High magnetic induction and high grad non-orientation electrical steel and its making process

A technology of oriented electrical steel and manufacturing method, which is applied in the direction of manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of continuous casting slab collapse, increase in the number of inclusions, and affect the quality of final products, so as to reduce the precipitation of AlN and reduce the The effect of solid solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

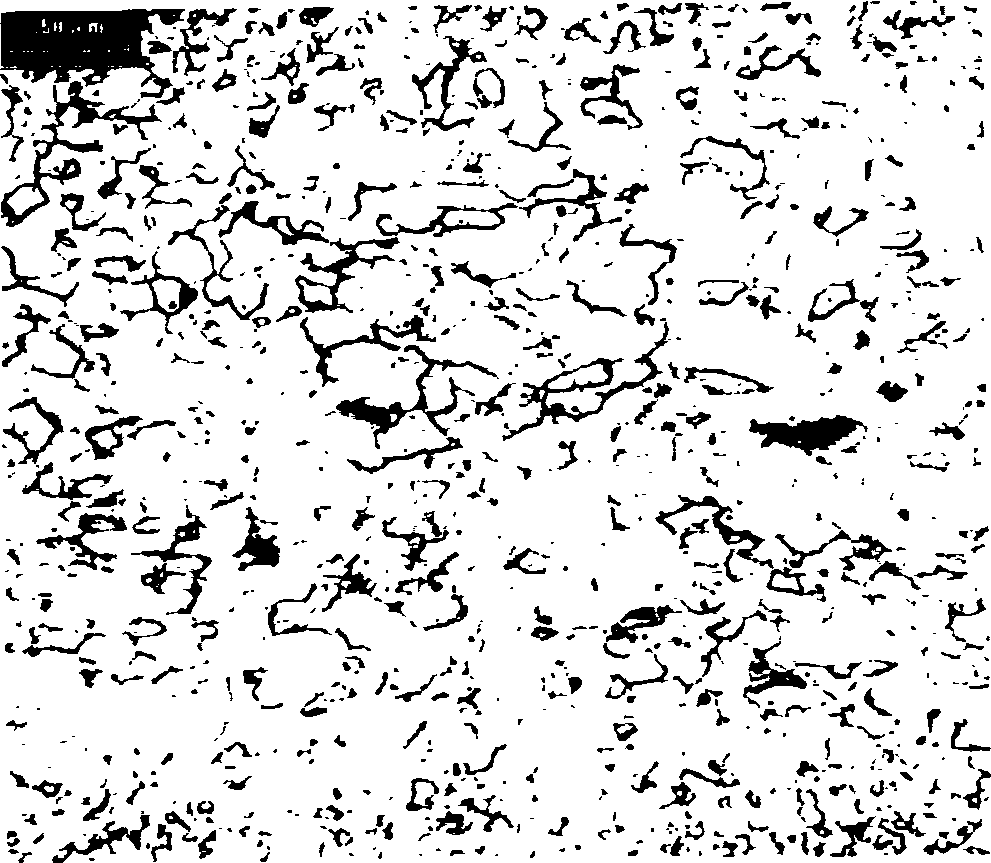

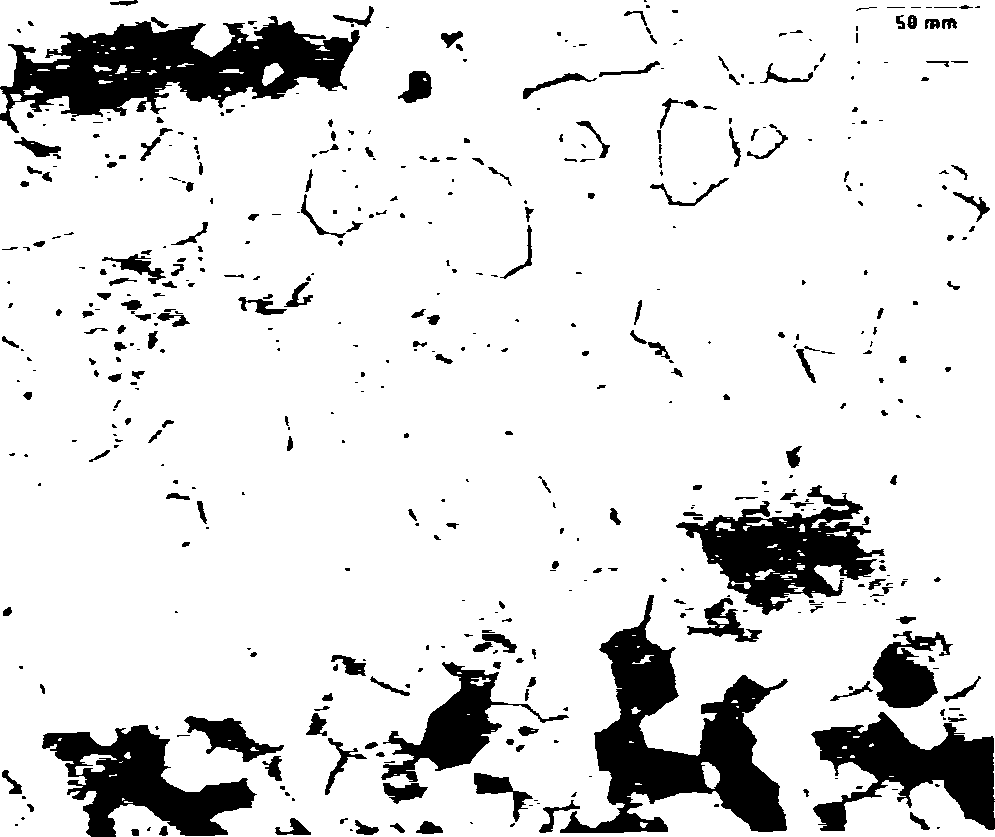

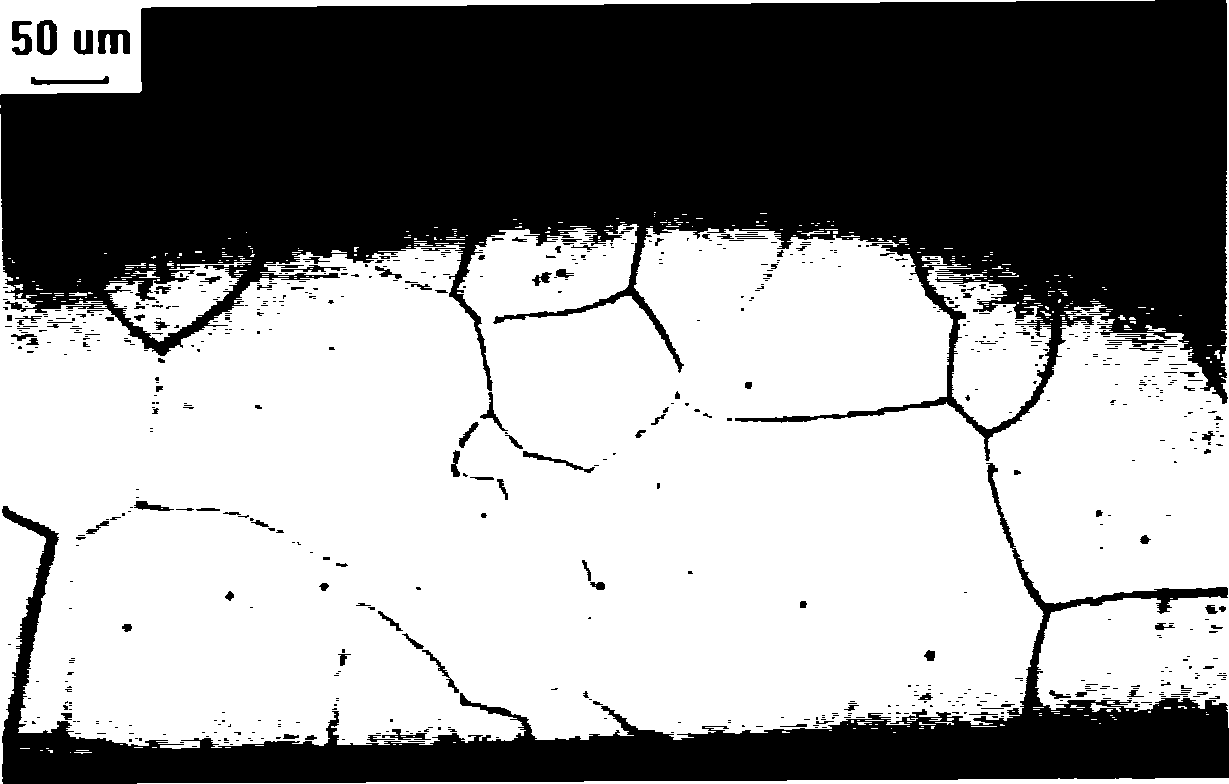

[0061] Invention steel A contains C: 0.0031%, Si: 2.00%, Al: 0.95%, Mn: 0.31%, Sn: 0.092%, B: 0.0009%, and the rest is iron and unavoidable impurities; the cumulative reduction ratio of rough rolling is 84% %, the reduction rate of one pass is 41%, the rough rolling finish rolling temperature is 1000°C; the finish rolling start rolling temperature is 918°C, the finish rolling temperature is 868°C, the coiling is 560°C, and the finish rolling reduction rates are respectively: 31% for the first pass, 29% for the second pass, 29% for the third pass, 71% for the fourth pass, and 18% for the fifth pass; normalization annealing is not used; the cold rolling reduction rate is 87% ( Finished steel strip thickness is 0.35mm); recrystallization annealing system: 1000°C×90 seconds, heating rate is 30°C / s, slow cooling rate is controlled at ≤15°C / s (1000°C→600°C), fast cooling rate is controlled It is 33°C / s. The annealing atmosphere adopts 30% H2+70% N2. The surface quality of the fini...

Embodiment 2

[0063] Invention steel B contains C: 0.0029%, Si: 2.00%, Al: 0.99%, Mn: 0.301%, Sb: 0.078%, B: 0.0009%, and the rest is iron and unavoidable impurities; the cumulative reduction ratio of rough rolling is 85% %, the reduction rate of one pass is 42%, the rough rolling finish rolling temperature is 990°C; the finish rolling start rolling temperature is 916°C, the finish rolling temperature is 868°C, the coiling is 729°C, and the finish rolling reduction rates are respectively: 31% for the first pass, 29% for the second pass, 30% for the third pass, 71% for the fourth pass, and 17% for the fifth pass; normalization is not used; the cold rolling reduction rate is 87.5% (finished product Strip thickness is 0.35mm); recrystallization annealing system: 1000°C×70 seconds, heating rate is 28°C / s, slow cooling rate is controlled at ≤15°C / s (1000°C→600°C), fast cooling rate is controlled at 31°C / s. The annealing atmosphere adopts 30% H2+70% N2. The surface quality of the finished board...

Embodiment 3

[0065] Invention steel C contains C: 0.0030%, Si: 2.01%, Al: 1.02%, Mn: 0.302%, Sn: 0.1%, B: 0.001%, and the rest is iron and unavoidable impurities; the cumulative reduction rate of rough rolling is 83% %, the reduction rate of one pass is 42%, the rough rolling finish temperature is 1000°C; the finish rolling start temperature is 915°C, the finish rolling temperature is 872°C, the coiling is 725°C, and the finish rolling reduction rates are: 30% for the first pass, 30% for the second pass, 30% for the third pass, 70% for the fourth pass, 17% for the fifth pass; normalization system: 1000℃×120 seconds; cold rolling reduction rate 86.5% (the thickness of finished steel strip is 0.35mm); recrystallization annealing system: 1000°C×80 seconds, heating rate is 28°C / s, slow cooling rate is controlled at ≤15°C / s (1000°C→600°C), The rapid cooling rate is controlled at 30°C / s. The annealing atmosphere adopts 30% H2+70% N2. The surface quality of the finished board is good, the avera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com