Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

708results about "Resistor housing/enclosing/embedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

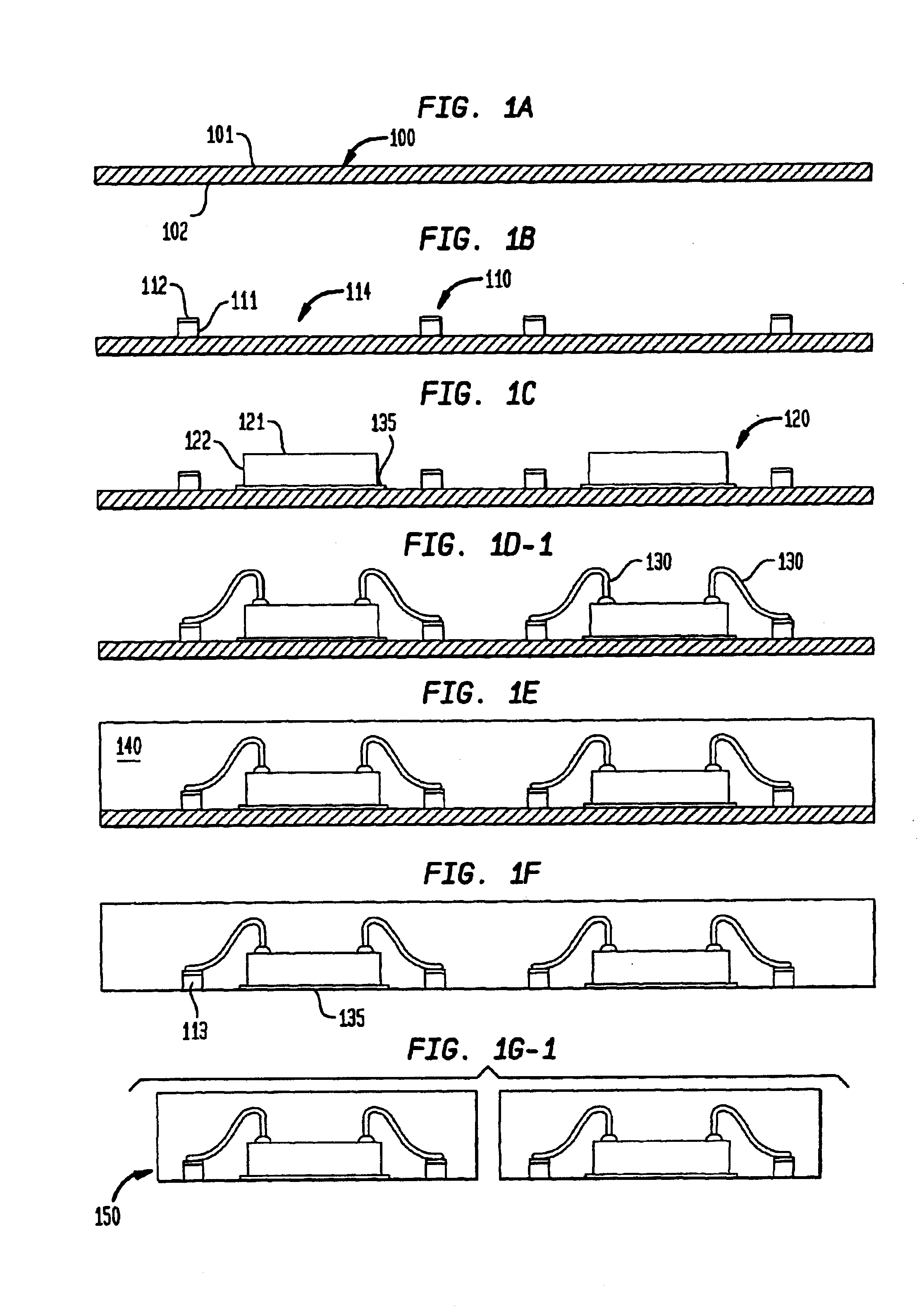

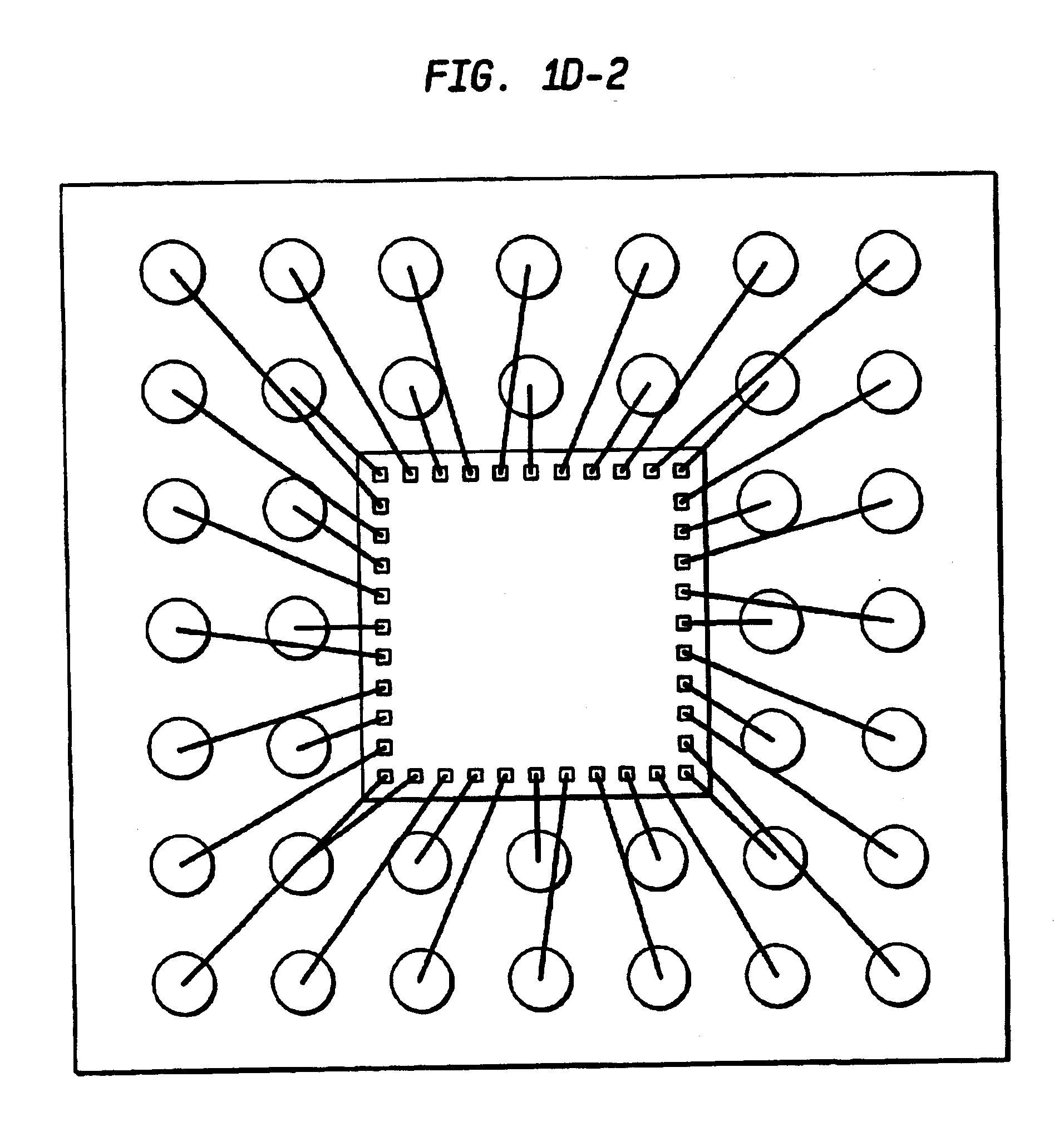

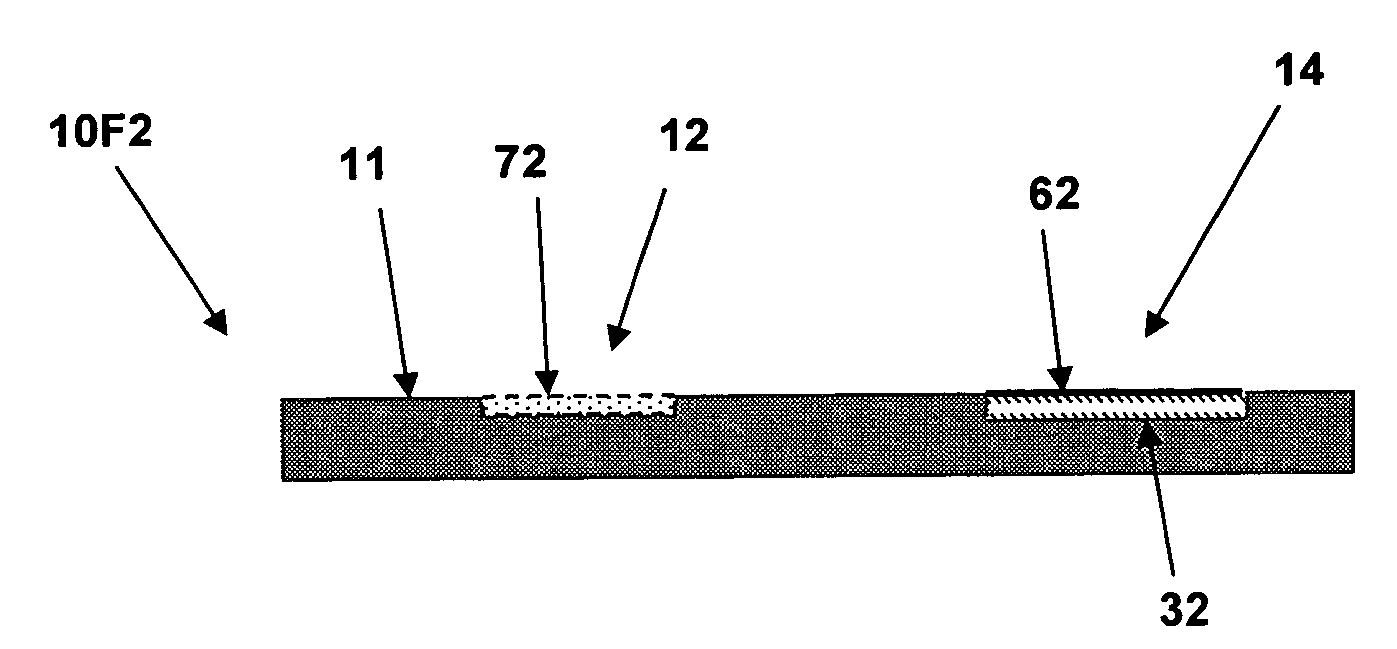

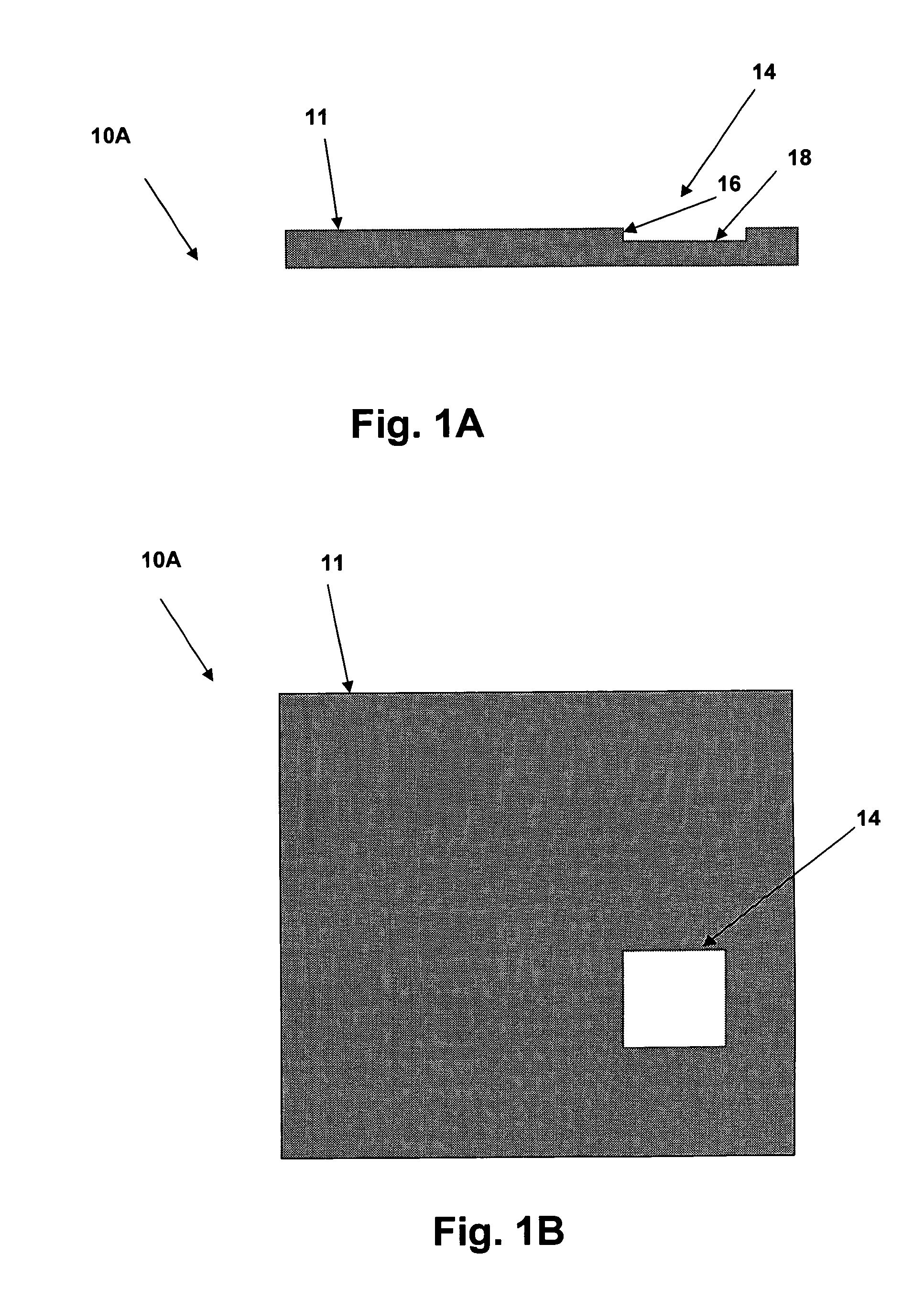

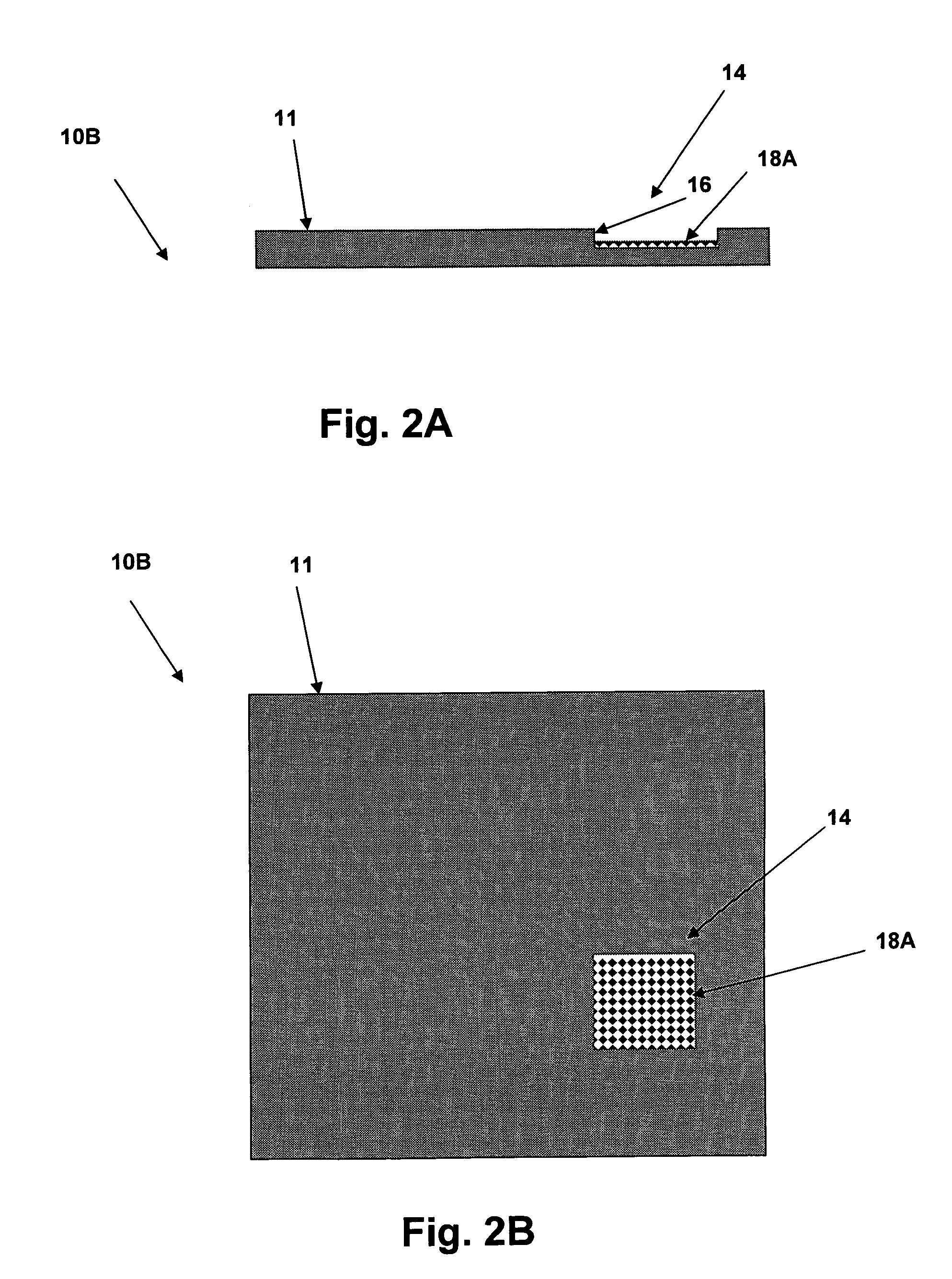

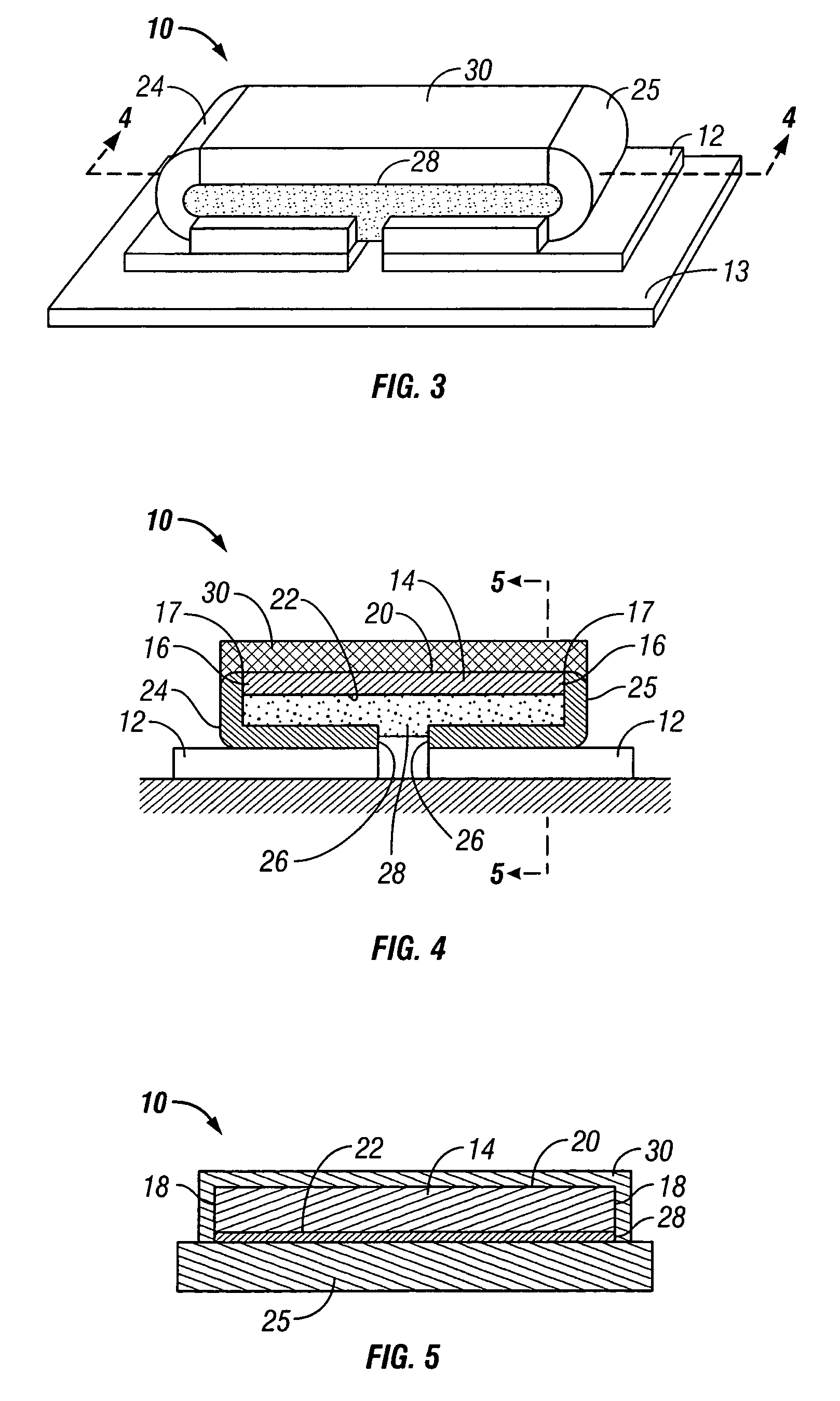

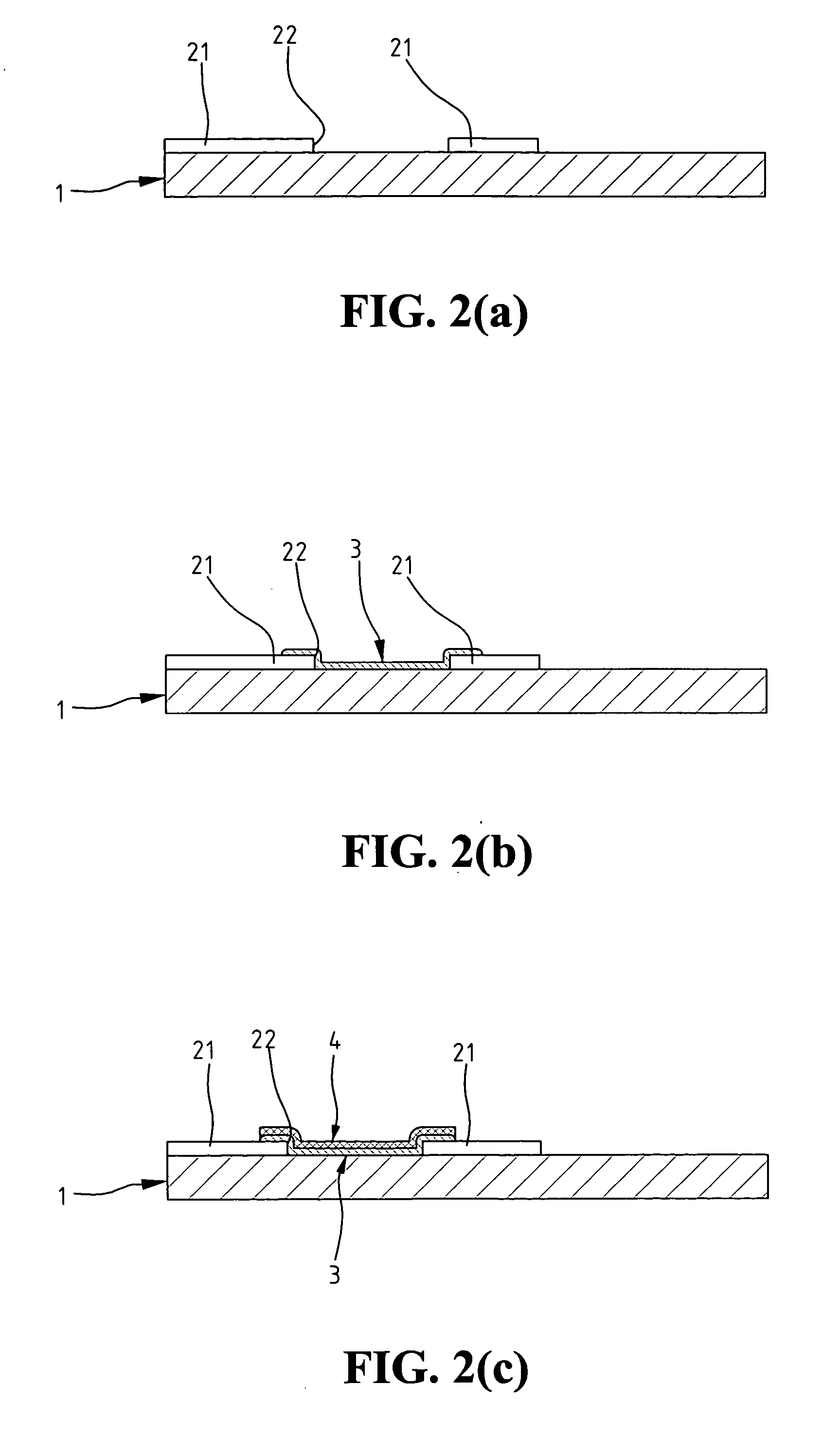

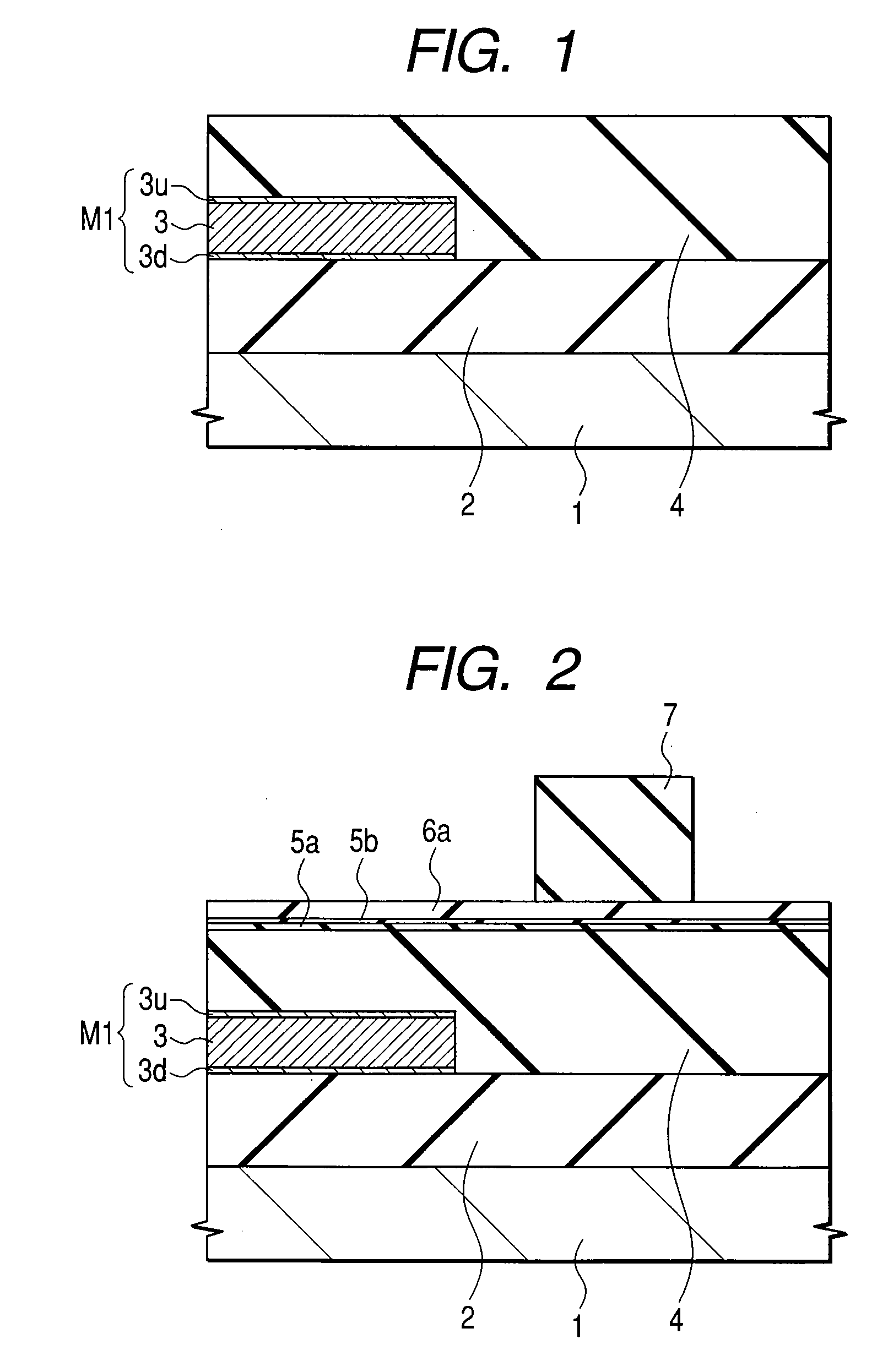

Methods for manufacturing resistors using a sacrificial layer

InactiveUS6856235B2Efficient preparationResistor terminals/electrodesSemiconductor/solid-state device detailsConductive materialsElectroplating

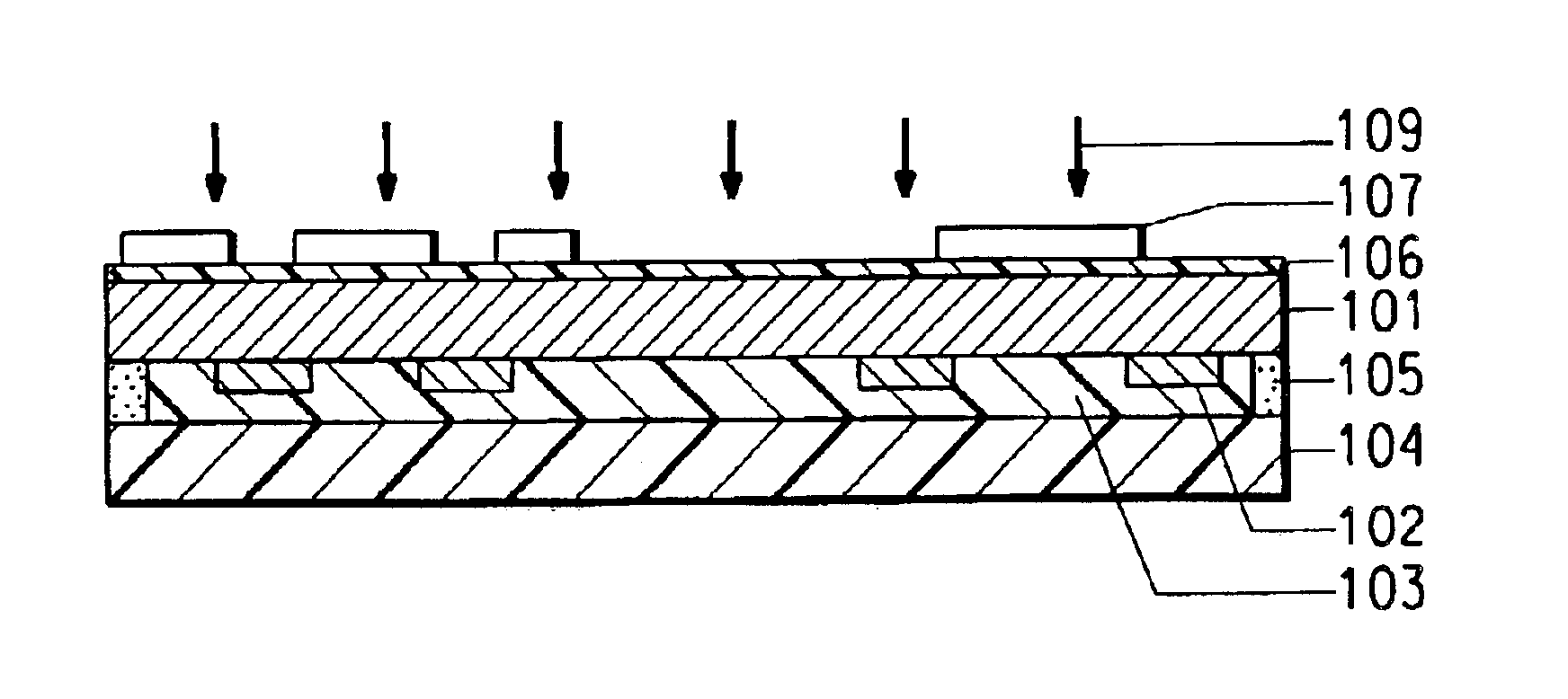

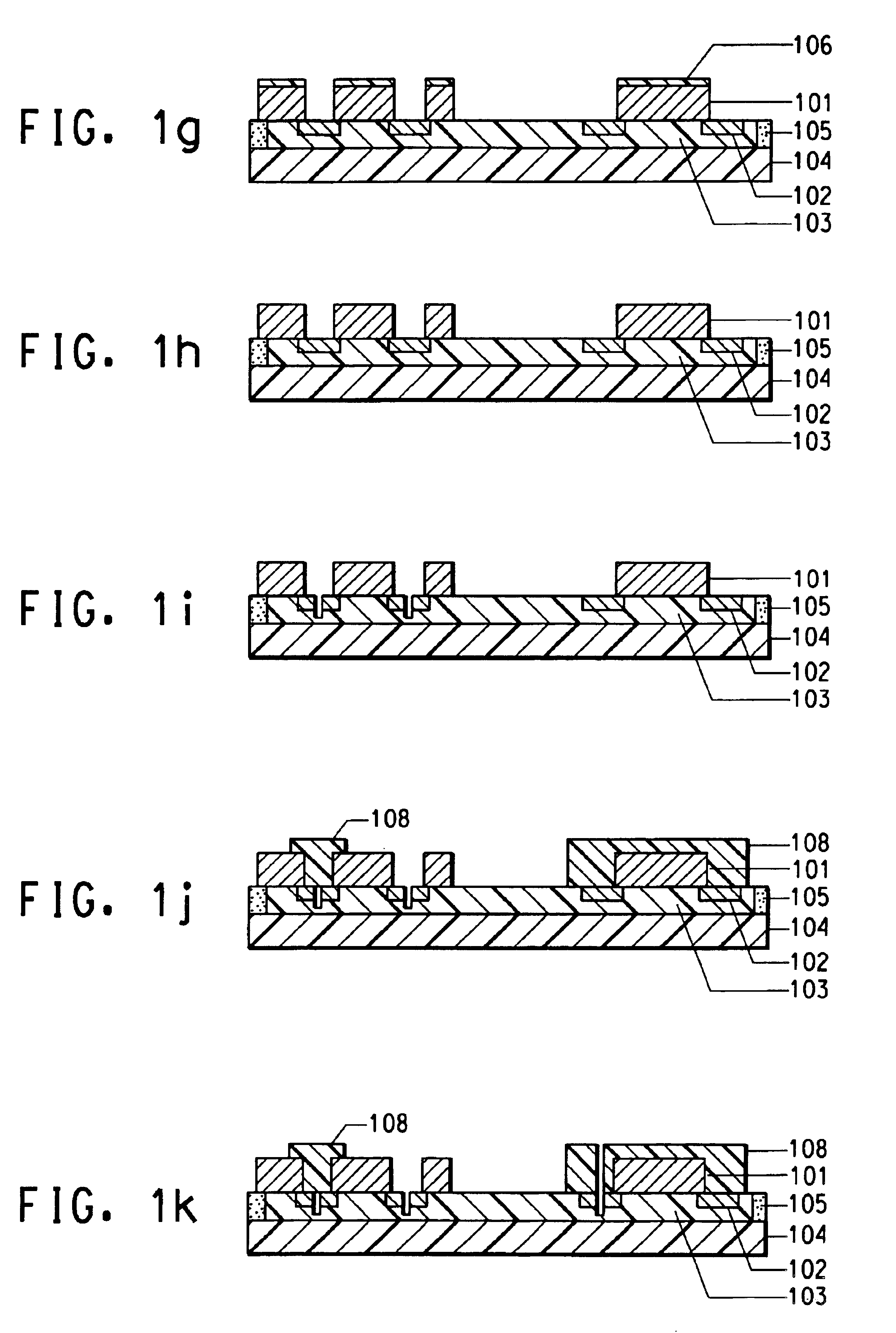

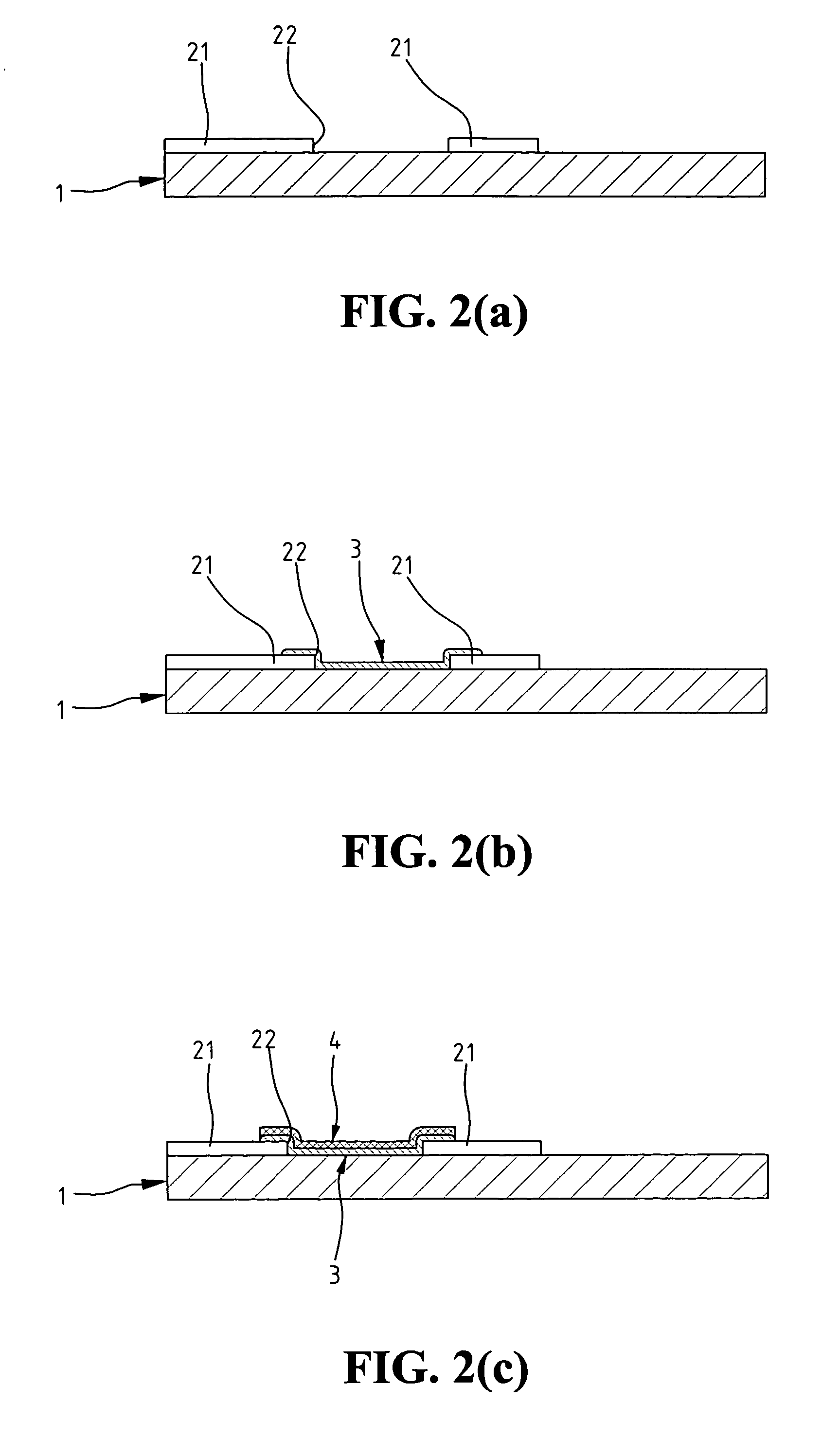

A method of making resistors includes providing a sacrificial layer. Conductive material is then formed over a region of the sacrificial layer. Resistive material is then deposited over the first surface of the sacrificial layer such that the resistive material covers the sacrificial layer and the conductive material. A portion of the sacrificial layer is then removed to expose the conductive material. A method of making resistors includes the steps of providing a sacrificial layer, removing at least a portion of the sacrificial layer from regions of the sacrificial layer so as to create a plurality of cavities within the sacrificial layer, plating said cavities with a conductive material, disposing resistive material over the first surface of the sacrificial layer such that resistive material covers the sacrificial layer and said conductive material, and removing at least a portion of said sacrificial layer to expose the conductive material. In another embodiment, a method of making resistors includes the steps of providing a sacrificial layer having a roughened first surface and a second surface, depositing resistive material over the first surface of the sacrificial layer such that the resistive material covers the first surface of the sacrificial layer, and selectively etching the sacrificial layer to form electrodes.

Owner:TESSERA INC

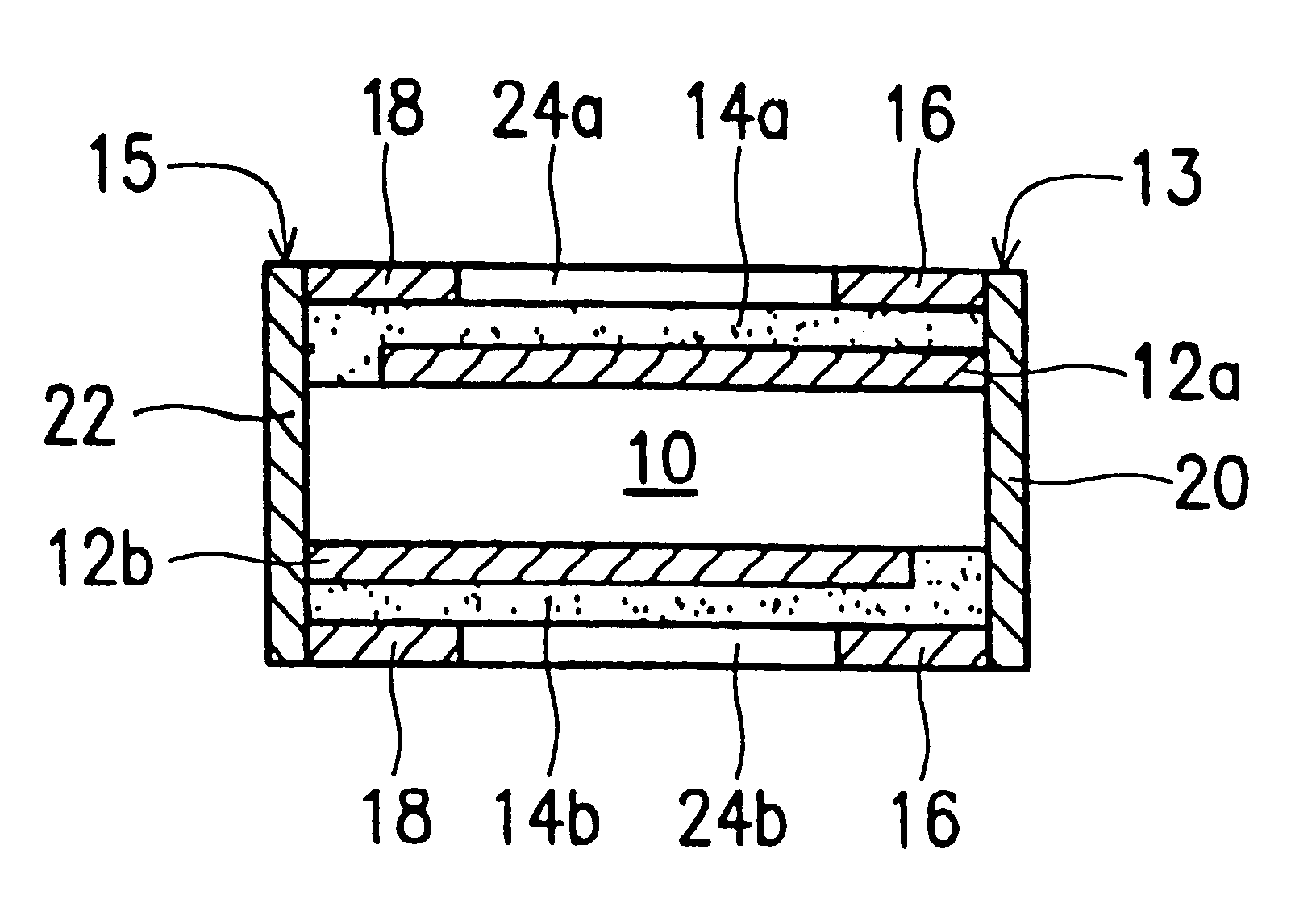

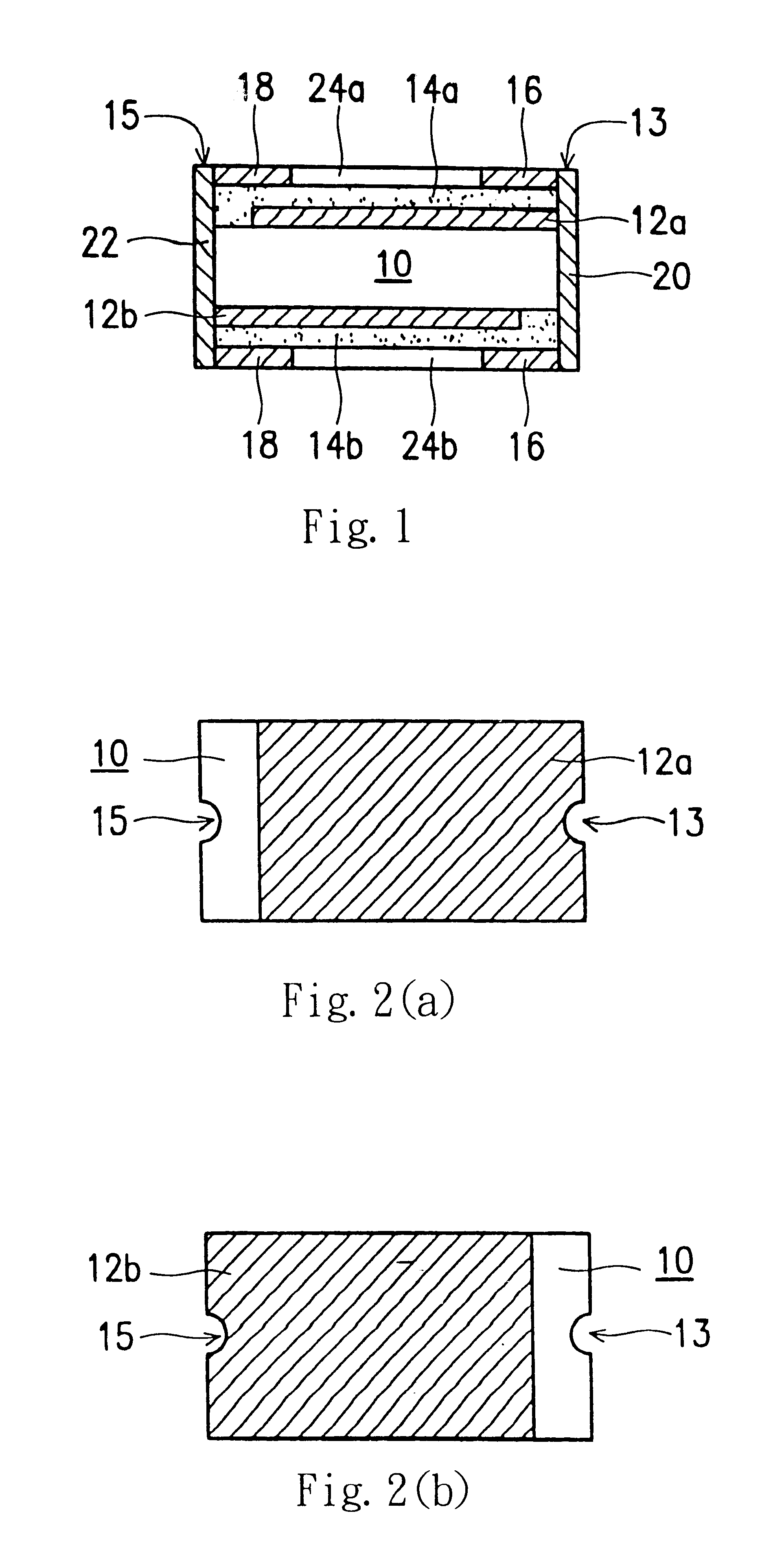

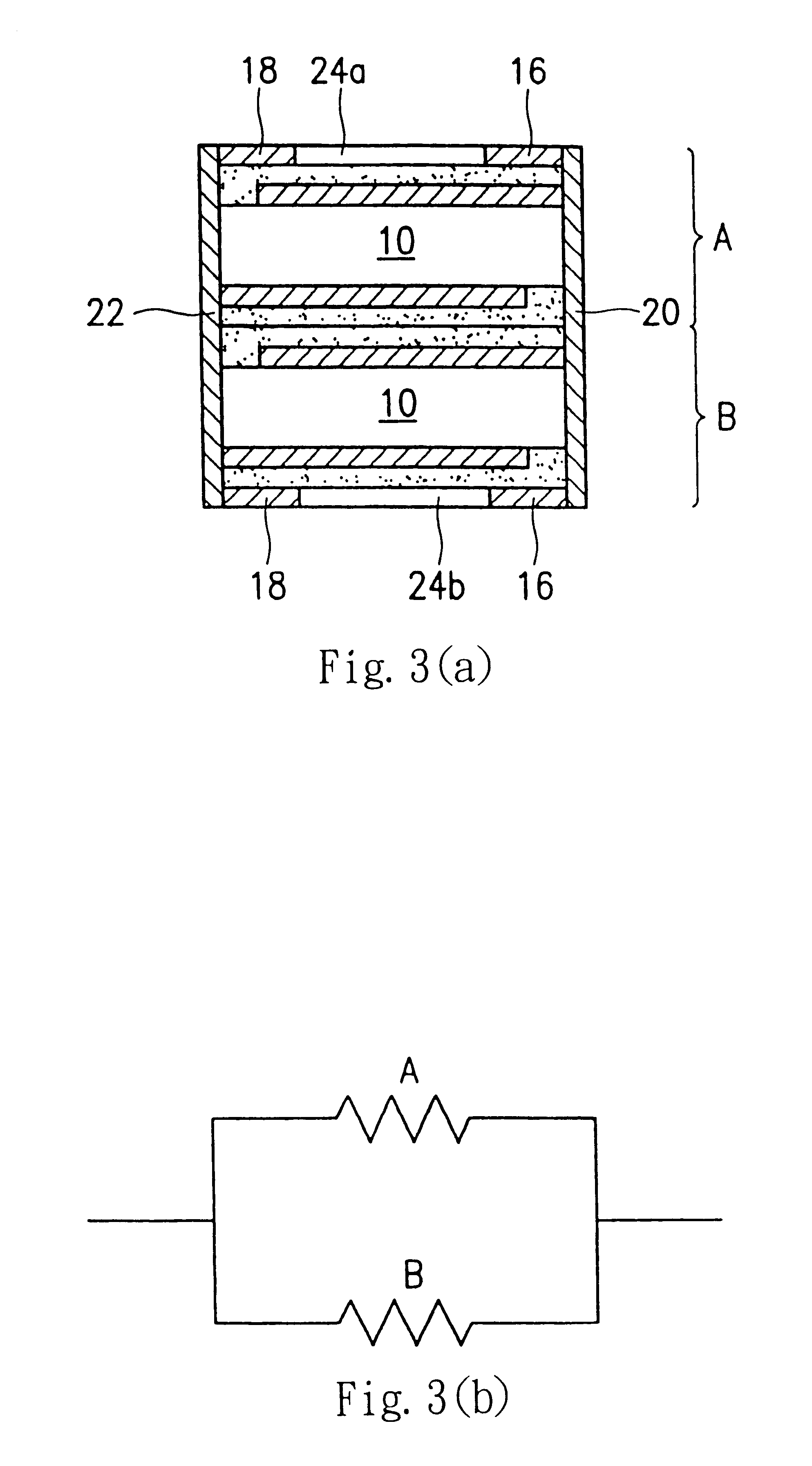

Surface mountable over-current protecting device

InactiveUS6377467B1Easy to installGood dimensional stabilityResistor terminals/electrodesNegative temperature coefficient thermistorsElectrical resistance and conductancePlanar electrode

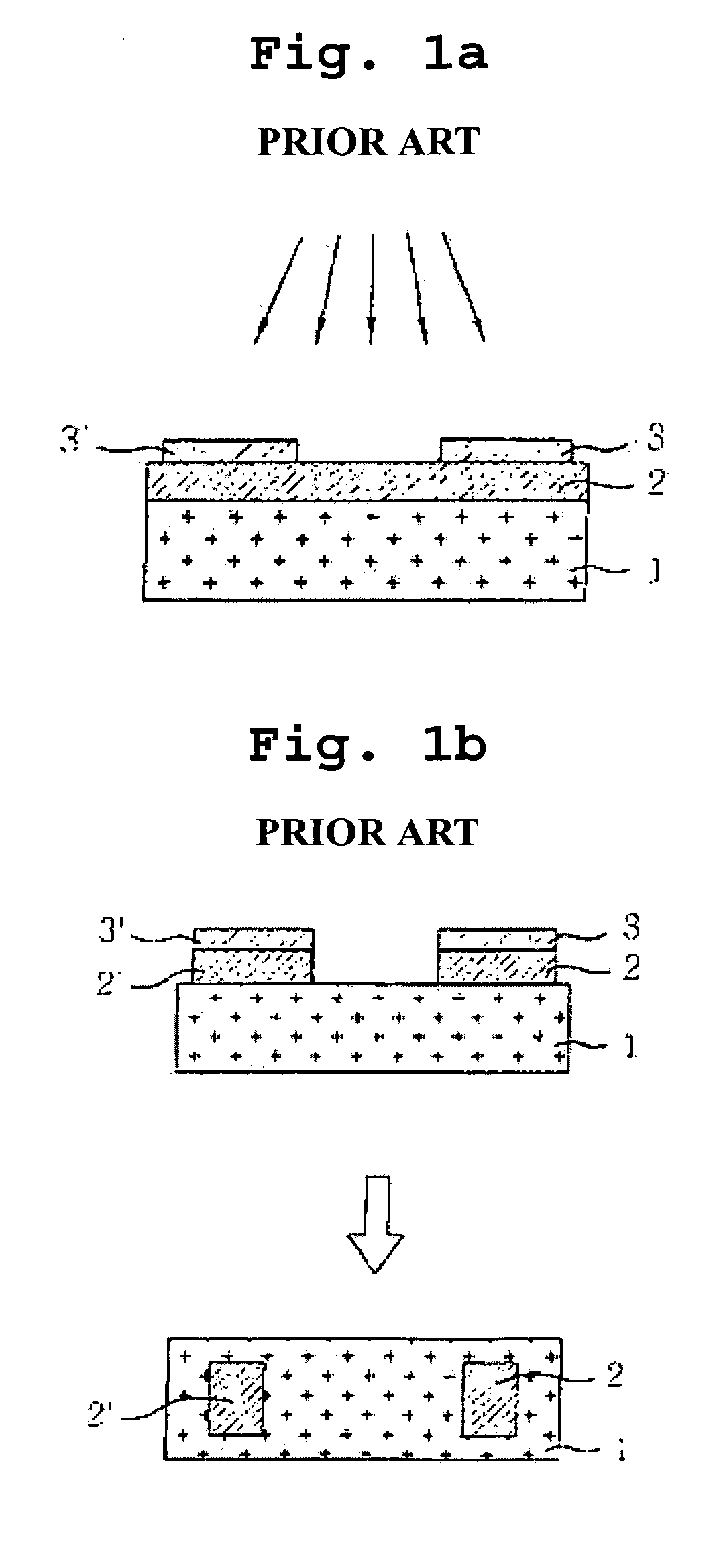

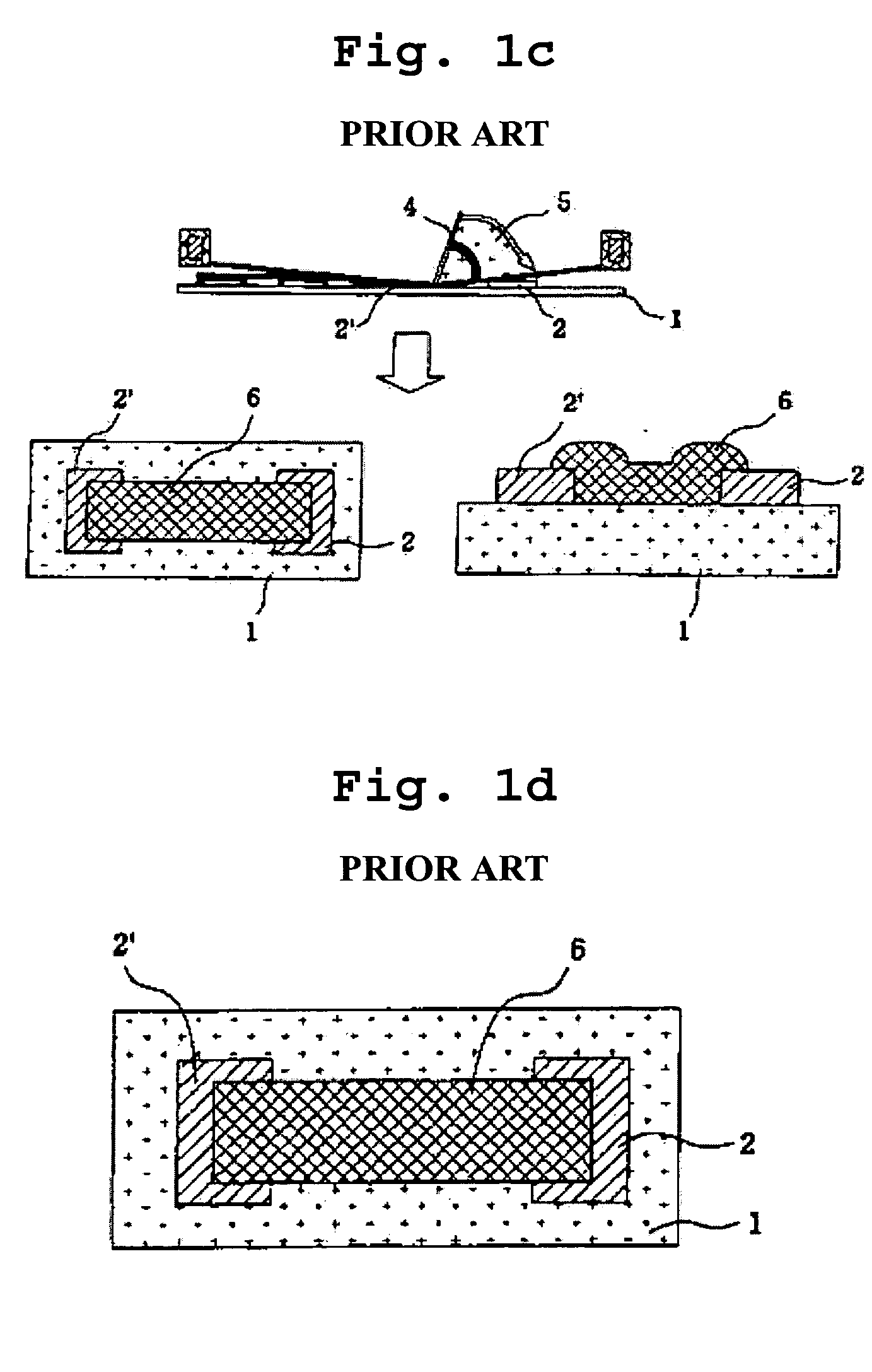

The present invention relates to a novel thermal-sensitive resistive apparatus, such as PTC and NTC, which allocates planar electrode films on the top and bottom surfaces of a prior art thermal-sensitive resistive apparatus, such as a PTC apparatus, to laminate with an outer electrode layer. A plurality of interconnection vias are electroplated with conductive material to connect to any plane. It is convenient to surface mount the apparatus of the present invention on a printed circuit board. The present invention can largely increase the dimensional stability of components and overcome the disadvantage that thermal diffusion of the prior are surface mounted resistive apparatus is affected easily by line width and environments.

Owner:POLYTRONICS TECH

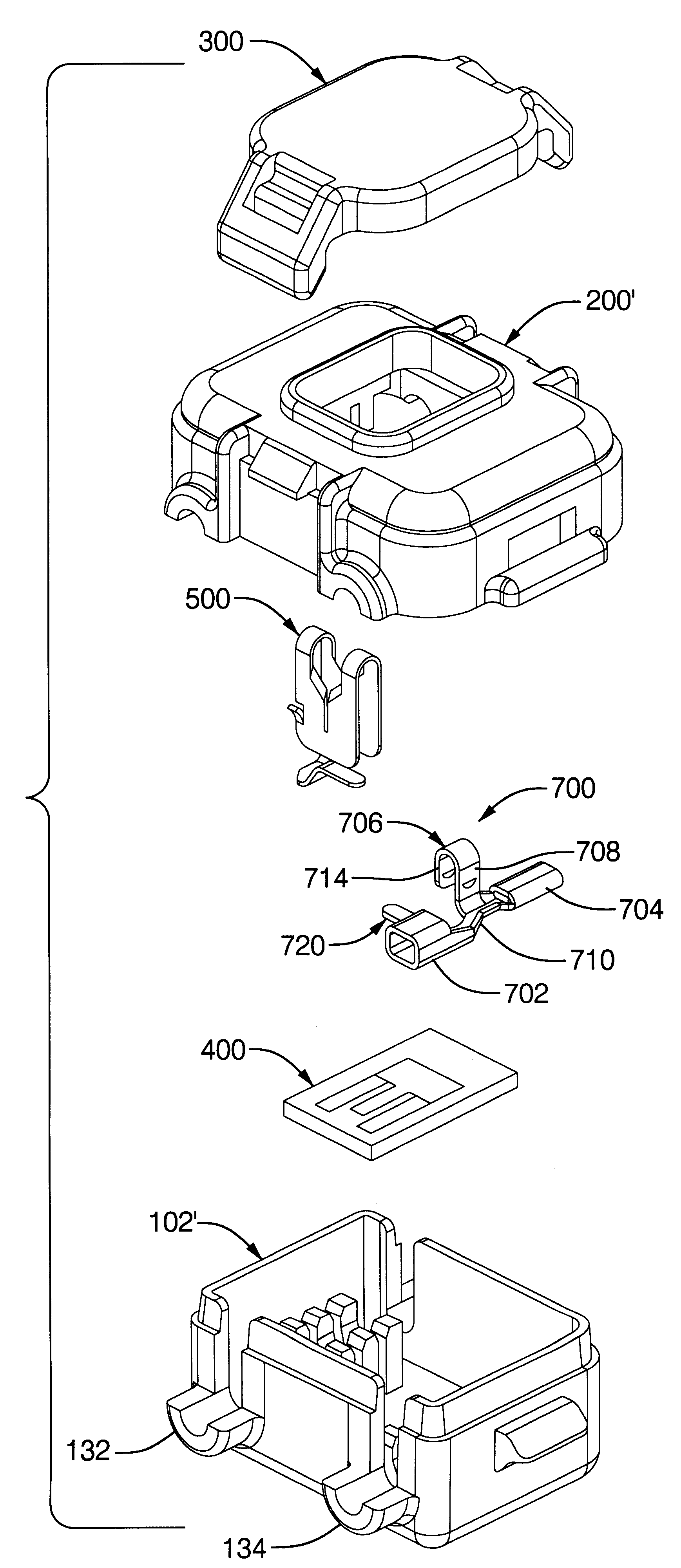

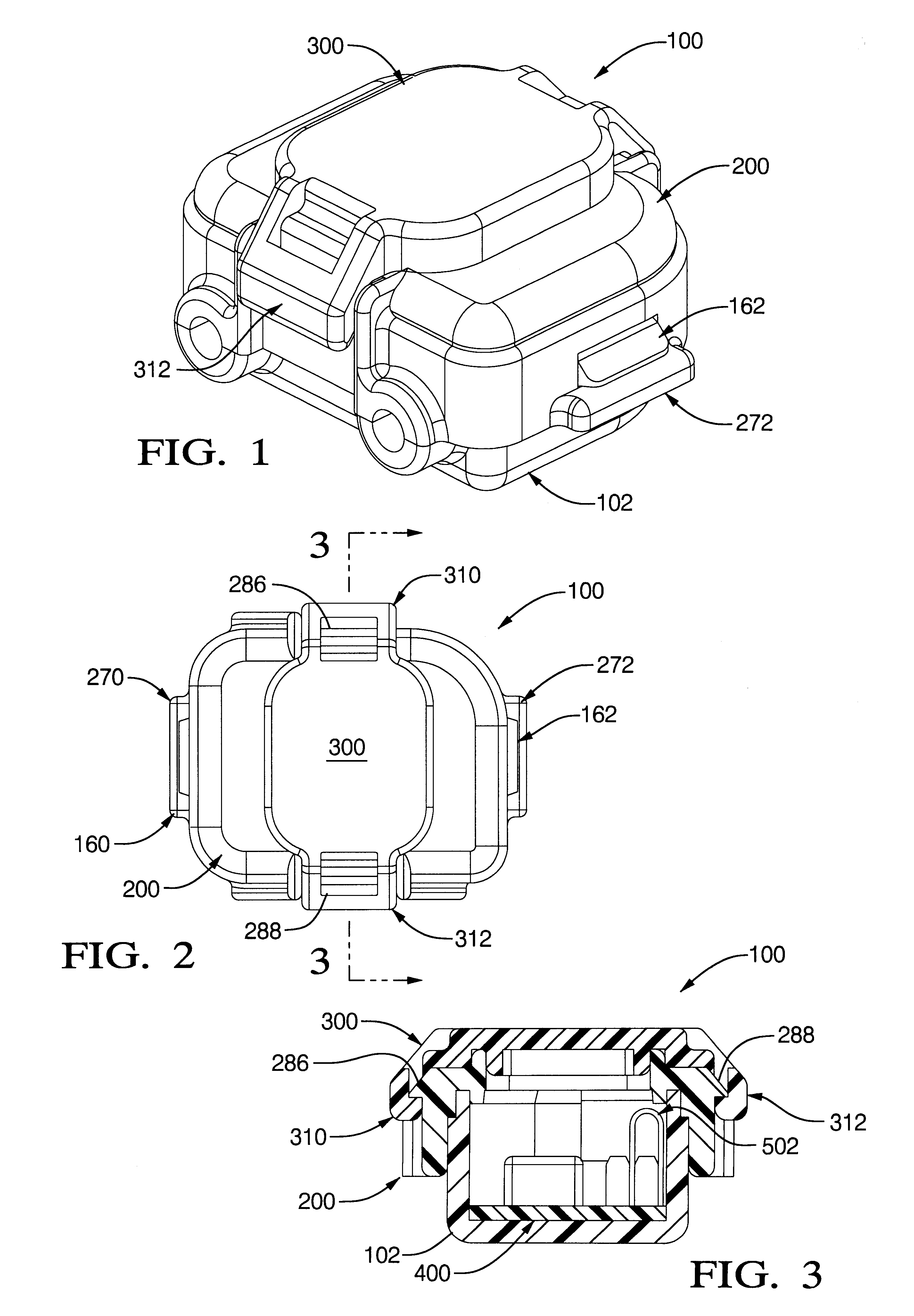

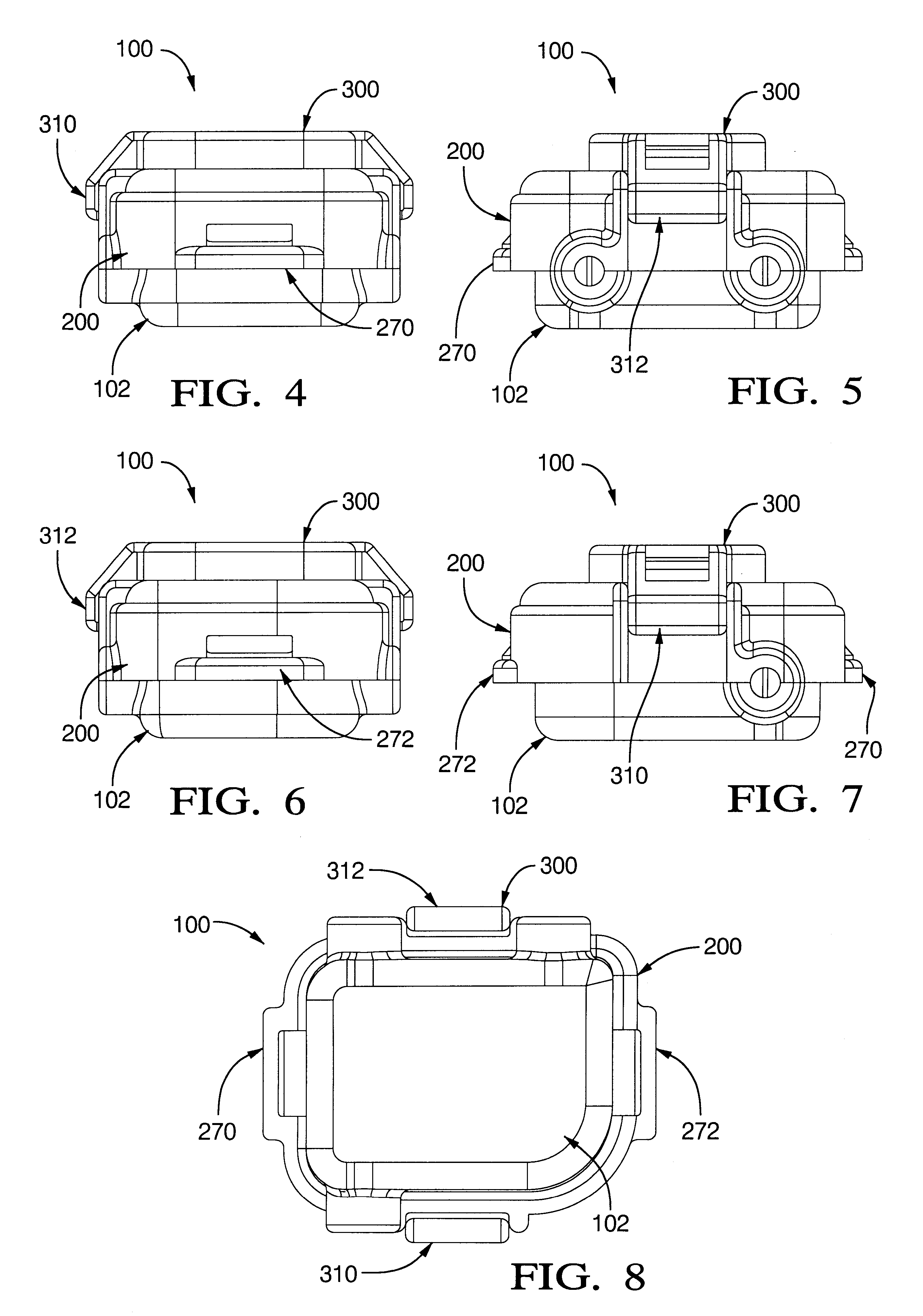

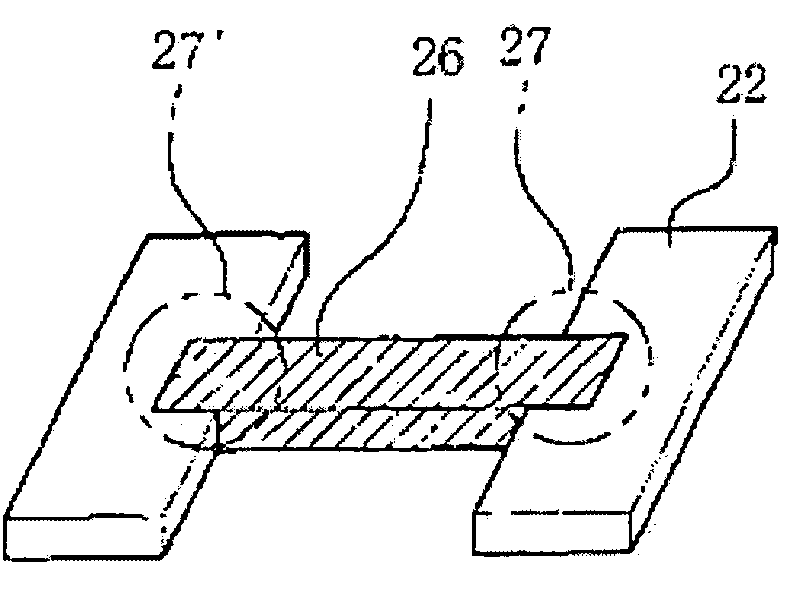

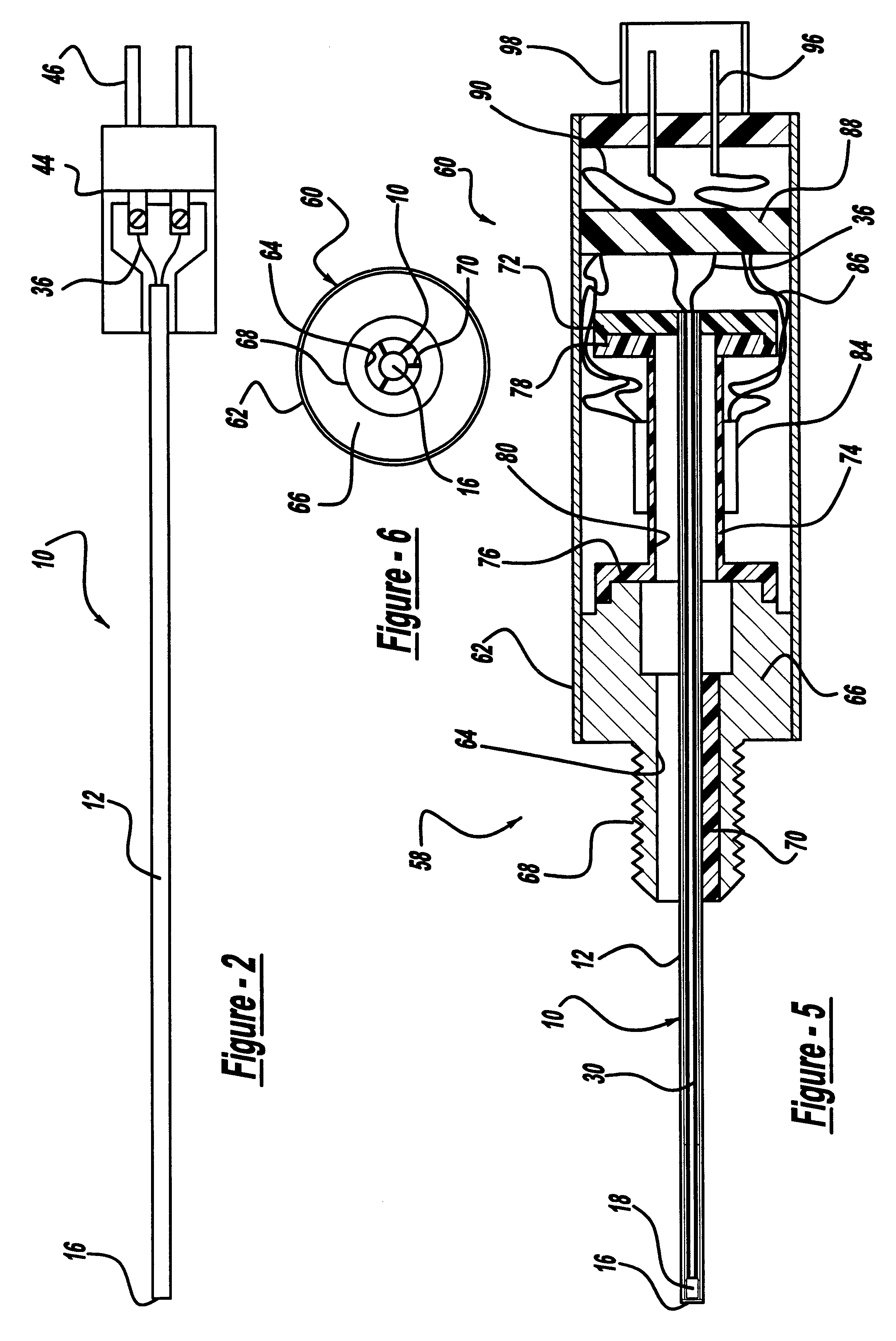

Trim resistor connector and sensor system

InactiveUS6208233B1Overcome disadvantagesFixed resistors with intervening connectorsFluid pressure measurement by electric/magnetic elementsSealantSensor system

An improved IDC trim resistor connector assembly made up of a generally open top cup shape connector with side wall slots and an interior first array of terminal posts arranged for passage therethrough of a first lead wire of sensor circuitry. A first stamped metal IDC terminal is push-on mounted on the terminal posts for IDC cradling and electrically and mechanically receiving and connecting to the first lead wire. A conventional trim resistor substrate is loose mounted but accurately positioned on the connector bottom wall and has an "E" pattern of resistive material adapted for center leg laser trimming to calibrate the associated sensor circuitry. A first IDC terminal spring leg overlap contacts one side leg of the trim resistor E-pattern and thereby spring clamps the resistor substrate. A cover is snap-latch mounted on the connector and has an access opening to enable laser trimming of the trim resistor after cover installation. One end of a second lead wire is received in a second IDC metal terminal in turn mounted on a second array of connector-interior terminal posts and also having a spring leg overlap electrically contacting and clamping the other E-pattern side leg. Spring barbs on the terminals anchor the same once fully inserted downwardly onto the terminal posts. Connector locking tangs and cover locking ears provide snap-on retention of the cover on the connector, and press-in / keeper internal cover projections cause push-down assembly of the lead wires as the cover is latched onto the connector. Cover locking tangs and cap latching ears provide snap-together locking of a cap on the cover when the cap is pushed down on the cover to seal the access opening after completion of laser trimming and in-filling of the covered container with sealant. In a second embodiment a crimp-type terminal, also provided with a spring clamping leg, is fastened to the second lead wire and has a barbed mounting strap clasping a modified second terminal post array when fully installed thereon.

Owner:DELPHI TECH INC

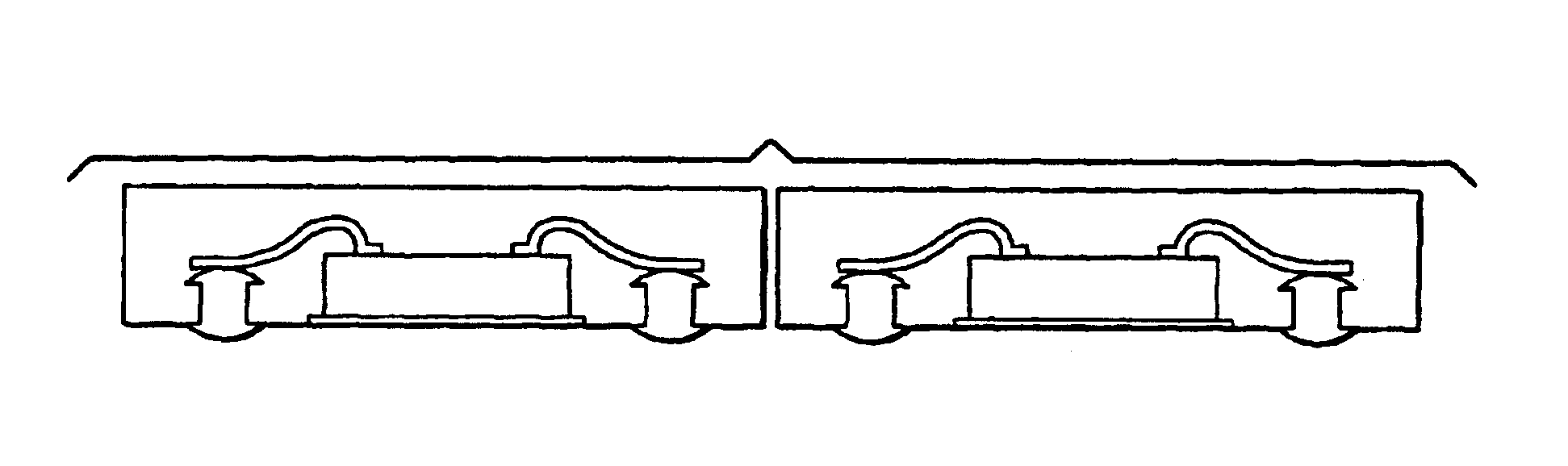

Method for making an integrated circuit substrate having embedded passive components

InactiveUS7334326B1Low incremental costIncremental costPrinted circuit assemblingElectrolytic capacitorsConductive pasteConductive materials

A method for making an integrated circuit substrate having embedded passive components provides a reduced cost and compact package for a die and one or more passive components. An insulating layer of the substrate is embossed or laser-ablated to generate apertures for insertion of a paste forming the body of the passive component. A resistive paste is used to form resistors and a dielectric paste is used for forming capacitors. A capacitor plate may be deposited at a bottom of the aperture by using a doped substrate material and activating only the bottom wall of the aperture, enabling plating of the bottom wall without depositing conductive material on the side walls of the aperture. Vias may be formed to the bottom plate by using a disjoint structure and conductive paste technology. Connection to the passive components may be made by conductive paste-filled channels forming conductive patterns on the substrate.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Method to embed thick film components

InactiveUS6860000B2Printed circuit assemblingInsulating substrate metal adhesion improvementEngineeringMetallic substrate

The invention is directed to a method to embed a thick film resistor composition into a printed wiring board comprising the steps of applying a reinforcing composition onto a resistor composition disposed on a metallic substrate forming an assembly wherein the resistor composition is at least partially coated with the reinforcing composition; processing the assembly; and applying the assembly onto at least one side of an organic substrate forming a component wherein the organic substrate is at least partially coated with an adhesive layer and wherein the reinforcing composition side of the assembly is embedded into the adhesive layer. The reinforcing composition allows laser trimming of the fired resistor and also eliminates cracking during lamination steps of the invention.

Owner:CHEMTRON RES

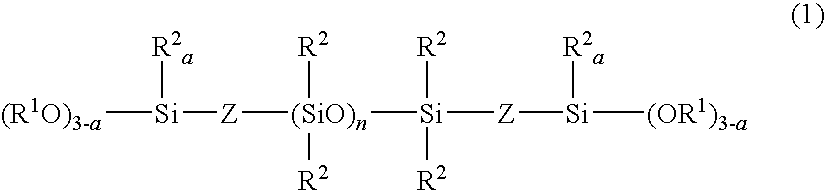

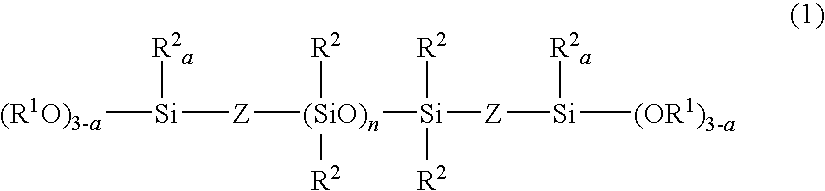

RTV silicone rubber composition for electric and electronic part protection, circuit boards, silver electrodes, and silver chip resistors

InactiveUS7553901B2Prevent and retard partPrevent short-circuitingLayered productsSemiconductor/solid-state device detailsSulfur containingElectron

RTV silicone rubber compositions are provided comprising (A) an organopolysiloxane, (B) an organosilicon compound or partial hydrolytic condensate thereof, and (C) a non-aromatic amino-bearing compound. The compositions, when electric and electronic parts having a copper, silver or other metal portion on their surface are encapsulated or sealed therewith, can prevent or retard the parts from corrosion with sulfur-containing gas.

Owner:SHIN ETSU CHEM IND CO LTD

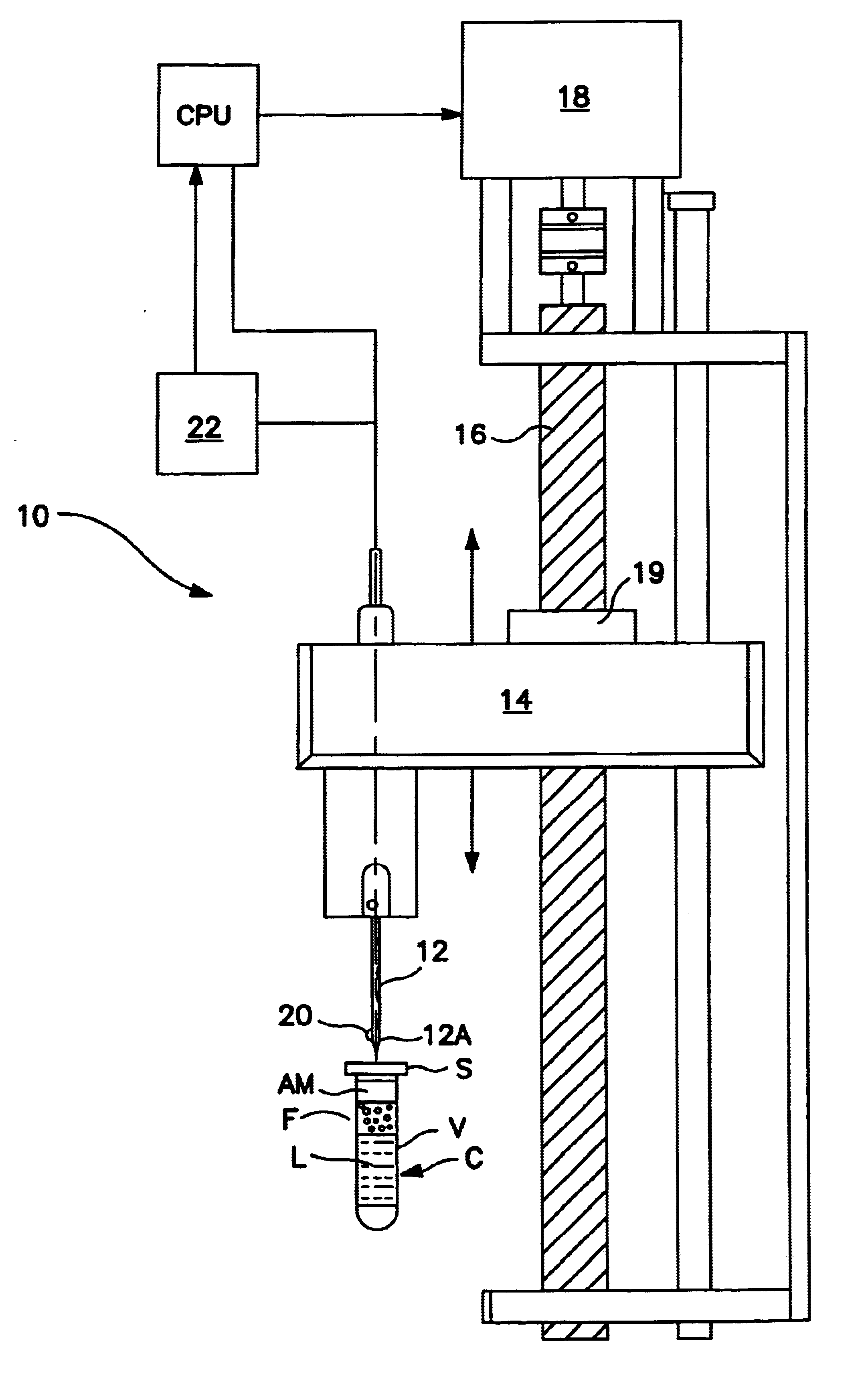

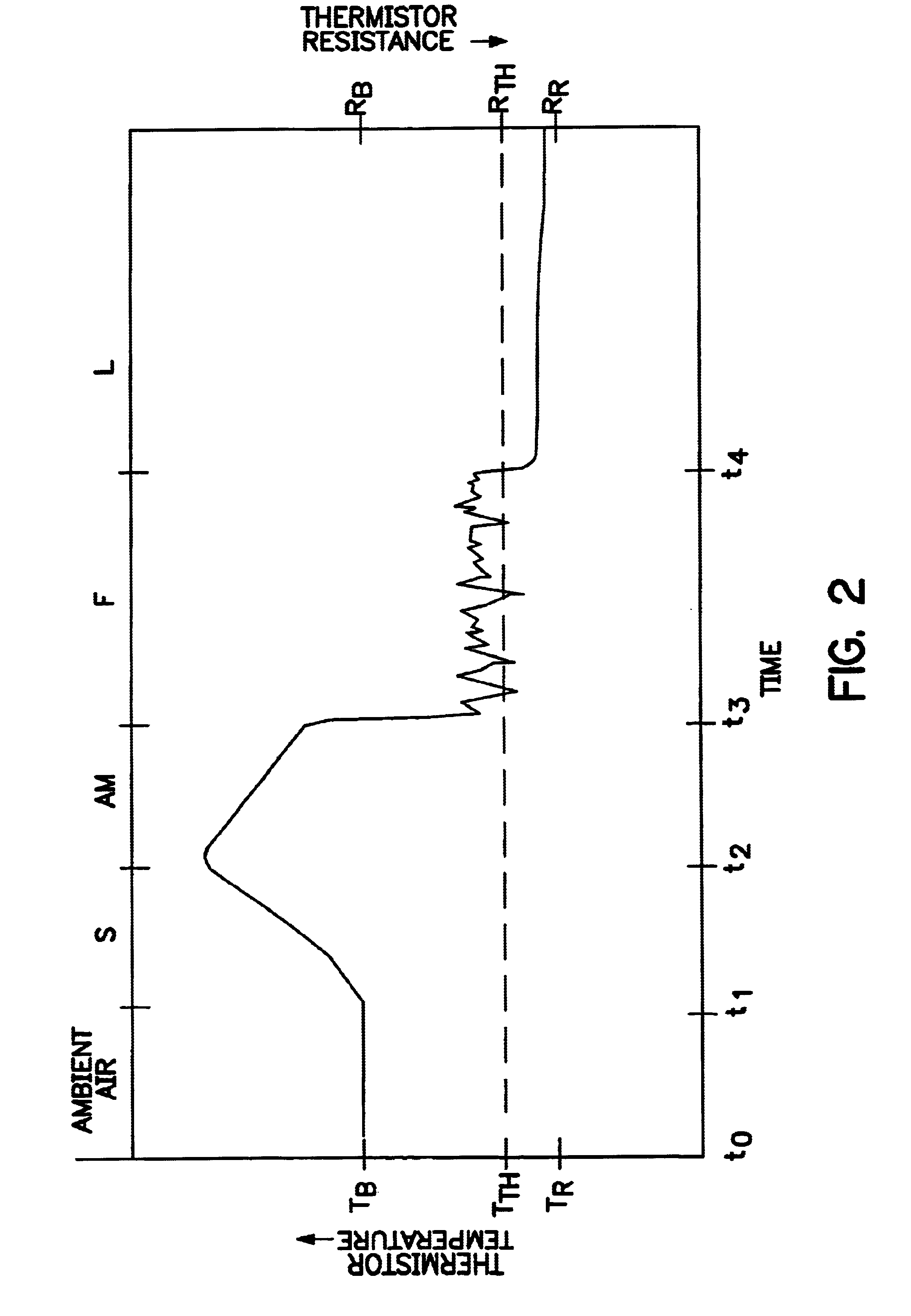

Method and apparatus for aspirating liquid from a container

InactiveUS6908226B2Thermometer detailsThermometers using electric/magnetic elementsElectricityElectrical resistance and conductance

A method and apparatus for aspirating a liquid (e.g., blood) from a container uses an electrically biased thermistor element, mounted proximate the tip of a liquid-aspirating probe, to determine that the probe is safely submerged within a body of liquid to be aspirated at all times during the aspiration process. Also disclosed are different aspiration probe assemblies that are useful in the method and apparatus of the invention.

Owner:BECKMAN COULTER INC

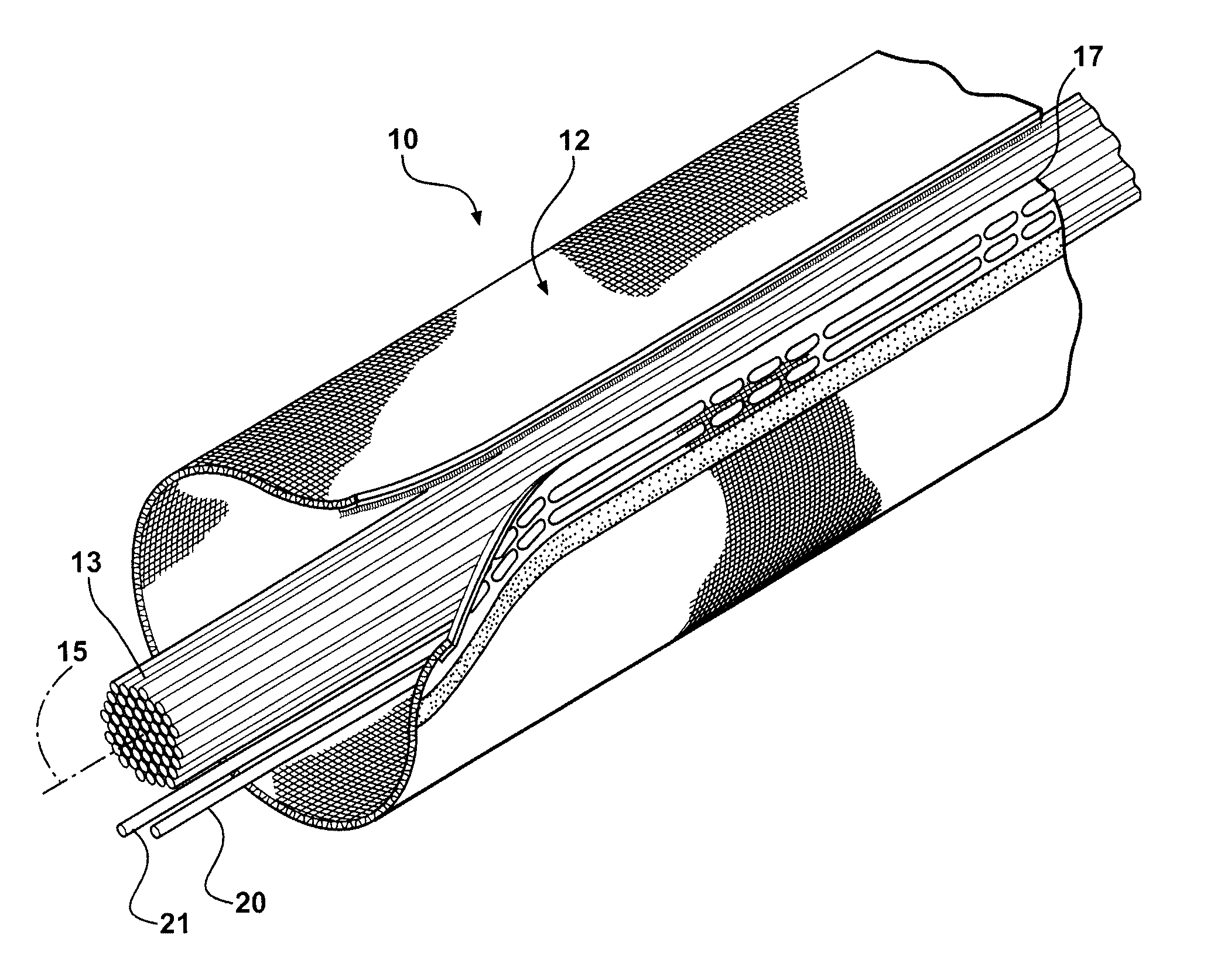

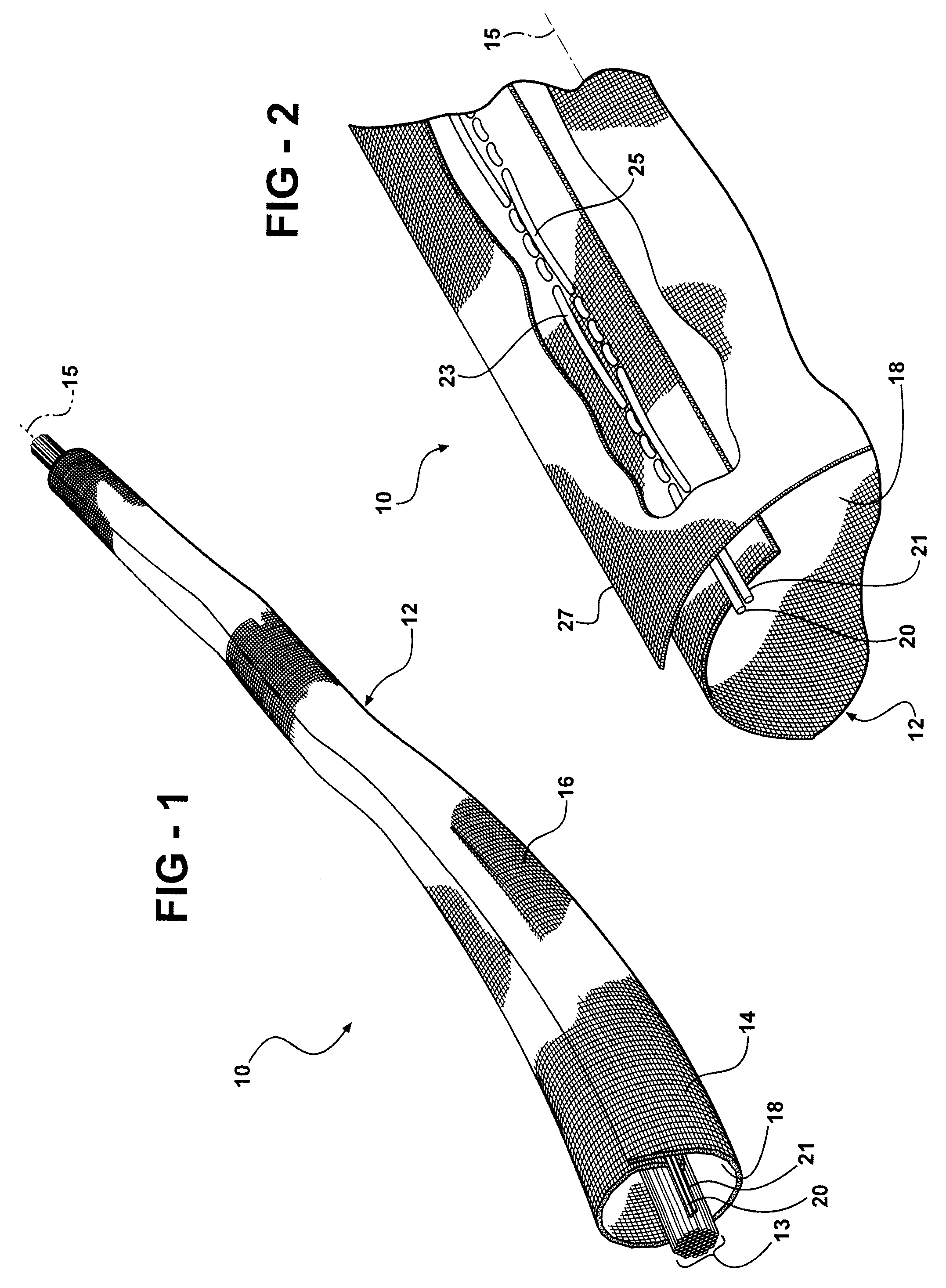

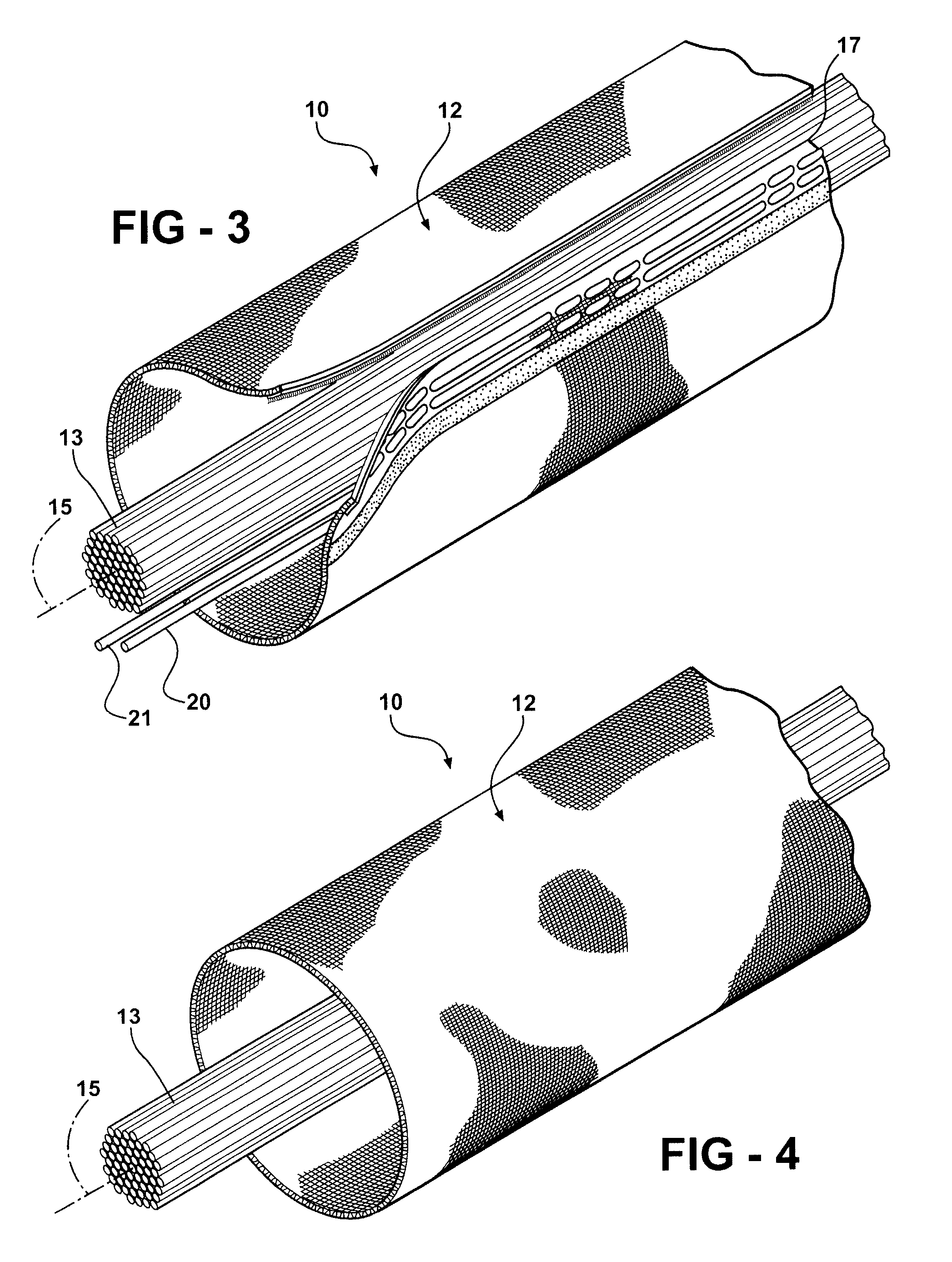

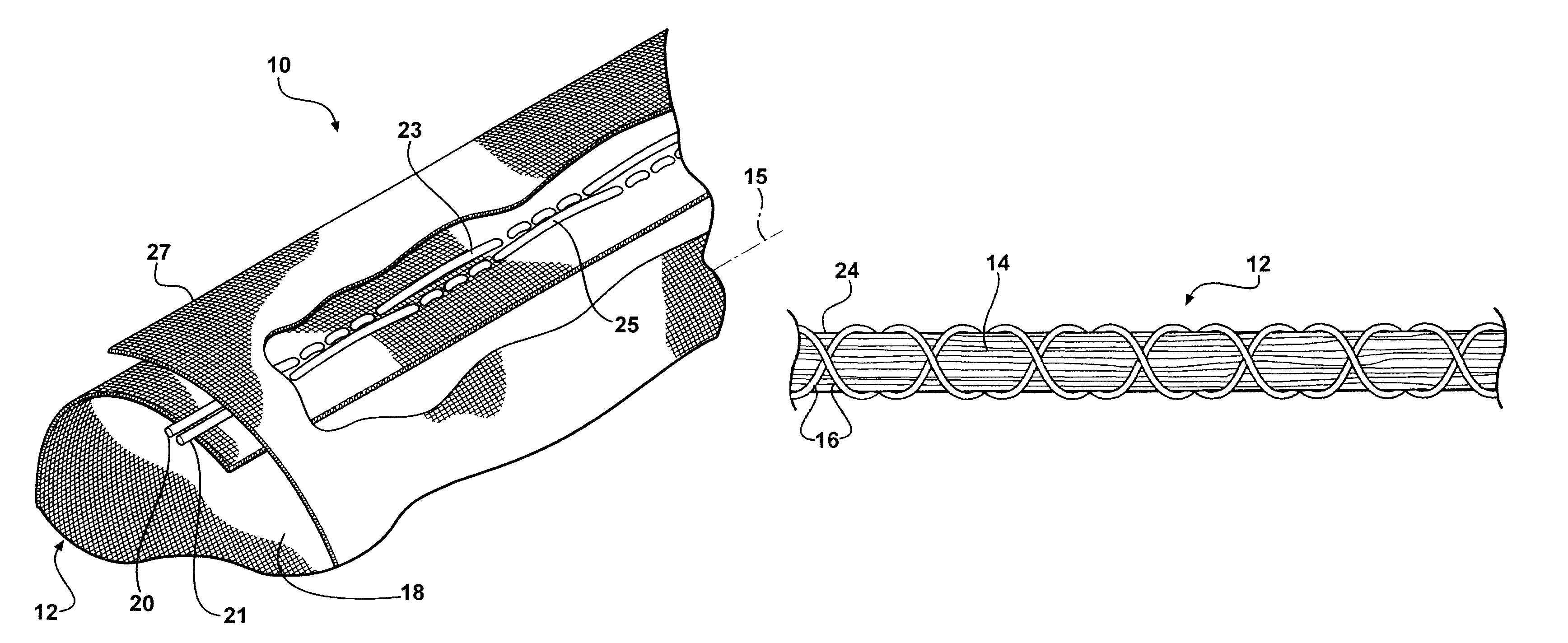

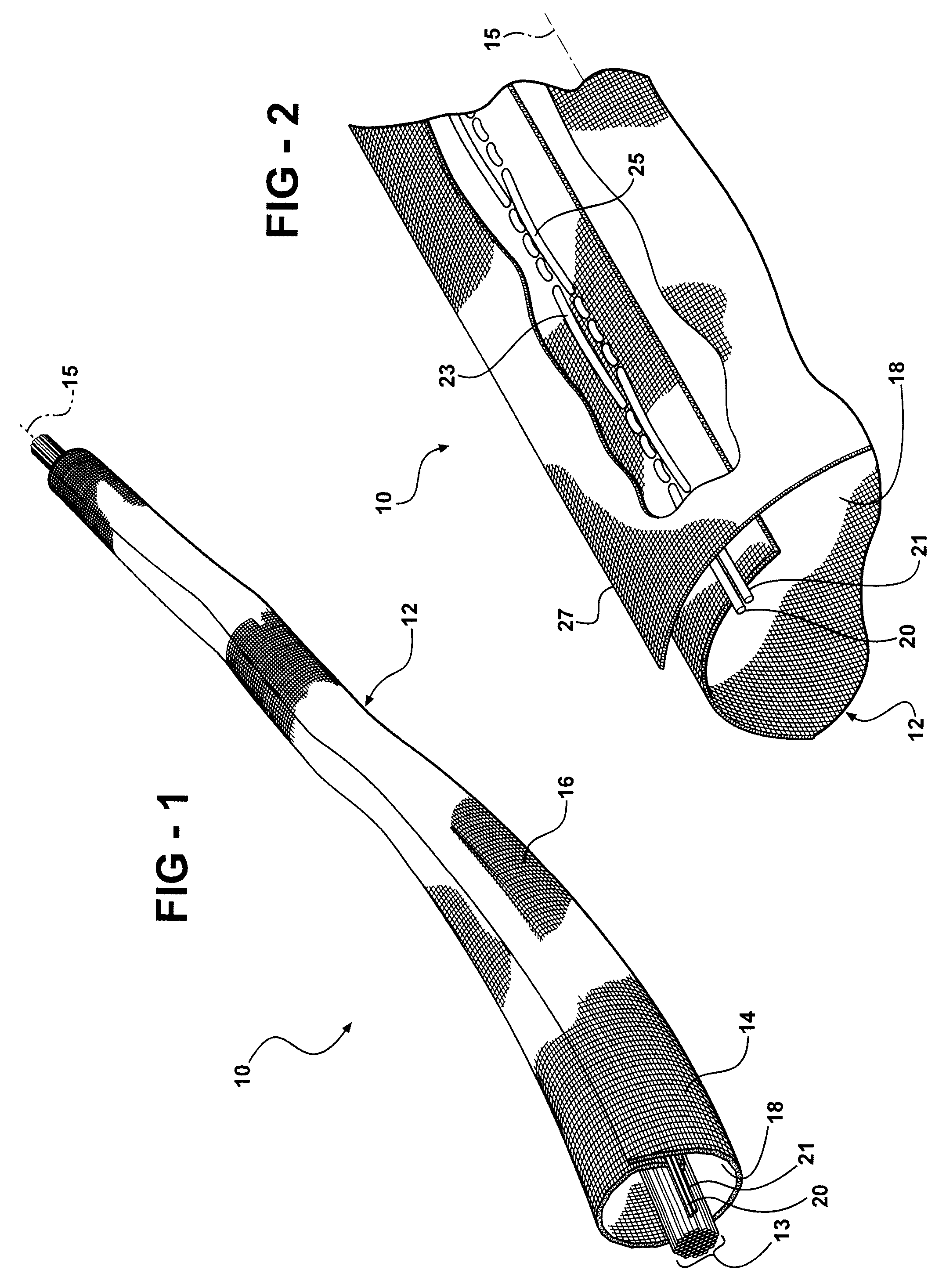

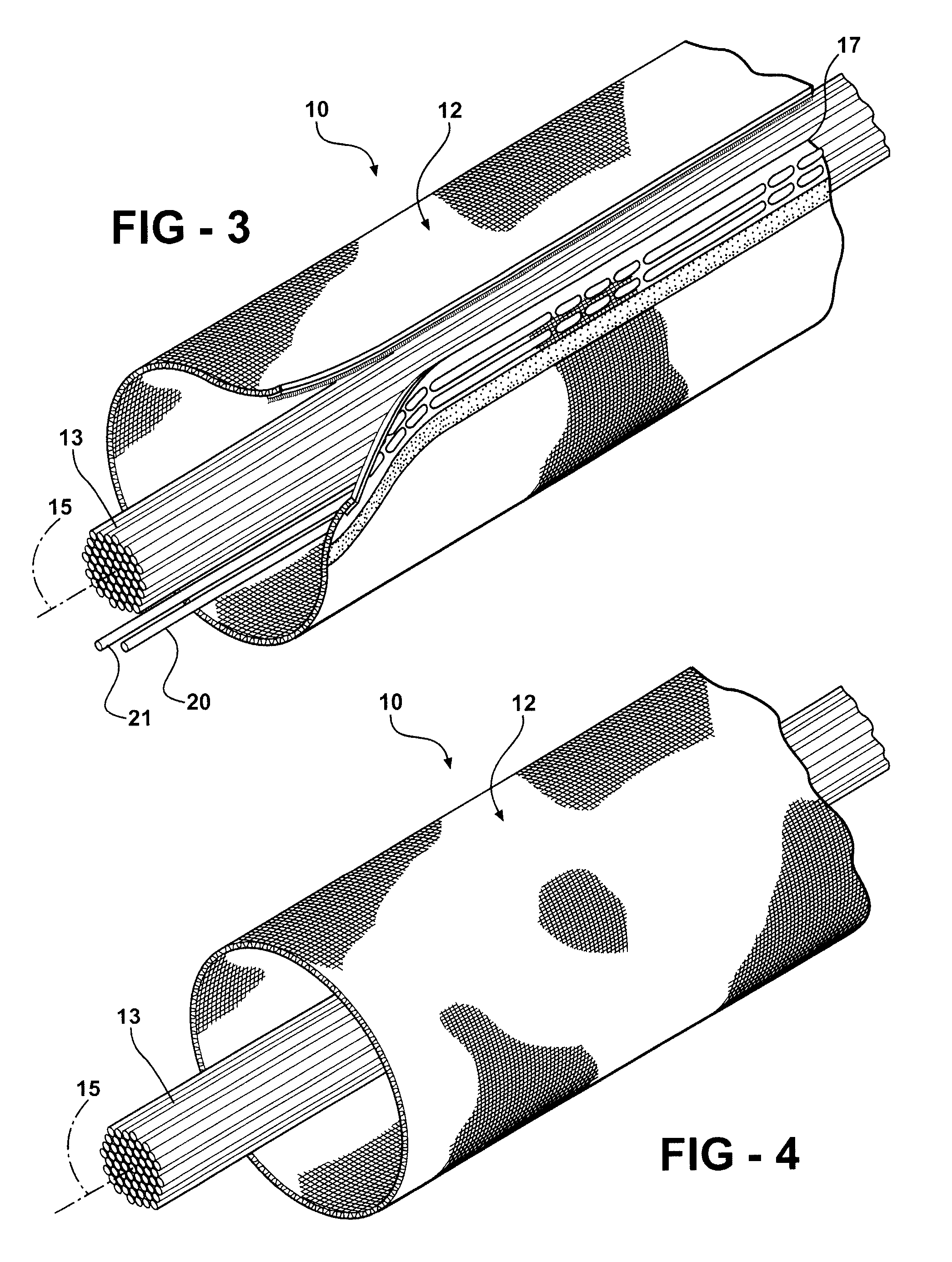

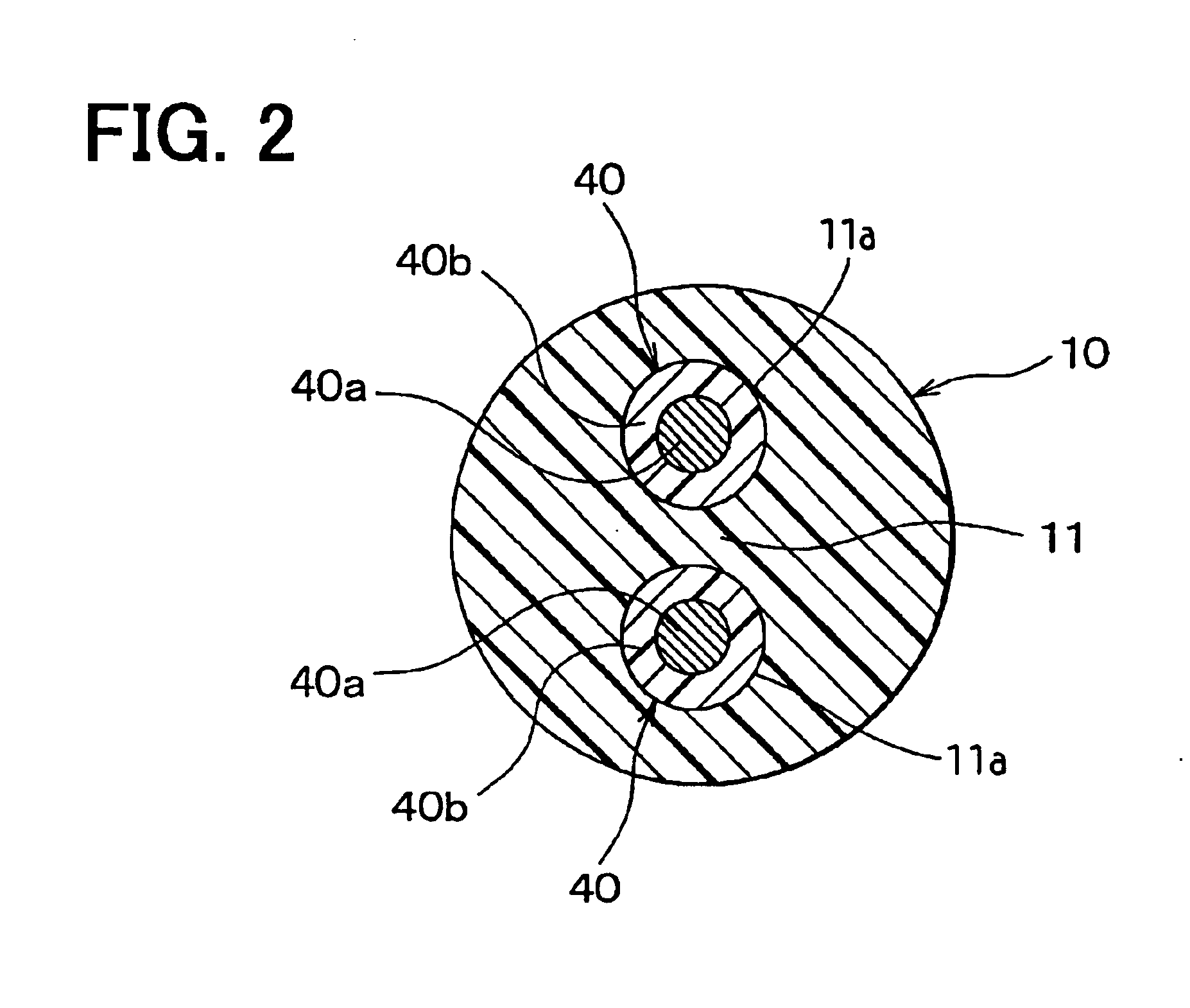

Protective sleeve fabricated with hybrid yarn having wire filaments and methods of construction

ActiveUS20070275199A1Provide protectionImprove conductivityLayered productsPedestrian/occupant safety arrangementYarnArchitectural engineering

A fabric sleeve and hybrid yarn filament used in construction of the sleeve for protecting elongate members against at least one of EMI, RFI or ESD, and methods of construction of the sleeve and hybrid yarn filament. The sleeve includes at least one interlaced hybrid yarn filament having a non-conductive filament and at least one conductive wire filament overlying an outer surface of the non-conductive filament. The hybrid yarn filament is arranged in electrical communication with itself or other hybrid yarn filaments to provide uniform shielding against EMI, RFI, and / or ESD.

Owner:FEDERAL MOGUL WORLD WIDE LLC

Method of producing printed circuit board with embedded resistor

InactiveUS20050175385A1Improve workabilityResistance value change remains constantSemiconductor/solid-state device detailsSolid-state devicesProduction rateScreen printing

Disclosed is a method of producing a printed circuit board (PCB) with an embedded resistor, in which a resistor with a desired shape and volume is precisely formed using a resistor paste so that resistance values according to a position of the PCB are uniform, thereby a laser trimming process is omitted or minimally utilized. The method has advantages in that a production time of the PCB is shortened and productivity is improved because an operation condition is rapidly set without being greatly affected by the position precision of a printing device. Other advantages of the method are that the resistor paste with a relatively uniform thickness is secured through a screen printing process, thereby easily forming the resistor and improving resistance tolerance.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

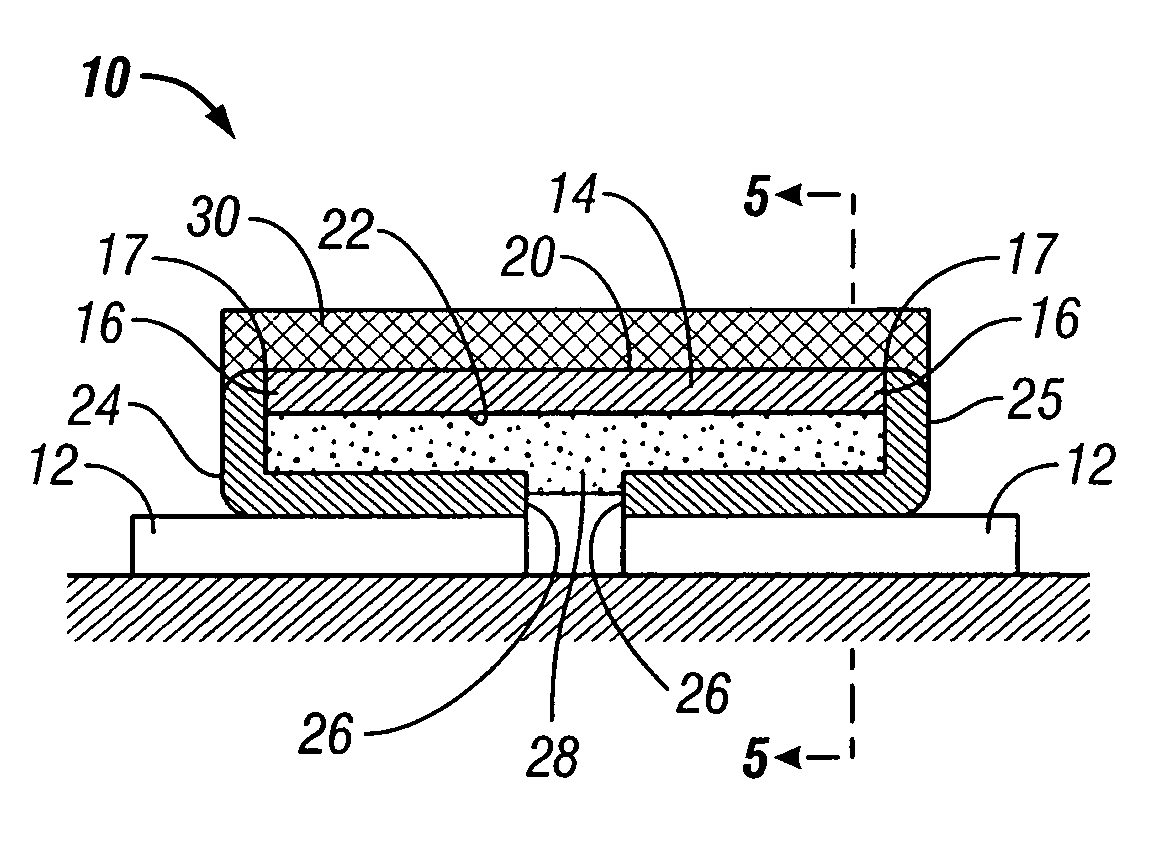

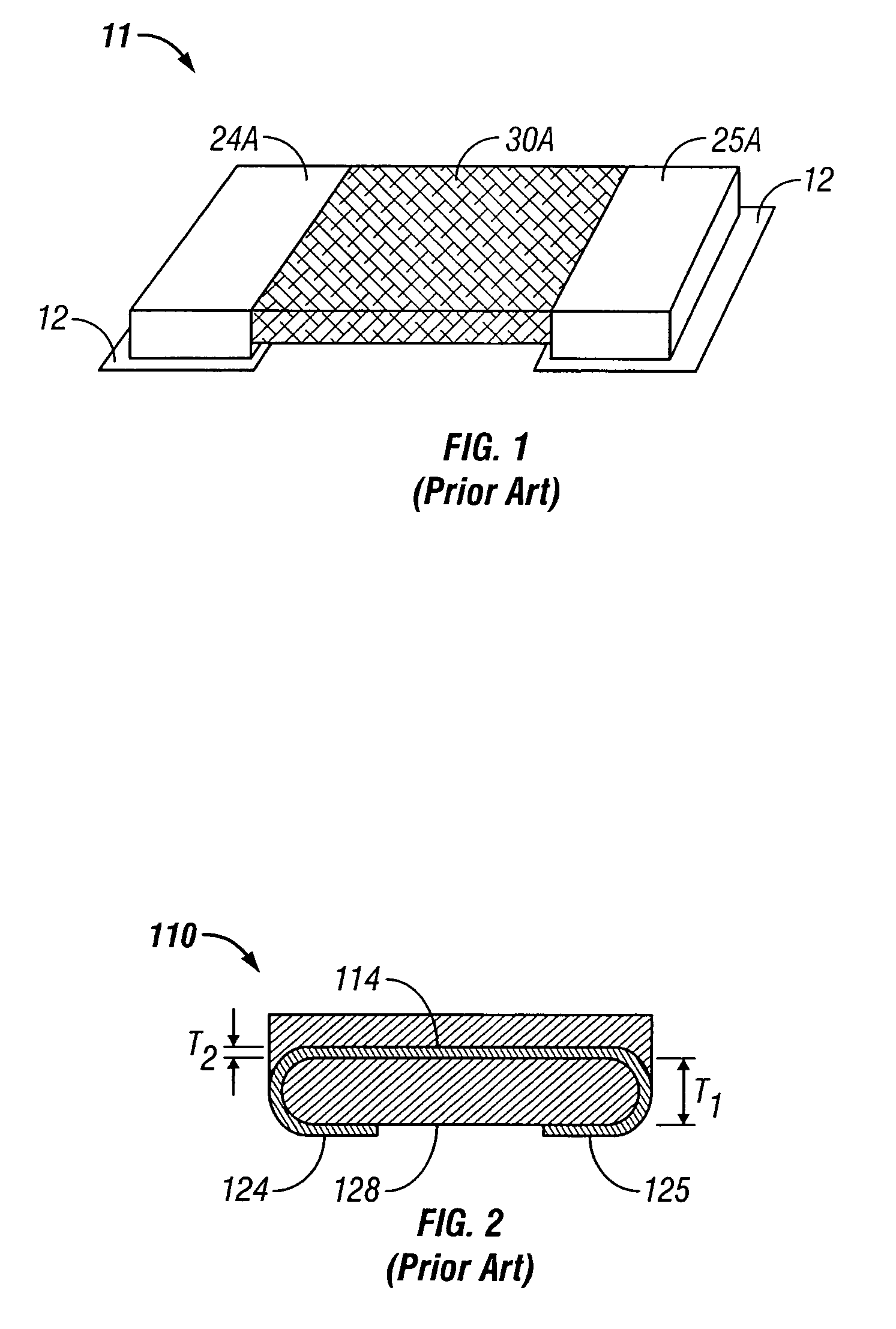

Surface mount electrical resistor with thermally conductive, electrically insulative filler and method for using same

ActiveUS7190252B2Improve abilitiesResistor chip manufactureResistor terminals/electrodesSurface mountingEngineering

Owner:VISHAY DALE ELECTRONICS INC

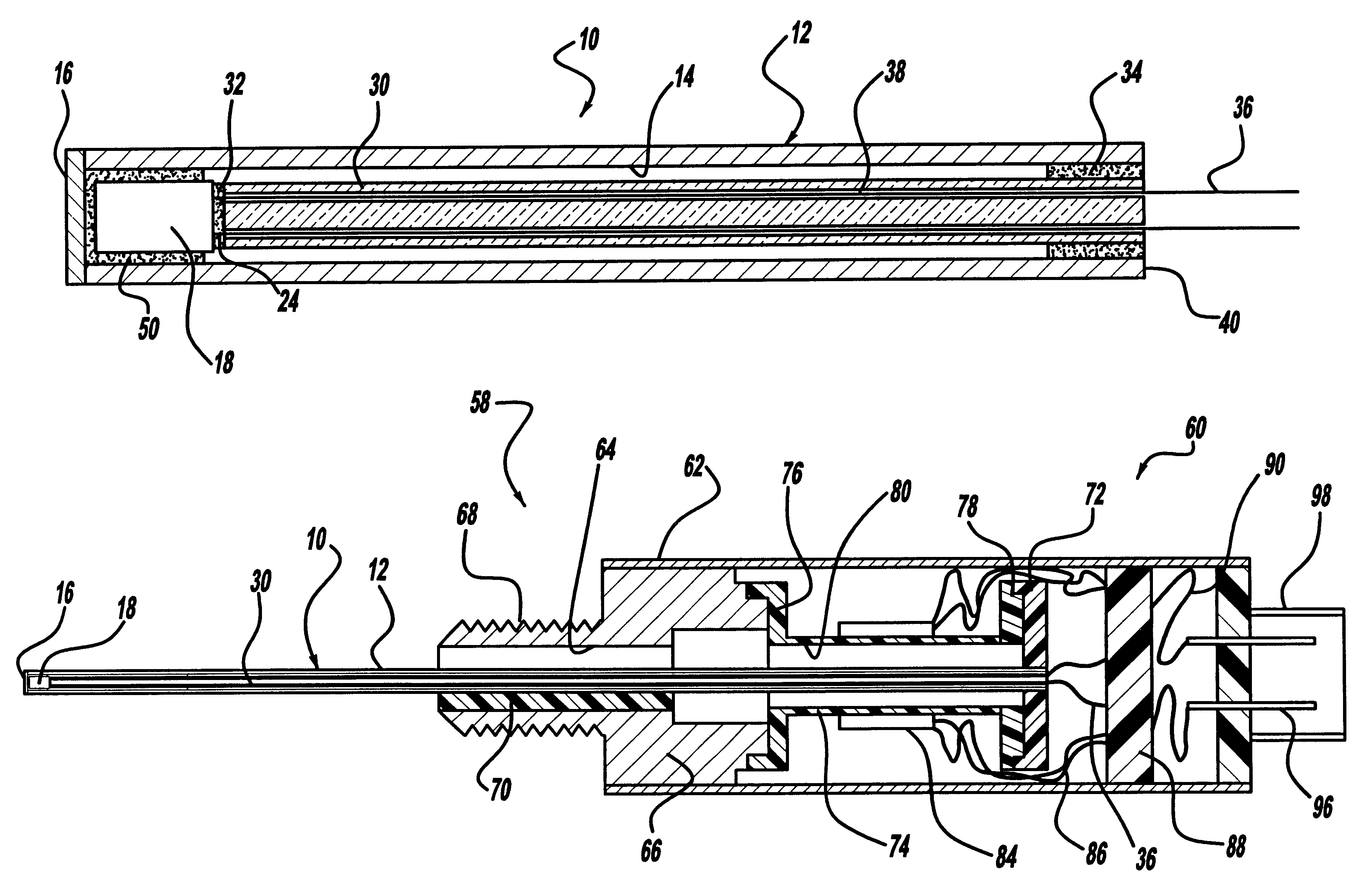

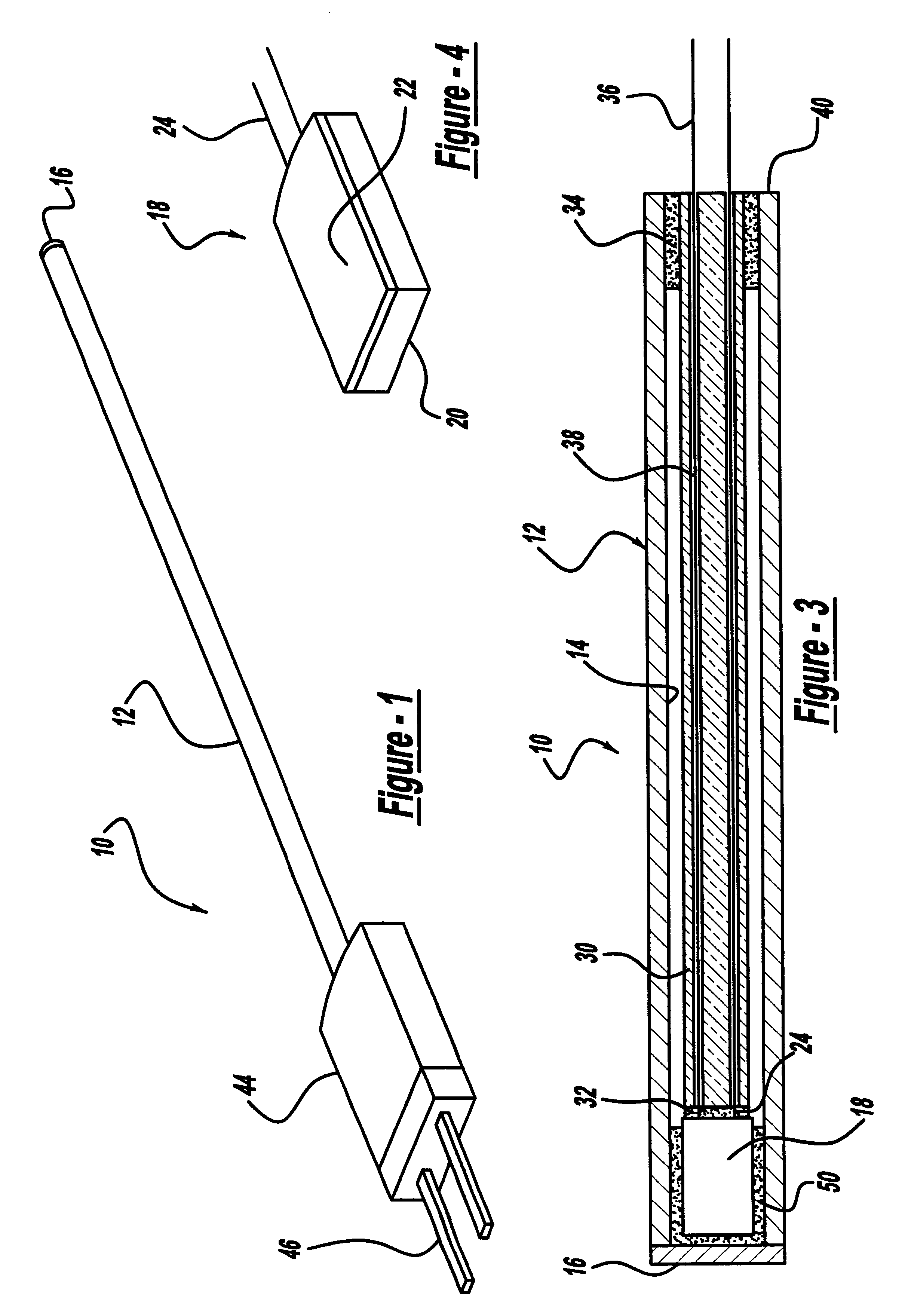

Precision temperature probe having fast response

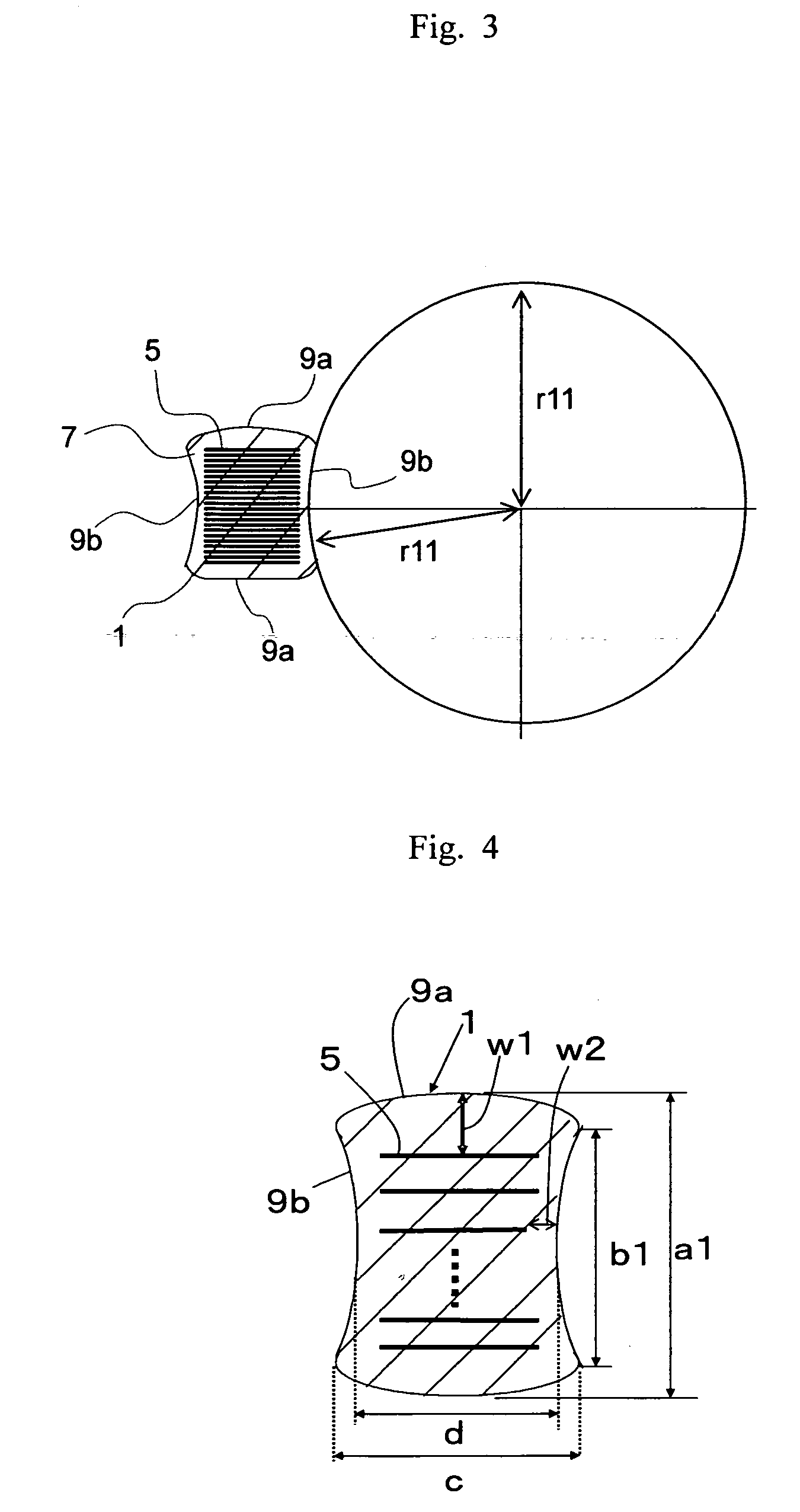

InactiveUS6592253B2Thermometer detailsThermometers using electric/magnetic elementsTransducerResistive element

A temperature probe (10) including a cylindrical thermally conductive housing (10) and a temperature sensor (18) employing a resistive temperature element (22) mounted therein. The temperature sensor (18) is mounted at one end of the housing (12) by a thermally conductive potting material (50). Signal wires (36) electrically couple to the resistive element (22) extend through an elongated insulated member (30) and out of an end of the housing (12) opposite the sensor (18). Changes in the temperature of the housing are quickly transferred to the resistive temperature element (22) through the conductive potting material (50). In one embodiment, the probe (10) is combined with a pressure transducer (60) to provide a pressure and temperature sensing device.

Owner:NORTHROP GRUMMAN SYST CORP

12kv fixed-sealed resistant voltage divider

ActiveCN101075490AReduce volumeReduce power consumptionResistor housing/enclosing/embeddingNon-adjustable resistorsElectromagnetic interferenceEngineering

A 12kv resistance divider includes wire terminal, signal terminal, earthing terminal, ceramic wafer, resistance wire, and a green color protection layer covered by a black protection layer then rubber.

Owner:BEIHAI GALAXY SWITCH DEVICES

Protective sleeve fabricated with hybrid yarn having wire filaments and methods of construction

ActiveUS7576286B2Provide protectionImprove conductivityLayered productsProtective fabricsYarnArchitectural engineering

A fabric sleeve and hybrid yarn filament used in construction of the sleeve for protecting elongate members against at least one of EMI, RFI or ESD, and methods of construction of the sleeve and hybrid yarn filament. The sleeve includes at least one interlaced hybrid yarn filament having a non-conductive filament and at least one conductive wire filament overlying an outer surface of the non-conductive filament. The hybrid yarn filament is arranged in electrical communication with itself or other hybrid yarn filaments to provide uniform shielding against EMI, RFI, and / or ESD.

Owner:FEDERAL MOGUL WORLD WIDE LLC

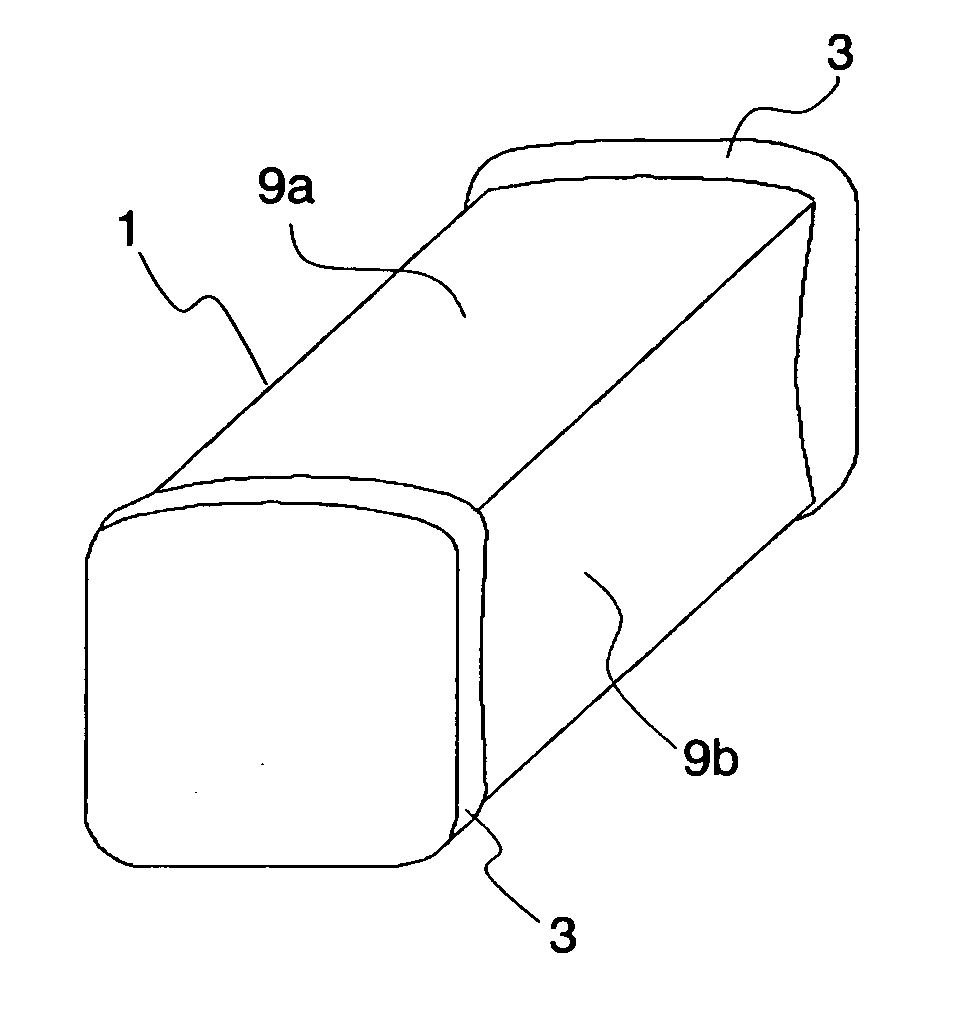

Chip-type electronic component

ActiveUS20050264975A1Improve visibilityHigh mechanical strengthFixed capacitor electrodesFixed capacitor dielectricVisibilityElectrical conductor

In a chip-type electronic component of the present invention, at least one surface of a ceramic body is a convexly curved surface. Specifically, at least one surface in a thickness direction of the ceramic body may be convexly curved, and the side surface of the ceramic body may be concavely curved. Alternatively, only one surface may be a convexly curved surface. This chip-type electronic component has a high visibility and a high mechanical strength, though it is small. Moreover, in a chip-type electronic component comprising a ceramic body that is formed by alternately laminating insulating layers and conductor layers, and a pair of external electrodes, the thickness in a laminate direction at the central part between external electrodes of the ceramic body is made greater than the thickness of the end surface. This prevents breakage of the external electrodes and also enlarges the ceramic body.

Owner:KYOCERA CORP

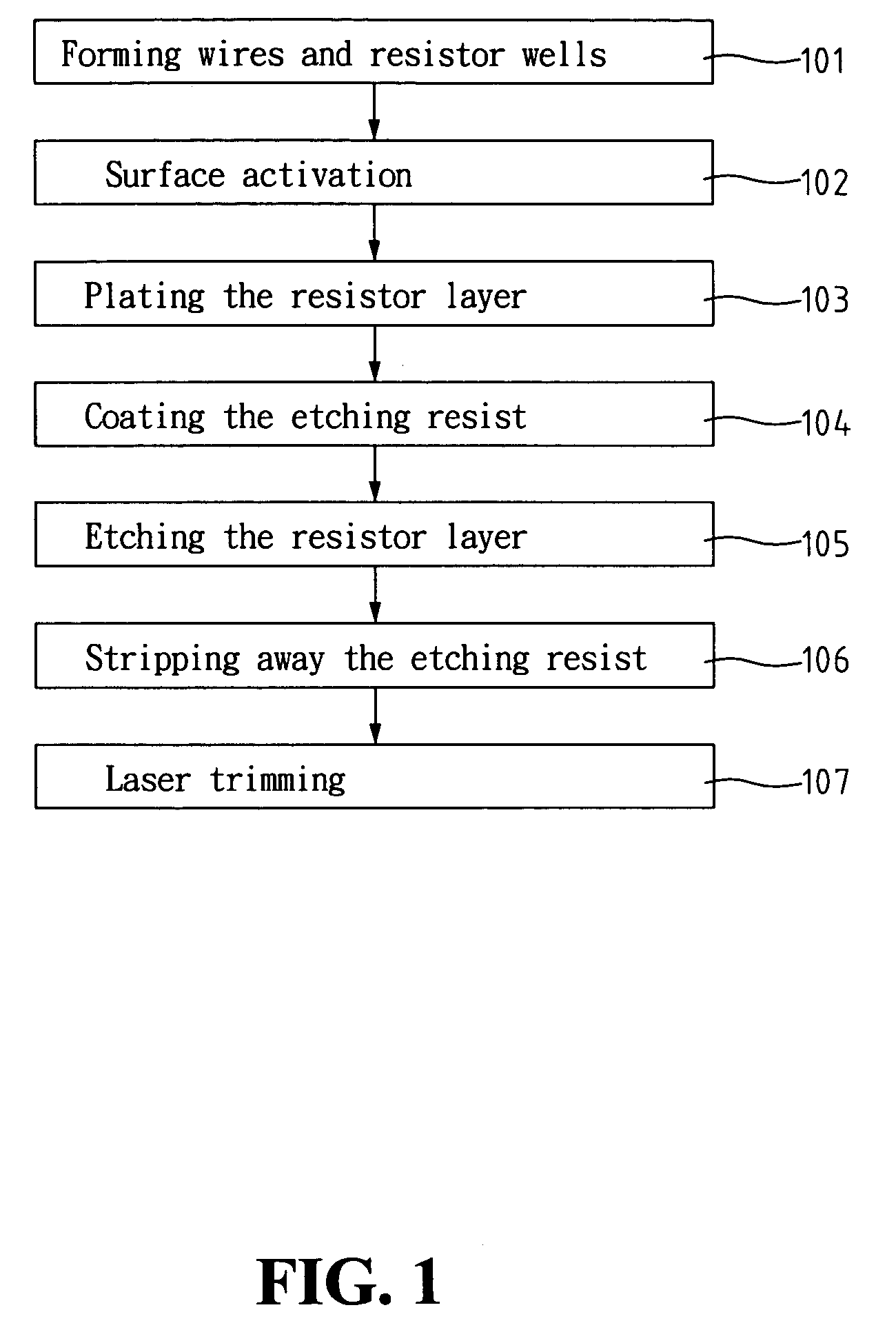

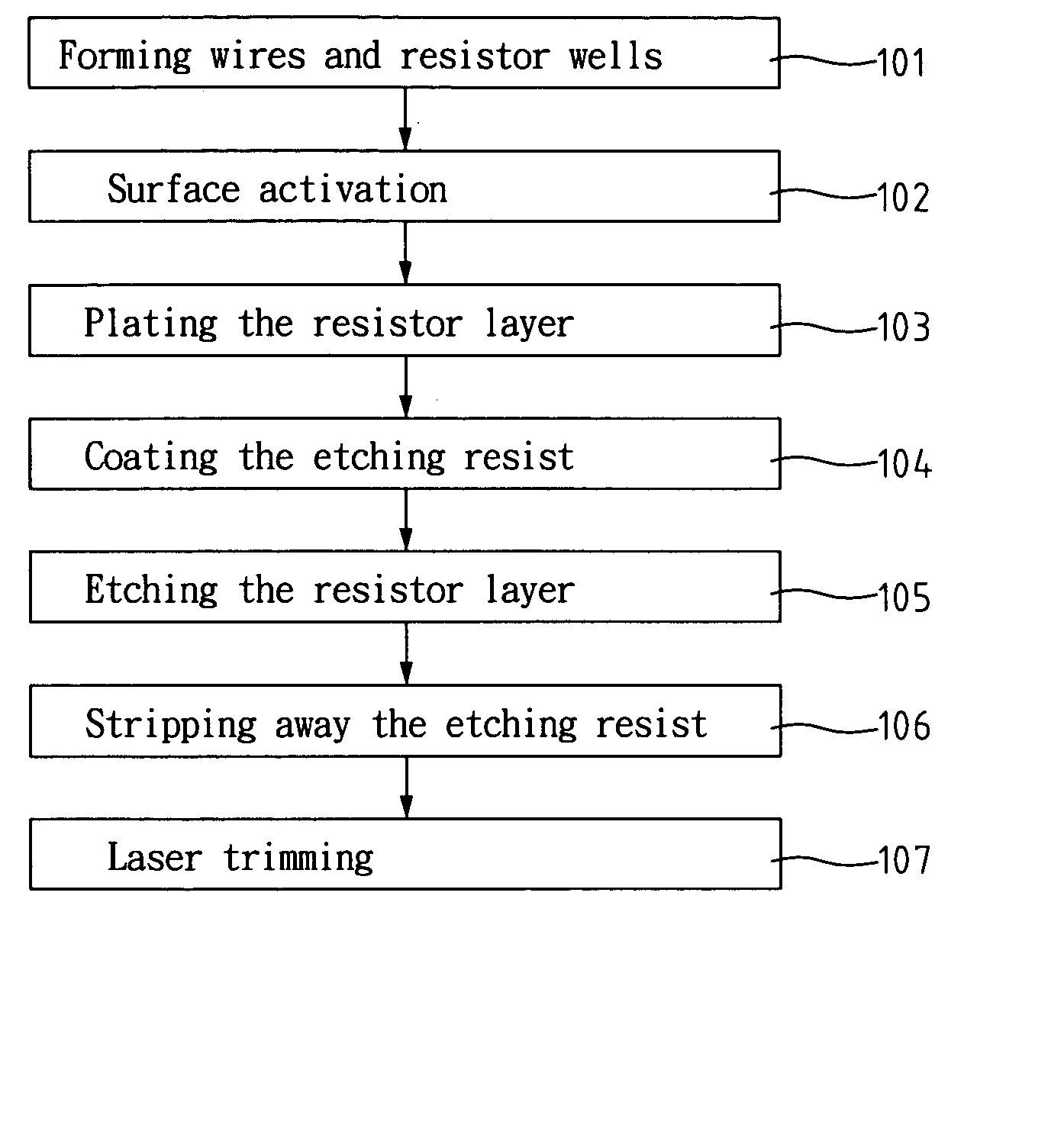

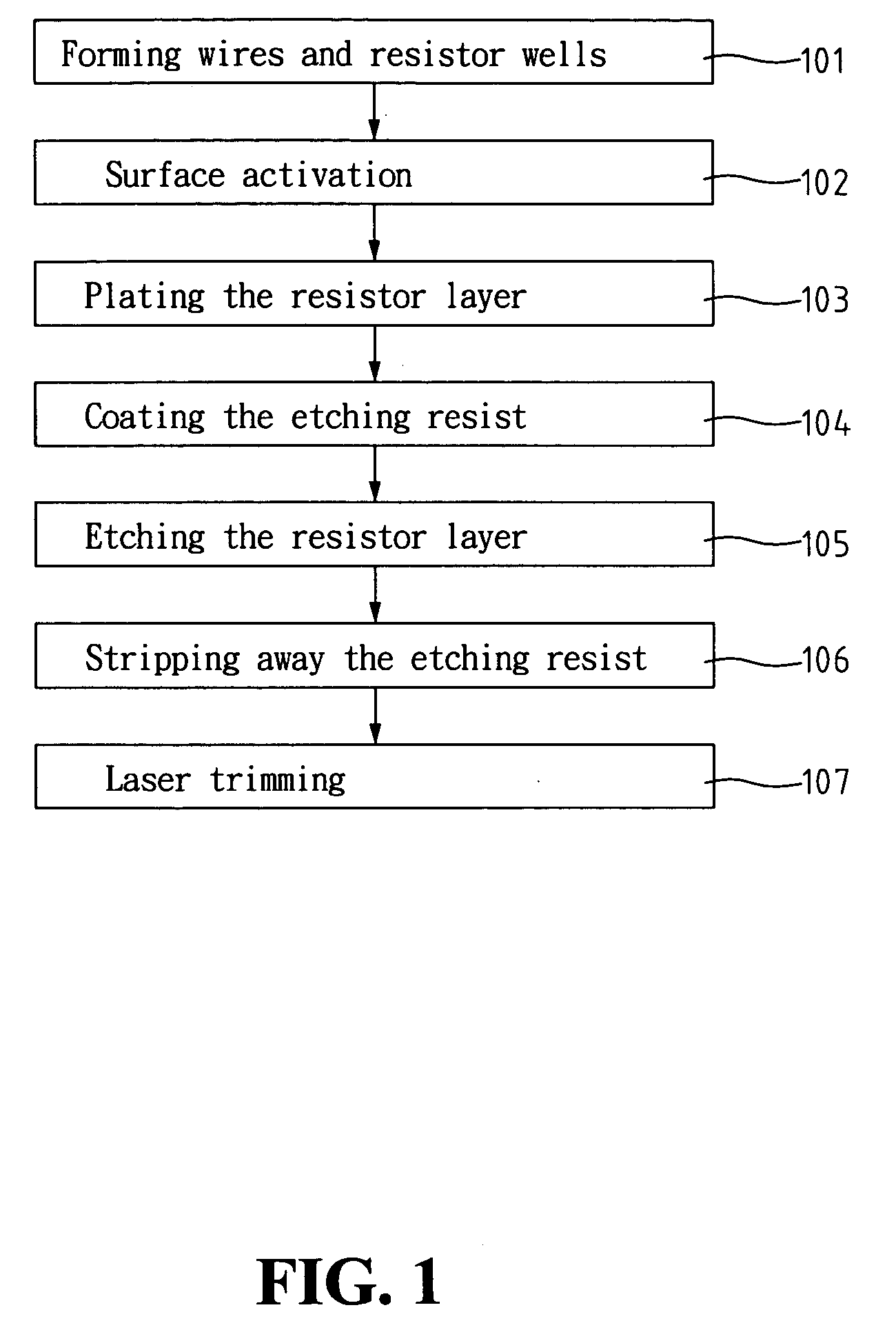

Method for fabricating embedded thin film resistors of printed circuit board

InactiveUS7213327B2Finer circuit layoutSmall sizePrinted circuit assemblingElectrically conductive connectionsManufacturing cost reductionPrinted circuit board

A method for fabricating the embedded thin film resistors of a printed circuit board is provided. The embedded thin film resistors are formed using a resistor layer built in the printed circuit board. Compared with conventional discrete resistors, embedded thin film resistors contribute to a smaller printed circuit board as the space for installing conventional resistors is saved, and better signal transmission speed and quality as the capacitive reactance effect caused by two connectors of the conventional resistors is avoided. The method for fabricating the embedded thin film resistors provided by the invention can be conducted using the process and equipment for conventional printed circuit boards and thereby saving the investment on new types of equipment. The method can be applied in the mass production of printed circuit boards and thereby reduce the manufacturing cost significantly.

Owner:SU SUNG LING

Compact potentiometer

InactiveUS6040756ACompact designResisitors with sliding contactResistor housing/enclosing/embeddingEngineeringHigh resolution

A sensor is disclosed that fits in a compact package. This compact sensor is ideal for sensing rotary positions and for accommodating one or more potentiometers. The resistor track is parallel and opposed to the collector track, and the wiper is placed between the two tracks to swipe both of them in one embodiment. This allows a short package, because the tracks are opposed to each other rather than being in a line, and a narrow package, because the tracks are not placed side by side. Another advantage of the invention is that putting the resistor track on a larger radius and the collector track on a smaller radius allows the resistor track to be longer. Having a longer resistor track allows a higher resolution, yet a package containing the potentiometer will still be relatively small. Several potentiometers may be placed in the sensor to provide redundancy yet retain compactness.

Owner:CTS CORP ELKHART

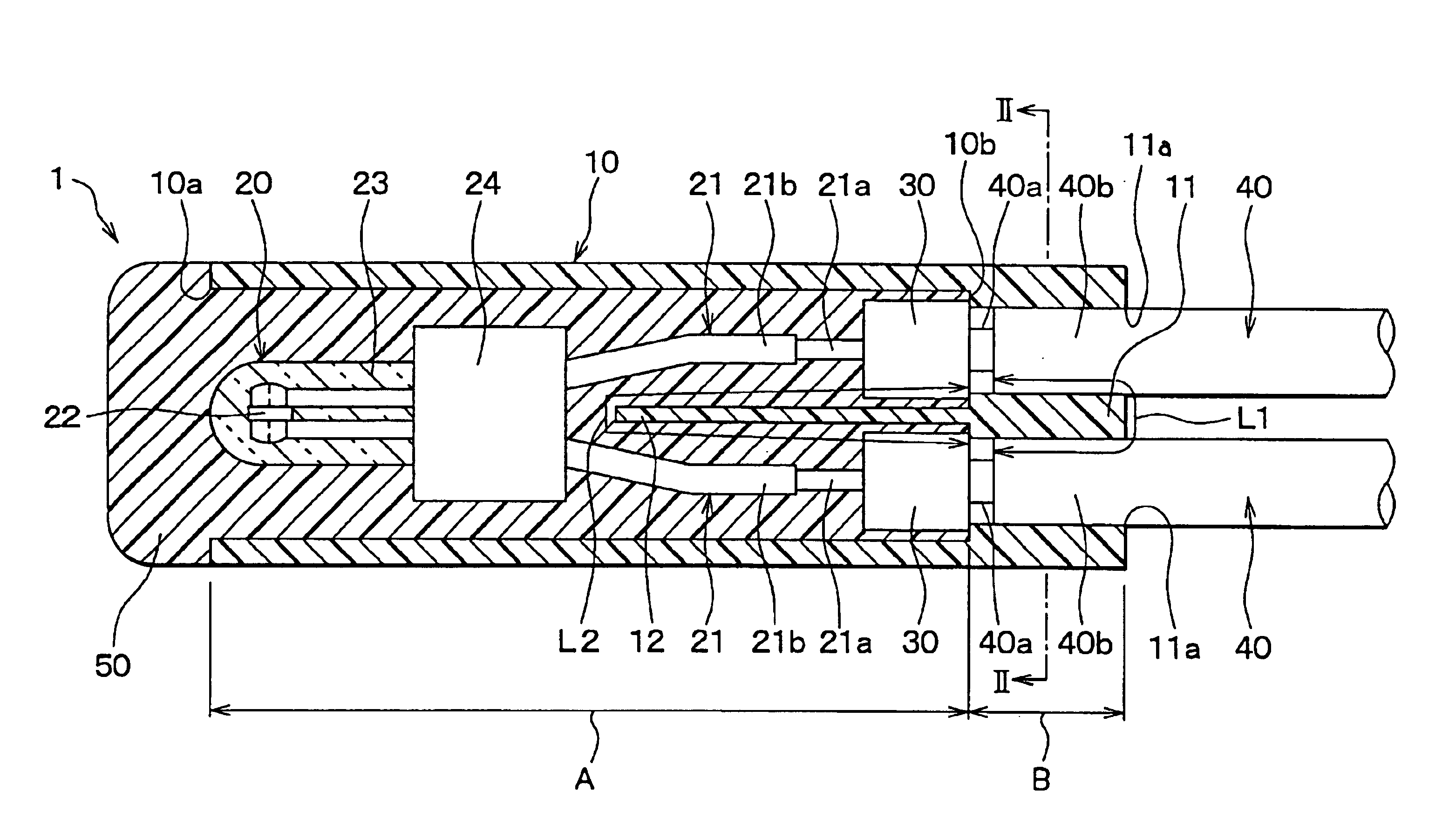

Temperature sensor and method for manufacturing the same

ActiveUS6918696B2Improve reliabilityReduce the possibilityThermometer detailsLine/current collector detailsBiomedical engineeringElectric wire

A temperature sensor includes a casing having a first part and a second part, a temperature detector for detecting temperature of fluid and a pair of outside wires connecting to the temperature detector. The casing further includes a mold portion and an insert portion. The mold portion is disposed in the first part of the casing. The insert portion is disposed in the second part of the casing, and includes a pair of holes for inserting the outside wires therein. The temperature detector is disposed in the first part of the casing. Each outside wire extends from the second part of the casing to an outside of the casing through the hole.

Owner:SHIBAURA ELECTRONICS CO LTD

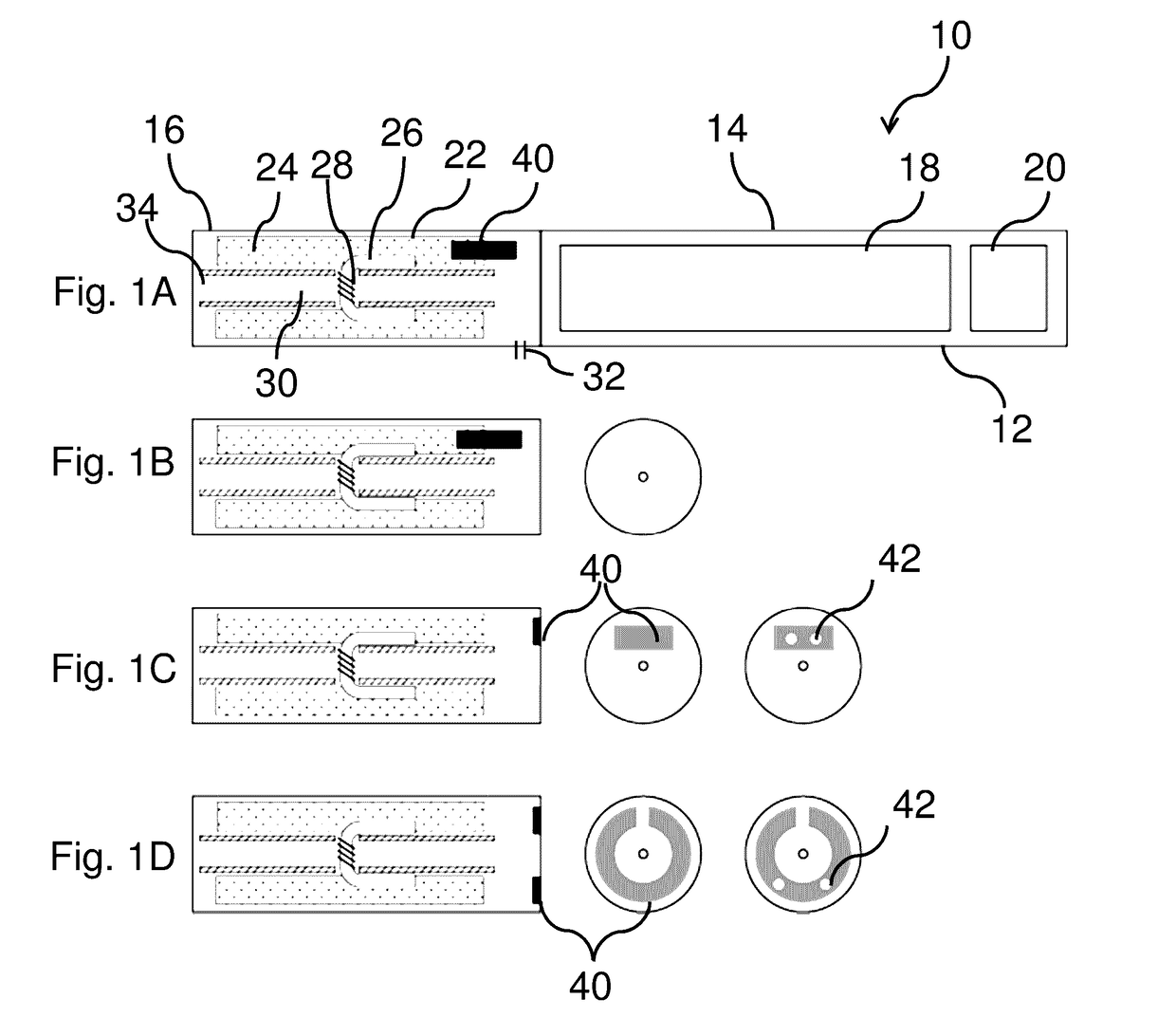

Cartridge for an aerosol-generating system with customizable indentification resistance

ActiveUS20170135405A1Increase flexibilitySimplify production and manufactureTobacco devicesResistor housing/enclosing/embeddingElectrical resistance and conductanceEmbedded system

In a method of manufacturing a cartridge of an electronic vaping device, wherein the cartridge includes a pre-vapor formulation storage element, an electrical resistor is physically manipulated to change a resistance of the electrical resistor from a first resistance value to a second resistance value, the second resistance value indicative of a pre-vapor formulation substrate contained in the pre-vapor formulation storage element. The electrical resistor is then mounted to a portion of the cartridge.

Owner:AKRIA CLIENT SERVICES LLC

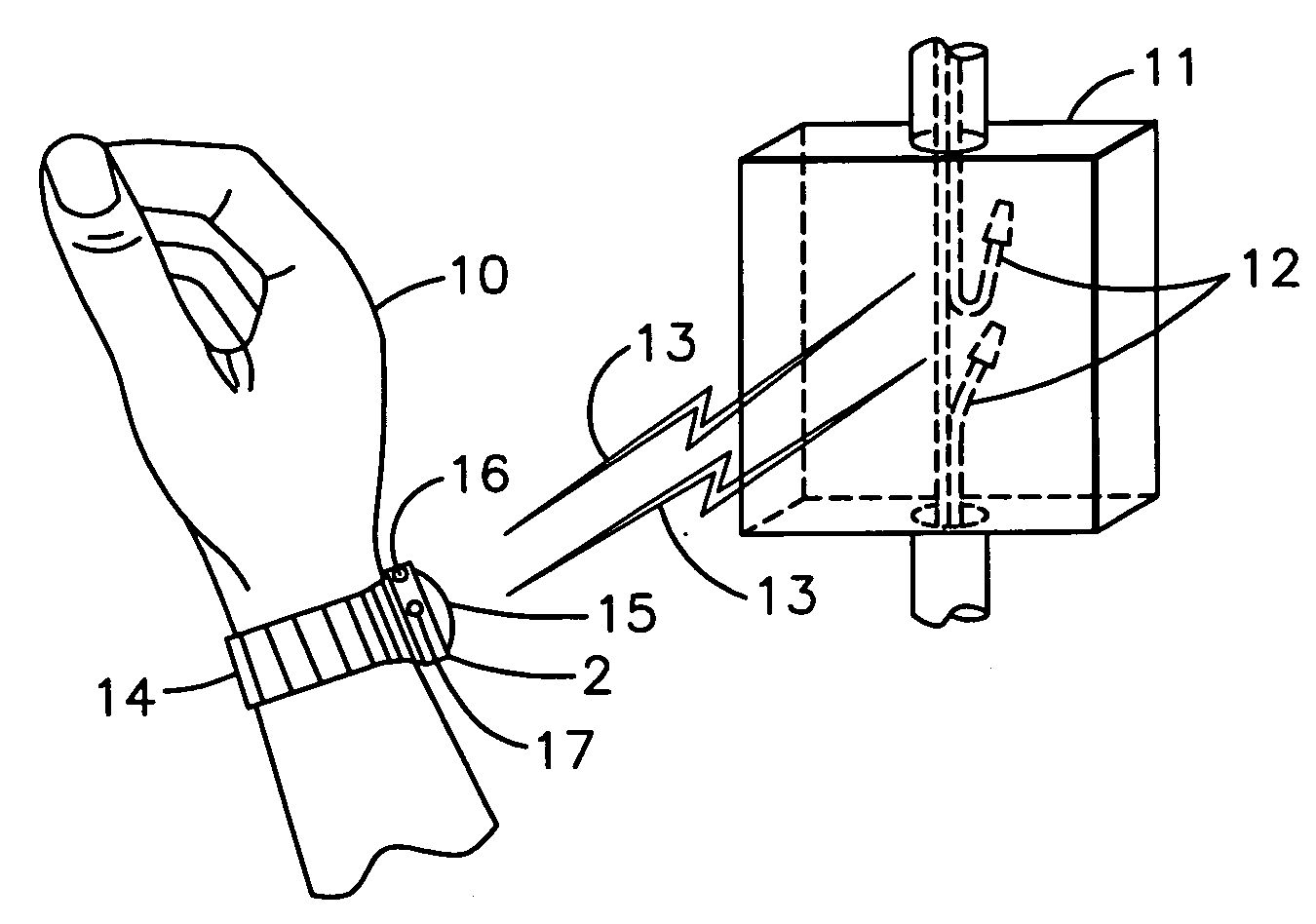

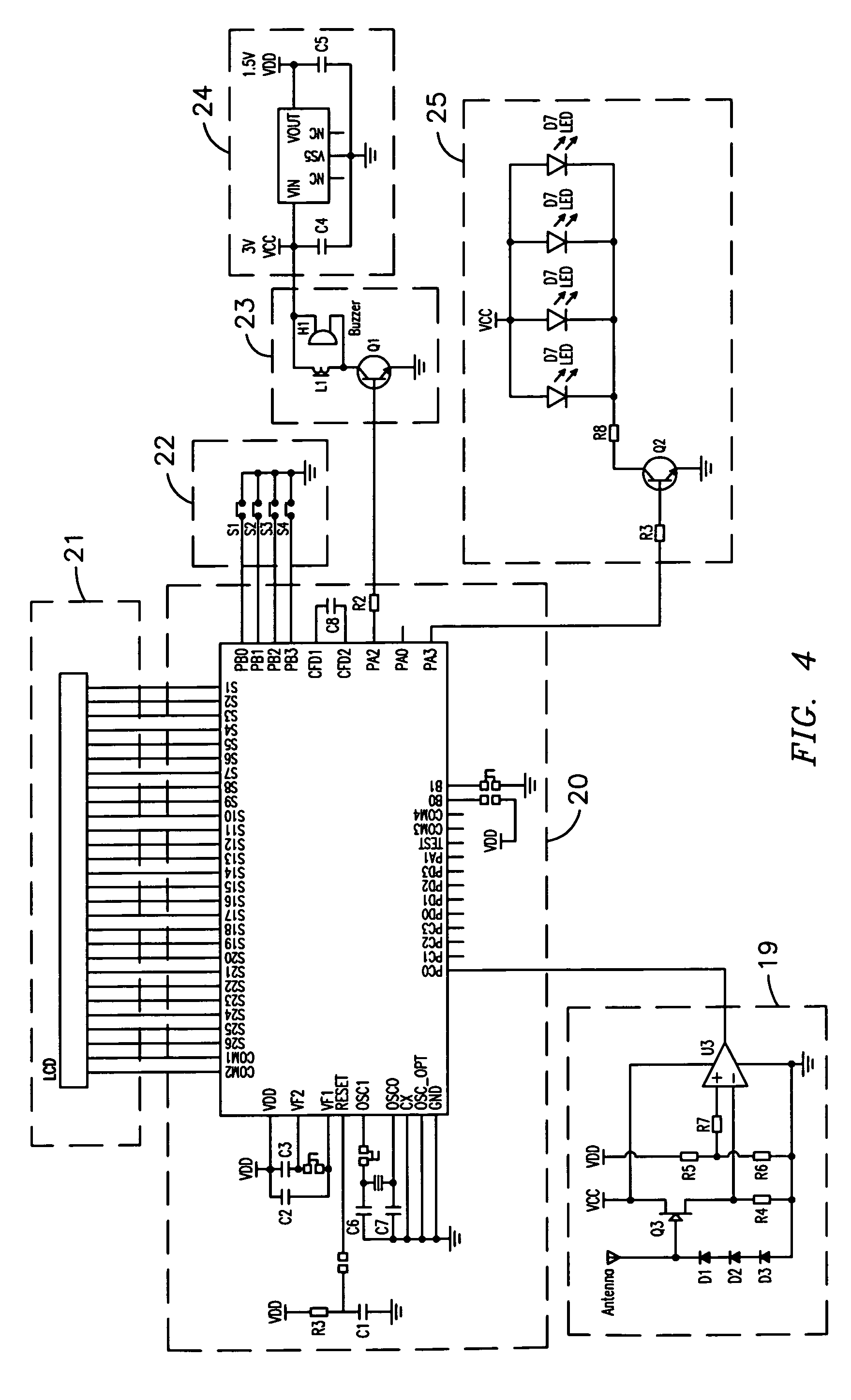

Wrist-wearable electrical detection device

InactiveUS20080024265A1Readily available for useResistor housing/enclosing/embeddingElectrical measurementsEngineeringControl circuit

A wrist-wearable detection device 2 for detecting a electrical potential of a pre-set magnitude within a certain proximity to the detection device. Detective circuitry 1 has a detection coil 3 that detects an electrical potential field generated by an electrically active field. The electrical potential is analyzed and compared by control circuit 20 against pre-set levels such as 60 Hz frequency, which in turn activates audible, visual (LED light) and for a vibratory indicator when in the presence of an electrical potential of a pre-set magnitude. The detector 2 is preferably incorporated into a wrist watch with controls (16, 17 and 18) which can be easily worn and thus always available for use.

Owner:JONES RICHARD K

Method for fabricating embedded thin film resistors of printed circuit board

InactiveUS20050196966A1Finer circuit layoutSmall sizePrinted circuit assemblingElectrically conductive connectionsManufacturing cost reductionHigh volume manufacturing

A method for fabricating the embedded thin film resistors of a printed circuit board is provided. The embedded thin film resistors are formed using a resistor layer built in the printed circuit board. Compared with conventional discrete resistors, embedded thin film resistors contribute to a smaller printed circuit board as the space for installing conventional resistors is saved, and better signal transmission speed and quality as the capacitive reactance effect caused by two connectors of the conventional resistors is avoided. The method for fabricating the embedded thin film resistors provided by the invention can be conducted using the process and equipment for conventional printed circuit boards and thereby saving the investment on new types of equipment. The method can be applied in the mass production of printed circuit boards and thereby reduce the manufacturing cost significantly.

Owner:SU SUNG LING

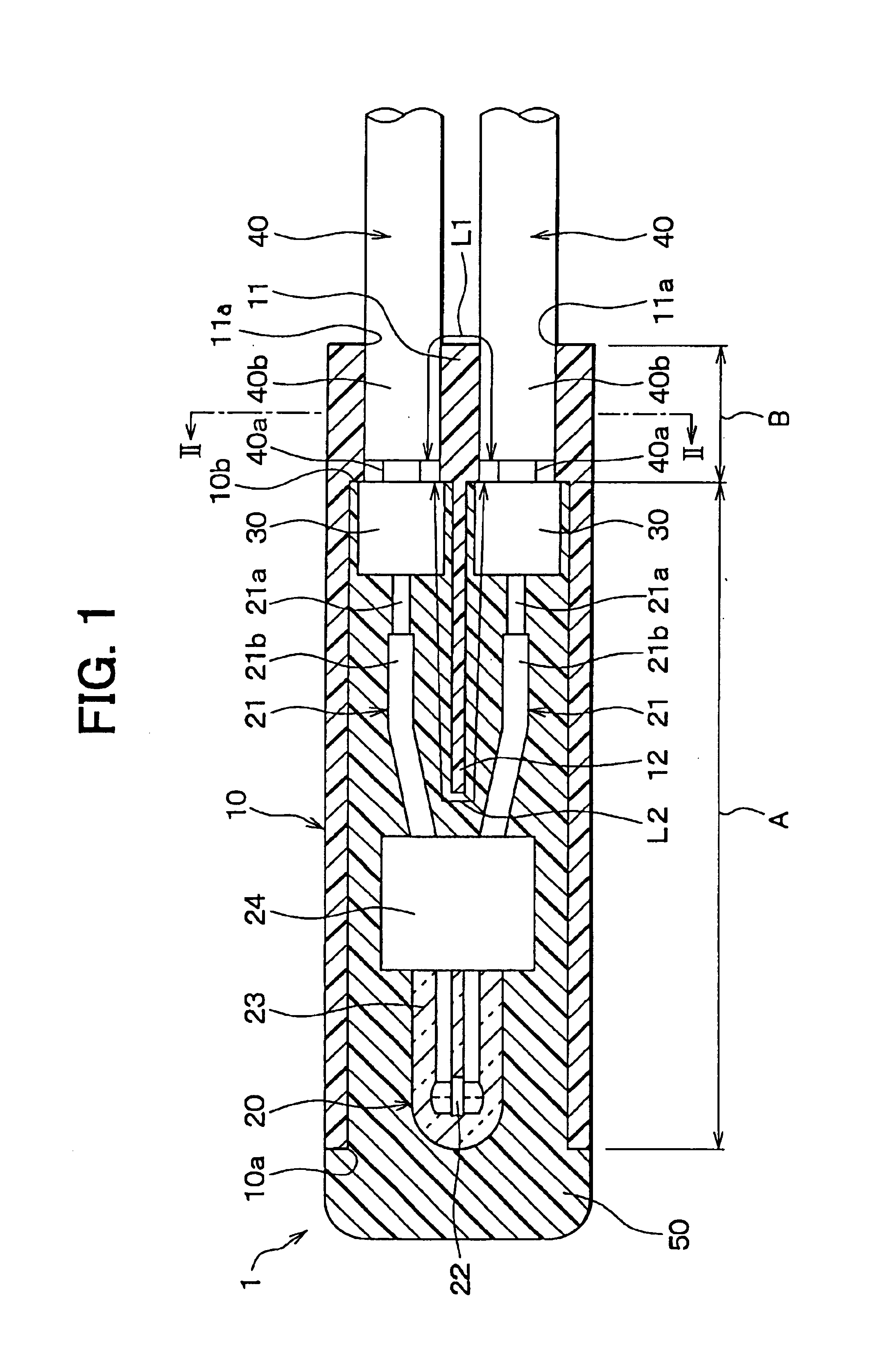

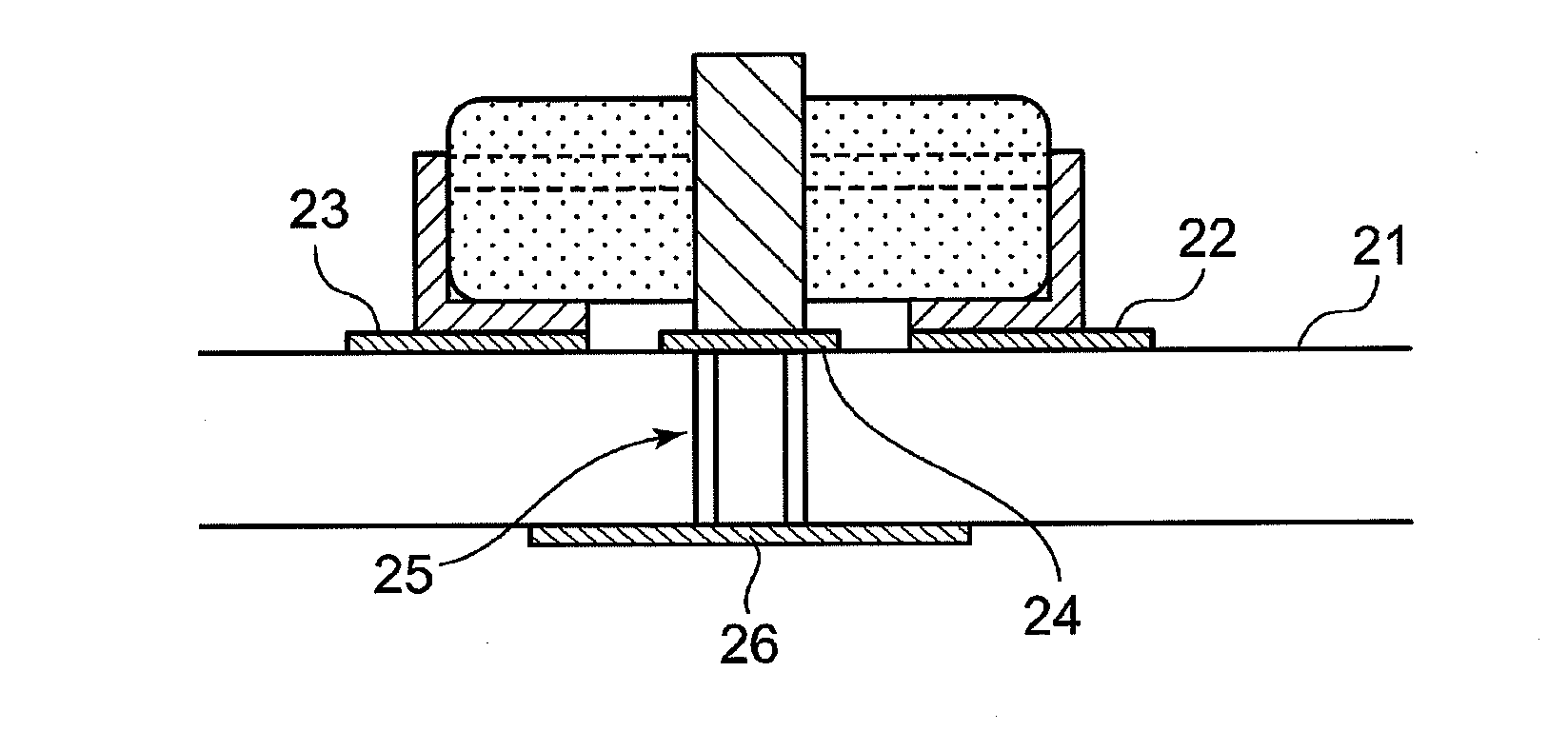

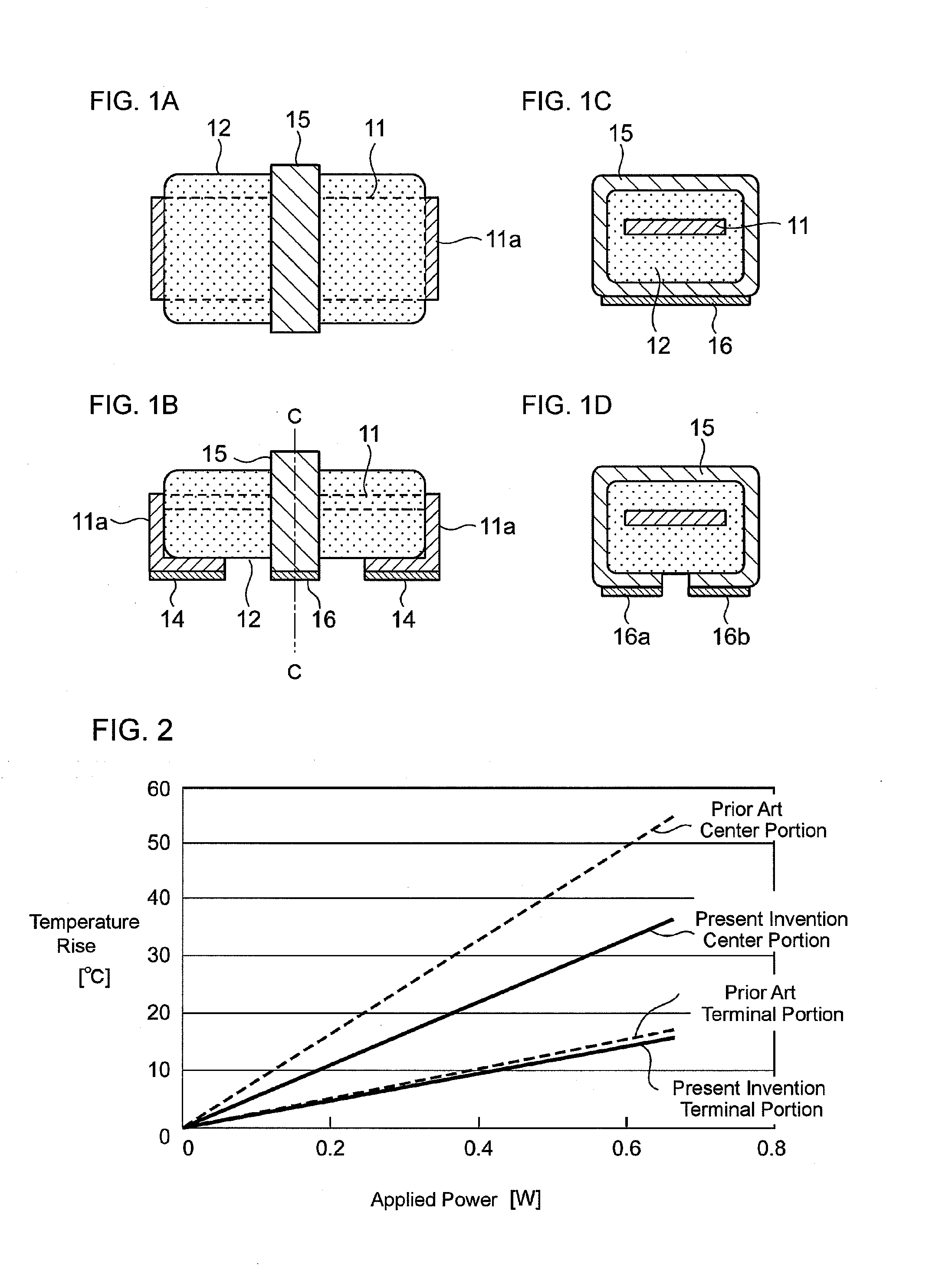

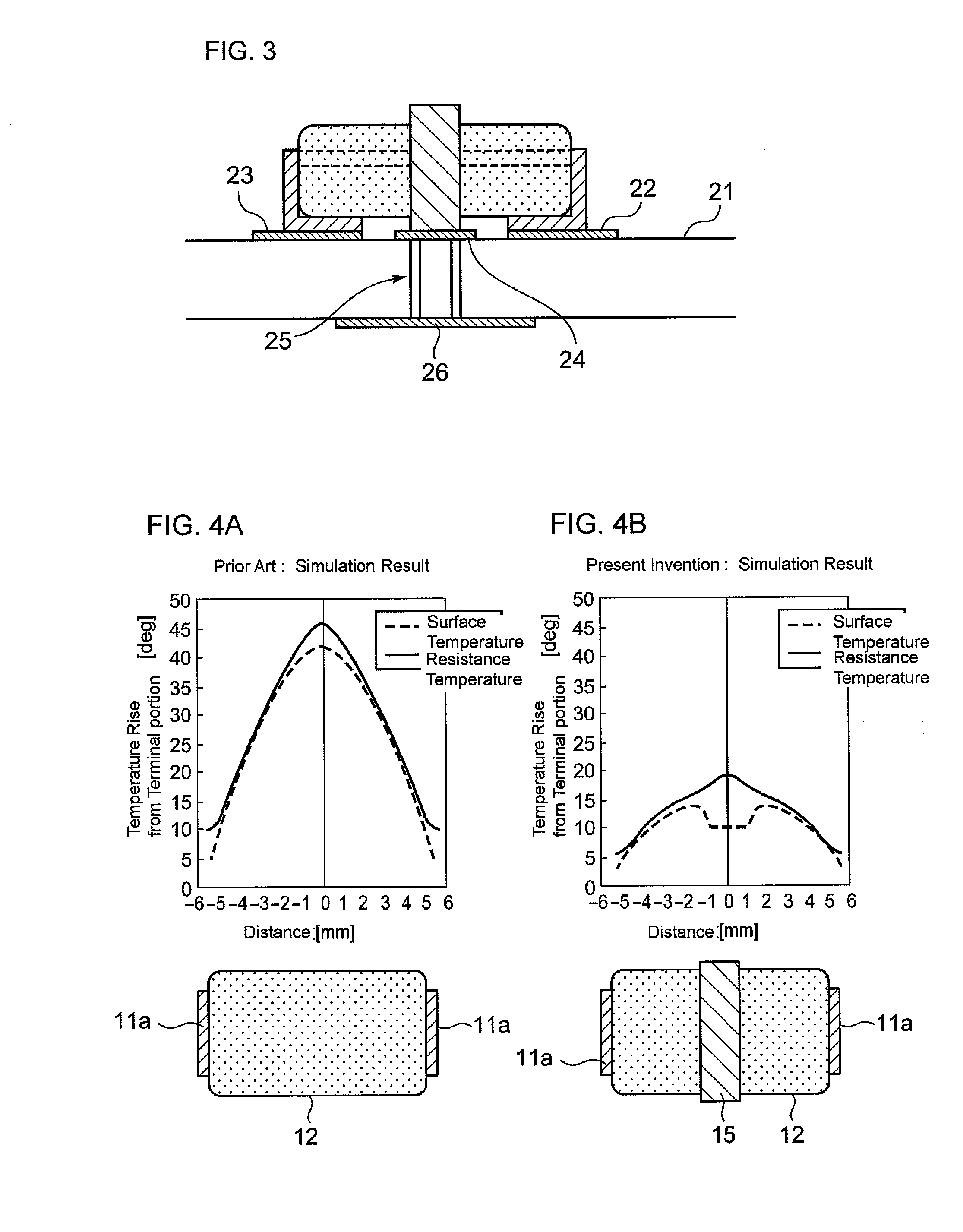

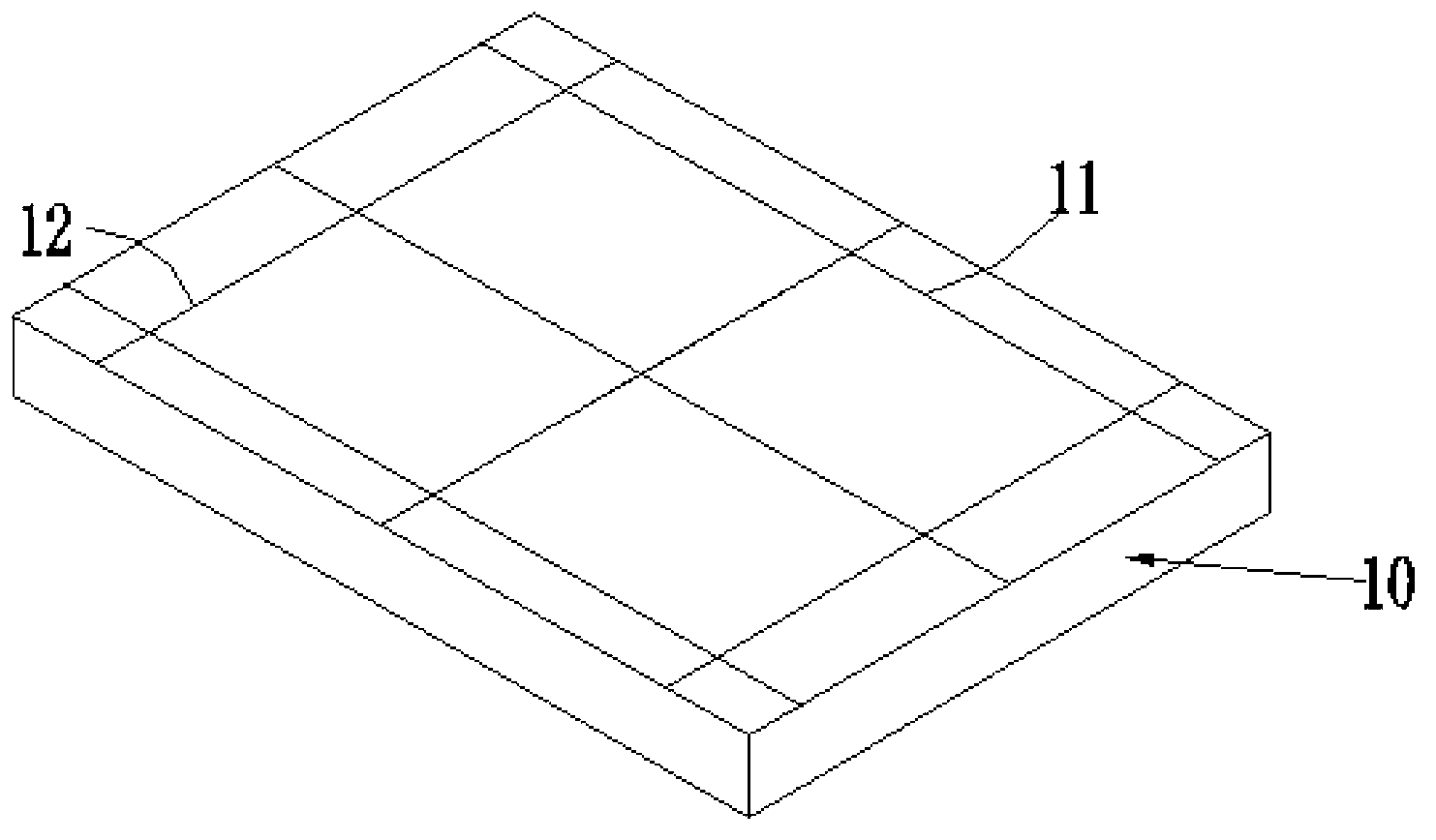

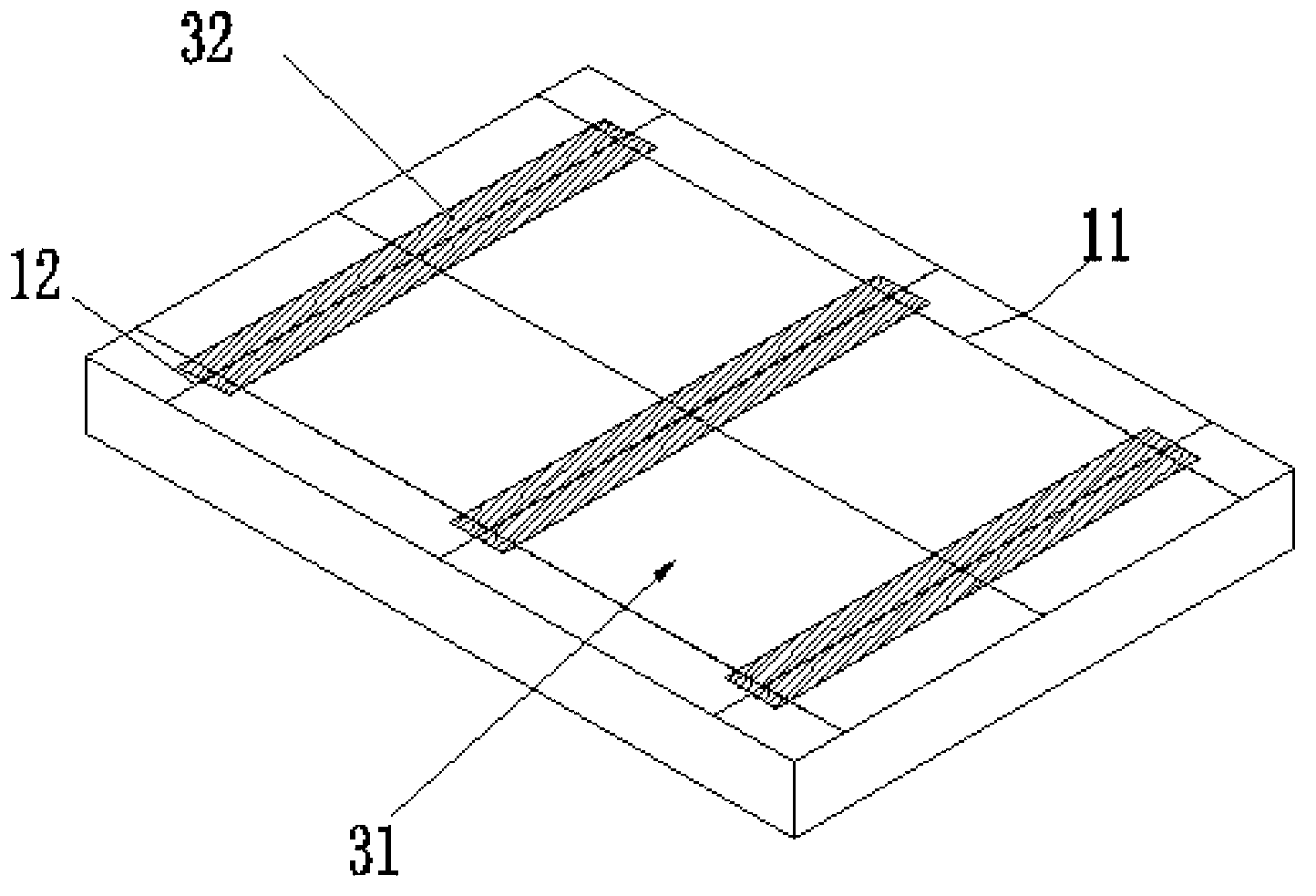

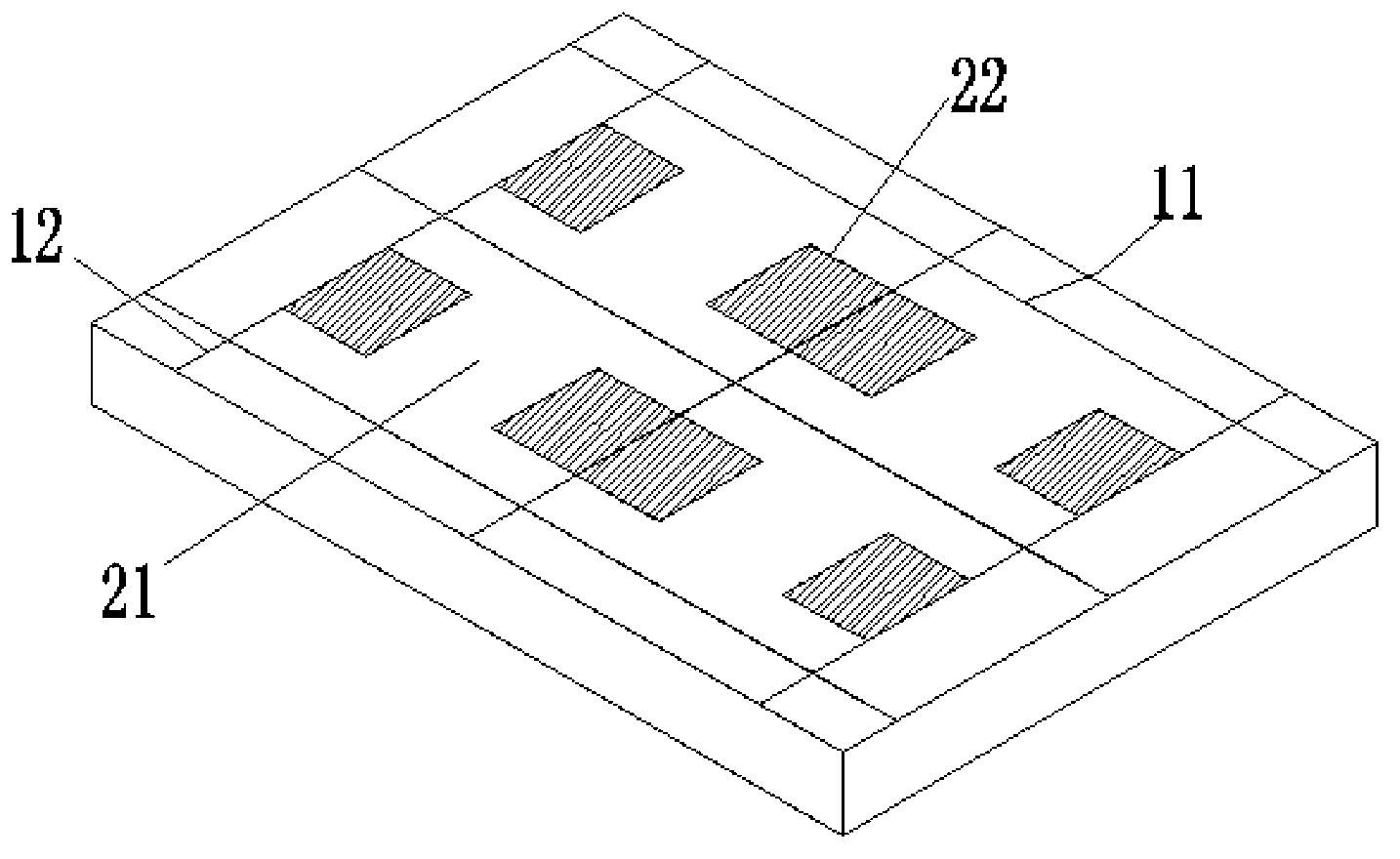

Resistor device

ActiveUS20100328021A1Effective absorptionIncreased power capacityEnvelope/housing resistor manufactureResistor terminals/electrodesElectrical resistance and conductanceSurface mounting

The resistor device is provided with a resistive plate (11) of metal plate material, which is used as a resistance body; a radiative plate (15) of metal plate material, which is spaced from the resistive plate and intercrossed on the resistive plate; a molded resin body (19), which encloses an intercrossing portion of the resistive plate and the radiative plate; terminal portions of the resistive plate (11a), which comprises so that both ends of the resistive plate extending from the molded resin body are bent along an end face and a bottom face of the molded resin body; and terminal portions of the radiative plate (15a), which comprises so that both ends of the radiative plate extending from the molded resin body are bent along an end face and a bottom face of the molded resin body. Accordingly, the surface-mountable resin-sealed metal plate resistor device is enabled to increase the power capacity drastically and to improve the reliability without changing most of the size.

Owner:KOA CORP

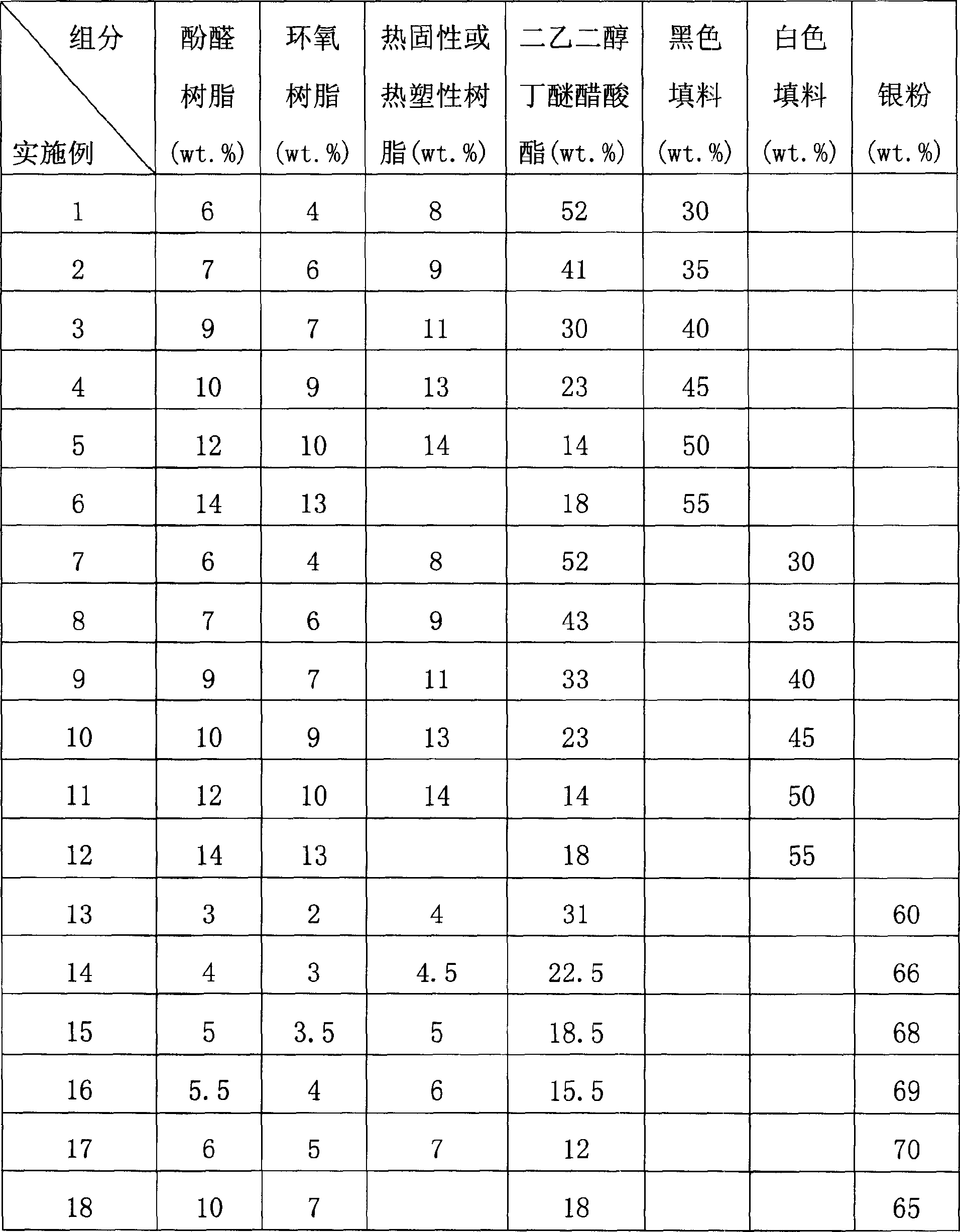

Resin size used for chip resistor

InactiveCN1512522AHigh resistance precisionReduce manufacturing costOther chemical processesResistor housing/enclosing/embeddingEpoxyOrganic solvent

This invention relates to resin sizing material used in sheet resistors including an adhesive and a filler, among which, the adhesive is a mixture of bakelite and epoxy resin formed in an organic solution, the filler is one of white, black fillers or a noble metal powder. The said sizing material is used in a secondary enveloper, markers and end electrodes of the resistor and completely solidified under 160-250deg.C not influencing the sheet resistors.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Insulated fiber sensor apparatus and method

An insulated fiber sensor apparatus is used in a composite that includes a number of fibers in a matrix. An insulated fiber is connected with the composite and is covered with insulation such that the insulation separates the insulated fiber from the matrix and from the number of fibers in the matrix. Further, a measurement device is connected with the insulated fiber. According to one aspect of the invention, the fibers are carbon fibers.

Owner:HSIAO KUANG TING

Organopolysiloxane composition and electronic part encapsulated therewith

ActiveUS20050059772A1Prevent and retard partReduce resistanceOther chemical processesSemiconductor/solid-state device detailsElectronic componentMetal powder

An organopolysiloxane composition comprising 0.01% to less than 0.5% by weight of a sulfidable metal powder is provided. When a silver-containing precision electronic part is encapsulated or sealed with the cured composition, the metal powder in the cured composition is sulfided with sulfur-containing gas for thereby preventing or retarding the corrosion of the electronic part with the sulfur-containing gas.

Owner:SHIN ETSU CHEM IND CO LTD

Thick-film anti-vulcanization paster resistor and manufacturing method thereof

ActiveCN103165250AImprove anti-sulfur performanceProlonged vulcanization pathEnvelope/housing resistor manufactureResistor housing/enclosing/embeddingTinningVulcanization

The invention discloses a thick-film anti-vulcanization paster resistor and a manufacturing method thereof. A second front side electrode is added to a first front side electrode so as to form an overlapped and intersected structure of the second front side electrode and a resistor layer as well as the second front side electrode and a first protecting layer; and the expansion coefficient of a second protecting layer is matched with that of the second front side electrode. Due to the structural method design, a vulcanization route is greatly prolonged, so that the anti-vulcanization property of the paster resistor is improved, and moreover, the phenomenon that the electrode is corroded by vulcanization gas from cracks caused in wave peak soldering or reflow soldering of a PCB (Printed Circuit Board) of the resistor because of the difference of expansion coefficients of an electro-nickelling layer, an electro-tinning layer and the second protecting layer. Therefore, the production cost of the thick-film anti-vulcanization paster resistor is greatly lowered, and the thick-film anti-vulcanization paster resistor can be widely applied to ordinary electronic products.

Owner:UNIROYAL ELECTRONICS IND

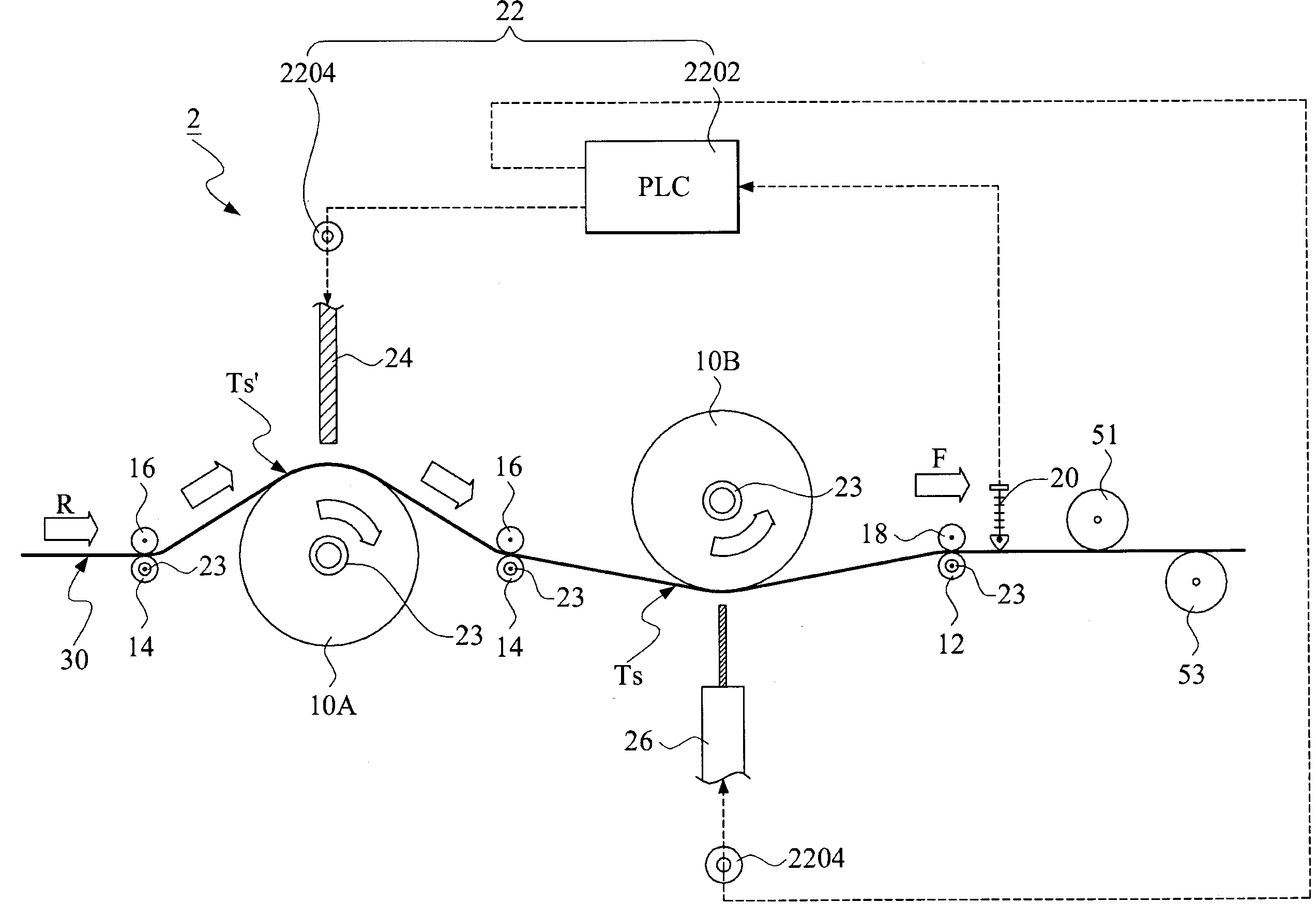

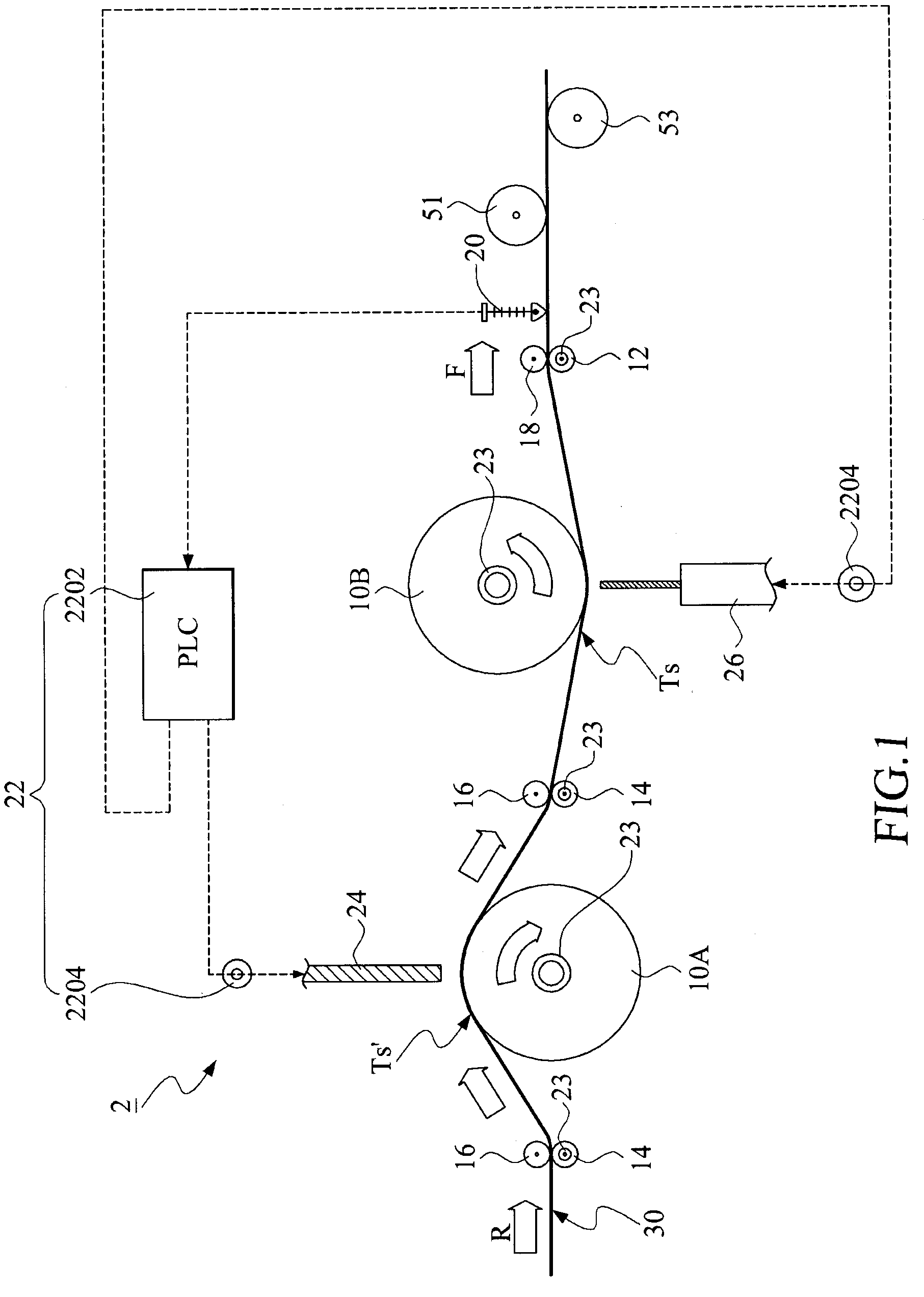

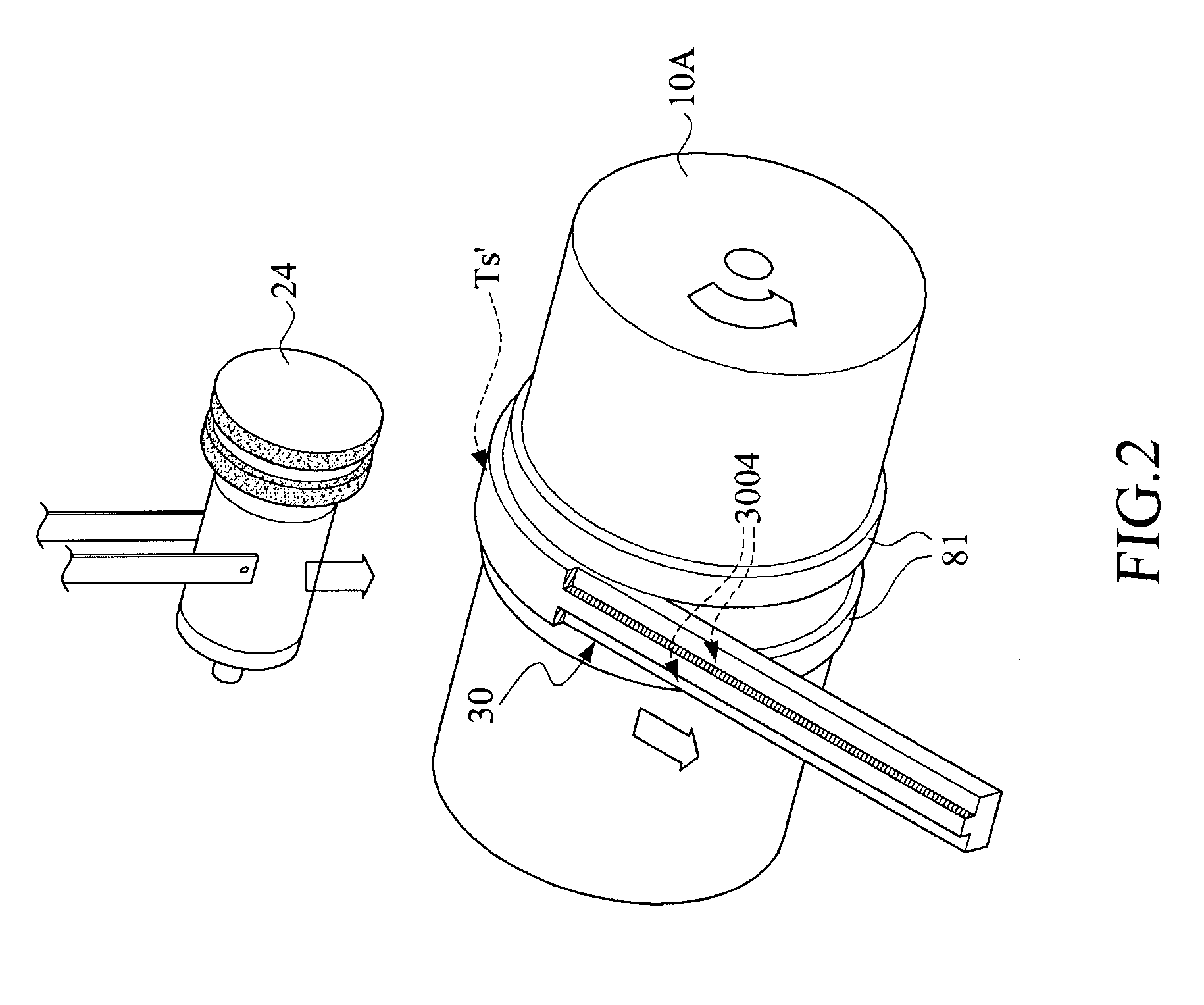

Method and apparatus for manufacturing ultralow-resistance current sensors

ActiveUS20090272169A1Easy maintenanceSmall sizeEnvelope/housing resistor manufactureElectrical measurement instrument detailsElectrical resistance and conductanceCurrent sensor

A method for manufacturing ultralow-resistance current sensors of size 0402 to 4518 of IEEE specifications includes the steps of: a raw metallic strip being pressed to roll over a first tension roller, a cutting tool over the first tension roller being fed to cut the raw metallic strip so as to form a deep groove thereof along the moving metallic strip, an insulating material being filled into and along the deep groove so as to form an lengthwise insulating portion of the metallic strip, and the metallic strip with the insulating portion being segmented into a plurality of ultralow-resistance current sensors.

Owner:PAN JEN HUAN

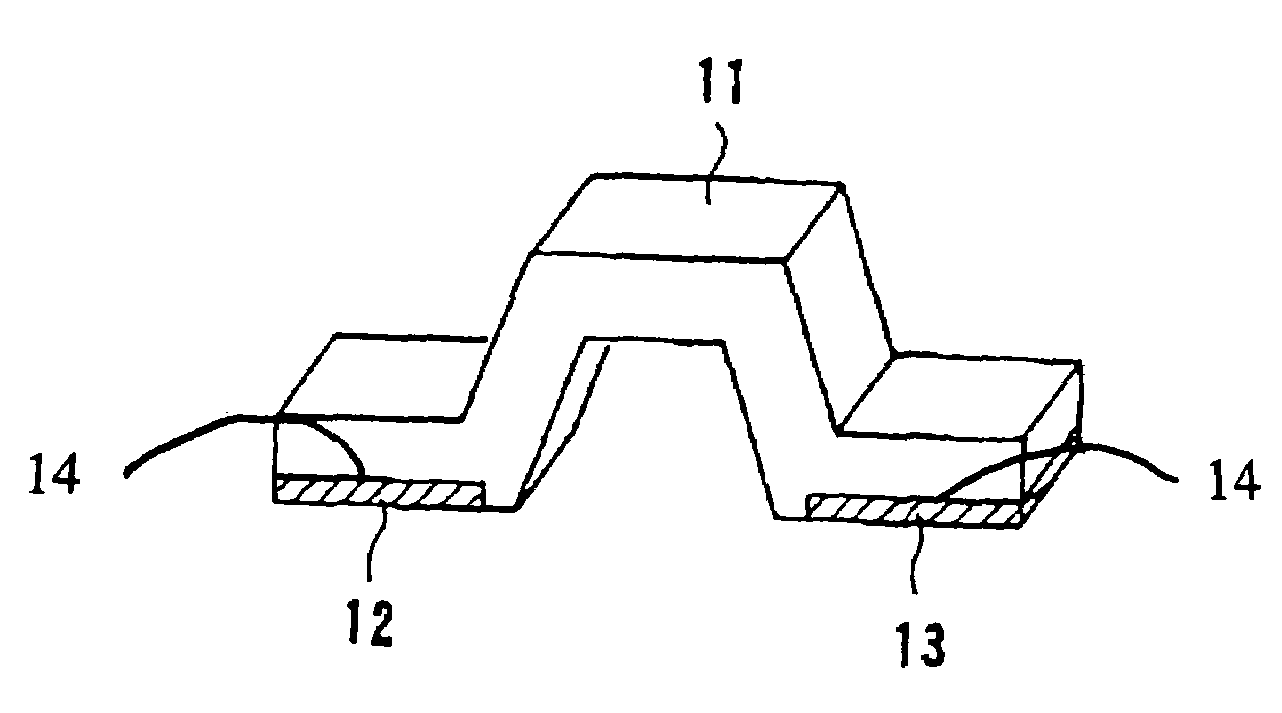

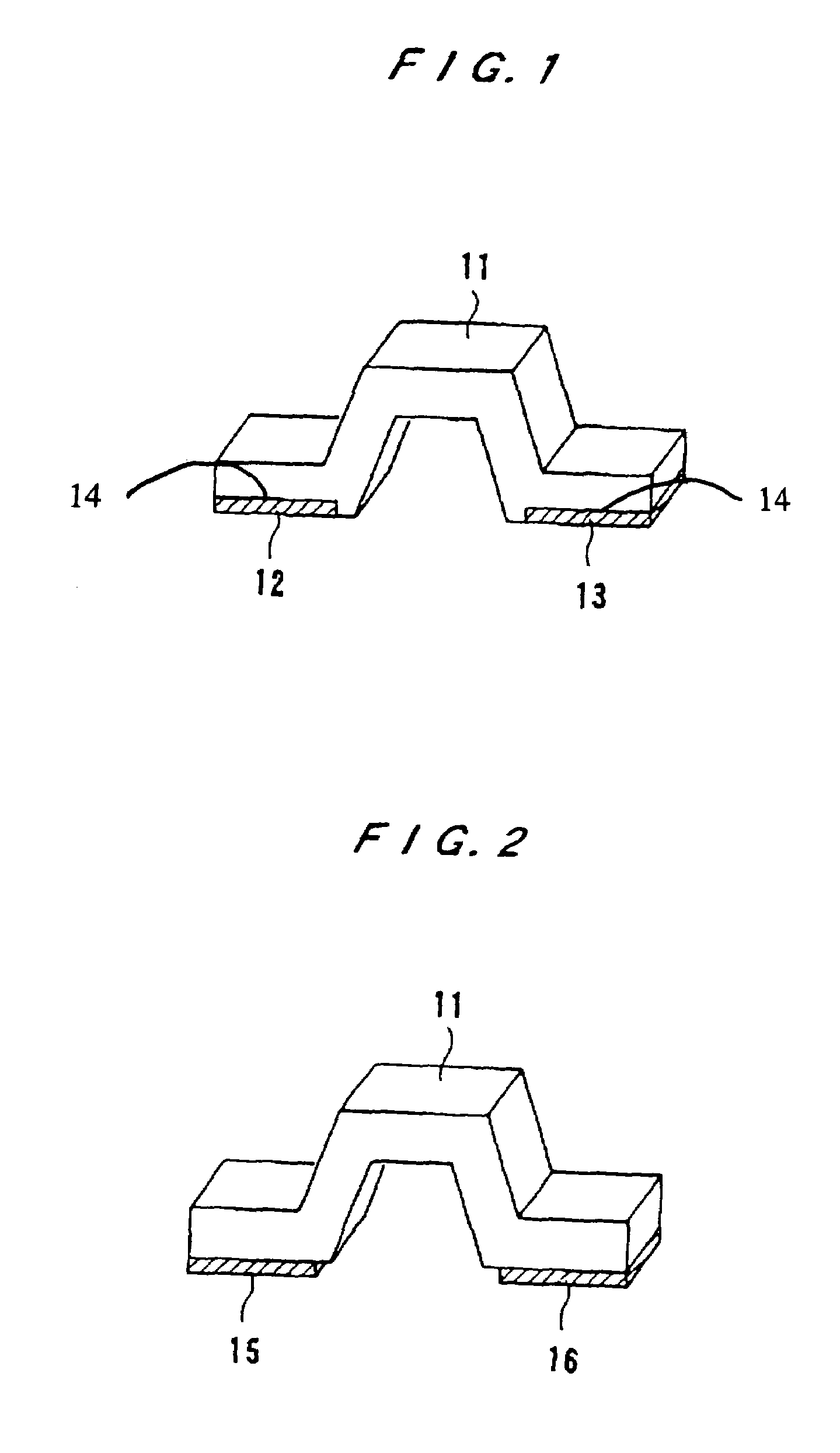

Low resistance value resistor

InactiveUS7042330B2Change directionSpeed up the flowCurrent collector arrangementsResistor terminals/electrodesElectrical resistance and conductanceCurrent distribution

The low resistance value resistor 11 has two electrodes 12,13 of metal strips having a high electrical conductivity. The metal strips are affixed on the resistor body by means of rolling and / or thermal diffusion bonding. A fused solder layer is formed on a surface of each electrode comprised by the metal strip. Thus, sufficient bonding strength and superior current distribution in the resistor body is obtained. Further, a portion of the resistor body is trimmed by removing a portion of the body material along a direction of current flow between the electrodes to adjust a resistance value. Thus, a precise resistor value and superior characteristics of temperature coefficient of resistance (TCR) can be obtained.

Owner:KOA CORP

UV curable protective encapsulant

InactiveUS20050121665A1Low level of water absorption and shrinkageSemiconductor/solid-state device detailsSolid-state devicesOligomerPhotoinitiator

The present invention discloses encapsulant materials for use in glob top and / or dam and fill applications comprising base oligomer / monomers preferably having an acrylated / methacrylated or vinylene-containing oligomer / polymer, one or more multifunctional acrylate monomers, one or more thixotropic agents and, optionally, fillers, additives, photoinitiators and / or pigments. The encapsulant has low levels of water absorption and shrinkage.

Owner:HENKEL KGAA

Semiconductor device and method for manufacturing the same

InactiveUS20090015369A1Reduce parasitic capacitanceResistance change ratioSemiconductor/solid-state device detailsSolid-state devicesSputteringTantalum nitride

A resistor R1 formed by forming a first resistor layer 5a of 20 nm thickness including a tantalum nitride film at a concentration of nitrogen of less than 30 at % and a second resistor layer of 5 nm thickness including a tantalum nitride film at a concentration of nitrogen of 30 at % or more successively by a reactive DC sputtering method using tantalum as a sputtering target material and using a gas mixture of argon and nitrogen as a sputtering gas, and then fabricating the first and the second resistor layers, in which the resistance change ratio of the resistor can be suppressed to less than 1% even when a thermal load is applied in the interconnection step, by the provision of the upper region at a concentration of nitrogen of 30 at % or more.

Owner:HITACHI LTD

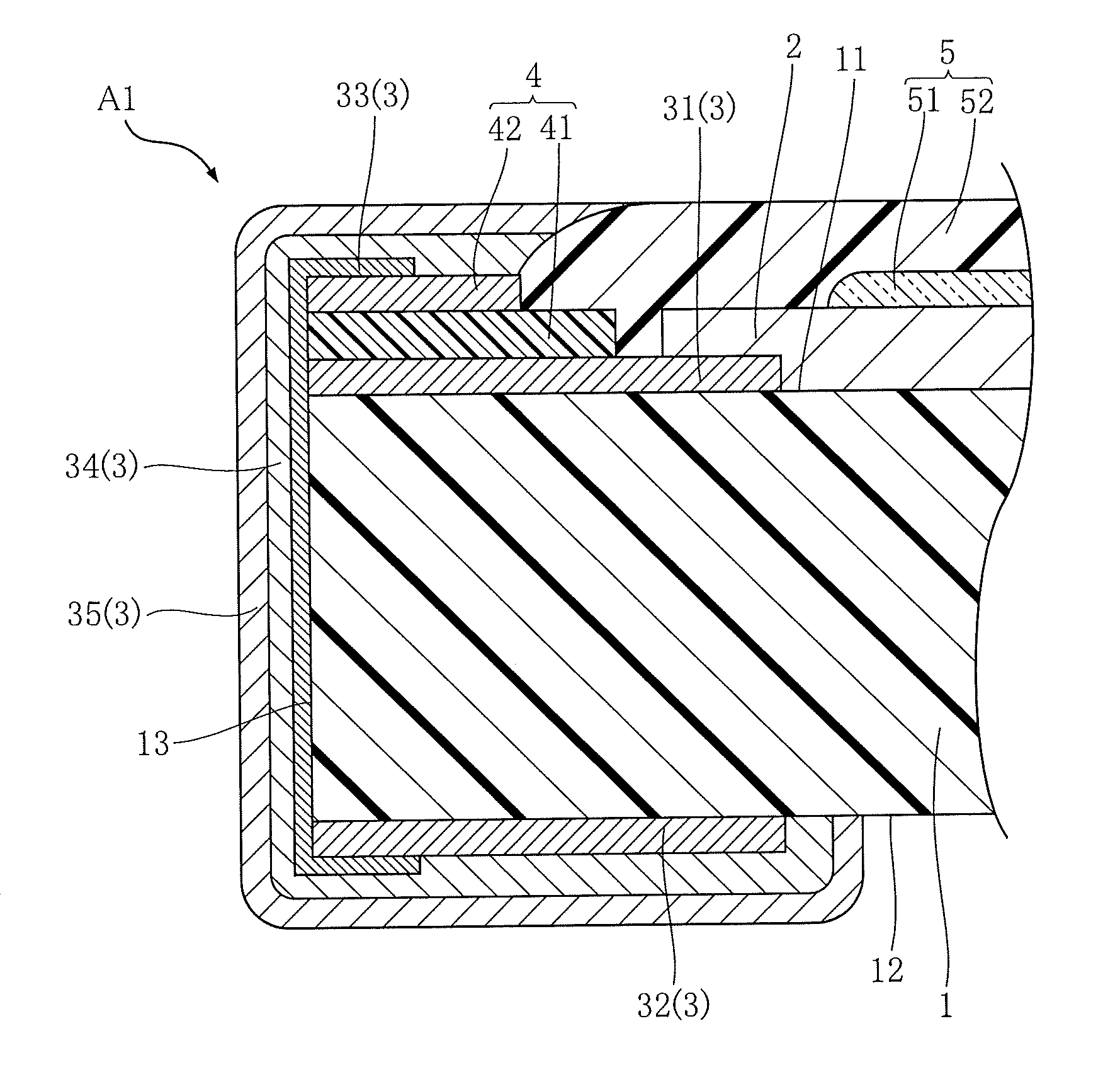

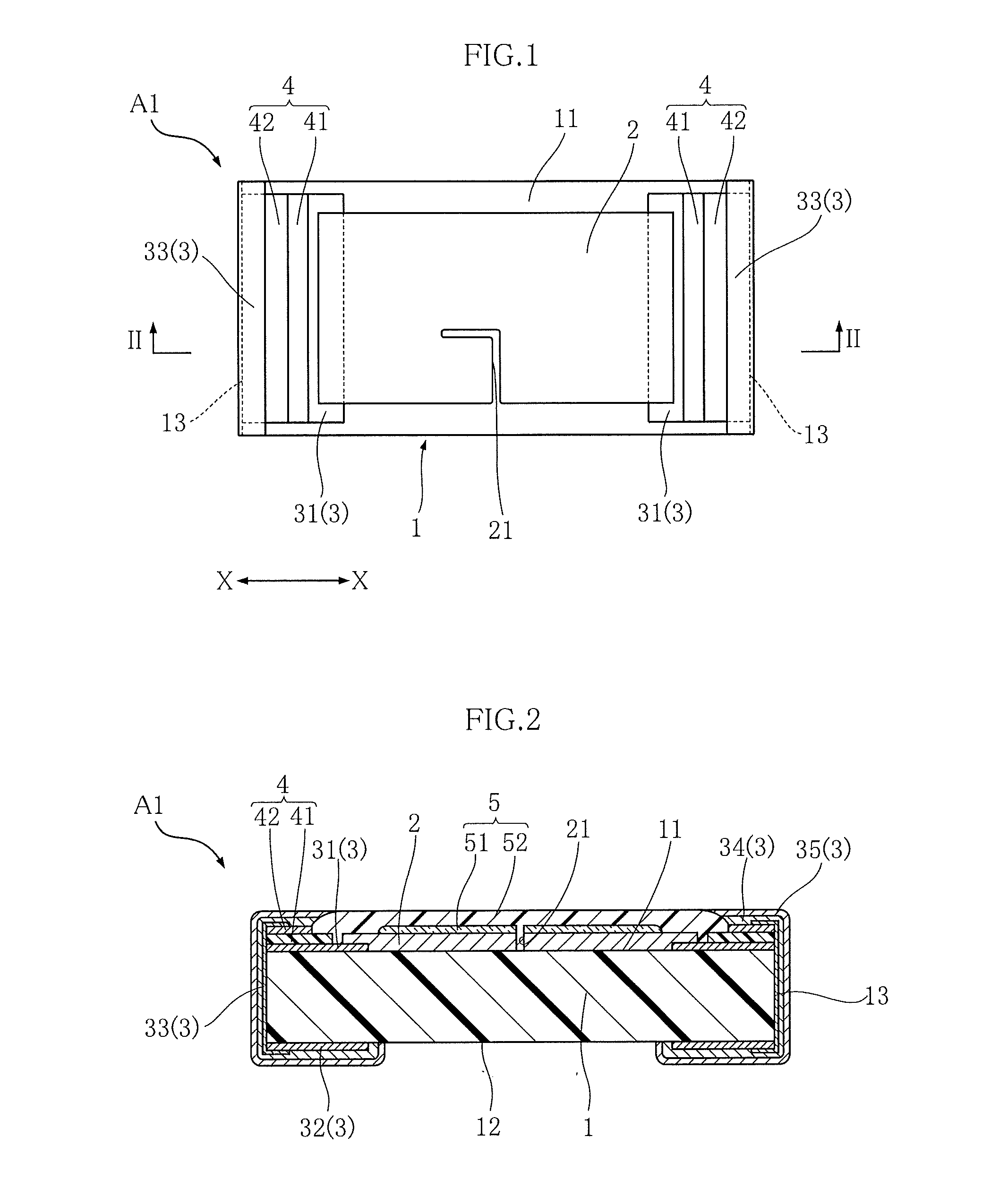

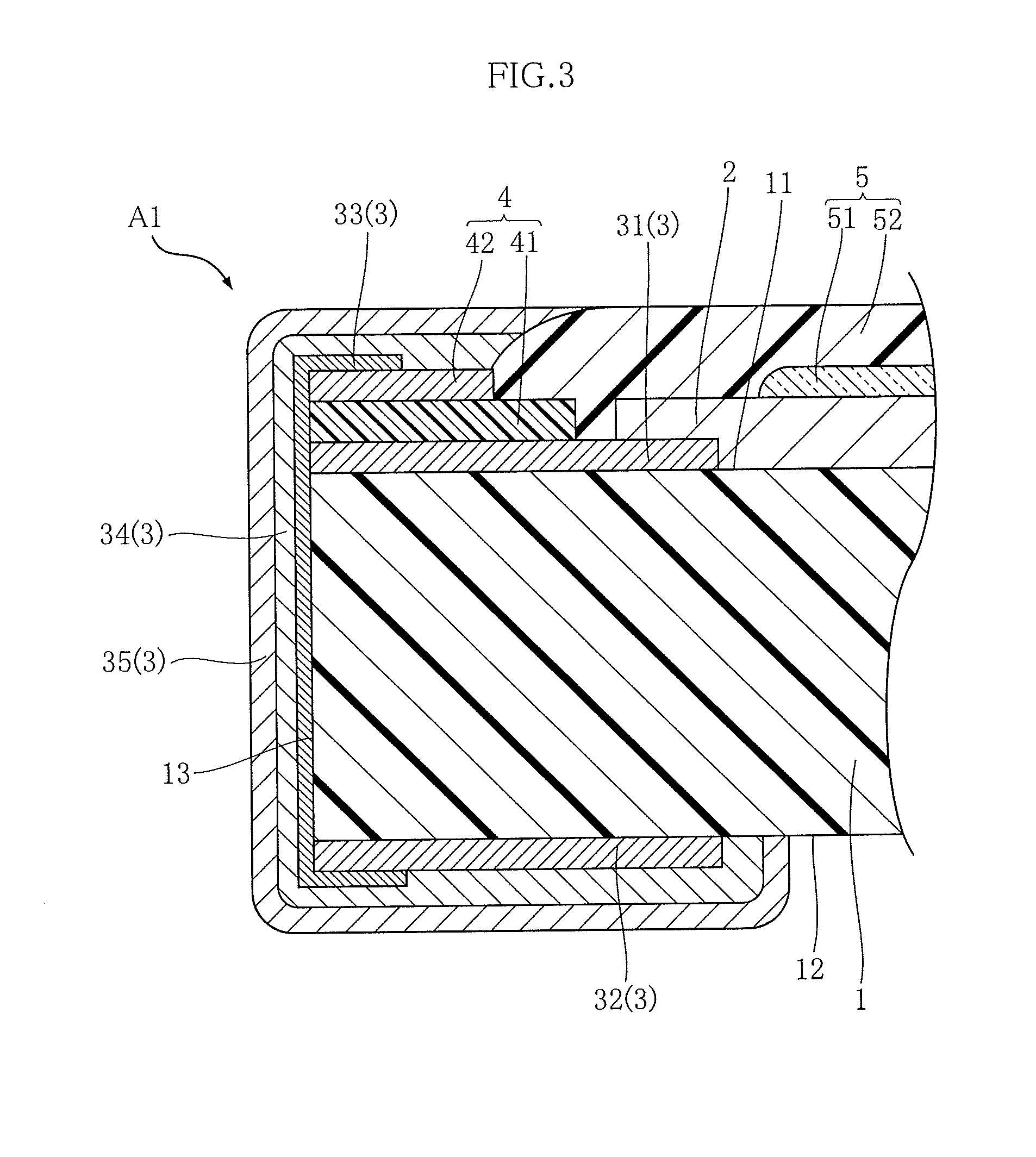

Chip resistor and method for manufacturing the same

ActiveUS20160247610A1Improve sulfur resistanceLow costResistor chip manufactureEnvelope/housing resistor manufactureEngineeringElectrical and Electronics engineering

A chip resistor includes an upper electrode provided on a substrate, a resistor element connected to the upper electrode, and a side electrode connected to the upper electrode. The side electrode, arranged on a side surface of the substrate, has two portions overlapping with the obverse surface and reverse surface of the substrate, respectively. An intermediate electrode covers the side electrode, and an external electrode covers the intermediate electrode. A first protective layer is disposed between the upper electrode and the intermediate electrode, and held in contact with the upper electrode and the side electrode. The first protective layer is more resistant to sulfurization than the upper electrode. A second protective layer is disposed between the first protective layer and intermediate electrode, and held in contact with the first protective layer, side electrode and intermediate electrode.

Owner:ROHM CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com