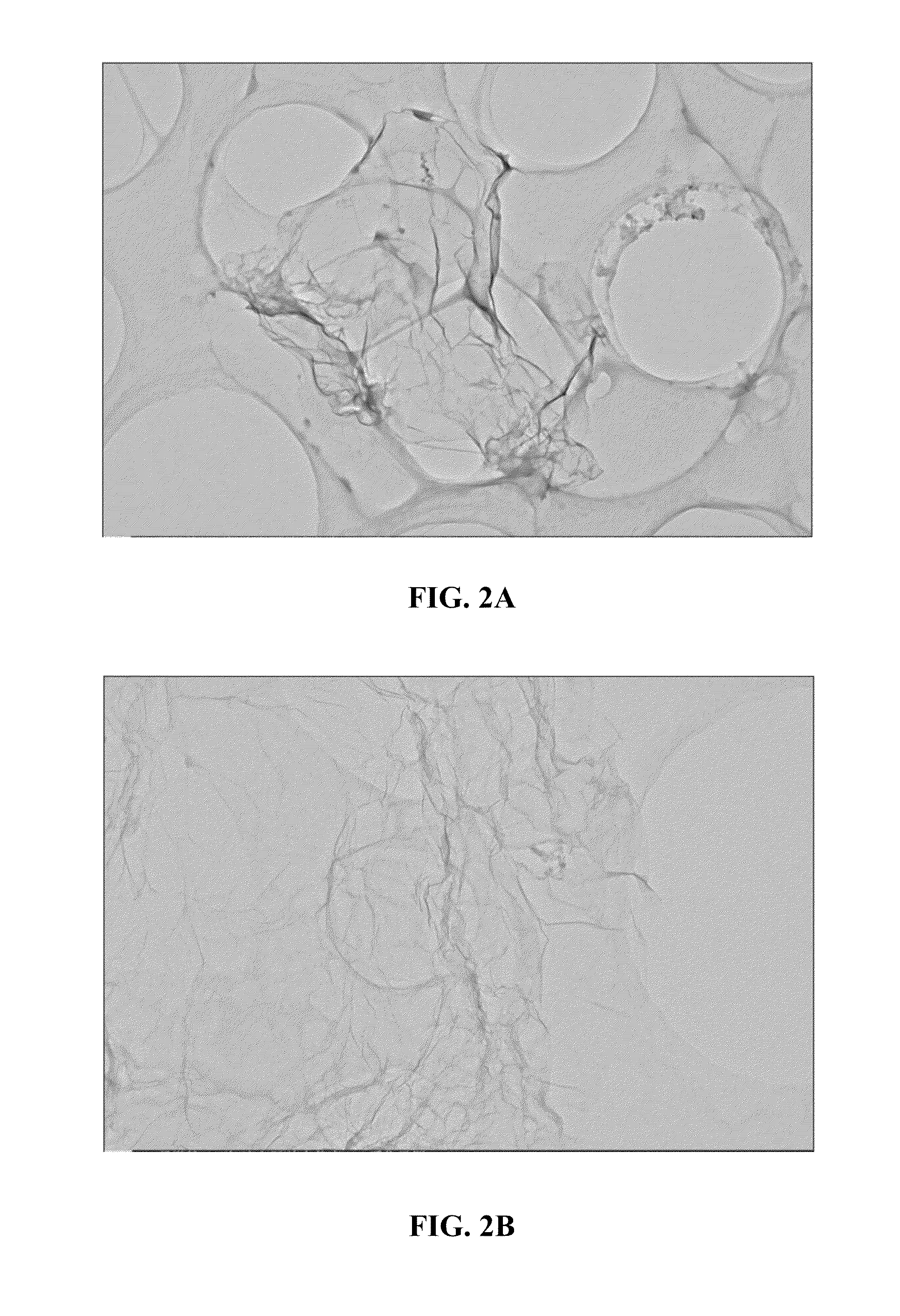

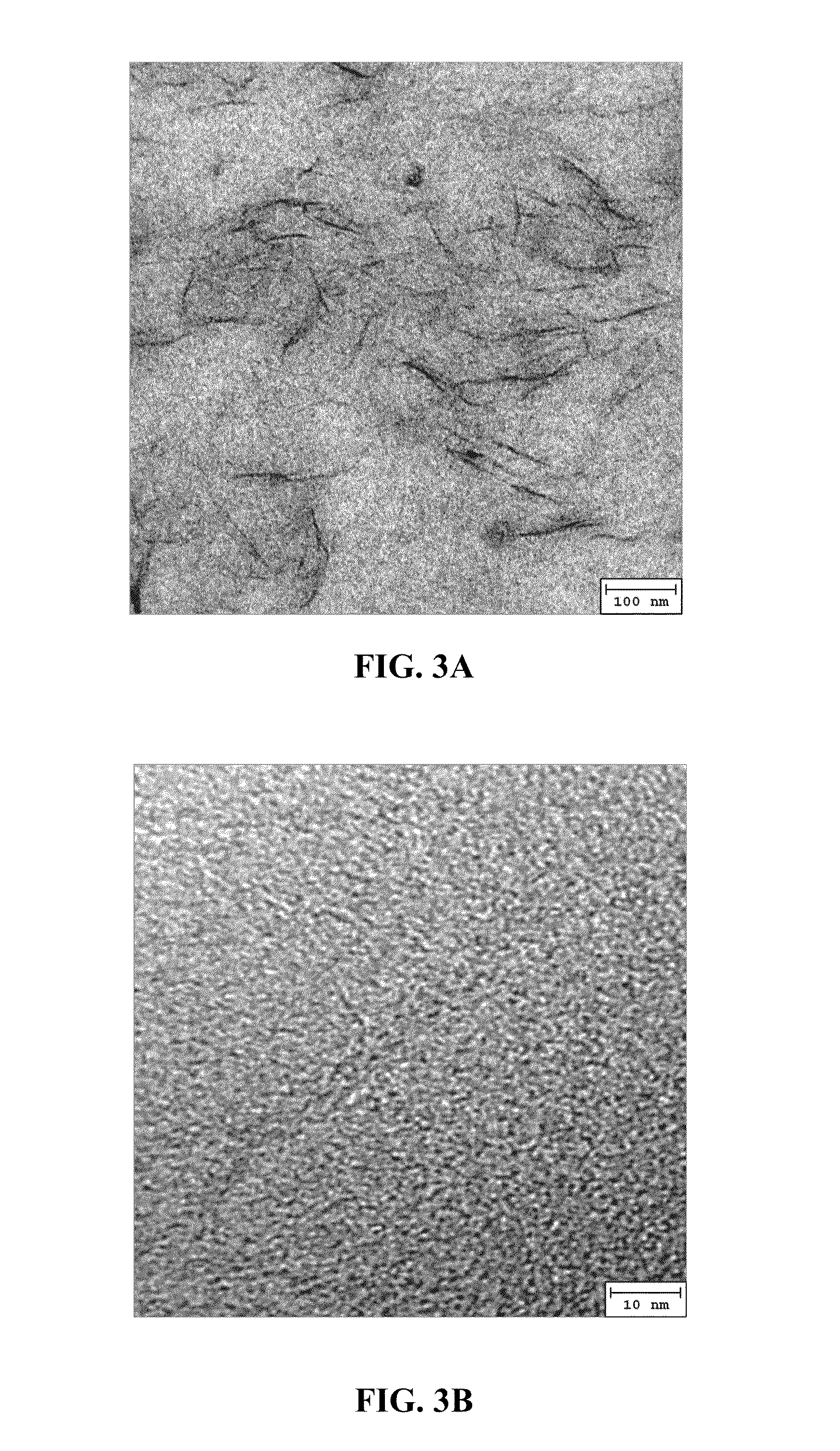

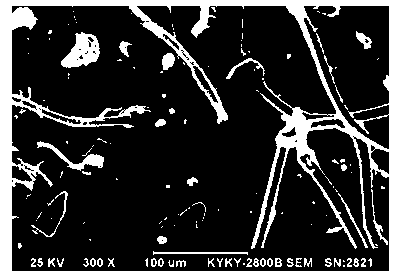

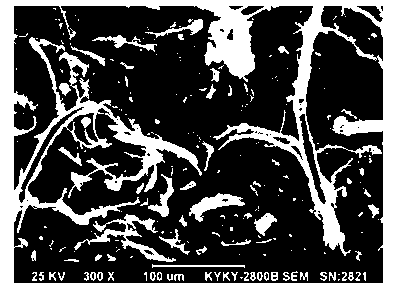

Chemically functionalized submicron graphitic fibrils, methods for producing same and compositions containing same

ActiveUS20110133132A1Different propertyGood hardening effectMaterial nanotechnologyLayered productsMicron scaleFiber

The present invention provides a chemically functionalized submicron graphitic fibril having a diameter or thickness less than 1 μm, wherein the fibril is free of continuous thermal carbon overcoat, free of continuous hollow core, and free of catalyst. The fibril is obtained by splitting a micron-scaled carbon fiber or graphite fiber along the fiber axis direction. These functionalized graphitic fibrils exhibit exceptionally high electrical conductivity, high thermal conductivity, high elastic modulus, high strength and good interfacial bonding with a matrix resin in a composite. The present invention also provides several products that contain submicron graphitic fibrils: (a) paper, thin-film, mat, and web products; (b) rubber or tire products; (c) energy conversion or storage devices, such as fuel cells, lithium-ion batteries, and supercapacitors; (d) adhesives, inks, coatings, paints, lubricants, and grease products; (e) heavy metal ion scavenger; (f) absorbent (e.g., to recover spill oil); (g) sensors; (h) friction and brake components; (i) radiation-shield components; (j) catalyst carrier; and (k) composite materials.

Owner:GLOBAL GRAPHENE GRP INC

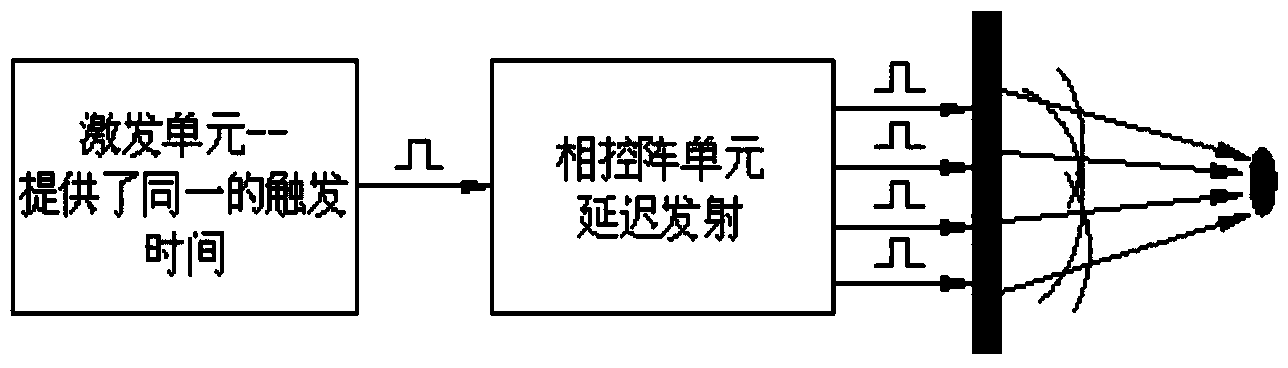

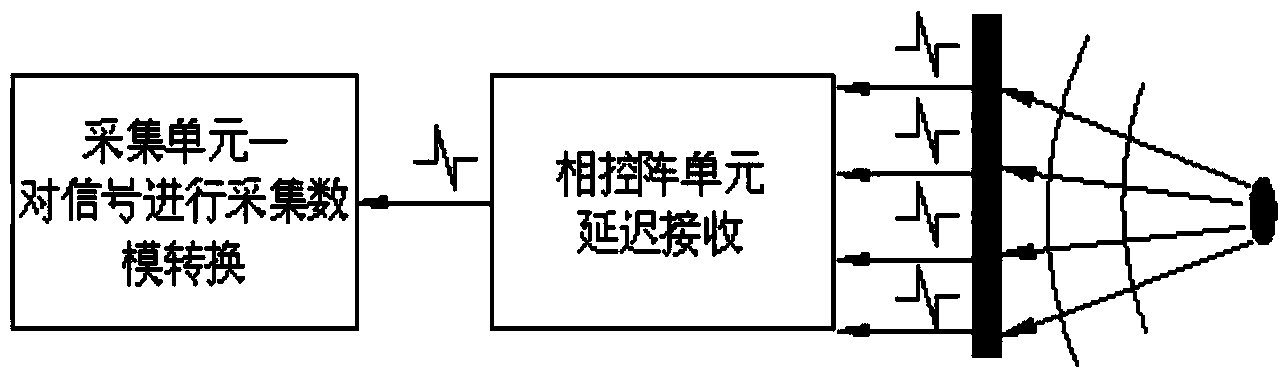

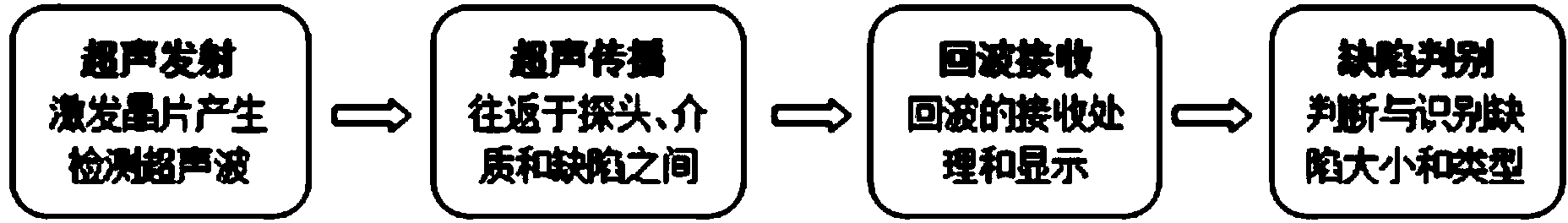

Phased-array ultrasonic detection method for interfacial de-bonding of composite material

InactiveCN103901108AEnables real-time non-destructive testingImprove detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesInterfacial bondingUltrasound

The invention discloses a phased-array ultrasonic detection method for interfacial de-bonding of a composite material. The method comprises the following steps: (1) sequentially triggering each wafer of a phased-array probe to generate ultrasonic signals, superposing the ultrasonic signals, propagating the ultrasonic signals inside the composite material, and reflecting the ultrasonic signals during the interface de-bonding or interfacial de-bonding of the composite material; (2) superposing the reflected ultrasonic signals, receiving the ultrasonic signals by using the phased-array probe, performing data processing, and then outputting a phased-array scanning image through a phased-array display instrument; (3) comparing an ultrasonic detection image during the good interfacial bonding of the composite material with an ultrasonic detection image during the interfacial de-bonding of the composite material to judge whether the composite material has a de-bonding defect. The method has the advantages of high detection accuracy, simple operation process and the like.

Owner:SOUTH CHINA UNIV OF TECH

Refractory and thermal-insulating spray coating material and preparation method and application thereof

The invention discloses a refractory and thermal-insulating spray coating material, and a preparation method and an application thereof. The refractory and thermal-insulating spray coating material comprises two parts, namely a prefabricated slurry and a curing agent, wherein the prefabricated slurry is prepared with a refractory aggregate and a binder; the weight of the refractory aggregate is 60-63 percent of the total weight of the refractory and thermal-insulating spray coating material; the weight of the binder is 34-37 percent of the total weight of the refractory and thermal-insulating spray coating material; and the weight of the curing agent is 3-6 percent of the total weight of the refractory and thermal-insulating spray coating material. According to the preparation method, the refractory and thermal-insulating spray coating material is prepared by evenly mixing the weighed refractory aggregate, the weighed binder and the weighed curing agent in sequence. A large-aperture spray gun for spraying coarse sand is adopted for quickly spraying the uniformly stirred slurry onto the surface of the inner wall of a furnace lining to prevent the slurry from being cured due to long-term storage, and then the refractory and thermal-insulating spray coating material is put into production directly. The refractory and thermal-insulating spray coating material has high interfacial bonding strength with the furnace lining, high resistance against furnace gas erosion, excellent thermal shock stability and high infrared radiance.

Owner:武汉钢铁有限公司

PVC modified material and method for preparing same

InactiveCN101338059AHigh heat-resistant deformation temperatureImprove the interface binding forceFoaming agentDouble bond

The utility model discloses a PVC modified material and a preparation method thereof; the PVC modified material consists of components with the following weight portions: 100 portions of PVC, 2 portions to 100 portions of SAN, 0.2 portion to 30 portions of compatibilizer, 1 portion to 10 portions of processing modifier, 5 portions to 80 portions of inorganic filler, 0 portion to 10 portions of heat stabilizer, 0 portion to 10 portions of lubricant, 0 portion to 10 portions of anti-oxidant, and 0 portion to 5 portions of foaming agent. In the utility model, the SAN is adopted as the modifying component and maleic anhydride multipolymer is added as the compatibilizer to modify the PVC. The SAN has quite high heat resistant deformation temperature; the maleic anhydride multipolymer compatibilizer can effectively improve the interfacial bonding force between matrix resin and the inorganic filler, so as to further improve the deformation resistant capability of the material. The molecular structures of the SAN and the compatibilizer are not provided with unsaturated double bonds, have not significant impact on the weatherproof performance of the PVC blending modified material and are suitable to be used on occasions with requirement for the weatherproof performance. The prepared PVC modified material has obviously improved weatherproof performance, is excellent in weatherproof and low in cost.

Owner:广东波斯科技股份有限公司

Flexible unbonded pipe and a method for producing such pipe

InactiveUS20070036925A1Easy to produceImprove corrosion stabilityLamination ancillary operationsLayered product treatmentHydrogenEngineering

The present invention relates to a flexible unbonded pipe comprising an inner liner capable of forming a barrier against outflow of a fluid which is conveyed through the pipe, and one or more armouring layers on the outer side of the inner line. The flexible unbonded pipe comprises at least one polymer layer and one film layer, said polymer layer being bonded to said film layer. The film layer may preferably be a metal film layer, such as aluminum film, stainless steel film or duplex film. The polymer layer may preferably be cross-linked polyethylene. The interfacial bonding between the polymer layer and the film layer should preferably be sufficiently strong to prevent creation of gas pockets between the layers when subjected to an increased pressure of aggressive fluids (hydrogen, sulphides, methane and carbon dioxide) on the film side of the pipe. Thereby, it is possible to protect armour layer(s) from aggressive fluids.

Owner:NAT OILWELL VARCO DENMARK

Process for preparing completely delaminated graphene oxide/rubber nanocomposite

A process for preparing a completely delaminated graphene oxide / rubber nanocomposite. The process combines emulsion compounding with flocculation or spray drying, retains the morphology of graphene oxide / rubber composite in a liquid state, and achieves highly dispersed and highly delaminated morphology dispersed on nano scale. Furthermore, a substance able to produce ionic bonding or chemical bonding with the surface functional groups of graphene oxide is added to graphene oxide / hydrosol, as a surfactant, thus the interfacial bonding between graphene oxide and the rubber is increased. The composite is subjected to subsequent compounding and vulcanization to prepare a vulcanizate with dynamic performance, such as a high tensile strength, stress at a definite elongation, tearing strength, etc.

Owner:BEIJING UNIV OF CHEM TECH

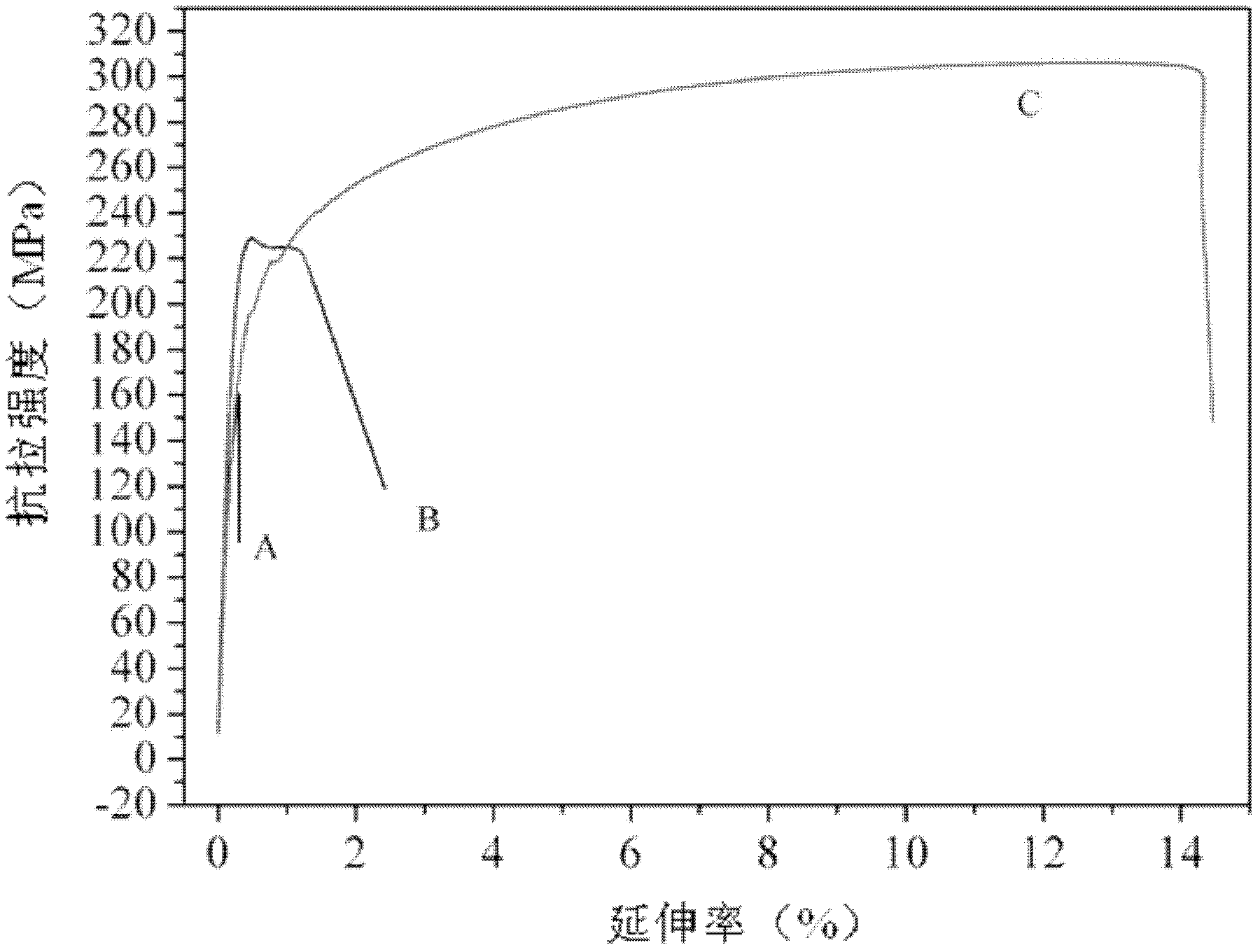

Pantograph slide composite material and preparation method thereof

InactiveCN102206771AHigh tissue densityEnhanced interface bindingLiquid/solution decomposition chemical coatingMixed materialsHardness

A pantograph slide composite material and a preparation method thereof relate to a copper-based pantograph slide composite material and a preparation method thereof. The invention solves the problems of poor interfacial wettability and low interfacial bonding strength between a ceramic reinforced phase and coppor in existing copper-based pantograph slide composite materials. The composite material of the invention is prepared by copper powder and ceramic particles, wherein the surface of the ceramic particle has a chemical copper plate layer. A mixed material is obtained by mixing the ceramic particles with chemical copper plate layers on the surfaces and the copper powder, and then the mixed material is processed by a hot-pressing sintering process or a combined process of hot-pressing sintering and hot extrusion. The Ti3AlC2 ceramic particles inside the composite material have uniform distribution, high structure density, good interfacial bonding performance, and good mechanical properties; the density is up to 99.86%-100.79%; the hardness is up to 92.3-93.3 HB; the tensile strength is up to 230-300 MPa; and the friction coefficient is 0.15-0.4.

Owner:HARBIN INST OF TECH

Method for testing interfacial bonding strength of ceramic fiber-reinforced resin matrix composite material

ActiveCN104122202AImplement statistical measurementsSolve the fragileUsing mechanical meansMaterial analysisAdhesivePaperboard

The invention discloses a method for testing the interfacial bonding strength of a ceramic fiber-reinforced resin matrix composite material and relates to ceramic fibers. The method comprises the following steps: bonding the ceramic fibers to a hard paper frame by virtue of an instant adhesive, for straightening and solidifying the ceramic fibers; preparing an embedding mold, putting the ceramic fibers and the hard paper frame into the embedding mold, and introducing resin into the embedding mold; after the resin is solidified, cutting an embedded end together with the embedding mold so as to obtain a sample, and polishing; when the embedding depth of the sample is lower than 1mm, bonding the embedded end with a primary cut part by virtue of quick-dry resin after the polishing process; burning out two sides of the paper frame at an un-embedded end by virtue of naked flame, averagely cutting the upper end of the paper frame according to the quantity of the ceramic fibers, and bonding and reinforcing the paper frame by virtue of a hard paperboard with area equal to that of the cut paper frame; firstly fixing the embedded end at a lower clamp of a testing machine, and then fixing a reinforcing section to an upper clamp of the testing machine; carrying out a single-filament draw-out experiment; recording each withdrawal force value given by a testing machine; observing the shape of an withdrawn end, and measuring the maximal withdrawing length of the single fiber; and calculating the interfacial bonding strength between the fiber and the resin.

Owner:XIAMEN UNIV

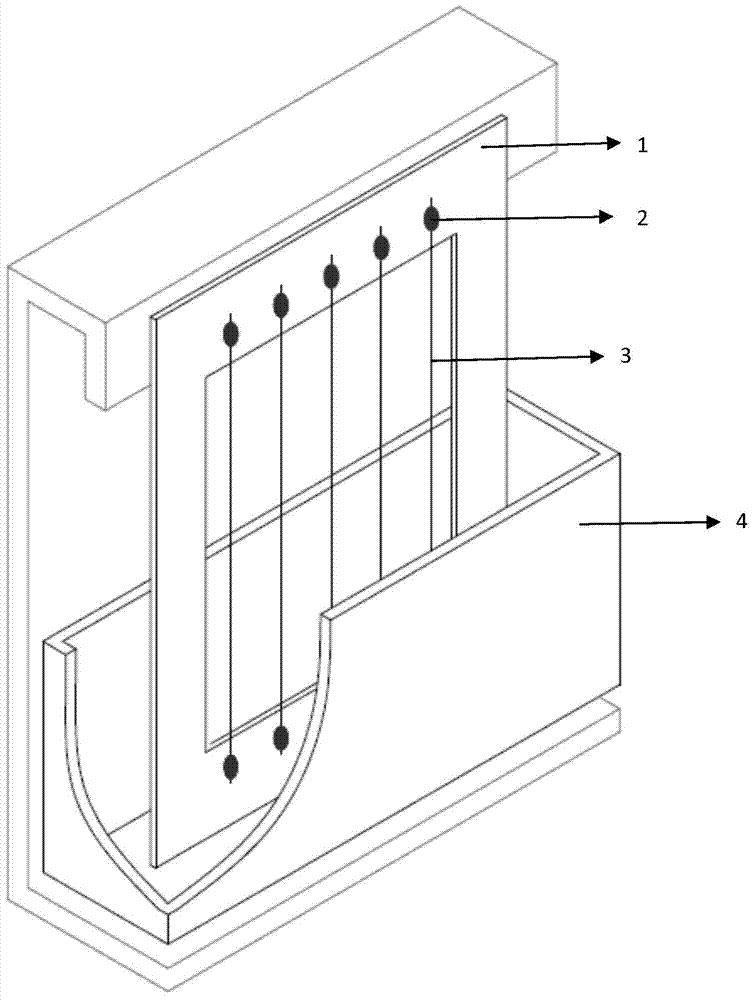

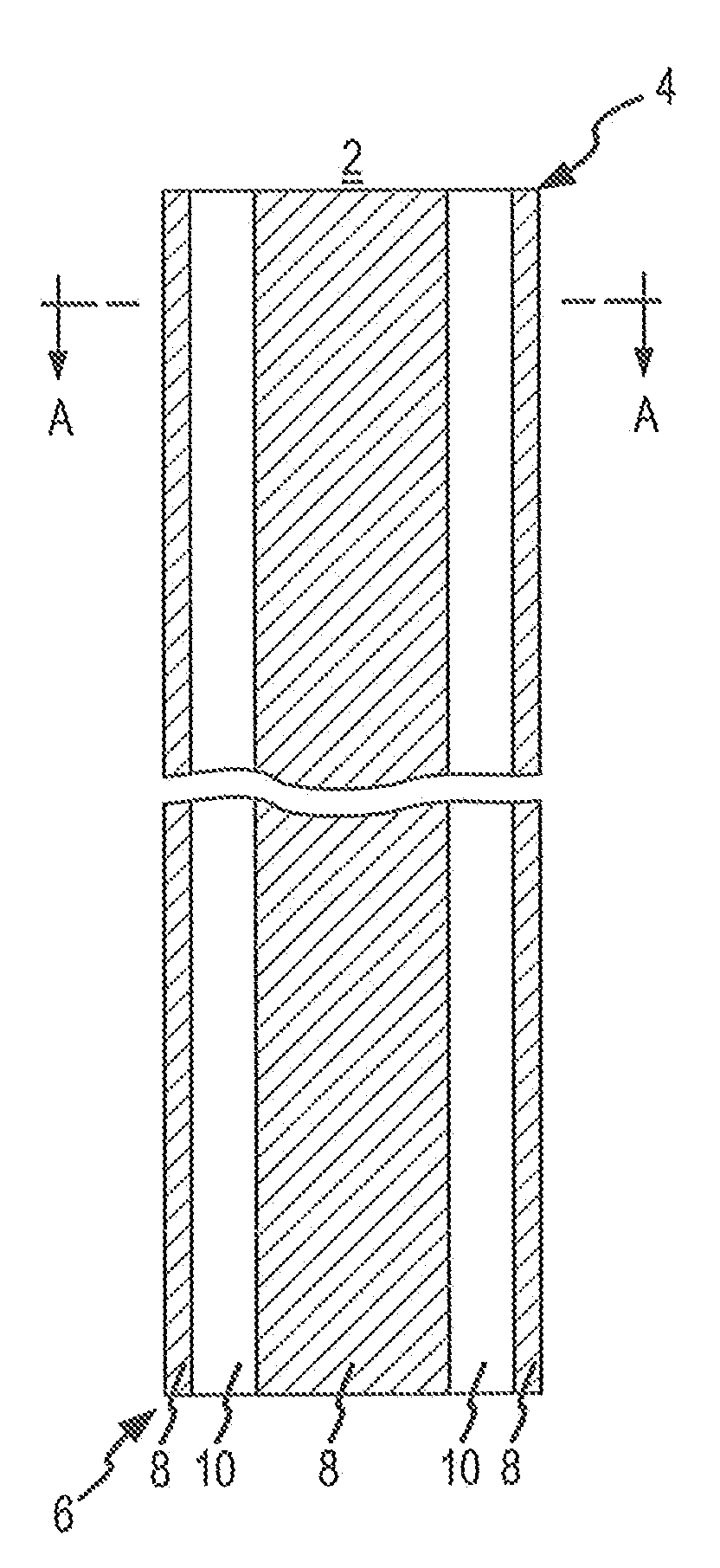

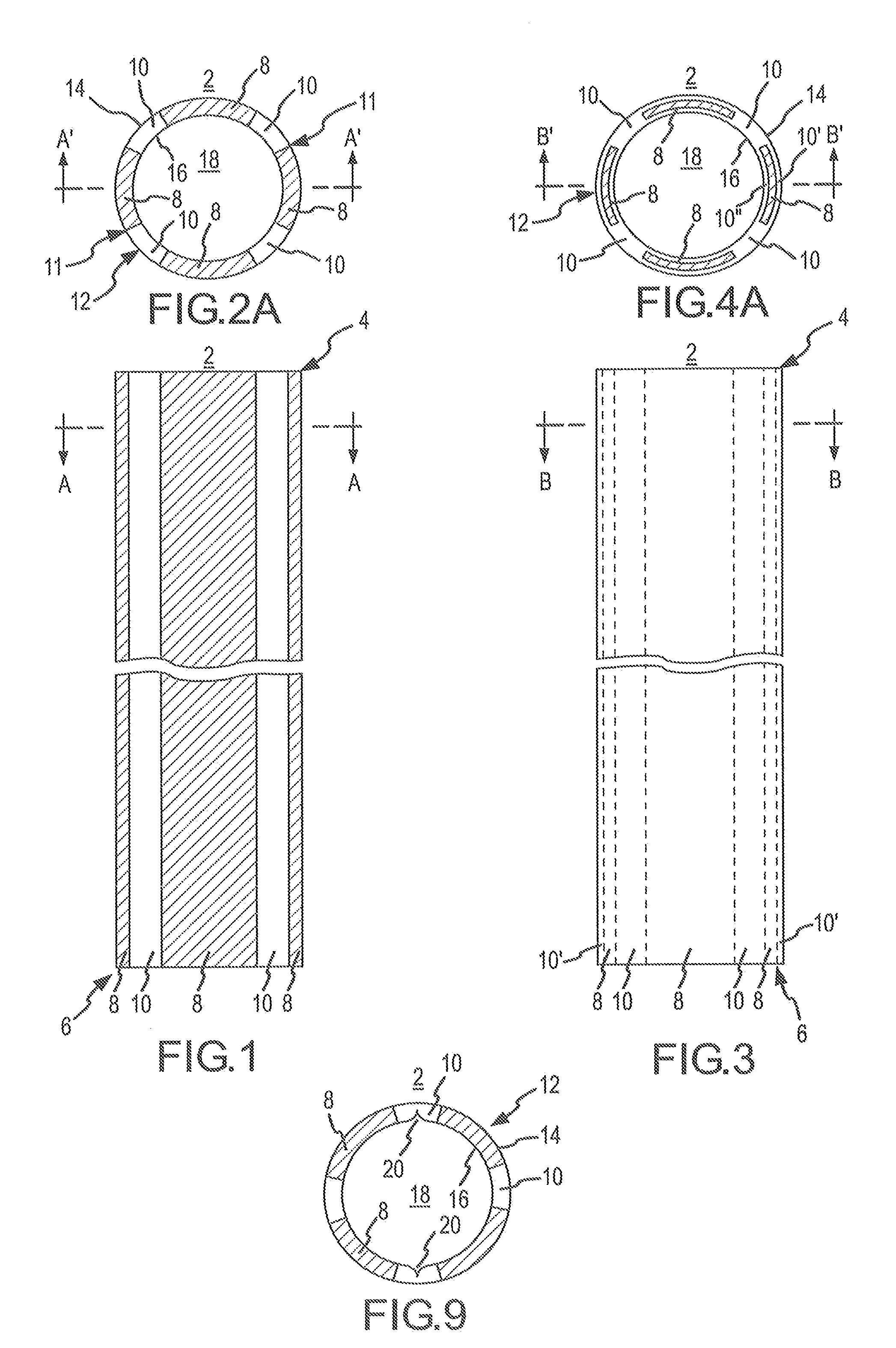

Peelable Atraumatic Tip and Body For a Catheter or Sheath

ActiveUS20080208128A1Improve melt adhesionPromote divisionGuide needlesInfusion syringesStress concentrationEngineering

A splittable / peelable tubular body (2) of a catheter or sheath wherein the tubular body (2) has a splittable / peelable atraumatic tip (14) is disclosed. The atraumatic tip (4) is generally softer than the tubular body (2). The tubular body (2) and atraumatic tip (4) each comprise a peel mechanism longitudinally extending along their respective lengths. The peel mechanisms are formed by longitudinally extending regions of interfacial bonding (11) between first and second longitudinally extending strips (8, 10) of polymer material. Each strip (8, 10) forms at least a portion of an outer circumferential surface of the tubular body (2) and atraumatic tip (4). A region of stress concentration extends along the region of interfacial bonding. The stress concentration facilitates the splitting of the tubular body (2) and atraumatic tip (4) along their respective peel mechanisms.

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

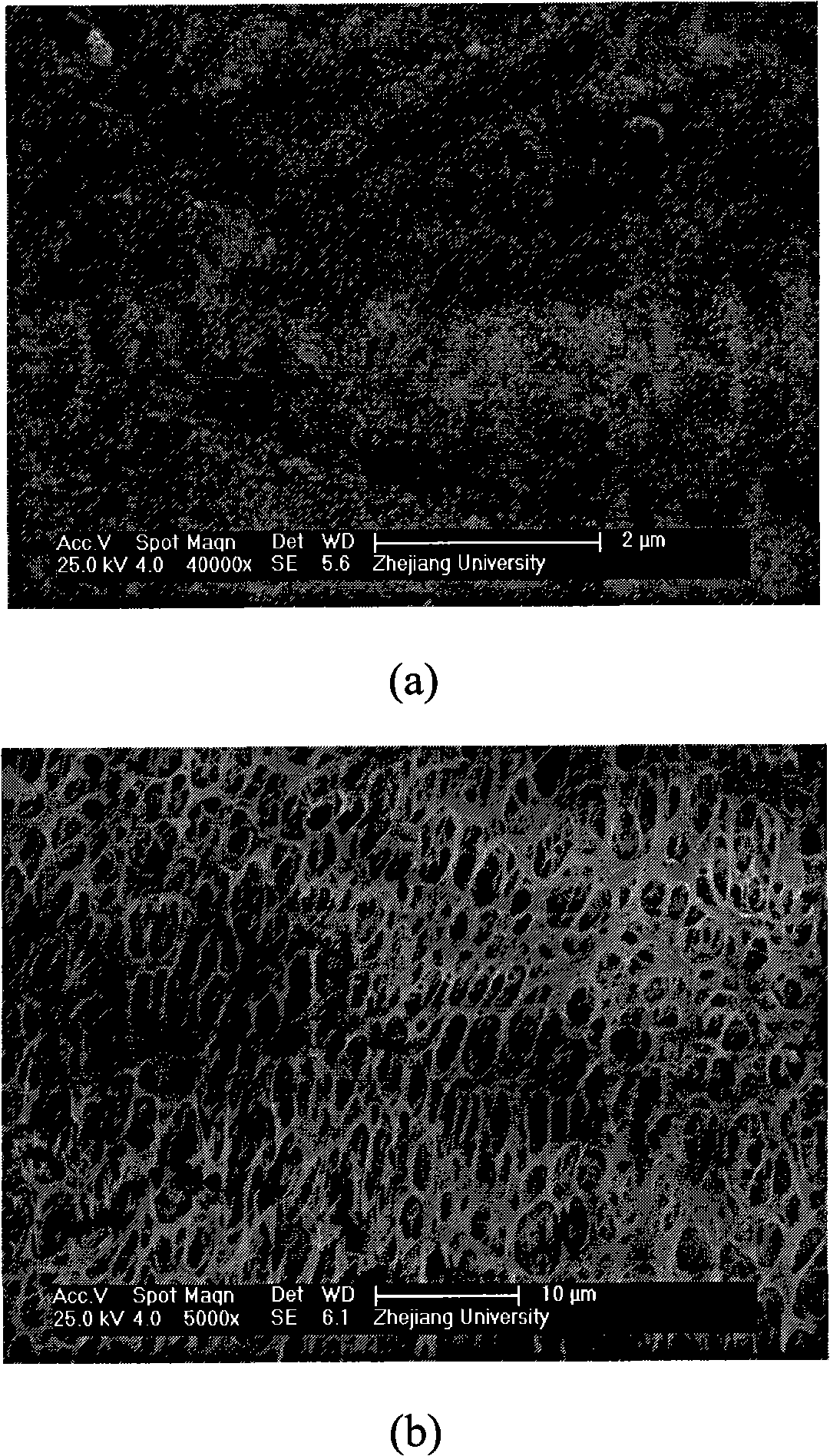

Recovery method of carbon-fiber reinforced resin-base composite material with pretreatment modes

ActiveCN103897213AImprove recycling efficiencyIncreased pore sizePlastic recyclingBulk chemical productionRecovery methodCarbon fibers

The invention discloses a recovery method of a carbon-fiber reinforced resin-base composite material with pretreatment modes, which is characterized by comprising the following steps: carrying out heat-moisture treatment, loop speed-up aging treatment or water-jet impact treatment on a carbon-fiber reinforced resin-base composite material, and carrying out supercritical reaction to obtain high-performance carbon fibers, thereby implementing recovery of the carbon-fiber reinforced resin-base composite material. The heat-moisture treatment and loop speed-up aging treatment in the method enable the interfacial structure of the material to generate new pores and cracks, so that the resin base generates the phenomena of swelling and plasticizing, the pore size in the resin base is increased, and a small amount of resin base is stripped from the carbon fibers; the water-jet impact treatment mode can lower the interfacial bonding property of the material and previously destroy the structure of the resin base; all the three modes can enhance the mass diffusion of the supercritical fluid in the resin base, accelerate the degradation of the resin base in the supercritical fluid environment and enhance the recovery efficiency of the carbon fibers.

Owner:HEFEI UNIV OF TECH

Preparation method of polyaniline modified multi-wall carbon canotube/epoxy resin composite material

InactiveCN101955631AStrong interfaceImprove mechanical propertiesPigment treatment with macromolecular organic compoundsEpoxyIn situ polymerization

The invention discloses a preparation method of a polyaniline modified multi-wall carbon canotubes / epoxy resin composite material. The preparation method comprises the following steps of: firstly, modifying the surfaces of multi-wall carbon canotubes with conducting macromolecular polyaniline through the doping of a functional protonic acid and the in situ polymerization of aniline; then, dispersing the multi-wall carbon canotubes with surfaces modified by polyaniline to an epoxy resin macromolecular solution, and adding a curing agent after removing the solvent; and finally, carrying out vacuum degassing, pouring into molds, heating and curing to prepare the composite material. The preparation method has simple process, low production cost and obvious reinforcing and toughening effects, and can effectively prevent the aggregation of the multi-wall carbon canotubes in epoxy resin and increase the dispersibility and the interfacial bonding of the multi-wall carbon canotubes in the epoxy resin. In addition, the conducting polyaniline is coated on the surfaces of the multi-wall carbon canotubes, and thus, the polyaniline modified multi-wall carbon canotubes / epoxy resin composite material acquires good mechanical properties and good antistatic function.

Owner:CIVIL AVIATION UNIV OF CHINA

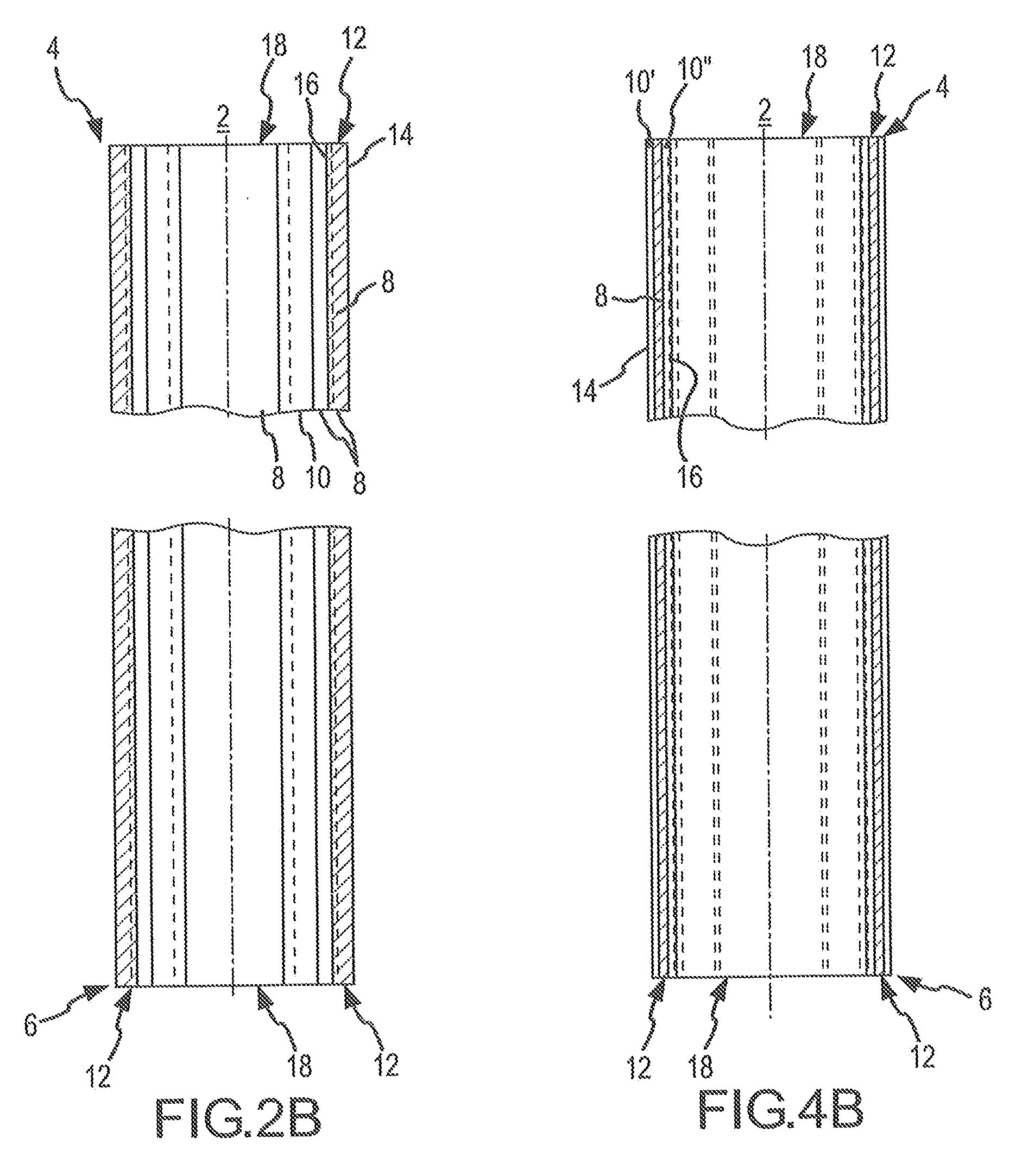

A kind of sic-tac coating/matrix synergistically modified c/c composite material and preparation method thereof

ActiveCN102295474AMitigate Thermal MismatchHigh coefficient of thermal expansionSurface layerHigh density

The invention discloses a SiC-TaC coating / matrix collaborative modified C / C composite material and its preparation method. The composite material provided by the invention comprises two parts. The portion below the surface of the C / C composite material is the matrix modified portion with the thickness being 0.1-10mm. In addition, carbide in the C / C composite material emerges in gradient distribution. The portion which is deposited on the surface of a carbon material is a coating portion with the thickness being 10-300 microns. The preparation method of the composite material comprises the following steps of: cutting a C / C green body at the density of 0.80g / cm<3>-1.60g / cm<3> into an annular shape or a plate shape, followed by ultrasonic cleaning and drying, placing into a multifunctional CVD furnace, depositing carbide on the surface layer and surface of the C / C green body by controlling deposition parameters, further densifying the green body by the use of pyrolytic carbon so as to obtain the high-density coating / matrix collaborative modified C / C composite material. The main advantages of the invention are as follows: by the penetration of carbide through the surface layer of the C / C composite material, the thermal expansion coefficient of the matrix is raised, the interfacial bonding state is improved, a continuous transition of carbide is formed between the coating and the matrix, and the metallurgical bonding is accomplished between the coating and the matrix.

Owner:CENT SOUTH UNIV

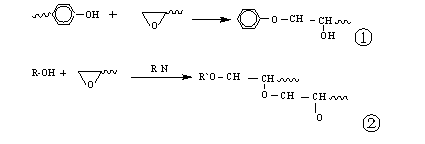

Surface modification method of aramid, and reinforced natural rubber material and preparation method thereof

The invention discloses a surface modification method of aramid, a reinforced natural rubber material and a preparation method thereof. The surface modification method of aramid comprises the following steps of: dipping aramid fibre for 0.5-3h by using phosphoric acid solution at 20-50 DEG C, after cleaning and drying, dipping aramid fibre for 1-2h by using acetone solution of epoxy resin with the mass percentage concentration of 5-20% at normal temperature, and then modifying the surface of aramid after drying. According to the invention, active groups of surface modified aramid and terminated hydroxyl of epoxy resin and liquid rubber are chemically reacted simultaneously at mixing temperature, so that the interfacial bonding strength is improved; liquid rubber and matrix rubber are vulcanized together in the subsequent vulcanizing process of mixing rubber, so that a cross-linked network tightly combined with aramid fibre is formed; the problem that the matrix rubber in an original physical manner forms a self cross-linked network while being vulcanized is overcome, and therefore, negative phenomena of a rubber and aramid fibre interface can be reduced; and the aramid reinforced rubber composite material having good interfacial bonding and fibre dispersion can be formed.

Owner:GUIZHOU UNIV

Method for preparing nano fiber reinforcement toughening resin base composite material

ActiveCN101397372ASolve the problem of poor interface compatibilityImprove interface performanceFilament/thread formingSolubilityResin matrix

Owner:BEIJING UNIV OF CHEM TECH

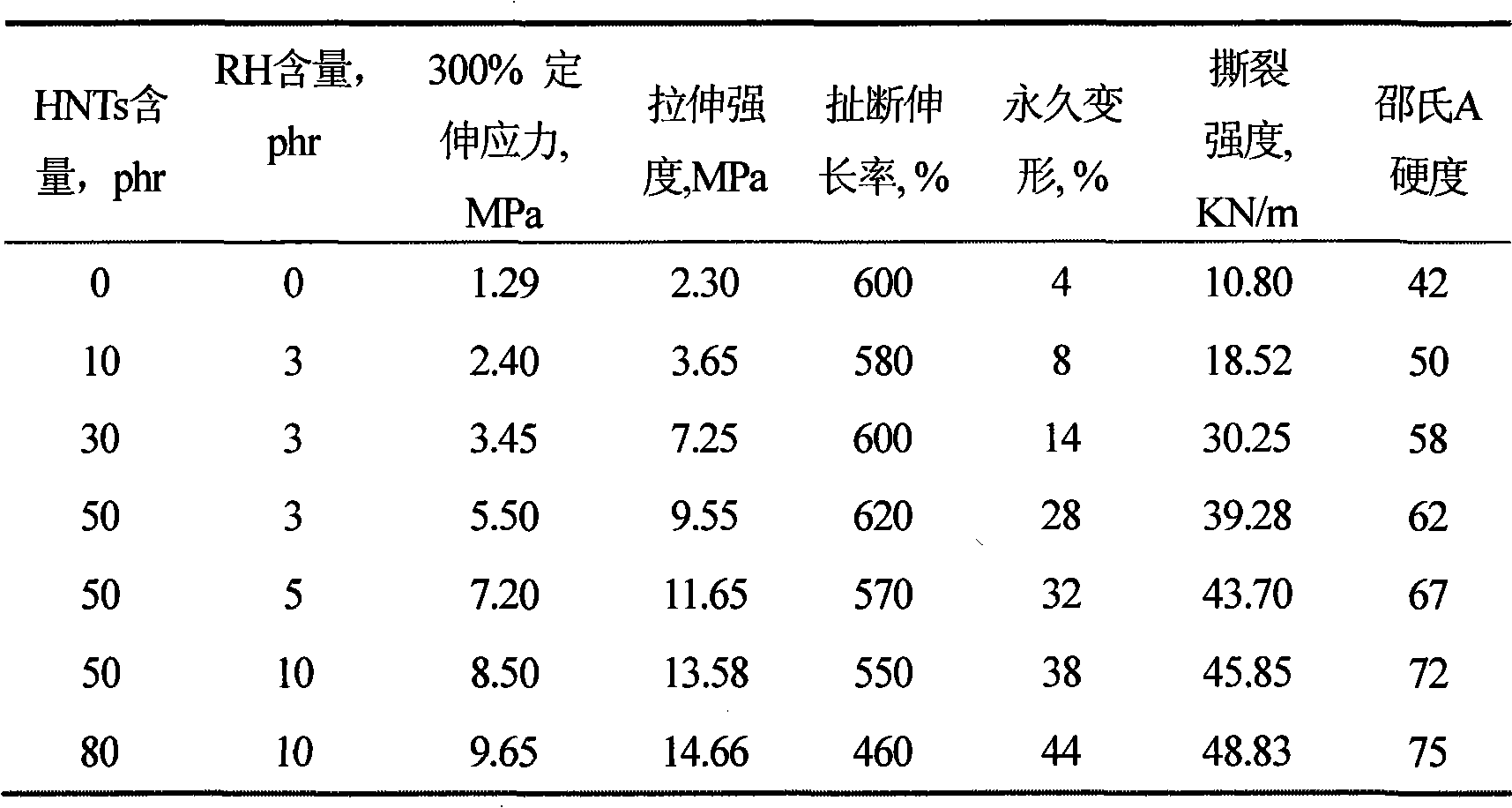

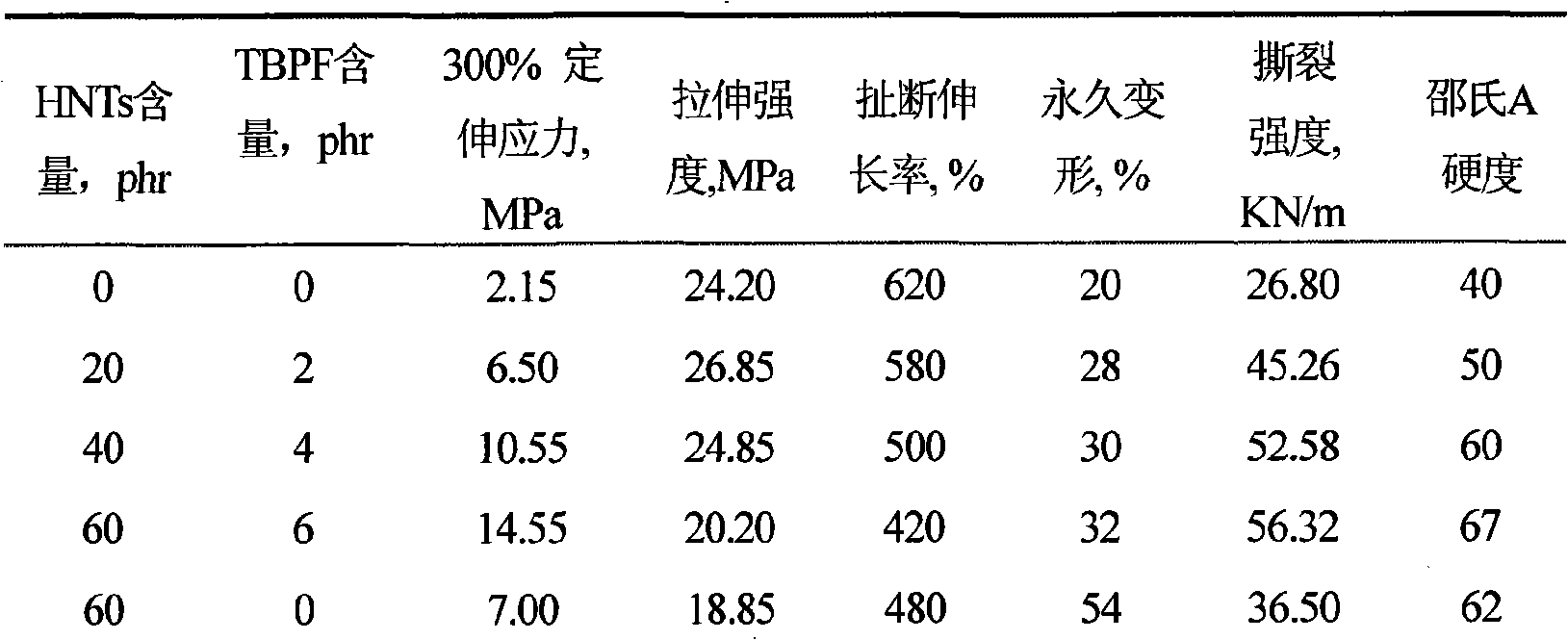

Preparation method for rubber/keramite nano-tube nano-composite material

The invention relates to preparation method of rubber / halloysite nanotube nano-composite material, the invention adopts the preparation method that the rubber, the halloysite nanotube and modifying agent are mixed according to the mass ratio of 100:5 to 100 : 0.5-20 through the ordinary rubber pugging equipment and technique, then the sulphation is performed through the ordinary sulphidizing process and equipment to realize the in-situ modification, and finally, the rubber / halloysite nanotube nano-composite material with nano-dispersion, good interfacial bonding and good performance. Wherein, the modifying agent comprises compound in-situ generated phenolic resin, alkyl phenolic resin, modified rubber, methacrylic acid metal salt and one or more than one mixture (s) in the sulfur-containing organosilane coupling agent. The preparation method of rubber / halloysite nanotube nano-composite material has the advantages that the defects that the rubber / halloysite nanotube nano-composite material is difficult to be dispersed, the interfacial bonding is not good, the performance can not be improved observably can be overcome, and the preparation method can be applied in a variety of rubber products, rubber toughening plastics and binding agents and the like.

Owner:SOUTH CHINA UNIV OF TECH

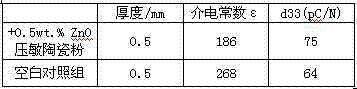

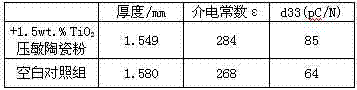

Piezoelectric composite material and preparation method thereof

The invention provides a piezoelectric ceramic, polyvinylidene fluoride (PVDF) and pressure-sensitive material three-phase composite material with high piezoelectric property. The pressure-sensitive material is added to a piezoelectric ceramic / PVDF piezoelectric composite material as an intermediate layer, so as to play a bridging role; the interfacial bonding properties of the piezoelectric ceramic and the PVDF are improved; coupling between the piezoelectric ceramic and the PVDF is increased; electron migration between ceramic particles is promoted; and the polarization voltage of a ceramic phase is improved. In addition, due to the nonlinear current-voltage characteristics of the pressure-sensitive material, when the pressure-sensitive material is added to the piezoelectric ceramic and PVDF composite material, the polarization-resistant voltage of the piezoelectric composite material is improved; and the overall piezoelectric property of the composite material is improved. Therefore, the piezoelectric composite material is simple in process, and low in cost; the piezoelectric composite film with excellent overall performance and large size can be prepared; and the piezoelectric composite material is expected to be applied to a piezoelectric touchpad, thus industrialized production is achieved.

Owner:SUZHOU PANT PIEZOELECTRIC TECH

A kind of preparation method of cermet coating with intermetallic compound as bonding phase

InactiveCN102296289ASimple structureAccelerated corrosionMetallic material coating processesCeramic compositeCeramic coating

The invention discloses a structure design and preparation method of a metal-ceramic coating with an intermetallic compound as a binding phase, which adopts a mechanical alloying process to prepare a metastable structure metal / ceramic composite powder with a high volume fraction of a ceramic hard phase. By cold spraying the precipitation coating and heat treatment process, the in-situ generation of the intermetallic compound binder phase and the control of the interface between the particle interface, the ceramic hard phase and the binder phase interface are used to obtain the intermetallic compound-based metal with controllable interface bonding. Ceramic coating. The intermetallic compound-based cermet coating prepared by the method has the structural characteristics of high volume fraction of ceramic hard phase, good dispersibility, in-situ generation of intermetallic compound binding phase and controllable bonding of particle interface.

Owner:JIUJIANG UNIVERSITY

Integrated forming method of multi-material part adopting gradient lattice structure

ActiveCN107774996AImprove cooling effectIncrease productivityAdditive manufacturing apparatusTransportation and packagingMulti materialAdditive ingredient

The invention belongs to the field of rapid manufacturing and discloses an integrated forming method of multi-material part adopting a gradient lattice structure. The method comprises steps as follows: (1) preparation of aluminum-based composite powder suitable for SLM forming: aluminum alloy powder and enhanceosome particles are mixed in various mass ratios, and then, each part of the aluminum-based composite powder is subjected to ball milling; (2) an aluminum substrate is fixed on a forming table board of SLM equipment to be preheated; (3) part forming: aluminum-based composite powder in different ratios is replaced for forming an upper layer, and the multi-material part adopting the gradient lattice structure and having continuously changing structures and ingredients is manufactured;(4) the part is cooled and subjected to linear cutting, and the part adopting the gradient lattice structure is obtained. The aluminum-based composite powder is uniformly distributed and has good interfacial bonding properties, the problem that interfaces of metal and ceramic are not matched is well solved, suddenly changed interfaces are eliminated, sudden change of physical performance due to the suddenly changed interfaces is eliminated, and heat stress is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Silicified diamond/SiC composite material preparation method

InactiveCN108257925AEnhanced interface bindingIncrease productivitySemiconductor/solid-state device detailsSolid-state devicesMicroparticleThermal expansion

The invention discloses a silicified diamond / SiC composite material preparation method, which belongs to the field of electronic packaging materials. Diamond particles and silicon powder are firstly subjected to wet mixing, sintering is carried out after thorough grinding, the diamond surface and the silicon powder react, and a layer of silicon carbide coating is generated; then, the diamond particles with the surface coated with the silicon carbide and the silicon powder are mixed, an organic binder is added at the same time, grinding is carried out, mixing on a mixer is carried out, and uniform composite particles are obtained; the composite particles are subjected to prepressing and debinding and are transferred to a vacuum infiltration furnace, a silicon burial method is adopted for vacuum infiltration, and a compact diamond / SiC composite material is prepared. The silicon powder is adopted to modify the diamond particles, the interfacial bonding between diamond and silicon is improved, the compactness of the obtained diamond / SiC composite material is more than 95%, the hardness is above HRA 80, the bending strength exceeds 200 MPa, the thermal conductivity reaches 600 W / mK, andthe thermal expansion coefficient 1.5 to 4*10<-6> / K. Thus, multiple products with complex characters, complex curvature and large size can be prepared at one time, the production efficiency is high,and the cost is low.

Owner:UNIV OF SCI & TECH BEIJING

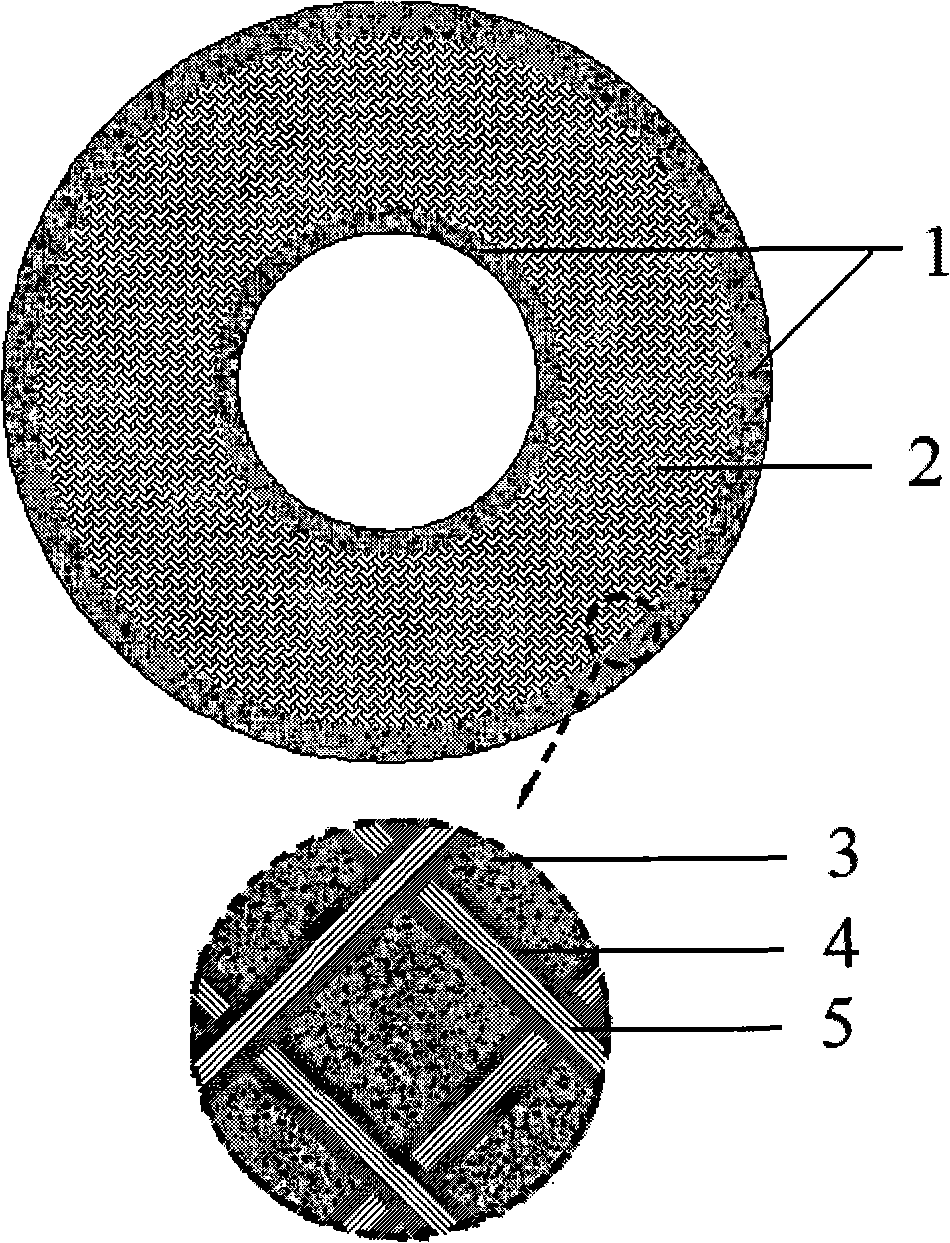

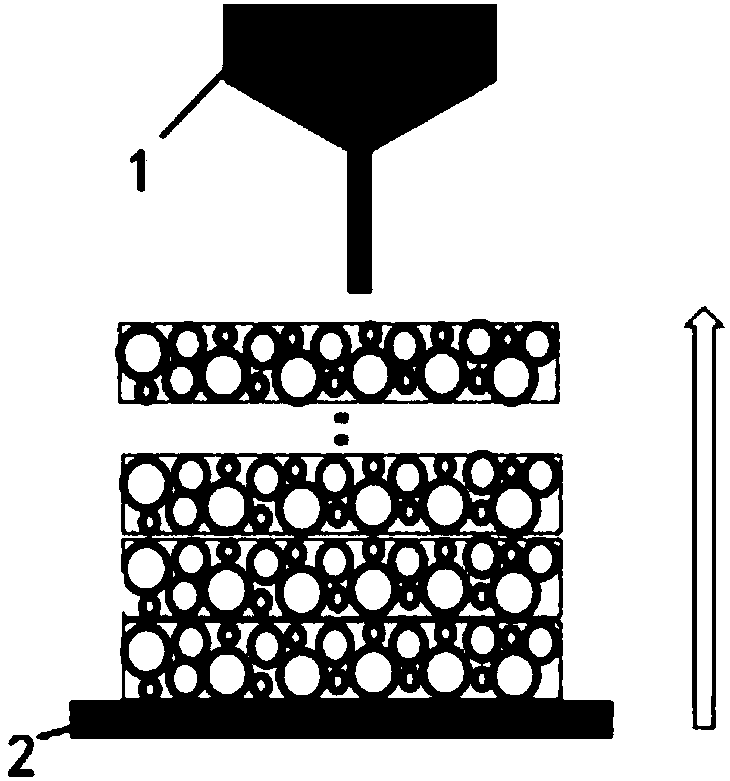

Liner material for improving interfacial bonding of HTPB propellant and preparation method thereof

The invention discloses a liner material for improving interfacial bonding of an HTPB propellant and a preparation method thereof. The liner material provided by the invention comprises two parts, namely an interpenetrating polymer network I and an interpenetrating polymer network II, wherein the interpenetrating polymer network I comprises a curing agent of isocyanate, a chain extender of dihydric alcohol or diamine, a cross-linking agent of a multiple active functional group compound and a plasticizer, and also comprises adhesives comprising hydroxyl-terminated polybutadiene, nitrine or polyether and other hydroxyl-terminated macromolecule dihydric alcohols. The interpenetrating polymer network II comprises an epoxy resin, polyacrylate, polyurethane, polysiloxane, a vinyl ester resin and other resins. According to the invention, a novel technology can be provided to adapt to a propellant liner, so that the interfacial bonding property between the liner and the propellant is improved.

Owner:SHANGHAI XINLI POWER EQUIP RES INST

Amorphous and nanocrystalline glass-coated articles

InactiveUS20050000599A1Rapidly solidify molten alloyGlass making apparatusInorganic material magnetismDynamic balanceGlass vessel

A drawn glass-coated metallic member has a thermal contraction coefficient differential such that the thermal contraction coefficient of the glass is less than that of the metallic member. The thermal contraction coefficient differential is maintained within a predetermined range during drawing. The glass is placed under residual compression, interfacial bonding between said glass and said wire is substantially uniform, and surface cracking and bond breaks between metal and glass are substantially prevented. A dynamic balance is maintained between the surface tension of the molten alloy and the resistance to high temperature deformation by the glass vessel in which it is contained, enabling the production of glass-coated amorphous or nanocrystalline alloy members having predefined cross-sectional shapes.

Owner:DEMODULATION

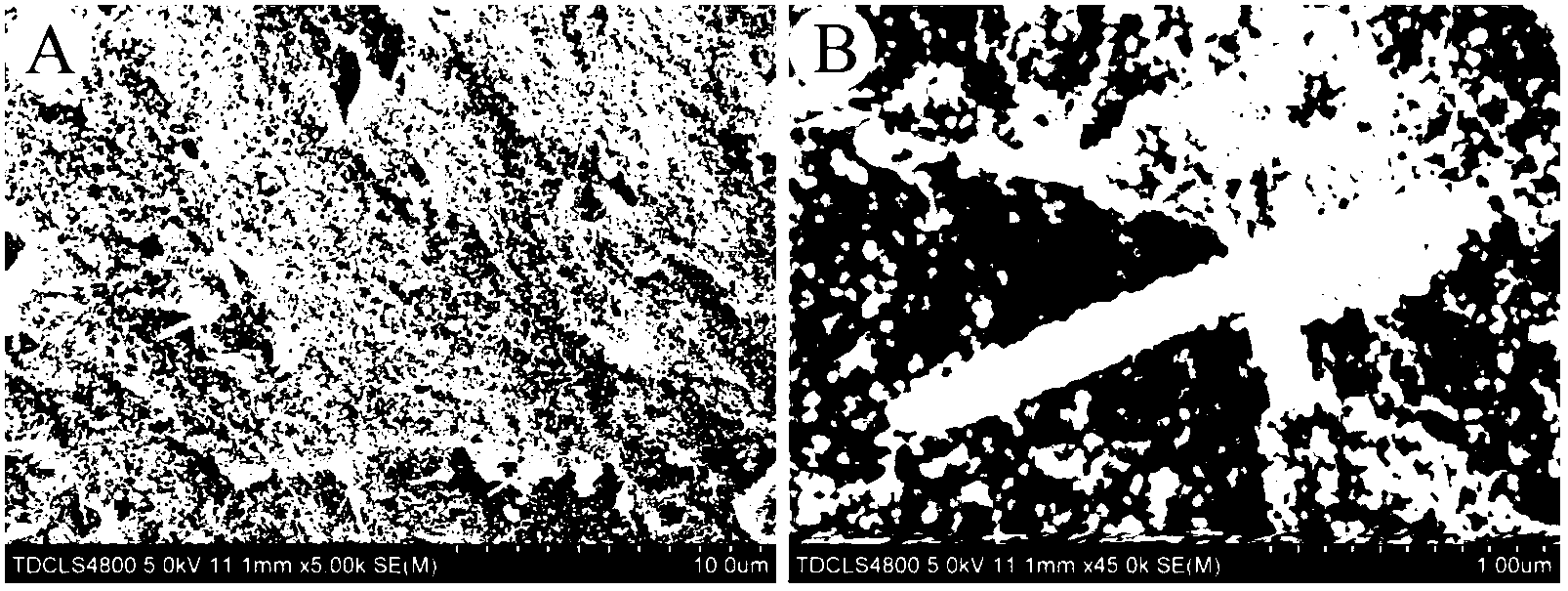

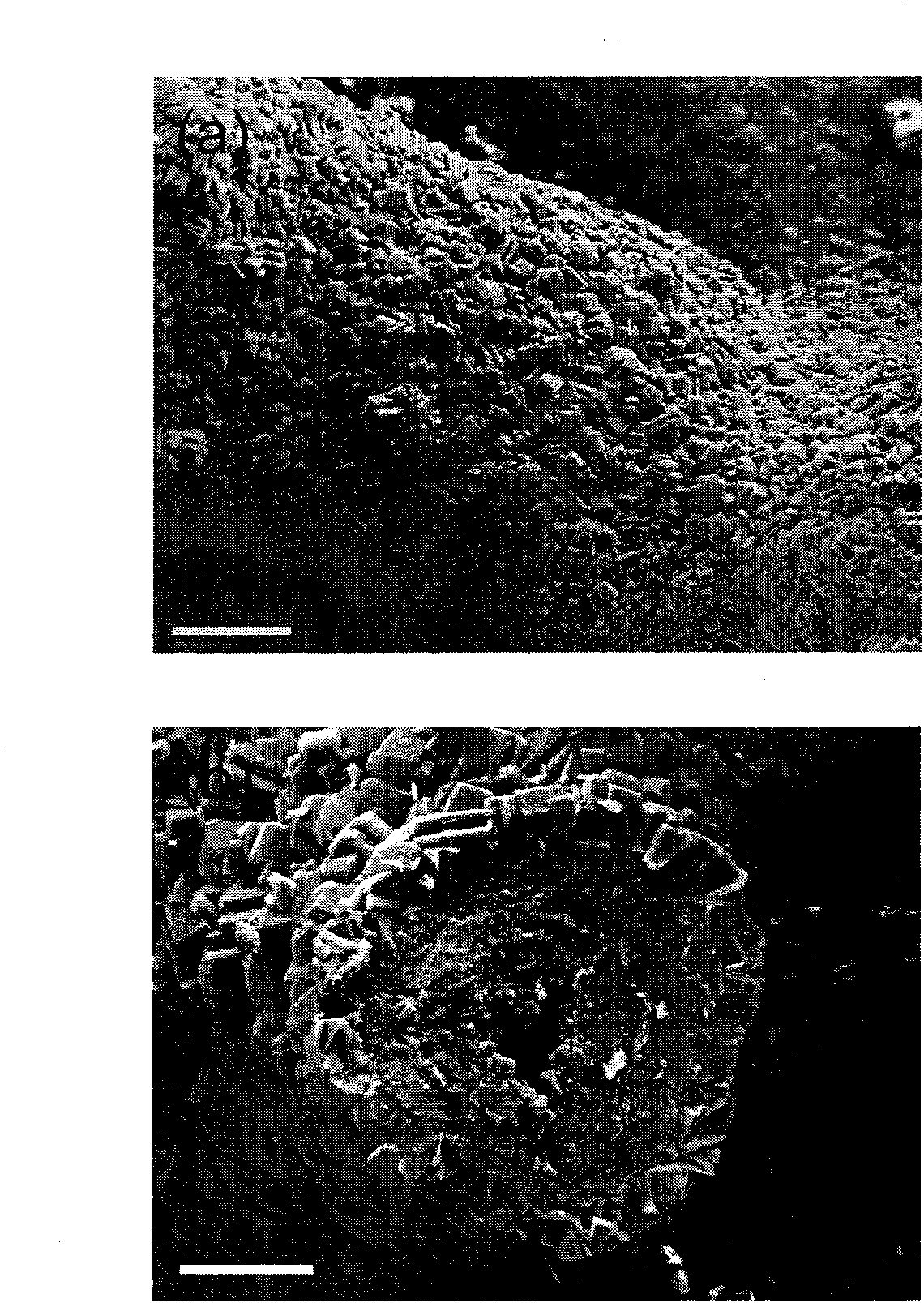

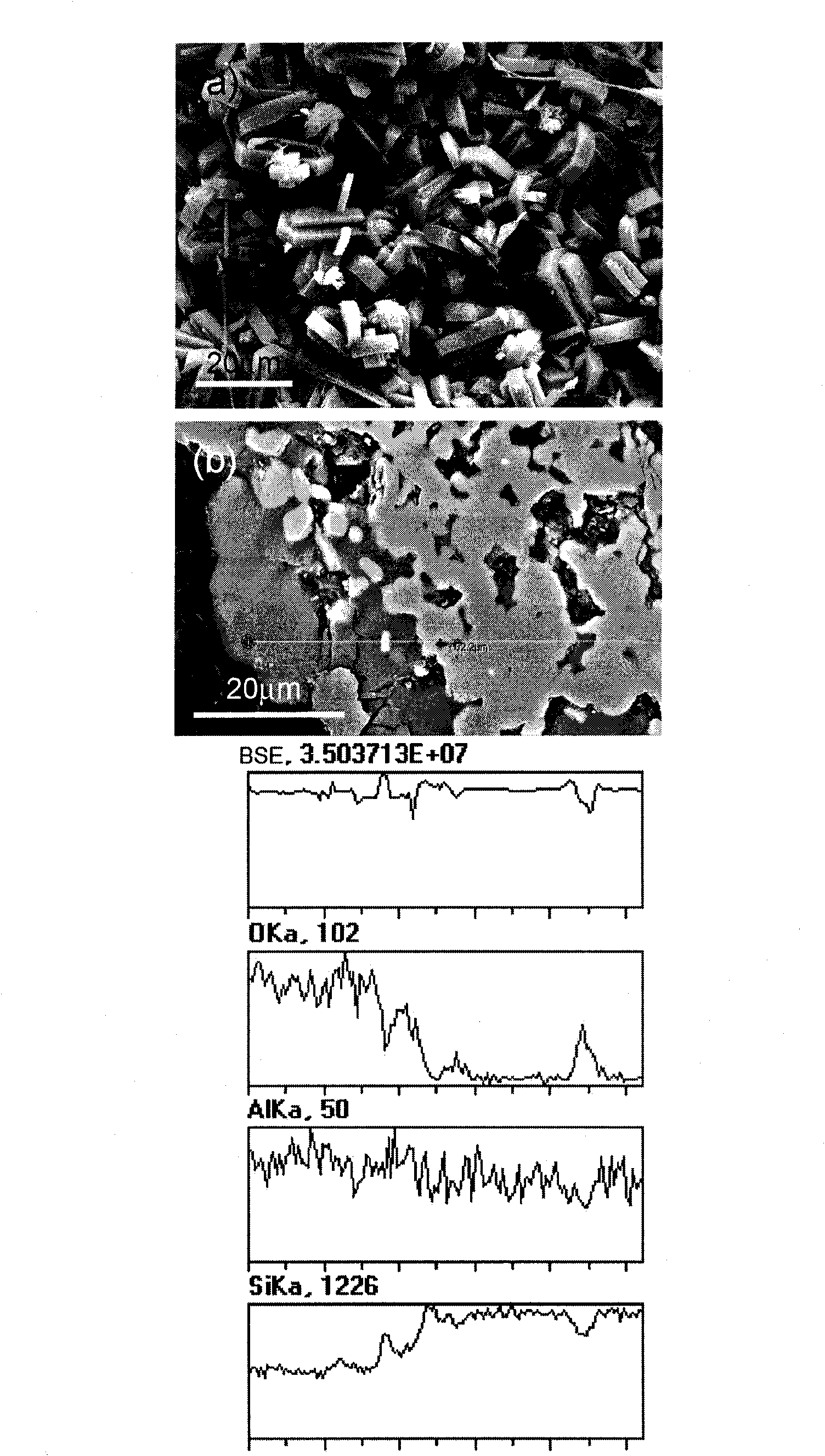

Preparation method for molecular sieve coating material on porous silicon carbide ceramic surface

InactiveCN101857462AIntensity effectImprove the bonding strength of the interfaceMolecular sieve catalystsCrystalline aluminosilicate zeolitesInterfacial bondingRaw material

The invention relates to a preparation technique for a molecular sieve coating material, in particular to a preparation method for a molecular sieve coating material on a porous silicon carbide ceramic surface. Porous silicon carbide ceramic is used as a carrier, solid raw materials such as silicon blocks, quartz, silicon-aluminum composite oxide sintered powder with adjustable silicon-aluminum atomic ratio and the like are used as a silicon source or a silicon-aluminum source, and the raw materials are synthesized through in-situ hydrothermal reaction. The porous silicon carbide ceramic surface is provided with microporous structures. The use of the solid silicon source or silicon-aluminum source can enable the release speed of the silicon source or silicon-aluminum source for the growth of crystal nucleus to be controllable. Thereby, the prepared molecular sieve coating is evenly loaded on the surface of the silicon carbide ceramic carrier, the silicon-to-aluminum ratio can be accurately controlled, and the composite material formed by the molecular sieve and the porous silicon carbide ceramic has unique microporous / macroporous structures; and the chemical bonding between the molecular sieve and the porous silicon carbide ceramic is realized and the interfacial bonding strength is high. The invention has the advantages that the technology of the method is simple, the operation is convenient, the complex equipment is not required, the preparation cost is low and the method is more suitable for industrialized mass production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method for achieving strong metallurgical bonding on dissimilar metal interface

ActiveCN108817083AImprove the bonding strength of the interfaceAvoid the problem of long time high temperature heating before rolling formingMetal rolling arrangementsInterfacial bondingDissimilar metal

The invention relates to a preparation method for achieving strong metallurgical bonding on a dissimilar metal interface and belongs to the technical field of dissimilar metal composite materials. Thepreparation method is characterized in that the high performance dissimilar metal composite material achieving strong metallurgical bonding on the interface is obtained by fully exerting the advantages of existing hot rolling composite method and cold rolling composite method and overcoming the defects of the methods, combining steps of polishing, laminating, room temperature rolling, short-timeheating, high-temperature rolling and the like and controlling times and temperatures in the preparation process of the dissimilar metal composite material cooperatively. The preparation method provided by the invention has the advantages that the preparation method is simple in process, low in energy consumption, short in period, less in equipment investment, low in cost and high in efficiency, and can achieve strong metallurgical bonding on the dissimilar metal interface by using existing polishing equipment, heating furnace and rolling mills (one rolling mill or arbitrarily arranged two rolling mills); compared with the interfacial bonding strength of the dissimilar metal composite material prepared by the existing hot rolling composite method and cold rolling composite method, the interfacial bonding strength is improved by over 20-50%, and the application range of the high performance dissimilar metal composite metal is wider.

Owner:UNIV OF SCI & TECH BEIJING

Surface modification method for waste rubber powder

ActiveCN107674238AImprove mechanical propertiesIncreased durabilityPlastic recyclingEpoxyPolymer science

The invention belongs to the technical field of high polymer materials and particularly relates to a surface modification method for waste rubber powder. The method comprises the following specific steps: firstly, carrying out clear water treatment on the surface of the waste rubber powder; secondly, carrying out alkaline solution treatment on the surface of the waste rubber powder; thirdly, carrying out coupling agent treatment on the surface of the waste rubber powder; fourthly, carrying out nano-silica coating treatment on the surface of the waste rubber powder; fifthly, carrying out crushing treatment on the modified waste rubber powder aggregate. Compared with the prior art, the surface modification method of the waste rubber powder disclosed by the invention, has the advantages thatthe comprehensive mechanical properties of the waste rubber powder as well as interfacial compatibility and interfacial bonding strength between the waste rubber powder and cementing materials such asepoxy resin and cement paste can be significantly improved.

Owner:SHANXI PROVINCIAL RES INST OF COMM

Polymer composite structure

InactiveUS20040053067A1Synthetic resin layered productsConstructions elementsPolypropylenePolymer composites

Two-component polymer composite structures are described, such as a composite structure that includes a first polymer structure and a second polymer structure adhered to one another through interfacial adhesion provided by a semicrystalline random copolymer with 70-88 mole % propylene units and alpha olefin units having 2 or from 4 to 10 carbon atoms, the semicrystalline random copolymer having a heat of fusion of from 2 to 90 J / g and a crystallinity of from 2% to 65% of the crystallinity of isotatic polypropylene.

Owner:EXXONMOBIL CHEM PAT INC

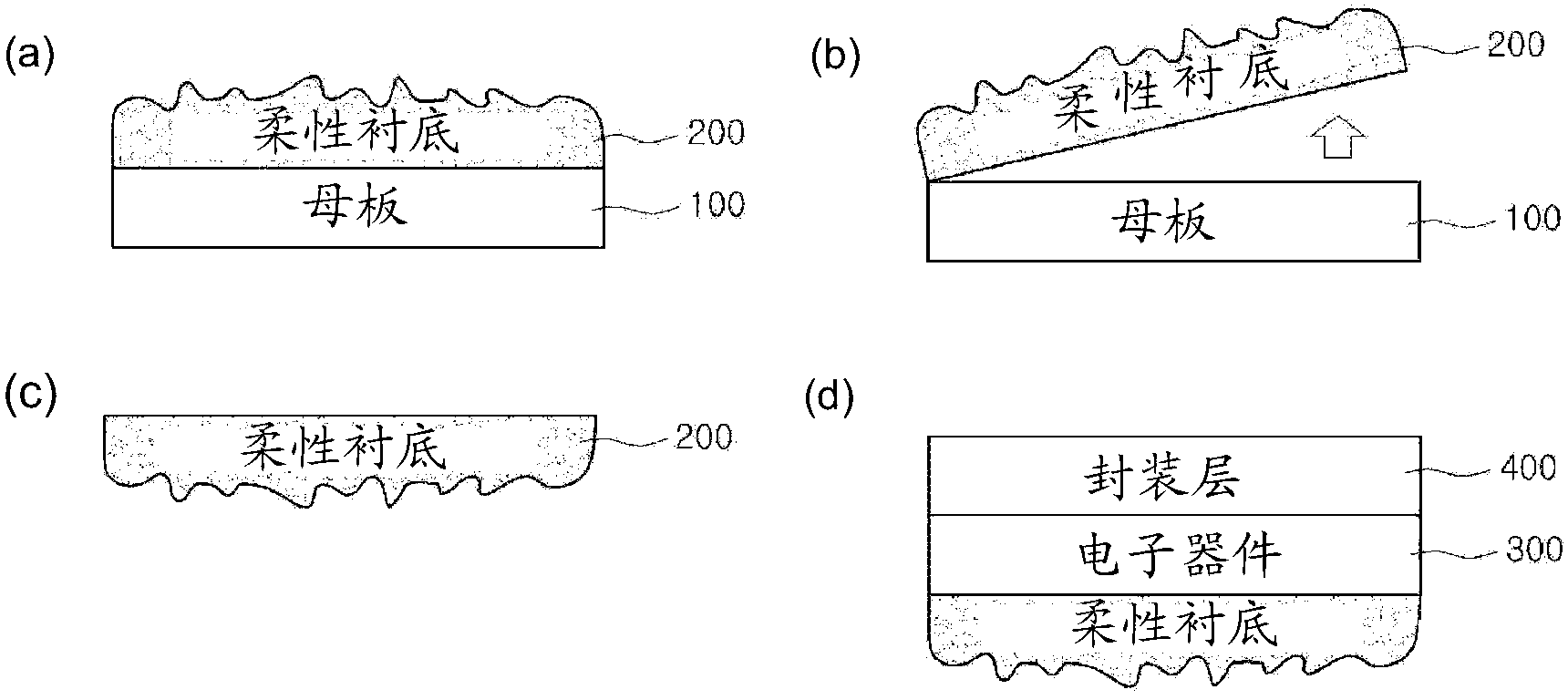

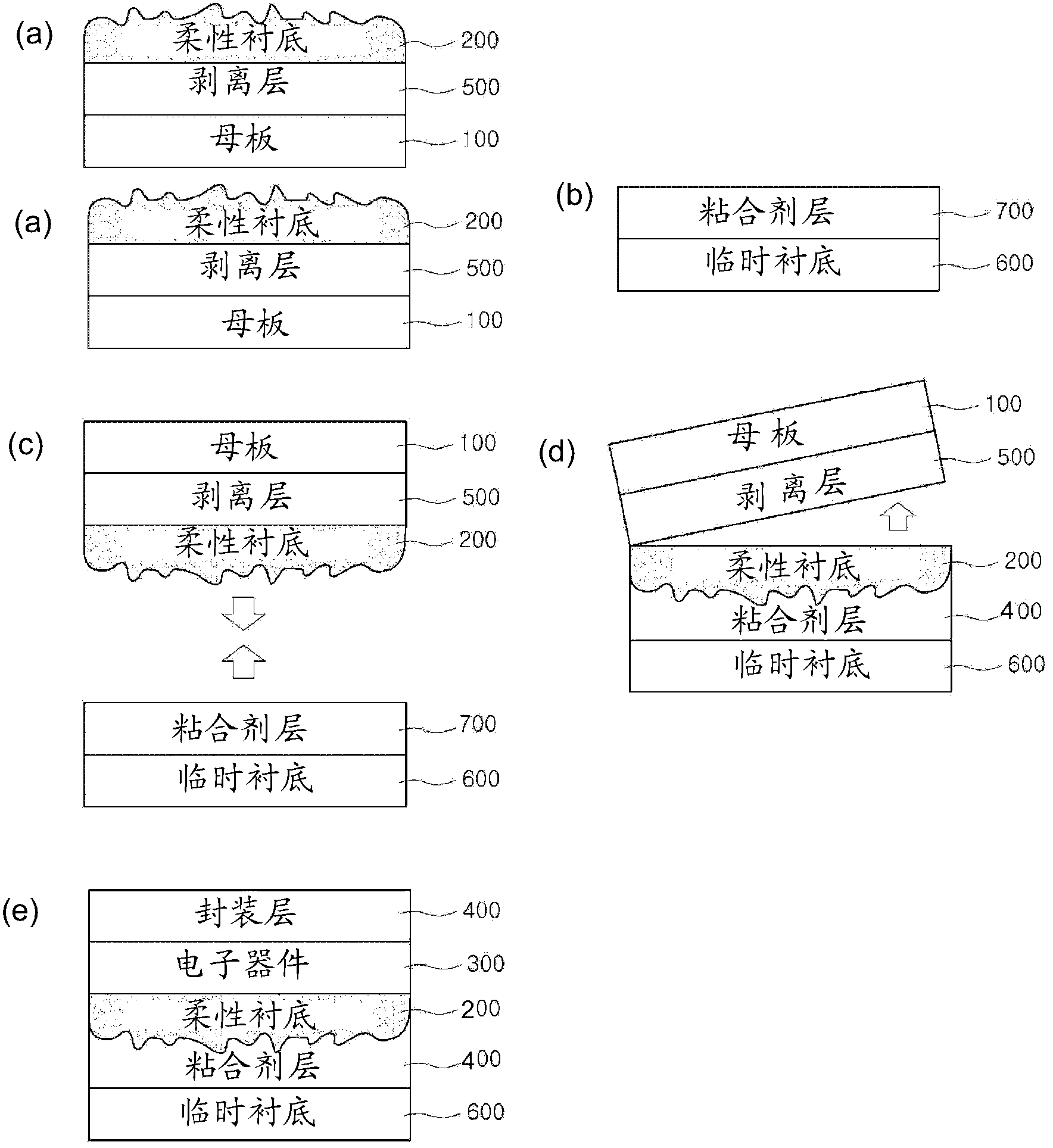

A flexible electronic device, method for manufacturing same, and a flexible substrate

InactiveCN103140953ALow costSolve surface roughness related defectsCircuit bendability/stretchabilityFinal product manufactureState of artSurface roughness

The present invention relates to resolving the issues concerning the deterioration in the performance and yield of a flexible electronic device, which are caused by low manufacturing temperature, high surface roughness, a high thermal expansion coefficient, and the bad handling characteristics of a typical flexible substrate. The method for manufacturing a flexible electronic device according to the present invention includes: forming a flexible substrate on a motherboard while physically separating the interface therebetween so that the interfacial bonding therebetween has a yield strength less than that of the flexible substrate; and forming an electronic device on the separated surface of the flexible substrate which had previously been in contact with the motherboard.

Owner:POHANG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com