Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2524 results about "Potassium feldspar" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium feldspar refers to a number of minerals in the feldspar group, and containing potassium: Orthoclase (endmember formula KAlSi3O8), an important tectosilicate mineral that forms igneous rock. Microcline, chemically the same as orthoclase, but with a different crystalline structure.

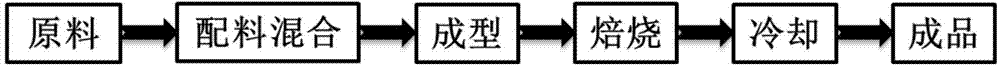

Production method of once-fired super-spar ceramic tile and ceramic tile

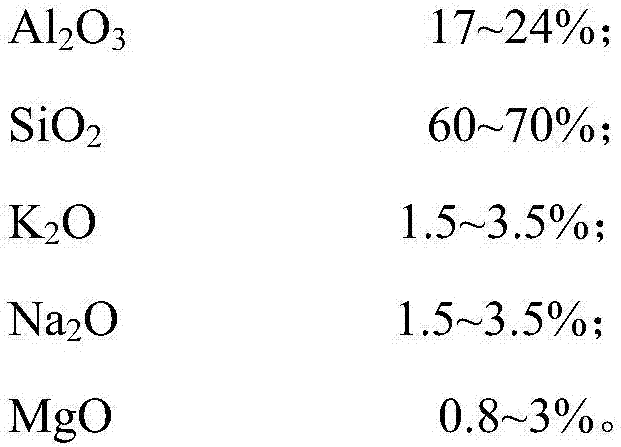

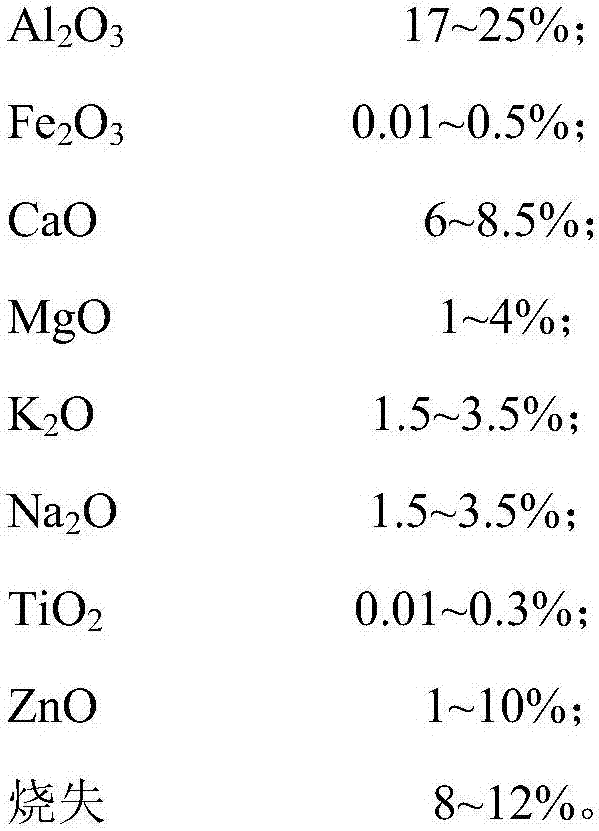

The invention relates to a production method of once-fired super-spar ceramic tile and the ceramic tile. The production method of the once-fired super-spar ceramic tile comprises the following steps: preparing green body powder; pressing a tile body; cleaning the green body; pouring ground glaze; printing; pouring overglaze; firing a glaze body at a high temperature; polishing; performing surface treatment; performing edge polishing; and packaging to obtain a finished product, wherein the overglaze comprises the following components in parts by weight: 5 to 13 parts of quartz powder, 3 to 20 parts of potassium feldspar, 20 to 28 parts of soda feldspar, 12 to 18 parts of dolomite, 3 to 6 parts of fired talc, 3 to 8 parts of kaolin, 14 to 22 parts of calcined kaolin, 3 to 8 parts of zinc oxide, 7 to 14 parts of barium carbonate and 3 to 6 parts of grammite. According to the invention, the problems that microlite has low wear resistance and is difficult to process in the prior art are solved, and the defect of water ripples caused by the situations that fully-polished glaze absorbs dirt, bottom is easy to expose and the tile surface is uneven is also solved. The super-spar product produced with the method has the advantages that the microlite is transparent, bright and smooth like a mirror and does not absorb dirt completely; and the fully-polished glaze is light, thin and wear-resistant.

Owner:周予

Transparent lead-free fritted glaze with low expansion coefficient and preparation method thereof

The invention relates to a transparent lead-free fritted glaze with low expansion coefficient and a preparation method thereof. The fritted glaze comprises the following chemical ingredients of: 59 to 66 percent of SiO2, 10 to 15 percent of Al2O3, 5 to 10 percent of B2O3, 3 to 6 percent of CaO, 4 to 8 percent of MgO, 0 to 3 percent of K2O, 0 to 2 percent of Na2O, 0 to 1 percent of Li2O, 1 to 5 percent of ZnO and 0 to 2 percent of SrO; and the fritted glaze comprises the raw materials of: 10 to 25 percent of kaolin, 15 to 30 percent of quartz, 10 to 25 percent of potassium feldspar, 0 to 8 percent of dolomite, 2 to 6 percent of grammite, 10 to 20 percent of roasted talc, 1 to 6 percent of zinc oxide, 2 to 8 percent of boric acid, 5 to 15 percent of calcium borate, 1 to 5 percent of alumina, 0 to 2 percent of lithium carbonate and 0 to 3 percent of strontium carbonate. The expansion coefficient of the fritted glaze is 3.7-4.5*10-6 / DEG C (RT to 500 DEG C), the melted temperature is 1400 DEG C to 1500 DEG C, the glaze firing temperature is 1130 DEG C to 1230 DEG C; and the transparent lead-free fritted glaze has fine and bright glaze surface, high transparency, low expansion coefficient as well as no lead precipitation and is particularly suitable for double-fired hard porcelain body with lower expansion coefficient.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Method for preparing porcelain granules by using fly ash

InactiveCN101585698AImprove protectionSave natural resourcesFluid removalCeramic materials productionExpanded clay aggregateSlurry

The invention discloses a method for preparing porcelain granules by using fly ash, which comprises the following steps: putting fly ash, potassium feldspar and quartz as raw materials into a ball mill respectively, dry-milling the raw materials, sieving the milled raw materials respectively, removing iron from the sieved fly ash, putting the fly ash after iron removal, the sieved potassium feldspar and quartz and kaolin into the ball mill, and wet-milling and evenly mixing the materials to form mixed slurry; and granulating the mixed slurry by adopting a pressure type spray granulator, putting the granules into an alumina crucible, placing the alumina crucible into a silicon-carbon rod resistance furnace, sintering and naturally cooling the granules, and taking out the granules to obtain the high-strength porcelain granules. The method for preparing the porcelain granules by using the fly ash is not only favorable for saving natural resources and reducing the production cost, but also favorable for environmental protection. The fly ash does not need to be crushed by a high-power crusher, and the fly ash is mixed evenly. The production process is easy to control, and has little energy consumption; the strength of the prepared fly ash porcelain granules can reach 60 to 120MPa; and the porcelain granules have good properties of light weight, high temperature resistance, corrosion resistance and the like, and can be used as a fracturing propping agent for middle and deep layer oil-gas fields.

Owner:SHAANXI UNIV OF SCI & TECH

Lightweight ceramisite prepared from coal ashes and gasification slag as well as preparation method and application thereof

ActiveCN104774023ASignificant environmental benefitsImprove performanceSolid waste disposalCeramicwareSlagExpanded clay aggregate

The invention relates to the technical field of building materials, and in particular relates to lightweight ceramisite prepared from coal ashes and gasification slag as well as a preparation method and an application thereof. The lightweight ceramisite is prepared from the following raw materials with the following components in parts by weight: 100 parts of base materials comprising 40-90 parts of coal ashes, 10-30 parts of gasification slag, 0-20 parts of potassium feldspar and 0-20 parts of albite; and 0-4 parts of additional auxiliaries which are selected from one or two of semicoke or silicon carbide, wherein the coal ashes account for 40-90%, and the gasification slag particles account for 10-30%; and the sintering temperature is 1120-1200 DEG C, the energy consumption is reduced, the raw material distribution is relatively wide and the raw materials are easily available. The lightweight ceramisite has bulk density lower than or equal to 700 kg / m<3>, is smaller in weight, higher in strength, wider in raw material distribution and easier to obtain, and the barrel pressure strength can be higher than 10 MPa.

Owner:北京大学包头创新研究院

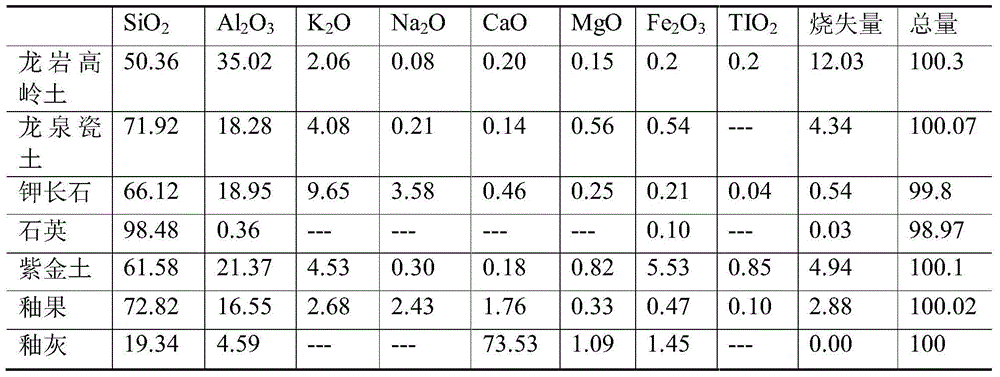

Longquan celadon crackle glaze wine bottle and preparation method thereof

ActiveCN104150873ANovel preparation methodSatisfy the wine storage functionClaywaresPotassiumWine bottle

The invention relates to a longquan celadon crackle glaze wine bottle and a preparation method thereof. Raw material proportions of a blank material, an internal glaze and an external glaze of the bottle are respectively described as follows: the blank material comprises: 40-55% of Longyan kaolin, 15-25% of Longquan china clay, 8-20% of potassium feldspar, 7-15% of quartz and 5-10% of zijin clay; the internal glaze comprises: 65-70% of glaze fruit, 12-25% of glaze ash and 5-10% of zijin clay; and the external glaze comprises: 60-70% of potassium feldspar, 8-15% of quartz, 8-13% of Longyan kaolin, 8-15% of glaze ash, 5-13% of zijin clay and 0.2-0.4% of Fe2O3. On the basis of above raw materials, the longquan celadon crackle glaze wine bottle is prepared by following steps: preparing slurry, performing an injection moulding process to obtain a wet blank; performing a drying process, a trimming process and a biscuiting process to complete a blank manufacturing process; and finally applying the internal glaze and the external glaze and performing a glazing firing process to obtain a finished product of the longquan celadon crackle glaze wine bottle. The bottle is free of stripes on the internal glaze. The external glaze is decorated through crackles. The bottle is good in quality and is free of internal leakage of wine. The method is low in cost and good in effect.

Owner:龙泉市尚唐瓷艺发展有限公司 +1

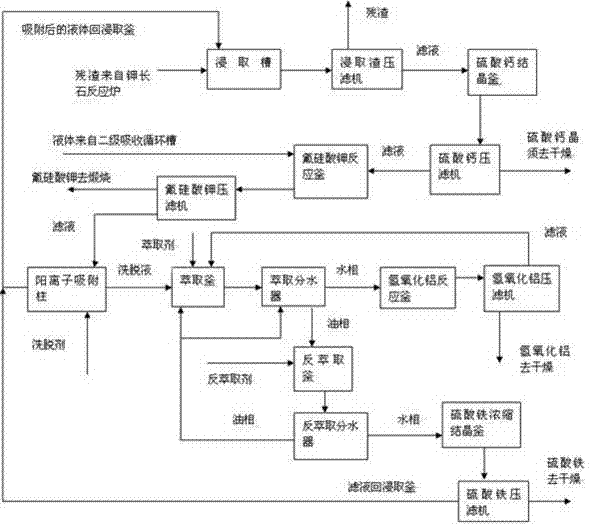

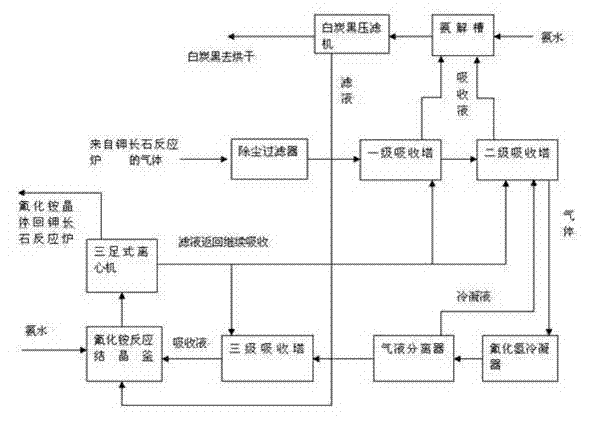

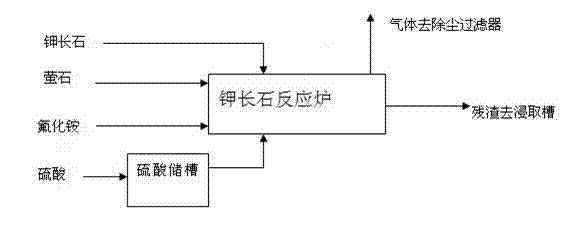

Process for decomposing potassium feldspar by adopting low-temperature semidry method for comprehensive utilization

ActiveCN103172074AAvoid wastingLower requirementSilicon halogen compoundsSilicaAluminium hydroxideDecomposition

The invention relates to potassium feldspar decomposition and comprehensive utilization technology and in particular relates to a process for decomposing potassium feldspar by adopting a low-temperature semidry method for comprehensive utilization. The process comprises the steps of fully mixing potassium feldspar, fluorite and sulfuric acid, then adding the mixture to a converter reactor to react at 180-250 DEG C, separating SiF4 and HF generated through a reaction from a system under the condition of negative pressure, carrying out absorption with ethanol and water solution to prepare white carbon black, recovering fluorine resources in the process from the solution in the forms of ammonium fluoride and other aids by adopting the method of adding ammonia water and applying the recovered fluorine sources to decomposition of potassium feldspar and carrying out a series of processes such as extraction on the solids after a reaction to obtain calcium sulfate whisker, potassium fluosilicate, aluminium hydroxide and ferric sulfate products. Compared with the method for decomposing potassium feldspar by a high temperature method, the process has the advantages that the reaction conditions are mild and the requirements for equipment are lower; the white carbon black is directly prepared through gas hydrolysis, thus avoiding the tedious course from solid phase separation; and the fluorine resources introduced to the decomposition course are recycled by adopting the mode of ammonium fluoride, thus avoiding waste of the fluorine resources.

Owner:LUOYANG FLUORIDE & POTASSIUM TECH +1

Flux-cored wire for austenitic stainless steel all-position welding

ActiveCN102229029AGood workmanshipGood slag removalWelding/cutting media/materialsSoldering mediaElectrolysisPotassium

The invention relates to a flux-cored wire for austenitic stainless steel all-position welding, and the flux-cored wire is composed of a flux core and an external stainless steel belt, wherein, the flux core accounts for 22-24wt% of the flux-cored wire, and the flux core comprises the following components in percentage by weight: 20-23% of metal chromium powder, 7-8.5% of metal nickel powder, 2-4% of electrolytic manganese metal, 3-4% of aluminium powder, 0.5-1% of ferrotitanium, 32-34% of rutile, 1-2% of quartz, 2-4% of zircon sand, 4-6% of albite, 2-4% of potassium feldspar, 1-1.5% of cryolite, 1-1.5% of lithium carbonate, 0.1-0.5% of bismuth oxide and the balance of iron powder. The ratio of the albite to the potassium feldspar in the flux core is 1.2-2, the sum of the albite and the potassium feldspar is not more than 10wt% of the flux core, the external stainless steel belt is the austenitic stainless steel 304L, the carbon content is less than 0.025wt%, the diameter of the flux-cored wire is 0.9-1.2mm, and the flux-cored wire can be used for realizing the austenitic stainless steel all-position welding.

Owner:北京远达国际工程管理咨询有限公司 +1

Superfine dry granular porcelain glazed tile

The invention discloses a superfine dry granular porcelain glazed tile which belongs to the field of preparation of porcelain glazed tiles. The superfine dry granular porcelain glazed tile comprises agreen body, ground glaze and surface glaze, wherein the surface glaze comprises the following raw materials in percent by weight: 22-25wt% of potassium feldspar, 6-8wt% of calcined talc, 17-20wt% ofbarium carbonate, 2-5wt% of calcined alumina, 3-5wt% of calcined zinc oxide, 3-5wt% of quartz, 5-8wt% of kaolin, 6-8wt% of dolomite and 26-30wt% of 10,139 # dry granules. The green body of the tile islow in water absorption and high in breaking strength; the green body, the bottom glaze and the surface glaze are good in combinability, and the tile in good in flatness; the superfine dry granules form a slightly rugged surface in the surface glaze, and the grain size of each of granular crystals protruding out of the glaze is 0.12-0.18mm, so that an anti-skidding and abrasion-proof effect can be achieved on the glaze, and the defect that dirt is hided and adsorbed in the glaze can be overcome.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Preparation method of low-cost high-alumina ceramic thin plate

The invention relates to a preparation method of a low-cost high-alumina ceramic thin plate. The preparation method of the low-cost high-alumina ceramic thin plate is characterized by including the steps: 1) raw material treatment; 2) raw material proportioning and mixing: weighing raw materials including, in weight percent, 10%-25% of coal series kaolinite, 10%-25% of calcined bauxite, 20%-30% ofcommon kaolinite, 15%-25% of feldspar, 0-5% of talcum and 18%-25% of quartz to obtain a blank; adding reinforcing agents equivalently accounting for 0.1%-0.25% of the total weight of the blank, performing ball milling for 12-18 hours and uniformly mixing the raw materials to obtain mixed materials; 3) pelleting and aging; 4) semi-dry pressing; 5) drying; 6) glazing; 7) sintering to obtain the low-cost high-alumina ceramic thin plate. The feldspar is formed by mixing potassium feldspar with soda feldspar, and the weight ratio of K2O to Na2O of the mixed feldspar chemical composition is 2:1. The sintering temperature of the high-alumina ceramic thin plate prepared by the method is only 1180 DEG C, so that the ceramic thin plate is low in cost and high in strength.

Owner:WUHAN UNIV OF TECH

Household strengthen porcelain containing bone substances and production technology thereof

The invention relates to ceramics and a production technology thereof, in particular to a household strengthen porcelain containing bone substances and the production technology thereof. The strengthen porcelain body comprises petalite, powdered alumina, bone powder, quartz, Longyan braying, Guizhou soil, Zimo saved soil and humic acid sodium; the glaze comprises spodumene, fritted glaze 317, bone powder, kaolin, zirconia, potassium feldspar and aedelforsite; the production technology of the strengthen porcelain comprises the steps of batching, water adding and ball milling, sifting out, iron removing, filter pressing, primary smelting, ageing, refining, molding, drying, glazing and kiln firing. The product of the invention has the advantages of high mechanical strength, good thermal stability, fine and glossy glaze, high whiteness, good transmittance and the like.

Owner:CHAOZHOU LIANYUAN CERAMICS MFG

Imitated-marble whole-body ceramic tile and preparation method thereof

The invention discloses an imitated-marble whole-body ceramic tile comprising a whole-body green tile layer and an overglaze layer distributed on the whole-body green tile layer; the whole-body green tile layer comprises the raw materials in percentage by weight: 22-40% of potassium sand, 15-30% of sodium potassium feldspar, 10-20% of potassium feldspar, 10-22% of black clay, 2-10% of kaoline, 2-6% of bentonite, 1-4% of raw talcum and 2-10% of pigment; and the overglaze layer comprises the raw materials in percentage by weight: 30-60% of sodium potassium feldspar, 15-30% of kaoline, 5-10% of wollastonite, 5-10% of aluminum oxide, 2-8% of talcum, 2-10% of zinc oxide and 10-20% of calcium carbonate. By using the imitated-marble whole-body ceramic tile, the problem that the whole-body ceramic tile is difficult to oxidize in a firing process is solved, the whole-body ceramic tile of which the thickness is larger than 1cm can be prepared, the whole-body ceramic tile is good in oxidization performance, and pinholes, black lines, air bubbles and the like are not easy to produce in an intermediate layer; and meanwhile, due to the regulation of components and proportion of an overglaze, the problem that the texture of the overglaze of the whole-body ceramic tile cannot reach the surface texture of natural marble is solved, and the surface texture of the whole-body ceramic tile is closer to that of the natural marble.

Owner:广东金牌陶瓷有限公司

Daily-used fine porcelain with high property and preparation method thereof

The invention belongs to the technical field of daily-used ceramics, relating to daily-used fine porcelain with high property and a preparation method thereof. The chemical constituents of the daily-used fine porcelain are 52-60% of SiO2, 32-40% of Al2O3, 1-3% of K2O, 1-3% OF Na2O, 1.5-3.5% of CaO, 0.5-1.5% of MgO and 1-2% of P2O5. The adopted raw material formulation is as follows: 40-45% of kaoline, 15-25% of quartz, 10-15% of potassium feldspar, 10-20% of alumina and 8-15% of antireflective agent. The daily-used fine porcelain of the invention integrates three characteristics of high strength, high white and high transparence, and has the characteristics of good molding property, wide sintering arrange and high thermal stability and the like, thereby overcoming the defect of bad light transmittance of normal strengthened porcelain, and solving the problems of uneasy molding and narrow sintering arrange of high-grade porcelain such as steatite porcelain and bone porcelain. The porcelain is sintered at the temperature of 1270-1320 DEG C, is easy to be produced and promoted, and is hopeful to become novel high-grade daily-used fine porcelain after bone porcelain and steatite porcelain.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Clear glaze and method for manufacturing same

InactiveCN101182238AWide firing temperatureNot prone to chromatic aberrationPotassium feldsparCalcite

The invention discloses a transparent glaze and a preparation method thereof. The weight percentages of ach component of the transparent glaze are 10 percent to 35 percent of potassium feldspar powder, 8 percent to 25 percent of calcite, 8 percent to 10 percent of kaolin, 2 percent to 5 percent of quartz, 9 percent to 15 percent of calcined kaolin, 5 percent to 8 percent of burning talc, 3 percent to 5 percent of alumina, 1 percent to 3 percent of barium carbonate, 3 percent to 10 percent of transparent of fusion cake, 0.15 percent to 0.35 percent of methyl, 0.2 percent to 0.4 percent of tripolyphosphate and 15 percent to 30 percent of water. The weight percentage of the glaze material fineness is that the 250 meshes sieve residue is less than 0.15 percent. The technical process of the manufacturing method is as follows: the raw material enters the factory for testing, proportioning, ball milling, detecting, removing iron, sieving and storing in a storehouse for using. The sintering temperature of ball milled glaze slurry is 1200 DEG C to 1210 DEG C, and the sintering period is 50min to 65min. The application range of the invention is wide; the performance of the glaze material is good; the glaze surface is smooth and is not easy for producing chromatic aberration; the cost can be reduced by about 35 percent.

Owner:霍炳祥

Potassium feldspar powder production and preparation method

The invention discloses a potassium feldspar powder production and preparation method, and belongs to machining technologies of potassium feldspar powder. The method comprises the steps of ore washing treatment, preliminary screening treatment, crushing treatment, primary ball milling treatment, primary screening treatment, primary cyclone treatment, primary magnetic separation treatment, secondary ball milling treatment, secondary screening treatment, secondary cyclone treatment, secondary magnetic separation treatment, third cyclone treatment and thickening and dehydration treatment, and potassium feldspar mineral powder with the moisture content being lower than 16% and the brightness being higher than 60% is obtained.

Owner:贺州市骏鑫矿产品有限责任公司

Moon-white Song-dynasty official and brother kiln glaze material, moon-white Song-dynasty official and brother kiln porcelain and preparation method of porcelain

The invention relates to moon-white Song-dynasty official and brother kiln porcelain, a moon-white Song-dynasty official and brother kiln glaze material and a preparation method of the porcelain. The moon-white Song-dynasty official and brother kiln porcelain comprises a porcelain body and a glaze layer, wherein a preform body for preparing the porcelain body consists of the following materials by weight percent: 30% of stone-layer porcelain clay, 40% of Mudaikou purple gold clay and 30% of Yuandi porcelain clay; the glaze material for preparing the glaze layer consists of the following materials by weight percent: 20%-35% of Baoxi Wutou glaze clay, 7%-10% of quartz powder, 2%-5% of Mudaikou purple gold clay, 18%-23% of limestone, 15%-20% of potassium feldspar, 17%-10% of kaolin and 8%-10% of talcum powder. The preparation method comprises the following steps: forming paste, drying the porcelain body, performing biscuit firing, applying internal and external glaze and performing glaze firing on the basis of the raw materials. The moon-white Song-dynasty official and brother kiln porcelain is pure and mild in glaze color, good in thermal stability and high in overall quality.

Owner:龙泉市建春青瓷厂

New process for comprehensively utilizing potassium feldspar

InactiveCN102557050AMaximize the value of silicon resourcesResource value maximizationSilicaCement productionDecompositionFiltration

The invention discloses a new process for comprehensively utilizing potassium feldspar. The new process comprises the following steps of: performing primary sintering on the potassium feldspar added with potassium carbonate or sodium carbonate, leaching the sintering clinker in a mixed solution of potassium hydroxide and potassium carbonate, and filtering, wherein the obtained filter residue is araw material for secondary sintering, the obtained filtrate is subjected to carbon decomposition and filtration, partial silicon dioxide is recovered from filter residue for producing white carbon black, part of the filtrate is used for producing potassium salt and part of the filtrate returns to the primary leaching procedure; and performing secondary sintering, namely sintering primary sintering clinker leaching residue added with limestone and potassium carbonate, leaching the sintering clink in a mixed solution of potassium hydroxide and potassium carbonate, and filtering, wherein filter residue is taken as a cement production raw material, filtrate is added with calcium oxide for pressure desilication treatment, a solution subjected to desilication is subjected to carbon decomposition and filtration, and aluminum hydroxide is recovered from filter residue for producing diversified alumina. In the process of primary sintering and secondary sintering, the filtrate subjected to carbon decomposition and filtration is subjected to desilication, concentration and other processes, and the potassium carbonate can be recovered. By the process, the potassium feldspar value resource canbe utilized maximally, the potassium carbonate can be recycled, and environment is protected.

Owner:KUNMING METALLURGY INST

Glaze and preparation of embossment phantom glazed brick

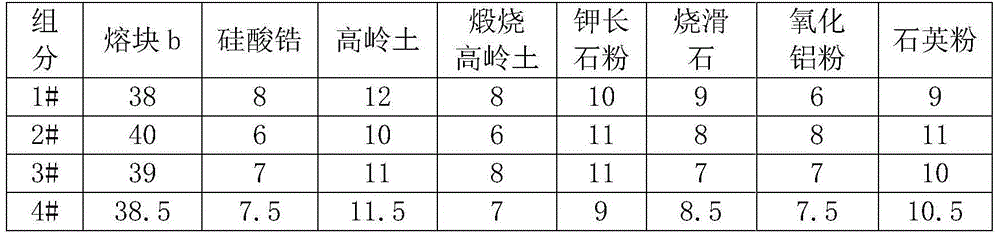

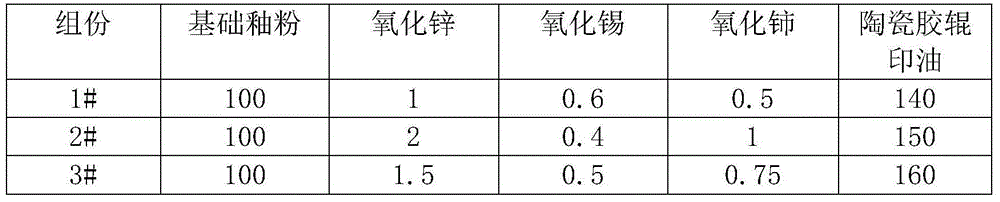

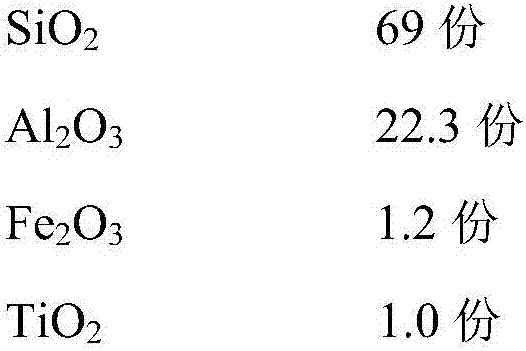

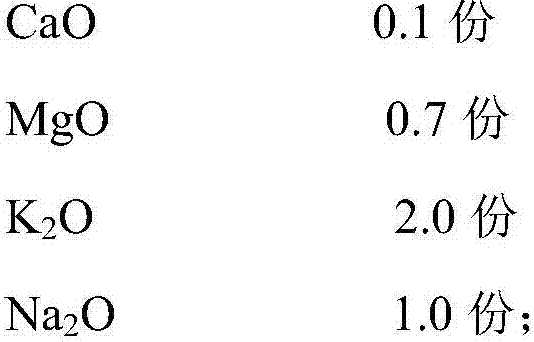

The invention discloses a glaze and preparation of an embossment phantom glazed brick. The glaze comprises a ground glaze, a surface glaze and an embossment phantom printing glaze, wherein the ground glaze is prepared from a frit b, zirconium silicate, kaolin, calcined kaolin, potassium feldspar powder, fired talc, aluminum oxide powder, quartz powder, carboxymethyl cellulose, sodium tripolyphosphate and water; the surface glaze is prepared from a frit, the frit b, a frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water; the embossment phantom printing glaze is prepared from parent glaze powder, zinc oxide, tin oxide, cerium oxide and ceramic adhesive roll-printing oil; the parent glaze powder is prepared from the frit c, kaolin, carboxymethyl cellulose, sodium tripolyphosphate and water. The preparation method comprises the following steps: sequentially applying the ground glaze and the surface glaze on a green brick, then printing the embossment phantom printing glaze, performing inkjet printing, and finally firing to obtain the embossment phantom glazed brick. The product disclosed by the invention has unique decorative effect and visual aesthetic feeling; moreover, each indicator can reach the standard requirements, so that the product has relatively strong universality, and is easily popularized in the industry.

Owner:GUANGDONG WINTO CERAMICS +3

Environmental friendly sustained-release long-acting compound fertilizer and method of preparing the same

The invention discloses an environment-friendly slow-releasing long-standing compound fertilizer which belongs to polyelement compound fertilizer and a production method thereof. The fertilizer comprises the following raw material ingredient (by parts by weight): 10-40 parts of powdered rock phosphate, 10-40 parts of potassium feldspar, 15-40 parts of coal gangue, 10-20 parts of magnesite powder, 10-30 parts of nitrogenous fertilizer, 8-18 parts of swell soil, 1-3 parts of kieselguhr and 0.3-1 part of trace element; the powdered rock phosphate, the coal gangue and proper amount of coke are roasted for 8-16 hours at 500-800 DEG C, cooled, crushes and screened by a 60-mesh sieve. The invention provides an environment-friendly energy-saving fertilizer capable of improving soil with comprehensive effective fertilizer composition, slow releasing and high fertilizer utilization ratio. Meanwhile, the environment-friendly slow-releasing long-standing compound fertilizer is suitable for various soils and growth of various crops and the preparation method thereof is provided. The problems of low fertilizer utilization ratio, environment pollution, hardening soil, high production cost and the like in the prior art are solved.

Owner:吕庆淮

Antibacterial ceramic tile capable of releasing negative oxygen ions and preparation method thereof

The invention belongs to the technical field of ceramic materials and in particular relates to an antibacterial ceramic tile capable of releasing negative oxygen ions and a preparation method thereof. The antibacterial ceramic tile capable of releasing the negative oxygen ions comprises a green body and a glaze layer, wherein the glaze layer is prepared from the following raw materials: potassium feldspar, potassium feldspar, calcite, calcined talc, zinc oxide, barium carbonate, alumina, a frit, calcined soil and kaolin; and the antibacterial ceramic tile also comprises antibacterial ceramic glaze additives capable of releasing the negative oxygen ions. The produced ceramic tile has the effects of permanently releasing the negative oxygen ions, emitting far-infrared rays, cleaning self, resisting to bacteria and purifying the air; and meanwhile, a ceramic glaze surface contains multiple mineral substances and trace elements, such as germanium and strontium, which are beneficial to human health.

Owner:山东统一陶瓷科技有限公司

Complete polishing glaze archaizing brick overglaze and preparation method thereof

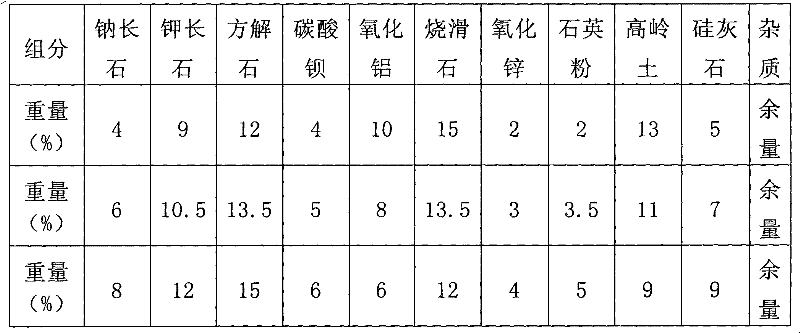

The invention relates to a complete polishing glaze archaizing brick overglaze and a preparation method thereof. The complete polishing glaze archaizing brick overglaze is prepared from the following raw materials by weight percent: 4-8% of albite, 9-12% of potassium feldspar, 12-15% of calcite, 4-6% of barium carbonate, 6-10% of alumina, 12-15% of burnt talcum, 2-4% of zinc oxide, 2-5% of quartz powder, 9-13% of kaolin, 5-9% of wollastonite and the balance of impurities. The preparation method comprises the following steps: carrying out ball milling in a ratio of weighed raw material to ballstone to ethylene glycol to squeegee oil of 1: (1.8-2): 0.25: 0.3, and simultaneously controlling the fineness degree as follows: the screenings of 325-mesh sieve is 0.3-0.4%; printing on ground glaze and fancy glaze layers through 100-mesh silk screen by using a continuous printing process; and finally, firing through a liquefied gas raceway kiln firing system. According to the invention, the purposes of improving the stability of the process and the quality of the product, reducing glaze material loss in production process, reducing cost and simultaneously avoiding the generation of a screen sticking problem in production are achieved.

Owner:霍镰泉

Production raw material of foamed glass and process for producing foamed glass

The invention relates to raw materials for producing foam glass and a method for applying the same to produce the foam glass. The compositions by weight portion of the raw materials are: 380 to 580 portions of quartz sand, 105 to 250 portions of potassium feldspar, 130 to 270 portions of albite, 115 to 200 portions of dolomite, 5 to 25 portions of calcite, 150 to 250 portions of calcined soda, 0.5 to 30 portions of glauber salt, 1.0 to 12 portions of magnesium carbonate and 1.0 to 8.5 percent of potassium carbonate. The method comprises the following steps that: firstly, various raw material compositions are mixed into uniform glass mixture; secondly, the glass mixture is melted and cooled into cullet; thirdly, ball milling, foaming and annealing of the cullet are performed, and then foam glass is obtained. The method can automatically control and adjust the chemical compositions of the glass and add various functional compositions as required to meet the demand of producing the foam glass with different performances by adoption of common mineral and chemical raw materials of the natural world.

Owner:ZHEJIANG ZHENSHEN INSULATION TECH CORP

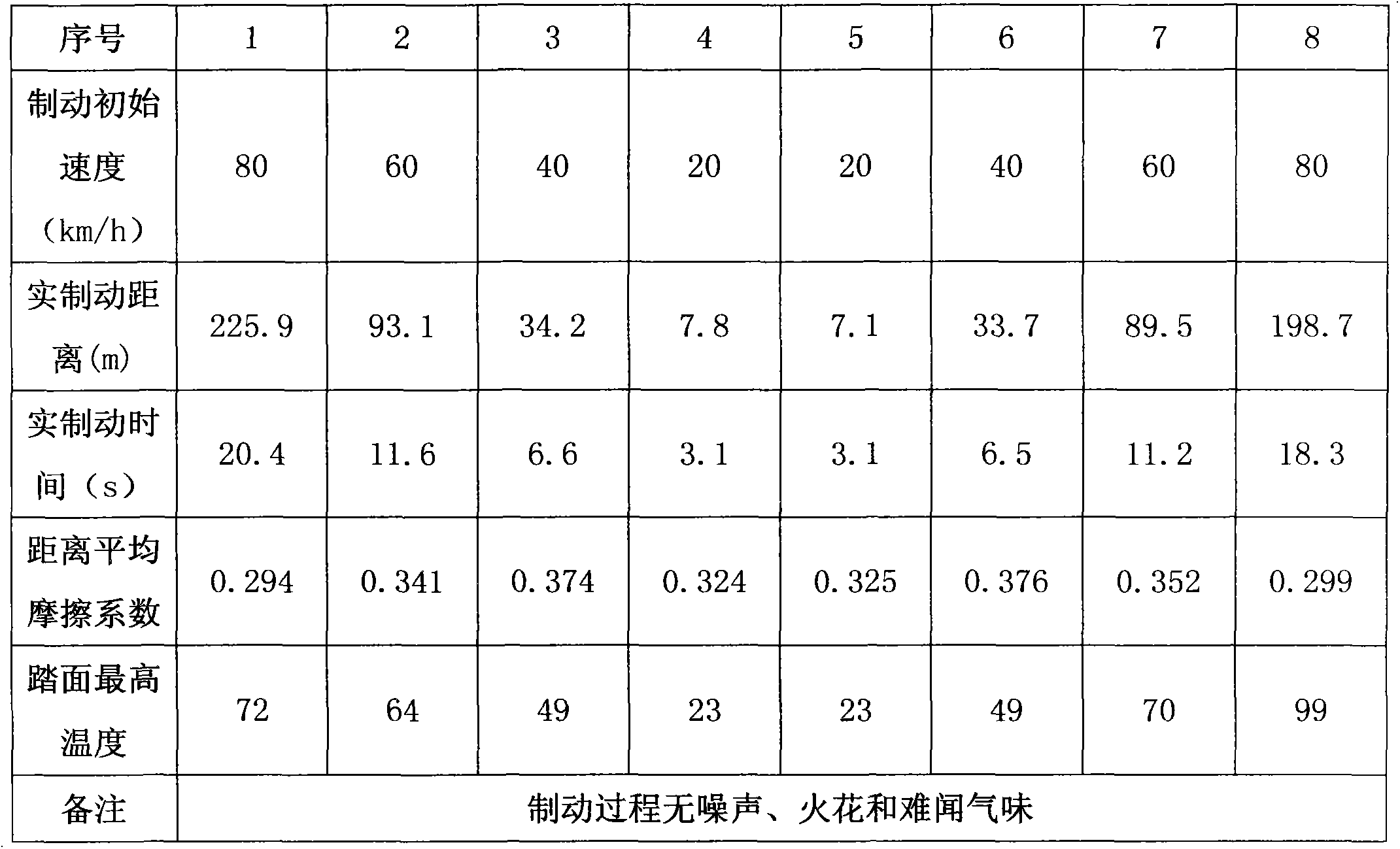

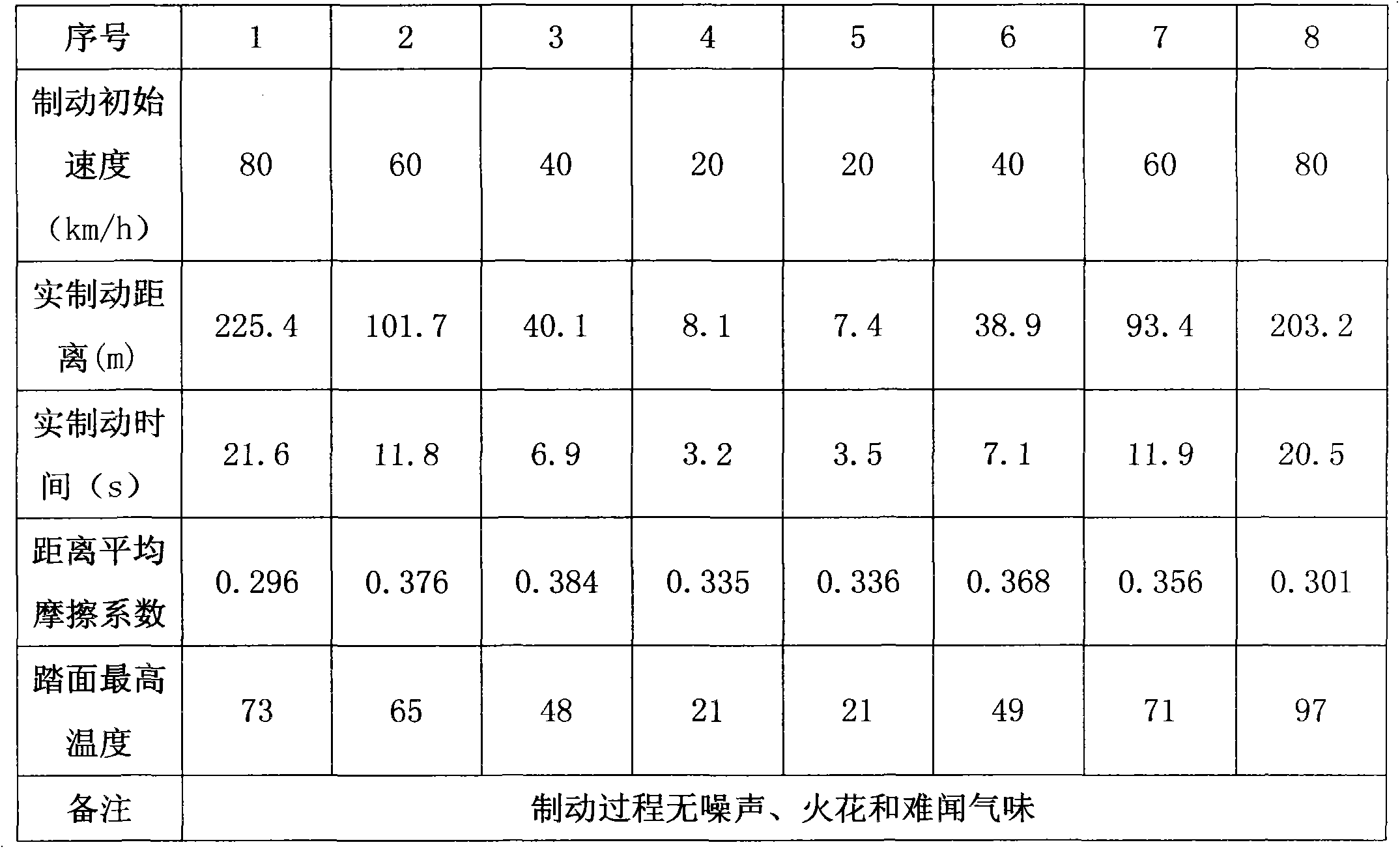

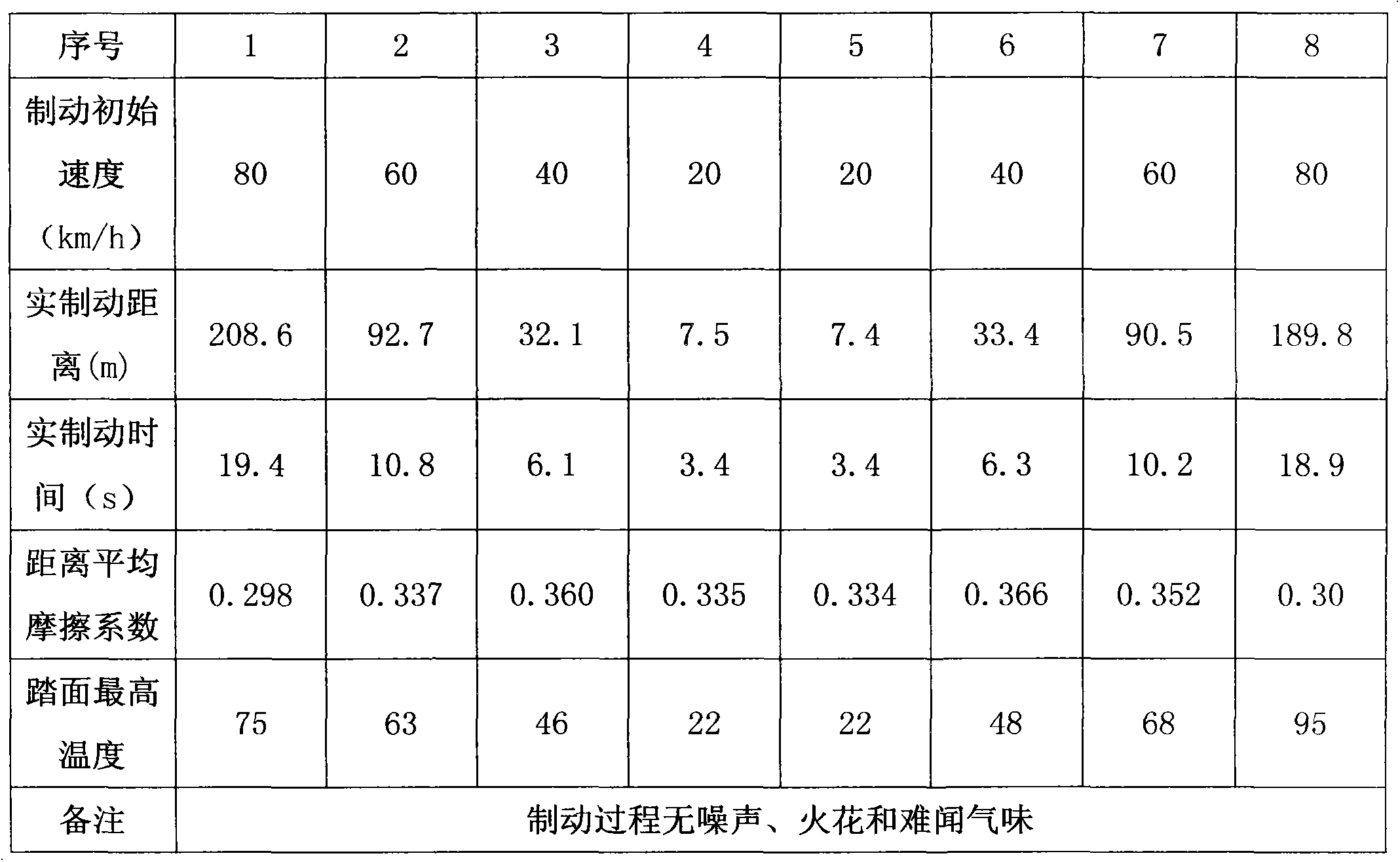

Friction material of disc brake pad, disc brake pad and preparation technology of disc brake pad

ActiveCN102965078AOvercoming performance deficienciesImprove performanceOther chemical processesFriction liningFiberPotassium

The invention discloses a friction material of a disc brake pad. The friction material comprises the following raw materials in parts by weight: 13-18% of cashew nut shell oil-modified phenolic resin, 9-16% of butyronitrile rubber powder, 3-7% of steel wool fiber, 6-11% of calcium sulfate whisker, 2-5% of potassium feldspar powder, 3-6% of graphite, 2-6% of brown fused alumina, 3-5% of antimony sulfide, 11-16% of baryta powder, 5-9% of chromite powder, 6-11% of heavy calcium carbonate, 2-4% of zircon sand and 3-6% of brass powder. Visibly, in the preparation raw materials, the cashew nut shell oil-modified phenolic resin is adopted for replacing ordinary phenolic resin as an organic carrier of a brake pad material, so that the shortcomings of poor resistance to thermal ablation, high abrasiveness, low anti-impact strength and the like of the ordinary phenolic resin are eliminated, the performance defects of the friction material of the disc brake pad caused by the ordinary phenolic resin can be avoided, and the overall performance of the friction material of the disc brake pad can be further improved.

Owner:SHANDONG GOLD PHOENIX

Ceramic-fiber-paper-based friction plate and production method thereof

ActiveCN102878232AGuaranteed stabilityGuaranteed oil conductivityNon-macromolecular organic additionPaper/cardboardAdhesiveBoron carbide

The invention relates to a ceramic-fiber-paper-based friction plate and a production method thereof and aims to provide the friction plate which is high in friction coefficient and fine in wear resistance and the production method which is simple in procedure and easy and convenient for production. According to the technical scheme, the ceramic-fiber-paper-based friction plate comprises ceramic fiber, carbon fiber, aramid pulp fiber, long staple cotton paper, diatomite, cashew shell oil friction powder, calcium carbonate whisker, boron carbide, potassium feldspar powder, rubber granule, iron sulfide, mica, alum, magnesia, cashew shell oil modified phenolic resin, powdered fluorine rubber, butyronitrile rubber latex, boron-tung oil modified phenolic resin and moderate additives. The production method includes the steps of firstly, producing pretreatment material, mixing material and size and performing papermaking to produce raw paper of ceramic-fiber-paper-base friction material; and secondly, soaking the raw paper in adhesive, cutting into strips after hot-pressing solidification, and adhering to a friction plate core plate to obtain the ceramic-fiber-paper-based friction plate.

Owner:杭州克尔菲利科技有限公司

Process for refining hematite type potassium feldspar sand powder

The invention provides a process for refining hematite type potassium feldspar sand powder. The process comprises the following steps: firstly crushing potassium feldspar to be formed into particles, and then adopting dry method ore grinding or wet method ore grinding to obtain sand powder or sand mortar; screening the sand powder prepared through a dry method, and adopting a multistage high magnetic separator to conduct magnetic separation; adopting the magnetic separator to conduct magnetic separation on the sand mortar prepared through wet method sand making, and adopting an electromagnetic separator to conduct magnetic separation on the classified sand mortar, then dehydrating, drying, calcinating iron not removed completely through a boiling furnace to be removed through high magnetic separation, removing the iron still not removed through a pickling manner, and finally separating quartz particles from potassium feldspar through a flotation method so as to obtain the high purity potassium feldspar sand powder. The refining process not only can meet requirements of domestic glass, ceramic and enamel industries on high-brightness potassium feldspar sand powder, but also can conduct industrial production, is environment-friendly, has no waste acid, waste water or waste gas discharge, and is an environment-friendly refining production line.

Owner:HUANGGANG NORMAL UNIV

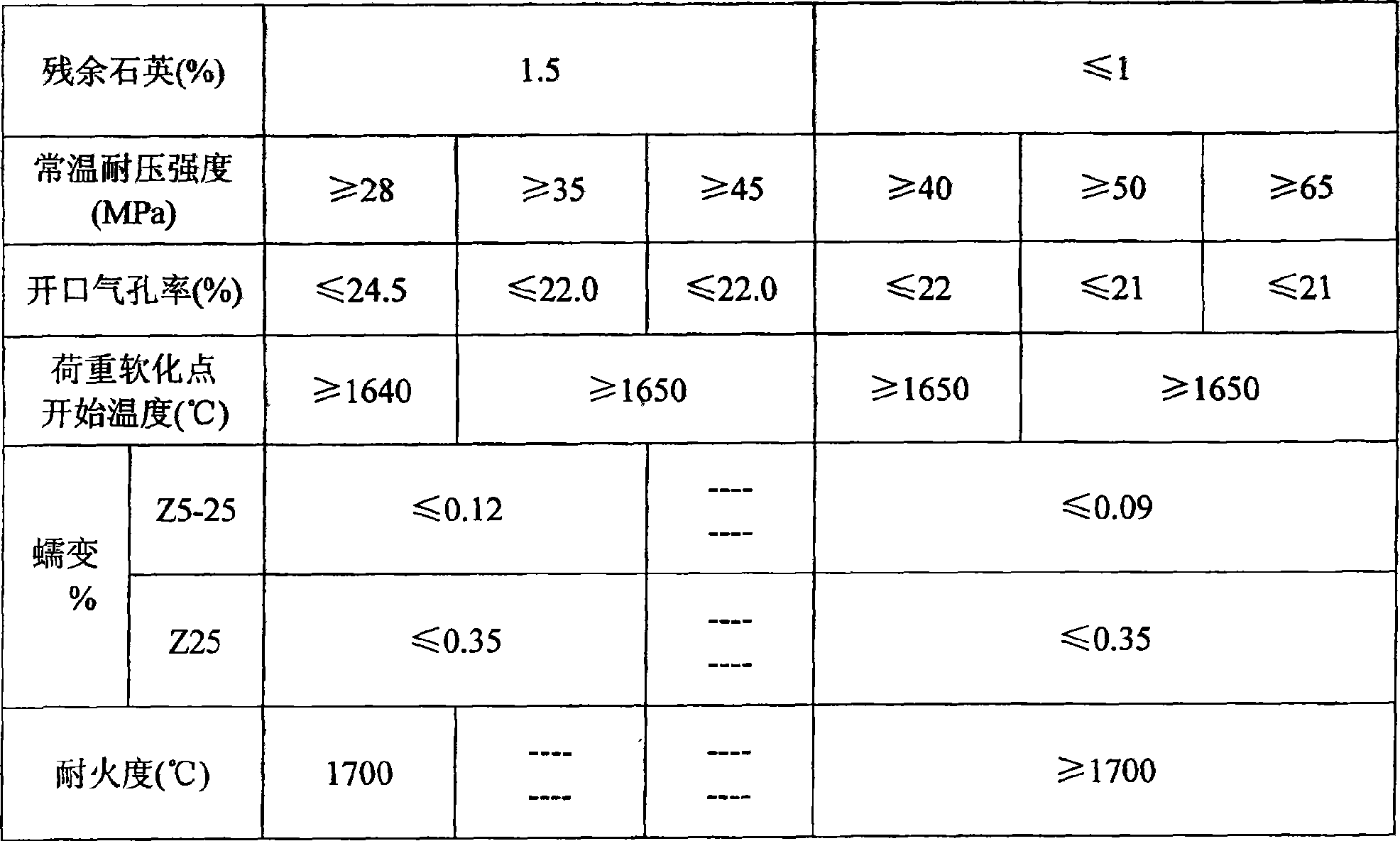

Silicon brick for 7.63-meter coke oven

The invention relates to the corhart technical field, in particular to quartz bricks for 7.63m coking chamber. The invention overcomes the drawbacks of the prior quartz bricks for 7.63m coking chamber that as difference exists in the quality and choice of the corhart, the particle fineness and size distribution of the material are unreasonable, iron content is above the standard. The weight percentage compositions of the formulation of the invention are as follows: twenty-five percent to thirty-five percent of silica coarse power, forty-one percent to forty-seven percent of silica middle power, ten percent to twenty percent of fine powder formed by fifty percent of silicon and residual fifty percent of silica brick, and ten percent to twenty percent of residual silica brick. The material further comprises accessories of one point nine percent to two point one percent of mineralizer mixed by manganese powder and potassium feldspar according to a proportion of one to one, seven point five percent to eight point five percent of lime cream and zero point nine percent to one point one percent of paper pulp. The invention is superior over the prior quartz bricks of the prior 7.63m coking chamber in terms of physicochemical indexes of the silica brick made by the formulation of the invention, such as chemical composition, compressive strength, porosity and refractability, etc., particularly in terms of lower content of bengala ( Fe2O3). The invention has the advantages of rich source of the material, reasonable fineness of aggregate and size distribution.of particles. The quartz brick can meet the design and complication degree of and dimensions of shapes of bricks for the 7.63 coking chamber and is suitable for mass production of the coking chamber.

Owner:山西盂县西小坪耐火材料有限公司

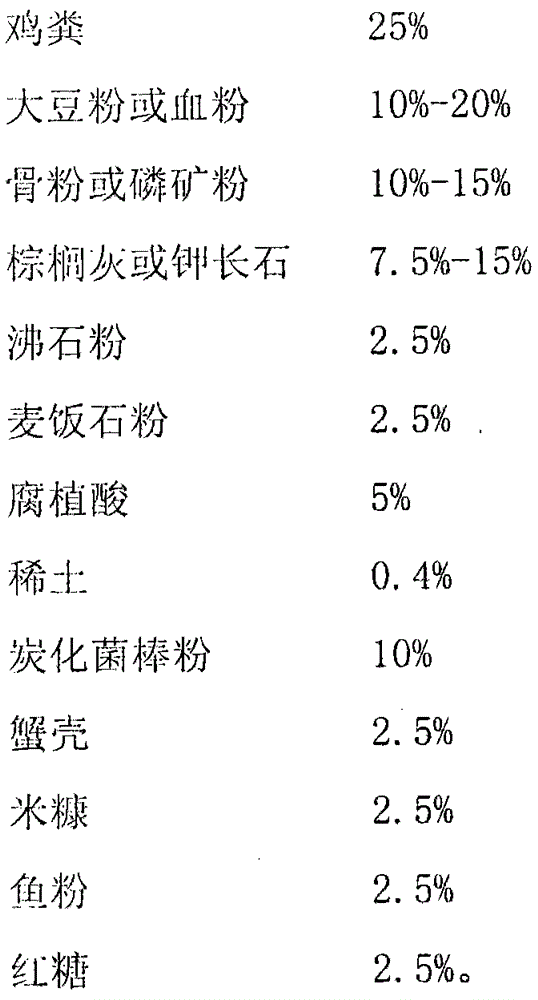

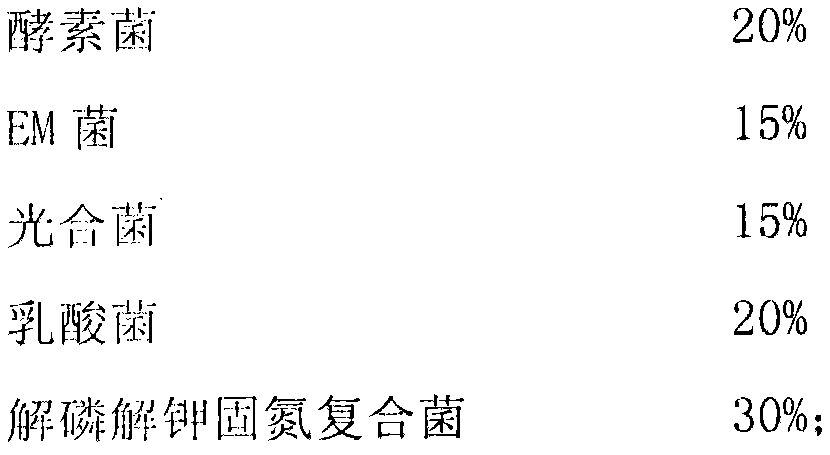

High-efficiency biological organic fertilizer for organic crops and preparation method thereof

InactiveCN104926530AMeet the needs of growthImprove the environmentBio-organic fraction processingOrganic fertiliser preparationPotassiumRare earth

The invention discloses high-efficiency biological organic fertilizer for organic crops. The high-efficiency biological organic fertilizer is characterized in that raw materials for preparation include strains and organic matter and minerals, the strains include enzyme bacterium, EM bacterium, photosynthetic bacterium, lactic acid bacterium and phosphorous-dissolving potassium-dissolving nitrogen-fixing composite bacterium, and the organic matter and minerals include chicken manure, soybean powder or blood powder, bone powder or phosphorite powder, palm ash or potassium feldspar, zeolite powder, medical stone powder, humic acid, rare earth, carbonized bacterium stick powder, crab shell, rice bran, fish meal and brown sugar. Nutrition facts of the high-efficiency biological organic fertilizer can meet needs of crop growing, the fertilizer can be applied once for all, and additional fertilizing is not needed. After soil environment is improved for two to three years, diseases and pests are reduced and disappear gradually, and insecticide application is not needed afterwards, so that organic planting is realized truly while processed agricultural products are organic products indeed.

Owner:解中强

Wet water high anti-skid ink-jet ceramic tile with sunken glaze effect and preparation method of tile

The invention provides a wet water high anti-skid ink-jet ceramic tile with a sunken glaze effect and a preparation method of the tile. The preparation method includes sequentially applying anti-skidsurface glaze, decorative patterns, bright effect glaze and anti-skid protective glaze on a blank body, and then firing, wherein the mineral composition of the composition of the anti-skid surface glaze comprises 40-50% of potassium feldspar, 0-10% of albite, 7-10% of kaolin, 8-12% of quartz, 8-11% of calcined alumina, 0-5% of nepheline, 2-4% of zinc oxide, 7-10% of zirconium silicate and 6-10% ofbarium carbonate; and the mineral composition of the composition of the anti-skid protective glaze comprises 48-58% of potassium feldspar, 0-10% of albite, 10-20% of kaolin, 0-5% of quartz, 0-4% of nepheline, 2-5% of calcined alumina, 10-15% of barium carbonate and 5-8% of zinc oxide. The anti-skid ceramic tile can be used as a decorative material with a good decorative effect, excellent pollution resistance and anti-skid performance, and can be applied to the field of home decoration.

Owner:MONALISA GRP CO LTD

Composition brake shoe for urban rail vehicle and manufacturing method thereof

ActiveCN103410893AImprove brittlenessImprove heat resistanceFriction liningCarbon fibersHexamethylenetetramine

The invention relates to a composition brake shoe for an urban rail vehicle and a manufacturing method of the composition brake shoe for the urban rail vehicle. The composition brake shoe comprises the following components of, by weight, 10-15 parts of butadiene-acrylonitrile rubber, 10-20 parts of cashew nut shell oil modified phenolic resin, 6-10 parts of basalt fibers, 4-8 parts of carbon fibers, 8-15 parts of steel fibers, 5-8 parts of sepiolite fibers, 2-6 parts of hexamethylenetetramine, 5-8 parts of iron oxide powder, 5-7 parts of crystalline flake graphite, 5-7 parts of chromite, 6-9 parts of barium sulfate, 3-6 parts of potassium feldspar and 5-8 parts of frictional powder. The manufacturing method of the composition brake shoe is a dry method production technology, and comprises the steps of steel back production, abrasive blasting processing, shaping, burdening, mixing, hot compacting, heat processing, subsequent processing, finished product forming and inspection. The manufactured composition brake shoe is inspected through the 1:1 rack test, is excellent in friction and abrasion resisting performance, stable in brake performance, safe and environmentally friendly, and solves the problem that the friction coefficient drops too fast under the conditions of damascene of the composition brake shoe for the urban rail vehicle, hot cracks, hot spots and rain and snow weather.

Owner:GUANGXI UNIV FOR NATITIES

High-temperature domestic porcelain metallic bright glaze and product decorated by same

The invention relates to a high-temperature domestic porcelain metallic bright glaze and a product decorated by the same. The bright glaze produced by using natural mineral raw materials and industrial pure raw materials comprises the following materials by weight percent: 10-25 percent of potassium feldspar, 10-30 percent of albite, 0-35 percent of quartz, 0-10 percent of barium carbonate, 0-10 percent of wollastonite, 0-10 percent of kaolin, 0-5 percent of zinc oxide, 1-10 percent of aluminum oxide, 1-10 percent of bone ash, 1-5 percent of purple clay and 10-35 percent of ferric phosphate, and the glaze is obtained by mixing, ball-milling and screening the raw materials. The fabrication technology of the glaze is basically the same as the common porcelain glaze, the cost is low, not only can the pure color be guaranteed through redesigning of the formula of the glaze, but also the burning temperature of the glaze is increased to 1380 DGE C, so that the decoration effect of domestic porcelain is greatly enriched, and the high-temperature domestic porcelain metallic bright glaze has wide application prospect.

Owner:HUNAN KARPERY INDAL +1

Green body of red soil ceramic and formula of transmutation glaze of red soil ceramic

The invention relates to a green body of red soil ceramic. The green body of the red soil ceramic is prepared from the following raw materials: red soil, quartz, talc, limestone and dolomite; the transmutation glaze of the red soil ceramic is prepared from the following raw materials: potassium feldspar, albite, calcium oxide, barium oxide, kaolin, quartz powder, sodium tripolyphosphate, titaniumoxide, rutile, zinc oxide and a coloring agent. By addition of other mineral raw materials, chemical raw materials and the like, the physical performance and the chemical performance of the green body are changed and the technical problems that the green body glaze of the red soil product is difficult to combine and the product is loose and fragile are solved; the firing temperature of the glaze is reduced from 1,310 DEG C to 1,230 DEG C, so thatthe firing temperature is reduced by 80 DEG C, the using amount of the fuel and the discharge quantity of harmful gas are reduced, environmental protection is contributed and production cost is greatly saved; and by development of the lead-free transmutation glaze, the lead-free transmutation glaze is suitable for being combined with the green body of the red soil ceramic, so that the problem of pollution to the ceramic decorative environment is solved fundamentally.

Owner:FUJIAN JIAMEI GRP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com