Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103 results about "Anorthite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anorthite is the calcium endmember of the plagioclase feldspar mineral series. The chemical formula of pure anorthite is CaAl₂Si₂O₈. Anorthite is found in mafic igneous rocks. Anorthite is rare on the Earth but abundant on the Moon.

Lightweight dry refractory

A dry refractory composition having superior insulating value. The dry refractory composition also may have excellent resistance to molten metals and slags. The composition includes filler lightweight material, which may be selected from perlite, vermiculite, expanded shale, expanded fireclay, expanded alumina silica hollow spheres, bubble alumina, sintered porous alumina, alumina spinel insulating aggregate, calcium alumina insulating aggregate, expanded mulllite, cordierite, and anorthite, and matrix material, which may be selected from calcined alumina, fused alumina, sintered magnesia, fused magnesia, silica fume, fused silica, silicon carbide, boron carbide, titanium diboride, zirconium boride, boron nitride, aluminum nitride, silicon nitride, Sialon, titanium oxide, barium sulfate, zircon, a sillimanite group mineral, pyrophyllite, fireclay, carbon, and calcium fluoride. The composition also may include dense refractory aggregate, which may be selected from calcined fireclay, calcined Chamotte, a sillimanite group mineral, calcined bauxite, pyrophyllite, silica, zircon, baddeleyite, cordierite, silicon carbide, sintered alumina, fused alumina, fused silica, sintered mullite, fused mullite, fused zirconia, sintered zirconia mullite, fused zirconia mullite, sintered magnesia, fused magnesia, sintered spinel, and fused spinel refractory grog, a heat activated bonding agent, and a dust suppressant.

Owner:ALLIED MINERAL PROD

Method for extracting lithium and other alkali metal elements from lepidolite mineral

InactiveCN101974678AEfficient extractionEasy to optimizeProcess efficiency improvementRubidiumPotassium

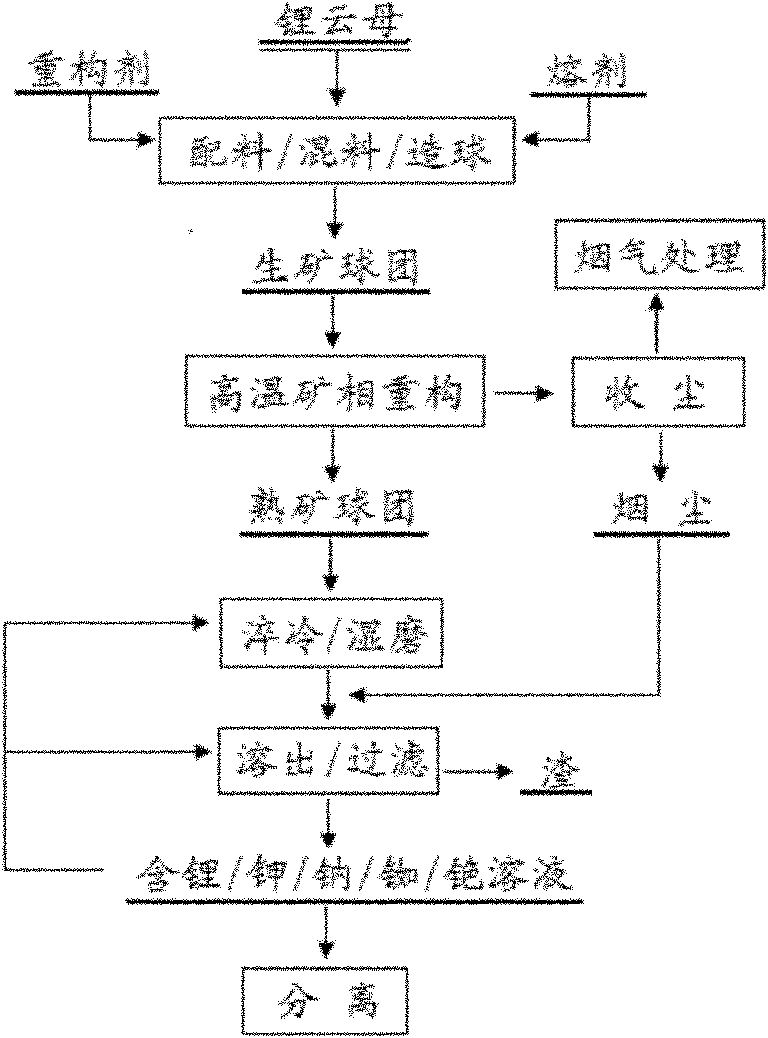

The invention discloses a high-temperature mineral phase reconstruction method for extracting lithium and other alkali metal elements from lepidolite mineral, comprising the following steps: mixing raw materials, pelletizing, calcining at high temperature, water quenching, ball milling, dissolving out, producing compounds and the like. The invention teaks raw mineral component composition to design target reconstruction mineral and composition to obtain the purpose of optimizing processes, lowering energy consumption and cost of treatment process and efficiently extracting lithium, potassium, rubidium, caesium and the like. Silicon and aluminum in lepidolite can enter anorthite type mineral phase (CaO.Al2O3.2SiO2, (Ca, Na)O. (Al, Si)2O3.2SiO2) and calcium ash quarry phase (CaO.SiO2) after mineral phase reconstruction, and do not dissolve in water and aqueous solution. After mineral phase reconstruction reaction, fluorine in lepidolite enters calcium fluoride mineral phase and does not dissolve in water and aqueous solution. Lithium and other alkali metal elements in lepidolite enter salt (chloride, sulfate) or alkali (hydroxide) phase of lithium and other alkali metal elements after mineral phase reconstruction reaction and can be dissolved in water and aqueous solution.

Owner:CENT SOUTH UNIV

Protection from kinetic threats using glass-ceramic material

InactiveUS20050119104A1Highly effectiveEffective protectionGlass/slag layered productsArmour platesEngineeringAnorthite

A method for protecting an object from kinetic threats using a glass-ceramic is disclosed. The energy of impact is dissipated as a localized pulverization of the glass-ceramic without extensive shattering of the glass-ceramic. Further, a specific Anorthite glass-ceramic is provided and demonstrated to provide effective protection from multiple kinetic threats.

Owner:FIRST IN JERUSALEM BUSINESS

Anorthite light refractory brick and preparation method thereof

The invention relates to an anorthite light refractory brick and a preparation method thereof and belongs to the field of refractory materials. The brick comprises 35-37% of Al2O3, 40-50% of SiO2, less than 1% of Fe2O3, 10-15% of CaO and less than 1.1% of Na2O+K2O. The volume concentration is in a range from 480Kg / m3 to 510Kg / m3, the compressive strength is more than 1.0 Mpa, the thermal conductivity is 0.14W / m.K below 400 DEG C, and the reheating linear change rate is 1200 DEG C *24h<-1.0%. According to the preparation method, raw materials are normal, large in quantity, easy to obtain and low in cost in the market. The requirement of the preparation method for devices is low.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Protection from kinetic threats using glass-ceramic material

InactiveUS7284469B2Highly effectiveEffective protectionGlass/slag layered productsArmour platesEngineeringAnorthite

A method for protecting an object from kinetic threats using a glass-ceramic is disclosed. The energy of impact is dissipated as a localized pulverization of the glass-ceramic without extensive shattering of the glass-ceramic. Further, a specific Anorthite glass-ceramic is provided and demonstrated to provide effective protection from multiple kinetic threats.

Owner:FIRST IN JERUSALEM BUSINESS

Method for decomposing potassium feldspar to extract soluble potassium

InactiveCN101831561AHigh extraction rateLow firing temperatureProcess efficiency improvementPotassium feldsparAnorthite

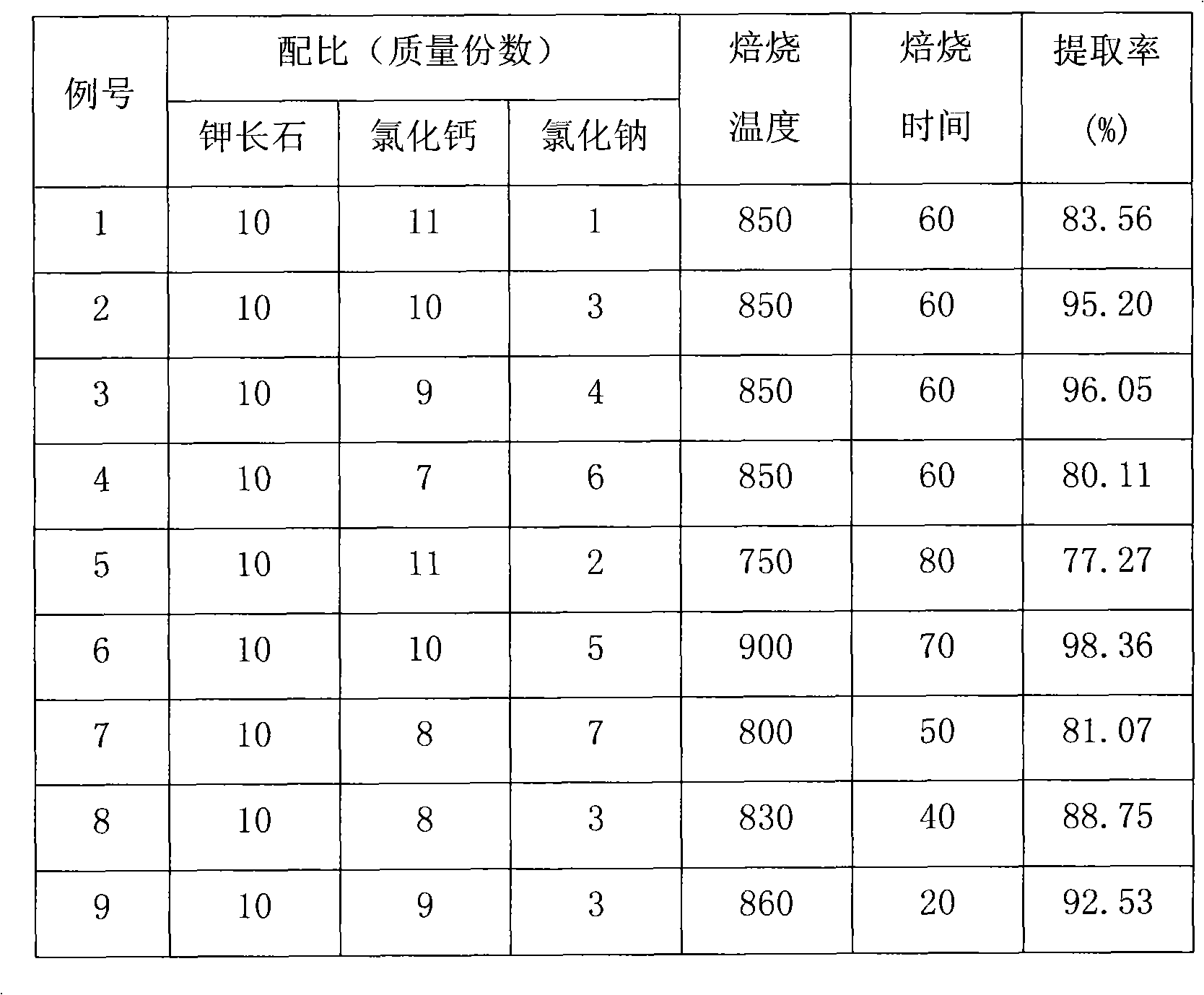

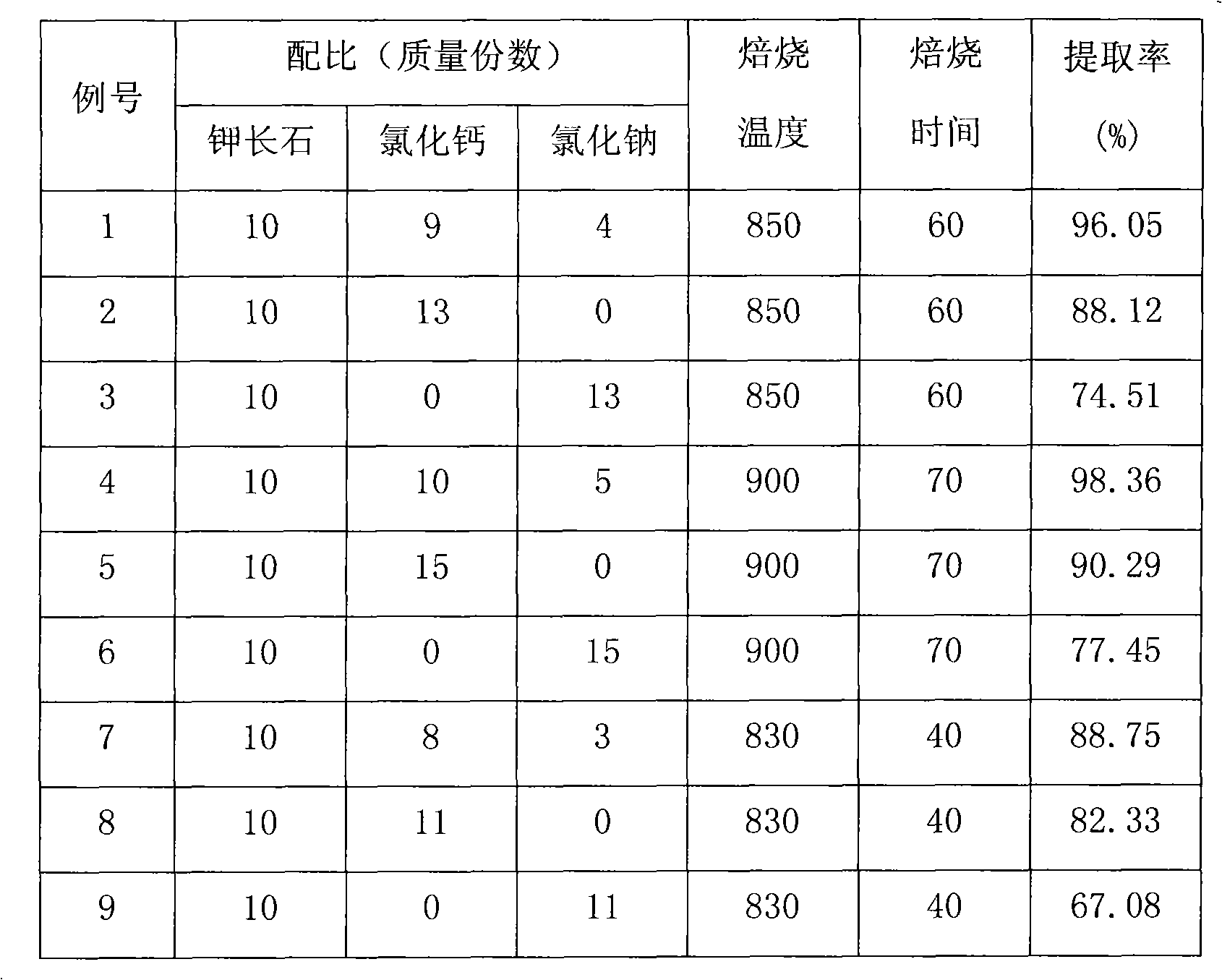

The invention discloses a method for decomposing potassium feldspar to extract soluble potassium, comprising the following steps of: crushing and grinding potassium feldspar used as a raw material; mixing with the ground potassium feldspar, calcium chloride and sodium chloride which are used as a combined assistant, and fully stirring, wherein the ratio by mass part of the potassium feldspar to the calcium chloride to the sodium chloride is 10:(7-11):(1-6); roasting the mixture at the temperature of 750-900DEG C for 20-80 minutes; leaching the product with water; and evaporating, condensing and separating the filtered filtrate to obtain a potassium chloride product. The potassium chloride product can be used for producing potassic fertilizer; and main components of filter residue are anorthite and soda feldspar which can be used for producing cement, microcrystalline glass and other building materials. In the method, the selected assistant has low price and wide sources and the obtained potassium extract rate is high; in addition, the method is applicable for the production of extracting the potassium from the potassium feldspar.

Owner:EAST CHINA UNIV OF SCI & TECH

Manufacture of ceramic tiles from industrial waste

The present inveniton relates to a process of forming ceramic tiles having the appearance of tiles produced from clays. The process includes melting a material to form a glass melt, treating the glass melt to produce a solid glass product, grinding the solid glass product to produce glass particles having a particle size of less than 200 microns, mixing the glass particles with a first additive to form a glass power mixture having a composition of 55 to 99 wt.% glass particles and 45-1 wt.% first additive, forming the glass powder mixture into tiles by dry pressing, where the tiles have a primary crystalline phase selected from the group consisting of nepheline, diopside, anorthite, wollastonite, melilite, merwinite, spinel, akermanite, gehlenite, crystalline phases based on iron substitutions in the crystalline phase, and mitures thereof. The process includes a devitrifying step where the solid glass product is devitrified prior tothe grinding step or the glass particles in the tile are devitrified after the forming step.

Owner:沃特克有限公司 +1

Dielectric material with low temperature coefficient and high quality

A dielectric material is disclosed which has a small absolute value of the temperature coefficient of resonance frequency and a high coefficient of unloaded quality. Also disclosed are a process for producing the dielectric material and multilayer and other circuit boards containing the dielectric material. The dielectric material is a highly densified material having a water absorption lower than 0.1%, which is obtained by mixing 95.5 to 99.5 percent by weight mixture of a glass frit and a strontium compound with 0.5 to 4.5 percent by weight titanium dioxide, compacting the resultant mixture, and sintering the compact at a relatively low temperature around 930 DEG C. This dielectric material is a glass ceramic containing strontium anorthite (SrAl2Si2O8) as the main crystalline phase, and may contain the TiO2, which remains unchanged after sintering. The absolute value of the temperature coefficient of resonance frequency of the dielectric material is 20 ppm / DEG C. or lower, preferably 10 ppm / DEG C. or lower, more preferably 5 ppm / DEG C. or lower. The product of the unloaded quality coefficient and resonance frequency is 1,800 GHz or larger, preferably 2,500 GHz or larger. This material therefore has excellent dielectric properties.

Owner:NGK SPARK PLUG CO LTD

Anorthite light refractory brick and preparation method thereof

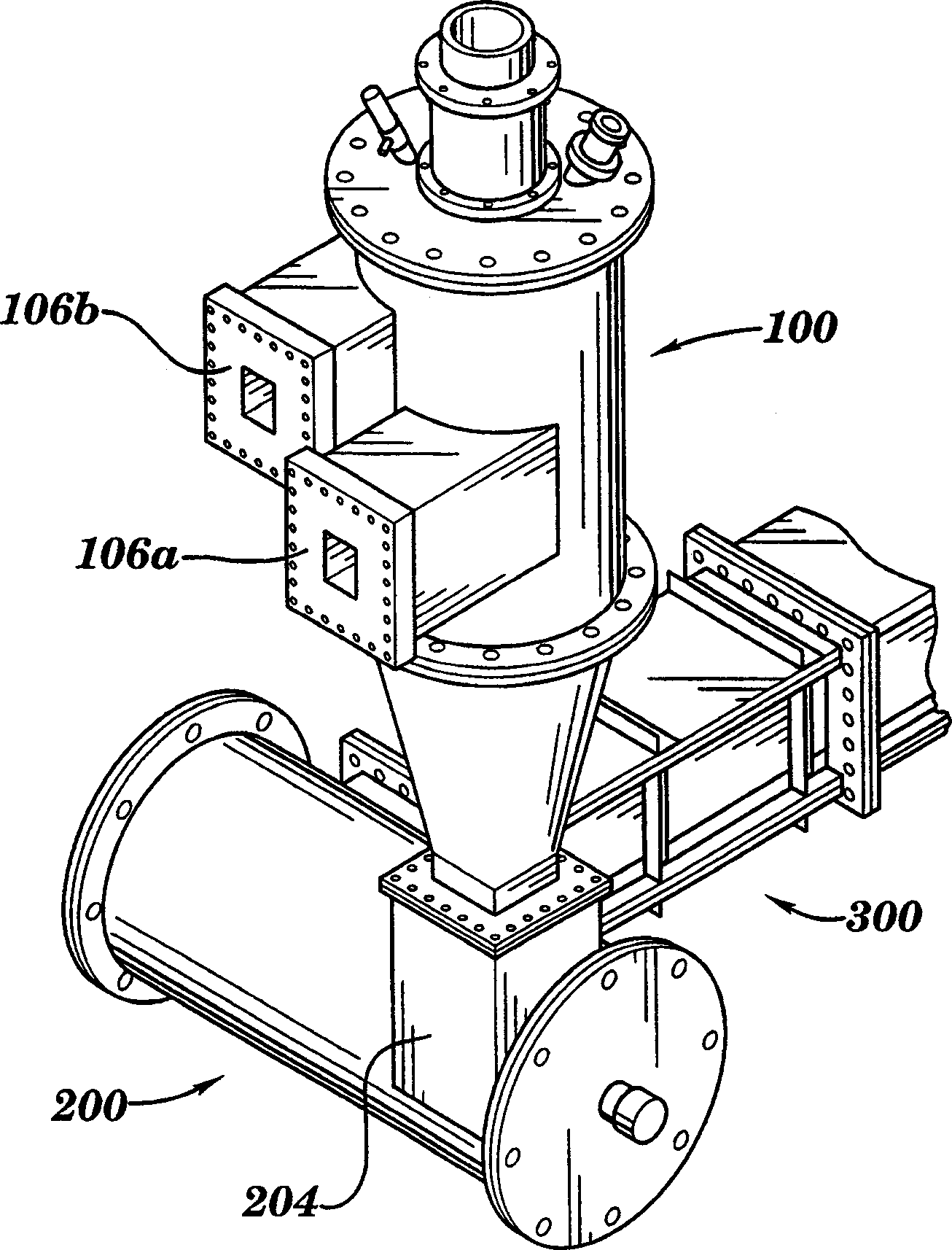

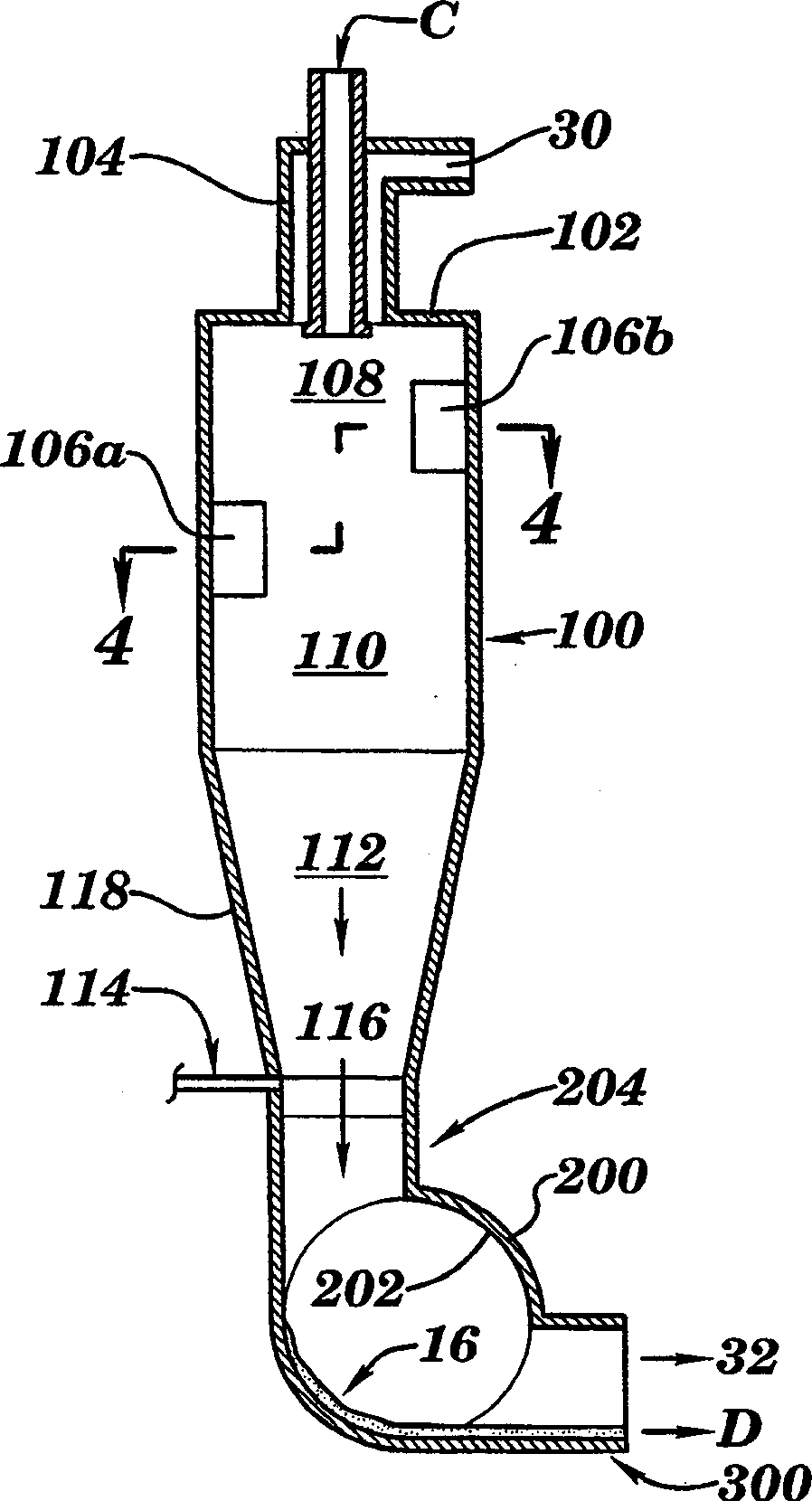

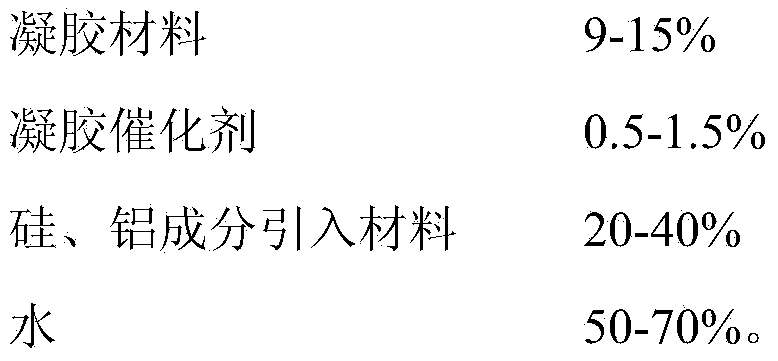

The invention belongs to the field of fireproofing materials, and particularly relates to an anorthite light refractory brick and a preparation method thereof. The preparation method comprises steps of dispersing a gel material in water, and adding a gel catalyst for incomplete reaction to form an inorganic gel system; constantly stirring the inorganic gel system so as to disperse the introduced silicon and aluminum components in the gel system to be mixed uniformly to obtain a mixed material; molding the mixed material, then maintaining, curing, drying, calcining, and producing through a manufacture procedure so as to obtain the refractory brick. The preparation method is simple and easy to operate, is environment-friendly, uses the raw materials according to local conditions, is convenient for production organization, has no special requirements on equipment, can produce products with excellent properties, and has remarkable energy conservation effect.

Owner:史新明

Jade-like ceramic tile and preparation method thereof

ActiveCN110963793AHigh whitenessGood color and lusterCeramic shaping apparatusCelluloseSodium phosphates

The invention discloses a jade-like ceramic tile. A light-transmitting material comprises the following raw materials by mass percentage: 12%-20% of clay, 3%-5% of potassium feldspar, 3%-7% of albite,30%-50% of anorthite, 12%-22% of wollastonite, 5%-8% of aluminum oxide, 1%-3% of bentonite, 0.1%-0.3% of sodium carboxymethyl cellulose and 0.1%-0.3% of sodium tripolyphosphate, wherein the anorthiteis prepared by mixing aluminum oxide, silicon dioxide and calcite according to a molar ratio of 1:2:1 and then carrying out high-temperature solid-phase artificial synthesis. The material has high whiteness and excellent permeability, and also has good high-temperature resistance. The invention further discloses a preparation method of the ceramic tile, the process is simple, and the green body of the prepared jade-like ceramic tile has high crystalline phase content and high strength, surface permeation decoration can be directly carried out without applying cover glaze, the cost is low, andthe jade-like artistic effect is remarkable.

Owner:FOSHAN OCEANO CERAMICS

Jointed body of glass-ceramic and aluminum nitride sintered compact and method for producing the same

InactiveUS20020193229A1Easy to getIncrease resistanceSemiconductor/solid-state device detailsSolid-state devicesX-rayOptical communication

A bodiesize, low electric resistance and high heat-spreading electric circuit substrate, which is suitable for an electric circuit used at microwave of 1 GHz or more as used in the field of wireless communication such as portable telephones or optical communication, is provided. A jointed body of glass-ceramic with aluminum nitride sintered bodiesaid glass-ceramic containing crystals having the strongest line in the range of 2theta=27.6°-28.2° in powder X-ray diffraction using CuKalpha line, e.g., anorthite crystals, and having a composition containing 0.5-30 mass % of Zn component in terms of oxide, not more than 10 mass % in total of Ti component and Zr component in terms of corresponding oxides and not more than 5 mass % of Pb component in terms of oxide. Said jointed body is prepared by forming a layer of amorphous glass of above composition on an aluminum nitride sintered body, and thereafter heating the composite at temperatures not lower than the softening point of said amorphous glass, e.g., 600-1100° C., and concurrently crystallizing the same by said heating.

Owner:TOKUYAMA CORP

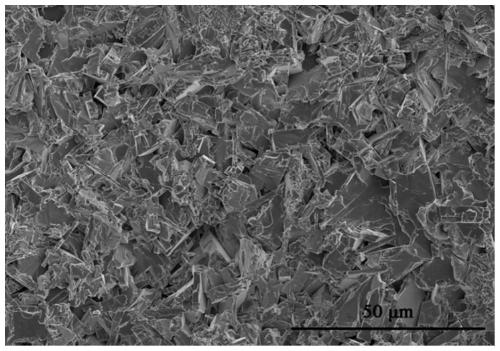

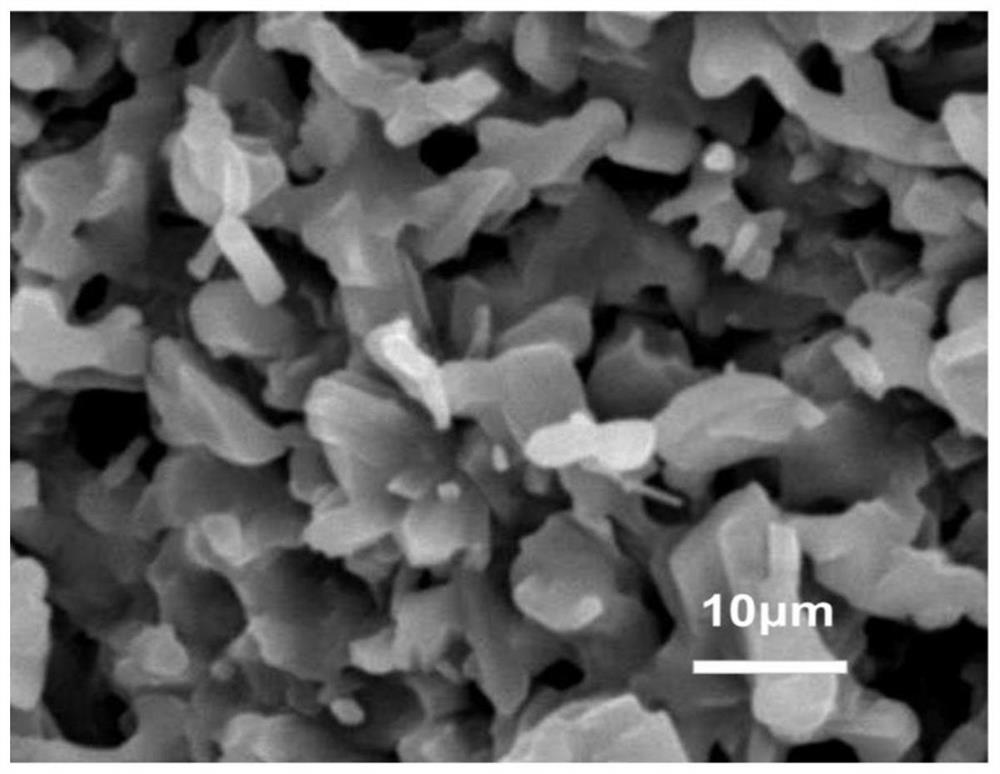

Zircon-free anorthite-based opaque glaze and preparation method thereof

The invention discloses a zircon-free anorthite-based opaque glaze, which comprises the following raw materials: 5-10 wt% of clay, 0-10 wt% of potassium feldspar, 20-40 wt% of albite, 5-20 wt% of quartz, 10-25 wt% of calcite, 0-10 wt% of wollastonite, 8-15 wt% of aluminum oxide, 1-10 wt% of zinc oxide, 3-8 wt% of calcined talc, 1-15 wt% of glass powder and 0.5-1.5 wt% of a nucleating agent. The invention also discloses a preparation method of the zircon-free anorthite-based opaque glaze. According to the invention, by using the low-cost raw materials and optimizing the formula system, flaky orblocky anorthite crystals are separated out from the interior of the glaze layer, and the three-dimensional crystallization is combined, so that the good glaze opacifying effect is achieved while thewhiteness and the hardness of the glaze are also improved, and the product performance is effectively improved; the raw materials do not contain radioactive elements and are harmless to the environment and human bodies; the opaque glaze is wide in application range and beneficial to popularization and application.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Method for manufacturing high-tenacity ceramics through tricalcium phosphate

The invention belongs to the field of ceramic industry, and discloses a method for manufacturing high-tenacity ceramics through tricalcium phosphate. The method comprises the following steps that, by weight, 5%-15% of the tricalcium phosphate and 85-95% of ceramic blanks are evenly smashed, mixed, milled in the mode of wet ball milling, dried and ground into powder, green ceramic bodies are manufactured through dry pressing molding and the green ceramic bodies are sintered in a kiln to form the high-tenacity ceramics. According to the high-tenacity ceramic samples manufactured through the method, needle-shaped mullite and anorthite serve as the main crystalline phase, cristobalite serves as the auxiliary crystalline phase, and a Si-O system and P-O system composite glass phase serves as the binding phase. Through the structure, thermal expansion coefficients between the crystalline phases and between the crystalline phases and the glass phase are better matched, micro-cracks can be effectively reduced in the ceramic sintering process, and the tenacity of ceramic products is greatly improved.

Owner:SOUTH CHINA UNIV OF TECH

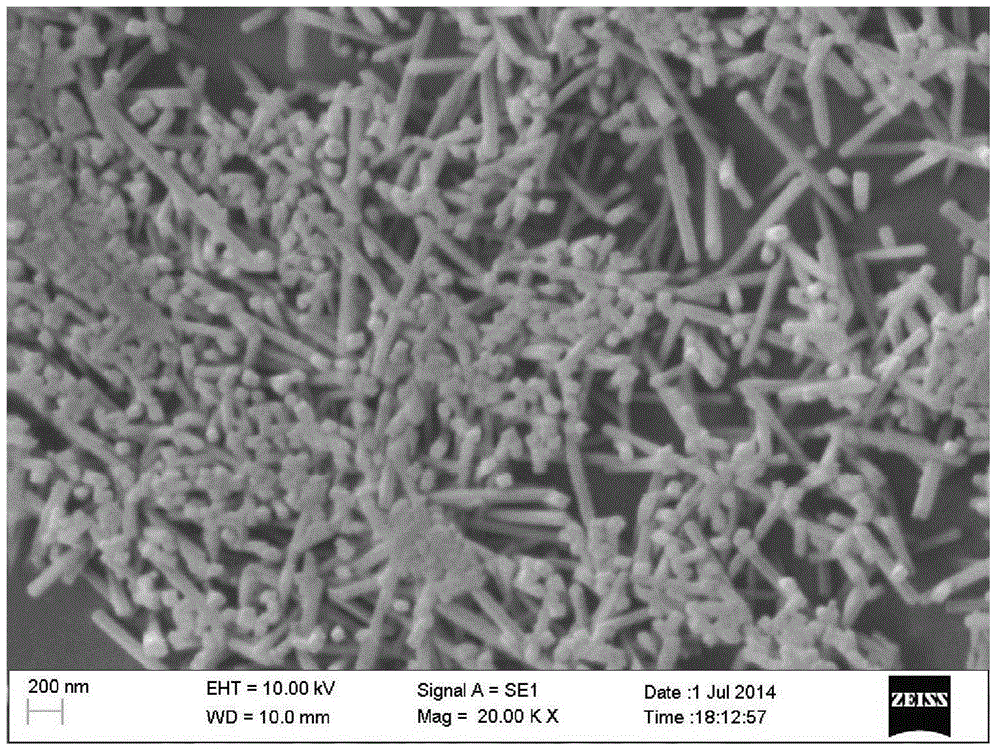

Lightweight anorthite microporous refractory aggregate and preparation method thereof

The invention relates to lightweight anorthite microporous refractory aggregate. The lightweight anorthite microporous refractory aggregate is prepared by the steps of mixing and ball-milling kaolin, bauxite, silica powder, limestone and calcium hydroxide, adding dextrin, sintering and crushing. In the prepared refractory aggregate, the main phase is anorthite; in the presence of the anorthite phase, the aggregate has the characteristic of high stability when being used in the reducing atmosphere environment; the starting material has high purity and the mixed impurity components are small, so that the anorthite phase content of the finally obtained product is high, and the product has small shrinkage deformation and high high-temperature volume stability and contributes to maintenance ofthe whole structure of industrial kiln furnace wall lining; materials are ground and prepared, so that the materials are dispersed uniformly and have small granularity; and the air holes in the aggregate have small aperture which is micro-scale and have closed spherical structures, so that microporous aggregate has low thermal conductivity coefficient and high strength.

Owner:HENAN UNIV OF SCI & TECH

Anorthite-mullite complex-phase high-temperature resistant material and preparation method thereof

The invention relates to an anorthite-mullite complex-phase high-temperature resistant material and a preparation method thereof, belonging to the technical field of refractory materials. The complex-phase high-temperature resistant material takes limestone, quartz powder and gamma-alumina as main raw materials; the limestone which accounts for 1.0-31wt% of total ingredients, the quartz powder which accounts for 28.2-37.5wt% of total ingredients and the gamma-alumina which accounts for 31.5-72wt% of total ingredients are burdened; after wet milling and mixing, the bonding agent is added for dry pressing and shaping; the mixture is sintered at the temperature of 1400-1600DEG C to obtain the anorthite-mullite complex-phase high-temperature resistant material. The anorthite-mullite complex-phase high-temperature resistant material prepared with the preparation method has excellent high temperature resistance, thermal shock resistance and low thermal conduction performance, the cost of the complex-phase high-temperature resistant material containing the anorthite and the mullite can be effectively lowered, and meanwhile, a new technological approach can be opened for comprehensively and efficiently utilizing the anorthite and the mullite.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

Easy-to-clean ceramic product for daily use and preparation method thereof

The invention discloses an easy-to-clean ceramic product for daily use. The ceramic product comprises a green body and a surface glaze layer, the surface glaze layer covers the surface of the green body, and the thickness of the surface glaze layer is about 1-2 mm; the surface glaze layer is prepared from the following raw materials in parts by weight; 300 to 370 parts of anorthite, 45 to 58 partsof diatomite, 30 to 35 parts of purple gold soil, 34 to 40 parts of kaolin, 42 to 52 parts of bentonite, 27 to 36 parts of quartz sand, 15 to 18 parts of nano zinc oxide, 55 to 68 parts of nano silicon carbide, 32 to 38 parts of nano silicon, 11 to 14 parts of partial graphene oxide and 4 to 6 parts of rare earth. The surface roughness value of the easy-to-clean domestic ceramic product reaches 4.31 nm (rm s), and the easy-to-clean domestic ceramic product is very smooth and flat in surface, not prone to contamination and easy to clean; wear resistance is excellent, scratching is not prone tohappening in the using process, contamination is not prone to happening, and cleaning is easy; fluorine-containing compounds or components are not added, so that no fluorine element enters the humanbody in the use process, and the health of the human body is facilitated.

Owner:福建省德化县紫嘉工艺有限公司

Low-temperature wear-resistant frit, wear-resistant glaze using same and glazed tile

The invention discloses a low-temperature wear-resistant frit. Raw materials of the low-temperature wear-resistant fritcomprise wollastonite, dolomite, kaolin, aluminum oxide and a strong fluxing agent, and the raw materials do not contain feldspar; the adding amount of the dolomite is greater than 8%, the adding amount of the wollastonite is greater than 20%, and the adding amount of the aluminumoxide is less than 12% in percentage by mass. According to the low-temperature wear-resistant frit provided by the technical scheme, the introduction of feldspar is avoided in the formula, so that the wear resistance of the low-temperature wear-resistant frit is improved, and the defects in the prior art are overcome. According to the wear-resistant glaze using the low-temperature wear-resistantfrit, anorthite and mullite are separated out of the low-temperature wear-resistant frit to serve as main crystalline phases, so that the wear resistance of the glaze is improved. In addition, the invention also provides a glazed tile using the wear-resistant glaze, the wear resistance of the glazed tile is 4-grade 2100 revolutions, and the wear resistance loss of the glazed tile is 0.042-0.05 g at 6000 revolutions.

Owner:FOSHAN DONGPENG CERAMIC +1

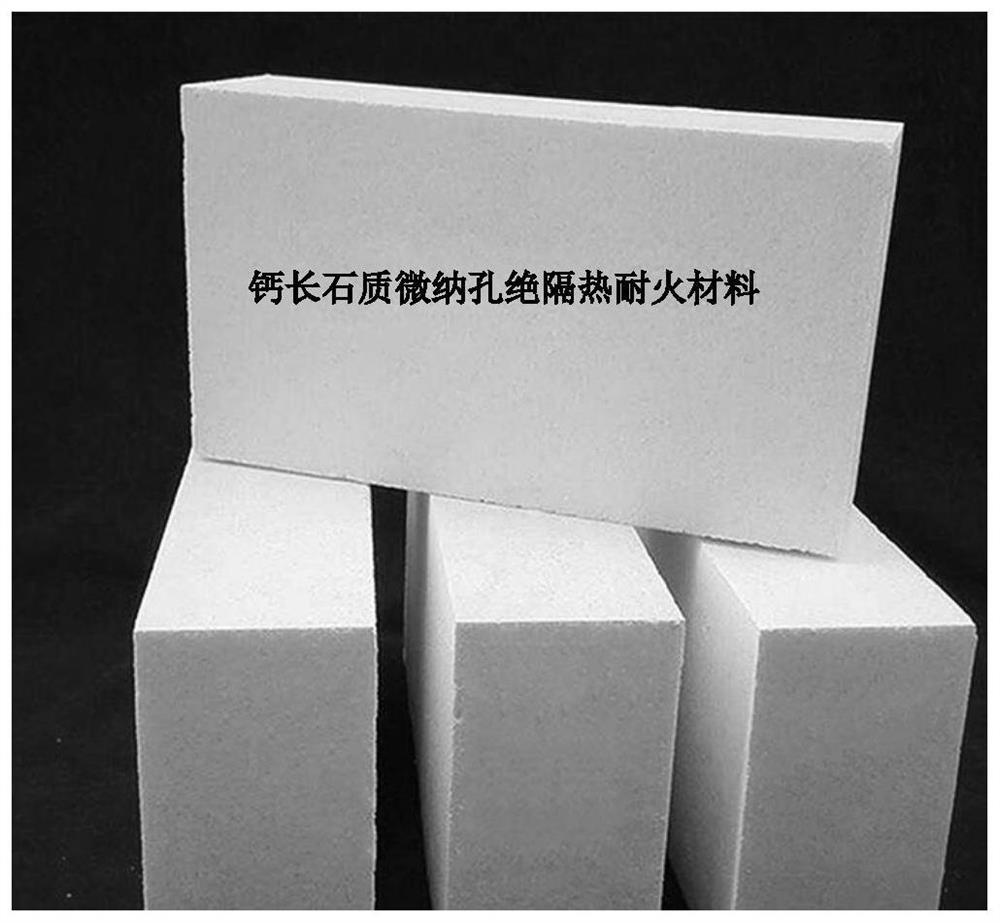

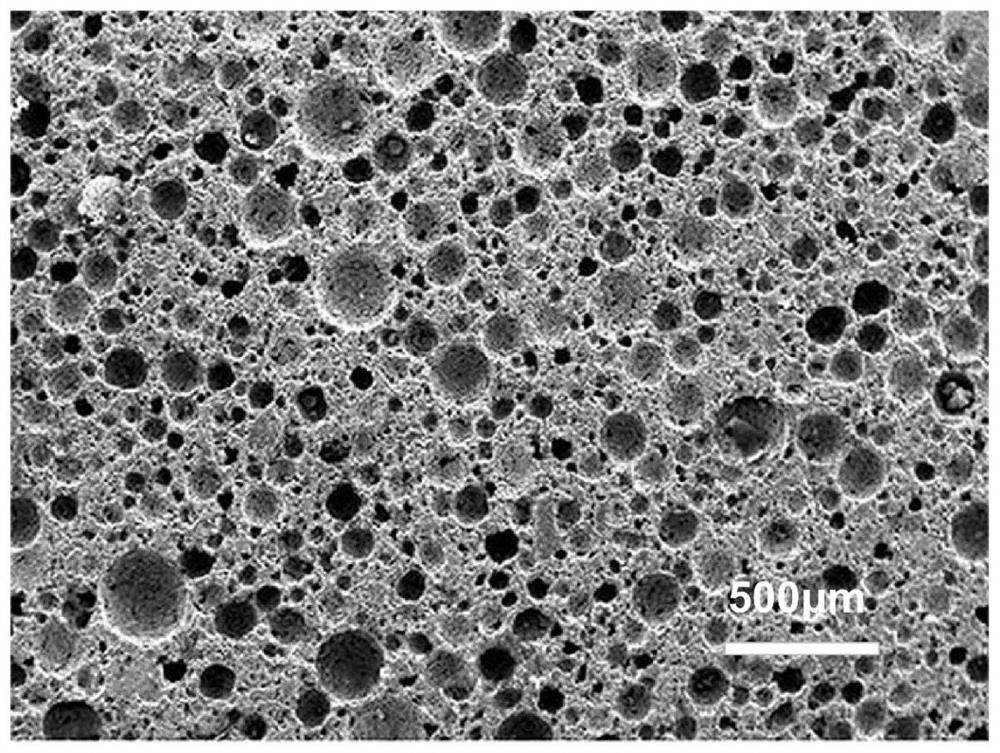

Aorthite micro-nano pore heat insulation refractory material and preparation method thereof

The invention belongs to the field of refractory materials, and particularly relates to an anorthite micro-nano pore heat insulation refractory material and a preparation method thereof. The anorthite micro-nano pore heat insulation refractory material is mainly prepared from a basic raw material, an additive and water. The anorthite micro-nano pore heat insulation refractory material is white, faint yellow or yellow in appearance, the principal crystalline phase of the product is anorthite, the mass content of CaO in the chemical composition is 4-22 wt%, the pore size distribution is 0.006-250 [mu] m, the average pore size is 0.1-19 [mu] m, and the pore structure of the micro-nano size ensures that the product has better heat insulation performance under the conditions of low volume density and high strength. The preparation method is green, environment-friendly and pollution-free, and the structure and performance of the product are easy to accurately regulate and control.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

High-strength and high-toughness graphene composite ceramics

The invention discloses high-strength and high-toughness graphene composite ceramic. The high-strength and high-toughness graphene composite ceramic comprise a green body and a glaze material, whereinthe green body is prepared from ferric oxide, anorthite, potassium feldspar, attapulgite, spodumene, graphene, nanometer titanium dioxide fiber powder, silicon carbide crystal whiskers, barium sulfate and glass microbeads; and the glaze material is prepared from kaolin, graphene, nanometer titanium dioxide fiber powder, bamboo charcoal powder, silicon carbide crystal whiskers, barium sulfate, glass microbeads, potassium feldspar, quartz sand, talcum powder, olivine, bamboo charcoal powder, ferric oxide, aluminum oxide, magnesium oxide, zirconium silicate, zinc oxide and lutetium oxide. A fiber reinforcing technology is introduced, use of the graphene is combined, and the barium sulfate and the glass microbeads are compounded, so that the dispersibility of the graphene is improved; according to proper proportion, the components can exert a remarkable synergistic effect and obviously enhance the strength and the toughness of the ceramic; furthermore, the obtained ceramic material has aremarkable adsorbing and removing ability on air pollutants and has excellent corrosion resistance; and the application range is wide, and the preparation method is simple and suitable for industrialized production.

Owner:林荣铨

Abrasion-resistant ceramic tile and production technology thereof

The invention discloses an abrasion-resistant ceramic tile and a production technology thereof. The abrasion-resistant ceramic tile is prepared from the following components in parts by weight: 10 to 20 parts of diatomite, 5 to 10 parts of kaolin, 3 to 8 parts of bentonite, 12 to 18 parts of quartz sand, 50 to 80 parts of albite, 25 to 40 parts of anorthite, and 20 to 35 parts of sanidine. The abrasion-resistant ceramic tile has the advantages that by adopting the traditional production technology of ball milling, spraying, drying and granulating, pressing and forming, high-temperature firing, and low-temperature firing, the technology is simple; the strength is higher, the water absorbing rate is low, and the problem of radioactivity exceeding the standard is solved.

Owner:肥西县碧涛建材有限公司

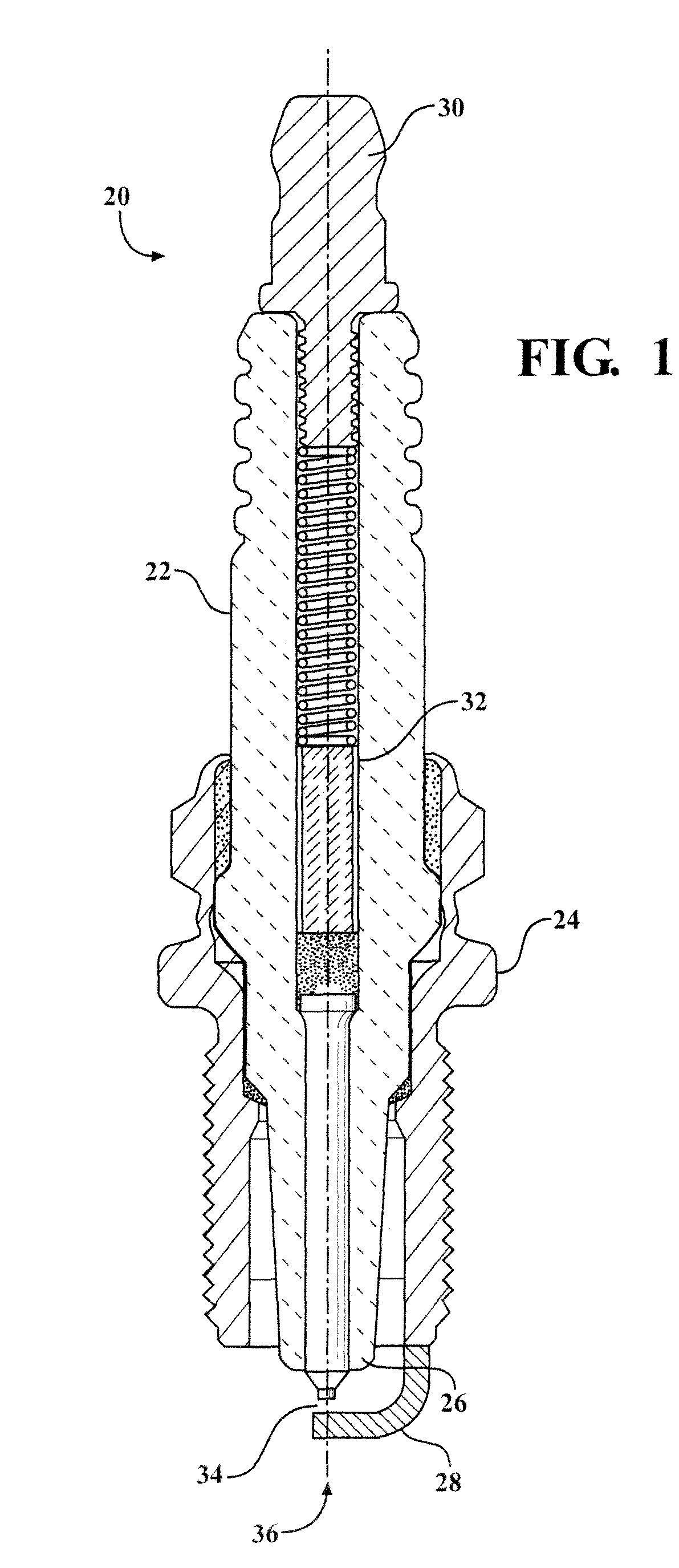

Alumina ceramic for spark plug insulator

ActiveUS8614542B2Improve conductivityHigh strengthElectric discharge tubesDischarge tube main electrodesAluminateMullite

A spark plug includes an insulator formed of a ceramic material. The ceramic material comprises Al2O3 in an amount of 98.00 wt % to 99.50 wt %; Group 2 oxides in an amount of 0.16 wt % to 0.70 wt %; SiO2 in an amount of 0.25 wt % to 0.75 wt %, Group 4 oxides in an amount of 0.01 wt % to 0.16 wt %, Group 1 oxides in an amount less than 0.0060 wt %, and P2O5 in an amount of less than 0.0040 wt %. The Al2O3 is formed of particles having a D50 median particle size by volume of 1.2 μm to 1.8 μm. The ceramic material is pressed, sintered, and formed to a predetermined shape. The sintered ceramic material includes a glass phase comprising the Al2O3, Group 2 oxides, and SiO2. The sintered ceramic material also includes secondary crystals of calcium hexa-aluminate (CaAl12O19) spinel (MgAl2O4), anorthite (CaAl2Si2O8), and mullite (Al6Si2O13).

Owner:FEDERAL MOGUL IGNITION

Sanitary ceramic formula and preparation method

ActiveCN111533530AHigh refractorinessSmall degree of deformationCeramic materials productionClaywaresChemical compositionMullite

The invention relates to the field of preparation processes of sanitary ceramics, in particular to a formula and a preparation method of sanitary ceramics, which improve the refractoriness of a greenbody and reduce the deformation degree of the green body by adjusting the raw material composition of the formula and optimizing the chemical composition. In the mineral composition of a common feldspar porcelain body, a proper amount of wollastonite raw material is introduced, the content of an anorthite crystalline phase is increased on the basis of original mullite and quartz crystalline phases, and a proper amount of closed independent pores are formed, so that the shrinkage rate and the volume density are reduced; by introducing a proper amount of the borocalcite flux, an (O = B-O-B = O)structure can be provided, the integrity and compactness of a network structure around the pores of the borocalcite flux are ensured, and the sizes of the independent pores are controlled within a certain range so as to avoid reduction of the firing strength.

Owner:HUIDA SANITARY WARE

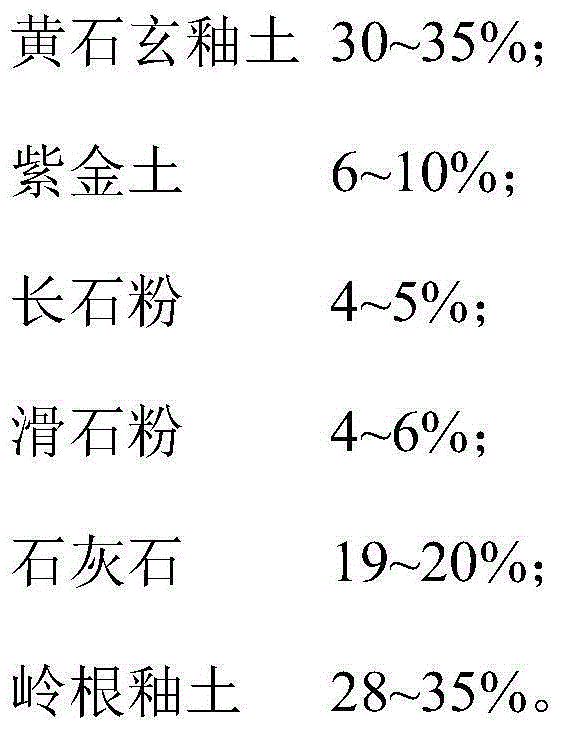

Preparation method and glaze material of celadon secret color glaze

The present invention provides a preparation method and a glaze material of a celadon secret color glaze. According to the present invention, Huangshixuan glaze soil, purple-gold soil, feldspar powder, talc powder, limestone and Ling'gen glaze soil are adopted as raw materials, air in the glaze can not float out of the glaze surface during the glaze firing process while a lot of small gas bubbles are formed, a certain number of undissolved quartz particles are remained in the glaze when the temperature of the porcelain forming stage is 1280-1310 DEG C, a large amount of anorthite crystals are formed, light entering the glaze layer produces the scattering due to the formed small gas bubbles, the formed quartz particles and the formed anorthite crystals so as to make the glaze layer have the transparent jade texture, and after the thermal expansion and contraction, the glaze layer cracks so as to form the stereoscopic vision effect of the smooth and rich jade; the prepared celadon secret color glaze has characteristics of green, mild and moist glaze color, good thermal stability and wide adaptability; and the preparation method is scientific and rational, and is easy to perform, and the obtained celadon secret color glaze product has characteristics of high yield and good product porcelain quality.

Owner:郑峰

Preparation process of crackle-free powder bluish-green glaze craft porcelain

The invention discloses a preparation process of crackle-free powder bluish-green glaze craft porcelain. The craft porcelain comprises a green body and glaze, the green body comprises the following raw materials: feldspar, Dehua kaolin, Dehua quartz, dolomite, sepiolite, diatomite, spodumene, zirconium silicate, titanium oxide and tin oxide. The glaze comprises the following raw materials: anorthite, brucite, diopside, Dehua quartz, frit, manganese oxide, ferric oxide, titanium oxide and nickel oxide. By improving the basic formula of the glaze, the fired porcelain is greenish green and elegant in glaze color and soft in glaze surface gloss, the jade-like effect is achieved, brucite in the glaze is matched with manganese oxide, ferric oxide and nickel oxide, the porcelain is fired under aspecific process, and it is guaranteed that the fired porcelain is bluish green and elegant in glaze color.

Owner:福建省德化县嘉发陶瓷有限公司

Cement chemistries

ActiveUS10233127B2Calcium/strontium/barium carbonatesSolid waste managementOXALIC ACID DIHYDRATEAluminum silicate

A cementitious composition comprising a crystalline phase and an amorphous phase, and an activator selected from the group of materials comprising inorganic bases. In some cases the crystalline phase is gehlenite. In some cases the crystalline phase is anorthite. In some cases the amorphous phase is amorphous calcium aluminum silicate. In some cases the activator is elected from OPC (1-70 wt %), free lime (1-20 wt %), calcium hydroxide (1-20 wt %), and alkali hydroxides (NaOH, KOH 1 to 10 wt %), individually or in combination. A low lime cementitious material is cured by reaction with a curing reagent that includes a reagent chemical that is synthesized from CO2. Examples of such a reagent are oxalic acid and tartaric acid.

Owner:SOLIDIA TECH

Glass-ceramic tiles and preparation method thereof

The invention discloses glass-ceramic tiles. The tiles are prepared from the following components in parts by weight: 10-25 parts of crystalline frit, 10-20 parts of quartz, 5-10 parts of wollastonite, 10-30 parts of diopside, 5-10 parts of anorthite, 5-10 parts of fluorite, 0-1.5 parts of coloring metal oxide powder, 0-5 parts of feldspar and 0-5 parts of clay. The preparation method comprises the following steps: firstly, preparing a powder blank, then performing sheeting forming, performing primary firing, then performing primary polishing, performing secondary firing and finally performingaftertreatment to obtain the finished glass-ceramic tiles. Microcrystalline phases of various oxides are produced from ceramic raw materials under the high temperature condition, oxides of titanium,zirconium or lead are prevented from being used as crystal nuclei, radiation and lead hazards are prevented, and the glass-ceramic tiles prepared with the multiple-sintering method have the characteristics of high surface compactness, high transparency, rich texture, better hardness and wear resistance and the like; meanwhile, fluorite is used as a fluxing agent and a dyeing assistant agent, so that ceramic is not easy to fade.

Owner:安徽磐盛新型材料科技有限公司

High-strength glass and preparation technology thereof

The invention discloses a high-strength glass. The high-strength glass comprises the following raw materials in parts by weight: 60-80 parts of quartz sand, 10-20 parts of alumina, 5-10 parts of sodaash, 3-8 parts of dolomite, 2-6 parts of calcium carbonate, 3-6 parts of bauxitic clay, 7-16 parts of anorthite, 5-15 parts of high-purity magnesium oxide, 3-8 parts of nano silica, 2-8 parts of zincoxide, 5-10 parts of sodium nitrate, 8-15 parts of calcite, 3-8 parts of yttrium oxide, 2-6 parts of boron oxide, 1-5 parts of titanium dioxide, 4-10 parts of a composite colouring agent, and 1-5 parts of a clarificant. The method comprises the following steps: 1) weighing raw materials; 2) crushing the raw materials; 3) melting and moulding the raw materials; 4) performing annealing; 5) performing surface pretreatment; 6) performing strengthening treatment; and 7) performing drying treatment. The high-strength glass solves the disadvantages of the insufficient glass intensity in the prior art, the preparation technology is simple, and realization is easy.

Owner:HEFEI LIYUTAI GLASS PROD CO LTD

Wear-resistant transparent glaze, wear-resistant glazed brick and preparation method thereof

The invention discloses a wear-resistant transparent glaze that is prepared from the following raw materials in percentage by weight: 3 to 7 percent of nanoscale anorthite, 20 to 30 percent of albite,18 to 28 percent of fused quartz, 6 to 10 percent of kaolin, 40 to 50 percent of transparent frit, 0.01 to 0.5 percent of dispersing agent and 0.01 to 0.1 percent of plasticizer. By introducing special raw material components such as nanoscale anorthite, fused quartz and transparent frit, the raw material components of the glaze can play a synergistic effect in the conventional fusing and firingprocess, so a large amount of anorthite crystalline phases can be efficiently generated, and then the hardness, wear resistance and light transmission performance of the glaze are effectively and synchronously improved.

Owner:GUANGXI OCEANO CERAMICS CO LTD

Special toughened high-temperature-resistant ceramic for fuel engine cylinder liners and preparation method thereof

The invention discloses a special toughened high-temperature-resistant ceramic for fuel engine cylinder liners and a preparation method thereof. The special ceramic is prepared from the following raw materials in parts by weight: 42-54 parts of anorthite, 24-36 parts of kyanite, 38-49 parts of zirconite, 22-34 parts of bauxite, 16-22 parts of magnesium oxide, 13-19 parts of molybdenum disilicide, 2-4 parts of lanthanum oxide, 10-15 parts of silicon nitride, 5-10 parts of ferric oxide, 4-7 parts of hafnium boride, 11-17 parts of calcium oxide, 1-3 parts of thorium oxide, 5-8 parts of sorbitol, 2-4 parts of sodium oleate, 4-7 parts of triisopropanolamine, 3-5 parts of carboxymethyl alantin sodium, 10-15 parts of water glass, 8-14 parts of polyvinyl acetate, 3-6 parts of hydroxypropyl distarch phosphate and a right amount of deionized water. The molybdenum disilicide, silicon nitride, hafnium boride and sintering technique are adopted to enhance the heat resistance and toughening performance of the ceramic; abundant stable lanthanum oxide, calcium oxide and thorium oxide stabilizers are utilized to lower the sintering temperature and difficulty; and by using the stabilizers, the high-temperature resistance is up to 2000-2500 DEG C, the high-temperature resistance time is up to 760-850 hours, the toughness KIc is 4-6, and the folding strength is 400-600 MPa.

Owner:南通拓创光电材料科技有限公司

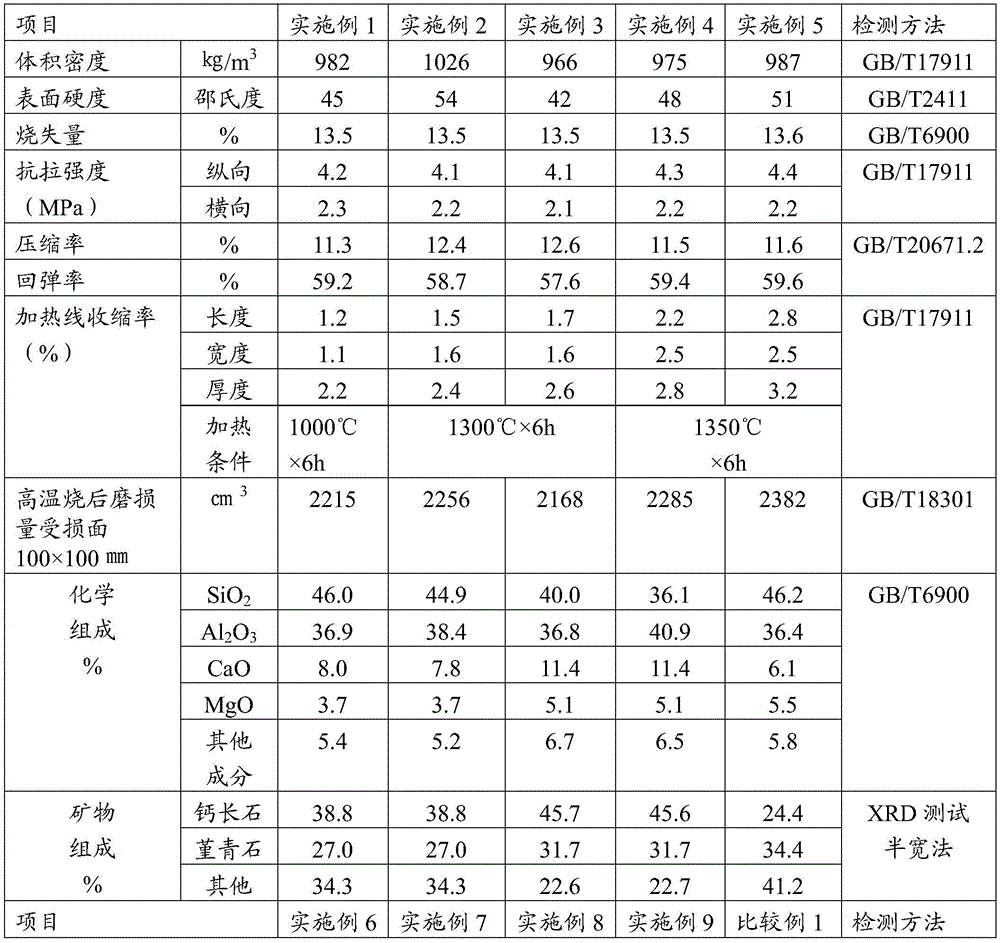

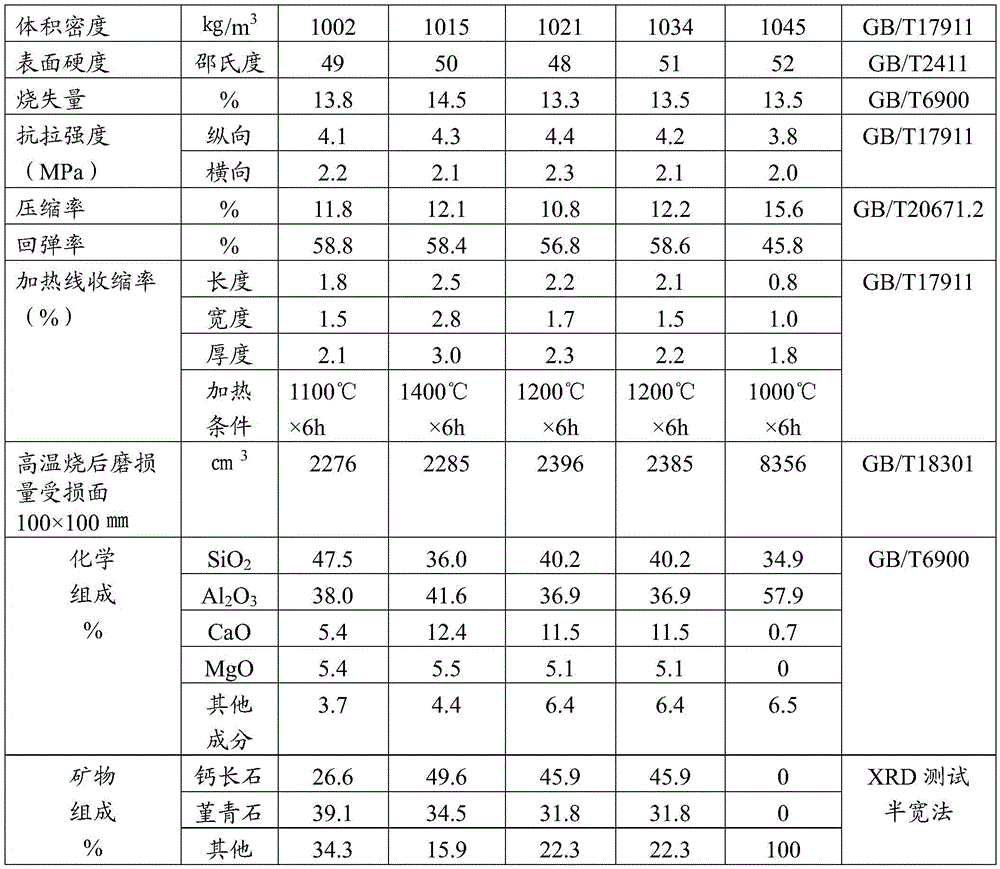

Ceramic fiber sealing pad plate and preparation method thereof

ActiveCN105622080AImprove high temperature wear resistanceExtended service lifeEngine sealsFiberChemical composition

The invention provides a ceramic fiber sealing pad plate, which has the chemical composition of 30 to 48 parts by mass of SiO2, 30 to 42 parts by mass of Al2O3, 5 to 13 parts by mass of CaO and 3 to 8 parts by mass of MgO. Through the chemical composition of the ceramic fiber sealing pad plate provided by the invention, anorthite and dichroite mineral facies in a specific proportion range can be formed, wherein the anorthite and dichroite mineral facies can greatly improve the high-temperature wear-resistant performance of the sealing pad plate and can prolong the service life. The result shows that the long-time use temperature of the ceramic fiber sealing pad plate reaches 900 DEG C or higher than 900 DEG C; the highest use temperature can reach 1200 DEG C or higher than 1200 DEG C; a heatproof roller of the assembled ceramic fiber sealing pad plate has good high temperature wear resistance; the service life at least reaches 20 days or more, and can reach 60 days or more to the highest degree.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com