Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1144results about How to "Lower manufacturing requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

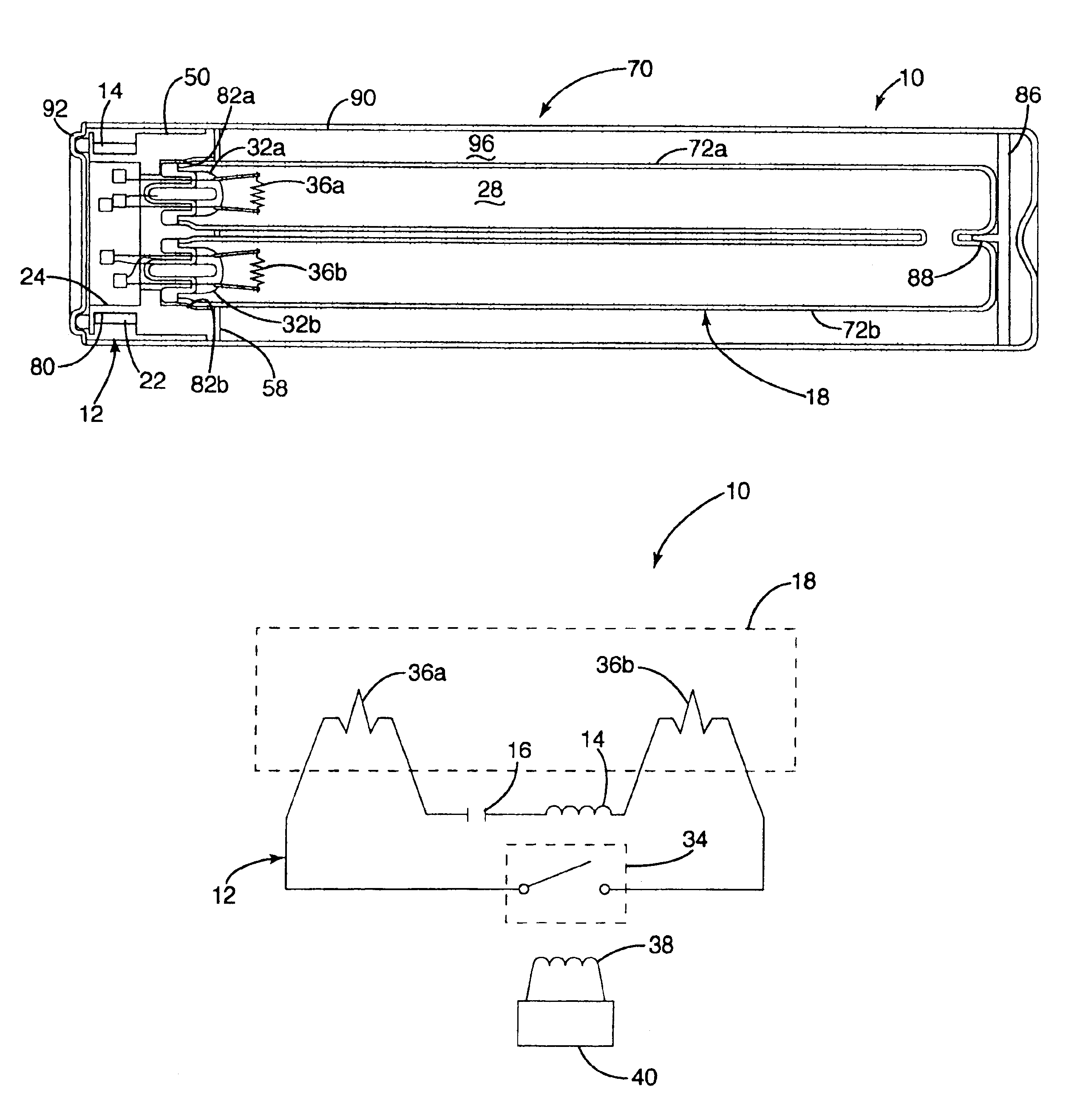

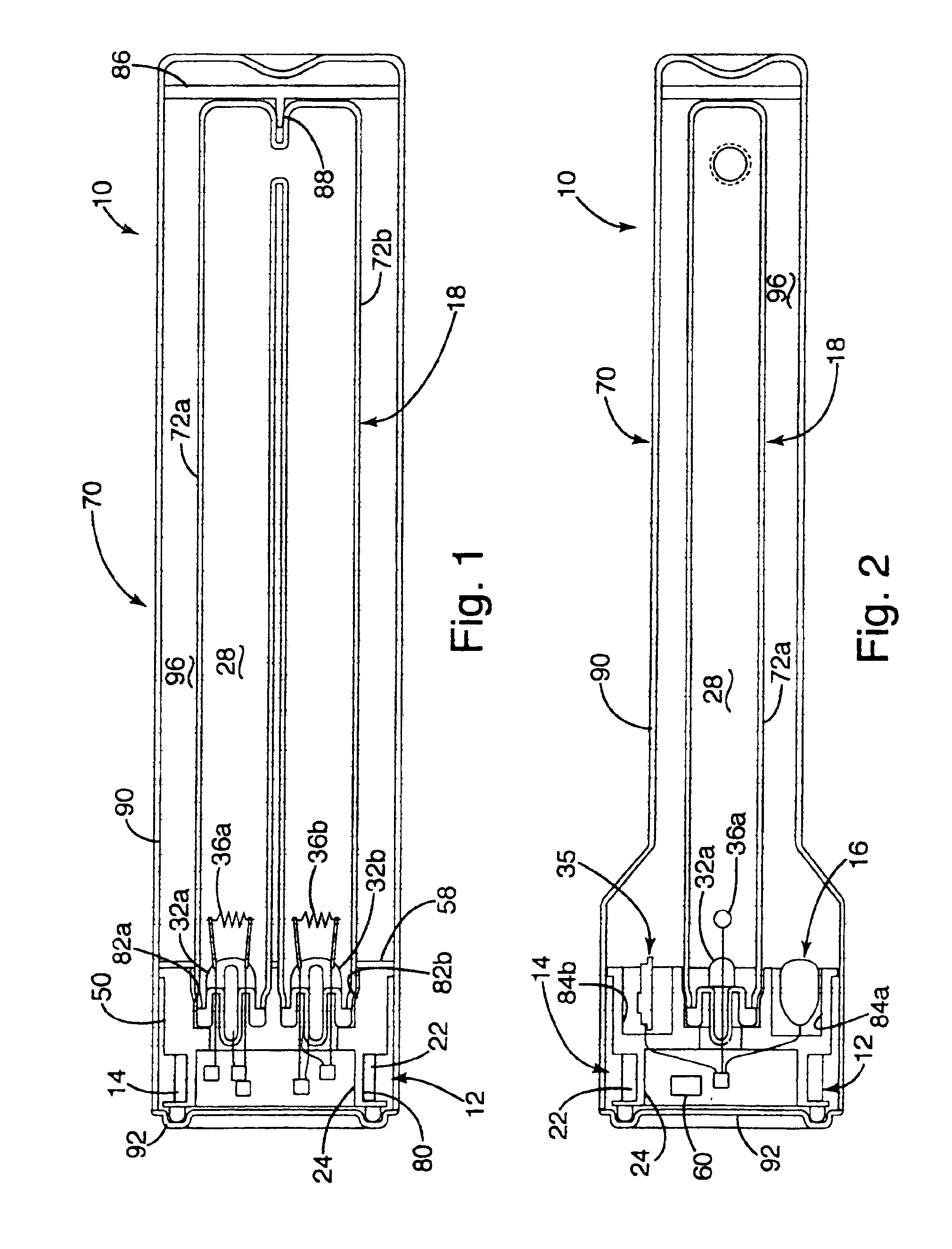

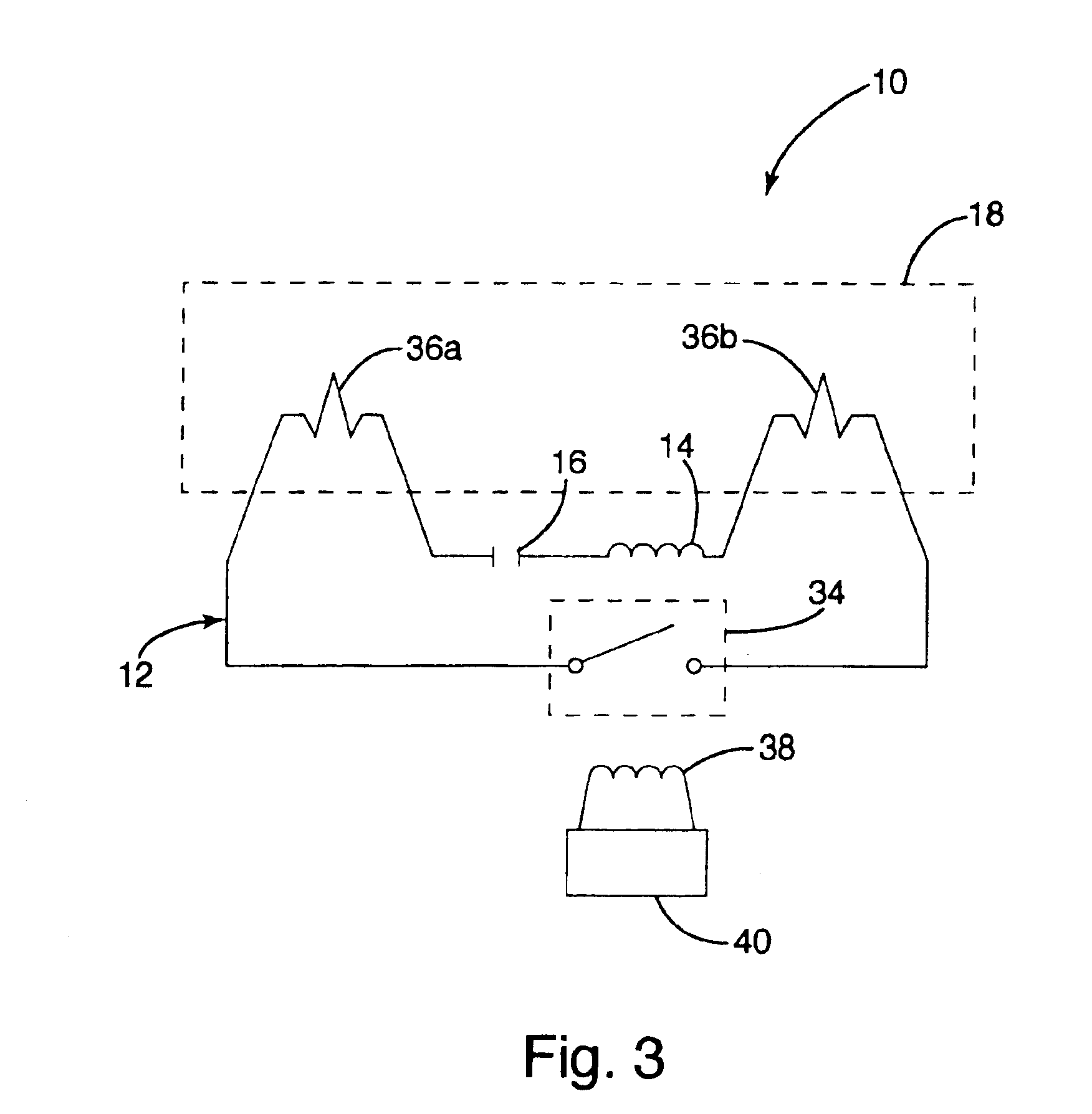

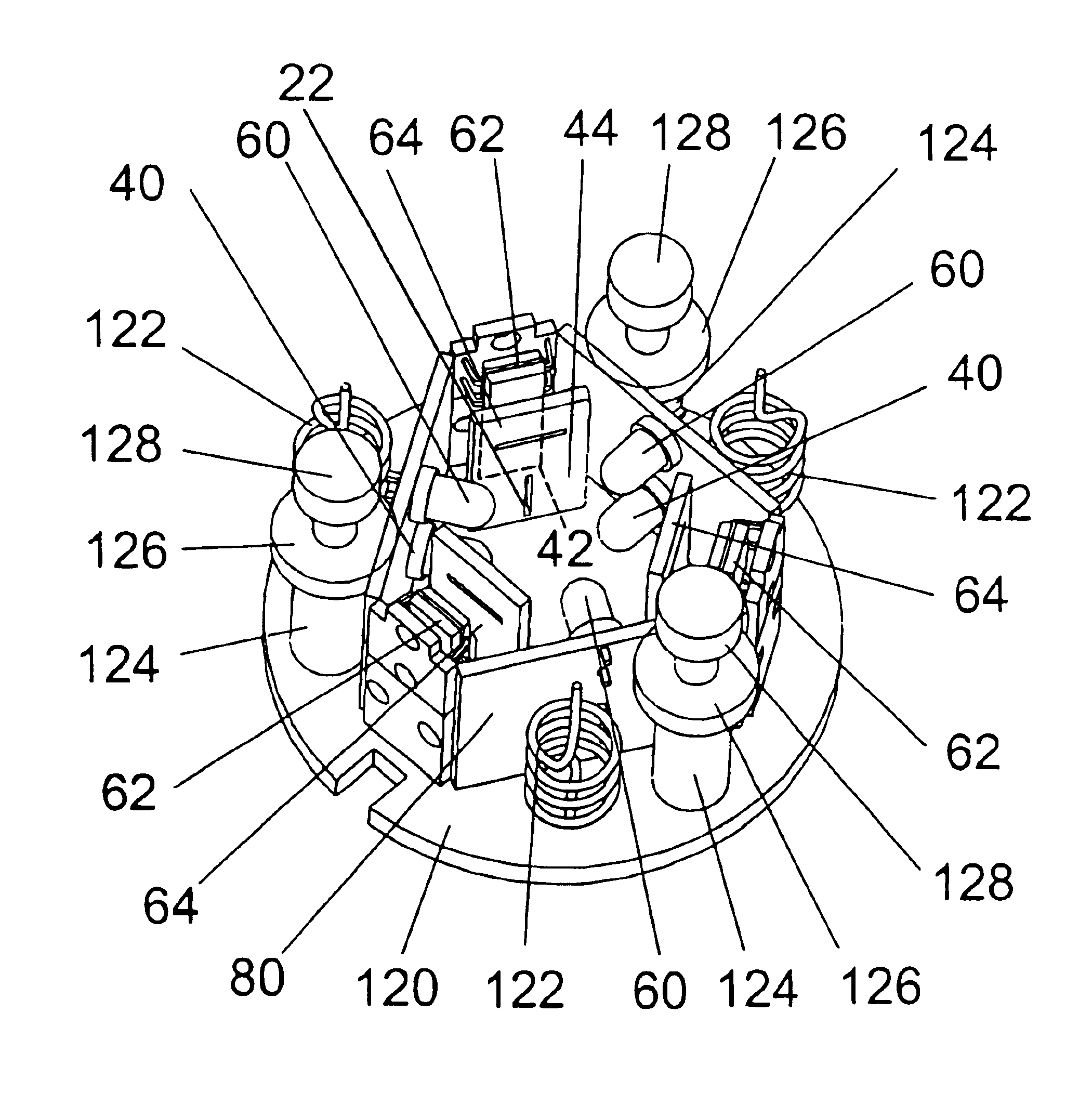

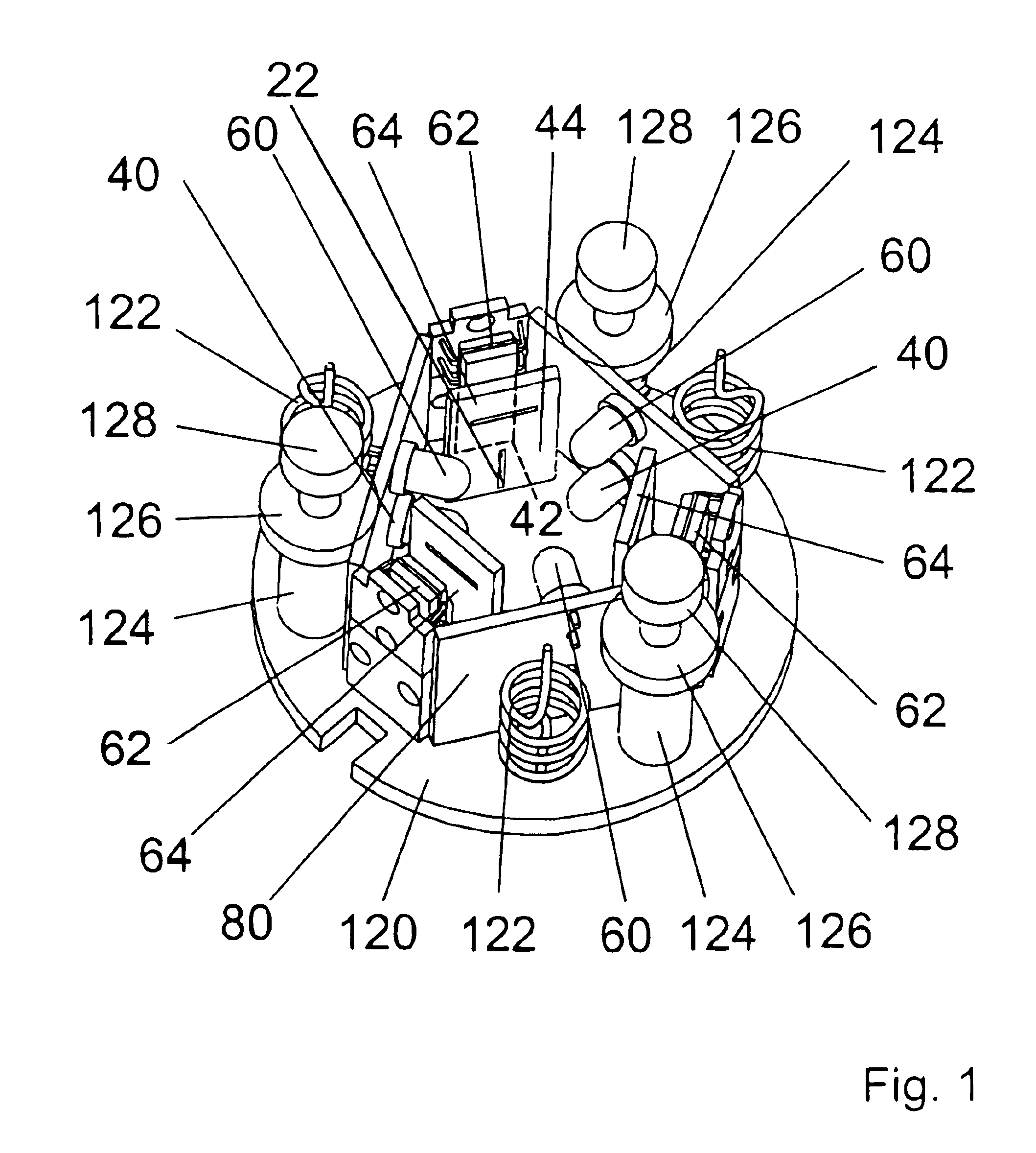

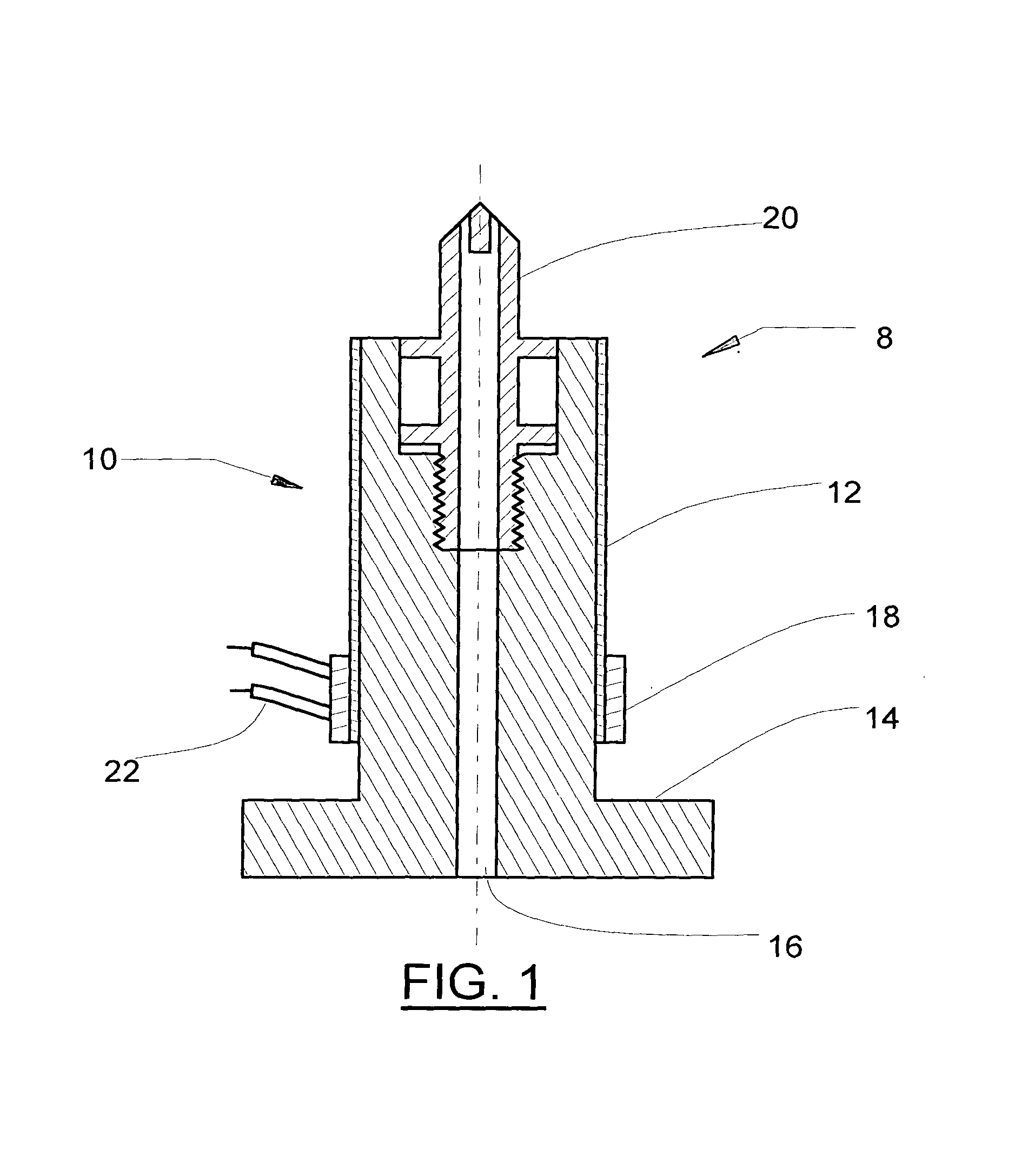

Inductively powered lamp assembly

InactiveUS6917163B2Quiet operationLess-precise alignmentPoint-like light sourceElongate light sourcesResonanceCapacitor

A lamp assembly configured to inductively receive power from a primary coil. The inductively powered lamp assembly includes a lamp circuit including a secondary and a lamp connected in series. In a first aspect, the lamp circuit includes a capacitor connected in series with the lamp and the secondary to tune the circuit to resonance. The capacitor is preferably selected to have a reactance that is substantially equal to or slightly less than the reactance of the secondary and the impedance of the lamp. In a second aspect, the inductively powered lamp assembly includes a sealed transparent sleeve that entirely encloses the lamp circuit so that the transparent sleeve is fully closed and unpenetrated. The transparent sleeve is preferably the lamp sleeve itself, with the secondary, capacitor and any desired starter mechanism disposed within its interior.

Owner:PHILIPS IP VENTURES BV

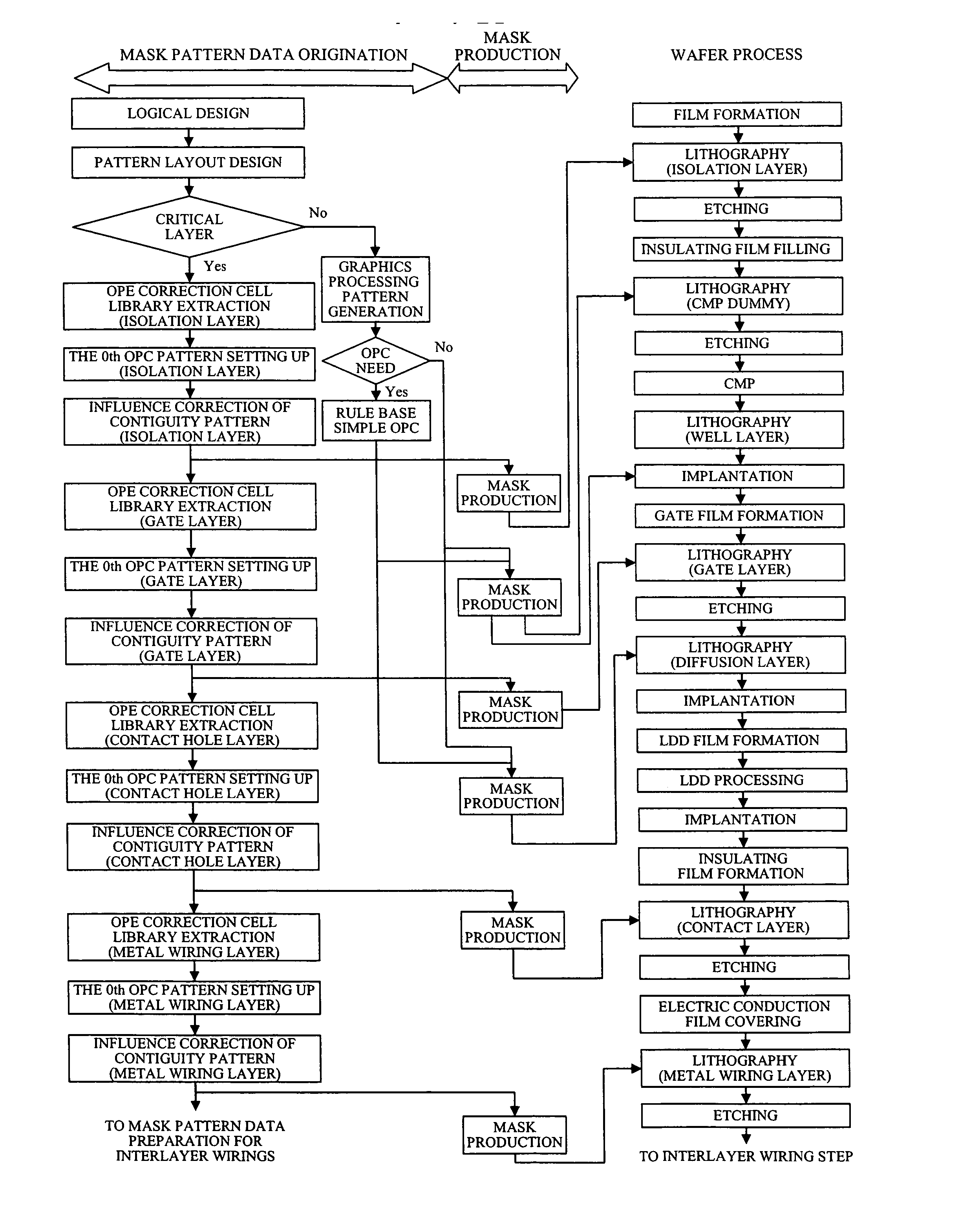

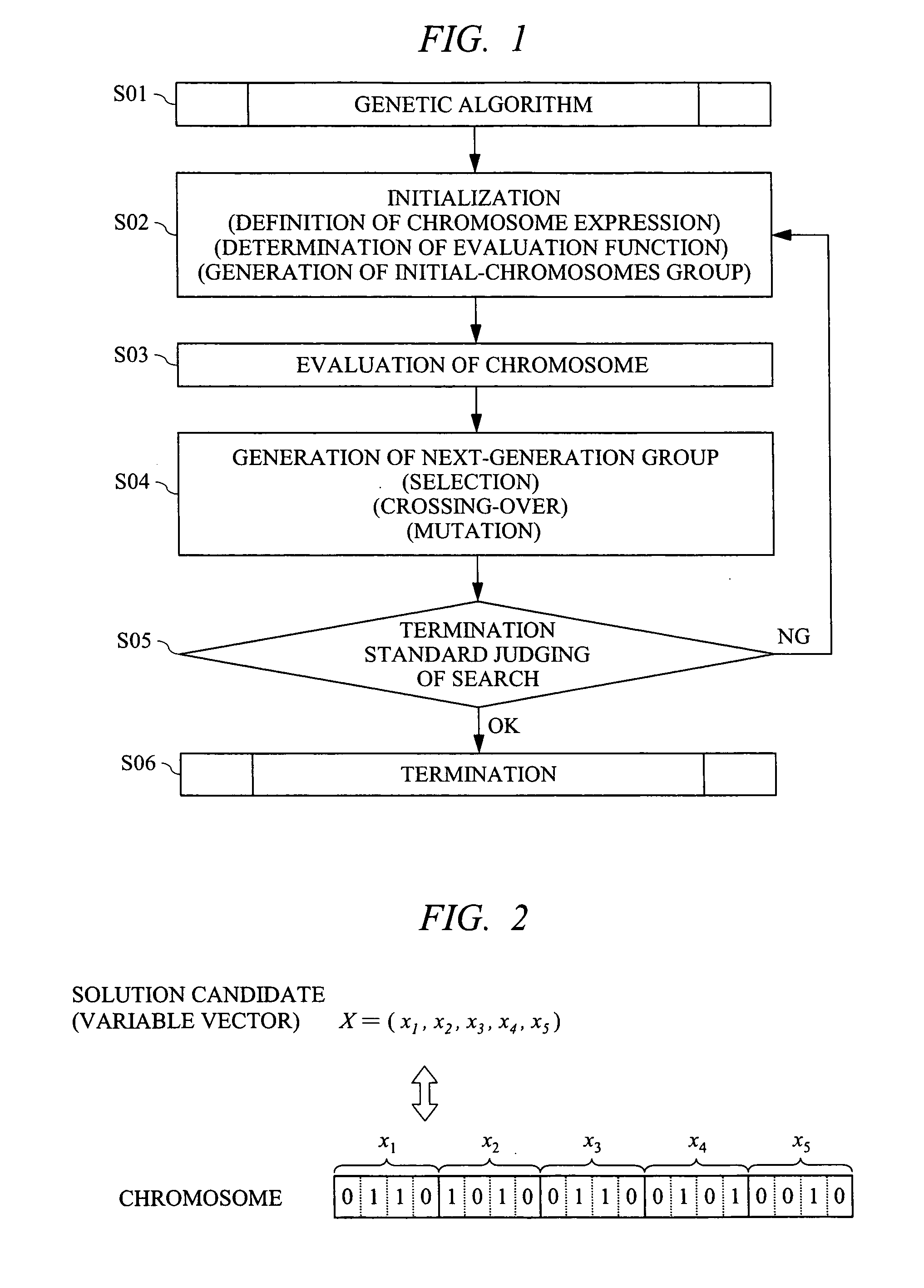

Mask pattern design method and manufacturing method of semiconductor device

InactiveUS20070074145A1Extended processing timeLower manufacturing requirementsOriginals for photomechanical treatmentSpecial data processing applicationsDevice materialSemiconductor chip

To a cell library pattern which makes the basic constitution of a semiconductor circuit pattern, OPC processing is performed beforehand, and a semiconductor chip is produced using this cell library pattern. Since it is influenced by the pattern of the cell arranged to the circumference and the pattern arranged around other cells at this time, correction processing (optimization processing) is performed. The part of this correction processing is a portion in which a pattern faces between cell boundaries in the inside of the region specified from the cell boundary, and proximity effect correction is performed by making the width, the length, and the position of this portion into variables. Or proximity effect correction is performed by making a polygon into a variable. Or sizing is done and proximity effect correction is performed.

Owner:RENESAS TECH CORP

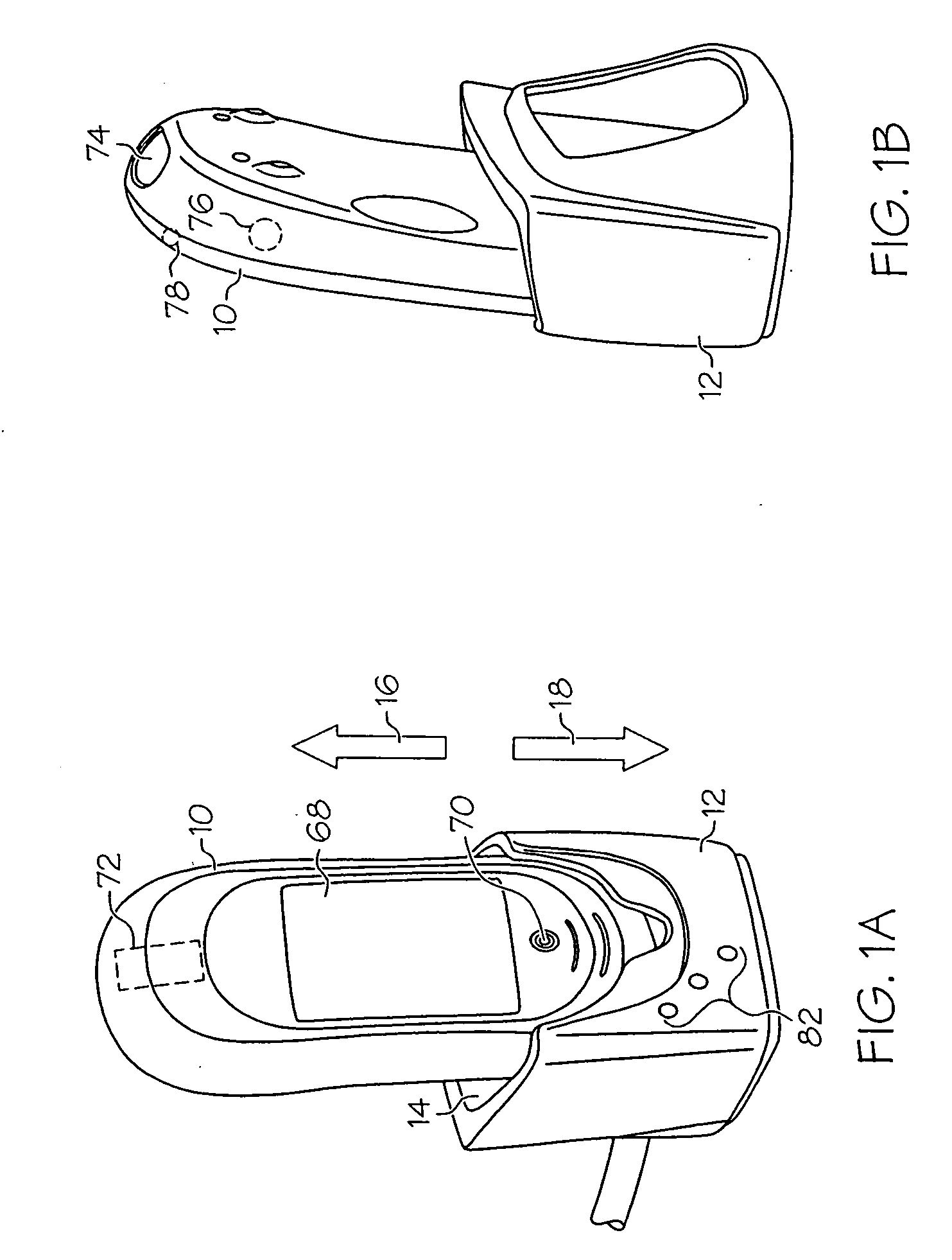

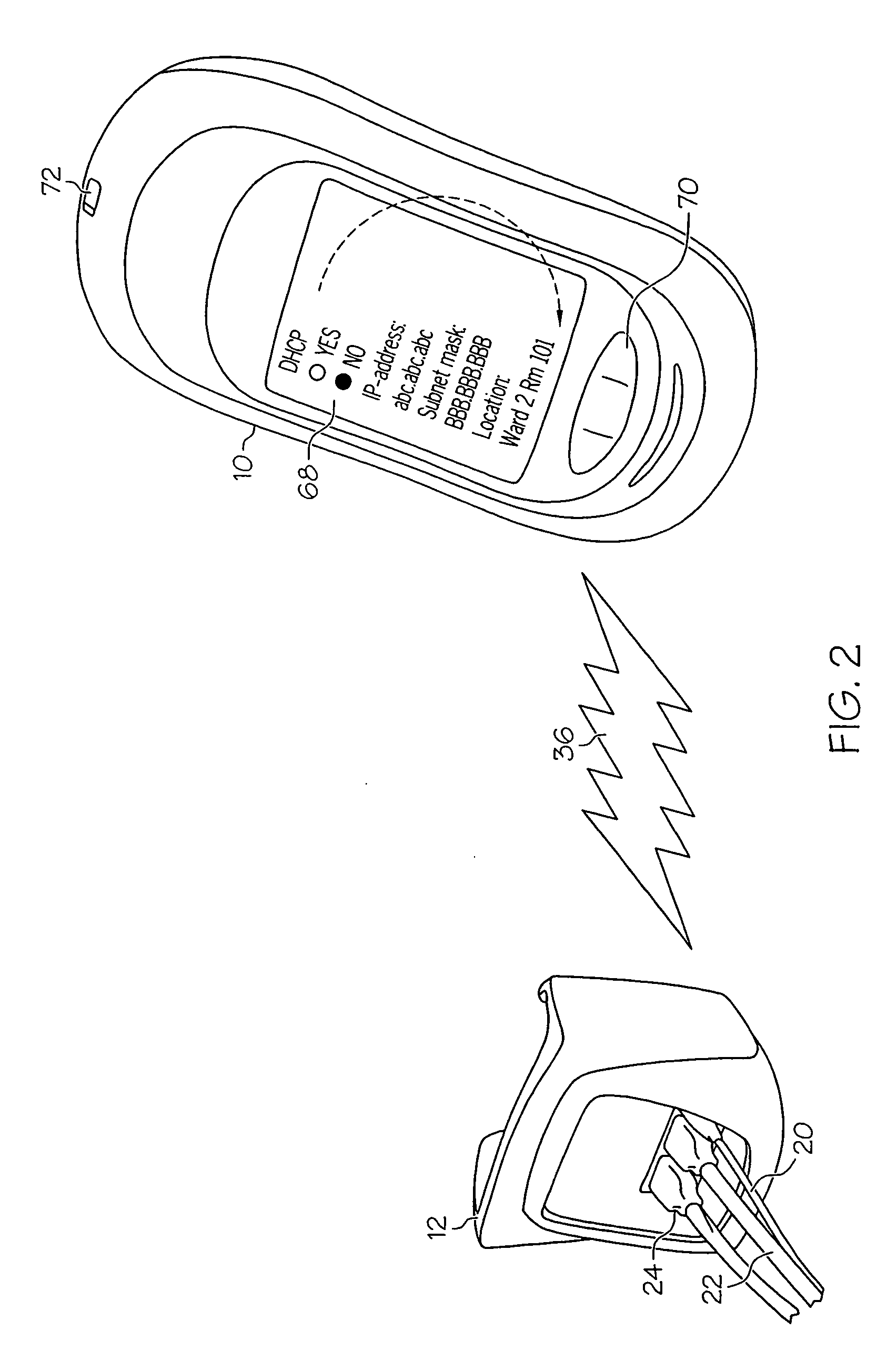

Apparatus and method to administer and manage an intelligent base unit for a handheld medical device

ActiveUS20070255114A1Reduce complexityLower manufacturing requirementsLocal control/monitoringDiagnostic recording/measuringElectricityData stream

Apparatuses and methods thereof to administer and manage a base unit for a handheld medical device are disclosed. In one embodiment, a base unit of the invention is in communication with a handheld medical device. The base unit is configured to provide an electrical connection to a power source to charge a battery of the handheld medical device. The base unit is also configured to perform an update to the operation of the base unit, wherein the update is initiated by the base unit upon receiving from the handheld medical device a data stream with information indicating that an update is contained in the data stream.

Owner:ROCHE OPERATIONS

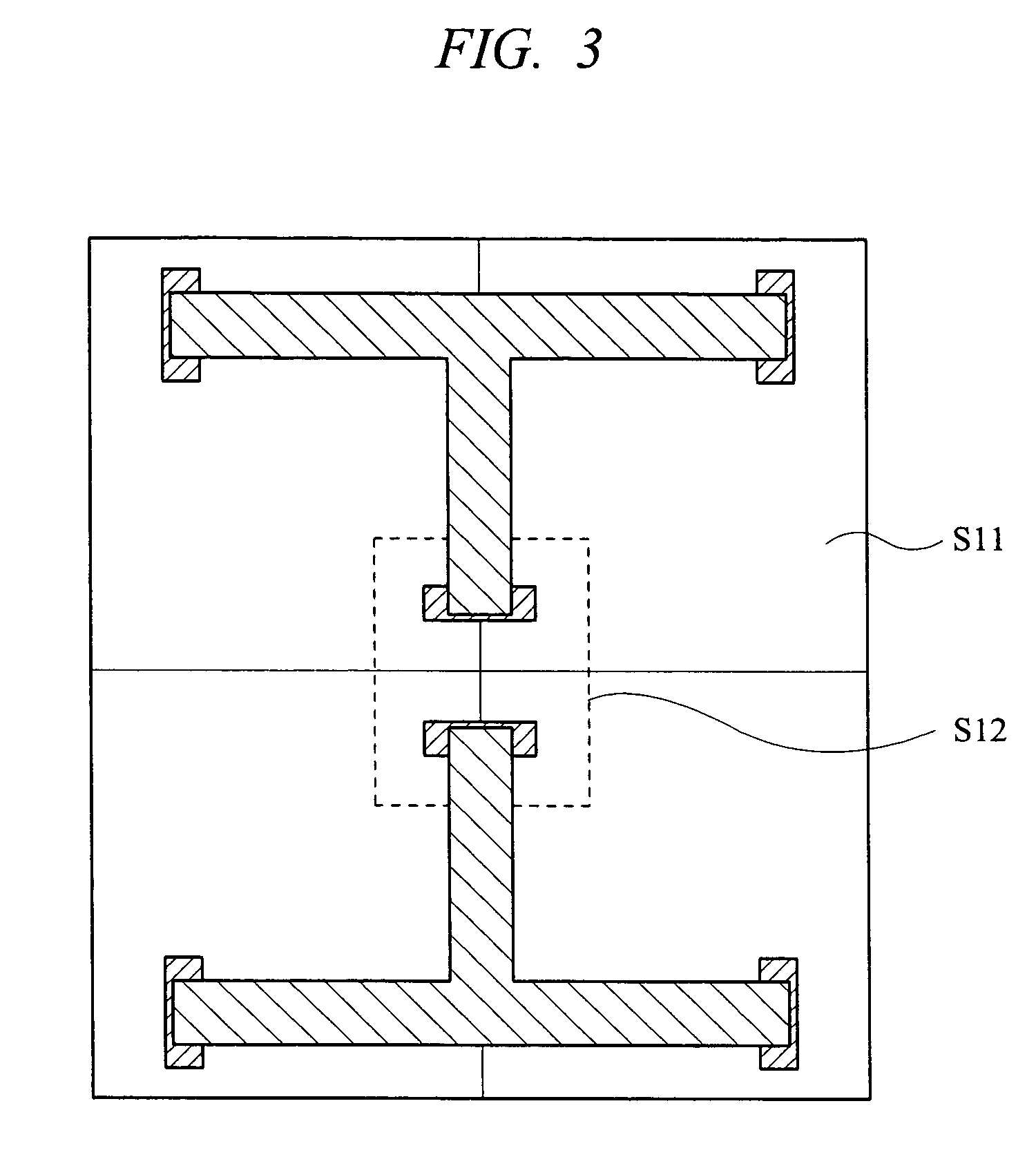

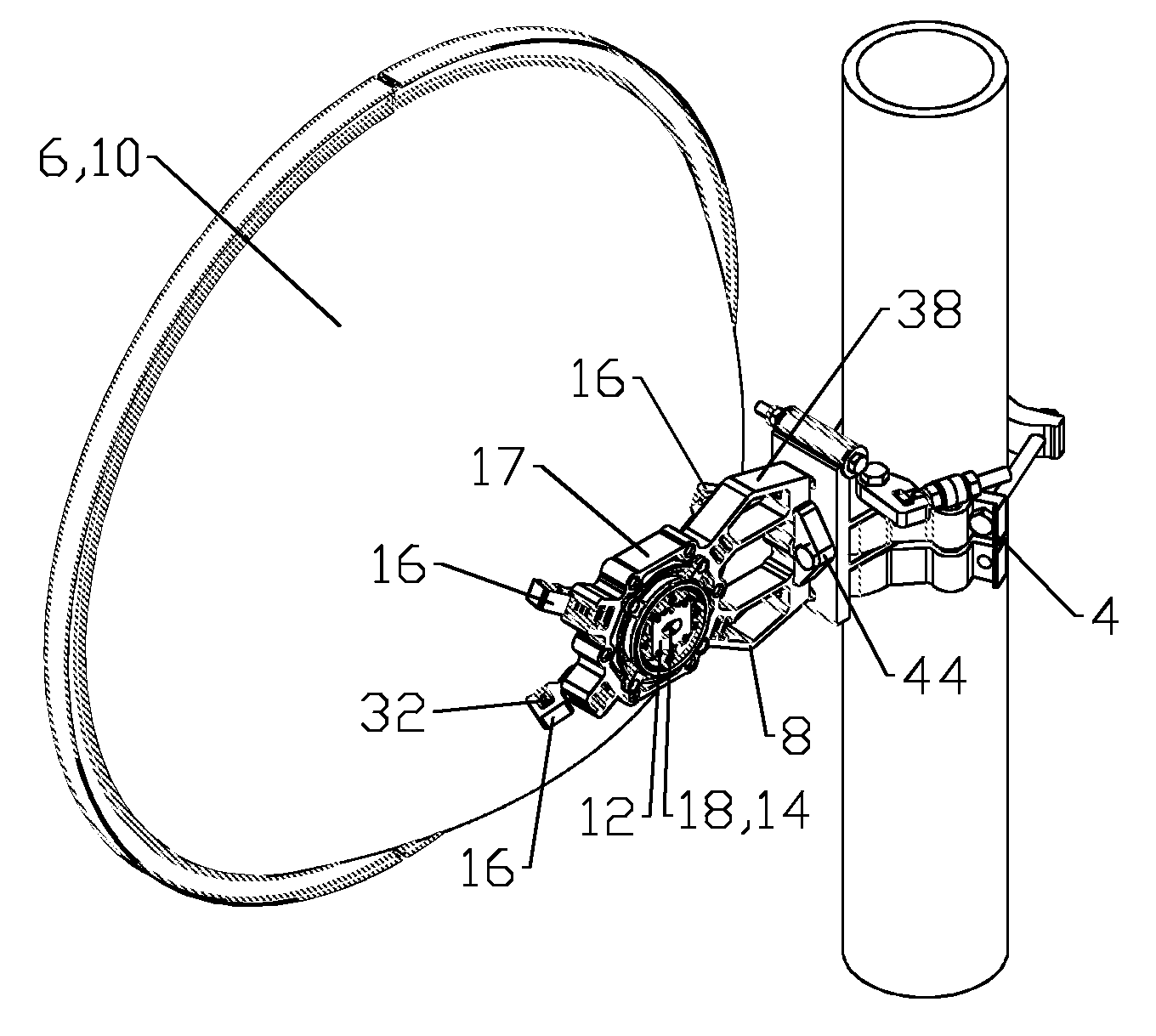

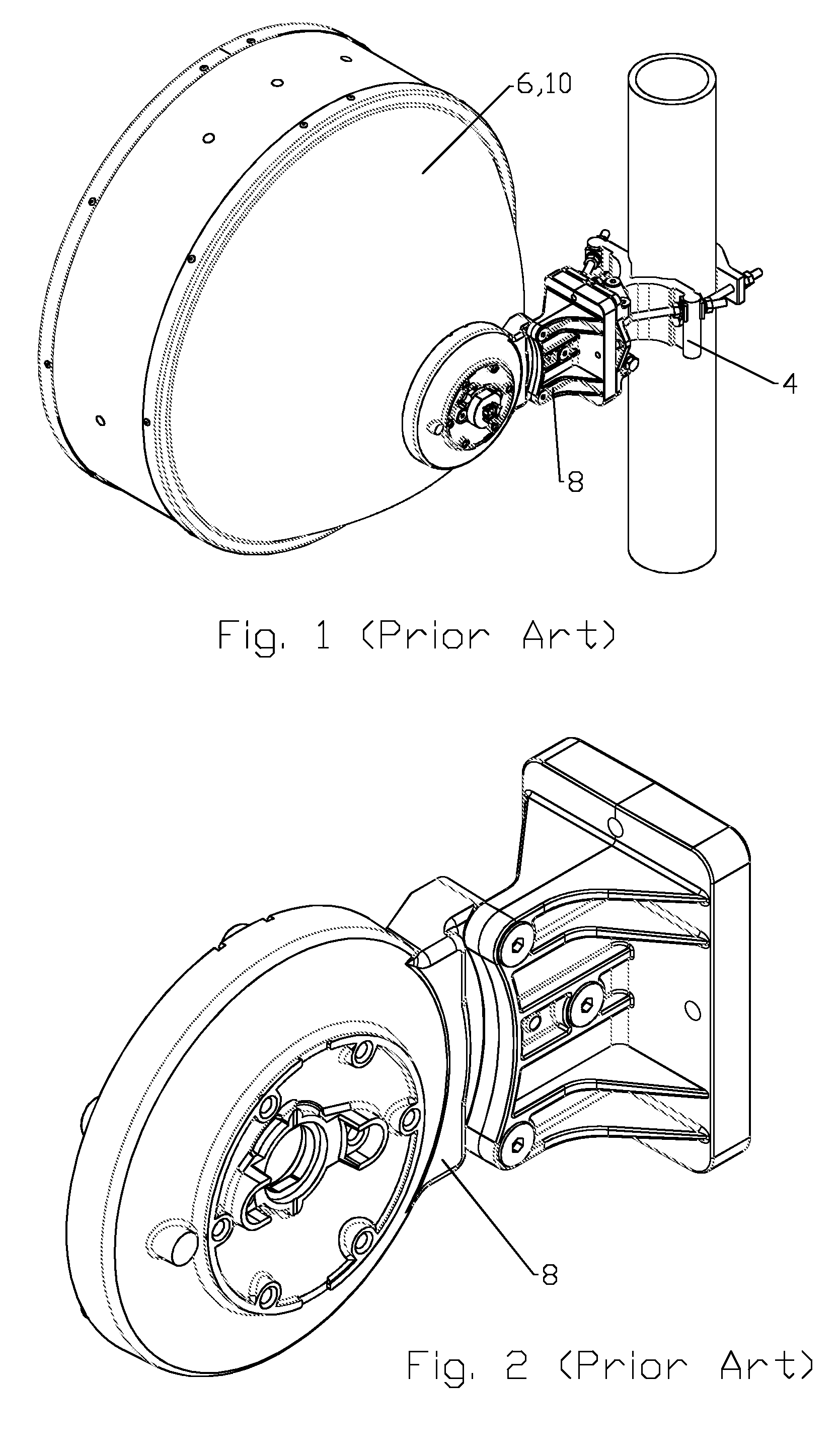

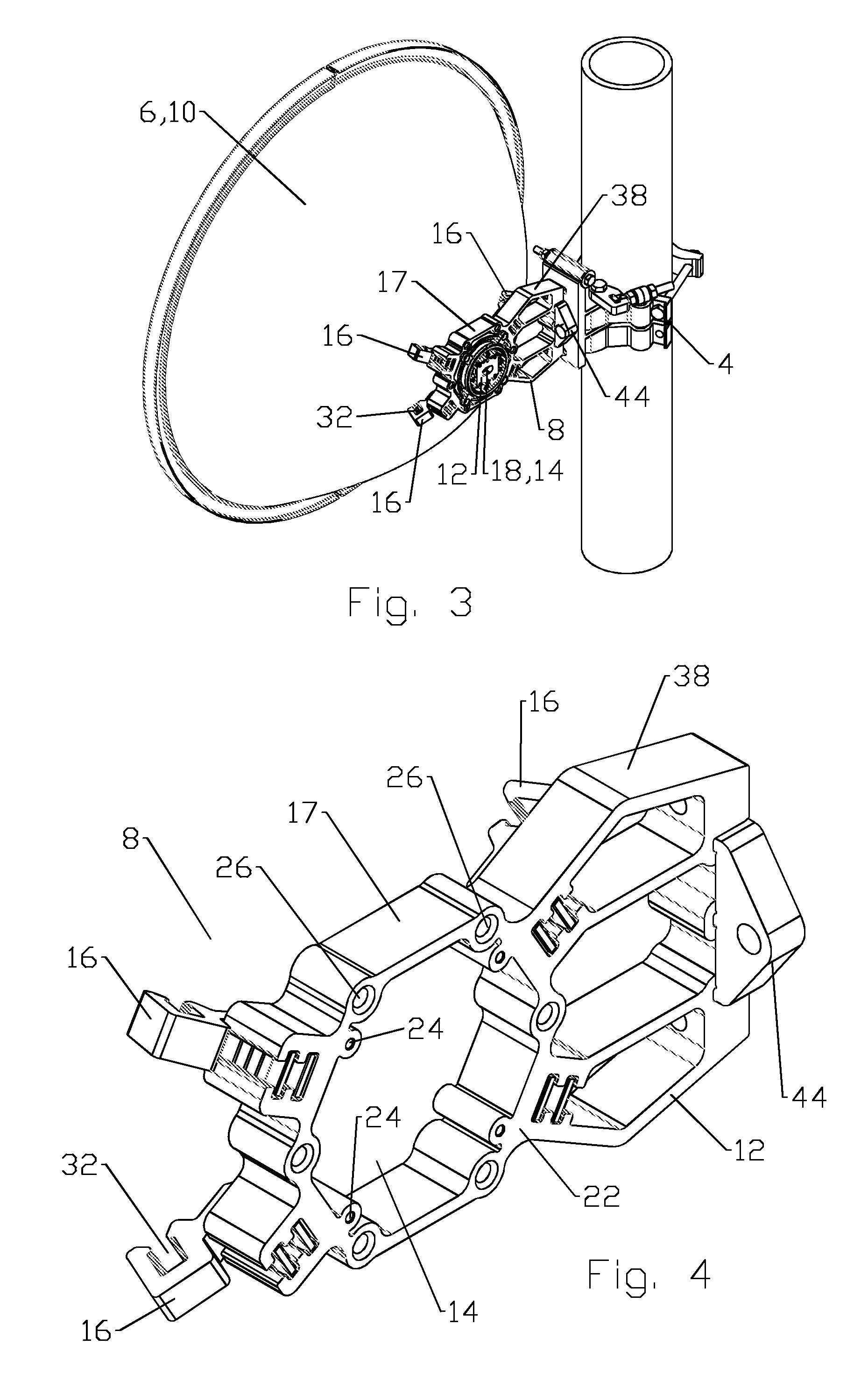

Mounting hub for antenna

ActiveUS9065172B2Low costLower manufacturing requirementsAntenna supports/mountingsEngineeringElectrical and Electronics engineering

An antenna hub for a reflector dish has a frame with a feed aperture. A plurality of feet are coupled to the frame; each of the feet provided with a dish fastener coupling axis normal to a dish surface contacting each of the feet when the reflector dish is seated upon the feet, the feed bore of the reflector dish aligned coaxial with the feed aperture. The frame and feet may be formed via extrusion.

Owner:COMMSCOPE TECH LLC

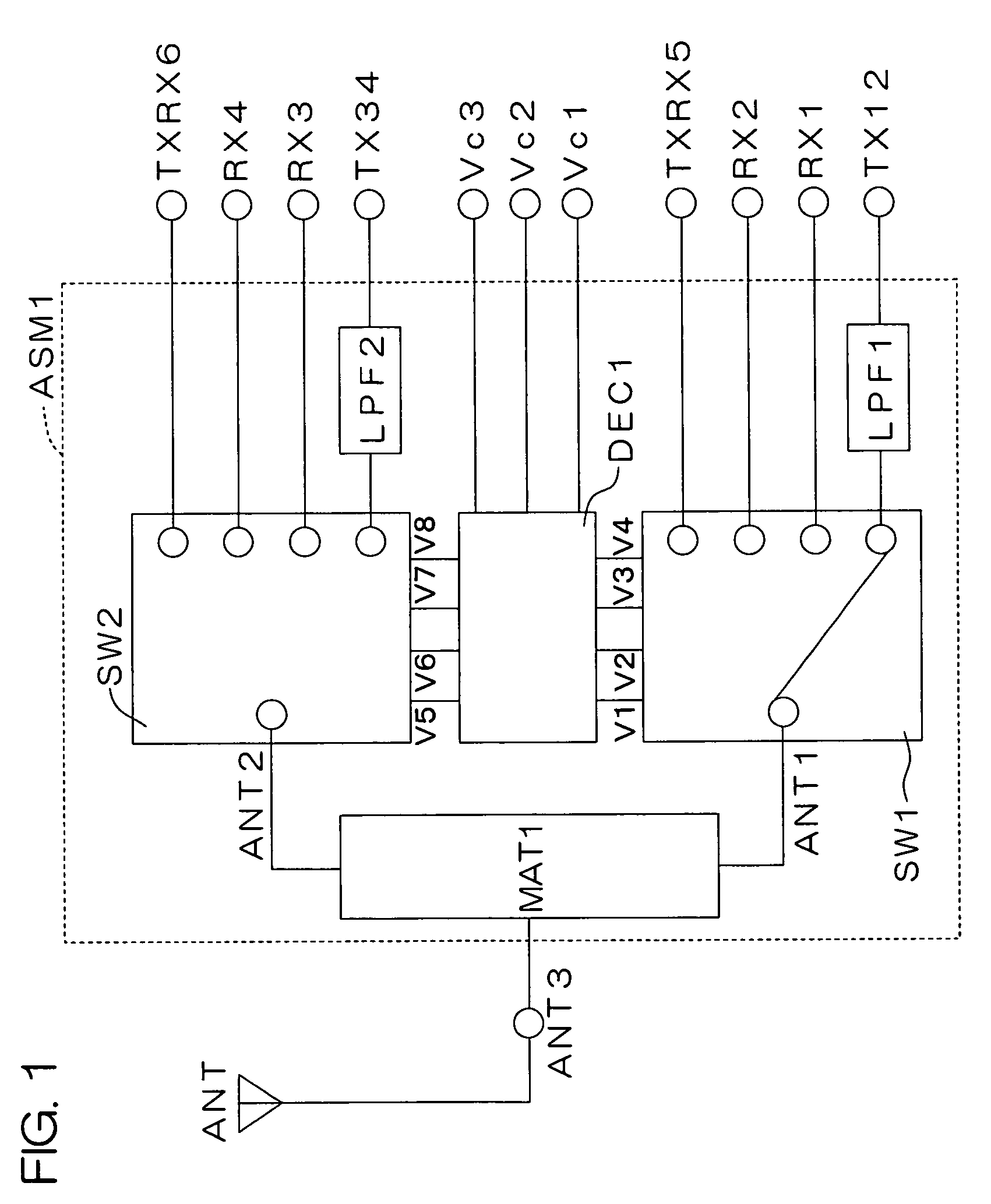

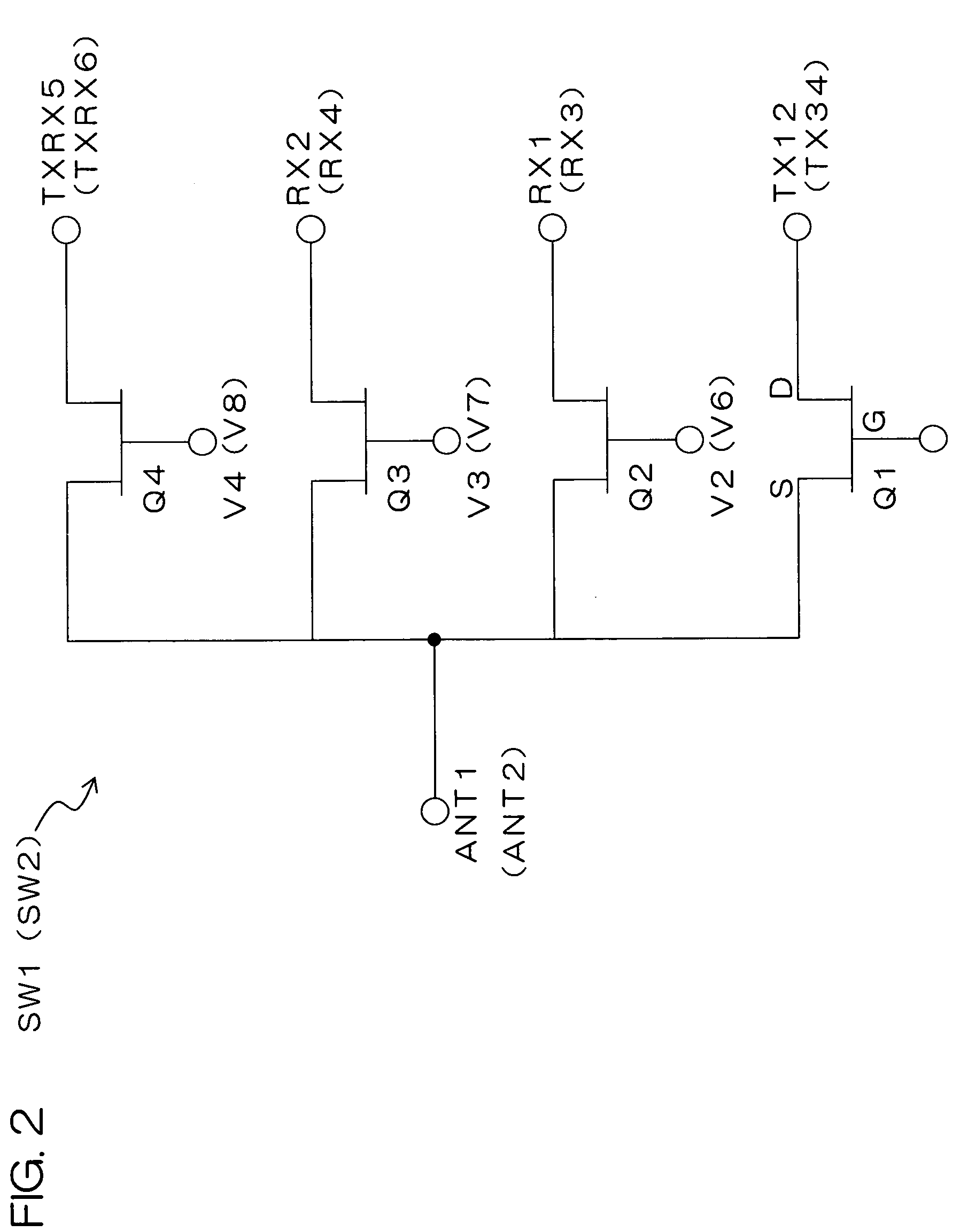

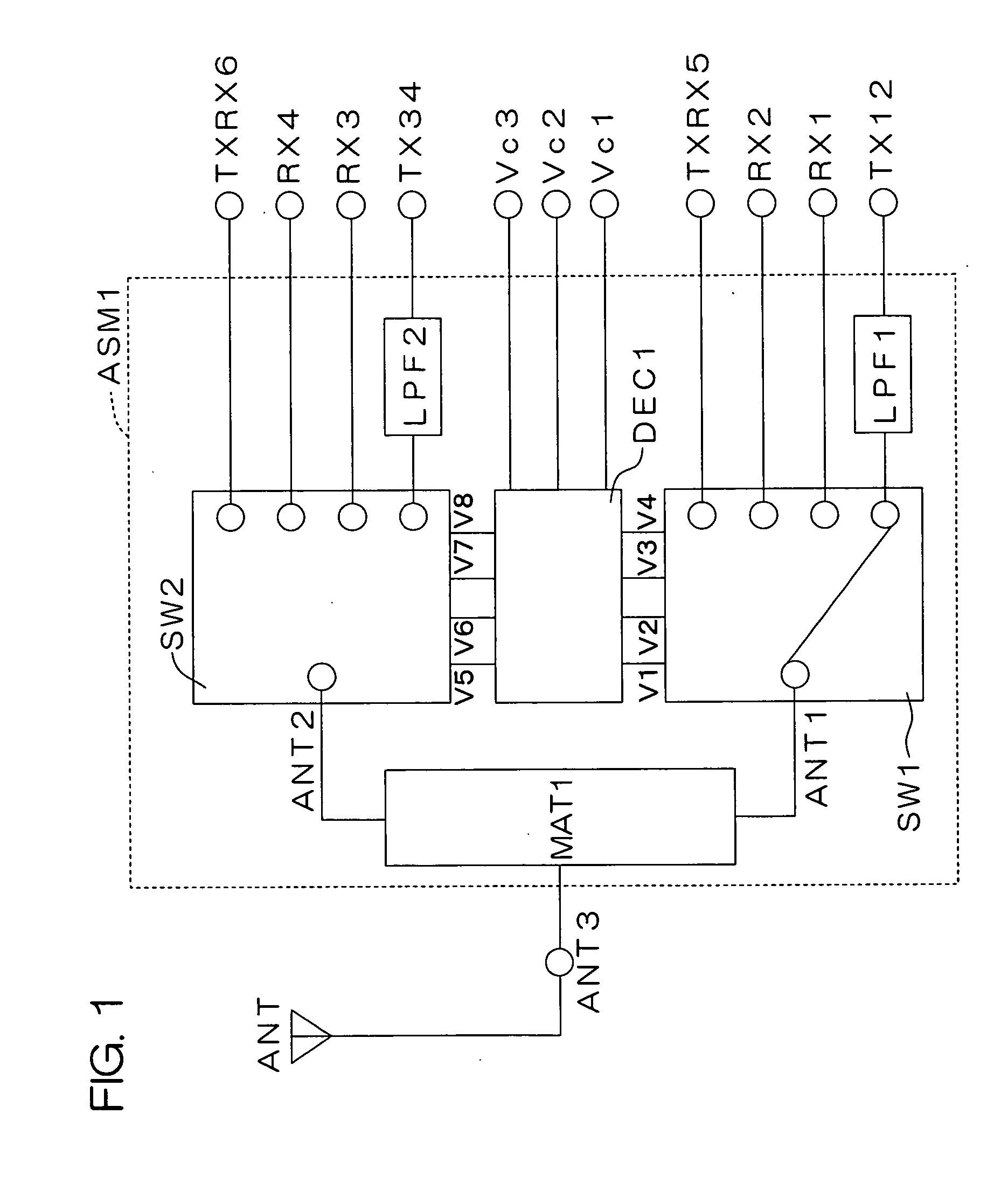

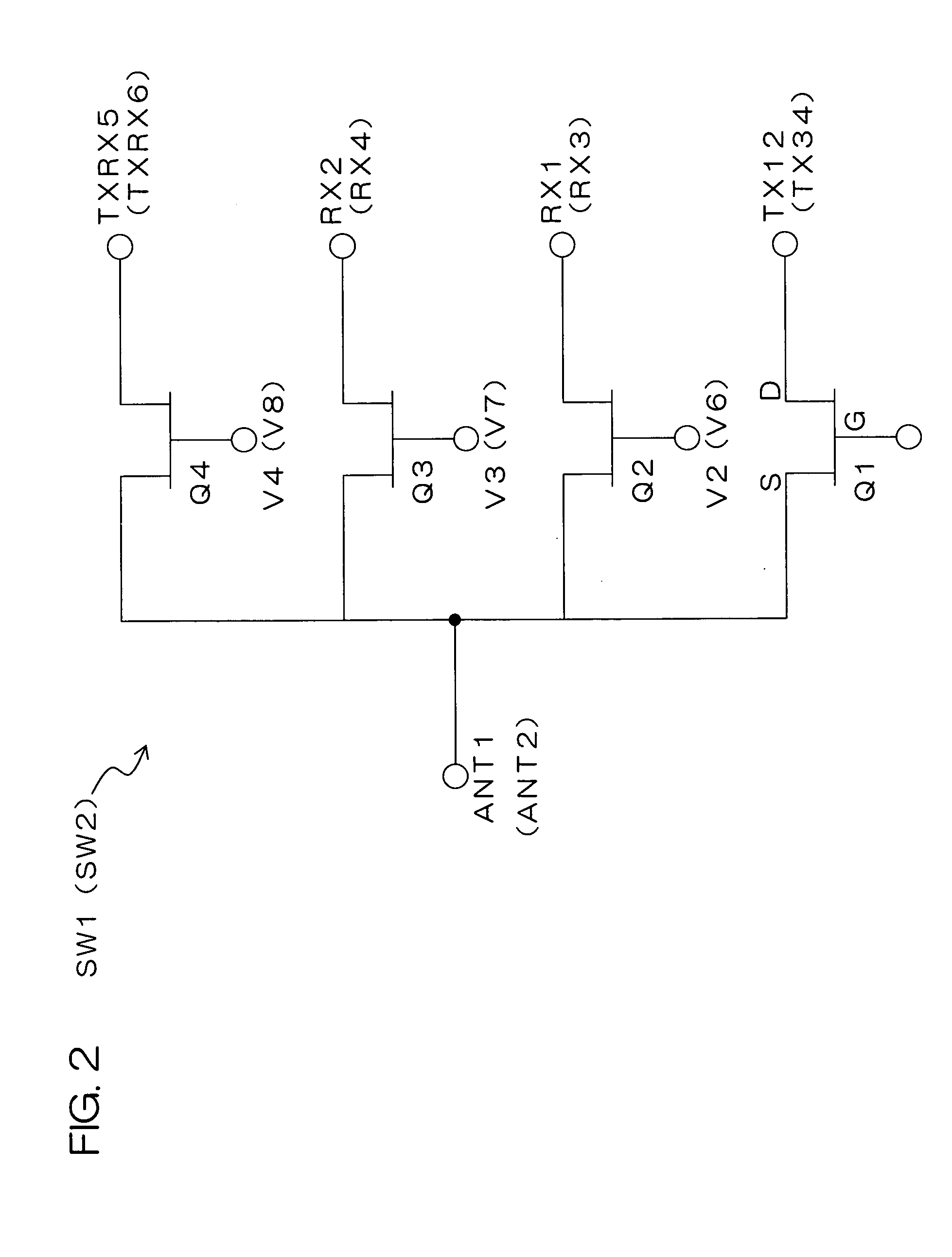

High-frequency switching circuit, high-frequency module, and wireless communications device

InactiveUS7596357B2Low costReduce designActive element networkTelephonic communicationCommunications systemEngineering

Owner:KYOCERA CORP

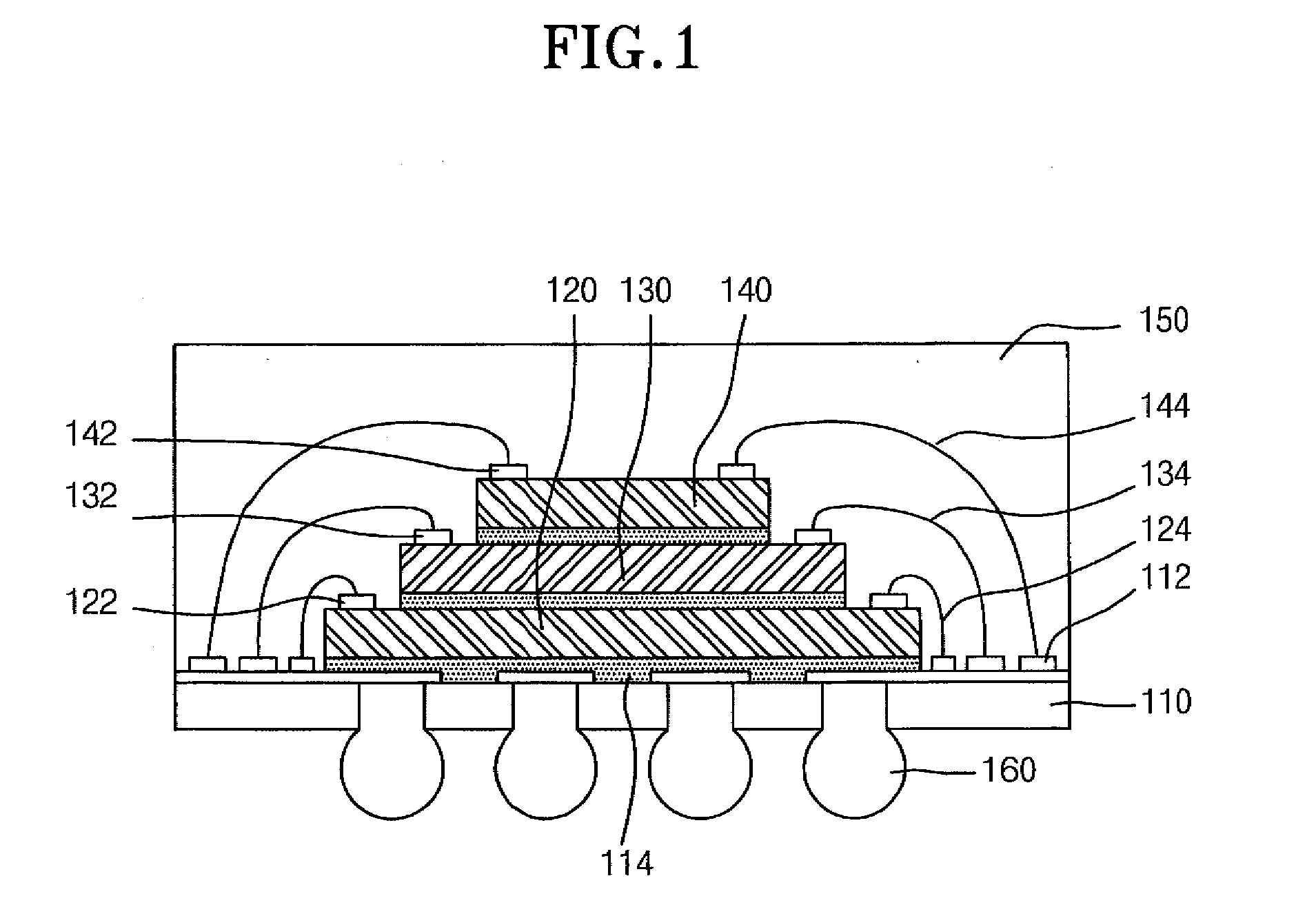

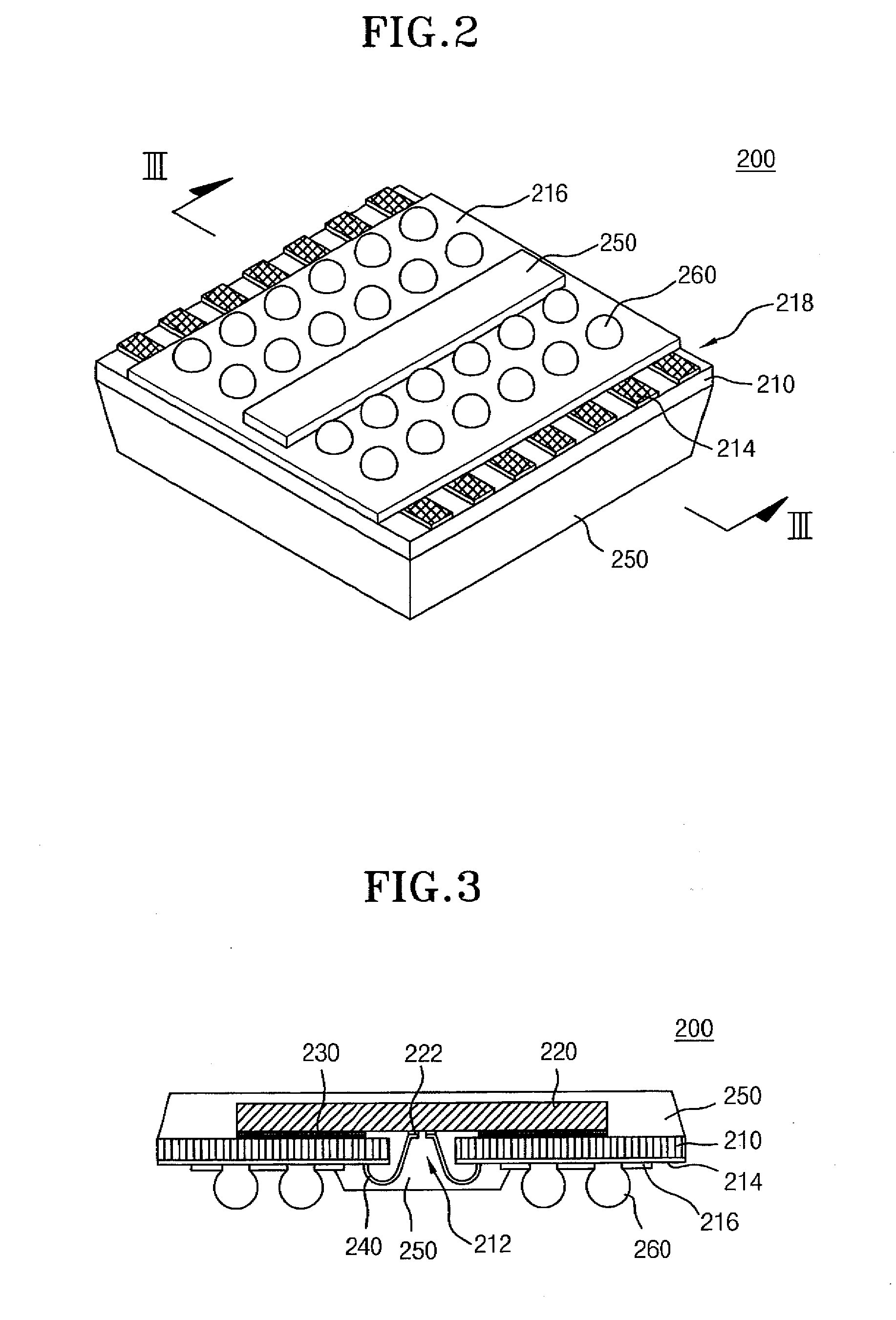

Semiconductor stack package for optimal packaging of components having interconnections

InactiveUS20080054434A1Easy to packLower manufacturing requirementsSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorInsulation layer

A stack package comprises a first semiconductor package having a substrate which is formed with a plurality of conductive patterns on a lower surface thereof and with an insulation layer on the lower surface thereof including the conductive patterns, the insulation layer having grooves for exposing the portions of the conductive patterns disposed at least both end portions of the substrate; a second semiconductor package located below the first semiconductor package and having the same structure as the first semiconductor package; conductive adhesives formed on the exposed end portions of the conductive patterns of the first and second semiconductor packages; and a plurality of clip-shaped conductors clipped on both ends of the second semiconductor package and having first ends and second ends which electrically and mechanically connect the conductive patterns of the first semiconductor package and the conductive patterns of the second semiconductor package to each other via the conductive adhesives.

Owner:SK HYNIX INC

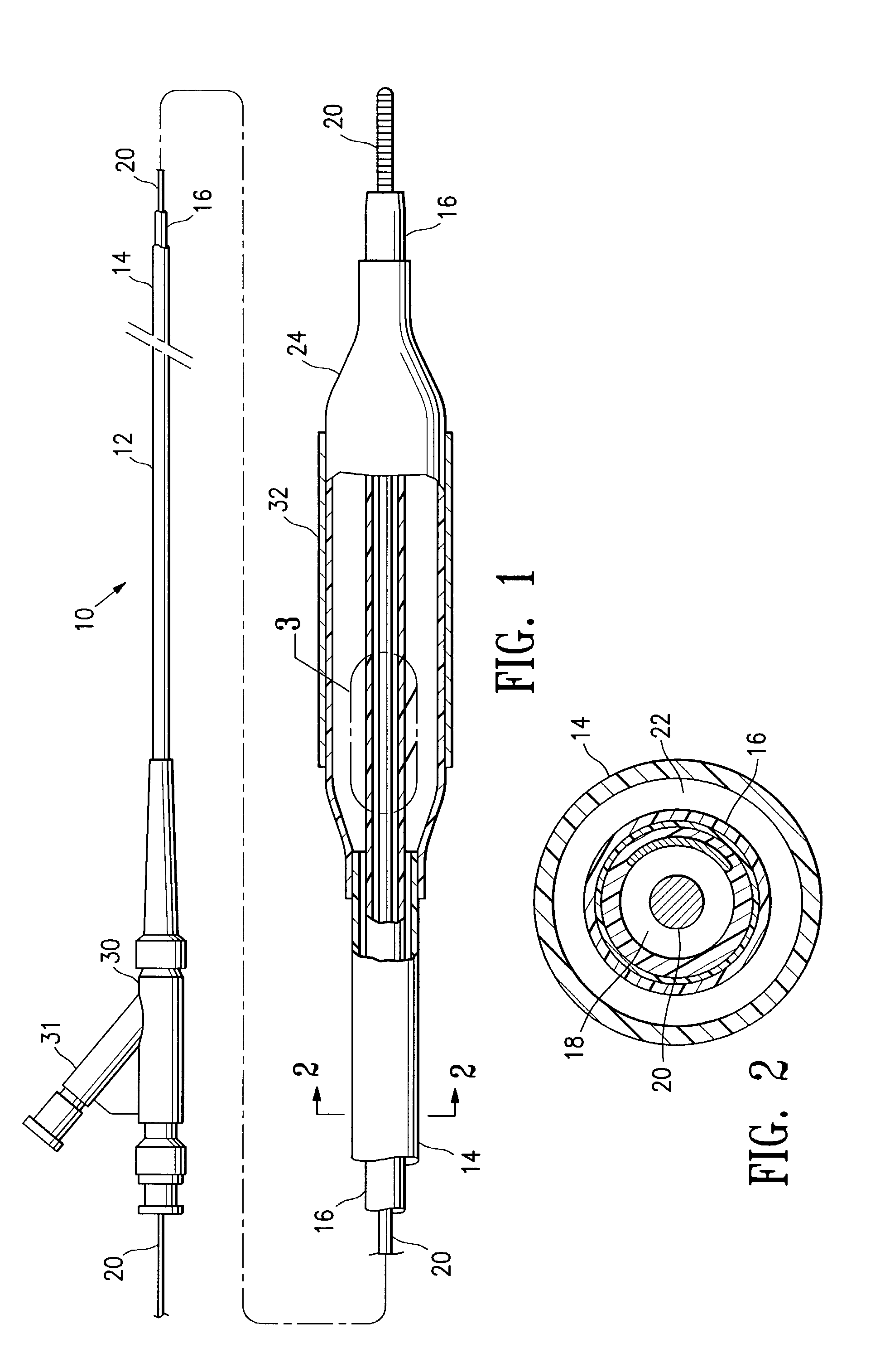

Coil reinforced multilayered inner tubular member for a balloon catheter

A catheter having an elongated shaft formed of a polymeric tubular member with at least a section having a lubricious inner layer defining the guidewire lumen, a coiled support member at least partially embedded in the lubricious inner layer, and an outer layer on an outer surface of at least a distal portion of the lubricious inner layer. In a presently preferred embodiment, the coil supported polymeric tubular member forms an inner tubular member of a balloon catheter.

Owner:ABBOTT CARDIOVASCULAR

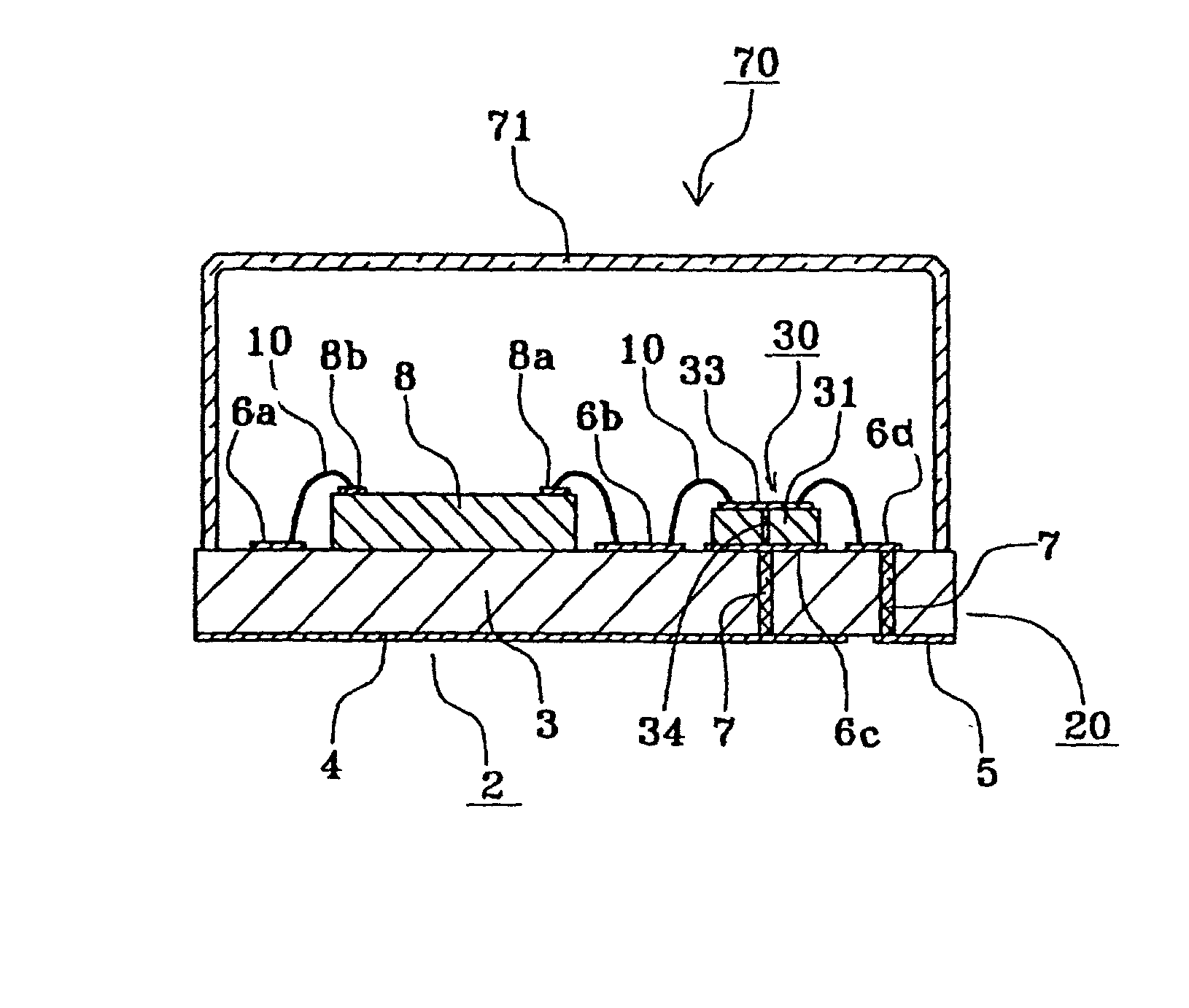

Light emitting device

InactiveUS7579203B2Low costIncrease productionSolid-state devicesSemiconductor/solid-state device manufacturingLight emitting deviceSemiconductor components

An inexpensive light emitting device and inexpensive electric equipment are provided. A substrate on which a semiconductor element or a light emitting element is formed and a color filter are manufactured by separate manufacturing processes, and they are bonded to each other to complete the light emitting device. Thus, the yield of the light emitting device is improved and the manufacture period is shortened.

Owner:SEMICON ENERGY LAB CO LTD

Arrangement for the detection of relative movements or relative position of two objects

InactiveUS6804012B2Lower manufacturing requirementsProtection overloadInput/output for user-computer interactionAcceleration measurement using interia forcesRelative motionPersonal computer

Owner:SOC CIV GALILEO 2011

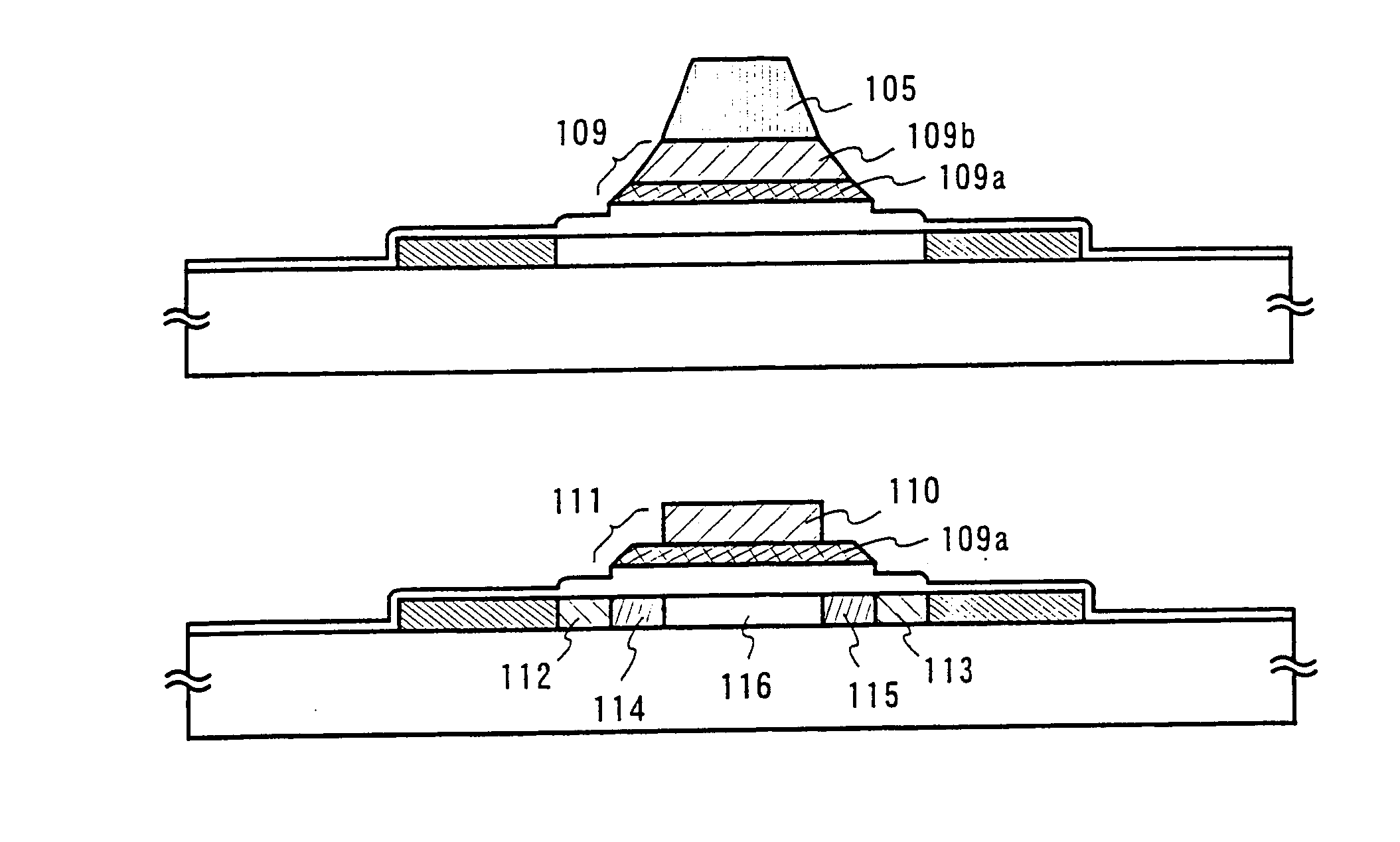

Light emitting device and fabricating method thereof

InactiveUS6706544B2Increase productionLower manufacturing requirementsSemiconductor/solid-state device testing/measurementSolid-state devicesRespiratorActive layer

The light emitting device according to the present invention is characterized in that a gate electrode comprising plurality of conductive films is formed, and concentration of impurity regions in an active layer are adjusted with making use of selectivity of the conductive films in etching and using them as masks. The present invention reduces the number of photolithography steps in relation to manufacturing the TFT for improving yield of the light emitting device and shortening manufacturing term thereof, by which a light emitting device and an electronic appliance are inexpensively provided.

Owner:SEMICON ENERGY LAB CO LTD

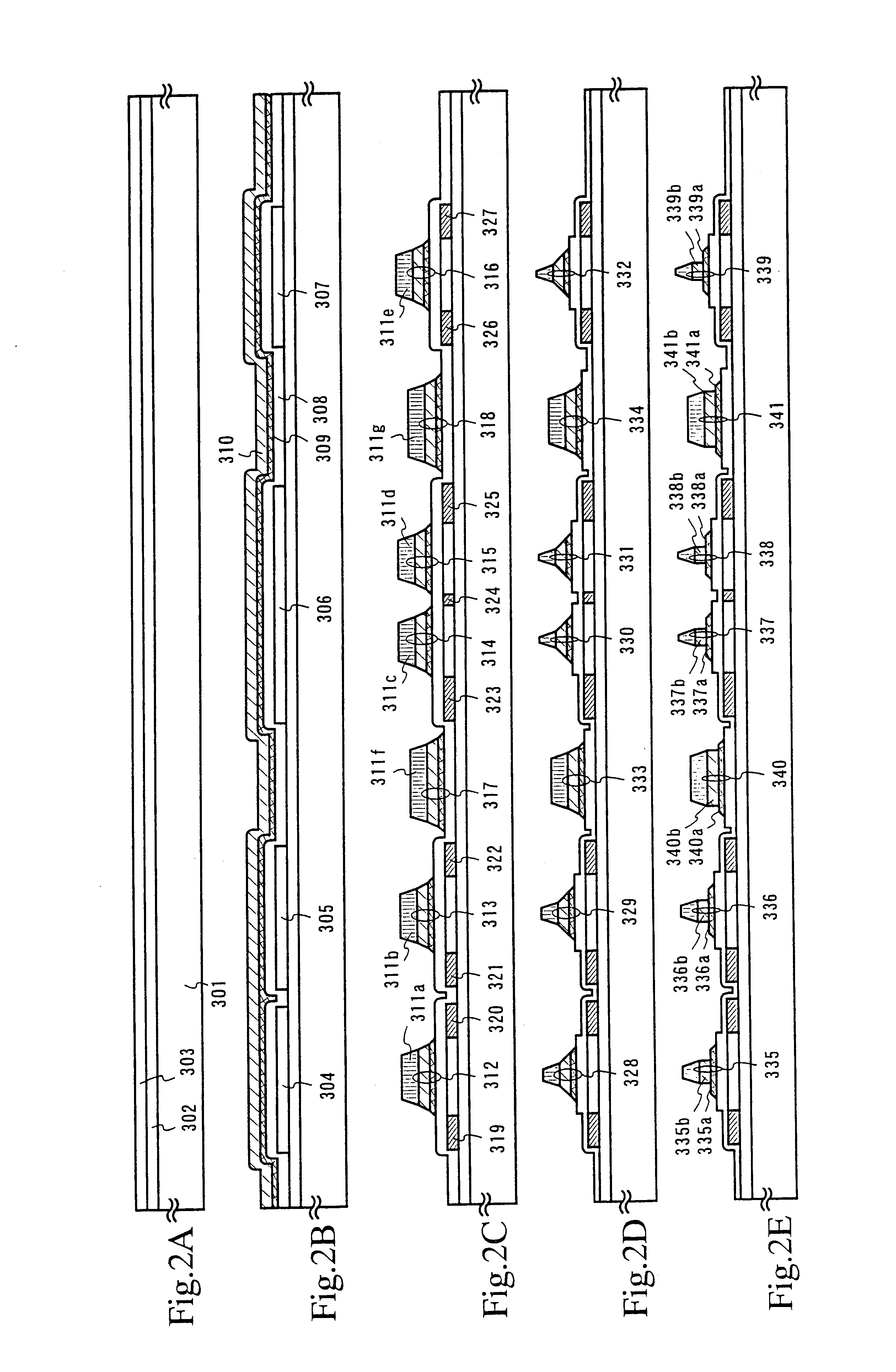

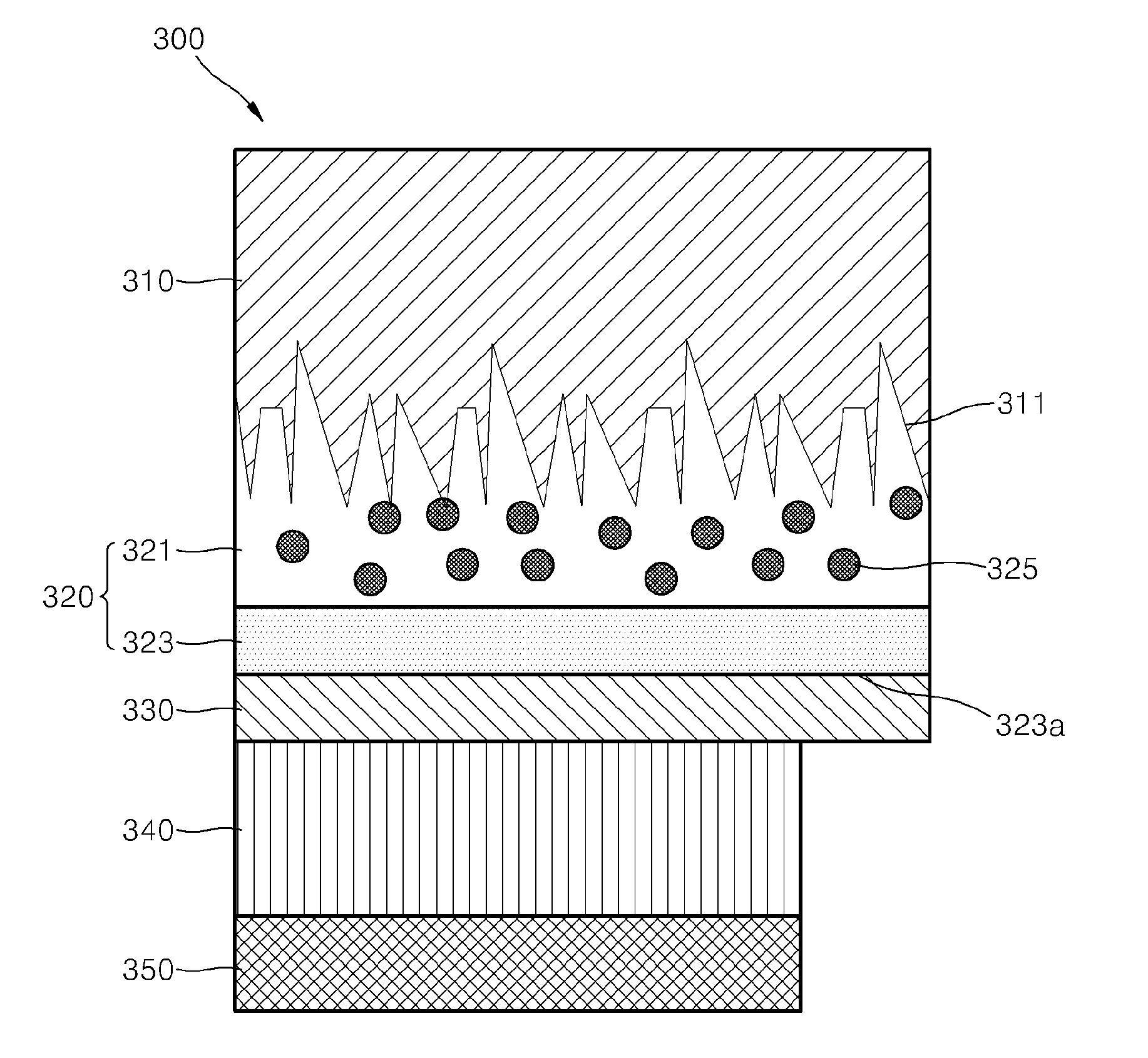

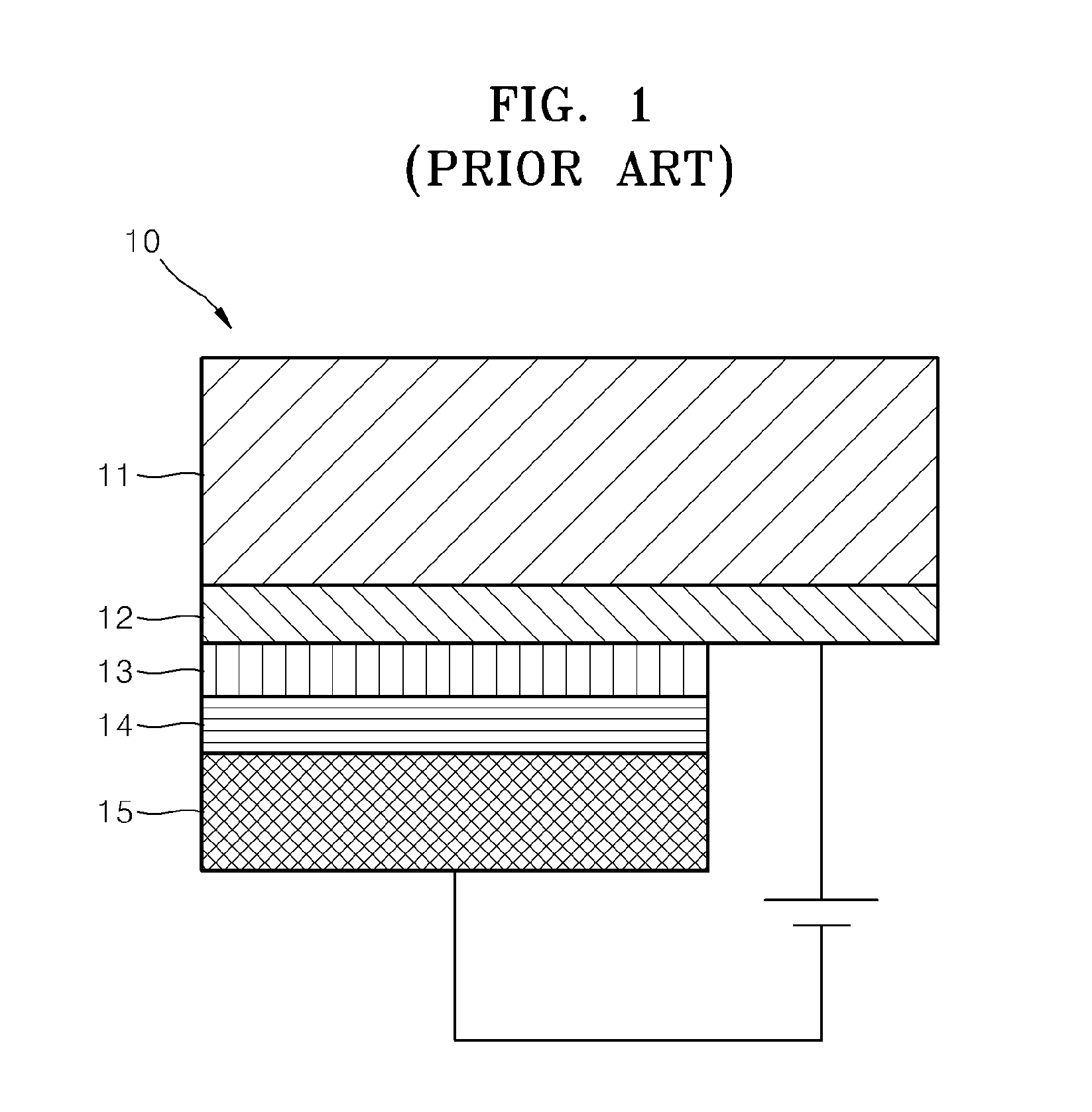

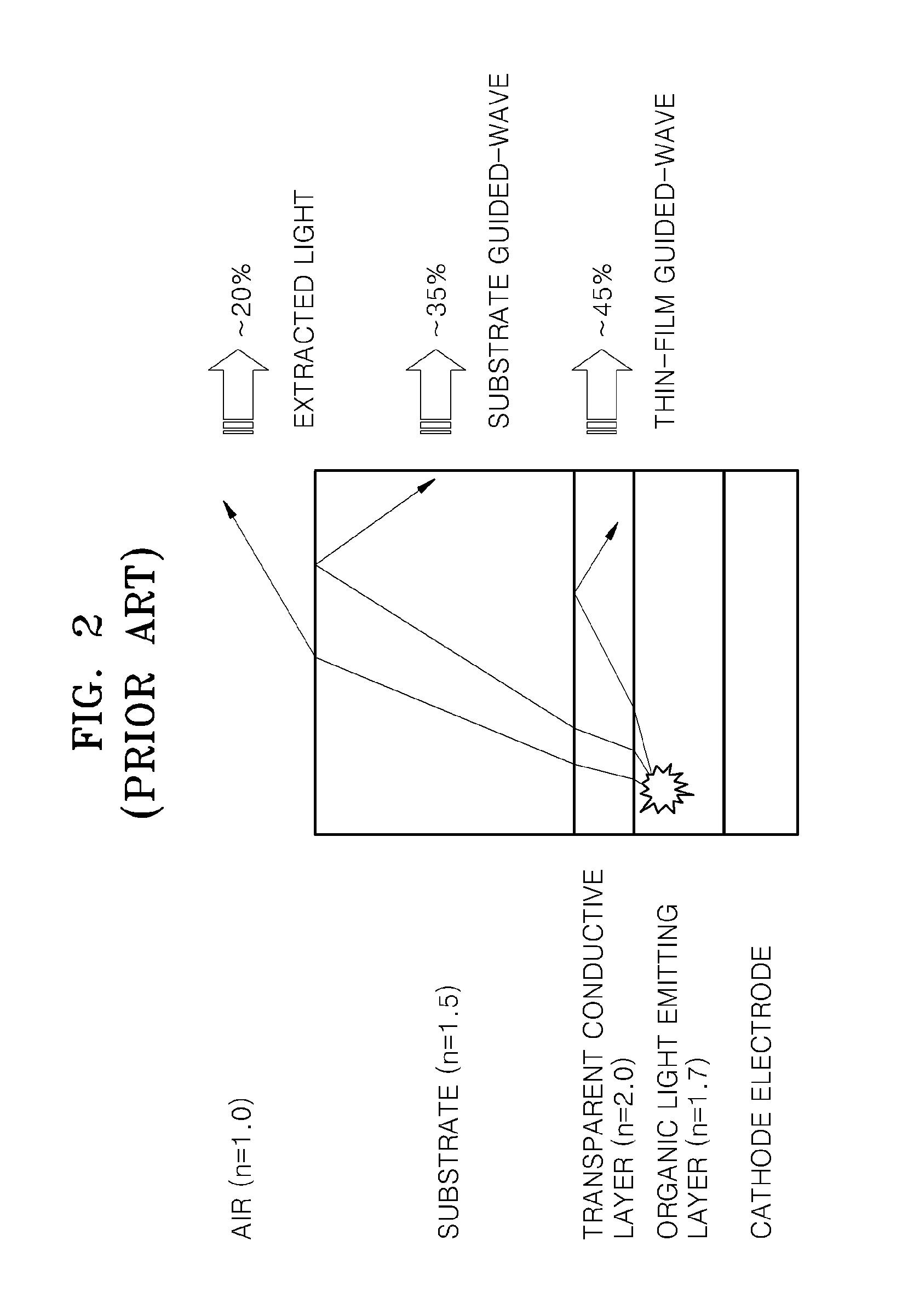

Substrate for surface light emitting device and method of manufacturing the substrate, surface light emitting device, lighting apparatus, and backlight including the same

ActiveUS20120155093A1Not be reduceLower manufacturing requirementsSolid-state devicesOptical articlesThin membraneEngineering

A substrate for a surface light emitting device in which a transparent electrode, an organic thin film layer, and a cathode electrode are sequentially stacked, the substrate including: a transparent support substrate; and a highly refractive layer that is disposed between the support substrate and the transparent electrode and comprises at least one layer having a refractive index that is equal to or greater than a refractive index of the support substrate, wherein the highly refractive layer comprises a light diffusion unit that diffuses light incident from the transparent electrode and a planarized surface that contacts the transparent electrode. Accordingly, a Haze value of the highly refractive layer is set to be 5% or less, and a diameter of bubbles existing in the highly refractive layer is set to be 1 / 10th or less of a thickness of the highly refractive layer.

Owner:SAMSUNG ELECTRONICS CO LTD

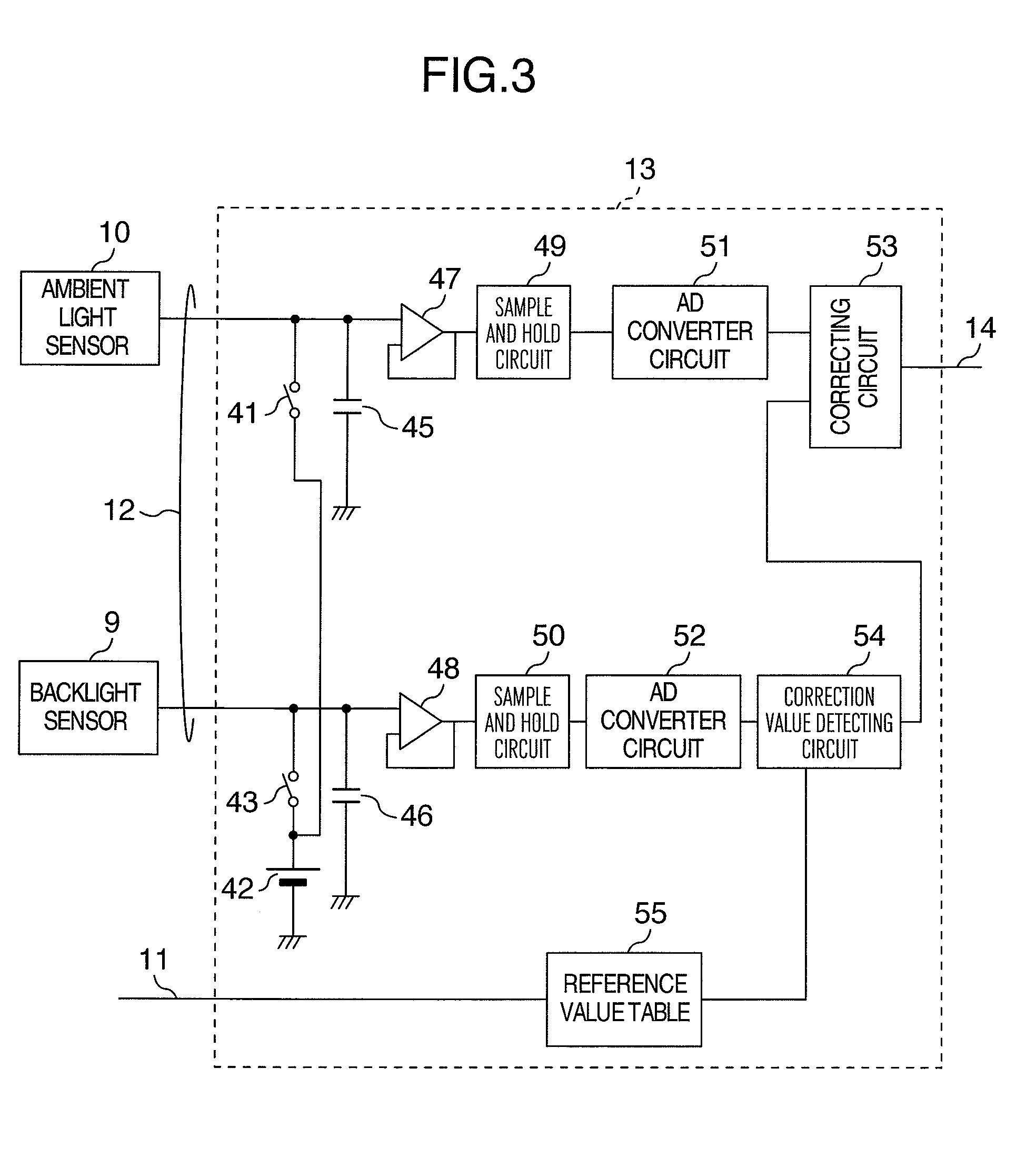

Display Device

InactiveUS20070268241A1Manufacturing variation can be decreasedImprove output accuracyStatic indicating devicesLiquid-crystal displayDisplay device

An ambient light sensor 10 and a backlight sensor 9 are located on the liquid crystal panel 6 adjacently to each other, for correcting a variation of an output characteristic of the ambient light sensor 10. This location keeps the manufacturing variation of each liquid crystal panel 6 even in these two light sensors 9 and 10. A degree of variation of an output of the backlight sensor 9 for sensing a ray of backlight from a backlight module relative to a predetermined reference value is detected. Based on the detected result, the output of the ambient light sensor 10 is corrected. This operation makes it possible to improve sensing accuracy of the ambient light sensor 10 and keep the light modulation even in each liquid crystal panel provided with the ambient light sensor 10.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

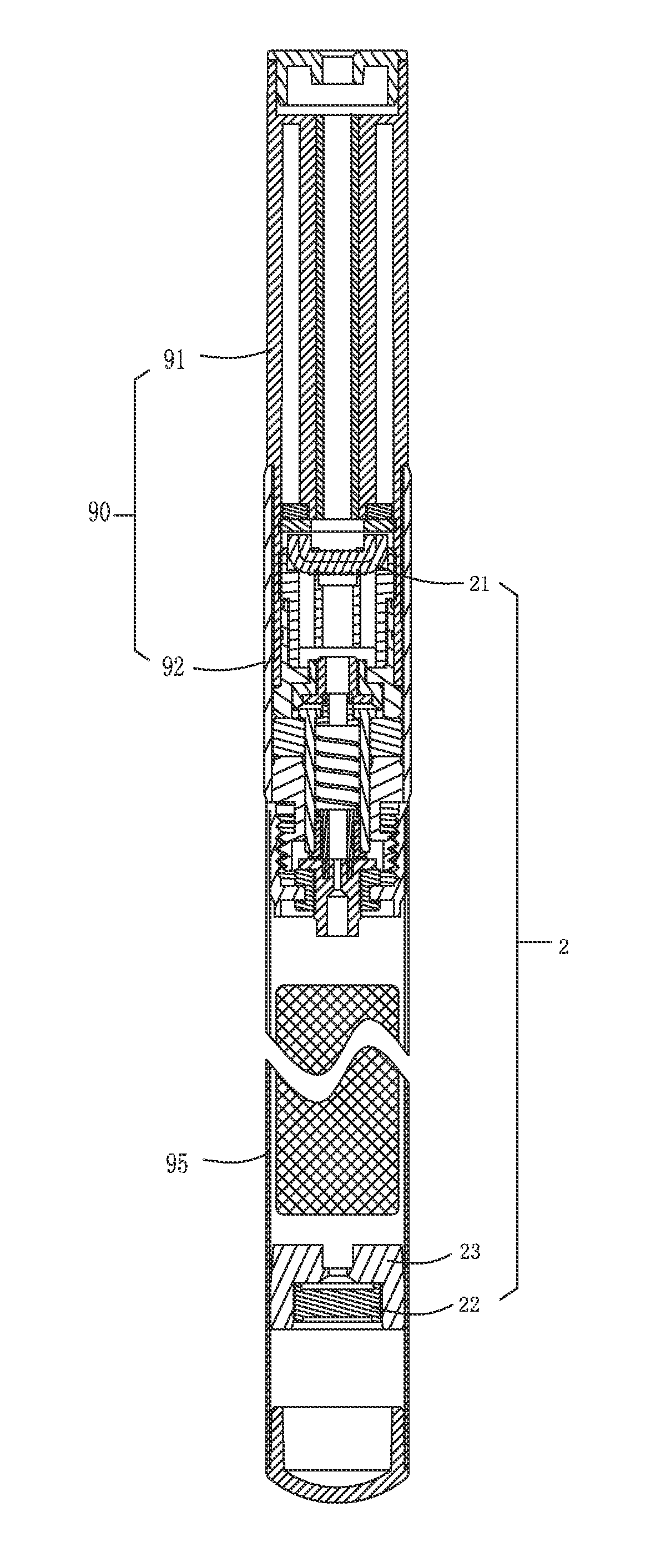

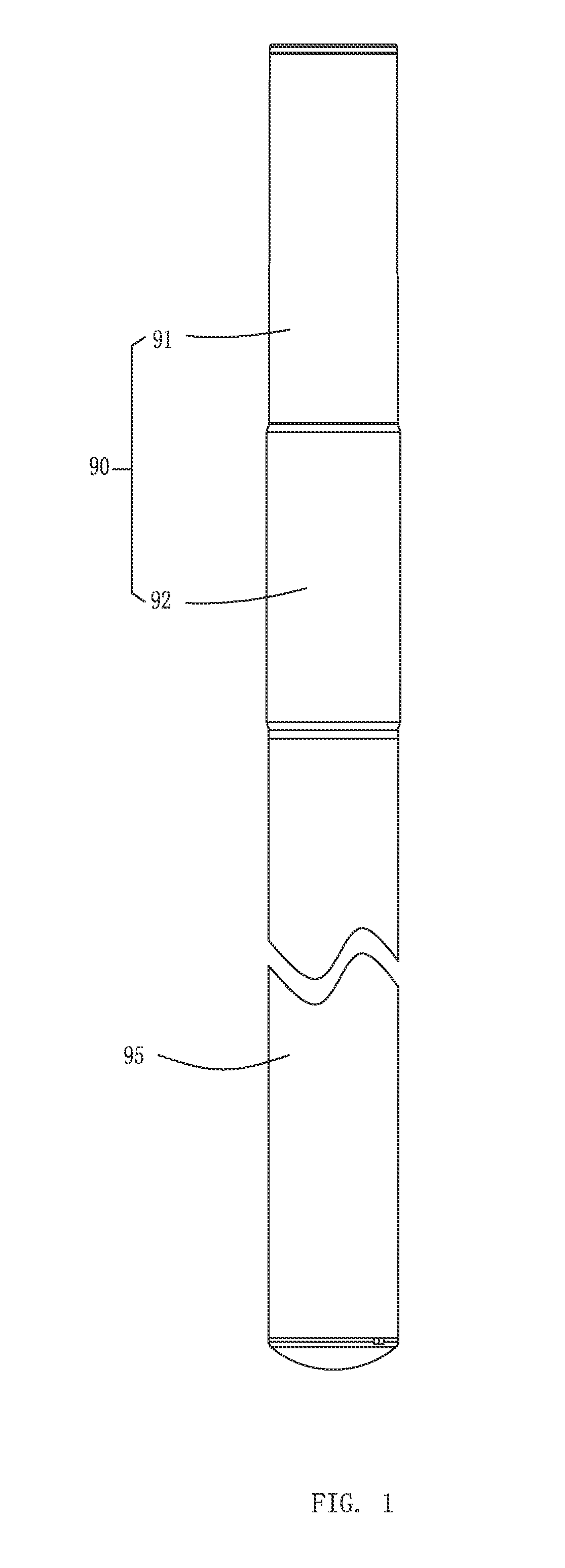

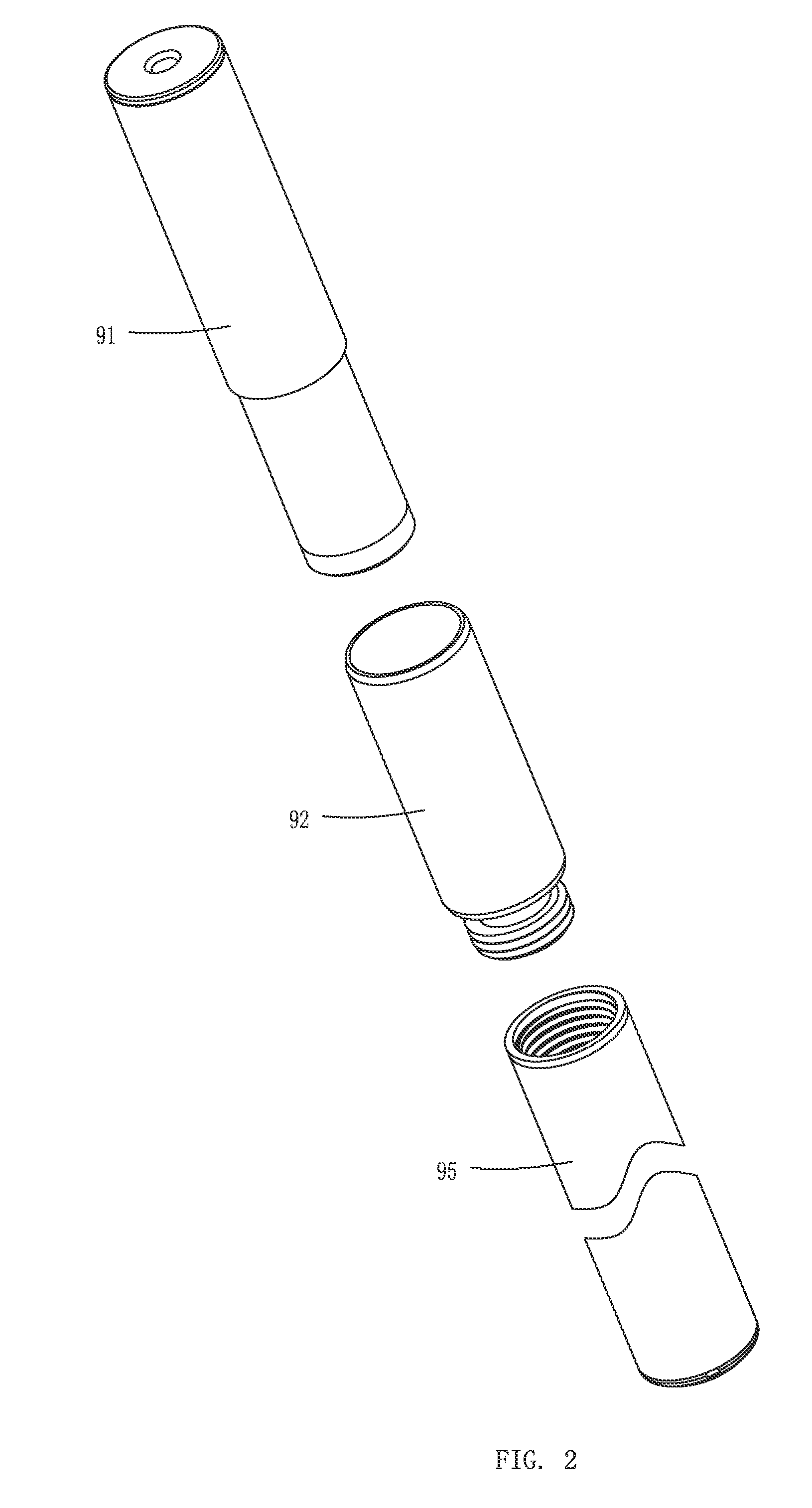

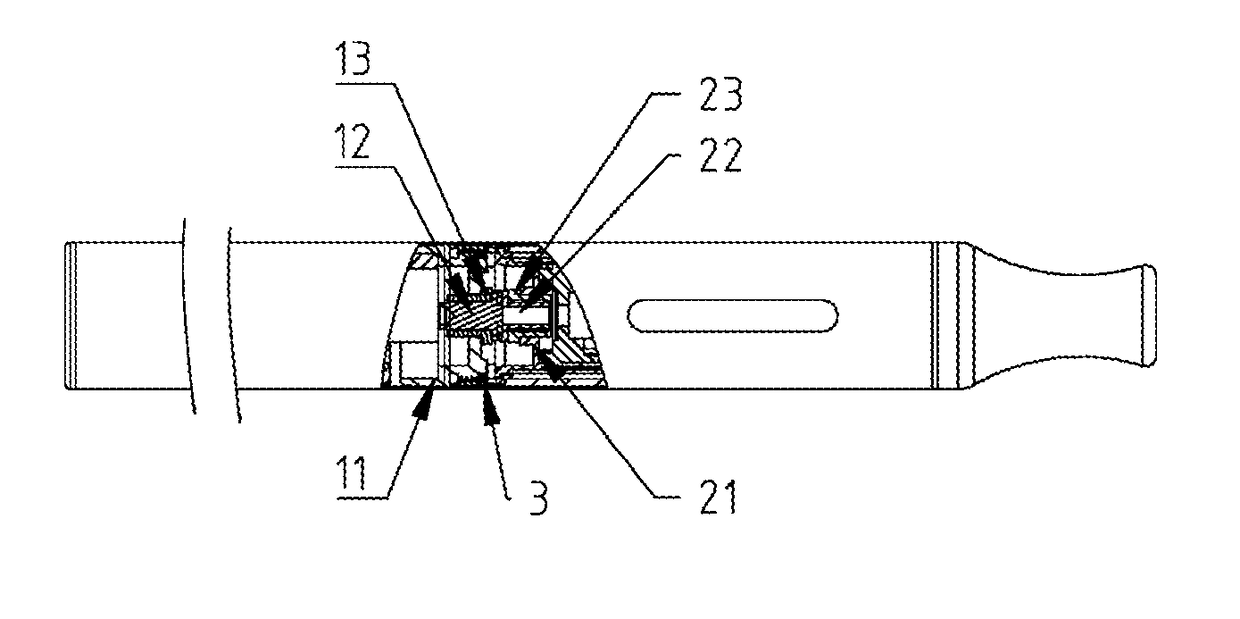

Smoke Condensation Resistant Electronic Cigarette

InactiveUS20140150784A1Increase the amount of smokeReduce smokeTobacco devicesInhalatorsEngineeringElectronic cigarette

A smoke condensation resistant electronic cigarette includes absorption stem and a power source stem which are connected with each other detachably; an atomizer for transforming cigar liquid stored in the absorption stem into smoke and a smoke path for conducting the smoke out of the absorption stem are provided in the absorption stem. Here a smoke condensation resisting mechanism for preventing cooling and condensing of the smoke on an inner wall of the smoke path during flowing process is disposed in the absorption stem. The electronic cigarette of the present invention increases amount of smoke taken in by a smoker and prevents cigar liquid drips being inhaled by the smoker or greatly reducing amount of smoke taken in by the smoker. In addition, it facilitates reduction of manufacture and using cost, and also facilitates assembly, disassemble and replacement of the electronic cigarette.

Owner:HUIZHOU KIMREE TECH

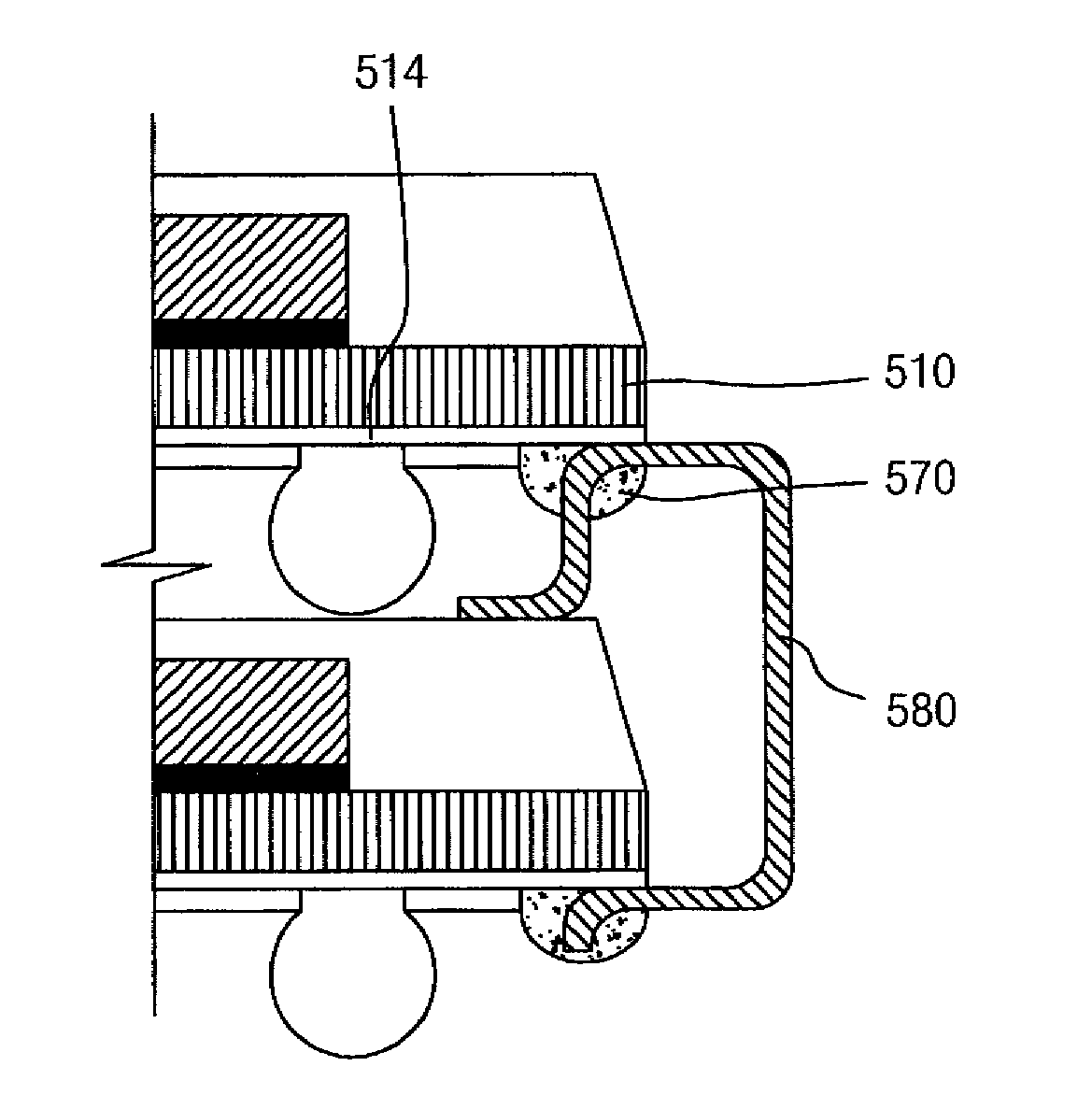

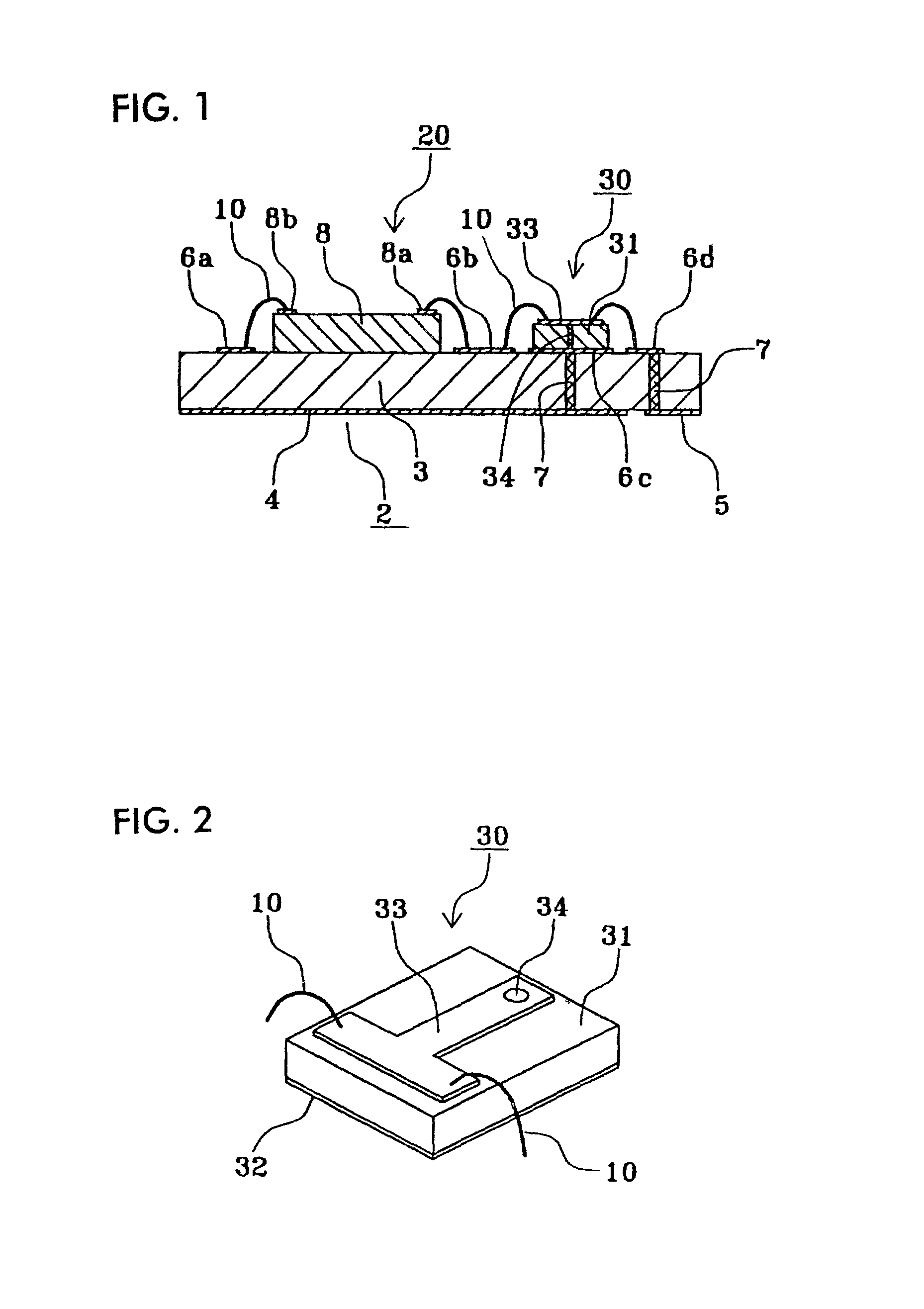

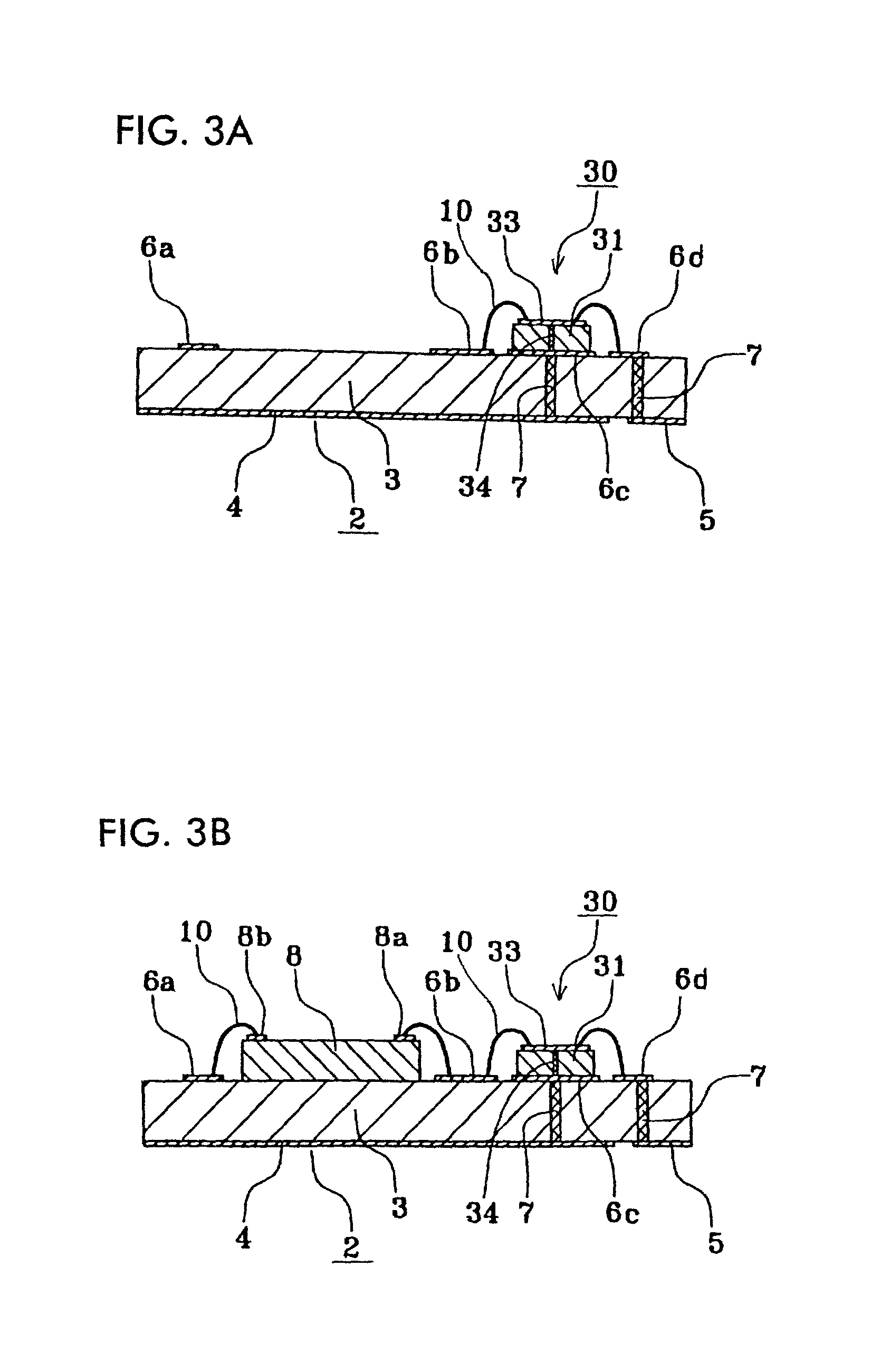

High-frequency circuit board unit, high frequency module using the same unit, electronic apparatus using the same module, and manufacturing method for the high-frequency circuit board unit

InactiveUS20020072147A1Improve breakdown voltageImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesDielectric substrateSemiconductor

A ground electrode and a terminal electrode are formed on a first main surface of dielectric substrate forming a circuit board. Wiring electrodes are formed on a second main surface of the dielectric substrate. A semiconductor device and a filter are mounted on the wiring electrodes. A strip line electrode of the filter is connected to the ground electrode of the circuit board for conducting direct current, via a through-hole provided in the filter, a ground electrode of the filter, the wiring electrode, and a through-hole provided in the circuit board. With this arrangement, the terminal electrode is connected to a high-frequency signal terminal of the semiconductor device via the filter.

Owner:MURATA MFG CO LTD

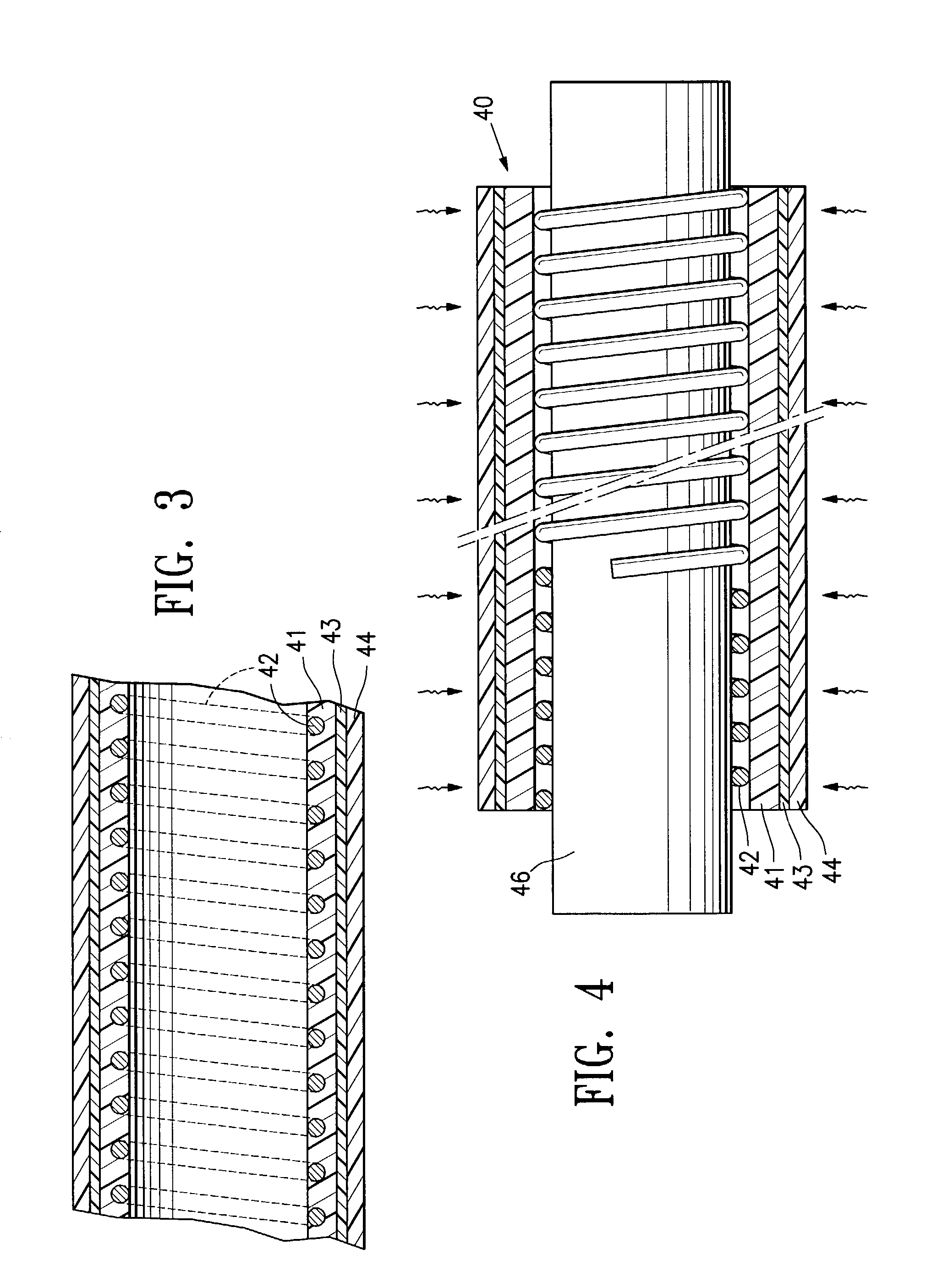

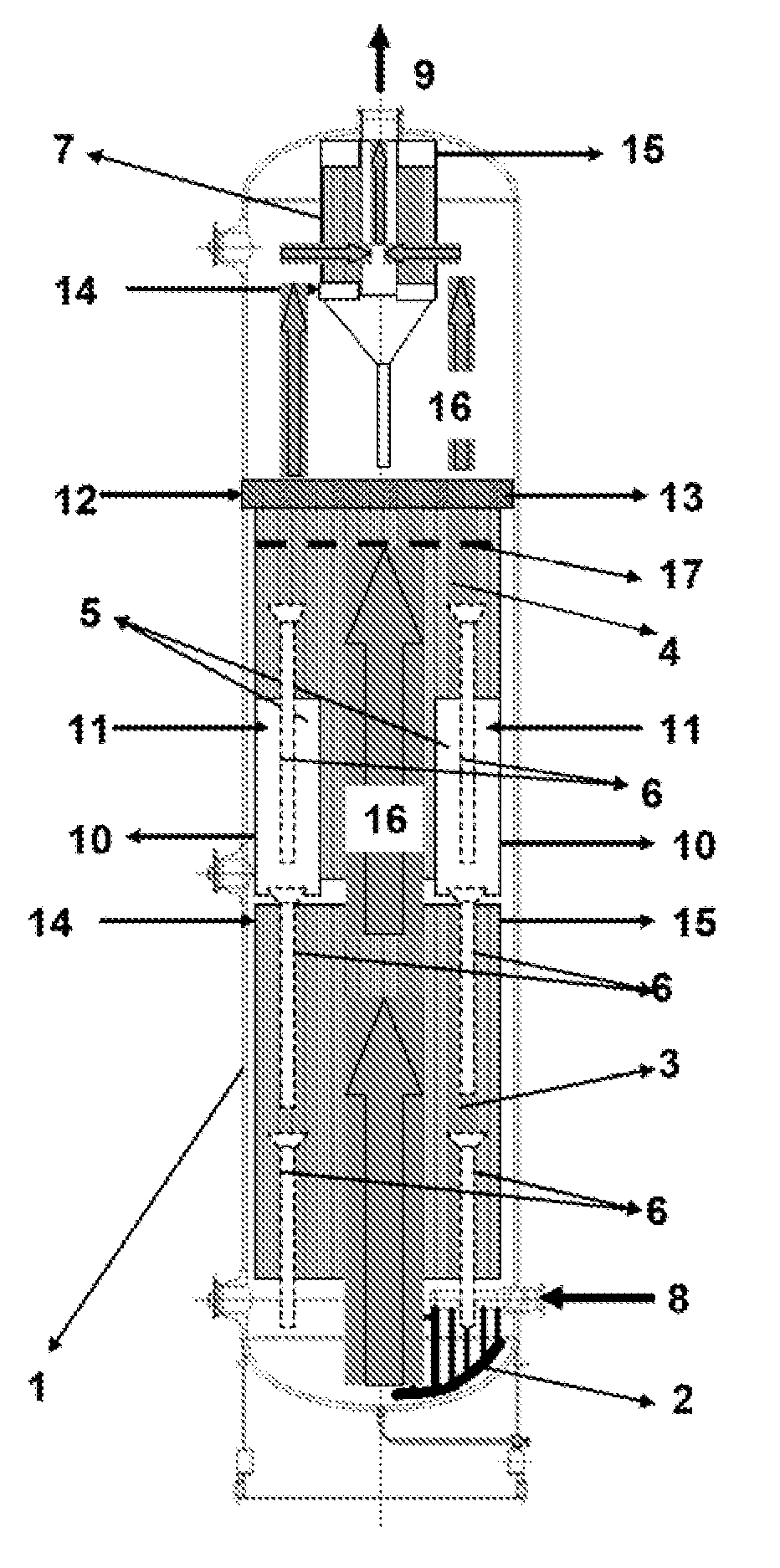

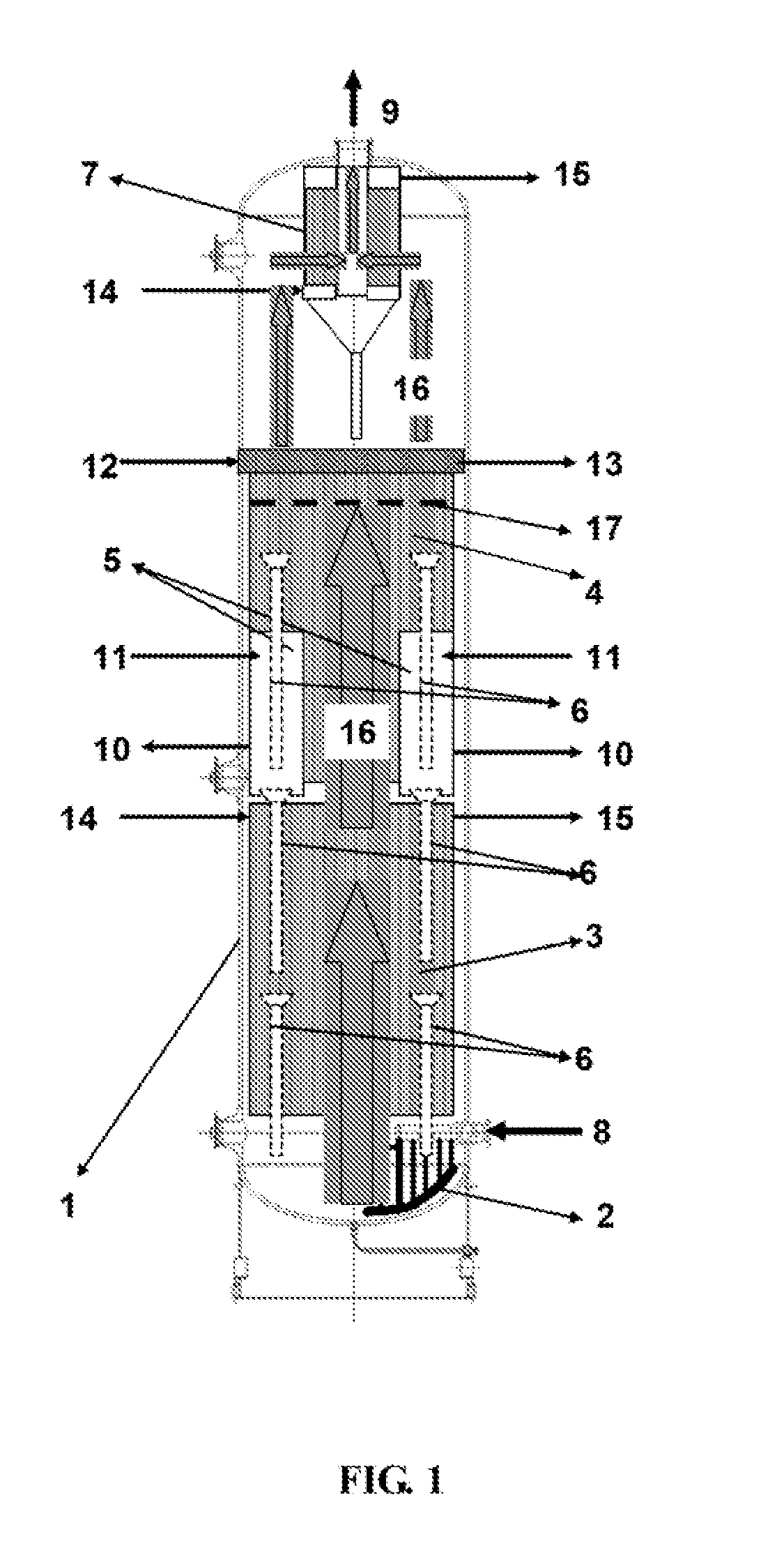

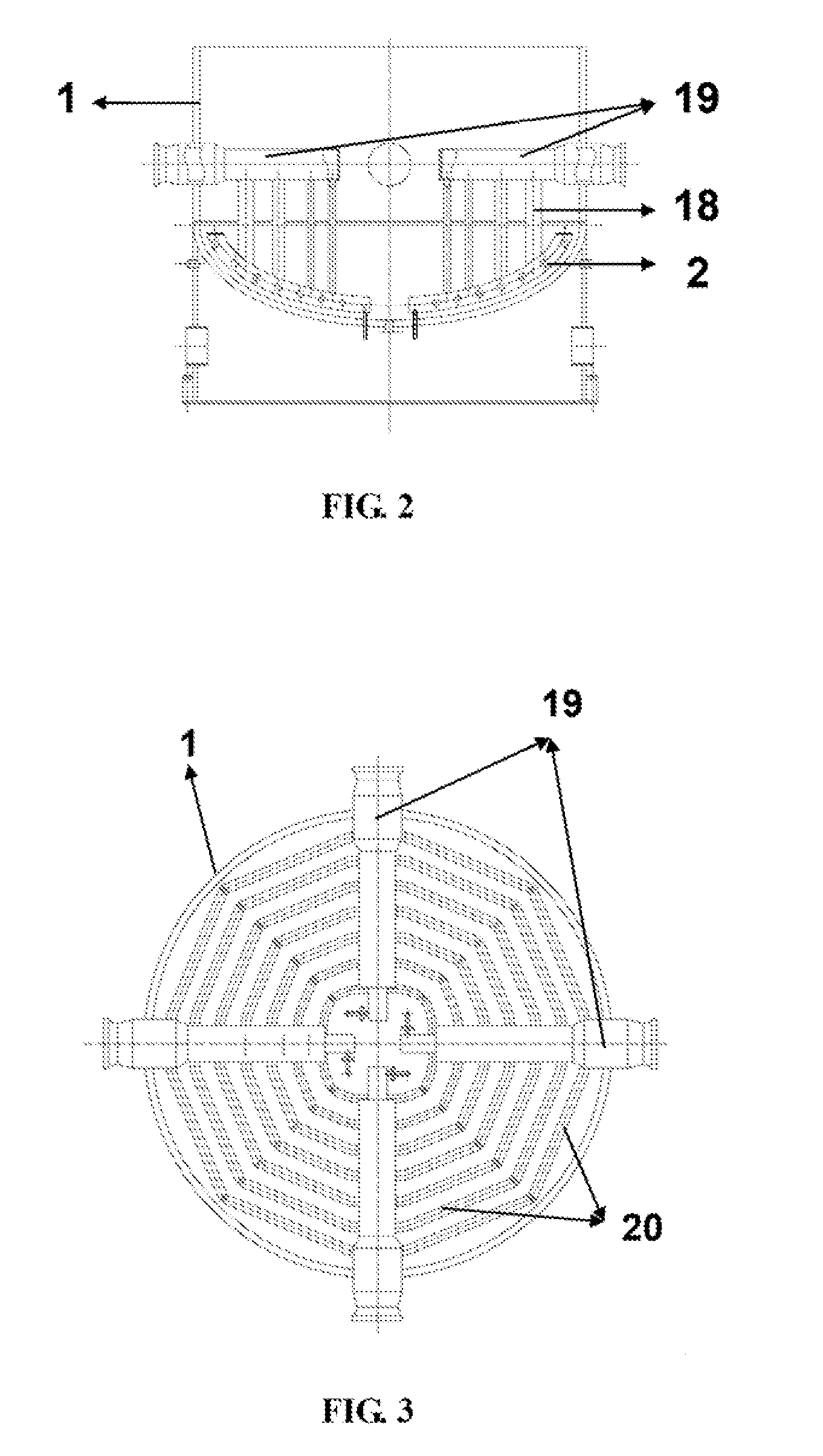

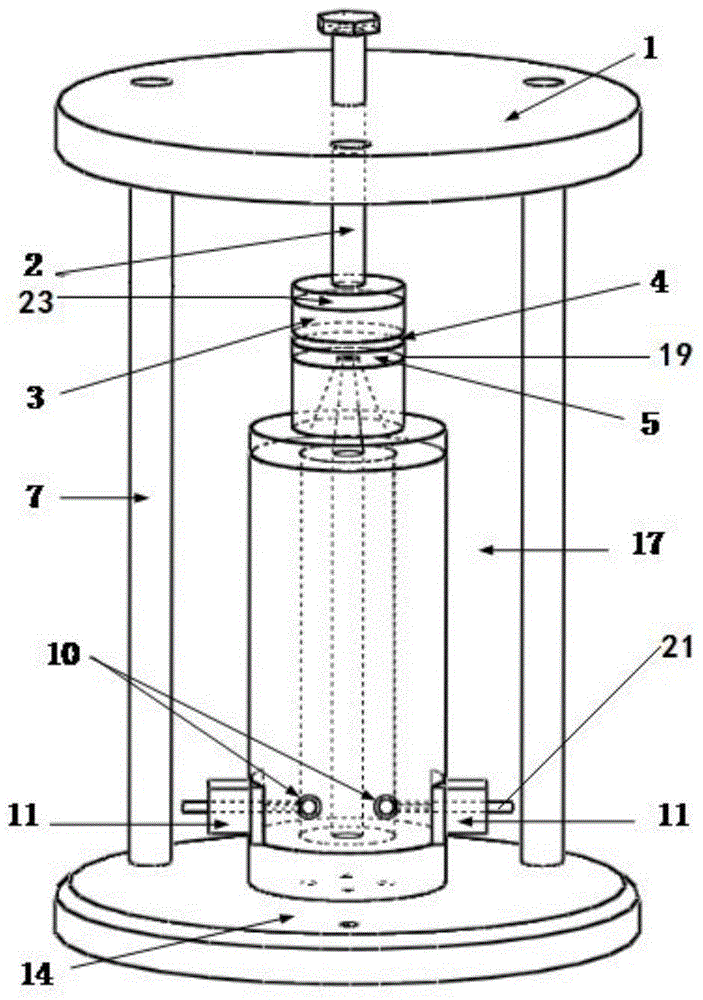

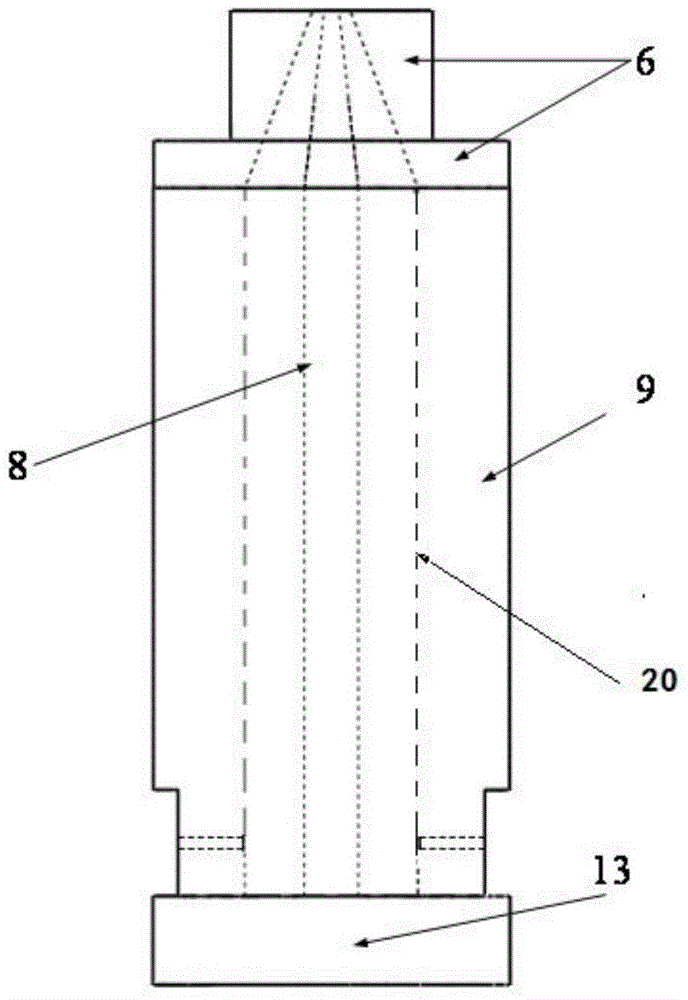

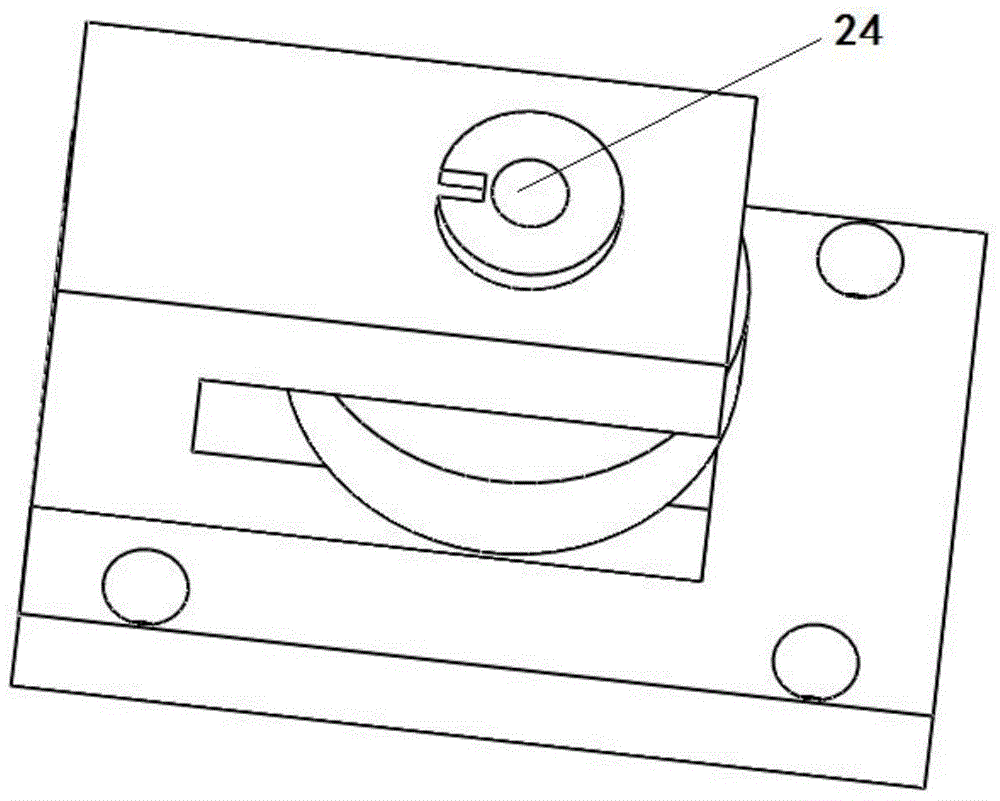

Gas-liquid-solid three-phase suspension bed reactor for fischer-tropsch synthesis and its applications

ActiveUS20100216896A1High activitySimple structureHydrocarbon from carbon oxidesPhysical/chemical process catalystsGas phaseFiltration

A Fischer-Tropsch synthesis three-phase suspension bed reactor (“suspension bed” also called “slurry bed”) and its supplemental systems, may include: 1) structure and dimension design of F-T synthesis reactor, 2) a gas distributor located at the bottom of the reactor, 3) structure and arrangement of a heat exchanger members inside the reactor, 4) a liquid-solid filtration separation device inside reactor, 5) a flow guidance device inside reactor, 6) a condensate flux and separation member located in the gas phase space at the top of reactor, 7) a pressure stabilizer, a cleaning system for the separation device; an online cleaning system for the gas distributor; an ancillary system for slurry deposition and a pre-condensate and mist separation system located at the outlet of upper reactor. This reactor is suitable for industrial scale application of Fischer-Tropsch synthesis.

Owner:SYNFUELS CHINA TECH CO LTD

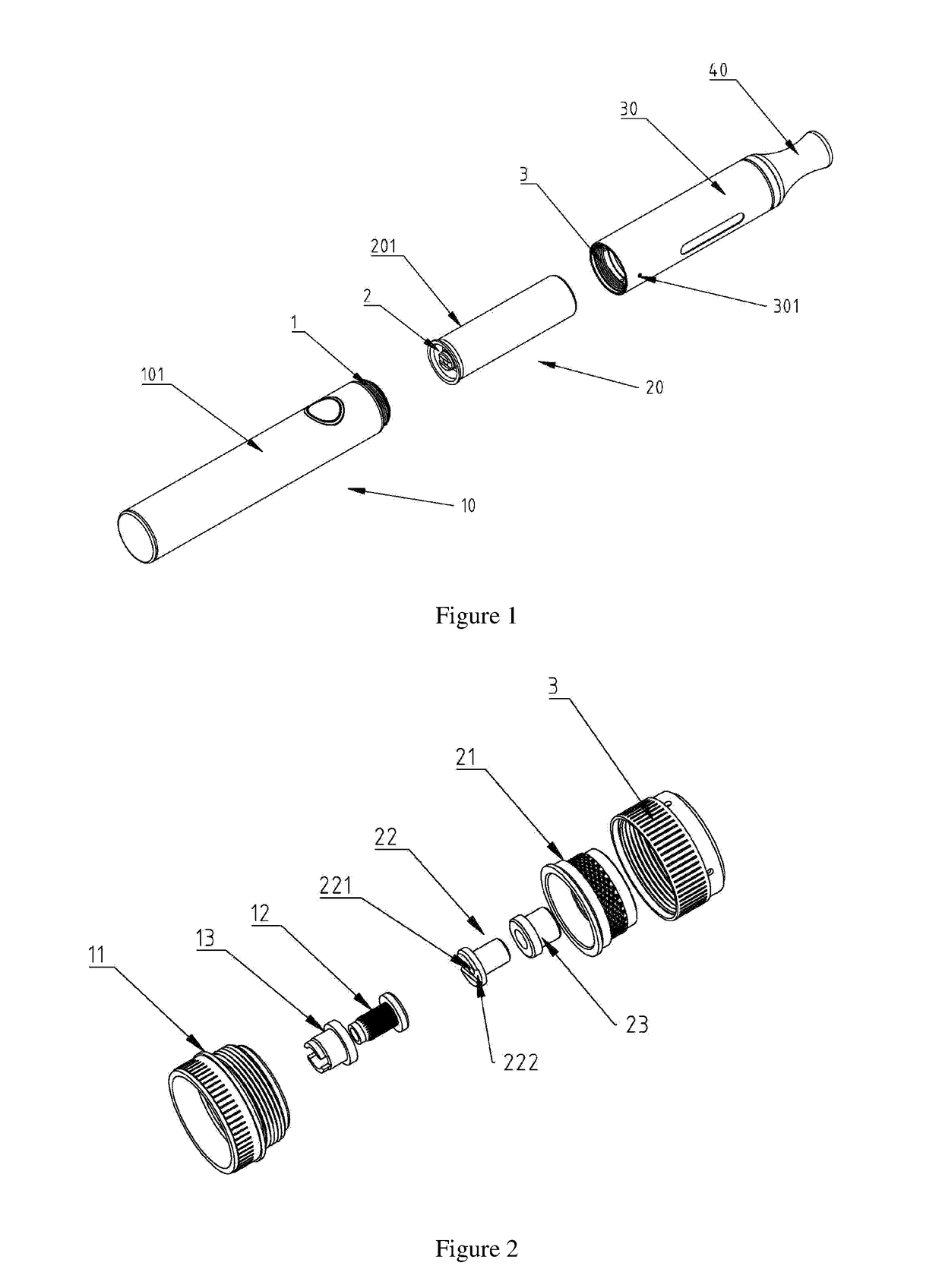

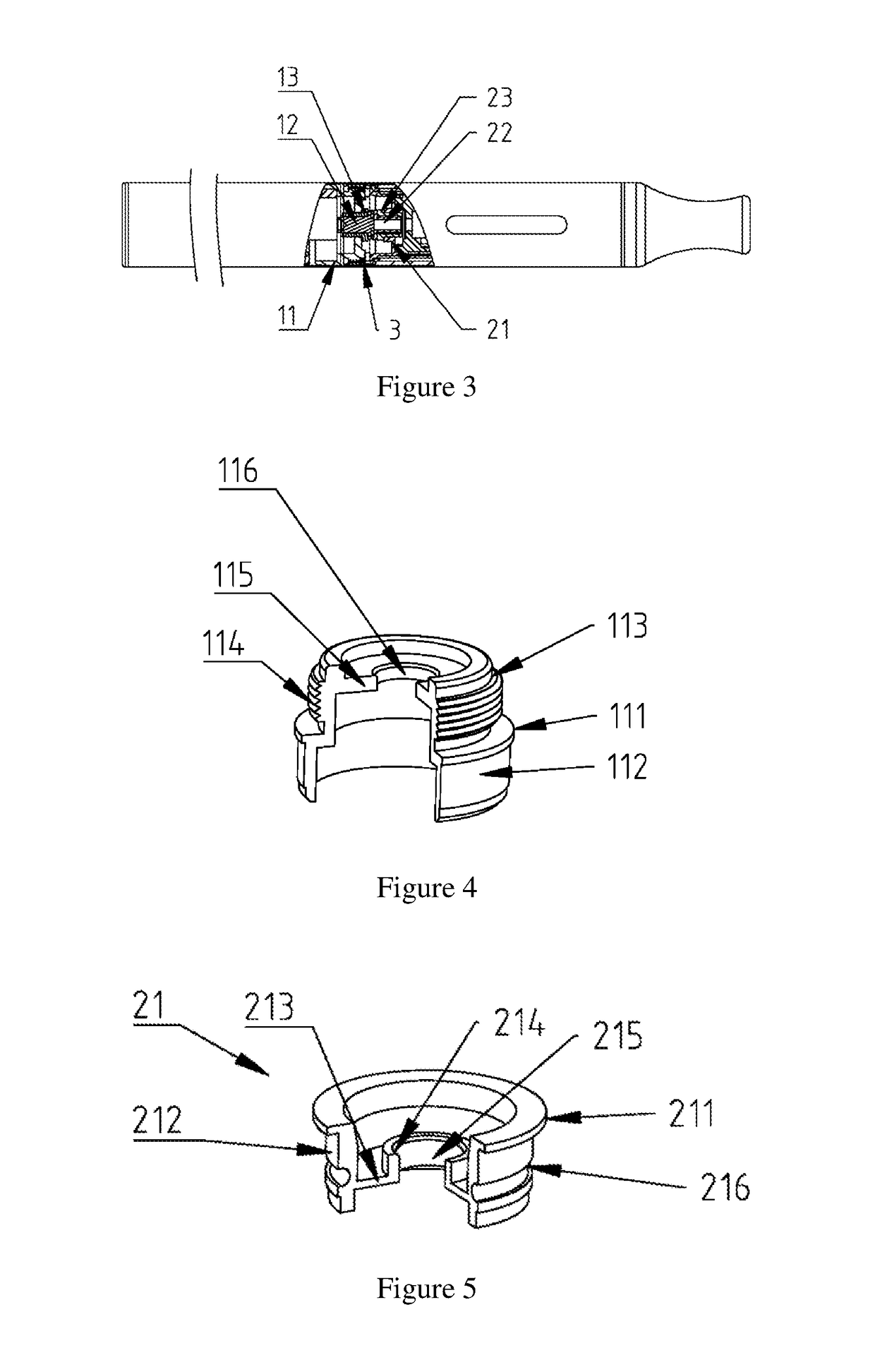

Electronic cigarette

ActiveUS20170150754A1Easy to removeConvenient disassemblyOhmic-resistance electrodesTobacco devicesElectronic cigaretteEngineering

Disclosed is an electronic cigarette, wherein a first connection portion (1) is arranged at an end of a casing tube (101) of a battery stick (10) adjacent to a vaporizer assembly, a second connection portion (2) is arranged at an end of a vaporizer tube body (201) adjacent to the battery stick (10), a third connection portion (3) is arranged at an end of a casing tube (30) of a vaporizer (20) adjacent to the battery stick (10). The second connection portion (2) and the first connection portion (1) abut against each other to be connected, the third connection portion (3) is detachably connected to the first connection portion (1) by means of a screw thread.

Owner:SHENZHEN HAPPY VAPING TECH LTD

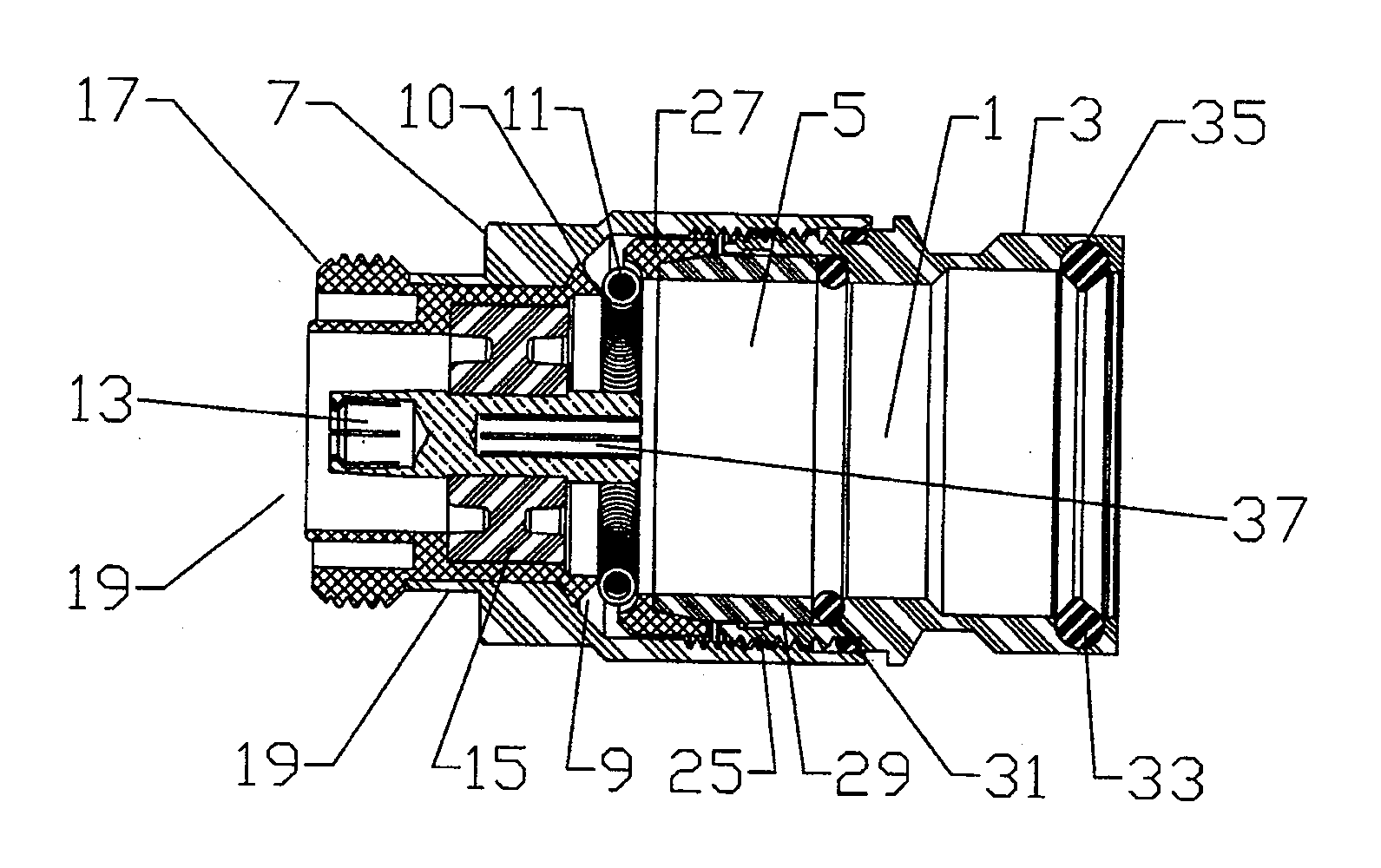

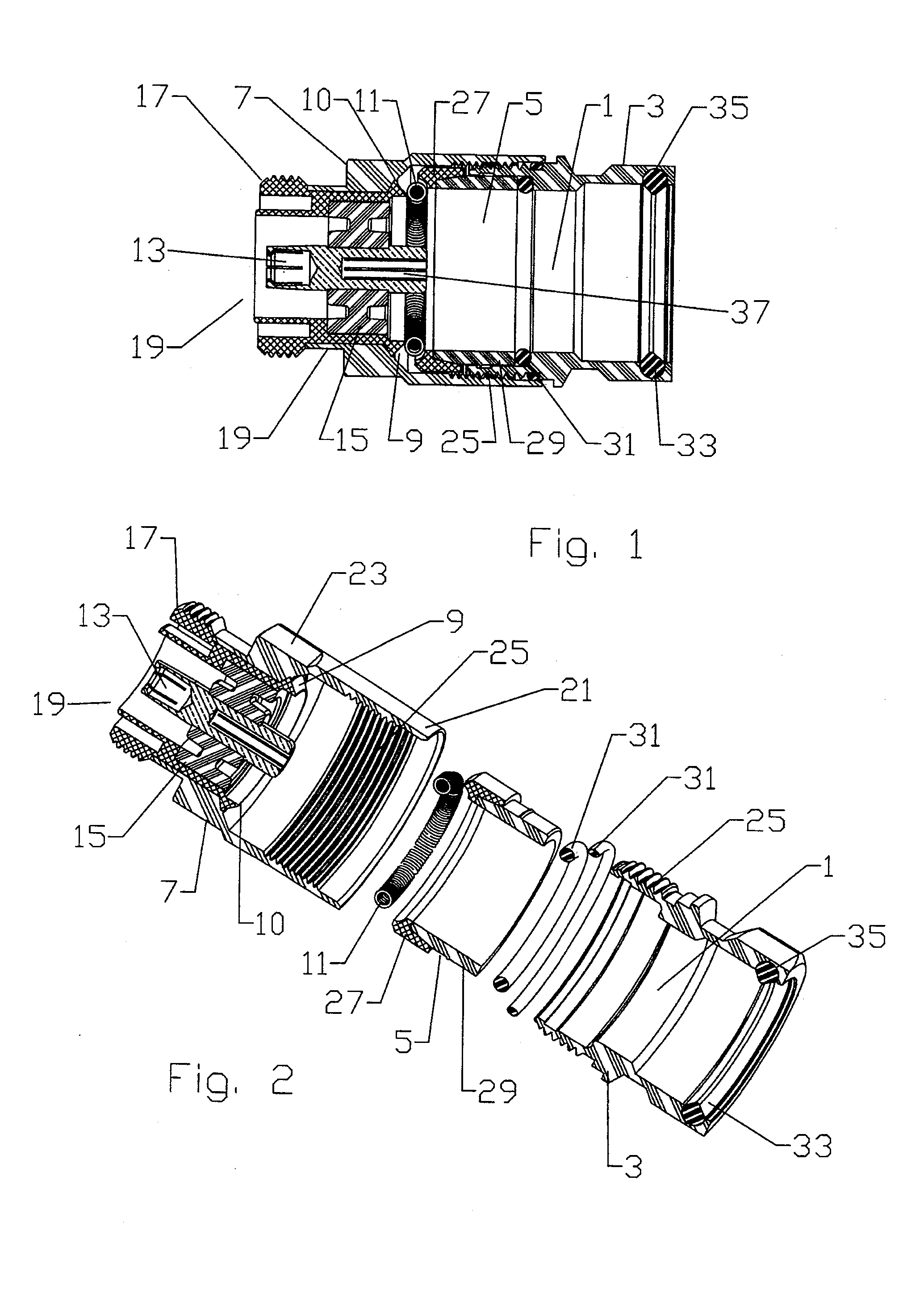

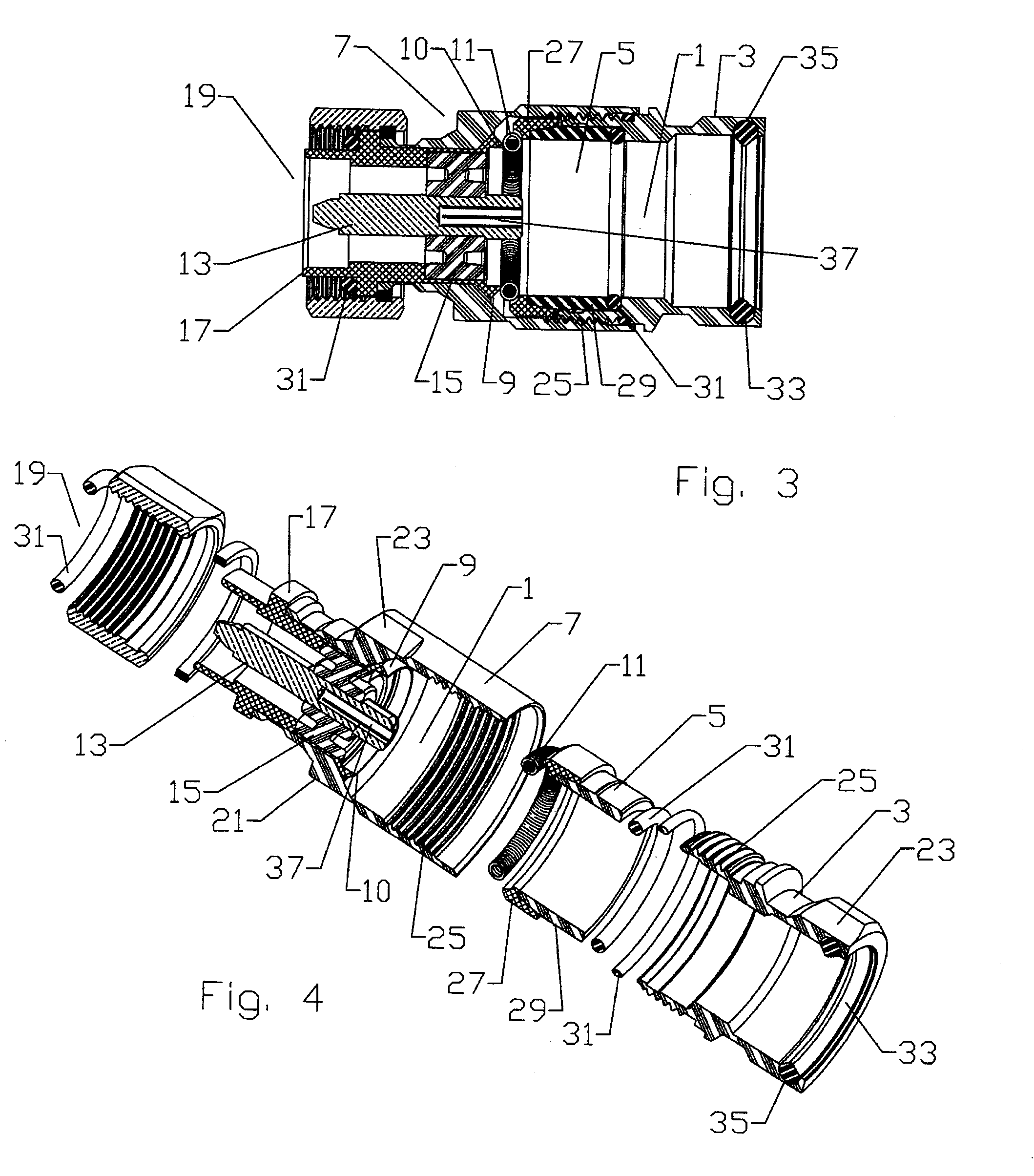

Multi-shot Connector Assembly and Method of Manufacture

InactiveUS20110003507A1Significant costSignificant materialTwo pole connectionsContact member cases/bases manufactureMultiple injectionCoaxial cable

A coaxial cable connector formed via multi-shot injection molding has a body formed by multiple injection molding layers of different injection moldable materials about a central inner contact to form an integral connector body. The connector body is provided with a coaxial dielectric spacer of dielectric polymer surrounding the inner contact; a coaxial inner body of injection molded metal composition surrounding an outer diameter of the dielectric spacer; and an outer body of polymer surrounding the inner body. Interlock features provide axial and / or rotational interlock between the layers of the connector.

Owner:ANDREW LLC

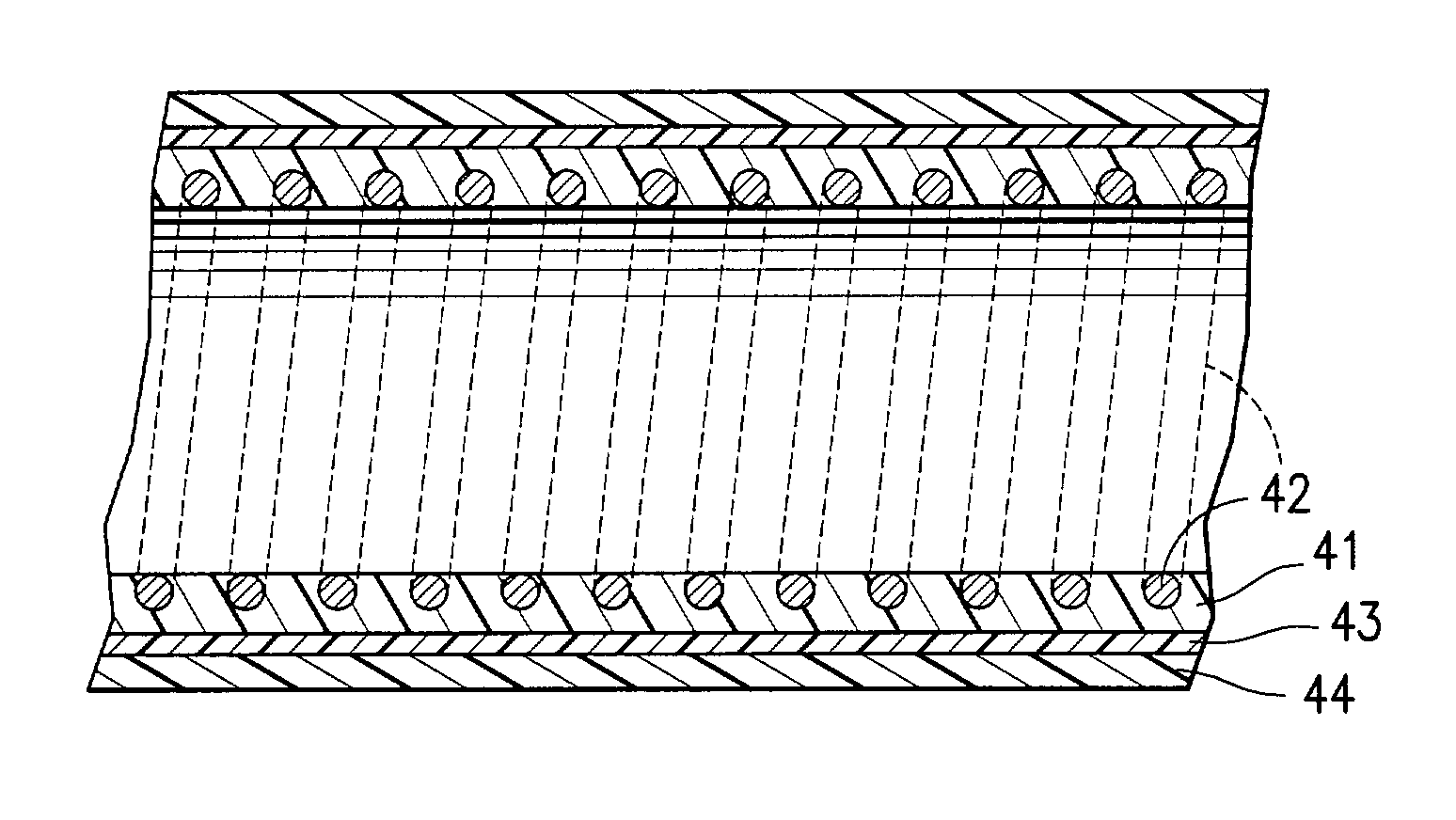

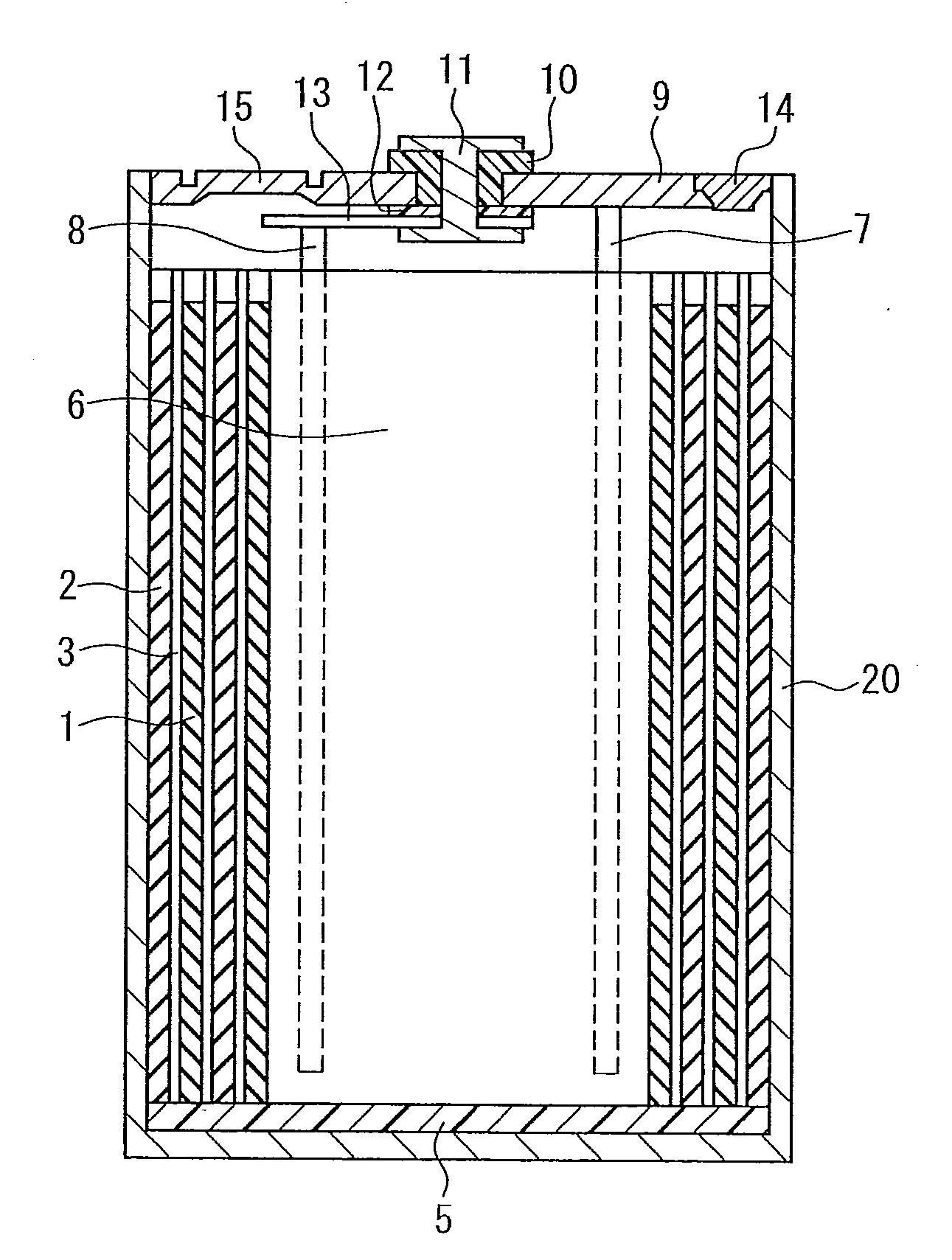

Electrochemical device and method for production thereof

ActiveUS20090325058A1Improve securityImprove productivityHybrid capacitor separatorsElectrolytic capacitorsPorous layerMaterials science

An electrochemical device of the present invention includes a positive electrode, a negative electrode, a non-aqueous electrolyte, and a separator. The separator includes a first porous layer composed mainly of a thermoplastic resin and a second porous layer composed mainly of insulating particles with a heat-resistant temperature of 150° C. or higher. The first porous layer is disposed to face the negative electrode.

Owner:MAXELL HLDG LTD

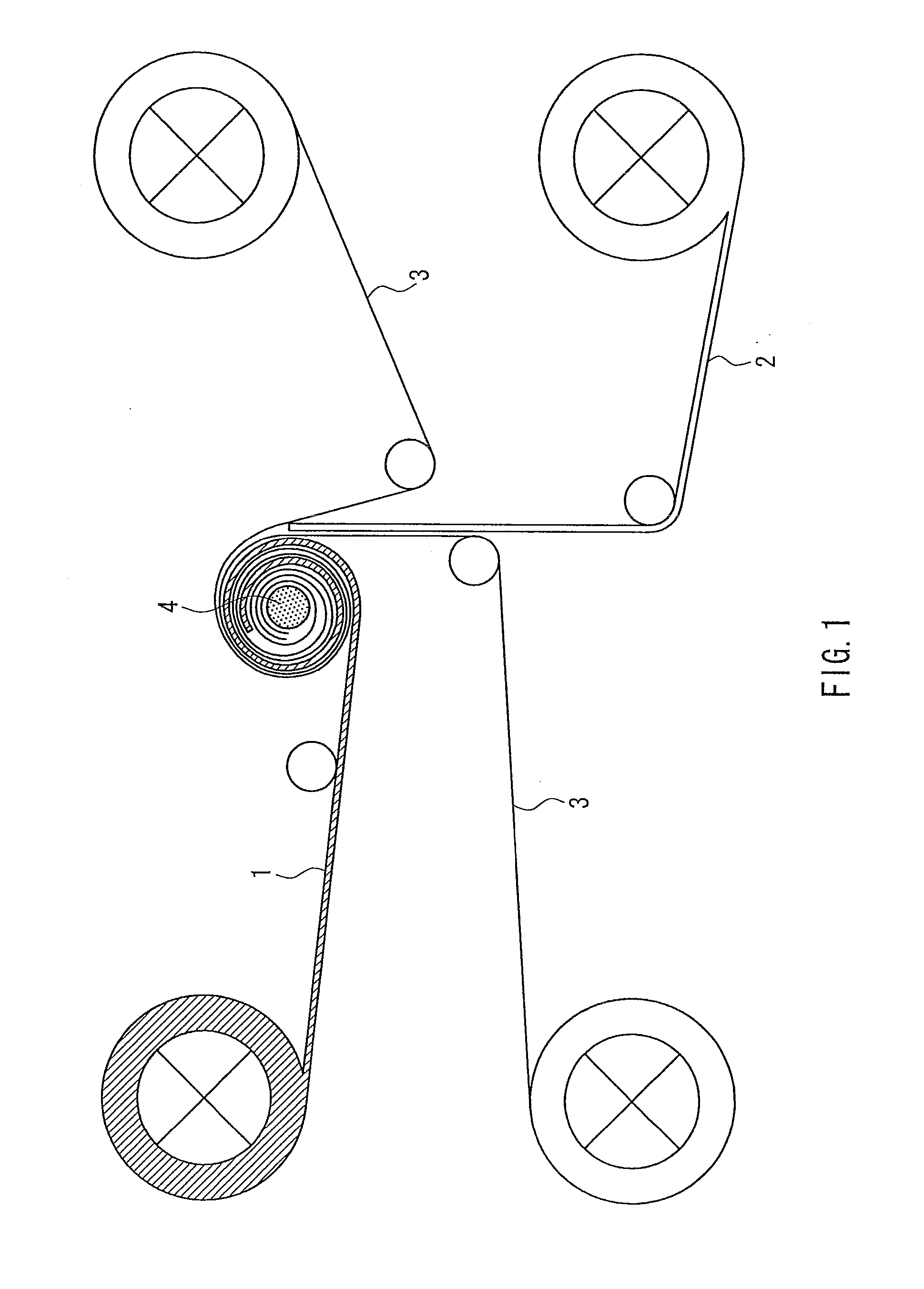

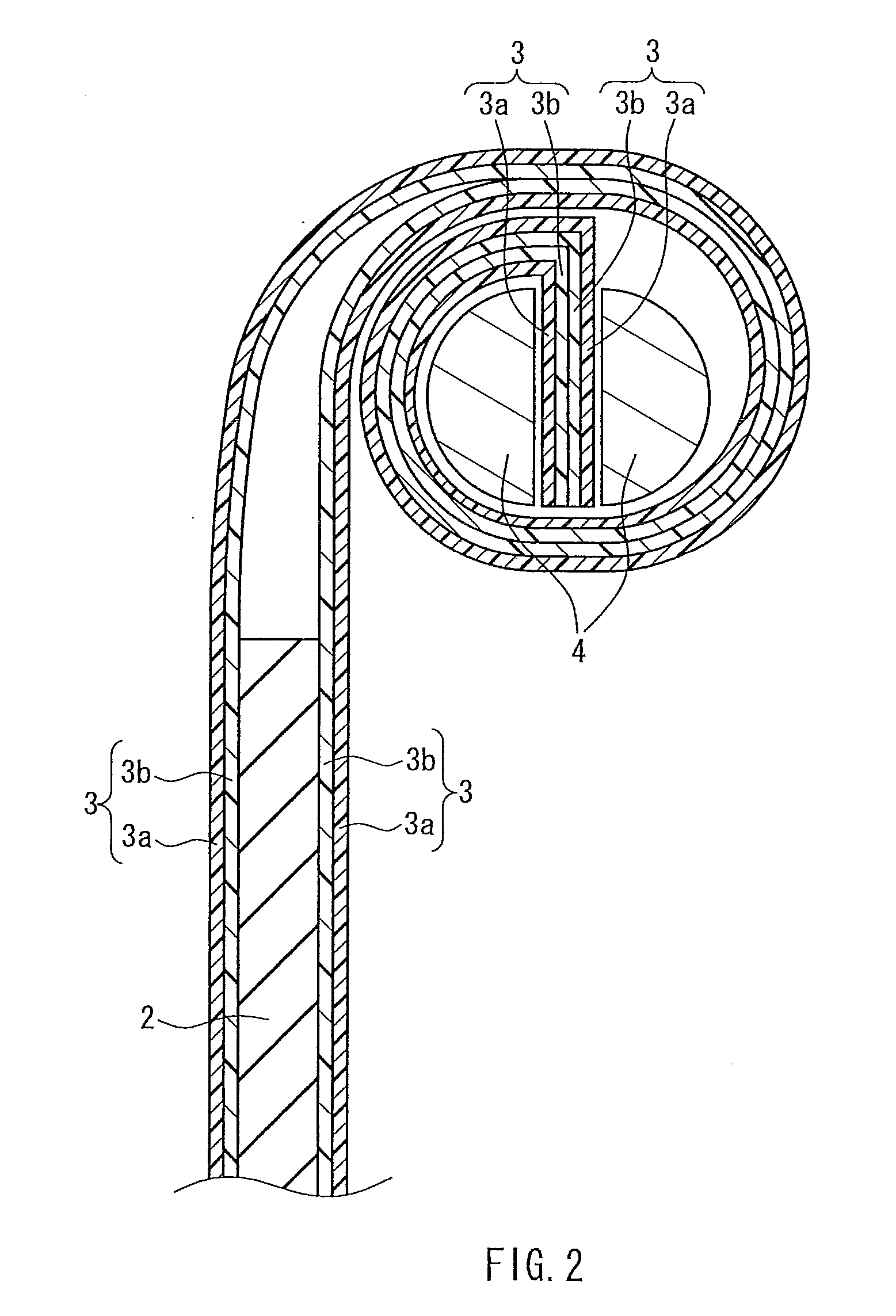

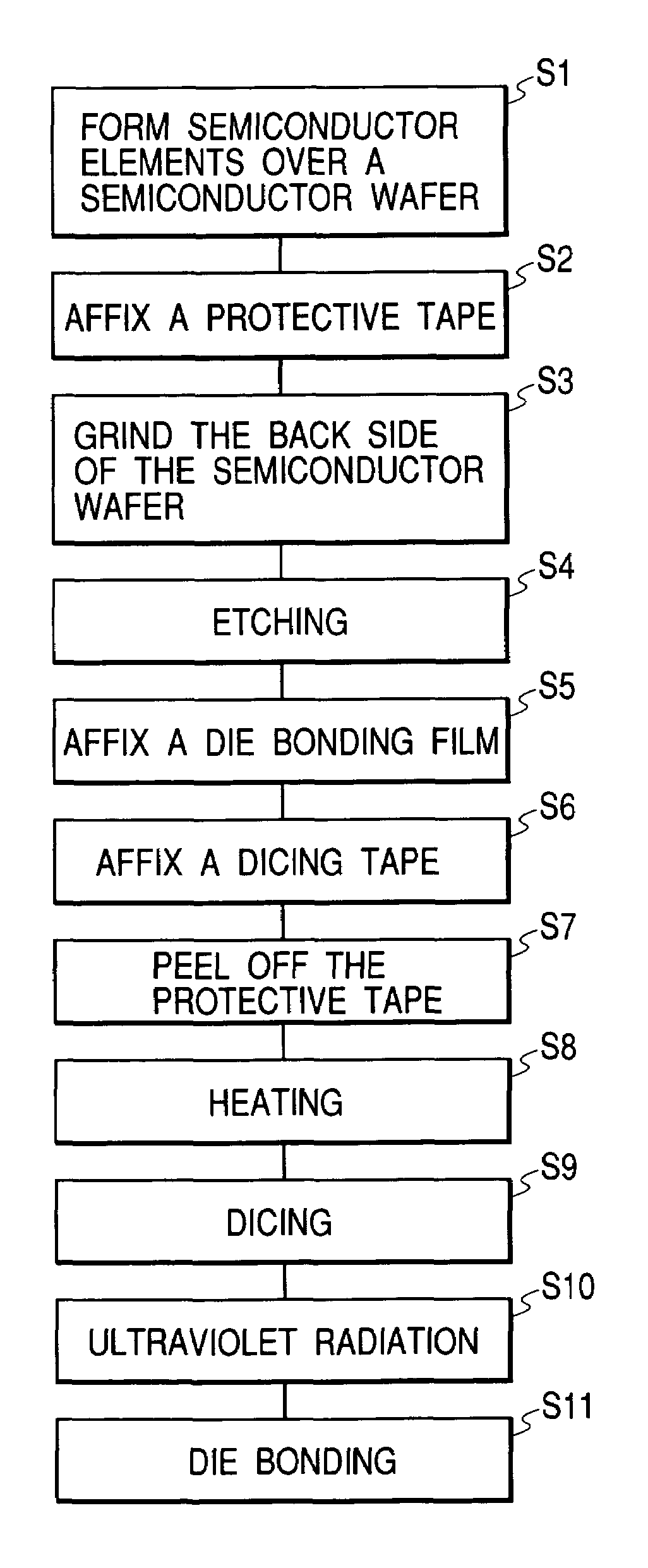

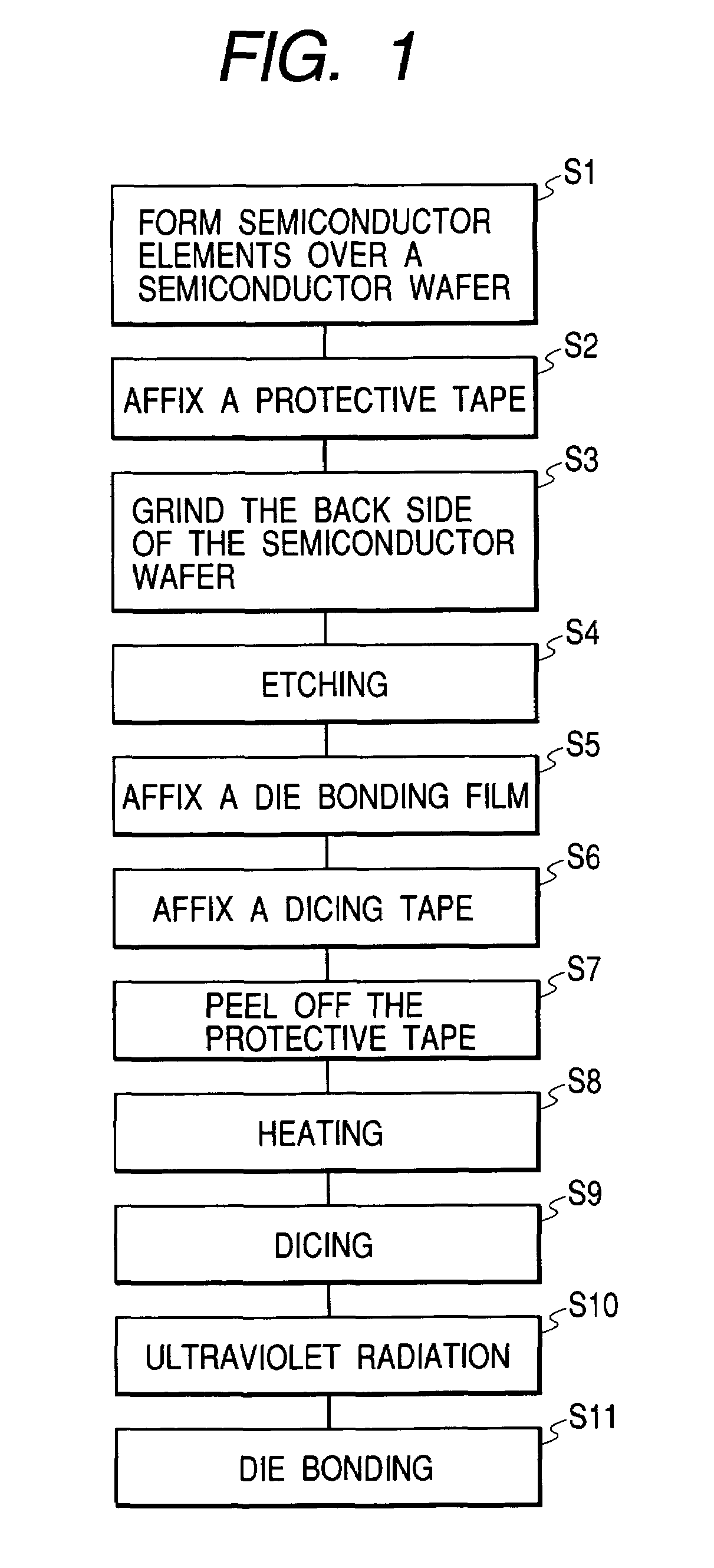

Fabrication method of semiconductor circuit device

InactiveUS7122447B2Prevent wrinklingEasier for the semiconductor wafer to warpSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorDicing tape

When a semiconductor wafer is formed to be thin, steps need to be taken to prevent warping of the wafer. For this purpose, a protective tape is affixed to a surface of the semiconductor wafer, and a back side of the semiconductor wafer is then ground to a predetermined thickness. A die bonding film is affixed to the back side of the semiconductor wafer, and a dicing tape is affixed on the die bonding film. The dicing tape that is affixed to the semiconductor wafer is held by a holding jig. The protective tape is peeled off from the wafer surface, and the die bonding film is heated to improve the adherence between the semiconductor wafer and the die bonding film. The semiconductor wafer is subjected to dicing for separation into individual semiconductor chips. The semiconductor chips are then die-bonded in a predetermined number onto a wiring substrate to fabricate a semiconductor device.

Owner:RENESAS ELECTRONICS CORP

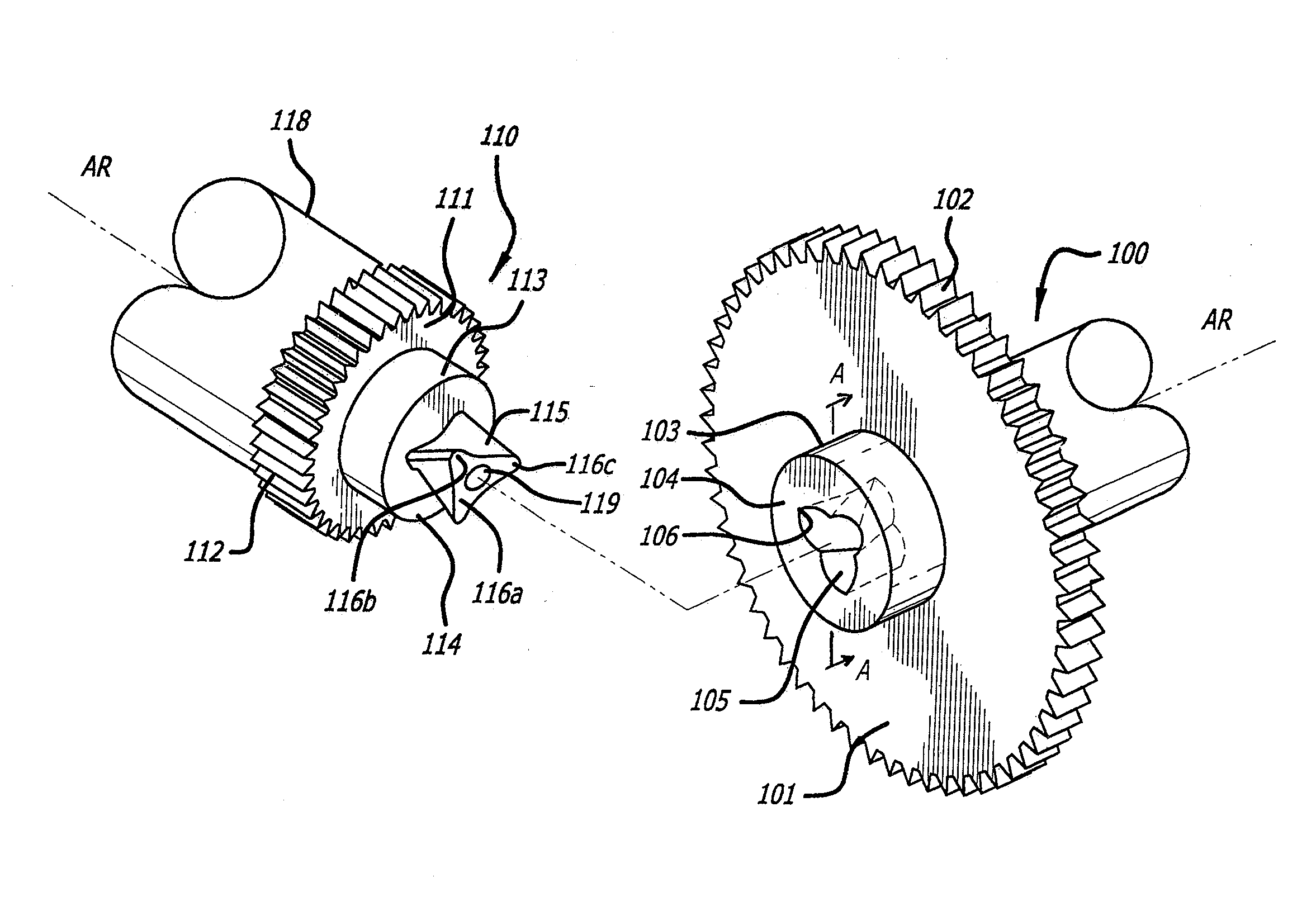

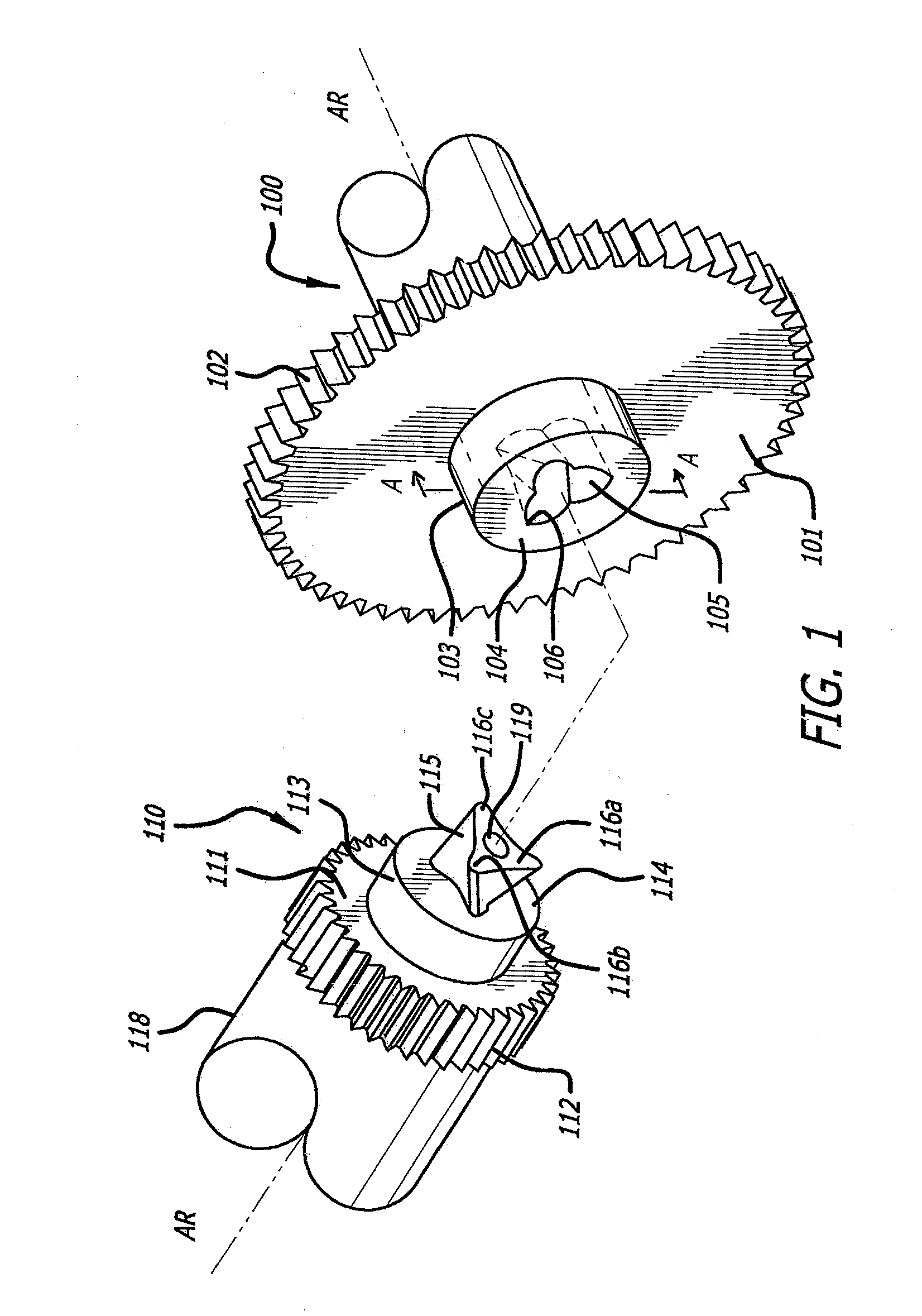

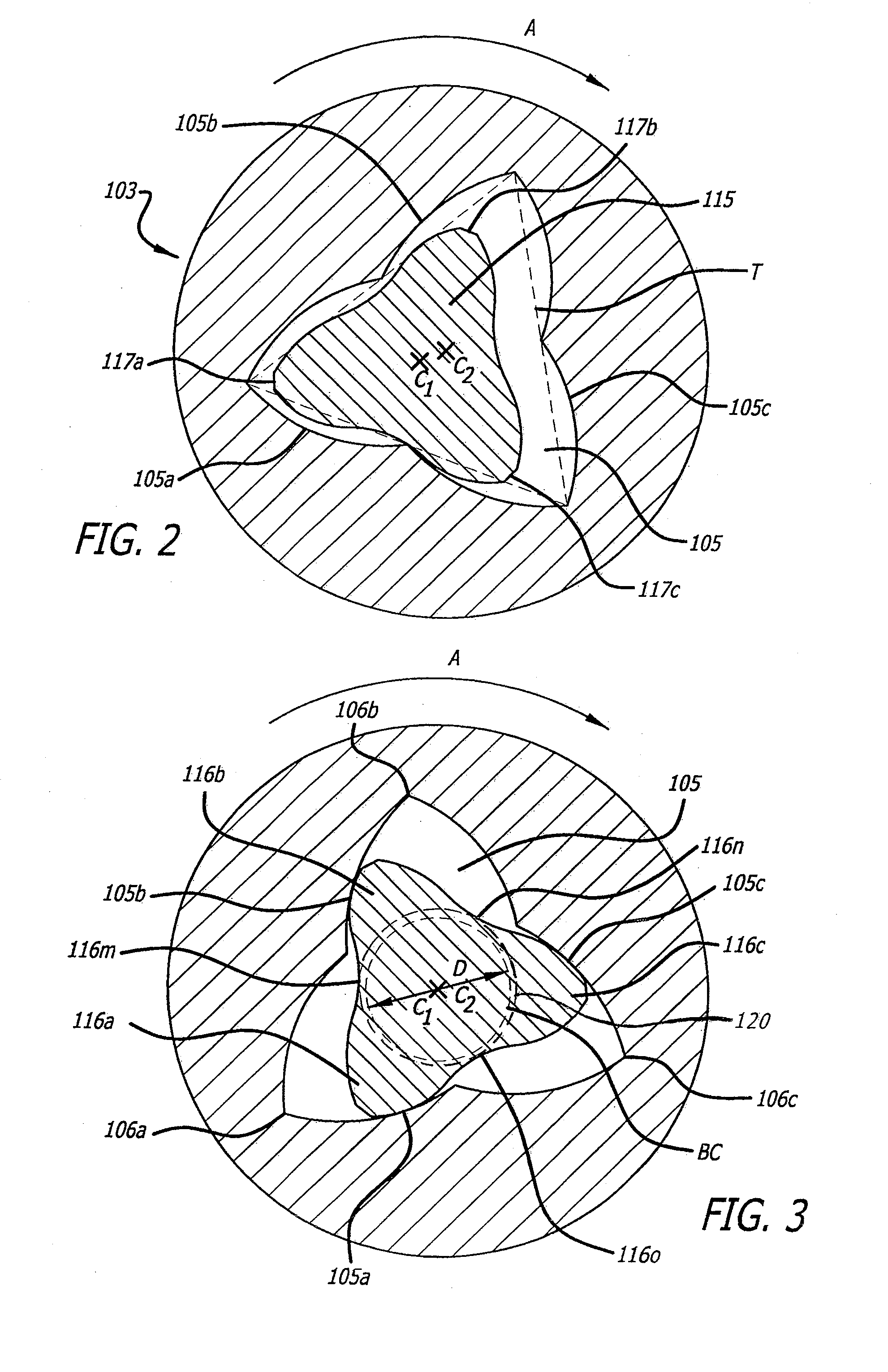

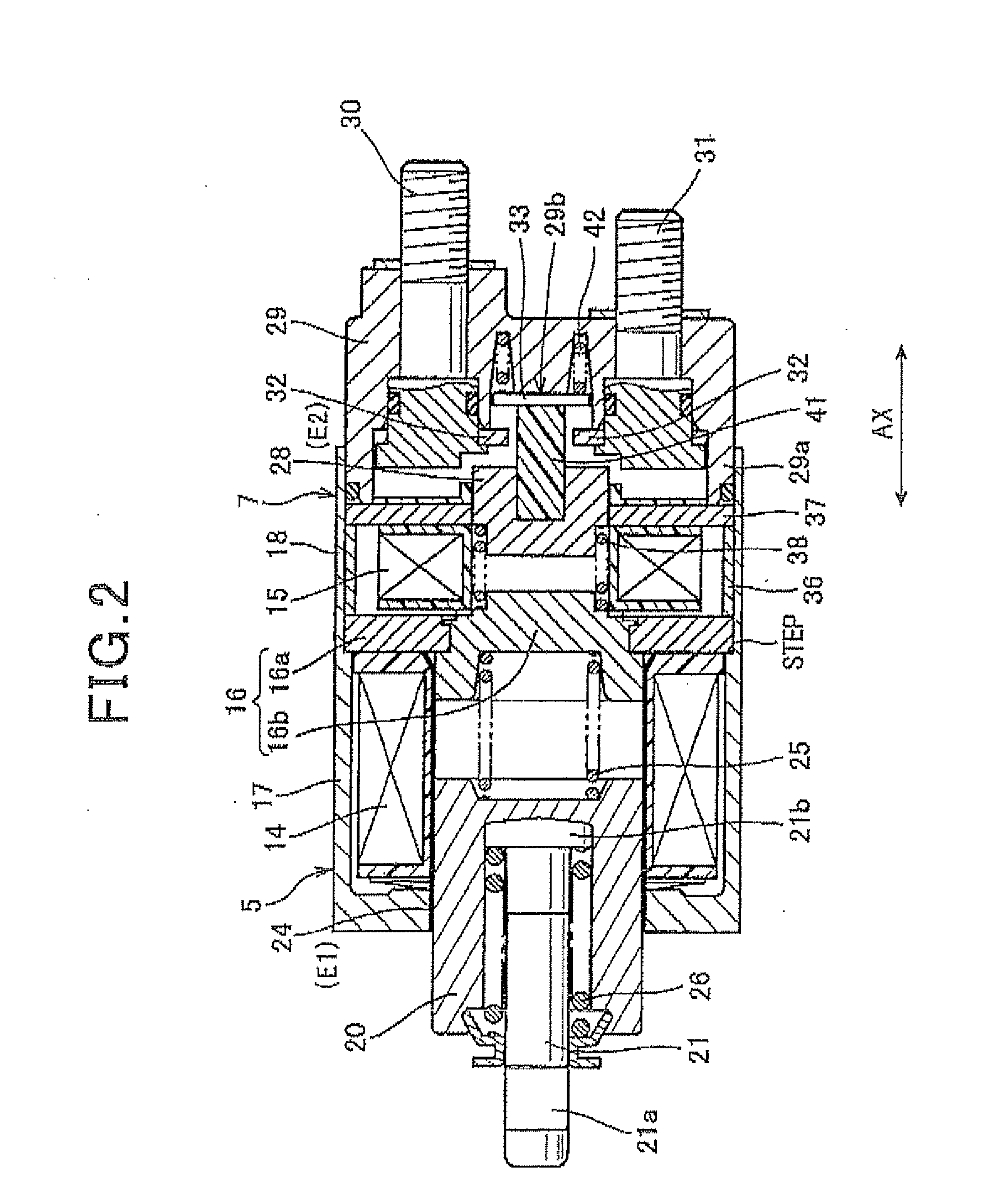

Rotating Drive Shaft Coupling

ActiveUS20130058710A1Reduce maintenanceLower manufacturing requirementsCouplings for rigid shaftsElectrographic processDrive shaftCoupling

A rotatable coupling is used with a replaceable developer cartridge and electrostatographic image devices. The coupling has a driven portion and a driving portion. The driven portion has a shaft with a connecting portion that has a plurality of helical involute teeth extending outwardly. The driving portion has an end with a gear shaft and a twisted petaline recess in the gear shaft. The sides of the recess are engageable with the helical involute teeth so that the driving portion drives the driven portion and transmit torque.

Owner:RAINBOW TECH INT LTD

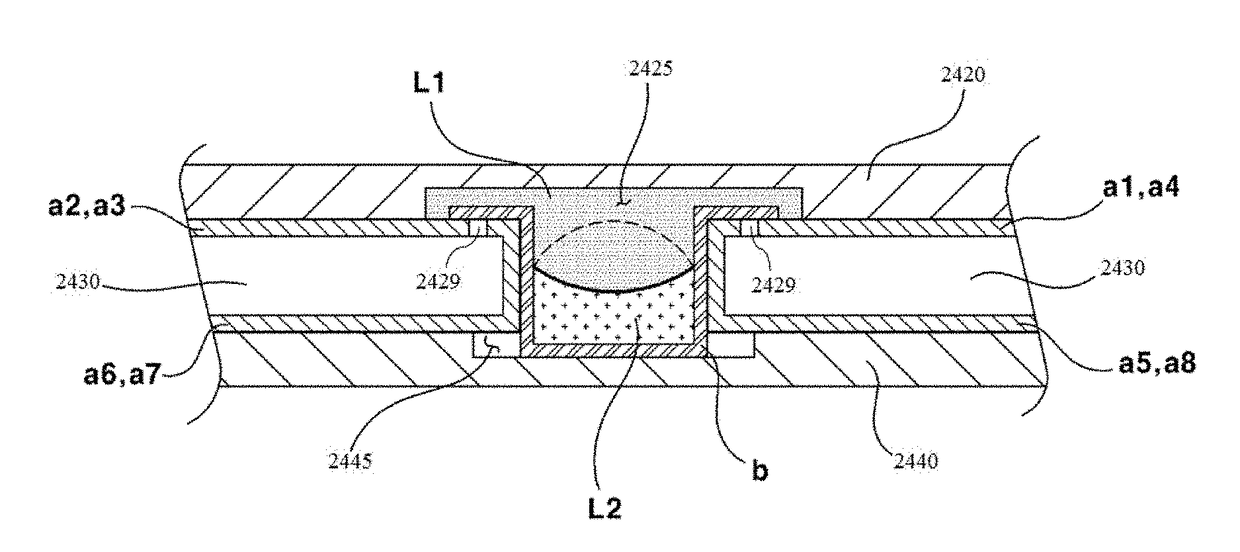

System and method for testing microwave complex permittivity of dielectric material

InactiveCN104407232ALower manufacturing requirementsShorten test timeResistance/reactance/impedenceElectricityResonant cavity

The invention provides a system and a method for testing microwave complex permittivity of a dielectric material. The system comprises a coaxial-open-type resonant cavity and a coupling quantity adjuster. The method includes the steps: a, recording resonant frequency f0 of the system without any sample loaded in a testing range and a quality factor Q0 of a corresponding frequency point; b, testing thickness d of a to-be-tested sample, and testing to acquire resonant frequency f1 of the system after the sample is loaded in the testing range and a Q1 of a corresponding loaded quality factor; c, utilizing a perturbation theory of the resonant cavity to extract complex permittivity of a to-be-tested material. By the system and the method, high-accuracy testing of the complex permittivity of the microwave dielectric material is realized, and troublesome precise calibration does not need to be performed on a network analyzer, so that testing time is reduced, and requirements, on sample manufacturing, of testing are lowered.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

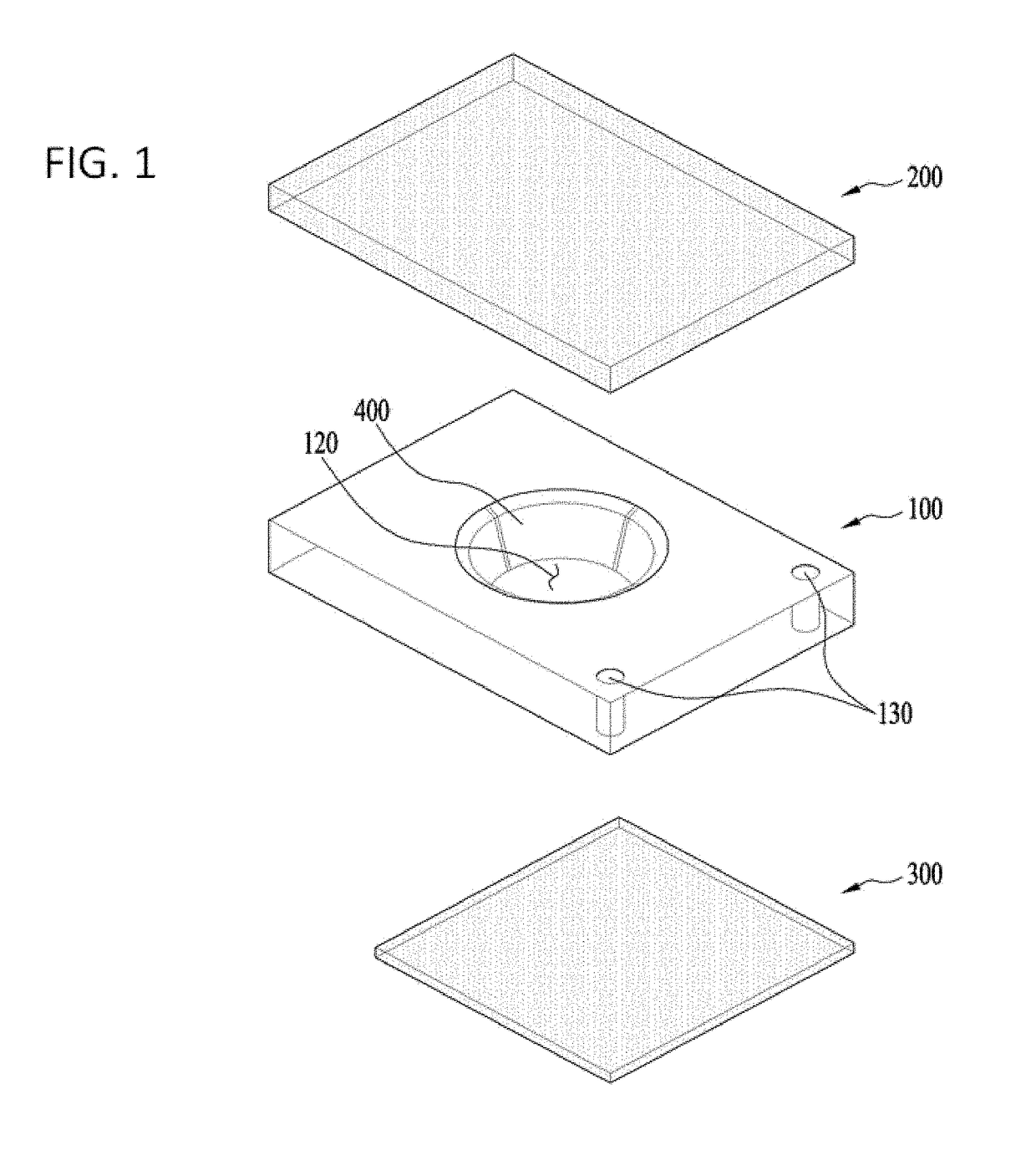

Camera Module Including Liquid Lens, Optical Device Including the Same, and Method of Manufacturing Camera Module Including Liquid Lens

ActiveUS20170315274A1Simple structureReduce space sizeTelevision system detailsPrintersComputer moduleCamera module

An embodiment of a camera module includes a holder configured such that the upper and lower portions of the holder are open and such that a first hole and a second hole, opposite to the first hole, are formed in the side surface of the holder, a first lens unit coupled to the upper portion of the holder, a second lens unit coupled to the lower portion of the holder, and a liquid lens disposed in the first hole and the second hole of the holder between the first lens unit and the second lens unit, the liquid lens protruding outward from the side surface of the holder, wherein at least a portion of the liquid lens may be spaced apart from the inner surface of the holder.

Owner:LG INNOTEK CO LTD

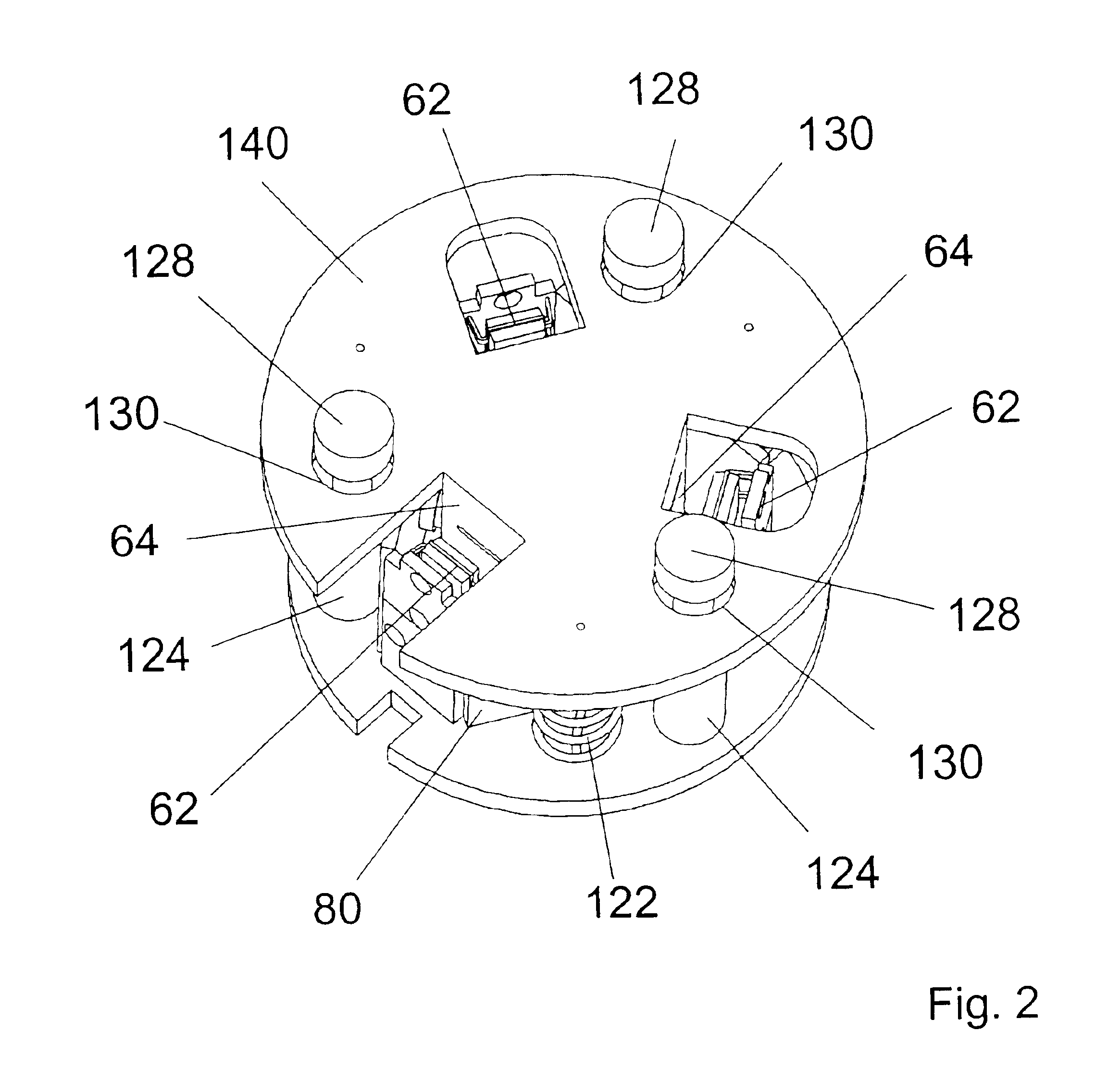

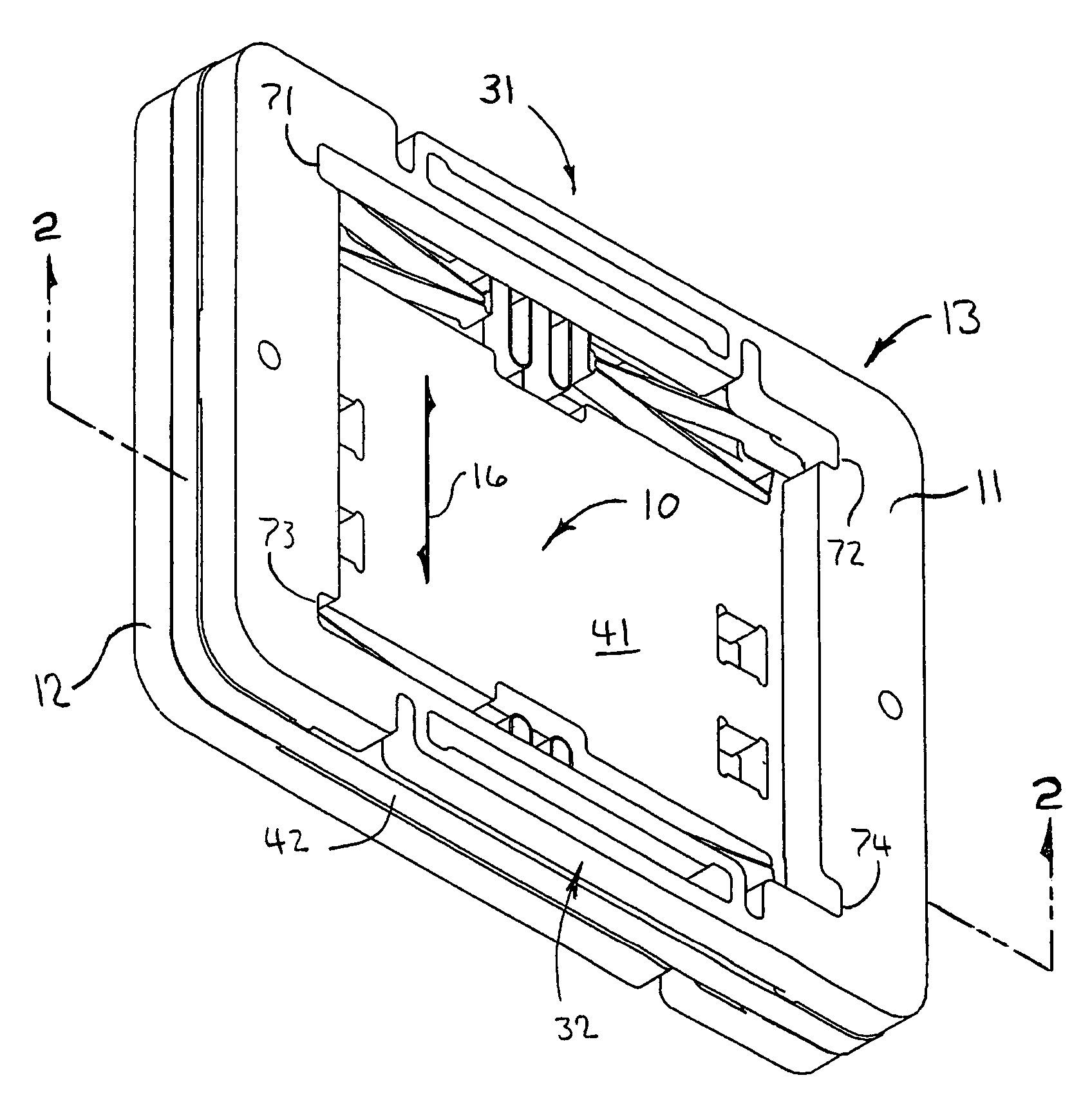

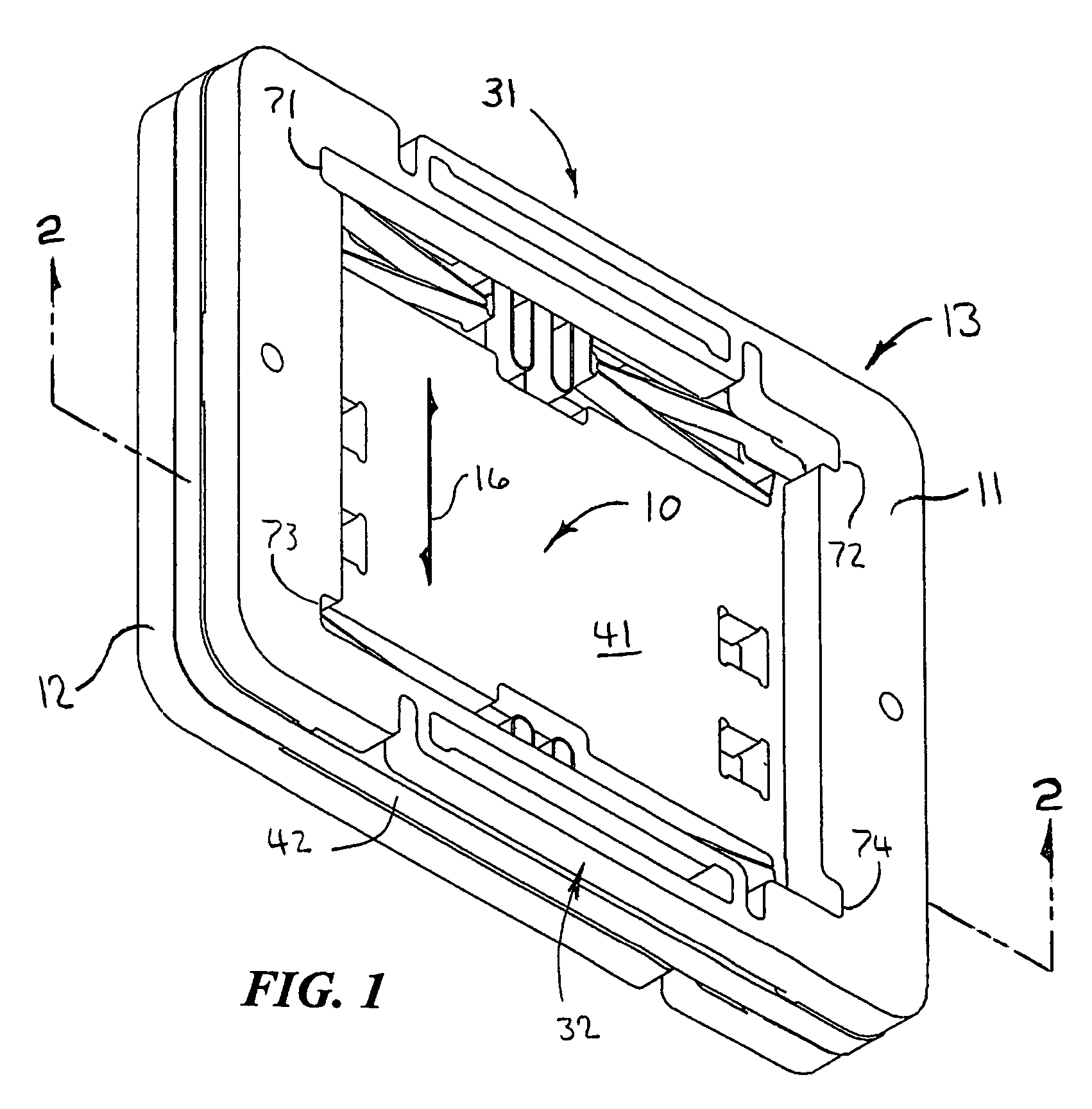

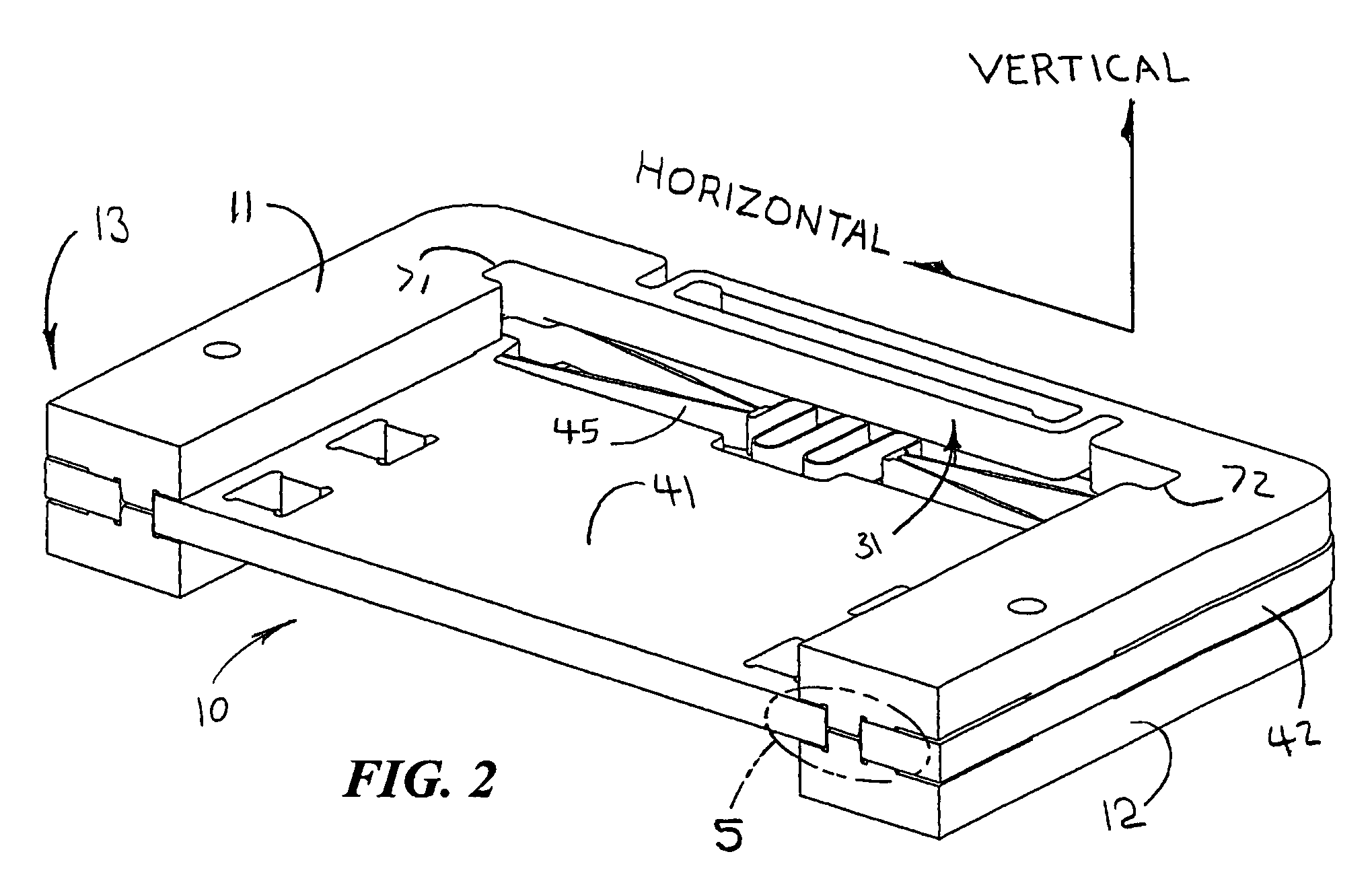

Camera snubber assembly

ActiveUS7646969B2FocusEasy to zoom inTelevision system detailsProjector focusing arrangementEngineeringDegrees of freedom

A method and system for limiting the motion of components such as the optics of a camera are disclosed. The system can comprise a stage and a snubber assembly for controlling motion of the stage in six degrees of freedom. For example, the snubber assembly can permit movement in one translational degree of freedom while substantially limiting motion in the other five degrees of motion so as to facilitate focusing and / or zooming of a camera while inhibiting misalignment of the optics and while providing some protection against shock and vibration. Such motion control can be achieved while mitigating costs associated with precision manufacturing of the snubber assembly.

Owner:DIGITALPTICS MEMS

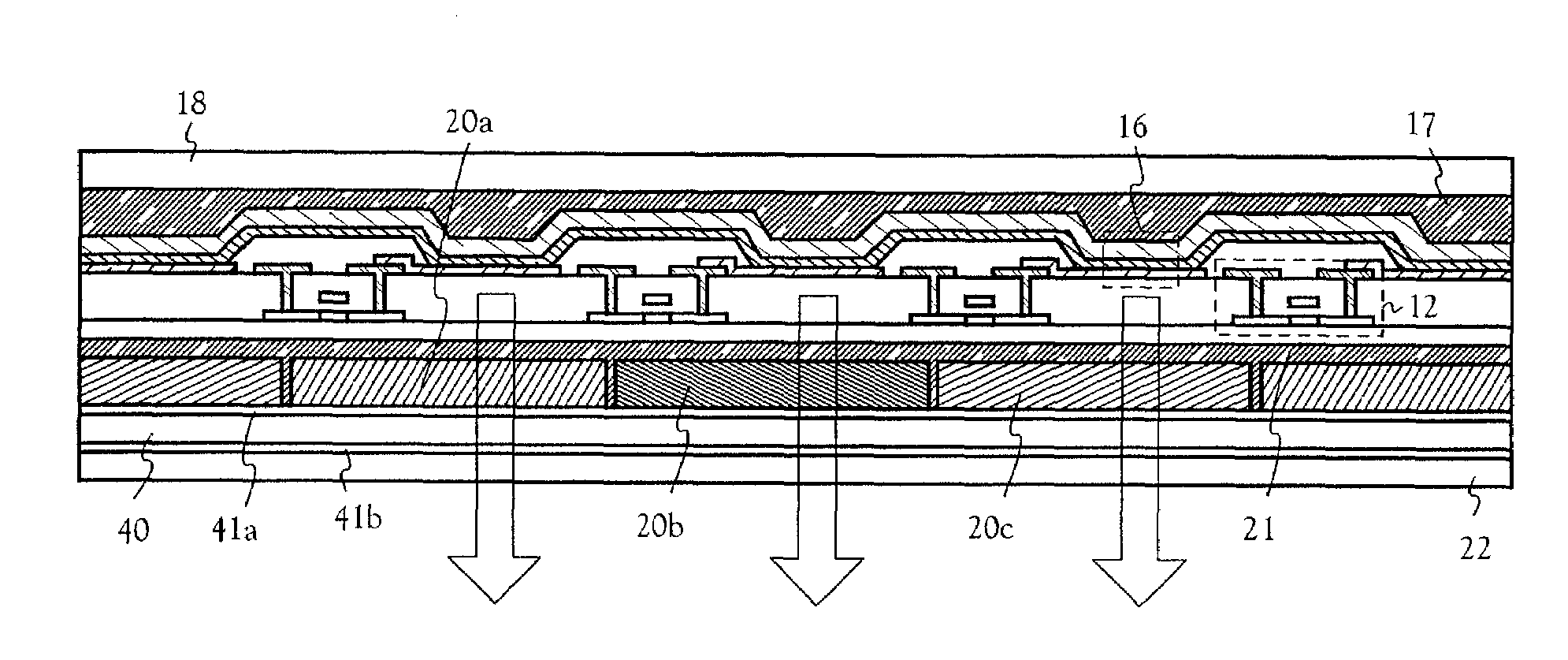

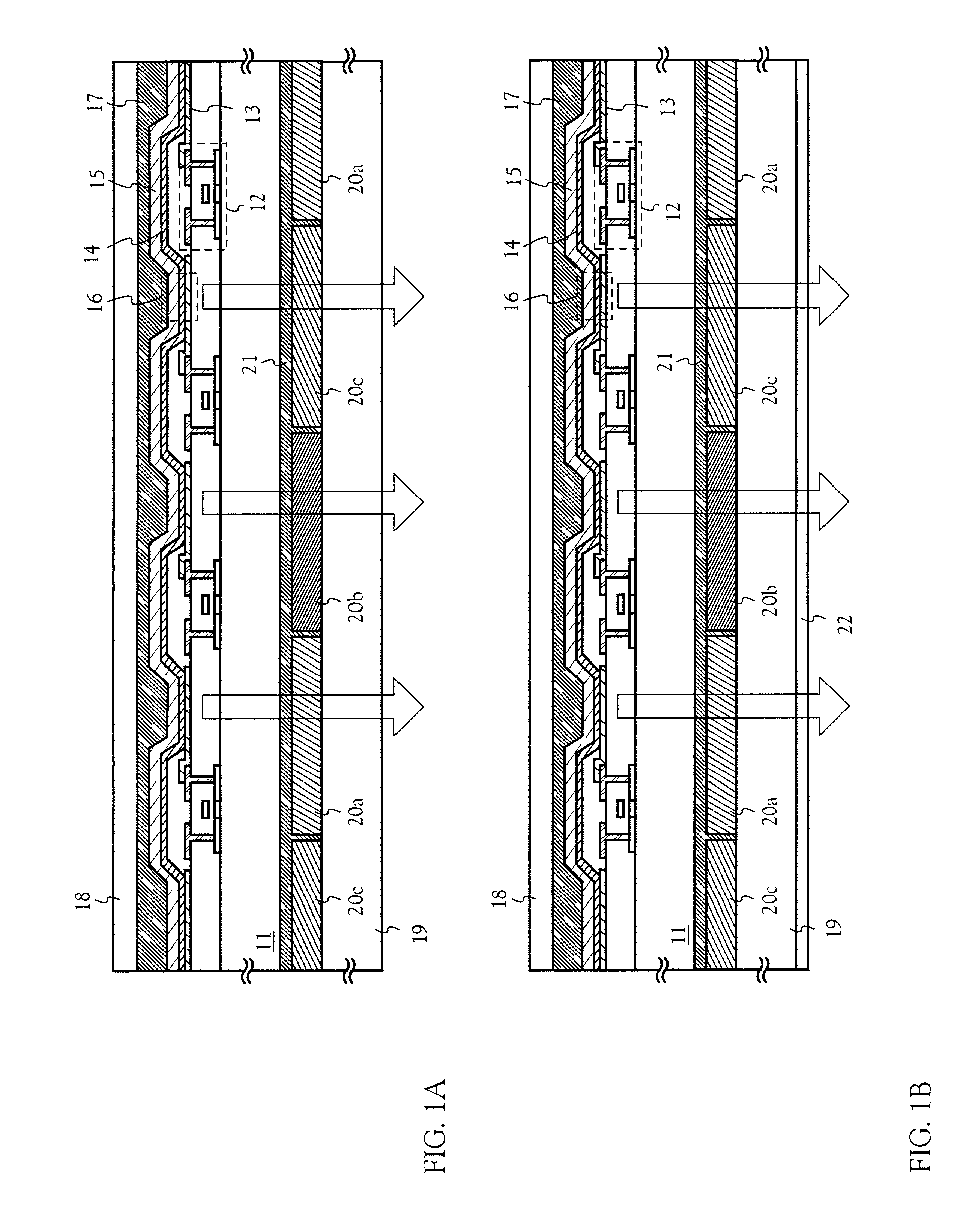

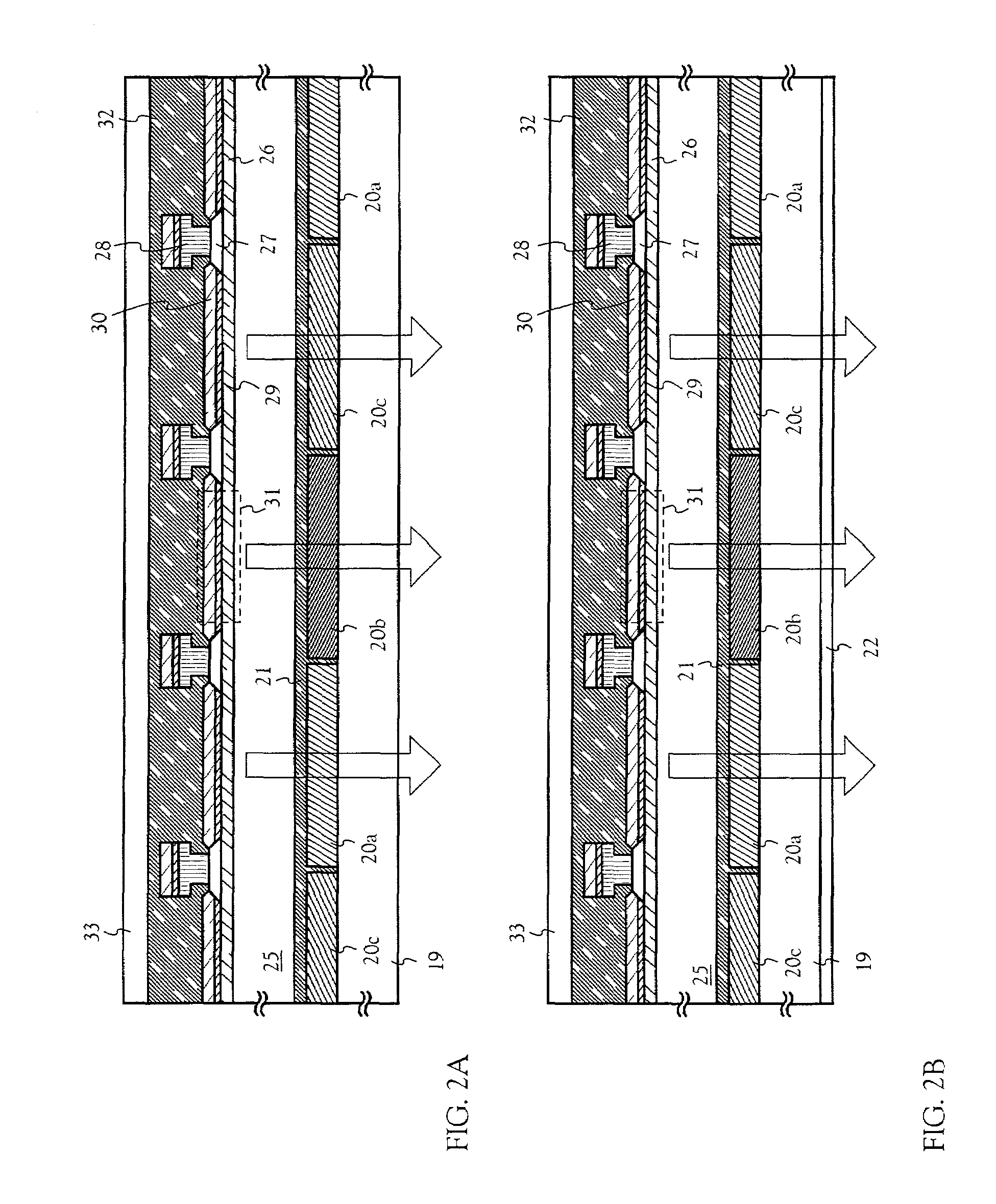

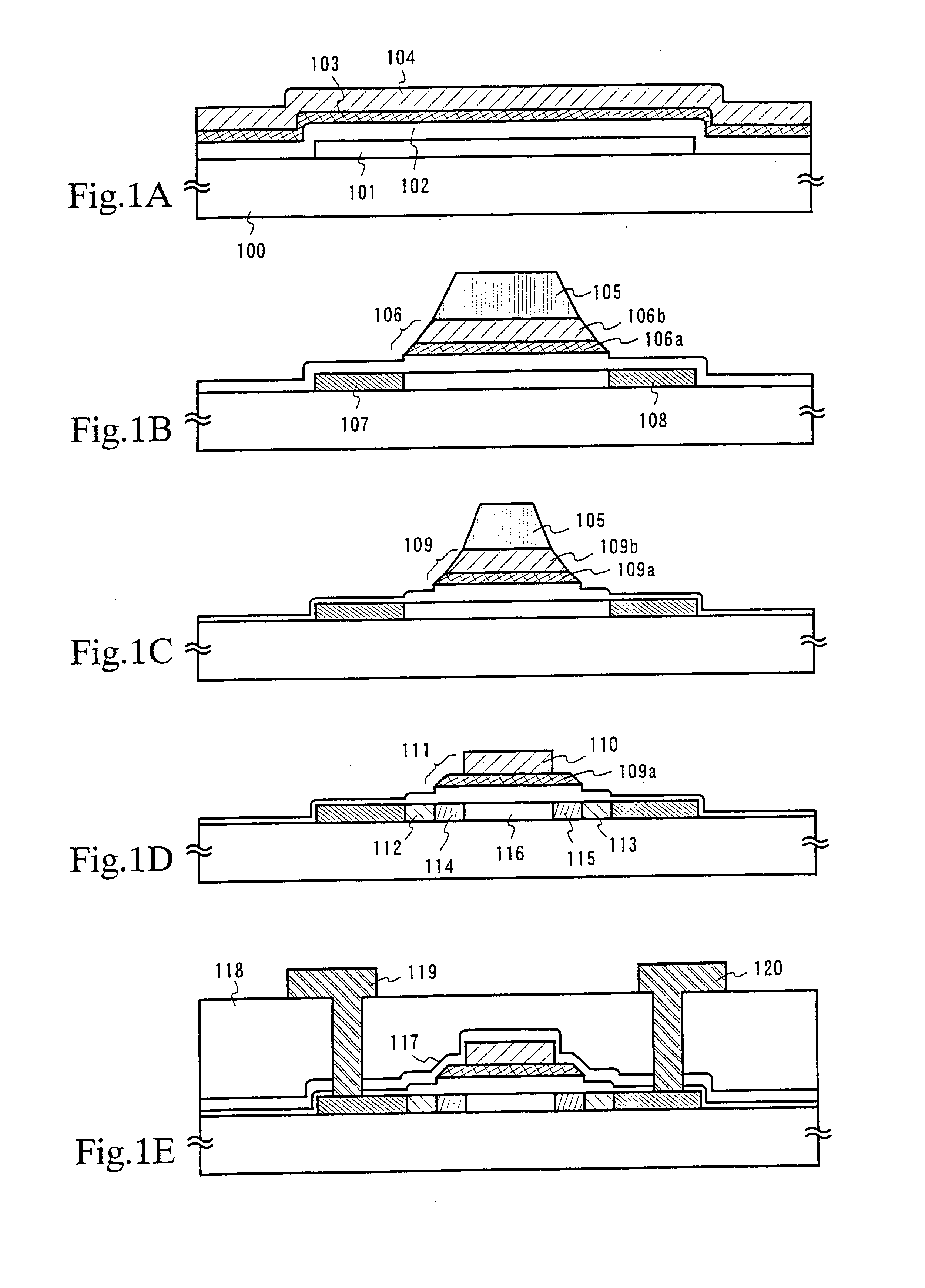

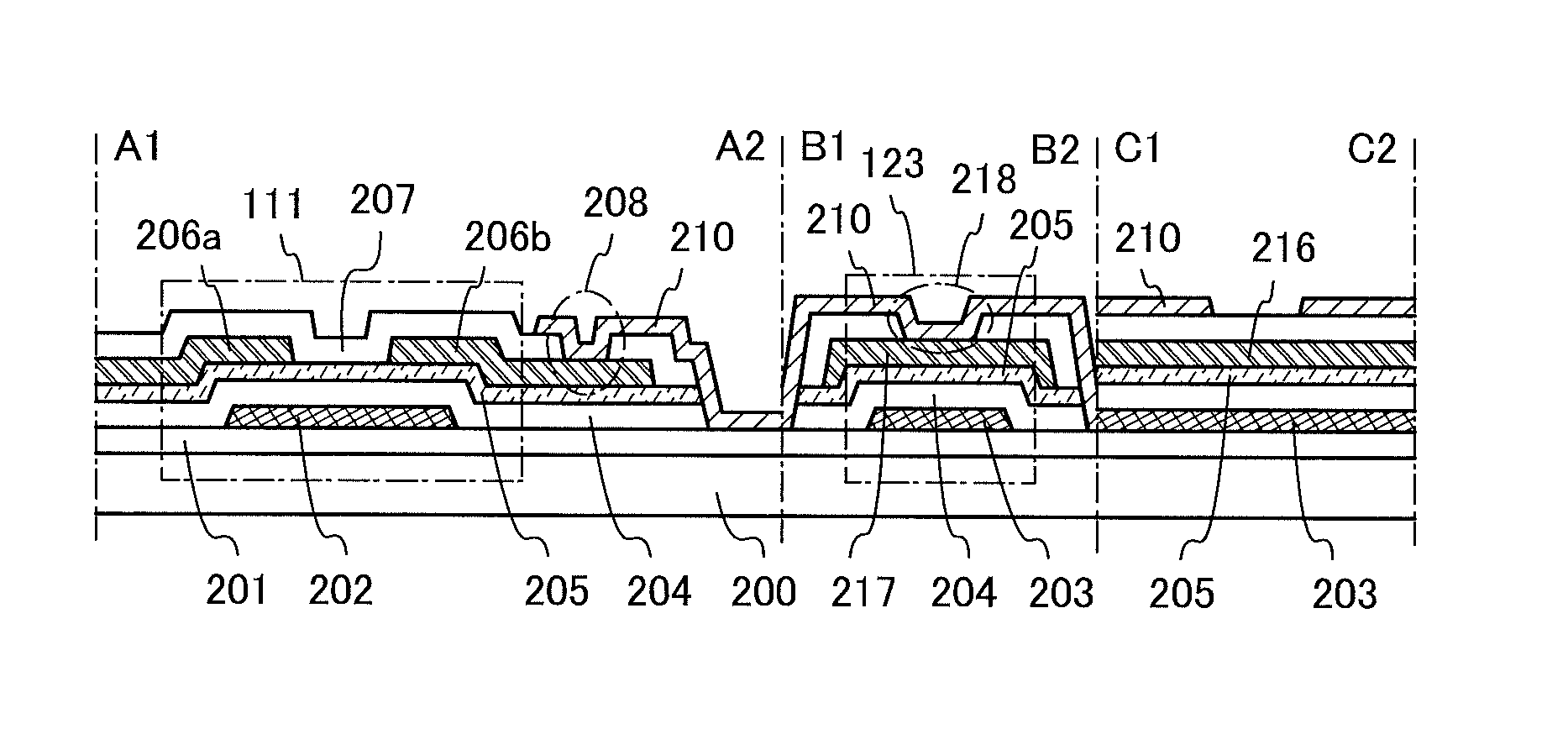

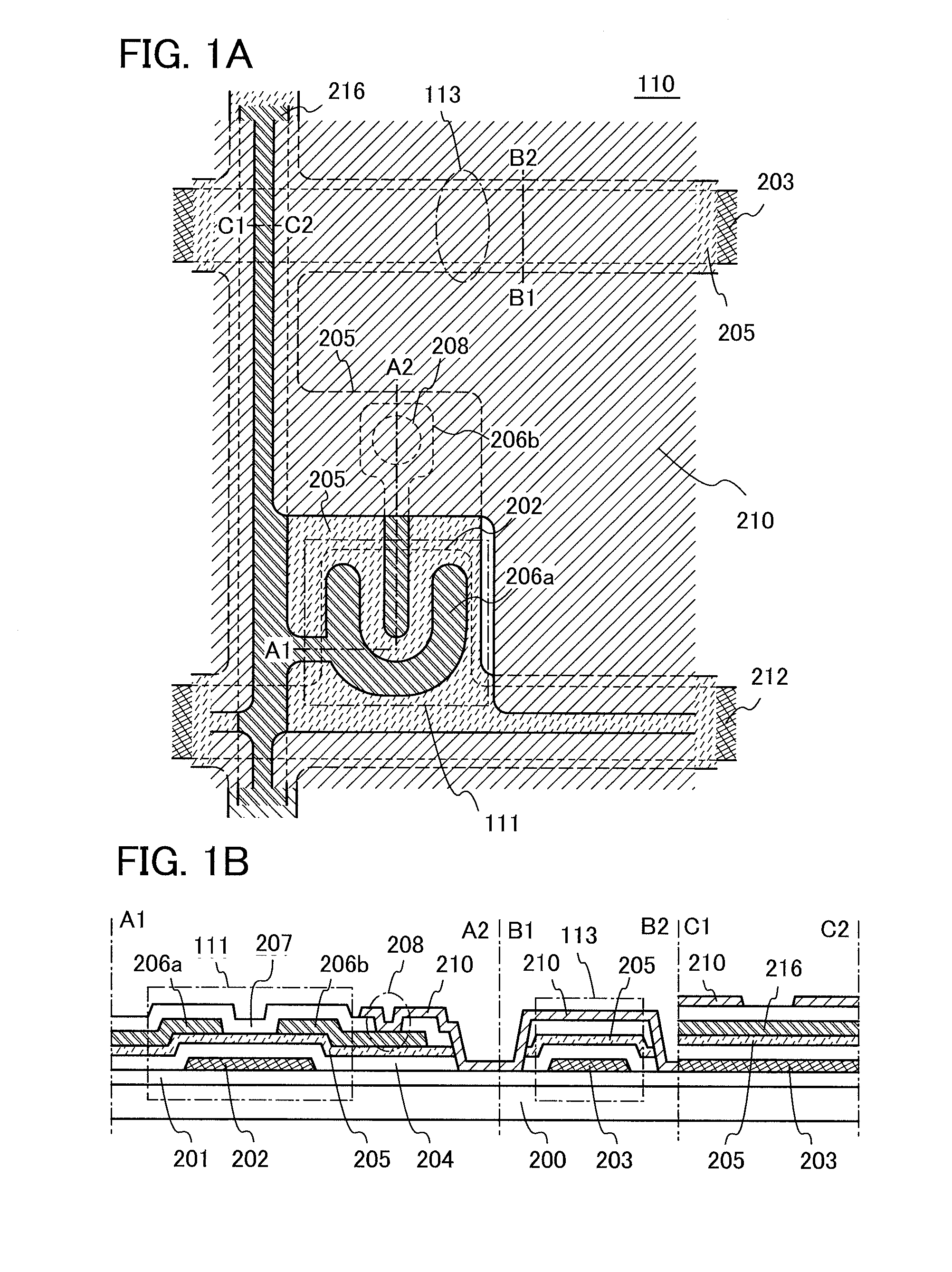

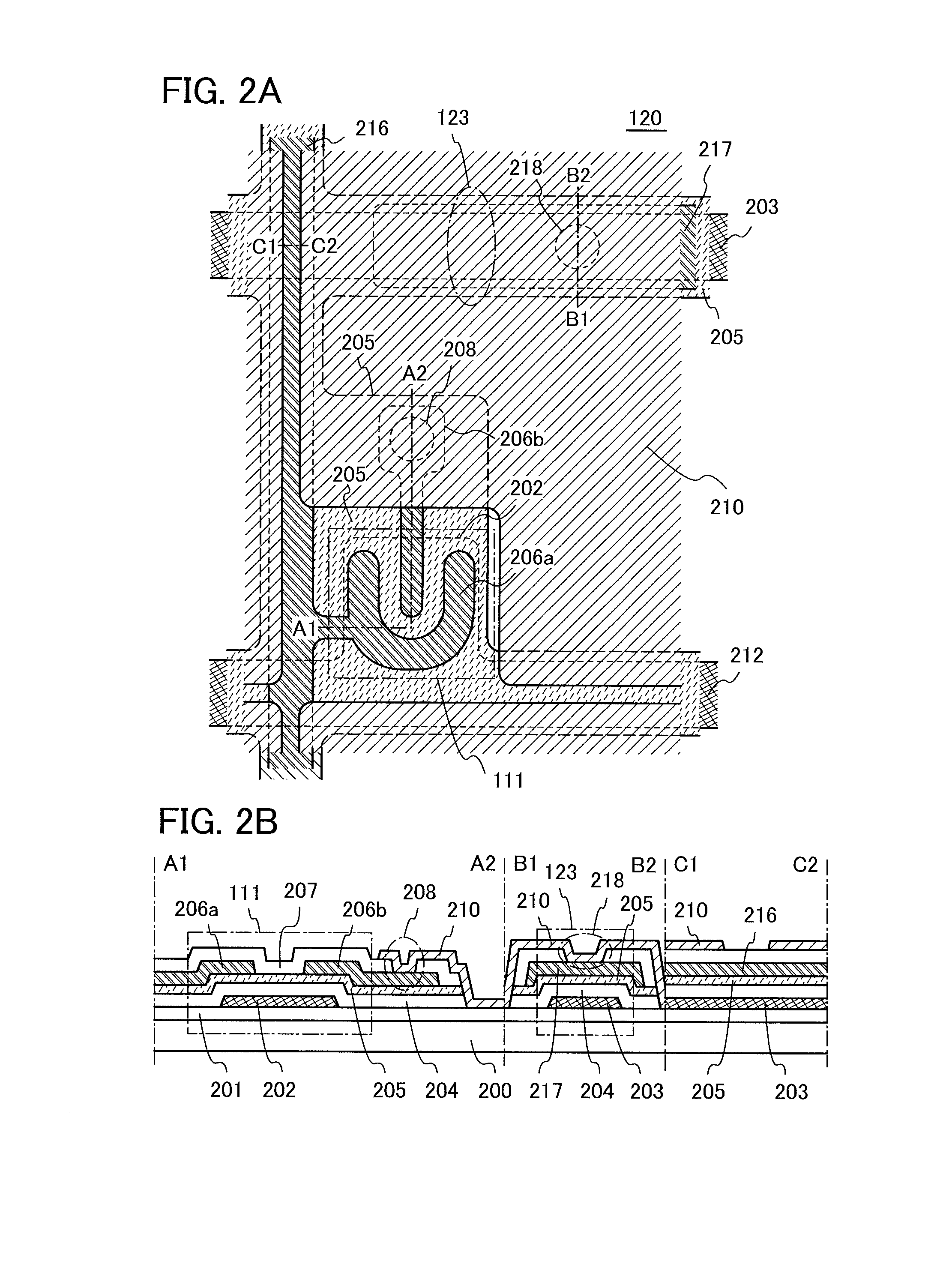

Manufacturing methods of thin film transistor, liquid crystal display device, and semiconductor device

InactiveUS20120052625A1Improve productivityLow costSolid-state devicesSemiconductor/solid-state device manufacturingProduction rateLiquid-crystal display

A liquid crystal display device is provided with high productivity at low cost by reducing manufacturing steps of the liquid crystal display device. A liquid crystal display device with less power consumption and high reliability is provided. Etching of a semiconductor layer and formation of a contact hole that connects a pixel electrode and a drain electrode are performed by one photolithography process and one etching step, whereby the number of photolithography processes is reduced. A liquid crystal display device can be provided with high productivity at low cost by reducing the number of photolithography processes. Further, an oxide semiconductor is used for the semiconductor layer, whereby a liquid crystal display device with less power consumption and high reliability can be provided.

Owner:SEMICON ENERGY LAB CO LTD

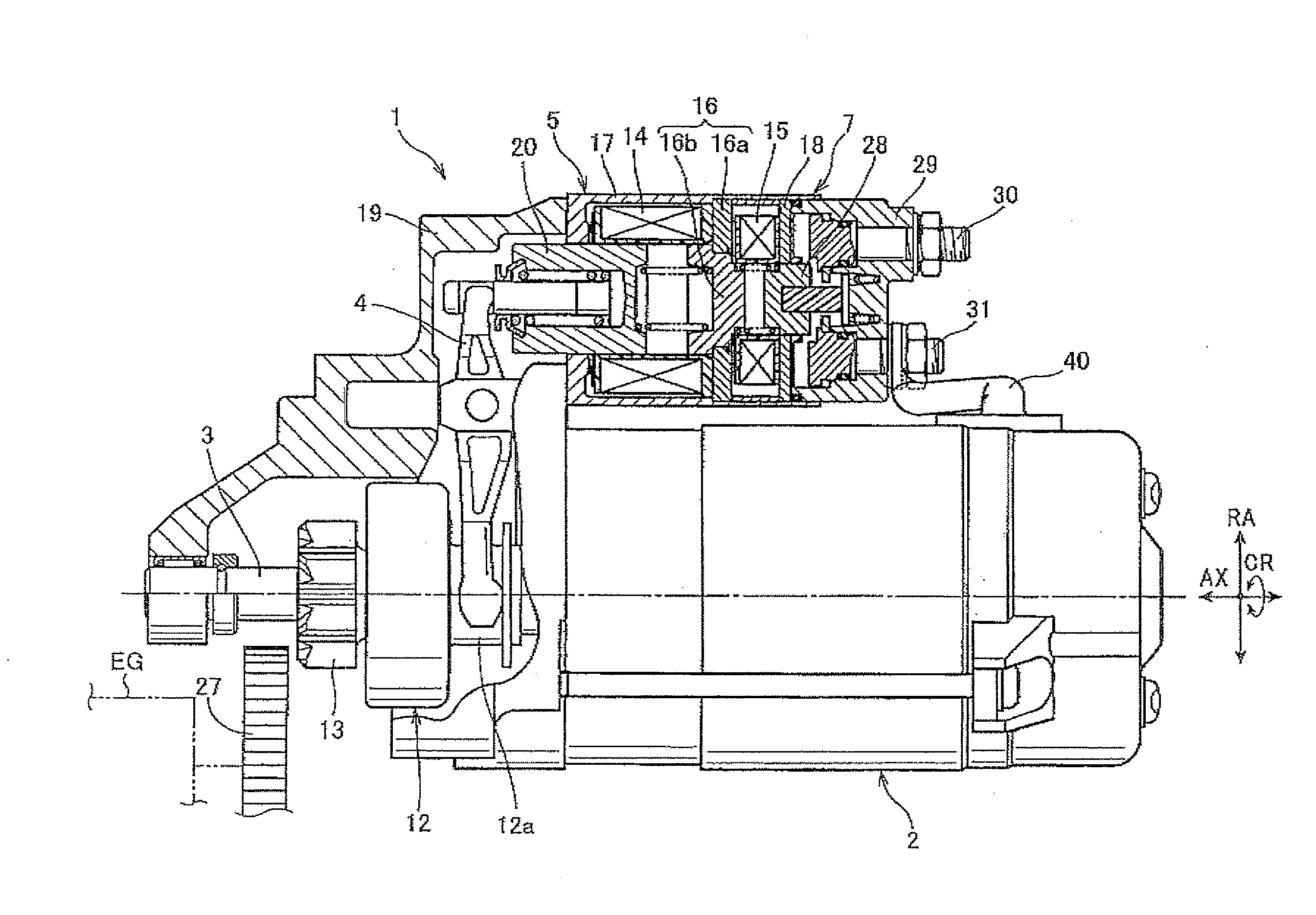

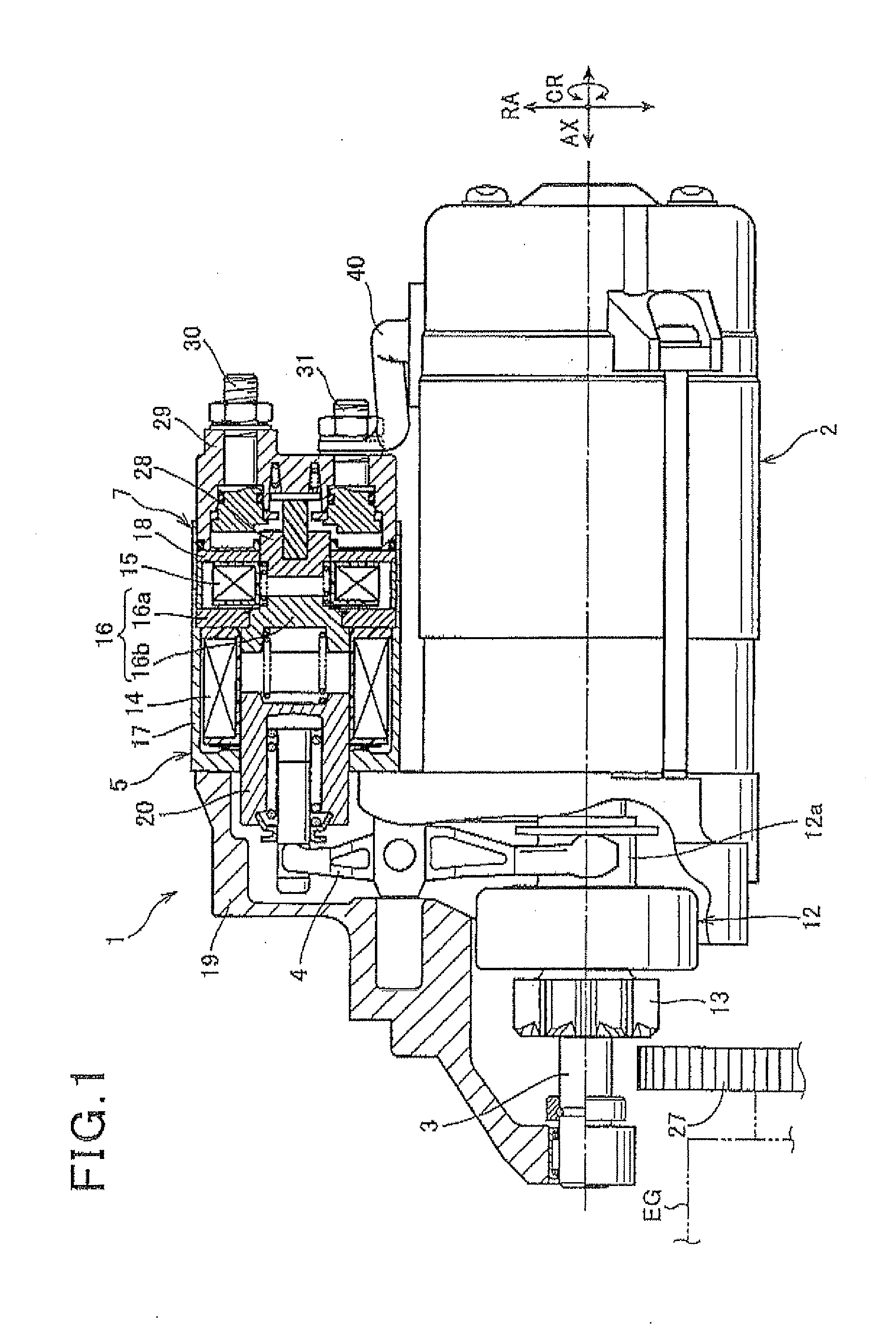

Apparatus for starting engine mounted on-vehicle

ActiveUS20100264765A1Reduce the differenceLower manufacturing requirementsPower operated startersElectric motor startersSolenoid valveExcitation current

Owner:DENSO CORP

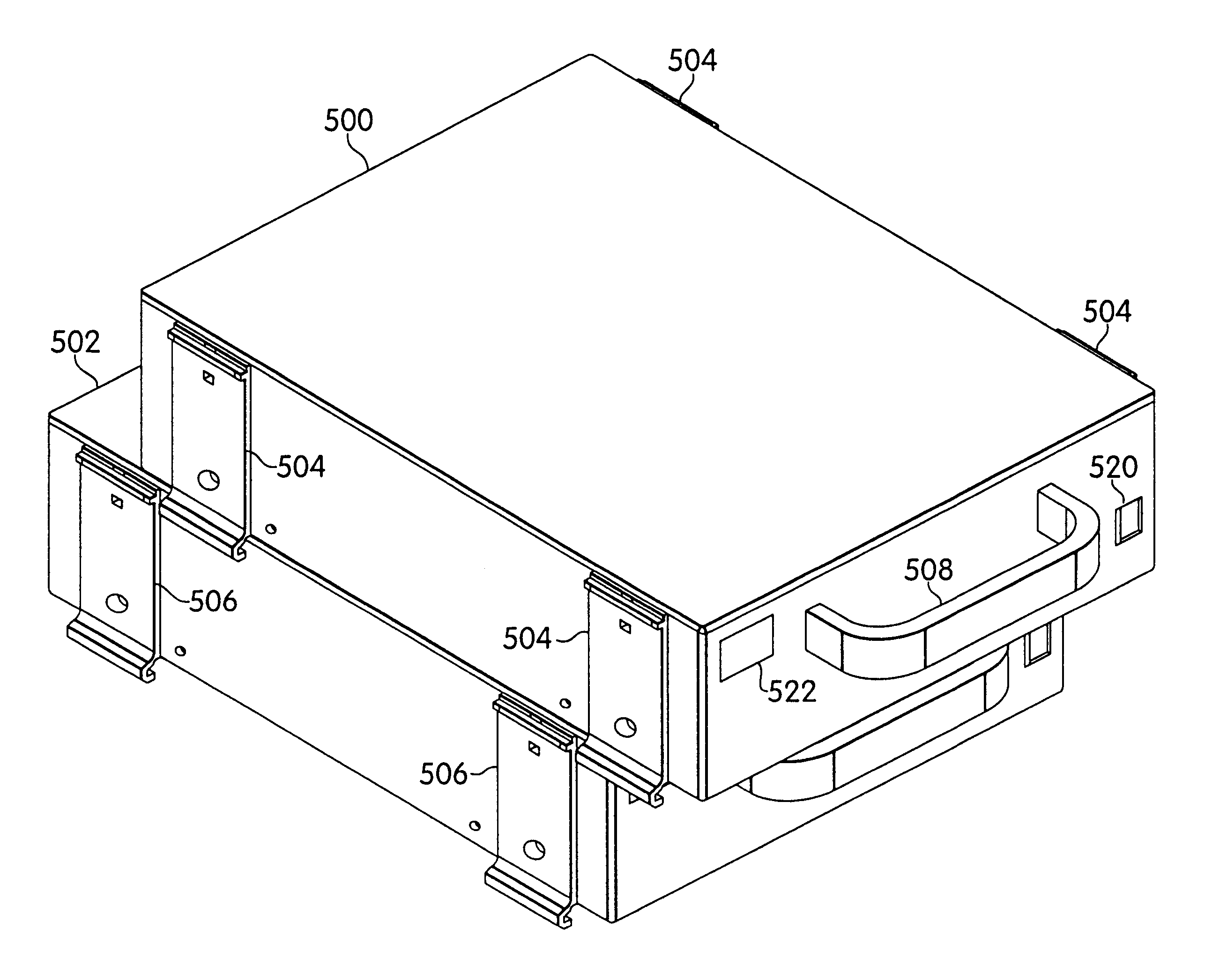

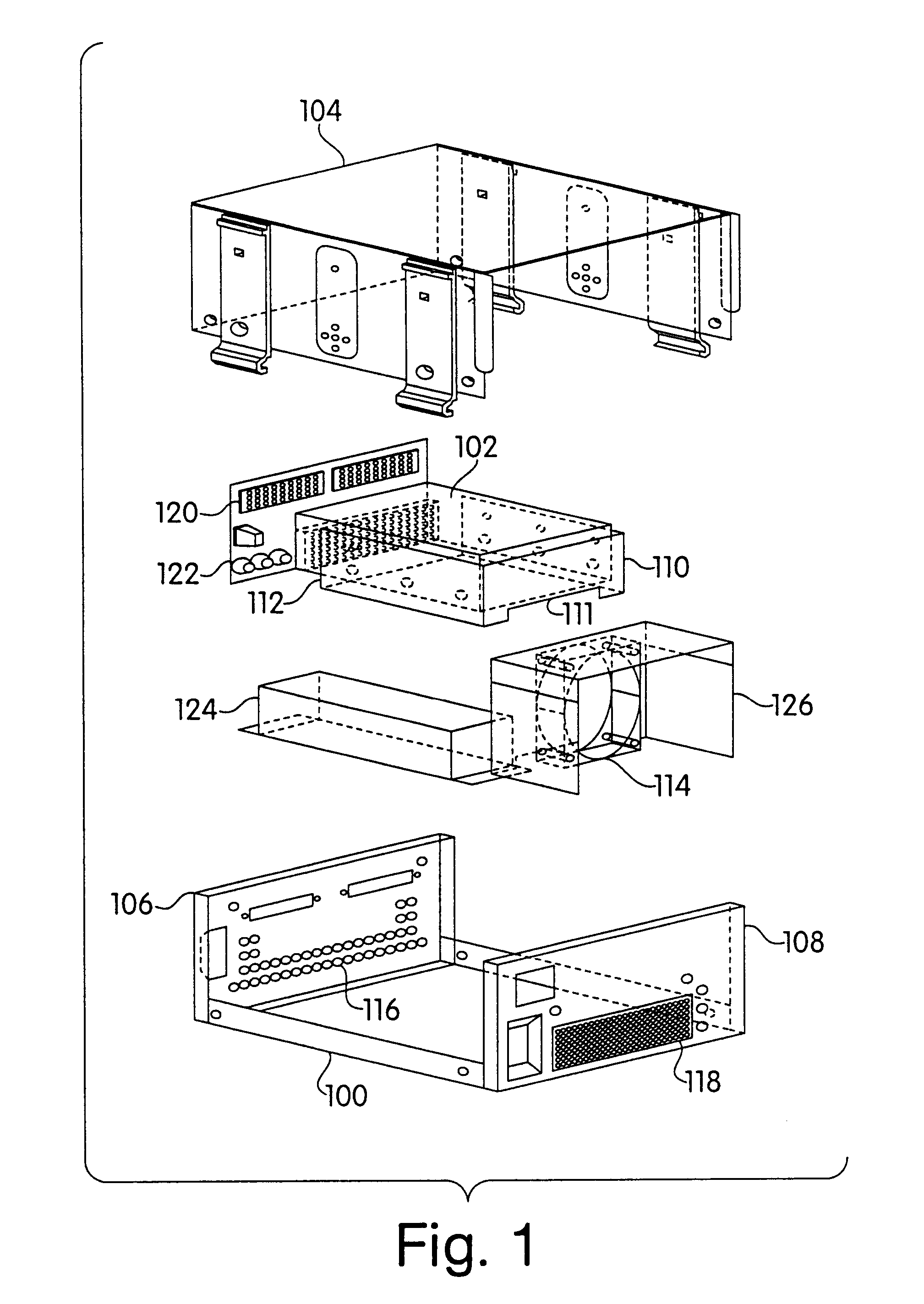

Disk drive enclosure

InactiveUS6301105B2Reduce noiseMinimum amount of noiseDigital data processing detailsRecord information storageTemperature controlLocking mechanism

Owner:AVID TECHNOLOGY

Non-volatile storage

ActiveUS20130198439A1Reduce manufacturing costImprove access performanceMemory architecture accessing/allocationMemory adressing/allocation/relocationTranslation tableControl unit

The non-volatile storage SSD has non-volatile NVM, RAM capable of being accessed at a higher speed than this NVM, and a control unit for controlling accesses to the NVM and to the RAM. The control unit stores in the NVM an address translation table (LPT) that translates a logical address given to access this NVM to a physical address after dividing it into multiple tables, and stores in the RAM the multiple address translation tables-sub on RAM (LPT-SRs) that have been divided into multiple tables.

Owner:HITACHI LTD

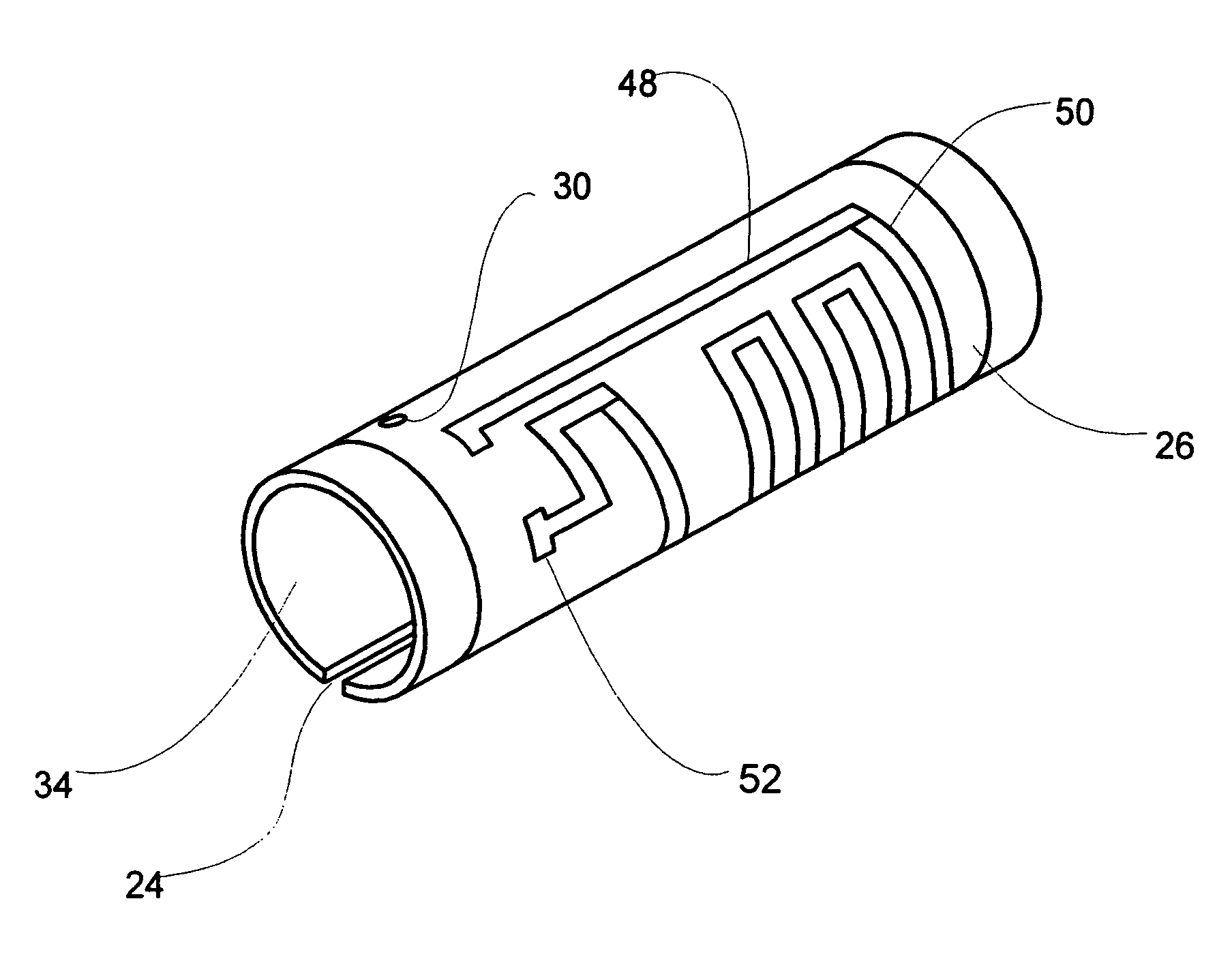

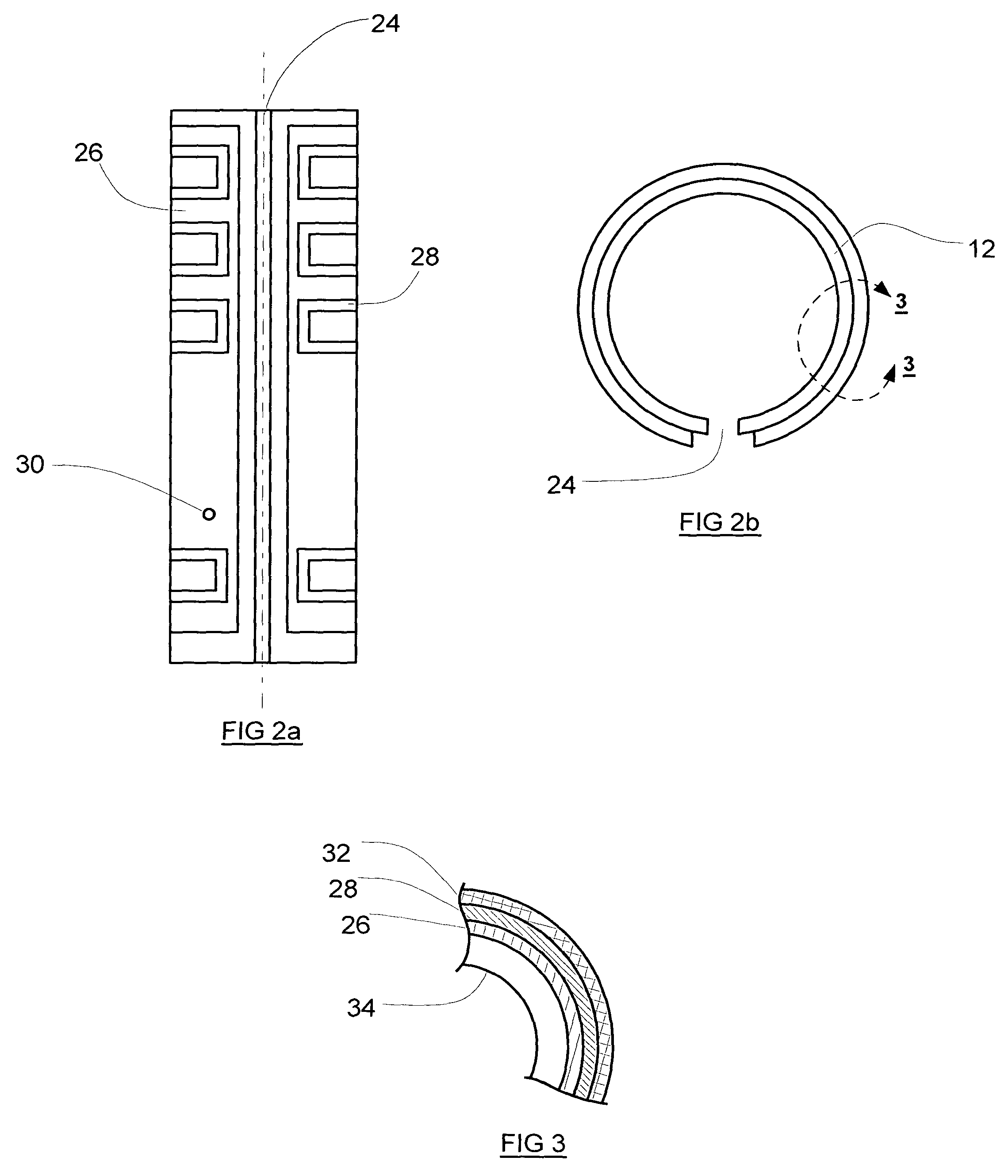

Thick film heater apparatus

InactiveUS7241131B1Stable and repeatable temperature profileOptimized and precise temperature profileConfectionerySweetmeatsContact padEngineering

A thick-film electric heater having thick-film layers applied directly on a thermally conductive non-flat substrate. Preferably, the substrate is cylindrically shaped. A dielectric layer is silk-screened on the substrate surface. A resistive layer is silk-screened on the dielectric layer to form a circuit for the generation of heat. The resistive layer has at least one resistive trace in a pattern that is discontinuous circumferentially. At least a pair of silk-screened contact pads are applied in electrical communication with the resistive layer for electrical connection to a power source. An insulation layer is applied over the resistive layer.

Owner:HUSKY INJECTION MOLDING SYST LTD +1

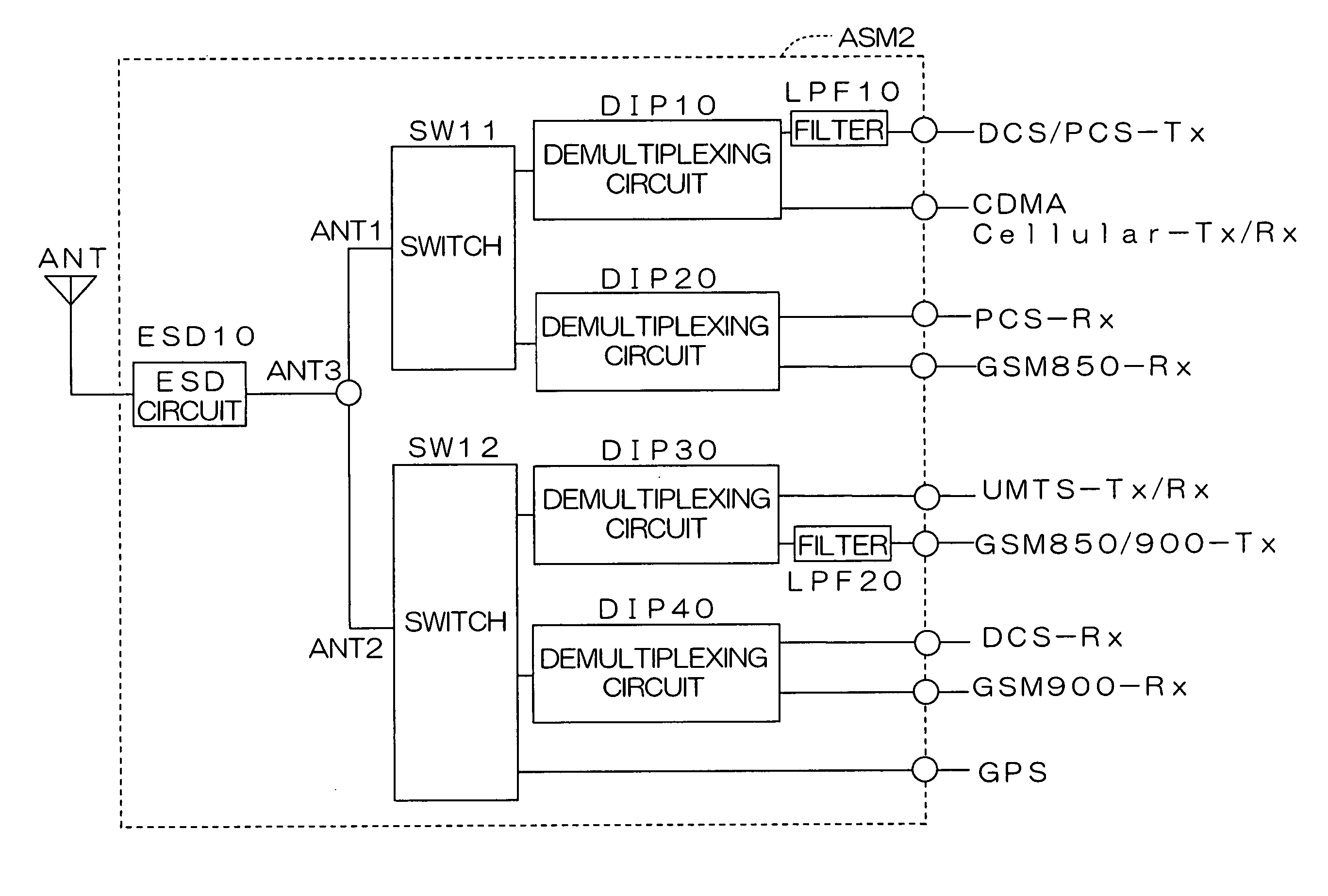

High-frequency switching circuit, high-frequency module, and wireless communications device

InactiveUS20050197095A1Low costReduce designActive element networkTelephonic communicationCommunications systemEngineering

The present invention provides a high-frequency switching circuit comprising: two or more high-frequency switches SW1 and SW2 provided correspondingly to a plurality of communication systems having mutually different frequency bands; and a control circuit DEC1 adapted to control the switching of the two or more high-frequency switches SW1 and SW2, in which a common antenna terminal ANT3 and common terminals ANT1 and ANT2 of the respective high-frequency switches SW1 and SW2 are connected via a matching circuit MAT1 having a filtering function capable of allowing passage of direct current. When one path of the high-frequency switch SW1 is turned on, the other paths of the high-frequency switch SW1 and all paths of the high-frequency switch SW2 can be turned off.

Owner:KYOCERA CORP

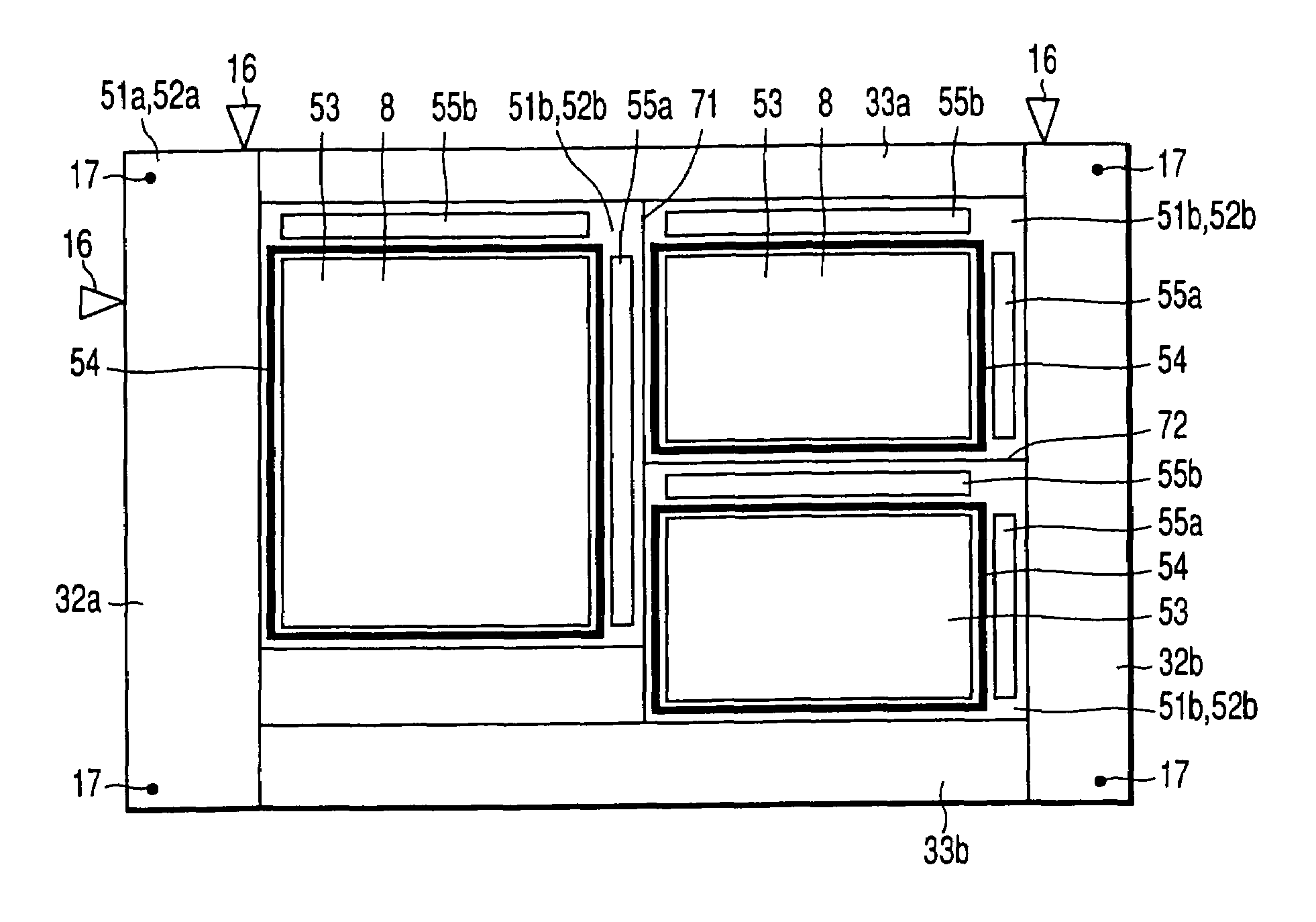

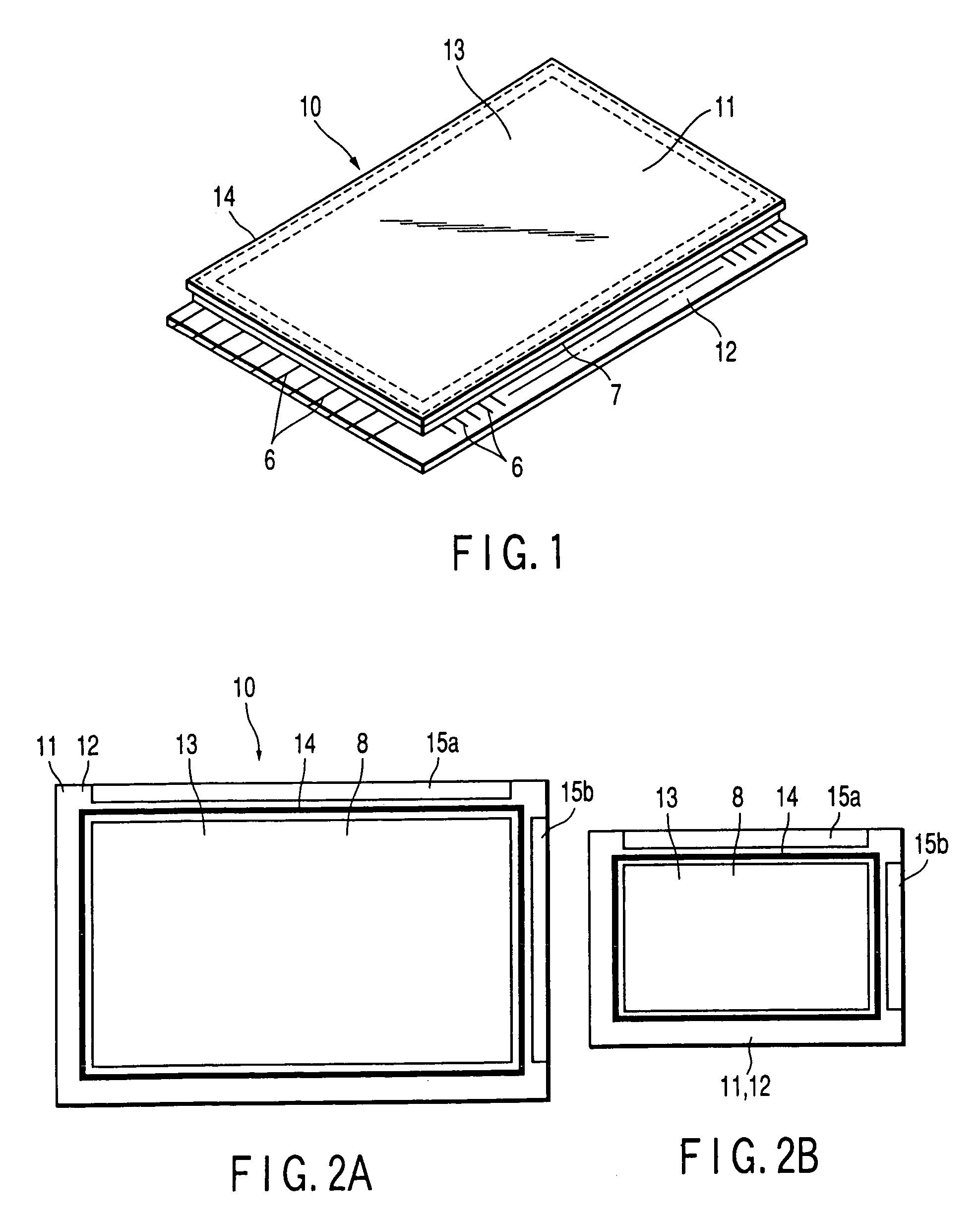

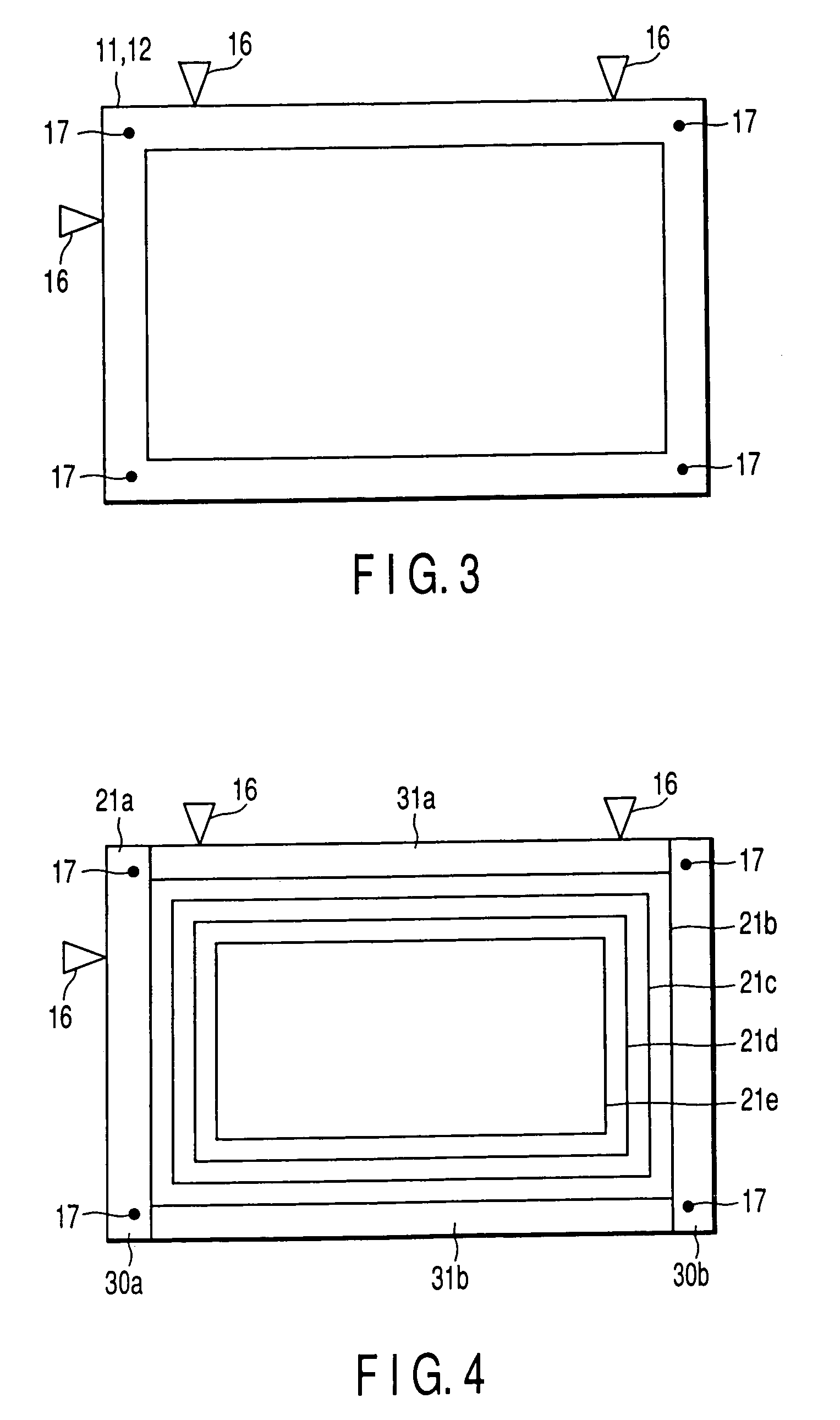

Method of manufacturing flat display panels of different sizes from a common base substrate

InactiveUS7273403B2Lower manufacturing requirementsNarrow widthSparking plugsStatic indicating devicesCommon baseDisplay device

In a method of a manufacturing flat display apparatuses by working flat substrates, a flat substrate is prepared having a first region which is used as a flat display apparatus and a second region outside the first region. After the first region is worked as desired, the second region is cut and separated from the flat substrate.

Owner:KK TOSHIBA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com