Aluminum alloy plate for battery lid for use in molding of integral explosion-proof valve, and method for producing same

A technology of aluminum alloy plate and manufacturing method, which is applied in the direction of battery cover/end cover, battery, manufacturing tools, etc., can solve the problem of valve automatic fracture, etc., achieve small working pressure deviation, excellent repeated fatigue resistance, and excellent processing softening property Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0106]

[0107] 〔Preparation of test materials〕

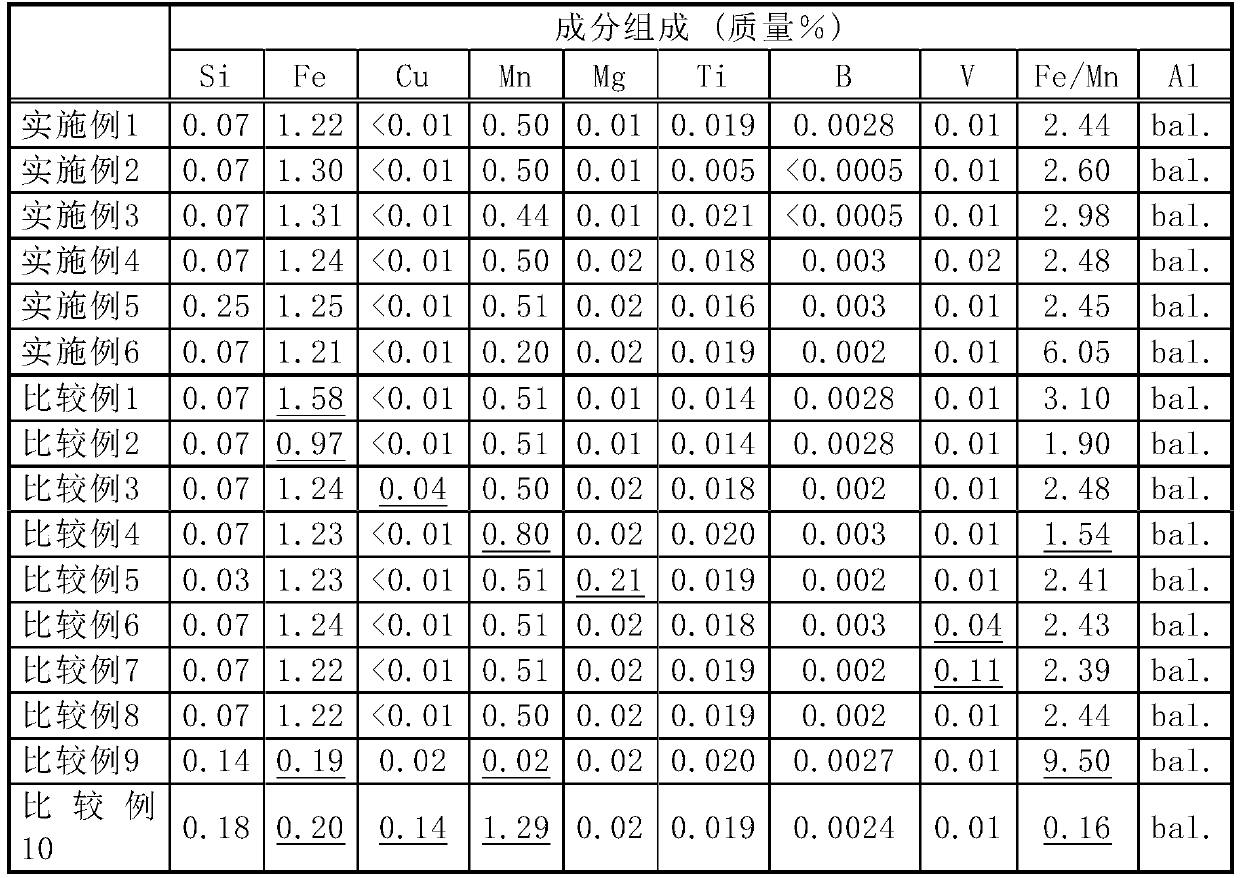

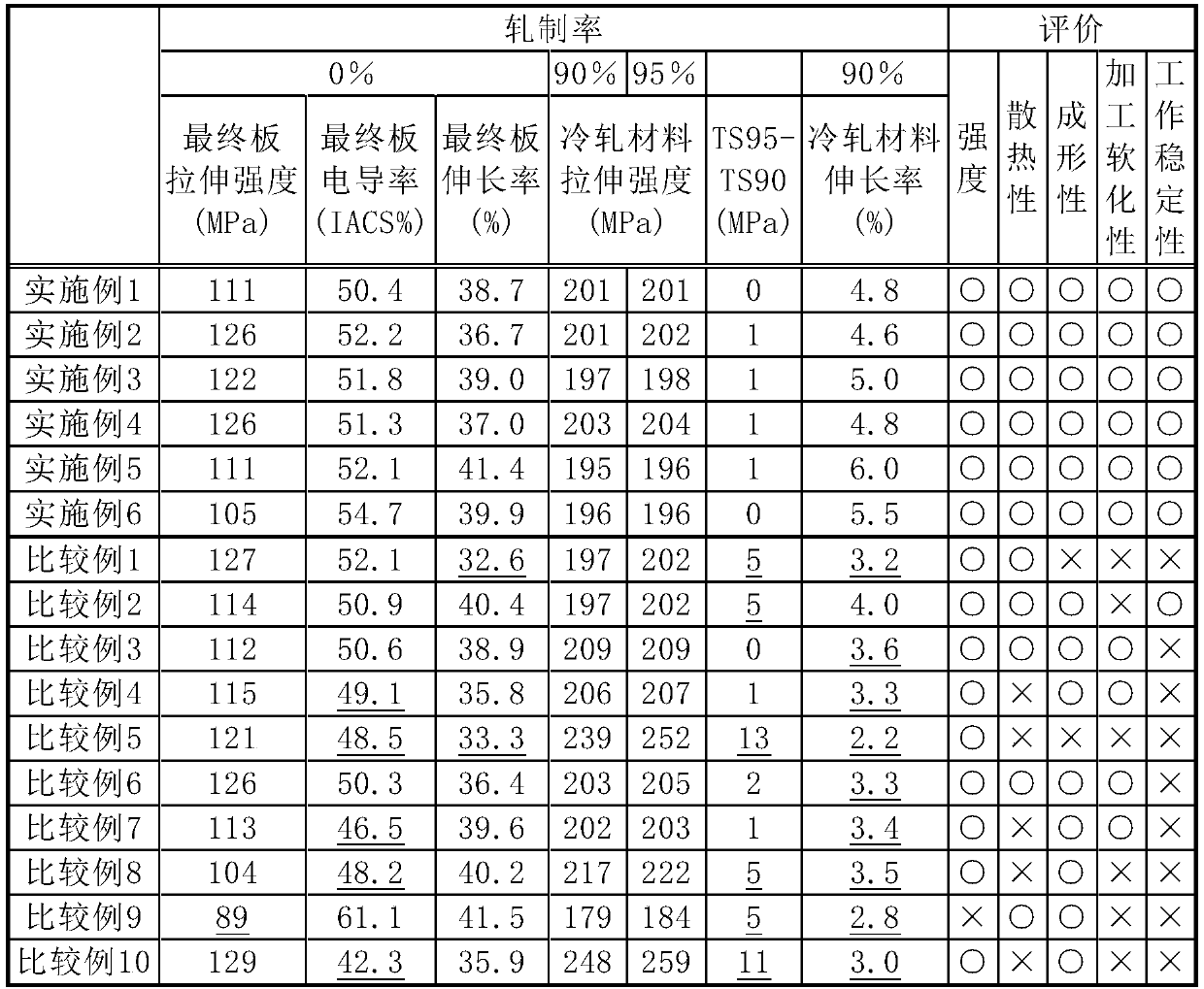

[0108] 5 kg of ingots with component compositions of 16 levels (Examples 1-6, Comparative Examples 1-10) were inserted into No. 20 crucibles, and the crucibles were heated in a small electric furnace to melt the ingots. Next, insert a spray gun into the melt, and feed N at a flow rate of 1.0 L / min. 2 The gas was degassed for 5 minutes. Thereafter, it was allowed to rest for 30 minutes, and dross floating to the surface of the melt was removed with a stirring rod. Then, the crucible was taken out from the small electric furnace, the melt was poured into a mold with an inner size of 250×200×30 mm to make an ingot, and the melts of Examples 1 to 6 and Comparative Examples 1 to 10 were obtained from the melt in each crucible. Each test material. The disc samples of these test materials were analyzed for composition by emission spectroscopic analysis. The results are shown in Table 1.

[0109] [Table 1]

[0110] [Composition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com