Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2187 results about "Roll forming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roll forming, also spelled roll-forming or rollforming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities.

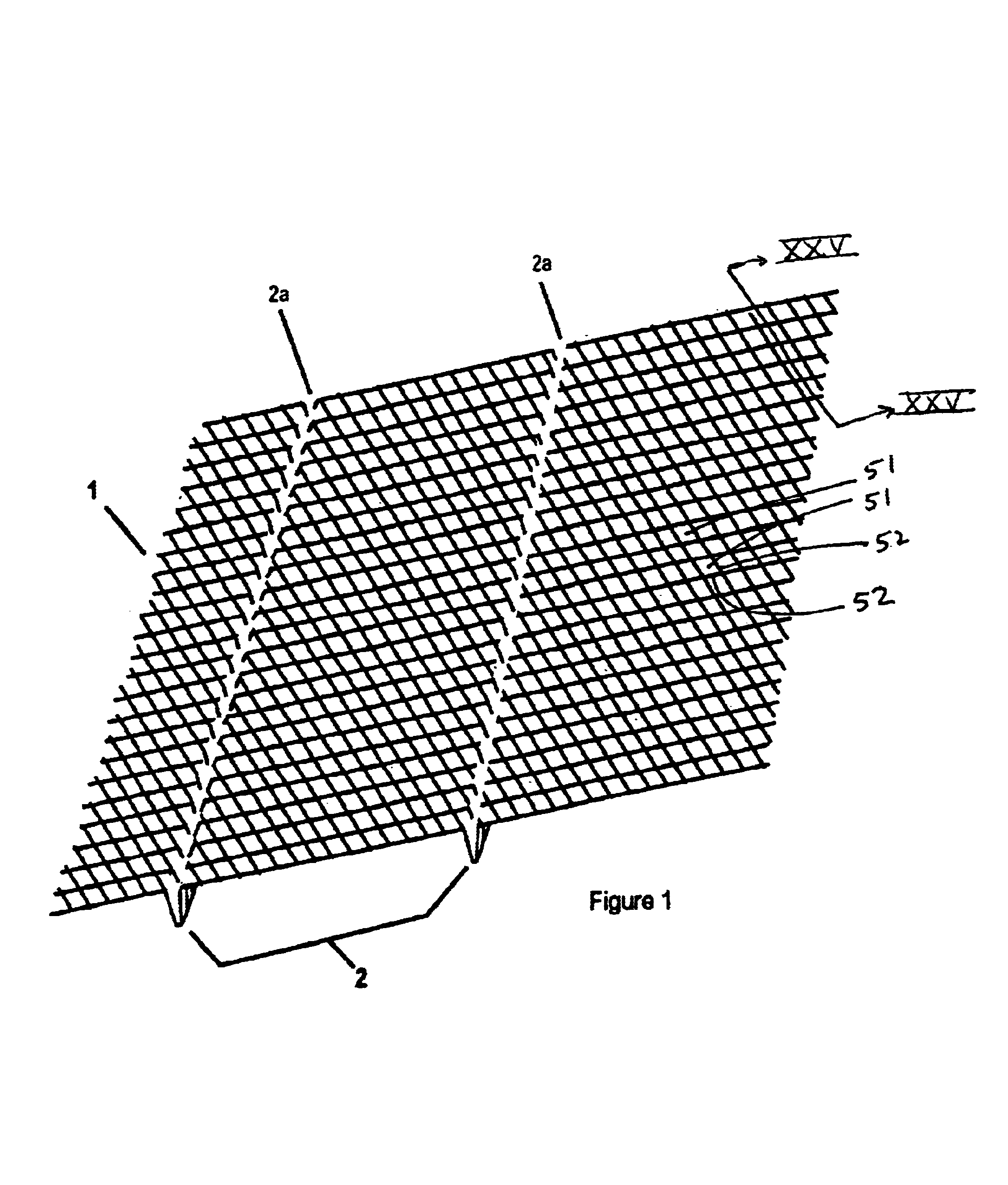

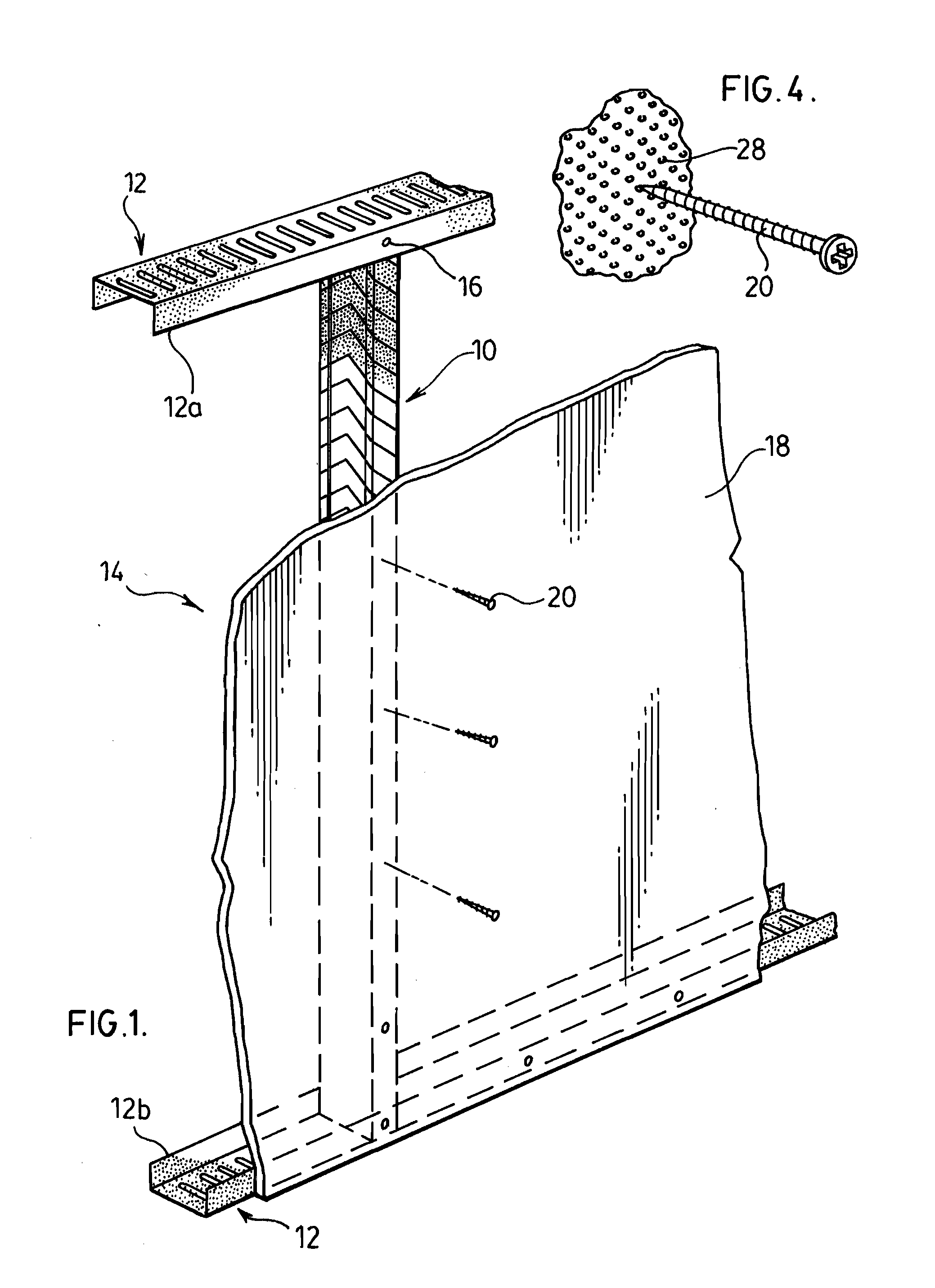

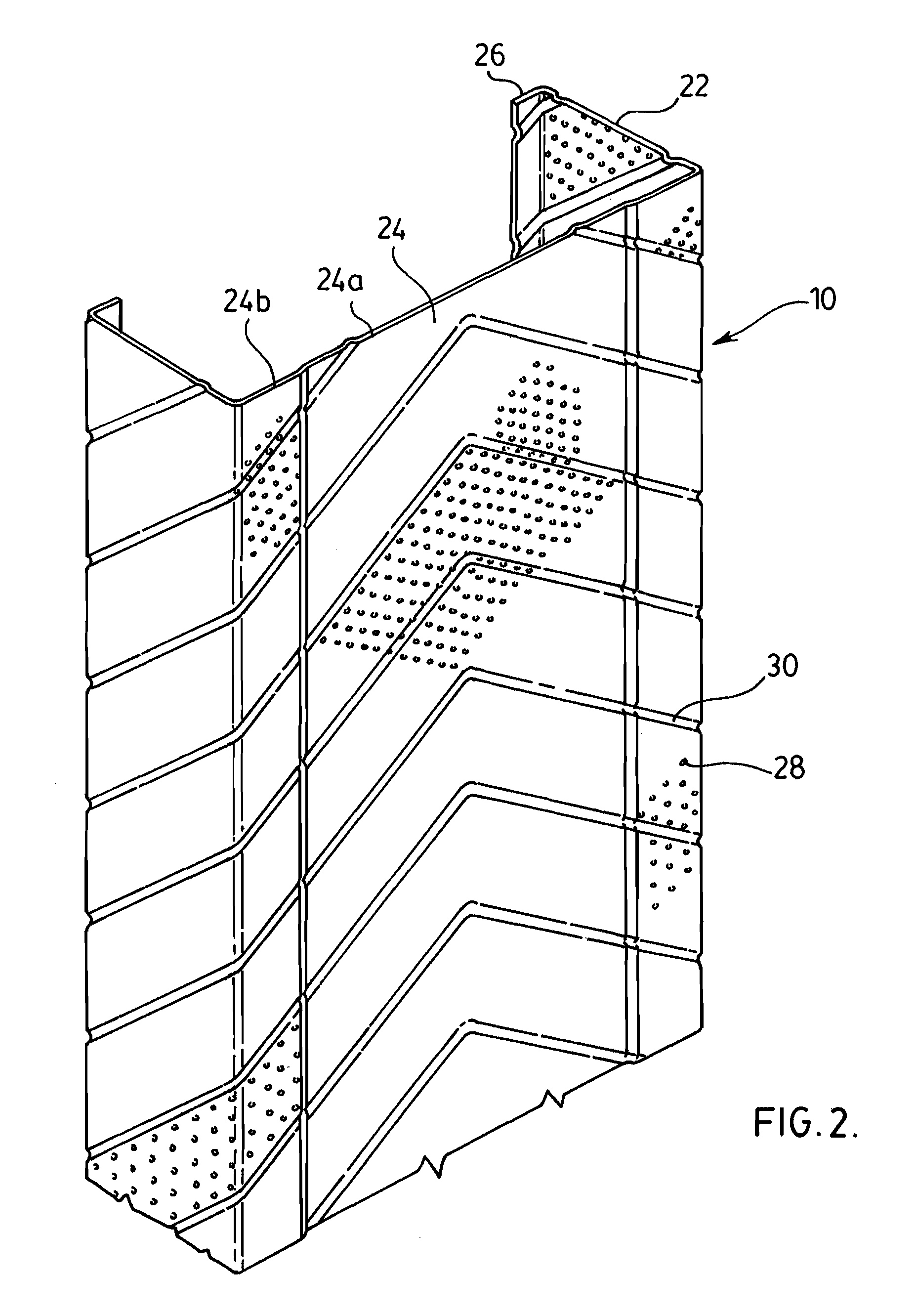

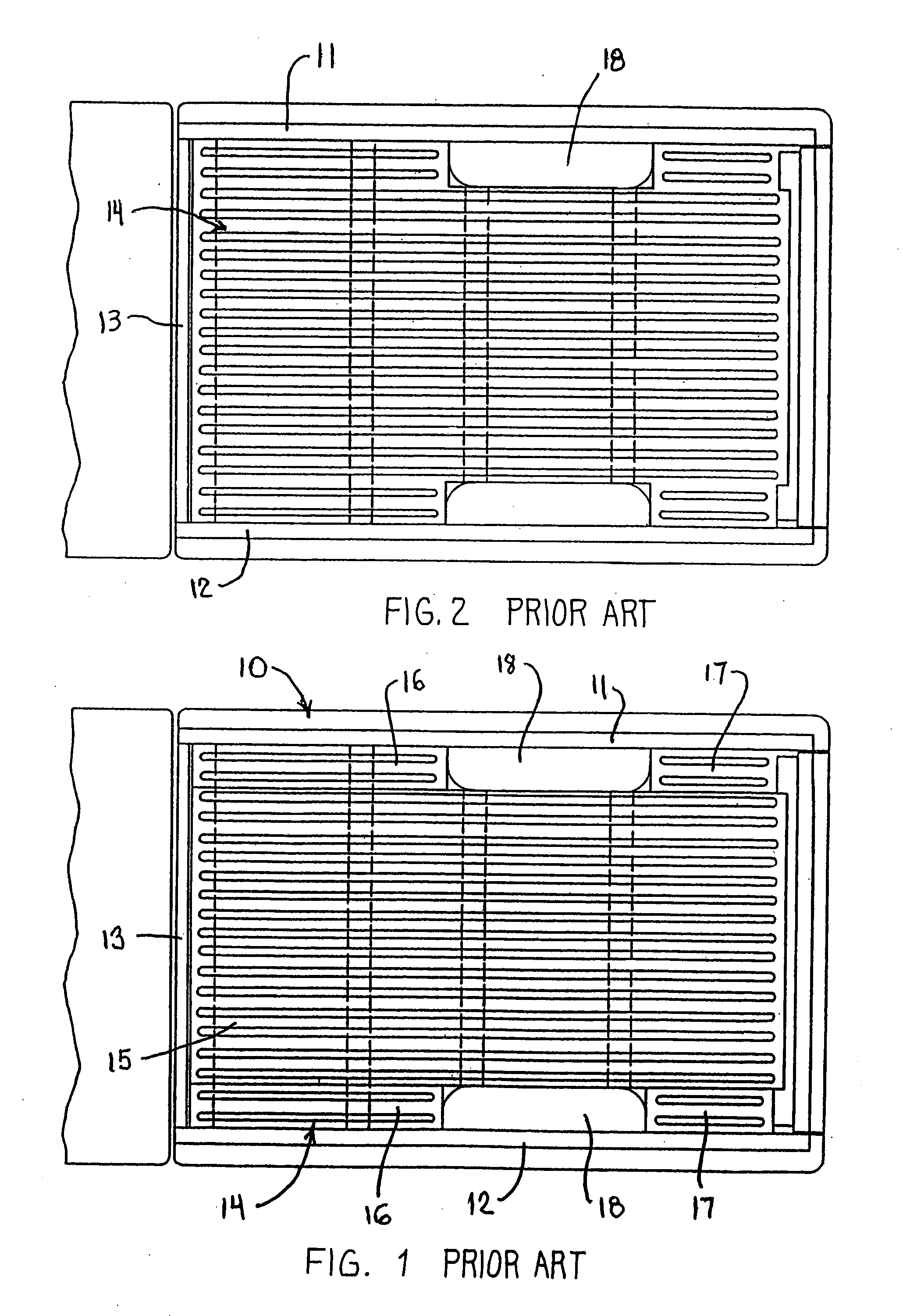

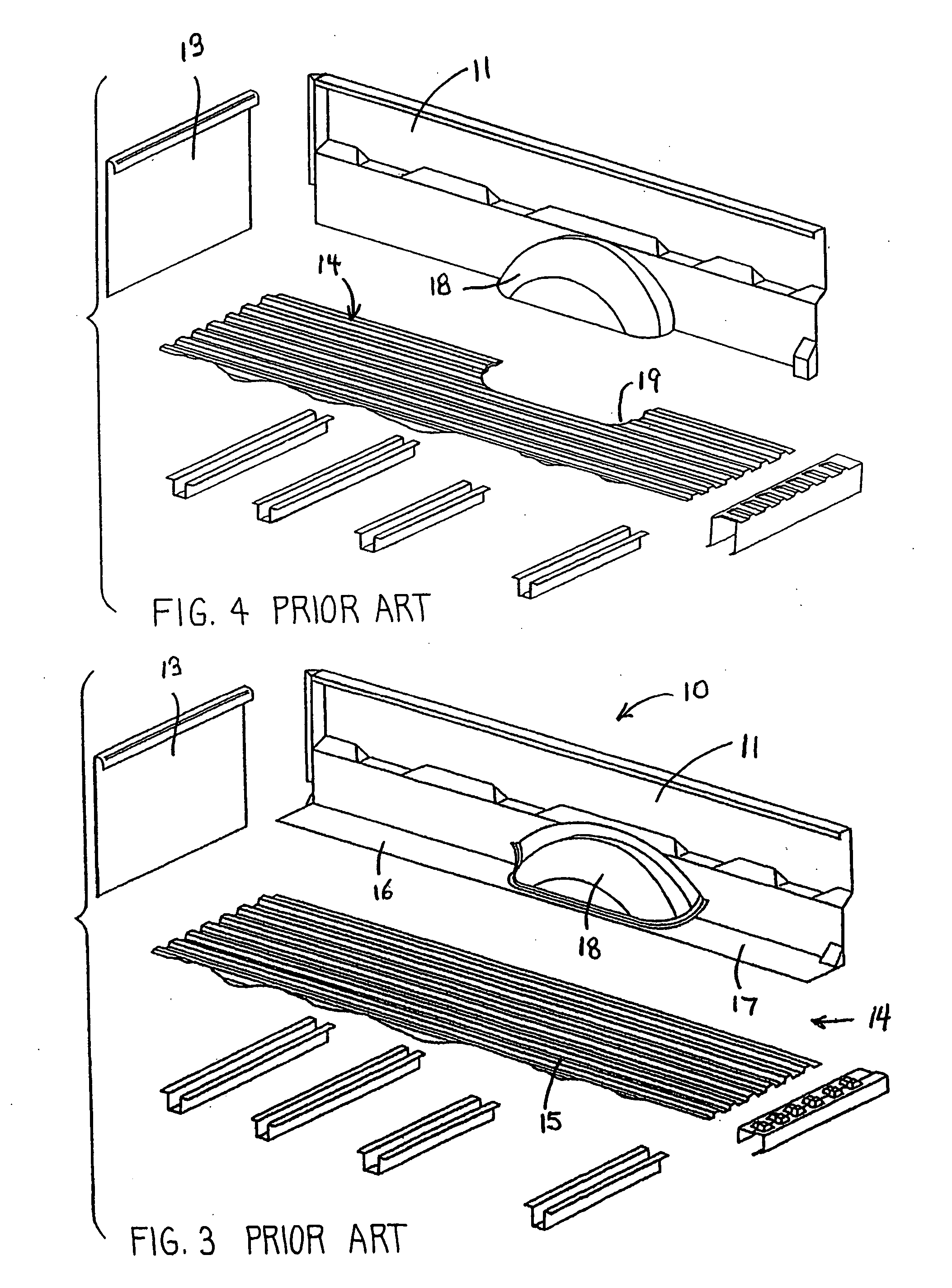

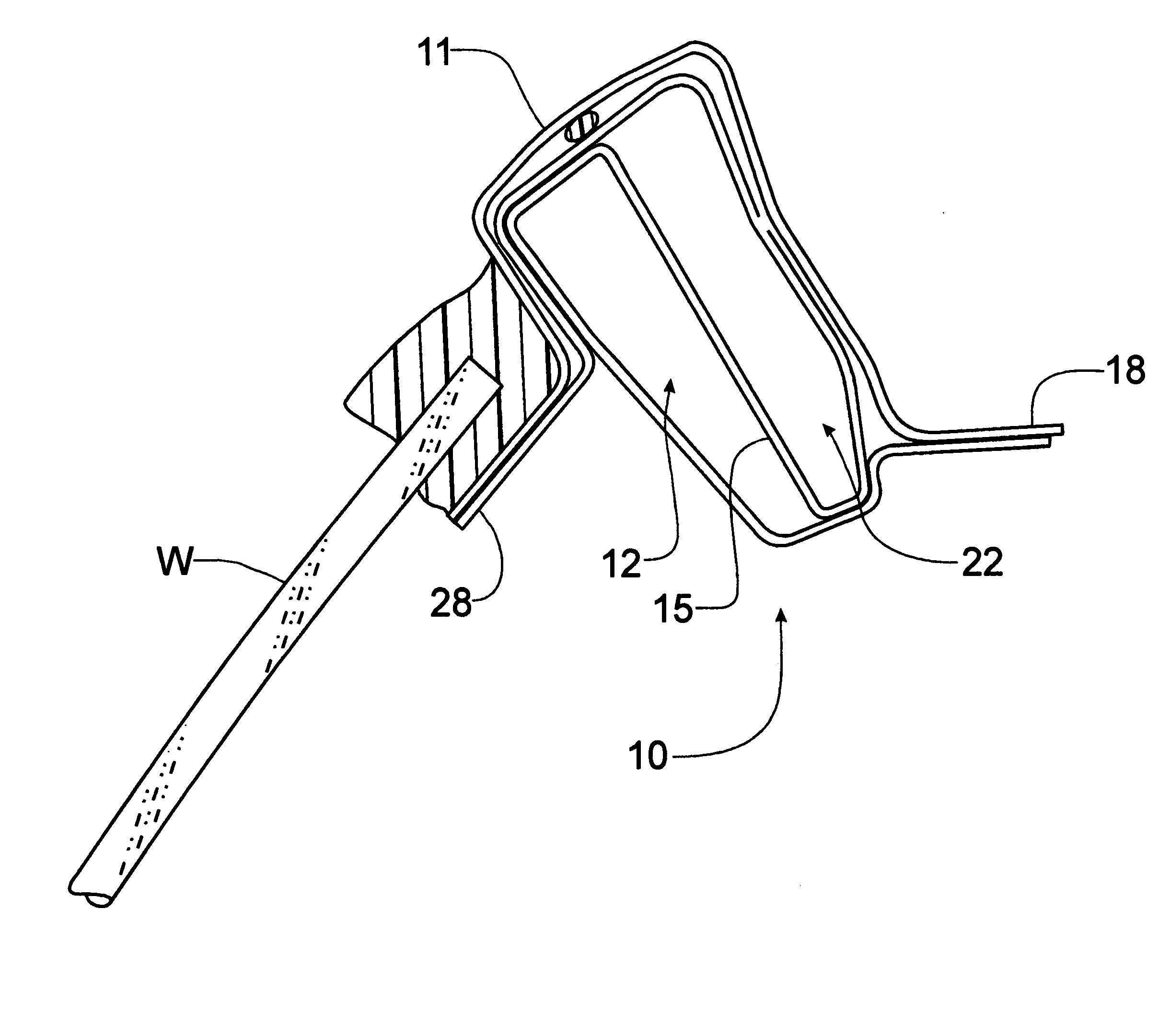

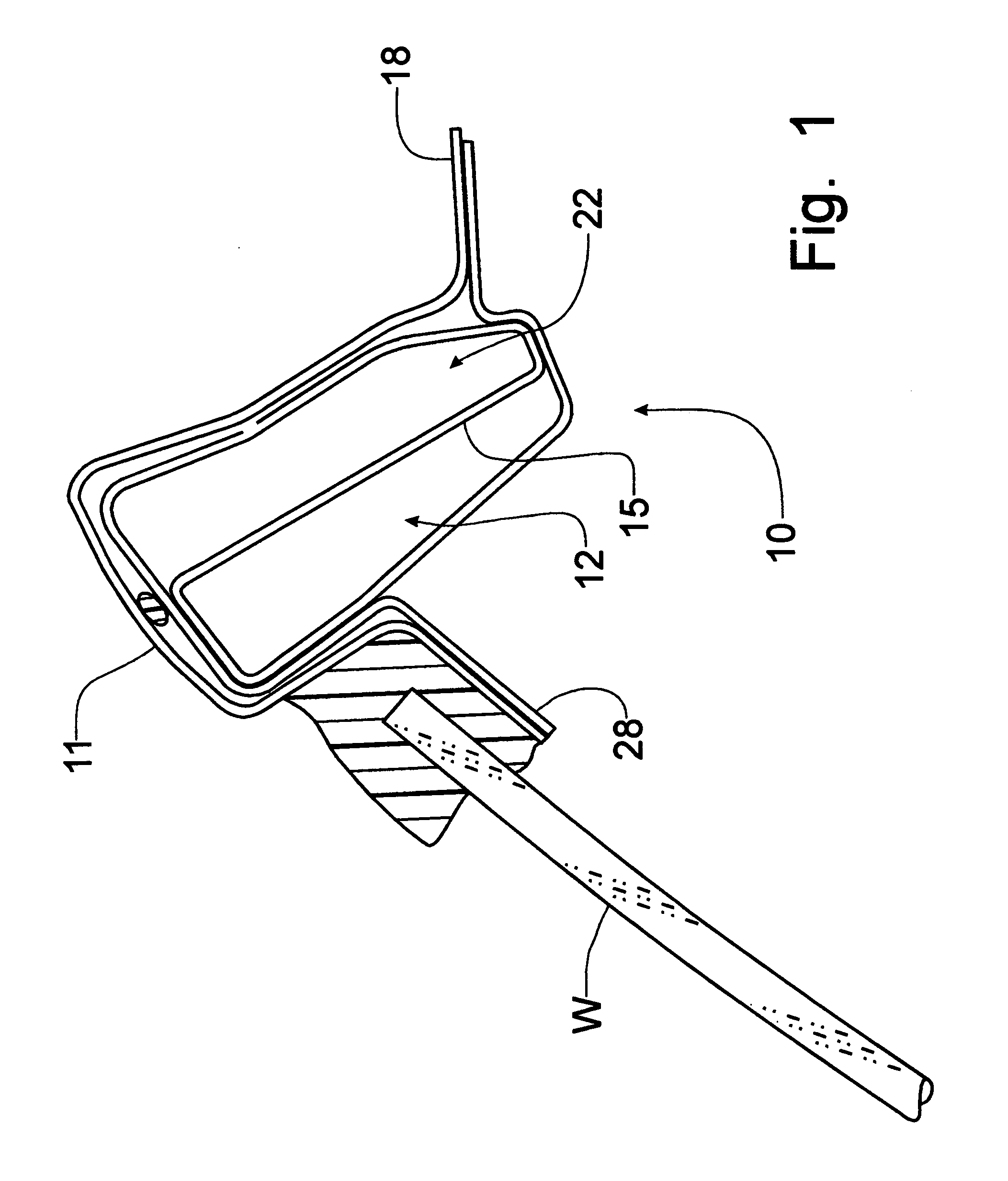

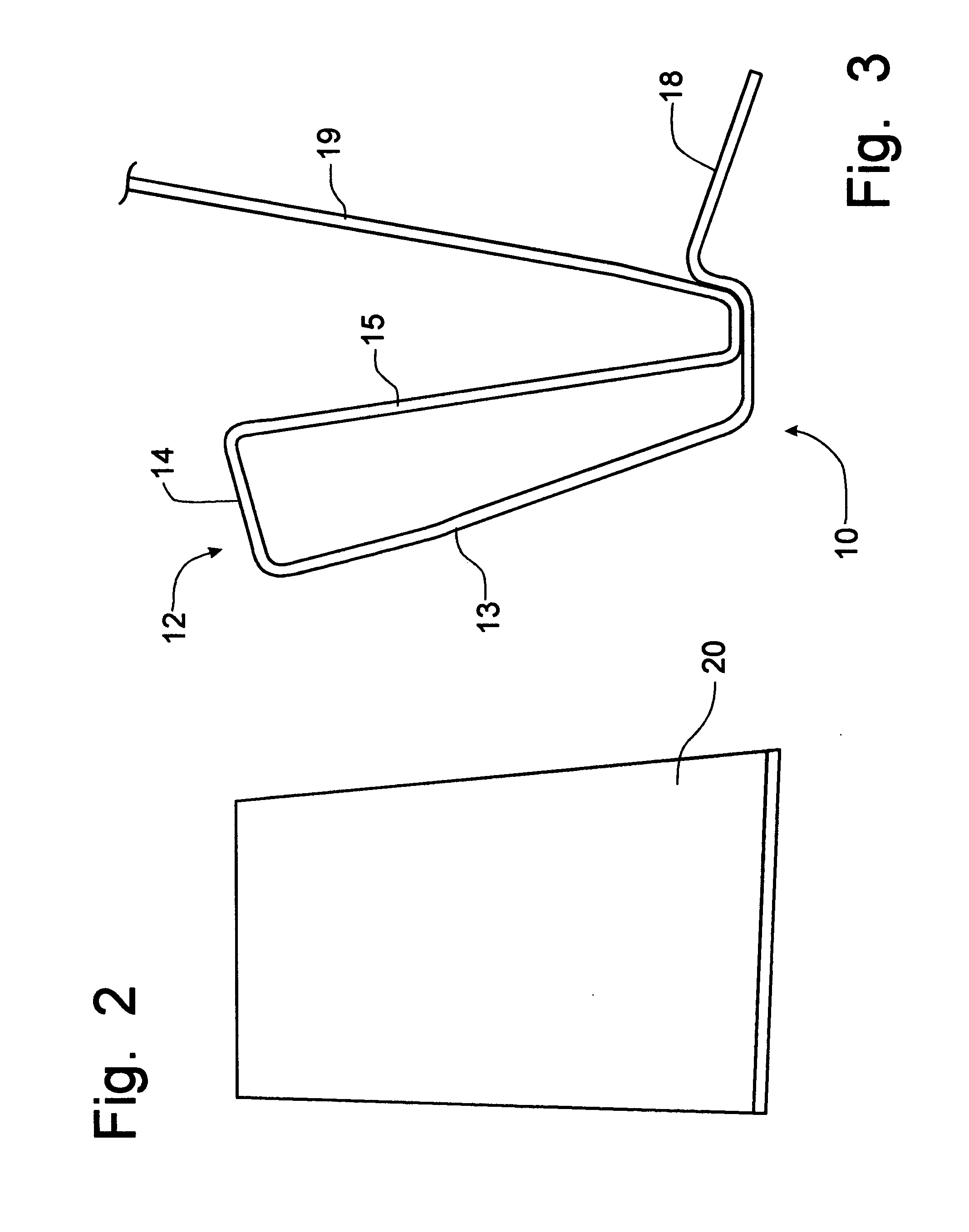

Non clogging screen

ActiveUS6951077B1Sufficient self-cleaning propertyRoof coveringStationary filtering element filtersVertical planeRoll forming

An improved gutter shield device includes a first connecting plane of roll formed metal, a second filtering plane of roll formed metal and metallic or polymer cloth, and a third connecting plane of roll formed metal combined into an integral unit.An elongated strip of roll formed metal includes a rear vertical plane adapted to seat beneath shingles of a roof structure. The rear vertical plane is crimped by roll forming onto the second and rear longitudinal edge of a forward extending plane that combines a fine filtering membrane with an underlying skeletal support of expanded metal as an integral unit. The expanded metal and filtering membrane so joined contain two or more v-shaped downward extending longitudinal channels within the forward extending plane that transverse the length of the forward extending plane parallel to it's first edge. The forward extending plane is bound on a first and forward longitudinal edge by a first plane of that comprises a roll formed angled z-shaped connecting metal strip for securing the gutter shield to an inwardly extending flange of a k-style gutter.

Owner:MGP MFG

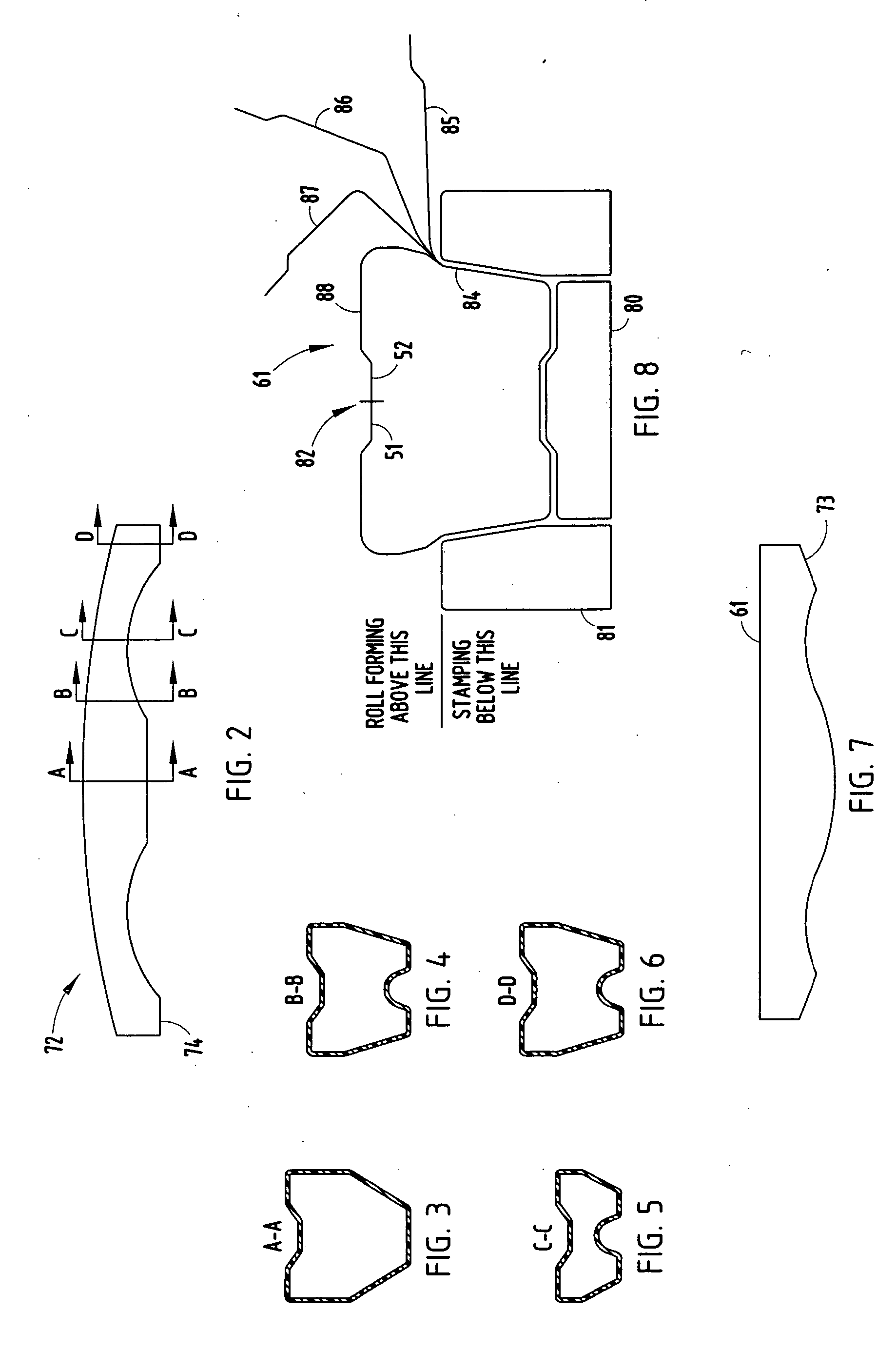

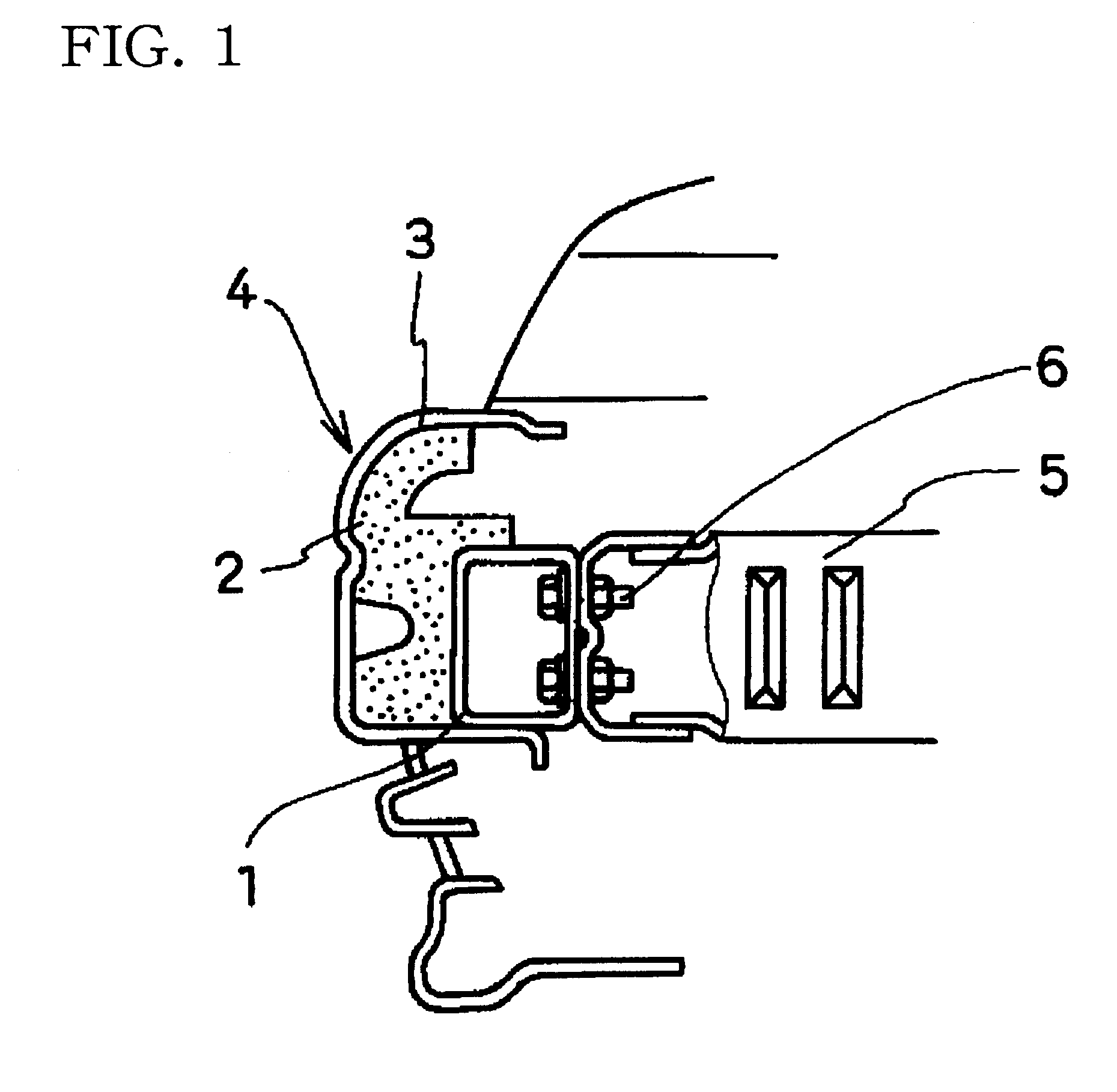

Vehicle bumper beam

A bumper beam includes an open front section made from a high-strength material such as ultra-high-strength steel (UHSS) material, and further includes a mating back section made of lower-strength material attached to a rear side of the front section along abutting flanges. The front and back sections combine to define different tubular cross sections. The front section can be roll-formed, and the back section can be stamped, thus taking advantage of roll-forming processes' ability to form high-strength materials, while allowing the back section to have a more complicated shape and be stamped. The abutting flanges telescopingly overlap in a fore-aft direction of the vehicle and are welded together at locations that potentially experience shear upon impact, but the flanges of the front section are captured within the flanges of the backs section, thus providing impact strength even if the attachment locations shear off.

Owner:SHAPE CORP

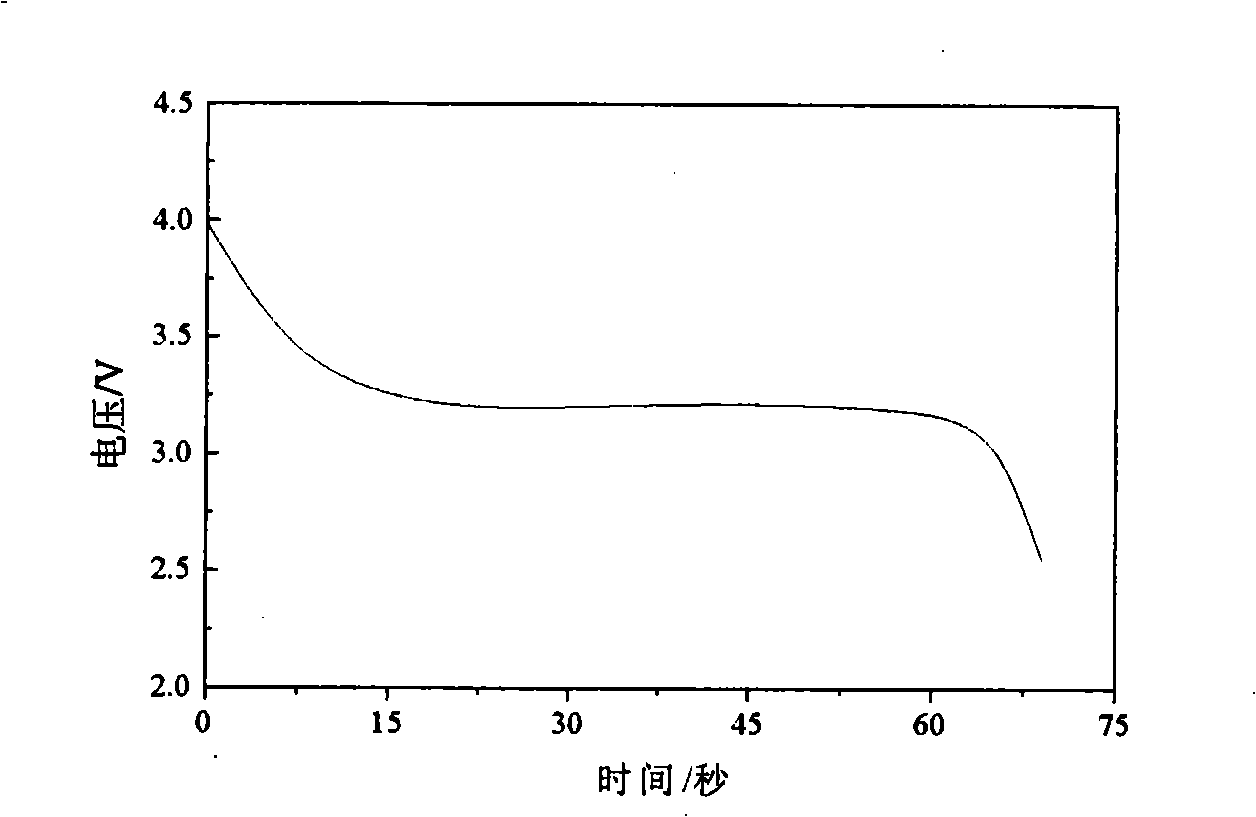

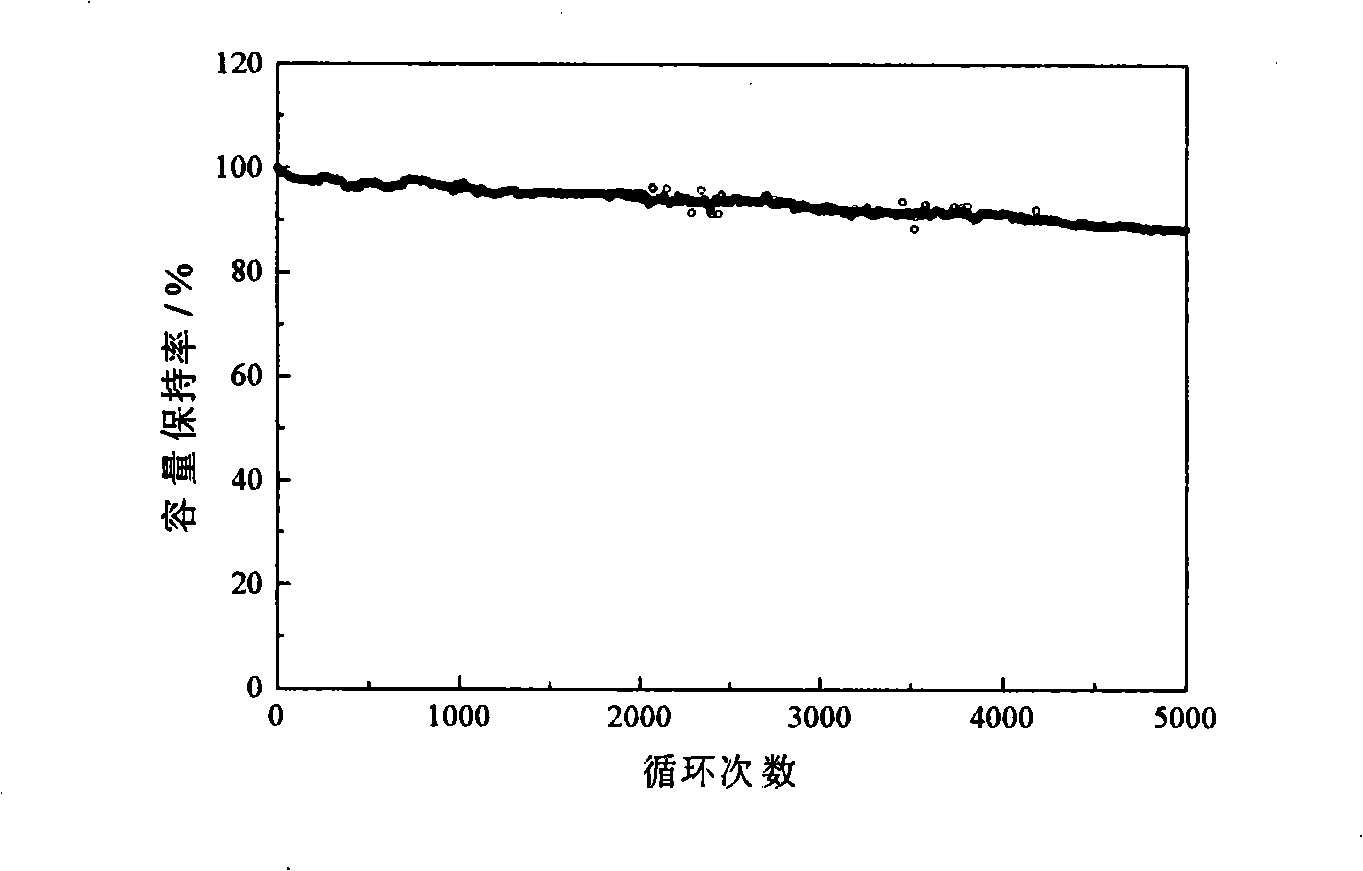

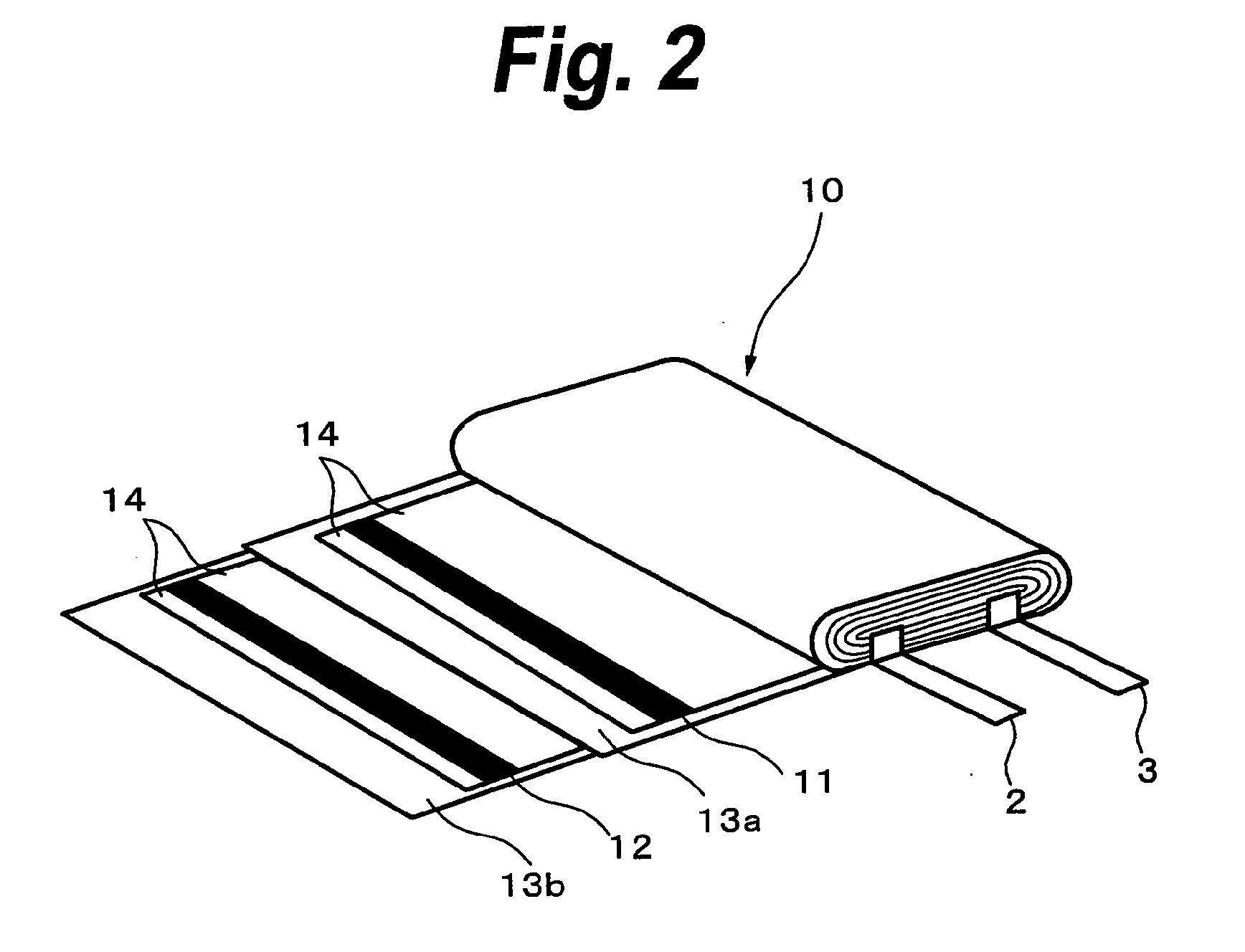

Energy storage device with both capacitor and lithium ion battery characteristics and manufacturing method thereof

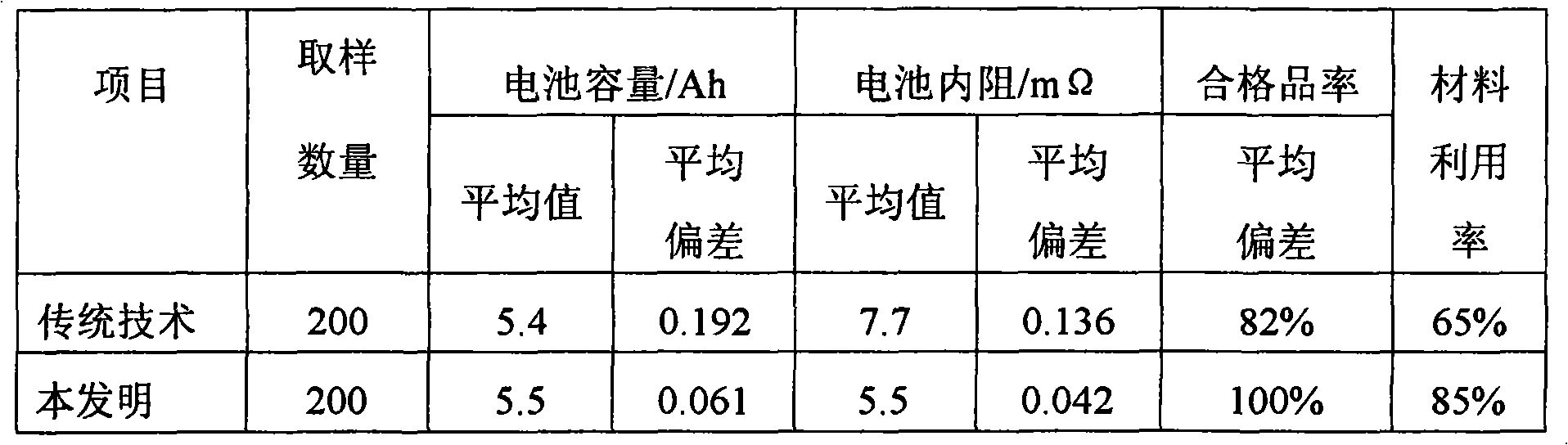

InactiveCN101320821AIncrease energy densityImprove power densityFinal product manufactureActive material electrodesCapacitanceHigh energy

An energy storage device having both characteristics of super capacitor and lithium ion battery and manufacturing method thereof are provided. The invention adopts the mixture of anode material of lithium ion battery and electrode material of super capacitor or composite material as anode active substance, and uses the mixture of cathode material of the lithium ion battery and electrode material of the super capacitor or composite material as cathode active substance. In the electrode active substance, the electrode material of the lithium ion battery has a content of 20% to 95%; the electrode material of the super capacitor has a content of 5% to 80%. The electrode active substance is mixed with the bonder, conducting agent, additive and solvent etc to prepare slurry, then experience steps of coating, drying, roll forming, parting, so that the anode sheet and cathode sheet of the super capacitance battery are produced. By adopting multi-core winding parallel connection and the assembling technology of the winded wore parallel to the narrow arrangement, the anode sheet, the cathode sheet and the membrane are loaded in the battery shell and then welded, dried, dehydrated, and injected with electrolyte, then activated by electricity to obtain super capacitance battery with high energy density and high power density.

Owner:CENT SOUTH UNIV

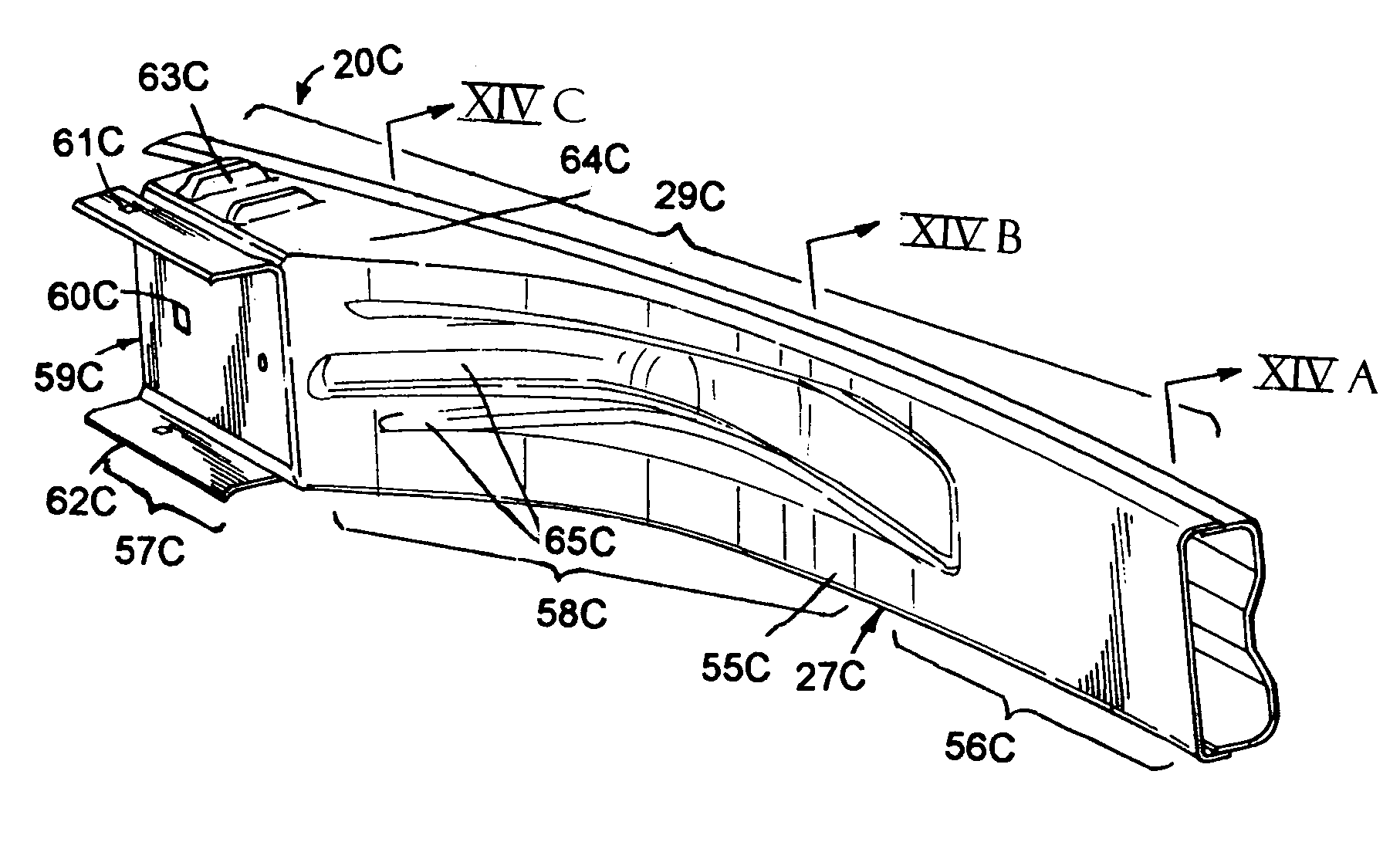

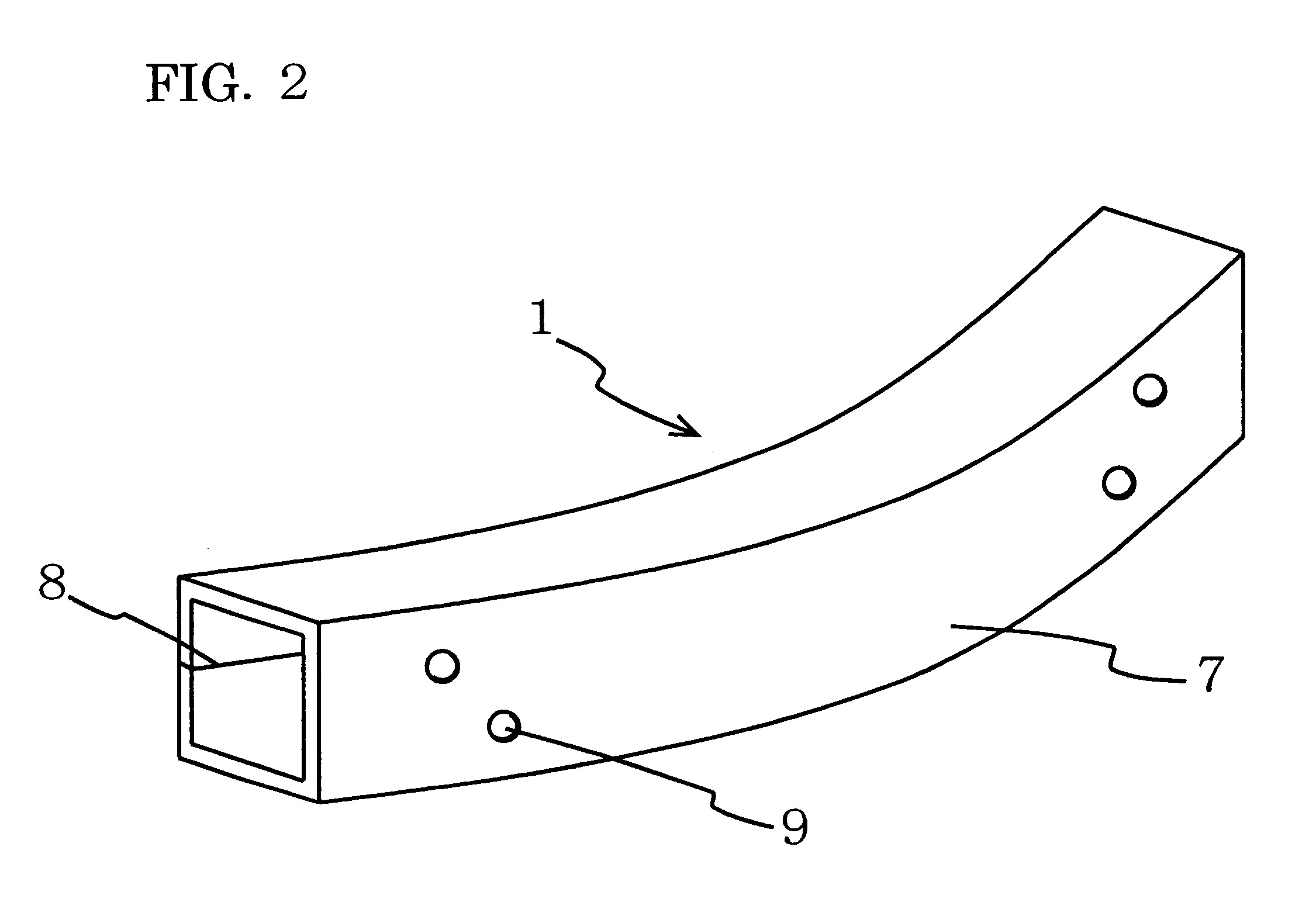

Tapered crushable polygonal structure

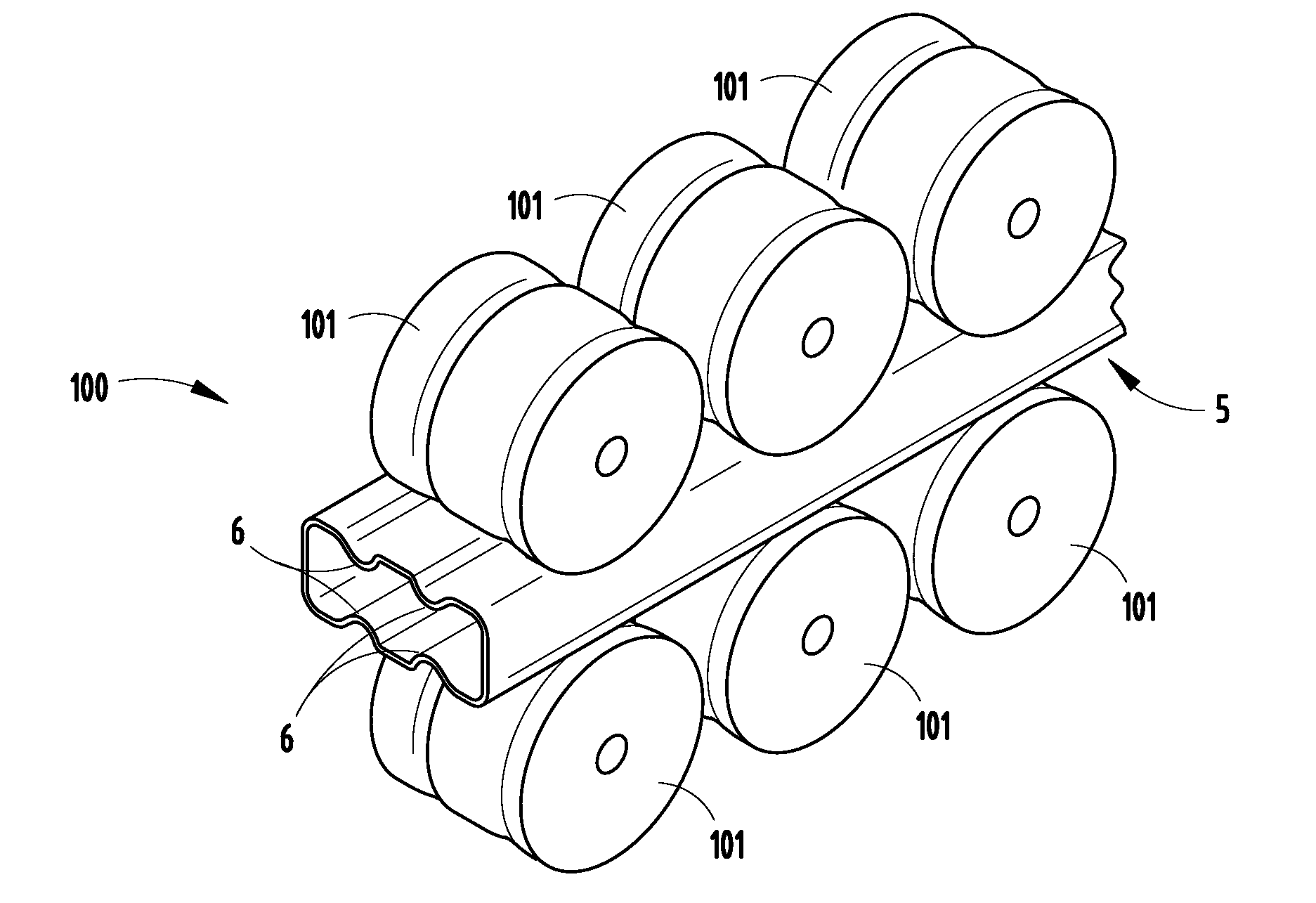

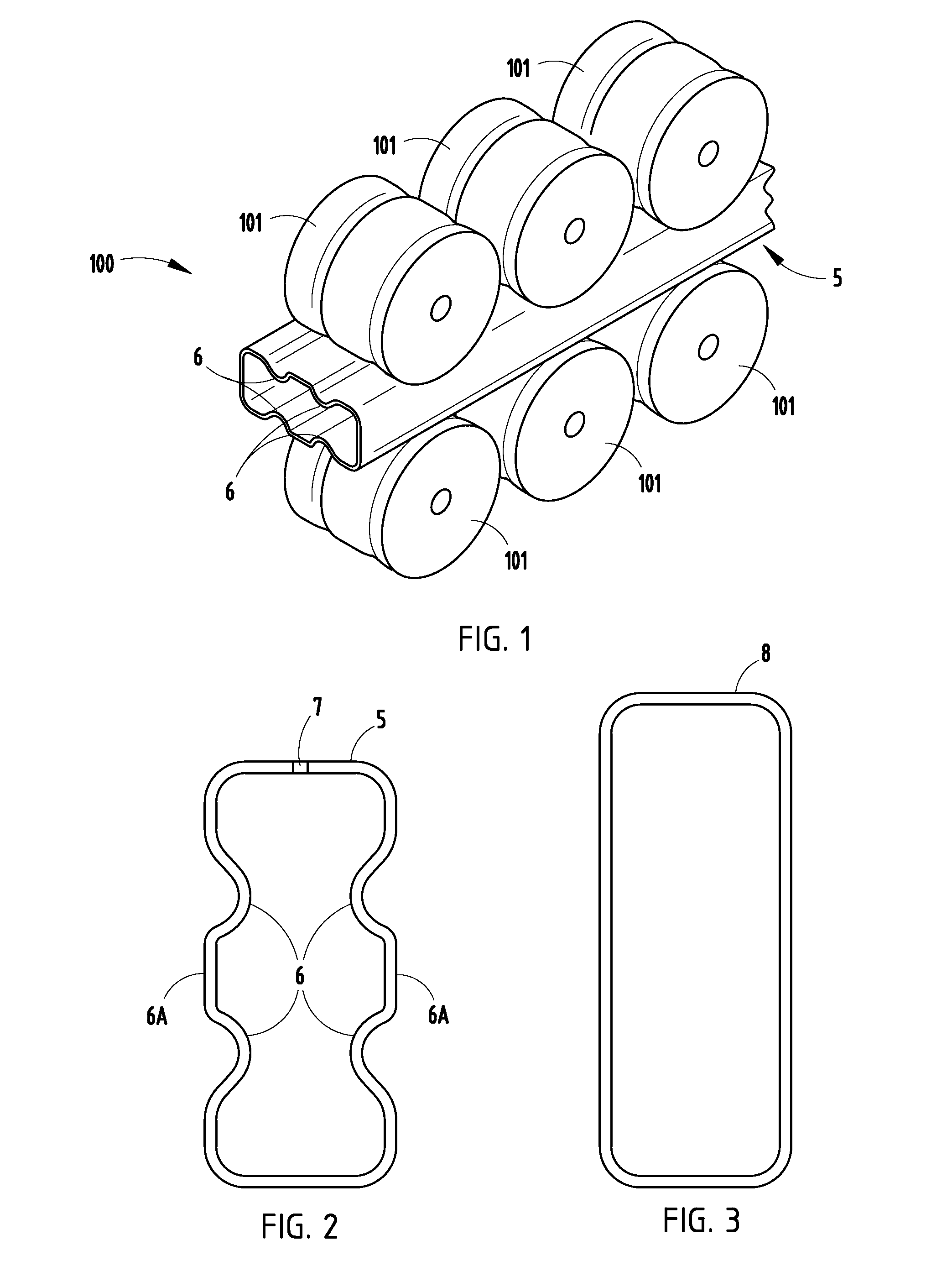

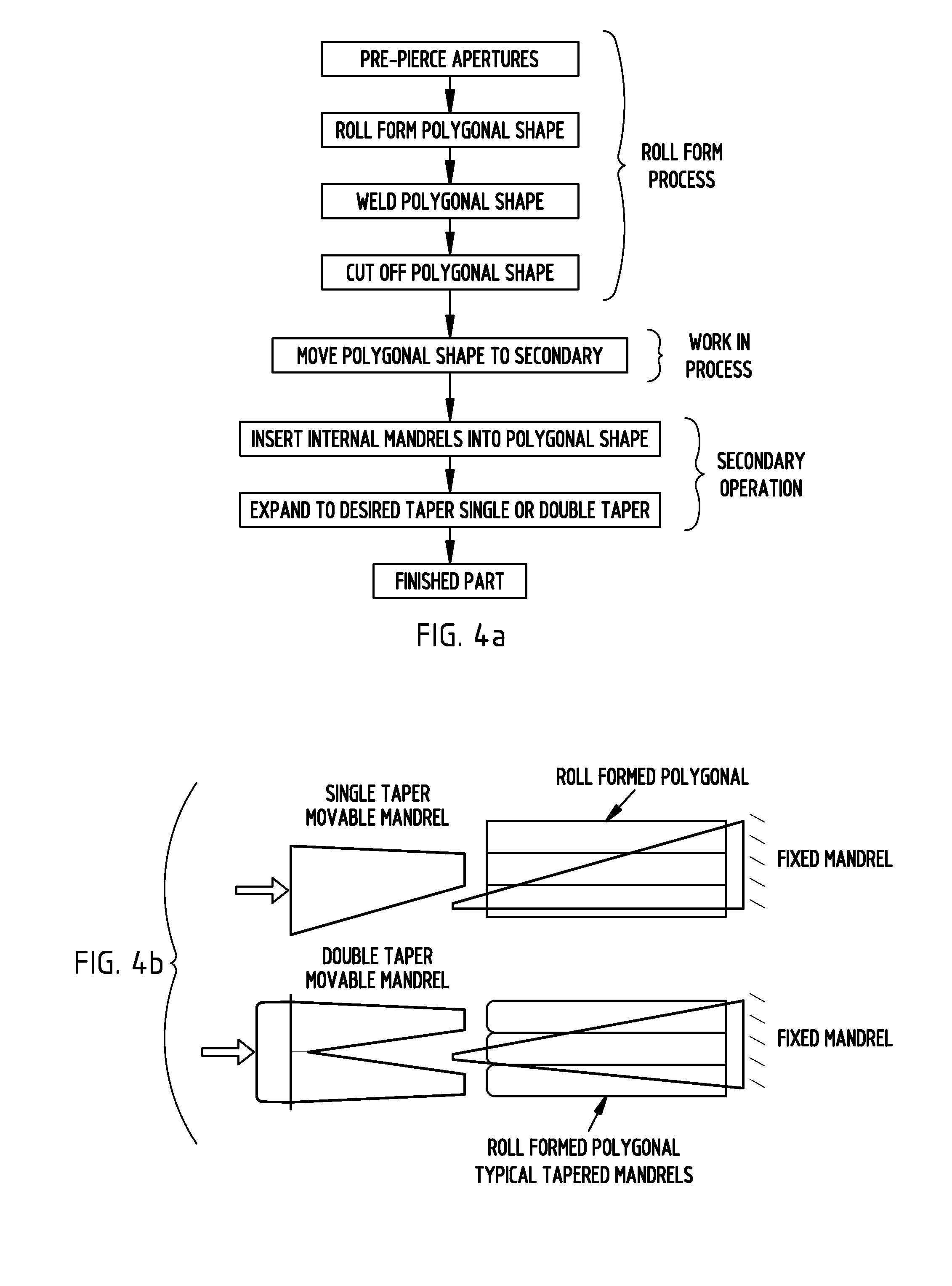

InactiveUS20090102234A1Improve abilitiesOptimal and low cost processVehicle seatsUnderstructuresEngineeringRoll forming

An energy management structure includes an elongated polygonal tube with at least four walls, the tube having a larger first end and a smaller second end, at least two of the walls including a longitudinally-extending channel-shaped tapered rib starting at the smaller second end and extending toward the larger first end. The ribs become shallower near the larger first end. The walls include crush initiators so that the ribs do not provide undesired strength to the tube during a longitudinal impact. A related method includes roll-forming a polygonal tubular shape with at least four walls, at least two of the walls including longitudinally-extending channel-shaped ribs, and reforming the tubular shape into a tapered polygonal shape with a larger end and a smaller end, the ribs becoming shallower as the ribs extend closer to the larger end.

Owner:SHAPE CORP

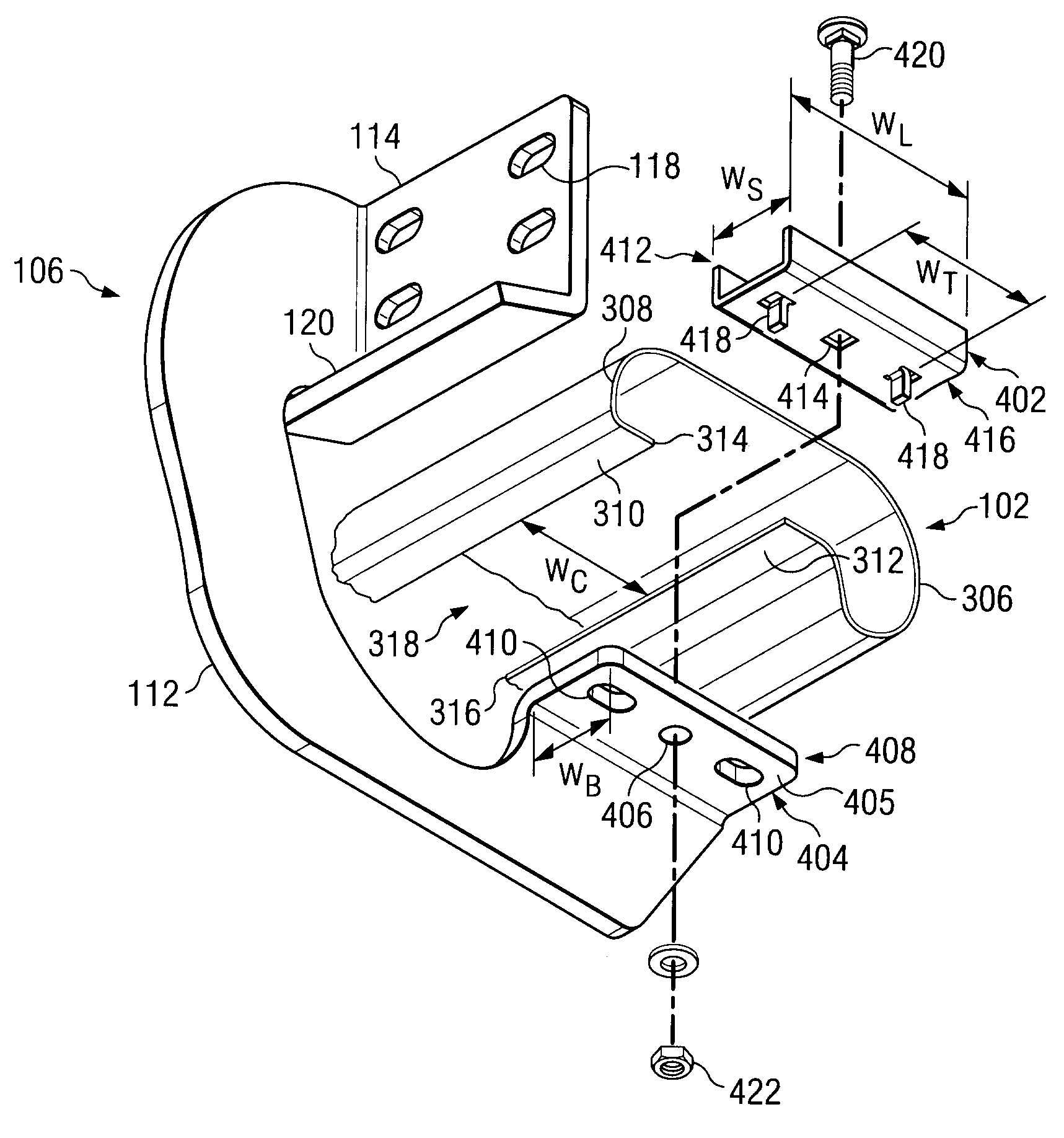

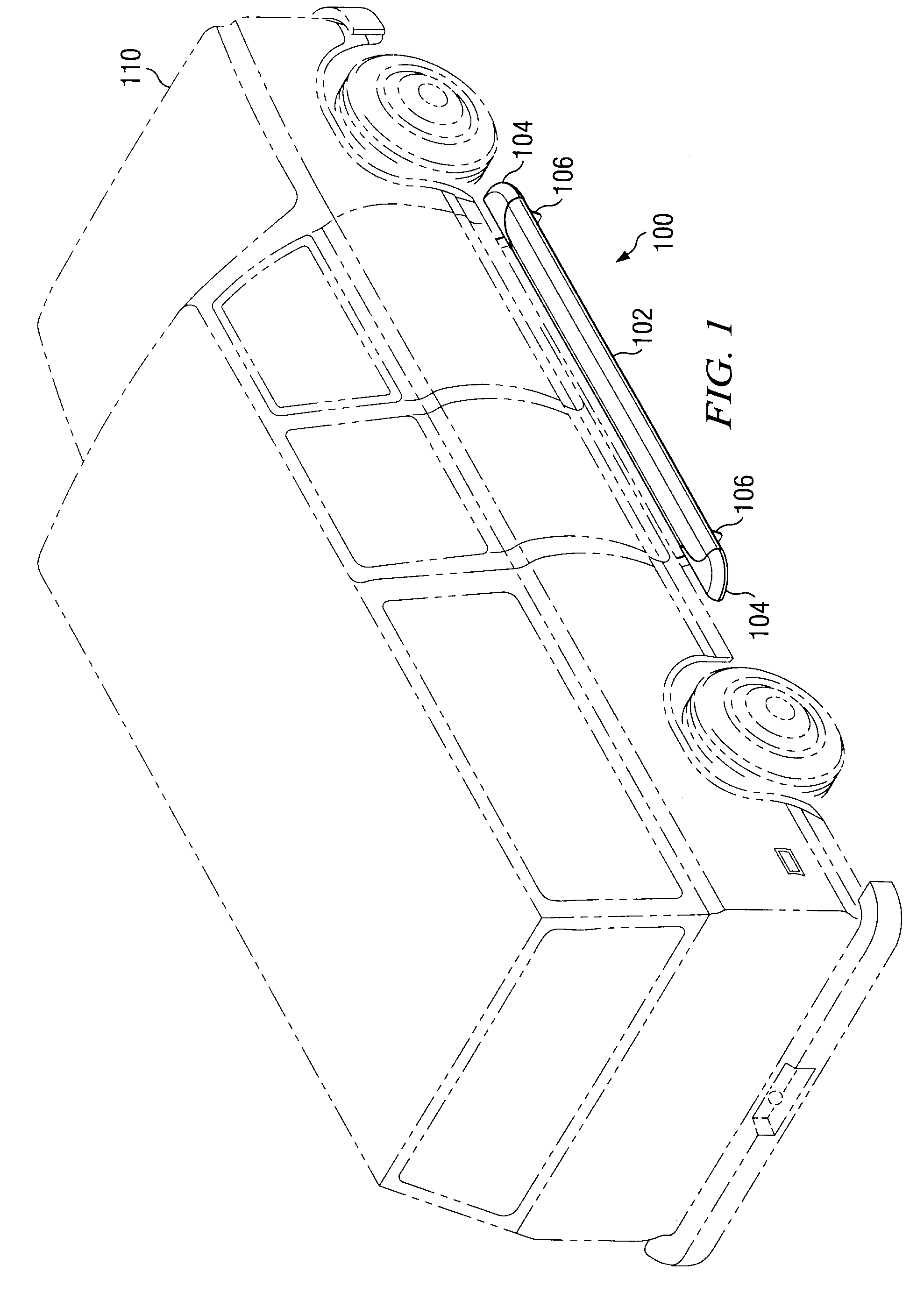

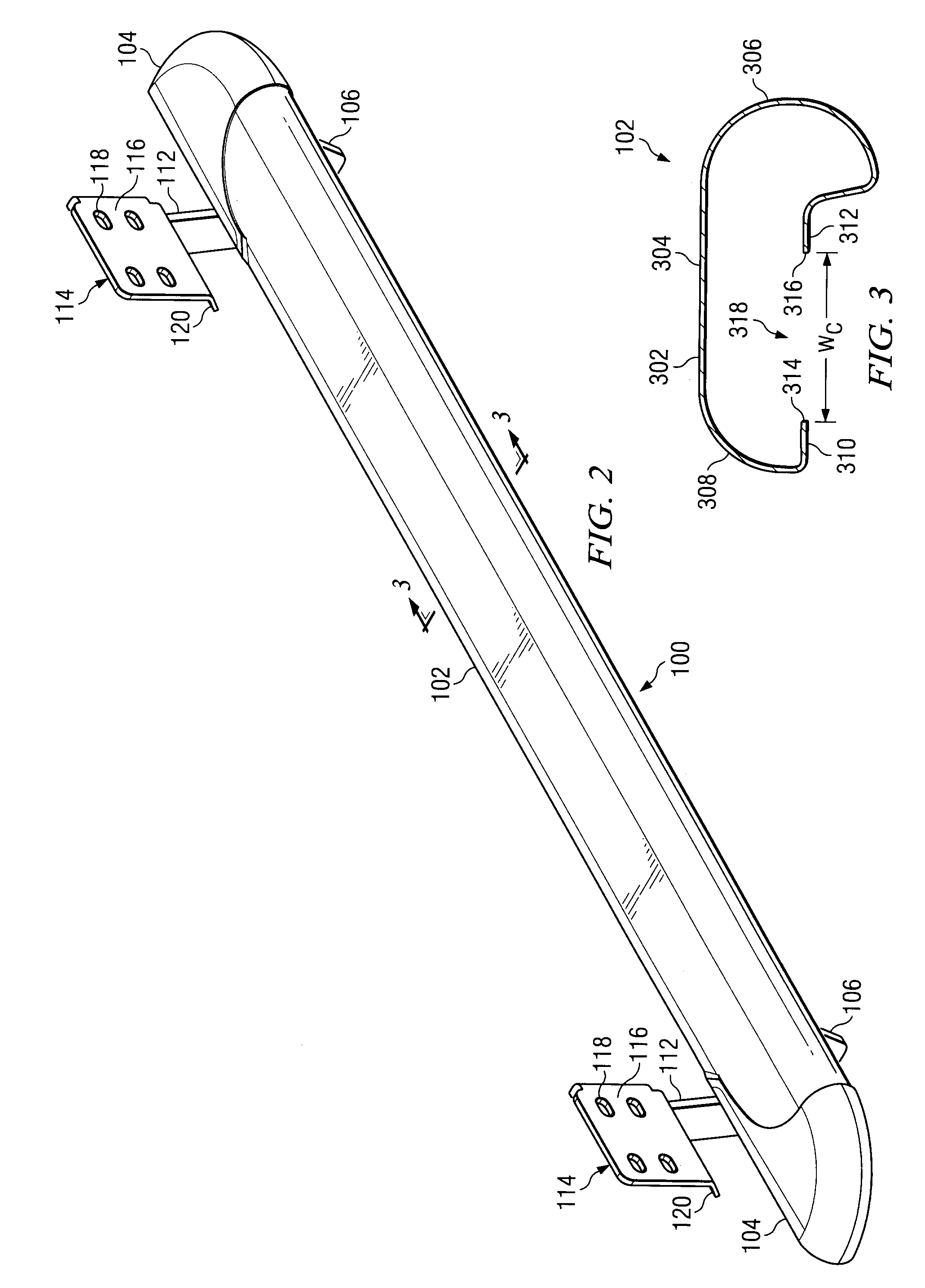

Roll formed step rail for a vehicle

A roll formed step rail for a vehicle comprises an elongated rail body including a continuous rail wall of substantially uniform thickness. The rail wall describes a continuous cross-sectional profile between two elongated free edges, the cross-sectional profile of the rail being substantially uniform along the length of the rail body. The cross-sectional profile of the rail body includes a relatively flat top portion disposed between a substantially semi-circular front curved portion and a substantially quarter-circular rear curved portion. A rear mounting lip extends forward from the rear curved portion to one of the elongated free edges. A front mounting lip extends upward and then rearwards from the front curved portion to another of the elongated free edges. The elongated free edges are generally in line with one another, but spaced apart to define a longitudinal channel therebetween having a predetermined width. The rail body is formed from a sheet of material by a process of roll forming.

Owner:IRON CROSS AUTOMOTIVE

Vehicle bumper beam

A bumper beam includes an open front section made from a high-strength material such as ultra-high-strength steel (UHSS) material, and further includes a mating back section made of lower strength material attached to a rear side of the front section along abutting flanges. The front and back sections combine to define different tubular cross sections along their length, thus providing selected stiffness and strength at critical areas of the bumper beam. The front section can be roll-formed, and the back section can be stamped, thus taking advantage of roll-forming processes' ability to form high-strength materials, while allowing the back section to have a more complicated shape and be stamped. For example, the back section can be made from a material selected from a group consisting of HSLA steel, aluminum, and / or polymeric material. The back section is attached to the beam using welding or mechanical attachment.

Owner:SHAPE CORP

High-strength easy-formation atmospheric corrosion resisting steel

The invention relates to high strength easily forming atmospheric corrosion resistant steel. The invention provides the high strength easily forming atmospheric corrosion resistant steel aiming at the problems in existing steel that the weatherability is bad and the service life is lowered under the condition that the thickness is thinned. The high strength easily forming atmospheric corrosion resistant steel is composed of components of following weight percent: C: 0.04-0.09%, Si: 0.10-0.50%, Mn: 1.20-1.70%, P: <=0.020%, S: < =0.010%, Cu: 0.20-0.60%, Cr: 0.40-0.80%, Ni: 0.20-0.50% and Nb: 0.03-0.07%, and also comprises one or a plurality of Mo: <=0.20%, Ti: <=0.03% and Als: <=0.035%, and allowance is Fe and unavoidable impurity. The yield strength of the steel of the invention is more than or equal to 550MPa, the tensile strength is more than or equal to 650MPa, the percentage elongation is more than or equal to 18%, the corrosion resistance is equivalent to SPA-H steel which is used for previous containers, and the steel has excellent welding performance, cold roll forming performance and low temperature impact toughness, which is beneficial for extending and applying.

Owner:武钢集团有限公司

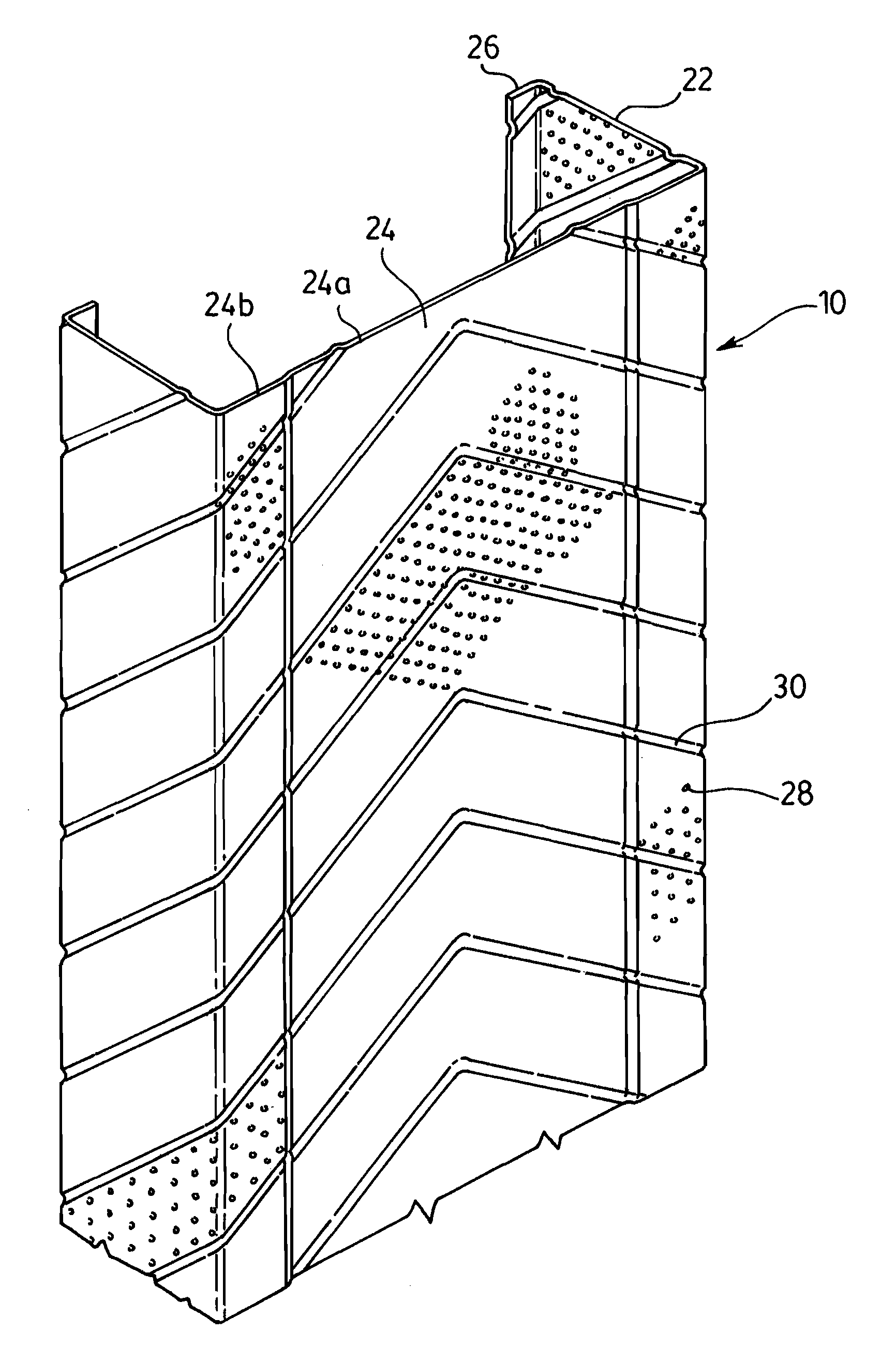

Light Weight Metal Framing Member

The present invention provides for a lightweight metal framing member having a plurality of depressions and a plurality of reinforcing ribs on the surface thereof, the depressions and ribs both being inwardly oriented and cooperating to aid in stiffening of the metal stud. The present invention also provides a method of manufacturing a metal framing member having a plurality of depressions and a plurality of reinforcing ribs on the surface thereof, the depressions and ribs both being inwardly oriented and cooperating to aid in stiffening of the metal stud. The method utilizes a cold roll forming apparatus having a first roller with a plurality of projections on its surface and a second roller having a surface provided with holes aligned with the projections on the surface of the first roller to form the depressions in the surface of the material having clearly defined edges generally aligned with the plane of the metal sheet. A second roll forming apparatus is used having a first roller with projections on its surface to form the reinforcing ribs in the surface of the sheet material and a second roller to allow for a softer transition between the surface of the sheet material and the edges of the reinforcing ribs and so as not to unduly deform the depressions formed in the first roll forming step. A third roll forming apparatus is used having rollers to form the metal stud or track.

Owner:BAILEY METAL PROD

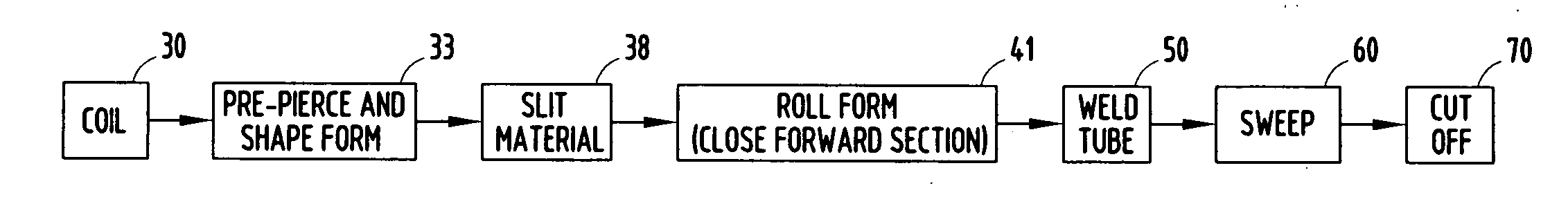

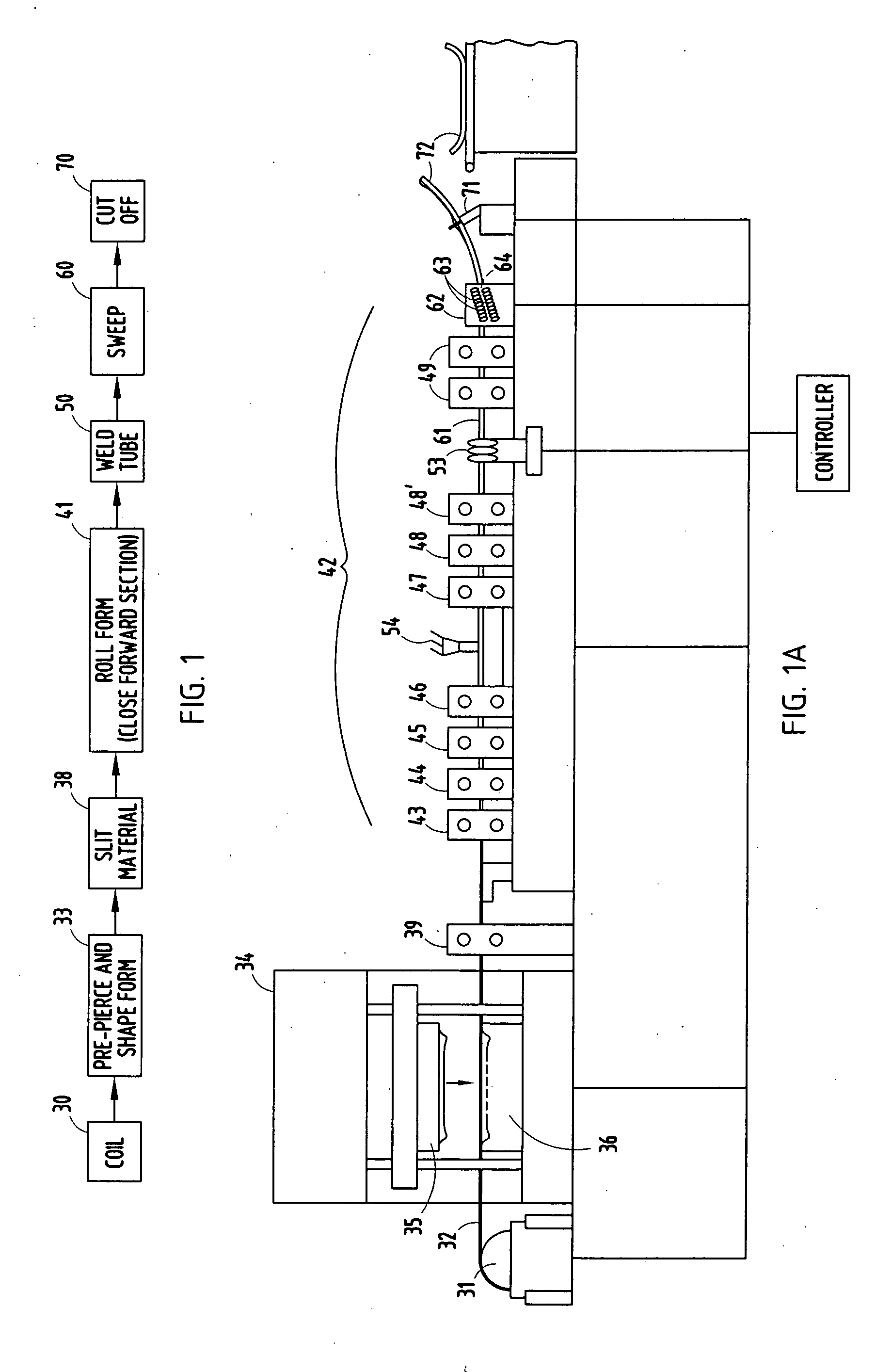

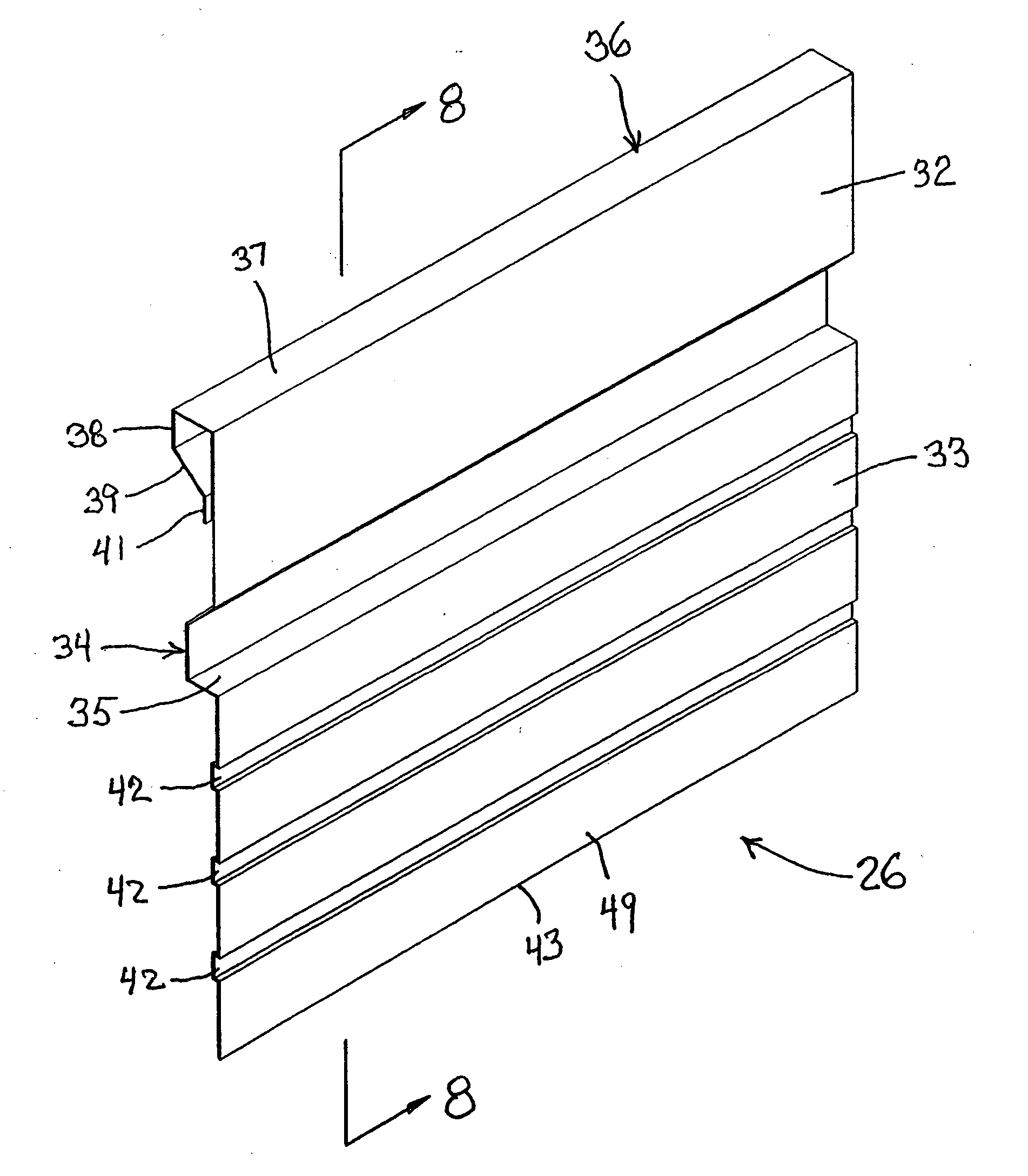

Continuous process of roll-forming stamped sheet

An apparatus includes a press with dies configured to deform a strip of material by drawing material primarily from a width direction, a slitter set to cut the deformed strip to a uniform desired width dimension, and a roll-former with rolls configured to shape linear portions of the deformed and now uniform-width strip into a continuous beam. The apparatus further includes a welder for welding abutting edges of the sheet together to form a permanent tube, a sweep station for imparting a longitudinal shape to the continuous beam, and a cut-off for cutting the continuous beam into segments useful as vehicle bumper beams. A controller controls timing of various components. The beam segments are optimized in specific regions for local strength and minimized weight, and features can be incorporated into the beam segments such as coplanar mounting surfaces.

Owner:SHAPE CORP

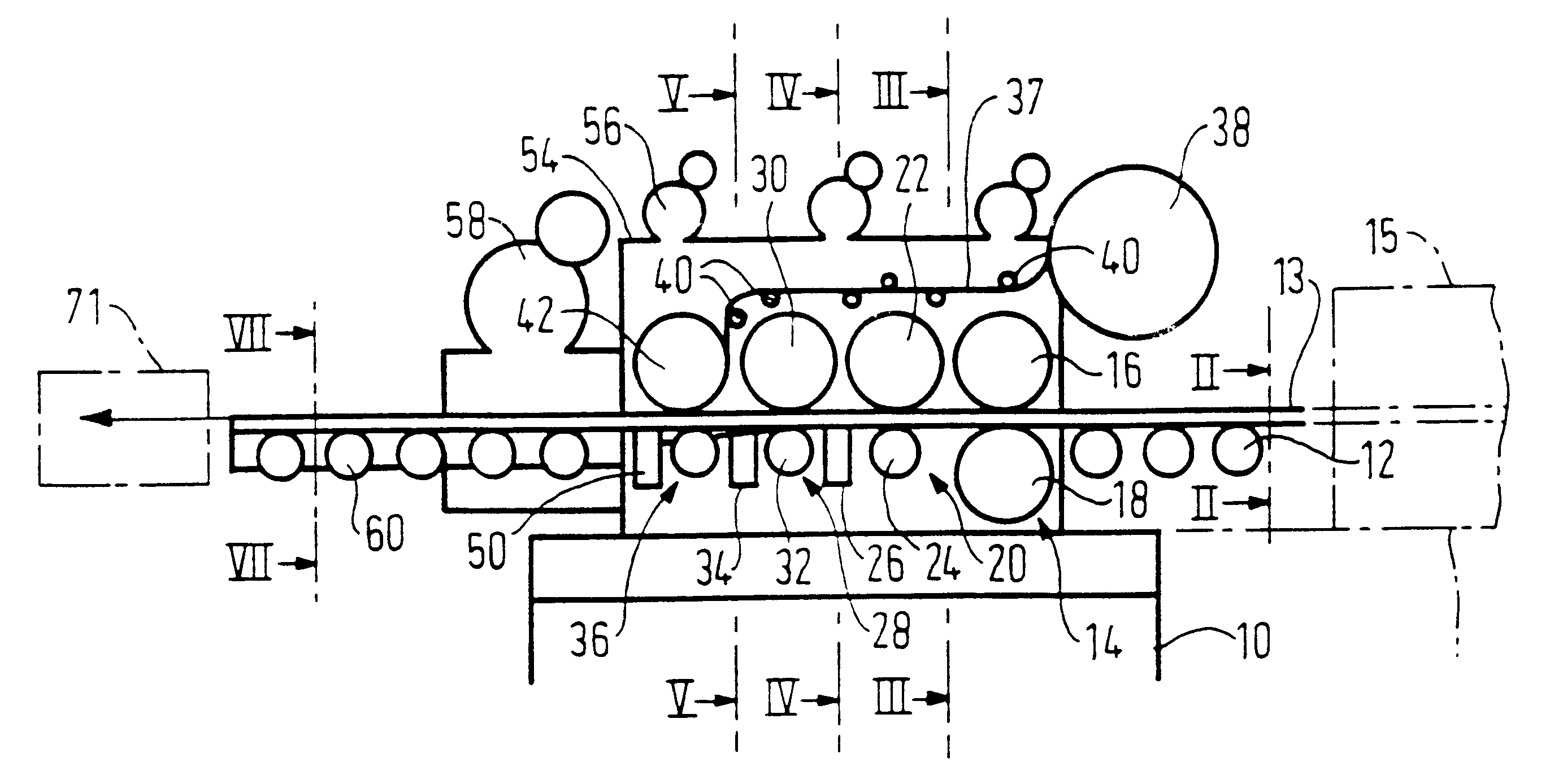

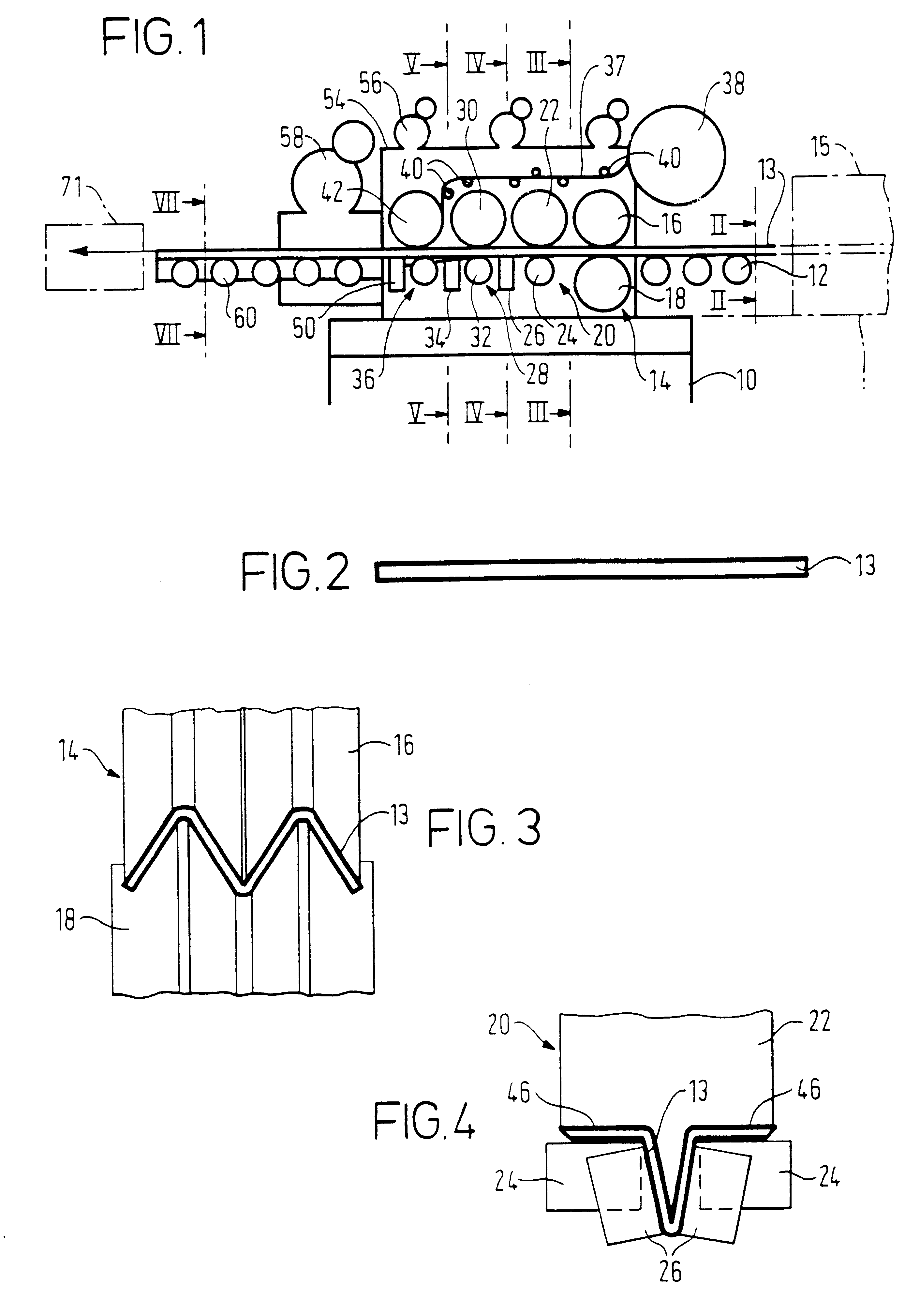

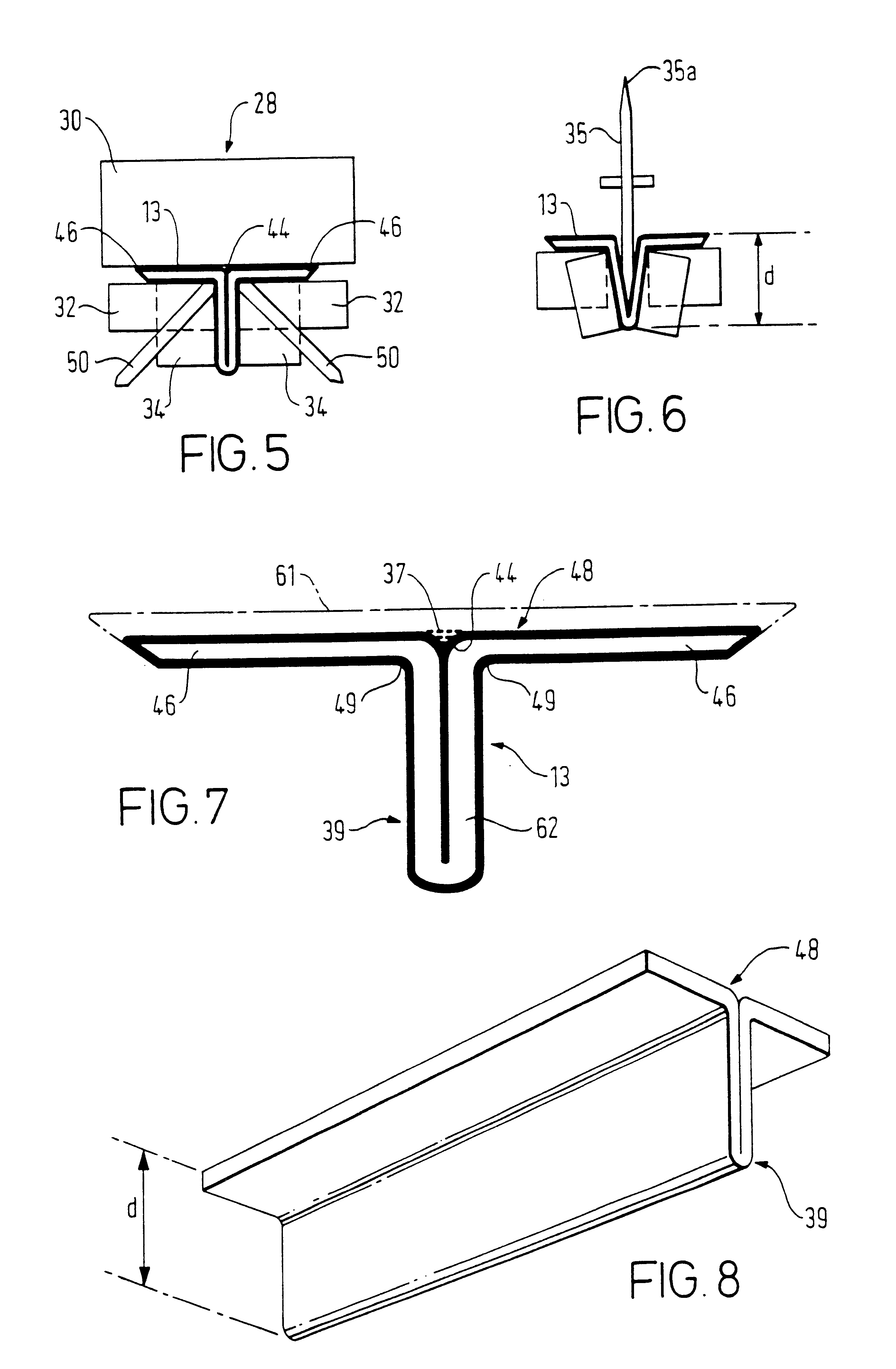

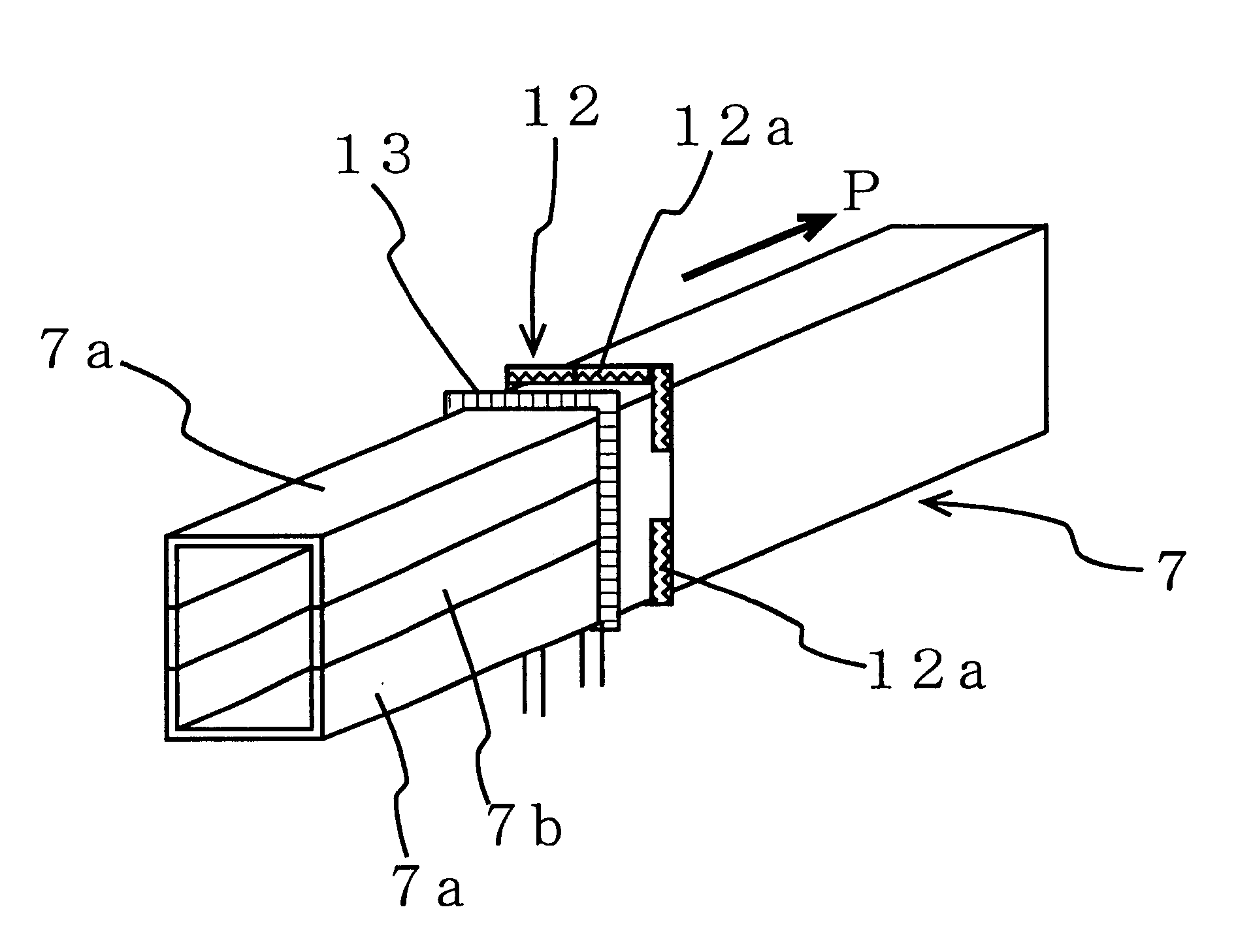

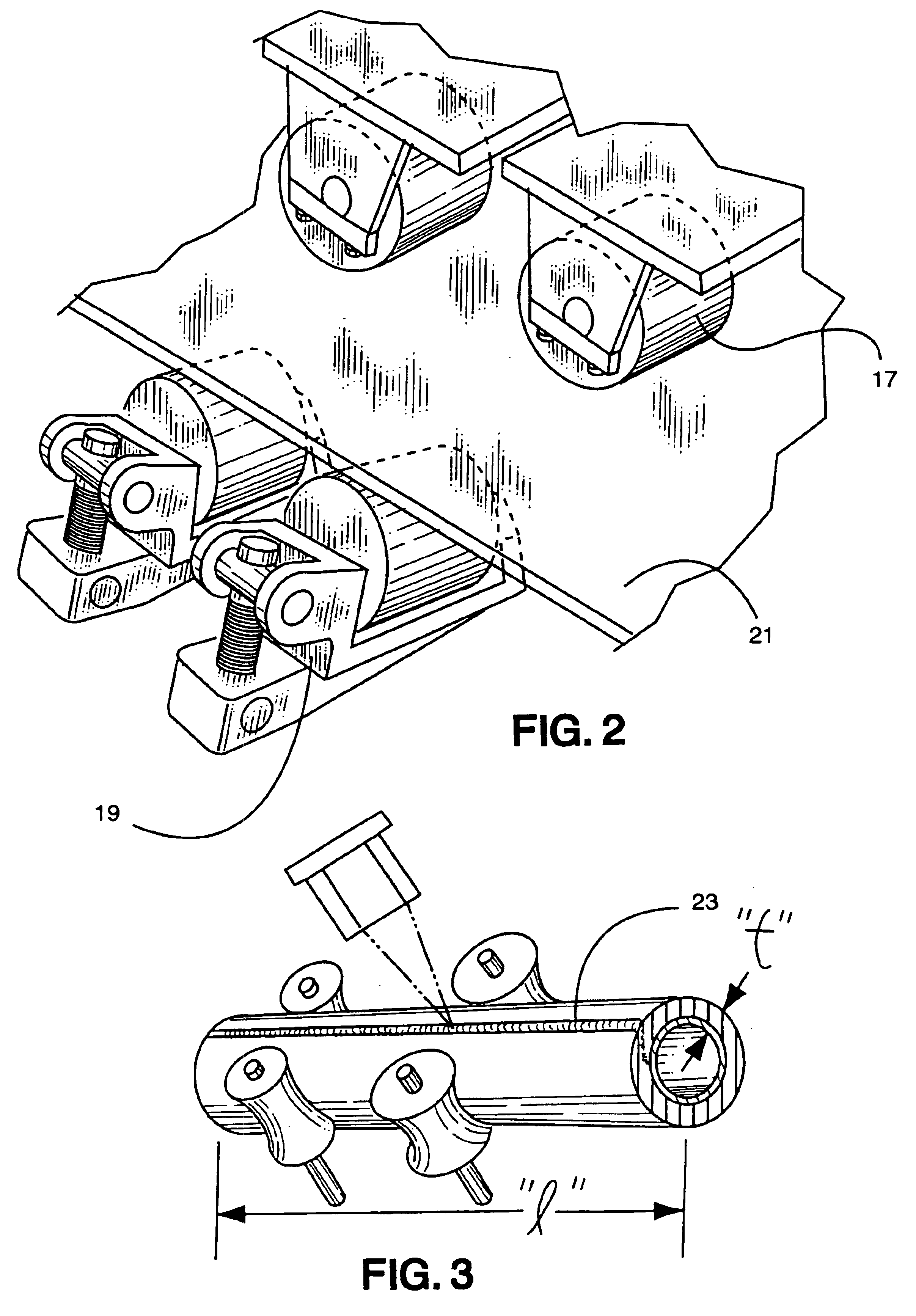

Roll forming machine

The roll forming machine comprise a series of rollers 14, 20, 28 and 36 for shaping a fabric 13 such as a fabric impregnated with a curable matrix. A feed roller 36 is provided for feeding a length of material 37 such as a tow of fibres onto the fabric during or subsequent to the shaping process. The roll forming process is particularly useful in the manufacture of blade stiffeners for an aircraft wing.

Owner:AIRBUS OPERATIONS LTD

Roll-formed product and vehicle bumper using the same

A roll-formed product is formed from a steel sheet having a tensile strength of not greater than 400 MPa and is locally reinforced. Such a roll-formed product is excellent in formability and shock absorbing ability and is of high strength. The roll-formed product can be used as, for example, a vehicle bumper. The roll-formed vehicle bumper can also be made at a lower cost.

Owner:AISIN SEIKI KK

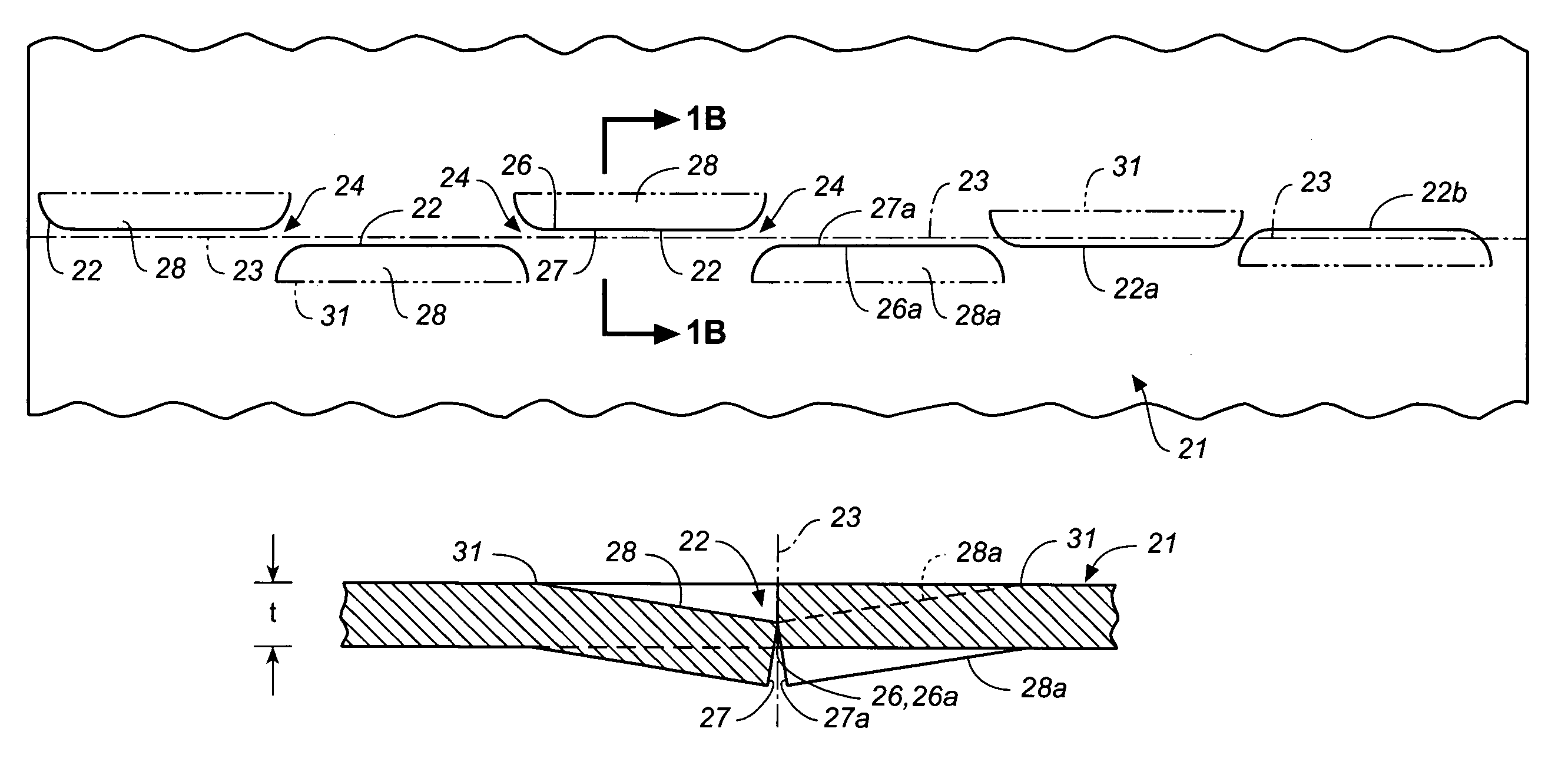

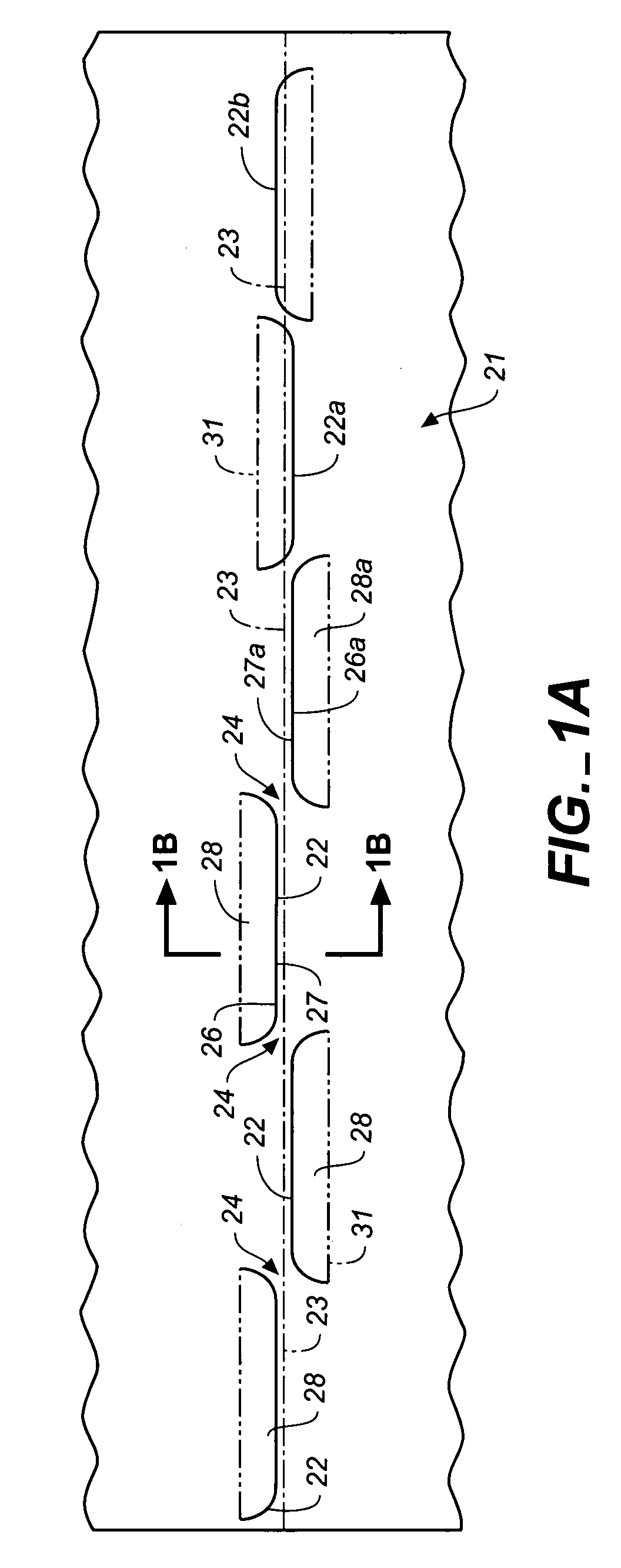

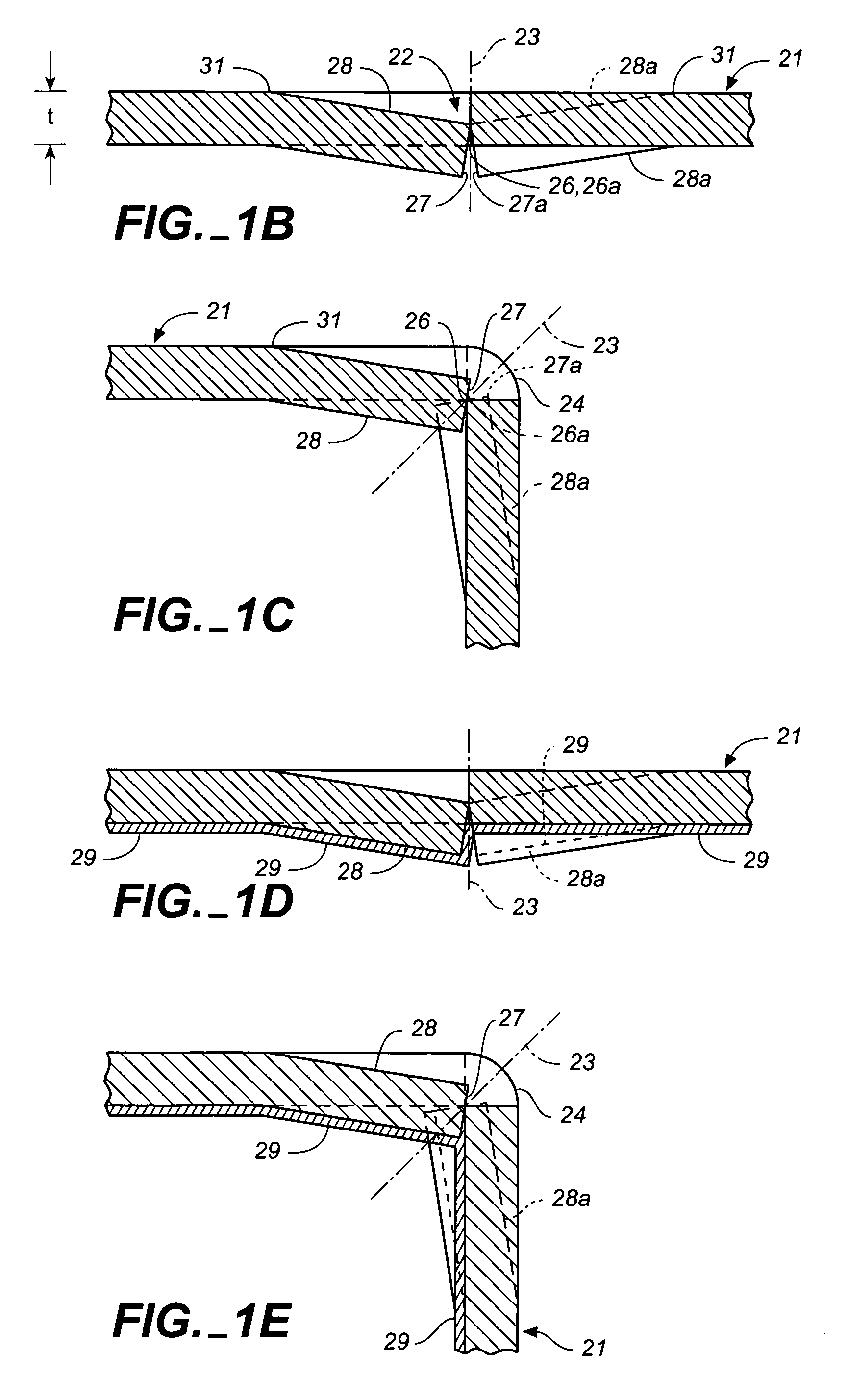

Method for forming sheet material with bend controlling displacements

A method of preparing a sheet of material for bending along a bend line comprising the step of forming of at least one displacement in the thickness direction of the sheet of material with a portion of the periphery of the displacement closest to the bend line providing an edge and opposed face configured in position to produce edge-to-face engagement of the sheet on opposite sides of the periphery during bending. The forming step is preferably accomplished using one of a stamping process, a punching process, a roll-forming process and an embossing process. A sheet of material suitable for bending using the process also is disclosed, as are the use of coatings, shin guards and displacing the area of the sheet between bending inducing slits.

Owner:IND ORIGAMI INC CA US

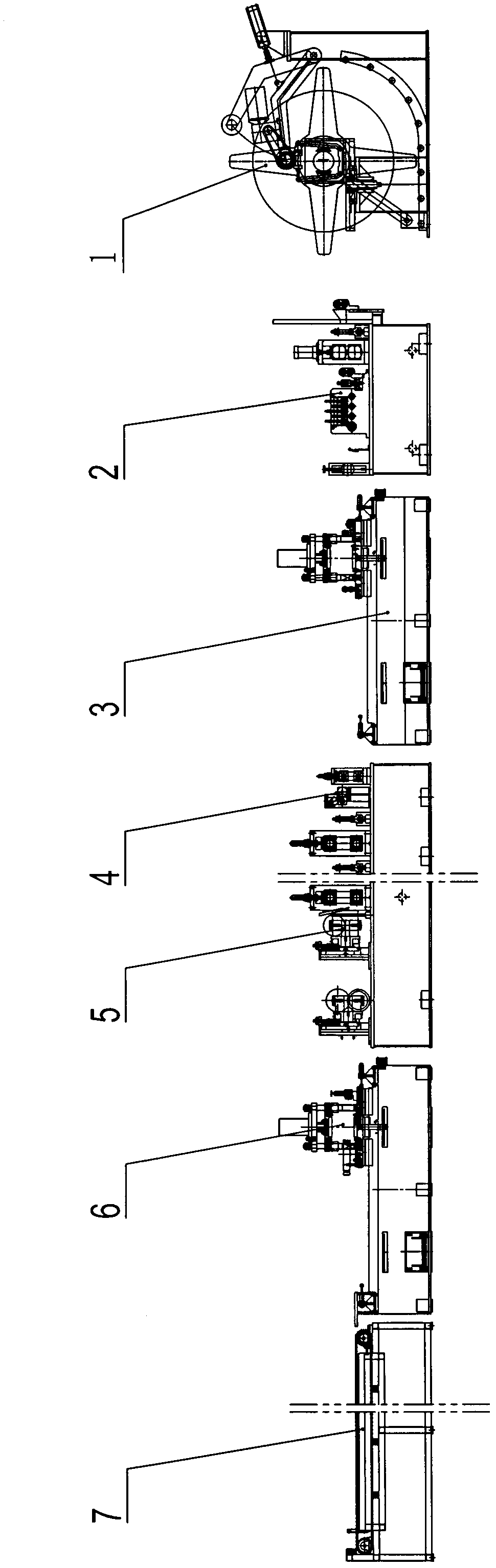

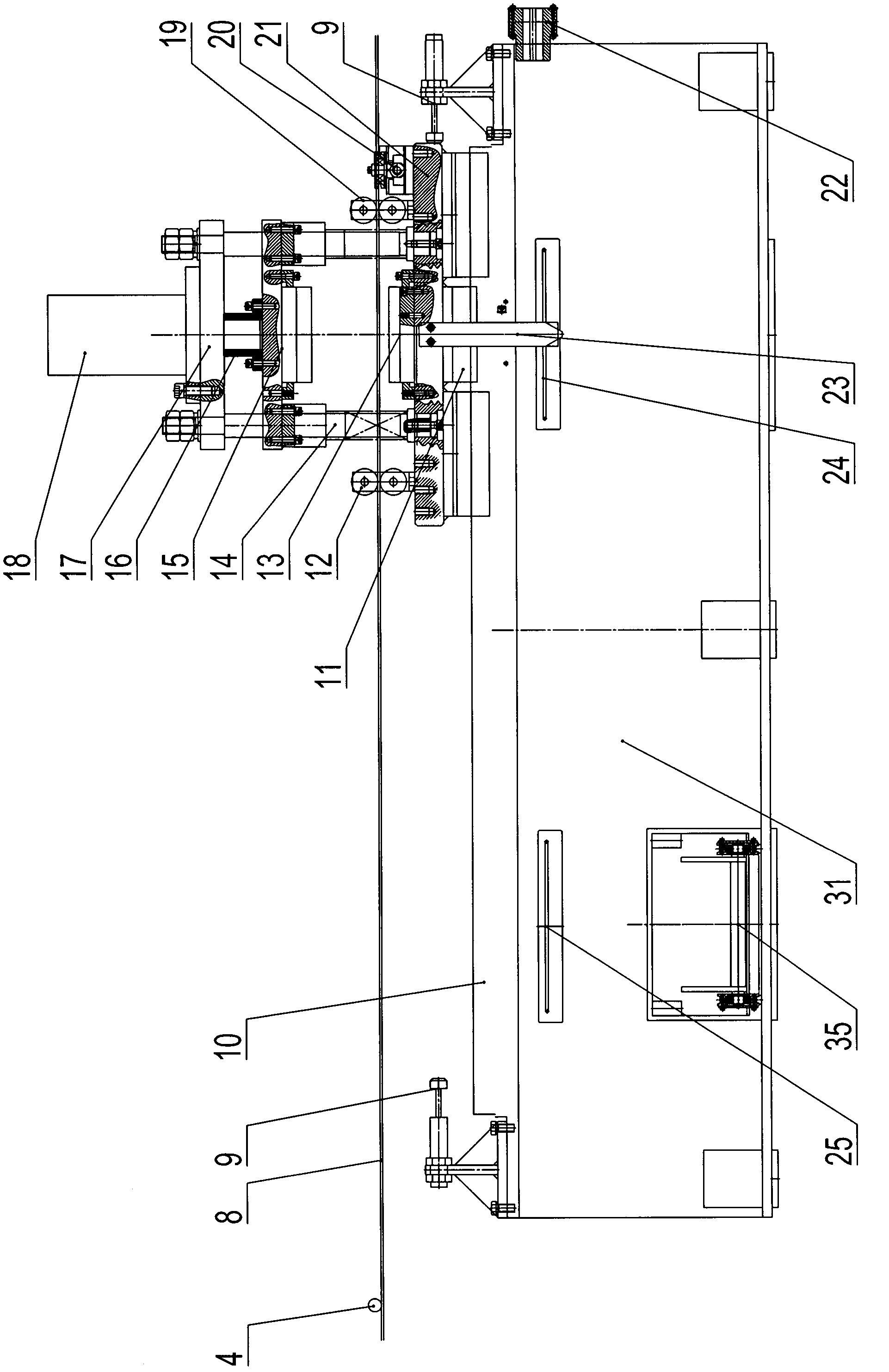

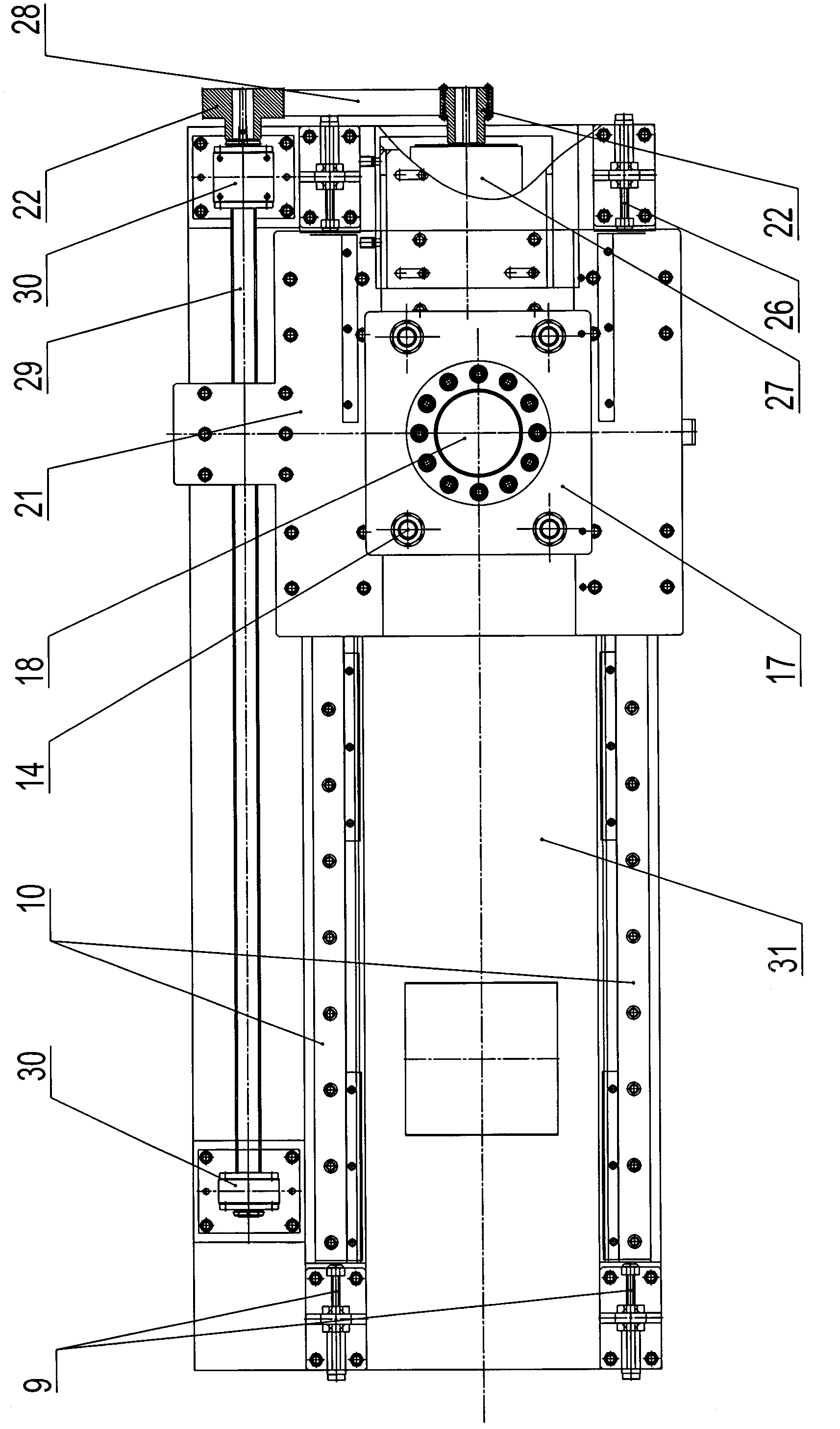

Roll forming processing method for online punching and production line

The invention relates to a roll forming processing method for online punching and a production line in the technical field of sheet roll forming. The method comprises the following steps of: emptying, leveling, punching, roll forming, cutting and blanking. The punching step comprises the following specific steps of: detecting a real-time displacement signal of the linear motion of a sheet; driving a punching mechanism to move at an accelerated speed according to the displacement signal and drive the sheet to a set punching position along the movement direction of the sheet; driving the punching mechanism to track the linear motion of a coiled sheet and keep moving synchronously with the sheet; in a process of keeping synchronous movement with the sheet, allowing the punching mechanism to punch a hole at the set position on the sheet; and returning the punching mechanism to an initial position. The invention also provides the production line for implementing the method. Punching is performed after a servo motor controlled by a programmable logic controller (PLC) drives a workbench to track the sheet. The processing method and the production line can improve sheet processing accuracy and increase sheet processing speed and can be used for molding, punching and processing sheets with fixedly shaped cross sections.

Owner:YANGZHOU NANYANG WELDING PIPE MOLD CO LTD

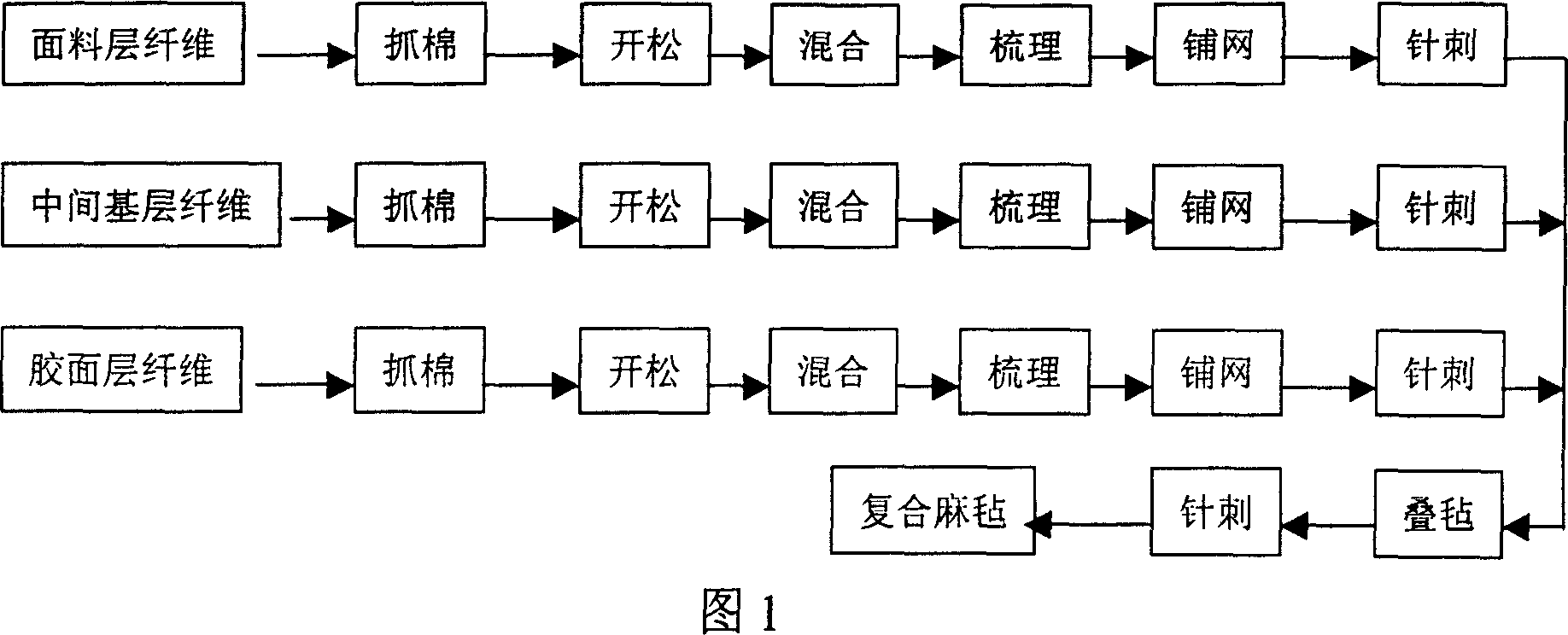

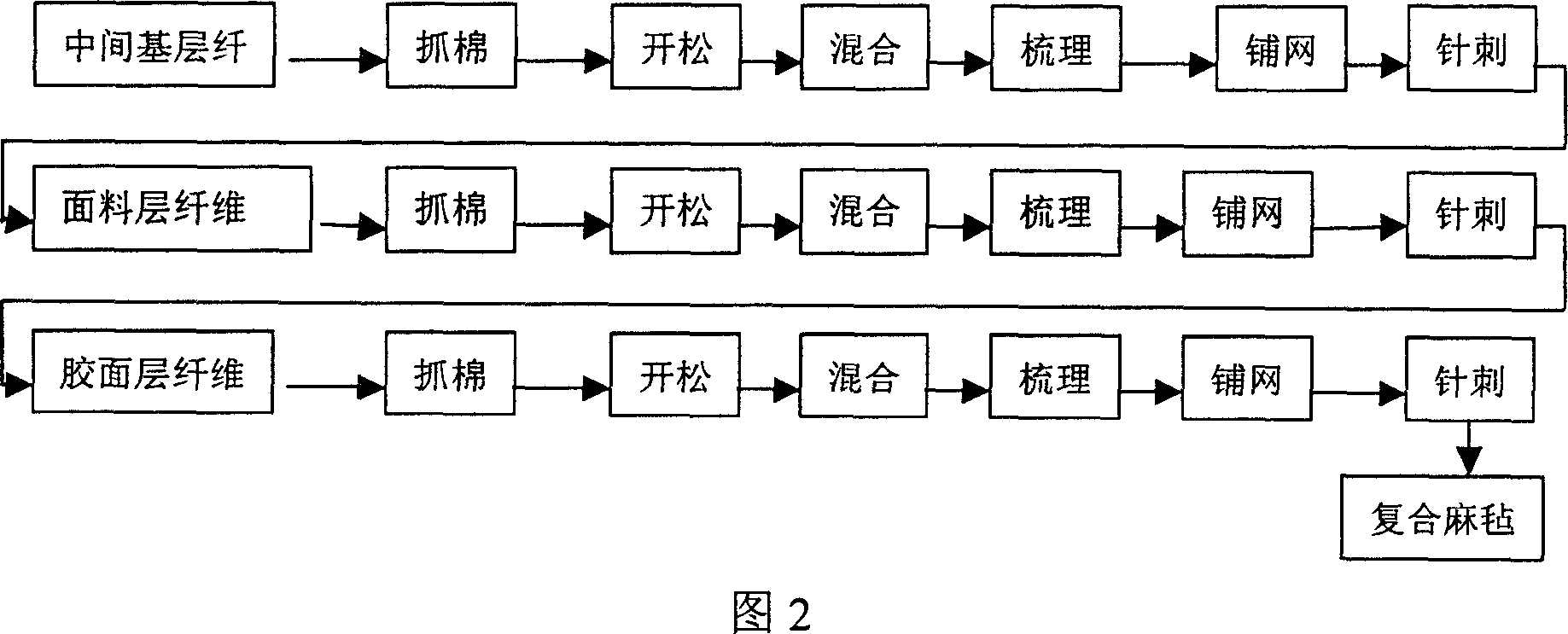

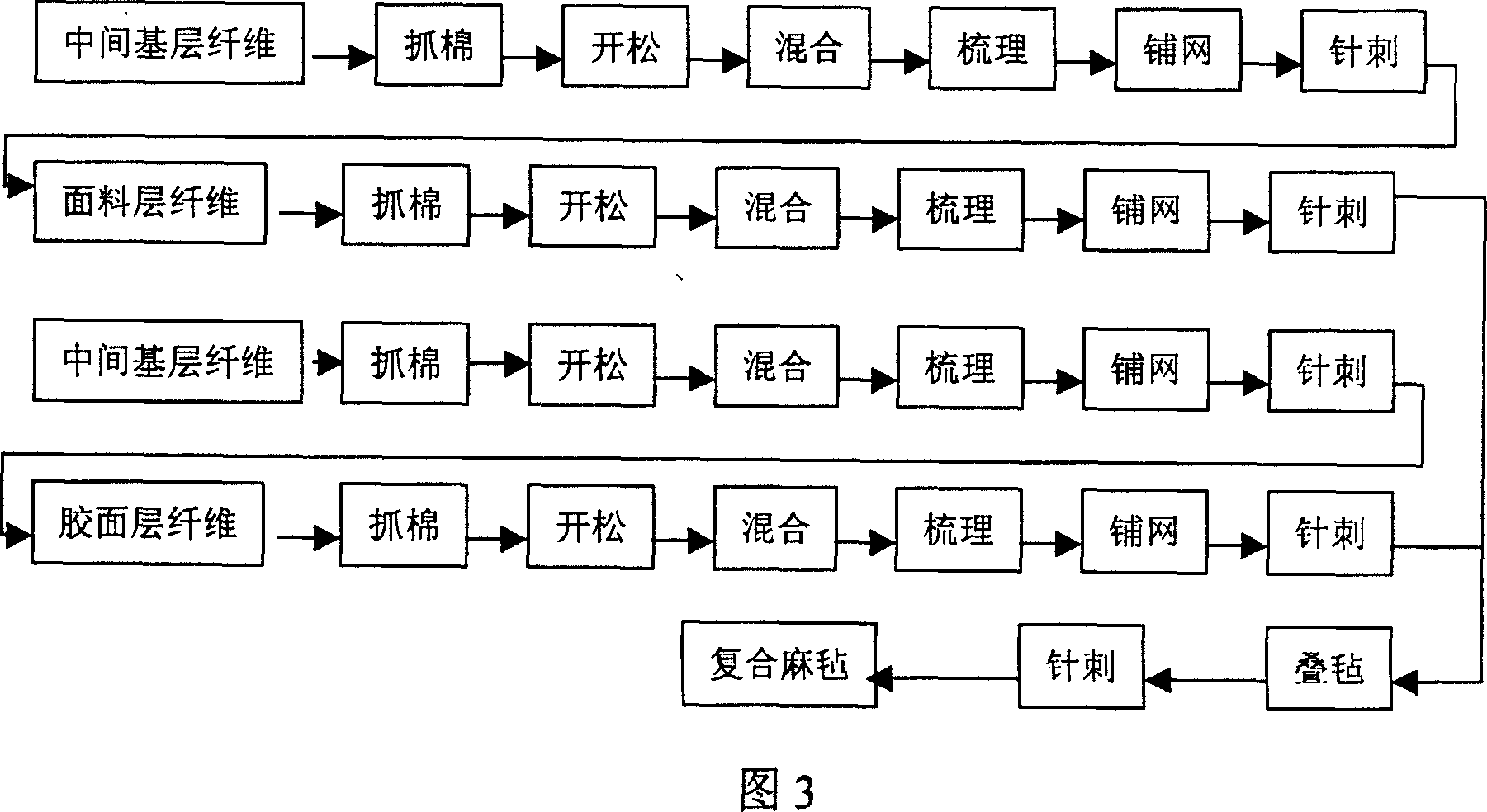

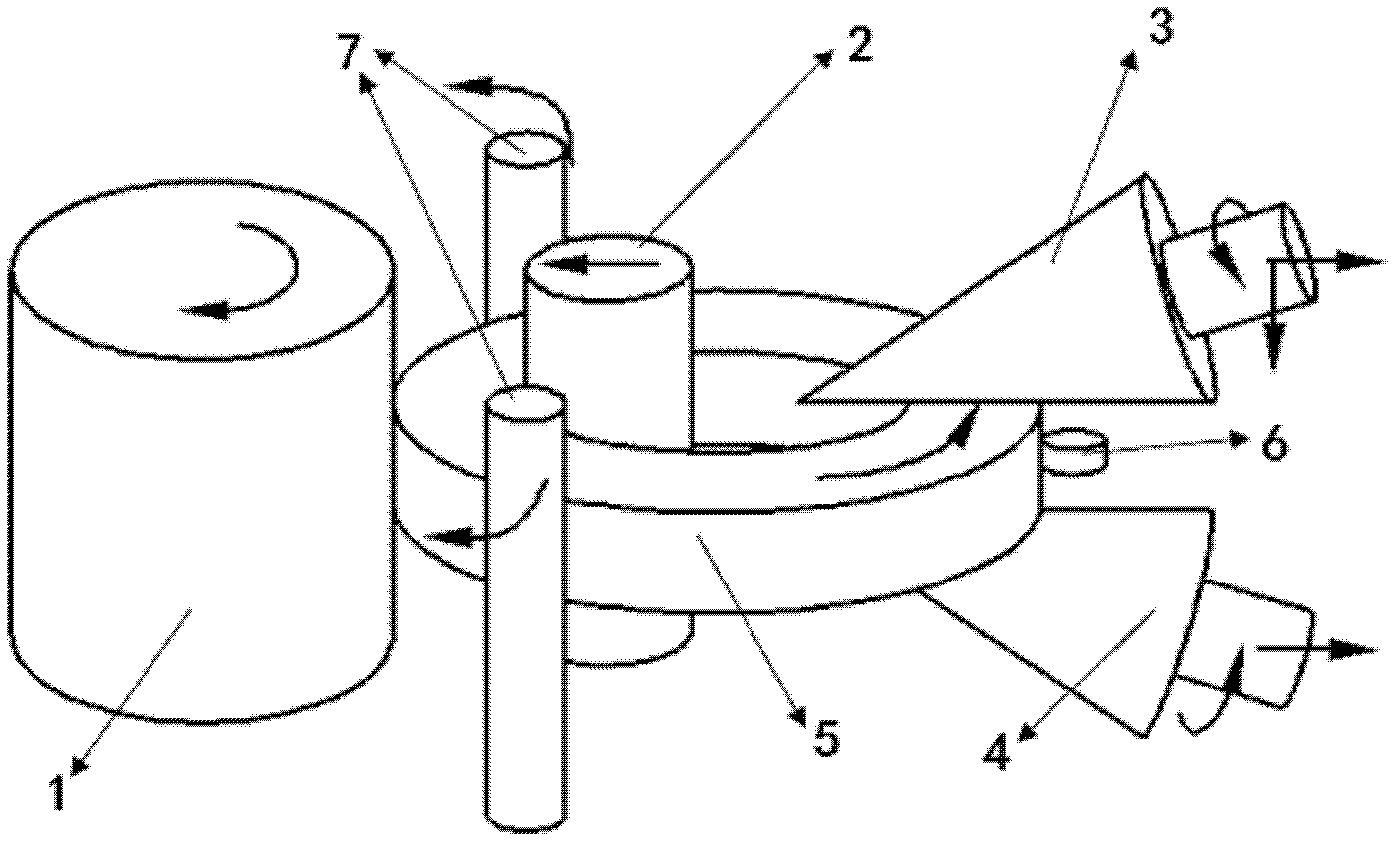

Composite board made of natural firilia for automobile inner decoration use and its producing method

ActiveCN101045310AImprove rigidityAvoid warpingWood working apparatusDomestic articlesPolyesterPolymer science

A composite bast fiber board for the internal decoration of car is composed of adhesive layer, sandwich substrate layer and surface layer, and is prepared through sequentially spreading said three layers, needling to become a composite bast felt, and hot pressing. Said sandwich substrate is made of the mixture of bast fibers (37-45%), polyester fibers (10-20%) and polypropylene fibers (35-53%).

Owner:铜陵华源汽车内饰材料有限公司

Fine-grain roll-forming method for large annular piece made of high alloy steel

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS +1

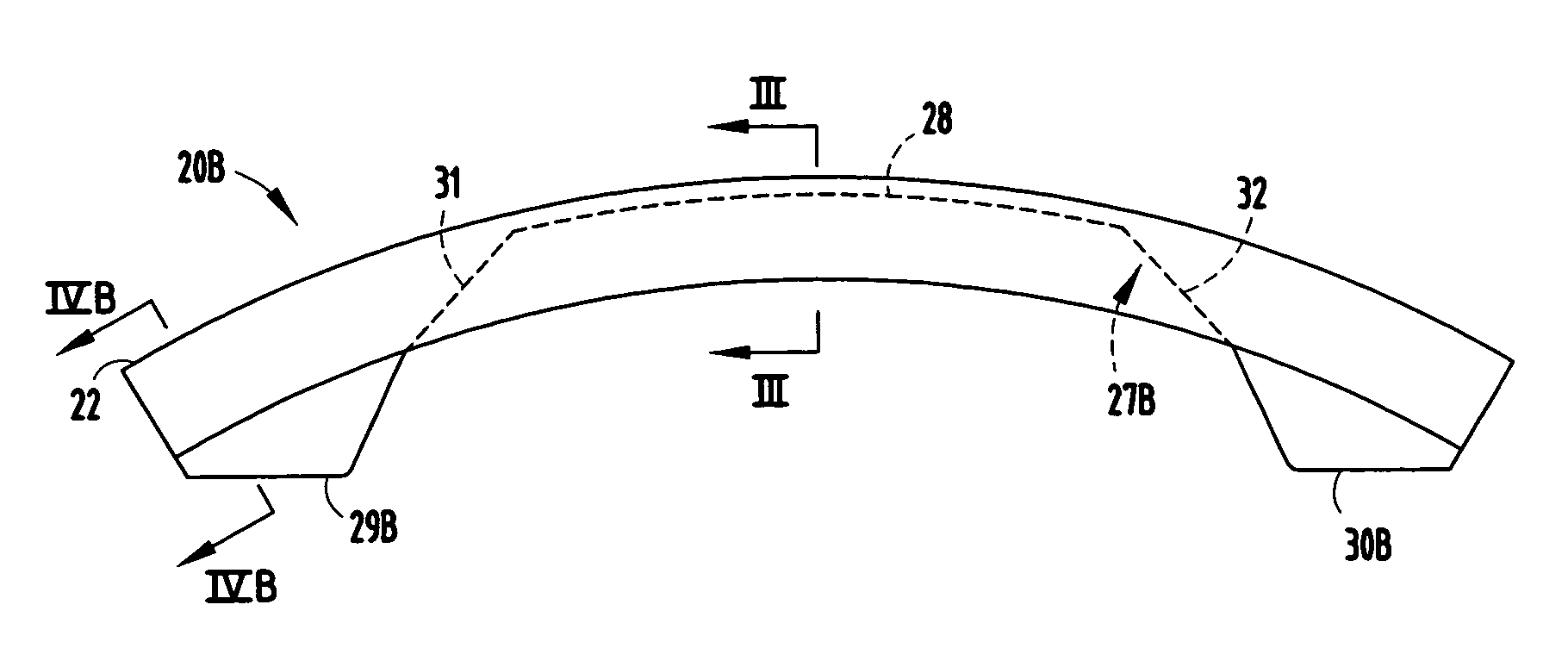

Cross member for vehicle bumper bar and method for making same

A two step system or stage is provided to manufacturer a bumper of “B” shape cross section including a roll forming-welding stage where a straight cross member of a length to mount on the front or rear of various models of automobiles and the bending stage where any curvature or sweep is introduced into the cross member as required by the design of the automobile. The roll forming welding stage include the spot or tack welding of the front wall to the web followed immediately by welding together without any gaps therebetween the abutting longitudinal edges utilizing a high frequency welder. Thus, the “B” shaped cross section of the bumper may be used to make different bumpers of various lengths and curvatures.

Owner:ZOHAR TT ACQUISITION LLC

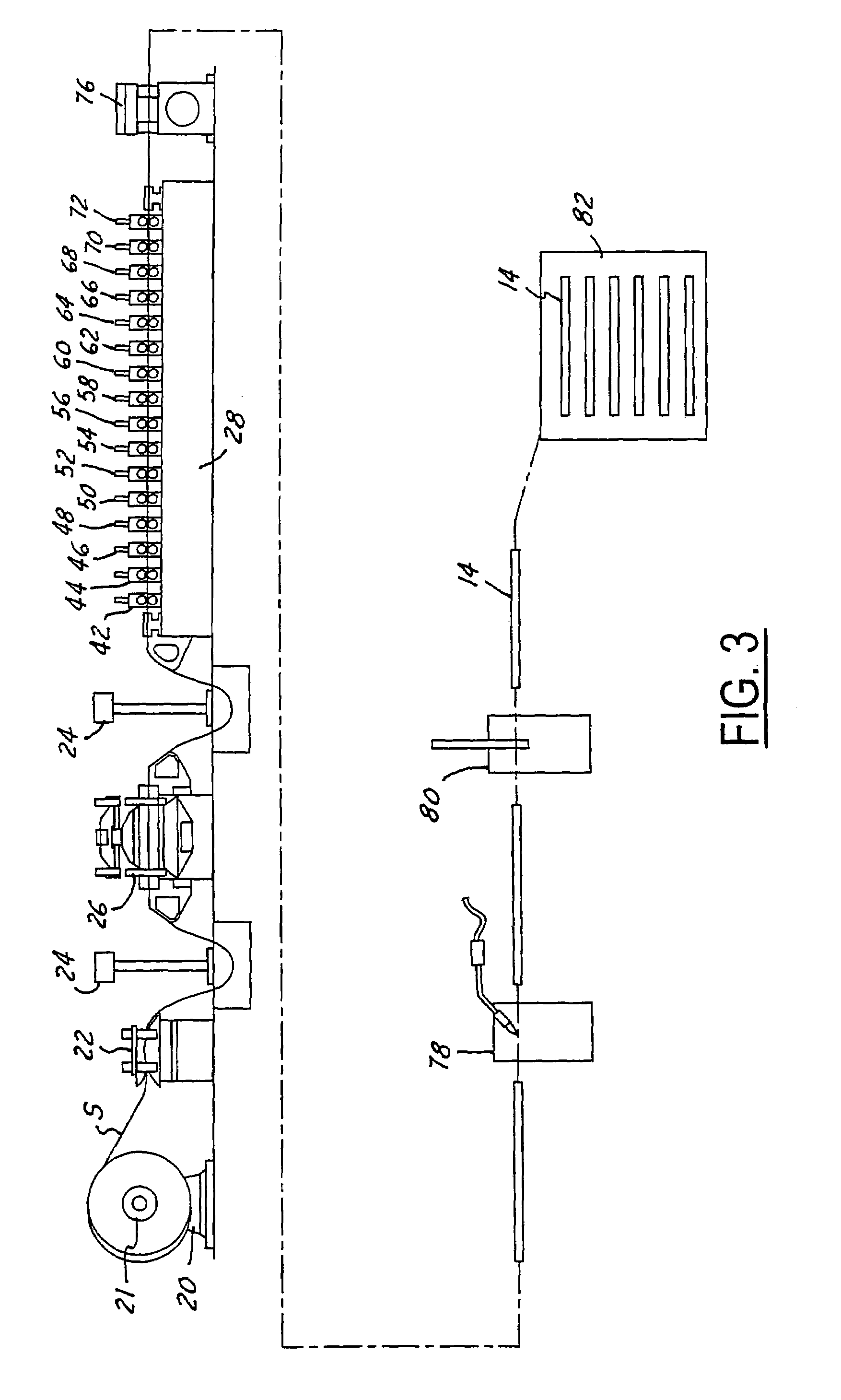

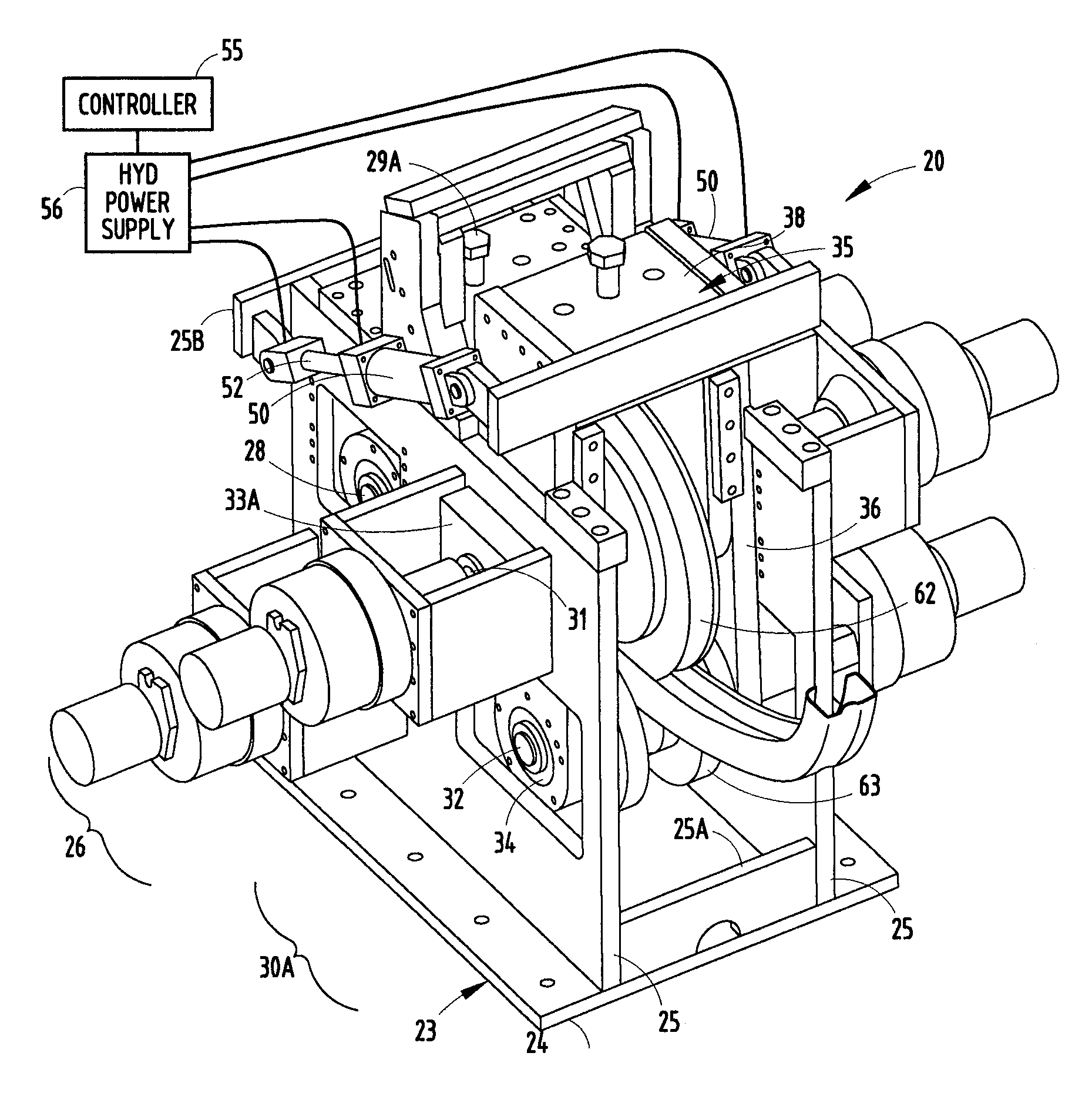

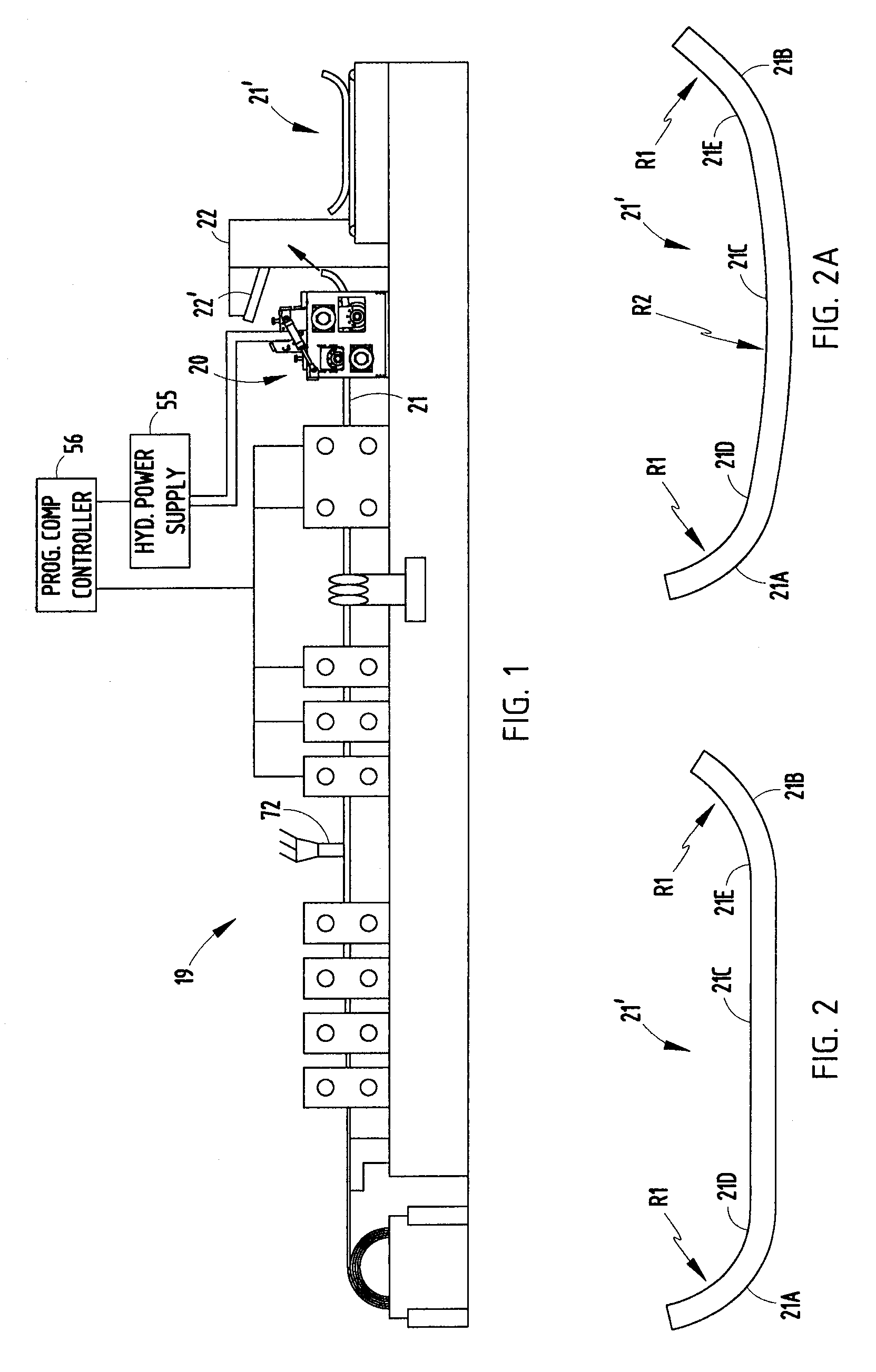

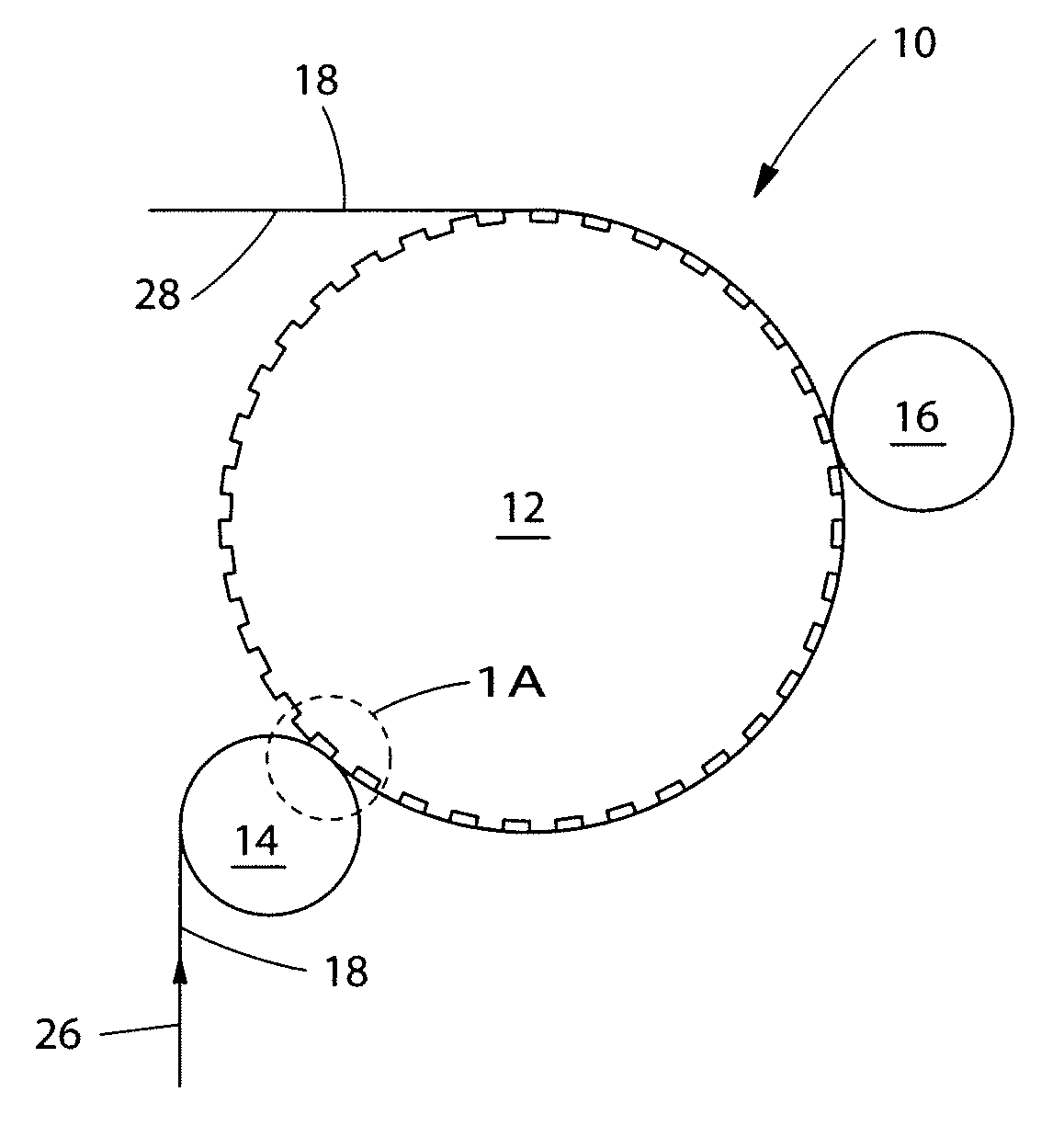

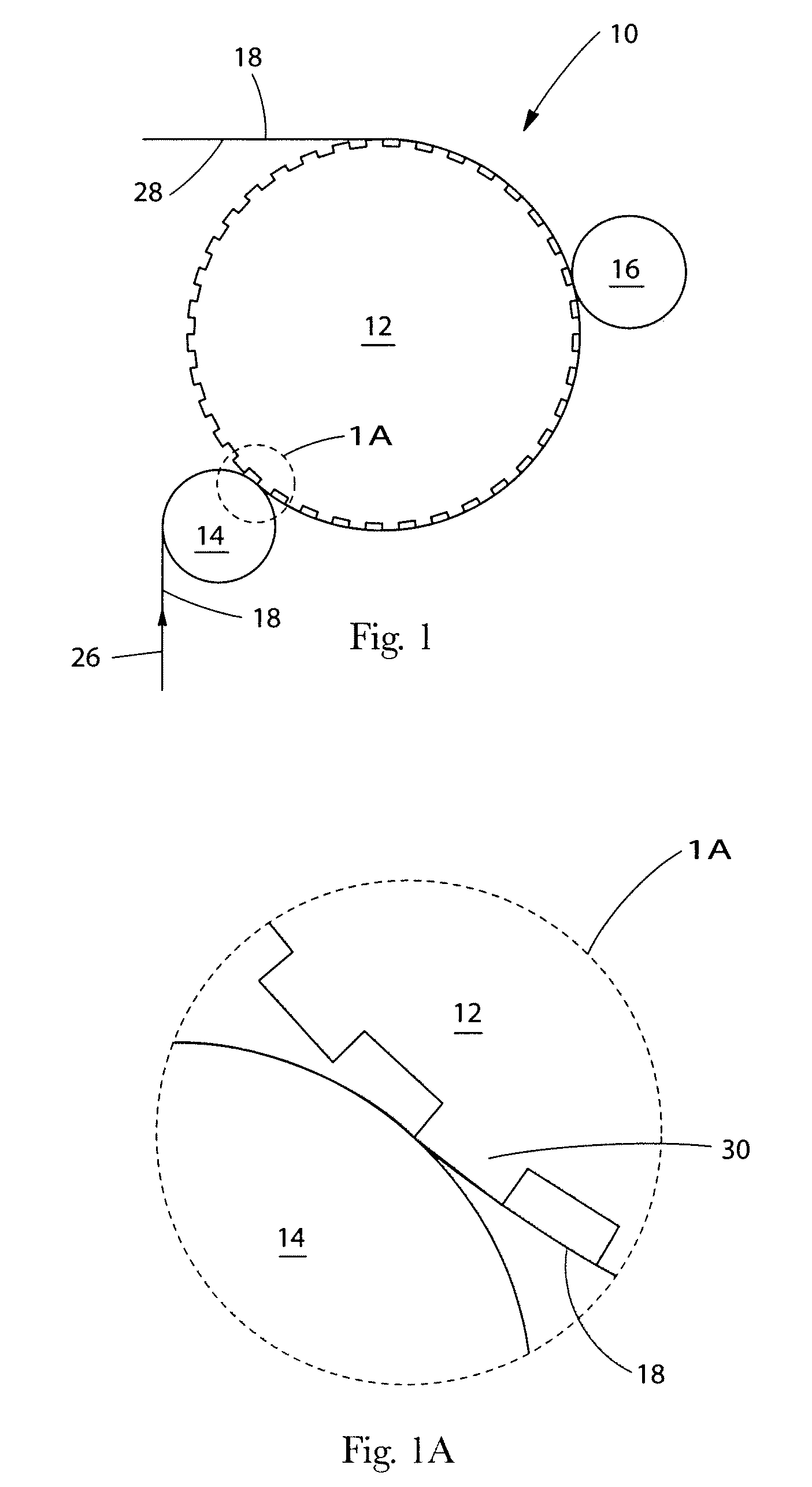

Roll-former apparatus with rapid-adjust sweep box

A computer controlled roll-forming apparatus is adapted to provide a repeating pattern of different longitudinal shapes to a continuous beam “on the fly” during the roll-forming process. A sweep station of the apparatus includes a primary bending roller tangentially engaging the continuous beam along the line level and an armature for biasing the continuous beam against the primary bending roller for a distance partially around a downstream side of the primary bending roller to form a sweep. Actuators adjustably move the armature partially around the downstream side of the primary bending roller between multiple positions for imparting a series of different longitudinal shapes. Internal and external mandrels control wall stability to allow even sharper sweeps. In one form, the apparatus also includes a coordinated cut-off, so that when separated into bumper beam segments, the ends of the individual beam segments have a greater sweep than their center sections.

Owner:SHAPE CORP

Roll-formed panels for vehicle box assembly

An improved vehicle box assembly with an upright front or side panel defined by a monolithic one-piece roll-formed steel sheet member having a desired three-dimensional configuration. The sheet steel member is roll-formed in the lengthwise direction thereof. The panel has a channel, preferably a closed tubular channel on the front panel, roll-formed along one edge of the sheet steel during forming of the panel. The closed tubular edge rail is preferably closed by a seam weld which extends lengthwise therealong and is performed in line with the roll-forming operation. The roll-formed panel is preferably provided with a flat shelf deformed horizontally to extend lengthwise along the panel downwardly from the top rail.

Owner:PULLMAN IND

Process for producing flue gas denitration catalyst and flue gas denitration catalyst produced with the process

InactiveCN101428215AEasy to shapeHigh mechanical strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPowder mixtureFlue gas

The invention relates to a method for preparing a catalyst for flue gas denitrification. The method comprises the following steps: step 1: preparing a powder mixture of titanium dioxide nanoparticles, binders and auxiliaries; step 2: preparing an oxalic acid solution of tungsten and vanadium; step 3: mixing the powder mixture produced in the step 1 and the solution produced in the step 2 to obtain a catalyst slurry; and step 4: uniformly spreading the catalyst slurry produced in the step 3 on a surface-treated stainless steel net, rolling and molding, drying and calcining to obtain the final catalyst. Furthermore, the invention also relates to a catalyst for flue gas denitrification, which is prepared by the method. The catalyst with high mechanical strength and excellent catalytic activity overcomes the problem that the prior catalyst for flue gas denitrification has poor mechanical strength after molding.

Owner:HARBIN INST OF TECH

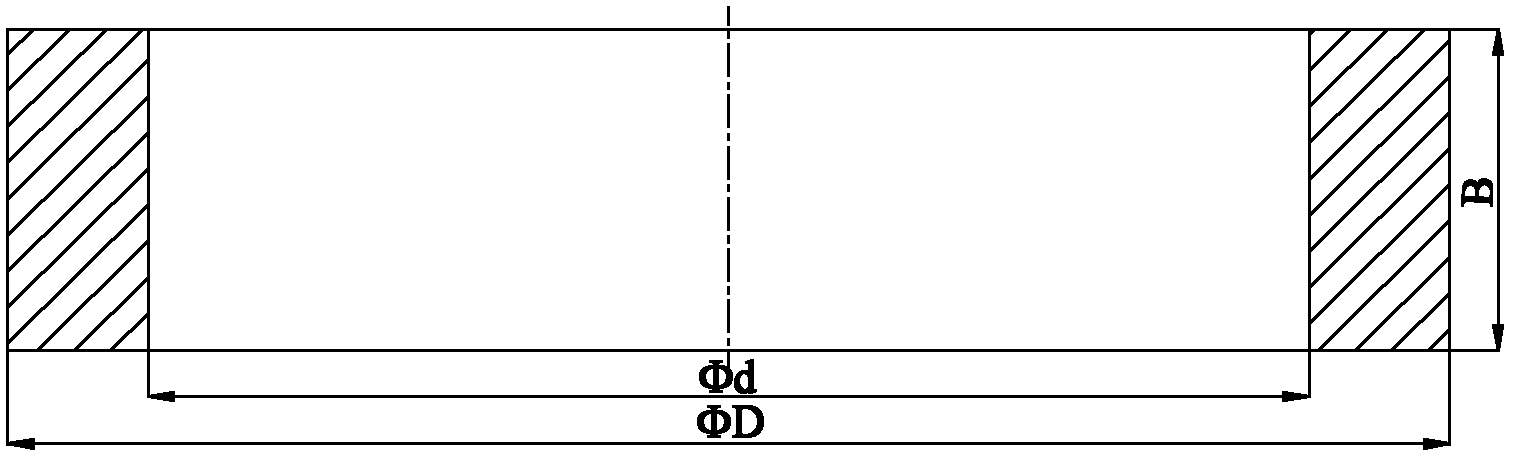

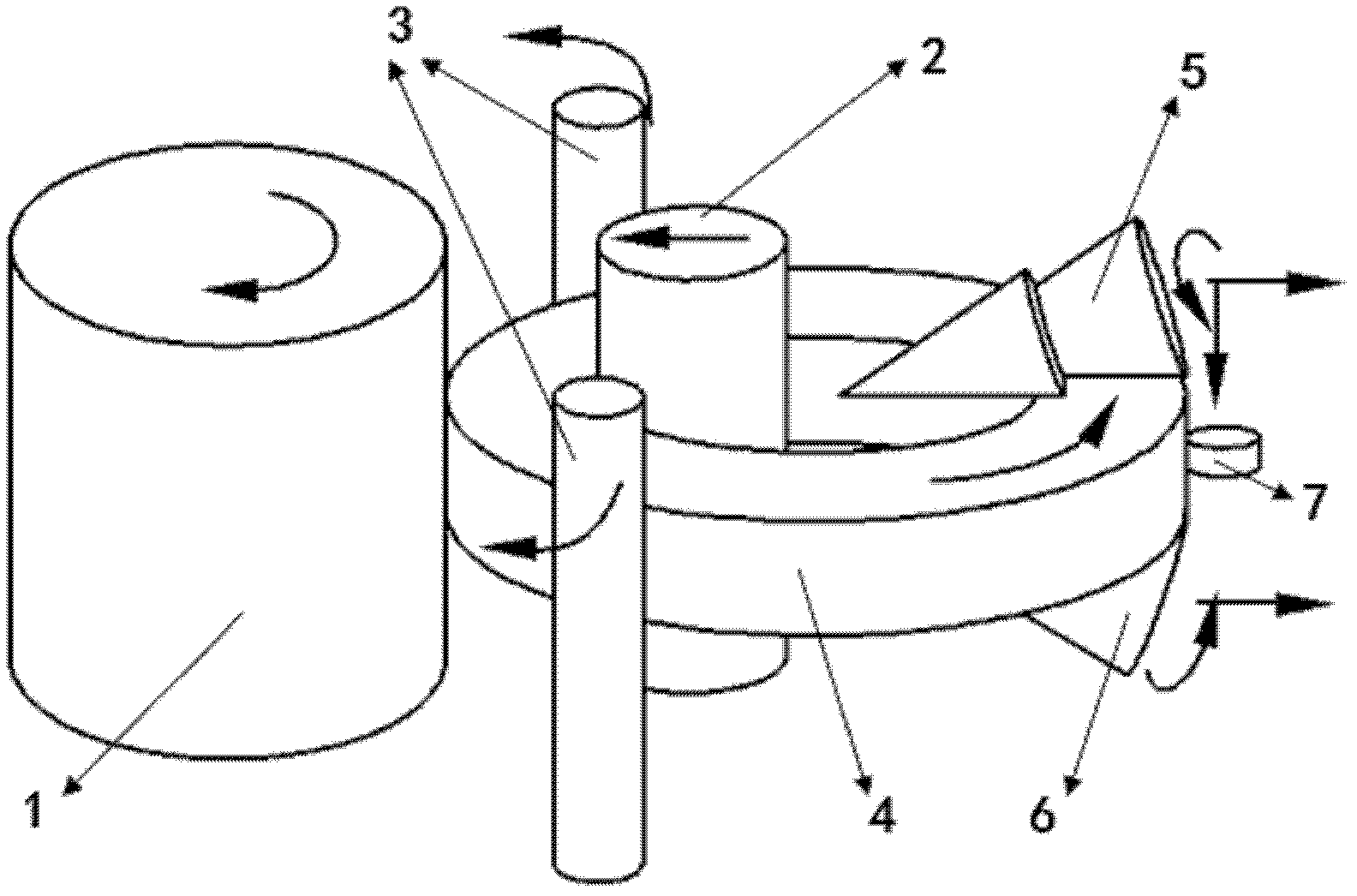

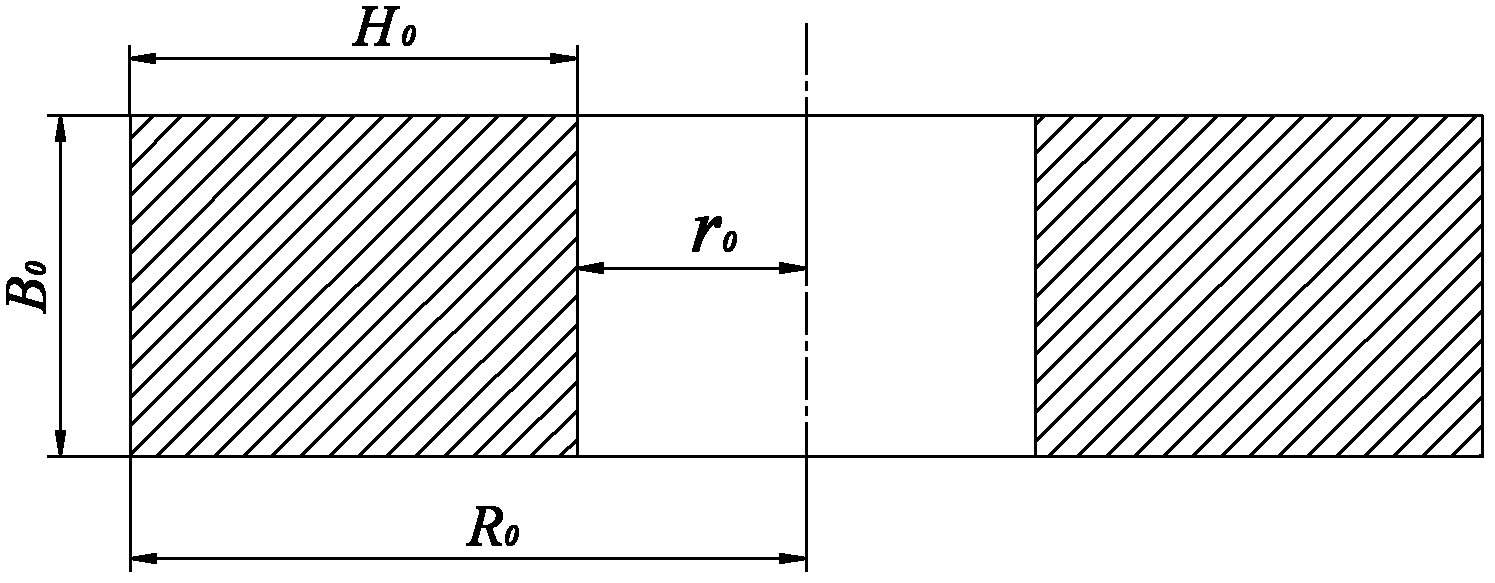

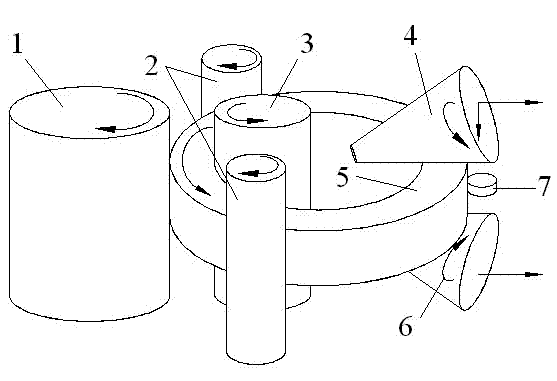

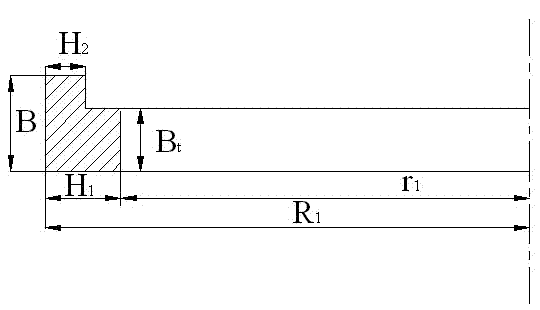

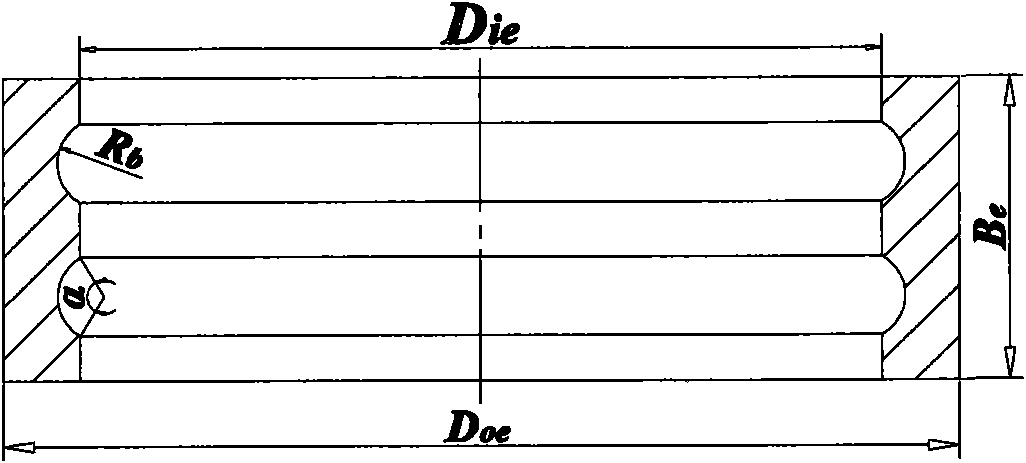

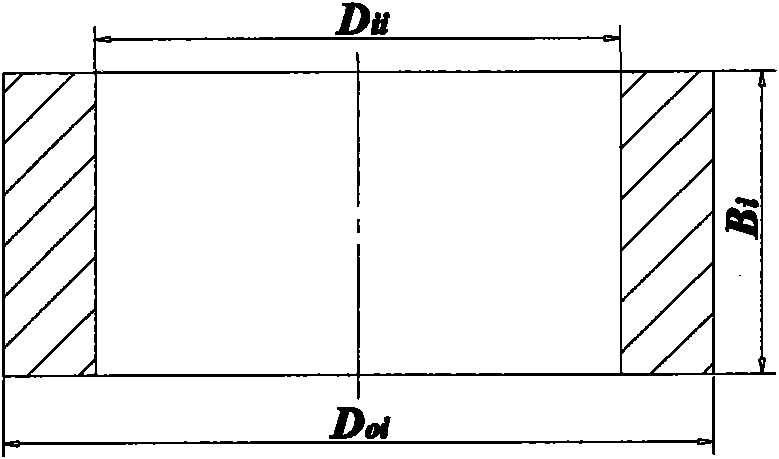

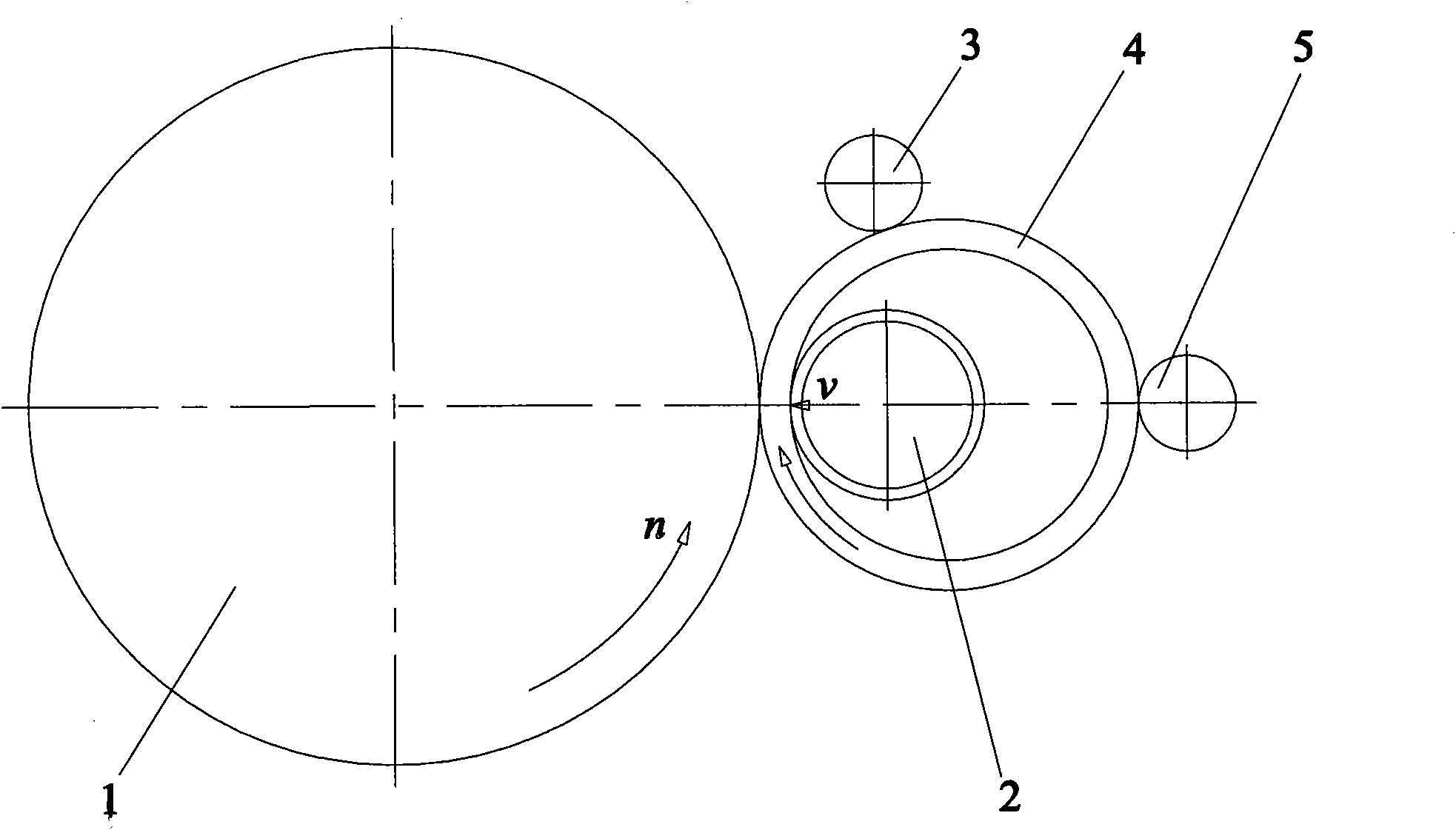

Radial and axial roll-forming method for large internal-stage annular piece

The invention relates to a radial and axial roll-forming method for a large internal-stage annular piece. The method comprises the following steps of: (1) making a blank, namely performing hot-forging, upsetting, punching and slug-stamping on a bar material, and thus obtaining an annular piece blank for rolling; (2) designing a roll hole pattern, namely determining the size of the roll hole pattern according to a roll linear speed, an equipment parameter, a roll deformation condition and the size of the annular piece blank, and determining the size of the axial roll hole pattern according to the roll linear speed, the equipment parameter, the annular piece blank and the size of the annular piece blank; and (3) roll-forming, namely putting the obtained annular piece blank on an annular rolling machine for rolling, controlling an upper conical roller and a lower conical roller to move backwards in real time during rolling to make the bottom end of the annular rolling machine always contact outer diameters of the upper end face and the lower end face of the annular piece, controlling the rolling process by rationally distributing a feeding speed and a feeding amount according to three stages, namely pre-rolling, rolling and shaping rolling, and when the outer diameter of the detected annular piece reaches a preset value, finishing the rolling process. The method has the characteristics of high production efficiency, low production cost and high product quality.

Owner:ZHANGJIAGANG HAILU ANNULAR FORGINGS +1

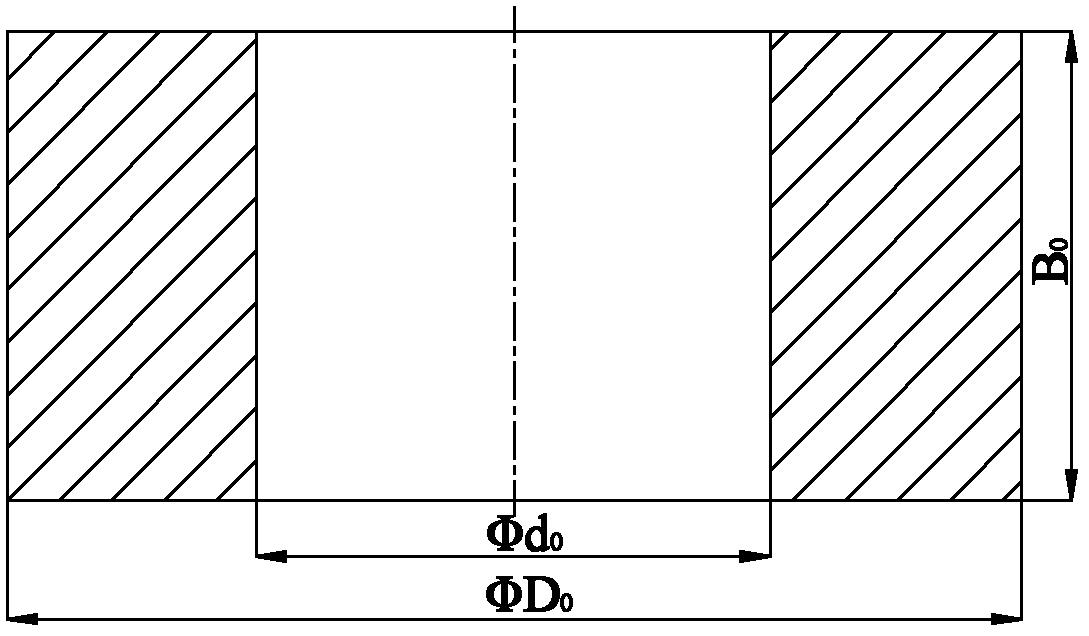

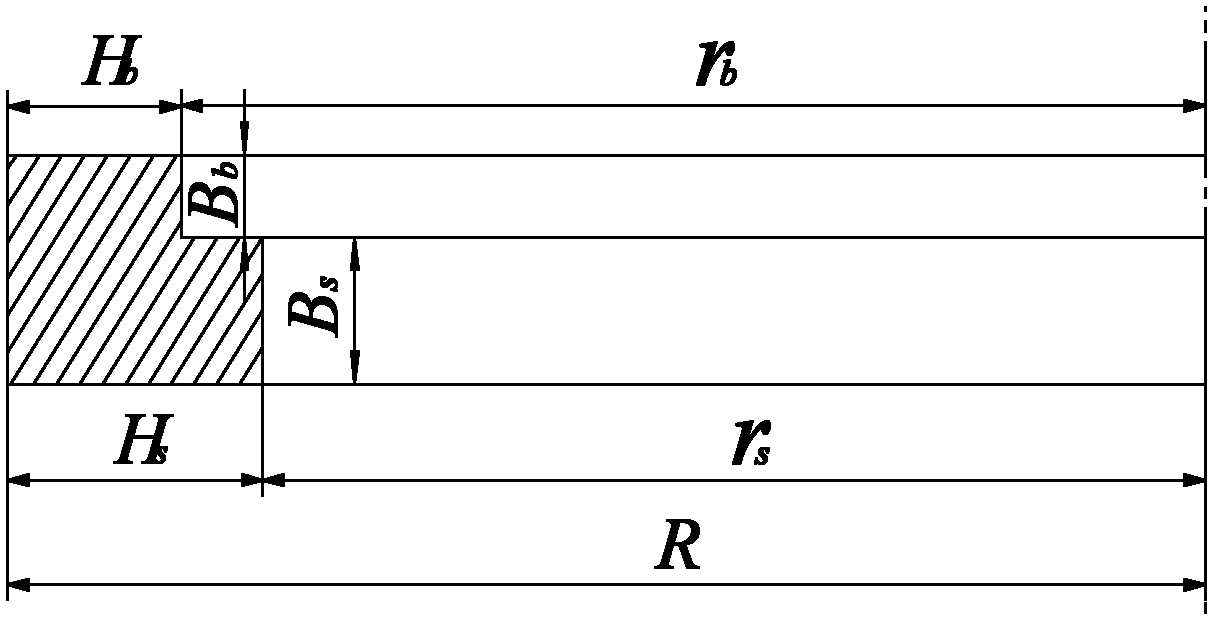

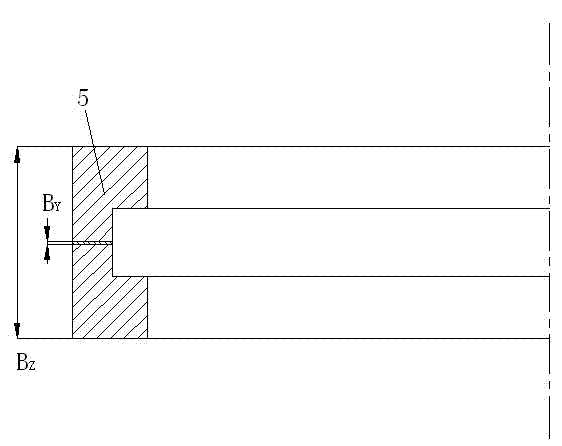

Symmetric rolling forming method of large inner-step ring parts

The invention relates to a symmetric rolling forming method of large inner-step ring parts, mainly comprising the following steps of: (1) blanking, upsetting, punching, punching the wad, and preparing a ring part blank used for rolling, wherein the size of the ring part blank is determined by the size of the ring part, a rolling ratio, and a radial feed / axial feed ratio; (2) designing a rolling groove, wherein the rolling groove is composed of a driven roller working surface and a core roller working surface and sizes of the driven roller working surface and the core roller working surface are determined by a rolling linear speed, equipment parameters, rolling deformation conditions, the ring part blank size, and the ring part size; (3) rolling forming which comprises placing the well-prepared ring part blank on a ring rolling machine and controlling the rolling process in a way that the feed speed and the feed amount are reasonably distributed according to three stages of pre-rolling, main rolling, and shaping rolling, and ending the rolling process when an outer diameter of the tested ring part achieves a predetermined value; and (4) machining cutting which comprises placing the well-rolled ring part on a sawing machine and cutting the ring part into two required inner-step ring parts from a high portion in the middle. The symmetric rolling forming method provided by the invention has the characteristics of good production stability, high efficiency, and high product performance.

Owner:汇洲智能技术集团股份有限公司 +1

Manufacturing method of silver-tungsten carbide-carbon electrical contact material

InactiveCN1658346AImprove compactnessHigh hardnessContact materialsManufacturing technologyCircuit breaker

This invention relates to a manufacturing method of a silver-tungsten carbide-carbon electric contactor. It adopts silver powder, tungsten carbide and graphite powder as the raw materials and manufactures the silver-tungsten carbide-carbon electric contactor material through chemical coating and solid agglomeration techniques, and belongs to the field of electric components breaker switch manufacturing technology. The characteristic of this invention is: adopt silver powder, slab tungsten carbide powder, graphite powder and a little additive metal powder as the raw materials. At first mix the slab tungsten carbide powder, the graphite powder and the additive metal powder, and use chemical coating technique to get silver coating compound powder, and then pass through cold roll forming, agglomeration, re-rolling to get AgWC12C3 electric contactor material with tungsten carbide grains arrayed directionally. The AgWC12C3 electric contactor material made by this invention has fine compactness, high rigidity and conductive power. This material can be applied to many kinds of breakers with large capacity, the breakers with plastic covers and automatic switches.

Owner:SHANGHAI UNIV

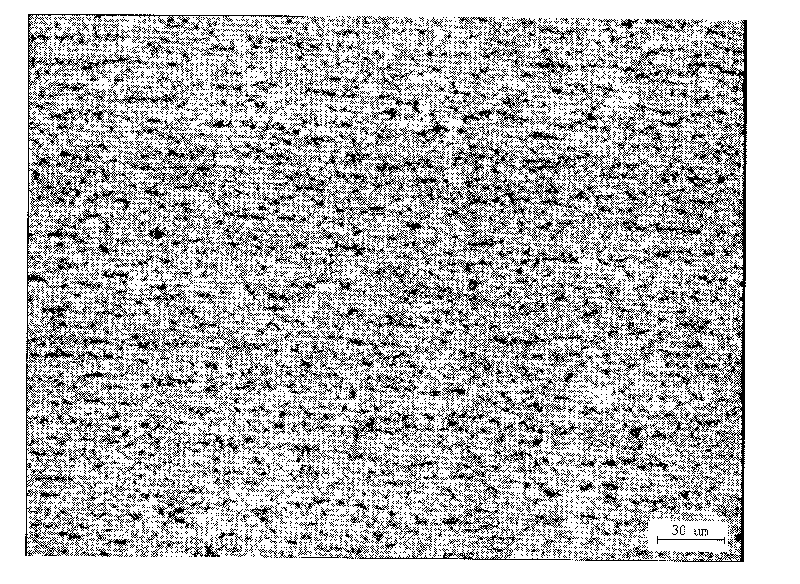

Cold ring rolling forming method for double-flute section ring

ActiveCN101829745AImprove distributionImprove tissue performanceRollsMetal rolling arrangementsFlutePunching

The invention relates to a cold ring rolling forming method for a double-flute section ring. The method comprises the following implementation steps of: (1) preforming, namely uniformly heating a bar section to the forging temperature from room temperature; upsetting, punching and punching wad to form a ring roughcast used for ring rolling; and designing the size of the ring roughcast; (2) roll pass design; and (3) ring rolling forming by using a ring rolling machine, wherein a core roll stops feeding and a ring rolling process is finished when the outside diameter of an obtained double-flute section ring is measured to reach a predetermined value; and the ring roughcast finally forms the double-flute section ring in a predetermined size. In the method, the double-flute section ring is produced by adopting a cold ring rolling process; the double-flute section ring is formed through continuous local plastic deformation of a rectangular section ring by reasonably designing the ring roughcast, ring rolling pass and forming parameters; and therefore, the consumption of raw materials and processing time are reduced, metal streamline distribution and organization properties of the ring are improved, work efficiency and product quality are improved, and production cost is reduced.

Owner:WUHAN UNIV OF TECH +1

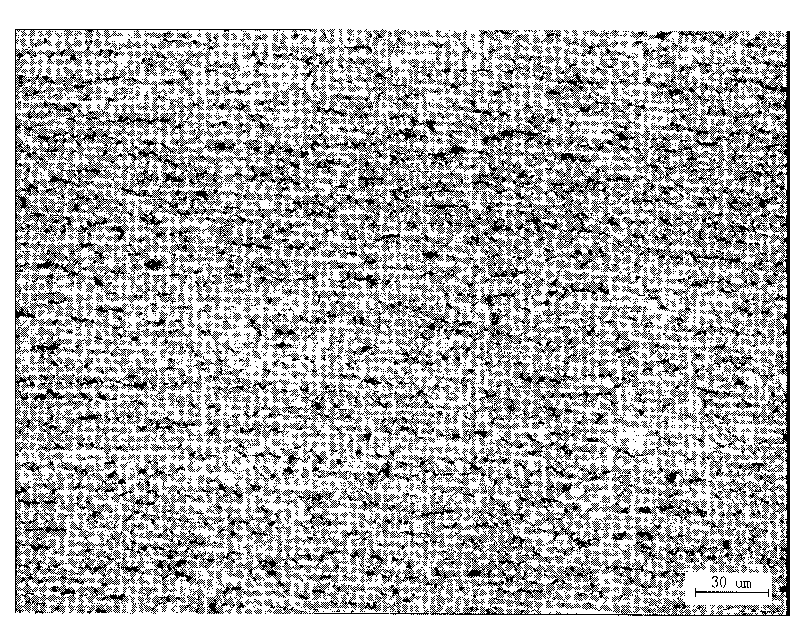

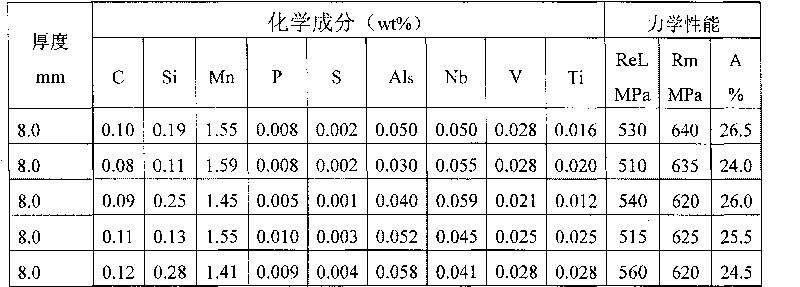

610MPa automobile girder steel and production method thereof

ActiveCN101748329AGood low temperature impact propertiesTemperature control deviceChemical compositionRoll forming

The invention discloses a 610MPa automobile girder steel, and the weight percentage (wt%) of the chemical composition of the steel is as follows: C: 0.08 to 0.12; Si: 0.10 to 0.30; Mn: 1.40 to 1.60; P: less than or equal to 0.010; S: less than or equal to 0.005; Nb: 0.040 to 0.060; V: 0.020 to 0.030; Ti: 0.010 to 0.030; Al: 0.030 to 0.060; Ca: tiny amount; and the rest is iron and residual trace impurities. The invention also discloses a production method for the 610MPa automobile girder steel, which adopts a 2250mm hot rolling line, and a continuously cast slab is heated to 1200 DEG C to 1250 DEG C; after rough rolling, the temperature is 1000 DEG C to 1050 DEG C, the continuously cast slab enters a finishing mill via a heat cover and is rolled, the finish rolling temperature is 820 DEG C to 880 DEG C, and the rolled steel coil is rapidly cooled to 530 DEG C to 580 DEG C by way of laminar cooling, and is then coiled. Since the chemical composition and the production technique are adopted, the tensile strength of an automobile girder is larger than 610MPa, the yield strength is larger than 500MPa, the specific elongation is larger than 20 percent, minus 60 DEG C longitudinal impact energy AKV is larger than 70J, and the automobile girder has excellent cold formability and high fatigue strength. The product is applicable to heavy-duty automobile members such as side members and cross members, which are produced by cold-roll forming and stamping forming techniques.

Owner:MAANSHAN IRON & STEEL CO LTD

Method for manufacturing a reinforced structural component, and article manufactured thereby

A reinforced structural component is manufactured by forming an intermediate structural member which defines a channel extending along at least a portion of its length. A support member is disposed in the channel and affixed to the intermediate structural member. A second forming operation is carried out on the combination of the intermediate structural member and support member so as to partially enclose and fixedly retain the support member therein. The method may be applied to metallic and nonmetallic structures, and may be utilized in conjunction with high speed metal forming processes such as roll forming. Disclosed herein are structures made according to the method as well as use of the method in the manufacture of structural components for motor vehicles.

Owner:NOBLE ADVANCED TECH

Extended nip embossing process

The present invention provides a process for embossing a web substrate. The process comprises the steps of: (a) juxtaposing a first pattern roll in an axially parallel relationship with a second pattern roll forming a first nip; (b) providing the first pattern roll with first pluralities of raised elements and recesses comprising a first embossing pattern; (c) providing the second pattern roll with second pluralities of raised elements and recesses comprising a second embossing pattern; (d) contacting the web substrate at the first nip; (e) embossing the web substrate; (f) juxtaposing the first pattern roll in an axially parallel relationship with a third pattern roll to form a second nip; (g) providing the third pattern roll with third pluralities of raised elements and recesses comprising a third embossing pattern; (h) after step (e), contacting the embossed web substrate at the second nip; and, (i) further embossing the embossed web substrate at the second nip.

Owner:THE PROCTER & GAMBLE COMPANY

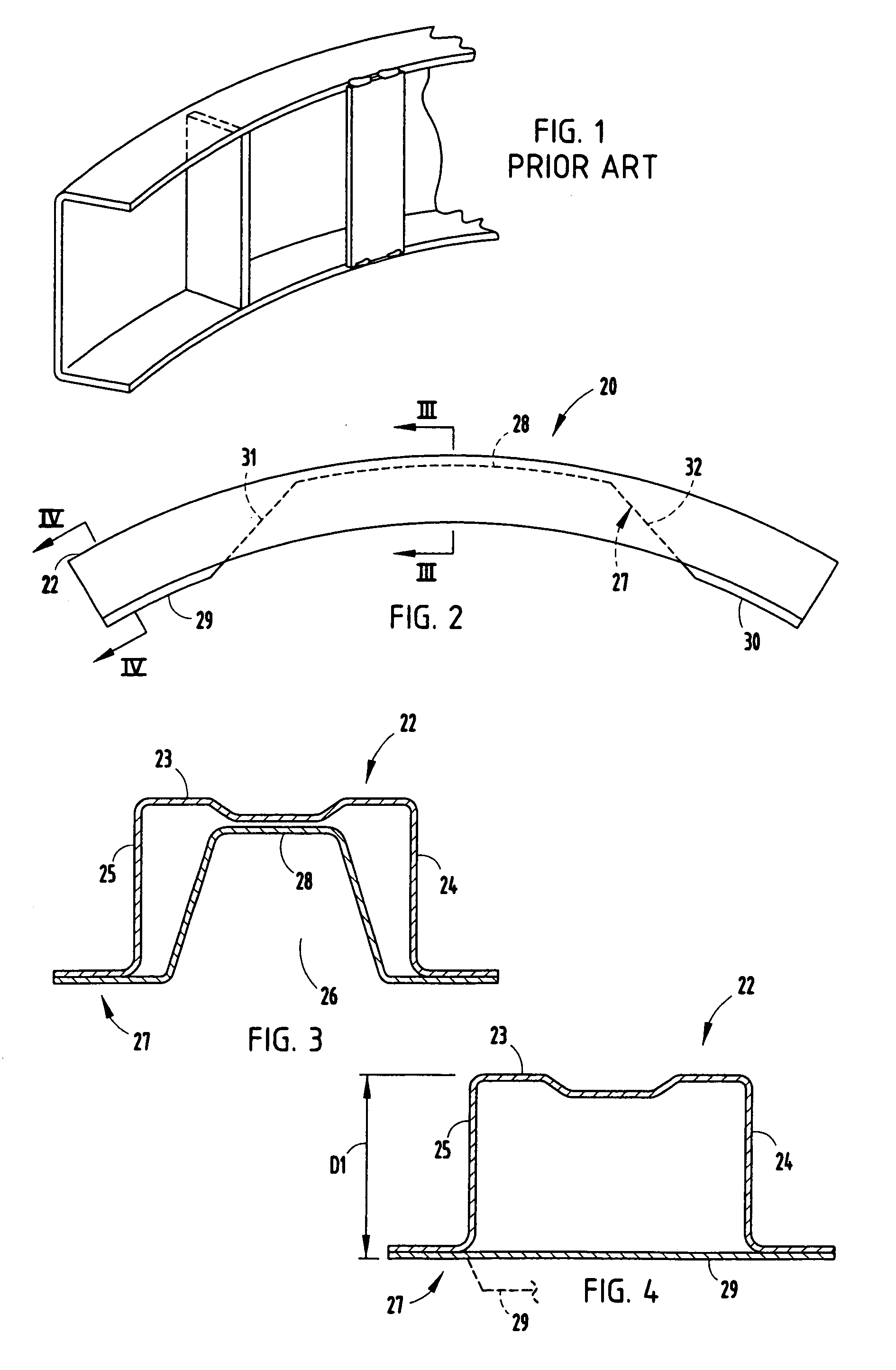

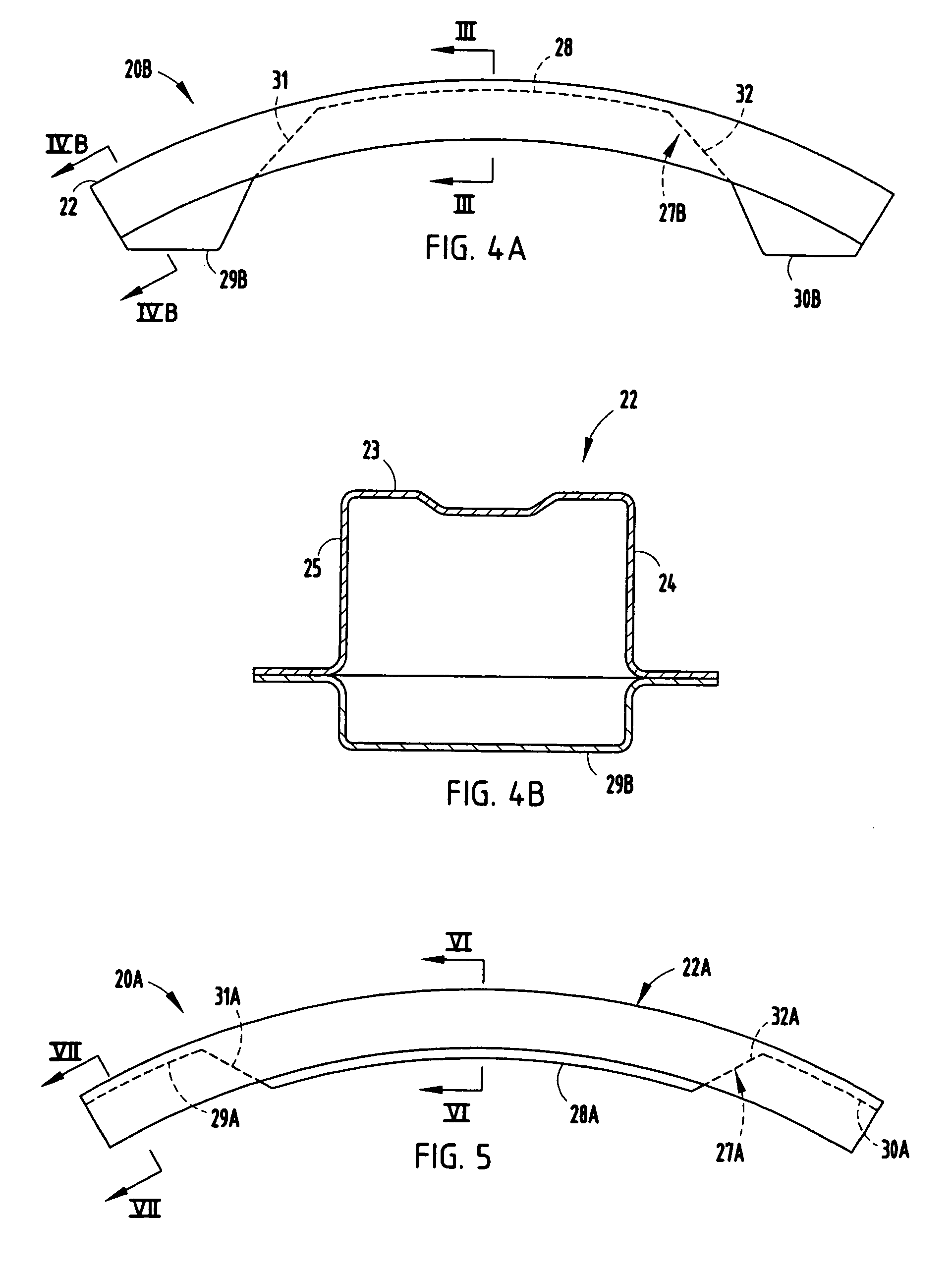

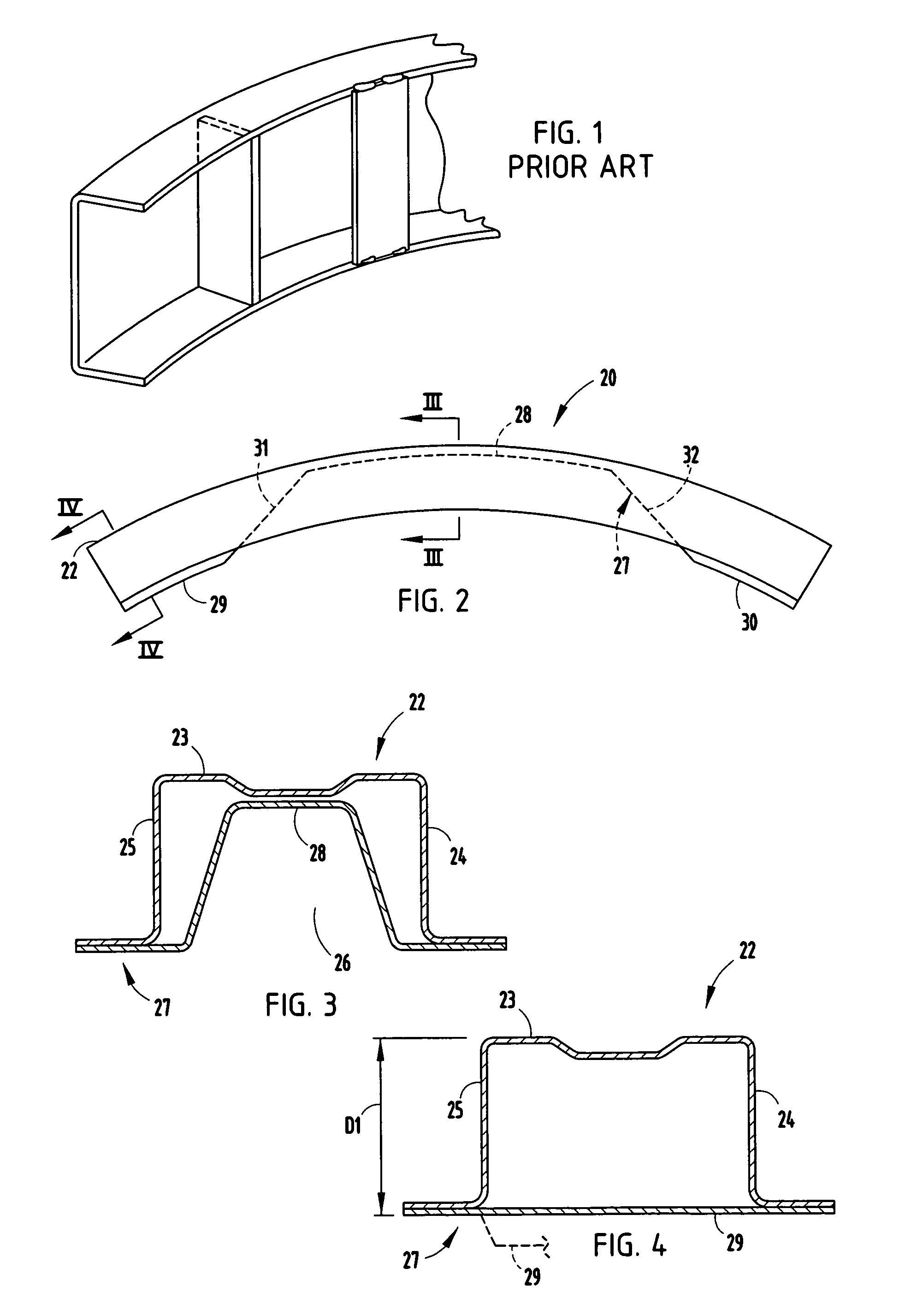

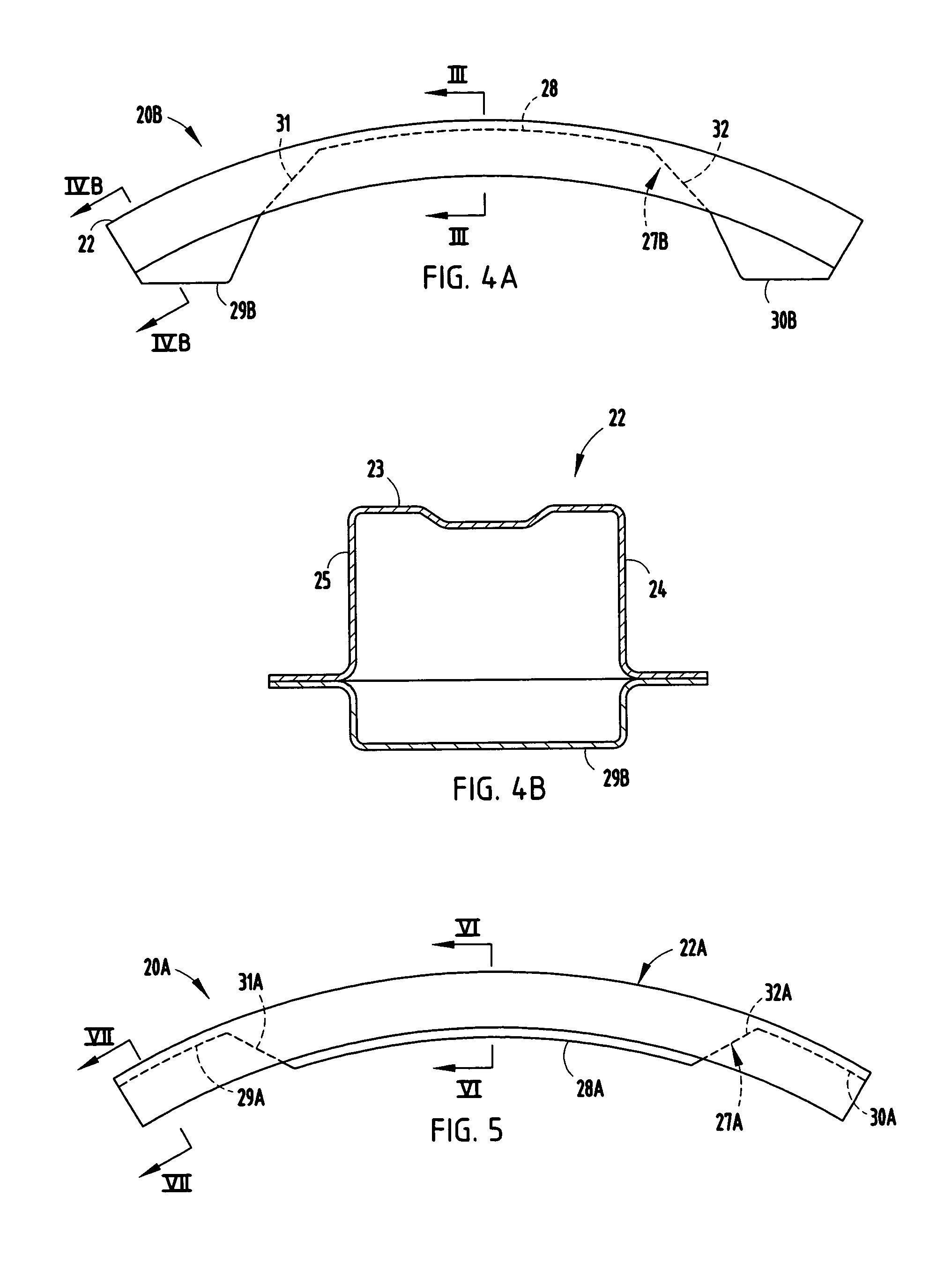

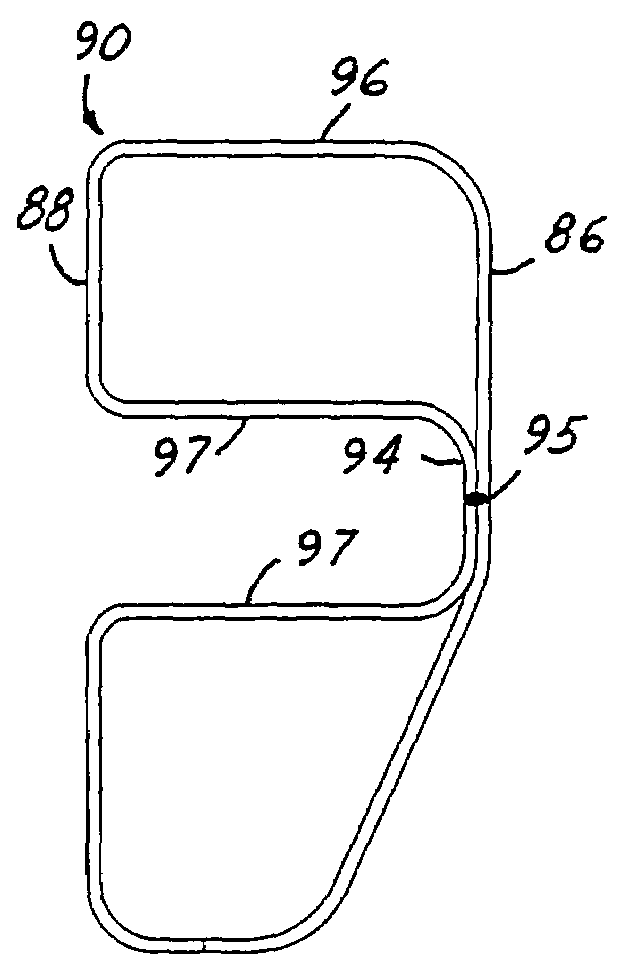

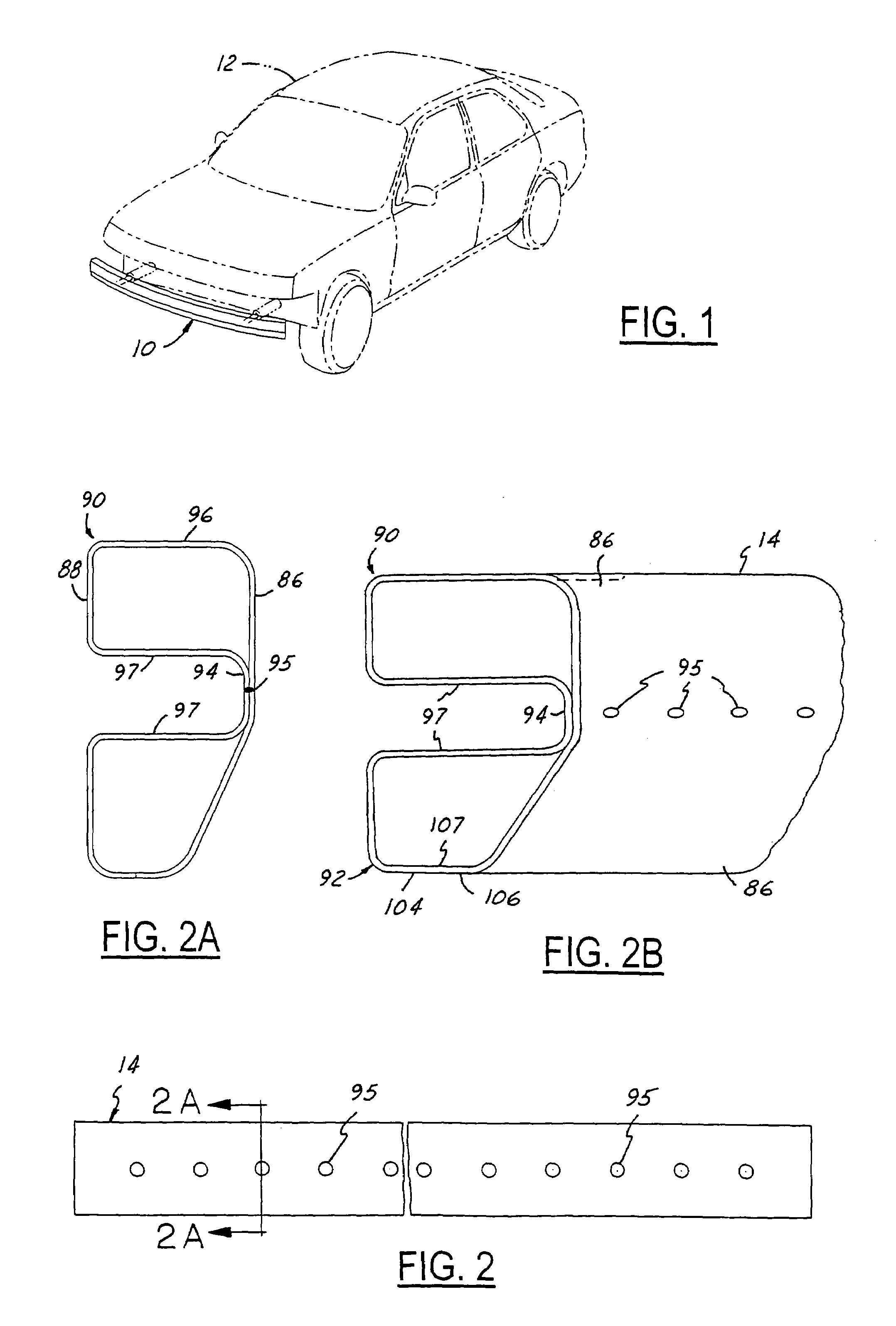

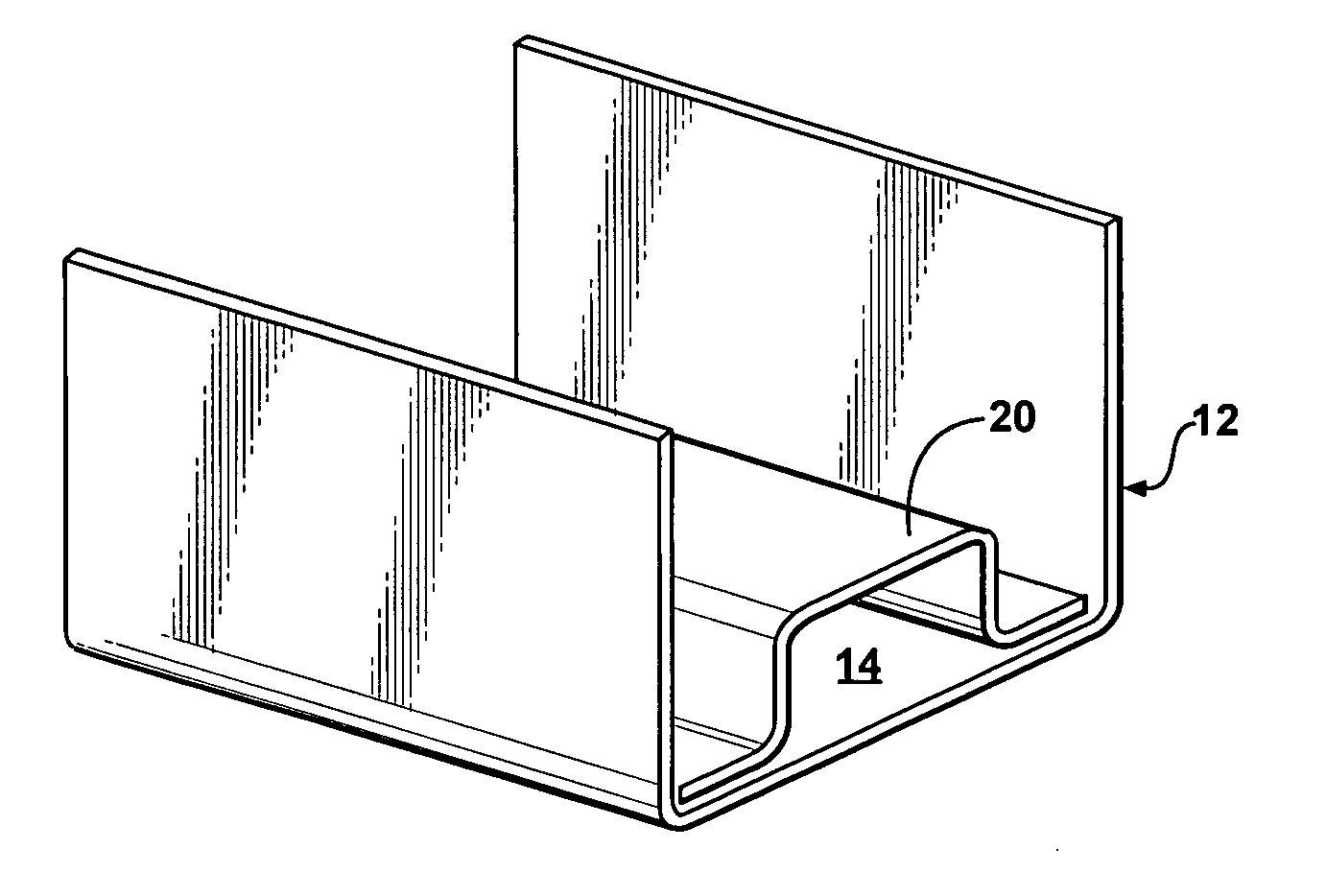

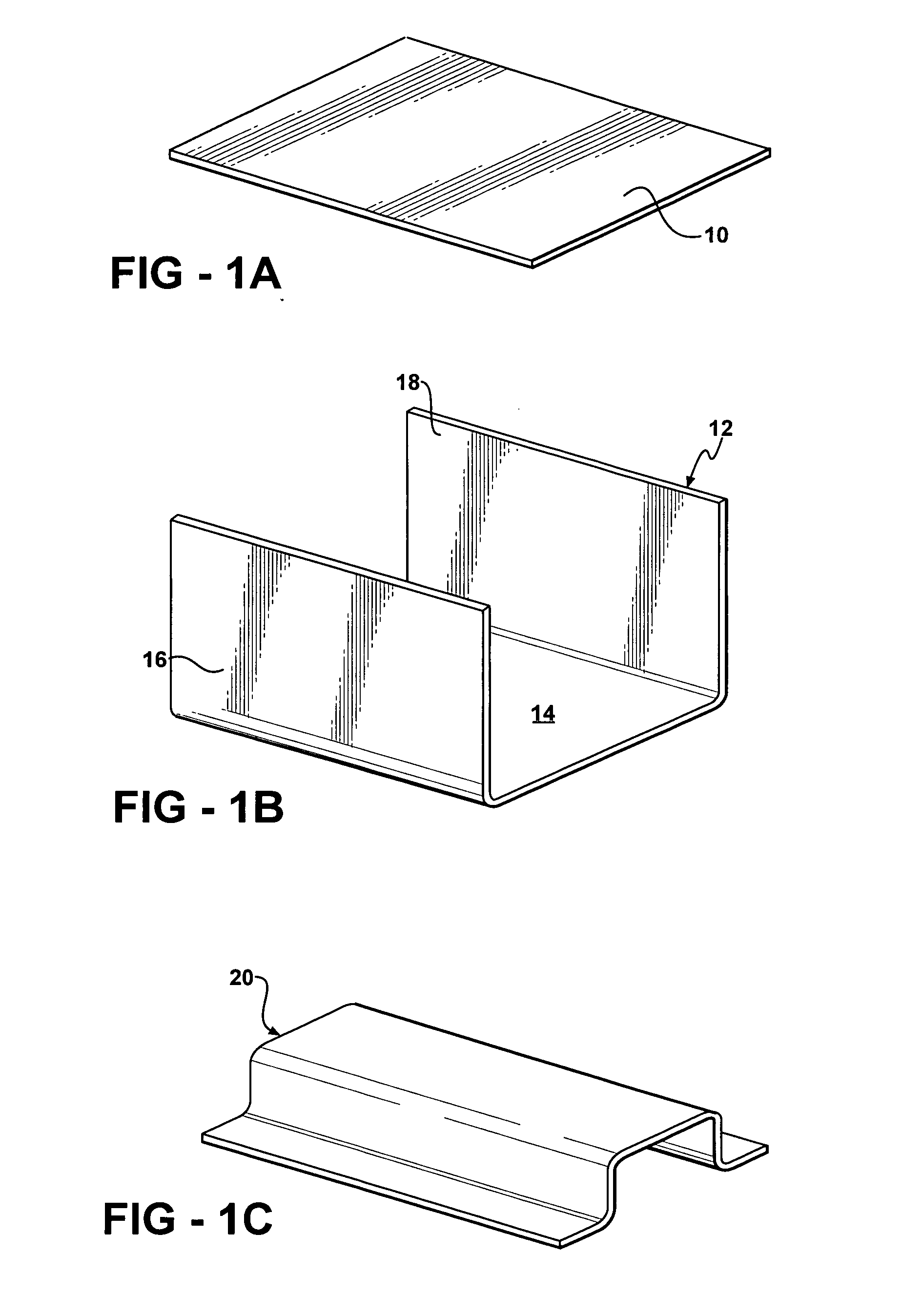

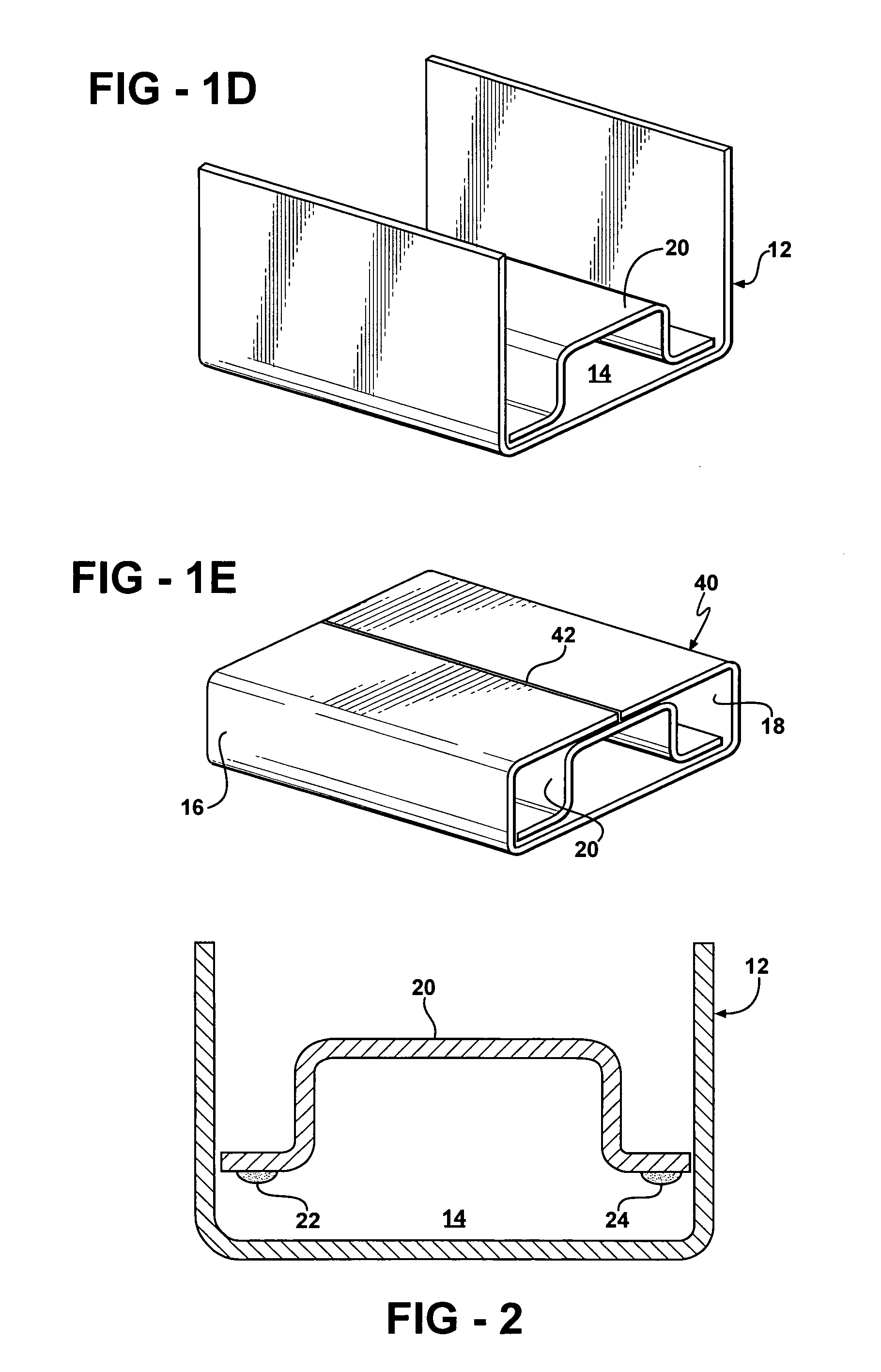

Roll-formed structural member with internal web

InactiveUS20080052908A1High strengthImprove rigidityVehicle seatsSuperstructure subunitsRoll formingEngineering

A roll-forming process for the manufacture of a structural member can be used in the manufacture of an automotive vehicle. The roll-forming process creates a component that has multiple cells with an integral internal web separating the cells, enhancing the strength, rigidity and stiffness of the component for any given size and shape. The roll-forming process starts with a piece of sheet metal and rolls the sheet metal into a desired shape and then rolls the tube back over on itself to create a second cell with the internal reinforcing web positioned between two structural cells of the beam. The rolled form is then welded into the formed shape to create the structural beam. The two cells of the beam can be the same general size or be formed as completely disparate sizes, depending on the design requirements of the structural member.

Owner:FORD MOTOR CO

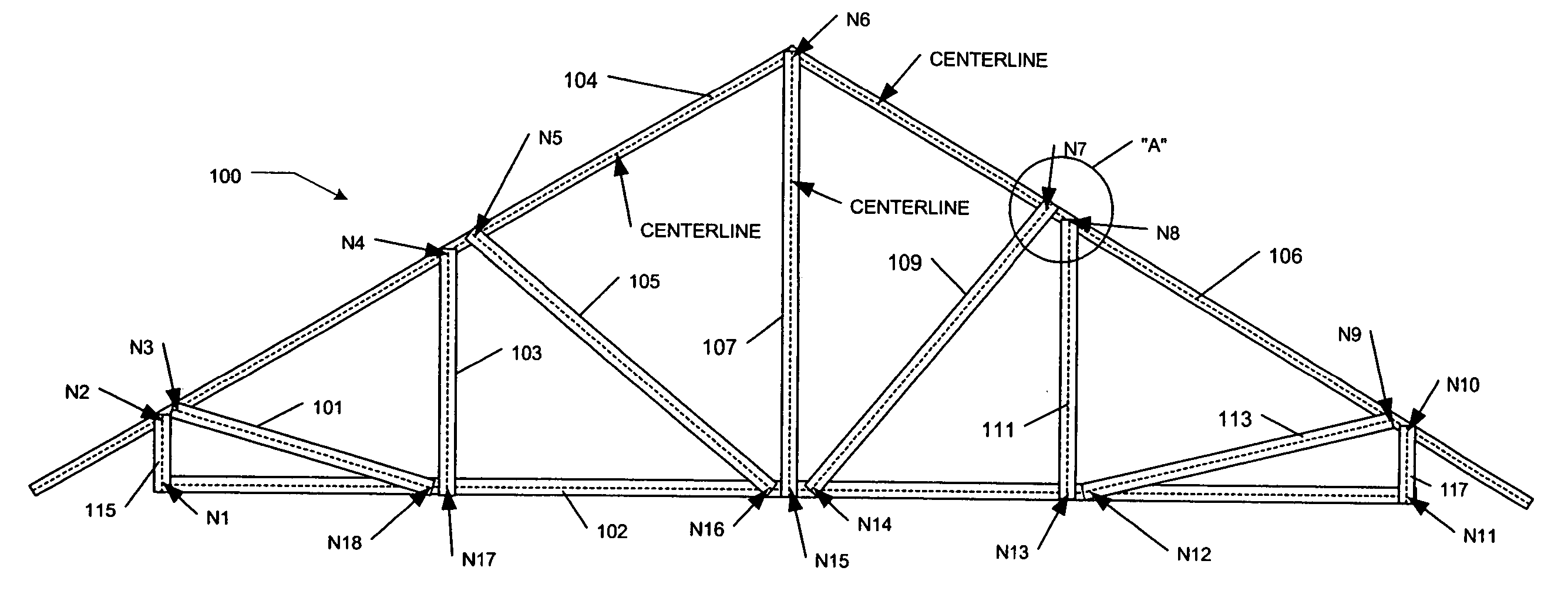

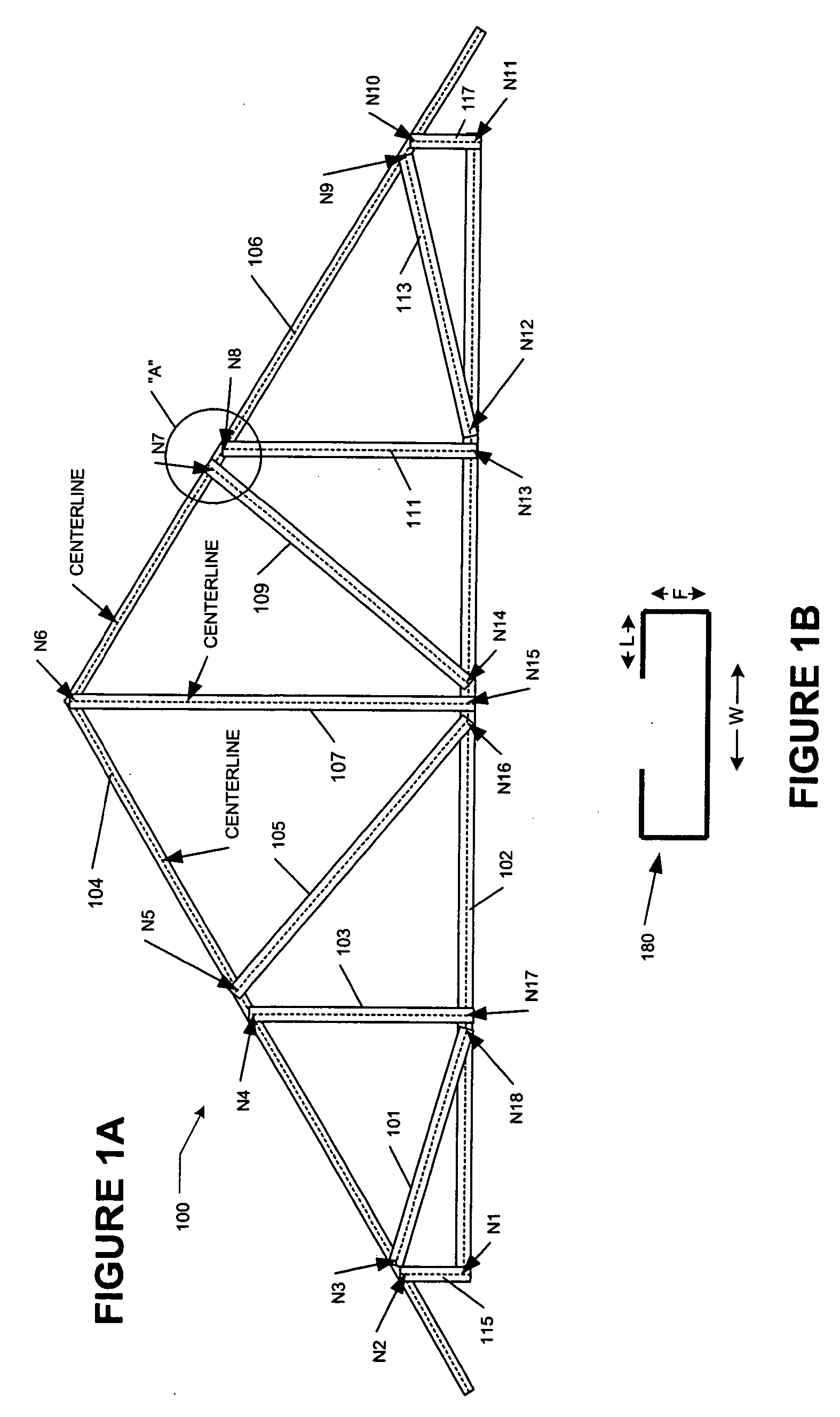

Truss manufacturing method and system

Methods and systems are provided for making one or more structural stud trusses without the need for using a jig when the truss is assembled. In one embodiment, data identifying a plurality of structural stud members for making the truss is generated. The data includes data for each stud including physical stud parameters and one or more locations for an alignment guide where another member is to connect with it. A roll forming machine is controlled with the generated data to produce the plurality of stud members whereby the roll forming machine applies one or more alignment guides onto each member based on locations identified in the generated data. Finally, after all or some of the stud members are formed, the members are assembled to form the truss using the alignment guides to align connecting members with each other in order to fasten them together.

Owner:KARDOSZ TIMOTHY J +1

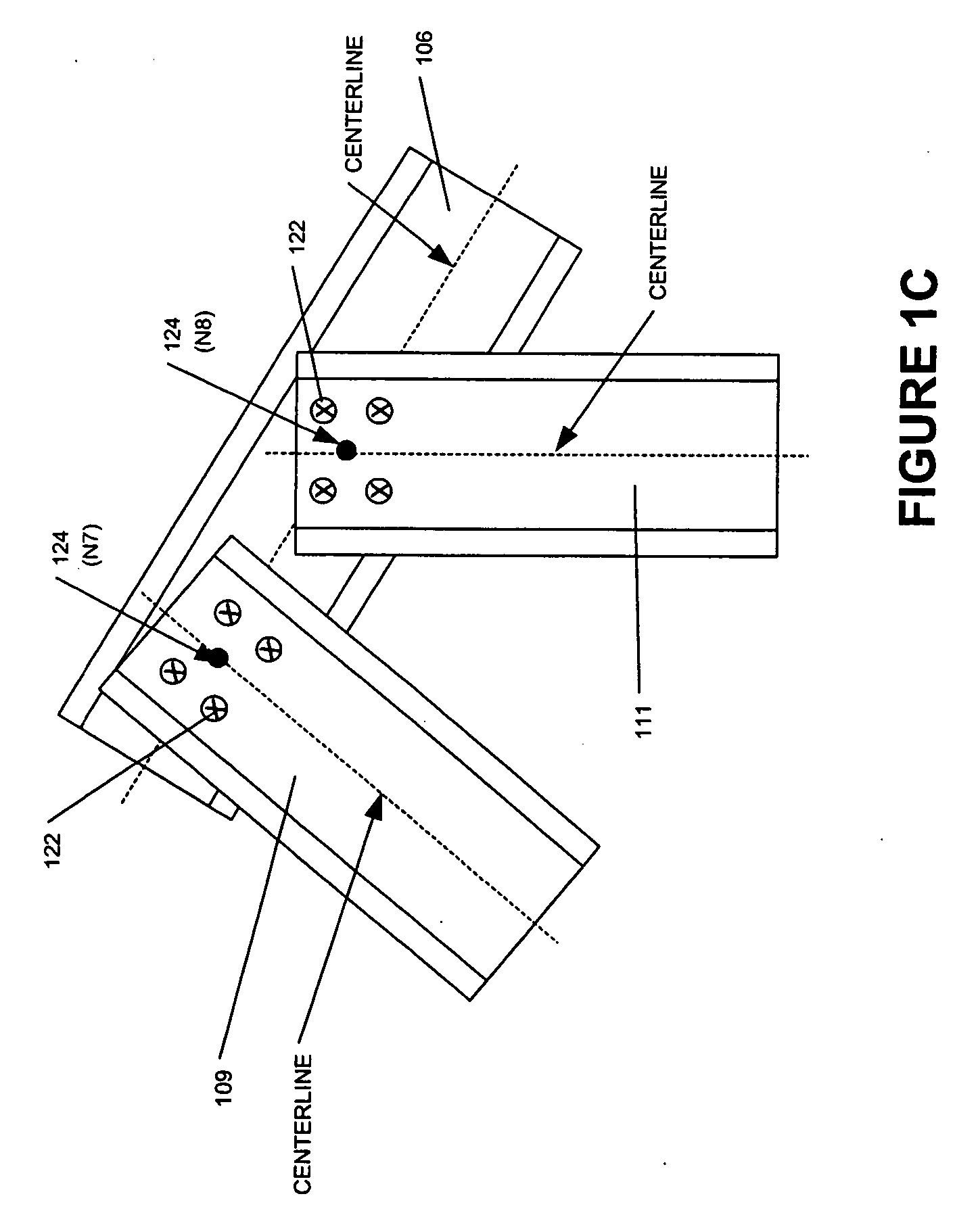

Method of manufacturing cold worked, high strength seamless CRA PIPE

InactiveUS6880220B2High tensile strengthHigh yield strengthSoldering apparatusArc welding apparatusRoll formingCorrosion

A process produces a welded seamless PIPE having good yield strength and excellent corrosion and / or erosion resistance. Up to a maximum outside diameter corrosion and / or erosion resistant CRA PIPE is cold worked from a welded hollow, rather than using the traditional seamless pierced hollow method. A high-speed roll-forming mill is also utilized, rather than using the slow traditional break press to form the welded hollow. Welded hollow dimensions can be achieved which comply with the method of cold working's capability to produce the yield strengths and dimensional tolerances required to meet the service criteria of the PIPE's intended application.

Owner:CORROSION RESISTANT ALLOYS

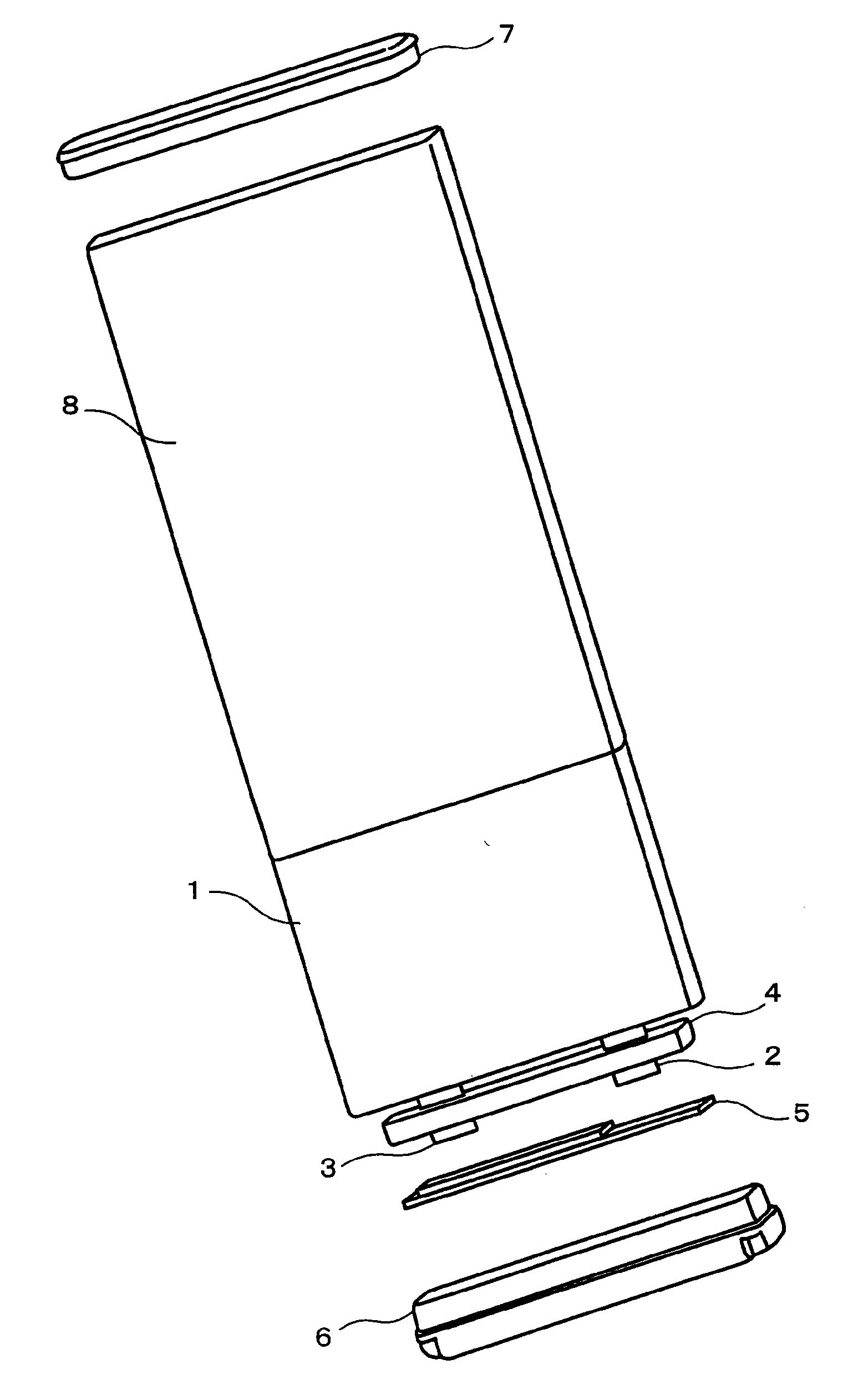

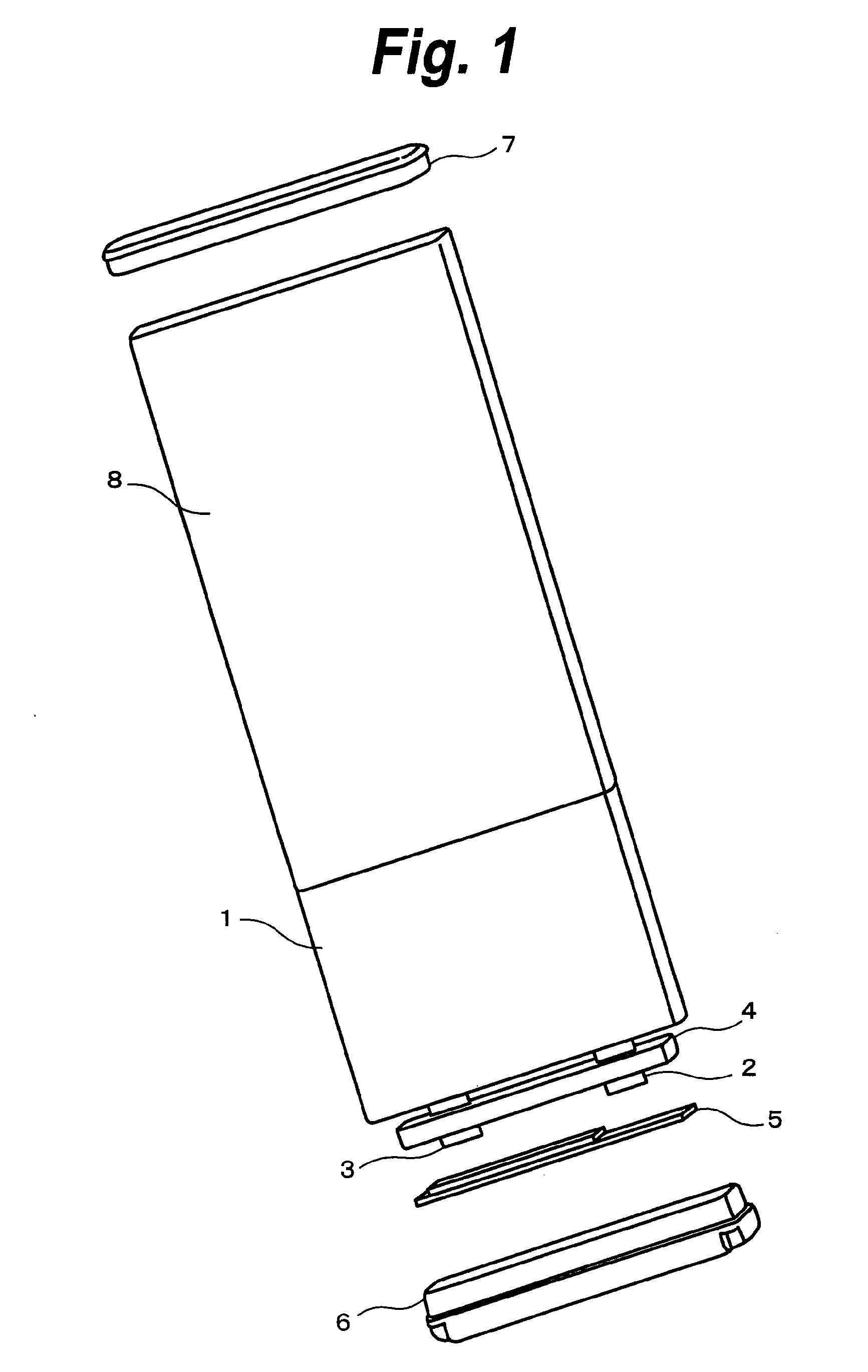

Battery Pack

By using a DI molding method or a roll forming method, a casing member made of a thin cylindrical metal pipe is formed and molded so as to almost coincide with a shape of a battery element, thereby forming an outer casing. A power generating element to which a circuit board has been connected is enclosed in the outer casing and opening portions of the outer casing are closed by a front cap and a rear cap formed by, for example, a resin molding, thereby forming a battery pack. The power generating element is used by externally covering the battery element with a laminate film or the battery element is enclosed as it is into the outer casing. To suppress the penetration of the moisture into the battery, it is also possible to mix a moisture trapper for absorbing the moisture into a resin material of the front cap and rear cap and suppress the penetration of the moisture.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com