Unidirectional silicon steel sheet excellent in adhesion of insulating coating film imparting tensile force and its mfg. method

An insulating skin, single-orientation technology, applied in the direction of manufacturing tools, magnetic materials, magnetic objects, etc., can solve the problems of insufficient reduction of iron loss and difficulty in film adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

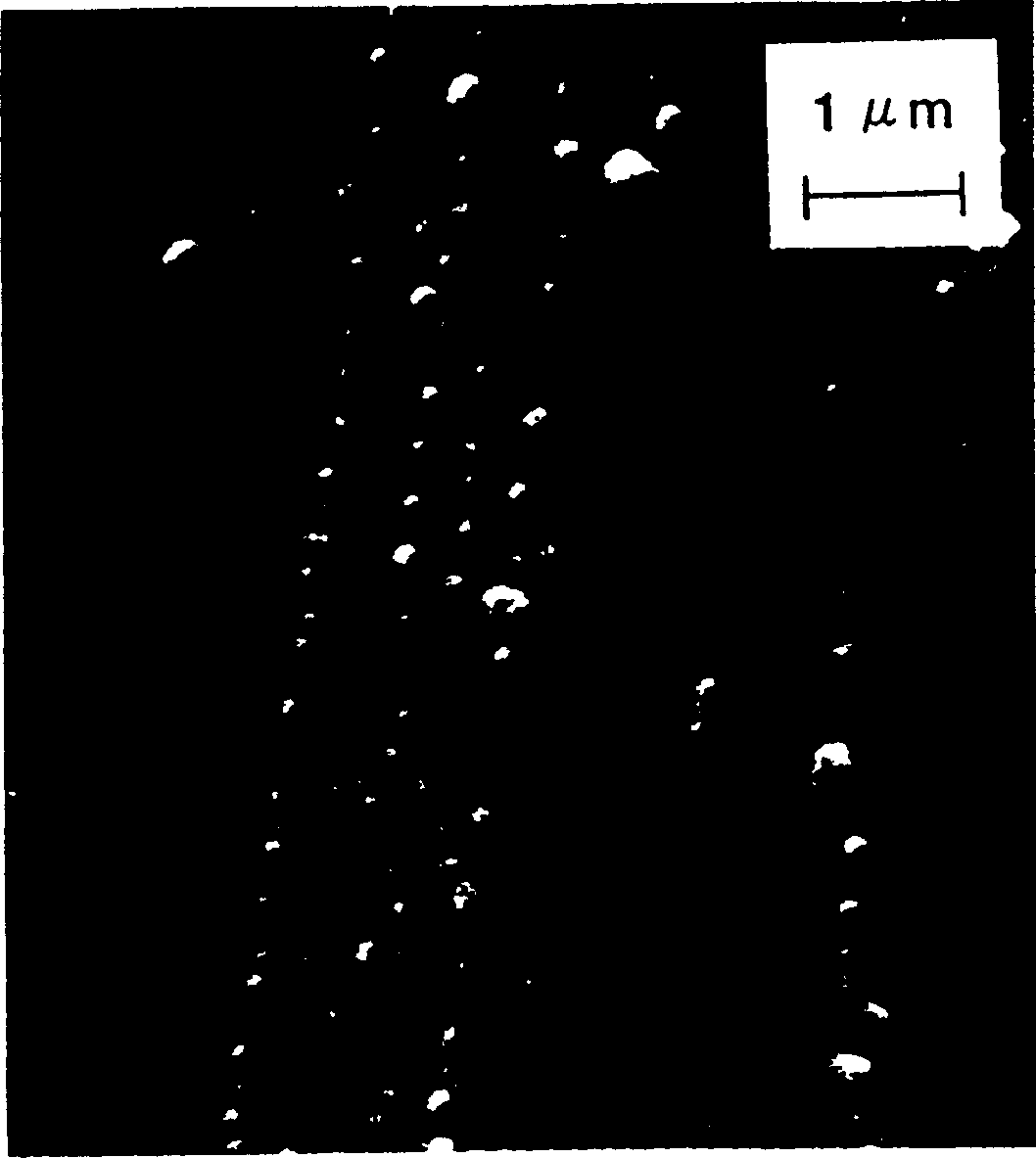

Image

Examples

Embodiment 1

[0141] Decarburization annealing is carried out on the cold-rolled sheet used for the manufacture of unioriented silicon steel sheet with a thickness of 0.225mm and a Si content of 3.30%, and then it is pickled in a mixed solution of ammonium fluoride and sulfuric acid to dissolve and remove the surface oxide layer. Next, aluminum oxide powder is coated by electrostatic coating method, and finished annealing is carried out in a dry hydrogen atmosphere at a temperature of 1200°C for 20 hours. There were no inorganic minerals on the surface of the double-recrystallized single-oriented silicon steel sheet thus produced, and had specular luster. With respect to this steel sheet, a sample (Example) in which the surface of the steel sheet was wiped with a brush with alumina abrasive grains and a sample in which the above-mentioned wiping was not performed (Comparative Example) were prepared. Then, heat treatment is performed at a temperature of 900°C in an atmosphere of 50% nitrogen...

Embodiment 2

[0146] Decarburization annealing is carried out on the cold-rolled sheet with a thickness of 0.225mm and a Si content of 3.35% for the manufacture of single-oriented silicon steel sheets, and the surface is coated with an annealing separator mainly composed of magnesium oxide and bismuth chloride. paste and dry. Next, finish annealing for 20 hours at a temperature of 1200° C. in a dry hydrogen atmosphere to obtain a unidirectional silicon steel sheet that has undergone secondary recrystallization substantially free of inorganic minerals on the surface. Subsequently, a sample (Example) which was acid-washed with 2% nitric acid for 5 seconds at room temperature to form minute irregularities on the surface and a sample which was not pickled (Comparative Example) were prepared. Then, the steel sheet was heat-treated in an atmosphere of 25% nitrogen, 75% hydrogen, and a dew point of -15°C at a temperature of 1150°C to form an external oxide-type oxide film mainly composed of silico...

Embodiment 3

[0151] Decarburization annealing is performed on a cold-rolled sheet with a thickness of 0.225mm and a Si content of 3.25% for the production of a single-oriented silicon steel sheet, and a water slurry of an annealing separator mainly composed of alumina is coated on the surface and dried . Next, finish annealing for 20 hours at 1200°C in a dry hydrogen atmosphere to obtain a unidirectional silicon steel sheet that has undergone secondary recrystallization and has a specular luster substantially free of inorganic minerals on the surface. For the steel sheet, a sample (Example) in which the surface of the steel sheet was wiped with a brush with silicon carbide abrasive grains (Example) and a sample in which the above-mentioned wiping was not performed (Comparative Example) were prepared. Then, heat treatment is performed at a temperature of 800°C in an atmosphere of 30% nitrogen, 70% hydrogen, and a dew point of -2°C to form an external oxidation type oxide film. Subsequently...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com