Low-expansion ceramic billet as well as preparation method and application thereof

A low-expansion, ceramic billet technology, applied in the field of ceramic materials, can solve the problems of high equipment cost, narrow application range, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

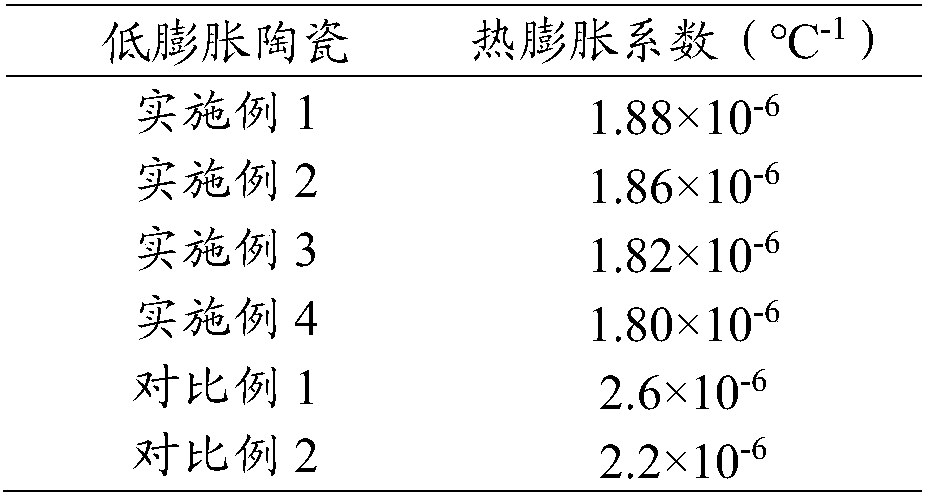

Examples

Embodiment 1

[0037] Prepare raw materials, respectively weigh 15kg of cordierite, 20kg of petalite, 20kg of talc, 4kg of mullite and 41kg of kaolin, wherein the particle size of cordierite and petalite raw materials is 40 mesh, talc, mollite The particle size of the stone and kaolin raw materials is 200 mesh.

[0038] Put the raw materials of talc, mullite and kaolin into the ball mill, add 65kg of grinding balls and 117kg of water at the same time, carry out wet grinding, and test the slurry with a particle size analyzer. When the D97 in the particle size distribution in the slurry reaches 12μm, that is A primary billet was produced.

[0039] Add cordierite and lithium petalite raw materials to the primary billet, add 35kg of grinding balls and 63kg of water at the same time, continue wet grinding, and test the slurry with a particle size analyzer; when the D97 in the particle size distribution in the slurry reaches 60μm , Stop ball milling to get low expansion ceramic blank.

[0040] S...

Embodiment 2

[0049] Basically the same as Example 1, the difference is:

[0050] The raw materials include 20kg of cordierite, 16kg of petalite, 16kg of talc, 7kg of mullite, 40kg of kaolin and 1kg of spodumene, wherein the particle size of cordierite and petalite is 80 mesh, and talc The particle size of mullite and kaolin is 325 mesh, and the particle size of spodumene is 100 mesh. During wet ball milling, the D97 of the particle size distribution of the particles in the primary blank reached 15 μm, and the D97 of the particle size distribution of the particles in the low expansion ceramic blank reached 80 μm. The temperature of glaze firing is 1250 ℃, and the time is 2.5 hours.

Embodiment 3

[0052] Basically the same as Example 1, the difference is:

[0053] The raw materials include 18kg of cordierite, 17kg of petalite, 18kg of talc, 4kg of mullite, 42kg of kaolin and 1kg of spodumene, wherein the particle size of cordierite and petalite raw materials is 60 mesh, The particle size of talc, mullite and kaolin raw materials is 250 mesh, and the particle size of spodumene is 60 mesh. During the wet ball milling, the D97 of the particle size distribution of the particles in the primary blank reached 13 μm, and the D97 of the particle size distribution of the particles in the low expansion ceramic blank reached 70 μm. The temperature of glaze firing is 1250 DEG C, and the time is 3.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com