Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

19244 results about "Heating furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

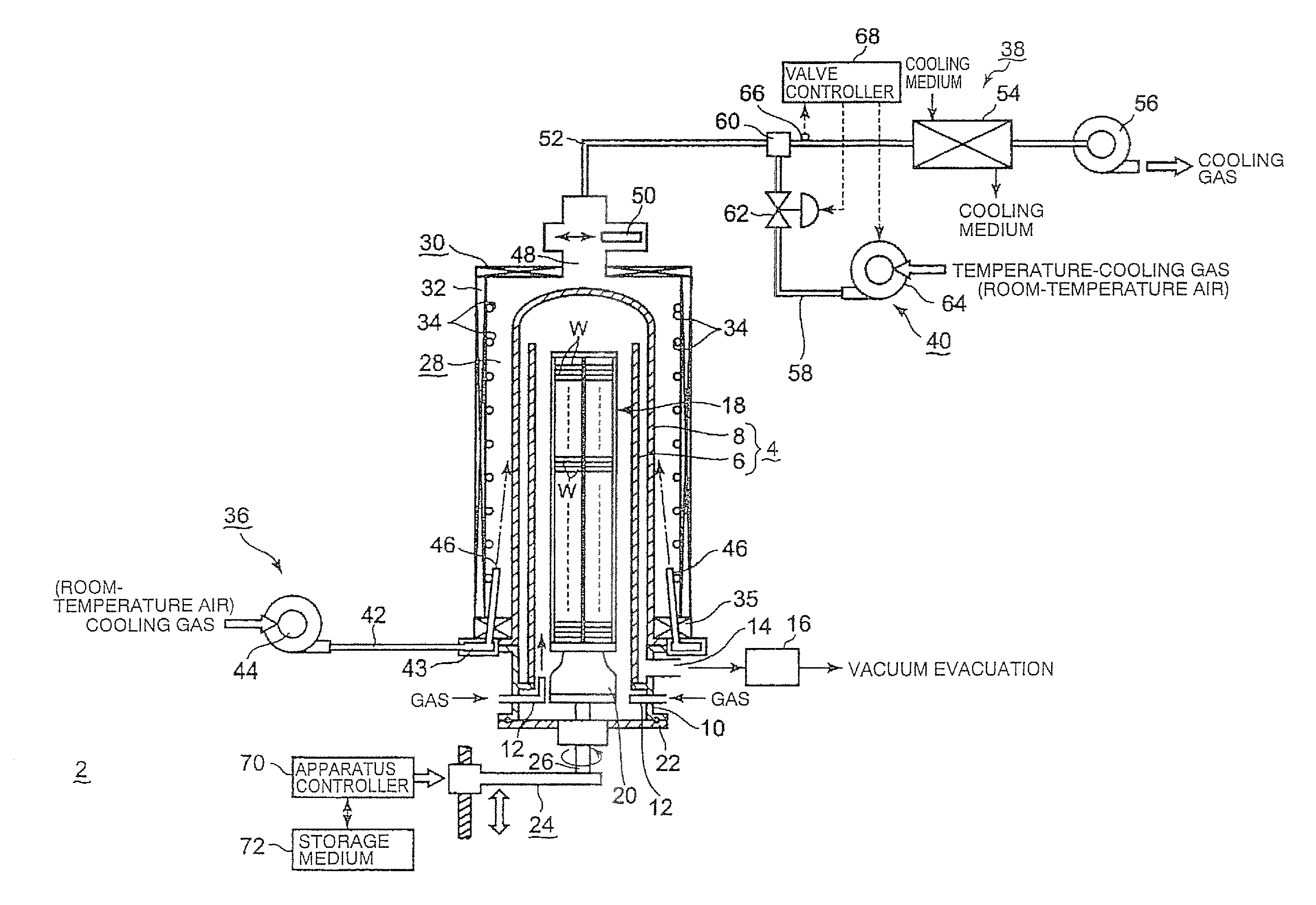

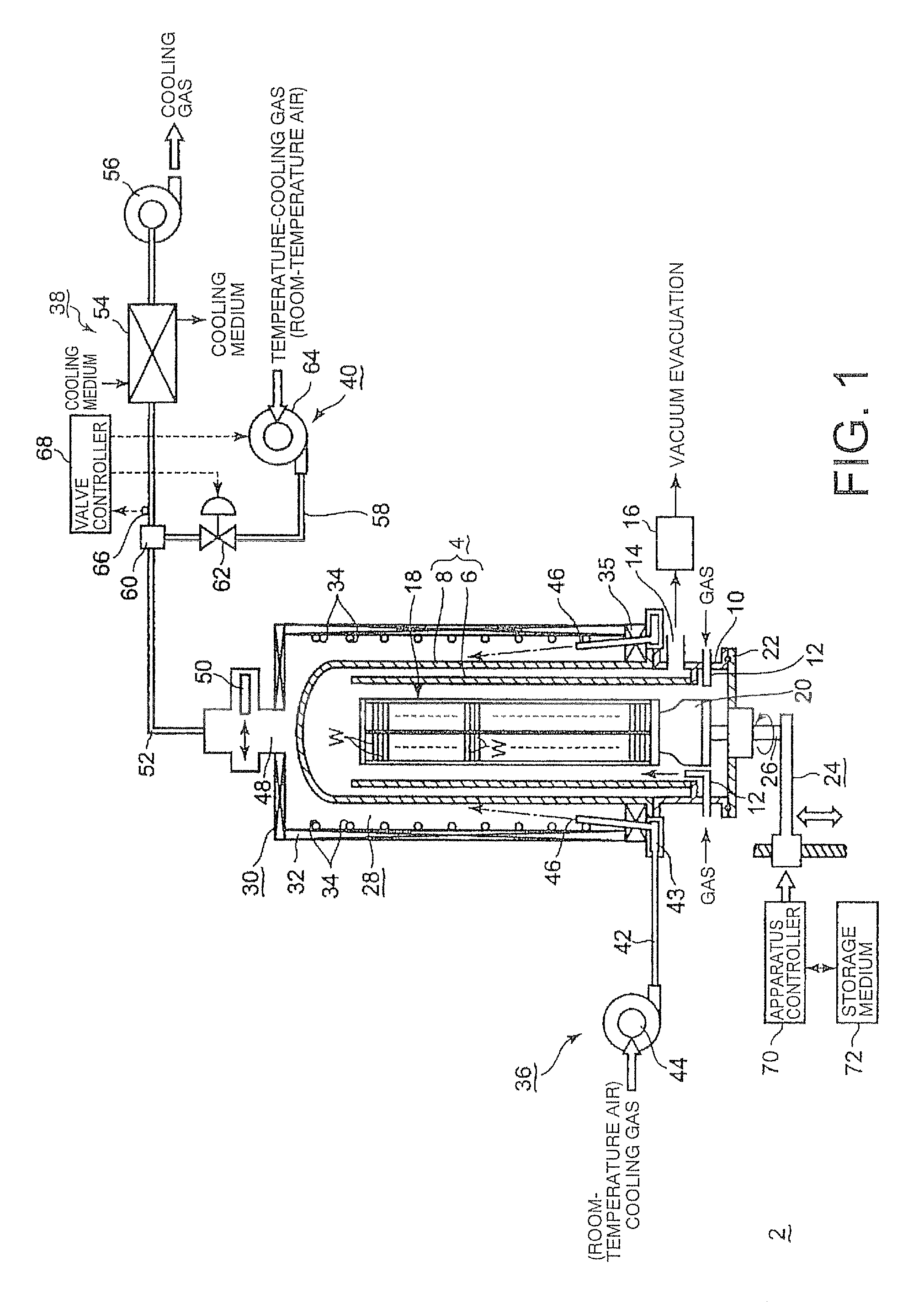

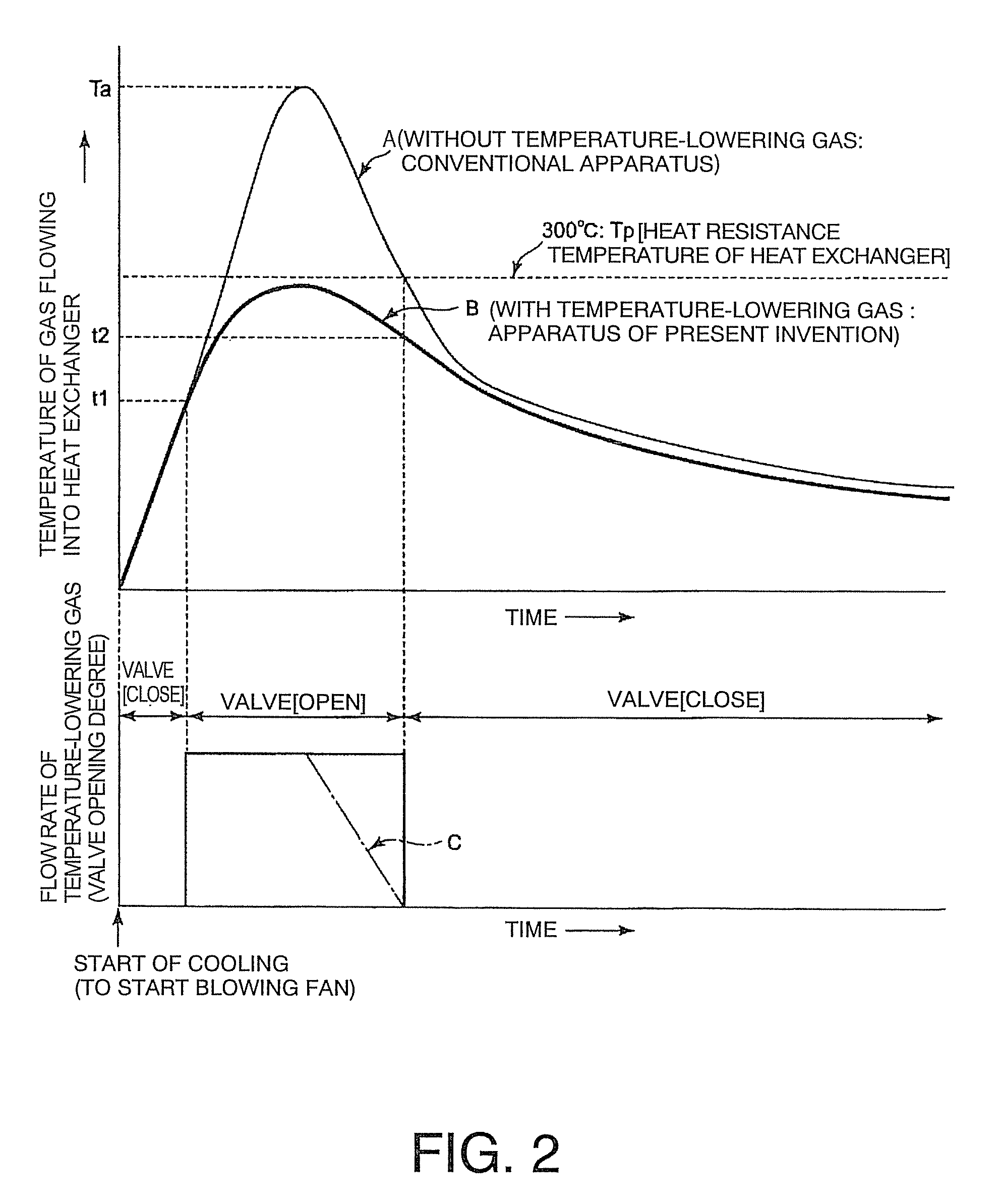

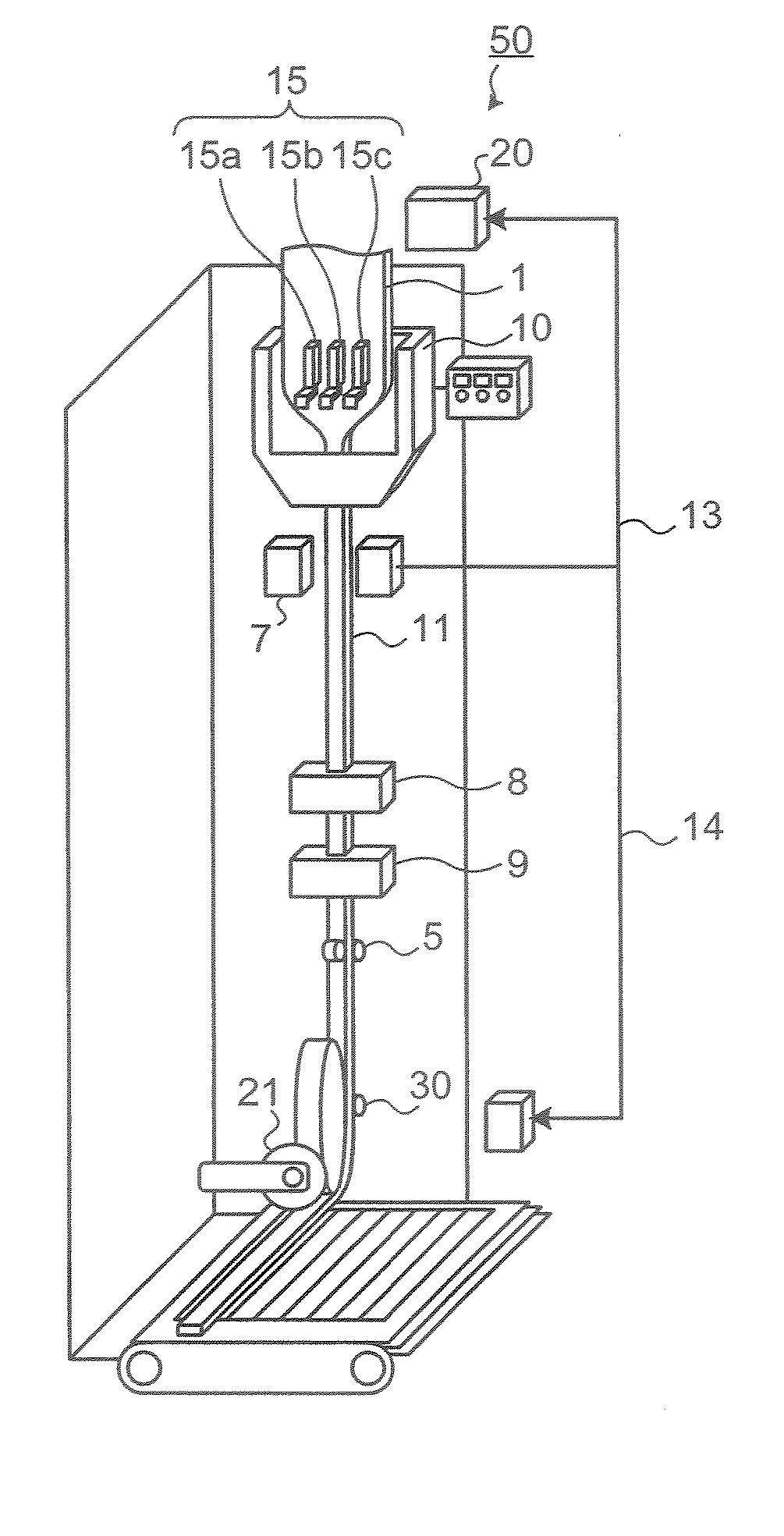

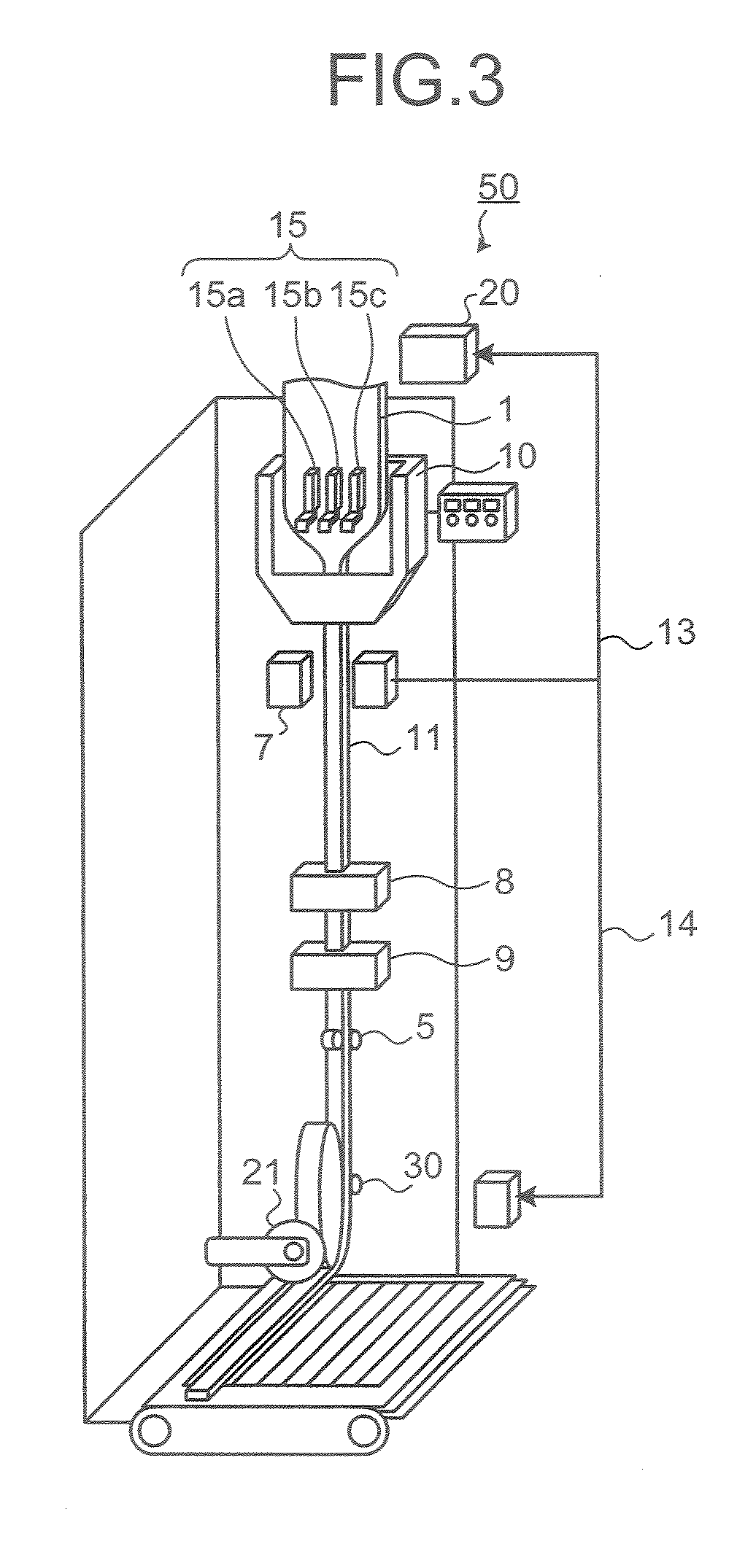

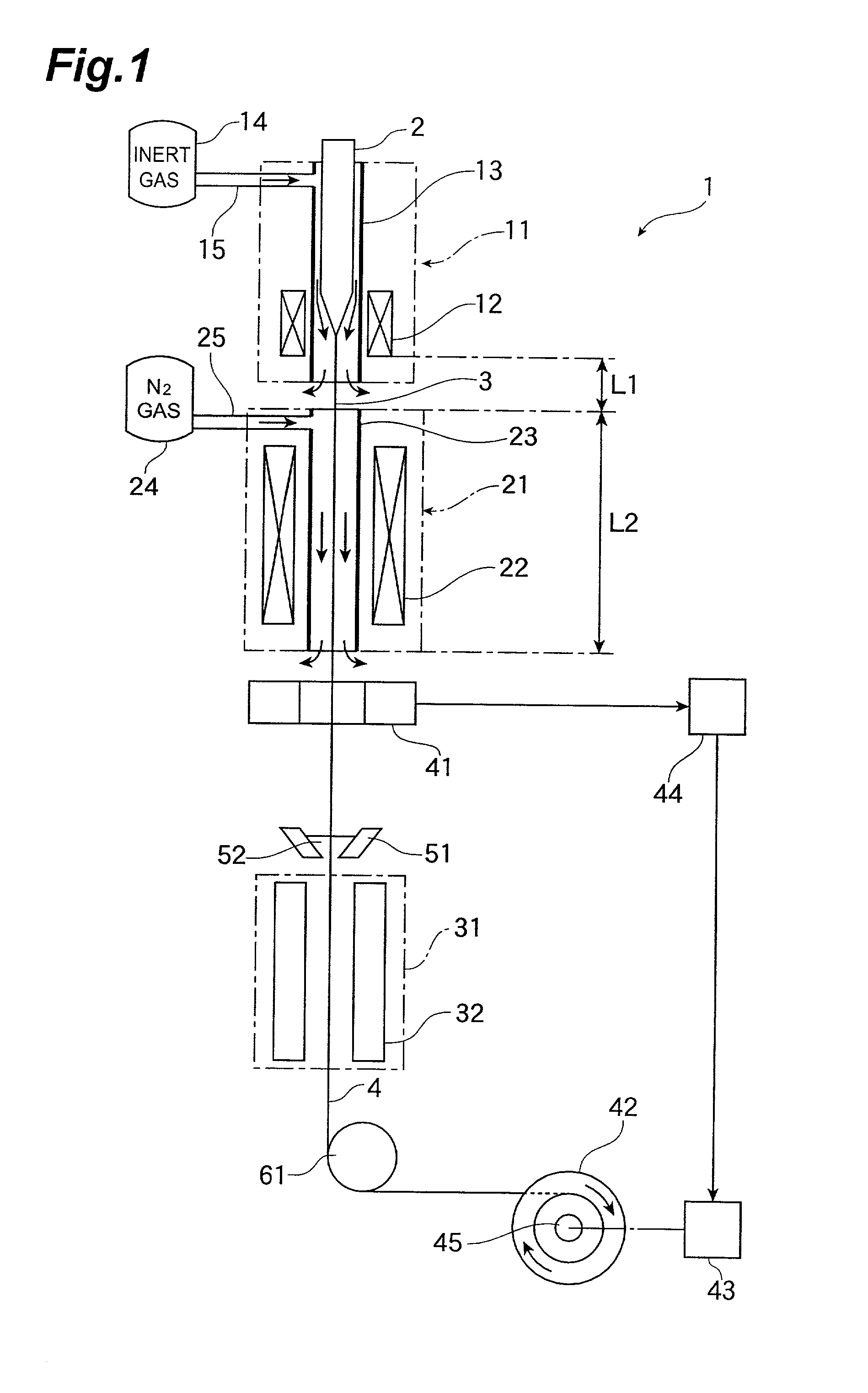

Thermal processing apparatus and cooling method

InactiveUS9099505B2Efficient solutionLow heat resistanceAfter-treatment apparatusSemiconductor/solid-state device manufacturingProcess engineeringHeating furnace

A thermal processing apparatus including: a cylindrical processing vessel; a support unit to be loaded into and unloaded from the vessel; and a heating furnace surrounding an outer periphery of the vessel, with a cooling space therebetween. The furnace is connected to a cooling-gas introduction unit, including a gas introduction passage to which a blowing fan is connected, for introducing a cooling gas into the cooling space during a temperature lowering operation after a thermal process. The furnace is connected to a cooling-gas discharge unit, including a heat exchanger, a suction fan, and a gas discharge passage, for discharging the cooling gas of a raised temperature from the cooling space. Connected to the gas discharge passage at a position upstream of the heat exchanger is a temperature-lowering gas introduction unit for introducing a temperature-lowering gas to the cooling gas of a raised temperature so as to lower its temperature.

Owner:TOKYO ELECTRON LTD

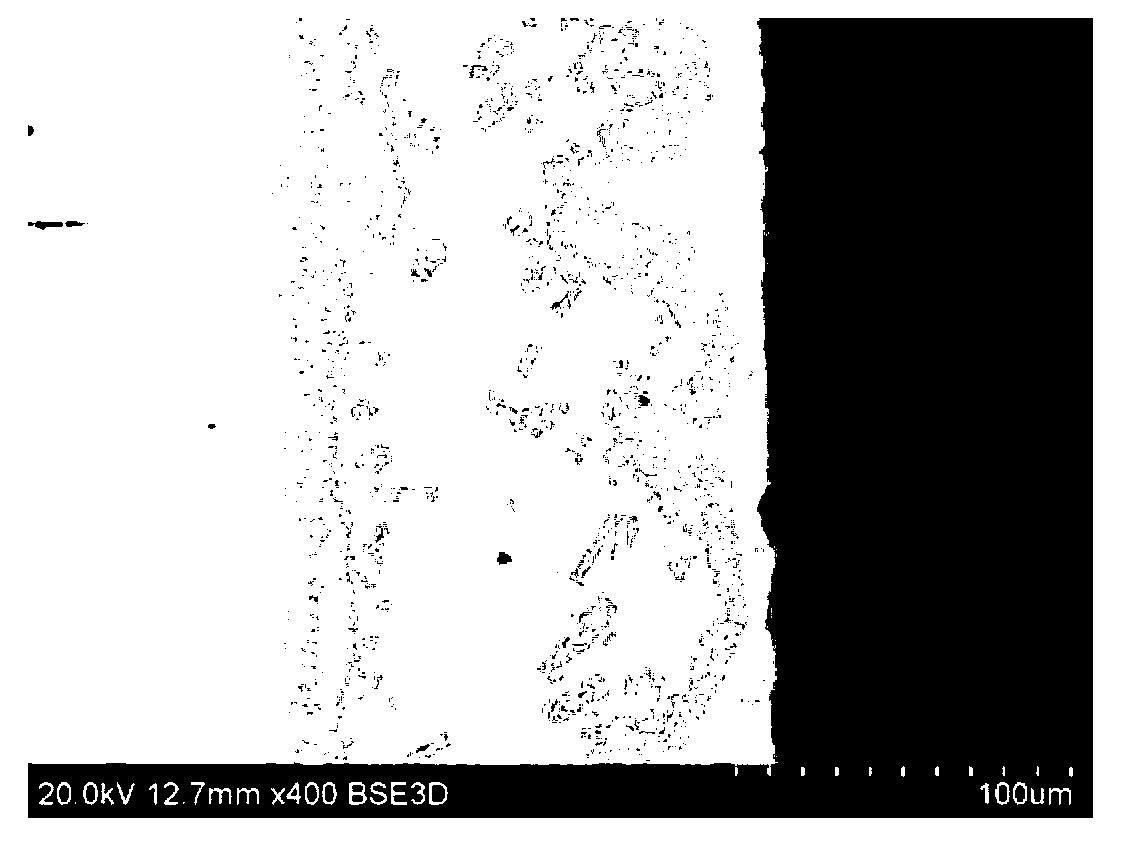

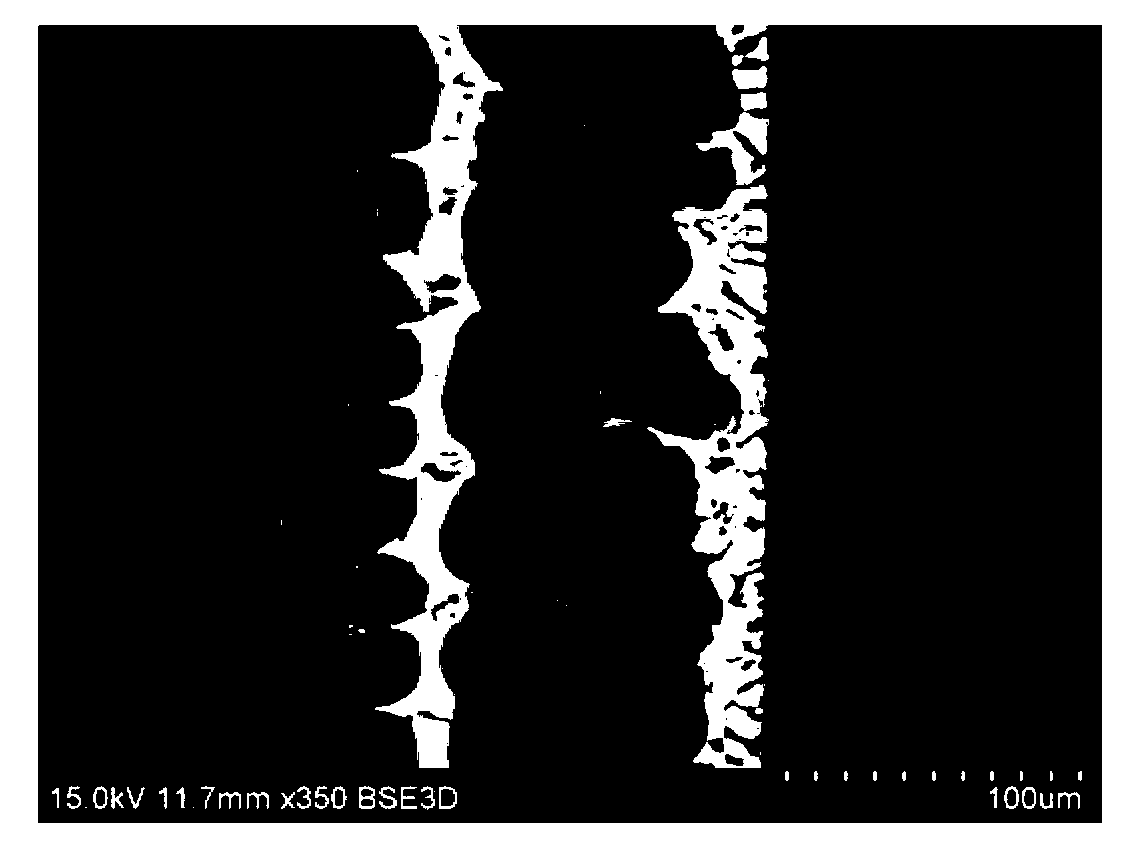

Metal material having good resistance to metal dusting

InactiveUS6623869B1Excellent in metal dusting resistanceIncreased durabilityChemical industryCorrosion preventionMetal dustingMetallic materials

A metallic material of the invention which comprises, in mass %, C: not more than 0.2%, Si: 0.01-4%, Mn: 0.05-2%, P: not more than 0.04%, S: not more than 0.015%, Cr: 10-35%, Ni: 30-78%, Al: not less than 0.005% but less than 4.5%, N: 0.005-0.2%, and one or both of Cu: 0.015-3% and Co: 0.015-3%, with the balance substantially being Fe, and of which the value of 40Si+Ni+5Al+40N+10 (Cu+Co), wherein the symbols of elements represent the contents of the respective elements, is not less than 50 and has excellent corrosion resistance in an environment in which metal dusting is ready to occur and, therefore, can be utilized as or in heating furnace pipes, piping systems, heat exchanger pipes and so forth to be used in a petroleum refinery or in petrochemical plants, and can markedly improve the equipment durability and safety.

Owner:NIPPON STEEL CORP

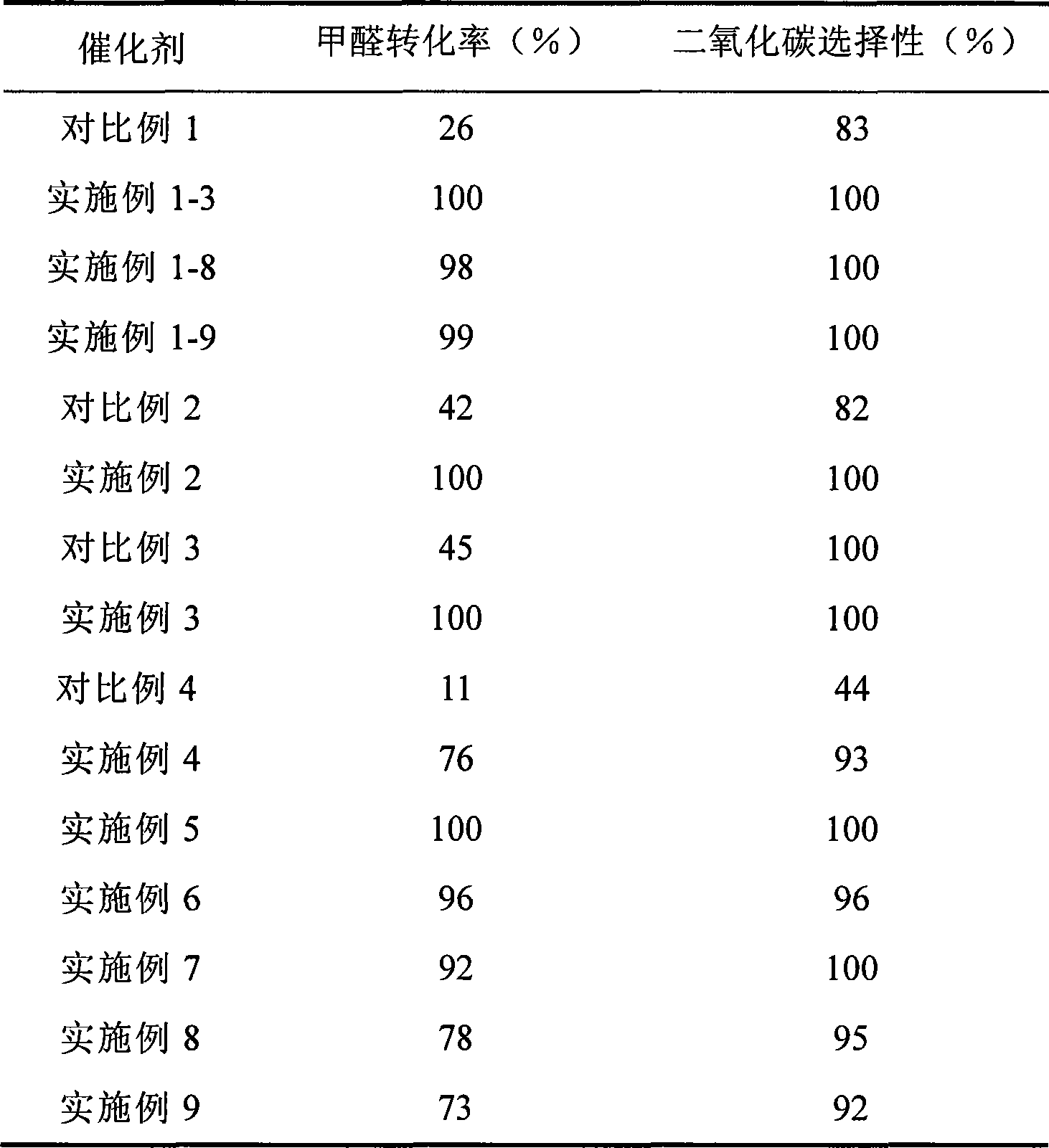

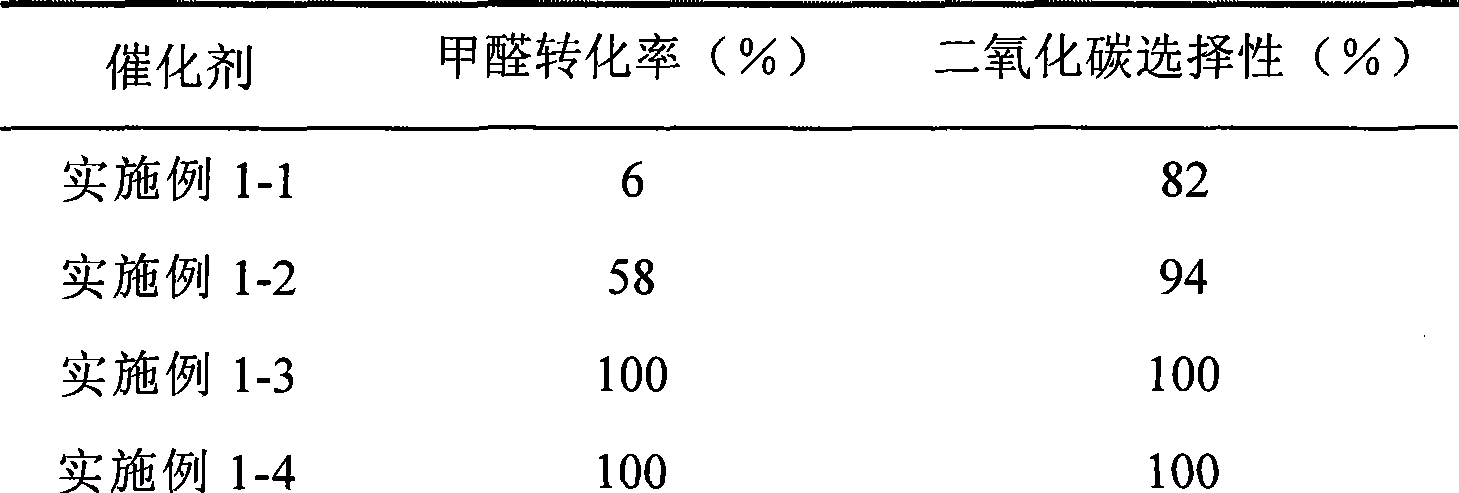

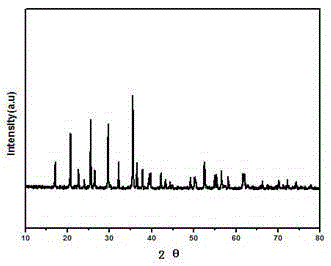

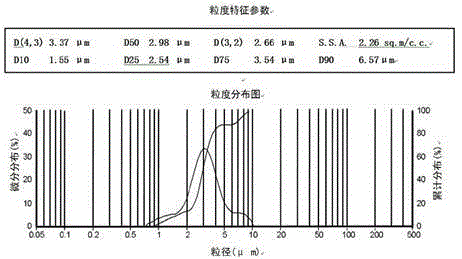

Catalyst for complete oxidation of formaldehyde at room temperature

ActiveCN101380574AEasy to makeEasy to operateDeodrantsMetal/metal-oxides/metal-hydroxide catalystsPorous carbonPt element

The invention provides a high selectivity catalyst used for catalyzing and completely oxidizing formaldehyde with low concentration at room temperature. The catalyst can catalyze formaldehyde completely so as to lead the formaldehyde to be converted into carbon dioxide and water at room temperature. In addition, the conversion rate of formaldehyde remains 100% within a long period of time, without complex auxiliary facilities such as light source, a heating oven and the like, and external conditions. The catalyst comprises three parts which are inorganic oxide carrier, noble metal component and auxiliary ingredient. Porous inorganic oxide carrier is one of cerium dioxide, zirconium dioxide, titanium dioxide, aluminium sesquioxide, tin dioxide, silicon dioxide, lanthanum sesquioxide, magnesium oxide and zinc oxide or the mixture thereof or composite oxide thereof, zeolite, sepiolite and porous carbon materials. The noble metal component of the catalyst is at least one of platinum, rhodium, palladium, gold and silver. The auxiliary ingredient is at least one of the alkali metals of lithium, sodium, kalium, rubidium and cesium. The loading of the noble metal component used in the catalyst of the invention is 0.1 to 10% according to weight converter of metal elements and the selective preference is 0.3 to 2%. The loading of the auxiliary ingredient is 0.2 to 30% according to weight converter of metal elements and the selective preference is 1 to 10%. When the loading of the auxiliary ingredient is lower than 0.2% or higher than 30%, the activity of the catalyst for catalyzing and oxidizing formaldehyde at room temperature is decreased remarkably.

Owner:广东顺德中科鸿图环境材料有限公司

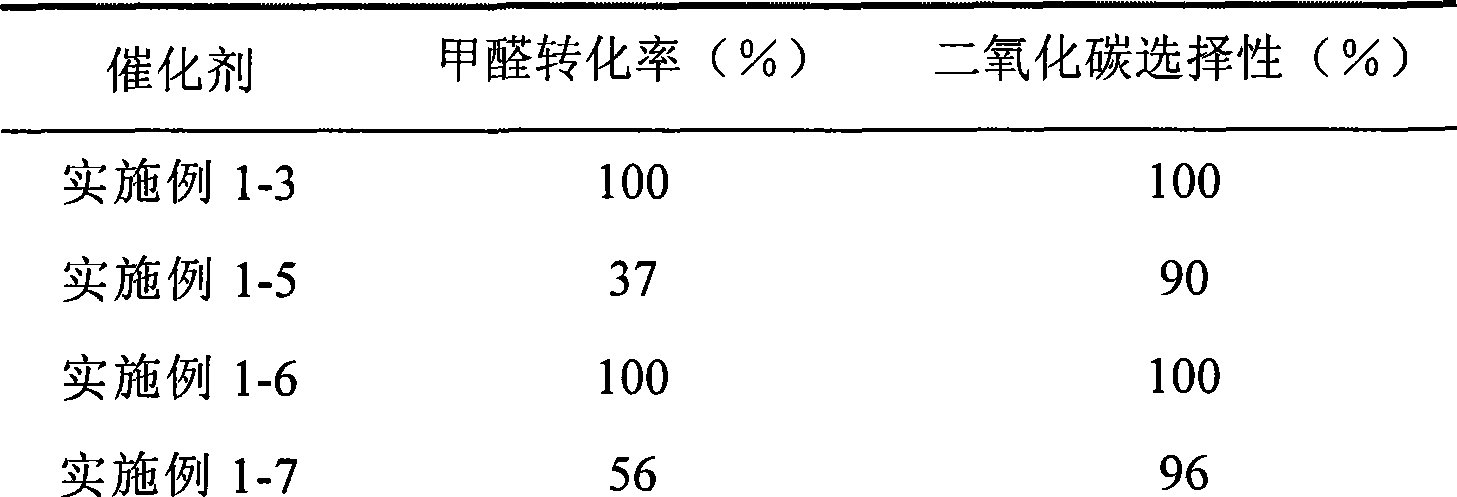

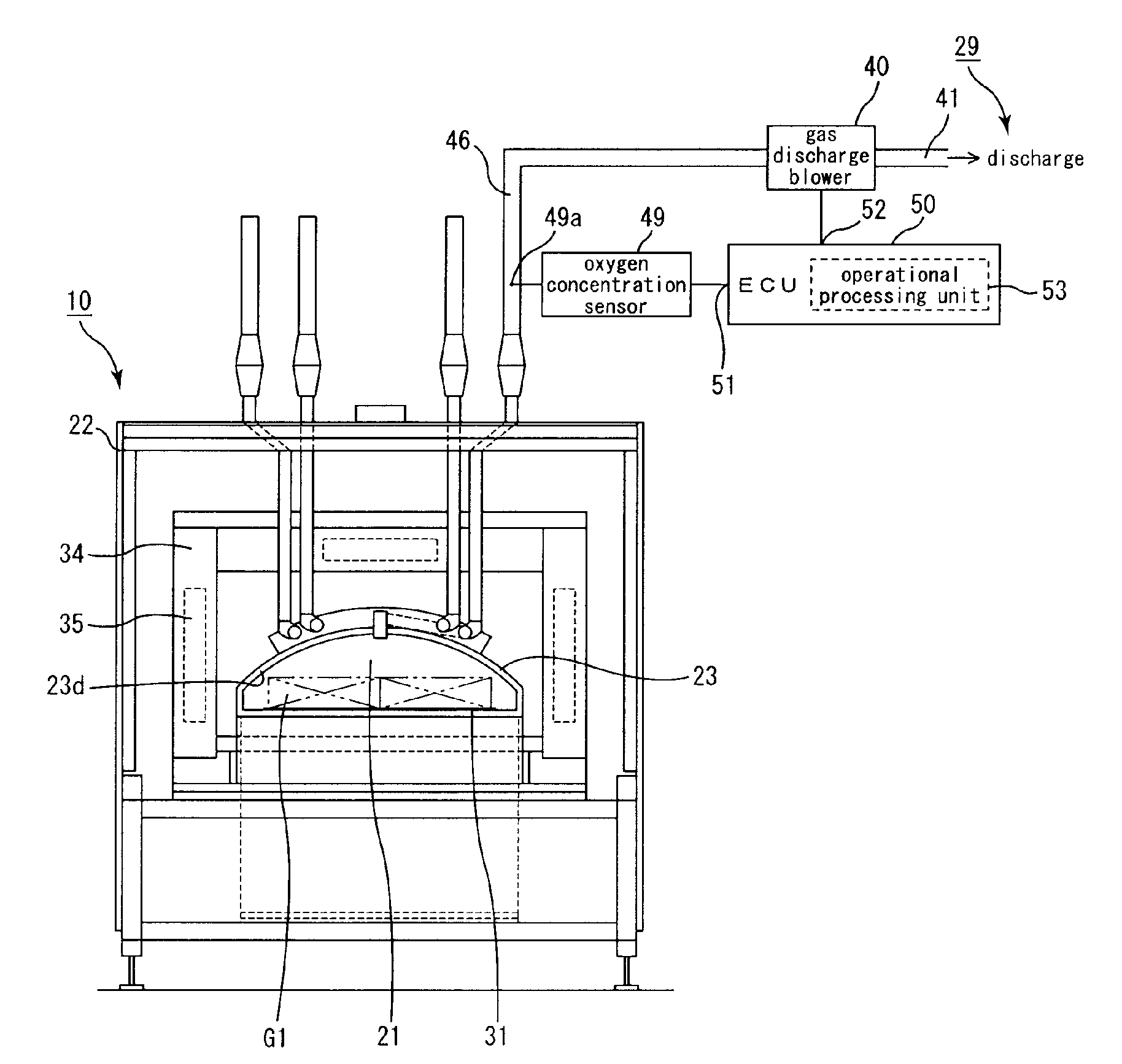

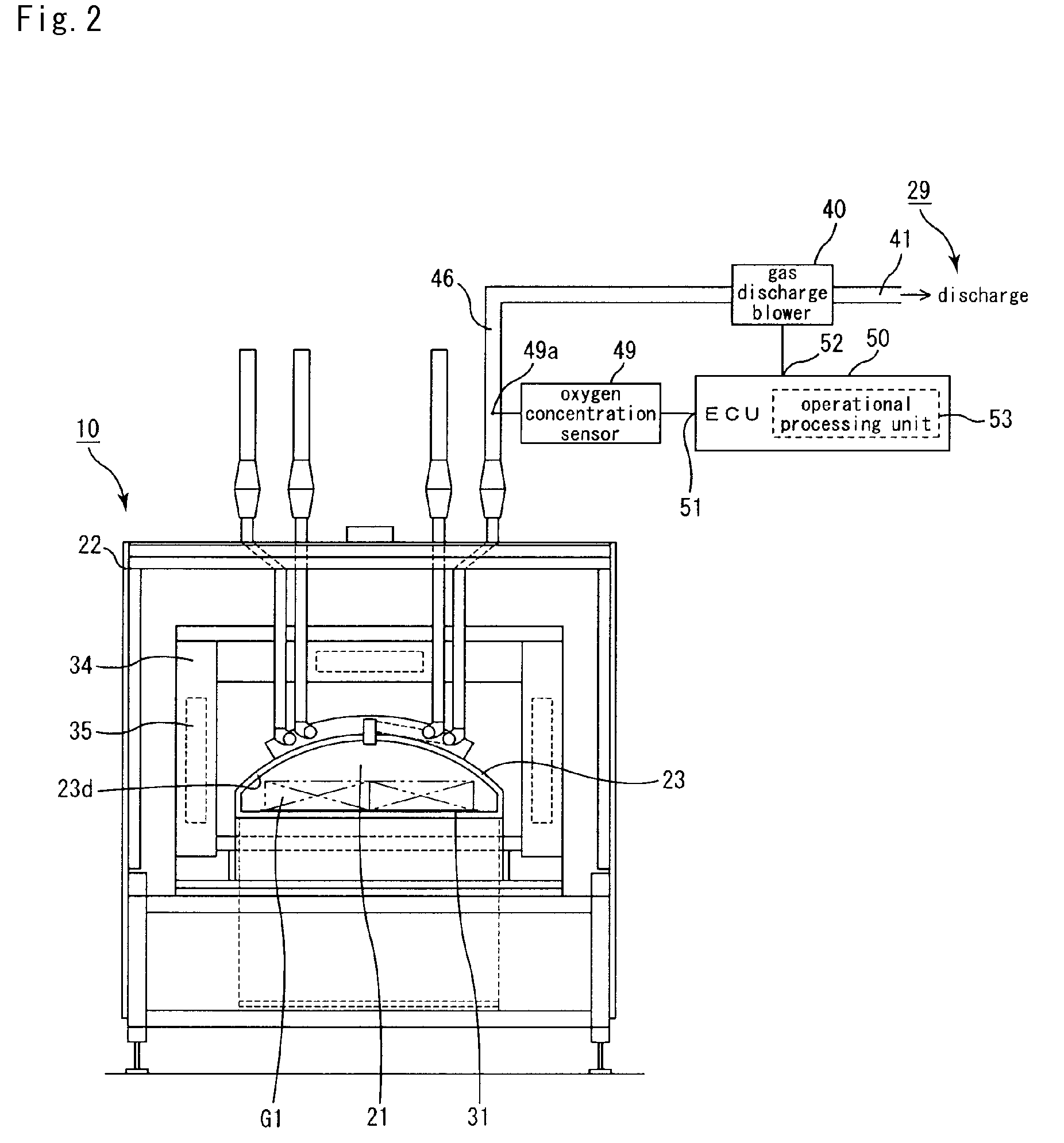

Heating furnace and method for manufacturing honeycomb structure

InactiveUS20080197544A1Increase temperatureMaintainance of heating chambersCeramic shaping apparatusMeasurement deviceHeating furnace

A heating furnace for calcining an object to be heated. The heating furnace includes a wall defining a furnace space and configured to receive the object in the furnace space, and a heating device configured to raise a temperature within the furnace space. The heating furnace also includes an oxygen supply channel configured to introduce gases containing oxygen into the furnace space. The oxygen supply channel is formed as an opening in a part of the wall surrounding the furnace space. The heating furnace further includes a gas discharge channel fluidly connected to the furnace space and configured to discharge gases in the furnace space to an outside of the furnace space, and a measurement device installed in the gas discharge channel and configured to measure properties of the gases passing through the gas discharge channel.

Owner:IBIDEN CO LTD

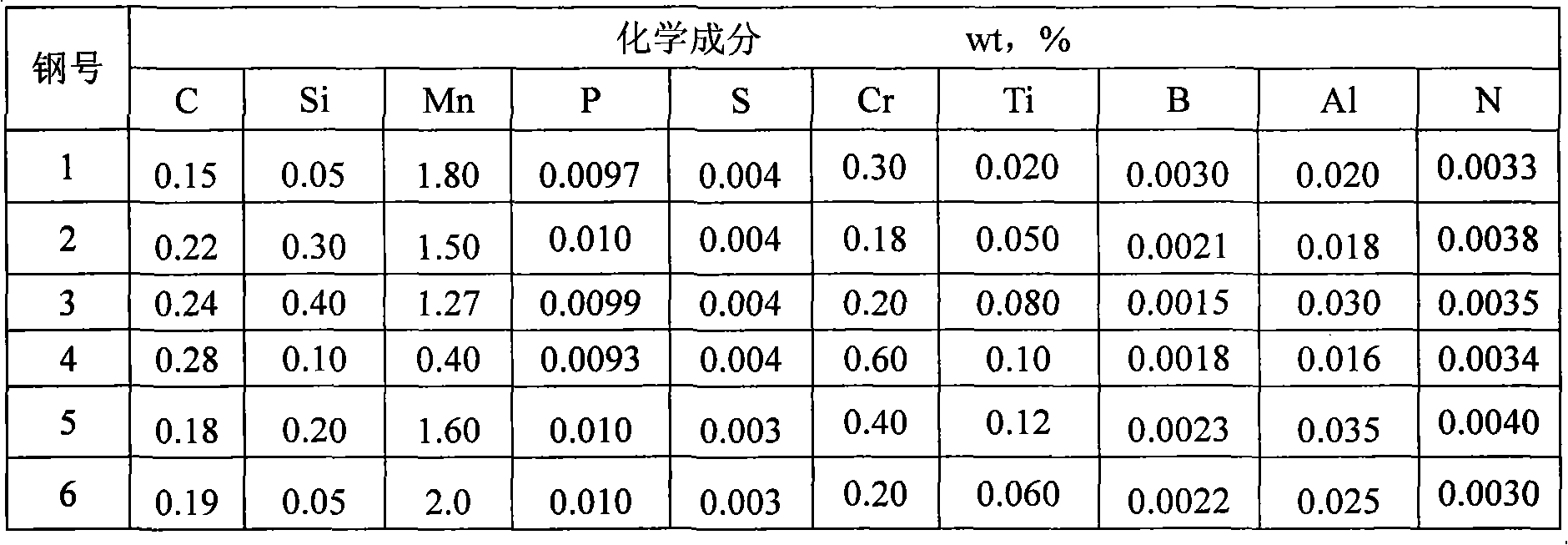

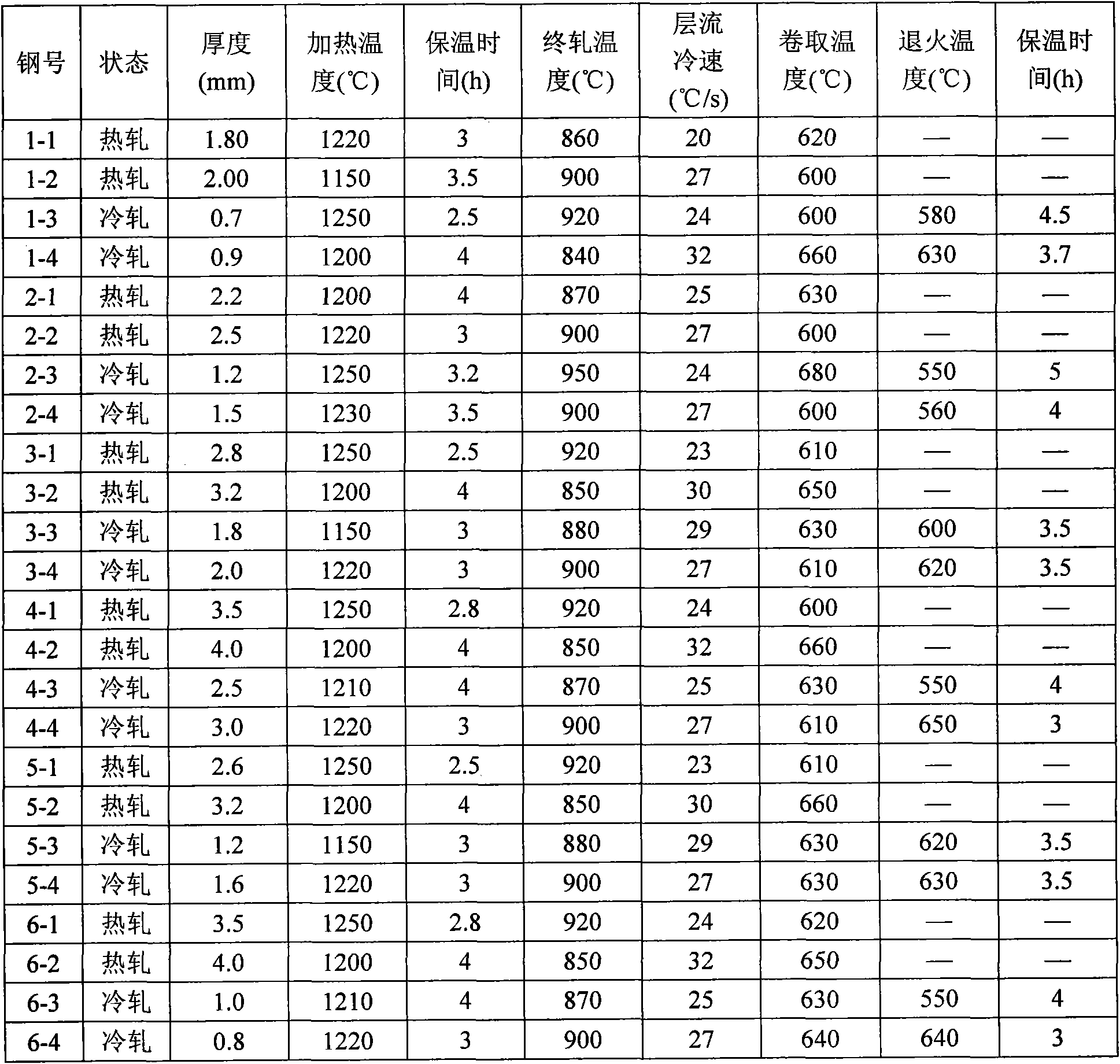

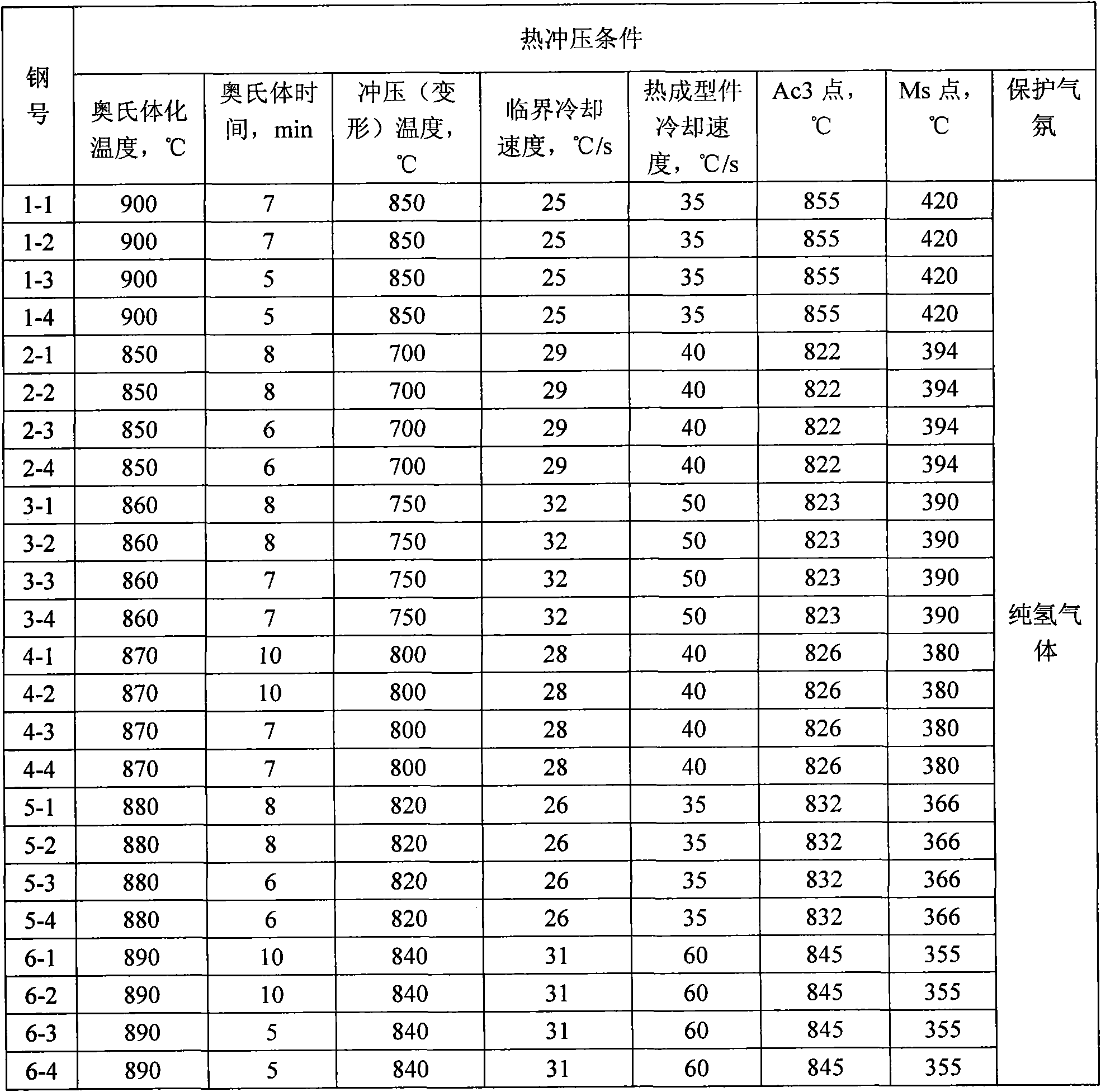

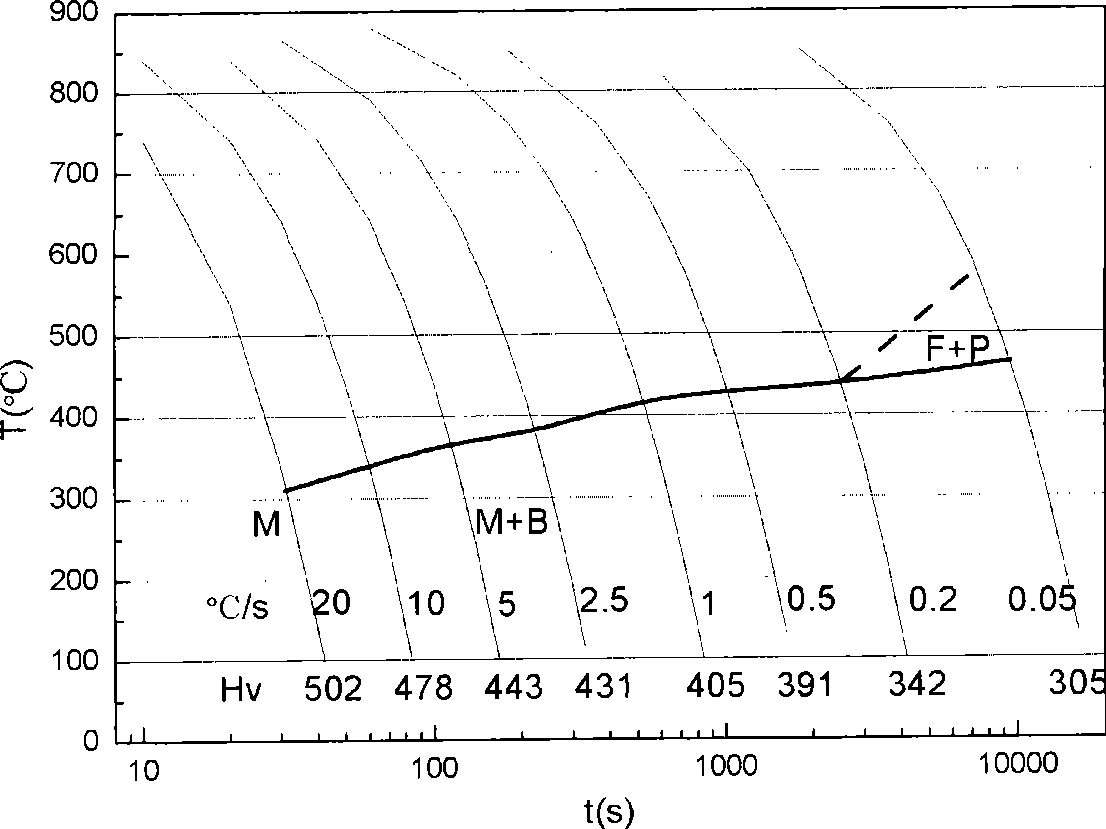

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

Improvement method of needle coke used refined aromatic hydrocarbon oil

InactiveCN104560082AIncrease contentSimple processCoke ovensTreatment with polymerisationVapor–liquid separatorRoom temperature

The invention relates to an improvement method of needle coke used refined aromatic hydrocarbon oil. The improvement method of the needle coke used refined aromatic hydrocarbon oil comprises the following steps: taking oil rich in aromatic hydrocarbon, heating the oil to 400-490 DEG C by a heating furnace, introducing the oil into a polymerization tower, taking the material at the bottom of the polymerization tower and introducing the material into a flash tower, taking the flashed material at the bottom of the flash tower, cooling the material to the room temperature, introducing the material into a gas-liquid separator, controlling the vacuum degree in the gas-liquid separator to be 5-10kpa, taking the material at the bottom of the gas-liquid separator, and enabling the material to flow into a refined aromatic hydrocarbon oil buffering tank to prepare the raw material which is refined aromatic hydrocarbon oil for producing needle coke. The improvement method of the needle coke used refined aromatic hydrocarbon oil is simple in process; the oil rich in aromatic hydrocarbon with low content of aromatic hydrocarbon in domestic oil refining plant is processed, the content of the aromatic hydrocarbon is increased; the prepared refined aromatic hydrocarbon oil is applicable to production of the needle coke.

Owner:SHANDONG YIDA NEW MATERIAL

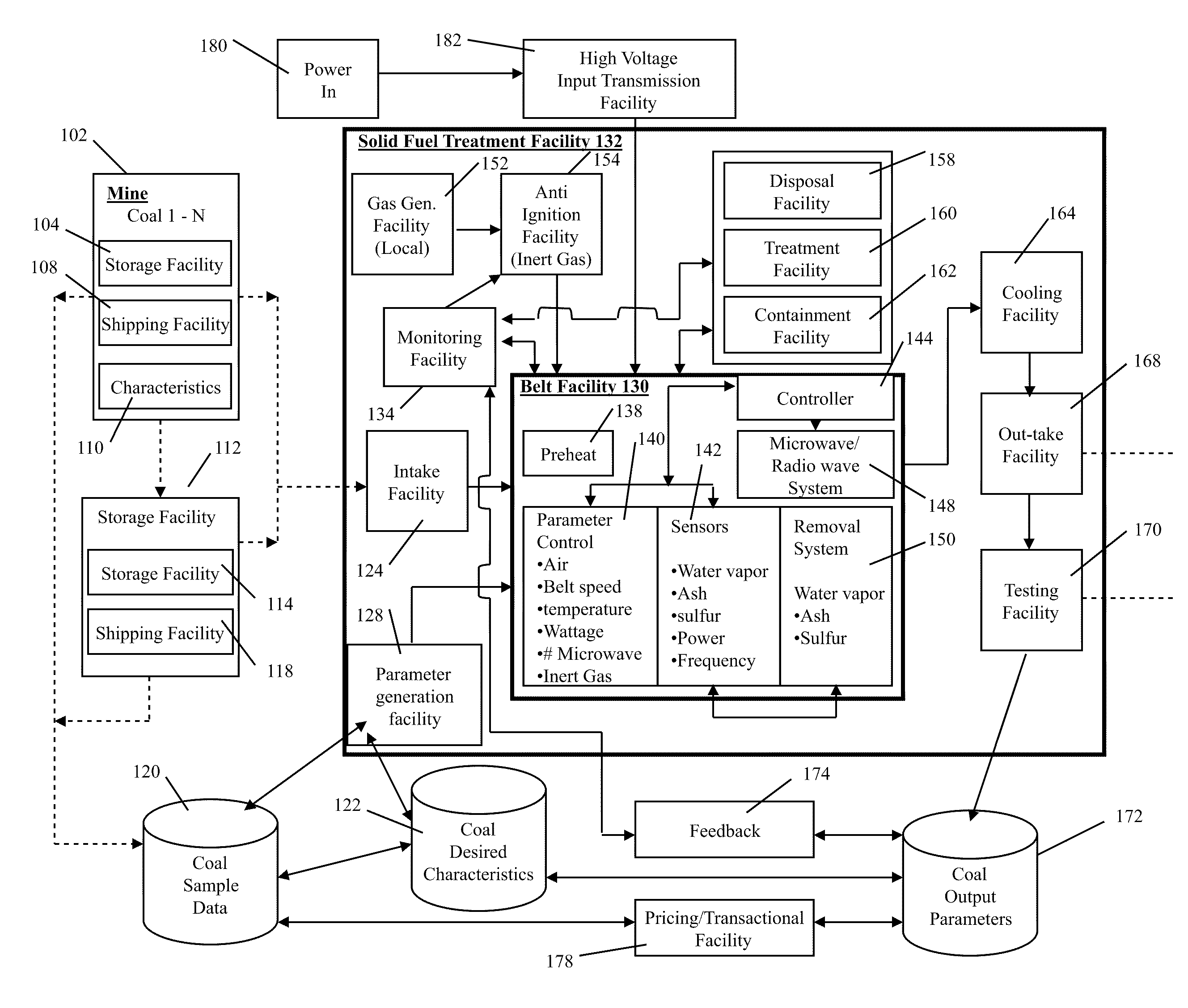

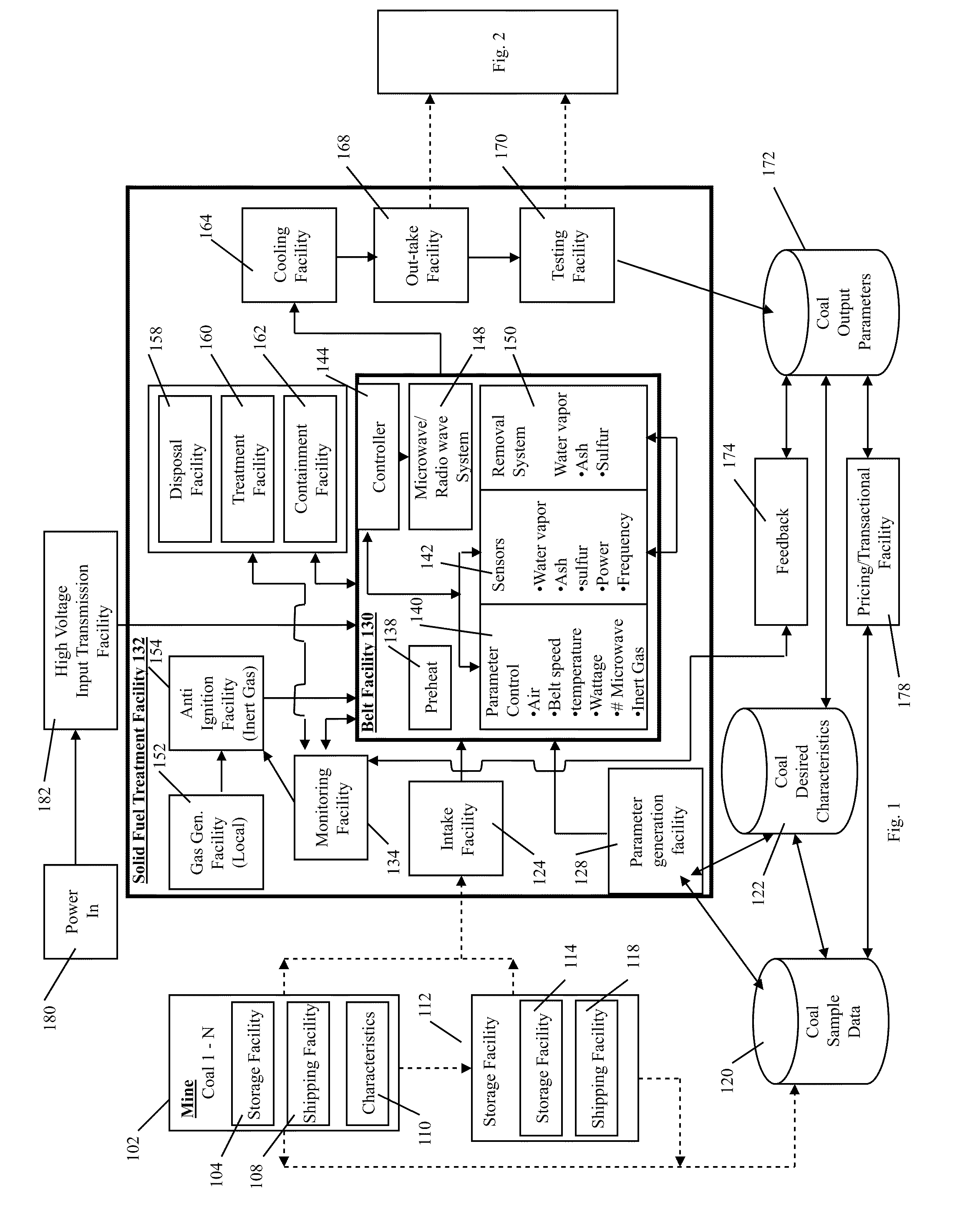

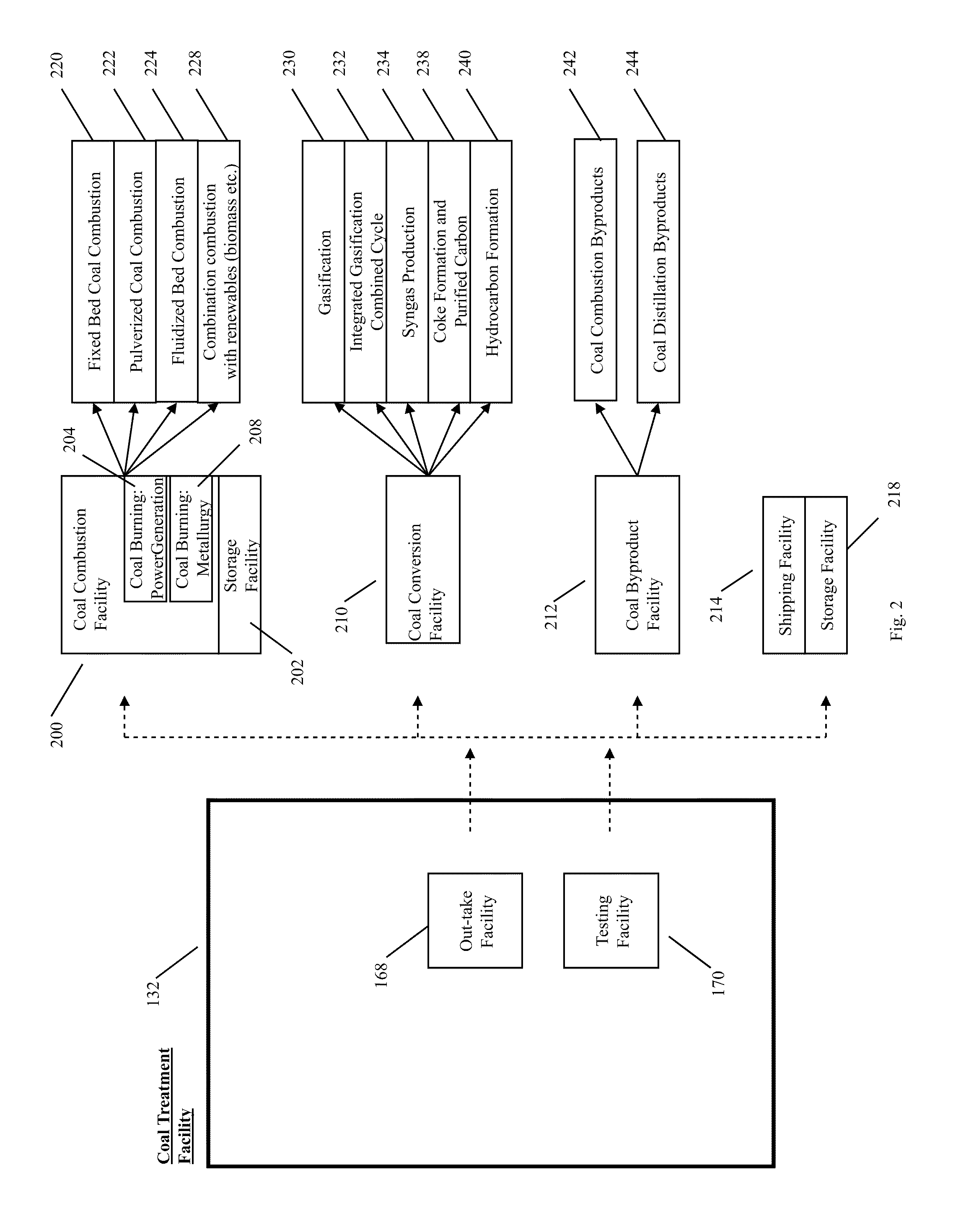

Methods and systems for processing solid fuel

InactiveUS20090272028A1Minimize return lossLow microwave lossBiofuelsSolid fuelsFuel treatmentSolid fuel

In embodiments of the present invention, a method of heat treating a solid fuel briquette may include heating the solid fuel briquette using energy from at least one of a heat furnace or an electromagnetic energy system of a solid fuel treatment facility as the solid fuel briquette is moved through the treatment facility to a specified internal temperature, and sealing the heat-treated solid fuel briquette in a vessel for a duration of time.

Owner:COALTEK INC

Flexible composite middle layer brazing alloy and method of utilizing brazing ceramic and metal

InactiveCN102699558AEnables direct brazingIncreased shear strengthWelding/cutting media/materialsSoldering mediaHeating furnaceUltimate tensile strength

The invention discloses flexible composite middle layer brazing alloy and a method of utilizing brazing ceramic and metal, and relates to the composite brazing alloy and the method of utilizing the brazing ceramic and metal. The flexible composite middle layer brazing alloy and the method aim at solving the problems that the conventional method is high in cost and the forming of brittle compound of a joint can not be restrained. The flexible composite middle layer brazing alloy is prepared from upper layer brazing alloy, a flexible middle layer and lower layer brazing alloy. The brazing method comprises the steps of: cleaning greasy dirt and impurity on a pre-welding surface; processing the upper-layer brazing alloy, the flexible middle layer and the lower-layer brazing alloy into small sheets; and ultrasonically cleaning and airing ceramic to be welded, metal to be welded, the upper layer brazing alloy, the flexible middle layer and the lower layer brazing alloy by acetone, assembling a workpiece to be welded, and putting the workpiece to be welded into a vacuum heating furnace to braze. According to the method disclosed by the invention, the operation is simple; the residual stress of the joint is released by adding the flexible middle layer; and the forming of the brittle compound of the joint is restrained, and the shearing strength of the joint is improved by 30-109%. The method disclosed by the invention is used for brazing the ceramic and the metal.

Owner:HARBIN INST OF TECH

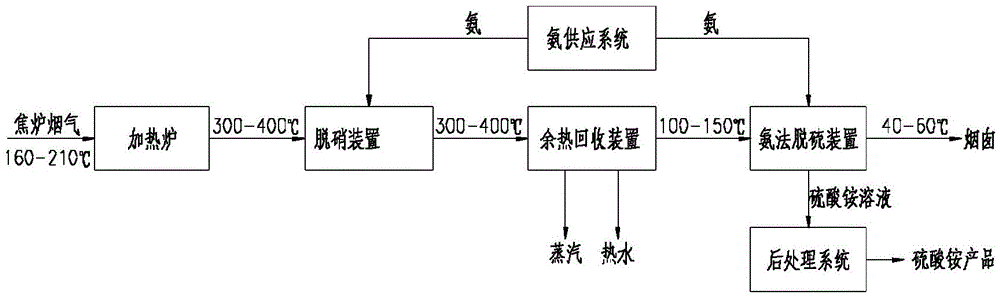

Coke oven flue gas desulfurization, denitration and waste heat recovery integrated method

InactiveCN104923046ASimple processWork lessDispersed particle separationEnergy inputFlue gasReaction temperature

The invention relates to a coke oven flue gas desulfurization, denitration and waste heat recovery integrated method. Flue gas from a coke oven firstly enters a heating furnace to be heated to 300 to 400 DEG C, and then the flue gas enters a denitration device for removing nitrogen oxide in the flue gas through a denitration reducer and a denitration catalyst, wherein the denitration reducer is ammonia; and the flue gas discharged from the denitration device is subjected to heat recovery through a waste heat recovery device and cooled to 100 to 150 DEG C, and then the flue gas enters an ammonia desulfurization device for removing sulfur dioxide in the flue gas. Both a desulfurization absorbent and the denitration reducer in the method are ammonia, and public ammonia is supplied to a system, so that operation and maintenance work is reduced. The heating furnace for heating and the waste heat recovery device are arranged, so that the flue gas temperature reaches the optimal denitration and desulfurization reaction temperatures respectively, relatively high denitration and desulfurization efficiency can be achieved, and flue gas waste heat can be recycled for greatly reducing the operation cost of coke oven flue gas treatment.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

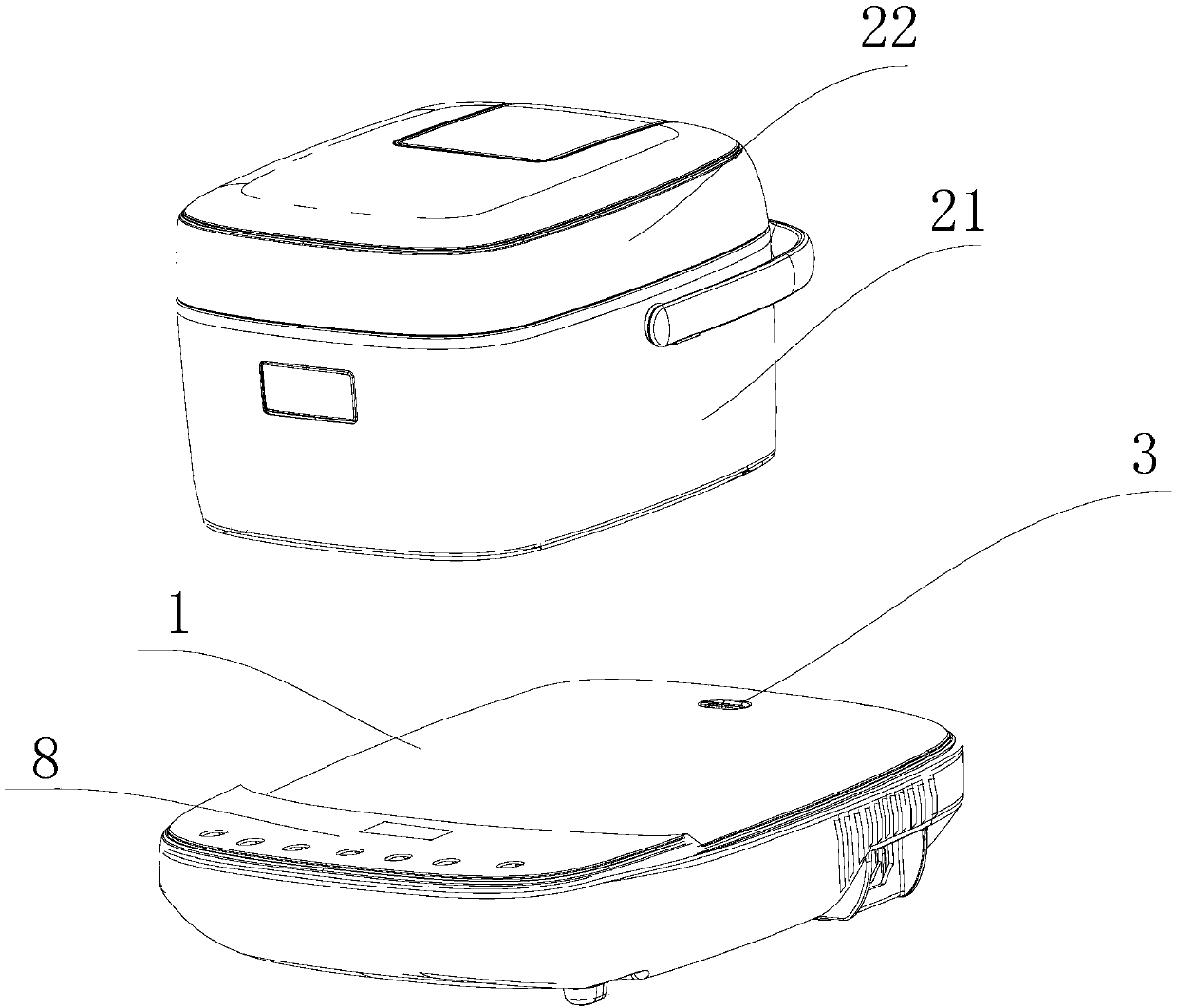

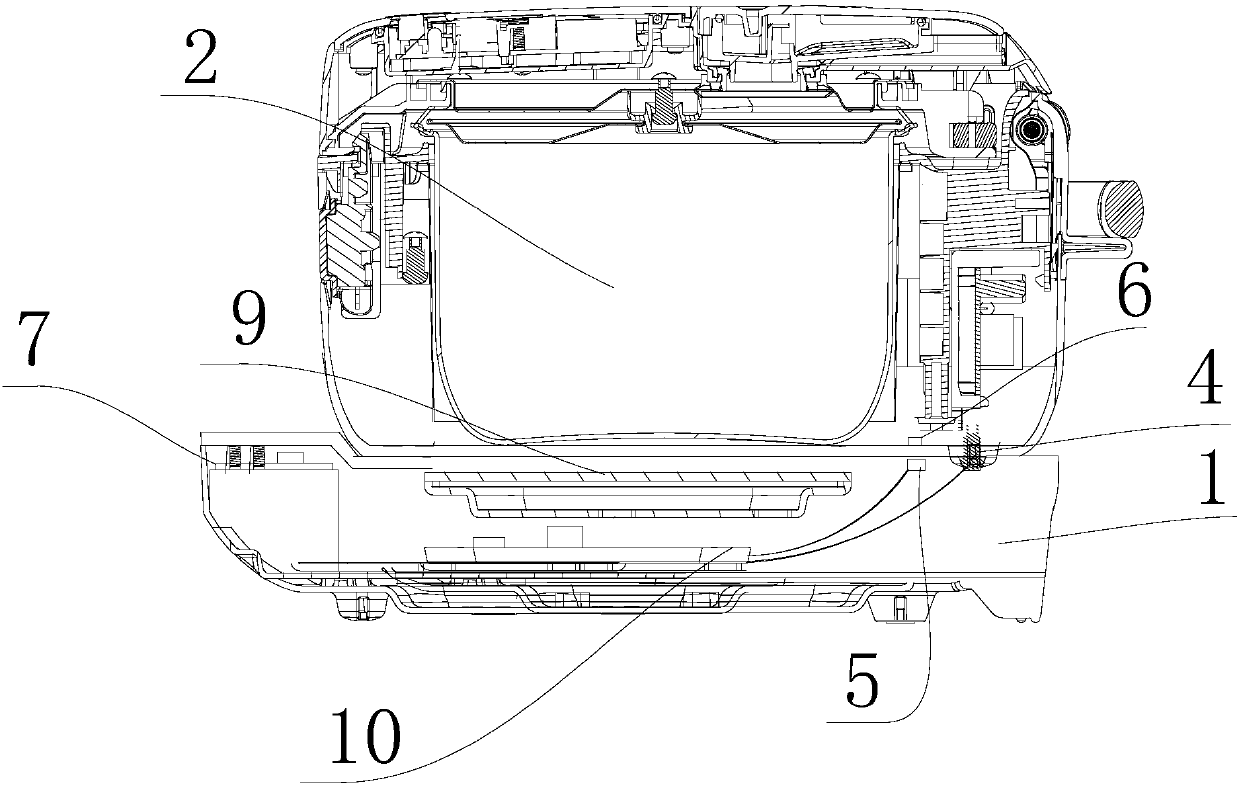

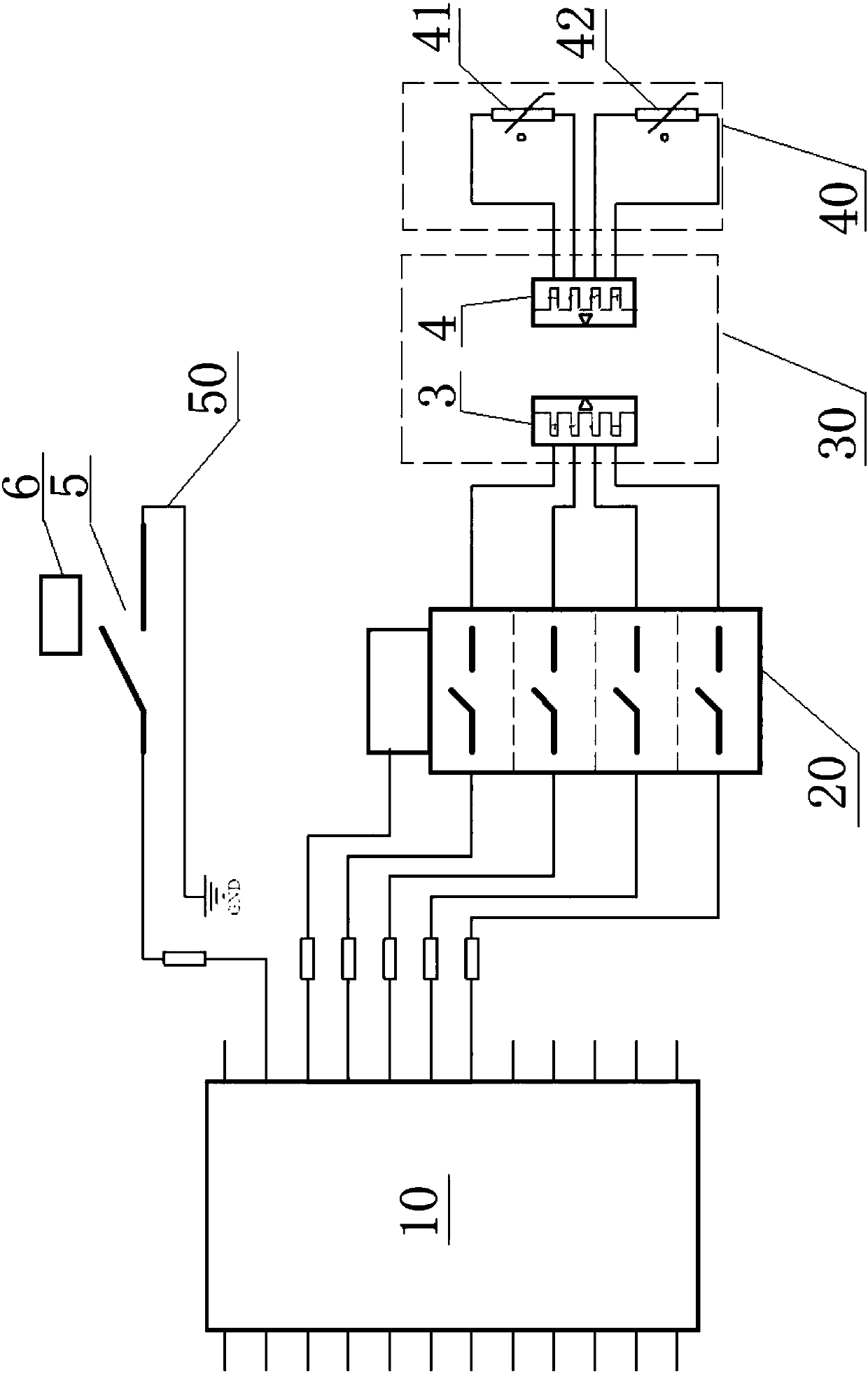

Induction cooker heating device

PendingCN107726388ARealize the use effectSave separate placement spaceDomestic stoves or rangesLighting and heating apparatusElectricityComputer module

The invention discloses an induction cooker heating device. A main control chip module (10) connected with a heating control circuit is arranged in a cooker body (1), and the cooker body is provided with a circuit coupling interface A (3) of the heating control circuit. A sensor module (40) is arranged in a pot body (2), and a circuit coupling interface B (3) electrically connected with the sensormodule is arranged in the bottom of the pot body. When the bottom seat of the pot body is on the top of the cooker body, the circuit coupling interface B is jointed with the circuit coupling interface A, so that the main control chip module can be electrically connected with the sensor module so as to control heating. An induction cooker of the induction cooker heating device can be used alone orconduct combined use, the functions are complete, and the individual placement space of the induction cooker is saved. The assembly structure is consistent with user usages. During assembly, whetherthe pot body is assembled in place or not can be detected and short-circuit protection can be realized through a pot assembly detection module and a switching circuit module. Thus, the damage of a main control chip is prevented, and the equipment safety and reliability is high.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

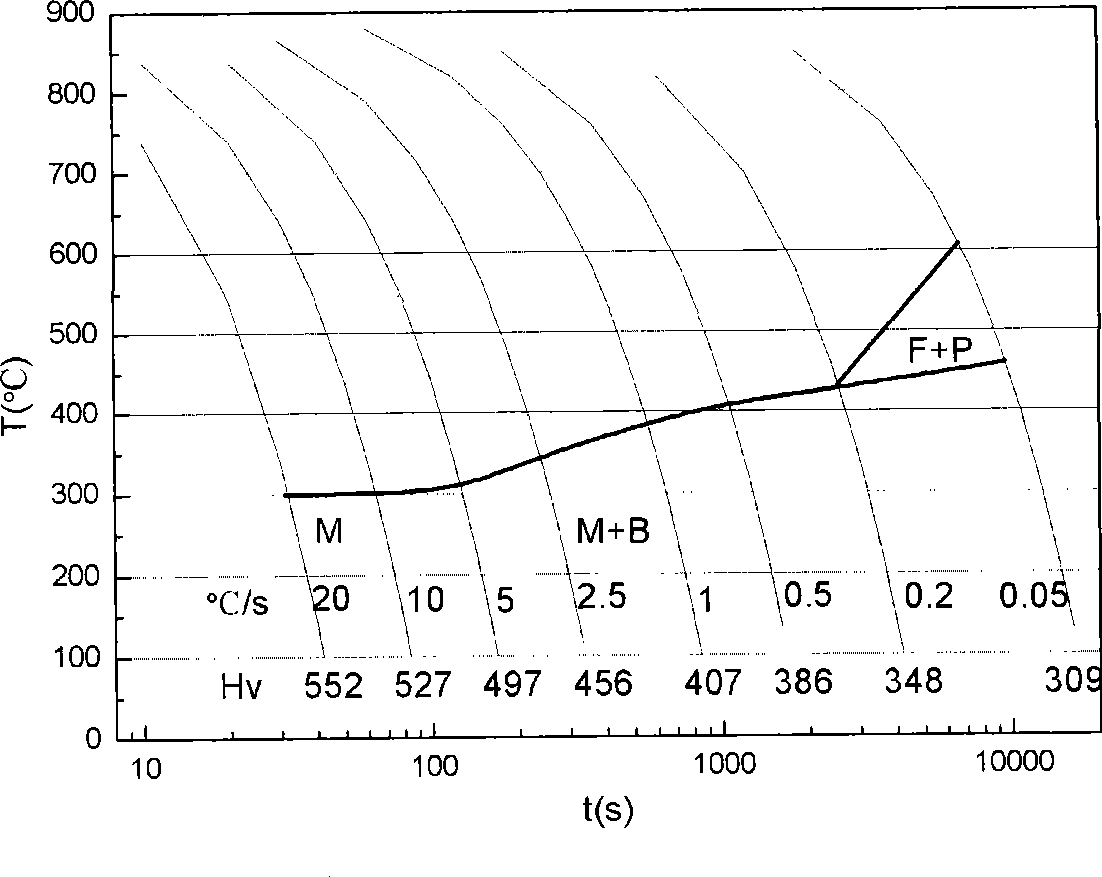

High-performance marine mooring chain steel and manufacturing method thereof

InactiveCN101519751AGood weather resistanceImprove corrosion resistanceMetal rolling arrangementsIngotHeating furnace

The invention relates to high-performance marine mooring chain steel and a manufacturing method thereof. The method comprises the following steps: a. tapping compositions comprise the following by weight percentage: C: 0.16 to 0.27, Mn: 0.40 to 1.45, Si: 0.15 to 0.50, Cr: 1.25 to 2.50, Ni: larger than 0 and less than 1.20, Mo: 0.20 to 0.60, Al: 0.01 to 0.06, N: 0.004 to 0.015, S: not larger than 0.005, P: not larger than 0.015, Cu: larger than 0 and less than 0.50, and the balance of Fe; b. a steel ingot or a continuous casting billet is casted after the steps of primary smelting in an electric stove or a converter, external refining and vacuum degassing; c. the charging temperature of a heating oven is not larger than 900 DEG C, the heating rate is not larger than 150 DEG C / h; when being raised to 1100 to 1300 DEG C, the temperature is kept for more than 40 minutes, cogging bloom or rolling by a finisher is carried out, and the finishing temperature is not larger than 1050 DEG C; and d. after heated at the temperature of 1000 to 1250 DEG C, the cogged ingot is hot-rolled or forged into round steel, the finishing temperature is not larger than 1050 DEG C, and after rolling, the steel is air-cooled, slow cooled or softening heat-treated at the temperature of not less than 600 DEG C. The performance of finished products achieves or exceeds the requirement of level 4.5 and level 5 of mooring chain steel.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

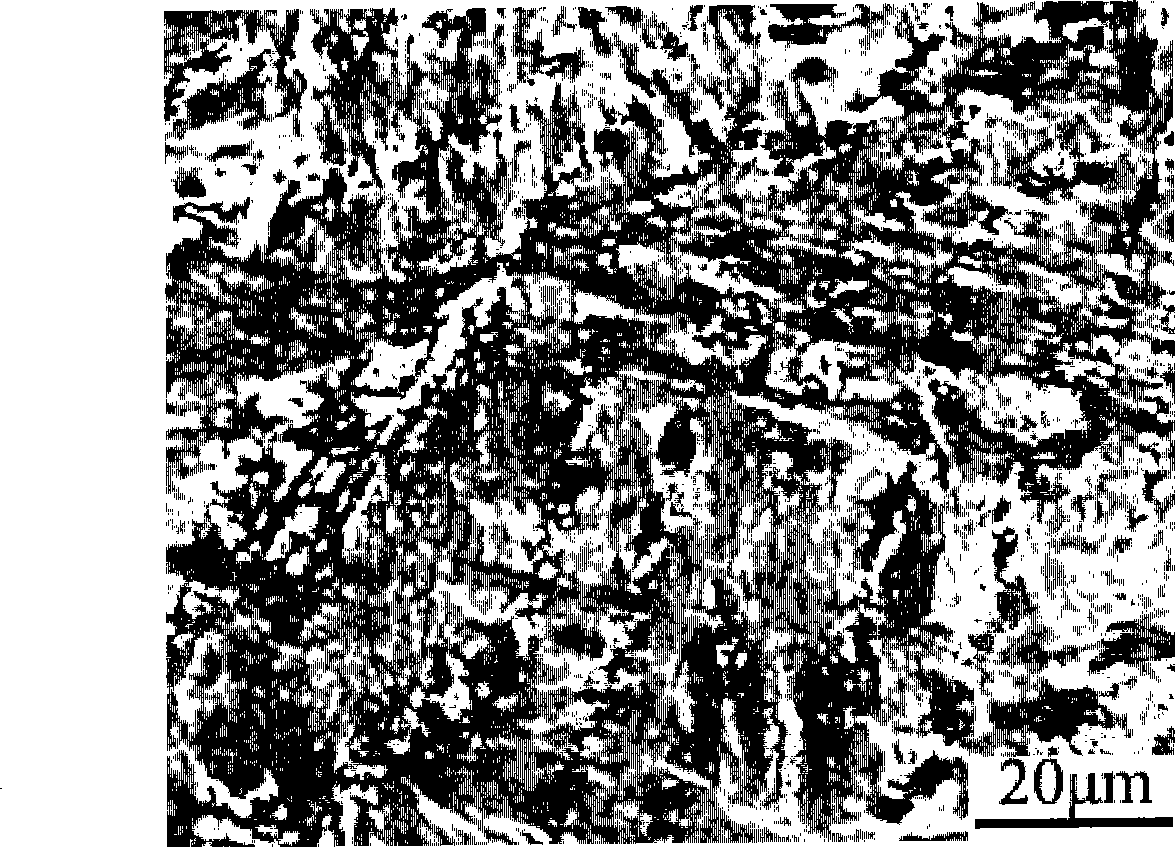

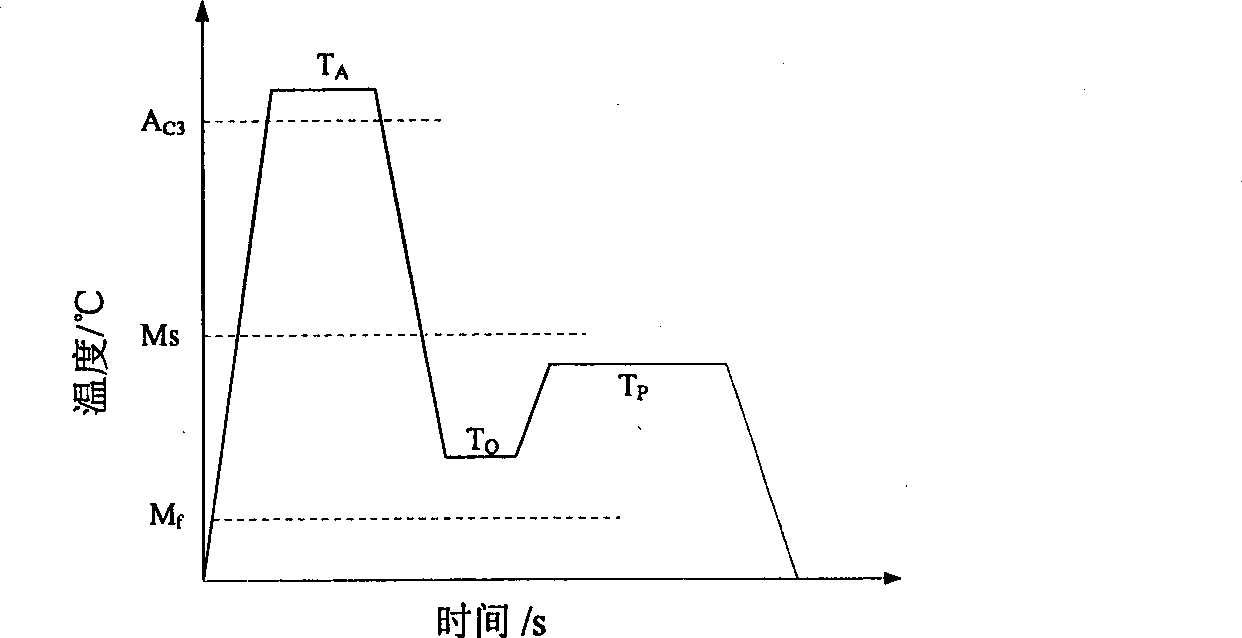

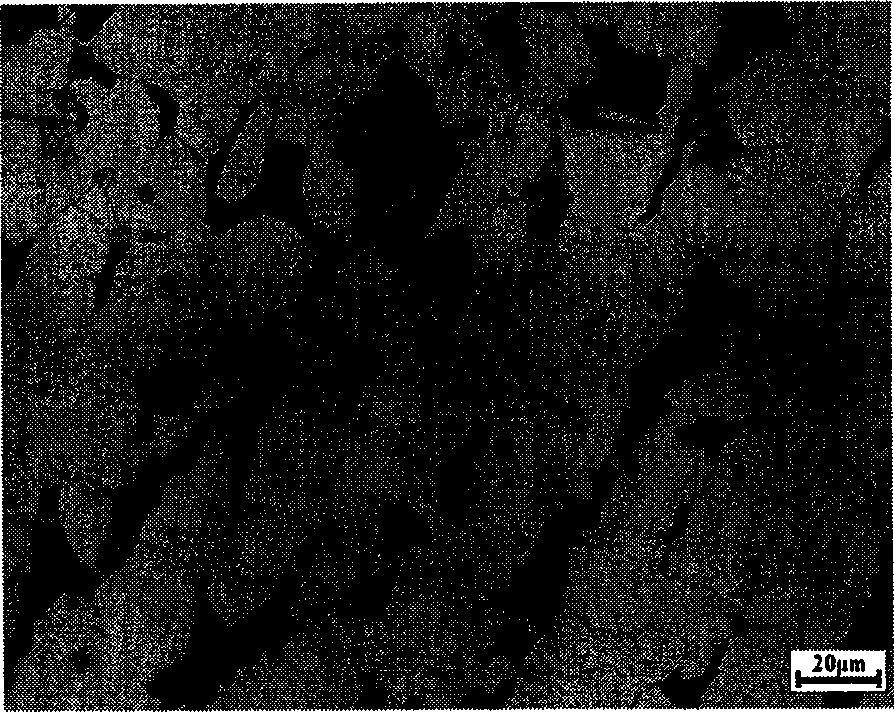

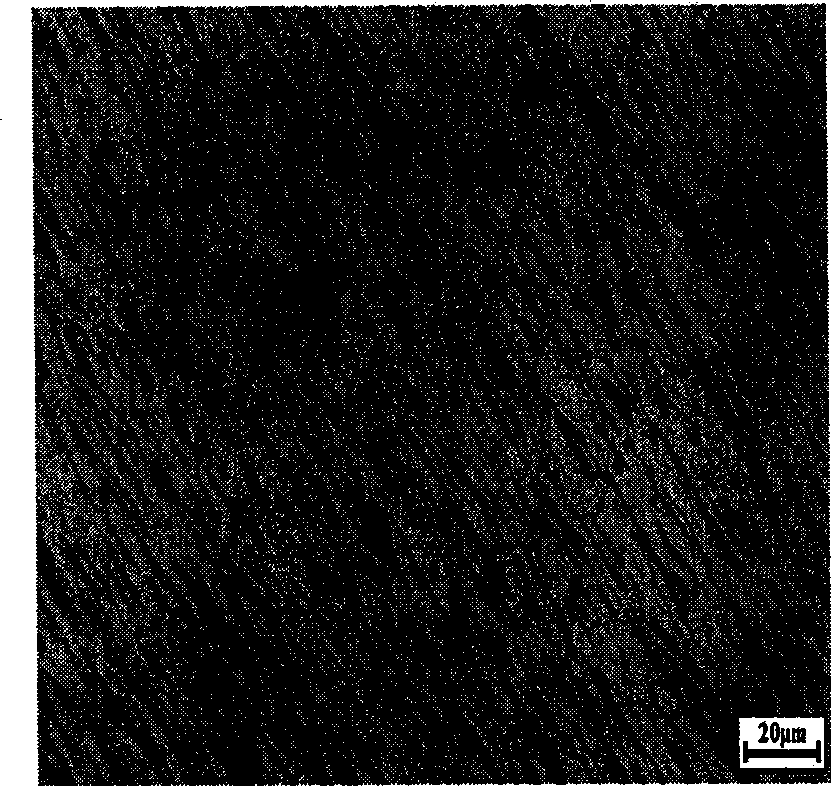

Low-alloy high-strength C-Mn-Al Q & P steel and method of manufacturing the same

The invention relates to a low-alloyed and high-strength Q and amp of a C-Mn-Al system; P steel; and a manufacturing method thereof, which belong to the technical field of metal materials. The method comprises the following processing steps of: (1) smelting and cast blocking: the mass percentages of the components are as follows: 0.16 percent to 0.25 percent of C, less than or equal to 0.40 percent of Si, 1.20 percent to 1.60 percent of Mn, 1.0 percent to 1.5 percent of Al, less than or equal to 0.02 percent of P, less than or equal to 0.008 percent of S and the balance of ferrite. (2) rolling: after the multi-pass hot-rolling of rough rolling and finish rolling, wherein, the deformation of roughing pass is 10 percent to 30 percent, the total deformation of the finish rolling is more than 60 percent, a hot rolled plate is subjected to multi-pass cold rolling, the deformation is 5 percent to 50 percent, and the plate is rolled to be a thin plate with the thickness being 0.6 to 2.0mm. (3) heat treating: firstly, austenitizing of 850 to 930 DEG C is carried out in a heating furnace, temperature is kept for 100 to 200 seconds and then rapid quenching is carried out to reach 230 to 250 DEG C, the temperature is kept for 20 to 40 seconds, after that the temperature is kept in 300 to 400 DEG C for 120 to 3600 seconds, at last fast cooling is carried out to room temperature (the speed of the cooling is not less than 10 DEG C / s). The Q and amp and the P steel have economic components, good quality of the surface, high strength and good shaping resistance. The strength and ductility product can reach over 37000MPa question mark percent.

Owner:UNIV OF SCI & TECH BEIJING

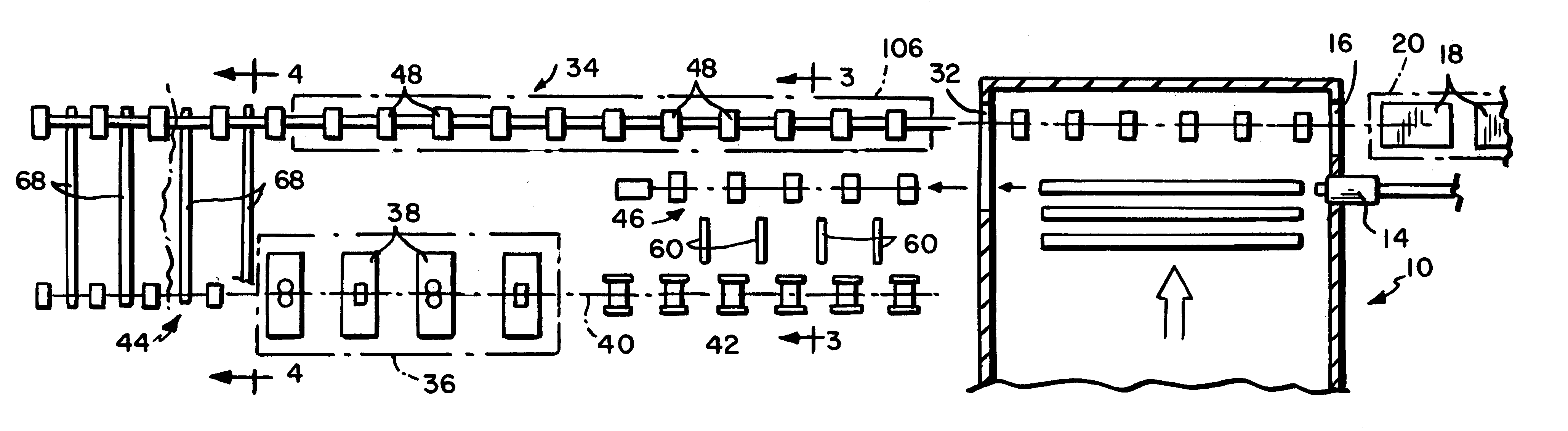

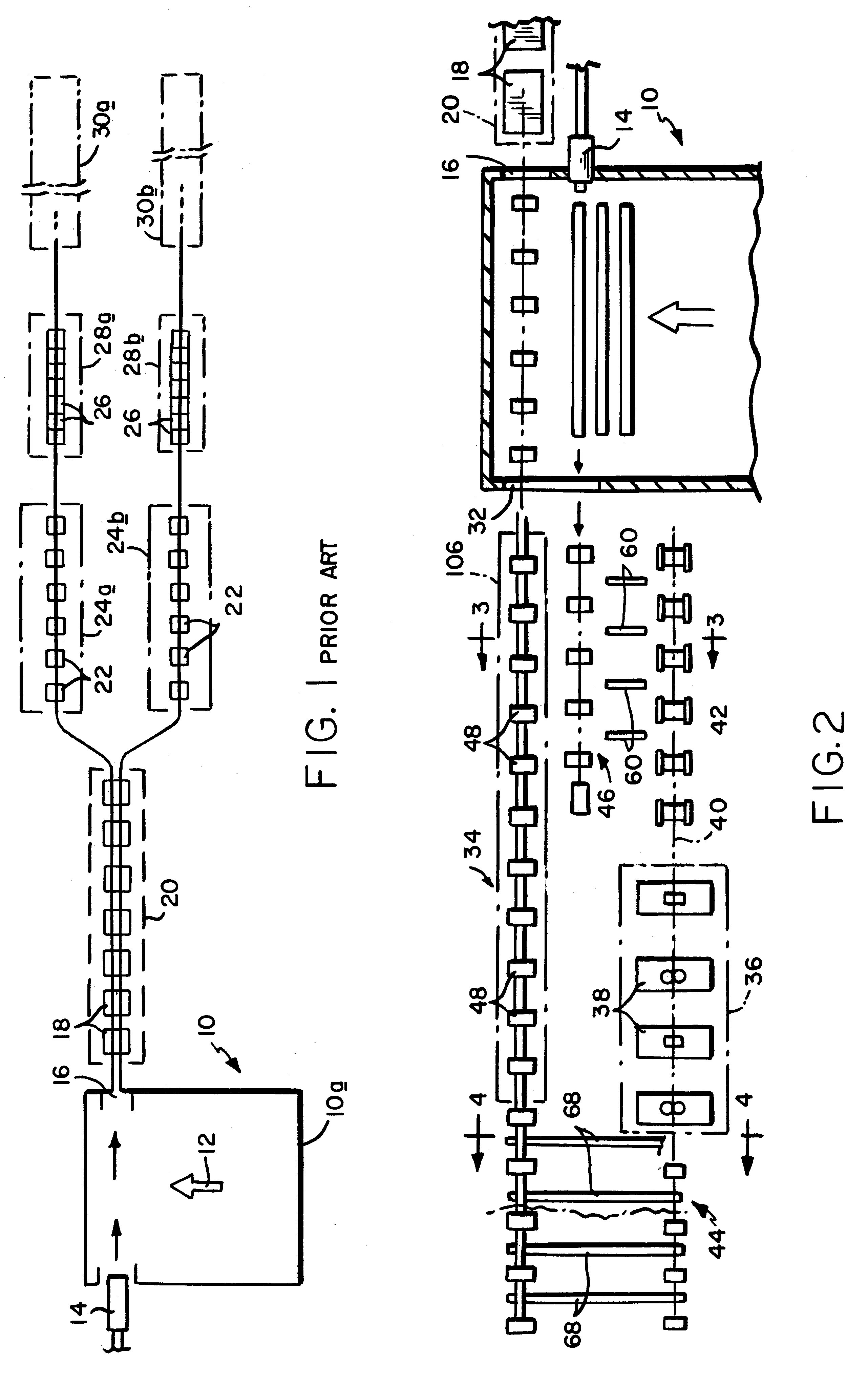

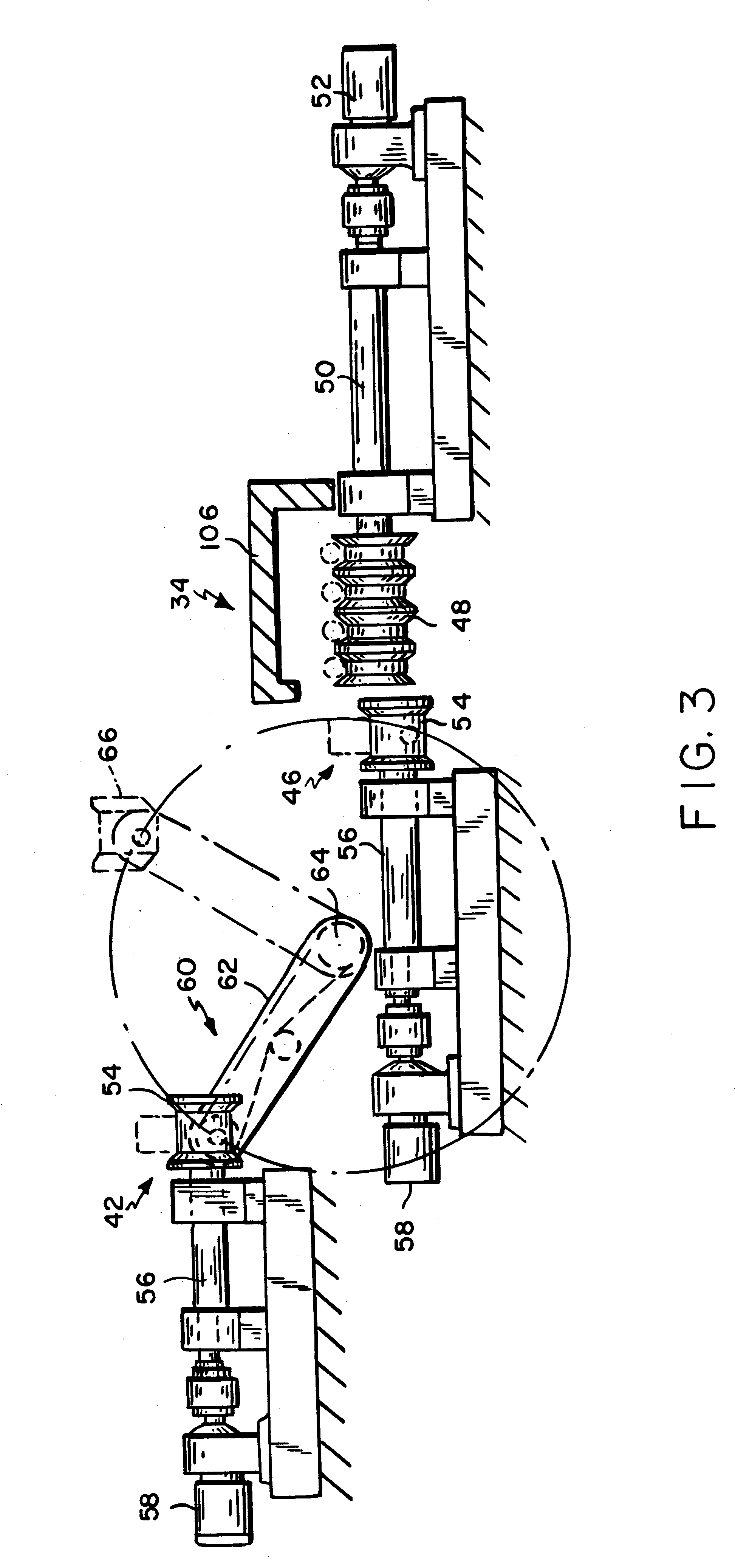

Apparatus for and method of processing billets in a rolling mill

A rolling mill has roughing, intermediate and finishing roll stands on a first side of a billet reheating furnace, and a breakdown mill on an opposite second side of the furnace. Billets are heated to an elevated rolling temperature in the furnace and are then ejected to the second side of the furnace for rolling in the breakdown mill before being directed back through the furnace for continued rolling into finished products at the first side of the furnace in the roughing, intermediate and finishing roll stands.

Owner:MORGAN CONSTR CO

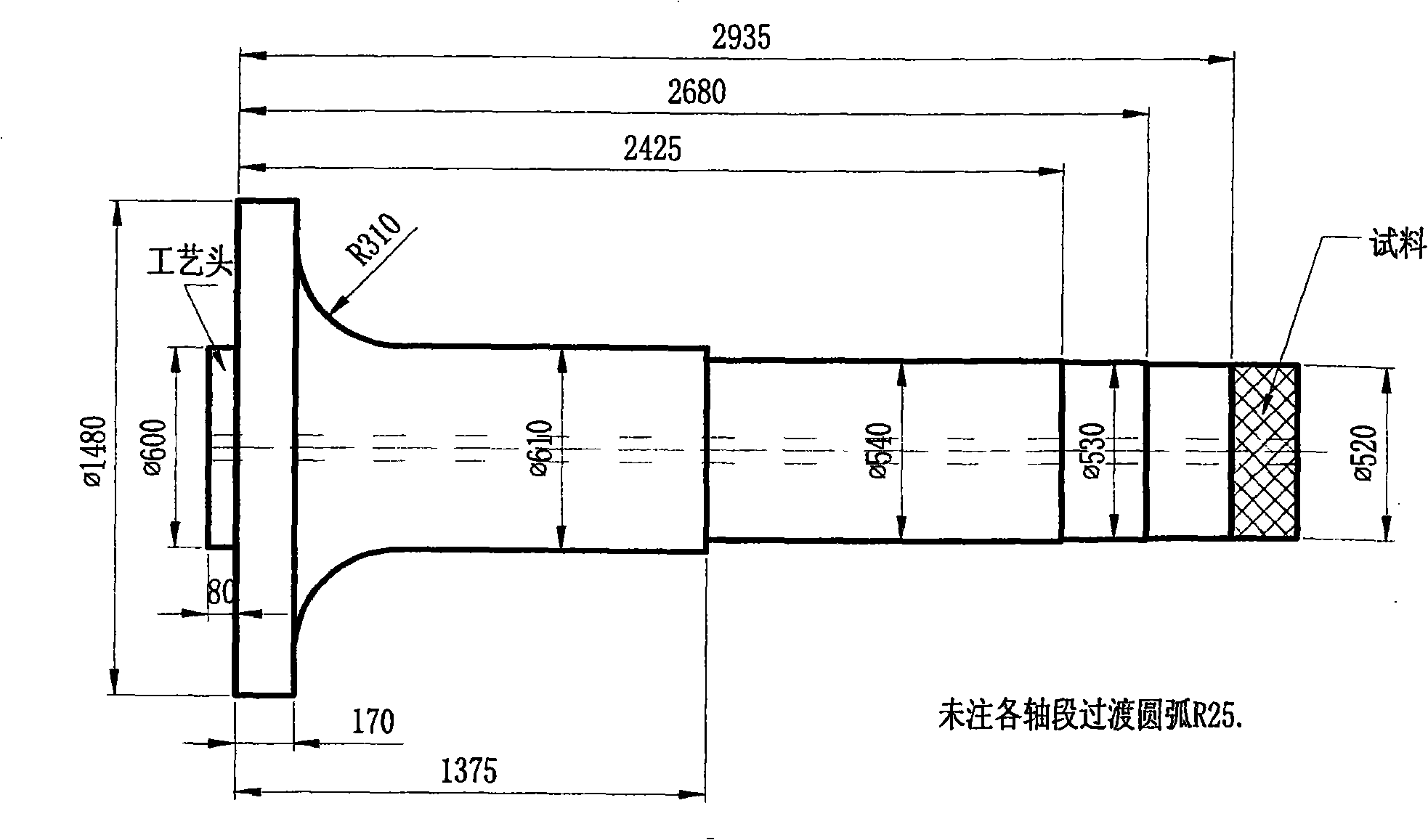

Method for producing wind-electricity principal axis with gathering stock full fibre upset forging

InactiveCN101314202ASolve the strength problemSolve process problemsShaftsFurnace typesElectricityIngot

The invention relates to a method for producing a wind-power mainshaft by local continuous upsetting and all-fibre upset forging. The method comprises the following: step one, the heating of steel ingot; step two, forging; step three, first heat processing; step four, rough machining and ultrasonic inspection; step five, quenching and tempering and heat processing; step six, fine machining, wherein, during the step two, the forging comprises that: (1) a first fire, during which, a steel ingot is subject to upset forging at a forging temperature of between 1250 and 900 DEG C; firstly, the bottom of the steel ingot is sawed off, and the steel ingot is subject to capping and upset forging; (2) a second fire, during which, the steel ingot is stretched towards various directions, marked and subject to intermediate billet cogging; after a pole part is molded, scrap on a T end is chopped and removed; after the forging is finished, the steel ingot returns to a heating furnace for being reheated; (3) a third fire, during which, the steel ingot is subject to local continuous upsetting and all-fibre upset forging; (4) a fourth fire, during which, the steel ingot is subject to rolling and leveling; the pole part is stretched; the disc edge of a hub end on the head part of an intermediate billet material after the local continuous upsetting and all-fibre upset forging is subject to rolling operation; after the rolling, the intermediate billet material is inserted into a leaking disc component again; the end face of the disc is pressed and leveled; after the shaping of the disc end is completed, a manipulator clamps the disc and stretches the pole part of the intermediate billet material to a dimension of a forgeable piece; thus, the mainshaft forging is completed. The method can improve the fatigue resisting strength of a wind-power mainshaft forging piece.

Owner:JIANGYIN ZENKUNG FORGING CO LTD

Process for Producing Glass Strip, Glass Strip and Glass Substrate

InactiveUS20070271957A1Improve flatnessReduce adhesionSynthetic resin layered productsGlass reforming apparatusInternal pressureSurface roughness

A manufacturing method of a glass strip, the method including a heating and drawing process of heating and softening a glass plate preform (1), drawing the glass plate preform to have a desired thickness and forming a glass strip (11), wherein at the heating and drawing process the glass plate preform (1) is drawn so that an internal pressure of a heating furnace (3) is kept positive relative to an atmospheric pressure and so that gas flows introduced to both surfaces of the glass plate preform (1) respectively are equal to each other within the heating furnace (3). It is possible to improve a surface roughness and obtain a desired surface roughness.

Owner:FURUKAWA ELECTRIC CO LTD

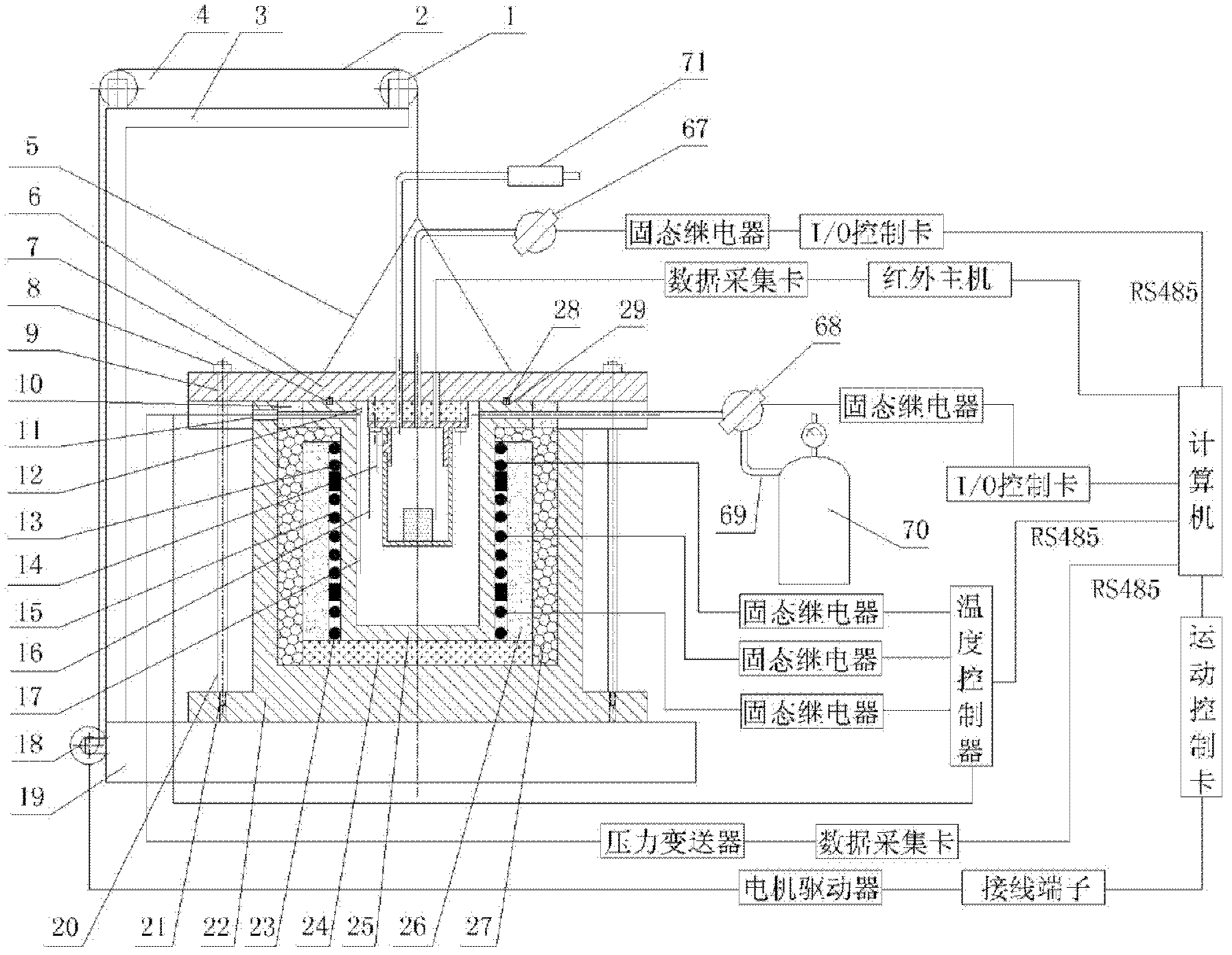

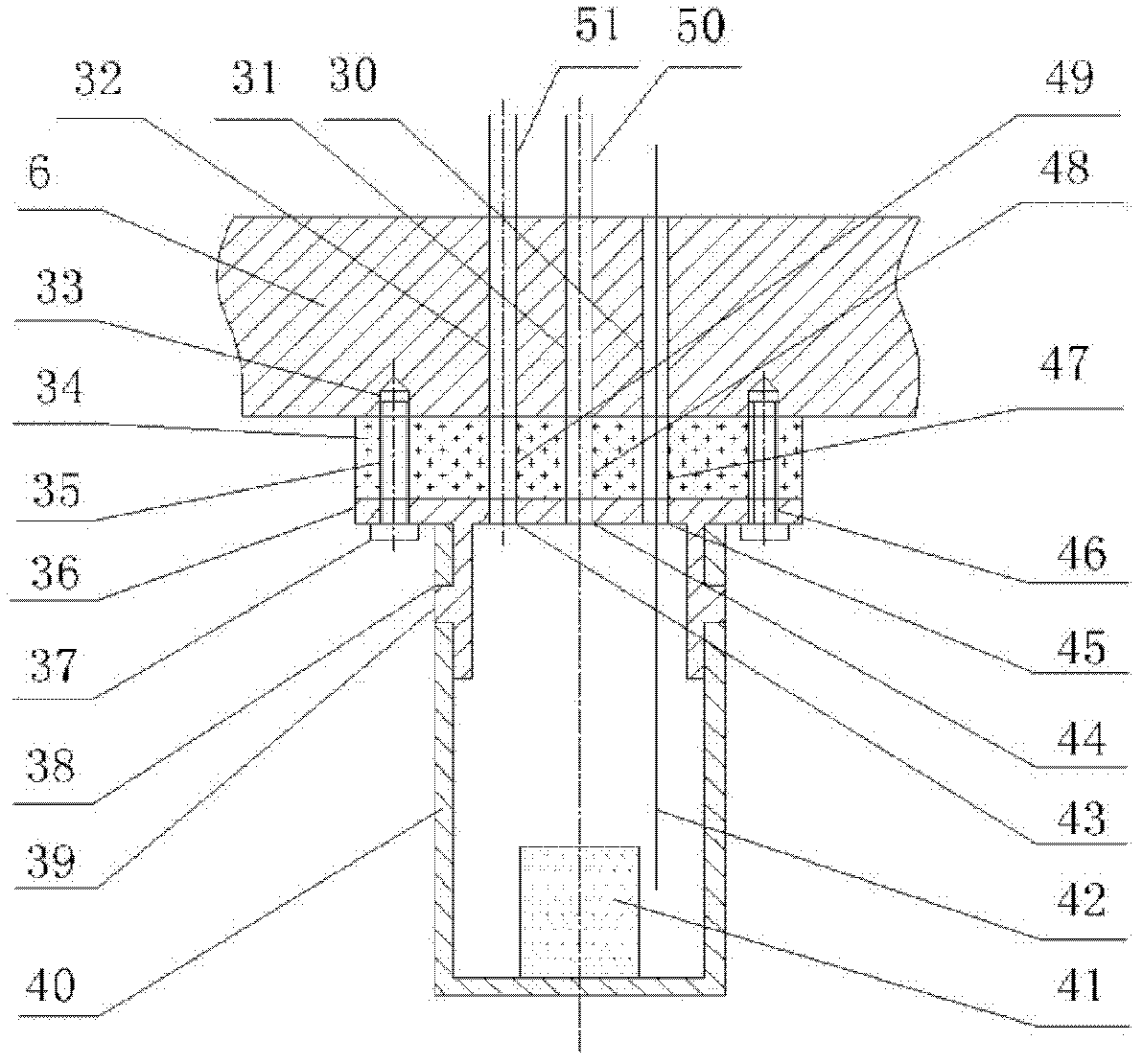

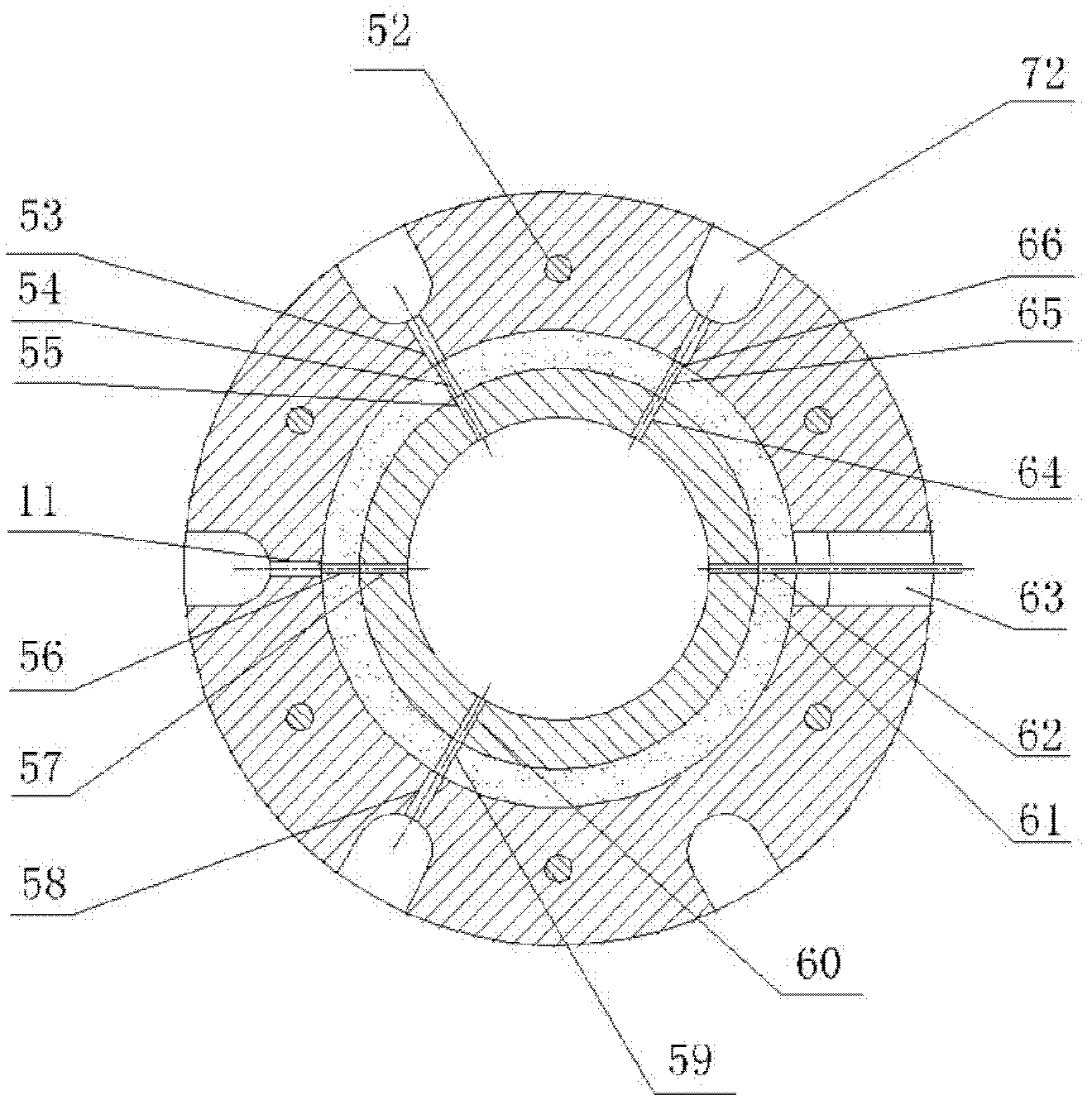

Testing system for critical pressure during thermal explosion of explosives

InactiveCN102608160ARealize multi-point temperature controlImprove uniformityMaterial exposibilityData acquisitionData treatment

The invention discloses a testing system for critical pressure during thermal explosion of explosives. The testing system comprises a pressure-resistance heating unit, a pressure control unit, a sample loader unit, a decomposed product detection unit and a computer; the pressure-resistance heating unit comprises a single-cavity heating furnace body, wherein a temperature sensor which is connected with the computer is arranged in a furnace cavity, and temperature, temperature rise speed and pressure of the single-cavity heating furnace body are controlled by the computer; the pressure control unit comprises a high-pressure gas cylinder, a pressurizing gas channel pipe, a pressurizing electromagnetic valve, a heat conduction layer extension edge pressurizing pipe, a pressure-releasing gas channel pipe, a pressure-releasing electromagnetic valve, a safety valve gas channel pipe, a safety valve and a pressure sensor; the sample loader unit comprises an L-shaped bracket, a stepping motor, two fixed pulleys, a steel wire rope, a furnace cover, a sample reservoir bracket and a sample reservoir; the decomposed product detection unit comprises an infrared sensor which is arranged in the sample reservoir; and the computer is provided with a data acquisition card, a graphic display control and a data processing unit and can be used for identifying the critical state of thermal decomposition to combustion or explosion and acquiring a critical pressure parameter.

Owner:XIAN MODERN CHEM RES INST

Radiant tube burner

PCT No. PCT / JP95 / 01916 Sec. 371 Date May 23, 1996 Sec. 102(e) Date May 23, 1996 PCT Filed Sep. 22, 1995 PCT Pub. No. WO96 / 09496 PCT Pub. Date Mar. 28, 1996With respect to a radiant tube burner to be used for heating a heating furnace or the like, to suppress the generation of NOx accompanying combustion, to make the structure thereof fit for a radiant tube burner equipment, to simplify the control of a fuel supply system and an air supply system, and to prevent the coking. Furthermore, to provide a combustion control scheme appropriate to a radiant tube burner. For these purposes, the present invention placed the respective tips of a fuel nozzle, e.g., pilot burner joint-use nozzle (11), and an air throat (13) in the end of a radiant tube (3) and moreover has a combustion air injection port (33) of the air throat (13) provided to be deviated in contact with or near to the inner circumferential wall surface of the radiant tube (3). In addition, a control device (307) for making a burner burn alternately.

Owner:NIPPON KOKAN KK +1

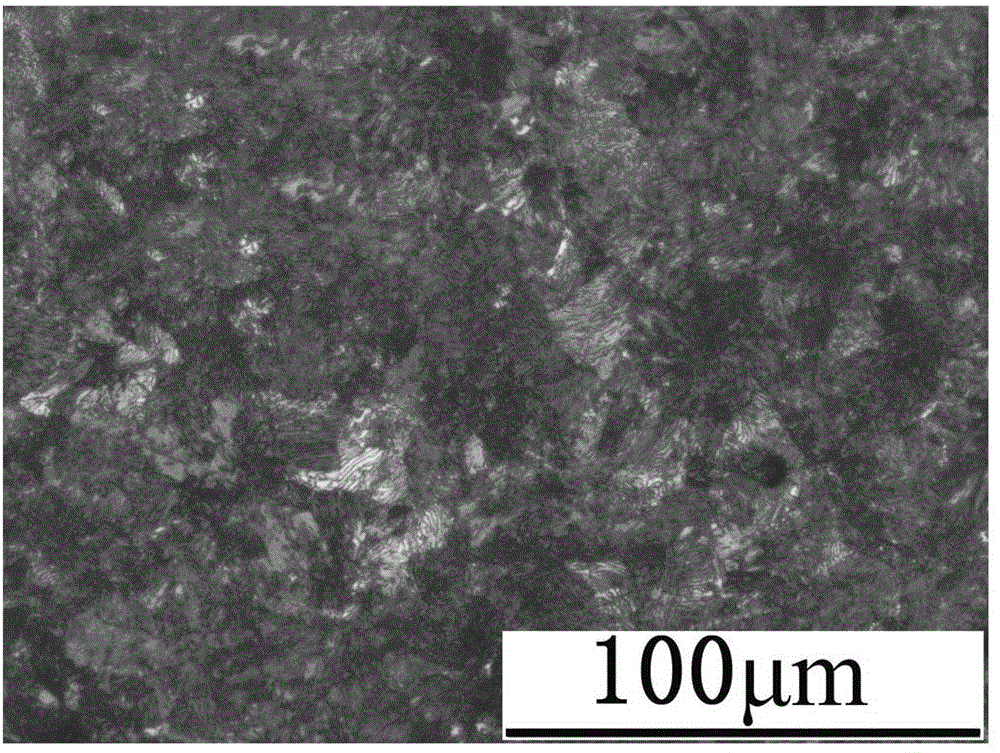

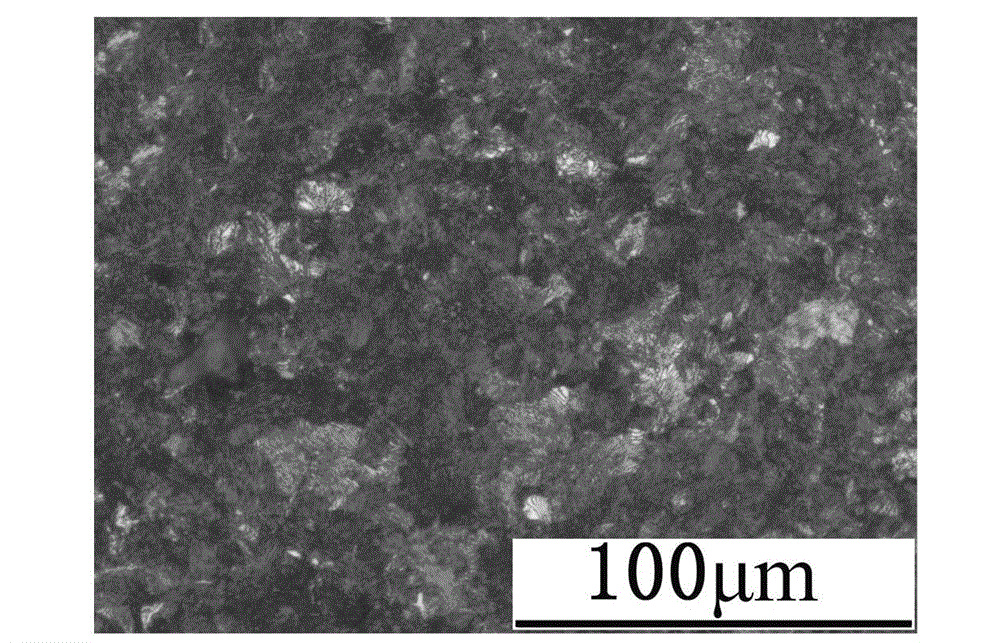

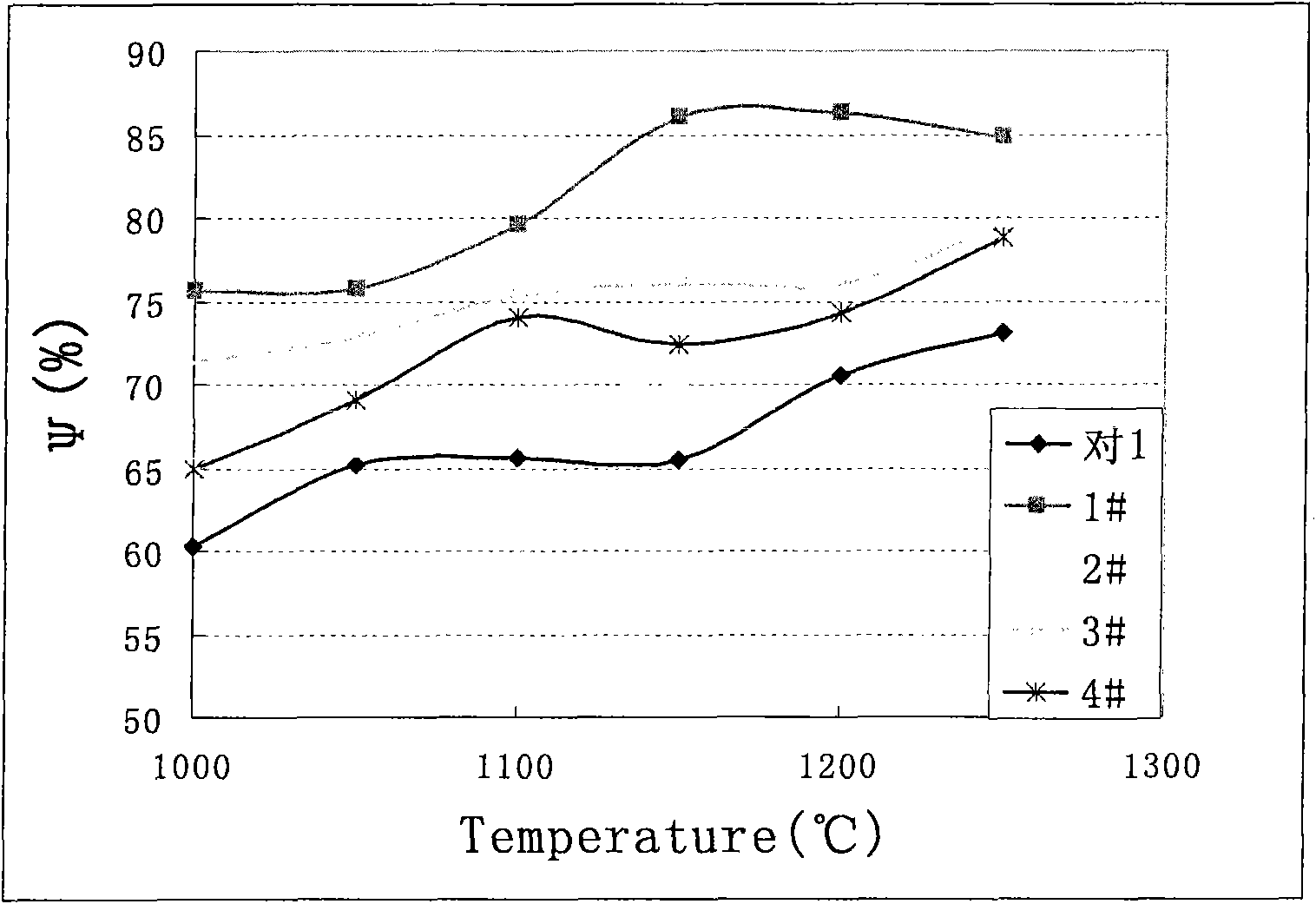

Production process for 82B wire rod used for high strength prestressed steel wire and wire rod thereof

The invention relates to a production process for an 82B wire rod used for a high strength prestressed steel wire and a wire rod thereof. The production process achieves objects of refining grains, improving the metallographic structure and obtaining high sorbite rate, improves strength and plasticity of the 82B wire rod used for the high strength prestressed steel wire and realizes an object of optimizing a metallographic structure and mechanical properties of the 82B wire rod used for the high strength prestressed steel wire, by optimally designing chemical components of the 82B wire rod used for the high strength prestressed steel wire, adjusting heating procedures of a heating furnace before rolling, and employing controlled rolling and controlled cooling techniques. The high power quality and mechanical properties of the 82B wire rod with a nominal diameter of 6.5 mm used for the high strength prestressed steel wire reach the national standard of the hot rolling wire rod used for the prestressed steel wire and steel strand, and meet production requirement of downstream users.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

Diphase stainless steel and manufacturing method thereof

The invention discloses a diphase stainless steel, which comprises the following components in percentage by weight: less than or equal to 0.05 percent of C, 0.2 to 1.0 percent of Si, 0 to 2.0 percent of Mn, 22 to 27 percent of Cr, 0 to 2.0 percent of W, less than or equal to 0.1 percent of S, less than or equal to 0.03 percent of P, 0 to 0.003 percent of B, more than 0 and less than or equal to 0.2 percent rare earth of which the Ce content is more than 50 percent, and the balance of Fe and inevitable impurities, wherein a casting blank of the diphase stainless steel comprises over 60 percent of isometric crystal. A method for manufacturing the diphase stainless steel comprises the following steps of: performing smelting, die casting or continuous casting to form the casting blank, wherein the thickness of a steel die is more than 30 mm during the die casting to ensure that the cooling velocity of the steel is more than 10 DEG C per minute, and in the process of the continuous casting, the degree of superheating of the casting is between 30 and 100 DEG C, and the casting speed is over 1.2 meters per minute; putting the casting blank into a heating furnace, heating the casting blank to the temperature of between 1,100 and 1,250 DEG C, performing heat preservation on the casting blank, and then forging or hot-rolling the casting blank to a required thickness; and annealing and pickling a steel plate or a plate coil after forging or hot-rolling, and controlling the annealing temperature to be between 1,000 and 1,100 DEG C. The diphase stainless steel has high corrosion resistance and high hot-working performance, and can be widely applied in the fields of petroleum, chemical industry, papermaking, marine engineering and the like in rigorous corrosion environments.

Owner:BAOSTEEL SPECIAL STEEL CO LTD +1

Continuous casting slab high-temperature oxidation resistant coatings and preparation process thereof

InactiveCN101693791AGood anti-oxidation effect at high temperatureRaw materials are easy to getCoatingsOxidation resistantSuspending Agents

The invention relates to a preparation process of continuous casting slab high-temperature oxidation resistant coatings, which is characterized in that less than 120 meshes of powder, reductant containing carbon, inorganic binders, surfactants, suspending agents and the like with the compositions such as 25-55 wt% SiO2, 10-20 wt% Al203, 11-23 wt% MgO and the like are respectively grinded and mixed evenly, then water is used to be mixed and stirred sufficiently evenly, and finally the density of the coatings are adjusted within 1200-1500 kg / m3. The coatings can not only be sprayed onto continuous casting slabs at normal temperature, but also be sprayed onto high-temperature casting slabs, form continuous whole protective coating layers under the action of high temperature, effectively reduce temperature drop of the casting slabs and oxidation burning loss in even heating process of a heating furnace without changing original performance of matrixes, and effectively decrease dilution of alloying elements on the surfaces of the casting slabs. After the casting slabs are out of the heating furnace, natural spalling capability of the coating layers is strong, and oxidation matrixes of the casting slabs are smooth. Raw materials of the oxidation resistant coatings are easy to be obtained, and the coatings have low cost and simple preparation process and are adaptable to oxidation resistance for various steels when being heated at 700-1300 DEG C / 2-8 hours.

Owner:UNIV OF SCI & TECH BEIJING

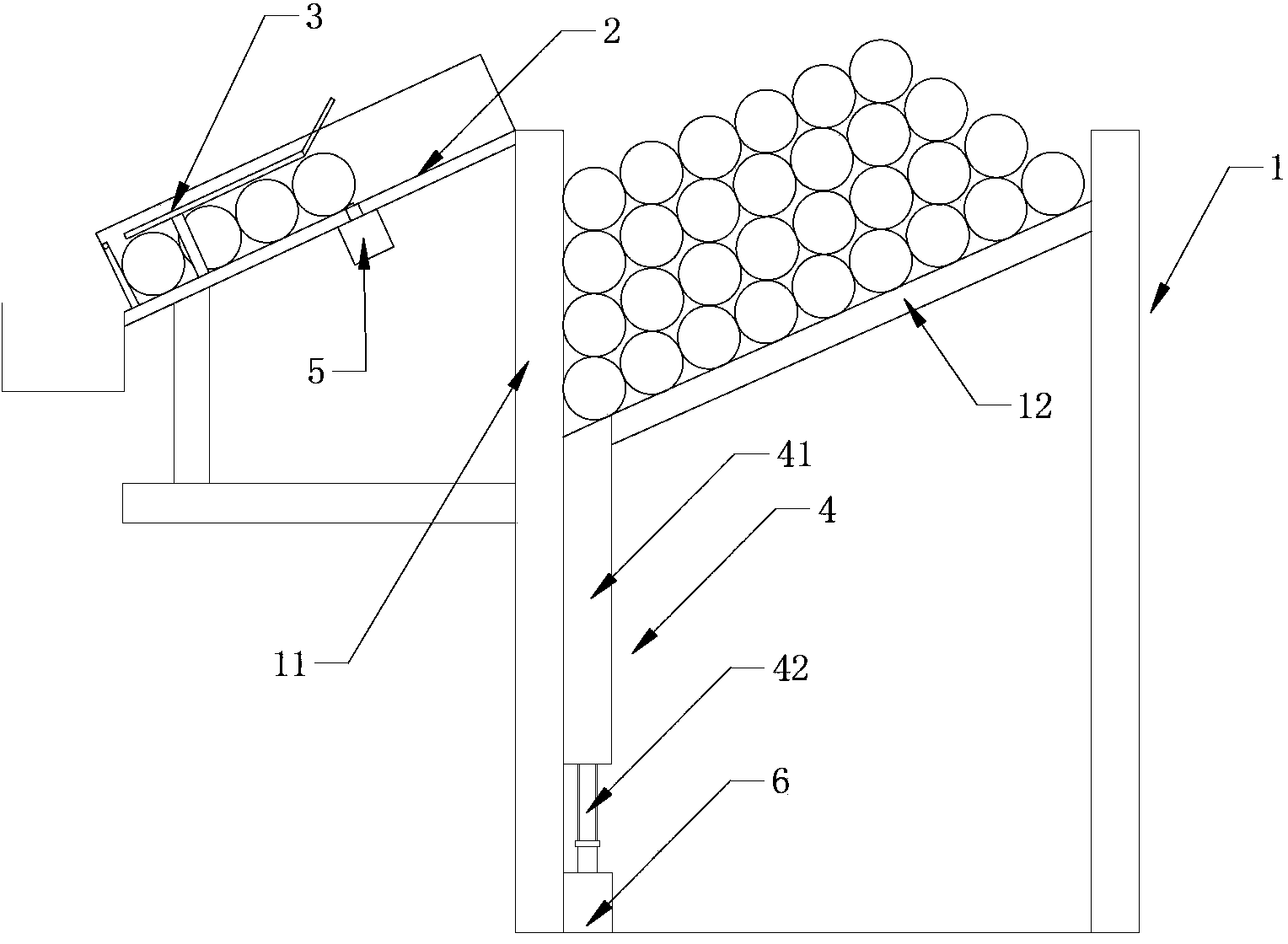

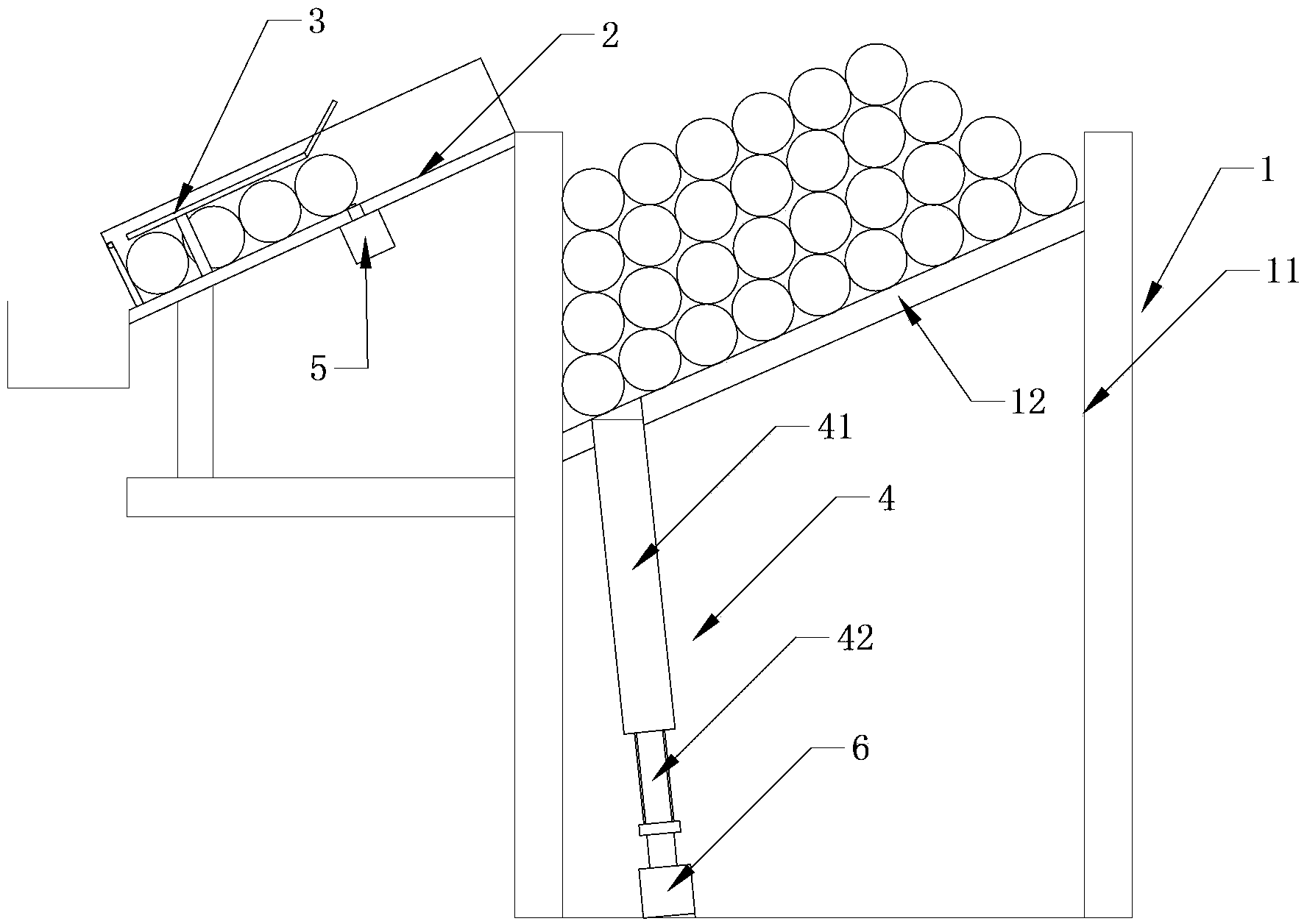

Metal rod automatic feeding device for heating furnace

The invention discloses a metal rod automatic feeding device for a heating furnace. The metal rod automatic feeding device for the heating furnace comprises a material storage box and a material guide groove, wherein the material storage box comprises a material storage chamber, a bottom plate of the material storage chamber is arranged obliquely, the material guide groove is formed in the outer wall of the material storage chamber and is located at a lower side of the oblique bottom late, the material guide groove is also arranged obliquely, and the oblique direction of the material guide groove is the same as the oblique direction of the bottom plate. A material blocking device used for blocking or releasing a metal rod is arranged on the material guide groove and is in linkage with a material pushing device of the heating furnace, a first sensor used for detecting the position of the metal rod is arranged on the material guide groove, a passing groove is formed in the bottom plate, a jacking mechanism is installed under the material storage chamber, a power end of the jacking mechanism penetrates through the passing groove and can push a metal plate into the material guide groove, the jacking mechanism is connected with a jacking power device, and the first sensor and the jacking power device are both connected with a controller. The automatic feeding device can replace workers for material feeding, improves feeding efficiency, is operated along with existing equipment synchronously, saves manpower and reduces cost.

Owner:JIANGSU HONGBAO HARDWARE

Method of sheet billet continuously casting and rolling to produce thin strip steel coil

ActiveCN101108394AShort production processSave construction investmentMetal rolling arrangementsProduction lineStrip mill

A method of using thin plate adobe continuous casting and rolling to producing thin band steel coil is provided, which belongs to rolling metal at once after continuous casting, in particular relating to thin standard band steel production method. The invention is characterized in that: a conticaster, a swing shear, a roller-hearth type heating furnace, a scale breaker, a vertical miller, 7 mill groups, laminar flow cooling device and reeling machine are connected to a CSP produce line, the produce line adopts reasonable temperature system, rolling equipment, rolling way and combining with cooling after rolling, the molten steel after continuous casting is a casting adobe of 50 to 70mm thick and 900 to 1300 wide, after cutting, heating, scale breaking, proceed continuous rolling to form a thin band of 1.2 to 1.5mm thick and 900 to 1300 wide, then after cooling to reel steel coil. The production flow is short, the equipment is few, the investment is less and the running expense is low; The technics and equipment is reasonable and high efficient, double locomotive and double flow casting, heating by two furnaces, seven rolling machines roll continuously, the production is smooth and saves energy with high production efficiency; the product performance is even and stable, the board shape is regular with high accuracy and good surface quality.

Owner:MAANSHAN IRON & STEEL CO LTD

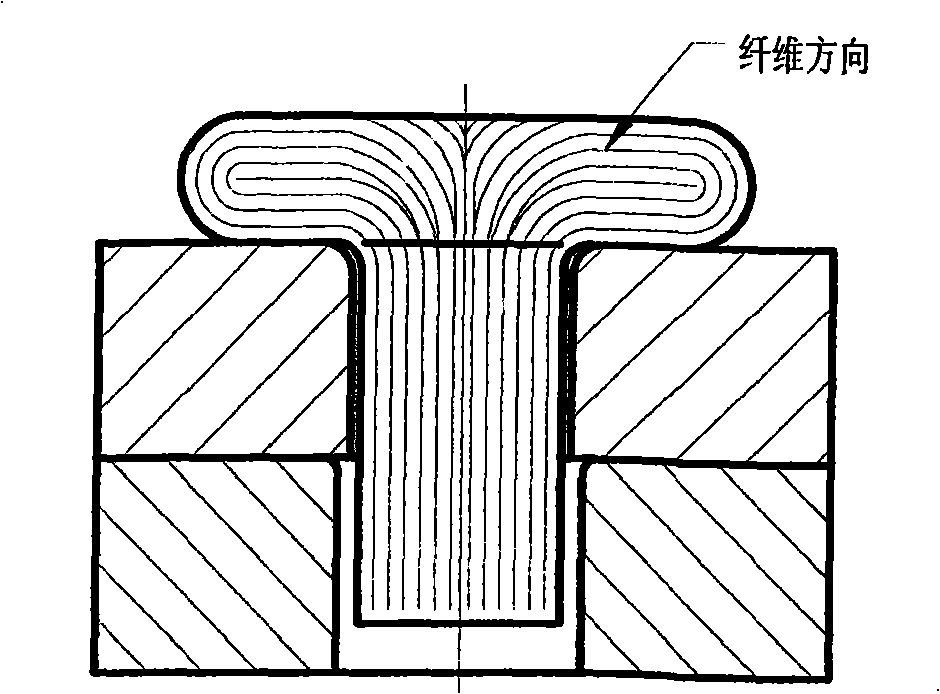

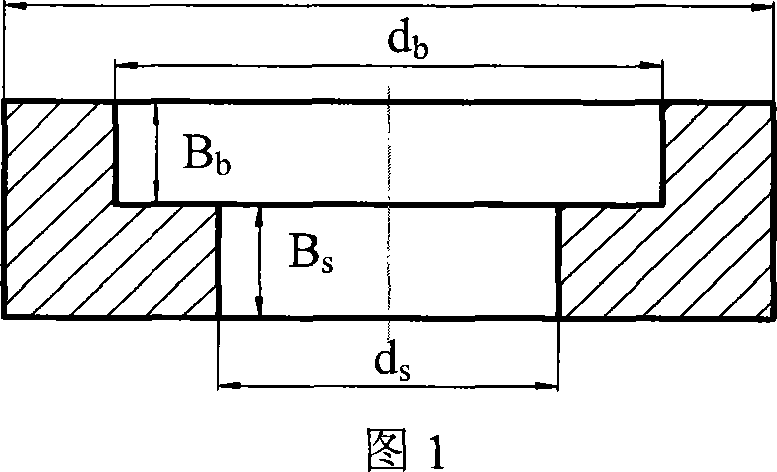

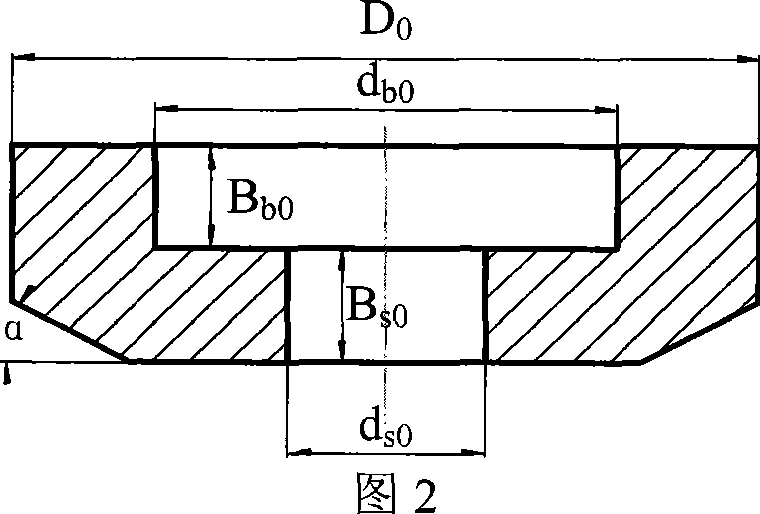

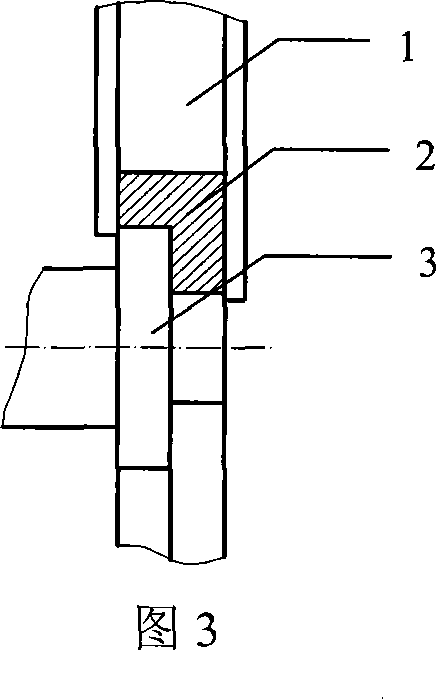

Inner step profile section ring parts rolling forming method

InactiveCN101053887AImprove metal structureImprove performanceFurnace typesHeat treatment process controlHeat deflection temperatureThermal state

The invention relates to a rolling forming method of a ring with inner step section. The rolling forming method of a ring with inner step section is characterized in that it comprises the following steps: 1) blanking; 2) preforming: uniformly heating the material section from room temperature to a heat distortion temperature with high plasticity and low resistance, then upsetting, piercing and stamping the material section in thermal state to fabricate ring blank for rolling; 3) rolling by a ring rolling mill: heating the ring blank in a heating furnace, taking out when the temperature reaches the heat distortion temperature and putting the ring blank into the ring rolling mill to carry out rolling, during the rolling process, excellent lubrication is maintained between the ring blank and the rollers, and the ring forging is formed by multiple rolling the ring blank; 4) mechanical cutting processing the ring forging to form the ring with inner step section. Accordingly, the invention has advantages of low cost and high production efficiency.

Owner:WUHAN UNIV OF TECH

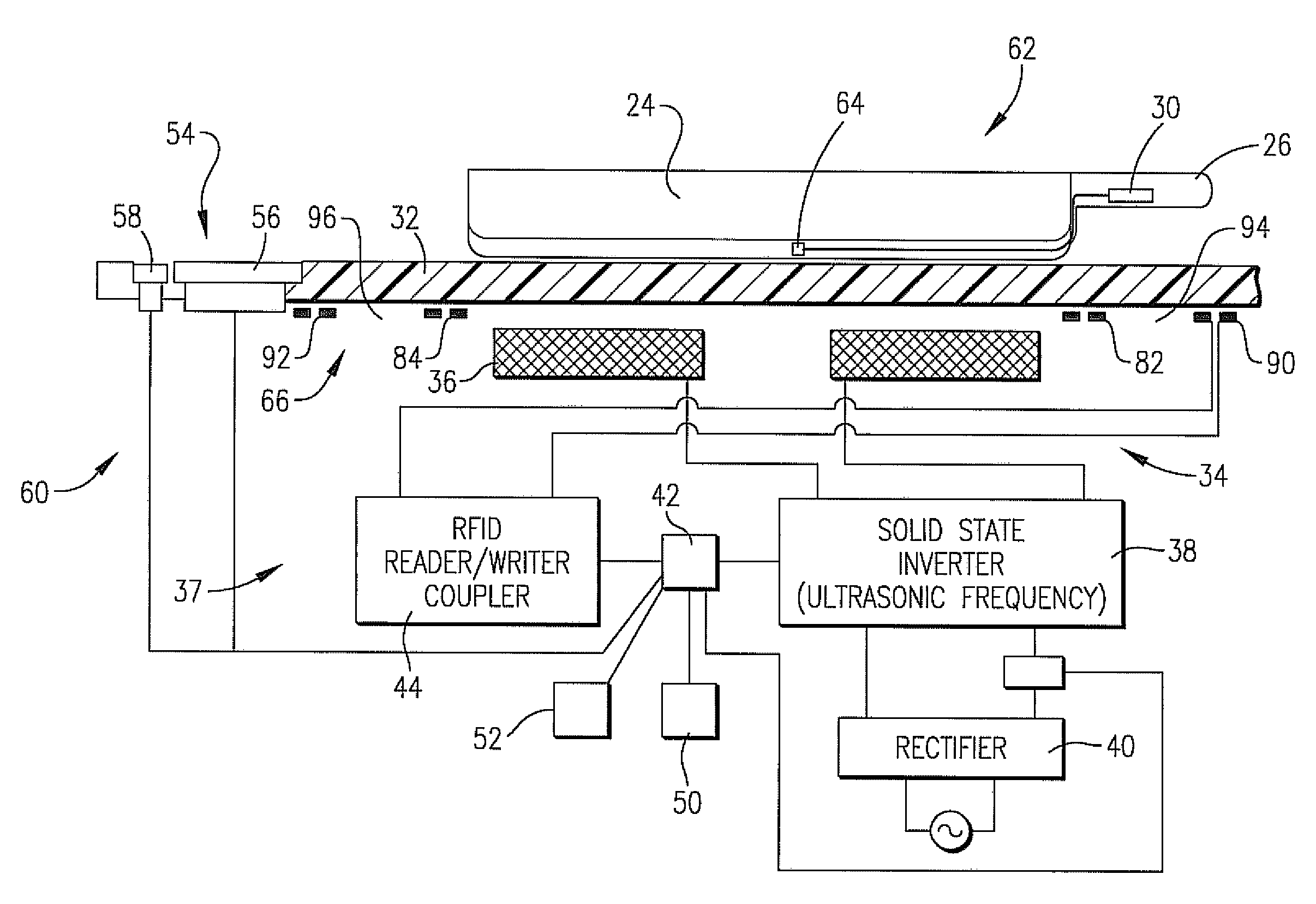

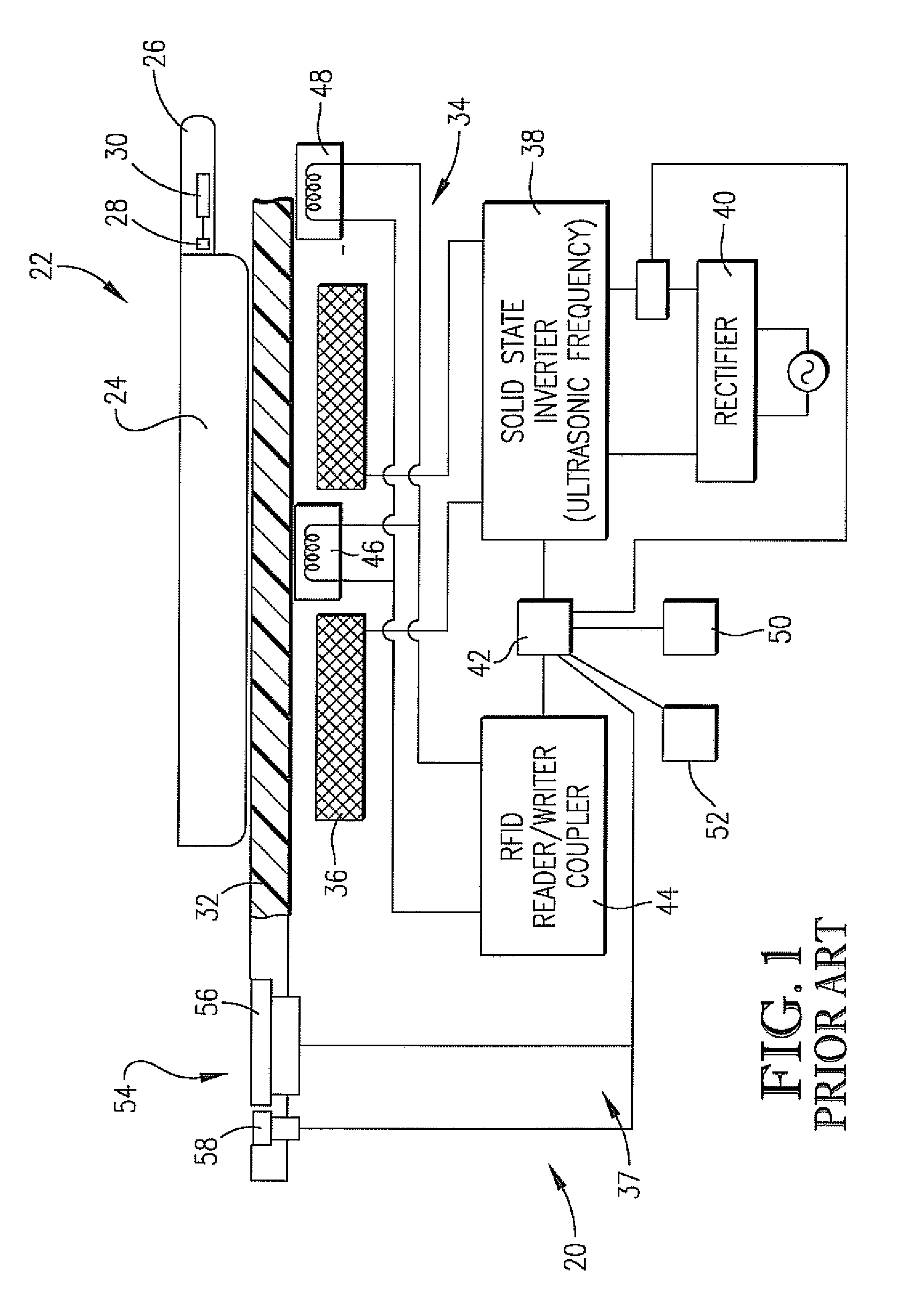

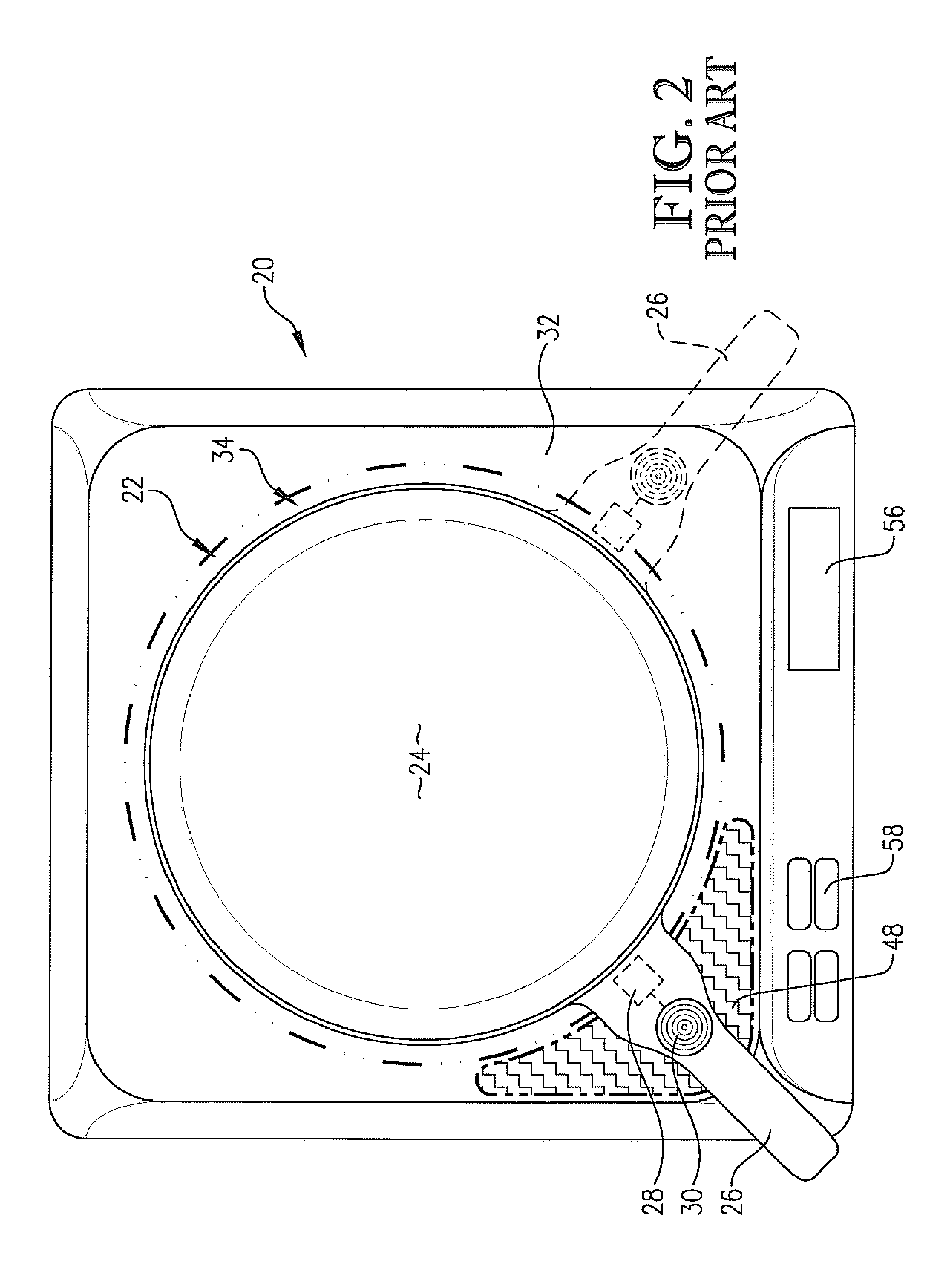

Radio frequency antenna for heating devices

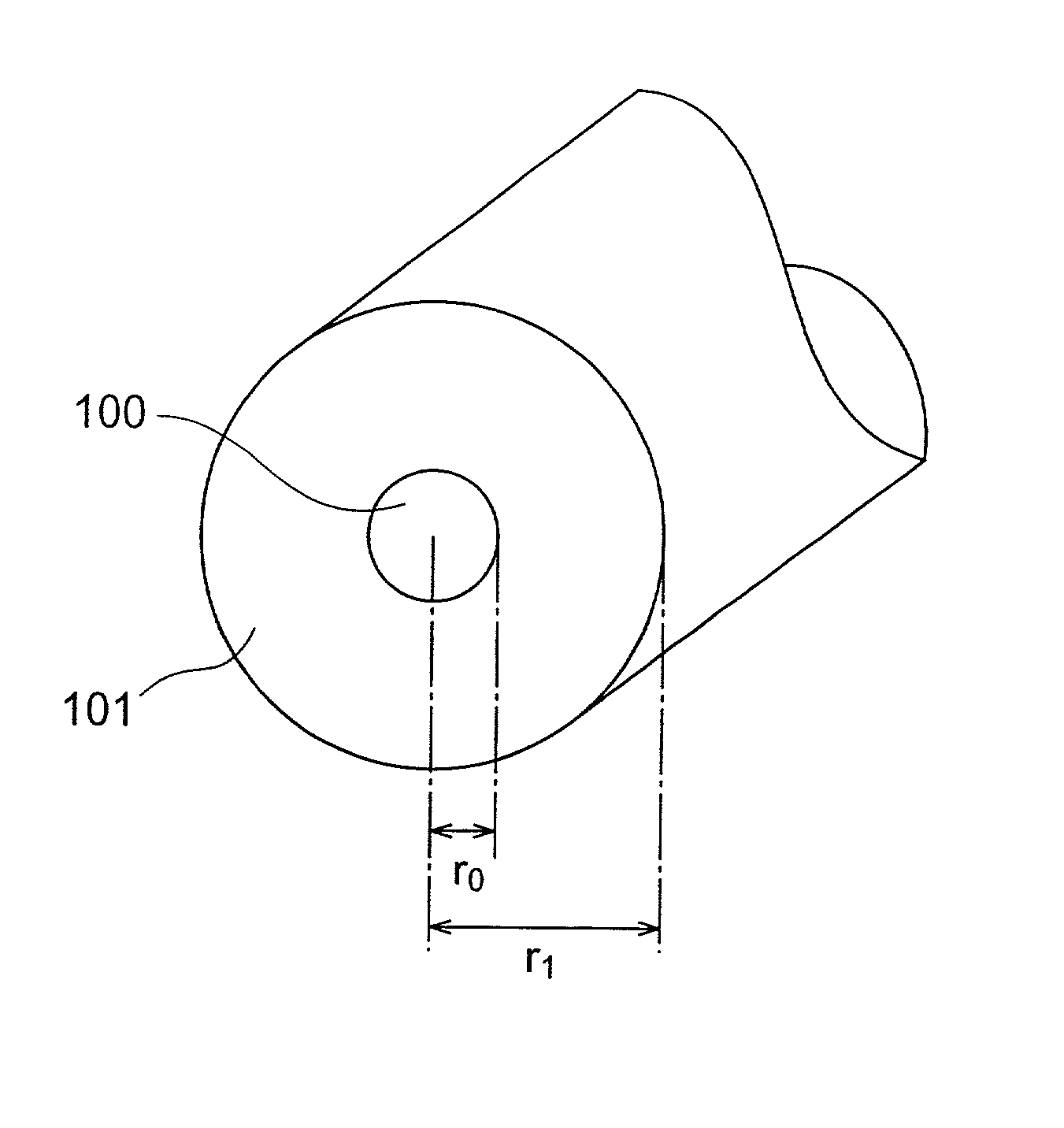

ActiveUS20090194526A1Little induced voltage (noise)Reduce areaElectric signalling detailsInduction heating controlInduction heaterEngineering

The present invention provides an improved antenna assembly (66) designed to maintain RF communication between an object (22, 64, 148) to be heated, and a heating assembly (20, 60) such as an induction heater having a hob (34) equipped with an induction work coil (36). The antenna assembly (66) provides substantially continuous RF communication about the entirety of the hob (34), so that the object (22, 64, 148) can be rotated through substantially 360E, or displaced radially, without loss of RF communication. The preferred antenna assembly (66) includes an antenna (67) mounted upon a substrate (68) and presenting a plurality of continuous, conductive antenna loops (70, 72) oriented to cooperatively and substantially around the hob (34). Each of the loops (70, 72) has an inner section (82, 84) proximal to the hob (34) and defines a respective, enclosed RF communication zone (94,96) outboard of and disposed about the hob (34); the zones (94,96) cooperatively define a substantially continuous RF communication zone outboard of and disposed about the hob (34). The antenna assembly (66) also includes antenna circuitry 97 including tuning assemblies (98, 100) and a terminal network (102). In alternative forms, radiant, resistant heating, or other types of heating hobs can be used.

Owner:TSI TECH

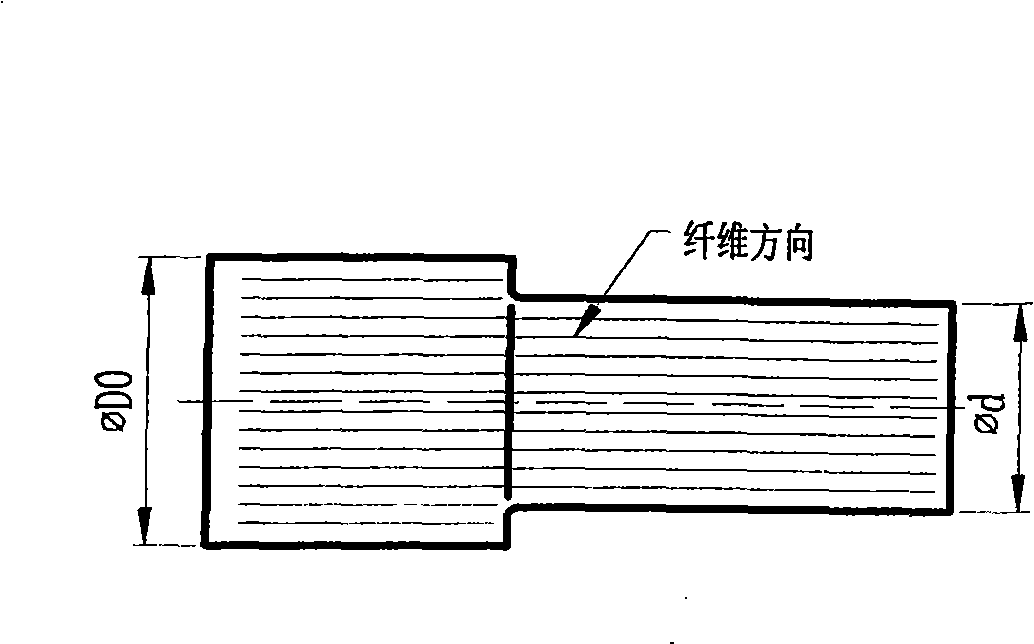

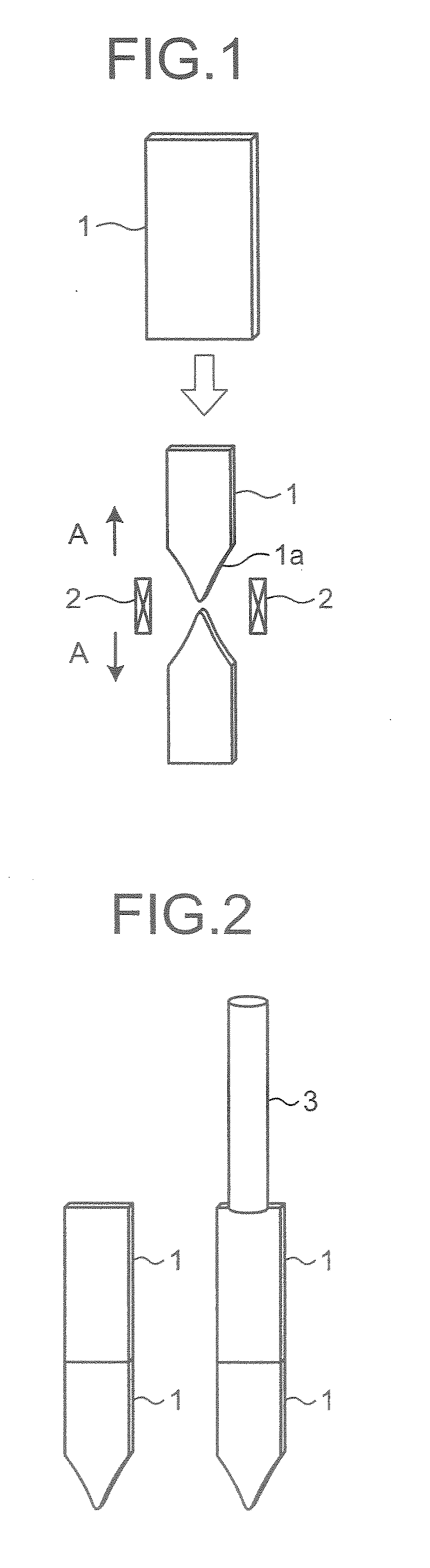

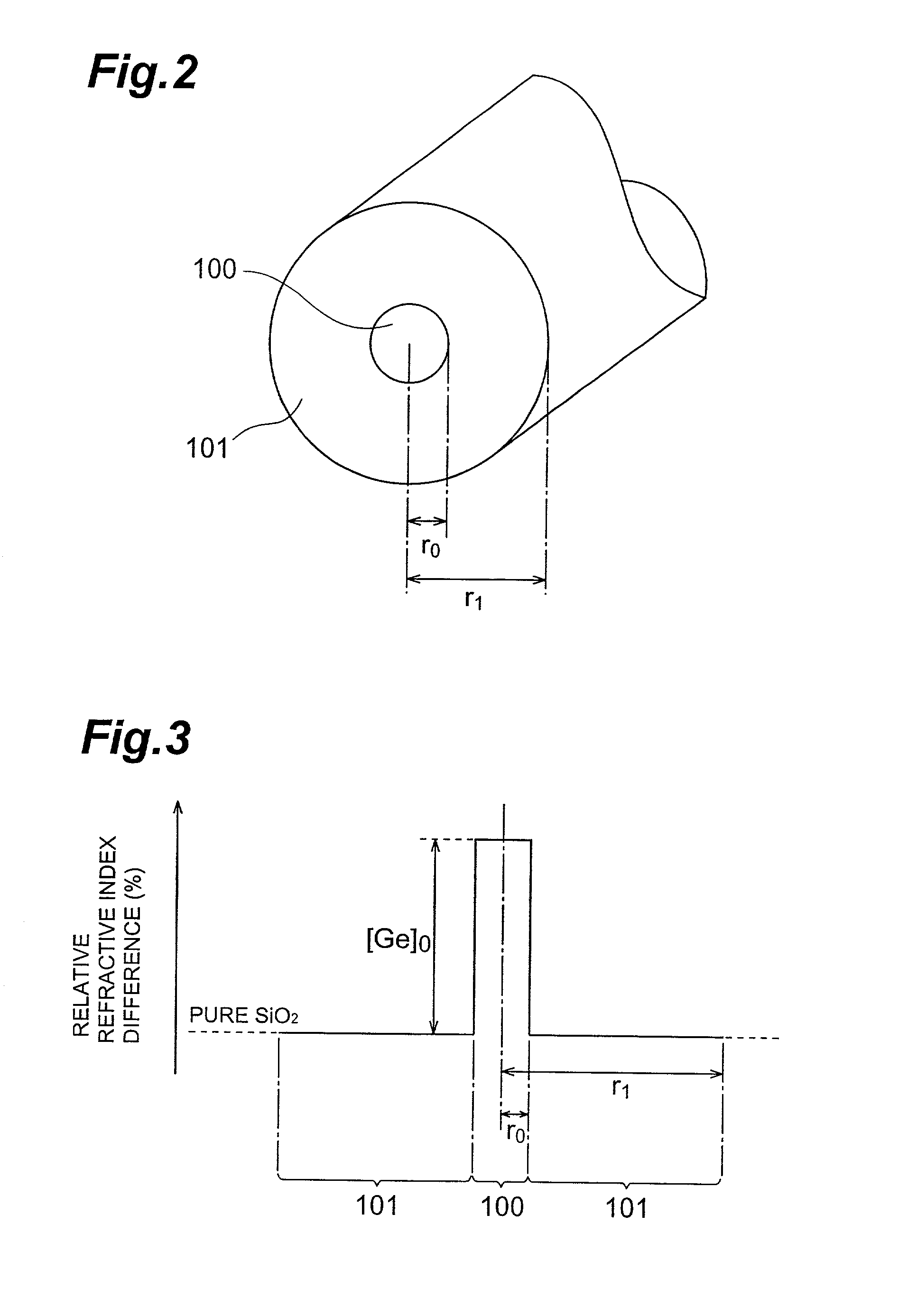

Optical fiber and method of making the same

InactiveUS20020044753A1Reduce transmission lossOptical fibre with multilayer core/claddingGlass fibre drawing apparatusRayleigh scatteringFiber

An optical fiber preform 2 having a viscosity ratio Reta=eta0 / etat of 2.5 or less between the core average viscosity eta0 and the total average viscosity etat is prepared, and is drawn by a drawing furnace 11 so as to yield an optical fiber 3, which is then heated to a temperature within a predetermined range so as to be annealed by a heating furnace 21 disposed downstream the drawing furnace 11. Here, upon annealing in the heating furnace 21, the fictive temperature Tf within the optical fiber lowers, thereby reducing the Rayleigh scattering loss. At the same time, the viscosity ratio condition of Reta<=2.5 restrains the stress from being concentrated into the core, thereby lowering the occurrence of structural asymmetry loss and the like. Hence, anoptical fiber which can reduce the transmission loss caused by the Rayleigh scattering loss and the like as a whole, and a method of making the same can be obtained.

Owner:SUMITOMO ELECTRIC IND LTD

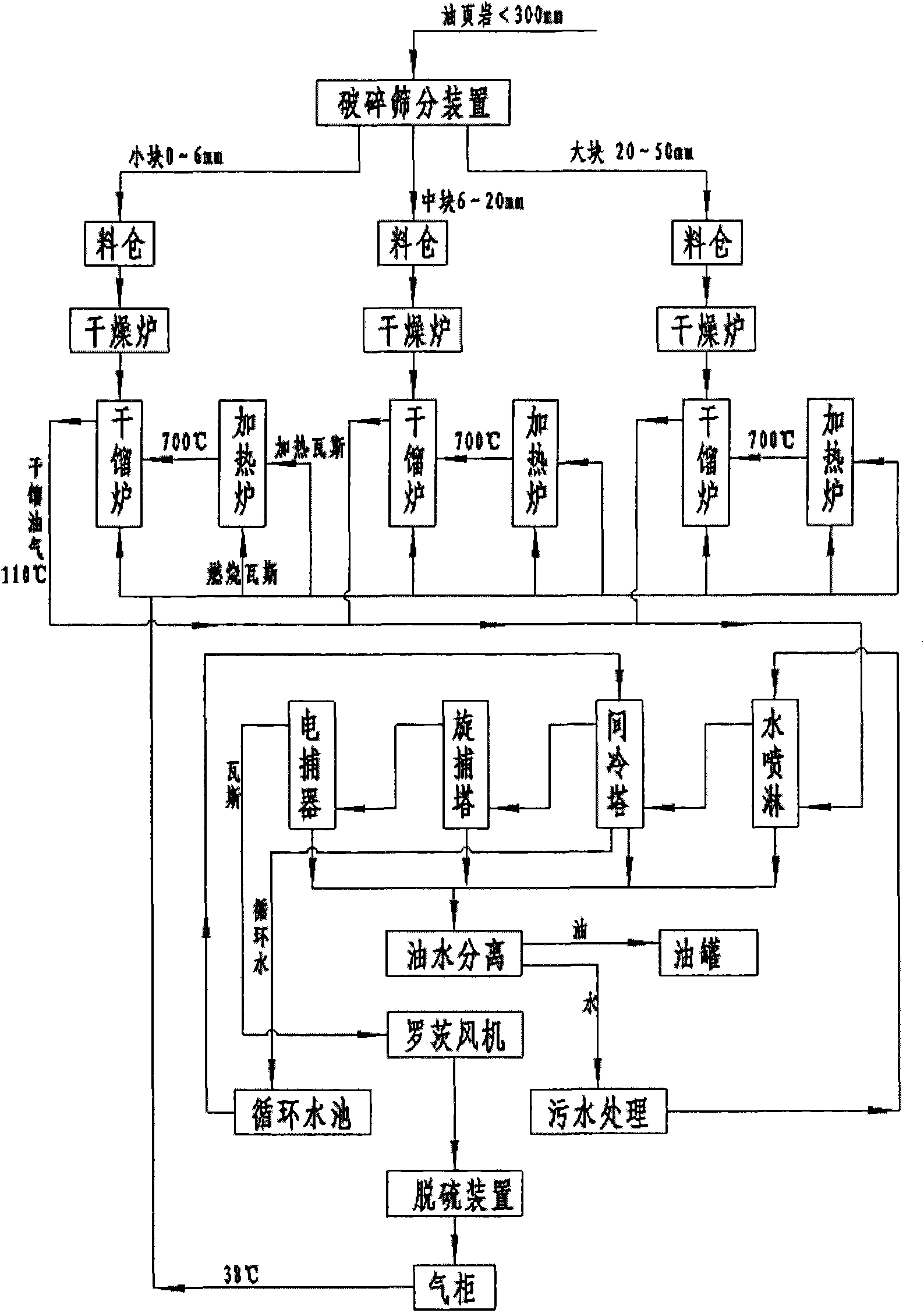

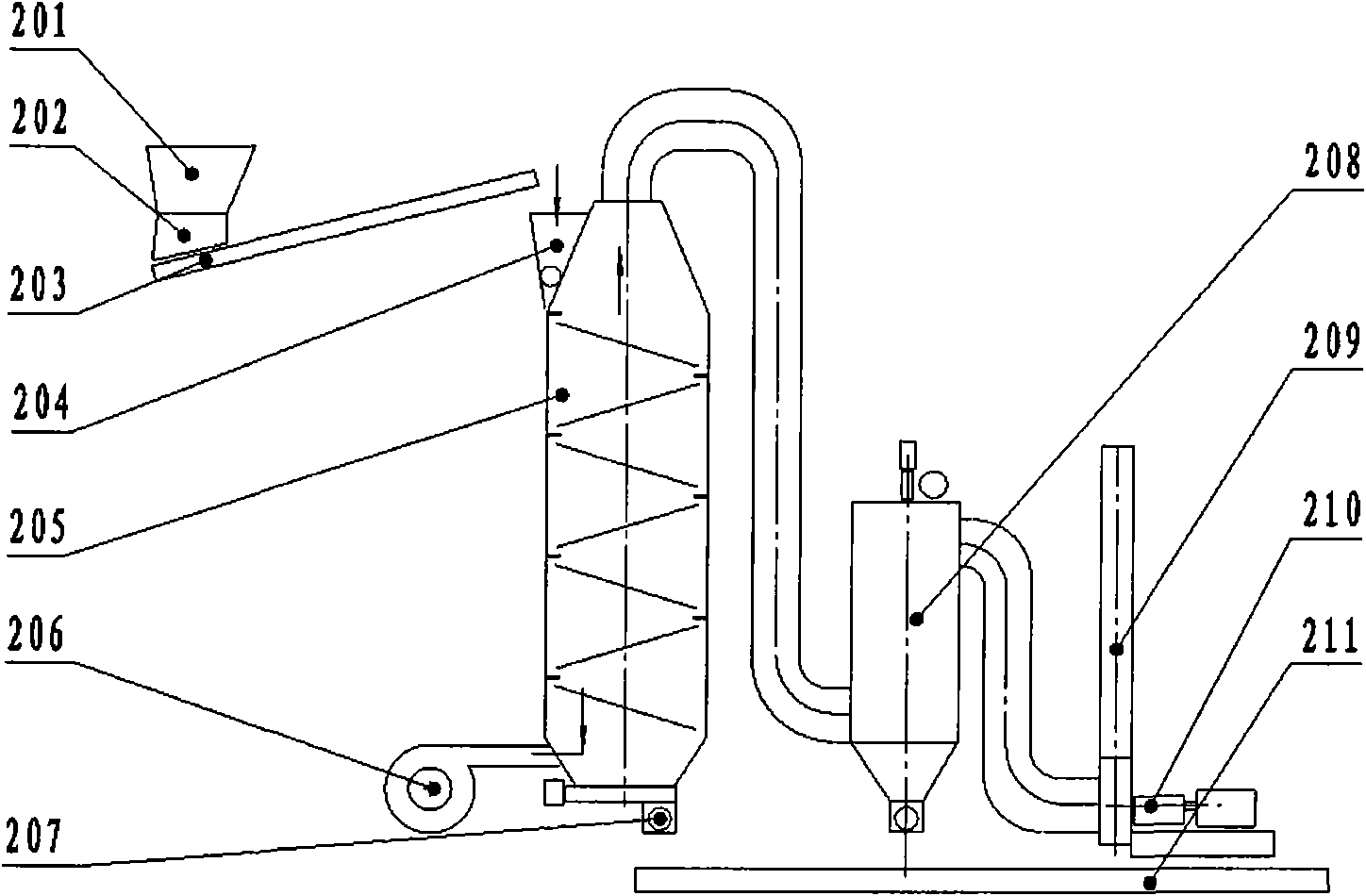

Huadian type process and device for dry distillation of oil shale

ActiveCN101942313AGuaranteed to be heatedGuaranteed temperature requirementsDirect heating destructive distillationCombustible gas purificationHeat carrierCooling tower

The invention provides a process and device for carrying out stage dry distillation on oil shale under the state of full recycle, with the gas as the heat carrier. The oil shale is divided into three different sizes (such as 0-6mm, 6-20mm and 20-50mm) through crushing and screening, and the oil shale is firstly dried and heated to the temperature between 50 DEG C and 150 DEG C by the waste smoke exhausted from gas heating furnaces and then enters into the different sizes of furnaces for dry distillation to undergo dry distillation. After being treated by water spraying and an indirect cooling tower, a rotary trapper and an electric trapper for oil collection, the dry distillation oil and gas undergo oil-gas-water separation, and after separation, the oil enters into a storage tank, the water enters into a circulating water tank and the first part of gases serves as the heat carrier and is recycled, the second part of gases is used as the fuels for the heating furnaces and the third part of gases is used as the fuel gases for power generation.

Owner:辽宁成大能源科技有限公司

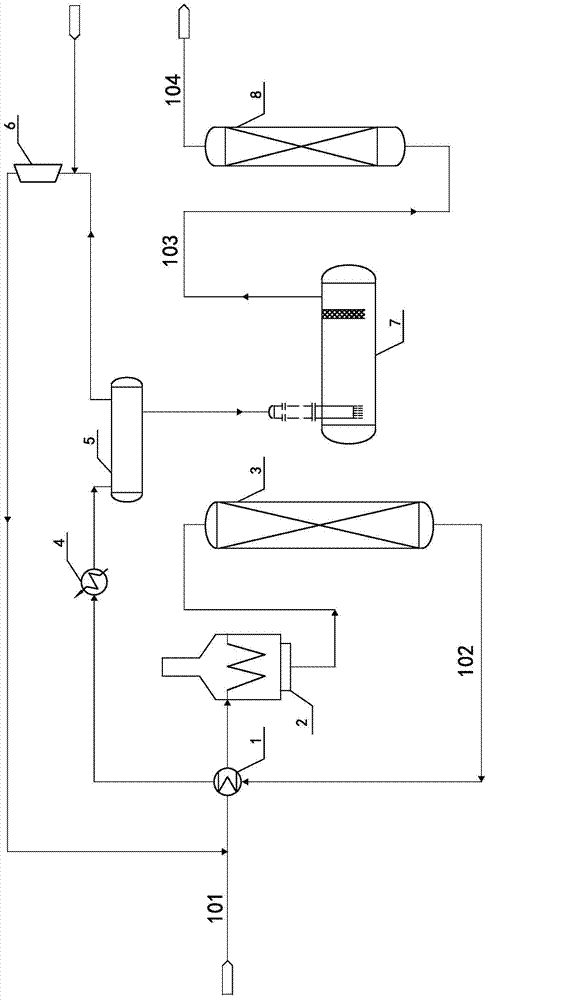

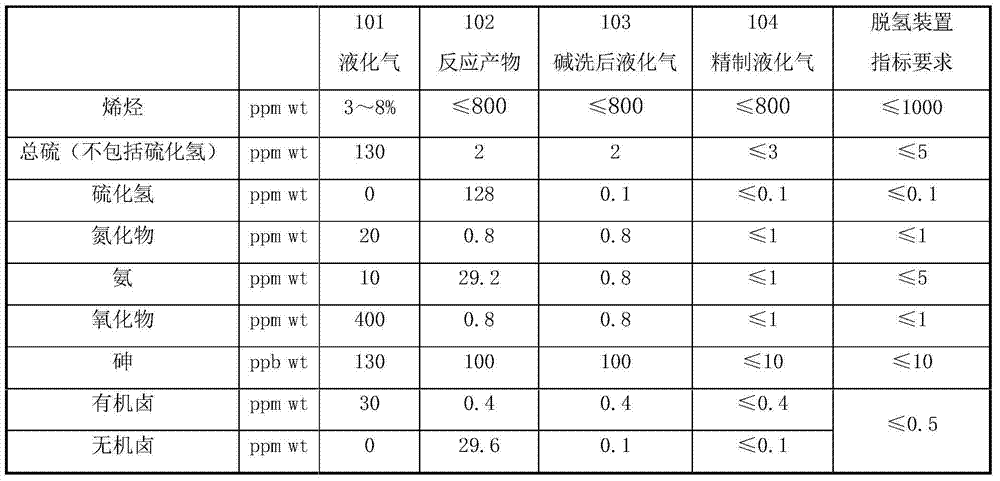

High-temperature hydrogenation and purification process for liquefied gas materials

The invention relates to a purification process of liquefied gas and particularly provides a high-temperature hydrogenation and purification process for liquefied gas materials. The high-temperature hydrogenation and purification process is characterized by comprising the following steps: (1) carrying out heat exchange on raw material liquefied gas and a reactor outlet product in a heat exchanger, heating by a heating furnace to a reaction temperature, then feeding the material into a reactor from the top, carrying out saturation hydrogenation on olefin in the material to obtain alkane, and respectively hydrogenating and converting sulfide, oxide, nitride and halide into hydrogen sulfide, water, ammonia and hydrogen halide; (2) carrying out sufficient heat exchange on the reactor outlet product and the raw material by an efficient heat exchanger, carrying out water cooling by a water cooler and enabling the material to enter a gas-liquid separation tank, compressing a flashing gas phase and fresh hydrogen by a compressor and circulating to the raw material liquefied gas; (3) enabling the flashing liquid phase to enter an alkali washing deposition tank and carrying out fiber membrane alkali washing to remove hydrogen sulfide, ammonia and hydrogen halide; (4) enabling the material which is subjected to the alkali washing to enter a dearsenicator, and removing arsenic and metal to obtain refined liquefied gas. The high-temperature hydrogenation and purification process mainly aims at a project which is very strict in requirement on the impurity content of a catalyst, and is short in flow, small in investment, low in cost and less in solid wastes.

Owner:山东海成石化工程设计有限公司

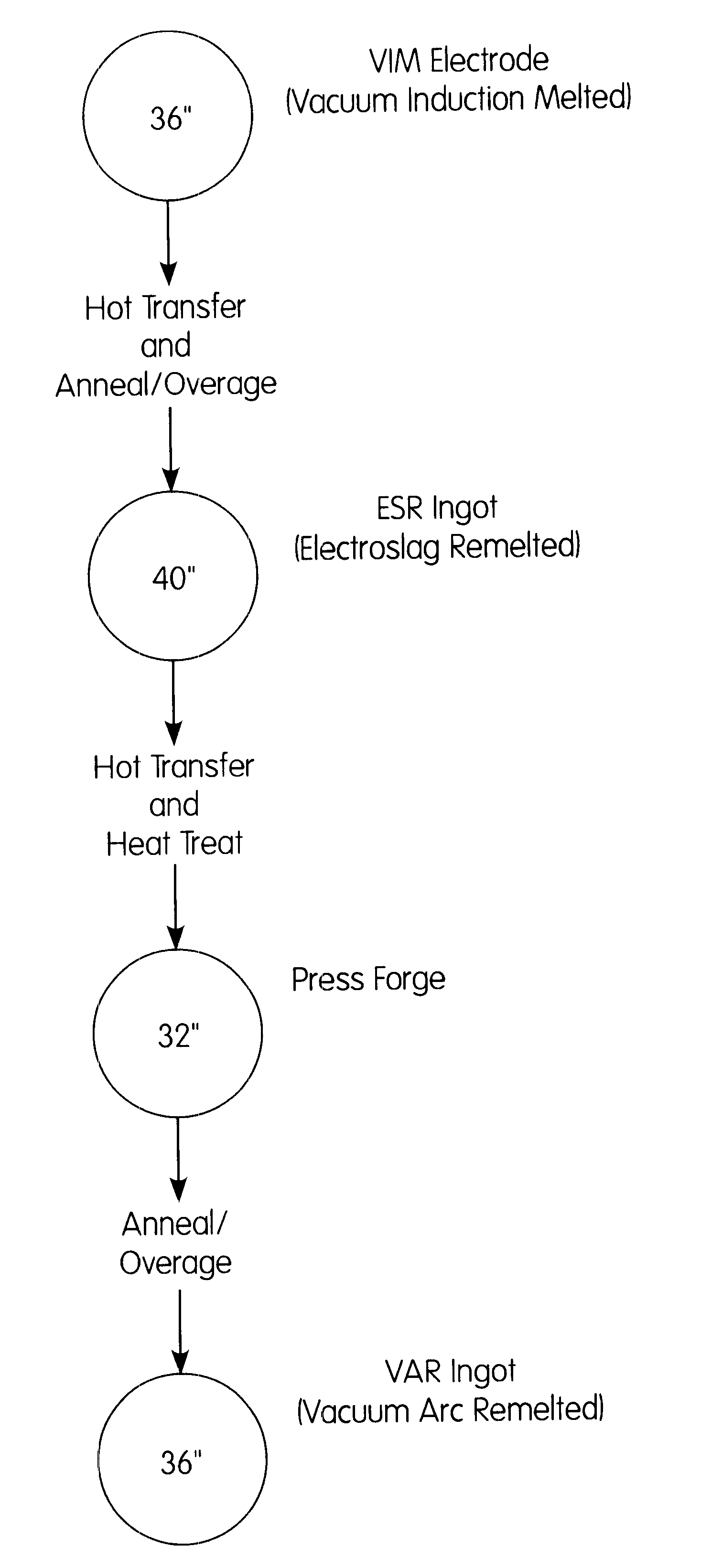

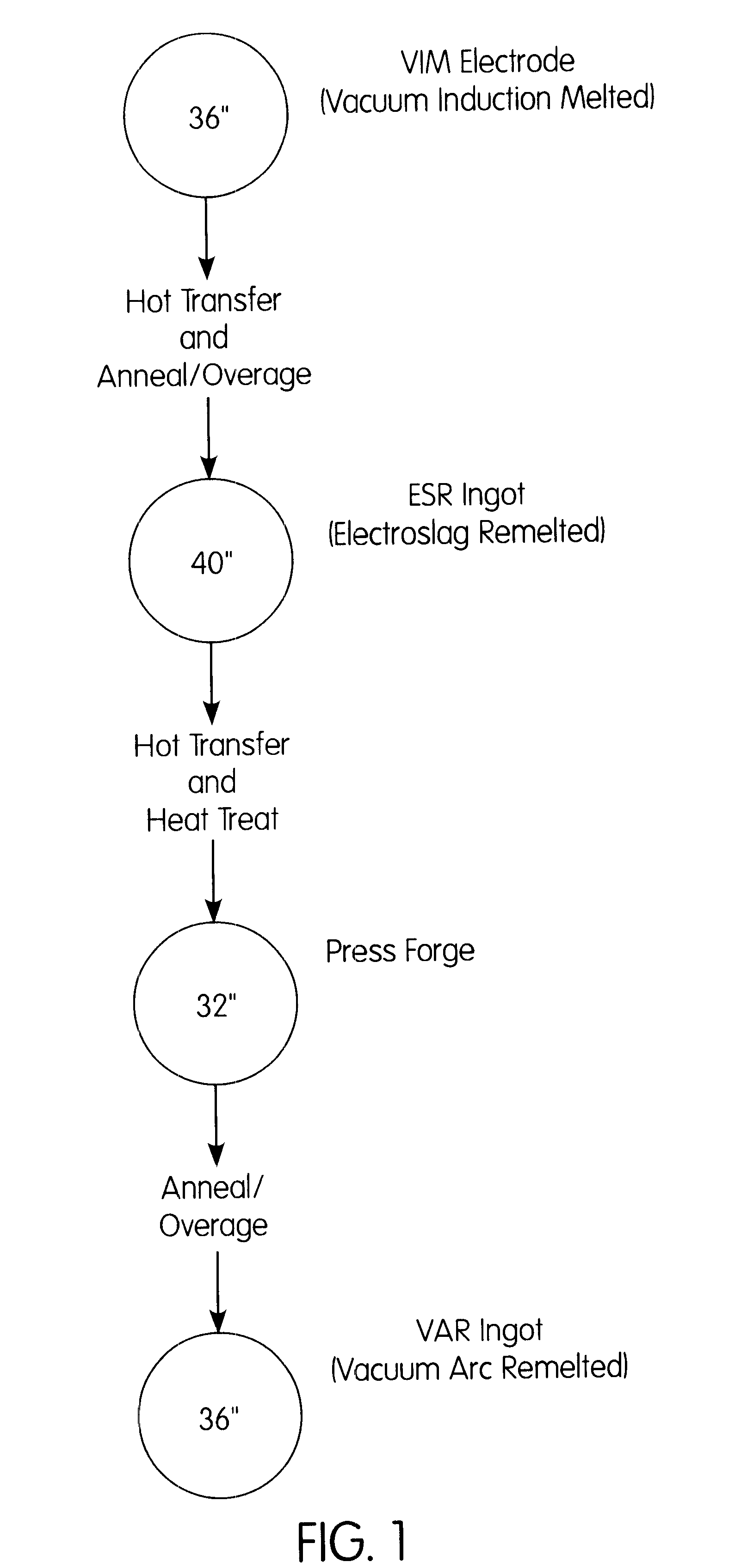

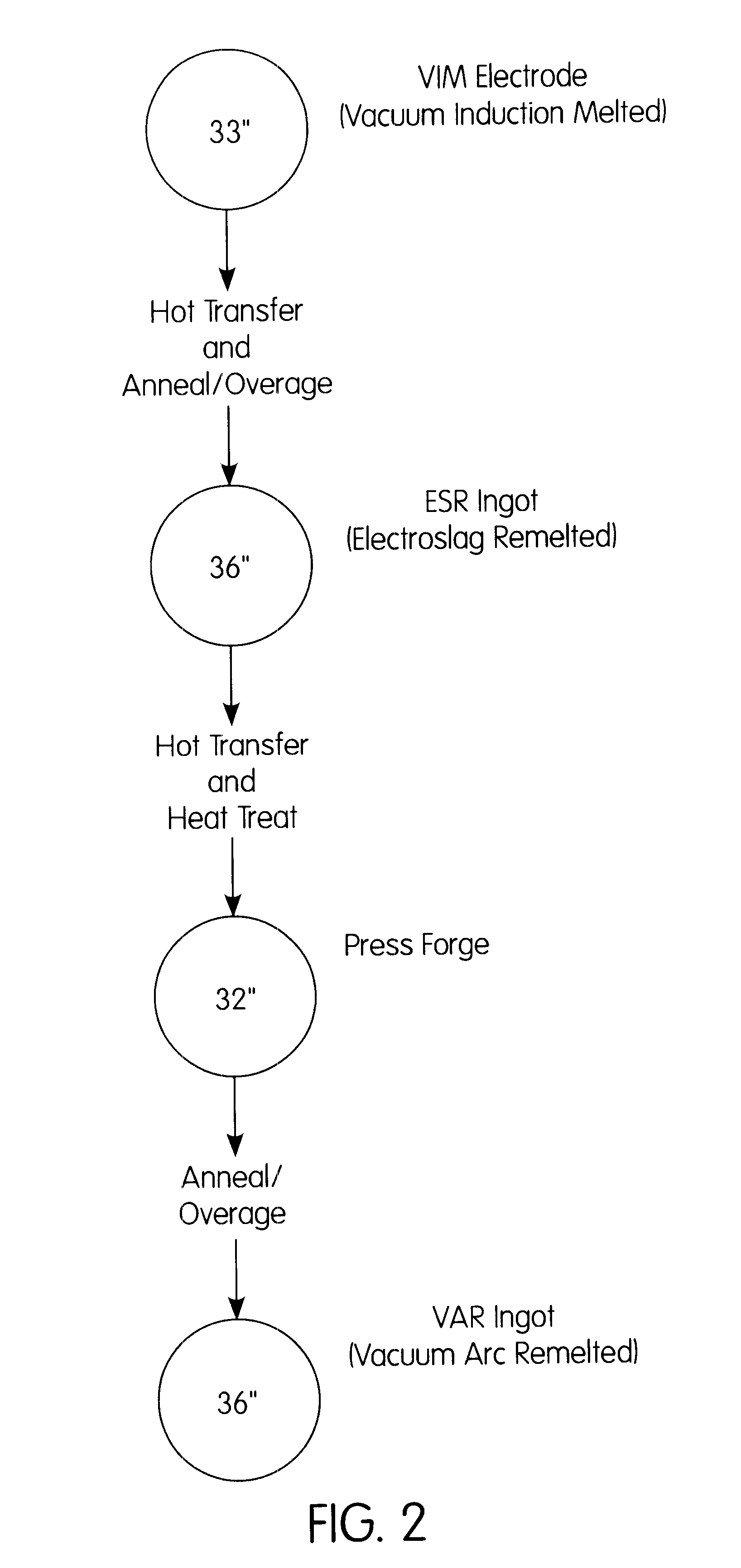

Method for producing large diameter ingots of nickel base alloys

InactiveUS6416564B1Inhibit thermal stressLarge caliberWelding/cutting media/materialsElectric furnaceCasting moldHeating furnace

A method of producing a nickel base alloy includes casting the alloy within a casting mold and subsequently annealing and overaging the ingot at at least 1200° F. (649° C.) for at least 10 hours. The ingot is electroslag remeelted at a melt rate of at least 8 lbs / min (3.63 kg / mm.), and the ESR ingot is then transferred to a heating furnace within 4 hours of complete solidification and is subjected to a novel post-ESR heat treatment. A suitable VAR electrode is provided form the ESR ingot, and the electrode is vacuum arc remelted at a melt rate of 8 to 11 lbs / minute (3.63 to 5.00 kg / minute) to provide a VAR ingot. The method allows premium quality VAR ingots having diameters greater than 30 inches (762 mm) to be prepared from Alloy 718 and other nickel base superalloys subject to significant segregation on casting.

Owner:ATI PROPERTIES

Method for comprehensive harmless recovery and utilization of waste lithium ion power battery

ActiveCN105428745AReduce wasteEasy to keepWaste accumulators reclaimingBattery recyclingPower batteryElectrical battery

The present invention relates to a method for comprehensive harmless recovery and utilization of a waste lithium ion power battery. The method comprises the following steps: disassembling a waste battery pack, and measuring and collecting good battery cells to re-combine the good batteries for gradient utilization; sufficiently discharging defective waste lithium ion power battery cells, and disassembling the power battery cells in an oxygen-isolated environment; performing heat treatment on a fetched core pack in a heating furnace, and collecting a distilled solvent by means of condensation; disassembling the core pack from which the solvent is distilled off to obtain a membrane material, a positive electrode plate and a negative electrode plate; placing the positive electrode plate and the negative electrode plate in a rotary kiln of 200-600 DEG C to be subjected to heat treatment; sorting electrode plates, which have been subjected to the heat treatment, by using a pulverizer and a powder sorter separately, so as to obtain an aluminum powder, a copper powder, a waste positive electrode powder and a waste negative electrode powder; and repairing the positive electrode powder and the negative electrode powder separately. According to the method provided by the present invention, a fully-dry closed-circuit recovery process is adopted, thereby achieving the harmless recovery and utilization of the waste lithium ion power battery.

Owner:北京赛德美资源再利用研究院有限公司

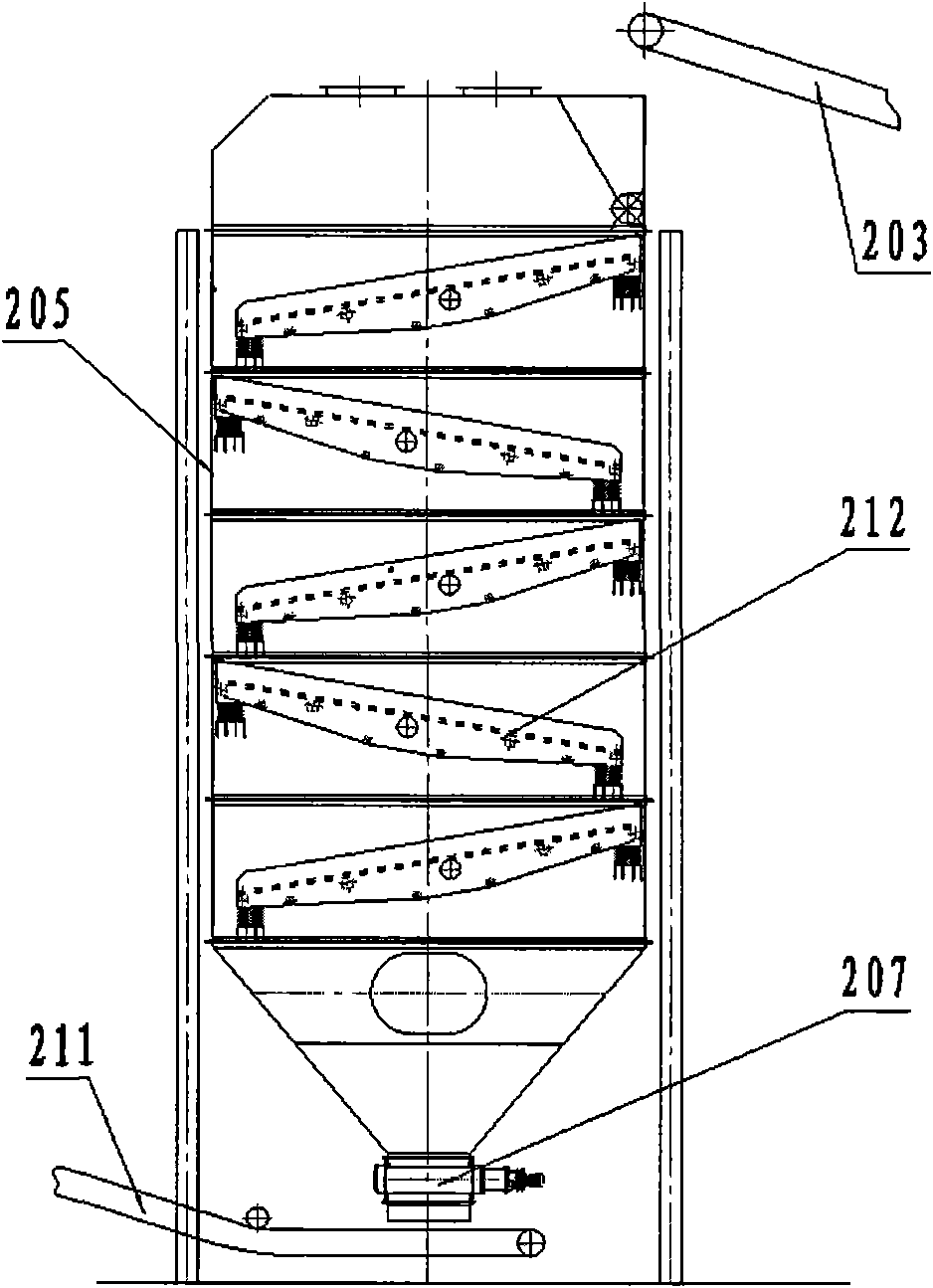

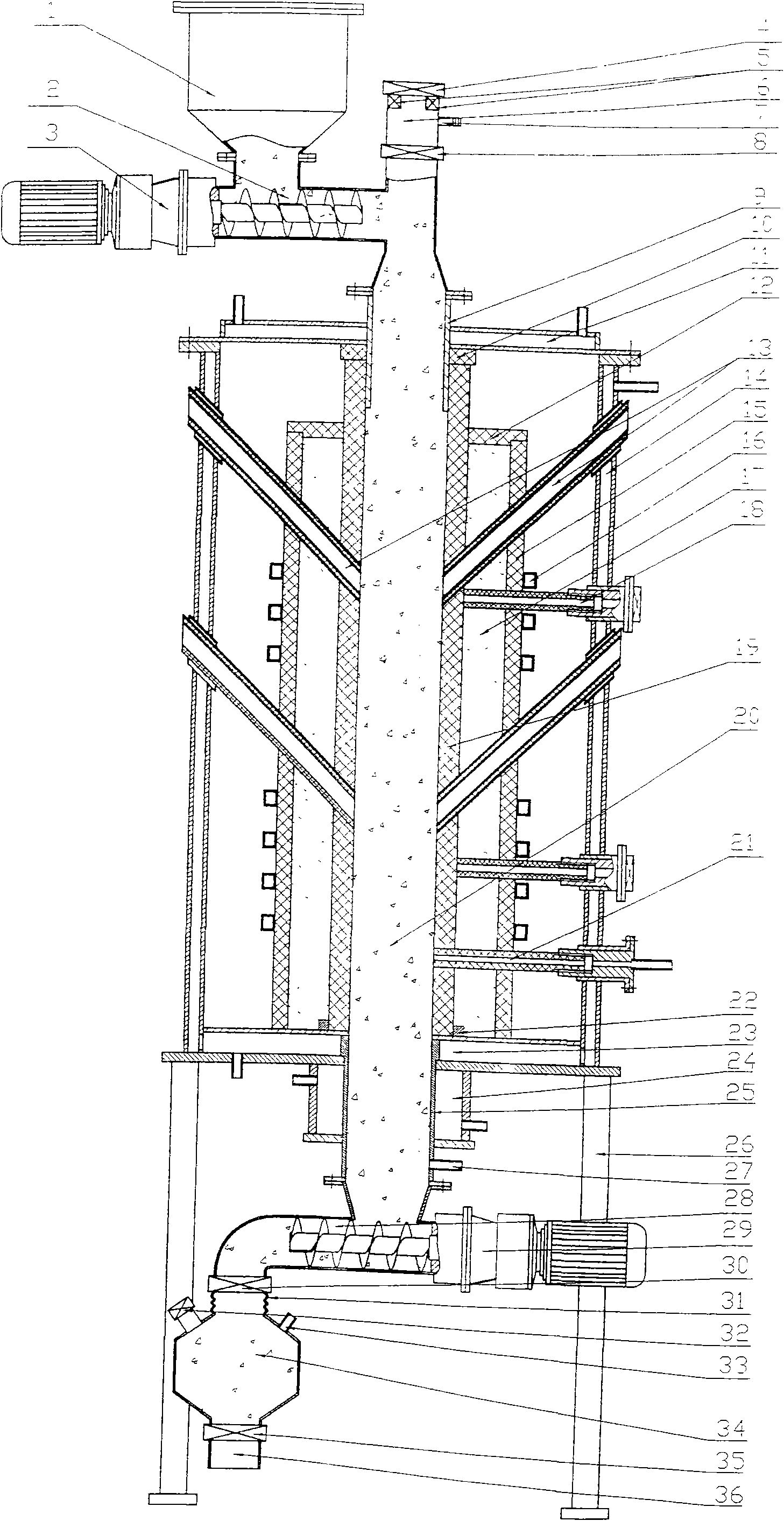

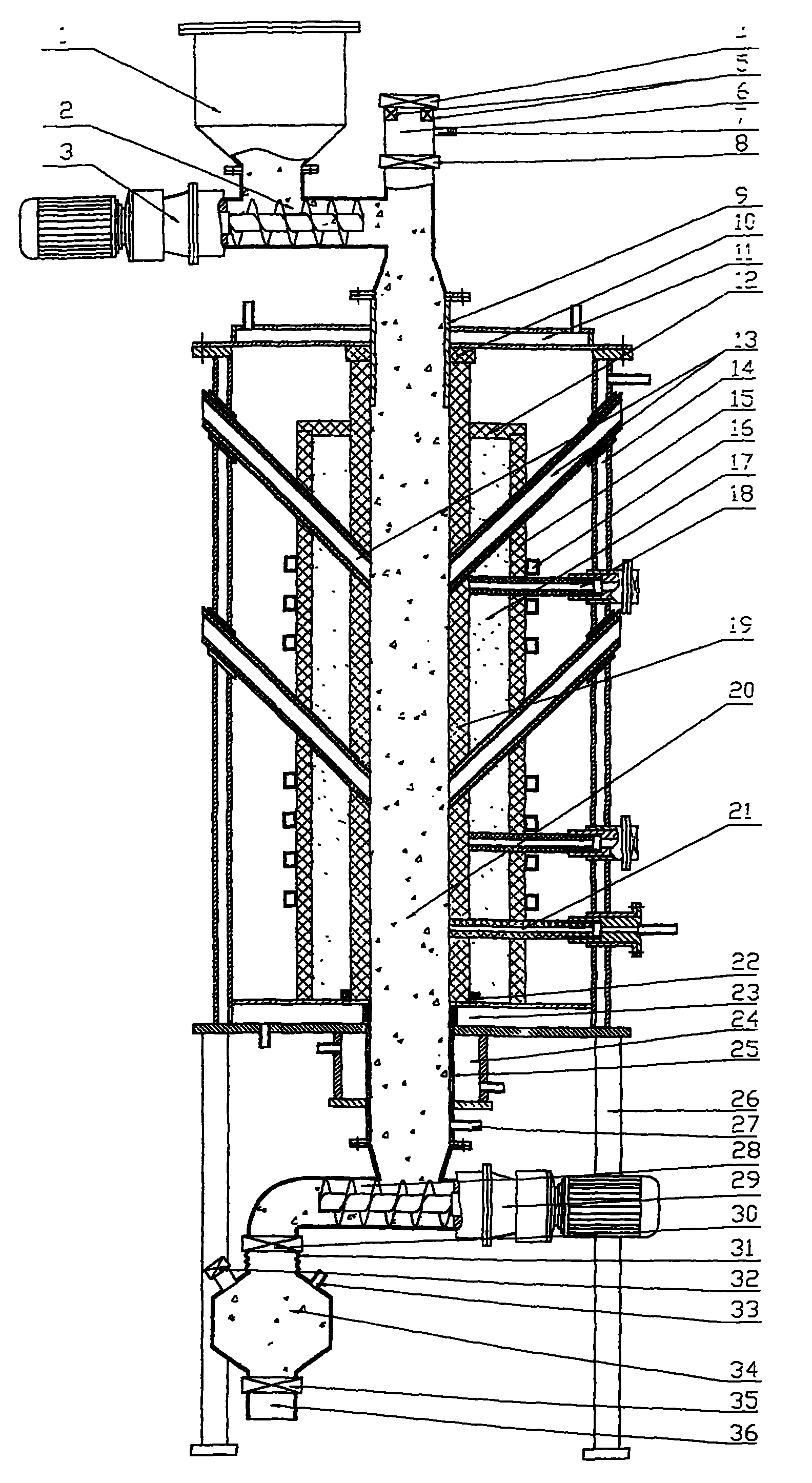

Graphite purification and graphitizable high temperature vertical continuous induction heating furnace

The invention relates to a graphite purification and graphitizable high temperature vertical continuous induction heating furnace, comprising a furnace body, a hearth, an induction heating coil, an observation window device, a material inlet device, a material outlet device and the like. The heater furnace is in a vertical structure and adopts a continuous working mode and induction heating; the highest use temperature is 3000 DEG C; the hearth is a cylindrical space, the material inlet device is connected above the hearth while the material outlet device is connected below the hearth; the materal enters into the hearth under the coordinated action of the material inlet device and the material outlet device, falls down and passes through the hearth at an even speed; ash content and volatile matter content in the material are changed into volatile substances under the action of hearth temperature and purified gas in the temperature environment; and the volatile substances are discharged out of the furnace from a discharge pipe under the action of high temperature reaction pressure and scavenge gas, thus realizing continuous purification or continuous graphitizable process by one step. The induction heating furnace can make up for the insufficiencies of hydrofluoric acid wet process purification, and is characterized by high efficiency, low energy consumption and environment protection.

Owner:株洲弗拉德科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com