Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

378 results about "Nitrogen plasma" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vapor deposition method for ternary compounds

InactiveUS20100102417A1High resistivitySolid-state devicesSemiconductor/solid-state device manufacturingNitrogen plasmaGas phase

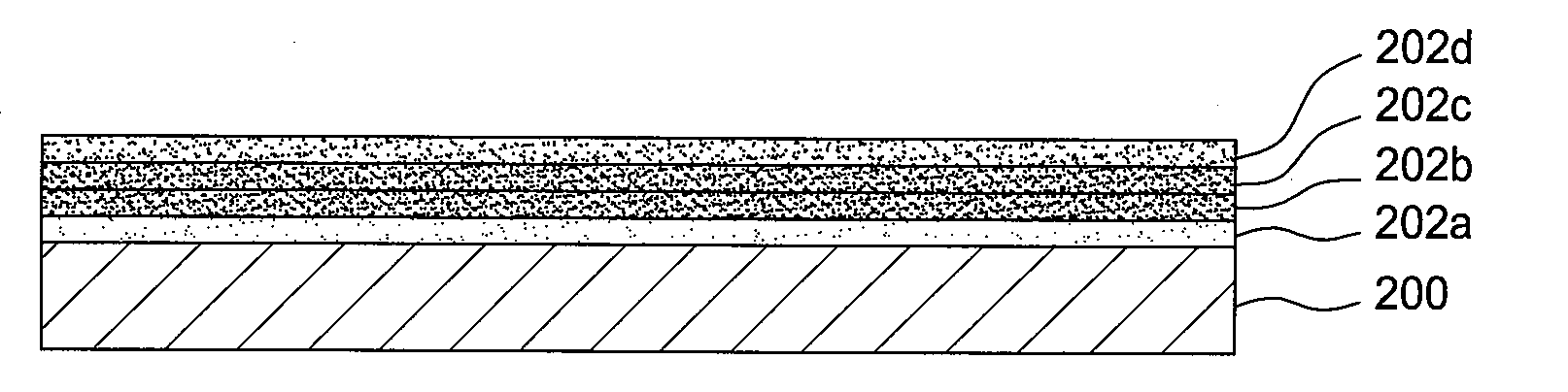

Embodiments provide a method for depositing or forming titanium aluminum nitride materials during a vapor deposition process, such as atomic layer deposition (ALD) or plasma-enhanced ALD (PE-ALD). In some embodiments, a titanium aluminum nitride material is formed by sequentially exposing a substrate to a titanium precursor and a nitrogen plasma to form a titanium nitride layer, exposing the titanium nitride layer to a plasma treatment process, and exposing the titanium nitride layer to an aluminum precursor while depositing an aluminum layer thereon. The process may be repeated multiple times to deposit a plurality of titanium nitride and aluminum layers. Subsequently, the substrate may be annealed to form the titanium aluminum nitride material from the plurality of layers. In other embodiments, the titanium aluminum nitride material may be formed by sequentially exposing the substrate to the nitrogen plasma and a deposition gas which contains the titanium and aluminum precursors.

Owner:APPLIED MATERIALS INC

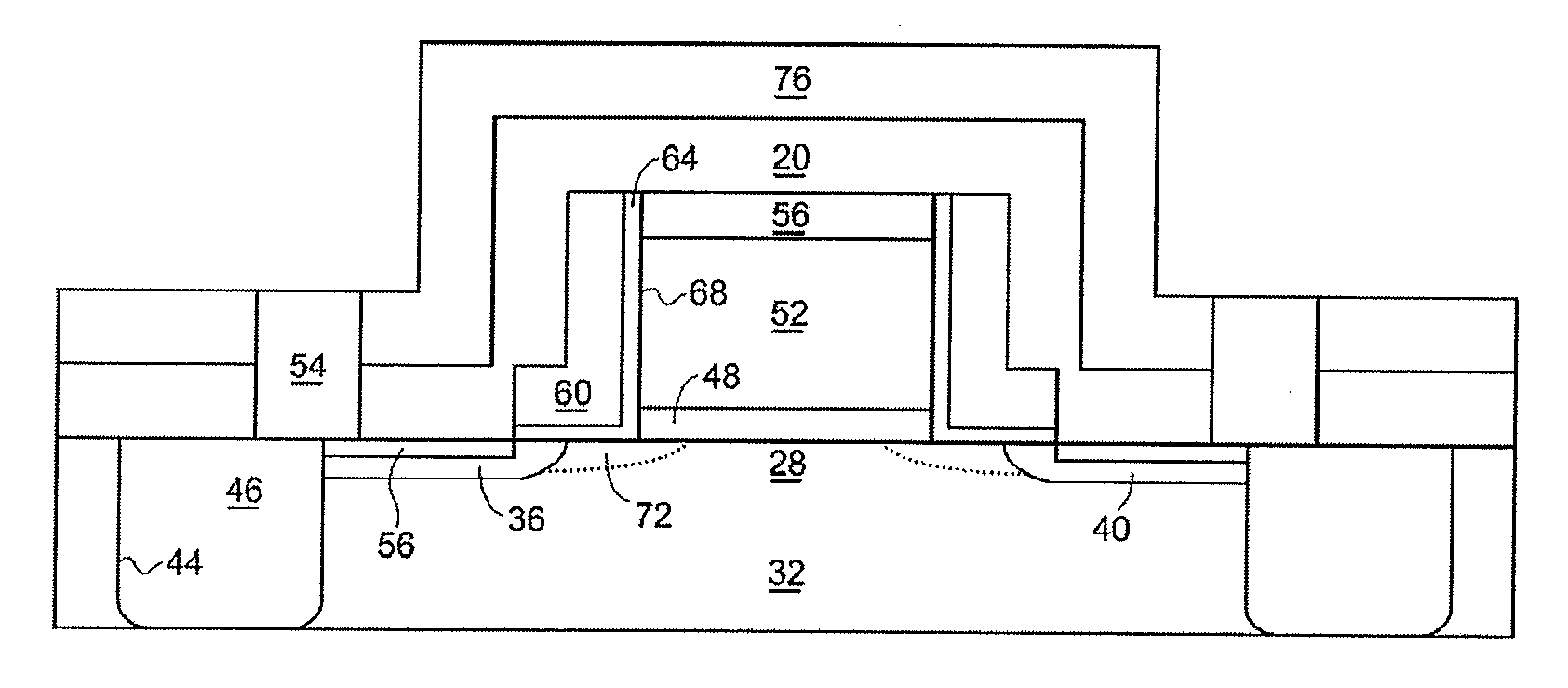

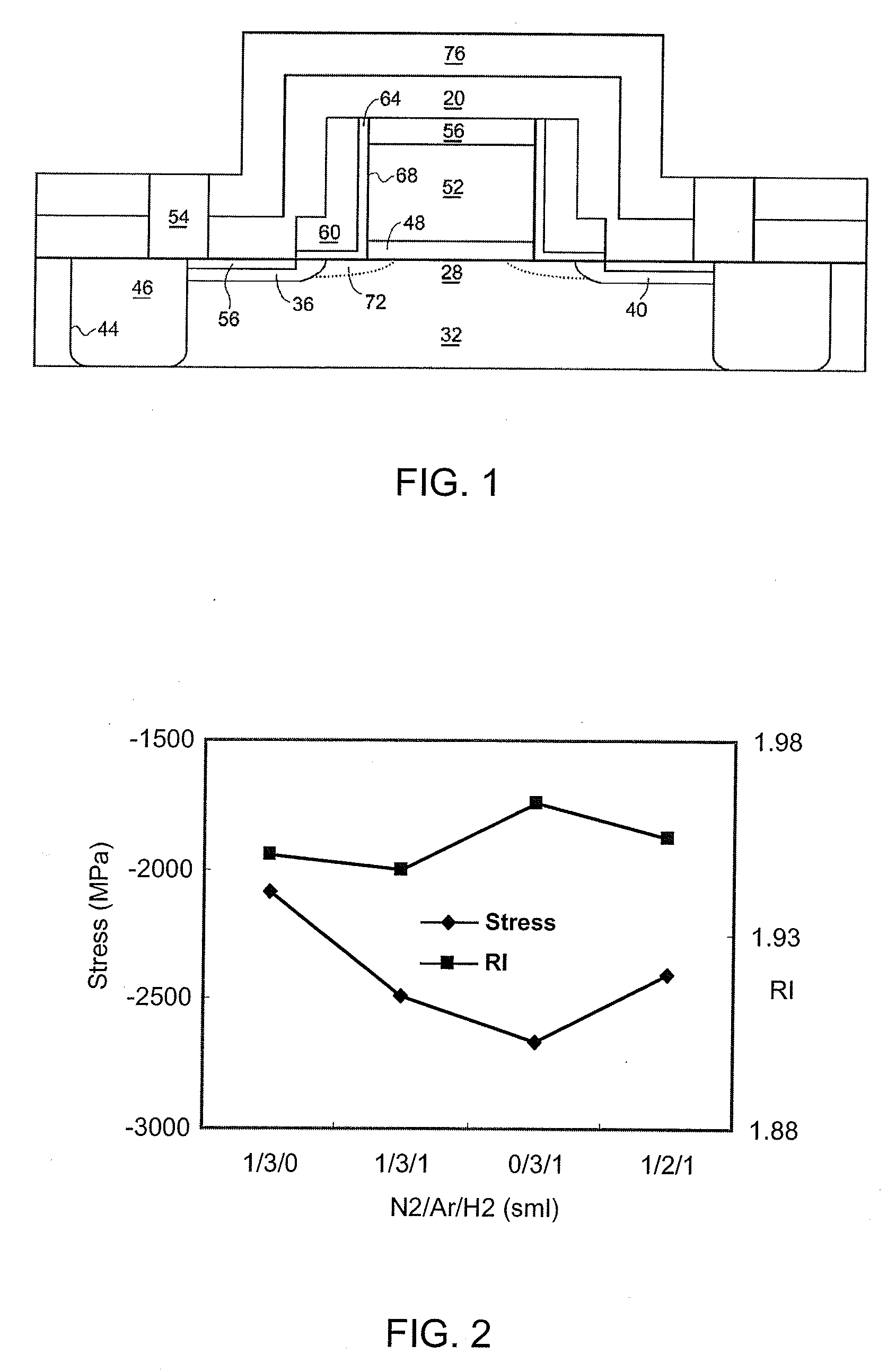

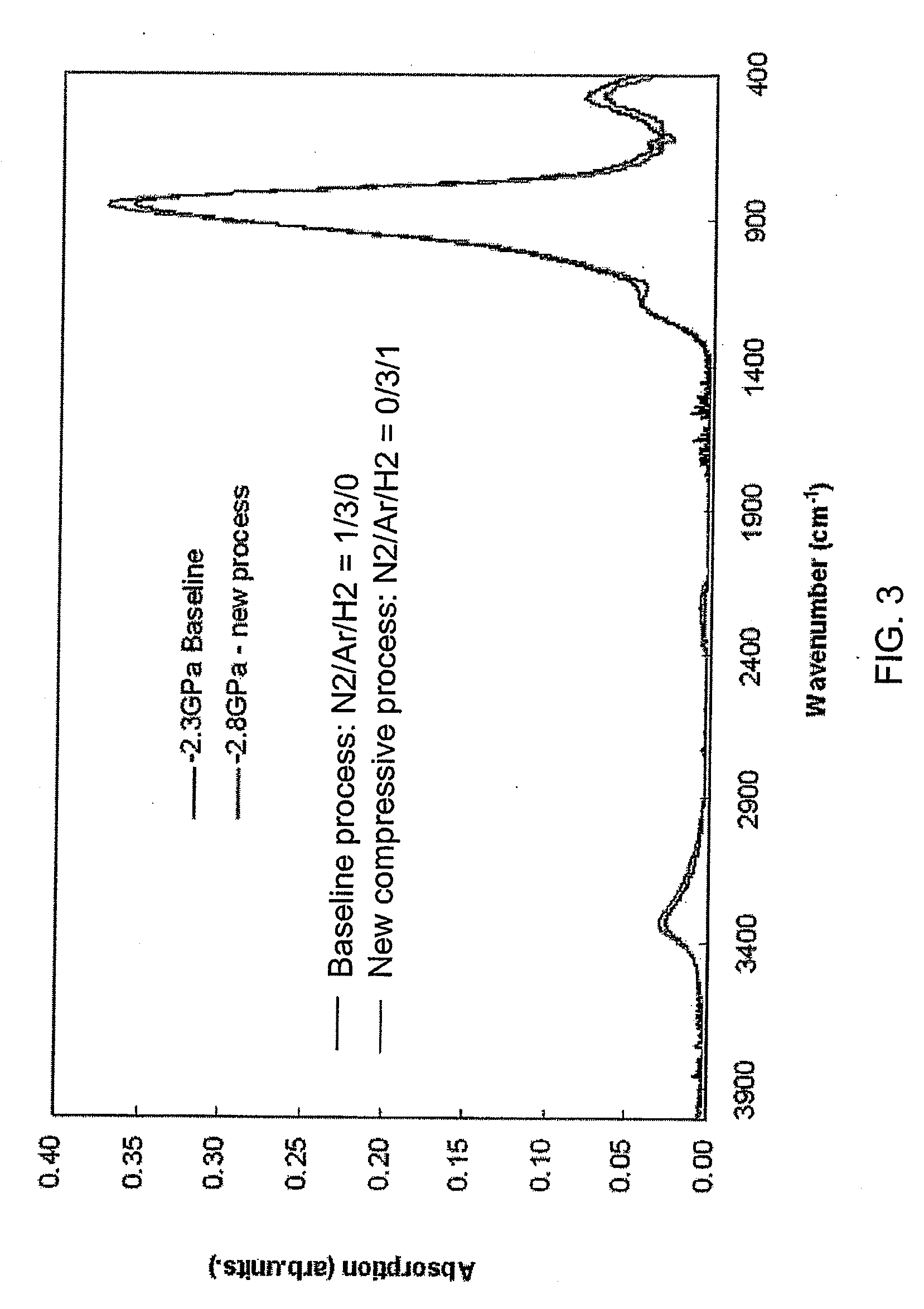

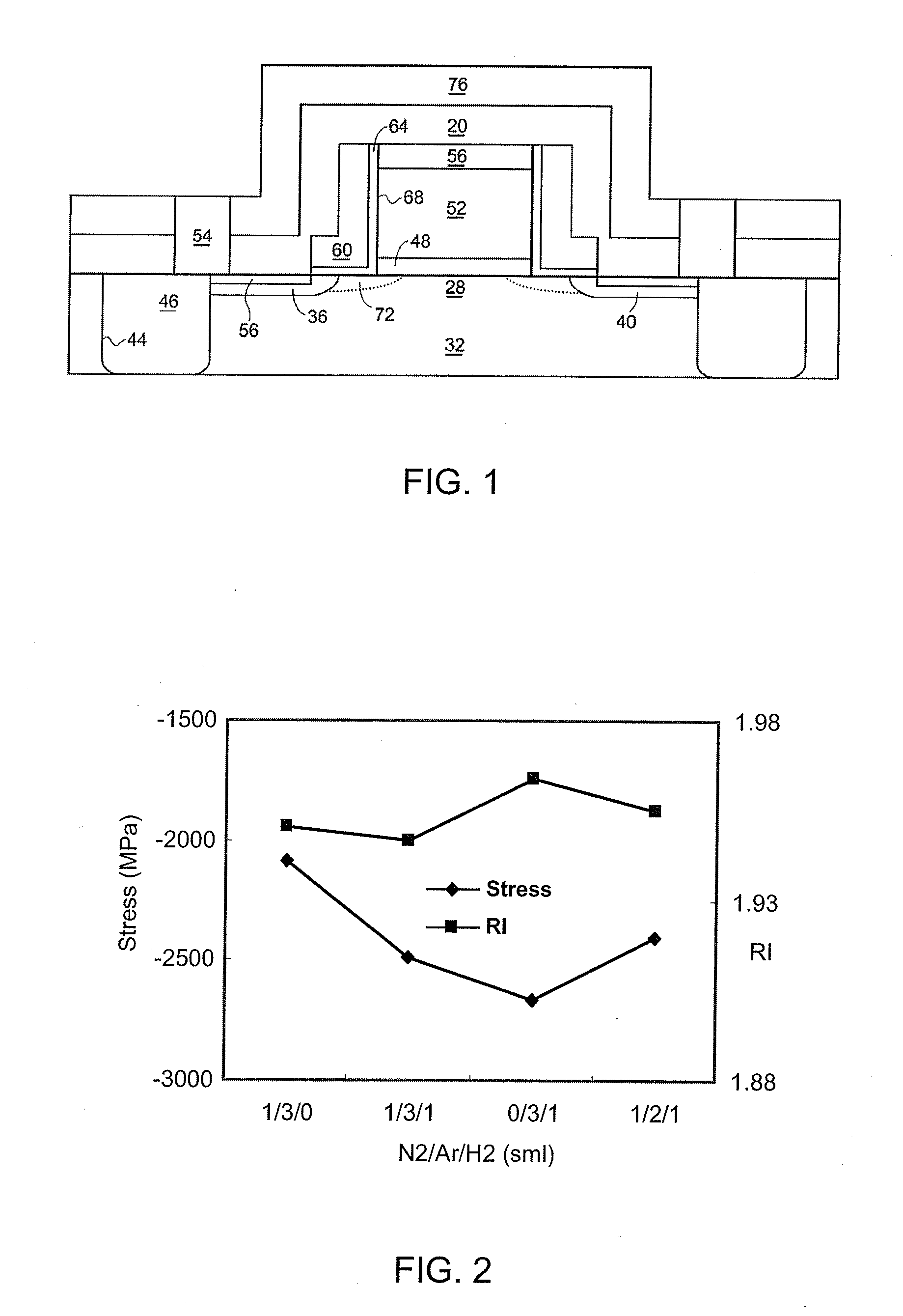

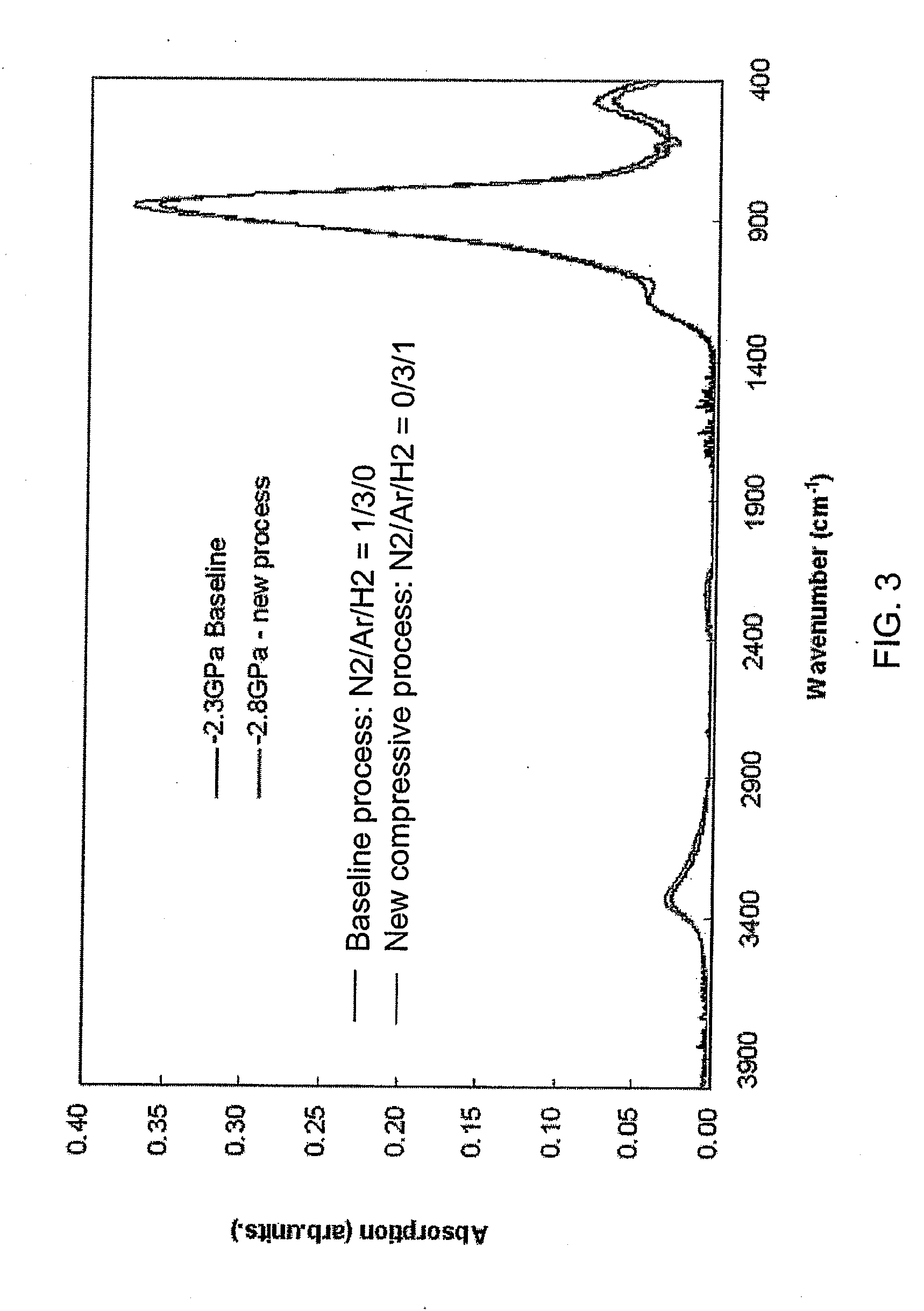

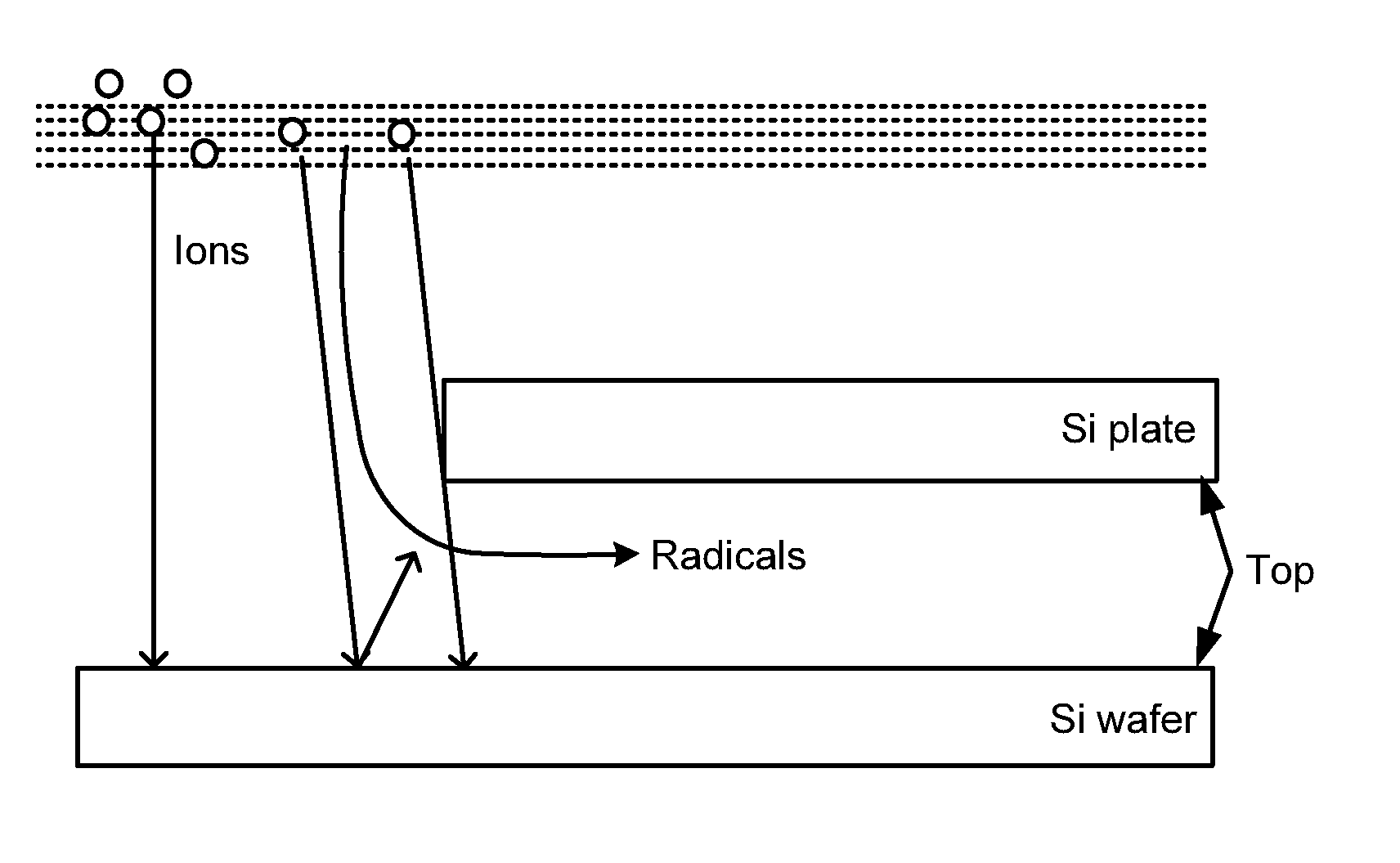

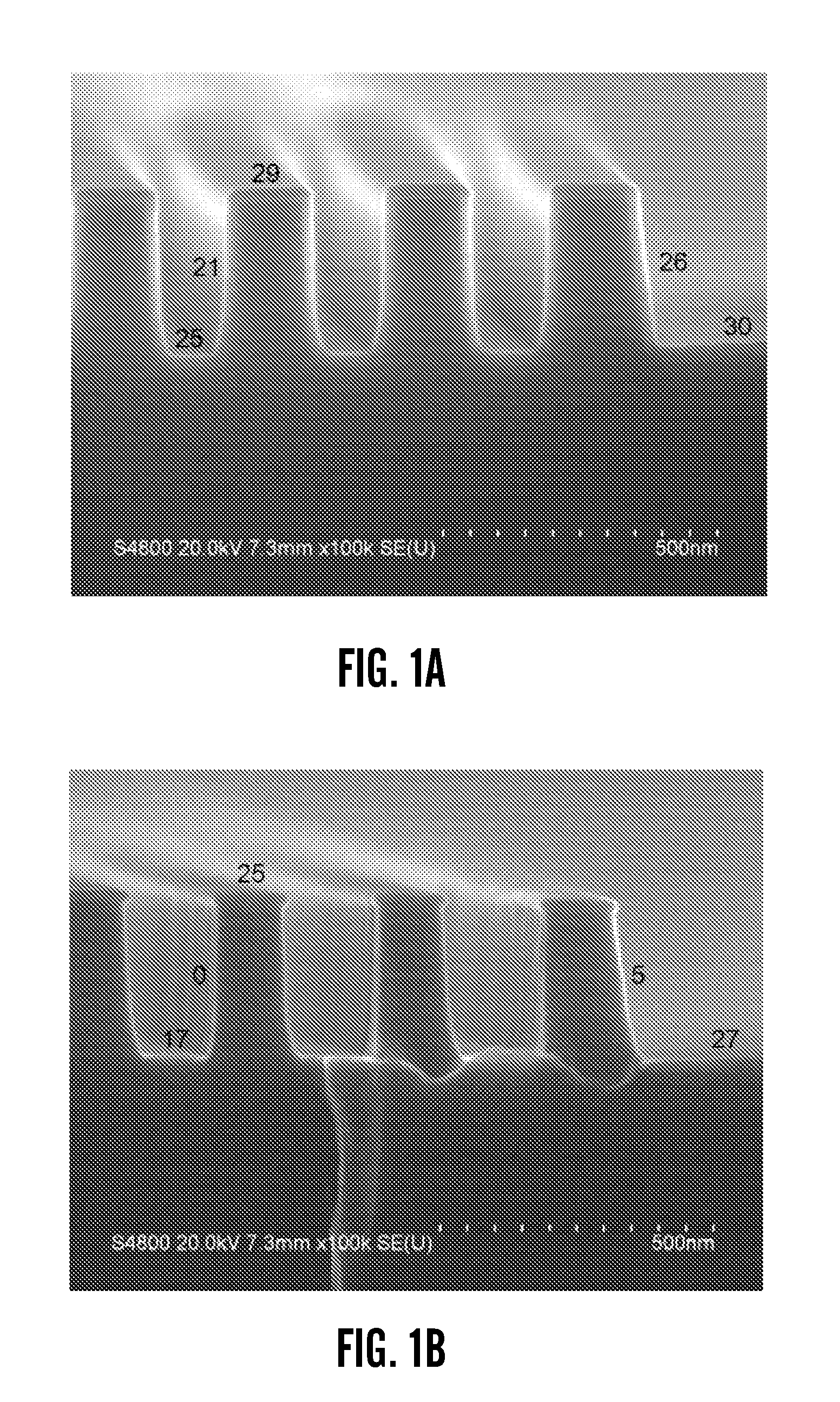

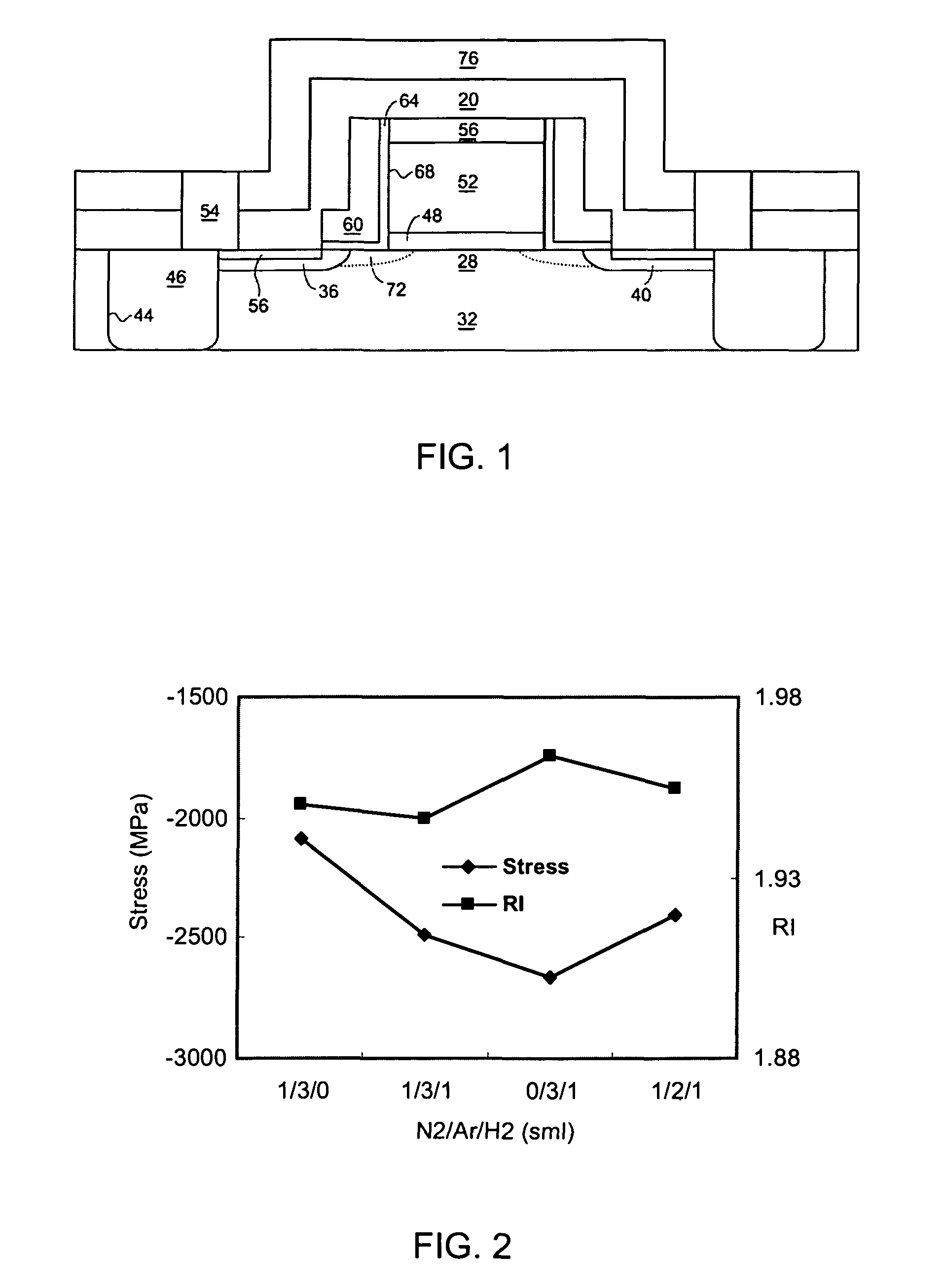

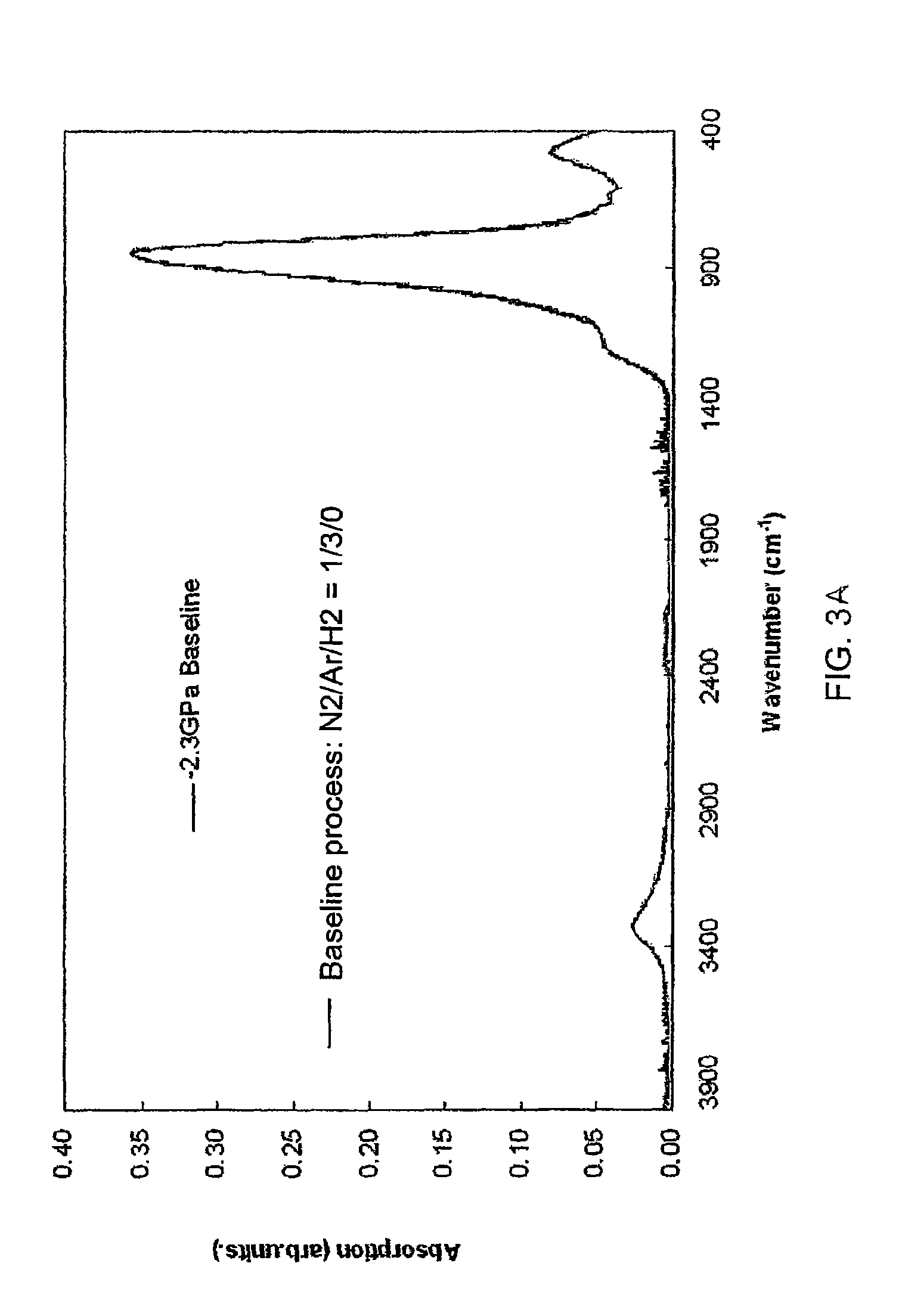

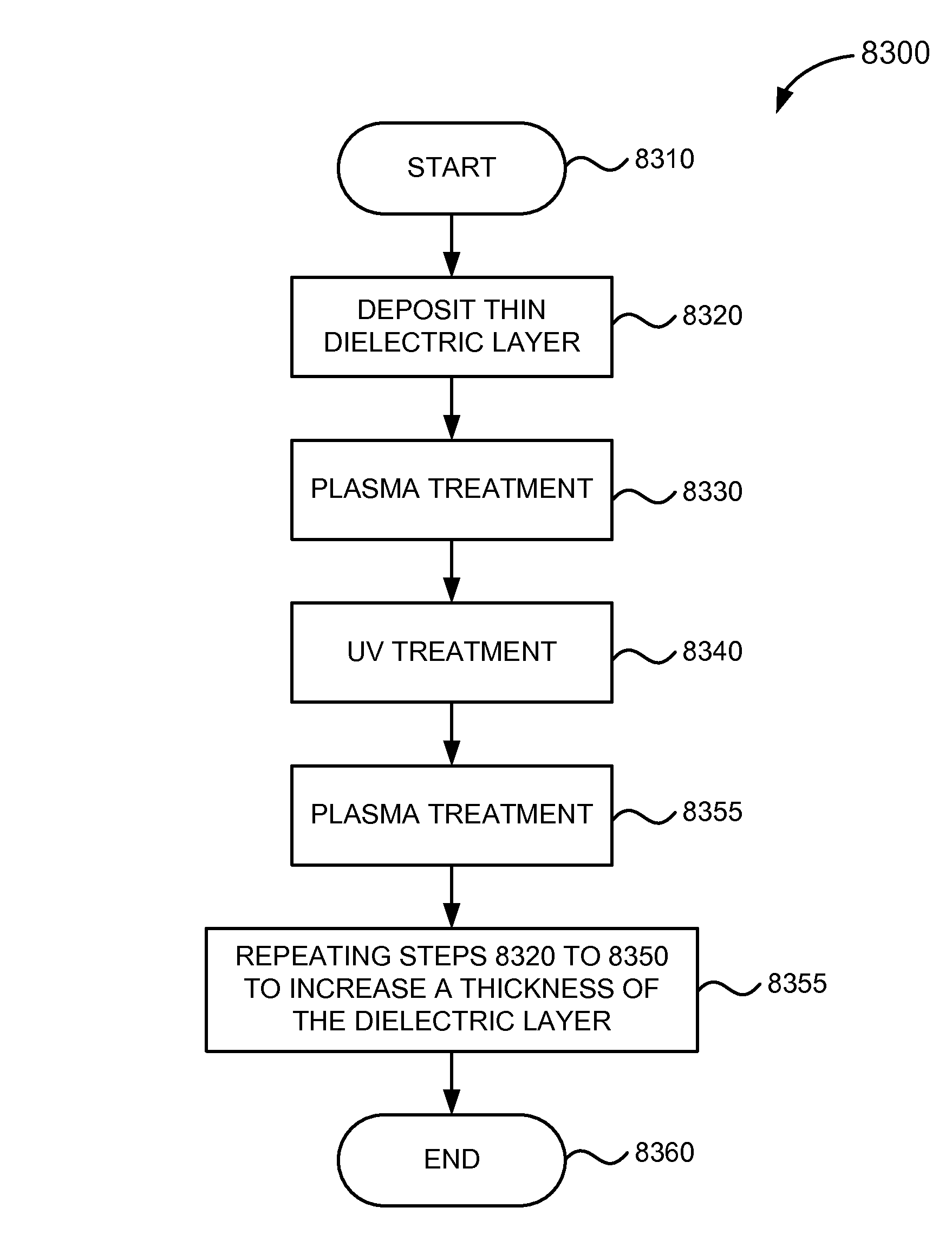

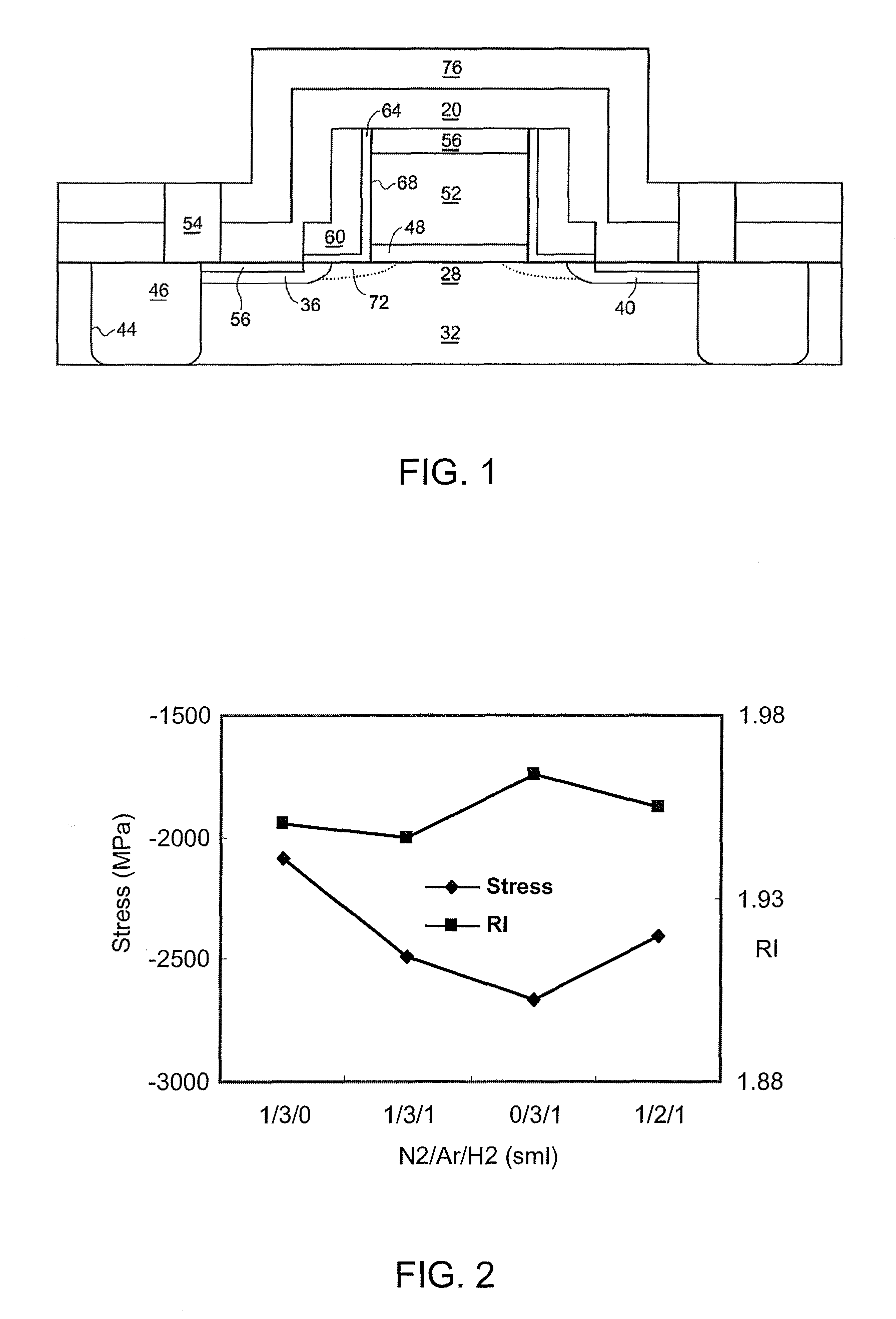

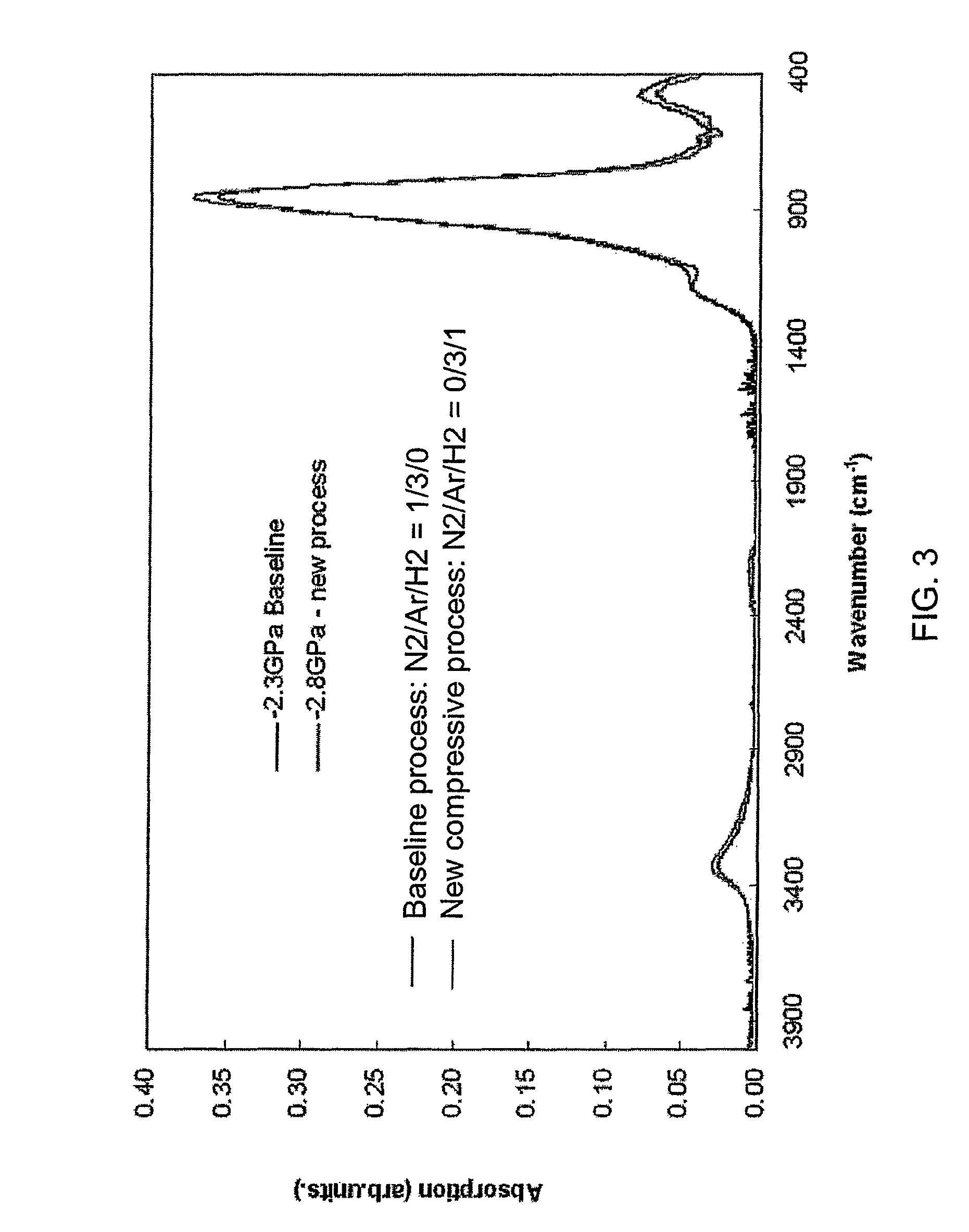

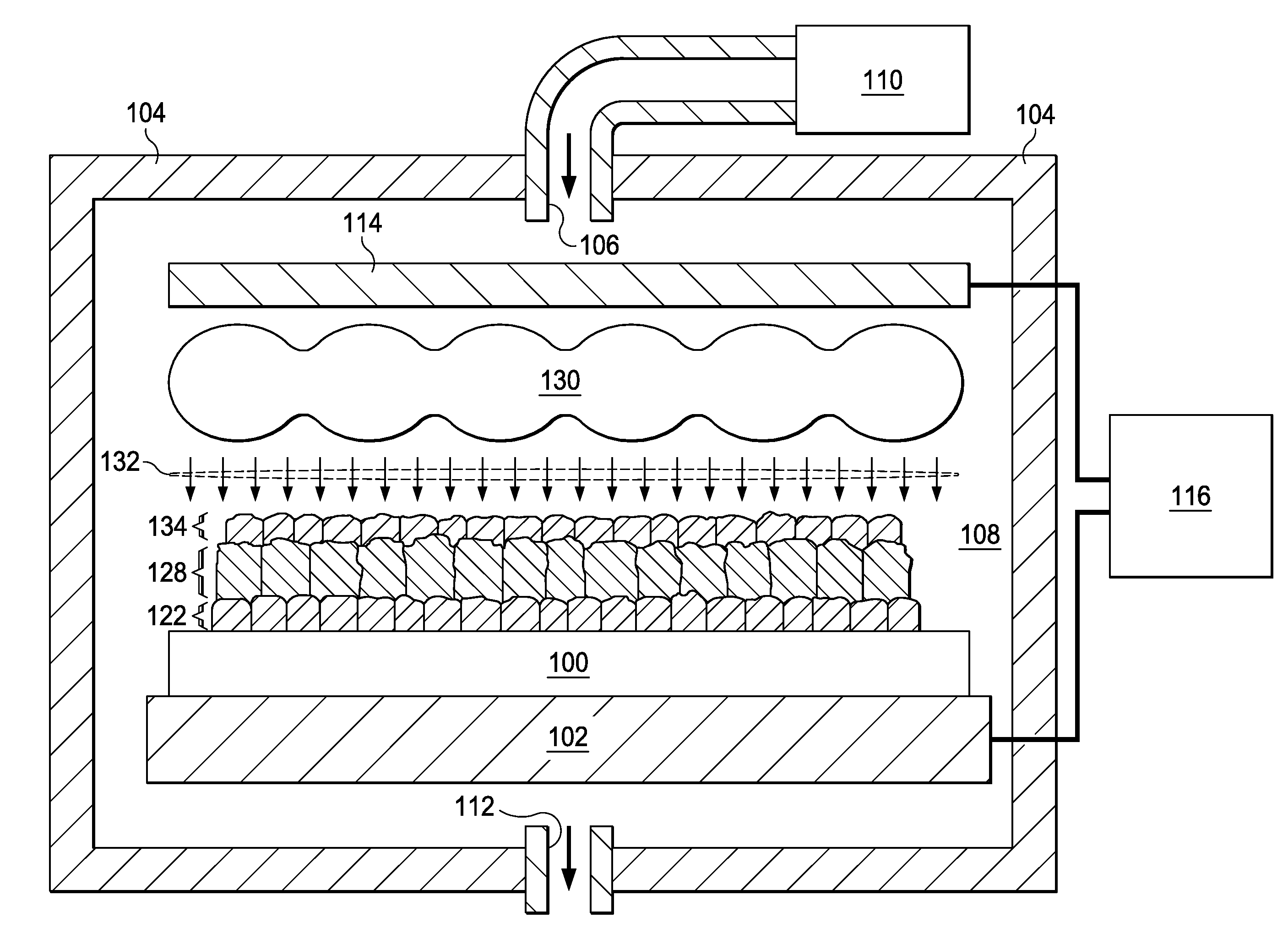

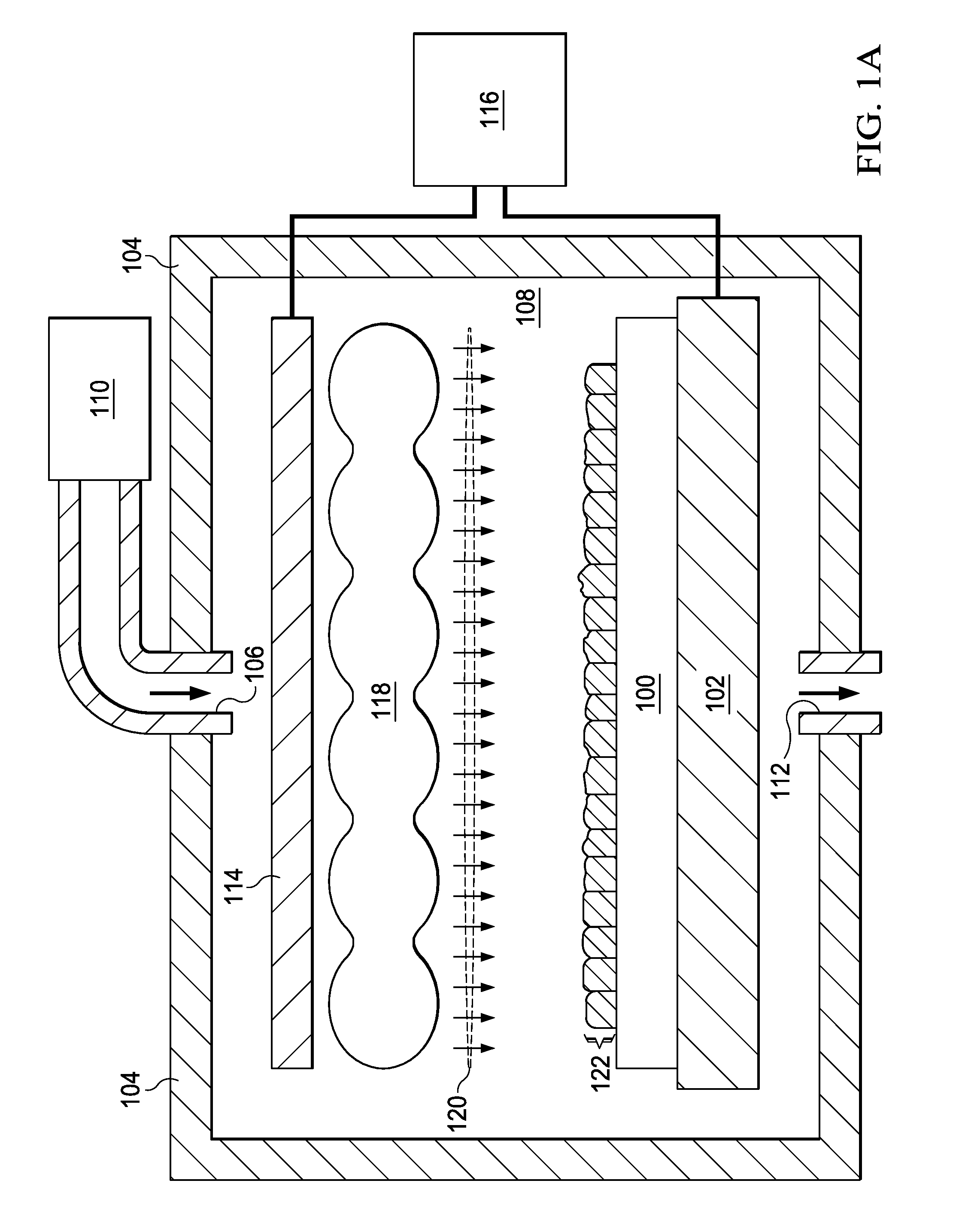

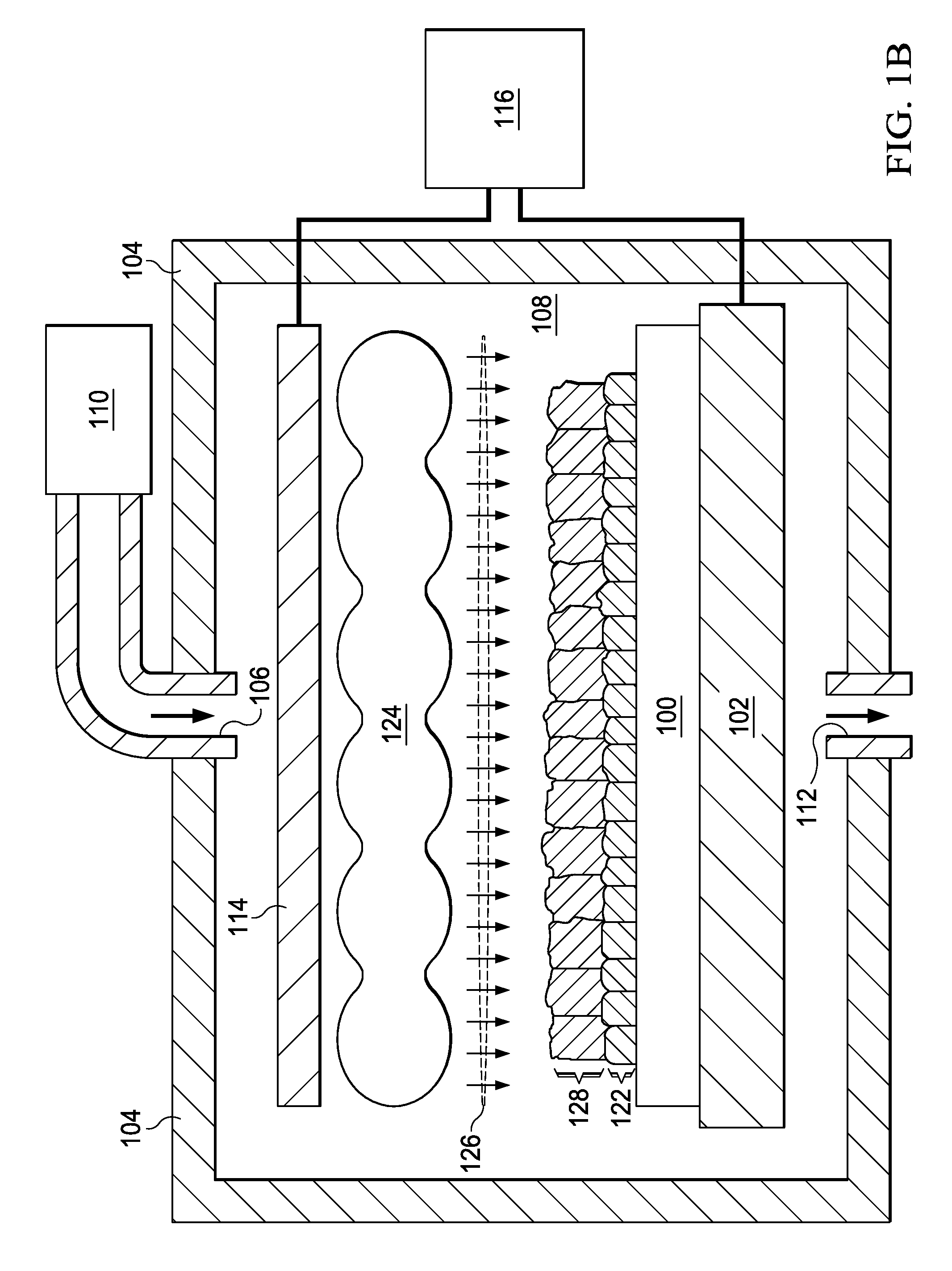

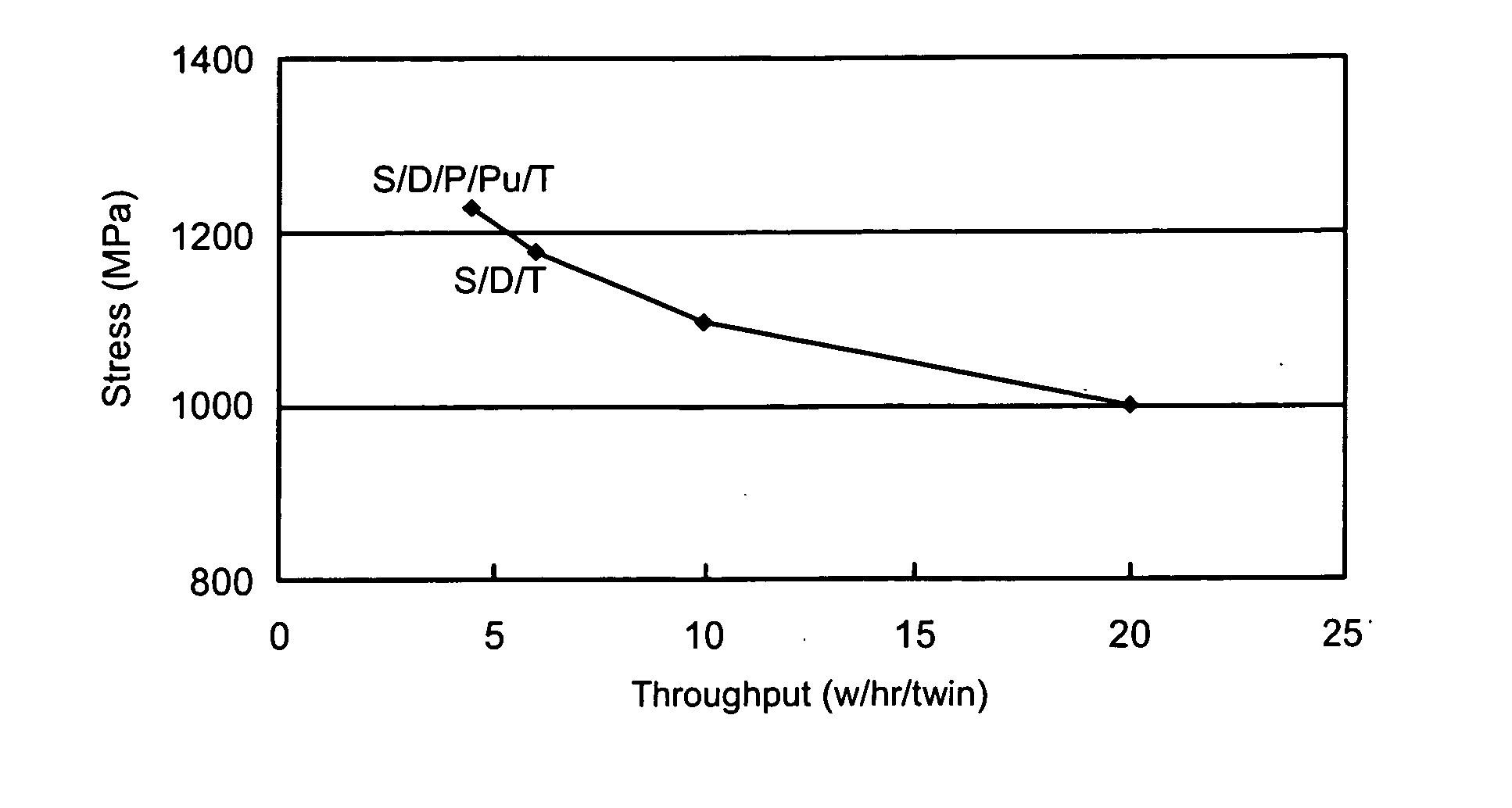

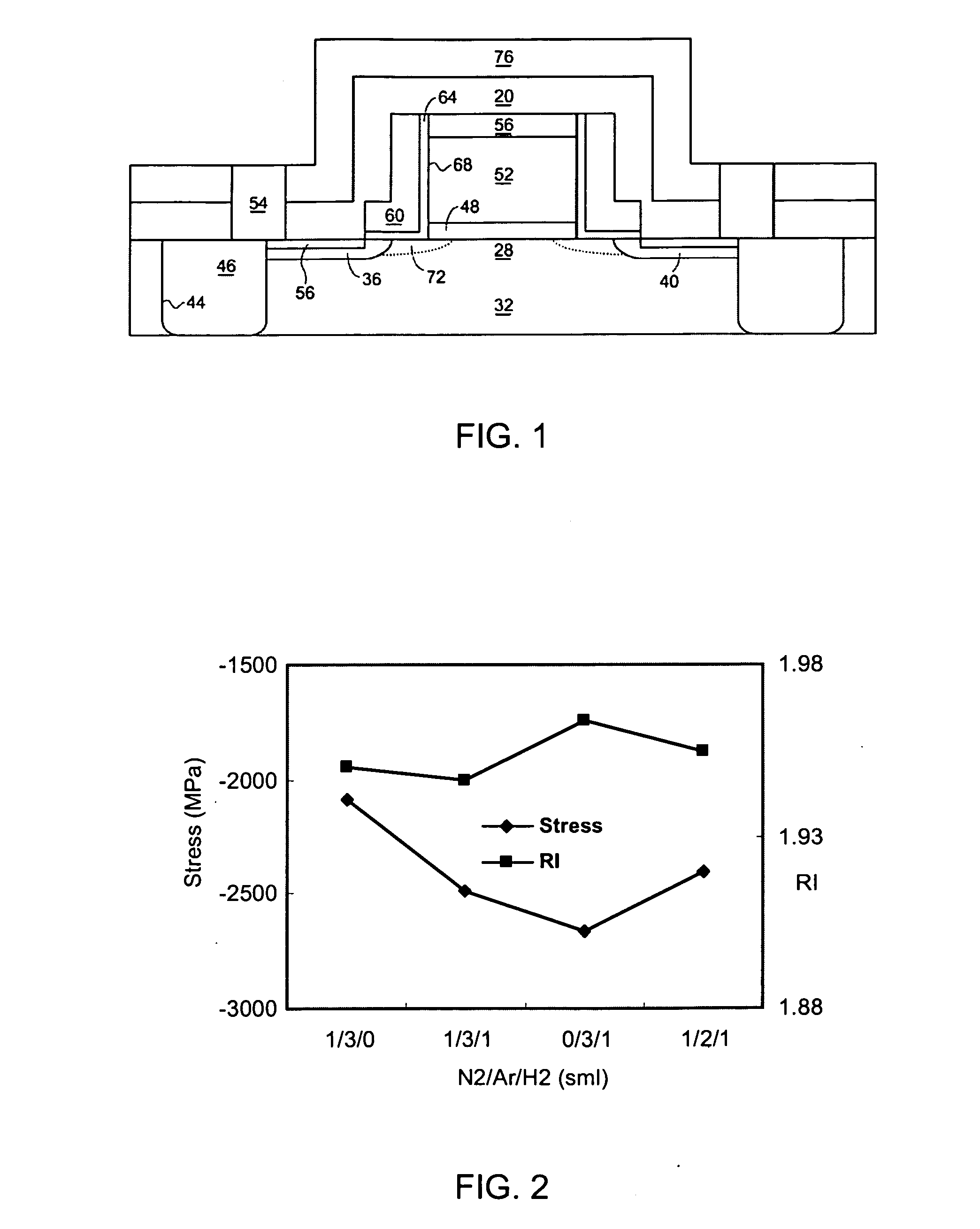

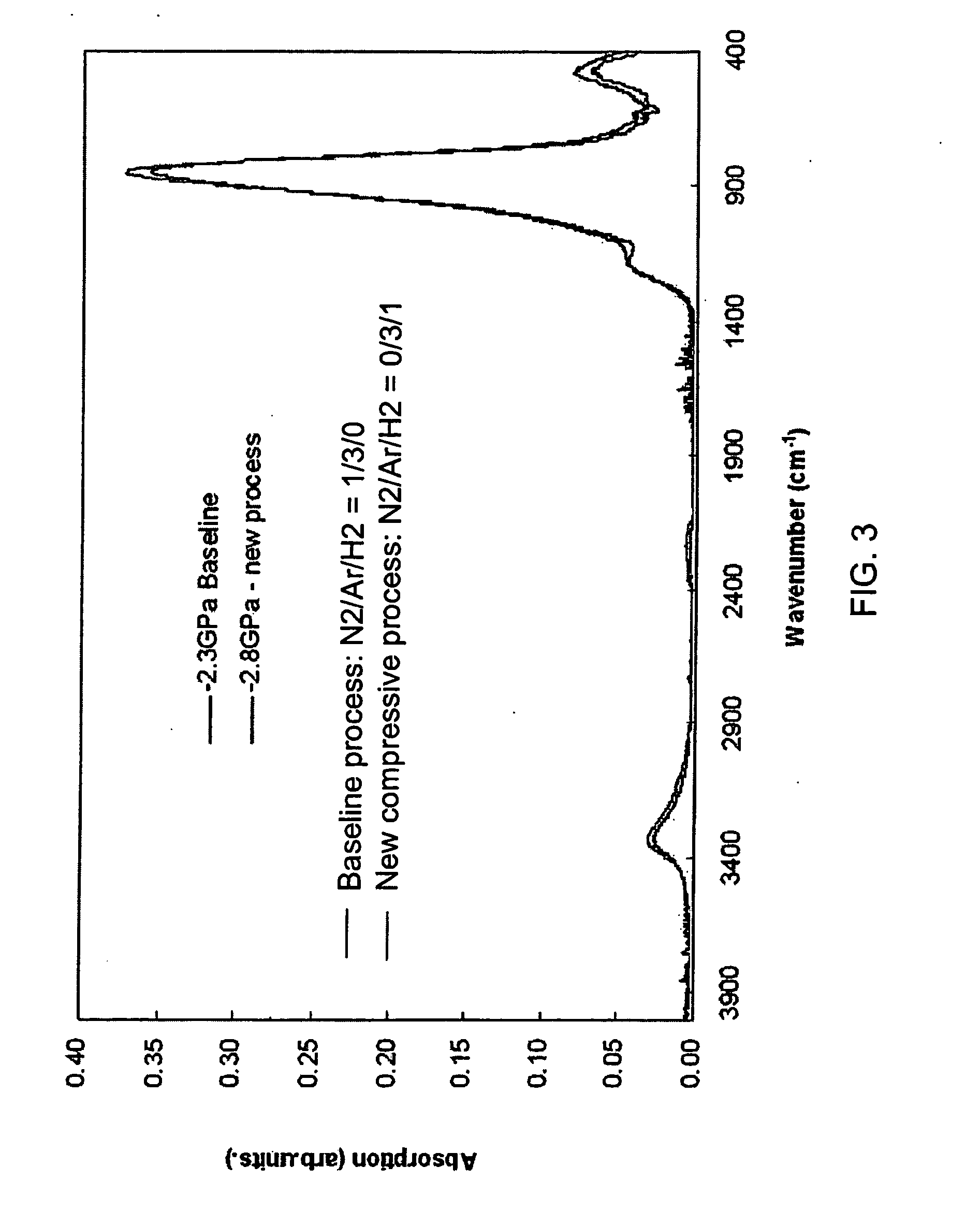

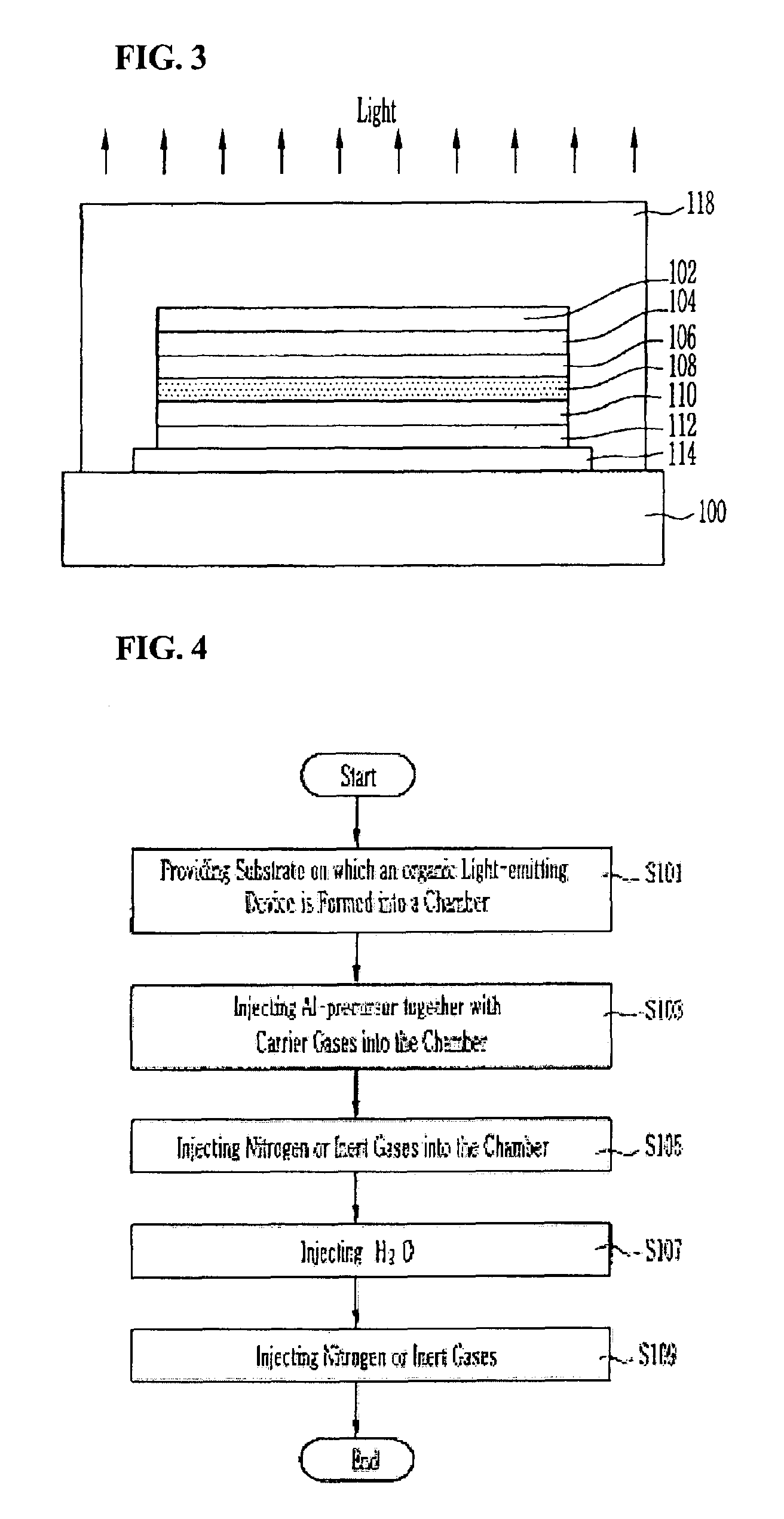

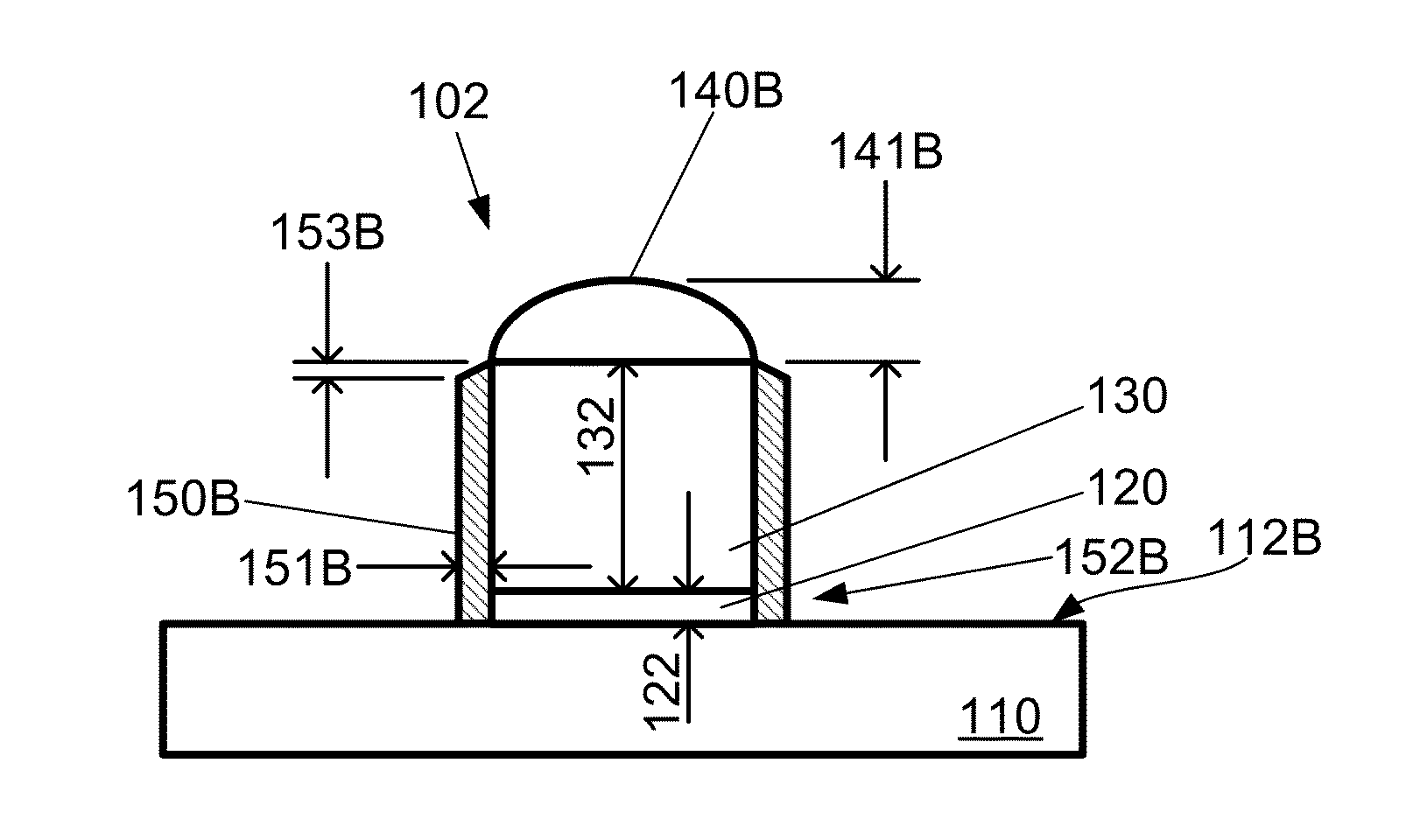

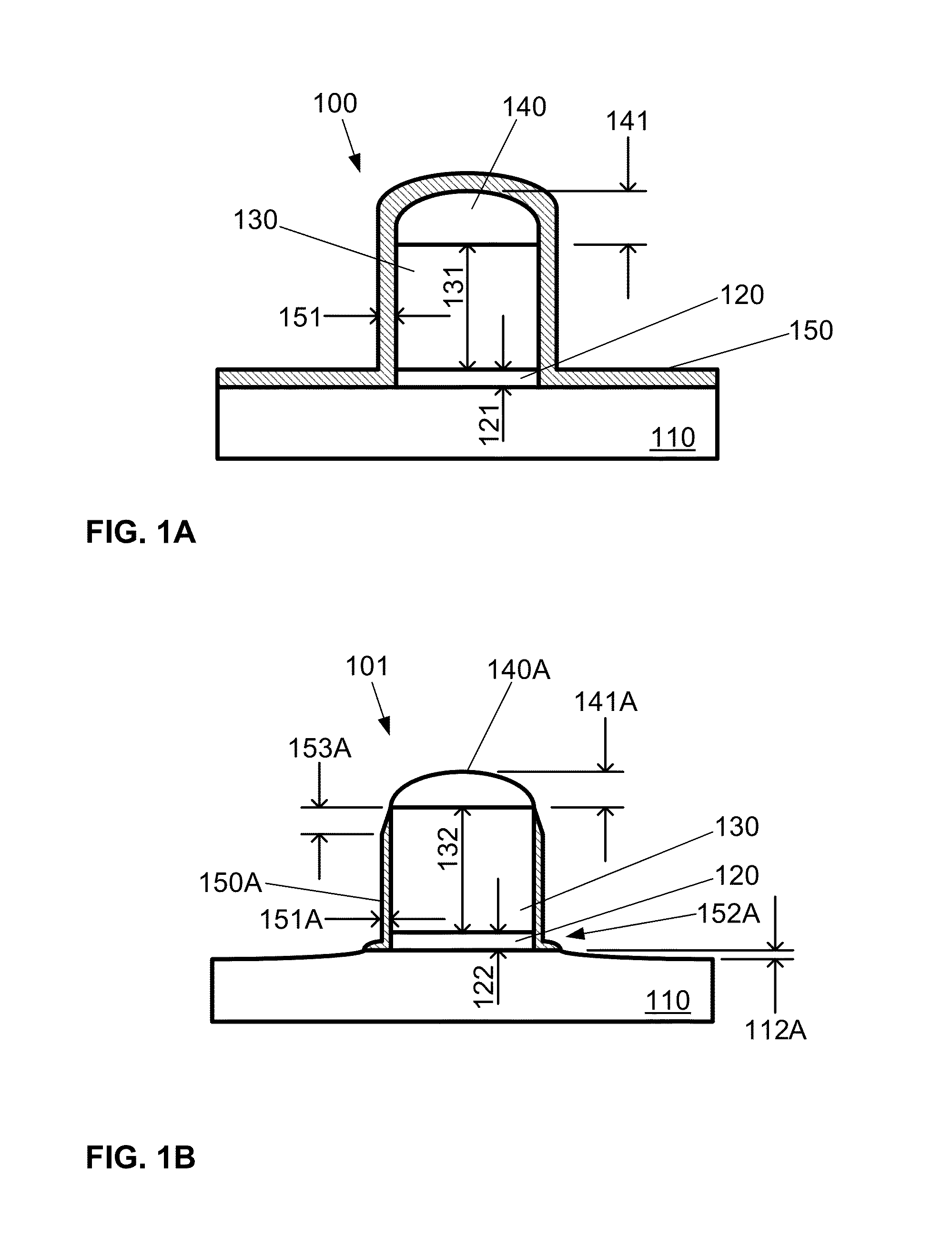

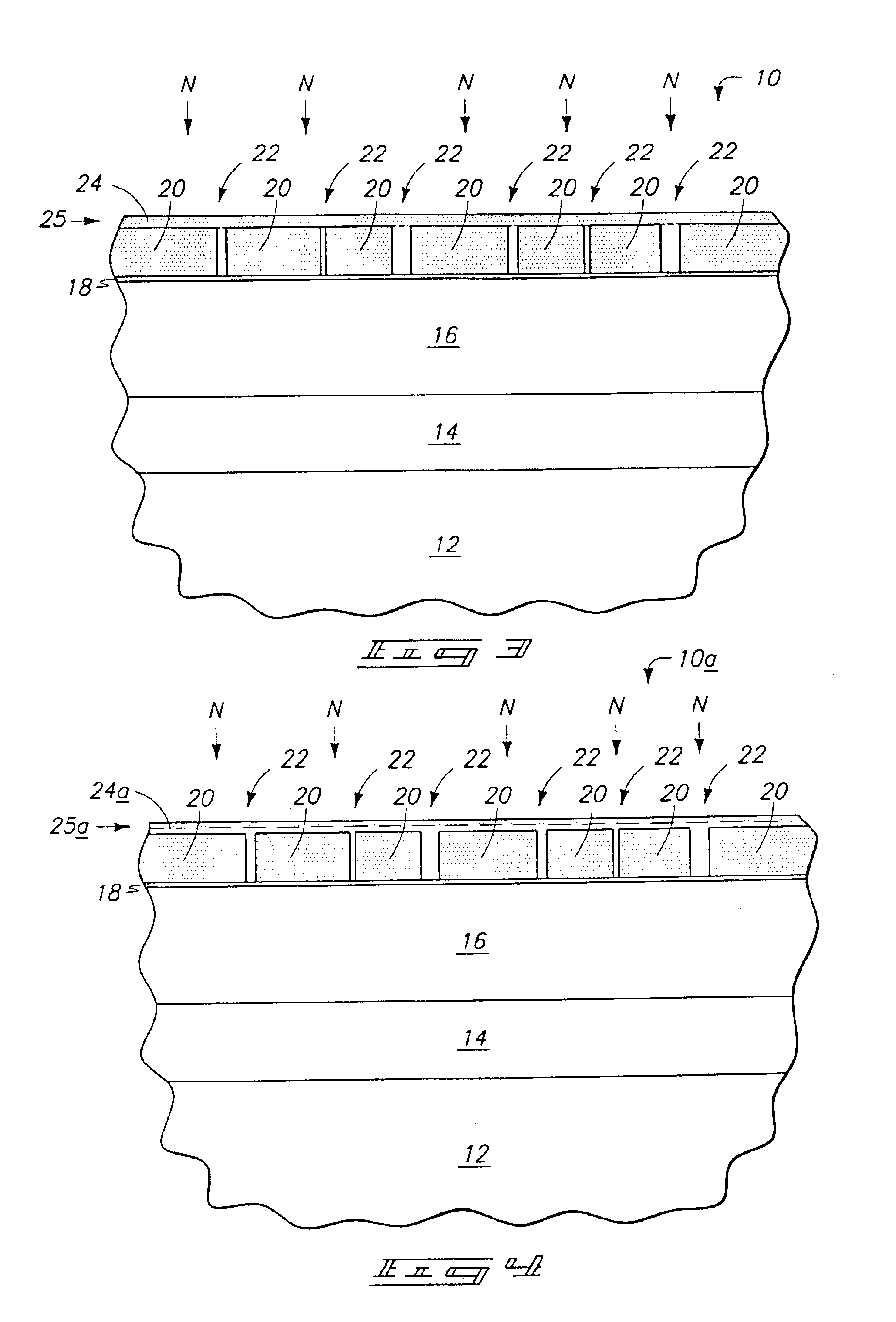

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

ActiveUS20080020591A1Improve performanceFilm stress is increasedTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaUV curing

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with alternative embodiments, a deposited silicon nitride film is exposed to curing with ultraviolet (UV) radiation at an elevated temperature, thereby helping remove hydrogen from the film and increasing film stress. In accordance with still other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

InactiveUS20120196450A1Increase pressureImprove performanceTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaHydrogen

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with some embodiments, a deposited silicon nitride film is exposed to curing with plasma and ultraviolet (UV) radiation, thereby helping remove hydrogen from the film and increasing film stress. In accordance with other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

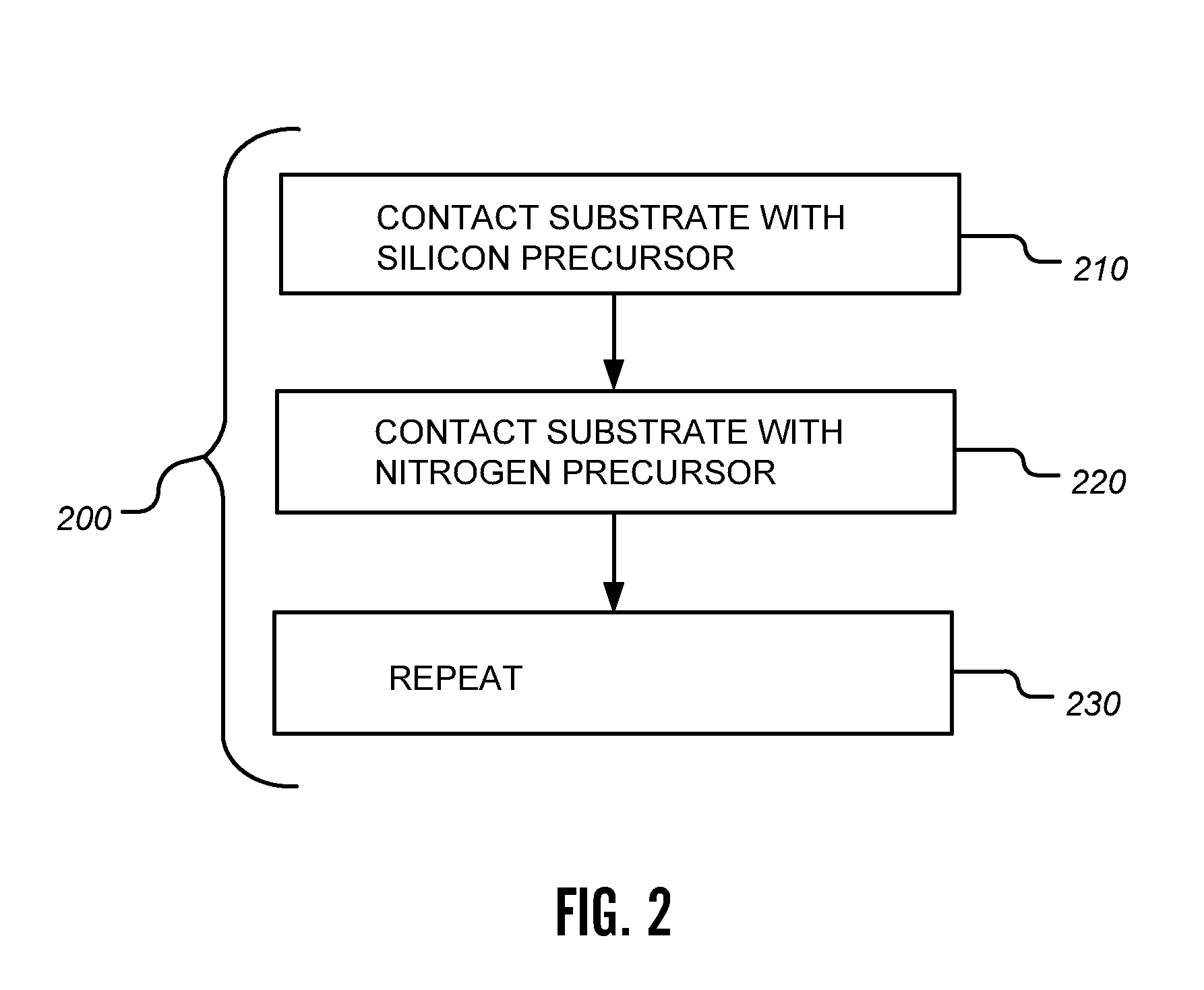

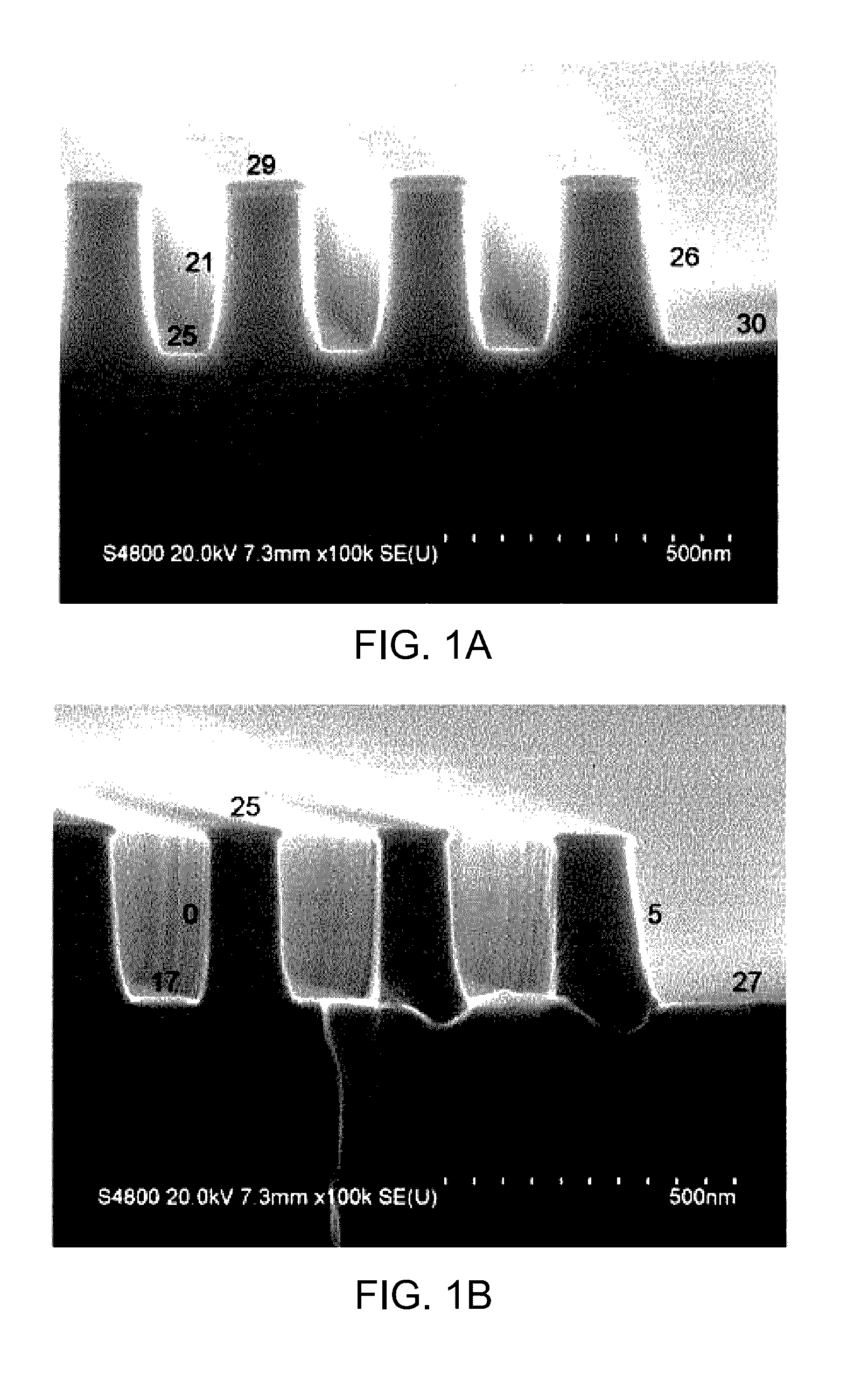

Deposition of SiN

ActiveUS20160079054A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen plasmaAtomic layer deposition

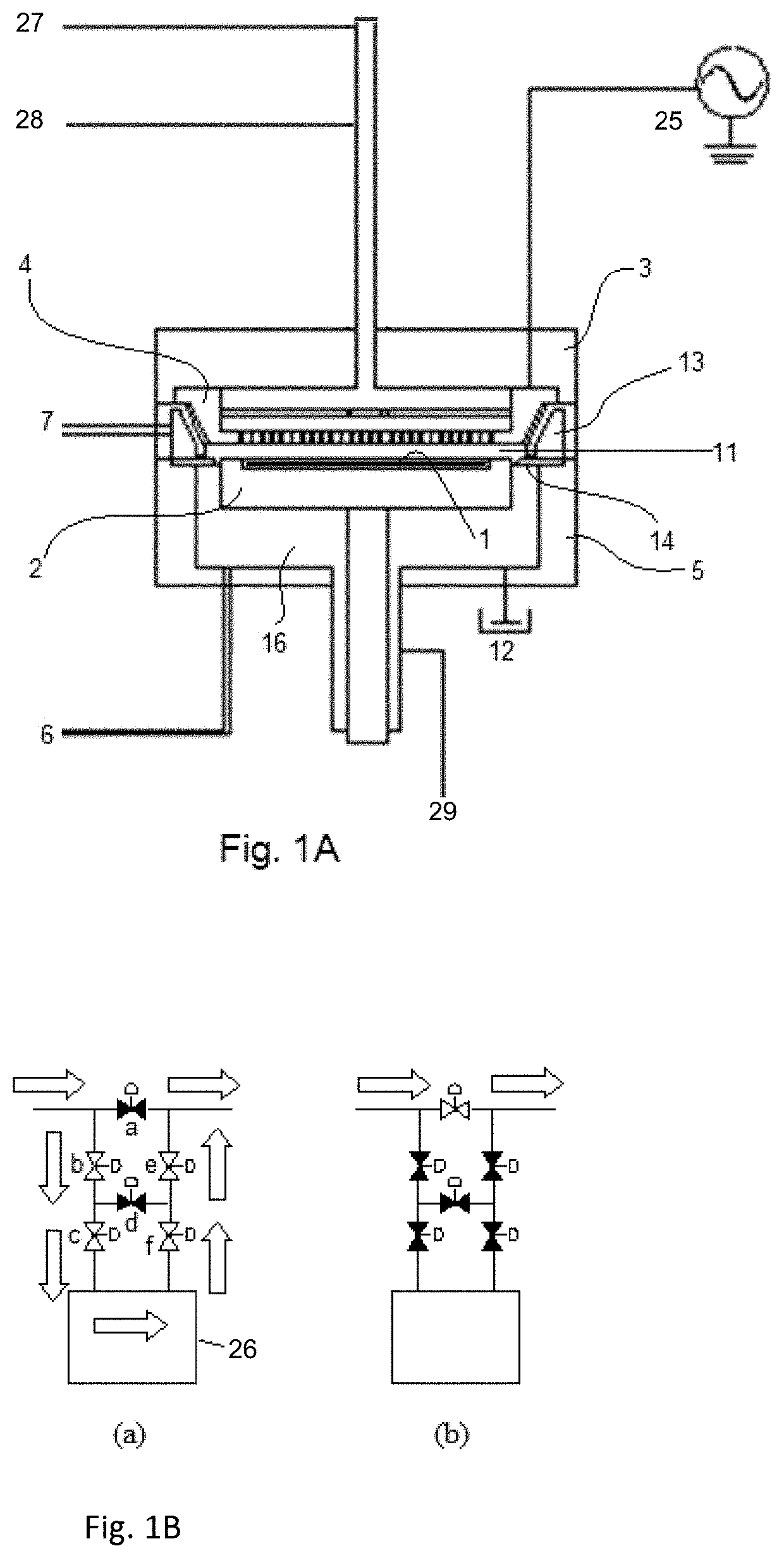

Methods and precursors for forming silicon nitride films are provided. In some embodiments, silicon nitride can be deposited by atomic layer deposition (ALD), such as plasma enhanced ALD. In some embodiments, deposited silicon nitride can be treated with a plasma treatment. The plasma treatment can be a nitrogen plasma treatment. In some embodiments the silicon precursors for depositing the silicon nitride comprise an iodine ligand. The silicon nitride films may have a relatively uniform etch rate for both vertical and the horizontal portions when deposited onto three-dimensional structures such as FinFETS or other types of multiple gate FETs. In some embodiments, various silicon nitride films of the present disclosure have an etch rate of less than half the thermal oxide removal rate with diluted HF (0.5%). In some embodiments, a method for depositing silicon nitride films comprises a multi-step plasma treatment.

Owner:ASM IP HLDG BV

Method to increase tensile stress of silicon nitride films using a post PECVD deposition UV cure

ActiveUS8129290B2Increasing the thicknessSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen plasmaThin membrane

High tensile stress in a deposited layer such as silicon nitride, may be achieved utilizing one or more techniques, employed alone or in combination. High tensile stress may be achieved by forming a silicon-containing layer on a surface by exposing the surface to a silicon-containing precursor gas in the absence of a plasma, forming silicon nitride by exposing said silicon-containing layer to a nitrogen-containing plasma, and then repeating these steps to increase a thickness of the silicon nitride created thereby. High tensile stress may also be achieved by exposing a surface to a silicon-containing precursor gas in a first nitrogen-containing plasma, treating the material with a second nitrogen-containing plasma, and then repeating these steps to increase a thickness of the silicon nitride formed thereby. In another embodiment, tensile film stress is enhanced by deposition with porogens that are liberated upon subsequent exposure to UV radiation or plasma treatment.

Owner:APPLIED MATERIALS INC

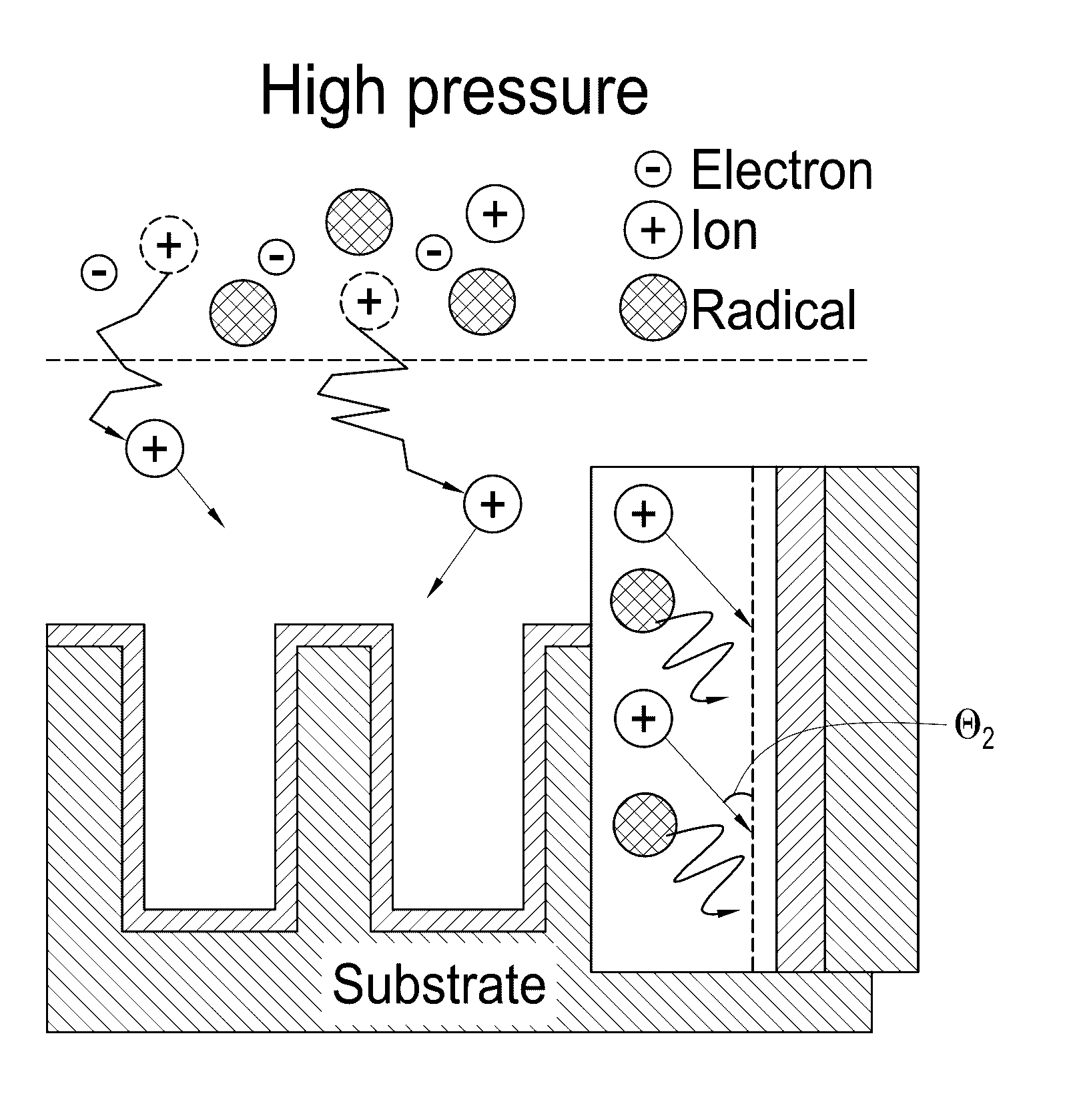

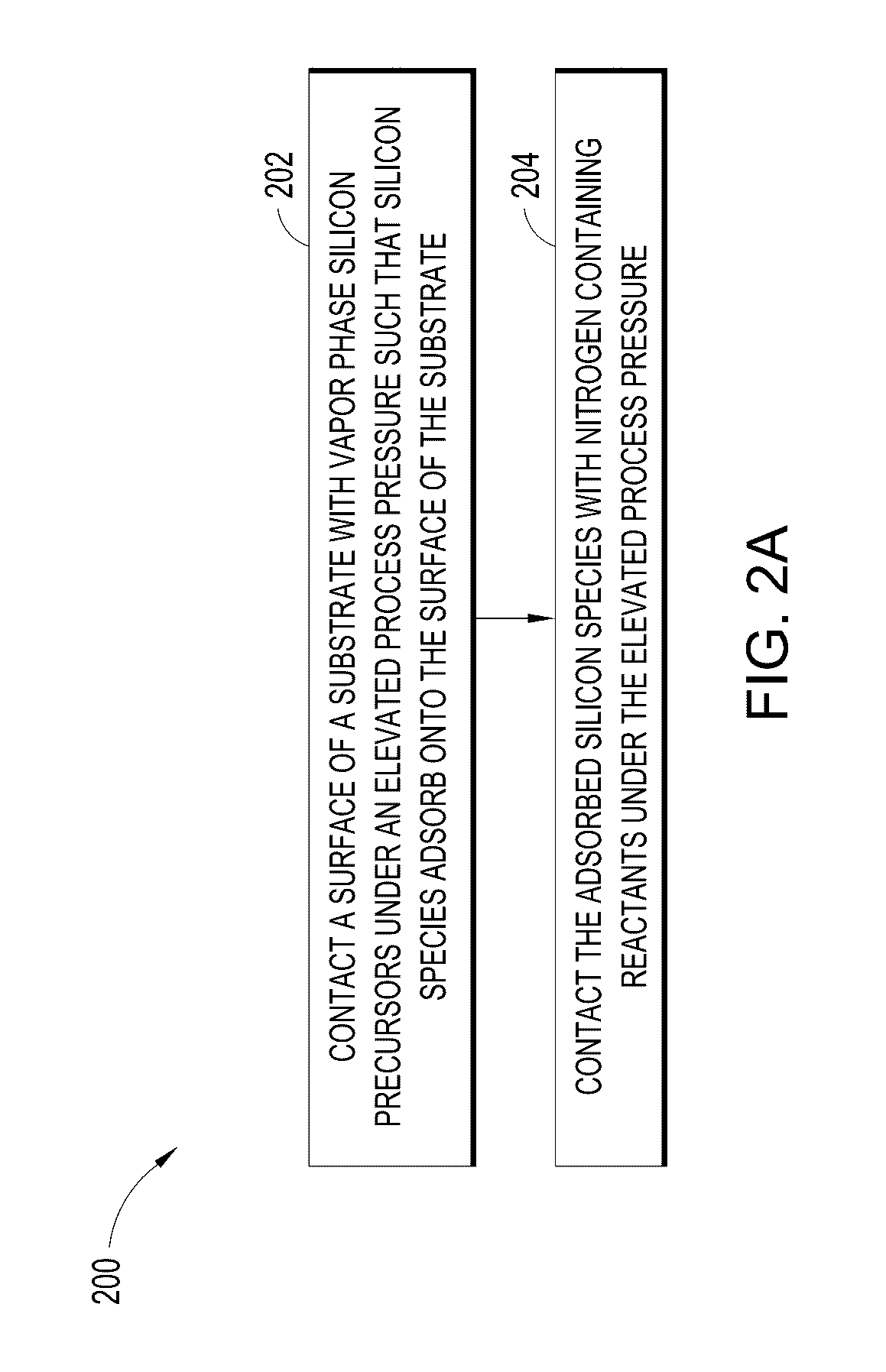

FORMATION OF SiN THIN FILMS

ActiveUS20170062204A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen plasmaHigh pressure

Methods of forming silicon nitride thin films on a substrate in a reaction space under high pressure are provided. The methods can include a plurality of plasma enhanced atomic layer deposition (PEALD) cycles, where at least one PEALD deposition cycle comprises contacting the substrate with a nitrogen plasma at a process pressure of 20 Torr to 500 Torr within the reaction space. In some embodiments the silicon precursor is a silyly halide, such as H2SiI2. In some embodiments the processes allow for the deposition of silicon nitride films having improved properties on three dimensional structures. For example, such silicon nitride films can have a ratio of wet etch rates on the top surfaces to the sidewall of about 1:1 in dilute HF.

Owner:ASM IP HLDG BV

Method to increase silicon nitride tensile stress using nitrogen plasma in-situ treatment and ex-situ UV cure

ActiveUS8138104B2Increase pressureImprove performanceTransistorSemiconductor/solid-state device manufacturingNitrogen plasmaHydrogen

Stress of a silicon nitride layer may be enhanced by deposition at higher temperatures. Employing an apparatus that allows heating of a substrate to substantially greater than 400° C. (for example a heater made from ceramic rather than aluminum), the silicon nitride film as-deposited may exhibit enhanced stress allowing for improved performance of the underlying MOS transistor device. In accordance with alternative embodiments, a deposited silicon nitride film is exposed to curing with ultraviolet (UV) radiation at an elevated temperature, thereby helping remove hydrogen from the film and increasing film stress. In accordance with still other embodiments, a silicon nitride film is formed utilizing an integrated process employing a number of deposition / curing cycles to preserve integrity of the film at the sharp corner of the underlying raised feature. Adhesion between successive layers may be promoted by inclusion of a post-UV cure plasma treatment in each cycle.

Owner:APPLIED MATERIALS INC

MODULATED DEPOSITION PROCESS FOR STRESS CONTROL IN THICK TiN FILMS

ActiveUS20100032842A1Liquid surface applicatorsIncorrect coupling preventionNitrogen plasmaDeposition process

A multi-layer TiN film with reduced tensile stress and discontinuous grain structure, and a method of fabricating the TiN film are disclosed. The TiN layers are formed by PVD or IMP in a nitrogen plasma. Tensile stress in a center layer of the film is reduced by increasing N2 gas flow to the nitrogen plasma, resulting in a Ti:N stoichiometry between 1:2.1 to 1:2.3. TiN films thicker than 40 nanometers without cracks are attained by the disclosed process.

Owner:TEXAS INSTR INC

PLASMA ENHANCED ATOMIC LAYER DEPOSITION (PEALD) OF SiN USING SILICON-HYDROHALIDE PRECURSORS

ActiveUS20190333753A1High side-wall conformalityReduce and eliminate voidSemiconductor/solid-state device manufacturingChemical vapor deposition coatingNitrogen plasmaHydrogen

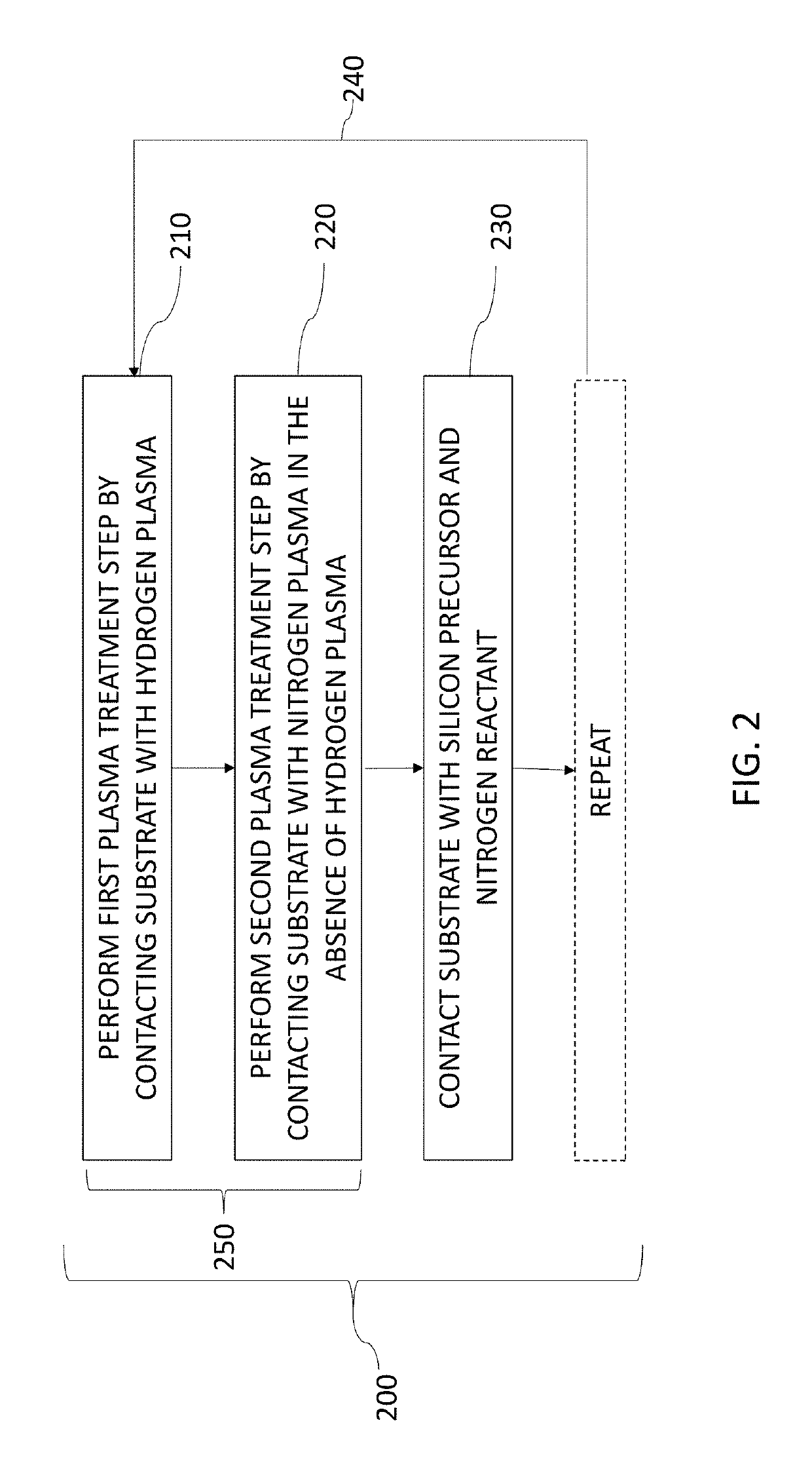

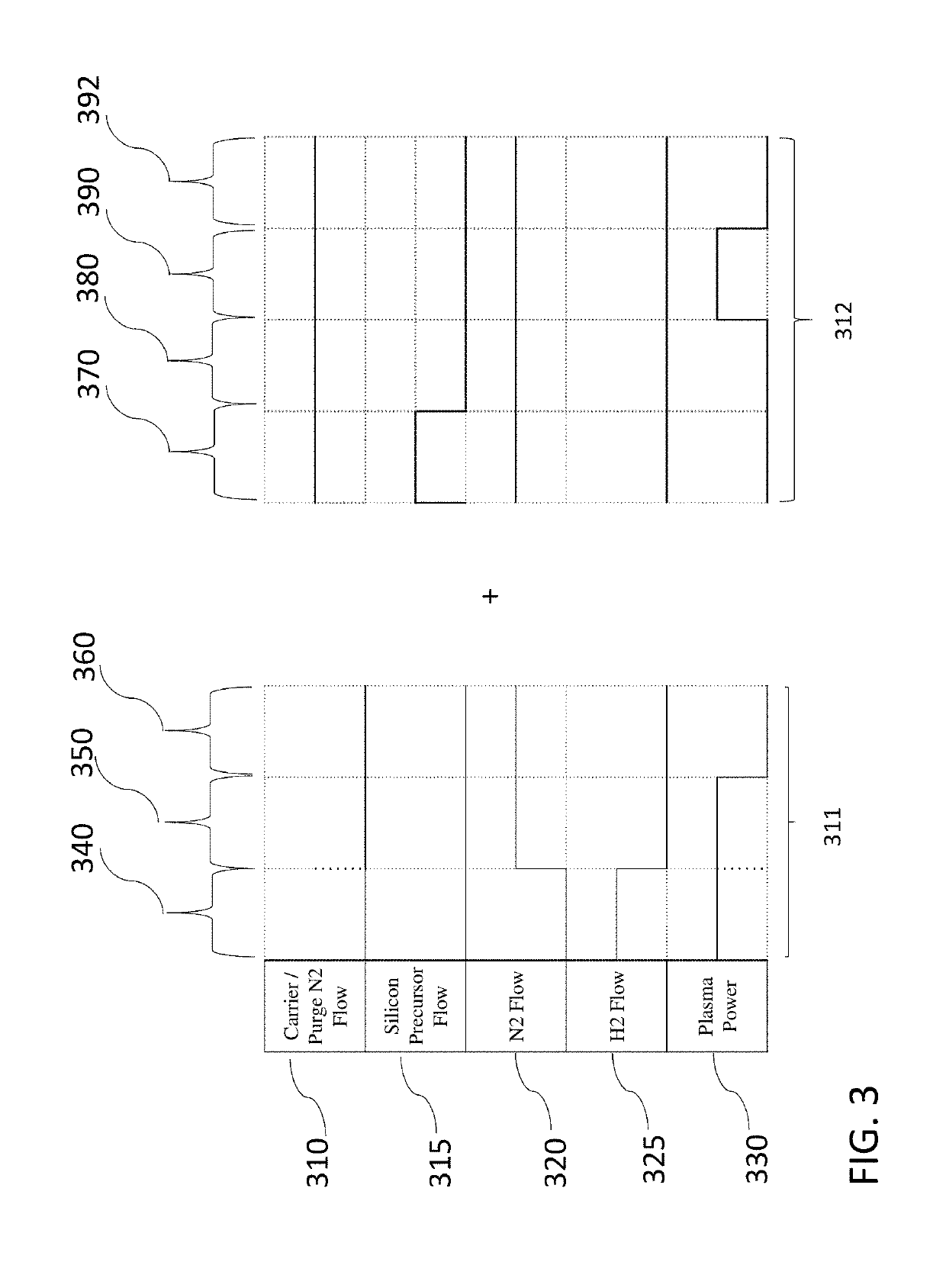

Methods for forming silicon nitride films are provided. In some embodiments, silicon nitride can be deposited by atomic layer deposition (ALD), such as plasma enhanced ALD. One or more silicon nitride deposition cycle comprise a sequential plasma pretreatment phase in which the substrate is sequentially exposed to a hydrogen plasma and then to a nitrogen plasma in the absence of hydrogen plasma, and a deposition phase in which the substrate is exposed to a silicon precursor. In some embodiments a silicon hydrohalide precursors is used for depositing the silicon nitride. The silicon nitride films may have a high side-wall conformality and in some embodiments the silicon nitride film may be thicker at the bottom of the sidewall than at the top of the sidewall in a trench structure. In gap fill processes, the silicon nitride deposition processes can reduce or eliminate voids and seams.

Owner:ASM IP HLDG BV

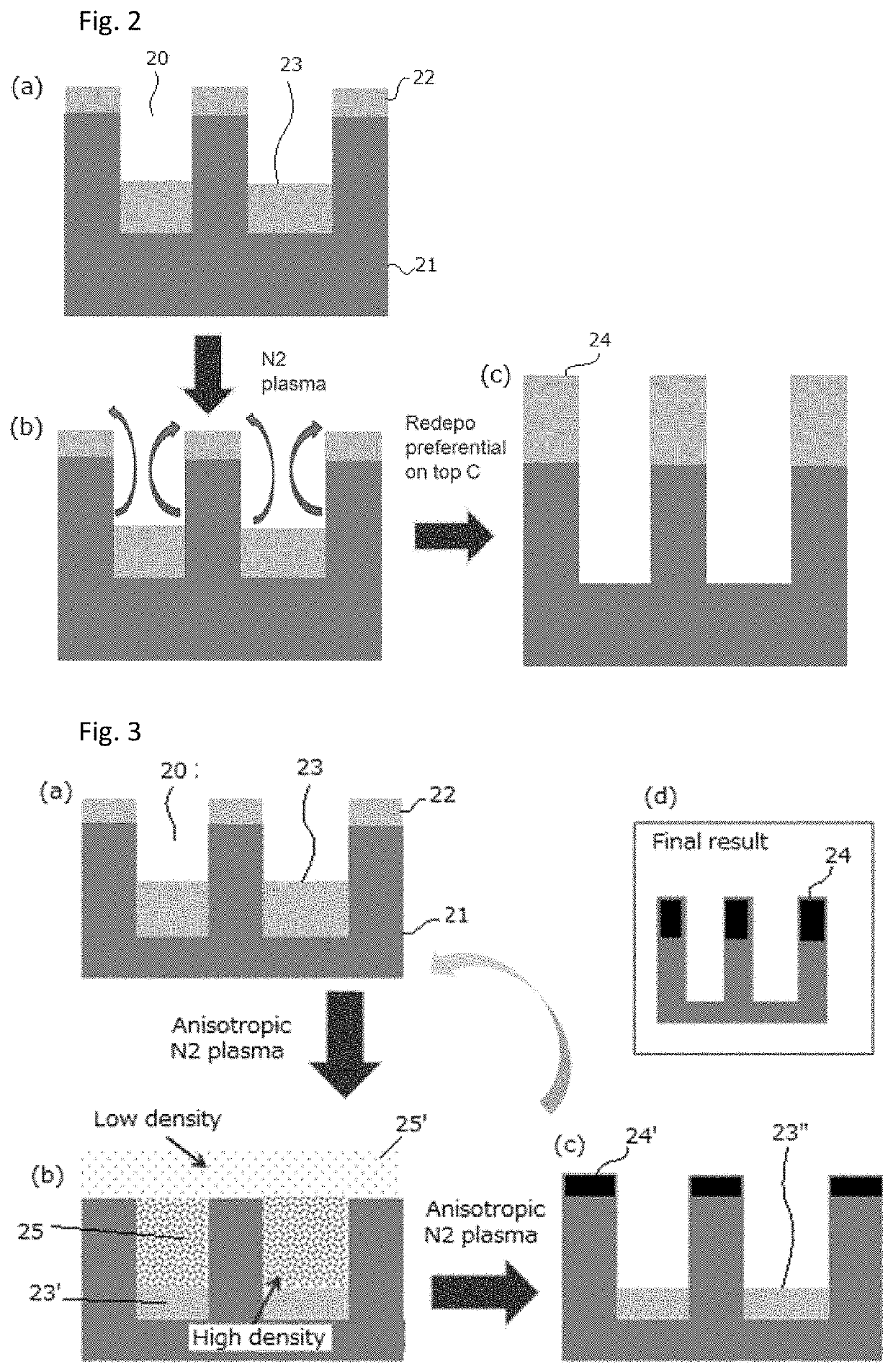

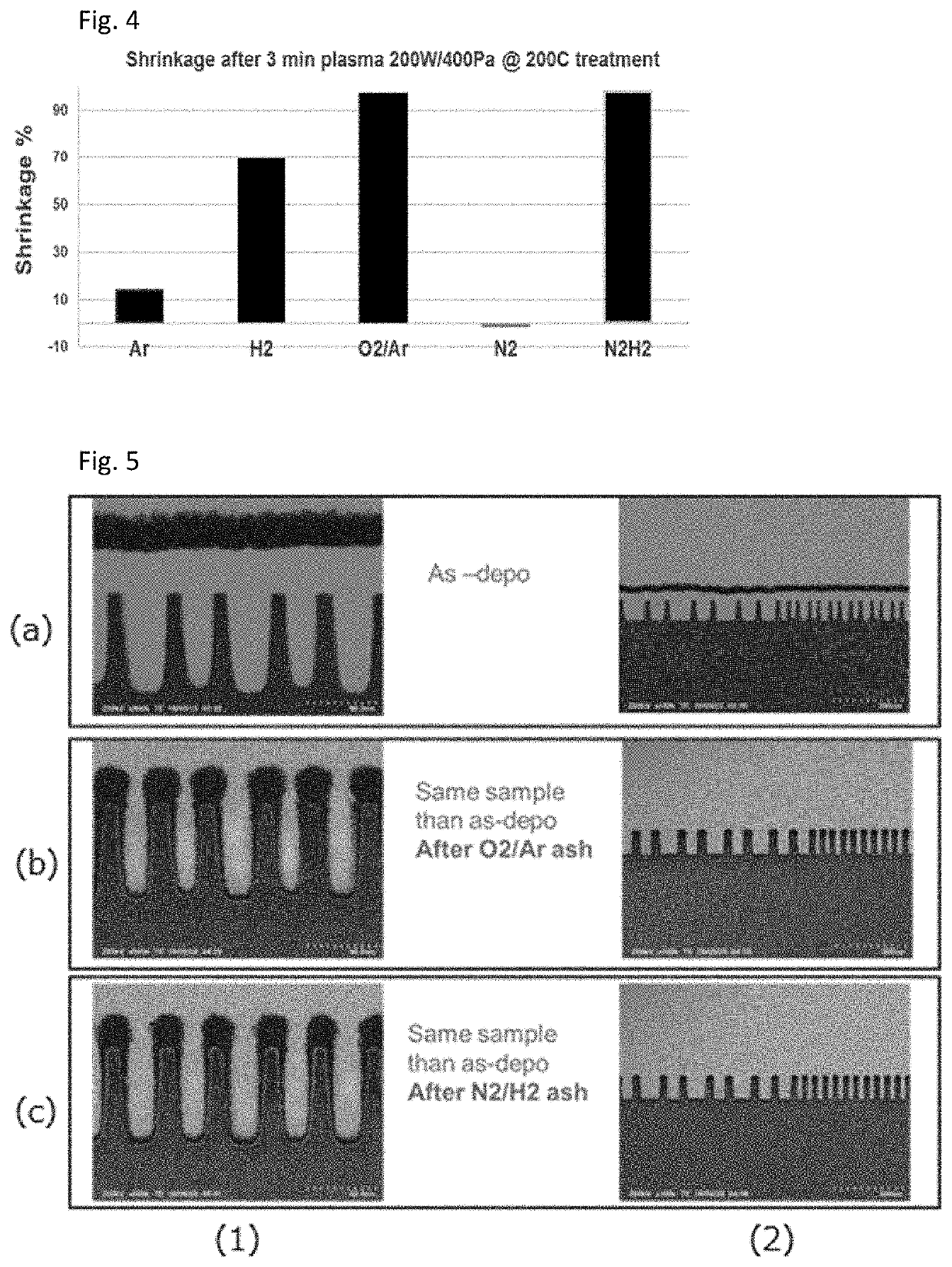

Method of forming topology-controlled amorphous carbon polymer film

In exemplary embodiment, a method of top-selective deposition using a flowable carbon-based film on a substrate having a recess defined by a top surface, sidewall, and a bottom, includes steps of: (i) depositing a flowable carbon-based film in the recess of the substrate in a reaction space until a thickness of the flowable carbon-based film in the recess reaches a predetermined thickness, and then stopping the deposition step; and (ii) exposing the carbon-based film to a nitrogen plasma in an atmosphere substantially devoid of hydrogen and oxygen so as to redeposit a carbon-based film selectively on the top surface.

Owner:ASM IP HLDG BV

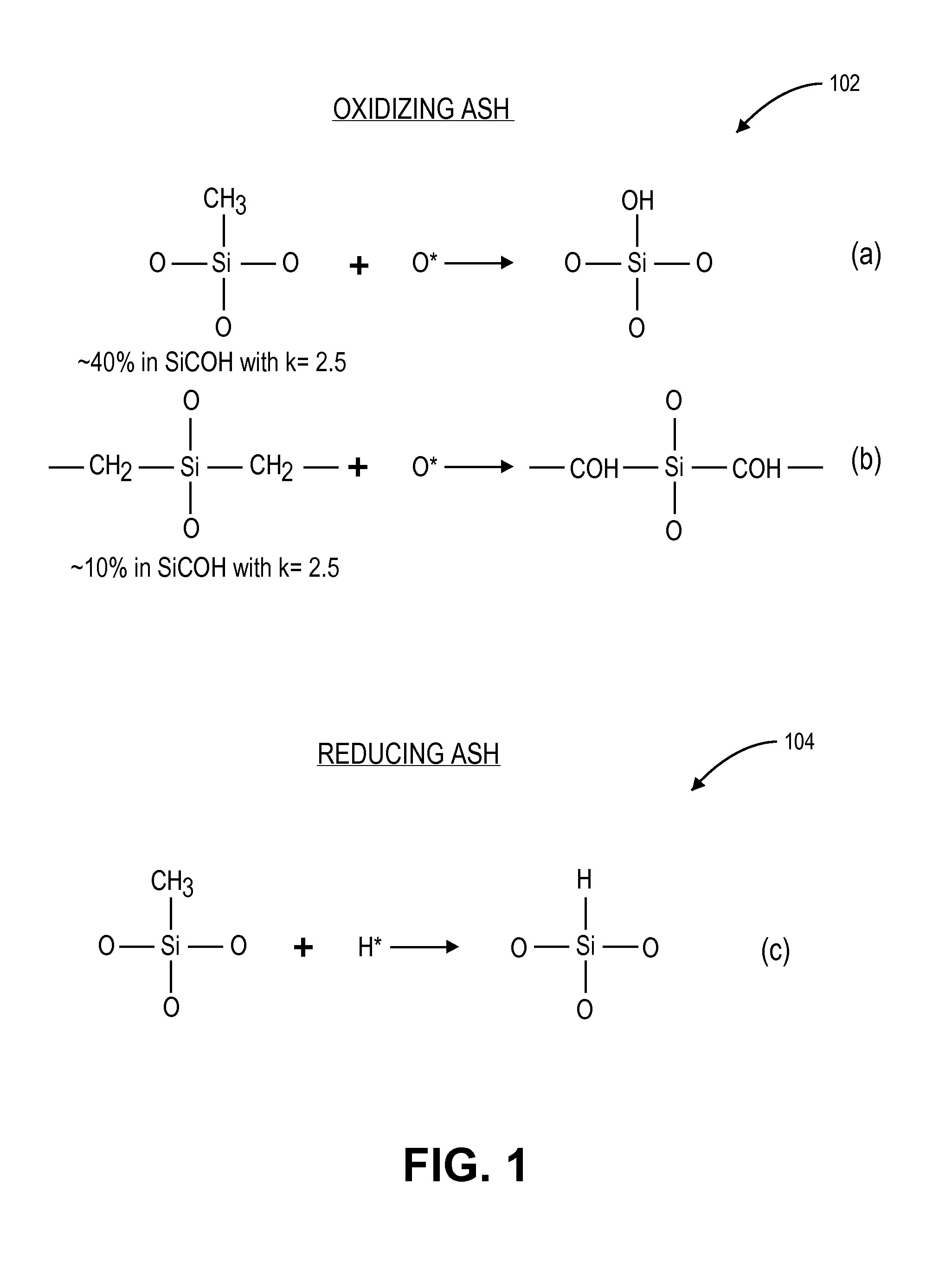

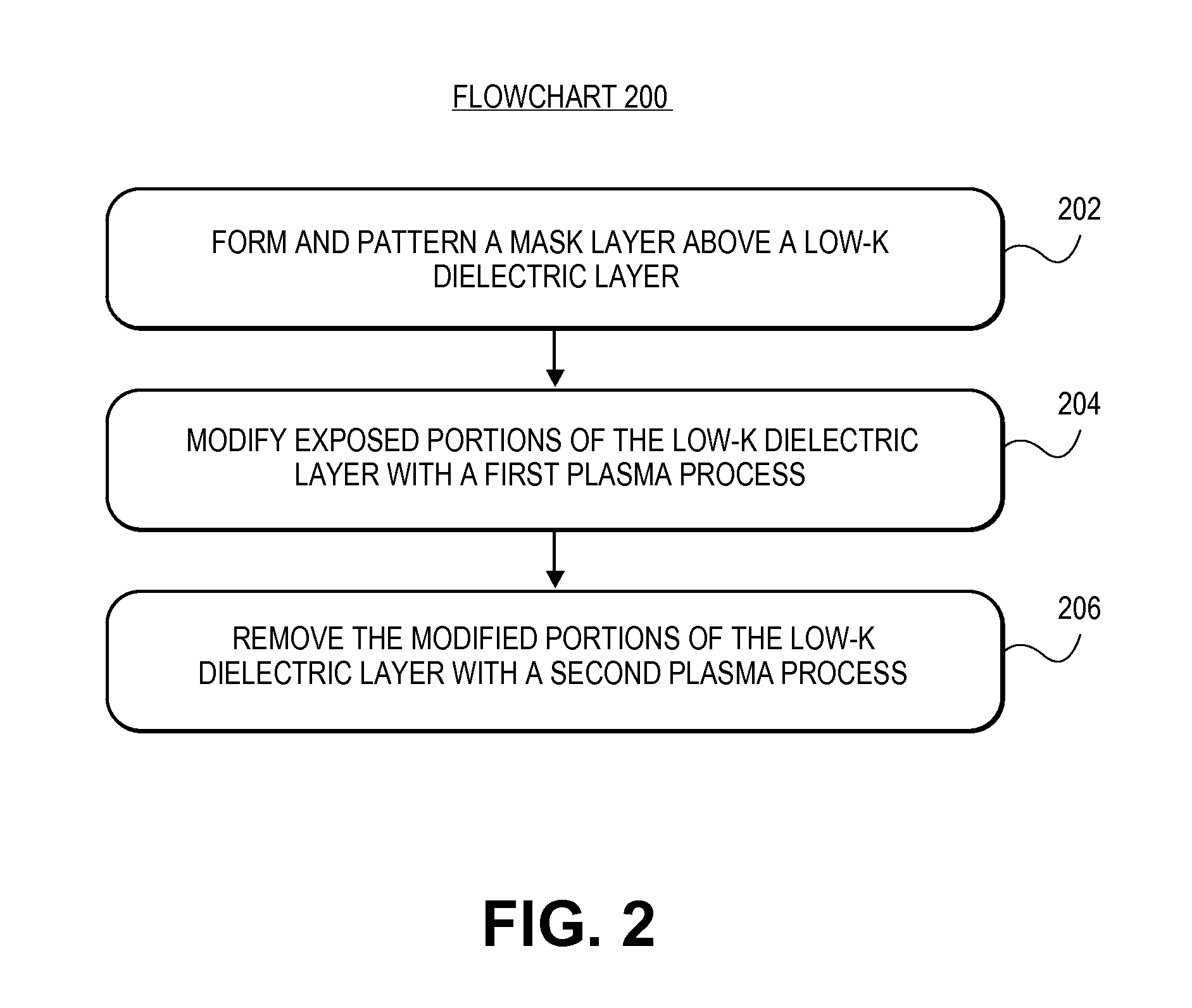

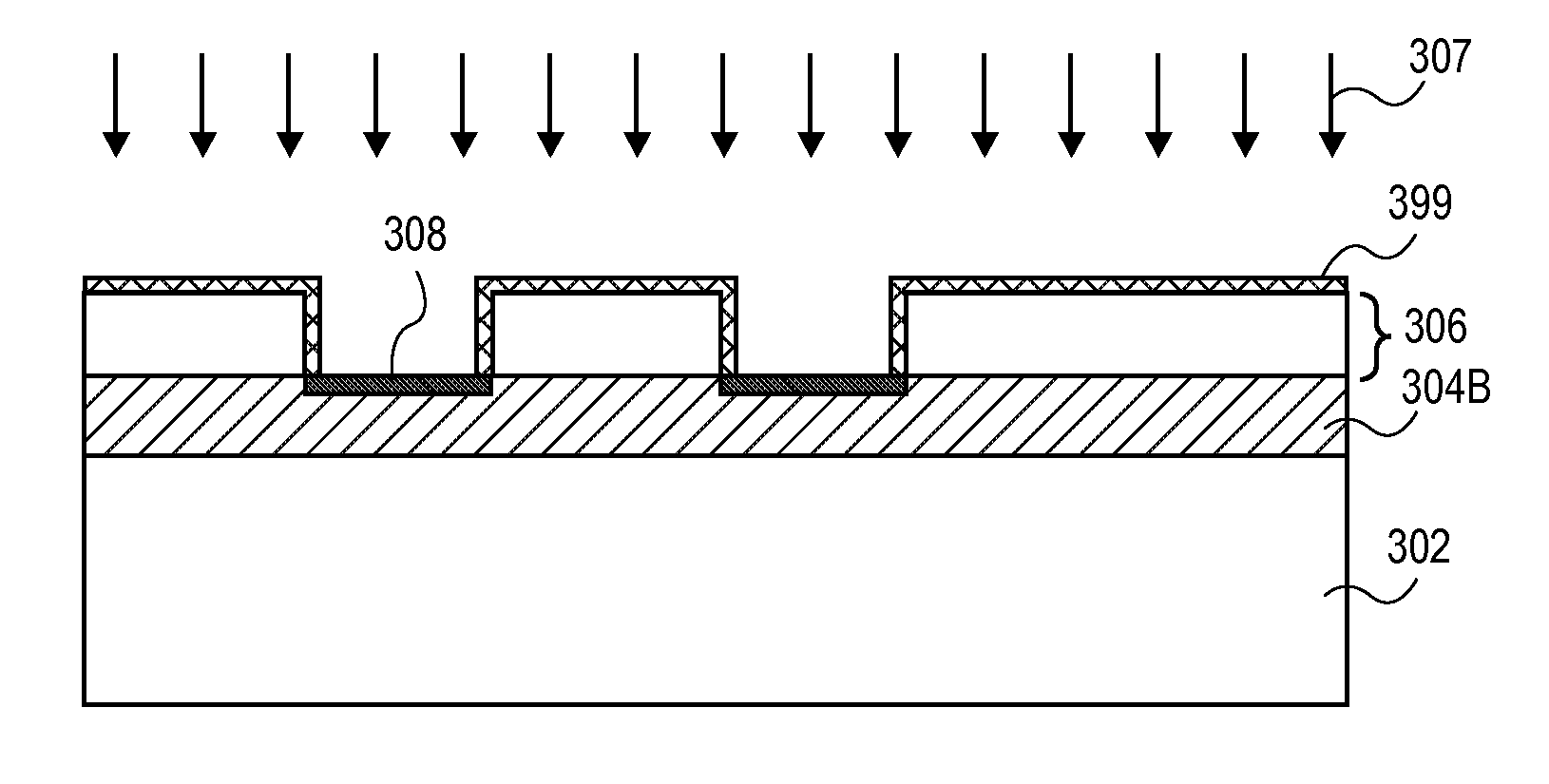

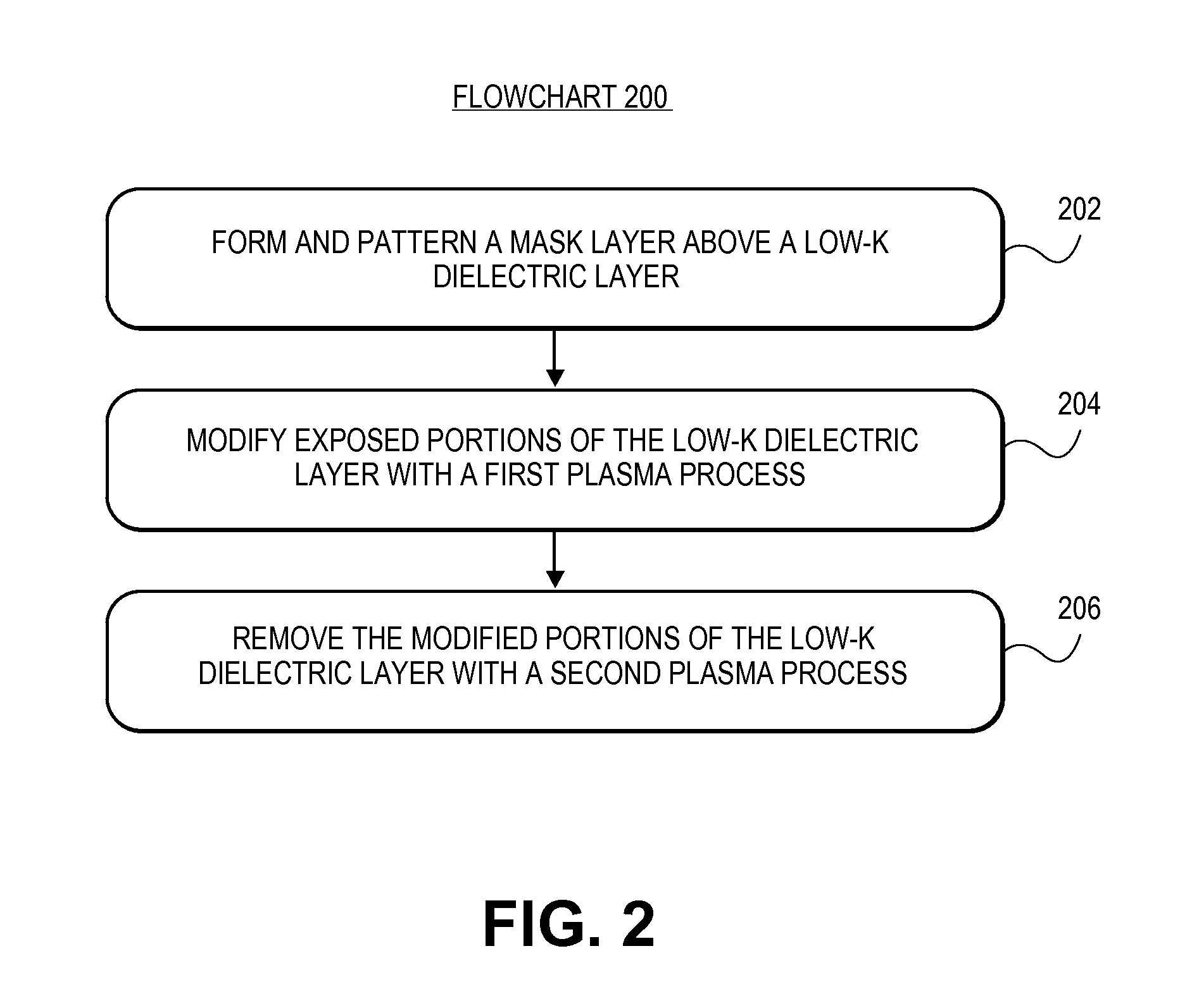

Method of patterning a low-k dielectric film

ActiveUS9165783B2Electric discharge tubesSemiconductor/solid-state device manufacturingNitrogen plasmaRemote plasma

Methods of patterning low-k dielectric films are described. In an example, a method of patterning a low-k dielectric film involves forming and patterning a mask layer above a low-k dielectric layer, the low-k dielectric layer disposed above a substrate. The method also involves modifying exposed portions of the low-k dielectric layer with a nitrogen-free plasma process. The method also involves removing, with a remote plasma process, the modified portions of the low-k dielectric layer selective to the mask layer and unmodified portions of the low-k dielectric layer.

Owner:APPLIED MATERIALS INC

Method to increase tensile stress of silicon nitride films using a post PECVD deposition UV cure

ActiveUS20060269693A1Increasing the thicknessPretreated surfacesSemiconductor/solid-state device manufacturingNitrogen plasmaPlasma treatment

High tensile stress in a deposited layer such as silicon nitride, may be achieved utilizing one or more techniques, employed alone or in combination. High tensile stress may be achieved by forming a silicon-containing layer on a surface by exposing the surface to a silicon-containing precursor gas in the absence of a plasma, forming silicon nitride by exposing said silicon-containing layer to a nitrogen-containing plasma, and then repeating these steps to increase a thickness of the silicon nitride created thereby. High tensile stress may also be achieved by exposing a surface to a silicon-containing precursor gas in a first nitrogen-containing plasma, treating the material with a second nitrogen-containing plasma, and then repeating these steps to increase a thickness of the silicon nitride formed thereby. In another embodiment, tensile film stress is enhanced by deposition with porogens that are liberated upon subsequent exposure to UV radiation or plasma treatment.

Owner:APPLIED MATERIALS INC

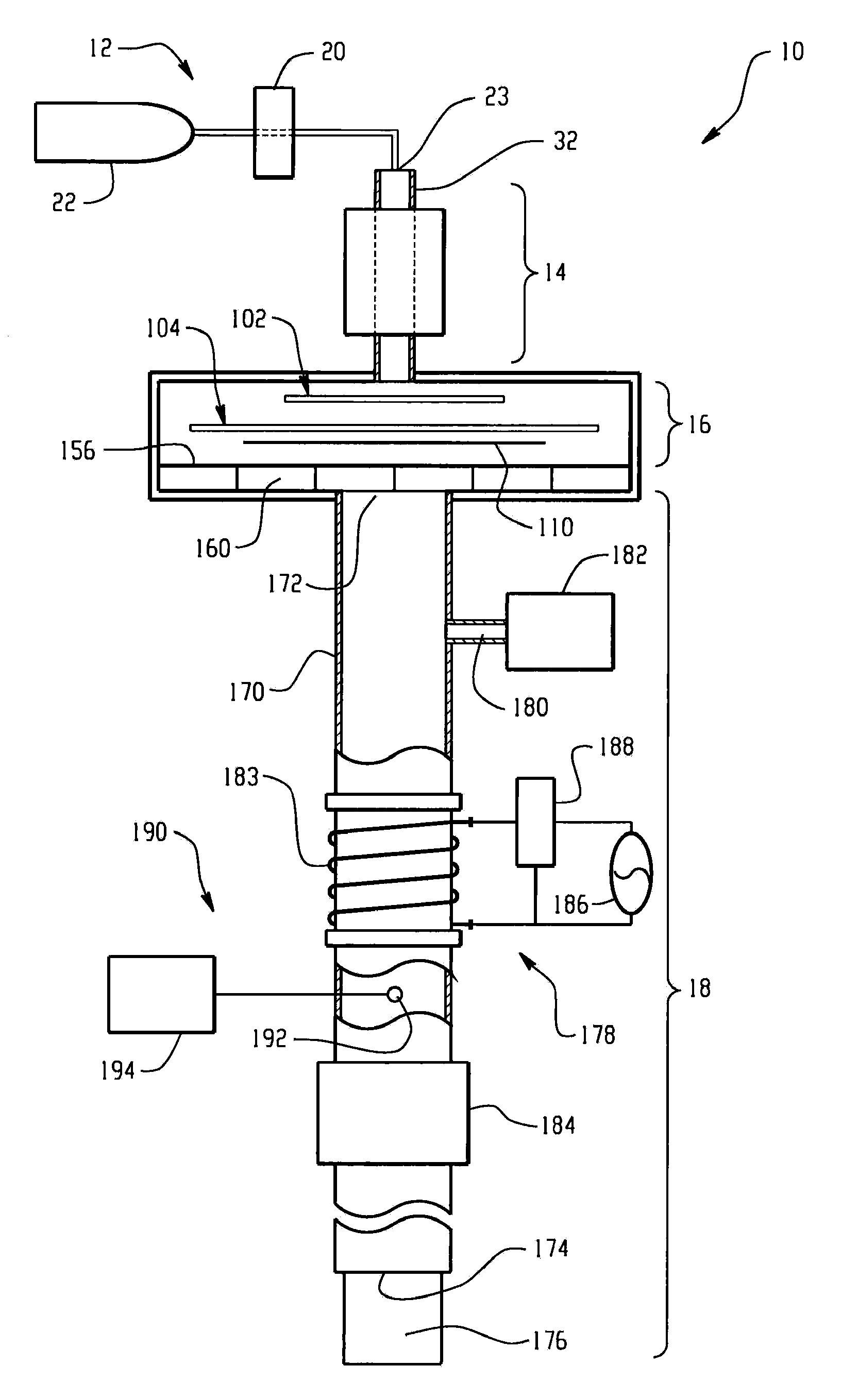

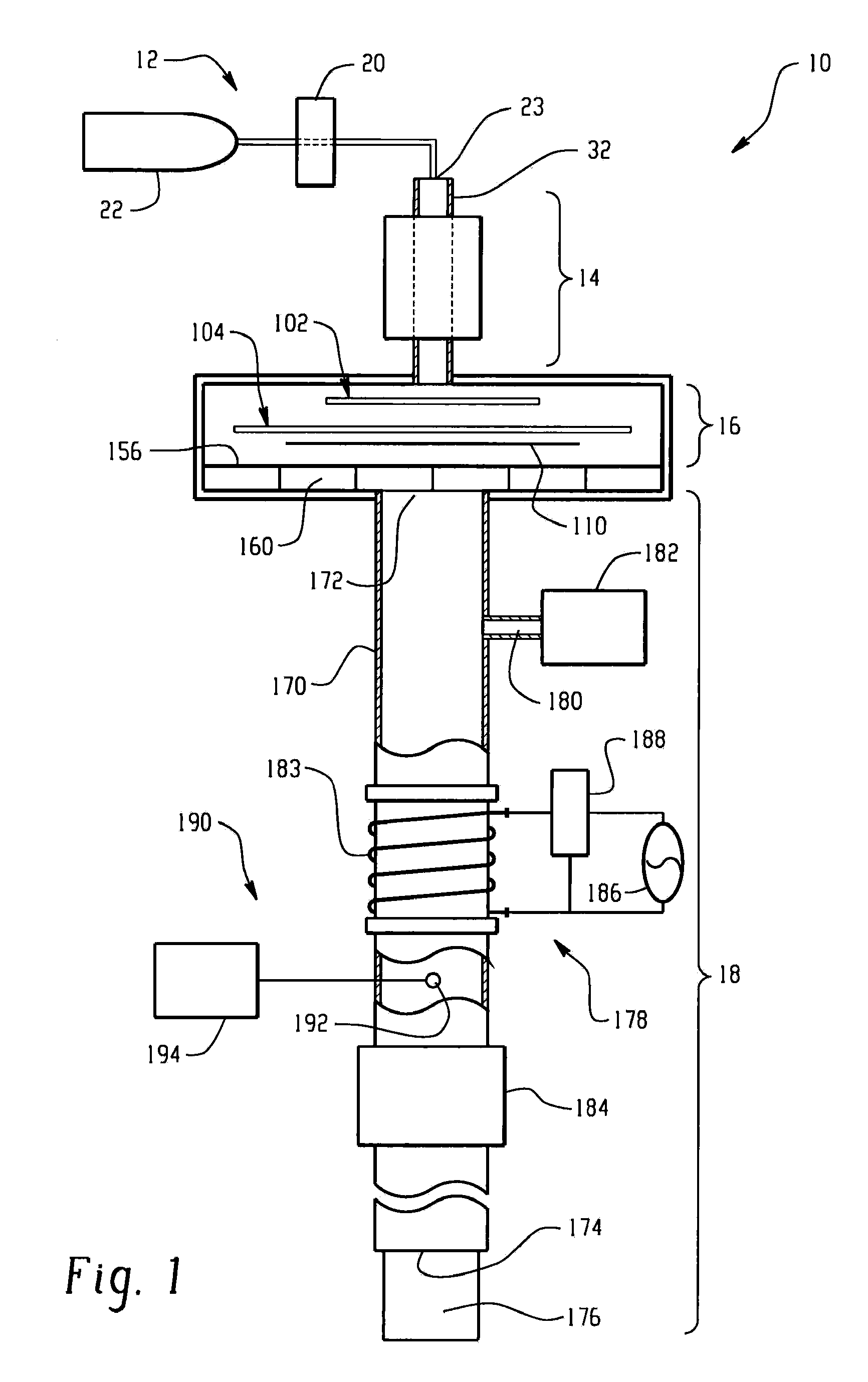

Method and Apparatus for Growing a Group (III) Metal Nitride Film and a Group (III) Metal Nitride Film

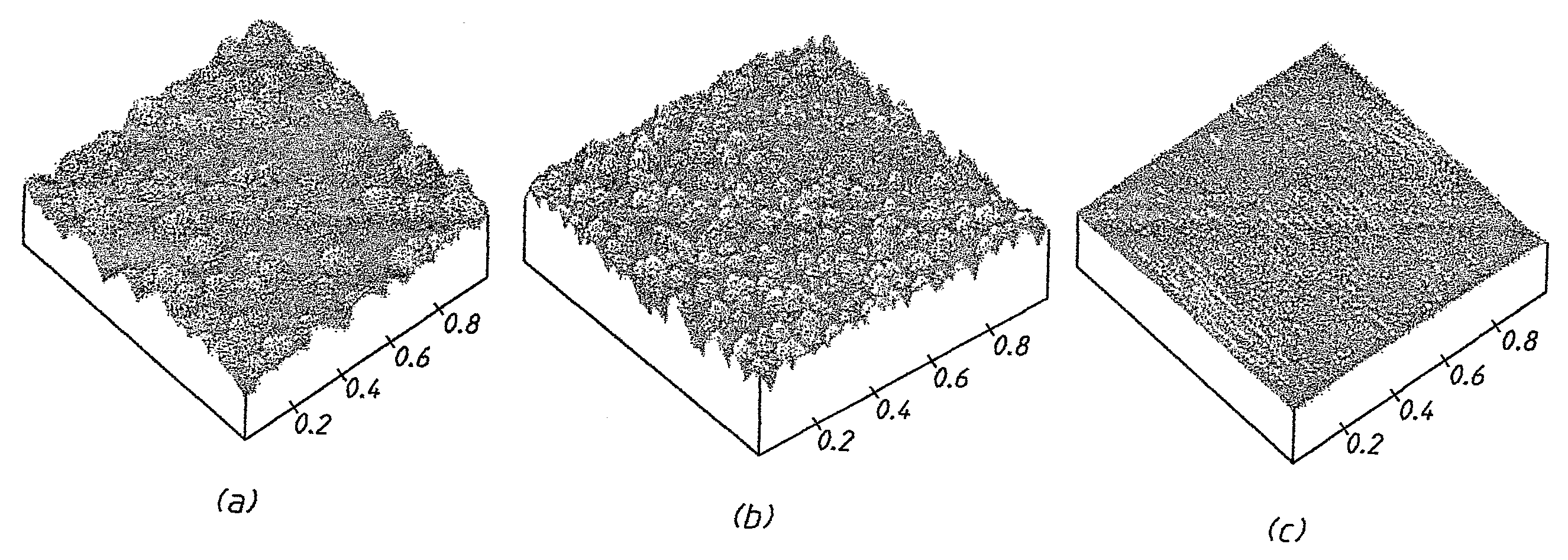

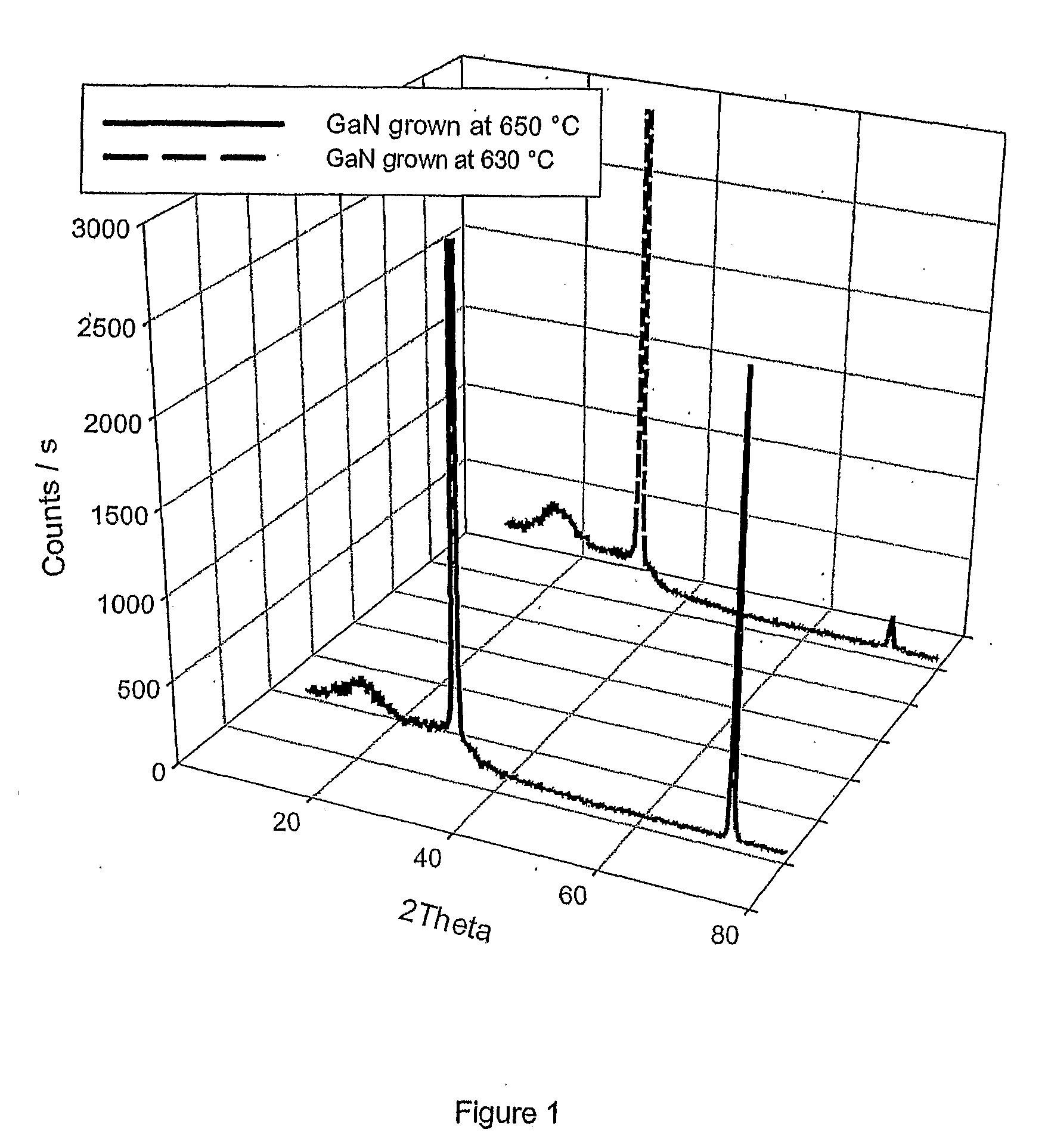

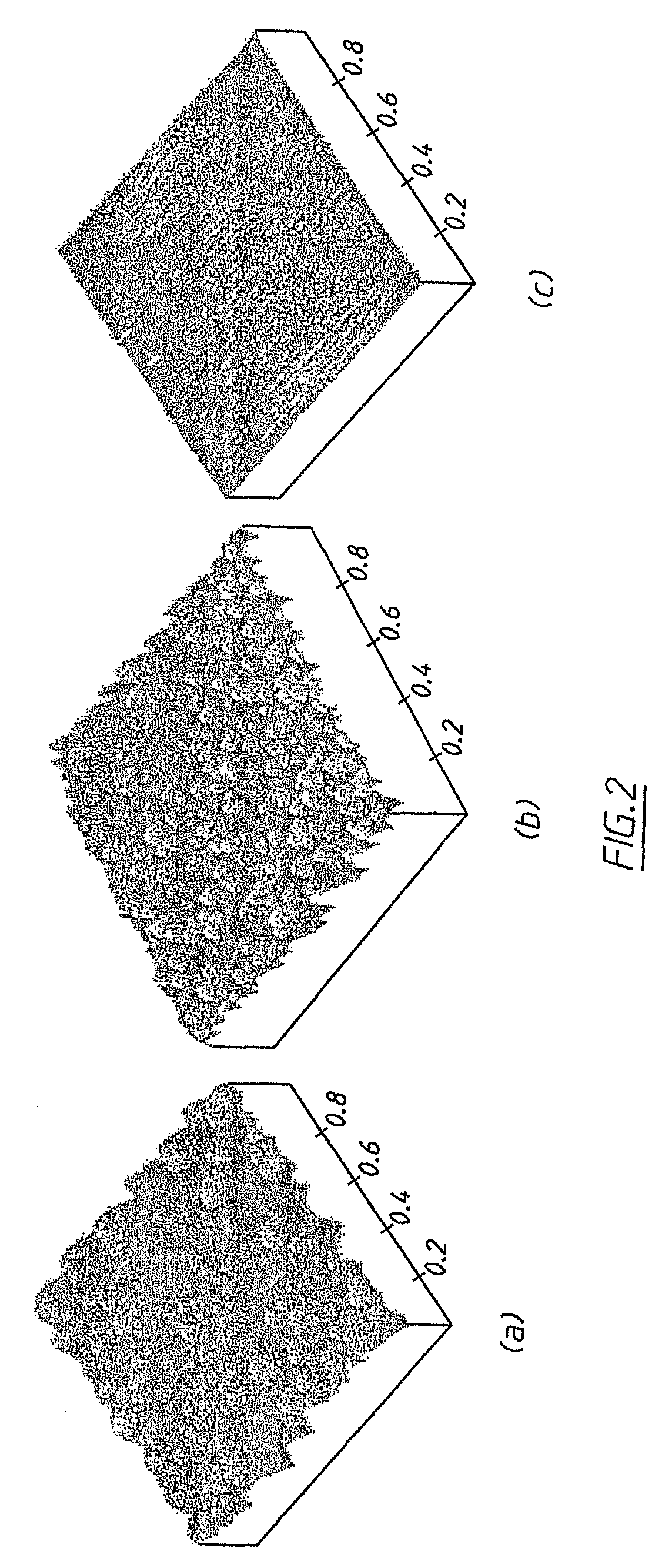

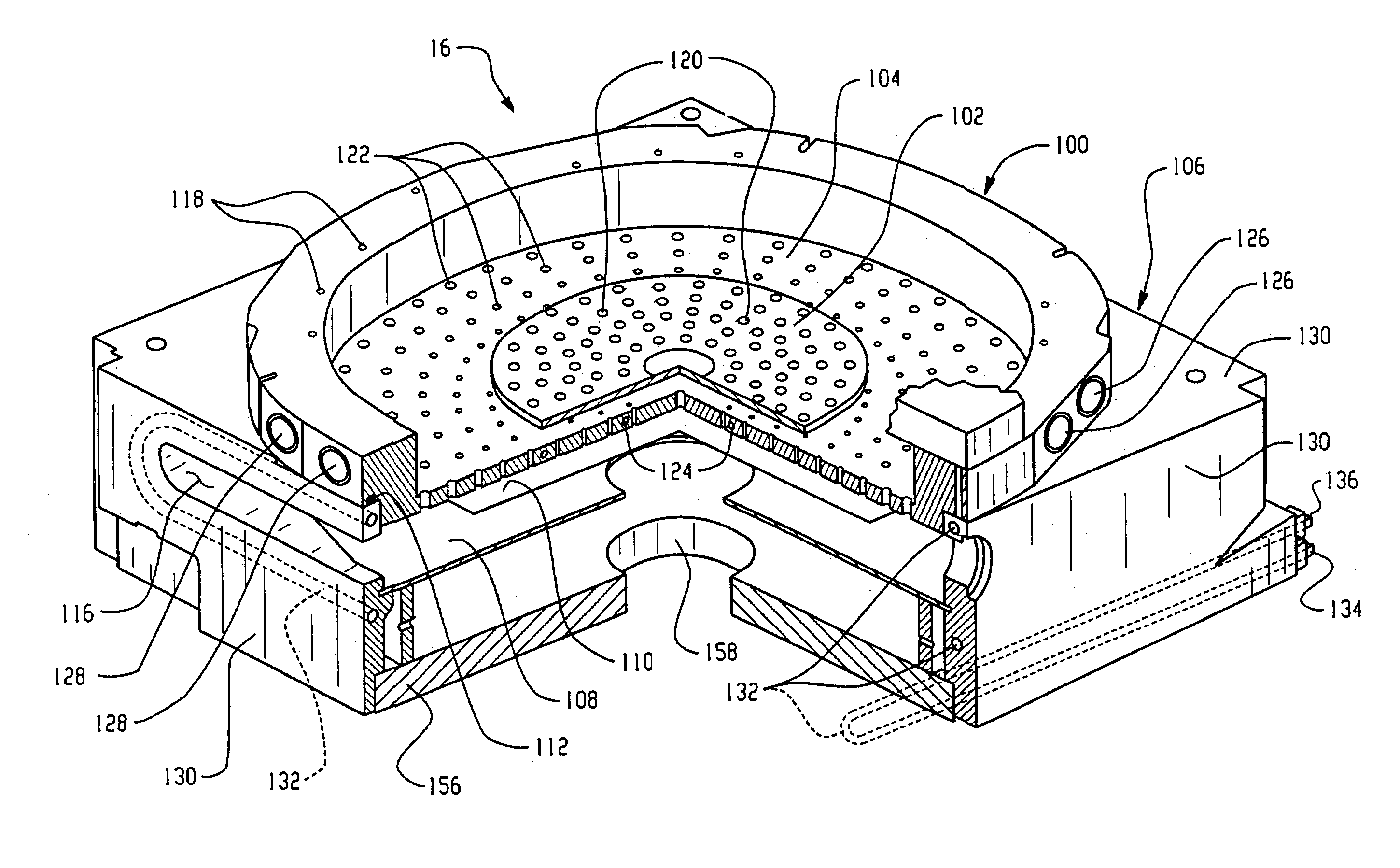

ActiveUS20080272463A1Harsh operating conditionPolycrystalline material growthSemiconductor/solid-state device manufacturingNitrogen plasmaRemote plasma

A process and apparatus for growing a group (III) metal nitride film by remote plasma enhanced chemical vapour deposition are described. The process comprises heating an object selected from the group consisting of a substrate and a substrate comprising a buffer layer in a growth chamber to a temperature in the range of from about 400° C. to o about 750° C., producing active neutral nitrogen species in a nitrogen plasma remotely located from the growth chamber and transferring the active neutral nitrogen species to the growth chamber. A reaction mixture is formed in the growth chamber, the reaction mixture containing a species of a group (III) metal that is capable of reacting with the nitrogen species so as to form a group (III) metal nitride film and a film of group (III) s metal nitride is formed on the heated object under conditions whereby the film is suitable for device purposes. Also described is a group (III) metal nitride film which exhibits an oxygen concentration below 1.6 atomic %.

Owner:GALLIUM ENTERPRISES

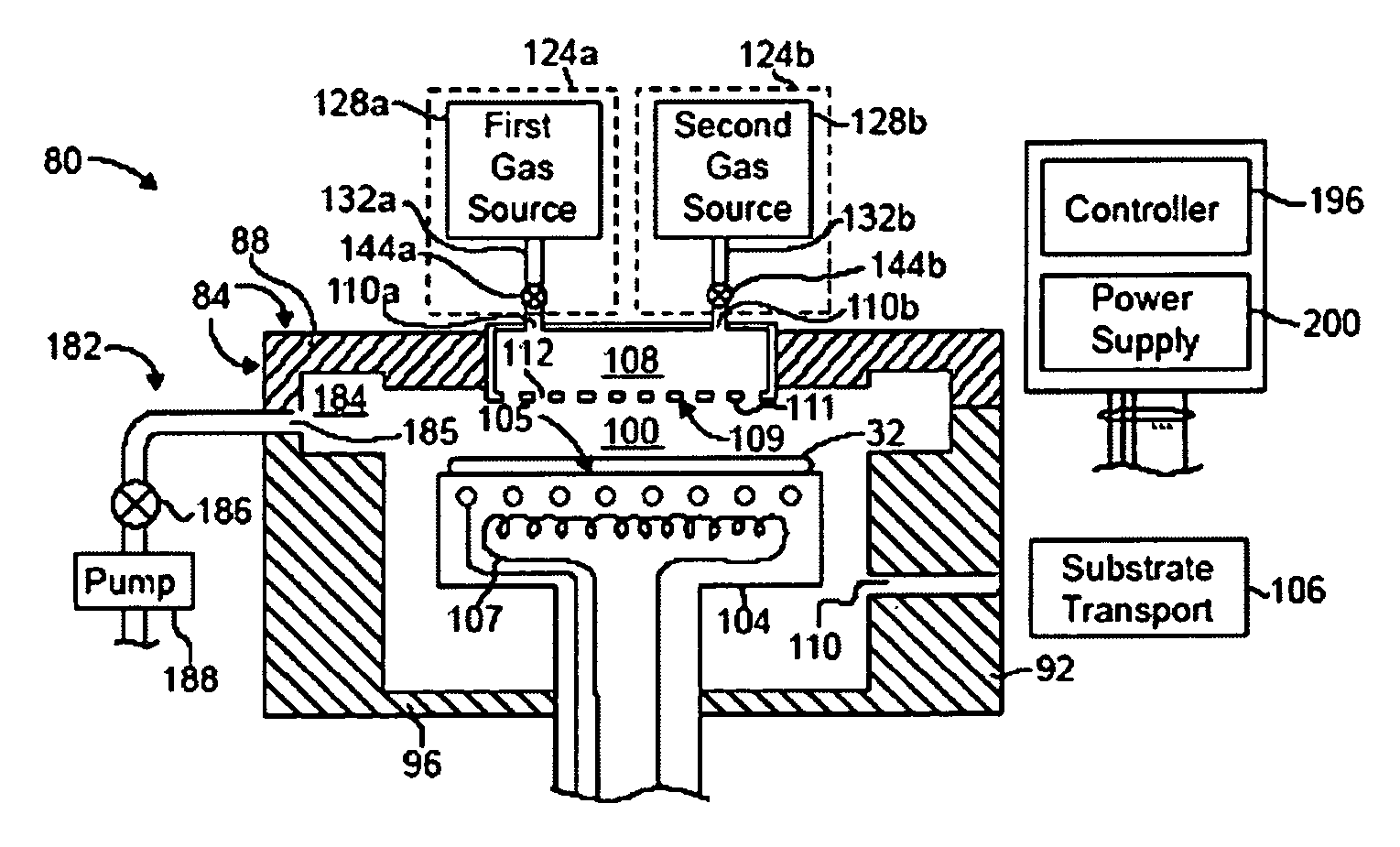

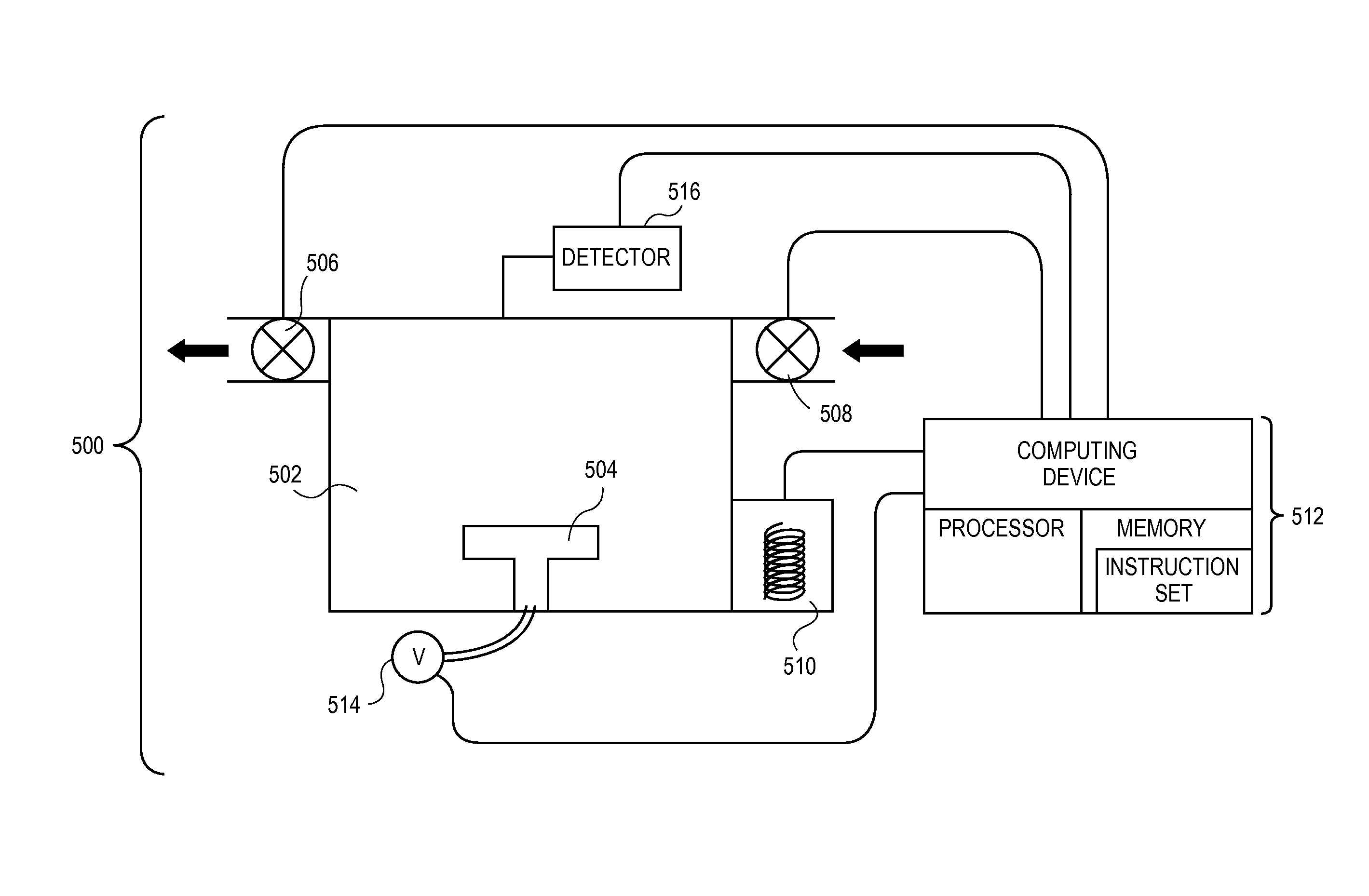

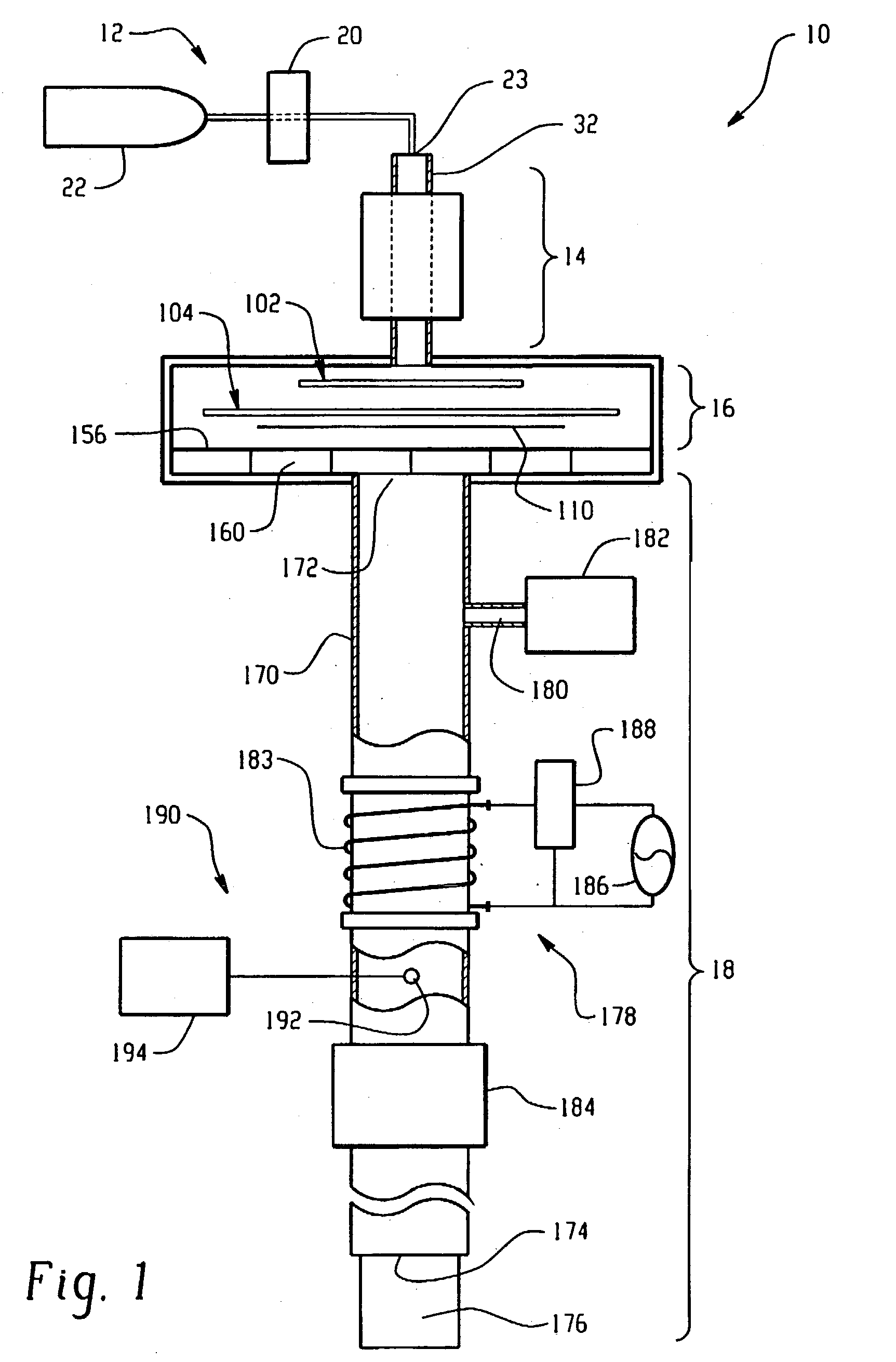

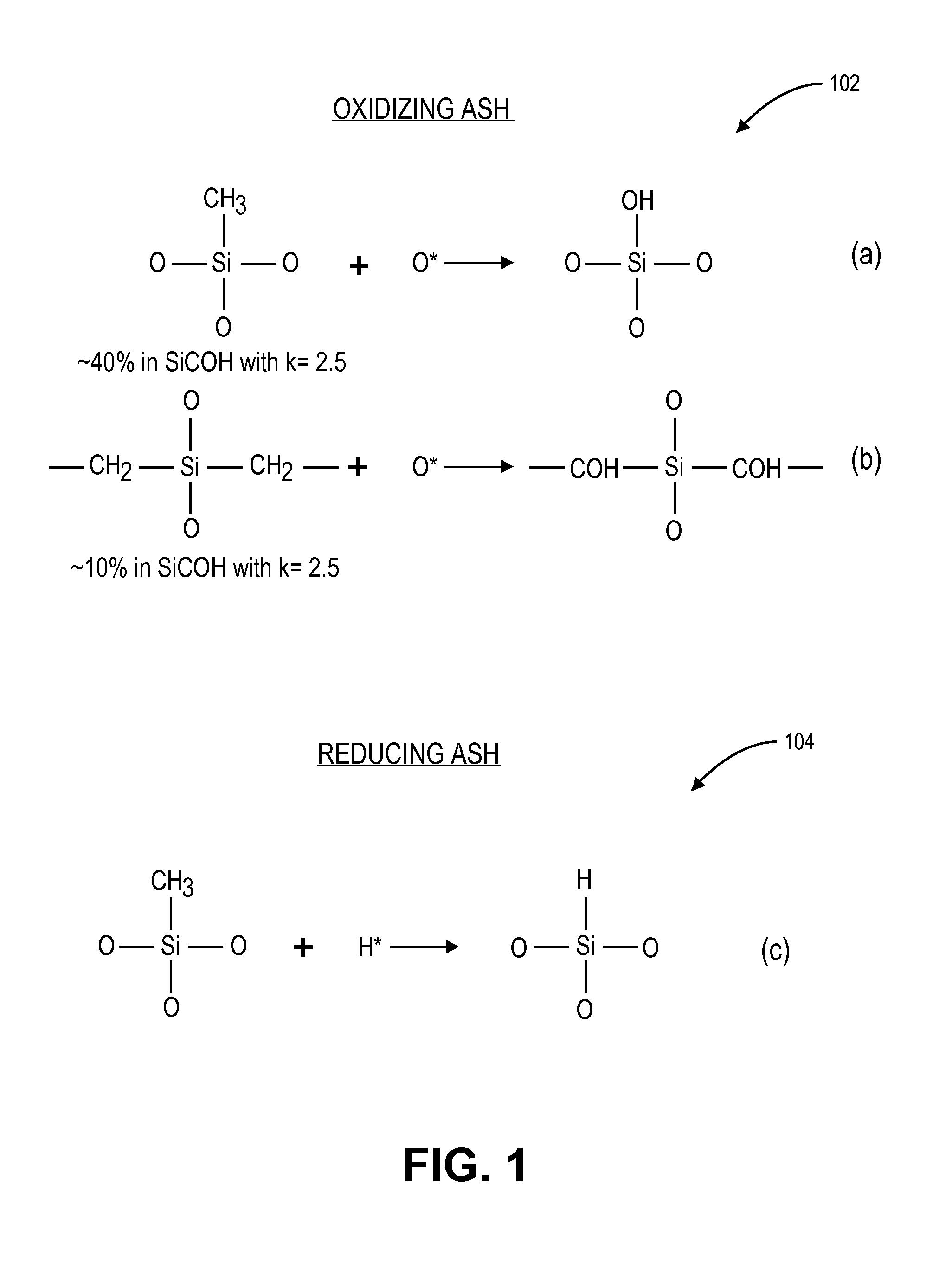

Plasma ashing apparatus and endpoint detection process

InactiveUS20040235299A1Enhance photoresist removalFlexible process platformElectric discharge tubesSemiconductor/solid-state device manufacturingNitrogen plasmaCombustion chamber

A plasma ashing apparatus for removing organic matter from a substrate including a low k dielectric, comprising a first gas source; a plasma generating component in fluid communication with the first gas source; a process chamber in fluid communication with the plasma generating component; an exhaust conduit in fluid communication with the process chamber; wherein the exhaust conduit comprises an inlet for a second gas source and an afterburner assembly coupled to the exhaust conduit, wherein the inlet is disposed intermediate to the process chamber and an afterburner assembly, and wherein the afterburner assembly comprises means for generating a plasma within the exhaust conduit with or without introduction of a gas from the second gas source; and an optical emission spectroscopy device coupled to the exhaust conduit comprising collection optics focused within a plasma discharge region of the afterburner assembly. An endpoint detection process for an oxygen free and nitrogen free plasma process comprises monitoring an optical emission signal of an afterburner excited species in an exhaust conduit of the plasma asher apparatus. The process and apparatus can be used with carbon and / or hydrogen containing low k dielectric materials.

Owner:LAM RES CORP

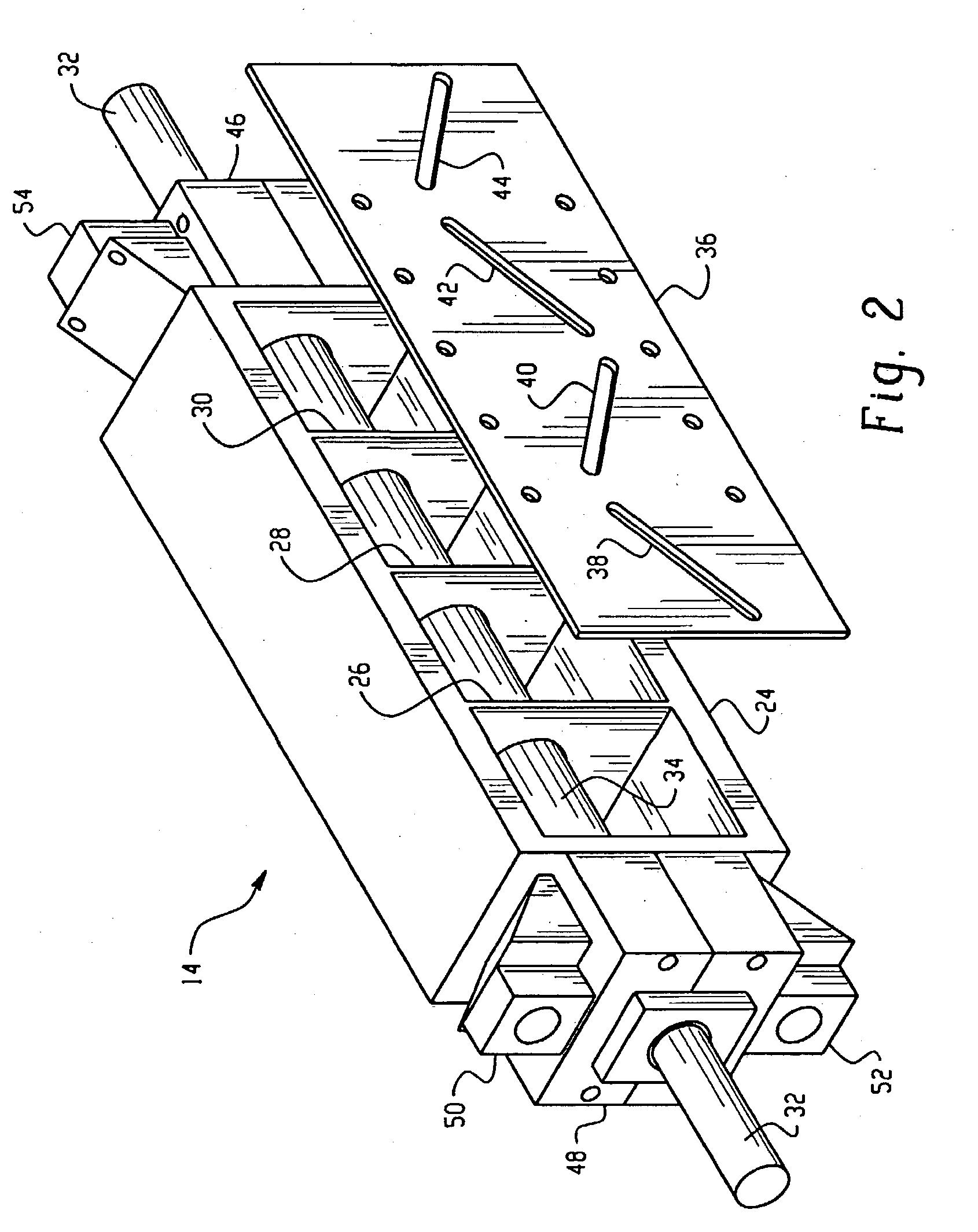

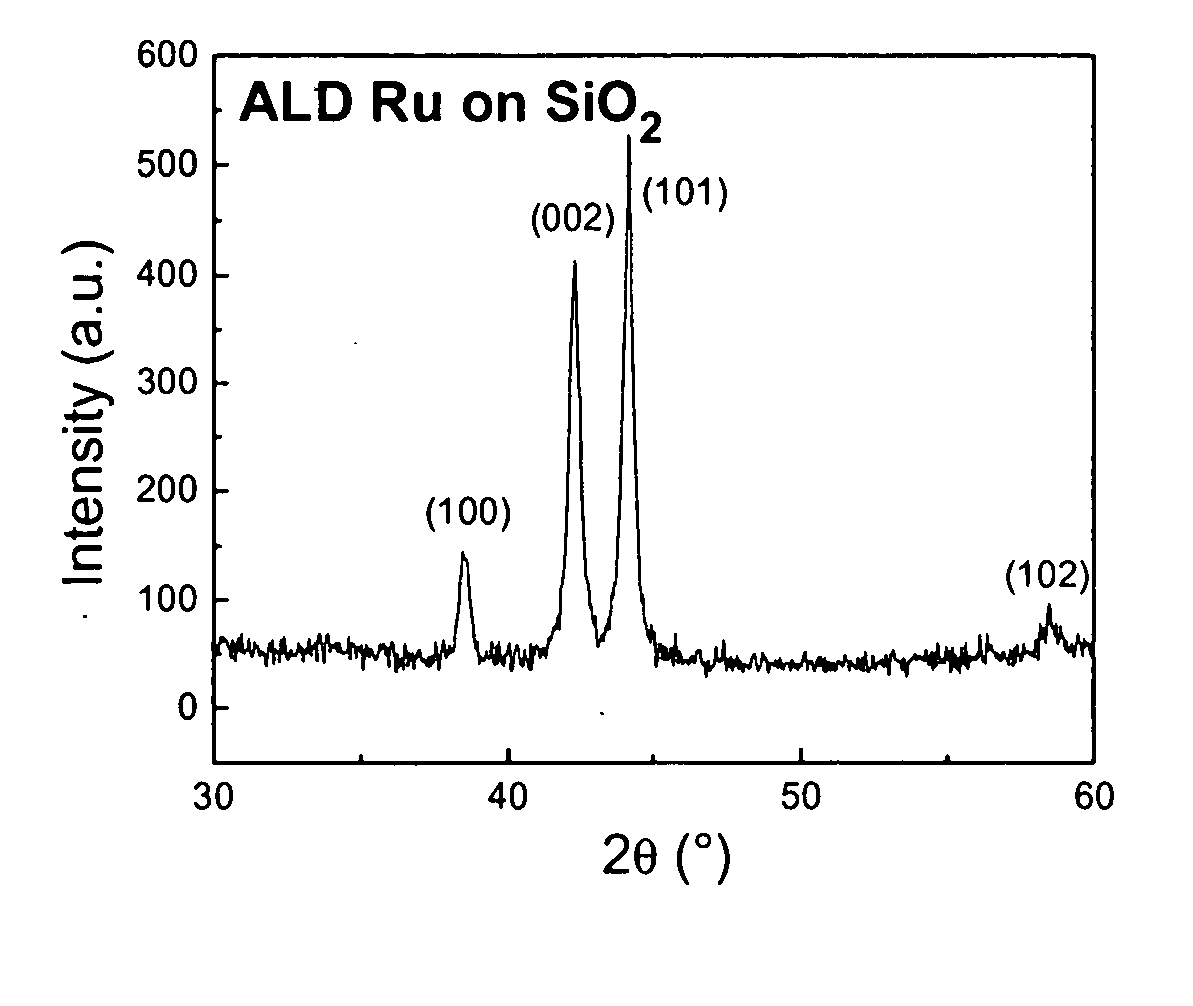

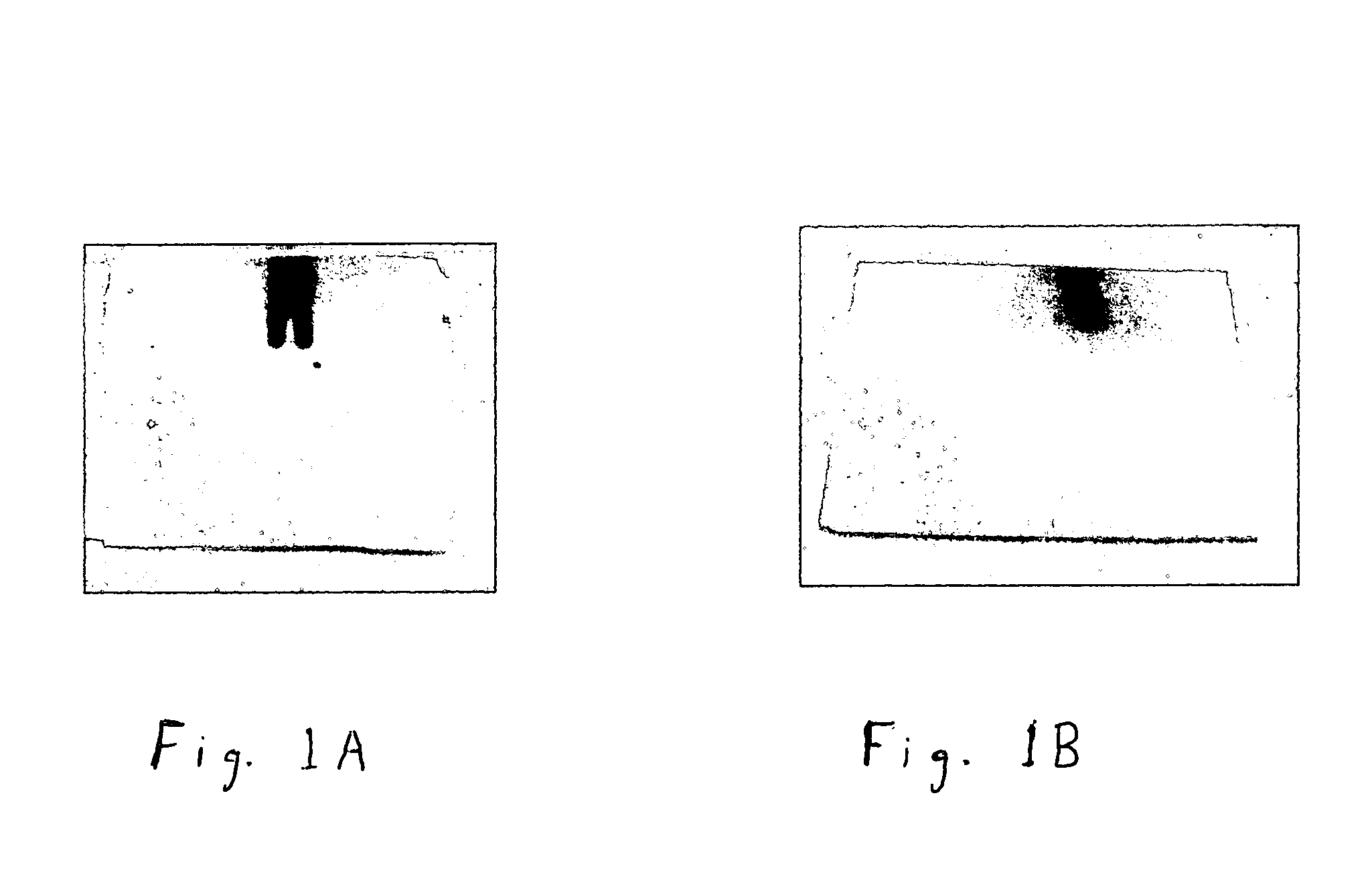

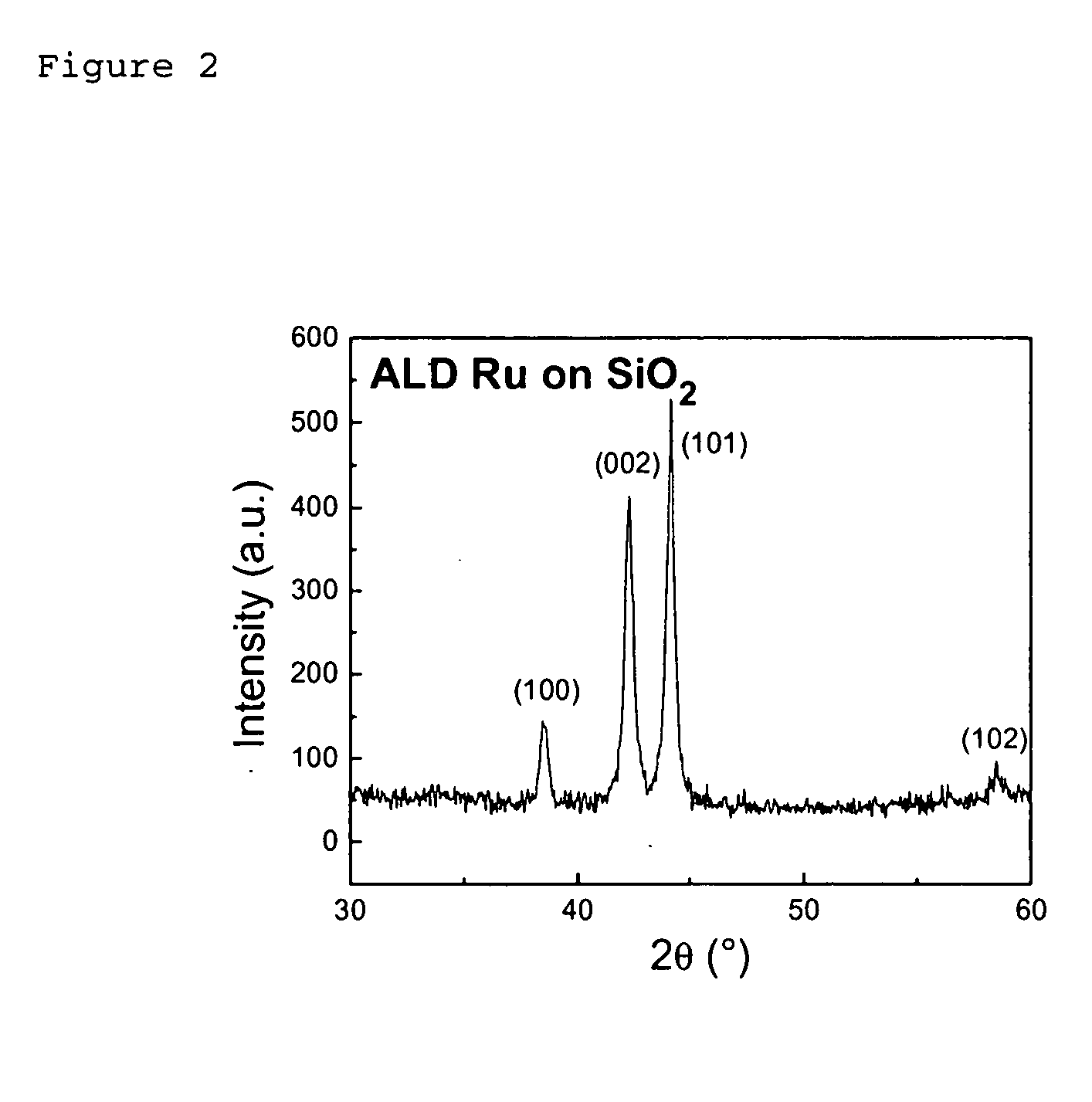

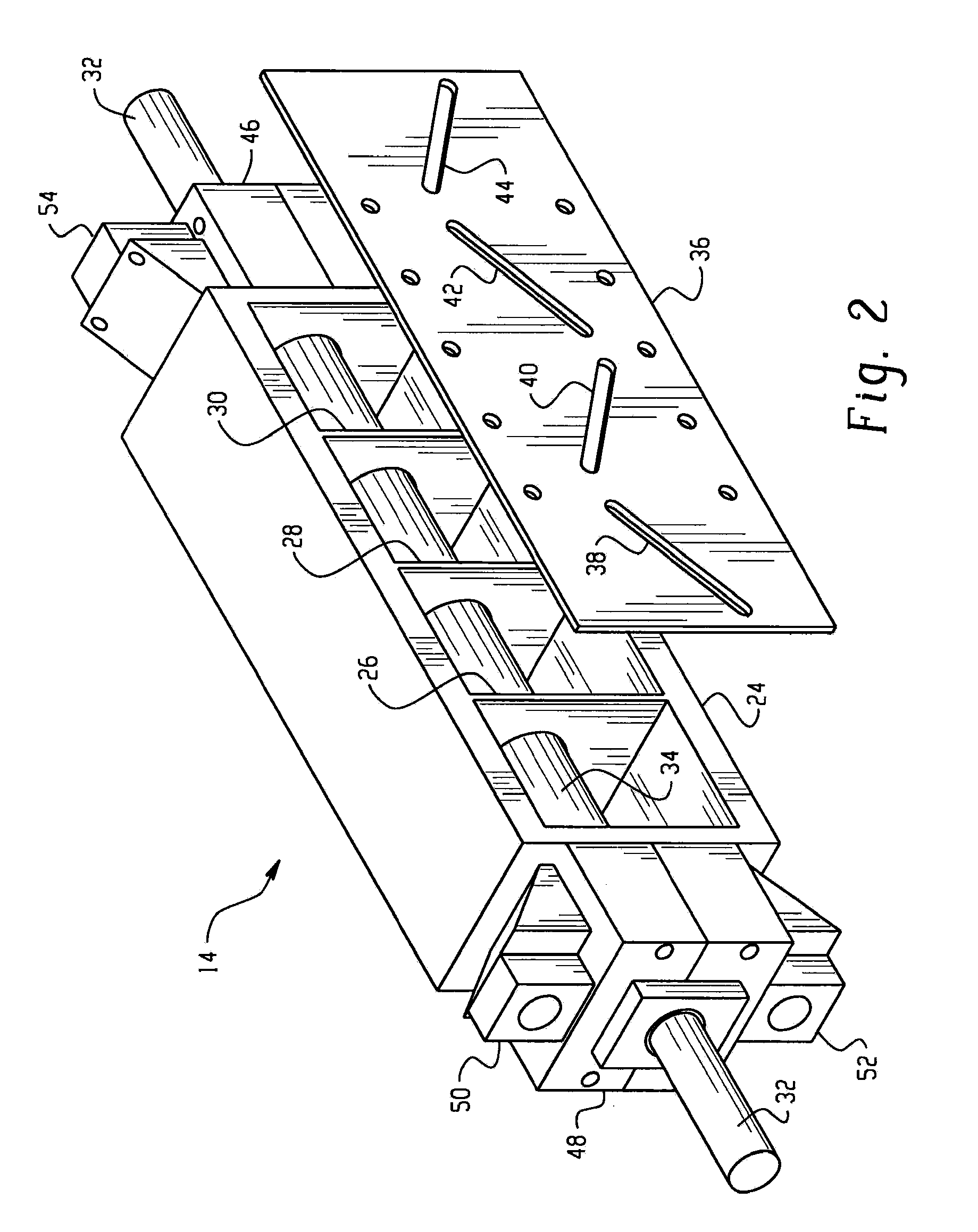

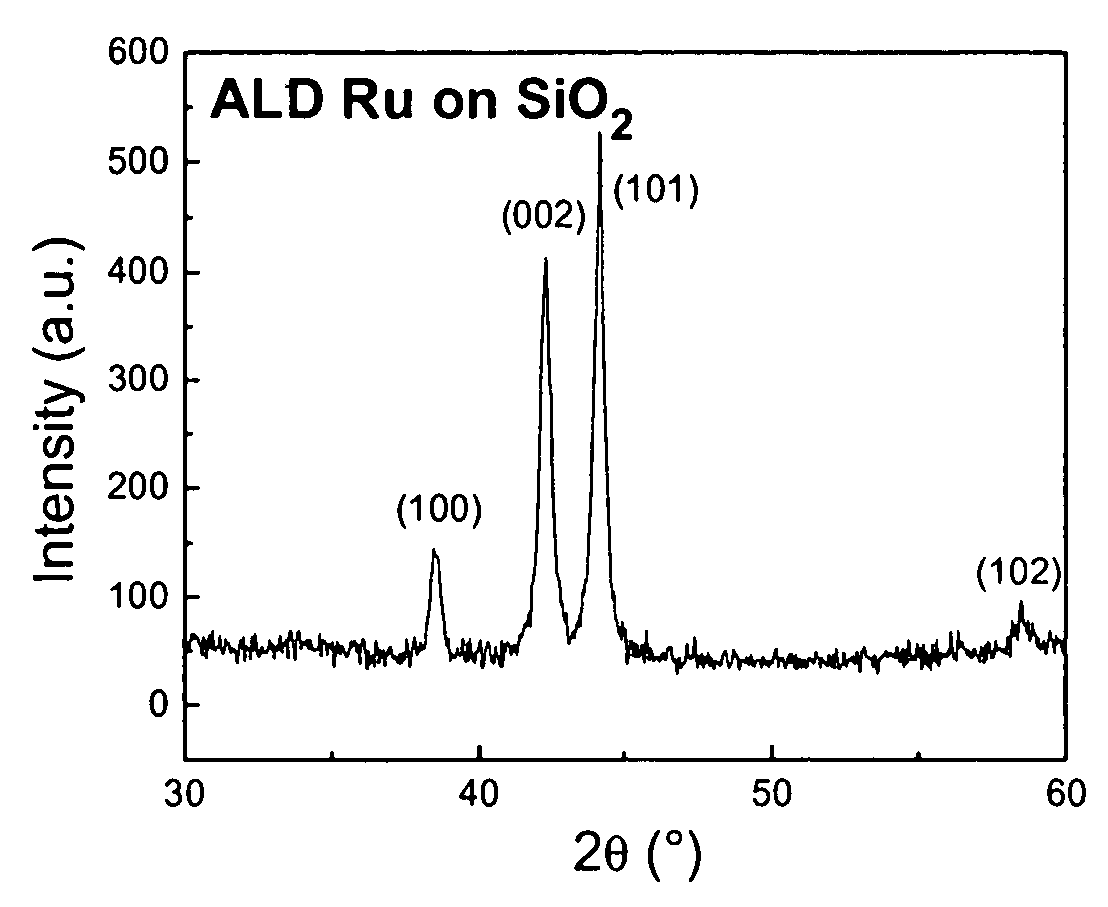

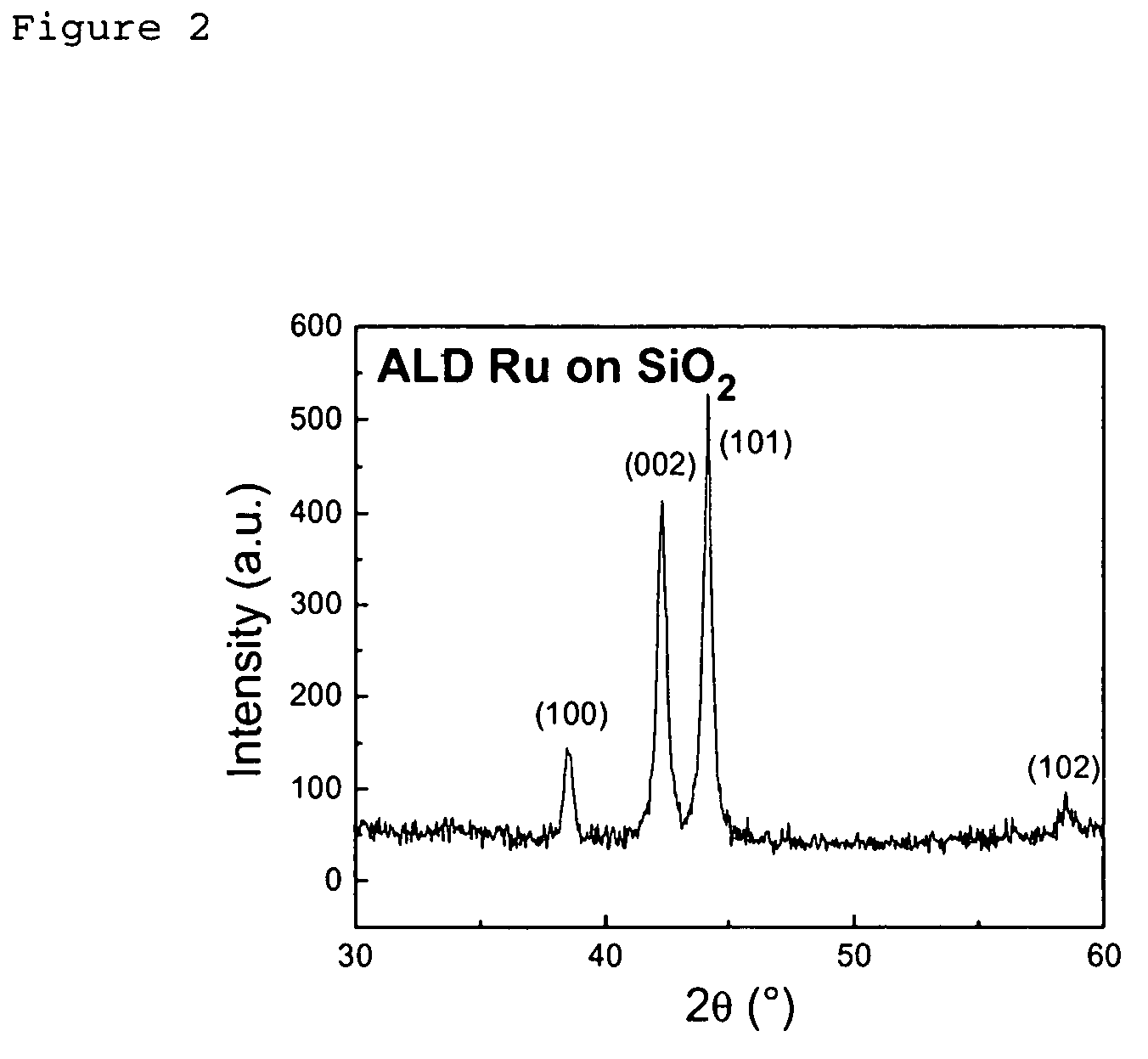

Ald deposition of ruthenium

InactiveUS20050118807A1None be problem freeLow impurity contentSemiconductor/solid-state device detailsSolid-state devicesCMOSCopper interconnect

A method to deposit nucleation problem free ruthenium by ALD. The nucleation problem free, relatively smooth ruthenium ALD film is deposited by the use of plasma-enhanced ALD of ruthenium underlay for consequent thermal ruthenium ALD layer. In addition, oxygen or nitrogen plasma treatments of SiO2 or other dielectrics leads to uniform ALD ruthenium deposition. The method has application as a direct plating layer for a copper interconnect or metal gate structure for advanced CMOS devices.

Owner:IBM CORP

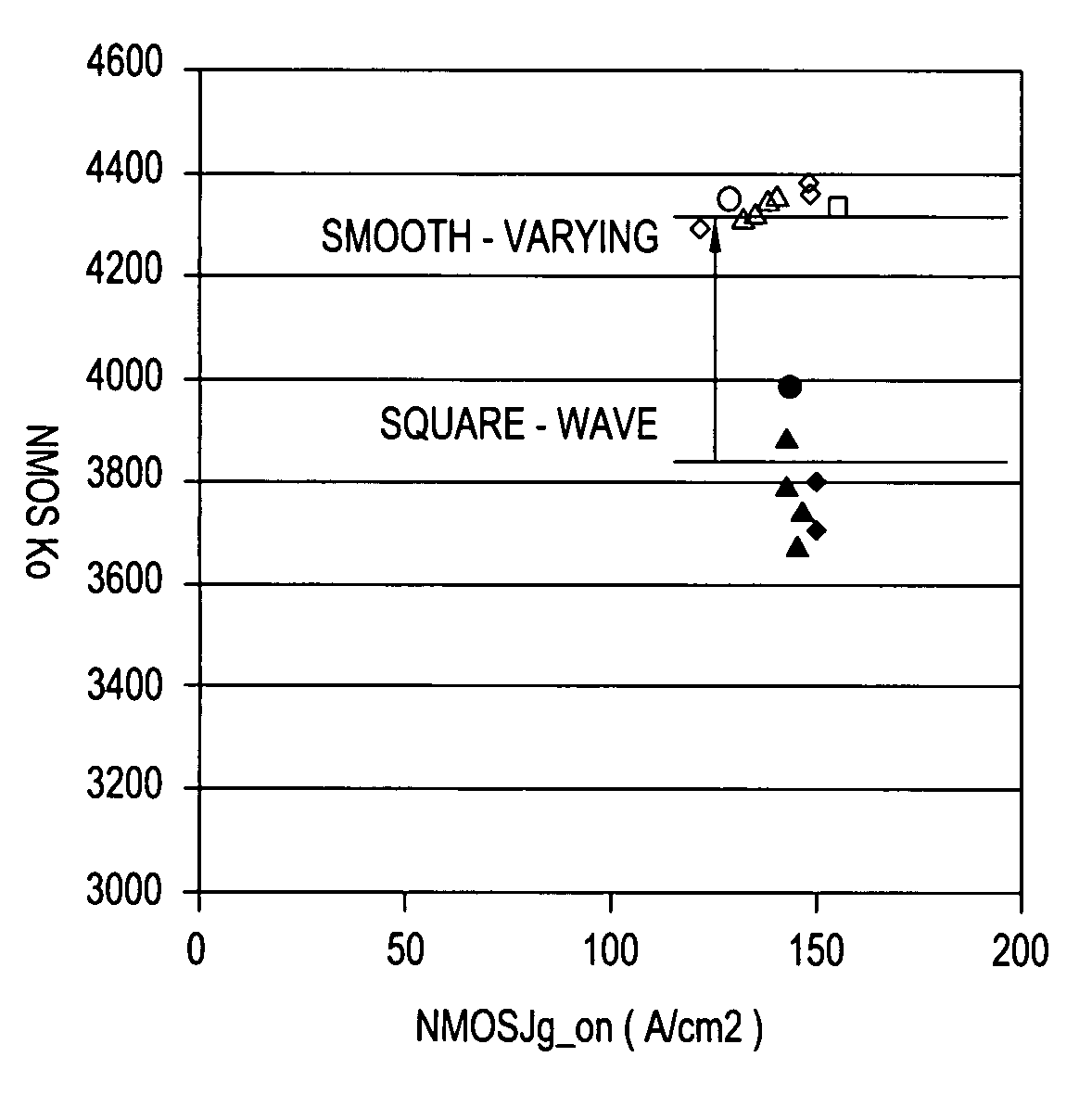

Method and apparatus for plasma nitridation of gate dielectrics using amplitude modulated radio-frequency energy

ActiveUS7179754B2Reduce the temperatureTransistorSolid-state devicesElectron temperatureGate dielectric

Owner:APPLIED MATERIALS INC

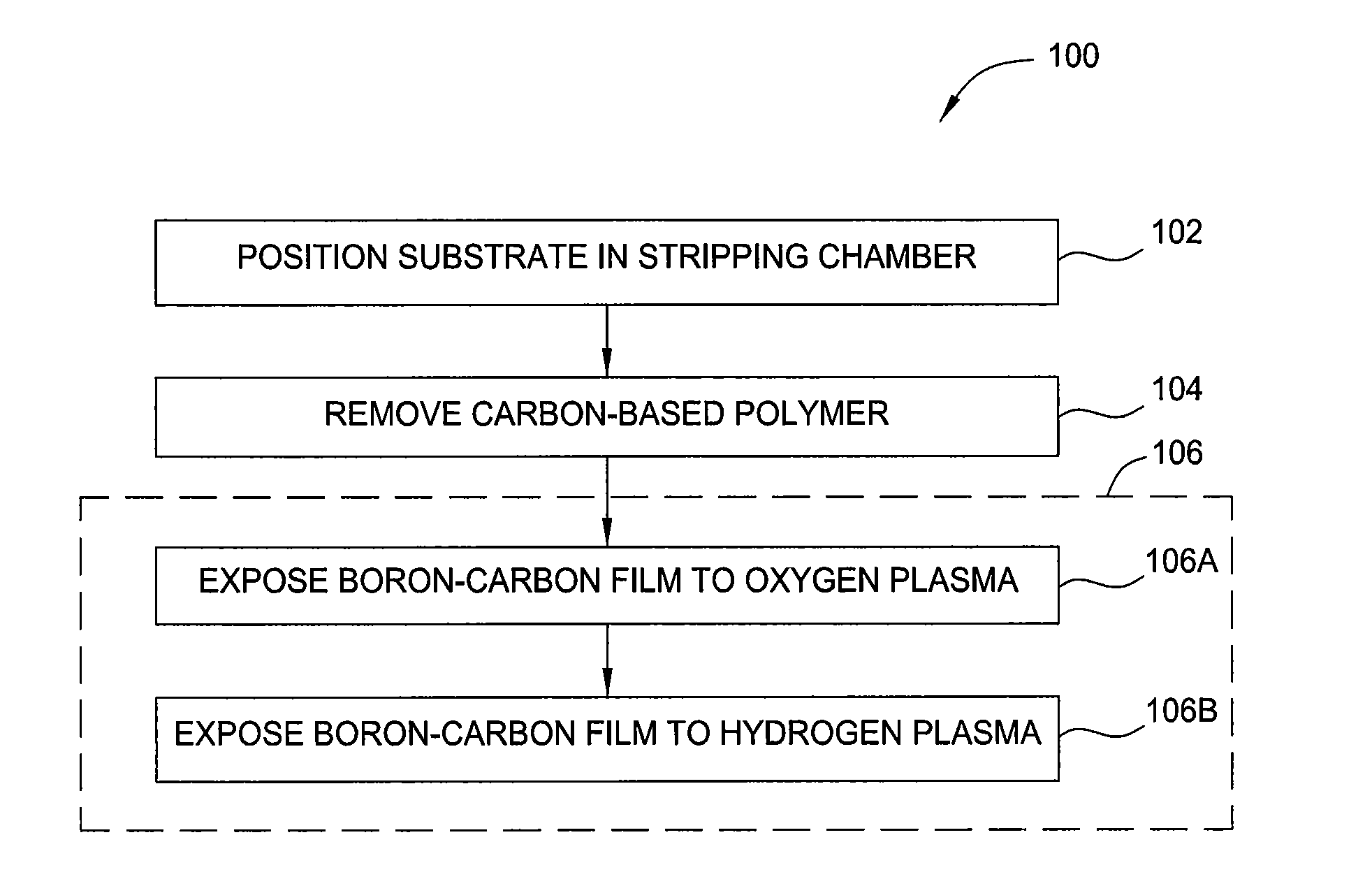

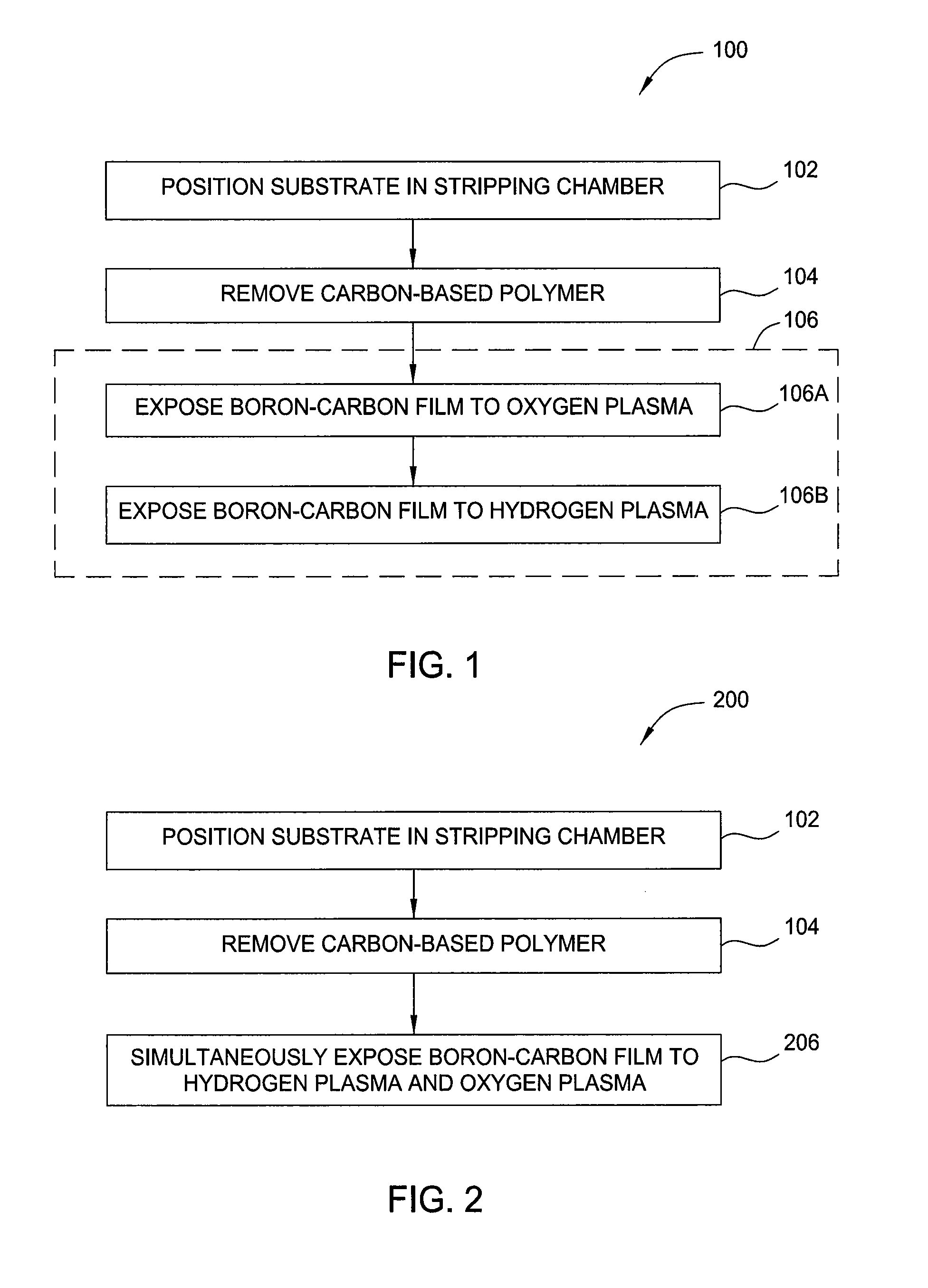

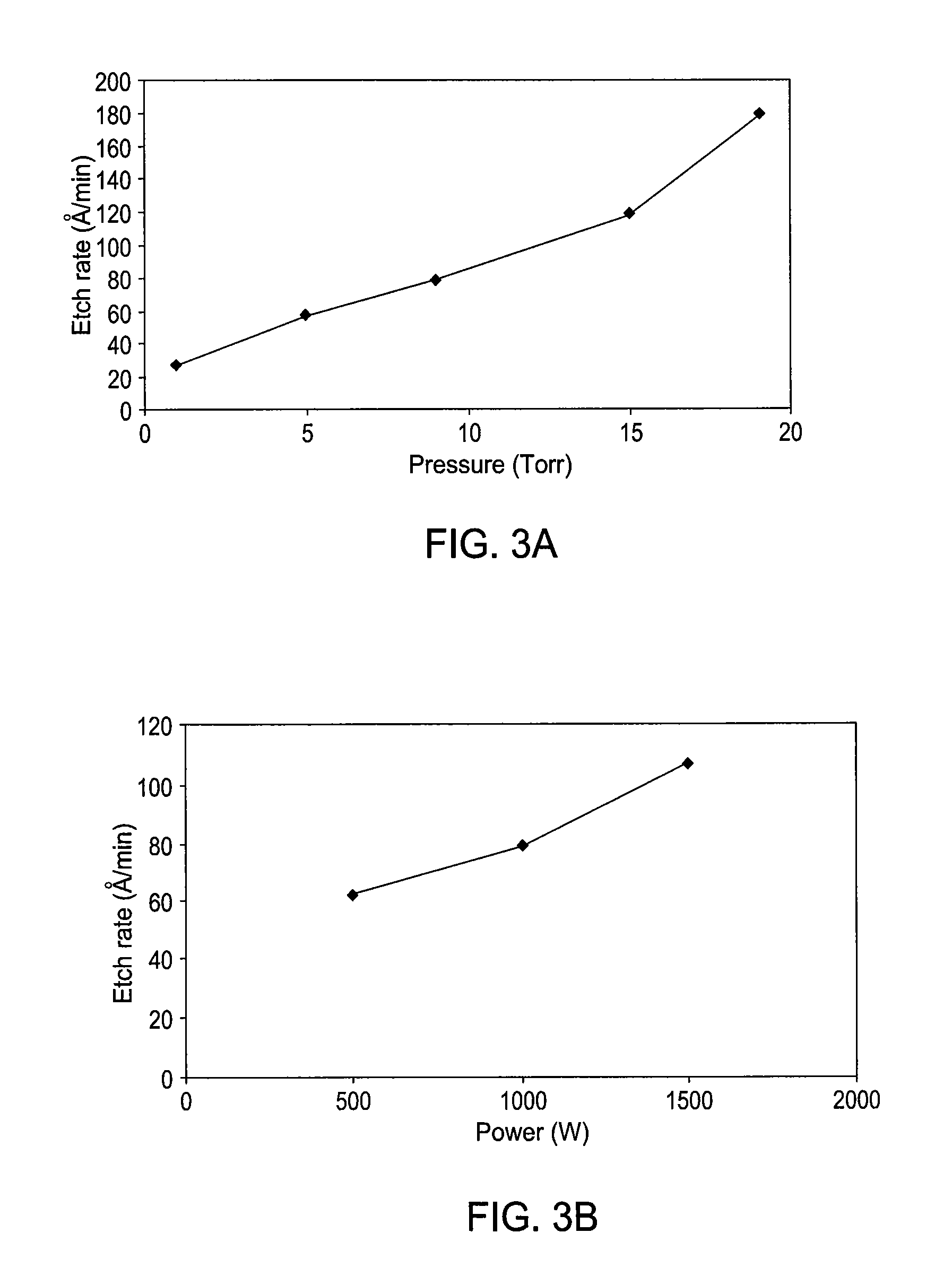

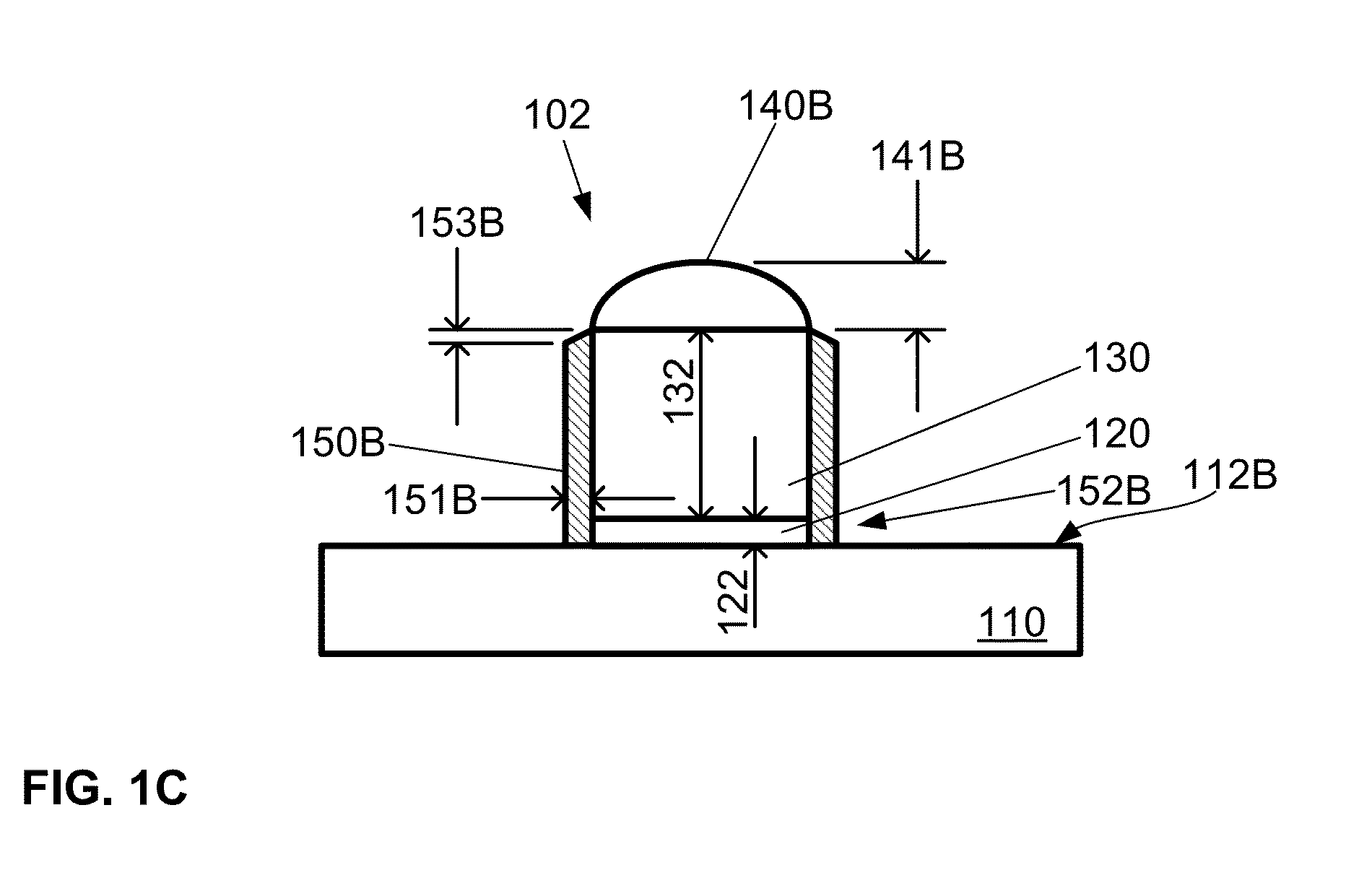

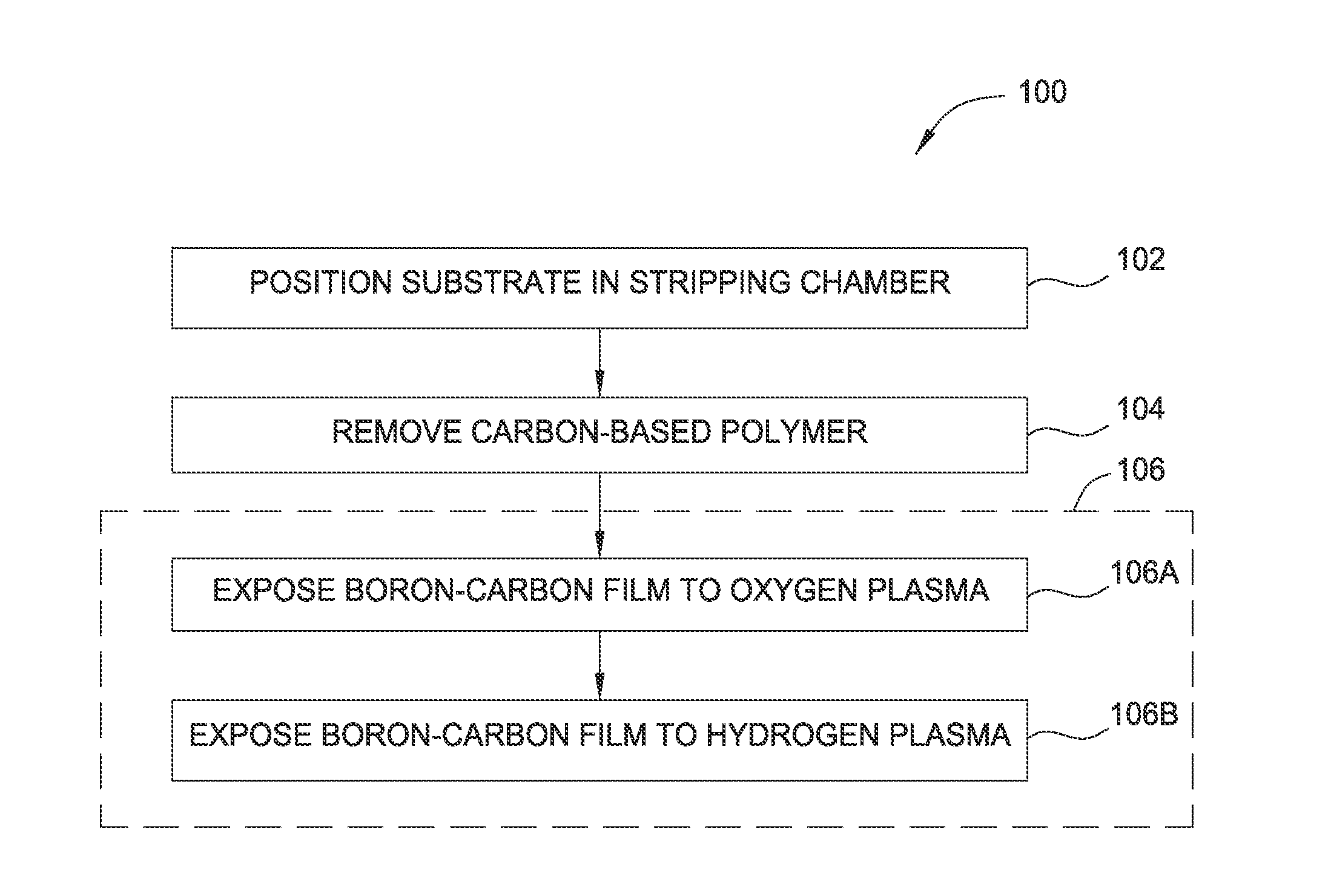

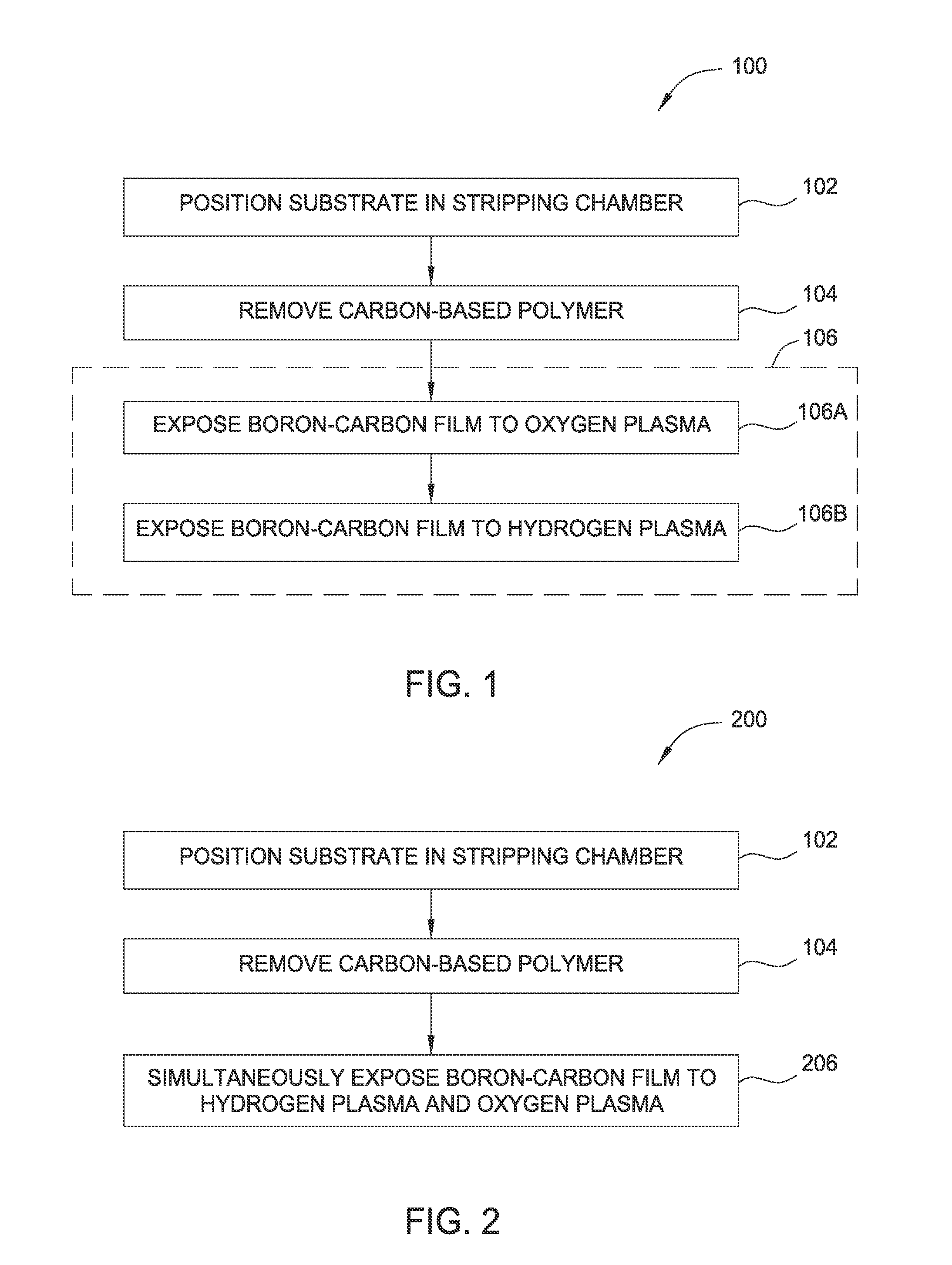

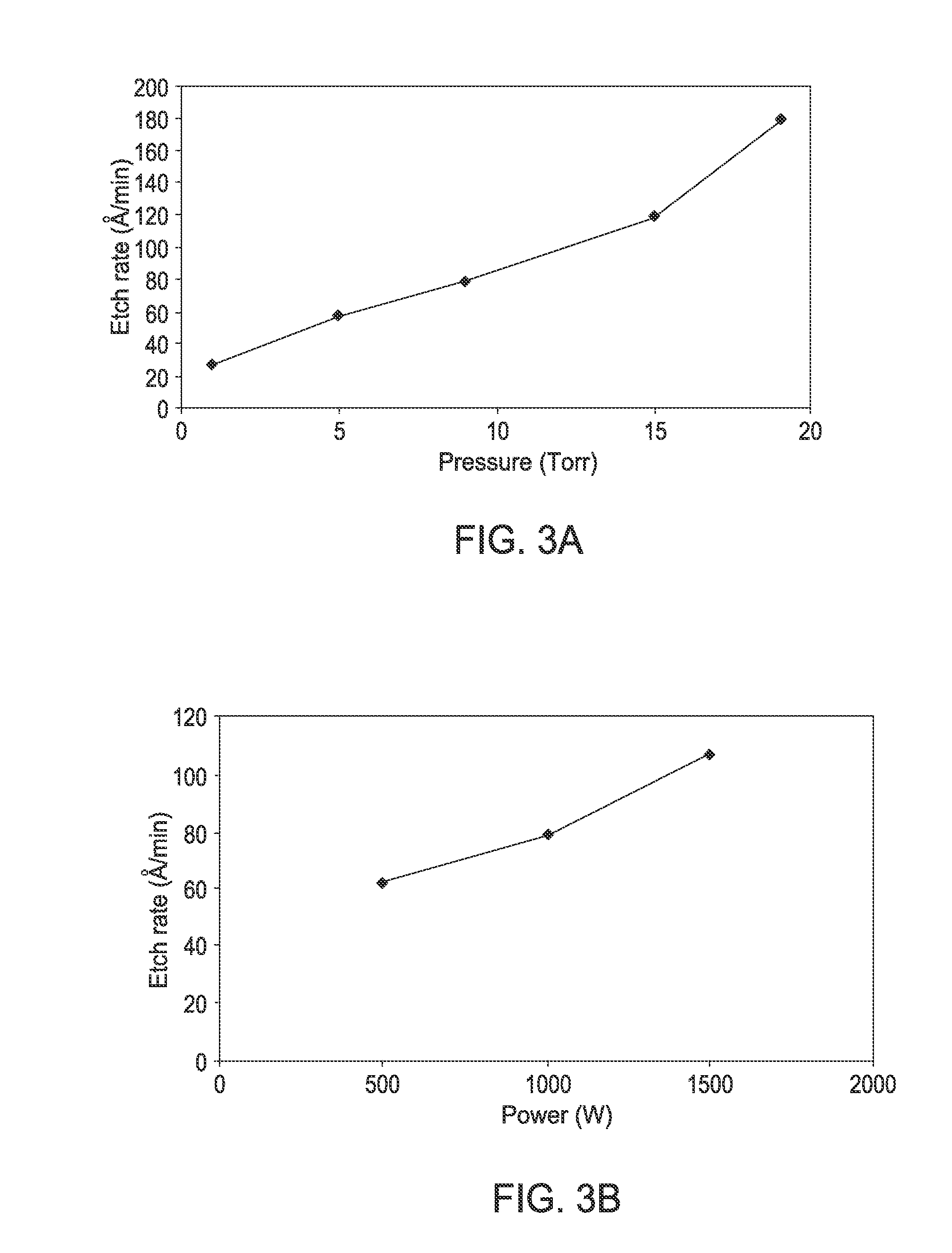

Methods of dry stripping boron-carbon films

ActiveUS20120285492A1Semiconductor/solid-state device manufacturingCleaning using gasesCarbon filmNitrogen plasma

Embodiments of the invention generally relate to methods of dry stripping boron-carbon films. In one embodiment, alternating plasmas of hydrogen and oxygen are used to remove a boron-carbon film. In another embodiment, co-flowed oxygen and hydrogen plasma is used to remove a boron-carbon containing film. A nitrous oxide plasma may be used in addition to or as an alternative to either of the above oxygen plasmas. In another embodiment, a plasma generated from water vapor is used to remove a boron-carbon film. The boron-carbon removal processes may also include an optional polymer removal process prior to removal of the boron-carbon films. The polymer removal process includes exposing the boron-carbon film to NF3 to remove from the surface of the boron-carbon film any carbon-based polymers generated during a substrate etching process.

Owner:APPLIED MATERIALS INC

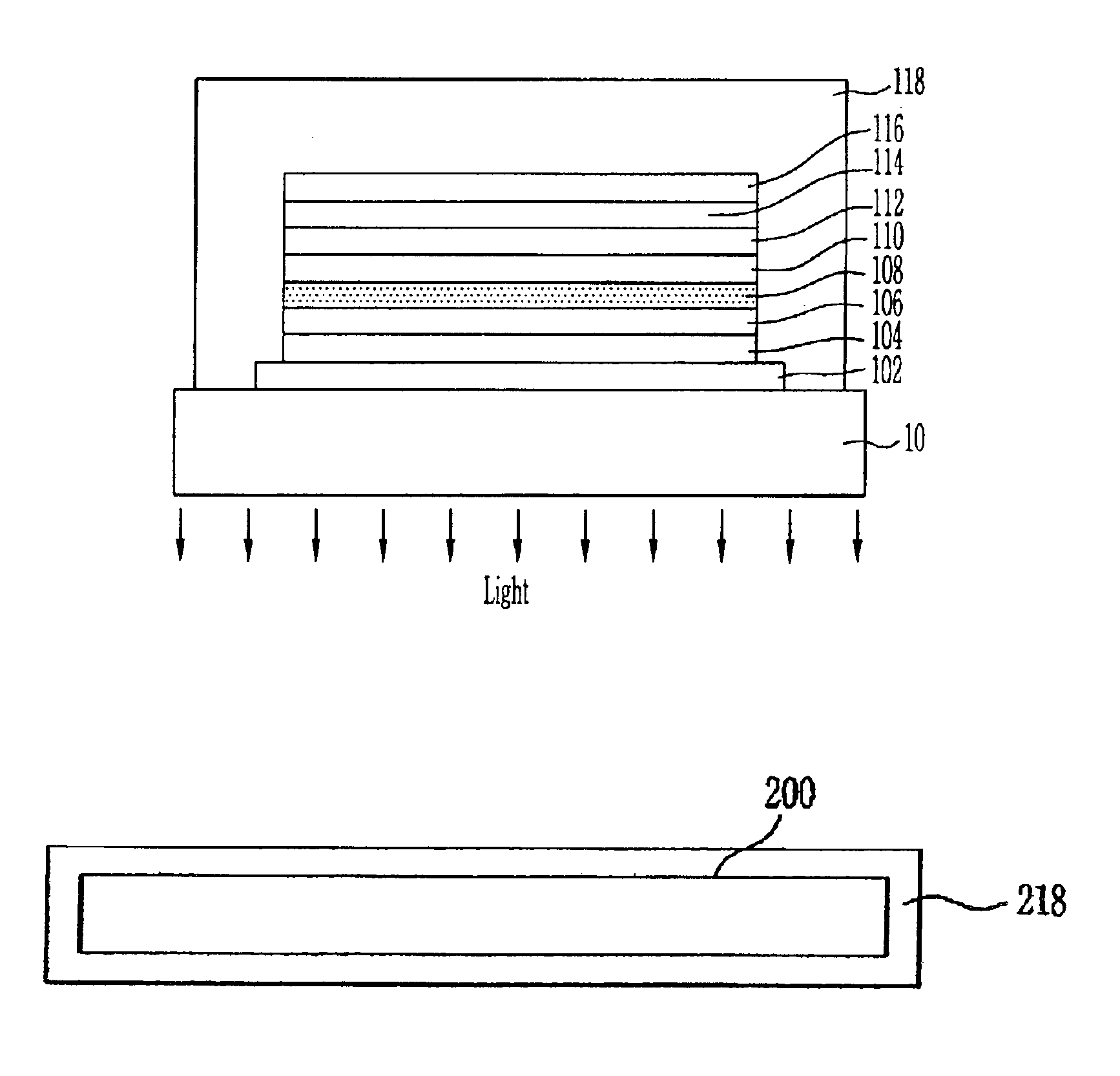

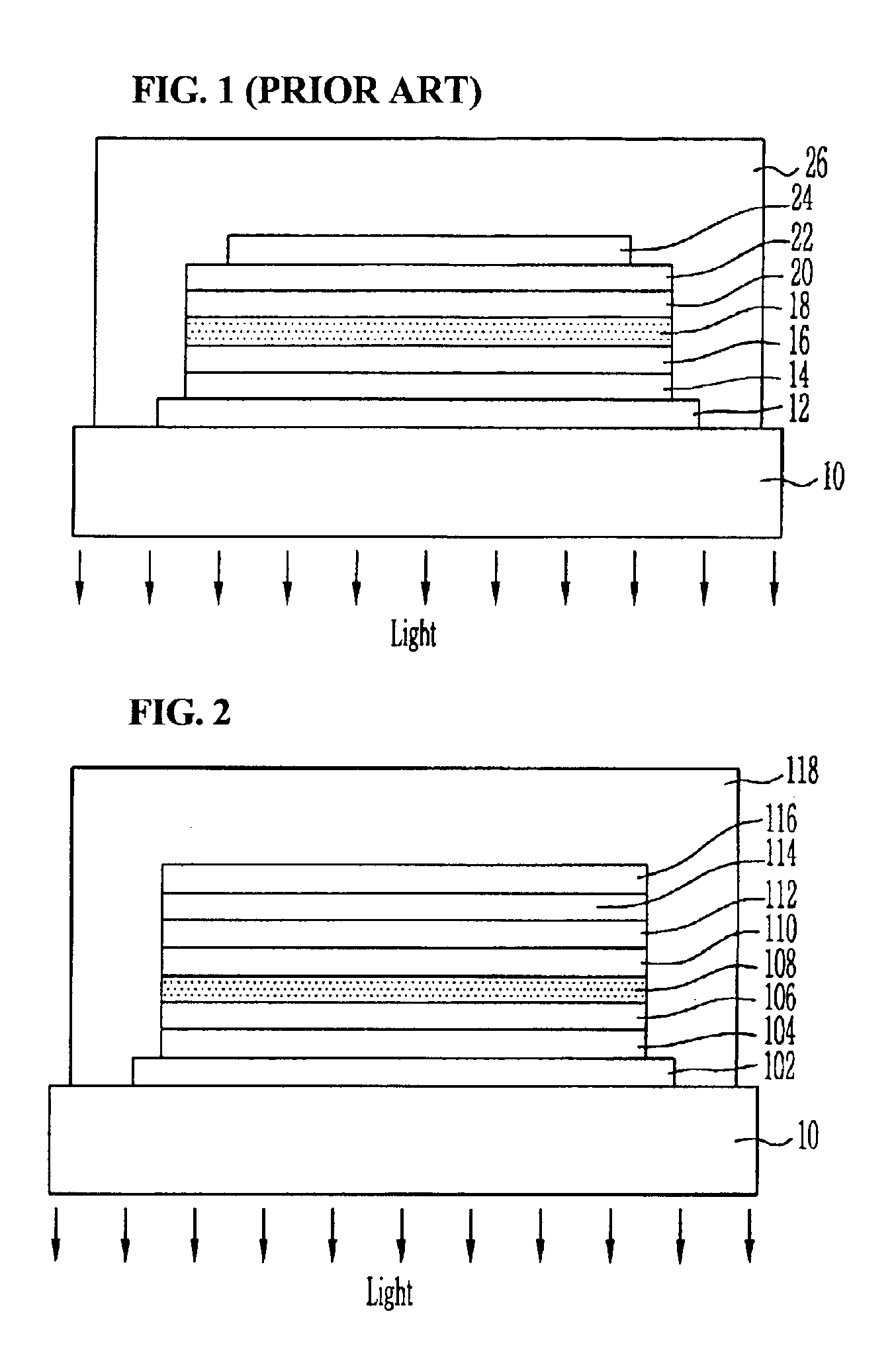

Flat panel display device and method of forming passivation film in the flat panel display device

InactiveUS6926572B2Improve featuresSimple processSolid-state devicesPretreated surfacesNitrogen plasmaOxygen plasma

A method of forming a passivation film in a flat panel display device includes forming the flat panel display device on a substrate, bringing the flat panel display device into a chamber in order to form the passivation film, injecting precursors containing constituent elements of the passivation film into the chamber where the precursors include at least oxygen plasma, ammonia plasma, or nitrogen plasma, and forming the passivation film of an inorganic insulating material at a temperature of 20-220° C. through a surface chemical reaction between the precursors by a plasma enhanced atomic layer deposition method.

Owner:UNILOC 2017 LLC

Laminate utilizing a metal layer activated by nitrogen plasma treatment

InactiveUS7026054B2Improve adherabilityImprove dynamical strengthLiquid surface applicatorsInsulating substrate metal adhesion improvementNitrogen plasmaShell molding

A laminate includes a metal layer which is formed on and covers a surface of an insulating substrate activated by a plasma treatment by any method selected from a sputtering method, a vacuum depositing method and an ion plating method. The substrate is obtained by molding a resin composition containing 20 to 150 parts by mass of a fibrous filler having an average fiber diameter of 0.1 to 5 μm and an average fiber length of 10 to 50 μm relative to 100 parts by mass of a base resin comprising a thermoplastic resin and a thermosetting resin.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Spacer material modification to improve k-value and etch properties

ActiveUS20150249017A1Electric discharge tubesSemiconductor/solid-state device manufacturingNitrogen plasmaOxygen plasma

A method for performing a spacer etch process is described. The method includes conformally applying a spacer material over a gate structure on a substrate, and performing a spacer etch process sequence to partially remove the spacer material from a capping region of the gate structure and a substrate region on the substrate adjacent a base of the gate structure, while retaining a spacer sidewall positioned along a sidewall of the gate structure. The K-value of high-K spacer materials are reduced to an acceptable range with oxidation using an oxygen plasma treatment. The etch rate of low-K spacer materials are reduced to a target range using a nitrogen plasma treatment. Integration of the spacer etch processing is selected based on impact to the other structures in the substrate.

Owner:TOKYO ELECTRON LTD

Methods of dry stripping boron-carbon films

Embodiments of the invention generally relate to methods of dry stripping boron-carbon films. In one embodiment, alternating plasmas of hydrogen and oxygen are used to remove a boron-carbon film. In another embodiment, co-flowed oxygen and hydrogen plasma is used to remove a boron-carbon containing film. A nitrous oxide plasma may be used in addition to or as an alternative to either of the above oxygen plasmas. In another embodiment, a plasma generated from water vapor is used to remove a boron-carbon film. The boron-carbon removal processes may also include an optional polymer removal process prior to removal of the boron-carbon films. The polymer removal process includes exposing the boron-carbon film to NF3 to remove from the surface of the boron-carbon film any carbon-based polymers generated during a substrate etching process.

Owner:APPLIED MATERIALS INC

Method of patterning a low-k dielectric film

ActiveUS20140120726A1Electric discharge tubesSemiconductor/solid-state device manufacturingNitrogen plasmaRemote plasma

Methods of patterning low-k dielectric films are described. In an example, a method of patterning a low-k dielectric film involves forming and patterning a mask layer above a low-k dielectric layer, the low-k dielectric layer disposed above a substrate. The method also involves modifying exposed portions of the low-k dielectric layer with a nitrogen-free plasma process. The method also involves removing, with a remote plasma process, the modified portions of the low-k dielectric layer selective to the mask layer and unmodified portions of the low-k dielectric layer.

Owner:APPLIED MATERIALS INC

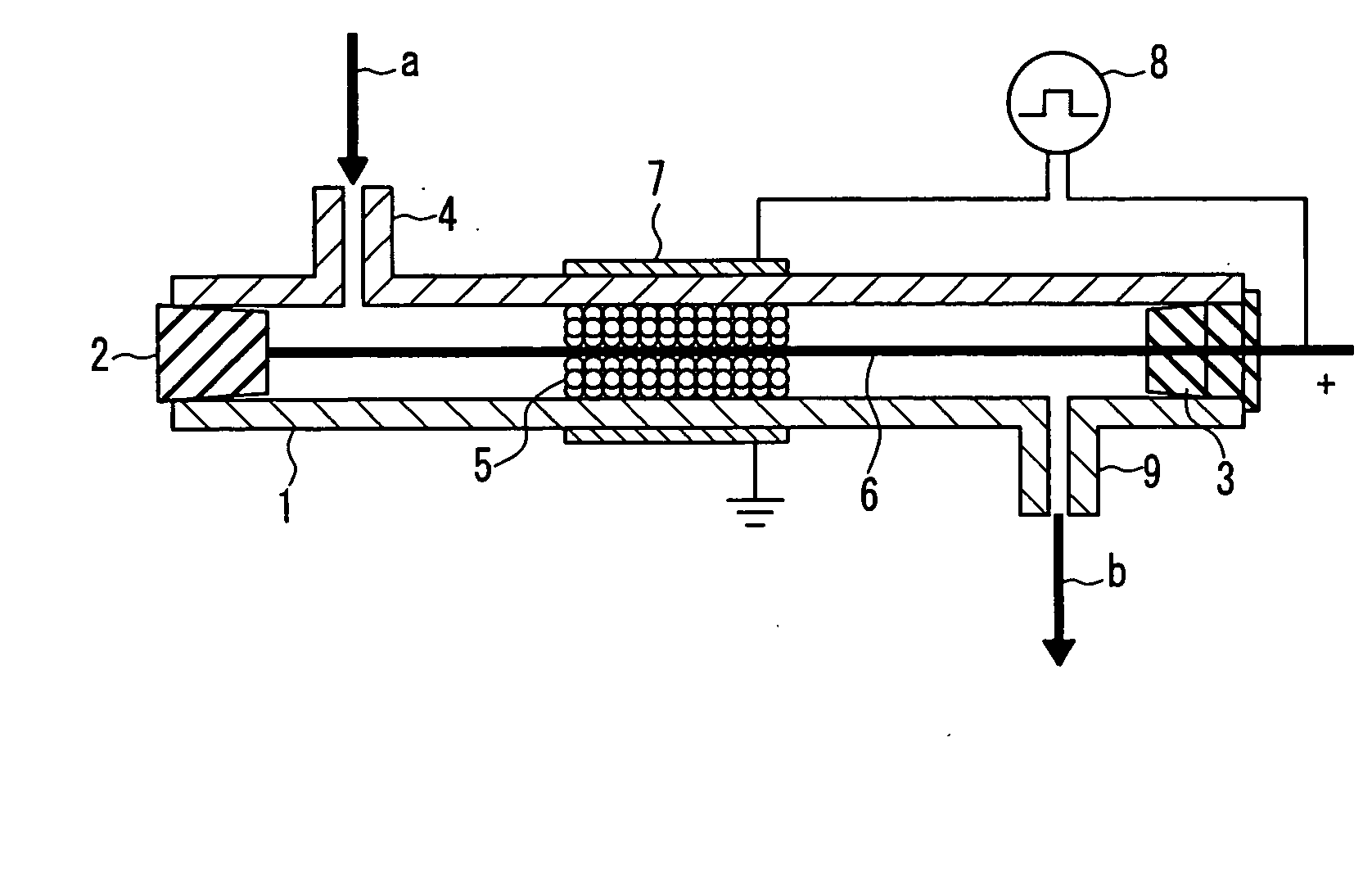

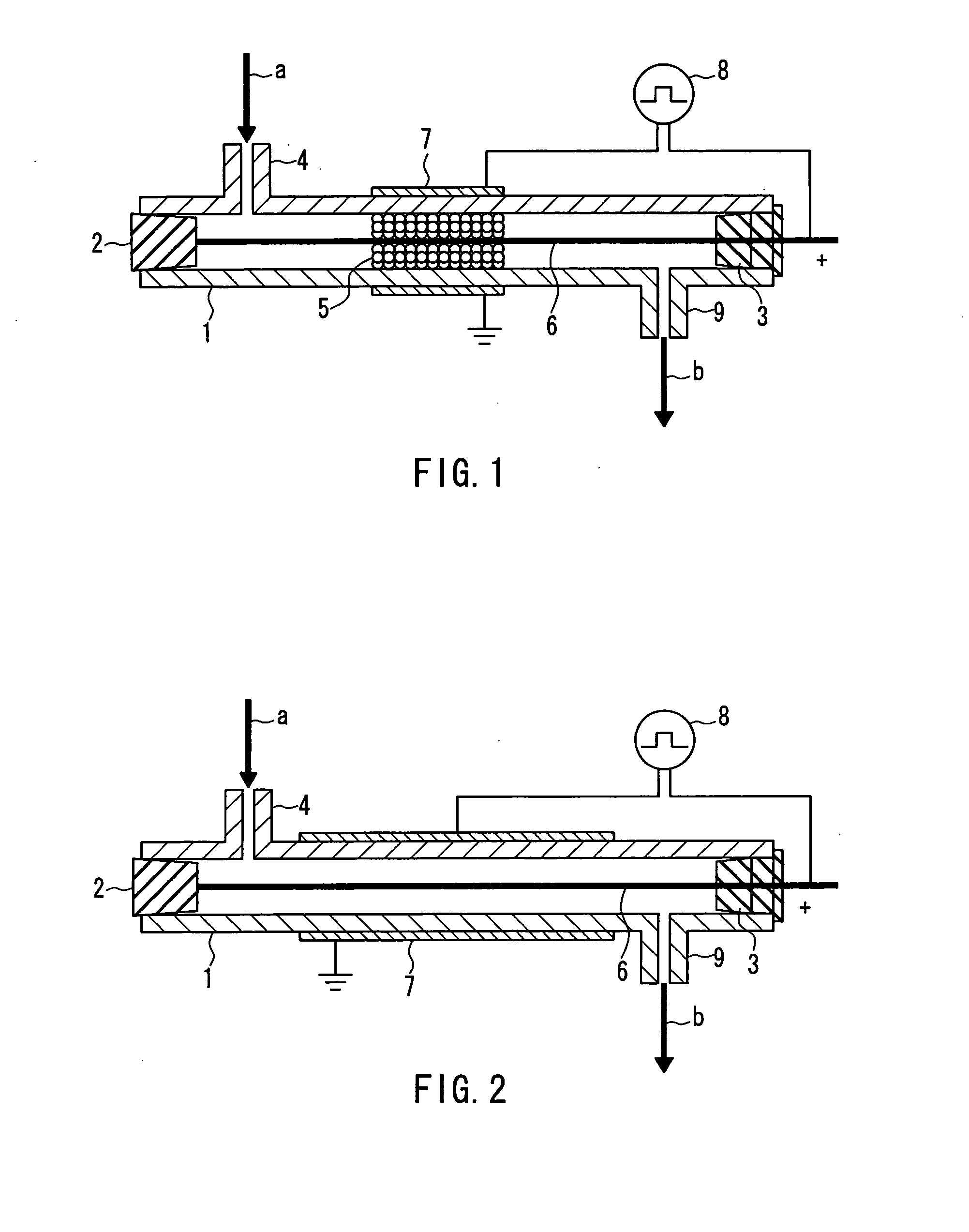

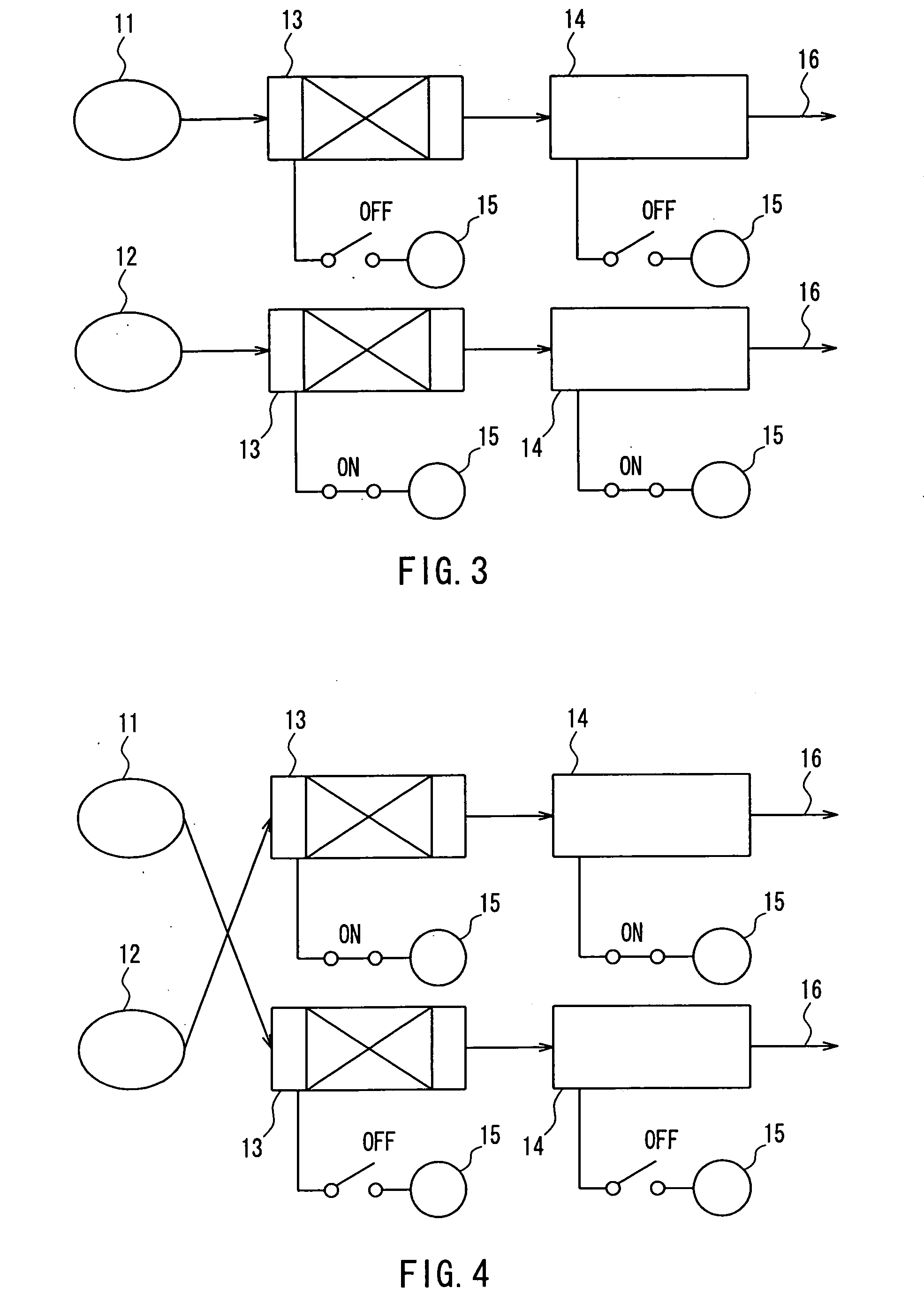

Method and apparatus for treating exhaust gas

InactiveUS20070071657A1Component can be removedHigh activityCombination devicesNitrogen compoundsNitrogen plasmaElectric discharge

A method for treating exhaust gas includes: adsorbing target components in the exhaust gas with an adsorbent (5); introducing a nitrogen gas with an oxygen concentration of 10 vol % or less and a purity of 90 vol % or more into the adsorbent (5); and applying (6, 7, 8) nonthermal plasma to the adsorbent (5). After the adsorbent (5) adsorbs the target components in the exhaust gas, the nitrogen gas is introduced into the adsorbent (5), and then an electric discharge is generated so that the nonthermal plasma of the nitrogen gas is applied to the adsorbent (5) and causes desorption of the target components and regeneration of the adsorbent (5). This method can remove the target components effectively from oxygen-containing exhaust gas by using nitrogen gas plasma with high activity as a result of ionization of a nitrogen gas and combining adsorption, desorption by the nitrogen gas plasma, and nitrogen plasma treatment.

Owner:PUBLIC UNIVERSITY CORPORATION OSAKA CITY UNIVERSITY

Plasma ashing apparatus and endpoint detection process

InactiveUS20100055807A1Semiconductor/solid-state device testing/measurementElectric discharge tubesNitrogen plasmaHydrogen

A plasma ashing apparatus for removing organic matter from a substrate including a low k dielectric, comprising a first gas source; a plasma generating component in fluid communication with the first gas source; a process chamber in fluid communication with the plasma generating component; an exhaust conduit in fluid communication with the process chamber; wherein the exhaust conduit comprises an inlet for a second gas source and an afterburner assembly coupled to the exhaust conduit, wherein the inlet is disposed intermediate to the process chamber and an afterburner assembly, and wherein the afterburner assembly comprises means for generating a plasma within the exhaust conduit with or without introduction of a gas from the second gas source; and an optical emission spectroscopy device coupled to the exhaust conduit comprising collection optics focused within a plasma discharge region of the afterburner assembly. An endpoint detection process for an oxygen free and nitrogen free plasma process comprises monitoring an optical emission signal of an afterburner excited species in an exhaust conduit of the plasma asher apparatus. The process and apparatus can be used with carbon and / or hydrogen containing low k dielectric materials.

Owner:LAM RES CORP

ALD deposition of ruthenium

InactiveUS7074719B2Low impurity contentElimination of nucleationSemiconductor/solid-state device detailsSolid-state devicesCMOSNitrogen plasma

Owner:INT BUSINESS MASCH CORP

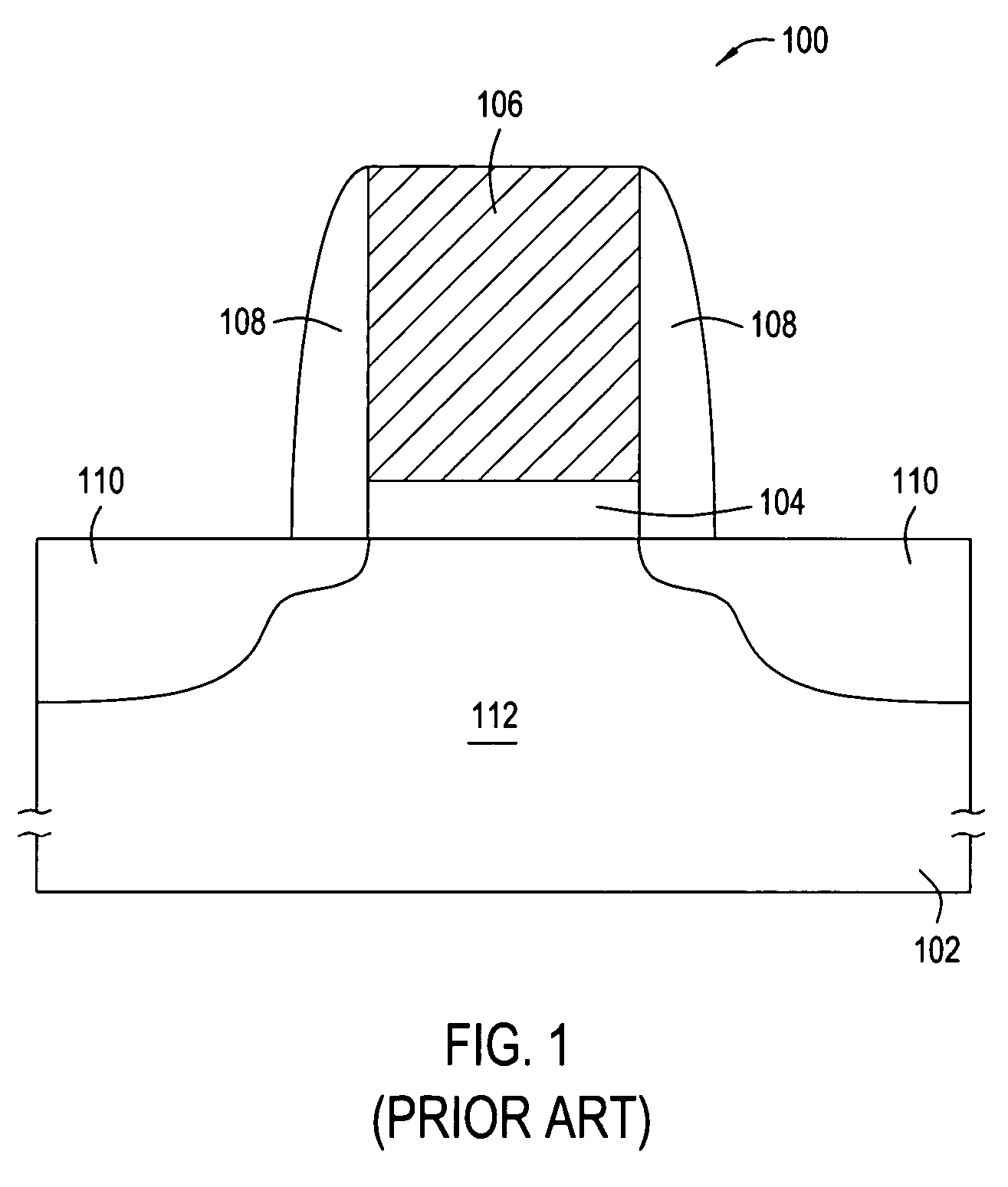

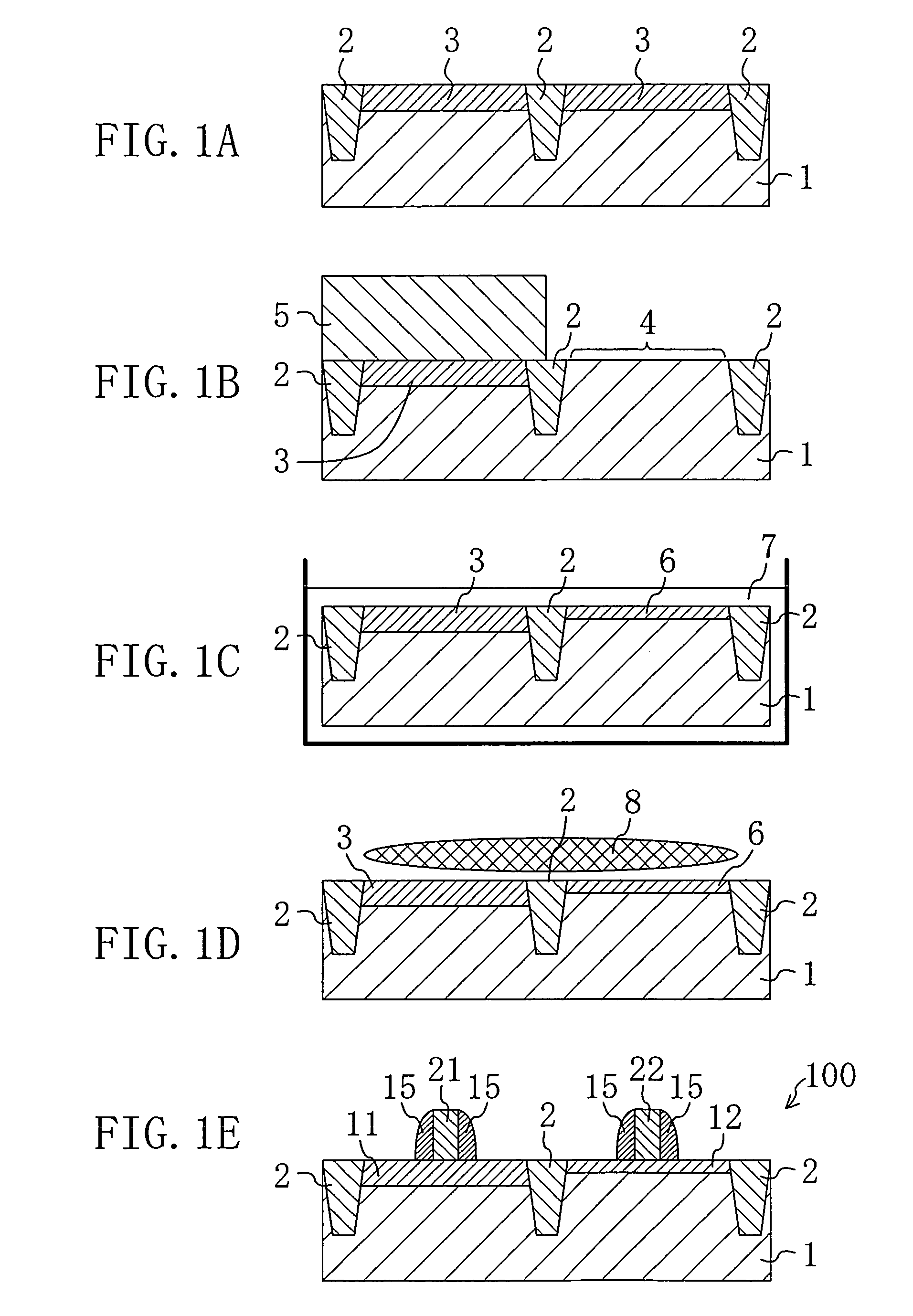

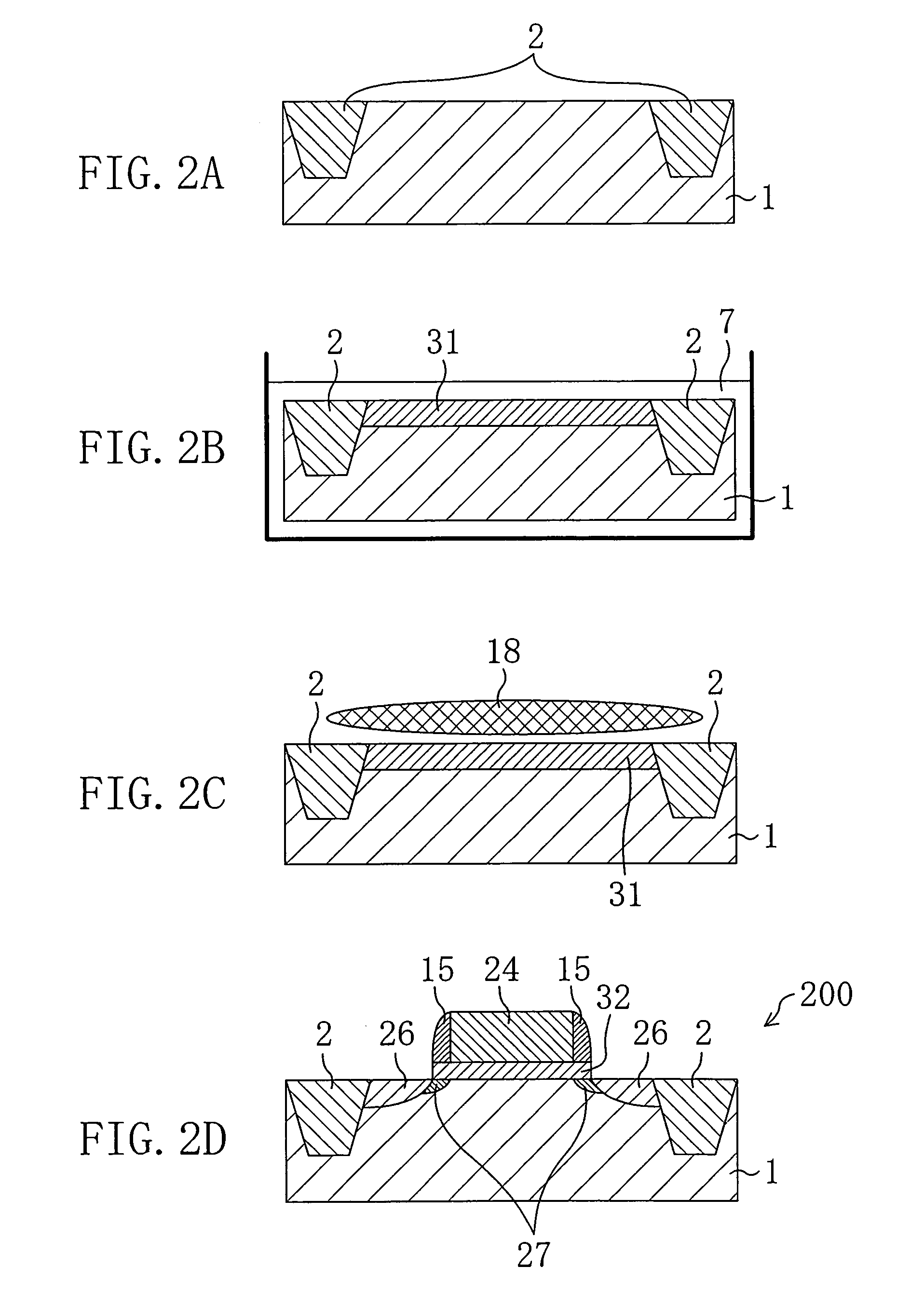

Method for fabricating semiconductor device and semiconductor device

InactiveUS7098154B2TransistorSemiconductor/solid-state device manufacturingNitrogen plasmaSemiconductor

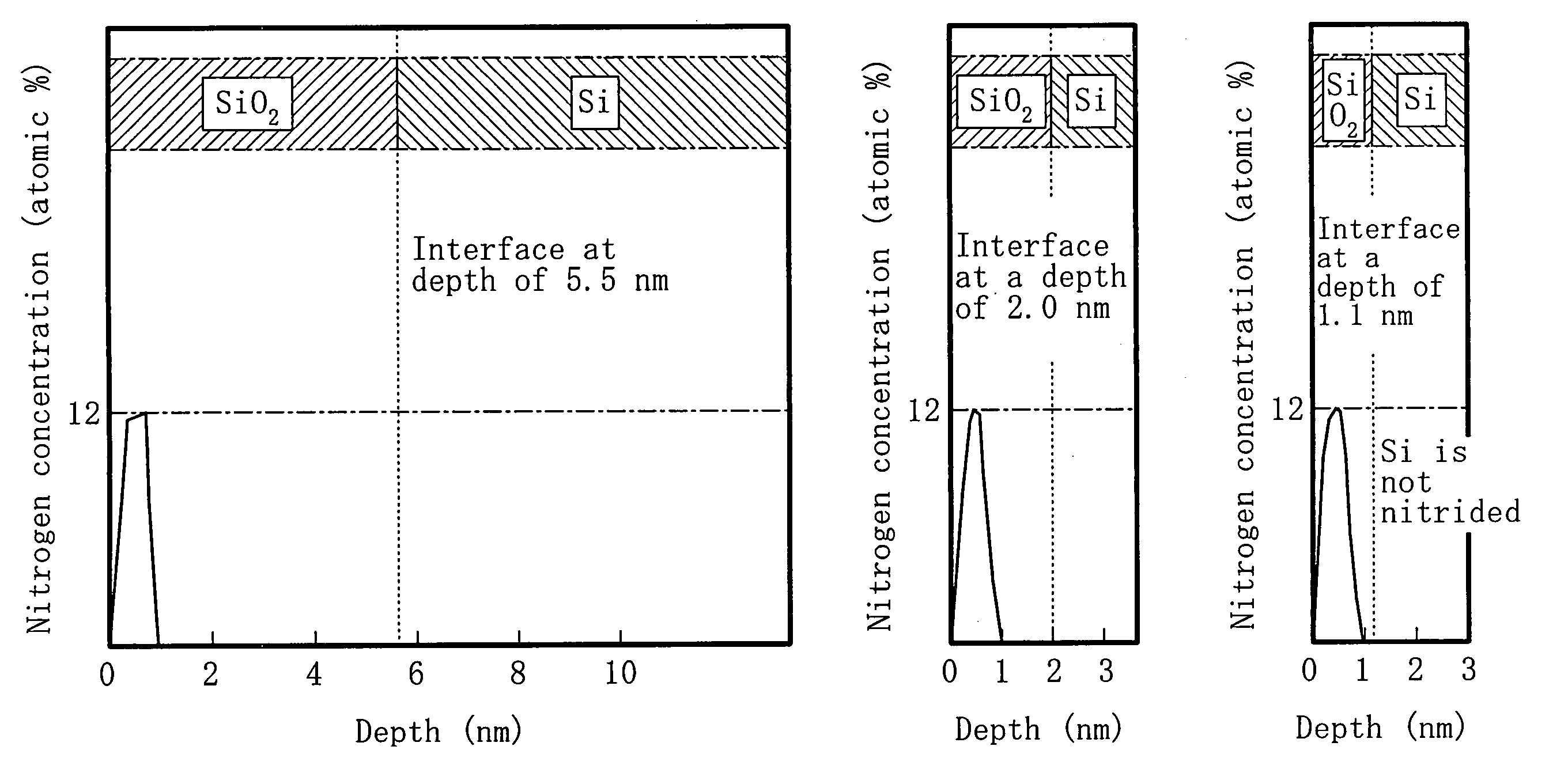

Part of a first oxide film formed by thermal oxidation is removed by etching. A second oxide film is formed in the part of substrate from which the first oxide film has been removed using heated nitric acid. The two oxide films are nitrided by a nitrogen plasma having a low energy so as to be first and second gate insulating films, i.e., oxynitride films, respectively.

Owner:RPX CORP

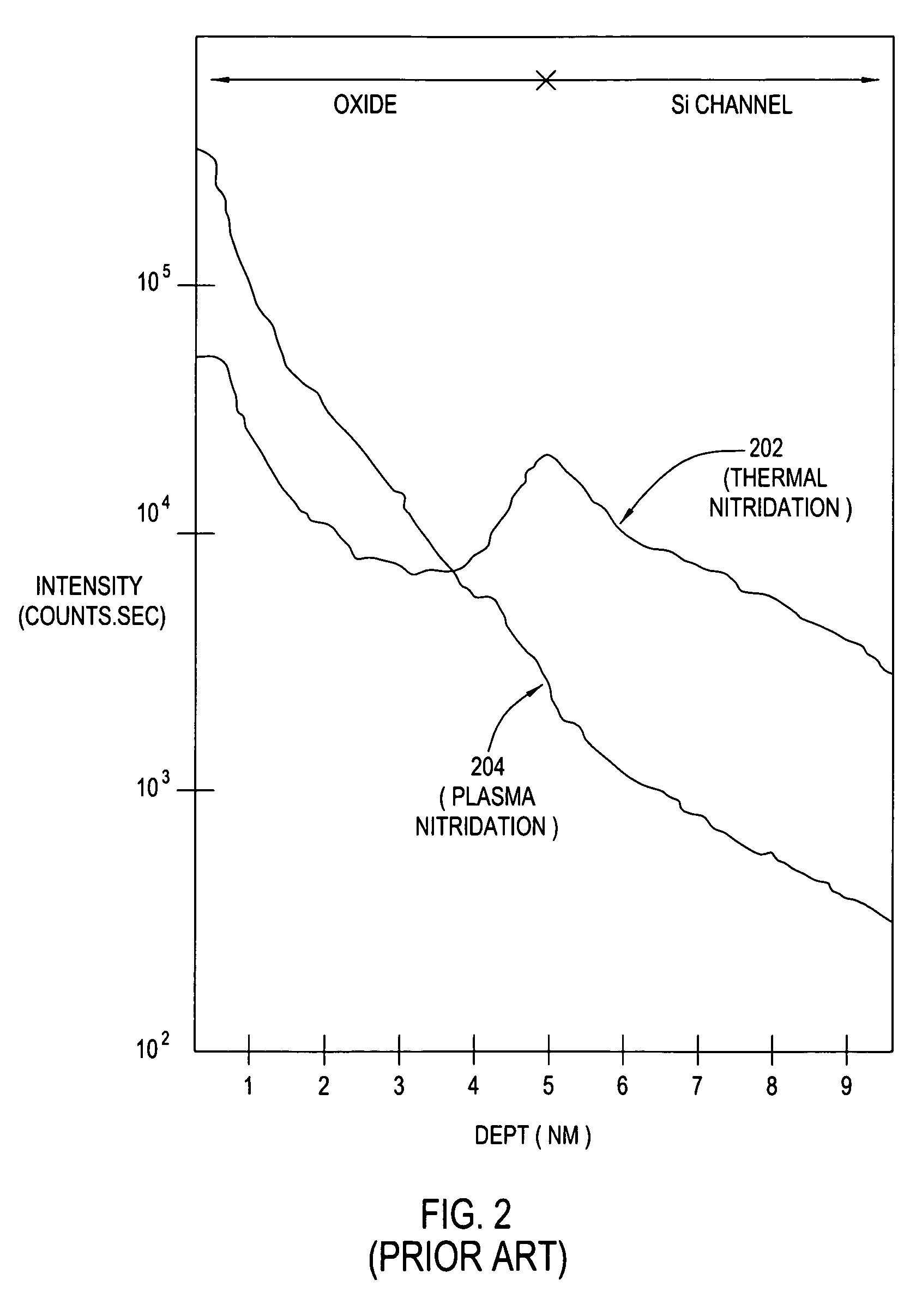

CMOS sion gate dielectric performance with double plasma nitridation containing noble gas

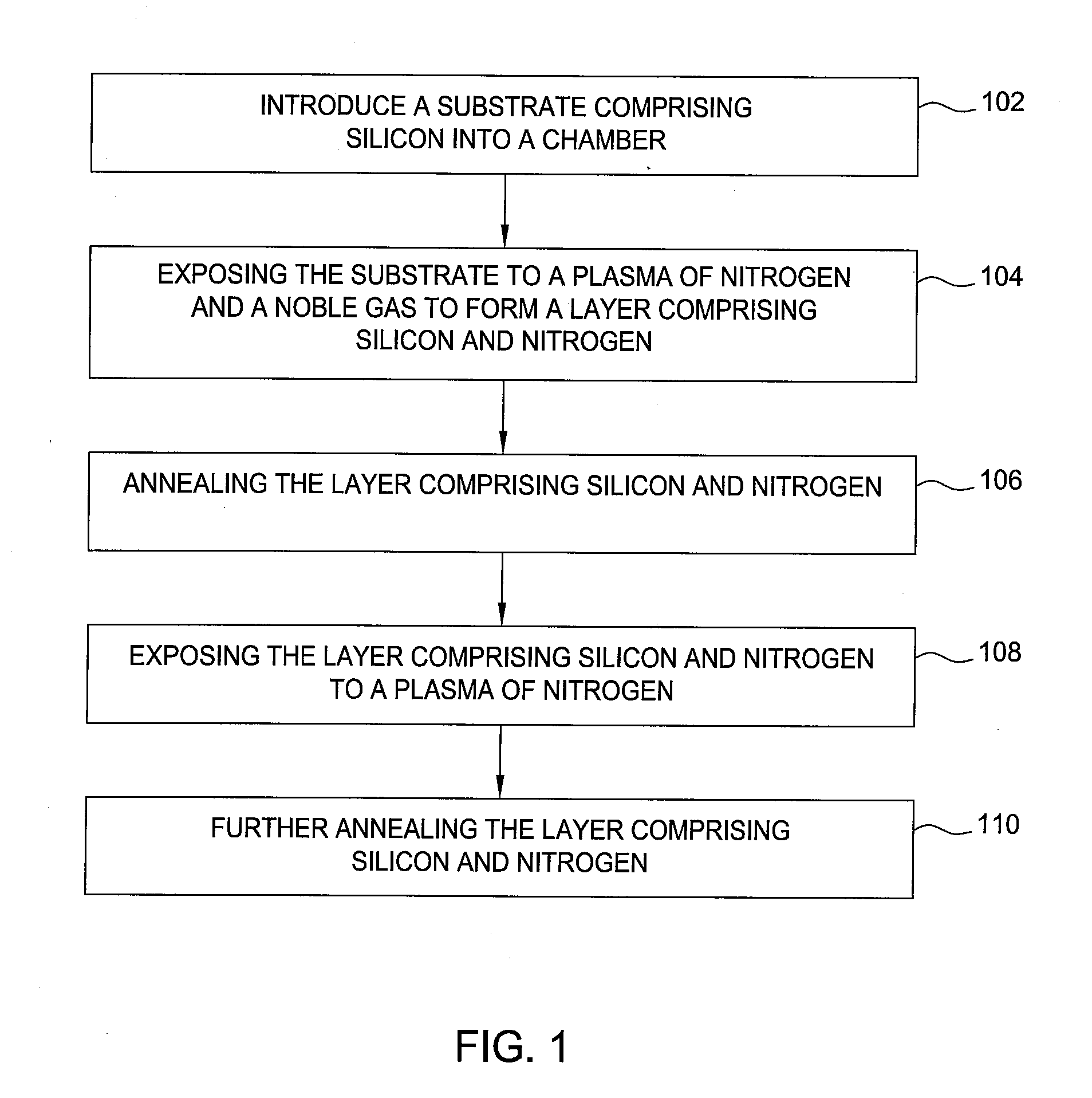

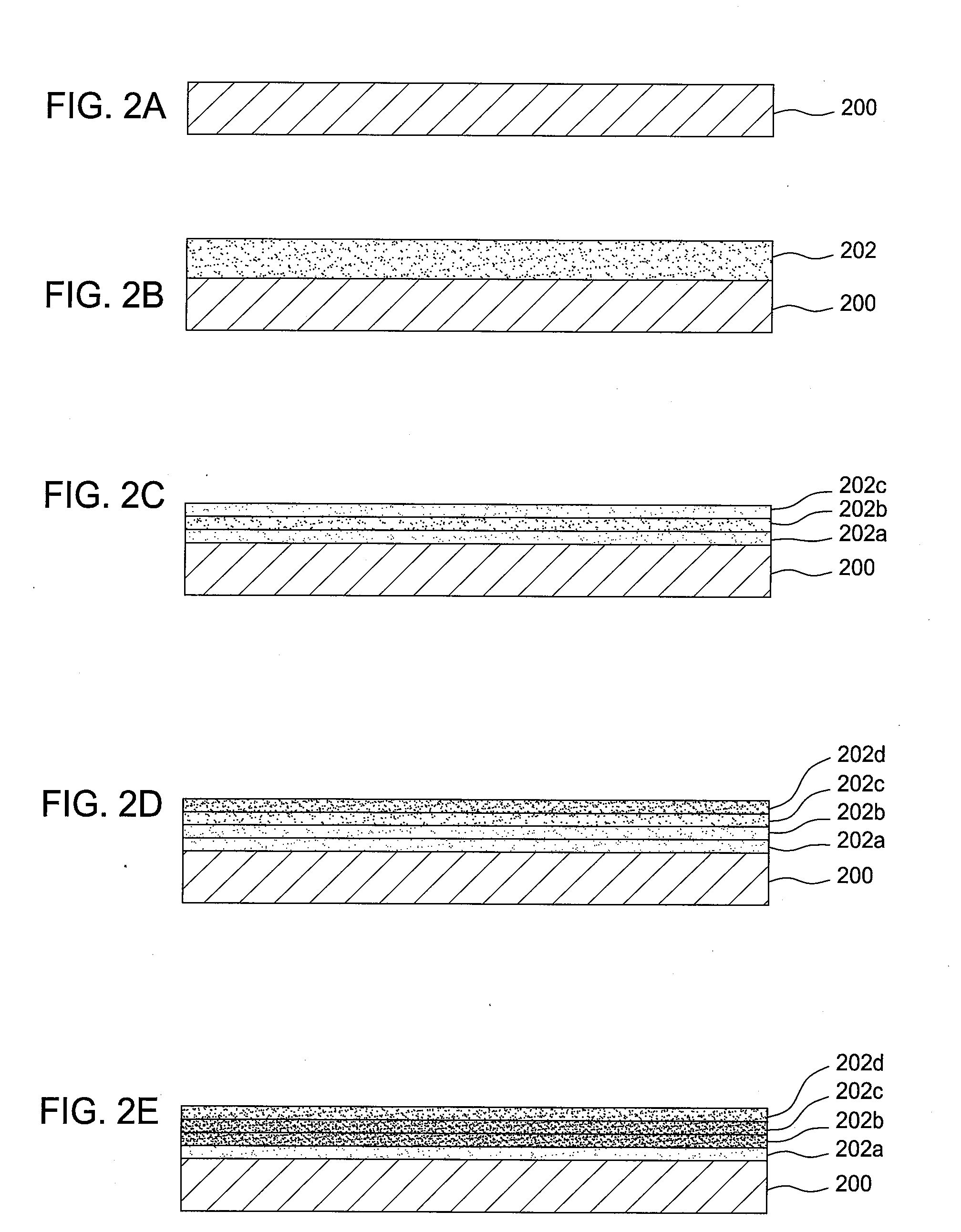

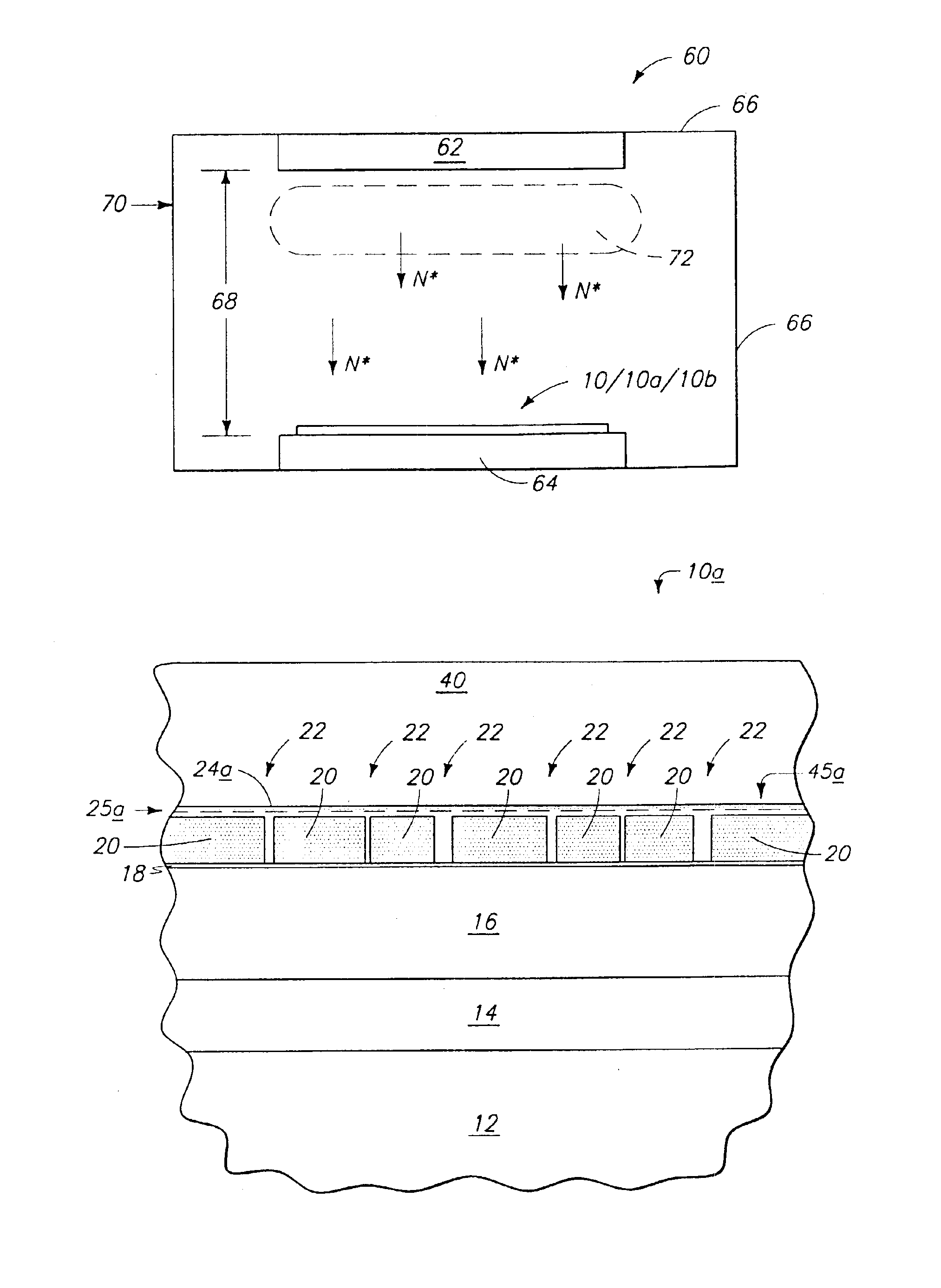

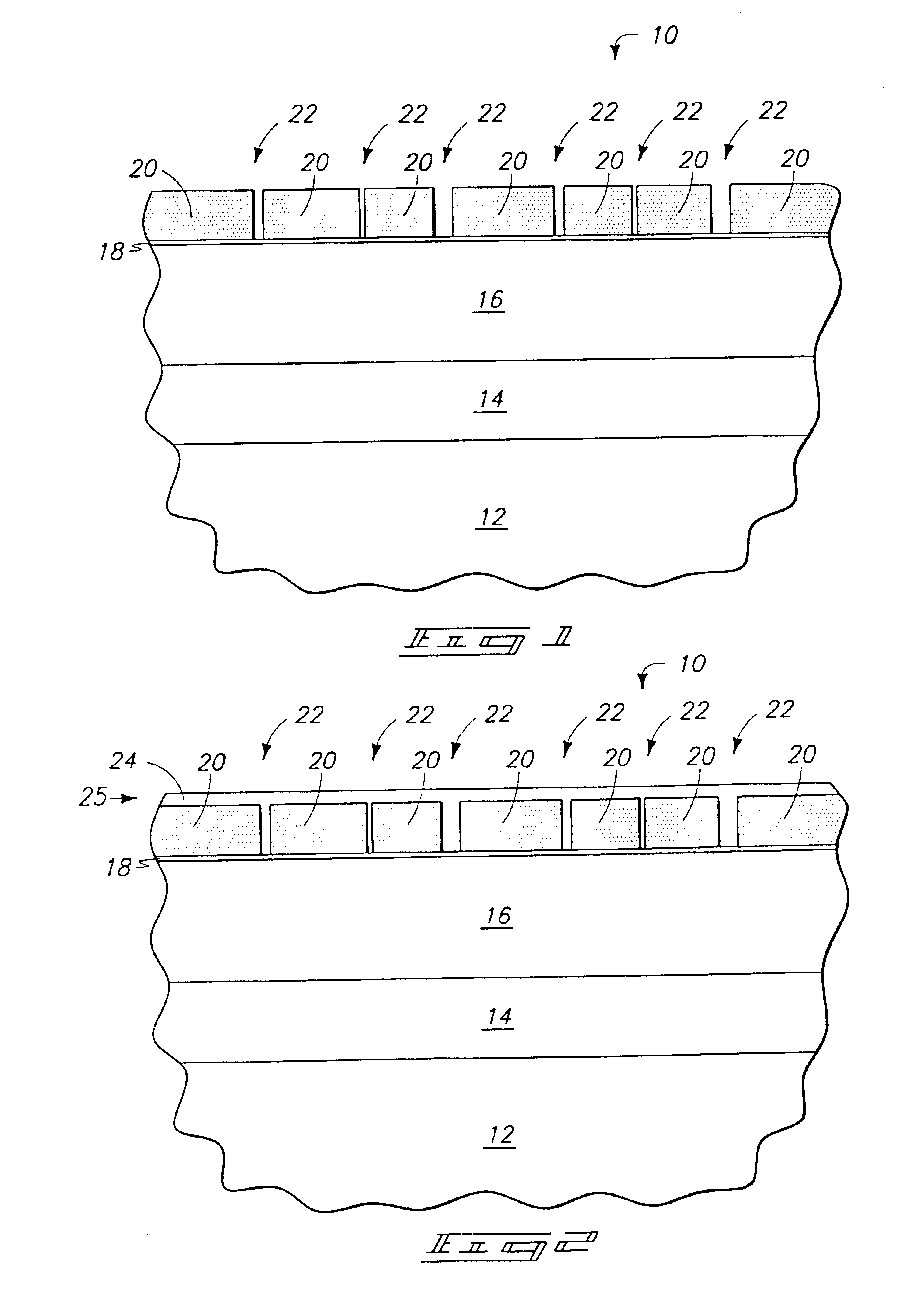

A method of forming a layer comprising silicon and nitrogen on a substrate is provided. The layer may also include oxygen and be used as a silicon oxynitride gate dielectric layer. In one aspect, forming the layer includes exposing a silicon substrate to a plasma of nitrogen and a noble gas to incorporate nitrogen into an upper surface of the substrate, wherein the noble gas is argon, neon, krypton, or xenon. The layer is annealed and then exposed to a plasma of nitrogen to incorporate more nitrogen into the layer. The layer is then further annealed.

Owner:APPLIED MATERIALS INC

Method of forming a capacitor dielectric layer

InactiveUS6875707B2High dielectric constantSemiconductor/solid-state device manufacturingCapacitorsNitrogen plasmaSilicon oxide

A method of forming a capacitor includes forming first and second capacitor electrodes over a substrate. A capacitor dielectric region is formed intermediate the first and second capacitor electrodes, and includes forming a silicon nitride comprising layer over the first capacitor electrode. A silicon oxide comprising layer is formed over the silicon nitride comprising layer. The silicon oxide comprising layer is exposed to an activated nitrogen species generated from a nitrogen-containing plasma effective to introduce nitrogen into at least an outermost portion of the silicon oxide comprising layer. Silicon nitride is formed therefrom effective to increase a dielectric constant of the dielectric region from what it was prior to said exposing. Capacitors and methods of forming capacitor dielectric layers are also disclosed.

Owner:MICRON TECH INC

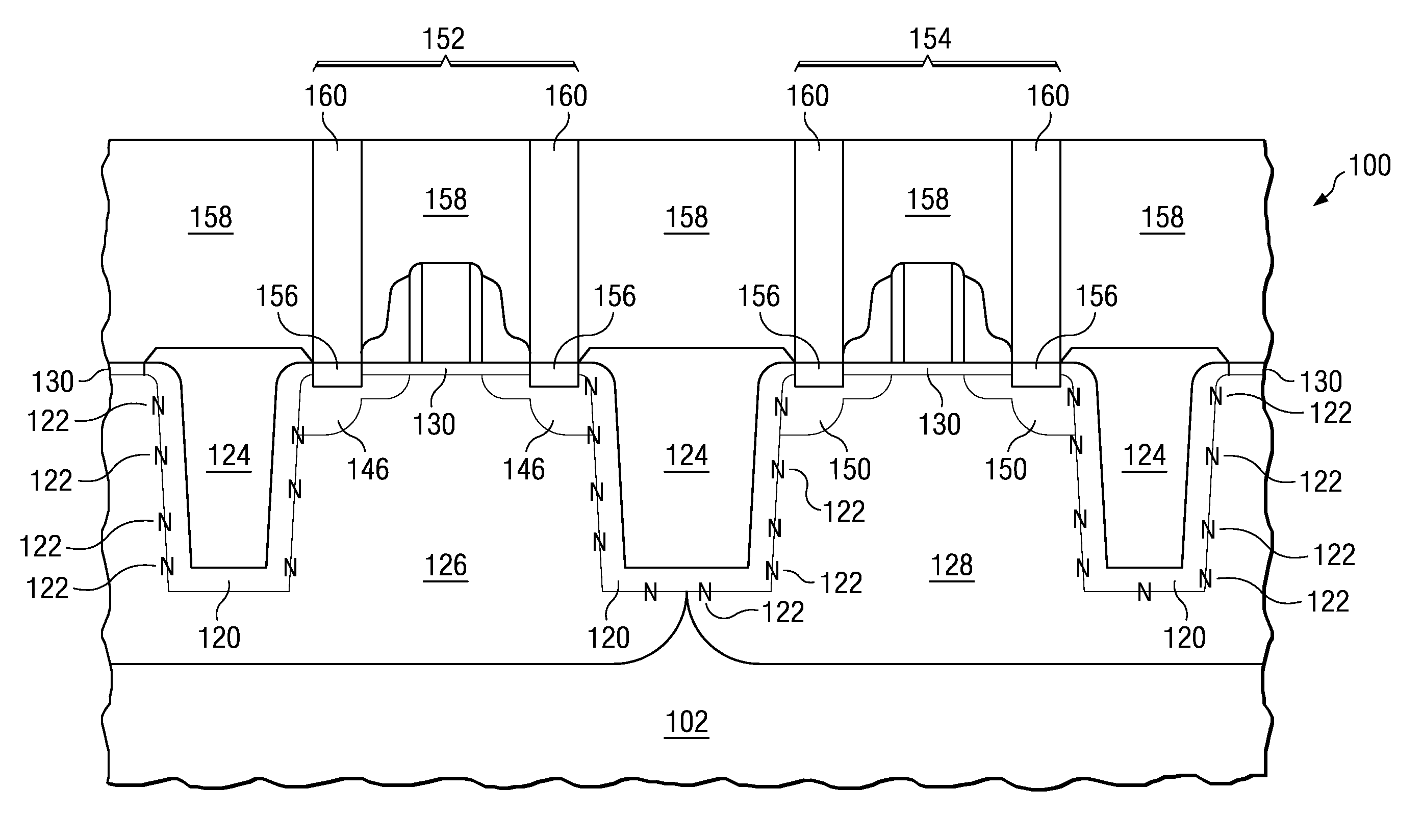

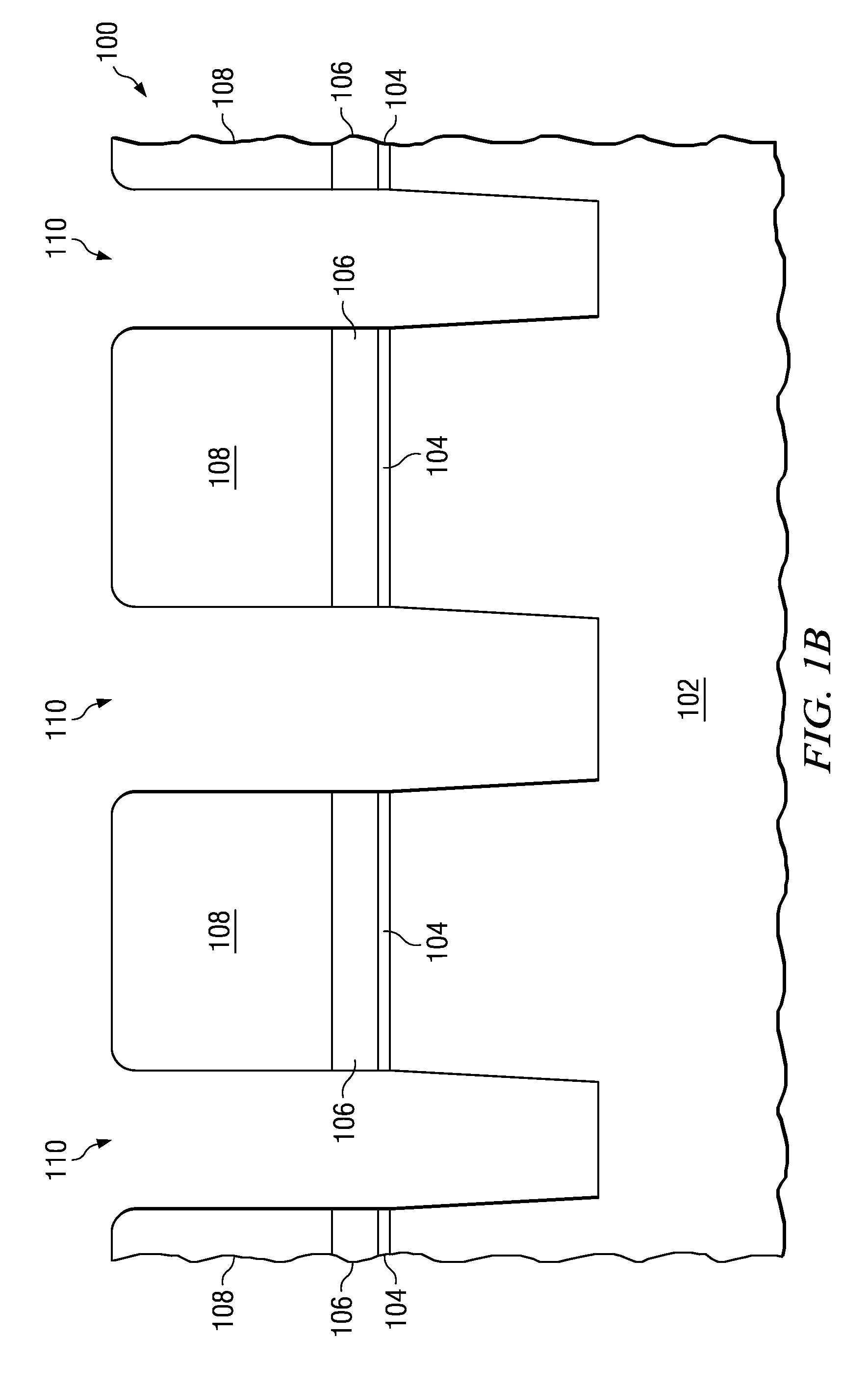

STRAIN MODULATION IN ACTIVE AREAS BY CONTROLLED INCORPORATION OF NITROGEN AT Si-SiO2 INTERFACE

ActiveUS20090159981A1TransistorSemiconductor/solid-state device manufacturingNitrogen plasmaCharge carrier mobility

Adding nitrogen to the Si—SiO2 interface at STI sidewalls increases carrier mobility in MOS transistors, but control of the amount of nitrogen has been problematic due to loss of the nitrogen during liner oxide growth. This invention discloses a method of forming STI regions which have a controllable layer of nitrogen atoms at the STI sidewall interface. Nitridation is performed on the STI sidewalls by exposure to a nitrogen-containing plasma, by exposure to NH3 gas at high temperatures, or by deposition of a nitrogen-containing thin film. Nitrogen is maintained at a level of 1.0·1015 to 3.0·1015 atoms / cm2, preferably 2.0·1015 to 2.4·1015 atoms / cm2, at the interface after growth of a liner oxide by adding nitrogen-containing gases to an oxidation ambient. The density of nitrogen is adjusted to maximize stress in a transistor adjacent to the STI regions. An IC fabricated according to the inventive method is also disclosed.

Owner:TEXAS INSTR INC

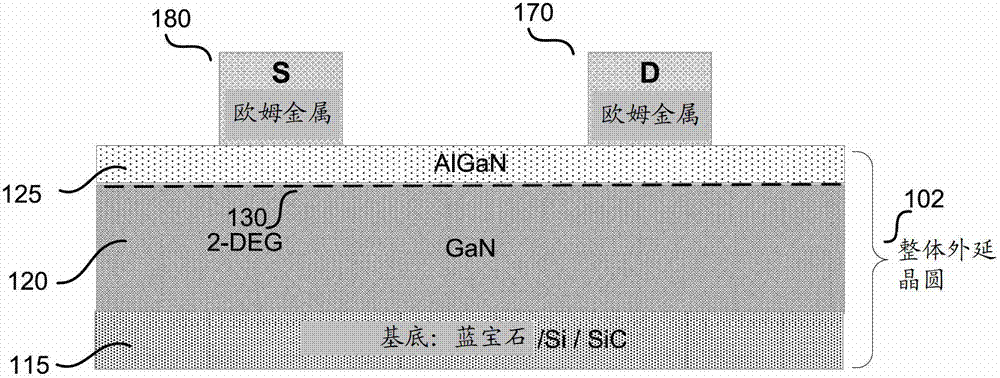

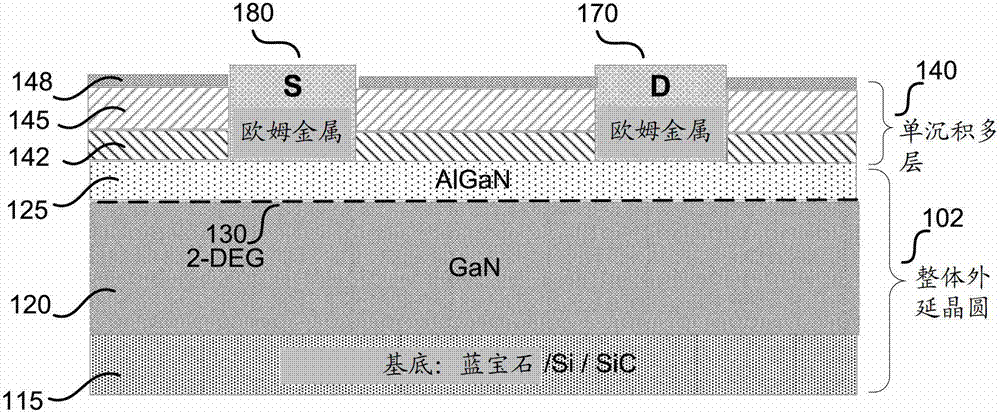

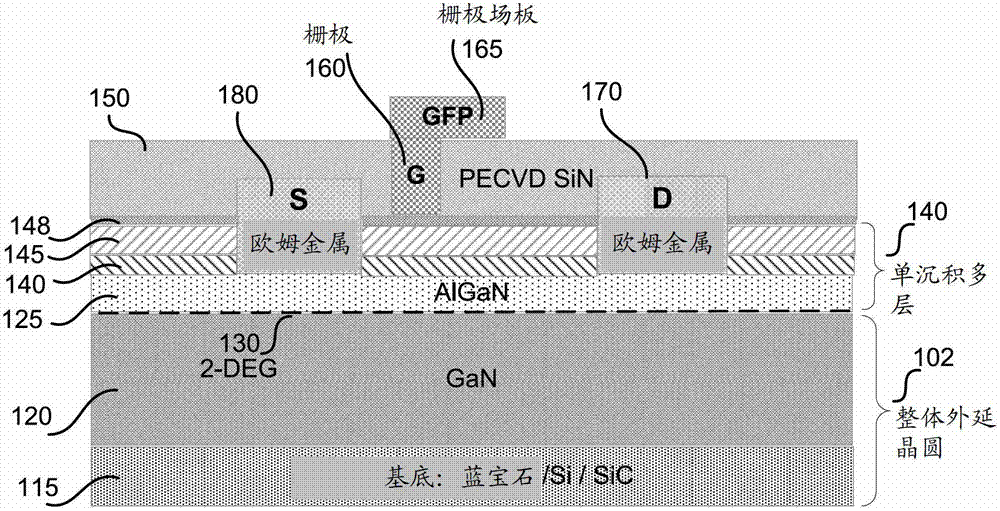

GaN high voltage HFET with passivation plus gate dielectric multilayer structure

ActiveCN103137476ASemiconductor/solid-state device detailsSolid-state devicesNitrogen plasmaGate dielectric

A method of fabricating a multi-layer structure for a power transistor device includes performing, within the reaction chamber, a nitrogen plasma strike, resulting in the formation of a nitride layer directly on the nitride-based active semiconductor layer, and then exposing a top surface of the nitride layer to a second source. A subsequent nitrogen-oxygen plasma strike results in the formation of an oxy-nitride layer directly on the nitride layer. The nitride layer comprises a passivation layer and the oxy-nitride layer comprises a gate dielectric of the power transistor device.

Owner:POWER INTEGRATIONS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com