Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

848 results about "Pyrophyllite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pyrophyllite is a phyllosilicate mineral composed of aluminium silicate hydroxide: Al₂Si₄O₁₀(OH)₂. It occurs in two forms (habits): crystalline folia and compact masses; distinct crystals are not known.

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

Bleed hole stemming and method for producing the same

ActiveCN101219900AGood sintered strengthEasy to openBlast furnace componentsBlast furnace detailsPyrophylliteGraphite

The invention relates to a stemming at a taphole; the weight percentages of the components are the following: 20 to 40 of corundum, 10 to 20 of silicon carbide, 3 to 10 of silicon nitride, 10 to 23 of coke powders, 1 to 5 of graphite powders, 3 to 10 of sericite, 1 to 5 of active alumina micropowders, 5 to 15 of clay, 5 to 10 of pyrophyllite, 1 to 3 of metal powders, and +15 to 25 of water-free binder. The stemming adds a plurality of materials with plasticity and good cohesiveness to cause the stemming to easily block the hole and fill interspaces, with good binding performance of new stemming and old stemming; materials with medium and high temperature expansion are added to reduce the size of the stemming contraction at high temperature, and cracks can be avoided; materials with sintering function within different temperature areas are added, so the stemming has good sintering strength in different temperature scopes; materials with high-temperature resistance and good erosion resistance are added, and thus the stemming has high strength at high temperature, washing resistance and erosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

Special high-property coating for chemical equipment

InactiveCN104946082AIncrease viscosityIncrease crosslink densityFireproof paintsEpoxy resin coatingsPyrophylliteMelamine phosphate

The invention discloses a special high-property coating for chemical equipment. The special high-property coating comprises the following raw materials: novolac epoxy resin, phosphorus-containing acrylic resin, boric acid modified organic silicon resin, polytetrafluoroethylene resin, polyvinylidene fluoride, a carbon nano tube, ammonium polyphosphate, pentaerythritol, alumina powder, pyrophyllite powder, graphite, expanded perlite, modified attapulgite, cerium oxide, n-butyl alcohol, n-amyl alcohol, ethanediol, water, amine resin, melamine polyphosphate, N-phenyl-N'-cyclohexyl p-phenylene diamine, dodecanol, dipropylene glycol mono butyl ether, dimethyl phthalate, a coupling agent and an auxiliary agent. The special high-property coating for the chemical equipment, which is disclosed by the invention, has the advantages of good corrosion resistance and high-temperature resistance, high adhesive power and excellent flame-retardant property, can be used for the chemical equipment, is difficult to desquamate, good in protection effect and capable of prolonging the service life of the chemical equipment.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Water-based paint for iron casting through lost foam casting die

InactiveCN102921880AHigh temperature strengthSuitable for high temperature breathabilityFoundry mouldsFoundry coresSODIUM METAPHOSPHATECellulose

The invention discloses a water-based paint for an iron casting through a lost foam casting die. The paint comprises refractory aggregate, binders, a suspending agent, additives and a dispersing agent, wherein the refractory aggregate comprises high aluminum powder, zircon powder and pyrophyllite; the binders comprise silica sol or white emulsion, polyvinyl acetate emulsion, bentonite and sodium hexametaphosphate; the suspending agent comprises sodium carboxymethylcellulose; the additives comprise Tween, octanol, sodium carbonate, cryolite and iron oxide powder; and the dispersing agent is water. According to the paint, suitable ingredients are chosen, the content is adjusted, a suitable mixing process is adopted, and therefore performances such as normal temperature and high-temperature strength, suitable high-temperature permeability and good leveling property, suspension property and painting performance of a coating can be satisfied completely. The paint is suitable for gray iron castings with different trademarks and enables the expendable casting die to be stripped with the iron casting easily, particularly for stripping in flakiness of a sintered coating during cleaning, and the possibilities for diverse defect generation on the surface of the iron casting are reduced; and simultaneously, pollution of coating components to the environment is reduced greatly due to the selection of phosphate assistant.

Owner:XUZHOU PENGJU SNAPDRAGON ARTS & CRAFTS

Thin porcelain brick and production method thereof

The invention relates to a thin porcelain brick and a production method thereof, wherein the production method comprises the following steps: 1. mixing blank raw materials comprising 4.5 to 5 percent of ball clay, 5 to 6 percent of black mud, 6 to 8 percent of Yichun kaolin, 6 to 10 percent of Beihai kaolin, 6 to 13 percent of Dehua pyrophyllite, 4 to 10 percent of Paishan pyrophyllite, 12 to 16 percent of sodium-potassium feldspar powder, 12 to 15 percent of weathered potassium feldspar, 8 to 15 percent of superfine pottery stone, 8 to 16 percent of sodium-potassium feldspar, 5.5 to 6 percent of Zhuji porcelain sand and 0.8 to 1.3 percent of lignin and lignin derivative; 2. adding water accounting for 50 to 60 percent of the weight of a powder material, 0 to 0.1 percent of polymethyl cellulose sodium (CMC) and 0.1 to 1 percent of sodium tripolyphosphate (STPP), putting into a ball mill, and controlling the ball milling fineness to have 0.5 to 1 percent of sieve residue through a 325-mesh sieve; 3. preparing the powder material containing 5 to 7 percent of water through iron removal, sieving and spray drying of the obtained mud; 4. ageing the powder material for 24 hours, then molding through pressing, and drying at the temperature of 150 to 200 DEG C to enable the water content of a blank to be below 0.3 percent; and 5. placing into a kiln for sintering, wherein the early period time of sintering is 6 to 15 minutes, the high temperature time is 15 to 30 minutes ,and the cooling time is 5 to 10 minutes. In the invention, the thin porcelain brick can be produced under the condition of traditional process equipment, and each item of performance index reaches or exceeds a porcelain brick standard GB / T4100-2006.

Owner:DEQING NABEL CERAMIC

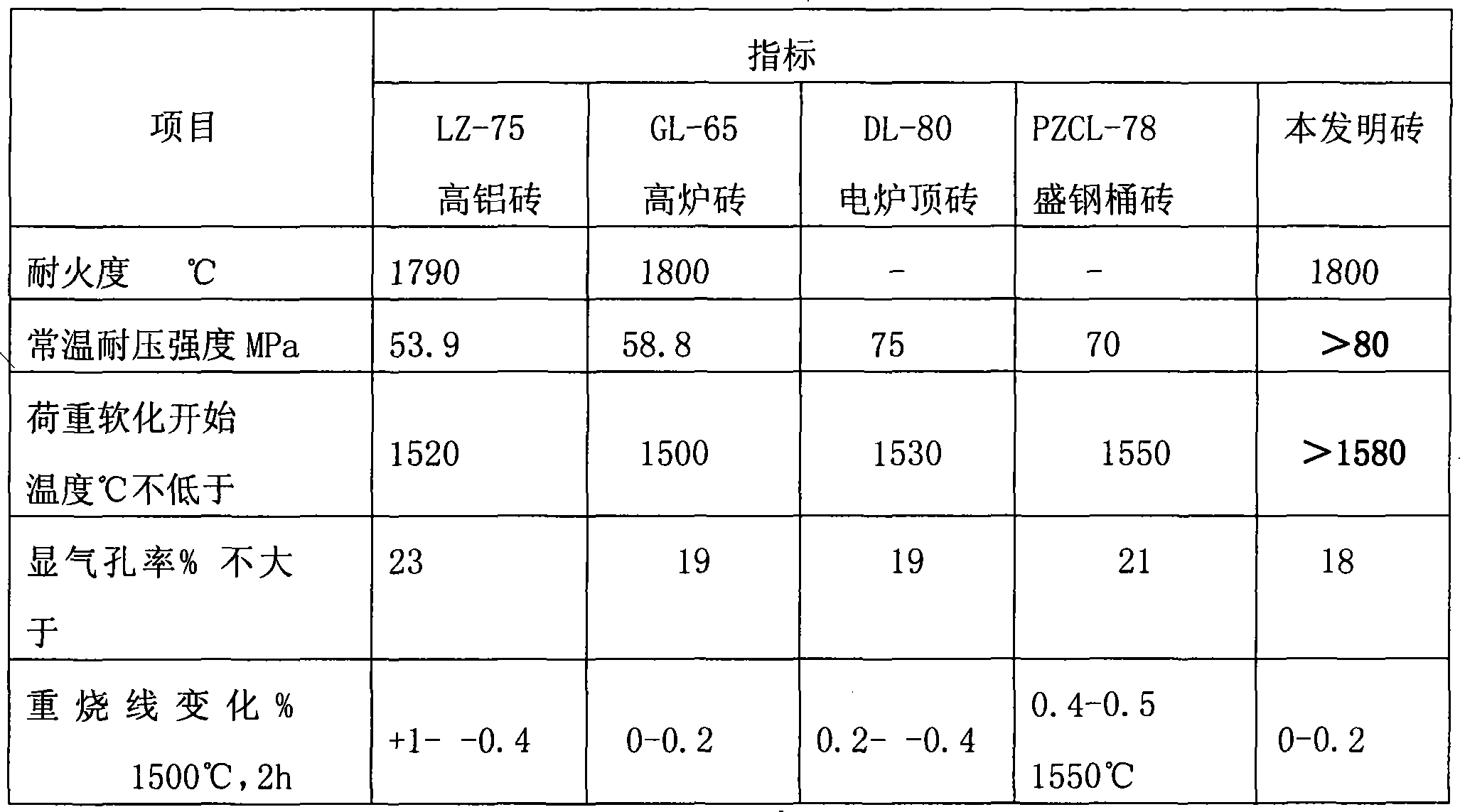

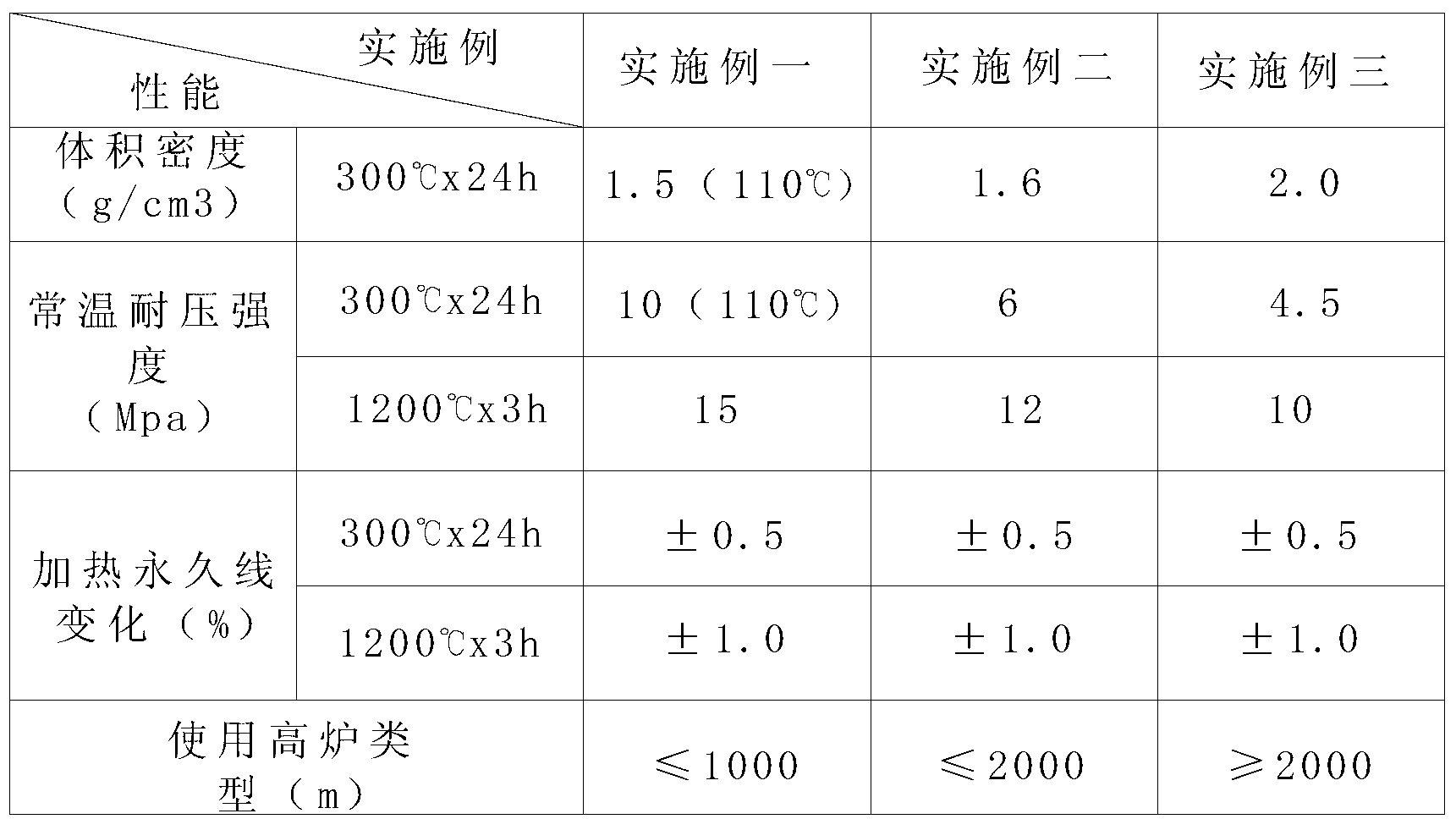

Low-temperature burning high-aluminum refractory brick and preparation method thereof

The present invention provides a low-temperature braking high-aluminum refractory brick and the preparing method thereof, and the invention is characterized in that the refractory brick is prepared by the following main raw material and bonding agent; wherein: the main material comprises the raw material with the following weight proportion: wherein the bauxite chamotte with granularity 3-0.088mm for 50-70%, bauxite chamotte with granularity less than 0.088 for 7-20%, emery with granularity less than 0.088 for 5-20%, dry powder shaped pyrophyllite for 2-10%, and dry powder shaped refractory clay for 5-20%; and the adding amount of the bonding agent is 10-20% of the weight of the raw material. The high-alumina brick is obtained using the low ore grade bauxite chamotte with low temperature 1250-1350 DEG C, and the high-quality refractory brick has the advantages of: ordinary-temperature compressive strength above 80MPa, and the load softening staring temperature above 1580 DEG C.

Owner:巩义市金岭耐火材料有限公司

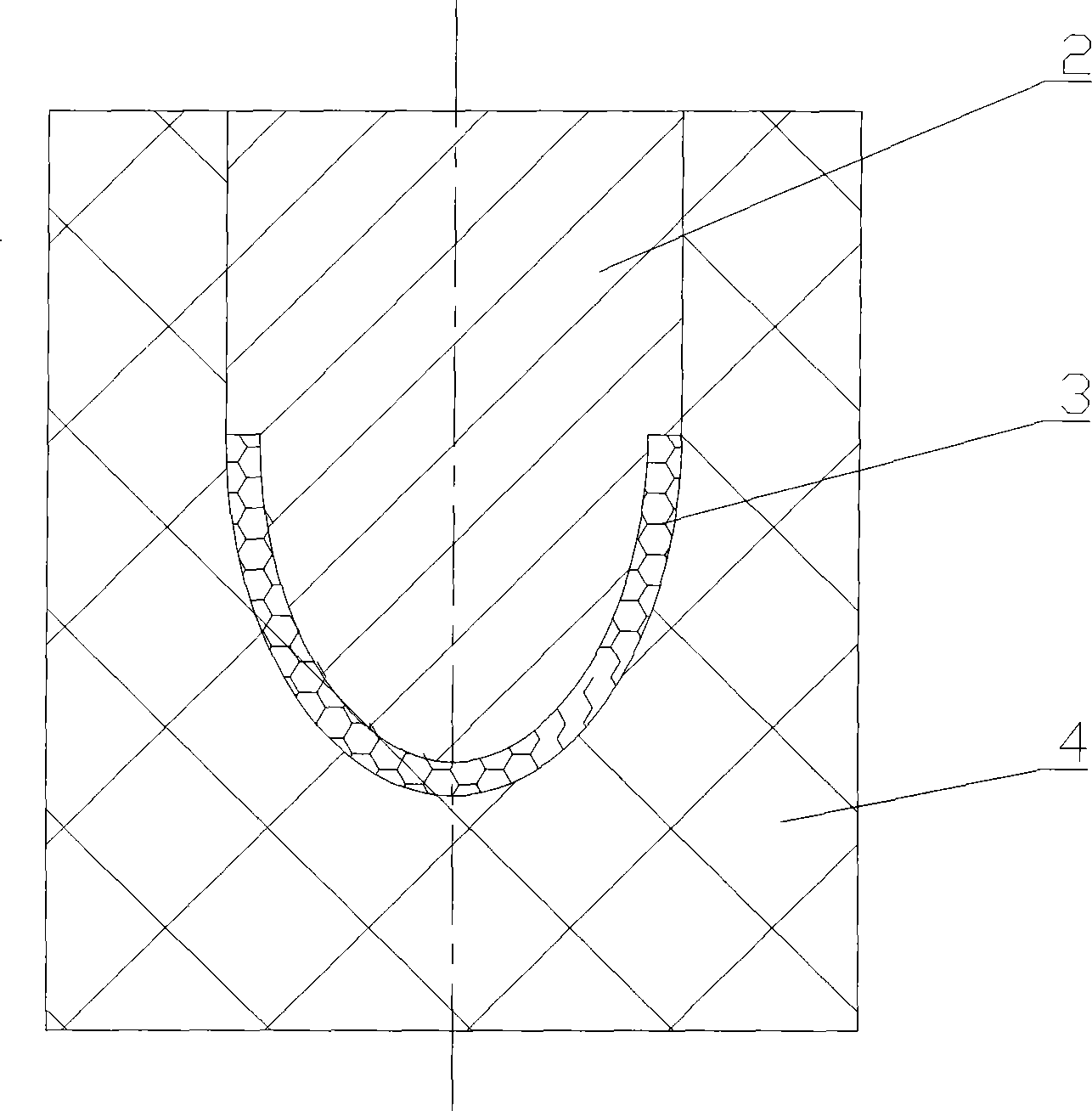

Novel stemming at tap hole

The invention discloses novel stemming at a tap hole. The stemming comprises the components in parts by weight as follows: 5-25 parts of corundum, 5-25 parts of high aluminum aggregate, 10-30 parts of silicon nitride combined with silicon carbide, 2-3 parts of silicon nitride iron, 5-15 parts of coke powder, 8-20 parts of clay, 1-5 parts of crystalline flake graphite, 5-10 parts of pyrophyllite, 4-7 parts of sericite, 5-10 parts of magnesium-aluminum spinelle, 2-4 parts of active alumina micro powder, 1-3 parts of metal powder and 15-20 parts of external composite binding agent. The composite binding agent comprises tar, modified phenolic resin and an organic solvent. The volume ratio of tar, modified phenolic resin to the organic solvent in the composite binding agent is 1:3:1. According to the invention, with the adoption of the composite binding agent formed by mixing tar and modified phenolic resin, smoke generated is less, the same plasticity to be combined with tar is met, the opening performance is good, the pressure resisting thermal shock resistance is good, and the adhesion strength is high. The depth of the tap hole can be prolonged and the furnace cylinder can be protected, the tapping time is prolonged, and the number of casts every day is reduced.

Owner:长兴云峰炉料有限公司

Low temperature process for making radiopac materials utilizing industrial/agricultural waste as raw material

ActiveUS20060066013A1Saving on accountConsiderable heat energyCeramic shaping apparatusNon-woven fabricsPyrophyllitePhosphate binder

Owner:COUNCIL OF SCI & IND RES

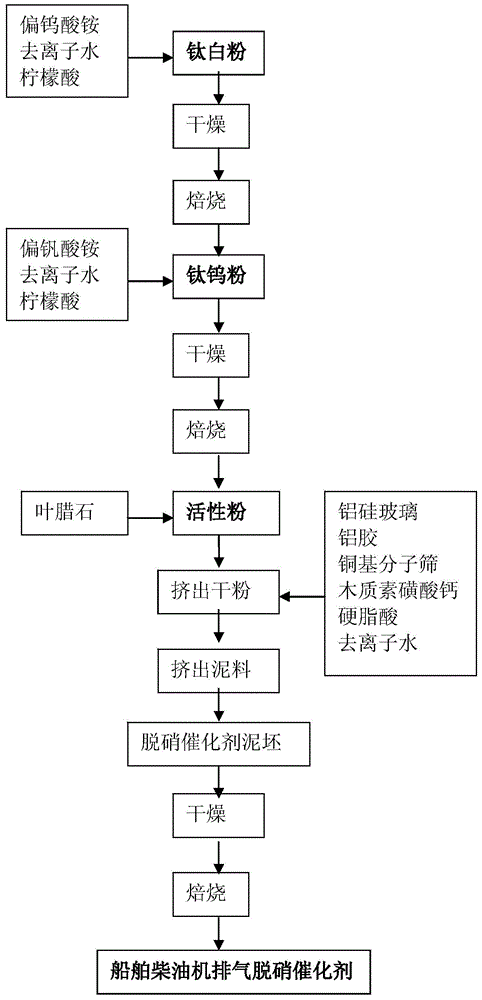

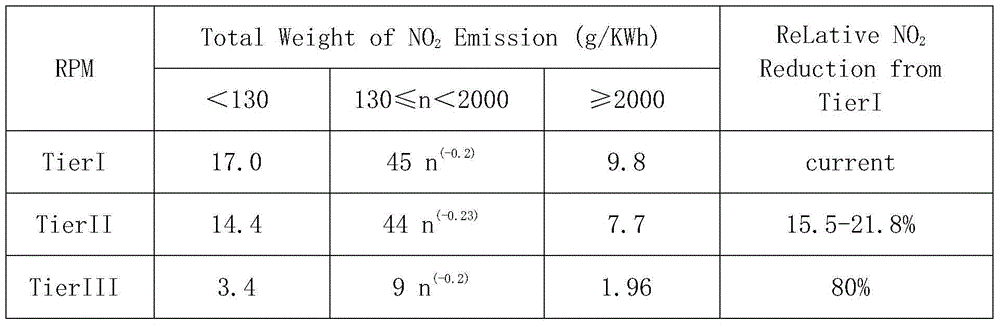

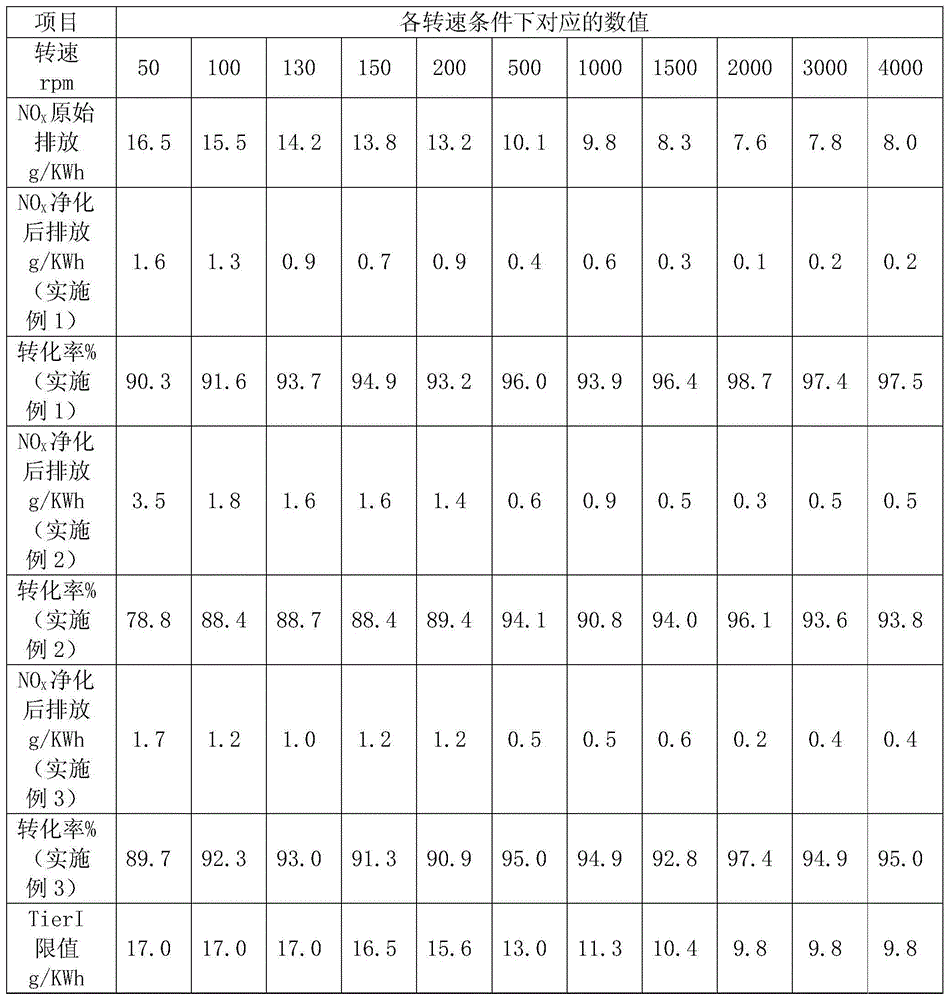

Ship diesel engine gas exhaust denitration catalyst preparation method

InactiveCN104415781AImprove denitrification efficiencyReduced service lifeMolecular sieve catalystsDispersed particle separationPyrophylliteEngineering

The invention relates to a ship diesel engine gas exhaust denitration catalyst preparation method, and belongs to the technical field of denitration catalysts. In the prior art, the denitration catalyst has the short service life and can not meet the denitration requirement under the low rotation speed of the ship diesel engine. With the ship diesel engine gas exhaust denitration catalyst preparation method of the present invention, the problems in the prior art can be solved. According to the present invention, pyrophyllite is adopted as a plasticizer and is added to active powder so as to obtain extruded dry powder, the extruded dry powder, Al-Si glass, an aluminum gel, a copper base molecular sieve, calcium lignosulfonate, stearic acid and a proper amount of deionized water are subjected to a shearing effect to prepare a pug, the pug is subjected to vacuum extruding to obtain a honeycomb-like denitration catalyst green body, and drying and calcination are performed to obtain the finished product, wherein the finished product has characteristics of high NOx harmful gas removal rate and high denitration efficiency.

Owner:SHANGHAI LANGT AUTOCATALYST

Thermal-insulation ceramic tile having low thermal conductivity coefficient and preparation method thereof

The invention discloses a thermal-insulation ceramic tile having low thermal conductivity coefficient and a preparation method thereof. The thermal-insulation ceramic tile is prepared from the following raw materials in parts by weight: 30-50 parts of calcite, 20-30 parts of quartz sand, 16-28 parts of pumice, 12-24 parts of pyrophyllite, 15-25 parts of expanded perlite, 10-15 parts of vitrified small balls, 6-12 parts of a steel slag micro-powder, 5-10 parts of tourmaline, 8-14 parts of coal cinder, 4-9 parts of sawdust, 3-6 parts of zirconium silicate, 2-5 parts of zinc borate, 6-9 parts of a coke powder, and 20-30 parts of modified clay. The prepared ceramic tile has the thermal conductivity coefficient of less than 0.2 W / m.K, has good heat-preservation and thermal-insulation properties, saves energy, has the characteristics of light weight, high strength, aging resistance, ultraviolet resistance and the like, and can be used for decoration of exterior walls of residences, wine shops, hotels, kindergartens, office buildings, factories, workshops, commercial buildings and the like.

Owner:安徽省亚欧陶瓷有限责任公司

Glaze composition

InactiveUS20080199708A1Liquid surface applicatorsGlass/slag layered productsPyrophyllitePlastic materials

A glaze composition which makes it possible that a base material for an inorganic calcined substance containing a lot of vitreous material is glazed without having corrosion. The glaze composition comprises a plastic material, a non-plastic material, and a solvent material, wherein the plastic material comprises at least one material selected from the group consisting of Gairome clay, Kibushi clay, kaolin and talc; the non-plastic material comprises at least one material selected from the group consisting of silica, calcined kaolin, pottery stone, pyrophyllite, pottery shards, chamotte and zircon; and the solvent material comprises at least one material selected from the group consisting of feldspar, lime stone, dolomite, zinc oxide and lithium carbonate.

Owner:NICHIHA CORP

Preparation method of porous slurry green body

The invention relates to a preparation method of a porous slurry green body, belonging to the technical field of ceramic and refractory materials. The method comprises five steps of: foam preparation, slurry blending, foam and slurry mixing, green body pouring and green body maintenance. The invention specifically comprises the following steps of: prefabricating bubbles in advance under the action of compressed air through a foaming device by adopting a physical foaming agent so as to provide fine, uniform and stable bubbles; and mixing high-alumina cement, Suzhou clay, pyrophyllite, lime and calcium carbonate according to a required proportion and then adding water to prepare a prefabricated slurry, wherein in the slurry, the high-alumina cement is used as one of ingredients to provide aluminum oxide and calcium oxide, and meanwhile, the characteristics of fast-solidification and fast-hardening of the high-alumina cement are adopted to accelerate the solidification and the hardening of pouring a green pouring body so as to ensure that on one hand, the bubbles are fixed as soon as possible to reduce bubble loss, and on the other hand, the green body is enhanced to reduce the deformation of the green body. The invention can easily prepare a green body with a drying density of 0.34-0.45kg / m<3>, and the compression strength of a corresponding drying green body is 0.15-0.50MPa.

Owner:NANJING TECH UNIV

Micro-porous mullite-silicon carbide multiphase fire resistant material and preparation method thereof

InactiveCN102432312AWith high strength and wear resistanceImprove insulation effectThermal insulationMullite

The invention relates to a micro-porous mullite-silicon carbide multiphase fire resistant material and a preparation method thereof. The micro-porous mullite-silicon carbide multiphase fire resistant material comprises the following ingredients: 25-30 wt% of super-grade bauxite particles having a particle size of no less than 1 mm and less than 3 mm, 24-27 wt% of super-grade bauxite particles having a particle size of no less than 0.1 mm and less than 1 mm, 10-15 wt% of SiC particles having a particle size of no less than 0.1 mm and less than1 mm, 10-15 wt% of super-grade bauxite fine powder having a particle size of less than 0.074 mm, 5-10 wt% of andalusite fine powder having a particle size of less than 0.088 mm, 2-5 wt% of pyrophyllite fine powder having a particle size of less than 0.088 mm, 3-5 wt% of active alpha-Al2O3 micro powder, 3-5 wt% of SiO2 micro powder, 4-6 wt% of Guangxi white clay, 1-3 wt% of elemental Si powder, and 1-2 wt% of Al powder, 1-2 wt% of dextrin, 0.4-0.6 wt% of calcium lignosulphonate, and 2-4 wt% of water. The micro-porous mullite-silicon carbide multiphase fire resistant material is prepared by mixing the ingredients, aging the mixture, moulding, drying and sintering. The prepared material has a uniform structure, has the average aperture less than 5 mum, has the characteristics of high strength, wear resistance, good thermal insulation performance, and excellent anti-alkali, chlorine, and sulfur compound erosion performance, and can meet the requirement of novel dry method cement production.

Owner:WUHAN UNIV OF SCI & TECH

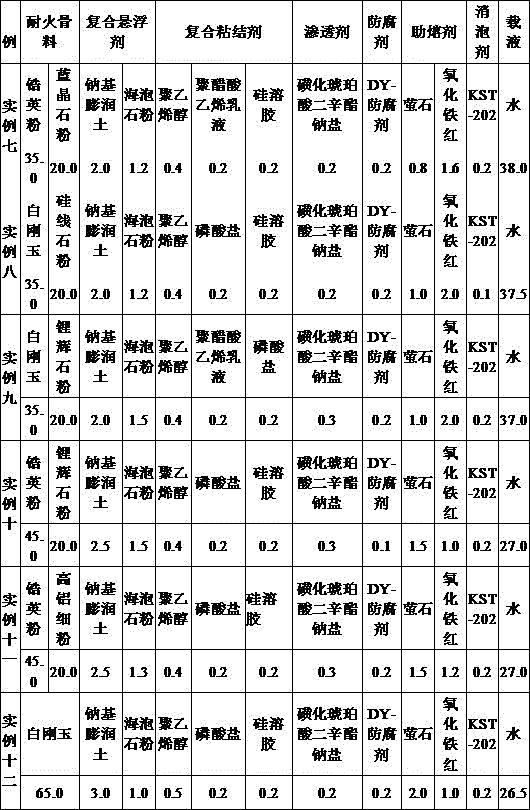

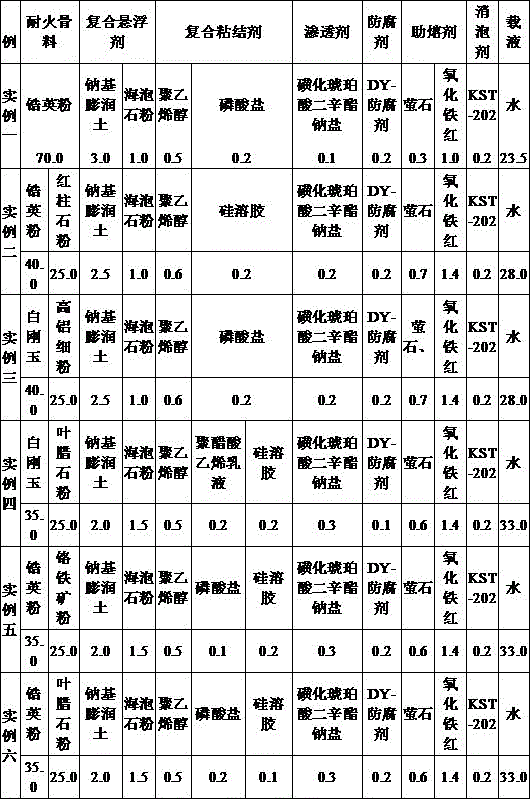

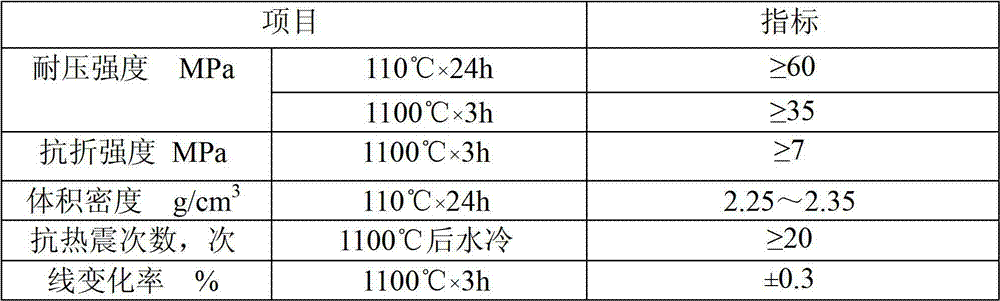

Preparation method of water based flow coating for 3D printing sand mold

ActiveCN105665620ANo pollution in the processImprove securityFoundry mouldsFoundry coresWater basedPyrophyllite

The invention relates to the technical field of 3D printing sand mold casting and in particular to a water based flow coating for a 3D printing sand mold and a preparation method of the water based flow coating. The water based flow coating is prepared from zircon powder, white corundum, high-aluminum fine powder, ferrochrome mineral powder, pyrophyllite powder, sillimanite powder, cyanite powder, andalusite powder, spodumene powder, sodium bentonite, sea-foam stone powder, polyvinyl alcohol, polyvinyl acetate emulsion, phosphate, silica sol, sulfonated dioctyl succinate sodium salt, preservative, a defoaming agent, fluorite, iron oxide red and water. The water based flow coating for the 3D printing sand mold has the advantages of excellent mobility, appropriate permeability, good leveling property, high-efficiency suspension stability, appropriate coating thickness, super strong anti-burn-on property, environment protection, no pollution and high efficiency.

Owner:NINGXIA KOCEL MOLD

Raw materials and preparation method of anti-corrosion mullite brick

The invention discloses raw materials for preparing an anti-corrosion mullite brick, comprising calcium hexaluminate, andalusite, sillimanite, alumina, cordierite, pyrophyllite, kaolin, refractory oxide, foaming agent and binding agent. The preparation method includes the following steps: the sillimanite, alumina, cordierite, pyrophyllite, kaolin, refractory oxide and binding agent are added into a grinding machine to be ground after material preparation, so as to obtain base material; the calcium hexaluminate and andalusite are added into a kollermill to be mixed and milled for 5-10 minutes, water is added until the surface is wetted, so as to obtain particle aggregate, and the base material is added into the kollermill to be mixed, milled and stirred with the particle aggregate, so as to obtain mixture; and water is injected into the mixture and stirring is carried out to form muddy mixture and green brick is obtained, and the green brick is placed into a kiln to be sintered into the anti-corrosion mullite brick finished product. The mullite brick prepared by the raw materials and preparation method has the advantages of low thermal conductivity, good thermal insulation property and strong corrosion resistance.

Owner:JIANGSU ZHONGLEI ENERGY SAVING TECH DEV CO LTD

Anti-skinning spray coating material for cement kiln

ActiveCN102815955AGood thermal shock resistanceImprove high temperature strengthPyrophylliteSpray coating

The invention relates to a refractory spray coating material, in particular to an anti-skinning spray coating material for a cement kiln. The anti-skinning spray coating material comprises flint clay, SiC, Guangxi white mud, alpha-Al2O3 micro powder, high-aluminum fine powder, SiC fine powder, pure calcium aluminate cement, spodumene, pyrophyllite and polypropylene fibers. The anti-skinning spray coating material for the cement kiln can play an effectively anti-skinning role at the positions of a feed pipe, a smoke chamber and the like of the cement kiln, is excellent in medium-temperature and high-temperature resistance and outstanding in thermal shock stability performance and can avoid cracking during rapid temperature rise. Besides, the anti-skinning spray coating material for the cement kiln is rapid in construction by the aid of a semi-dry spray coating construction mode, and is low in rebound rate after construction.

Owner:JIANGSU HENGNAI FURNACE CHARGE GRP

Production process for glass fiber yarn

ActiveCN105948493AImprove product qualityEfficient use ofGlass making apparatusYarnYarnCooking & baking

The invention relates to a production process for glass fiber yarn. The production process comprises the steps: selecting the following raw material ingredients in percentage by weight: 1% to 30% of waste / used beaded glass, 1% to 40% of cullet, 1% to 30% of quartz sand, 22% to 35% of pyrophyllite, 3% to 15% of feldspar, 5% to 13% of borax, 1% to 4% of calcite, 3% to 7% of dolomite, 0.5% to 2% of fluorite, 2% to 5% of mirabilite and 0.2% to 0.5% of composite clarifier; and carrying out processes such as material preparing, melting, drawing, baking and yarn making, thereby producing the high-quality glass fiber yarn. According to the production process for the glass fiber yarn, disclosed by the invention, the waste / used beaded glass and the cullet serve as main raw materials, so that waste resources can be effectively utilized, and the pollution to environments is reduced; and the produced glass fiber yarn is stable in product quality, and the strength of the produced glass fiber yarn can meet requirements.

Owner:旌德县青川玻纤有限公司

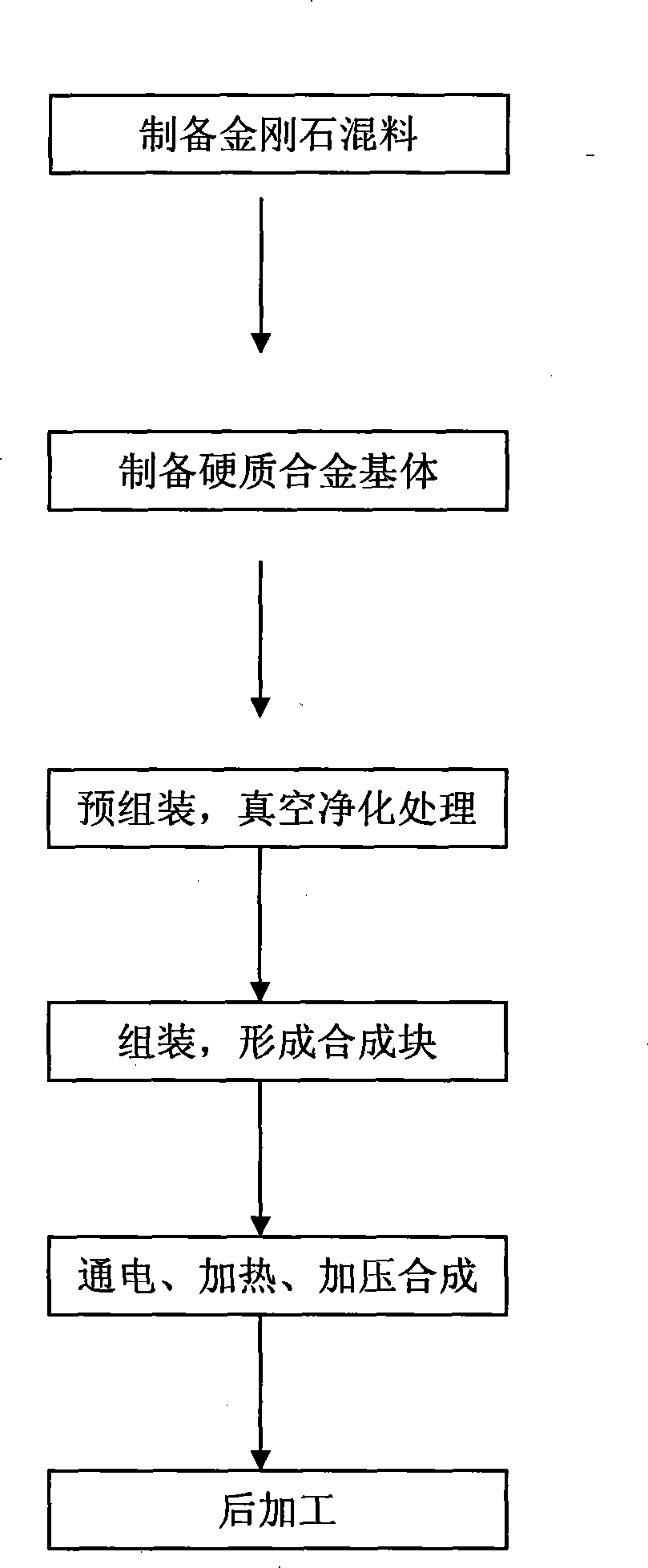

Protogenic diamond fine particle for precisio machining and production method thereof

ActiveCN102580618AGood self-sharpeningImprove processing efficiencyUltra-high pressure processesOctahedronPyrophyllite

The invention relates to a protogenic diamond fine particle for precision machining and a production method thereof. The diamond particle is 1-30 microns in size, is of the shape of hexahedron, octahedron or hexahedron-octahedron and has a nitrogen content of 200-500 ppm. The production method comprises the steps of: mixing graphite powder, a metal catalyst and a nitrogenous substance at a proportion of 0.4-1: 0.6-1.0: 0.01-0.05 for an isostatic cool pressing treatment; pressing the mixed material into a cylindrical synthesis column for vacuum sintering; then filling pyrophyllite synthetic block and performing a high-temperature and high-pressure treatment in a cubic press; the crushing the synthesis column and separating the crushed synthesis column by a swing bed to obtain the protogenic diamond fine particle for precision machining. The protogenic diamond fine particle has the advantages of being applicable for machining tools, such as fretsaws, ultra-thin saw blades and electroplated grinding wheels, being suitable for efficient precision machining of glass, monocrystalline silicon, polycrystalline silicon, sapphires and silicon carbide crystals and having high machining efficiency as well as long service life. The method, disclosed by the invention, has the advantages of being green, environment-friendly and energy-saving and having steady product performance, low cost and good application performance.

Owner:HENAN UNION ABRASIVES

High-temperature-resistant casting molding sand

InactiveCN106270366AHigh strengthImprove breathabilityFoundry mouldsFoundry coresCelluloseSodium metasilicate

The invention discloses high-temperature-resistant casting molding sand which comprises the following raw materials in parts by weight: 150-200 parts of quartz sand, 10-20 parts of ceramic microspheres, 5-15 parts of pyrophyllite, 5-15 parts of attapulgite, 10-20 parts of talcum powder, 15-30 parts of a refractory material, 2-5 parts of magnesium oxide, 5-15 parts of silica powder, 5-10 parts of gypsum crystal whisker, 5-10 parts of sodium abietate, 5-10 parts of sodium metasilicate, 2-6 parts of starch, 3-5 parts of cellulose gum, 1-3 parts of chlorinated paraffin, 5-15 parts of a synergist and 30-120 parts of water, wherein the synergist comprises 15-25 parts of titanium dioxide, 10-16 parts of modified coal ash and 3-5 parts of sodium hexametaphosphate. The high-temperature-resistant casting molding sand disclosed by the invention not only has the advantages of being good in high temperature resistance and easy to crush and clean, but also has the advantages of being good in strength, good in breathability and rapid to bake, calcine and cure.

Owner:蚌埠市北晨微型机床厂

Refractory heat insulation material and preparation method thereof

The invention relates to a refractory heat insulation material and a preparation method thereof. According to raw materials of the refractory heat insulation material, hole-closed perlite floating beads serve as heat insulation aggregate, bauxite, kaolin and pyrophyllite serve as refractory aggregate, potassium feldspar serves as a sintering agent and sodium-based bentonite serves as a forming agent. The preparation method includes the steps of stirring the raw materials, forming a blank through a mould, air-drying the blank, performing demoulding after low-temperature drying, and performing high-temperature ceramization and sintering forming on the blank. By fully utilizing the physicochemical characteristics of all the components, the overall performance of the refractory heat insulation material is optimized, and the prepared refractory heat insulation material has the advantages of being high in refractoriness and strength, small in bulk density, low in heat conductivity coefficient, good in heat insulation effect, environmentally friendly and the like and can be applied to heat insulation of heating furnaces or heat equipment in the machinery industry, the metallurgy industry, the chemical industry and the like and slow down heat energy diffusion to save energy.

Owner:HUBEI UNIV OF TECH

Ceramic plate for curtain wall decoration and preparation method thereof

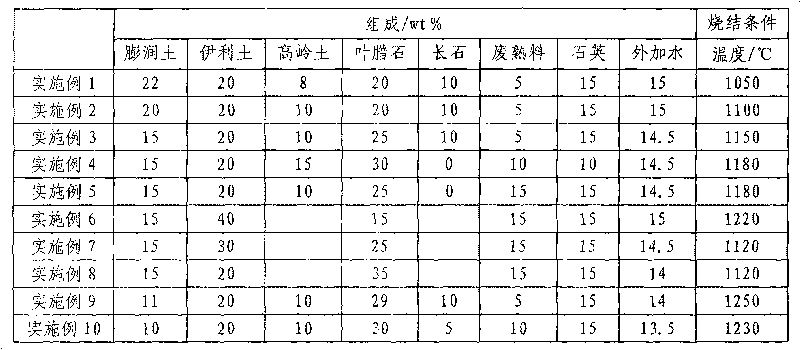

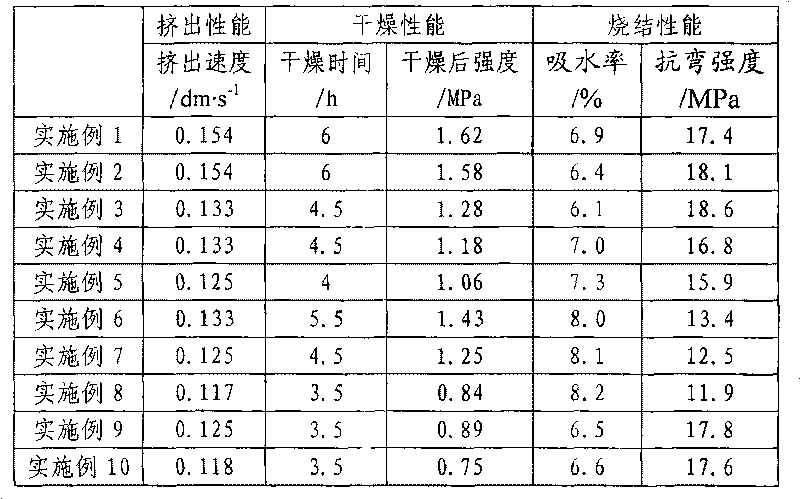

InactiveCN101718131AOvercome prone defectsOvercome the disadvantage of easy deformationConstruction materialWallsPyrophylliteSodium Bentonite

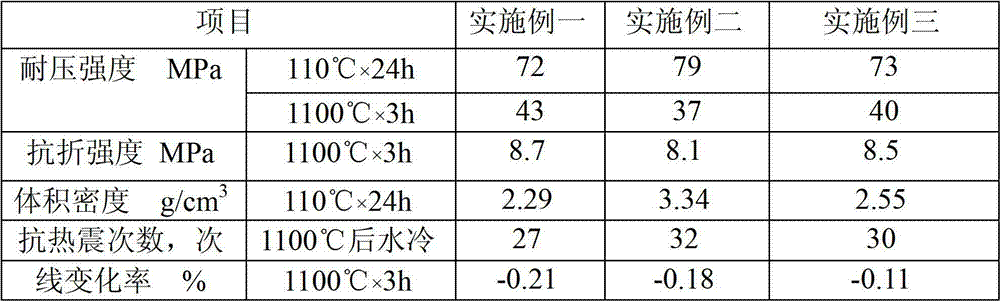

The invention relates to a ceramic plate for curtain wall decoration and a preparation method thereof. In the ceramic plate, a raw material formula comprises coarse ceramic aggregates and fine plastic materials, and ceramic slurry comprises the following components of bentonite, illitic soil, kaoline, pyrophyllite, quartz, feldspar, waste clinker, and water. The preparation method comprises the following steps of: uniformly mixing the ceramic raw materials according to a proportion of 45-65 wt% of aggregates and 35-55 wt% of plastic materials; then adding 12-16 wt% of water; shaping by using a spiral extruder; drying, and sintering at 1050-1350 DEG C in a raceway kiln. The obtained slurry has a favorable extrusion property, green bodies are easy to dry and sinter, and the ceramic plate has high strength, small contraction and difficult cracking.

Owner:XI AN JIAOTONG UNIV

Purification method for artificial diamond

The invention discloses a purification method for artificial diamond. The purification method comprises the following concrete steps: 1, mechanical crushing: mechanically crushing an artificial diamond synthetic rod into fine grains; 2, sintering and oxidation: removing most graphite by using a gas phase oxidation process; 3, crushing and dissociation: recovering catalyst metal by using a magnetic process and carrying out shaking-table sorting of a part of pyrophyllite; 4, separation and purification: totally remove residual graphite by using a flotation process and removing residual pyrophyllite by using a water elutriation method; and 5, drying and sorting: carrying out drying and sorting to obtain artificial diamond of different grades. The purification method has the advantages that purification process is simplified; severe pollution of a strong acid solution used in traditional purification processes to environment is mitigated; environmental protection is realized; and generation of harmful gas in the process of purification is reduced, so the working environment of operators is improved and the health of the workers is guaranteed.

Owner:江苏益林金刚石工具有限公司

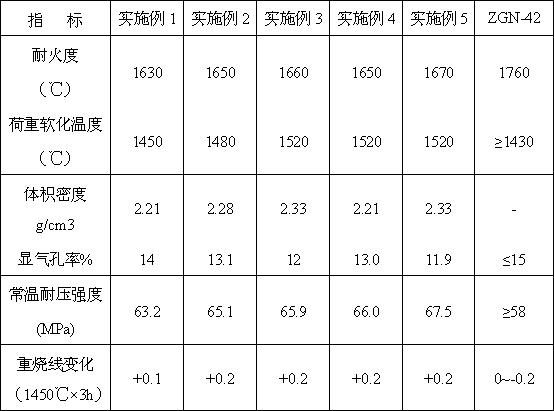

Pyrophyllite brick and preparation method thereof

The invention belongs to semi-silica refractory materials, and in particular relates to a pyrophyllite brick and a preparation method thereof. The pyrophyllite brick is prepared by mixing a pyrophyllite raw material, a pyrophyllite clinker, clay, an additive and a binding agent, and performing the processes of material preparing, aging, shaping, drying and sintering. The pyrophyllite brick prepared by the method has the characteristics of high load softening temperature, stable volume and slight expansion at an operating temperature, and can ensure that a brickwork is compact in structure, small in brickwork joint and good in integrity; and meanwhile, when the pyrophyllite brick is in contact with slag, because a high-viscosity liquid-phase 'enamel layer' formed on the surface, the pyrophyllite brick can block up slag infiltration, and the erosion resistance of the pyrophyllite brick is improved.

Owner:宜兴新威利成耐火材料有限公司

Water-dispersible granule containing paraquat dichloride and its preparing method

InactiveCN1376030AAvoid poisoning hazardsEfficient removalBiocideDead animal preservationSodium BentonitePyrophyllite

The present invention relates to a water dispersible granule containing Paraquat Dichloride and preparation method thereof. The paraquat, an active component of a nonselective herbicide, is generally known to be inactive due to its strong adsorption to minerals in the soil, particularly to extender such as clay, bentonite, talc, pyrophyllite, montmorillonite, etc. Paraquat is transformed into the water dispersible granule type, so that the dispersible granule type can have safety to human body and superior agrichemical effect than other formulation types such as soluble concentrate type or wettable powder type. The agrichemical composition according to the present invention is prepared by mixing and kneading 5-50 wt.% of paraquat, 5-30 wt.% of surfactant, 1-2 wt.% of disintergrant and the rest of carrier, forming granules out of kneaded mixture, and drying the granules.

Owner:DONGBU FARM HANNONG

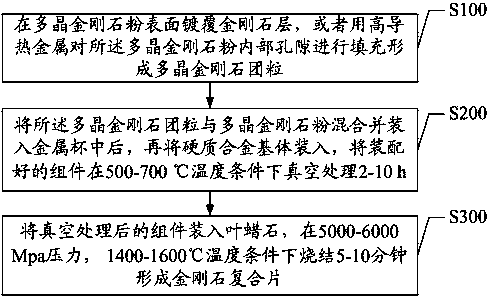

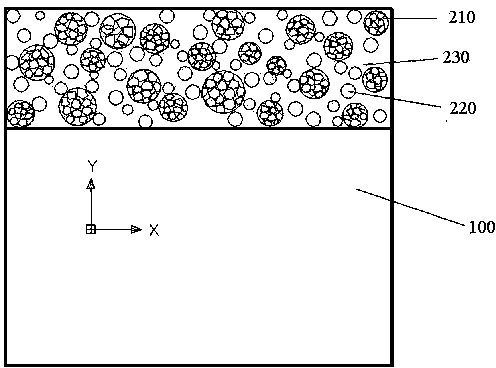

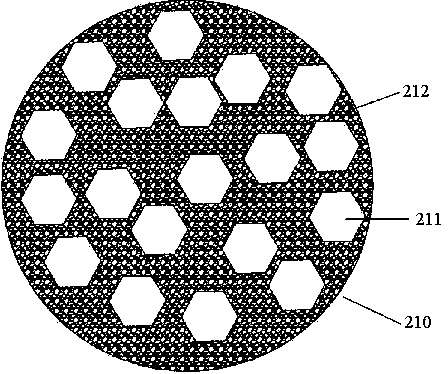

PDC with high thermal conductivity and preparation method thereof

ActiveCN103623747AHigh thermal conductivityPrevent infiltrationUltra-high pressure processesPyrophyllitePolycrystalline diamond

The invention discloses a PDC with high thermal conductivity and a preparation method thereof. The preparation method comprises the following steps: A. plating polycrystalline diamond powder with a diamond layer, or filling the inner holes of the polycrystalline diamond powder with metal with high thermal conductivity to form polycrystalline diamond granules; B. mixedly putting the polycrystalline diamond granules and polycrystalline diamond powder into a metal cup, then putting a hard alloy base body, and performing vacuum processing; C. putting pyrophyllite, then sintering to obtain the PDC. The PDC disclosed by the invention adopts the high-abrasion-resistance polycrystalline diamond with D-D bonds, and the high-abrasion-resistance polycrystalline diamond can protect the polycrystalline granules from being permeated by binding agents such as cobalt, nickel and iron when the polycrystalline granules are sintered at high temperature and under high pressure; the content of the metal binding agent on the PCD layer can be controlled directly in the synthesis process without the step of removing PDC accelerant metal after synthesis. With adoption of the preparation method, the high abrasion resistance of the polycrystalline powder after the high-temperature high-pressure sintering is reserved, and the thermal conductivity of the polycrystalline powder is improved.

Owner:SHENZHEN HAIMINGRUN SUPERHARD MATERIALS

Diatomite ceramic and preparation method thereof

ActiveCN103880397AQuality is hard and durableImprove adsorption capacityClaywaresCITRATE ESTERPyrophyllite

The invention discloses a diatomite ceramic mud and a diatomite ceramic product thereof. The diatomite ceramic mud is composed of the following components in percentage by weight: 38-53% of diatomite, 30-42% of kaoline, 2-4% of alumium oxide, 1-2% of borax glass, 1-4% of chromic oxide, 7-12% of feldspar, 2-4% of ardealite, 0-3% of pyrophyllite, 0-1% of silica powder and 0-2% of citrate. Compared with the prior art, the formula of the diatomite ceramic mud is obtained by the applicant by virtue of countless tests, the components in the formula function synergistically, and especially, 38-53% of diatomite is added to the formula so that the fired ceramic product is white and clean in glaze, hard and durable in quality, has outstanding adsorption capacity and is capable of effectively absorbing harmful gases in a room, decomposing harmful substances in air, and suppressing bacteria and sterilizing so as to purify the indoor air.

Owner:青岛泉佳美硅藻泥科技有限公司

Modified grouting material

The invention discloses a modified grouting material. The grouting material is prepared from raw materials in parts by weight as follows: 55-65 parts of portland cement, 10-15 parts of aluminate cement, 6-9 parts of a polymer emulsion, 25-35 parts of a mineral additive, 0.1-0.3 parts of a foam stabilizer, 4-8 parts of an activator, 0.1-0.3 parts of a water-retaining agent, 0.2-0.4 parts of a surfactant, 2-4 parts of bentonite, 0.2-0.6 parts of fine sand, 0.2-0.6 parts of sodium carbonate, 0.02-0.04 parts of ceramic fiber, 0.01-0.03 parts of emulsion powder, 0.02-0.04 parts of dolomite, 0.01-0.03 parts of pyrophyllite and 6-8 parts of methyl sodium silicate. Flexibility of polymer and rigidness of the mineral additive are jointly used for modification, the grouting material with excellent performance is obtained, and the application range is enlarged.

Owner:王璐

Preparing method of green man-made diamond

InactiveCN101224399AEasy to operateEasy to storePolycrystalline material growthUltra-high pressure processesPyrophylliteMass ratio

The invention relates to a preparation method of a green man-made diamond, which adopts plumbago as the material and FeNi or NiMnCo alloy as the catalyst, the mass ratio of the plumbago and alloy catalyst is that plumbago: FeNi or NiMnCo is equal to 1:0.3-1. The invention is characterized in that Mg3N2 additive is added into the plumbago, the mass ratio of the plumbago and the Mg3N2 is that plumbago: Mg3N2 is equal to 1:0.003-0.02; the preparation technique process is that: the powdery plumbago, Mg3N2 and alloy catalyst meeting the mass ratio are mixed evenly, pre-pressed into cylindrical bar stock and then are placed into a pyrophyllite synthesized block; then the assembled synthesized block is placed into a high pressure and high temperature chamber of a hexahedral anvil diamond press, then the temperature raises to 1550-2000K within 0.5-5 minutes and at the same time the block is pressurized at the pressure of 4.0-4.8 GPa, then is kept at the temperature for 0.5-3 minutes, and then the pressure is improved to 5.2-6.0 GPa, then is kept at the temperature for 10-20 minutes, then a green diamond crystal can be obtained after the heating process is stopped, the pressure is relieved and the impurities are removed. The method simplifies the technique process, reduces the manufacturing cost and is convenient for being carried out.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Diamond compound cutter bit head and its manufacturing method

InactiveCN101245705ACompact structureImprove impact resistanceCutting machinesPyrophyllitePower flow

The invention relates to a method for manufacturing a diamond compound cutting pick head and a diamond compound cutting pick head. The steps of the method are that (1) diamond mixed material is formed by mixing the diamond and metal powders according to the weight percentage of the diamond mixed material of 80 to 82 percent of diamond, 6 to 7 percent of silicon and 12 to 13 percent of cobalt; (2) the surface of a hard alloy is carried out by pretreating, oil removing and detarnishing to form a hard alloy basic body; (3) the diamond mixed material is put into a carbon tube, prepressed for molding and then is arranged into the hard alloy basic body to carry out vacuum purifying treatment; (4) the carbon tube is placed into a pyrophyllite and a conductive steel ring, Ti circle and carbon sheets are arranged between the two ends of the carbon tube and the pyrophyllite to form a compound block; (5) current accesses at the two ends of the conductive steel ring in the compound block and the carbon tube is taken as a heater to ensure six top hammers of alloy to carry out pressurizing on the compound block from six directions of front, back, left, right, up and down during the compounding process; (6) post processing is carried out. The method can manufacture the diamond compound cutting pick head with high anti-impaction and wear-resisting properties.

Owner:HUNAN FEIRAY COMPOSITE MATERIAL

Inorganic-organic composite grouting material

The invention discloses an inorganic-organic composite grouting material, which is prepared from the following raw materials in parts by weight: 60-70 parts of portland cement, 20-30 parts of aluminate cement, 5-10 parts of polymer emulsion, 30-40 parts of mineral admixture, 0.1-0.3 parts of defoaming stabilizer, 6-9 parts of excitant, 0.1-0.3 parts of water-retaining agent, 0.2-0.4 parts of surface active agent, 2-6 parts of bentonite, 0.3-0.5 parts of fine sand, 0.4-0.6 parts of sodium carbonate, 0.03-0.05 parts of ceramic fiber, 0.01-0.03 parts of emulsion powder, 0.03-0.05 parts of dolomite, 0.01-0.03 parts of pyrophyllite and 4-8 parts of methyl sodium silicate. According to the inorganic-organic composite grouting material provided by the invention, the flexibility of a polymer and the rigidity of the mineral admixture are utilized to carry out joint modification, so that the grouting material with favorable performance is acquired, and the application range of the grouting material is further widened.

Owner:王璐

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com