Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1122results about "Negative temperature coefficient thermistors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

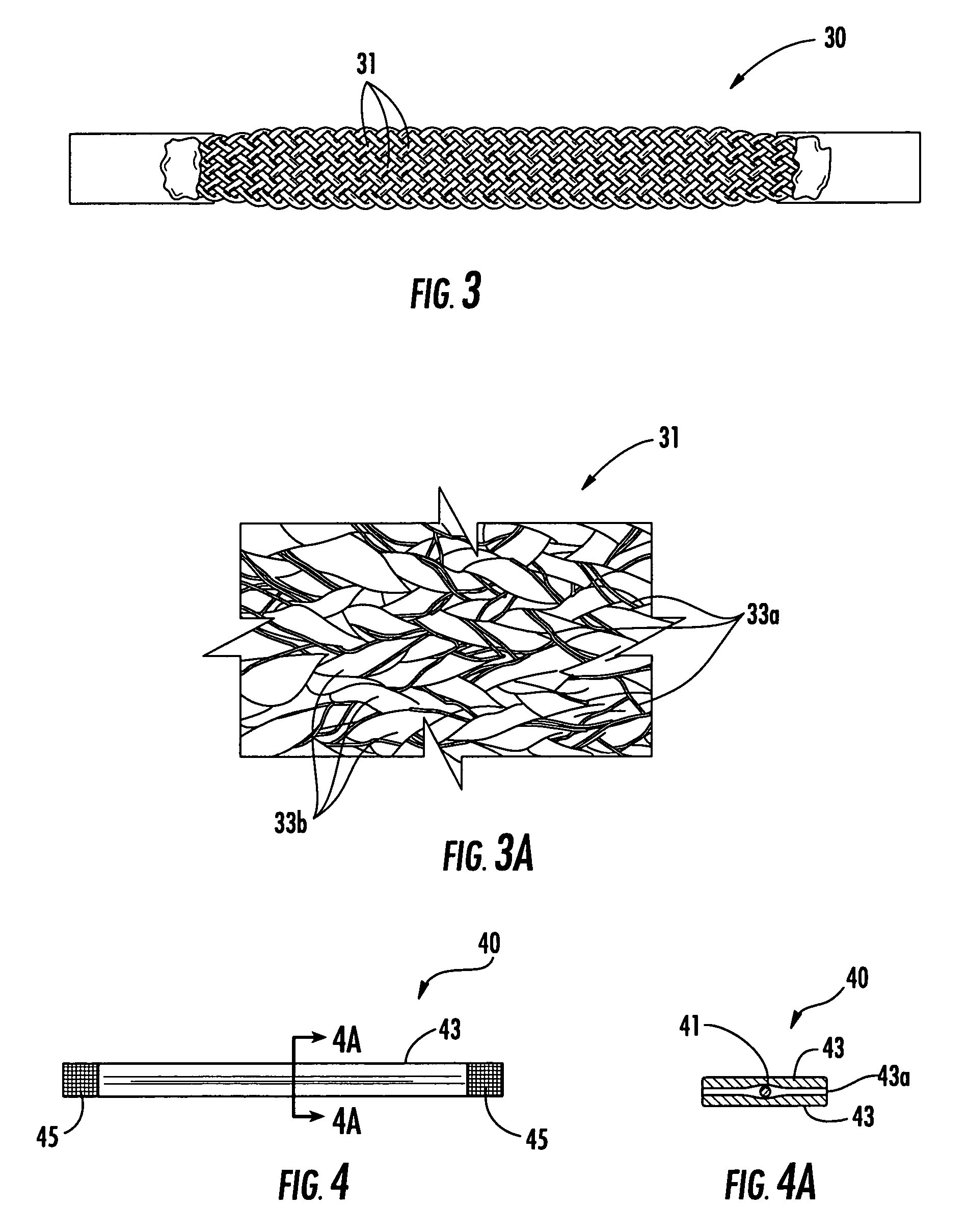

High temperature thermocouple design and fabrication

ActiveUS20080205483A1Low neutron cross-sectionsHigh melting temperatureThermoelectric device manufacture/treatmentThermometers using electric/magnetic elementsEngineeringThermocouple

A method for fabricating a thermocouple capable of long-term operation in high temperature, hostile environments without significant signal degradation or shortened thermocouple lifetime due to heat induced brittleness.

Owner:BATTELLE ENERGY ALLIANCE LLC

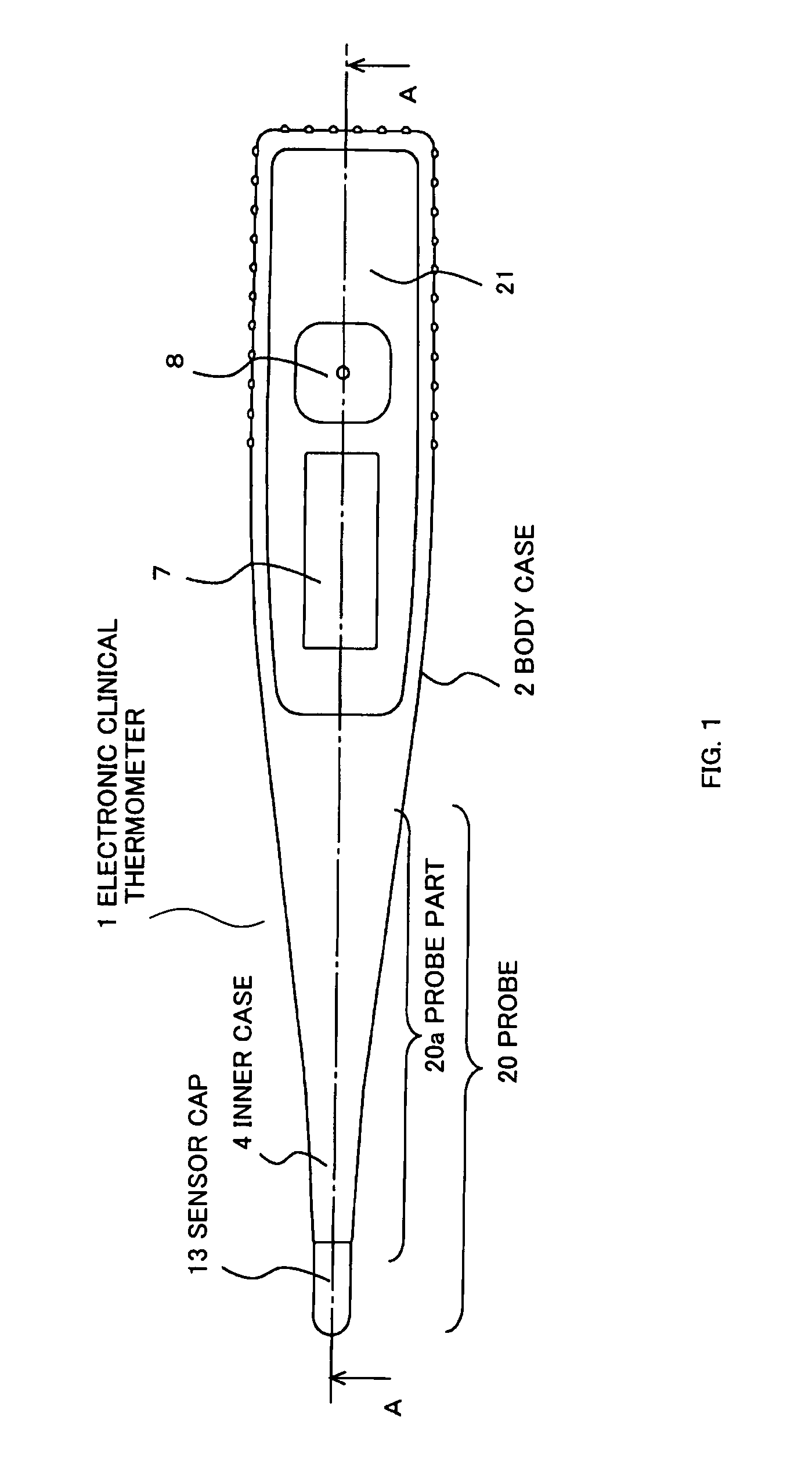

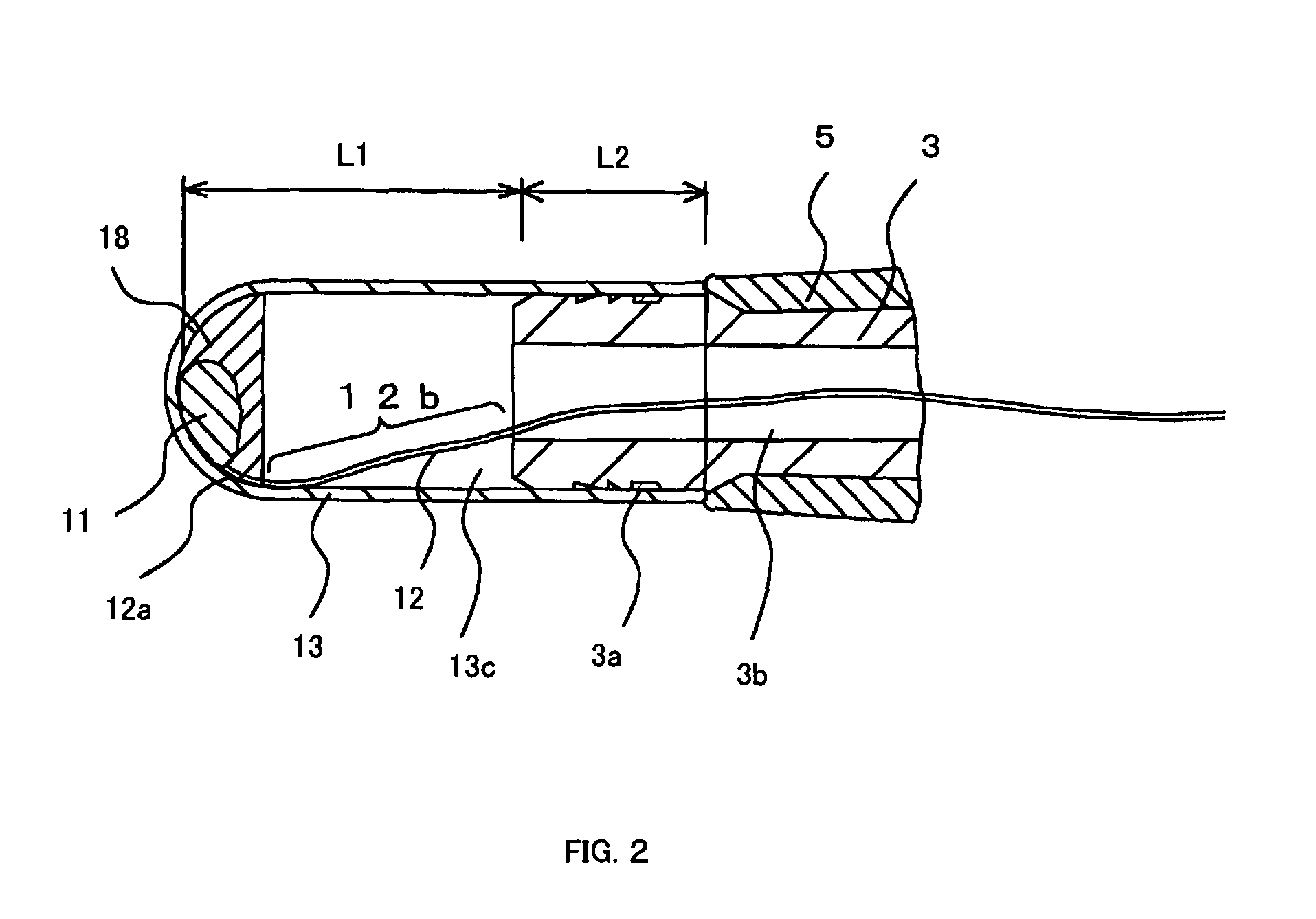

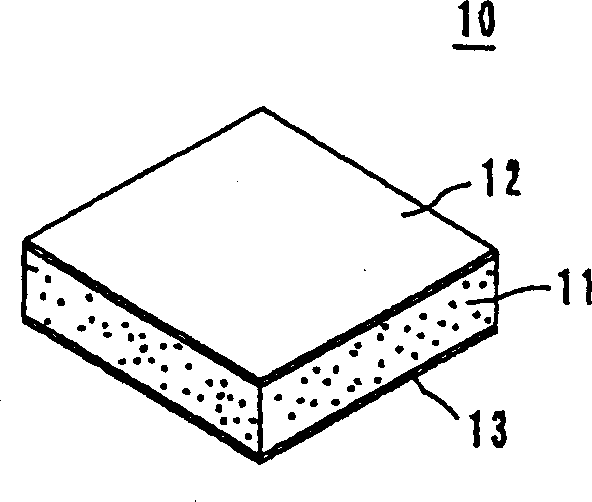

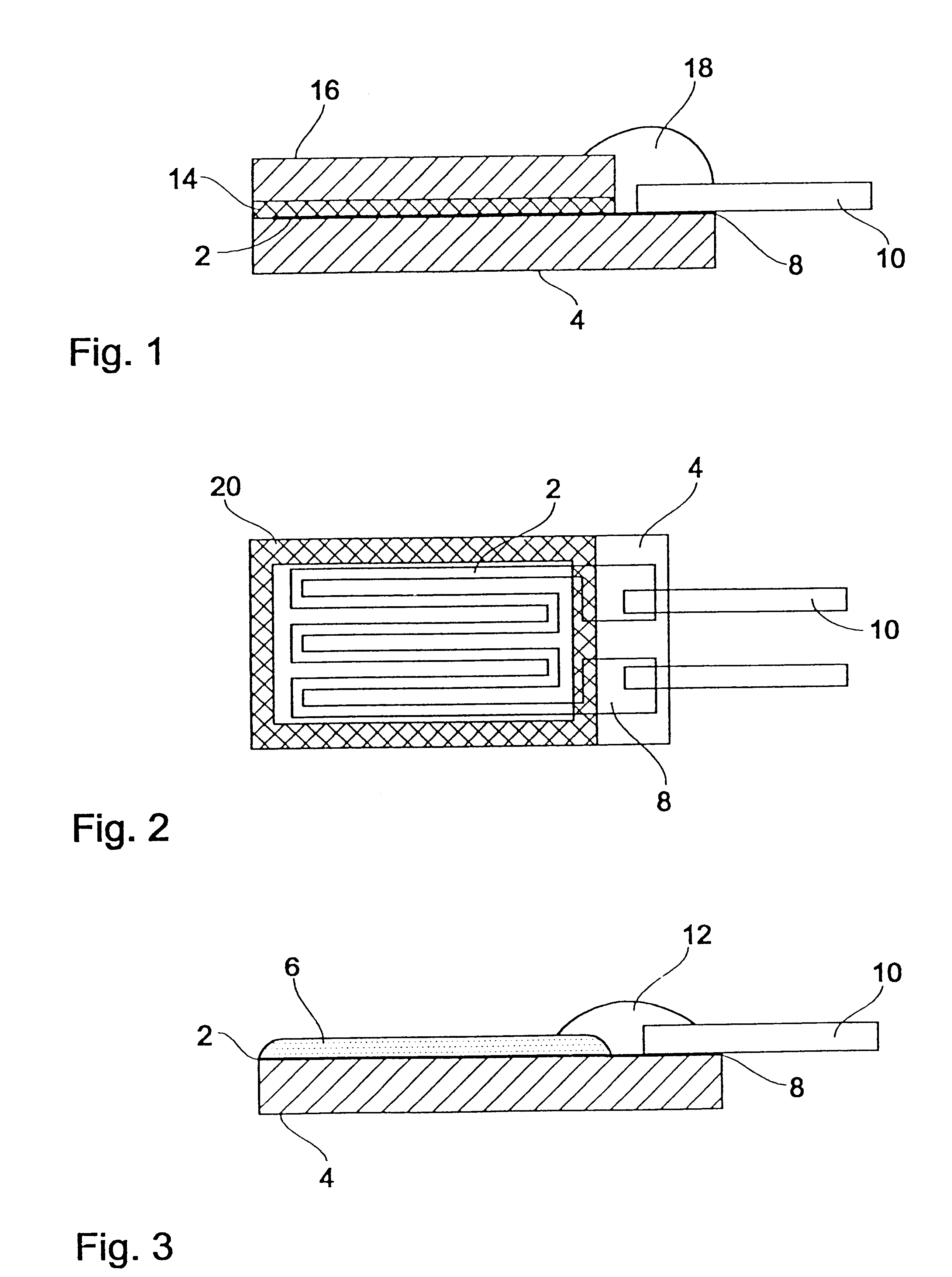

Electronic clinical thermometer and method of producing the same

InactiveUS7806587B2Thermometer detailsThermometers using electric/magnetic elementsBiomedical engineeringTemperature sensitive

A method of producing an electronic clinical thermometer is disclosed, the electronic clinical thermometer including a temperature-sensitive element, lead wire that is connected to the temperature-sensitive element, a body case having a probe part in which an insertion path for the lead wire to be inserted is formed, and a sensor cap having a cavity one end of which is opened and the other end is closed, both the lead wire projecting from the insertion path and the temperature-sensitive element being stored within the sensor cap, and the method includes a step for mounting the sensor cap on the probe part, in a state where the lead wire having the temperature-sensitive element mounted on the tip thereof projects from the insertion path of the probe part.

Owner:A STUCKI CO +1

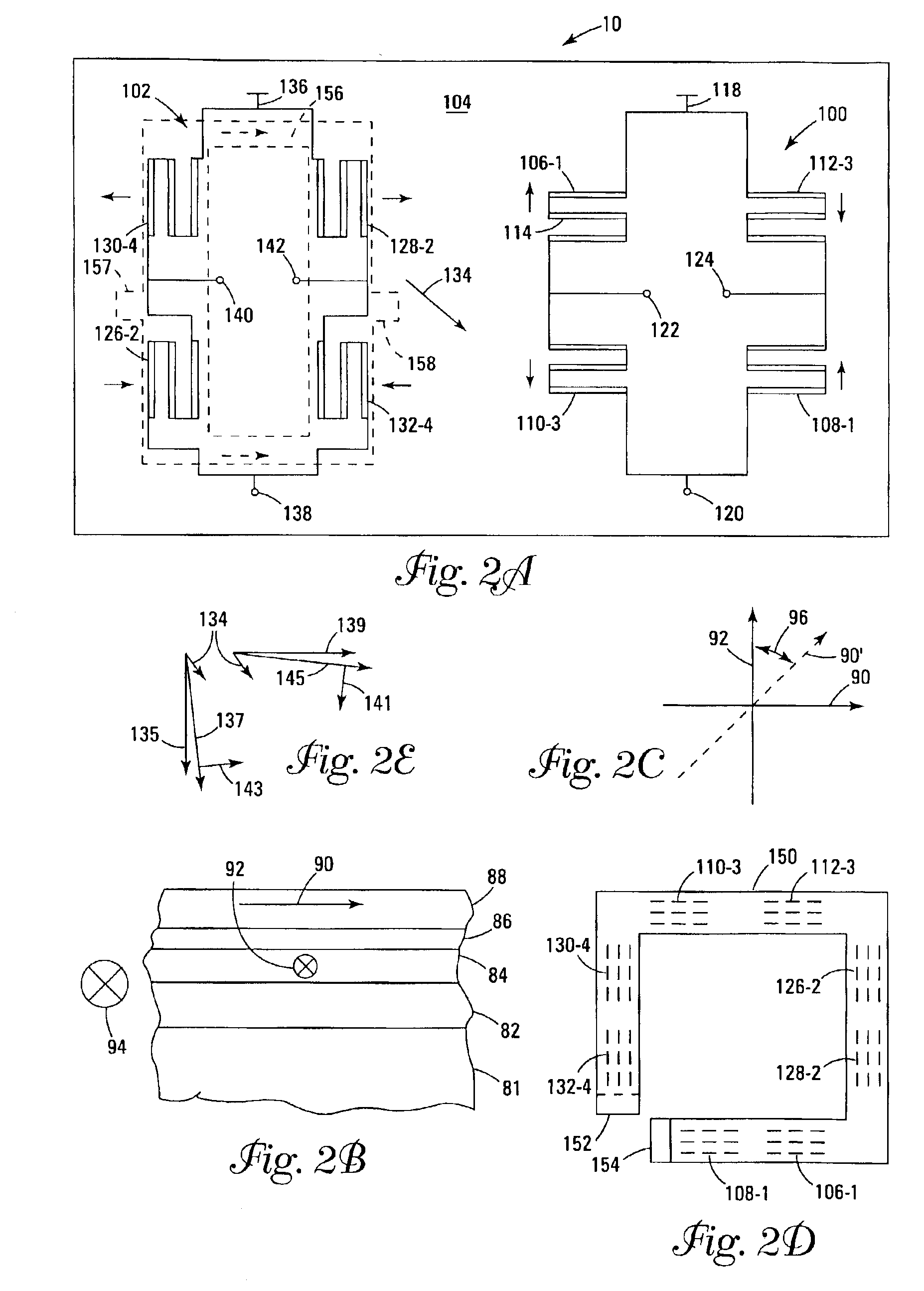

Dual axis magnetic sensor

A two-axis magnetic field sensor includes a substrate, a first sensor having at least one magnetoresistive element formed of GMR material on the substrate has a free layer having an easy axis of effective anisotropy field in a first direction. The first sensor is sensitive to magnetic field components perpendicular to the first direction. A current is caused to flow through the first sensor and variations in the resistivity of the first sensor due to the first magnetic field components are sensed. A second sensor having at least one magnetoresistive element formed of GMR material on the substrate has a free layer having an easy axis of effective anisotropy field in a direction substantially perpendicular to the first direction. The second sensor is sensitive to second magnetic field components perpendicular to its easy axis of effective anisotropy. A current is caused to flow through the second sensor and variations in the resistivity of the second sensor due to second magnetic field components are sensed.

Owner:HONEYWELL INT INC

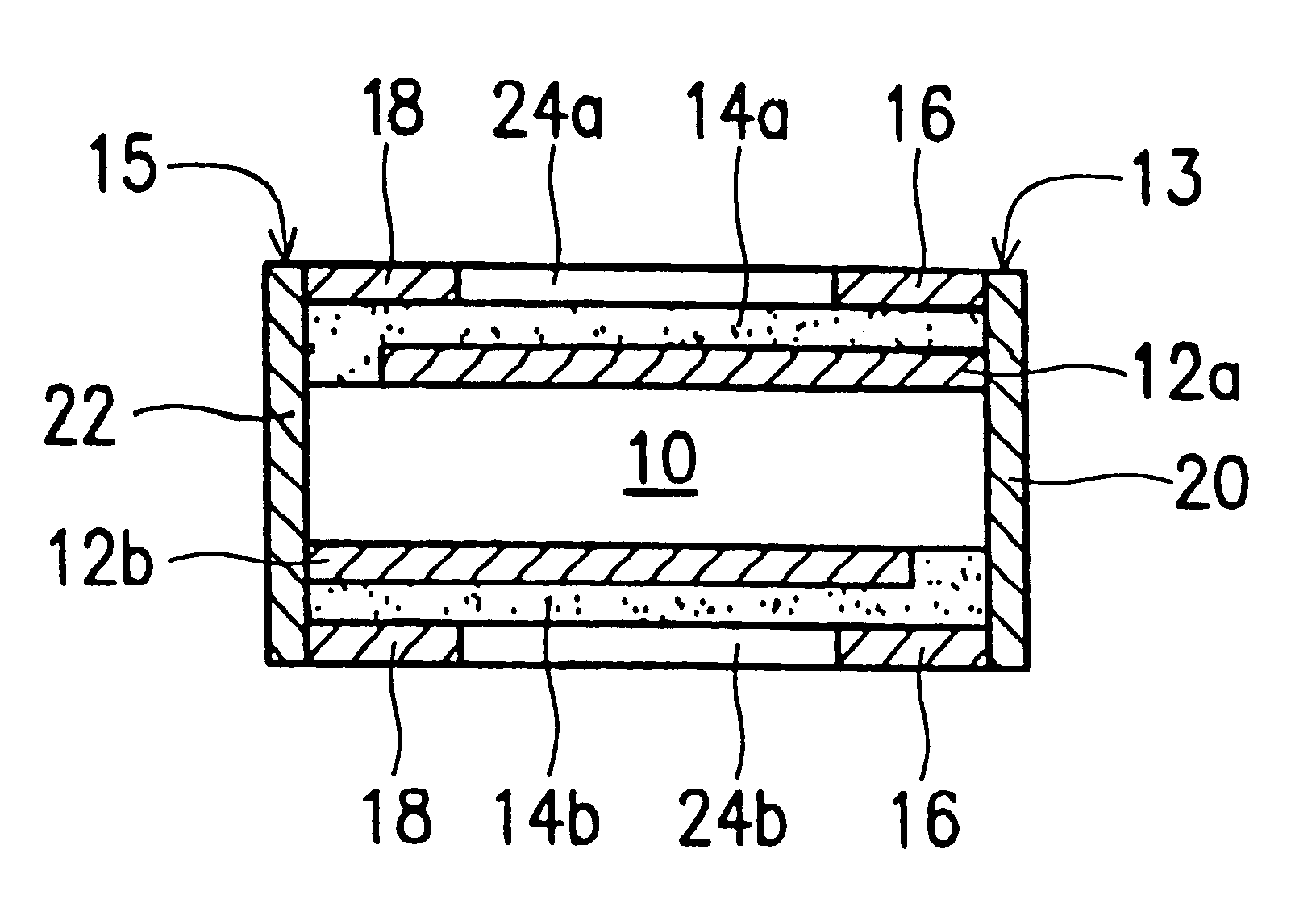

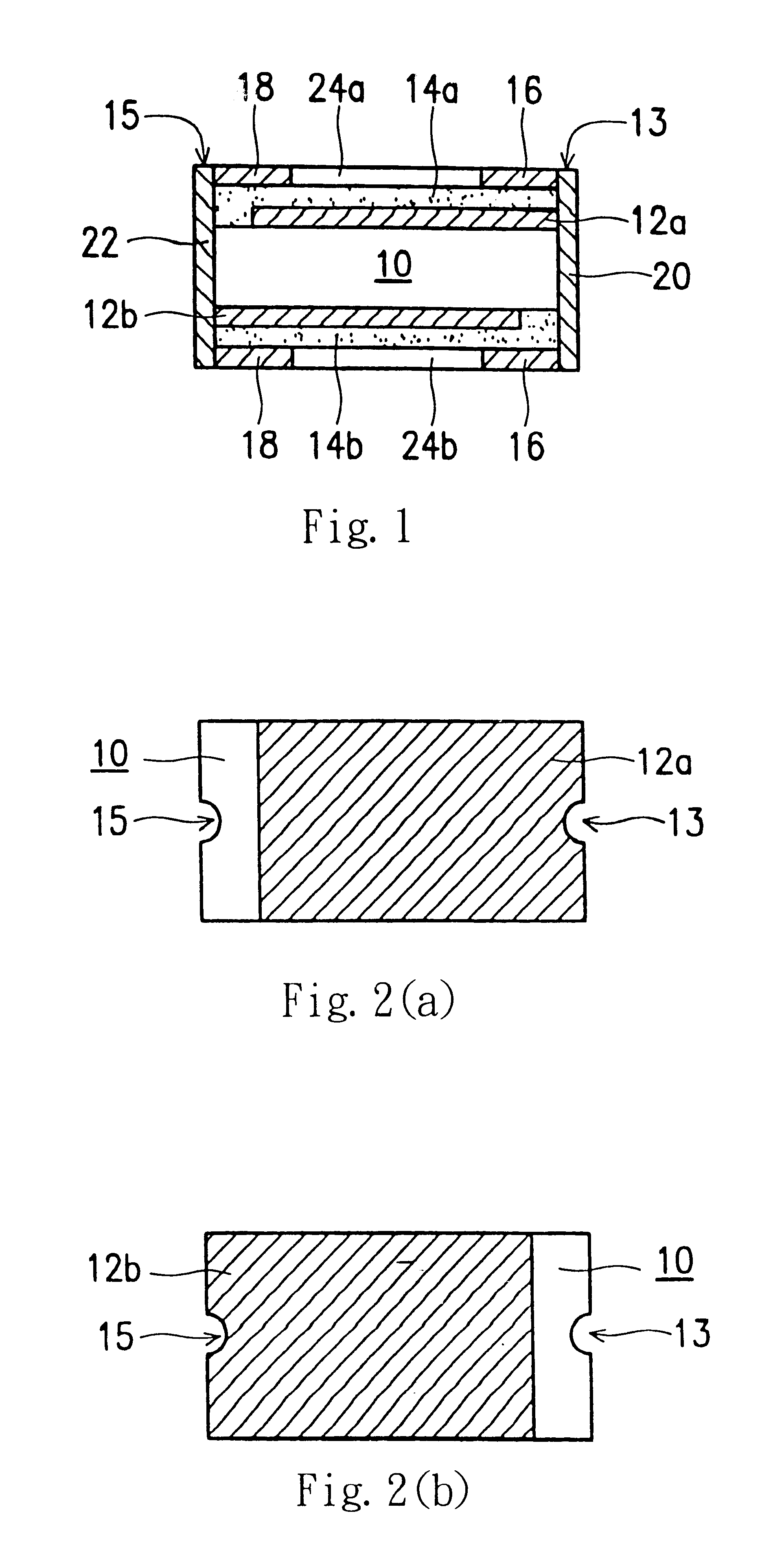

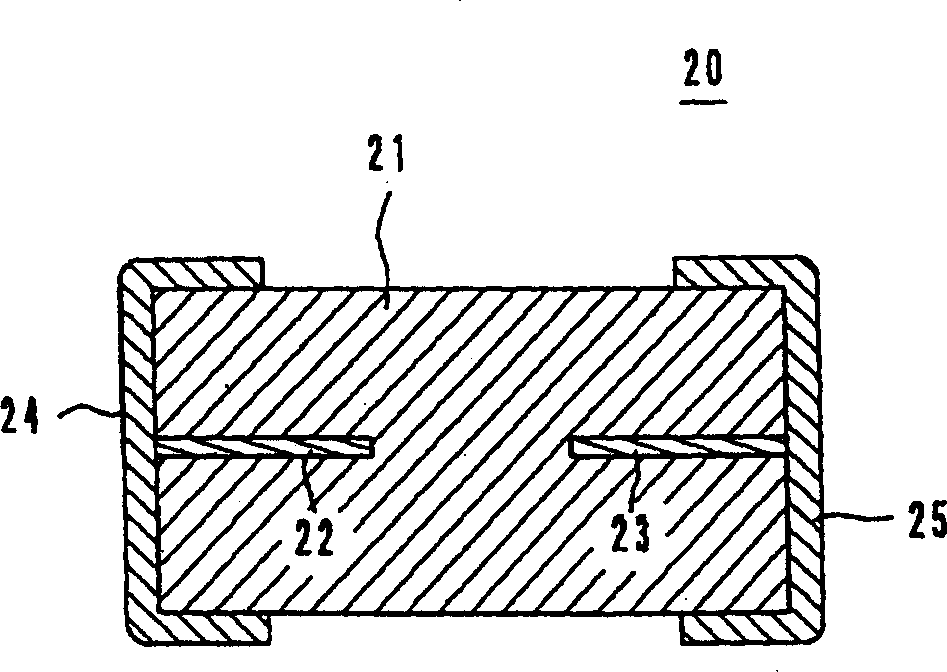

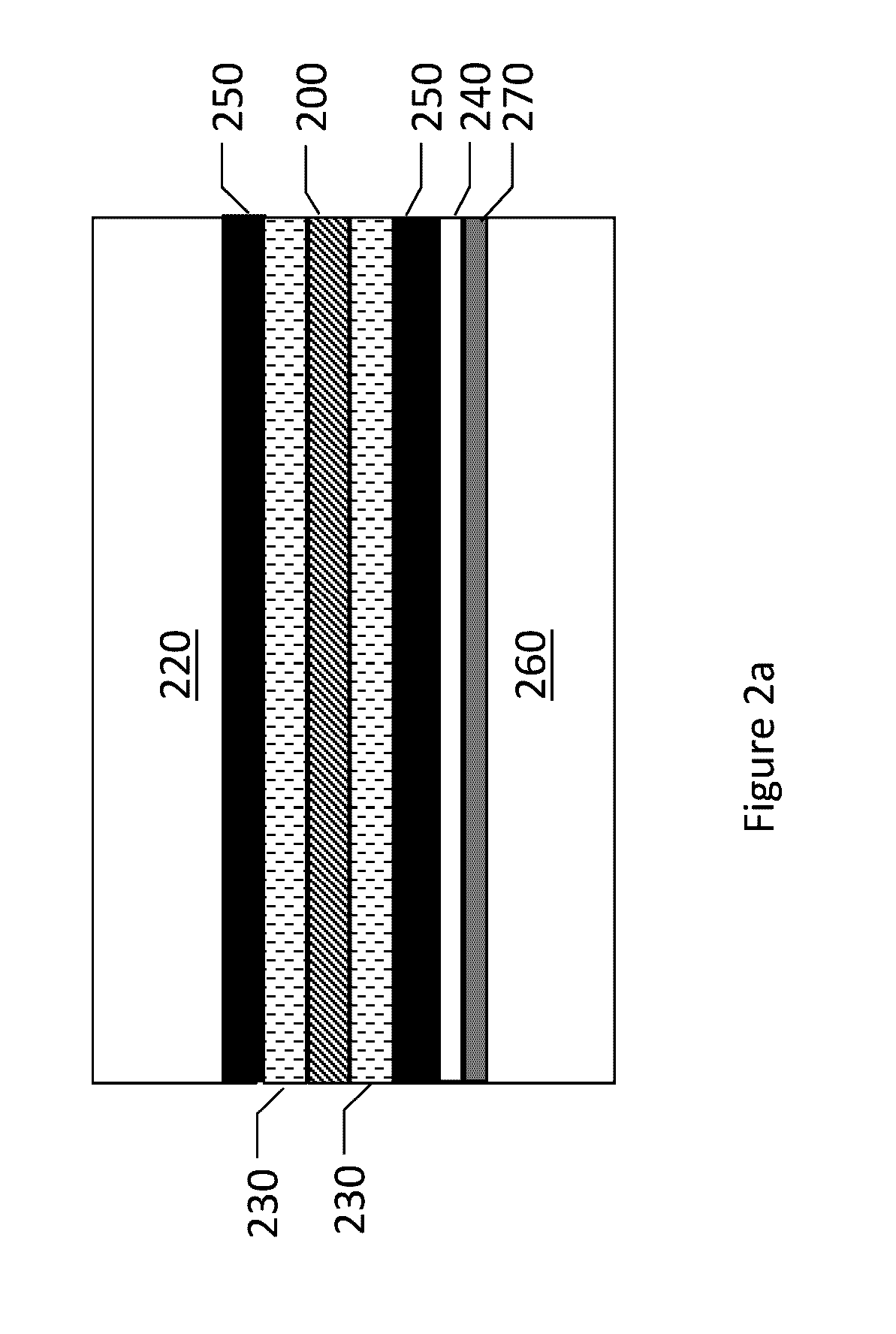

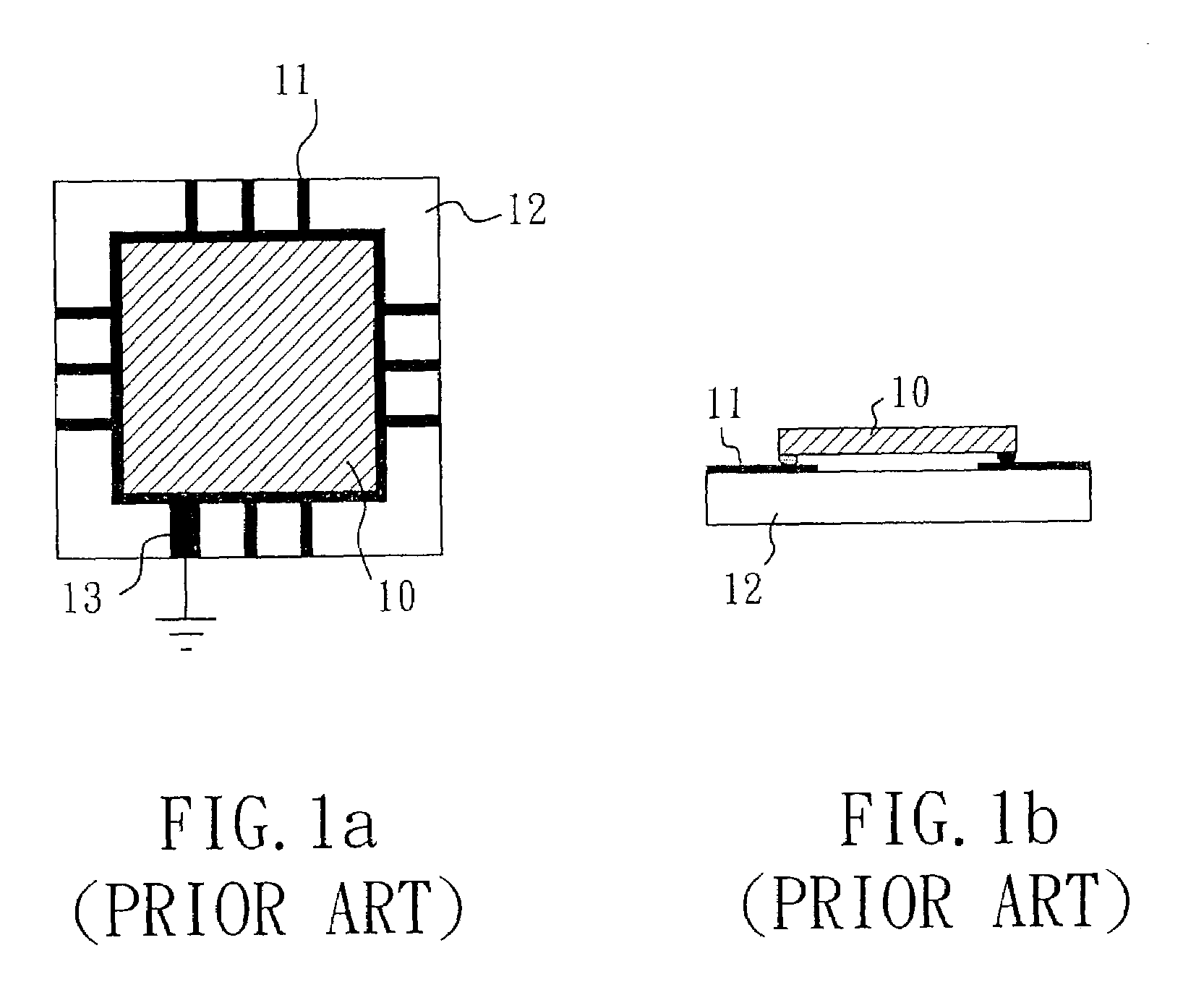

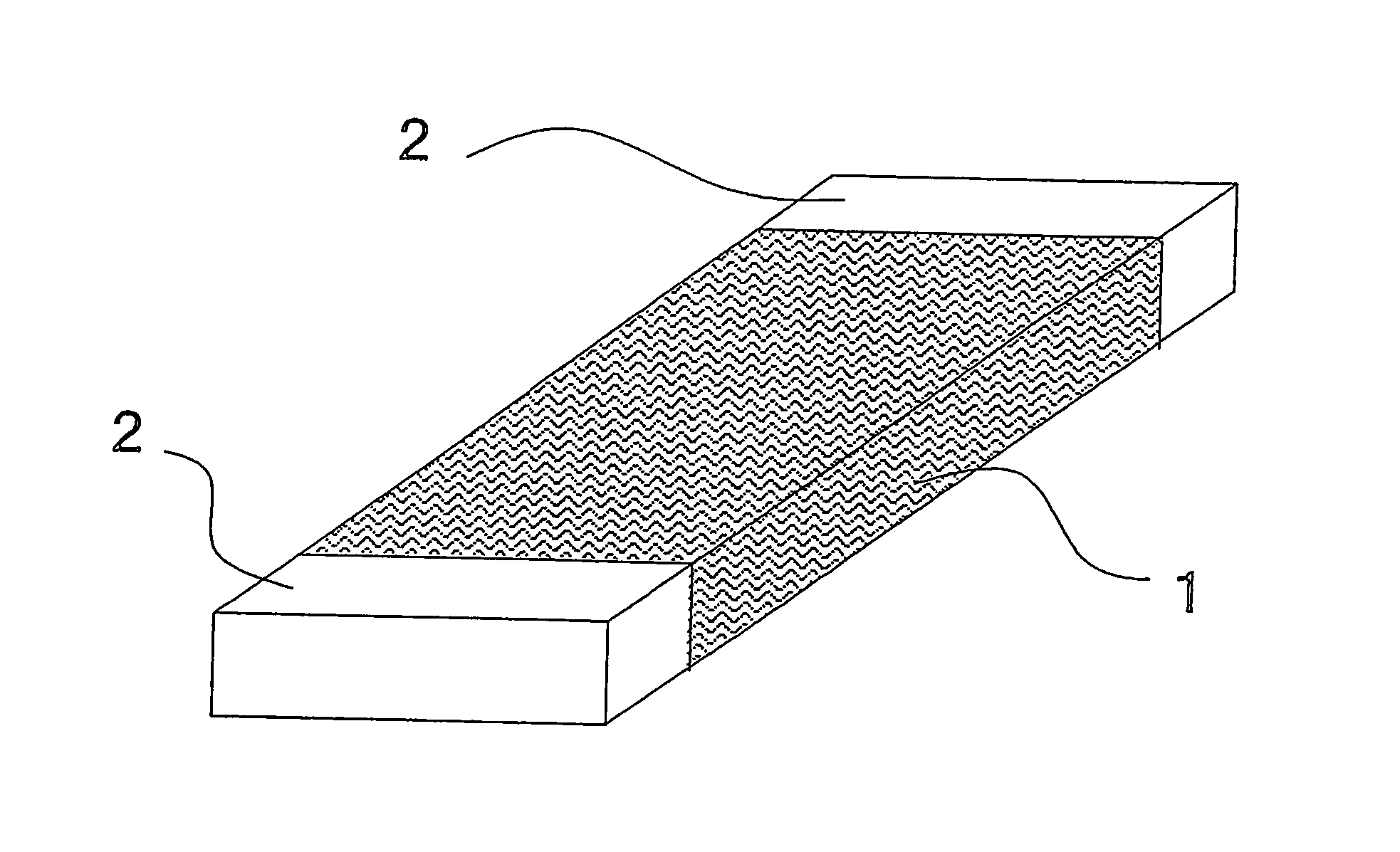

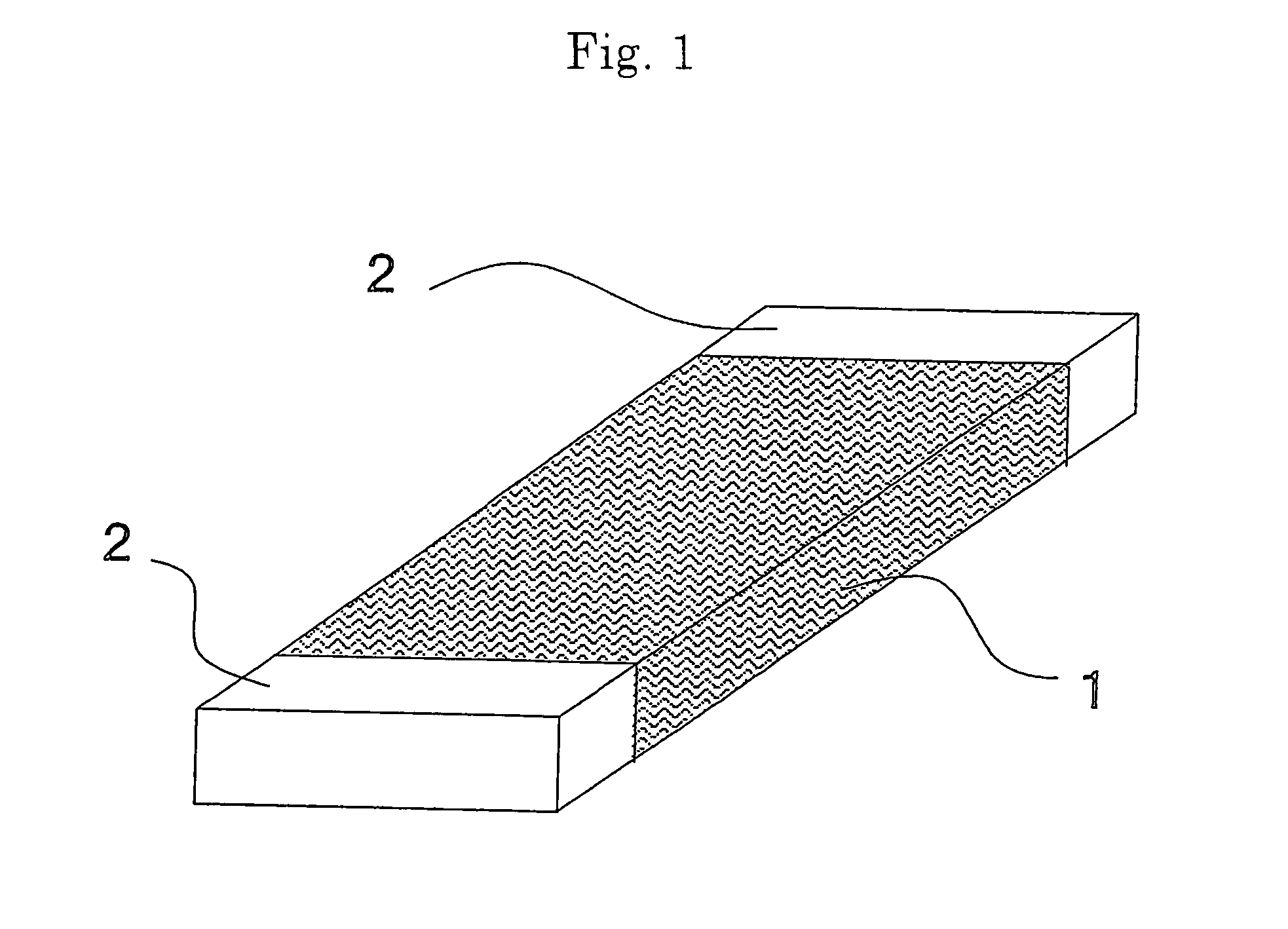

Surface mountable over-current protecting device

InactiveUS6377467B1Easy to installGood dimensional stabilityResistor terminals/electrodesNegative temperature coefficient thermistorsElectrical resistance and conductancePlanar electrode

The present invention relates to a novel thermal-sensitive resistive apparatus, such as PTC and NTC, which allocates planar electrode films on the top and bottom surfaces of a prior art thermal-sensitive resistive apparatus, such as a PTC apparatus, to laminate with an outer electrode layer. A plurality of interconnection vias are electroplated with conductive material to connect to any plane. It is convenient to surface mount the apparatus of the present invention on a printed circuit board. The present invention can largely increase the dimensional stability of components and overcome the disadvantage that thermal diffusion of the prior are surface mounted resistive apparatus is affected easily by line width and environments.

Owner:POLYTRONICS TECH

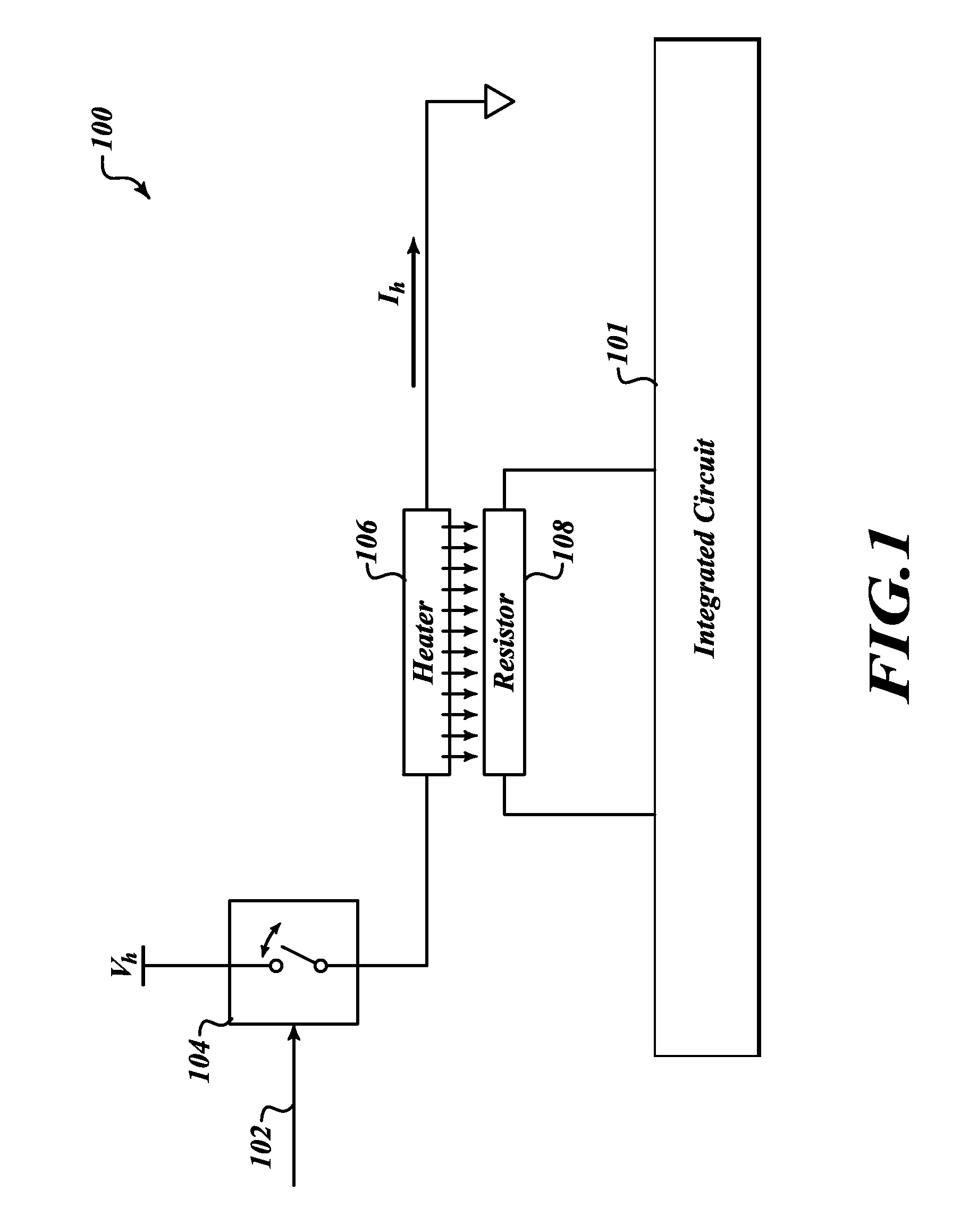

Dual thin film precision resistance trimming

ActiveUS20100073122A1Improve efficiencyIncrease resistanceSemiconductor/solid-state device detailsVacuum evaporation coatingElectrical resistance and conductanceEngineering

A trimmable resistor for use in an integrated circuit is trimmed using a heater. The heater is selectively coupled to a voltage source. The application of voltage to the heater causes the heater temperature to increase and produce heat. The heat permeates through a thermal separator to the trimmable resistor. The resistance of the trimmable resistor is permanently increased or decreased when the temperature of the resistor is increased to a value within a particular range of temperatures.

Owner:STMICROELECTRONICS SRL +1

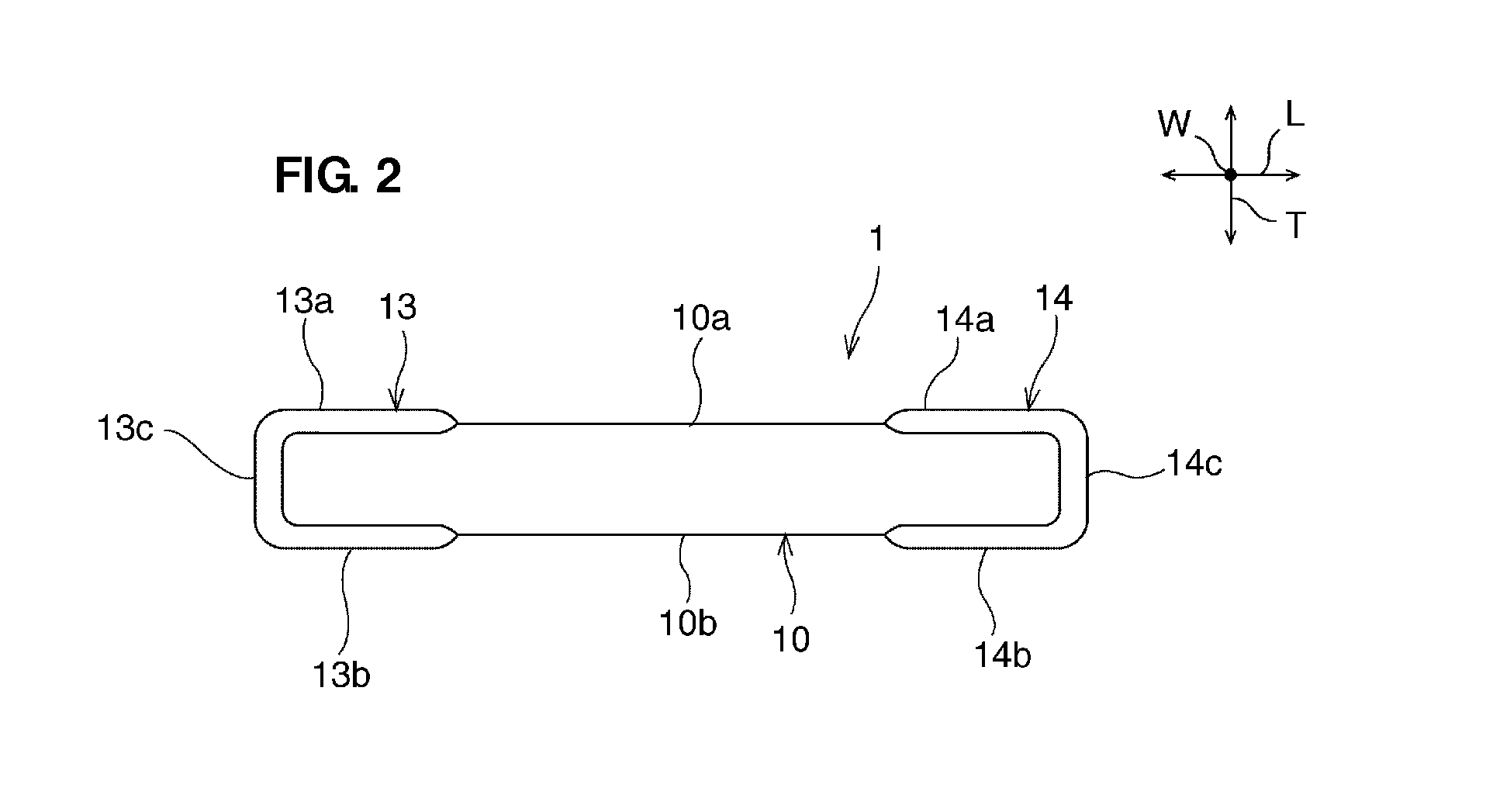

Method of manufacturing ceramic electronic component, ceramic electronic component, and wiring board

ActiveUS20120018205A1Minimize changesCharacteristic is prevented and minimizedResistor terminals/electrodesFinal product manufactureConductive pasteMetallurgy

A method of manufacturing a ceramic electronic component prevents variations in characteristics even when the ceramic electronic component is embedded in a wiring board. Ceramic green sheets containing an organic binder having a degree of polymerization in a range from about 1000 to about 1500 are prepared. A first conductive paste layer is formed on a surface of each of the ceramic green sheets. The ceramic green sheets are laminated to form a raw ceramic laminated body. A second conductive paste layer is formed on a surface of the raw ceramic laminated body. The raw ceramic laminated body formed with the second conductive paste layer is fired.

Owner:MURATA MFG CO LTD

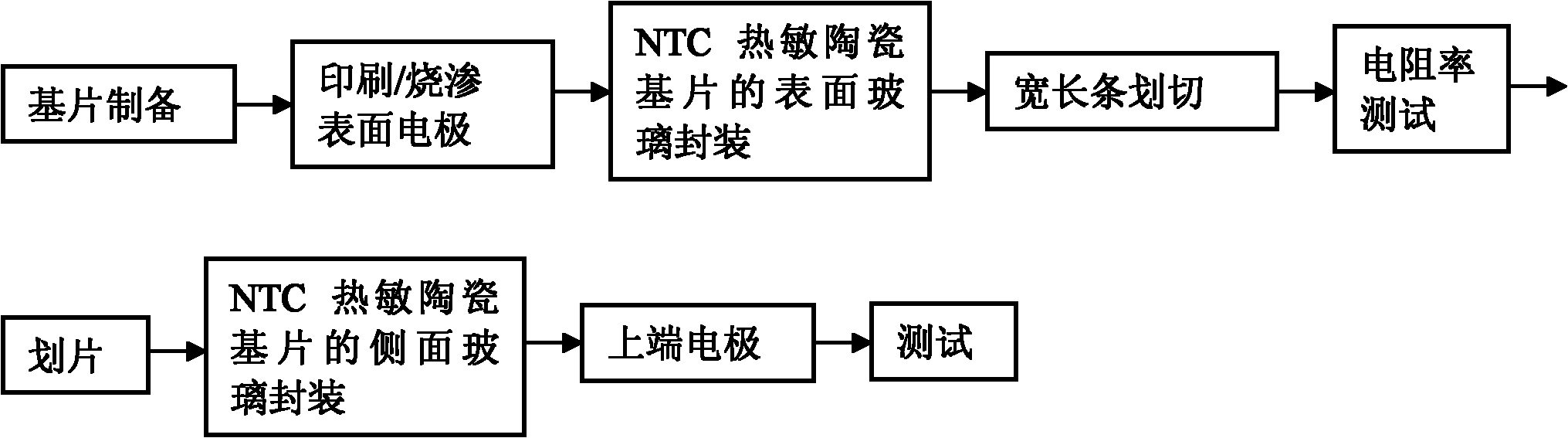

High evenness negative temperature coefficient heat-sensitive resistance material and its preparation method

ActiveCN101127266AImprove uniformityGood repeatabilityNegative temperature coefficient thermistorsMetal/alloy conductorsNegative temperatureHeat sensitive

The utility model relates to a thermistance material with high uniformity and negative temperature coefficient. The main formulation is one in the six systems of Mn-Ni-Cu, Mn-Co-Cu, Mn-Co-Ni-Cu, Mn-Co-Fe-Cu, Mn-Co-Ni or Mn-Co-Fe. The combination of at least two of the oxides as CaO, ZnO, SiO2, Al2O3, Fe2O3, MgO, Cr2O3, TiO2, Sb2O3, Bi2O3, SrO, Nb2O5 and B2O3 are added to the main formulation. The utility model also relates to a preparation method for preparing the thermistance material with high uniformity and negative temperature coefficient, comprising the following steps: mixture making, primary wet milling, drying, calcining, and secondary wet milling, drying and granulating, pressing and forming, and sintering. The utility model has the advantages that: the thermistance material with negative temperature coefficient (NTCR) made by the method has high uniformity and high repeatability; the specific resistance uniformity of the same batch material is all better than plus or minus 1%; the specific resistance error of different batches does not exceed plus or minus 2%; the error of value B does not exceed plus or minus 1%; the utility model is suitable for mass and large-scale production.

Owner:山东中厦电子科技有限公司

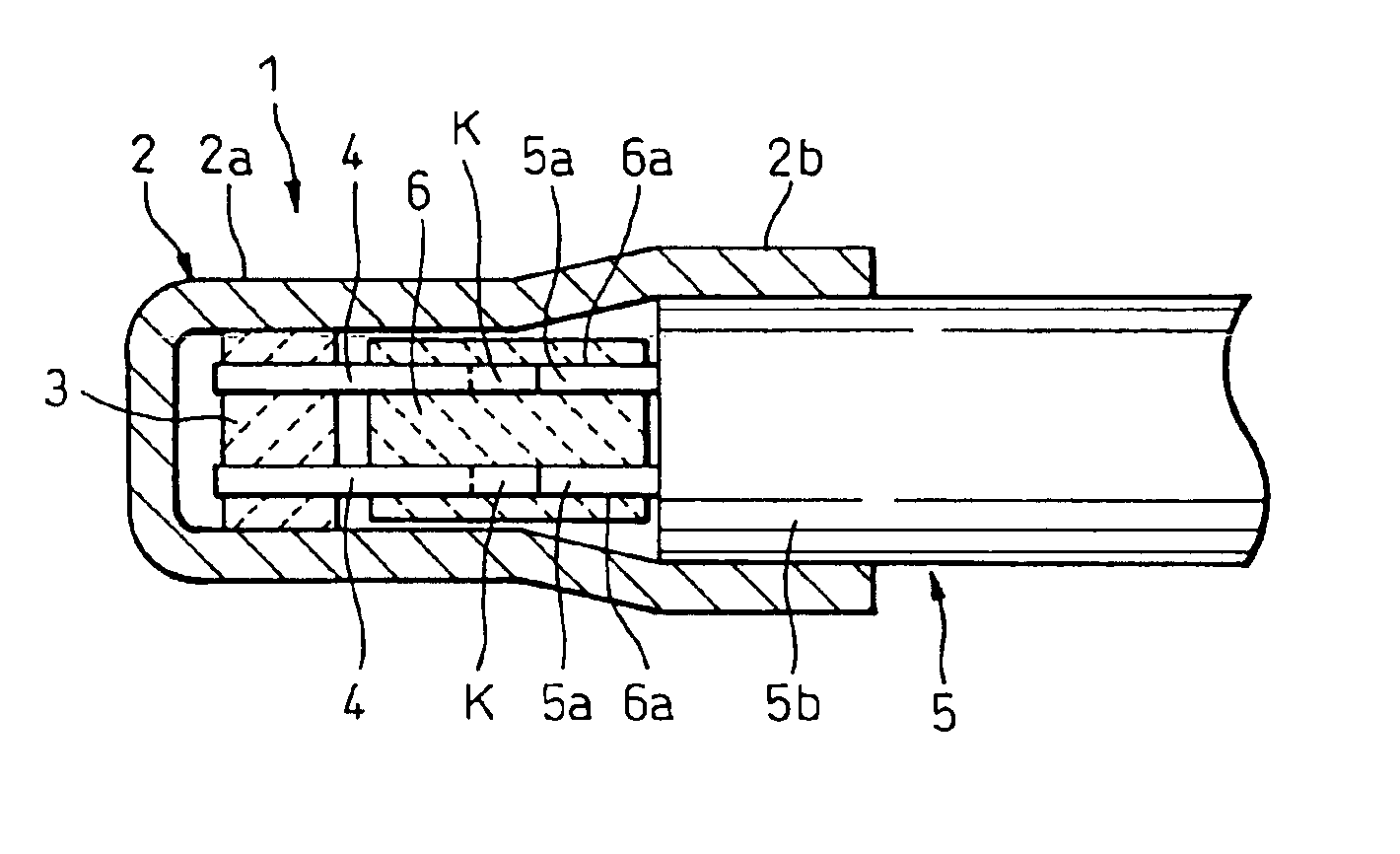

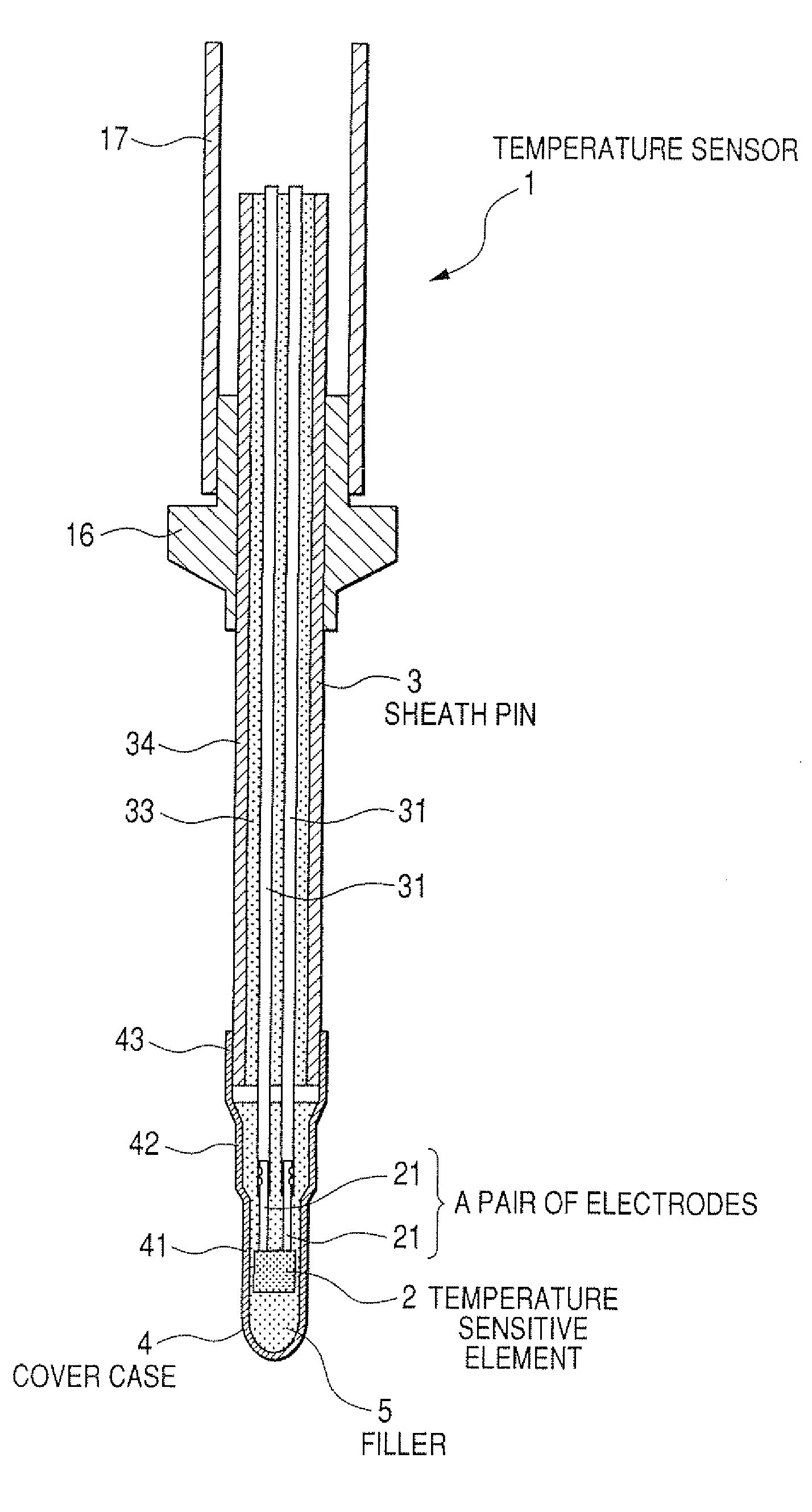

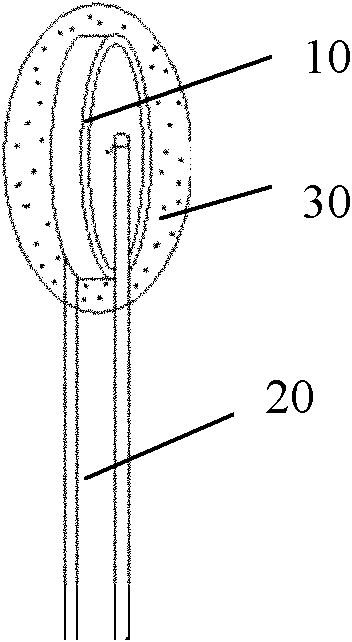

Thermistor temperature sensor

InactiveUS6899457B2Avoid breakingImprove vibrationThermometers using electric/magnetic elementsNegative temperature coefficient thermistorsEngineeringThermistor

An insulator 6 for holding electrode wires 4 is provided between a thermistor element 3 and a sheathed pin 5 which is a wiring, and the electrode wires 4, which are inserted into hole portions 6a of the insulator 6, are held therein not bonded to the insulator, whereby the vibration resistance of the electrode wires of the thermistor element is improved so that breaking of the electrode wires is prevented.

Owner:DENSO CORP

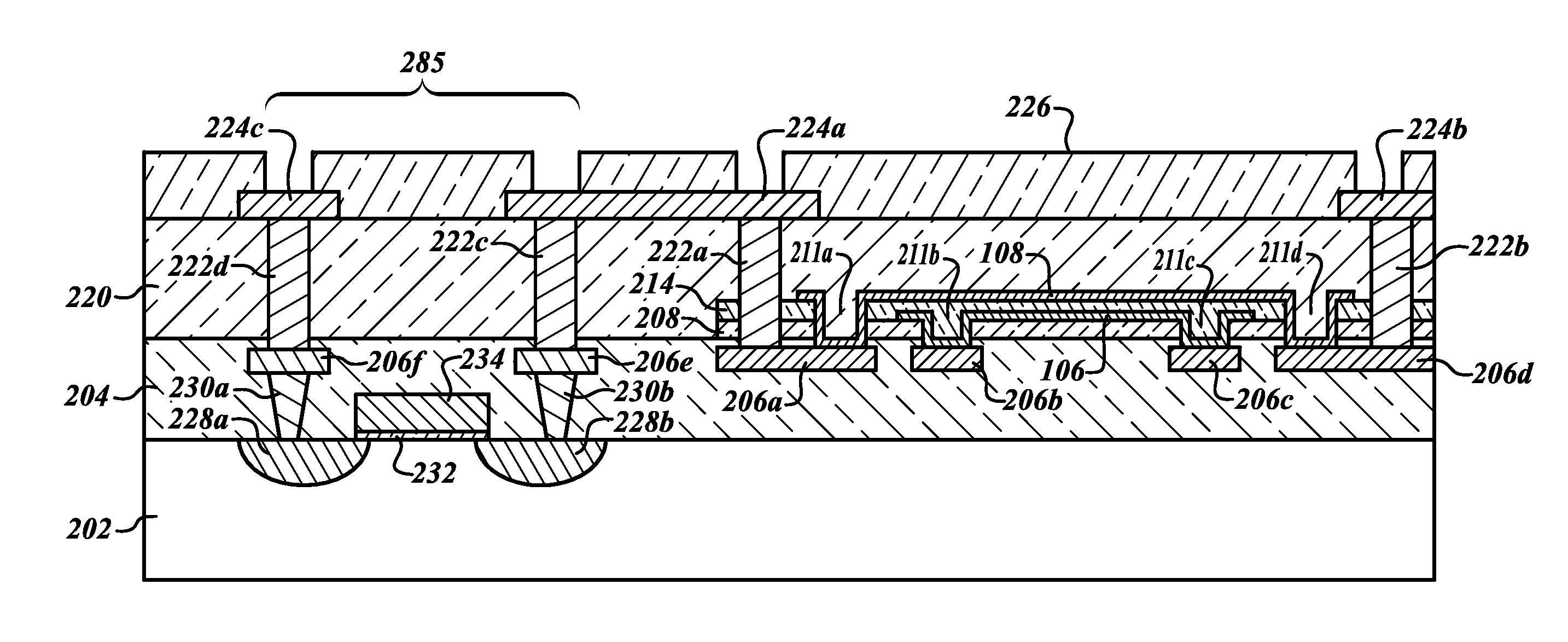

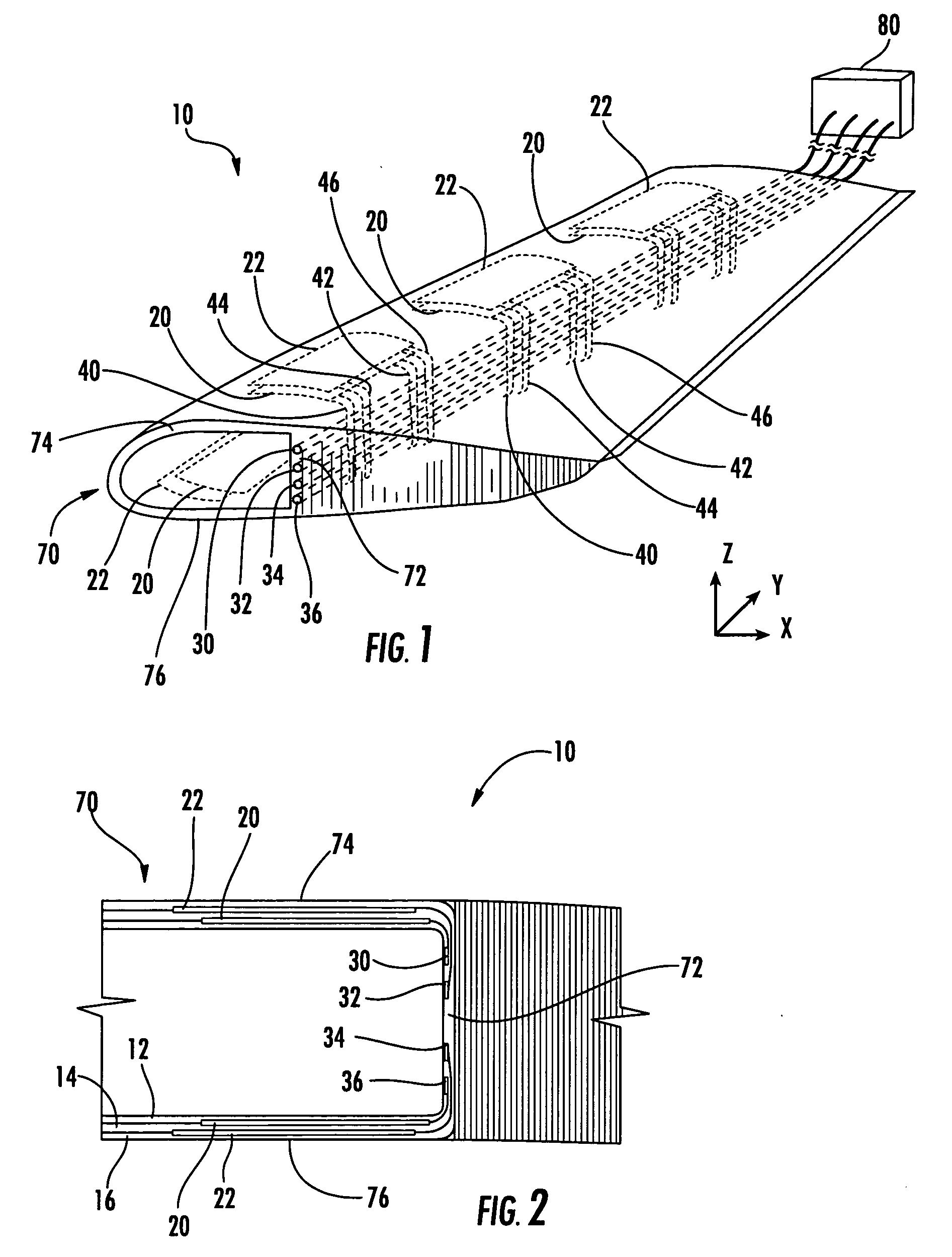

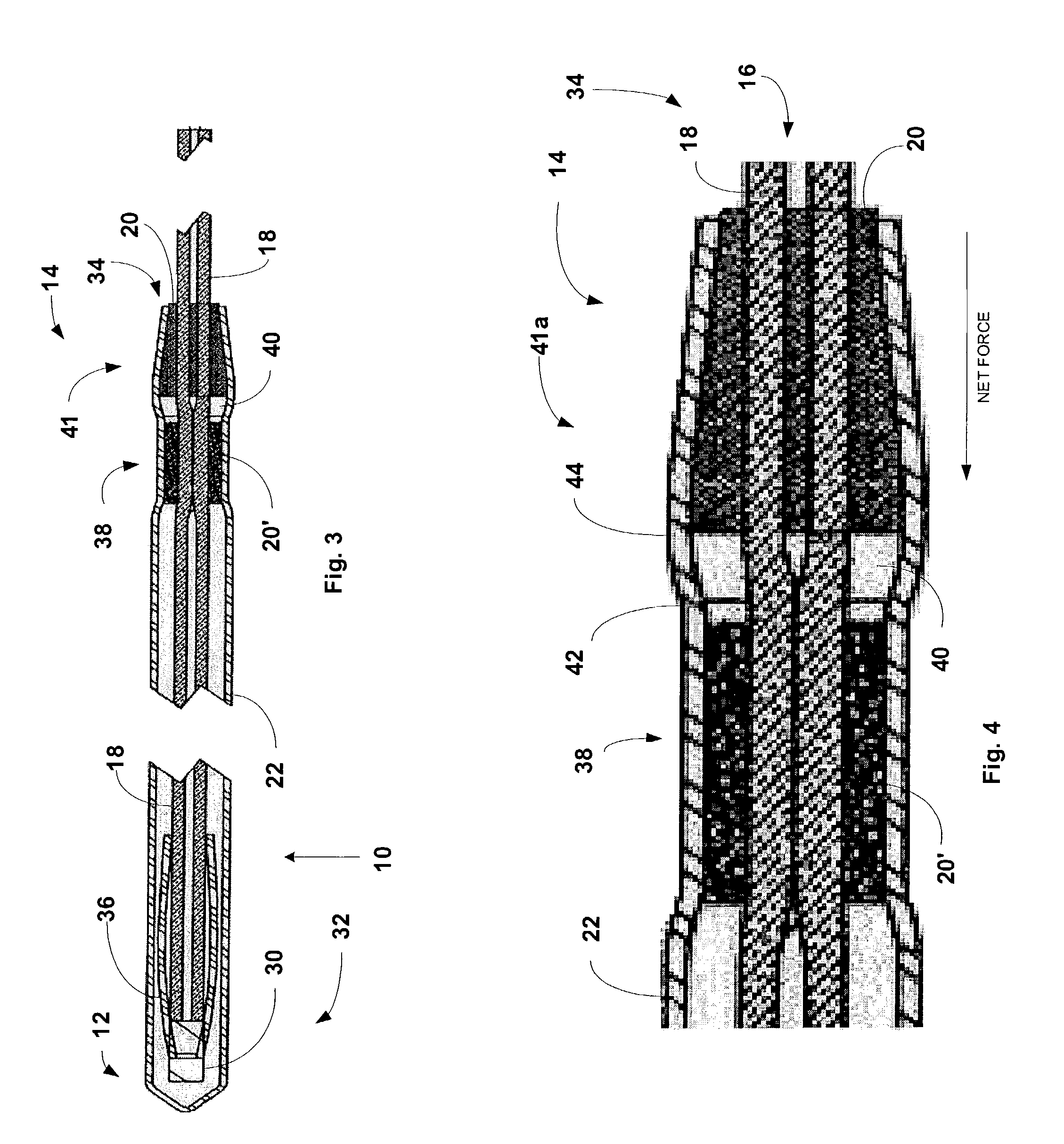

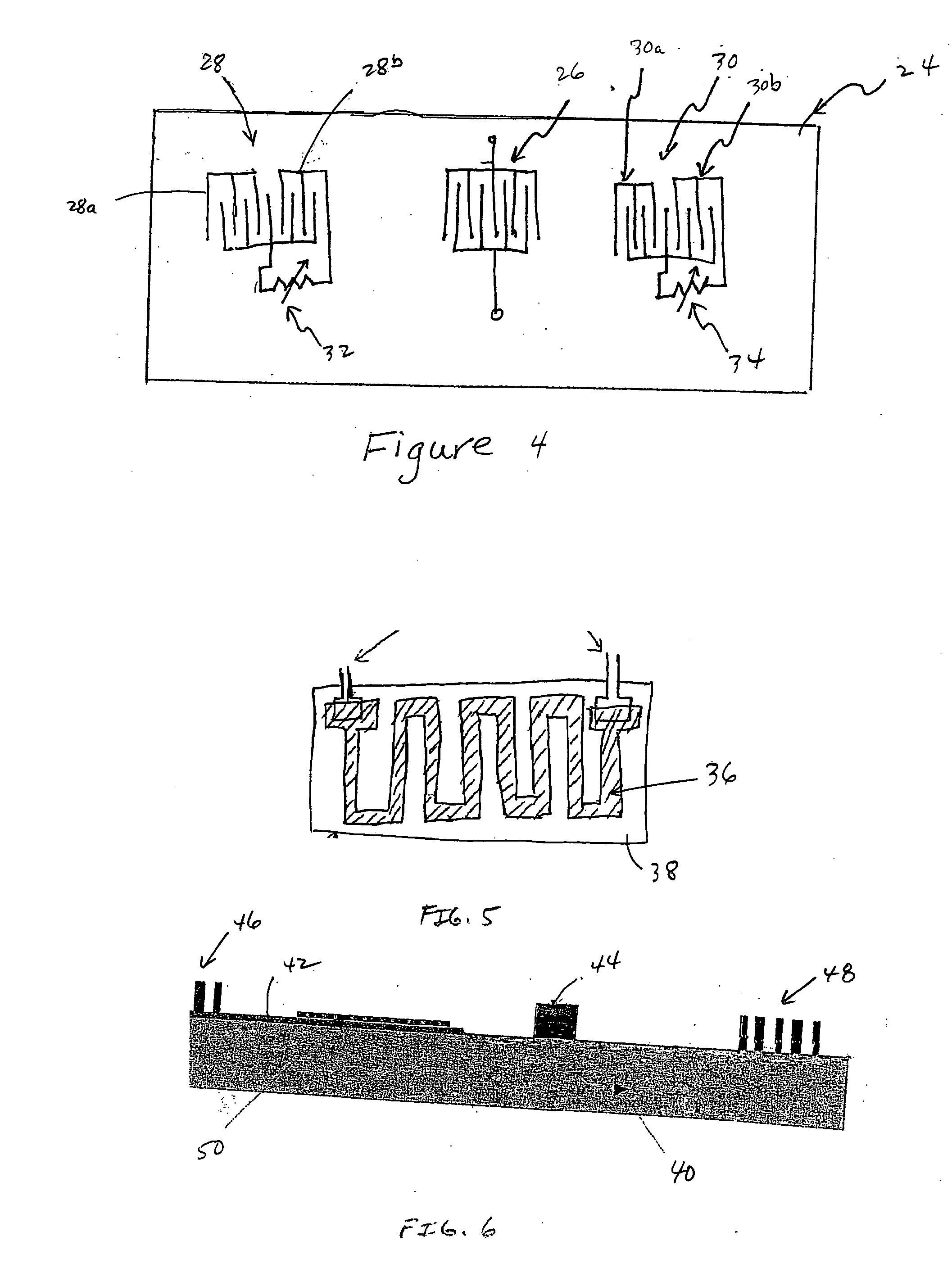

Structurally integrated circuit and associated method

ActiveUS20050257956A1Envelope/housing resistor manufactureLaminating printed circuit boardsElectrical devicesIntegrated circuit

A composite structural member with an integrated electrical circuit and an associated method of manufacture are provided. The structural member includes a plurality of layers of structural reinforcement material, and two or more electrical devices are disposed at least partially between the layers with an intermediate layer of the structural reinforcement material disposed between the electrical devices. At least one electrical bus is disposed in the structural member, and each electrical device is connected to the bus by a conductive electrode. Thus, the electrodes can extend through the intermediate layer of the structural reinforcement material to connect each of the electrical devices to one or more of the buses.

Owner:THE BOEING CO

Semiconductor ceramic with negative resistance temperature coefficient and negative temperature coefficient thermistor

InactiveCN1348192ALittle change in characteristicsInhibit swellingCeramicsNegative temperature coefficient thermistorsElectrical resistance and conductanceNegative temperature

A semiconductor ceramic having a negative temperature coefficient of resistance, the element comprising about 0.1 to 20 mol % of AMnO3 (A represents at least one of Ca, Sr, Ba, La, Pr, Nd, Sm, Eu, Gd, Th, Dy and Ho) and to a spinel composite oxide made of a solid solution of Mn and at least one element in Ti, V, Cr, Fe, Co, Ni, Cu, Zn, Mg and Al. As a perovskite Mn composite oxide, one or more of CaMnO3, SrMnO3, BaMnO3, LaMnO3, PrMnO3, NdMnO3, SmMnO3, EuMnO3, GdMnO3, TbMnO3, DyMnO3 and HoMnO3 may be used.

Owner:MURATA MFG CO LTD

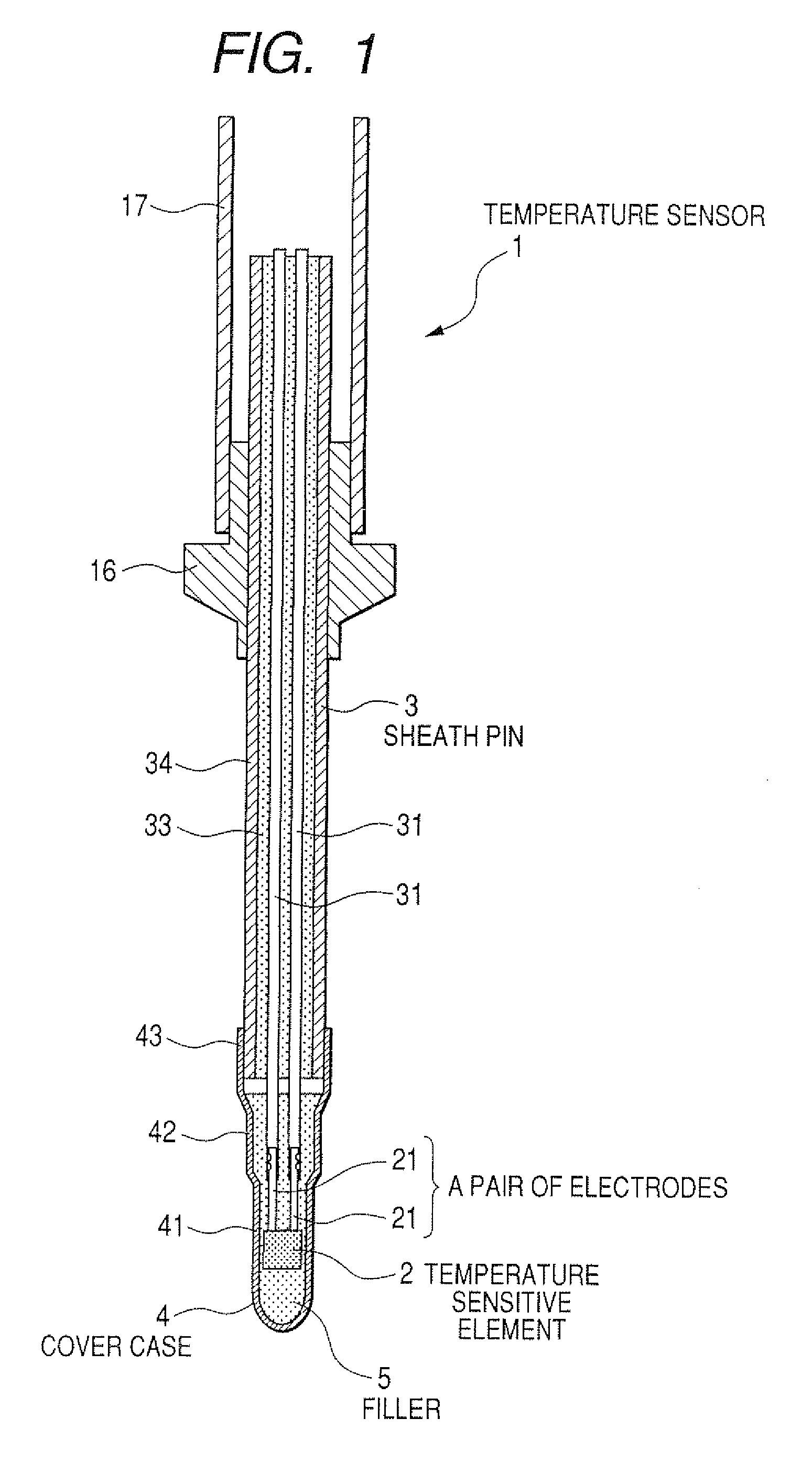

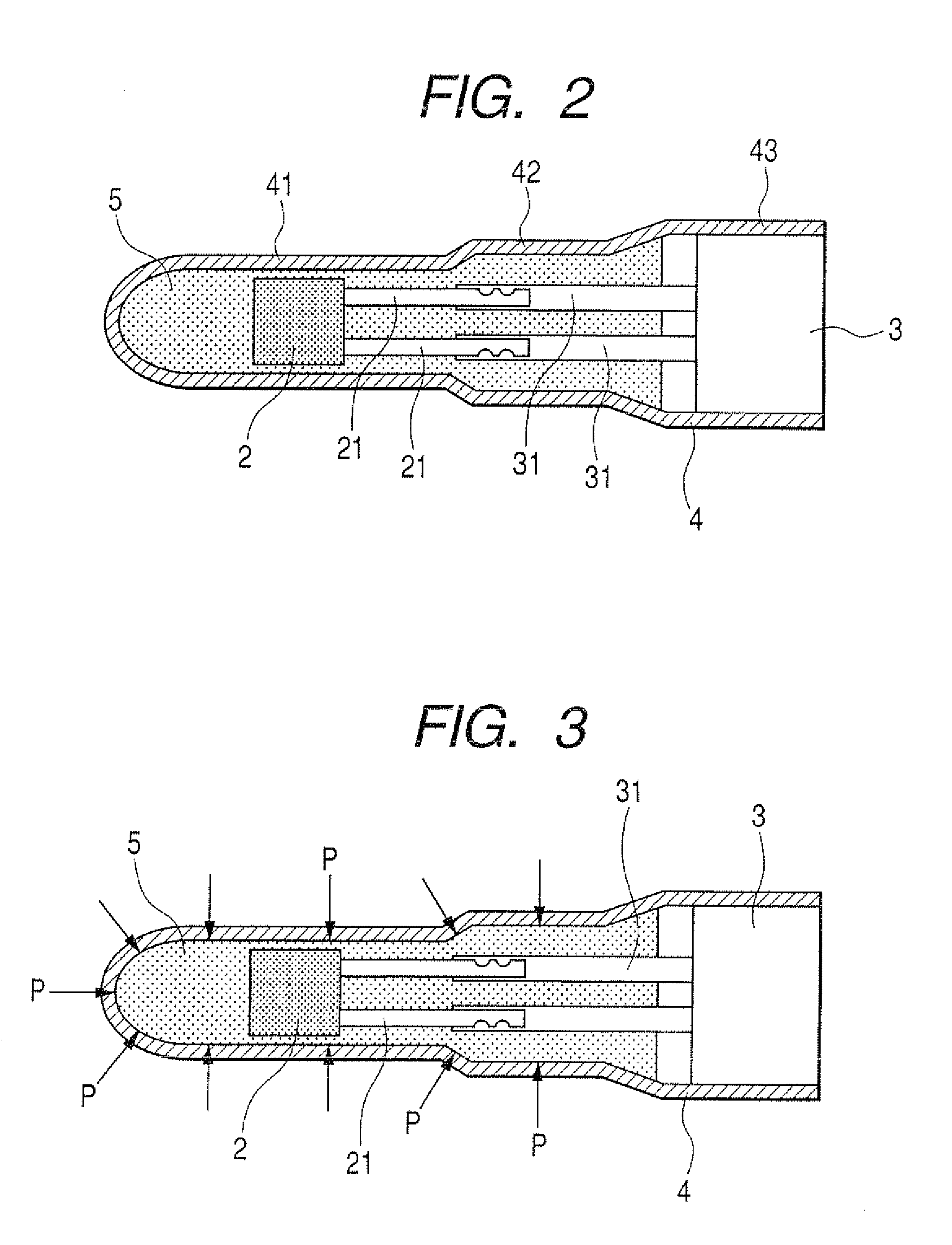

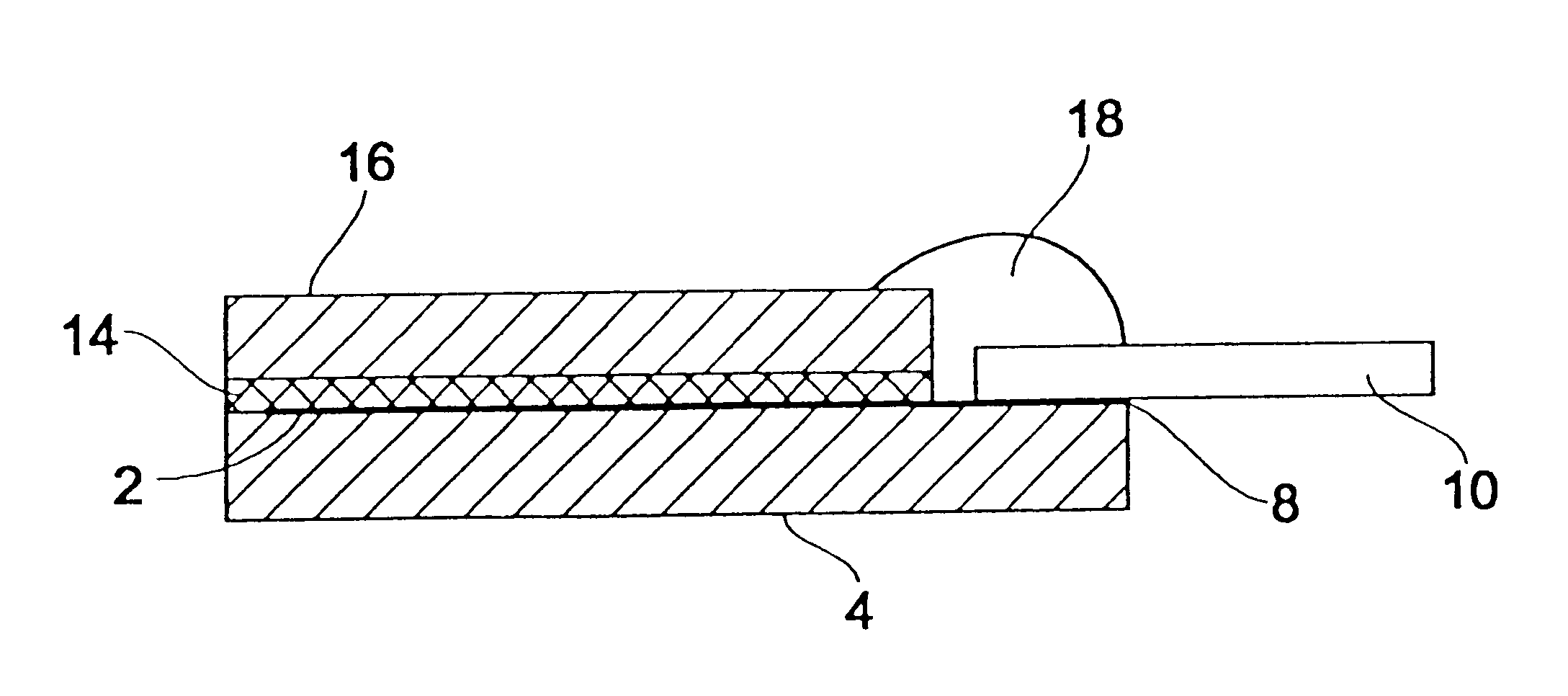

Temperature sensor and method of producing the temperature sensor

ActiveUS20080205484A1Avoid breakingImprove breathabilityThermometer detailsLine/current collector detailsPorosityElectrical resistance and conductance

In a temperature sensor having a temperature sensitive element, a sheath pin connected to the temperature sensitive element, and a cover case. The cover case, filled with a filler, accommodates the temperature sensitive element and the sheath pin. A hardening temperature of the filler is not less than an actual usage environment of the temperature sensor. Another temperature sensor has a temperature sensitive element exposed at a high temperature of not less than 750° C., a thermistor element, a sheath pin, an anti-vibration filler, and a metal cover case fixed to an end part of the sheath pin. The metal cover case accommodates the sheath pin and the thermistor element. The filler is made of a porous insulation material having a pore ratio within a range of 30 to 70% and filled around the thermistor element in the metal cover case.

Owner:DENSO CORP

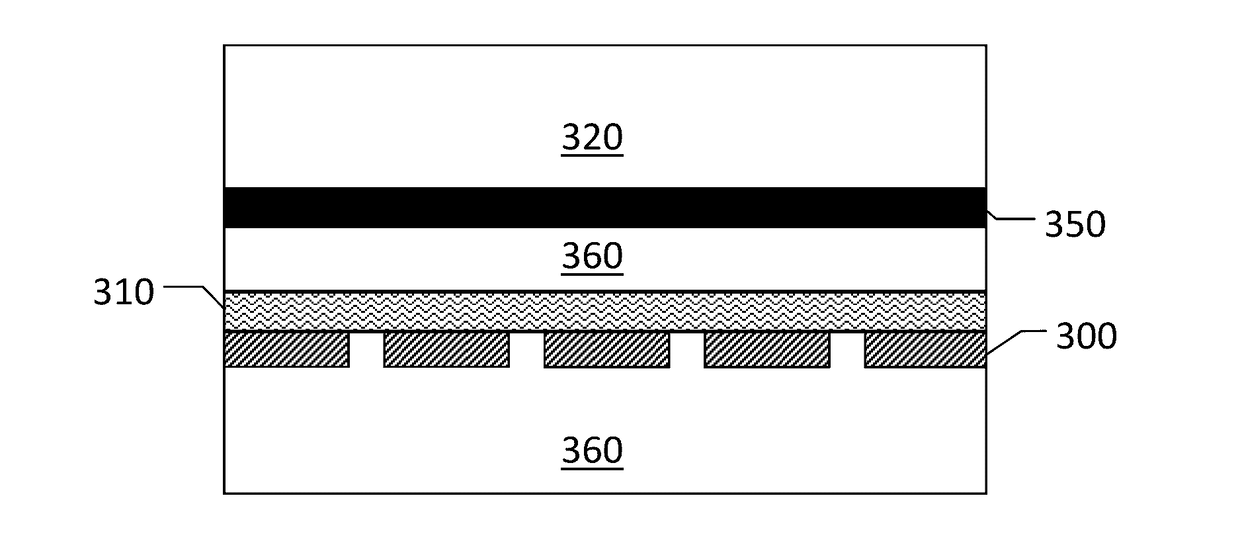

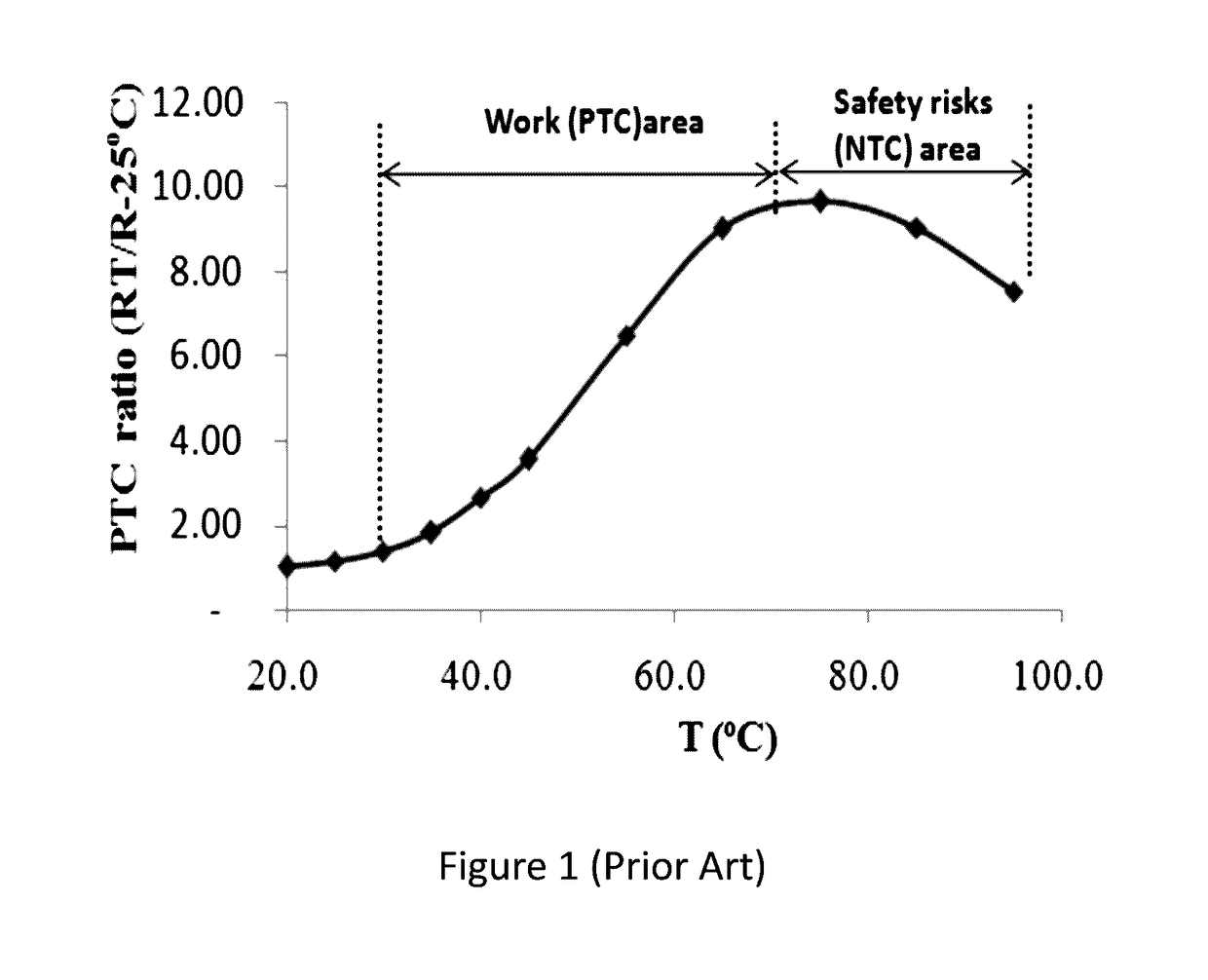

Electrically conductive PTC ink with double switching temperatures and applications thereof in flexible double-switching heaters

ActiveUS20170158898A1Eliminate the effects ofHigh PTC characteristicLighting and heating apparatusIce productionPolyesterCarbon composites

A double-switching heater includes a double-switching PTC ink deposited on a substrate to form one or more resistors. The double-switching PTC ink has a first resin that provides a first PTC effect at a first temperature range and a second resin that provides a second PTC effect at a second temperature range, where the second temperature range is higher than the first temperature range. The substrate may be a flexible substrate or a rigid substrate, and may bedeformable to generate a three-dimensional structure. The substrate may be: polyester, polyimide, polyamide, polypropylene, thermoplastic polyurethane, fiberglass, cement board, carbon composite materials, polyethylene terephthalate, polyethylene, aluminum, steel, glass composite, molded plastic, high-density polyethylene or styrene ethylene butylene styrene.

Owner:LMS CONSULTING GRP LLC

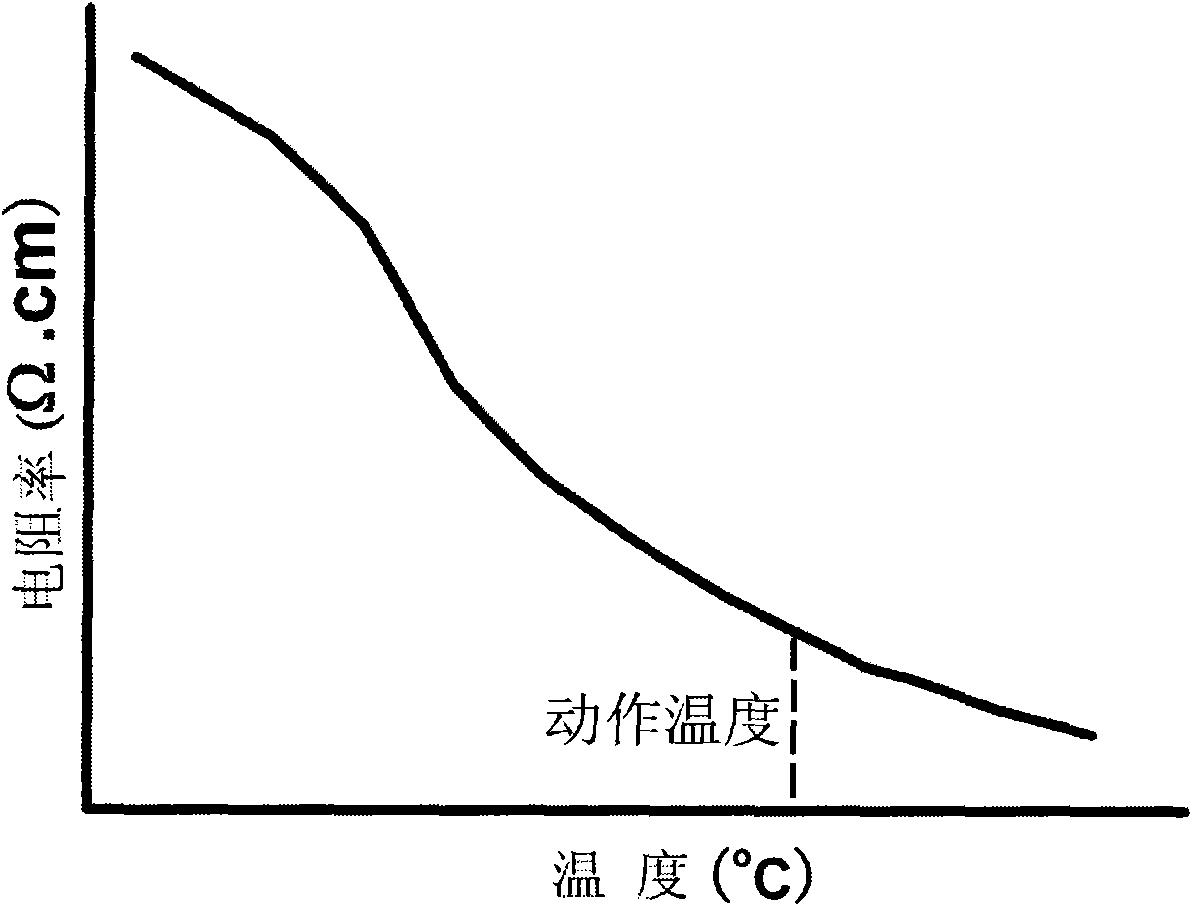

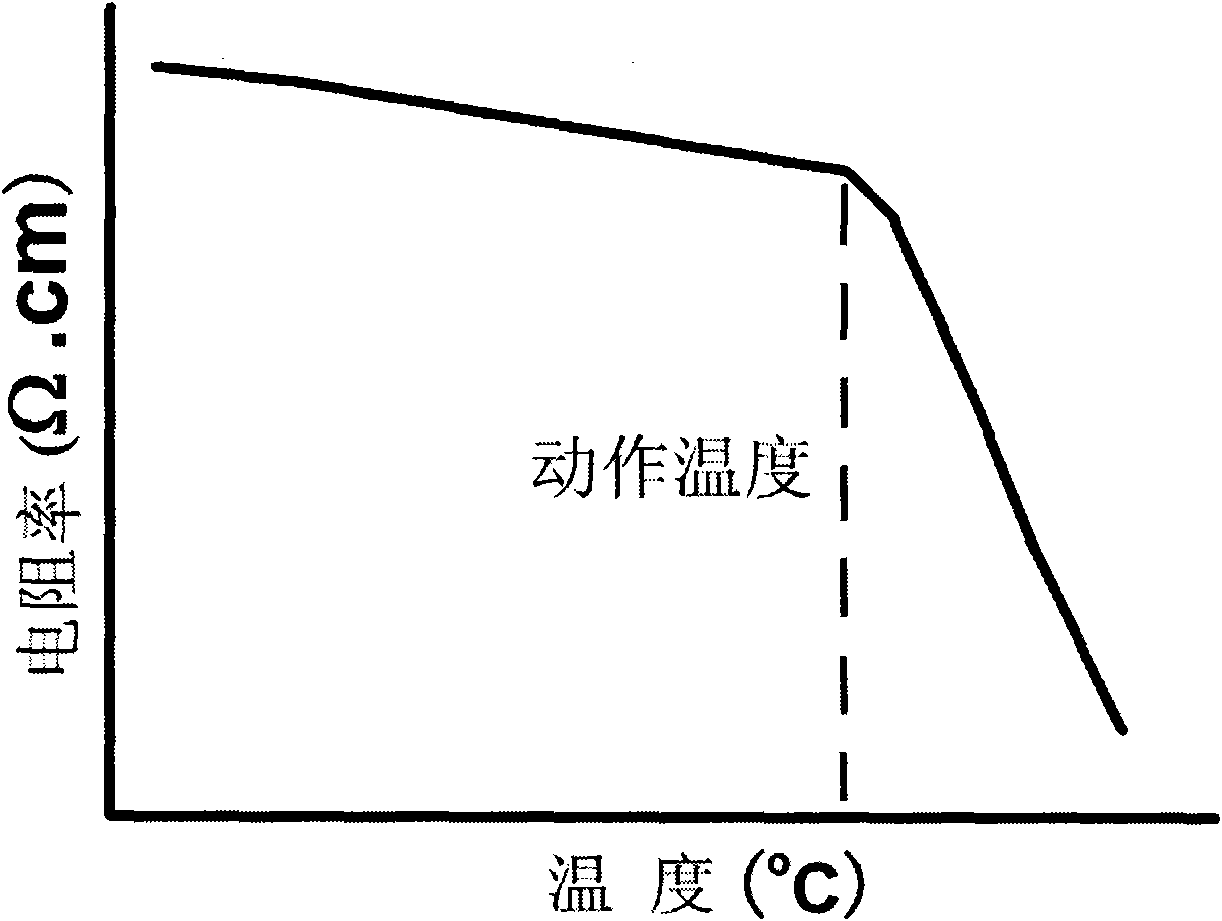

Negative temperature coefficient polymer composite material for temperature sensing cable and preparation method

InactiveCN101654530AImprove structural stabilityGood repeatabilityNegative temperature coefficient thermistorsNegative temperatureThermoplastic elastomer

The invention relates to a negative temperature coefficient polymer composite material for temperature sensing cables and a preparation method, belonging to the field of the preparation of macromolecule functional composite material and process technology of polymers; the invention has the characteristics that: rubber or thermoplastic elastomers are combined with different auxiliary polymers, conducting particles are added to prepare the macromolecule composite material with the characteristic of negative temperature coefficient. The material has the characteristics that the resistance changeis low below the room temperature and operating temperature, and then is rapidly reduced after reaching the operating temperature, and overcomes the disadvantages that the traditional NTC macromolecule composite material has obvious resistance change below the room temperature and the operating temperature, and the resistance change is low close to the operating temperature, so as to lead the prepared temperature sensing cables to have high sensitivity, to have little effect to environment temperature and good repetitiveness.

Owner:TSINGHUA UNIV

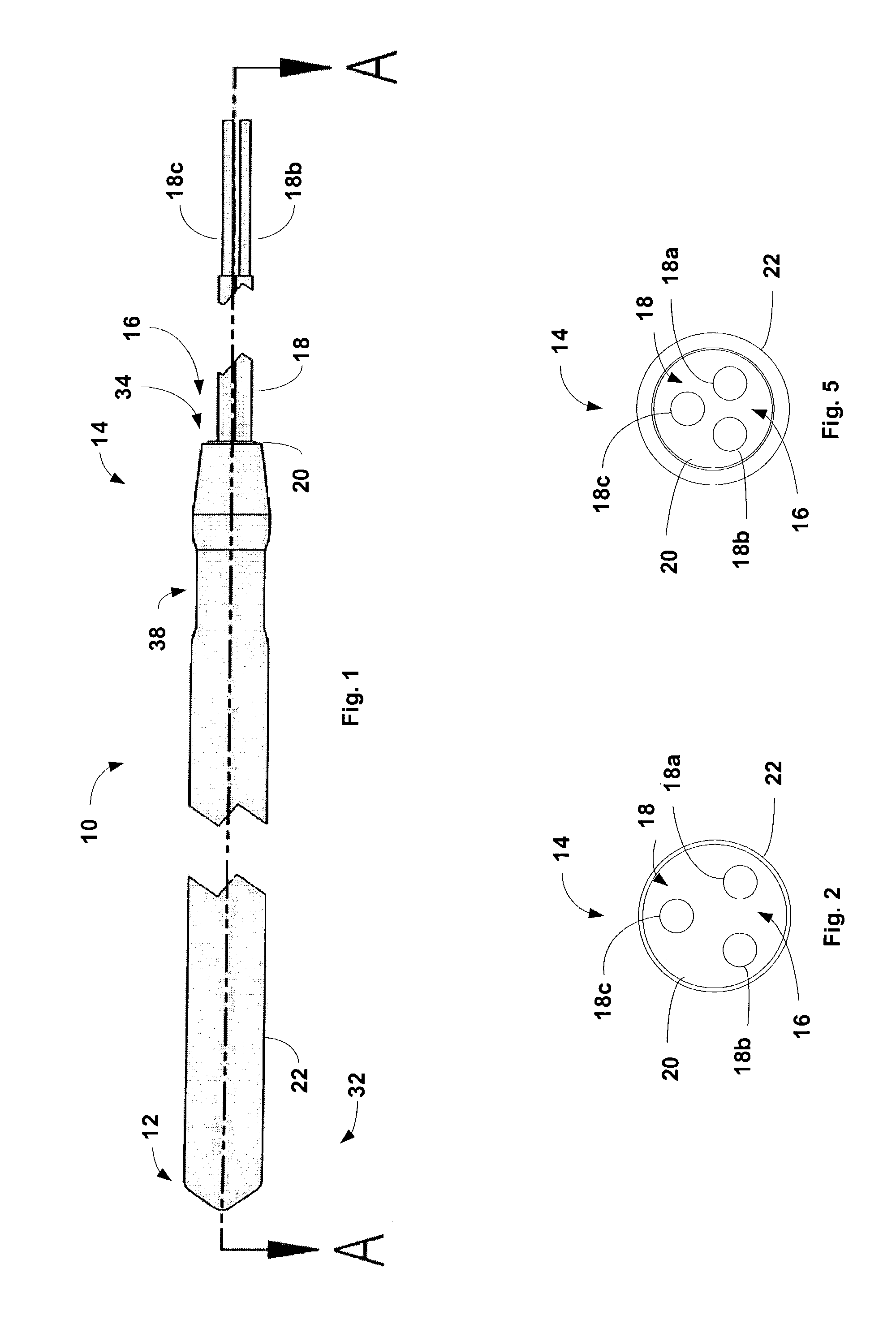

Temperature sensor and method of manufacturing

ActiveUS7855632B1Improved property against impactIncrease vibrationThermometer detailsThermometers using electric/magnetic elementsEngineeringElectrical and Electronics engineering

A temperature sensor includes an autonomous sensing element and a plurality of conductive wires connected to the sensing element. An electrical insulator surrounds the sensing element and the conductive wires for firmly holding the sensing element and conductive wires. The insulator includes substantially crushed and compacted powder insulation. A tube encases the insulator in a compressed manner and has a first end, a second end, a first portion having a first inside diameter located in the proximity of the first end and a second portion having a second inside diameter. The second inside diameter being greater than the first inside diameter. The sensing element is positioned within the second portion of the tube. Methods of manufacturing a temperature sensor are also included.

Owner:WATLOW ELECTRIC MFG

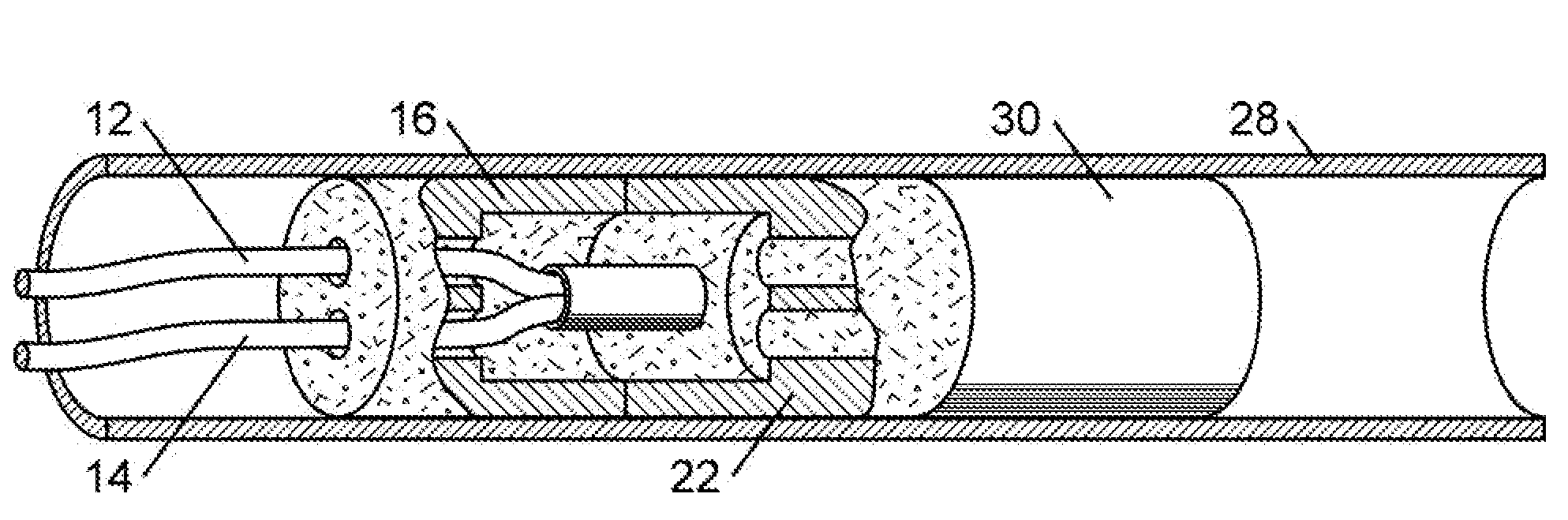

End seal design for temperature sensing probes

InactiveUS7060949B1Efficiently provideThermometer detailsOhmic-resistance waterproof/air-tight sealsEngineeringHeating element

An end seal for a temperature sensing probe. Electrical interface wiring is passed through a restraining element and is operatively coupled to a temperature sensing element or heater element mounted in the sheath. The sheath is formed around the restraining element in a shape that provides a net force inward as temperature variations expand and contract the restraining element.

Owner:WATLOW ELECTRIC MFG

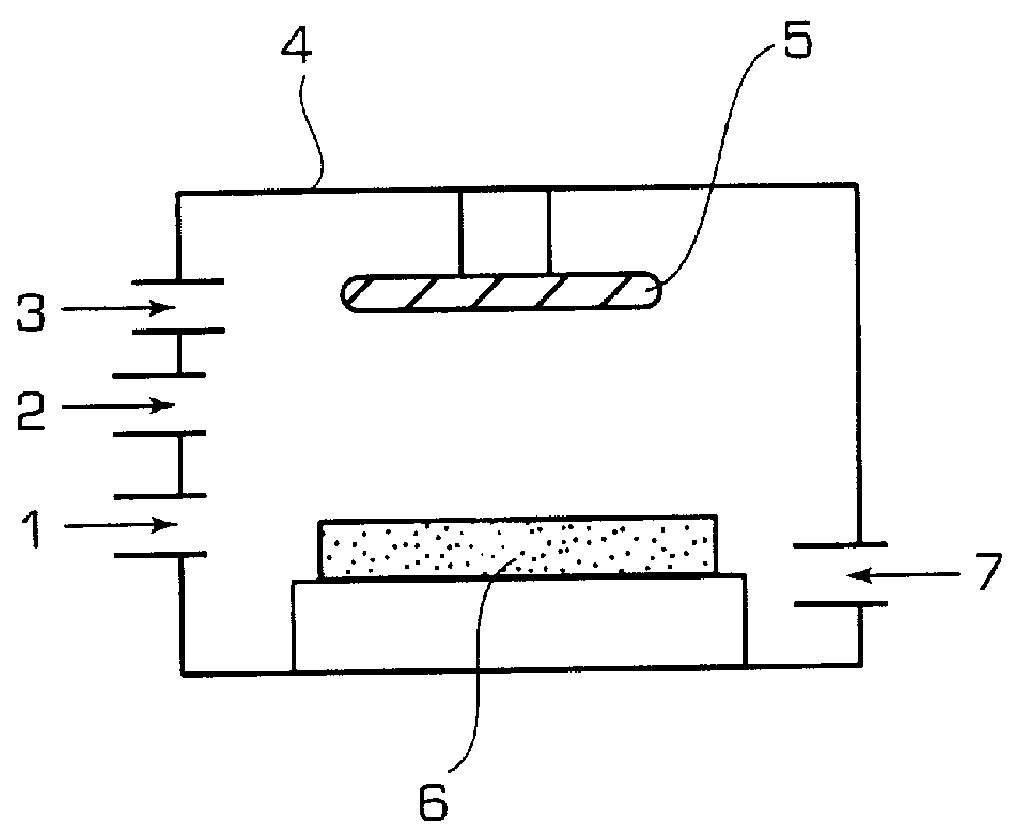

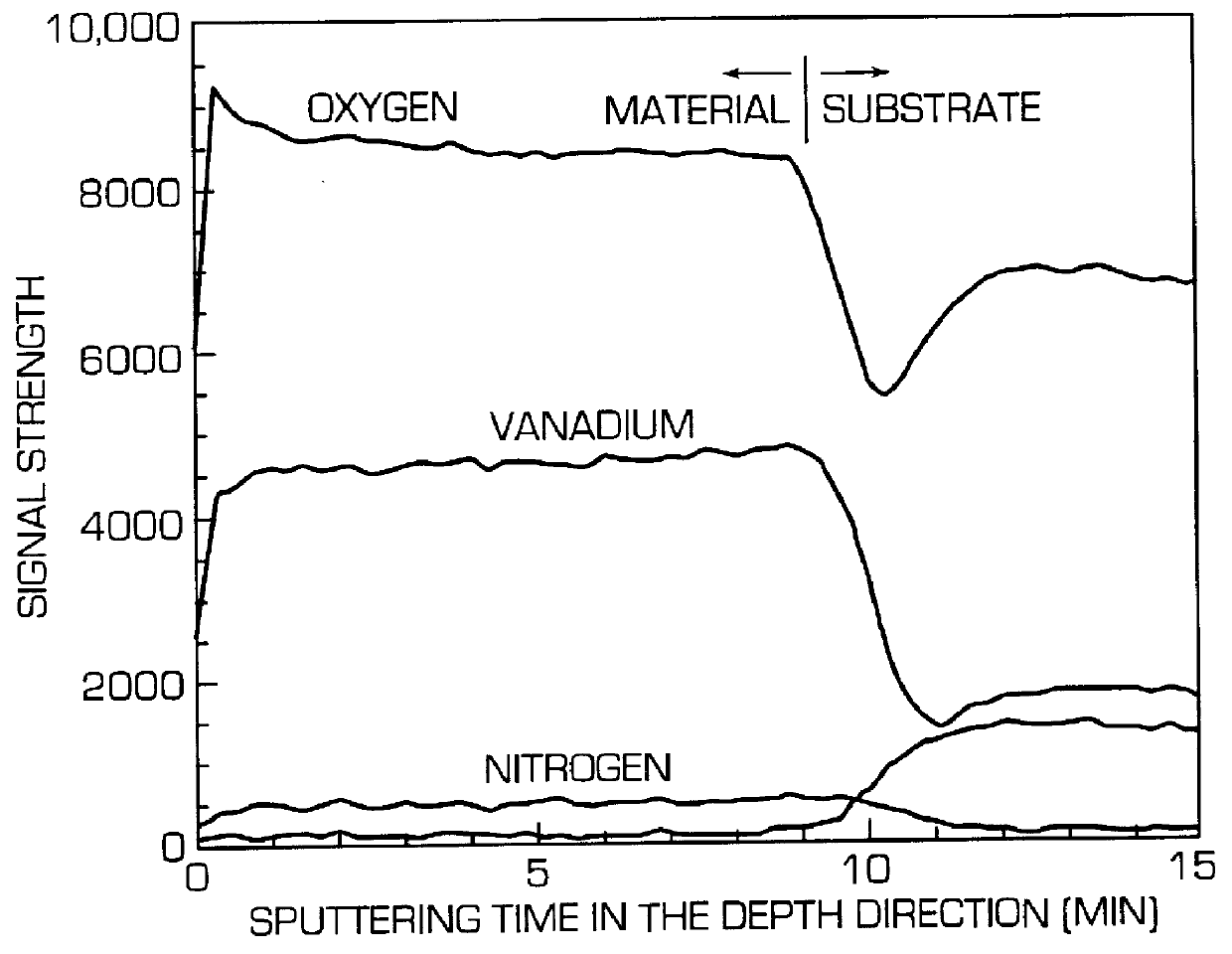

Thin-film temperature-sensitive resistor material and production process thereof

Described are a thin-film temperature-sensitive resistor material which comprises, at a temperature-sensitive resistor portion, a mixed crystal of a nitride and oxide of a transition metal such as vanadium preferably, that represented by the formula: MNxOy wherein 0<x<1, and 2< / =y< / =13 / 6, simultaneously exhibits a high temperature coefficient of resistance and a low specific resistance at about room temperature, and has excellent sensitivity at about room temperature; and a process for the production of a thin-film temperature-sensitive resistor material, which comprises forming its temperature-sensitive resistor portion by using a gas-atmosphere composed mainly of a nitrogen gas preferably, a mixed gas composed of nitrogen, argon and oxygen, and has a flow rate ratio of nitrogen to oxygen (nitrogen / oxygen) of 14 / 1 to 23 / 1.

Owner:NEC CORP

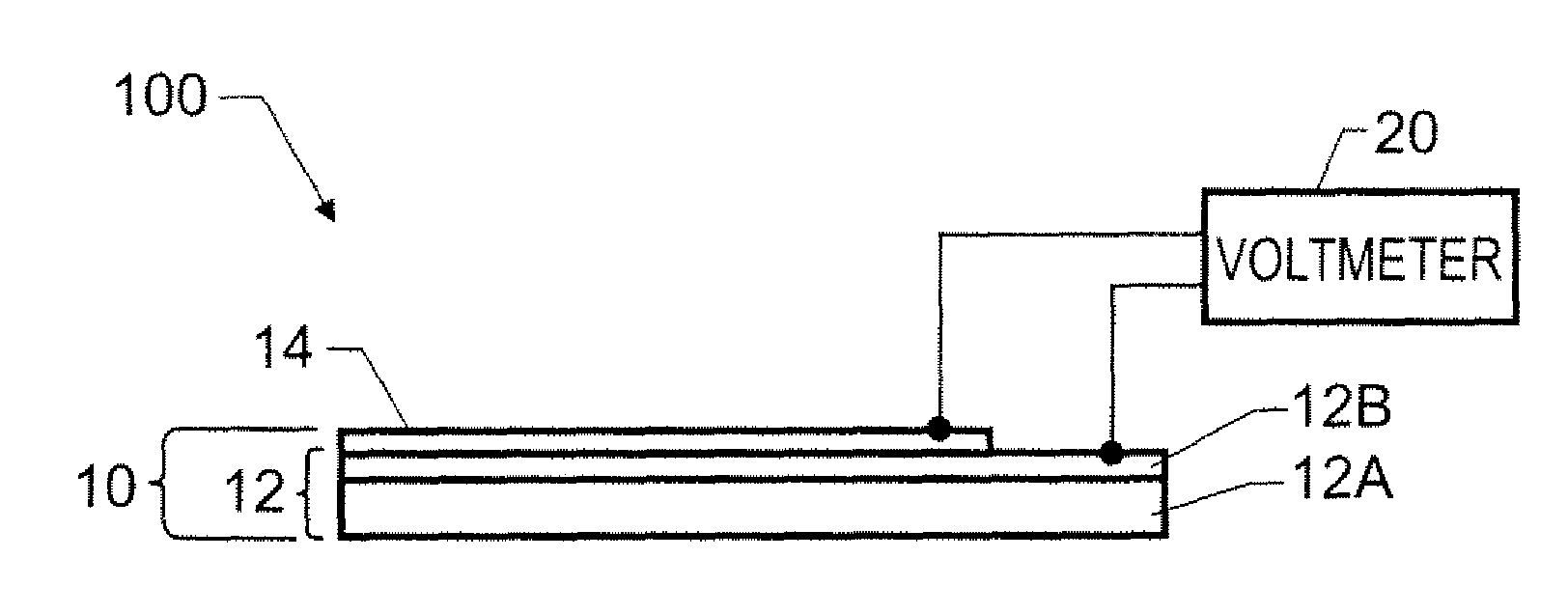

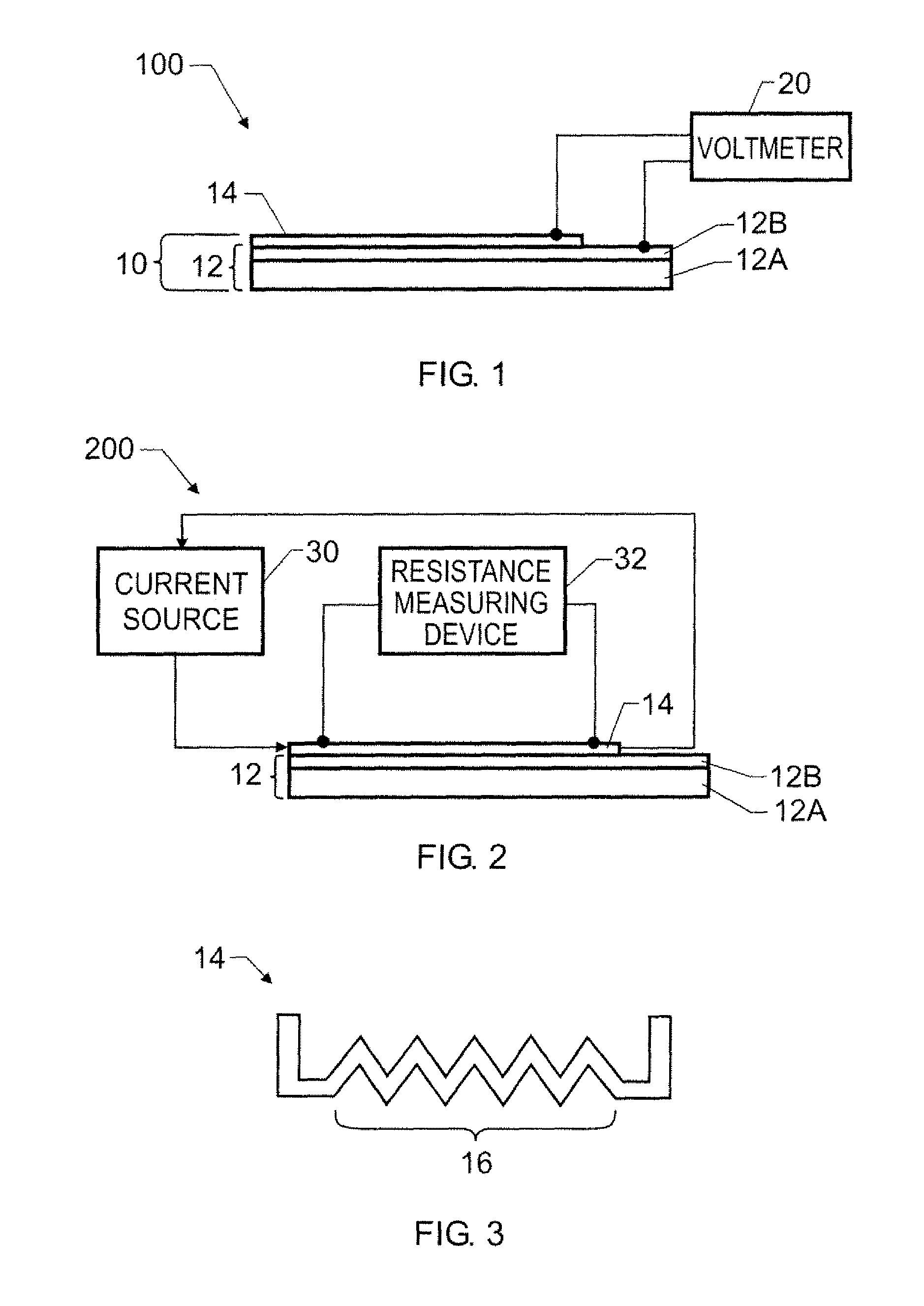

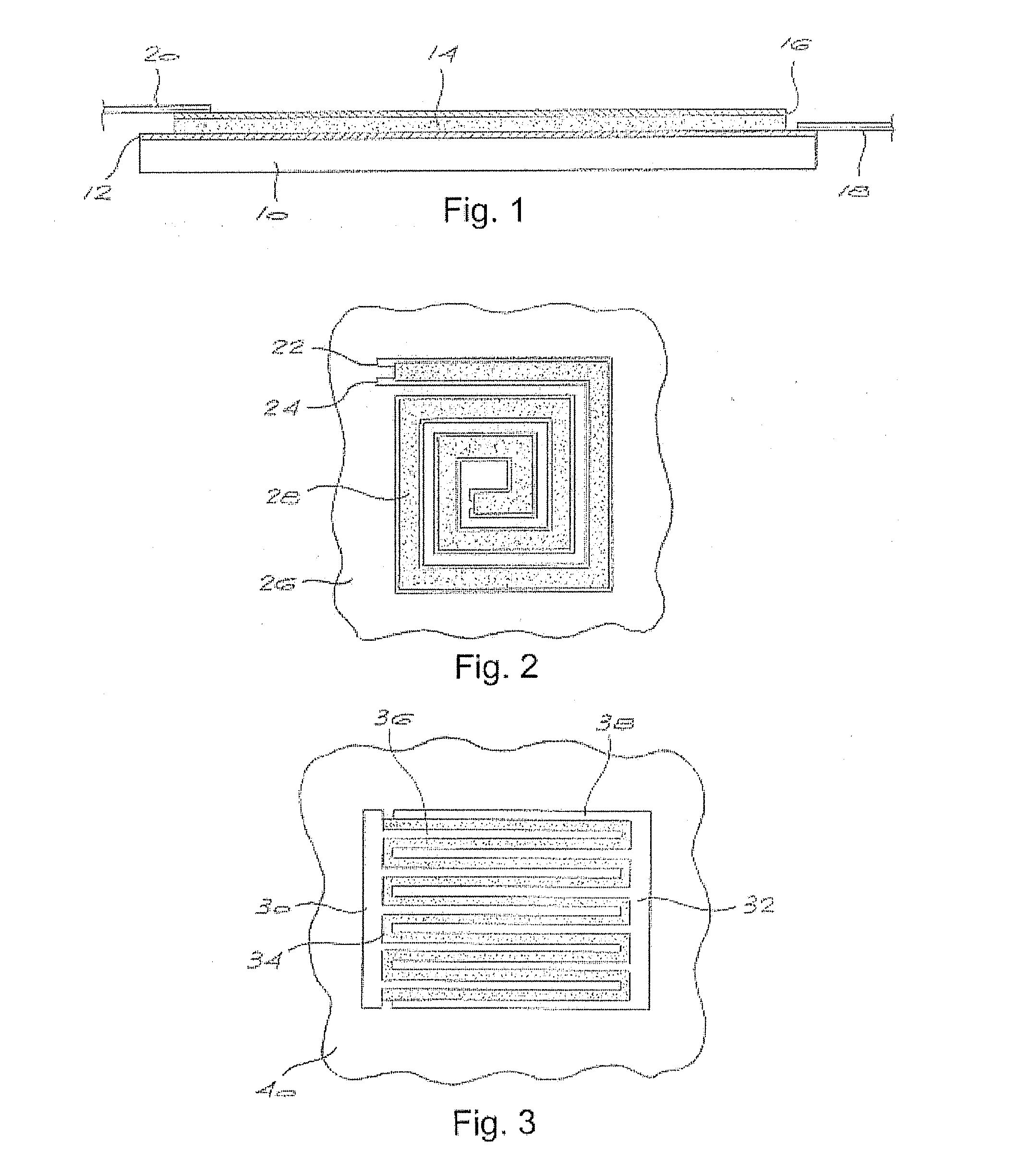

Flexible Thin Metal Film Thermal Sensing System

InactiveUS20100118916A1Current responsive resistorsThermometers using electric/magnetic elementsThin metalConductive materials

A flexible thin metal film thermal sensing system is provided. A thermally-conductive film made from a thermally-insulating material is doped with thermally-conductive material. At least one layer of electrically-conductive metal is deposited directly onto a surface of the thermally-conductive film. One or more devices are coupled to the layer(s) to measure an electrical characteristic associated therewith as an indication of temperature.

Owner:NASA

Platinum temperature sensor and its method of production

InactiveUS6653926B1Connected deterioration of property is preventedEnvelope/housing resistor manufactureThermometers using electric/magnetic elementsPlatinumMetallurgy

A Platinum temperature sensor comprises a ceramic substrate and a platinum thin-film resistor applied to said ceramic substrate, a ceramic cover layer and a connecting layer generated from a ceramic green layer by pressure and temperature treatment. The ceramic cover layer is connected with the ceramic substrate in such a way via the connecting layer that the platinum thin-film resistor is sealingly encapsulated with regard to the environment.

Owner:BORGWARNER BERU SYST

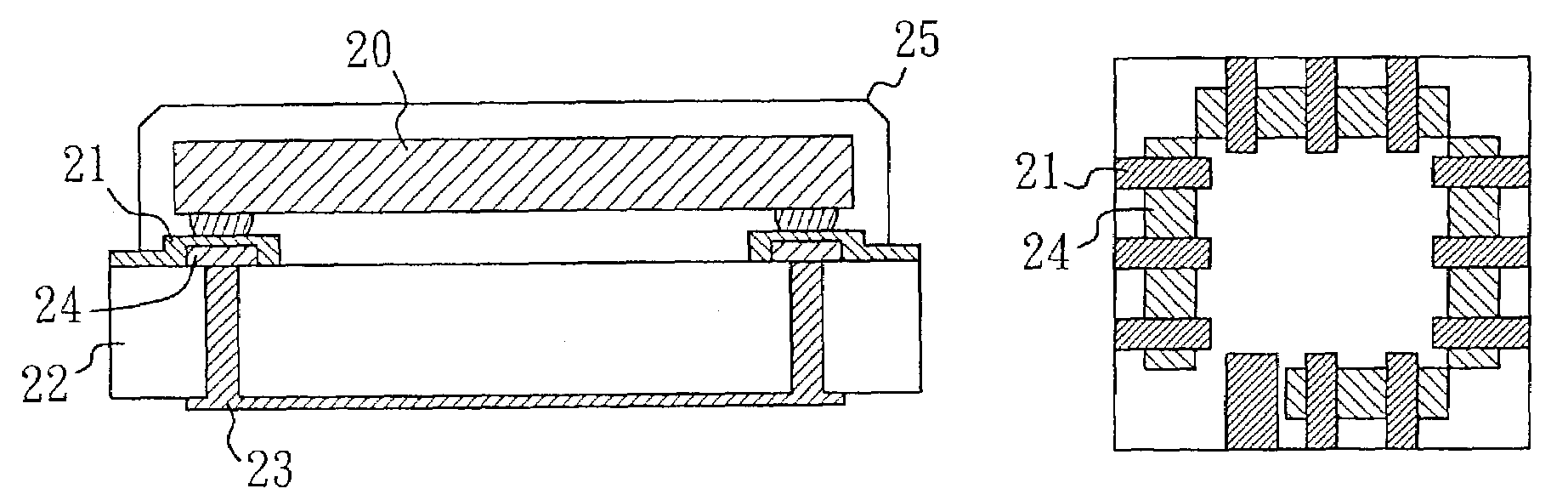

IC substrate having over voltage protection function

InactiveUS7053468B2Save spaceLow costSemiconductor/solid-state device detailsSolid-state devicesEngineeringPrinted circuit board

The present invention relates to an IC substrate provided with over voltage protection functions and thus, a plurality of over voltage protection devices are provided on a single substrate to protect an IC chip directly. According to the present invention, there is no need to install protection devices at respective I / O ports on a printed circuit board to prevent the IC devices from damage by surge pulses. Therefore, the costs to design circuits are reduced, the limited space is efficiently utilized, and unit costs to install respective protection devices are lowered down.

Owner:INPAQ TECH

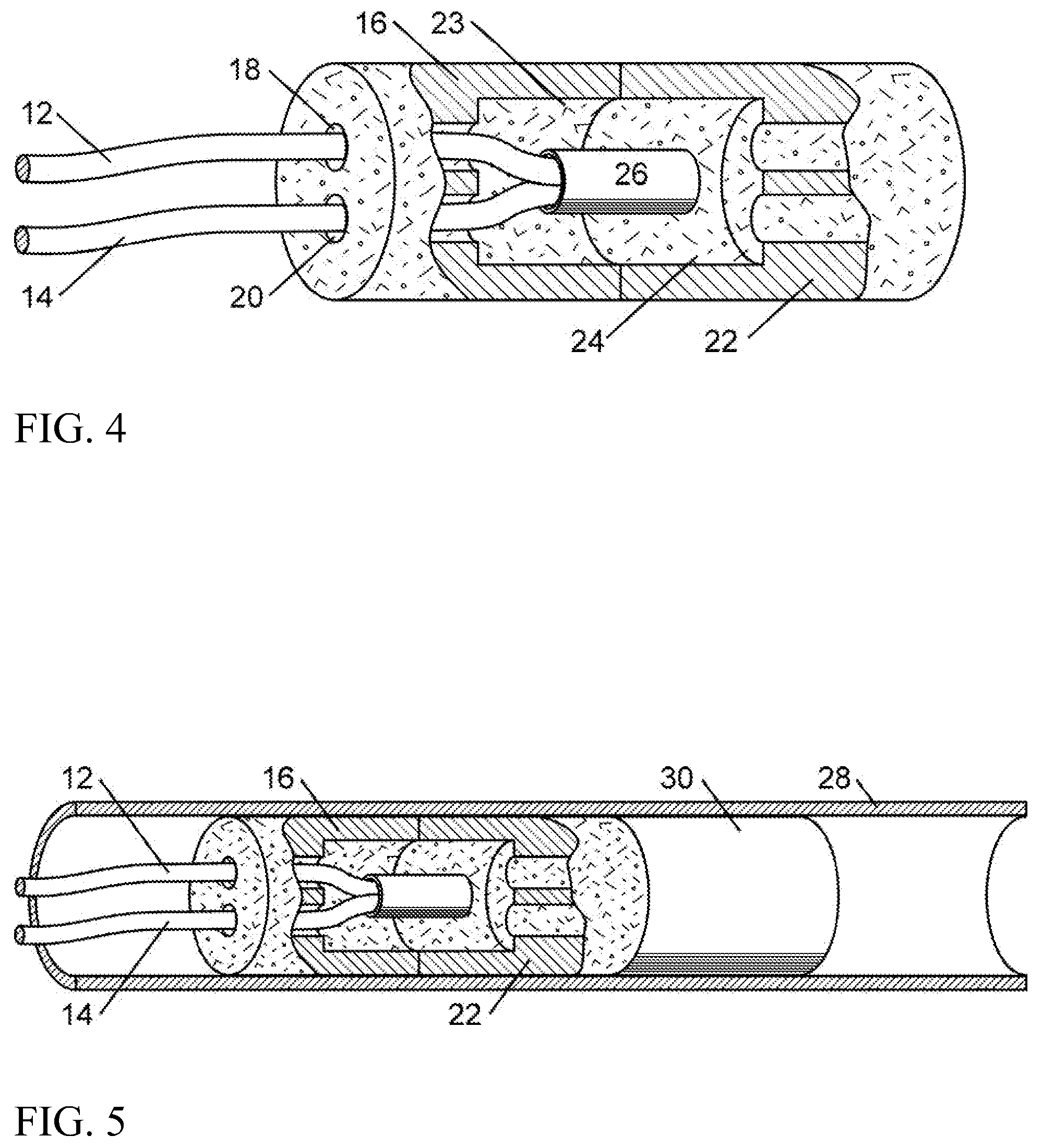

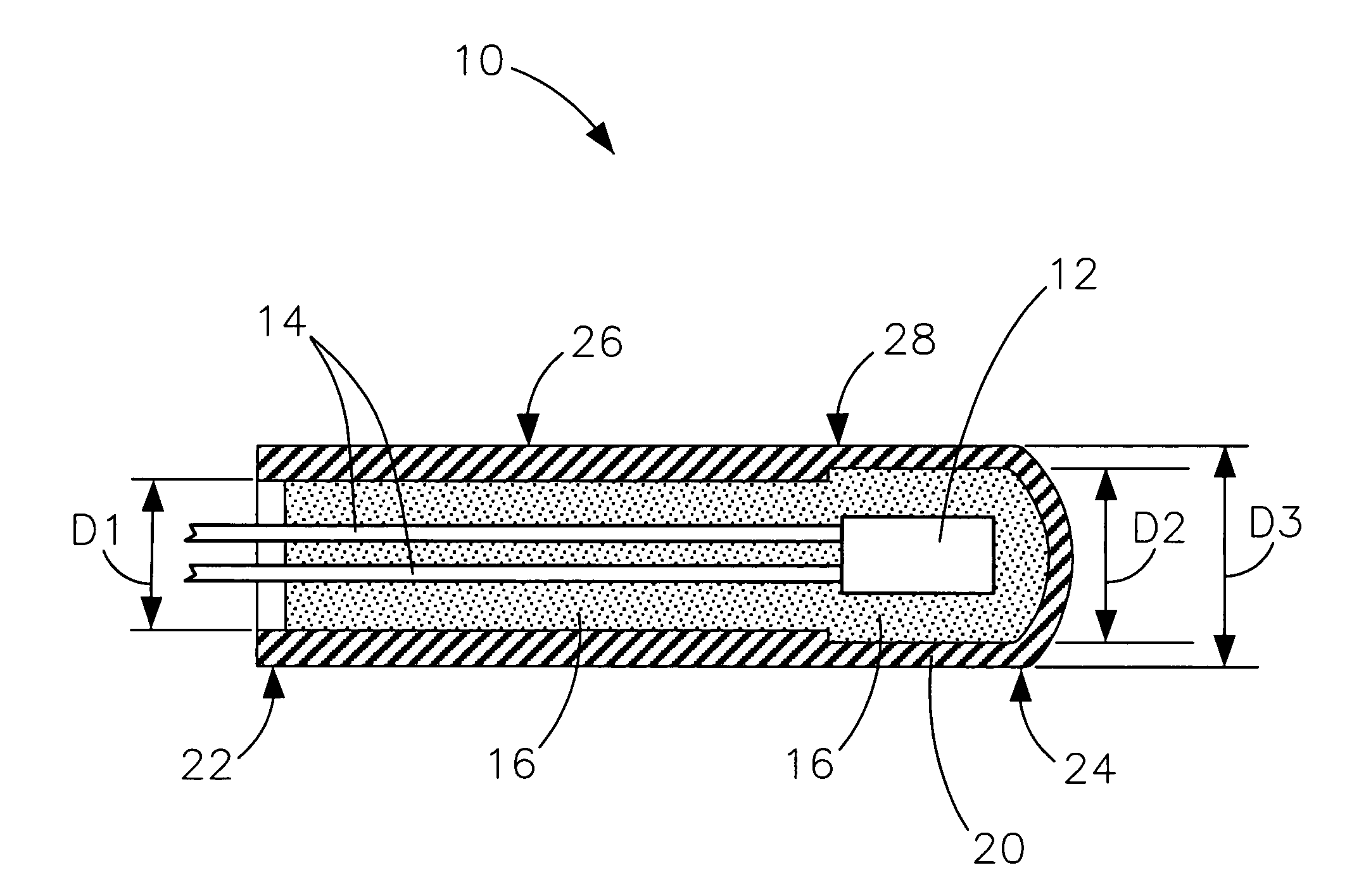

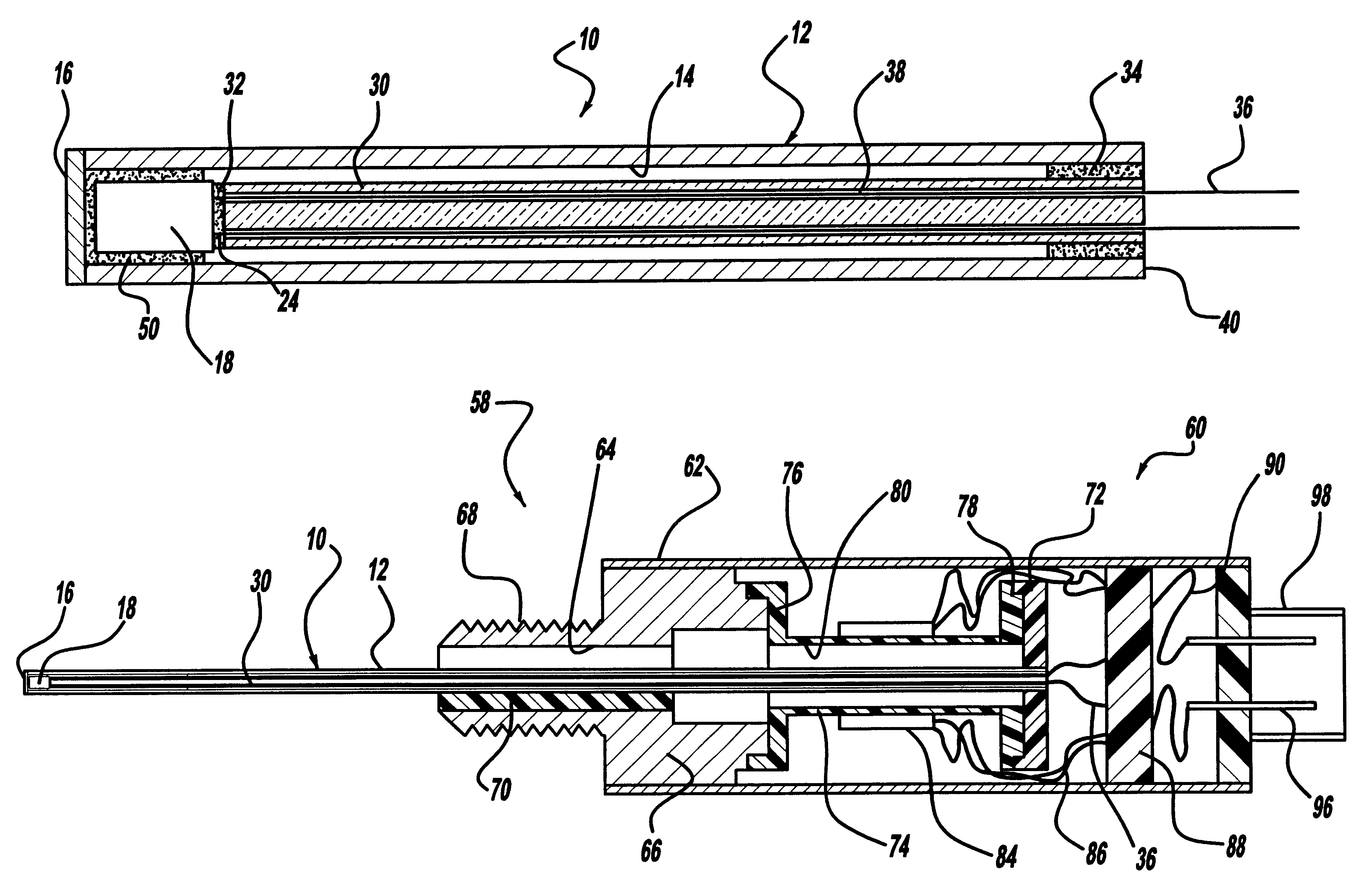

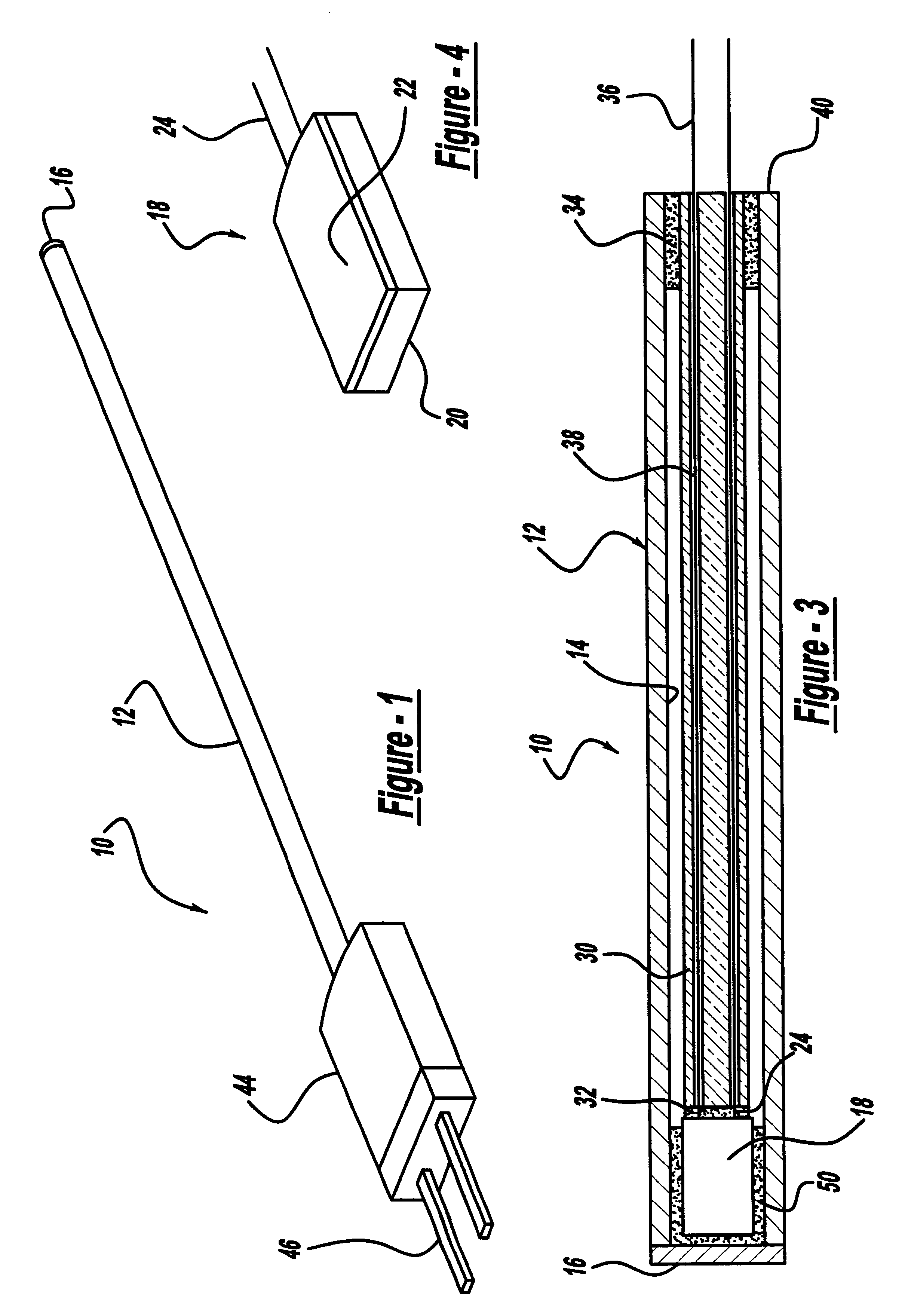

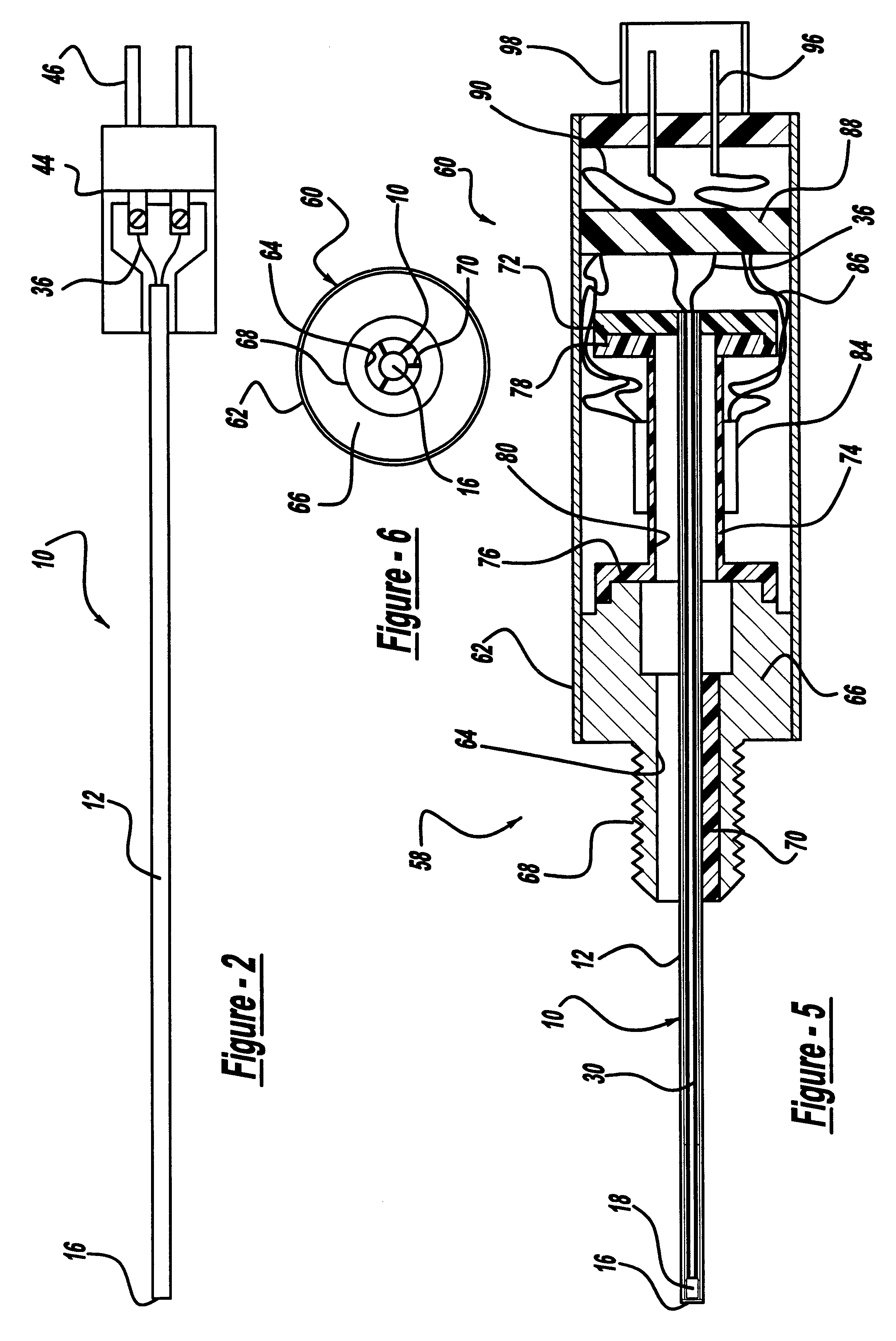

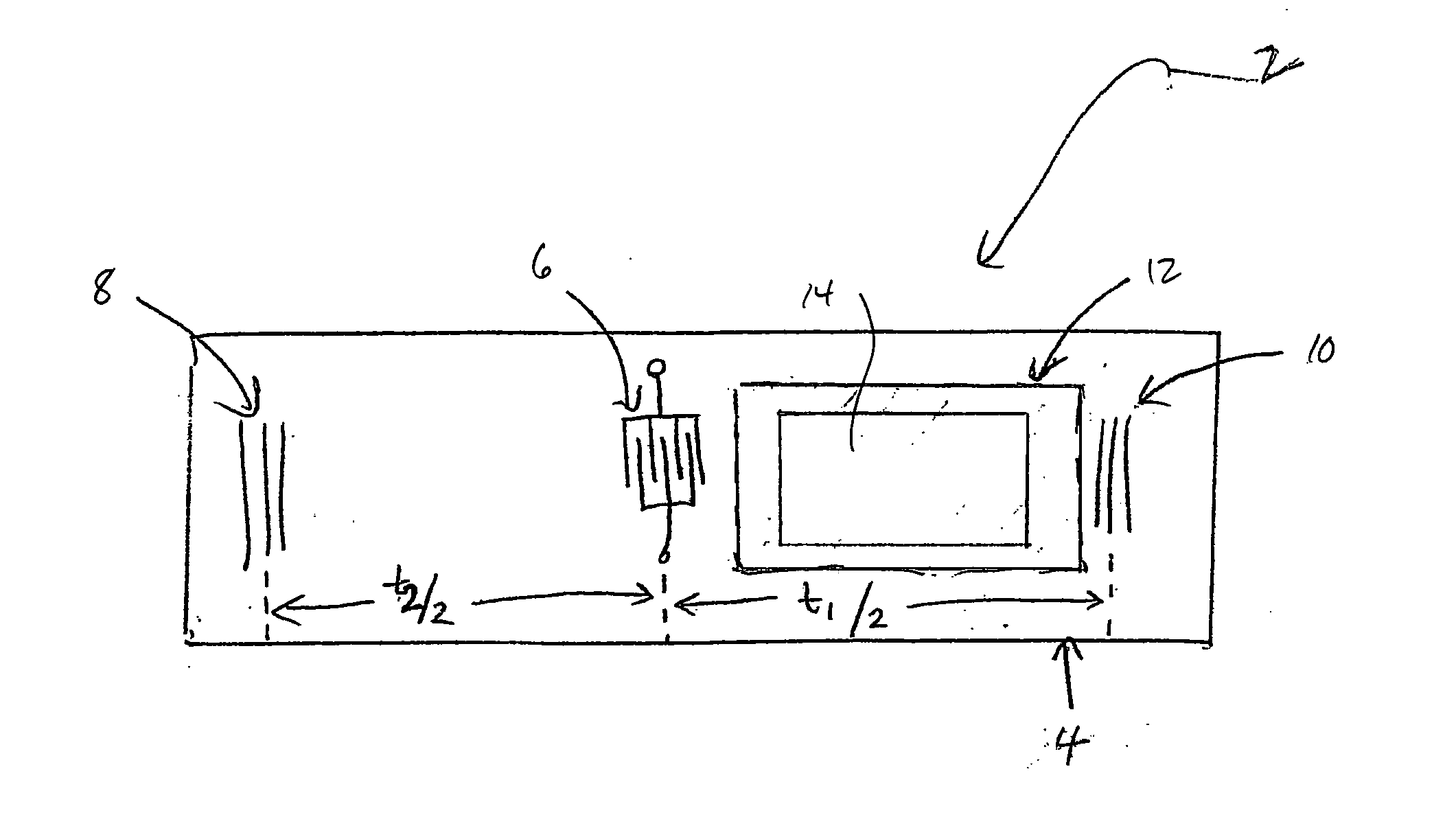

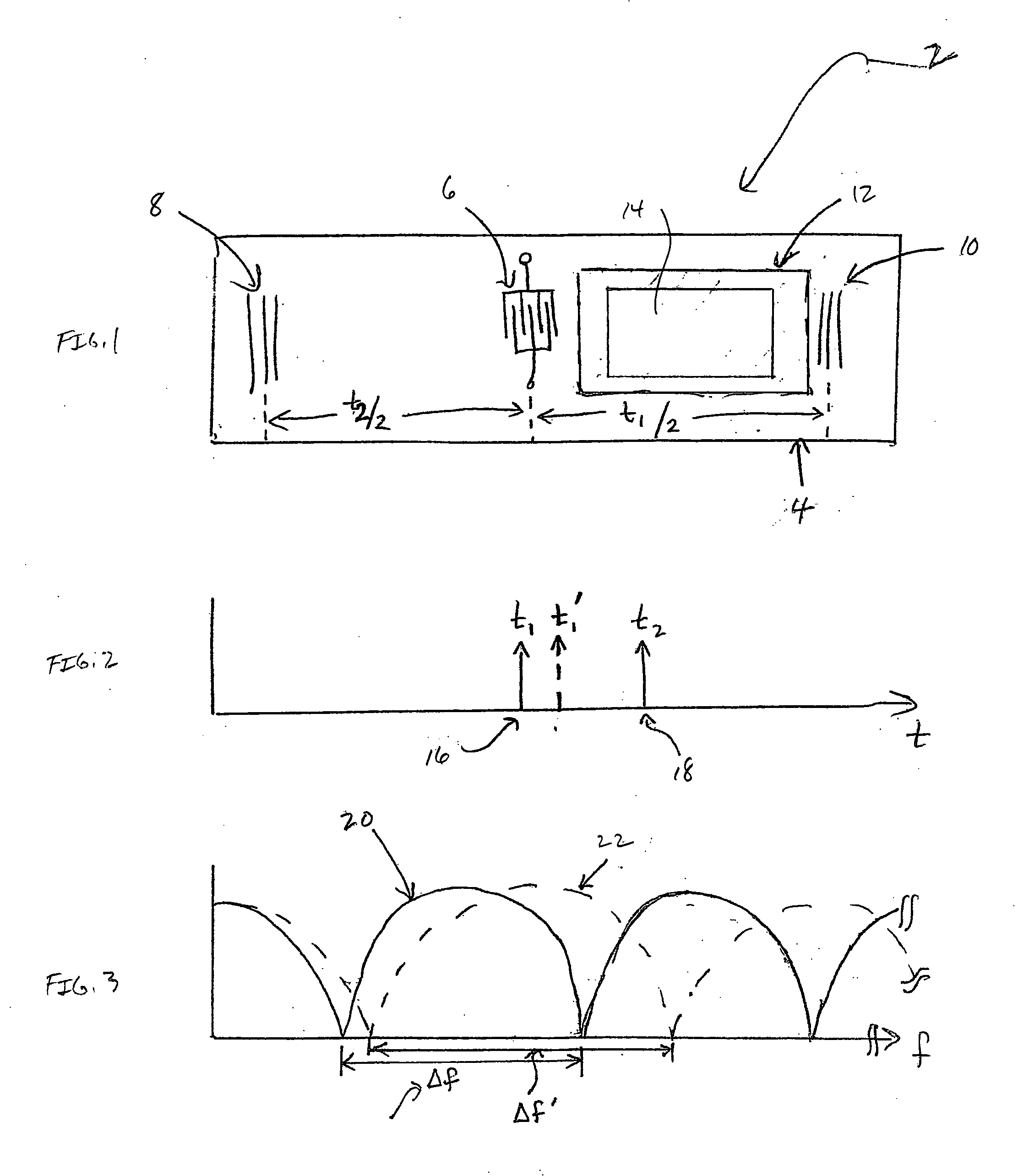

Precision temperature probe having fast response

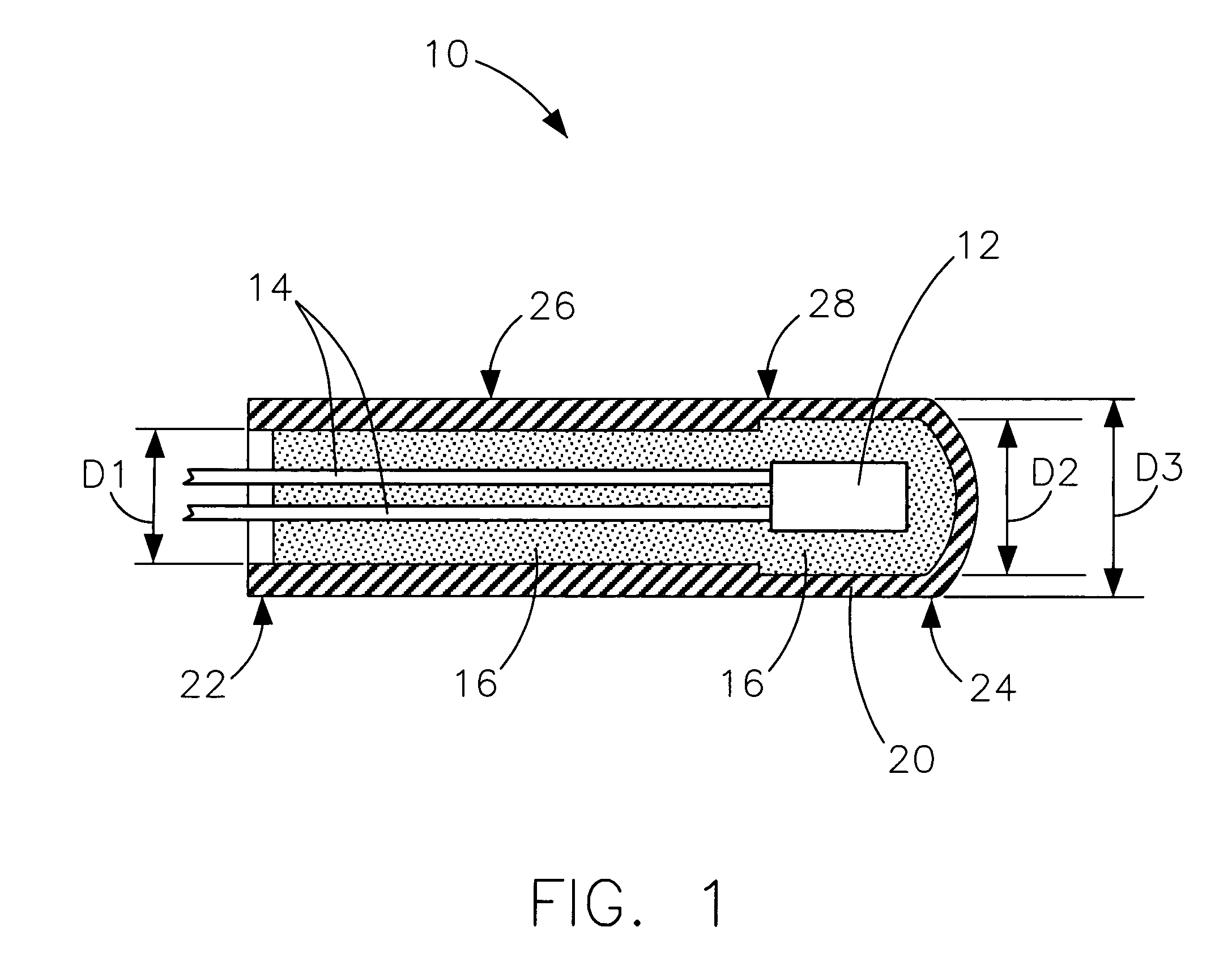

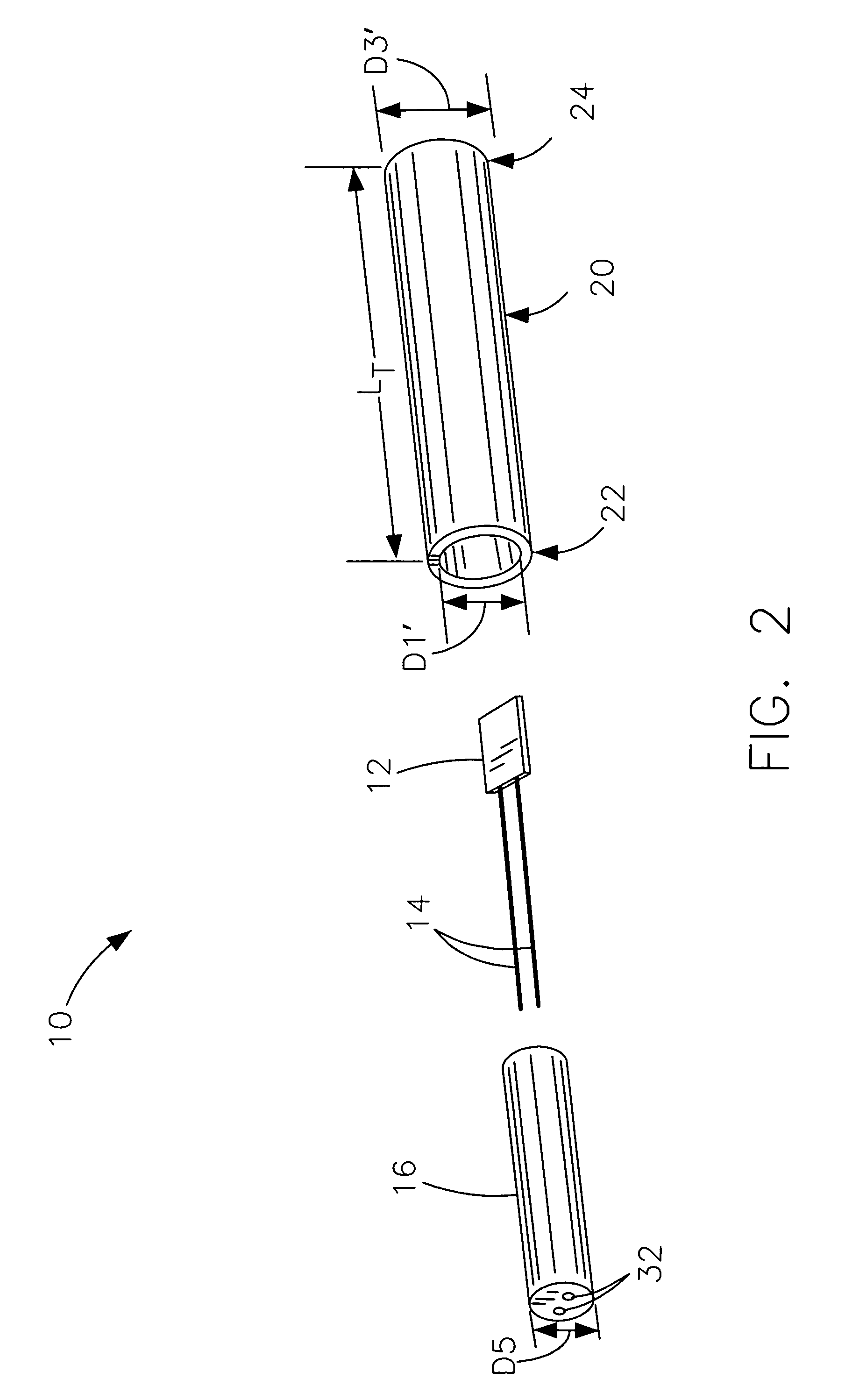

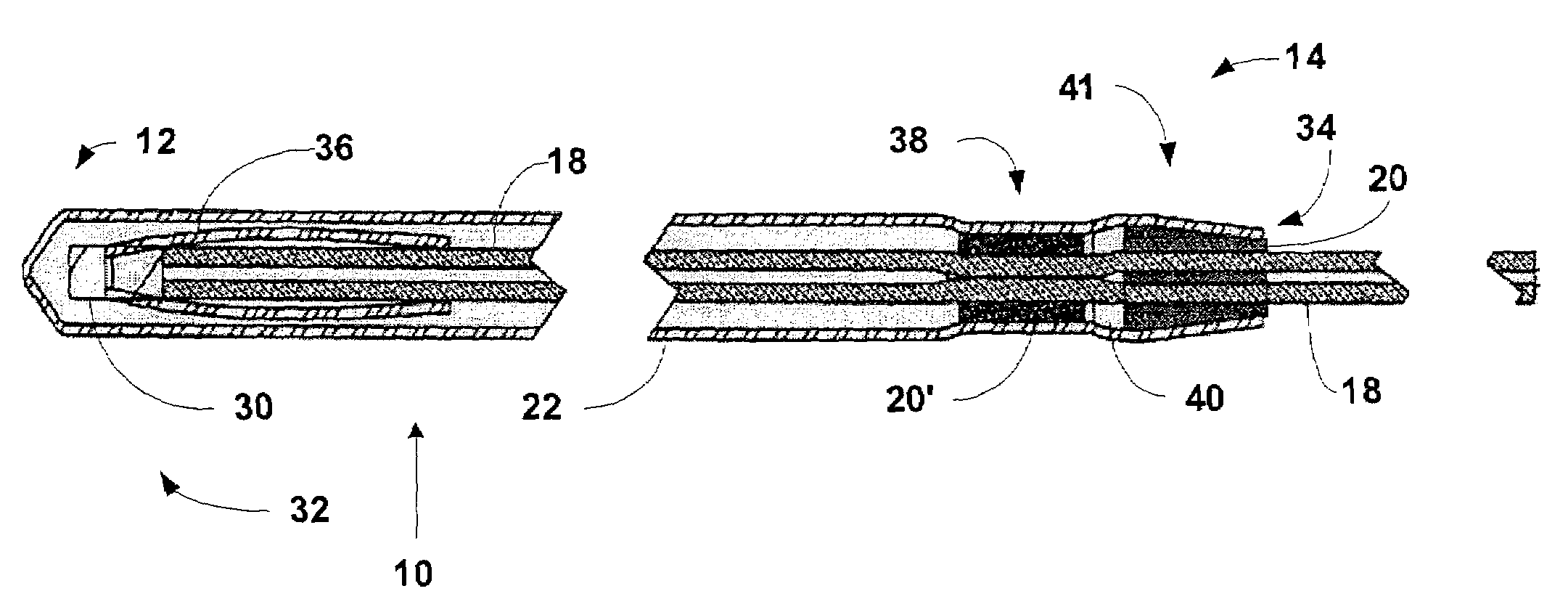

InactiveUS6592253B2Thermometer detailsThermometers using electric/magnetic elementsTransducerResistive element

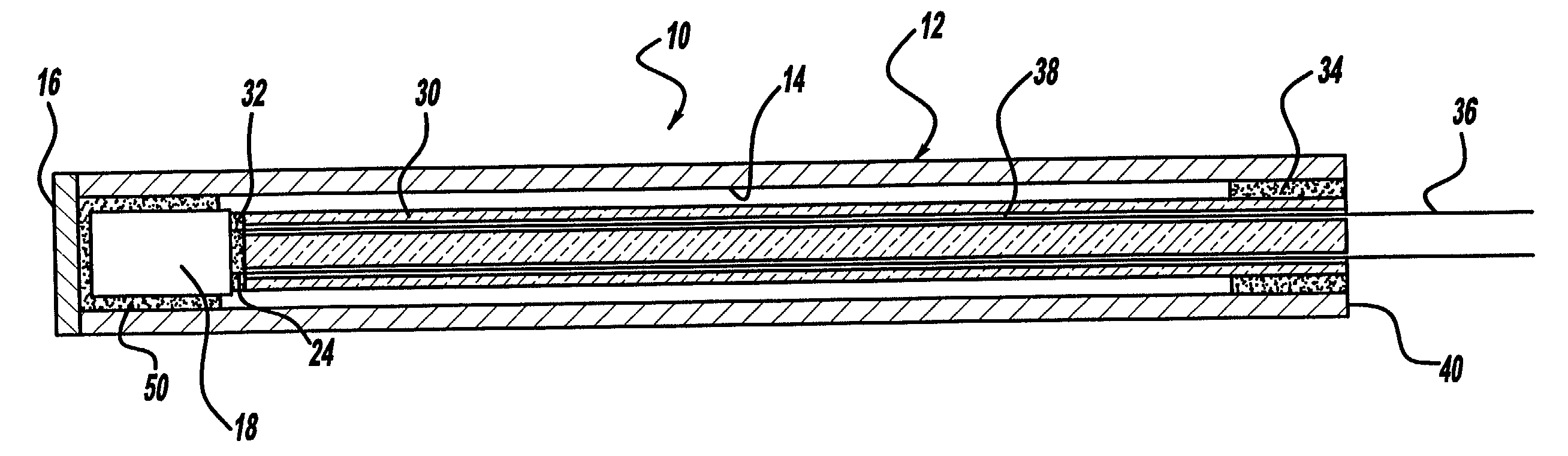

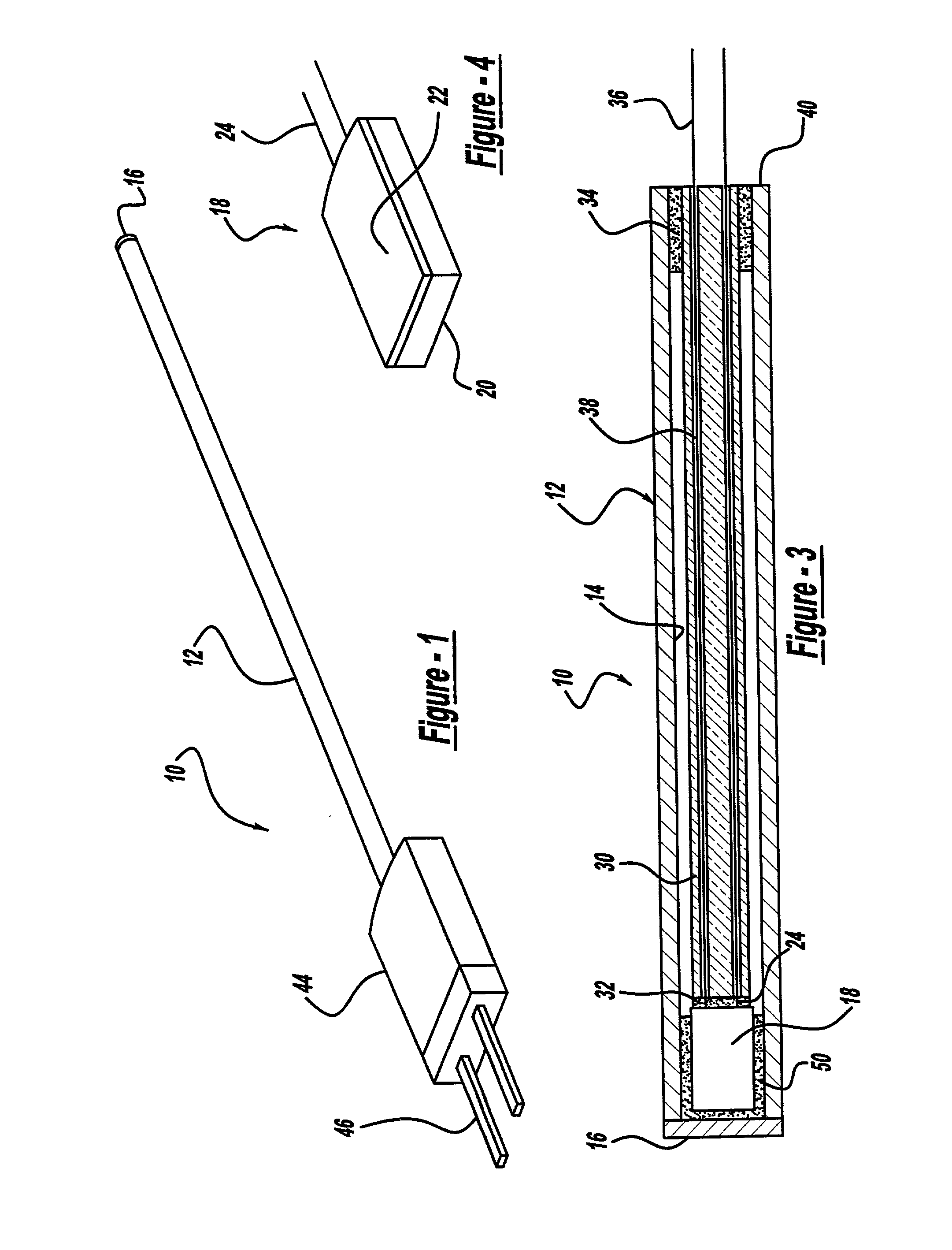

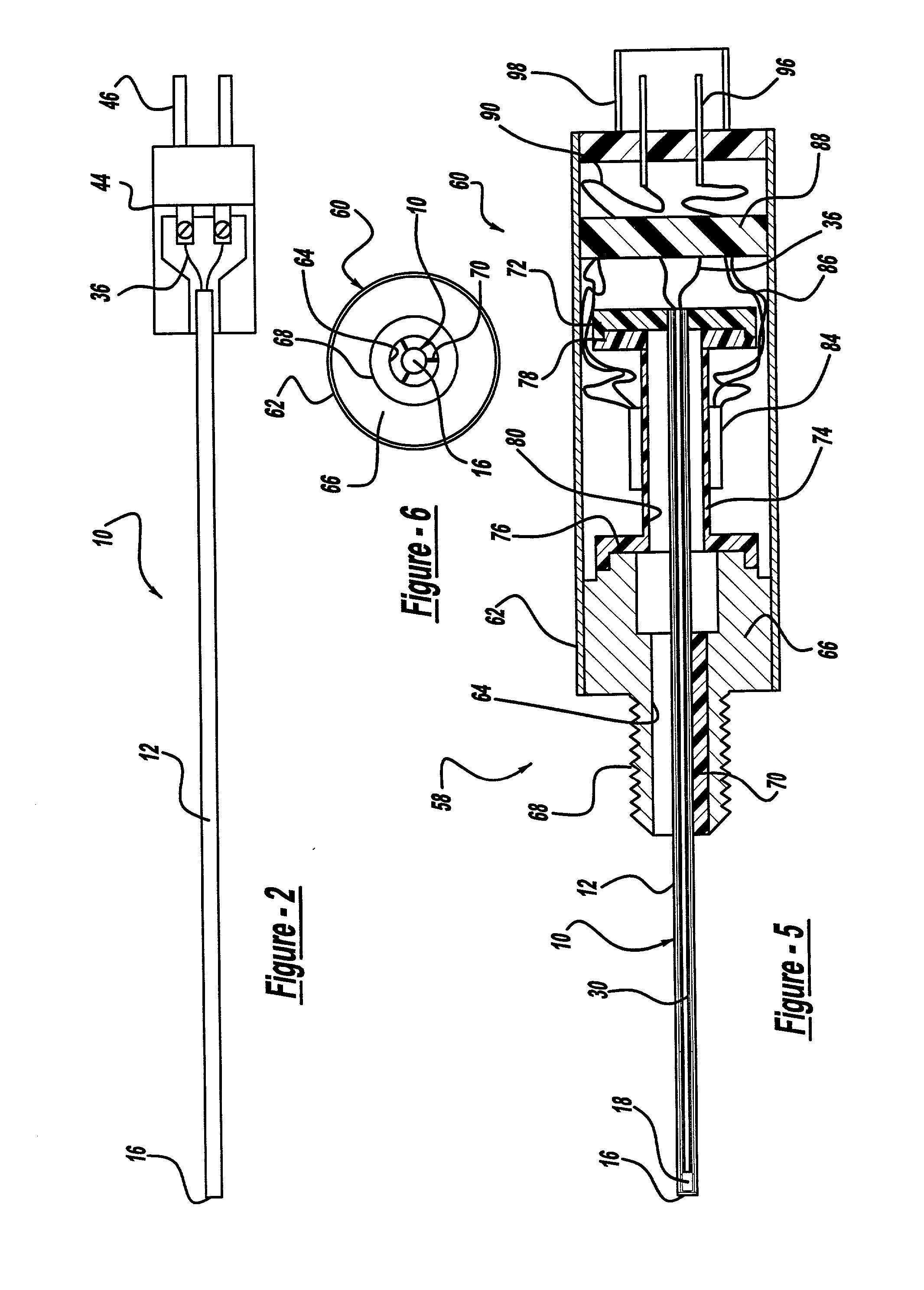

A temperature probe (10) including a cylindrical thermally conductive housing (10) and a temperature sensor (18) employing a resistive temperature element (22) mounted therein. The temperature sensor (18) is mounted at one end of the housing (12) by a thermally conductive potting material (50). Signal wires (36) electrically couple to the resistive element (22) extend through an elongated insulated member (30) and out of an end of the housing (12) opposite the sensor (18). Changes in the temperature of the housing are quickly transferred to the resistive temperature element (22) through the conductive potting material (50). In one embodiment, the probe (10) is combined with a pressure transducer (60) to provide a pressure and temperature sensing device.

Owner:NORTHROP GRUMMAN SYST CORP

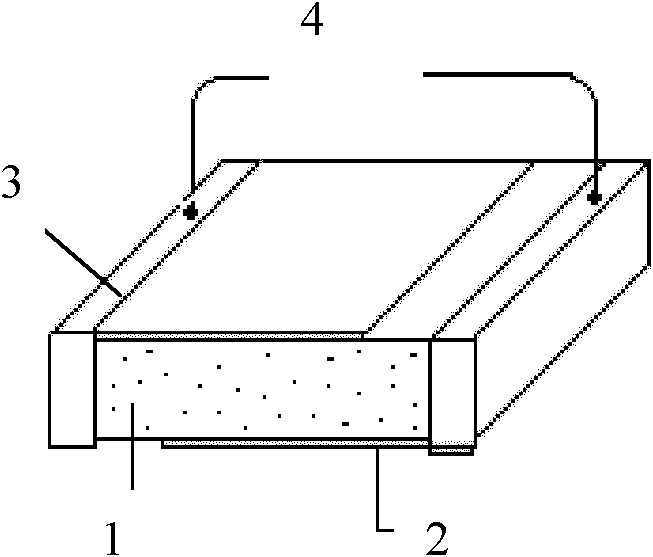

Surface-mounting high-precision large-power NTC (Negative Temperature Coefficient) thermistor and making method thereof

ActiveCN102034580AImprove pass rateResistor mounting/supportingNegative temperature coefficient thermistorsHigh resistanceHeat sensitive

Owner:ZHAOQING EXSENSE ELECTRONICS TECH

Precision temperature probe having fast response

InactiveUS20030067960A1Thermometer detailsThermometers using electric/magnetic elementsTransducerEngineering

A temperature probe (<bold>10< / highlight>) includihermally conductive housing (10) and a temperatureld>10< / highlight>) and a temperature sensor (<boldment (22) mounted therein. The temperature sensor element (<bold>22< / highlight>) mounted therein. Ta thermally conductive potting material (50). Signunted at one end of the housing (<bold>12< / highlig element (22) extend through an elongated insulatebold>50< / highlight>). Signal wires (<bold>36< / high) opposite the sensor (18). Changes in the temperant (<bold>22< / highlight>) extend through an elonga resistive temperature element (22) through the cot of an end of the housing (<bold>12< / highlight>) the probe (10) is combined with a pressure transds in the temperature of the housing are quickly trnsing device. old>22< / highlight>) through the conductive potting material (<bold>50< / highlight>). In one embodiment, the probe (<bold>10< / highlight>) is combined with a pressure transducer (<bold>60< / highlight>) to provide a pressure and temperature sensing device.

Owner:NORTHROP GRUMMAN SYST CORP

Printed Temperature Sensor

InactiveUS20130203201A1Efficient additionImprove the immunityThermoelectric device manufacture/treatmentPrinted electric component incorporationElectrical resistance and conductanceHeat sensitive

A method of producing a temperature sensing device is provided. The method includes forming at least one silicon layer and at least one electrode or contact to define a thermistor structure. At least the silicon layer is formed by printing, and at least one of the silicon layer and the electrode or contact is supported by a substrate during printing thereof. Preferably, the electrodes or contacts are formed by printing, using an ink comprising silicon particles having a size in the range 10 nanometres to 100 micrometres, and a liquid vehicle composed of a binder and a suitable solvent. In some embodiments the substrate is an object the temperature of which is to be measured. Instead, the substrate may be a template, may be sacrificial, or may be a flexible or rigid material. Various device geometries are disclosed.

Owner:PST SENSORS

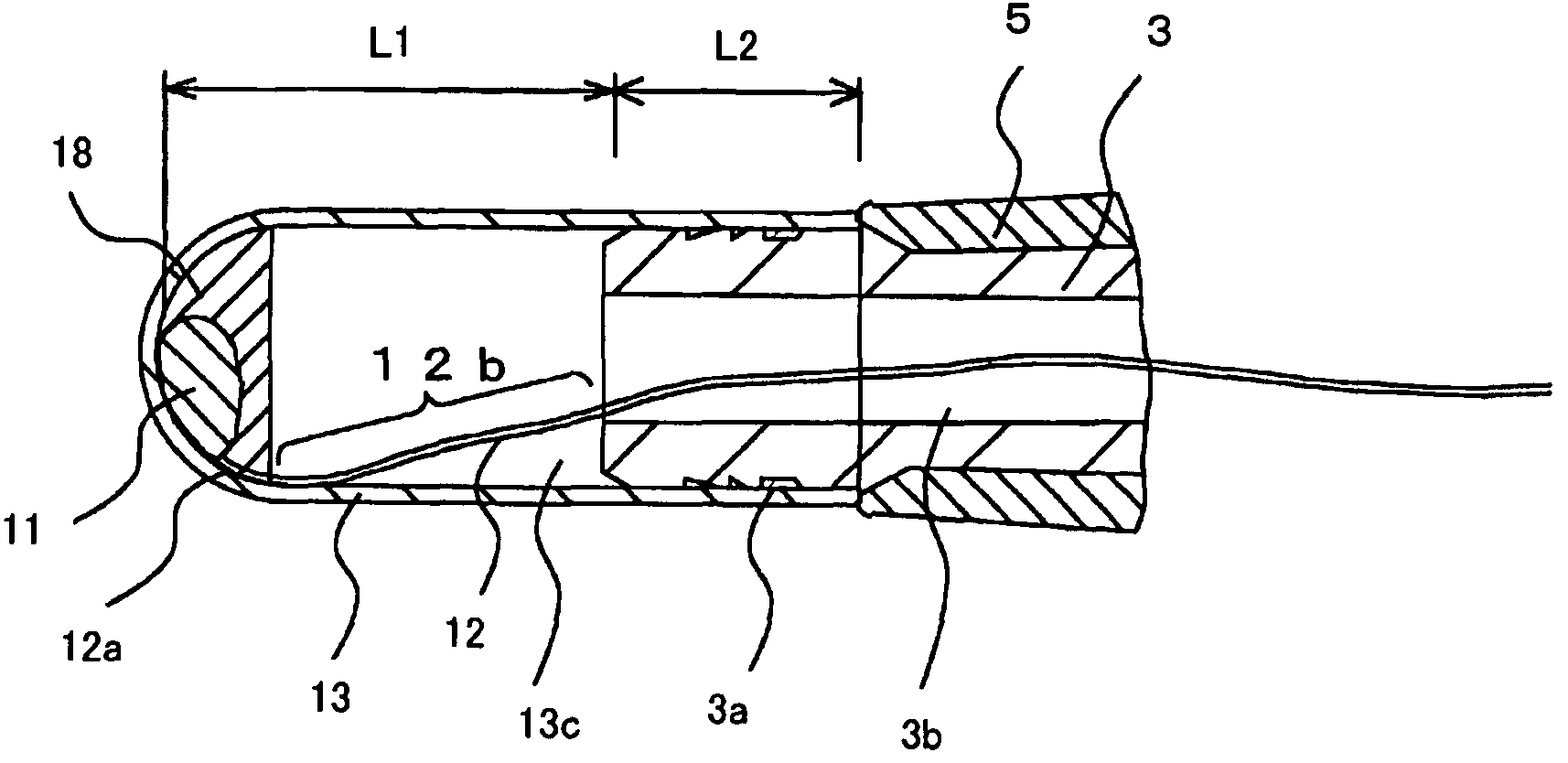

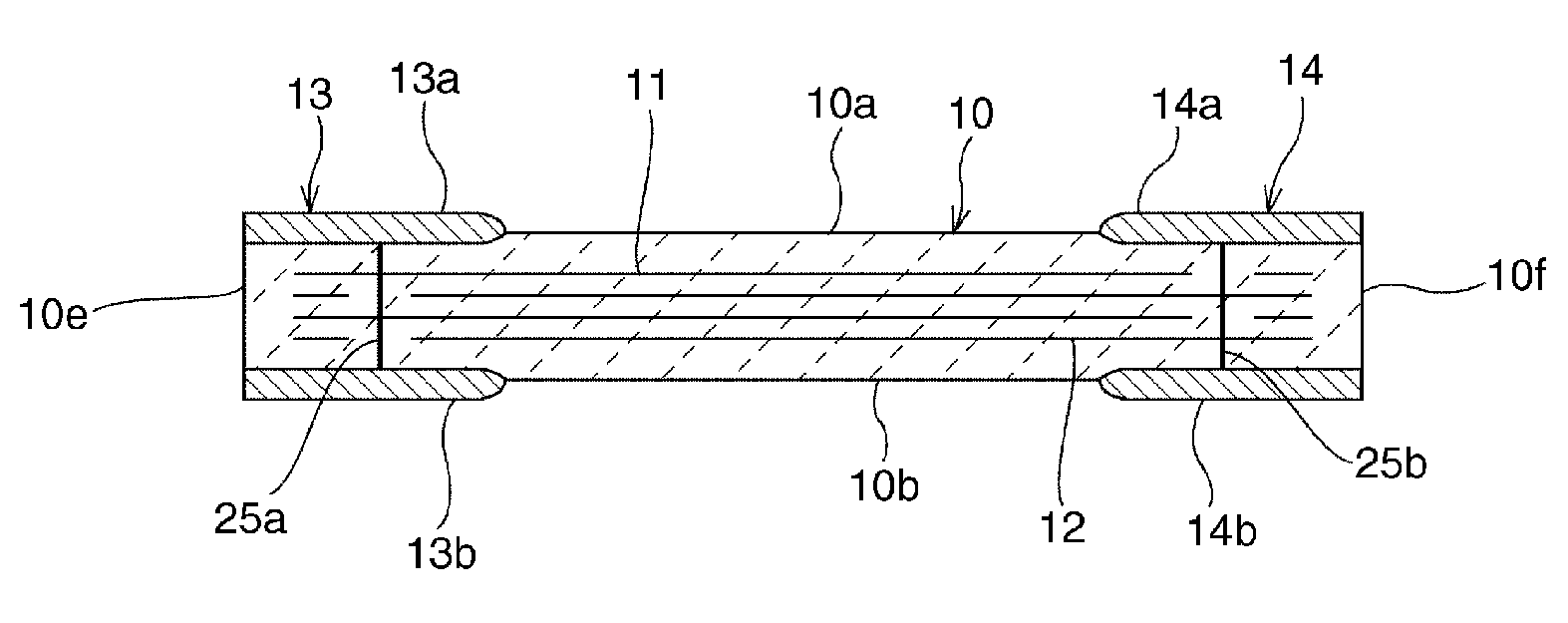

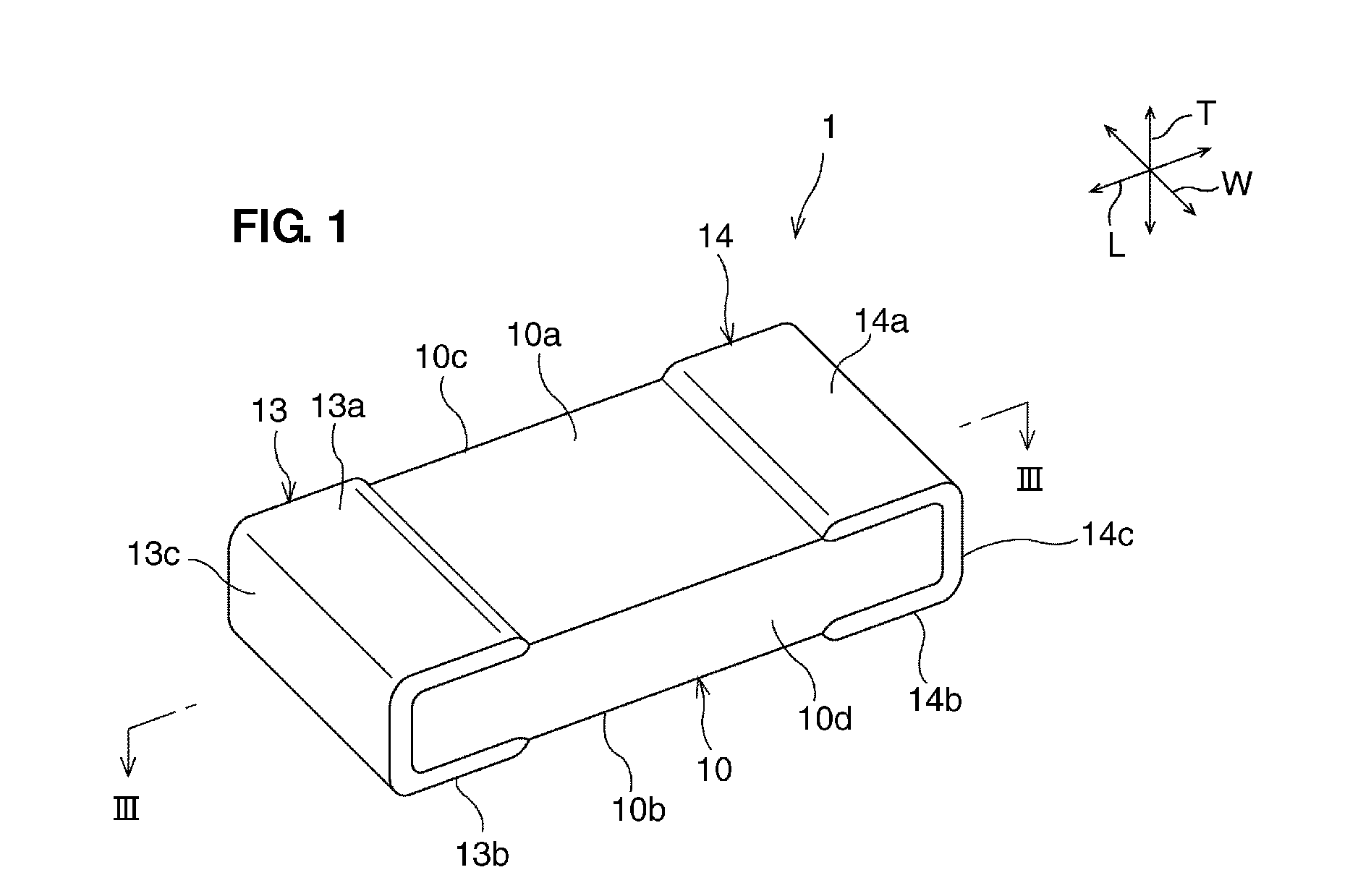

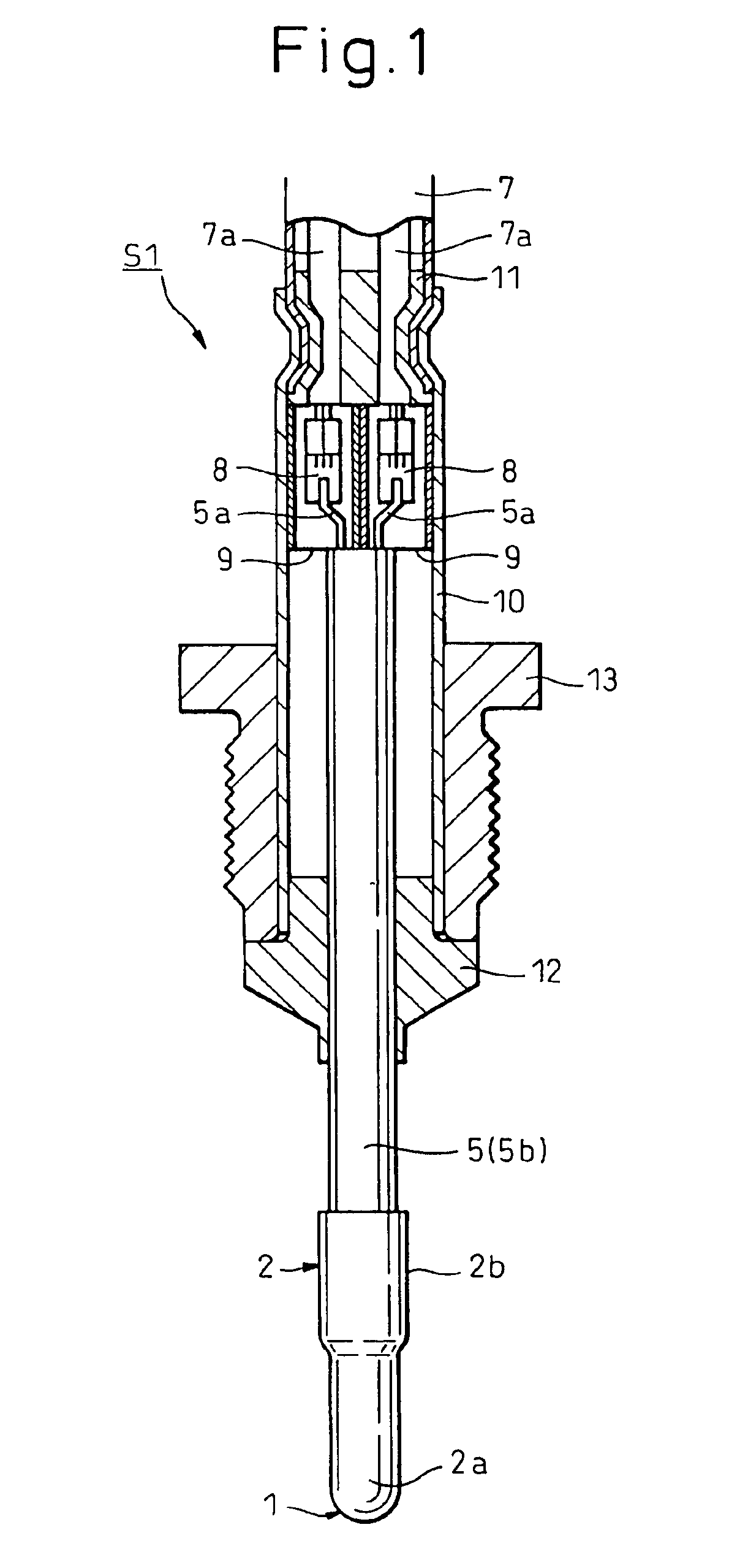

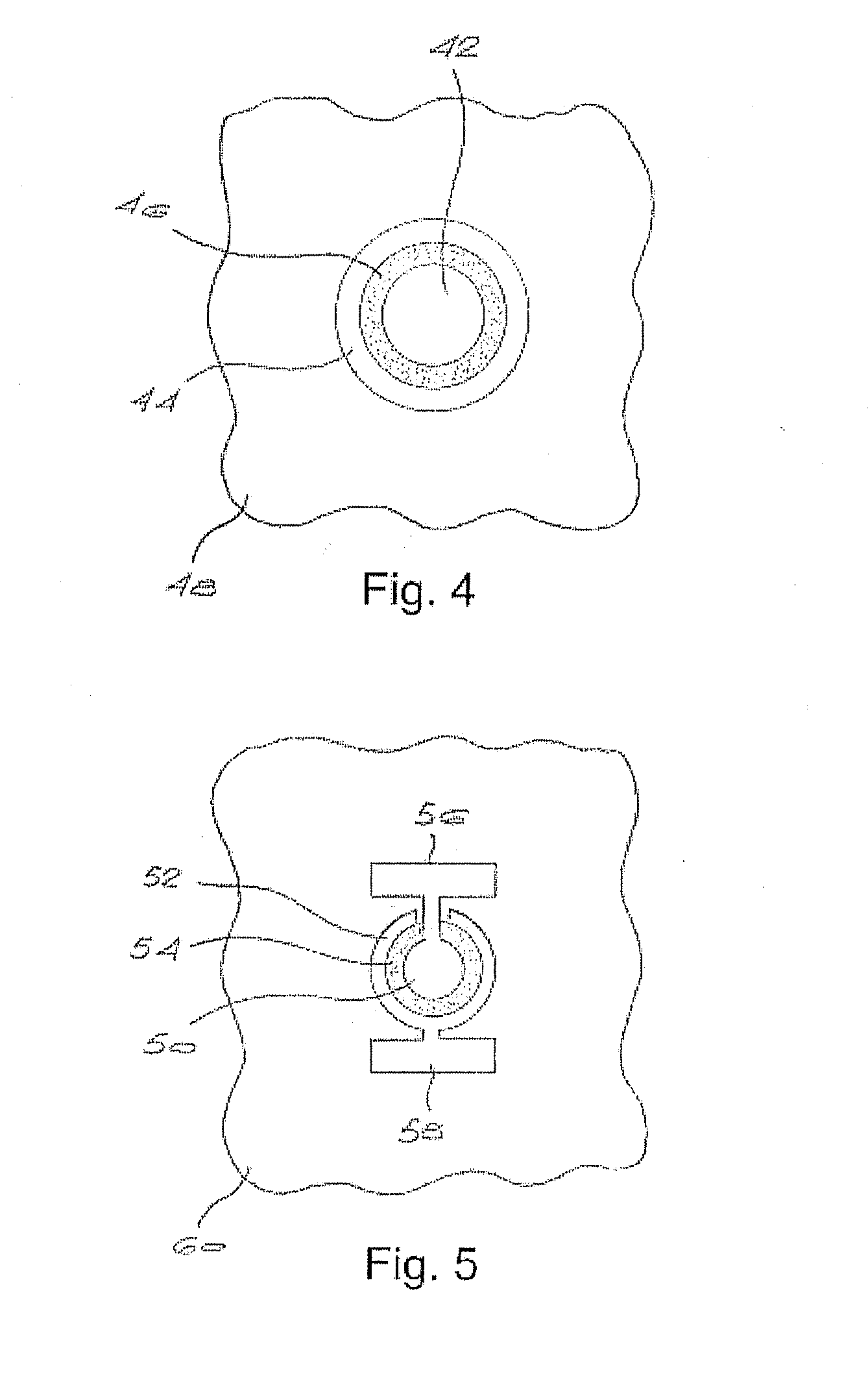

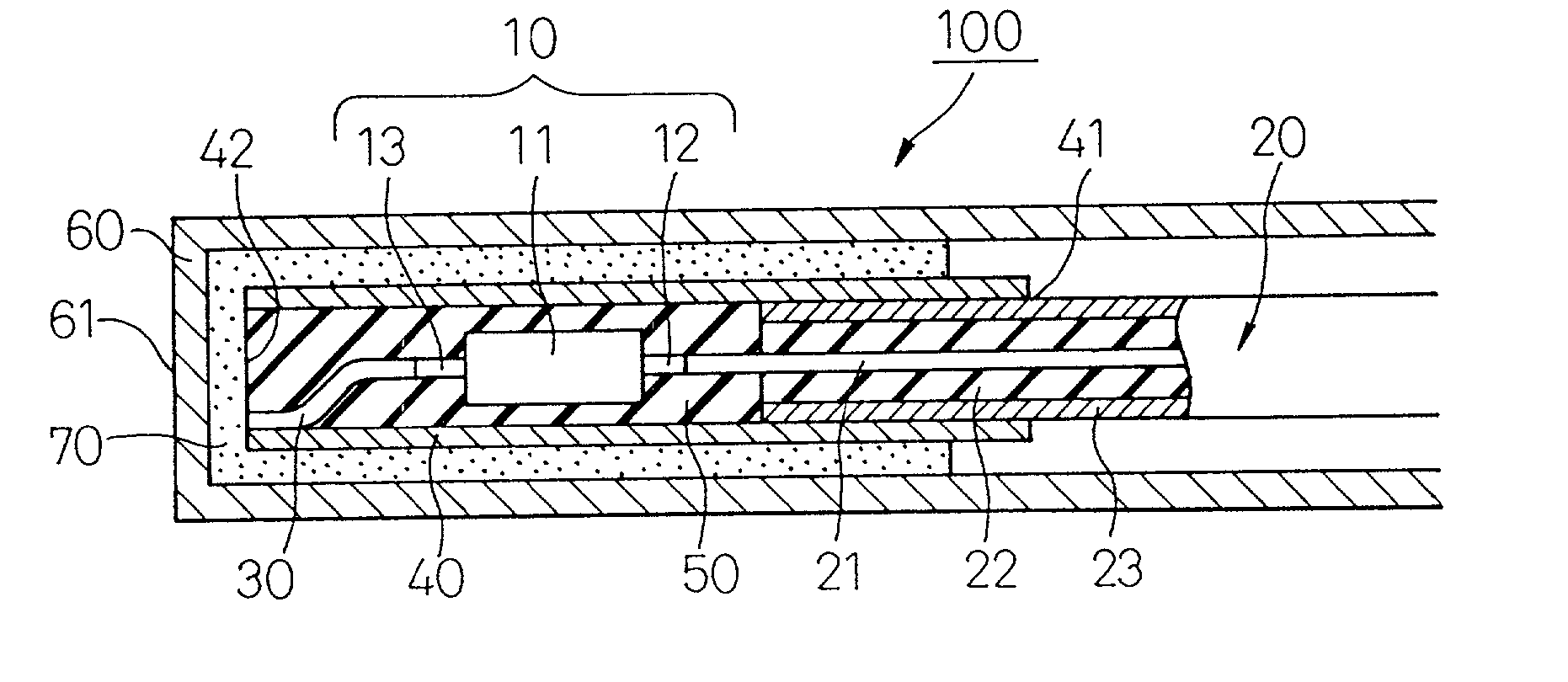

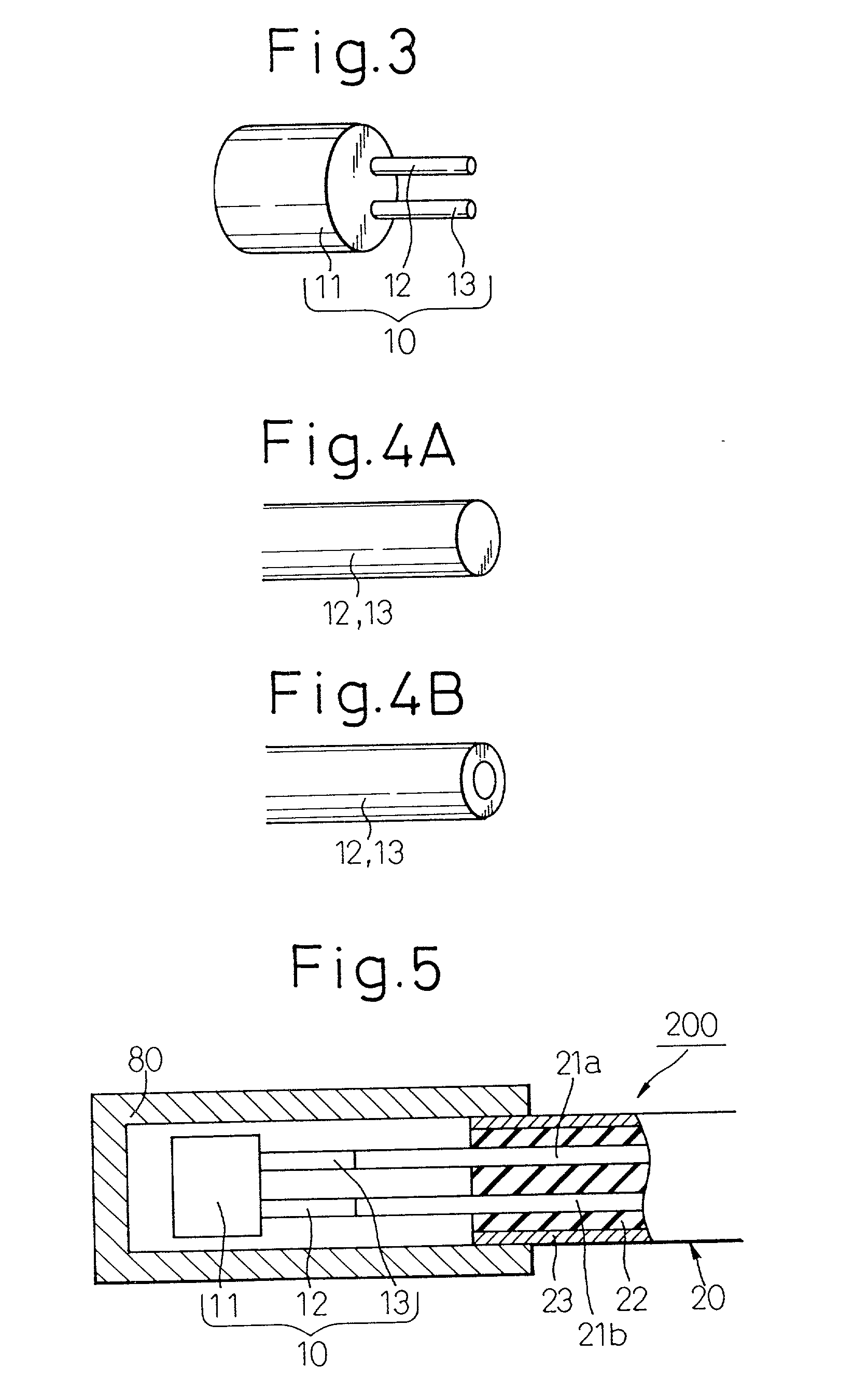

Thermostor-type temperature sensor

InactiveUS20020084884A1Improve usabilityAvoid breakingThermometers using electric/magnetic elementsNegative temperature coefficient thermistorsAdhesiveEngineering

The present invention provides a thermistor-type temperature sensor equipped with a thermistor element having a thermistor section and electrode wires for acquiring thermistor signals that prevent breakage of electrode wires caused by high-frequency vibrations. Thermistor element (10) is equipped with thermistor section (11) and electrode wires (12) and (13) made of a dispersion-strengthened material having for its main component platinum or platinum alloy, and is insulated and held in cylindrical metal case (40) having opening (42) on one end by means of insulating powder (50). A bottomed, cylindrical metal protective tube (60) houses metal case (40) so that its bottom (61) covers opening (42). Heat-resistant adhesive (70) is juxtaposed in a gap between metal case (40) and protective tube (60) so as to seal opening (42) to prevent insulting powder (50) from spilling into this gap from opening (42).

Owner:DENSO CORP

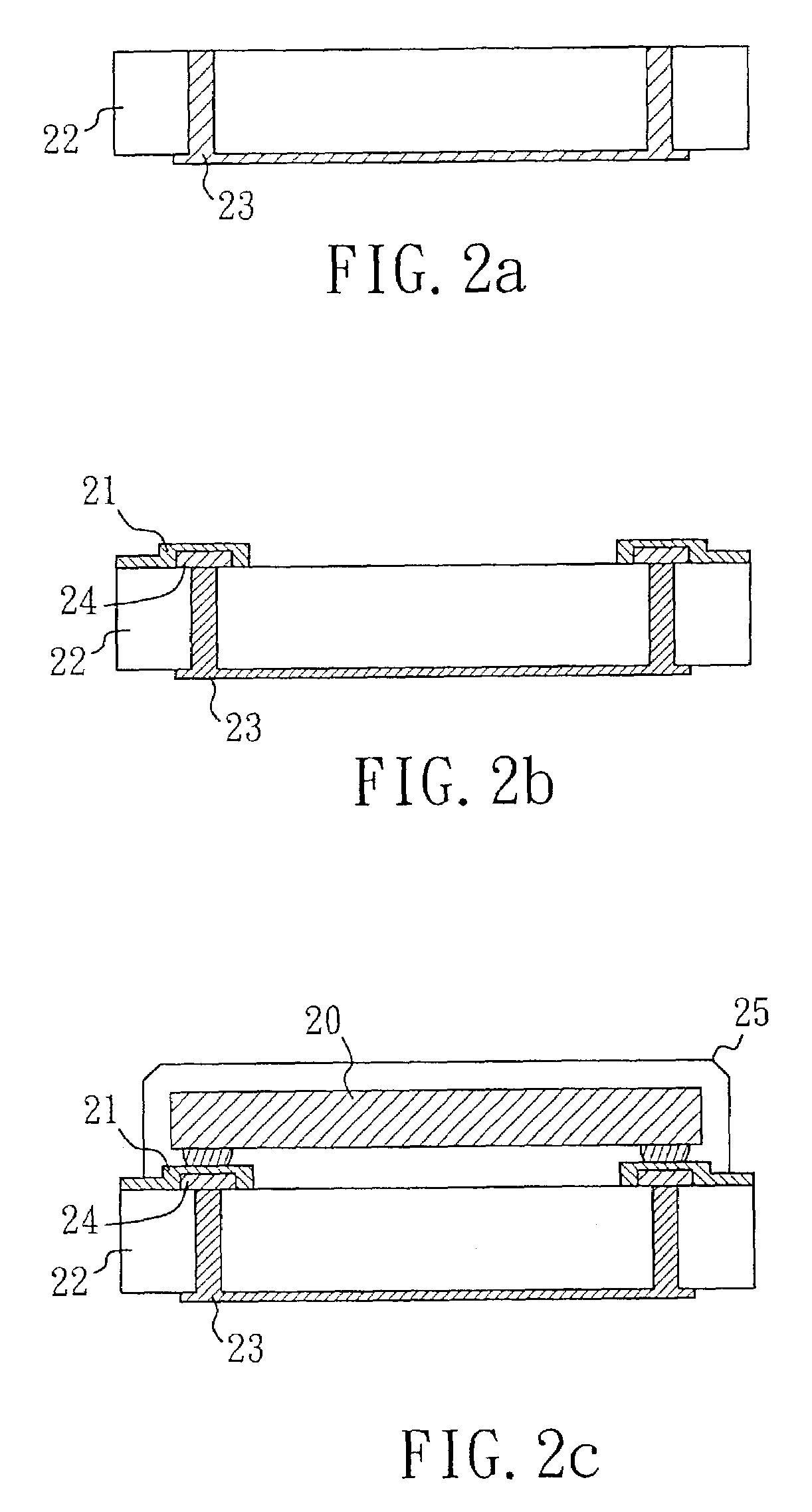

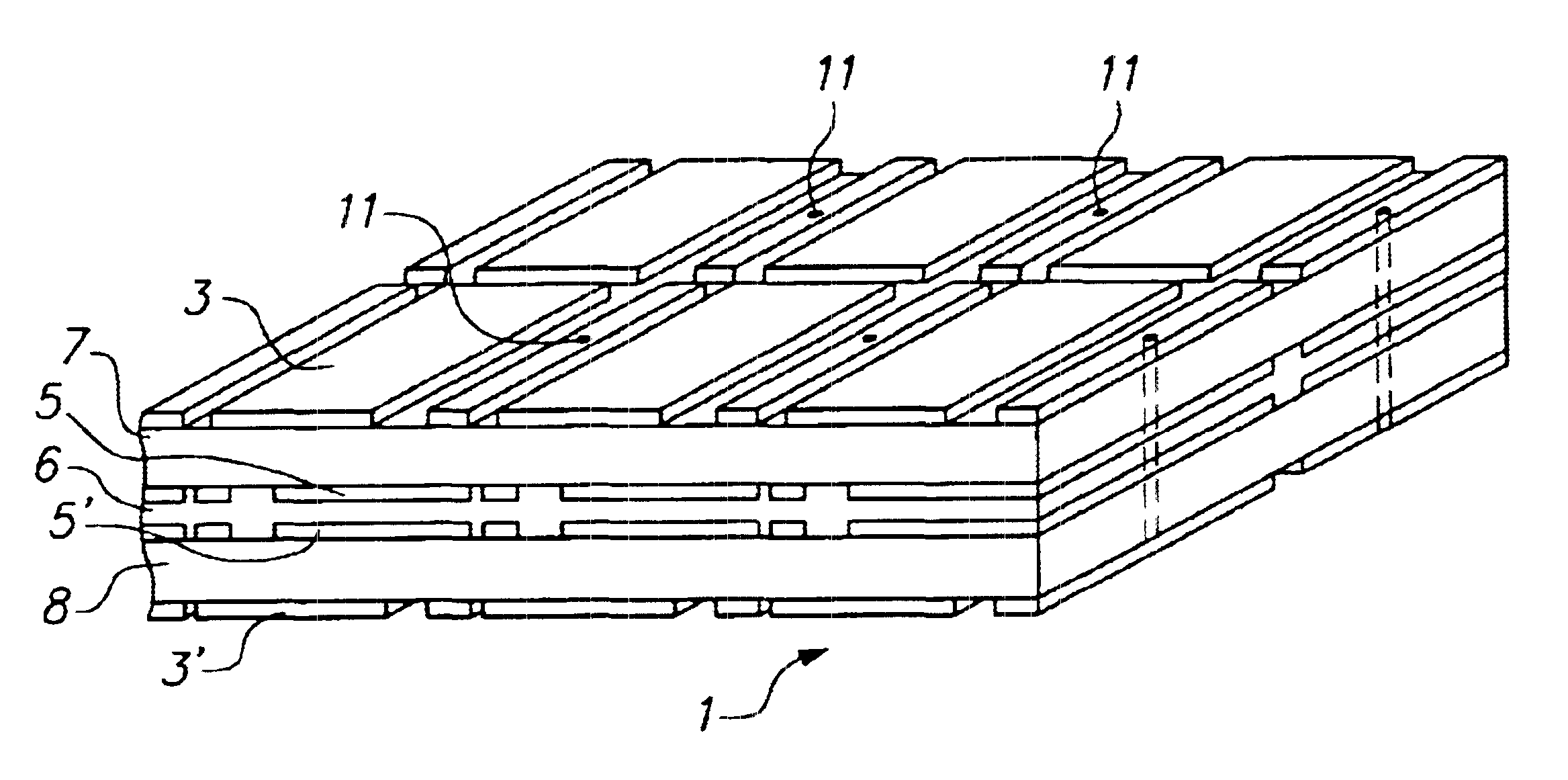

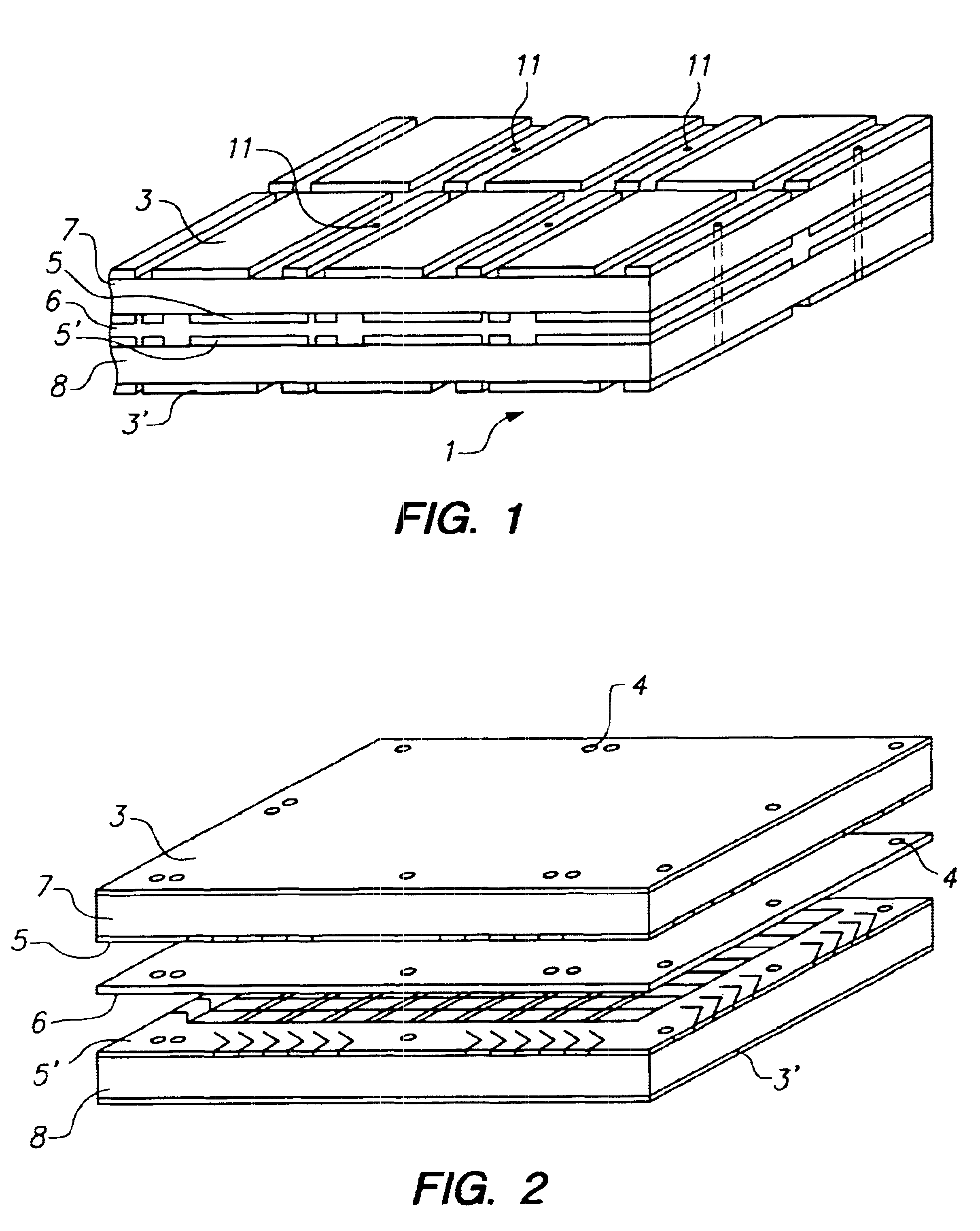

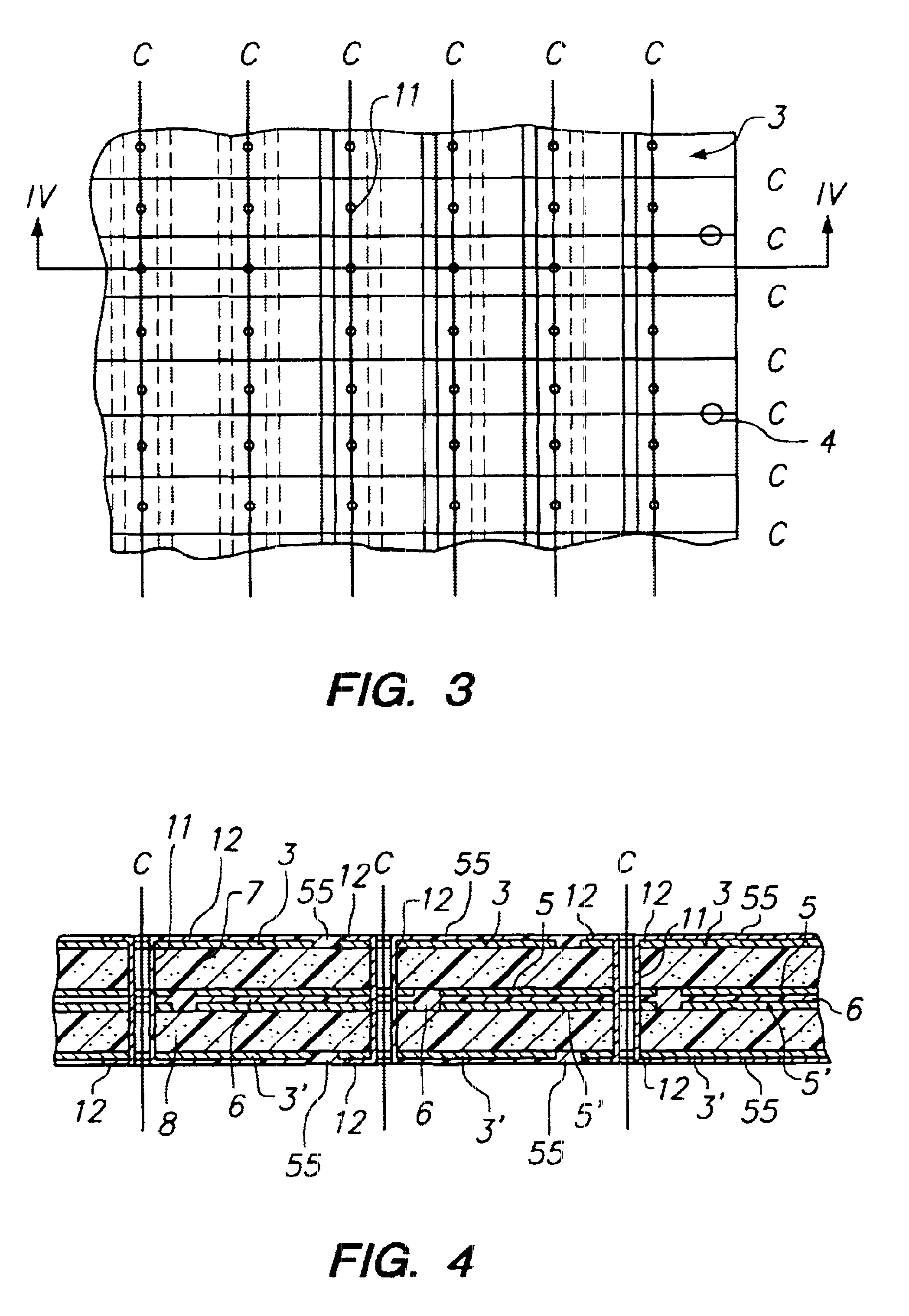

Process for manufacturing a composite polymeric circuit protection device

InactiveUS6640420B1Easy to buildInexpensively mass-producedResistor chip manufactureResistor terminals/electrodesConductive polymerElectrical and Electronics engineering

A process for manufacturing a composite polymeric circuit protection device in which a polymeric assembly is provided and is then subdivided into individual devices. The assembly is made by providing first and second laminates, each of which includes a laminar polymer element having at least one conductive surface, providing a pattern on at least one of the conductive surfaces on one laminate, securing the laminates in a stack in a desired configuration, at least one conductive surface of at least one of the laminates forming an external conductive surface of the stack, and making a plurality of electrical connections between a conductive surface of the first laminate and a conductive surface of the second laminate. The laminar polymer elements may be PTC conductive polymer compositions, so that the individual devices made by the process exhibit PTC behavior.

Owner:LITTELFUSE INC

Method for fabricating negative temperature coefficient thermistor

ActiveUS20090165289A1Easy to adjustEasy to obtainNegative temperature coefficient thermistorsPositive temperature coefficient thermistorsElectrical resistance and conductanceNegative temperature

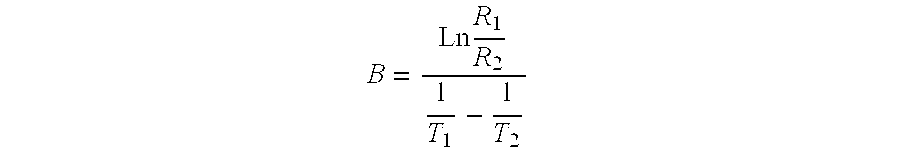

A method for fabricating a negative temperature coefficient thermistor is provided, including the steps of: (A) combining ceramic powders having a negative temperature coefficient of resistance, a polymer binder and a solvent to form a mixture; (B) removing the solvent and granulating the mixture to form granulous powders; (C) compressing the granulous powders to obtain a thermistor material with a specific shape; (D) curing the thermistor material at 80° C. to 350° C.; and (E) mounting an electrode to the thermistor material to form the negative temperature coefficient thermistor. The method can be performed in a low temperature without the problem of interface diffusion. Further, the desired resistance value and thermistor constant (B) can be easily adjusted and obtained by mixing ceramic powders with different characteristics of temperature coefficient of resistance and / or the addition of conductive metal powder.

Owner:IND TECH RES INST

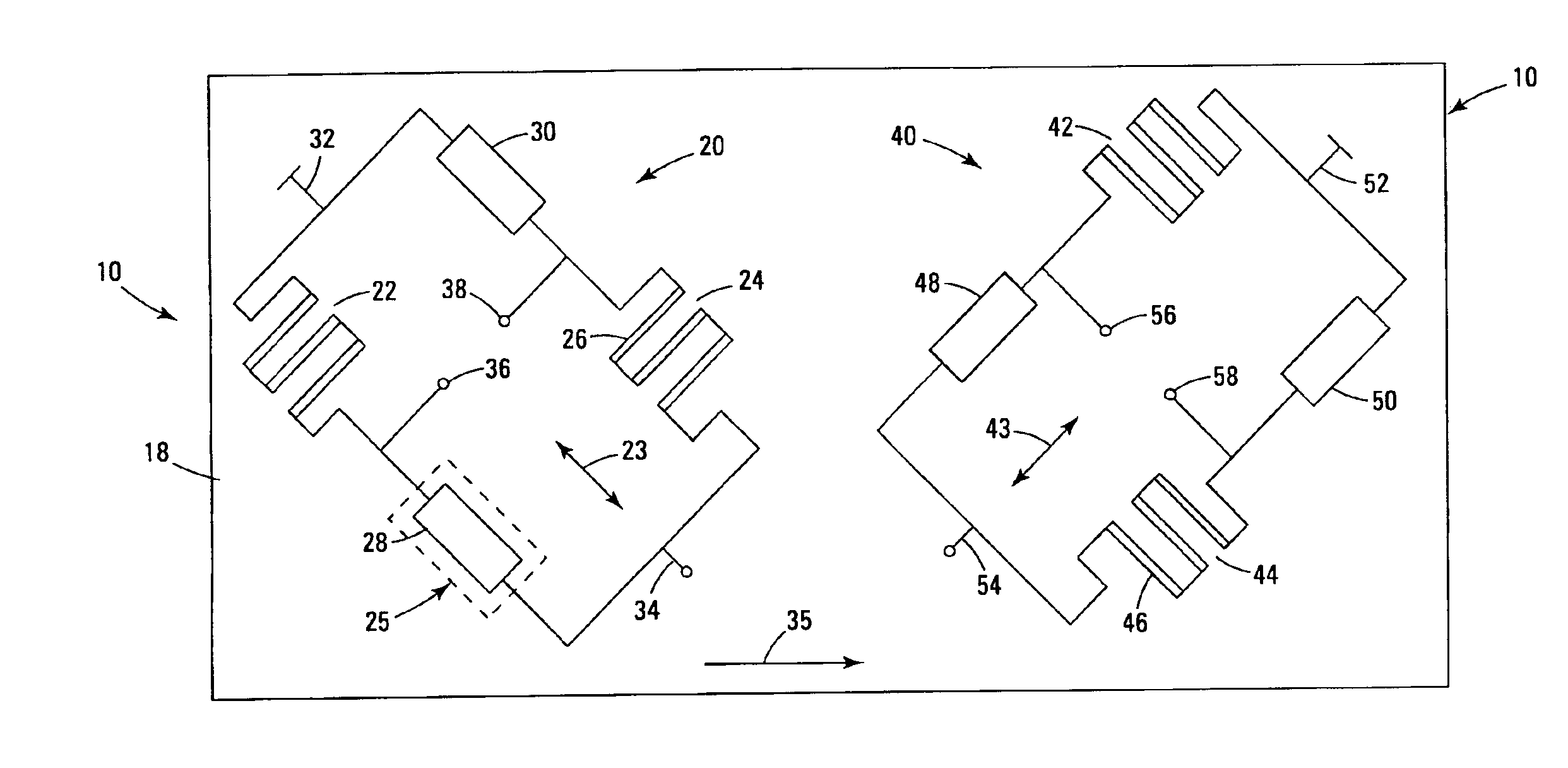

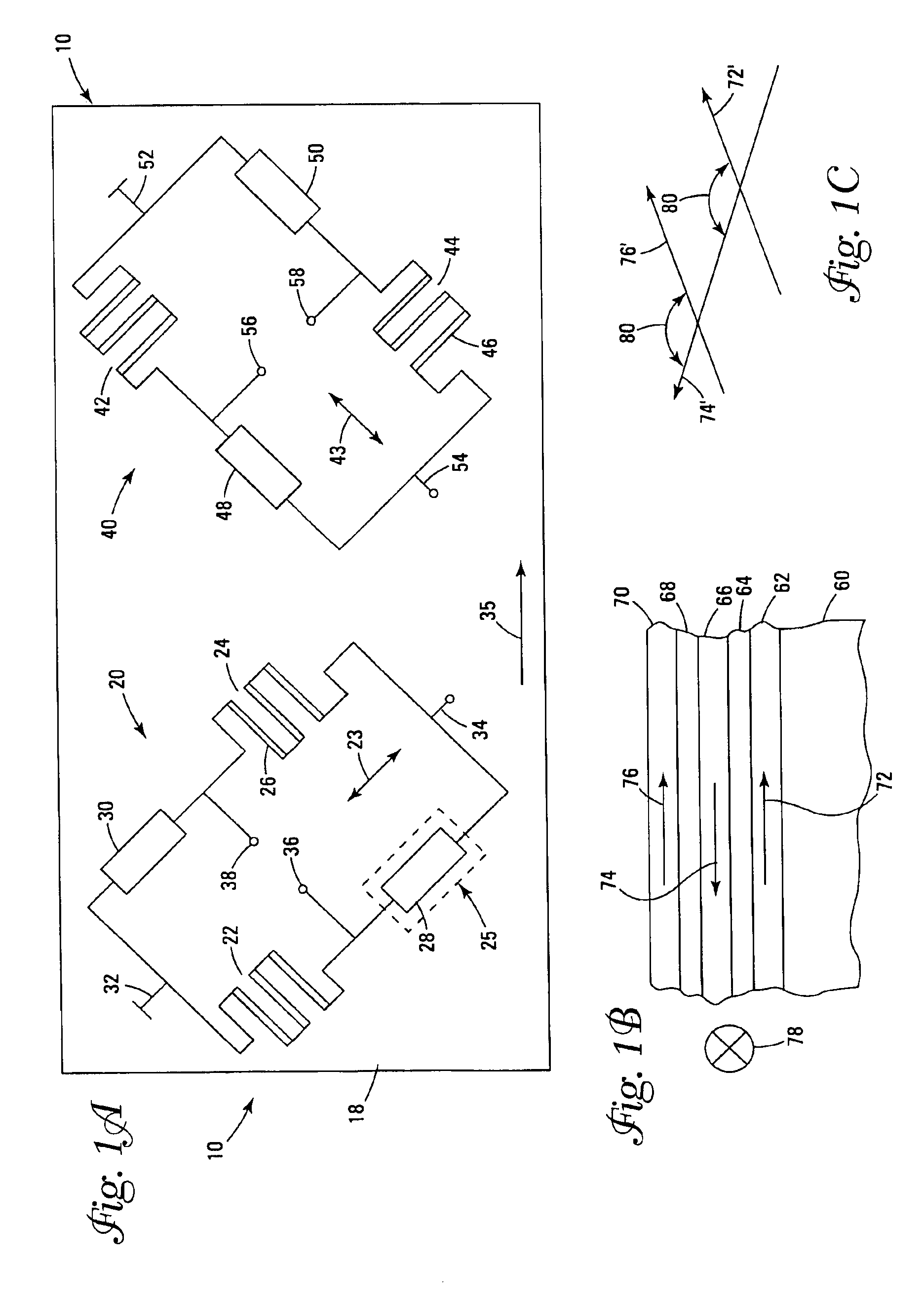

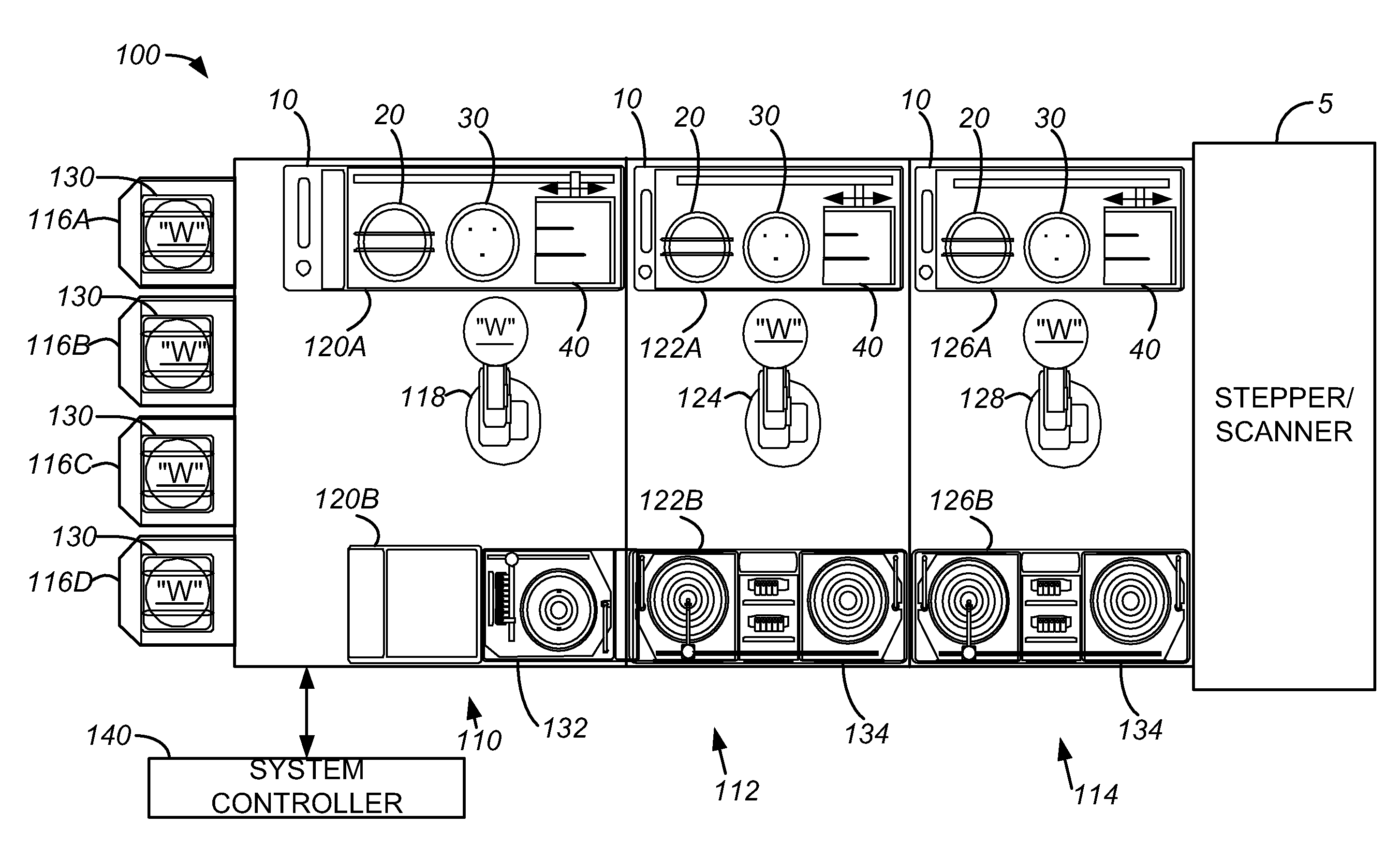

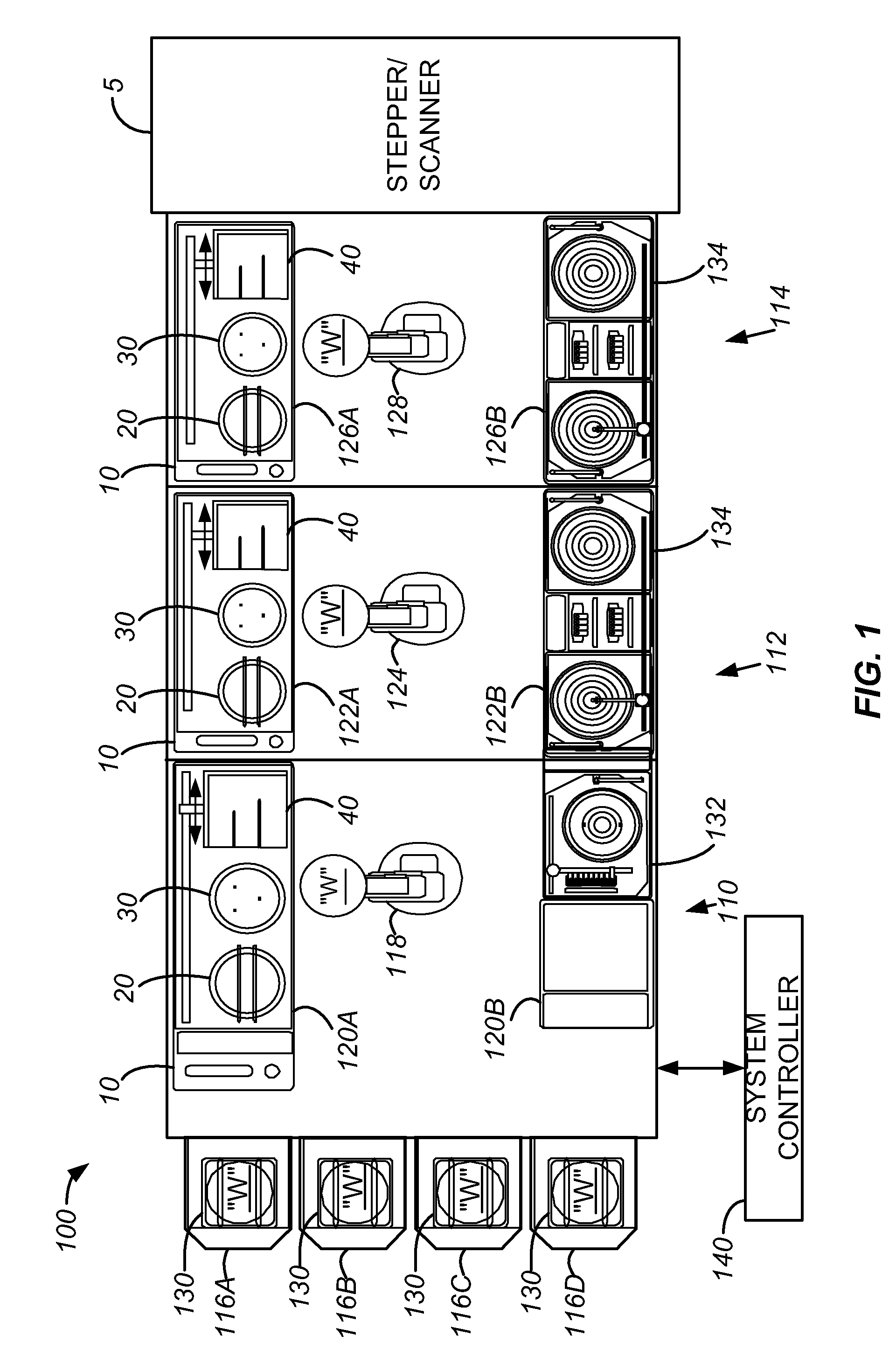

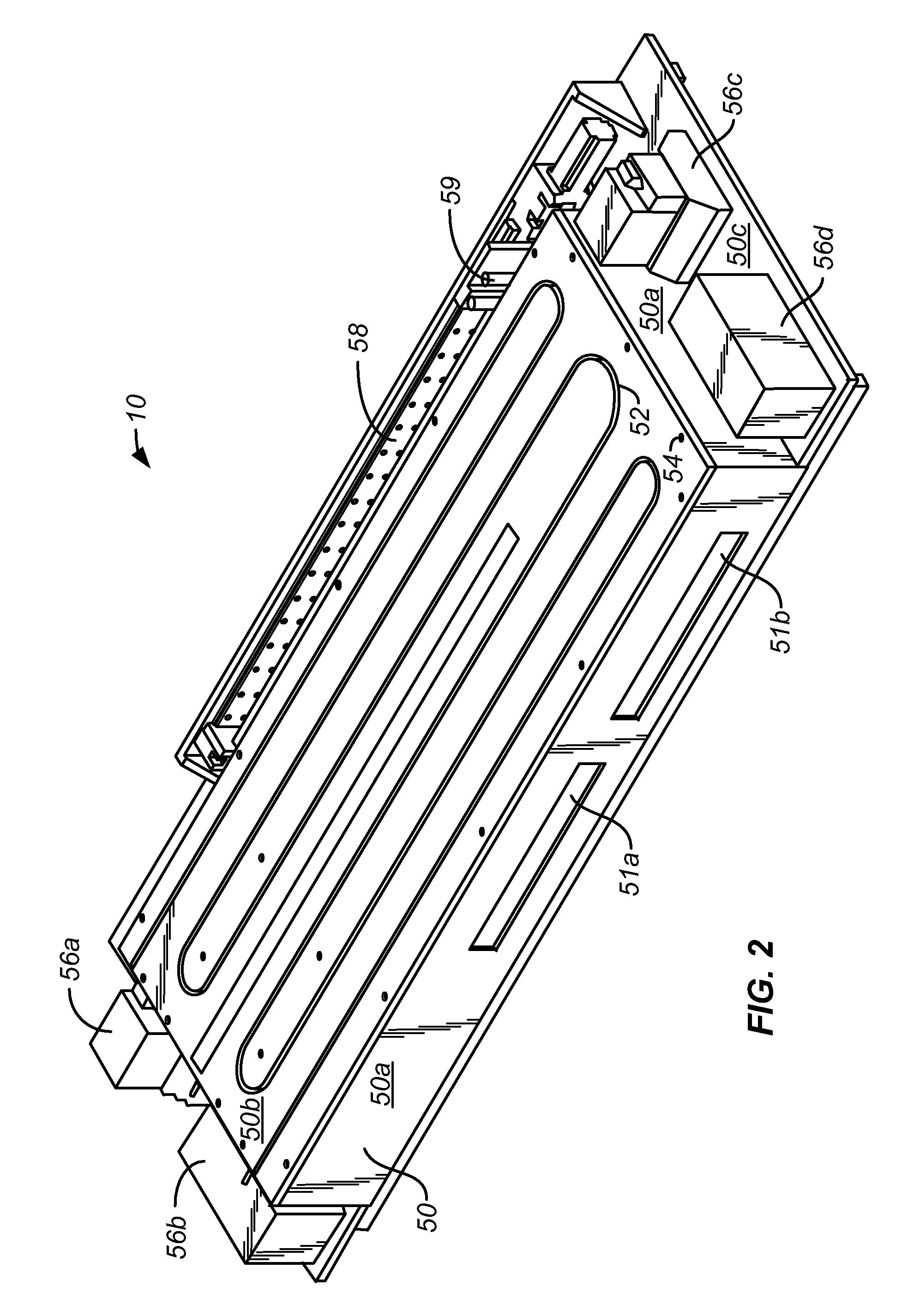

Interlaced rtd sensor for zone/average temperature sensing

InactiveUS20080224817A1Improve reliabilityGood repeatabilityThermometer detailsSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A device for heating a semiconductor wafer comprises a heating element arranged to conduct heat toward the wafer. The heating element can extend along a heating element path. An RTD sensor loop can extend along an RTD sensor path. The RTD sensor path can be positioned along the heating element path to measure a temperature that corresponds to the heating element. The RTD sensor loop can measure an average temperature along the heating element. Portions of the RTD sensor can be interlaced between portions of the heating element. The heating element path can be arranged with interstices between portions of the heating element path, and portions of the RTD sensor path can be positioned within the interstices to interlace the RTD sensor loop with the heating element. The RTD sensor loop can comprise a soft metal that is resistant to oxidation and extends along the RTD sensor path.

Owner:SOKUDO CO LTD

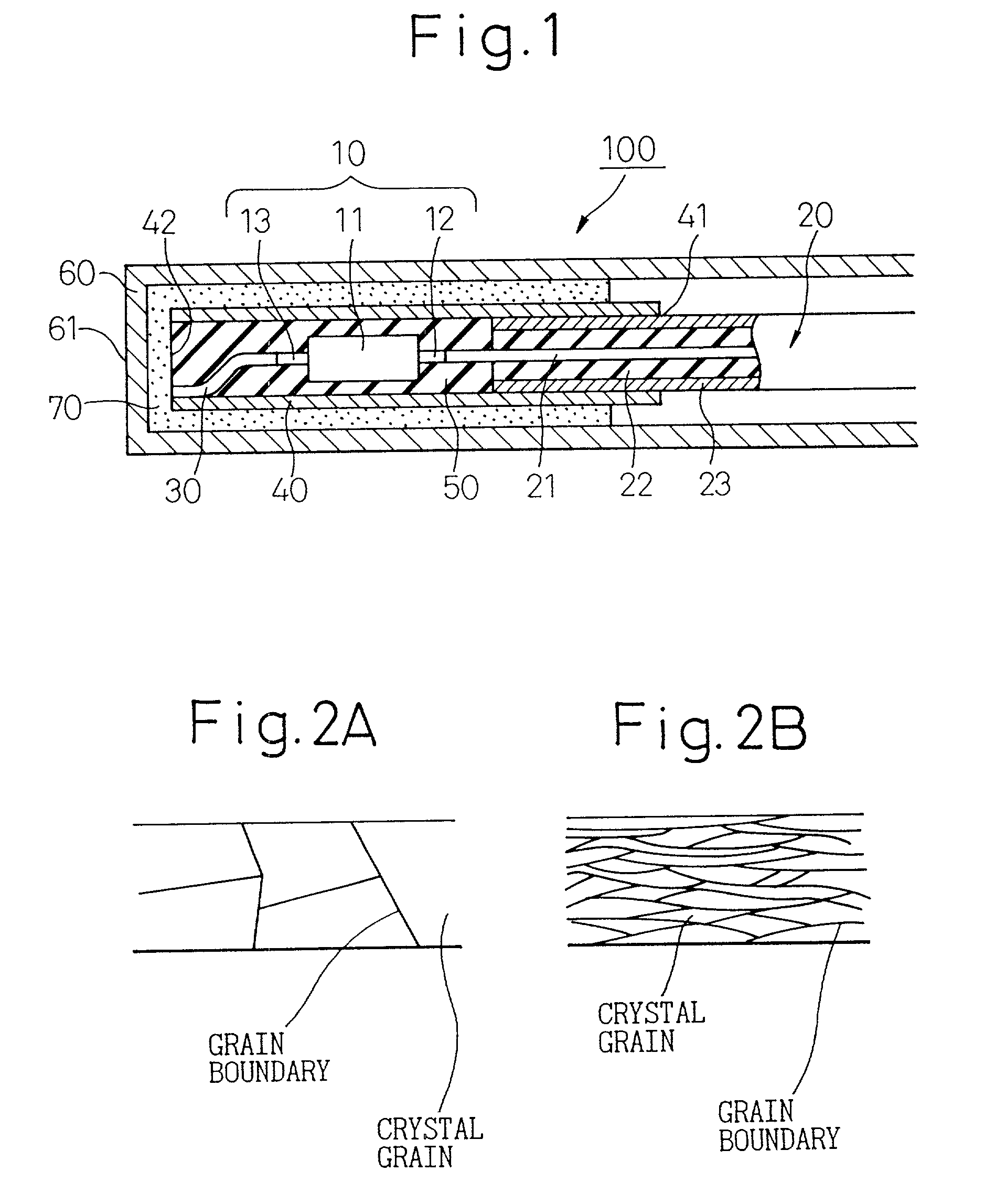

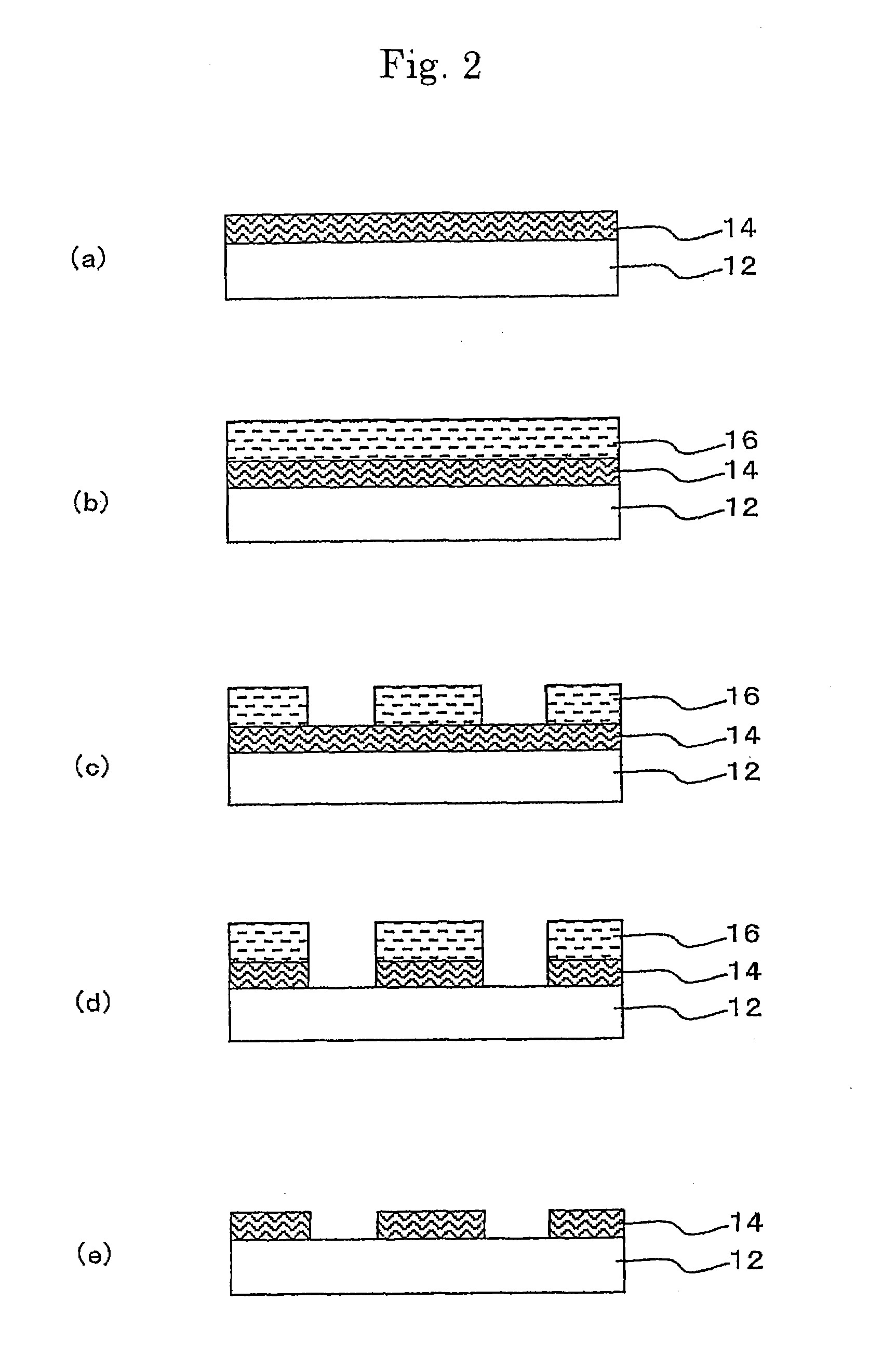

Resistance element, method of manufacturing the same, and thermistor

InactiveUS7217374B2Good duplicability and stabilityEasy and stable coatingMaterial nanotechnologyCurrent responsive resistorsCross-linkCarbon nanotube

To provide a resistance element having an electric resistance body with excellent stability and a method of manufacturing the same. The resistance element includes an electric resistance body, on a base body surface, consisting of a carbon nanotube structure layer 14, which configures a mesh structure in which at least plural carbon nanotubes are cross-linked to one another. The method of manufacturing the resistance element includes: an applying step of applying the base body surface 12 with a liquid solution containing carbon nanotubes having functional groups; and a cross-linking step of forming the carbon nanotube structure layer 14, used as an electric resistance body, that configures a mesh structure in which the plural carbon nanotubes are cross-linked to one another through curing of the liquid solution after application.

Owner:FUJIFILM BUSINESS INNOVATION CORP

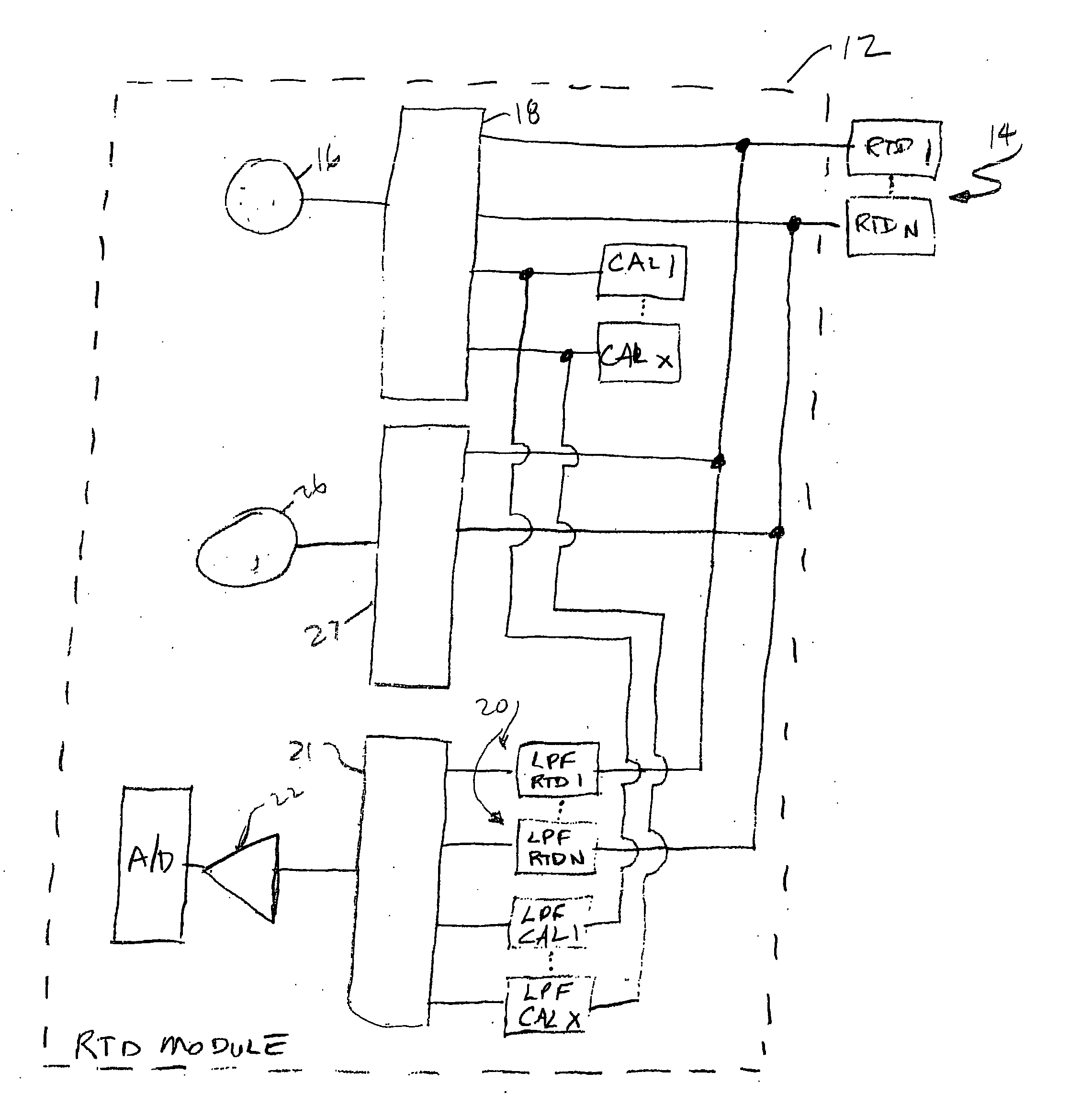

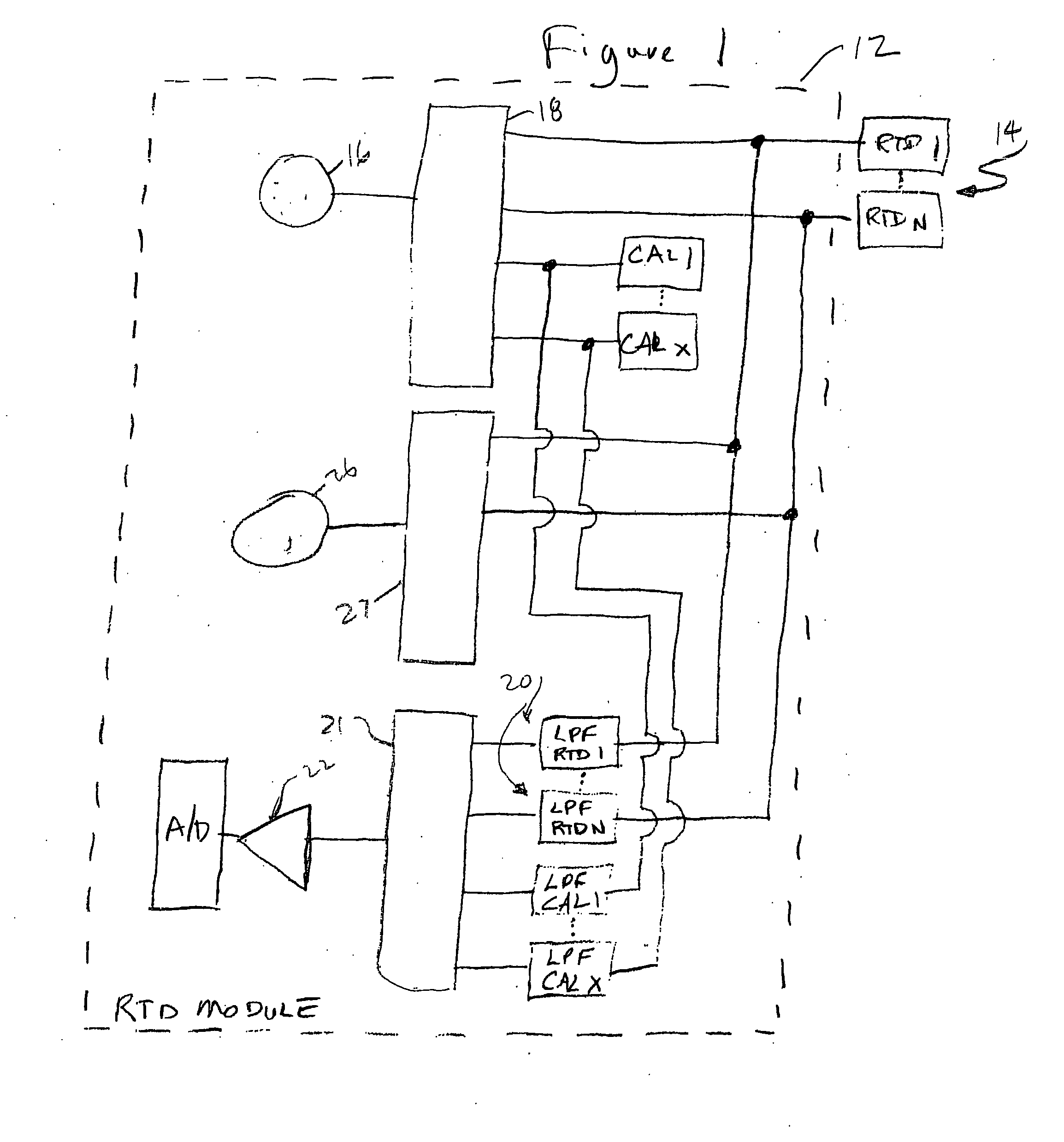

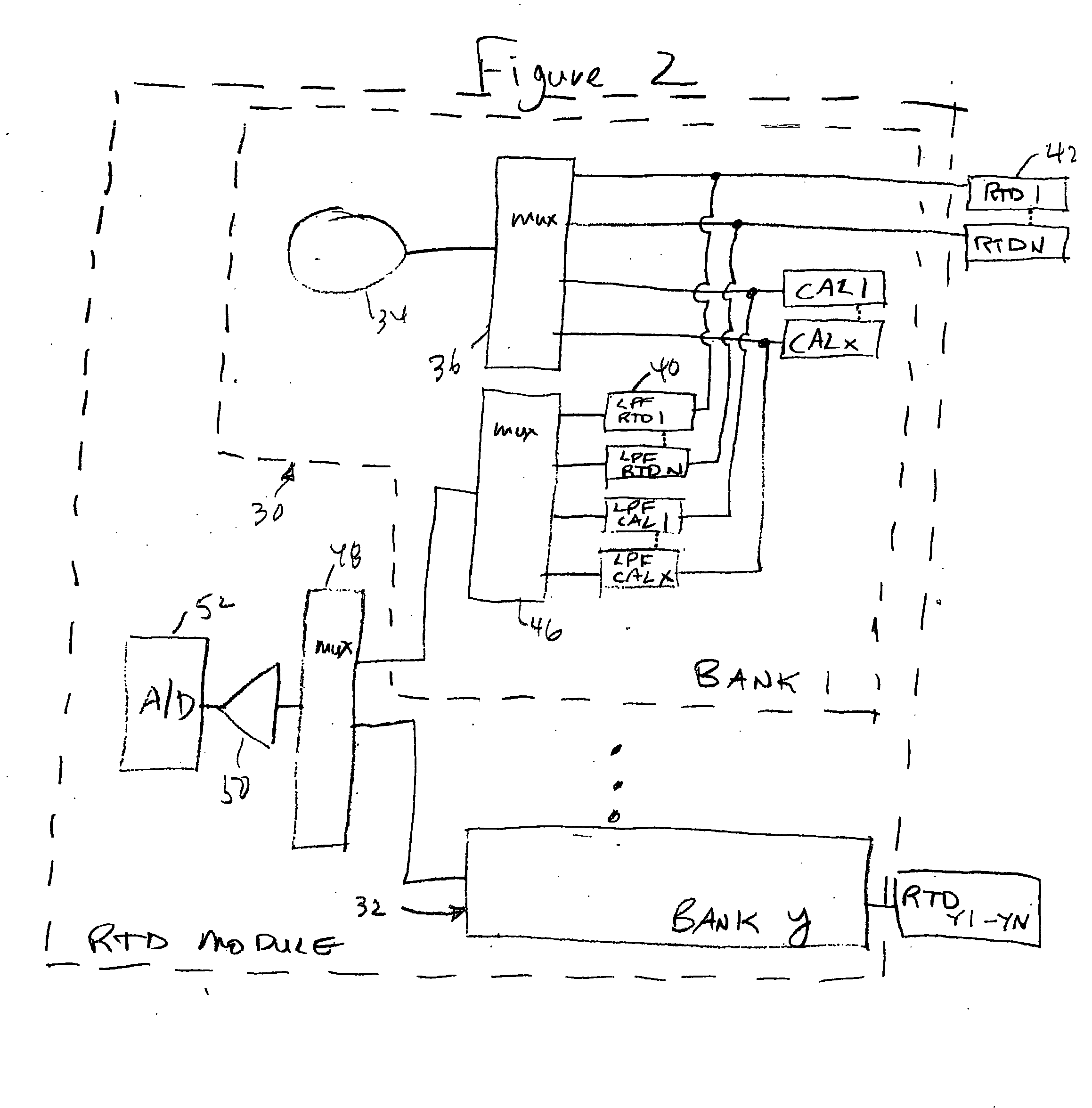

Resistive temperature device (RTD) module with improved noise immunity

ActiveUS20050052274A1Improve noise immunityReduce delaysThermometer detailsCurrent interference reductionElectrical resistance and conductanceMultiplexer

An RTD system includes multiple pluralities of RTDs and RTD bank assembly to which each plurality of RTDs are connected. Each RTD bank assembly includes a current source for the RTDs connected thereto, a multiplexer switching system for switching the current source successively between the RTDs, and a measurement function for measuring the voltage drop across the RTDs produced by the current source. The system includes a circuit for determining resistance of the RTD from the current applied thereto and the voltage drop there across. The system further includes a plurality of low pass filters associated, respectively, with each RTD, wherein the low pass filters are charged before the voltage measurement is made. The system includes a precharging arrangement where the low pass filter associated with the next RTD in a voltage sampling sequence is precharged, so that the delay between sampling of the voltage from the low pass filters associated with successive RTDs is significantly reduced. The system further includes low pass filters associated with calibration resistors which permit sampling of voltage values from the RTDs prior to the low pass filters associated therewith being fully charged, without error which would otherwise occur.

Owner:SCHWEITZER ENGINEERING LABORATORIES

Passive SAW-based hydrogen sensor and system

ActiveUS20070052516A1Small spacingFilm conductivity goes up dramaticallyAnalysing fluids using sonic/ultrasonic/infrasonic wavesMaterial nanotechnologyHydrogen concentrationSelf-assembled monolayer

A hydrogen detecting system is characterized by a passive surface acoustic wave (SAW) sensor. The sensor includes a piezoelectric substrate having a self assembled monolayer arranged on at least a portion of the substrate to create a hydrophobic surface. A palladium nanocluster thin film is deposited on the monolayer and an interdigital SAW transducer is disposed upon the piezoelectric substrate for conversion of an RF signal into an acoustic wave and vice versa. At least one additional SAW element is also disposed on the substrate and spaced from the SAW transducer. The SAW element receives a signal from the SAW transducer and produces a response signal. The response signal is modified by the palladium nanocluster film due to a change in conductivity of the palladium nanocluster film upon exposure to hydrogen. This change in the response signal is measured by an interrogator, and yields a measure of the hydrogen concentration to which the sensor was exposed.

Owner:SENSANNA

Popular searches

Using electrical means Body temperature measurement Magnitude/direction of magnetic fields Resistor housing/enclosing/embedding Component plug-in assemblages Resilient/clamping means Domestic articles Heating element materials Overvoltage protection resistors Cooling/ventilation/heating modifications

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com