Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

73 results about "Petalite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petalite, also known as castorite, is a lithium aluminium phyllosilicate mineral LiAlSi₄O₁₀, crystallizing in the monoclinic system. Petalite is a member of the feldspathoid group. It occurs as colorless, grey, yellow, yellow grey, to white tabular crystals and columnar masses. Occurs in lithium-bearing pegmatites with spodumene, lepidolite, and tourmaline. Petalite is an important ore of lithium, and is converted to spodumene and quartz by heating to ~500 °C and under 3 kbar of pressure in the presence of a dense hydrous alkali borosilicate fluid with a minor carbonate component. Petalite (and secondary spodumen formed from it) is lower in iron than primary spodumen making it a more useful source of lithium in e.g. the production of glass. The colorless varieties are often used as gemstones.

Heat resisting red porcelain chinaware

The invention discloses a heat-resistant purple sand ceramic tool. The manufacture material includes stock and glaze; wherein, the stock is formed by the following components according to weight percentage: 1 to 15 percent of purple sand soil, 25 to 38 percent of triphane, 5 to 30 percent of bauxite clay, 5 to 30 percent of kaolin, 2 to 6 percent of talc, 5 to 20 percent of alum clay, 5 to 20 percent of grog and 5 to 25 percent of attaclay; the glaze is formed by the following components according to weight percentage: 20 to 35 percent of paste, 10 to 25 percent of petalite, 15 to 25 percent of grog, 8 to 15 percent of clinker, 12 to 25 percent of yellow earth, 6 to 9 percent of iron red, 0 to 0.15 percent of trimeric sodium phosphate and 1 to 2 percent of water glass. The adoption of triphane in the material of ceramics can largely enhance the heat-resistant capability, and the ceramics can be heated by electricity or fire and even the firing without water causes no crack. The heat-resistant purple sand ceramics can be adopted either as tableware or as drinking vessel.

Owner:熊禄生

Black glass ceramic and production method thereof

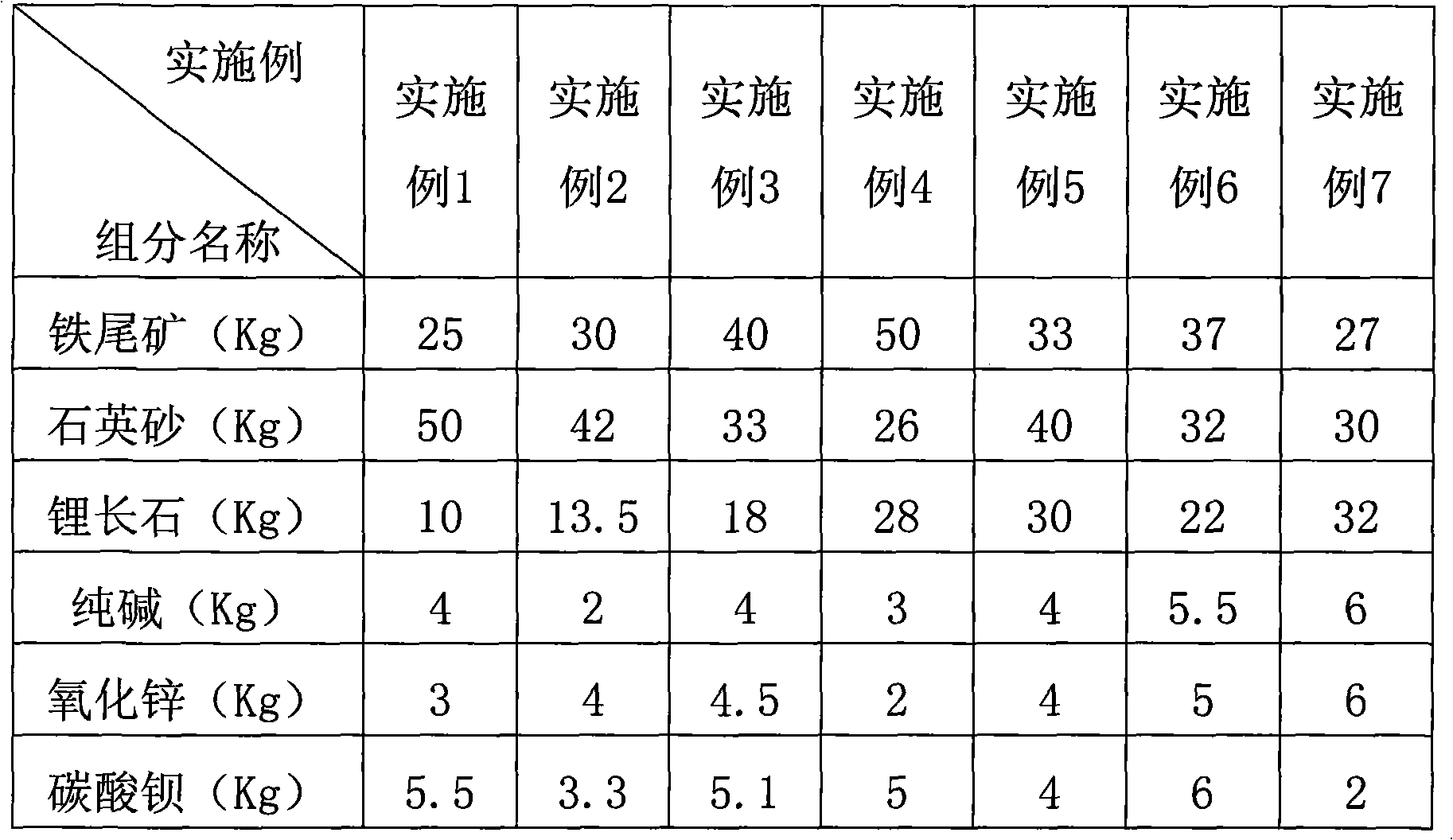

The invention discloses a black glass ceramic and a production method thereof in order to solve the problems of the conventional glass ceramic, i.e. single color and high production technique cost. The black glass ceramic is produced with the following components in part by weight: 25 to 50 parts of iron tailings, 20 to 50 parts of quartz sand, 10 to 32 parts of petalite, 2 to 6 parts of sodium carbonate, 2 to 6 parts of zinc oxide, 2 to 6 parts of barium carbonate, 0 to 0.1 part of copper oxide, 0 to 2 parts of manganese dioxide, 0 to 0.2 part of cobalt oxide, 0 to 2 parts of chromic oxide and 0 to 3 parts of sodium nitrate. Since the invention utilizes the discarded iron tailings as the material of the black glass ceramic, the waste is made profitable, pollution is reduced, the environment is protected, moreover, the physicochemical performance of the product can be enhanced, and the single-color problem of the black glass ceramic is solved; the corrosion of the refractory material of a glass furnace by molten glass is reduced, and thereby the service life of the equipment is prolonged; and the application range of the black glass ceramic is wide.

Owner:浮山县晋盛新型建筑材料有限责任公司

A kind of high lithium heat-resistant ceramic material

The invention belongs to the field of ceramic materials and relates to a high-lithium heat-resisting ceramic material. The high-lithium heat-resisting ceramic material is formed by combining and sintering petalite, Waring soil, kaolin and waste ceramic powder which are mainly used as raw materials. The high-lithium heat-resisting ceramic material is characterized by comprising the following raw materials in parts by weight: 40-55 parts of petalite, 12-20 parts of Guizhou kaolin, 20-30 parts of Waring soil, 5-10 parts of waste ceramic powder, 6-8 parts of Yichun kaolin, 6-8 parts of Zhongxia soil, 2-4 parts of Zhangzhou black soil, 2-4 parts of talcum powder, 2-4 parts of alumina and 3-6 parts of quartz powder. According to the invention, the produced heat-resisting ceramic pot has good thermal stability, i.e., the produced heat-resisting ceramic pot dose not break under the quenching condition at the temperature of 520 DEG C-20 DEG C; a quality index exceeds a standard requirement of GB / T258-2002; and the thermal stability is better, thus the prepared heat-resisting ceramic pot is longer in service life, is good in cooking effect, is clean and is easy to wash.

Owner:江西欣天利陶瓷有限公司

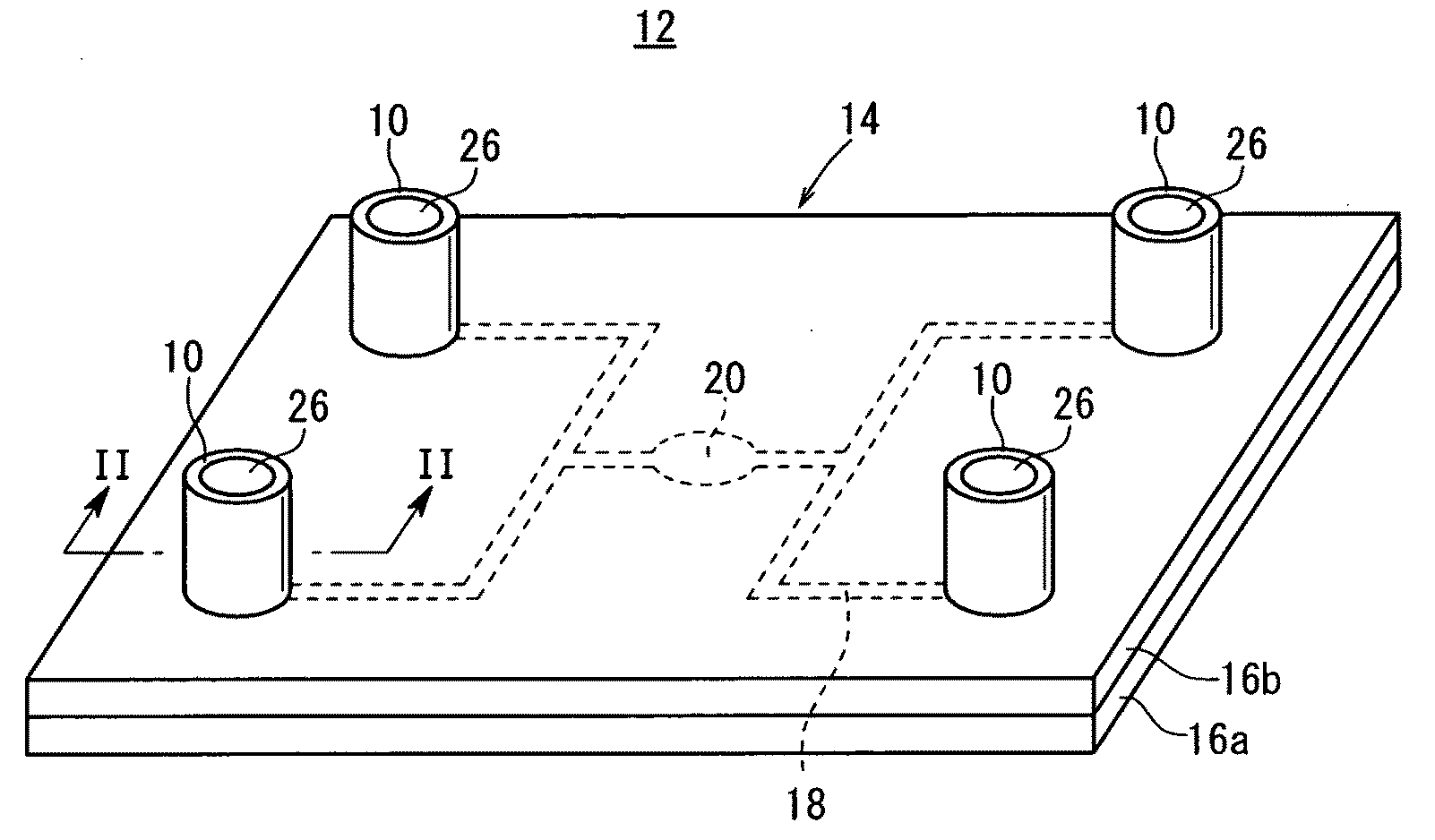

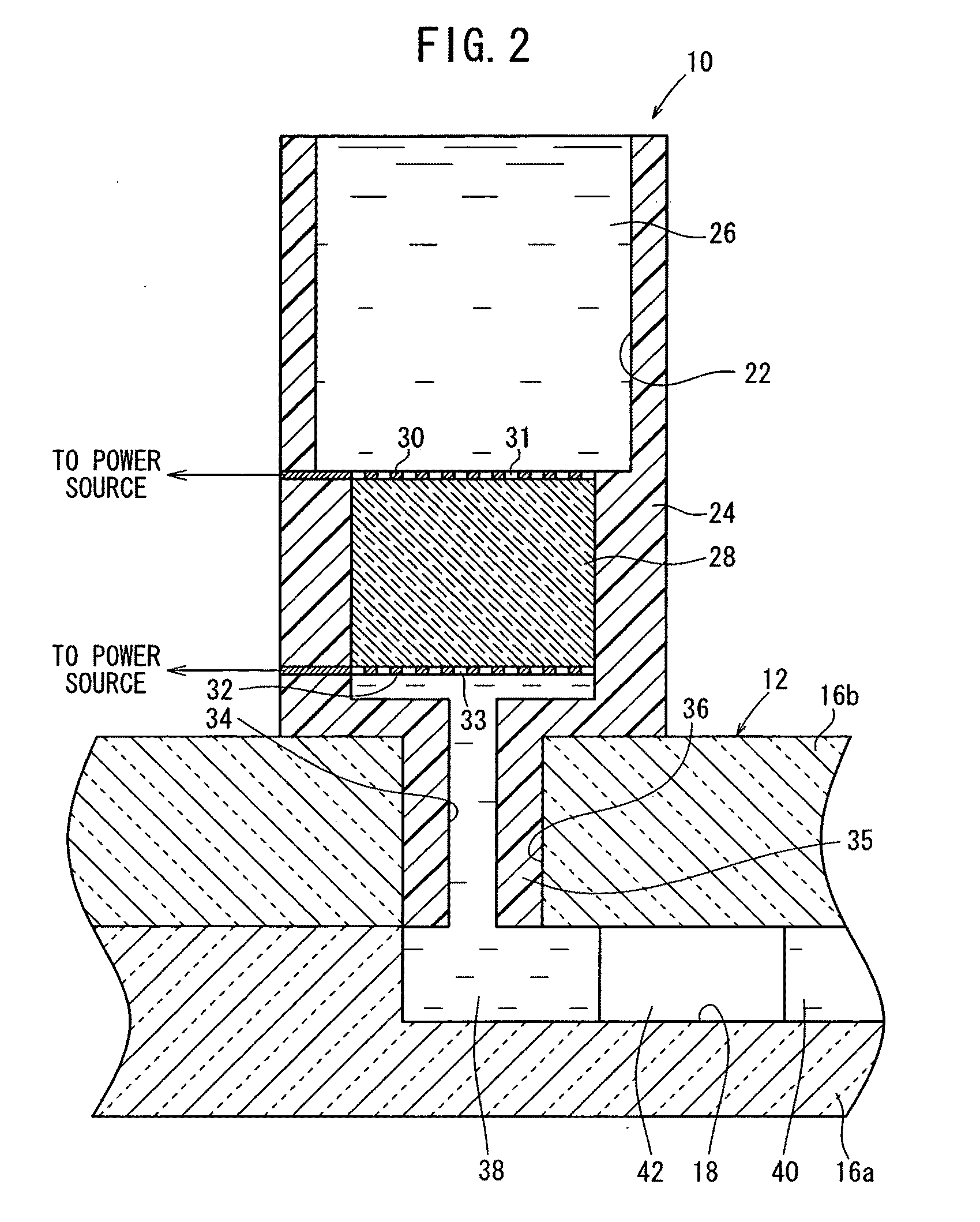

Electroosmotic material, method for production of the material, and electroosmotic flow pump

InactiveUS20090260990A1Increase flow rateGood pressure characteristicsSludge treatmentMaterial analysis by electric/magnetic meansKaoliniteAluminum silicate

A porous sintered material is produced which is suitable as an electroosmotic material constituting an electroosmotic flow pump. At least one member selected from BaO, SrO, CaO, TiO2, ZrO2, Na2O and K2O or at least one member selected from a natural mineral substance containing aluminum silicate (e.g., alkali feldspar, kaolinite, petalite), BaSiO3, BaTiO3, BaZrO3, BaSiO3 and SiC is added in the total amount of 0.05 to 10 parts by weight to 100 parts by weight of fused quartz or fused silicate (matrix: SiO2). The matrix may be SiO2—Al2O3 which is composed of either one of fused quartz and fused silicate and fused alumina added thereto.

Owner:NANO FUSION TECH

Selenium-rich ceramic appliance and preparation technology thereof

The invention relates to a selenium-rich ceramic appliance. A ceramic appliance body is fired from raw materials in parts by mass as follows: 30-50 parts of selenium-rich soil, 35-45 parts of petalite, 5-15 parts of spodumene, 1-15 parts of quartz, 10-15 parts of kaolin, 5-8 parts of microcrystalline ceramic powder, 1-3 parts of halloysite nanotubes, 0.5-1 part of nano tungsten carbide powder, 0.5-1 part of nano technetium oxide powder and 0.3-0.5 parts of polyacrylamide. The inner wall of the ceramic appliance body is coated with a selenium-containing coating. The selenium-rich ceramic appliance is prepared from main materials including cheaper petalite and selenium-rich soil, is coated with the selenium-rich coating, has good thermal shock resistance, crack resistance, wear resistance and heat conductivity and can separate out trace selenium element to supplement the human body with selenium.

Owner:JIANGXI JINGSHANG IND CO LTD

Glass ceramic with high elasticity modulus, and reinforced glass ceramic and preparation method thereof

The invention provides a glass ceramic with high elasticity modulus. The principal crystalline phase of the glass ceramic is composed of at least two selected from the group consisting of lithium silicate, lithium disilicate, petalite and ZrO2. The glass ceramic comprises 18%-30% of Li2O in molar percentage, and the crystal size of the glass ceramic is 10-80 nm; the elastic modulus of the glass ceramic is at least 90 Gpa. The glass ceramic comprises the following components in percentage by mol: 55-70% of SiO2, 3-10% of Al2O3, 1-6% of P2O5, 0.5-5% of ZrO2, 0.5-5% of Na2O, 18-30% of Li2O and 0-3% of Ta2O5. The glass ceramic further comprises at least one of the following oxides: 0 to 0.5% of CeO2, 0 to 0.5% of SnO2, 0 to 5% of B2O3, 0 to 5% of ZnO and 0 to 5% of MgO. The invention relates to the glass ceramic with high Li content; the network structure of the glass ceramic is compact; the obtained principal crystalline phase is composed of lithium disilicate and a beta quartz solid solution; due to the high crystallization ratio and crystal type of the glass ceramic, a material with elasticity modulus higher than 90 Gpa can be obtained; and a glass ceramic material with visible light transmittance higher than 90% can be obtained by controlling the crystal size, and the glass ceramic material can be used for window materials of aviation airplanes, high-speed rails, subways, carsand the like.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

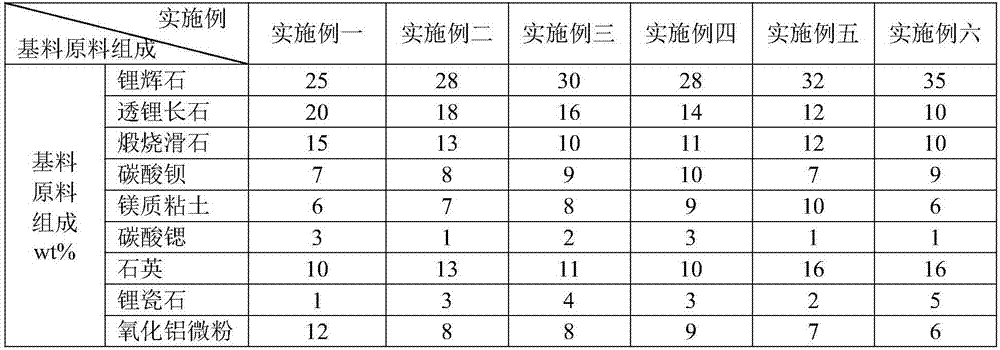

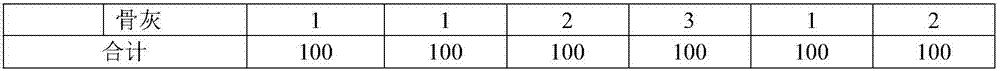

Low cost low expansion ceramic zirconium-free white glaze and preparation method thereof

The invention discloses a low cost low expansion ceramic zirconium-free white glaze, which comprises a basic material and additives. The basic material is composed of the following raw materials in percentage by weight: 20 to 35 wt% of spodumene, 10 to 25 wt% of petalite, 10 to 15 wt% of calcined talcum, 7 to 10 wt% of barium carbonate, 6 to 10 wt% of magnesite clay, 1 to 3 wt% of strontium carbonate, 10 to 20 wt% of quartz, 1 to 5 wt% of lithium containing porcelain stone, 6 to 12 wt% of alumina micro powder, and 0 to 3 wt% of bone ash. The additives are hydroxypropyl methyl cellulose and sodium tripolyphosphate; wherein hydroxypropyl methyl cellulose accounts for 0.05 to 0.1 wt% of the basic material and sodium tripolyphosphate accounts for 0.20 to 0.30 wt% of the basic material. Furthermore, the invention also discloses a preparation method of the low cost low expansion ceramic zirconium-free white glaze. The low cost low expansion ceramic zirconium-free white glaze has the advantages of low production cost, safe application, no radiation, high whiteness, good melting performance, and adjustable expansion coefficient; can well meet the use requirements of various low expansion ceramic blanks, and is beneficial for the development of low expansion ceramic industry.

Owner:JINGDEZHEN CERAMIC INSTITUTE

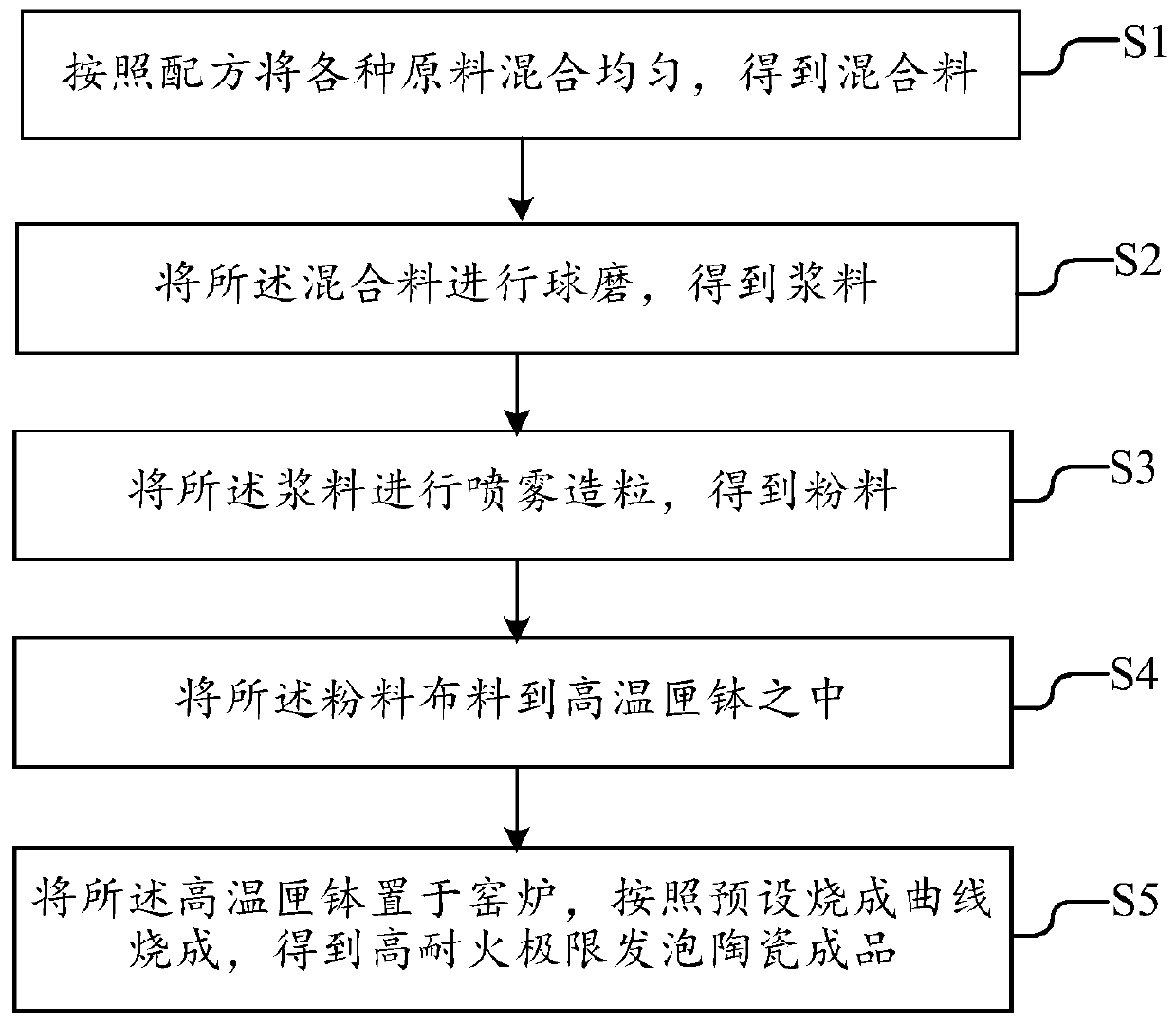

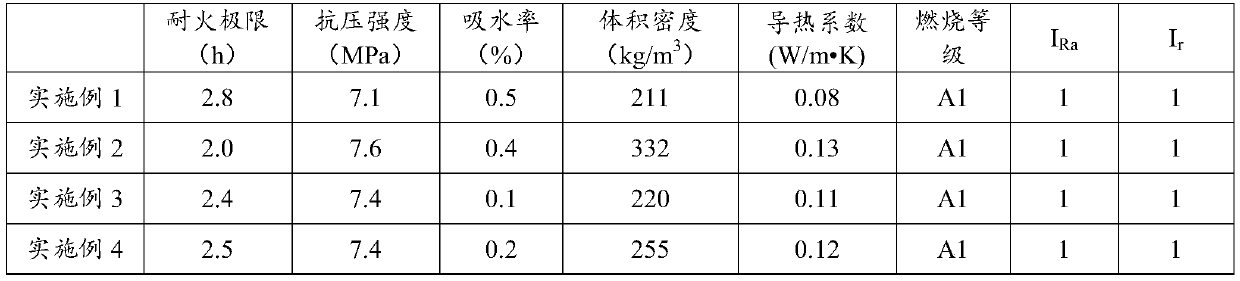

High fire resistance limit foamed ceramic and preparation method thereof

InactiveCN110526681AReduce crystallization tendencySmall coefficient of thermal expansionCeramic materials productionCeramicwareThermal expansionLithium compound

The invention discloses a high fire resistance limit foamed ceramic. The foamed ceramic is mainly prepared by the following raw materials in parts by weight: 90-95 parts of Luoyuan red tailings, 1-5 parts of a lithium compound, 1-3 parts of clay, 0.5-1 part of a foaming agent, and 0.2-1 part of a stabilizer, and the sum of parts by weight of each raw material component is 100 parts, wherein the lithium compound is one or more selected from spodumene, lithium porcelain stone, lithia mica, amblygonite, petalite, lithia mica, and zinnwaldite. The lithium-containing compound is added into the formula, the Li particle has a small radius and large electric field strength, so that the Li particle has the effect of strengthening a network, and thereby a thermal expansion coefficient of the foamedceramic can be reduced, crystallization tendency is reduced, fire resistance of the foamed ceramic can be improved, and application fields of the foamed ceramic is broadened.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Green red brown-extracting glaze and ceramic material

Owner:江西欣天利陶瓷有限公司

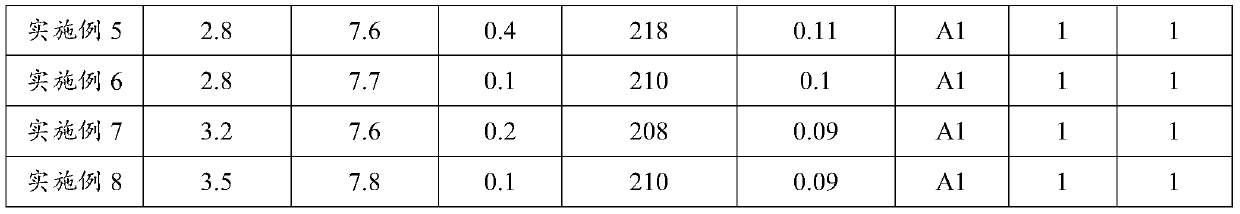

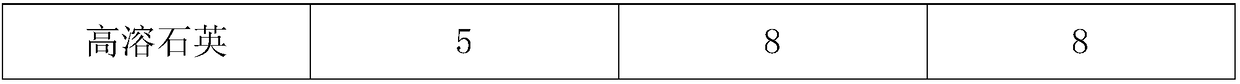

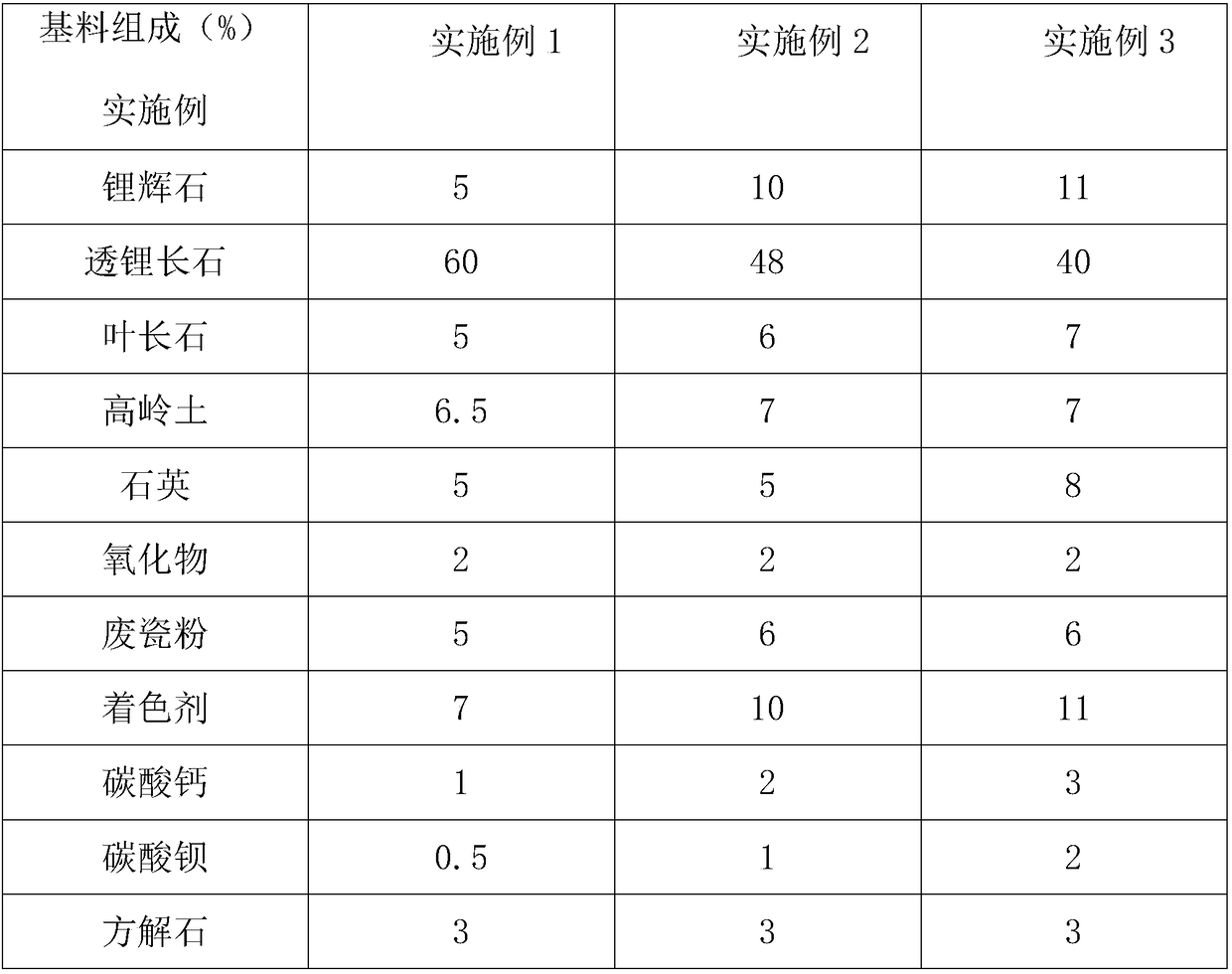

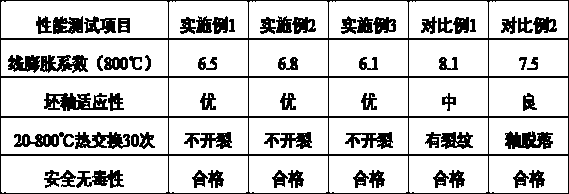

Preparation method of black glaze heat-resistant ceramic pot

The invention discloses a black glaze heat-resistant ceramic pot. The black glaze heat-resistant ceramic pot comprises a ceramic pot blank and black glaze. The ceramic pot blank comprises the following base material components: petalite 30-40%, kaolin 20-40%, clay 10-30%, aluminium oxide 5-10%, alkaline earth 5-10% and high-solubility quartz 5-15%. The black glaze comprises the following base material components: spodumene 5-15%, petalite 45-60%, petalite 5-10%, kaolin 5-12%, quartz 5-10%, oxide 2-3%, useless porcelain powder 5-10%, a colorant 7-12%, calcium carbonate 1-3%, barium carbonate 0.5-2% and calcite 3-5%. The invention further provides a preparation method of the black glaze heat-resistant ceramic pot. The oxide is added in glaze, the glossy of a glaze surface is improved, the opacity of the glaze is improved, the refractive index of glaze to light is increased, the useless porcelain powder is added, resources are recycled, furthermore, air pores and needle holes in the glazesurface are reduced, the quality of the glaze surface is improved, the ratio in pigment is strictly controlled, and the manufactured ceramic pot is bright in color, high in coloring degree and worthyof being popularized widely.

Owner:江西帮企陶瓷股份有限公司

White ceramic product capable of being used for open fire and preparation method thereof

The invention provides a white ceramic product capable of being used for open fire and a preparation method thereof. The white ceramic product comprises a green body and glaze applied to the surface of the green body. The green body comprises the following components in parts by weight: 20-40 parts of kaolin; 15-30 parts of potassium feldspar; 15-25 parts of quartz; 8-15 parts of high-transmittance silica powder; 4-10 parts of cordierite; 1-5 parts of zirconium oxide; and 1-3 parts of yttrium oxide. The glaze is prepared from the following components in parts by weight: 10 to 20 parts of petalite; 5 to 20 parts of potassium feldspar; 3 to 8 parts of spinel; 5 to 10 parts of fused quartz; 3 to 5 parts of calcined talc; 2 to 6 parts of fumed silica; 4 to 8 parts of high-temperature low-expansion frit; 4 to 8 parts of mica hematite; and 1 to 5 parts of titanium dioxide. The white ceramic product is reasonable in formula; the glaze is not prone to cracking and falling off in a heating process, so that the white ceramic product can be made into white ceramic cookers, tea sets and the like capable of being for open fire; and the white ceramic product has high safety and reliability and along service life.

Owner:福建省德化县中国白陶瓷有限责任公司

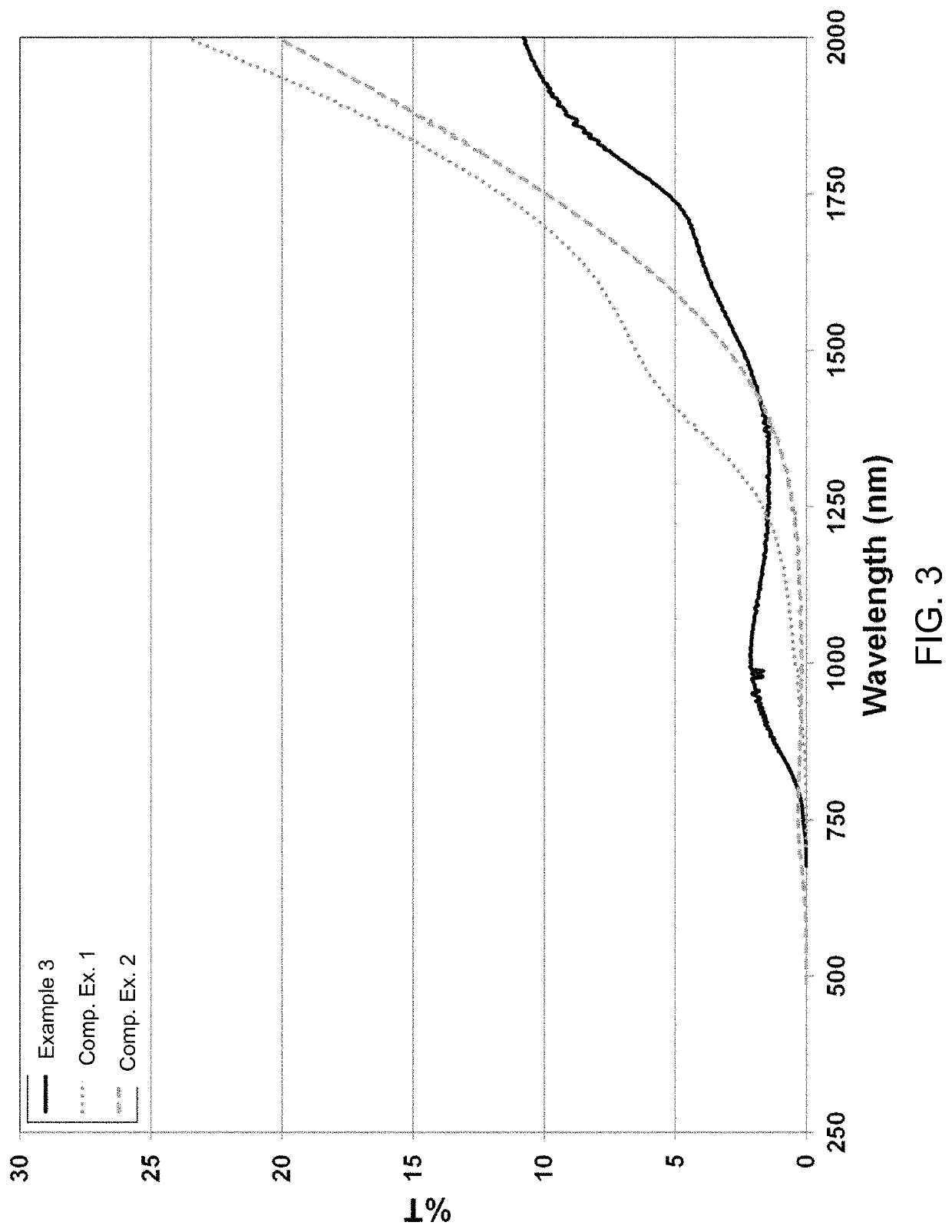

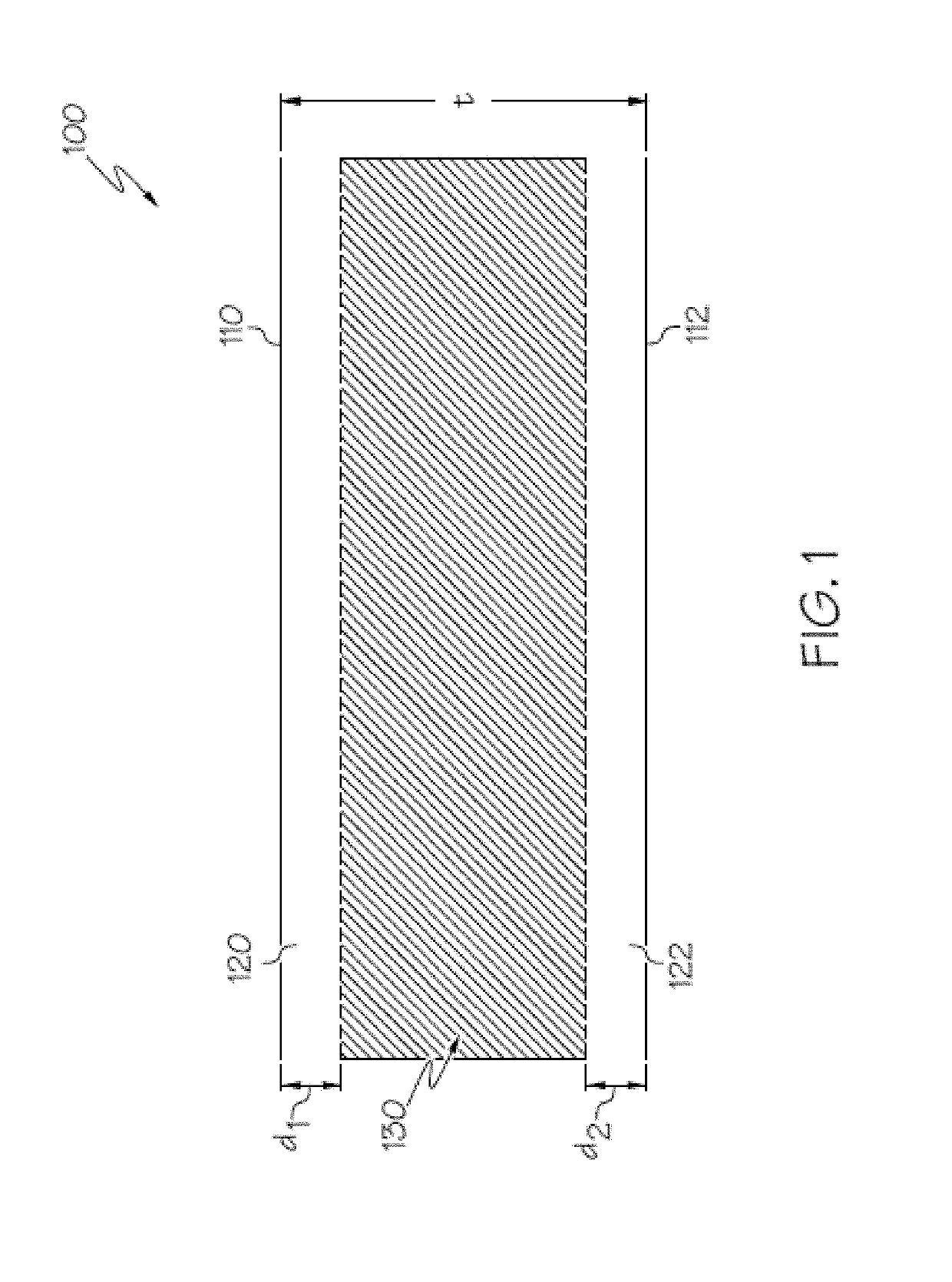

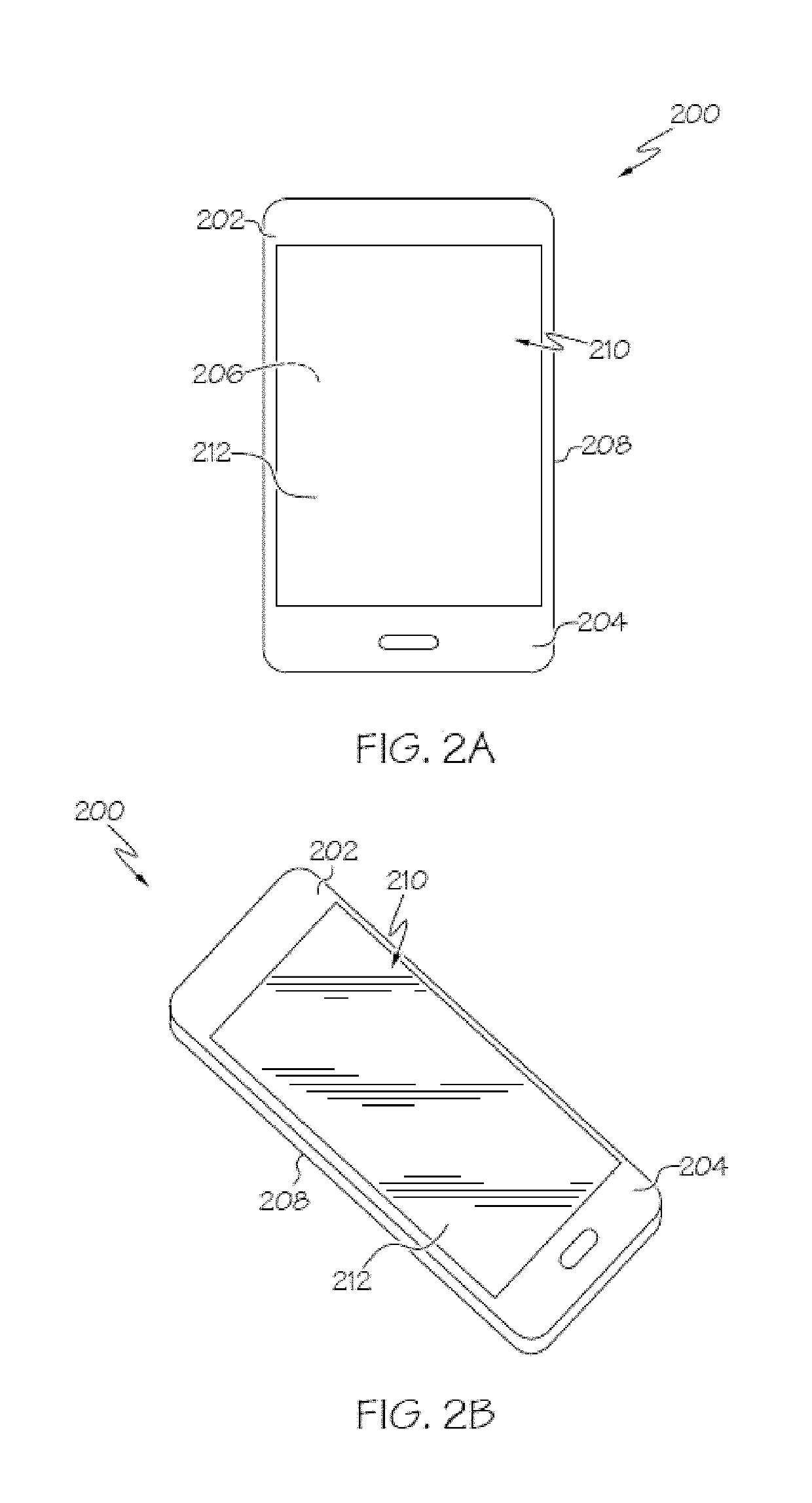

Black lithium silicate glass ceramics

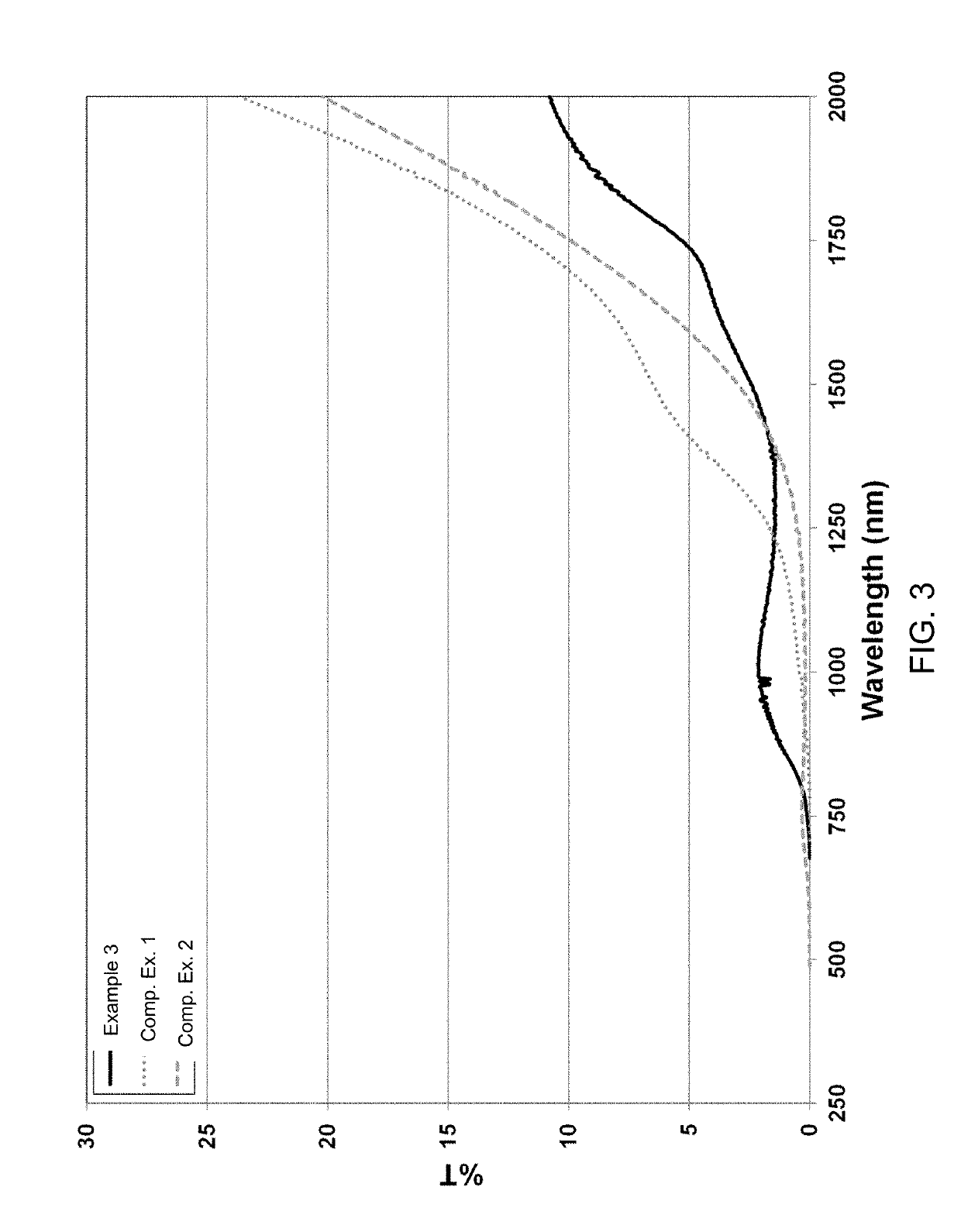

ActiveUS10723649B2Casings with display/control unitsCasings/cabinets/drawers detailsSilicate glassPhysical chemistry

A black lithium silicate glass ceramic is provided. The glass ceramic includes lithium silicate as a primary crystal phase and at least one of petalite, β-quartz, β-spodumene, cristobalite, and lithium phosphate as a secondary crystal phase. The glass ceramic is characterized by the color coordinates: L*: 20.0 to 40.0, a*: −1.0 to 1.0, and b*: −5.0 to 2.0. The glass ceramic may be ion exchanged. Methods for producing the glass ceramic are also provided.

Owner:CORNING INC

Vein-proof additive for casting and preparing method thereof

InactiveCN110000328ARelieve thermal expansionAvoid Veining DefectsFoundry mouldsFoundry coresPyrophylliteMineral particles

The invention relates to a vein-proof additive for casting and a preparing method thereof. The vein-proof additive comprises 5-15% of special mold sand, 8-25% of silicate particles, 30-55% of lithiumcontaining mineral particles, 8-20% of titanium containing mineral particles and 8-20% of iron oxide powder, wherein the special mold sand comprises at least one of zircon sand, chromite sand, olivinesand and ceramsite; the silicate particles are of a layered structure and comprise at least one of shale, pyrophyllite and mica; the lithium containing mineral particles comprise at least one of spodumene, amblygonite and petalite; the titanium containing mineral particles comprise at least one of ilmenite, rutile, anatase titanium dioxide, brookite and leucoxene; and the iron oxide powder comprises iron oxide black and iron oxide red. On account of the common vein casting flaws of resin sand castings, the invention provides the vein-proof additive product which has a remarkable vein-proof effect, is low in cost and does not affect the strength of sand cores.

Owner:GANSU KOCEL CHEM

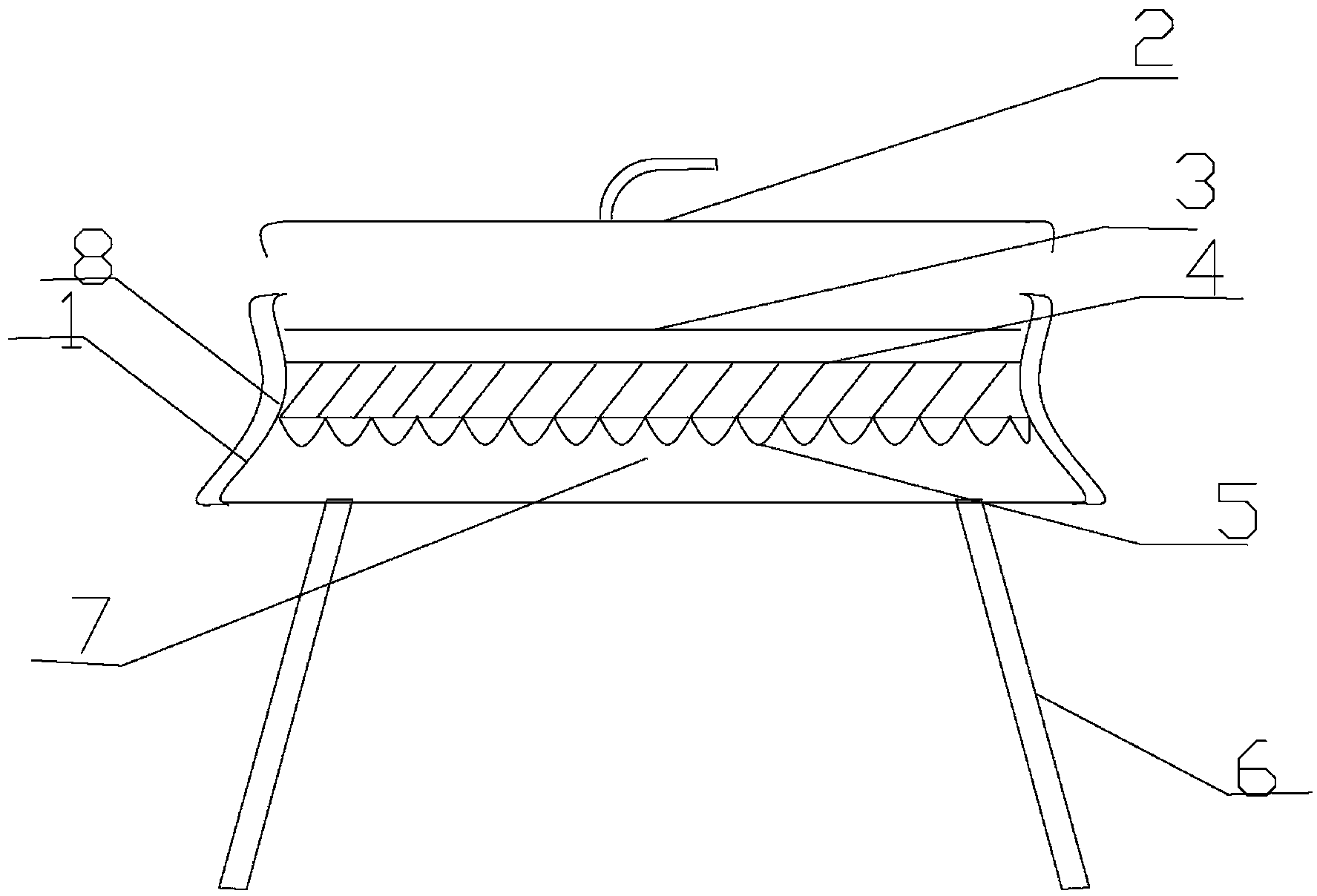

Rapidly synthesized polishing-free cordierite ceramic sheet for microwave oven and production method thereof

Provided are a rapidly synthesized polishing-free cordierite ceramic sheet for a microwave oven and a production method of the rapidly synthesized polishing-free cordierite ceramic sheet. The production method comprises the following steps: basic materials including 35-55% of mullite, 15-35% of attaclay, 10-25% of black soil, 0-10% of cordierite, 0-10% of petalite, 0-5% of kaolin, 0-2% of calcium carbonate, 0-2% of potassium feldspar and 0-10% of Al2O3 are prepared according to weight ratio, the additives are polyvinyl alcohol (PVA) and sodium humate, the above all powdery basic materials are subjected to ball-milling to be crushed, the two additives are added into the basic material and are subjected to proper ball-milling to be fully mixed, then the basic materials and the additives are screened through a screen with 200-400 meshes, the iron in the basic materials and the additives is attracted, then the basic materials and the additives are sprayed with mist, dried to make powder, mechanical pressed, applied with glaze, and rapidly sintered at the intermediate temperature of 1220-1300 DEG C to make the product. According to the invention, the raw ores of mullite and attaclay are used to make the sheet, so that the cost of raw materials is greatly lowered, the glaze can be co-fired at one time, and the cordierite crystalline phase is rapidly synthesized by taking advantages of lattice imperfection of various raw mineral materials. The sheet can be pressed very thin and flat so as to avoid polishing.

Owner:湖南嘉盛电陶新材料股份有限公司

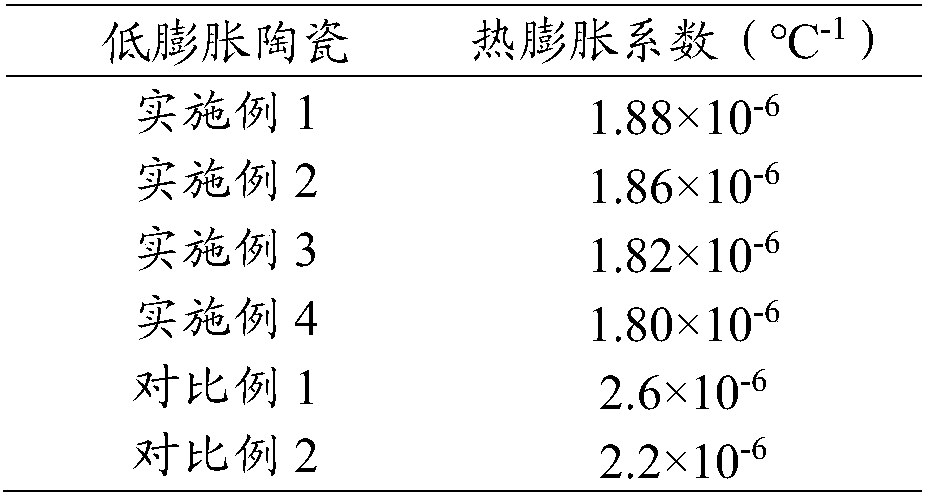

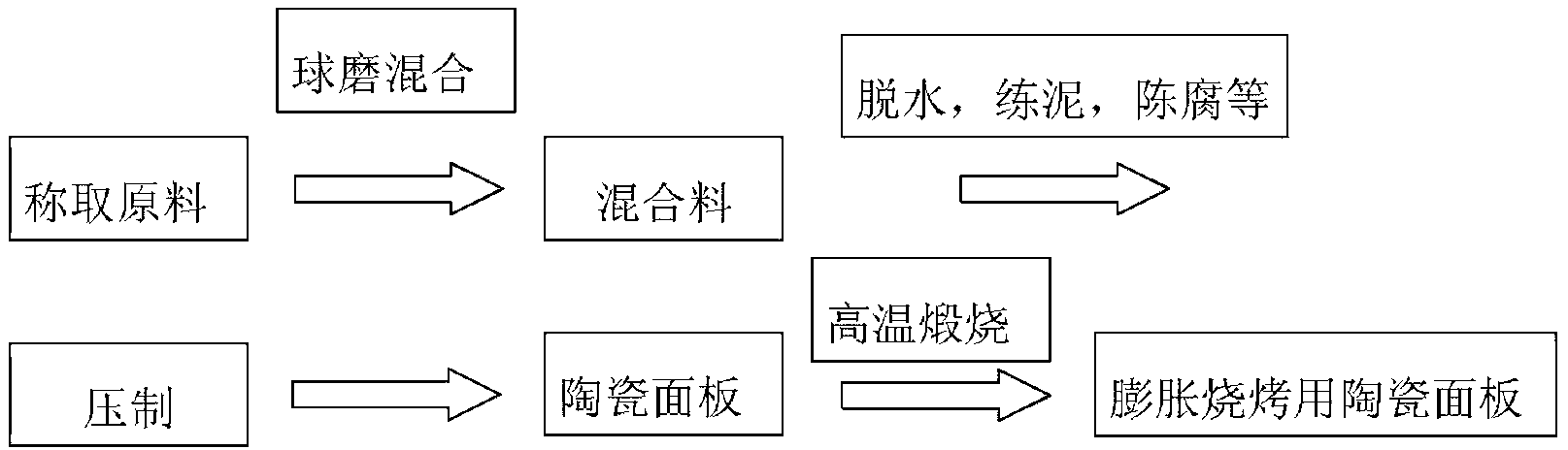

Low-expansion heat-resistant ceramic plate and manufacturing method thereof

InactiveCN108395231ASmall expansion coefficientImprove heat resistancePolishing machinesCordieritesTalc

The invention discloses a low-expansion heat-resistant ceramic plate and a manufacturing method thereof. Raw materials for manufacturing a plate material are as follows: 23-28 wt% of kaolin, 3-6 wt% of talc, 23-28 wt% of cordierite, 18-21 wt% of bauxite, 4-6 wt% of a scrap reclaimed material and 18-20 wt% of a boron plate sagger waste material. Raw materials for manufacturing a glaze material areas follows: 65-70 wt% of petalite, 10-13 wt% of potassium feldspar, 5-7 wt% of zinc oxide, 4-6 wt% of kaolin, 6-7 wt% of calcined talc and 1-3 wt% of lithium carbonate. The surface of the plate material is coated with the glaze material, and then firing and polishing are carried out to obtain the low-expansion heat-resistant ceramic plate. The low-expansion heat-resistant ceramic plate has the advantages that (1) the formula of the glaze material is changed, a glaze layer is thickened, and the glaze layer is polished, so that the ceramic plate is more beautiful, the expansion coefficient is smaller, the heat resistance is better, water seepage is avoided, and the properties are more close to the properties of microcrystalline glass; and (2) the manufacturing process is relatively simple, mechanical full-automatic processing can be realized, the cost can be controlled, and the price is lower than the price of microcrystalline glass.

Owner:佛山市骏美特种陶瓷有限公司

Novel ceramic glaze

The invention discloses a novel ceramic glaze. The novel ceramic glaze is characterized by comprising, by weight, 15-60 parts of pyrophyllite, 15-37 parts of montmorillonite, 5-14 parts of zinc borate, 11-34 parts of sepiolite, 17-41 parts of petalite, 10-29 parts of ceramic fibers, 1-7 parts of coffee sawdust, 3.5-14.2 parts of vanadium pentoxide, 10-20 parts of scallop shell powder, 5.7-18.4 parts of aluminum oxide, 1-3 parts of copper oxide, 4-9 parts of wollastonite, 13-28 parts of nitrile butadiene rubber and 27-64 parts of borax. The using effect same with the using effect of a glaze where titanium dioxide is added can be achieved without adding the titanium dioxide, so that the preparation cost of the glaze is reduced, a lot of treasures and resources are saved, and due to the facts that the cost is reduced on the premise that quality is guaranteed, and market competitiveness is improved, the novel ceramic glaze is already exported in large quantity.

Owner:QINGDAO QIANXIANG ENVIRONMENTAL PROTECTION TECH

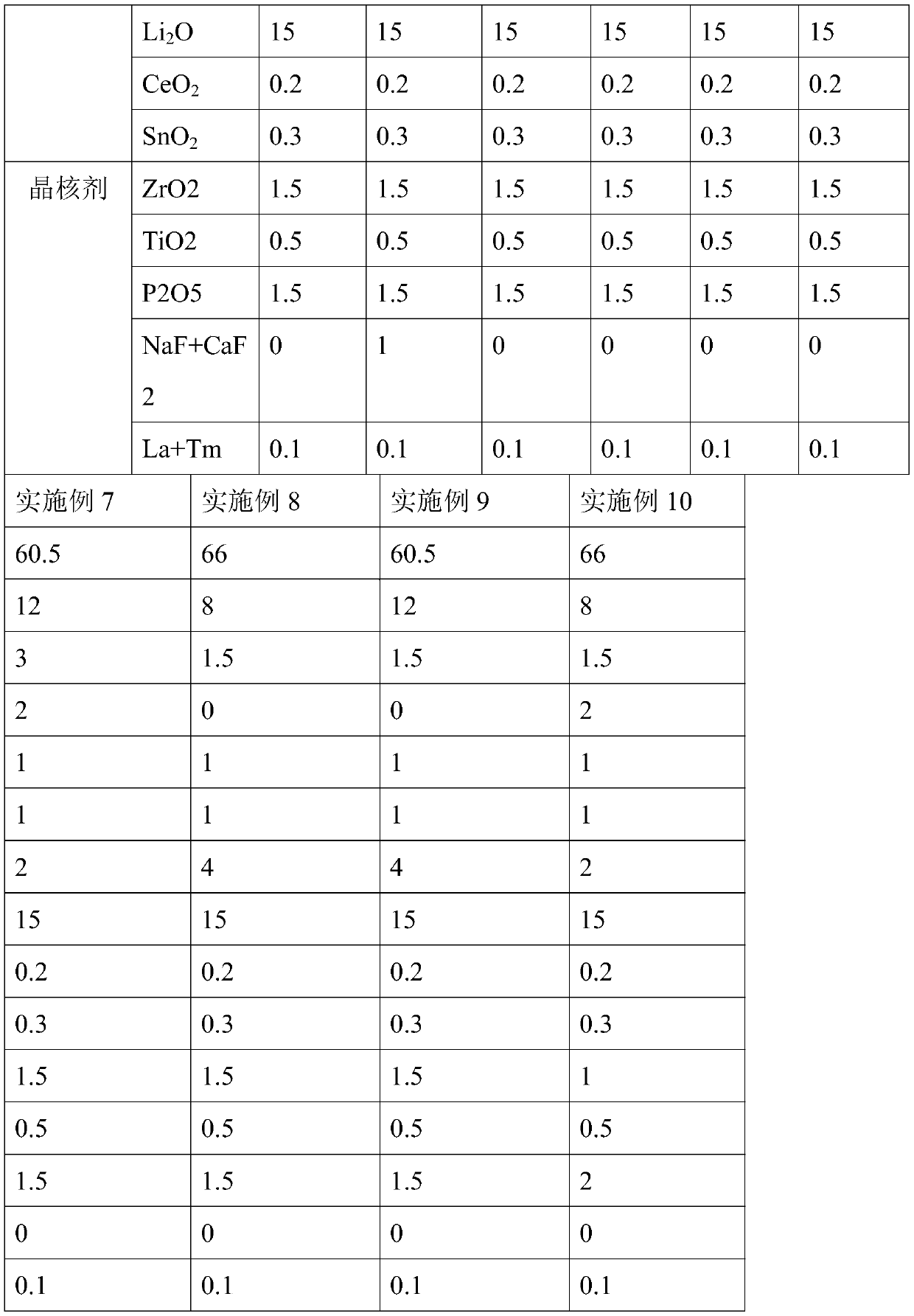

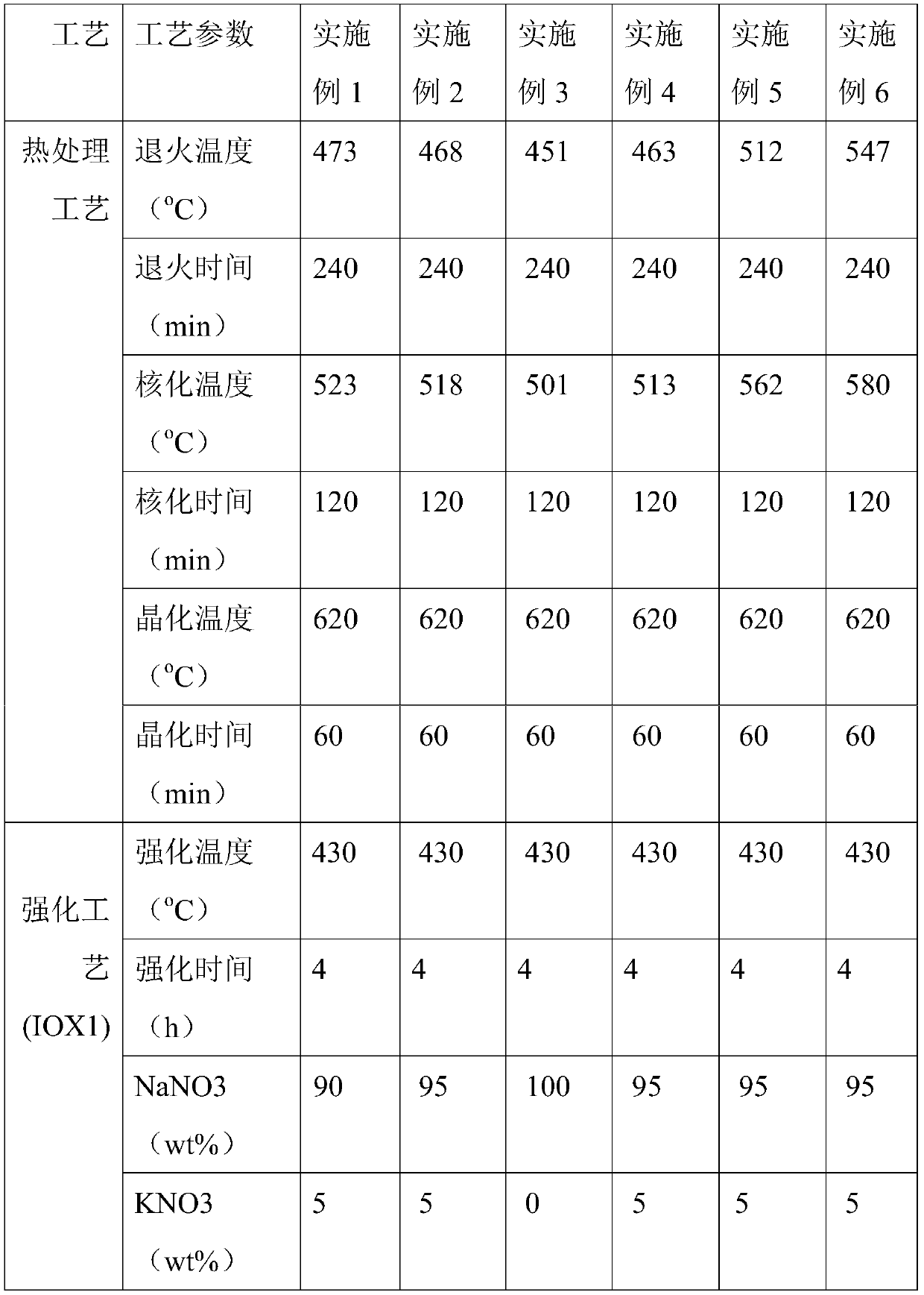

Multi-crystal-nucleus composite transparent glass ceramic and preparation method thereof

ActiveCN110981206AImprove resistance to damageHigh fracture toughnessMaterial nanotechnologyGlass meltingGlass-ceramic

The invention discloses multi-crystal-nucleus composite transparent glass ceramic and a preparation method thereof. The preparation method of the multi-crystal-nucleus composite transparent glass ceramic comprises the following steps that: S1, multiple nucleating agents are added during glass melting; S2, plain glass with a certain boundary dimension is obtained after processing; S3, the plain glass obtained in S2 is placed under the condition that the temperature is T1 and heated for 1-6 hours for annealing treatment, after annealing treatment is completed, the plain glass is placed under thecondition that the temperature is T2 and is heated for 1-6 hours and subjected to nucleation treatment, after nucleation treatment is completed, the plain glass is placed under the condition that thetemperature is T3 and heated for 0-3 hours for crystallization treatment, and T1 is smaller than T2. According to the invention, the glass ceramic containing various crystal nucleuses and crystal phases of lithium disilicate and petalite is prepared, the nucleation and crystallization energy required by the crystal precipitation is reduced through the multiple crystal nucleuses, the heat treatment temperature and the heat treatment time can be reduced, the crystal ratio can be adjusted, and the glass ceramic prepared through the preparation method has characteristics of enhanced damage resistance, good fracture toughness and wide application range.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

Low-expansion ceramic billet as well as preparation method and application thereof

The invention provides a preparation method of a low-expansion ceramic billet. The preparation method comprises the following steps: providing the following raw materials in percentage by weight: 15 to 20 percent of cordierite, 16 to 20 percent of petalite, 16 to 20 percent of talc, 4 to 7 percent of mullite and 40 to 43 percent of kaolin; carrying out wet ball grinding on the talc, the mullite, the kaolin and a solvent, thus preparing an initial billet with particle size distribution D97 being 12 to 15 micrometers; carrying out wet ball grinding on the cordierite, the petalite and the initialbillet, thus preparing the low-expansion ceramic billet with particle size distribution D97 being 60 to 80 micrometers. According to the preparation method, the use amount of the petalite is reduced,and the raw material cost is reduced; furthermore, the prepared low-expansion ceramic billet is applicable to relatively-low-cost rolling forming of equipment, but not limited to isostatic forming.

Owner:湖南嘉盛电陶新材料股份有限公司

A high-performance low-expansion crucible and a preparing method thereof

A high-performance low-expansion crucible and a preparing method thereof are disclosed. The crucible is formed by a crucible base material and a crucible coating material. The crucible base material comprises, by mass, 40-60% of petalite, 5-15% of spodumene, 5-15% of Suzhou kaolin, 1-3% of purple mujie clay, 1-5% of black talc, 10-25% of Guizhou soil, 0-3% of white carbon black and 5-10% of zirconia micro powder. The crucible coating material comprises 0-15% of petalite, 85-100% of functional material micro powder, 0.1-0.5% of an additive dispersant and 0.1-0.5% of an adhesive. A finished product of the crucible is prepared by mixing materials, ball milling, sieving, filter pressing to remove water, vacuum pugging, forming, drying to obtain a crucible blank, spraying the inner surface of the crucible blank with the crucible coating material and finally firing. The crucible is low in production cost and good in forming performance, effectively improves thermal shock resistance and mechanical strength of a product and effectively prolongs the service lifetime, thus facilitating technical progress and application development of the crucible industry.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Bone china and preparation method thereof

The invention discloses a bone china and a preparation method of the bone china. The bone china is composed of the following components in percentage by weight: 40-50% of bone ash, 2-6% of quartz powder, 2-6% of kibushi clay, 10-15% of petalite, 12-15% of Longyan washing mud, 12-15% of Hunan feldspar, and 10-20% of aluminum oxide. The preparation method of the bone china comprises the steps of: mixing bone ash by a ball mill, pouring slurry into a slurry well, repeatedly washing with water and stirring, and carrying out pressure filtering to obtain a bone cake; and ball-milling the bone cake with the other components, removing iron, injecting slurry and molding, drying, carrying out biscuit firing, glazing, and firing glaze. The obtained bone china has high plasticity, and can be used for preparing 1.5mm thin film china; and the bone china has good heat shock resistance, and does not crack in 180-200 DEG C water.

Owner:潮州市海鸿陶瓷制作有限公司

Petalite heat-resisting ceramic material with strong forming stability

The invention belongs to the field of ceramic materials, and relates to a petalite heat-resisting ceramic material with strong forming stability. The petalite heat-resisting ceramic material is prepared by combining and sintering petalite, bauxite, quartz, kaolin and waste porcelain powder which are utilized as main raw materials. The ceramic material provided by the invention is characterized by being prepared from the following raw materials in parts by weight: 20-45 parts of petalite, 8-15 parts of bauxite, 2-6 parts of quartz, 20-32 parts of ordinary kaolin, 2-4 parts of aluminum oxide, 10-20 parts of lime mud (or named as 'Guangxi Beihai mud'), 2-5 parts of magnesium soil, 5-10 parts of waste porcelain powder, and 0.3-0.6 parts of carboxymethylcellulose. The petalite heat-resisting ceramic material provided by the invention has the advantages that an effect that the ceramic material does not crack under the condition of quick cooling at 480 DEG C-20 DEG C can be achieved, the forming stability is good in the process of production, the merit factor of products can reach over 90%, and a ceramic pot product is clean and easy to wash; and meanwhile, the petalite heat-resisting ceramic material has the beneficial effects of white product, good texture, glossiness, no blemish, and the like.

Owner:饶国良

Ceramic glaze, ceramic ware and preparation method of ceramic ware

InactiveCN108545941ASmall coefficient of linear expansionImprove adaptabilityCalcium magnesiumMaterials science

The invention relates to a ceramic glaze, a ceramic ware and a preparation method of the ceramic ware. The ceramic glaze is prepared from the following raw materials by weight percent: 20%-40% of petalite, 20%-40% of spodumene, 10%-20% of kaolin, 5%-15% of white carbon black, 5%-10% of zirconium silicate, 5%-10% of calcined talcum, 1%-5% of zinc oxide and 1%-5% of calcium-magnesium powder. The ceramic glaze prepared from the raw materials in a specific combination and proportion has a relatively low linear expansion coefficient and relatively good adaptability and can be applied to a heat-proof ceramic ware with a temperature difference over 600 DEG C, a glaze surface is observed under a 200-time microscope, the crystal pattern of the glaze surface is complete, and the glaze surface is notcracked, so that the problem that the glaze surface is microcosmically cracked is solved; and meanwhile, by utilizing a rapid sintering process, the production cost is greatly lowered.

Owner:湖南嘉盛电陶新材料股份有限公司

Black lithium silicate glass ceramics

ActiveUS20190161395A1Casings with display/control unitsCasings/cabinets/drawers detailsCalcium silicateSilicate glass

A black lithium silicate glass ceramic is provided. The glass ceramic includes lithium silicate as a primary crystal phase and at least one of petalite, β-quartz, β-spodumene, cristobalite, and lithium phosphate as a secondary crystal phase. The glass ceramic is characterized by the color coordinates: L*: 20.0 to 40.0, a*: −1.0 to 1.0, and b*: −5.0 to 2.0. The glass ceramic may be ion exchanged. Methods for producing the glass ceramic are also provided.

Owner:CORNING INC

Preparation method of ceramic inner pot used with electric heat pan

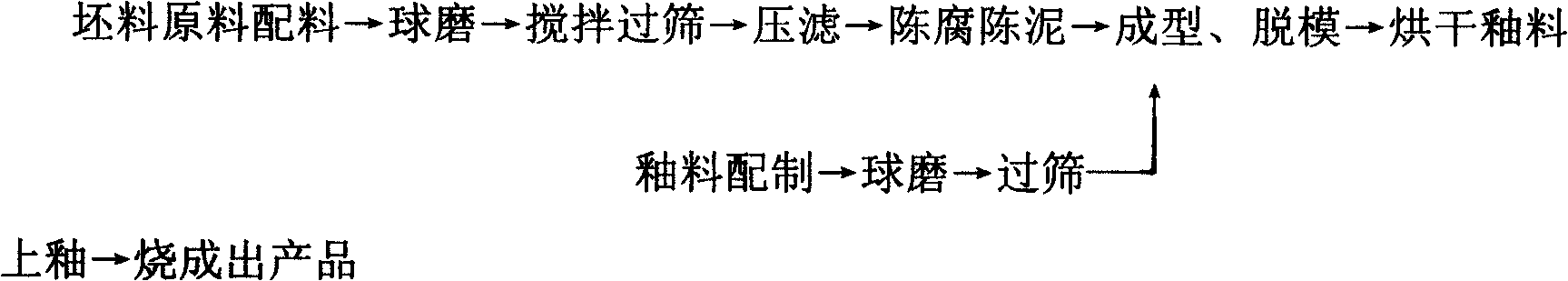

The invention relates to the field of ceramic, specifically to a preparation method of a ceramic inner pot used with an electric heat pan. A blank material of the invention comprises the following ingredients: kaolin, spodumene, petalite, talcum, clay, bentonite and waste ceramic. Glaze is composed of the following ingredients: kaolin, spodumene, petalite, magnesium oxide and calcium oxide. The preparation method of the ceramic inner pot used with an electric heat pan comprises the following steps: preparing for raw materials of the blank material and glaze, preparing the blank material and the glaze, cleaning and drying a plaster mold, moulding by rolling the standby blank material, fettling with a small steel knife to prepare a moulded product, glazing with the standby glaze, and sintering the glazed product with a kiln to obtain the ceramic inner pot used with an electric heat pan. The invention aims to provide a preparation method of the inner pot used with an electric heat pan. The ceramic inner pot has advantages of high qualified rate, high regularity, flat and smooth glaze layer, good fit between the bottom and wall of the pot and an arc-shaped heating element of the electric heat pan and good heat conduction effect.

Owner:GUANGDONG TONZE ELECTRIC CO LTD

Fluorescent ceramic tile

The invention discloses a fluorescent ceramic tile which is characterized by being prepared from the following substances in parts by weight: 11-43 parts of white feldspar, 1-41 parts of calcite, 35-70 parts of steel slag, 0.5-11.8 parts of ox bones, 10-50 parts of sodium aluminum silicate, 0.5-2.8 parts of calcium oxide, 10-30 parts of black clays, 0-15 parts of nepheline syenite, 2-41 parts of petalite, 10-57 parts of dolomite, 21-45 parts of hargil, 1-7 parts of sodium fluosilicate, 3-7 parts of long persistence phosphor and 40-68 parts of high-temperature calcium-based clinkers. The fluorescent ceramic tile disclosed by the invention has the beneficial effects that the fluorescent ceramic tile is resistant to high temperature, high in strength, resistant to wear, long in persistence and the like; moreover, the fluorescent ceramic tile is sintered at one time, so that the process is simplified and the energy resources are saved.

Owner:QINGDAO QIANXIANG ENVIRONMENTAL PROTECTION TECH

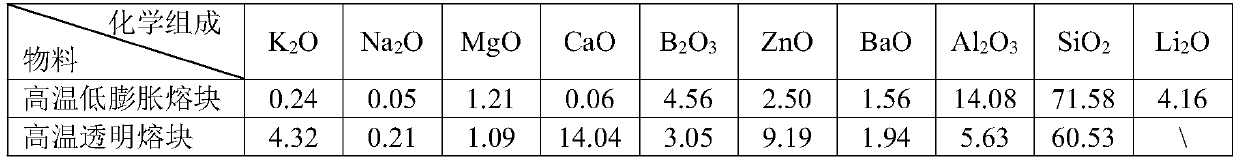

Easy-to-clean opal glaze suitable for low-expansion ceramics and preparation method and application of opal glaze

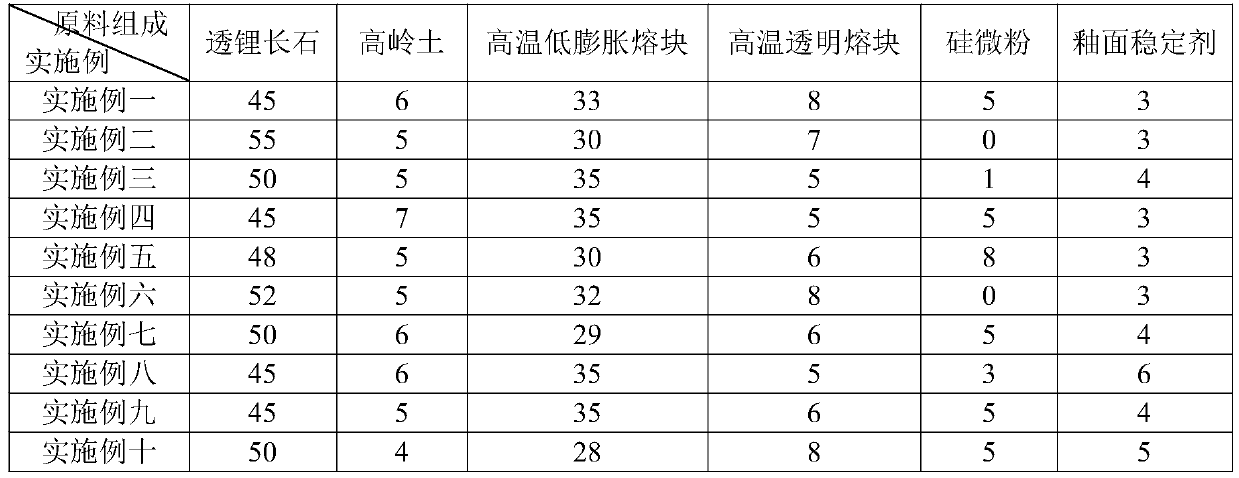

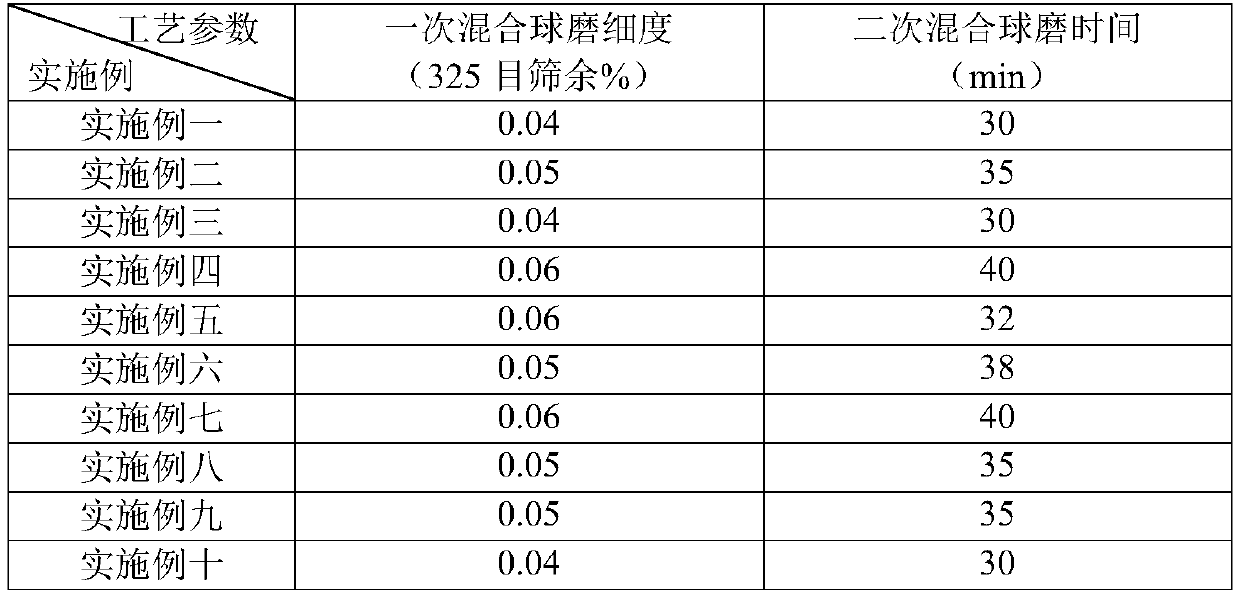

The invention discloses an easy-to-clean opal glaze suitable for low-expansion ceramics. The opal glaze is prepared from, by weight, 45-55% of petalite, 4-7% of kaolin, 25-35% of high-temperature low-expansion frits, 5-15% of high-temperature transparent frits, 0-10% of fine silicon powder and 3-6% of a glaze stabilizer. In addition, the invention also discloses a preparation method and application of the easy-to-clean opal glaze suitable for the low-expansion ceramics. The formulation system has a larger melting temperature range under an oxidizing atmosphere condition, which effectively solves the defect problems such as glaze face holes, and achieves the purpose of easy cleaning while having good stability. The preparation method can be based on a general production process of daily-useceramic glazes and daily-use ceramics, is suitable for various low-expansion ceramic green bodies, particularly provides a necessary condition for low-expansion ceramic pots matched with electric appliances, and has a promoting effect on the technological progress and application development of the low-expansion ceramic industry.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Durable porcelain and production technology thereof

ActiveCN108911704AImprove plasticitySmall expansion coefficientCeramic materials productionClaywaresLithiumKaolin clay

The invention discloses durable porcelain and a production technology thereof. A blank material of the durable porcelain comprises the following ingredients (by weight): 30-50 parts of magnesium stoneflour, 25-30 parts of feldspar powder, 28-35 parts of Xiaomei Gaojitou porcelain clay, 26-32 parts of Anfu porcelain clay, 22-26 parts of waste ceramic powder, 16-24 parts of waste glass powder, 5-12parts of dolomite, and 3-6 parts of barium carbonate. A glaze comprises the following ingredients (by weight): 30-60 parts of glaze stone, 20-25 parts of kaolin, 15-25 parts of quartz, 10-20 parts ofdolomite, 5-8 parts of petalite and 3-6 parts of boric acid. By raising plasticity of the glaze while reducing expansion coefficient of the glaze, cracking of sintered glaze is effectively reduced, and smoothness of the glaze is improved; and the petalite can promote melting between the blank material and the glaze and improve whiteness, transmittance and smoothness of the product; and by introducing magnesium oxide through dolomite, introducing silicon dioxide through kaolin and quartz and adjusting contents of ingredients in the formula and adjusting silicon-to-magnesium ratio of the glaze,impact strength of the glaze is raised and the glaze is not easy to crush, break and crack.

Owner:LONGQUAN OUJIANG CELADON CO LTD

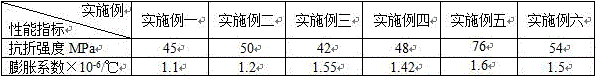

Ceramic glaze with high cold and hot shock resistance, ceramic body and preparation methods thereof

ActiveCN108726878ASmall expansion coefficientImprove pass rateCooking-vessel materialsClaywaresShock resistanceZinc

The invention relates to ceramic glaze with high cold and hot shock resistance. The ceramic glaze is prepared from the following raw materials in percentage by weight: 40 to 80% of petalite, 3 to 10%of kaolin, 3 to 25% of quartz, 1 to 7% of talcum, 1 to 6% of zinc oxide and 1 to 6% of barium carbonate. The ceramic glaze disclosed by the invention can present silky luster after being covered to aceramic body, an expansion coefficient of the ceramic glaze is small, whiteness of the ceramic glaze can reach 67.8, and the ceramic glaze is prevented from peeling after cooking for 2,200 times.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

Aluminum oxide-based wear-resisting cutting ceramic and preparation method thereof

InactiveCN104387039AImprove conductivityHigh mechanical strengthPolyethylene glycolAluminum ammonium sulfate

Owner:HEFEI WANWEI ELECTRICAL EQUIP ENG

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com