Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1890 results about "Test material" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Materials testing is a diligent approach to ensuring that your infrastructure and vital equipment will provide continued production, undergo minimal degradation and are designed with optimal performance in mind. Materials testing can also supply a wealth of information about the materials you are developing or incorporating...

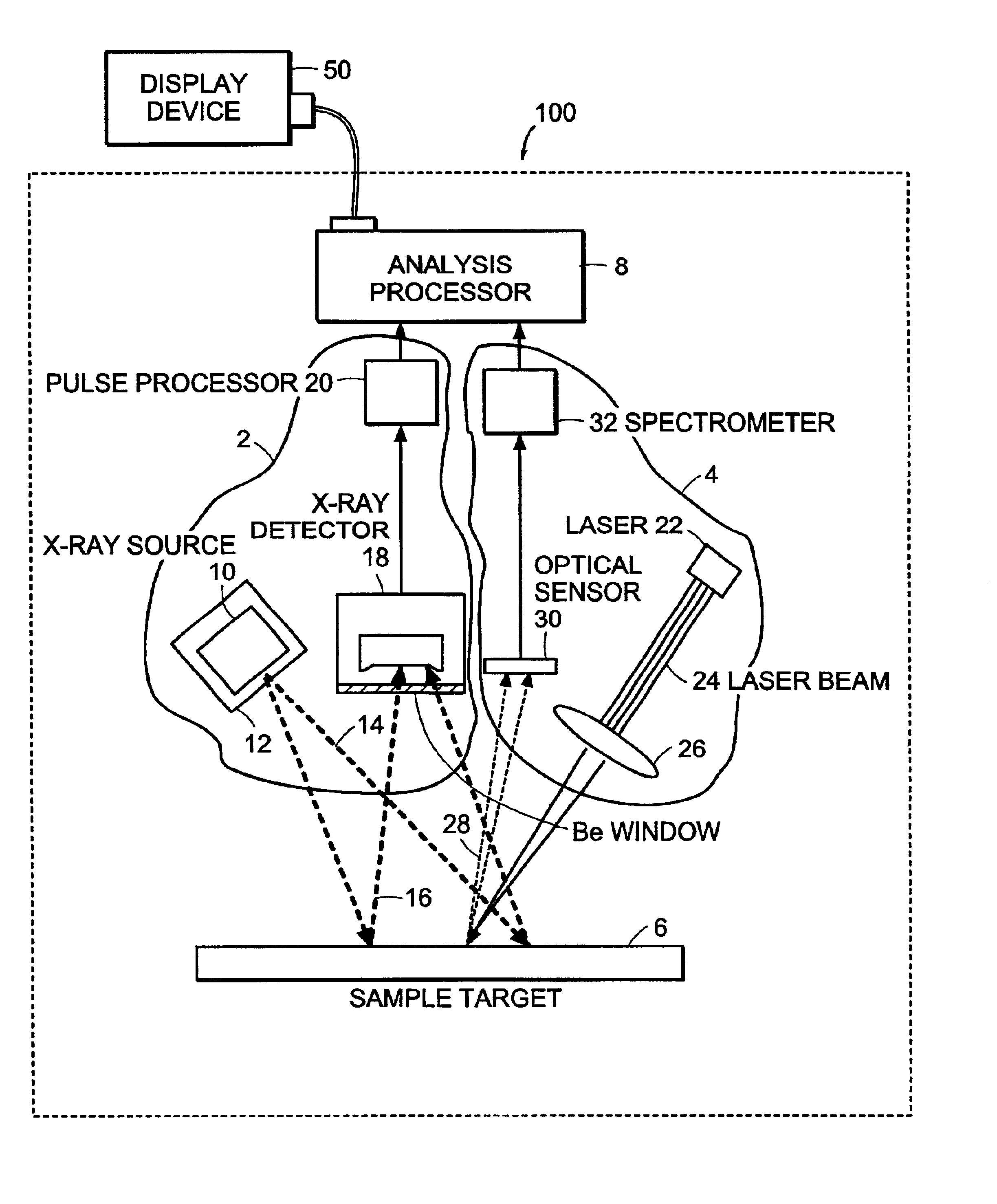

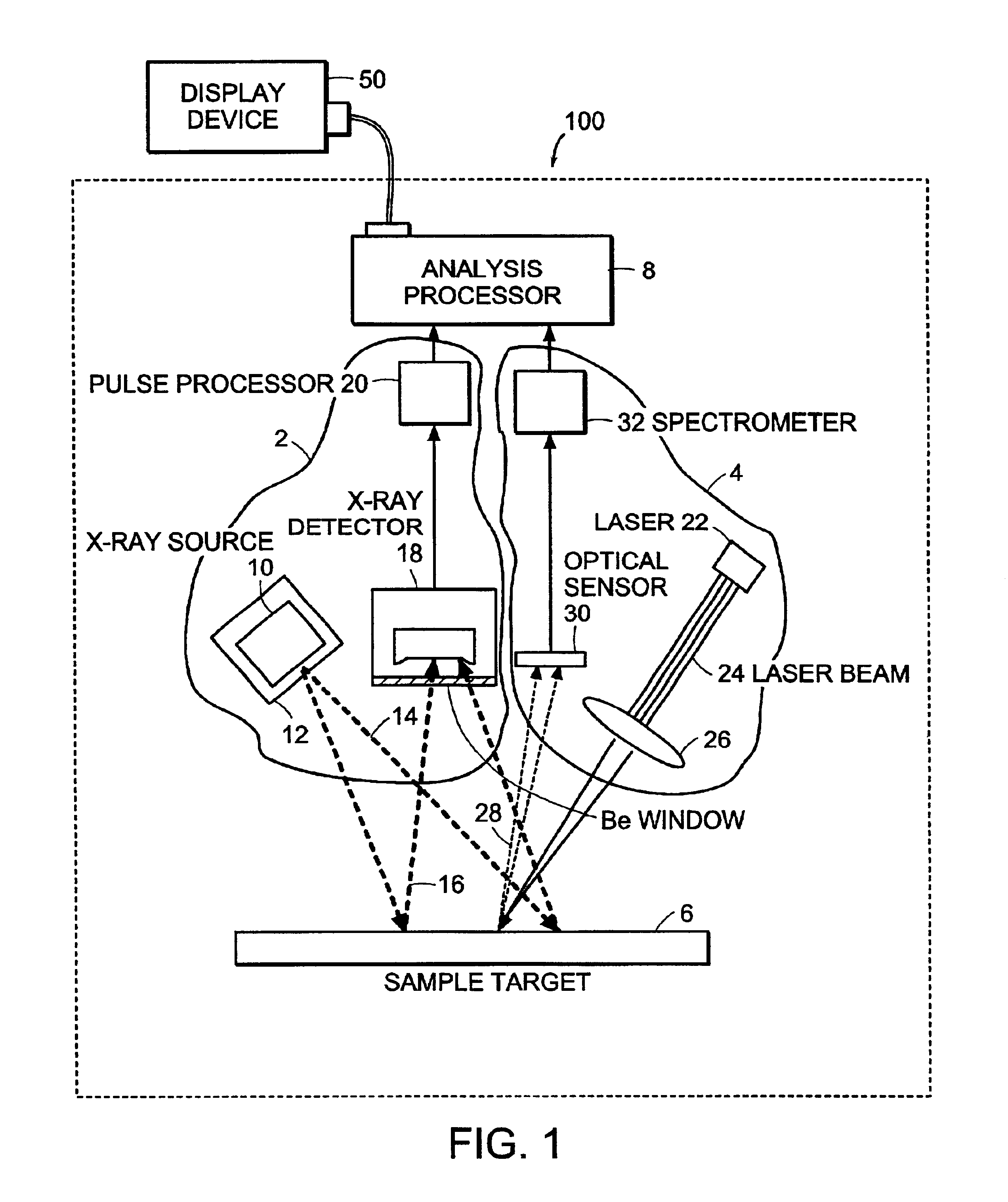

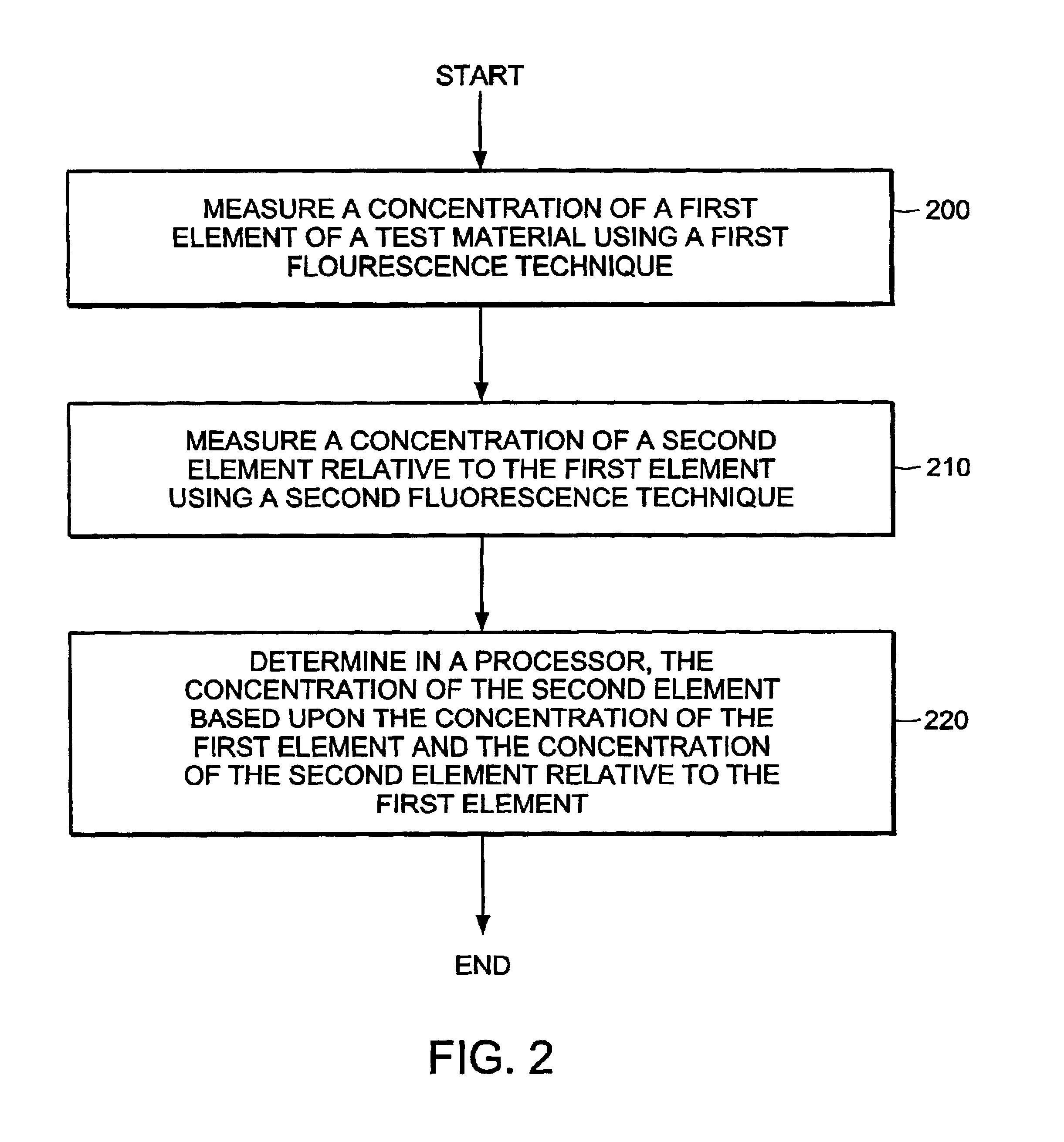

X-ray fluorescence combined with laser induced photon spectroscopy

A device and method for identifying the composition of a target sample. The target sample may be a matrix such as a metal alloy, a soil sample, or a work of art. The device includes an x-ray fluorescence detector that produces an x-ray signal output in response to the target sample. The device also includes an optical spectroscope that produces an optical signal output in response to the target sample. Further, a processor is included that analyzes and combines the x-ray signal output and the optical signal output to determine the composition of the test material. In one embodiment, the optical spectroscope is a laser induced photon fluorescence detector.

Owner:THERMO NITON ANALYZERS

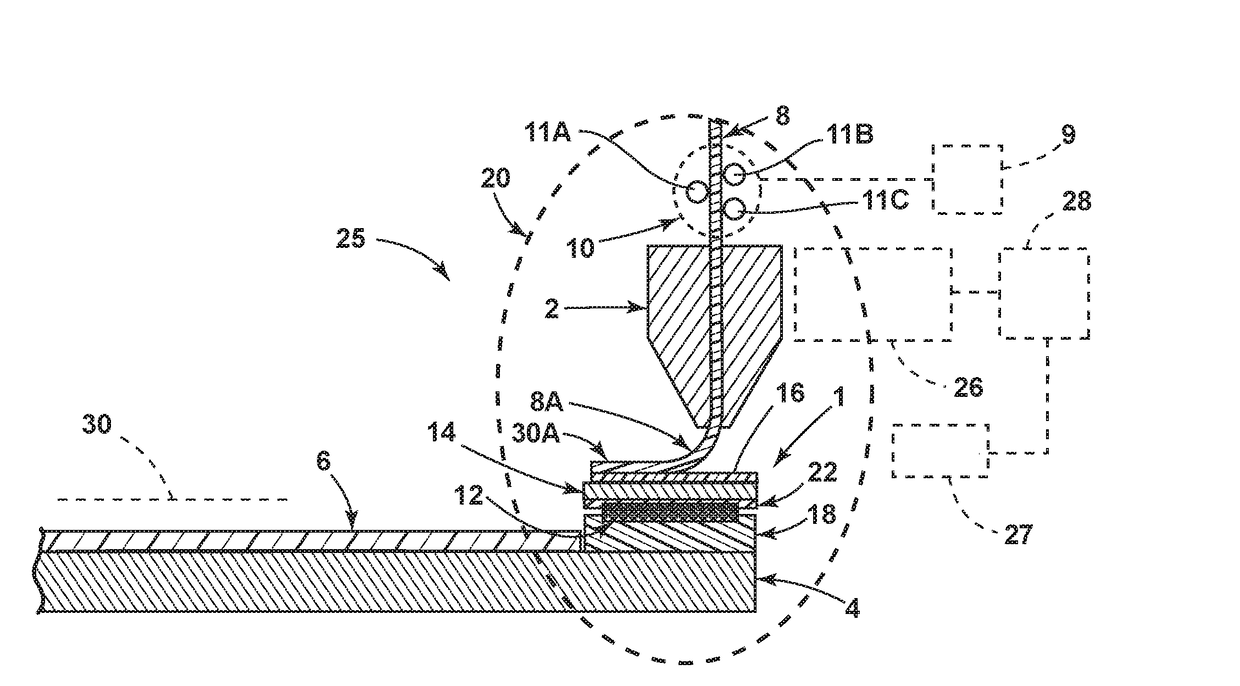

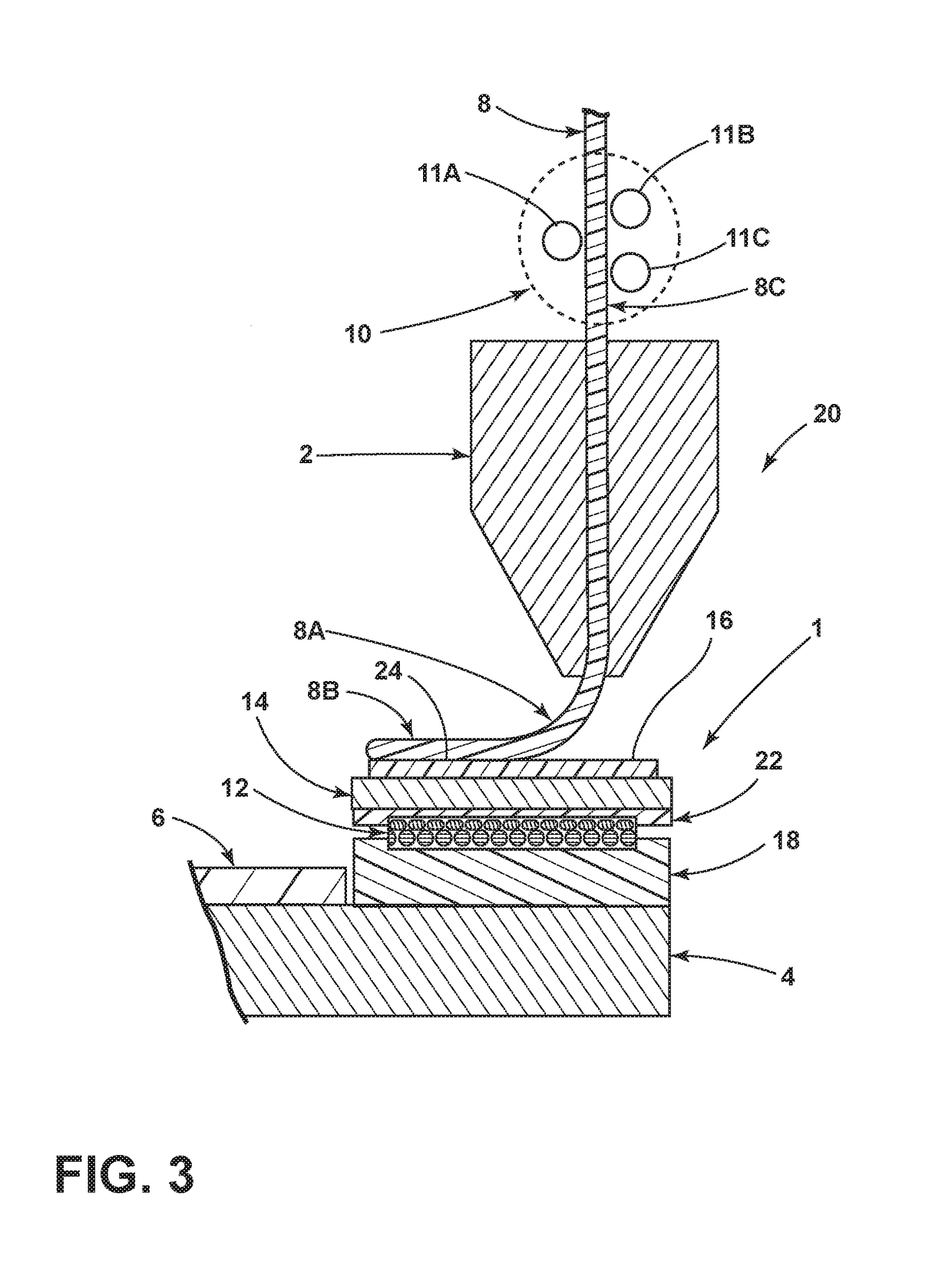

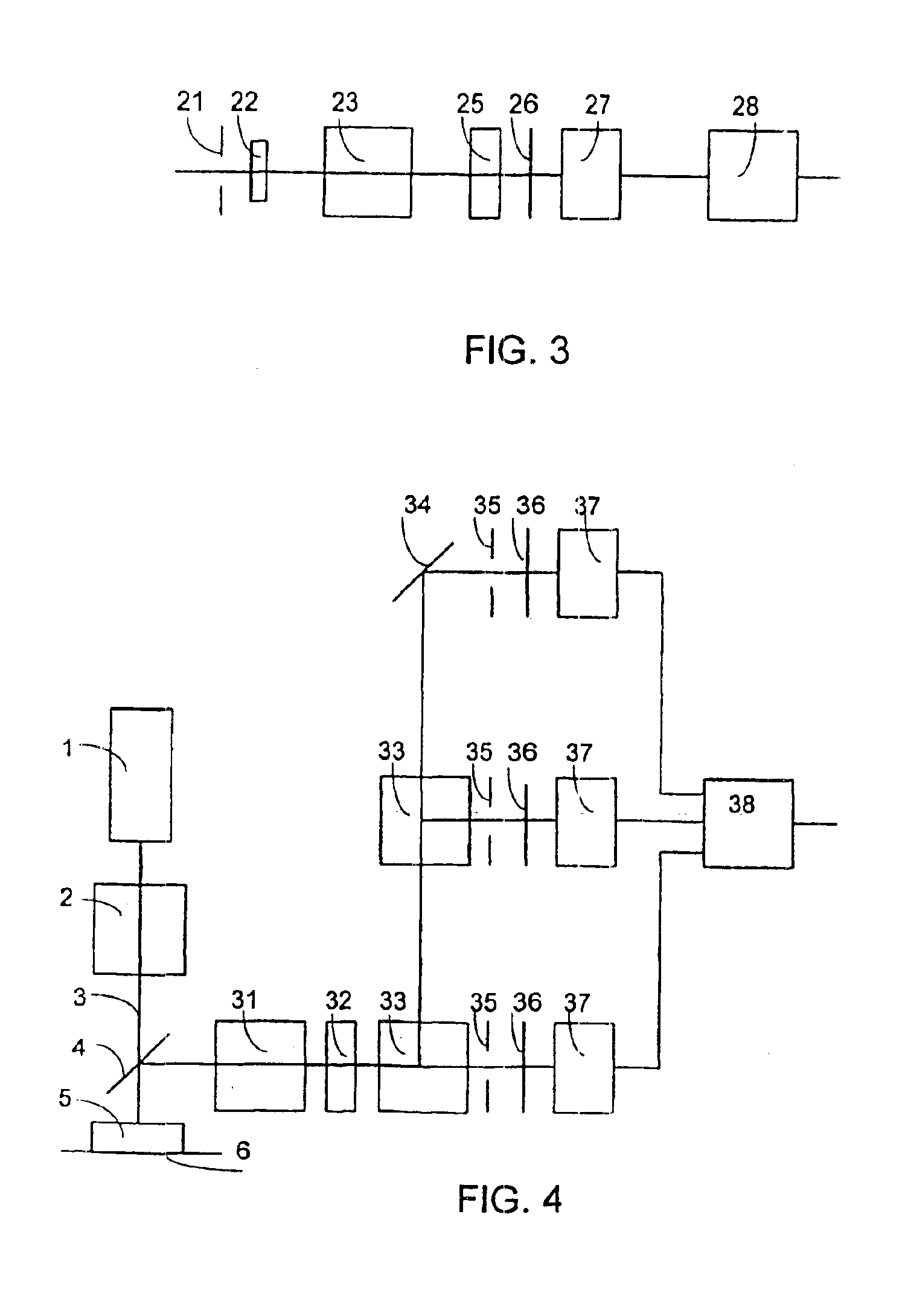

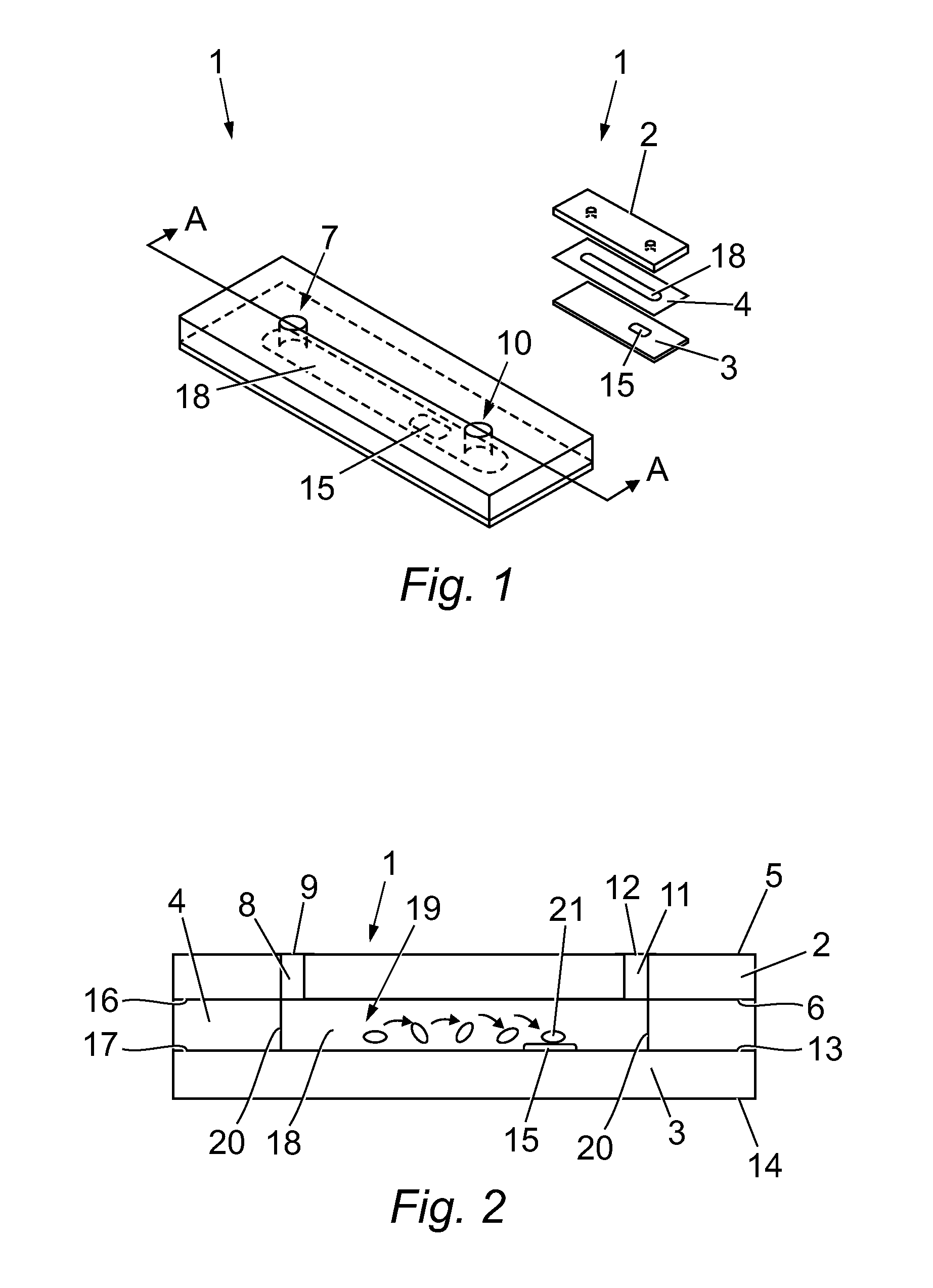

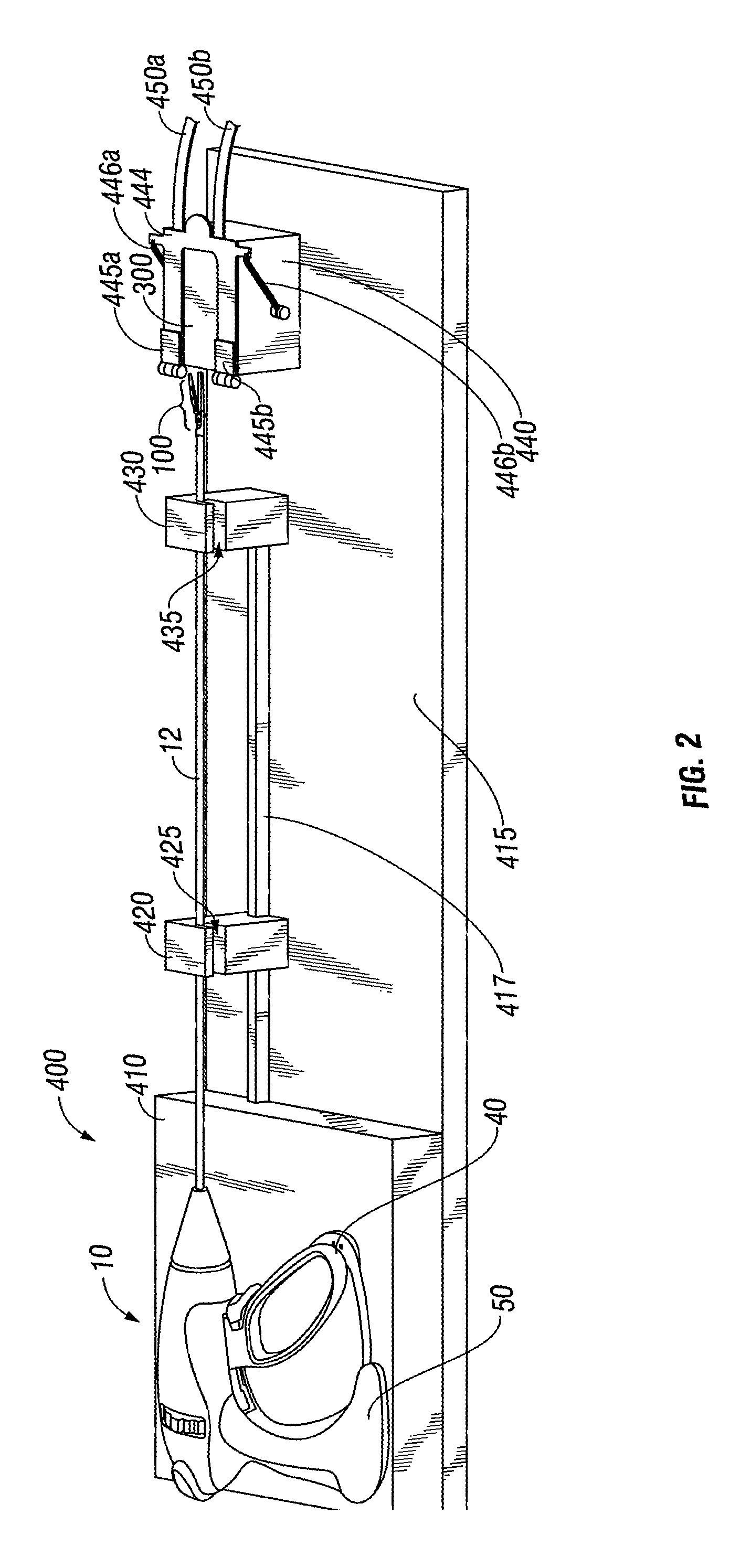

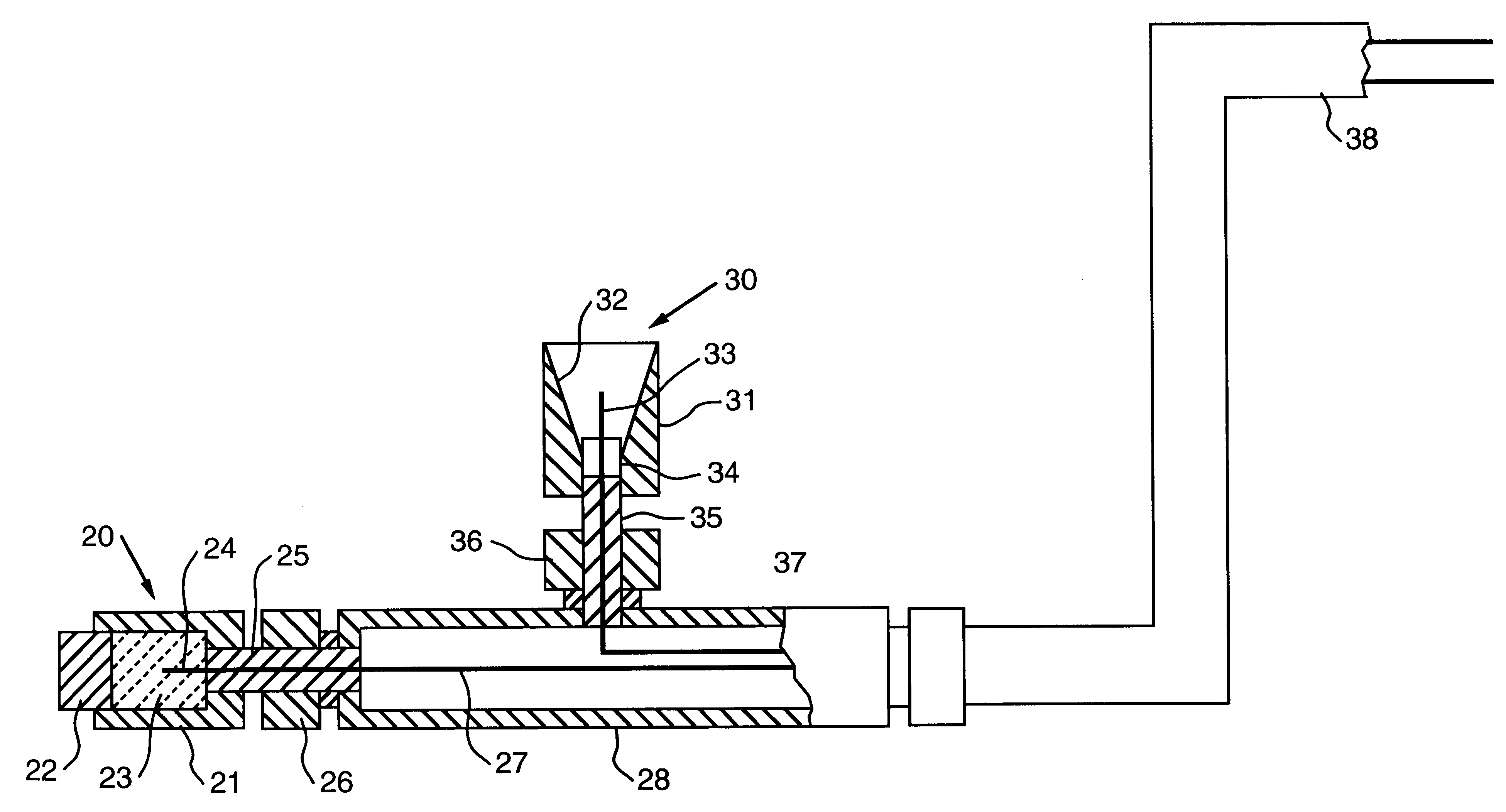

Adhesion test station in an extrusion apparatus and methods for using the same

ActiveUS20170129186A1Small and accurate loadEasy to adjustManufacturing platforms/substratesAdditive manufacturing with liquidsEngineeringTest material

A method of controlling an additive fabrication process includes providing a primary substrate and a test substrate. Polymer test material is extruded onto the test substrate utilizing an extrusion head. The extrusion head is moved relative to the test substrate, and a force required to move the extrusion head relative to the test substrate is measured to thereby generate test data. A part is fabricated by extruding polymer material onto the primary substrate utilizing the extrusion head. The test data is utilized to control at least one process parameter associated with extruding polymer material onto the primary substrate.

Owner:NASA

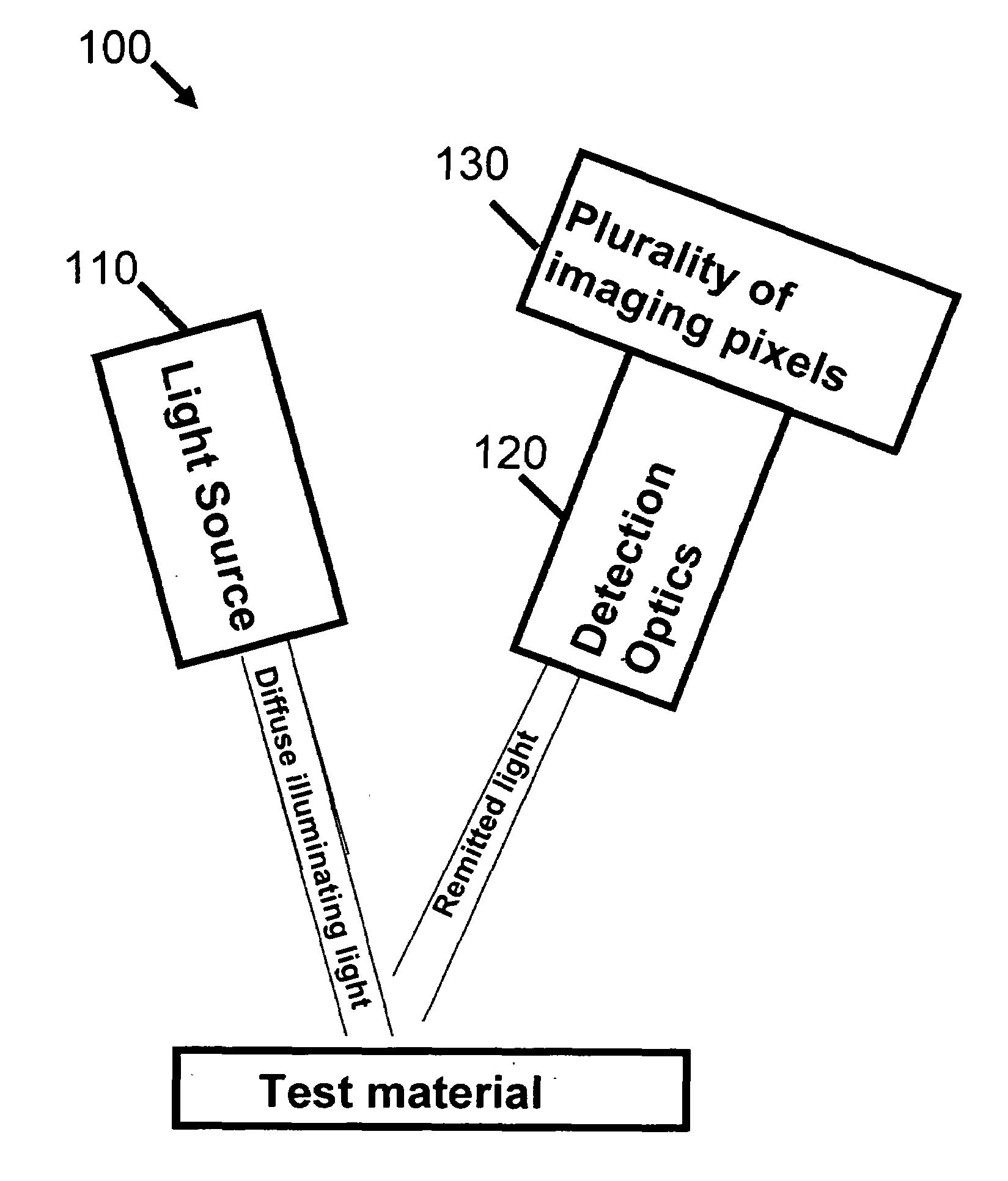

System and method for imaging sub-surface polarization-sensitive material structures

InactiveUS7289211B1Light intensityConvenient lightingPolarisation-affecting propertiesDiagnostic recording/measuringAngle of incidenceMedical imaging

A method of visually quantifying a test material along with an imaging apparatus for practicing the method is disclosed. The method comprises: (a) illuminating the test material at a known angle of incidence with diffuse light of a known and adjustable polarization state; (b) receiving light from the test material with a polarization state modified by the test material; (c) measuring an intensity of the polarization components of the received light for each illuminated pixel substantially simultaneously; (d) calculating the Stokes Vector in two dimensions for each illuminated pixel; and (e) creating an image map for the known polarization state. The method may also include adjusting the known polarization or the incident angle of the diffuse light to create additional image maps. The method and apparatus are intended for use in medical imaging including minimally invasive surgery.

Owner:WALSH JR JOSEPH T +1

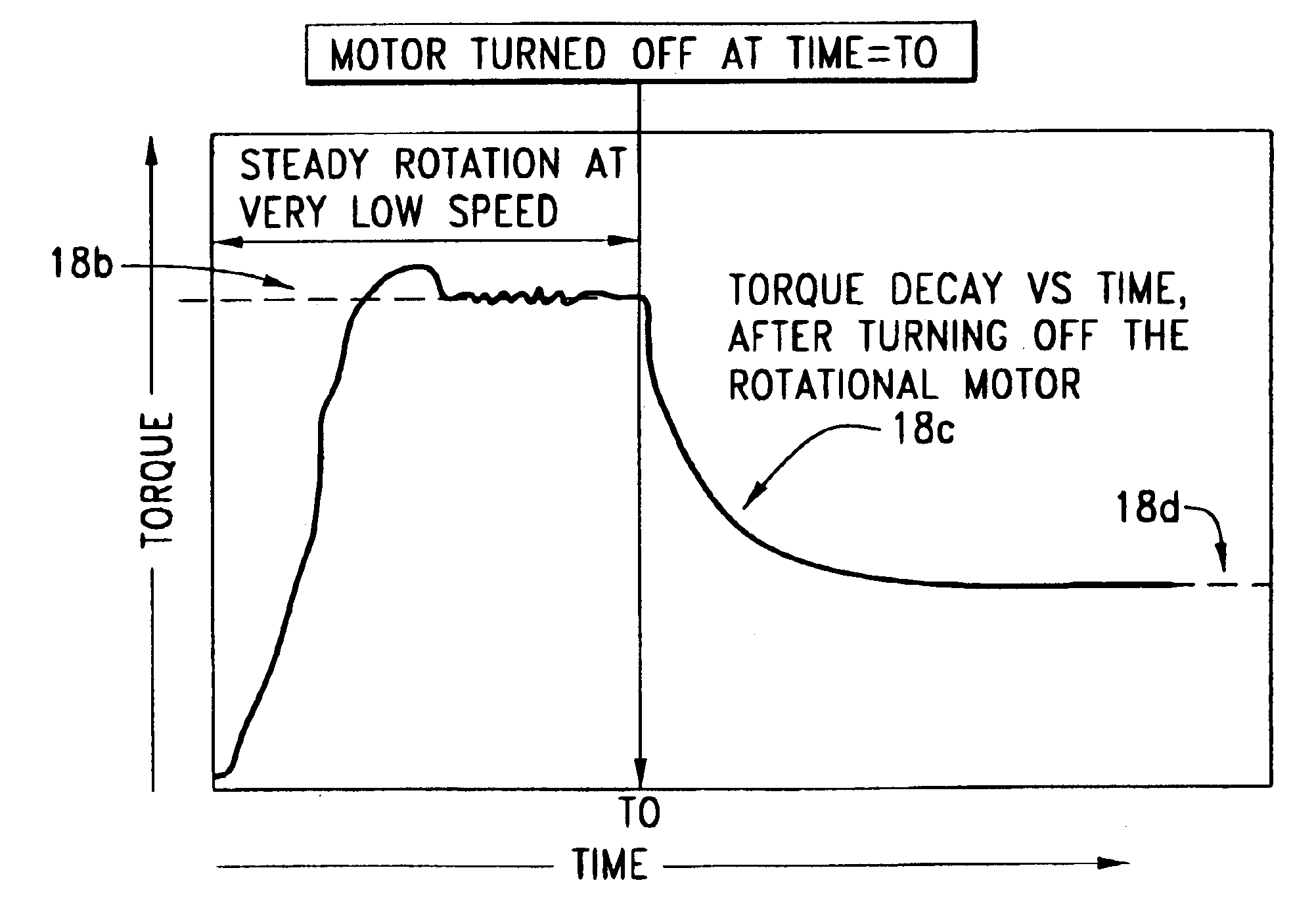

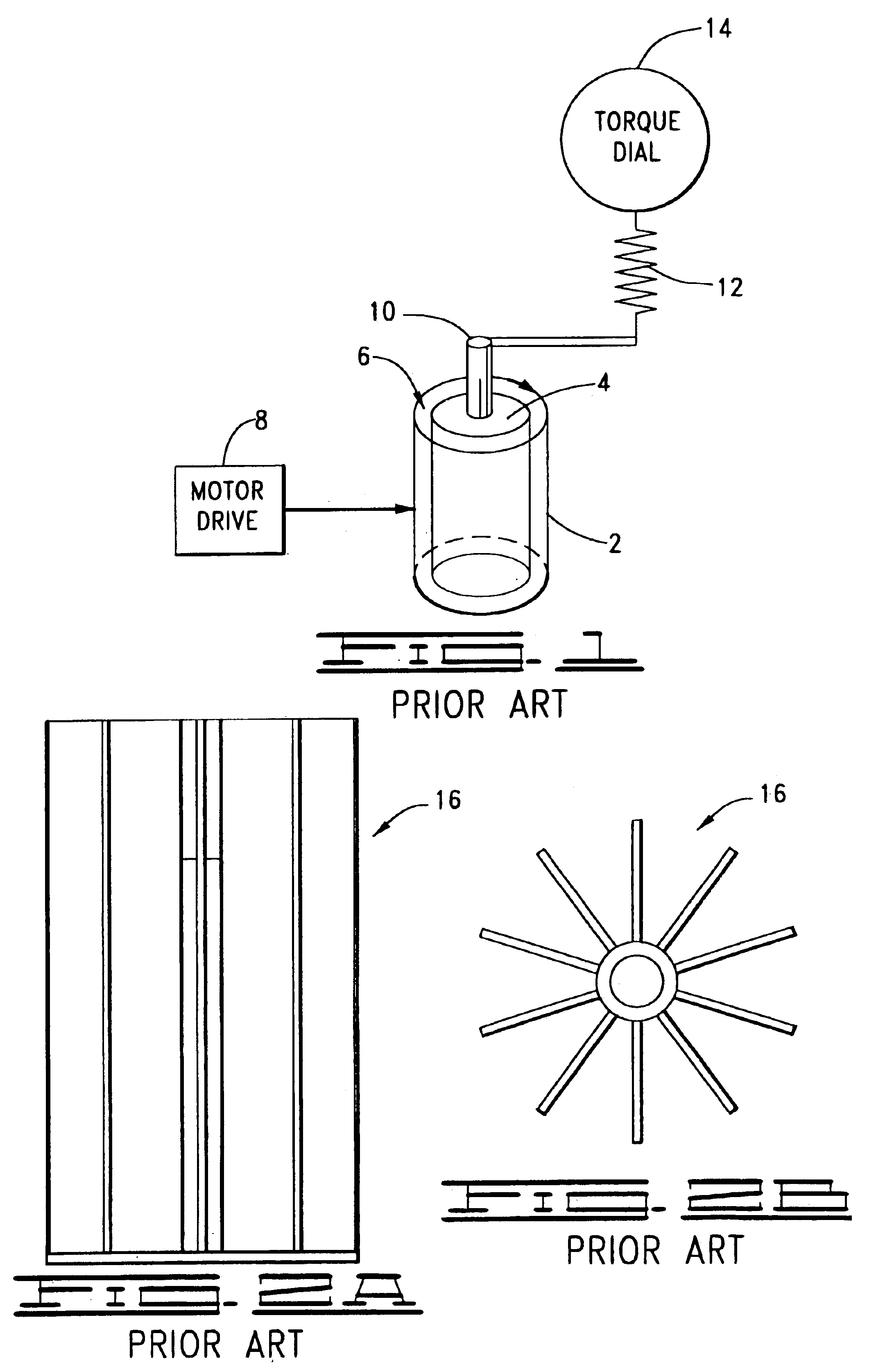

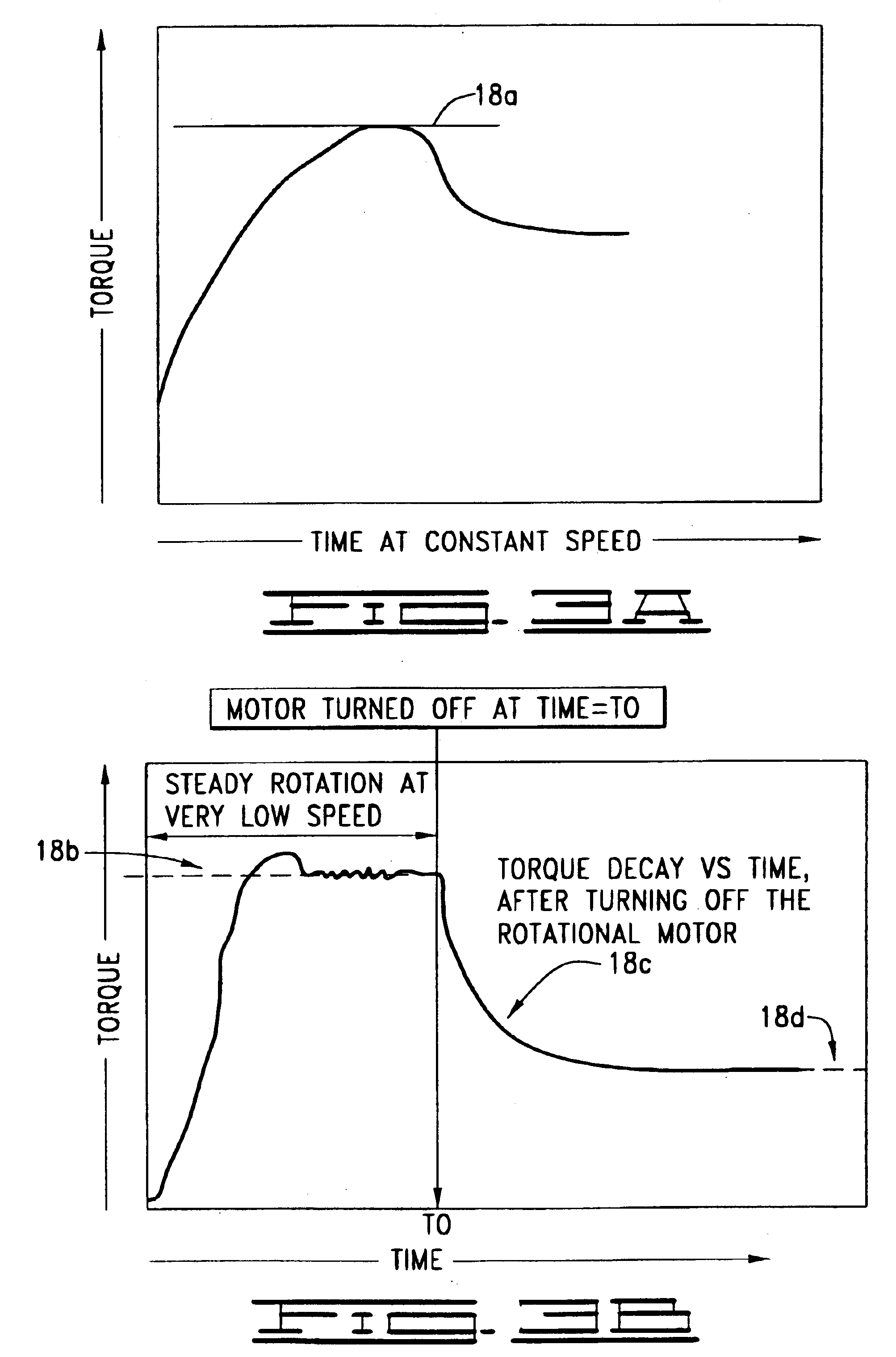

Yield point adaptation for rotating viscometers

InactiveUS6874353B2Readily and accurately measure yield stressCost effectiveFlow propertiesParticulatesEngineering

A conventional Couette viscometer is transformed to measure yield point, also known as yield stress, and other rheology of various fluids, including ones with particulates. A rotating viscometer includes a driven portion, a responsive body, a standard spring, and a plurality of fins. The fins have predetermined shapes such that the rotating viscometer and the standard spring, connected to the responsive body having at least a portion of the fins, are sensitive to detect yield stress of a test fluid composition in response to a selected rotation imparted to the driven portion. A method of measuring yield stress includes operating a standard rotating viscometer modified with a plurality of intermeshing fins such that a standard spring of the standard rotating viscometer responds to a torque that is related to yield stress and that is imposed by a stressed test material on a portion of the fins connected to the spring.

Owner:HALLIBURTON ENERGY SERVICES INC

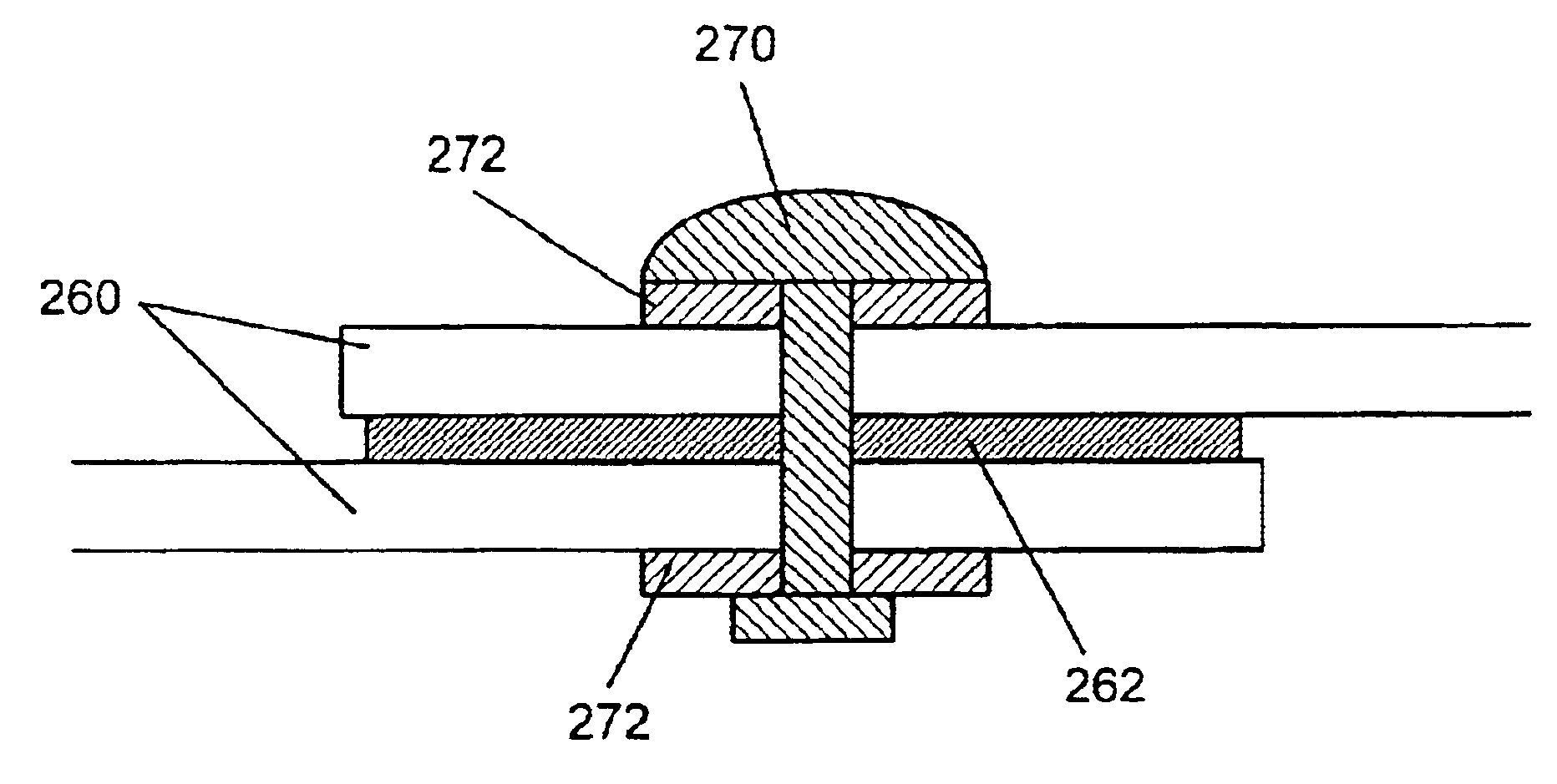

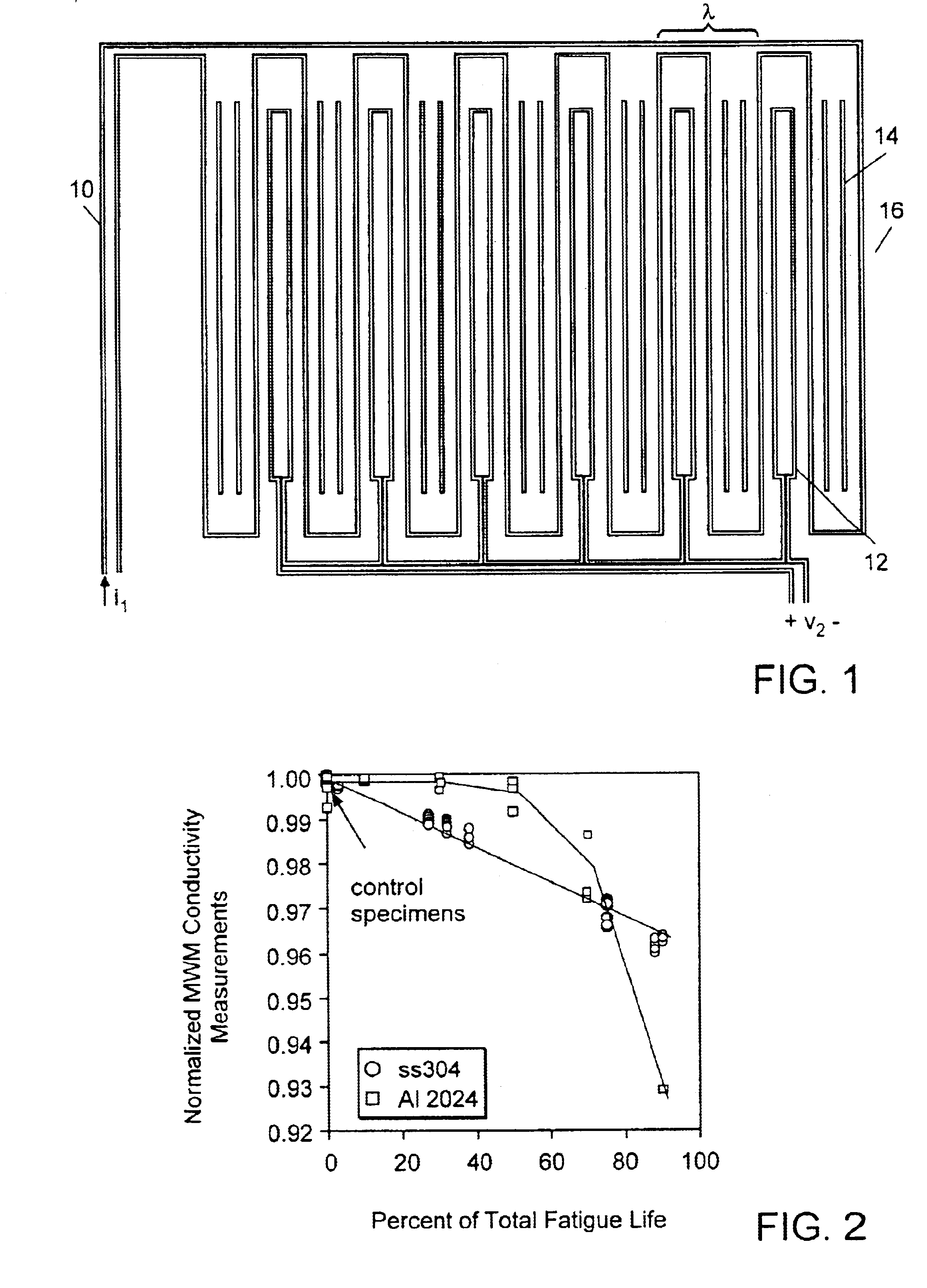

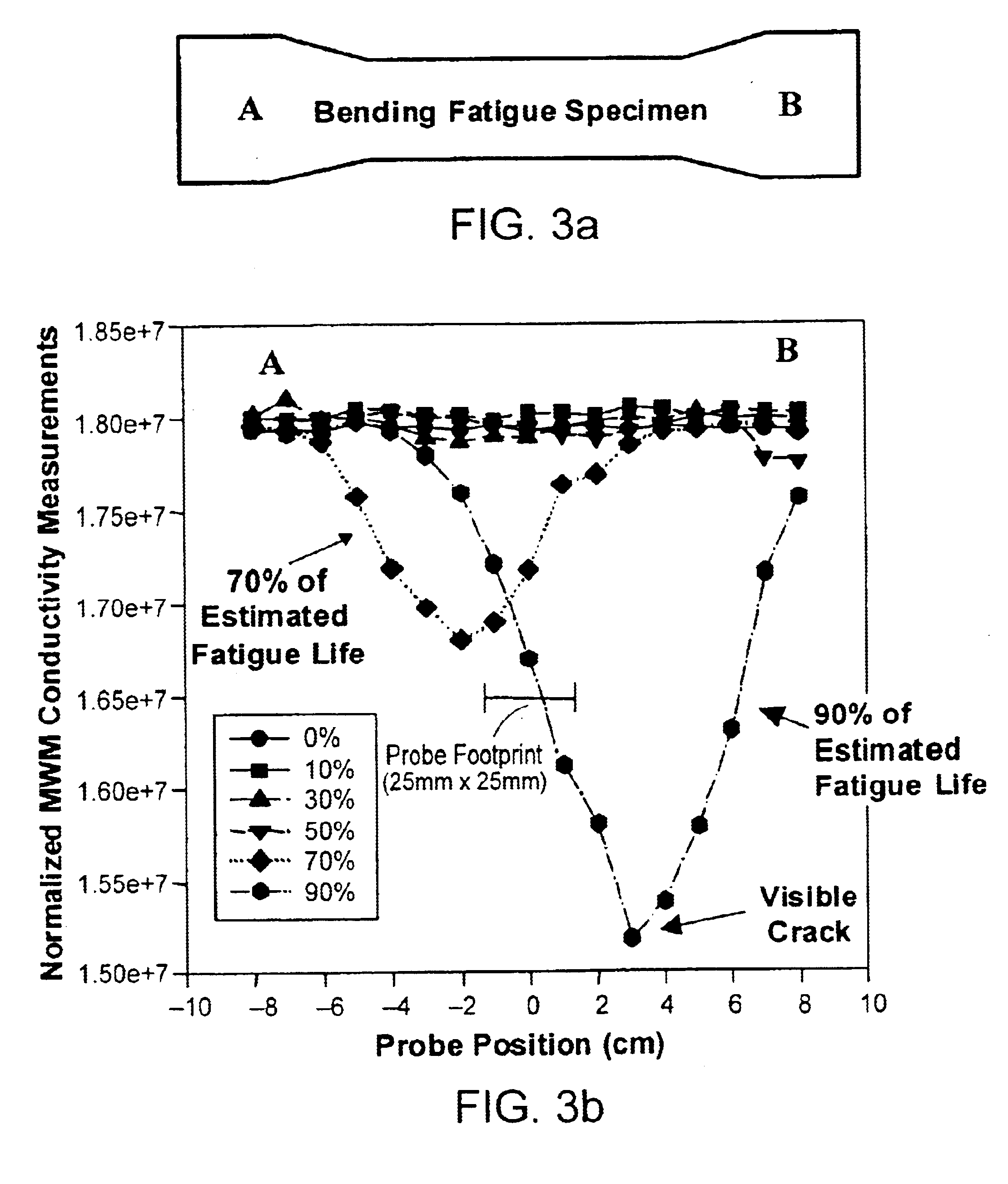

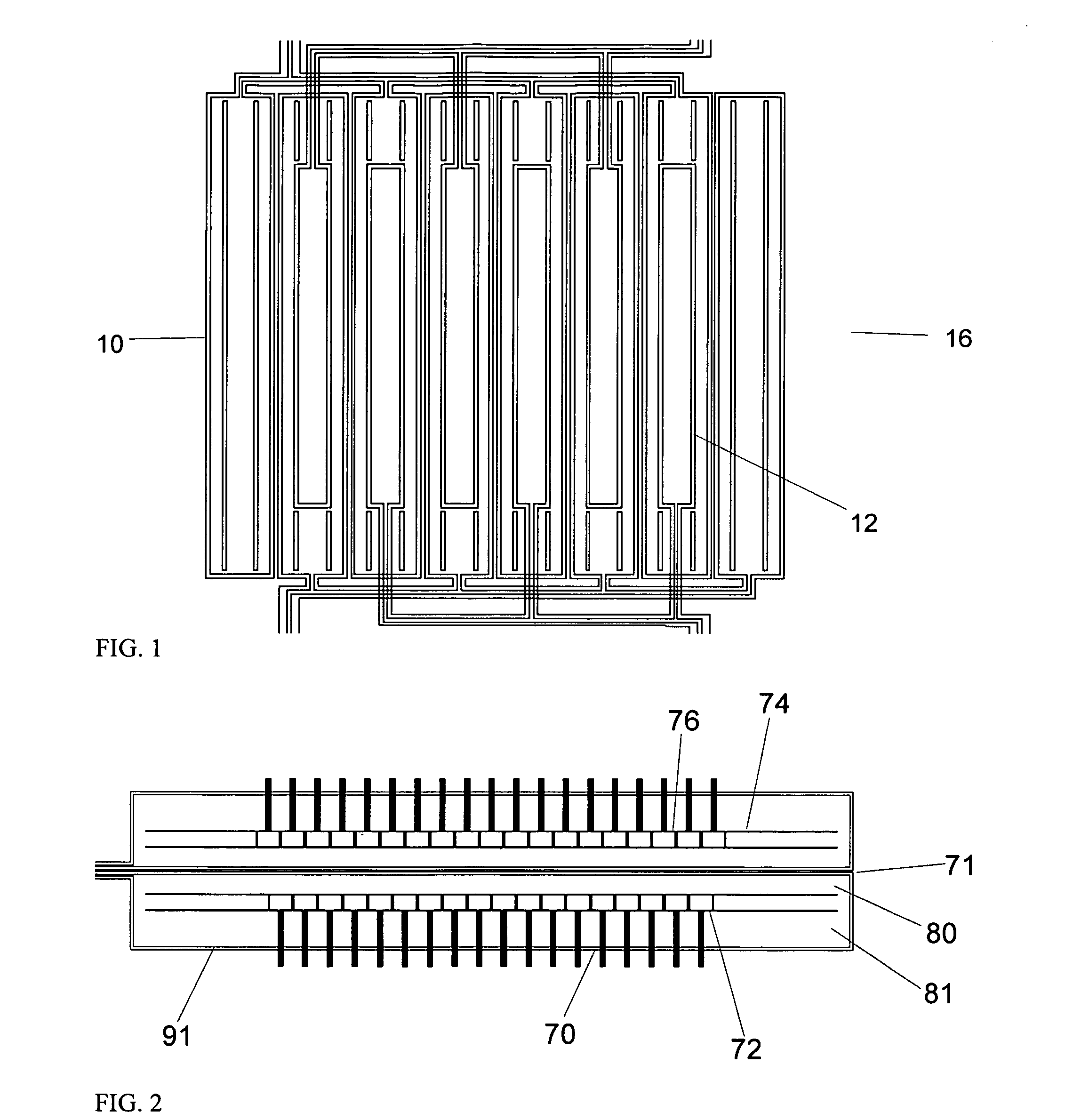

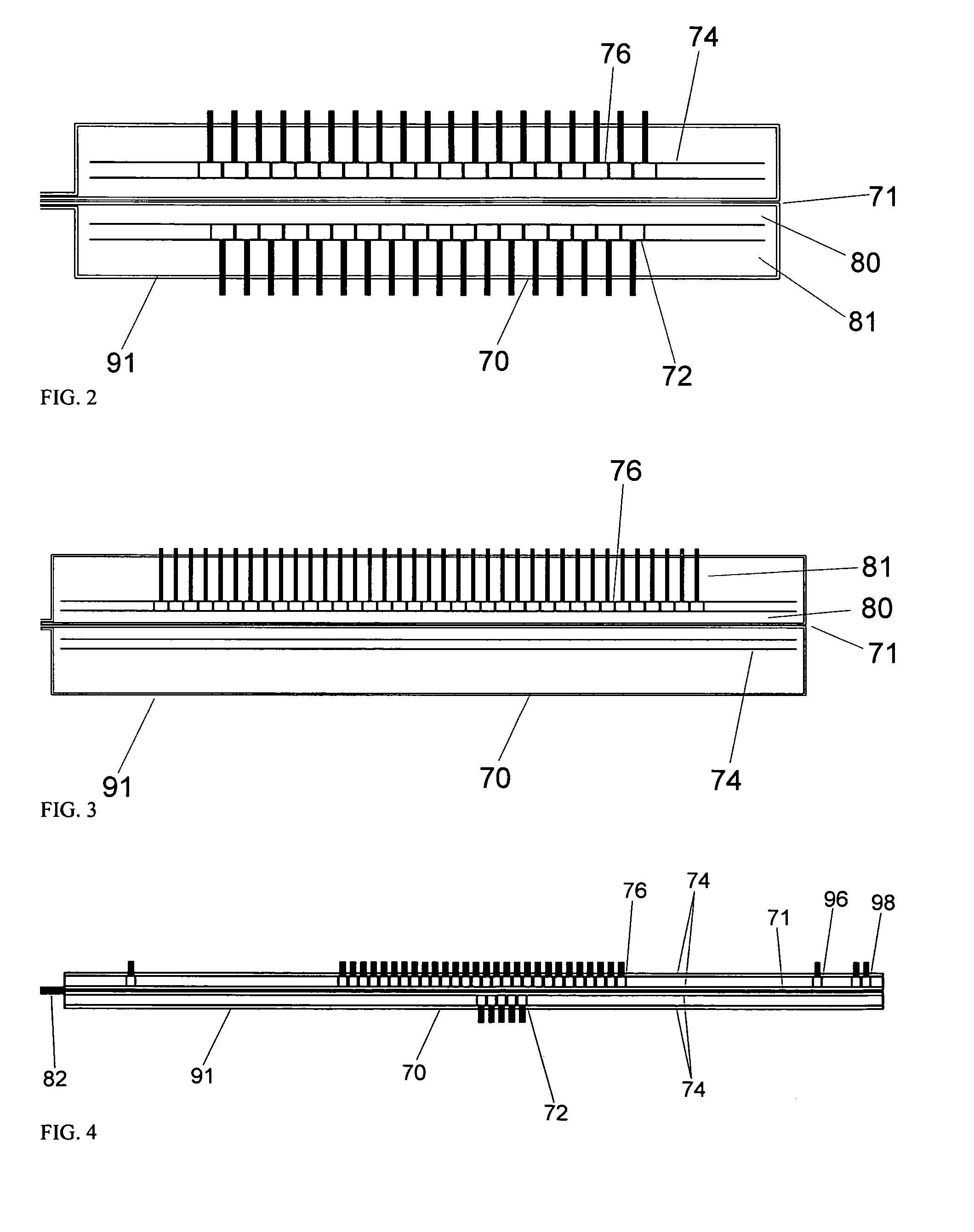

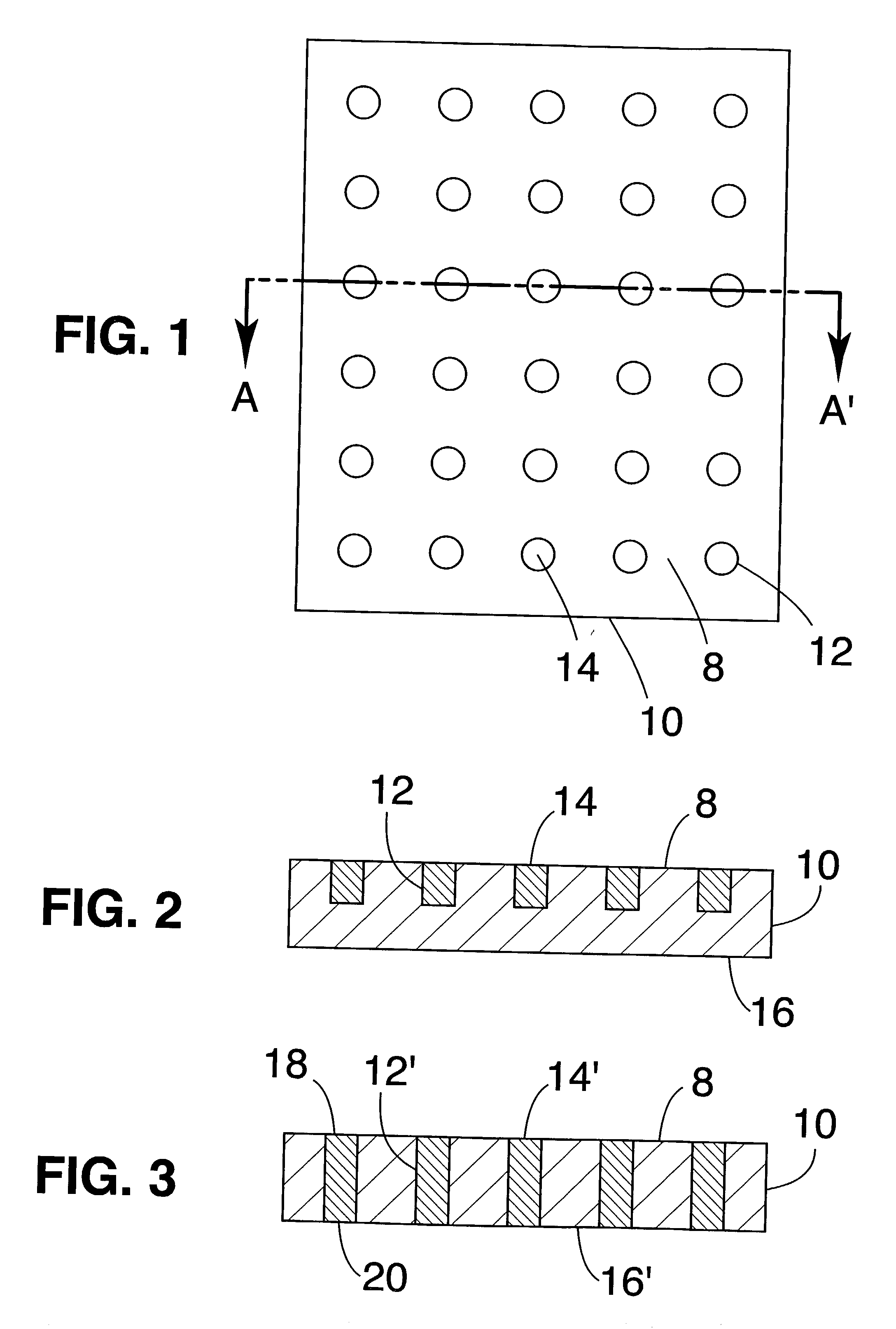

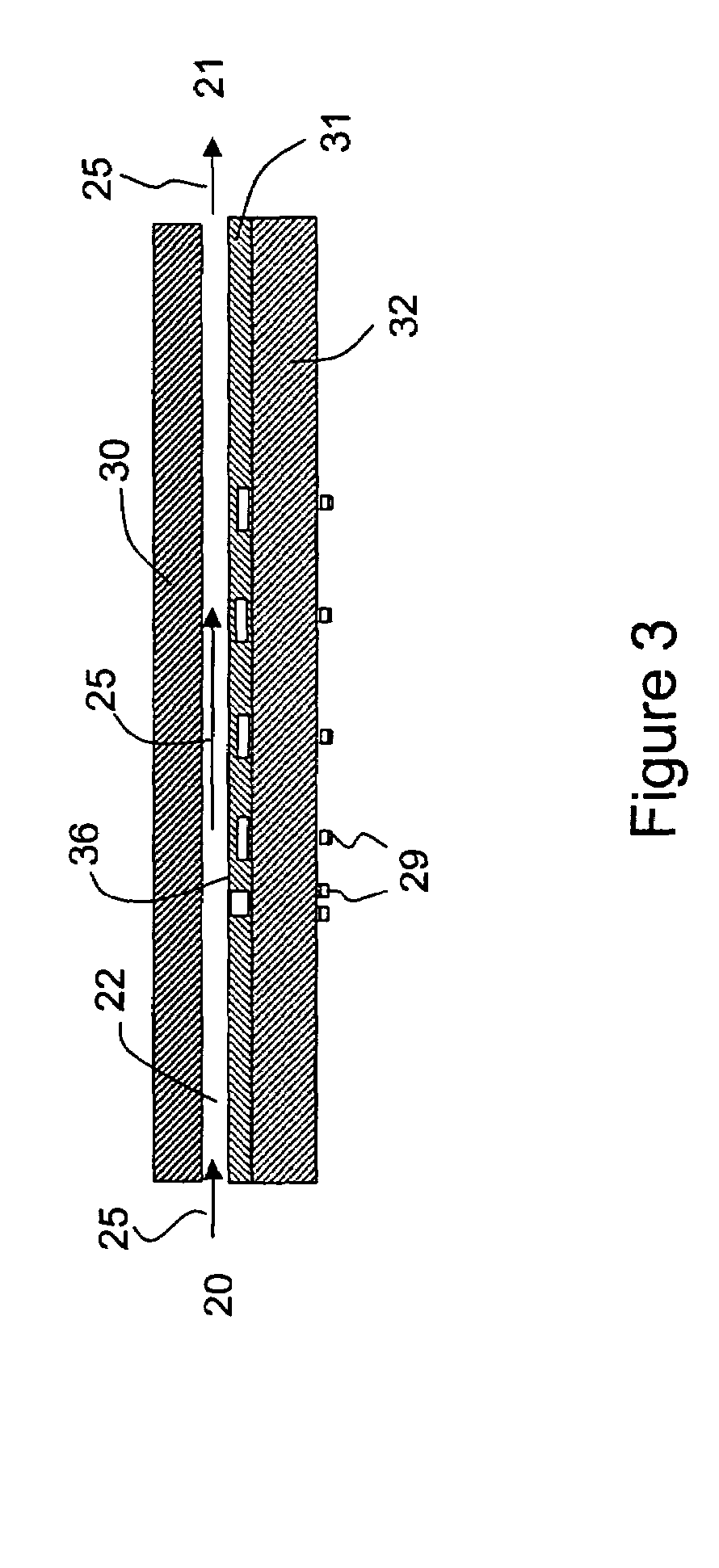

Surface mounted and scanning spatially periodic eddy-current sensor arrays

InactiveUS6952095B1Promote accurate modelingIncreased depth of sensitivityMagnetic property measurementsElectric/magnetic roughness/irregularity measurementsSurface mountingCurrent sensor

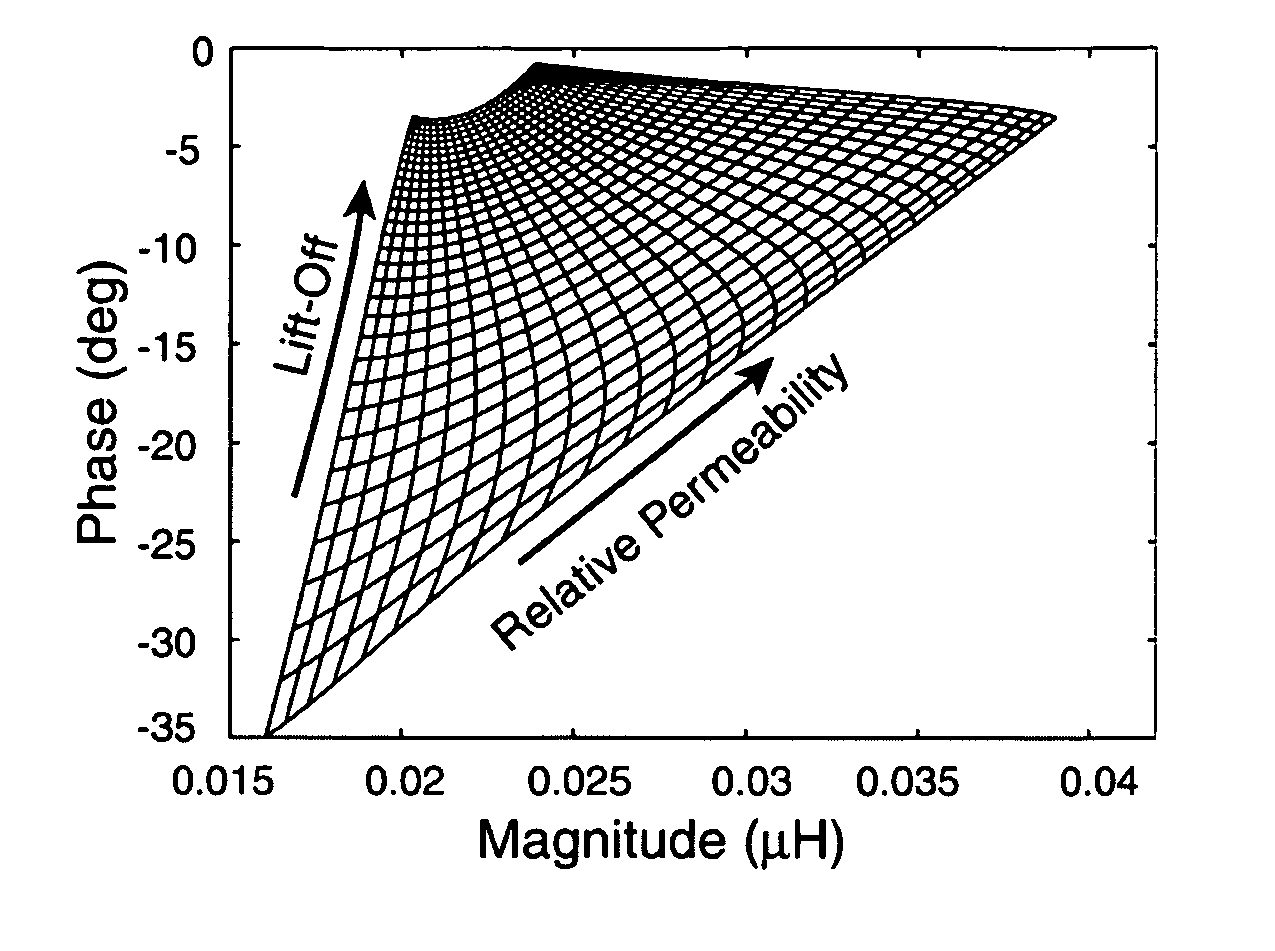

Inductive sensors measure the near surface properties of conducting and magnetic material. A sensor may have primary windings with parallel extended winding segments to impose a spatially periodic magnetic field in a test material. Those extended portions may be formed by adjacent portions of individual drive coils. Sensing elements provided every other half wavelength may be connected together in series while the sensing elements in adjacent half wavelengths are spatially offset. Certain sensors include circular segments which create a circularly symmetric magnetic field that is periodic in the radial direction. Such sensors are particularly adapted to surround fasteners to detect cracks and can be mounted beneath a fastener head. In another sensor, sensing windings are offset along the length of parallel winding segments to provide material measurements over different locations when the circuit is scanned over the test material. The distance from the sensing elements to the ends of the primary winding may be kept constant as the offset space in between sensing elements is varied. An image of the material properties can be provided as the sensor is scanned across the material.

Owner:JENTEK SENSORS

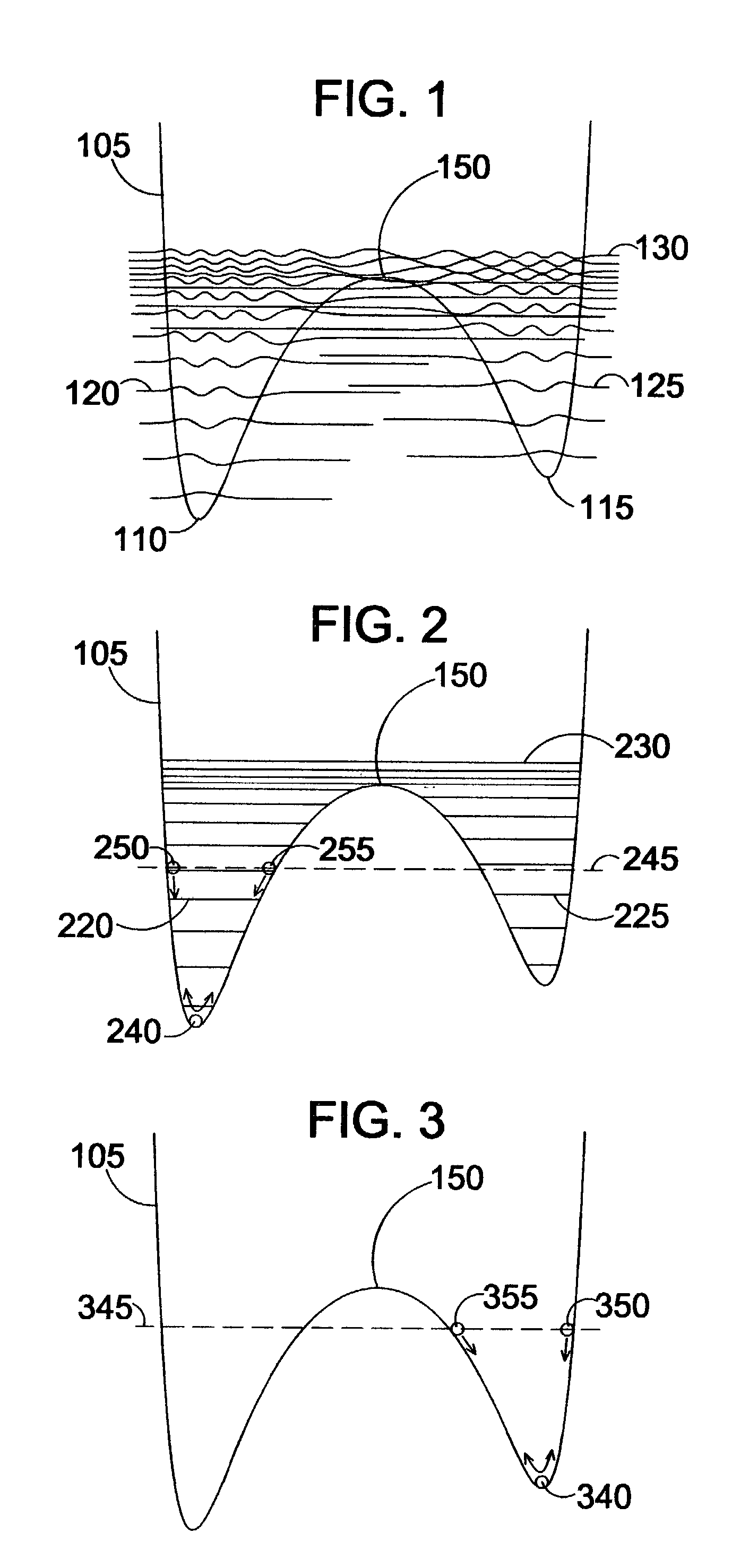

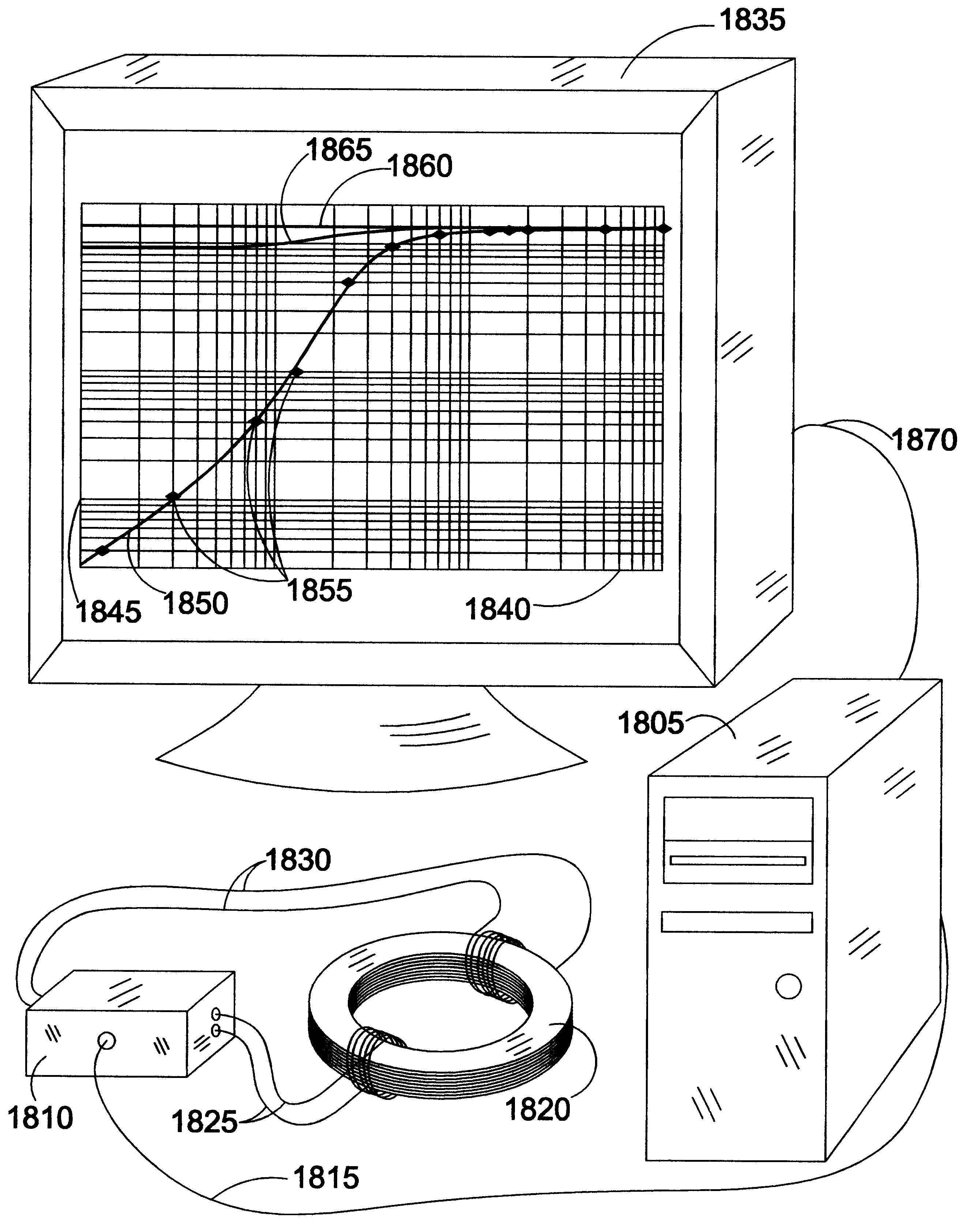

System and method for quantifying material properties

InactiveUS20020157478A1Simple processOptimize economyForce measurementMeasurement arrangements for variableElement analysisComputational model

A materials characterization method models dynamic, non-linear, temperature-dependent stress, strain, hysteresis, creep, and loss of elasticity at high strain, both in test samples and in Finite Element Analysis (FEA). Incorporating universal properties of statistical mechanics and adapting domain models from ferromagnetics to the higher-dimensional realm of stress tensors, the model is applicable to polymers, rubbers, liquids, and metals in elastic and plastic deformation. The model quantifies the dynamics of both plastic and brittle failure. Apparatus and methods are shown for testing material samples and matching the computational model to sample characteristics, leading to a set of characterizing parameters and predictive simulations using those parameters. Though apparatus and testing protocols of the invention yield optimum characterizations, pre-existing data from conventional testing yield useful results.

Owner:SEALE JOSEPH B

System and method for testing microwave complex permittivity of dielectric material

InactiveCN104407232ALower manufacturing requirementsShorten test timeResistance/reactance/impedenceElectricityResonant cavity

The invention provides a system and a method for testing microwave complex permittivity of a dielectric material. The system comprises a coaxial-open-type resonant cavity and a coupling quantity adjuster. The method includes the steps: a, recording resonant frequency f0 of the system without any sample loaded in a testing range and a quality factor Q0 of a corresponding frequency point; b, testing thickness d of a to-be-tested sample, and testing to acquire resonant frequency f1 of the system after the sample is loaded in the testing range and a Q1 of a corresponding loaded quality factor; c, utilizing a perturbation theory of the resonant cavity to extract complex permittivity of a to-be-tested material. By the system and the method, high-accuracy testing of the complex permittivity of the microwave dielectric material is realized, and troublesome precise calibration does not need to be performed on a network analyzer, so that testing time is reduced, and requirements, on sample manufacturing, of testing are lowered.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

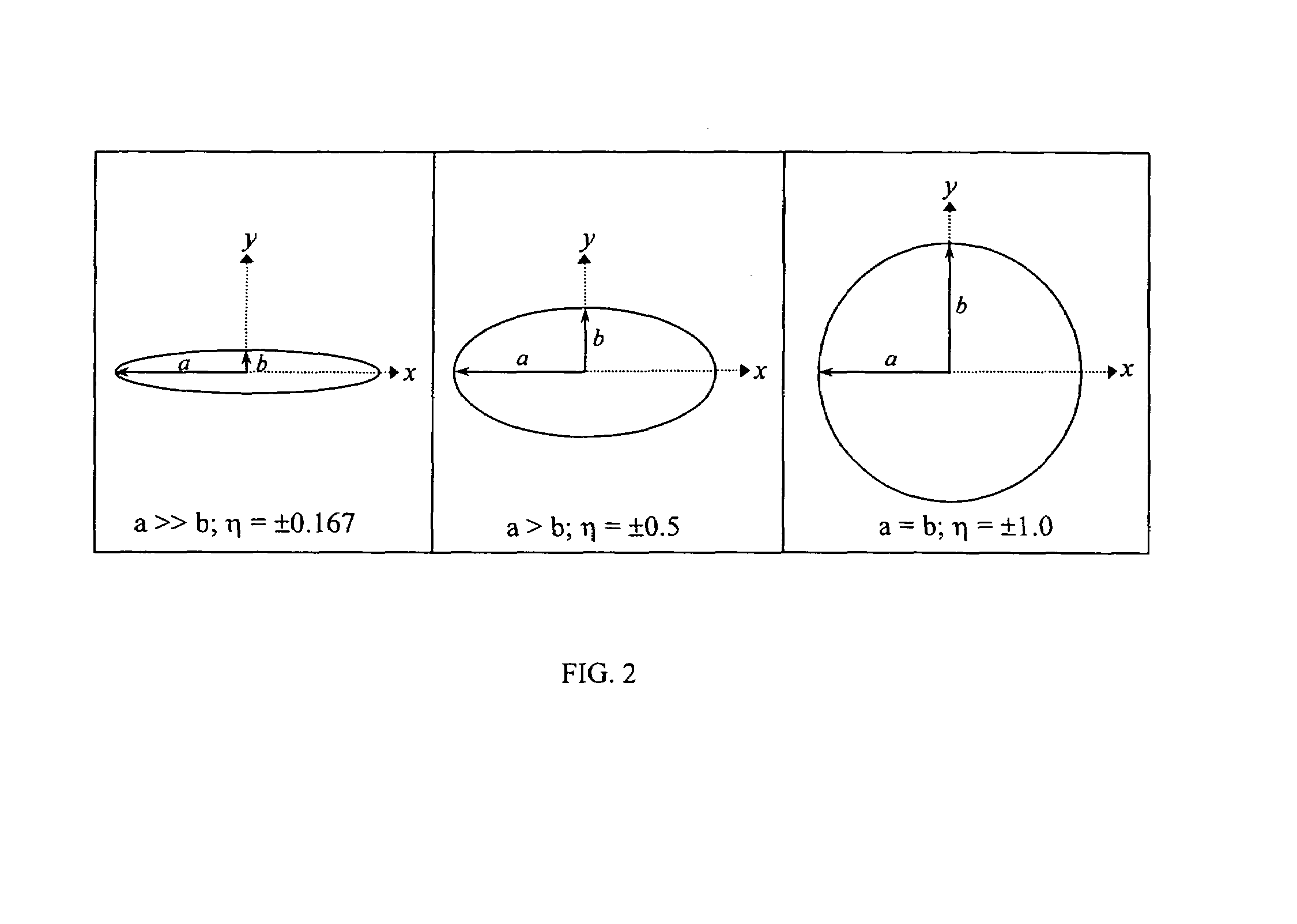

Method and apparatus for determining the polarization properties of light emitted, reflected or transmitted by a material using a laser scanning microscope

InactiveUS6856391B2Sure easyPolarisation-affecting propertiesPhotoelectric discharge tubesLaser scanning microscopeLight beam

The invention relates to a method and apparatus for determining the polarization properties of light emitted, reflected or transmitted by a material using a laser scanning microscope with the tested material being illuminated point by point with a laser beam of known polarization state. According to the invention the light beam with a polarization state modified by the material or the light emitted by the material is being examined by measuring the intensity of two different polarization components of a selected light beam received from each point of said material essentially at the same time and assigning a signal obtained by processing the two intensity signals to a respective point of an image of said material. The apparatus has a polarization state generator between the laser light source and the material being tested, and a detector in a light beam for determining the intensity of light with a polarization state modified by the material or the intensity of light emitted by the material, the improvement of which is that a means for dividing the polarization components in space or time is used in front of the detector.

Owner:MAGYAR TUDOMANYOS ACAD SZEGEDI BIOLOGIAI KOEZP

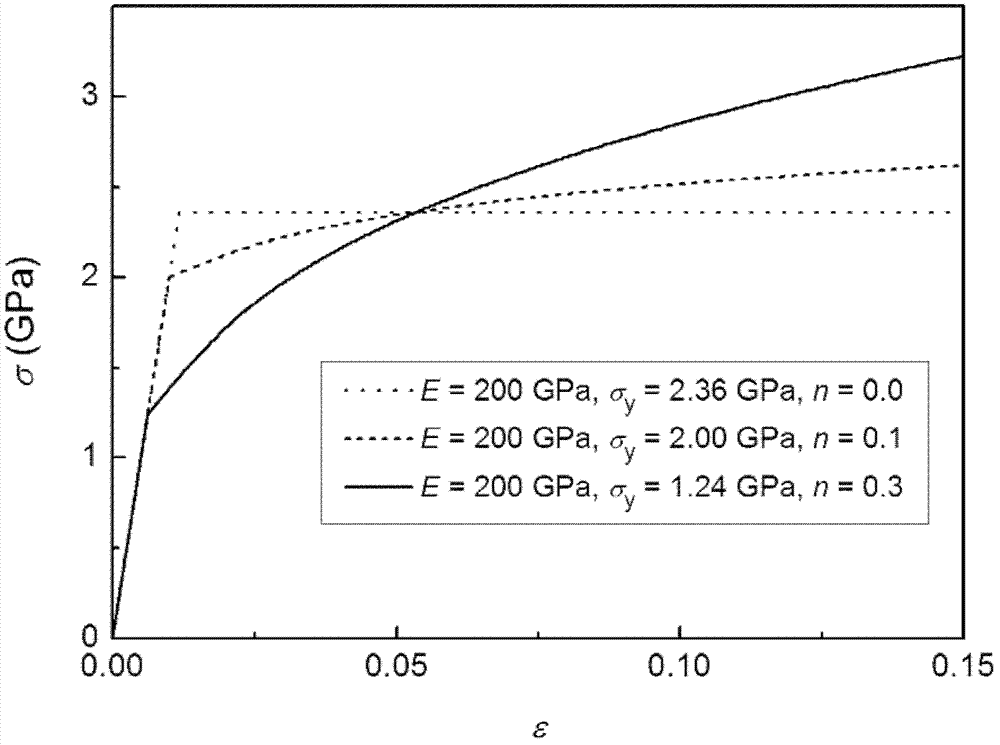

Process for characterizing elastoplasticity of metal material through indentation method

The invention discloses a process for characterizing the elastoplasticity of a metal material by introducing an extra residual area through an indentation method, belonging to the field of researches on the mechanical properties of a material. Experiment devices required by the method mainly comprise an indentor, and an atomic force microscope or a three-dimensional optical imaging system. The method mainly comprises the following steps: indenting a material to be tested through the indentor to obtain an indention load displacement curve, extracting relevant parameters from the indention load displacement curve, substituting the extracted parameters to an established model, and calculating to obtain the elastoplasticity of the material. The method mainly has the following advantages: different materials having similar indention curves can be successfully separated, and the obtained solution is only; and the solution obtained through back-stepping has a high precision. So the only high-precision elastoplasticity of the indented material can be obtained through back-stepping by utilizing the theoretic model in the invention.

Owner:XIANGTAN UNIV

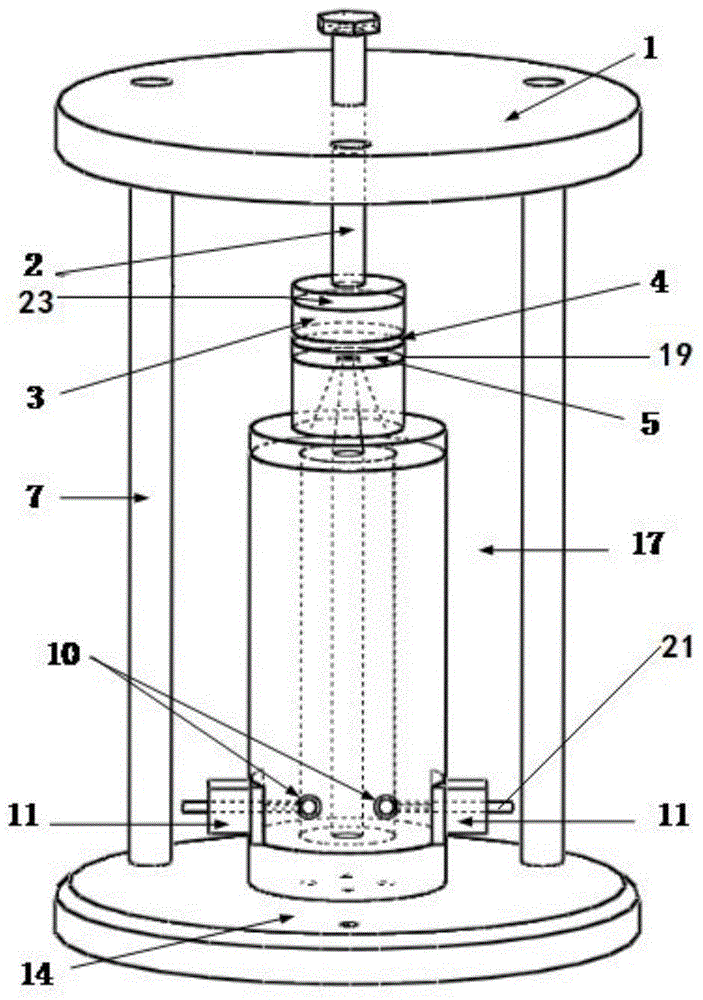

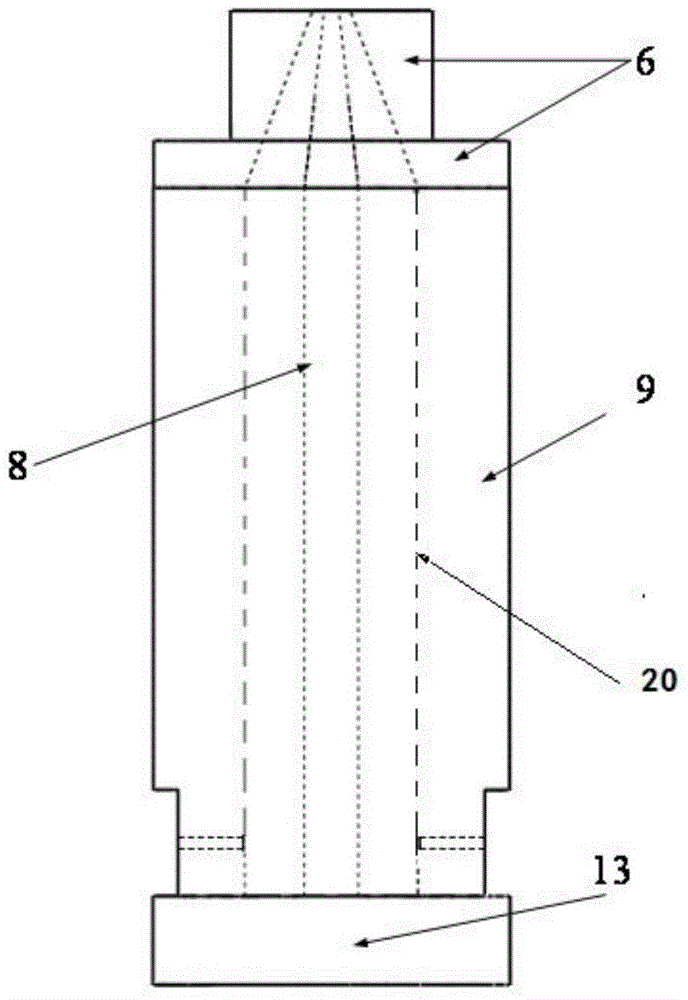

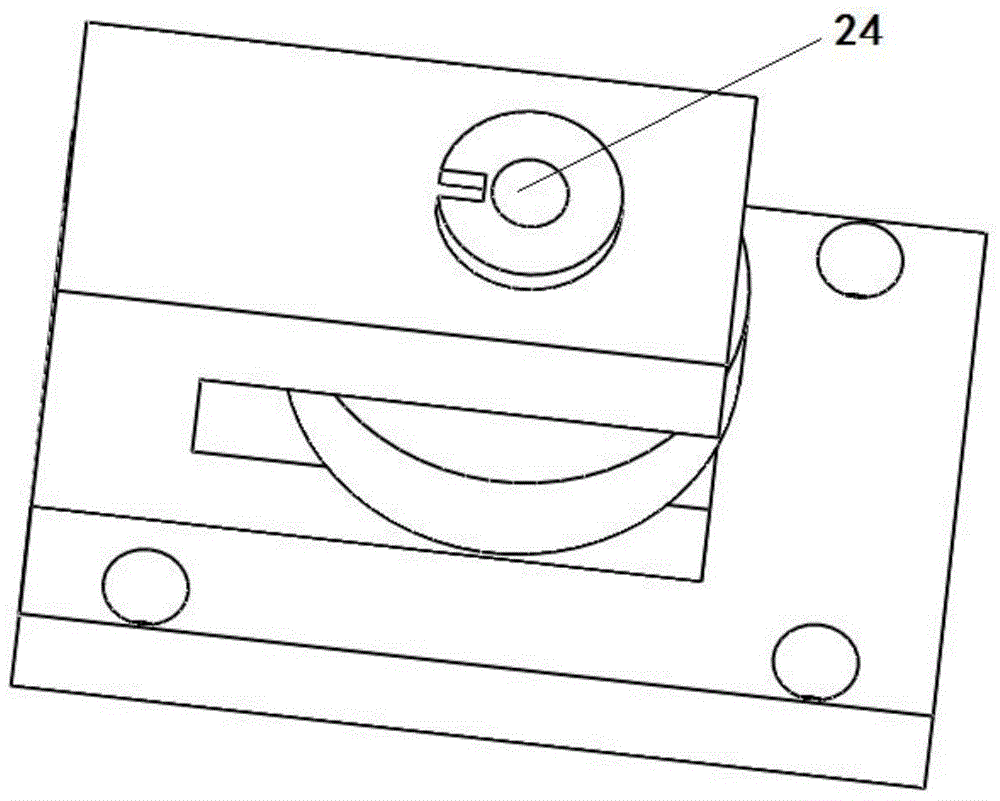

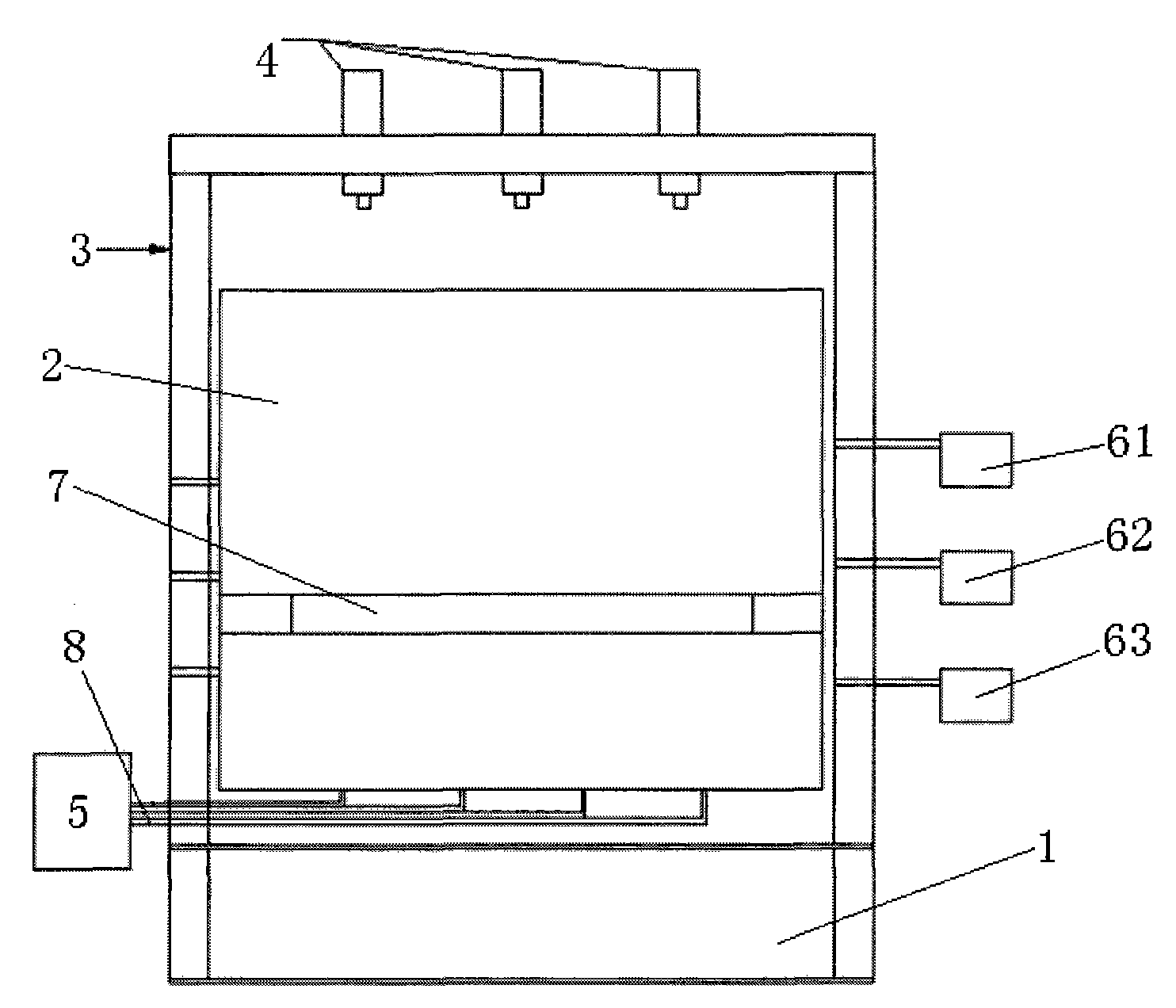

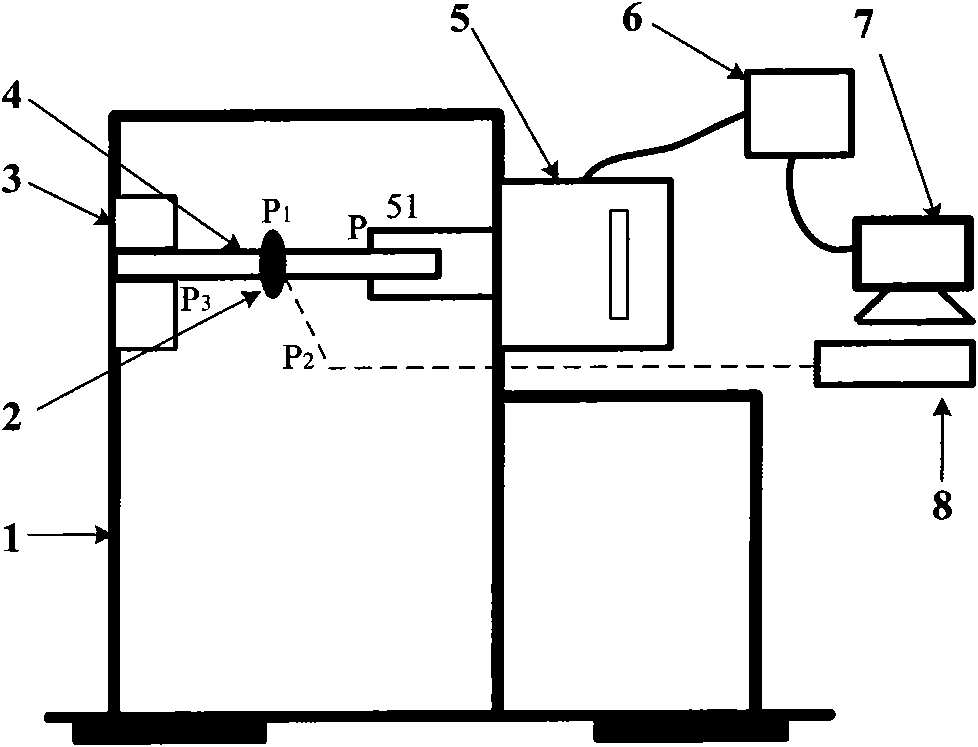

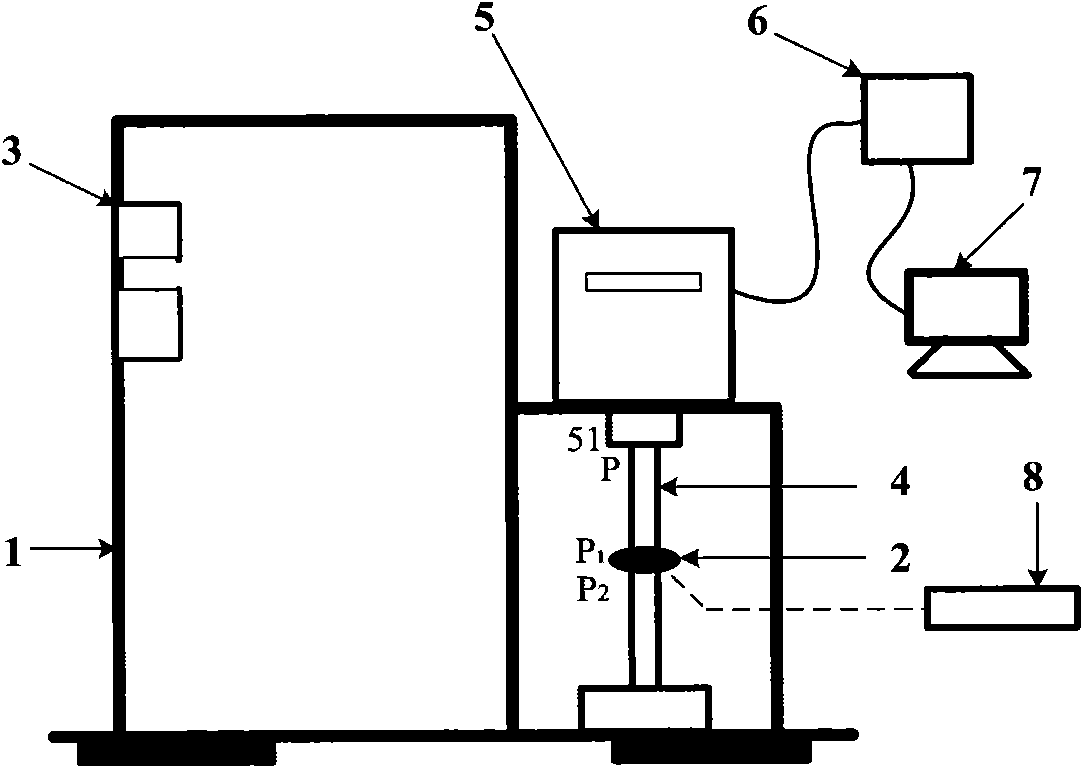

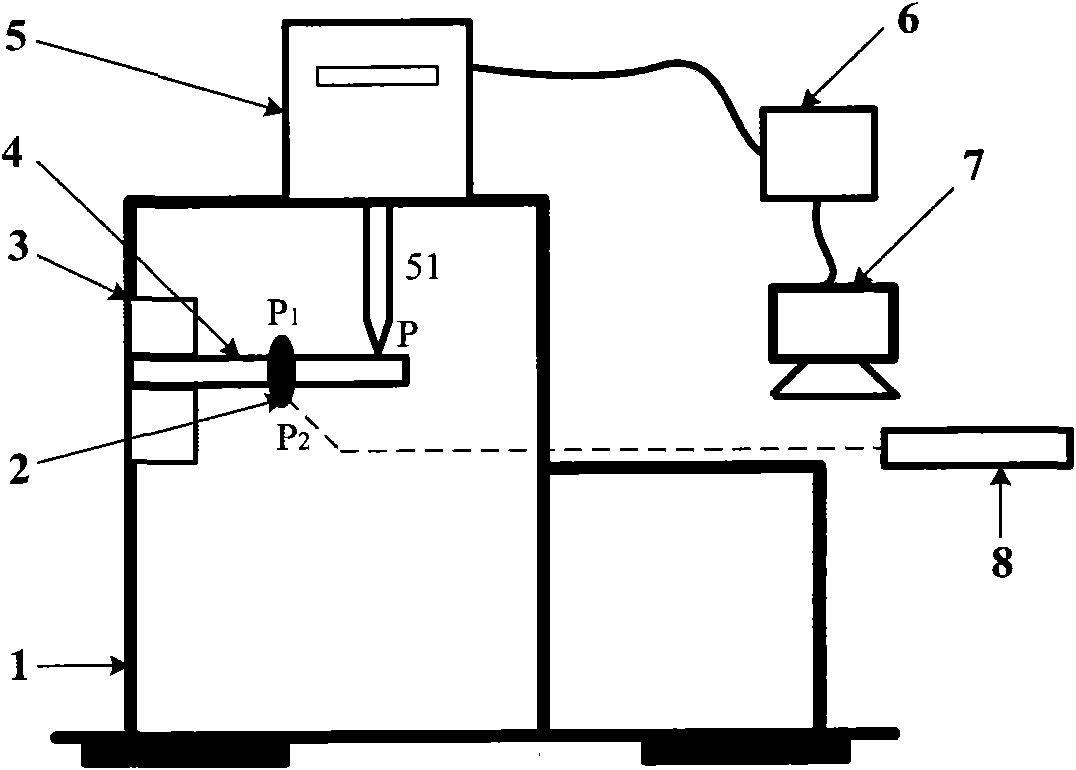

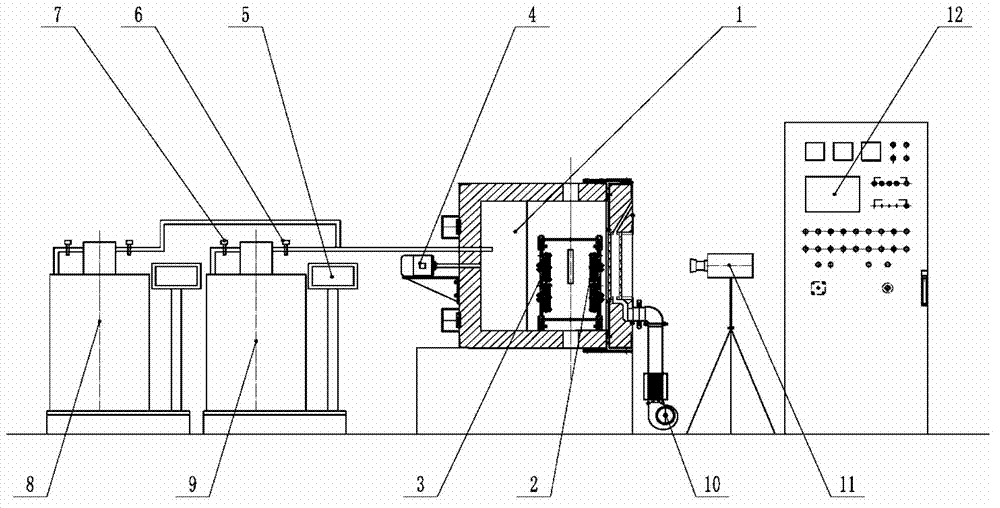

Geomechanics test platform for water invasion regularity of mine

InactiveCN101576458AMonitor changes in real timeMaterial strength using tensile/compressive forcesPore water pressureData acquisition

The invention discloses a geomechanics test platform for the water invasion regularity of a mine, which comprises a base, a box body, a reaction frame, a pressurized jack, a hydraulic control system and a data acquisition system and the like. When simulating the water invasion of the mine, test material is paved in the box body according to a calculated similarity ratio; an electrode, a stress sensor and a pore water pressure sensor are paved on a coal seam bottom plate by layers; and a data cable is led out from a pore preserved on a side surface. By filling water into the paved test material through the bottom plate of the box body, when the water in an aquifer is saturated, a pore preserved for coal mining in the front of the box body is opened for excavation, simultaneously, the hydraulic control system continue to fill water according to the pre-calculated water pressure, and the data acquisition system is started to record the test data until water invasion occurs at the bottom plate, and then excavation is stopped and the test is ended. The system structure is simple, can effectively simulate the water invasion regularity of the mine, and solves the problems that the indoor test can not simulate the role of seepage and erosion of confined water.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

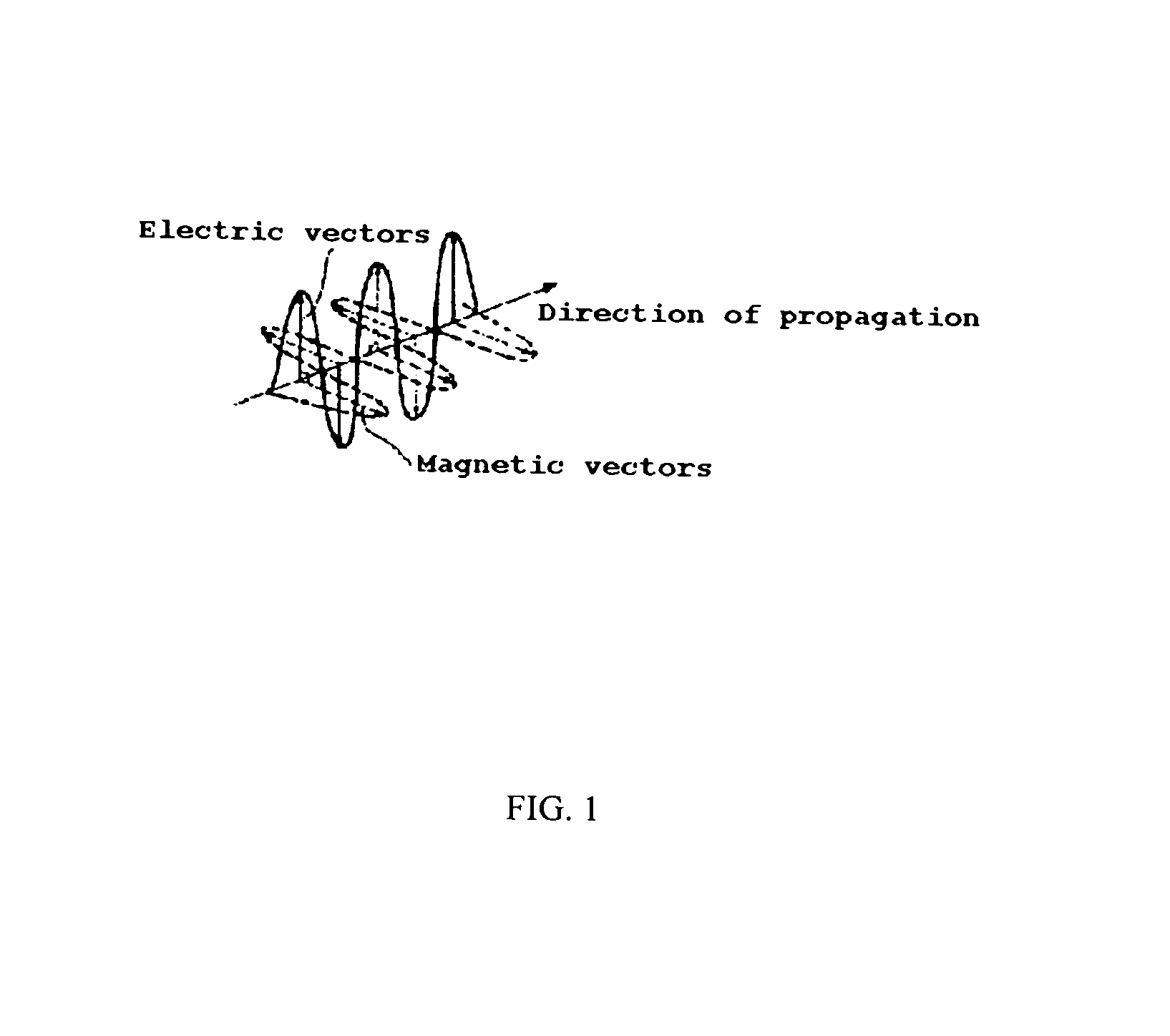

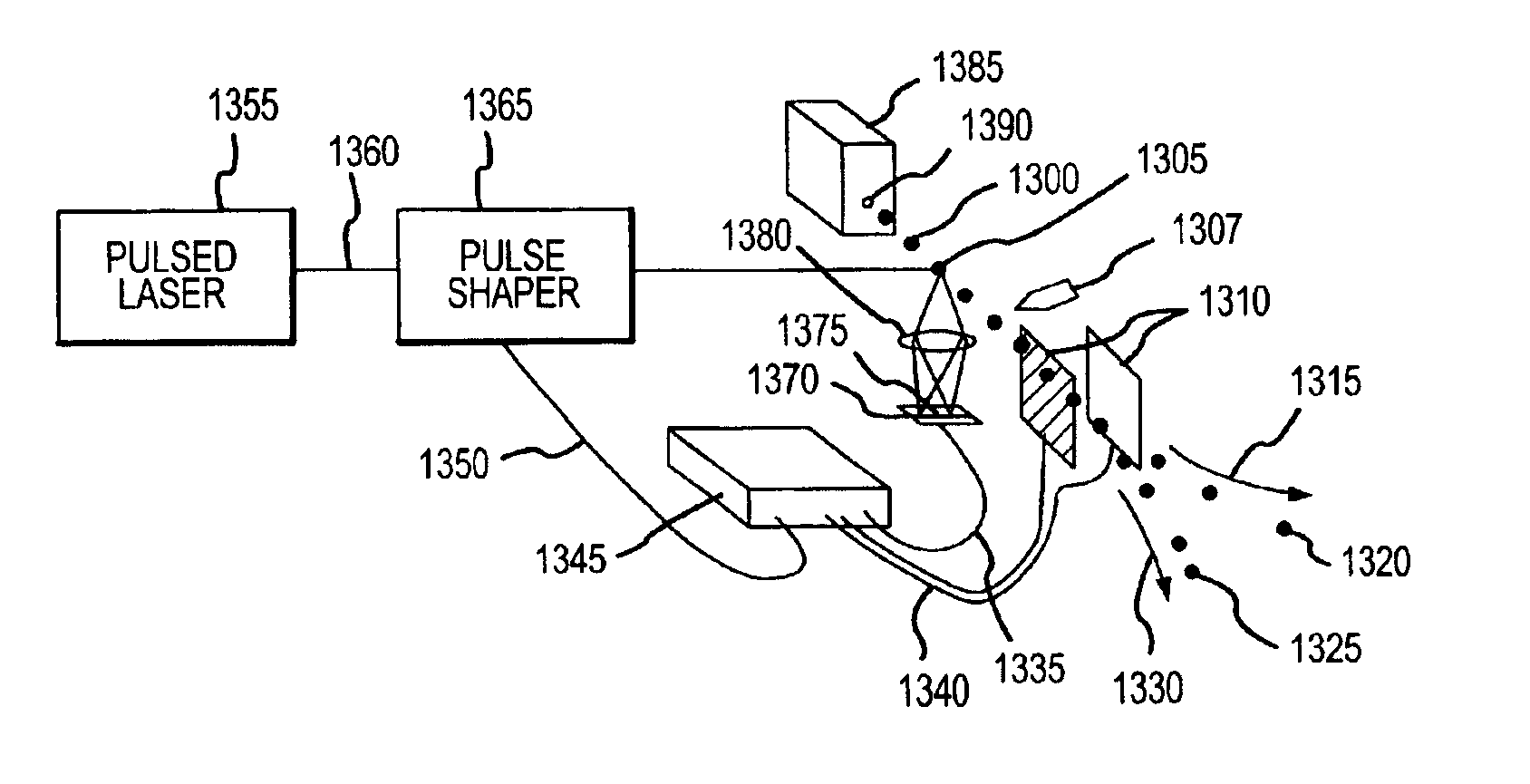

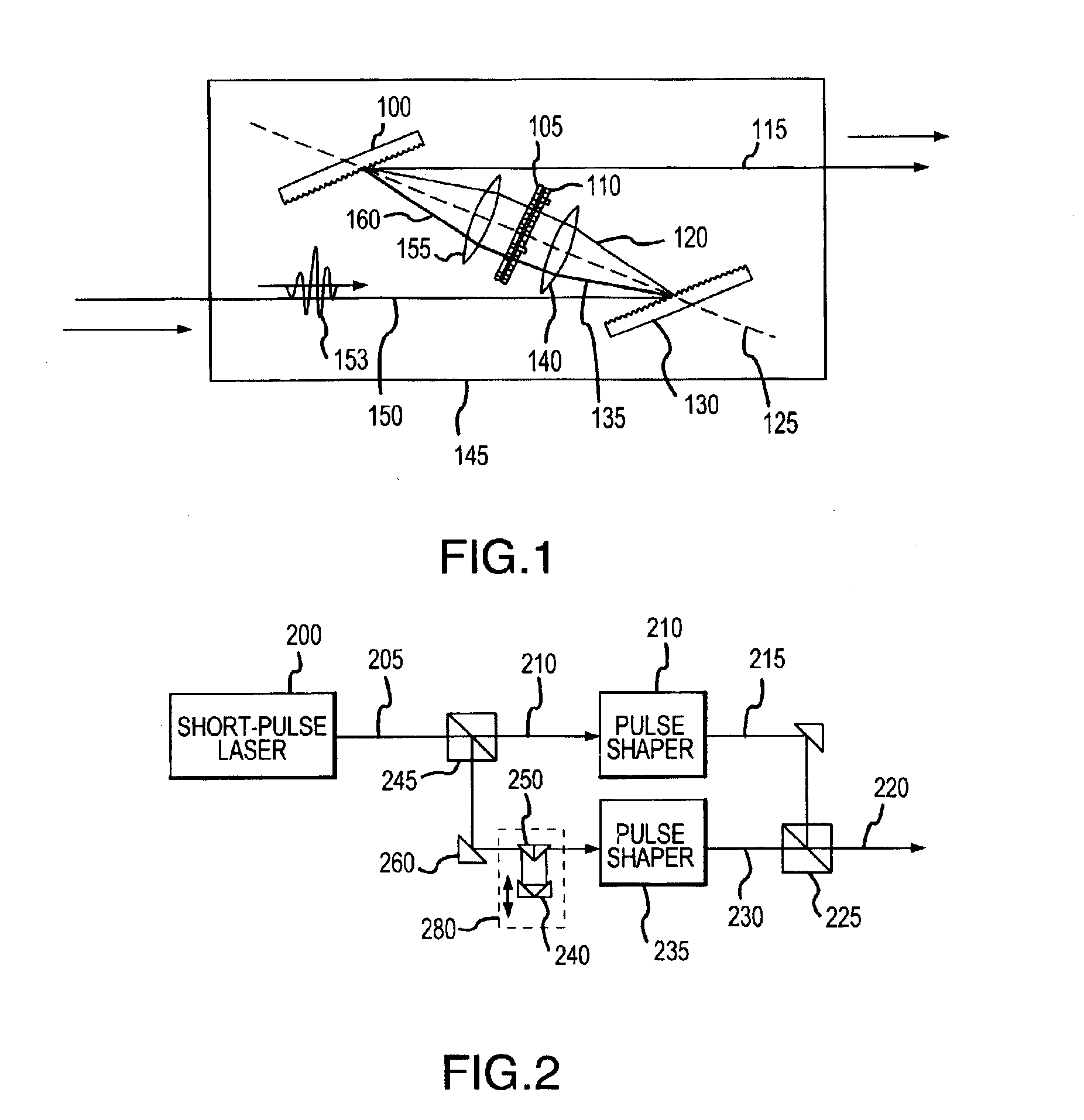

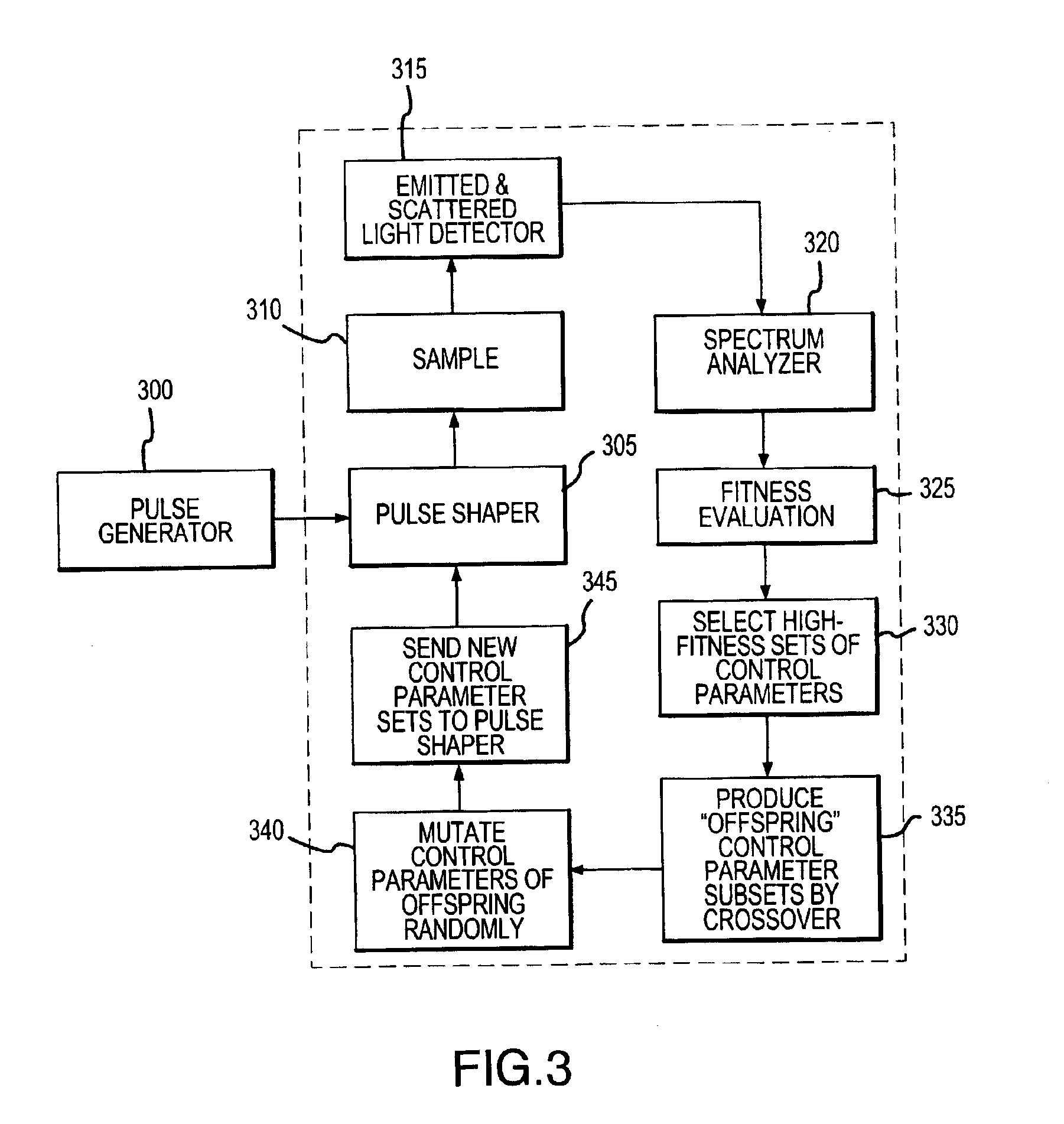

Quantum resonance analytical instrument

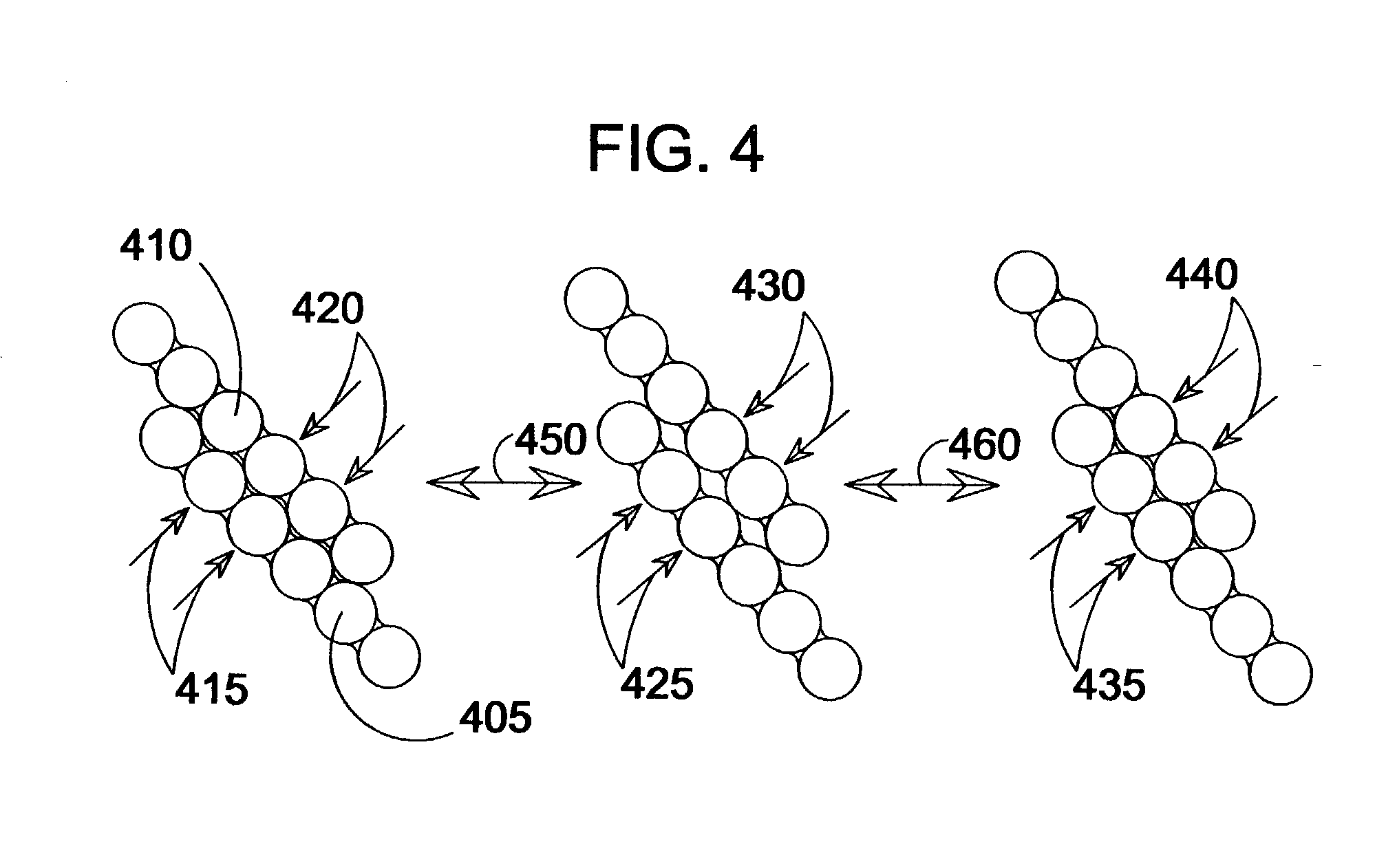

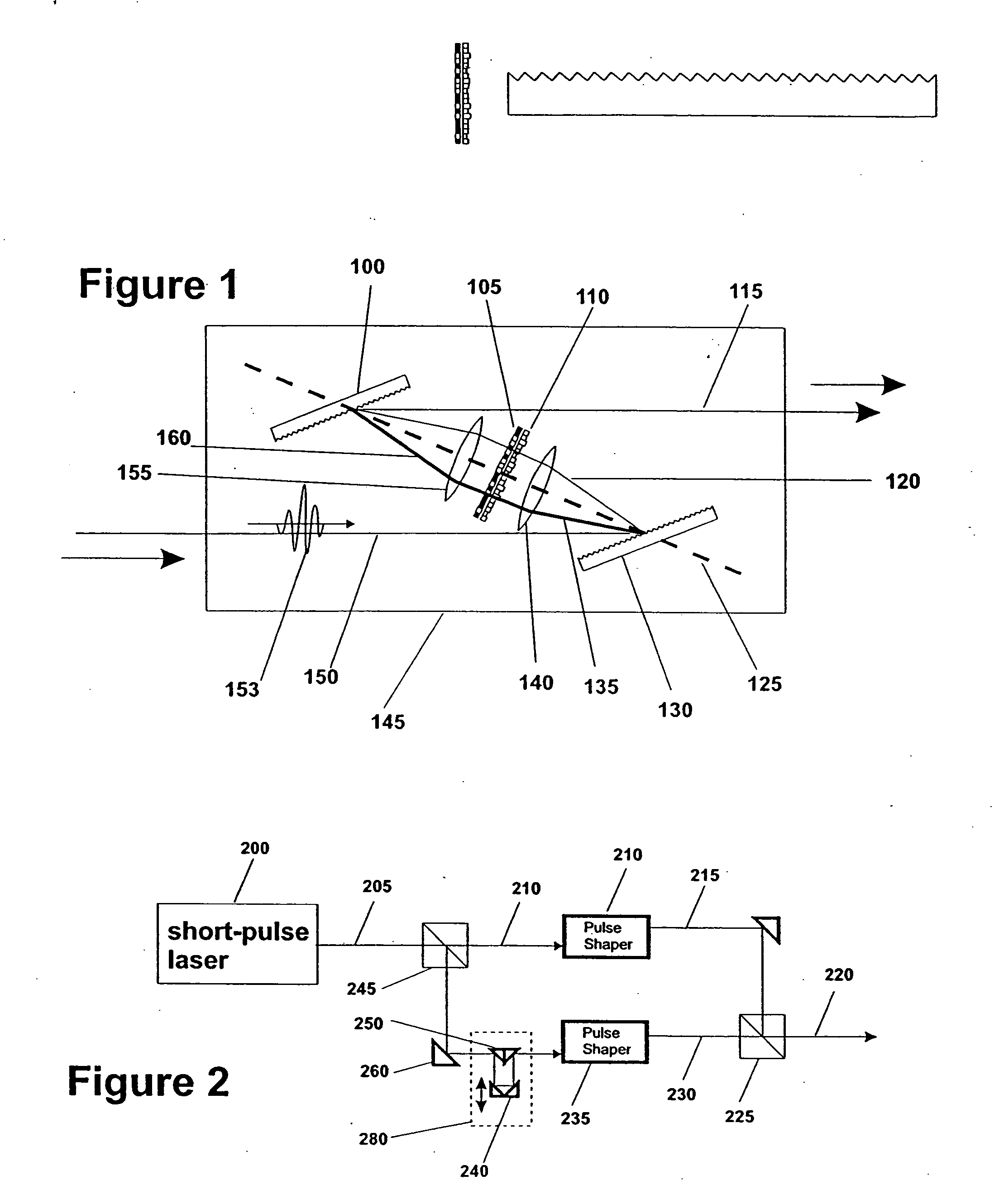

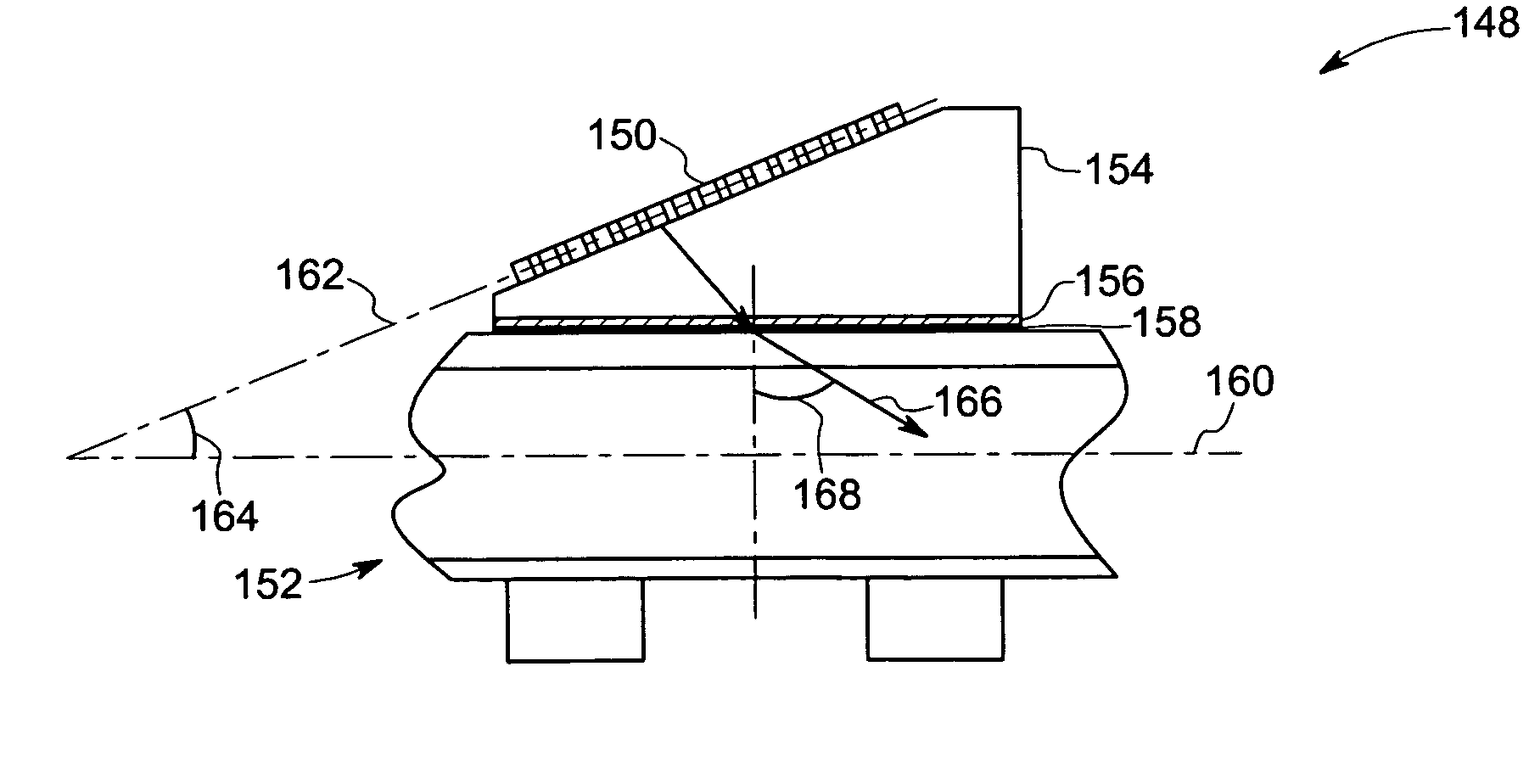

Quantum resonance fluorescent microscope systems for detecting component substances in a specimen are described. The systems are based on exciting the sample containing the material with a femtosecond to nanosecond probe pulse of collimated light, which is tailored to optimize detection of a given material by separating the probe pulse into component features of frequency, polarization, phase and / or amplitude. The component features are independently shaped and formed into a composite pulse selected to optimize a signature response pulse received from the material. In some cases, two independently re-shaped pulses are combined, where one re-shaped pulse has two mixed polarization states and the other re-shaped pulse is linearly polarized. These two pulses are made to intersect at an angle of 90 degrees so that the combined pulse has electric field in each of the XYZ axes. Selection of the appropriate shapes for the component features of the pulses for a given material is accomplished by testing variations in the features on the material, assigning a fitness value to variants that tend to optimize a distinctive spectral response from the material, and using a genetic algorithm to select the combination of component features that enhances the distinctiveness of the response received over a typical background.

Owner:MCGREW STEPHEN P

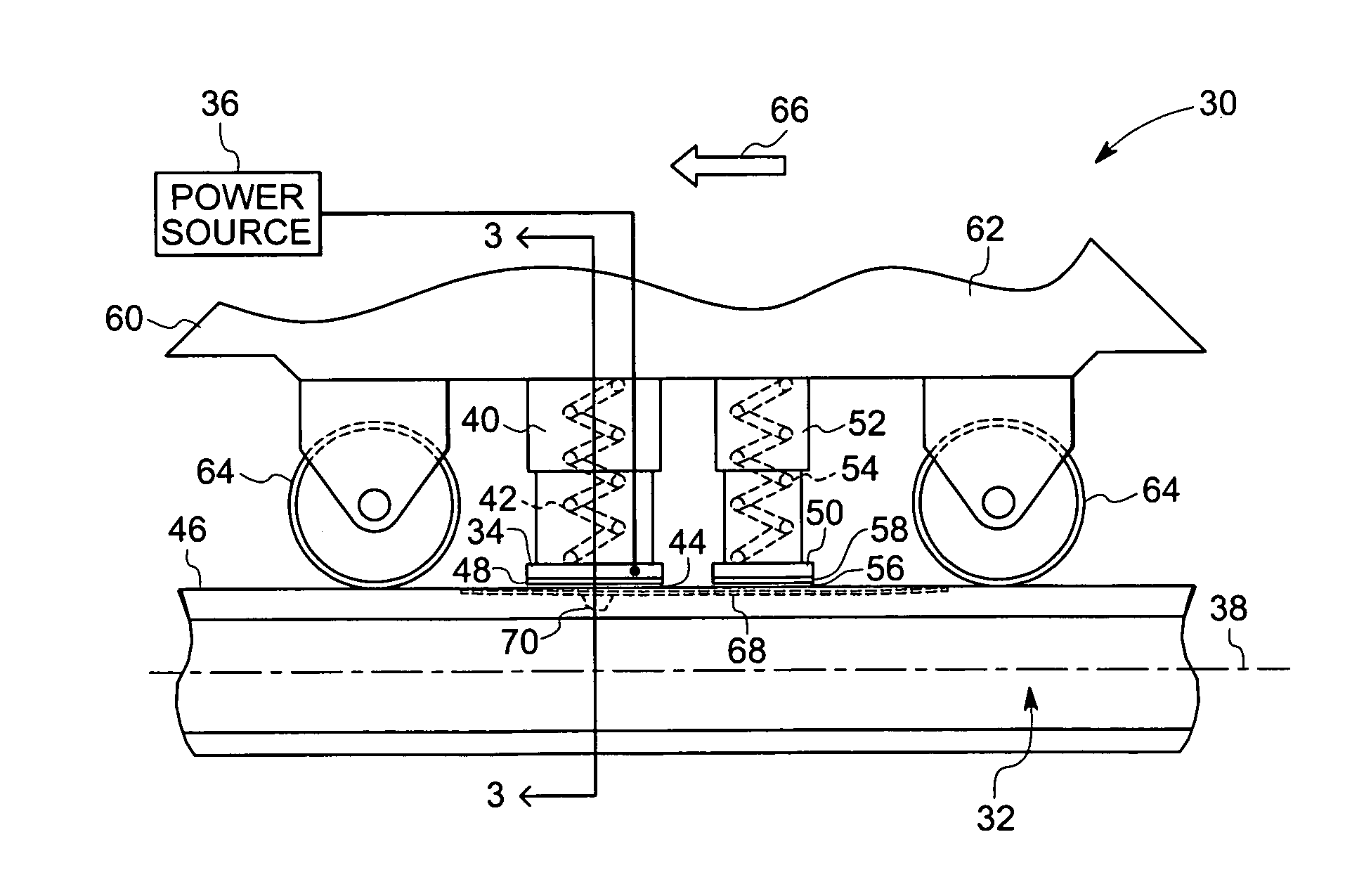

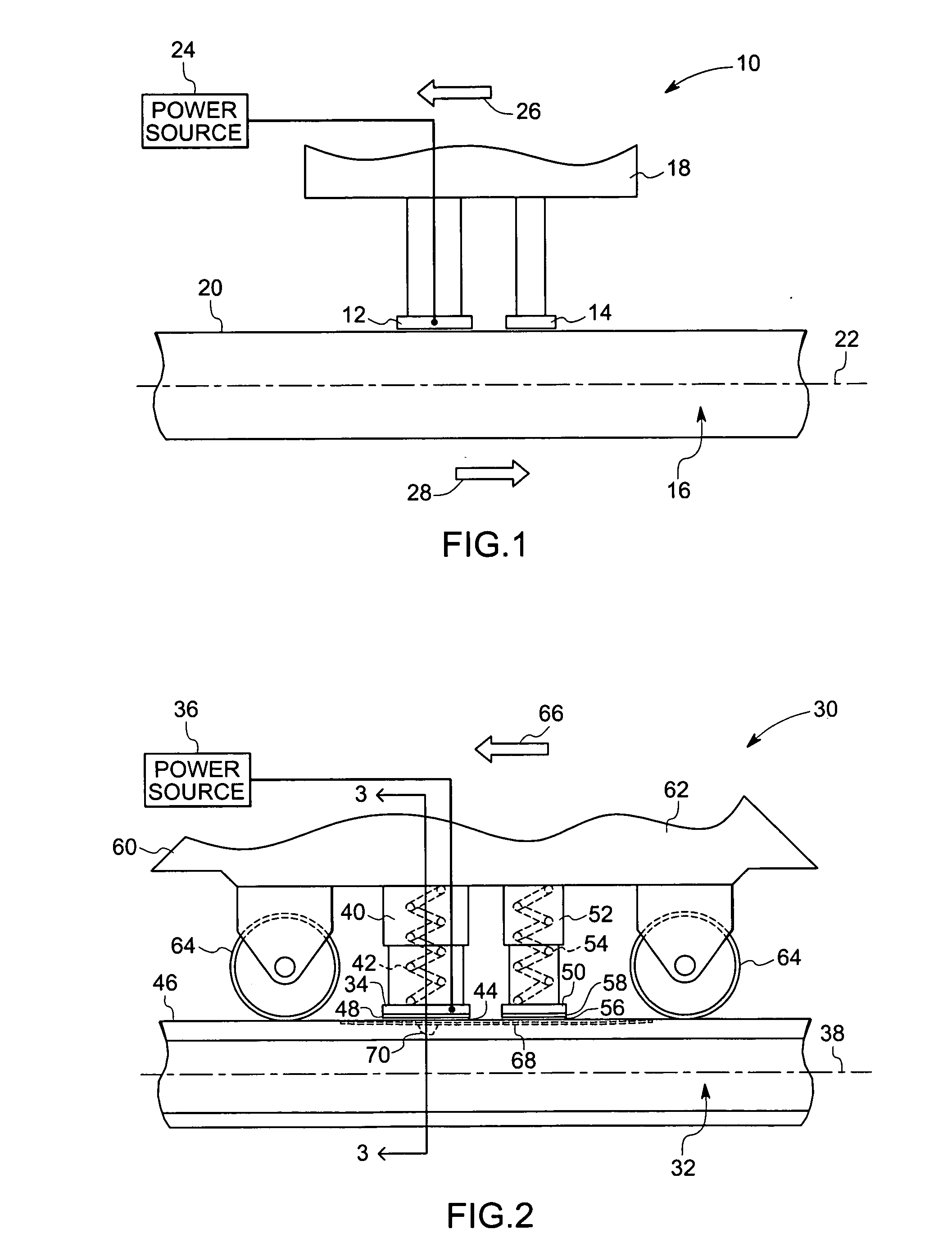

Method and apparatus for phased array based ultrasonic evaluation of rail

ActiveUS20060065055A1Solve the slow test speedEasy to testAnalysing solids using sonic/ultrasonic/infrasonic wavesUsing subsonic/sonic/ultrasonic vibration meansSonificationEngineering

In accordance with one embodiment, the present technique provides a testing apparatus for testing material integrity of an object. The exemplary testing apparatus includes a phased array transducer, which is disposed external to the object. The phased array transducer is configured to transmit a first set of ultrasonic signals and to receive a second set of ultrasonic signals. The testing apparatus further includes logic circuitry coupled to the phased array transducer. The logic circuitry is configured to dynamically control apertures for transmitting the first set of ultrasonic signals and receiving the second set of ultrasonic signals based on a region of interest and a testing speed.

Owner:PROGRESS RAIL SERVICES

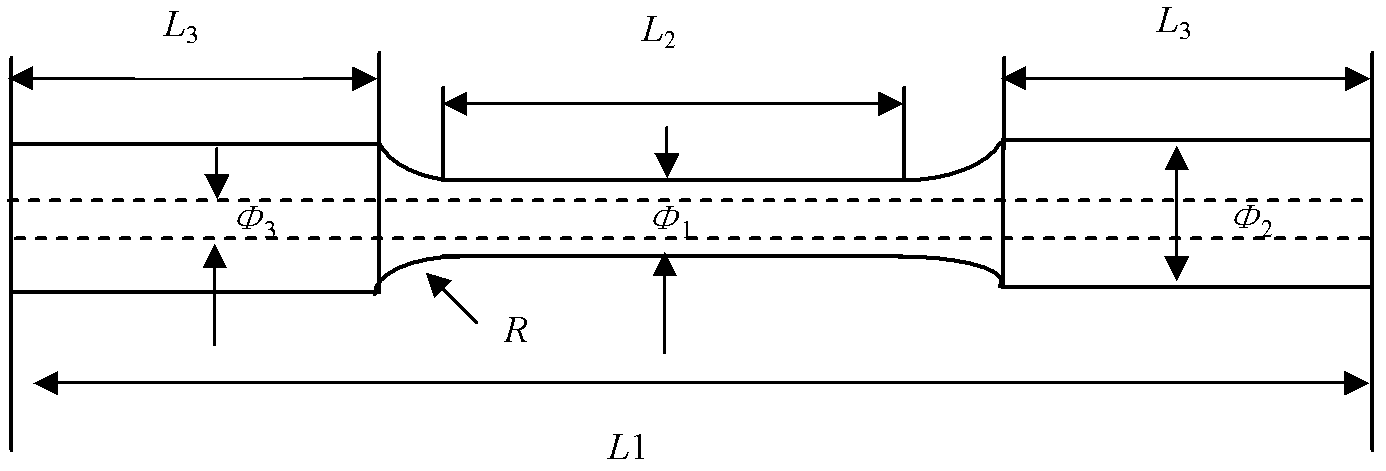

Method for detecting mechanical properties of local heating loading test material under high temperature oxidation environment and device thereof

ActiveCN101936854ASimple test operationSave test costMaterial strength using tensile/compressive forcesMaterial strength using steady bending forcesFlexural strengthMechanical property

The invention provides a test method capable of simply and conveniently testing mechanical properties of tensile strength, compressive strength, bending strength and fracture toughness of ceramic material and composite material thereof under superhigh temperature oxidation environment with the temperature of more than 1500 DEG C and a test device thereof. The test device is composed of a test frame, a fixed sample system, a loading system, a superhigh temperature flaming heating system, a record display system and a non-contact type infrared temperature measuring system. The method includes that acetylene or gasoline aeration flaming technology is adopted to locally and rapidly heat a sample, so that local temperature thereof reaches more than 1500 DEG C, a portable tester is utilized to apply bending, stretching or compressive load on the sample, and load value is recorded, thus obtaining mechanical properties of material. The invention has the advantages that operation is simple, the technology of local high temperature and synchronous loading on superhigh temperature sample is realized, superhigh temperature mechanical properties which can not be tested before such as strength and toughness of material can be conveniently measured under superhigh temperature oxidation environment by utilizing the test device of the invention.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

System and method for quantifying material properties

InactiveUS6631647B2Optimize overall economy and utilityThe testing process is simpleForce measurementMeasurement arrangements for variableHysteresisModel dynamics

A materials characterization method models dynamic, non-linear, temperature-dependent stress, strain, hysteresis, creep, and loss of elasticity at high strain, both in test samples and in Finite Element Analysis (FEA). Incorporating universal properties of statistical mechanics and adapting domain models from ferromagnetics to the higher-dimensional realm of stress tensors, the model is applicable to polymers, rubbers, liquids, and metals in elastic and plastic deformation. The model quantifies the dynamics of both plastic and brittle failure. Apparatus and methods are shown for testing material samples and matching the computational model to sample characteristics, leading to a set of characterizing parameters and predictive simulations using those parameters. Though apparatus and testing protocols of the invention yield optimum characterizations, pre-existing data from conventional testing yield useful results.< / PTEXT>

Owner:SEALE JOSEPH B

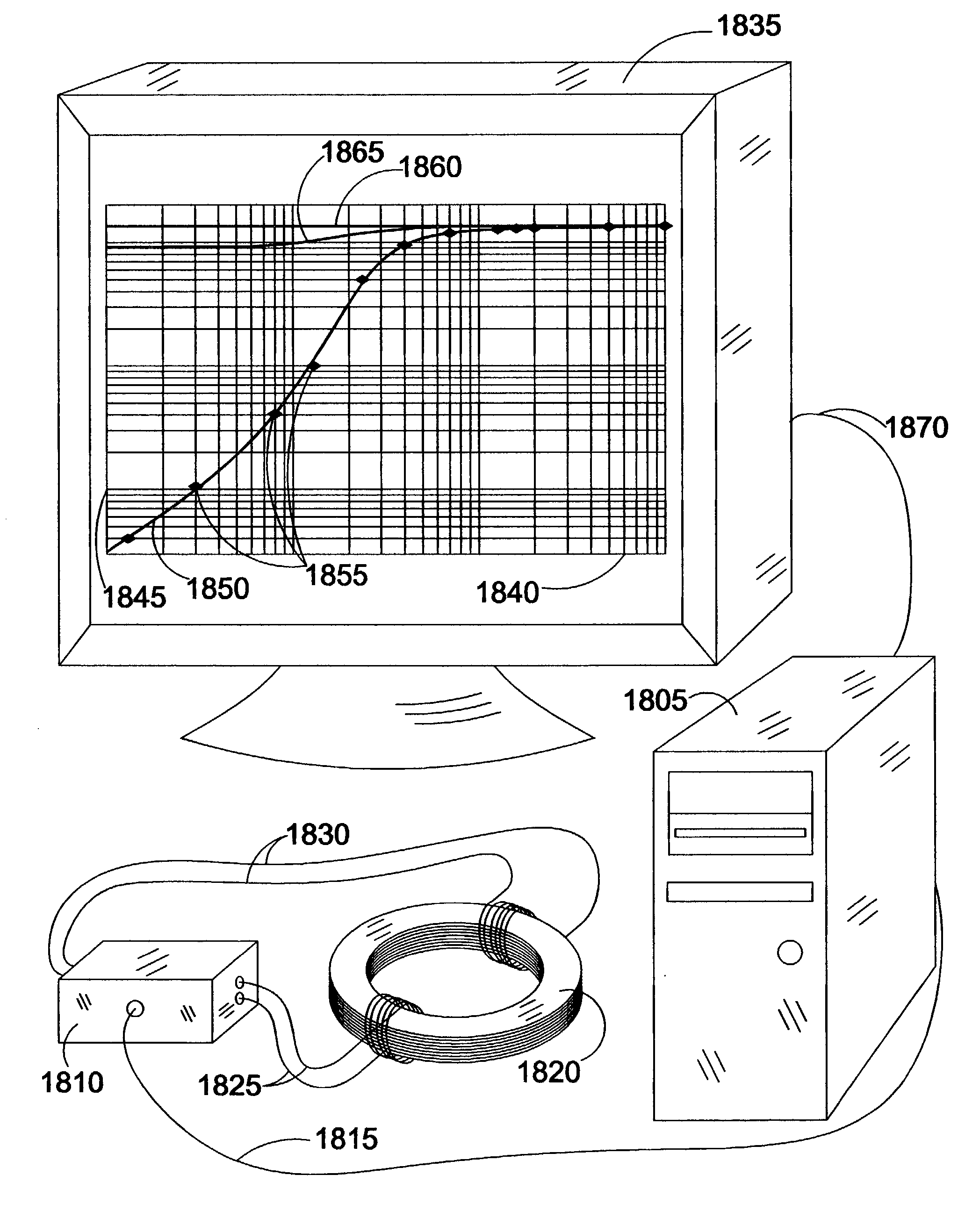

Material condition monitoring with multiple sensing modes

Methods are described for assessing material condition. These methods include the use of multiple source fields for interrogating and loading of a multicomponent test material. Source fields include electric, magnetic, thermal, and acoustic fields. The loading field preferentially changes the material properties of a component of the test material, which allows the properties of the component materials to be separated. Methods are also described for monitoring changes in material state using separate drive and sense electrodes with some of the electrodes positioned on a hidden or even embedded material surface. Statistical characterization of the material condition is performed with sensor arrays that provide multiple responses for the material condition during loading. The responses can be combined into a statistical population that permits tracking with respect to loading history. Methods are also described for measuring the stress in the material by independently estimating effective electrical properties, such as magnetic permeability or electrical conductivity, using layered models or predetermined spatial distributions with depth that are then correlated with the stress.

Owner:JENTEK SENSORS

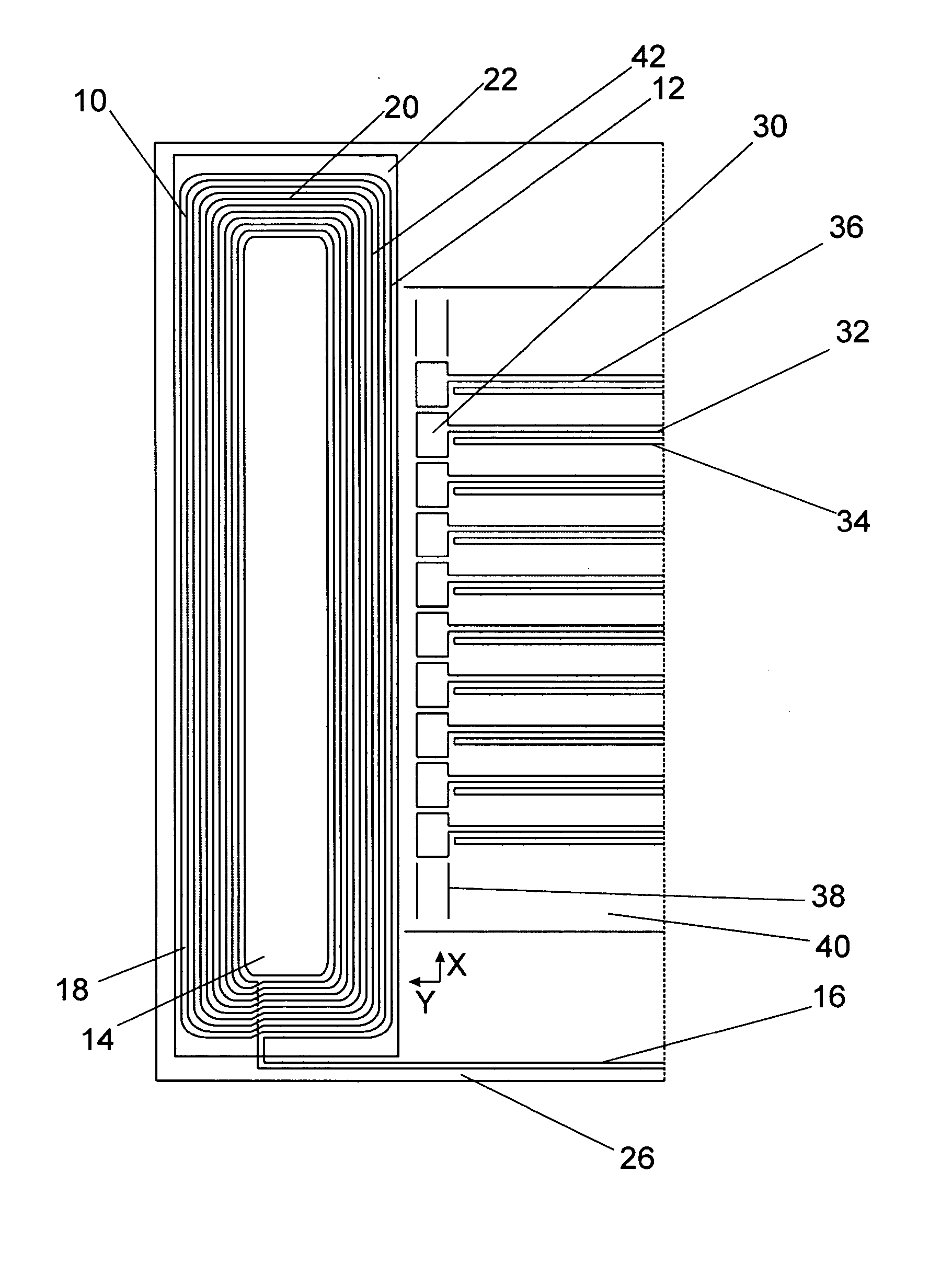

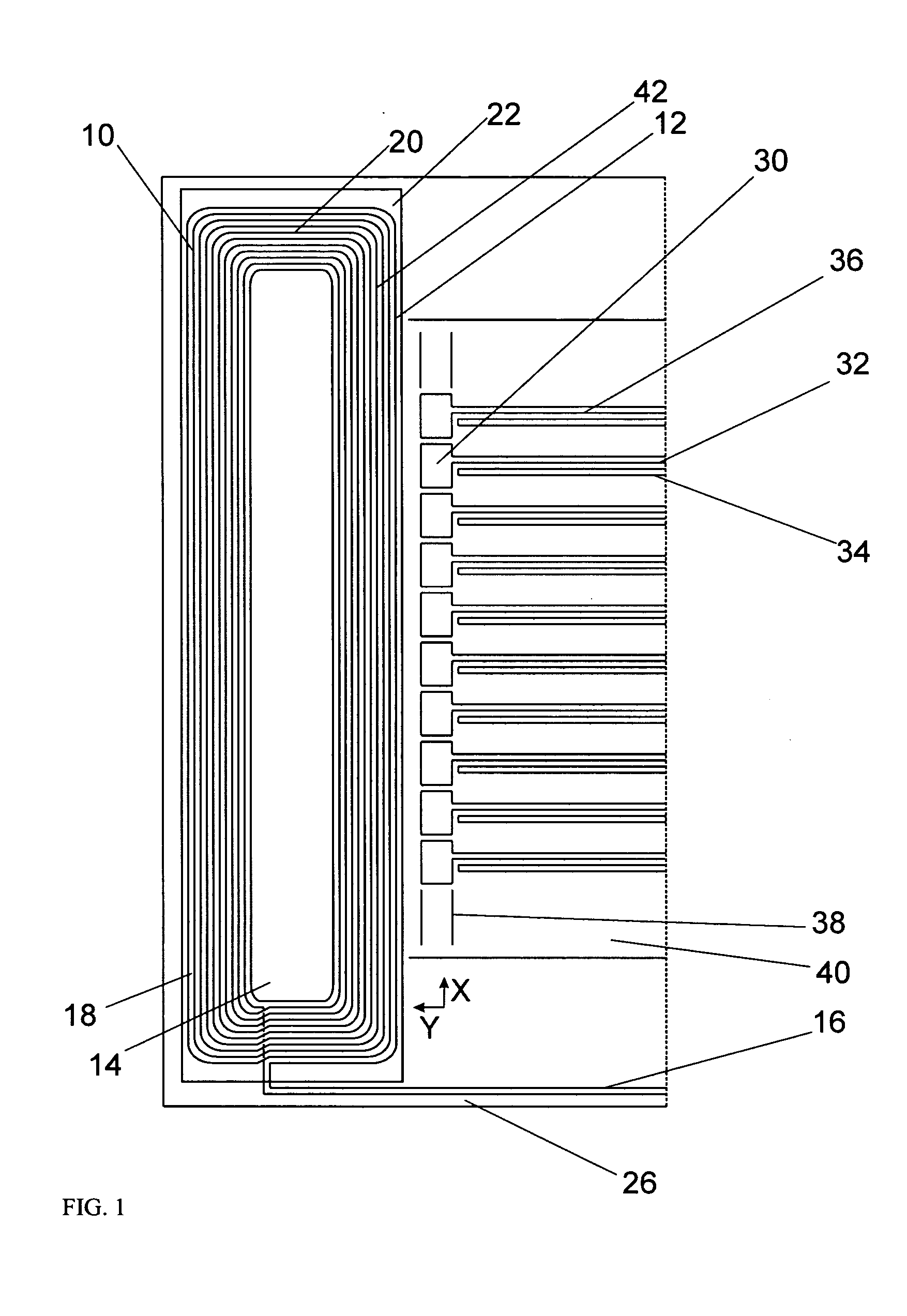

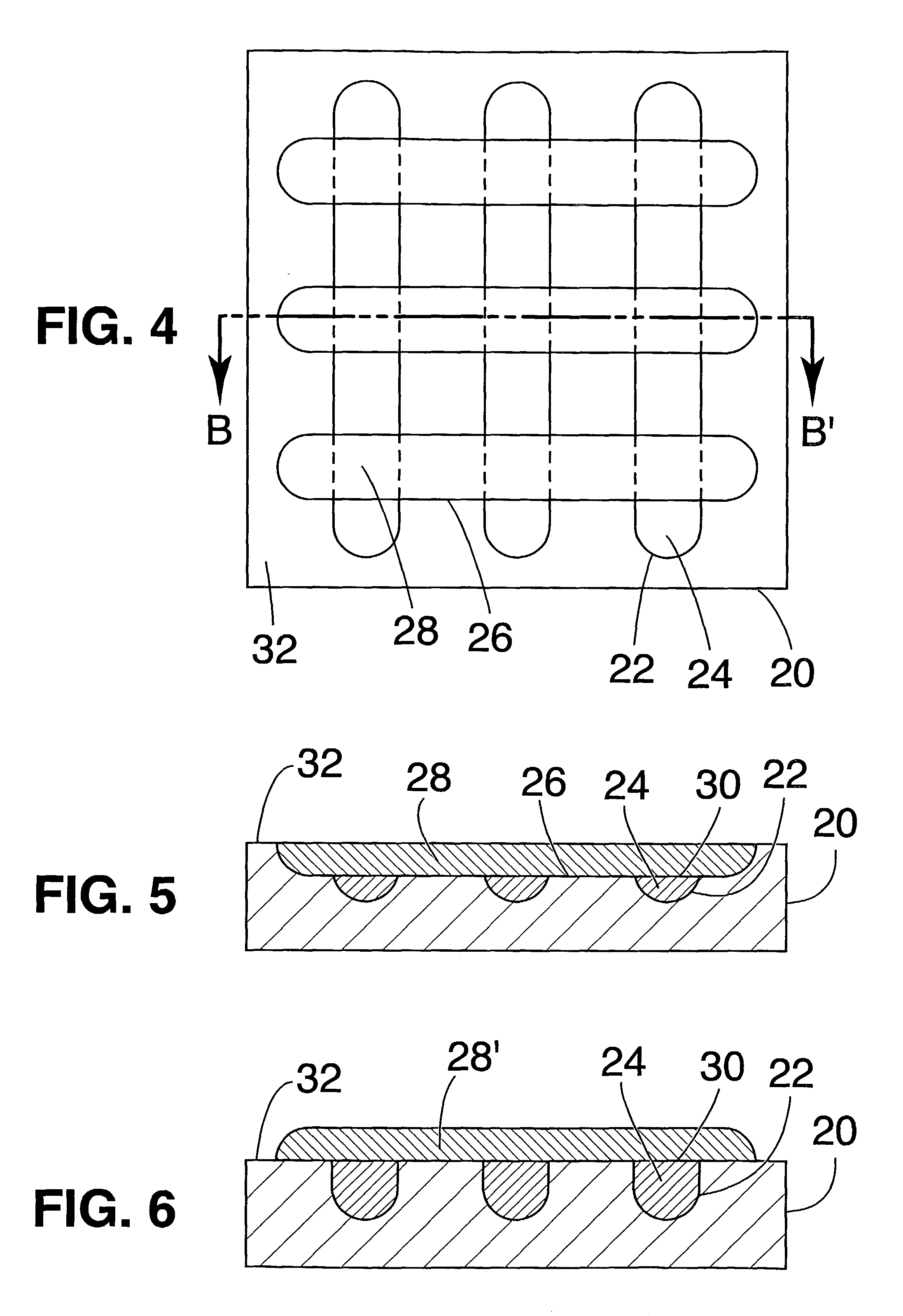

Hybrid wound/etched winding constructs for scanning and monitoring

InactiveUS20050007106A1Promote accurate modelingImprove ObservabilityMagnetic property measurementsMaterial magnetic variablesSensor arraySurface mounting

Combined wound and micro-fabricated winding constructs are described for the inspection of materials and the detection and characterization of hidden features or flaws. These constructs can be configured as sensors or sensor arrays that are surface mounted or scanned over conducting and / or magnetizable test materials. The well-defined geometry obtained micro-fabricated windings and from carefully wound coils with known winding positions permits the use of model based inversions of sensed responses into material properties. In a preferred embodiment, the primary winding is a wound coil and the sense elements are etched or printed. The drive or sense windings can also be mounted under fasteners to improve sensitivity to hidden flaws. Ferrites and other means may be used to guide the magnetic flux and enhance the magnetic field in the test material.

Owner:JENTEK SENSORS

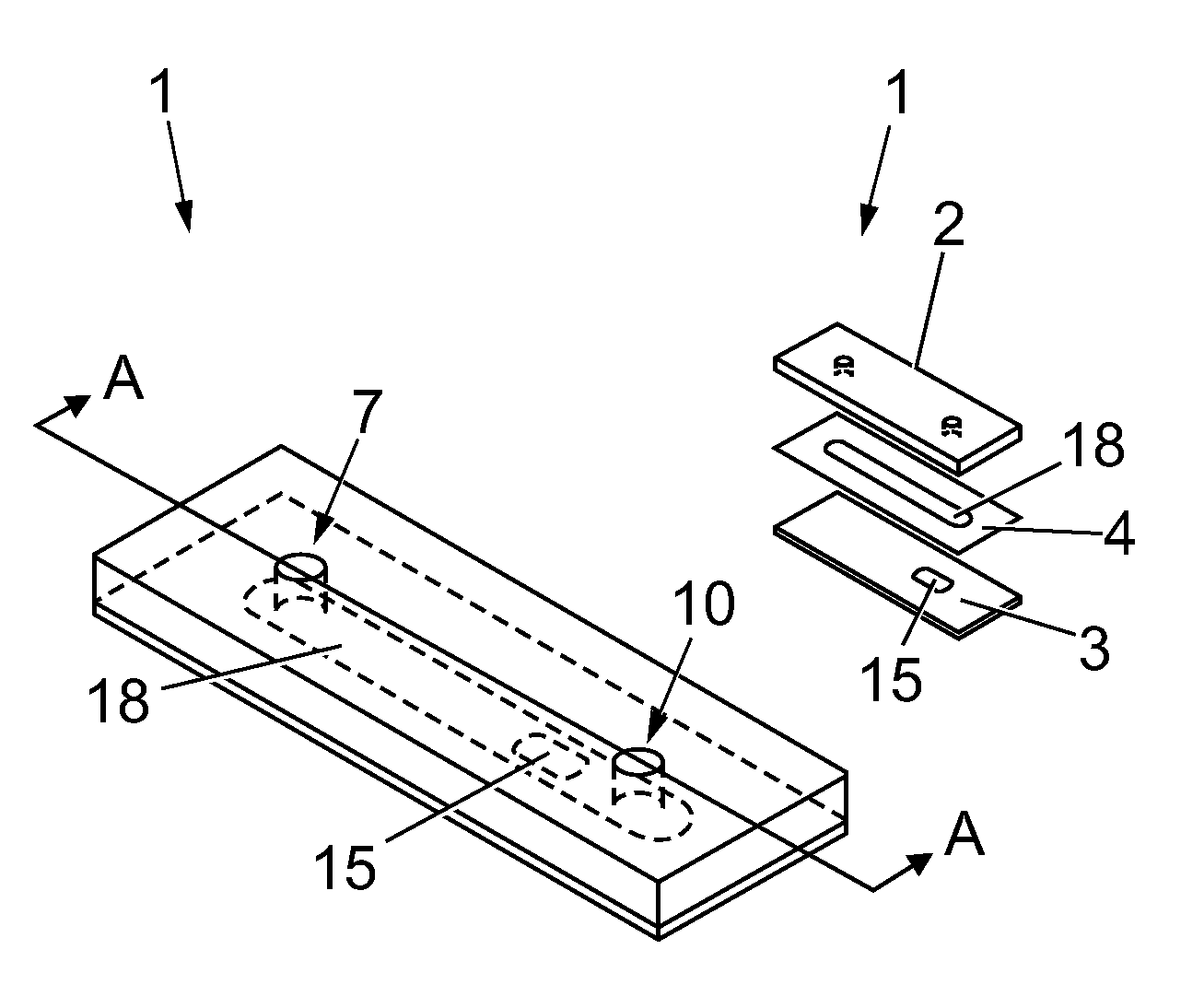

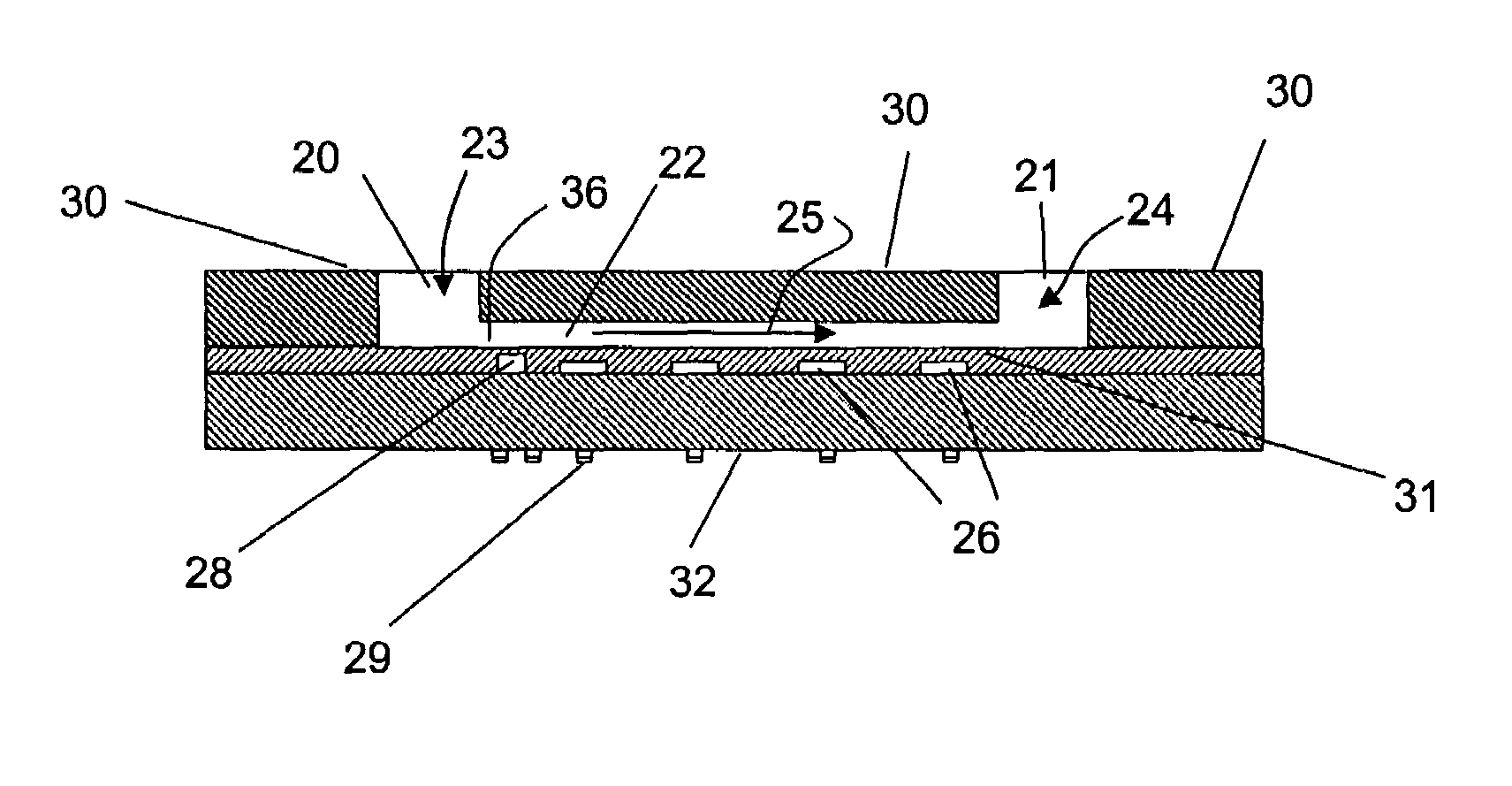

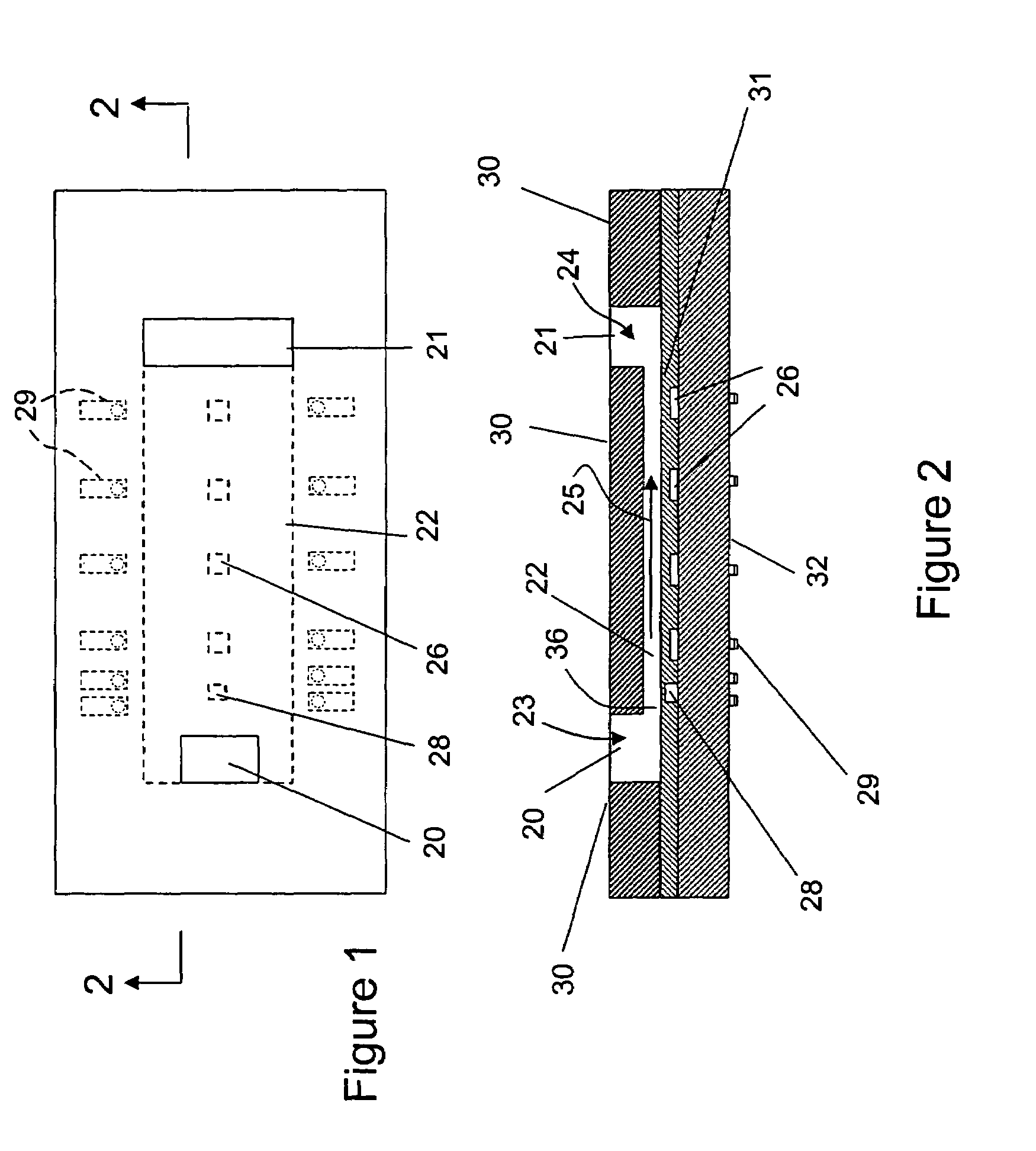

Microfluidic device for assessing object/test material interactions

ActiveUS20110045993A1Easy to controlConstant forceImage enhancementImage analysisTest materialMechanics

An object / test material interaction microti iridic device comprising a sample inlet adapted to receive a fluid sample comprising a plurality of objects, an outlet adapted to output the fluid sample from the device, at least one internal surface defining a flow cavity within the device, wherein the flow cavity extends between and is connected to the sample inlet and the outlet for flow of the fluid sample through the flow cavity, the flow cavity comprises a test area to which at least one test material is attached and which is situated in the flow cavity for flow of the fluid sample over the test area, and the flow cavity has an aspect ratio which, when the flow cavity is substantially filled by the fluid sample, provides a substantially constant shear force between the test area and the fluid sample flowing over the test area. The invention further comprises a system incorporating the device, methods of use of the device and system, and methods of analysing interactions.

Owner:DUBLIN CITY UNIVERSITY +1

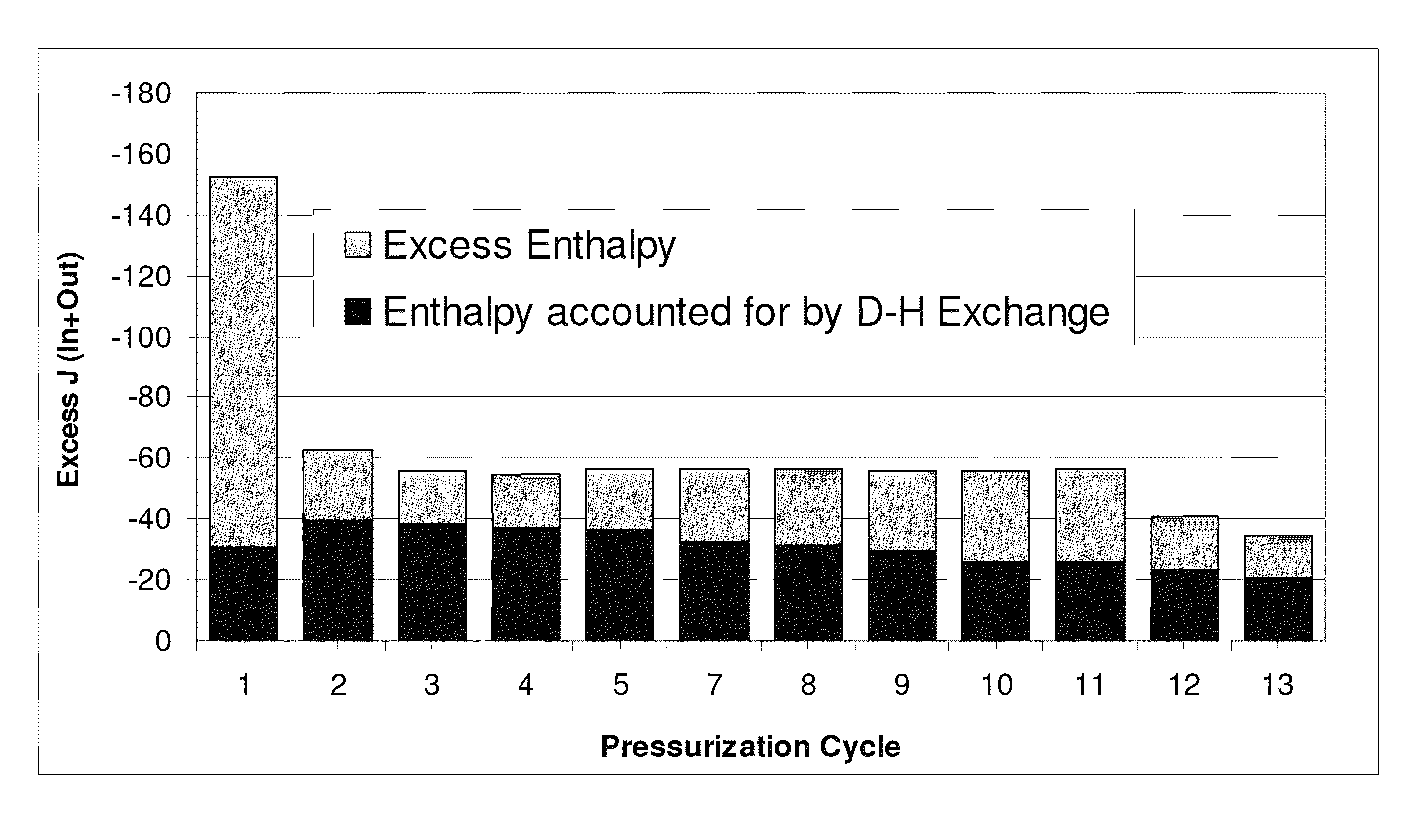

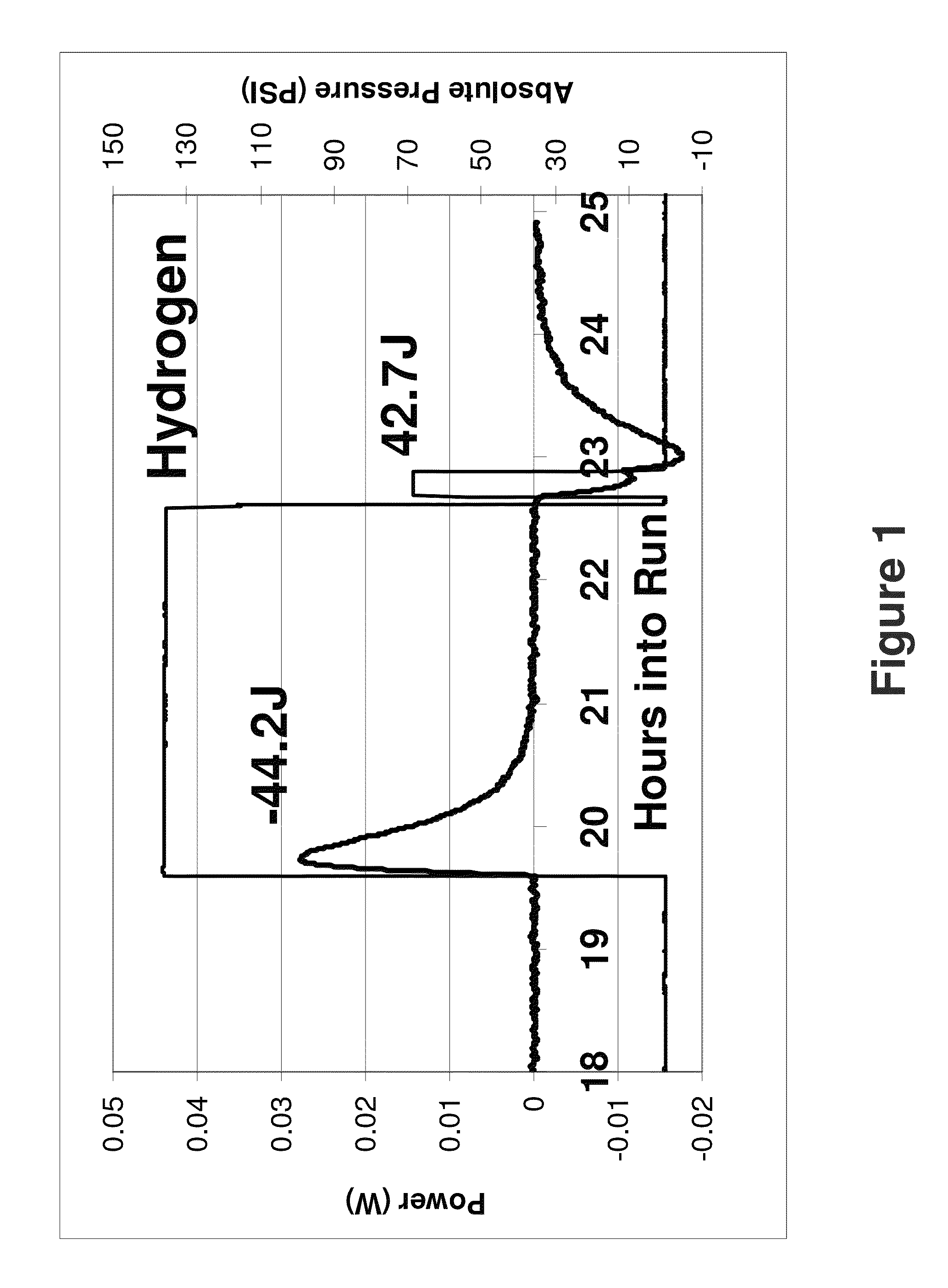

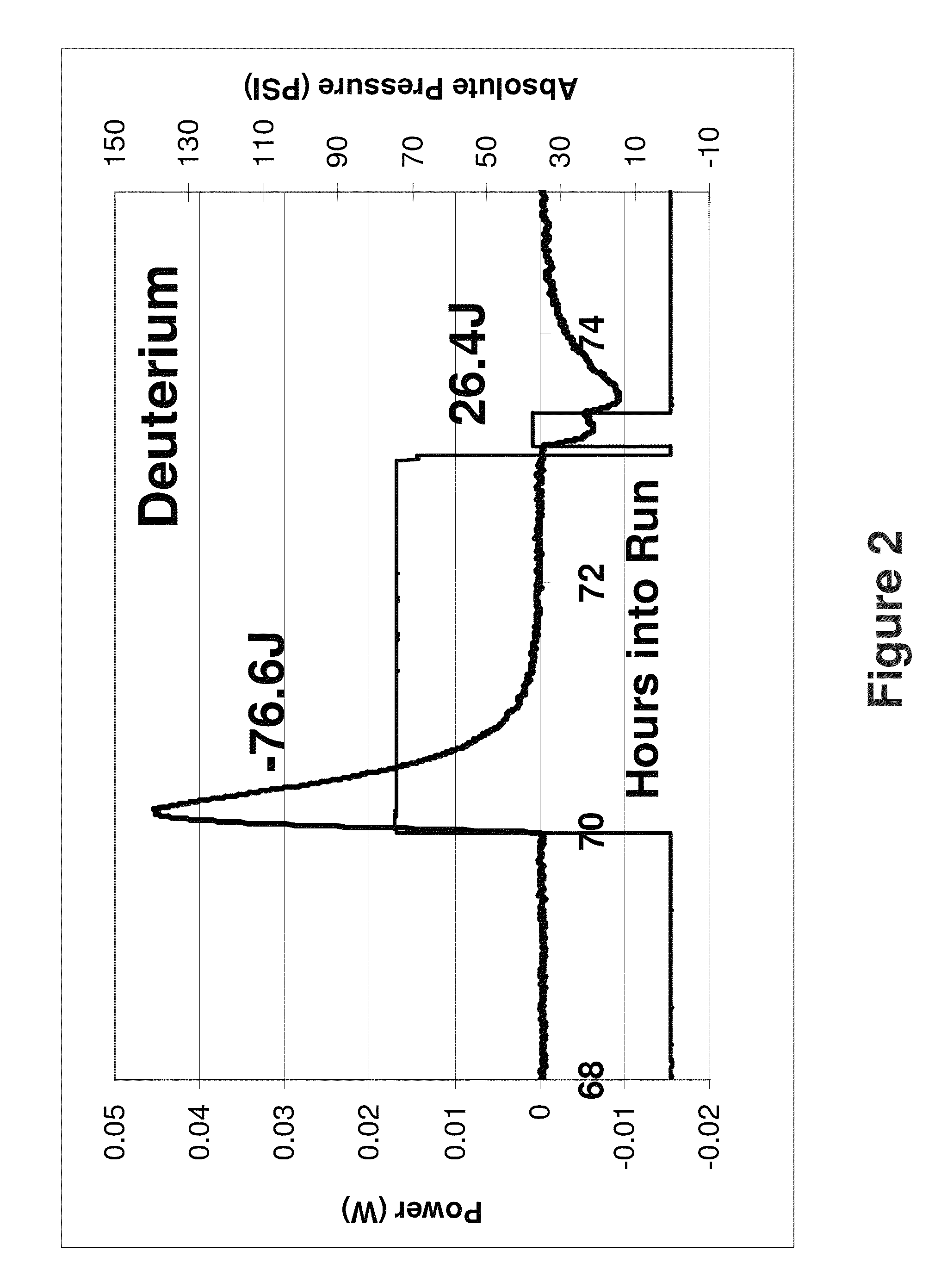

Excess enthalpy upon pressurization of nanosized metals with deuterium

A method for producing excess enthalpy by impregnating metallic precursors on an oxide support that reduces sintering and particle growth; drying the impregnated support at a temperature where the particle growth is minimal; reducing the metallic precursors at a second temperature where the particle growth results in supported metallic particles 2 nm or less in size; and pressurizing the supported metallic particles in the presence of deuterium. The metal particles may comprise palladium, platinum, mixtures thereof, or mixtures of palladium and / or platinum with other elements. Also disclosed is a method for measuring excess enthalpy by placing a test material in a pressure vessel; heating the pressure vessel; evacuating the pressure vessel; introducing deuterium, hydrogen, or both into the pressure vessel; measuring the enthalpy generated during pressurization; again evacuating the pressure vessel; and measuring the enthalpy used during depressurization.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

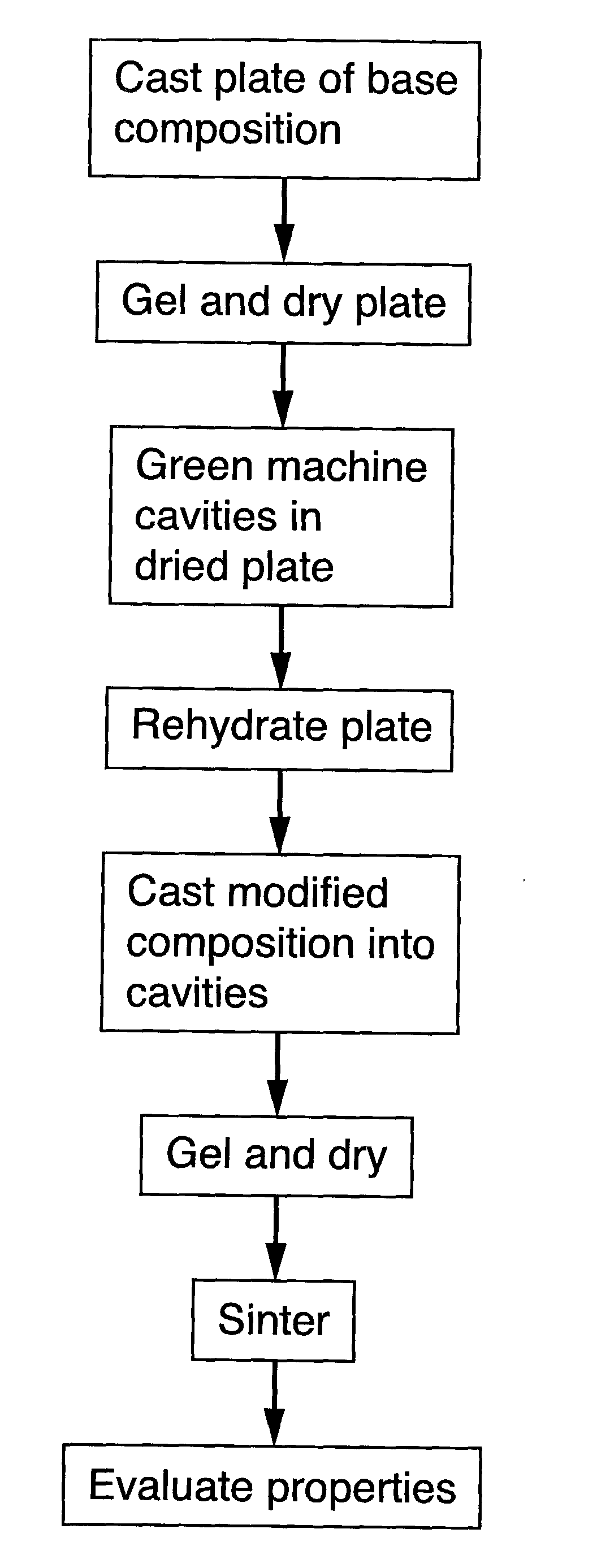

Combinatorial synthesis of ceramic materials

InactiveUS20040062911A1Overcome limitationsRealistic and physical propertyButtonsLayered productsTest materialCombinatorial synthesis

A combinatorial library includes a gelcast substrate defining a plurality of cavities in at least one surface thereof; and a plurality of gelcast test materials in the cavities, at least two of the test materials differing from the substrate in at least one compositional characteristic, the two test materials differing from each other in at least one compositional characteristic.

Owner:UT BATTELLE LLC

Micro slit viscometer with monolithically integrated pressure sensors

InactiveUS7290441B2Smooth inner surfaceReduce manufacturing costMaterial analysis by optical meansDirect flow property measurementTest sampleMicrometer

An improved micro slit viscometer includes a combined micrometer depth rectangular slit flow channel with monolithically integrated multiple pressure sensors in the flow channels and a pumping system that injects a test sample to the channel at a desired flow rate. Pressure sensing diaphragm of the monolithically integrated pressure sensors is smooth to minimize the flow disturbance thereby measuring accurate local pressures. With the measurement of the pressures at various locations of the channel the true viscosity of test sample can be calculated. The viscometer may consist of multiple flow channels and thus the true viscosity at multiple shear rates can be measured simultaneously for a given flow rate thereby obtaining a full viscosity curve as a function of shear rate of non-Newtonian liquids in a much faster manner. The viscometer needs only a miniscule amount of sample, which minimizes a waste of test material. The flow channels and the monolithically integrated pressure sensors are fabricated using microfabriaction processes on wafers and combined, which greatly reduce the production costs.

Owner:RHEOSENSE

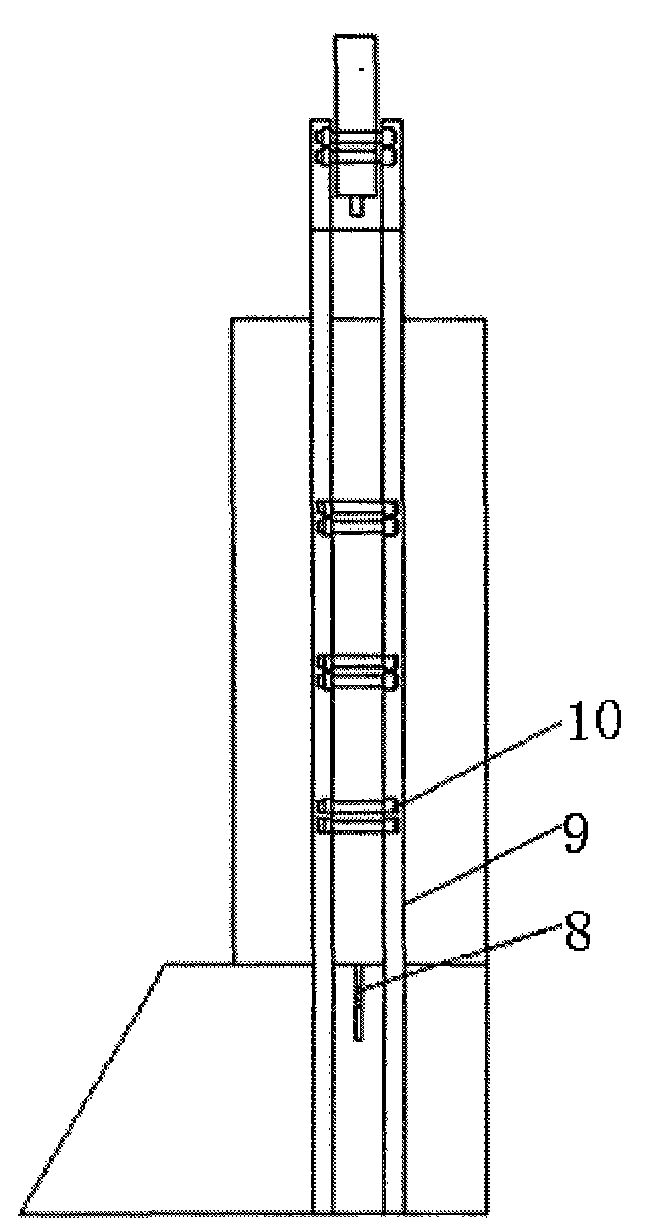

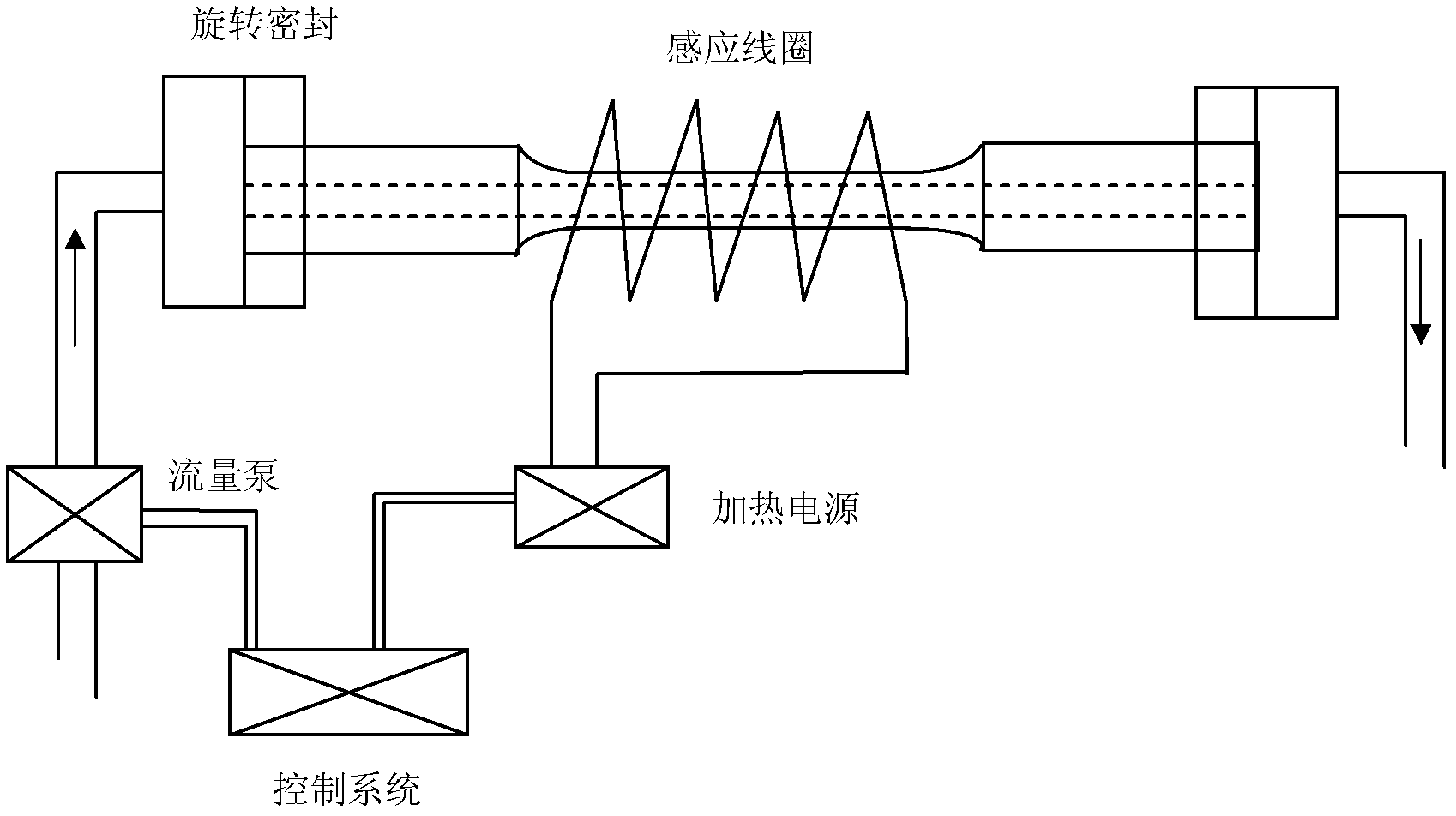

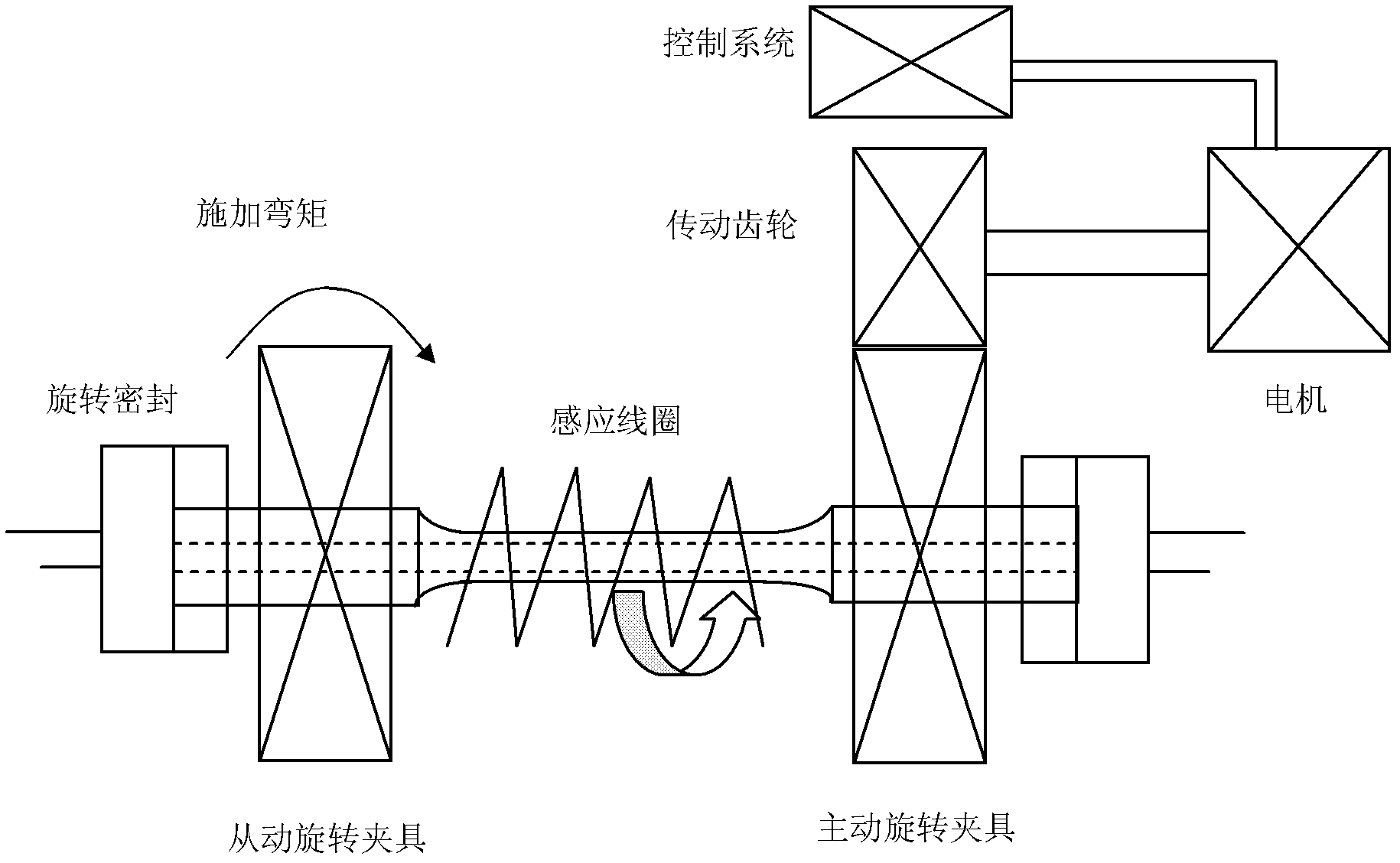

Thermal-force coupling fatigue test device and method

The invention relates to a thermal-force coupling fatigue test device and method, belonging to the field of metal material performance test and analysis. The device comprises a tested material test sample, a cold-thermal fatigue system and a stress fatigue system, wherein the test sample comprises a clamping section, a test section and a transition section; the cold-thermal fatigue system comprises a high frequency induction coil, a rotary seal device, a flow pump, a temperature sensor, a heating power supply, a cooling medium pipeline and a control system; and the stress fatigue system mainly comprises a driving rotating fixture, a driven rotating fixture, a transmission gear, a motor and a motor control system. The method comprises the following steps of: connecting and fixing the test sample with the cold-thermal fatigue system and the stress fatigue system, and carrying out cold-thermal fatigue while stress fatigues under different stresses are carried out to obtain a curve which shows variation of stress fatigue life along with cyclic stress; and adjusting parameters of the cold-thermal fatigue, thus influence of cold-thermal fatigue temperature to fatigue limit can be obtained.

Owner:UNIV OF SCI & TECH BEIJING

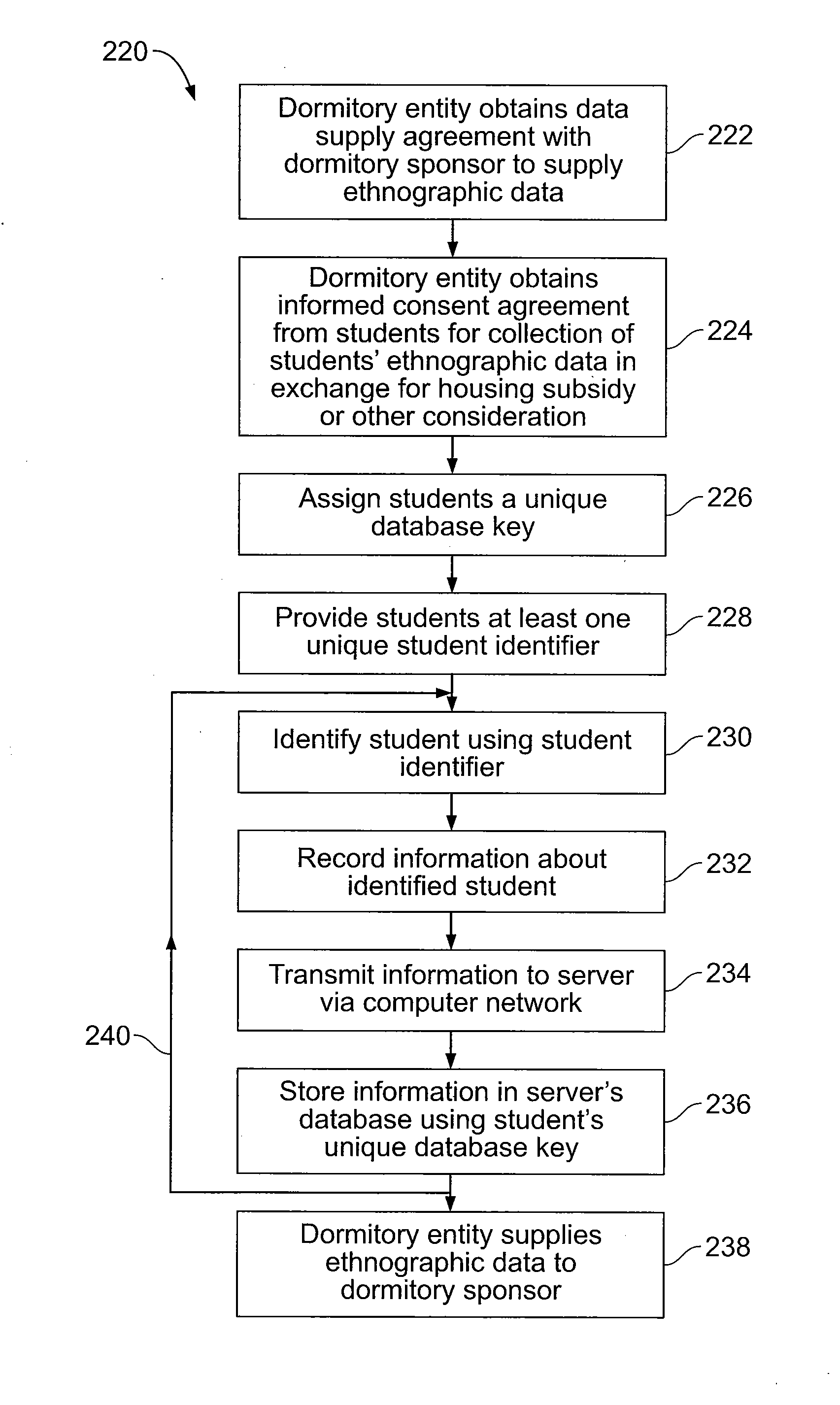

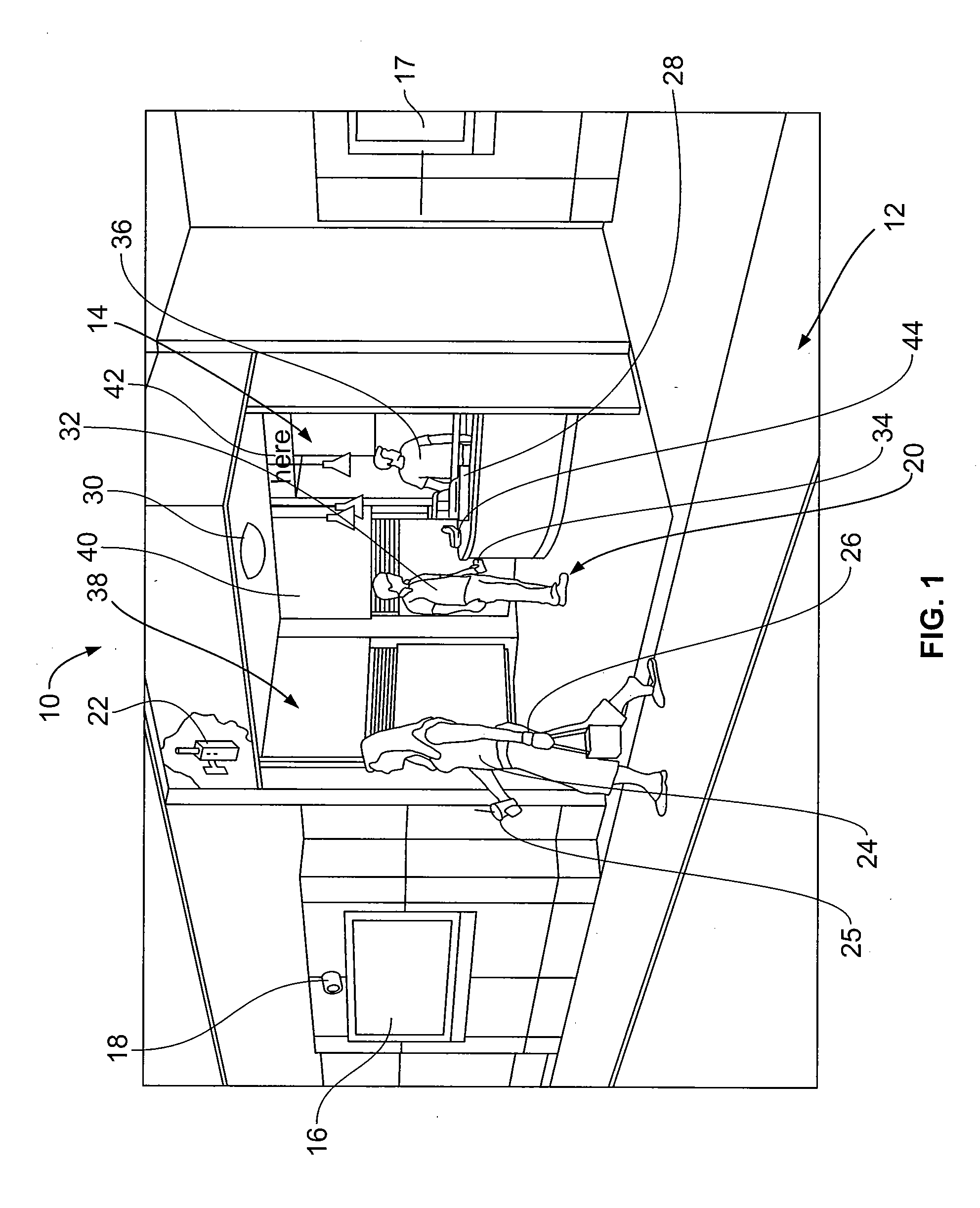

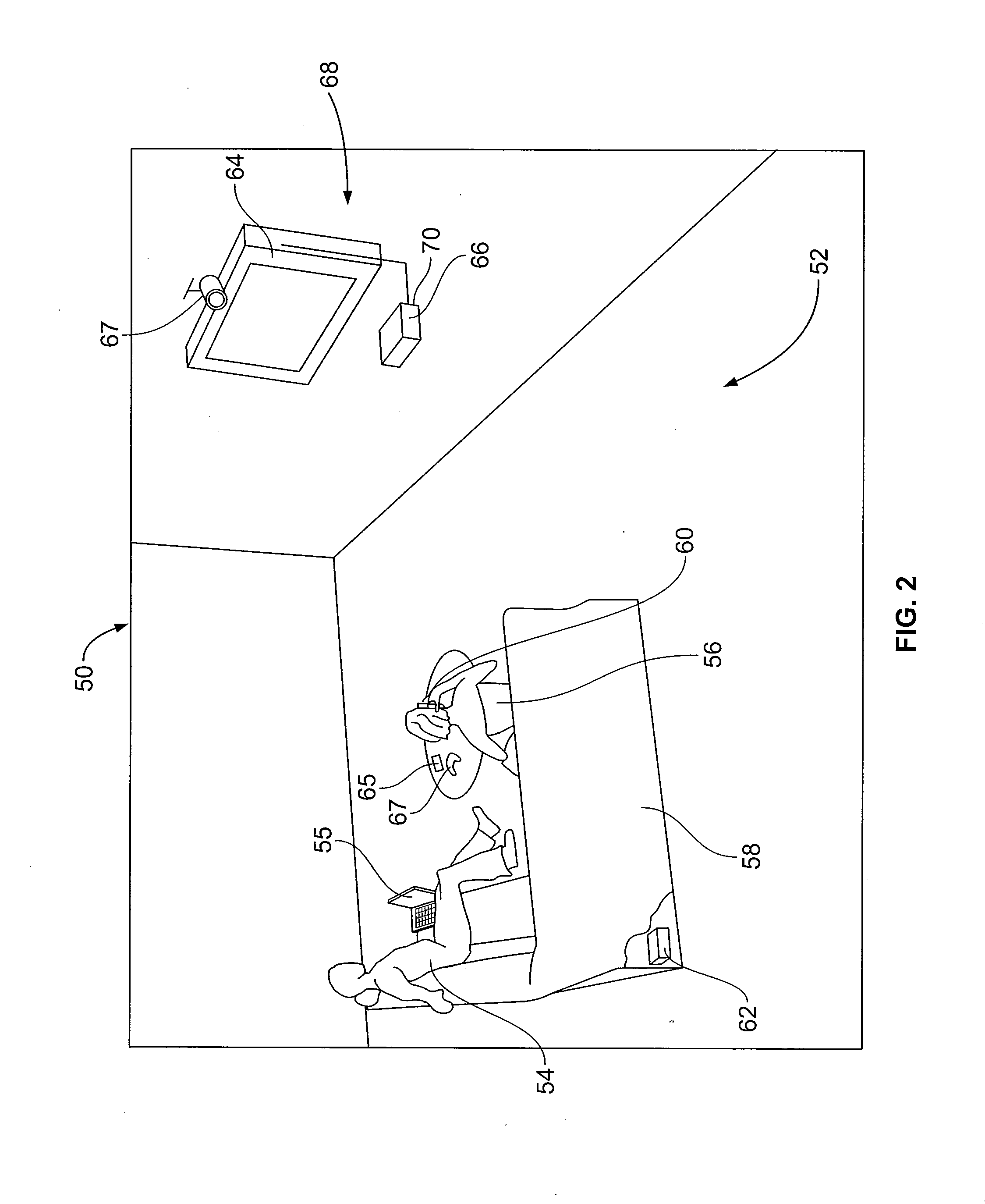

Method and apparatus to monitor human activities in students' housing

InactiveUS20120130770A1Low costSave researcher ' timeMarket predictionsDiscounts/incentivesCost effectivenessTest material

A method and apparatus for collection of ethnographic data from a building housing a population, which includes modern surveillance equipment, marketing and other testing materials, and may comprise an agreement between the dormitory and a dormitory sponsor to collect ethnographic data and provide test products and other materials in a dormitory equipped as a real-world social laboratory. This synergy between dormitory sponsorship, dormitory management, and students allows for easy, organized and cost effective experimentation and data mining of the valuable student demographic with incentive to the parties involved.

Owner:HEFFERNAN JAMES W +1

A multi-axis creep fatigue prediction method based on ABAQUS

ActiveCN109885874AGain creep damageIntuitiveMaterial strength using tensile/compressive forcesDesign optimisation/simulationFatigue damageElement model

The invention discloses a multi-axis creep fatigue prediction method based on ABAQUS, and the method comprises the steps of S1, building an ABAQUS finite element model, and defining a viscoplastic constitutive equation of a to-be-tested material through a user subprogram UMAT; S2, determining model parameters required by the viscoplastic constitutive equation; S3, establishing a fatigue damage calculation model and a creep damage calculation model of the multi-axis stress-strain state of the to-be-tested material; S4, establishing an ABAQUS finite element model in a multi-axis stress-strain state, and calculating to obtain a stress-strain tensor of each cycle on the basis of the defined viscoplastic constitutive equation and model parameters; and S5, calculating equivalent stress and equivalent plastic strain through a user subprogram USDFLD, and superposing fatigue damage and creep damage of each cycle through a linear cumulative damage criterion on the basis of the fatigue damage calculation model and the creep damage calculation model in combination with the stress strain tensor to obtain the crack initiation life.

Owner:EAST CHINA UNIV OF SCI & TECH

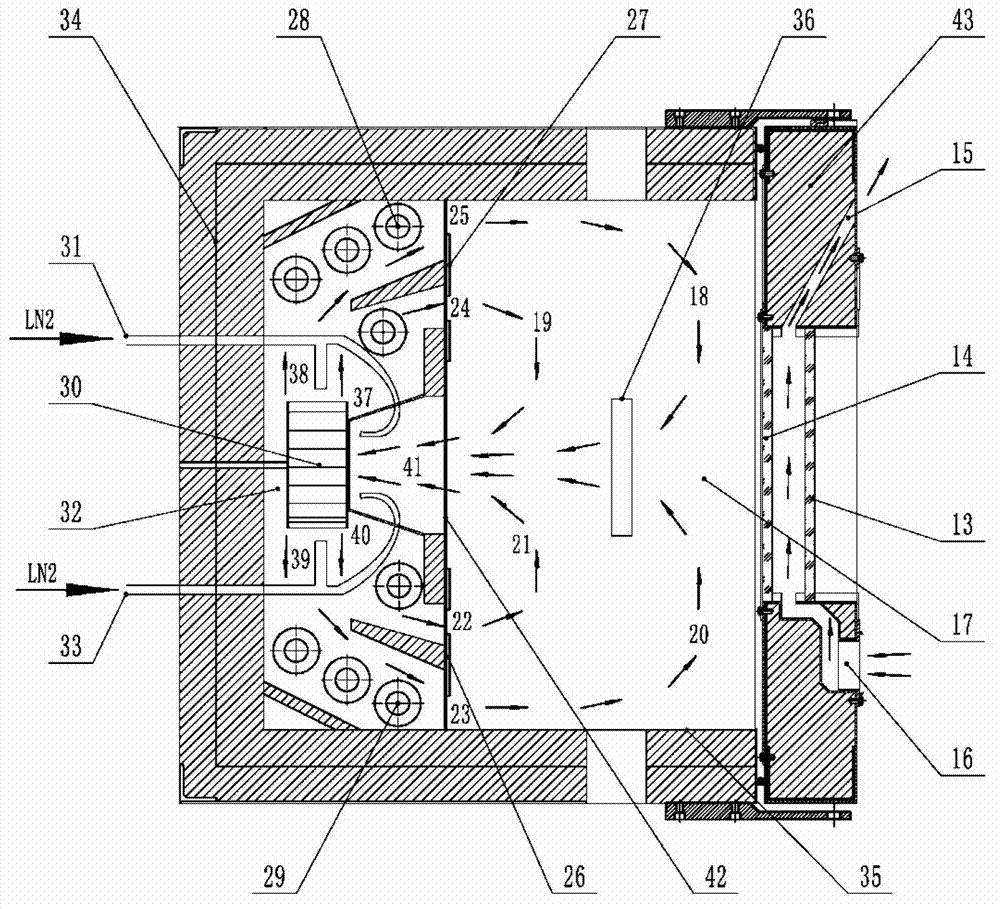

High-low temperature dynamic cold-hot circulation thermodynamic test system

InactiveCN102879278ARealize two-way cooling and heating cycleLow temperatureMaterial strength using tensile/compressive forcesLiquid nitrogen containerEngineering

The invention discloses a high-low temperature dynamic cold-hot circulation thermodynamic test system suitable for mechanics performance testing under a high-low temperature environment. A test box adopts a design of an inner cavity and an outer cavity; inner and outer cavity baffles are provided with four air outlets from top down and air suction holes in the center; the test box further comprises an optical strain observation window, a defrosting air heater and a multi-point direct-current illumination source; and in addition, the test system further comprises a dual-output PID (Proportion Integration Differentiation) controller, a DIC (Digital Image Correlation) full strain measurement instrument and an automatic switchover liquid nitrogen refrigerating system. According to the high-low temperature dynamic cold-hot circulation thermodynamic test system, the defects that the conventional thermal steady state test system has no thermal transient state and thermal circulation functions and liquid nitrogen cannot be fed without interruption due to limitation of liquid nitrogen container volume on low-temperature refrigeration are solved, and the technical problems of interference and the like of high-temperature hot wave impact and low-temperature frost fog on full strain measurement are solved at the same time, so that the purposes of obtaining the mechanical performance of a test material under the high-low temperature environment in the processes of thermal steady state, thermal transient state, cold-hot circulation and the like and synchronously measuring a sample strain field are achieved.

Owner:TSINGHUA UNIV

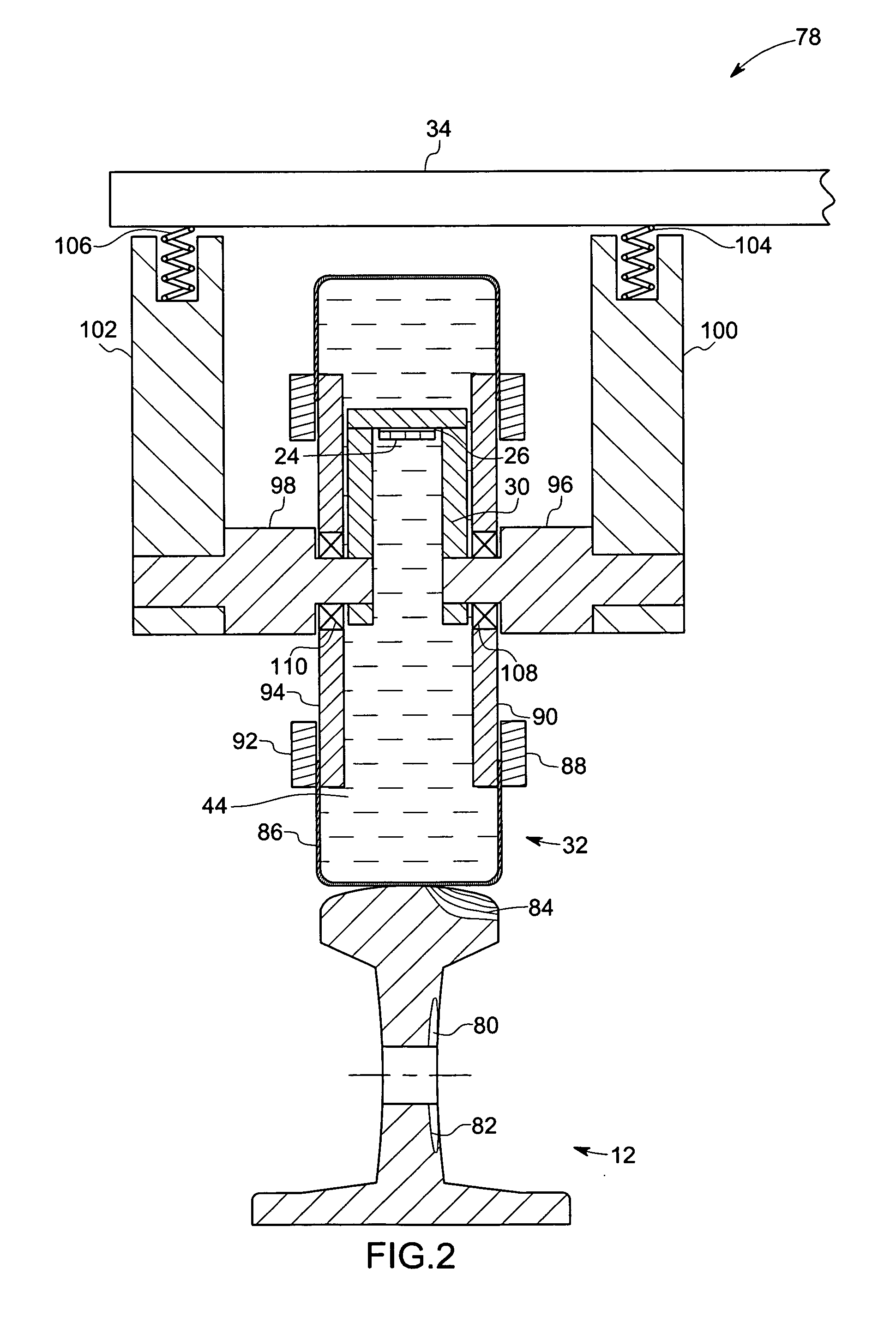

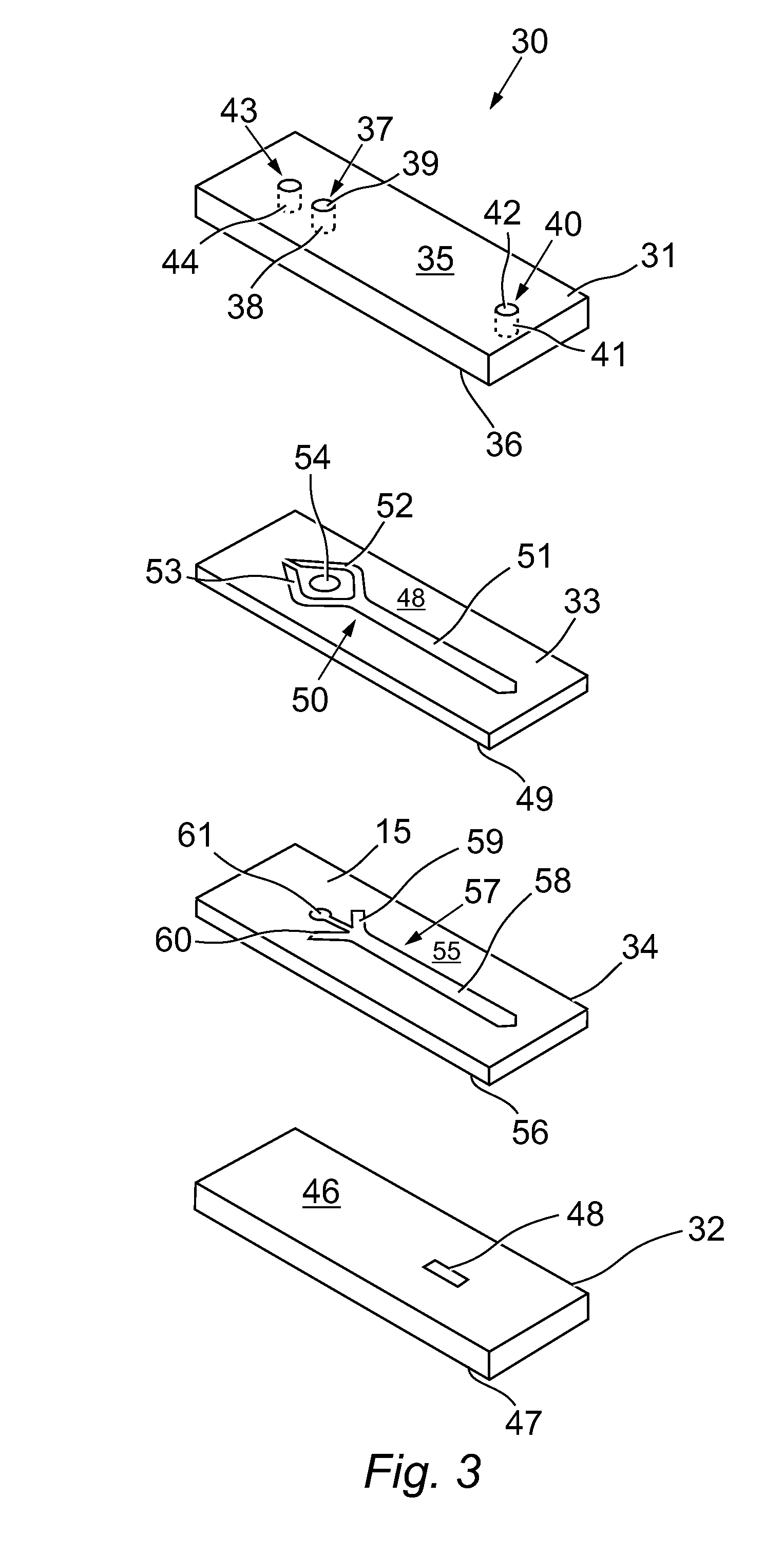

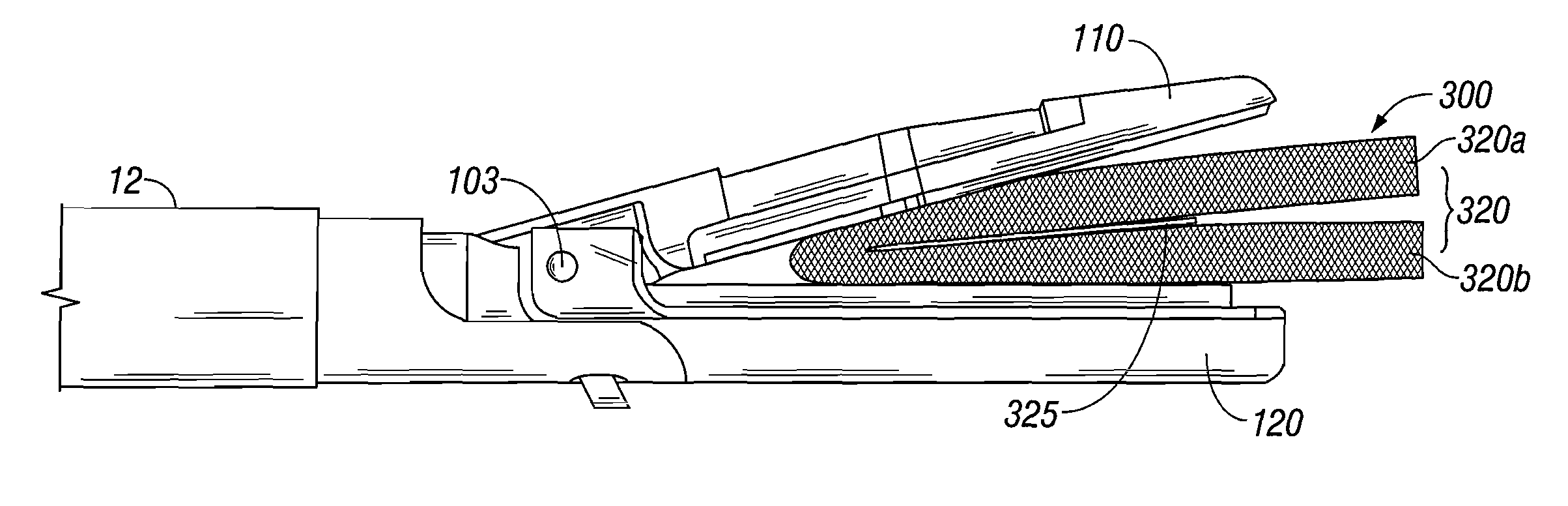

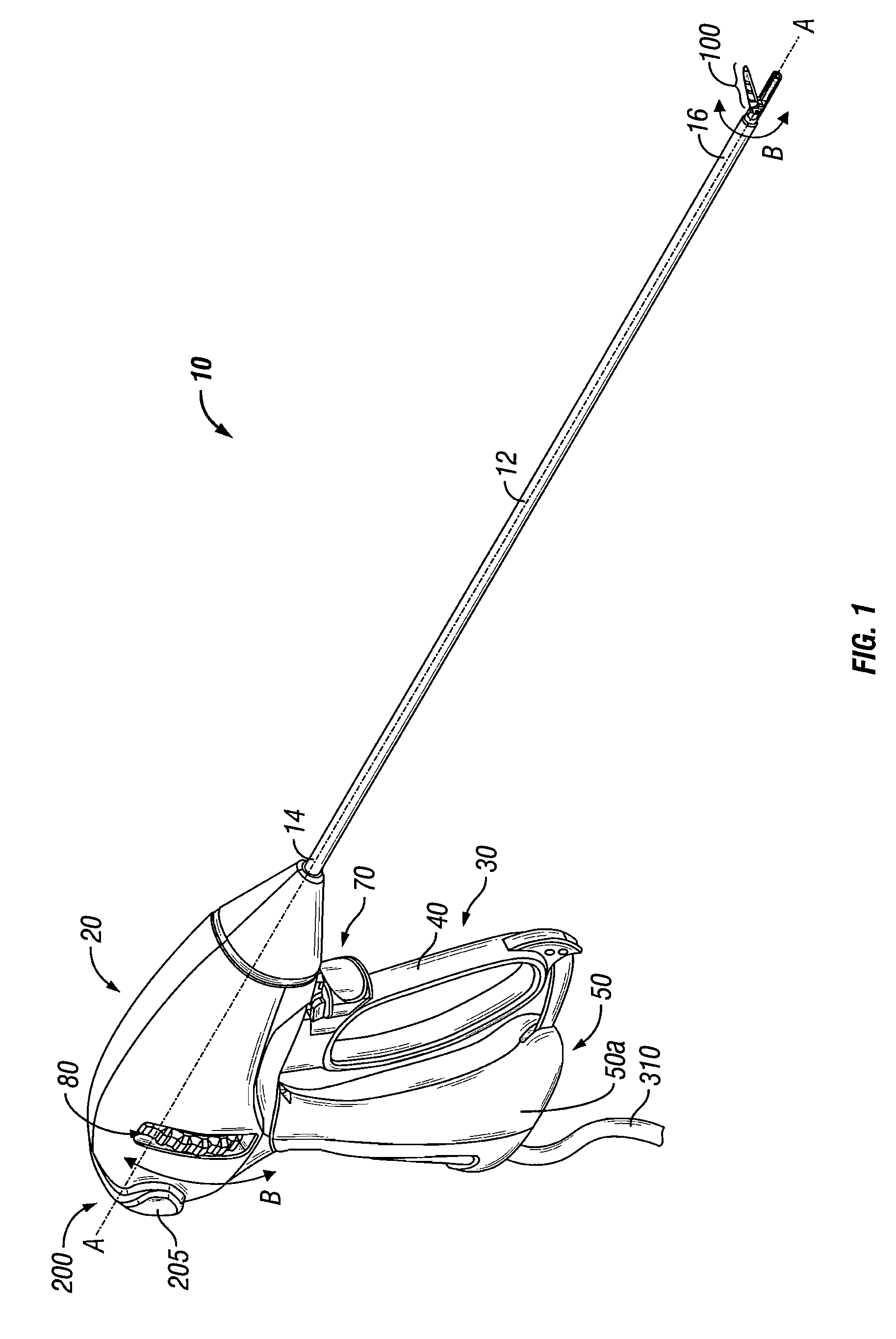

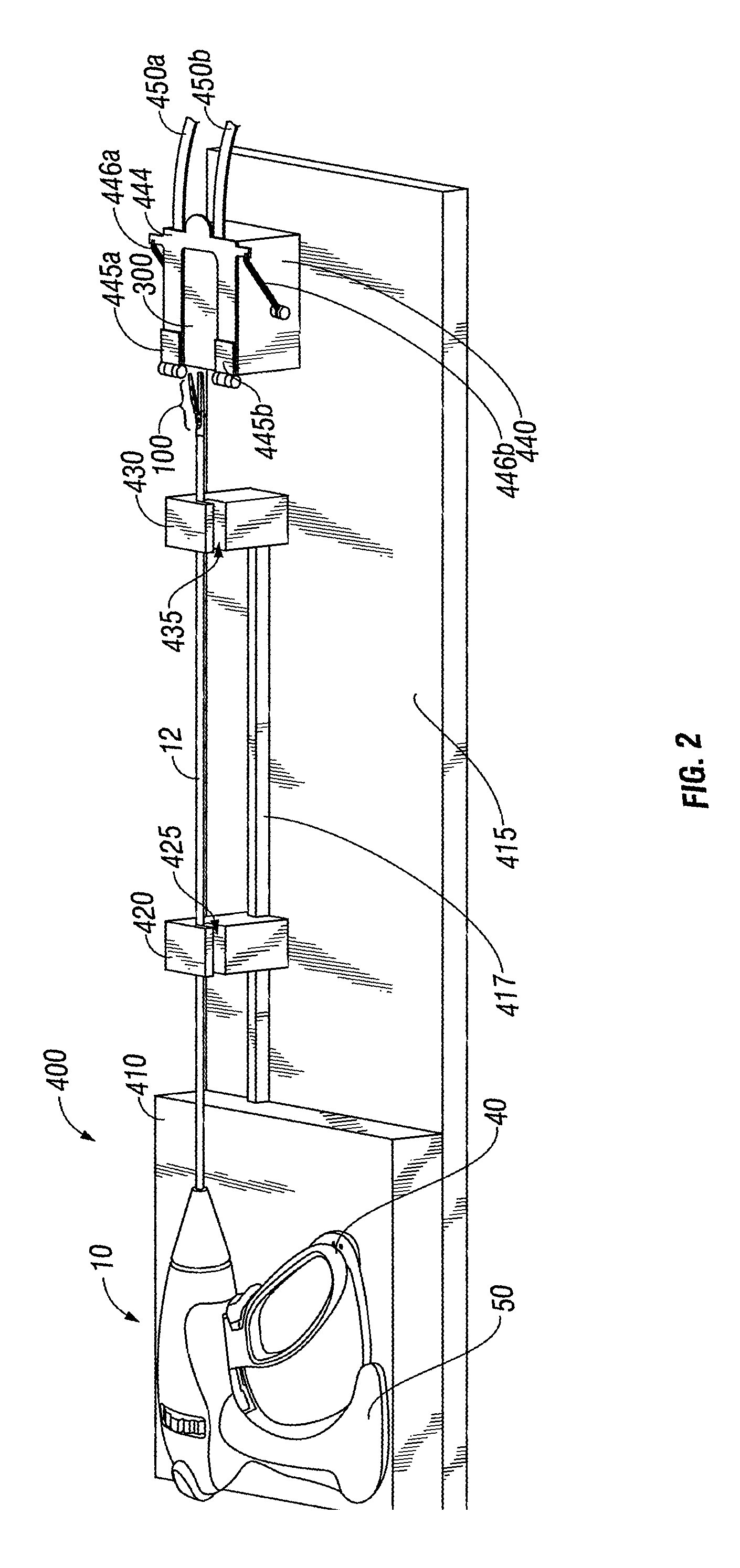

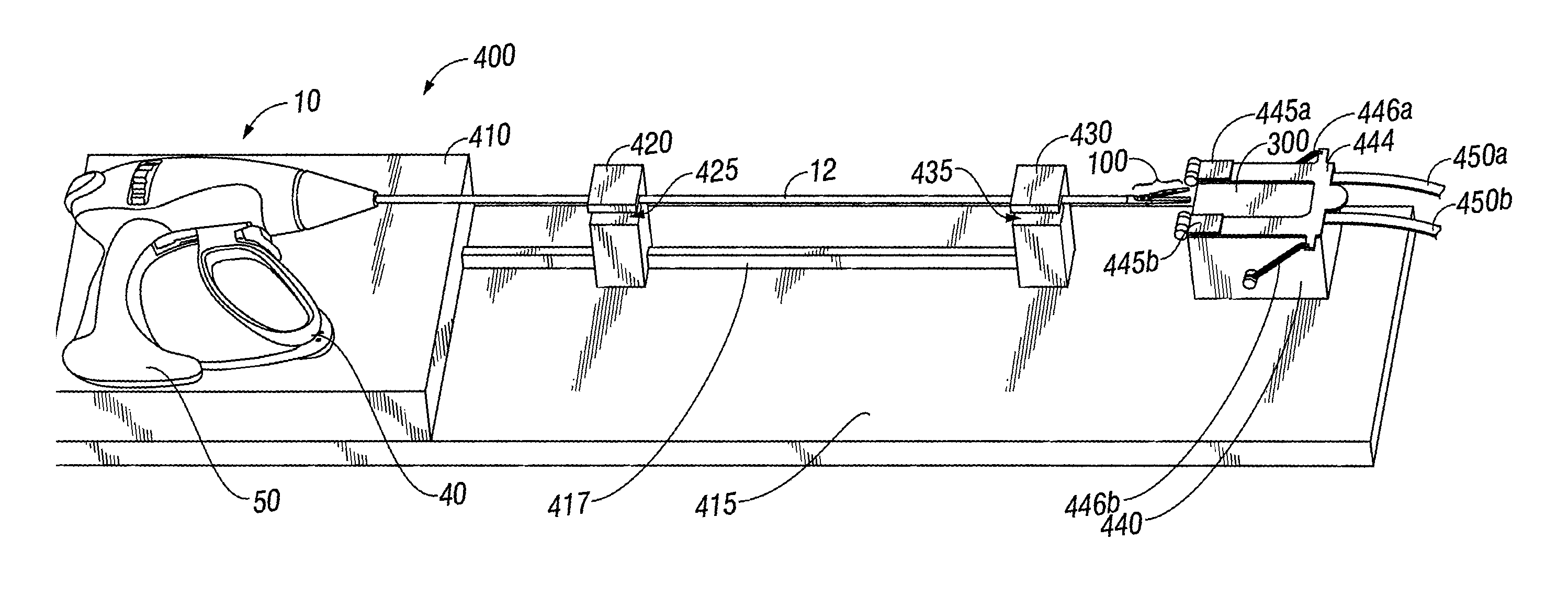

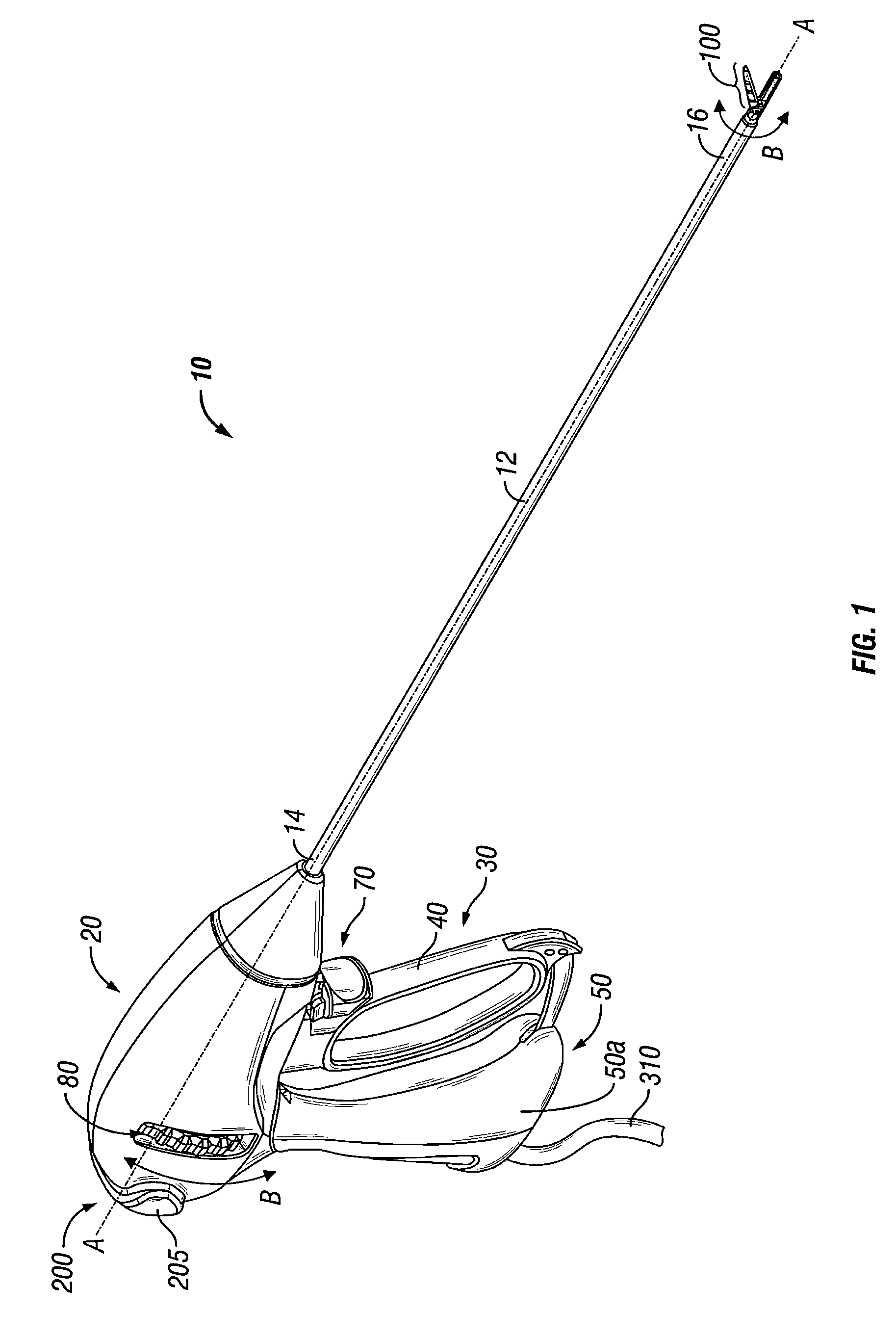

Apparatus and method for measuring pressure between jaw members

Testing system for measuring closure pressure between jaw members of electrosurgical forceps. The testing system includes a testing platform, a pair of selectively adjustable instrument supports, a testing stand. The platform has an elongated bed that supports an instrument rest, which supports the electrosurgical forceps. The pair of instrument supports are associated with the elongated bed and secure the forceps atop the elongated bed. The testing stand is disposed at a distal end of the elongated bed and supports a piece of testing material. The testing stand includes a layer of visco-elastic material and a pressure sensitive film. The layer of visco-elastic material forms a pocket. The pressure sensitive film is disposed within the pocket of the visco-elastic layer. The pressure sensitive film is adapted to electromechanically communicate with a diagnostic system to measure the closure pressure between jaw members when they are in a clamped configuration.

Owner:TYCO HEALTHCARE GRP LP

Method and apparatus for testing material integrity

InactiveUS20050285588A1Base element modificationsElectrical testingElectrical conductorEddy current effect

In accordance with one embodiment, the present technique provides a testing apparatus for testing material integrity in an object. The testing apparatus includes an electrical conductor and a sensing device. In the exemplary testing device, the electrical conductor extends in a generally linear direction and is configured to route current in a direction generally transverse to a longitudinal axis of the object being tested. Routing of current through the electrical conductor creates remote field eddy current effect, which, in turn, affects a magnetic field around the test object. The testing apparatus also includes a sensing device located at a distance from the electrical conductor and configured to detect magnetic fields generated in response to current routed through the electrical conductor.

Owner:GE GLOBAL SOURCING LLC

Apparatus and method for measuring pressure between jaw members

Owner:TYCO HEALTHCARE GRP LP

Quantum resonance analytical instrument

Quantum based systems for detecting materials in a sample, including biological, chemical and physical materials are described. The systems are based on exciting the sample containing the material with a femtosecond to nanosecond probe pulse of collimated light, which is tailored to optimize detection of a given material by separating the probe pulse into component features of frequency, polarization, phase and / or amplitude. The component features are independently shaped and formed into a composite pulse selected to optimize a signature response pulse received from the material. Selection of the appropriate shapes for the component features of the pulse for a given material is accomplished by testing variations in the features on the material, assigning a fitness value to variants that tend to optimize a distinctive spectral response from the material, and using a genetic algorithm to select the combination of component features that enhances the distinctiveness of the response received over a typical background.

Owner:MCGREW STEPHEN P

Simulated corrosion test device and method for abyssal environment

InactiveCN103115862AWon't flow outImprove solubilityWeather/light/corrosion resistanceAutomatic controlEngineering

The invention relates to a simulated corrosion test device for an abyssal environment, belonging to the field of simulated test devices for the corrosion property of materials in the abyssal environment. The device comprises an autoclave, a refrigeration system, an air pump, a pressurizing system, a sample delivery device, an exhaust pipe, a dissolved oxygen sensor, an ultrasonic Doppler flowmeter, a pressure sensor, a temperature sensor, a salinity sensor, a pH meter, a drain pipe, a stirring motor, stirring blades and a control cabinet. The device has the advantages that the conditions of temperature, pressure intensity, seawater flow velocity, pH value, salinity and dissolved oxygen concentration of the abyssal environment can be simulated, the automation of control on environment conditions can be realized during a corrosion test, and a convenient indoor simulated test device for testing the corrosion property of the materials in the abyssal environment is provided.

Owner:JIANGSU UNIV

Method and apparatus for testing material utilizing differential temperature measurements

A method and apparatus for timely and accurate measurement of material parameters are disclosed. A test sensor measures the temperature of a sample of material as it is heated up and / or cooled down. A reference sensor is used to obtain differential temperature measurements as the temperature of the test sample is varied. A differential temperature trace is generated and analyzed in order to determine various characteristics of the material being tested. In one embodiment, the sodium fluoride to aluminum fluoride ratio (NaF:AlF3) and alumina concentration in a Hall bath aluminum smelting operation are determined in order to efficiently control smelting of aluminum metal. In this embodiment, bath temperature and liquidus temperature may be measured and compared in order to determine the amount of superheat of the bath and to prevent the operation of smelters at higher temperatures than necessary.

Owner:ARCONIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com