Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1312results about How to "Improve the bonding strength of the interface" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

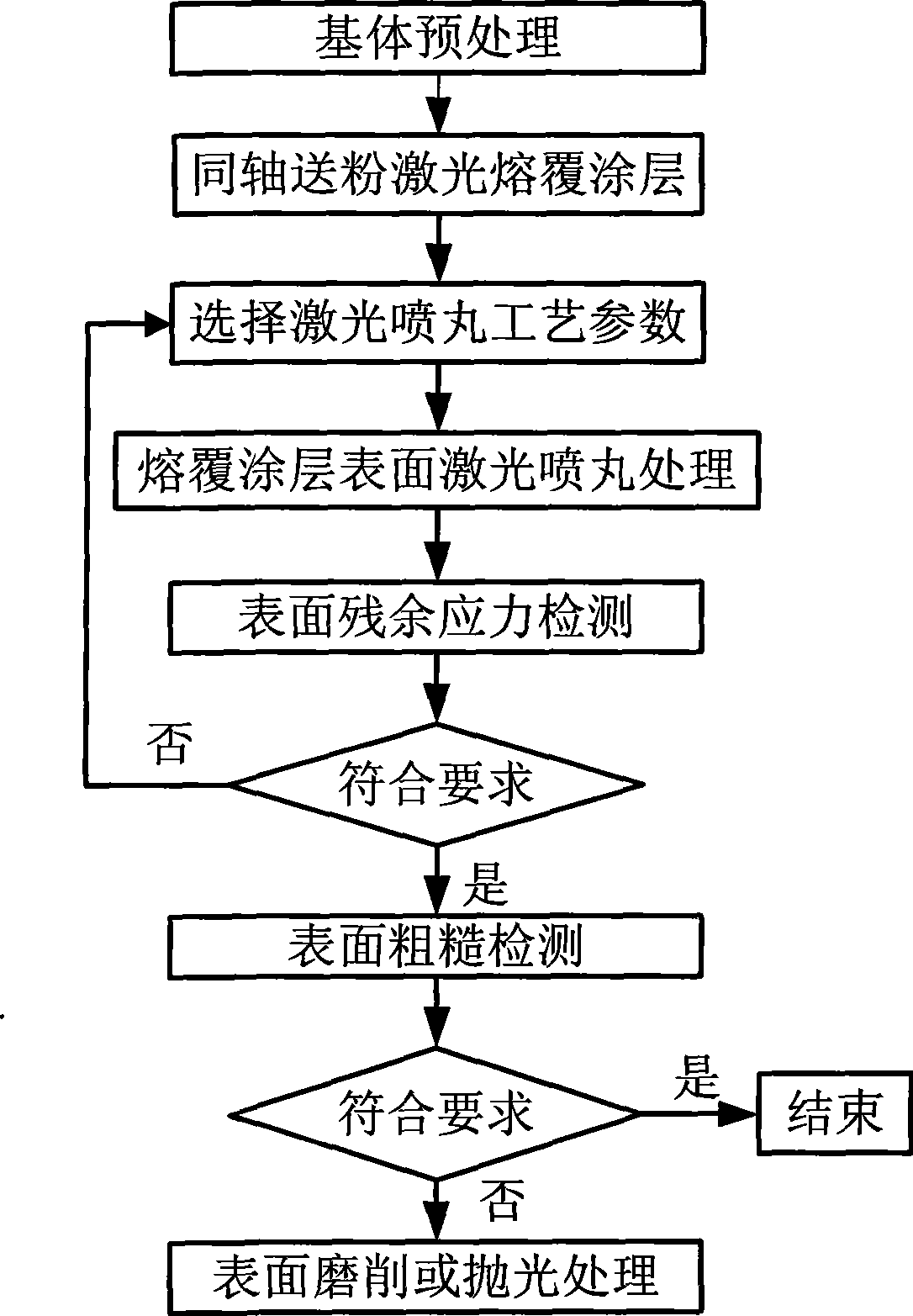

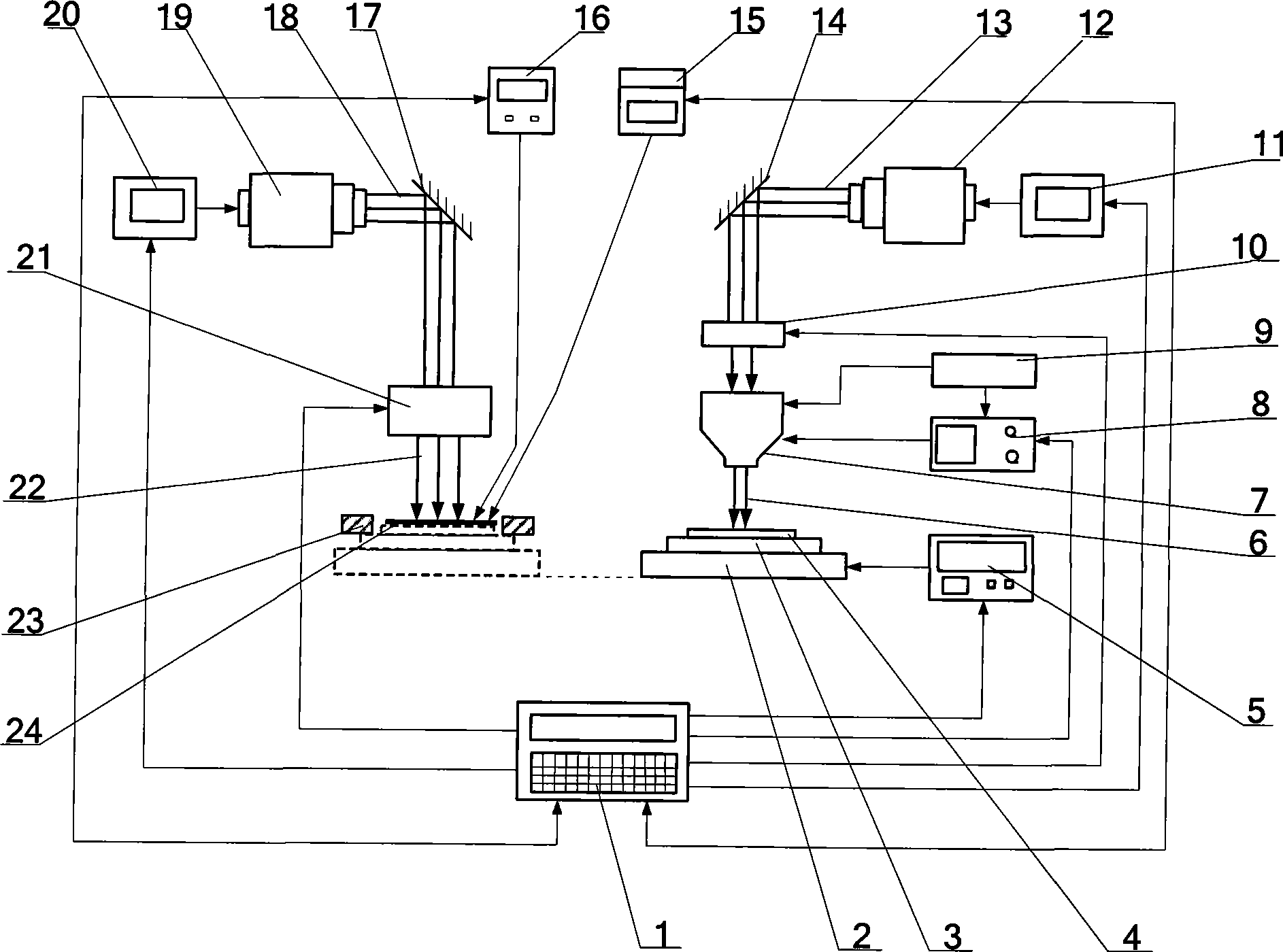

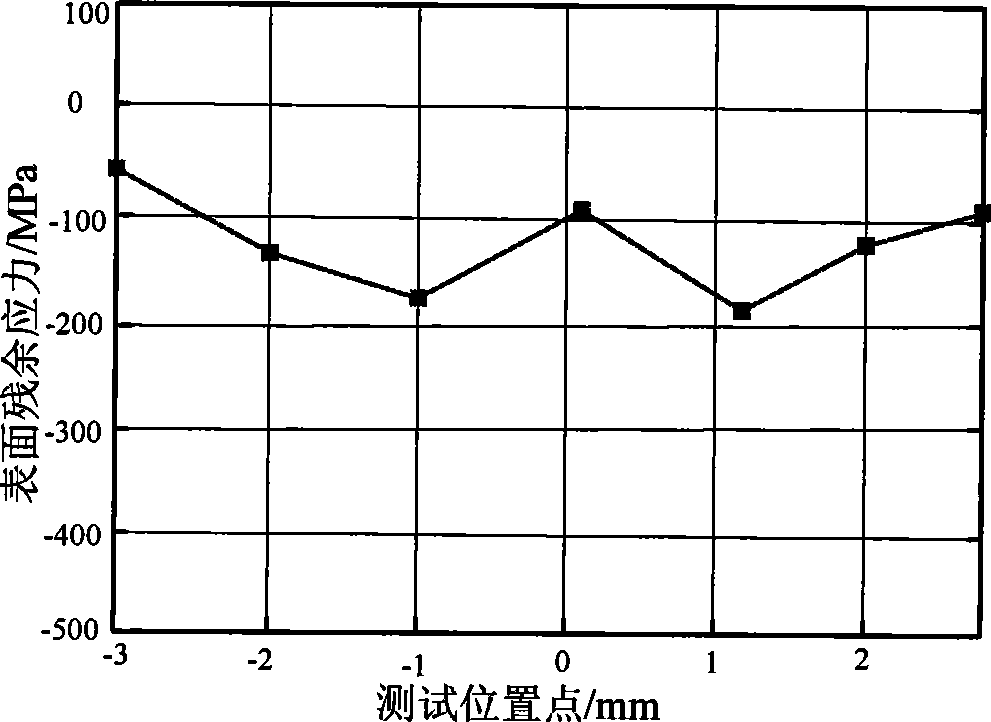

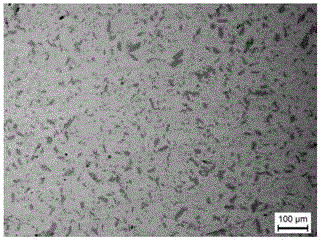

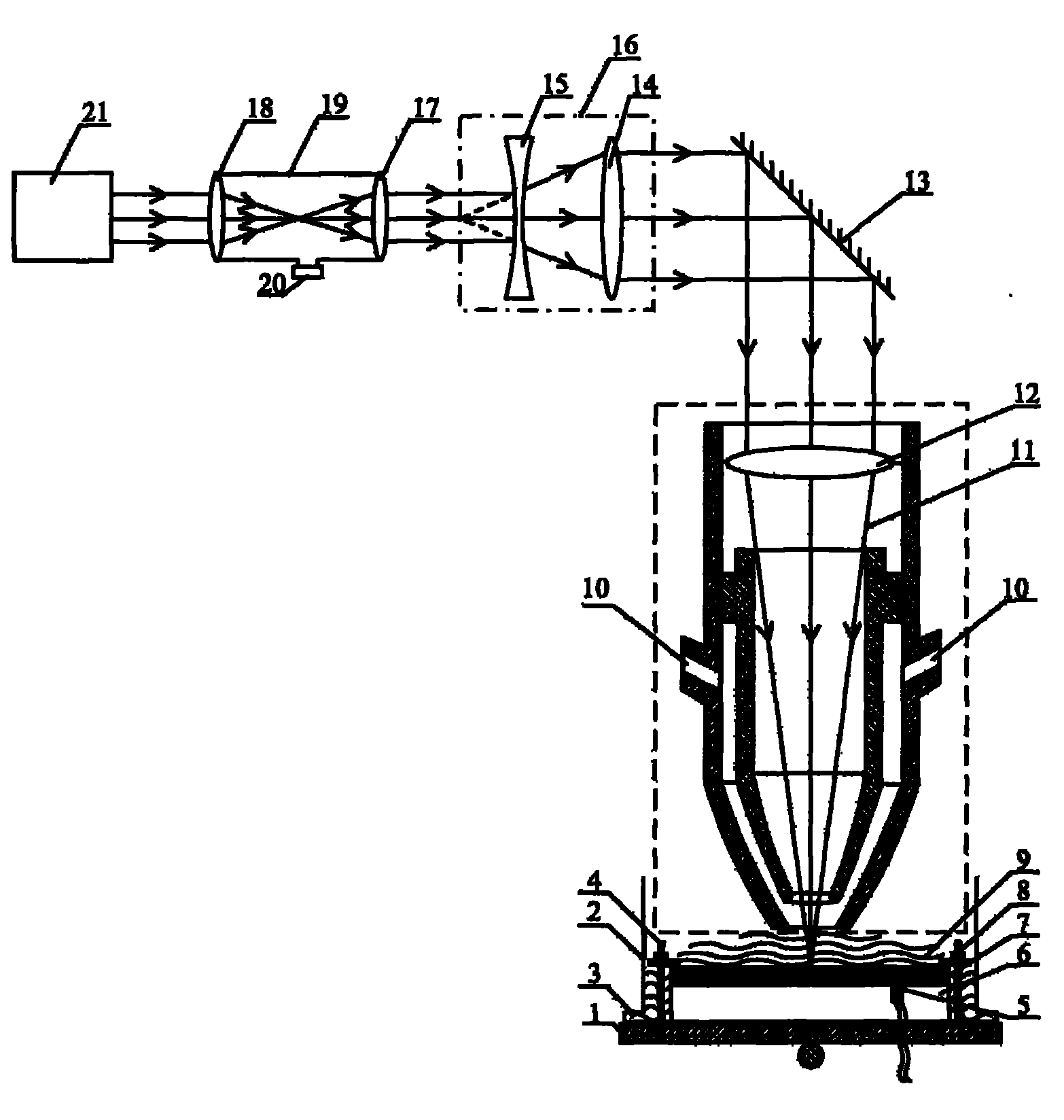

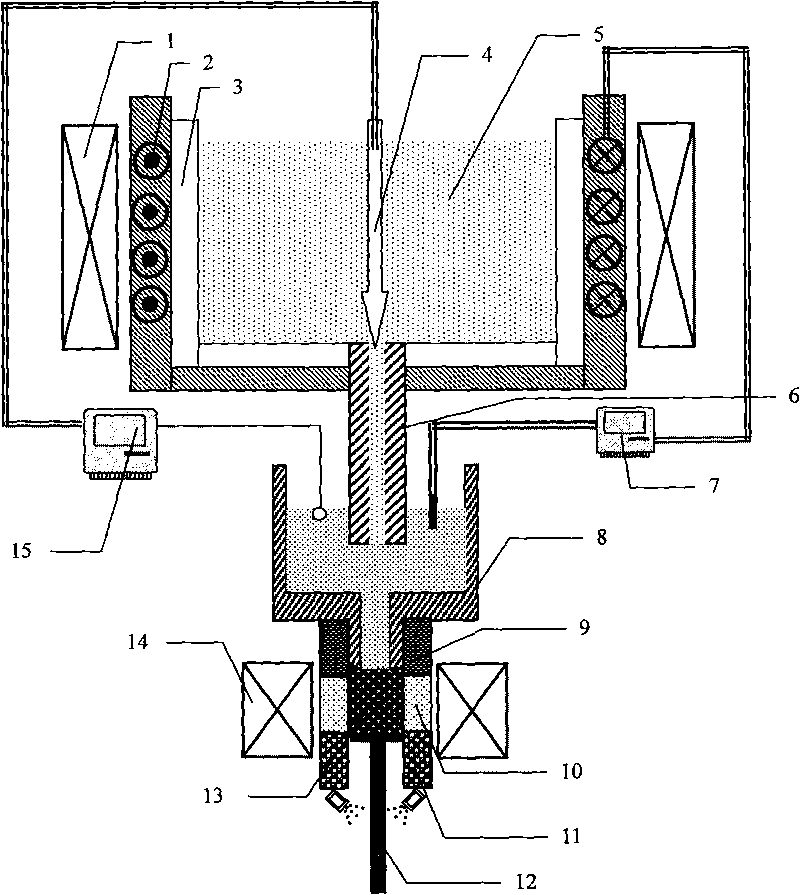

Method and device for strengthening surface modification by combination of laser cladding and laser peening

InactiveCN101392382AQuality improvementResidual stress distribution state changesMetallic material coating processesCoated surfaceSurface roughness

The invention provides a method for modifying a composite surface based on laser cladding and combining laser shock peening, and a device thereof. The method provided by the invention is characterized in that a coaxial and powder feeding type fast axial flow CO2 laser cladding unit clads a layer of coating on the surface of a substrate; then a neophane glass impulse laser shock peening unit is used for the shock peening on the surface of the cladded coating; a measurement feedback system is utilized to detect the surface roughness and the distribution state of residual stress of the cladded coating; the precise control over the surface roughness and the residual stress of the coating is realized by a central control and processing system so as to obtain a high quality surface-cladded coating with good performance. The device comprises the coaxial and powder feeding type laser cladding unit, the laser shock peening unit, a digital control working system, the measurement feedback system and the central control and processing system, and is under integrated control by a computer. The method and the device of the invention can reduce residual tensile stress and improve the quality of the cladded coating and prolong the service life thereof.

Owner:JIANGSU UNIV

Abrasion resistant ceramic coating

The invention discloses a brushing-proof abrasion-proof and erosion-proof ceramic paint, which is characterized by the following: selecting at least one of electric-melting brown corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum and electric melting mullite with different grain sizes as main material and at least one of compact corundum, electric-melting subwhite corundum, electric-melting white corundum, carborundum, silicon nitride and boron nitride as auxiliary material; using CA50 calcium aluminate cement or pure calcium aluminate cement as binder and nanometer micro-silica powder and active alpha-Al2O3 micropowder as reinforcer; making hyperdrying active high-effective dehydragent, sodium citrate and sodium hexametaphosphate as composite additive; loading in the strength stirrer to stir 12-17min; blending evenly; packing.

Owner:CHONGQING LUOMAN NEW MATERIAL TECH CO LTD

High-entropy alloy reinforced aluminum-based composite material and preparation method thereof

ActiveCN104388764AImprove the bonding strength of the interfaceImprove the state of the interfaceHigh entropy alloysRoom temperature

The invention belongs to the technical field of composite materials and discloses a high-entropy alloy reinforced aluminum-based composite material and a preparation method thereof. The composite material takes high-entropy alloy as a reinforcing phase and takes aluminum alloy as a base body. The preparation method of the composite material comprises the following steps: packaging high-entropy alloy particles and aluminum alloy powder into a ball milling tank, sealing and mixing the powder for 5-25 hours to obtain a mixed material; packaging the mixed material into a bag; applying a pressure of 5MPa to 15MPa at room temperature to compact the mixed material in the bag to obtain a semi-finished product; putting the compacted semi-finished product into thermal extruding equipment, preheating the semi-finished product to 400-480 DEG C, preheating a mold to 200-400 DEG C, keeping the temperature of the semi-finished product and the mold for 1-3 hours to finish the preheating process, and then performing hot extrusion formation at an extrusion pressure of 5MPa to 15MPa and at an extrusion ratio of 4 to 25 to obtain the high-entropy alloy reinforced aluminum-based composite material.

Owner:GUANGDONG XINGFA ALUMINUM +1

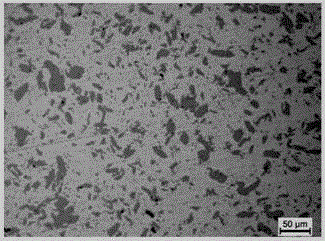

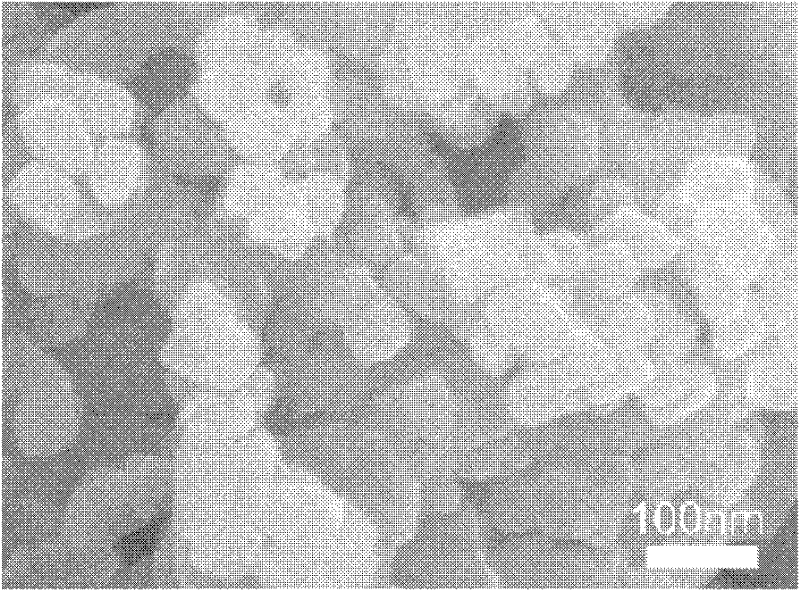

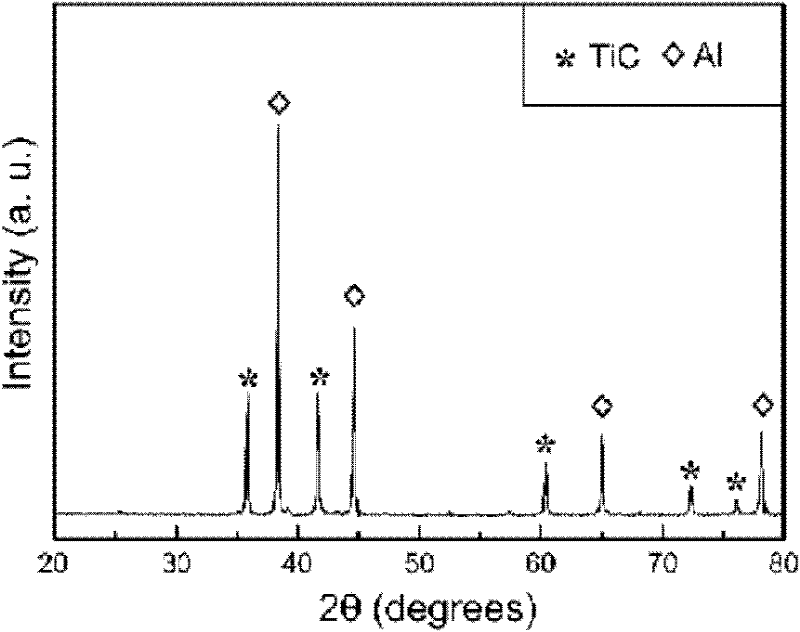

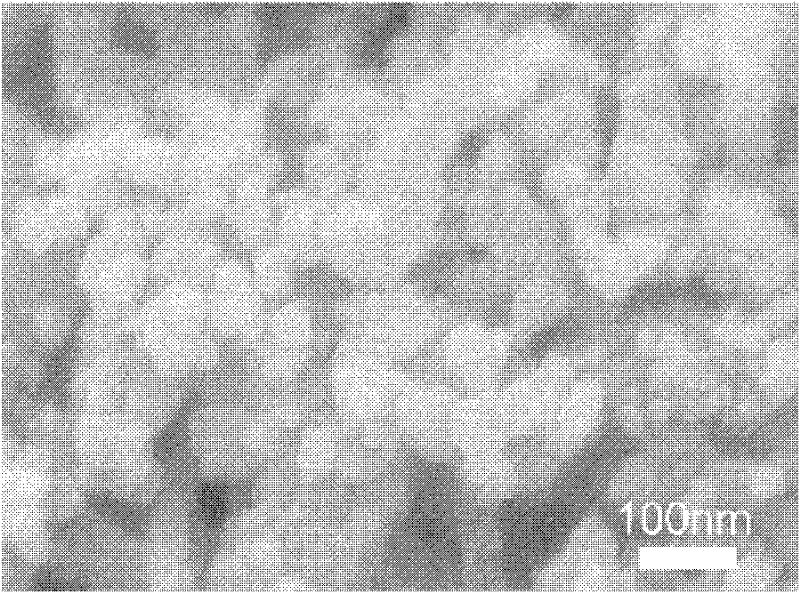

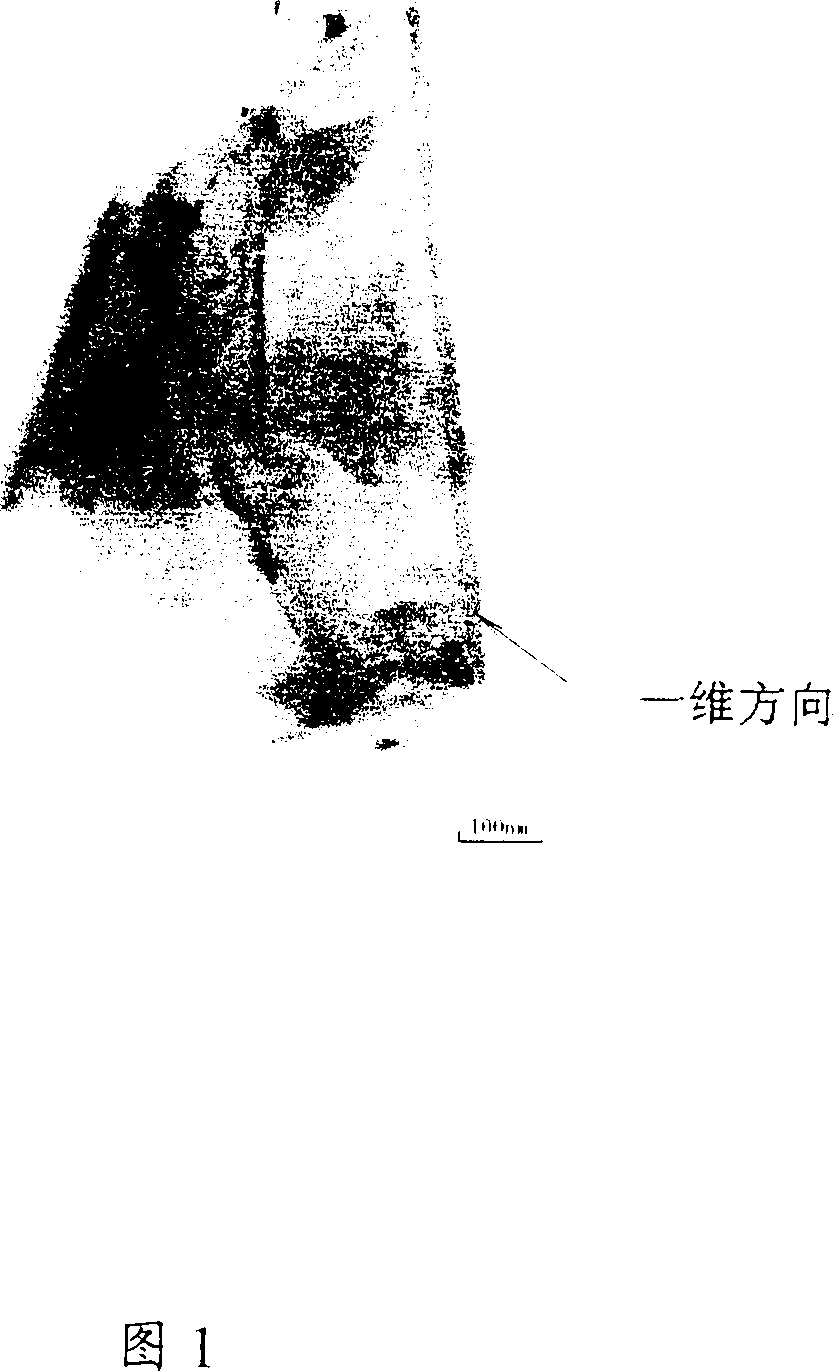

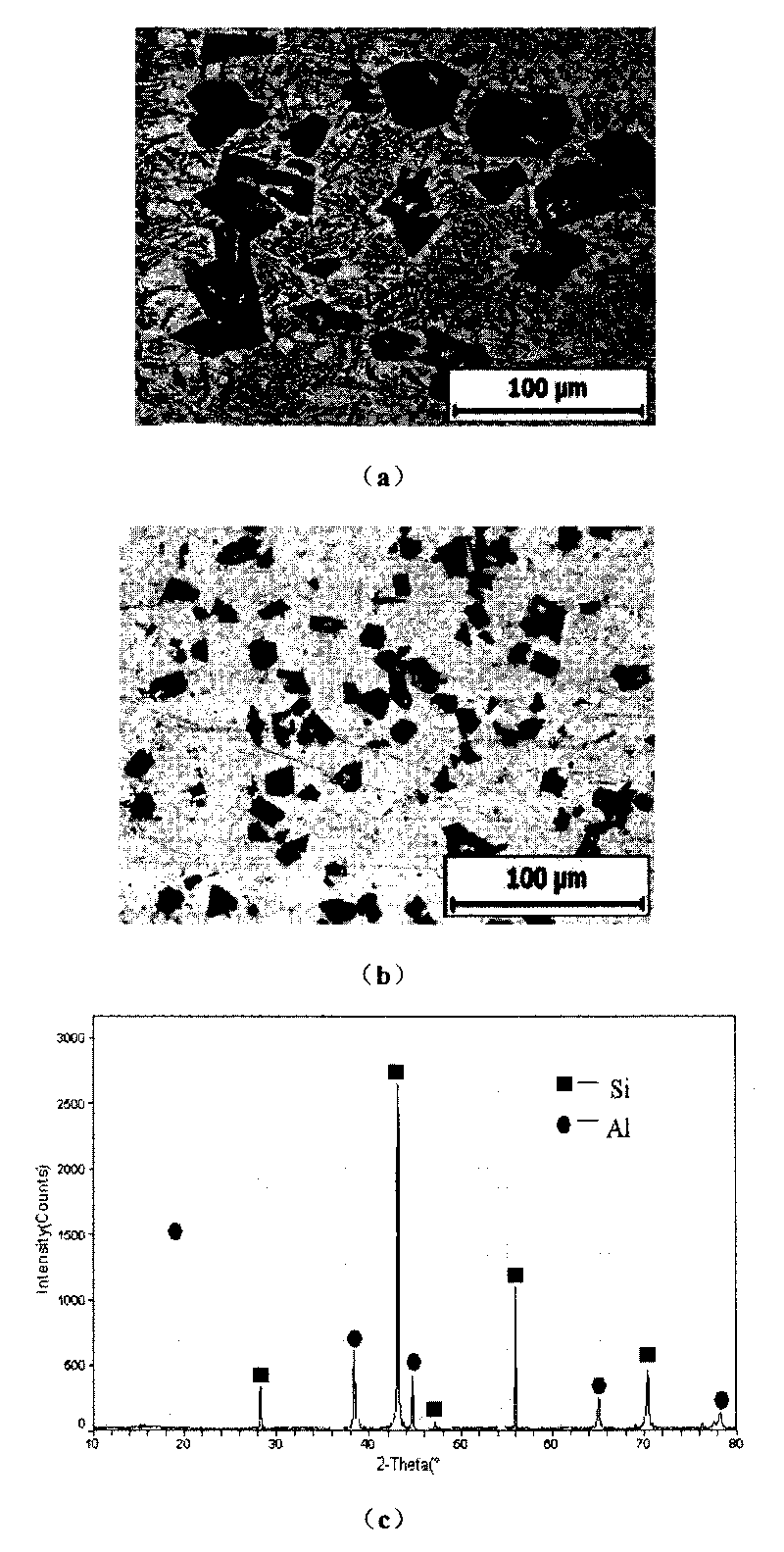

A kind of in-situ nano-tic ceramic particle reinforced aluminum matrix composite material and preparation method thereof

ActiveCN102260814APure surfaceImprove the bonding strength of the interfaceChemical reactionGraphite

The invention relates to an in situ nano TiC ceramic particle reinforced aluminum based composite material and a preparation method thereof. According to the invention, an in situ nano TiC ceramic particle reinforced aluminum or aluminum alloy based composite material is prepared by using a combustion synthesis chemical reaction method and a hot-press technology; and the size of the TiC ceramic particle synthesized by an in situ reaction is below 100 nm, and the weight percentage content of the TiC ceramic particle is 3-30. The preparation method comprises the following steps: 1) mixing reactant powder materials in a certain proportion and then making blanks; 2) evenly mixing in a drum-type ball mill and a triturator in turn; 3) pressing at the room temperature so as to form reaction prefabricated blocks; and 4) putting a graphite mould with the prefabricated blocks in a vacuum / atmosphere protected combustion reaction furnace with a hydraulic device and then initiating a combustion reaction, immediately applying an axial pressure of 40+ / -5 MPa to the prefabricated blocks once the combustion reaction occurs, and cooling the prefabricated blocks to room temperature along with the furnace after keeping the pressure for 30-40 seconds, so as to synthesize the nano TiC ceramic particle reinforced pure aluminum or aluminum alloy based composite material.

Owner:JILIN UNIV

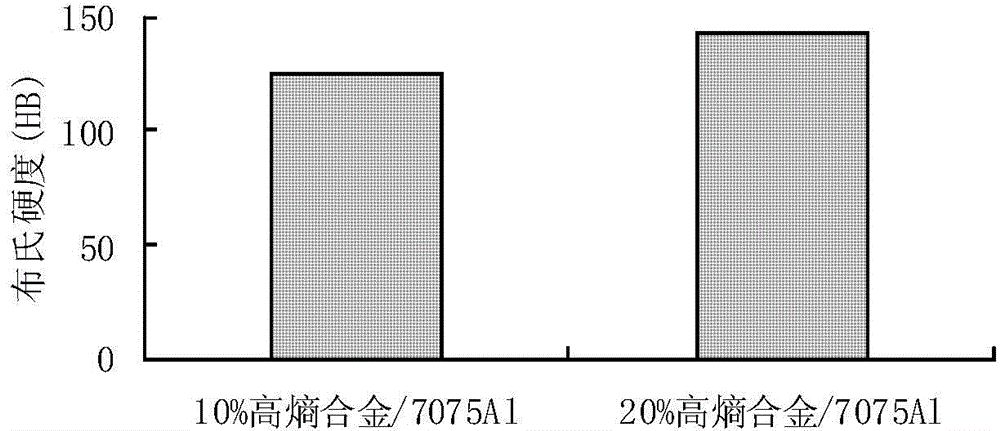

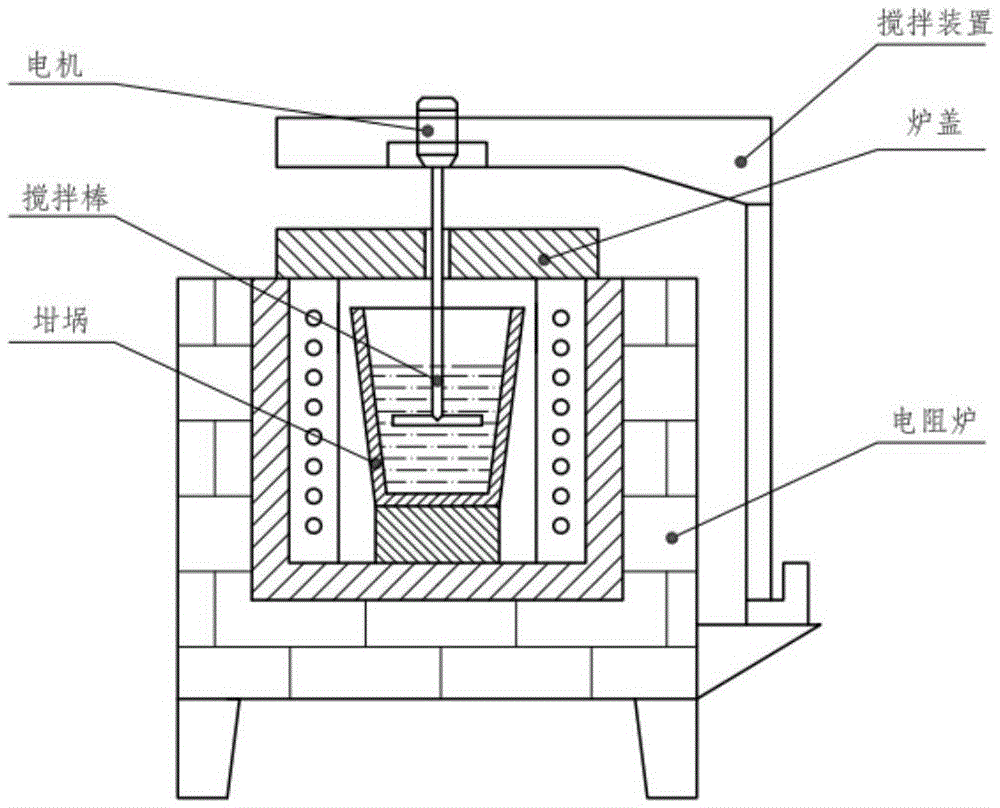

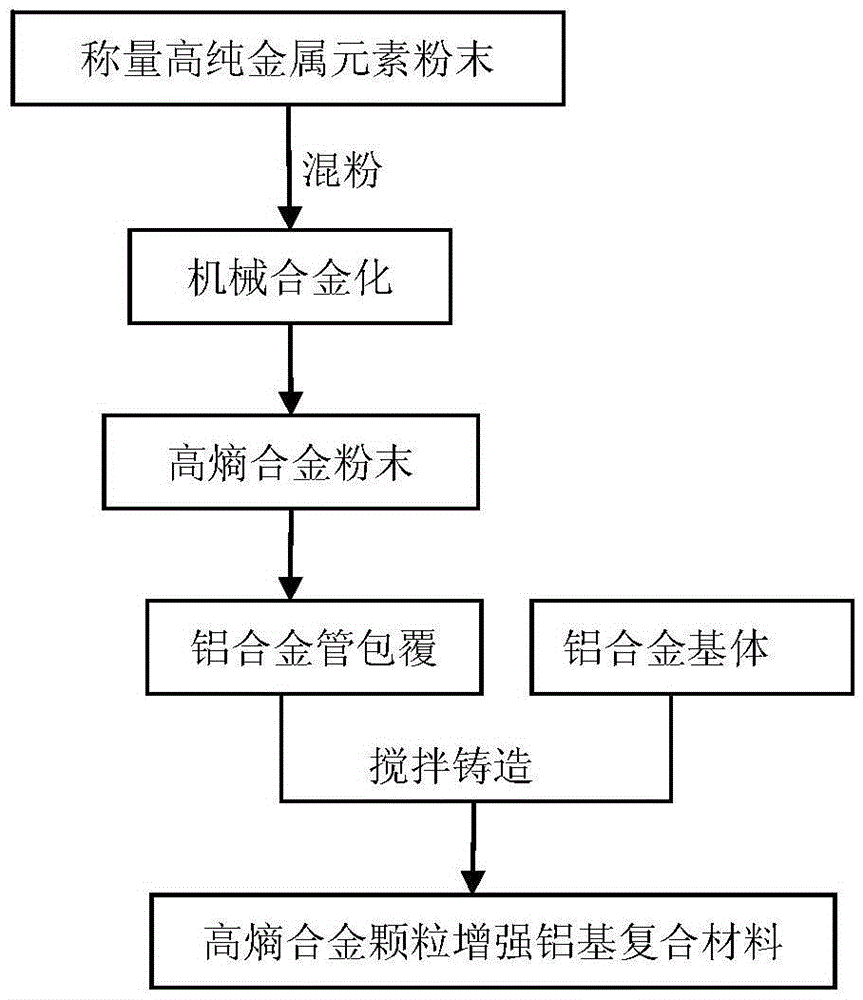

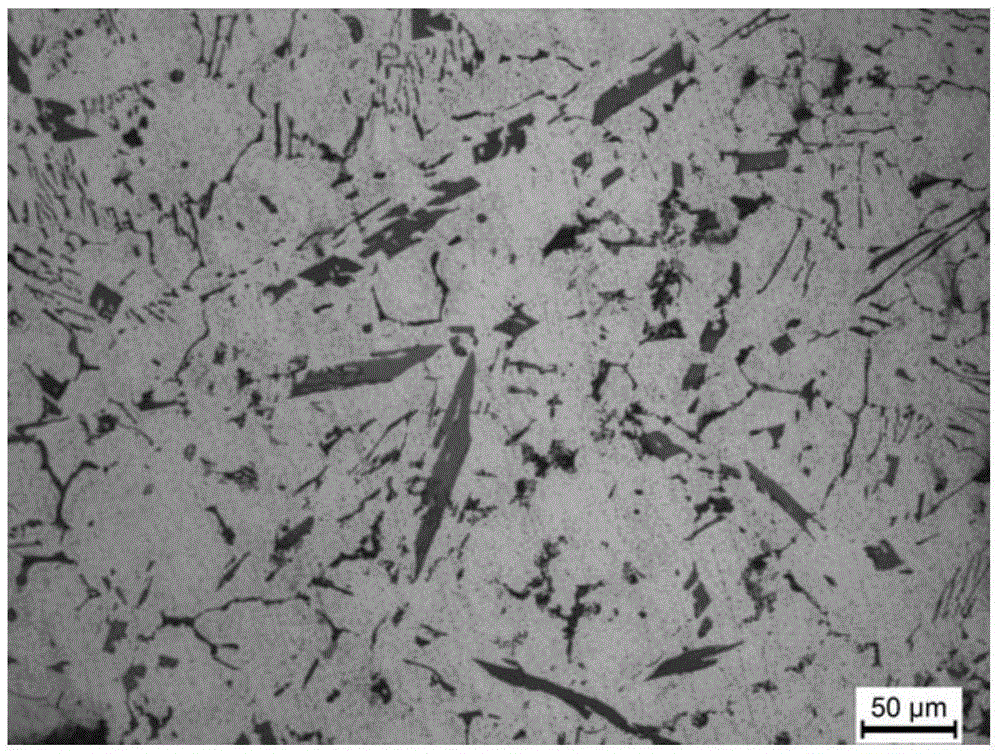

High-entropy alloy particle reinforced aluminum base composite material and stirring casting preparation process thereof

The invention discloses a high-entropy alloy particle reinforced aluminum base composite material and a stirring casting preparation process thereof. The preparation process adopts mechanical alloying to prepare high-entropy alloy powder and screen to obtain high-entropy alloy particles; the high-entropy alloy particles are sealed by adopting an aluminum alloy pipe having the same material with a basal body; the aluminum alloy pipe weighed in a segmented manner is added in the molten basal body; the high-entropy alloy particles are dispersed by a stirring mode; and the high-entropy alloy particle reinforced aluminum base composite material is prepared by a casting process. The high-entropy alloy particles are 0.1-35%; aluminum alloys are 65-99.9%; and the sum of the two is 1. The high-entropy alloy particles in the structure of the prepared composite material are uniformly dispersed; the high-entropy alloy and aluminum alloy interface bonding compatibility is excellent; the strength and the toughness are excellent; the preparation process is simple; the powder has no need to be treated; the cost is low; the stability is good; and the composite material is suitable for large-batch production and standard production, and is excellent in promotion and application prospect.

Owner:GUANGDONG XINGFA ALUMINUM +1

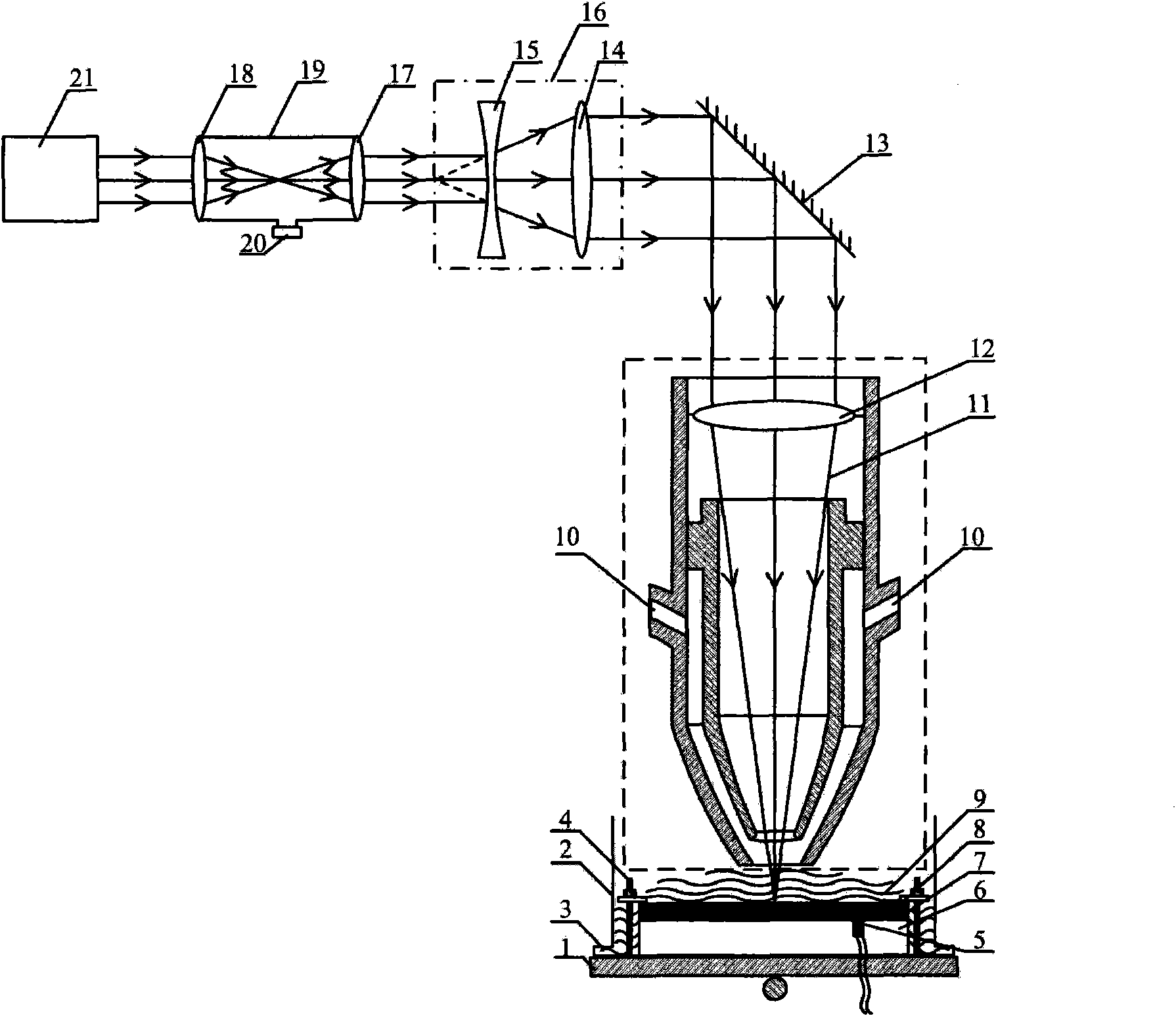

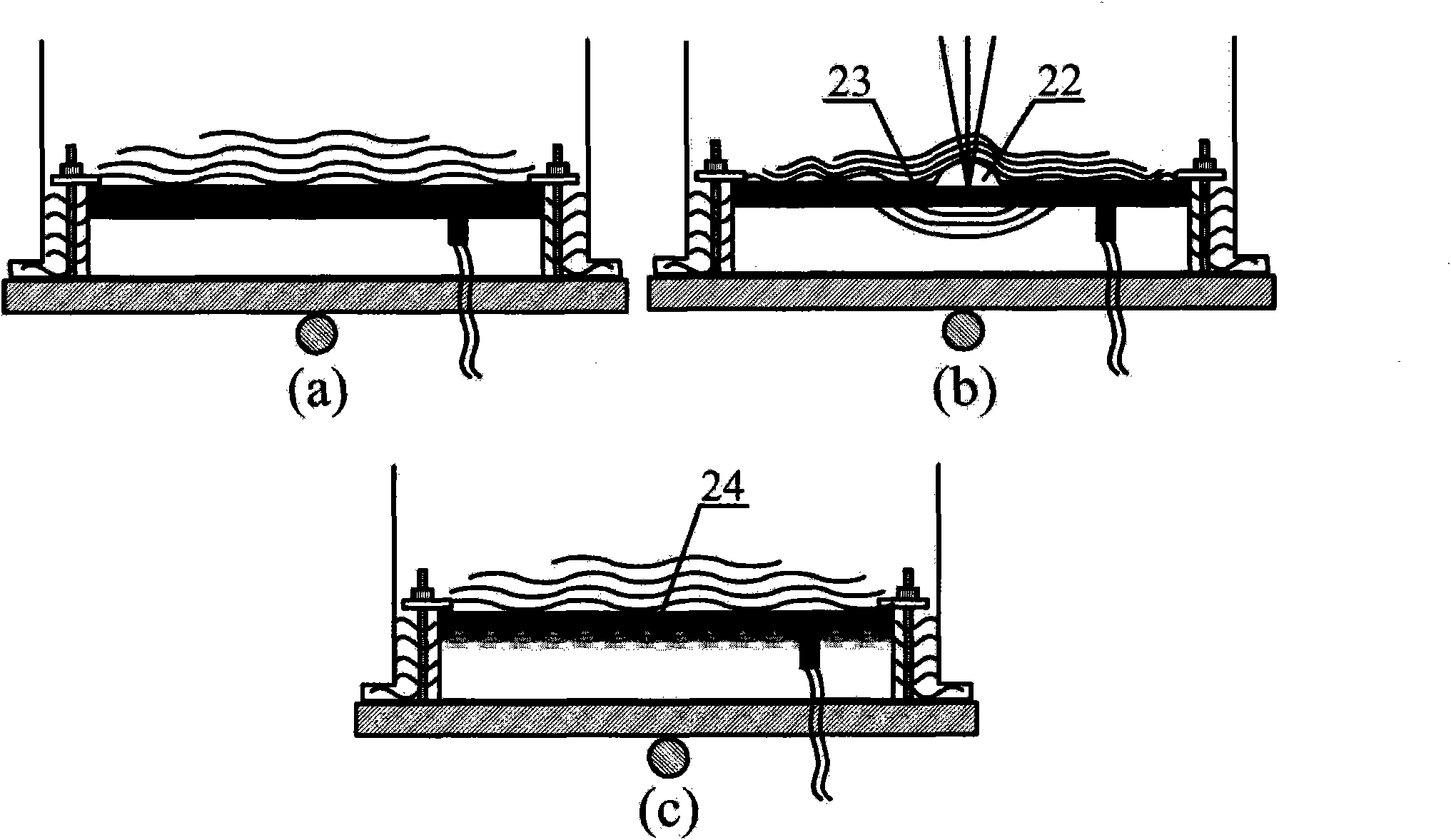

Nano coating preparation method and device based on ultrafast ultrahigh pressure photodynamics effect

InactiveCN101787528AChange compositionChange organizationMetallic material coating processesLaser beamsMechanical property

The invention discloses nano coating method and device based on ultrafast ultrahigh pressure photodynamics effect, belonging to the technical field of material surface. The invention is characterized by embedding or cold welding nanometer metal powder, nanometer nonmetal powder or compound nanometer powder which are precoated on the surface of a metal matrix in the surface layer of the metal matrix by means of laser induction mechanics effect, forming a thick nanometer particle strengthening layer or a coating layer which is called as a nano coating on the surface of the metal matrix, wherein the metal matrix is impacted and strengthened by laser. The device comprises a three-dimensional hexad working platform, a water tank, a clamp, a thermocouple, a coaxial synchronous water sender, a laser beam focusing system, a 45-degree fully-reflecting mirror, a laser beam optimizing system and a nanosecond laser. By the invention, the obtained surface nano coating has firm interface joint with the matrix and the mechanical property on the surface of the metal matrix is remarkably improved. The invention has simple technical process and lower cost, and is easy to realize automation and suitable for large-scale batch production.

Owner:JIANGSU UNIV

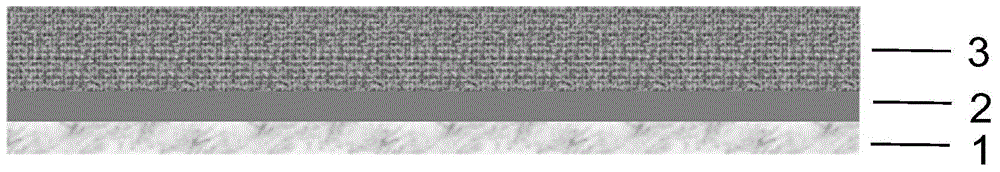

Integrated flexible electrode

ActiveCN104916809AReduce contact resistanceImprove flexibilityCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsIntegrated designSlurry

The invention discloses an integrated flexible electrode and belongs to the technical field of electrochemical cells. The integrated flexible electrode is composed of three layers which are successively a polymer layer, a graphene layer and an active material layer. According to the invention, the multi-component integrated design is realized. The graphene layer is formed by dispersing and coating graphene onto the polymer layer. The active material layer is formed by coating slurry onto the graphene layer. After drying, the integrated flexible electrode material is obtained. The integrated flexible electrode material has excellent flexibility and tensile strength and is applicable to flexible cells. A preparation method of the integrated flexible electrode is simple and easy to control, can be applied to various electrode materials and has potential application value. Mass and low-cost preparation can be realized.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing thermal barrier coating by laser compound plasma spraying

InactiveCN101768714AImprove thermal shock resistanceImprove mechanical propertiesMolten spray coatingEfficient propulsion technologiesAdhesivePlasma sprayed

The invention discloses a method for preparing a thermal barrier coating by laser compound plasma spraying, which relates to the field of surface coatings. The method comprises the following steps: 1) cutting a material to be treated into required size by adopting line cutting; 2) polishing the surface of the cut material by using abrasive paper; 3) cleaning the surface of the polished material by adopting pulse laser; 4) performing laser texturing treatment on the surface of the cleaned material to roughen the surface of the material; and 5) filling spraying material powder into a powder feeder, fixing the roughened material on a turntable, and preparing the thermal barrier coating by plasma spraying; or first preparing a middle adhesive layer, then repeating the cleaning and texturing processes in the steps 3) and 4), and preparing the thermal barrier coating by the plasma spraying process. The interface of the thermal barrier coating prepared by the method is firmly combined, and the thermal shock resistance and mechanical property of the thermal barrier coating are remarkably improved. The method has simple processes, is suitable for large-scale mass production, and can prepare the high-performance thermal barrier coating with firm interface combination.

Owner:JIANGSU UNIV

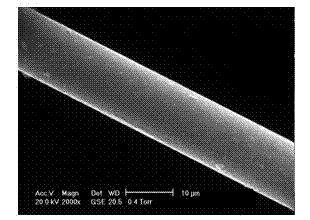

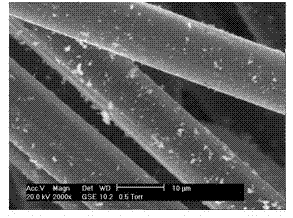

Aramid fiber surface metallization treatment method

The invention belongs to the field of fiber material surface metallization treatment and particularly relates to an aramid fiber surface metallization treatment method which takes hypophosphite as reductant and metal salt as the plating solution of the main salt to deposit a metal coating on the surface of aramid fiber through chemical plating. The surface metallization treatment process includes the steps of unoiling, coarsening, sensitizing, activating, carrying out preplating and carrying out chemical plating. Through the metallization treatment method disclosed by the invention, a uniform compact nonporous metal coating can be plated on the surface of the aramid fiber, and therefore the electrical conductivity and the corrosion resistance of the aramid fiber can be improved and the service life of the aramid fiber can be prolonged. The aramid fiber plated with the metal coating can also be used as reinforcement of metal matrix composite material so as to improve the mechanical property of the composite material.

Owner:KUNMING UNIV OF SCI & TECH

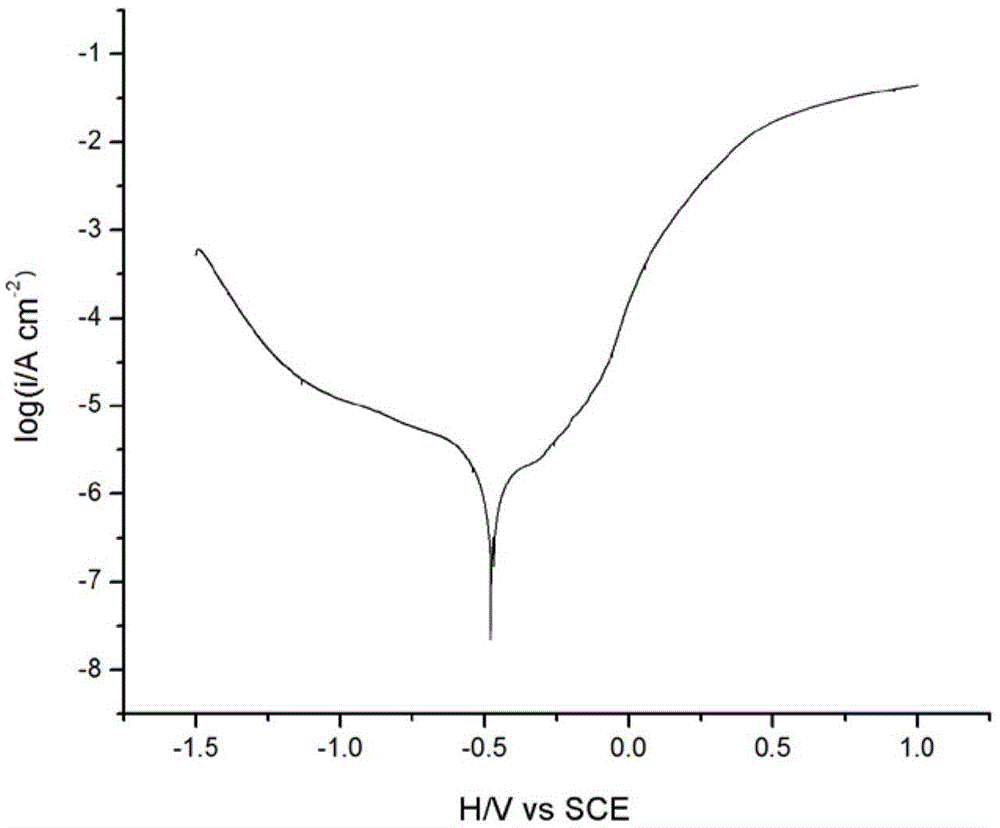

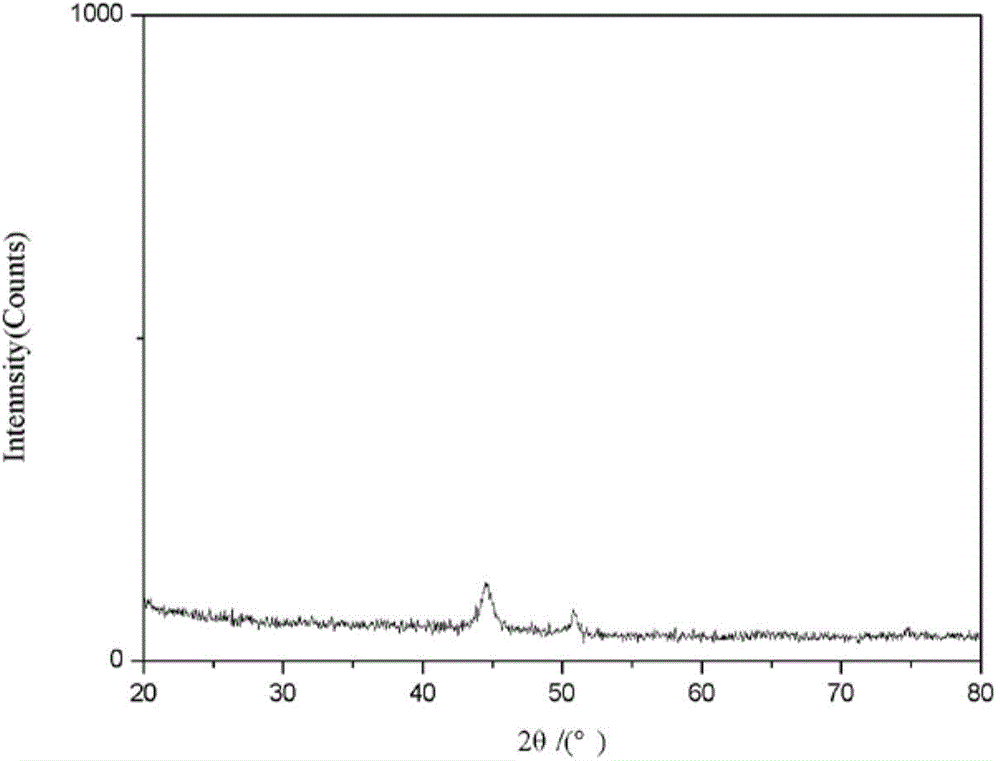

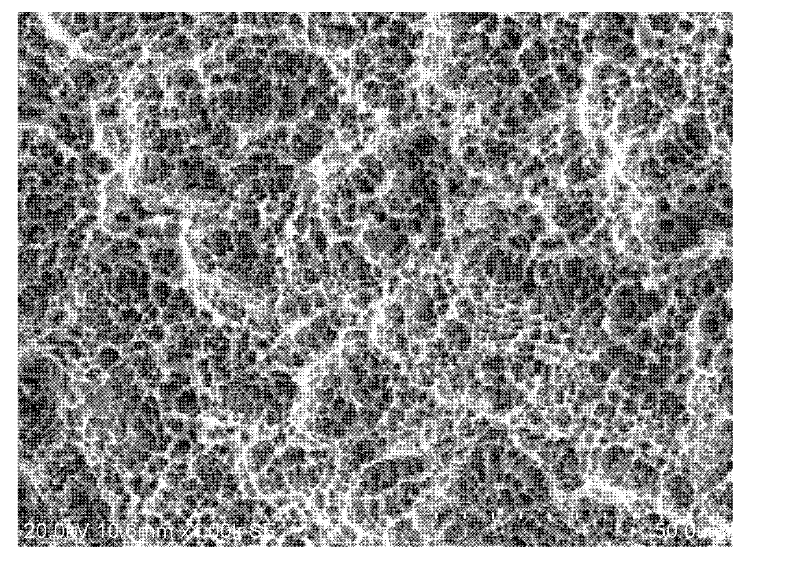

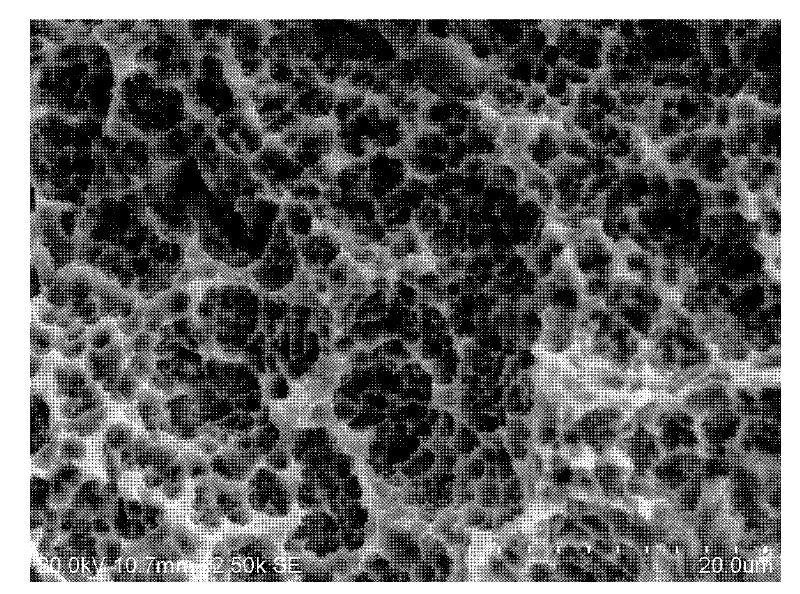

Iron-based amorphous coating and laser preparation method thereof

ActiveCN104480462ALow costImprove corrosion resistanceMetallic material coating processesAtmosphereIron based alloy

The invention discloses a laser preparation method of an iron-based amorphous coating. A formula formed by all the elements of the iron-based amorphous coating according to the weight percent is FeaCrbNicSidBeCf, wherein the sum of b, c, d, e and f is not more than 50. Powder can be used after the components are uniformly mixed in proportion according to a required weight ratio. Powder is fed by synchronous powder feeding and is cladded in an argon protection atmosphere to prepare an iron-based alloy coating and the iron-based alloy coating is subjected to laser remelting to prepare the iron-based amorphous coating. The prepared coating has few defects and higher corrosion resistance and has a whole amorphous structure.

Owner:NANJING UNIV OF SCI & TECH

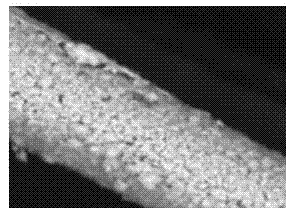

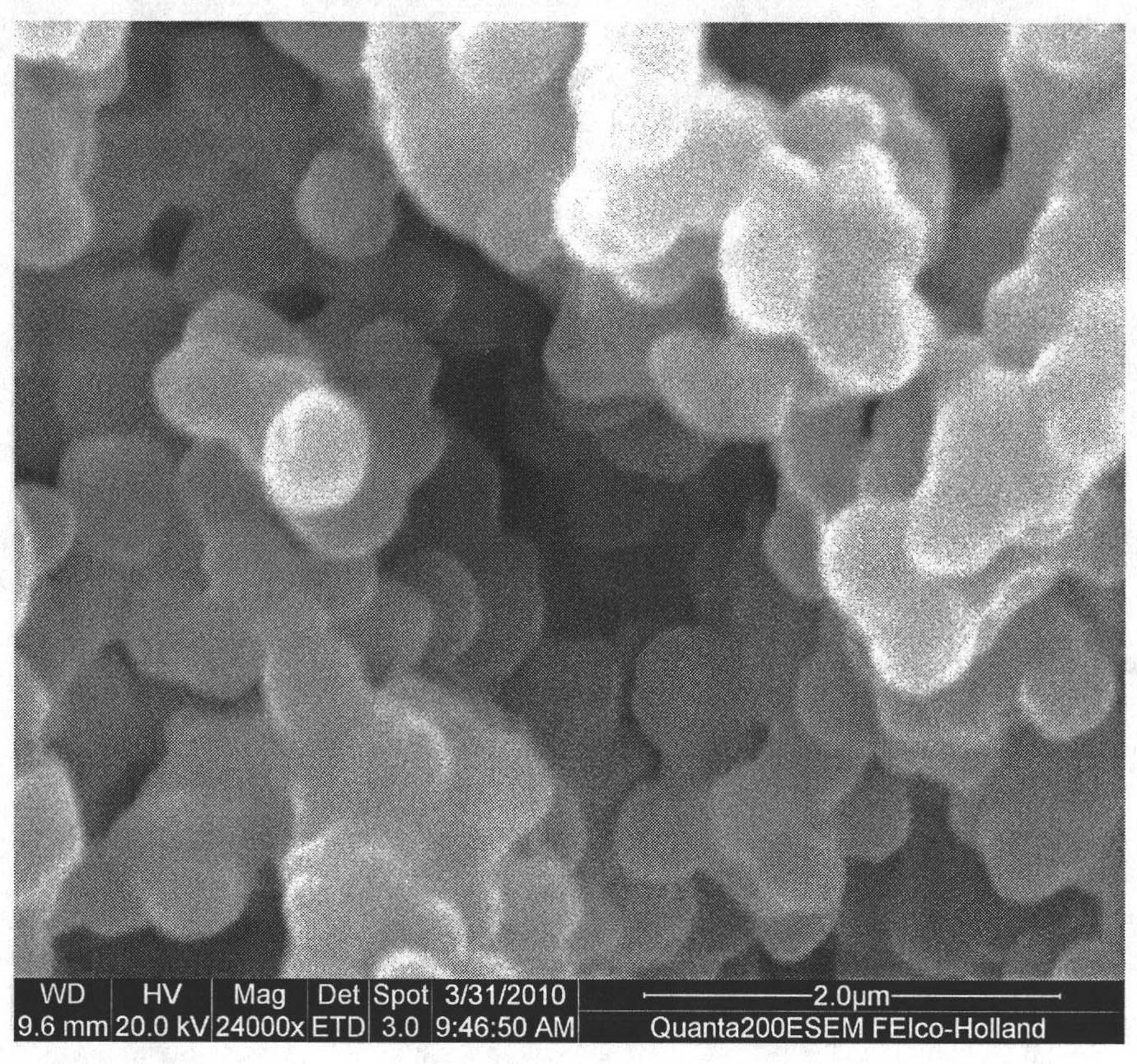

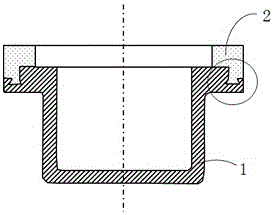

Surface processing technology for dental implant

InactiveCN102232876AGood surface morphologyGood rough surfaceArtificial teethCleaning using liquidsAcid etchingTitanium

The invention discloses a surface processing technology for a pure-titanium dental implant. The technology comprises the following steps: A, removing oil from the dental implant by ultrasonic cleaning; B, sandblasting the dental implant by white corundum to make the surface of the implant to be uniform gray in color and allow a three-dimensional porous structure to be formed on the surface of the dental implant; C, carrying out acid etching on the surface of the sandblasted dental implant with a mixed liquid with a certain concentration and a certain ratio of sulfuric acid to hydrochloric acid to allow gradually decreased multilevel scallops to be formed on the surface of the dental implant; and D, flushing and neutralizing the acid etched dental implant, and removing oil. According to the surface processing technology for the dental implant designed by the invention, the multilevel porous structure with biological activity is formed on the surface of the pure-titanium implant, so the biological activity of the pure-titanium implant is improved, the stability of the implant is improved, the bone combination speed of the dental implant is accelerated, the bone interfacial combination strength of the implant is enhanced, thereby the technology has the advantages of simple and high efficient technology, and low cost.

Owner:JIANGSU TRAUSIM MEDICAL INSTR

Graphene masterbatch

InactiveCN105017742AExcellent mechanical propertiesImprove antioxidant capacityNon-conductive material with dispersed conductive materialChemical LinkageMasterbatch

Disclosed is a graphene masterbatch including a base resin, electrically conductive carbon black, graphene nanoplatelets with modified surface and a dispersant. The modified surface of graphene nanoplatelet is formed by a modifying agent containing a coupling compound so as to possess hydrophobic and hydrophilic functional groups, which help graphene nanoplatelets form chemical bonding with carbon black and the base resin. Since the modified surface makes graphene nanoplatelets evenly dispersed in the base resin, the graphene masterbatch of the present invention is suitably melt blended with a polymer material to form a composite material such that graphene nanoplatelets are evenly dispersed in the polymer material, thereby enhancing junction strength, increasing mechanical properties, and improving anti-oxidation, acid / base resistance, and thermal conductivity.

Owner:北京烯创科技有限合伙企业(有限合伙)

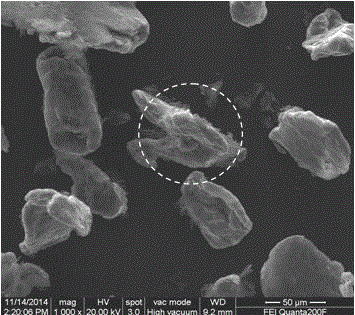

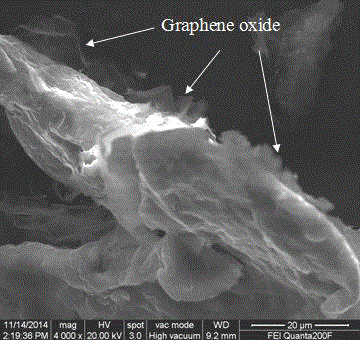

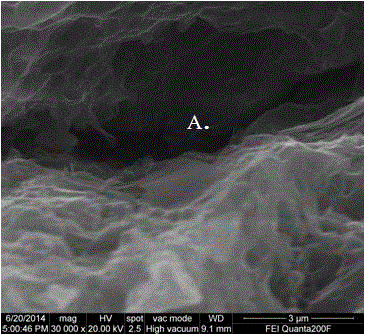

Preparation method of in-situ reduced graphene reinforced magnesium-matrix composite

The invention discloses a preparation method of an in-situ reduced graphene reinforced magnesium-matrix composite. The method comprises the following steps: dissolving graphite oxide in an appropriate amount of ethanol solution, and performing ultrasonic treatment for 0.5-2h to obtain a graphene oxide ethanol solution with concentration of less than or equal to 2mg / ml; adding appropriate AZ91 magnesium alloy powder with the particle size of less than or equal to 325 meshes into the mixed solution, and performing ultrasonic treatment and mechanical stirring for 2h to obtain mixed slurry; performing vacuum drying of the mixed slurry, transferring into a mould, and pressing into a composite green under the pressure of 100-600MPa at room temperature; sintering the composite green for 2-4h at 500-600 DEG C in argon protection; and finally performing hot extrusion of the sintered composite at 350-400 DEG C. The preparation method disclosed by the invention is simple in preparation process and safe and reliable; the reduced graphene has good dispersity in magnesium alloy; and the reduction byproduct MgO is good for improving the interface bonding strength so that the reinforcing effect is better and the performance of the composite is excellent. Compared with the method of directly adding graphene into the magnesium matrix, the cost is lower and the dispersity is better; and the preparation method is suitable for industrial preparation of a high-performance graphene reinforced magnesium alloy composite.

Owner:NANCHANG UNIV

Diffusion and connection method for ceramic and steel by adding active intermediate alloy

InactiveCN1721121AReduce microscopic gapIncrease contact areaNon-electric welding apparatusAlloyUltimate tensile strength

This invention discloses diffusion link method for ceramics and steel by adding active intermediate alloy with main character as follows: add active intermediate alloy between the contact surfaces of ceramics and steel needed welding, use upper and lower pressure heads to press the needed welding ceramics / steel workpiece; put into vacuum chamber to take expansion link with technical parameters of heat temperature 1060~1180Deg, heat preservation time 25~60min, pressure 8~16MPa, and vacuum degree 2.5í‡10-4í½1í‡10-5Pa. It solves efficiently the expansion link and obtains jointing with shear strength as high as 140MPa fit to use require for complex structure. The invention has advantages of low cost, simple and convenient technique, high applicability and easy to spread.

Owner:SHANDONG UNIV

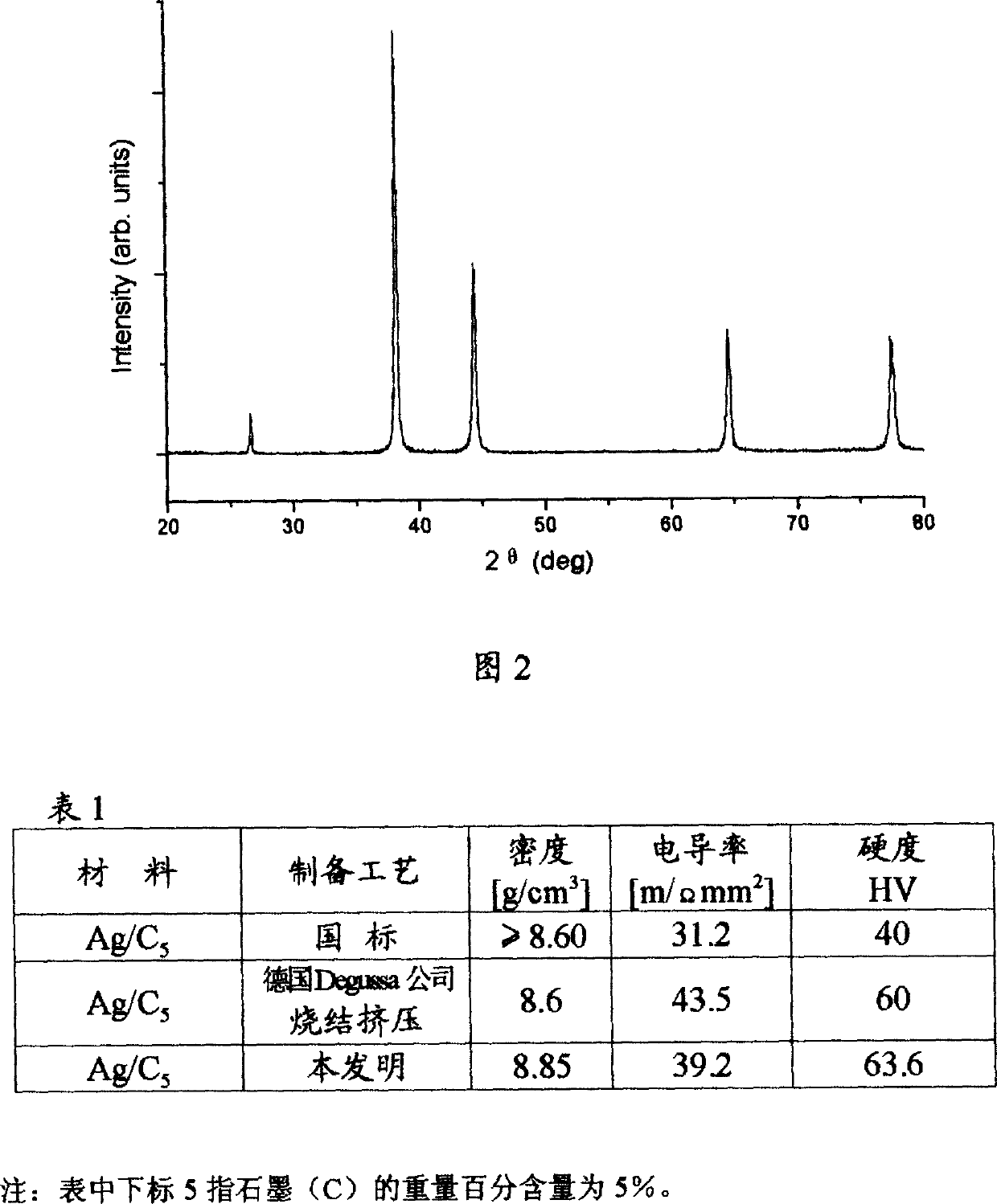

Process for preparing electric silver/graphite contact material by nano technique

InactiveCN1396025AImprove sinterabilityImprove the bonding strength of the interfaceContact materialsGraphiteNanometre

A process for preparing the silver / graphite material as electric contact by use of nanometre technique includes such steps as preparing graphite nanometre powder; adding silver nitrate solution; chemical coating; washing with water; drying and sintering. Its advantages are simple process, low cost and high quality of product.

Owner:EAST CHINA NORMAL UNIV

Method and device for preparing high-performance aluminum-base composite material under the action of pulsed magnetic field

The invention provides a method and a device for preparing high-performance aluminum-base composite material under the action of the pulsed magnetic field with the in situ crystallization method, belonging to the technical field of material preparation. The method comprises the following steps: smelting to synthesize compound material melt at the temperature of 10-200 DEG C higher than the compound material melt liquidus temperature and pouring the compound material melt into a specially-designed crystallizer to make the compound material melt solidify under the action of the pulsed magnetic field. The pulsed magnetic field has the key parameters of the pulse width of 1-500 ms and the amplitude strength of 0.1-50T. The pulsed electromagnetic force is applied to the process of solidifying the compound material melt under the action of the pulsed magnetic field so as to refine the matrix structure and the particle reinforced phase of the compound material at the same time, control the growth of the particle reinforced phase in cluster, increase the bonding strength of the interface of the particle reinforced phase and the matrix and obviously improve the performance of the composite material.

Owner:JIANGSU UNIV

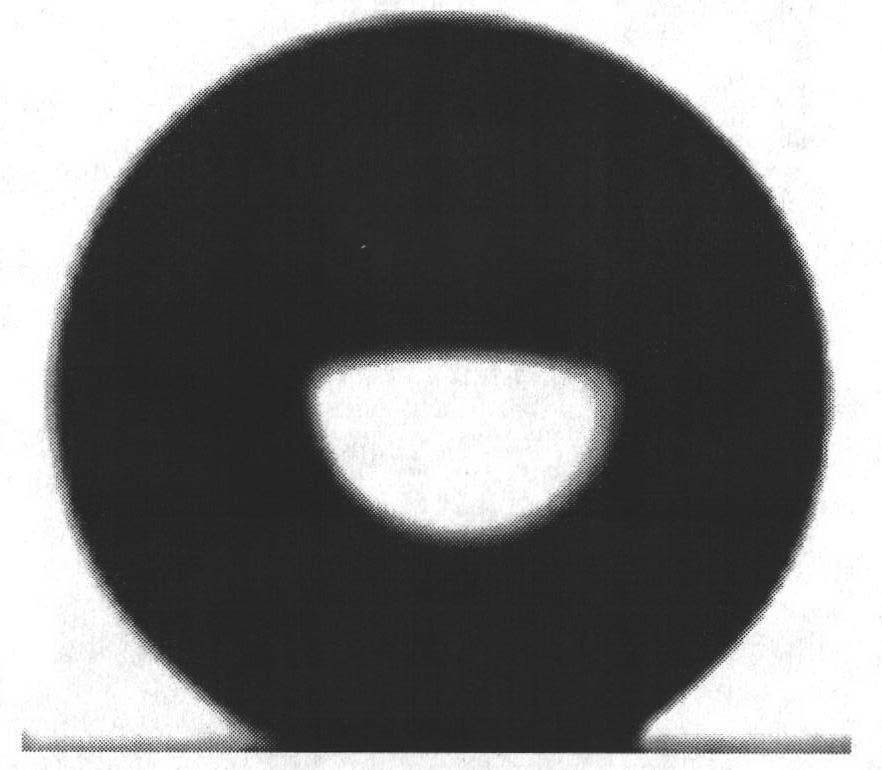

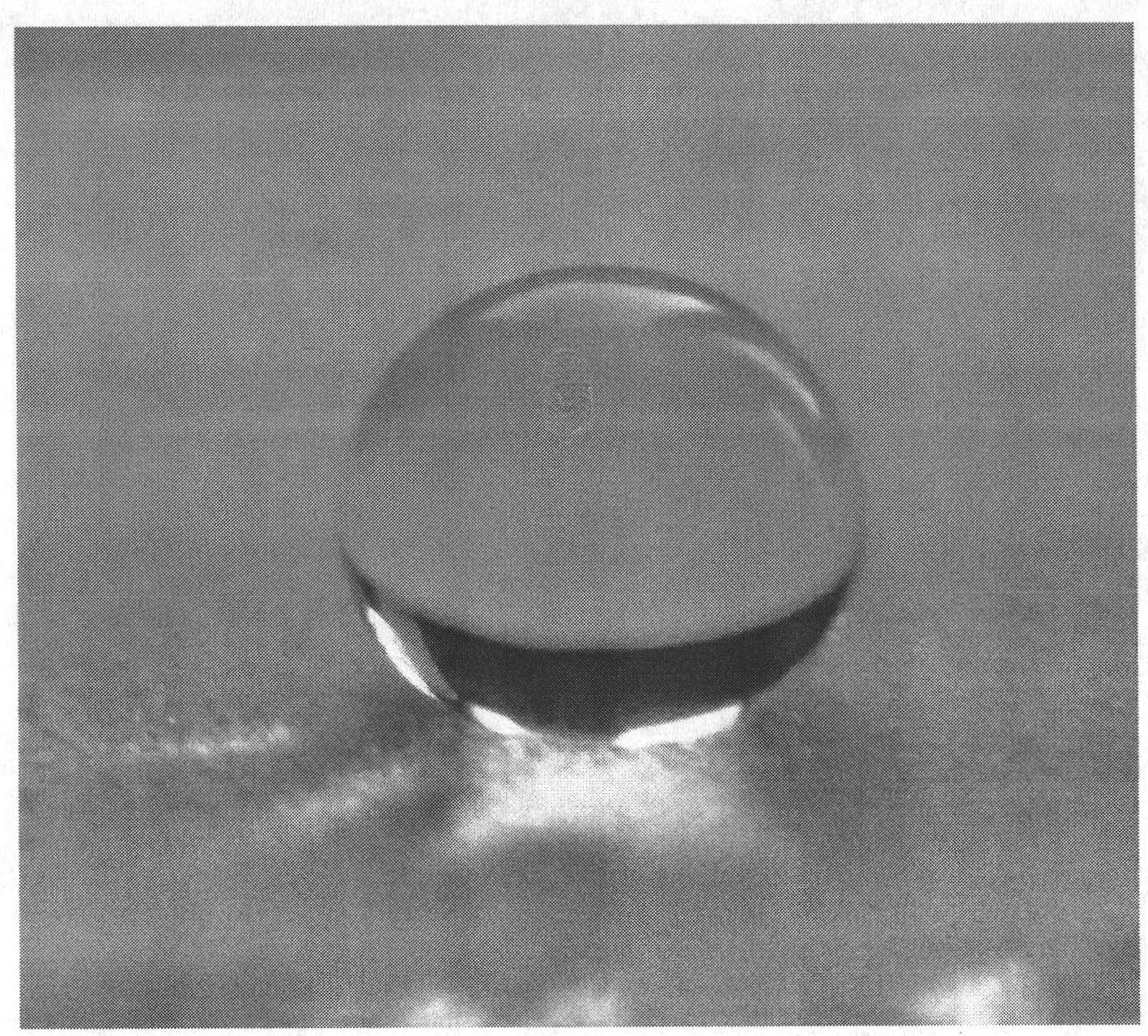

Method for preparing styrene grafted silicon dioxide superhydrophobic thin film

The invention discloses a method for preparing a styrene grafted silicon dioxide superhydrophobic thin film, which comprises: firstly, adding tetraethoxysilane into mixed solution of a catalyst and an alcohol solvent to obtain nano silicon dioxide spheres by reaction; secondly, adding the nano silicon oxide spheres into the alcohol solvent, and adding a silane coupling agent and the catalyst to obtain vinyl modified nano silicon oxide spheres; and finally, adding the vinyl modified nano silicon oxide spheres into a benzene or ketone organic solvent, adding an initiator and a styrene monomer in turn to obtain the styrene grafted silicon dioxide spheres, dispersing the styrene grafted silicon dioxide under ultrasonic waves, and preparing the styrene grafted silicon dioxide by using an organic or inorganic material as a substrate and by a coating method. The preparation process is simple and high in repeatability, the cost is low, and the promotion is more convenient.

Owner:QILU UNIV OF TECH

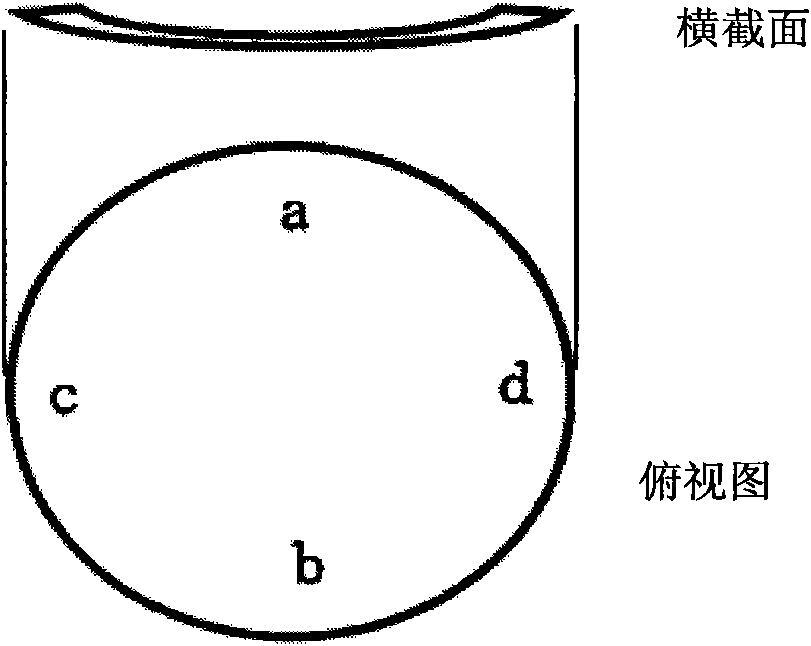

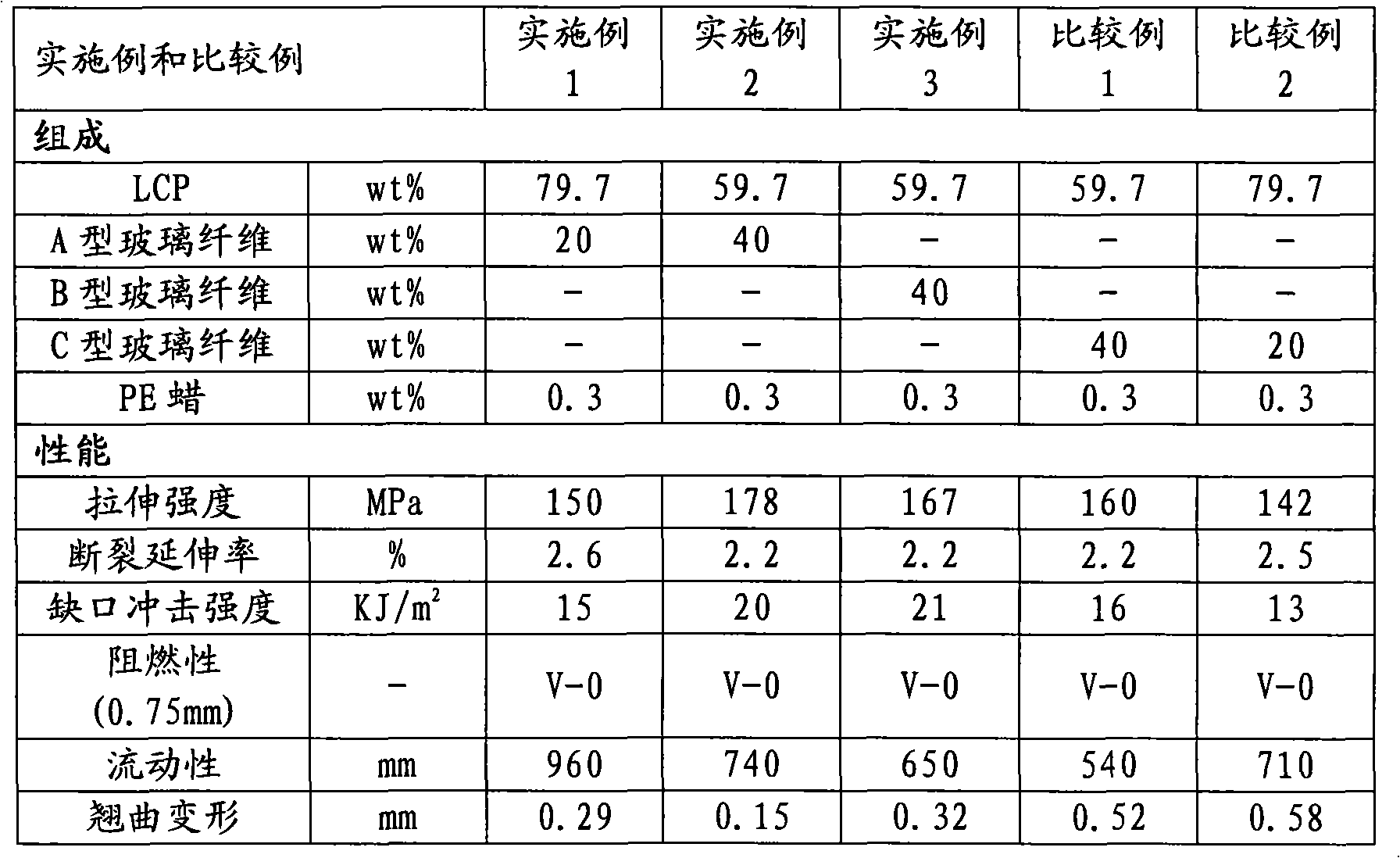

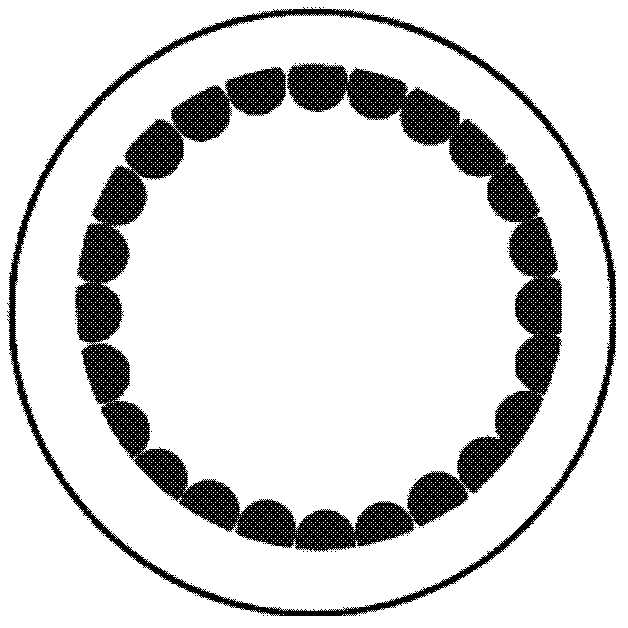

Liquid crystal polymer material reinforced by glass fibers with non-circular cross sections and preparation method thereof

InactiveCN101891938ALarge specific surface areaLarge interface contact areaLiquid crystal compositionsGlass fiberPolymer science

The invention provides a liquid crystal polymer material reinforced by glass fibers with non-circular cross sections. A liquid crystal polymer material with high flowability, low buckling deformation and high weld line strength is obtained by replacing a conventional liquid crystal polymer reinforced with glass fibers with circular cross sections with glass fibers with the non-circular cross sections, and particularly, the improvement effect achieved by adopting glass fibers with rectangular cross sections is more obvious.

Owner:KINGFA SCI & TECH CO LTD +1

Preparation method for active element sintered ZTA (Zirconia Toughened Alumina) particulate reinforced steel based compound grinding roller and grinding disk

The invention discloses a preparation method for an active element sintered ZTA (Zirconia Toughened Alumina) particulate reinforced steel based compound grinding roller and a grinding disk. The preparation method comprises the following steps: 1) uniformly mixing multiple active element powder, and then adding a defined amount of binding agents and fully mixing with ZTA particulates so as to uniformly cover the active element powder on the surfaces of the particulates, filling into a graphite mould, pressing, and then drying; 2) sintering, thereby obtaining a porous precast block; 3) fixing the precast block on a specific casting position and pouring molten metal, cooling and de-molding, thereby obtaining the compound grinding roller or grinding disk. According to the preparation method, the shape and size of the ZTA particulate precast block can be controlled through the mould and the technique is simple and has higher production efficiency, yield and practicability. Besides, the active element introduced into the interface can increase the wettability and binding strength of the interface and a compound layer structure with interactive distributed enhanced phase and base can ensure the longer service life of the grinding roller and the grinding disk under high stress effect.

Owner:XI AN JIAOTONG UNIV +1

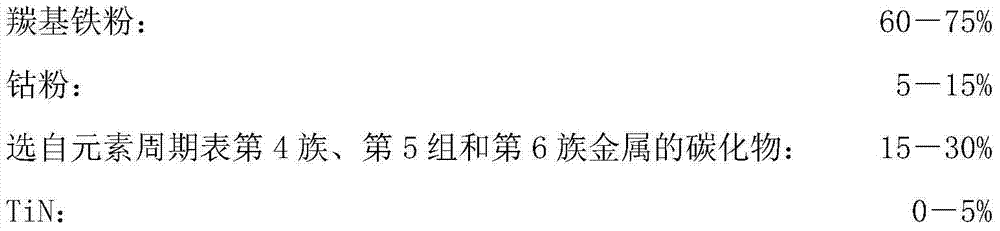

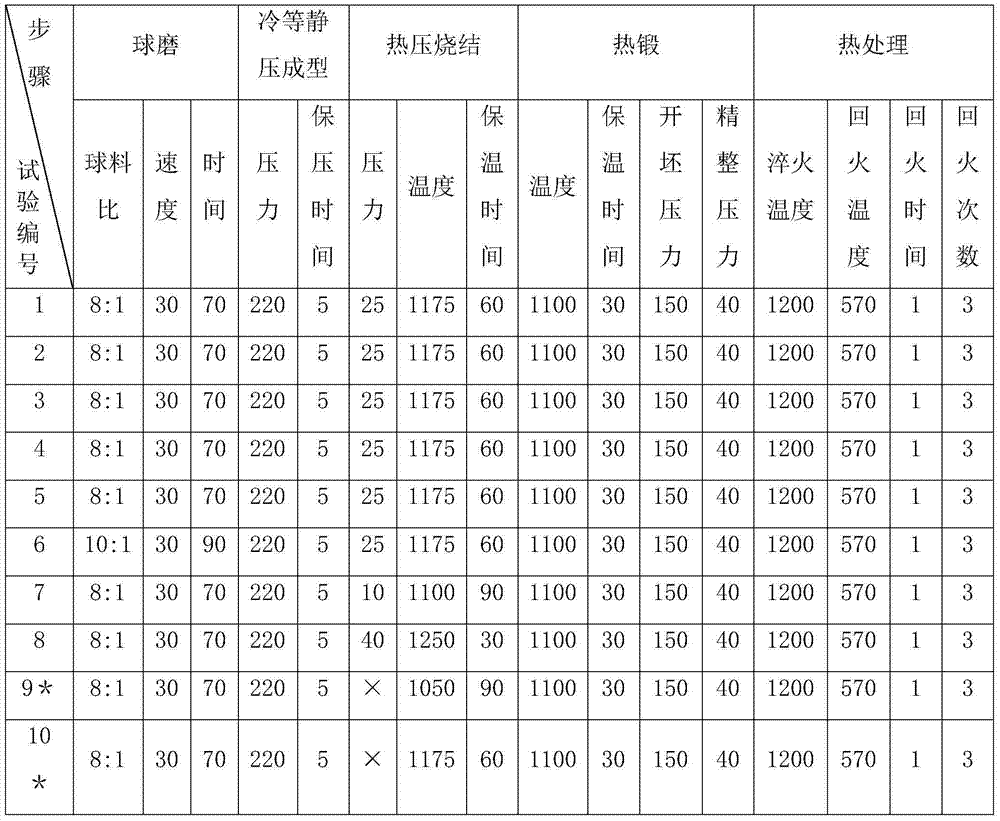

Powder metallurgy high-speed steel and preparation method thereof

The invention discloses powder metallurgy high-speed steel and a preparation method thereof. The method is simpler than the existing powder metallurgy high-speed steel preparation method, steps of high-speed steel mother alloy smelting, atomization for making powder and hot isostatic pressing are omitted, great equipment investment is not needed and the production cost of powder metallurgy high-speed steel is reduced. The impurity content of the powder metallurgy high-speed steel prepared by adopting the method provided by the invention is low and the using performance is excellent. The powder metallurgy high-speed steel provided by the invention is prepared through the steps of 1) preparing powder mixture: weighing raw materials according to set components and proportioning ratio, and mixing and ball-milling the raw materials in a roller-type ball mill to obtain the powder mixture; 2) molding: molding the powder mixture into pressed blanks through cold isostatic pressing; 3) sintering: sintering the pressed blanks in a vacuum or inert gas atmosphere by adopting a hot-pressing sintering technology, heating the pressed blanks to 1100-1250 DEG C during sintering, preserving heat for 30-90 minutes and keeping sintering pressure to be 10-40Mpa; 4) hot forging; 5) heat treatment.

Owner:长沙市萨普新材料有限公司

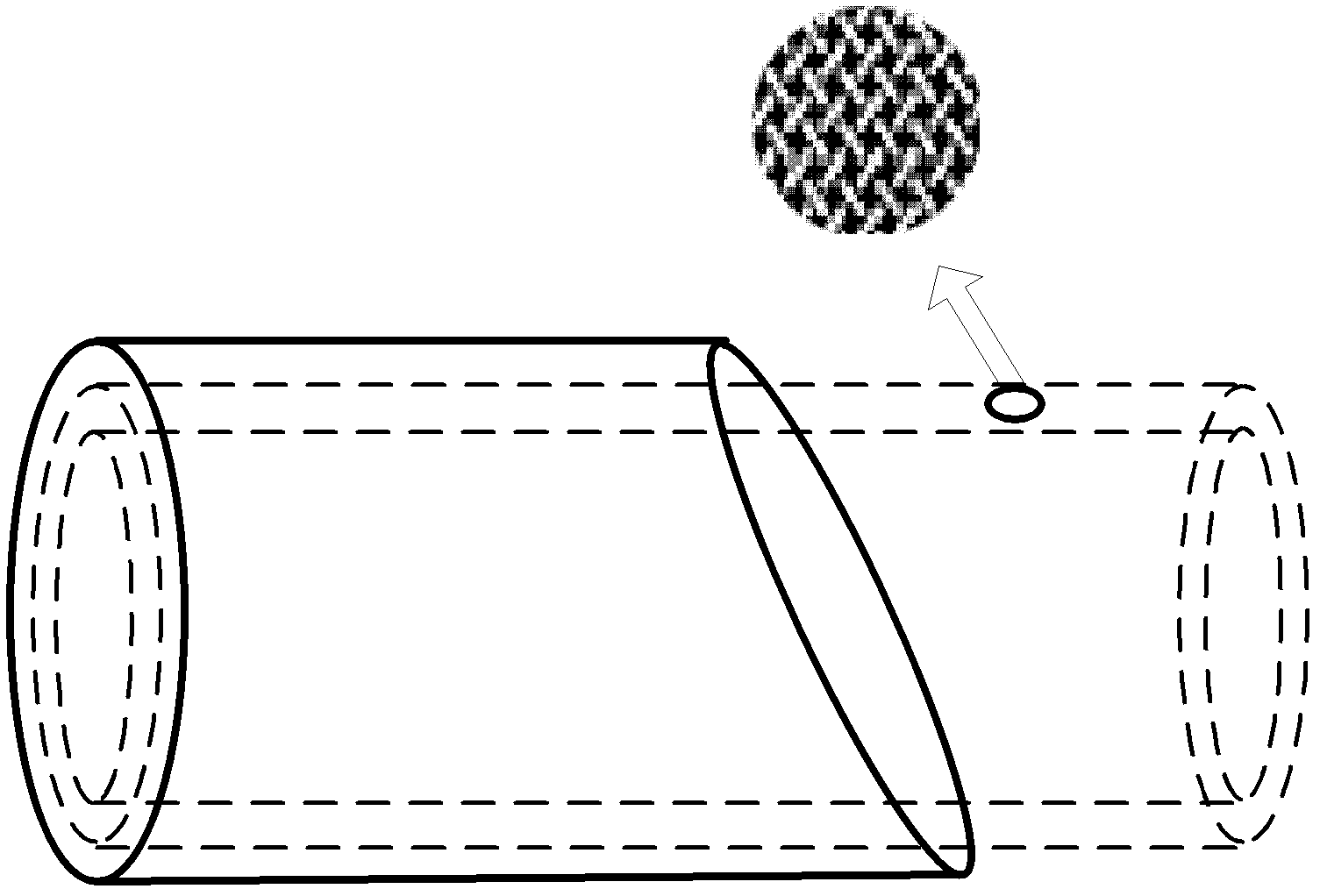

Preparation method of enhanced polyacrylonitrile hollow fiber membrane

InactiveCN102580577AImprove mechanical propertiesExtended service lifeSemi-permeable membranesMembranesHollow fibre membranePolymer science

The invention discloses a preparation method of an enhanced polyacrylonitrile hollow fiber membrane. The preparation method comprises the following steps of: (1) knitting a polyacrylonitrile fiber reinforcement body: knitting a polyacrylonitrile fiber hollow knitted tube by a two-dimensional knitting technology, wherein the polyacrylonitrile fiber hollow knitted tube is used as a reinforcement body of the hollow fiber membrane; (2) preparing polyacrylonitrile membrane casting liquid, wherein the polyacrylonitrile membrane casting liquid consists of the following components in percentage by mass: 3-25% of polyacrylonitrile resin, 50-95% of solvent and 2-30% of additive; (3) performing surface pretreatment of the reinforcement body: wetting the hollow knitted tube with low-polarity organic liquid for 1-60 seconds, wherein the low-polarity organic liquid is ethanol, glycerol, isopropyl alcohol or polyethylene glycol-600; and (4) preparing a hollow fiber membrane: co-extruding the hollow knitted tube and the membrane casting liquid through an annular spinning nozzle, and performing sufficient solidification in a coagulating bath to obtain the enhanced polyacrylonitrile hollow fiber membrane.

Owner:TIANJIN POLYTECHNIC UNIV

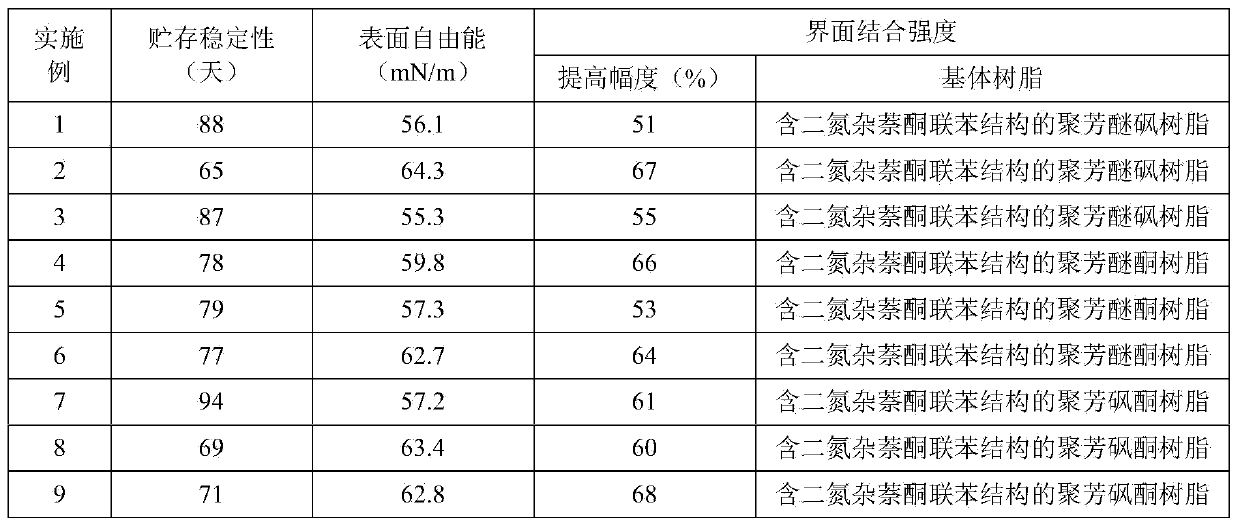

Emulsion type carbon fiber sizing agent containing nano material and preparation method of sizing agent

The invention discloses an emulsion type carbon fiber sizing agent containing a nano material. The sizing agent comprises the following components in percentage by mass: 0.1-2% of a main sizing agent, 0.01-1% of a nano material, 0.05-2% of an emulsion agent, 0.05-0.1% of a dispersing agent, 0.15-8% of an organic solvent and 86.9-99.64% of deionized water. The sizing agent has the advantages the interface binding strength with carbon fibers is high and the surface free energy of the sized carbon fibers is no less than 55mN / m.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

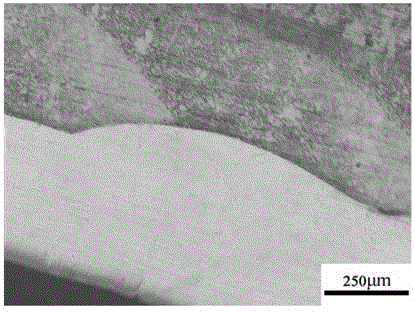

Method for connecting plastic and metal heterostructure

InactiveCN106393705AIncreased mechanical occlusionImprove the bonding strength of the interfaceLaser beam welding apparatusChemical LinkageTemperature control

The invention provides a method for connecting plastic and a metal heterostructure. The method comprises the following steps that S1, laser roughening treatment is conducted on the surface of a to-be-connected metal part, and local protrusions and dents are generated on the surface of the metal part, so that a metallic oxide layer is formed; S2, the metal part subjected to laser roughening treatment and a to-be-connected plastic part are hot-pressed, so that the metal part and the plastic part are bonded together; and S3, out-of-focus laser beams are adopted to penetrate through the plastic part so as to reach the interface between the plastic part and the metal part, and the portion, at the interface, of the plastic part is partially melted. According to the method for connecting the plastic and the metal heterostructure, operation is easy, the mechanical engaging and chemical bonding degree of the plastic and metal is increased through the required local protrusions and dents formed on the surface of the metal part and partial heating and temperature control of the interface, tight bonding of the plastic and the metal at the interface is facilitated, and the interface bonding strength and airtightness of the plastic and the metal heterostructure are improved accordingly.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

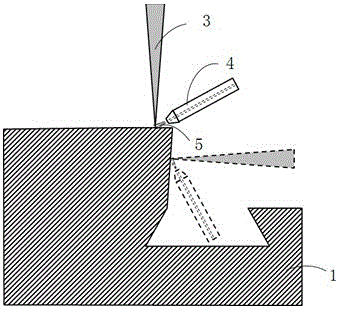

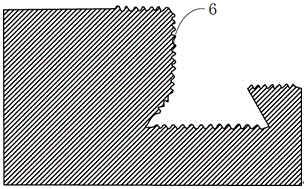

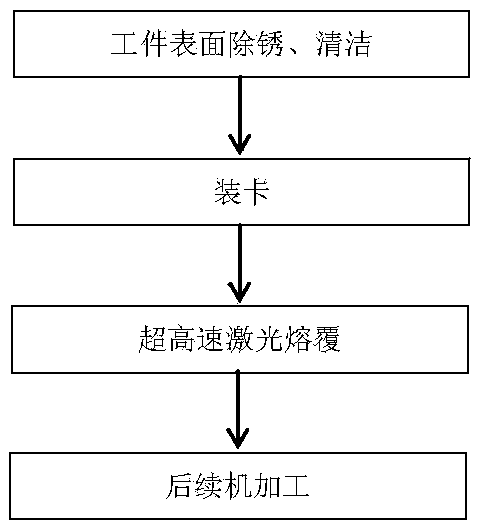

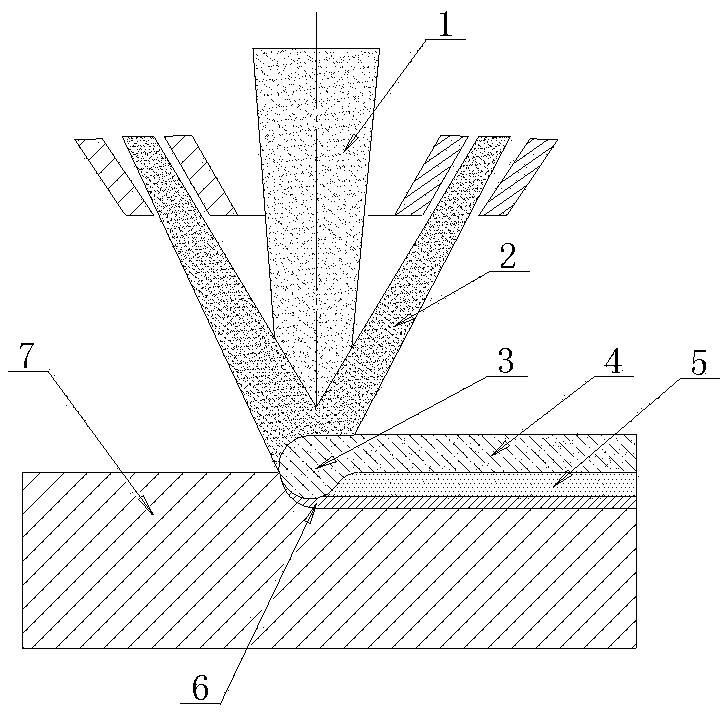

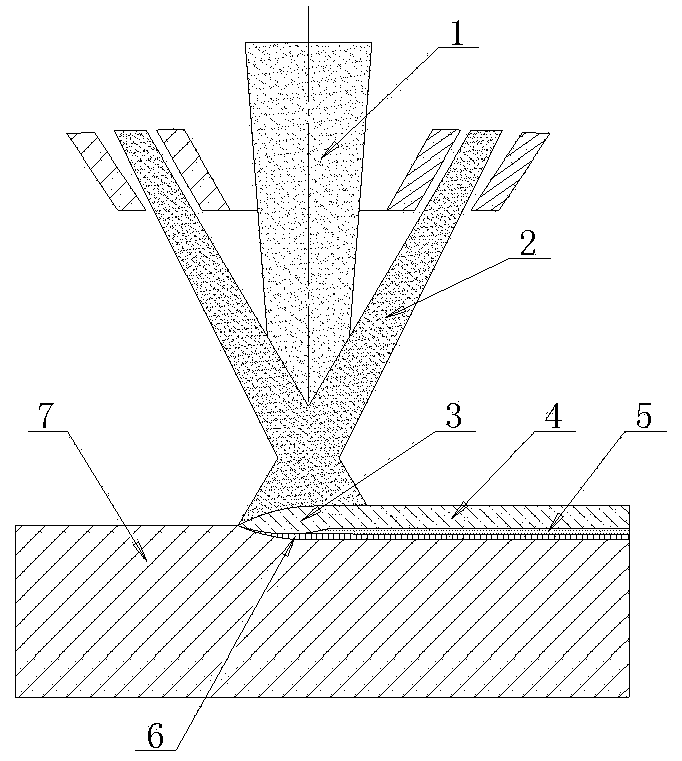

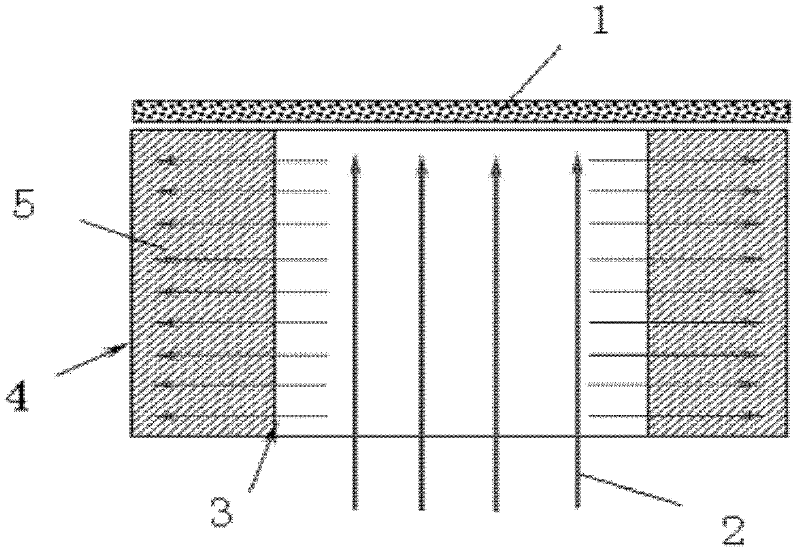

Ultrahigh-speed laser cladding technology

InactiveCN108103498AImprove the bonding strength of the interfaceHigh precisionMetallic material coating processesSurface finishLaser processing

The invention belongs to the field of laser processing, and particularly relates to an ultrahigh-speed laser cladding technology. The ultrahigh-speed laser cladding technology is characterized in thatultrahigh-speed laser cladding linear velocity is acquired through high-speed rotation of a workpiece, and a compact cladding layer is formed on the surface of the workpiece through interaction of laser and powder and adjustment and matching of technological parameters. Compared with traditional laser cladding, the ultrahigh-speed laser cladding technology has the advantages that efficiency is improved by 10 times, the obtained cladding layer is formed through complete metallurgical bonding, surface finish is high, the material utilization rate is high, energy consumption is low, production cost can be greatly reduced, and production efficiency is improved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Aramid fiber surface modification processing method

InactiveCN1936167APromote infiltrationFacilitate cross-linkingPhysical treatmentFibre typesLiquid mediumIrradiation

The invention relates to process method for aramid fiber surface modification that includes the following steps: drying aramid fiber, sealing the dried aramid fiber with gas medium or liquid medium in glass reactor, using gama radial of 60Co irradiating for 12-15 hours, under normal temperature and normal pressure, irradiation dose is 0.1-3000kGy. The invention has the advantages of simple technology, environment protection, high efficiency and suitable for industrial manufacturing.

Owner:HARBIN INST OF TECH

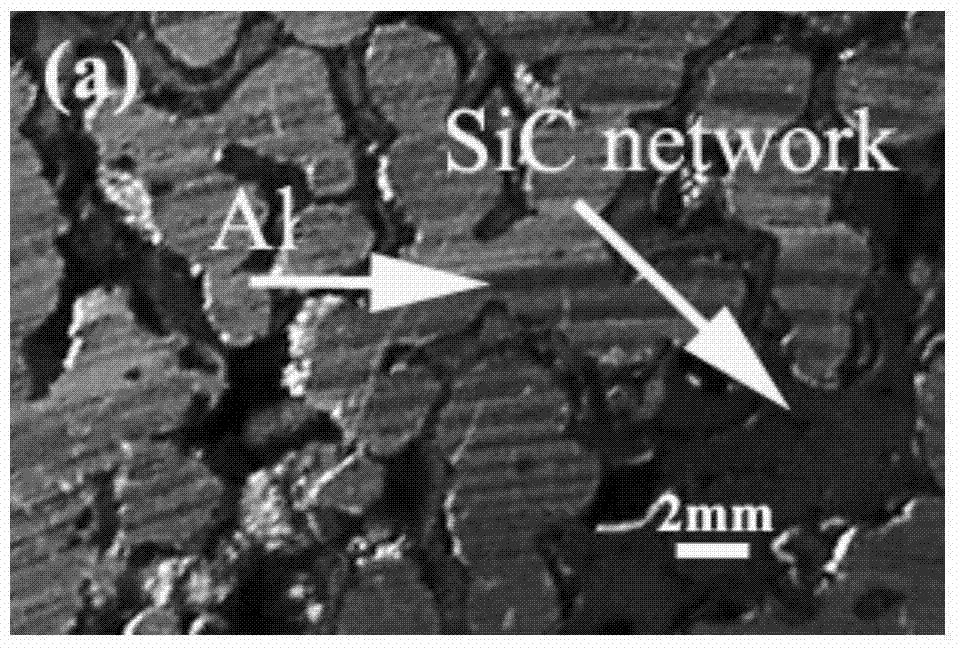

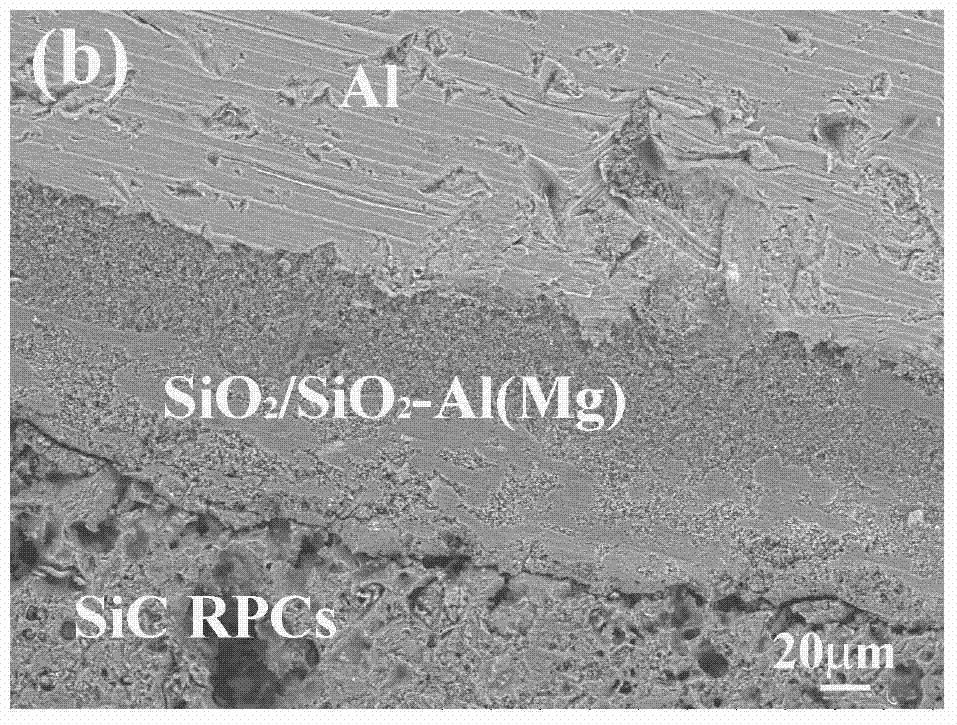

Preparation method of silicon carbide reinforced aluminum base composite material

The invention discloses a preparation method of a SiC / Al composite material. The method comprises the following steps: carrying out ball milling on alumina and / or silicon oxide powder and a dispersant by using a ball milling medium, adding a binder, and continuously carrying out ball milling to obtain a coating slurry, wherein a mass ratio of the powder to the dispersant to water to the ball milling medium to the binder is 1:0.005-0.01:0.1-0.4:2:0.01-0.03; immersing reticulated porous SiC ceramic in the coating slurry for full absorption, centrifuging, and drying; and embedding secondary-coated reticulated porous SiC ceramic into aluminum or aluminum alloy powder, carrying out vacuum pumping heating to fuse the aluminum or aluminum alloy, introducing argon, and carrying out heat insulation and pressure maintenance to obtain the SiC / Al composite material. The SiC / Al composite material obtained through the method is a bicontinuous phase, and the control of an interface structure and an interface reaction is realized through controlling the composition and performances of the coating slurry to realize strong combination between a silicon carbide matrix and the metal Al and uniform continuous distribution in a three dimensional space, so the segregation and the discontinuousness of the silicon carbide reinforcement are avoided, and the performances of the composite material are improved.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Ceramic part and production method thereof

PendingCN106977184AHigh densityImprove uniformityCeramic shaping apparatusInjection molding machineHigh heat

The invention relates to the technical field of powder metallurgy and particularly relates to a ceramic part and a production method thereof. The production method comprises (1) mixing granulation: putting ceramic powder into a mixer, heating the ceramic powder, adding a binder into the ceramic powder, carrying out mixing, and carrying out granulation through an extruder to obtain feed, (2) injection molding: placing the feed in an injection molding machine and carrying out injection molding to obtain an injected blank, (3) degreasing: placing the injected blank into an air furnace, carrying out hot degreasing, carrying out heating pre-sintering, carrying out furnace cooling and taking out a blank, and (4) sintering: putting the blank in a sintering furnace, carrying out sintering, and carrying out grinding and polishing to obtain a ceramic part. Through powder injection molding process and final degreasing and high temperature sintering, a fine ceramic part having a complex shape is obtained, the product has high compactness and good uniformity and is obtained by one step molding, the operation and control are simple, product quality is stable, production efficiency is high, a production cost is low and large-scale industrial production is realized.

Owner:深圳市星迪伟业科技有限公司

Method for improving interfacial properties of aramid fiber/epoxy resin composite material

InactiveCN101205686AEnhanced interface bindingPromote infiltrationPhysical treatmentEpoxyLiquid medium

An aramid fibre / epoxy resin composite interface performance improving method relates to a macromolecule material modification processing method. The invention solves the problems that the interface between the prior Kevlar-49 fibre and the prior epoxy resin has weak combination and the fiber surface modification processing method is not suitable for industrialized production. The Kevlar-49 fibre surface modification processing method of the invention is as follows: firstly the Kevlar-49 fibre is dried, then the dried Kevlar-49 fibre and liquid medium are sealed in a glass reactor; under the condition of normal temperature, normal atmosphere and the protection of protective gas, a gamma ray with <60>Co as radiation source is adopted to radiate; the radiation dosage is between 0.1 and 1000 kGy and the radiation dosage rate is between 3 and 7 kGy / h. The invention has the advantages of simple operation, stable technique, reliable product quality, environmental protection and industrialized production. The method of the invention improves the fibre surface energy, thereby improving the combination intensity of the interface between the fibre and the epoxy resin matrix and exerting the comprehensive performance of Kevlar-49 fiber reinforced composite farthest.

Owner:HARBIN INST OF TECH

Torpedo tank lining gunning repairing material, preparation method and applications thereof

The invention discloses a torpedo tank lining gunning repairing material, a preparation method and applications thereof, wherein the torpedo tank lining gunning repairing material comprises, by weight, 60-67 parts of a Al2O3-containing fireproof material after-using regenerating material, 3-7 parts of fireproof clay, 2-5 parts of flaky graphite, 3-7 parts of silicon carbide, 10-15 parts of an alumina homogeneous material, 3-6 parts of kyanite, 2-5 parts of alpha-Al2O3 micro-powder, 3-11 parts of a binder, and 1.2-3.4 parts of an admixture. According to the present invention, the torpedo tank lining gunning repairing material has characteristics of low raw material cost, wide regeneration material source, convenient cold-hot state gunning repairing, excellent thermal shock stability, strong repairing layer interface bonding strength, strong slag iron corrosion resistance, high torpedo tank operation rate, long service life, and the like.

Owner:武汉钢铁有限公司

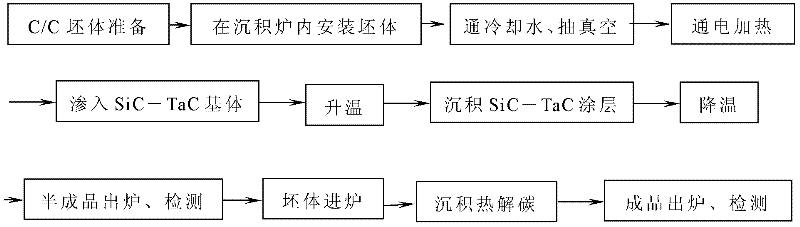

A kind of sic-tac coating/matrix synergistically modified c/c composite material and preparation method thereof

ActiveCN102295474AMitigate Thermal MismatchHigh coefficient of thermal expansionSurface layerHigh density

The invention discloses a SiC-TaC coating / matrix collaborative modified C / C composite material and its preparation method. The composite material provided by the invention comprises two parts. The portion below the surface of the C / C composite material is the matrix modified portion with the thickness being 0.1-10mm. In addition, carbide in the C / C composite material emerges in gradient distribution. The portion which is deposited on the surface of a carbon material is a coating portion with the thickness being 10-300 microns. The preparation method of the composite material comprises the following steps of: cutting a C / C green body at the density of 0.80g / cm<3>-1.60g / cm<3> into an annular shape or a plate shape, followed by ultrasonic cleaning and drying, placing into a multifunctional CVD furnace, depositing carbide on the surface layer and surface of the C / C green body by controlling deposition parameters, further densifying the green body by the use of pyrolytic carbon so as to obtain the high-density coating / matrix collaborative modified C / C composite material. The main advantages of the invention are as follows: by the penetration of carbide through the surface layer of the C / C composite material, the thermal expansion coefficient of the matrix is raised, the interfacial bonding state is improved, a continuous transition of carbide is formed between the coating and the matrix, and the metallurgical bonding is accomplished between the coating and the matrix.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com