Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1089 results about "Simple component" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

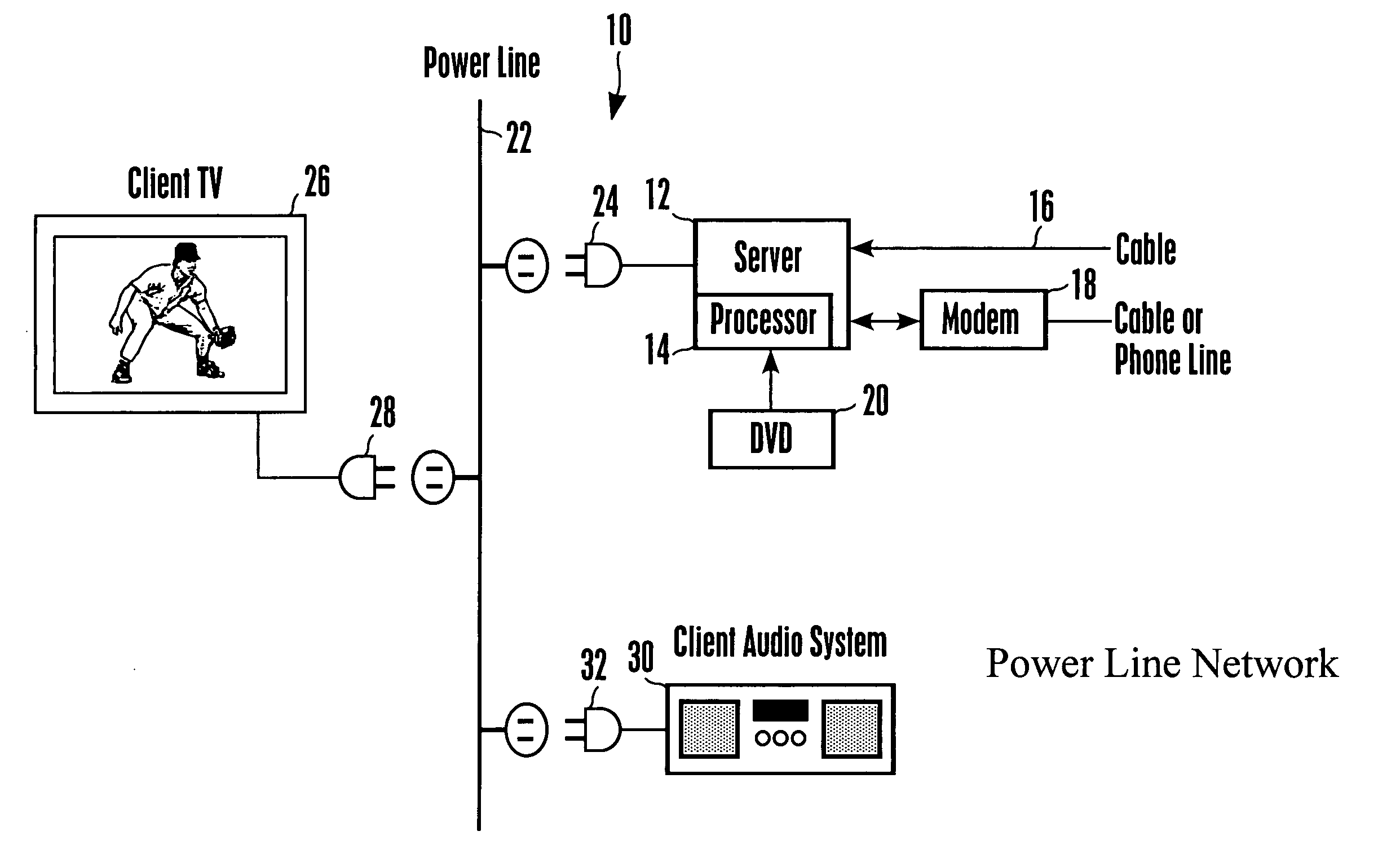

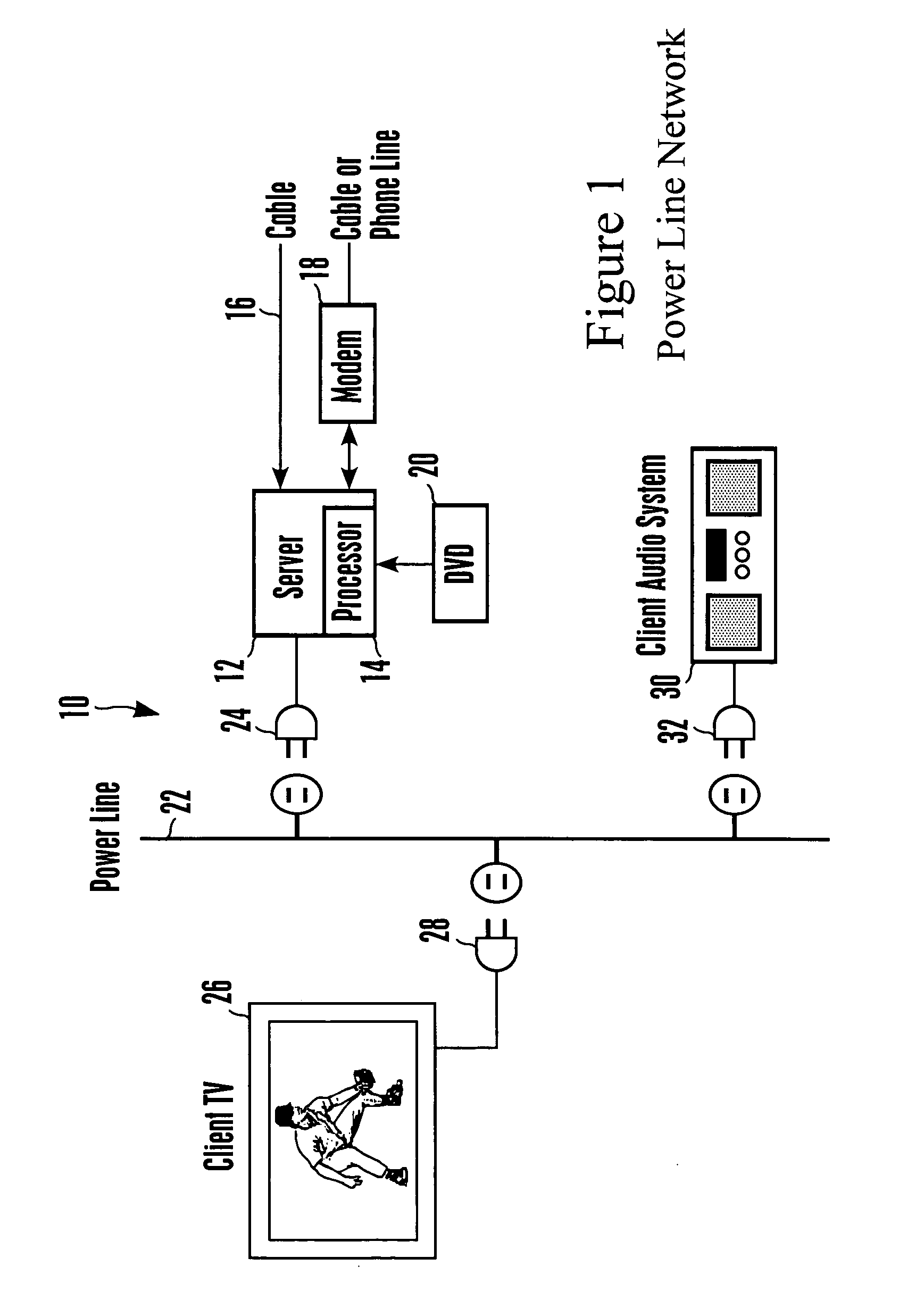

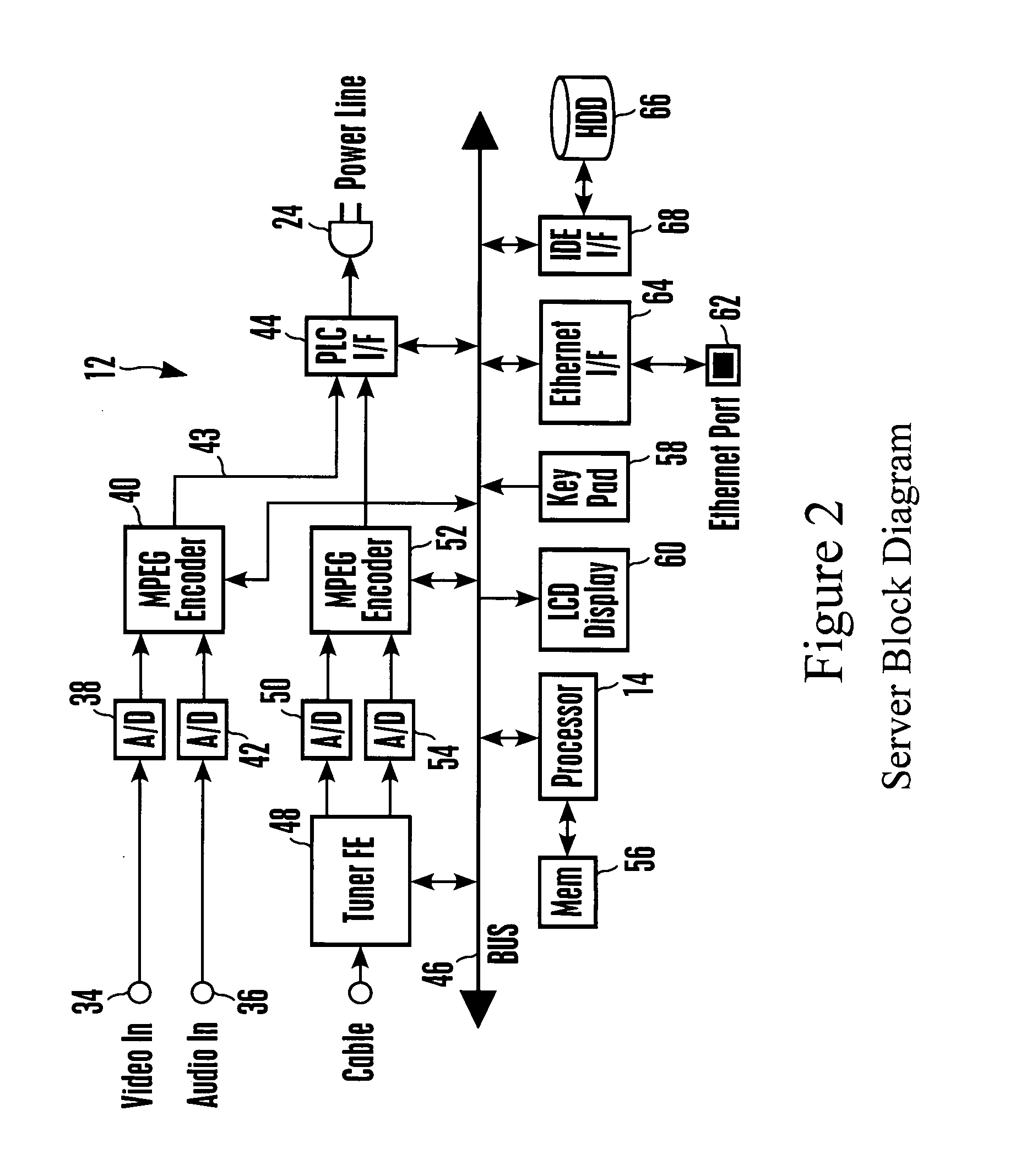

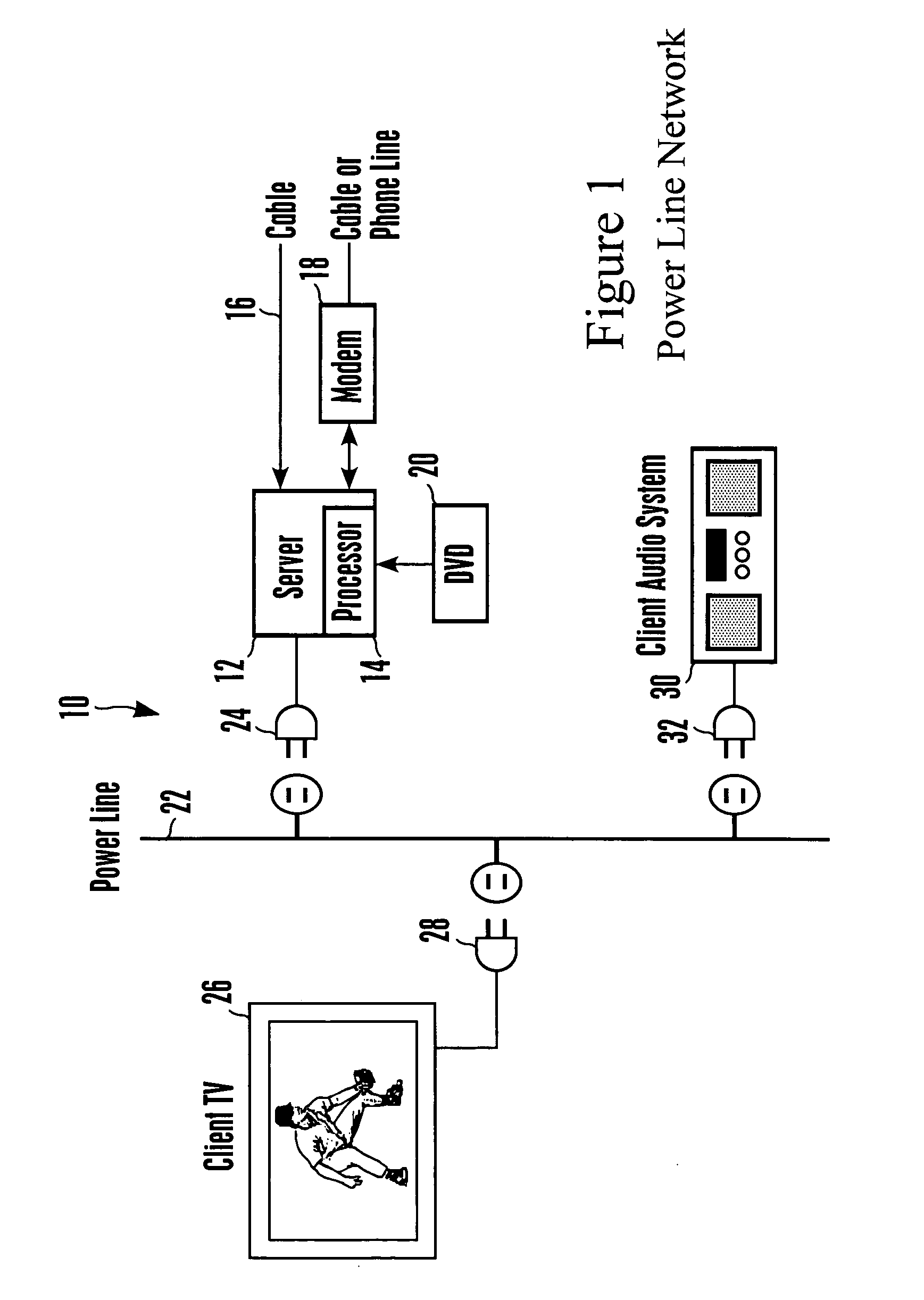

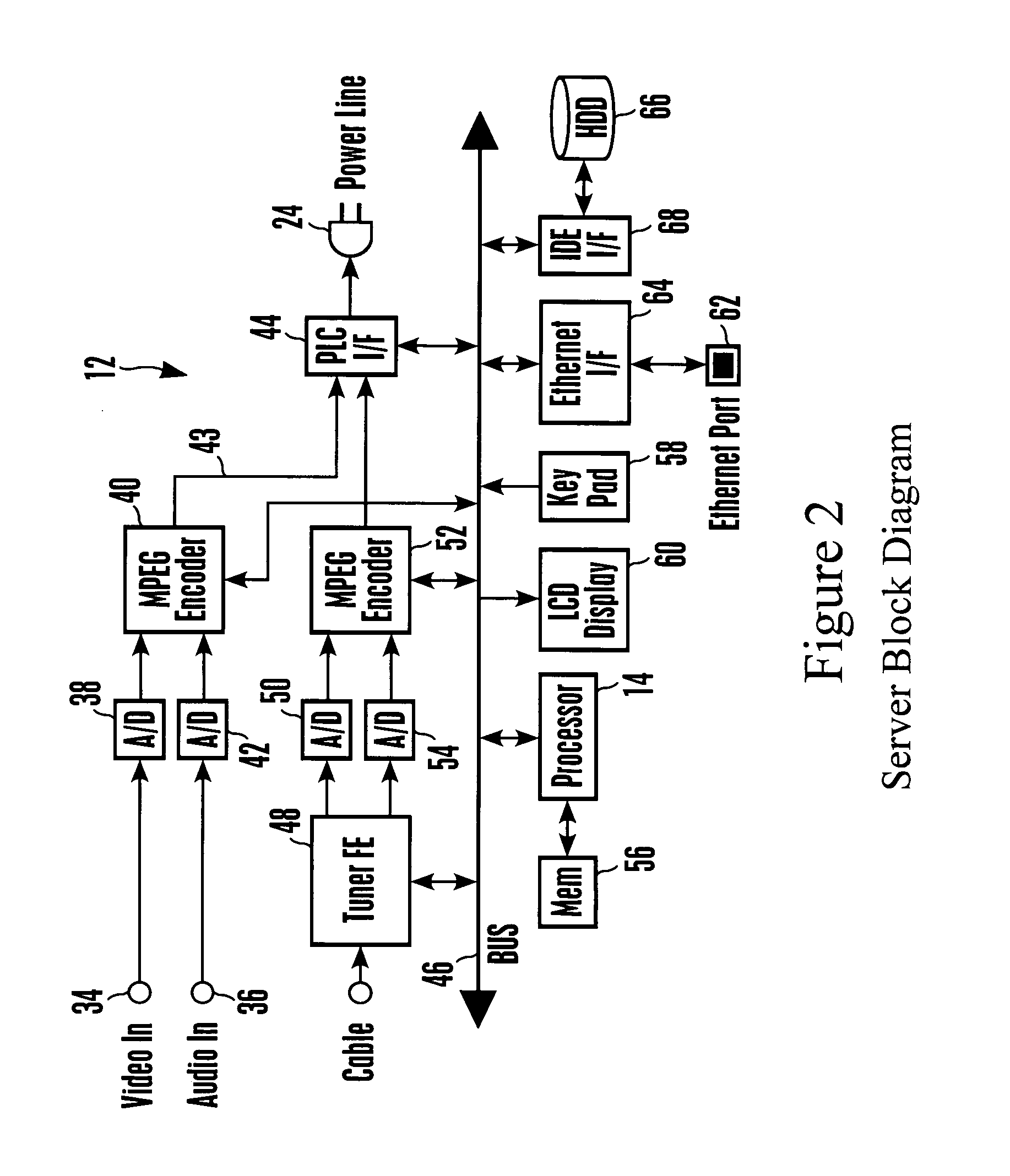

Universal network interface for home network

ActiveUS20050108760A1Special service provision for substationPulse modulation television signal transmissionSimple componentHome area network

Owner:SONY CORP +1

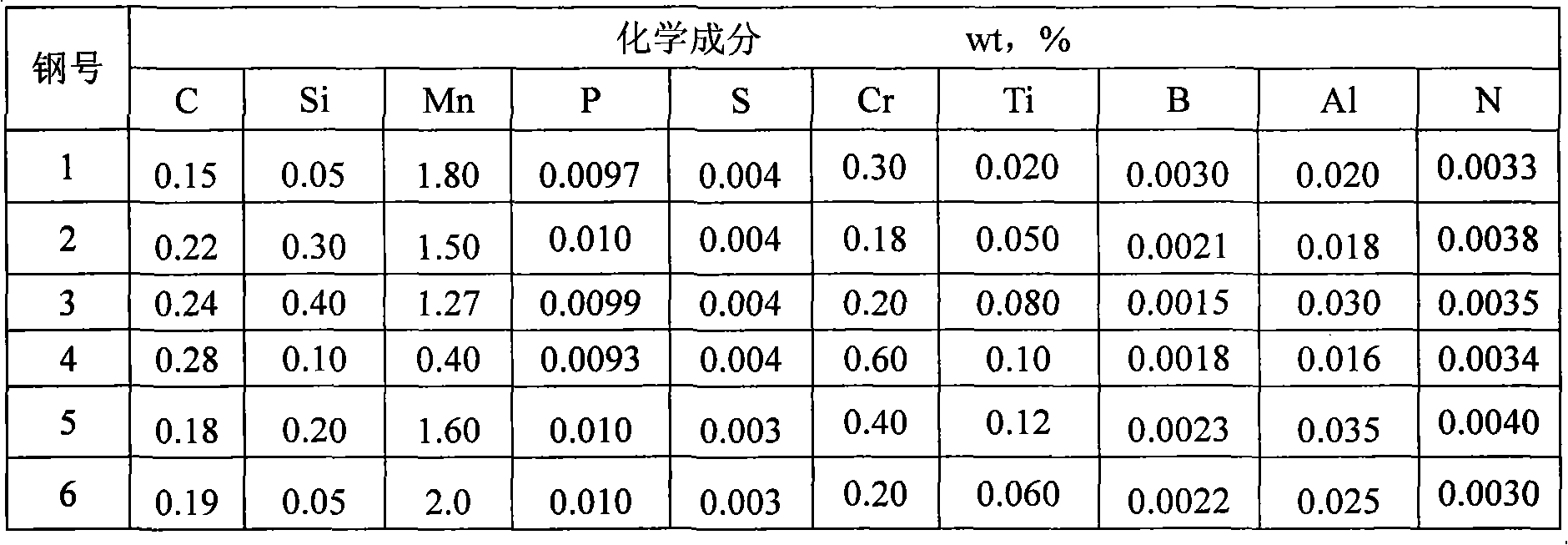

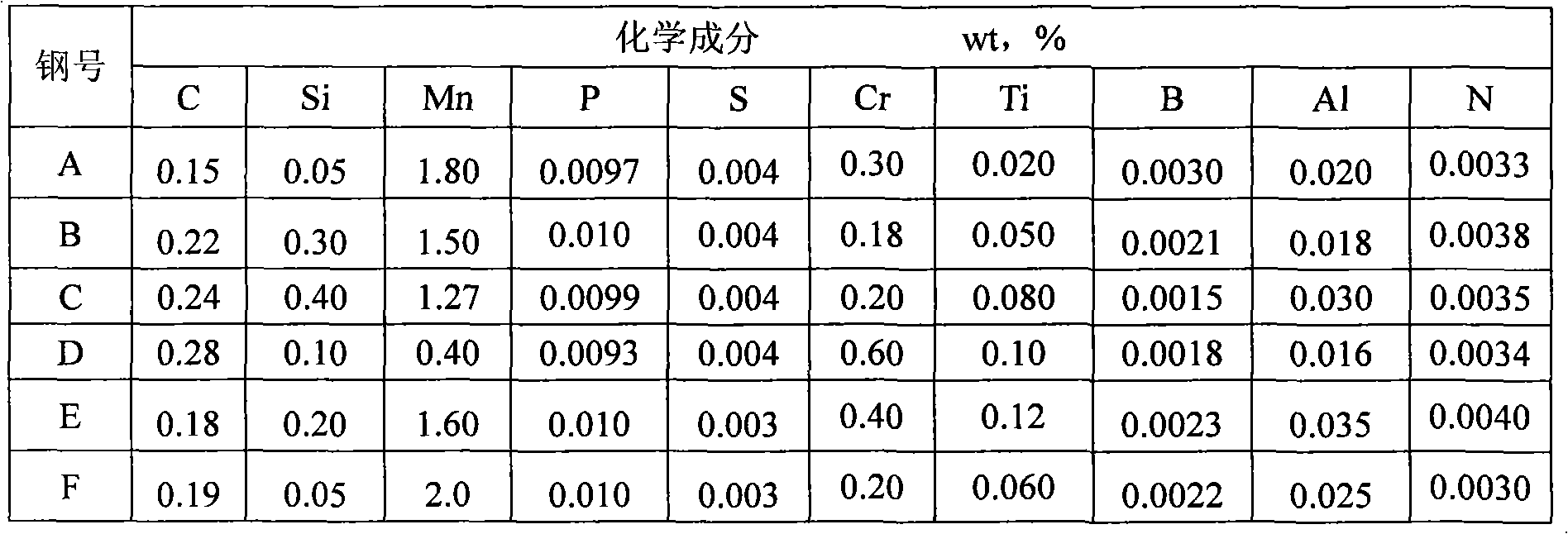

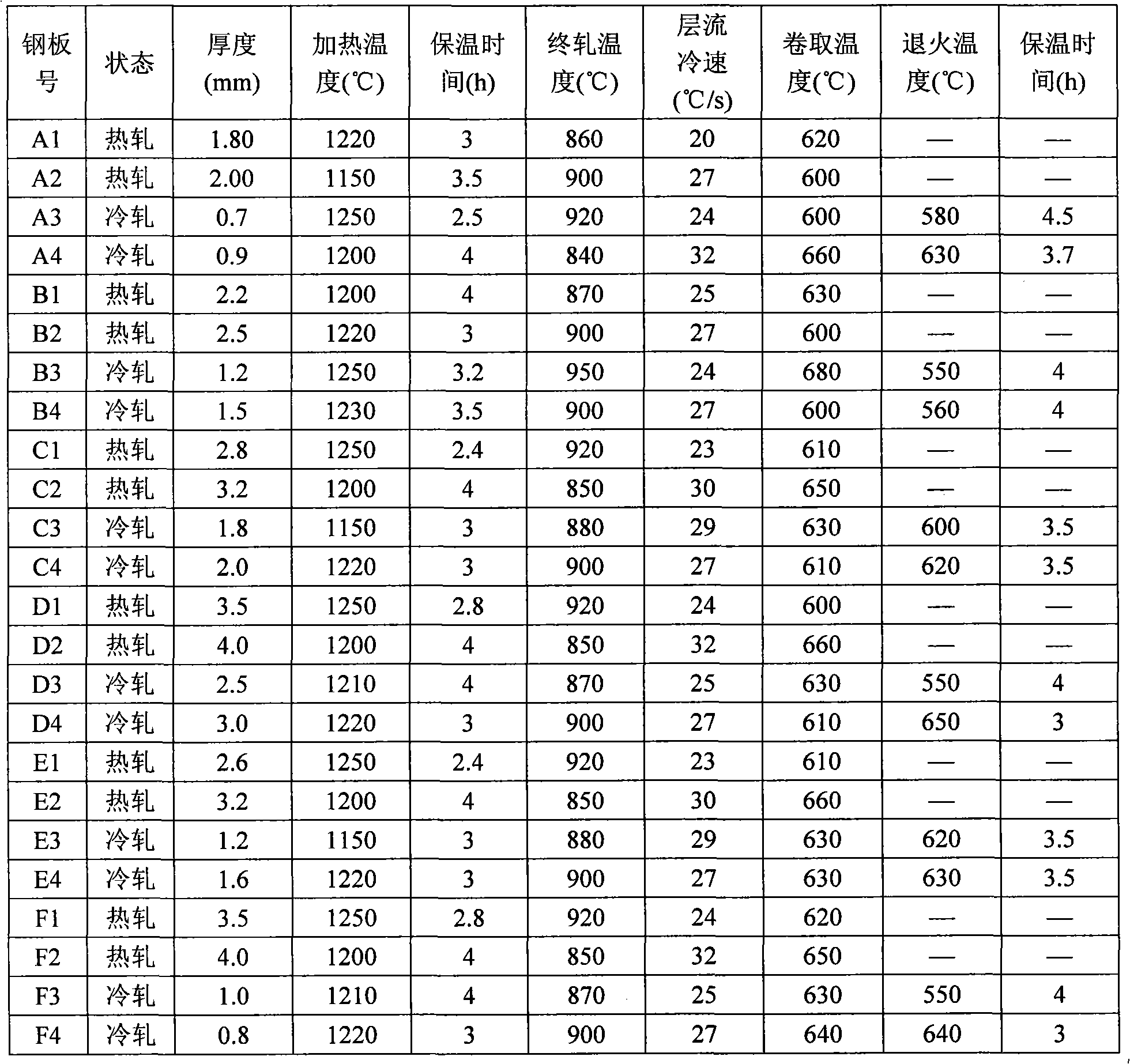

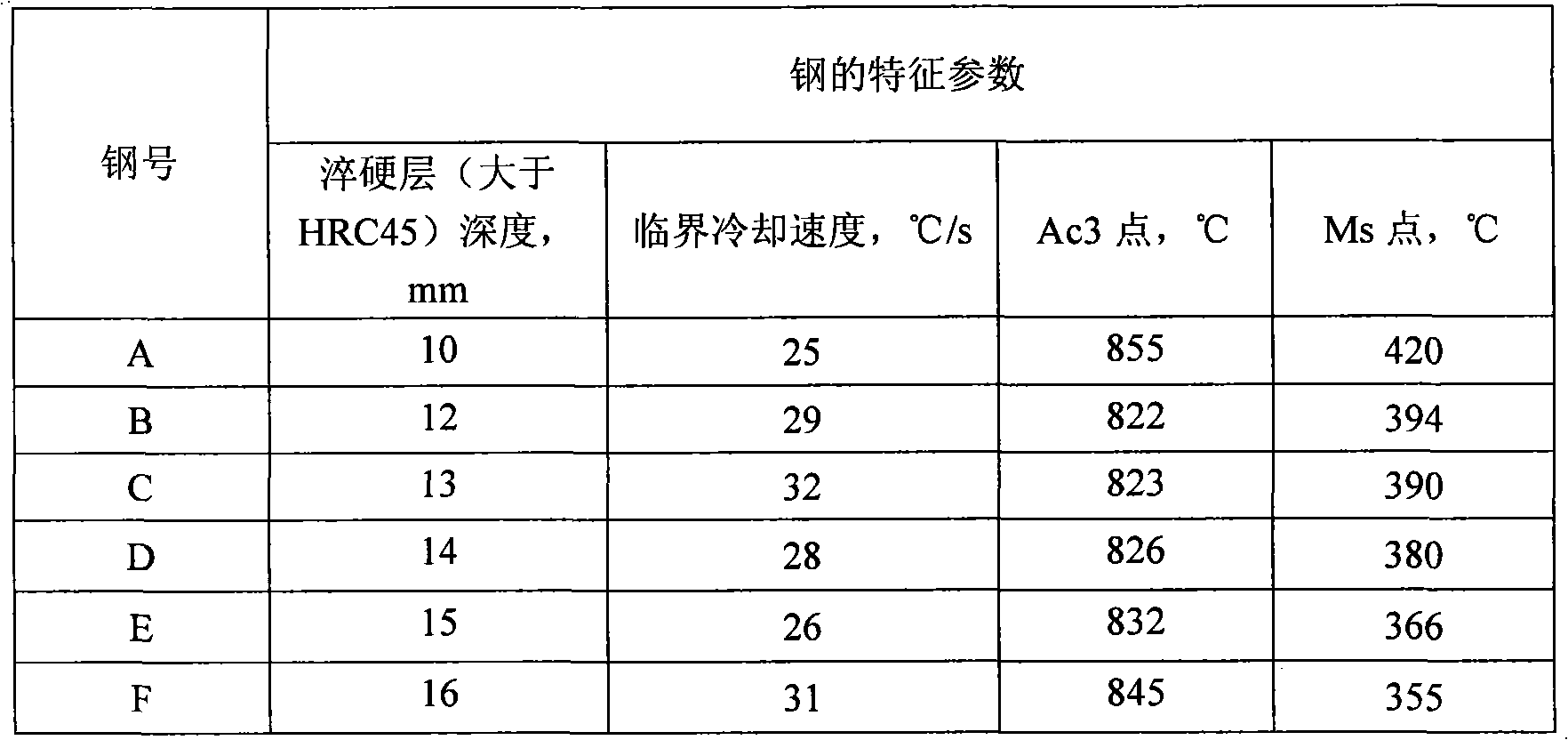

Steel plate for stamping and quenching and thermoforming method of steel plate

ActiveCN102031456ASimple compositionPlay the effect of weight reduction and energy savingHot stampingSimple component

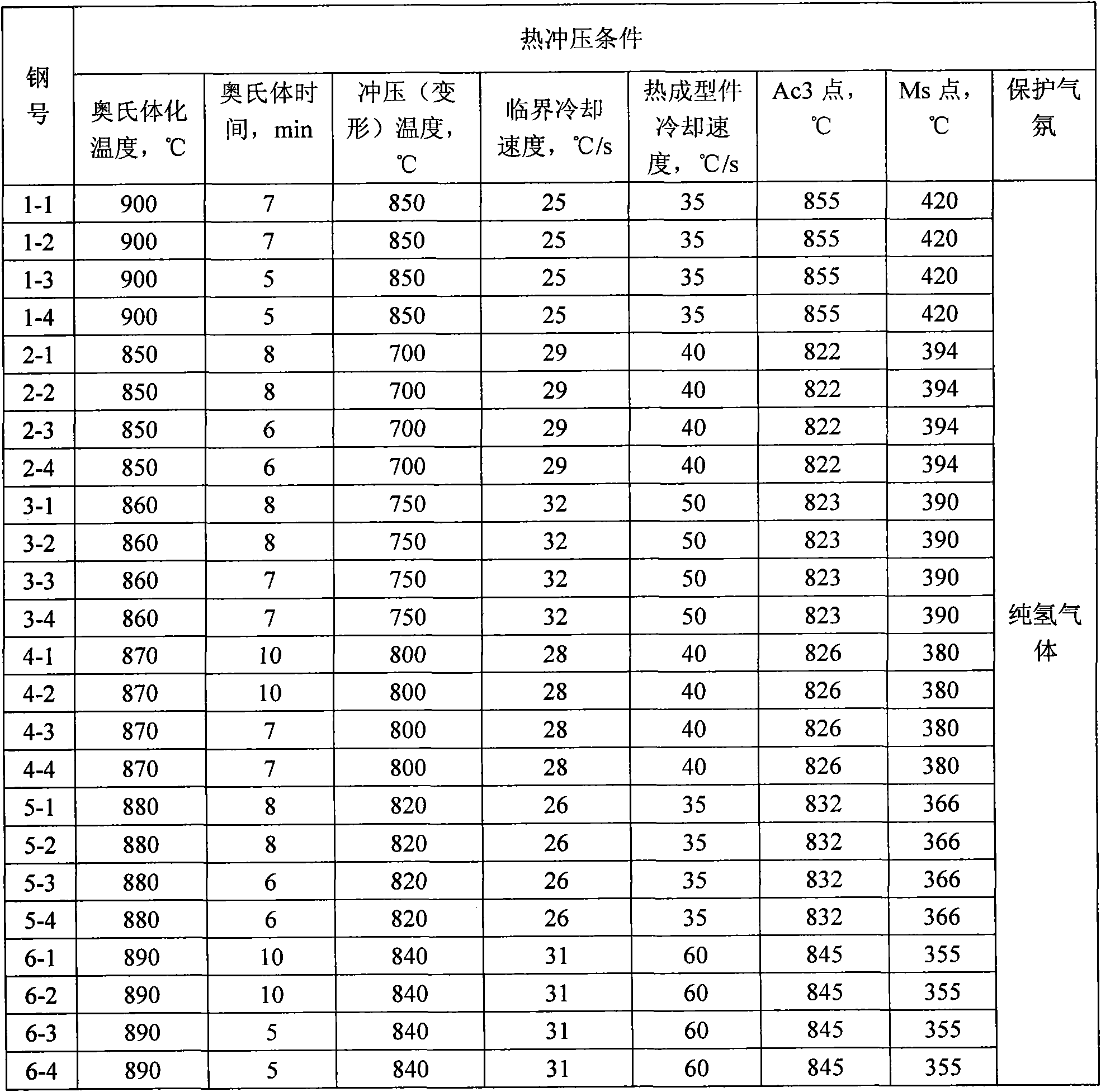

The invention discloses a steel plate for stamping and quenching and a thermoforming method of the steel plate. The steel plate comprises the following chemical components in percentage by weight: 0.14-0.28% of C, less than 0.40% of Si, 0.4-2.0% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 0.016-0.040% of Al, 0.15-0.8% of Cr, 0.015-0.12% of Ti, 0.0001-0.005% of B, less than or equal to 0.005% of N, and the balance of Fe and inevitable impurities. The thermoforming method comprises the following steps: blanking by shearing the steel plate, and heating at Ac3 to (Ac3+80) DEG C to carry out austenization; after insulating for 5-10 minutes in the heating furnace, immediately transferring the steel plate to a metal mold the inside of which is cooled by introducing water, and stamping at the high temperature of 650-850 DEG C; cooling the formed workpiece in the closed mold, and cooling the mold by water circulation in the mold, wherein the cooling rate is greater than the critical cooling rate when austenite forms martensite, and the temperature of the workpiece leaving the hot stamping production line is below 150 DEG C; and carrying out air-cooling to room temperature. The steel plate has the advantages of simple component system and favorable hardenability; and the substrate tissues, which are ferrite and pearlite, are processed by hot stamping andquenching to obtain the all martensitic structure. The tensile strength of the steel plate can be higher than 1300 N / mm<2>.

Owner:ANGANG STEEL CO LTD

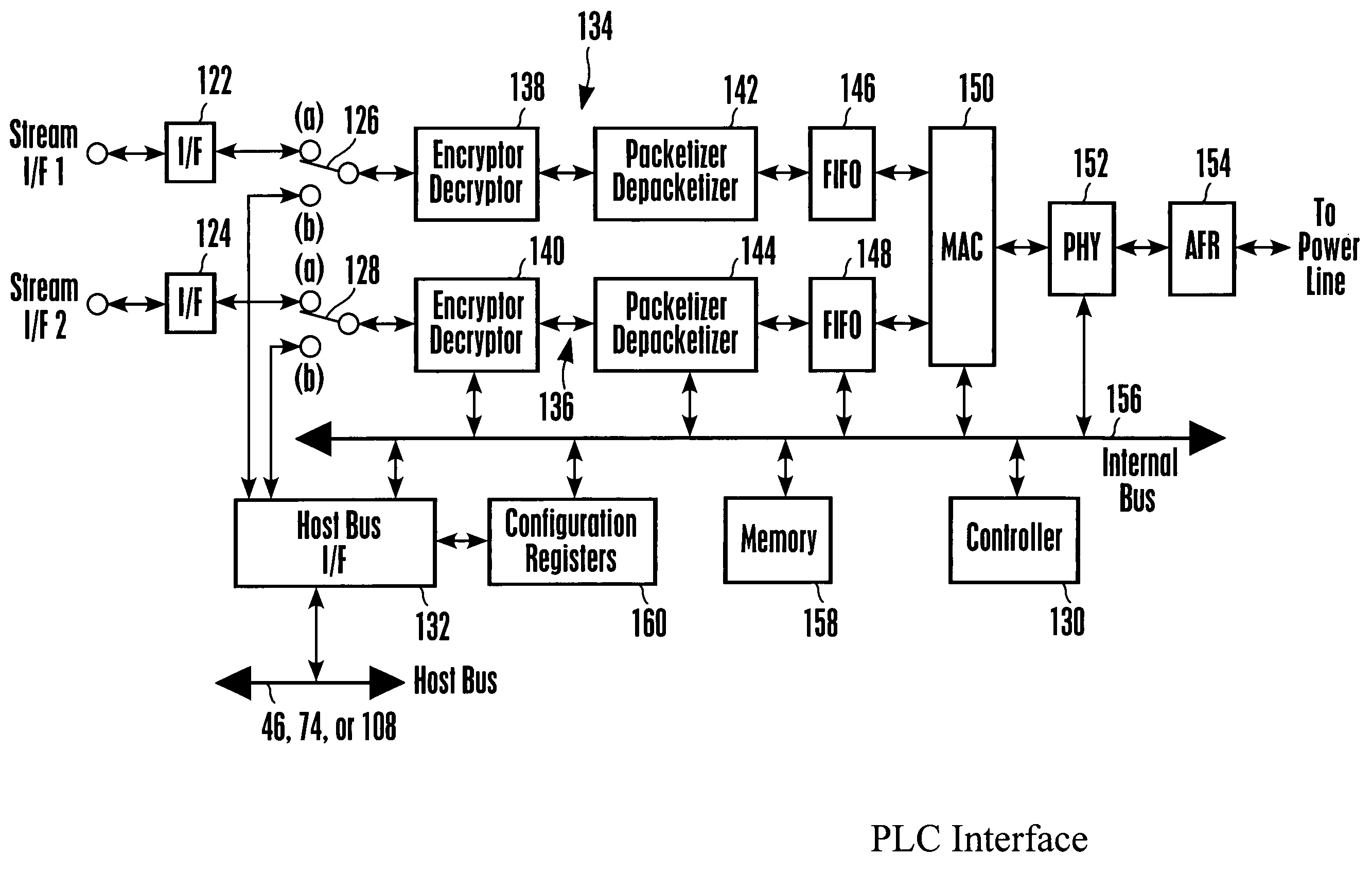

Plural interfaces in home network with first component having a first host bus width and second component having second bus width

ActiveUS7171506B2Special service provision for substationPulse modulation television signal transmissionSimple componentEmbedded system

Owner:SONY CORP +1

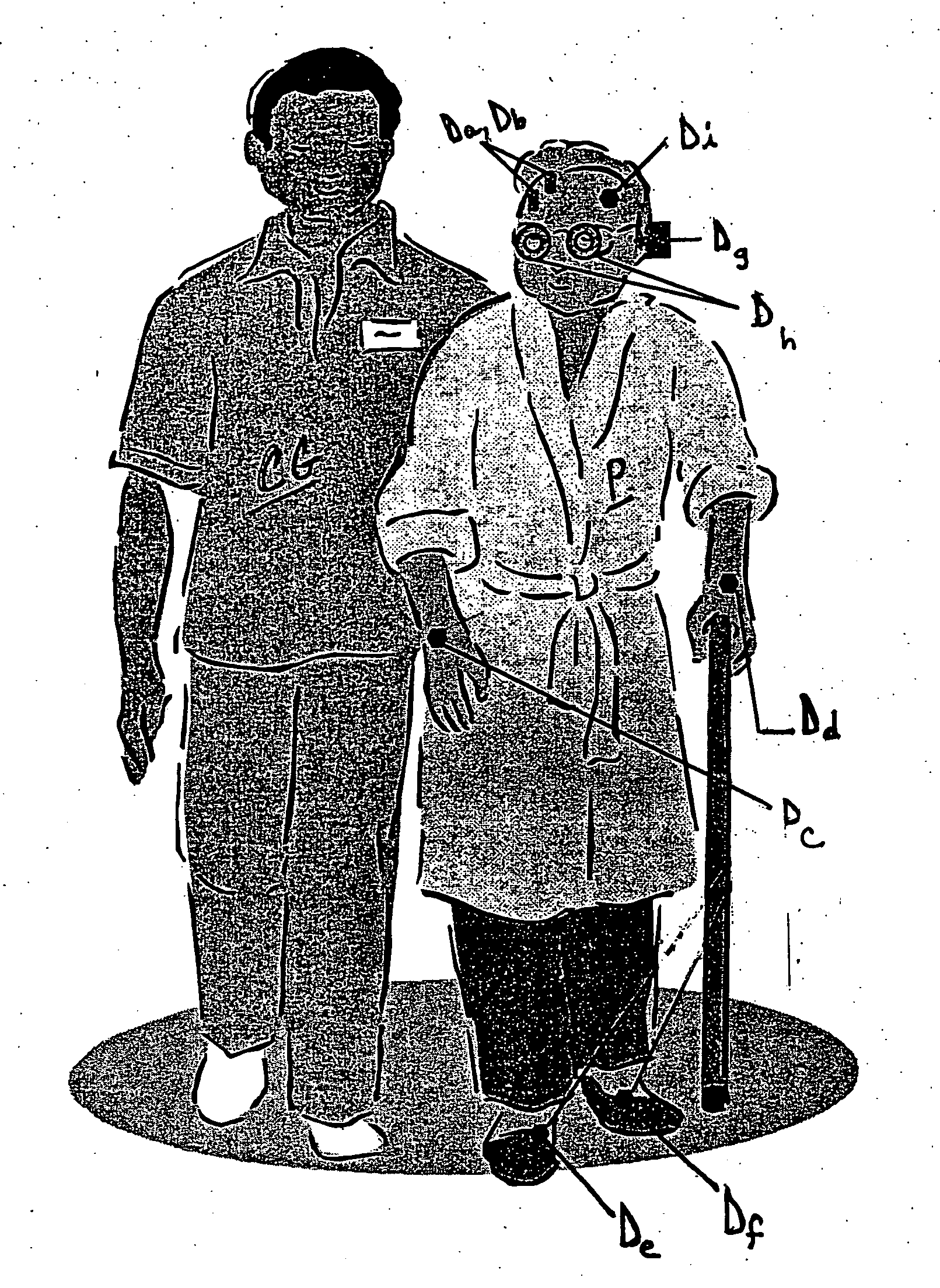

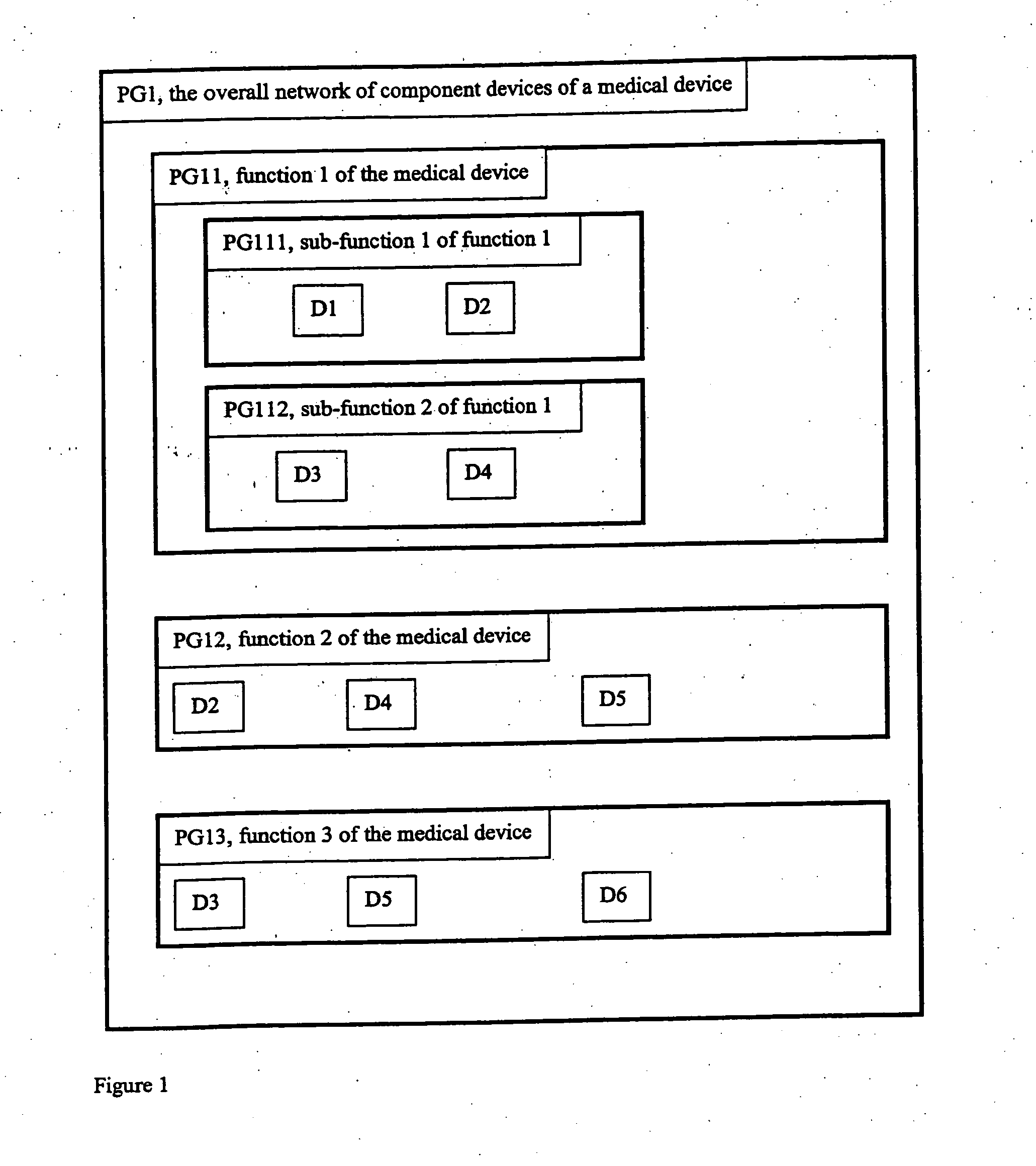

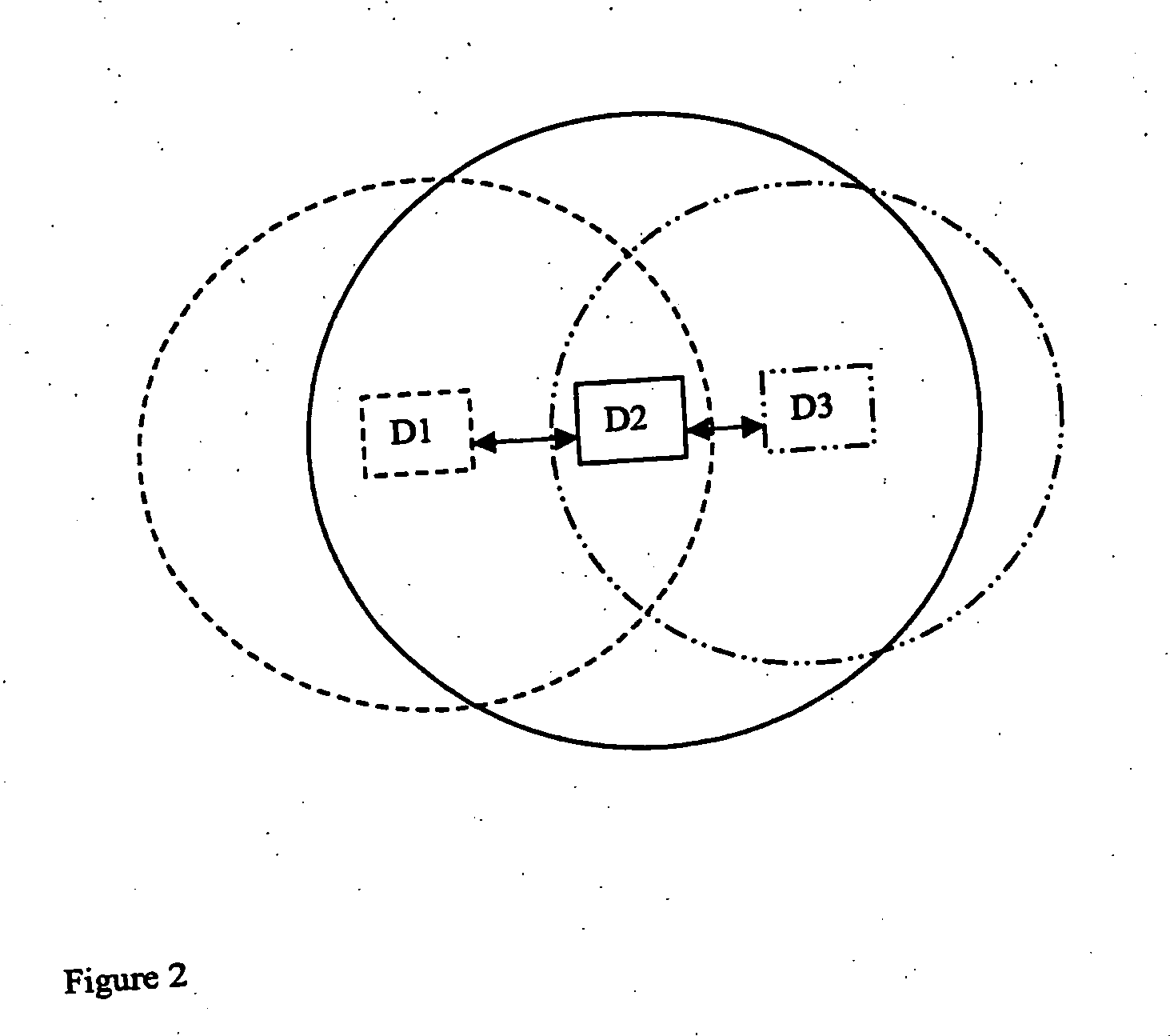

Embedded neural prosthesis

InactiveUS20070239211A1Easy to controlQuality improvementElectrotherapyDiagnostic recording/measuringHuman bodyTreatment effect

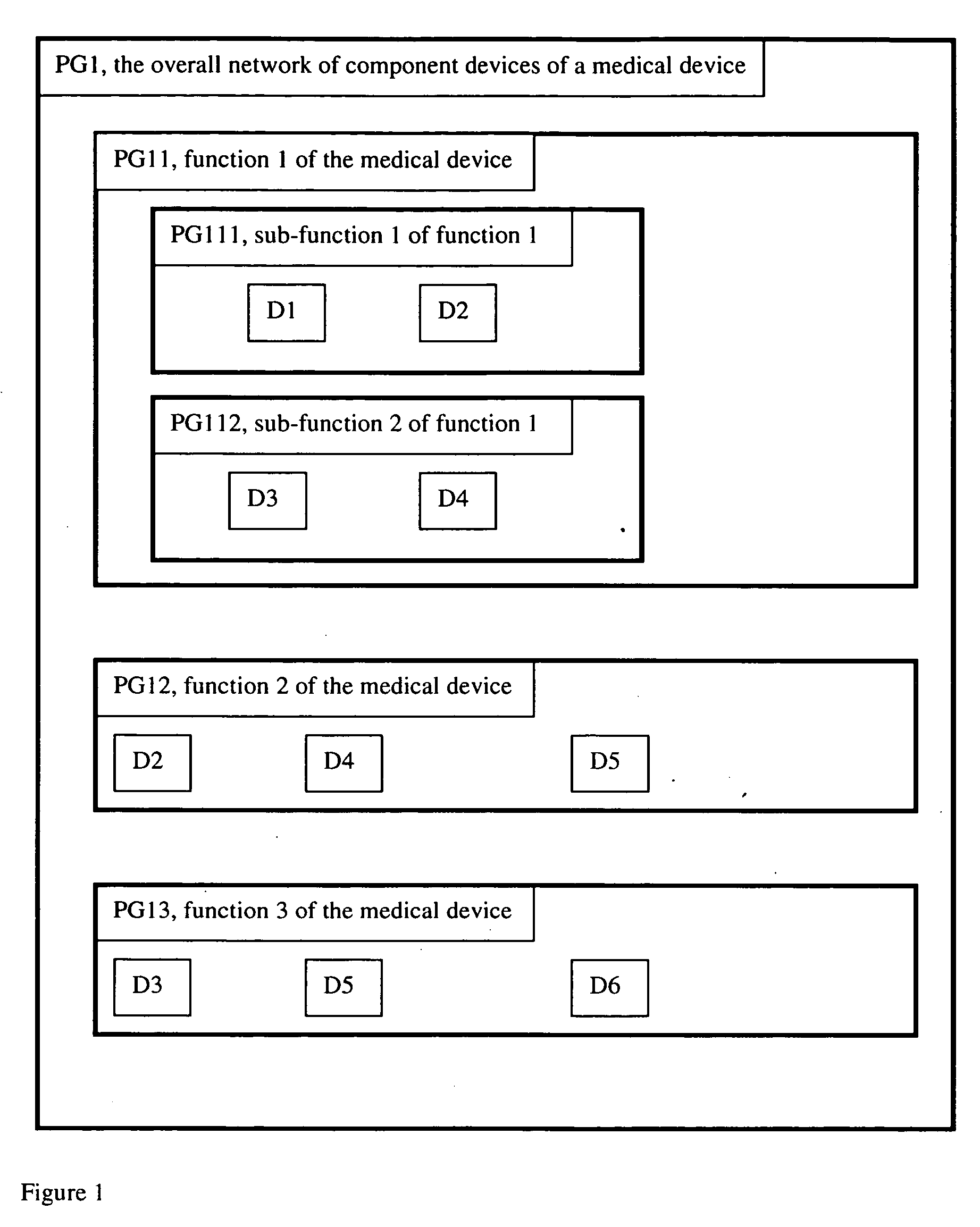

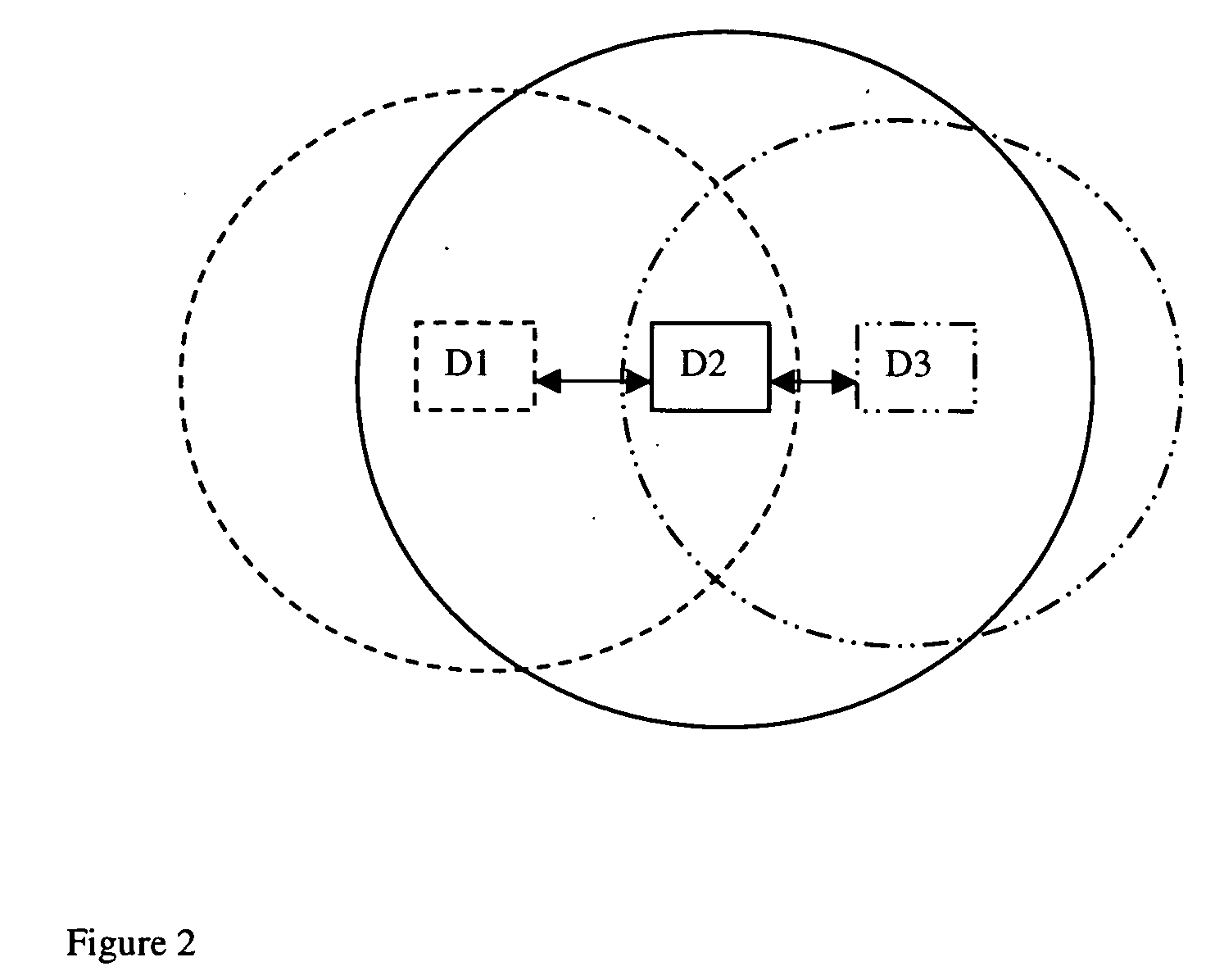

A neural prosthesis comprised of a network of component devices that sense, analyze, and communicate data to deliver a therapeutic effect to a patient. The network of component devices establish systems and methods for sensing physiological parameters in, on or around a human body and achieving a therapeutic effect based thereon. A network of various levels of component devices sense, process and communicate data between corresponding component devices, and self-organize into a hierarchy of peer groups of component devices to perform the task or function of the therapeutic effect upon completion of the tasks or functions of the various underlying levels of component devices. An overall Peer Group encompasses the various underlying levels of peer groups having the component devices therein. The sensing, computational, data distribution, communication or therapeutic effect tasks at the various levels are accomplished by the coordination of communication and functions between the plurality of relatively simple component devices of the network. Symmetric and asymmetric cryptography and other communication protocols are used to co-ordinate the tasks and functions of the component devices of the network. Therapeutic tasks such as drug delivery, executable actions, and stimuli delivery or suppression are thus efficiently distributed to a patient via the network. Component peer devices of the network can be implants, wearable devices with respect to a patient, or may be devices that are in the environment within which the patient is located.

Owner:LORINCZ ANDRAS +2

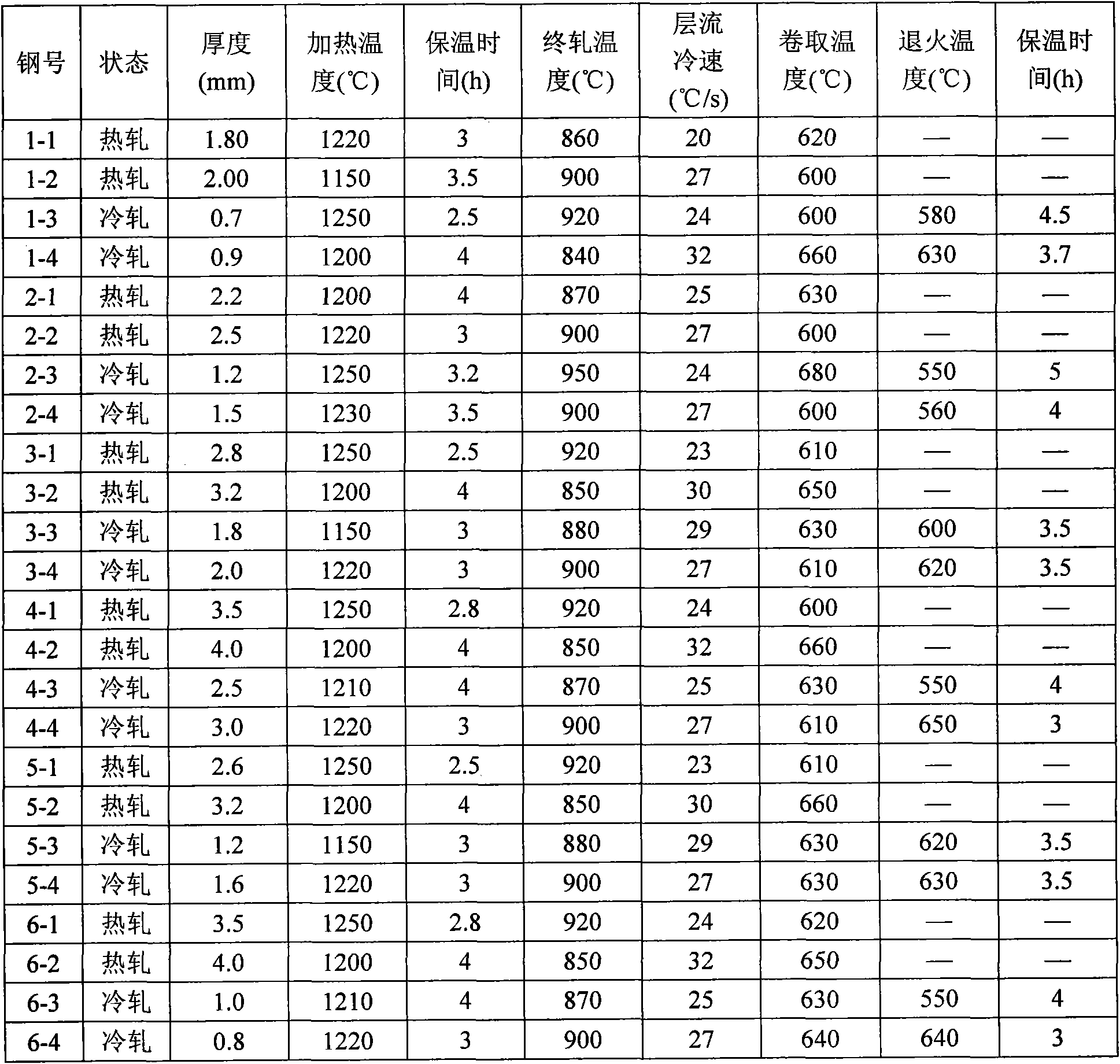

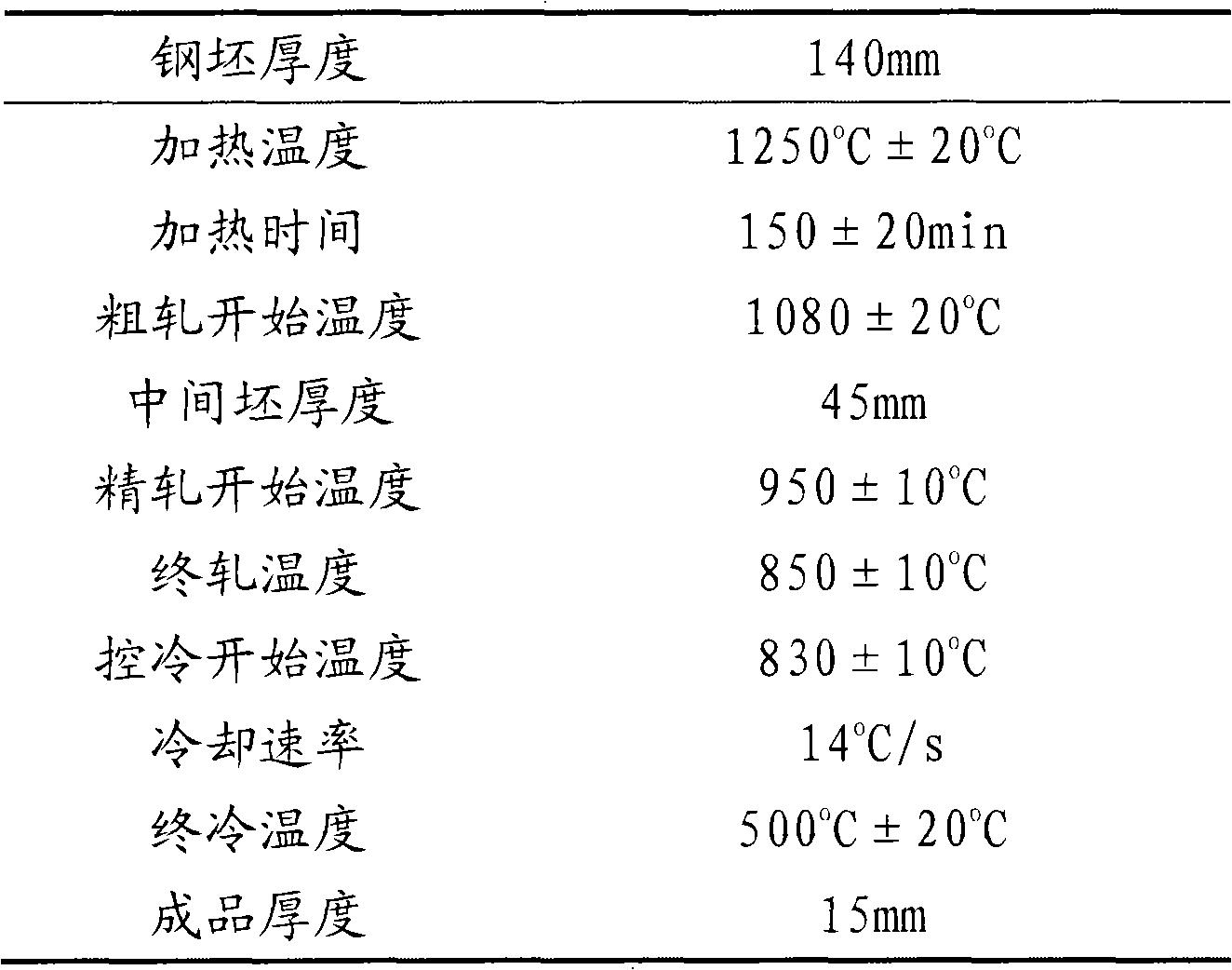

Steel plate for stamping and quenching and manufacturing method thereof

The invention discloses a steel plate for stamping and quenching and a manufacturing method thereof. The steel plate comprises the following chemical components in percentage by mass: 0.14 to 0.28 percent of C, less than 0.40 percent of Si, 0.4 to 2.0 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.004 percent of S, 0.016 to 0.040 percent of Al, 0.15 to 0.8 percent of Cr, 0.015 to 0.12 percent of Ti, 0.001 to 0.005 percent of B, less than or equal to 0.005 percent of N, and the balance of Fe and unavoidable impurities. The manufacturing method comprises the following steps of: heating a blank to 1,150 to 1,250 DEG C, preserving heat for 2.5 to 4 hours and performing rough rolling, and then performing finish rolling under multichannel pressure and at the final rolling temperature of between 830 and 950 DEG C, performing laminar cooling, and cooling to the rolling temperature at the cooling speed of more than 10 DEG C / s and the rolling temperature of between 600 and 680 DEG C. The cold-rolled steel plate is obtained by the following steps of: performing cold rolling on a hot rolled steel strip, annealing through a pure hydrogen gas cover furnace, and oiling and packaging. The annealing temperature is 550 to 650 DEG C and the heat preserving time is 3 to 5 hours. The steel has a simple component design and high hardenability. The depth of a hardening layer of more than HRC45 is 10 to 16mm. The steel plate consists of ferrite and pearlite. After thermal stamping and quenching, an all-martensite structure can be obtained. The tensile strength is above 1,300N / mm<2>.

Owner:ANGANG STEEL CO LTD

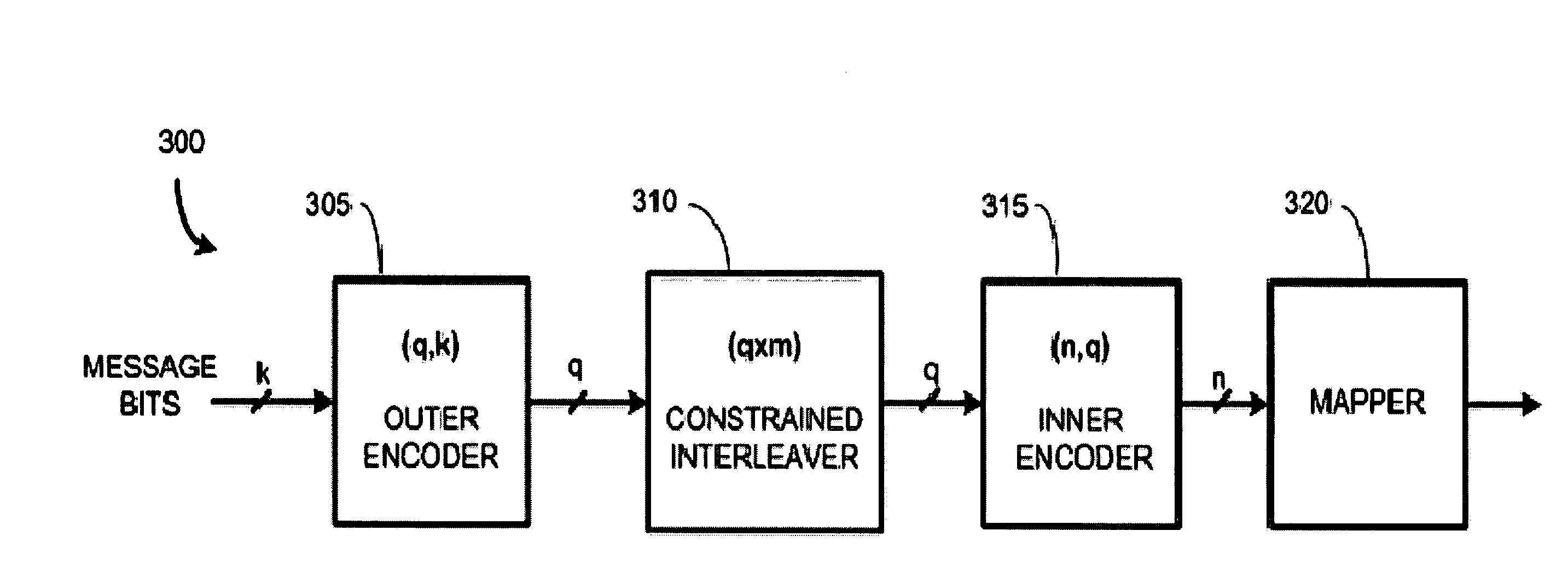

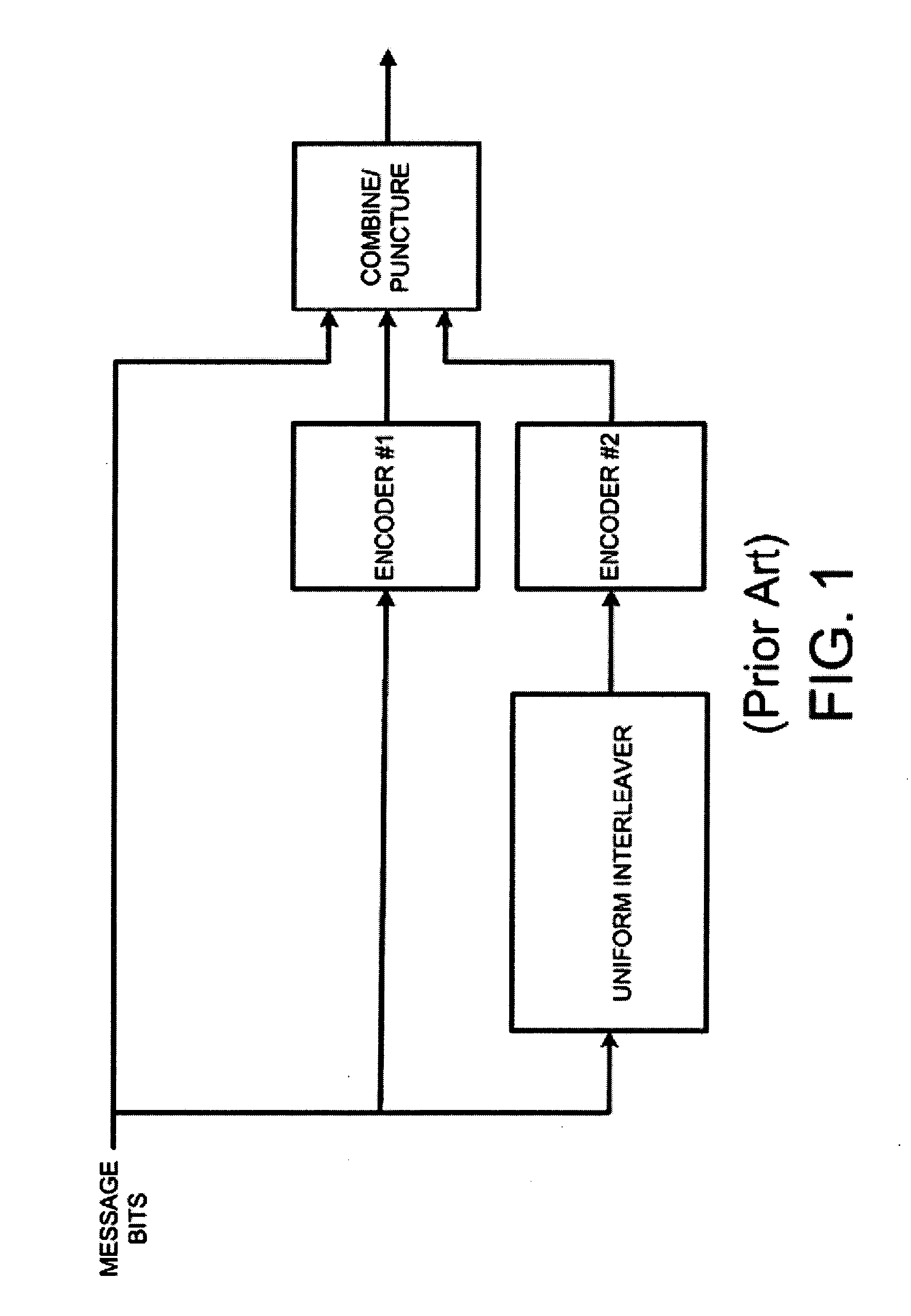

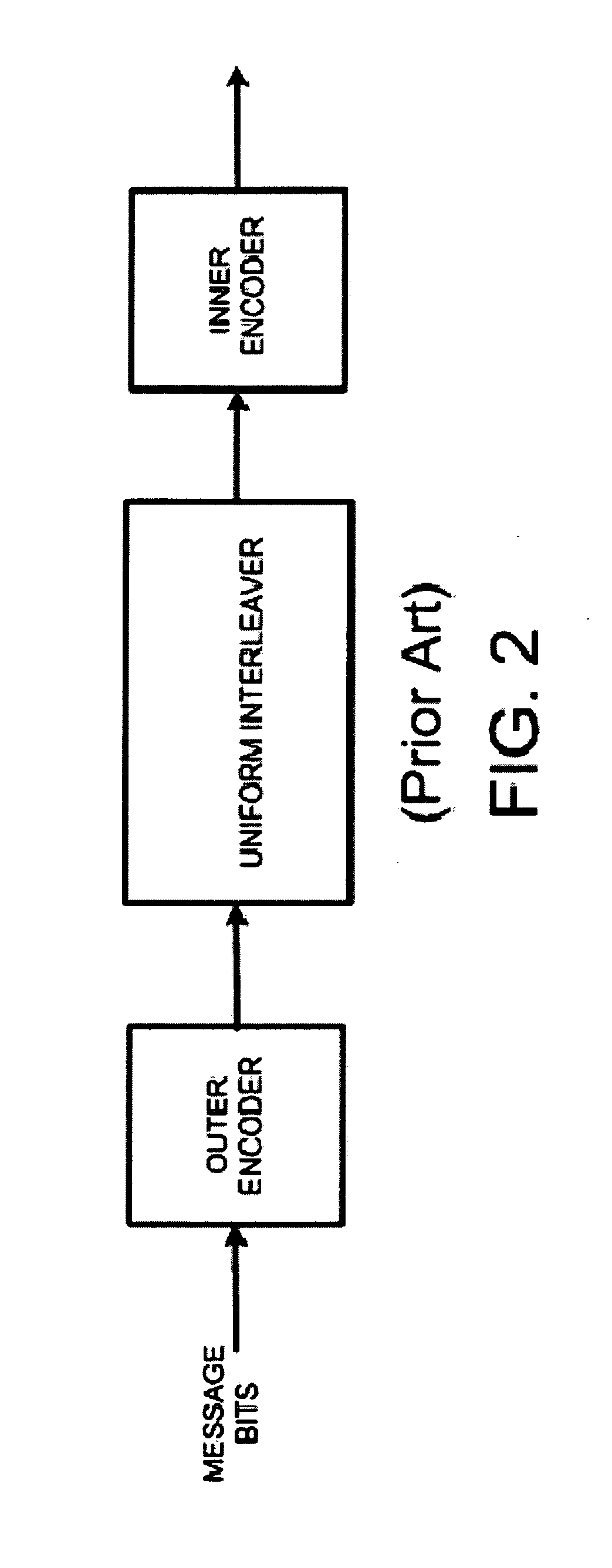

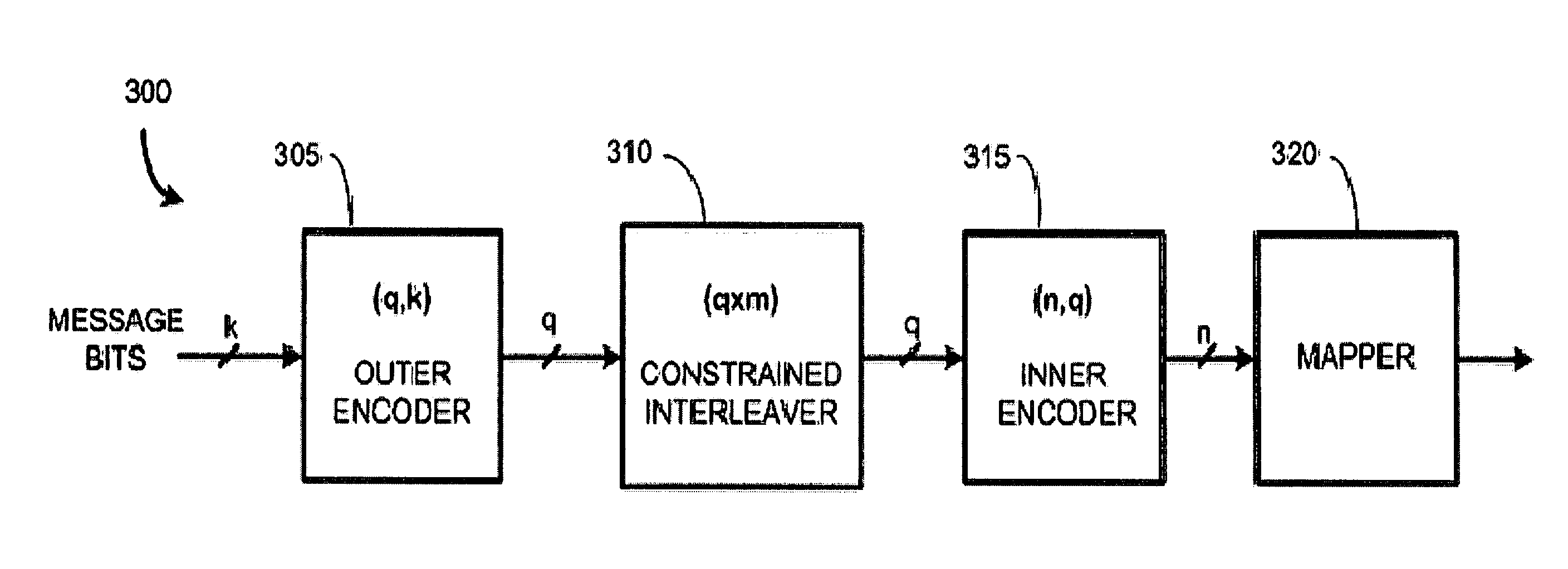

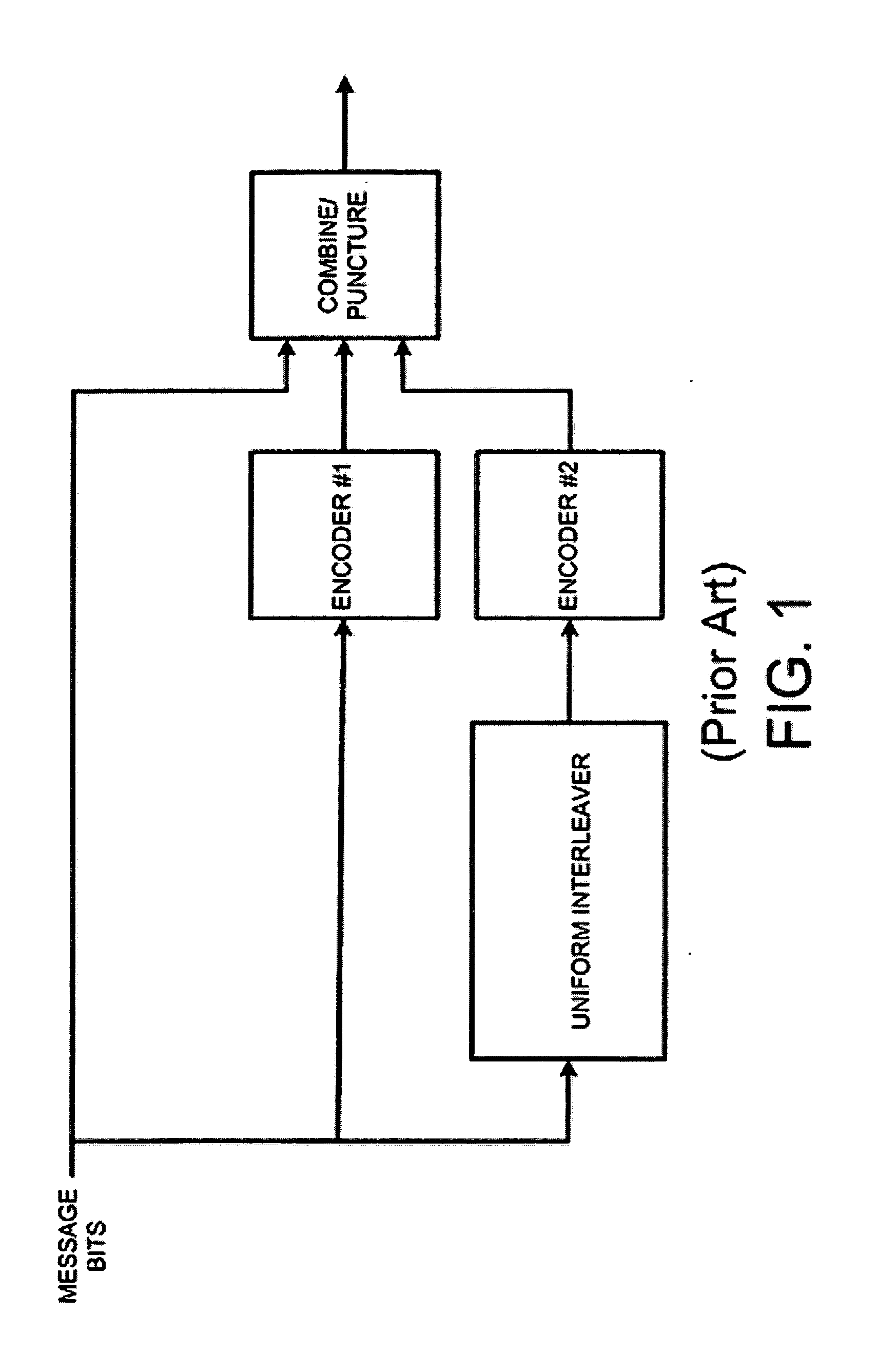

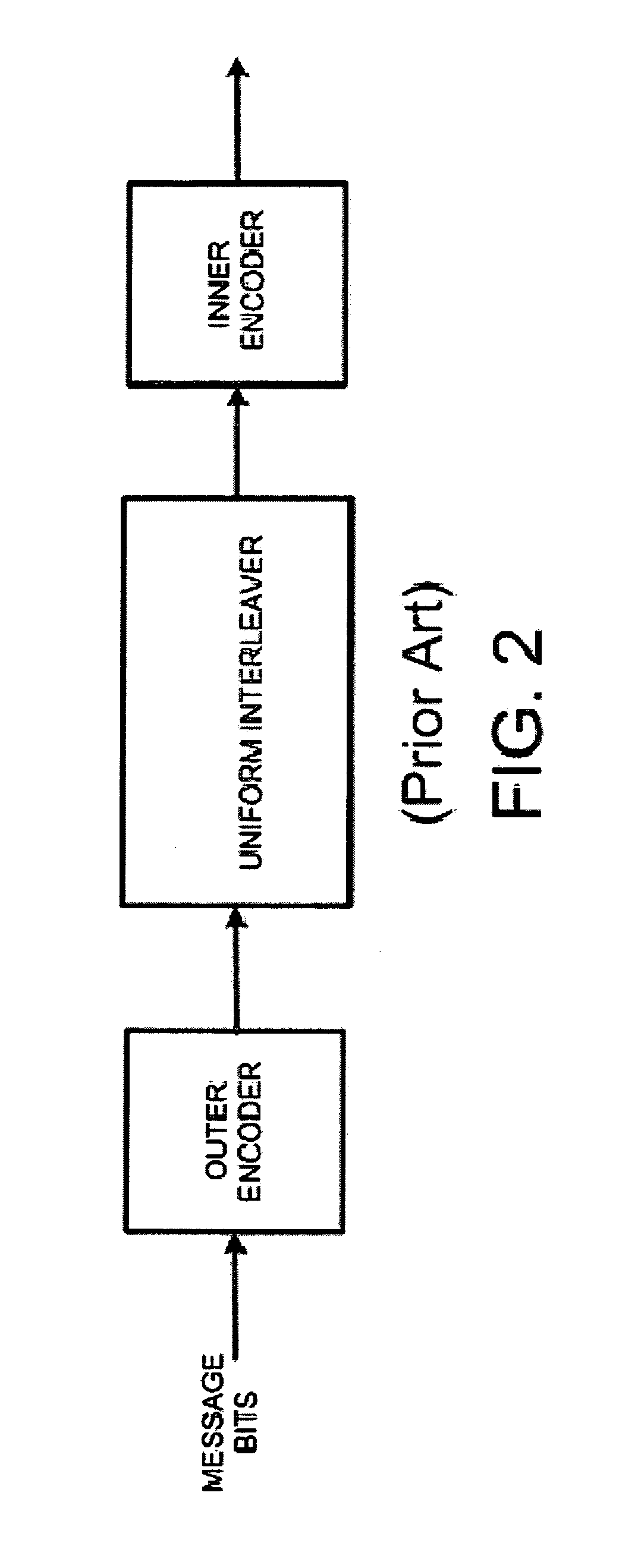

Encoding and decoding using constrained interleaving

InactiveUS20120063533A1Reduce measurementEfficient implementationAmplitude-modulated carrier systemsAmplitude demodulationSimple componentNoise margin

Serially-concatenated codes are formed in accordance with the present invention using a constrained interleaver. The constrained interleaver cause the minimum distance of the serial concatenated code to increase above the minimum distance of the inner code alone by adding a constraint that forces some or all of the distance of the outer code onto the serially-concatenated code. This allows the serially-concatenated code to be jointly optimized in terms of both minimum distance and error coefficient to provide significant performance advantages. These performance advantages allow a noise margin target to be achieved using simpler component codes and a much shorter interleaver than was needed when using prior art codes such as Turbo codes. Decoders are also provided. Both encoding and decoding complexity can be lowered, and interleavers can be made much shorter, thereby shortening the block lengths needed in receiver elements such as equalizers and other decision-directed loops. Also, other advantages are provided such as the elimination of a error floor present in prior art serially-concatenated codes. That allows the present invention to achieve much higher performance at lower error rates such as are needed in optical communication systems.

Owner:TRELLIS PHASE COMM LP

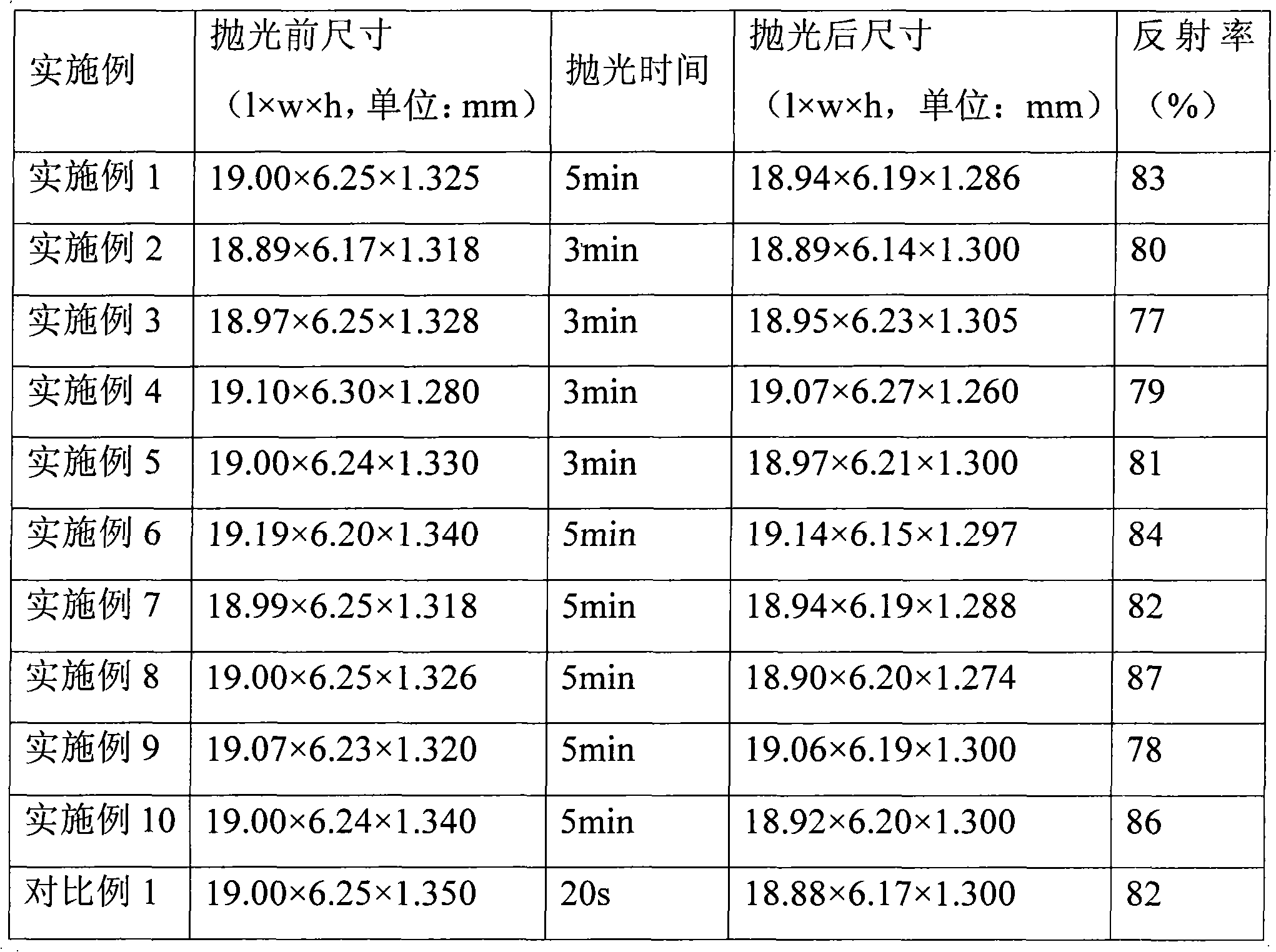

Chemical polishing liquid and polishing method

InactiveCN101851470AIncrease brightnessFlat surfacePolishing compositionsAcetic acidSimple component

The invention provides chemical polishing liquid, comprising sulfuric acid, hydrogen peroxide, acetic acid, an auxiliary oxidant, a brightening agent and an adjusting agent, and the PH of the polishing liquid is 1-3. The polishing liquid has simple components and easy control, the obtained chemical polishing surface has high brightness and smooth surface, and can achieve the mirror polishing effect. The polishing liquid can be widely applied in polishing of the surface of copper-zinc alloy.

Owner:深圳市新合富力科技有限公司

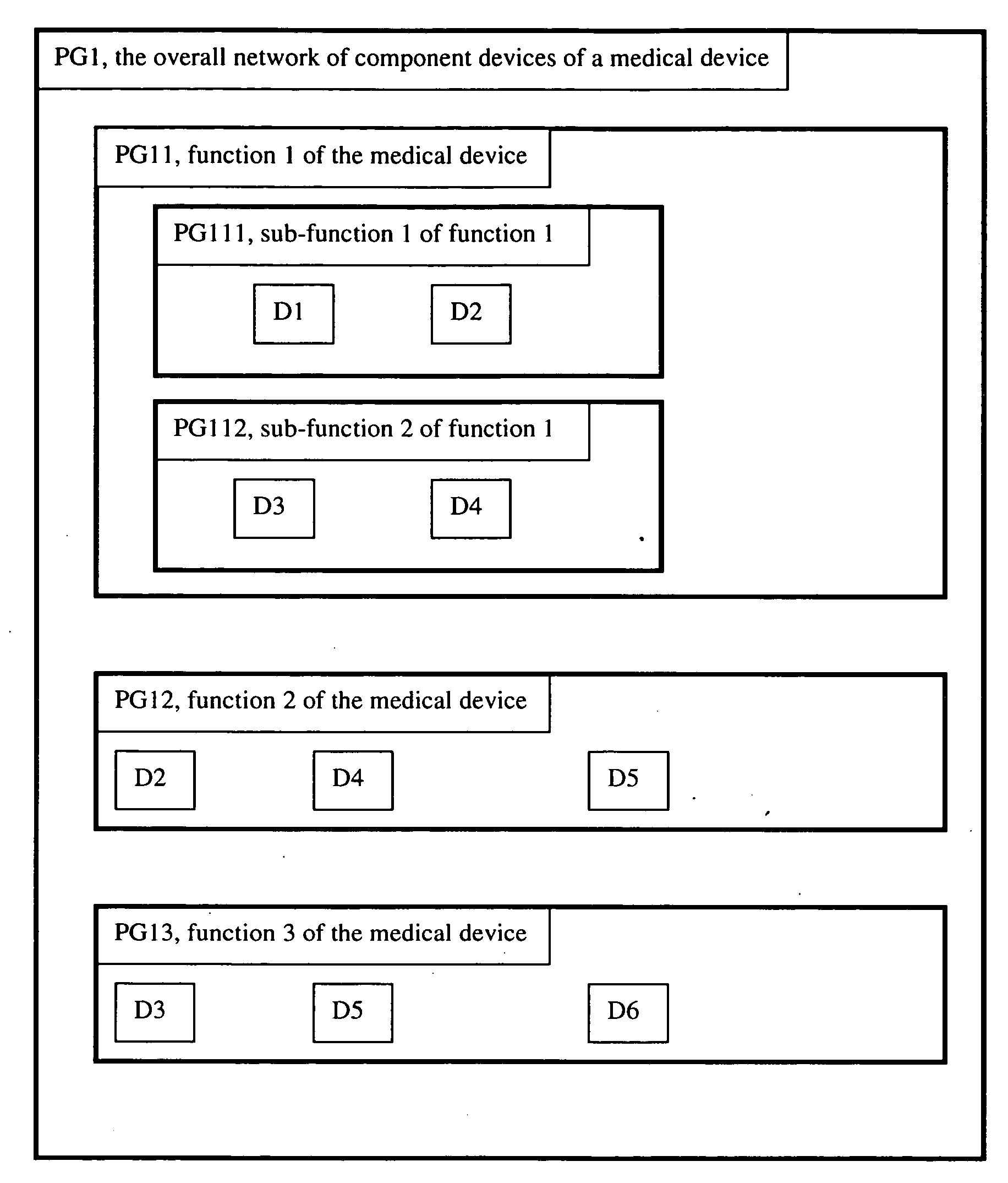

Systems and methods for sensing physiologic parameters of the human body and achieving a therapeutic effect

InactiveUS20070043591A1Good treatment effectLimited amountData processing applicationsDrug and medicationsHuman bodySimple component

Systems and methods for sensing physiological parameters in, on or around a human body and achieving a therapeutic effect based thereon. A network of various levels of component devices sense, process and communicate data between corresponding component devices, and self-organize into a hierarchy of peer groups of component devices to perform the task or function of the therapeutic effect upon completion of the tasks or functions of the various underlying levels of component devices. An overall Peer Group encompasses the various underlying levels of peer groups having the component devices therein. The sensing, computational, data distribution, communication or therapeutic effect tasks at the various levels are accomplished by the coordination of communication and functions between the plurality of relatively simple component devices of the network. Symmetric and asymmetric cryptography and other communication protocols are used to co-ordinate the tasks and functions of the component devices of the network. Therapeutic tasks such as drug delivery, executable actions, and stimuli delivery are thus efficiently distributed to a patient via the network. Component peer devices of the network can be implants, wearable devices with respect to a patient, or may be devices that are in the environment within which the patient is located.

Owner:MERETEI ATTILA +2

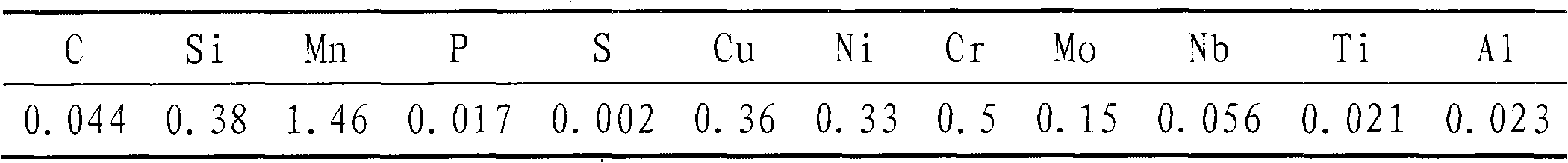

Non-quenched acicular structure high strength low yield ratio weathering resistant steel and production method thereof

InactiveCN101660108AThe ingredients are designed to be simpleObvious effectManufacturing convertersSimple componentHigh intensity

The invention relates to a non-quenched acicular structure high strength low yield ratio weathering resistant steel and a production method thereof. The steel comprises components by weight percent: basic components: 0.03-0.08% of C, 0.30-0.60% of Si, 1.30-1.80% of Mn, less than or equal to 0.015% of P, less than or equal to 0.010% of S, 0.30-0.60% of Cu, 0.20-0.50% of Ni, 0.40-0.80% of Cr, 0.10-0.40% of Mo, 0.030-0.080% of Nb and less than or equal to 0.04% of Ti; optional components are two or more in less than or equal to 0.04% of AlS and less than or equal to 0.40kg / t steel of RE or less than or equal to 0.005% of Ca; and the rest of Fe and impurities. Welding cold crack is low in susceptibility coefficient and high in corrosion resisting index. The steel has simple components as wellas excellent moldability, weatherability, weldability and low temperature toughness; meanwhile, the preparation technique is simple, heat treatment is not needed, the production period is short, and the production cost is low.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

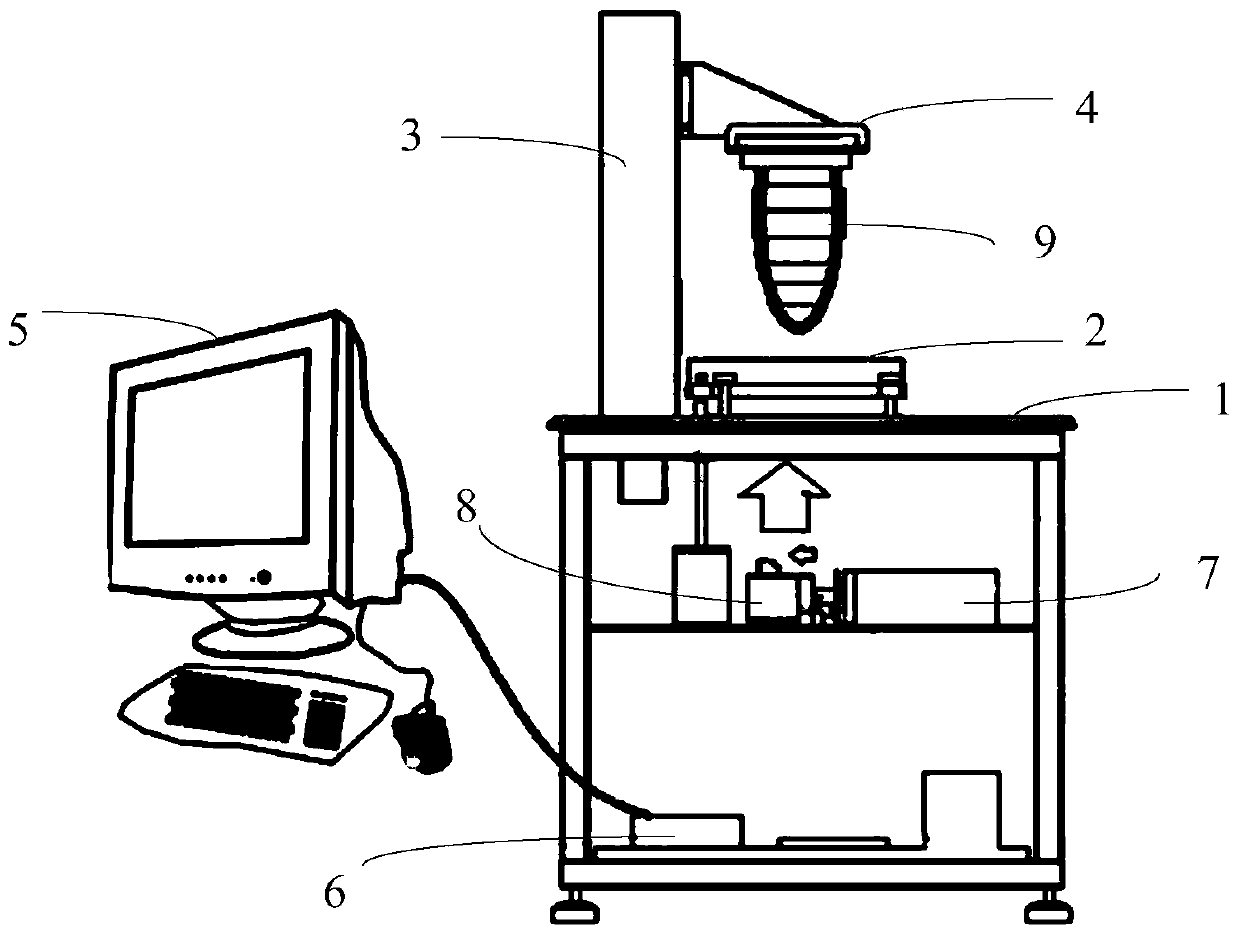

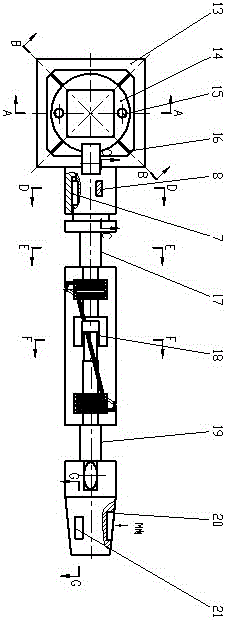

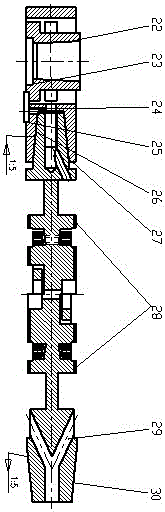

DLP principle based 3D printer

The invention discloses a DLP principle based 3D printer. The 3D printer includes: a resin tank, the bottom plate of which is light-transmitting; a vertical lifting mechanism, which is in fixed connection with a forming platform and is used for adjusting the distance between the resin tank and the forming platform; a computer, which is used for processing a three-dimensional model and segmenting the three-dimensional model into several profile graphs with certain thickness sequentially, and is connected to an electrical control device for controlling automatic lifting of the forming platform by the vertical lifting mechanism and controlling irradiation of a DLP projector on the liquid level of light-cured resin in the resin tank; and the DLP projector, which is arranged below the resin tank and is connected to the computer, and makes the graph light path of the profile graphs transmit the bottom plate of the resin tank so as to irradiate the light-cured liquid resin. According to the invention, the DLP projection technology is adopted and the light cured material forming technology is combined to form a set for system. The system has the characteristics of simple components and compact whole structure, the formed products have improved precision, the manufacturing cost is low, and the product forming speed is faster.

Owner:SHANGHAI KUNRONG IND

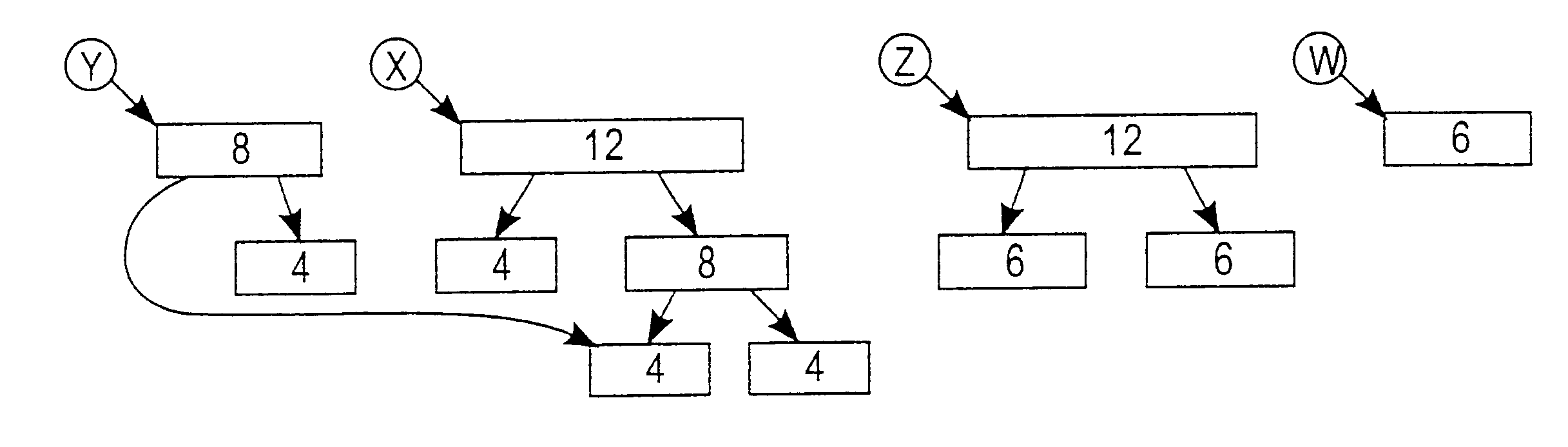

Aggregate structure identification and its application to program analysis

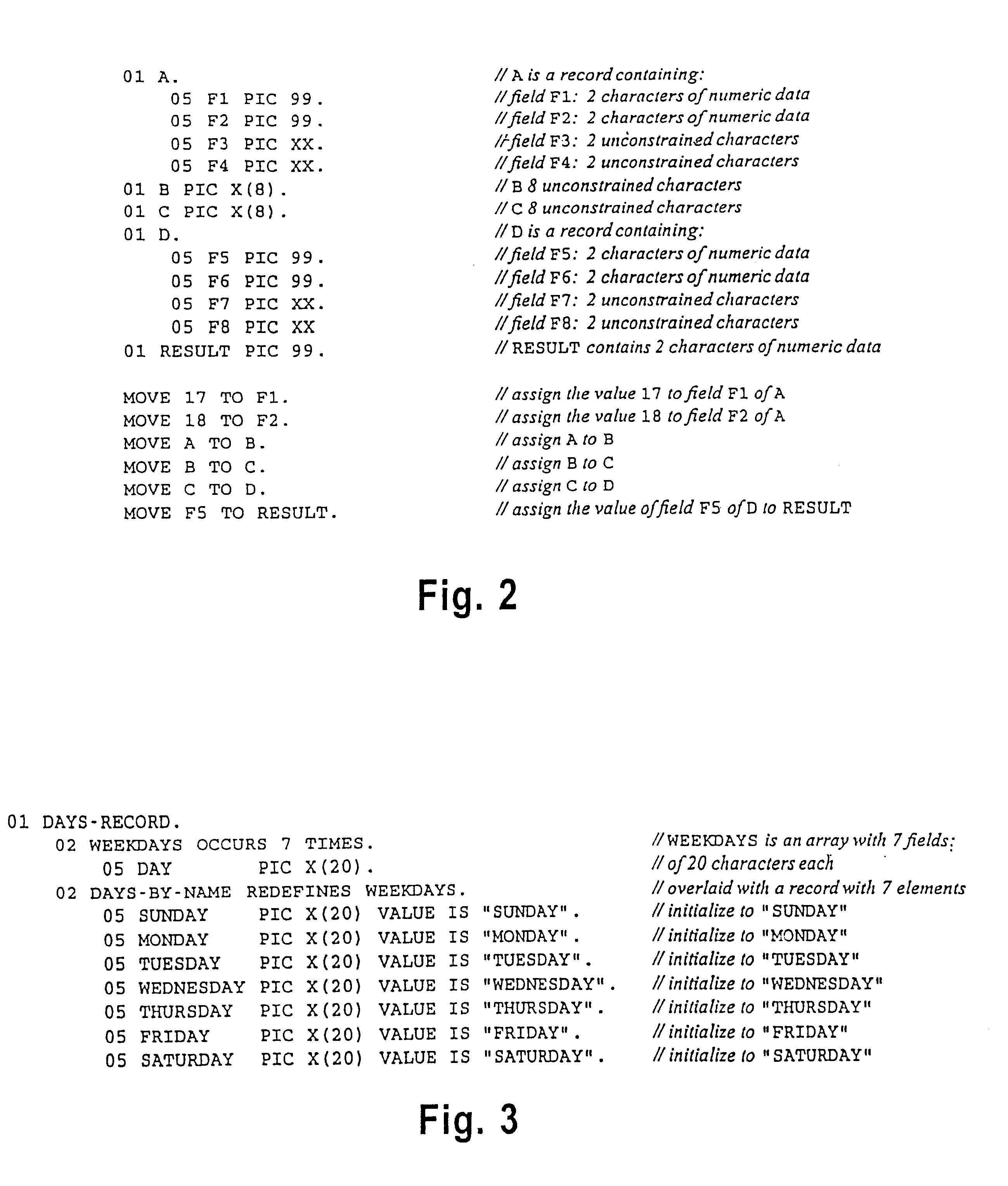

InactiveUS6279149B1Digital data processing detailsReverse engineeringArray data structureSimple component

An efficient program analysis method is provided for lazily decomposing aggregates (such as records and arrays) into simpler components based on the access patterns specific to a given program. This process allows us both to identify implicit aggregate structure not evident from declarative information in the program, and to simplify the representation of declared aggregates when references are made only to a subset of their components. The method can be exploited to yield: (i) a fast type analysis method applicable to program maintenance applications (such as date usage inference for the Year 2000 problem); and (ii) an efficient method for atomization of aggregates. More specifically, aggregate atomization decomposes all of the data that can be manipulated by the program into a set of disjoint atoms such that each data reference can be modeled as one or more references to atoms without loss of semantic information. Aggregate atomization can be used to adapt program analyses and representations designed for scalar data to aggregate data. In particular, atomization can be used to build more precise versions of program representations such as SSA form or PDGs. Such representations can in turn yield more accurate results for problems such as program slicing. Our techniques are especially useful in weakly-typed languages such as Cobol (where a variable need not be declared as an aggregate to store an aggregate value) and in languages where references to statically-defined sub-ranges of data such as arrays or strings are allowed.

Owner:IBM CORP

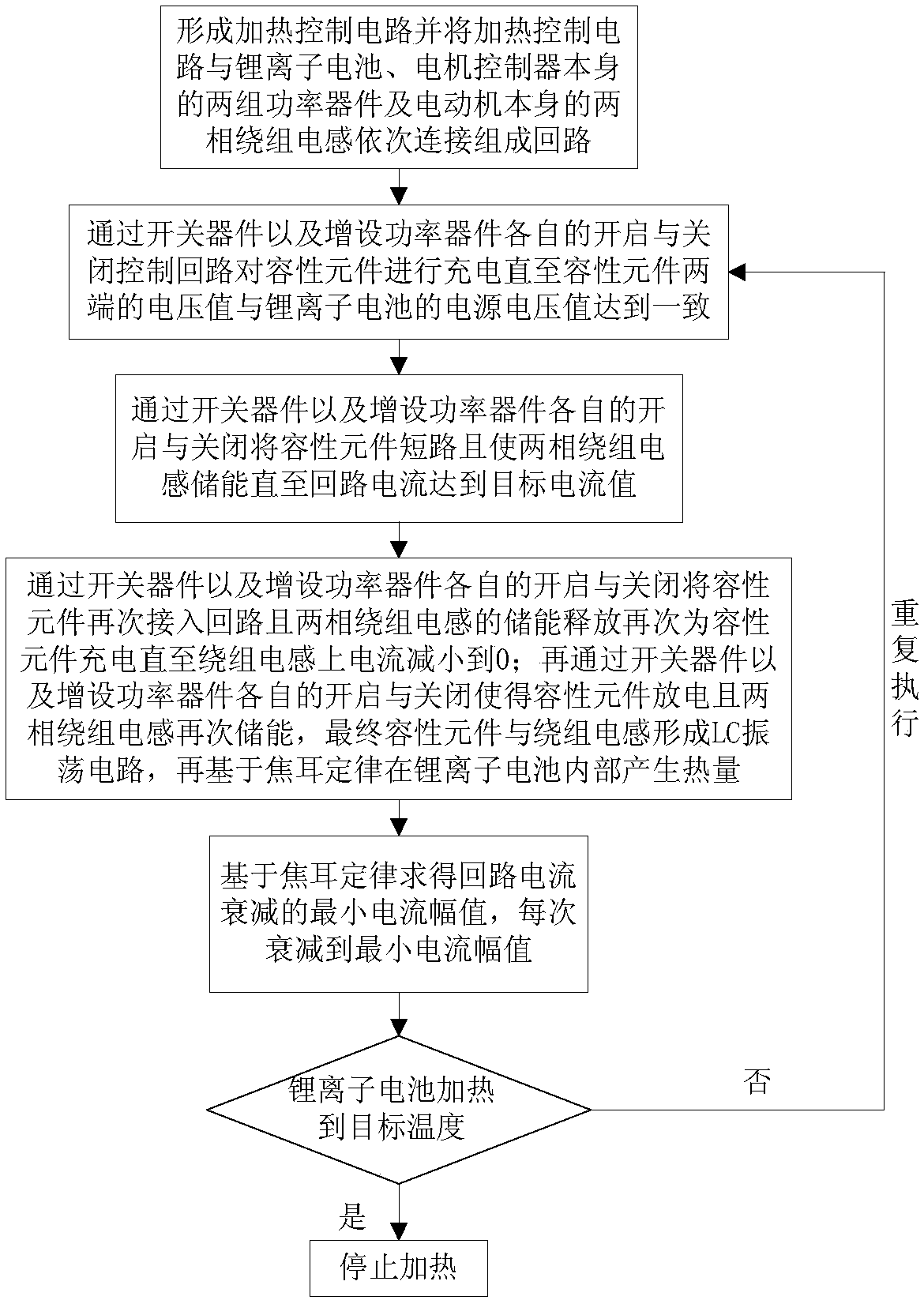

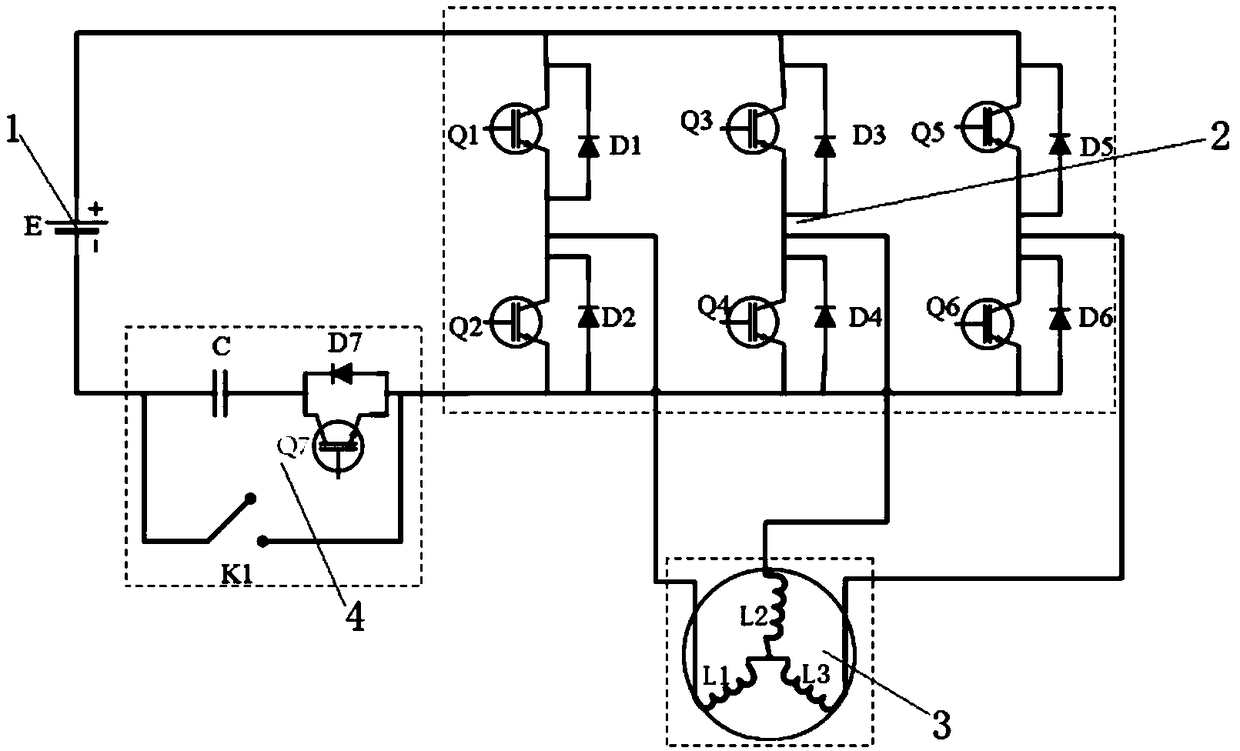

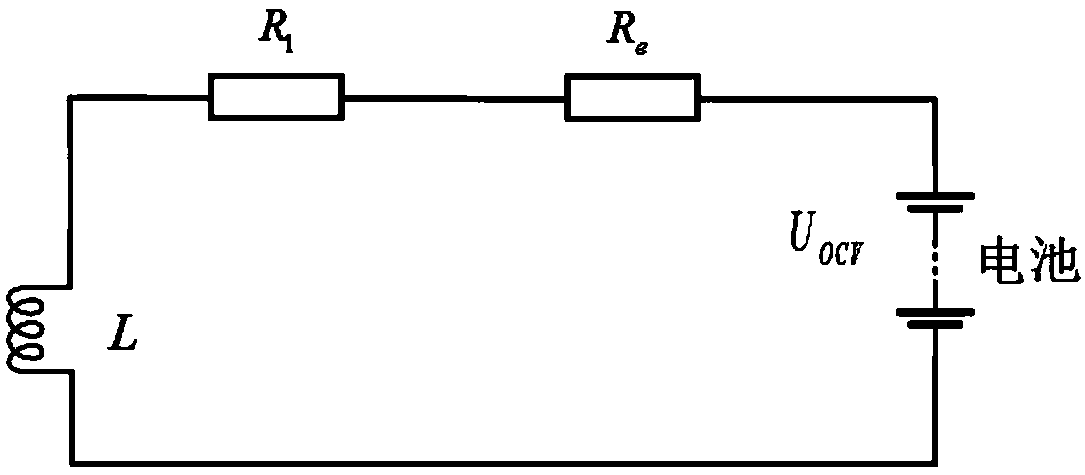

Low-temperature heating control method for lithium ion battery

ActiveCN108847513ASolve the problem of poor charge and discharge performanceExtended service lifeSecondary cellsVehicular energy storageElectrical batterySimple component

A low-temperature heating control method for a lithium ion battery includes the following steps: first selecting a capacitive component; connecting the capacitive component and an additional power device in series, and then connecting a switch device in parallel to form a heating control circuit; then sequentially connecting the heating control circuit with the lithium ion battery, two sets of power devices of a motor controller body, and two-phase winding inductance of a electromotor to form a loop; and controlling charge and discharge of the capacitive component and magnetic energy storage and release of the two-phase winding inductance by opening and closing of the switch device and the additional power device to enable an LC oscillating circuit to be formed between the capacitive element and the winding inductance, generating a high-frequency alternating current, generating heat inside the lithium ion battery based on a joule law, and allowing to repeatedly operating the heating process to achieve continuous oscillation and continuous heat production until heating the lithium ion battery to a target temperature. The low-temperature heating control method for the lithium ion battery can be achieved by only adding a simple component to an inherent structure of an electric vehicle, and has the characteristics of good heating effect, high thermal efficiency and low usage cost.

Owner:BEIHANG UNIV

Comprehensive utilization method for bittern

InactiveCN101691239ARealize closed loopSimple process controlCalcium/strontium/barium carbonatesIodineSimple componentChemistry

The invention relates to a comprehensive utilization method for bittern, which belongs to the technical field of salt chemical engineering. The bittern is a liquid mineral product, and is rich in multiple elements such as potassium, sodium, lithium, boron, bromine, iodine and the like; and at present, in the prior domestic bittern development and utilization, some simple components or components with high additional value in the elements are extracted, and the un-extracted components are discharged along with old bittern to be abandoned so as to cause serious waste of resources and pollute the environment. Through reasonable combination of processes of removing H2S from the bittern, settling magnesium, settling calcium and preparing calcium carbonate, preparing potassium-sodium mixed saltthrough primary salt preparation and secondary salt preparation, extracting potassium chloride through flotation, extracting boron, iodine, bromine, rubidium and cesium through acidification, preparing rubidium chloride and cesium chloride, extracting lithium and the like, the method implements step-by-step ordered extraction of main components; the toil yield of several main components reaches over 95 percent; and the method has the advantages of mutually exclusive loss in component extraction, implementation of closed cycle of processes, no mother liquor discharge, simple process control, low cost, high yield, environmental protection and the like.

Owner:DAZHOU HENGCHENG ENERGY GROUP

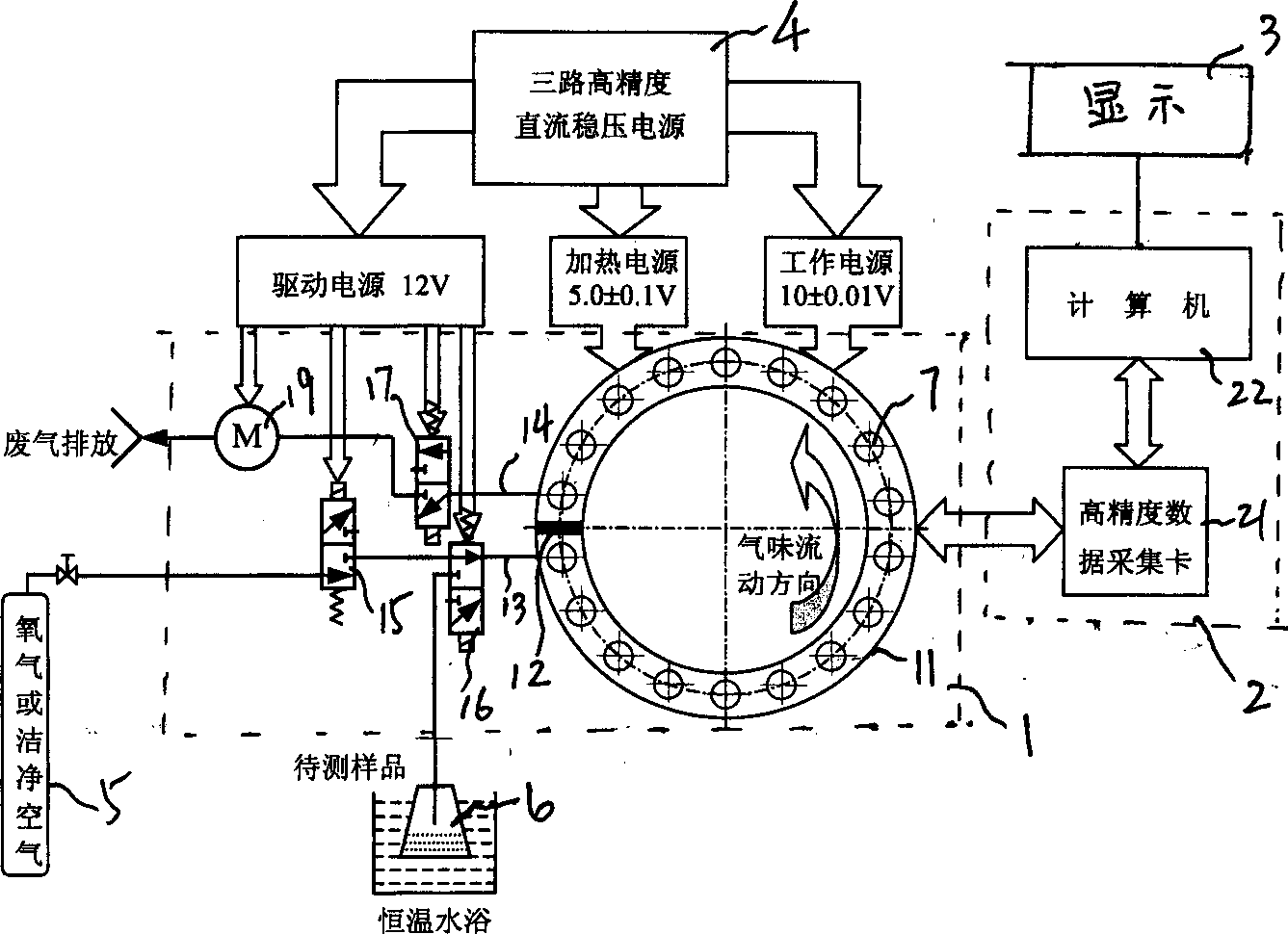

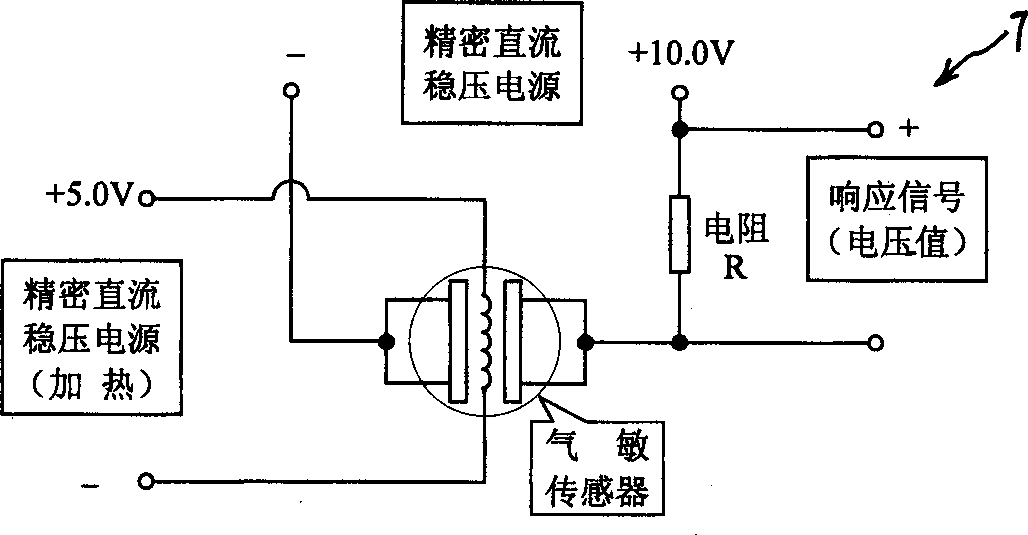

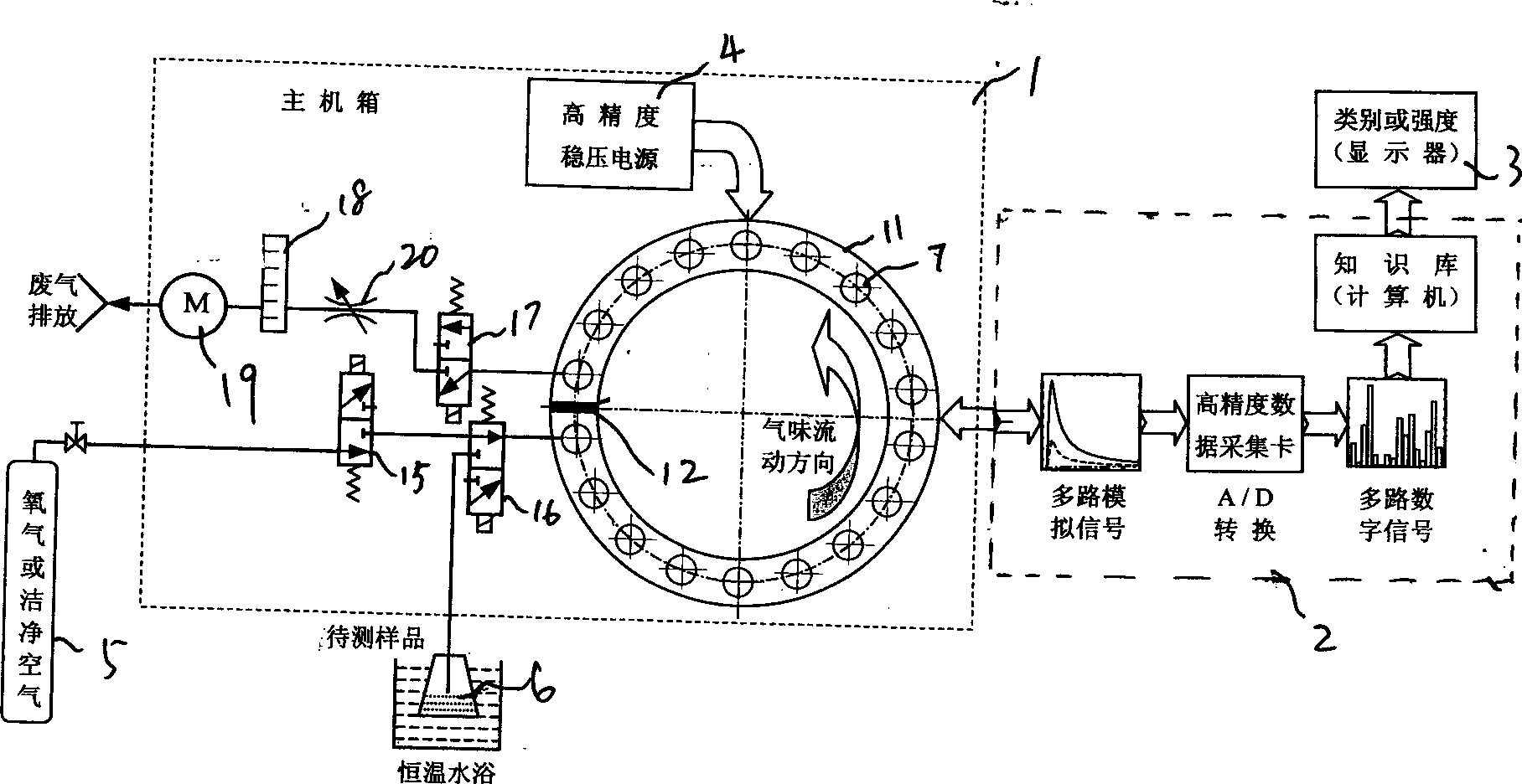

Olfactory simulator and its olfactory simulation testing method

InactiveCN1367381AConcentration did not decreaseSmall volumeMaterial resistanceGas detectorDisplay device

The present invention relates to an olfactory simulation device and its olfactory simulation testing method. Said device is formed from main machine box, computer processing portion, display portion and power supply circuit, and said method includes the following steps: a). the odor to be tested can be sucked into ring testing box by means of miniature diaphragm pump, said gas can be quickly passed through sensing membrane surface of every sensor, then discharged from outlet; b). every response produced by every gas sensor when the gas is passed through every sensor can be collected into datacollecting card, passed through A / D converter to obtain a multidimensional response signal; and c). said signal is processed by computer so as to can obtain the type of odor to be tested, integral intensity and its simple component composition, and can be displayed.

Owner:SHANGHAI HUIBI INTELLIGENCE SCI & TECH

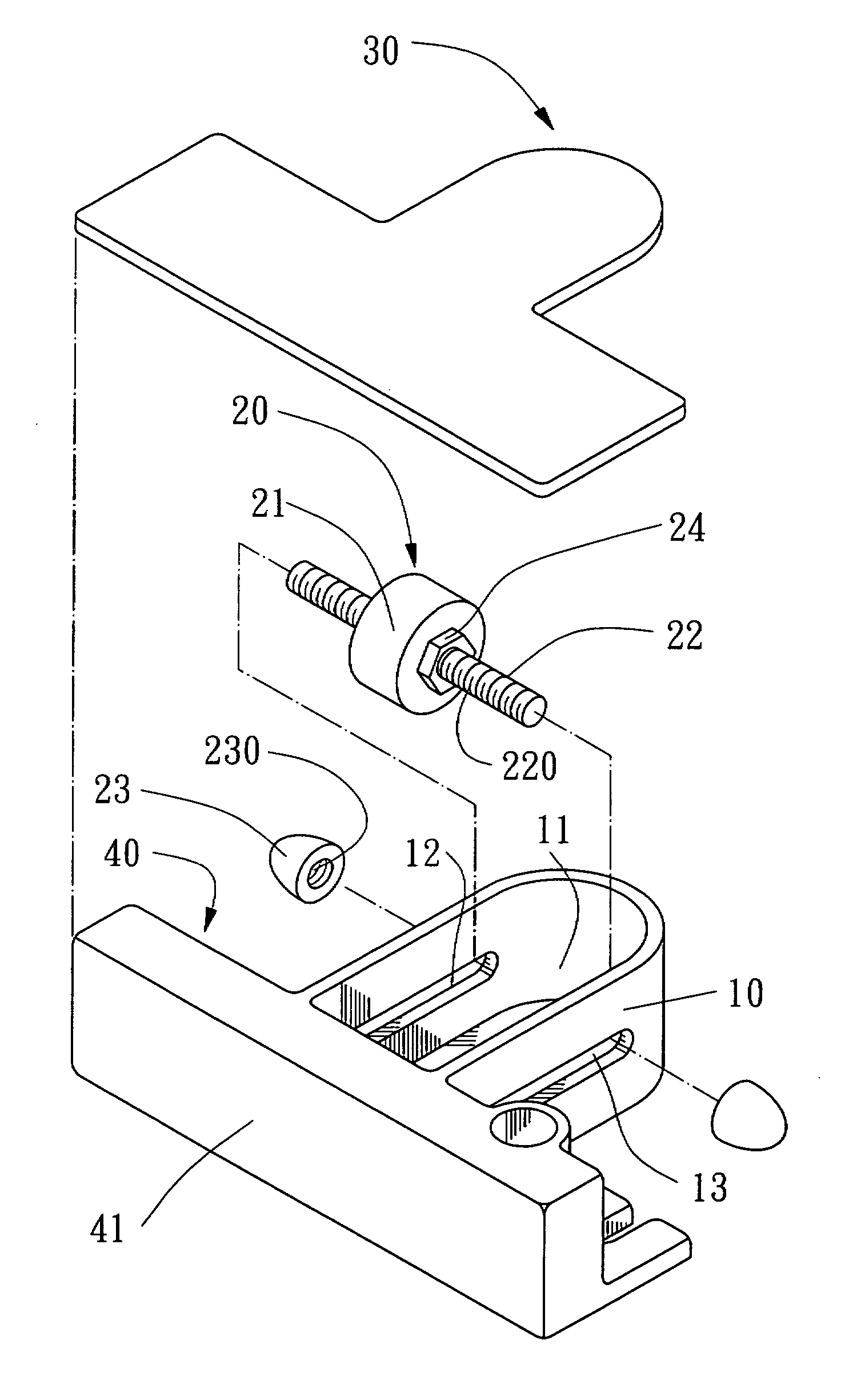

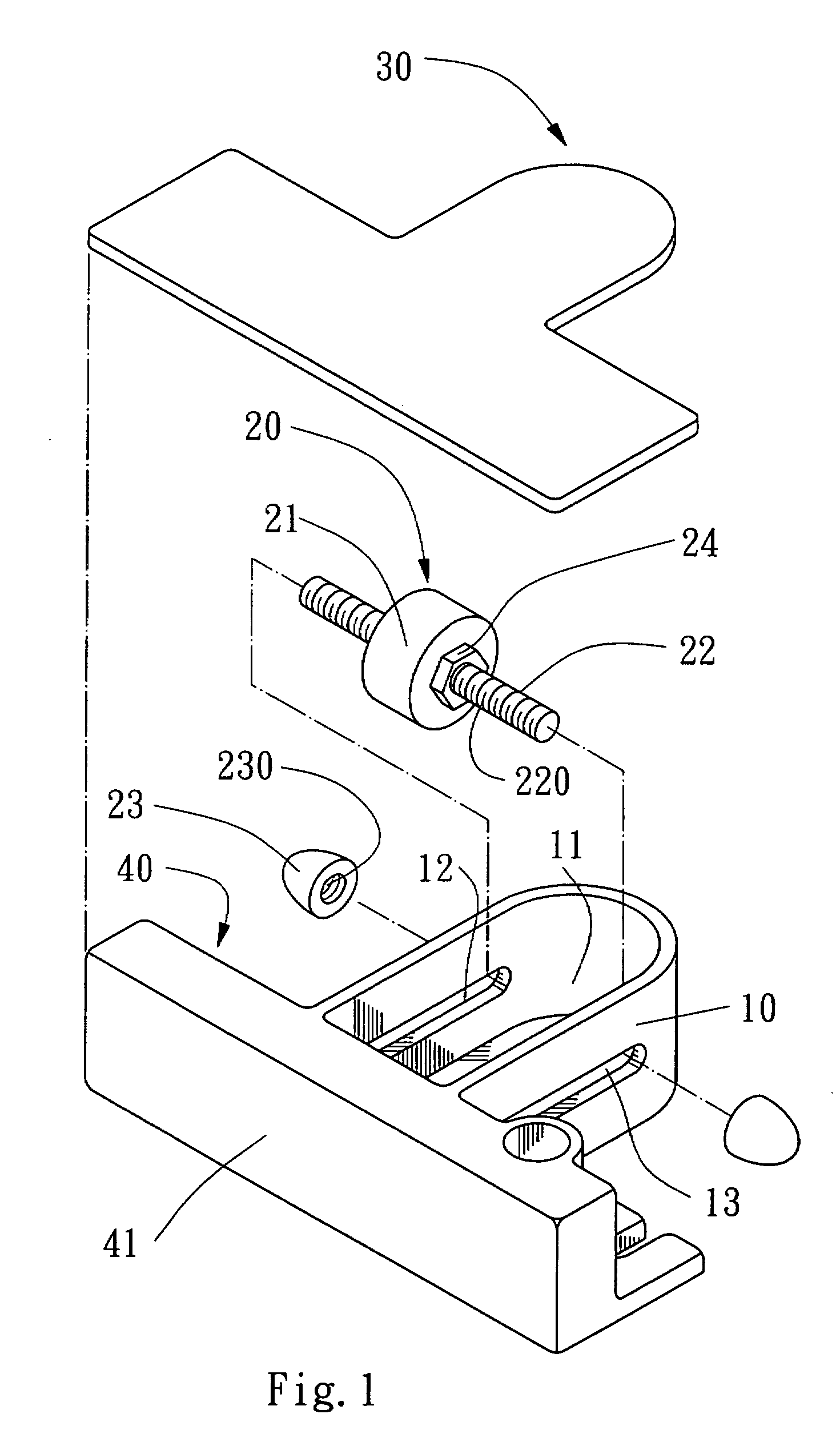

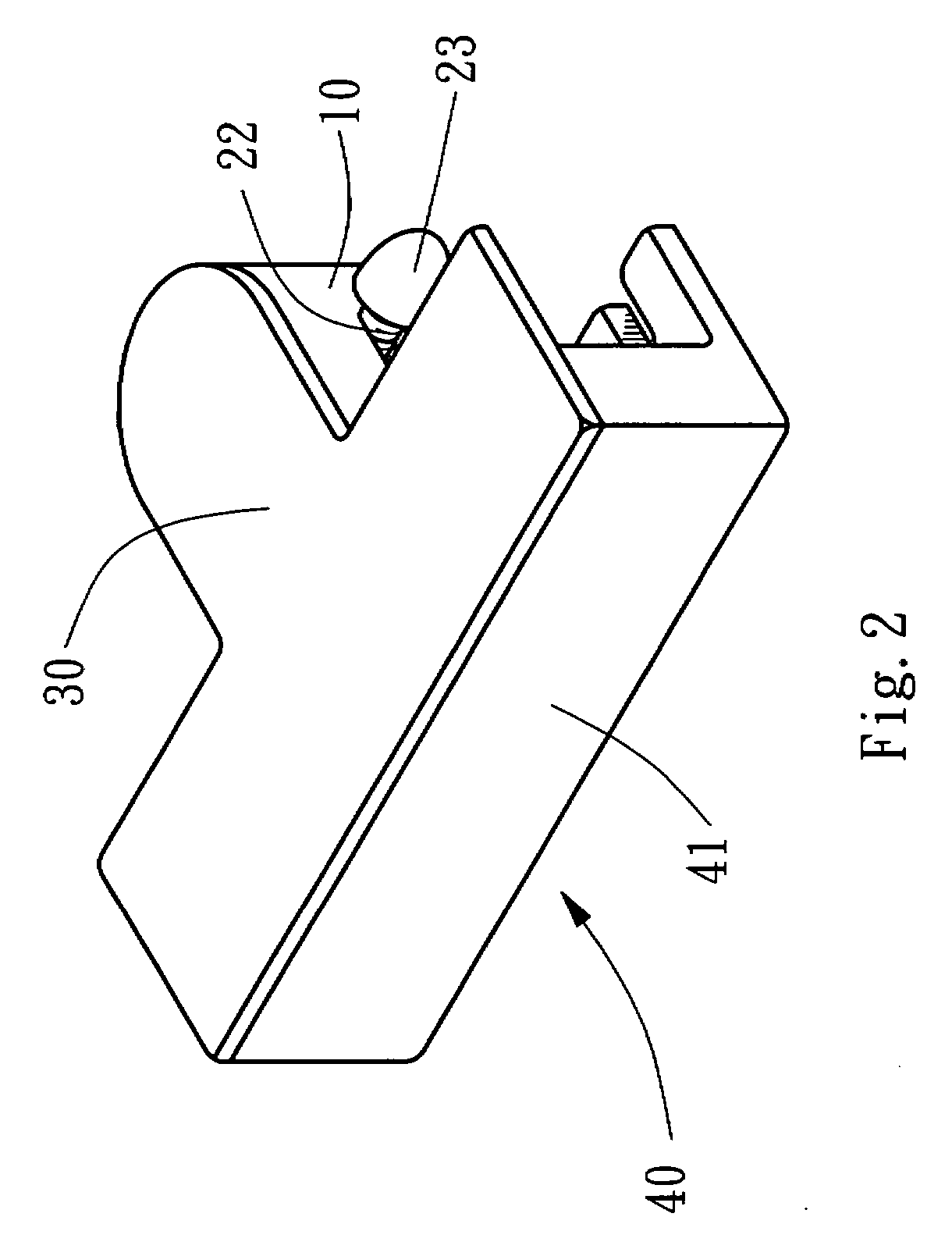

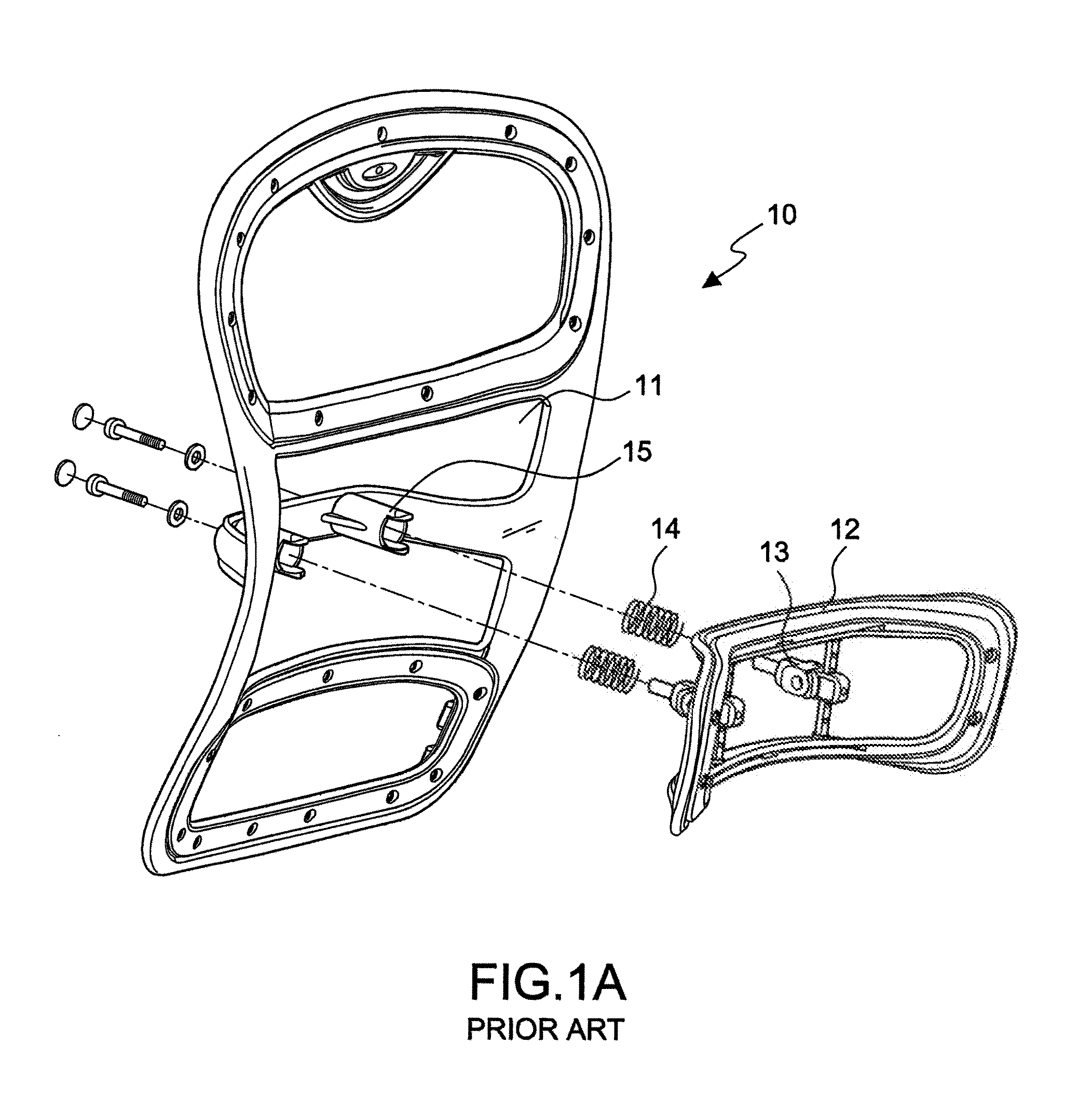

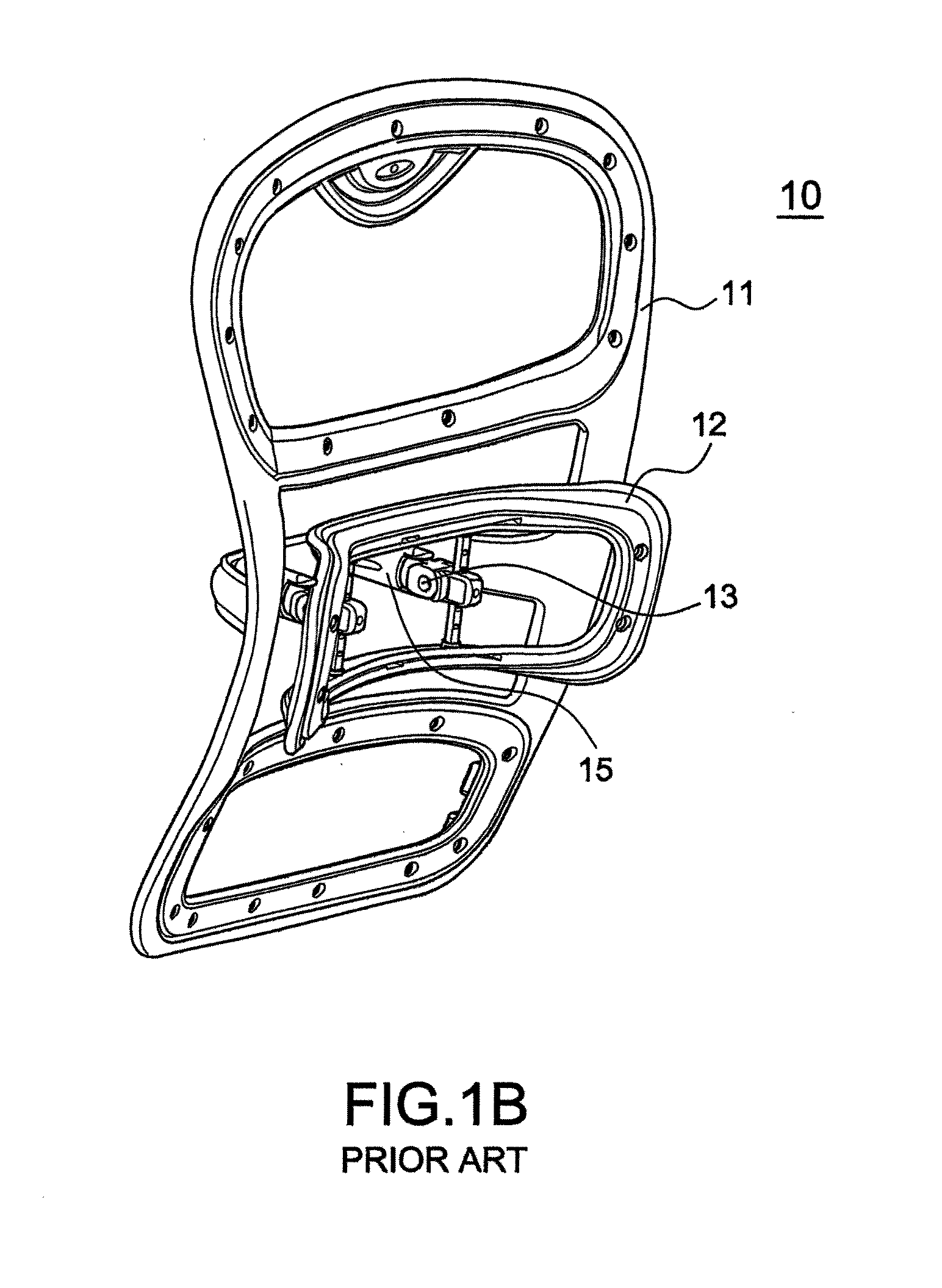

Golf club head weight-adjusting structure

InactiveUS20070249432A1Simpler weight-adjustingAdjustable center of gravityGolf clubsStringed racketsSimple componentGravity center

A golf club head weight-adjusting structure disposed perpendicularly at a rear position of the backside of a ball-striking plate comprises a containing body, an adjusting module and a cover panel. The containing body is extended from the rear of the backside of the ball-striking plate and forms a containing groove, and both sides of the containing groove include first and second slots. The adjusting module includes a weight member with its center screwed with the screw rod and pivotally coupled to the first and second slots. The screw rod includes a rotary element. A cover panel seals the containing groove of the containing body. With these simple components, the adjusting module increases the weight at the rear of the head to adjust and shift the center of gravity of the head backward and maintain the best central position when the adjusting module is installed to different golf club heads.

Owner:INVESTECH PRECISION CASTING

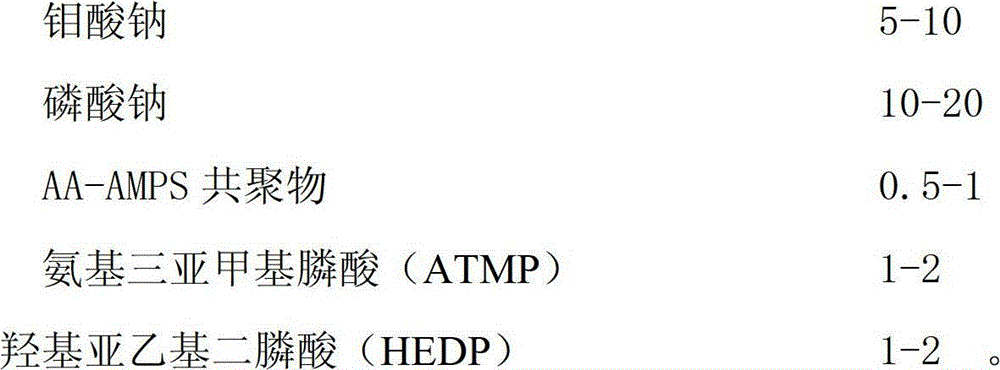

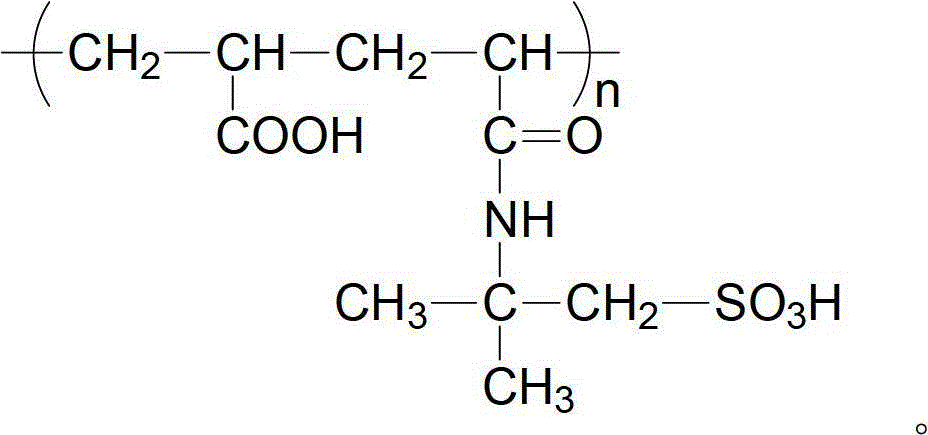

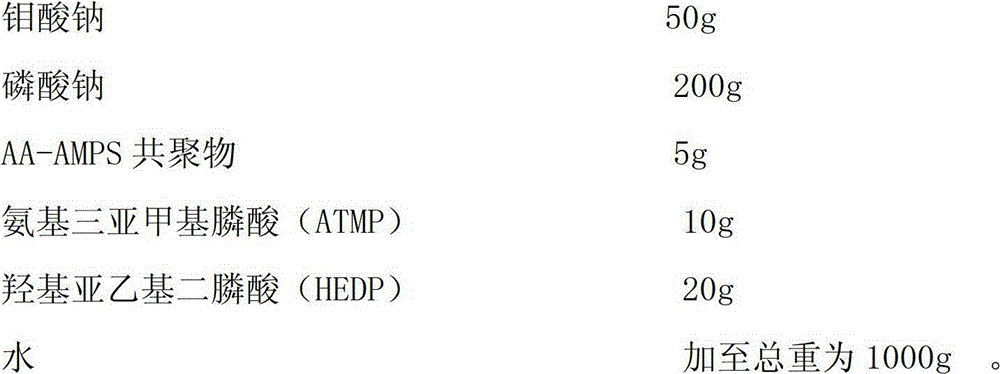

Oil field compound type anti-scale corrosion inhibitor and preparation method thereof

InactiveCN102911651AGood synergyGood scale and corrosion inhibitionBorehole/well accessoriesSodium phosphatesSimple component

The invention relates to an oil field compound type anti-scale corrosion inhibitor and a preparation method thereof, belonging to the technical field of corrosion inhibitor. The oil field compound type anti-scale corrosion inhibitor is characterized by comprising the components by mass percent: 5-10% of sodium molybdate, 10-20% of sodium phosphate, 0.5-1% of acrylic acid-2-acrylamido-2-methyl propane sulfonic acid (AA-AMPS) copolymer, 1-2% of amino trimethylene phosphonic acid and 1-2% of hydroxyl ethylidene diphosphonic acid (HEDP). The preparation method comprises the steps of: firstly, completely dissolving sodium molybdate and sodium phosphate by using water; then, adding the AA-AMPS copolymer under the condition of stirring until the copolymer is completely dissolved; subsequently, adding ATMP and the HEDP, and further stirring for dissolving; and finally, adding water until the concentration of the mixed solution is in accordance with the requirement, so as to obtain the oil field compound type anti-scale corrosion inhibitor. The inhibitor disclosed by the invention has the advantages of simple components, available raw materials, simple technology, high efficiency, low cost, low dosage, good scale inhibition, descaling and corrosion inhibition effects and the like, and is convenient to prepare, rapid.

Owner:E TECH ENERGY TECH DEV CORP

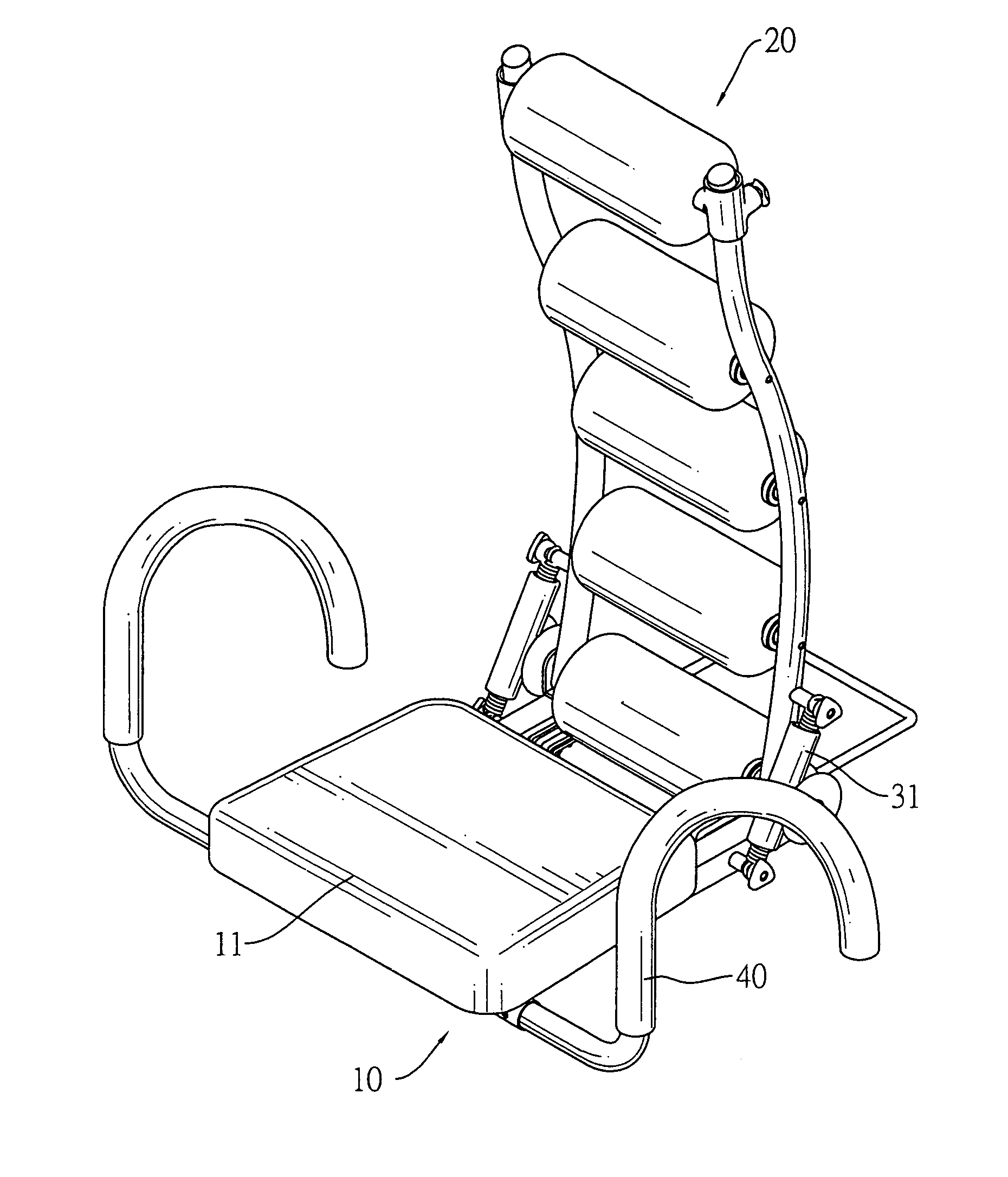

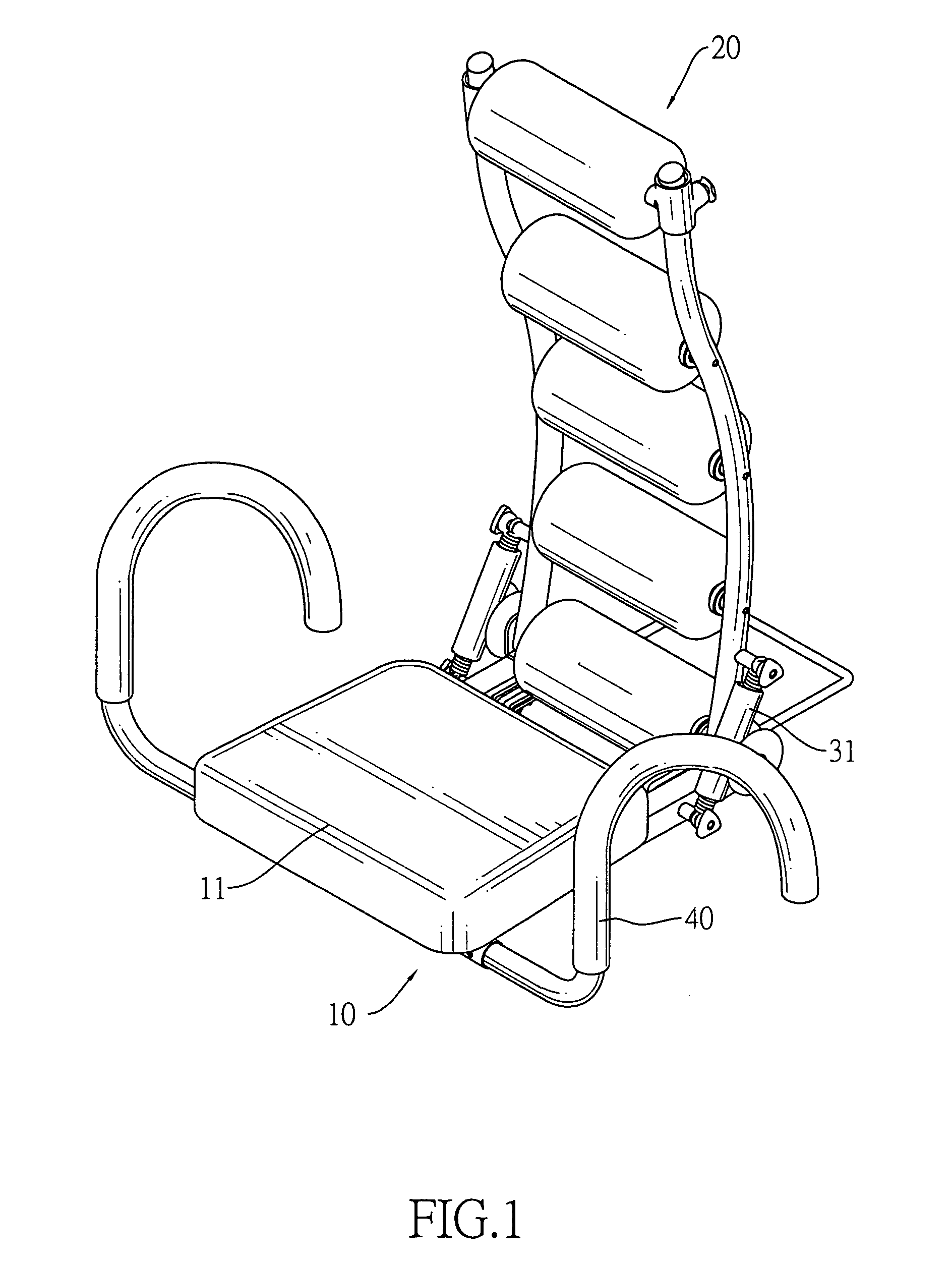

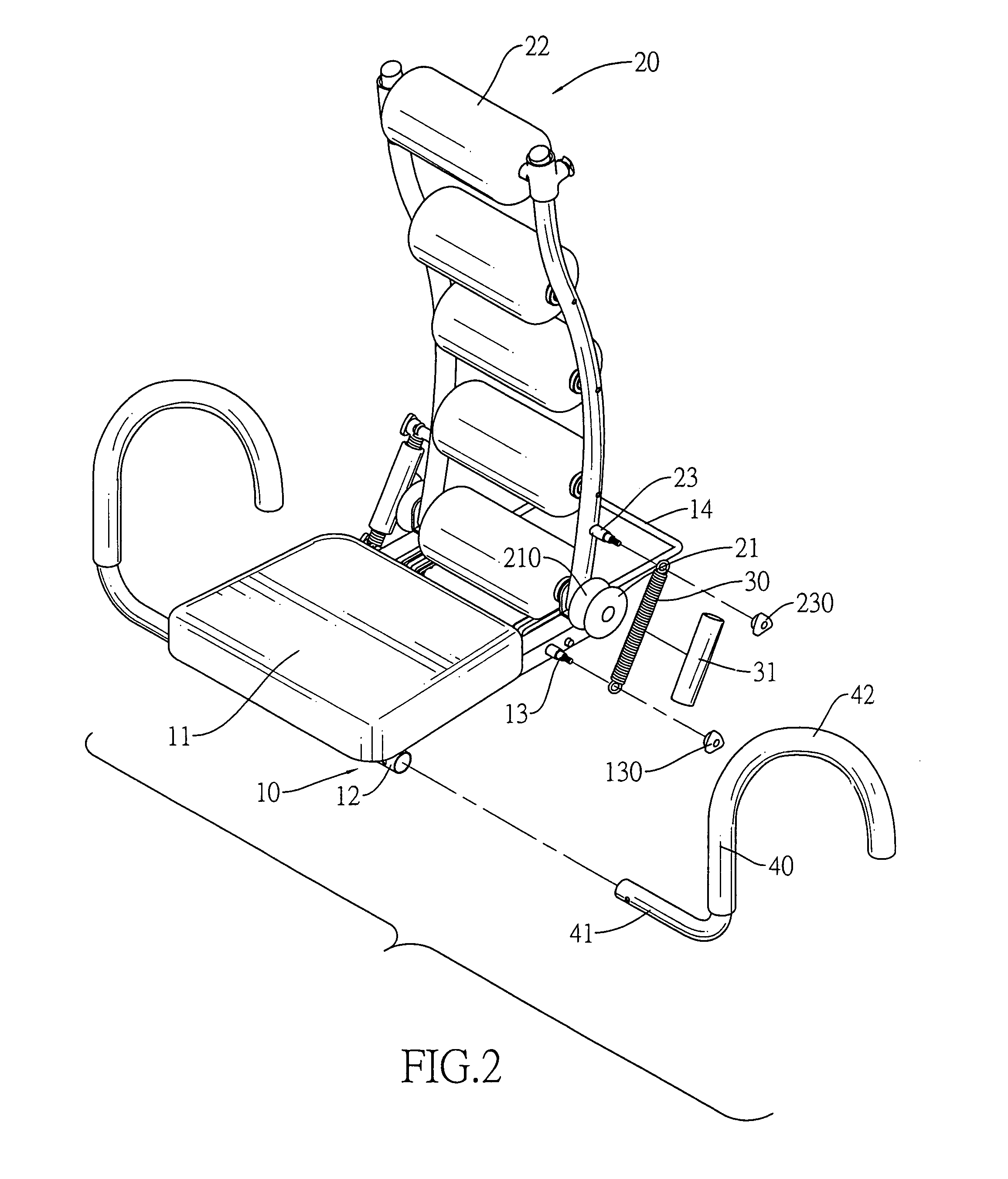

Back and abdomen exercising apparatus

A back and abdomen exercising apparatus includes a base and a back rest, and the backrest is provided at the rear portion of the base. The backrest is mounted on the base with two resilient members. A user sits on the base with back abutting against the backrest and presses the backrest backward, the resilient members provide a biasing force against the user. During the process, the muscle back and abdomen of the user is exercised and trained. In addition, the exercising apparatus has simple components, a simple operation method, a small size and light, and is convenient to carry.

Owner:E MISHAN & SONS

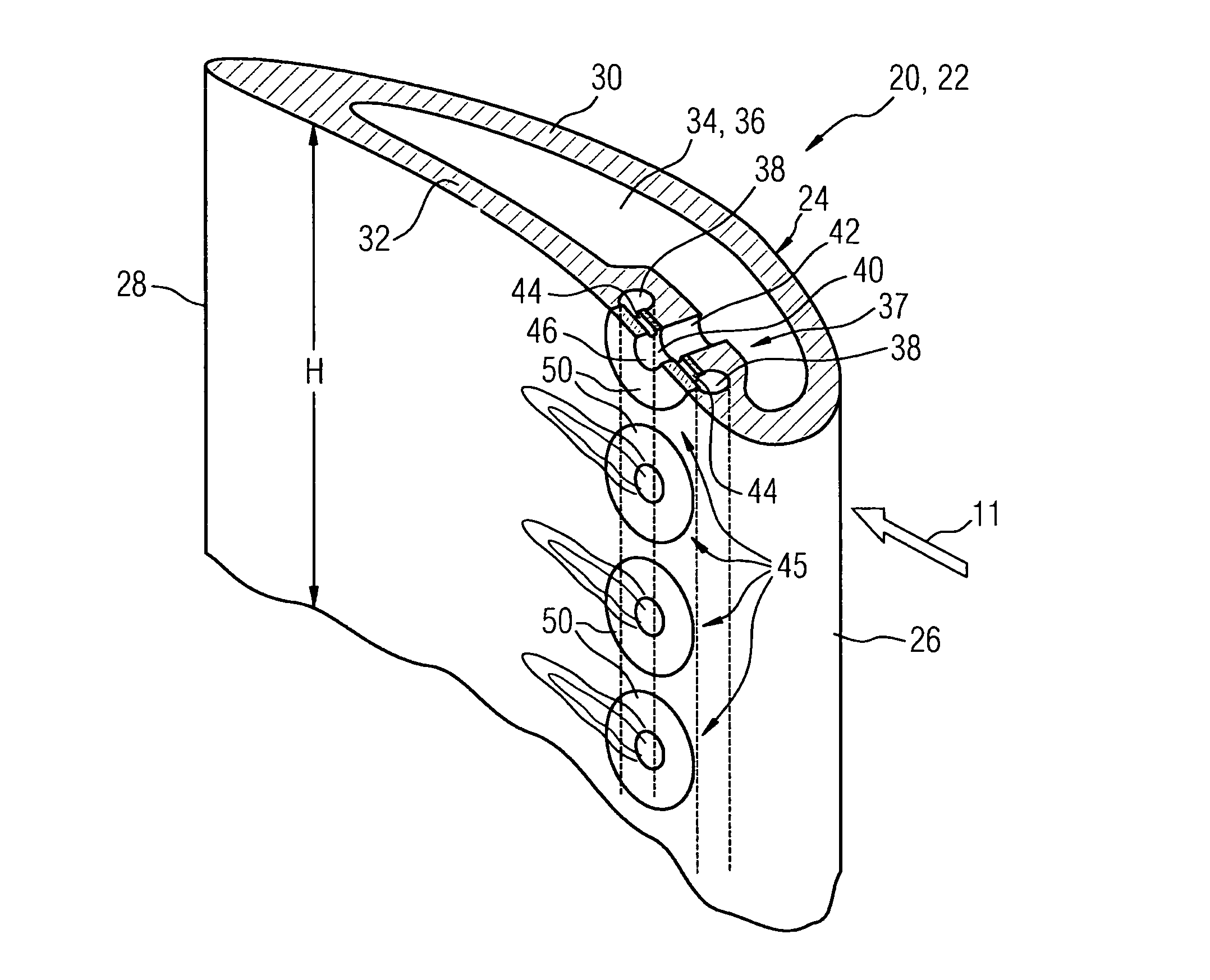

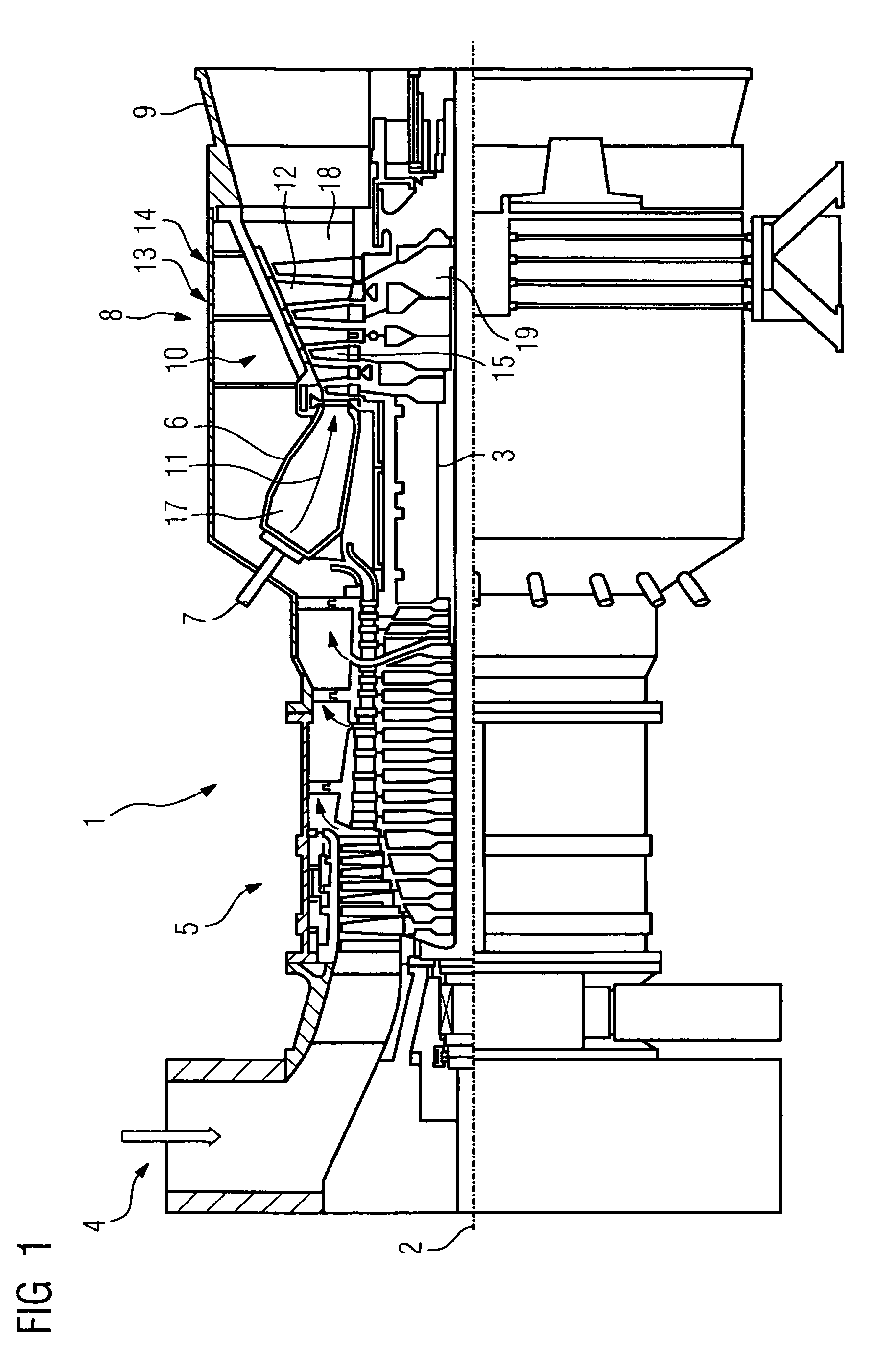

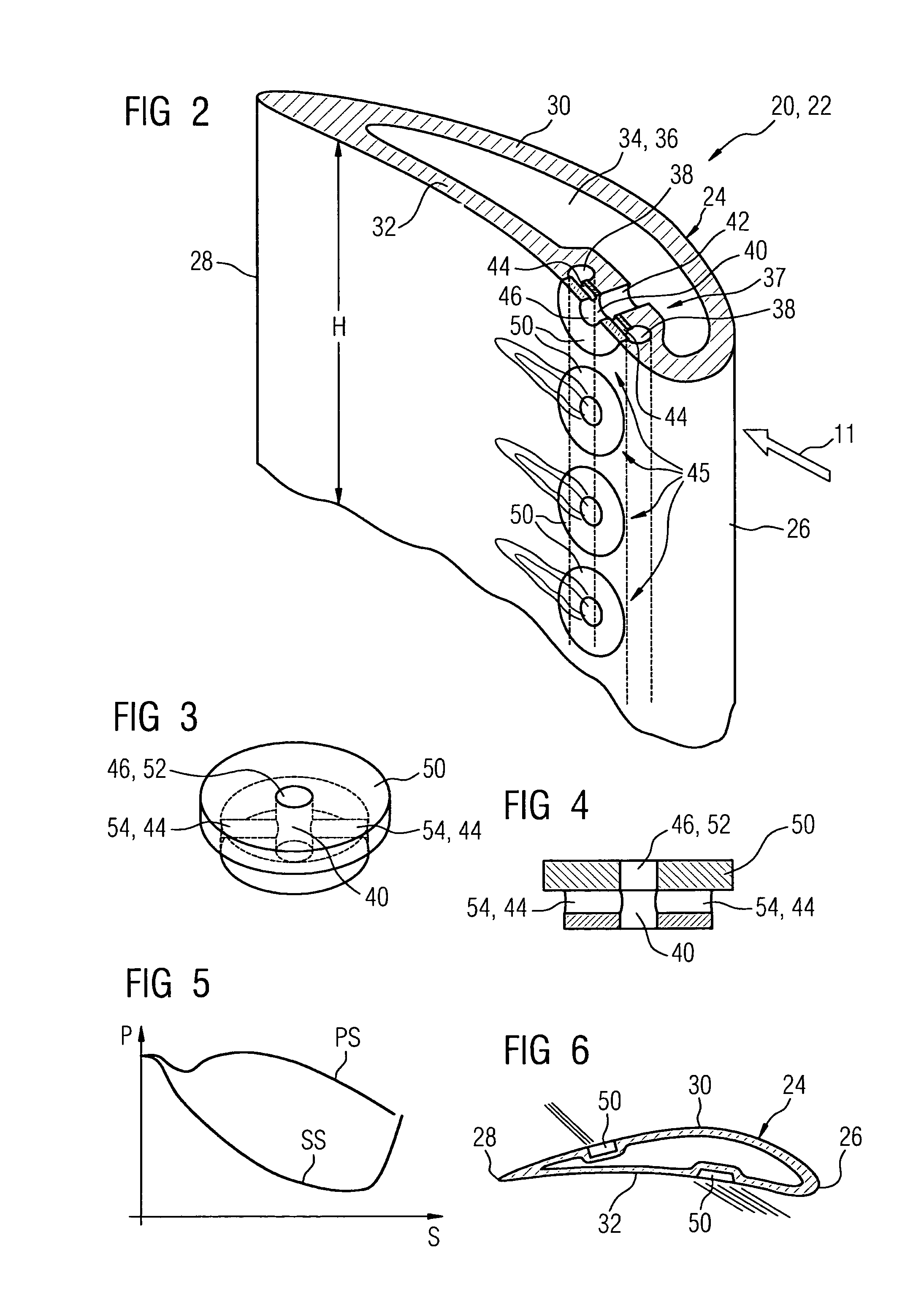

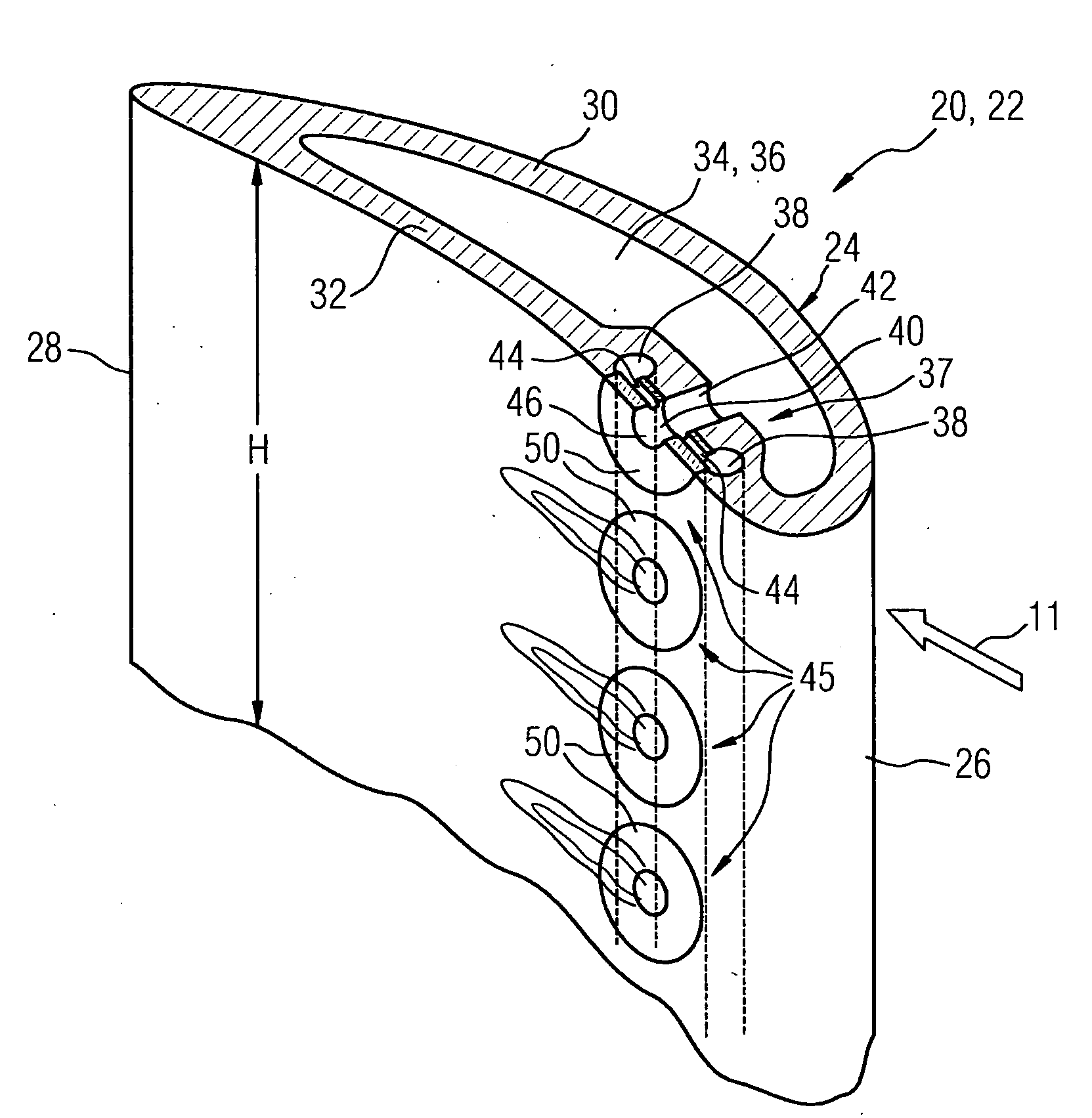

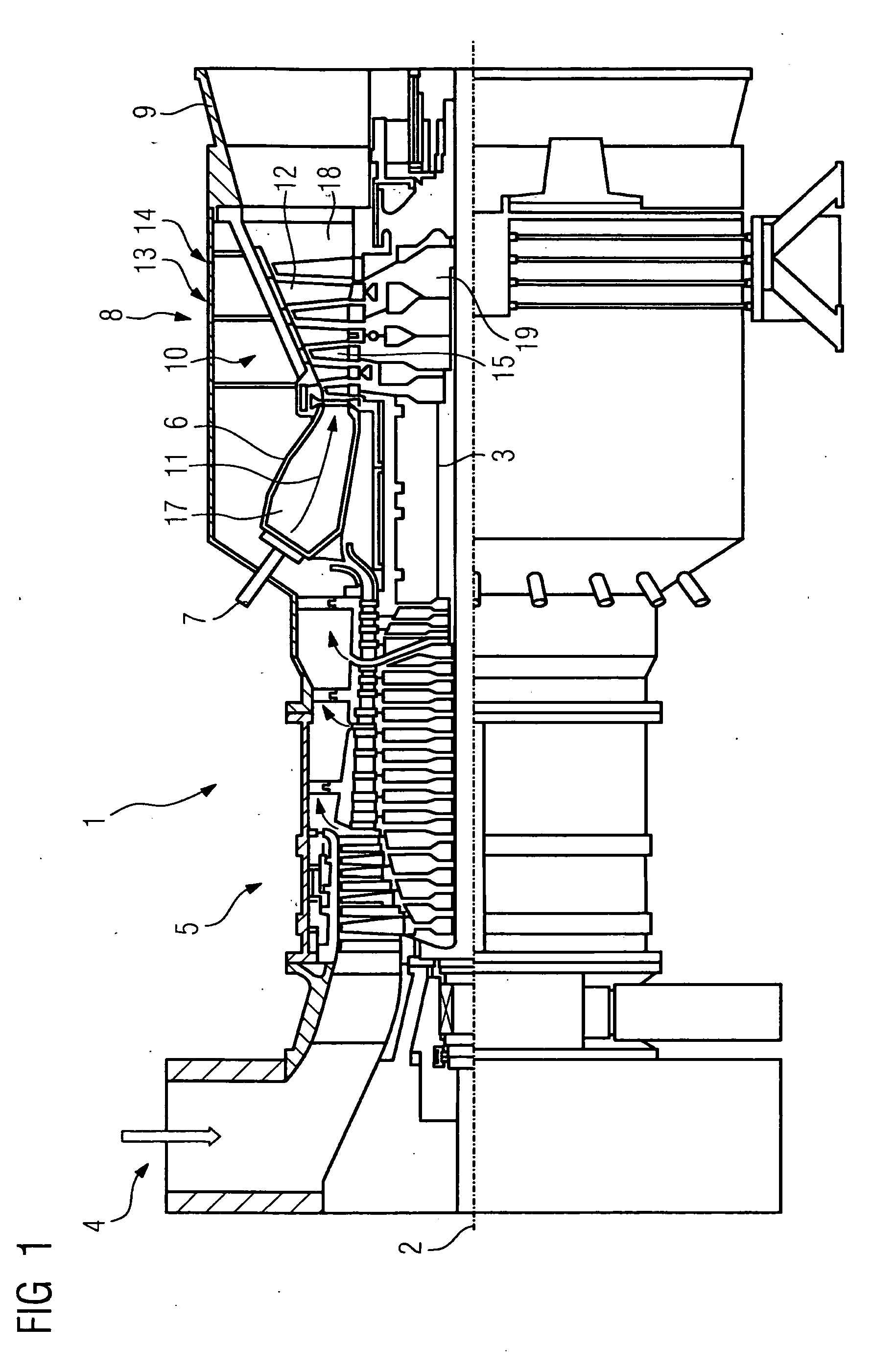

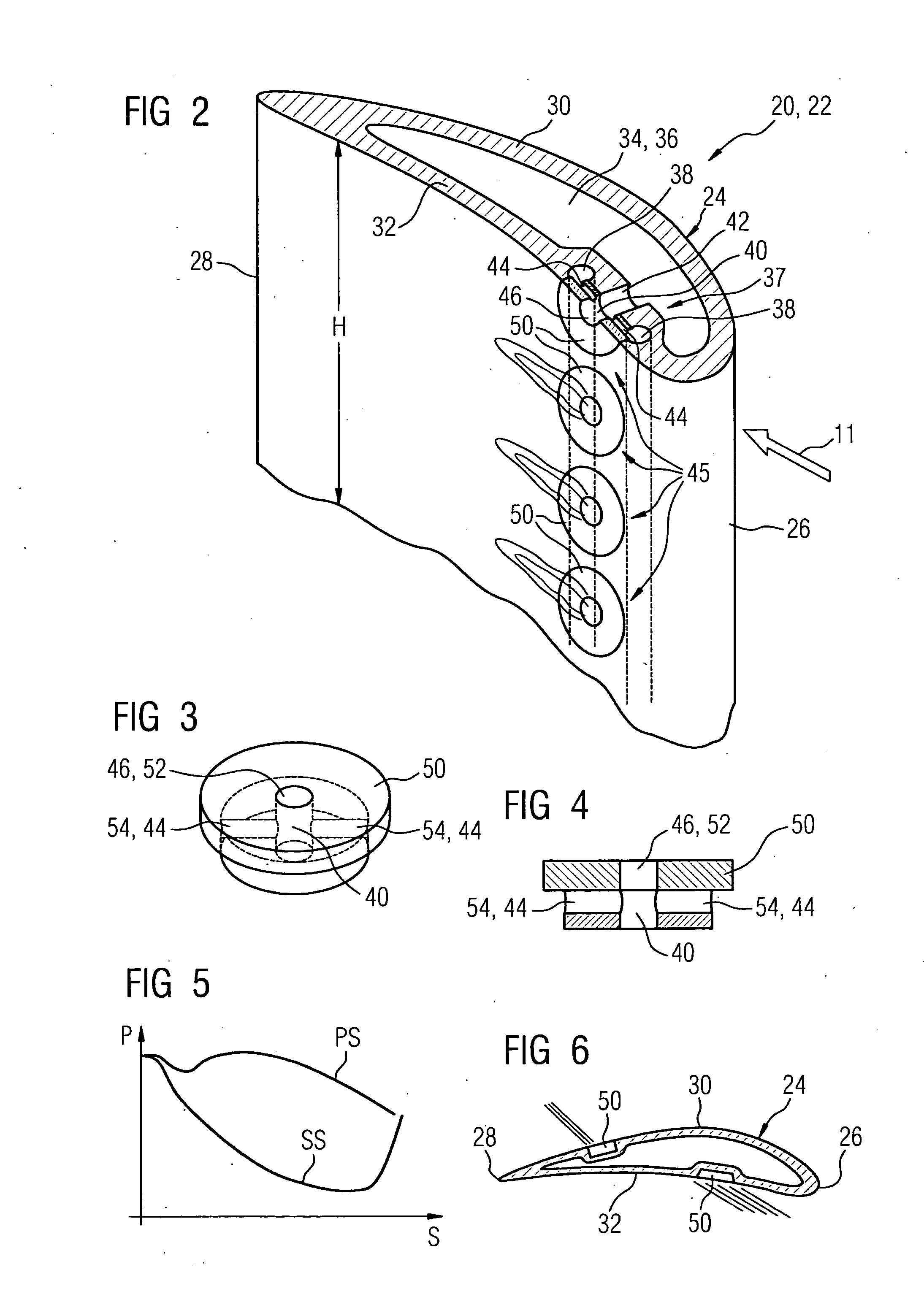

Media mixing insert for turbine blade in turbine engine

InactiveUS8047001B2Simple and cost-effectiveContinuous combustion chamberBlade accessoriesTurbine bladeSimple component

Owner:SIEMENS AG

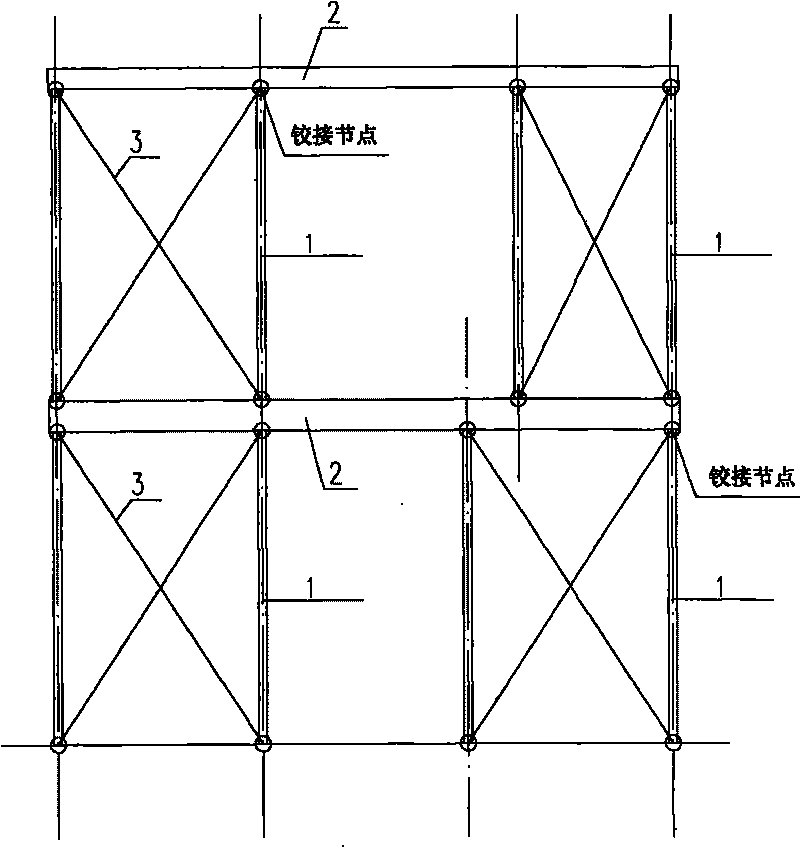

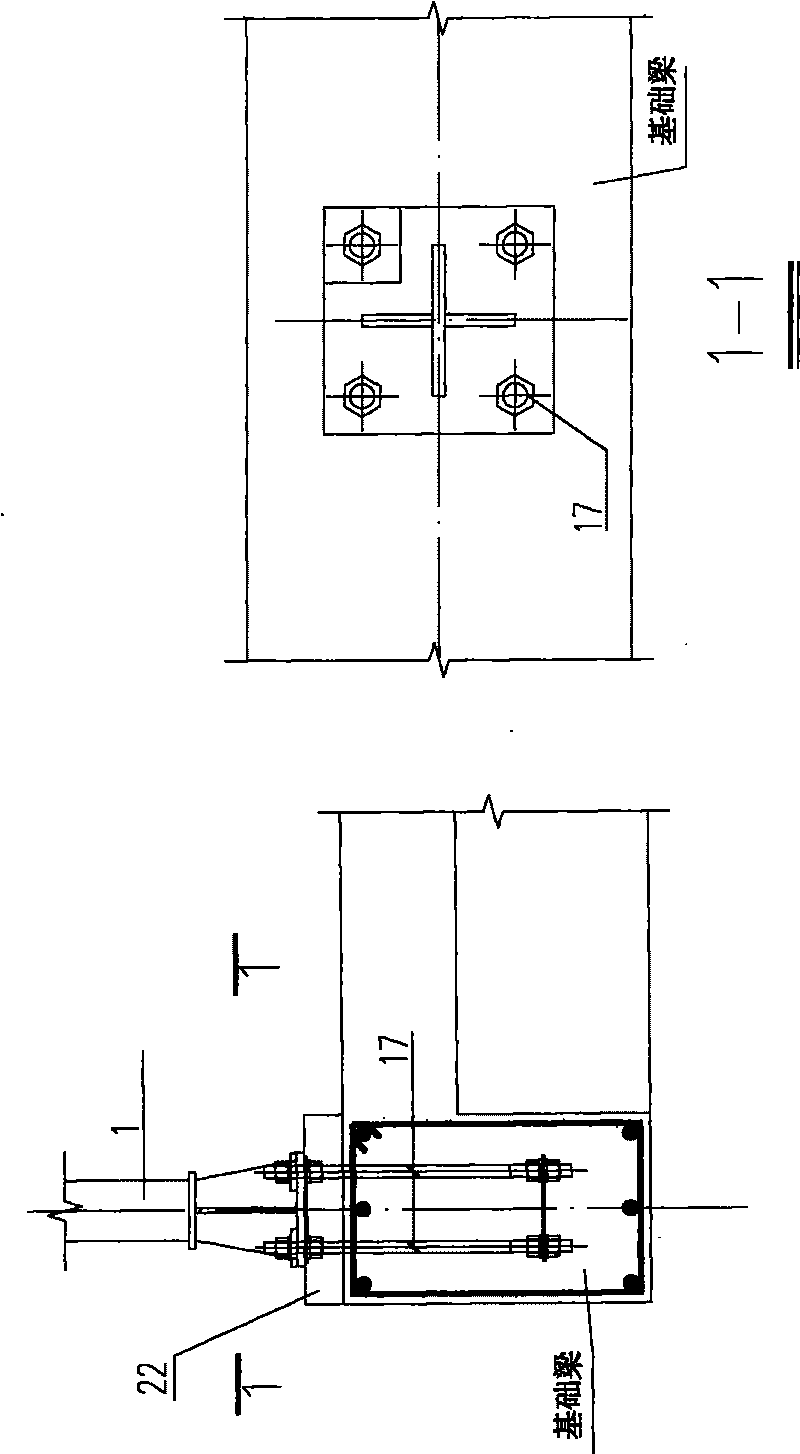

Structural system of industrial low storied dwelling

ActiveCN101748903AReasonable forceAvoid wastingBuilding constructionsDwelling buildingFloor slabSimple component

The invention belongs to the field of building structures, and in particular relates to a structural system of an industrial low storied dwelling adopting modularized design, factory production and field mounting. The structural system of the industrial low storied dwelling comprises steel columns, steel girders, inter-column supports, steel girder horizontal supports, floor slabs, connecting nodes between the steel columns and a foundation, the connecting nodes between the steel columns and the steel girders, the connecting nodes between the steel columns and the inter-column supports, the connecting nodes between the steel girders and the steel girder horizontal supports, rigid connection nodes between the steel girders, the connecting nodes between the steel girders and the floor slabs, roofing surrounding systems and wall surface surrounding systems, wherein the steel columns are connected with the foundation through pre-embedded bolts; the steel columns are connected with the steel girders through bearing type high-strength bolts; the steel columns are connected with the inter-column supports through ordinary bolts; the steel girders are connected with the steel girder horizontal supports through the ordinary bolts; the steel girders are in fully rigid connection through continuous girders; the slabs are connected with the steel girders through male pins or special fasteners; and each of the roofing surrounding systems and the wall surface surrounding systems is of a block type. The structural system of the invention has the characteristics of clear stress of the structure, simple component connection, convenient and quick mounting, attractive appearance, good rationality and economical efficiency of unit steel amount, and is favorable for industrial production.

Owner:宝业集团浙江建设产业研究院有限公司

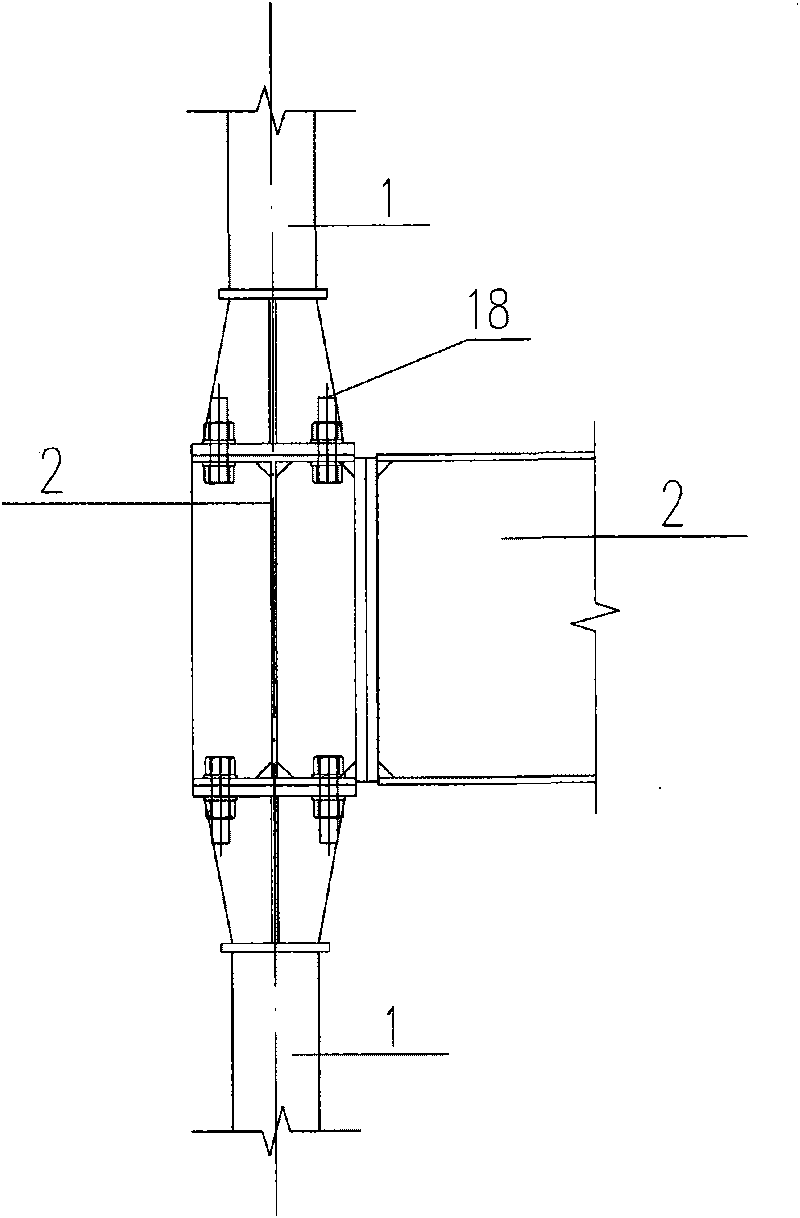

A segmented trace hinge moment balance

InactiveCN104990683AImprove securityLarge scale coverageAerodynamic testingMeasurement testImage resolution

The invention provides a segmented trace hinge moment balance and belongs to the technical field of aerospace force measurement test aerodynamic force measurement. The segmented trace hinge moment balance is of an all-steel-component combined structure. The segmented trace hinge moment balance comprises a measuring device, a thermal insulation device and a limiting protection device. The measuring device comprises a simple-component balance and a six-component beam balance, wherein the central axis of the simple-component balance is perpendicular to the central axis of the six-component beam balance; the simple-component balance is fixed at the free end of the six-component beam balance and is used for measuring a trace hinge moment, and the six-component beam balance measures all the aerodynamic force borne by a control surface and thus corrects the disturbance from the rest of aerodynamic force to the trace hinge moment, so that the resolution ratio and the accuracy of measurement can be improved. The thermal insulation device is arranged on the outer side of the measuring device, so that the heat protection performance and the thermal insulation performance of the measuring device are improved, the temperature effect is reduced, and the accuracy of trace hinge moment measurement in wind tunnel tests under the condition of a high Mach number is improved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

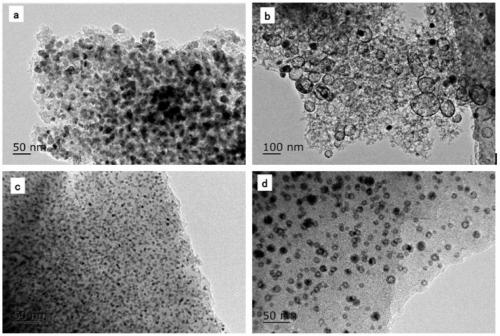

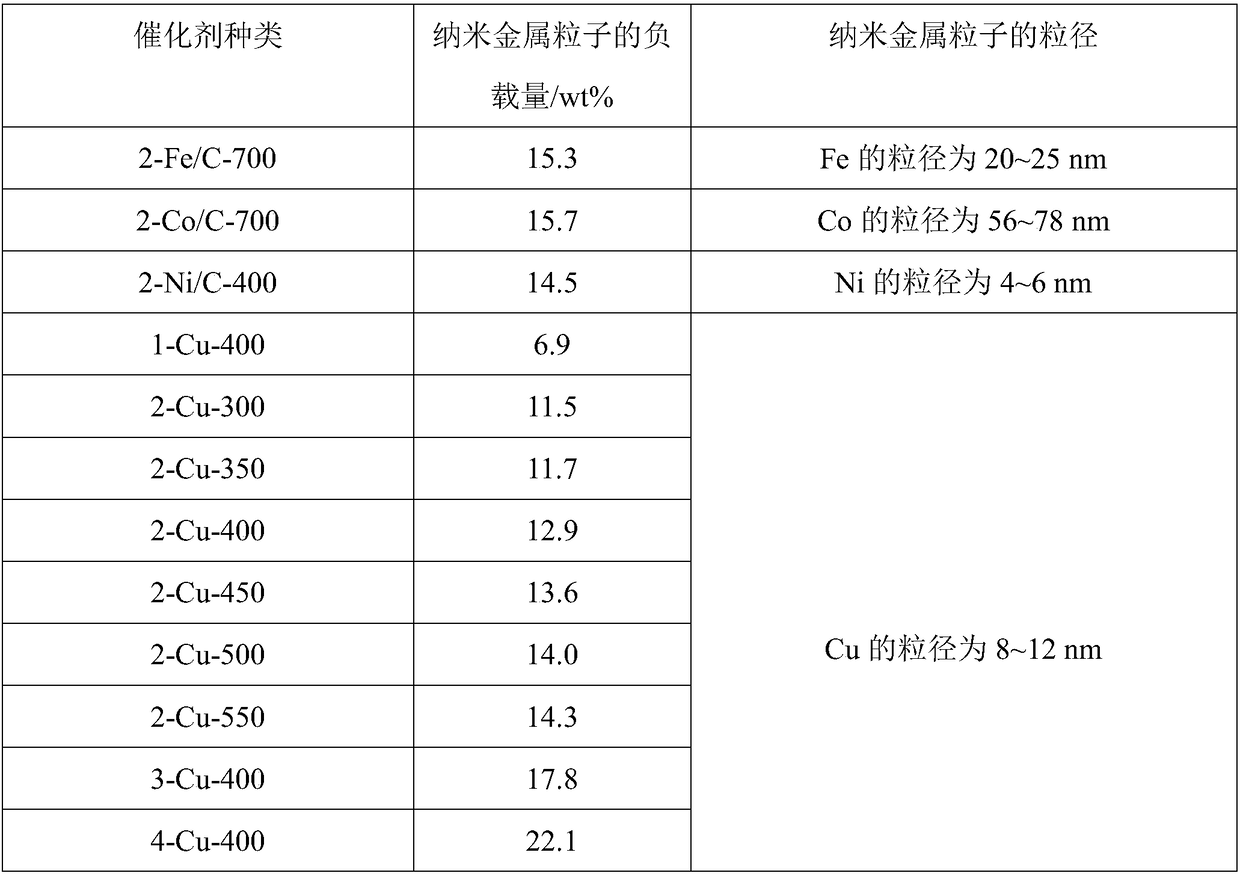

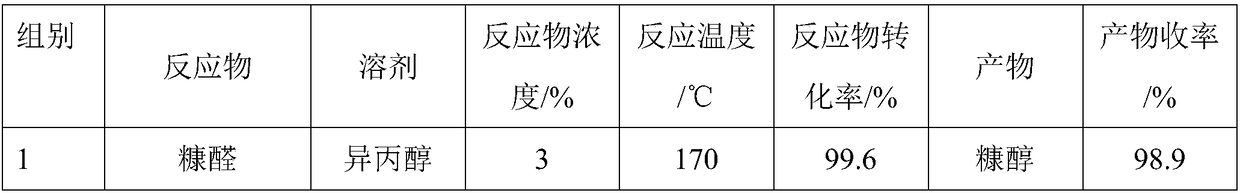

Biomass carbon-base material high-load nano-metal catalyst, as well as preparation method and application thereof

ActiveCN109364922ARaw greenEasy to makeMaterial nanotechnologyCatalyst carriersSimple componentCopper nitrate

The invention discloses a biomass carbon-based material high-load nano-metal catalyst, as well as a preparation method and application thereof. The catalyst is prepared by soaking shaddock peel powderin a nitrate solution having a certain concentration, drying and calcining, metal simple component serves as the active component, and organic carbon serves as the carrier; the nitrate is ferric nitrate, cobalt nitrate, nickel nitrate or copper nitrate; and the metal simple component is iron, cobalt, nickel or copper. The catalyst has the characteristics of environment-friendly raw materials, simple preparation process and high hydrogenation selectivity, has a good effect when being applied to a hydrogenation reaction of biomass derivatives, for instance, the furfuryl alcohol yield at a relatively low temperature of 170 DEG C can be 98,9 percent when the furfuryl alcohol is prepared by a furfuryl alcohol selective hydrogenation reaction.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

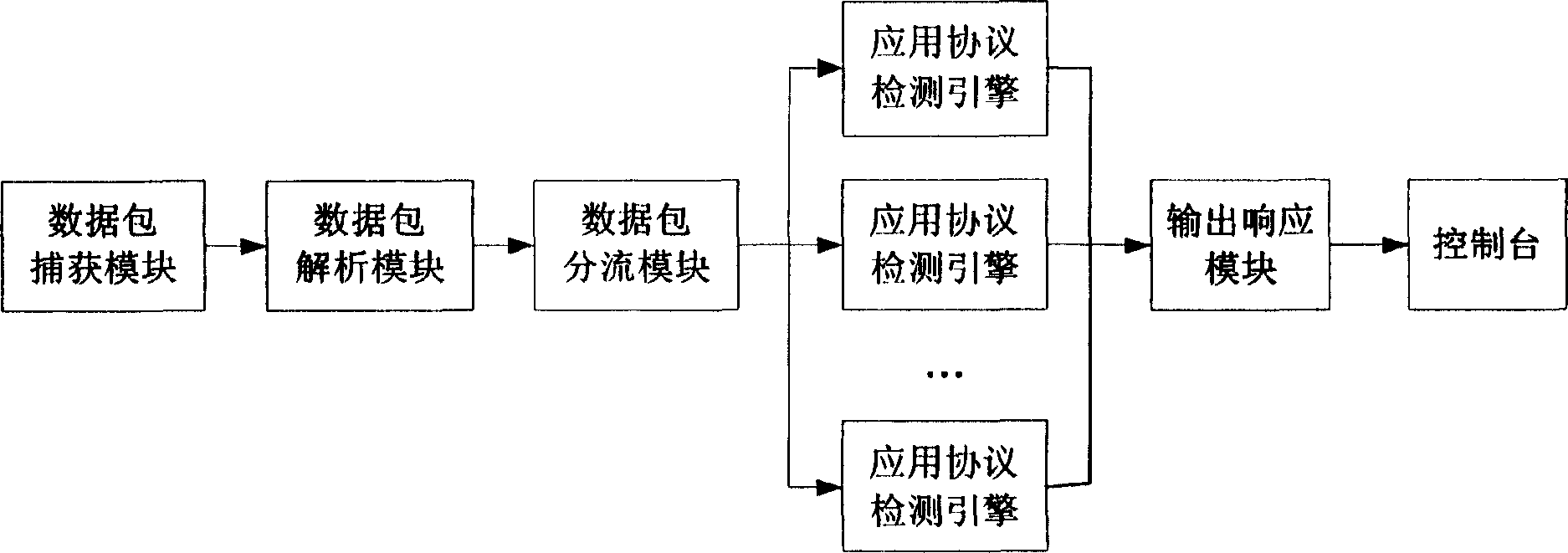

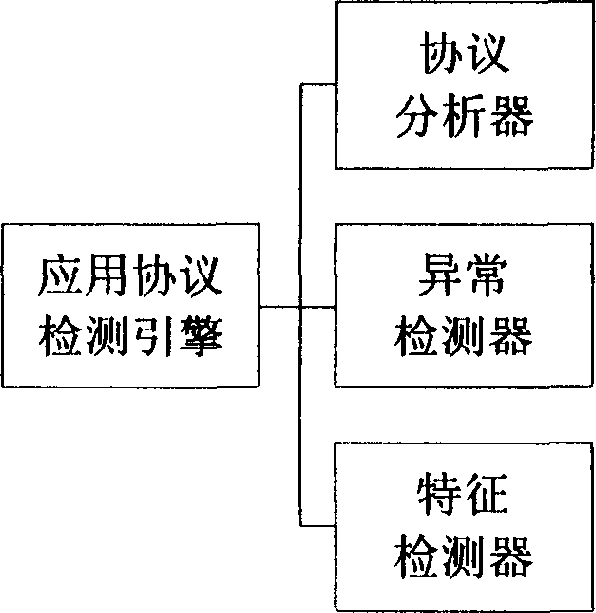

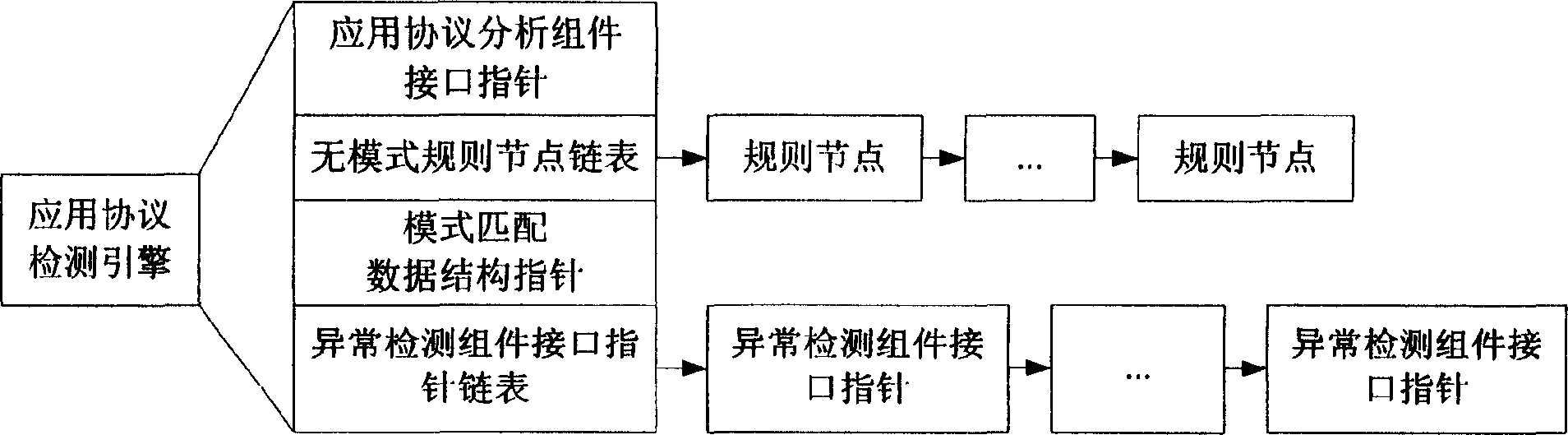

Network intrusion detection system and method based on application protocol detection engine

InactiveCN1738257AMake up for the defect of not being able to detect new attack methodsGuaranteed scalabilityData switching networksComponent Object ModelAnomaly detection

The invention provides a network invasion detecting system based on the application protocol detecting engine and its method. The application protocol detecting engine comprises three detector units as a application protocol analyzer, a abnormal detector and a feature detector while these detectors can all or partly use simply components object models and supply uniform calling interface. The character of said network invasion detecting method is that the invention comprises three steps as protocol analysis, abnormal detecting and feature detecting. The invention can solve the defect of present network invasion detecting system that the inability for detecting new invasion type; and the invention realizes components of the application protocol analyzer, the abnormal detector and the feature detector by the components technique, which allows the detecting component after decoding can connect the detecting system directly without decoding again, so the spreading and the maintenance of network invasion detecting system are improved.

Owner:PEKING UNIV

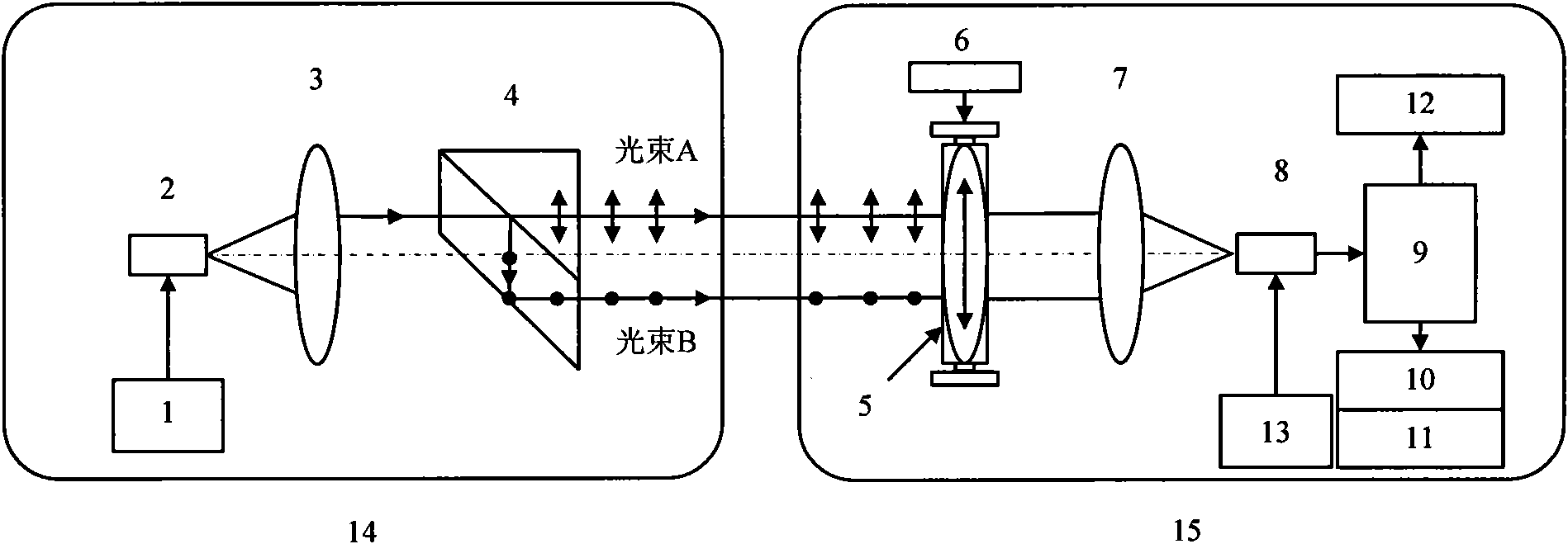

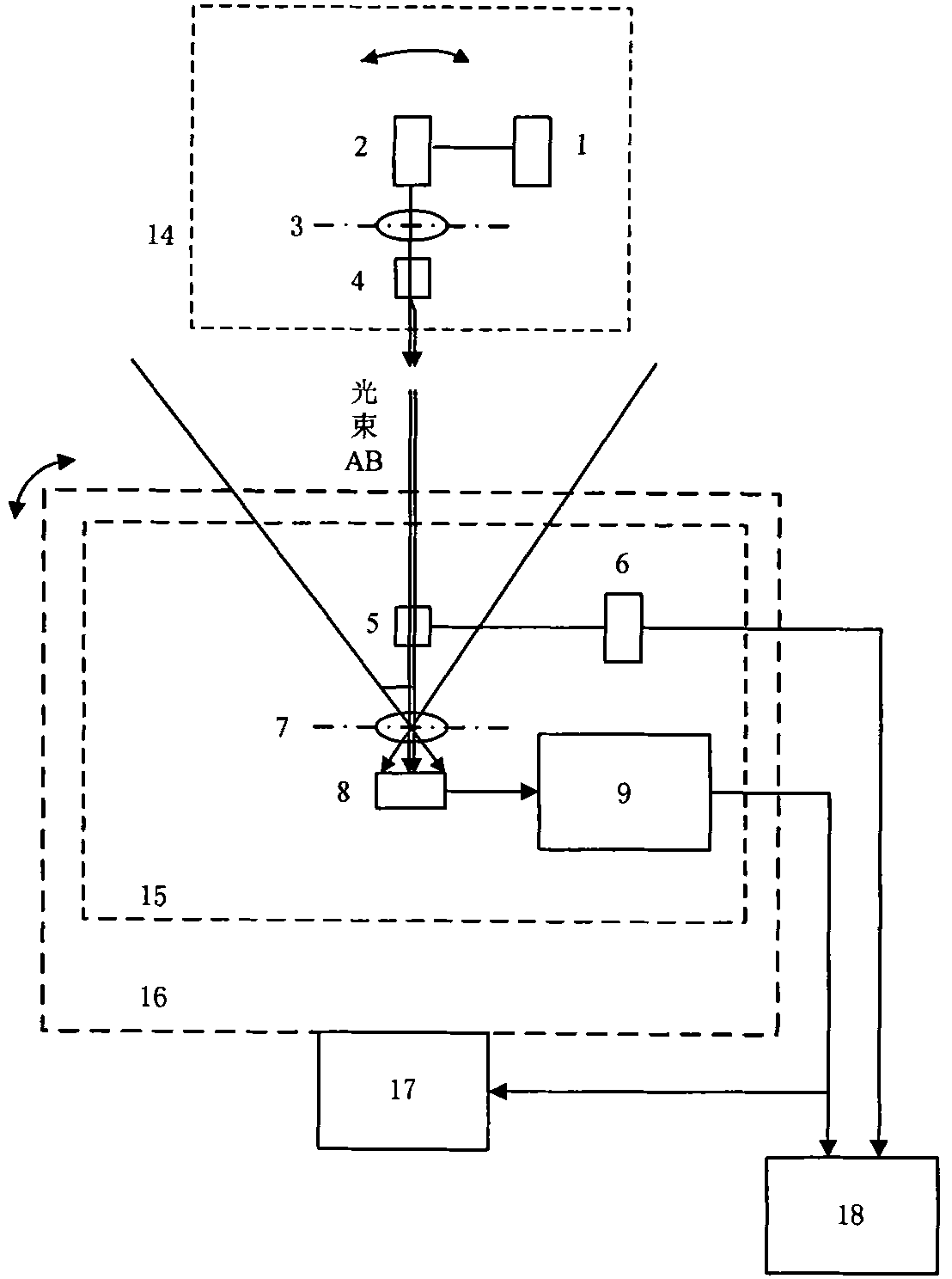

Light beam position and polarization angle common light path detection device and method

The invention discloses a light beam position and polarization angle common light path detection device and method based on a photoelectric position sensor. The method comprises the following steps: utilizing a lateral excursion and polarization dispersion prism to shape an incident light beam, outputting orthogonal parallel polarized lights with proportionable light intensities and realizing the contactless space position attitude transfer function; enabling a receiving system to utilize a rotary motor with a coder to drive an analyzer to detect the beacon light polarization through rotation at a constant angular velocity, utilizing the horizontal photoelectric effect of a PSD (Phase-sensitive Detector) to measure the light spot imaging position of beacon light and reversely pushing a beacon light beam position coordinate according to the imaging principle; utilizing light current generated by gathering incident light intensities on the surface of the PSD to detect the incident light intensities, comparing with an angle instantaneously fed back by the rotary motor, obtaining the synchronous polarization angle information of a beacon light beam after the phase sensitive detection, and achieving the function of simultaneously adjusting and detecting the beacon light track and the base vector angle on a same light path and a device. The light beam position and polarization angle common light path detection device has the benefits of simple structure and simple components and is suitable for the multi-dimensional angle measurement demands.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Medium-thickness ship plate steel with ultrahigh intensity and low-temperature impact toughness and manufacturing method thereof

ActiveCN101781742ASimple designImprove mechanical propertiesTemperature control deviceMetal rolling arrangementsSimple componentContinuous casting

The invention relates to medium-thickness ship plate steel with ultrahigh intensity and low-temperature impact toughness and a manufacturing method thereof. The ship plate steel comprises the following components in percentage by weight: 0.04 to 0.10 percent of C, 0.15 to 0.35 percent of Si, 1.20 to 1.70 percent of Mn, less than or equal to 0.020 percent of P, less than or equal to 0.010 percent of S, 0.04 to 0.08 percent of Nb, 0.10 to 0.20 percent of TiO, 0.20 to 0.50 percent of Cu, less than or equal to 0.30 percent of Cr, 0.20 to 0.50 percent of Ni, 0.02 to 0.05 percent of Al, 0.1 to 0.3 percent of Mo and the balance of Fe and impurities. A process comprises the following steps of: performing heating, heat insulation, two-stage rolling and cooling treatment on a precast continuous casting in sequence to manufacture finished product ship plate steel. The ship plate steel has simple component design, high comprehensive mechanical performance and high welding performance; and the preparation process is simple and easy to manipulate.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Pavement joint sealing material and preparation method thereof

ActiveCN101418127AEasy to useGood high and low temperature performancePaving detailsBuilding insulationsTO-18Simple component

The invention provides a pavement joint sealing material. The joint sealing material comprises the following components: 65 to 85 percent of petroleum asphalt, 9 to 18 percent of extract oil and 6 to 17 percent of styrene-butadiene-styrene segmented copolymer. The preparation method is as follows: the asphalt is heated to a temperature of between 100 and 200 DEG C; and the extract oil and the styrene-butadiene-styrene segmented copolymer are added and sheared for 35 to 95 minutes at a maintained preparation temperature of between 160 and 180 DEG C and at a shearing velocity of between 3,500 and 4,500 revolutions per minute until the mixture is uniformly mixed, and the pavement joint sealing material is obtained. The joint sealing material has the characteristics of simple components, good high temperature and low temperature resistance, and capability of being used for paving a pavement crack.

Owner:CHINA PETROLEUM & CHEM CORP +1

Turbine Blade for a Turbine

InactiveUS20090081048A1Simple and cost-effectiveContinuous combustion chamberPump componentsLine tubingTurbine blade

The invention relates to a blade for a turbine comprising a blade wall, a first channel for guiding a first medium and a second channel for guiding a second medium that can be supplied to the turbine blade separately from the first medium. In order to combine both media, which are supplied separately, into one mixture, a turbine blade has least one chamber which is arranged in the interior or in the blade wall and said chamber is connected to said channels via a respective connection line. In order to provide a particularly simple component that is economical to produce, the chamber and / or the outlet conduit are a least partially delimited and / or formed by an insert accommodated in the wall.

Owner:SIEMENS AG

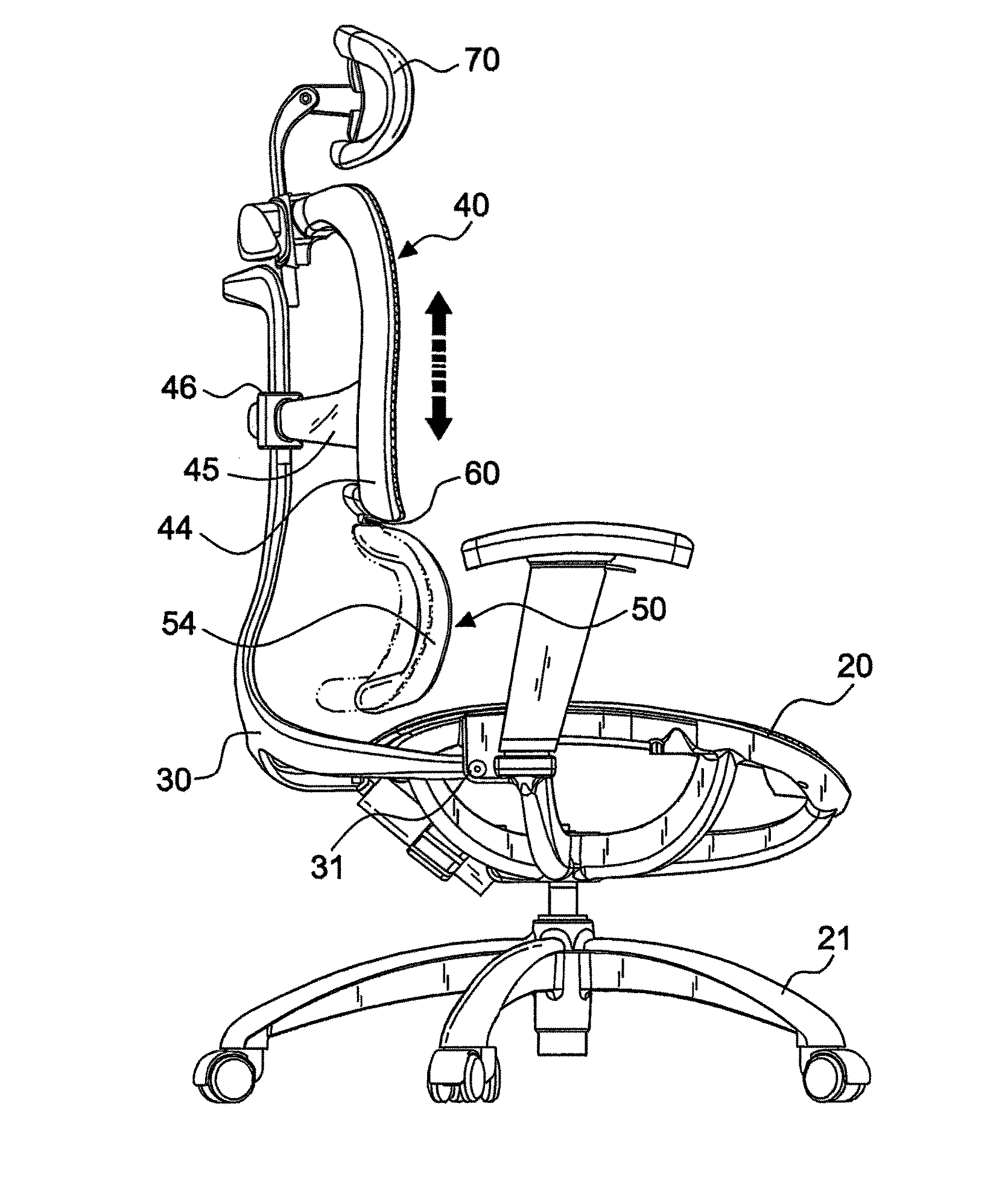

Automatic waistrest adjusting device for office chairs

InactiveUS20120193959A1Best ergonomic operation stateMost comfortable leaning condition for an individual's waistStoolsAdjustable chairsOffice chairSimple component

An automatic waistrest adjusting device for office chairs includes a waistrest combined with the bottom of a backrest, and the waistrest comes with a design of connecting a curved flexible metal plate and making use of whose flexibility to suspend the bottom of the waistrest that can be turned flexibly with a user's waist to achieve an ergonomic stepless angular adjustment to allow the user's waist to lean at the most comfortable position. The waistrest adjusting device combines the waistrest and the backrest by simple components and assembling method, and achieves the effects of preventing poor performance and quality caused by an elastic fatigue and extending the use life.

Owner:CHEN CHING MING

Encoding and decoding using constrained interleaving

InactiveUS20150039966A1Reduce measurementEfficient implementationCode conversionError correction/detection by combining multiple code structuresNoise marginSimple component

Serially-concatenated codes are formed in accordance with the present invention using a constrained interleaver. The constrained interleaver cause the minimum distance of the serial concatenated code to increase above the minimum distance of the inner code alone by adding a constraint that forces some or all of the distance of the outer code onto the serially-concatenated code. This allows the serially-concatenated code to be jointly optimized in terms of both minimum distance and error coefficient to provide significant performance advantages. These performance advantages allow a noise margin target to be achieved using simpler component codes and a much shorter interleaver than was needed when using prior art codes such as Turbo codes. Decoders are also provided. Both encoding and decoding complexity can be lowered, and interleavers can be made much shorter, thereby shortening the block lengths needed in receiver elements such as equalizers and other decision-directed loops. Also, other advantages are provided such as the elimination of a error floor present in prior art serially-concatenated codes. That allows the present invention to achieve much higher performance at lower error rates such as are needed in optical communication systems.

Owner:TRELLIS PHASE COMM LP

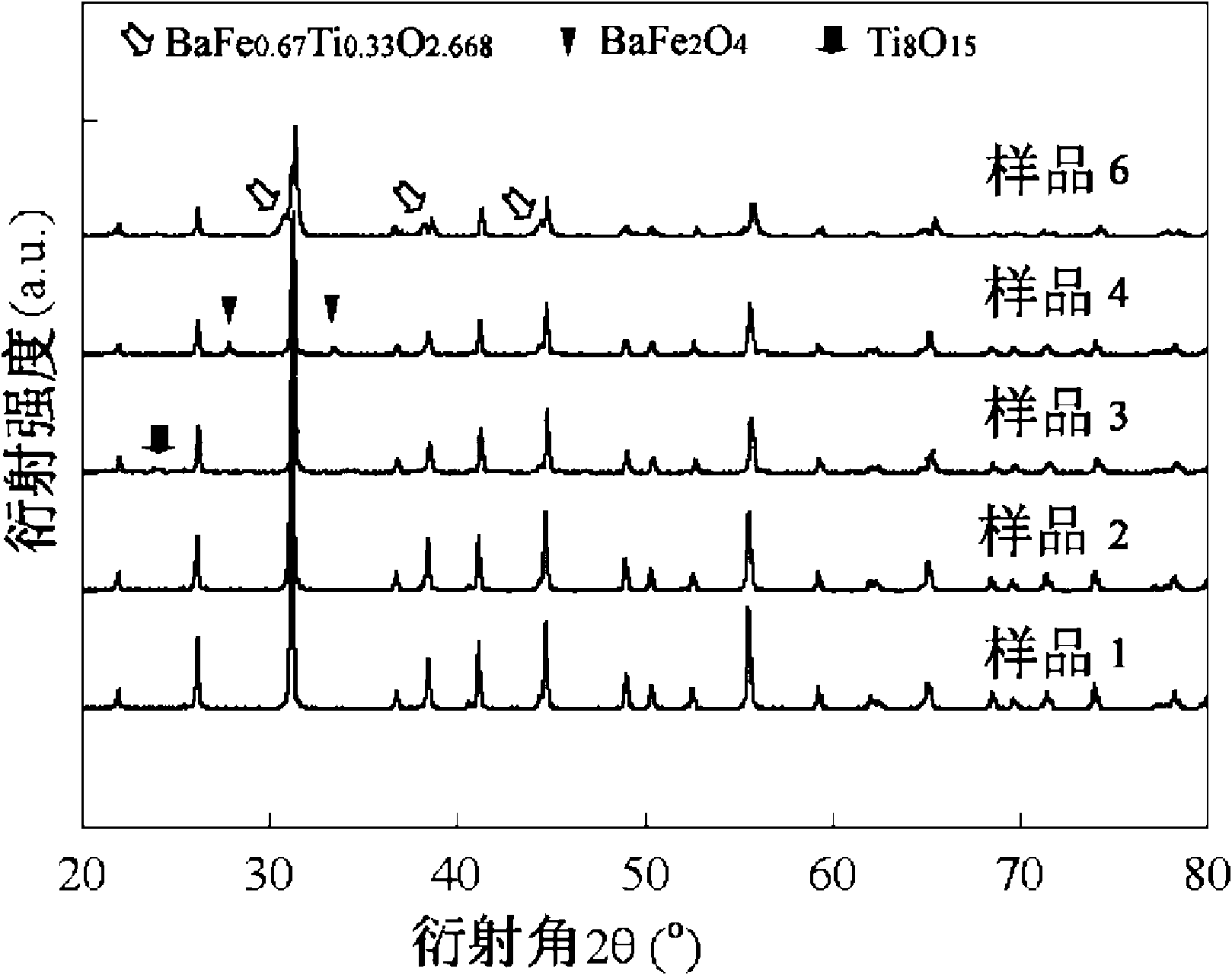

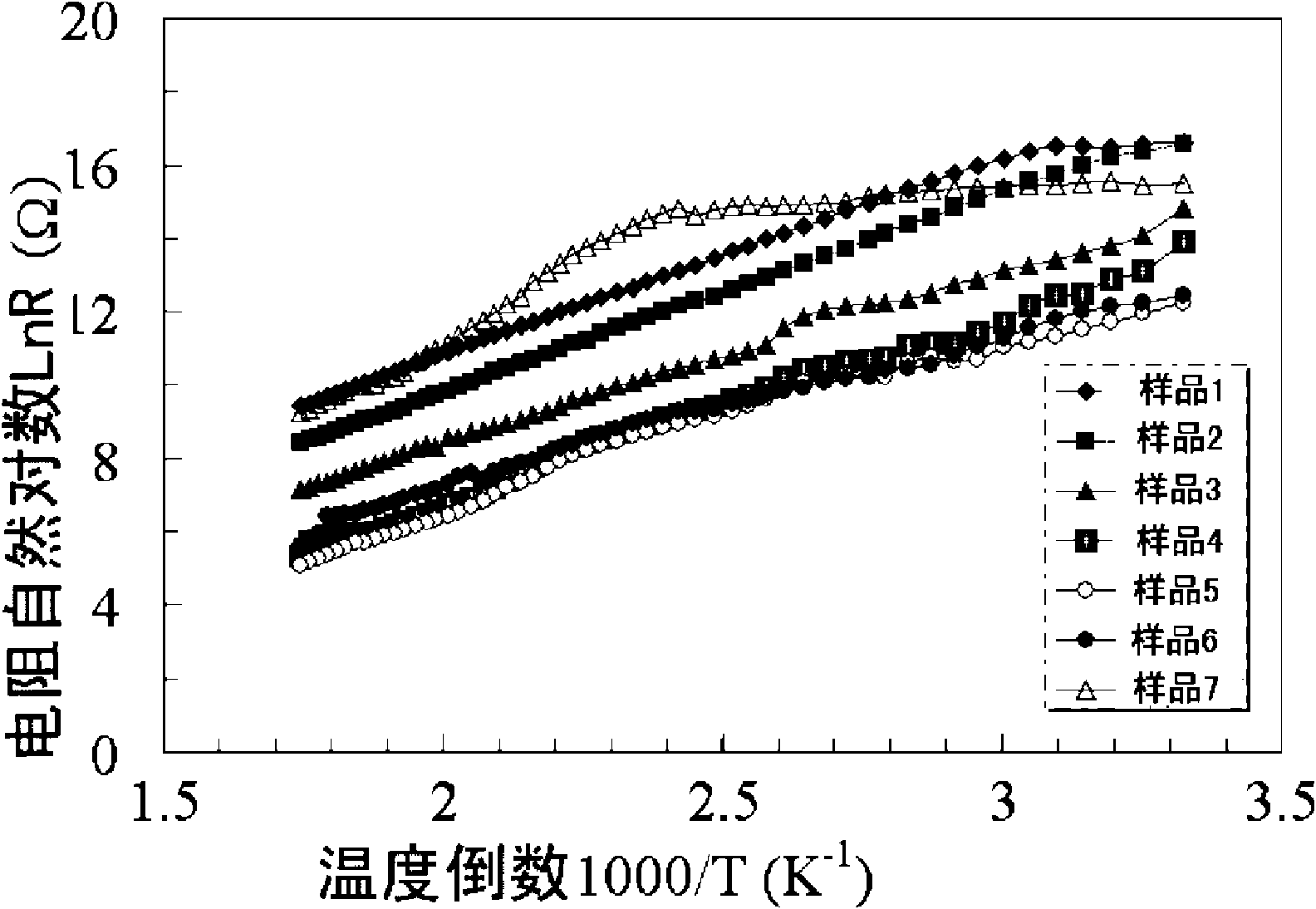

Thermal sensitive ceramic resistance material, resistance element and preparation method of resistance element

InactiveCN101580386AImprove consistencyEase of mass productionNegative temperature coefficient thermistorsSimple componentHeat sensitive

The invention discloses a thermal sensitive ceramic resistance material, a resistance element and a preparation method of the resistance element. The thermal sensitive ceramic resistance material is formed by iron doped with BaTiO3, and the molecular formula is BaTi FeO3; wherein x equals to 0.1 to 1; and the principal crystalline phase of the material is a hexagonal structure. The material of the invention is characterized by simple component design, wide regulating range of components and wide source of raw materials and is suitable for the preparation techniques of multiple ceramic materials; the material only contains one transition metal element of iron and the sintering temperature is lower than the volatilization temperature of the ferriferous oxide, thus effectively avoiding the volatilization problem of the principal component elements at high temperature in the preparation process. The material of the invention has good material constant value, is characterized by good stability, good consistency, good repetitiveness and controllable electrical characteristics such as resistance value, material constant, resistance temperature coefficient and the like, and is applicable to the temperature measurement, control and circuit compensation of automobiles, refrigerators and the like.

Owner:CENT SOUTH UNIV

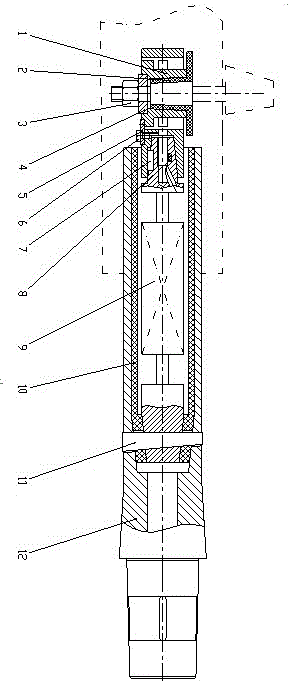

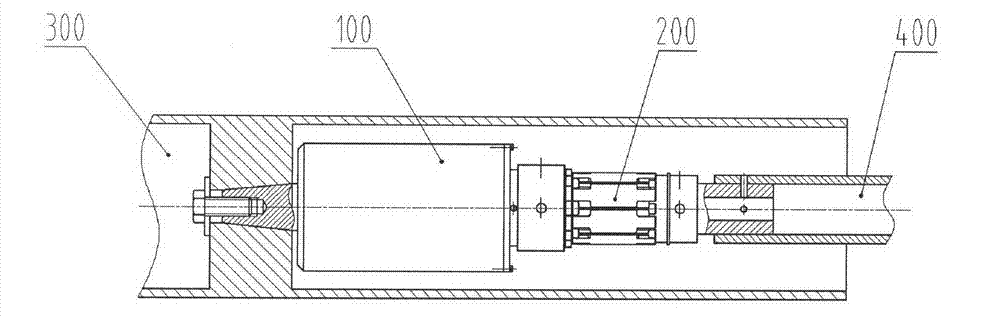

High-precision device for measuring rolling moment based on mechanical bearing support

ActiveCN102889973AImprove rigidityEliminate measurement effectsAerodynamic testingMeasurement deviceSimple component

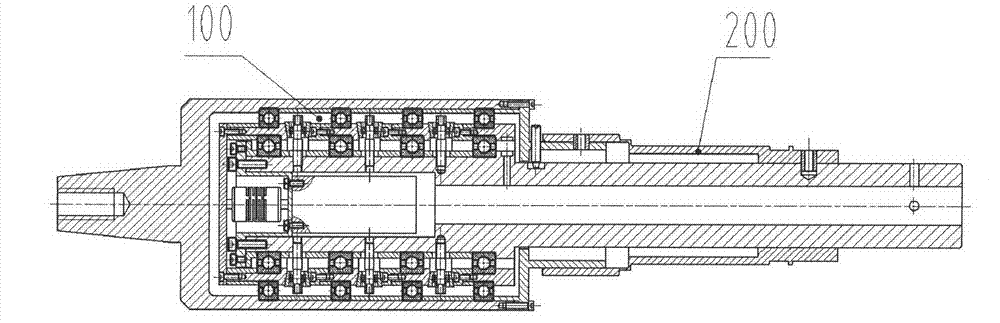

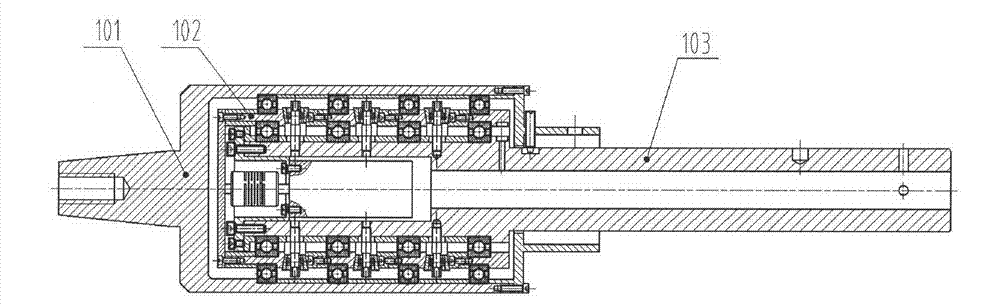

The invention discloses a high-precision device for measuring a rolling moment based on a mechanical bearing support, which is lower in researching and testing costs, higher in precision as comparison with the conversional high-precision rolling moment strain gauge balance and capable of meeting the requirement for small rolling moment wind channel measurement of a wind channel model in various attack angle states. The high-precision device comprises a simple component rolling moment balance (200) and a mechanical bearing support (100), wherein the mechanical bearing support (100) comprises a shell assembly (101), a rotary inner sleeve assembly (102) and a central shaft assembly (103); the rotary inner sleeve assembly (102) is arranged inside the shell assembly (101) by using an outer ring bearing and arranged on the central shaft assembly (103) by using an inner ring bearing; the front end of the shell assembly (101) is fixedly provided with a measured wind channel model (300); and the central shaft assembly (103) is provided with the simple component rolling moment balance (200) and fixed on a model supporting rod (400).

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com