Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

552results about How to "Reduce smoke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

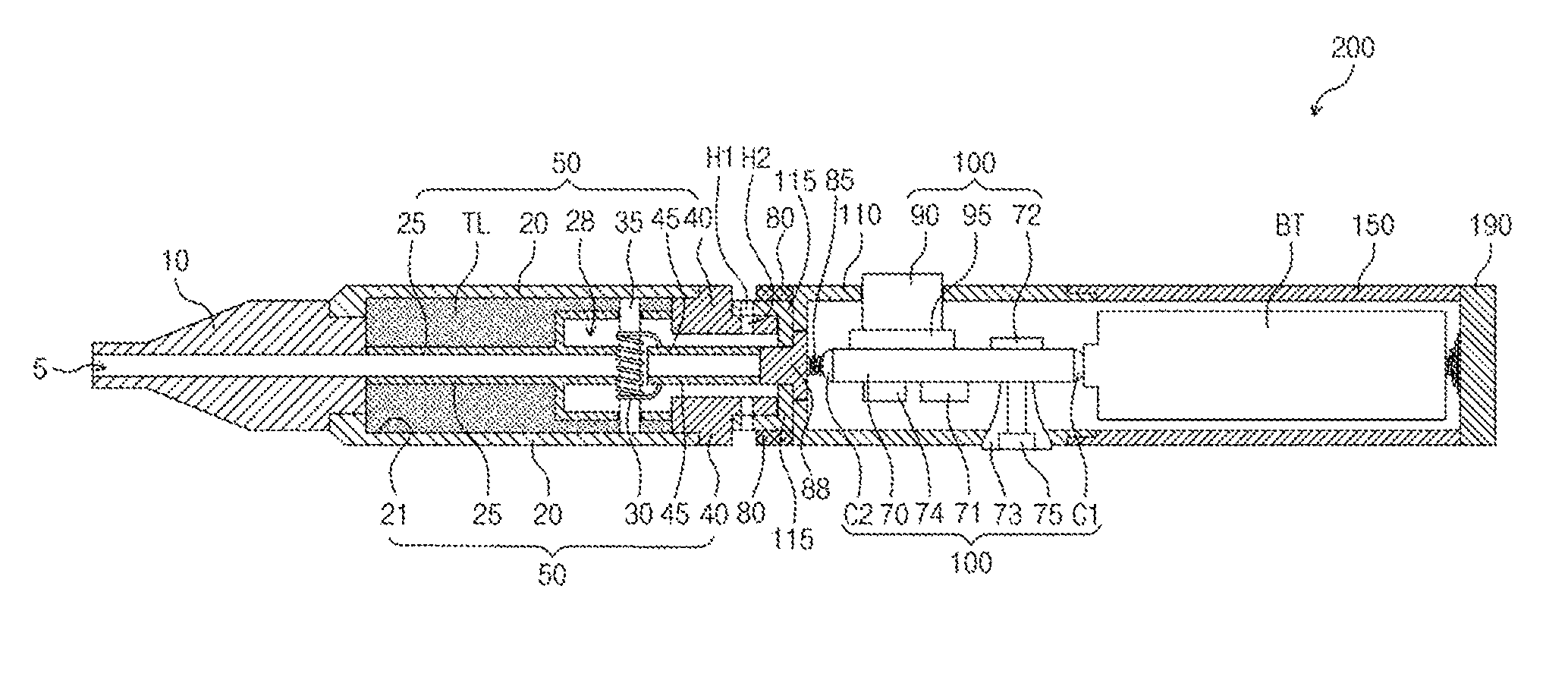

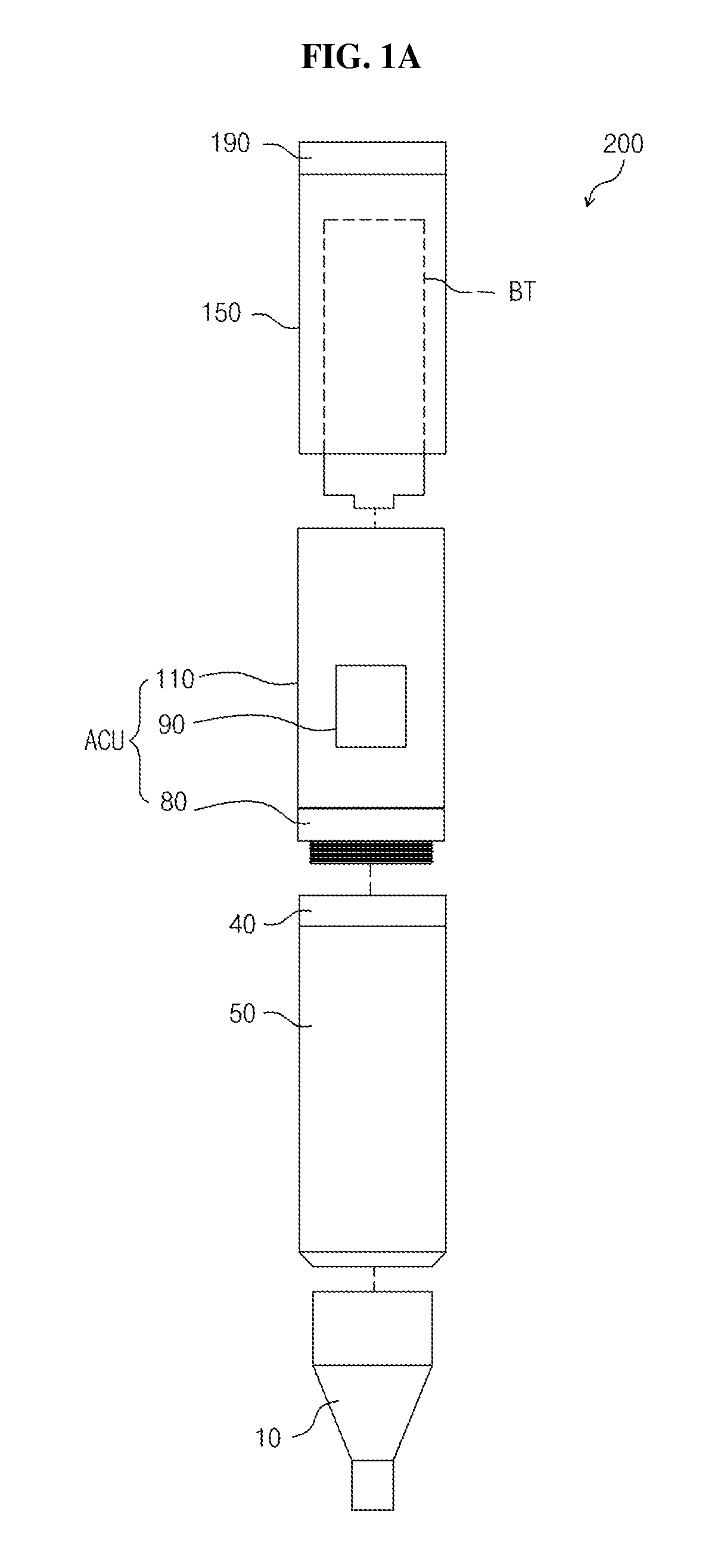

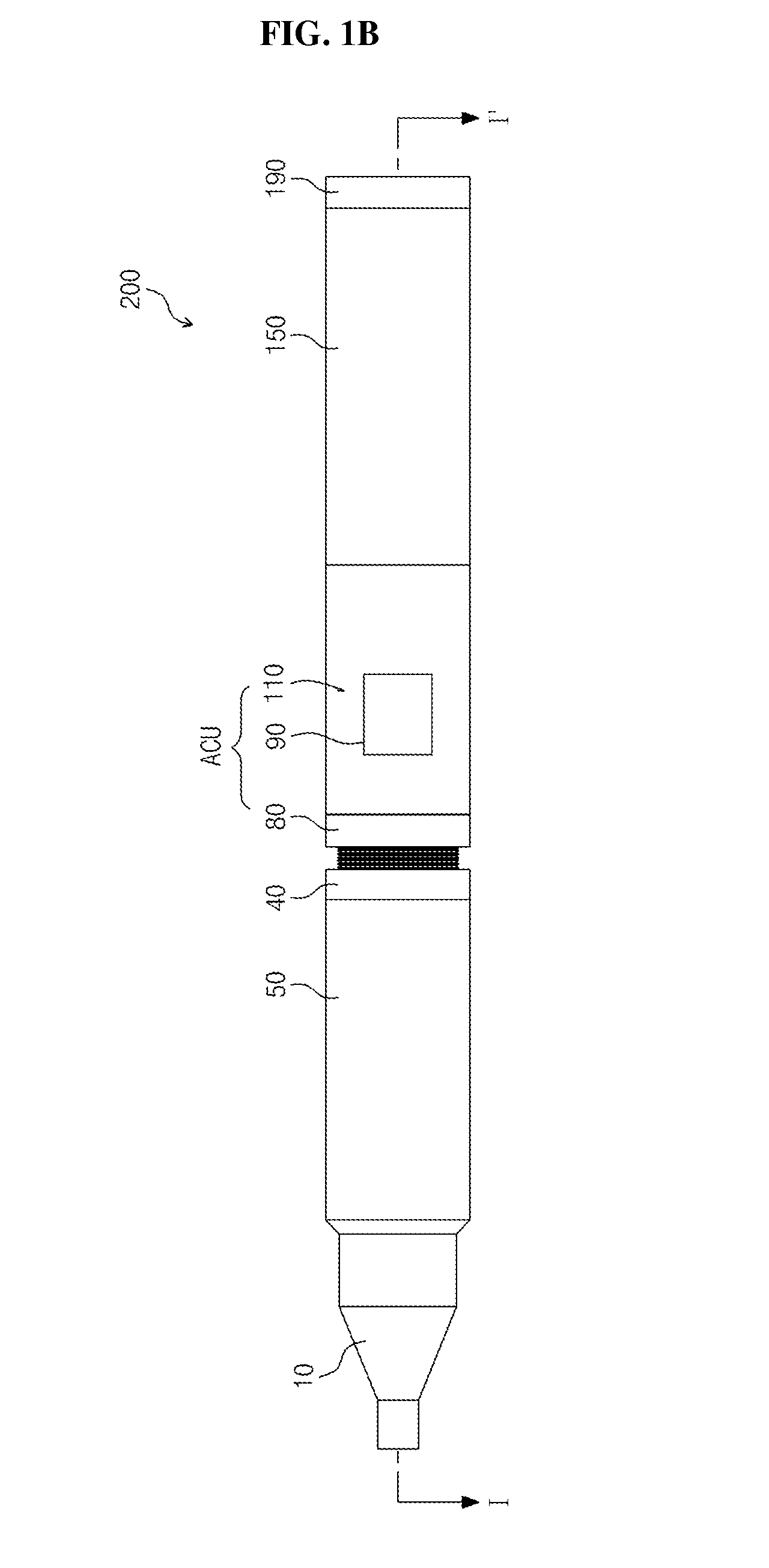

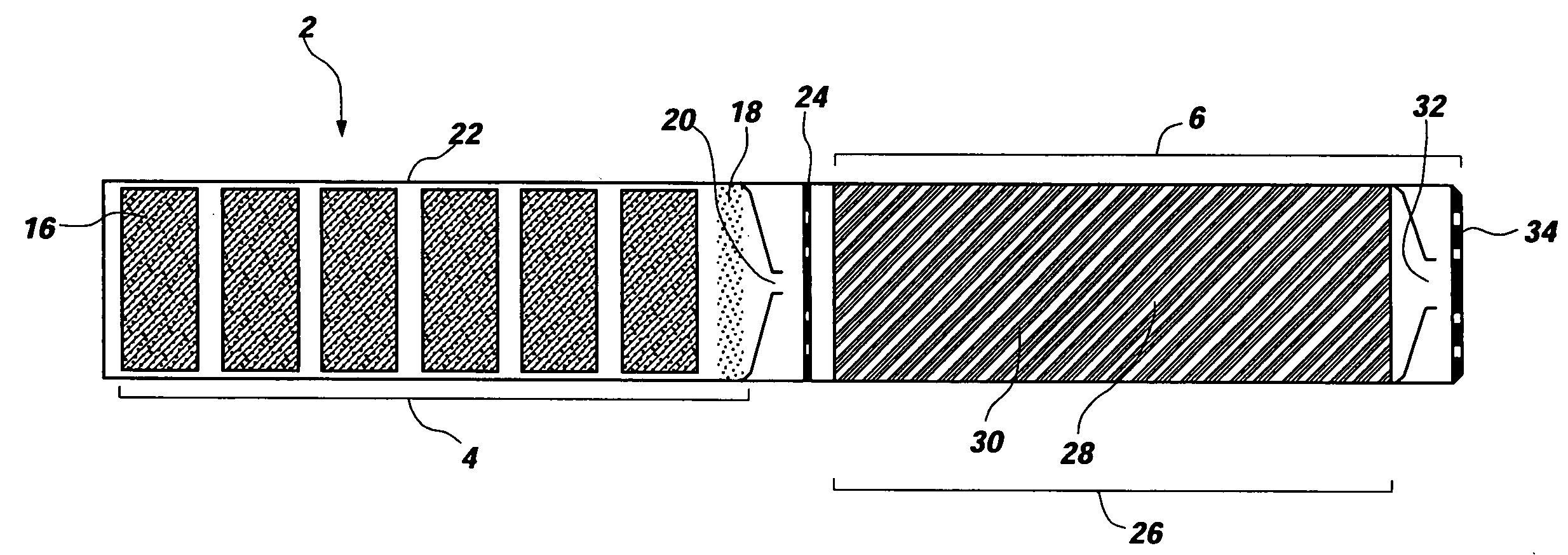

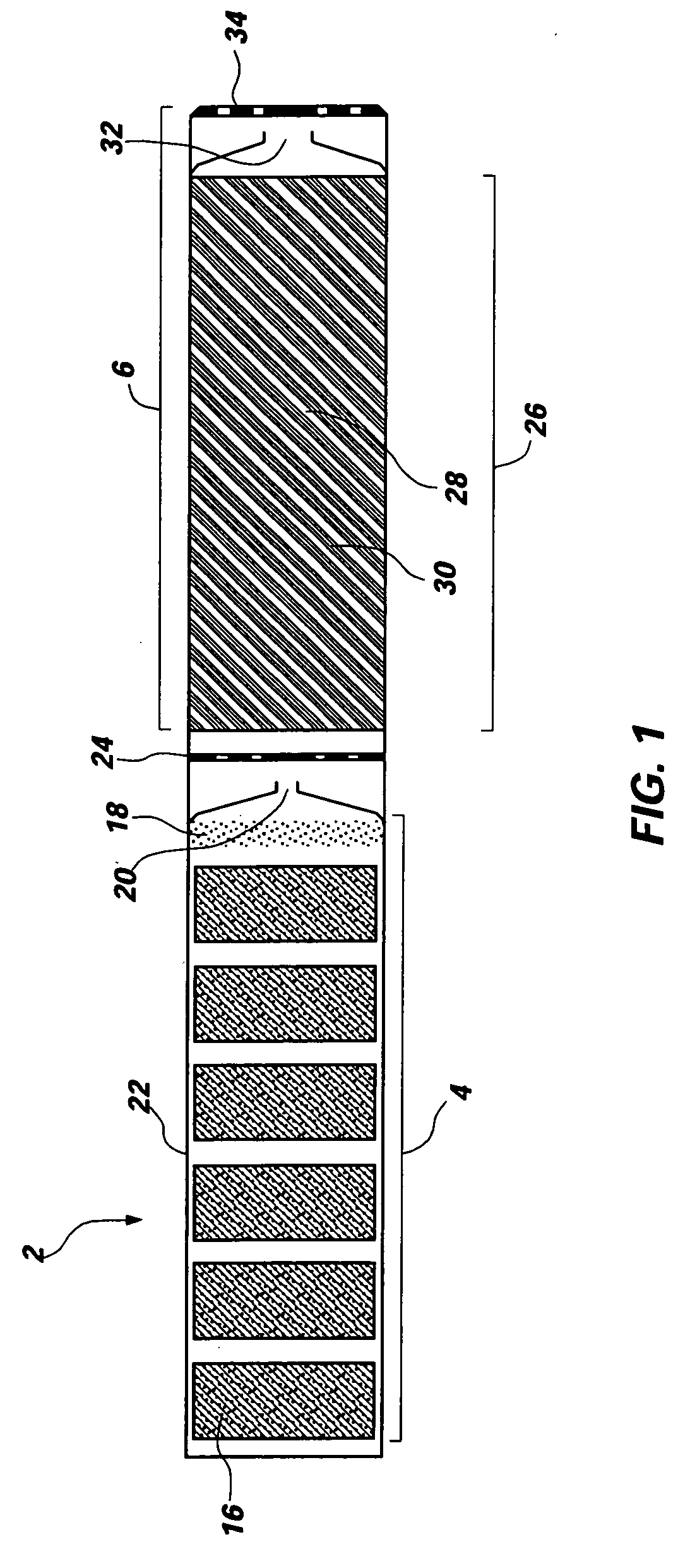

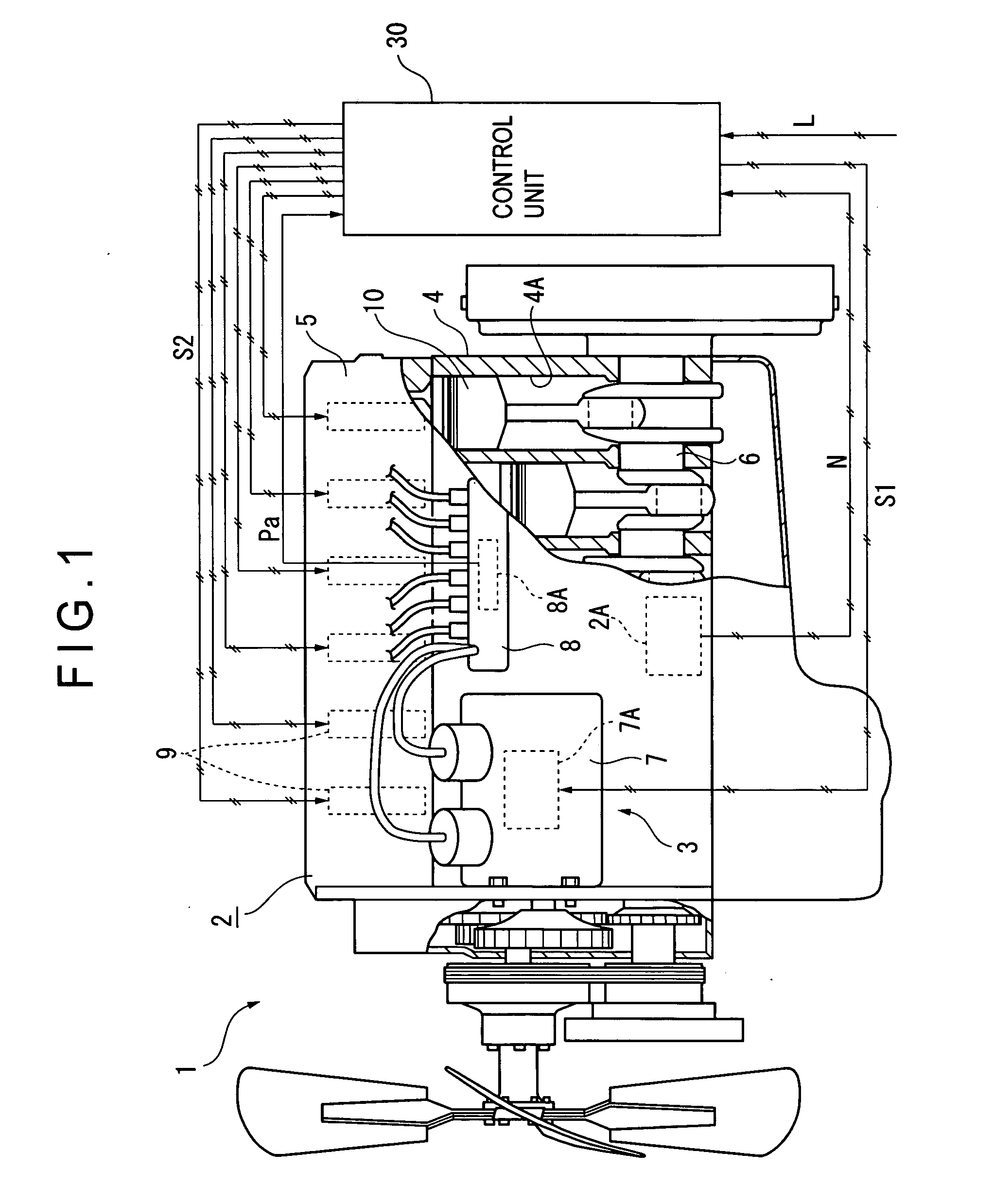

Atomization control unit and a portable atomizing apparatus having the same

InactiveUS20140334804A1Constant power supplyReduce smokeSteam generation heating methodsMedical devicesElectricitySource material

A portable atomizing apparatus according to the present invention includes a battery case, an atomizing device, a body case, a control unit, and a suction adjustment. The battery case receives a battery, and the atomizing device includes a heating member electrically connected to the battery for generating heat to atomize a source material. The body case is connected between the battery case and the atomizing device. Besides, the control unit is mounted inside the body case, electrically connected to the battery and to the heating member, so that the control unit receives an electrical power from the battery to control the output signal delivered to the heating member. Also, the suction adjustment opens or closes an air inlet of the atomizing apparatus so as to adjust the amount of air entering the atomizing apparatus.

Owner:ENBRIGHT

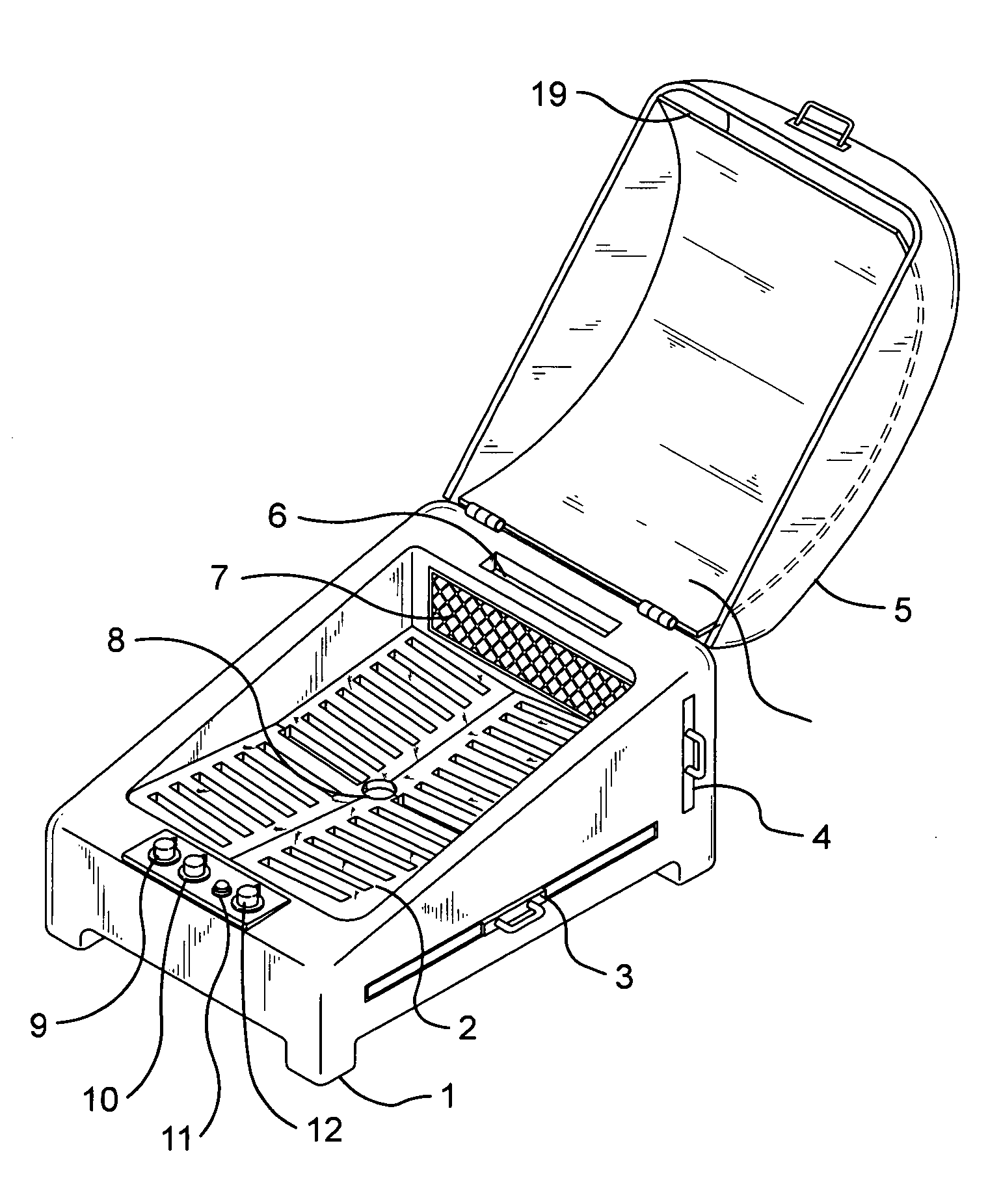

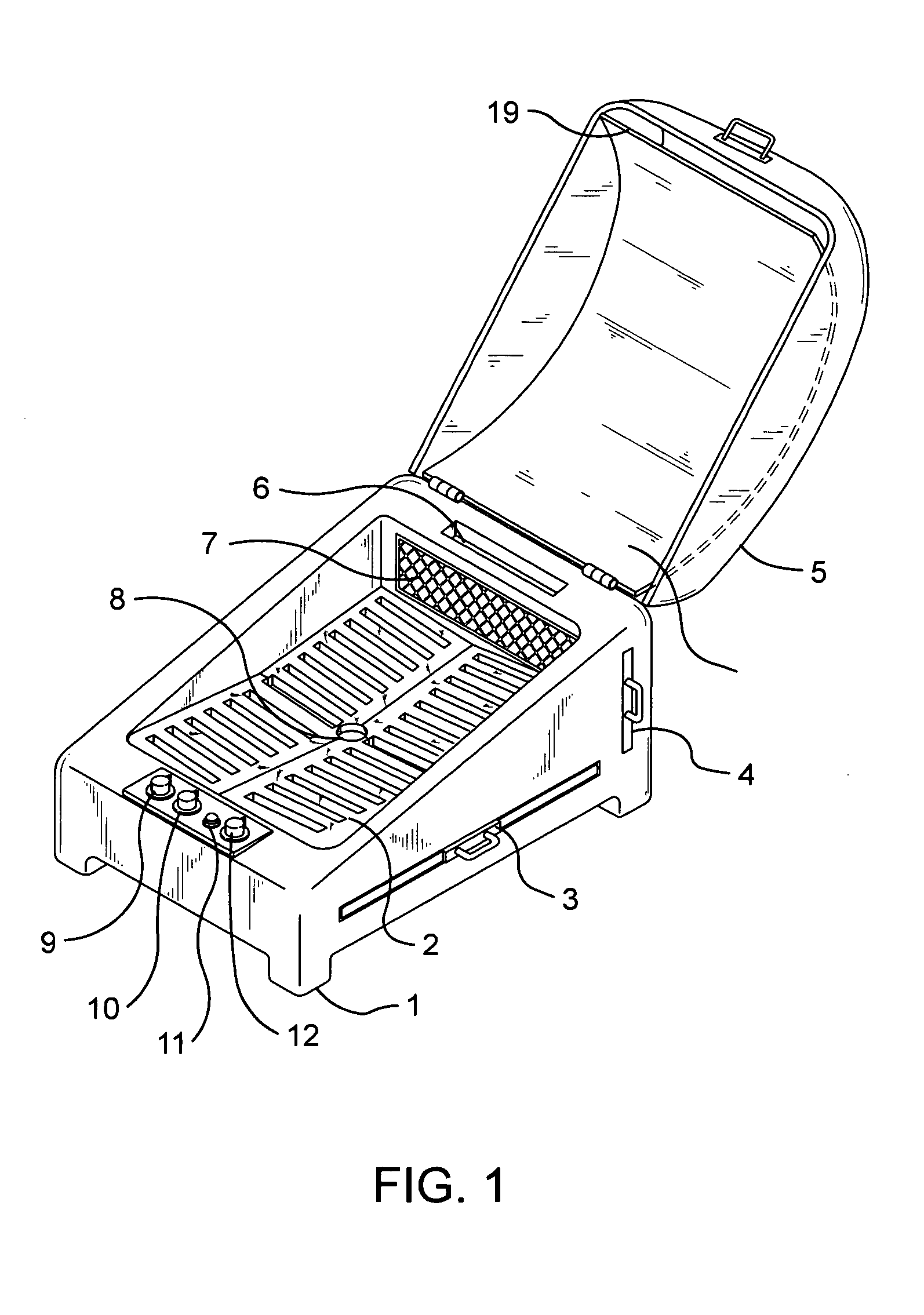

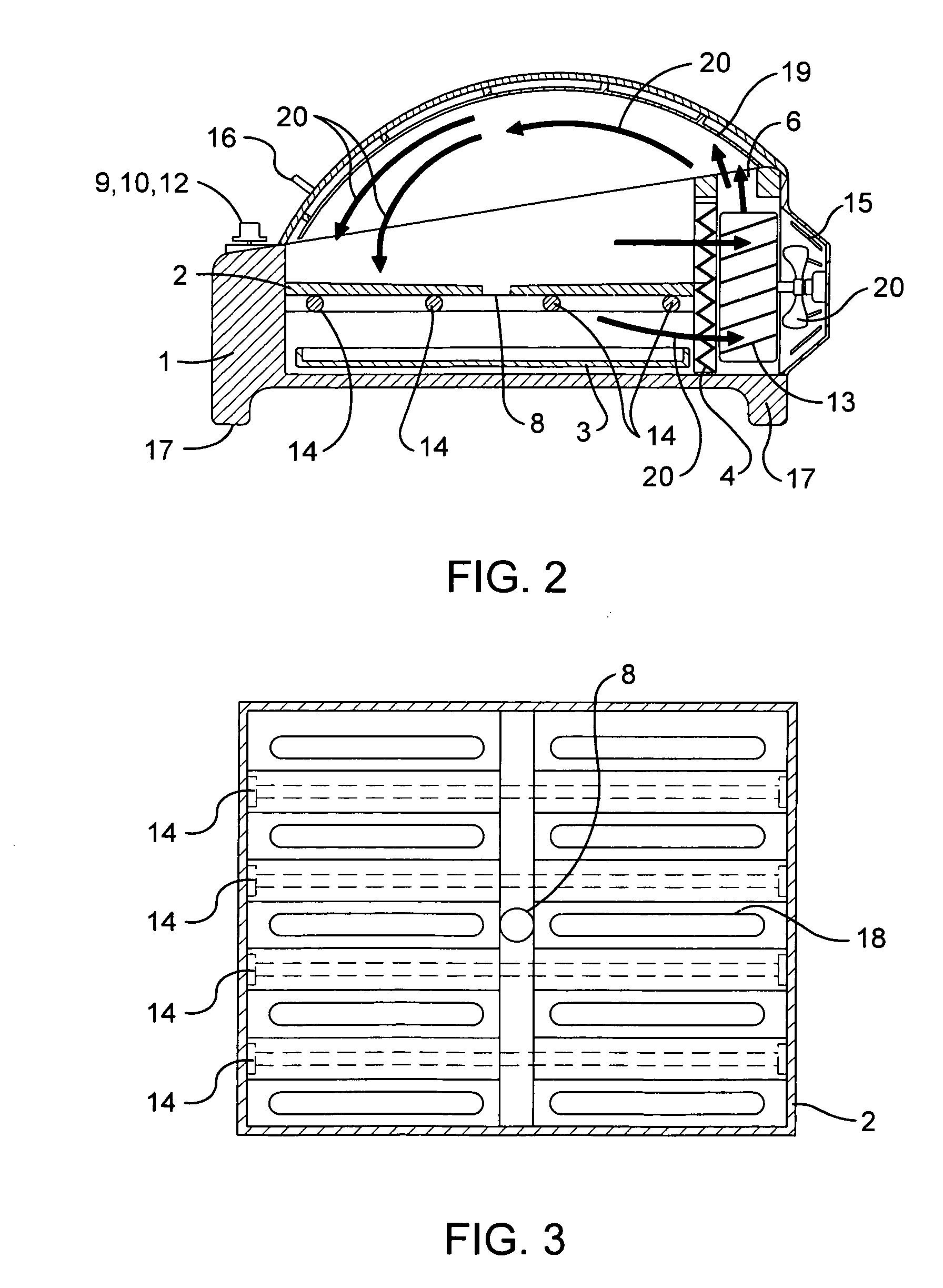

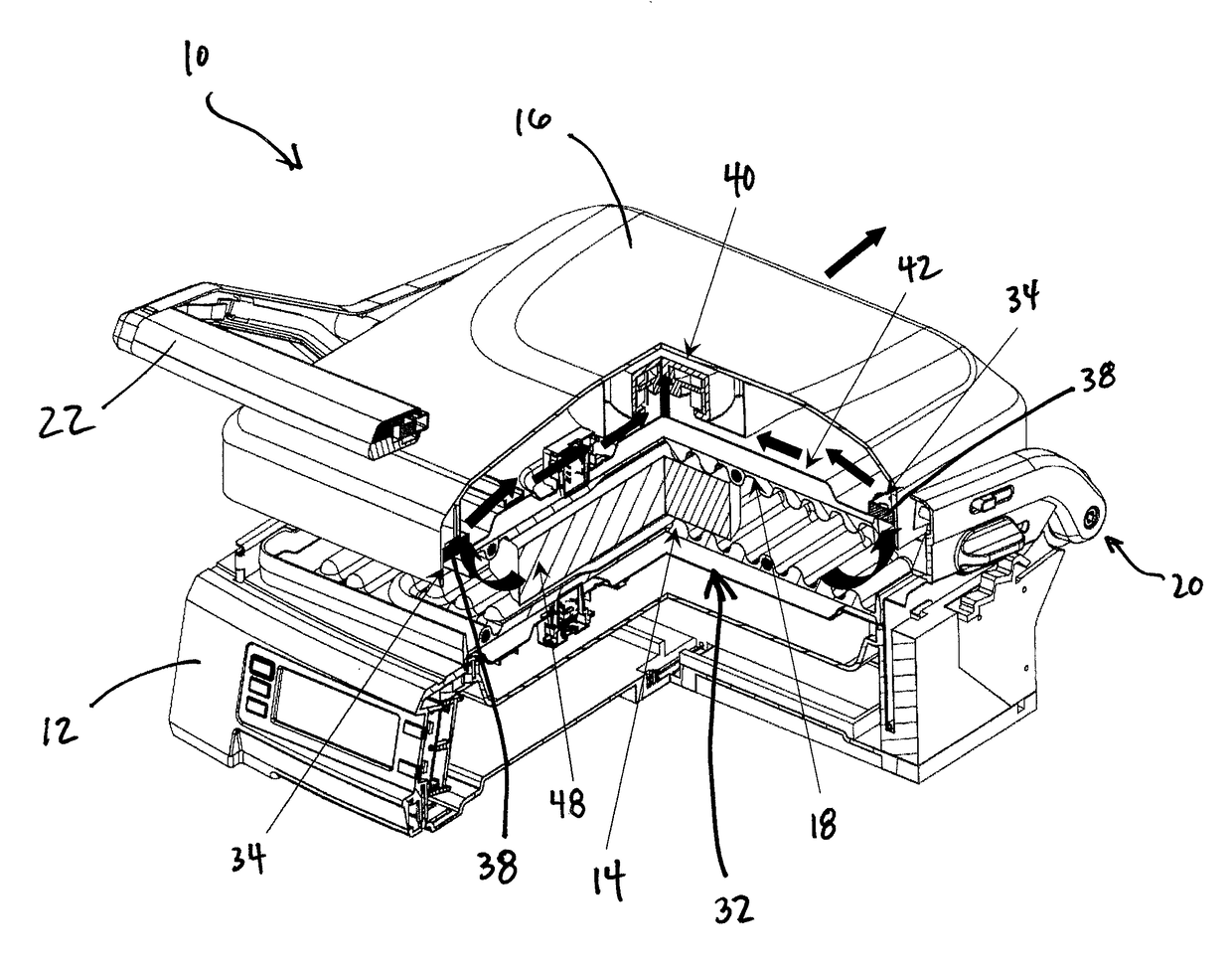

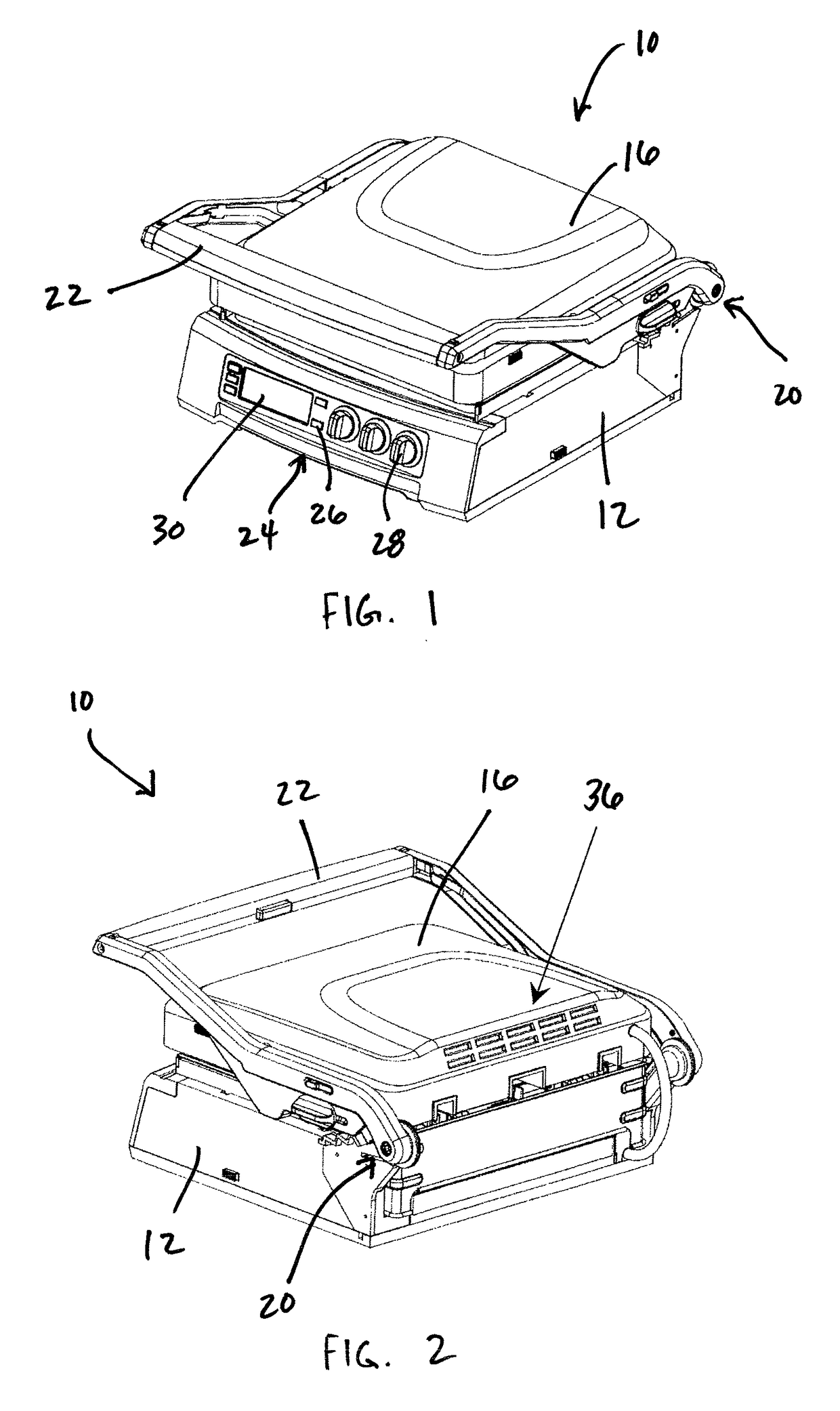

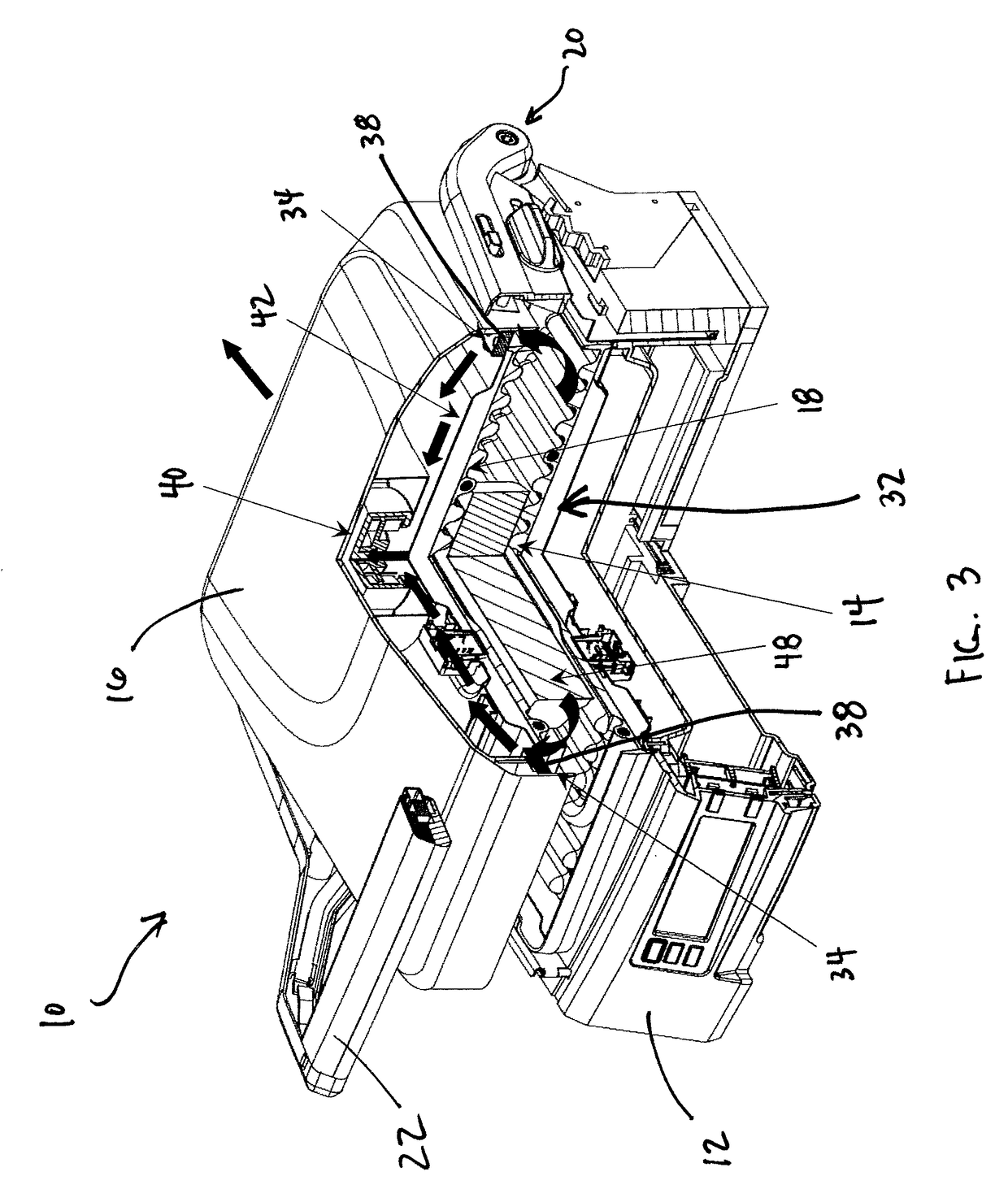

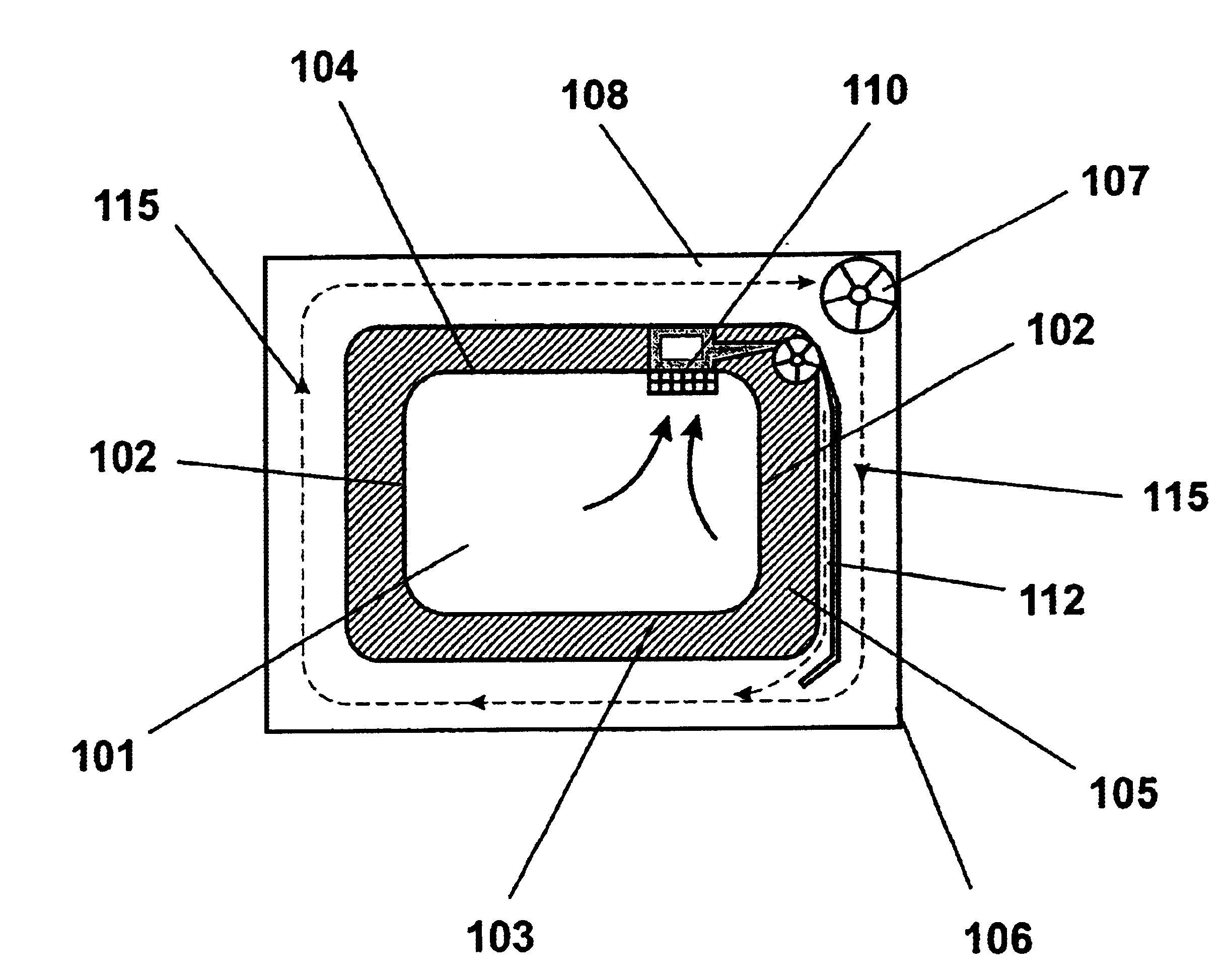

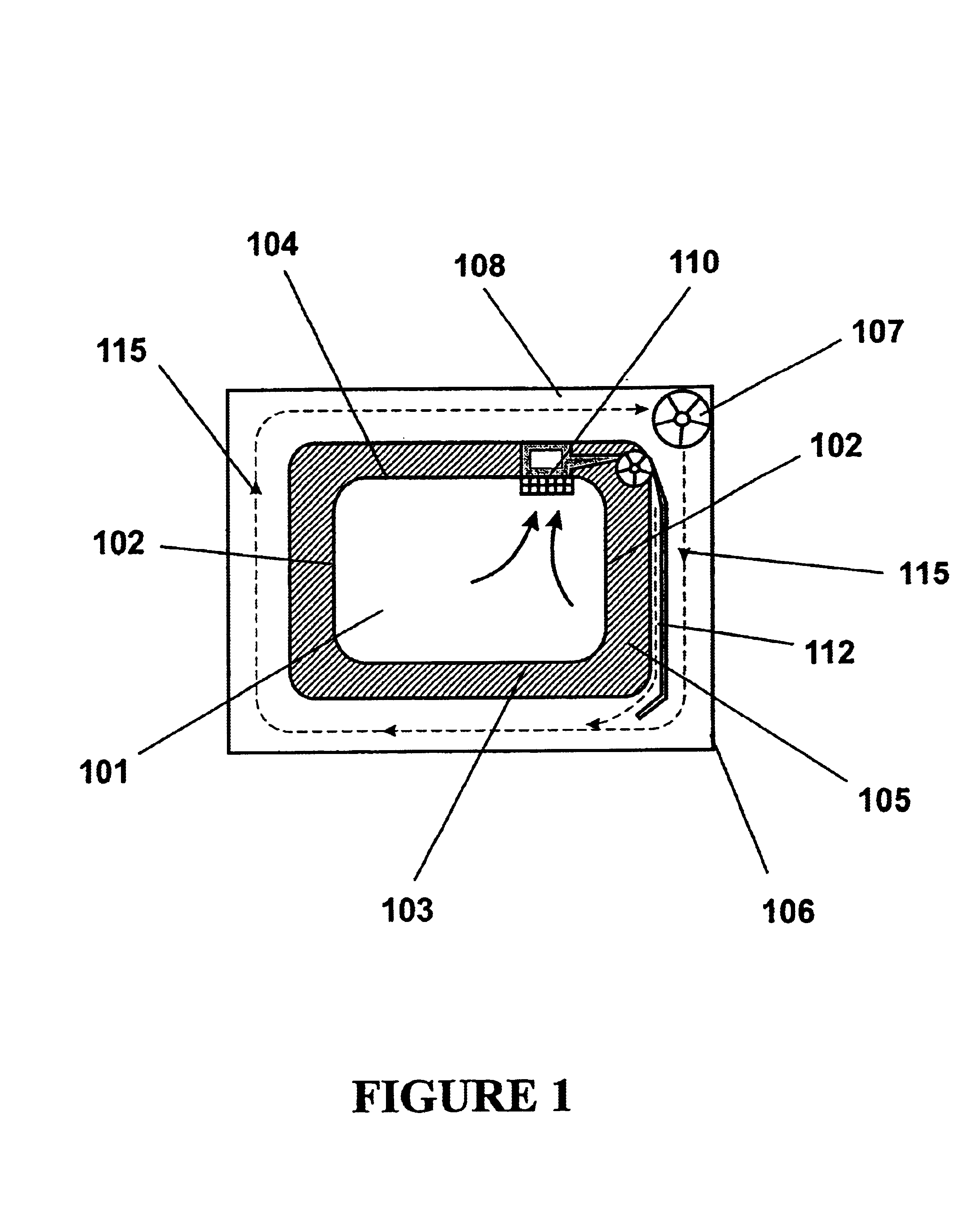

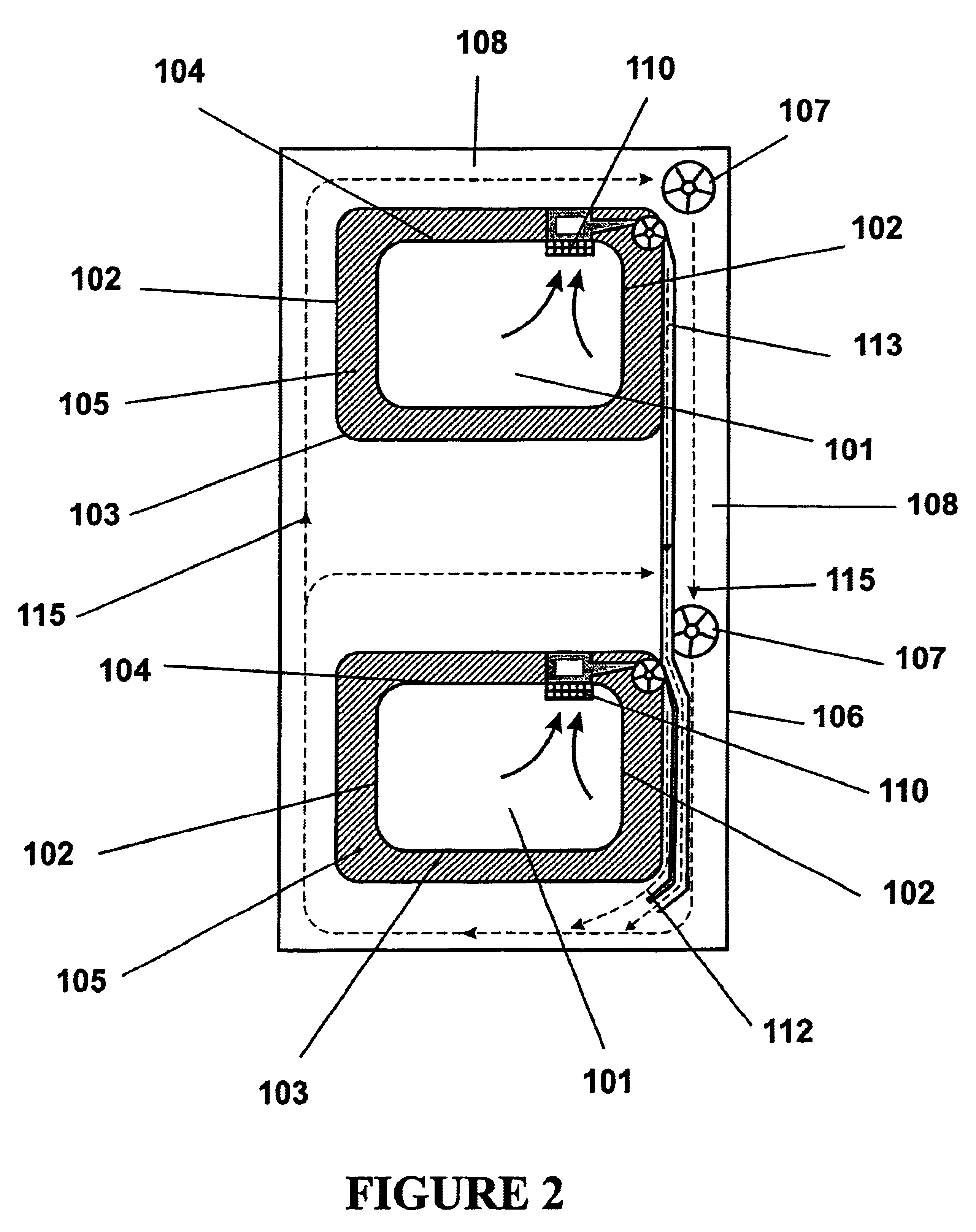

Convection grill

A portable electric grill for that has utilizes an electric fan to draw smoke and cooking odors through a filter then redirects and circulates the cleaner hot air around food to create convection heating thereby improve and making faster the cooking process. The grill can be used for indoor or outdoor use. It has a removable lid that when in the down position it provides the circulation of the hot air throughout the grill. It has a removable grill plate that either sits on top of heating elements or has heating elements imbedded in the grill plate. The grill plate is used for searing various foods and then allowing the convection air to cook the foods throughout. It has controls for regulating temperature, cooking time and fan speed. It has a pull-out grease tray to catch and dispose of drippings from cooking food. The filter is removable for cleaning.

Owner:JONES EDWARD MICHAEL

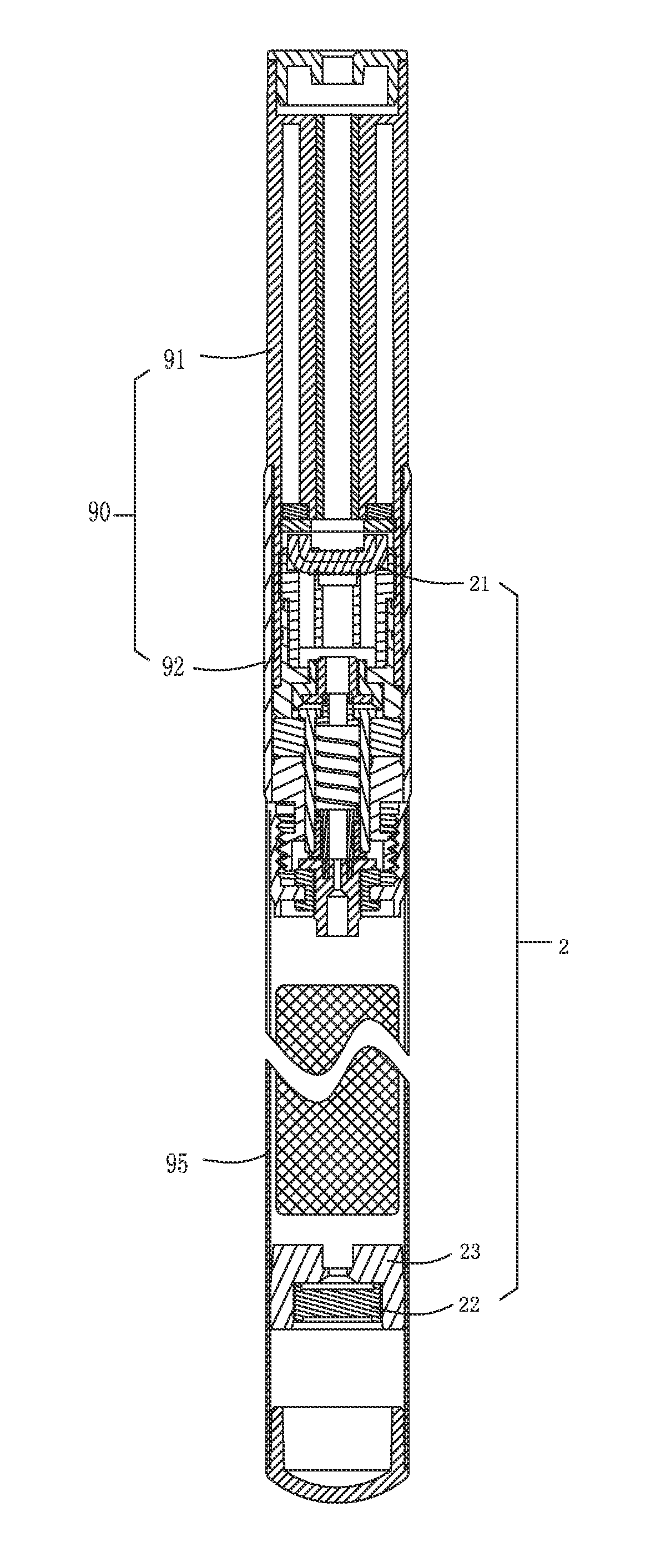

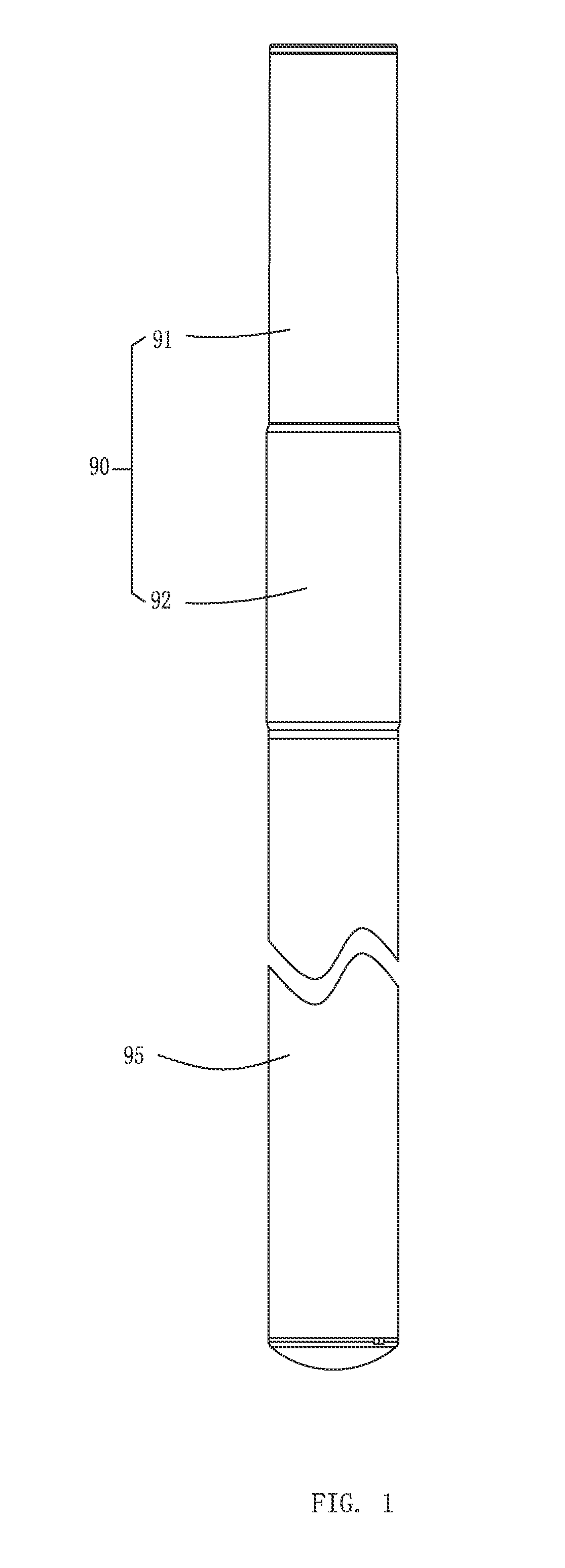

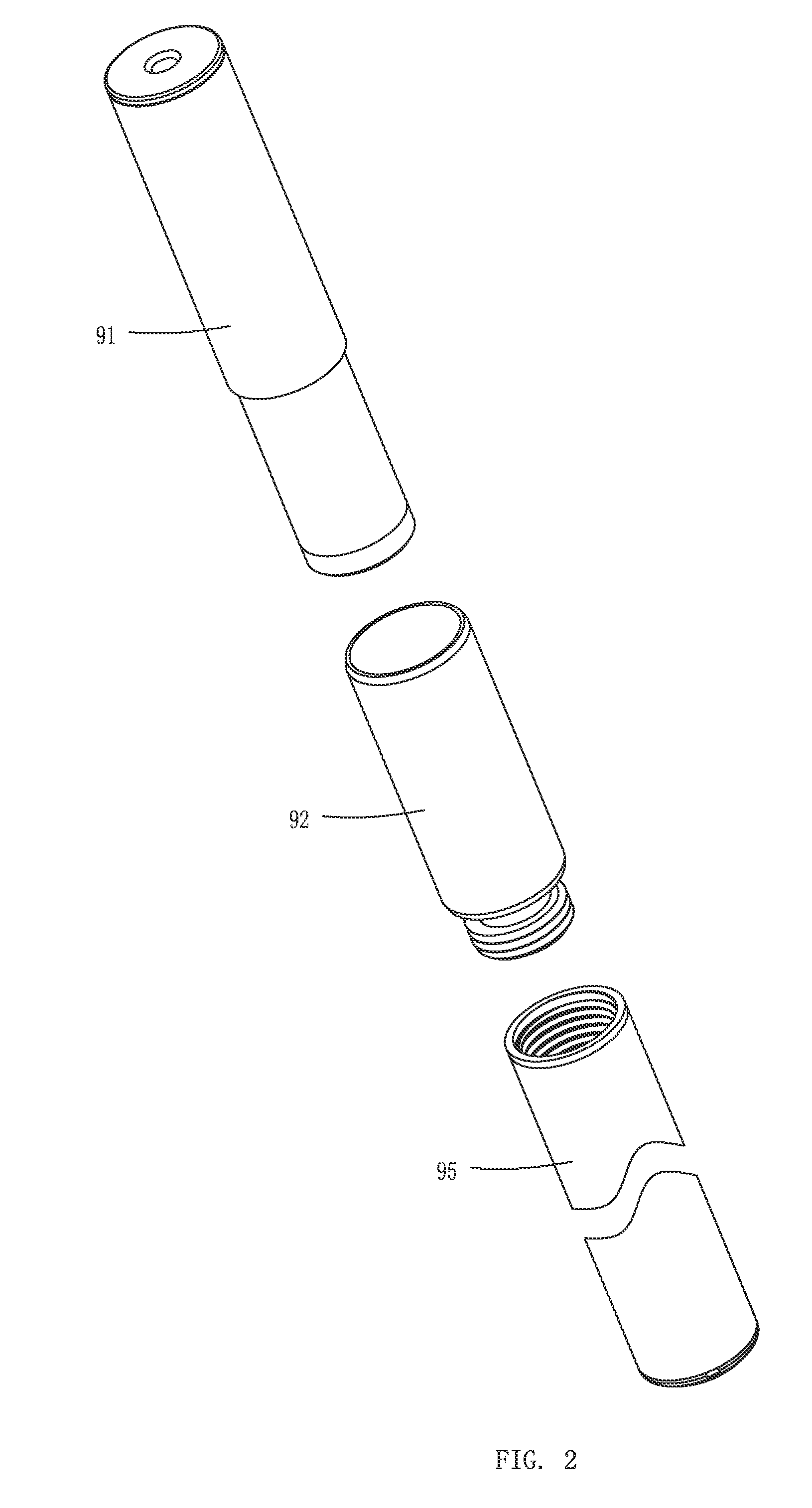

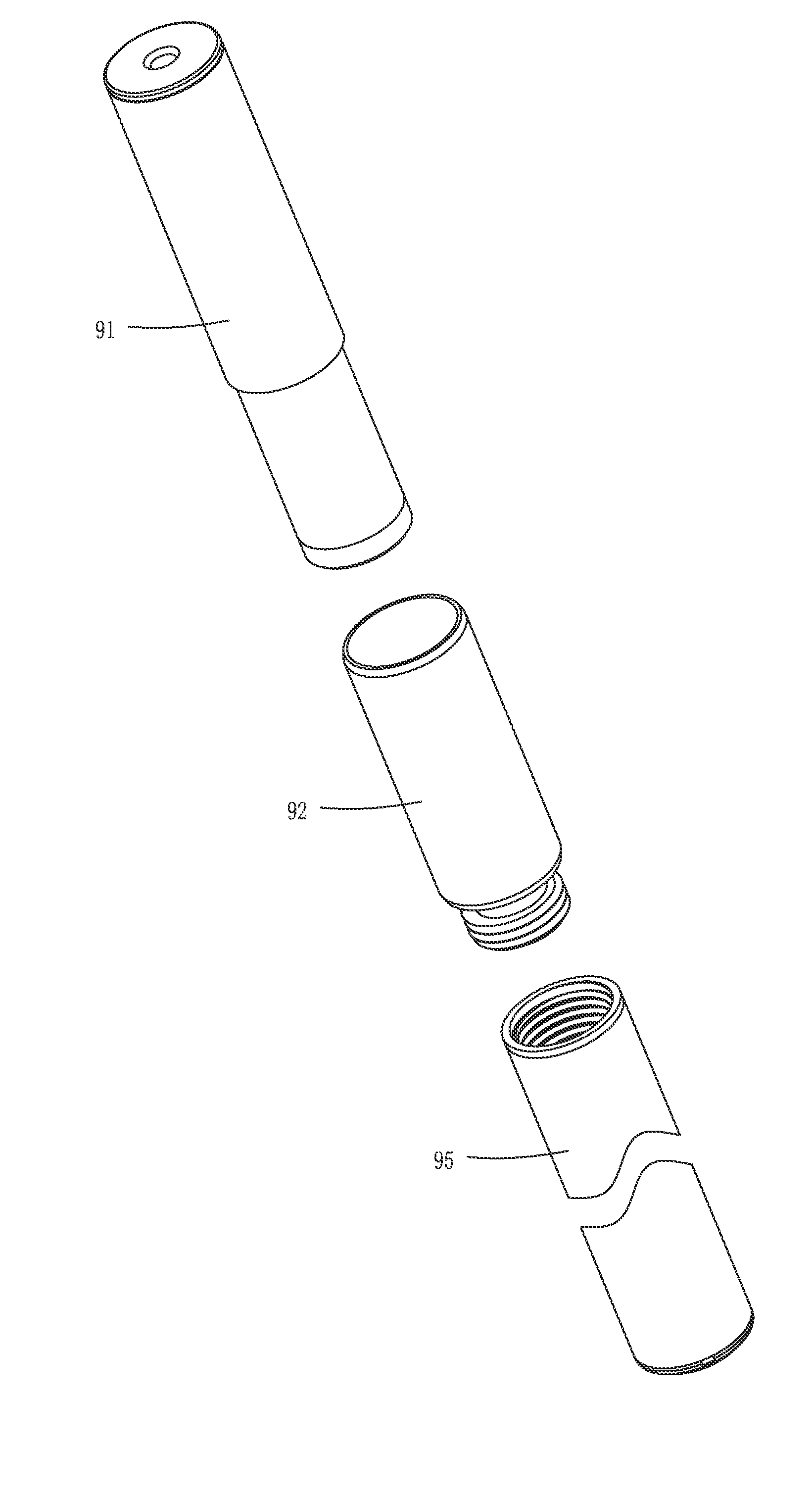

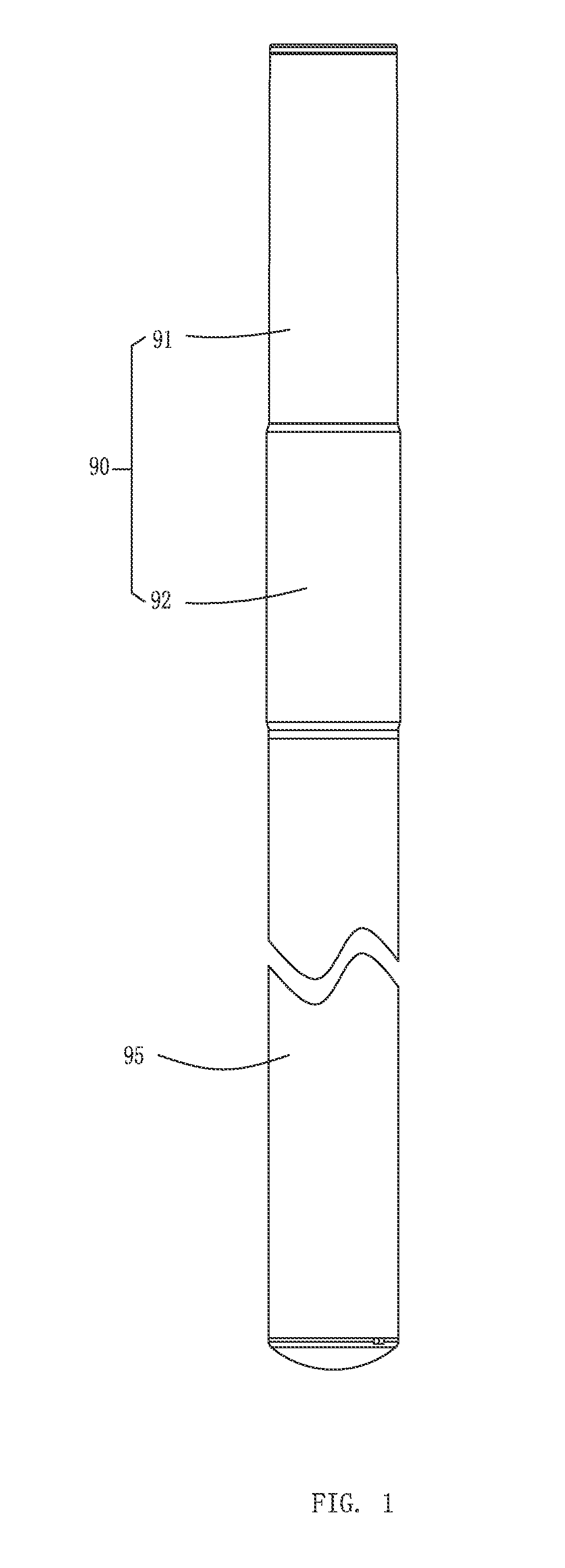

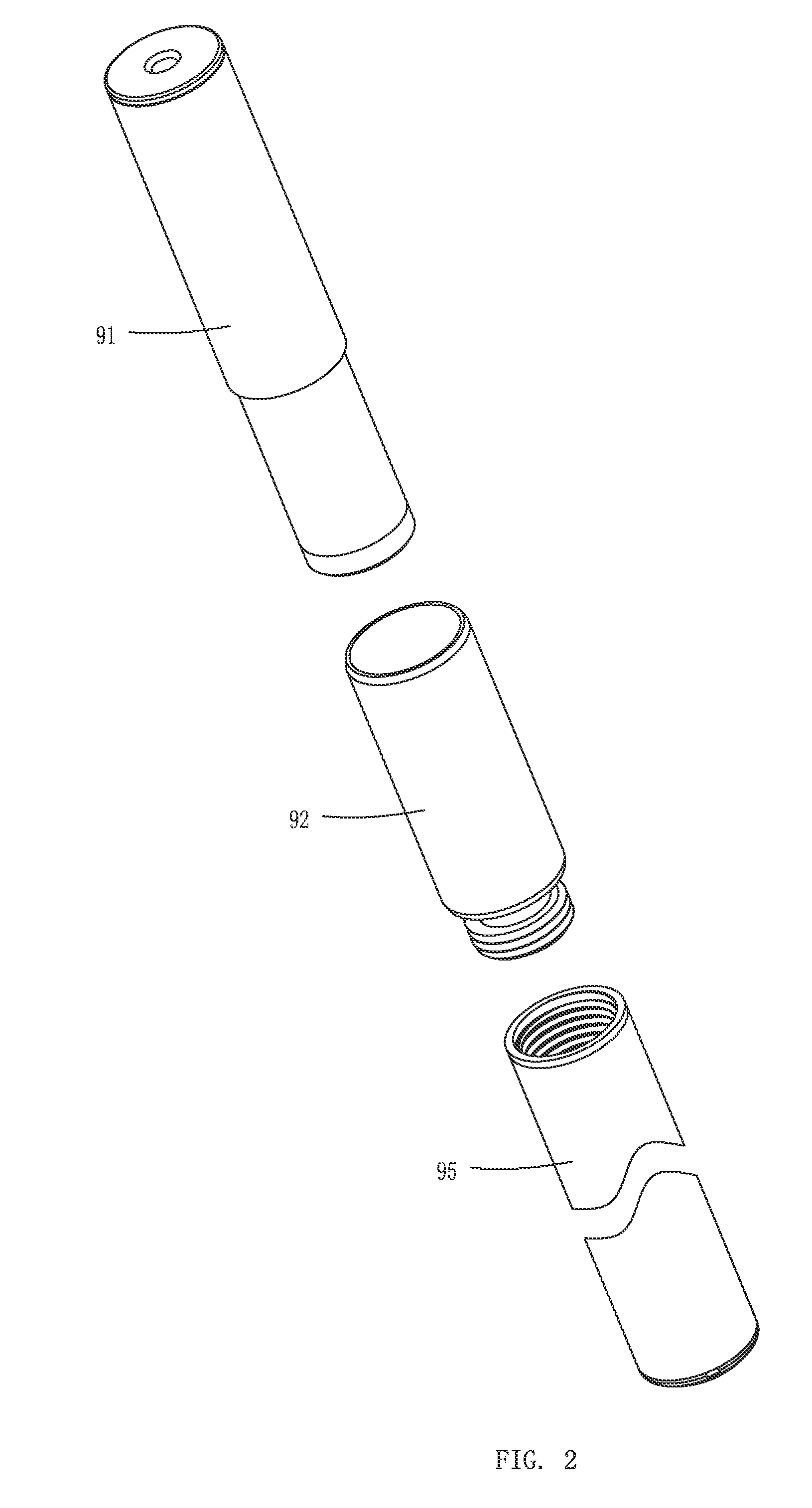

Smoke Condensation Resistant Electronic Cigarette

InactiveUS20140150784A1Increase the amount of smokeReduce smokeTobacco devicesInhalatorsEngineeringElectronic cigarette

A smoke condensation resistant electronic cigarette includes absorption stem and a power source stem which are connected with each other detachably; an atomizer for transforming cigar liquid stored in the absorption stem into smoke and a smoke path for conducting the smoke out of the absorption stem are provided in the absorption stem. Here a smoke condensation resisting mechanism for preventing cooling and condensing of the smoke on an inner wall of the smoke path during flowing process is disposed in the absorption stem. The electronic cigarette of the present invention increases amount of smoke taken in by a smoker and prevents cigar liquid drips being inhaled by the smoker or greatly reducing amount of smoke taken in by the smoker. In addition, it facilitates reduction of manufacture and using cost, and also facilitates assembly, disassemble and replacement of the electronic cigarette.

Owner:HUIZHOU KIMREE TECH

Smoke exhaust system for a cooking appliance

ActiveUS9636618B2Reduce associationReduce smokeGas treatmentDomestic stoves or rangesEngineeringSmoke

A cooking appliance includes a lower housing having a lower heating surface, an upper housing operatively connected to the lower housing and having an upper heating surface, and a smoke exhaust system. The smoke exhaust system includes an air inlet in a lower surface of the upper housing adjacent to the upper heating surface, an exhaust vent formed in the upper housing, and a fan disposed in the upper housing. The fan is configured to draw air through the inlet, into the upper housing, and expel the air through the exhaust vent.

Owner:CONAIR CORP

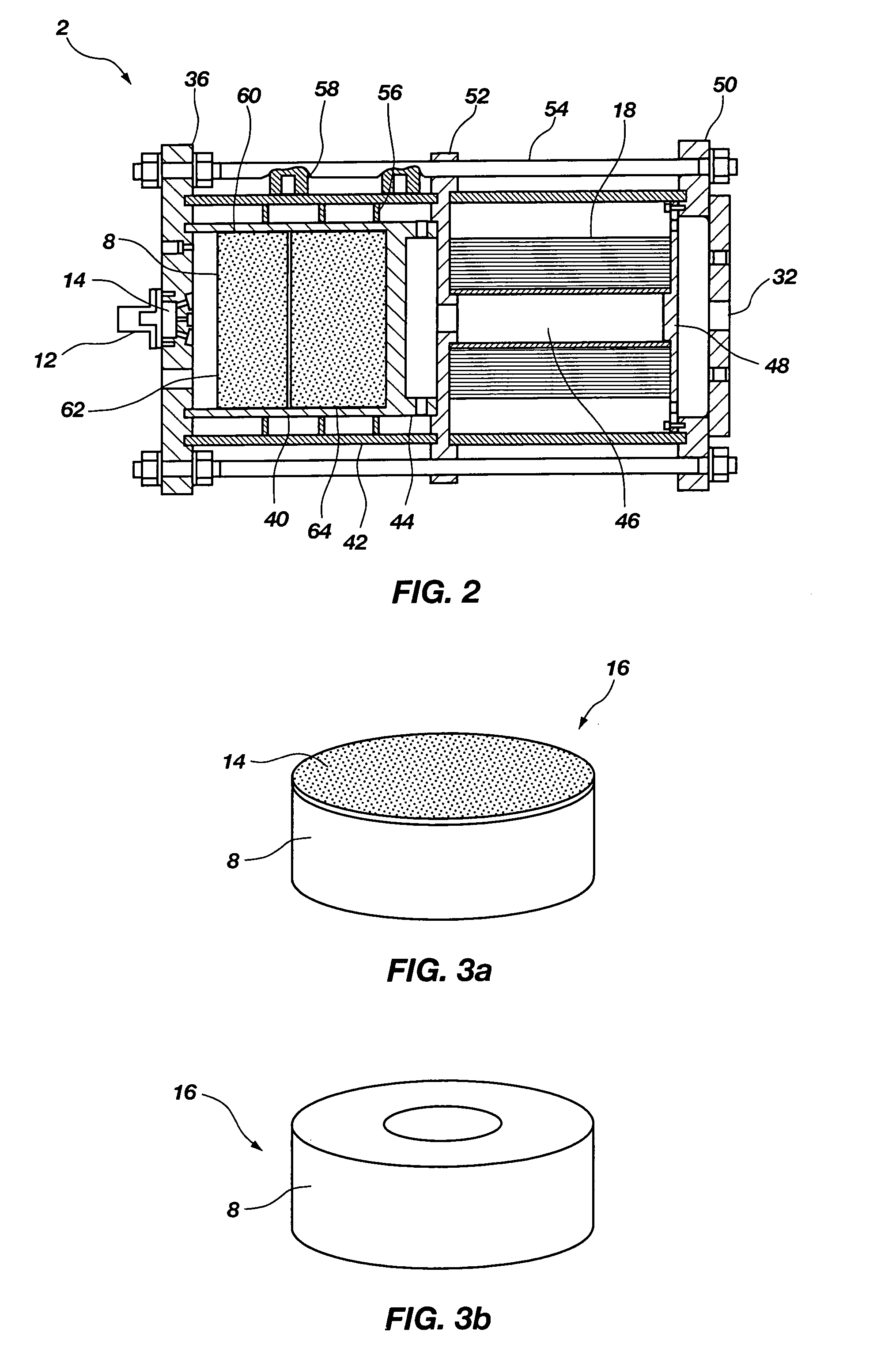

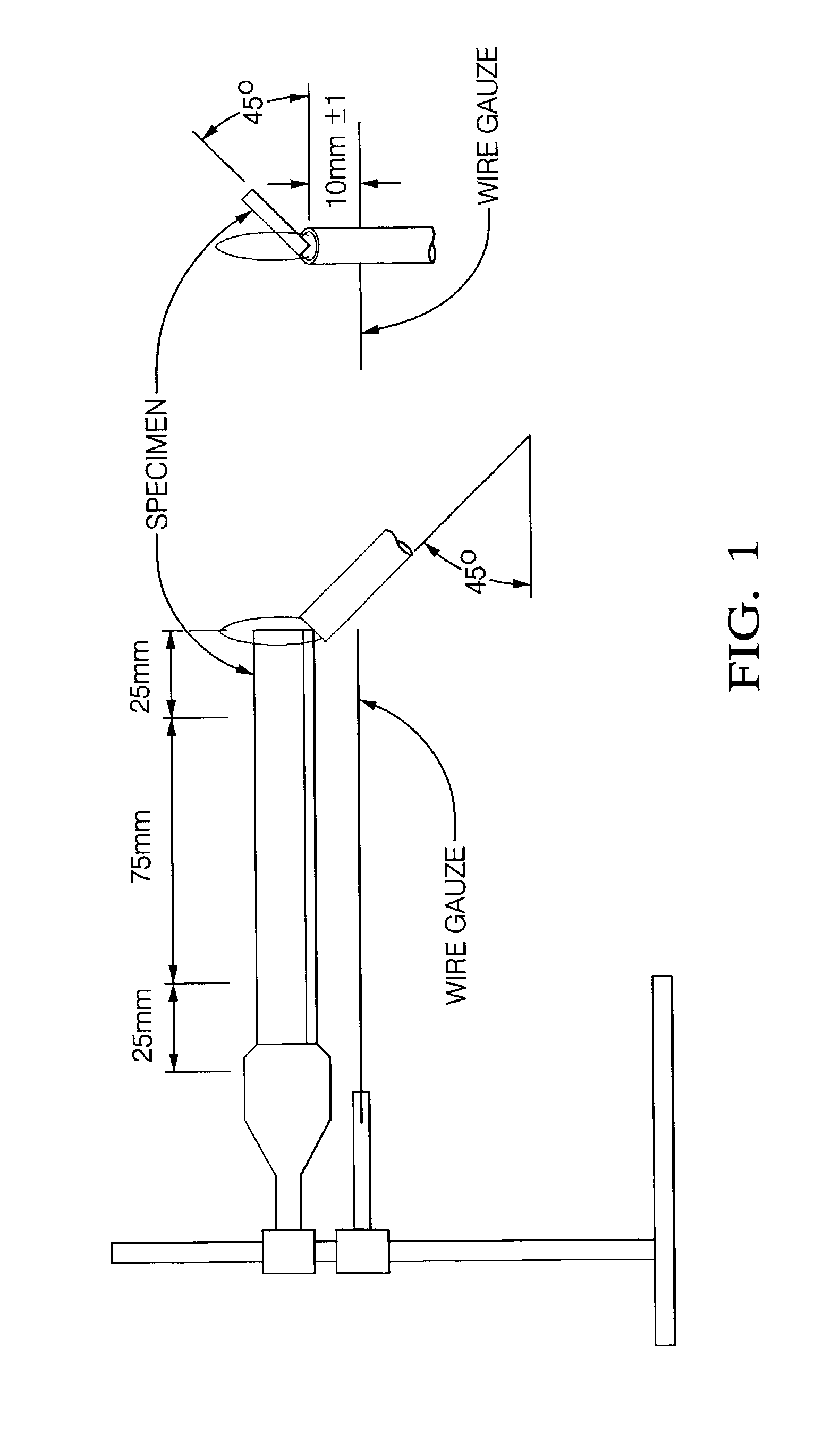

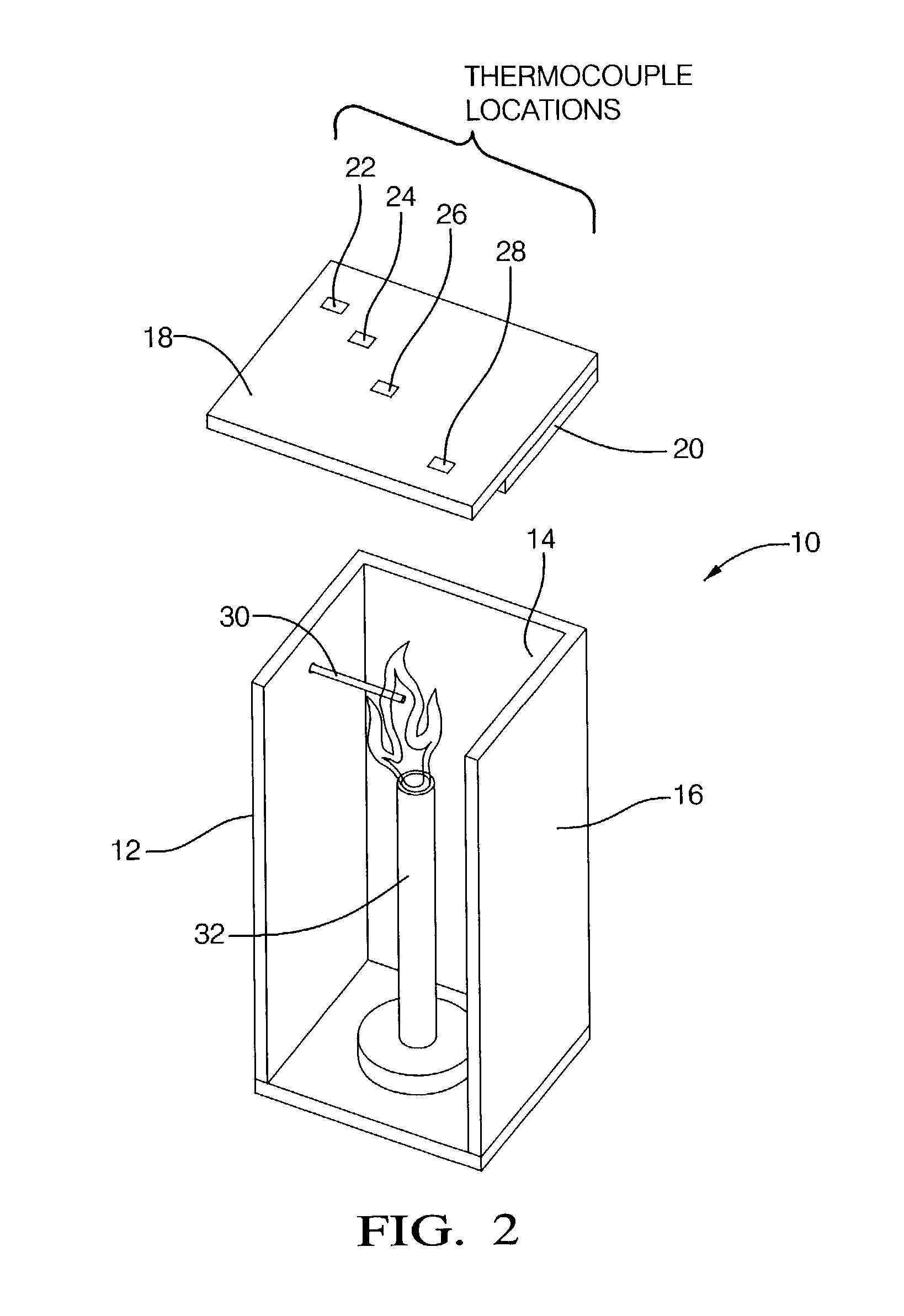

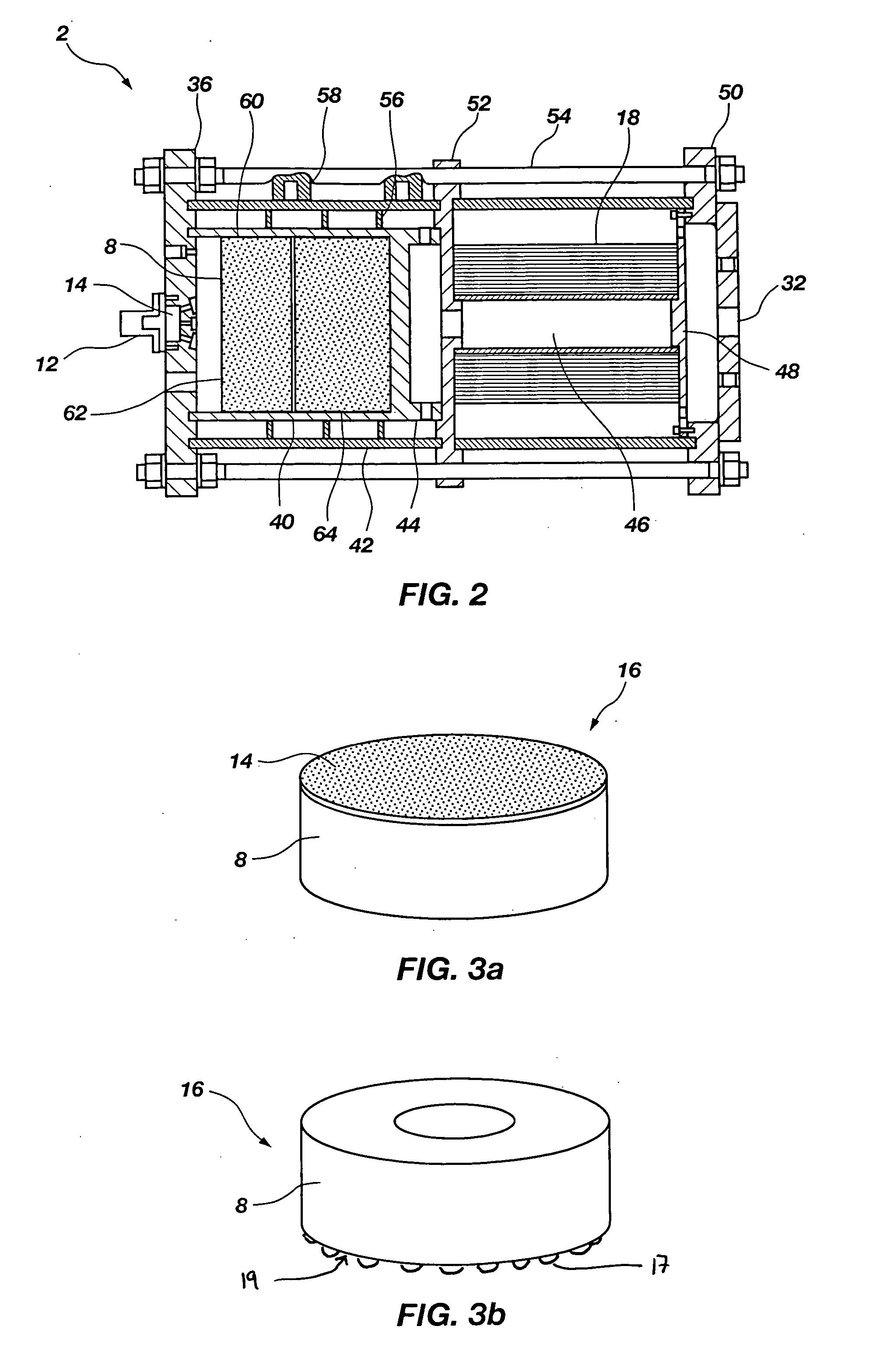

Man-rated fire suppression system

InactiveUS20050115721A1Reducing particulateReduce smokeFire rescueFire extinguisherParticulatesHeat management

A fire suppression system for producing an inert gas mixture having a minimal amount of carbon monoxide, particulates, or smoke. The inert gas mixture may be generated by combusting a gas generant. The gas generant may be a composition that includes hexa(ammine)-cobalt(III)-nitrate. The fire suppression system also includes a heat management system to reduce a temperature of the inert gas mixture. A method of extinguishing fires is also disclosed.

Owner:ORBITAL ATK INC

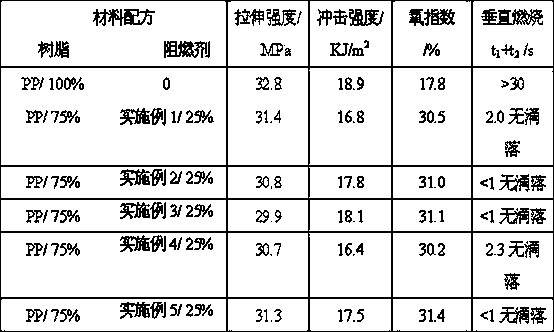

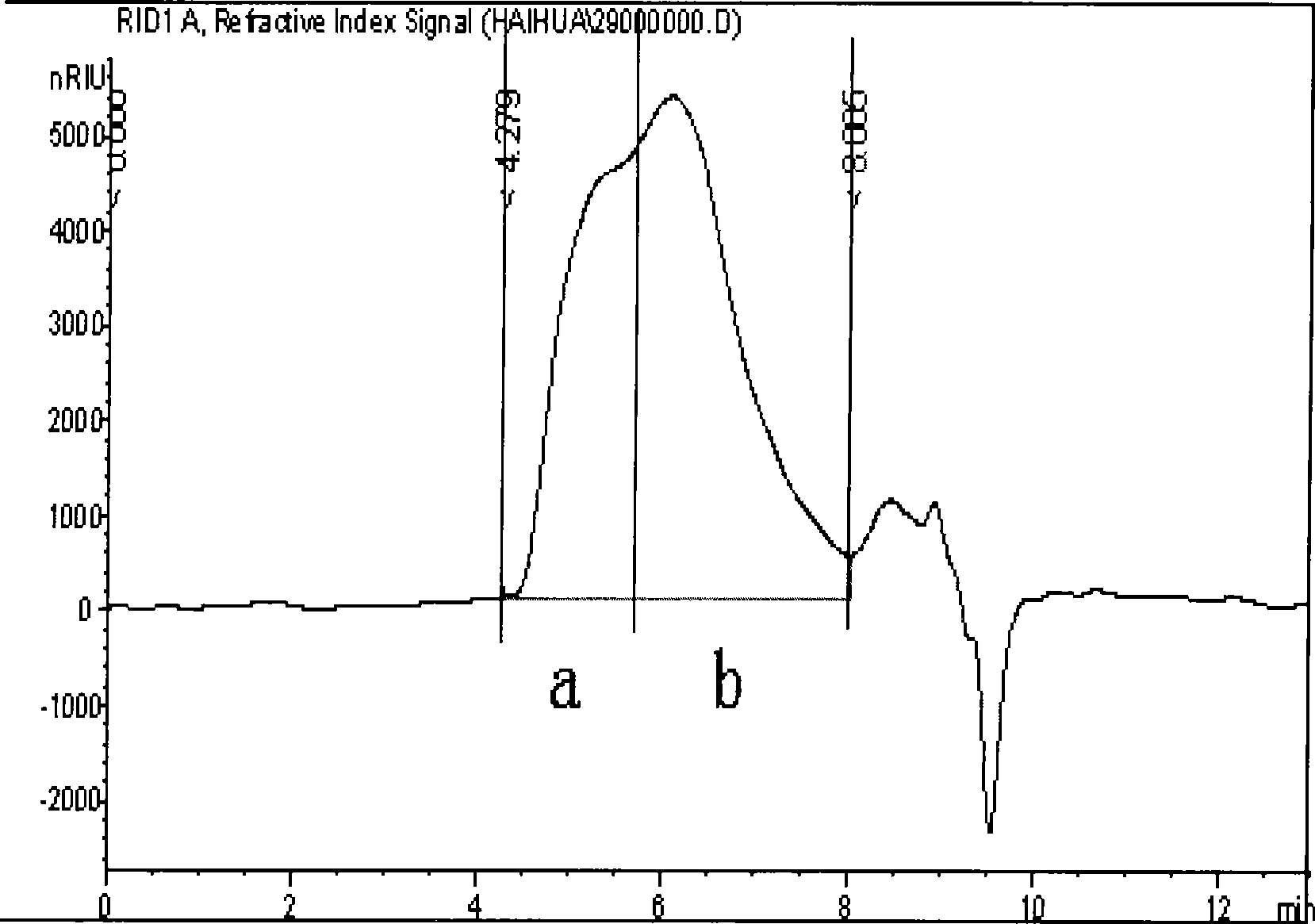

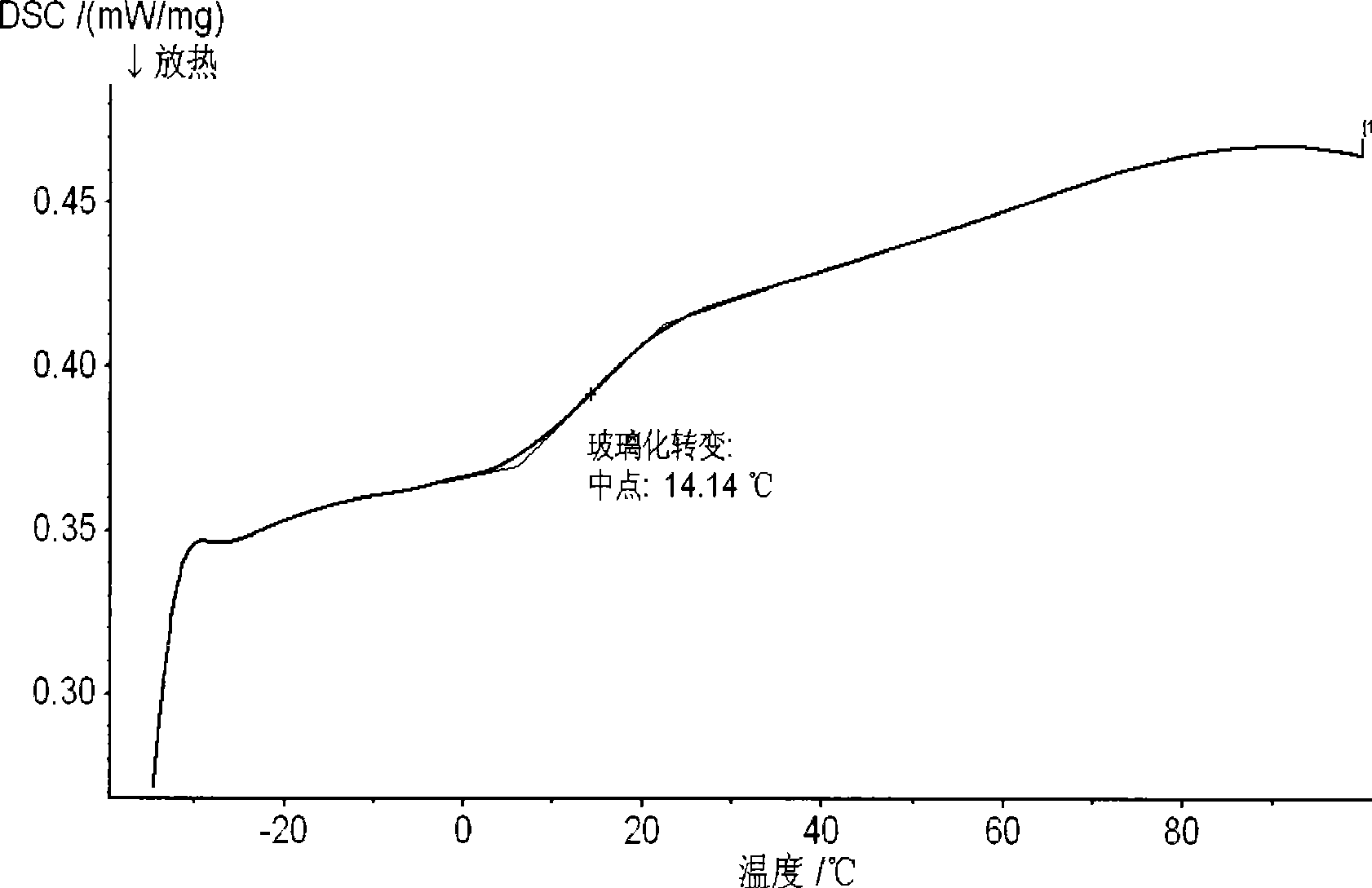

Composite flame retardant containing microcapsule-coated intumescent flame retardant and preparation method

InactiveCN103724666AHigh flame retardant efficiencyOvercome moisture absorptionPolymer scienceHindered amine light stabilizers

The invention belongs to the field of flame retardant materials, and particularly relates to a composite flame retardant containing a microcapsule-coated intumescent flame retardant and a preparation method. The composite flame retardant containing the microcapsule-coated intumescent flame retardant consists of the following components in percentage by mass: 60-94 percent of microcapsule intumescent flame retardant, 5-25 percent of flame-retardant synergist, 0.9-10 percent of smoke suppressant and 0.1-5 percent of hindered amine light stabilizer. The preparation method comprises the following steps: preparing the microcapsule-coated intumescent flame retardant; placing the microcapsule-coated intumescent flame retardant, the flame-retardant synergist, the smoke suppressant and the hindered amine light stabilizer into a high-speed mixer for mixing uniformly, and discharging to obtain the composite flame retardant containing the microcapsule-coated intumescent flame retardant. Multiple components in the composite flame retardant can play roles in retarding flame in a synergetic way, so that the flame retardance of a high polymer material is improved remarkably, the production of toxic and harmful smog in a burning process can be suppressed, and the flame retarding efficiency is increased greatly.

Owner:LIAONING TECHNICAL UNIVERSITY

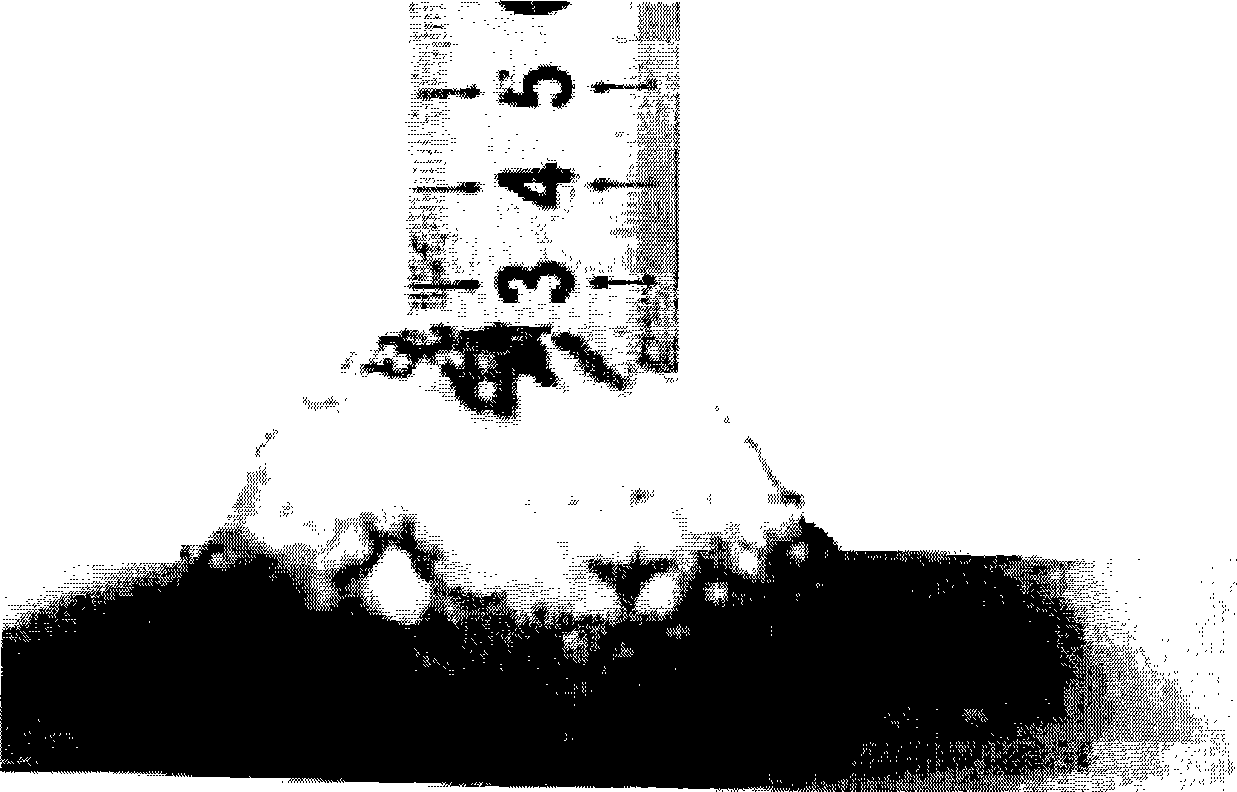

Ultrathin section steel structure fire-resisting paint and preparation thereof

The invention discloses an ultra-thin fireproof coating for a steel structure and a preparation method thereof. The coating has the characteristics of high gloss, good water resistance, strong adhesion force and so on of a solvent based ultra-thin fireproof coating, also has the advantages of water-based coatings by taking water as a medium, and satisfies the direction of developing low-pollution and environment-friendly coatings of the coating industry. The technical proposal comprises that the ultra-thin fireproof coating for the steel structure is prepared from the following components by weight portion: 10 to 35 portions of acrylic hybrid emulsion, 10 to 25 portions of dehydration and carbon-forming catalyst, 10 to 25 portions of carbon forming agent, 5 to 20 portions of foaming agent, 5 to 20 portions of flame retardant, 5 to 25 portions of pigment and filler, 3 to 10 portions of reinforcing agent, 5 to 10 portions of latent solvent, 1 to 5 portions of dispersant, 0.1 to 1 portion of foam killer, 0.2 to 2 portions of flatting agent, 0.2 to 2 portions of thickening agent, 1 to 5 portions of film forming additive, and the balance being water.

Owner:MARINE CHEM RES INST

Cooking appliance venting system

InactiveUS6913012B2Reducing otherReduce smokeSelf-cleaning stoves/rangesBaking ovenAir cleaningOperation mode

Owner:FISHER & PAYKEL APPLIANCES LTD

Smoke condensation resistant electronic cigarette

InactiveUS9364025B2Reduce the amount of solutionPreventing cigar liquid being inhaledTobacco devicesEngineeringElectronic cigarette

Owner:HUIZHOU KIMREE TECH

Environmental protection energy-saving diesel oil

The present invention is one kind of environment friendly energy-saving diesel oil and its compounding process, and belongs to the field of petroleum technology. The environment friendly energy-saving diesel oil is compounded with fatty methyl ester 5-50 wt%, base oil 10-60 wt%, GB diesel oil 5-50 wt%, cetane number improver 0.1-2 wt%, pour point depressant 0.1-2 wt%, viscosity regulator 1-10 wt%, deodorant 0.1-2 wt%, smoke-eliminating oil saver 0.1-2 wt%. The production process of the present invention is simple and low in cost, and the environment friendly energy-saving diesel oil has lowered consumption, high dynamic property, high stability, good low temperature starting performance and environment friendship.

Owner:姜彬

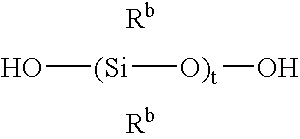

Method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles

The invention relates to a method for preparing flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles, which is characterized in that the method comprises the following technological process: adding methyl vinyl silicone rubber to a kneading machine; adding white carbon black and hydroxyl silicone oil; mixing the materials for 1+ / -0.1 hour at a nitrogen-supplying speed of 5+ / -0.1 cubic meter / hour at a temperature between 170 and 190 DEG C; cooling to 60+ / -5 DEG C; adding porcelainizing powder, aluminum silicate, chloroplatinic acid, zinc stannate and aluminum hydroxide; continuing to mix for 0.5+ / -0.05 hour; discharging the materials; filtering rubber in a rubber filter; cooling the obtained product to room temperature; adding 2,5-dimethyl-2,5-bis(tert-butylperoxy) hexane or peroxide bis(2,4-dichloro-benzoyl) serving as a curing agent to an open mill; mixing well; and obtaining the flame-retardant low-smoke halogen-free hot-vulcanized silicone rubber compounds for metro vehicles. As the method adopts halogen-free flame retardant and particularly adopts a porcelainizing smoke-cutting technique, smoke almost completely disappears after the product produced by the method burns for a plurality of minutes, and the inside of the product can be kept in good condition.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

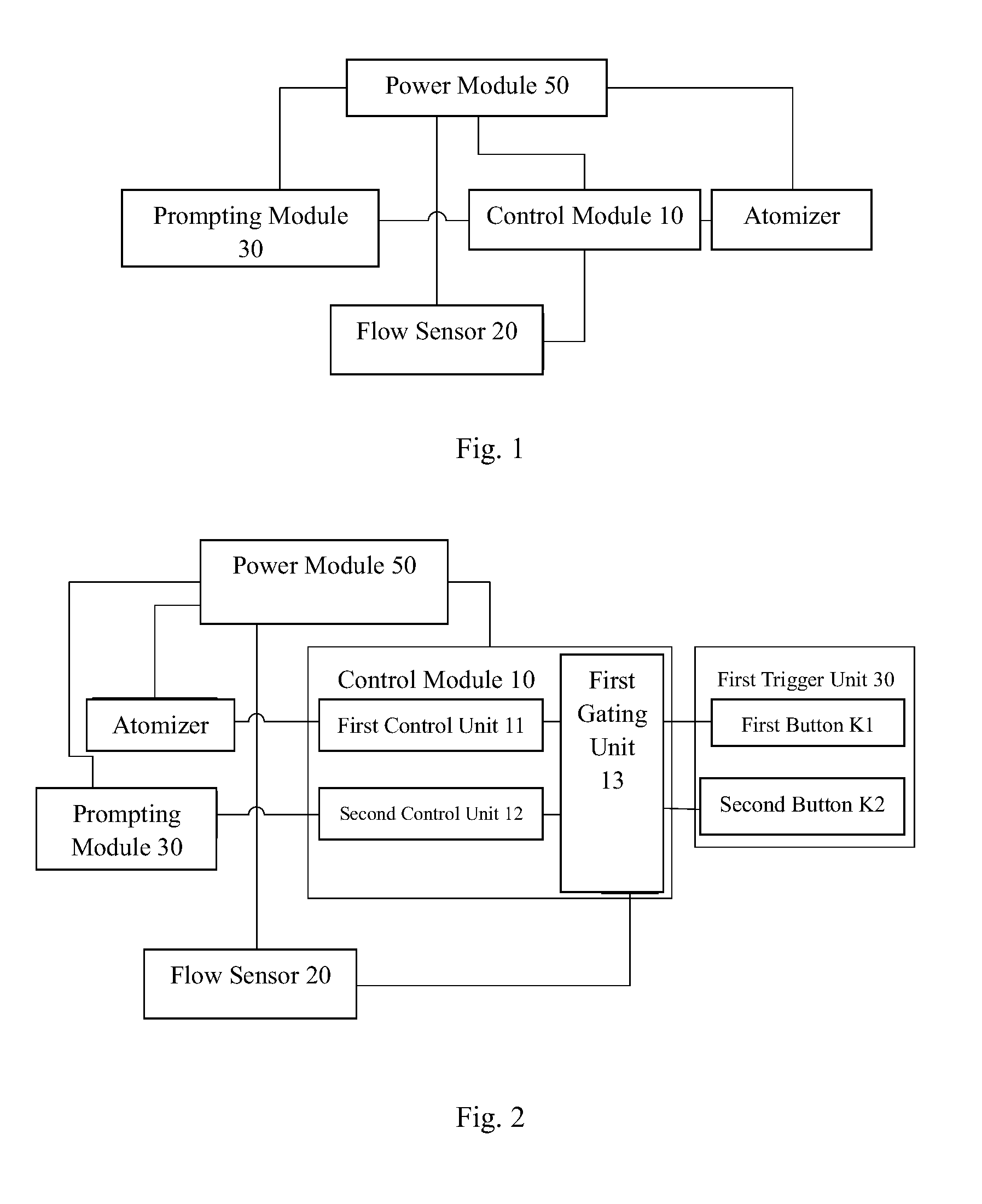

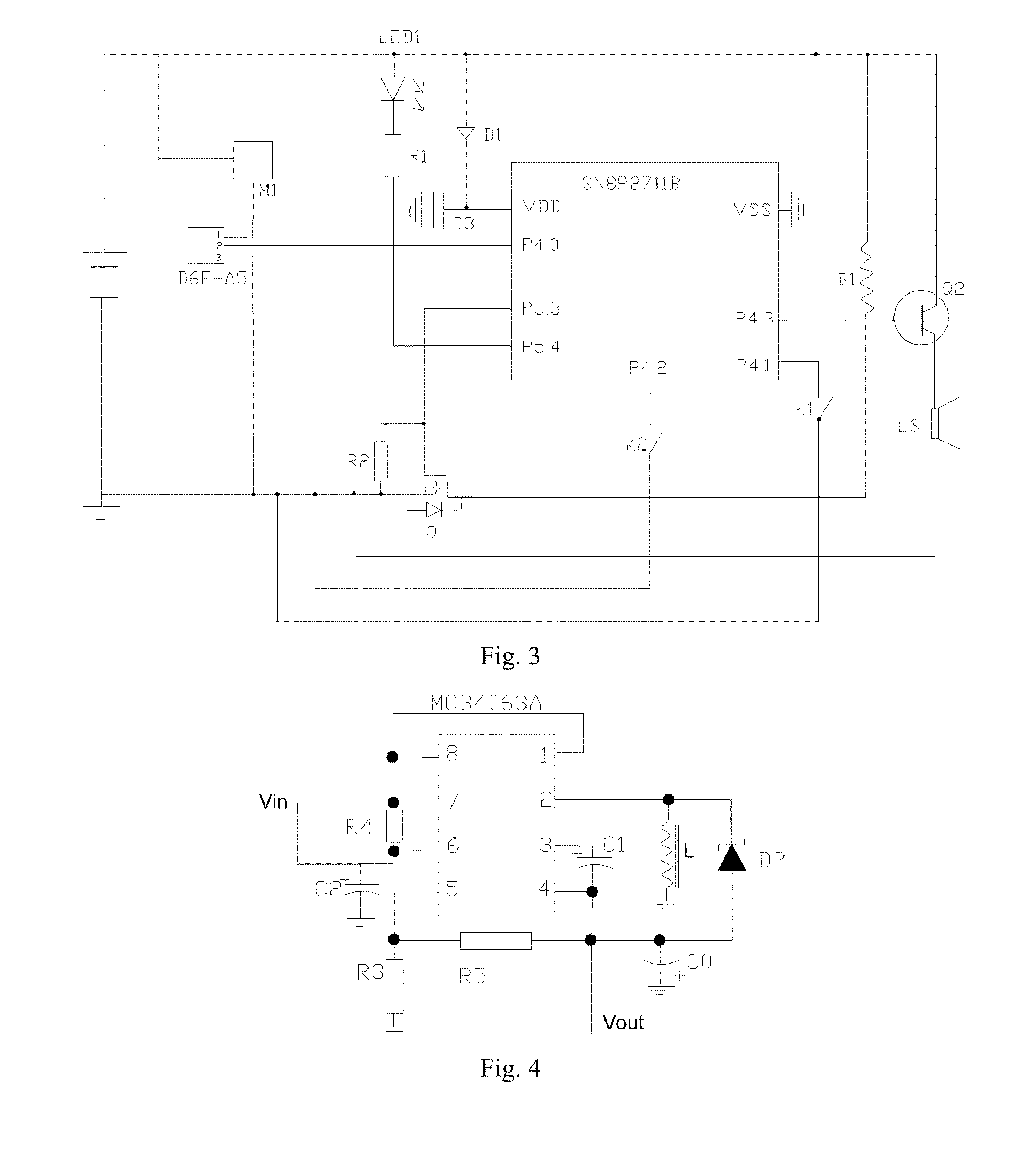

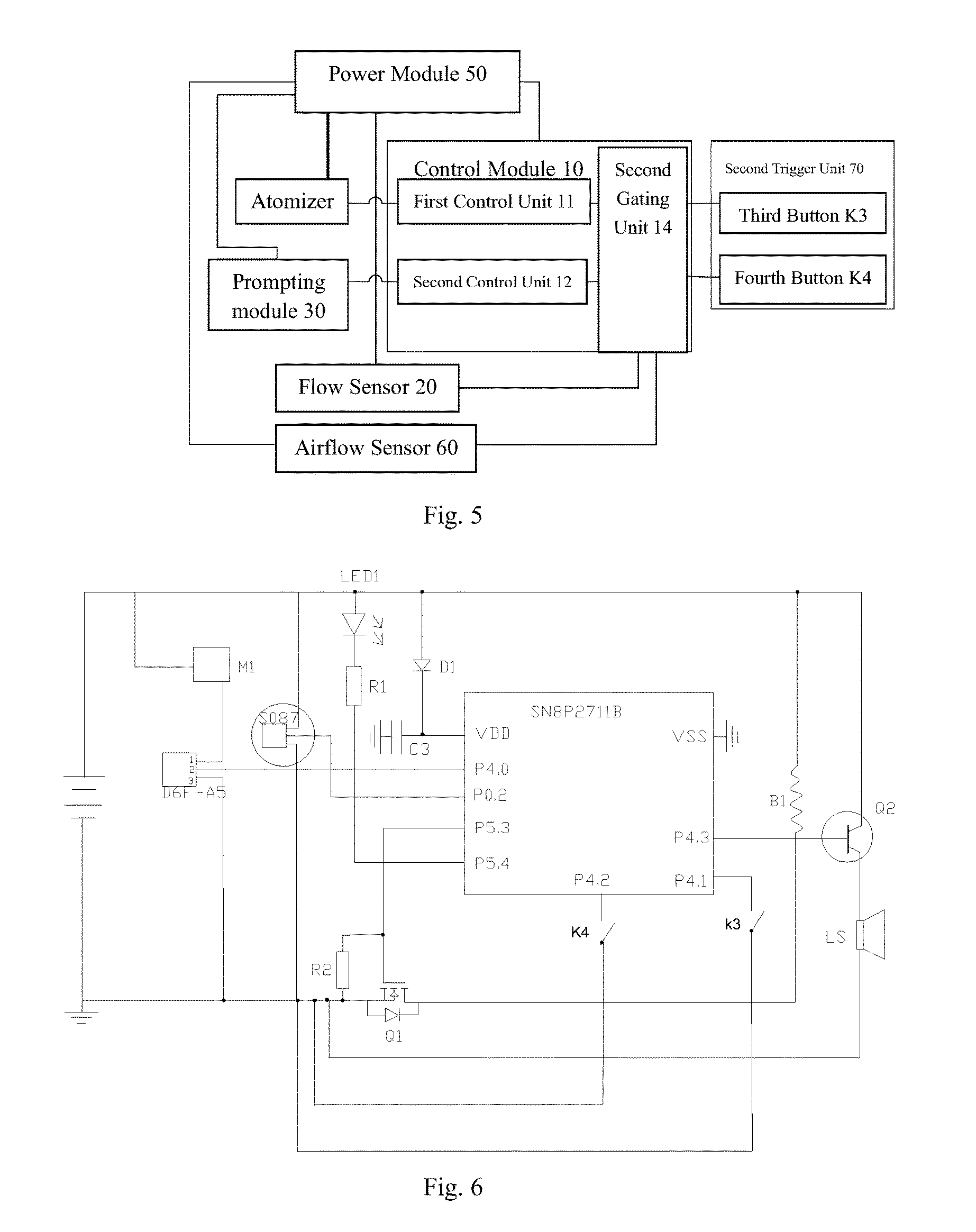

Electronic cigarette with lung capacity detection function and control method

InactiveUS20170020201A1Reduce smokeStop smokingTobacco devicesDiagnostic recording/measuringEngineeringElectronic cigarette

An electronic cigarette with a lung capacity detection function and a control method. The electronic cigarette comprises a control module (10) used for controlling the electronic cigarette to atomize cigarette liquid, a flow sensor (20) used for detecting an air flow volume exhaled or inhaled by a user and generating a flow signal, and a prompting module (30) used for generating prompting information. The flow sensor (20) and the prompting module (30) are respectively connected to the control module (10). The control module (10) is also used for controlling, according to the flow signal, the prompting module (30) to generate prompting information. The electronic cigarette has effects of prompting the user so as to protect health of the user and making functions of a production diversified.

Owner:KIMREE HI TECH

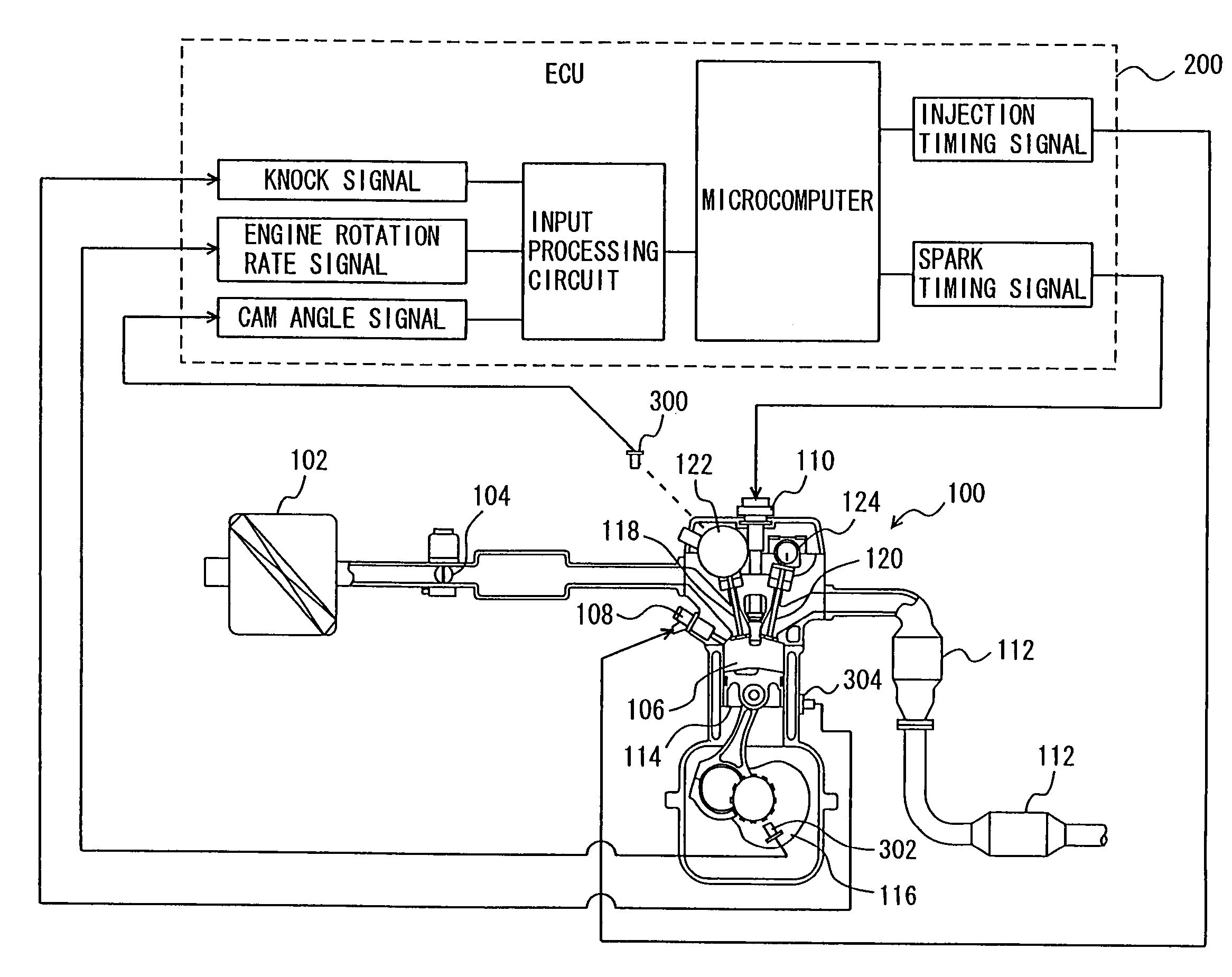

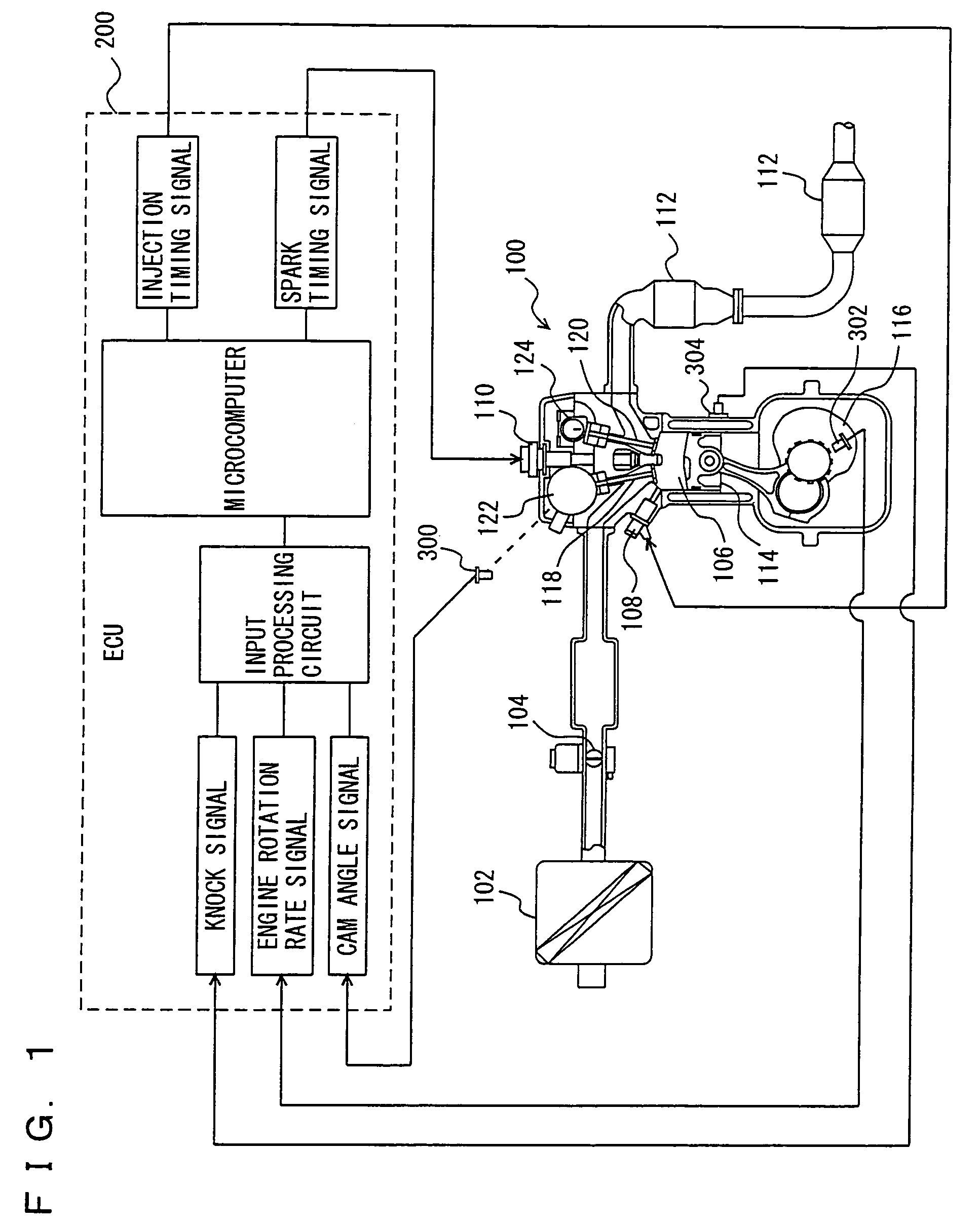

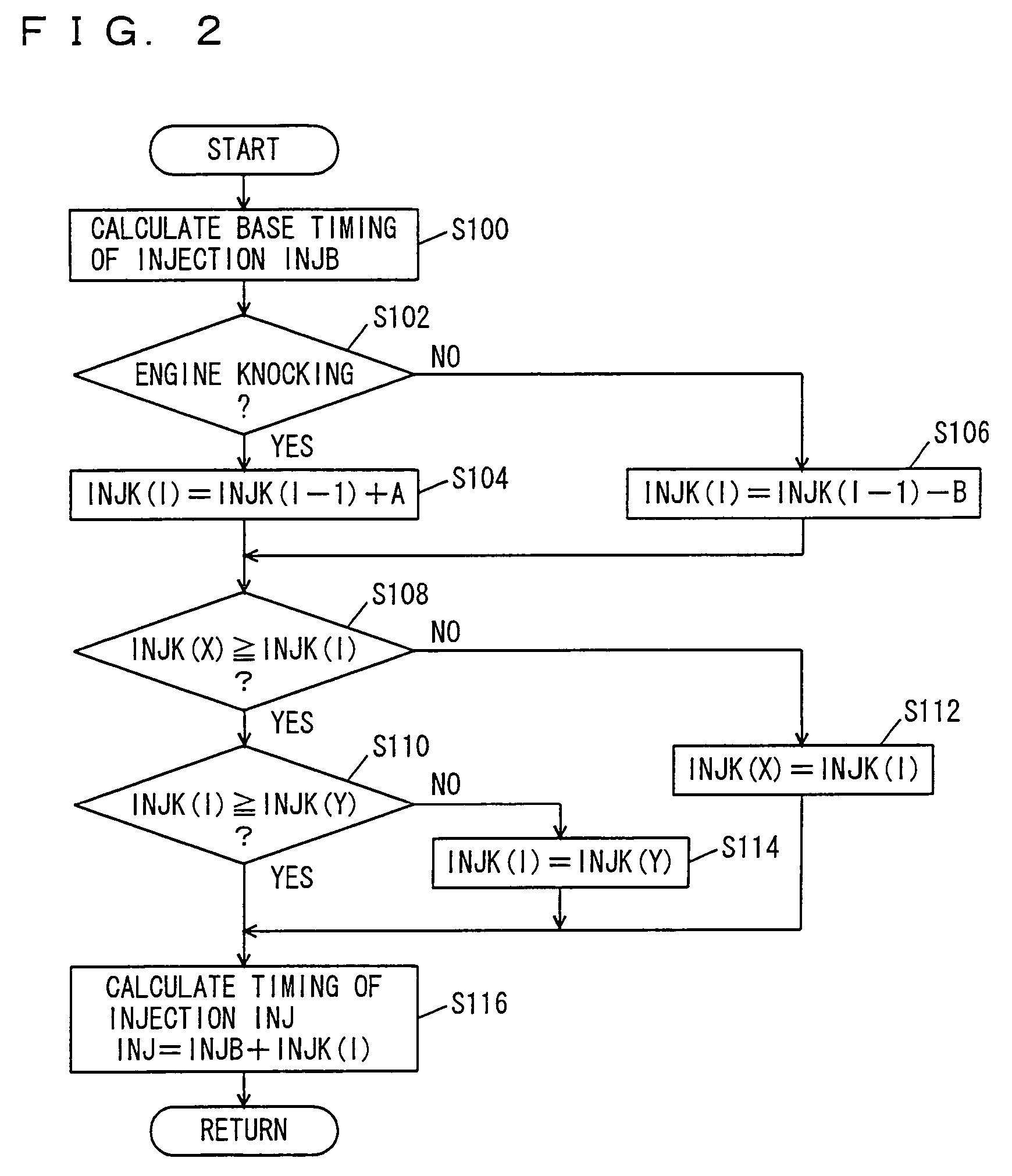

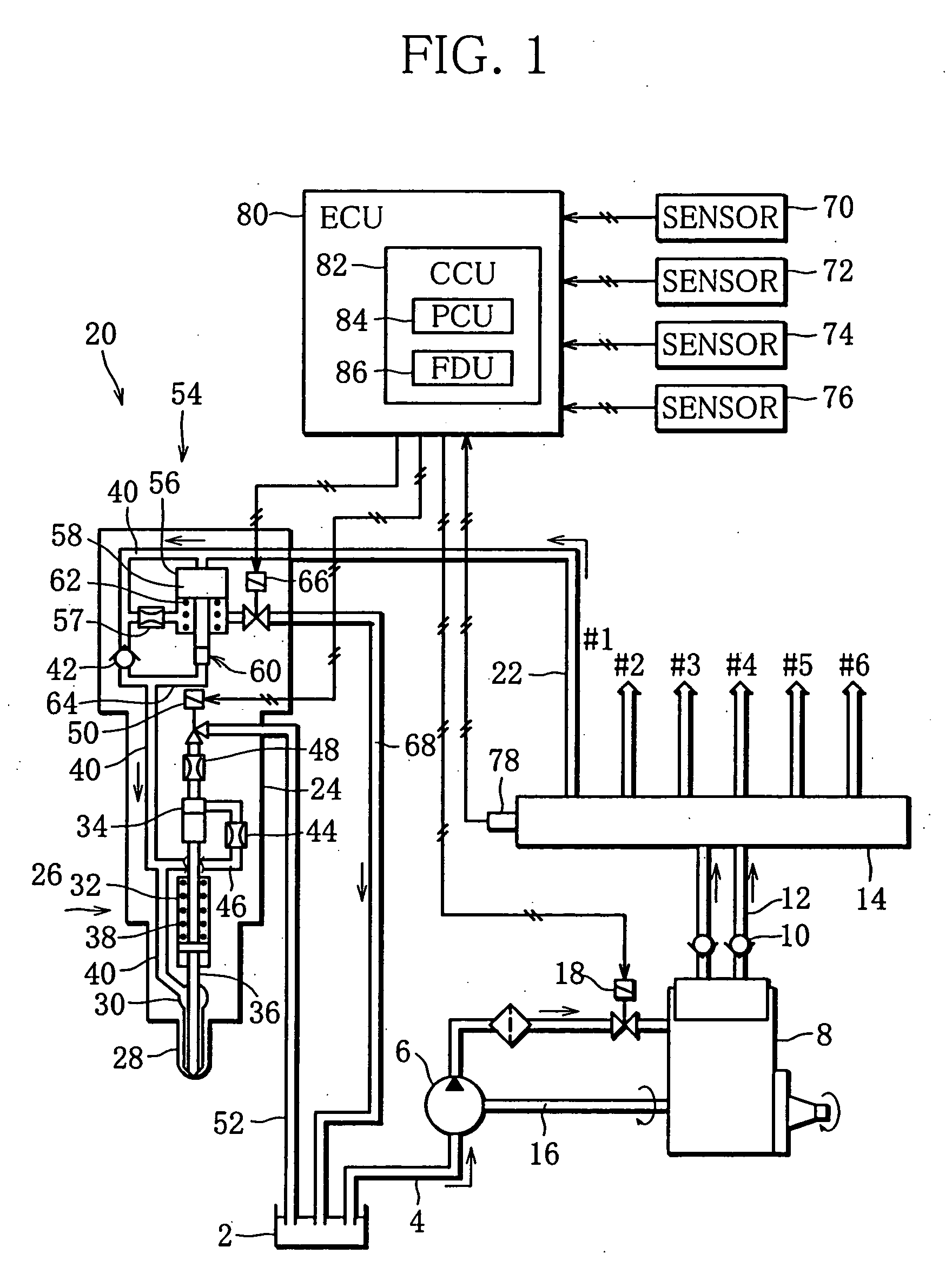

Control device for internal combustion engine

InactiveUS7246600B2Avoid knockingReduce smokeElectrical controlInternal combustion piston enginesEngineeringInternal combustion engine

Owner:NIPPON SOKEN +1

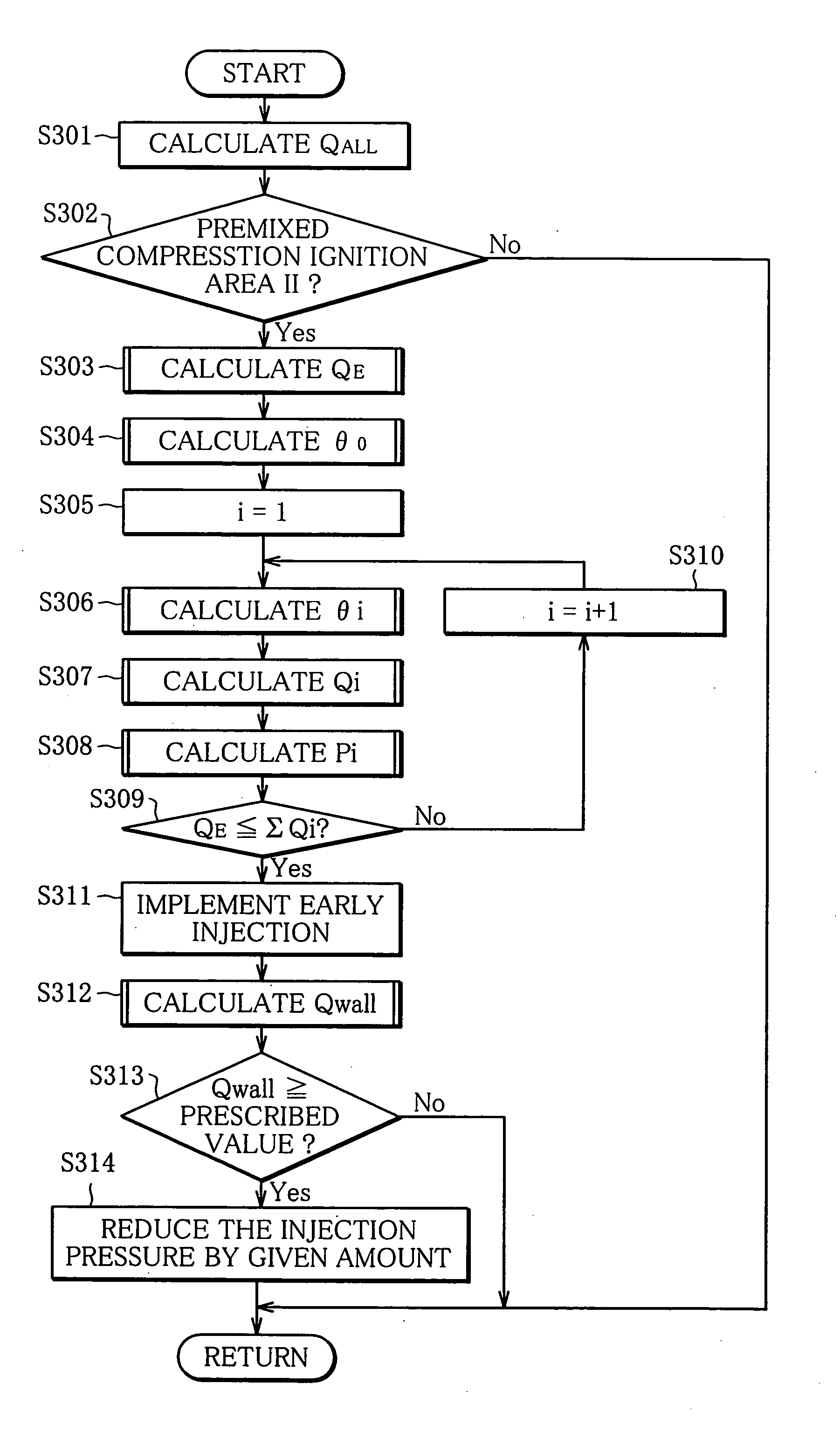

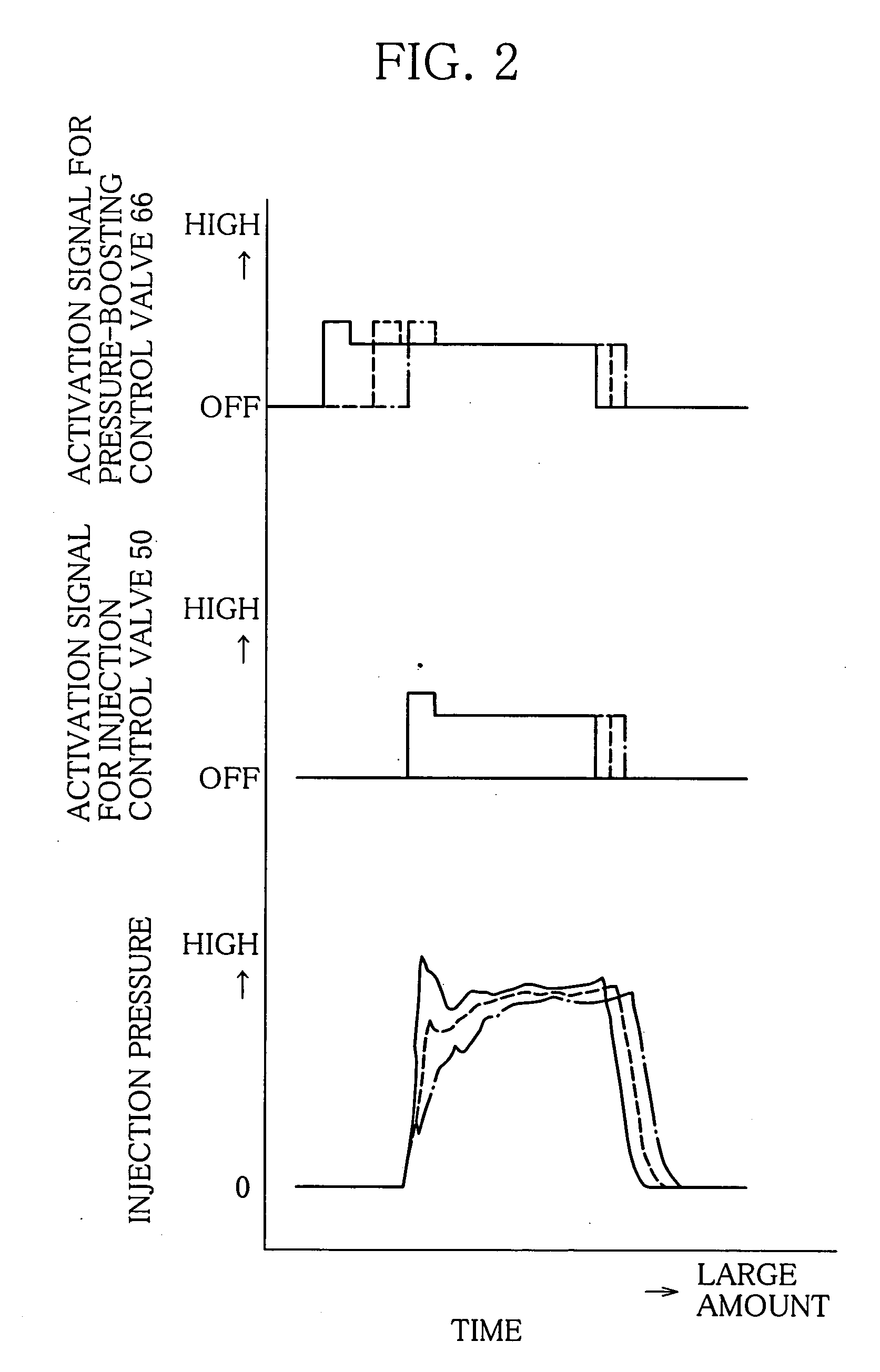

Control device for a diesel engine

InactiveUS20060219214A1Suppression of oil dilutionReduce smokeElectrical controlInternal combustion piston enginesTop dead centerInjection pressure

There are provided a diesel engine that injects fuel into air compressed in cylinders and combusts the fuel by spontaneous ignition, and a control unit that sets the fuel injection timing to an earlier time point than the compression top dead center to premix air and fuel and combusts the air-fuel mixture compressed in the cylinders by spontaneous ignition. The control unit injects the fuel to be injected in an early stage in a plurality of stages according to the operation state of the engine and individually adjusts the injection pressures of their respective stages according to the gas density and the gas temperature in the corresponding cylinder.

Owner:MITSUBISHI FUSO TRUCK AND BUS CORPORATION

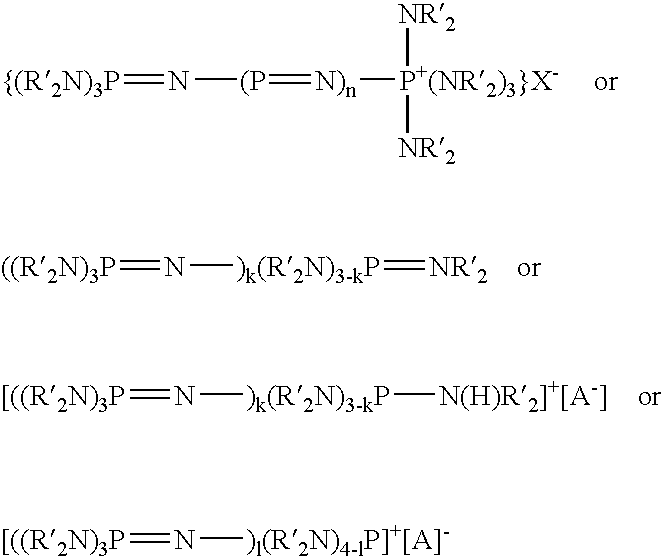

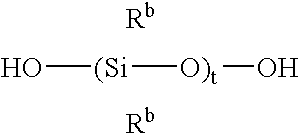

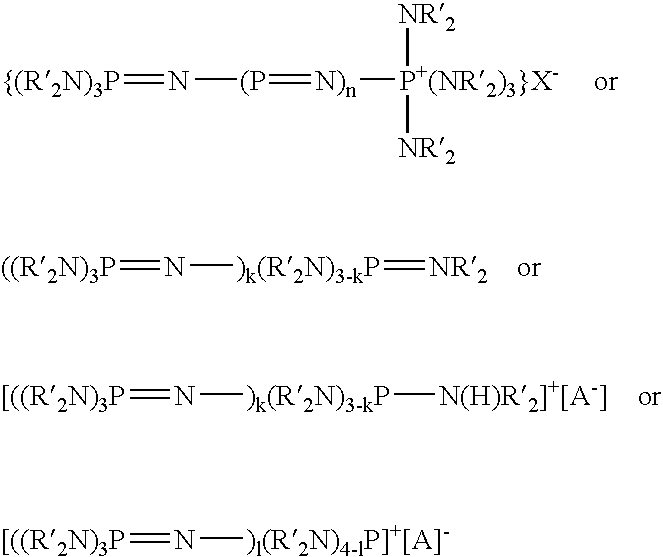

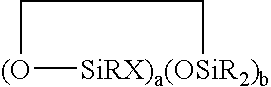

Silicone release coating compositions

InactiveUS20070167563A1Fast curingLower Level RequirementsPhosphorus organic compoundsCoatingsSiliconPlatinum group

A release coating composition according to the present invention comprises an alkenyl functional polysiloxane (1), a silicon hydride functional polysiloxane (11) and a catalyst (111) comprising a platinum group metal. The alkenyl functional polysiloxane (1) is an alkenylterminated polysiloxane prepared by siloxane polycondensation and / or equilibration using a phosphazene base catalyst followed by neutralisation with an acidic neutralising agent. The level of catalyst (III) in the composition can be as low as 2-40 parts per million platinum group metal by weight.

Owner:DOW CORNING CORP

Fire resistant paint, articles of manufacture, an apparatus for manufacture and a process for manufacture thereof

InactiveUS20130288031A1Reduce volatilityLow heat release rateFireproof paintsWater-setting substance layered productFlame spreadHeat resistance

A fire and heat resistant composition for providing or enhancing the fire resistance of a material. The composition consists of both chemical and physical integration. Physical application is a coating composition containing materials including a fire and heat resistance means, lower peak heat release means, lower heat released per unit time means, higher temperature gradient means, low flame spread means, high ignition delay means, low peak heat release means, low total heat release means, high thermal stability means, elastic and coating thickness encasement means and heat. Chemical applications consist of chemical additive which are naturally more fire safe.

Owner:L M J NATION SECURITY

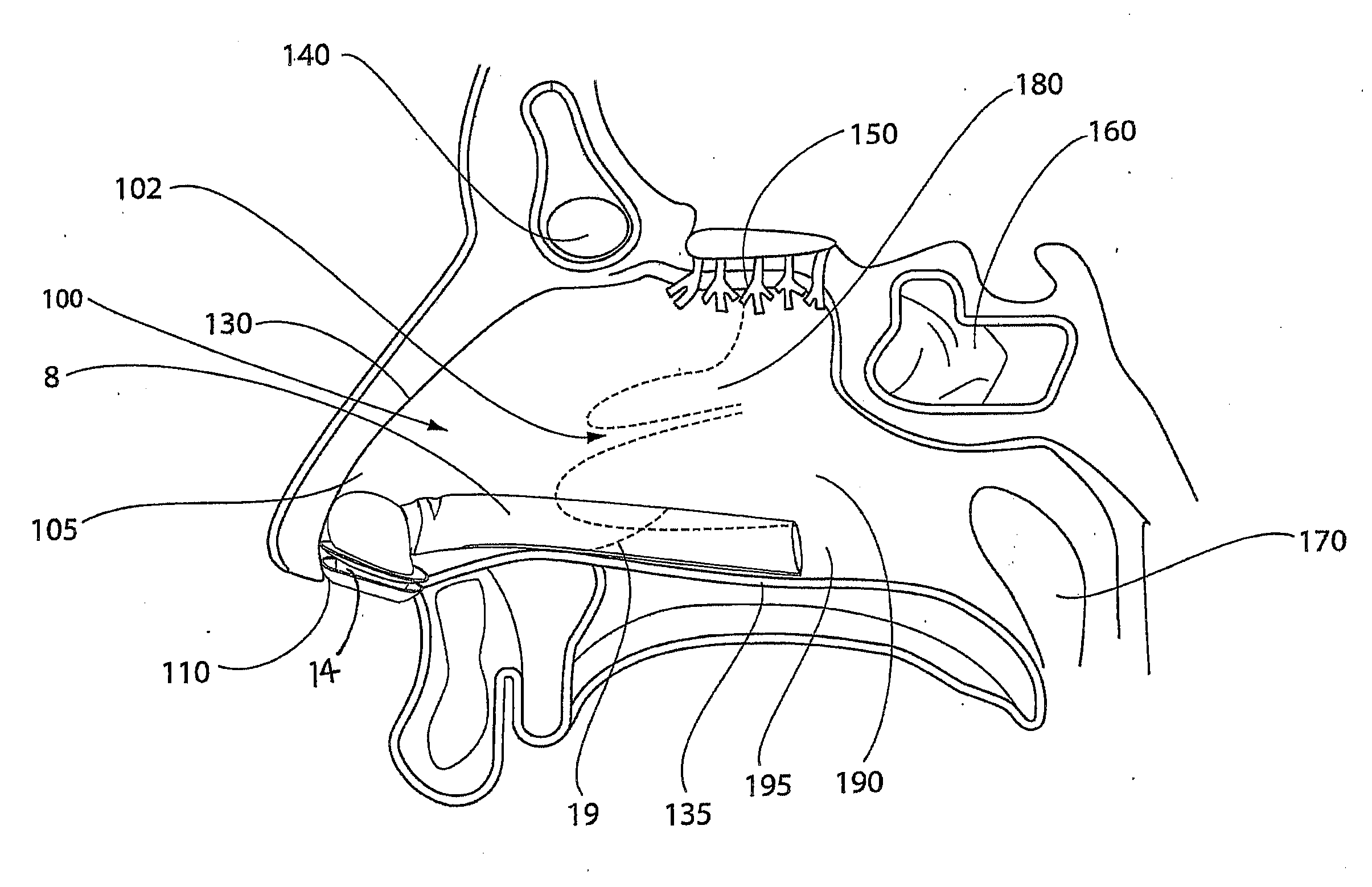

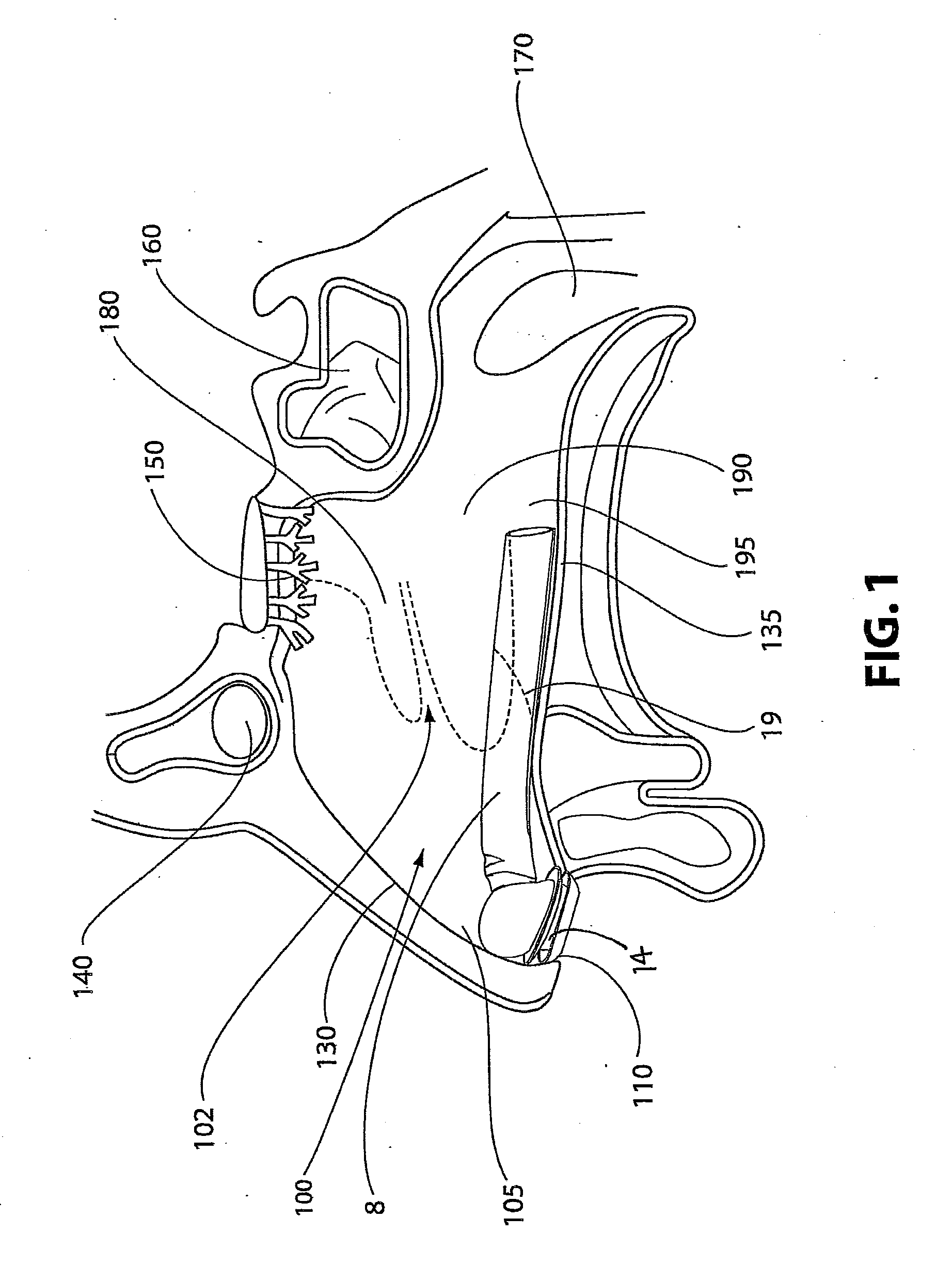

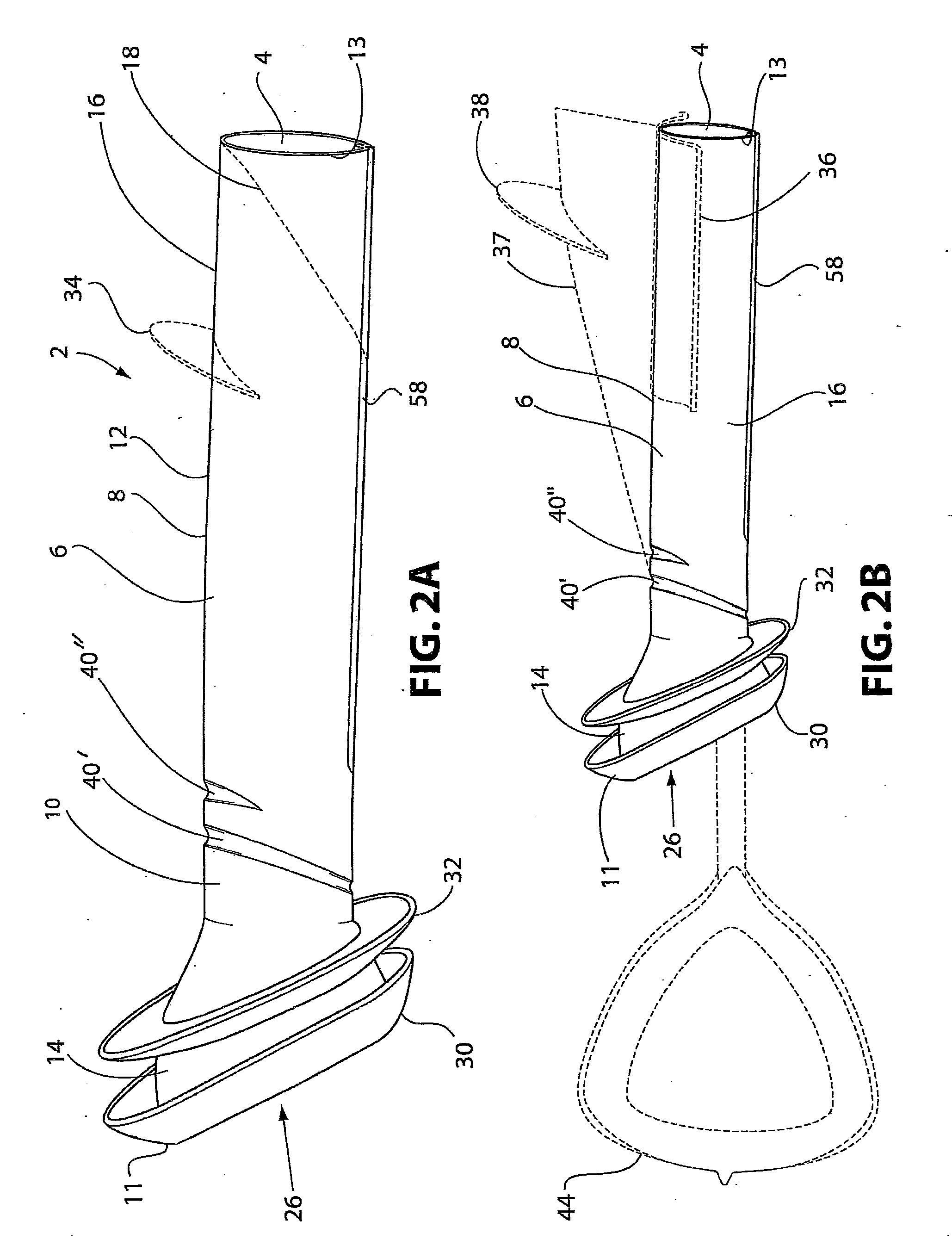

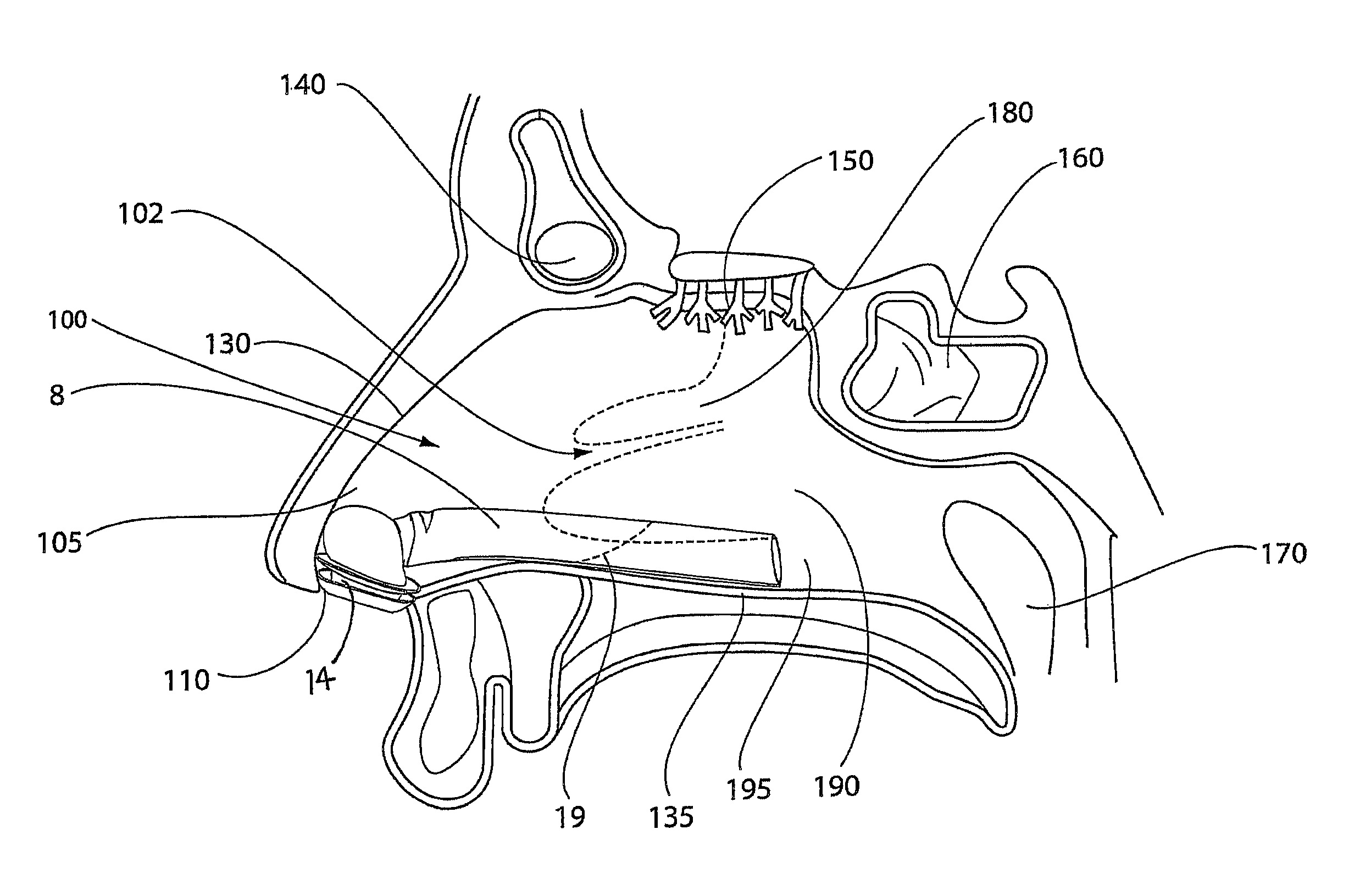

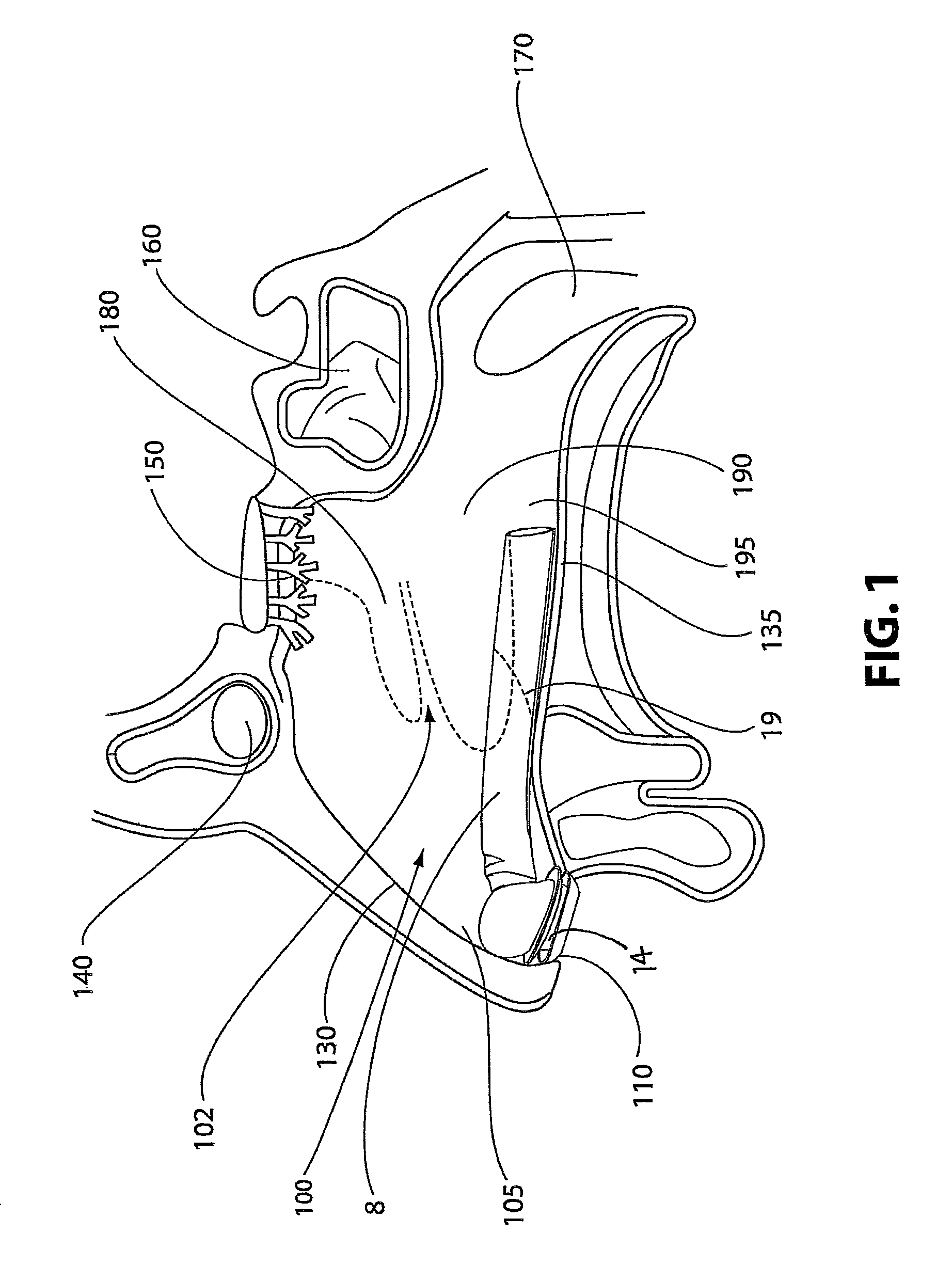

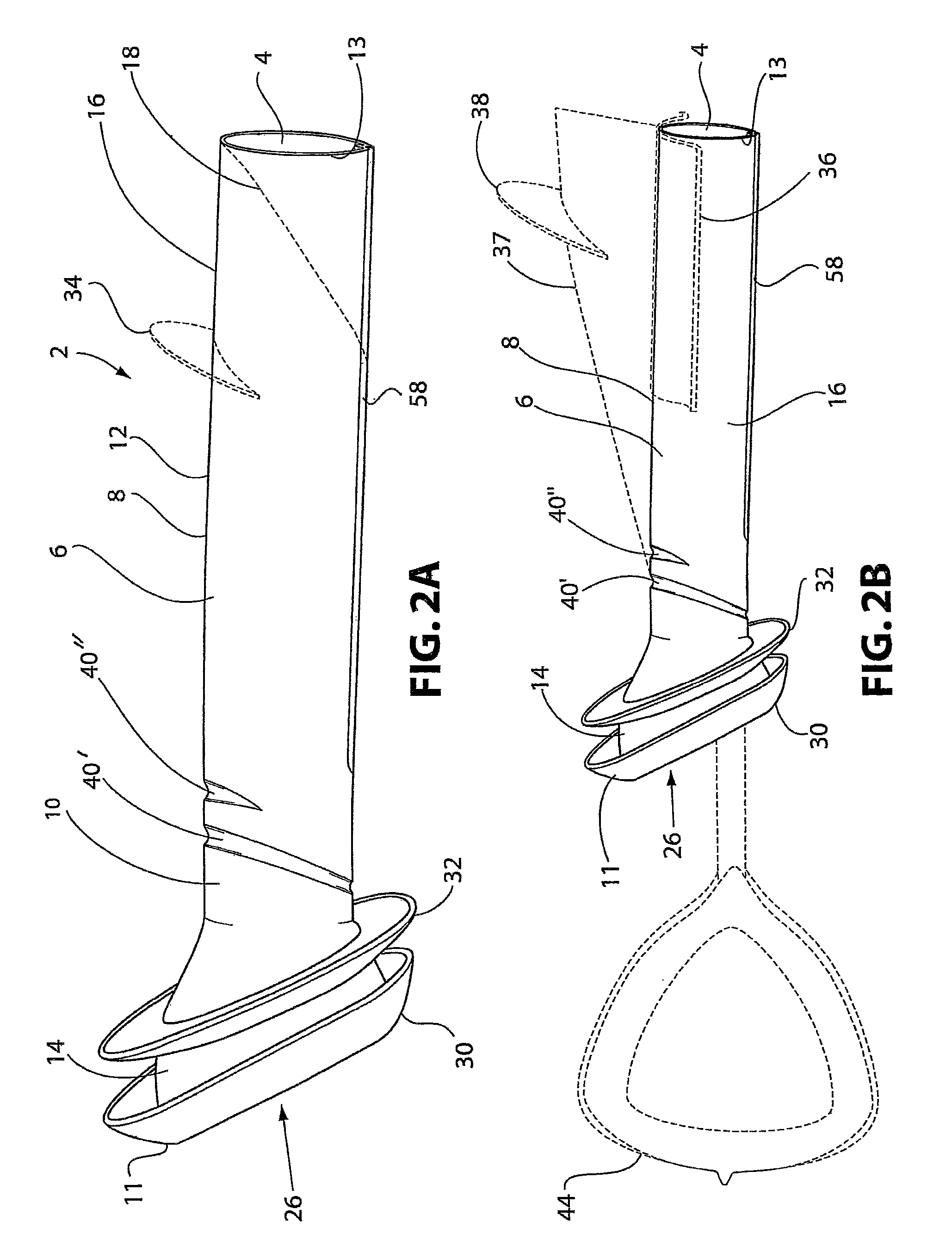

Nostril Inserts

ActiveUS20110048430A1Reducing and eliminating smokingReduce intensityTobacco devicesSnoring preventionNostrilNasal cavity

Methods of use of a nasal insert to support smoking cessation, and methods of use of a nasal insert to reduce or eliminate snoring, and a method of use of a nasal insert to reduce the severity or to eliminate obstructive sleep apnea, and a method of use of a nasal insert to gain smoother, easier breathing through the nose. The nasal insert comprises a body having an inner surface which defines an air passageway surrounded by an outer surface of soft, flexible material. The nasal insert body can have a first portion and a second portion where the outer surface of said nasal insert body is configured to the nasal cavity.

Owner:BECK ARNON ADVA

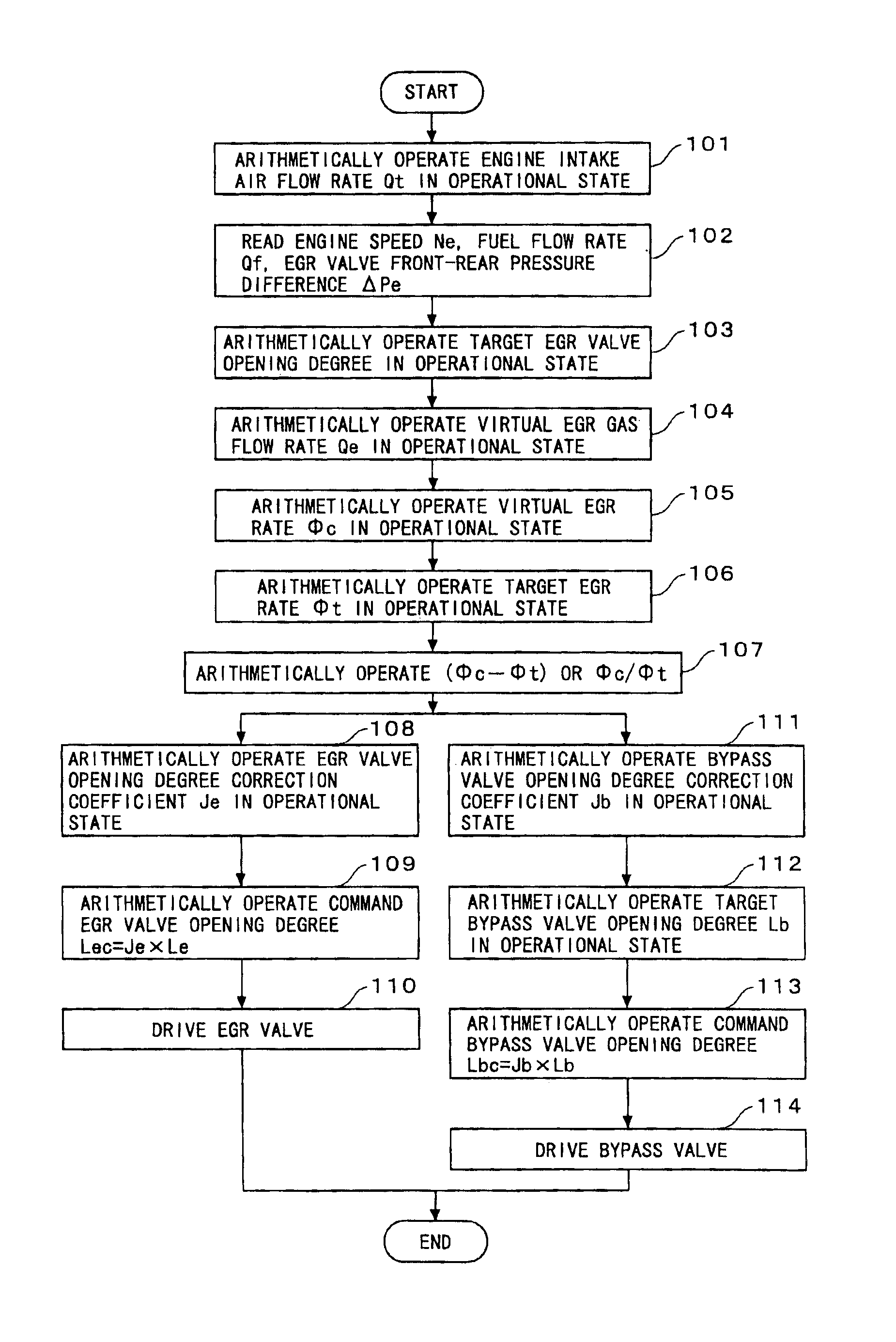

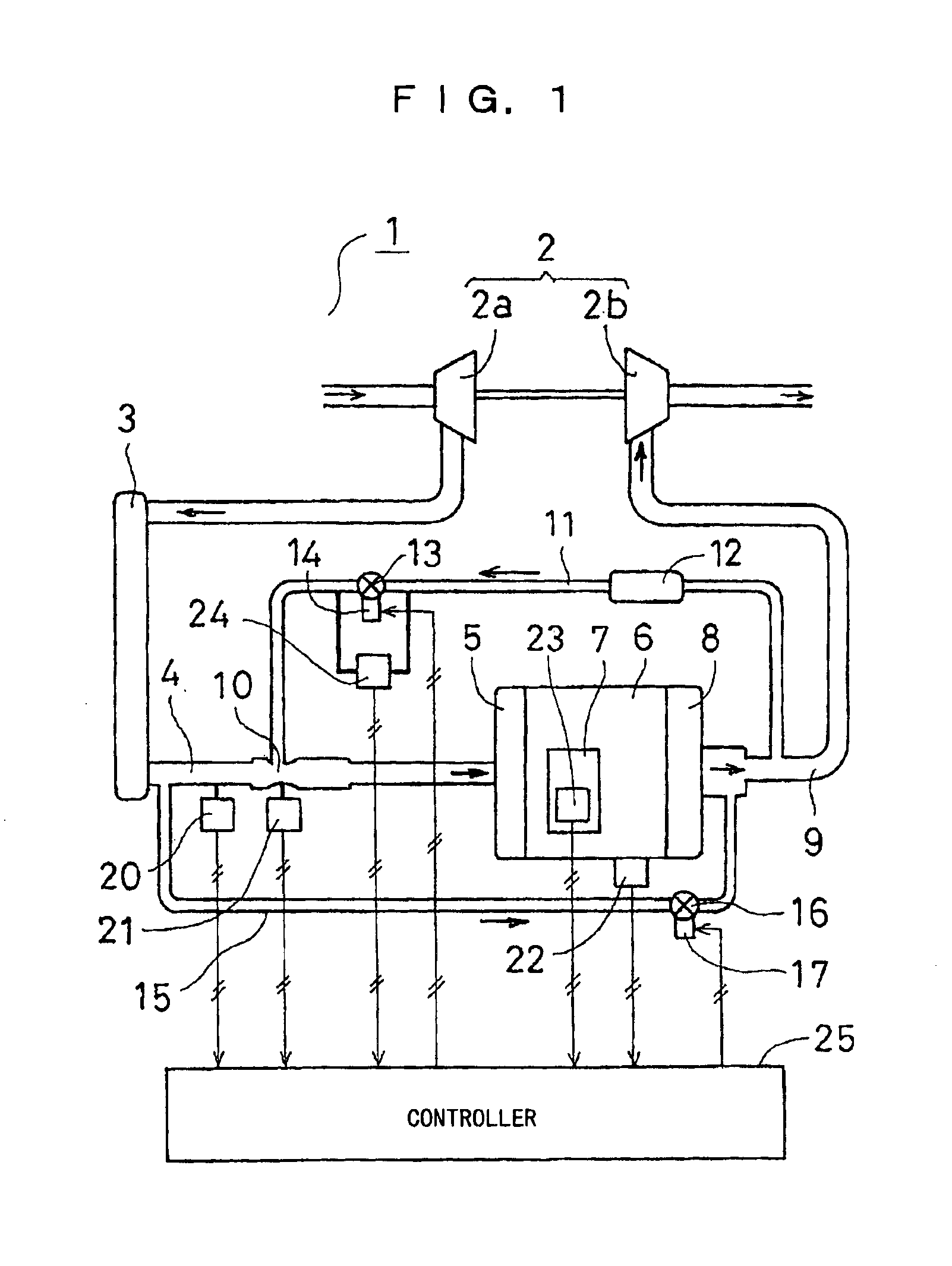

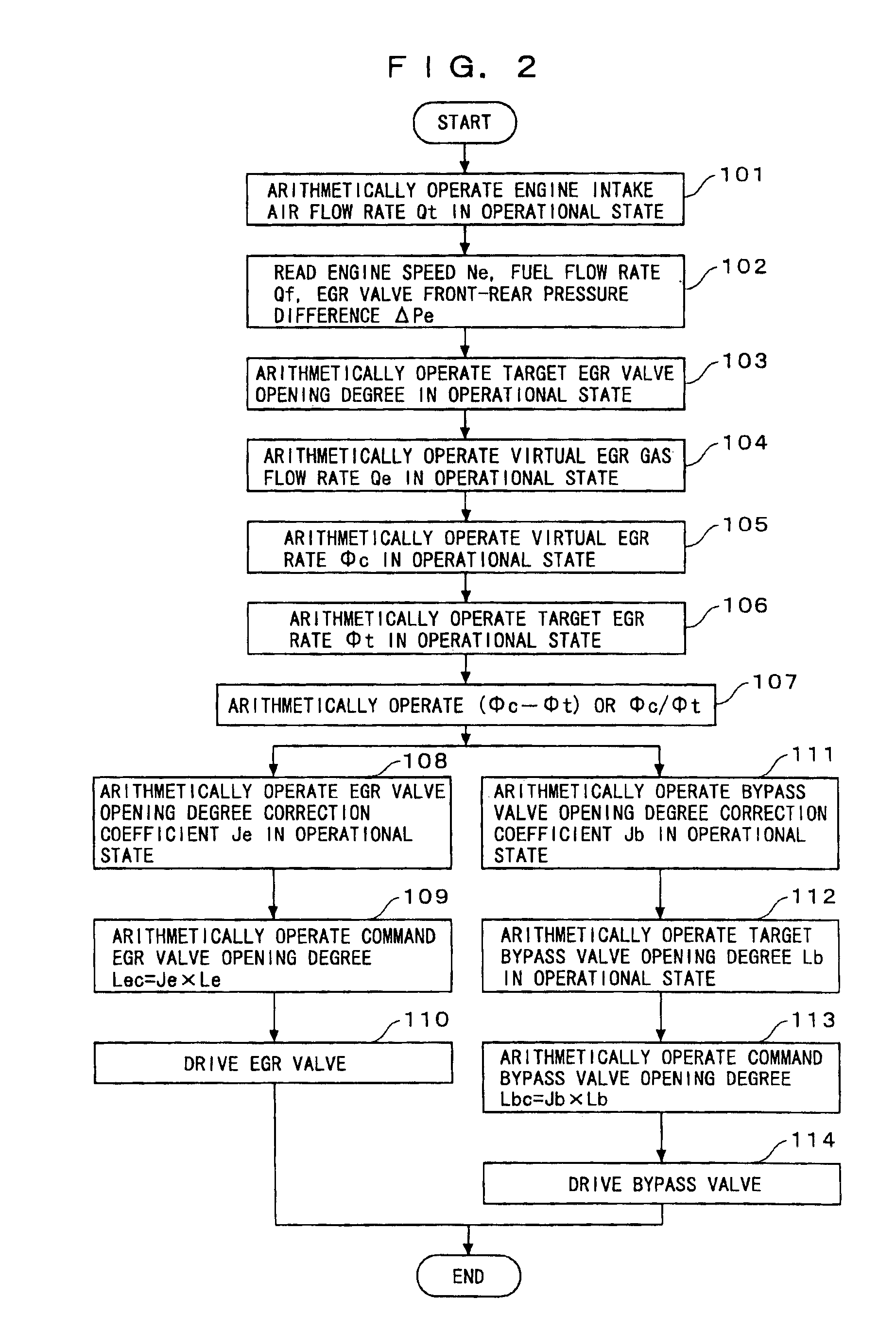

Control method of EGR system of engine

InactiveUS6868329B2Favorable controlPressure equalizationElectrical controlNon-fuel substance addition to fuelValve openingEngineering

A control method of an EGR system of an engine capable of effectively performing an EGR control at a time of rapid acceleration. For this purpose, an intake air flow rate of the engine is obtained, and from a target EGR valve opening degree and a difference in pressure in front of and behind the EGR valve, a virtual EGR gas flow rate is arithmetically operated. A virtual EGR rate is obtained from the intake air flow rate, the fuel flow rate and the virtual EGR gas flow rate, and a difference from or a ratio to a target EGR rate obtained from the engine speed and the fuel flow rate is obtained. A command EGR valve opening degree is obtained from an EGR valve opening degree correction coefficient obtained from the difference or the ratio, and the target EGR valve opening degree, whereby the EGR vale is driven.

Owner:KOMATSU LTD

Nasal inserts

ActiveUS8839790B2Reduce intensityReducing and eliminating smokingBreathing masksSnoring preventionNasal cavityNose

Methods of use of a nasal insert to support smoking cessation, and methods of use of a nasal insert to reduce or eliminate snoring, and a method of use of a nasal insert to reduce the severity or to eliminate obstructive sleep apnea, and a method of use of a nasal insert to gain smoother, easier breathing through the nose. The nasal insert comprises a body having an inner surface which defines an air passageway surrounded by an outer surface of soft, flexible material. The nasal insert body can have a first portion and a second portion where the outer surface of said nasal insert body is configured to the nasal cavity.

Owner:BECK ARNON ADVA

Intumescent fire retardant composition and method of manufacture thereof

InactiveUS20030158314A1Reduce smokeEasy to processFireproof paintsSpecial tyresGraphiteFire retardant

One embodiment of an intumescent composition comprises a halogenated polymer, antimony oxide, and intercalated graphite, while one embodiment of an intumescent additive mixture comprises antimony oxide and intercalated graphite. One embodiment of the method of making an intumescent composition comprises melt blending a halogenated polymer with antimony oxide, and intercalated graphite.

Owner:APTIV TECH LTD

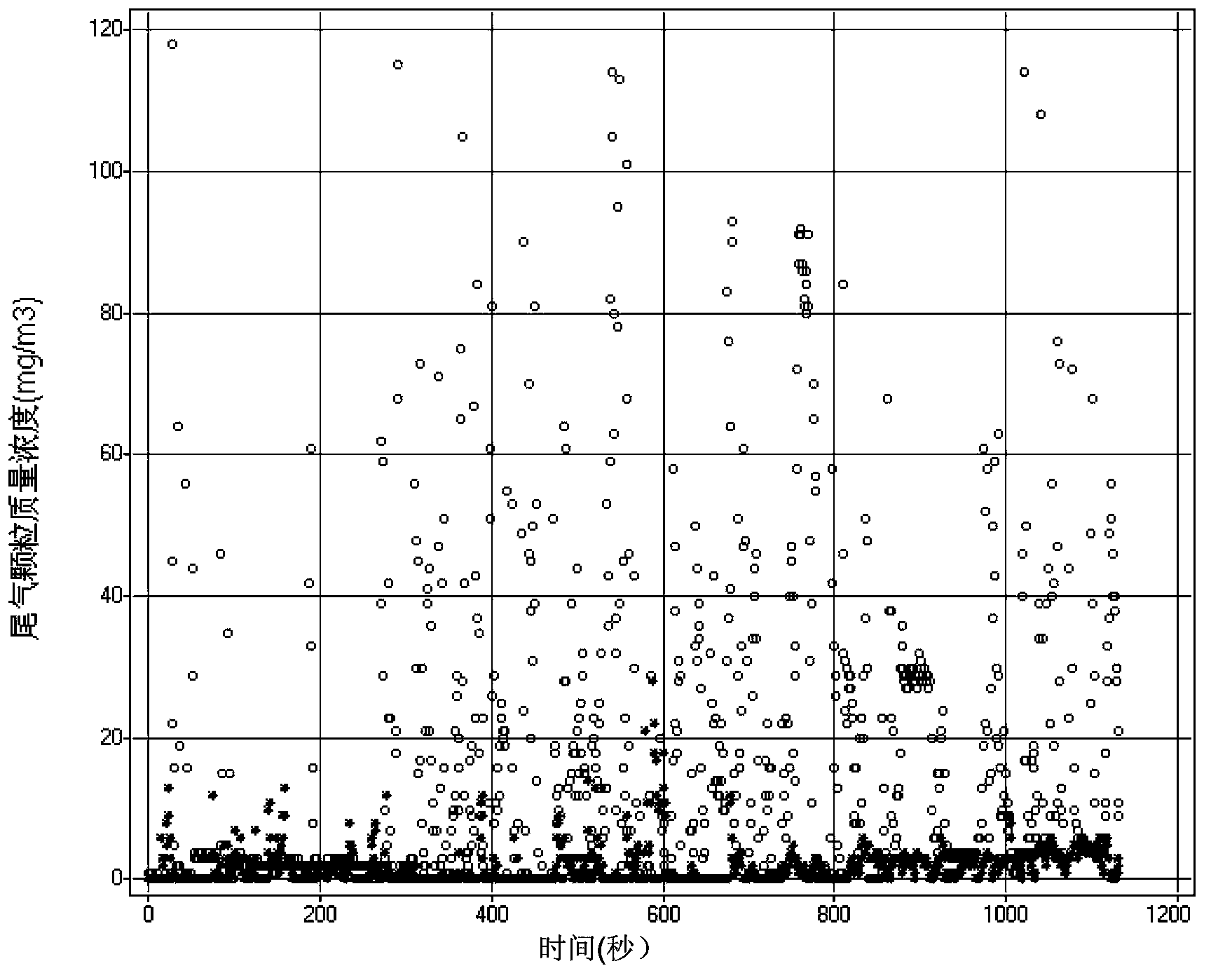

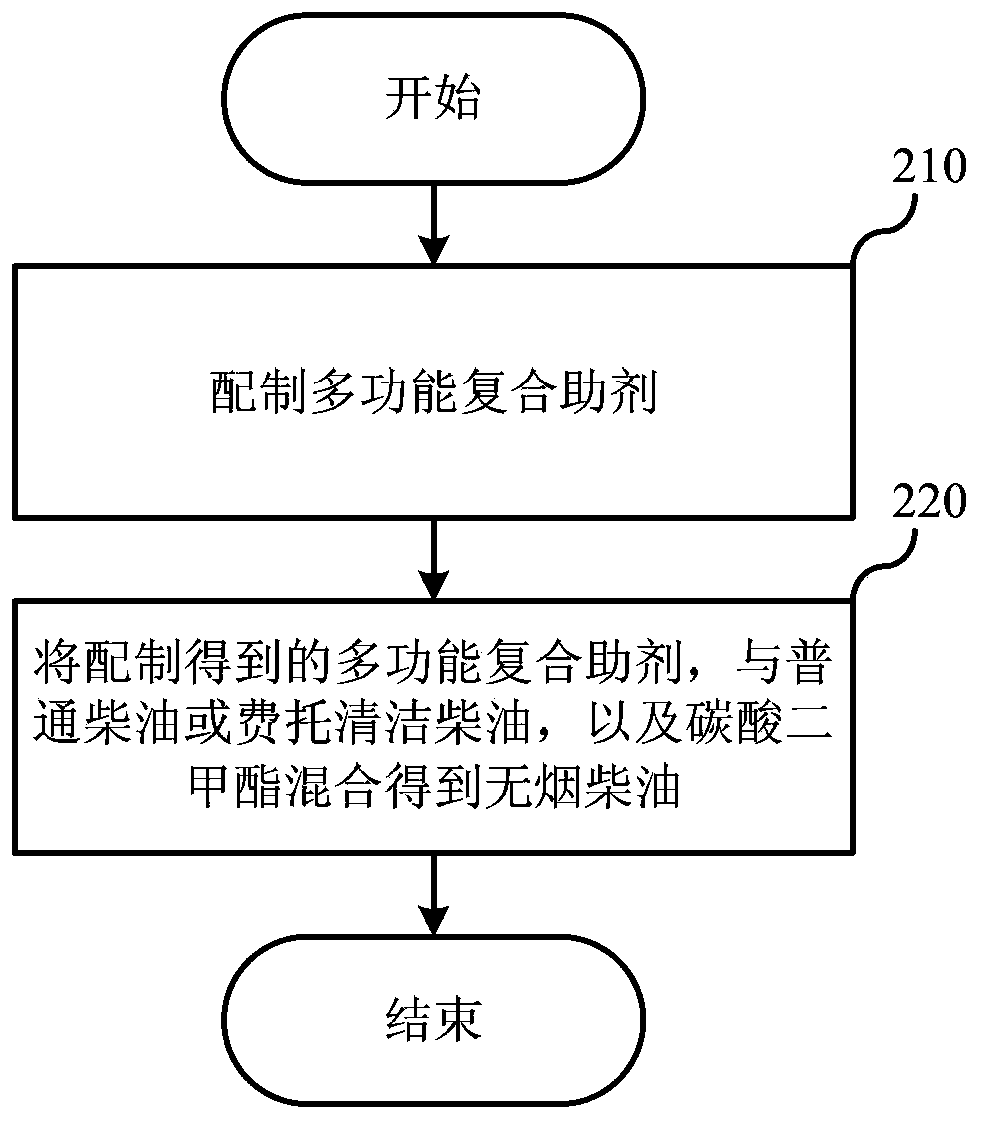

Smokeless diesel oil and preparation method thereof

ActiveCN103805297AEliminate emissionsImprove combustion effectLiquid carbonaceous fuelsParticulatesMethyl carbonate

The invention relates to the field of fuels, and discloses smokeless diesel oil and a preparation method thereof. The smokeless diesel oil comprises 70-95wt% of common diesel oil, 2-25wt% of dimethyl carbonate and 0-10wt% of a multifunctional compound additive. According to the smokeless diesel oil provided by the invention, particulate matter emission in the using process of means of conveyance (comprising various motor vehicles and ships) taking diesel oil as a fuel and machinery for engineering, mining and agriculture and forestry taking diesel engines as power can be greatly reduced or even eliminated without affecting other emission indexes. The smokeless diesel oil is clean and environment-friendly diesel oil, and is simple and convenient and feasible. The fuel system of the diesel engine needs not to be changed.

Owner:YASHENTECH CORP

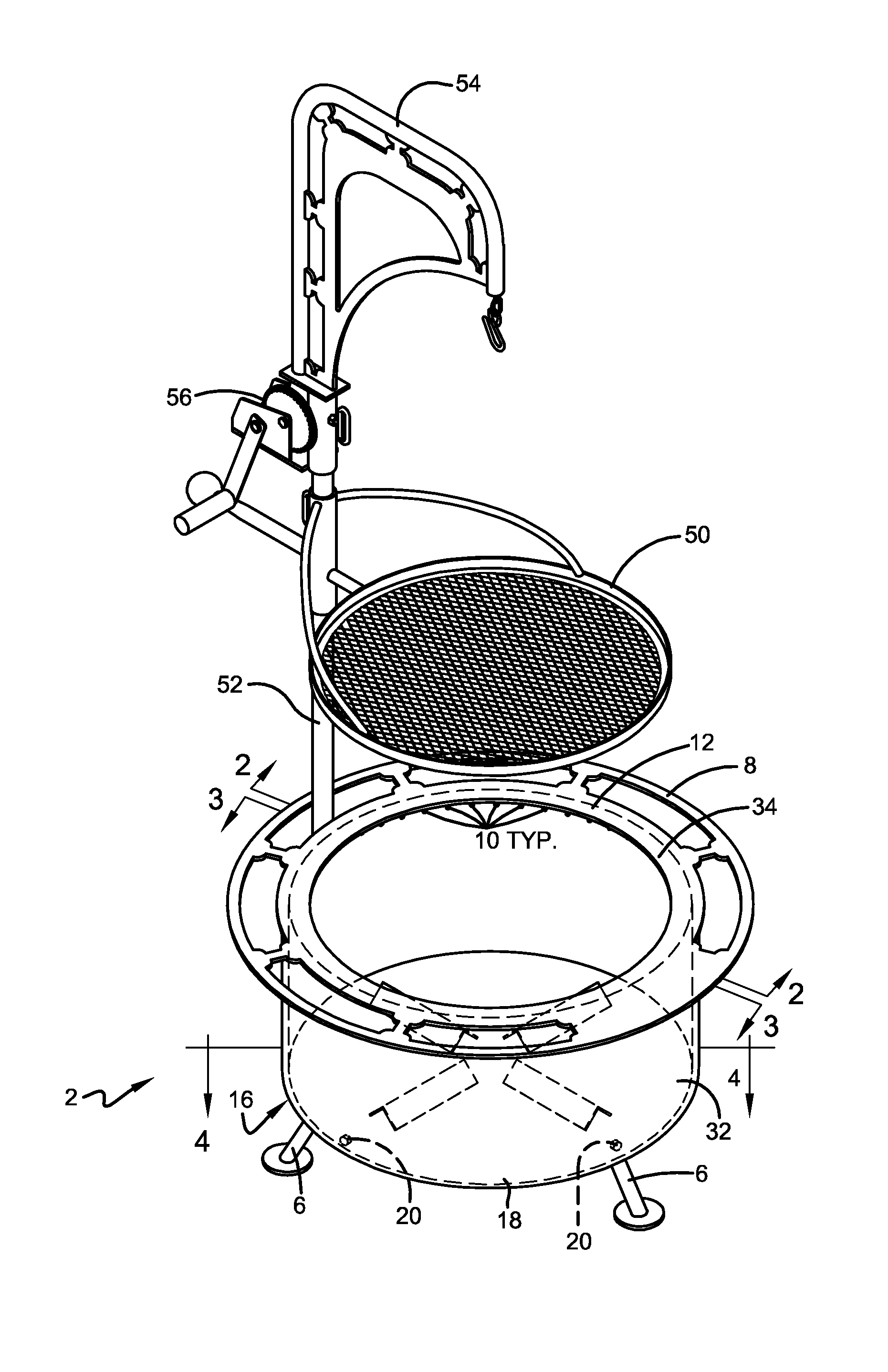

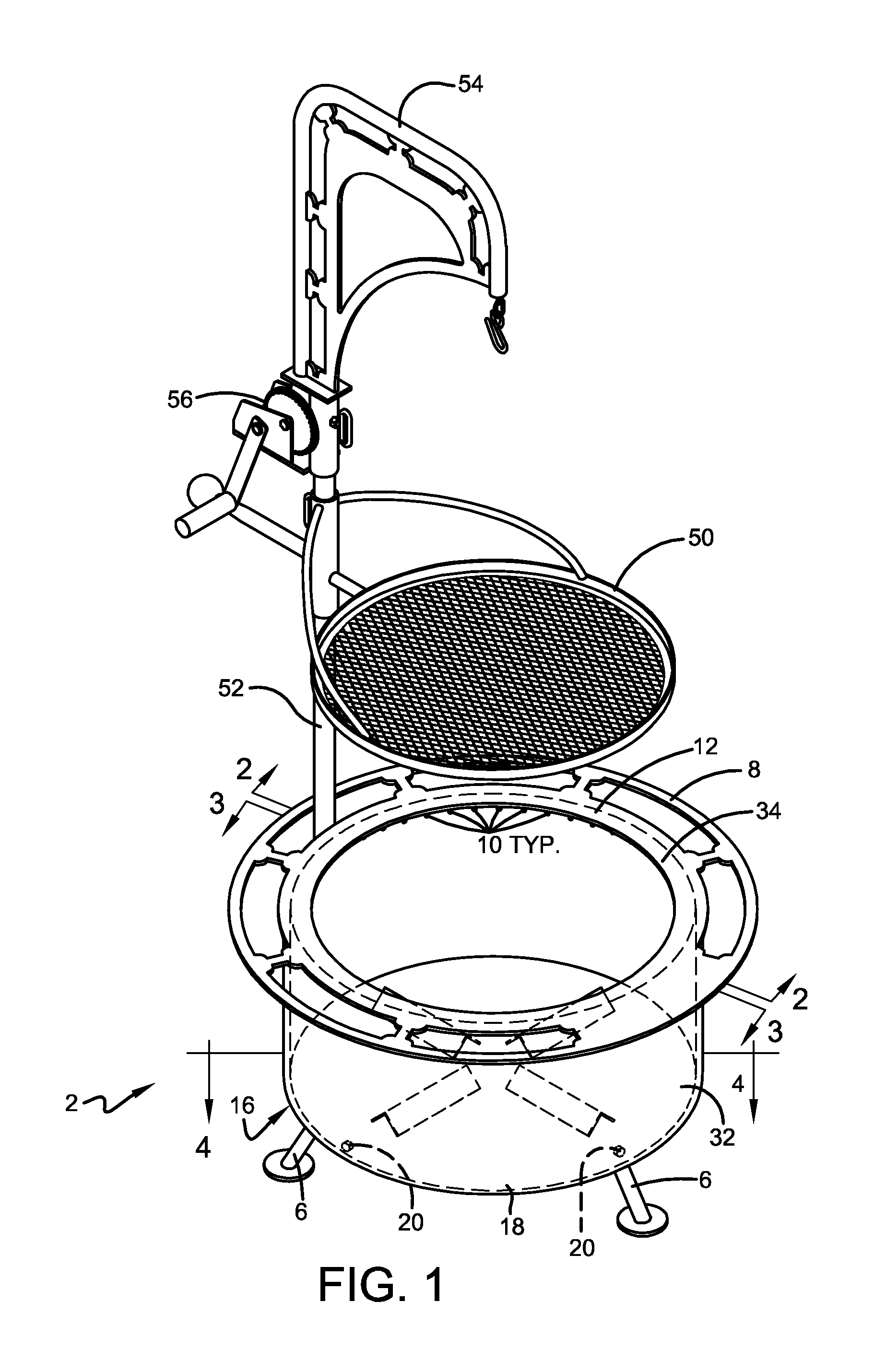

Reduced Smoke Outdoor Fire Burner

InactiveUS20150285507A1Reduce smokePromote combustionDomestic stoves or rangesLighting and heating apparatusCombustorEngineering

A device for containing a camp fire reduces the amount of smoke produced by the fire. The device reduces the amount of smoke by supplying air to the top of the fire to increase the combustion and thus reduce the smoke produced. In one configuration of the device, the air supplied to the top of the tire is heated prior to being introduced to the top of the fire. The disclosure also provides a configuration wherein the preheating of the air simultaneously cools the outer surface of the device.

Owner:TROYER JR DAN

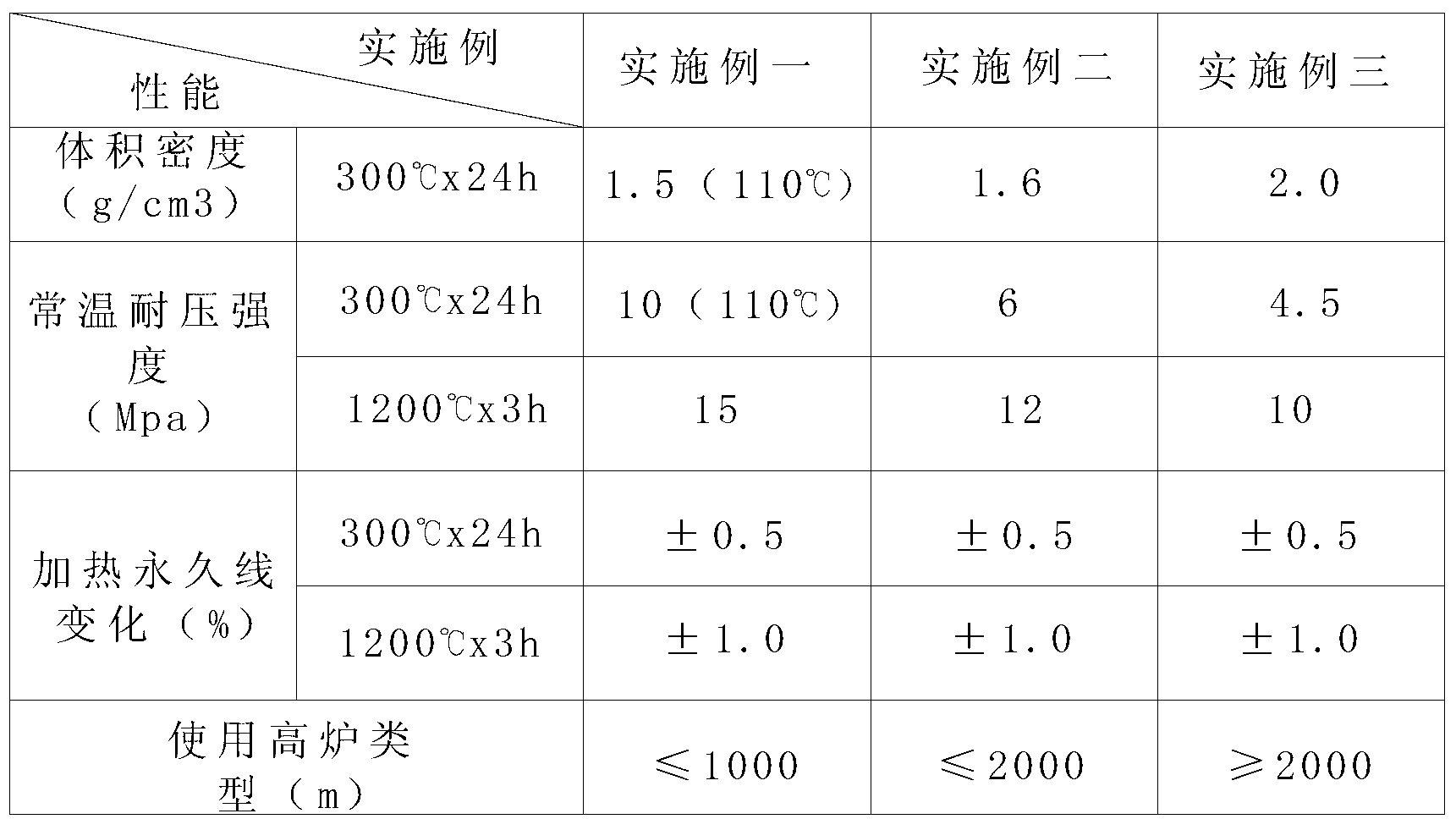

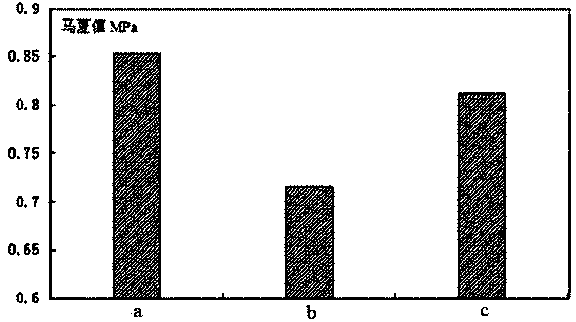

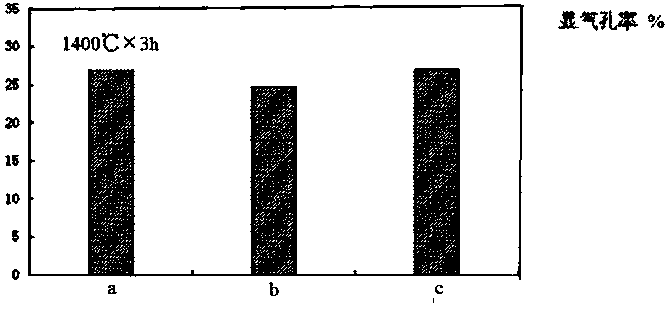

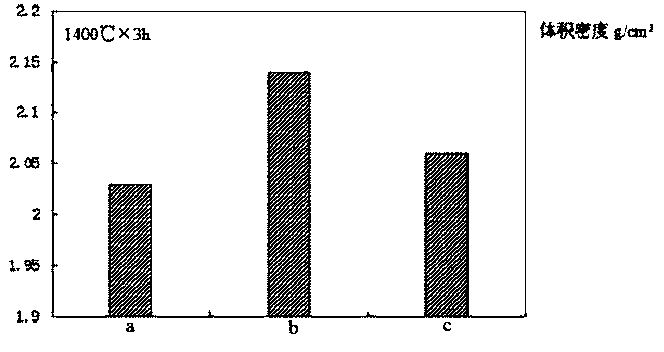

Novel stemming at tap hole

The invention discloses novel stemming at a tap hole. The stemming comprises the components in parts by weight as follows: 5-25 parts of corundum, 5-25 parts of high aluminum aggregate, 10-30 parts of silicon nitride combined with silicon carbide, 2-3 parts of silicon nitride iron, 5-15 parts of coke powder, 8-20 parts of clay, 1-5 parts of crystalline flake graphite, 5-10 parts of pyrophyllite, 4-7 parts of sericite, 5-10 parts of magnesium-aluminum spinelle, 2-4 parts of active alumina micro powder, 1-3 parts of metal powder and 15-20 parts of external composite binding agent. The composite binding agent comprises tar, modified phenolic resin and an organic solvent. The volume ratio of tar, modified phenolic resin to the organic solvent in the composite binding agent is 1:3:1. According to the invention, with the adoption of the composite binding agent formed by mixing tar and modified phenolic resin, smoke generated is less, the same plasticity to be combined with tar is met, the opening performance is good, the pressure resisting thermal shock resistance is good, and the adhesion strength is high. The depth of the tap hole can be prolonged and the furnace cylinder can be protected, the tapping time is prolonged, and the number of casts every day is reduced.

Owner:长兴云峰炉料有限公司

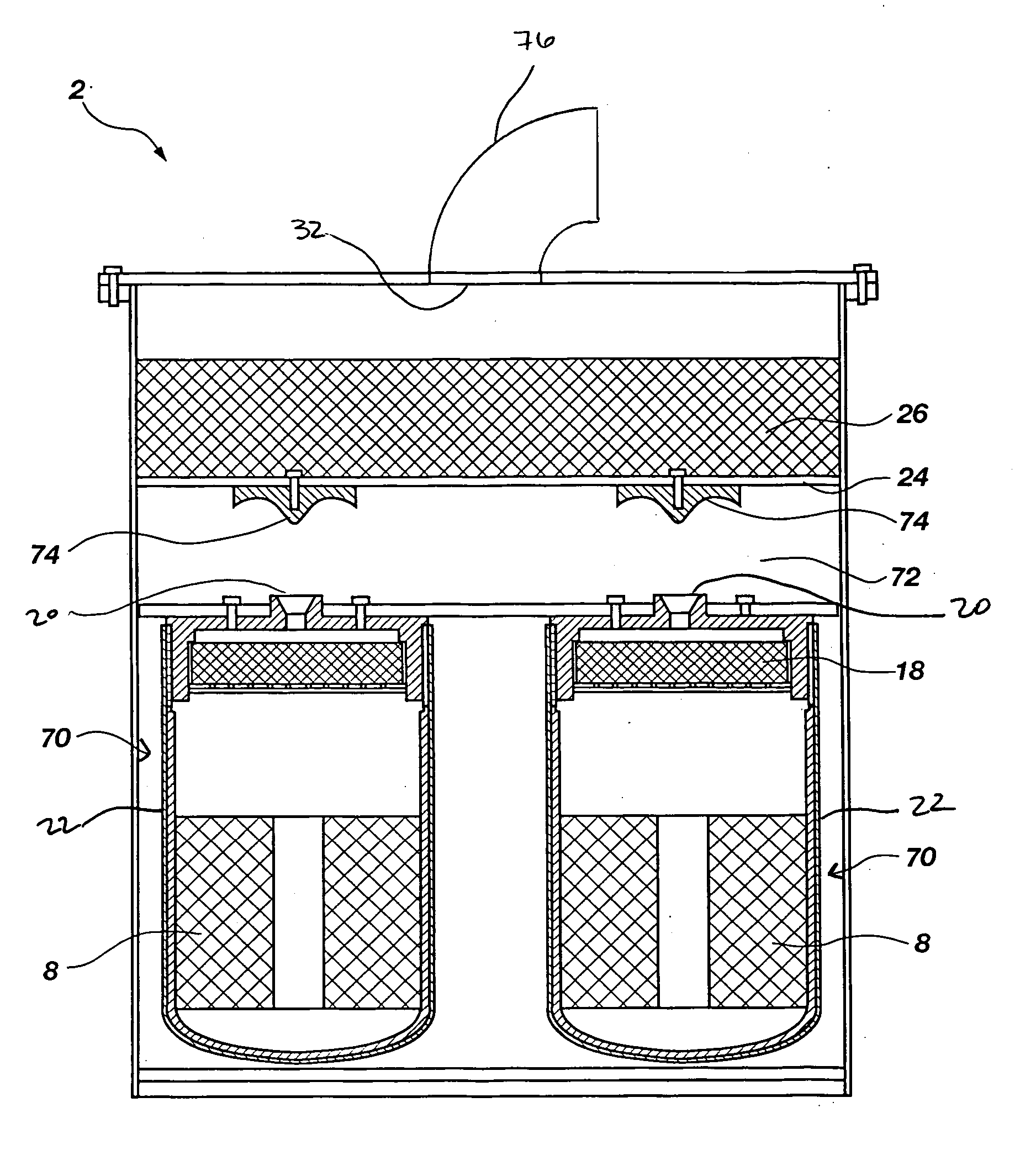

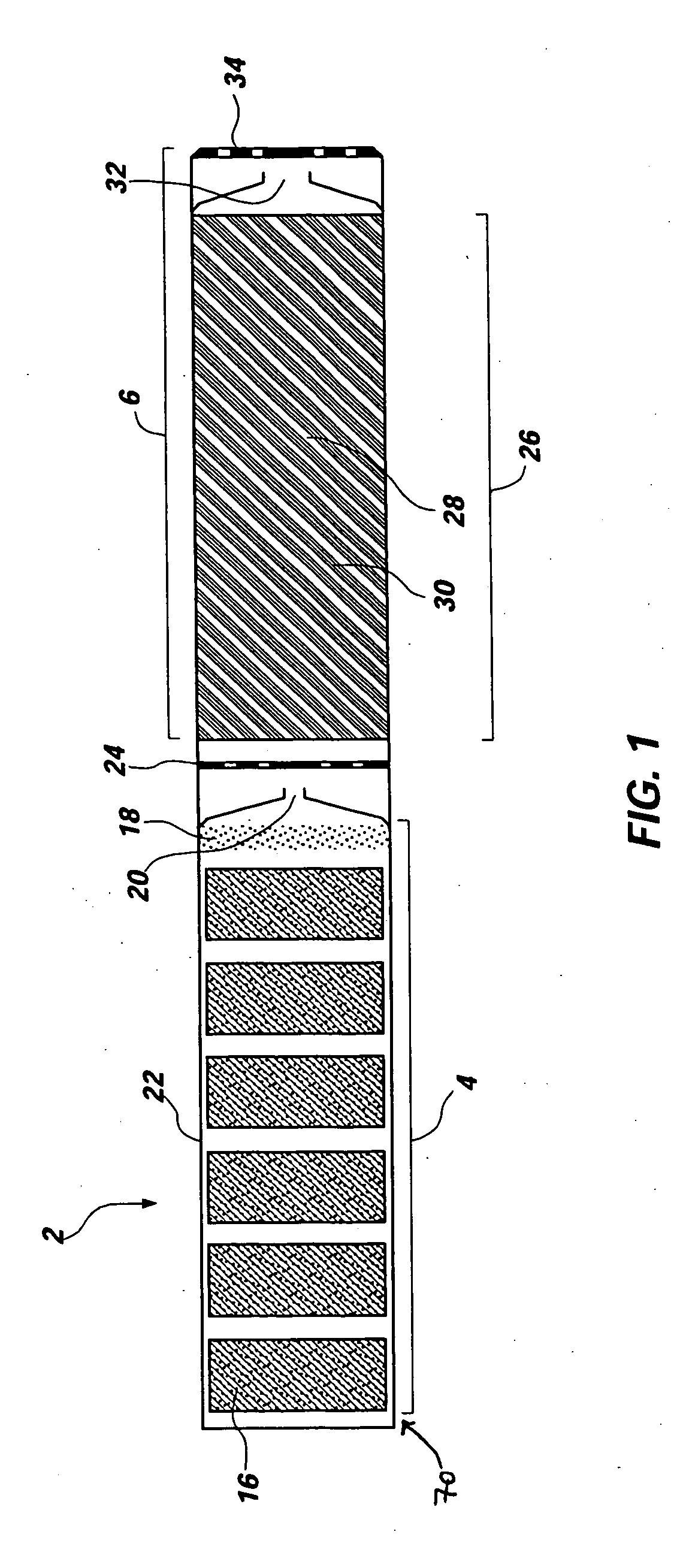

Man-rated fire suppression system and related methods

ActiveUS20060278409A1Reducing particulateReduce smokeFire rescueBoring toolsParticulatesThermal management system

A fire suppression system for producing an inert gas mixture having a minimal amount of carbon monoxide, particulates, or smoke. The inert gas mixture may be generated by combusting a gas generant. The gas generant may be a composition that includes hexa(ammine)-cobalt(III)-nitrate. The fire suppression system also includes a heat management system to reduce a temperature of the inert gas mixture. In one embodiment, the system includes multiple gas generators and is configured to ignite the respective gas generant of each gas generator in a predetermined, time based sequential order. For example, the gas generant of each gas generator may be ignited in a sequential order at specified time intervals. Methods of extinguishing fires are also disclosed.

Owner:NORTHROP GRUMMAN SYST CORP

Environment-friendly anhydrous tamping plug and preparation method thereof

The invention relates to an environment-friendly anhydrous tamping plug and a preparation method thereof and belongs to the field of fireproof materials. The environment-friendly anhydrous tamping plug comprises the following components by weight: 15-20 parts of coke, 22-43 parts of bauxite, 0-10 parts of brown aluminum oxide, 20-25 parts of silicon carbide, 0-8 parts of silicon nitride, 0-3 parts of silicon metal, 10-15 parts of clay, 3-6 parts of sericite and 15-20 parts of a binding agent, wherein the total parts of all materials, except for the binding agent, is 100 parts; the binding agent is composed of the following raw materials in parts by weight: 20-60 parts of carbon-containing resin, 20-50 parts of vegetable fat, 10-40 parts of linear phenolic resin and 5-10 parts of carbon powder. The environment-friendly anhydrous tamping plug has the following advantages of (1) being low in harmful substance content and harmless to a human body; (2) being free of smoke dust and hardly affecting the environment; (3) meeting the use requirements of flushing and casting operation of a blast furnace.

Owner:渑池金华新材料有限公司

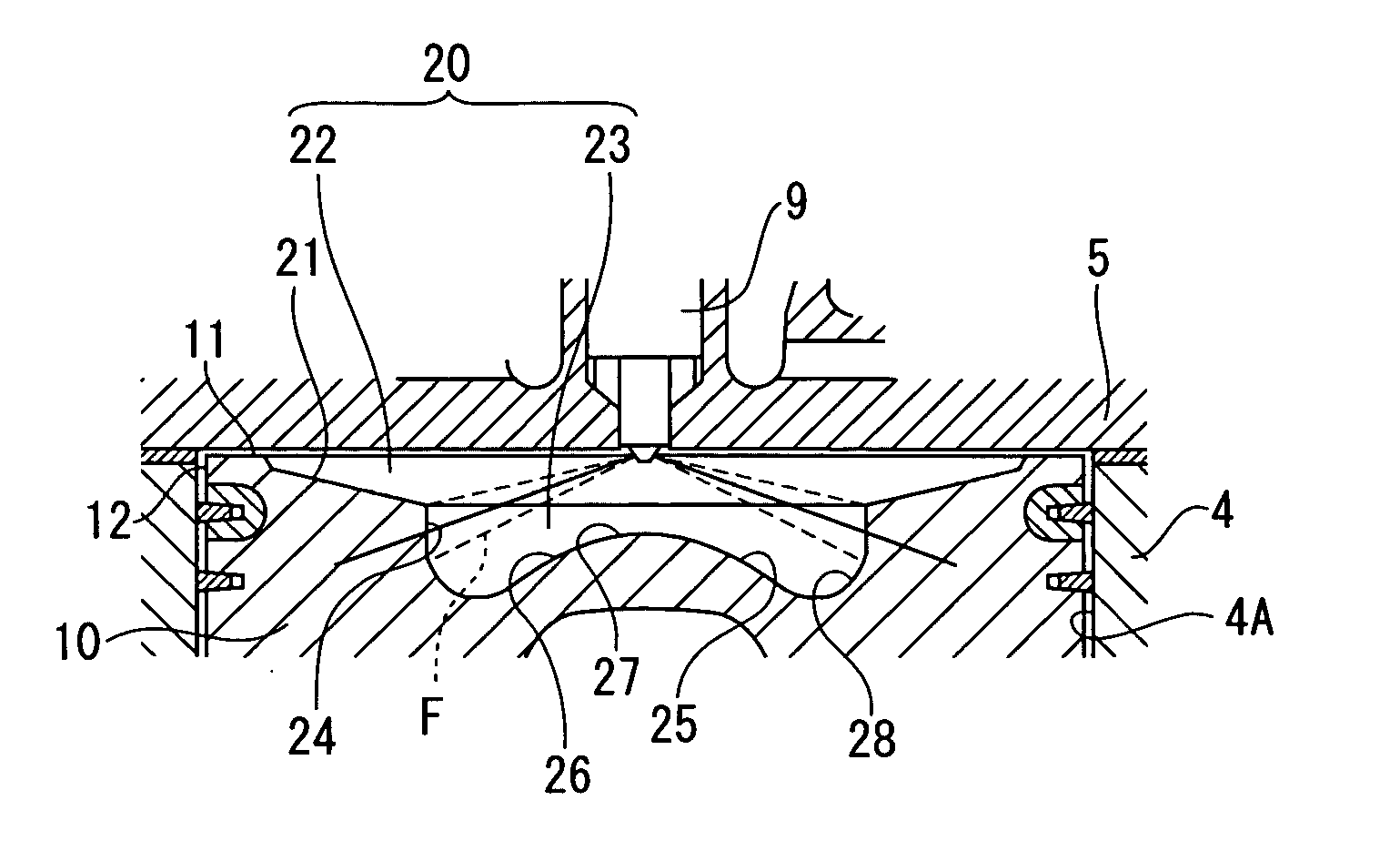

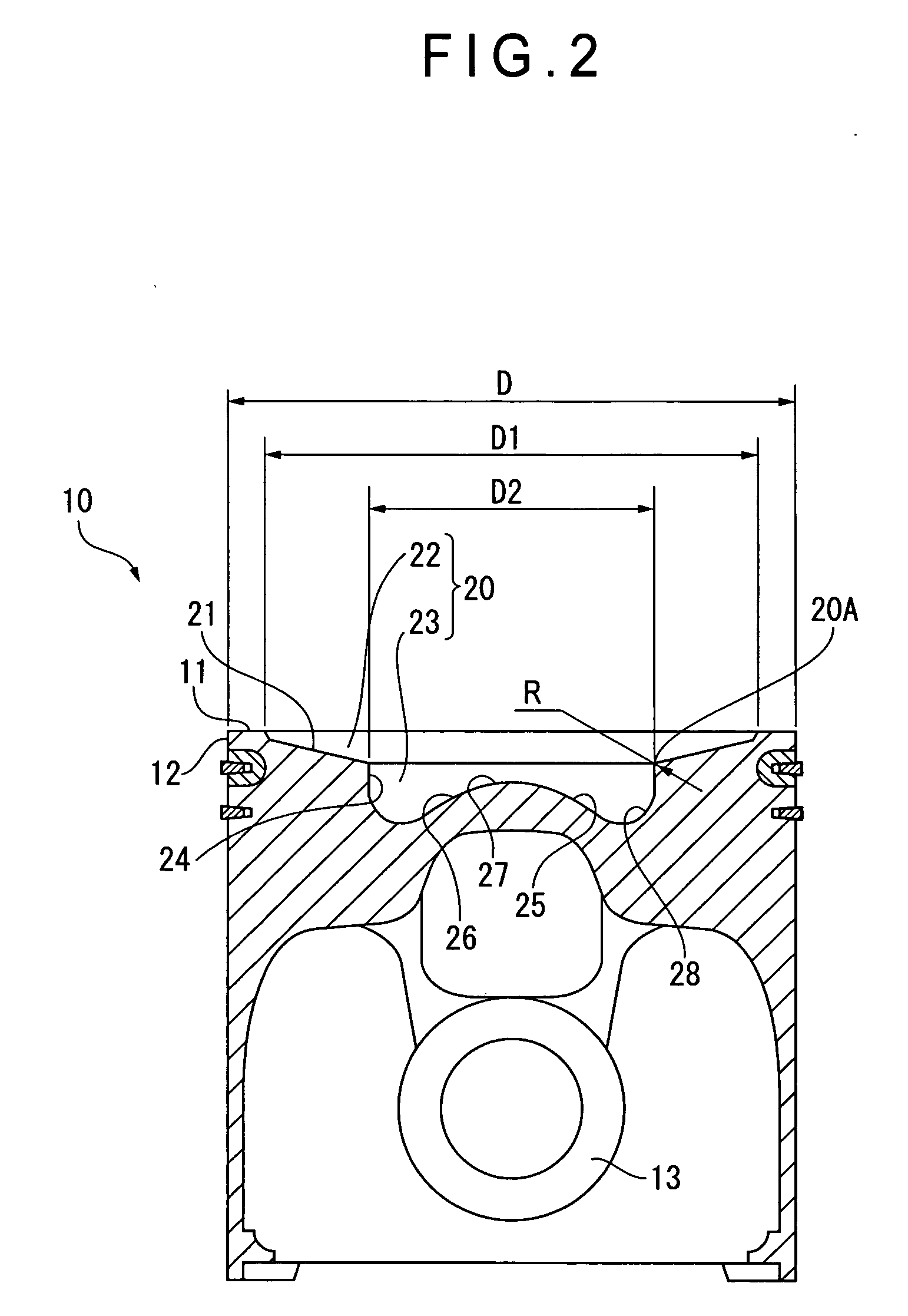

Direct injection diesel engine

ActiveUS20050115538A1Reduce smokeReduce fuel consumptionElectrical controlInternal combustion piston enginesCylinder headEngineering

A combustion chamber (20) opening toward a cylinder head (5) is provided on a top surface (11) of a piston (10), and this combustion chamber (20) comprises a first volume (22) having an inclined surface (20) and a second volume (23) further recessed from the first volume (22) toward a pin boss (13). Fuel spray F from a fuel injection nozzle (9) is injected toward an inner peripheral wall section (24) of the second volume (23) in a former stage of fuel injection and toward the inclined surface (21) of the first volume (22) in a later stage of fuel injection, and the percentage of the fuel injection period in the former stage against the total fuel injection period is set to the range from 40% to 70%.

Owner:KOMATSU LTD

Emulsion containing diesel oil, alcohol and water and its preparation method

InactiveCN1428405AImprove stabilityExtended shelf lifeLiquid carbonaceous fuelsEmulsionUltrasound - action

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

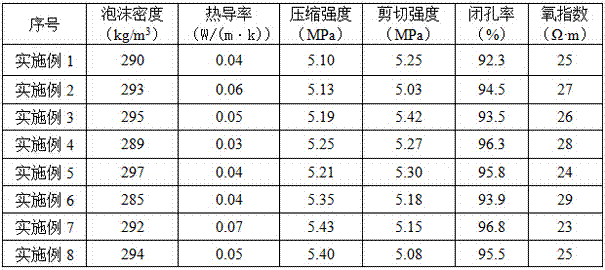

External wall thermal insulation material and preparation method thereof

InactiveCN105440657AImprove flame retardant performanceGood heat release rateFiberThermal insulation

The invention discloses an external wall thermal insulation material and a preparation method thereof. The external wall thermal insulation material is prepared from the following raw materials in parts by weight: 80-90 parts of methylene diphenyl diisocyanate, 65-75 parts of polyether polyol, 20-30 parts of straw fiber, 10-15 parts of glass fiber, 20-25 parts of organic nano-montmorillonite, 30-35 parts of flame retardant, 25-30 parts of smoke suppressor, 1-5 parts of reaction catalyst, 8-15 parts of crosslinking catalyst, 1-5 parts of coupling agent, 15-25 parts of deionized water and 1.5-5 parts of foam stabilizer. The prepared external wall thermal insulation material has the advantages of good fireproof property, high thermal insulation property, high wear resistance, high stability, high physical and mechanical properties, low cost and saving of energy.

Owner:NANYANG INST OF TECH

Silicone release coating compositions

InactiveUS7592412B2Fast curingIncrease speedPhosphorus organic compoundsCoatingsSiliconPlatinum group

Owner:DOW CORNING CORP

Environment-friendly converter bedding-face repairing material and preparation method thereof

The invention discloses an environment-friendly converter bedding-face repairing material and a preparation method thereof. The repairing material comprises the following ingredients by weight percent: 30 to 65 percent of sintering magnesium sand, 10 to 45 percent of waste magnesite-chrome bricks, 1 to 10 percent of asphalt powder, 5 to 15 percent of tar, 1 to 5 percent of ethanol, 1 to 5 percent of N-methyl-2-pyrrolidinone and 0 to 5 percent of o-xylene. The preparation method comprises the following steps: 1) pre-crushing the sorted sintering magnesium sand and recycled waste magnesite-chrome bricks; 2) uniformly mixing the pre-crushed sintering magnesium sand and waste magnesite-chrome bricks to obtain a mixed coarse material; 3) finely crushing the mixed coarse material to obtain a mixed fine material; 4) uniformly mixing the mixed fine material and asphalt powder in a stirring machine; 5) adding tar, ethernol, N-methyl-2-pyrrolidinone and o-xylene, and stirring the mixture for 10 to 25 minutes. The practices prove that the converter repairing material has good mobility, can be sintered easily, has long service life and generates little smoke when sintered.

Owner:武汉钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com