Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1530 results about "Grain structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The grain structure refers to the arrangement of the grains in a metal, with a grain having a particular crystal structure. The grain boundary refers to the outside area of a grain that separates it from the other grains.

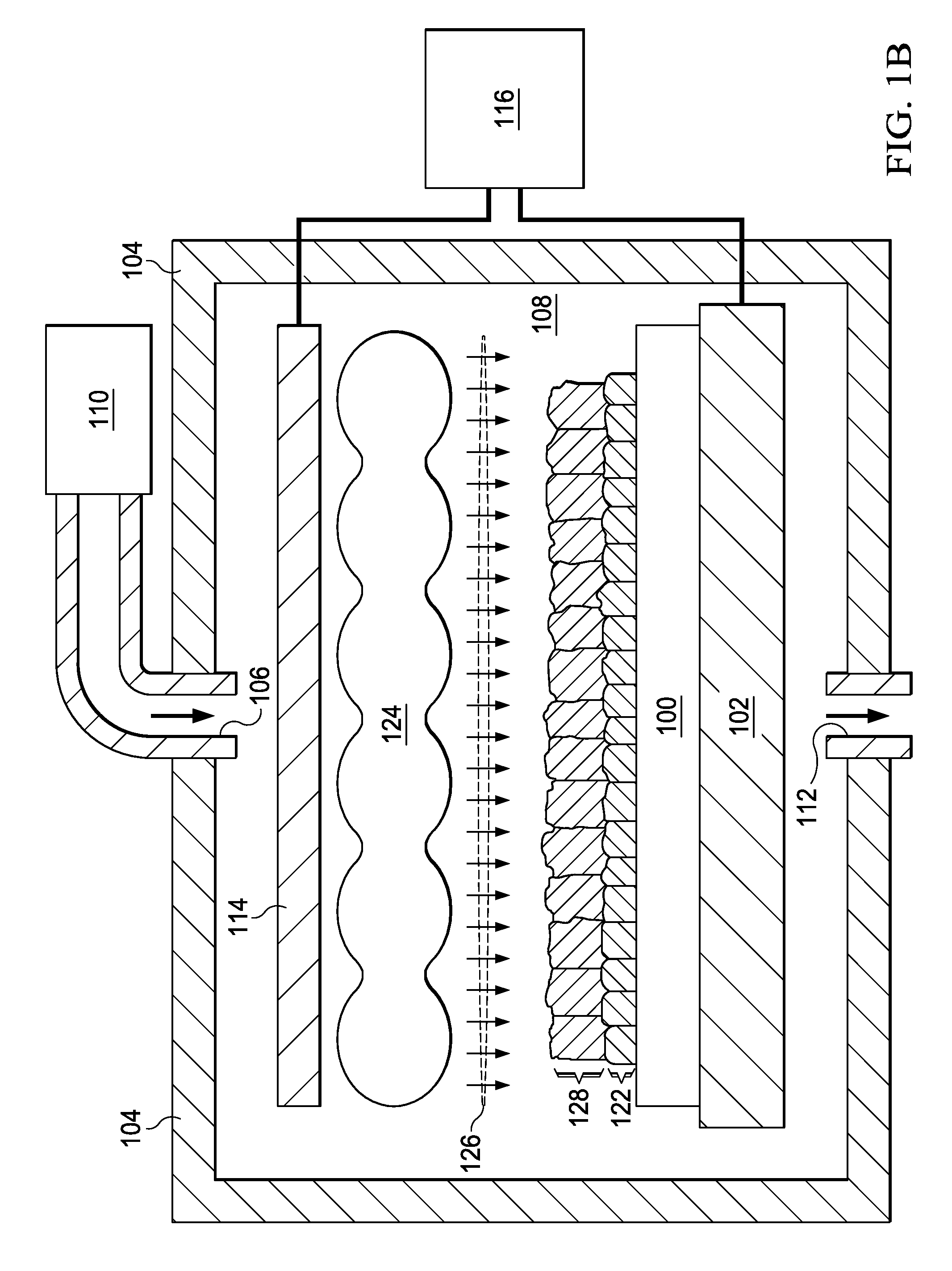

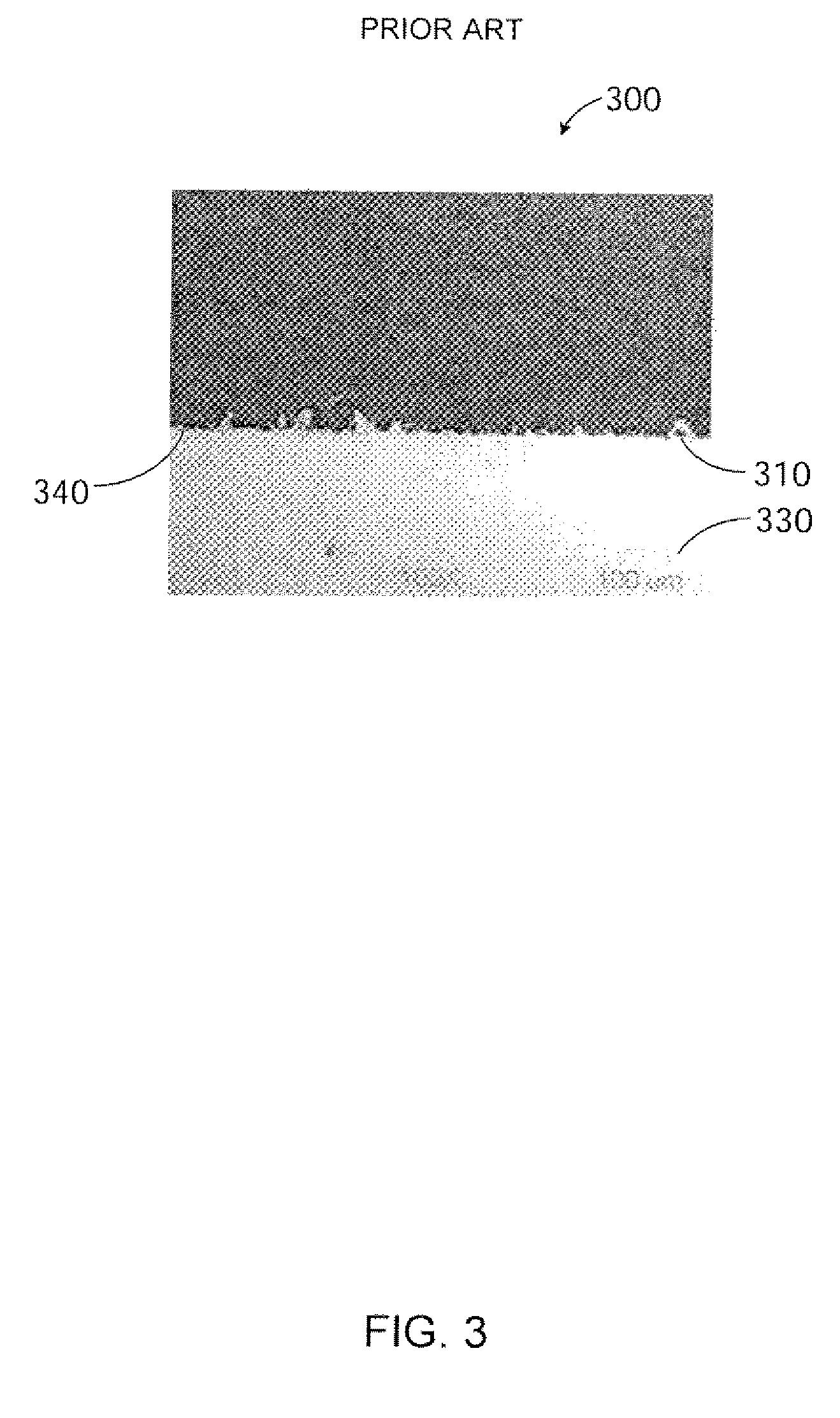

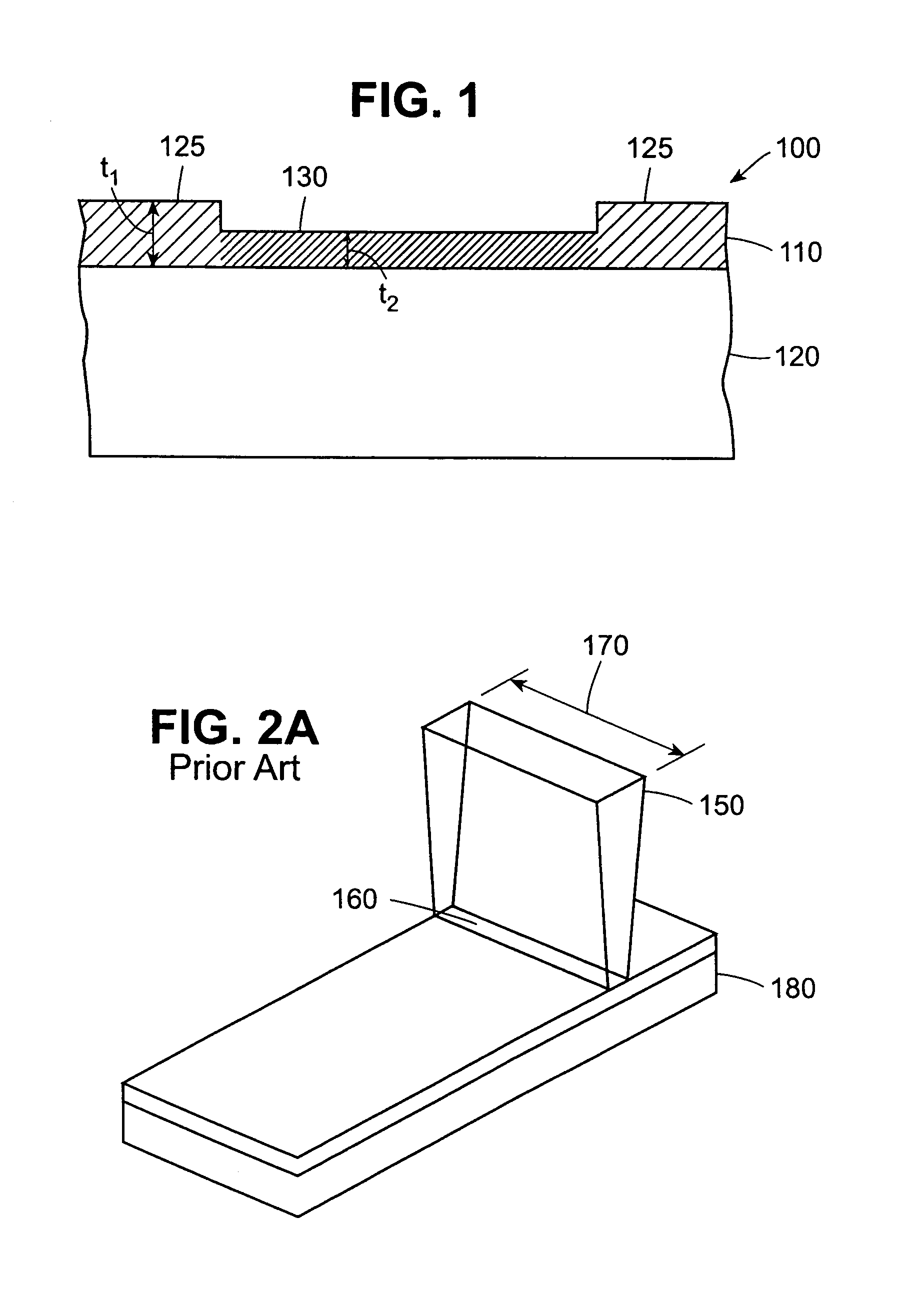

MODULATED DEPOSITION PROCESS FOR STRESS CONTROL IN THICK TiN FILMS

ActiveUS20100032842A1Liquid surface applicatorsIncorrect coupling preventionNitrogen plasmaDeposition process

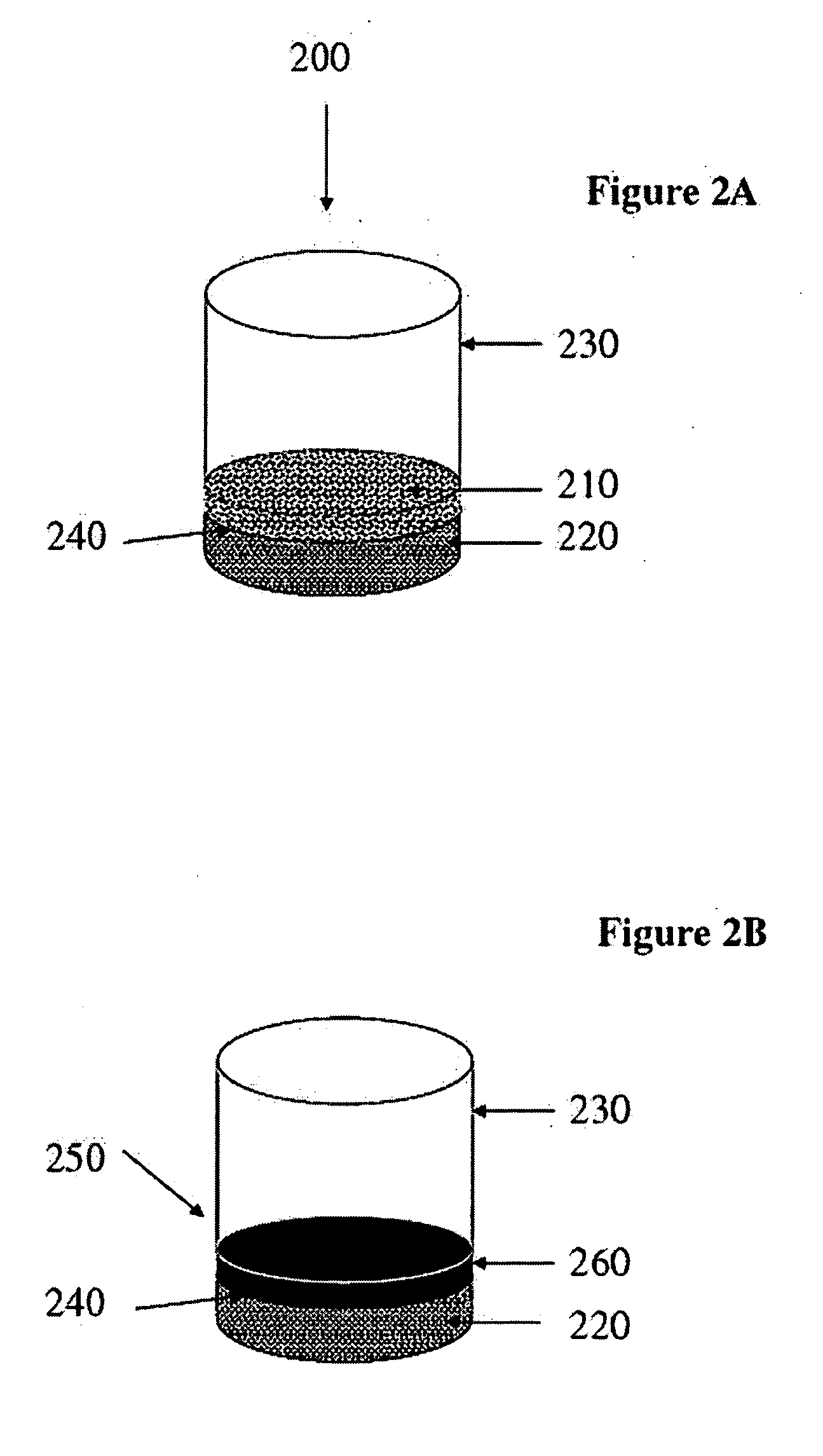

A multi-layer TiN film with reduced tensile stress and discontinuous grain structure, and a method of fabricating the TiN film are disclosed. The TiN layers are formed by PVD or IMP in a nitrogen plasma. Tensile stress in a center layer of the film is reduced by increasing N2 gas flow to the nitrogen plasma, resulting in a Ti:N stoichiometry between 1:2.1 to 1:2.3. TiN films thicker than 40 nanometers without cracks are attained by the disclosed process.

Owner:TEXAS INSTR INC

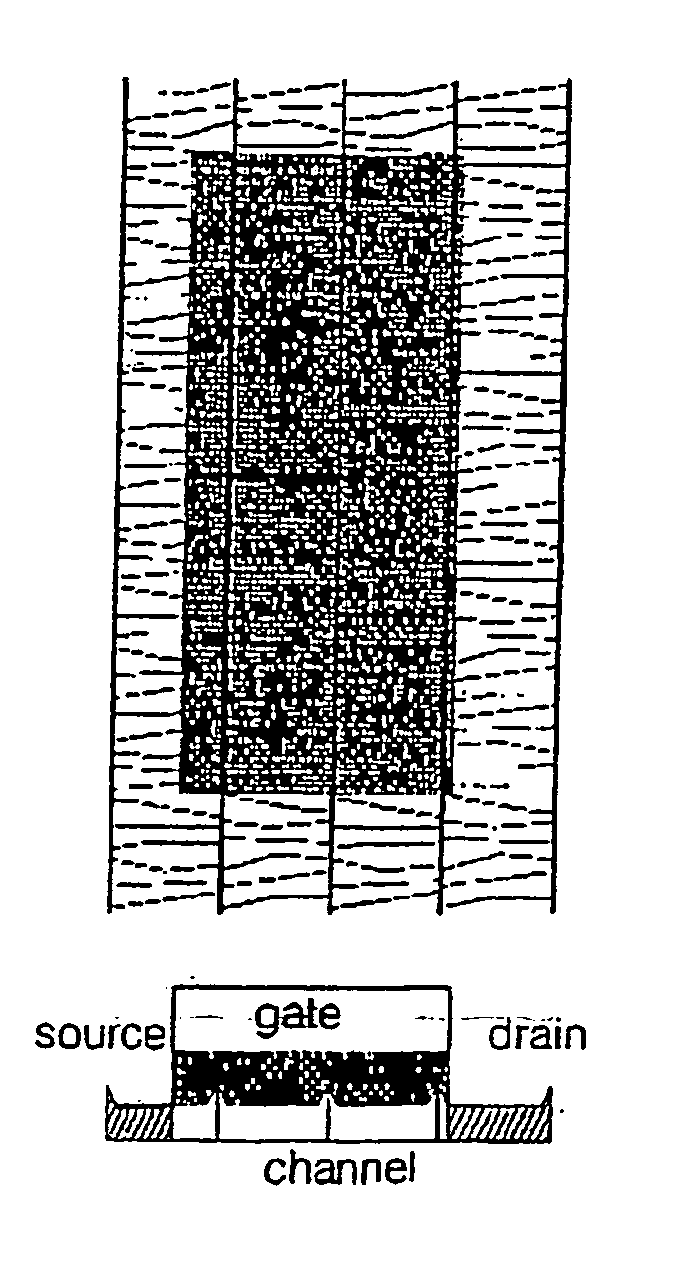

Fine Grained, Non Banded, Refractory Metal Sputtering Targets with a Uniformly Random Crystallographic Orientation, Method for Making Such Film, and Thin Film Based Devices and Products Made Therefrom

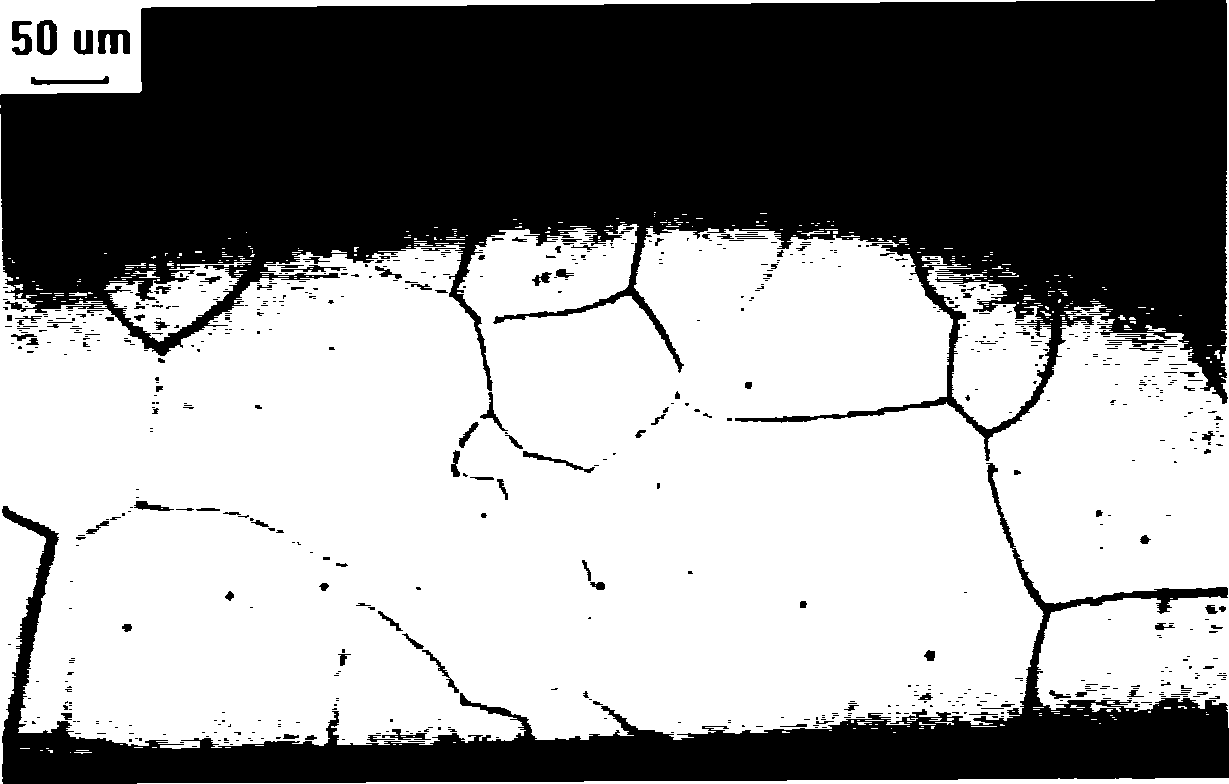

ActiveUS20080271779A1Cost-effectively createCost effectiveLiquid surface applicatorsMolten spray coatingFilm baseThermal expansion

The invention relates to a sputtering target which has a fine uniform equiaxed grain structure of less than 44 microns, no preferred texture orientation as measured by electron back scattered diffraction (“EBSD”) and that displays no grain size banding or texture banding throughout the body of the target. The invention relates a sputtering target with a lenticular or flattened grain structure, no preferred texture orientation as measured by EBSD and that displays no grain size or texture banding throughout the body of the target and where the target has a layered structure incorporating a layer of the sputtering material and at least one additional layer at the backing plate interface, said layer has a coefficient of thermal expansion (“CTE”) value between the CTE of the backing plate and the CTE of the layer of sputtering material. The invention also relates to thin films and their use of using the sputtering target and other applications, such as coatings, solar devices, semiconductor devices etc. The invention further relates to a process to repair or rejuvenate a sputtering target.

Owner:H C STARCK GMBH +1

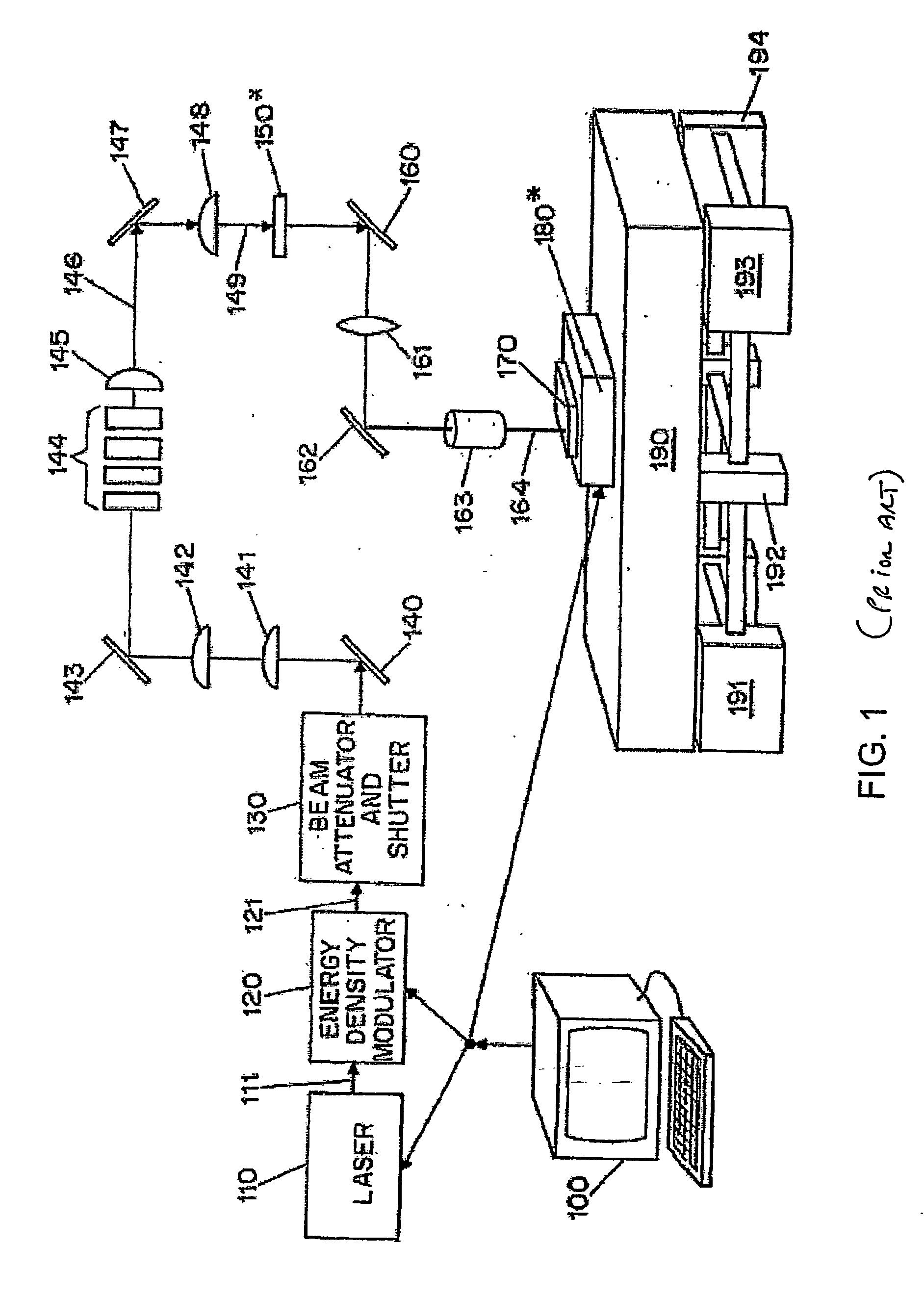

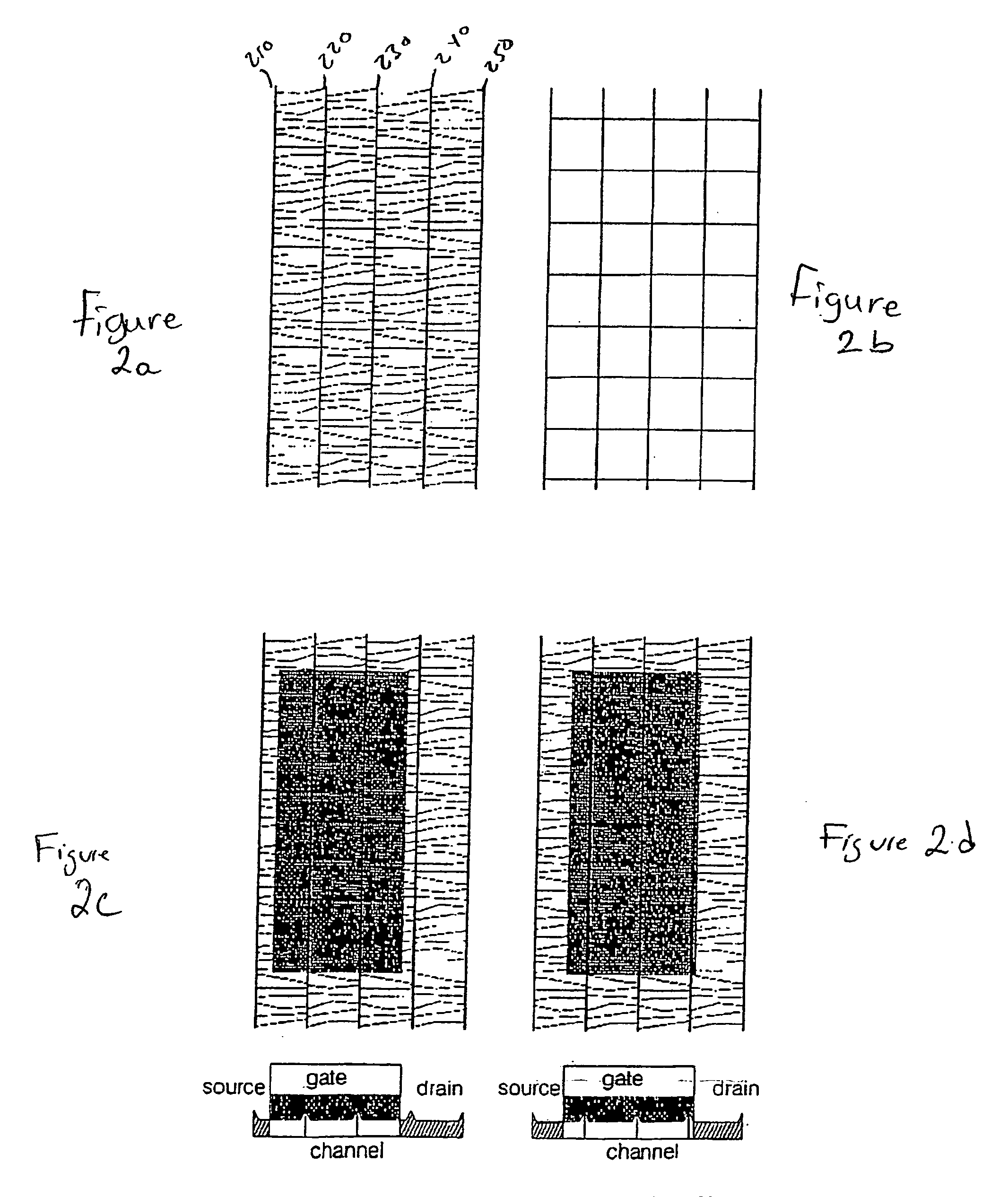

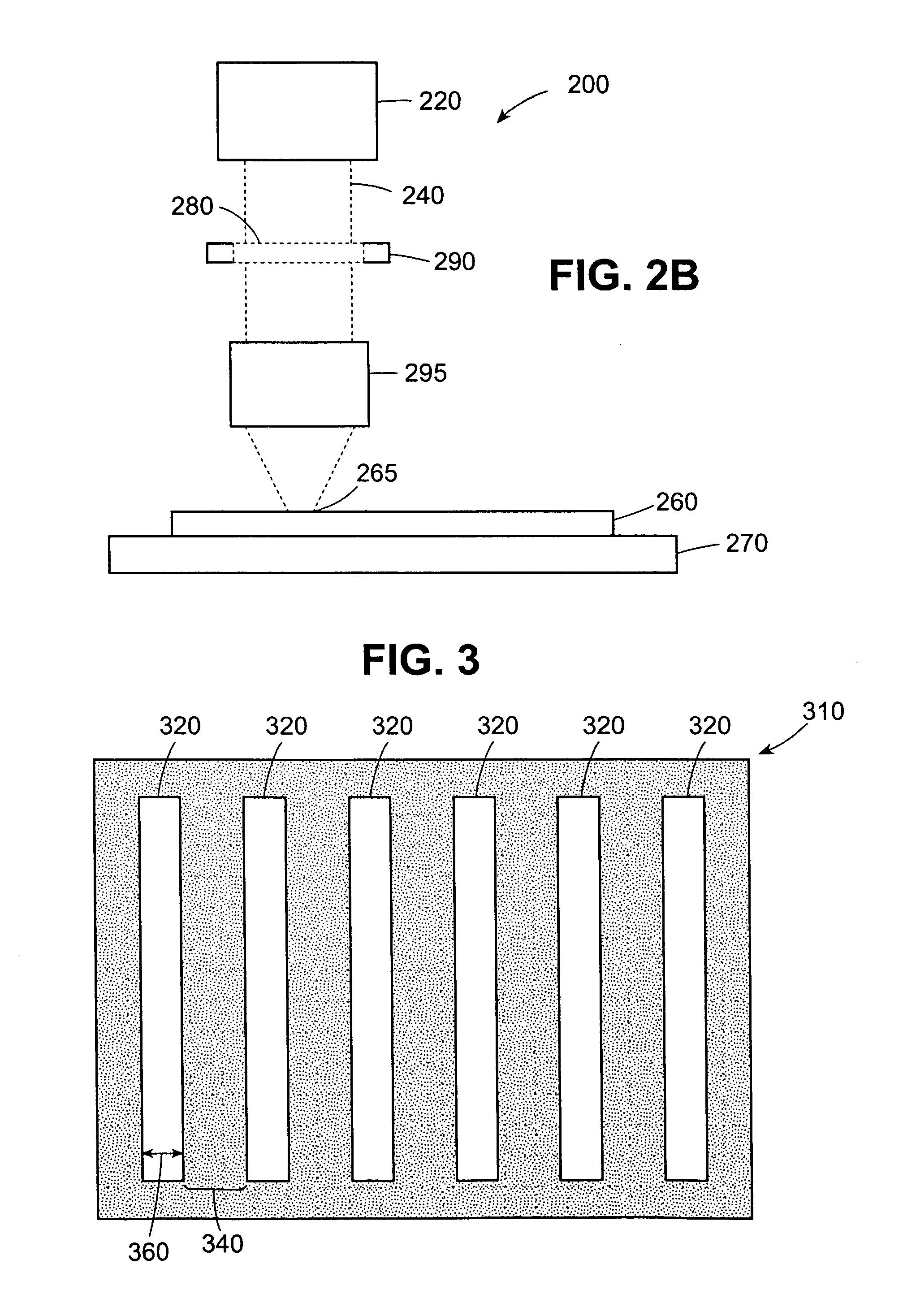

Polycrystalline tft uniformity through microstructure mis-alignment

InactiveUS20050034653A1Provide uniformityUniformityTransistorPolycrystalline material growthOptoelectronicsGrain structure

Methods of making a polycrystalline silicon thin-film transistor having a uniform microstructure. One exemplary method requires receiving a polycrystalline silicon thin film having a grain structure which is periodic in at least a first direction, and placing at least portions (410, 420) of one or more thin-film transistors on the received film such that they are tilted relative to the periodic structure of the thin film.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

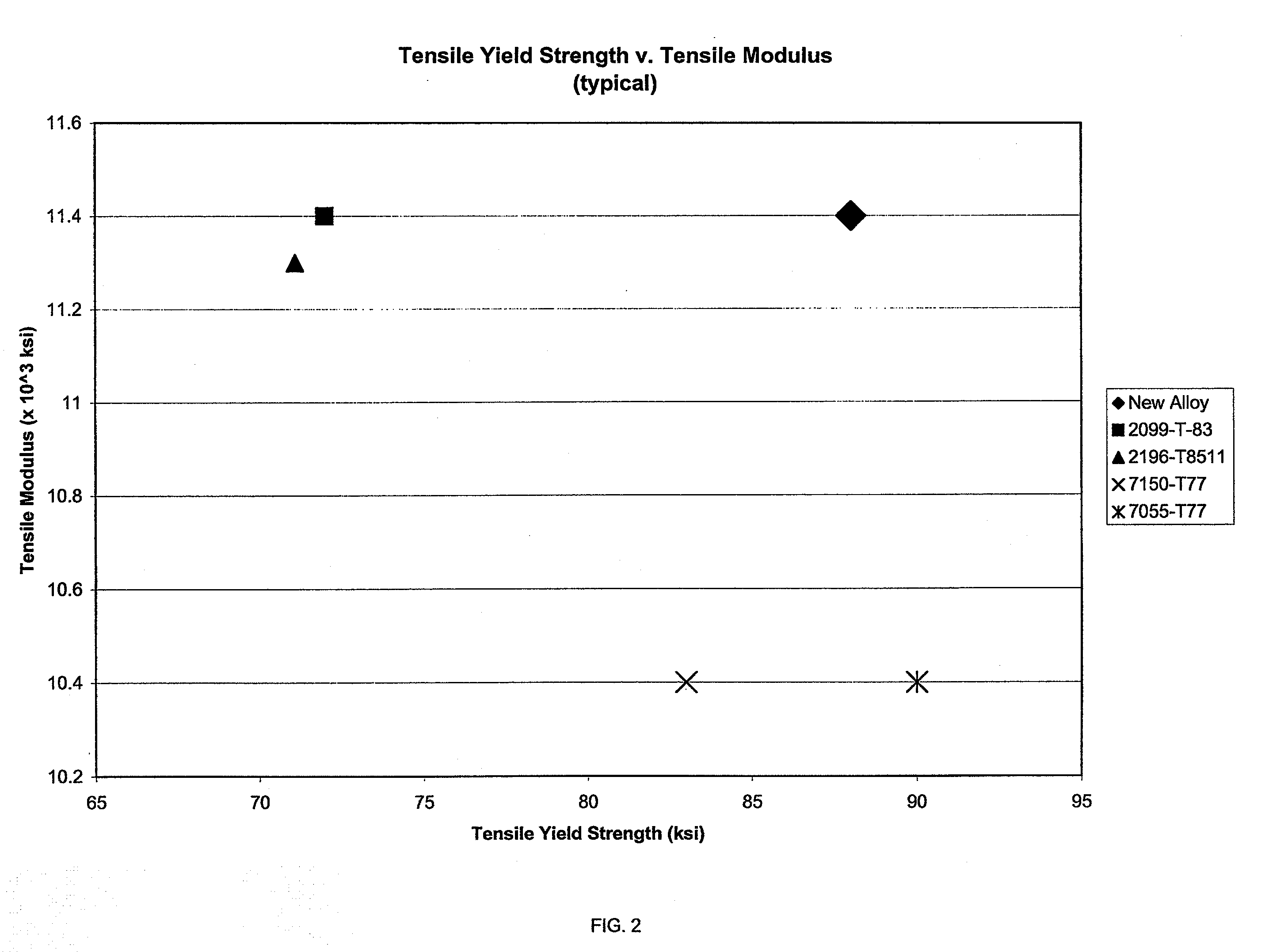

Aluminum-copper-lithium alloys

ActiveUS20090142222A1Improved combination of propertyImproved combination of mechanical property and corrosion resistant propertyLithiumGrain structure

Improved aluminum-copper-lithium alloys are disclosed. The alloys may include 3.4-4.2 wt. % Cu, 0.9-1.4 wt. % Li, 0.3-0.7 wt. % Ag, 0.1-0.6 wt. % Mg, 0.2-0.8 wt. % Zn, 0.1-0.6 wt. % Mn, and 0.01-0.6 wt. % of at least one grain structure control element, the balance being aluminum and incidental elements and impurities. The alloys achieve an improved combination of properties over prior art alloys.

Owner:ARCONIC TECH LLC

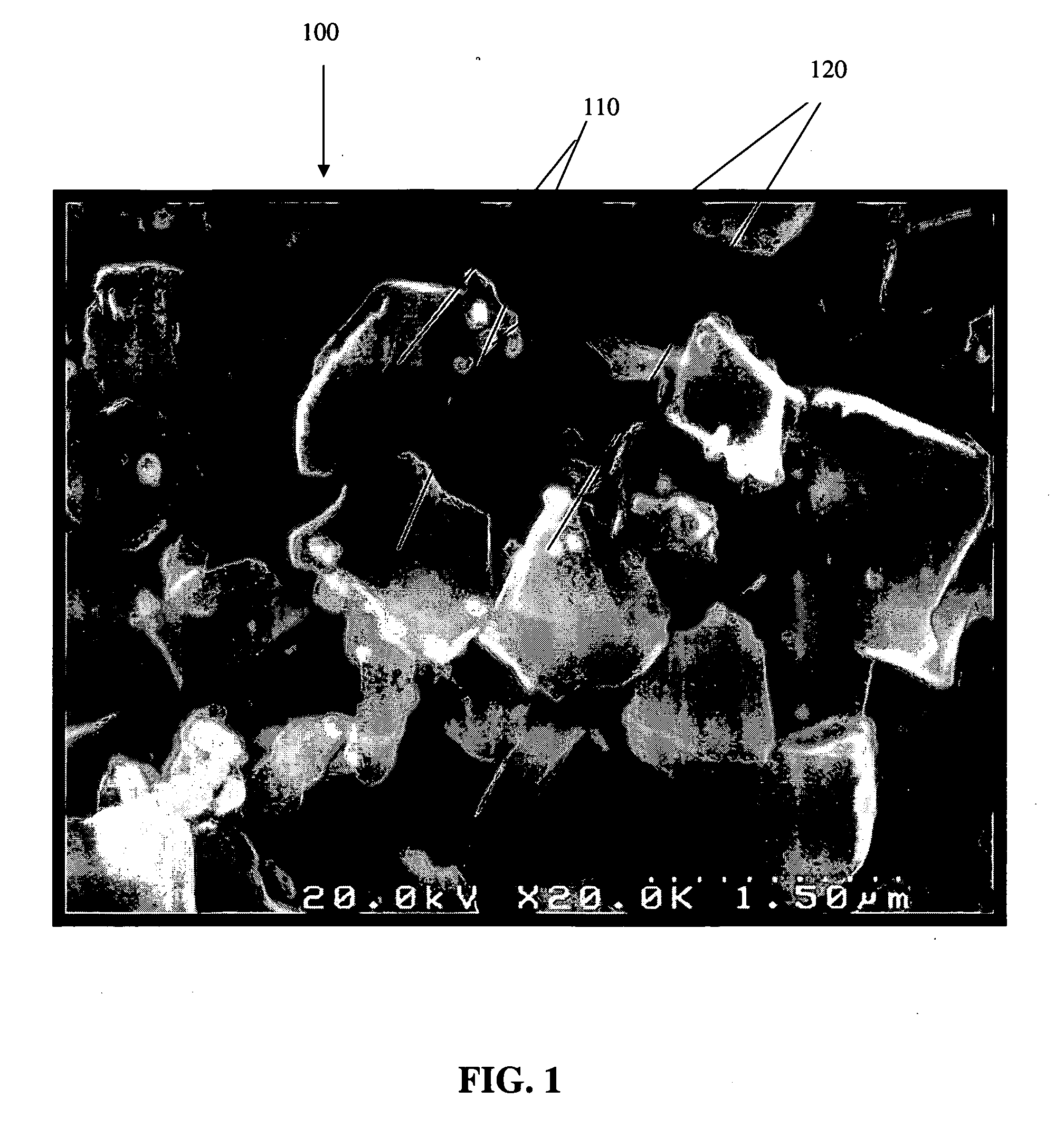

Sintered polycrystalline diamond material with extremely fine microstructures

InactiveUS20070056778A1Uniform particle sizePressurized chemical processDrill bitsPolycrystalline diamondHigh pressure

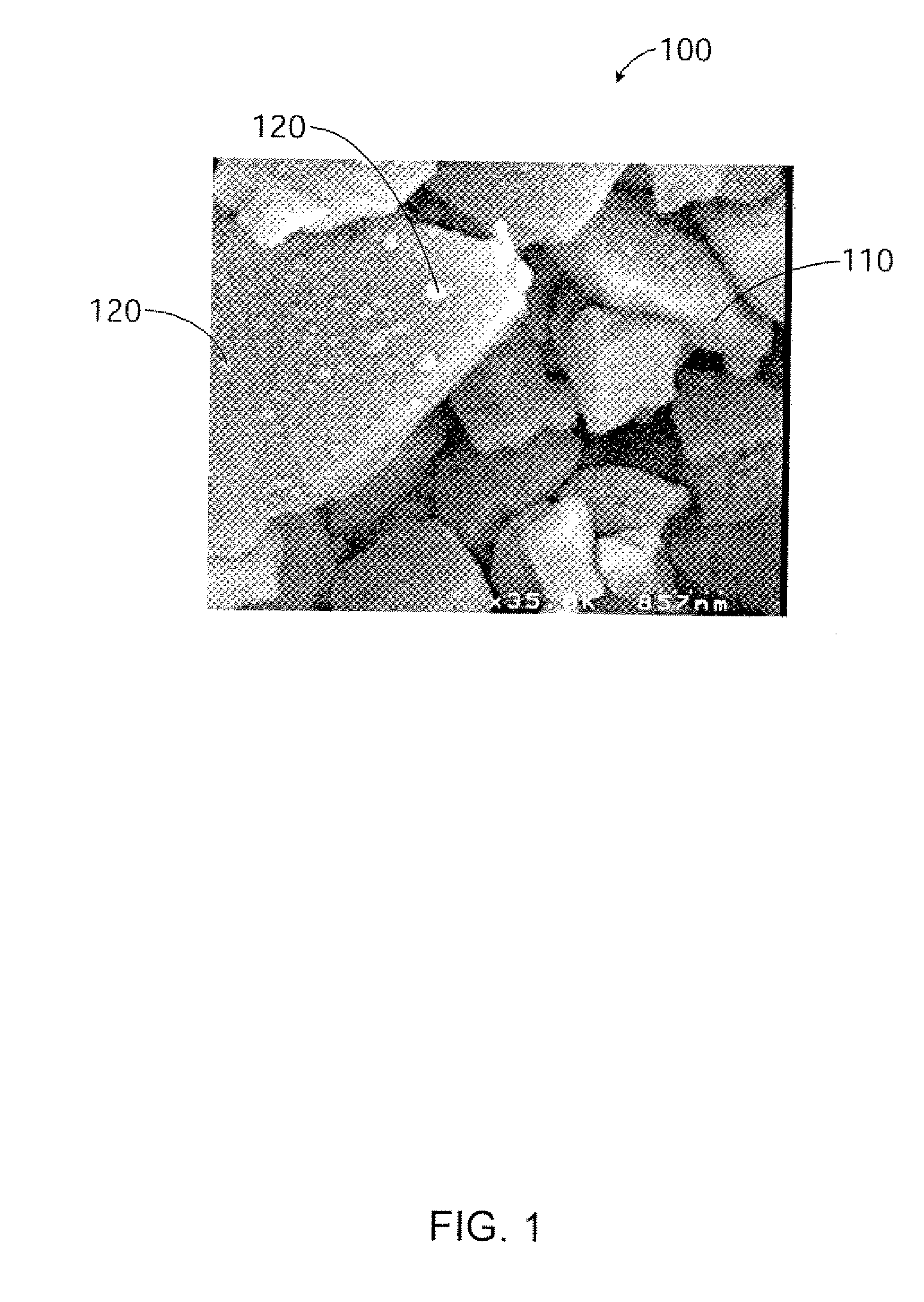

A sintered polycrystalline diamond material (PCD) of extremely fine grain size is manufactured by sintering a diamond powder with pre-blended catalyst metal under high pressure / high temperature (HP / HT) processing. The PCD material has an average sintered diamond grain structure of less than 1.0 μm.

Owner:DIAMOND INNOVATIONS INC

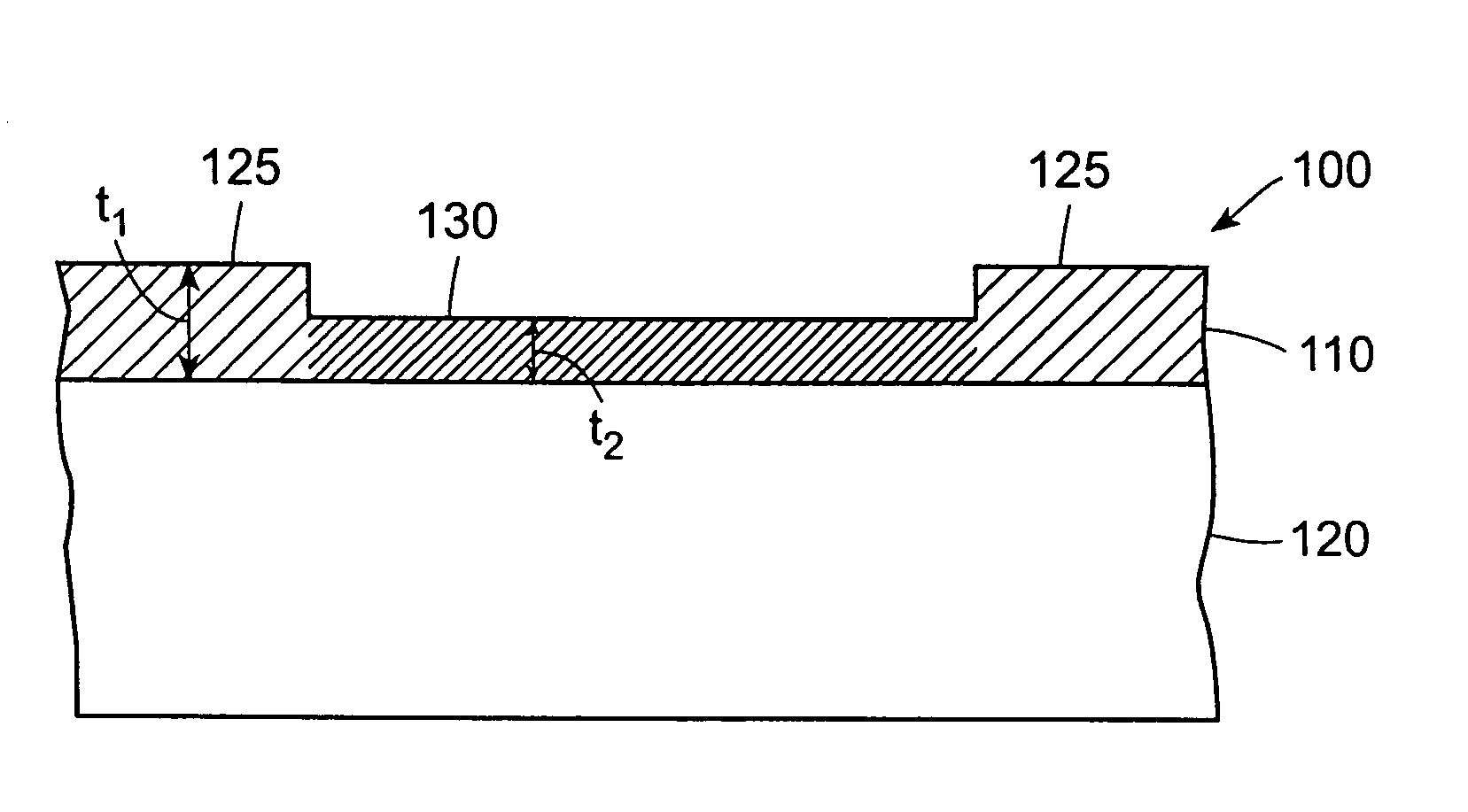

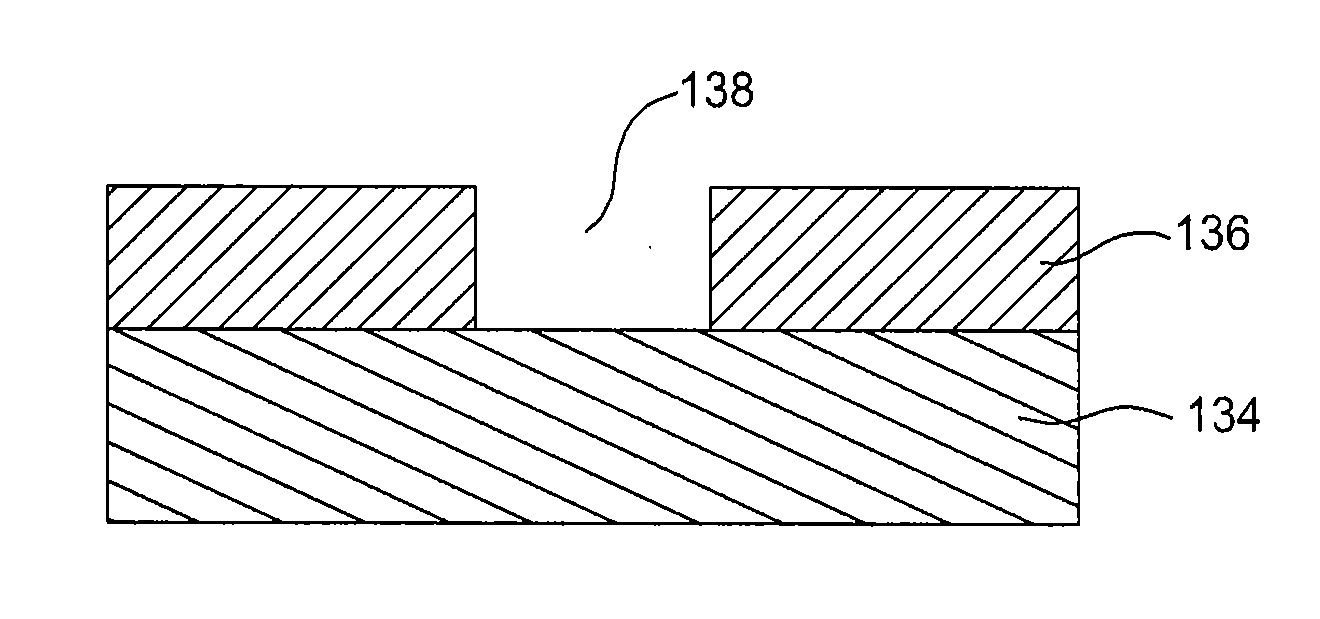

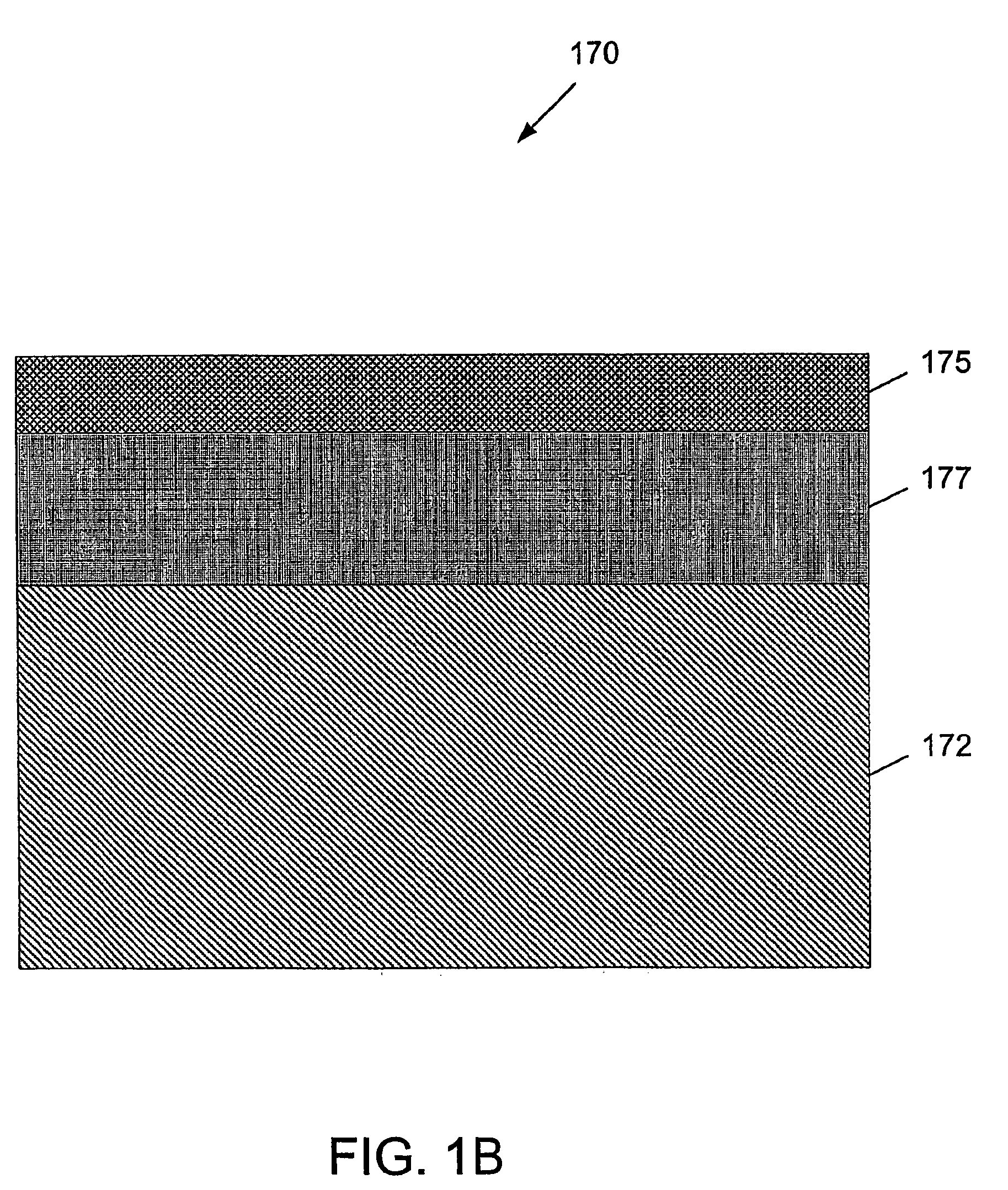

Laser-irradiated thin films having variable thickness

A crystalline film includes a first crystalline region having a first film thickness and a first crystalline grain structure; and a second crystalline region having a second film thickness and a second crystalline grain structure. The first film thickness is greater than the second film thickness and the first and second film thicknesses are selected to provide a crystalline region having the degree and orientation of crystallization that is desired for a device component.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

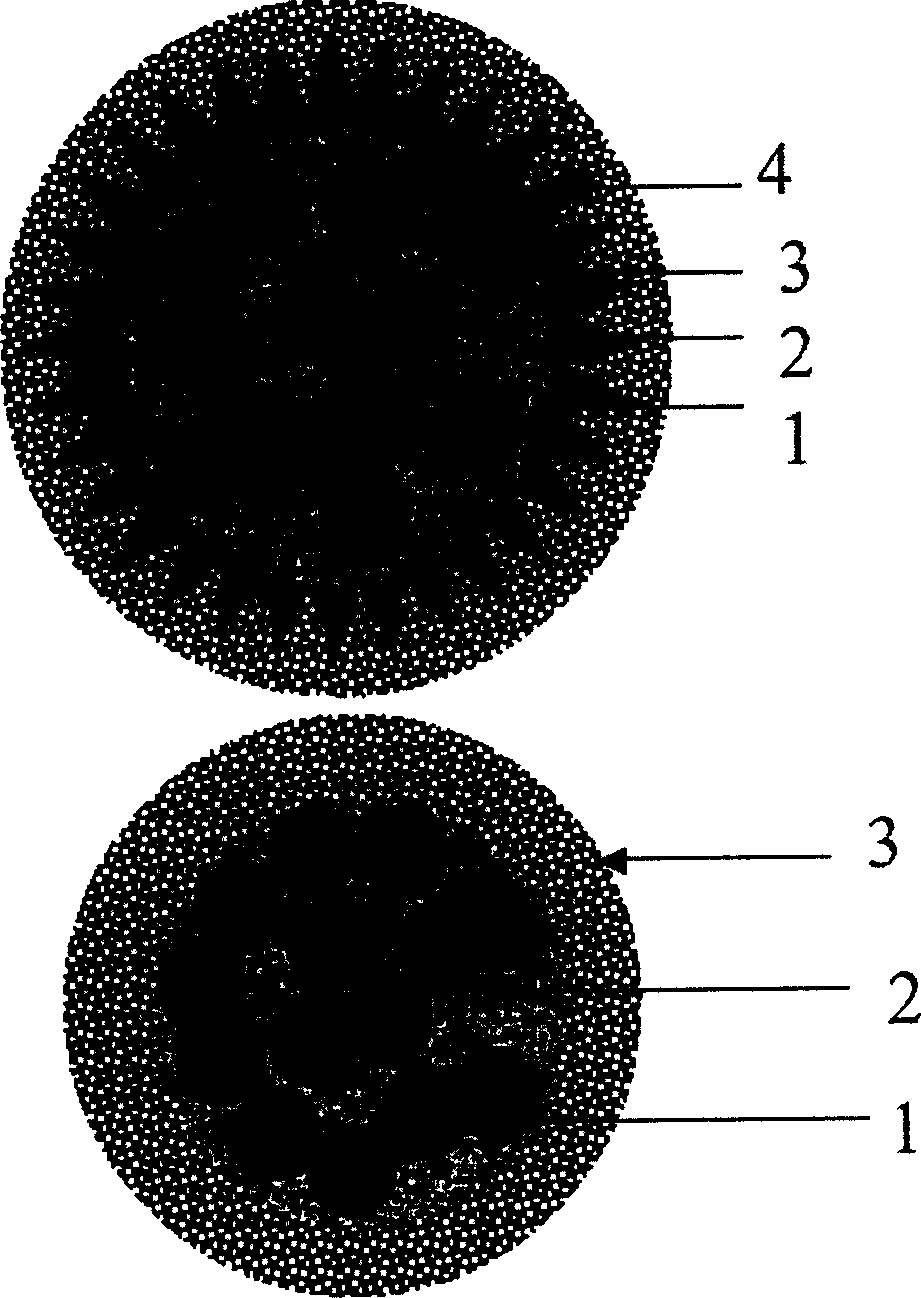

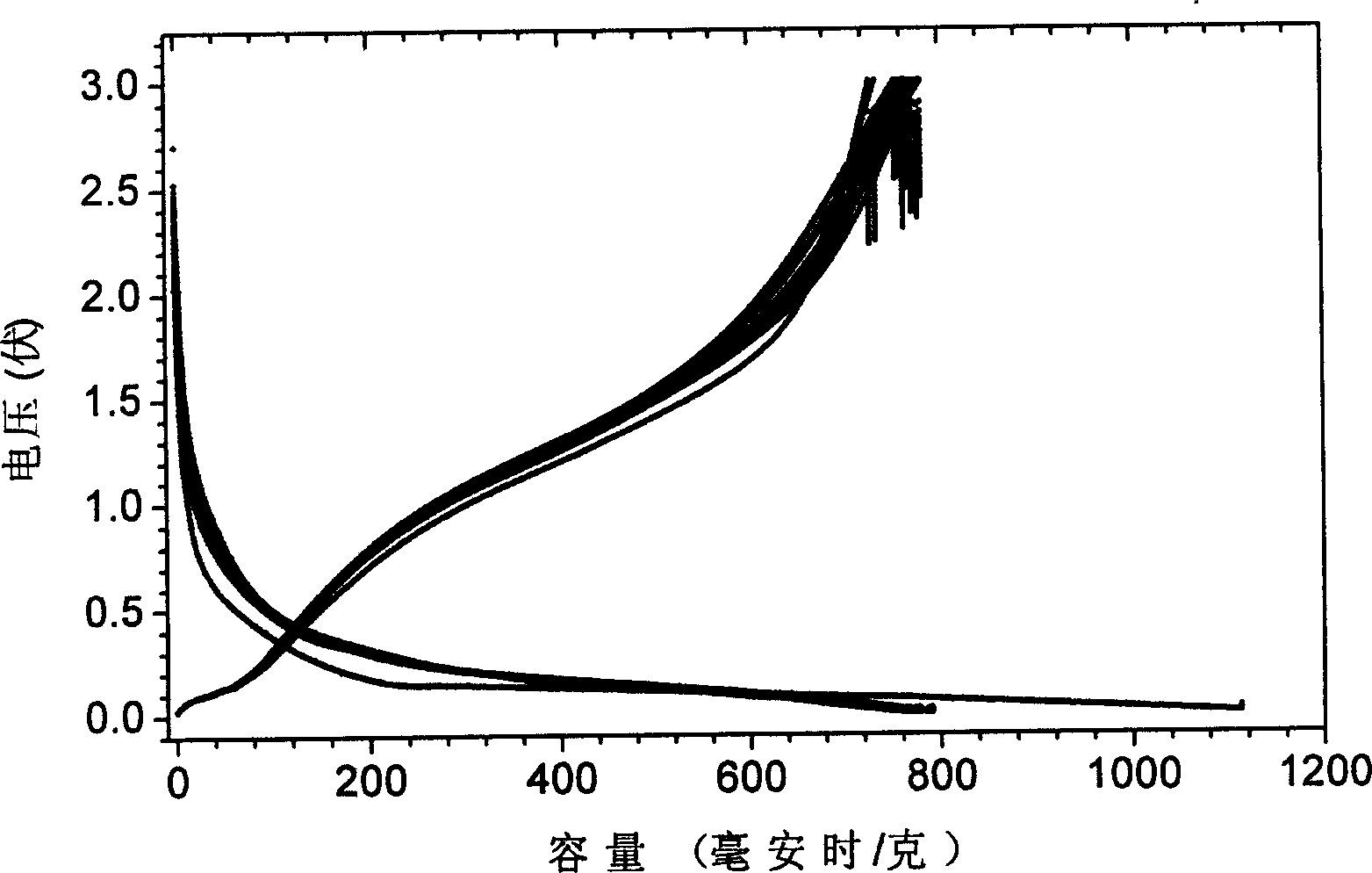

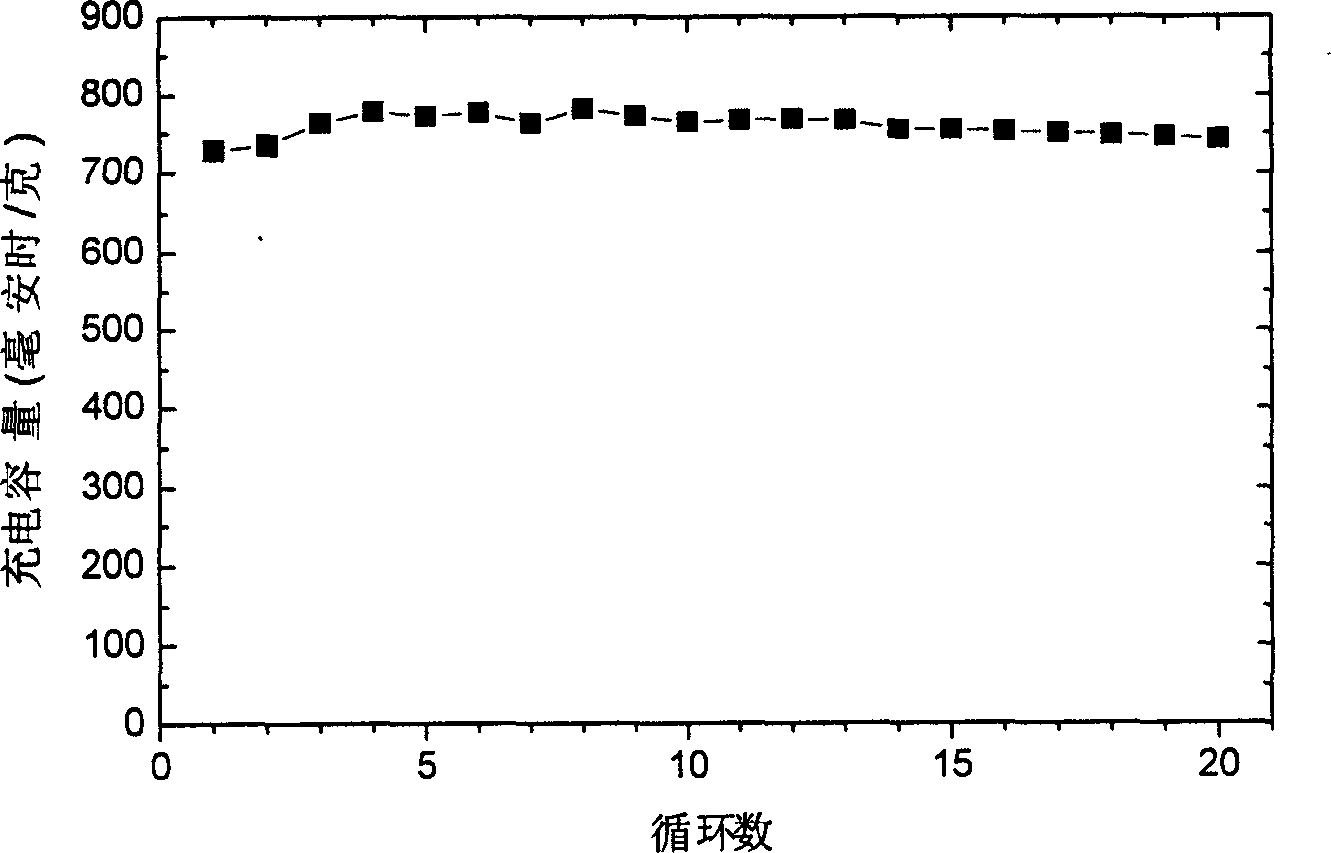

Negative electrode active material and use of secondary lithium battery

The invention has a grain structure with an outer shell and several inner cores. The grain size is from 100 nanometers to 100 microns. The inner cores are compound grain that includes active substance and conducting additive. The outer shell is a carbon layer. The active substance takes 20-95wt% of total cathode active material, and is mixture of one or several transition metallic compound selected from silicon and lithium storage whose thermodynamic equilibrium potential is less than 1.5v. The cathode material can be made by using mechanical process or thermal method, and can be directly used as cathode material or used with other existing cathode material.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD

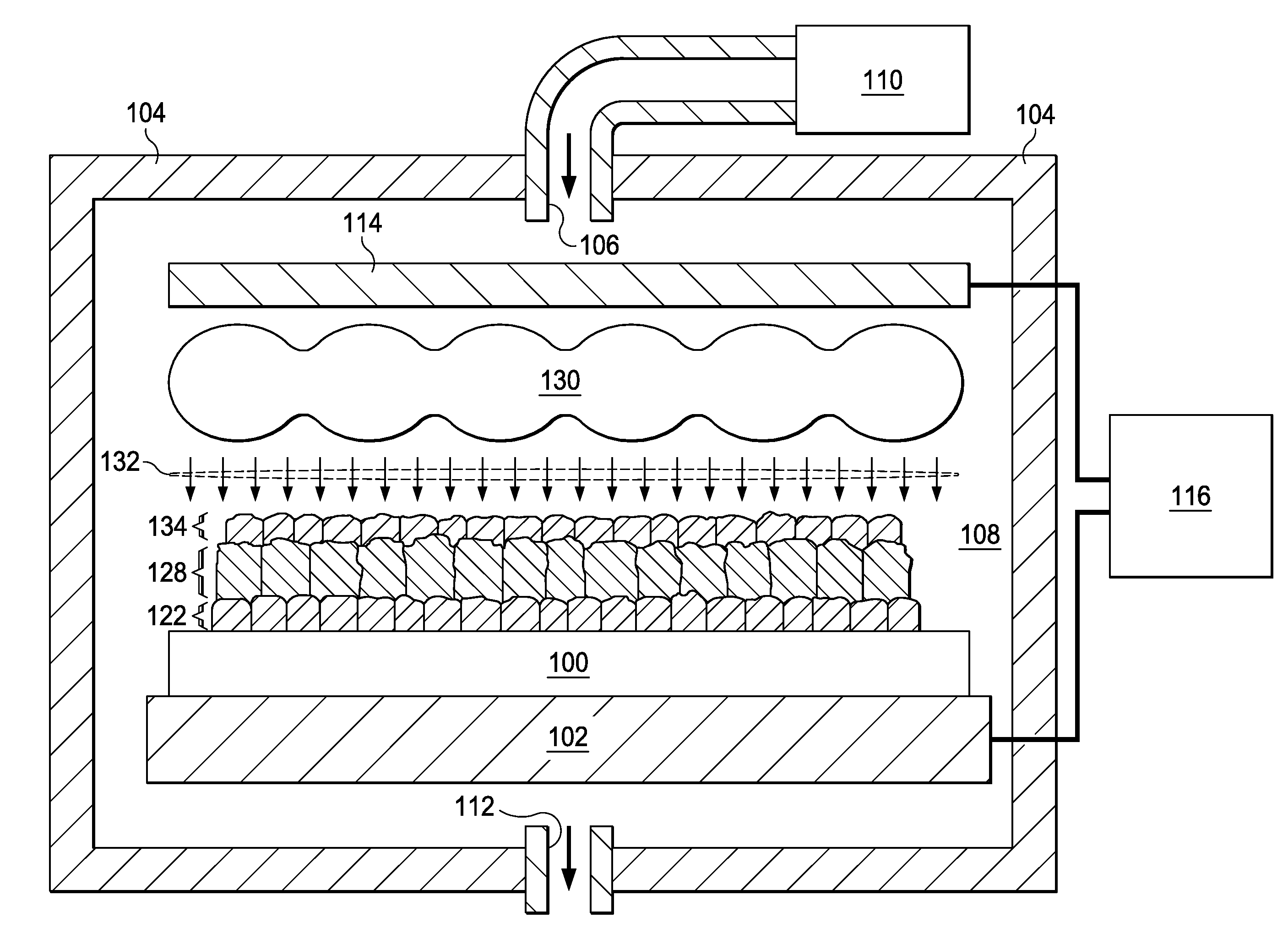

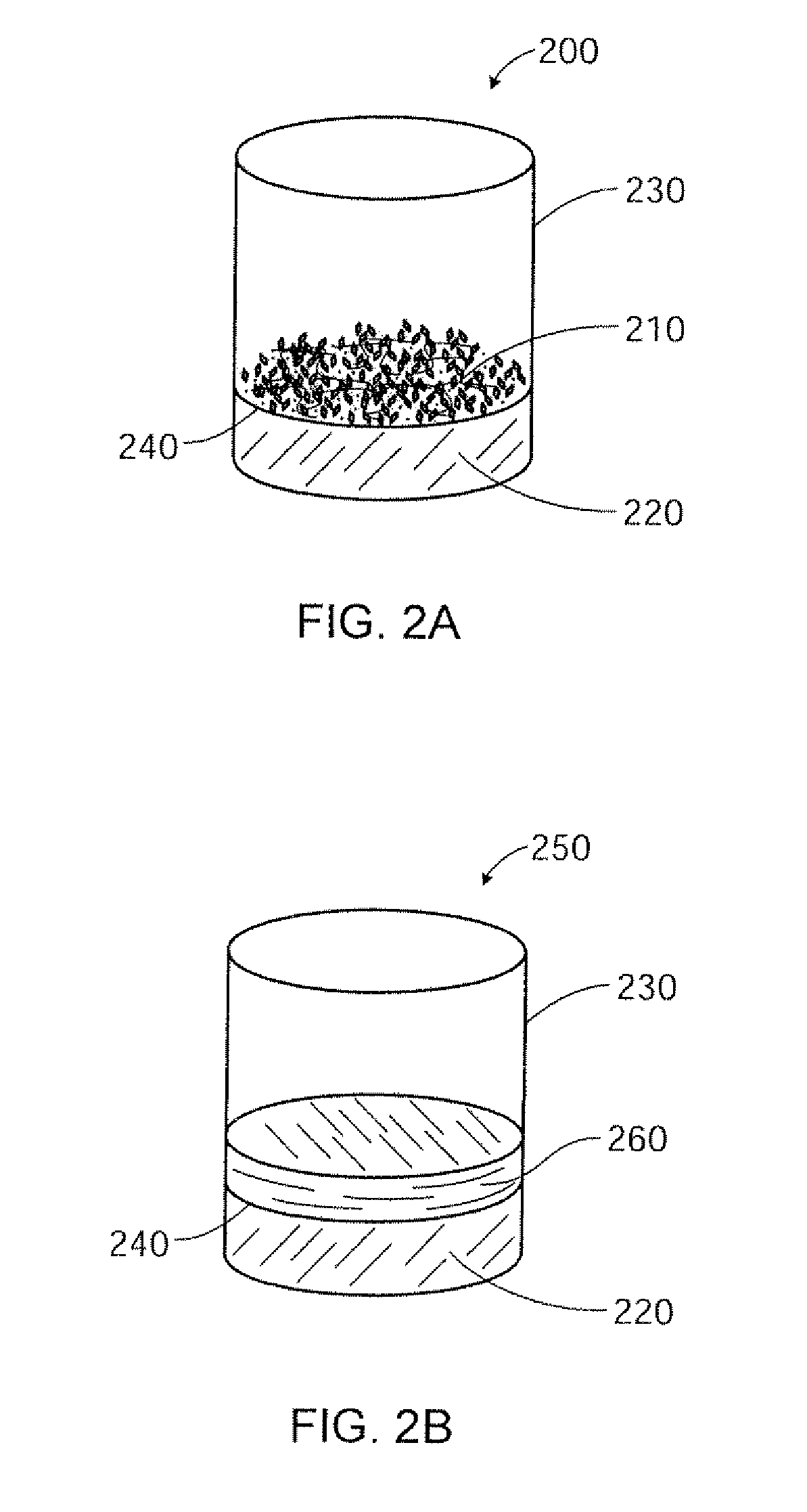

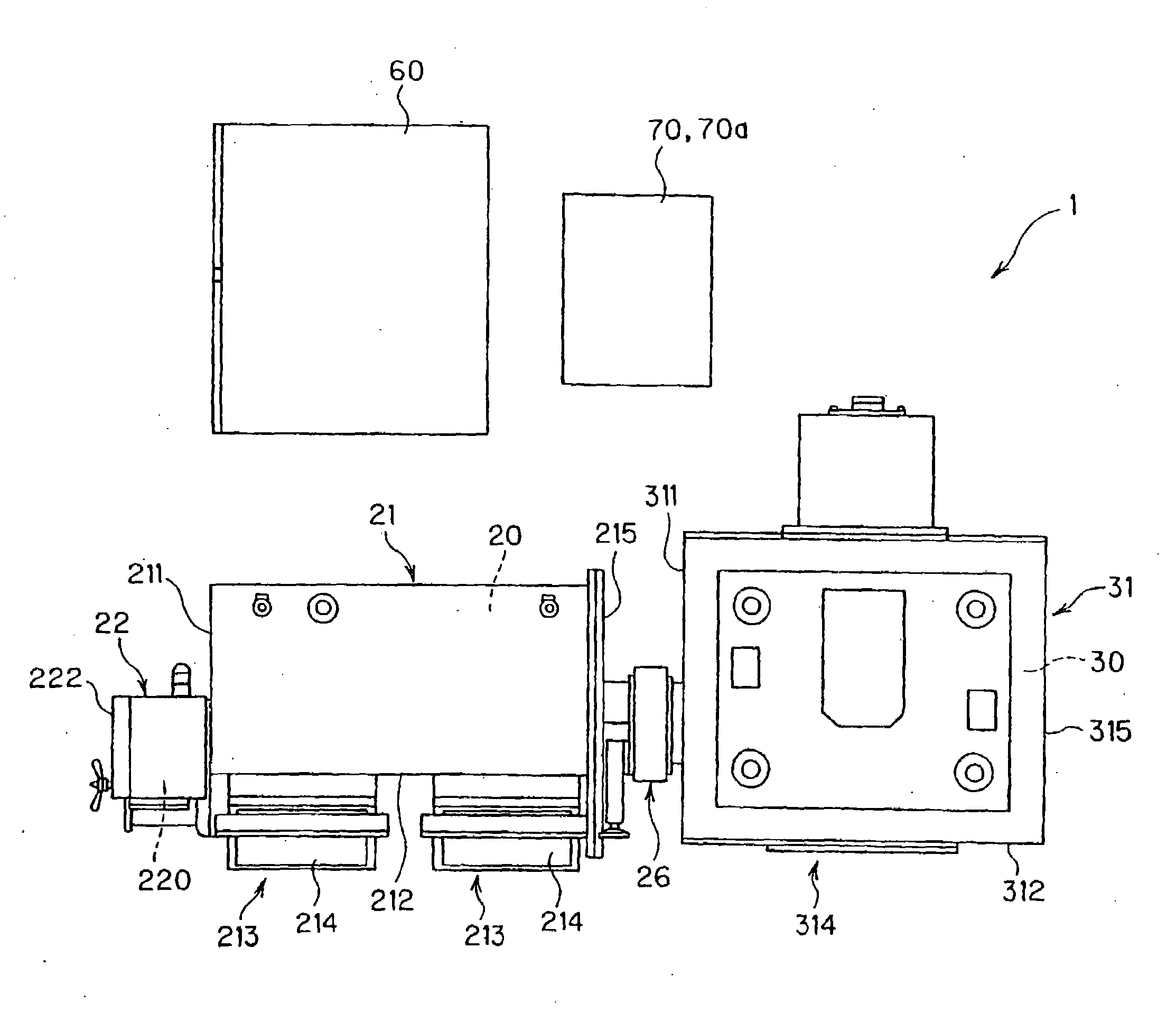

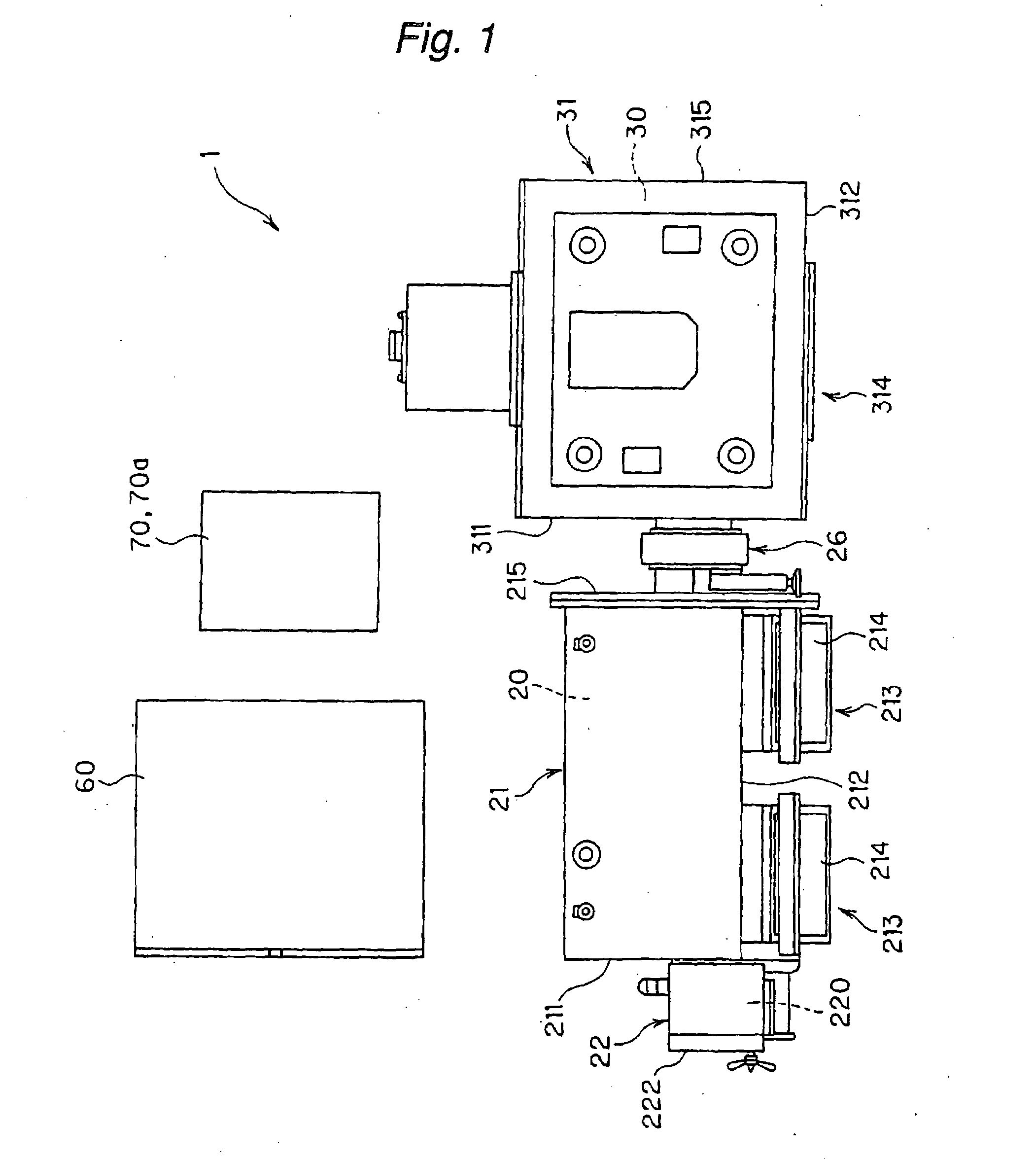

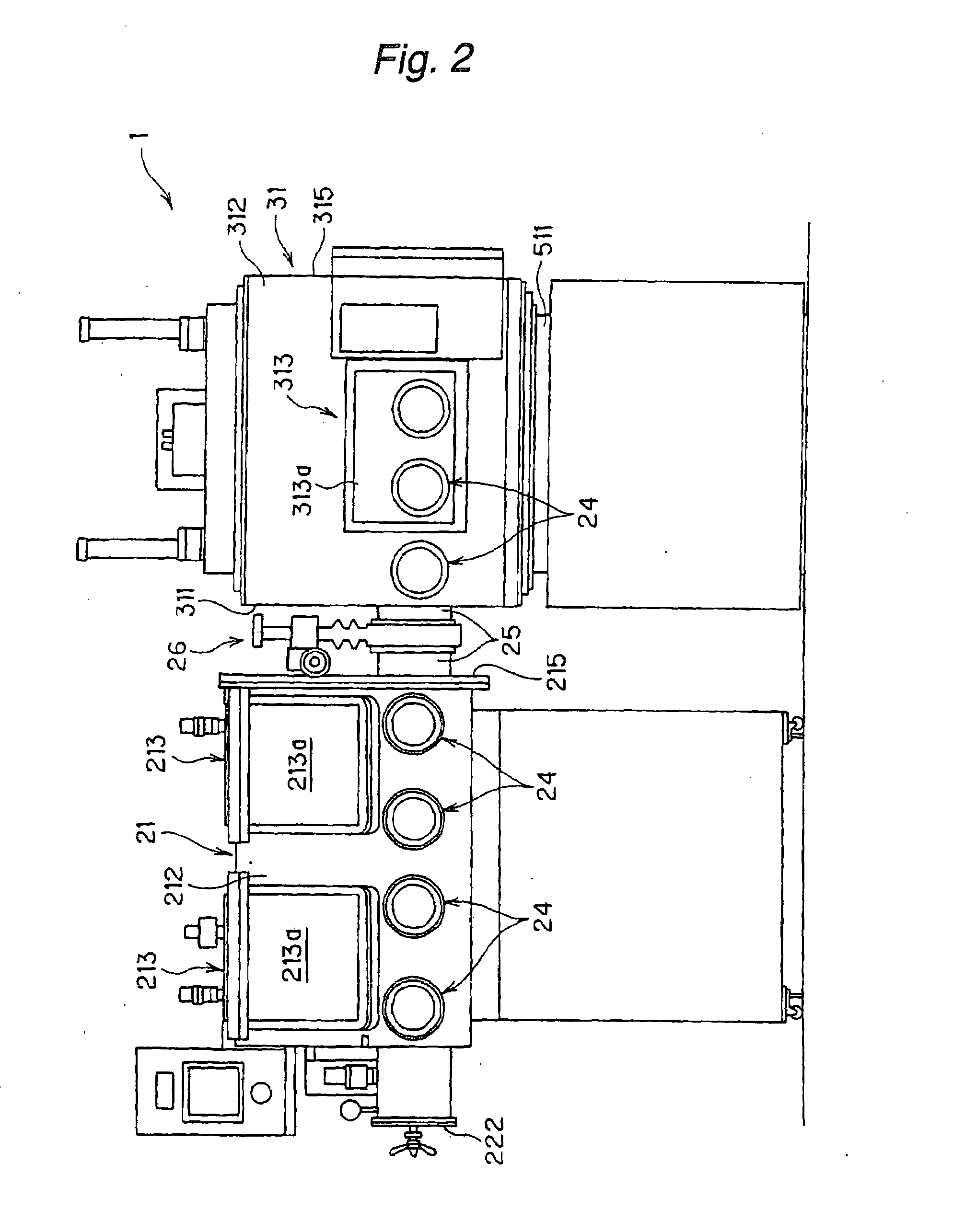

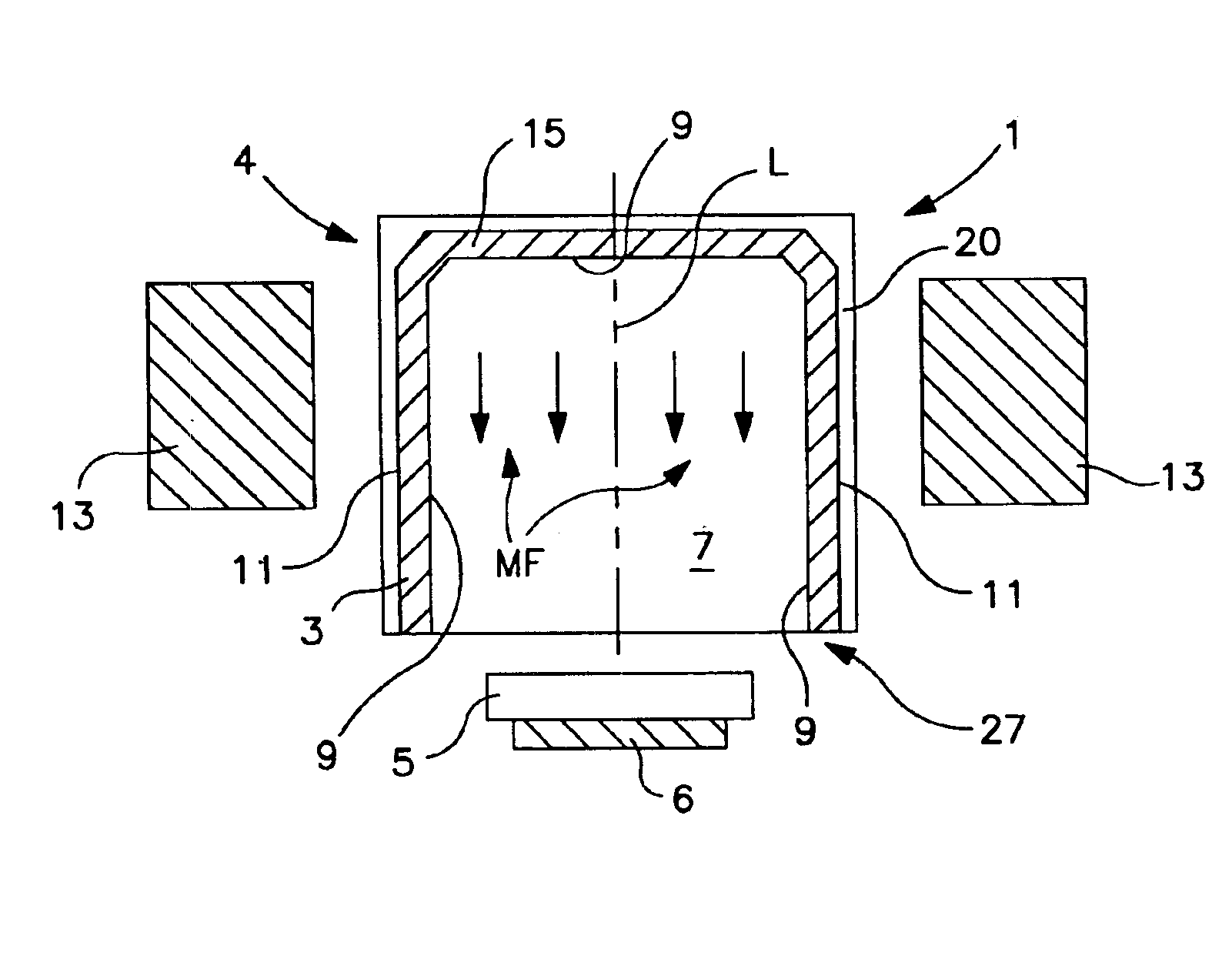

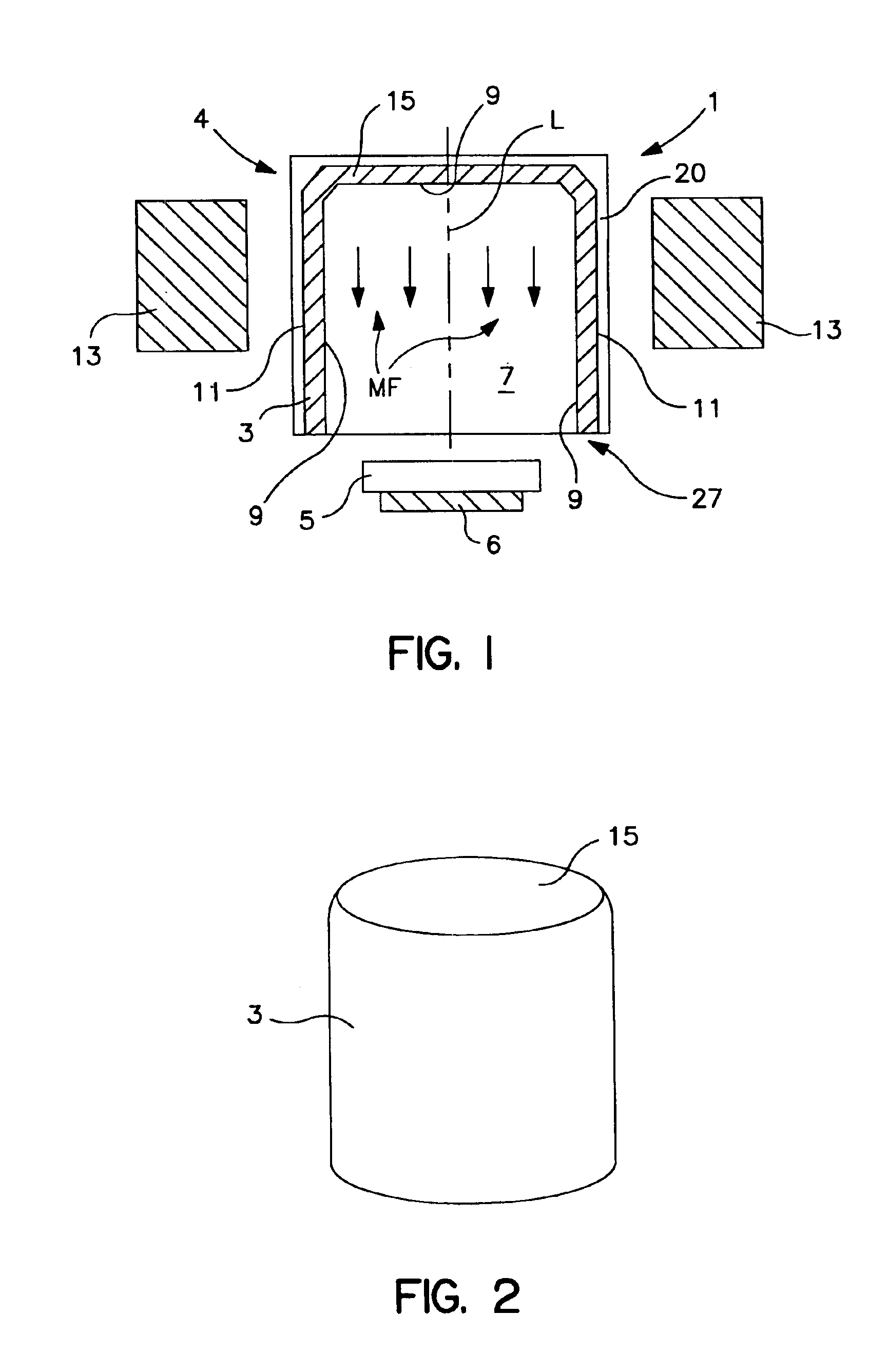

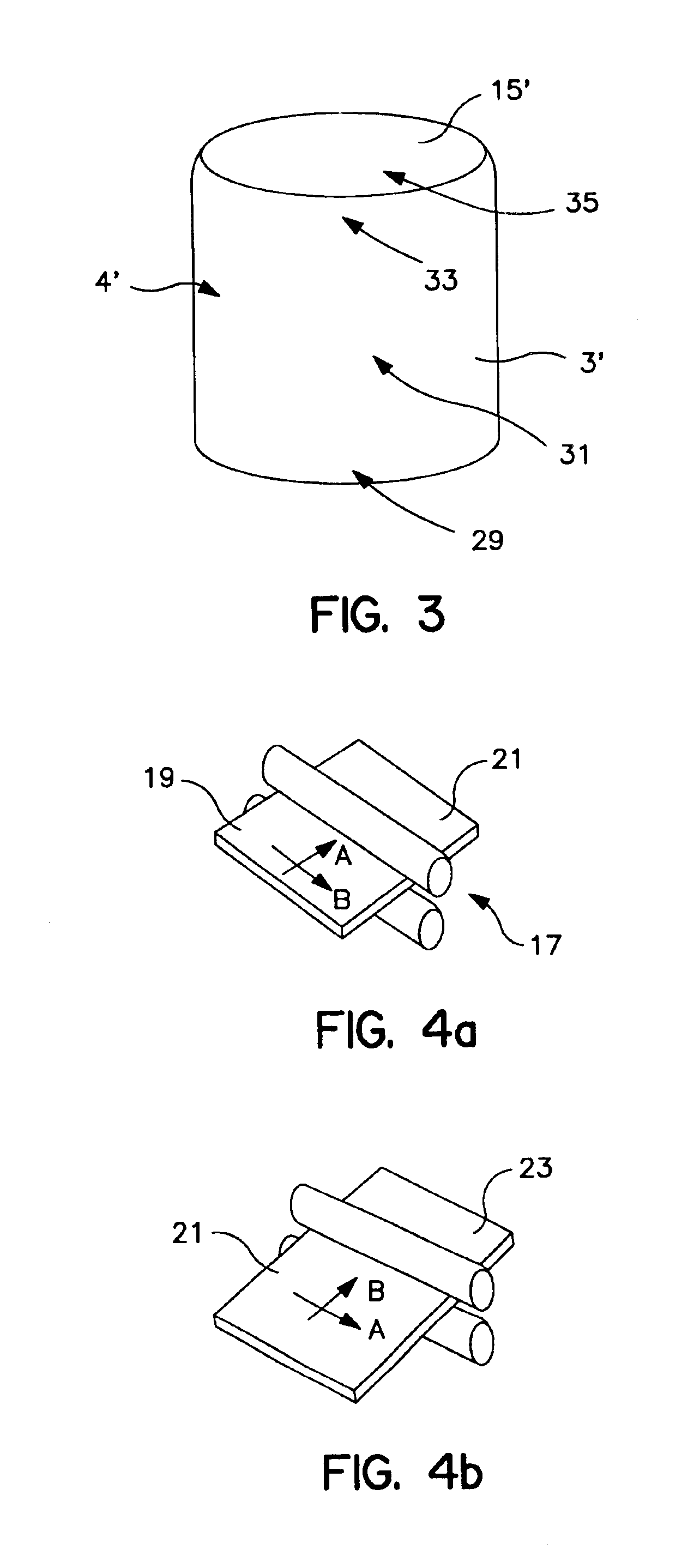

Nano-Precision Sintering System

InactiveUS20080175936A1Improve accuracyFunctionalNanostructure manufactureTransportation and packagingGrain structureNanometre

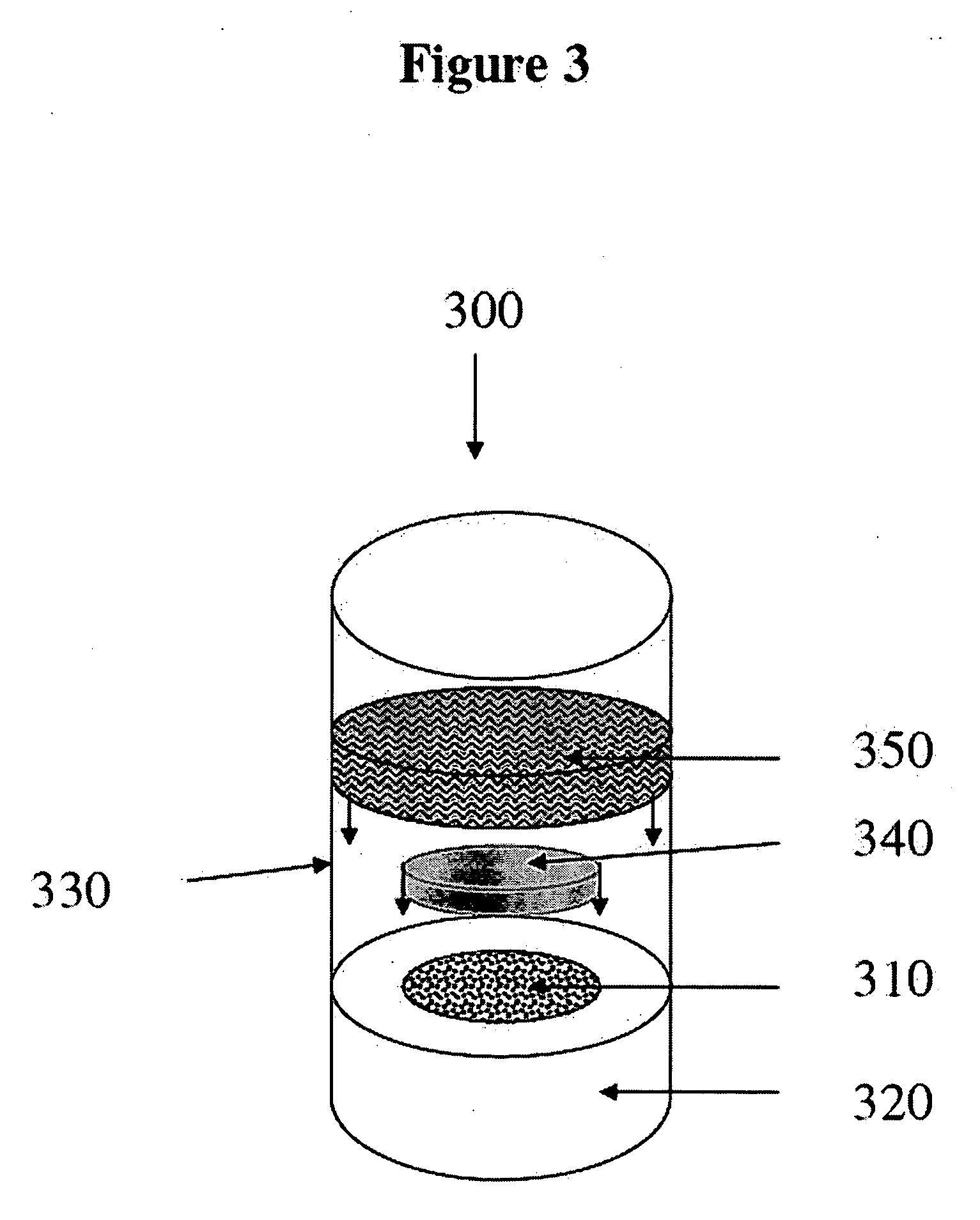

The present invention provides a nano-precision sintering system 1 for sintering a nano-sized powder of a material in the pulse energization and pressure sintering process to obtain a highly purified sintered compact having a nano-sized grain structure, said nano-precision sintering system 1 comprising: at least one pre-process chamber 20 defined by at least one sealed housing 21 having at least one glove and designed to be controlled into a predetermined atmosphere; a sintering process chamber 30 defined by a sealed housing 31 having at least one glove and designed to be controlled into a predetermined atmosphere; a shut-off system 26 disposed in a passage providing communication between the pre-process chamber and the sintering process chamber so as to block the communication between the two chambers selectively while keeping it in an air tight condition; and a pulse energization and pressure sintering machine 50 having a vacuum chamber “C” allowing for the sintering process to be carried out under a vacuum atmosphere, wherein the vacuum chamber is disposed in the sintering process chamber such that the former can be isolated from the latter.

Owner:FUJI ELECTRONICS IND

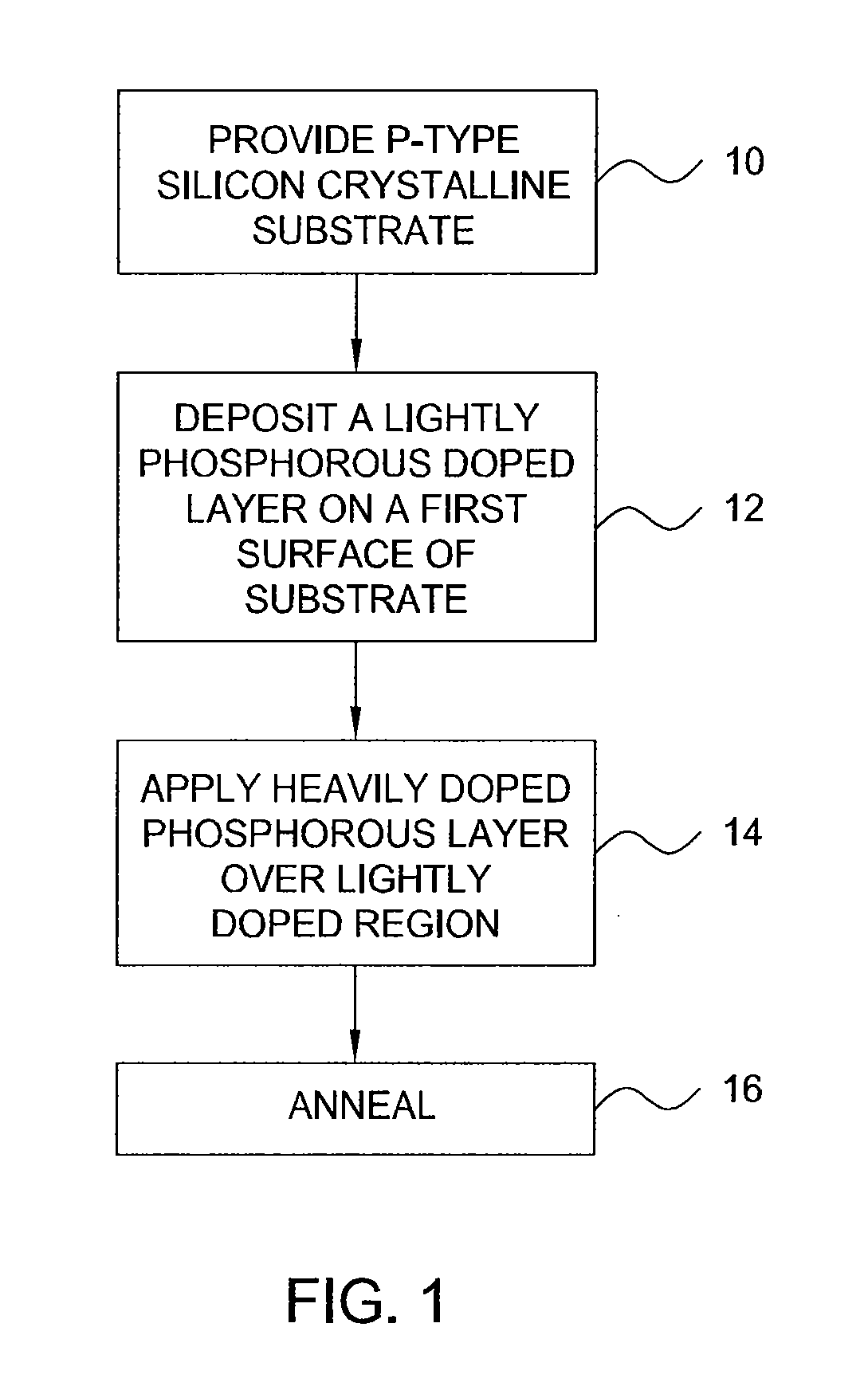

Methods of making an emitter having a desired dopant profile

InactiveUS20100240172A1Final product manufactureSemiconductor/solid-state device manufacturingDopantCrystal orientation

A method for obtaining a desired dopant profile of an emitter for a solar cell which includes depositing a first amorphous silicon layer having a first doping level over an upper surface of the crystalline silicon substrate, depositing a second amorphous silicon layer having a second doping level on the first amorphous silicon layer, and heating the crystalline silicon substrate and the first and second amorphous silicon layers to a temperature sufficient to cause solid phase epitaxial crystallization of the first and second amorphous silicon layers, such that the first and second amorphous silicon layers, after heating, have the same grain structure and crystal orientation as the underlying crystalline silicon substrate

Owner:APPLIED MATERIALS INC

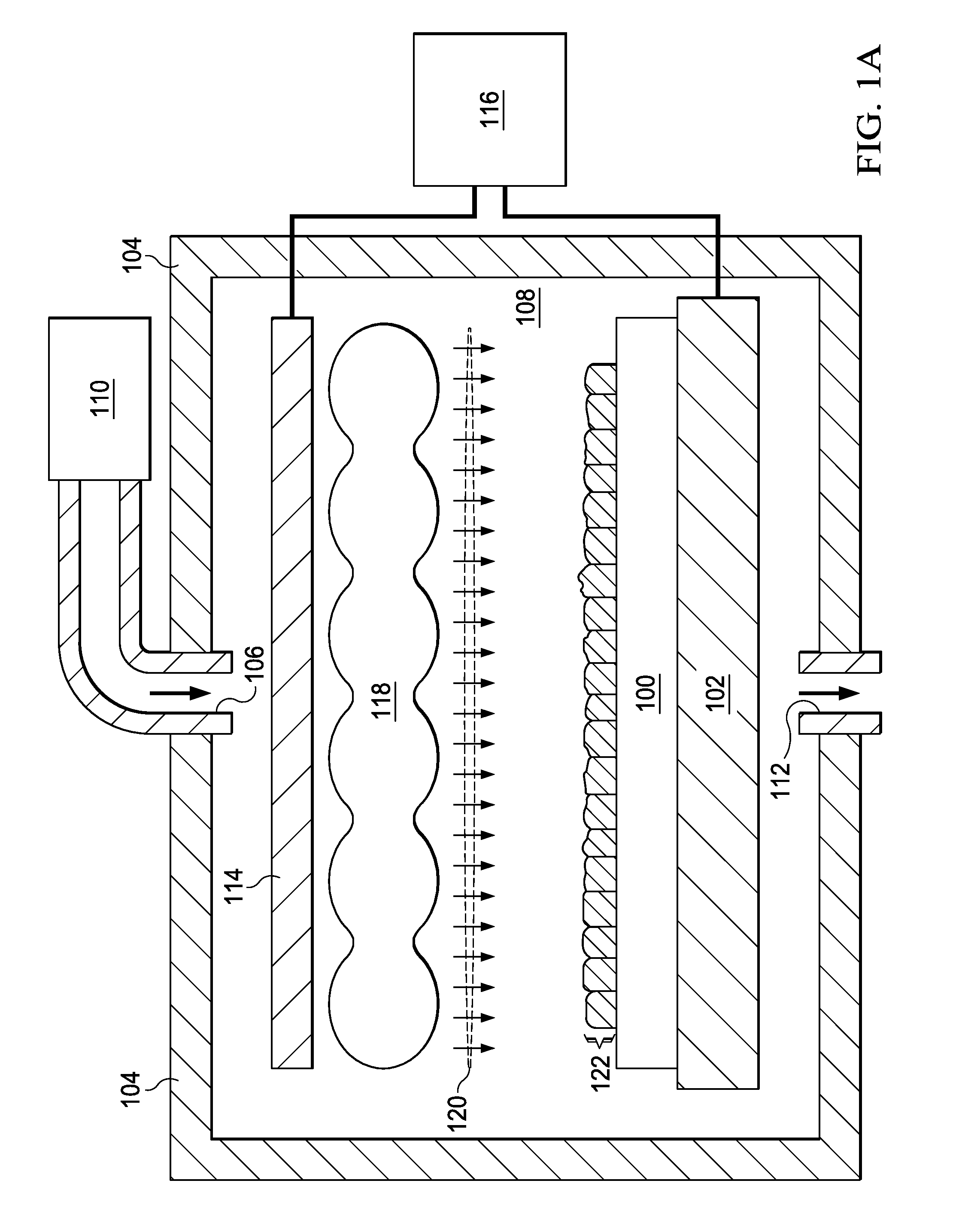

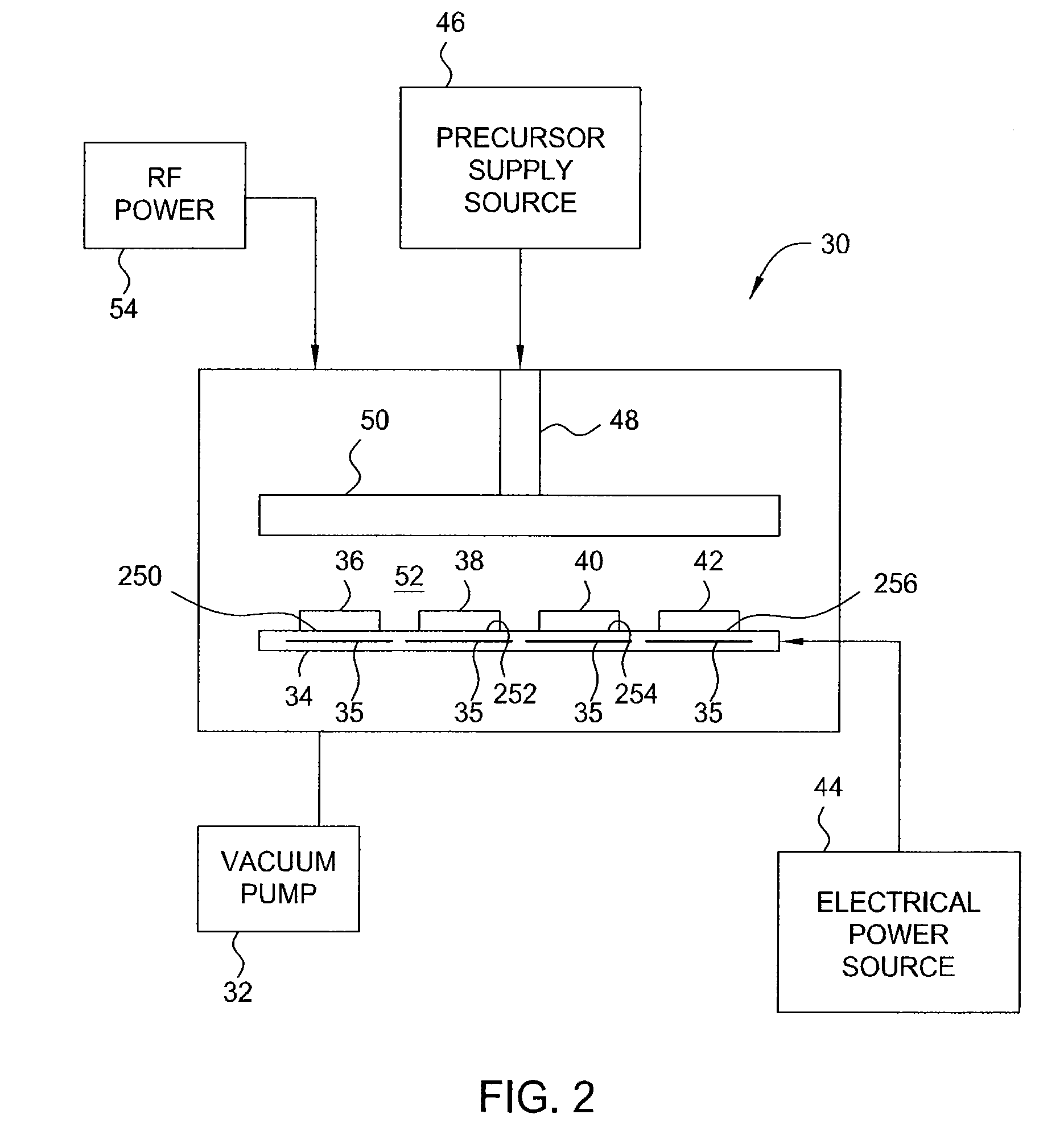

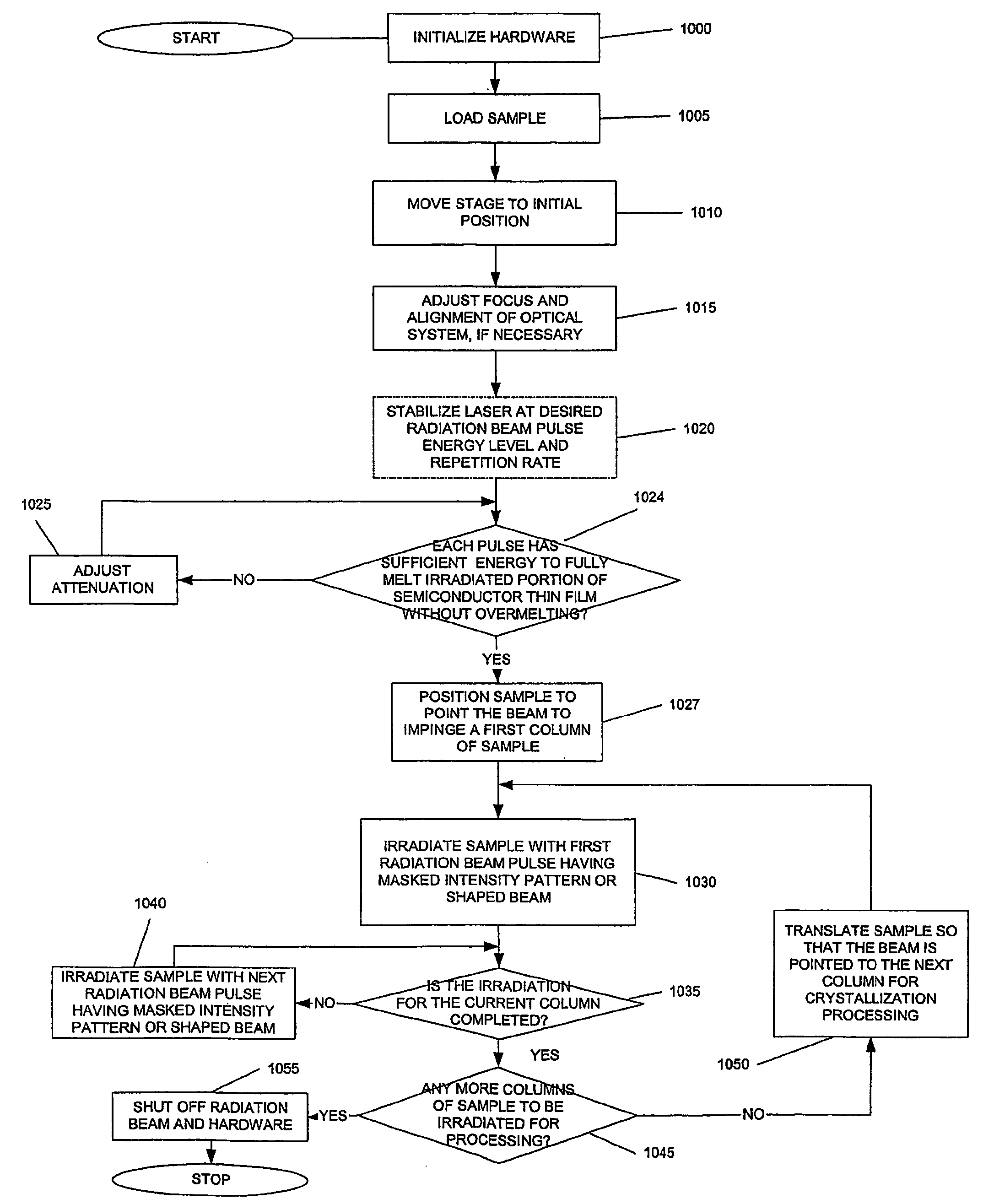

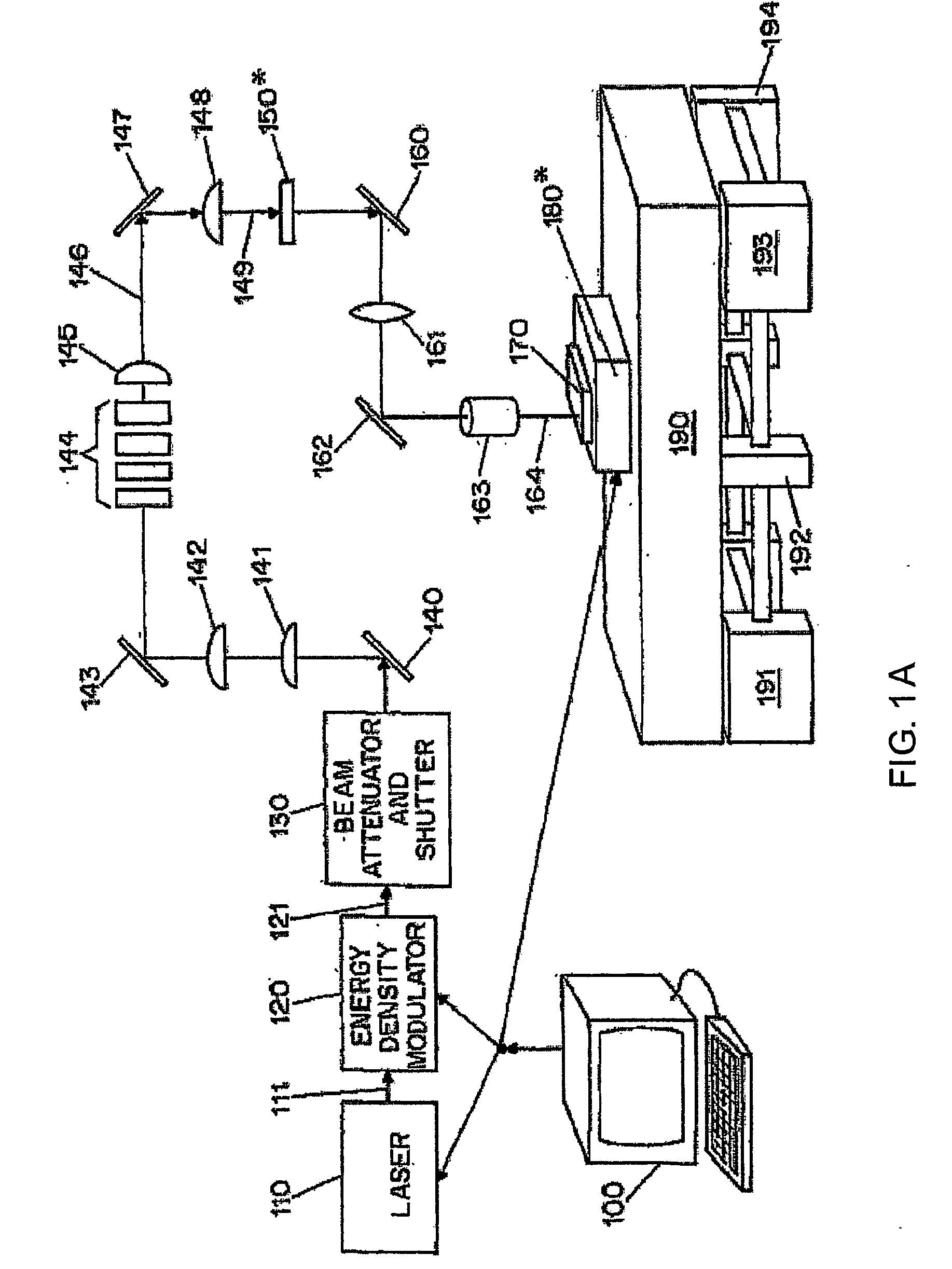

Process and system for laser crystallization processing of film regions on a substrate to provide substantial uniformity, and a structure of such film regions

InactiveUS20050202654A1Increase speedUniform materialAfter-treatment apparatusTransistorLaser crystallizationGrain structure

A process and system for processing a thin film sample (e.g., a semiconductor thin film), as well as the thin film structure are provided. In particular, a beam generator can be controlled to emit at least one beam pulse. With this beam pulse, at least one portion of the film sample is irradiated with sufficient intensity to fully melt such section of the sample throughout its thickness, and the beam pulse having a predetermined shape. This portion of the film sample is allowed to resolidify, and the re-solidified at least one portion is composed of a first area and a second area. Upon the re-solidification thereof, the first area includes large grains, and the second area has a region formed through nucleation. The first area surrounds the second area and has a grain structure which is different from a grain structure of the second area. The second area is configured to facilitate thereon an active region of an electronic device.

Owner:IM JAMES S

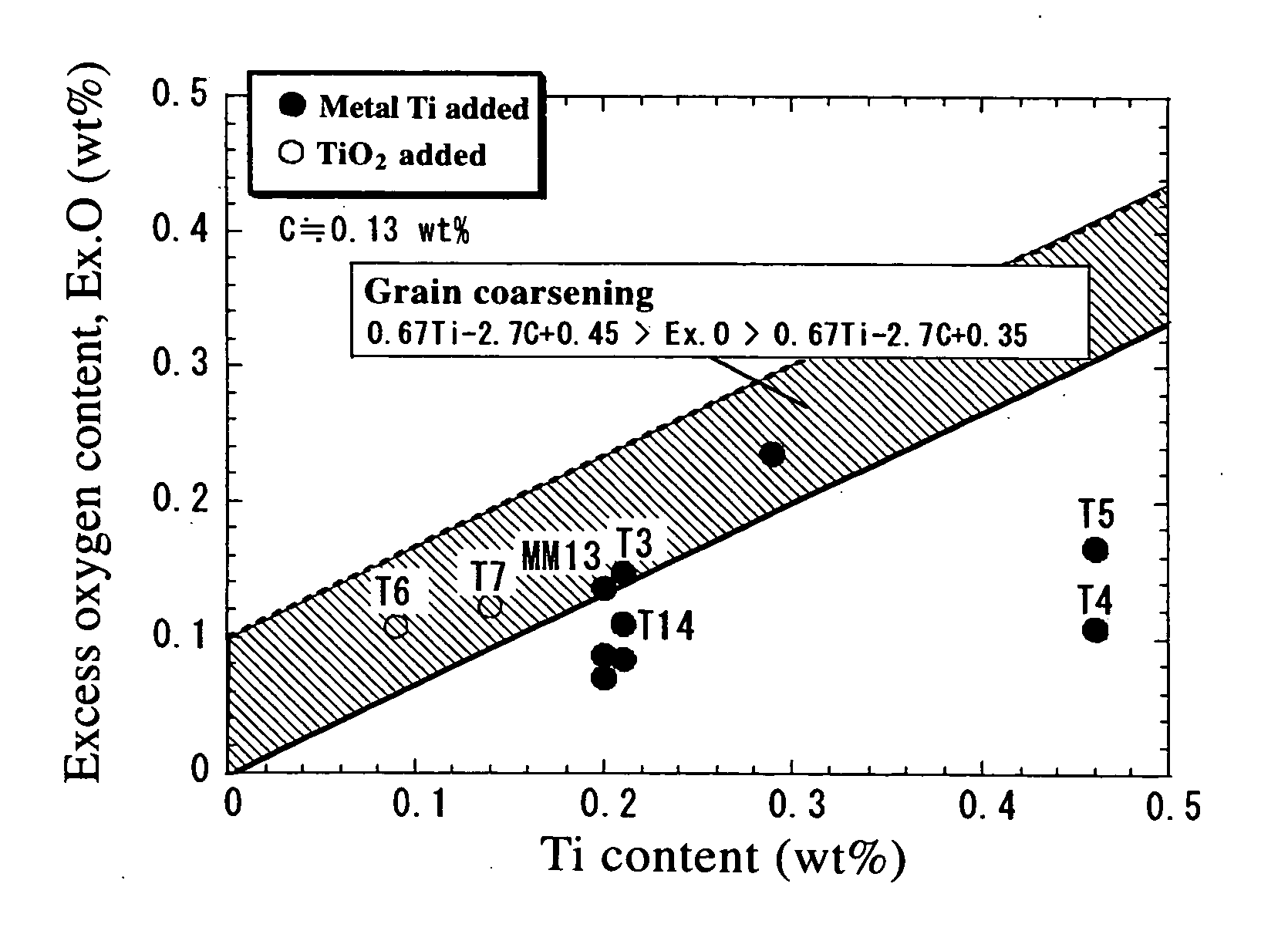

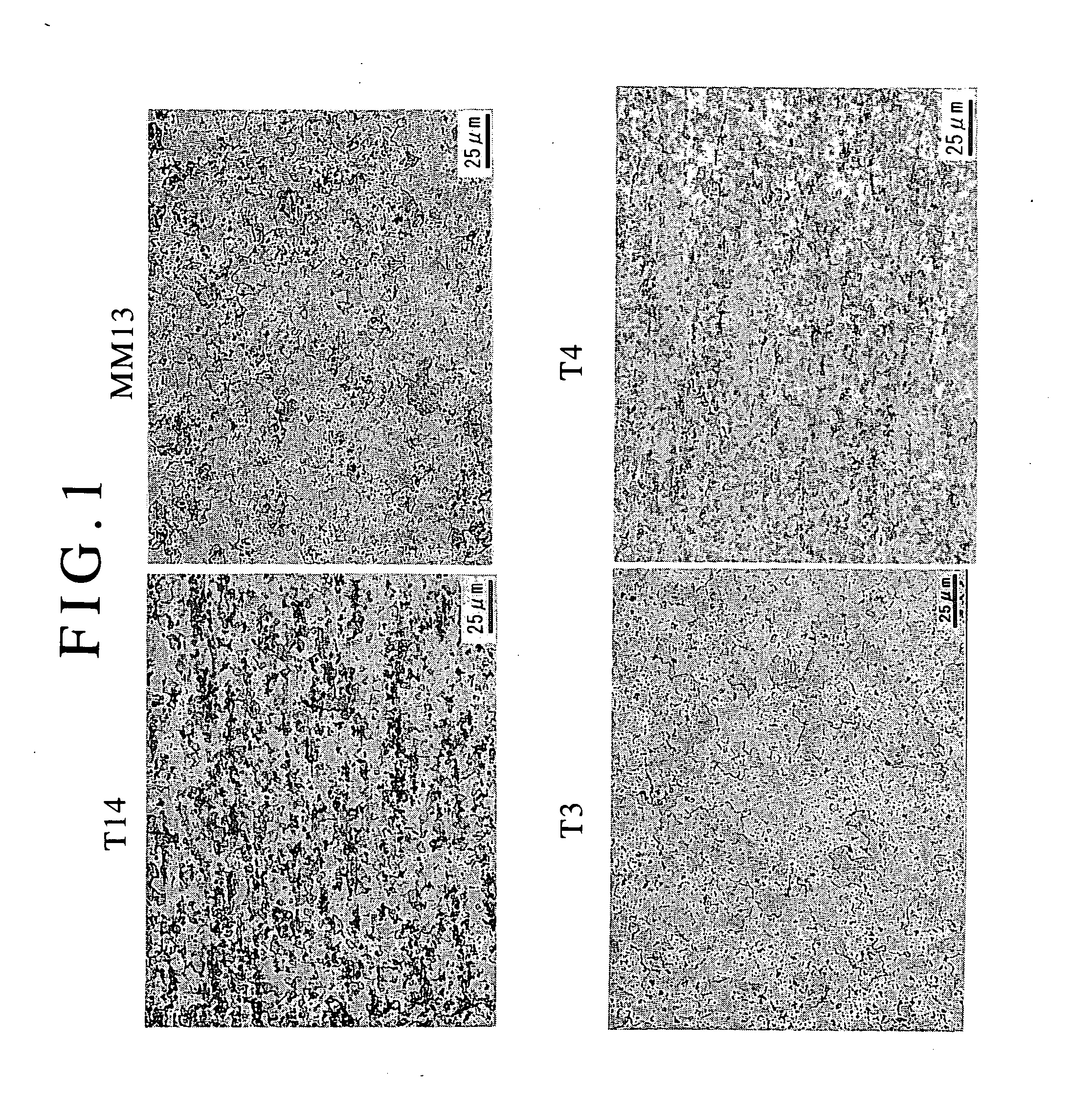

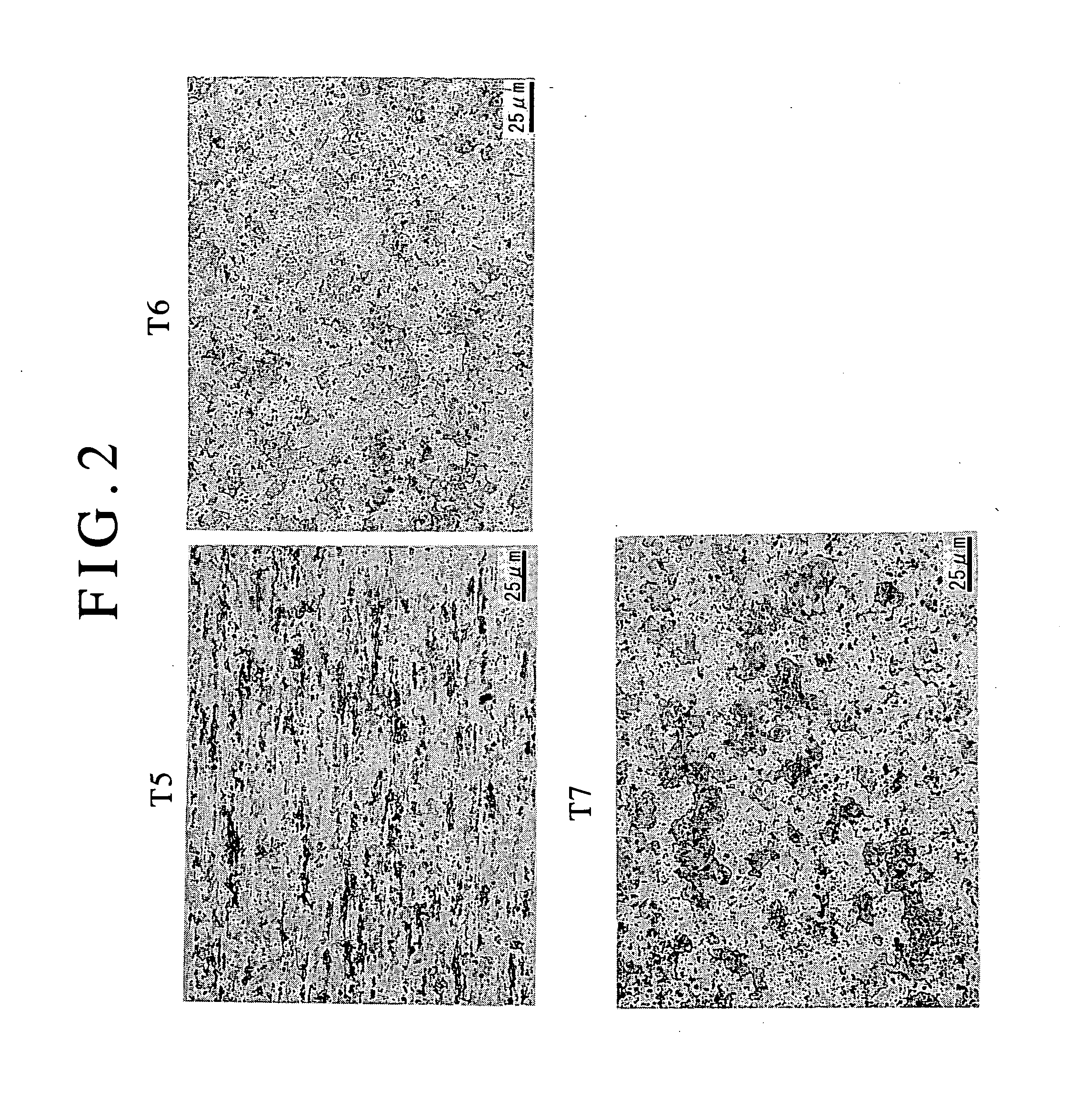

Method for producing dispersed oxide reinforced ferritic steel having coarse grain structure and being excellent in high temperature creep strength

InactiveUS20050042127A1Not lower C concentrationImprove creep strengthMagnetic materialsGrain structureUltimate tensile strength

Owner:JAPAN ATOMIC ENERGY AGENCY INDEPENDANT ADMINISTRATIVE CORP

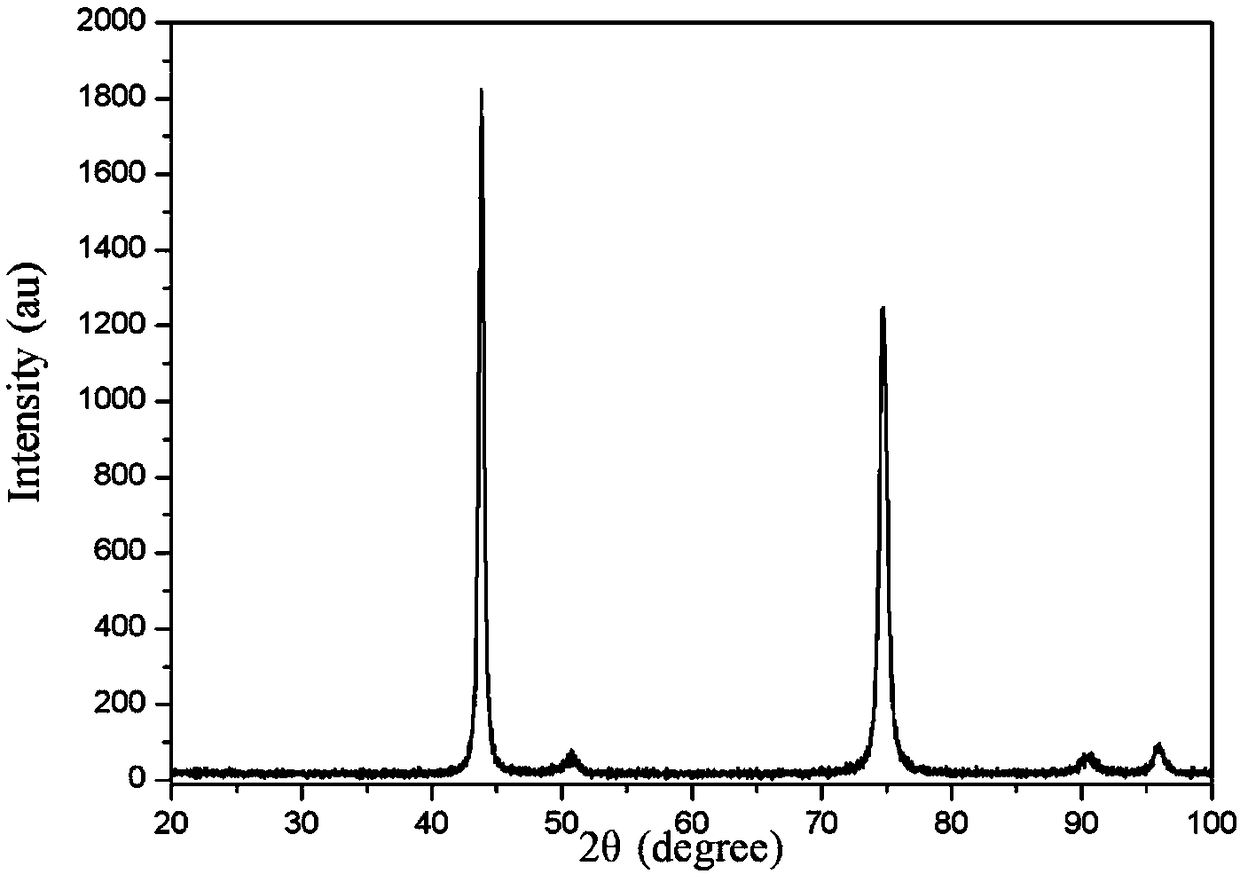

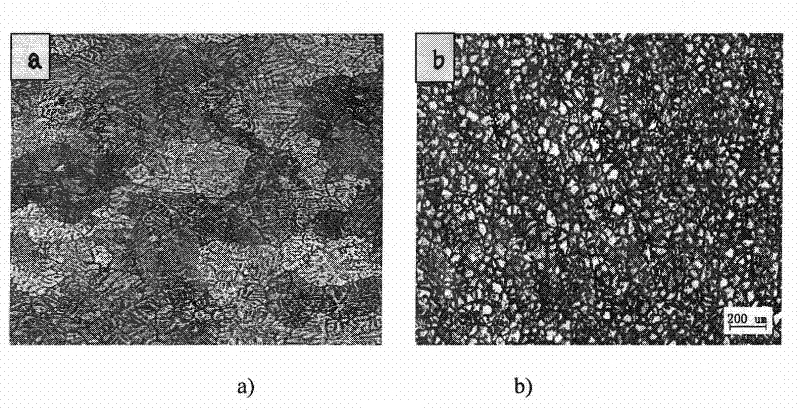

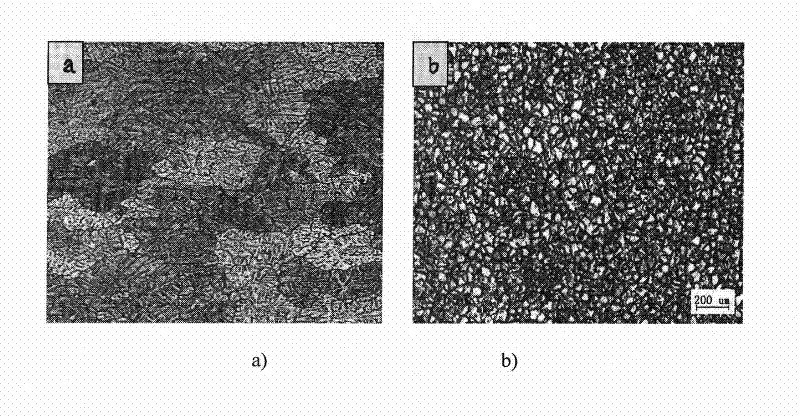

Preparation method of ultra-fine grain high-entropy alloy

The invention belongs to the technical field of metal materials and machining and relates to a preparation method of an ultra-fine grain high-entropy alloy. Firstly, smelting is conducted, an FeCoCrNiMn series high-entropy alloy is compounded to be an intermediate alloy composed of pure metal with the purity being higher than 99.5% or alloy elements, a vacuum furnace is adopted for smelting, and the furnace casting temperature is 1550-1600 DEG C; then after cast ingots are subjected to homogenization heat treatment at the temperature of 1000-1350 DEG C, strong deformation asynchronous and synchronous mixed cold rolling treatment is conducted, continuous rolling is conducted through single-pass large percent reduction, the total rolling quantity is no smaller than 85%, and alloy structure nanocrystallization is achieved; and the rolled alloy is subjected to annealing treatment under the temperature of 450-800 DEG C, and the high-entropy alloy of an ultra-fine grain structure is obtained. Compared with the prior art, the preparation method is simple in technique, easy to achieve on a plate rolling production line, high in production efficiency and low in cost; and the size of the prepared ultra-fine grain high-entropy alloy is large, the comprehensive mechanical performance is excellent, and the preparation method can be applied to the fields of engineering machinery, aeronauticsand astronautics, military industry, electronics, instruments and the like.

Owner:SHANGHAI JIAO TONG UNIV

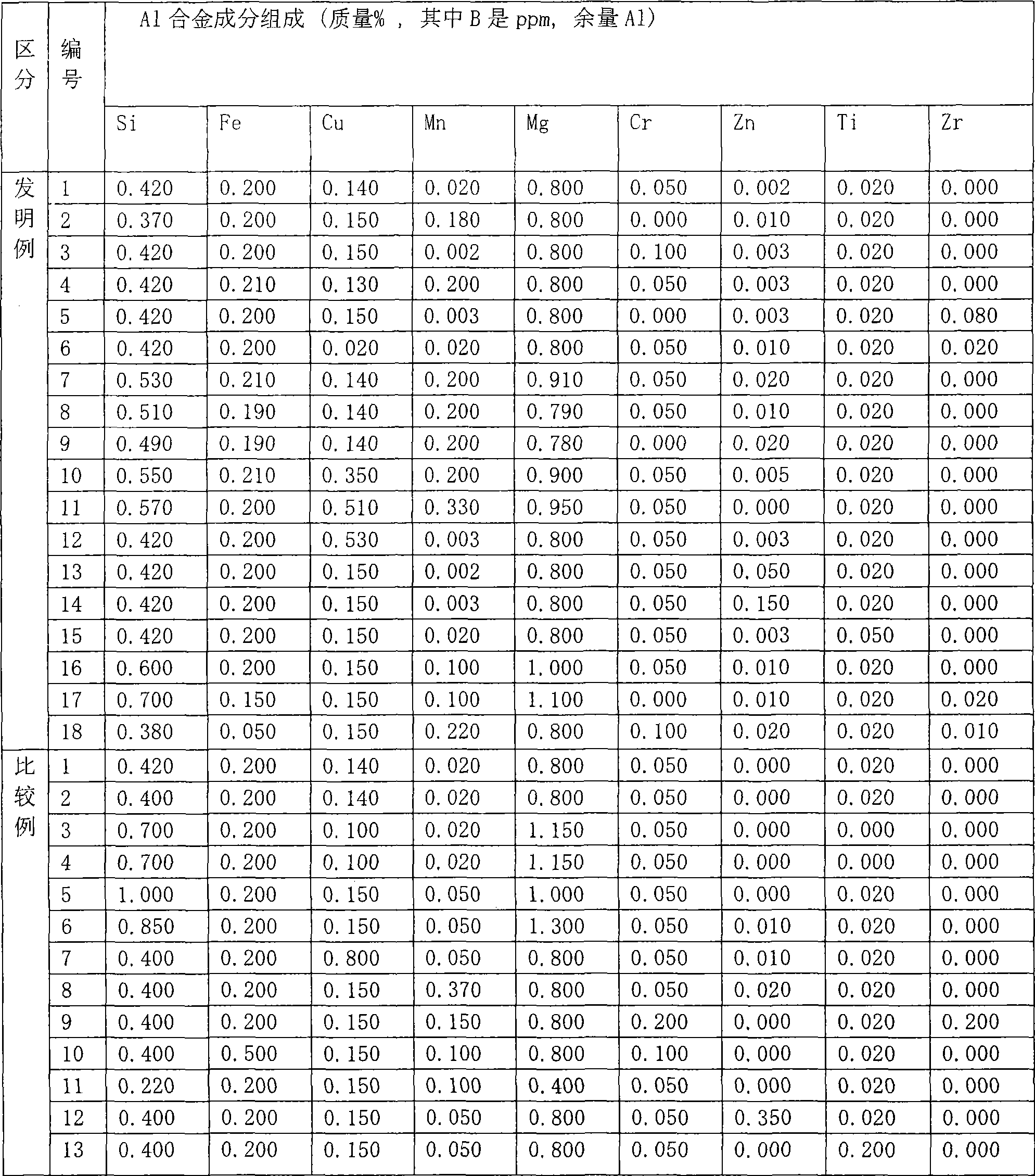

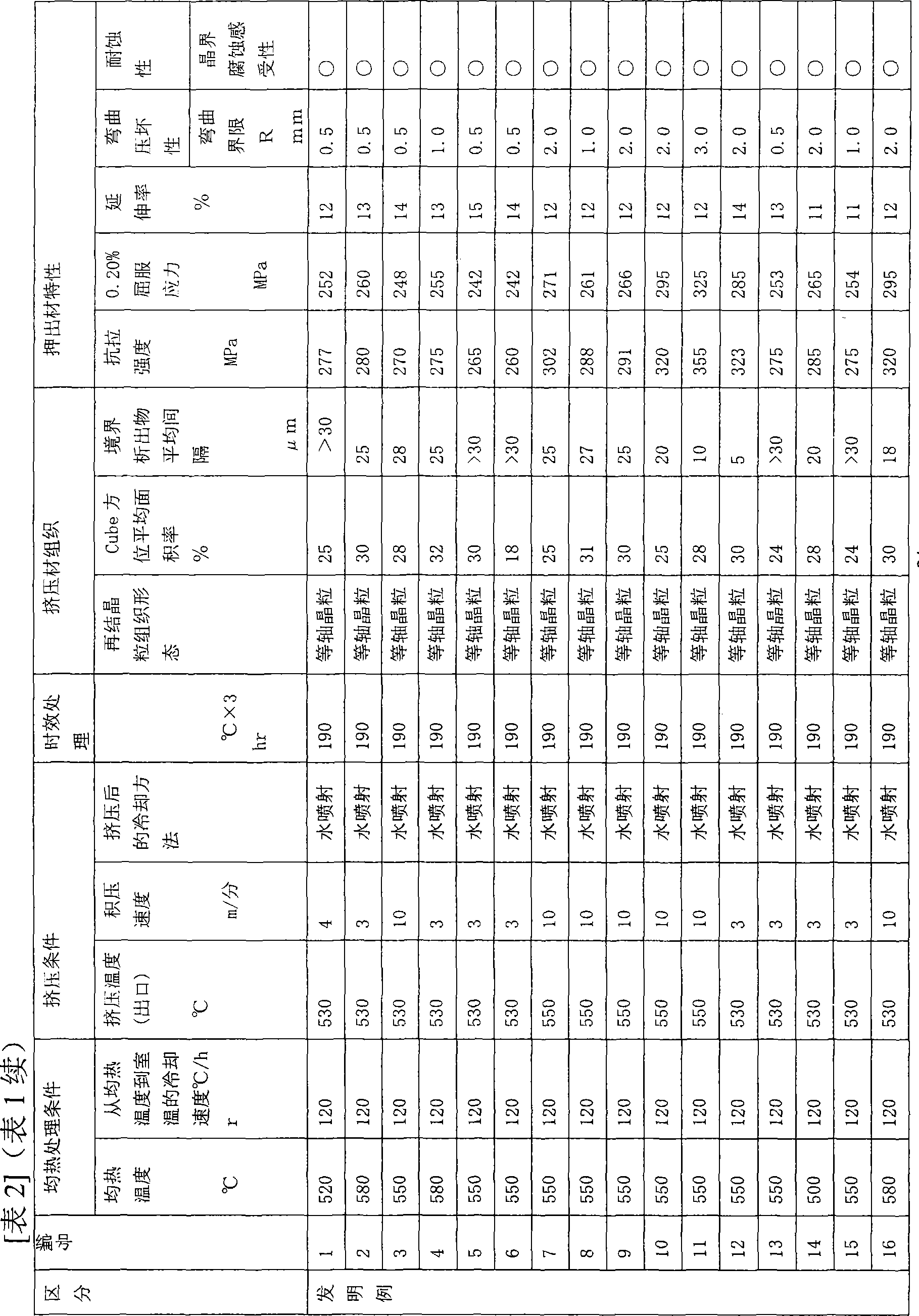

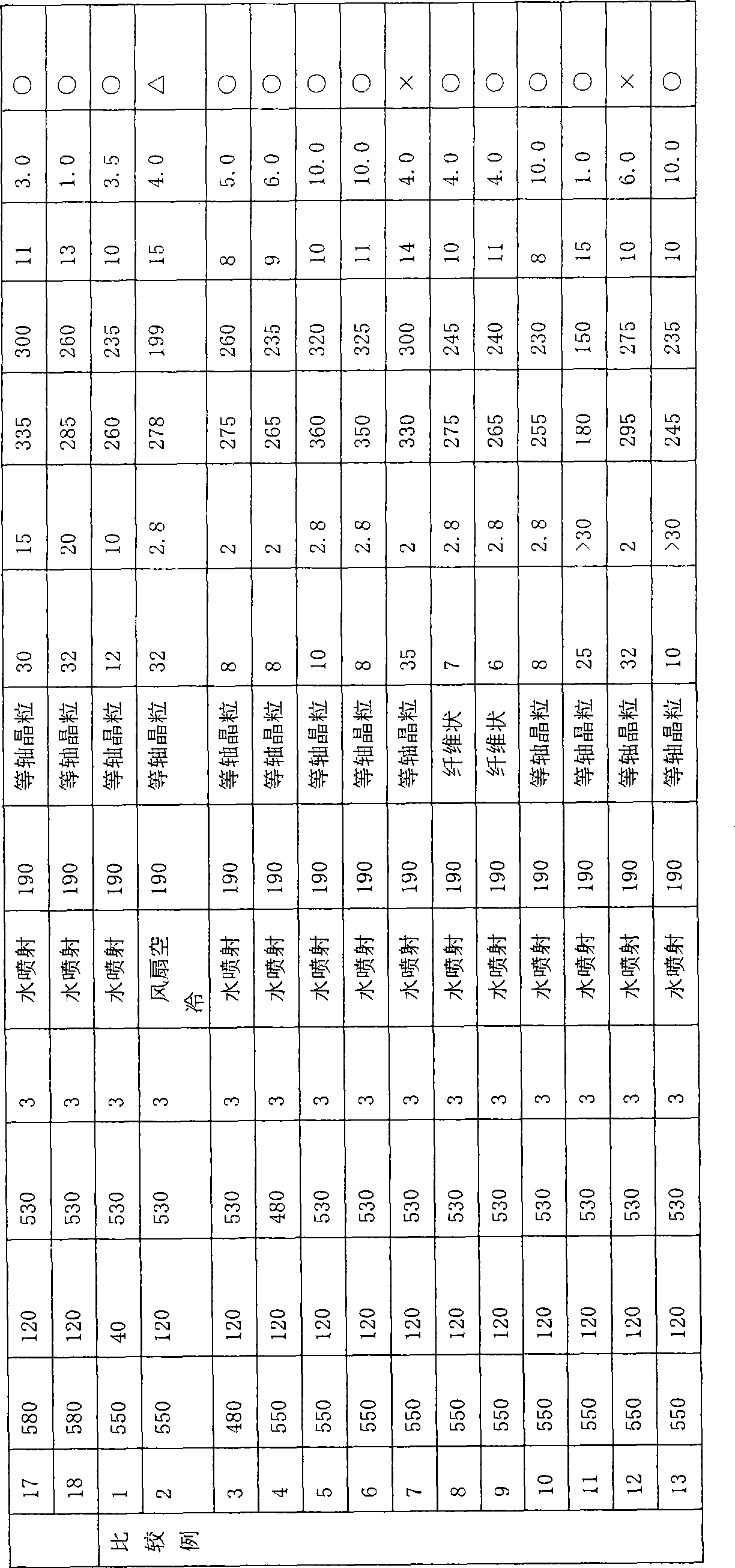

Extruded member of aluminum alloy excelling in flexural crushing performance and corrosion resistance and method for production thereof

An extruded member of Al-Mg-Si aluminum alloy specially composed of Mg, Si, Fe, Cu, Zn, Ti, etc. which has the equiaxed re-crystallized grain structure in which intergranular precipitates 1 mum or lager are separate from one another at large average intervals and there are many cube orientations over the entire thickness region thereof so that it excels in both flexural crushing performance and corrosion resistance. The extruded member is suitable for use as automotive body reinforcement members which need outstanding lateral crushing performance under severe collision conditions as well as good corrosion resistance.

Owner:KOBE STEEL LTD

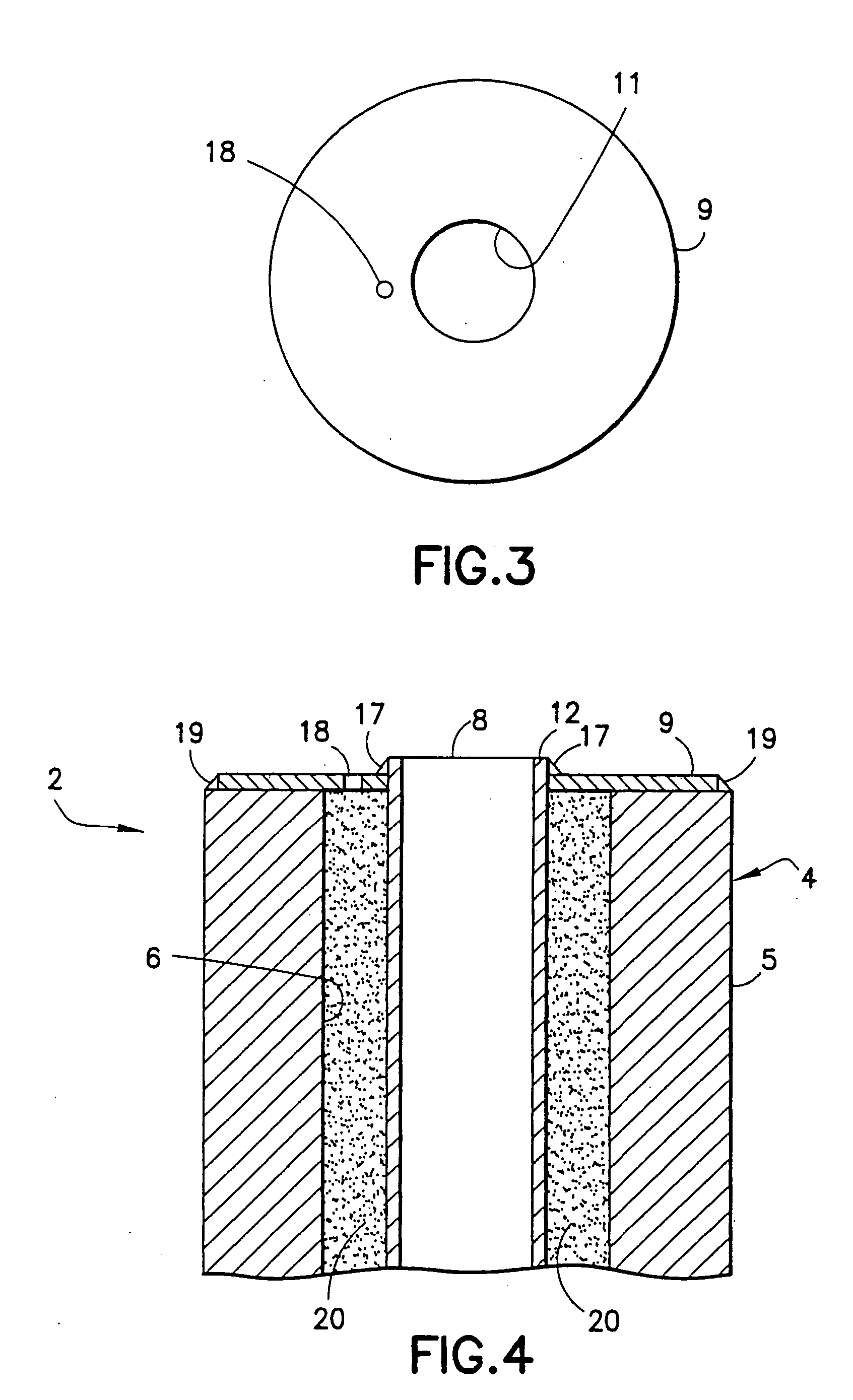

Hollow cathode target and methods of making same

InactiveUS6887356B2Simple, cost-effective, and reliable magnetron sputtering systemCellsElectric discharge tubesGrain structureMetal

Sputtering targets and methods of making sputtering targets are described. The method includes the steps of: providing a sputtering metal workpiece made of a valve metal; transverse cold-rolling the sputtering metal workpiece to obtain a rolled workpiece; and cold-working the rolled workpiece to obtain a shaped workpiece. The sputtering targets exhibits a substantially consistent grain structure and / or texture on at least the sidewalls.

Owner:GLOBAL ADVANCED METALS USA

High magnetic induction and high grad non-orientation electrical steel and its making process

InactiveCN1888112AReduce the amount of solid solutionReduce precipitationFurnace typesHeat treatment furnacesElectrical steelGrain structure

The present invention is high magnetic induction and high grade non-orientation electrical steel and its making process. The high magnetic induction and high grade non-orientation electrical steel consists of C not more than 0.0050 wt%, N not more than 0.0030 wt%, Si 1.50-2.50 wt%, Al 0.80-1.30 wt%, Mn 0.20-0.50 wt%, P not more than 0.030 wt%, S not more than 0.005 wt%, Sb 0.03-0.10 wt% or Sn 0.05- 0.12 wt%, and B 0.0005-0.0040 wt%, except Fe and inevitable impurities. Its making process includes initial rolling and high temperature winding to obtain ideal hot rolled steel belt structure; cold rolling to provide the energy for crystal grain growth in re-crystallizing annealing, and re-crystallizing annealing in controlled temperature to obtain ideal crystal grain structure. It has excellent surface quality, high magnetic induction and low iron loss, and is suitable for use in high efficiency motor iron core.

Owner:BAOSHAN IRON & STEEL CO LTD

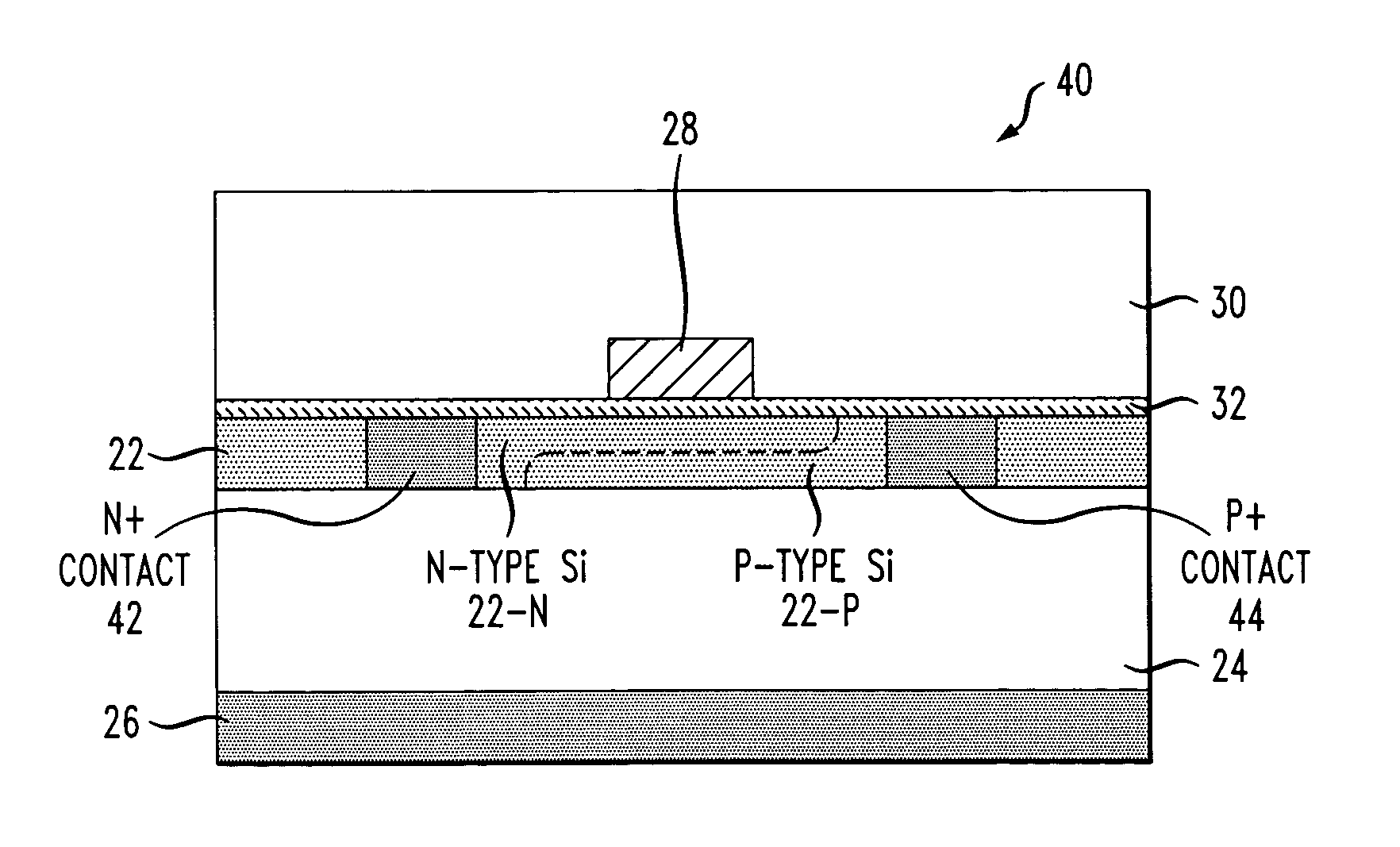

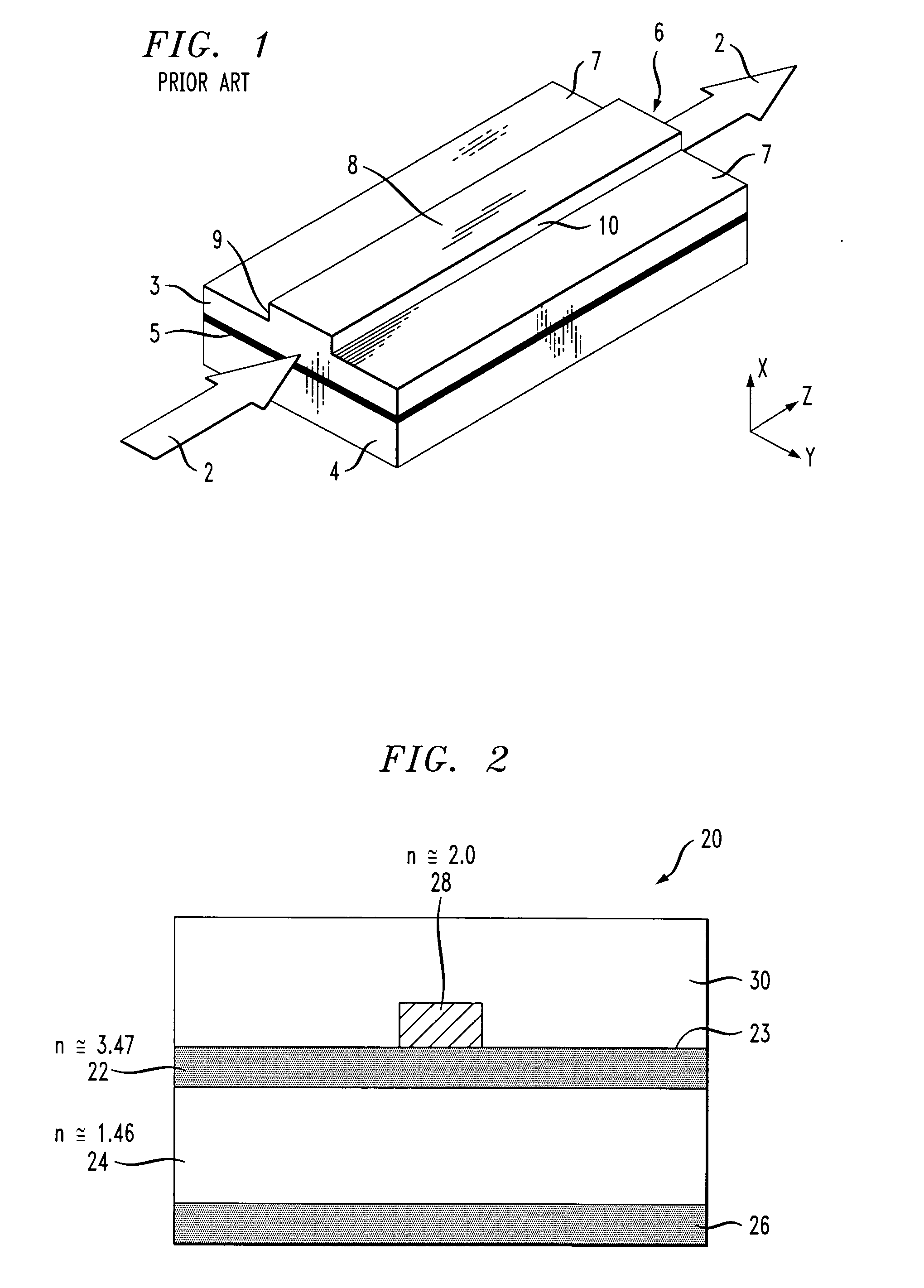

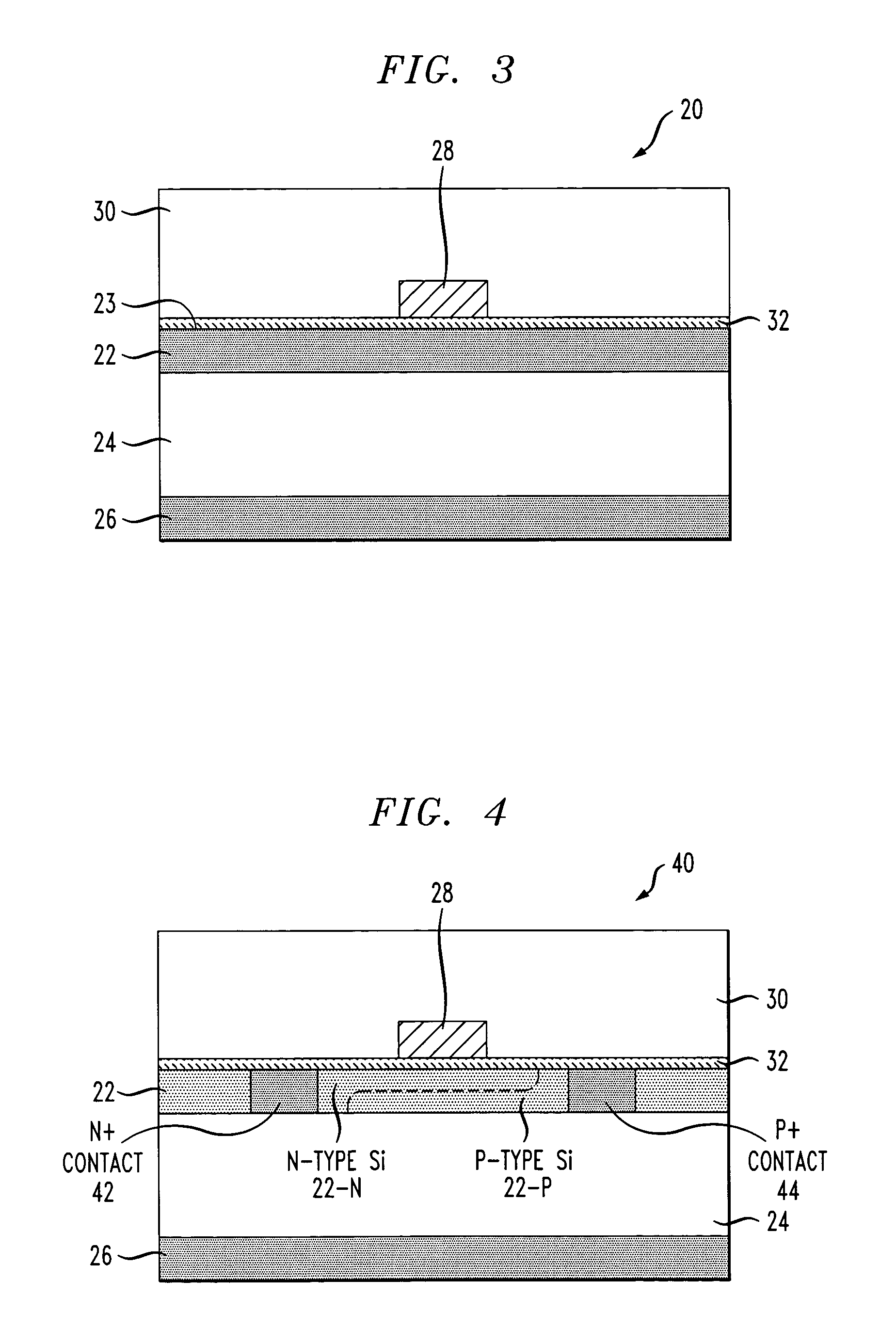

Ultra low-loss CMOS compatible silicon waveguides

InactiveUS20060133754A1Reduce lossReduce light lossOptical waveguide light guideNon-linear opticsBand shapeScattering loss

A low loss optical waveguiding structure for silicon-on-insulator (SOI)-based arrangements utilizes a tri-material configuration including a rib / strip waveguide formed of a material with a refractive index less than silicon, but greater than the refractive index of the underlying insulating material. In one arrangement, silicon nitirde may be used. The index mismatch between the silicon surface layer (the SOI layer) and the rib / strip waveguide results in a majority of the optical energy remaining within the SOI layer, thus reducing scattering losses from the rib / strip structure (while the rib / strip allows for guiding along a desired signal path to be followed). Further, since silicon nitirde is an amorphous material without a grain structure, this will also reduce scattering losses. Advantageously, the use of silicon nitride allows for conventional CMOS fabrication processes to be used in forming both passive and active devices.

Owner:CISCO TECH INC +1

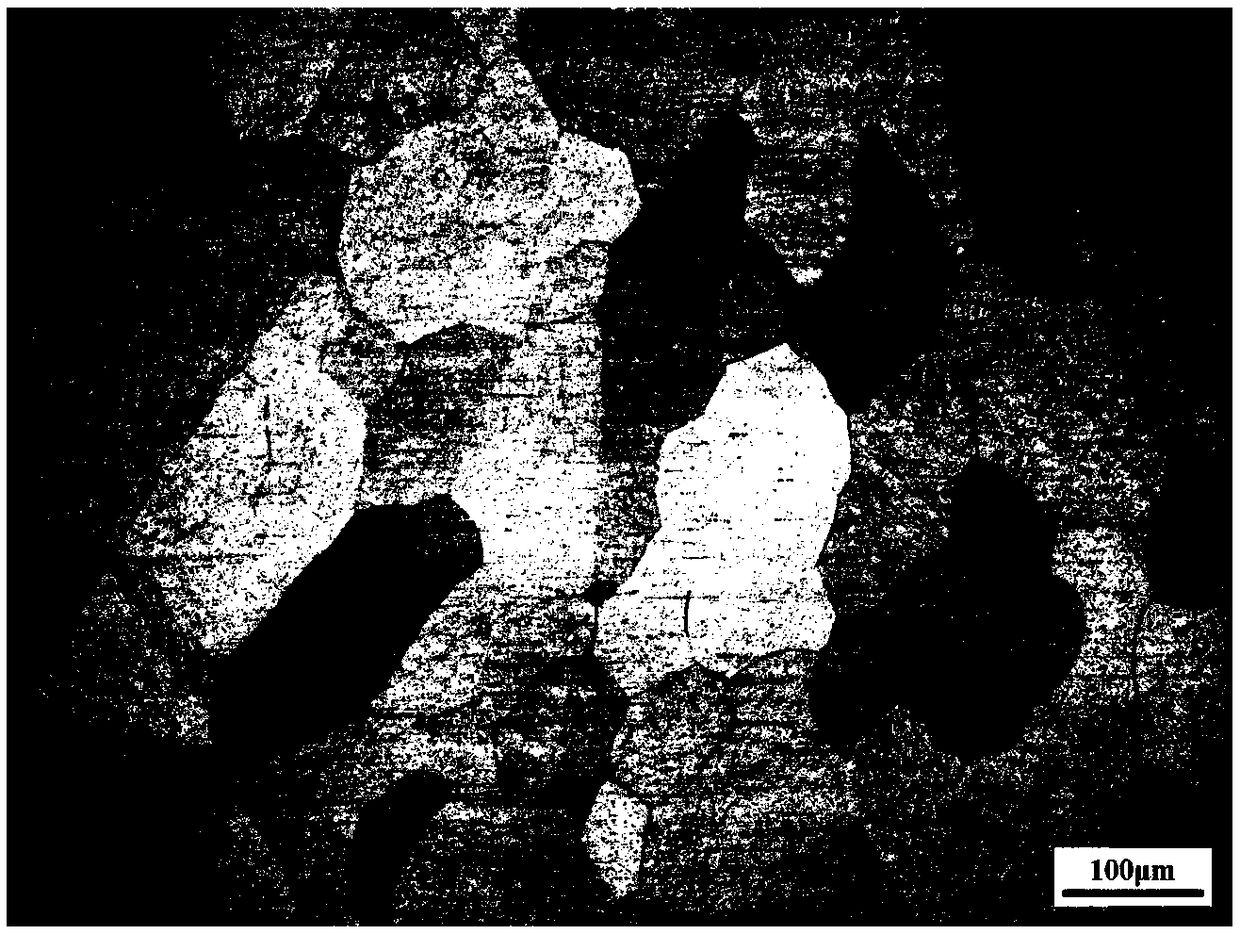

Al-Zn-Mg-Cu-Sc-Zr-RE alloy capable of being used as ultrahigh-strength cast aluminum alloy and preparation method thereof

ActiveCN102127665AChange the solidification methodReduced hot cracking tendencyRare-earth elementSolid solution

The invention discloses an Al-Zn-Mg-Cu-Sc-Zr-RE alloy capable of being used as an ultrahigh-strength cast aluminum alloy and a preparation method thereof. In the alloy, Zn and Mg with higher content are adopted, Sc and Zr are compositely microalloyed, and trace rare earth elements Er and / or Yb are added, so that the aims of increasing an eutectic phase proportion, thinning a grain structure, suppressing dendritic crystal growth and changing an alloy solidification mode are fulfilled to reduce the heat cracking tendency of the alloy and obviously improve the casting performance of the alloy. The alloy comprises the following components in percentage by weight: 7.0 to 8.0 percent of Zn, 1.5 to 2.5 percent of Mg, 1.4 to 2.0 percent of Cu, 0.2 to 0.5 percent of Mn, 0.15 to 0.25 percent of Sc,0.10 to 0.20 percent of Zr, 0.1 to 0.3 percent of Er and / or Yb and the balance of Al. The as-cast alloy can achieve high toughness performance through long-time variable-temperature homogenization, enhanced solid solution treatment and aging treatment, can be used for producing an aluminum alloy casting with the yield strength of more than 500MPa and the elongation rate of more than 5 percent andcan be used as an alternate material for the ultrahigh-strength wrought aluminum alloy.

Owner:有研金属复材技术有限公司

Polycrystalline diamond material with extremely fine microstructures

ActiveUS20090178345A1High melting pointHigh purityPigmenting treatmentOther chemical processesPolycrystalline diamondHigh pressure

A sintered polycrystalline diamond material (PCD) of extremely fine grain size is manufactured by sintering under high pressure / high temperature (HP / HT) processing, a diamond powder which is blended with a pre-milled source catalyst metal compound. The PCD material has an average sintered diamond grain structure of less than about 1.0 μm.

Owner:DIAMOND INNOVATIONS INC

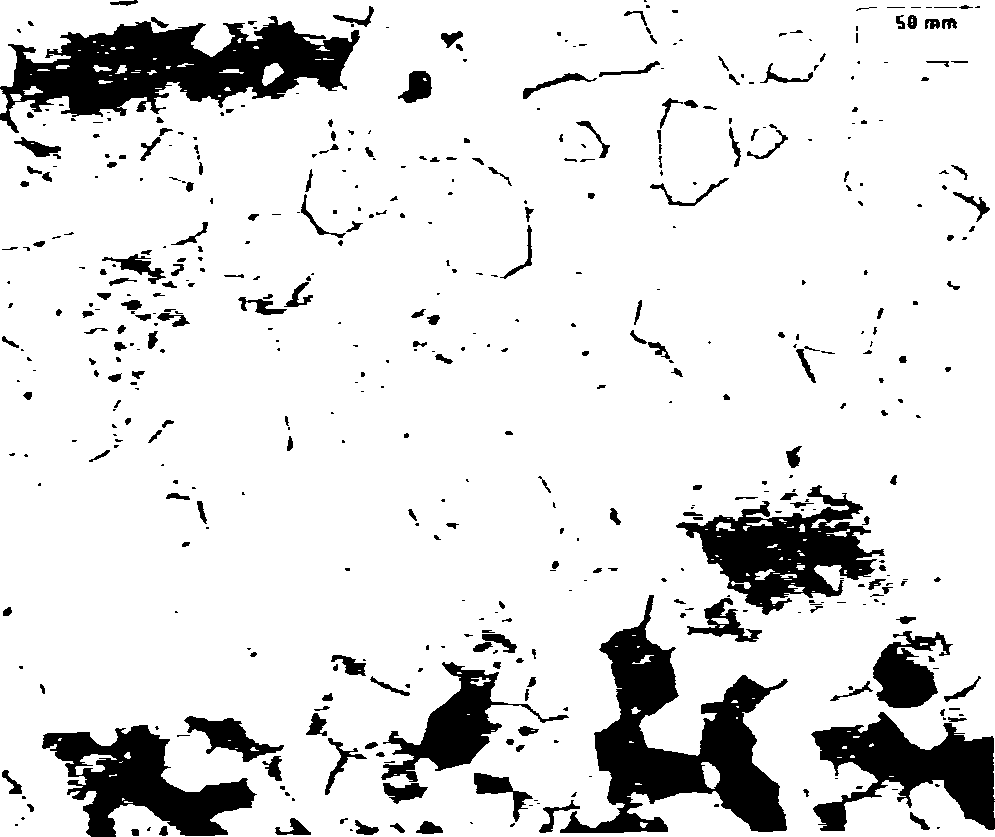

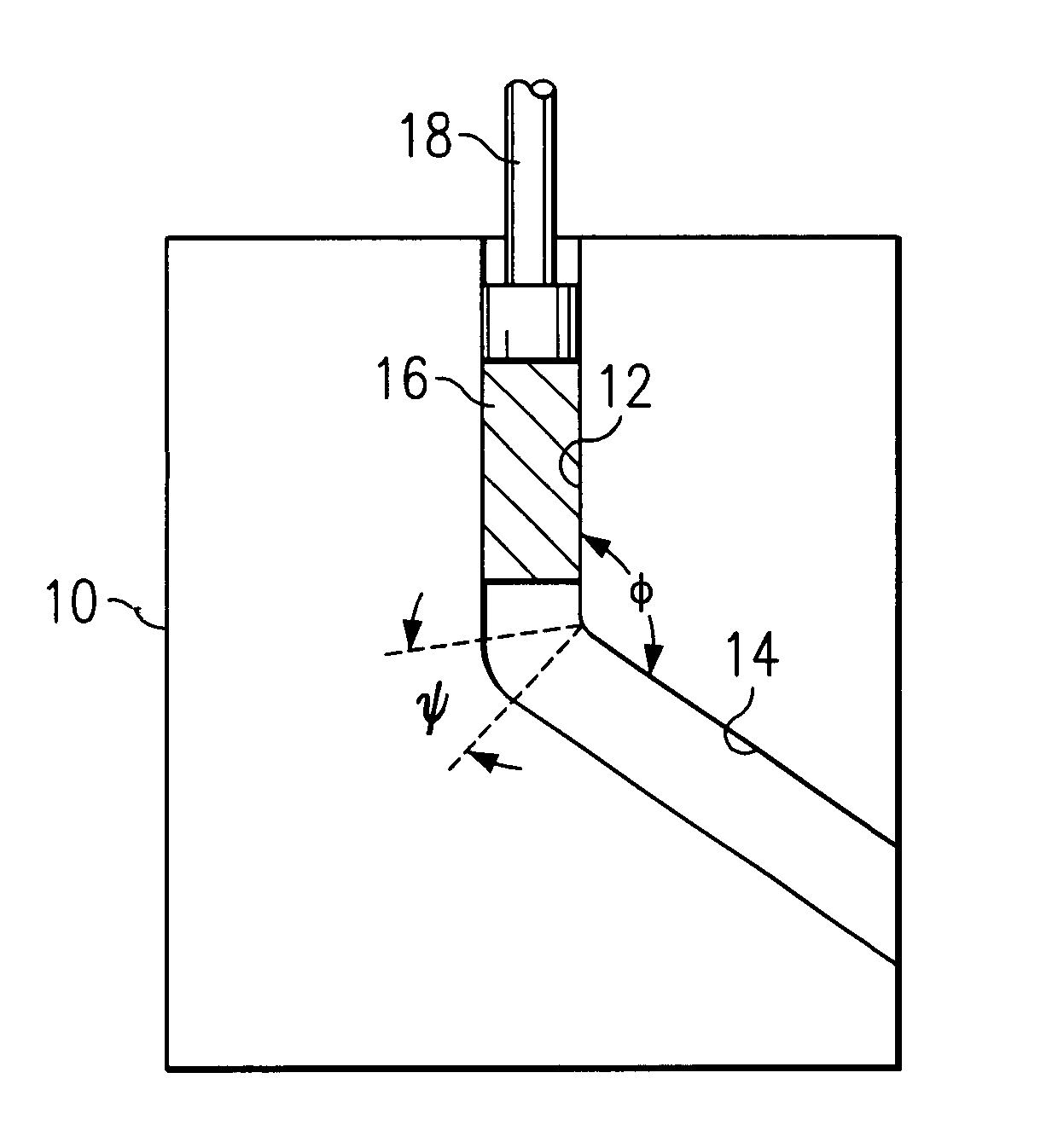

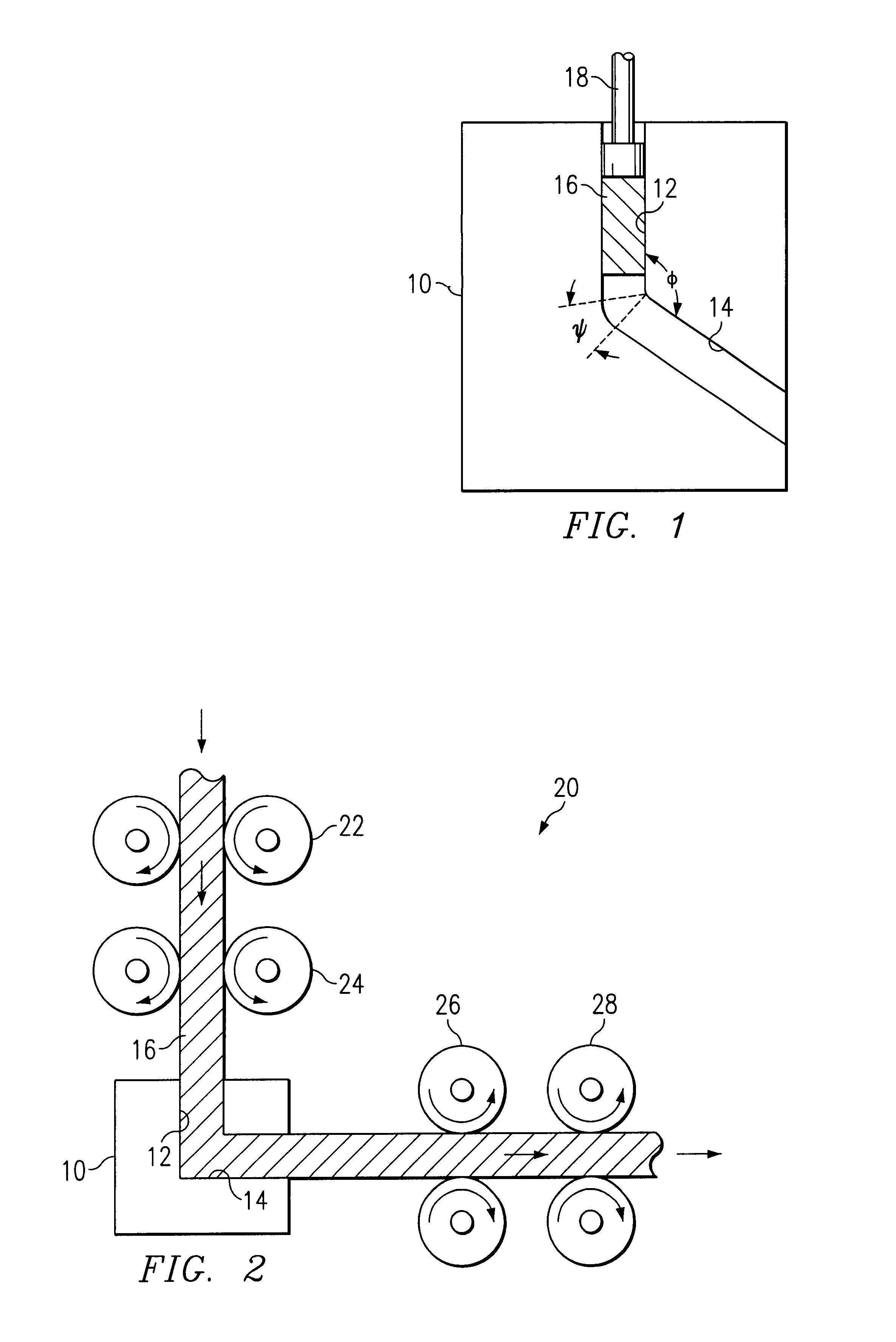

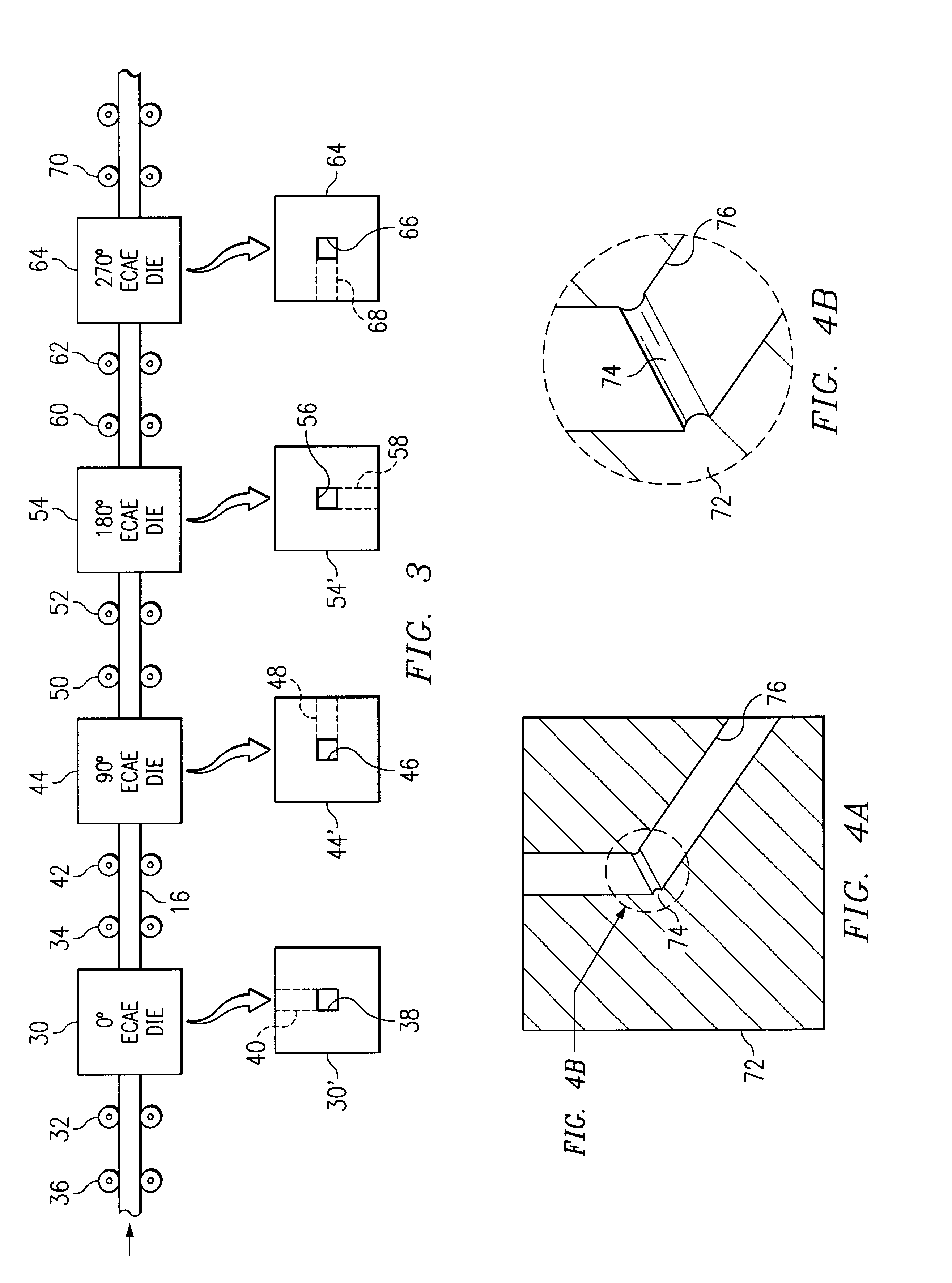

Continuous severe plastic deformation process for metallic materials

A method of processing a billet of metallic material in a continuous manner to produce severe plastic deformation. The billet is moved through a series of CSPD dies in one operation to efficiently produce a billet characterized by a controlled grain structure. The long billets of metal stock are moved along the processing path through the CSPD dies with plural sets of pinch rolls which grip the billet and push it into the entry channel of the dies. Other sets of pinch rolls pull the billet from the exit channel of the dies.

Owner:DATRON INTERCONTINENTAL MFG +3

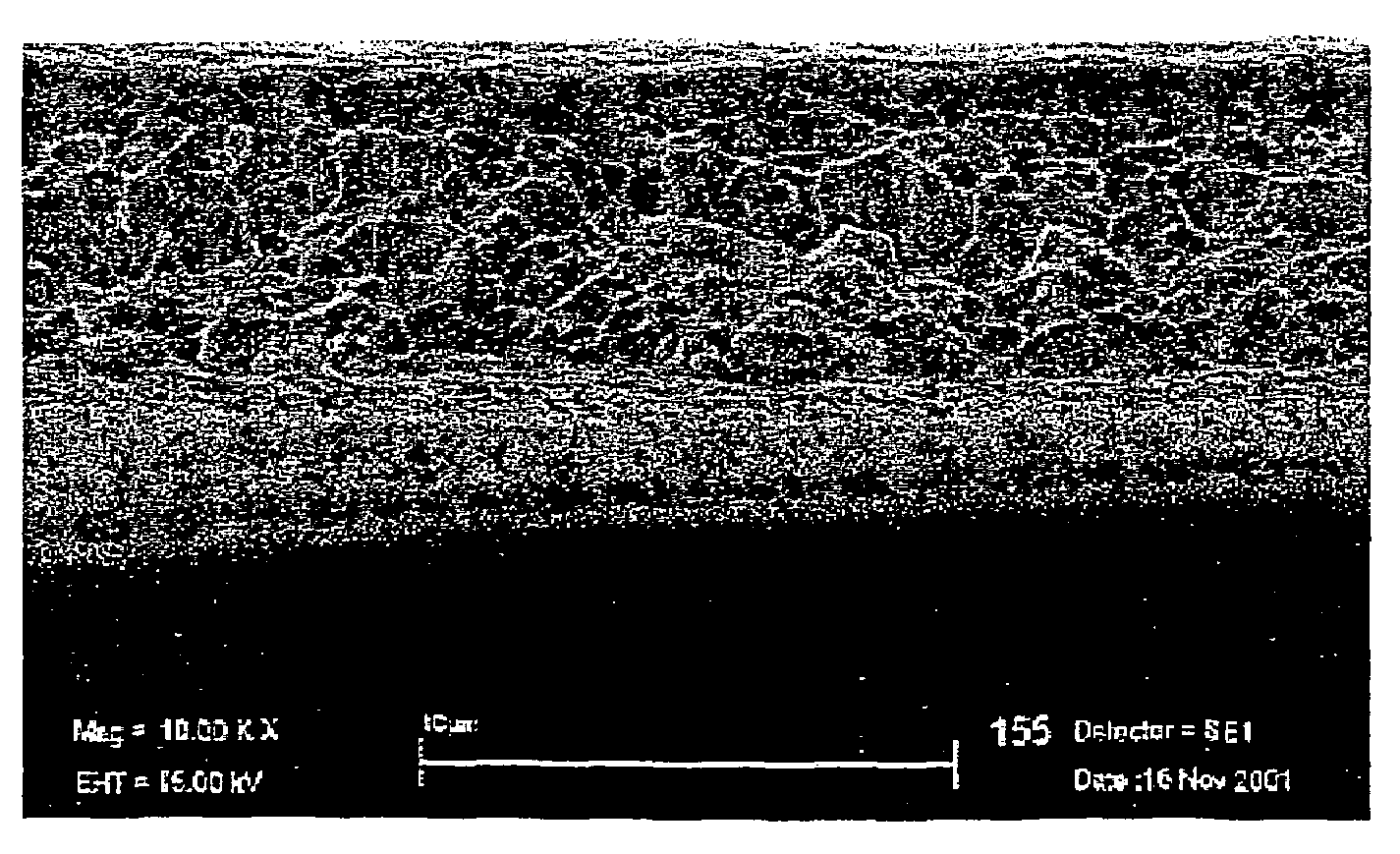

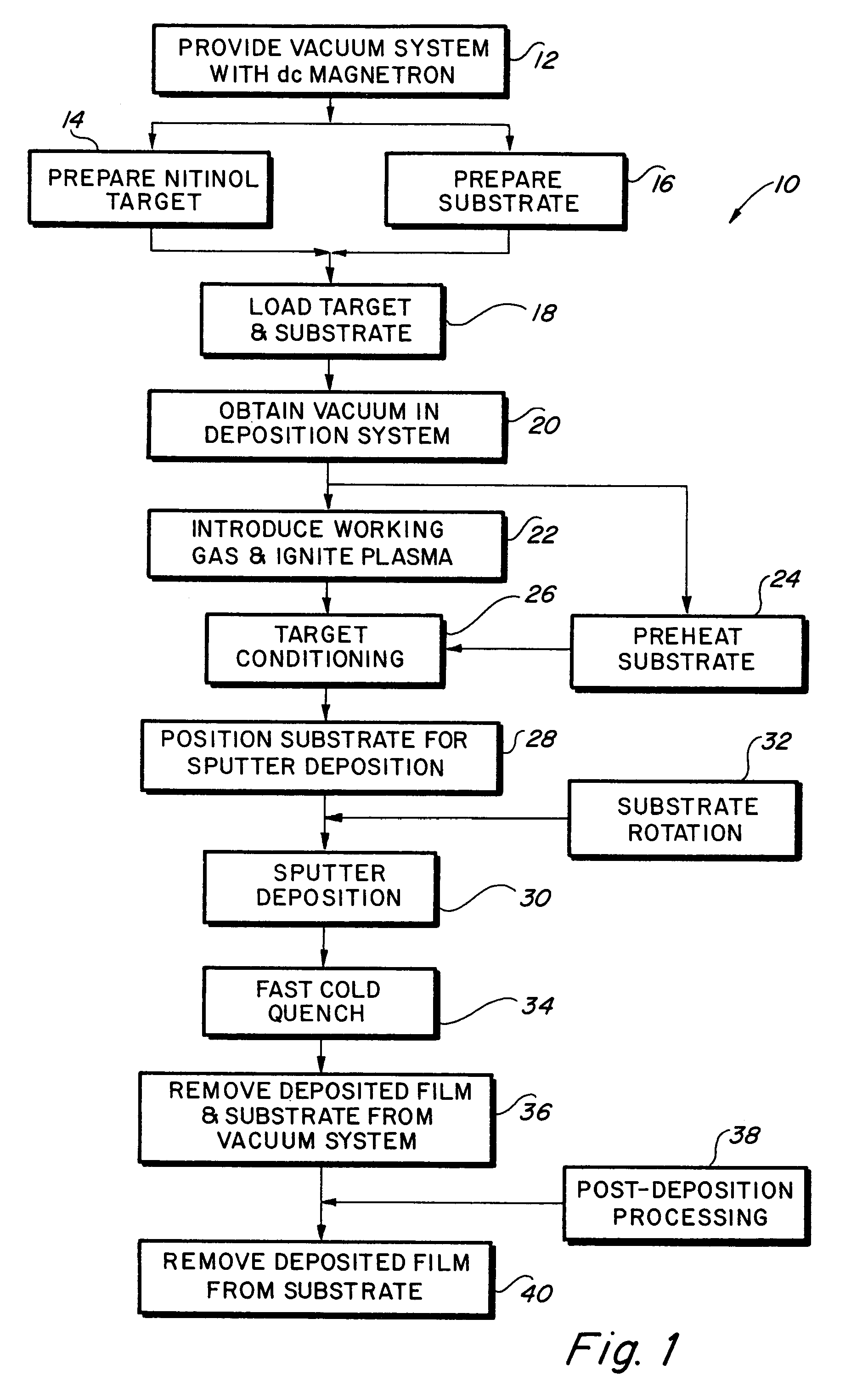

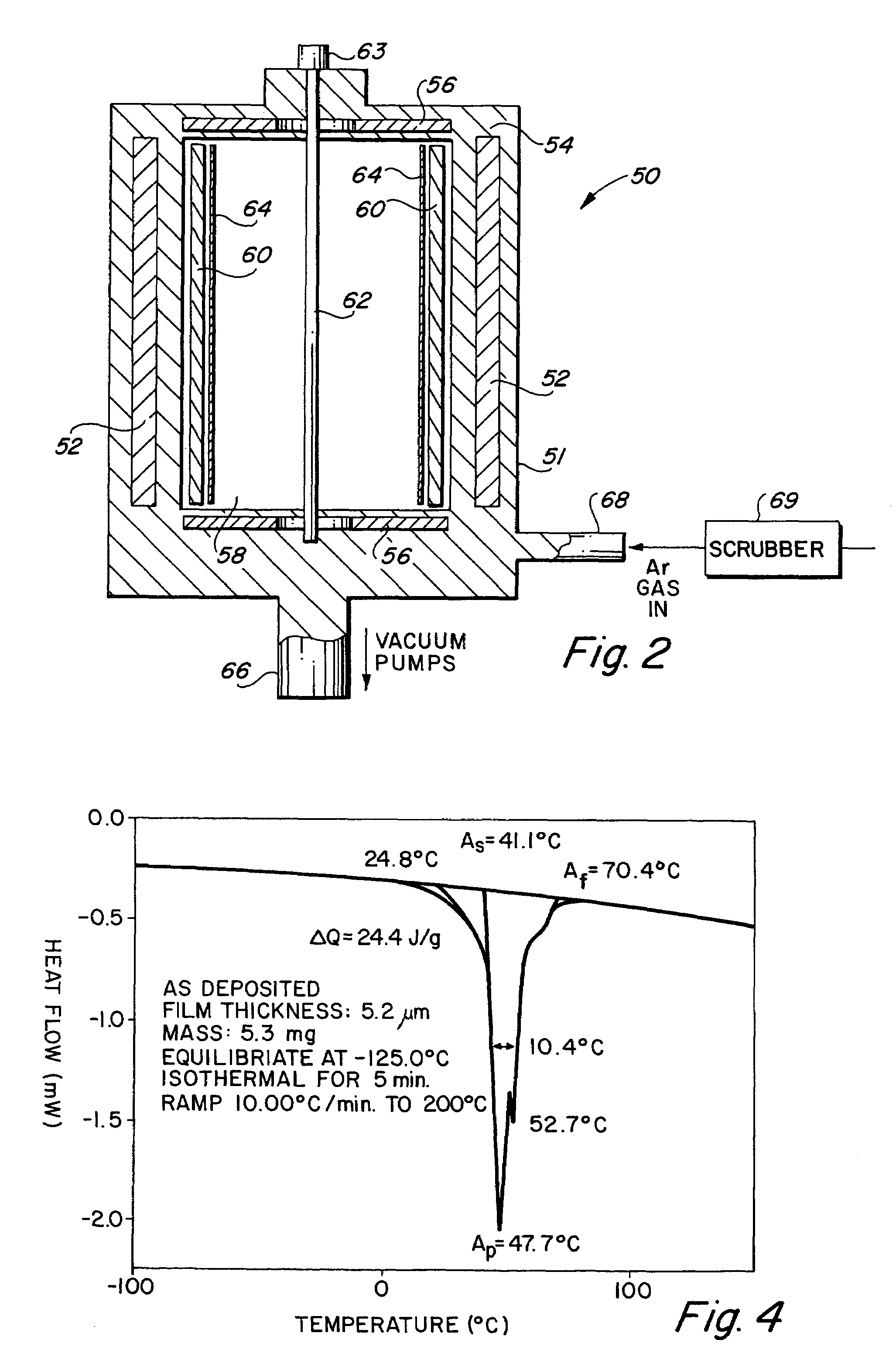

High strength vacuum deposited nitinol alloy films and method of making same

InactiveUS7335426B2Minimise scatteringControlled surface roughnessPig casting plantsThermometers using material expansion/contactionThin membraneTitanium

A vacuum deposition method for fabricating high-strength nitinol films by sputter depositing nickel and titanium from a heated sputtering target, and controlling the sputter deposition process parameters in order to create high-strength nitinol films that exhibit shape memory and / or superelastic properties without the need for precipitation annealing to attenuate the transition conditions of the deposited material. A vacuum deposited nitinol film having high-strength properties equal to or better than wrought nitinol films and which are characterized by having non-columnar crystal grain structures.

Owner:VACTRONIX SCI LLC

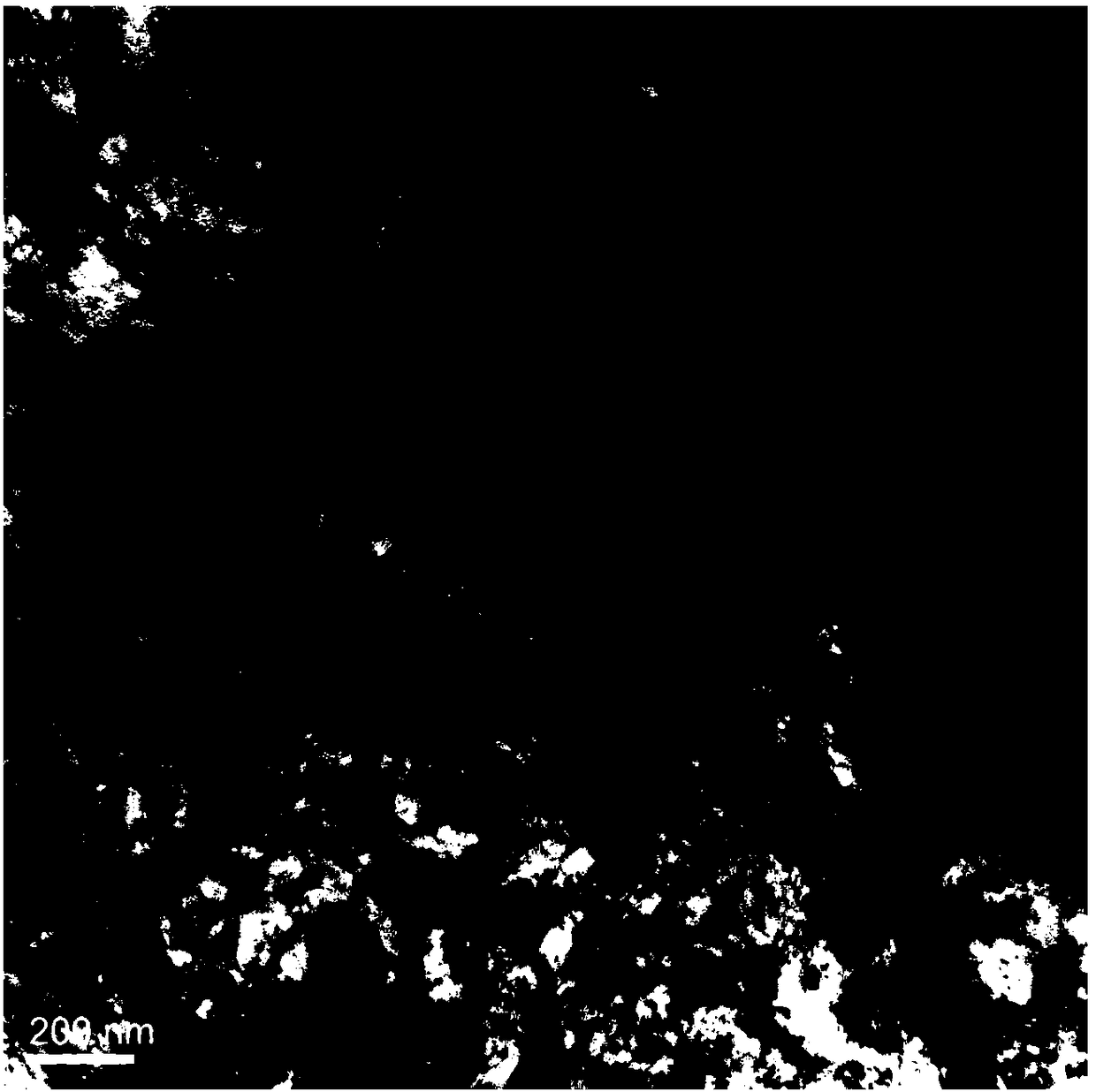

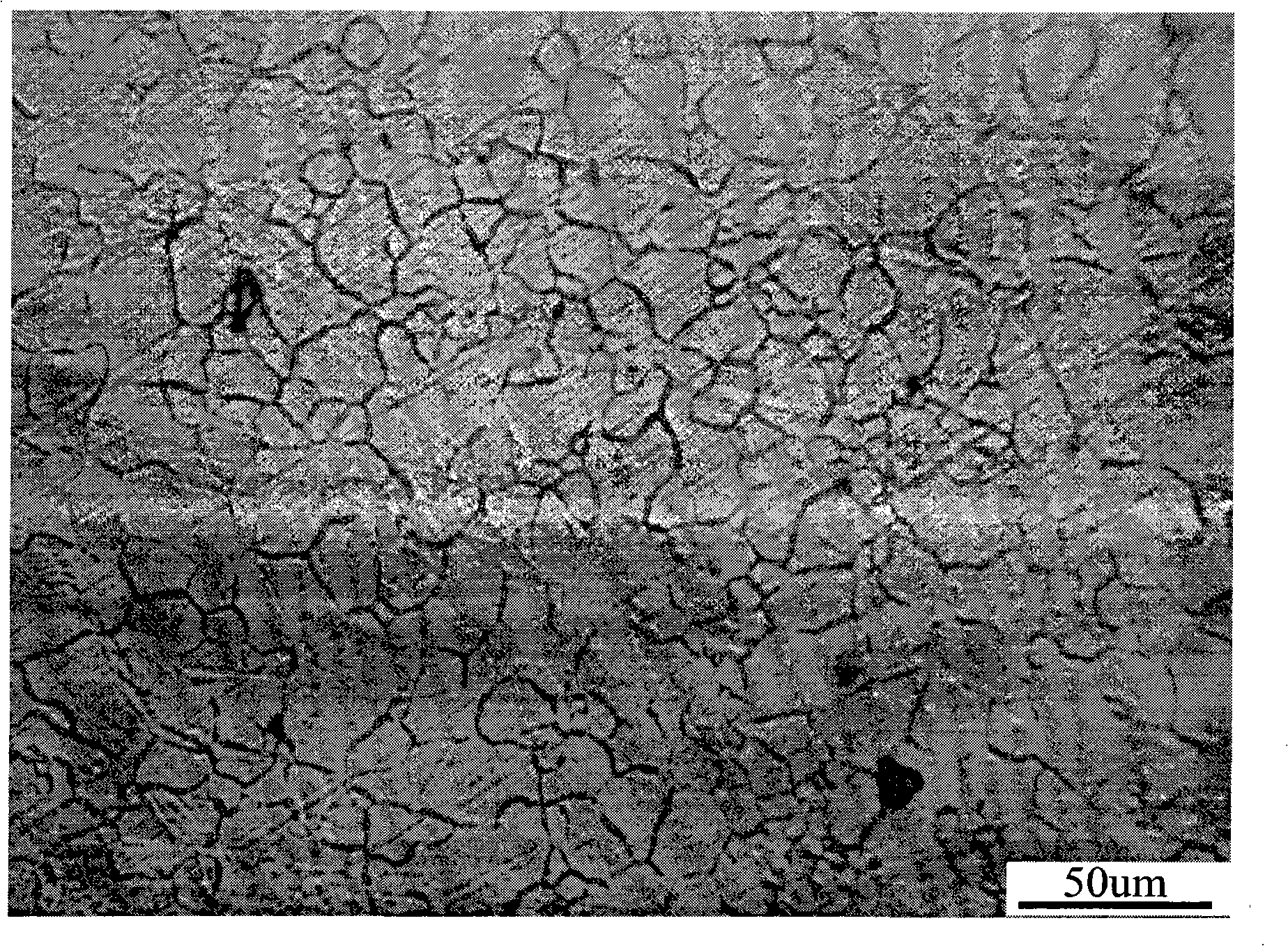

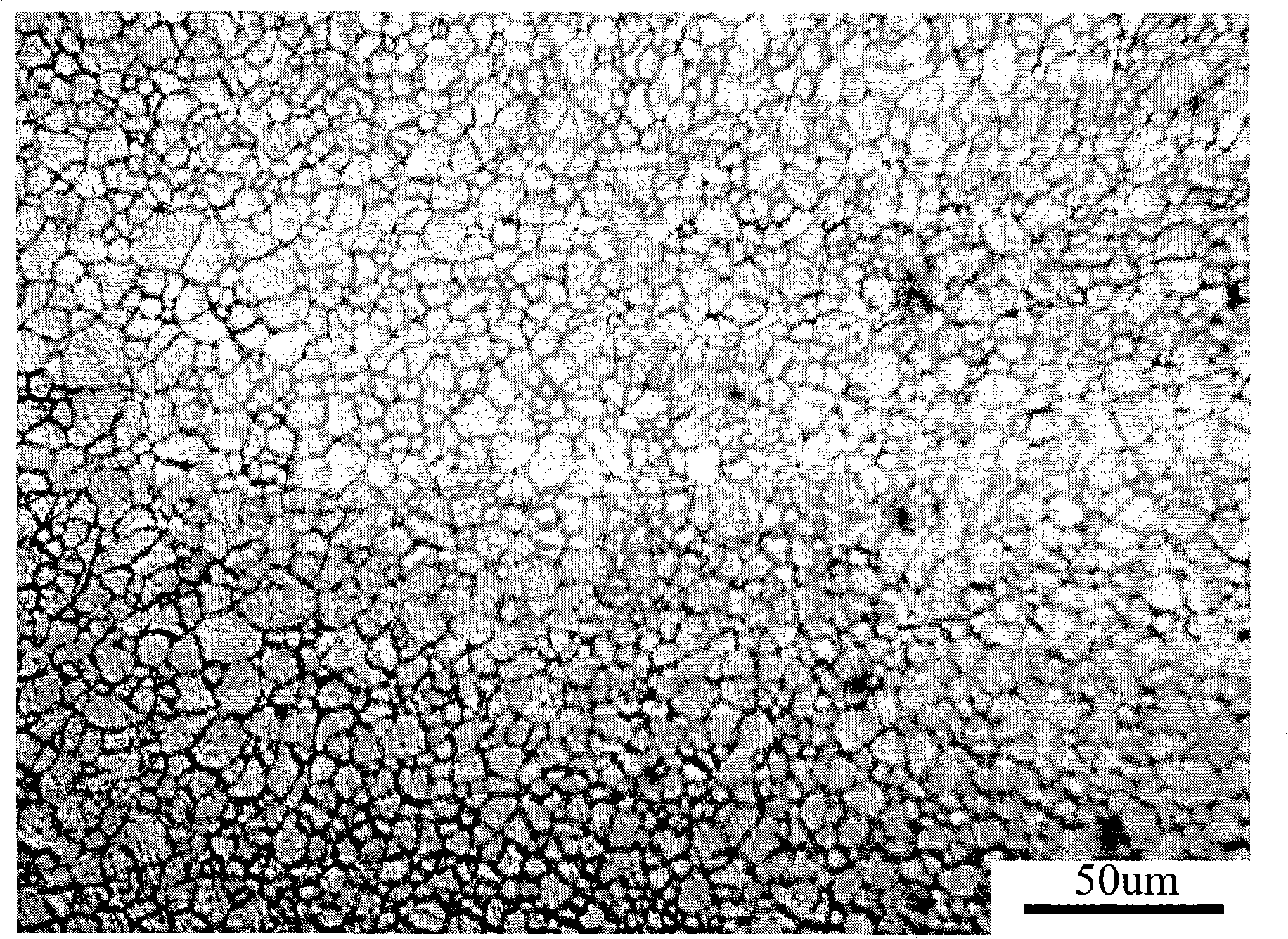

High speed processing method for realizing superfine crystal grain structure on metallic material surface

The invention relates to a method for processing the high-speed deformation on the surface of metallic material with nano structure, and particularly provides a method for realizing high-speed processing of the organization structure of ultra-fine grains. On the condition of room temperature or low temperature, by adopting a mechanical treatment method with high-speed plastic deformation, the nanoscale bulky crystalline grain structure on the surface layer of the metallic material is refined as equiaxial submicron crystalline grain or nano crystalline grain to form an ultra-fine organization structure of the crystalline grain on the surface layer of the metallic material. With the increase of the depth to the processing surface, the size of microstructure has the change of gradient, increasing from nanoscale and submicron size to micron size. Compared with the existing processing method for forming a surface ultra-fine crystalline grain structure, the high-speed processing method of the invention greatly reduces the roughness of the surface of the processed metallic material and increases the thickness of a deformation layer, and has simple processing method and high working efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

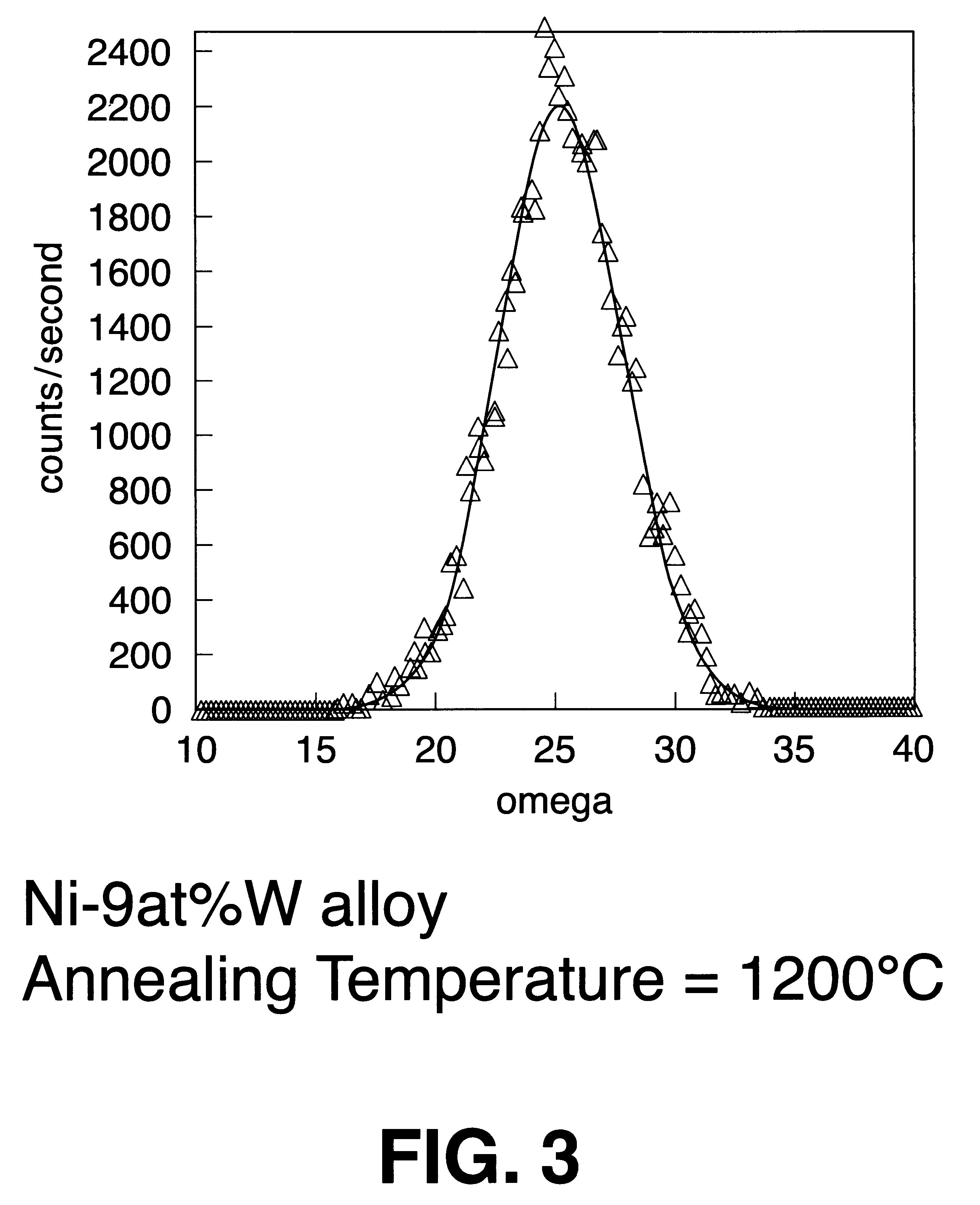

Biaxially textured articles formed by power metallurgy

InactiveUS6610414B2Inorganic material magnetismSuperconductor device manufacture/treatmentAl powderPowder mixture

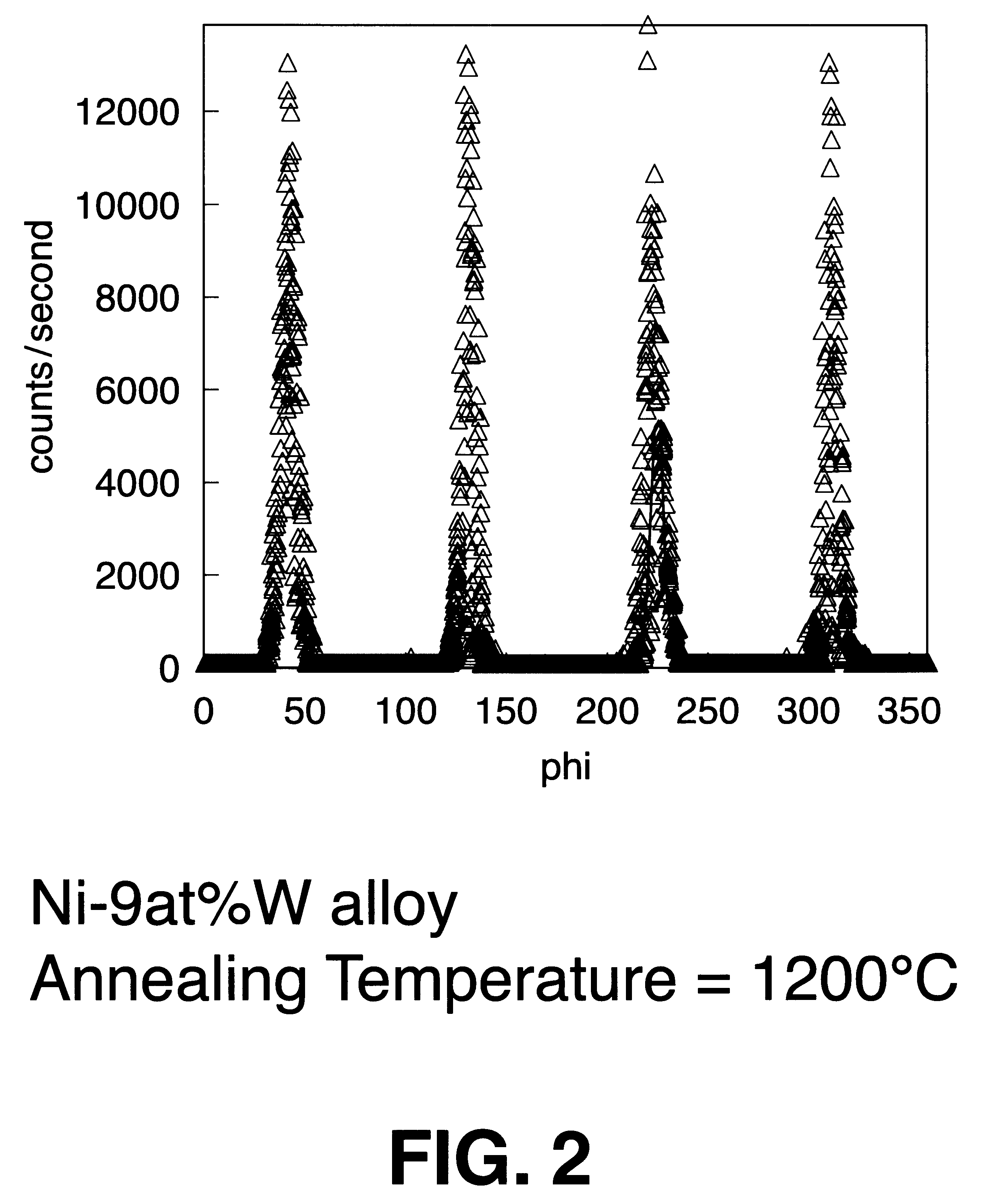

A biaxially textured alloy article having a magnetism less than pure Ni includes a rolled and annealed compacted and sintered powder-metallurgy preform article, the preform article having been formed from a powder mixture selected from the group of mixtures consisting of: at least 60 at % Ni powder and at least one of Cr powder, W powder, V powder, Mo powder, Cu powder, Al powder, Ce powder, YSZ powder, Y powder, Mg powder, and RE powder; the article having a fine and homogeneous grain structure; and having a dominant cube oriented {100}<100> orientation texture; and further having a Curie temperature less than that of pure Ni.

Owner:UT BATTELLE LLC

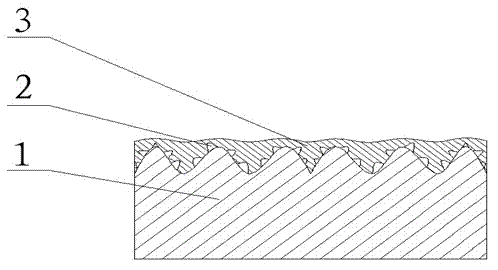

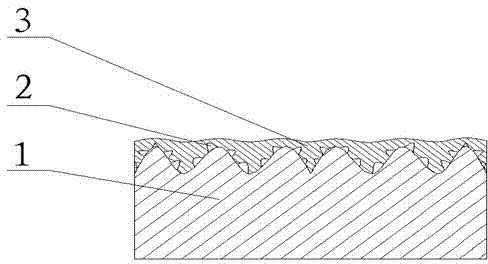

Nonstick cookware and manufacturing method thereof

The invention discloses nonstick cookware and a manufacturing method thereof, wherein the inner surface of the pot body of the nonstick cookware is provided with an uneven raised structure; a grain structure is distributed on the raised structure; and a nonstick coating covers outside the raised structure and the grain structure. The manufacturing method of the cookware comprises the following steps of: (1) forming the pot body of the cookware; (2) carrying out inner surface treatment on the pot body of the cookware to ensure that the uneven raised structure is formed at the inner surface of the pot body of the cookware; (3) carrying out meltallizing treatment on the cookware blank after being subjected to the roughening treatment to ensure that nanoscale hard metal-based or nonmetal-based grain structure is distributed on the raised structure of the pot body of the cookware; (4) spraying nonstick coatings on the inner surface of the pot body of the cookware after being subjected to the meltallizing treatment to ensure that the nonstick coating covers outside the raised structure and the grain structure; and (5) putting in a sintering channel at a temperature of 350-440 DEG C after the spraying to sinter for 5-20 minutes so as to obtain a finished product. The nonstick cookware disclosed by the invention is good in nonstick effect and abrasive resistance, simple in manufacturing process and suitable for large scale production.

Owner:谛卓(北京)咨询顾问有限公司

High-strength, high-damping metal material and method of making the same

A composite material includes a metallic second phase dispersed in a metallic matrix material. The metallic second phase has a grain structure that is at least partially martensitic. The second phase material is preferably an alloy of nickel and titanium, each present in the range from 48 to 52 atomic %, optionally in combination with further additives. The second phase particles can be present in the form of granular particles, wires, fibers, whiskers, or layers, making up 5 to 60 vol. % of the overall composite material. The matrix material is preferably an aluminum alloy. The composite material has a high damping capacity and a high tensile strength provided by the matrix, and a high damping capacity provided by the second phase. A method of making the composite material involves mixing a powdery matrix material and a powdery second phase material, and then heat and consolidating the mixture at a temperature of 400 to 700 ° C. and a pressure of 100 to 300 MPa.

Owner:DAIMLER AG

Alpha-beta titanium alloy tubes and methods of flowforming the same

Described herein are methods for forming titanium alloy tubes having an α-β grain structure. The methods include the steps of hot-working a titanium alloy workpiece at a temperature below the β-transus temperature of the workpiece and above the recrystallization temperature of the workpiece to produce an α-β titanium alloy preform hollow. Subsequently, the α-β titanium alloy preform hollow is flowformed, thereby forming a α-β titanium alloy tube.

Owner:ATI FLOWFORM PROD

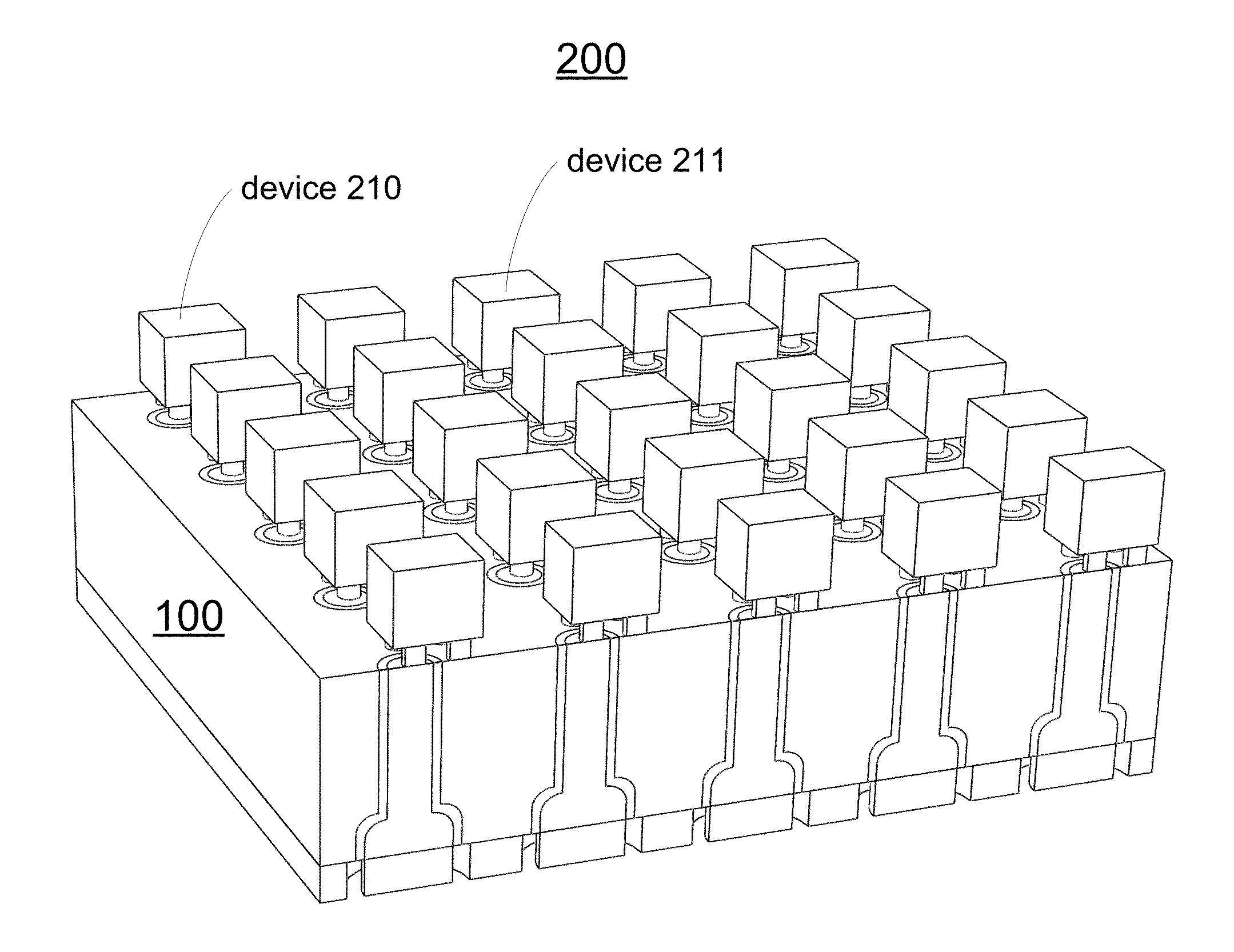

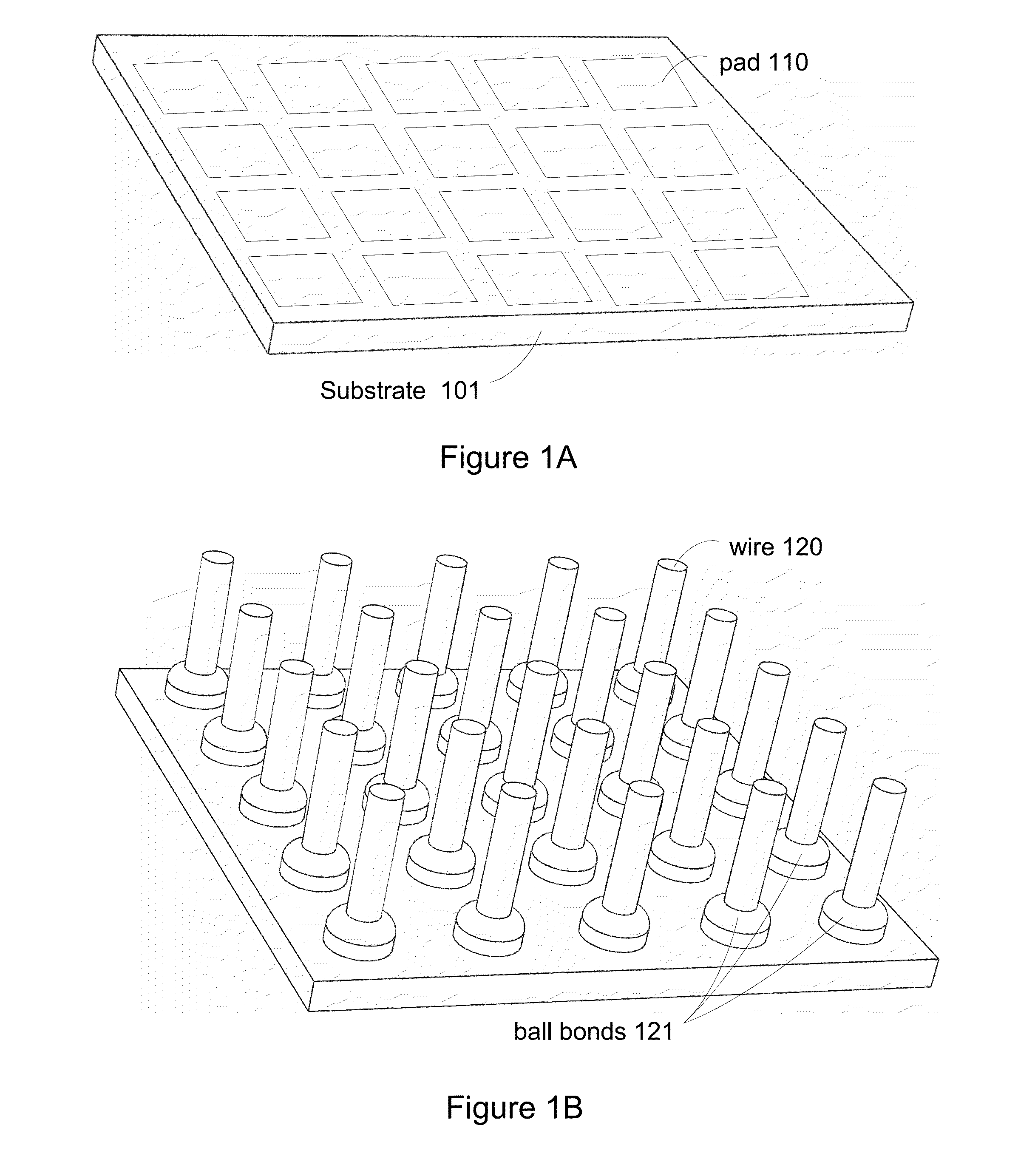

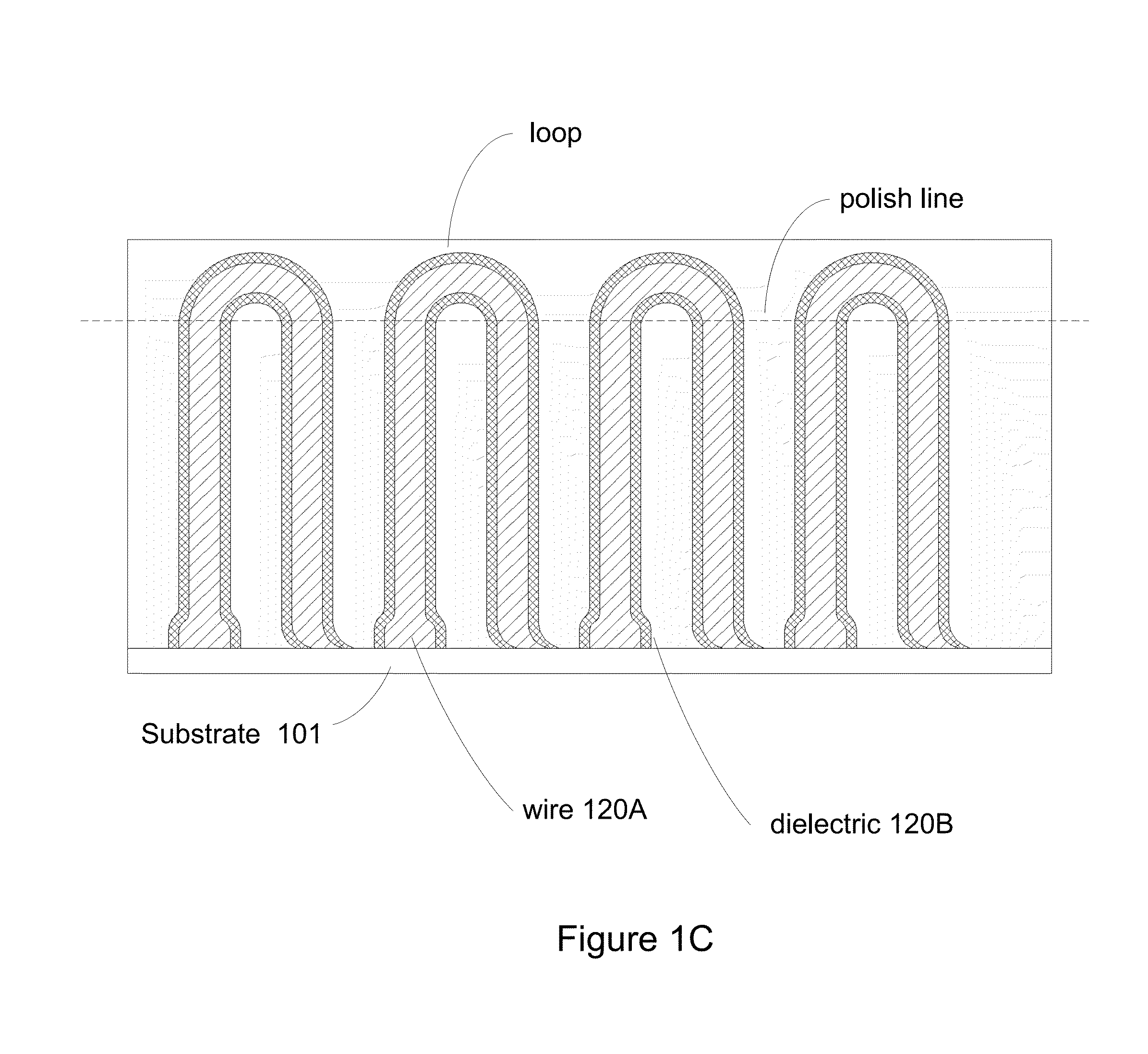

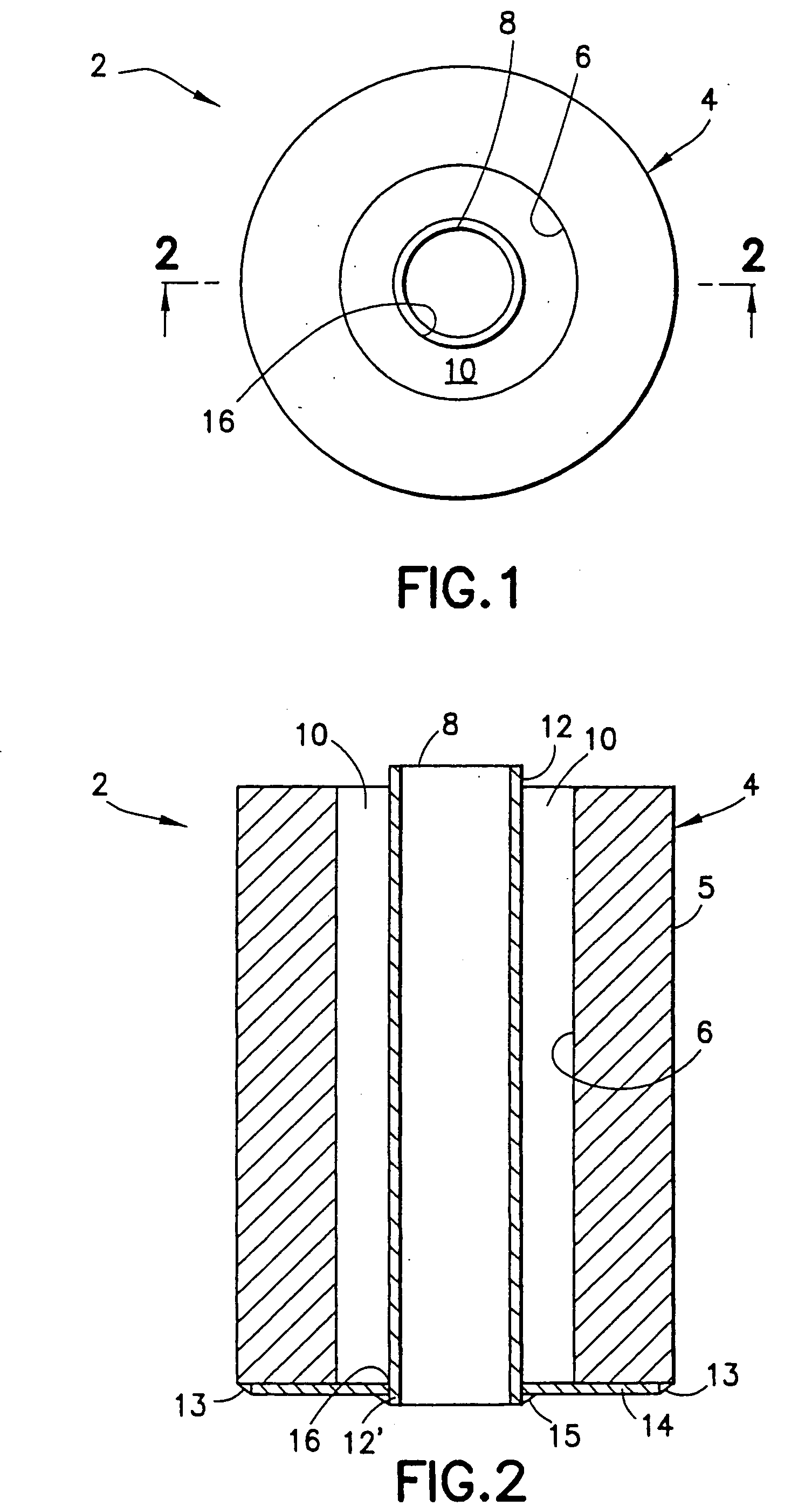

Heat spreading substrate with embedded interconnects

ActiveUS8946757B2Simple and cost-effective to manufactureSemiconductor/solid-state device detailsSolid-state devicesEngineeringGrain structure

Heat spreading substrate with embedded interconnects. In an embodiment in accordance with the present invention, an apparatus includes a metal parallelepiped comprising a plurality of wires inside the metal parallelepiped. The plurality of wires have a different grain structure than the metal parallelepiped. The plurality of wires are electrically isolated from the metal parallelepiped. The plurality of wires may be electrically isolated from one another.

Owner:INVENSAS CORP

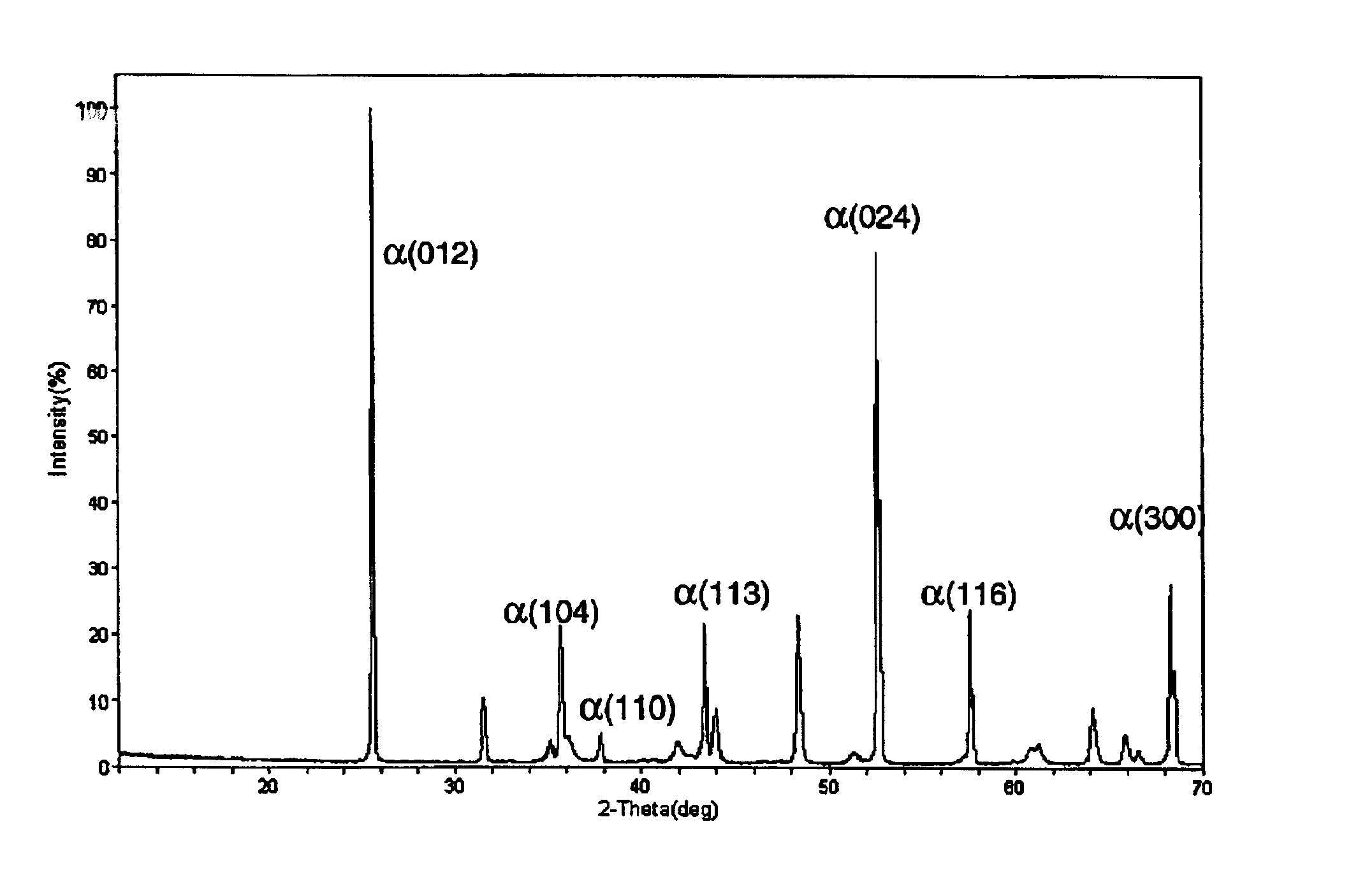

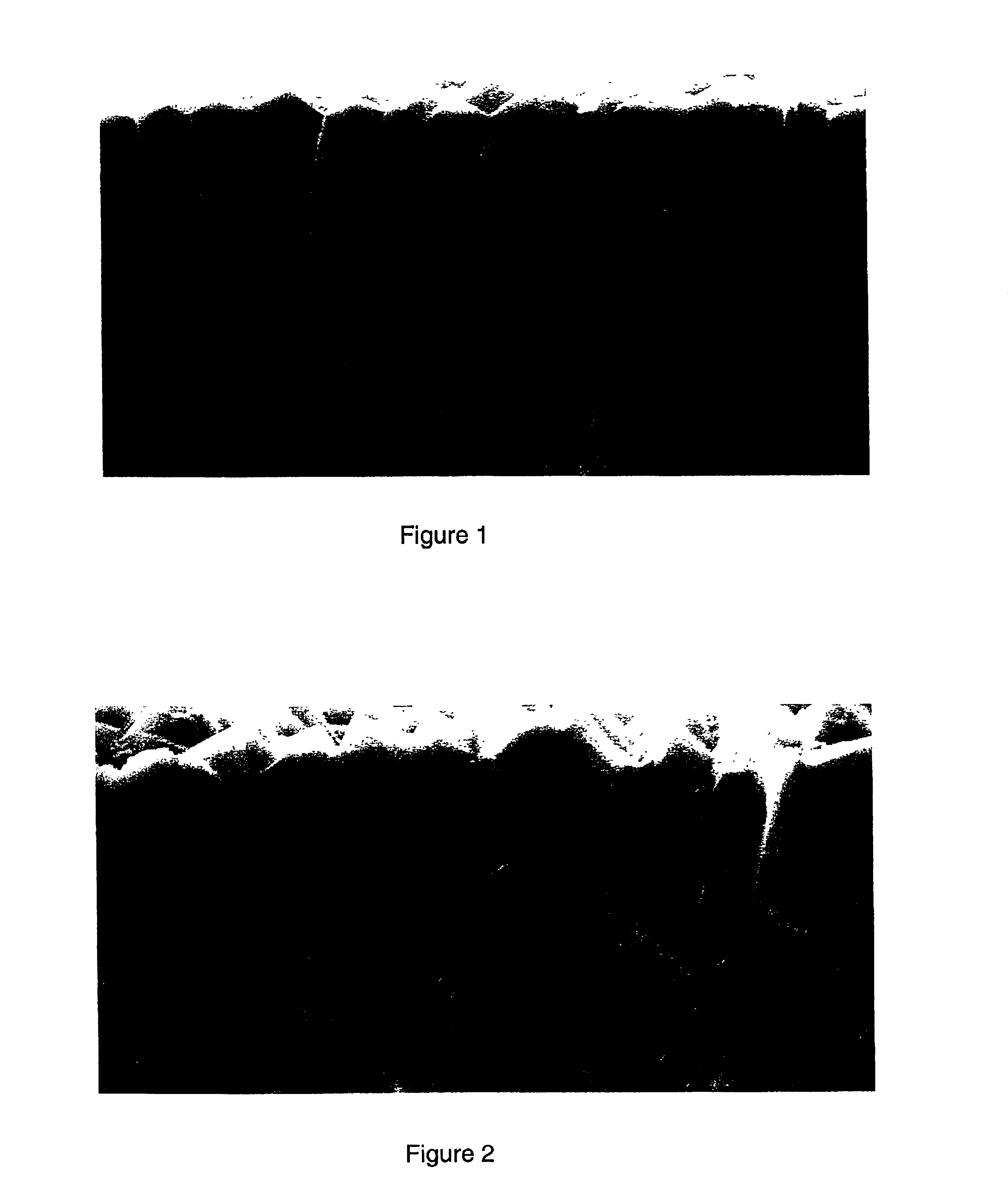

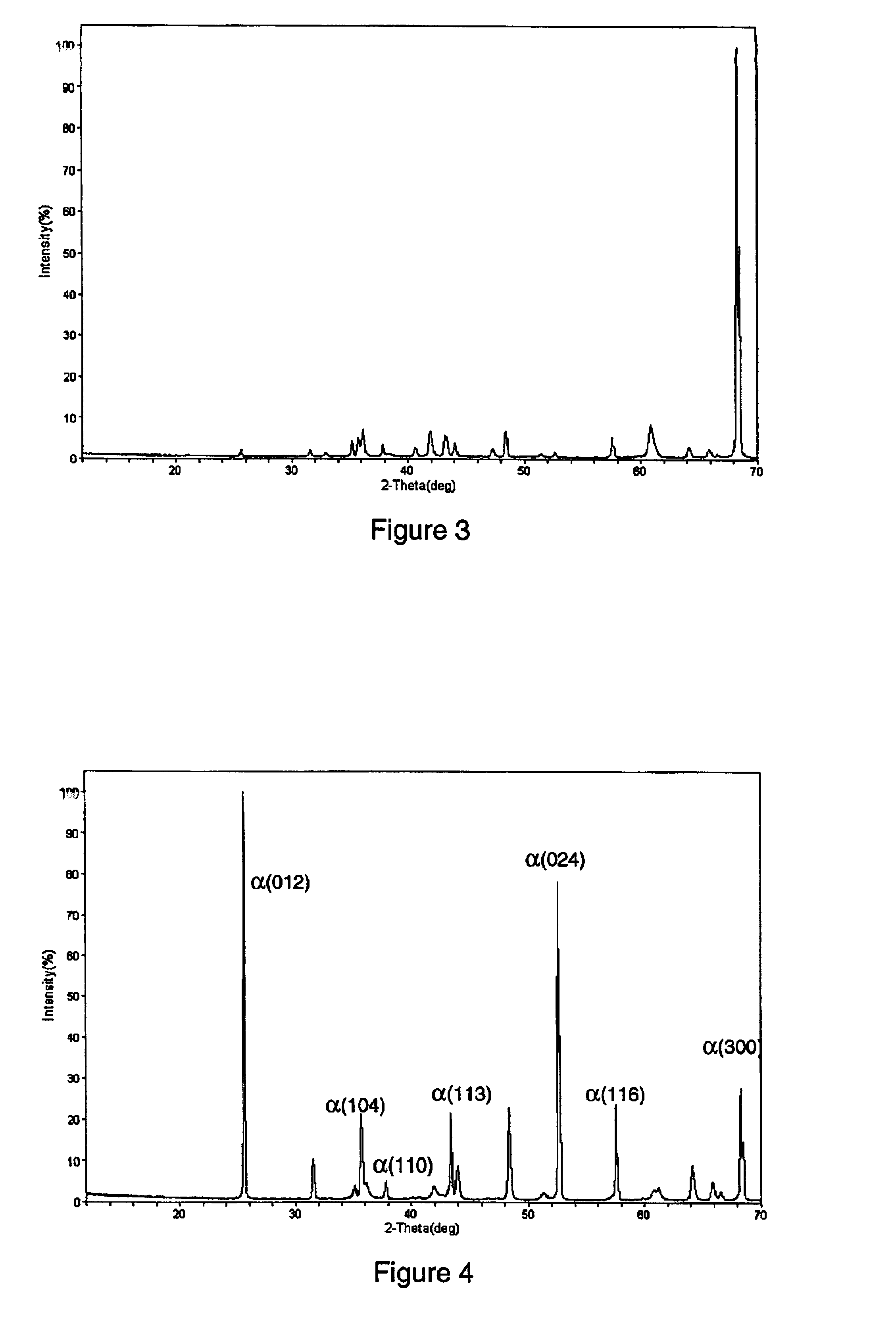

Alpha-alumina coated cutting tool

A coated cutting tool is composed of one or more layers of refractory compounds of which at least one layer is single-phase α-alumina with a pronounced columnar grain-structure and strong texture in the [300]-direction. The alumina layer is preferably deposited by CVD (Chemical Vapor Deposition) and the preferred microstructure and texture are achieved by adding a second metal halide, and a texture modifying agent, to the reaction gas. When coated cemented carbide cutting tools according to the invention are used in the machining of steel or cast iron, several important improvements compared to prior art have been observed, particularly in the machining of nodular cast iron.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

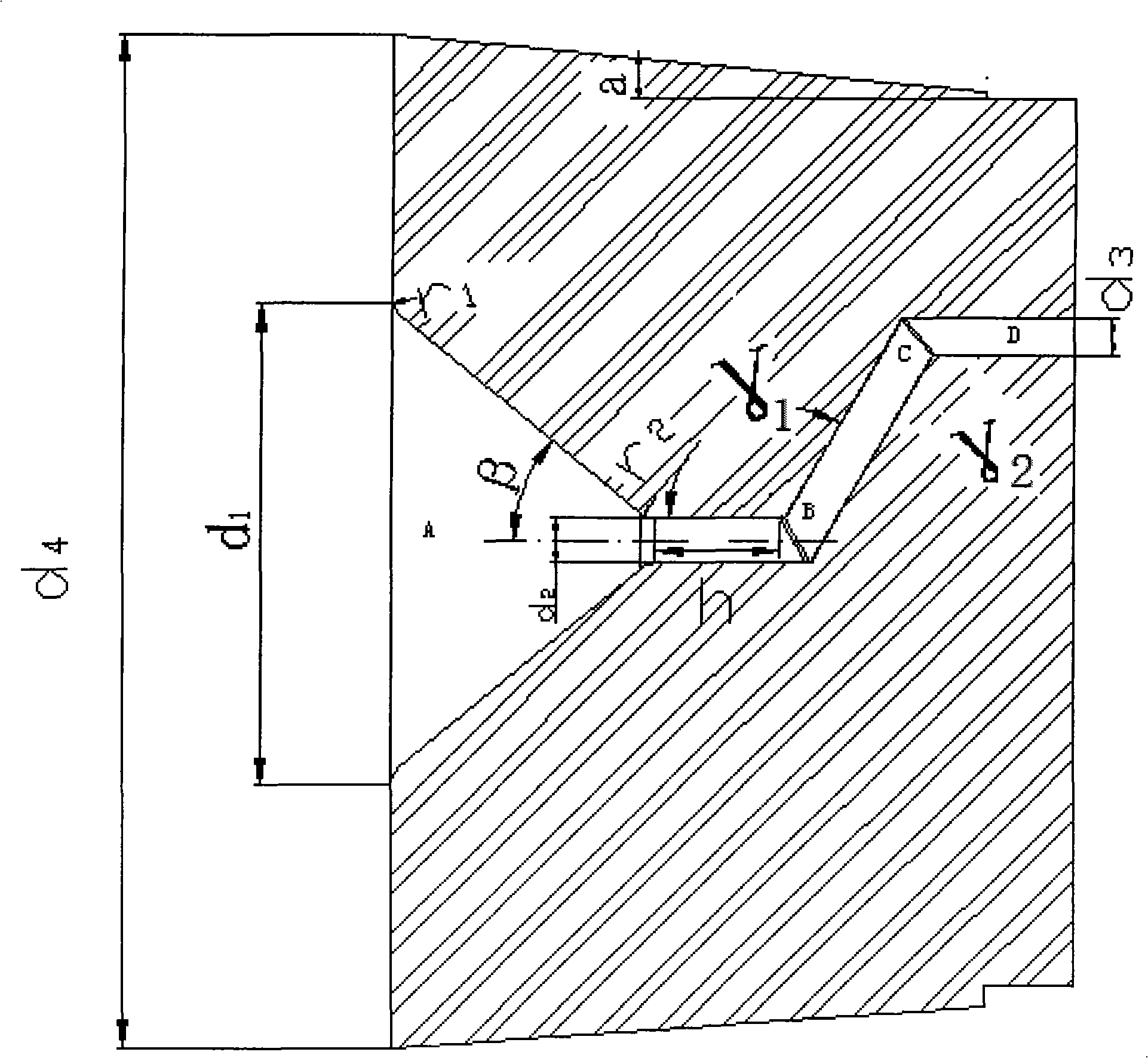

Method for preparing magnesium alloy section bar by continuous corner shearing and squeezing shaping and mold

InactiveCN101406906AImprove material plasticityImprove plasticityExtrusion diesExtrusion control devicesGrain structureHigh strain

The invention relates to a method for preparing a magnesium alloy section through continuous angle rotation shearing, extrusion and shaping and a mould. The method comprises the following steps: (1) a magnesium alloy blank material is subjected to homogenization treatment; (2) a mould of an extrusion mould with a plurality of angle rotation and molding is preheated; and the inside of a mould passage is evenly coated with lube; (3) an extrusion cylinder is heated to a temperature of between 175 and 325 DEG C; and (4) the homogenized blank material is heated to a temperature of between 200 and 350 DEG C; the extrusion ratio of the extrusion mould is between 4 and 100; and the magnesium alloy blank material is subjected to unidirectional extrusion at an extrusion speed of between 3 and 6 m / min so that the magnesium alloy blank material is subjected to compression and extrusion with high extrusion ratio and equal passage extrusion with a plurality of angle rotation. The magnesium alloy material prepared through the method has an ultrafine crystal grain structure, has the advantages of substantially improving the plasticity, low temperature superplasticity and high strain speed of the magnesium alloy material and has high yield stress.

Owner:CHONGQING UNIV

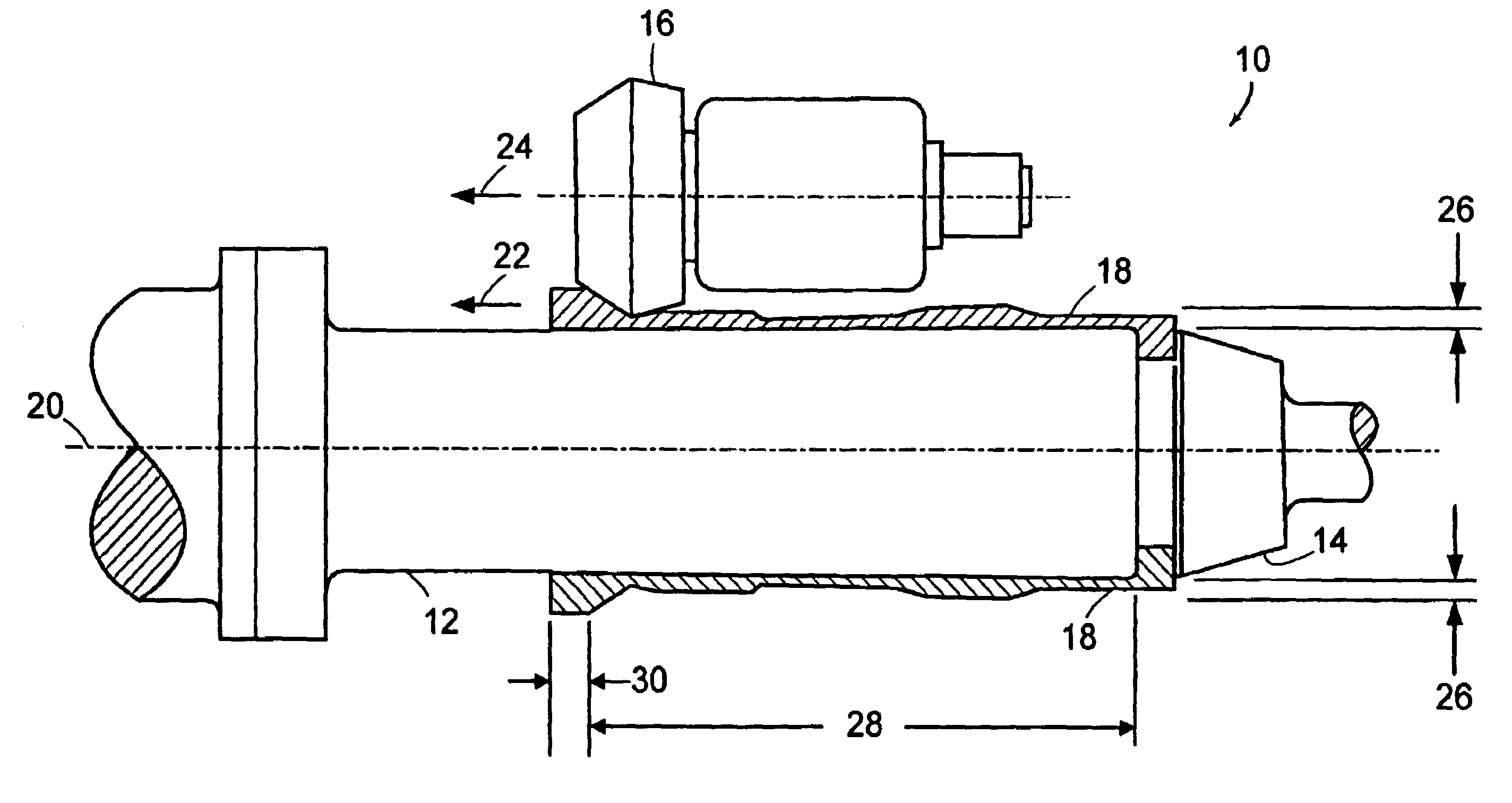

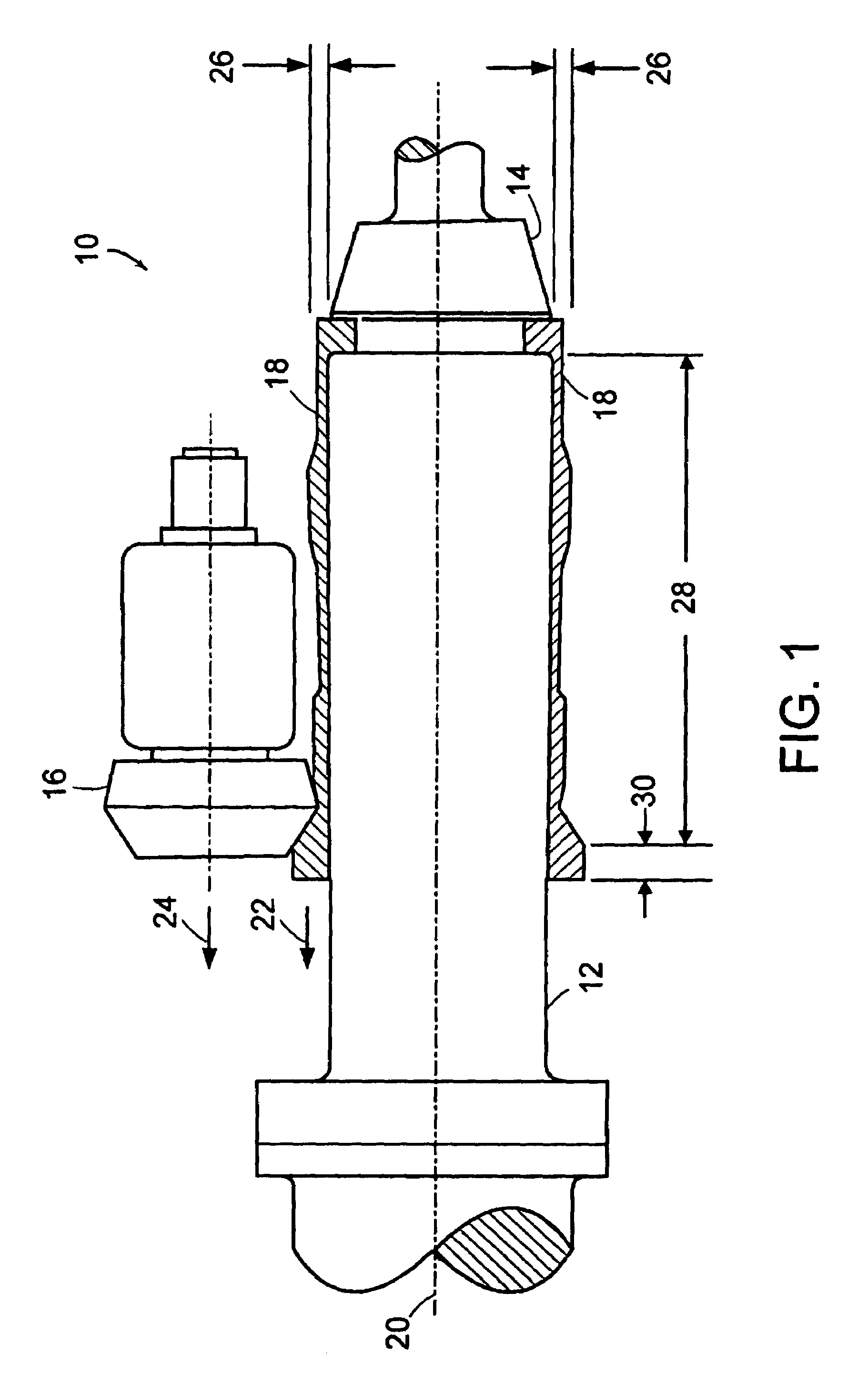

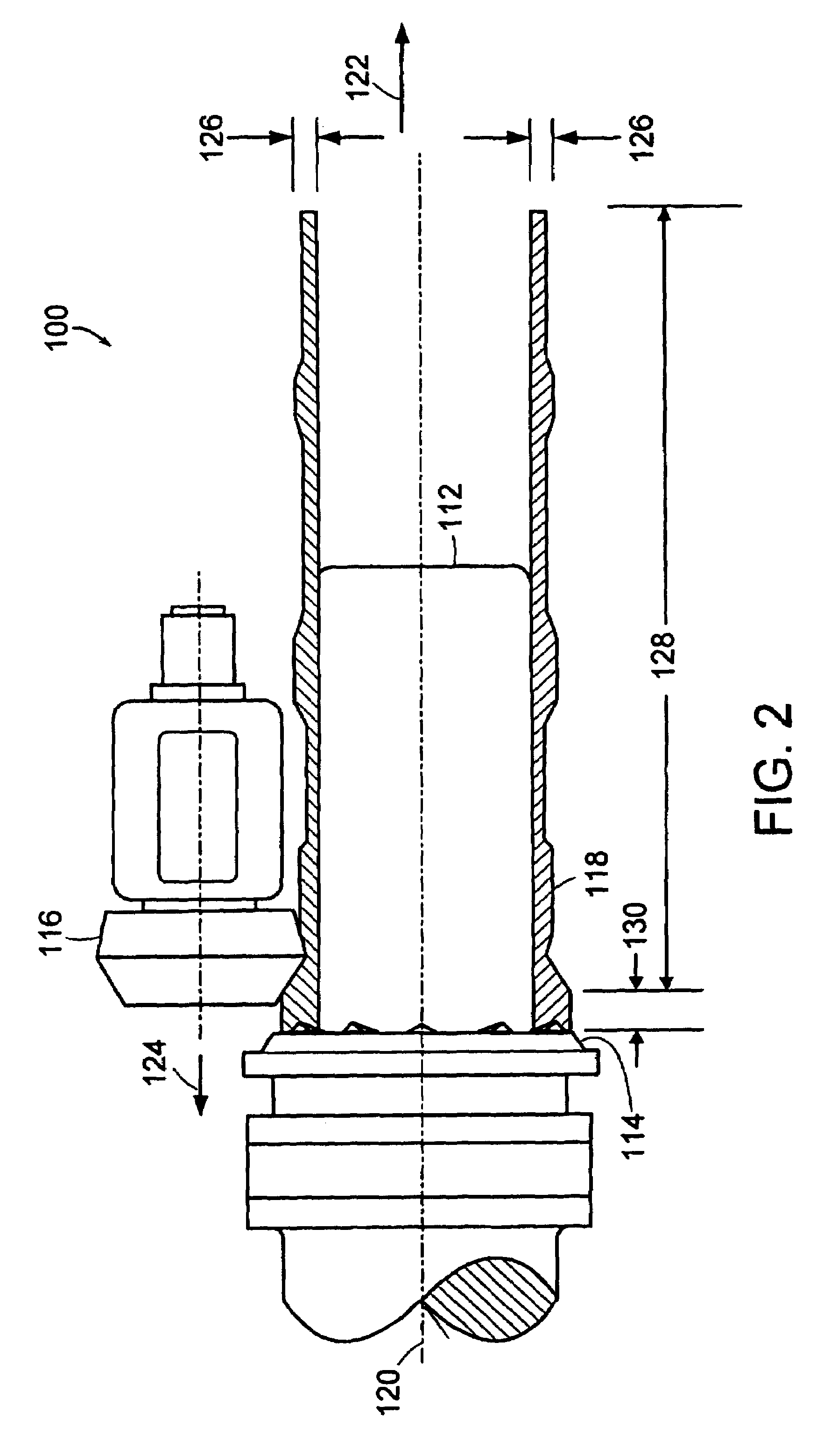

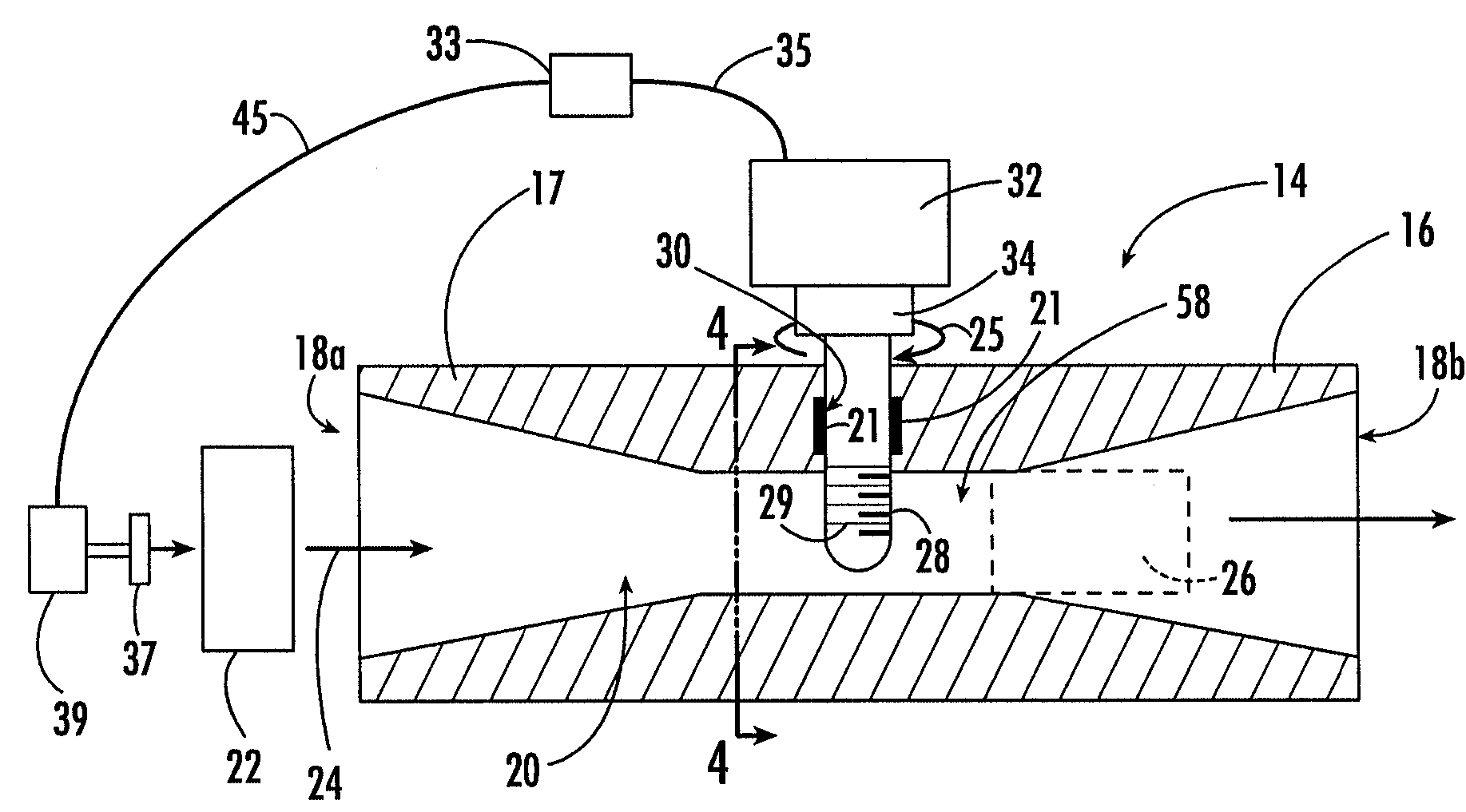

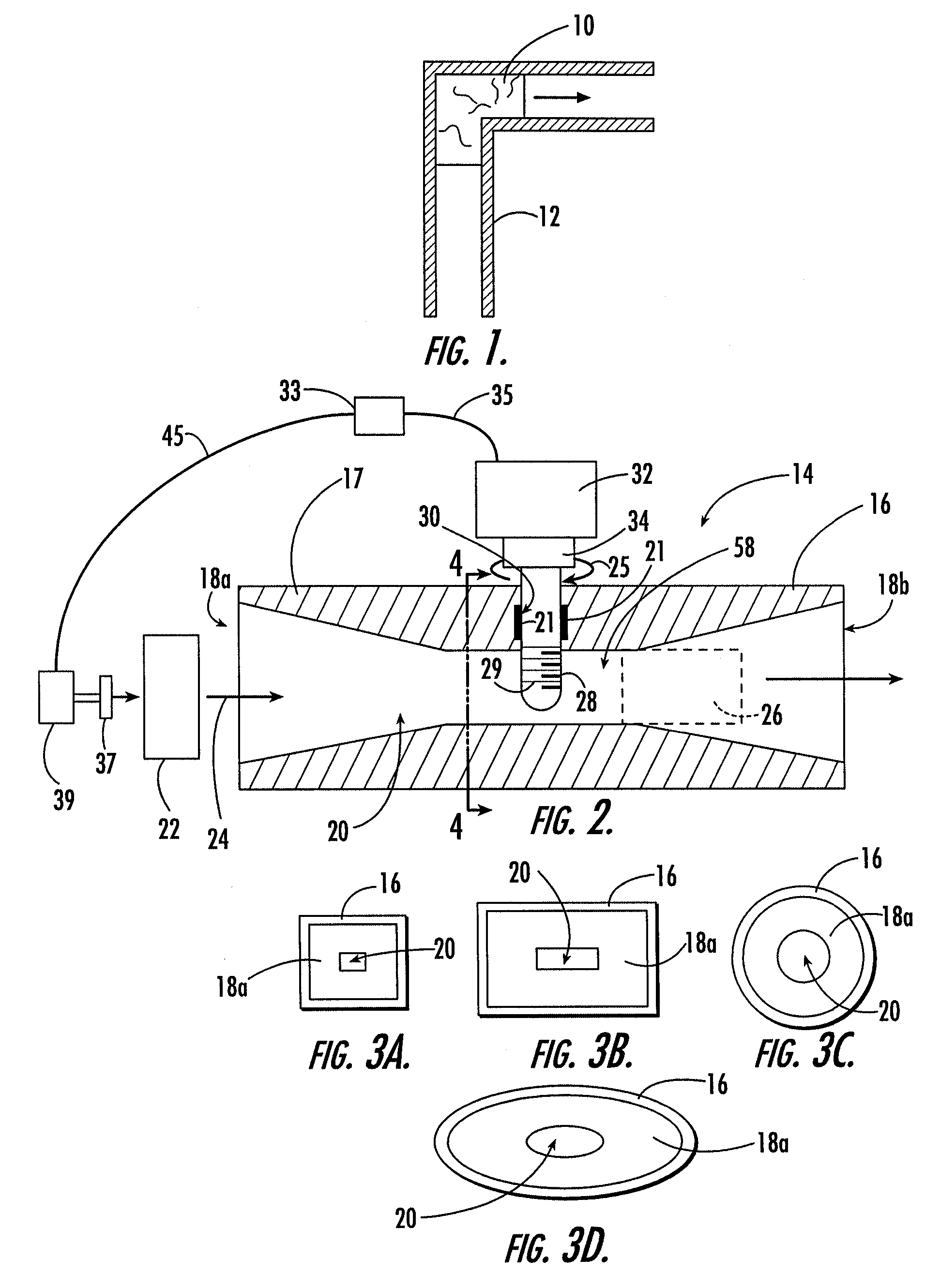

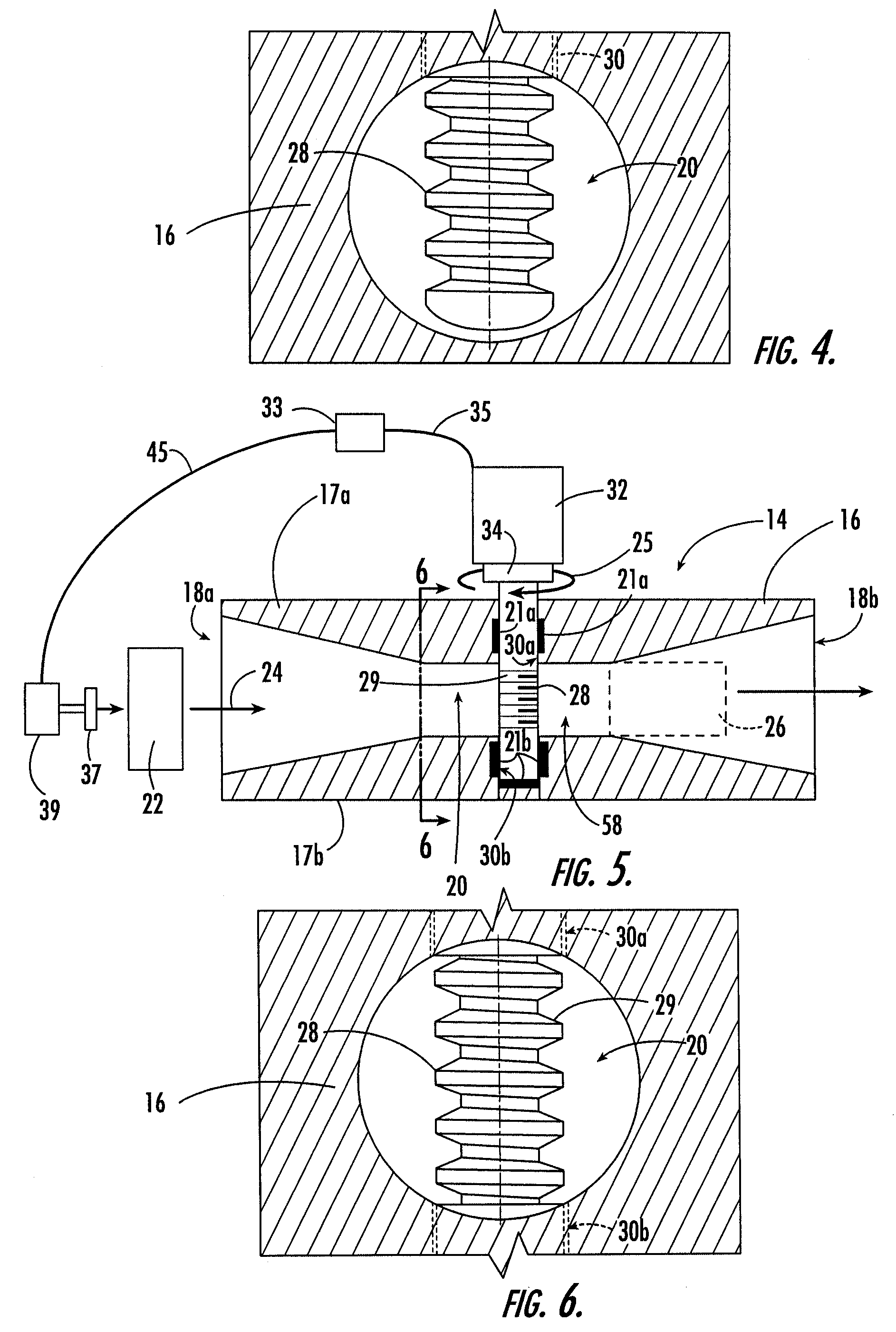

Method and apparatus for producing a refined grain structure

InactiveUS20030218052A2Improve material performanceLow costWelding/cutting media/materialsSoldering mediaGrain structureMechanical engineering

Abstract of the Disclosure The apparatus for operating on a workpiece includes a die defining first and second apertures and an interior therebetween. The first aperture and the interior of the die are structured to receive the workpiece. The interior of the die can be structured to shape the workpiece into a predetermined configuration. The apparatus includes at least one rotatable pin extending at least partially into the interior of the die. The pin is structured to at least partially stir the workpiece as the workpiece moves through the interior of the die to thereby refine the grain structure of the workpiece.

Owner:THE BOEING CO +1

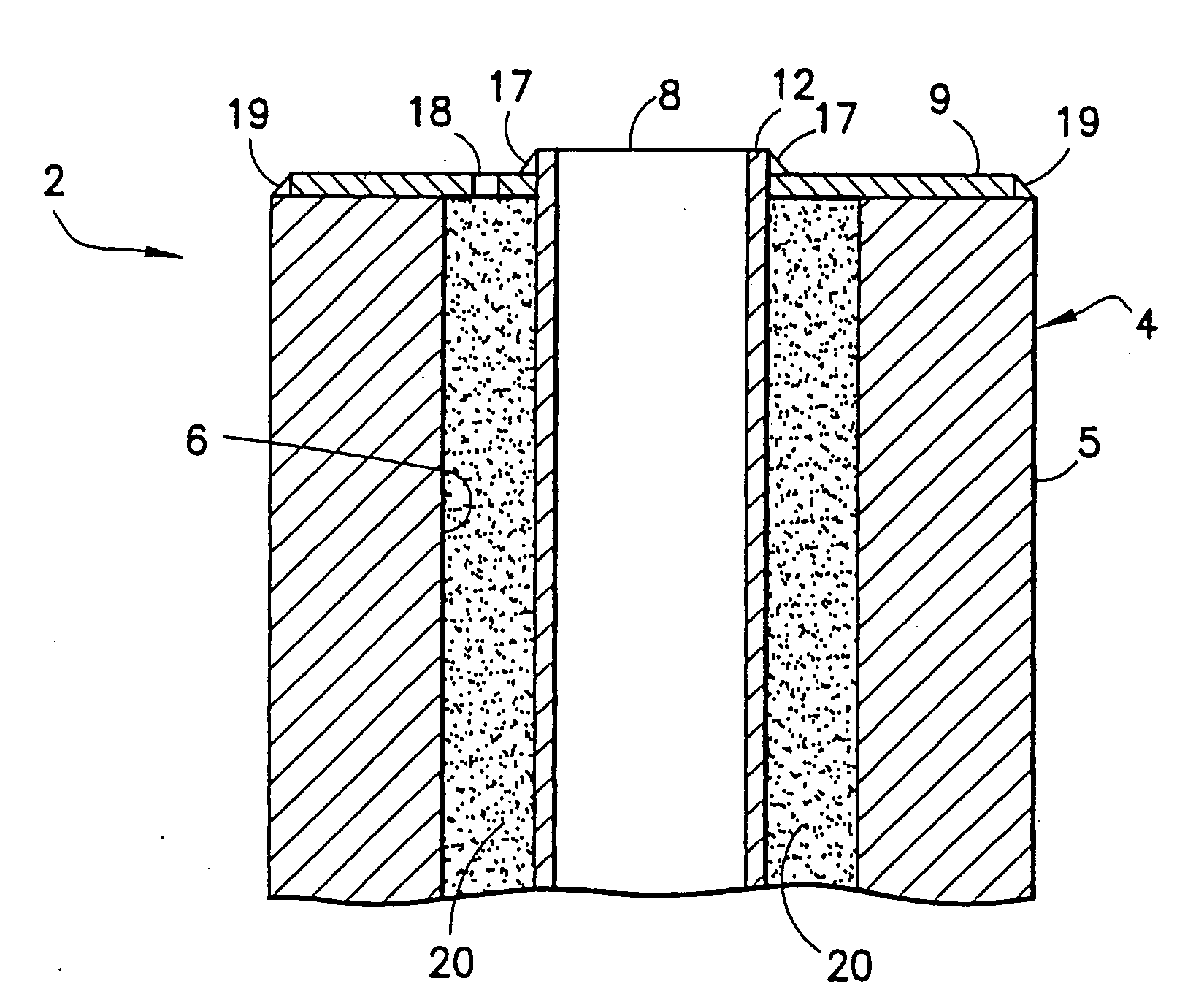

Composite tube for ethylene pyrolysis furnace and methods of manufacture and joining same

InactiveUS20050058851A1OptimizationSolve the real problemThermal non-catalytic crackingArc welding apparatusHigh resistanceHydrocotyle bowlesioides

A process for making a composite tube uniquely suited for use in ethylene pyrolysis furnaces wherein the tube comprises an outer shell made from a wrought or cast Fe—Ni—Cr heat resistant alloy and an inner core made from INCOLOY® alloy MA956 powder. The outer shell and powder core are heated and simultaneously extruded to form a composite tube. The process is carried out at temperature, and time at temperature, preferably less than 1200° C. so as to prevent recrystalization of the very fine grain structure in the alloy MA956. This un-recrystalized fine grain structure permits pilgering and / or cold drawing of the extruded composite tube to final size. The composite tube provided by the present invention is uniquely suited for use in the petrochemical and chemical process industries, so as to increase the efficiency and productivity of their respective processes. The thin core layer of alloy MA956 provides high resistance to carburization and coke formation heretofore caused by the hydrocarbon feedstock flowing through the composite tube, while the outer shell of Fe—Ni—Cr heat resistant alloy provides overall strength and rigidity to the tube. The use of the outer shell in the composite tube also solves the joining problem heretofore encountered in joining alloy MA956. A root pass or passes using an alloy MA956 filler metal followed by overlay welding passes using a filler metal compatible with the heat resistant alloy, such as INCONEL alloy 617 or FM 25 / 35, joins the outer shells of adjoining composite tubes and, thus, solves the welding problem.

Owner:HUNTINGTON ALLOYS CORP (US)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com