Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

423results about How to "Improve sinterability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cathode material for lithium secondary battery and method of producing same

InactiveUS20060121350A1Stable supplyImprove sinterabilityOxygen/ozone/oxide/hydroxideElectrode manufacturing processesElectrical batteryPhysical chemistry

Stable supply of a cathode material for a lithium secondary battery that exels in sinterbility and composition stability and can exhibit satisfactory battery performance is accomplished by reducing to 100 ppm or less both the contents of Na and S being impurity elements in multiple oxides as materials for a cathode material for a lithium secondary battery and carbonic salts as precursor materials for the production of a cathode material for a lithium secondary battery.

Owner:NIKKO MATERIALS CO LTD

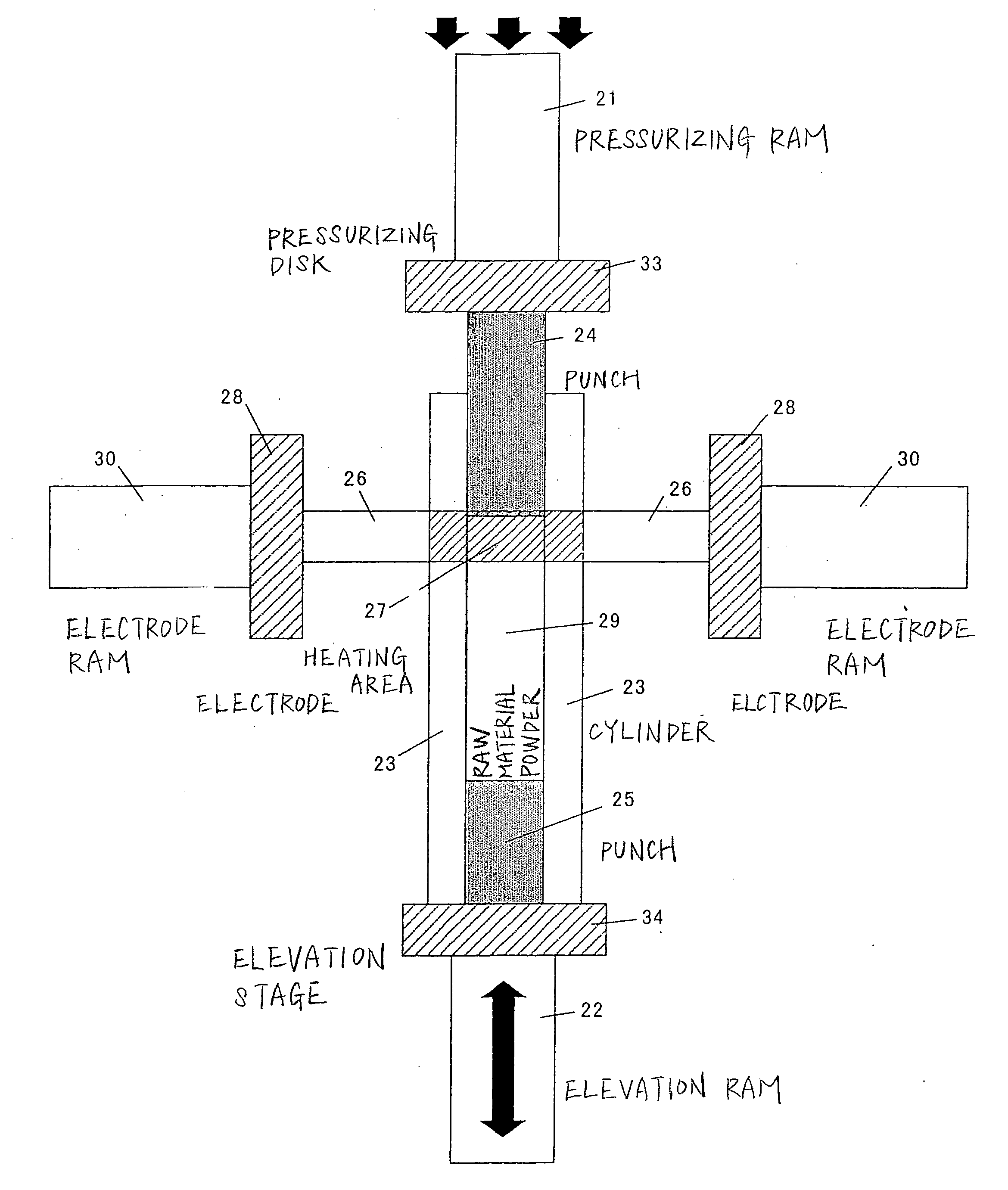

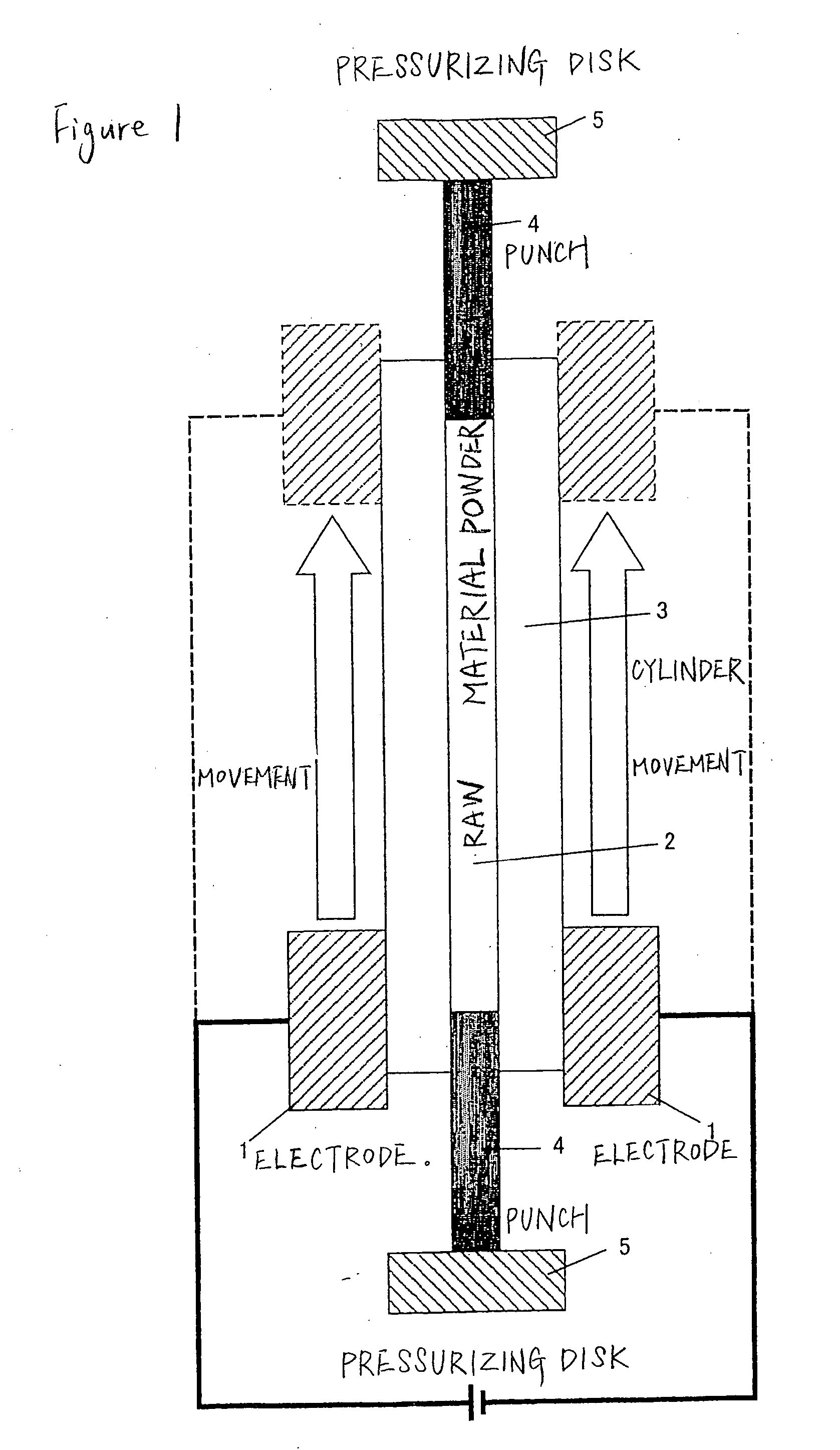

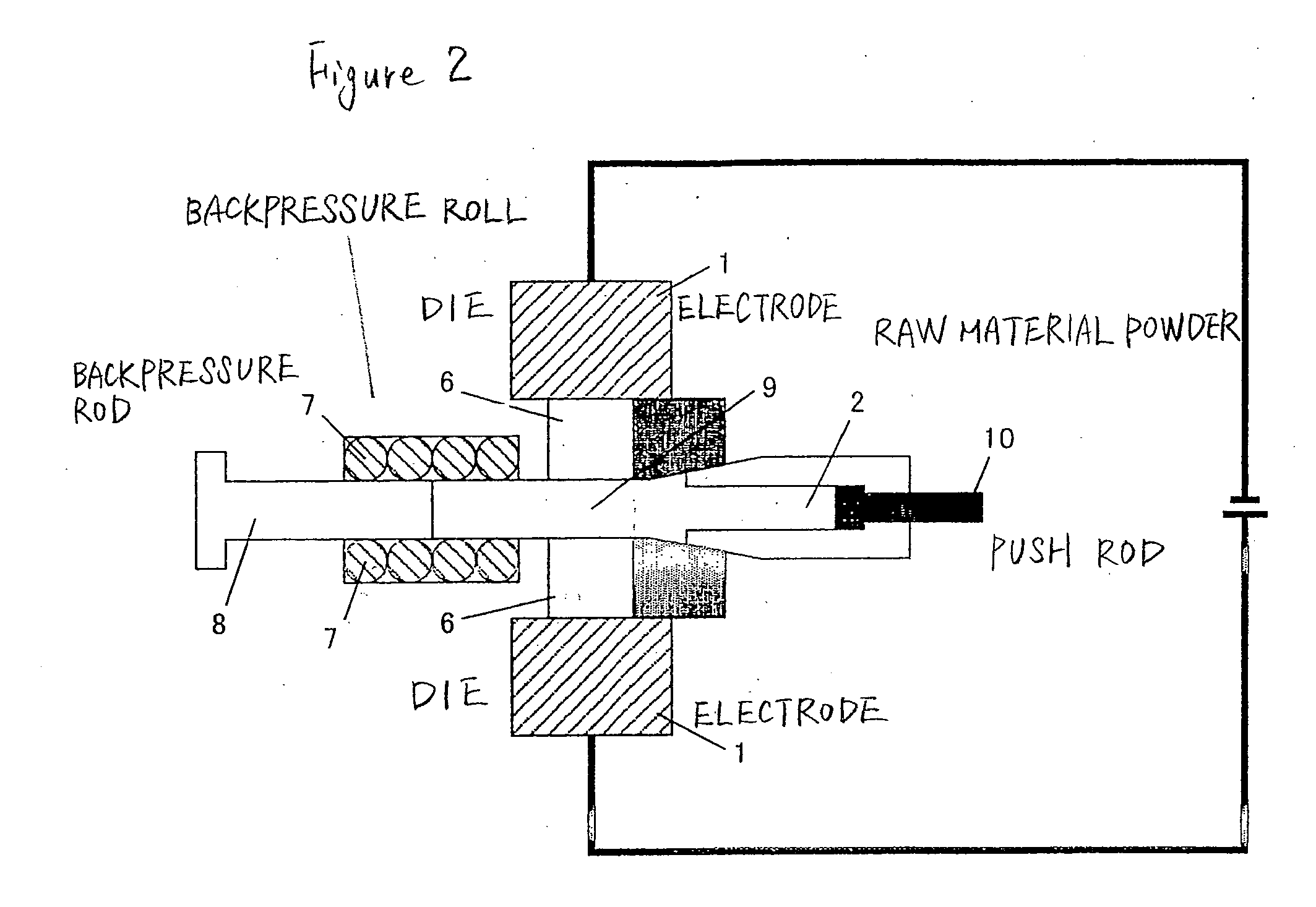

Sintering method and device

A method of performing direct current pressurized sintering to powder in a mold having a cylindrical molding space, wherein sintering is continuously effected while relatively moving a current portion and a sintering subject; and a sintering device characterized in that the vertical position of the current electrodes is unchanged and the mold and the sintering subject are successively moved with respect to the current electrodes, so as to effect continuous sintering. A sintering method and a sintering device that are superior in sintering ability are provided wherein even if the sintered body is in the form of a long-size rod or has an uneven cross-section, the sintered body is uniform in quality.

Owner:NAT INST OF ADVANCED IND SCI & TECH

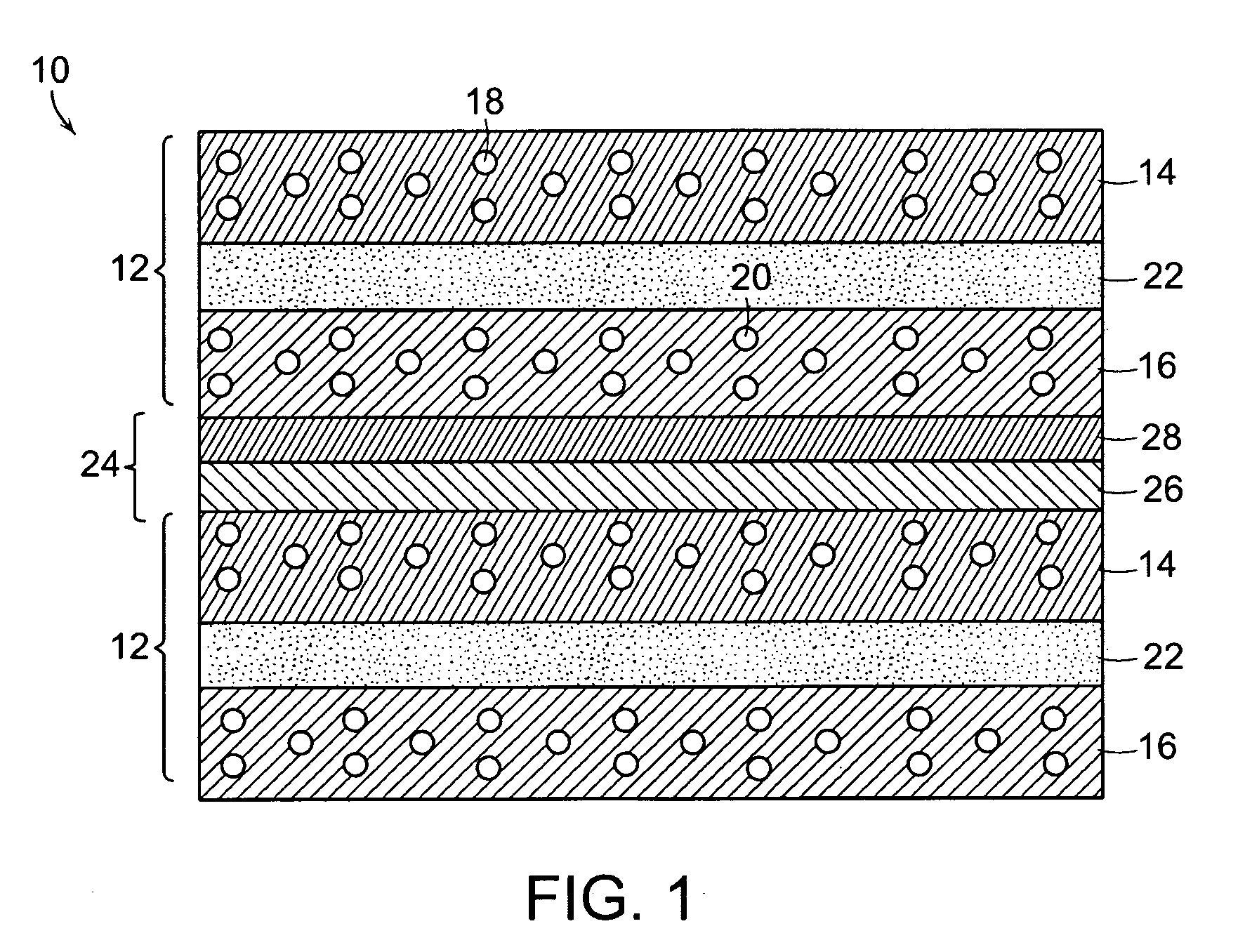

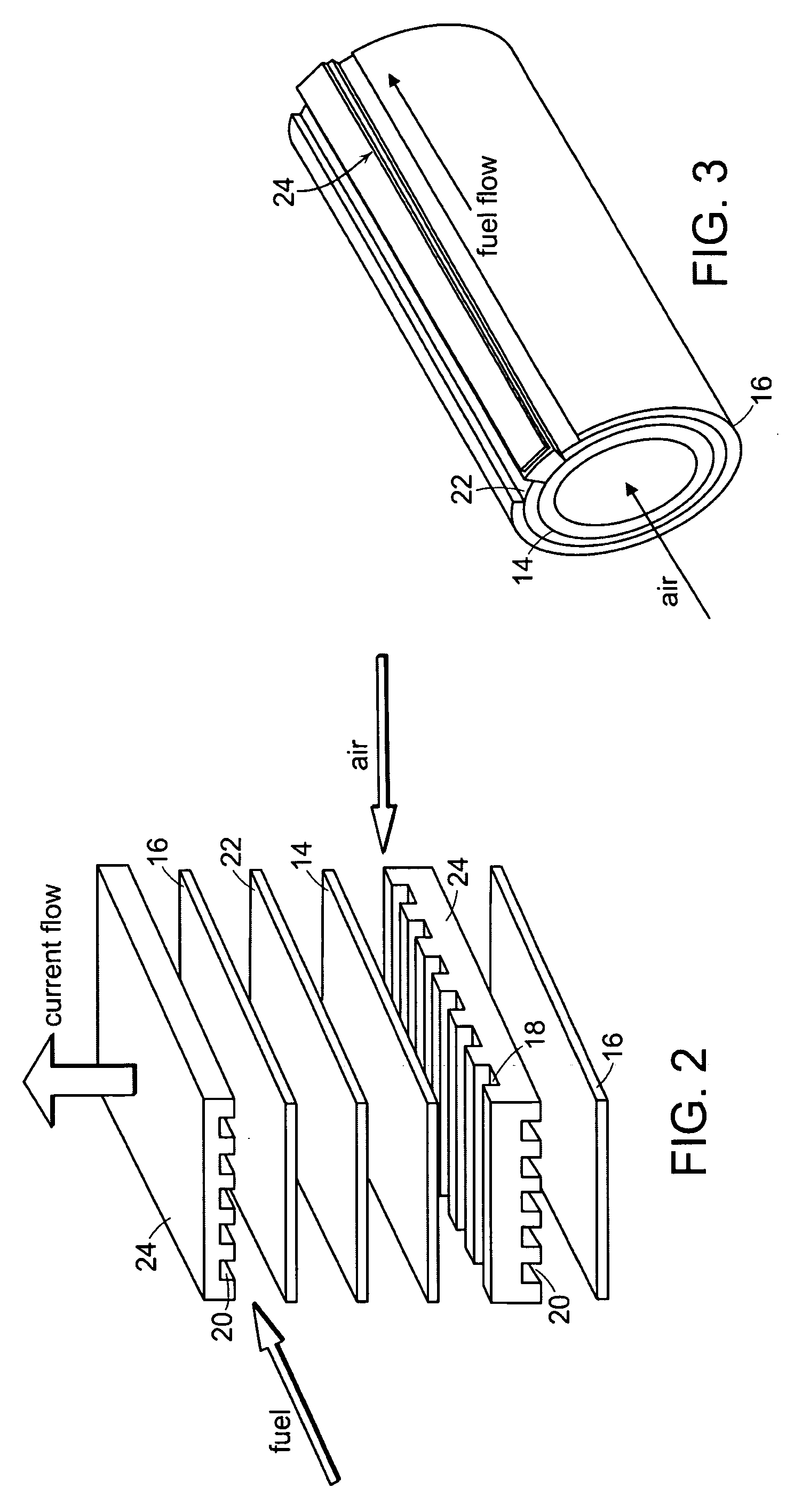

Bilayer interconnects for solid oxide fuel cells

InactiveUS20090186250A1Sinterability , stability and conductivity be improveLess oxygen vacancy formationPrimary cellsElectrode carriers/collectorsOxideBilayer

A solid oxide fuel cell (SOFC) includes a plurality of sub-cells. Each sub-cell includes a first electrode in fluid communication with a source of oxygen gas, a second electrode in fluid communication with a source of a fuel gas, and a solid electrolyte between the first electrode and the second electrode. The SOFC further includes an interconnect between the sub-cells. The interconnect includes a first layer in contact with the first electrode of each sub-cell, and a second layer in contact with the second electrode of each sub-cell. The first layer includes at least one material selected from the group consisting of a doped M-ferrite based perovskite, a doped M′-ferrite based perovskite, a doped MM′-ferrite based perovskite and a doped M′-chromite based perovskite, wherein M is an alkaline earth metal and M′ is a rare earth metal. The second layer includes a doped M″-titanate based perovskite, wherein M″ is an alkaline earth metal. A solid oxide fuel cell having a plurality of cells as described above is formed by connecting each of a plurality of sub-cells with an interconnect as described above.

Owner:SAINT GOBAIN CERAMICS & PLASTICS INC

Method for preparing black zirconia ceramics at low temperature

The invention relates to a method for preparing black zirconia ceramics at the low temperature and belongs to the technical field of the preparation of high-temperature structural material. The method respectively uses a homogeneous precipitation method for synthesizing a nanometer coloring agent, and a coprecipitation method for synthesizing nanometer zirconia powder, and adopts Fe-Co-Ni-Mn as a coloring agent. The zirconia powder is not added with any sintering additive, only added with small amount of coloring agent and sintered at the temperature of 1150-1350 DEG C, thus obtaining the black zirconia ceramics with excellent performance and bright color. As the homogeneous precipitation method is adopted for synthesizing coloring agent powder, the monodisperse nanometer particles with uniform powder granules, narrow size distribution and high purity are obtained so that the coloring agent easily colors the particles. As the coprecipitation method is used for synthesizing zirconia powder, nanometer particles with small granularity, big superficial area and high activity are obtained, and can reduce the temperature of the solid-phase reaction, greatly reduce the sintering temperature and solve the problem that the black coloring agent oxide decomposes and volatiles at the high temperature. Simultaneously the method adopts the Fe-Co-Ni-Mn as the coloring agent, thus avoiding the poisonous function of Cr on the human body.

Owner:TSINGHUA UNIV

Method for selective laser sintering for quick and direct production of injection die

InactiveCN1970202AImprove sinterabilityHigh strengthIncreasing energy efficiencyTotal factory controlEpoxySelective laser sintering

A selective laser sintering quick manufacturing of the mold comprises CAD three dimension model design, storing STL files after treatment by the section software, sending the STL data to SLS quick forming machine. Spreading a composite powder of polyamide and copper on the power bed of selective laser sintering machine, with copper powder grain side 200--400, their weight ratio ranging 2:1-7:1, scanning and sintering in the selected zone of the laser harness, laser speckle 10-250 mum, scanning distance 0.04-0.1mm, scanning speed 1000- 3000mm / s, single layer thickness 70-150 mum, repeating till the formation of the complete mold inlaid, coating the surface with epoxide resin or acrylic acid series solidification system, polishing the surface thereafter. It is simple in process, short in processing period, low in cost, suitable for small volume plastic parts pilot run, testing and production.

Owner:HUAZHONG UNIV OF SCI & TECH

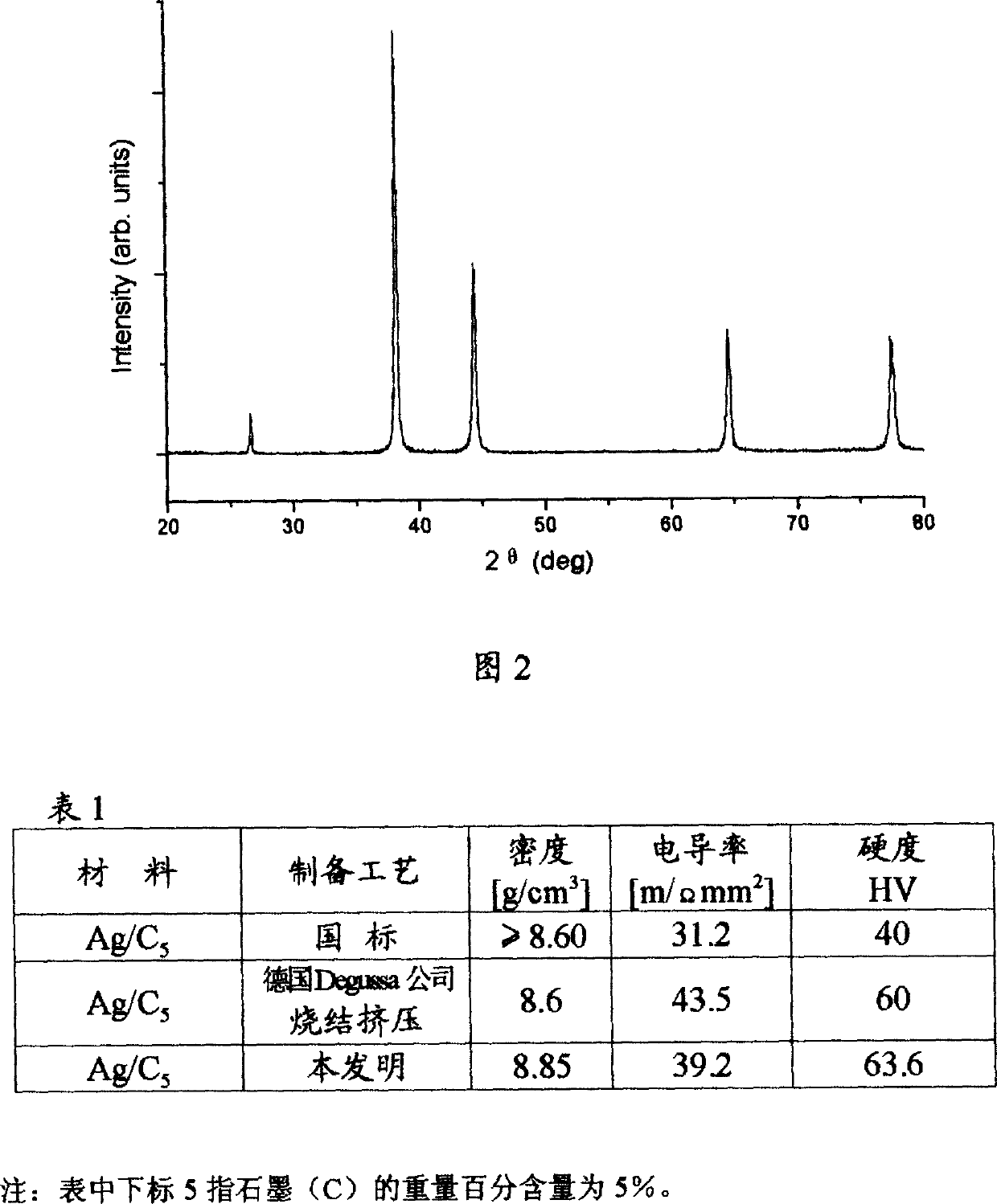

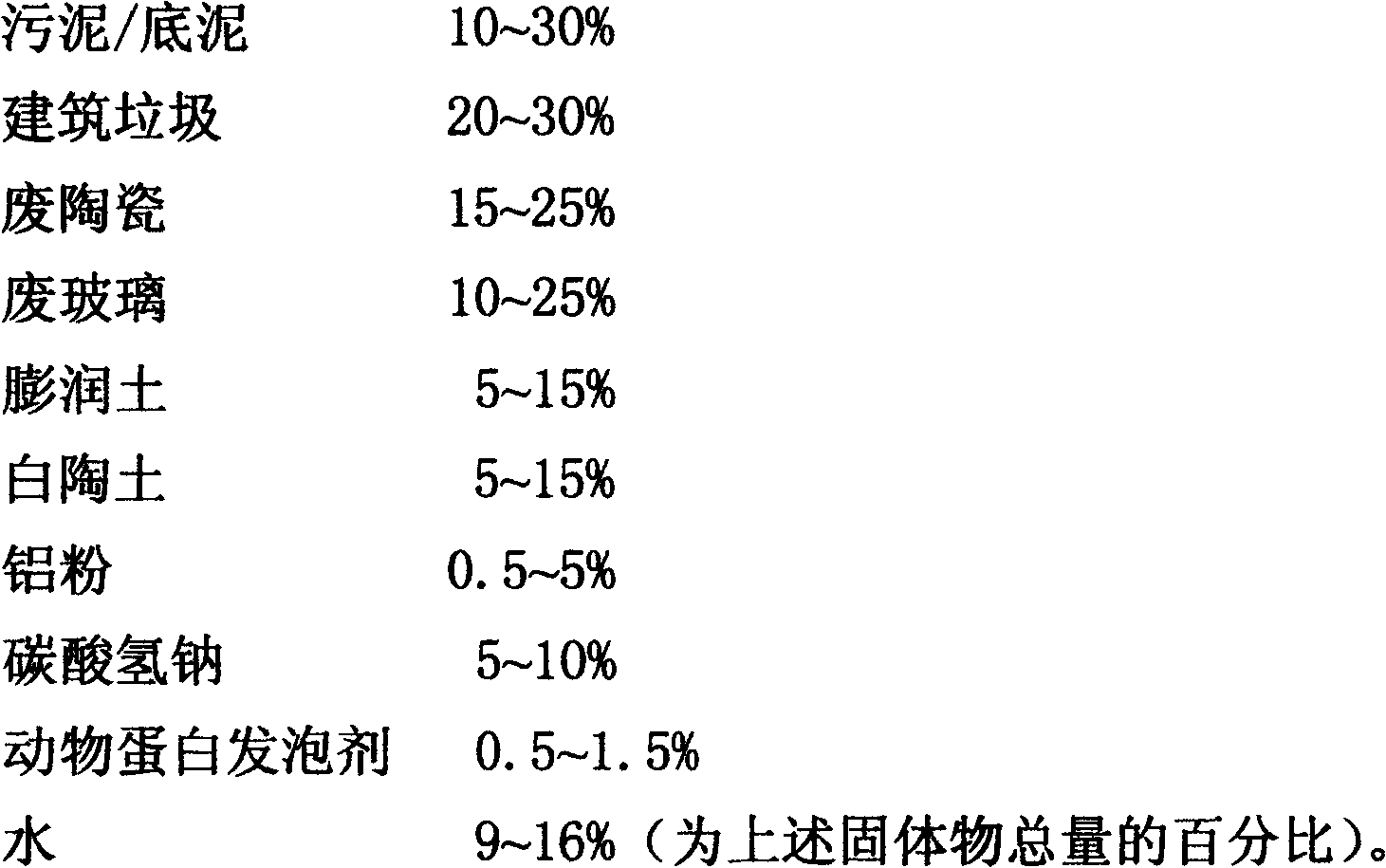

Process for preparing electric silver/graphite contact material by nano technique

InactiveCN1396025AImprove sinterabilityImprove the bonding strength of the interfaceContact materialsGraphiteNanometre

A process for preparing the silver / graphite material as electric contact by use of nanometre technique includes such steps as preparing graphite nanometre powder; adding silver nitrate solution; chemical coating; washing with water; drying and sintering. Its advantages are simple process, low cost and high quality of product.

Owner:EAST CHINA NORMAL UNIV

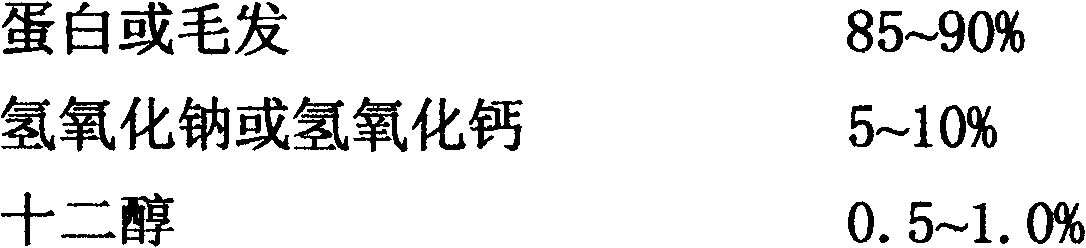

Preparation and application methods of selective laser sintering polypropylene powdery material

The invention relates to the technical field of high molecular materials and particularly relates to preparation and application methods of a selective laser sintering polypropylene powdery material. The method comprises the following steps: obtaining polypropylene powder by a freeze grinding method; grading and collecting by an airflow screening machine, selecting polypropylene powder with the granularity in a range of 200-800 meshes and returning coarse materials which do not meet the fineness requirement to a stock bin and continuously smashing; and adding 100 parts of polypropylene powder, 0.1-1 part of graphite powder, 0.01-0.5 part of antioxidant and 0.5-6 parts of metallic soap salt and uniformly mixing in a high speed mixer, wherein the granularity of the graphite powder is 1000-5000 meshes and the antioxidant is a compound antioxidant consisting of phenols and phosphonate or thioester in a weight ratio of 1:1. The polypropylene powder prepared by the invention has excellent sintering performance and the SLS (Selective Laser Sintering) formed piece prepared by the polypropylene powder has high mechanical property and dimensional precision.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

Paint for continuous casting pouring box work liner and preparing technique thereof

ActiveCN101508586AGood spreadabilityGood application effectMelt-holding vesselsFiberSodium phosphates

The invention discloses a painting for continuously cast pouring basket working lining and a producing technique thereof. The components of the painting is as follows according to parts by weight: 50-90 parts of forsterite raw material, 10-50 parts of magnesia, and 3-5 parts of composite additive, wherein the composite additive is at least one of organic fiber, paper fiber, lime, trimeric sodium phosphate, sodium hexametahposphate, clay or silicate. The producing technique of the painting is evenly mixing and stirring the forsterite raw material, the magnesia and the composite additive according to the parts by weight to lead the mixture to show no evident white trace, thereby obtaining the painting used for the continuously cast pouring basket working lining. The painting has excellent smearing, sintering, anti-scouring, anti-dreg erosion and anti-peeling properties, is free from collapsing and pollution, is environment-friendly, and has long service life, low production cost and simple and convenient preparation method.

Owner:WUGANG REFRACTORY CO LTD

High-strength light foam ceramic plate and manufacturing method thereof

InactiveCN102627469AEasy accessLow priceConstruction waste recoverySolid waste disposalEnvironmental resistanceSodium bicarbonate

The invention discloses a high-strength light foam ceramic plate and a manufacturing method thereof, and belongs to the field of building material manufacturing. The ceramic plate comprises the following materials in percentage by weight: 10-30 percent of sludge / bottom mud, 20-30 percent of building waste, 15-25 percent of waste ceramic, 10-25 percent of waste glass, 5-15 percent of bentonite, 5-15 percent of kaolin, 0.5-5 percent of aluminum powder, 5-10 percent of sodium bicarbonate, 0.5-1.5 percent of animal albumen foaming agent and 9-16 percent (percentage of total amount of the solid matters) of water. The manufacturing method comprises the following steps of: mixing and crushing the main raw material; adding the animal albumen foaming agent and water; granulating; filling a granular material into a refractory combined mould; leveling; filling in a kiln; firing; and performing cold processing to produce a ceramic plate finished product. The high-strength light foam ceramic plate has the advantages of high product strength, small volume weight, fire proofing, excellent freeze proofing, long-term water proofing, readily available main raw material which basically comes from environmental solid waste, has a wide source and is low in cost and adoption of the animal albumen foaming agent of small using amount and wide source; the manufacturing process has the advantages of simplicity, high efficiency, energy conservation, environmental friendliness, no secondary pollution; and the high-strength light foam ceramic plate can be used as thermal insulation decorative materials, fire barriers and the like of exterior walls of buildings.

Owner:SICHUAN UNIV

Method of preparing ultrafine alloy powder by coprecipitation coreduction

A process for preparing the superfine alloy powder by codeposition-coreduction method includes such steps as liquid-phase codeposition to prepare the precursor powder of each component in alloy, calcining to obtain nano-class composite metallic oxide powder, and reducing by H2 or decomposed ammonia in tubular reducing furnace while alloying to obtain superfine alloy powder.

Owner:UNIV OF SCI & TECH BEIJING

Alumina ceramic composition

Owner:HITACHI METALS LTD

Reproducible high-aluminum fireproof raw material utilizing ferrotitanium slag as main material and preparation method thereof

The invention relates to a reproducible high-aluminum fireproof raw material utilizing ferrotitanium slag as a main material and a preparation method thereof. The technical scheme is as follows: grinding ferrotitanium slag globules until the granularity is less than or equal to 100 mu m, putting the ferrotitanium slag powder into a muffle furnace, and incinerating at a temperature of 700-750 DEG C for 3-5 hours; adding 1-3mol / L hydrochloric acid solution into the incinerated ferrotitanium slag powder, wherein the mass ratio of the incinerated ferrotitanium slag powder to the hydrochloric acid solution is 1:(2-3); stirring, washing with water and performing suction filtration, thereby obtaining precursor ferrotitanium slag powder; then adding water which accounts for 10-15wt% of the precursor ferrotitanium slag powder into the precursor ferrotitanium slag powder, performing wet grinding until the granularity is less than or equal to 60 mu m, performing vacuum mud extrusion molding, and ageing the mixture for 36-48 hours; and putting the mixture into a resistance furnace, heating to 1500-1550 DEG C, performing heat preservation for 1-3 hours, and crushing, thereby obtaining the reproducible high-aluminum fireproof raw material utilizing the ferrotitanium slag as the main material. The preparation method has the characteristics of simple process, low production cost and no special requirements on equipment; and the prepared reproducible high-aluminum fireproof raw material is high in fire resistance and favorable in sintering performance.

Owner:WUHAN UNIV OF SCI & TECH +1

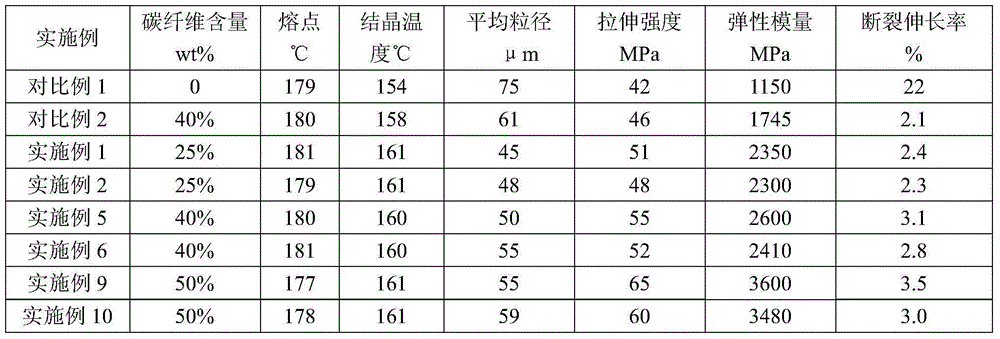

Preparation method of carbon fiber reinforced nylon composite micro-powder for selective laser sintering

The present invention discloses a preparation method of carbon fiber reinforced nylon composite micro-powder for selective laser sintering. The method comprises: carrying out surface pre-treatment on carbon fiber powder, adding the pre-treated carbon fiber powder and nylon particles into a polymer good solvent containing a dispersing agent, carrying out heating stirring to completely dissolve the polymer, adding a poor solvent of nylon to make the nylon gradually crystallize by adopting the carbon fibers as the crystal nucleus and be coated on the carbon fiber surface, carrying out suction filtration, drying, screening, and adding other auxiliary agents to obtain the carbon fiber reinforced nylon composite micro-powder for selective laser sintering. Compared to the method in the prior art, the method of the present invention has characteristics of no requirement of high-temperature and high-pressure equipment, simple process, economy, effectiveness, environmental protection, and easy performing; and the sintering performance of the prepared material is excellent, the carbon fiber content in the material is controllable, and the mechanical property of the obtained SLS molded member is substantially improved compared to the SLS molded member of the matrix resin material.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

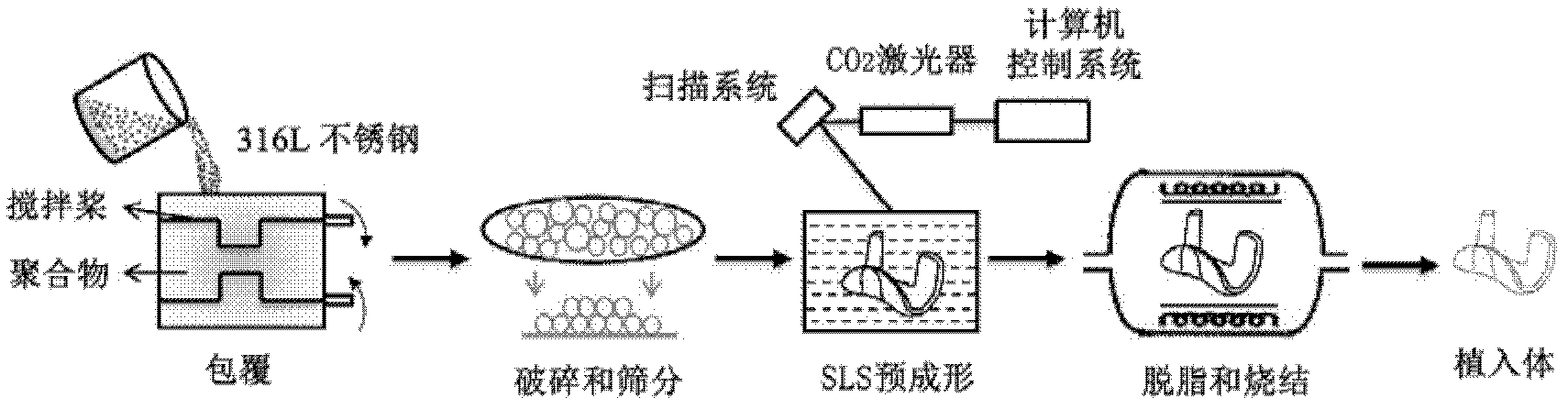

Method for preparing stainless steel biological porous implant material by selective laser sintering

The invention belongs to the field of biological medical porous metal implant materials, and provides a method for preparing a stainless steel biological porous implant material by selective laser sintering, which comprises the following steps: preparing thermoplastic polymer coated 316L stainless steel powder by a film coating method, and forming the powder by a selective laser sintering technique, thereby quickly preparing the biological medical porous metal implant material. The film coating technique mainly comprises the following steps: melting the thermoplastic polymer, coating the stainless steel powder, pulverizing, and screening the coated stainless steel powder. The method is simple and feasible; the coated 316L stainless steel powder has the advantages of favorable sintering property and high adhesive strength; and the selective laser sintering technology is utilized to form the coated stainless steel powder, and the after-treatment of degreasing and secondary sintering is combined to prepare the porous metal implant material. The microstructure and mechanical properties of the stainless steel biological porous implant material can be flexibly controlled by adjusting the technological parameters of the selective laser sintering and after-treatment, thereby achieving the goal of matching with natural bones. The technology has significant application value in the field of preparation of biological medical porous metal implant materials.

Owner:UNIV OF SCI & TECH BEIJING

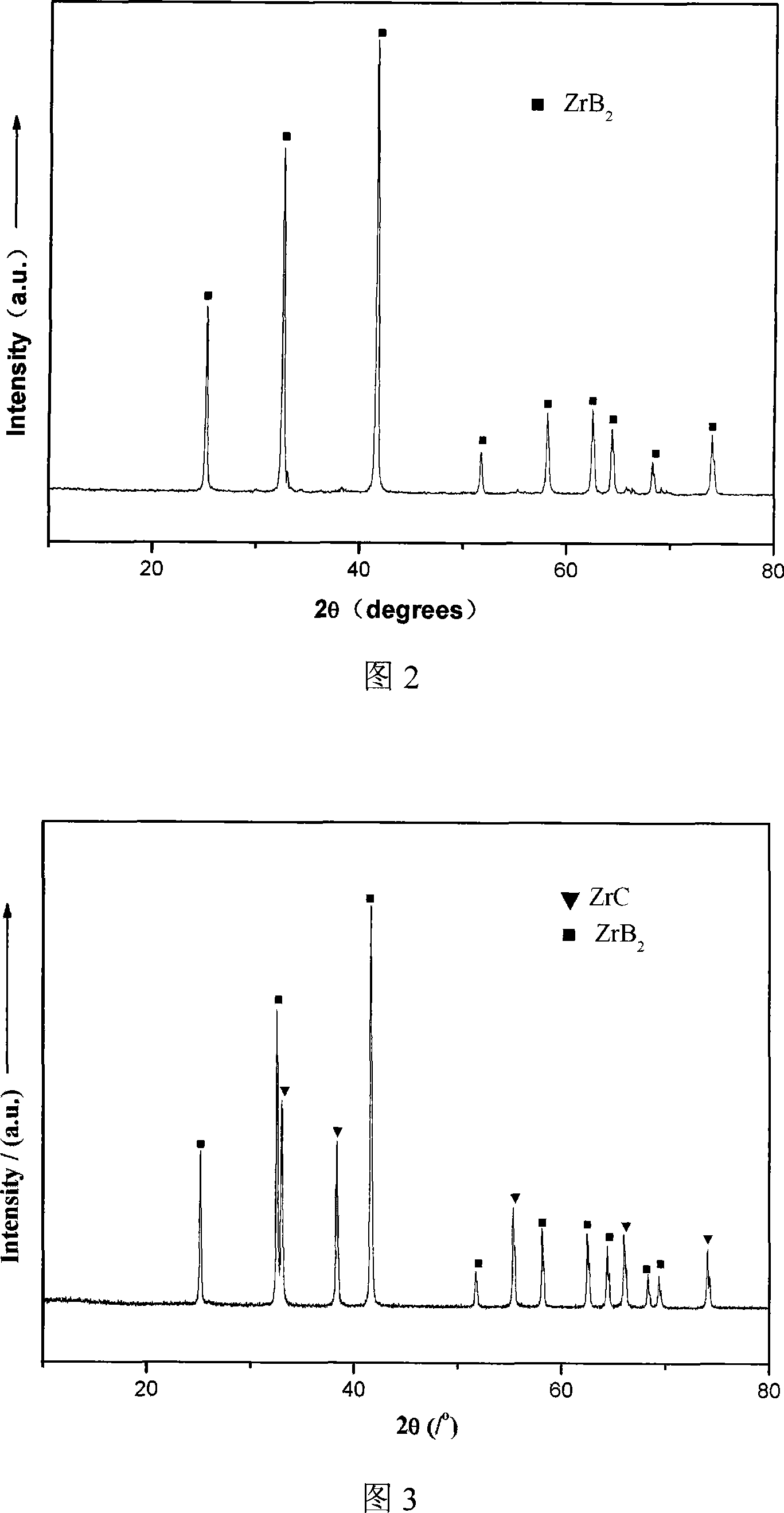

Method for rapidly preparing zirconium carbide ceramics powder

The invention relates to a preparation method of zirconium carbide ceramics powder; the method for rapidly preparing zirconium carbide ceramics powder is characterized in that: the method comprises the following steps: 1) raw material selection: the raw materials are selected according to 12:4-12:5 of mass ratio of zirconium propoxide solution and sugar and 8:32:1:1-8:64:2:4 of volume ratio of zirconium propoxide solution, normal propyl alcohol, chelant-acetic acid and water; the solvent acetic acid is selected according to (7-8)g:50ml of proportion of the sugar and the solvent acetic acid; 2) the preparation of dried gel power; 3) preparation of precursor powder; 4) heat treatment of the precursor powder; carbothermal reduction reaction is carried out under the conditions of high heating rate and short temperature preservation time, the synthesizing process of the zirconium carbide powder is shortened into dozens of minutes even several minutes, so as to obtain high-purity and refined zirconium carbide ceramics powder with good sintering character; single zirconium carbide phase can be analyzed by X-ray diffraction, the oxygen content in the product is 0.5-3 percent, and the free carbon content is from 0.2 to 2 percent; the crystal particles are uniform and tiny, and the mean grain size is less than 500nm.

Owner:WUHAN UNIV OF TECH

Al2O3/Ti(C,N) nano-composite metal ceramic die material and preparation method

The invention discloses an Al2O3 / Ti(C,N) nano-composite metal ceramic die material. The Al2O3 / Ti(C,N) nano-composite metal ceramic die material is characterized by being formed by performing hot-pressed sintering by taking nano-Al2O3 as a matrix, taking nano-Ti(C,N) as a hard dispersed phase, taking micron metals Mo, Ni and Cr as binding phases, and adding one or two of oxides Y2O3 and TiO2, and two or more of carbides TaC, NbC and VC as sintering aids. Compared with a die taking die steel or hard alloy as a material, the metal ceramic die material disclosed by the invention is more excellent in wear resistance, antioxidation and thermal shock resistance, and good in strength and toughness, as well as also has an application prospect in the aspects of tools and wear-resistant and corrosion-resistant components besides production for dies.

Owner:SHENYANG LIGONG UNIV

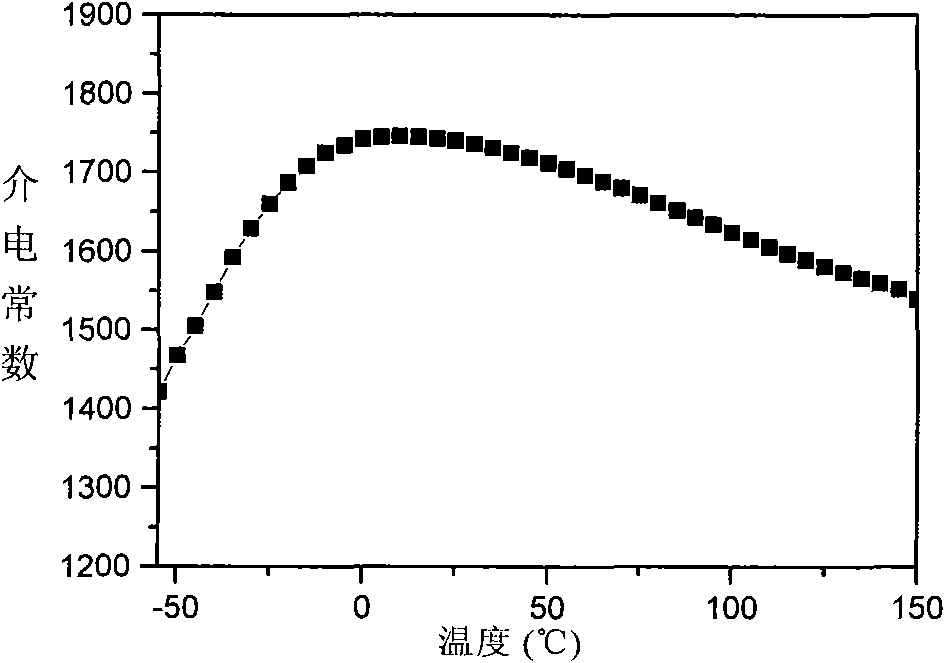

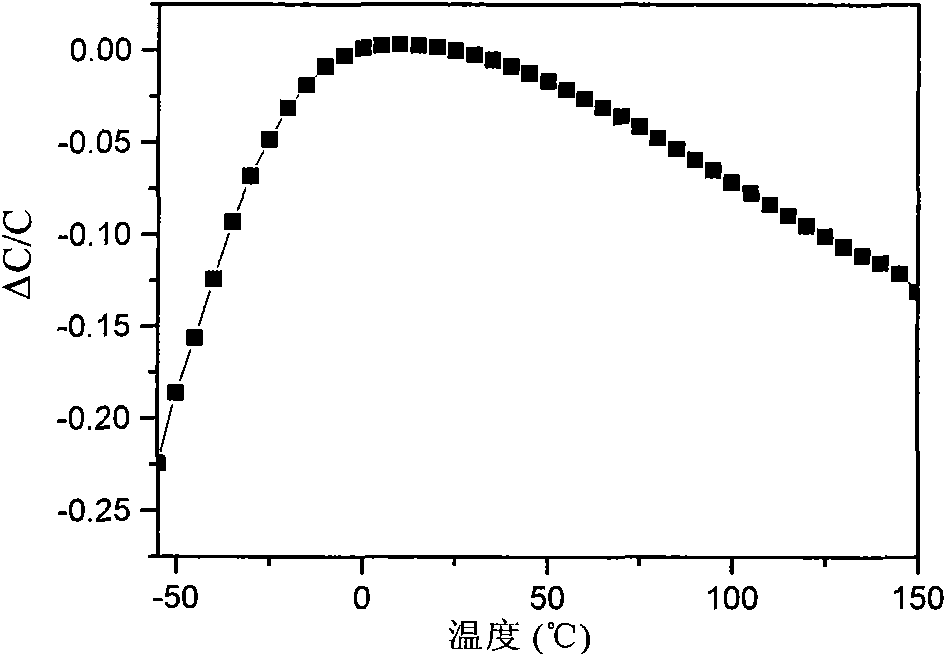

High-temperature stable medium material for multilayer ceramic capacitors and preparation method thereof

InactiveCN101560094ASimple processHigh dielectric constantFixed capacitor dielectricStacked capacitorsPolyvinyl alcoholCeramic capacitor

The invention discloses a high-temperature stable medium material for multilayer ceramic capacitors and a preparation method thereof. The medium material consists of a main component and a doping component; the chemical constitution of the main component is (1-x) BaTiO3-xBiScO3, wherein x is equal to between 0.5 and 0.15; the doping component is CaF2+4LiF, wherein the purity of the CaF2+4LiF is more than 99 percent and the molar doping quantity of the CaF2+4LiF is 1 to 5 percent of the total mol number of the main component. The preparation method comprises the following steps: firstly, using BaCO3 and TiO2 as raw materials and mixing the materials according to the stoichiometric proportion of the BaTiO3 to synthesize BaTiO3 powder with a tetragonal phase structure; secondly, mixing BaTiO3, Bi2O3 and Sc2O3 according to the stoichiometric proportion of (1-x) BaTiO3-xBiScO3, wherein x is equal to between 0.05 and 0.15; and finally, adding CaF2 and LiF powder which have a purity of more than 99 percent, mixing and ball milling the mixture in absolute ethanol for 48 hours, drying the milled mixture, adding a solution of polyvinylalcohol into the dried mixture for granulation, passing the product obtained after granulation through an 80 mesh sieve, subjecting the product to press forming and sintering and obtaining the medium material. The material has high dielectric constant, low dielectric loss and excellent temperature stability, can be sintered at intermediate temperature and is suitable to be sintered together with cheap base metals. The medium material can be used to produce multilayer ceramic capacitors having X8R and X9R properties.

Owner:WUHAN UNIV OF TECH

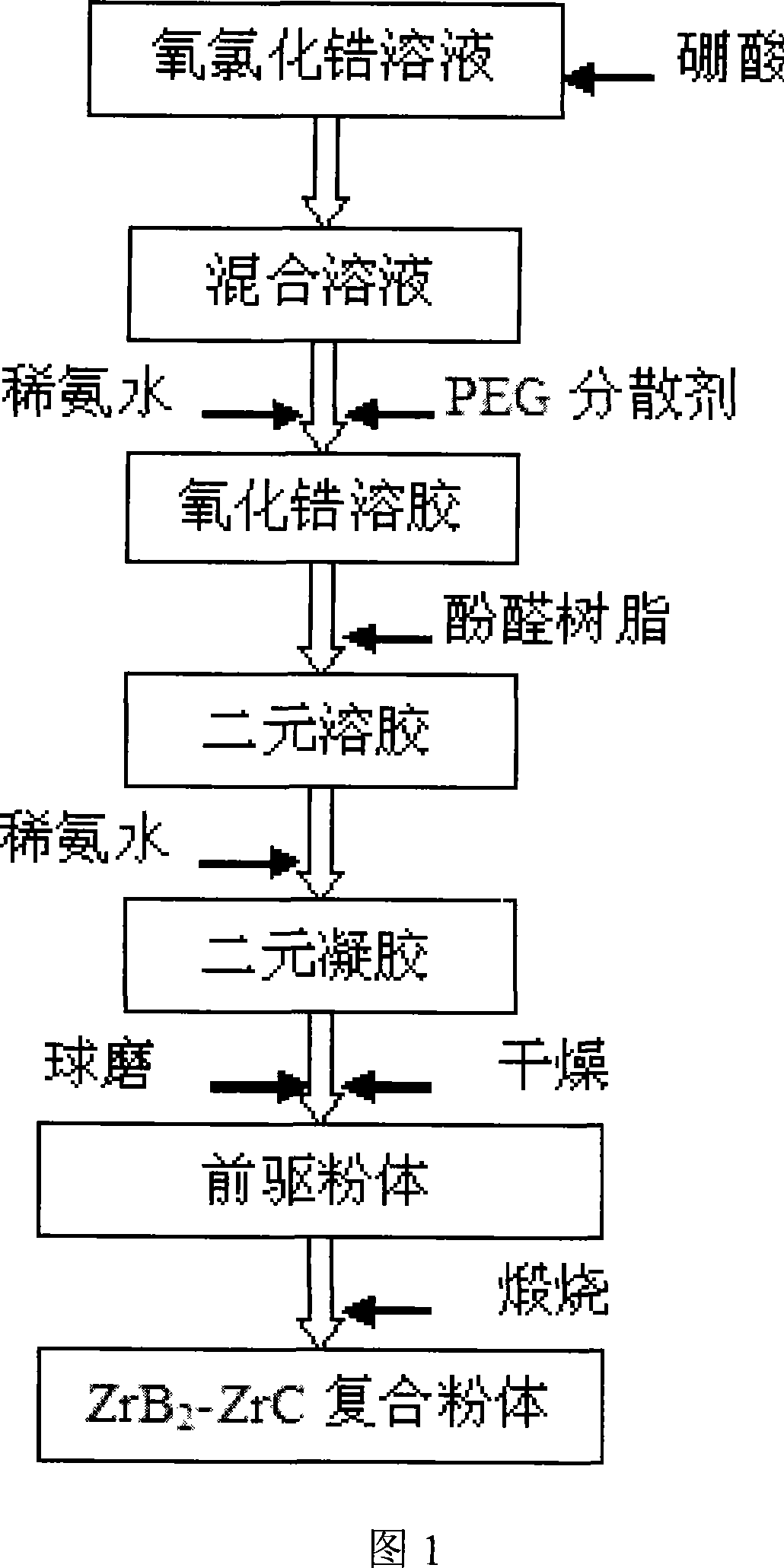

Method for preparing boron-carbon-zirconium material by liquid phase process

InactiveCN101205065AOvercoming is not easy to determine,Overcoming the disadvantages of toxic side effectsCalcium carbideMetal boridesZirconium oxychlorideElectron

The invention relates to a method for preparing boron carbon zirconium materials by liquid phase method, which belongs to the field of structural ceramics. By using carbothermal reduction as the basic principle and adopting zirconium oxychloride, boric acid and phenolic resin as the main materials, the method comprises the steps as follows: the phenolic resin is mixed with zirconia sol which is formed by titration of ammonia; then gel is formed by the titration of the ammonia; finally ball milling is carried out; after drying, screening and heat treatment, the ultrafine boron carbon zirconium materials can be obtained. The boron carbon zirconium materials which are prepared by the invention, with product granularity smaller than 200nm and excellent molding and sintering performance, can be applied to fields such as electron materials and refractory materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Rare earth electrode slurry of rare earth thick film circuit based on metal plate and its preparation technology

ActiveCN1909748AIntermolecular bonding strength and improved manufacturabilitySolid combinationOhmic-resistance electrodesNon-conductive material with dispersed conductive materialSolid phasesYttrium

The invention relates to a rare-earth electrode slurry of rare-earth circuit, based on the metal base board and a relative production, wherein it is characterized in that: said slurry is formed by solid material and organic solvent carrier, while their mass ratio is 70-90:30-10; the solid component comprises: silver, palladium, and yttrium composite power and micro-crystal glass powder, while their mass percentage is 99.4-94:0.6-6; said composite power is formed by silver, palladium, and yttrium powders at the ratio as 0.6-10:99-82:0.4-8; said micro-crystal glass is the one in SiO2-Al2O3-CaO-B2O3-Bi2O3-La2O3 group. And the production comprises: (1), preparing rare-earth micro-crystal glass powder; (2), preparing silver, palladium, and yttrium composite powder; (3), preparing organic solvent carrier; (4), mixing material in three-dimension and rolling with three rollers; (5), preparing the rare-earth slurry; (6), bottling. The invention is environment friendly and better humidity compatibility.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

Method for preparing self-lubricating coat in use for high temperature

A refractory self-lubricating coated layer is prepared through proportionally mixing Ni, Cr, Cr2O3, BaF2, CaF2 and Ag high-energy ball grinding, preparing slurry, coating on the target surface, baking, cold isostatic pressing for compacting it, and sintering at 800-1200 deg.C for 1-3 hr. Its strength is more than 40 MPa.

Owner:XI AN JIAOTONG UNIV

Cathode material for lithium secondary battery and manufacturing method thereof

ActiveUS7799301B2Excellent characteristicsImprove sinterabilityThiosulfates/dithionites/polythionitesConductive materialLithium carbonatePhosphoric acid

Owner:JX NIPPON MINING & METALS CORP

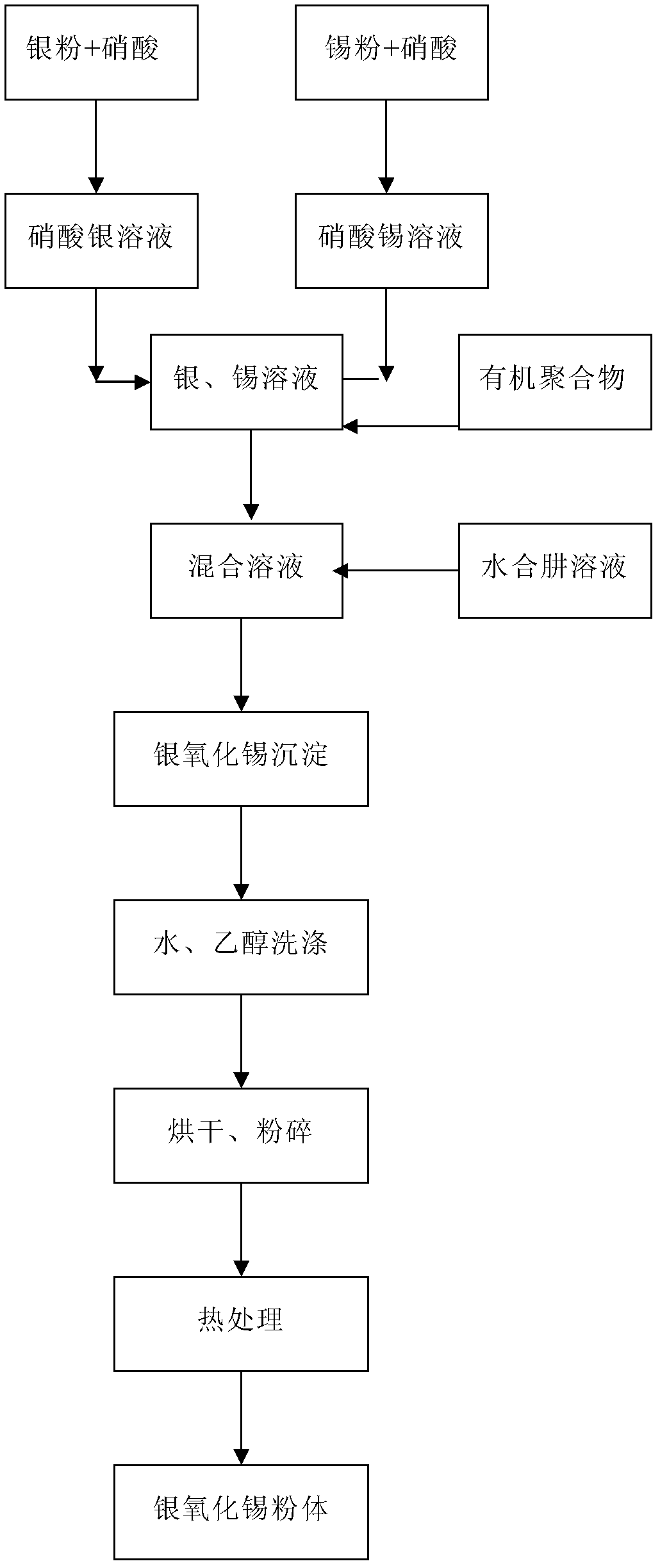

Preparation method for silver and stannic oxide composite powder and application thereof

The invention provides a preparation method for silver and stannic oxide composite powder and an application thereof. Particularly, Silver is dissolved into nitric acid to form an aqueous solution; dissolving metal stannic powder into deionized water at a low temperature (ice-water bath) to form a stannum nitride solution; mixing the above two solutions; adding the polymer into the mixture to obtain a mixed solution; dropwise adding hydrazine hydrate into the above solution; carrying out a redox reaction and obtaining sediments; and washing, drying, smashing and carrying out heat treatment on the sediments to obtain the silver and stannic oxide composite powder, wherein the particle diameter of the powder body is within the nanoscale range. The silver stannic oxide composite powder prepared with the method can be used for sintering and manufacturing a low-voltage electric contact. The technology is simple and easy to operate and has the advantages of high powder quality and low production cost.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

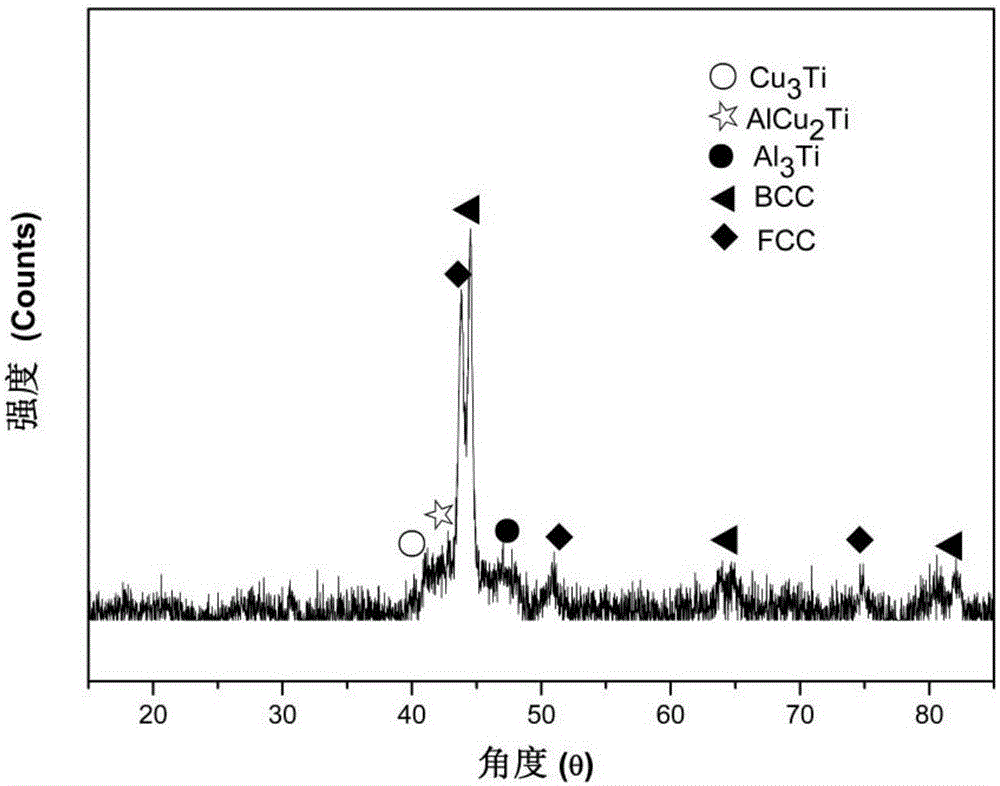

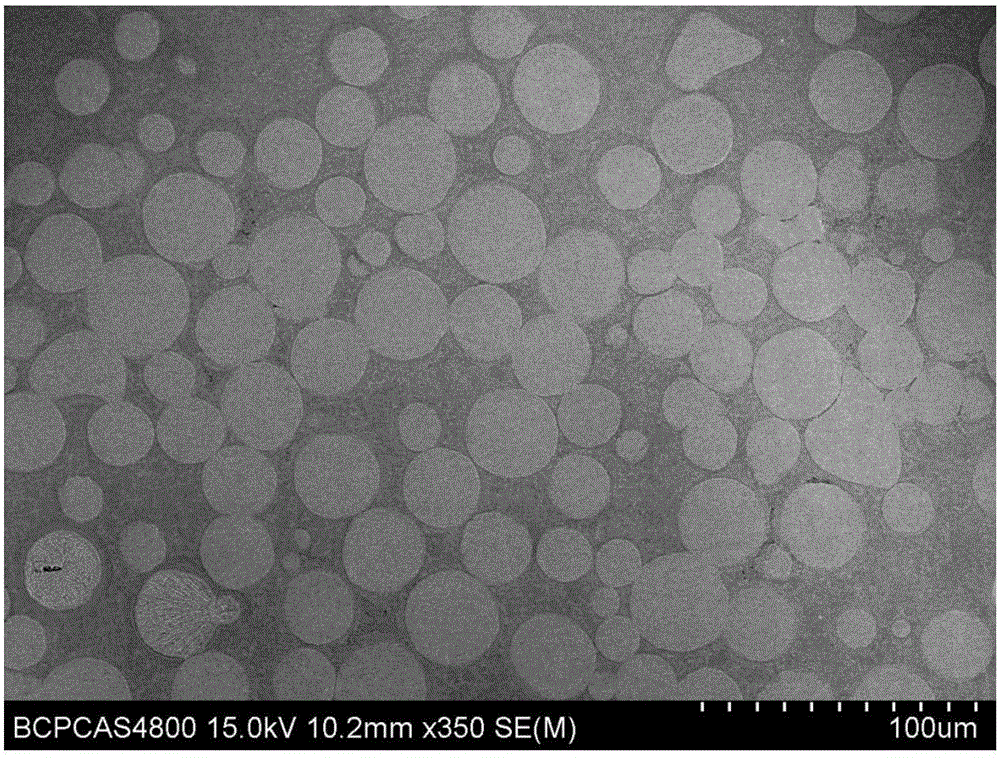

Aluminum-based amorphous/high-entropy alloy composite and preparation method thereof

The invention relates to an aluminum-based amorphous / high-entropy alloy composite and a preparation method thereof, belonging to the field of metal composites. The composite is relatively low in density and high in compressive strength and has certain deformability. The preparation method comprises the steps of placing metal powder of Al, Cu and Ti or Al, Fe and Ti or Al, Ni and Ti into a ball milling tank, injecting methylbenzene from a glove box with an Ar atmosphere to the ball milling tank, taking all the components out of the glove box after sealing the tank, and carrying out ball milling to obtain aluminum-based amorphous powder; preparing an original material from Al, Co, Cr, Fe and Ni metal blocks, and carrying out alloy smelting in vacuum by taking Ar as a protective gas to obtain a mother alloy ingot of AlCoCrFeNi high-entropy alloy; atomizing the obtained mother alloy ingot, and screening to obtain spherical high-entropy alloy powder with the particle size of 20-100mu m; and after carrying out ball milling and mixing on the obtained aluminum-based amorphous powder and the high-entropy alloy powder, placing the mixture into a hard alloy die to sinter to obtain the aluminum-based amorphous / high-entropy alloy composite.

Owner:北京中辰至刚科技有限公司

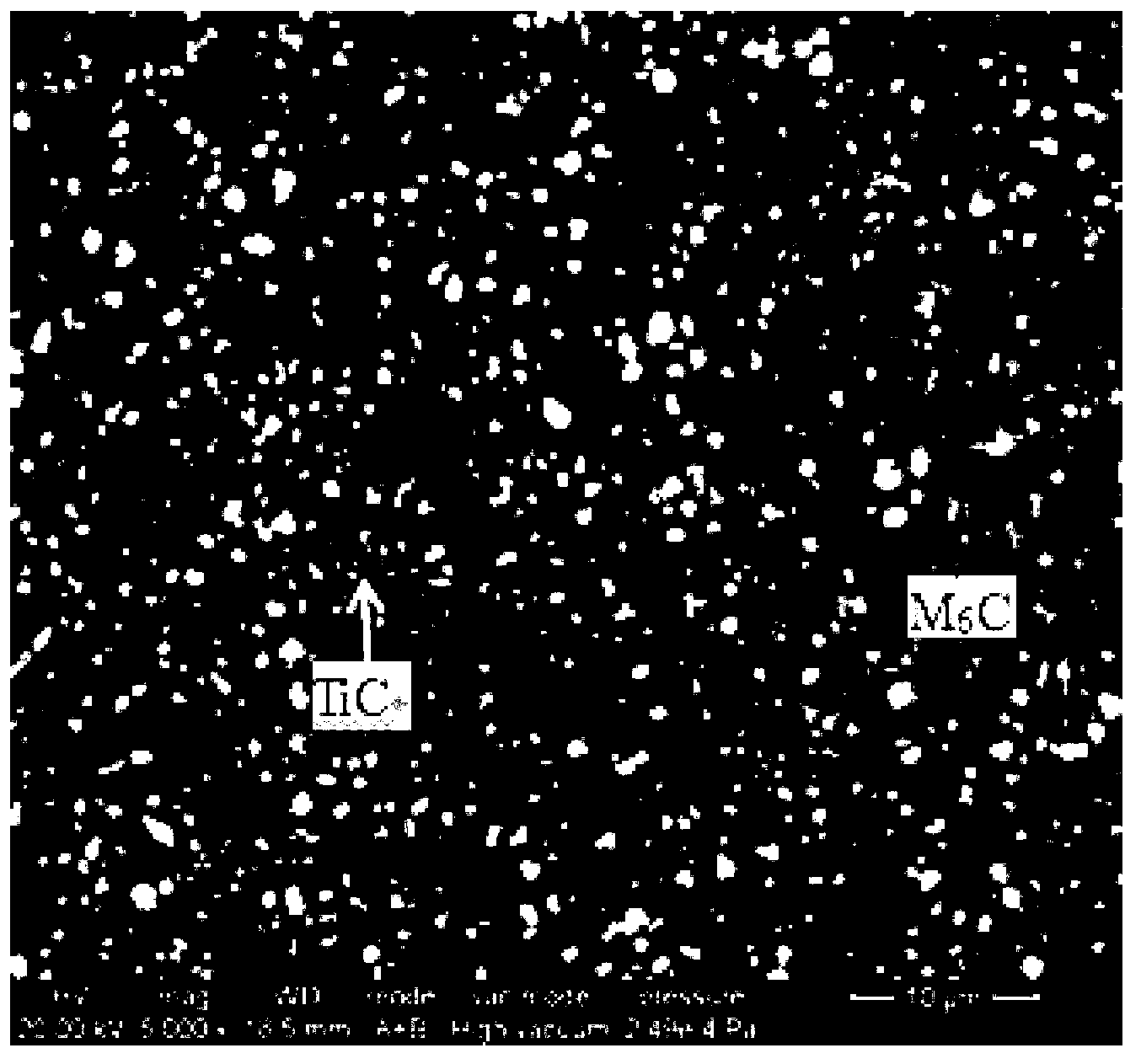

TiCp/M2 high-speed steel composite material and SPS (spark plasma sintering) preparation method thereof

The invention relates to a TiCp / M2 high-speed steel composite material and an SPS (spark plasma sintering) preparation method thereof. The method comprises the following steps: firstly mixing powder according to the mixture ratio of raw material powder; then performing high-energy ball milling till the average particle size of M2 high-speed steel powder particles is refined to below 20 mu m and TiC is refined to below 200nm; and further adopting SPS to perform fast sintering on the composite powder after high-energy ball milling. The obtained composite material comprises reinforcement phase nano-scale hard particles TiC and a precipitated submicron-scale M6C type composite carbide, a matrix is of M2 high-speed steel, a reinforcement body is of TiC particles, the TiC particles are dispersed and distributed in the matrix in the nano-scale particle size, and as for the composite material, the relative density is more than 98.5%, the hardness is 56-59HRC, and the volume wear loss is 1.77*10<-1>-1.34*10<-1>mm<3>. The process disclosed by the invention is simple and convenient, and the obtained material has the advantages of good anti-bending performance, high density and excellent comprehensive performances.

Owner:SOUTH CHINA UNIV OF TECH

High intensity low conductivity magnesium aluminate spinel brick

The invention relates to a high intensity low conductivity magnesium aluminate spinel brick. The high intensity low conductivity magnesium aluminate spinel brick comprises the following ingredients: 20-25% magnesium aluminate composite material with granularity of 5-3 mm, 20-25% magnesium aluminate composite material with granularity of 3-1 mm, 12-16% fused magnesite with granularity of 1-0 mm, 12-16% fused magnesite with granularity of 180 F, 10-12% magnesium aluminate composite material with granularity of 180 F, 4-8% fused magnesium aluminate spinel with granularity of 180 F, 2-5% Alpha-Al2O3 fine powder, and calcium lignosulphonate which accounts for 3.5-5 weight percentage of the raw material. The high intensity low conductivity magnesium aluminate spinel brick is suitable for cement rotary kiln, has good sintering performance, thermal shock resistance, erosion resistance and permeating resistance, and has good economic and social benefits.

Owner:TONGDA REFRACTORY TECH CO LTD +1

Method for preparing tungsten-copper base composite powder and sintered alloy made up by using said composite powder for making radiator

InactiveCN1428218AImprove sinterabilityImprove conductivityThin material handlingTungsten compoundsAmmonium paratungstateAmmonium metatungstate

The present invention relates to a method of producing W-Cu based composite powder, which is used in heat-sink materials for high-power integrated circuits, electric contact materials, etc, and to a method of producing a W-Cu based sintered alloy by using the composite powder. The method of producing tungsten-copper based composite powder includes first preparing composite oxide powder by dissolving ammonium metatungstate, [(NH4)6(H2W12O40).4H2O], as water-soluble tungsten salt, and copper nitrate or copper acetate in water to the desirable composition, followed by spray-drying and calcining; then preparing a tungsten oxide powder by separately calcining a tungsten-containing salt, such as ammonium paratungstate, (NH4)10(H10W12O46); forming ultra-fine tungsten-copper based composite oxide powder by mixing 20~75wt % of the composite oxide powder and 80~25wt % of the tungsten oxide powder to the desirable composition, followed by ball-milling; and reducing the ultra-fine tungsten-copper based composite oxide powder at temperature of 650~1,050 DEG C. If the composite powder is molded into a certain size and sintered thereafter in temperature of 1,110~1,450 DEG C., a W-Cu based sintered alloy of superior thermal and electric conductivities can be obtained thereby.

Owner:KOREA INST OF MACHINERY & MATERIALS

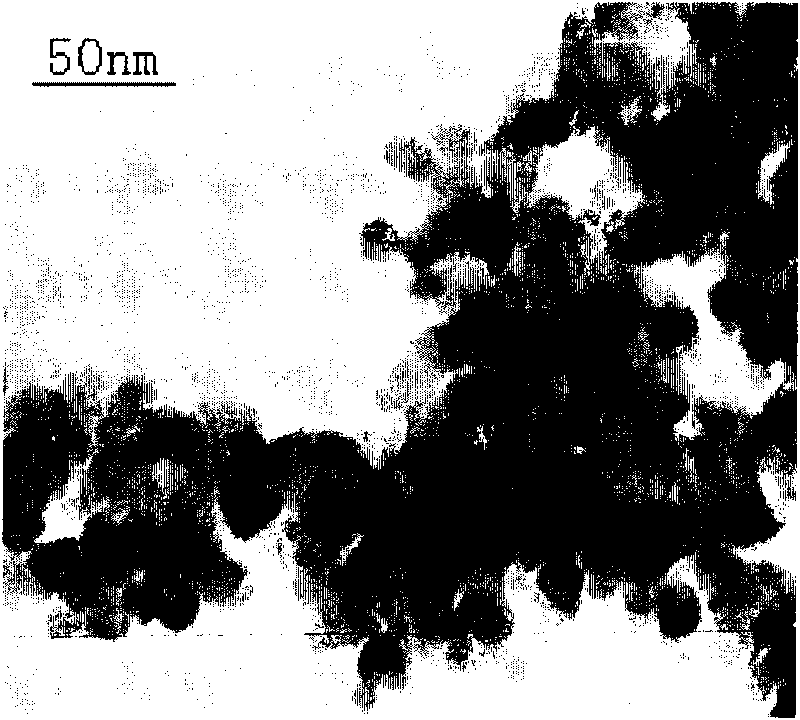

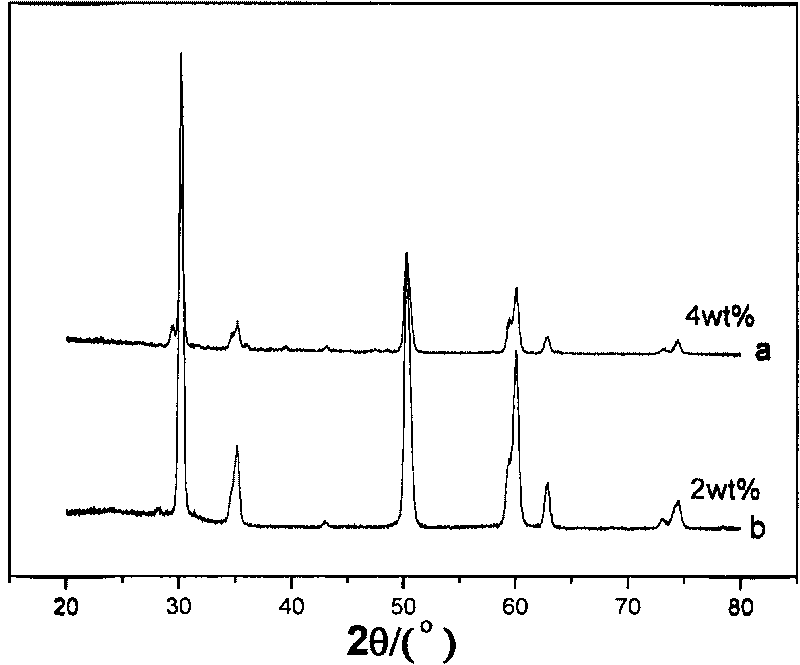

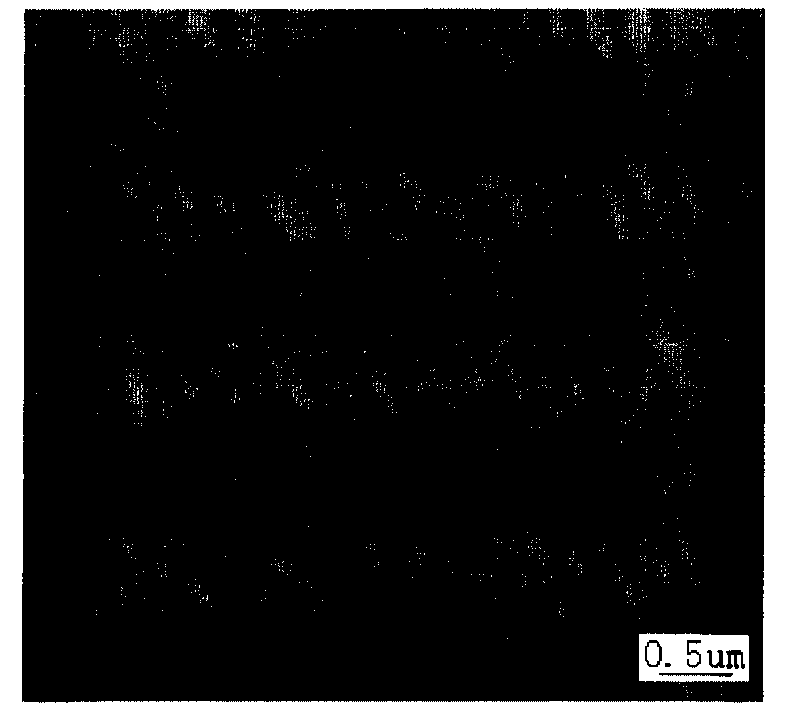

Photosensitive conductive paste and conductive body pattern formed thereby

InactiveCN1494090AImprove sinterabilityImprove conductivityNon-conductive material with dispersed conductive materialPhotosensitive materials for photomechanical apparatusConductive pasteX ray analysis

The purpose of the present invention is to provide a photosensitive conduction paste which is excellent in both of formability of high-fineness patterns and firing properties at <= 600 DEG C. The photosensitive conduction paste contains (A) silver powders having a low degree of crystallinity, (B) an organic binder, (C) a photopolymerizable monomer, and (D) a photopolymerization initiator, in which the silver powder (A) having the low degree of crystallinity exhibits a value of >= 0.15 DEG at a half peak width of the Ag (111) face peak in X-ray analysis patterns.

Owner:TAIYO INK MFG

Preparation method for indium tin oxide (ITO) powder and preparation method for ITO sintering body

Owner:宁夏中色新材料有限公司

Method for preparing furnace lining of metallurgical intermediate frequency furnace

The invention relates to a method for preparing a furnace lining of a metallurgical intermediate frequency furnace. According to the method, the furnace lining is prepared through sintering a dry-ramming material, wherein the dry-ramming material is prepared from the following ingredients in percentage by mass: 26-50% of abandoned skateboard particles, 5-20% of high-bauxite chamotte, 18-50% of corundum particles, 5-17% of magnesite particles, 1-7% of high-temperature burning promoting agent, 0.5-1% of quartz and 0.5-1% of boric acid; and the particle diameters of the abandoned skateboard particles and the high-bauxite chamotte are not greater than 10 mm, and the particle diameters of the corundum particles and the magnesite particles are not greater than 1 mm. Due to the adoption of the technical scheme, compared with the same industry that a large amount of plate-shaped corundum and extra-grade bauxite is used directly, the method has the advantages that used abandoned skateboard resources serve as an important raw material of ingredients, so that the energy consumption is reduced greatly, useful resources are recovered, the number of abandoned skateboards discharged into the environment is reduced greatly, the economic benefit is considerable and the environmental benefit is remarkable.

Owner:德清县力拓炉料有限公司

Improved process for producing copper alloy powder by water atomization method

The invention discloses an improved process for producing copper alloy powder by a water atomization method. The process includes the steps: (1) smelting by an intermediate frequency furnace: adding nonmetallic ore elements and salt in the smelting process; (2) performing water atomization pulverization; (3) performing vacuum suction filtering: adding composite antioxidants when suction filtering is performed; (4) treating the atomized water obtained by vacuum suction filtering, then recycling the treated atomized water, and drying, screening and packing the obtained copper alloy powder. The nonmetallic ore elements account for 0.5-0.7% of the weight of a copper block, the salt accounts for 0.3-0.5% of the weight of the copper block, an ejecting angle ranges from 40 degrees to 45 degrees, a spray nozzle is made of No.45 steel, the diameter of a package leaking hole ranges from 5mm to 8mm, atomization pressure ranges from 18Mpa to 25Mpa, the height of an atomization barrel is 3m, cooling water level ranges from 0.3m to 0.5m, and the composite antioxidants account for 0.05-0.15% of the weight of the copper block. By the aid of the improved process for producing the copper alloy powder by the water atomization method, the produced spherical copper alloy powder has the advantages of fine sphericity and formability, uniform components, excellent sintering property, less surface oxidation, low production cost, high production efficiency and stable product quality.

Owner:安徽旭晶粉体新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com