Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

417 results about "Forsterite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Forsterite (Mg₂SiO₄; commonly abbreviated as Fo; also known as white olivine) is the magnesium-rich end-member of the olivine solid solution series. It is isomorphous with the iron-rich end-member, fayalite. Forsterite crystallizes in the orthorhombic system (space group Pbnm) with cell parameters a 4.75 Å (0.475 nm), b 10.20 Å (1.020 nm) and c 5.98 Å (0.598 nm).

Periclase-magnesium aluminate spinel composite refractory brick and technique for producing the same

The invention relates to an alkaline composite refractory brick, which consists of a periclase-magnesium aluminate spinel flame retardant coating and a periclase-forsterite thermal-protective coating. The proportion of the alkaline composite refractory brick is as follows: 1) the proportion of the flame retardant coating is as follows: 29 to 48 percent of magnesite of between 5 and 1 millimeter, 7 to 16 percent of the magnesium aluminate spinel of between 3 and 1 millimeter, 6 to 20 percent of the magnesite of between 1 and 0.088 millimeter, 0 to 4 percent of desilicated zirconia granules of between 0.4 and 0.088 millimeter, 16 to 25 percent of the magnesite of less than 0.088 millimeter, 0 to 10 percent of magnesite micropowder of less than 0.020 millimeter, 0 to 5 percent of desilicated zirconia micropowder of less than 0.020 millimeter, 0 to 3 percent of calcium carbonate micropowder less than 0.020 millimeter, 0 to 6 percent of lanthanum oxide of less than 0.020 millimeter, and 0 to 0.3 percent of additional water reducing agent (sulfonated naphthaldehyde polymer, sulfonated melamine polymer and polycarboxylic acid or sodium salt thereof); and 2) the proportion of the thermal-protective coating is as follows: 0 to 20 percent of the magnesite of between 3.2 and 1.0 millimeter, 35 to 45 percent of the forsterite of between 3.2 and 1.0 meter, 5 to 15 percent of the magnesite of between 1.0 and 0.088 millimeter, 5 to 15 percent of the forsterite of between 1.0 and 0.088 millimeter, and 30 to 40 percent of grinding powder of the magnesite and the forsterite of less than 0.088 millimeter. The material has the advantages that the material improves the erosion resistance of the flame retardant coating by micropowder technology, and allows the sintering temperature of the flame retardant coating to be matched with that of the thermal-protective coating, thereby producing the periclase-magnesium aluminate spinel alkaline composite refractory brick which has excellent.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD +1

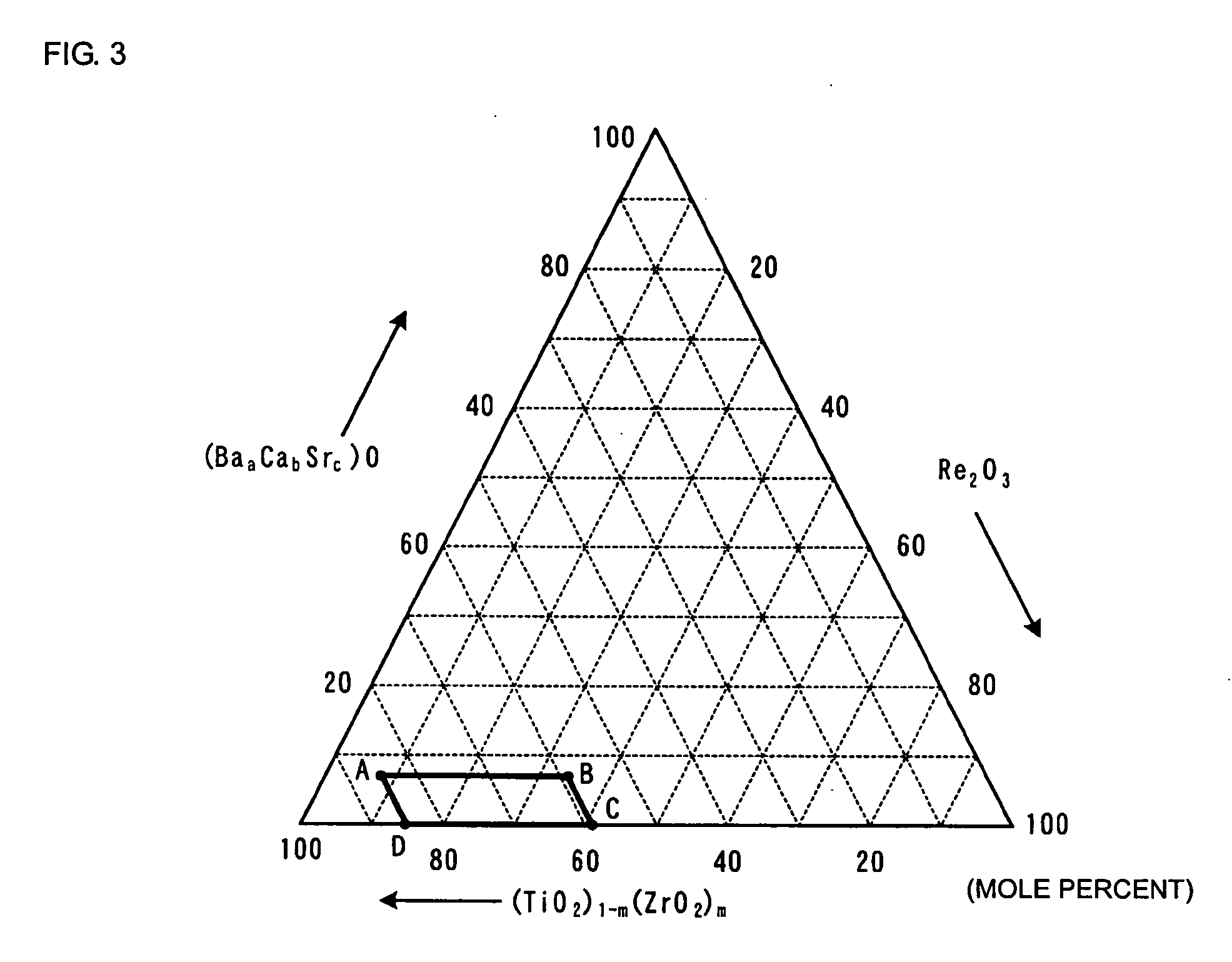

Glass ceramic composition, glass ceramic sintered body, and multilayer ceramic electronic device

ActiveUS20100046137A1Good chemical stabilityLow dielectric constantFixed capacitor electrodesFixed capacitor dielectricCapacitanceFlexural strength

A glass ceramic composition is provided which can be fired at a temperature of 1,000° C. or less to form a sintered body having a low relative dielectric constant, a small temperature coefficient of resonant frequency, a small change in capacitance before and after a loading test, a high Qf value, high electrical insulating reliability, and a high flexural strength. A glass ceramic composition forming glass ceramic layers laminated to each other in a multilayer ceramic substrate is also provided. The glass ceramic composition includes a first ceramic powder containing forsterite as a primary component; a second ceramic powder containing SrTiO3 and / or TiO2 as a primary component; a third ceramic powder containing BaZrO3 as a primary component; a fourth ceramic powder containing SrZrO3 as a primary component; and a borosilicate glass which contains Li2O, MgO, B2O3, SiO2, and ZnO, and also which contains at least one of CaO, BaO, and SrO.

Owner:MURATA MFG CO LTD

Magnesium-alloy metal-type casting coating and preparation method thereof

ActiveCN101658899ASimple componentsEasy to prepareFoundry mouldsFoundry coresSodium BentoniteSuspending Agents

The invention relates to a magnesium-alloy metal-type casting coating and a preparation method thereof. Magnesia and forsterite are used as refractory aggregates; titania, asbestos powder or talcum powder or diatomite, and the like are added as heat-insulation aggregates; a mixed caking agent with favorable high-temperature caking property and a compound suspending agent are selected; and boric acid is added as a flame retardant. The preparation method comprises the following steps: mixing the magnesia, the forsterite, the titania, and the asbestos powder or talcum powder or diatomite, and preparing A after ball milling; mixing the caking agent and bentonite, and adding water to activate so as to obtain B; mixing the boric acid, sodium carboxymethyl cellulose and polyacrylamide, and addingwater to activate so as to obtain C; and finally, mixing A, B and C, and carrying out ball milling or colloid milling for more than 30 minutes to obtain the magnesium-alloy metal-type casting coating. The coating has the advantages of favorable heat insulation, caking property, coating property, flame retardance, stability and durability, is beneficial to continuous production and convenient forobtaining magnesium-alloy metal-type castings with favorable surface quality and superior performance, and prolongs the service life of moulds.

Owner:SHANGHAI JIAO TONG UNIV

Forsterite-C-contained MgO-SiC-C fire-resistant material and preparation thereof

The invention relates to a forsterite-C-containing MgO-SiC-C material refractory and a method for preparing the same. The technical scheme comprises firstly mixing the 25-40wt% of magnesia particles with a grain size of 3-1mm, 20-35wt% of magnesia particles with a grain size of 1-0mm, 5-40wt% of forsterite-C mixed fine powders and 0-35wt% of magnesia fine powders, adding a 4-10wt% of bonding agent accounting for the weight of the mixed material, stirring or mulling for 10-30 minutes, drying after pressing formation, sintering at a reductive atmosphere with a sintering temperature of 1450-1700 DEG C and a heat preservation time of 4-8 hours, getting the MgO-SiC-C material composite refractory. The MgO-SiC-C material refractory prepared by adding the forsterite and carbon not only can solve the problem of magnesia resource shortage, reduces the production cost, but also the SiC prepared by the reaction of magnesia and carbon at a high temperature can reinforce the conjugation inside the material, and be useful for improving the refractory performance. The invention can also adopt low grade magnesia.

Owner:WUHAN UNIV OF SCI & TECH

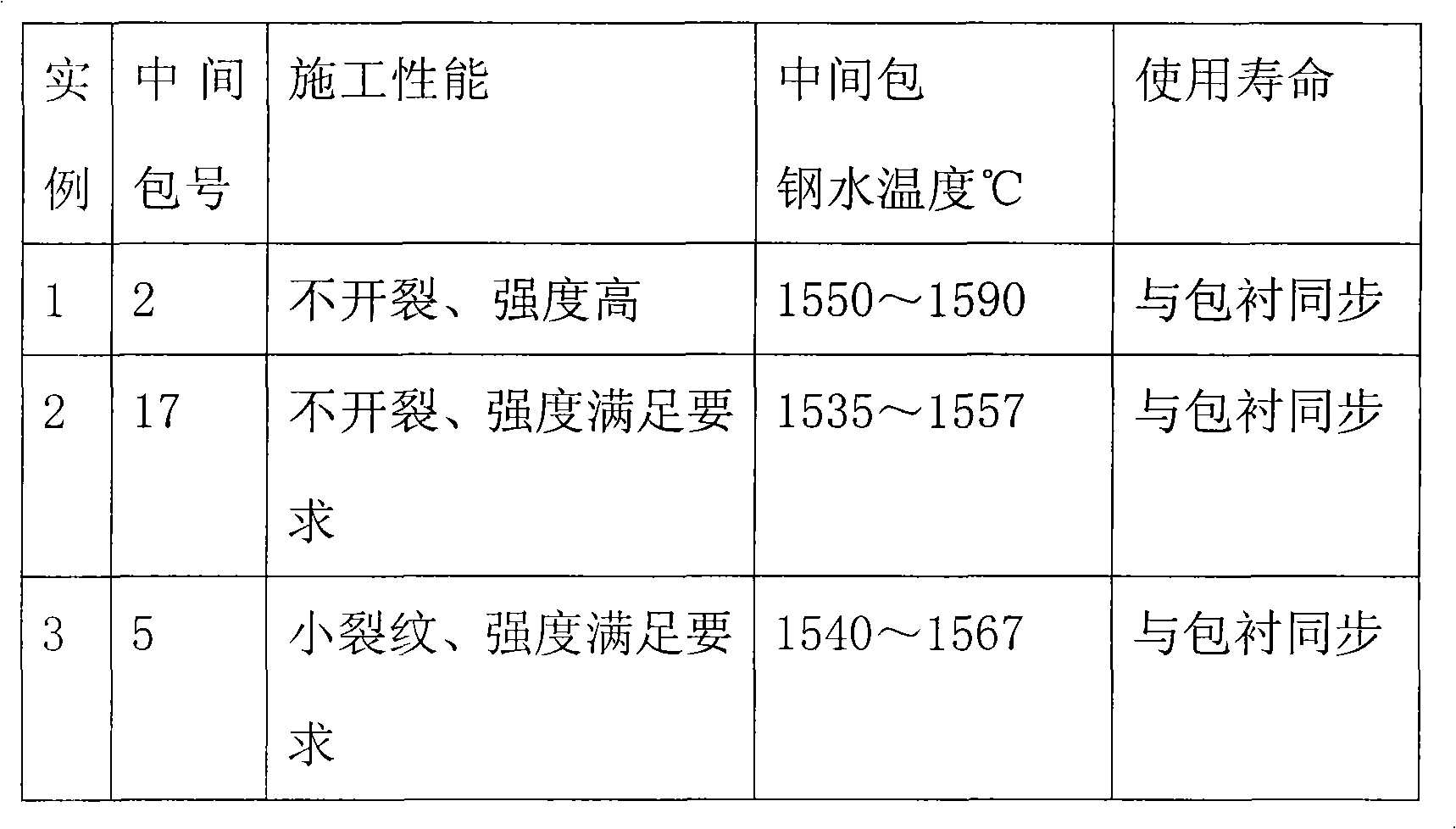

Tundish dry ribration material for continuous casting and its preparation method

InactiveCN1651352ANo irritating smellEasy constructionMelt-holding vesselsPolyvinyl alcoholRefractory

A lining material of tundish for conticasting is prepared from 6 primary raw materials including sintered magnesium sand, electrosmelted magnesium sand, forsterite, light forsterite, etc and 9 secondary raw materials including water glass, sodium tripolyphosphate, dextrin, starch, etc through proportionally mixing, stirring, loading in mould, vibrating, baking at 150-400 deg.C and demoulding.

Owner:WUHAN UNIV OF SCI & TECH

Magnesium gunning refractory for copper smelting-furnace

A magnesium gunning refractory used in copper smelting furnace can be used to gun and repair large area or partial erosive part of the furnace lining of nonferrous metals smelting furnace, the material thereof comprises aggregate, powder, binding agent and additive; the material of aggregate and powder comprises fused magnesite chrome sinter, fused magnesia, sintered magnesia and forsterite; the critical particle size of the aggregate is 0.1-5mm, and the particle size of the powder less than 0.088mm; the weight ratio is that fused magnesite chrome sinter 0-20%, sintered magnesia 10-30%, forsterite 0-20% for particle size of 3-5mm; sintered magnesia10-40%, forterite 10-40% for particle size of 1-3mm; fused magnesia 0-20%, sintered magnesia 5-20%, forsterite 5-20% for particle size of 0.1-1mm; fused magnesia 6-20%, forsterite 0-15% for particle size less than 0.088mm; binding agent 5%-15%; additive 6%-20%. The invention has the advantages of delaying the date of retirement, increasing the service life of the whole furnace lining, decreasing the repairing expenses and working intensity, and ensuring the continuity of production.

Owner:河南荣耀产业管理有限公司 +1

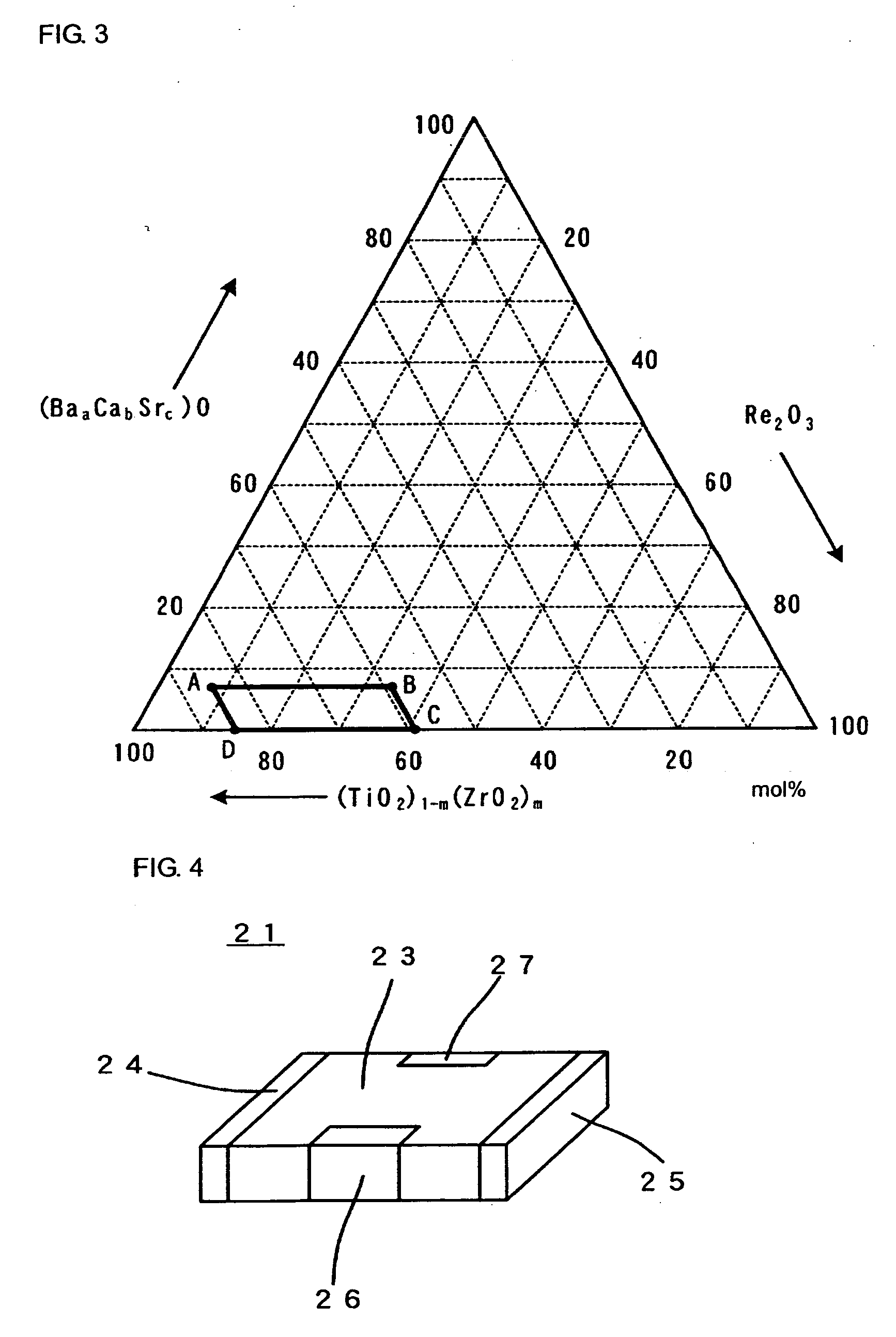

Glass-ceramic composition, glass-ceramic sintered body, and monolithic ceramic electronic component

InactiveUS20060287184A1Improve electrical insulation reliabilityReduced insulation performanceCeramic layered productsPrinted circuit manufactureStrontium titanateLithium oxide

A glass-ceramic composition contains first ceramic particles principally containing forsterite; second ceramic particles principally containing at least one selected from the group consisting of calcium titanate, strontium titanate, and titanium oxide; and borosilicate glass particles containing about 3% to 15% lithium oxide, about 20% to 50% magnesium oxide, about 15% to 30% boron oxide, about 10% to 45% silicon oxide, about 6% to 20% zinc oxide, 0% to about 15% aluminum oxide, and at least one additive selected from the group consisting of calcium oxide, barium oxide, and strontium oxide on a weight basis. The content of the borosilicate glass particles is about 3% or more; the lower limit of the content of the additive is about 2%; and the upper limit of the additive content is about 15%, about 25%, or about 25% when the additive is calcium oxide, barium oxide, or strontium oxide, respectively, on a weight basis.

Owner:MURATA MFG CO LTD

Paint for continuous casting pouring box work liner and preparing technique thereof

ActiveCN101508586AGood spreadabilityGood application effectMelt-holding vesselsFiberSodium phosphates

The invention discloses a painting for continuously cast pouring basket working lining and a producing technique thereof. The components of the painting is as follows according to parts by weight: 50-90 parts of forsterite raw material, 10-50 parts of magnesia, and 3-5 parts of composite additive, wherein the composite additive is at least one of organic fiber, paper fiber, lime, trimeric sodium phosphate, sodium hexametahposphate, clay or silicate. The producing technique of the painting is evenly mixing and stirring the forsterite raw material, the magnesia and the composite additive according to the parts by weight to lead the mixture to show no evident white trace, thereby obtaining the painting used for the continuously cast pouring basket working lining. The painting has excellent smearing, sintering, anti-scouring, anti-dreg erosion and anti-peeling properties, is free from collapsing and pollution, is environment-friendly, and has long service life, low production cost and simple and convenient preparation method.

Owner:WUGANG REFRACTORY CO LTD

Pouring material for forsterite tundish slag stop wall and production process thereof

The invention discloses a pouring material for a forsterite tundish slag stop wall and a production process thereof. The pouring material is prepared from the following raw materials in part by weight: 5 to 70 parts of forsterite, 15 to 85 parts of magnesium sand, 5 to 15 parts of corundum powder, 3 to 5 parts of composite additive, 0.1 part of organic fiber and 1 part of steel fiber. The production process comprises the following steps of: adding aggregates in the raw materials into a stirrer and mixing and stirring the aggregates uniformly, then adding the fine powder and the composite additive into the mixed aggregates and stirring the mixture for 2 to 3 minutes, adding water into the mixture and stirring the mixture for 2 to 3 minutes when all the materials are mixed and stirred uniformly, and performing discharge, vibration molding, curing, drying and packing. The formula cost of the product is reduced by adopting combined action of the forsterite and the magnesium sand; and the construction performance and the use performance of the product are ensured at the same time of improving the strength of the product by adopting the composite additive, organic fiber, steel fiber andthe like with good performance.

Owner:WUGANG REFRACTORY CO LTD

Hot patching material for large face of converter

The invention relates to a hot patching material for a large face of a converter. The technical scheme is that: a uniform and loose aggregate is prepared by mixing and stirring 80 to 85 weight percent of magnesite or forsterite serving as a main raw material, 10 to 15 weight percent of lactose or maltose serving as a binder, 0 to 5 weight percent of graphite serving as a carburant, and 0 to 5 weight percent of silica powder, ferrosilicon powder, aluminum powder and the like serving as combustion improvers. The hot patching material is mainly applied to patching the large face part of the converter, and has the characteristics of short sintering time, no toxic gas emission, high adhesive force with a converter body, long service life and the like.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

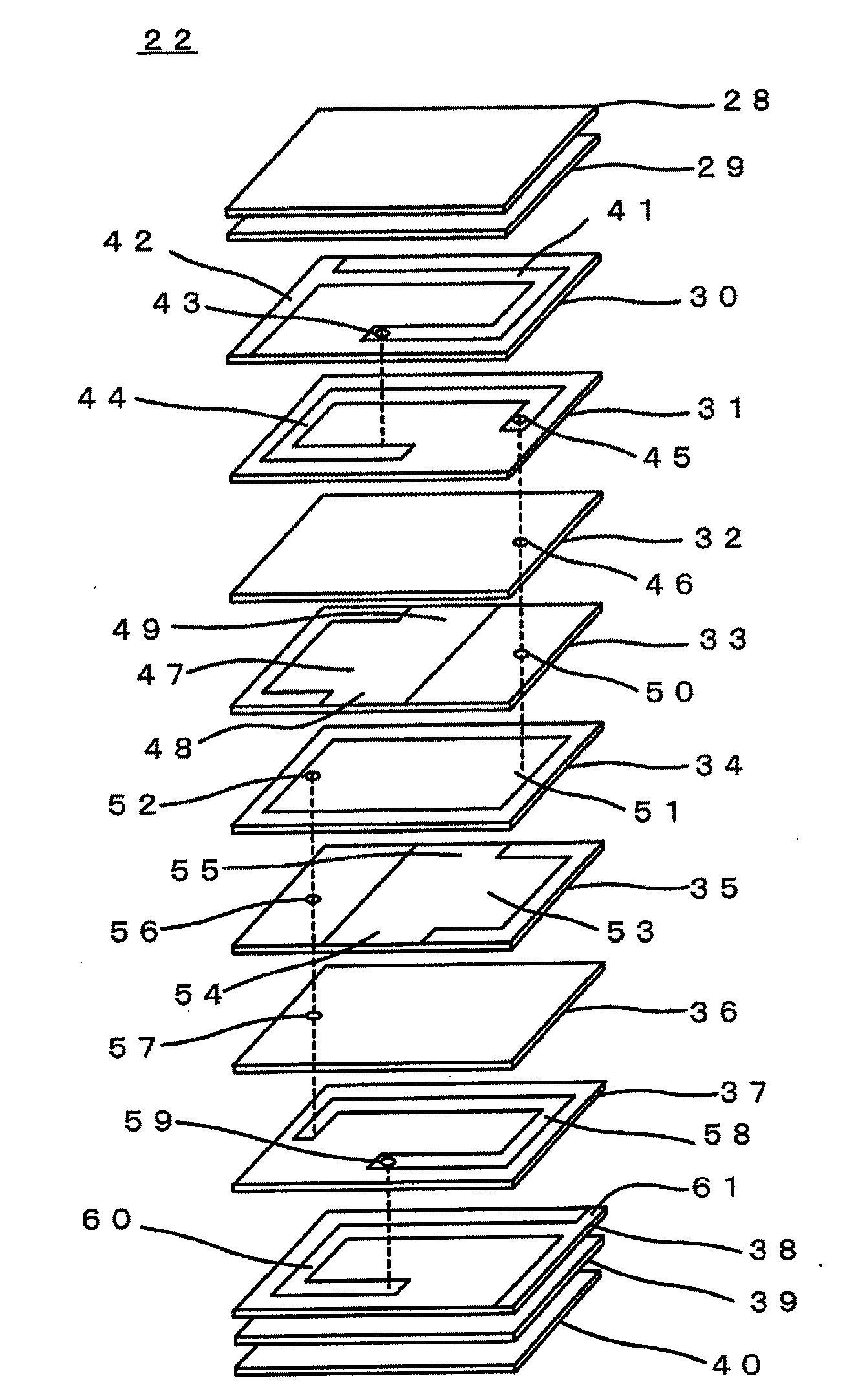

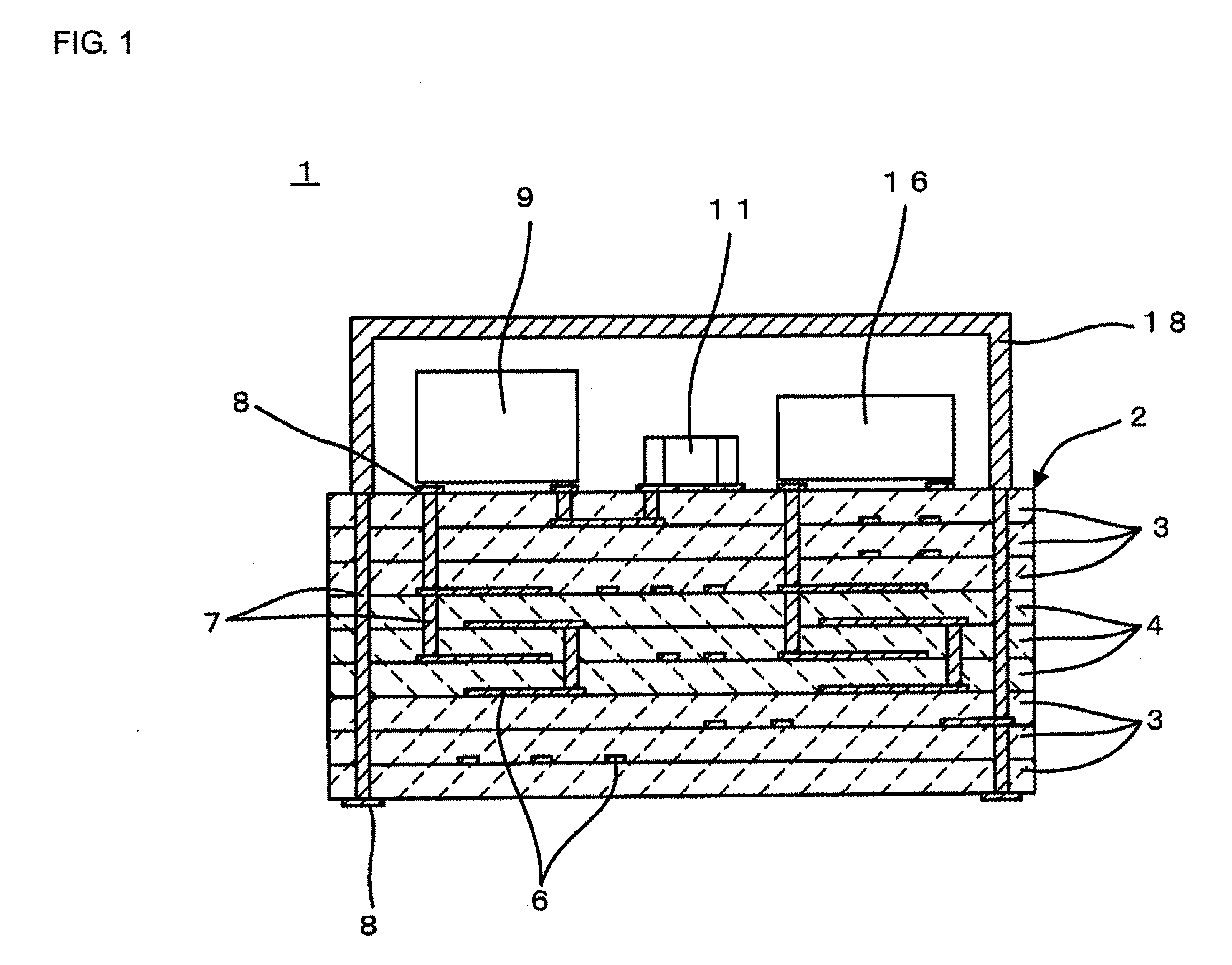

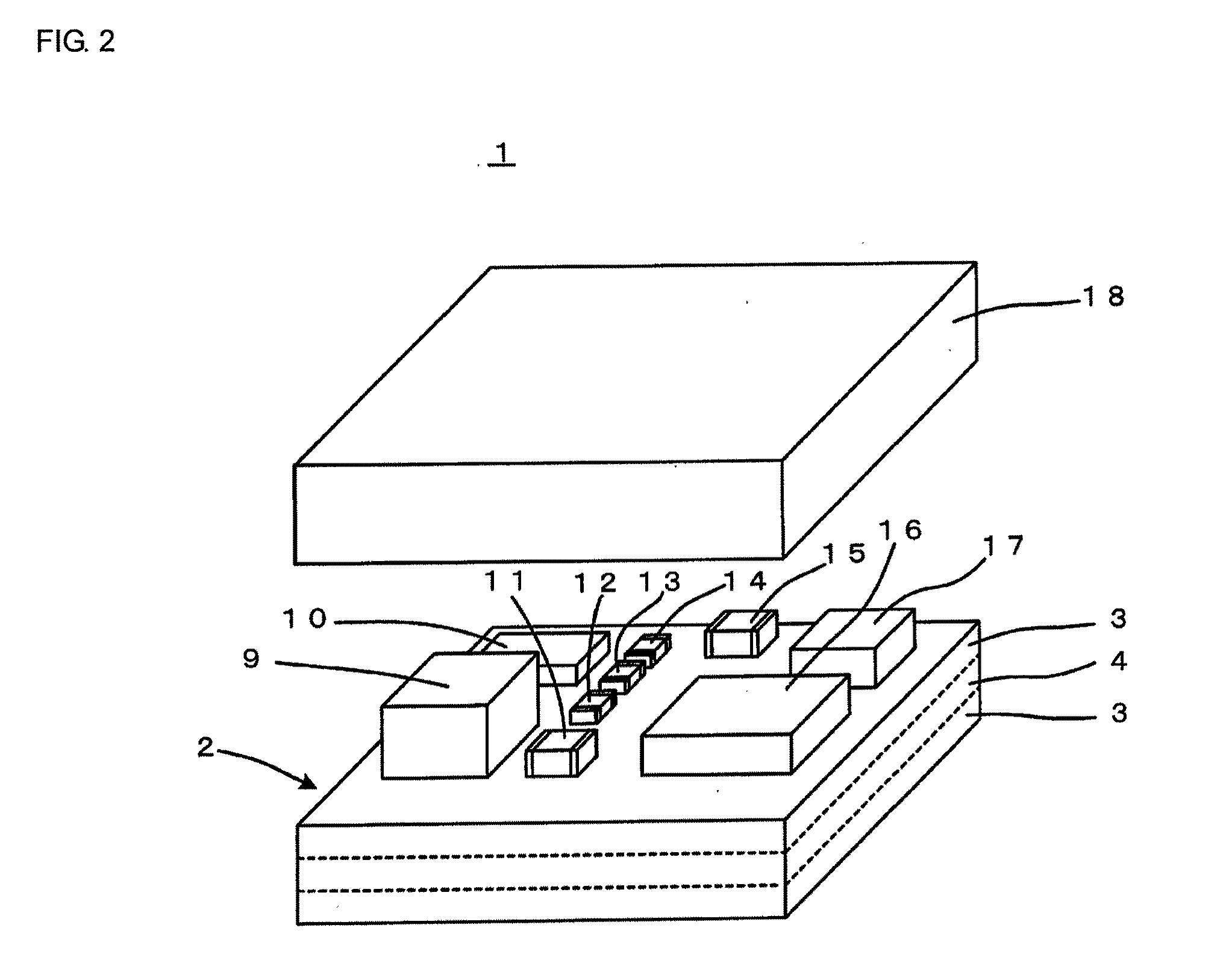

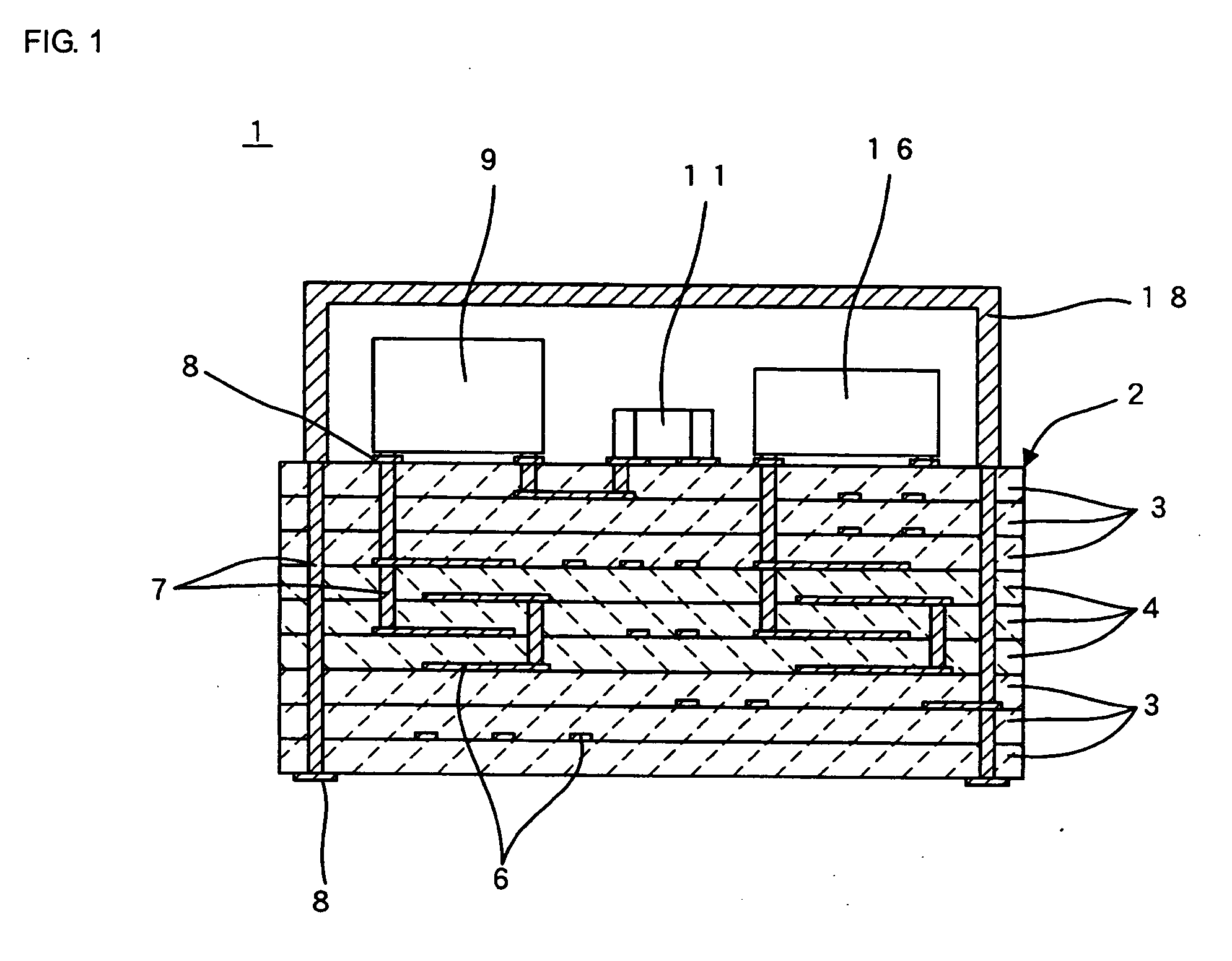

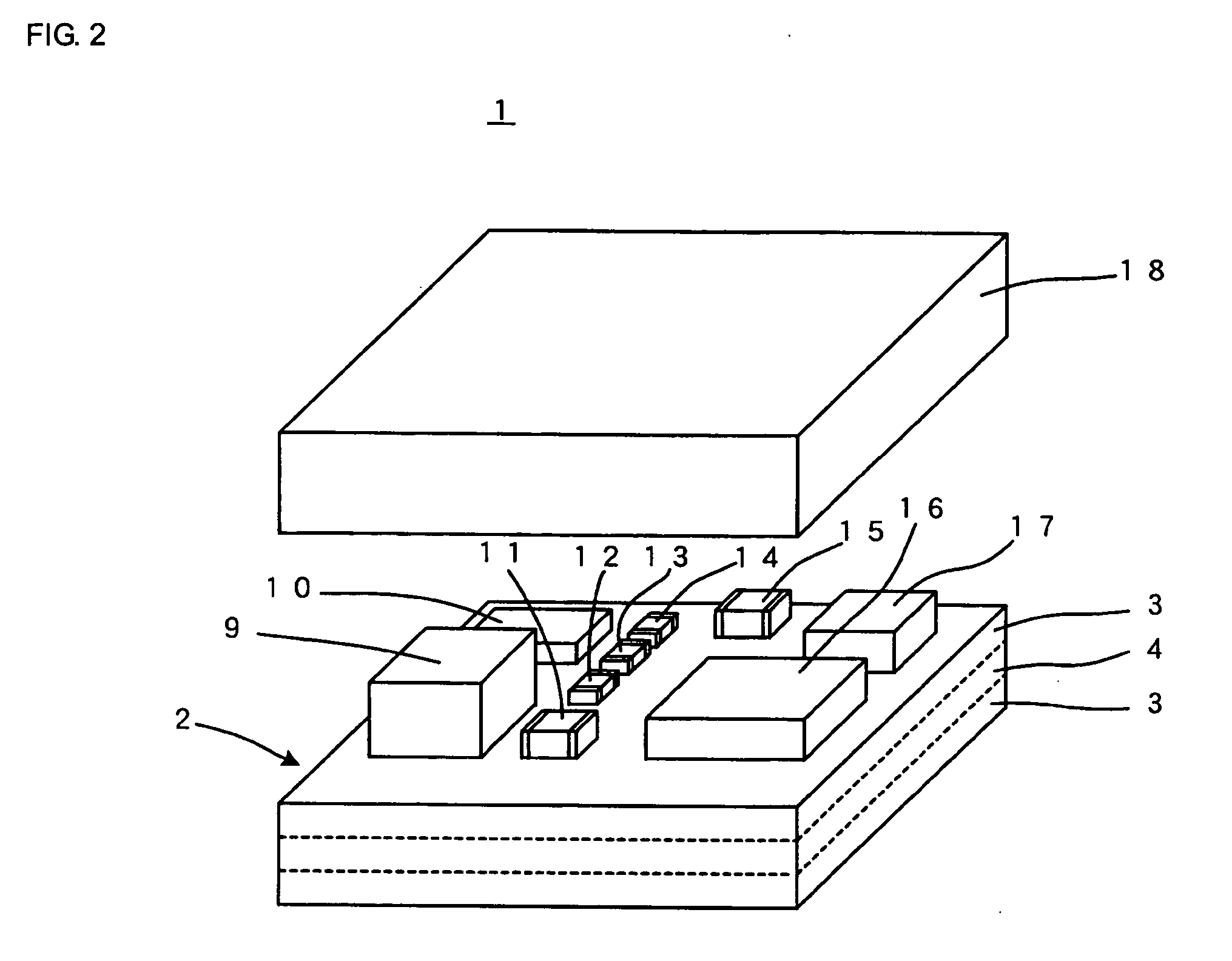

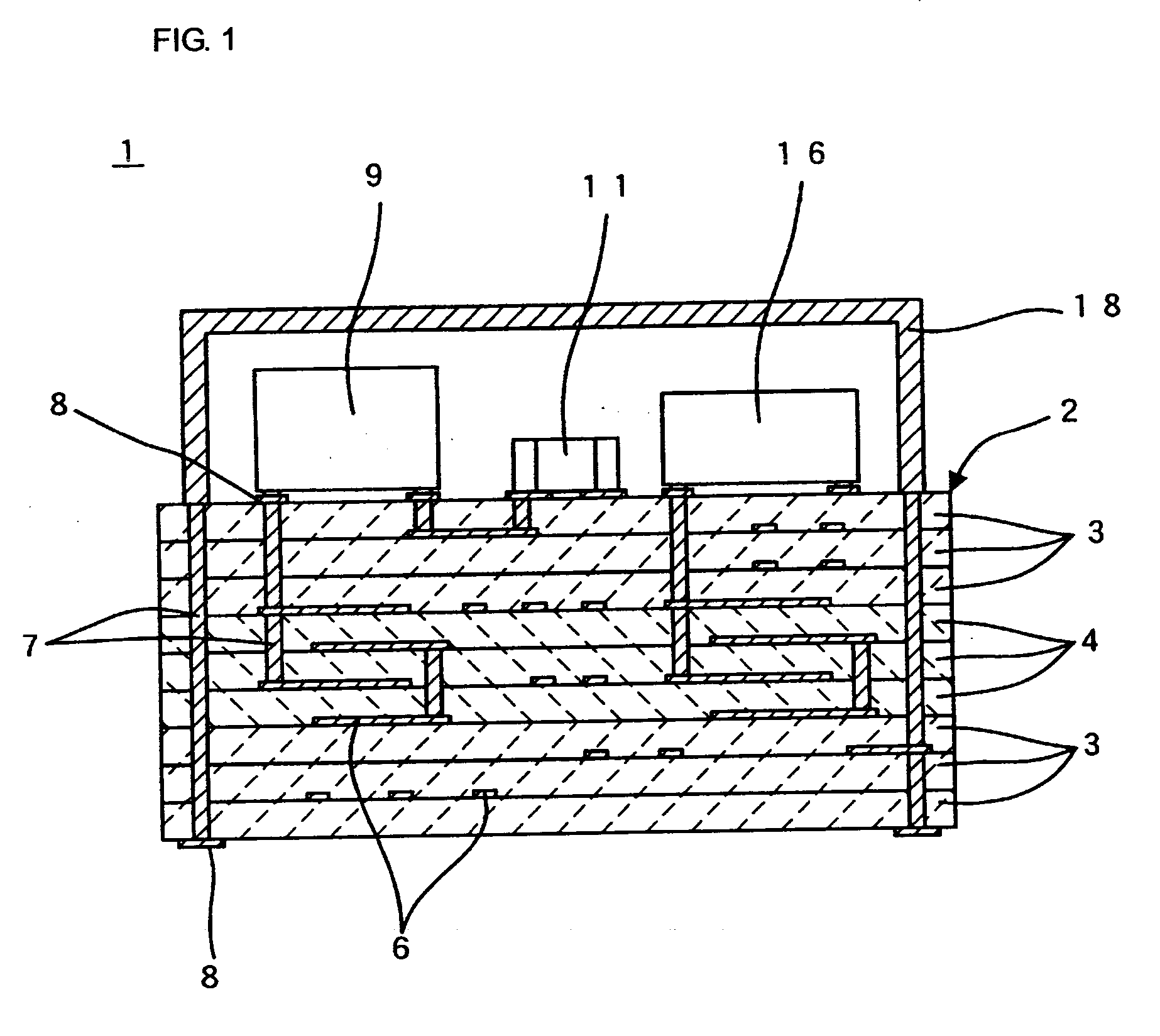

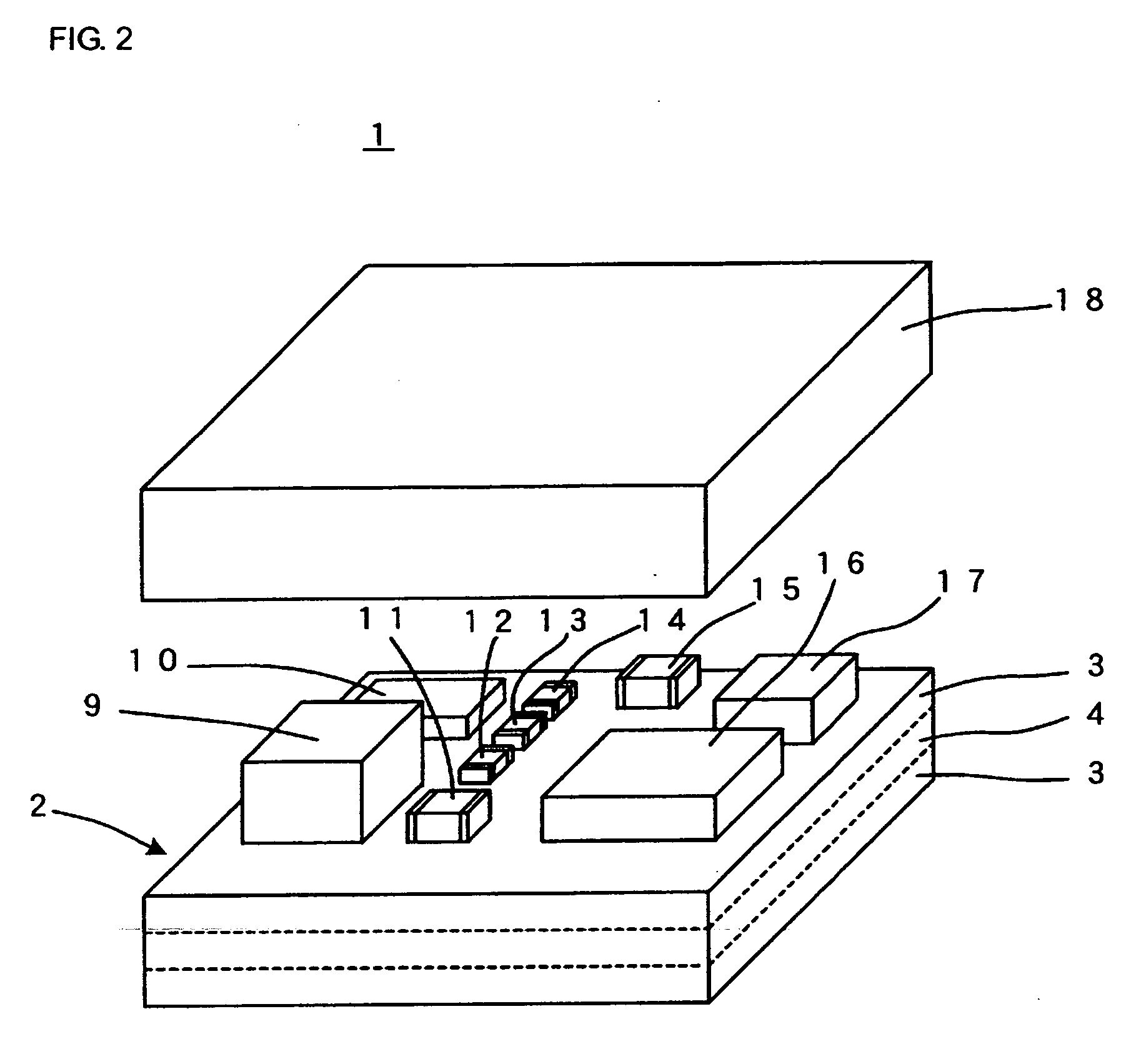

Insulating ceramic composition, insulating ceramic sintered body, and multilayer ceramic electronic component

InactiveUS20060293168A1High Qf valueLow dielectric constantFixed capacitor dielectricStacked capacitorsOlivineForsterite

An insulating ceramic composition forming insulating ceramic layers (3) stacked in a multilayer ceramic substrate (2) used in a monolithic ceramic electronic component, such as a multilayer ceramic module (1). The insulating ceramic composition contains a first ceramic powder mainly containing forsterite, a second ceramic powder mainly containing at least one compound selected from the group consisting of CaTiO3, SrTiO3, and TiO2, and a borosilicate glass powder. The borosilicate glass powder contains 3 to 15 percent by weight of lithium in terms of Li2O, 30 to 50 percent by weight of magnesium in terms of MgO, 15 to 30 percent by weight of boron in terms of B2O3, 10 to 35 percent by weight of silicon in terms of SiO2, 6 to 20 percent by weight of zinc in terms of ZnO, and 0 to 15 percent by weight of aluminum in terms of Al2O3. The insulating ceramic composition can be fired at a temperature of 1000° C. or less, and the resulting sintered compact has a low relative dielectric constant, a resonance frequency with a low temperature coefficient, and a high Q value.

Owner:MURATA MFG CO LTD

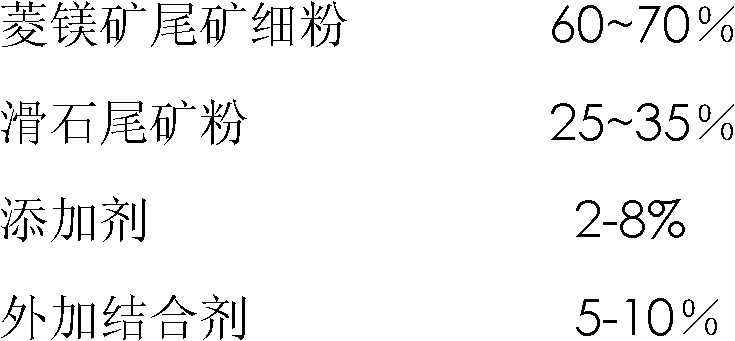

Method for synthesizing high-purity forsterite with magnesite tailings and talc tailings

The invention discloses a method for synthesizing high-purity forsterite by using magnesite tailings and talc tailings, which effectively utilizes tailings resources and can be used to produce high-density refractory materials used under high-temperature conditions above 1600°C. The present invention uses magnesite tailings and talc tailings as the main raw materials, adds additives and binders, and manufactures high-purity forsterite refractory raw materials through batching, mixing, molding, drying, high-temperature synthesis and crushing. The weight percent content of each component is as follows: 60-70% of fine magnesite tailings powder; 25-35% of talc tailings powder; 2-8% of additives; 5-10% of external binder. Using magnesite tailings and talc tailings to synthesize high-purity forsterite refractory raw materials, the use temperature is high (above 1600 ℃), the bulk density is high (greater than 2.55g / cm3), and the combined content of olivine and periclase is greater than 97%. The utility model has wide application field, comprehensive utilization of waste, and low production cost.

Owner:UNIV OF SCI & TECH LIAONING +1

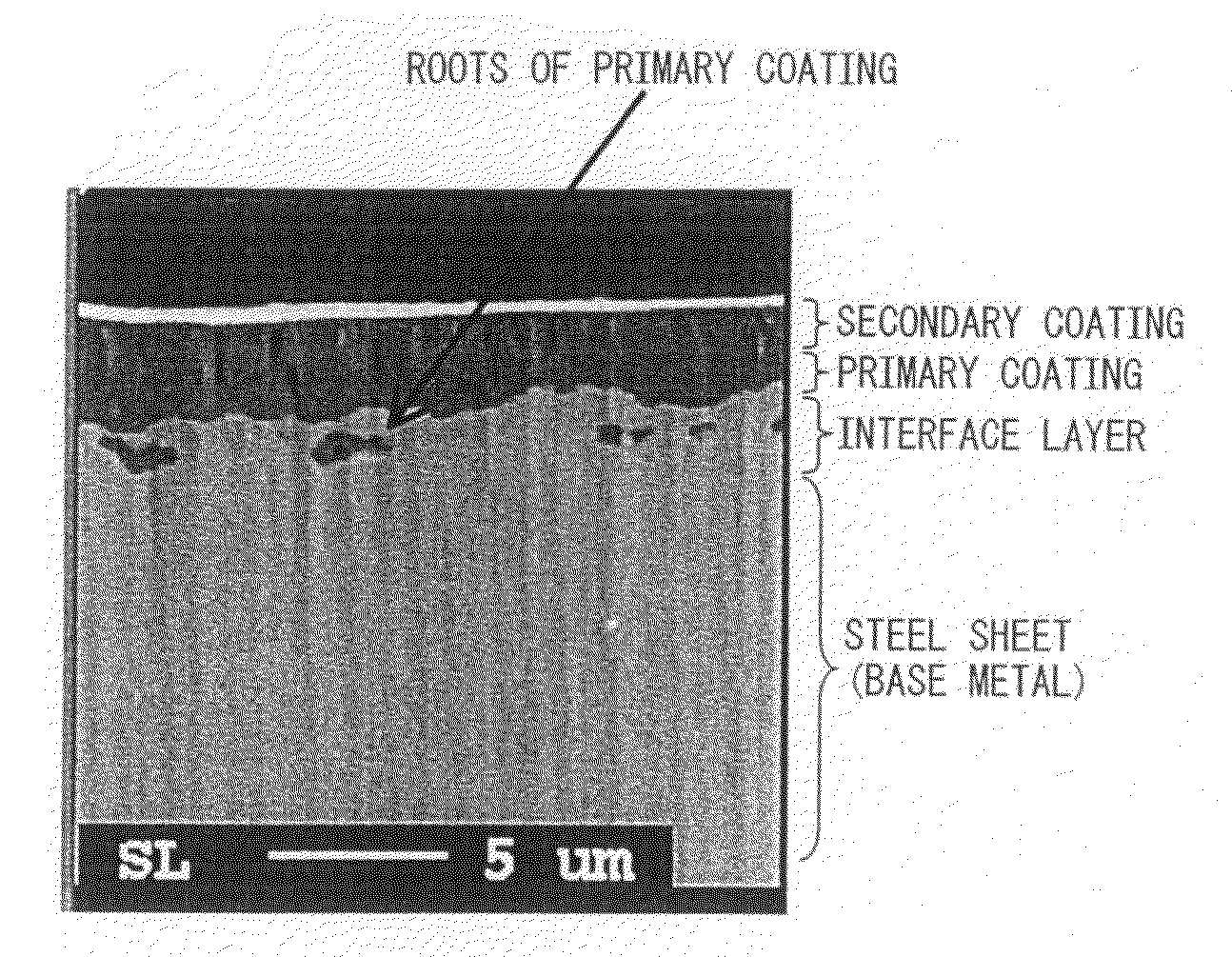

Grain-oriented electrical steel sheet excellent in coating adhesion and method of producing the same

ActiveUS20100055481A1Improve coating adhesionLow coating exfoliation area rateInorganic material magnetismSolid state diffusion coatingElectrical steelTransformer

Grain-oriented electrical steel sheet excellent in coating adhesion is provided. The steel sheet contains Si: 2 to 7% mass % and has a primary coating composed mainly of forsterite on its surface. A compound (A) containing one or more elements selected from among Ca, Sr and Ba, at least one rare earth metal, and sulfur is incorporated in the primary coating so as to reside in the interface layer between the primary coating and the steel sheet. As a result, occurrence of primary coating exfoliation at regions that are strongly worked during manufacture of a wound core transformer or the like is prevented.

Owner:NIPPON STEEL CORP

Light-colored alcohol-base paint

The light color alcohol-base paint is compounded with zirconite powder 15-25 wt%, brown alumina powder 20-35 wt%, mullite powder 5-15 wt%, flaky graphite powder10-25 wt%, forsterite powder 5-10 wt%, binder 2-4 wt%, suspending agent 15-25 wt%, assistant 0.01- 0.2 wt% and solvent 15-30 wt%. The light color alcohol-base paint has less pollution, low cost, capacity of preventing crack in sand model and capacity of avoiding molten iron permeation and sand fusion to raise casting quality.

Owner:沈阳金安铸造材料厂

Grain oriented electrical steel sheet and method for manufacturing the same

ActiveCN103069032AExcellent low iron loss characteristicsInorganic material magnetismFurnace typesTransformerOlivine

The present invention can provide a directional magnetic steel plate capable of further reducing iron loss of a material with a groove formed thereon for dividing a magnetic domain and capable of obtaining excellent low-iron-loss characteristics when incorporated into an actual transformer. This directional magnetic steel plate is obtained under the following conditions: the thickness of a forsterite coating at the bottom of a groove formed on the surface of the steel plate is 0.3 [mu]m or more; the groove frequency which is the abundance ratio of grooves having, immediately thereunder, crystal grains with an orientation 10 DEG or more different from the Goss orientation and a grain size of 5 [mu]m or more is 20% or less; the total tension to be applied to the steel plate by the forsterite coating and a tension coating is 10.0 MPa or more in the rolling direction and 5.0 MPa or more in the direction perpendicular to the rolling direction; and these total tensions satisfy the relationship of formula, 1.0 = A / B = 5.0 where A is the total tension applied in the rolling direction by the forsterite coating and the tension coating, and B is the total tension applied in the direction perpendicular to the rolling direction by the forsterite coating and the tension coating.

Owner:JFE STEEL CORP

MgO-SiC-C refractory material synthesized by forsterite-C and method

The invention relates to MgO-SiC-C refractory material synthesized by forsterite-C and a method. The technical proposal to be adopted is as follows: firstly, forsterite mineral powder and industrial carbon powder are blended according to molar ratio of 1: (1-5); and then the mixture is added with 4 to 10 wt% of bonding agent, stirred or mulled for 10 to 30 minutes, pressed to be formed and dried; and finally under the Ar gas condition, the mixture is sintered in the sintering temperature of 1530 to 1800 DEG C with heat preservation for 2 to 8 hours to obtain MgO-SiC-C refractory material synthesized by forsterite-C. The invention is characterized by comparatively simple processing technique, low producing cost, high producing efficiency, wide raw material source and being capable of reducing energy consumption of high temperature synthesis reaction. The prepared MgO-SiC-C refractory material has the advantages of excellent high temperature performance, anti-corrosion and good durability.

Owner:WUHAN UNIV OF SCI & TECH

Method of producing forsterite refractory

A method for producing forsterite refractory is characterized by comprising: a. mixing the raw magnesite flotation tailing or magnesite shaft kiln dust removing powder, light burning magnesite powder and cabosil, wherein the weight ratio Mgo / SiO[2] is 1.342-1.476; b. according to the weight ratio, uniformly mixing 80-100 portions of mixed materials obtained in step a and 0-20 portions of burnable lost property, additionally with 30-70 portions of water, producing briquette; drying the briquette obtained in step b at 15-50 DEG C for 3-24 hours, drying at 110 DEG C for 12 hours, burning at the oxidative atmosphere; keeping warm at 500-650 DEG C for 2-3 hours, 1500 DEG C for 3-5 hours. The invention uses the industrial waste to produce the forsterite refractory, greatly reduces the production cost of the forsterite refractory, decreases the dust pollution and improves the ecologic environment.

Owner:海城华宇耐火材料有限公司

Environmentally-friendly tundish dry material

InactiveCN102120704AExtended service lifeDoes not affect high temperature performanceSteelmakingPhosphate

The invention provides an environmentally-friendly tundish dry material, which can solve the problems that a large number of harmful irritant gases generated by solid phenolic resin pollute the environment and are unfavorable for clean steelmaking and environmental friendliness and the like in the prior art. The tundish dry material comprises the following components in percentage by weight: 87 to 96 percent of at least one of magnesite and forsterite, 1 to 5 percent of rosin, 1 to 5 percent of hydrosilicate, 0 to 2 percent of alumina fine powder, 0 to 1 percent of boron glass, 0 to 1 percentof silica micropowder and 0 to 0.5 percent of phosphate. The rosin and the hydrosilicate serve as compound binders, and advantages of the two binders are combined, so that the baking demolding strength of the dry material can be equivalent to that of a resin-bonded dry material and a large number of eutectics which influence the high temperature property of the dry material cannot be introduced simultaneously; therefore, the dry material has the characteristics of environmental friendliness and long service life.

Owner:山东耐材集团中齐耐火有限公司

Forsterite bakie coating material and method for making same

InactiveCN101117464AImprove high temperature resistanceLow priceFireproof paintsMelt-holding vesselsFiberOlivine

The present invention relates to a refractory coating for forsterite tundish and the preparation method thereof. The technical scheme adopted is that: 20-50 wt percent of forsterite sand, 25-55 wt percent of forsterite clinker, 15-30 wt percent of magnesia powder, 5-15 wt percent of magnesia-calcium sand powder are mixed with 1-5 wt percent of clay, which are coupled with 0-0.5 wt percent of organic fiber of the above ingredients, 0.5-2.0 wt percent of sodium hexametaphosphate and 0.3-1.0 wt percent of sodium tripolyphosphate, and then the present invention is prepared through the mixing of a mixer; when the present invention is in use, the present invention is added with water and stirred. The present invention takes forsterite as base material, and the products prepared is characterized in good high-temperature resistance, low cost, no pollution to molten steel, good durability, no adverse effect to human body and convenient use.

Owner:WUHAN UNIV OF SCI & TECH

Forsterite light brick and preparation method thereof

InactiveCN101713235AImprove insulation performanceImprove mechanical propertiesCeramic shaping apparatusHeat proofingSocial benefitsBrick

The invention relates to a forsterite light brick and a preparation method thereof. The method adopts the following technical scheme: mixing 60 to 95 weight percent of forsterite raw material and 5 to 40 weight percent of magnesium oxide; adding 25 to 45 weight percent of water, 0.05 to 0.5 weight percent of bonding agent, 0.1 to 0.5 weight percent of water reducer and 0 to 0.5 weight percent of mineralizer and uniformly mixing the mixture; adding foam made of 0.5 to 2 weight percent of foaming agent into the mixture; casting the mixture after uniformly stirring; naturally drying the mixture; baking the mixture at low temperature; and sintering the mixture at the temperature of between 1,300 and 1,550 DEG C, and preserving the heat for 2.5 to 12 hours. The forsterite light brick prepared by the invention has excellent compression strength, lower volume density and heat conductivity, and can be used in production of furnace construction insulating materials in steel, ceramic and other industries after being subjected to heat treatment at the temperature of between 1,300 and 1,550 DEG C; and the used forsterite raw material is forsterite tailings with few utilization value at present, which not only reduces production cost, but also can realize good economic and social benefit.

Owner:WUHAN UNIV OF SCI & TECH

Gunning mix for converter

InactiveCN101602612AGood adhesionImprove peeling resistanceManufacturing convertersGranularityMolten steel

The invention discloses a gunning mix for a converter, which comprises the following components in percentage by weight: 40 to 60 percent of forsterite of which the particle size is between 0.1 and 5 millimeters, 10 to 30 percent of dolomite of which the particle size is between 0.1 and 3 millimeters, 10 to 20 percent of sintered mid-range magnesia of which the particle size is between 0.01 and 0.088 millimeter, 0.5 to 5 percent of burning and coagulation accelerator, and 1 to 5 percent of bonding agent. When applied to the converter, the forsterite gunning mix prepared by adopting the formulation has the advantages of high adhesive rate, good spalling resistance, quick sintering, erosion resistance, scouring resistance and small high temperature expansion, and simultaneously is insusceptible to gun blockage during the construction. Besides, gunning mix has abundant available mineral products with low price so as to play a role of saving important energy resources, has no influence on the quality of molten steel in use, and is free from causing pollution to the environment.

Owner:陈红良

Grain-oriented electrical steel sheet and method for manufacturing same

ActiveCN104284994AReduce iron lossInorganic material magnetismThin material handlingBeta angleElectrical steel

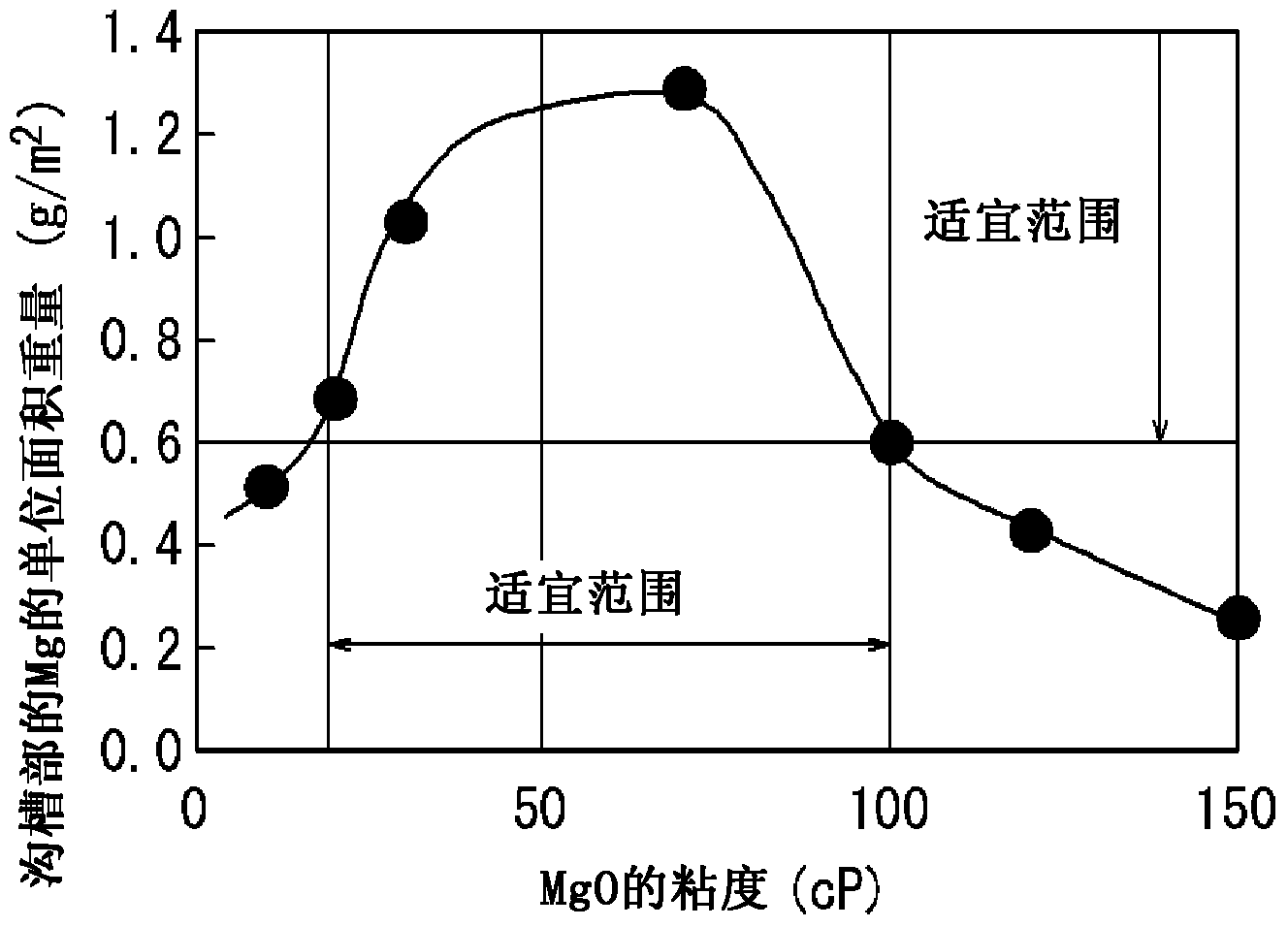

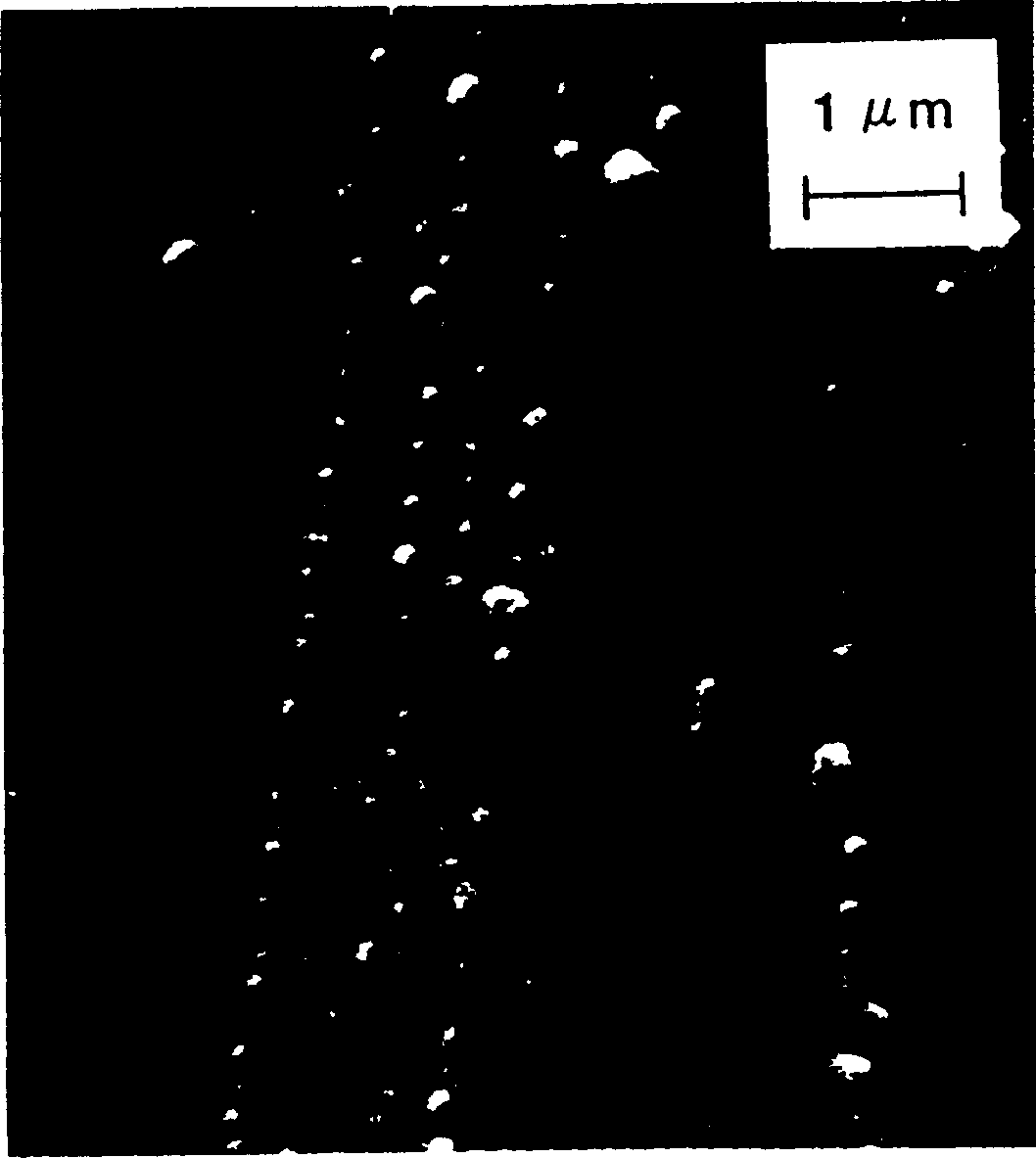

Provided is a grain-oriented electrical steel sheet having a linear groove forming an angle of 45° or less with the direction perpendicular to the direction of rolling, wherein a grain-oriented electrical steel sheet having low iron loss characteristics, on which a magnetic domain subdivision treatment by chemical means is used, is provided by setting the incidence of microparticles having a length of 1 mm or less in the rolling direction in a bottom part of the groove to 10% or less (also including cases in which microparticles are not present), providing a forsterite coating in which the Mg weight per side of the steel sheet is at least 0.6 g / m2 in the groove, and setting the angle (beta angle) between a rolling surface and the <100> axis of a secondary recrystallized grain oriented in the rolling direction of the steel sheet to an average value of 3° or less.

Owner:JFE STEEL CORP

Unidirectional silicon steel sheet excellent in adhesion of insulating coating film imparting tensile force and its mfg. method

The present invention provides a grain-oriented silicon steel sheet excellent in adhesiveness to tension-creating insulating coating films formed on the grain-oriented silicon steel sheet produced by removing inorganic mineral films composed of forsterite and so on with pickling or the like or by deliberately preventing the formation thereof, characterized by: having, at the interface between each of the tension-creating insulating coating films and the steel sheet, an external oxidation type membranous oxide film of 2 to 500 nm in average thickness mainly composed of amorphous silica and / or a mixed oxide film consisting of an external oxidation type membranous oxide film of 2 to 500 nm in average thickness mainly composed of amorphous silica and particulate oxides mainly composed of amorphous silica: and satisfying any one or more of the specified requirements.

Owner:NIPPON STEEL CORP

High-temp alkali-resistant material and use therreof in ceramic filler

A high-temp. alkali-resistant material mainly contains MgO, SiO2 and Al2O3. Its primary crystal phase is forsterite and spinel. Its features are high resistance to alkali corrosion at high temp and use for preparing ceramic filler of heat-accumulating thermal oxidizer to treat organic waste gas in wood industry.

Owner:兰州瑞玛化机有限公司 +1

Forsterite-carbon refractory brick and preparation method thereof

The present invention relates to forsterite-carbon refractory brick and its making process. The technological scheme of the present invention is that the forsterite-carbon refractory brick making process includes mixing forsterite clinker in 50-90 wt%, magnesia in 5-40 wt% and graphite in 5-20 wt%; adding antioxidant in 0-5 wt% and binding agent in 3-7 wt% through stirring or rolling for 15-30 min; pressing to form; and heat treatment at 150-240 deg.c for 12-24 hr. Where, the antioxidant is one or mixture of metal aluminum powder, metal silicon powder and metal magnesium powder; and the binding agent is phenolic resin or mixture of tar and asphalt. The forsterite-carbon refractory brick of the present invention has low cost, environment friendship, high stability, high heat resistance, excellent corrosion resistance and high slag permeation resistance, and can meet the requirement for use in steel making apparatus.

Owner:WUHAN UNIV OF SCI & TECH

Iron ore pellet and its preparation method

The invention discloses an iron ore pellet preparing method, Which comprises the following steps: putting 2-4wt% forsterite and 0. 2-0. 8wt% agglomerant in iron ore; mixing up water (the water content of mixture: 6-11wt%); making ball and drying; preheating at the temperature of 900-1000 deg. c for 15-25min; roasting at the temperature of 1260-1320deg. c for 20-40min; mixing up 20-40% jevigating, 5-10% polyacrylamide, 0-5% polypropylene, 0-5% sodium humate, 20-40% twaterproof putty powder, 3-5% caoline and 5-10% copperas in mass fraction to obtain agglomerant. The invention can improve the strength of green-ball and the heat endurance.

Owner:WUHAN UNIV OF SCI & TECH

Cordierite porous fireproofing material and preparation method thereof

The invention relates to a cordierite porous fireproofing material and a preparation method thereof, belonging to the technical field of fireproofing materials. The invention is characterized in that coal ash and natural raw mineral material magneiste or tailing thereof are main raw materials, and the cordierite porous fireproofing material is prepared by burdening, mixing, forming, drying, sintering and other technical processes. In the raw material proportion of the invention, the addictive amount of the coal ash is 2.0%-99.0% by weight and the addictive amount of the magneiste is 1.0-96.0% by weight; and in addition, the addictive amount of pore-forming agent is 0.0%-20.0% by weight and the addictive amount of binding agent is 0.1%-10.0% by weight. A main phase of the porous fireproofing material prepared at high temperature is cordierite and forsterite, which has the characteristics of high porosity, small volume density, high strength, good heat insulation, low cost and the like. The invention provides a brand new technical way for high-efficiency value-added utility of solid waste materials and gioberite such as the coal ash.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

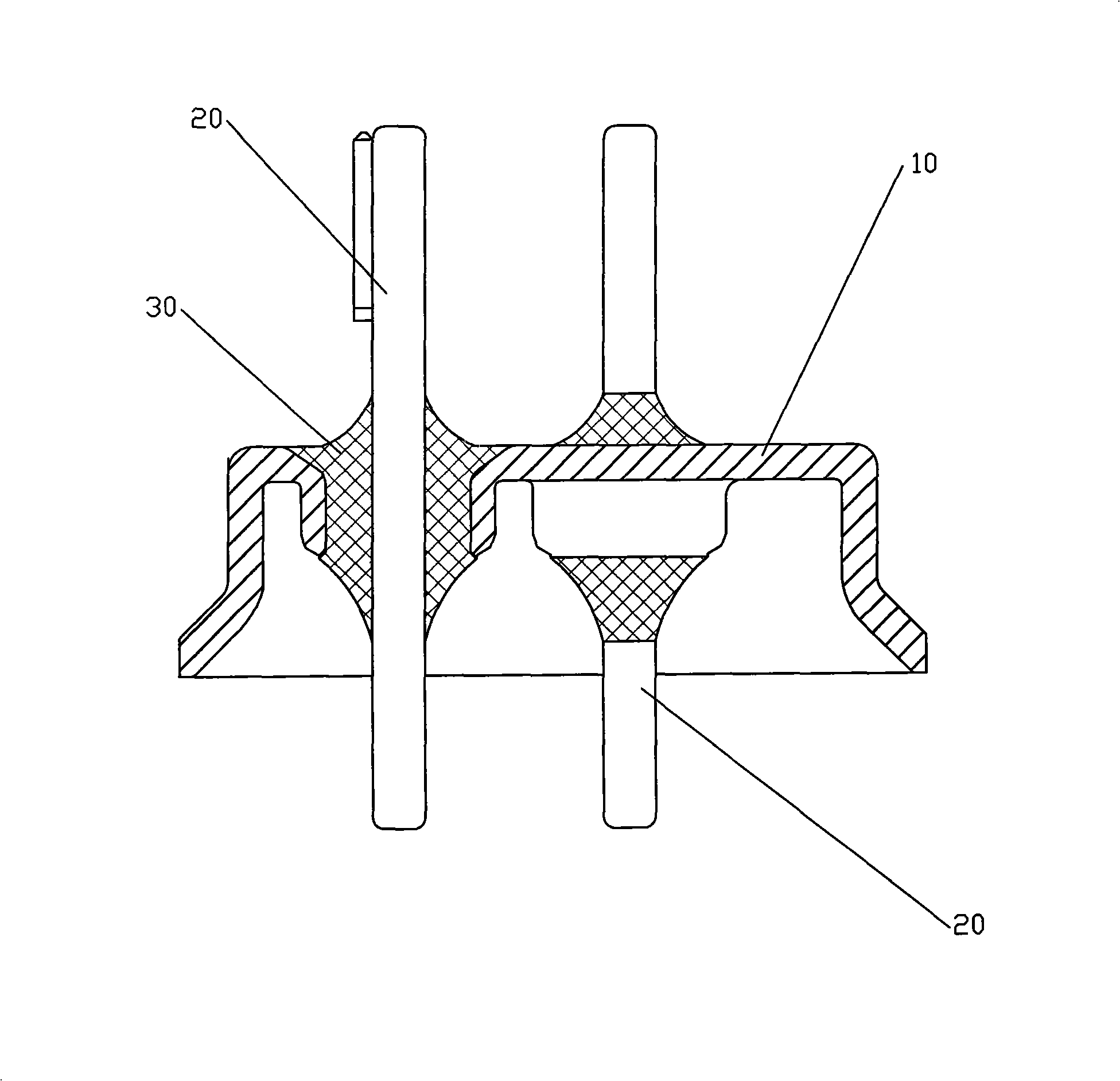

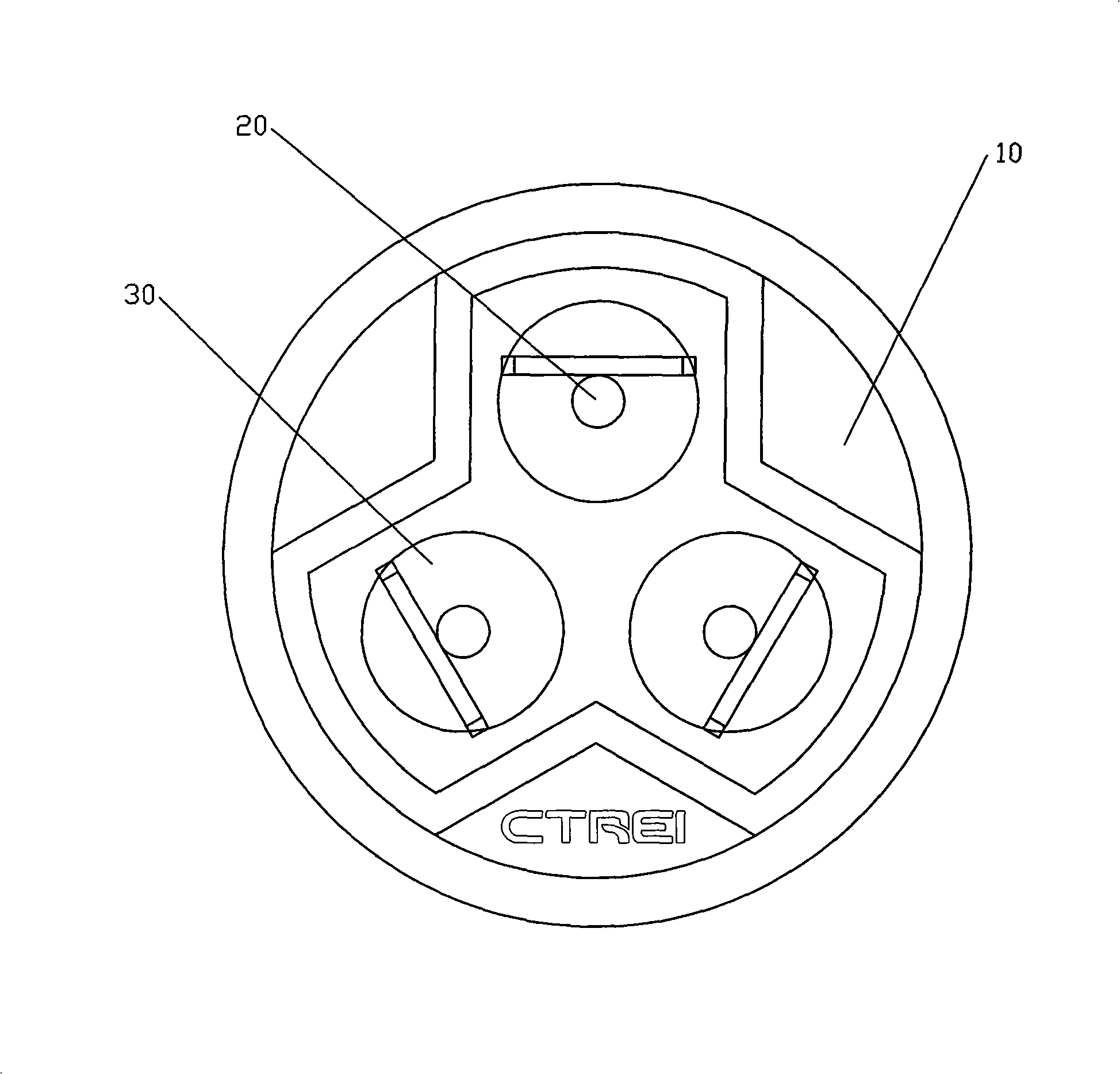

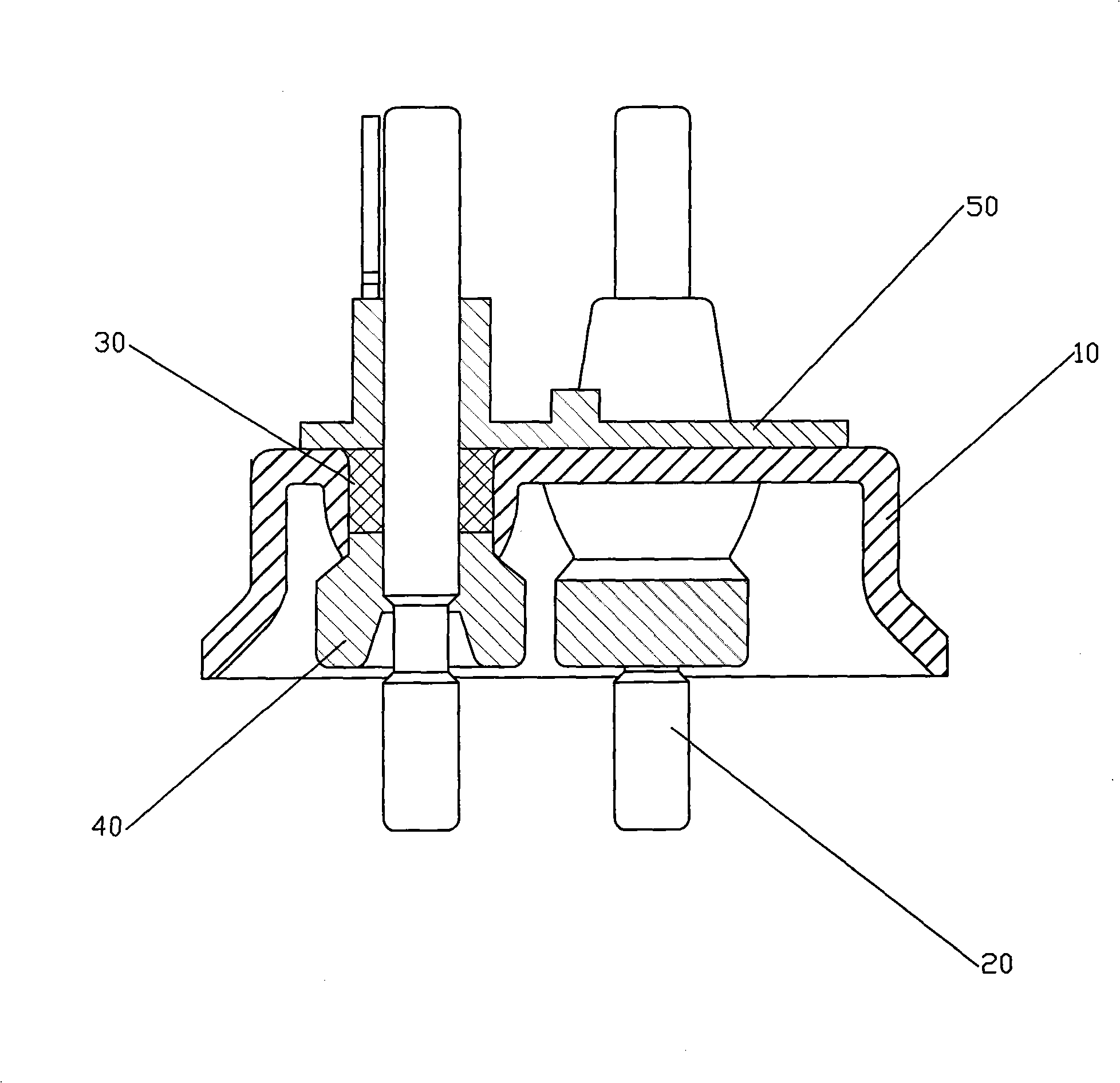

Connector post of refrigeration compressor

ActiveCN101404360AEasy to sinterPorcelain forming temperature rangeElectrically conductive connectionsCeramicsRefrigeration compressorSilicon oxide

The invention relates to a terminal part of a compressor, in particular to a binding post of a cold compressor of highly reliable ceramic insulation medium connection. The binding post comprises an end cover which is welded with a shell of the compressor, and a conductive pillar that is sealed and connected with the end cover by glass; wherein, the glass is used for playing the role of insulation and sealing, the conductive pillar is provided with an insulator separating the surface of the glass from the air, and the insulator is made of the following materials: 92-96% of aluminium oxide, 2-3% of silicon oxide, 1-3% of calcium oxide, 0.5-1.0% of bismuth oxide and 0.5-1.0% of antimony oxide. The binding post has the advantages that specially prepared aluminum oxide ceramics is adopted to replace steatite ceramics (or forsterite) to be taken as the insulator, so that the creep age distance is prolonged, and the phenomenon of overflash is avoided in the low vacuum environment, thereby effectively avoiding the serious result of compressor explosion. At the same time, the expansion of microcrack is prevented, and the probability of air leakage is effectively reduced, so that good connecting effect is formed.

Owner:CHAOZHOU THREE CIRCLE GRP

Insulating ceramic composition, insulating ceramic sintered body, and mulitlayer ceramic electronic component

InactiveUS7351674B2Low dielectric constantHigh Qf valueFixed capacitor dielectricStacked capacitorsCeramic sinteringLithium

An insulating ceramic composition forming insulating ceramic layers (3) stacked in a multilayer ceramic substrate (2) used in a monolithic ceramic electronic component, such as a multilayer ceramic module (1). The insulating ceramic composition contains a first ceramic powder mainly containing forsterite, a second ceramic powder mainly containing at least one compound selected from the group consisting of CaTiO3, SrTiO3, and TiO2, and a borosilicate glass powder. The borosilicate glass powder contains 3 to 15 percent by weight of lithium in terms of Li2O, 30 to 50 percent by weight of magnesium in terms of MgO, 15 to 30 percent by weight of boron in terms of B2O3, 10 to 35 percent by weight of silicon in terms of SiO2, 6 to 20 percent by weight of zinc in terms of ZnO, and 0 to 15 percent by weight of aluminum in terms of Al2O3. The insulating ceramic composition can be fired at a temperature of 1000° C. or less, and the resulting sintered compact has a low relative dielectric constant, a resonance frequency with a low temperature coefficient, and a high Q value.

Owner:MURATA MFG CO LTD

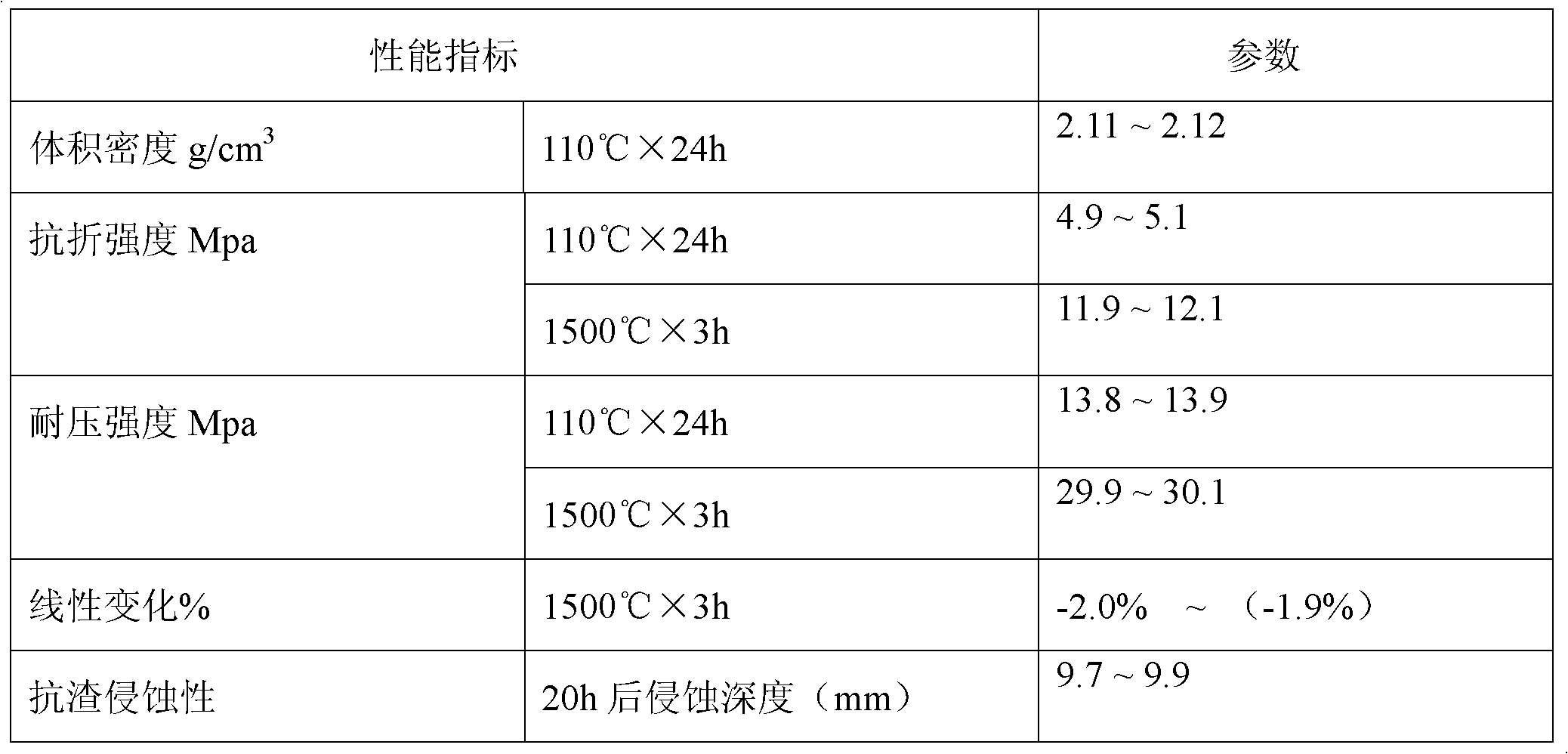

Work layer coating of steel casting tundish

The invention discloses a work layer coating of a steel casting tundish, which comprises the following raw materials in weight parts by proportion: 64 parts of forsterite, 31.5 parts of sintered magnesite, 2.5 parts of silicon micro-powder, 1 part of paper fiber, 0.5 part of sodium tripolyphosphate, 0.3 part of canary dextrin, 0.2 part of white mud, 0.01 part of anti-explosion fiber, 0.0013 part of sodium dodecyl sulfate and 0.001 part of aluminum powder. The work layer coating of the steel casting tundish, obtained in the invention, has enhanced folding and compressive strength and good high-temperature usability, and when applied to the tundish, the invention can achieve the effects of good smearing property, no phenomena of back-falling, flowing, bubbling, no phenomena of bursting and peeling during roasting, good corrosion resistance to alkali covering agent, strong molten steel flushing resistance, no deterioration of wrapping wall, and no pollution to the molten steel, thereby effectively meeting the working requirements on the rtundish and prolonging the service life.

Owner:德清凯瑞高温材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com