Fine-grain roll-forming method for large annular piece made of high alloy steel

A technology of high-alloy steel and ring parts, applied in the direction of metal rolling, etc., can solve the problems of large material burning loss, high noise, large machining allowance, etc., achieve low material loss and energy consumption, reduce production costs, The effect of high geometric precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

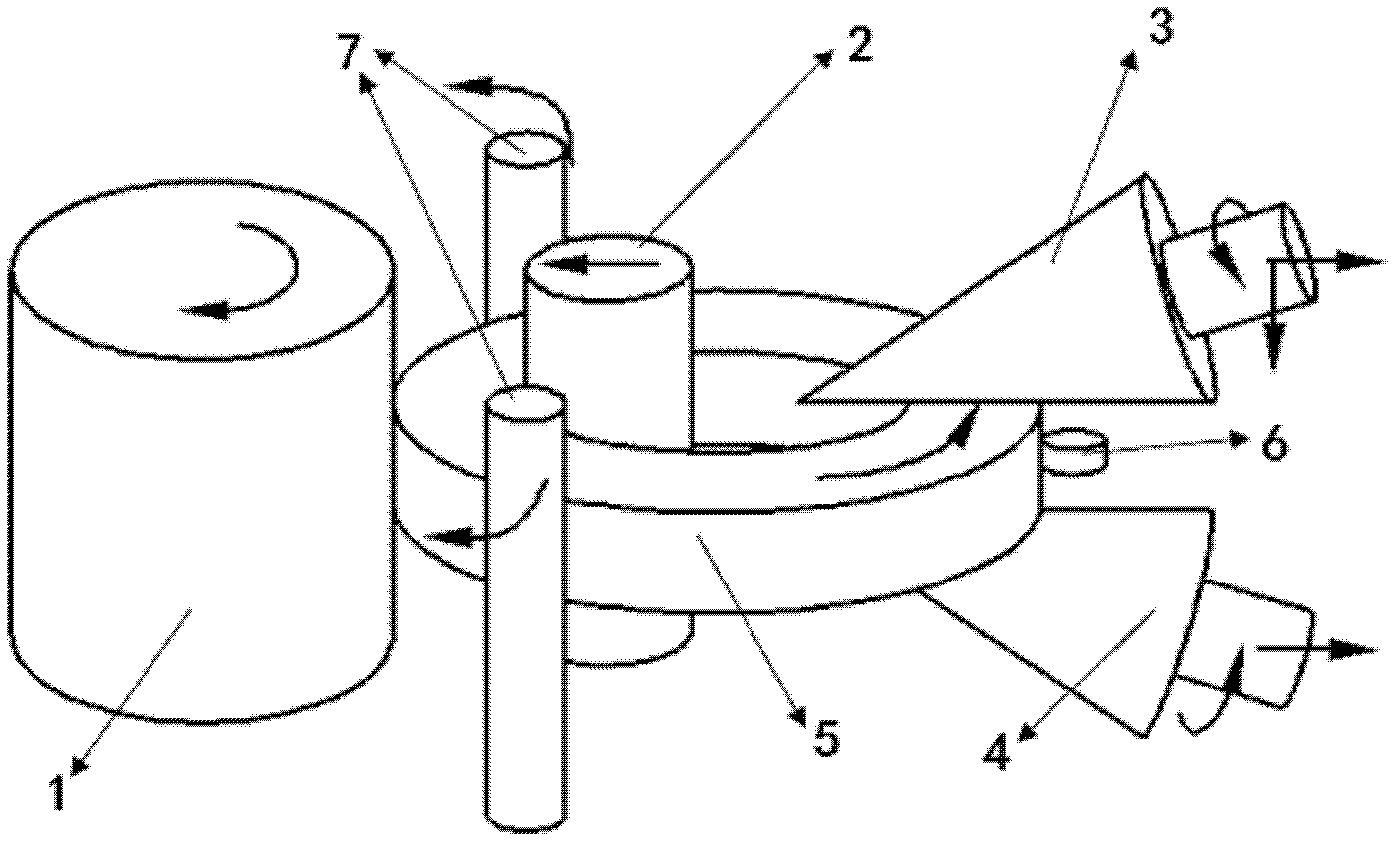

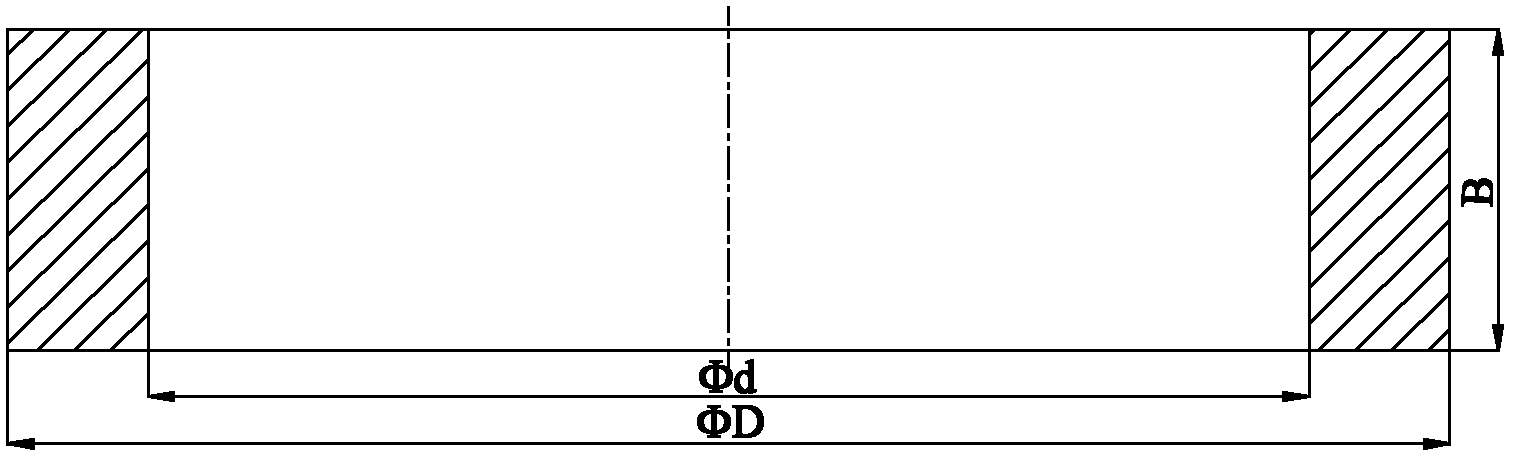

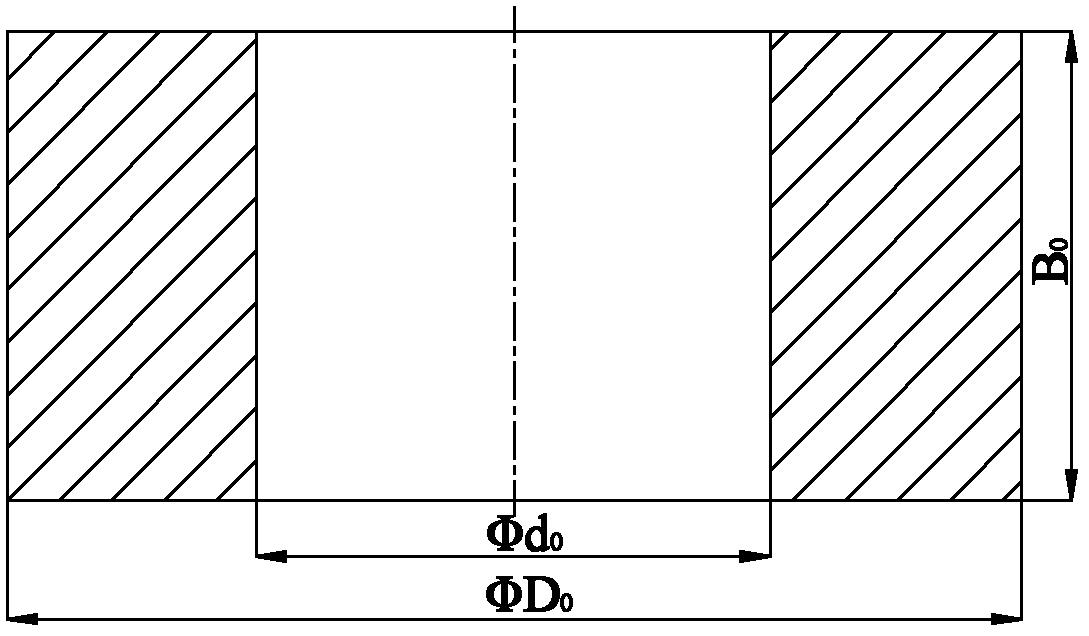

[0033] Taking a certain nuclear power pressure vessel connection pipeline with 304 stainless steel large-scale ring piece fine-grain rolling forming as a specific embodiment to illustrate the high-alloy steel large-scale ring piece fine-grain rolling forming method of the present invention, the 304 stainless steel large-scale ring piece that is required to be rolled is as follows figure 2 As shown, its dimensions are: the outer diameter D is 1420mm, the inner diameter D is 1140mm, and the height B is 310mm; figure 1 The method shown, the specific implementation steps are as follows:

[0034] (1) Cutting: After calculation, the weight of the ring is 1362kg, plus 10% of the blank weight and the weight of the skin, the total weight required for the material section is 1700kg. A round ingot with a diameter of Φ630mm is sawn into material sections with a length of 700mm by a sawing machine.

[0035] (2) Heating: first preheat the heating furnace to about 300°C, then load the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com