Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3224 results about "Conductive paste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

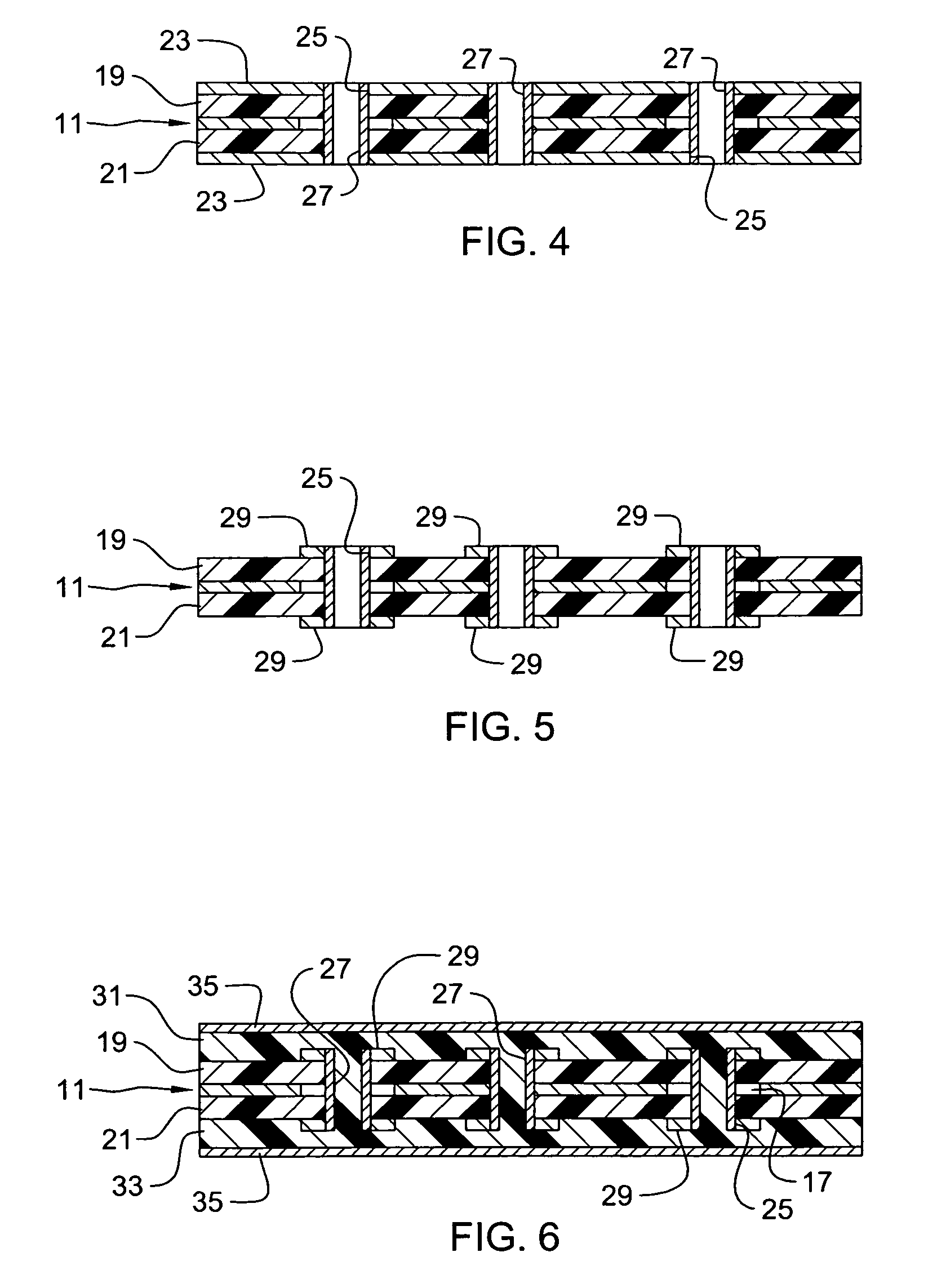

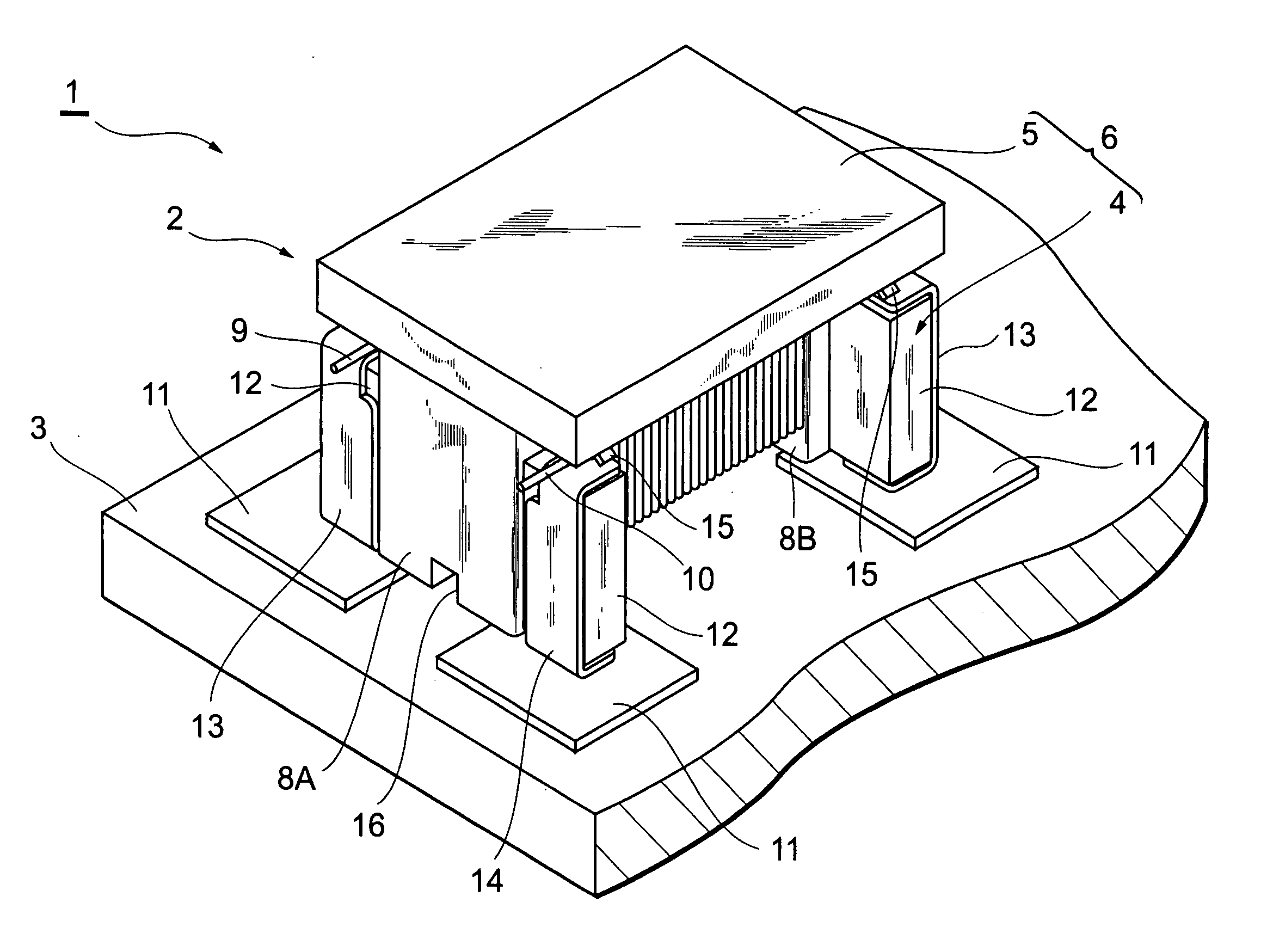

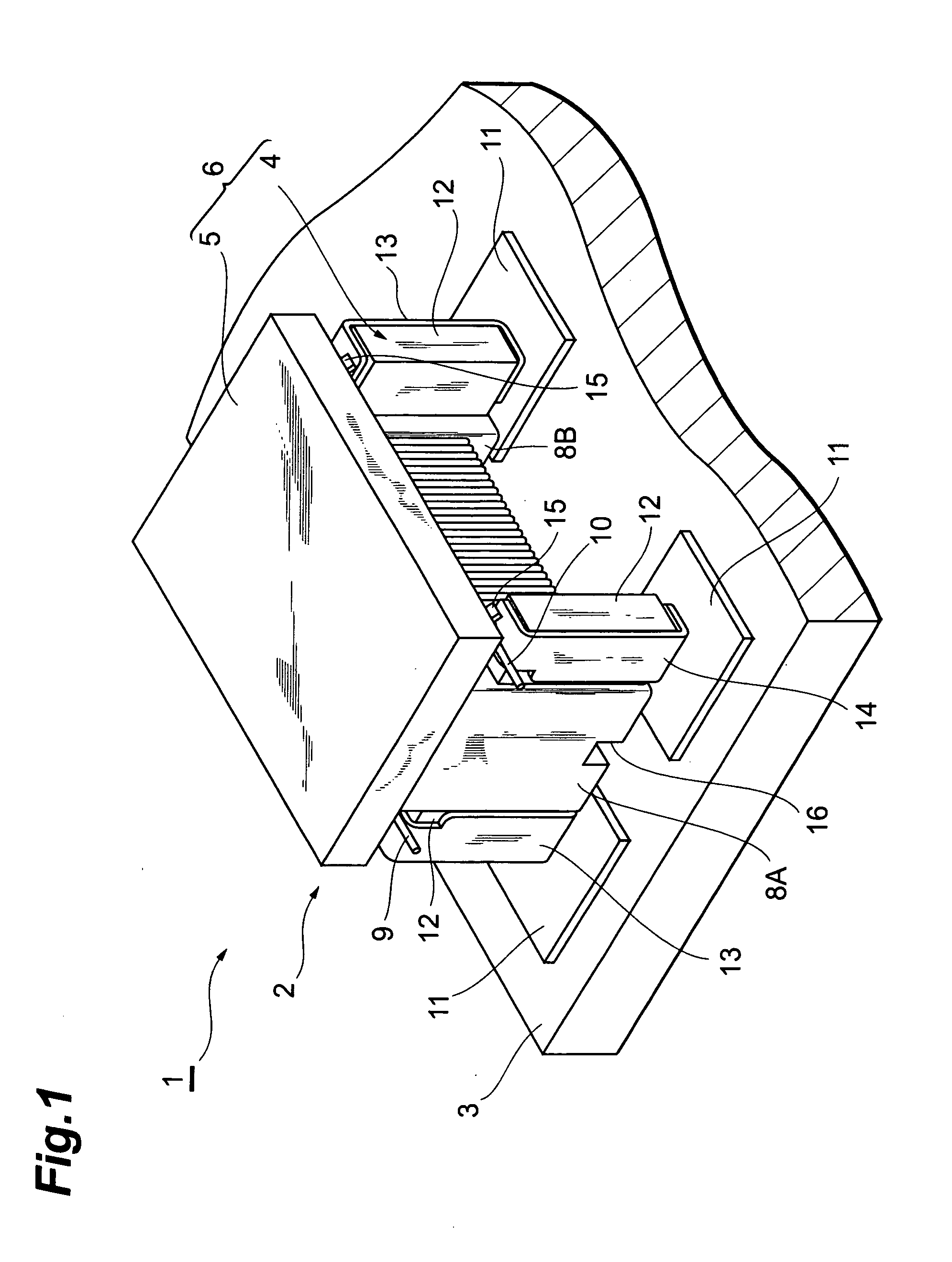

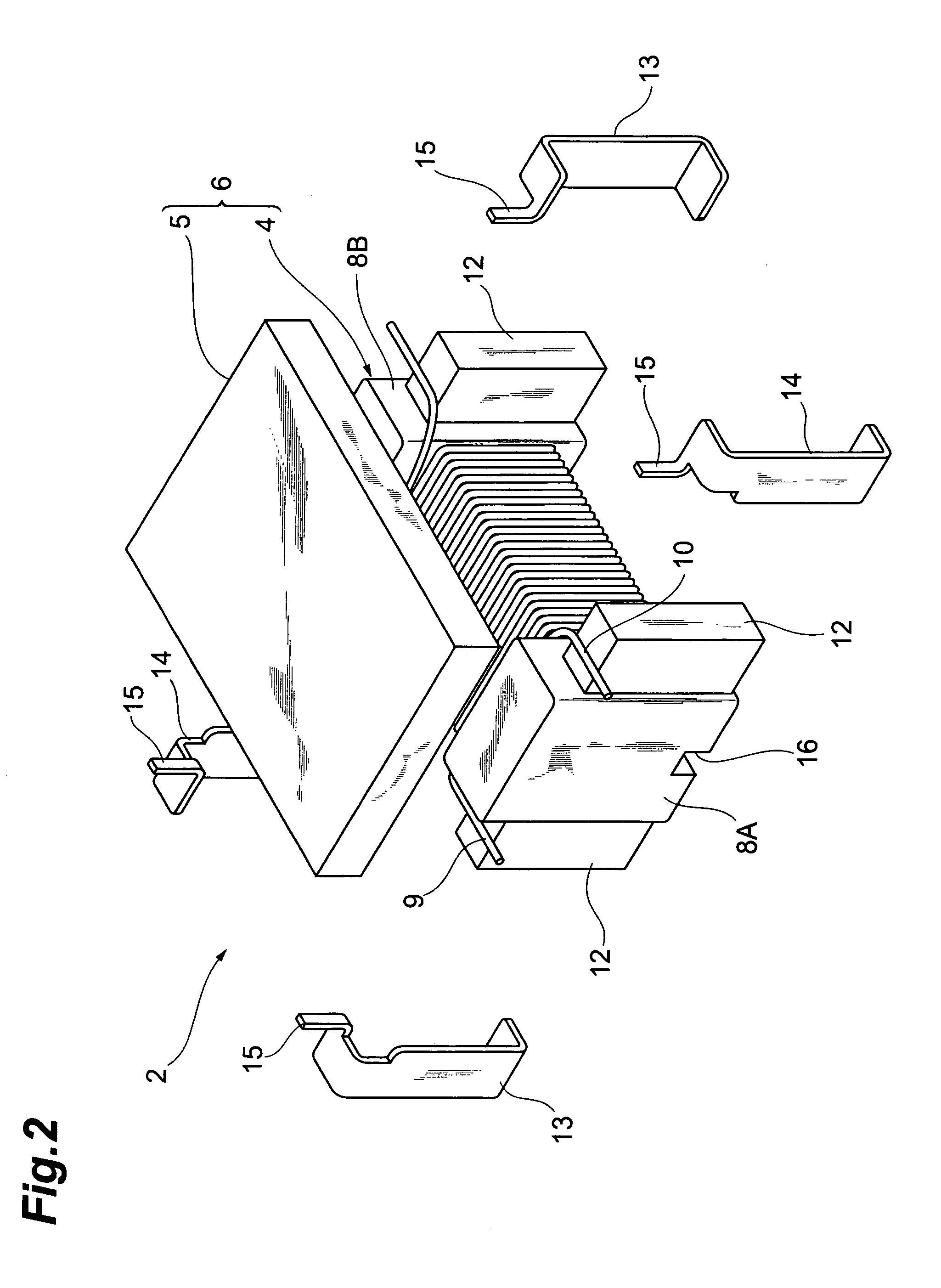

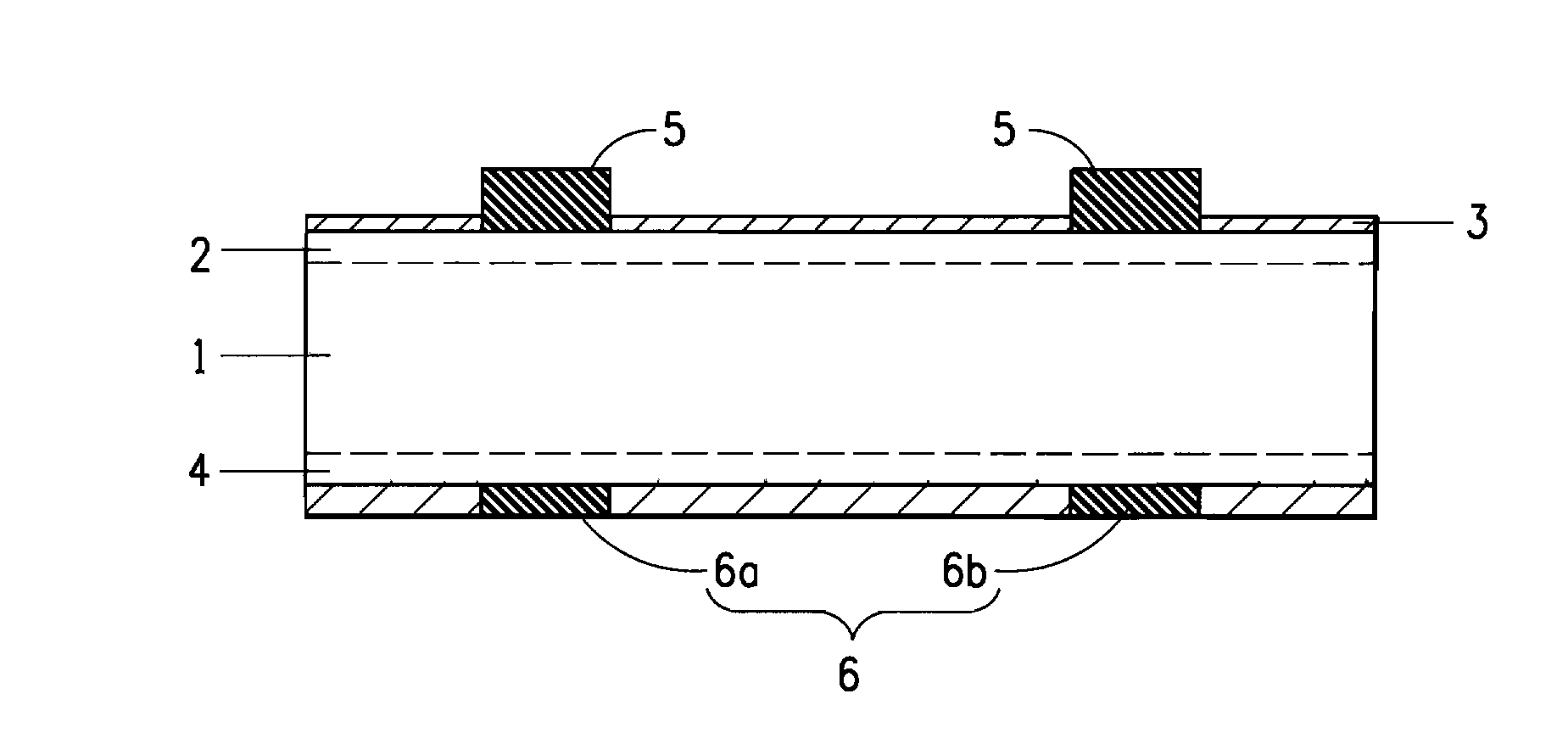

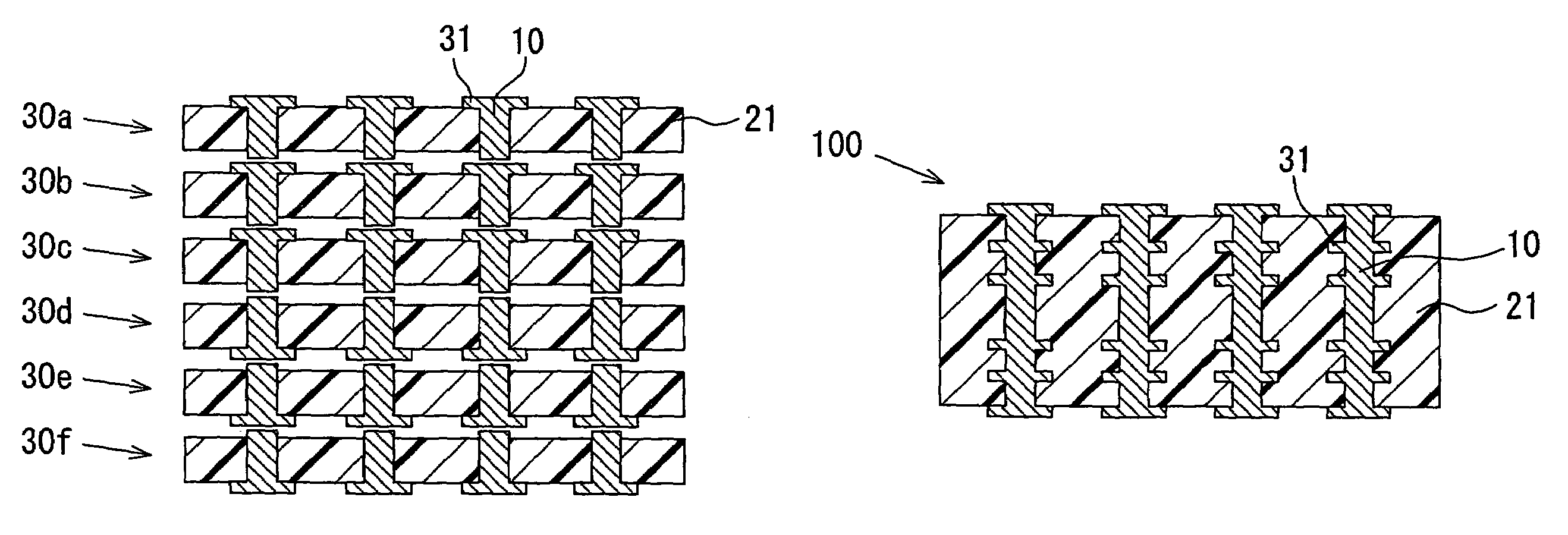

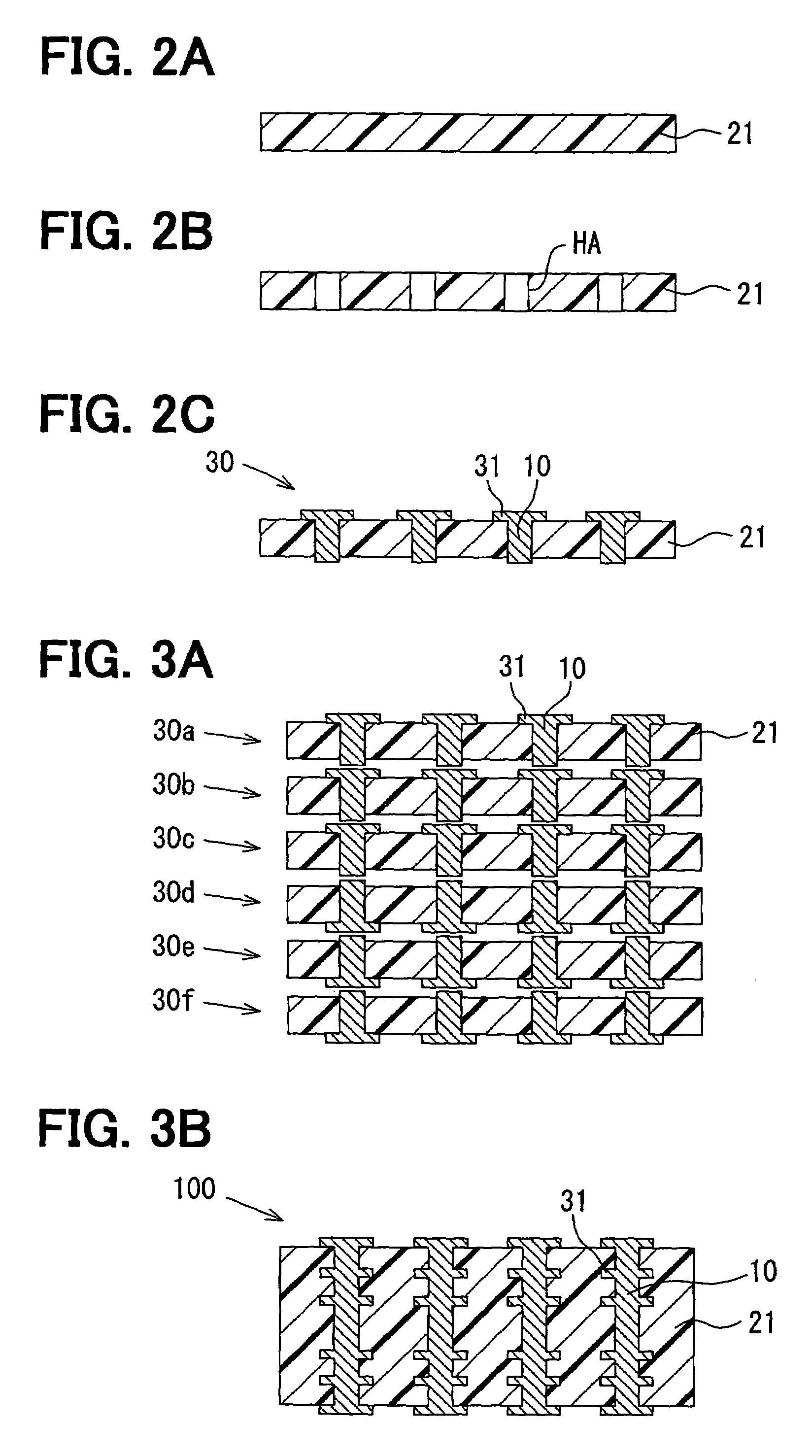

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6236115B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesEngineeringThermal expansion

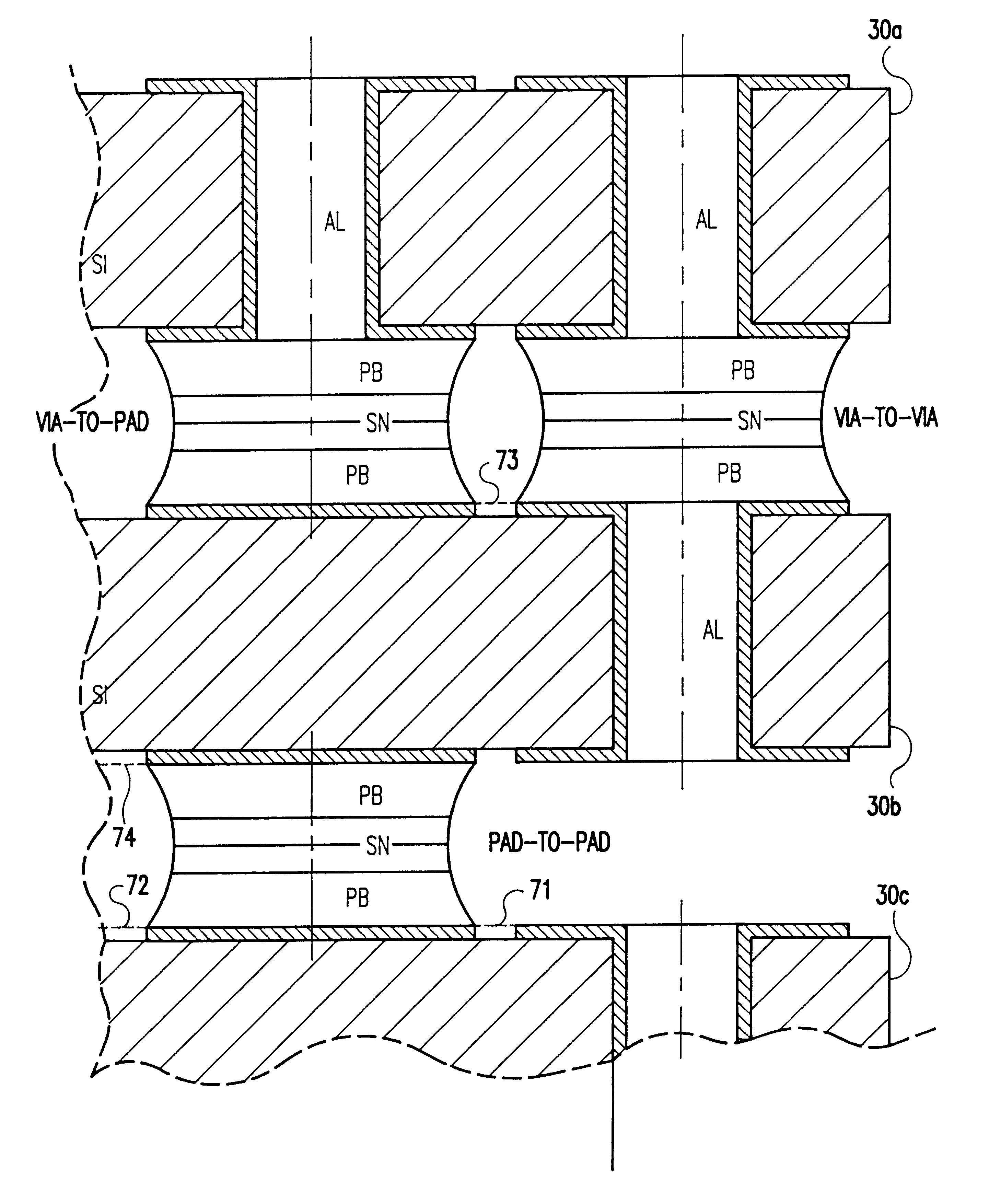

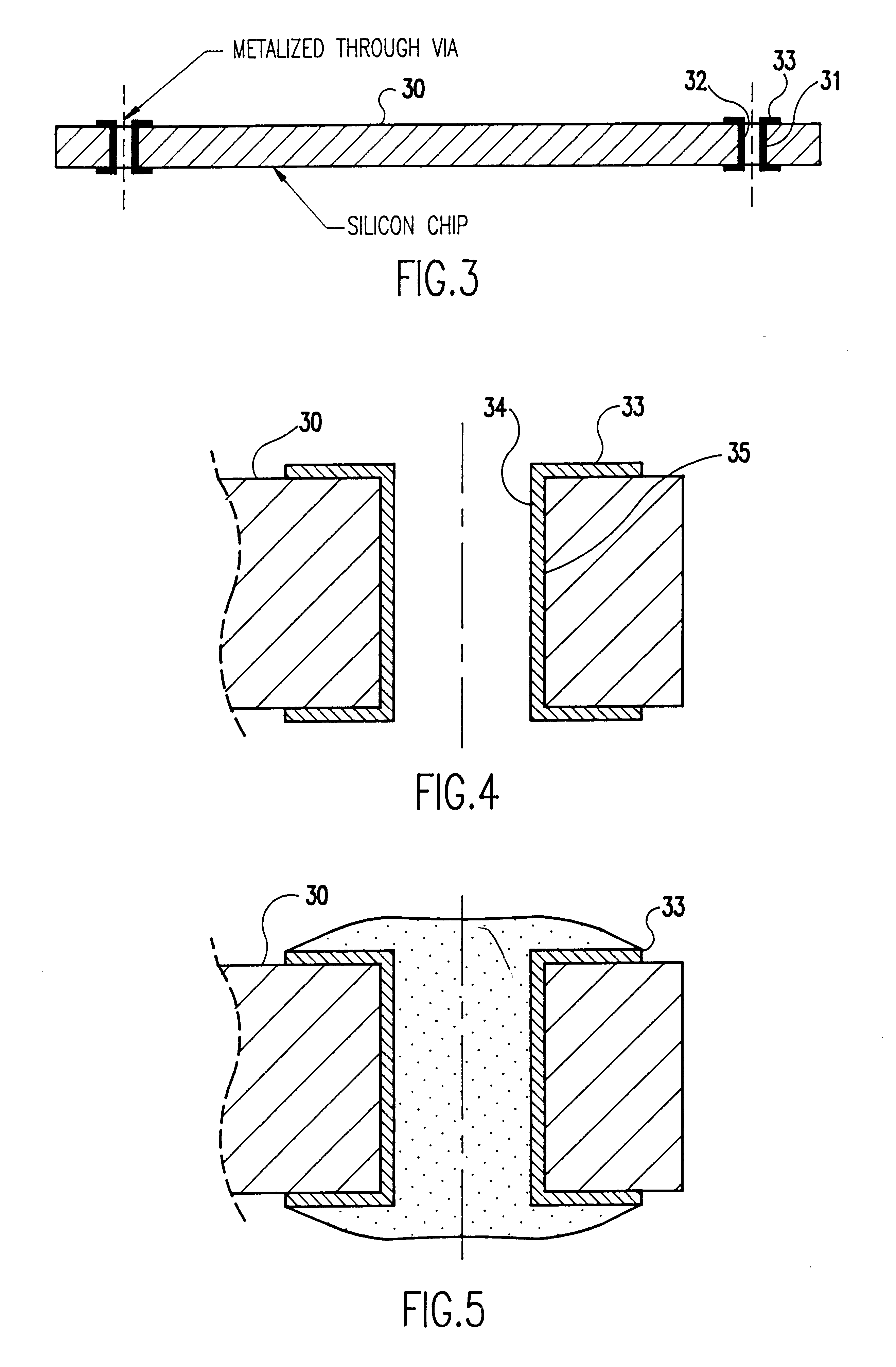

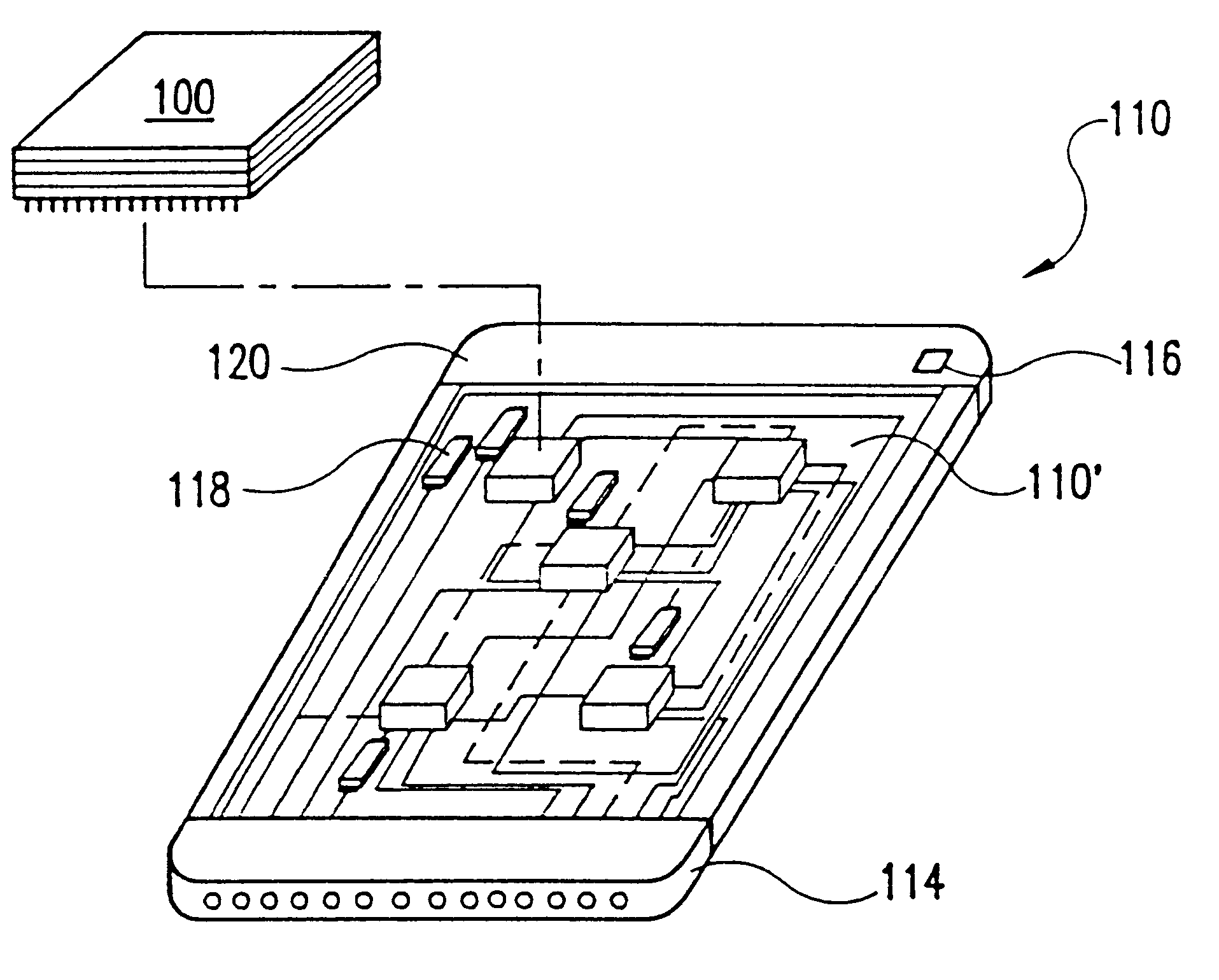

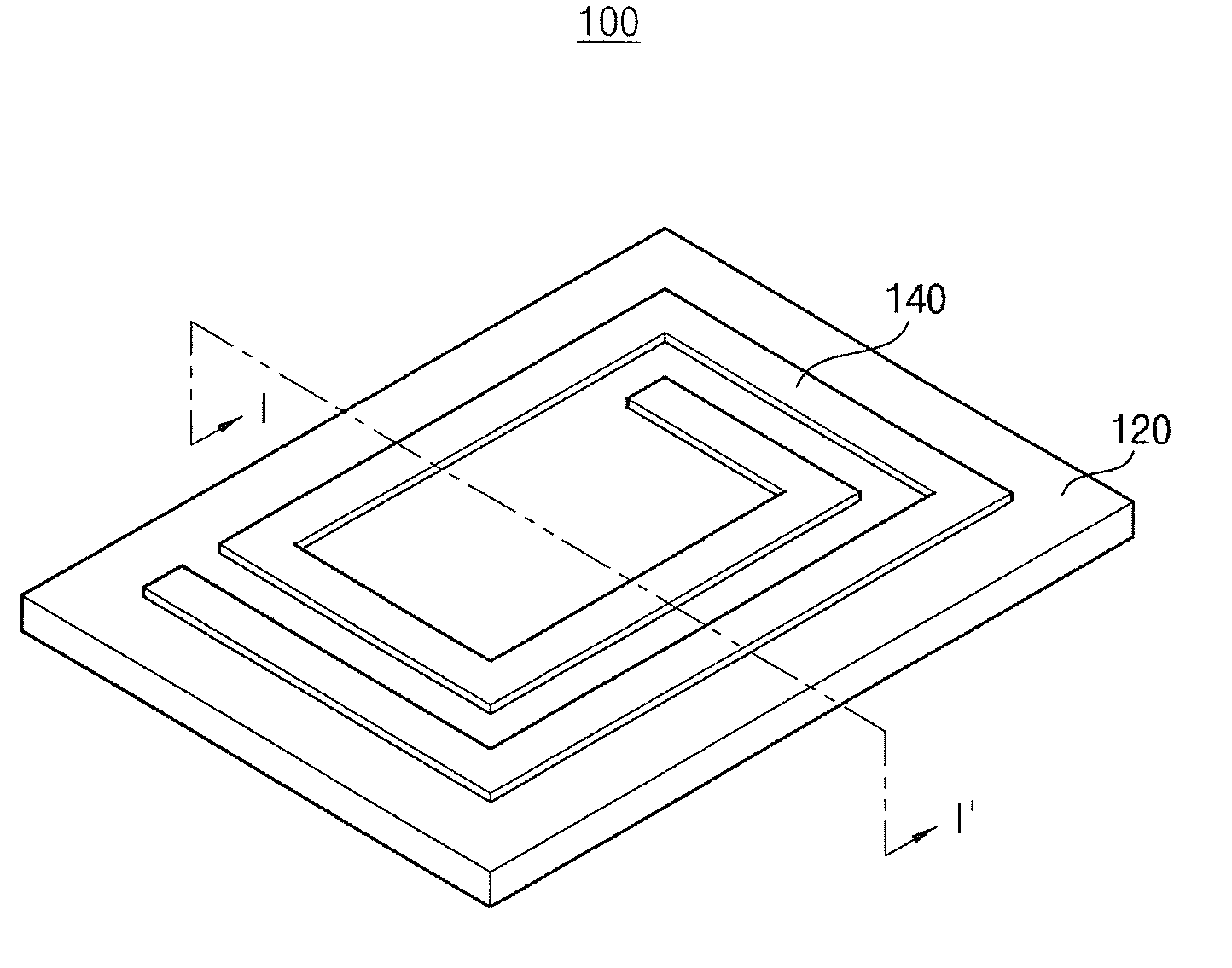

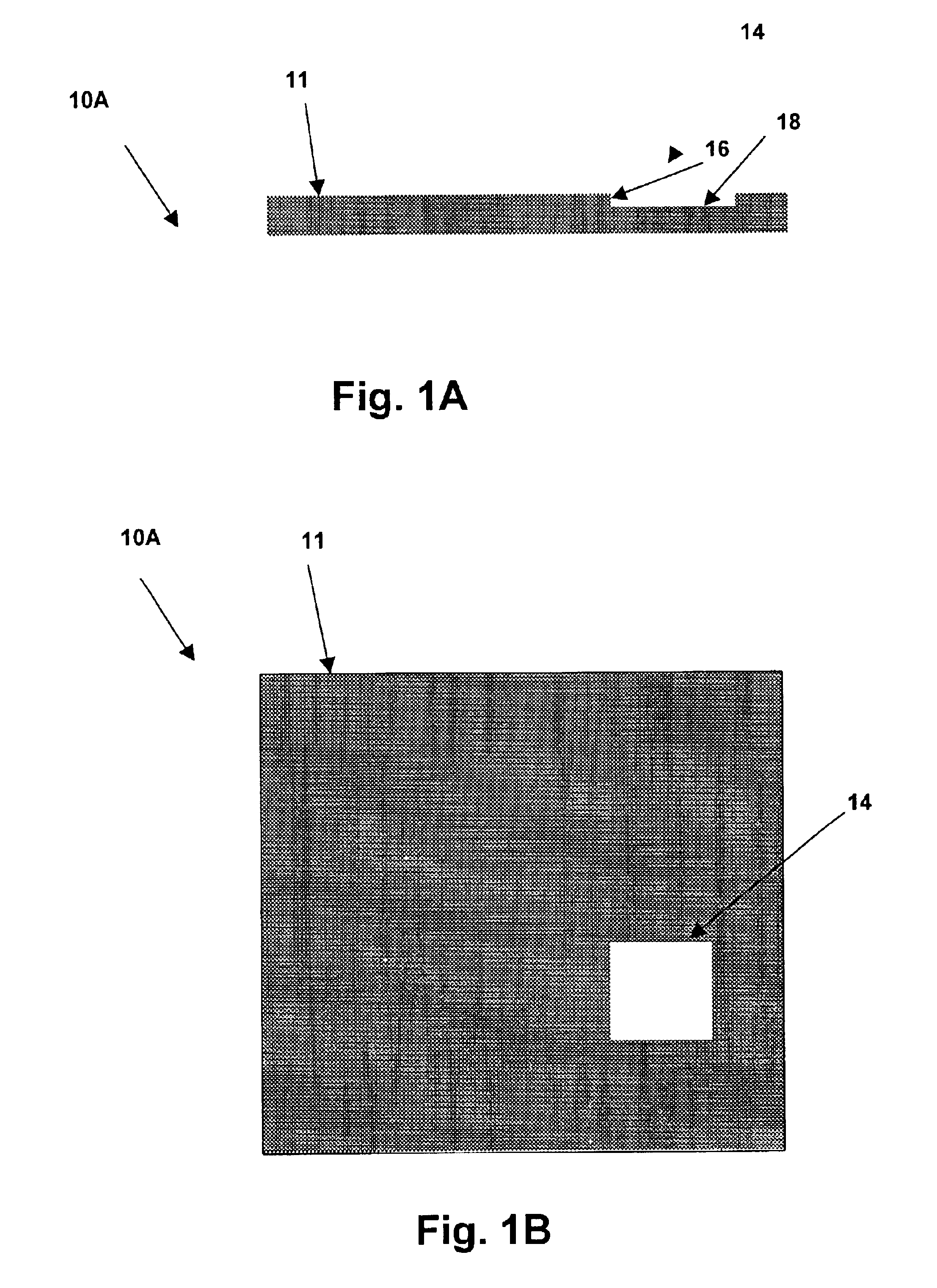

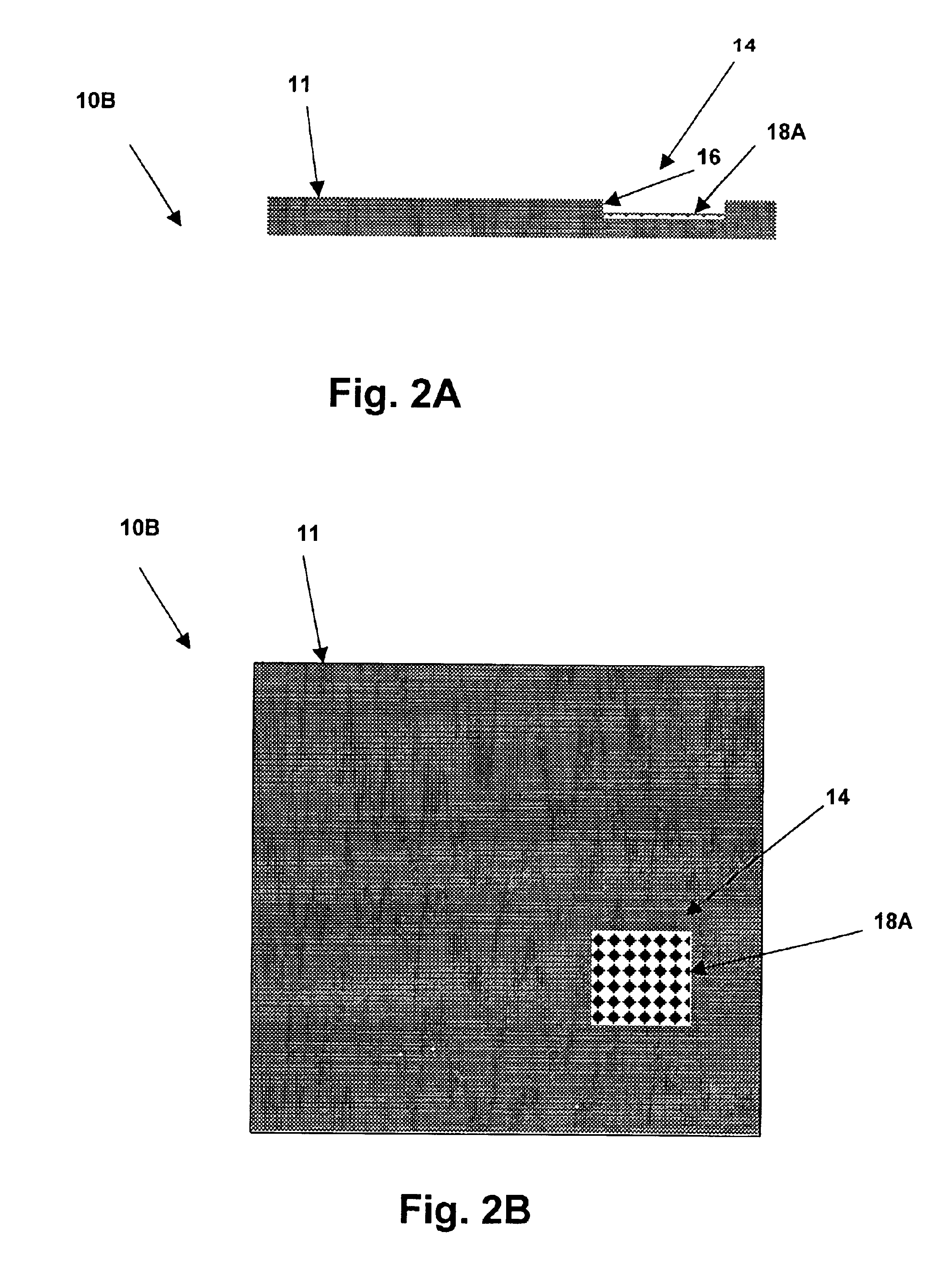

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:INT BUSINESS MASCH CORP

High density integrated circuit packaging with chip stacking and via interconnections

InactiveUS6187678B1Reduced connection exposureLarge capacitySemiconductor/solid-state device detailsSolid-state devicesThermal expansionPrism

Chip stacks with decreased conductor length and improved noise immunity are formed by laser drilling of individual chips, such as memory chips, preferably near but within the periphery thereof, and forming conductors therethrough, preferably by metallization or filling with conductive paste which may be stabilized by transient liquid phase (TLP) processes and preferably with or during metallization of conductive pads, possibly including connector patterns on both sides of at least some of the chips in the stack. At least some of the chips in the stack then have electrical and mechanical connections made therebetween, preferably with electroplated solder preforms consistent with TLP processes. The connections may be contained by a layer of resilient material surrounding the connections and which may be formed in-situ. High density circuit packages thus obtained may be mounted on a carrier by surface mount techniques or separable connectors such as a plug and socket arrangement. The carrier may be of the same material as the chip stacks to match coefficients of thermal expansion. High-density circuit packages may also be in the form of removable memory modules in generally planar or prism shaped form similar to a pen or as a thermal conduction module.

Owner:IBM CORP

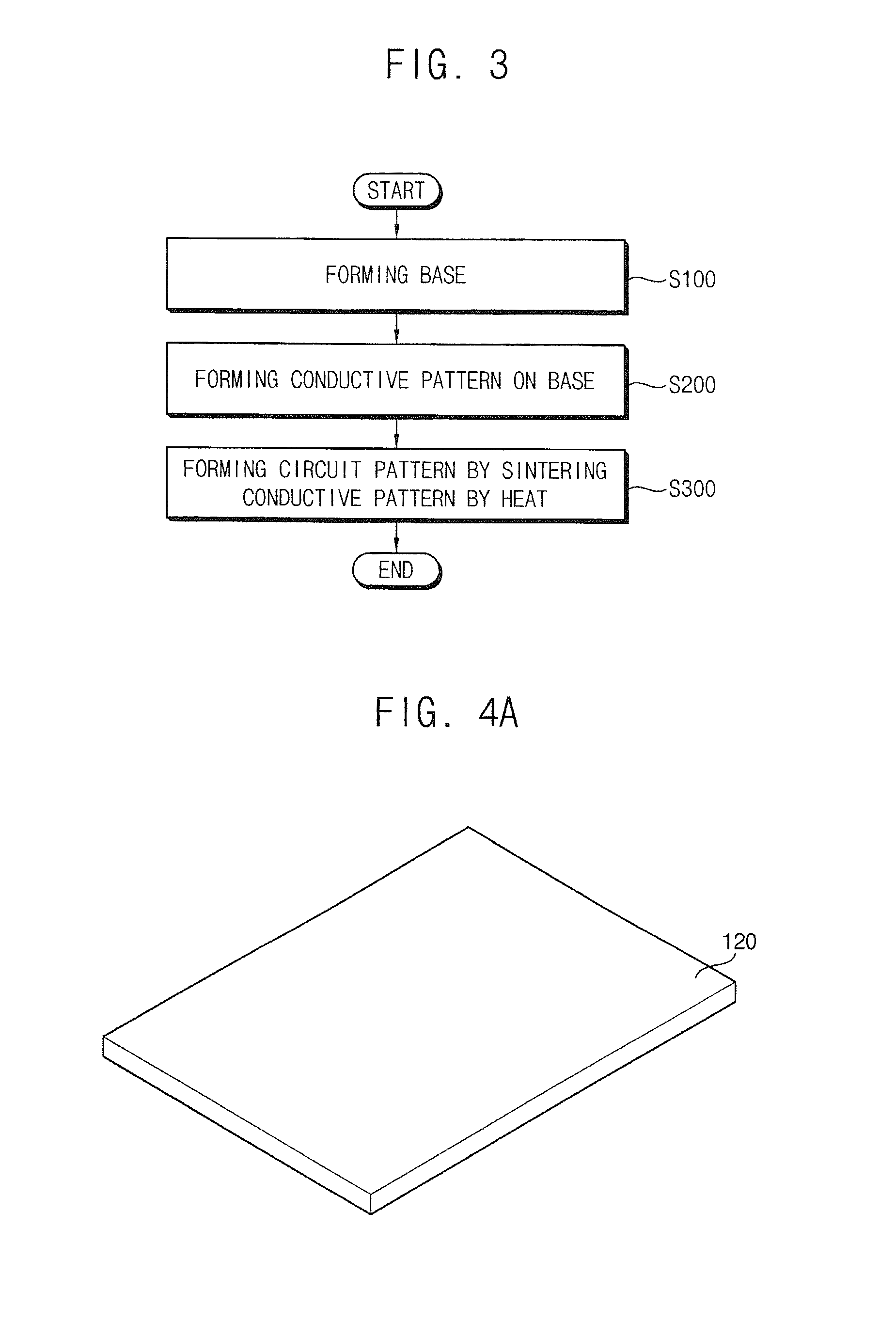

Method of manufacturing antenna using sintering of metal and antenna manufactured by the same

InactiveUS20120038514A1Reduce adverse effectsEasy to useSimultaneous aerial operationsPrinted electric component incorporationConductive pasteSynthetic resin

A method of manufacturing an antenna includes forming a base including a synthetic resin, forming a conductive pattern on the base and forming a circuit pattern by sintering the conductive pattern by applying heat. The conductive pattern includes a conductive paste and a binding material binding the base and the conductive pattern. The conductive paste includes a metal.

Owner:DYNATRON

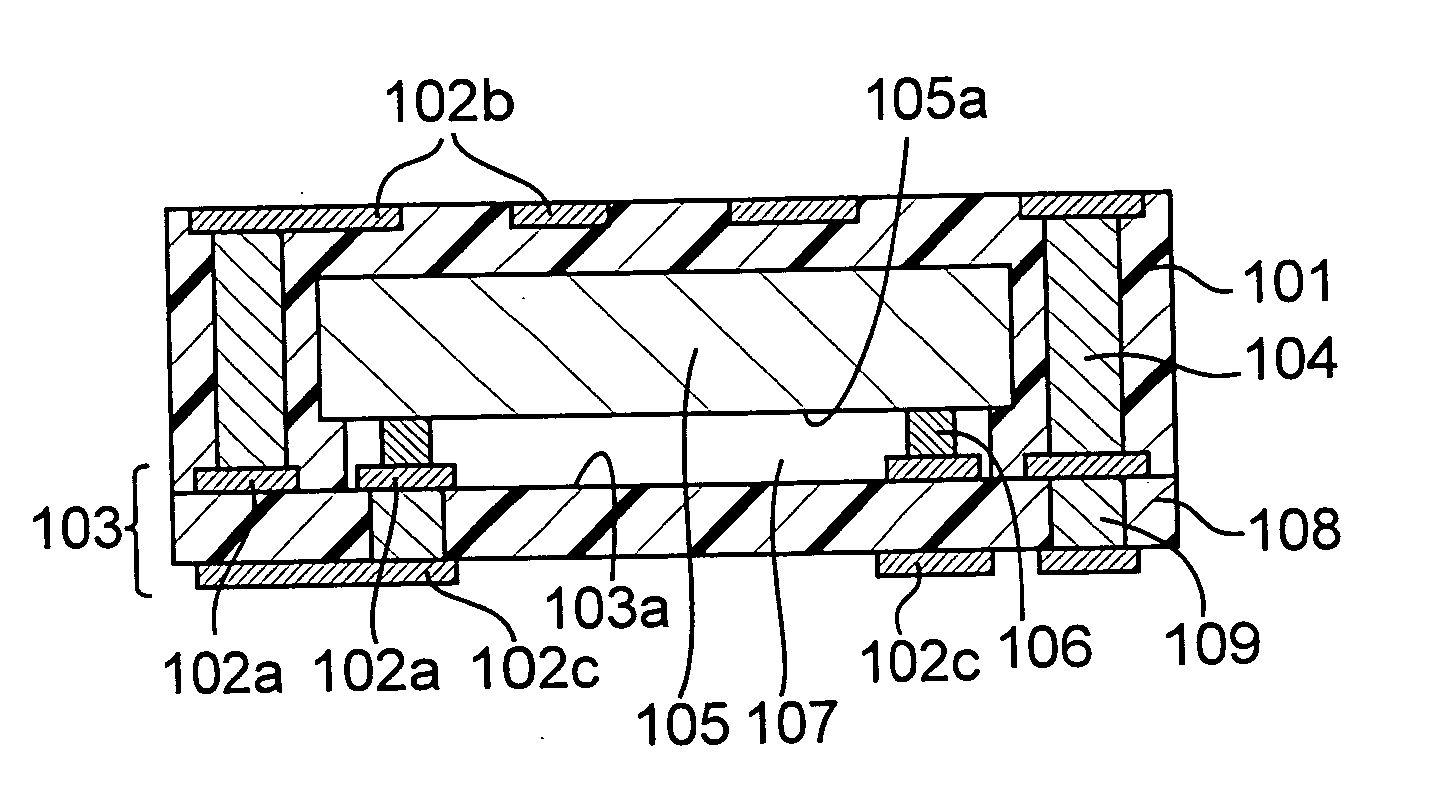

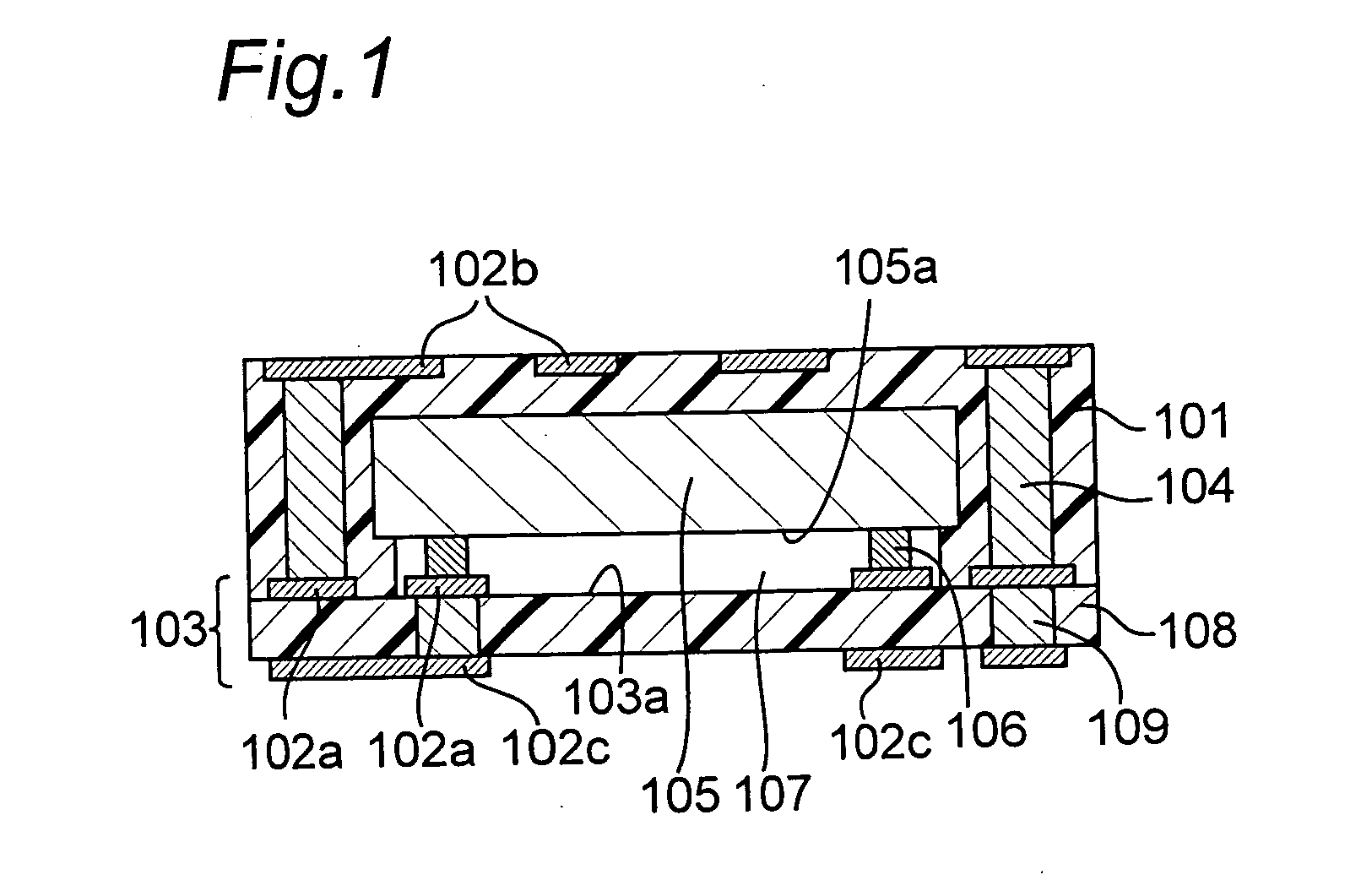

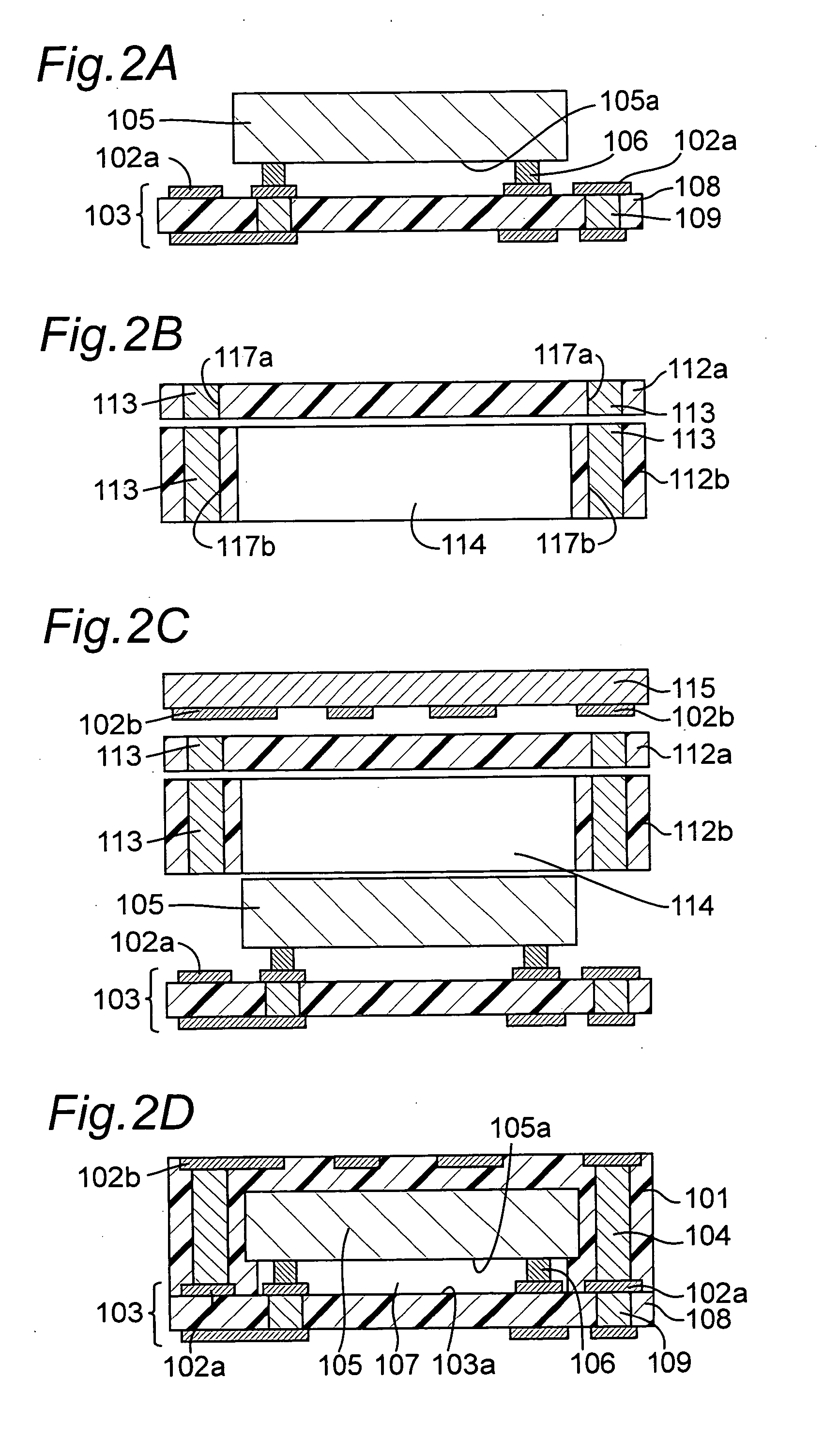

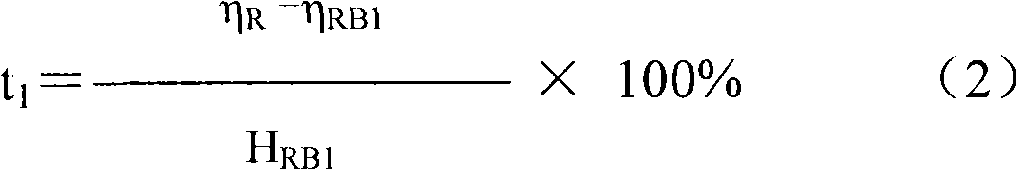

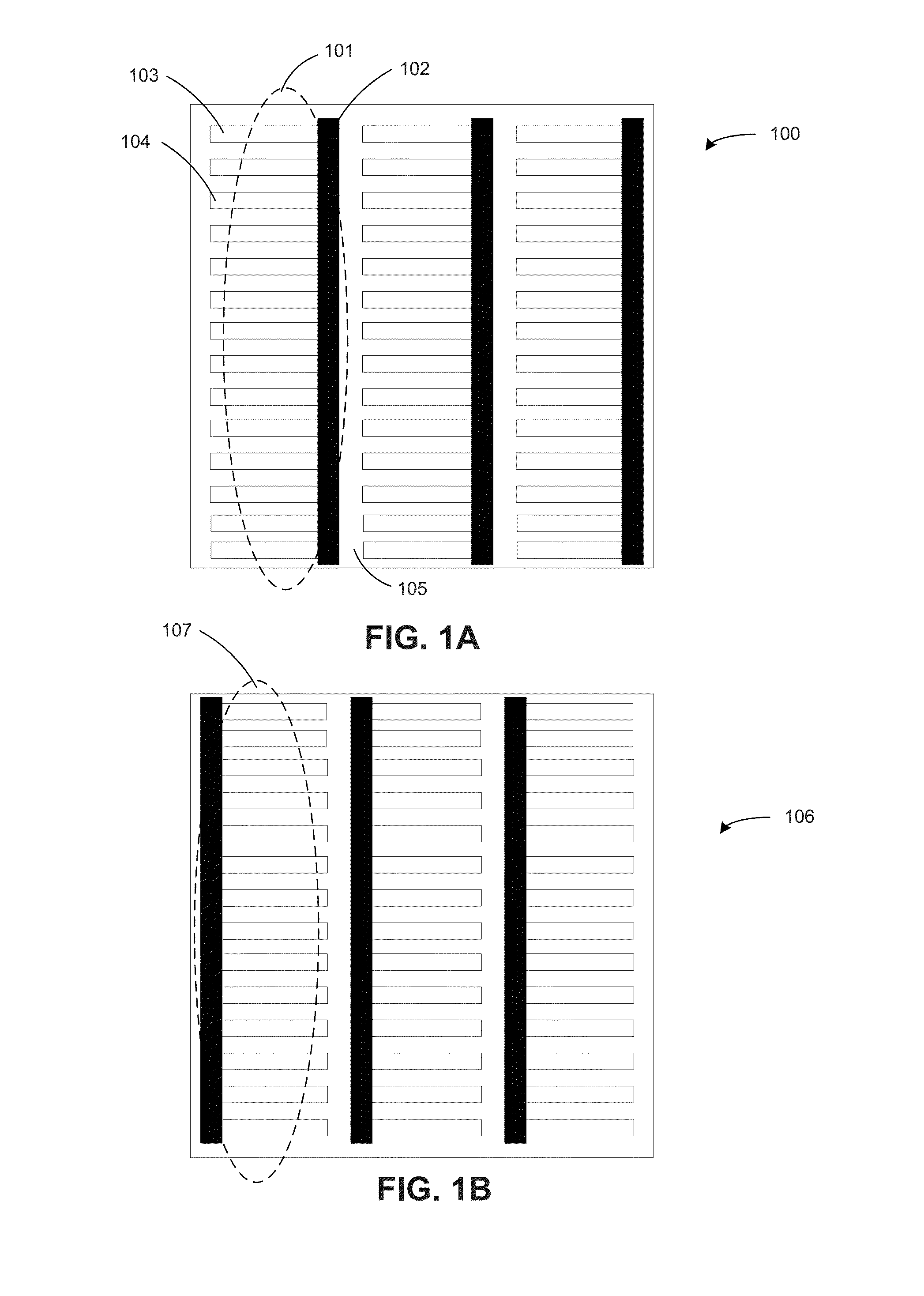

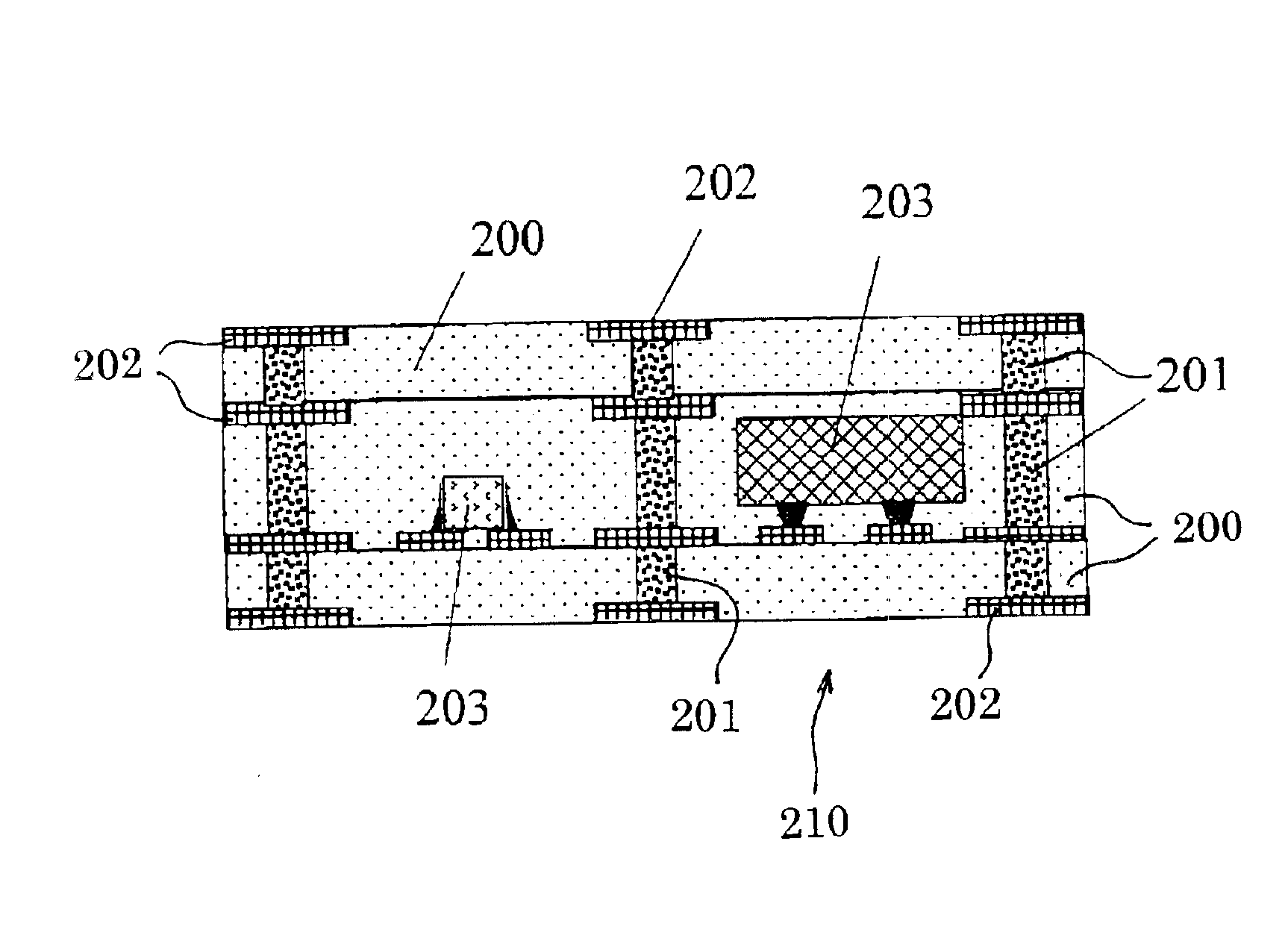

Module with a built-in semiconductor and method for producing the same

InactiveUS20050001331A1Easy to fillReduce areaTransistorSemiconductor/solid-state device detailsConductive pasteDevice material

In a module with a built-in semiconductor, higher densification is achieved by disposing inner vias close to a semiconductor device. A module which has a space 107 between a first wiring layer 102a and a built-in semiconductor device 105 is obtained by: mounting the semiconductor device 105 on a first wiring layer 102a of a wiring board 103 without using a sealing resin; stacking on the circuit board an electrically insulating substrate having a through bore (inner via) 104 filled with a conductive paste and an opening for receiving the semiconductor device, and a mold release carrier having a second wiring layer 102b in the stated order; and heating and pressurizing so that the semiconductor device 105 is incorporated in a core layer 101 which is formed by curing the electrically insulating substrate.

Owner:PANASONIC CORP

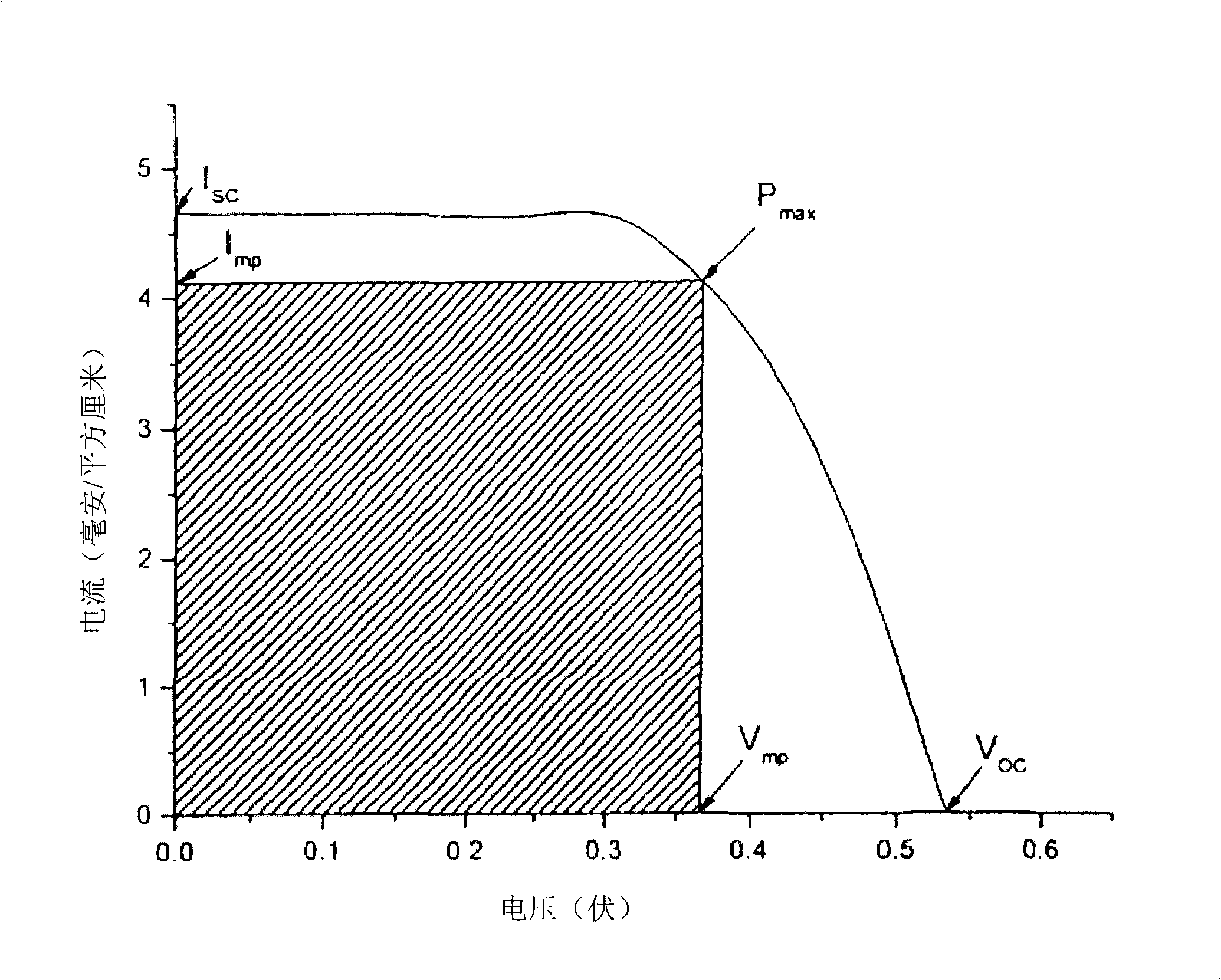

Conductive slurry for solar battery front side electrode and production method thereof

ActiveCN101295739AImprove photoelectric conversion efficiencyImprove adhesionFinal product manufactureNon-conductive material with dispersed conductive materialConductive pasteElectrical battery

The invention relates to a conductive paste for the surface electrode of a solar cell, which comprises conductive metal powders, organic carriers, adhesives, solvents and addition agent, wherein, the conductive paste also comprises additives which are selected from phosphorus pentachloride and one or more VIII group metal halide. The additive in the conductive paste of the invention can help improve the adhesive force between the conductive paste and silicon substrate, and lead adhesion between compounds obtained after electrode sintering and silicon substrate to be more firm; the formed compound does not have cracks and bubbles and the electrode surface is flat and smooth, thus providing the solar cell finally prepared with higher photoelectric conversion efficiency.

Owner:BYD CO LTD

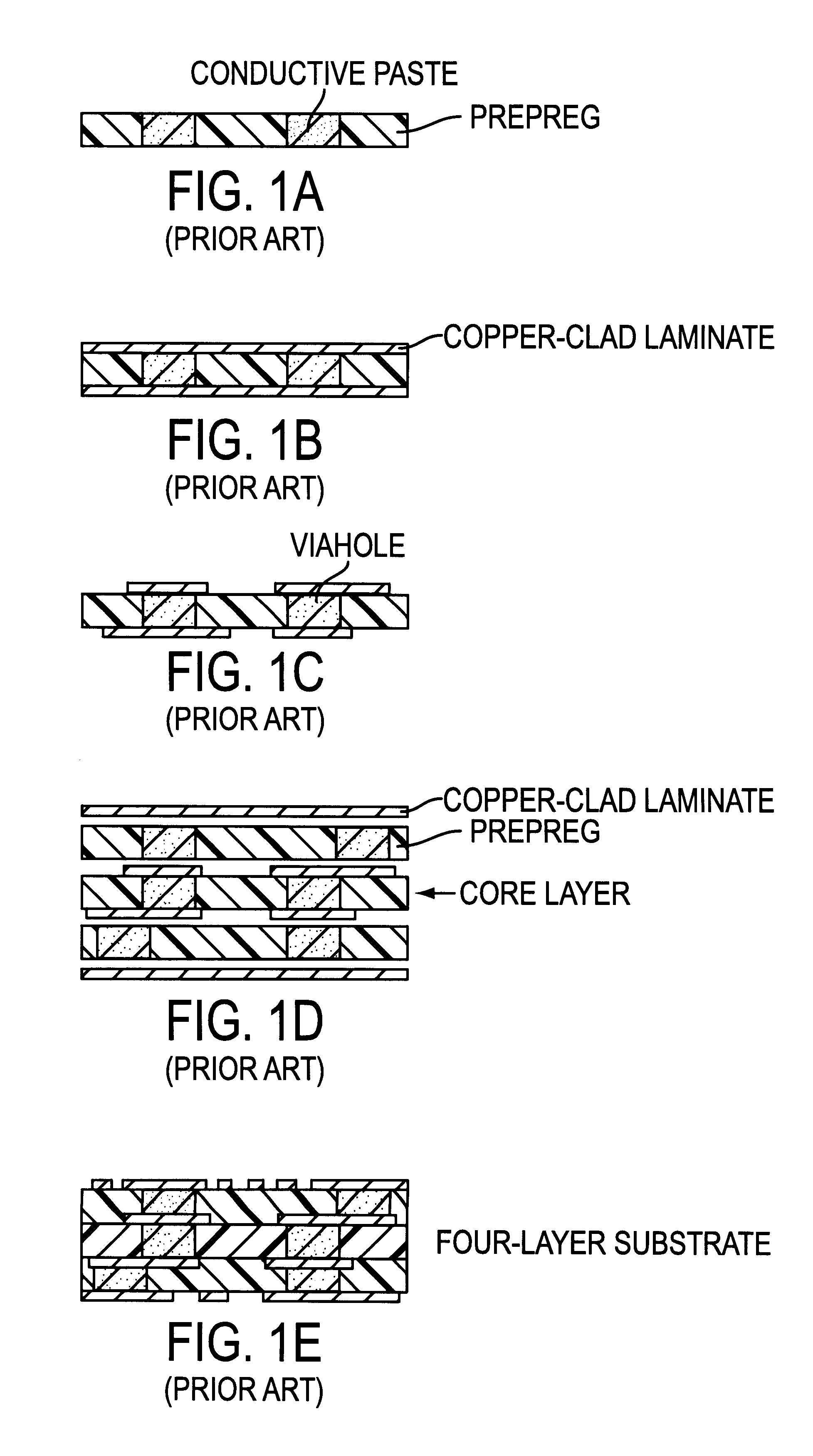

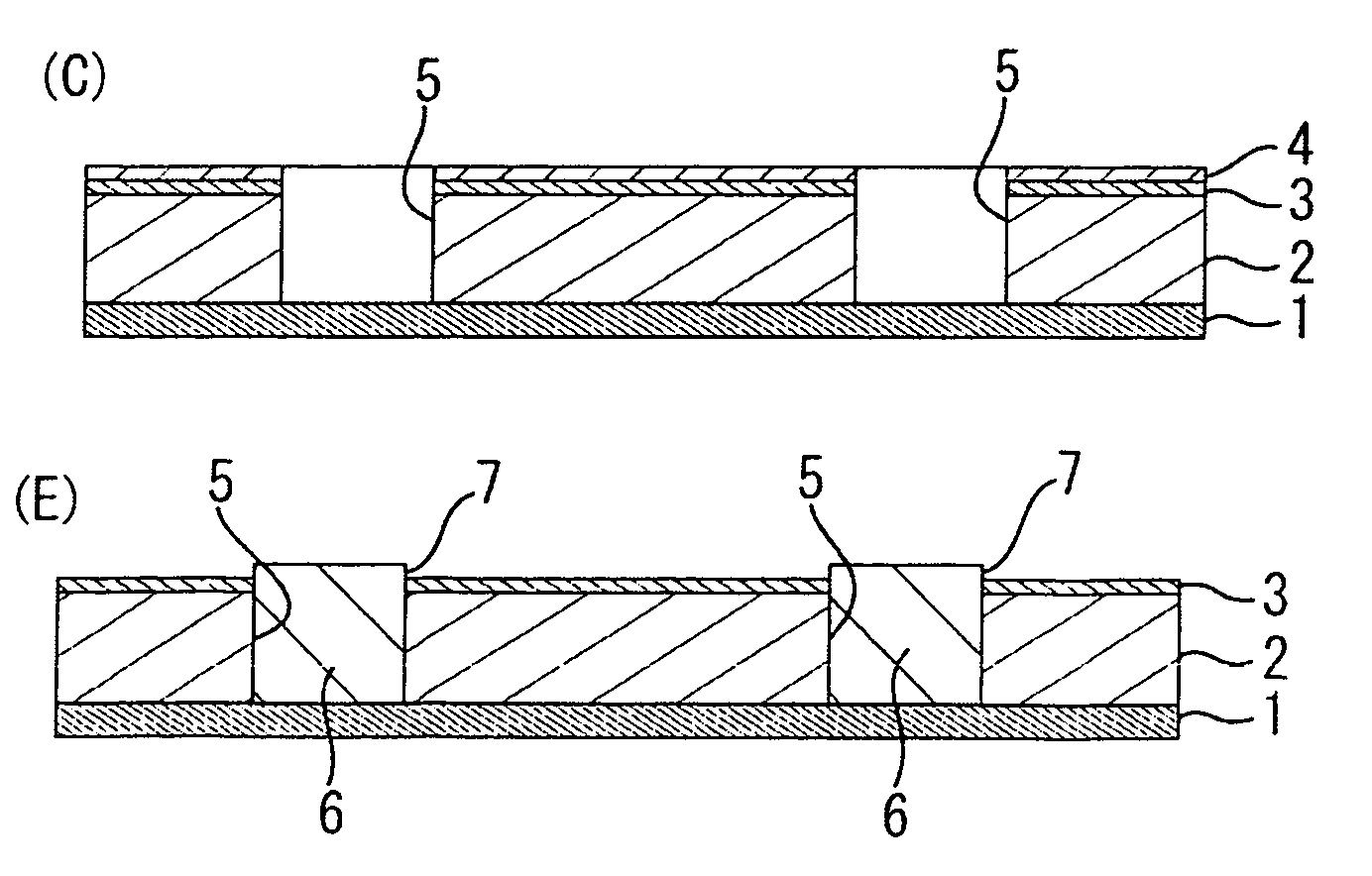

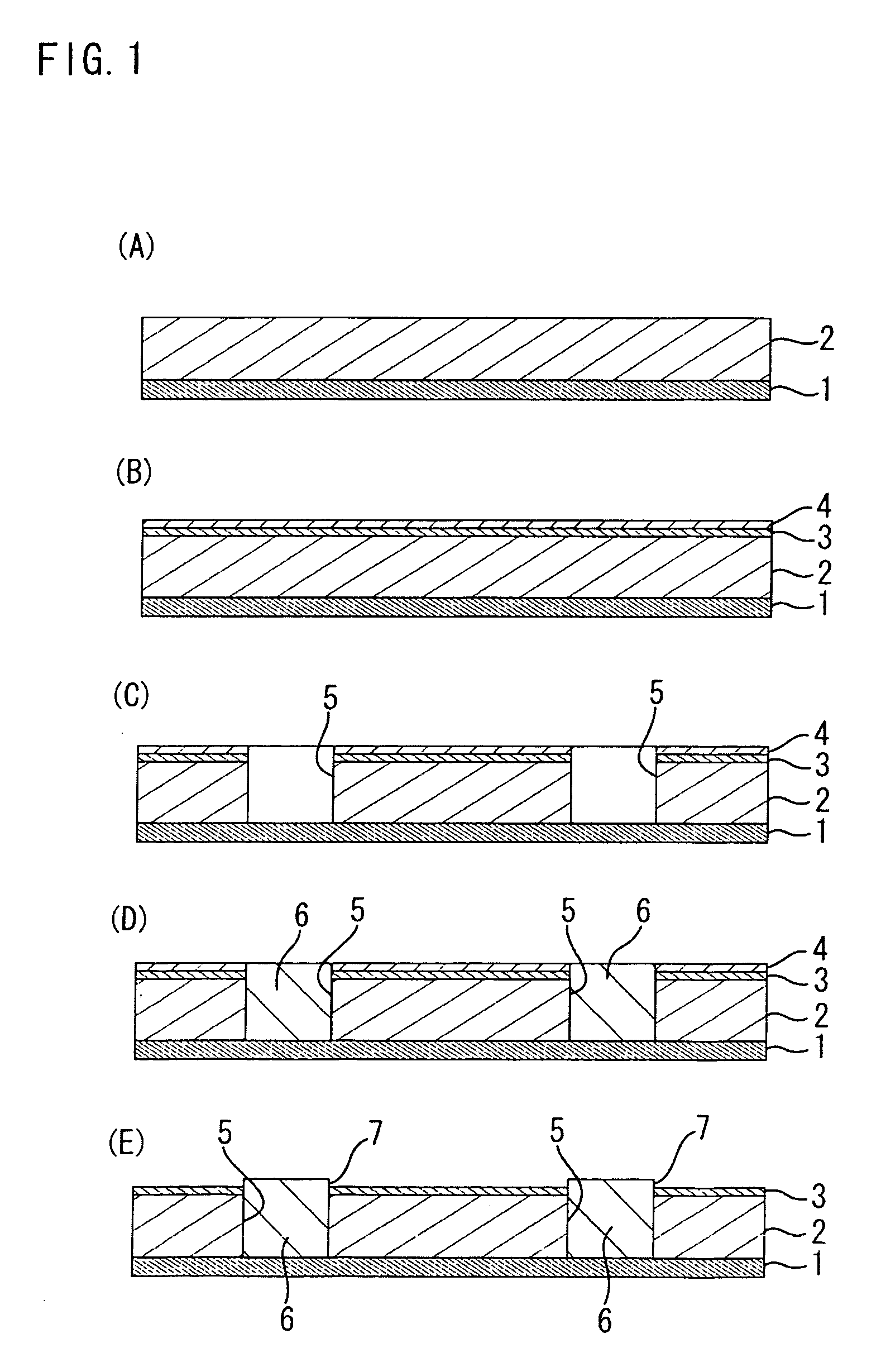

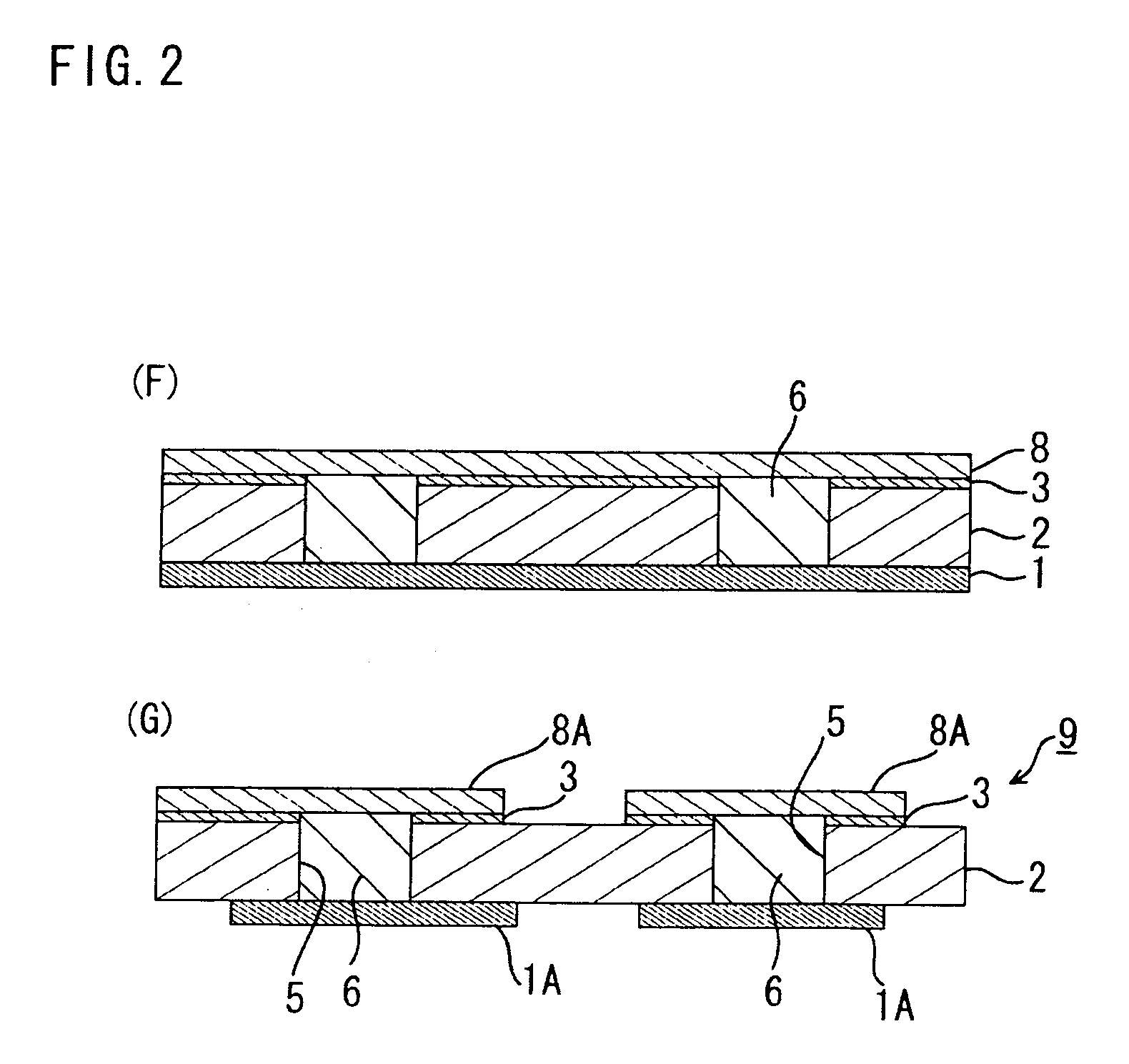

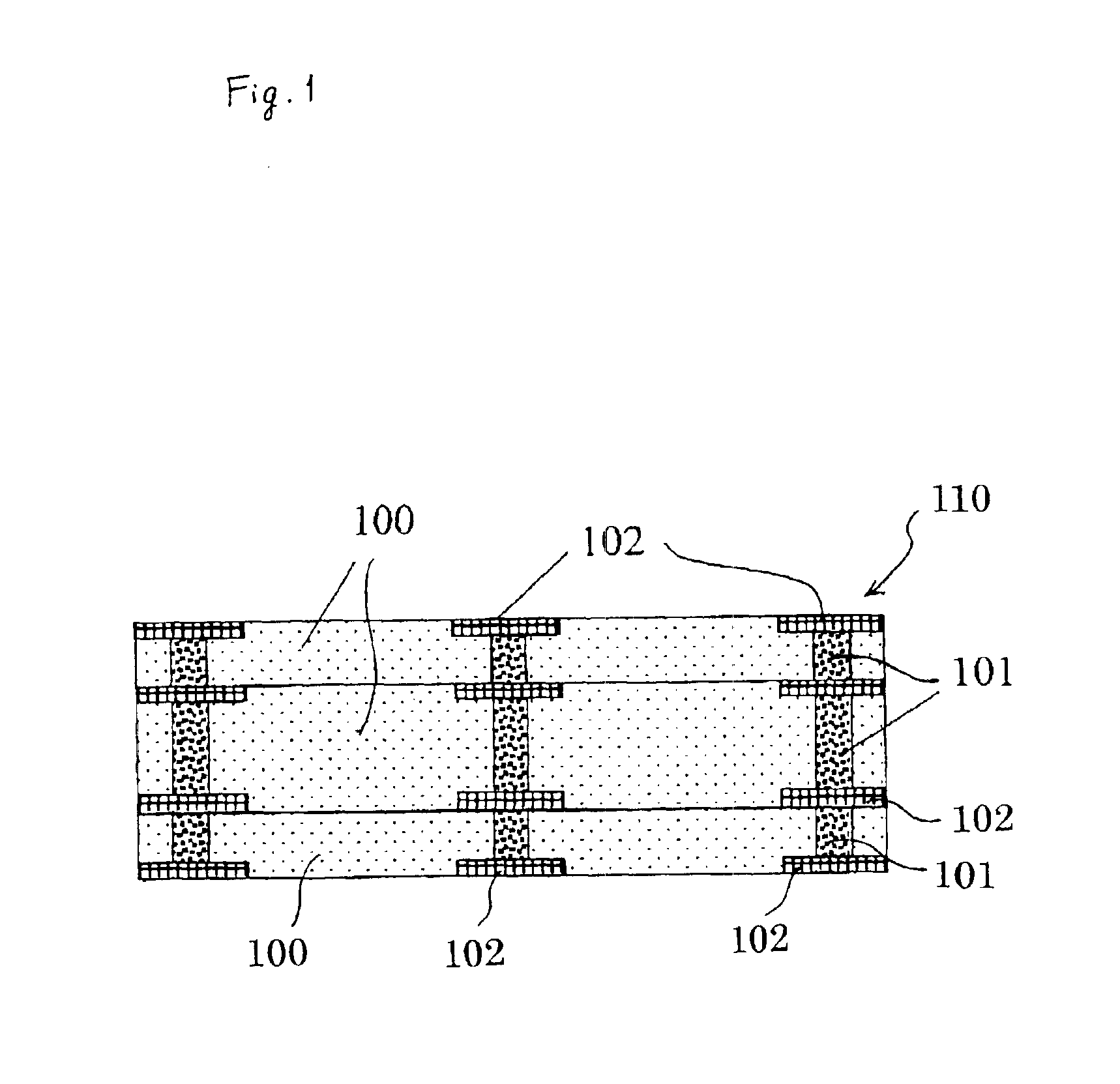

One-sided circuit board for multi-layer printed wiring board, multi-layer printed wiring board, and method of its production

InactiveUS6320140B1Printed circuit aspectsTwo-part coupling devicesConductive pastePrinted circuit board

A single-sided circuit substrate for a multilayer printed writing board has an insulating hard substrate, a conductor circuit formed on a surface of the substrate, an adhesive layer formed on the other surface, and at least one viahole through the substrate and the adhesive layer so as to pass these layers and contact with the conductor. The viaholes are filled with conductive paste. The invention also provides a multilayer printed wiring board having an IVH structure constituted with single-sided circuit hard substrates and a method of efficiently manufacturing the same with high yield.

Owner:IBIDEN CO LTD

Method of manufacturing printed-circuit board

InactiveUS6889433B1Reduced connection reliabilityHigh densityLine/current collector detailsInsulating substrate metal adhesion improvementConductive pasteEngineering

By filling a predetermined amount of conductive paste into an opening for forming a through hole or a VH formed in a resin insulating layer of a circuit board, and pressurizing the filled conductive paste under the condition of reduced pressure, removing air bubble strapped in the conductive paste.

Owner:IBIDEN CO LTD

Conductive paste

InactiveUS20060145125A1Pigmenting treatmentGroup 1/11 element organic compoundsConductive pasteAdhesive

The present invention provides an electroconductive paste that can contain a high proportion of an electroconductive powder, has excellent electroconductivity reliability and migration resistance, has a highly competitive price due to a reduced amount of silver plating, and is suitable for use in solder electrode formation, an electroconductive adhesive, etc. The electroconductive paste of the present invention comprises a binder and an electroconductive powder containing 80 to 97 wt % of a substantially spherical silver-coated copper powder in which the surface of a copper powder is coated with silver and the surface thereof is further coated with 0.02 to 0.5 wt % relative to the copper powder of a fatty acid, and 3 to 20 wt % of a flat-shaped silver-coated copper powder in which the surface of a copper powder is coated with silver and the surface thereof is further coated with 0.02 to 1.2 wt % relative to the copper powder of a fatty acid.

Owner:HITACHI CHEM CO LTD

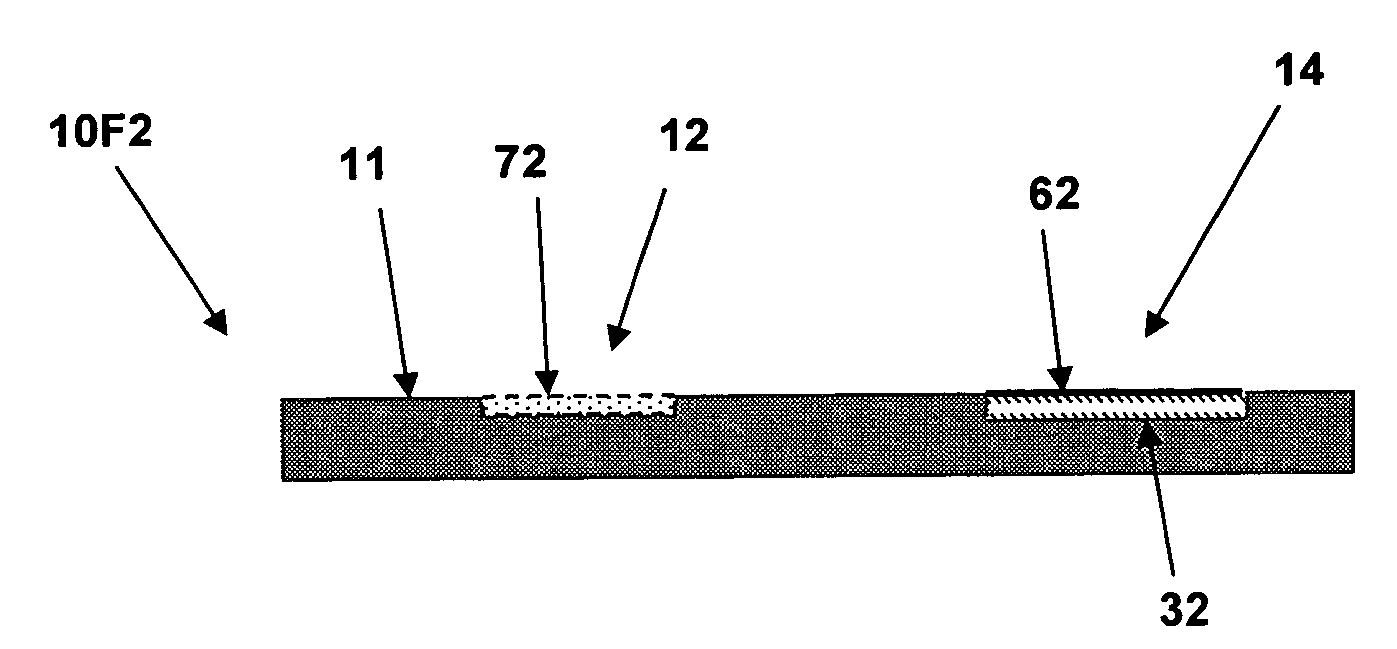

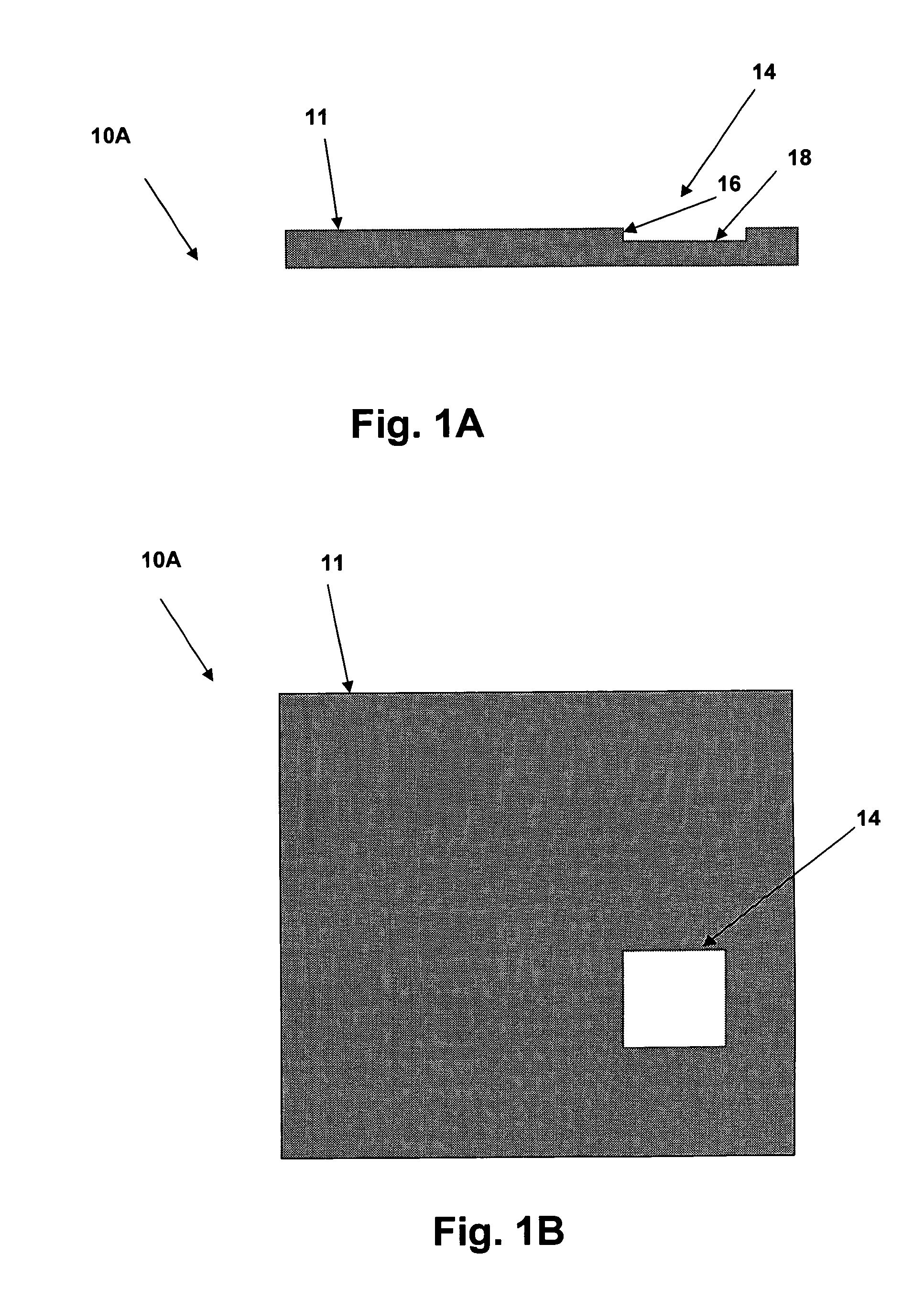

Circuitized substrate and method of making same

InactiveUS20090241332A1Low costLow resistivityPrinted circuit aspectsPrinted circuit manufactureConductive pasteElectrical connection

A circuitized substrate and method of making same in which a first plurality of holes are formed within two bonded dielectric layers and then made conductive, e.g., plated. The substrate also includes third and fourth dielectric layers bonded to the first and second with a plurality of continuous electrically conductive thru holes extending through all four dielectric layers. Conductive paste is positioned within the thru holes for providing electrical connections between desired conductive layers of the substrate and outer layers as well. A circuitized substrate assembly and method of making same are also provided.

Owner:I3 ELECTRONICS

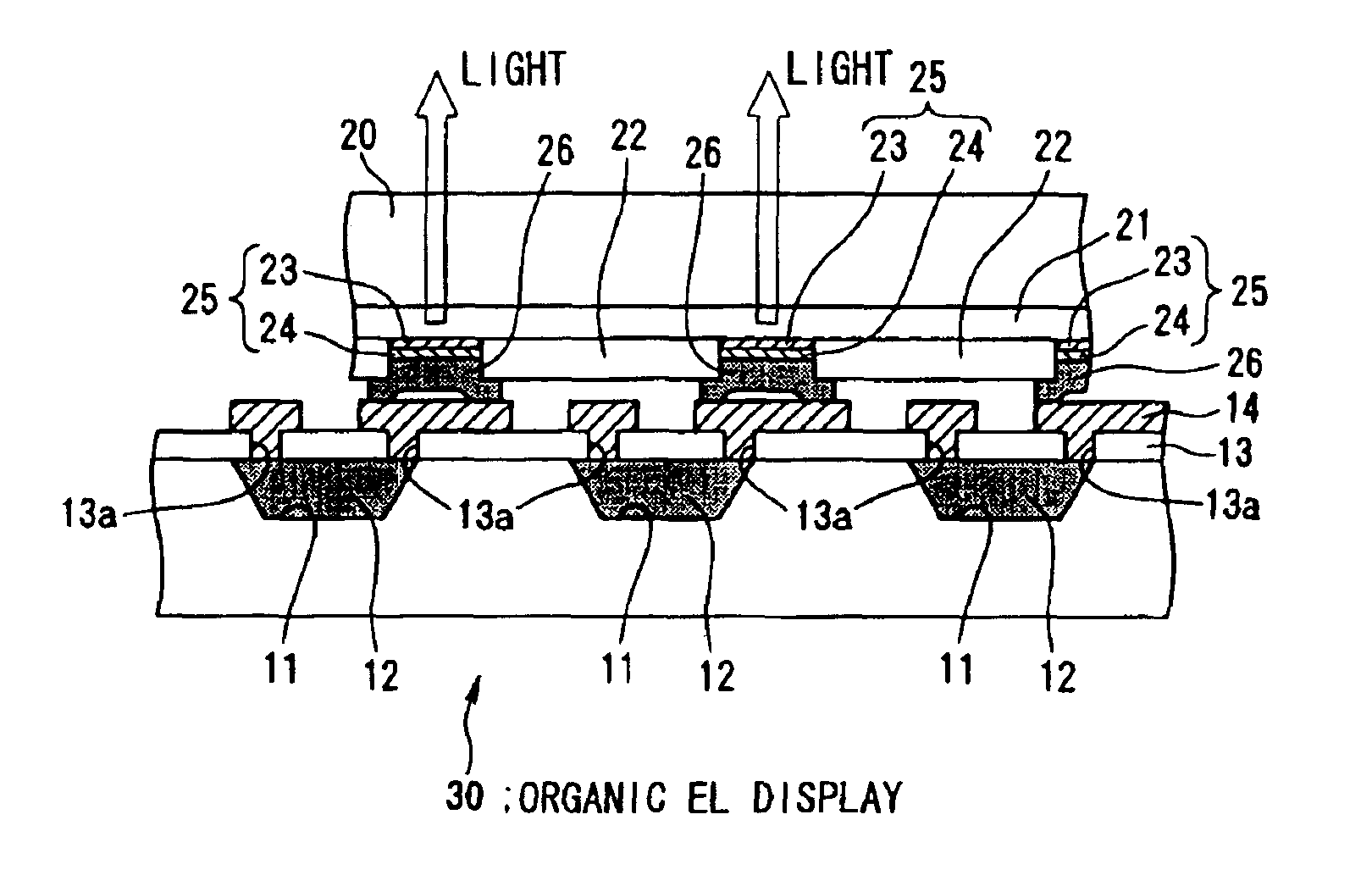

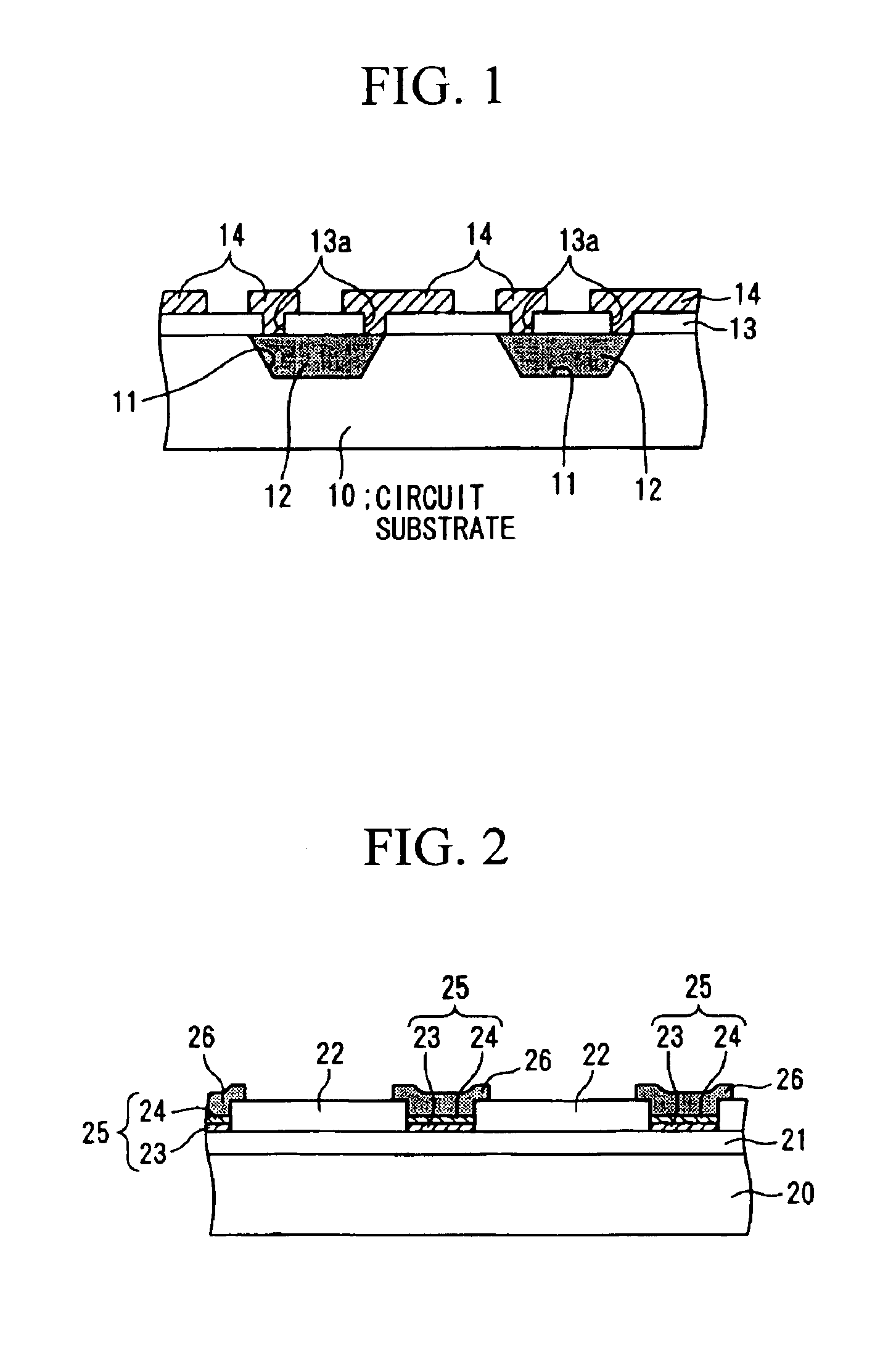

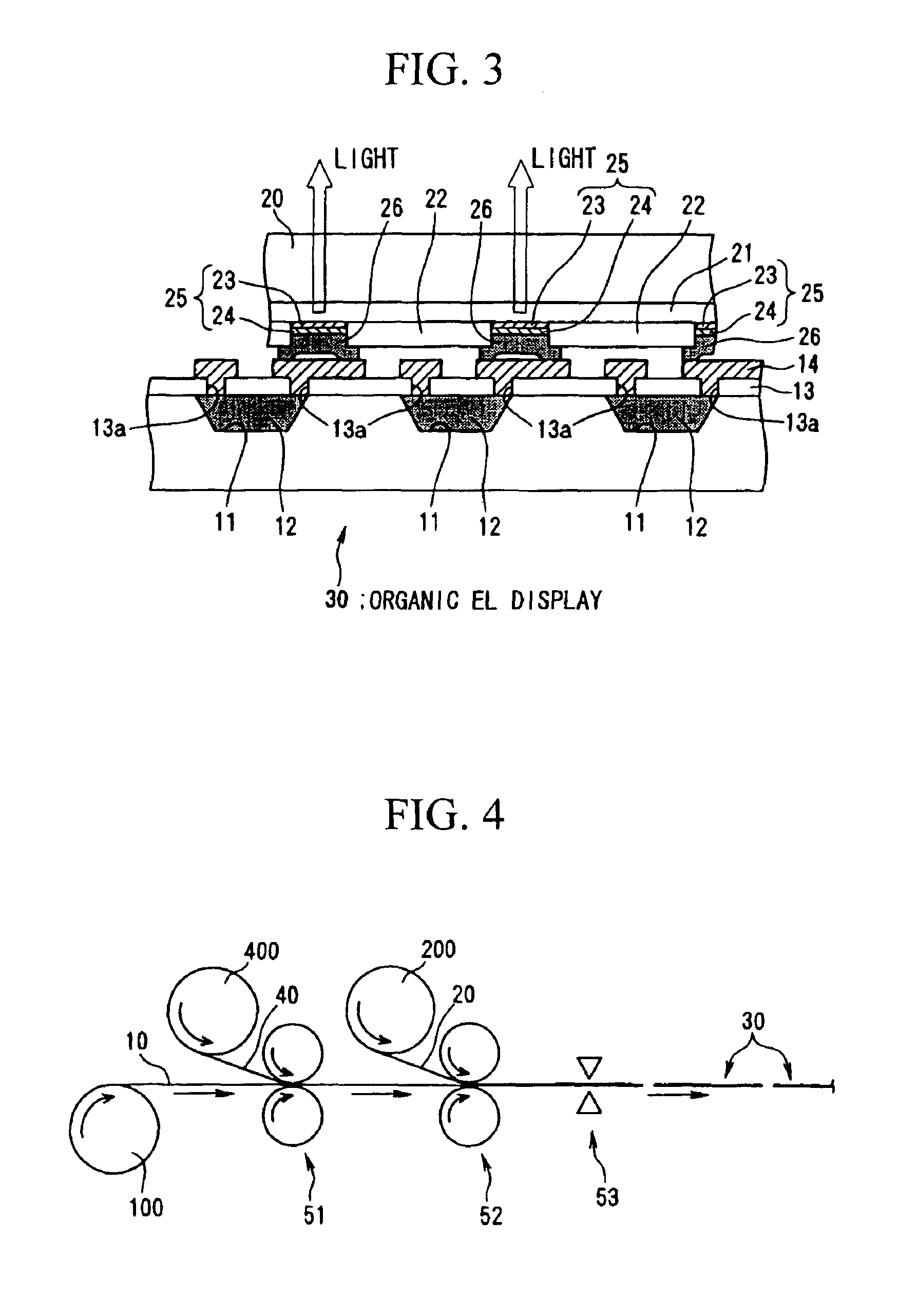

Organic electroluminescent display and manufacturing method thereof, electro-optic device and manufacturing method thereof, and electronic device

InactiveUS6919680B2Efficient preparationDischarge tube luminescnet screensElectroluminescent light sourcesAnisotropic conductive filmConductive paste

Owner:ELEMENT CAPITAL COMMERCIAL CO PTE LTD

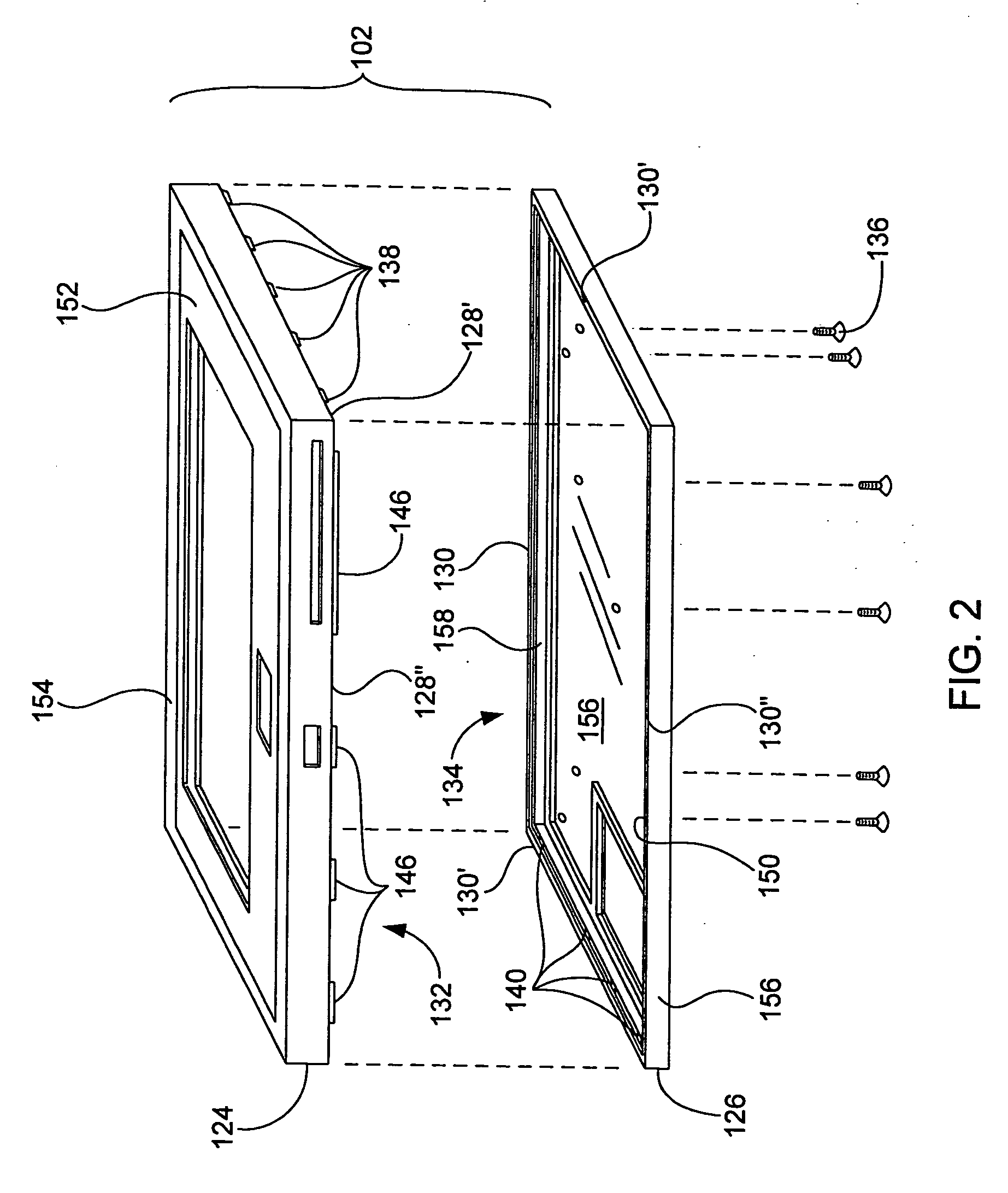

Computer enclosure

InactiveUS20050023022A1Printed circuit assemblingLine/current collector detailsConductive pasteEngineering

A computing device having an improved enclosure arrangement is disclosed. One aspect of the enclosure pertains to enclosure parts that are structurally bonded together to form a singular composite structure. In one embodiment, structural glue is used to bond at least two unique parts together. Another aspect of the enclosure pertains to enclosure parts that are electrically bonded together to form a singular integrated conductive member. In one embodiment, conductive paste is used to bond at least two unique parts together. The improved enclosure is particularly useful in portable computing devices such as laptop computers.

Owner:APPLE INC

Integrated circuit substrate having embedded passive components and methods therefor

InactiveUS6987661B1Incremental costMultiple fixed capacitorsFixed capacitor dielectricConductive pasteConductive materials

An integrated circuit substrate having embdedded passive components provides a reduced cost and compact package for a die and one or more passive components. An insulating layer of the substrate is embossed or laser-ablated to generate apertures for insertion of a paste forming the body of the passive component. A resistive paste is used to form resistors and a dielectric paste is used for forming capacitors. A capacitor plate may be deposited at a bottom of the aperture by using a doped substrate material and activating only the bottom wall of the aperture, enabling plating of the bottom wall without depositing conductive material on the side walls of the aperture. Vias may be formed to the bottom plate by using a disjoint structure and conductive paste technology. Connection to the passive components may be made by conductive paste-filled channels forming conductive patterns on the substrate.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

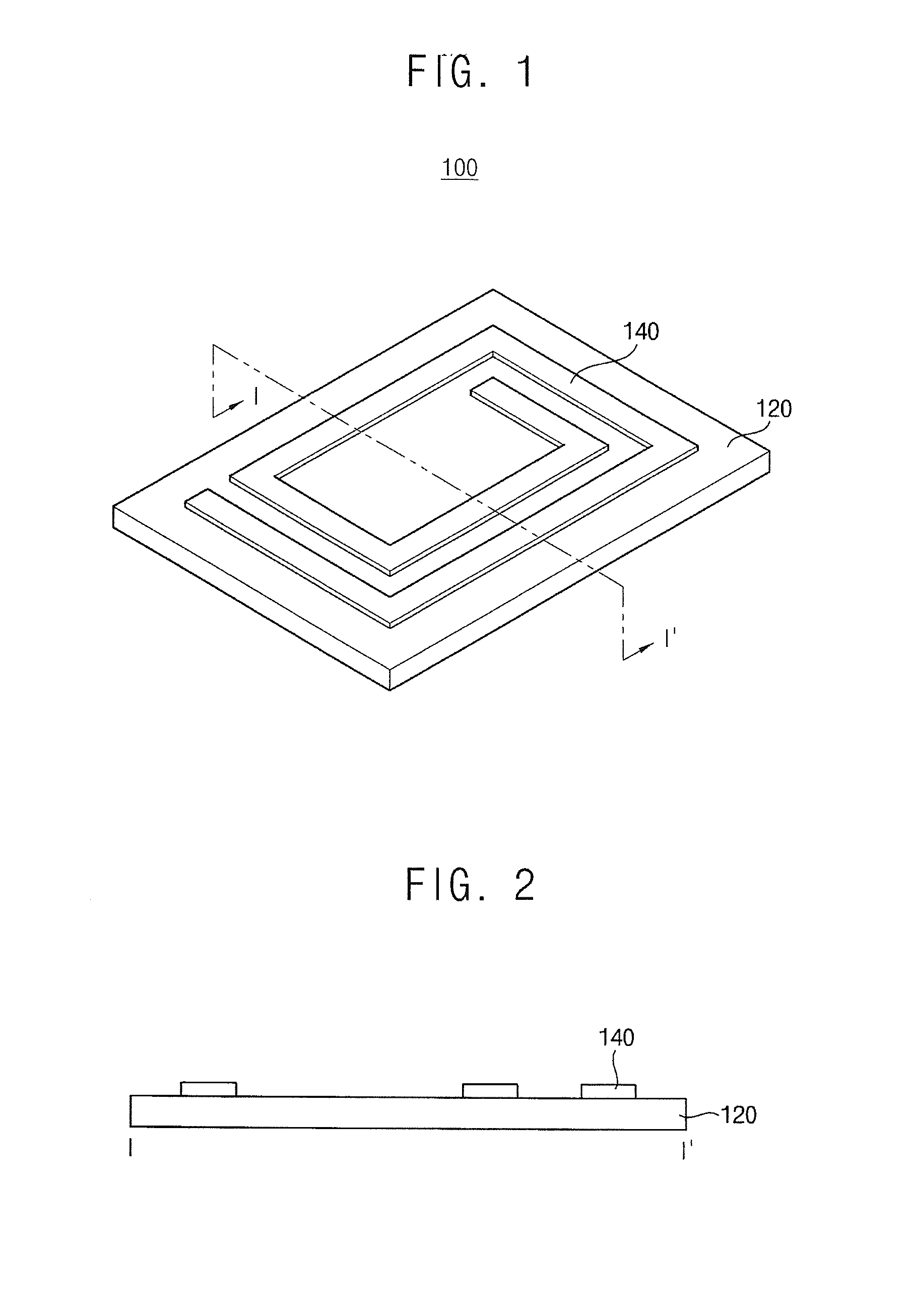

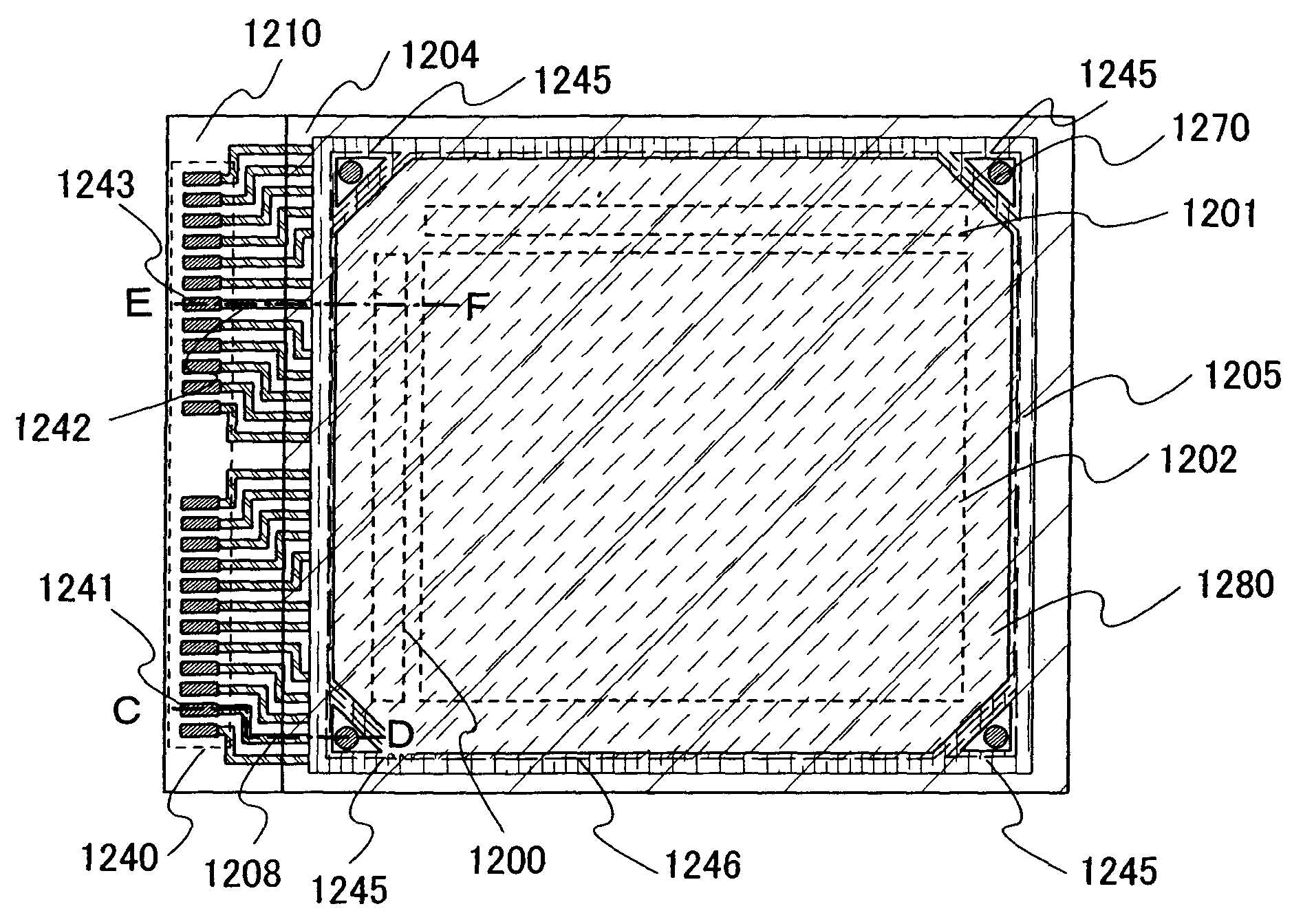

Liquid crystal display device and manufacturing method thereof

ActiveUS20080284970A1Reduce the amount requiredReduce display defectsNon-linear opticsConductive pasteDiffusion

To further ensure the electrical connection of a conductor between an opposite electrode of an opposite substrate and a connection wiring of a TFT substrate, and to prevent diffusion of impurities contained in a sealing material mixed with conductive particles or a conductive paste into a liquid crystal layer. In order to isolate the sealing material containing a conductive particle or the conductive paste from the liquid crystal layer, the shape of top surface of the sealing material is a shape in which a plurality of circular shapes are combined, which is a shape having no opening. Further, the sealing material forms a plurality of compartments such that a compartment in which a pixel region is provided and a compartment in which a conductor is provided are blocked out.

Owner:SEMICON ENERGY LAB CO LTD

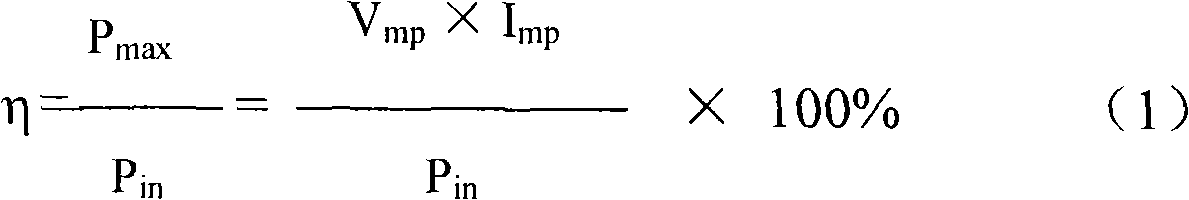

Conductive paste for forming a solar cell electrode

ActiveUS20110095240A1Good solar cell characteristicConductive materialNon-conductive material with dispersed conductive materialConductive pasteFrit

A conductive paste for forming a solar cell electrode, including: a conductive powder comprising silver as a main component; glass frit; and an organic vehicle, wherein the glass frit contains tellurium glass frit having tellurium oxide as a network-forming component. The conductive paste of the present invention makes it possible to form a solar cell electrode having a low dependence on firing temperature without causing problems due to fire-through into the substrate, and to thereby obtain a solar cell having good solar cell characteristics.

Owner:CHANGZHOU JUHE NEW MATERIAL CO LTD +1

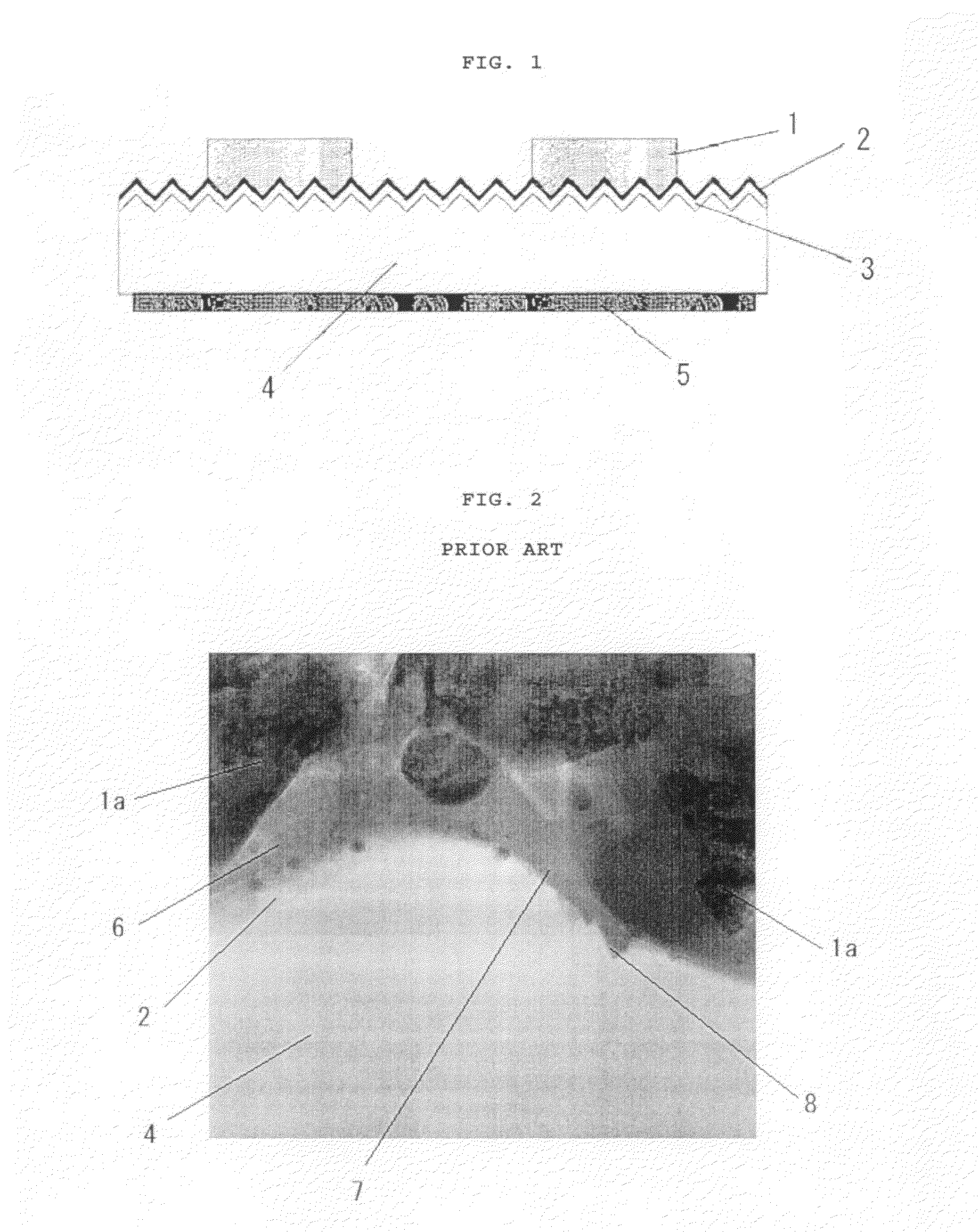

Method of making an antifogging window plate of synthetic resins

InactiveUS6024904AReduce the number of stepsFlat surfaceMouldsSynthetic resin layered productsConductive pasteEngineering

An antifogging window plate has a transparent film and a base both made of thermoplastic resins. Conductive lines and electrodes are printed using a conductive paste on one side of the film, which is then bonded to the base. One portion of each electrode is exposed as a terminal portion to be connected to an electric contact member. The window plate is made by injection molding with the surface of the film opposite from the printed surface being in contact with the cavity wall of the mold, so that the integration of the film with the base is effected simultaneously with the forming of base. Each contact member is subsequently fitted in an injection-molded void facing the terminal portion, or is secured in place at the same time as the injection molding.

Owner:TSUTSUNAKA PLASTIC IND

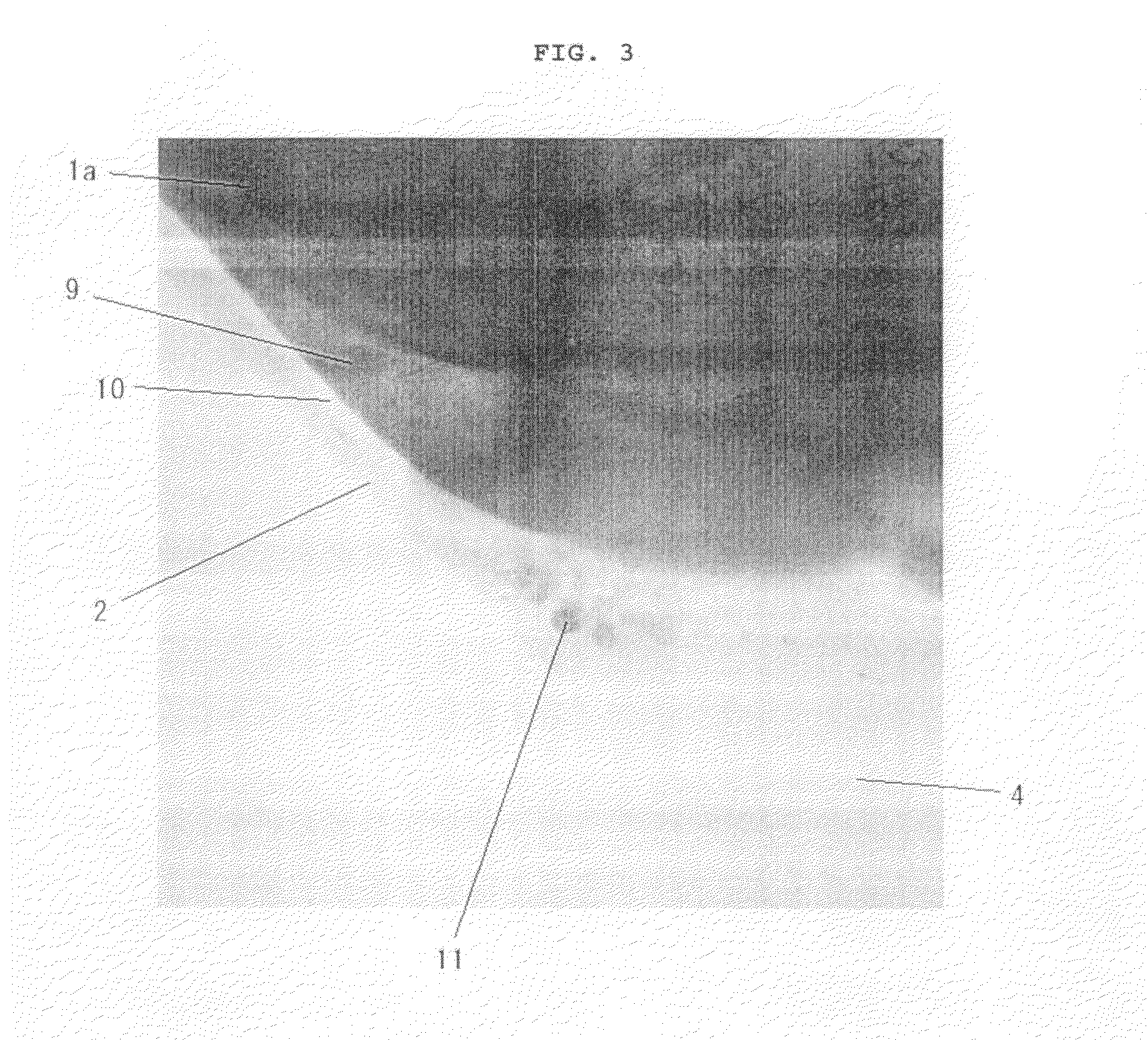

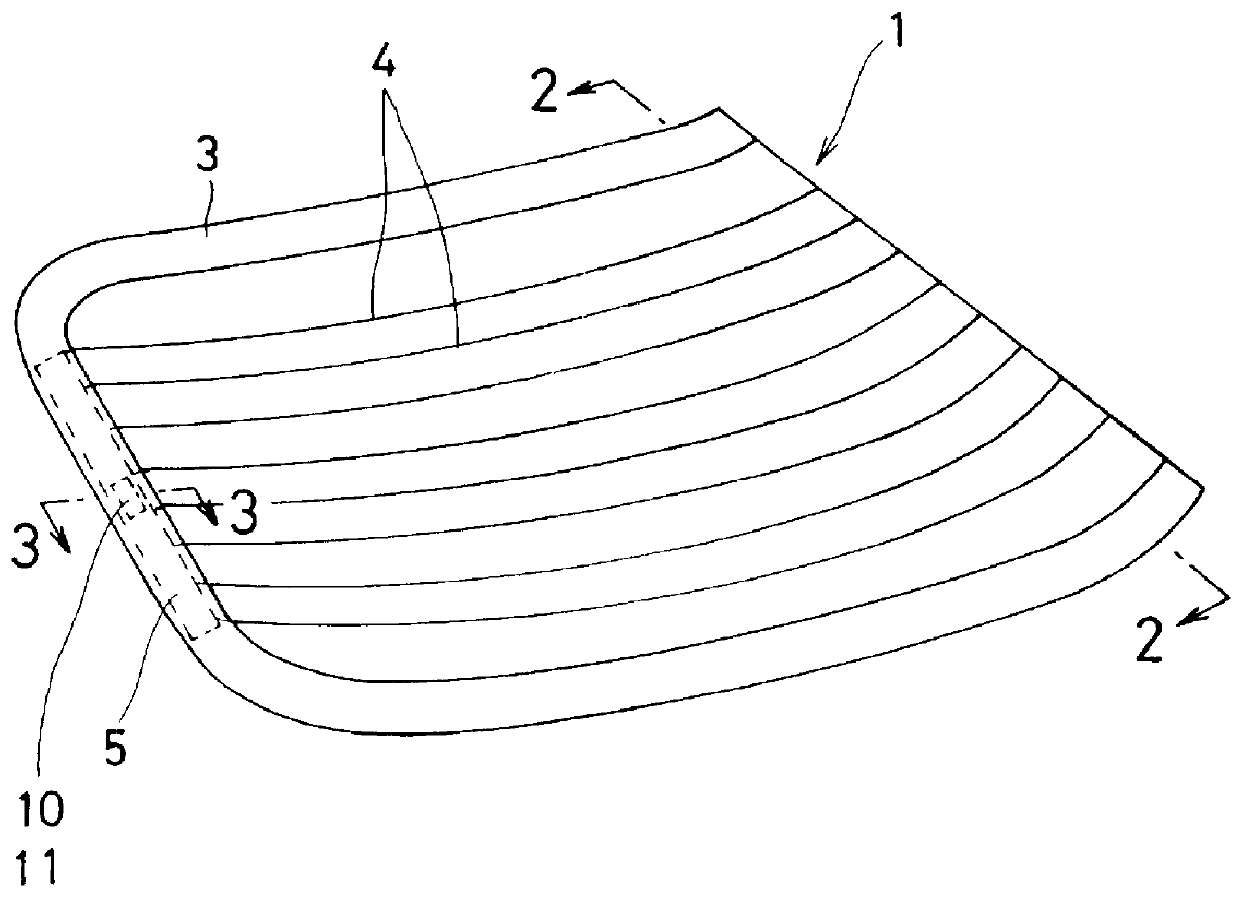

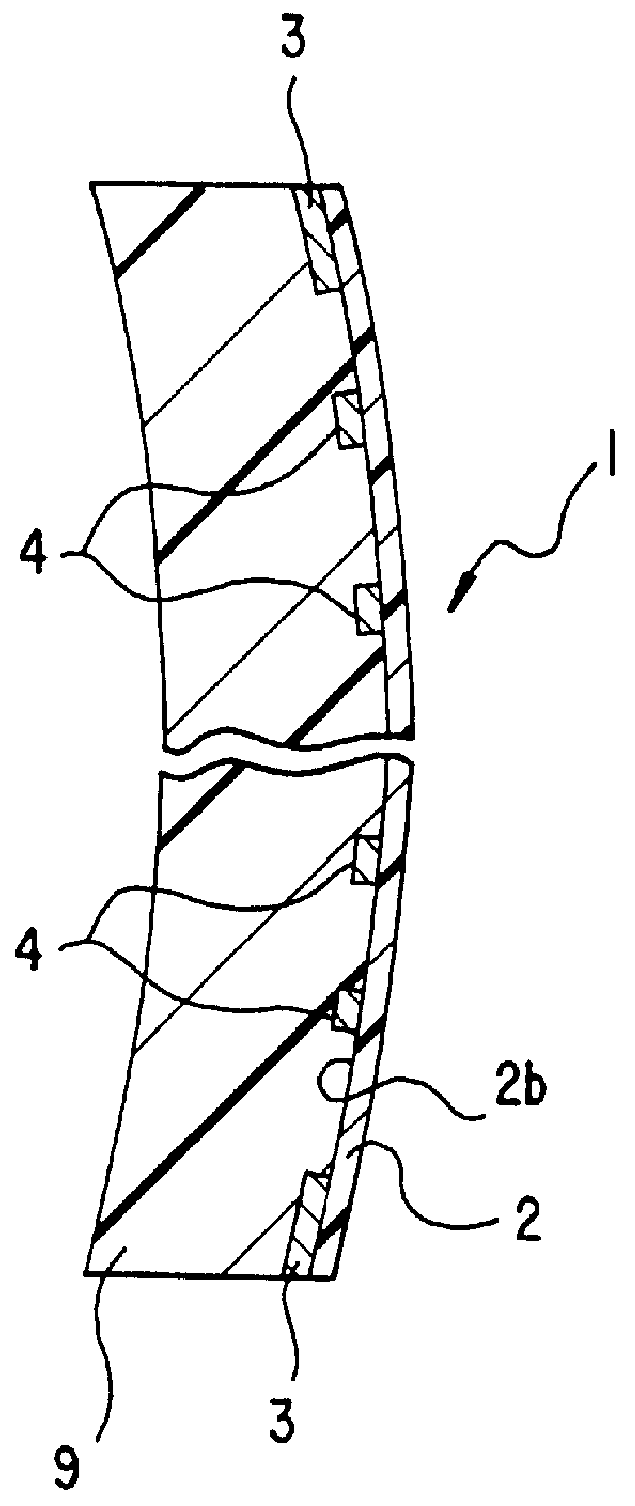

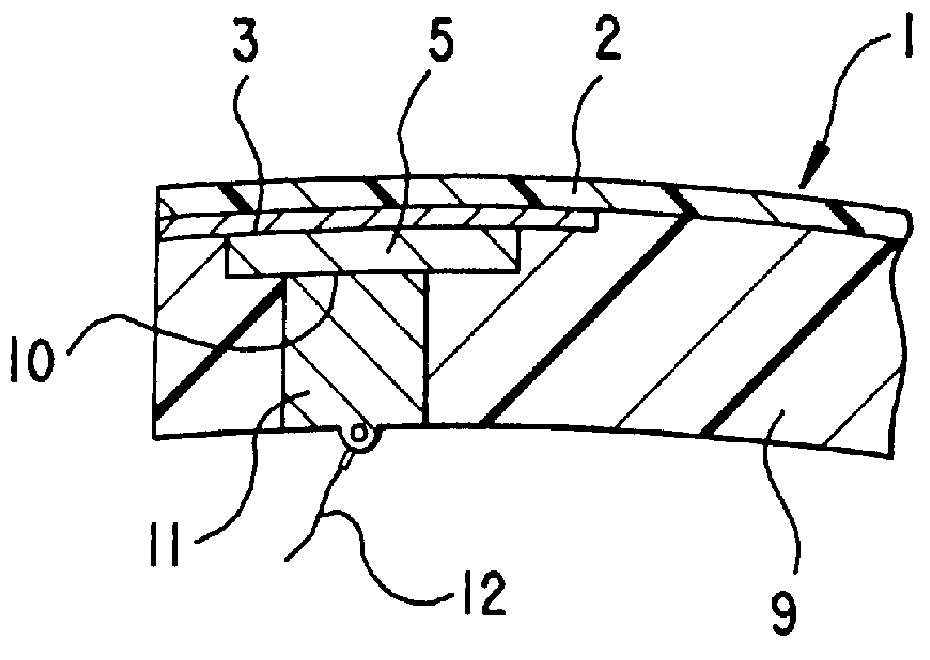

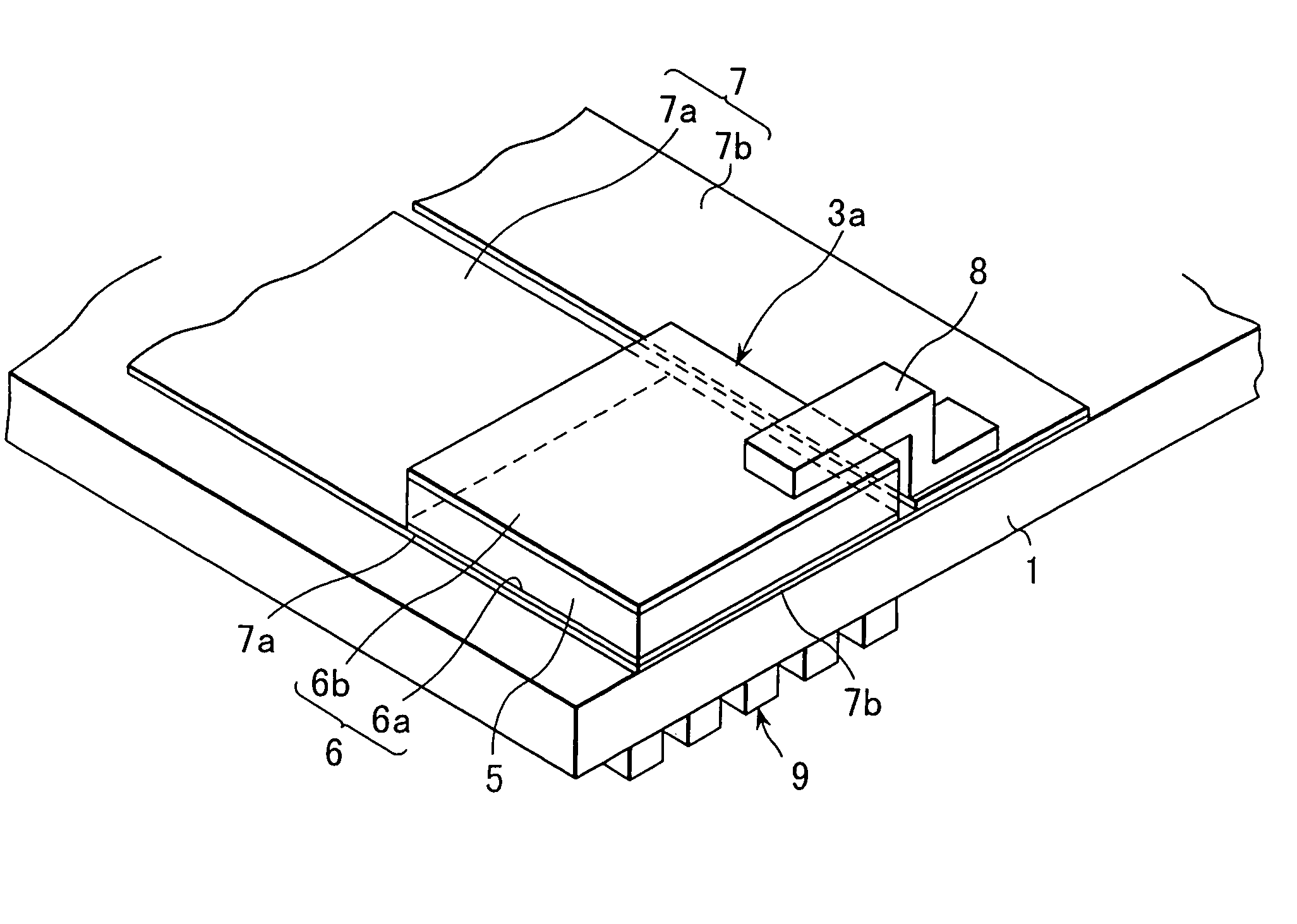

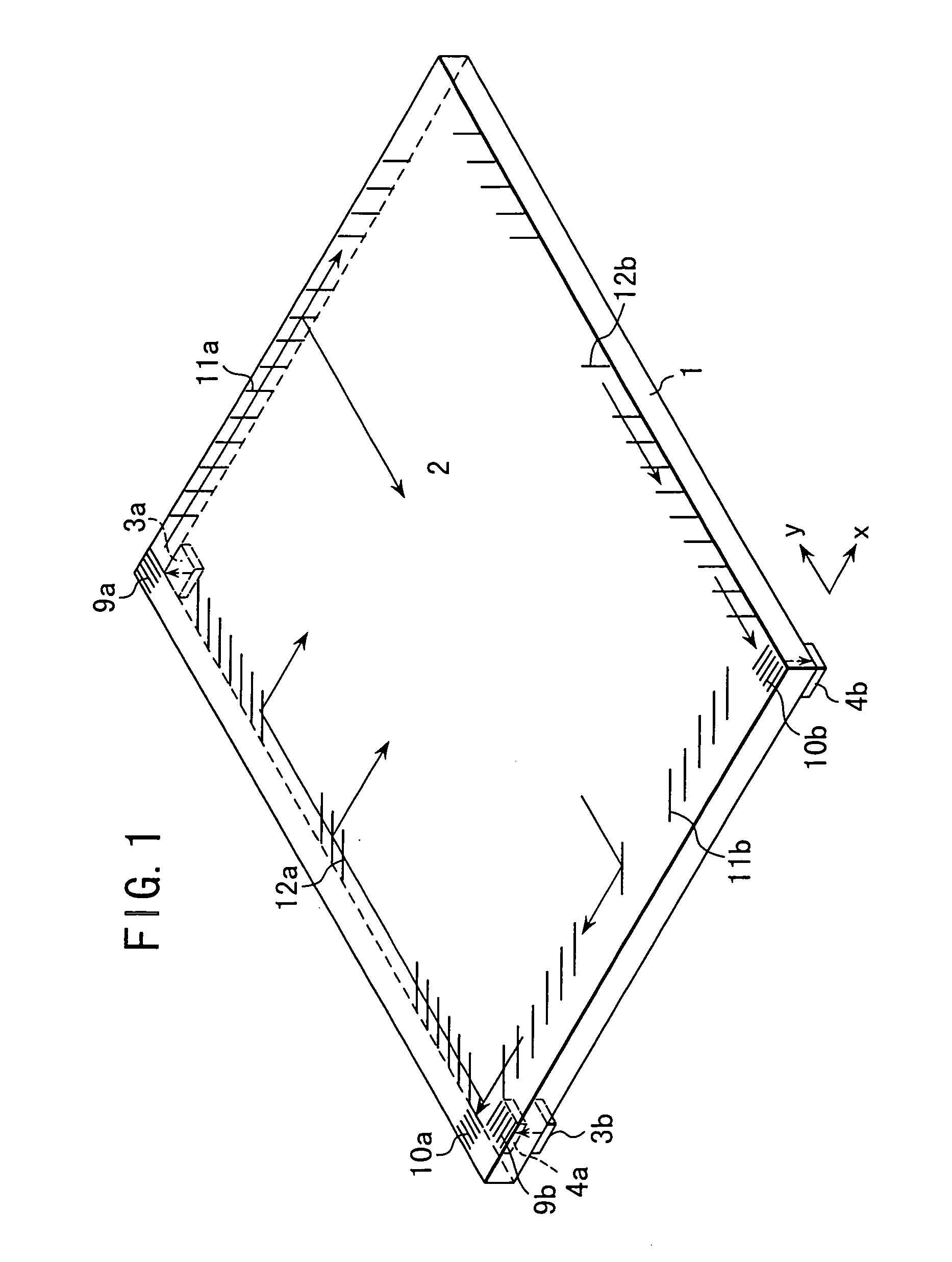

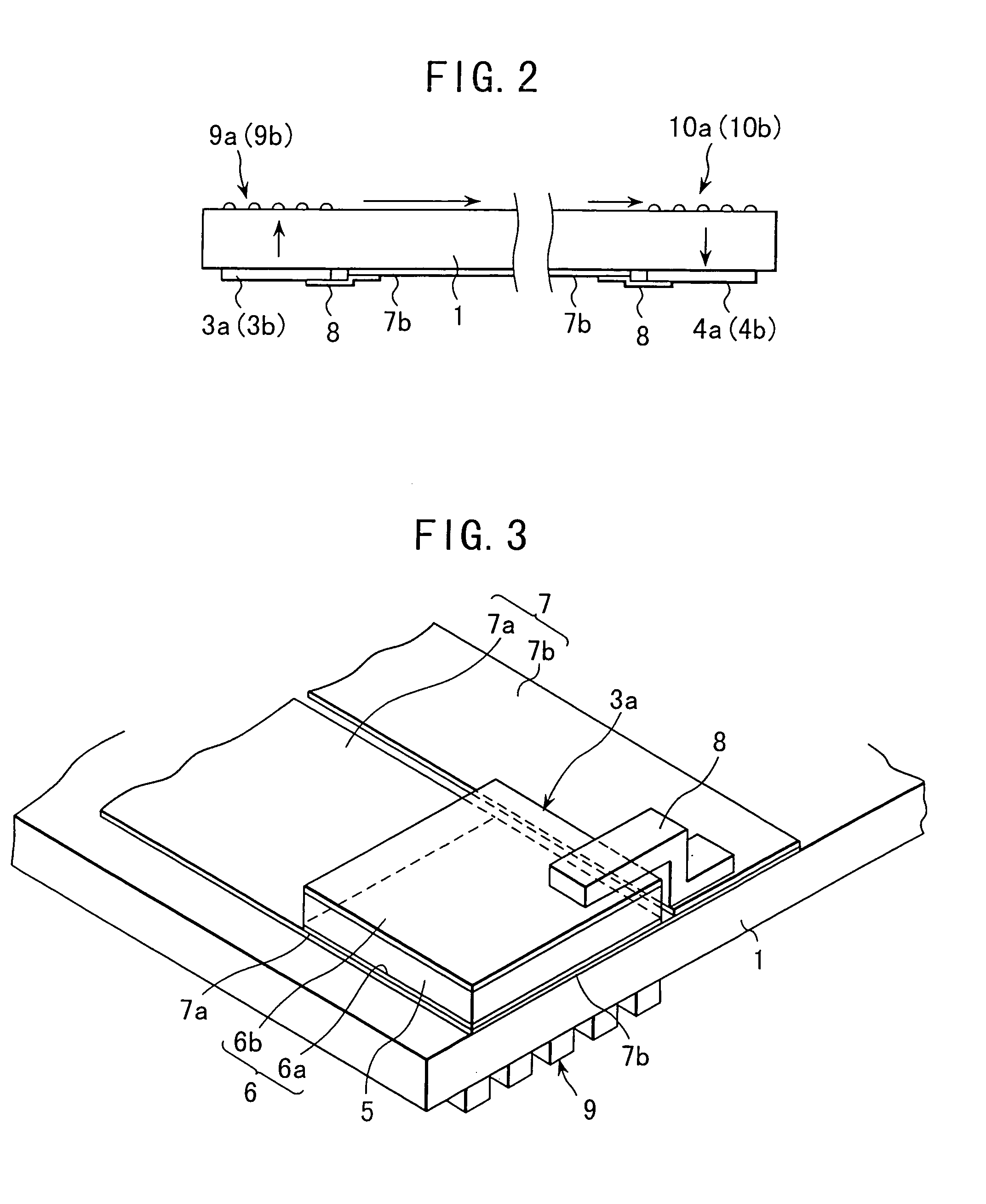

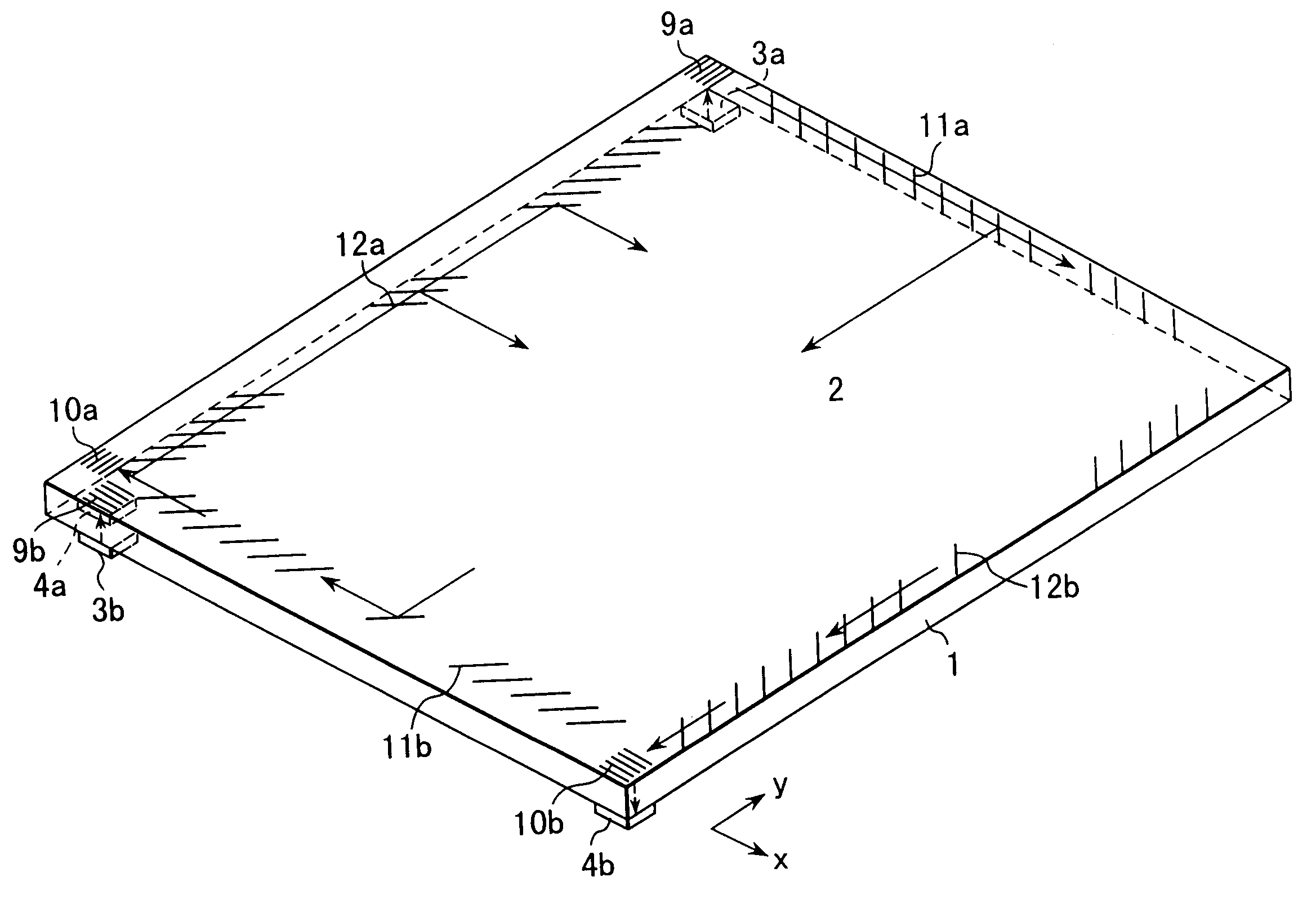

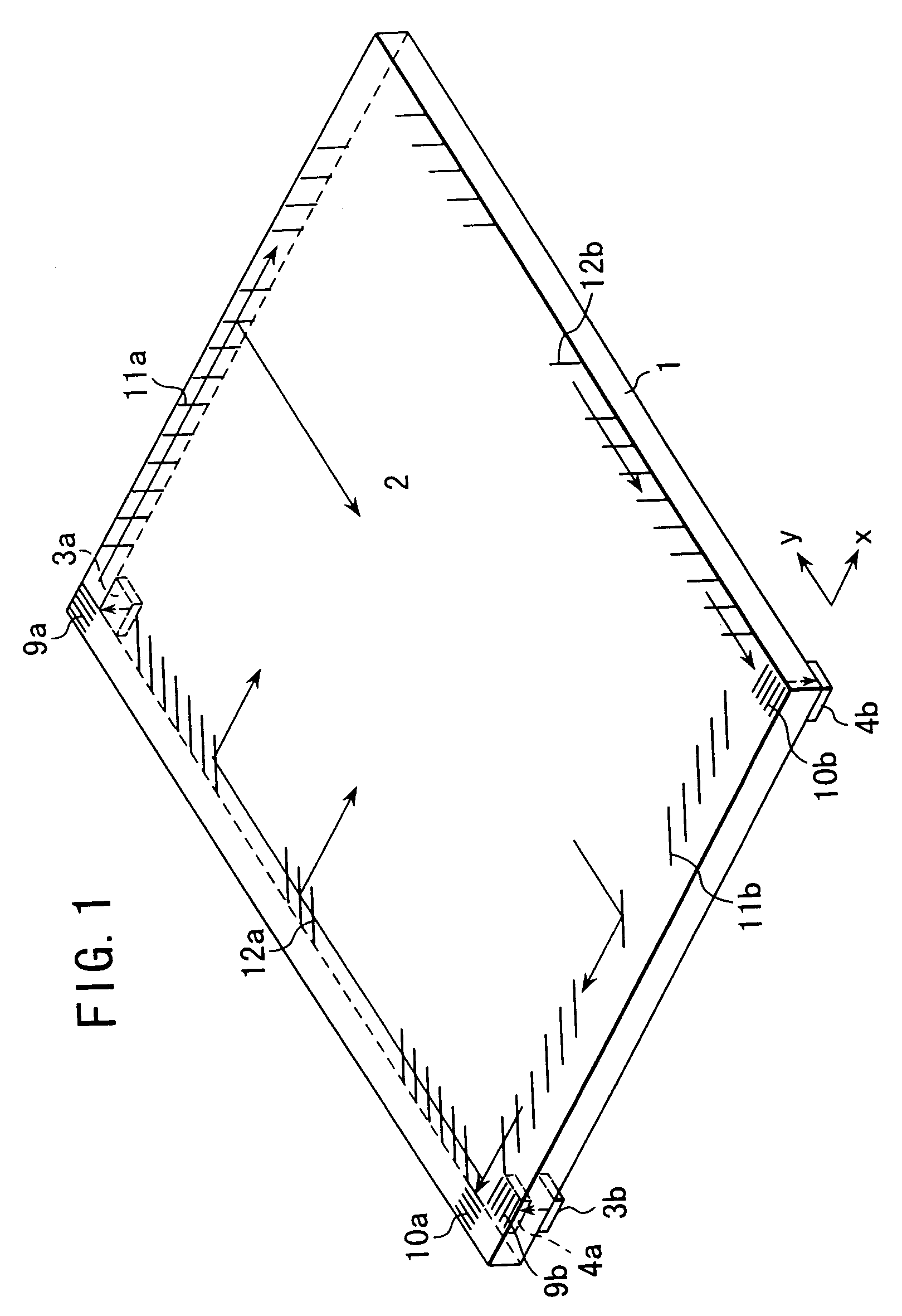

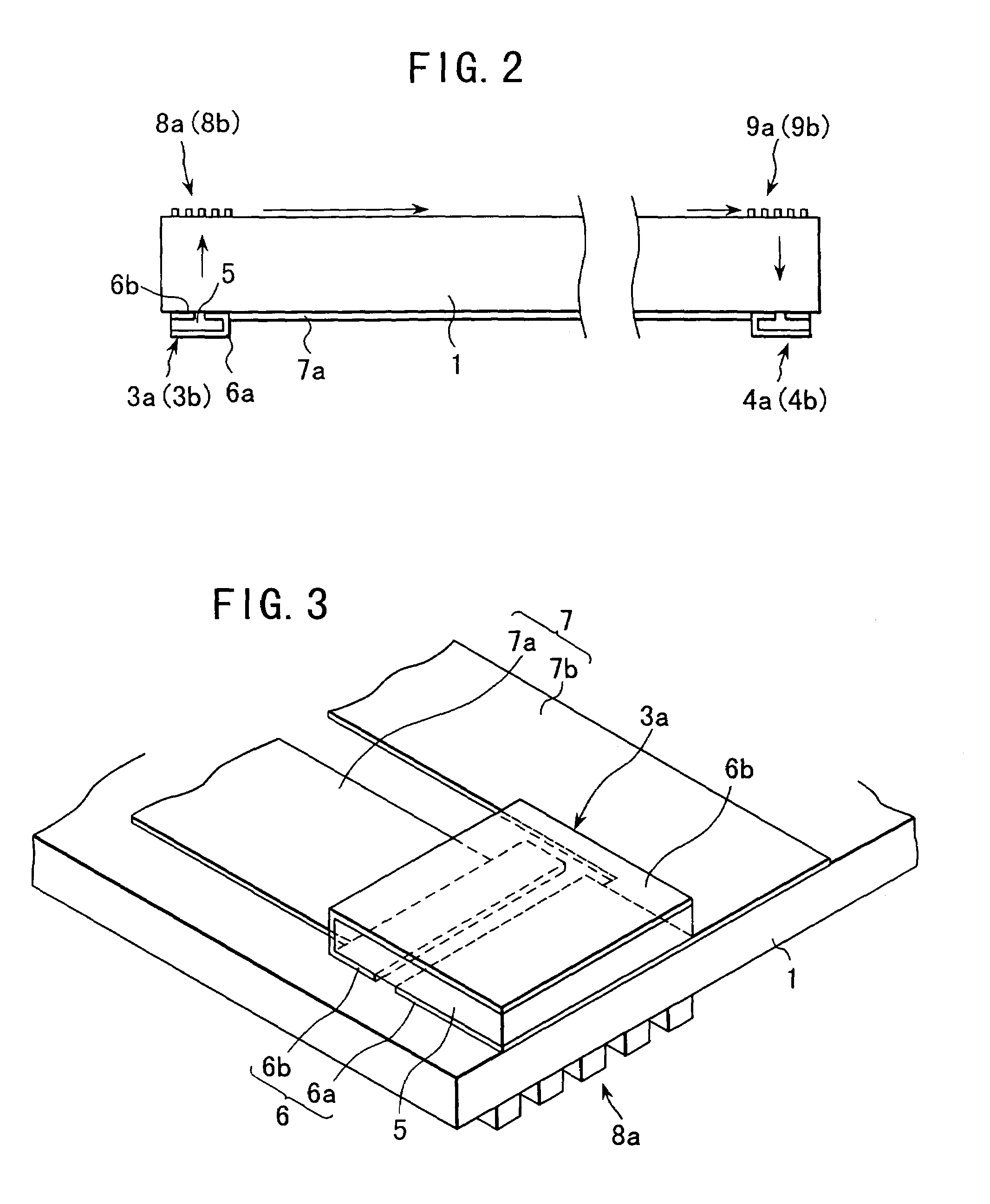

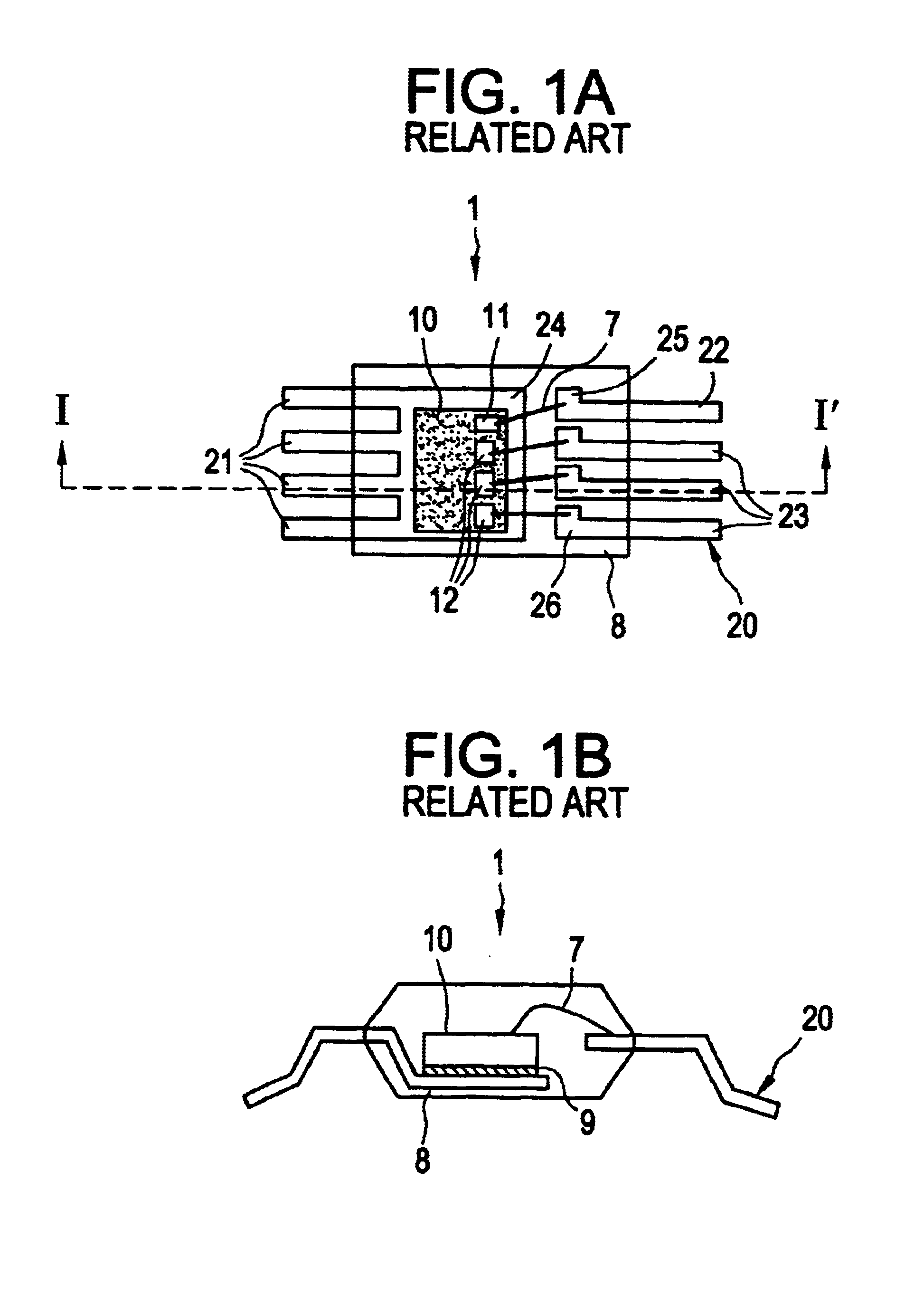

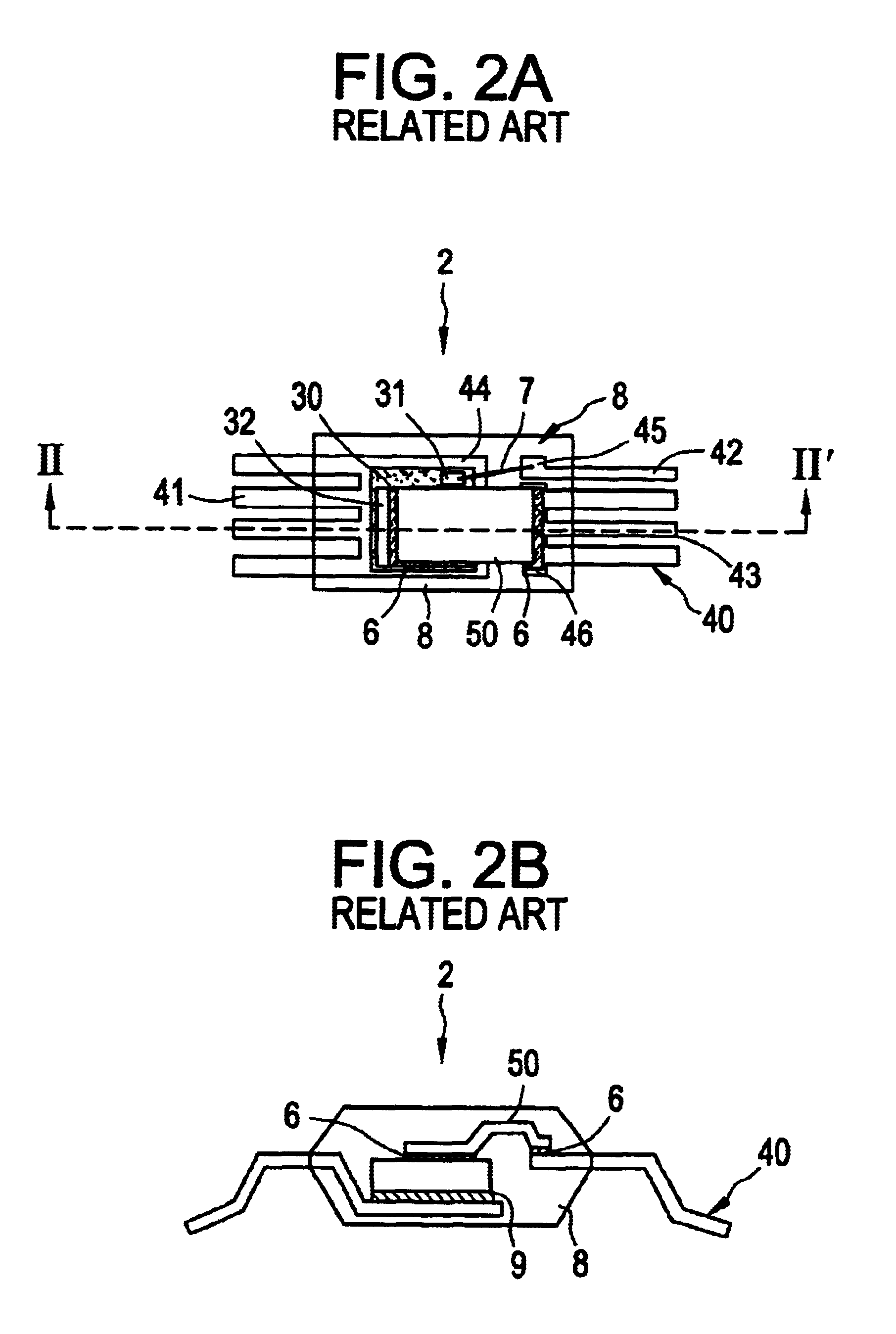

Acoustic contact detecting device

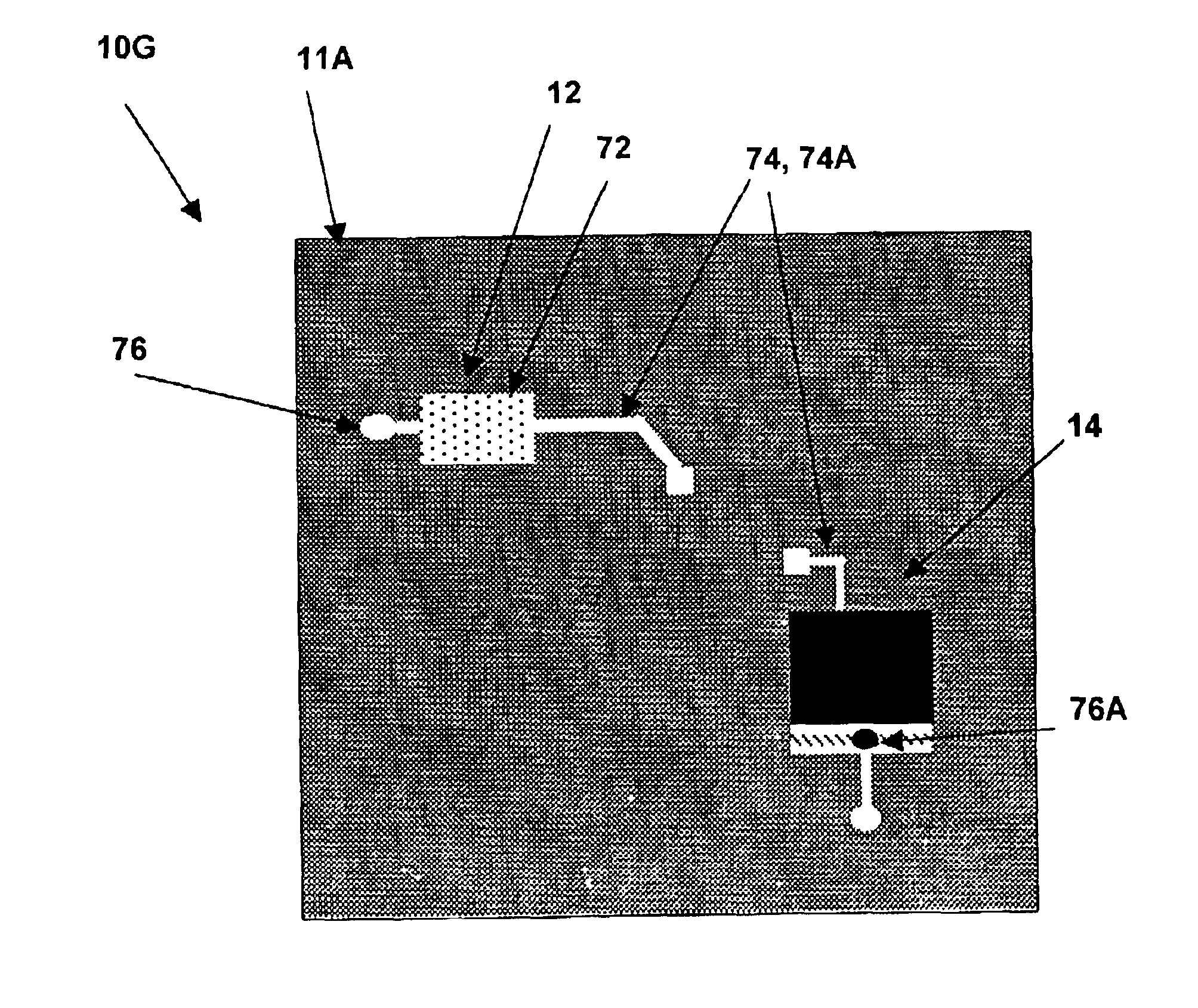

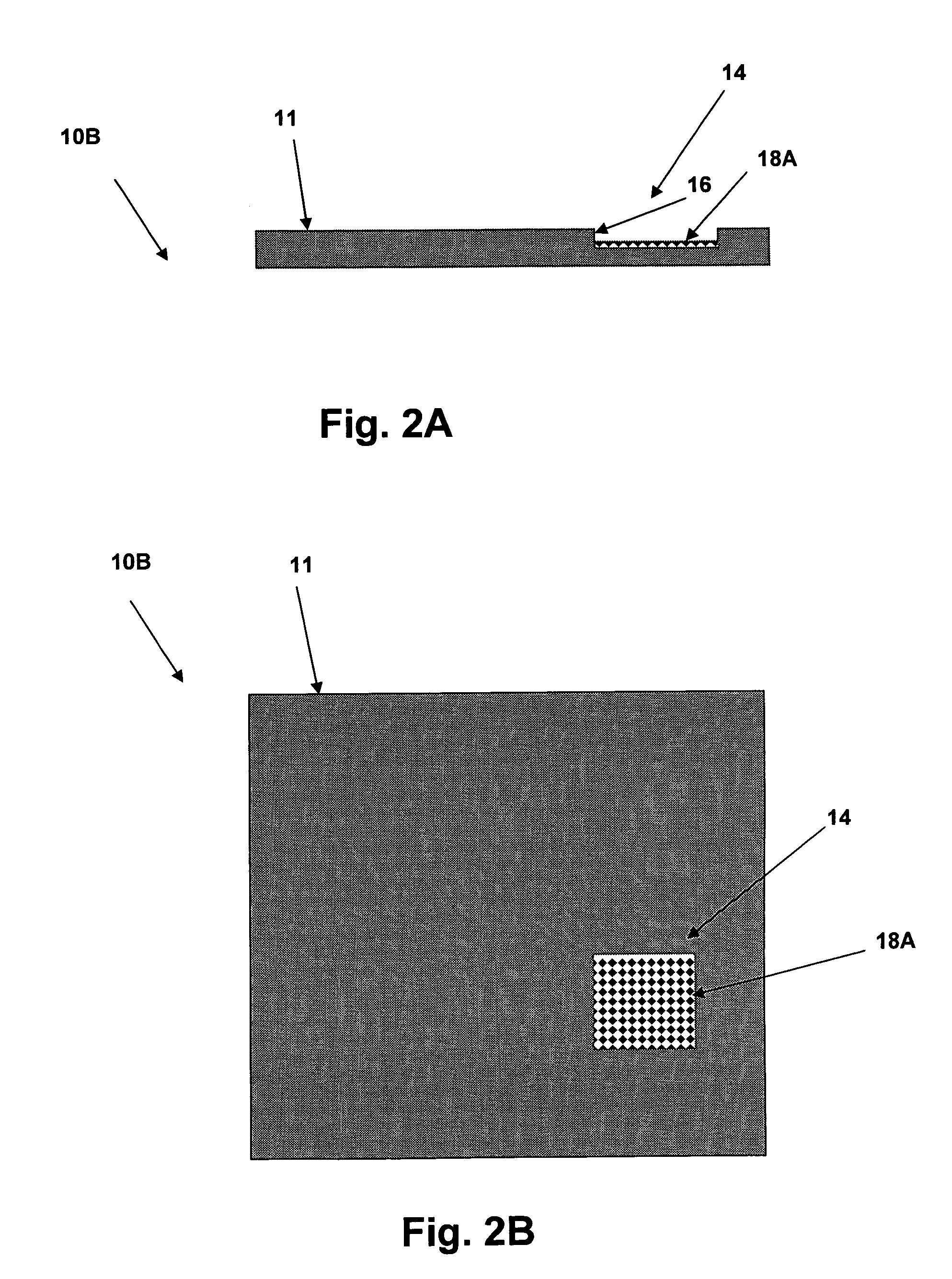

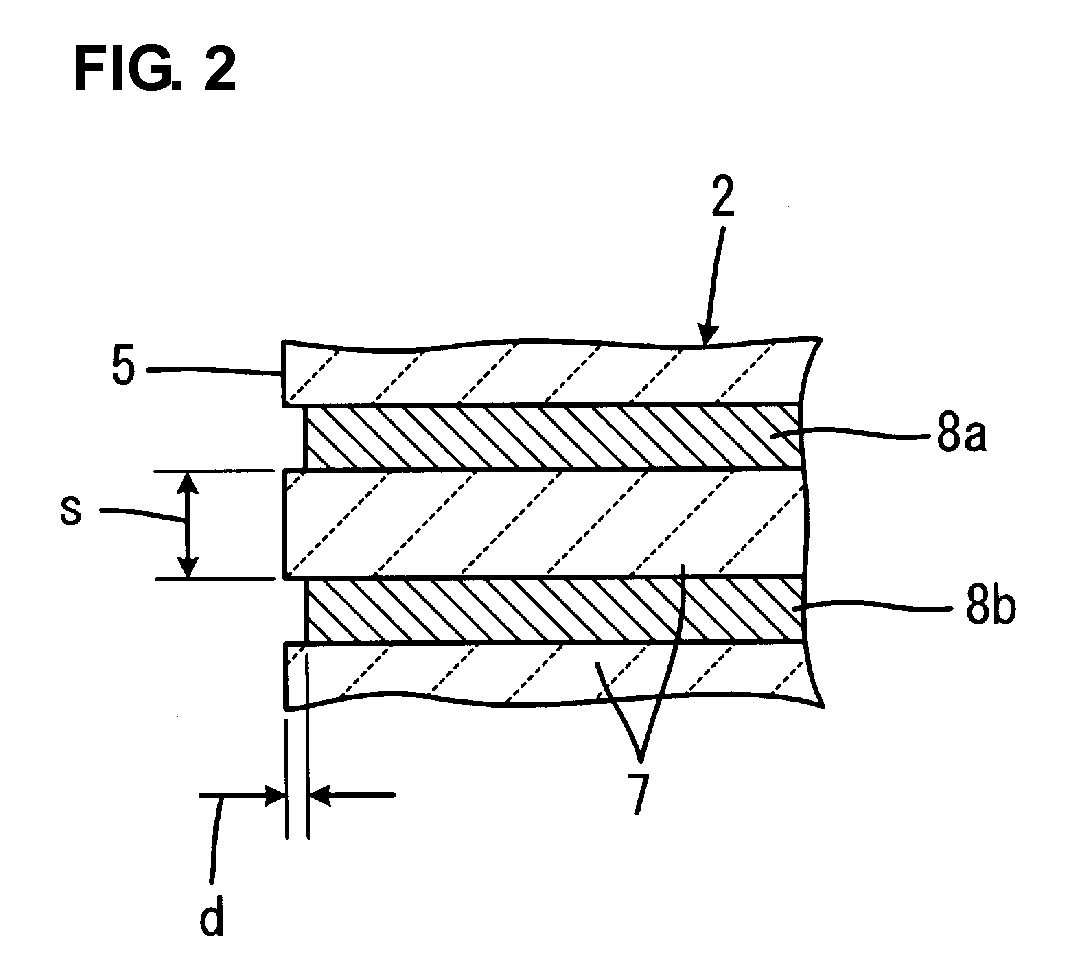

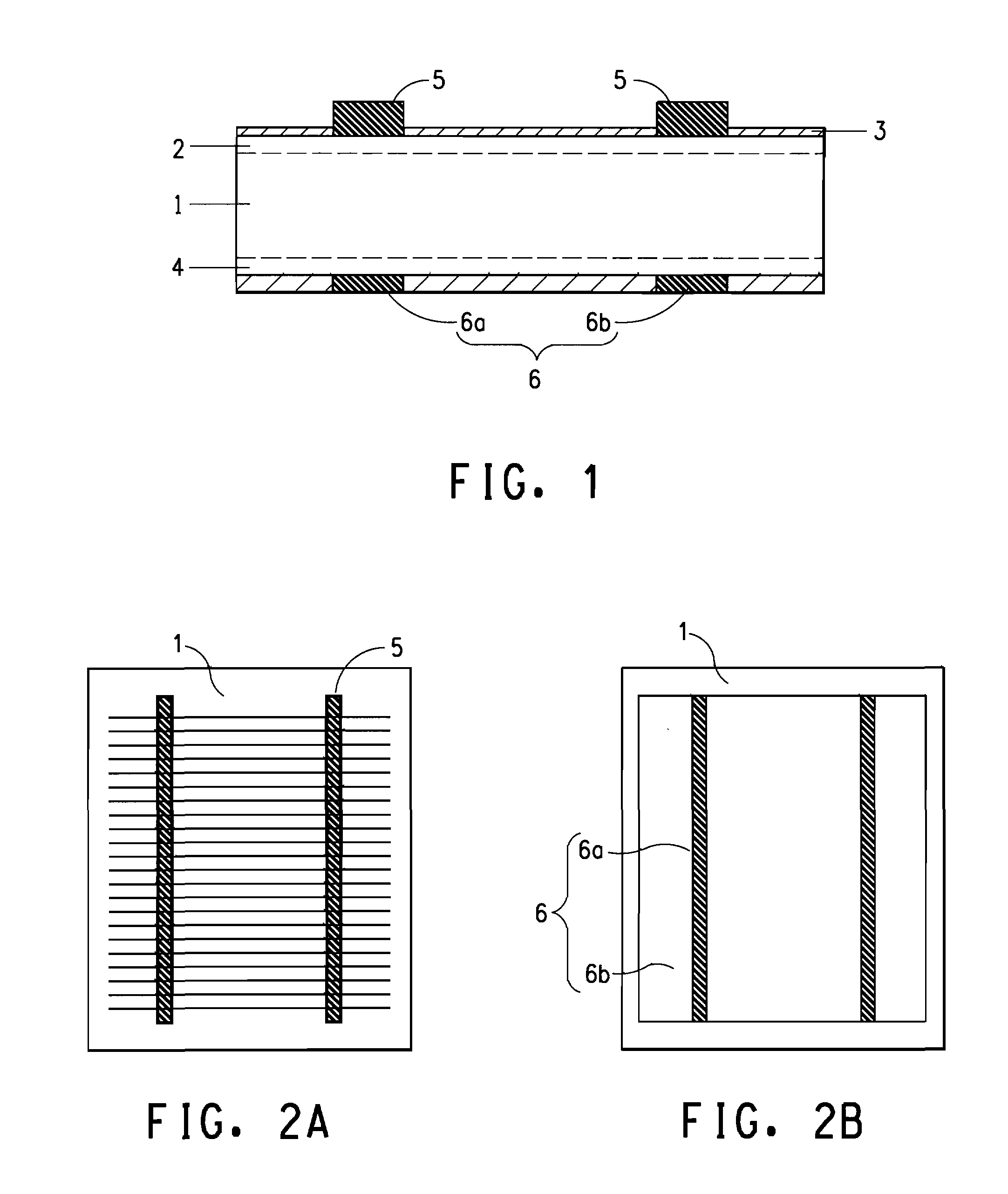

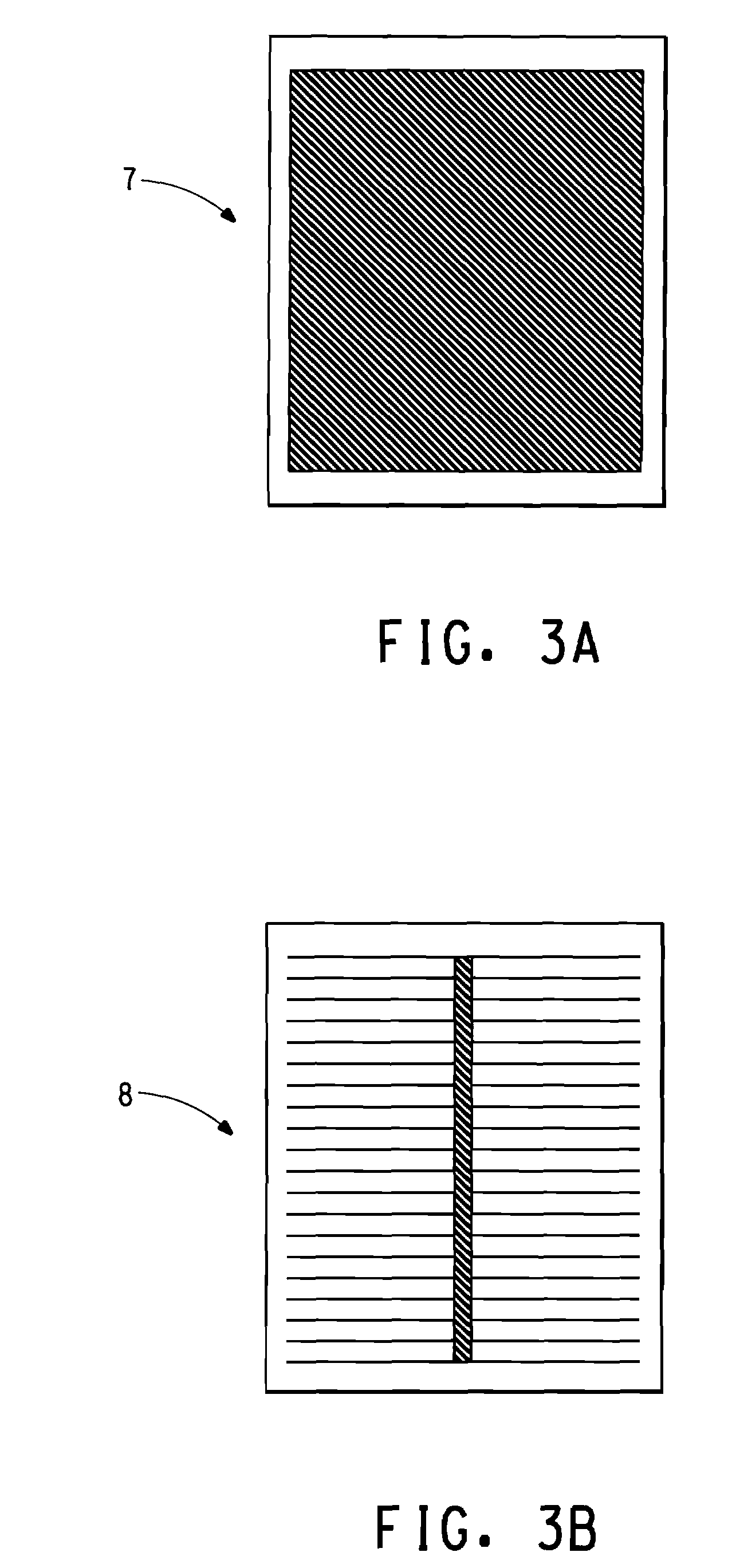

InactiveUS7193617B1Improve reliabilityEasy to manufacturePiezoelectric/electrostrictive transducersCathode-ray tube indicatorsConductive pasteSurface acoustic wave sensor

An object of the present invention is to provide a coordinate input device of touch-type capable of giving an electric signal to a transducer, even if a piezoelectric vibrator having electrodes on both surfaces thereof is employed.A device according to the present invention comprises: acoustic wave transducers (piezoelectric vibrators) 3a and 4a, each functioning for oscillating a bulk wave (a first wave) toward a top surface 2 of a substrate 1; a planar wiring 7 formed on a back surface of the substrate 1 by the method such as transfer printing with conductive paste, for supplying said piezoelectric vibrator with electric power; a connecting device 8 for connecting said planar wiring with an electrode of each of said acoustic wave transducers 3a and 4a; diffractive acoustic wave mode couplers 9a–10b, each functioning for converting said bulk wave into a surface acoustic wave (a second wave) and vice versa; and a means for detecting a scatter in the surface acoustic wave (the second wave) on the top surface of said substrate. Employing the combination of the planar wiring and the connecting device can resolve the problem of fragility associated with a cable wiring even in the piezoelectric vibrator having the electrodes on both surfaces thereof.

Owner:TOUCH PANEL SYST

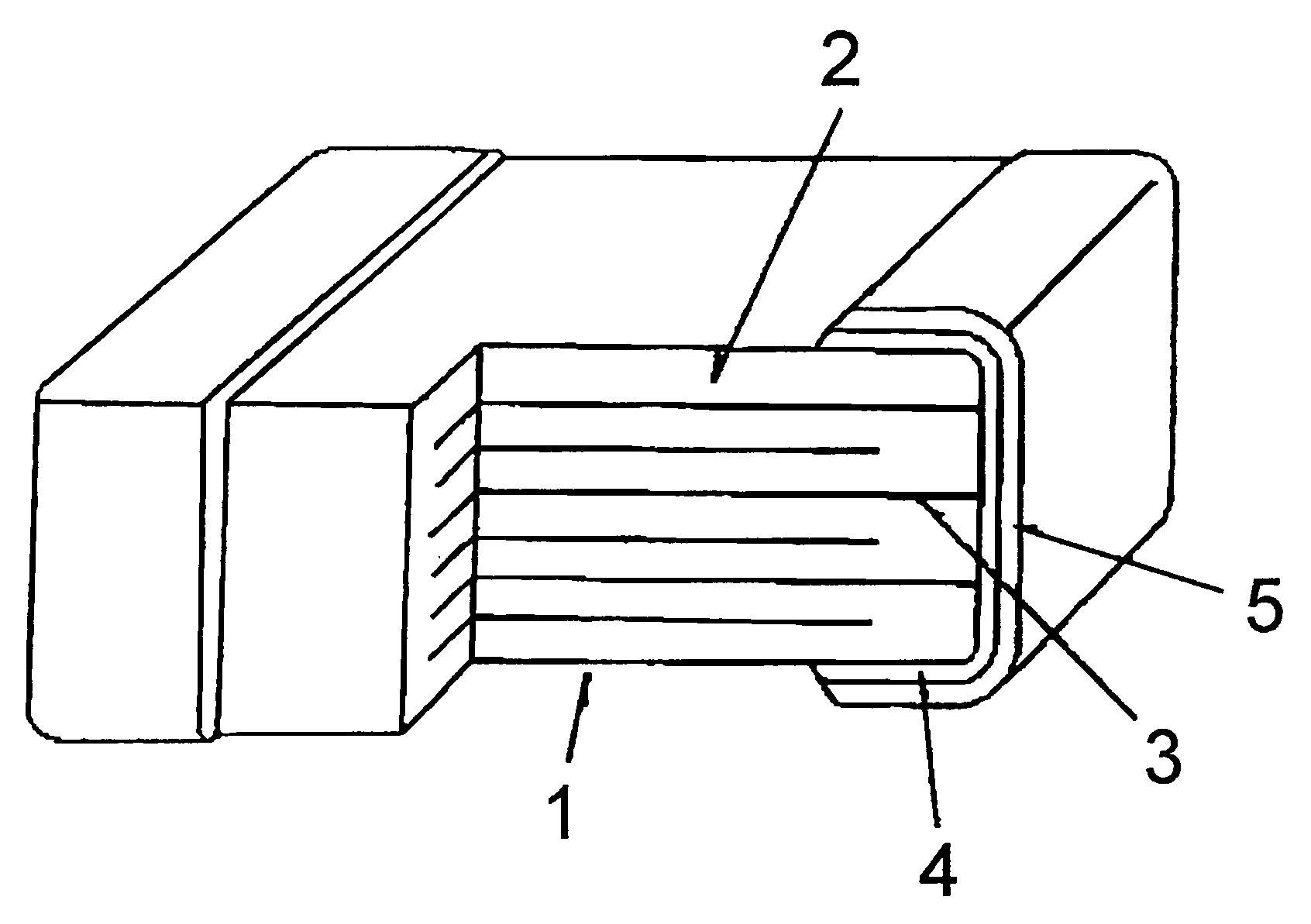

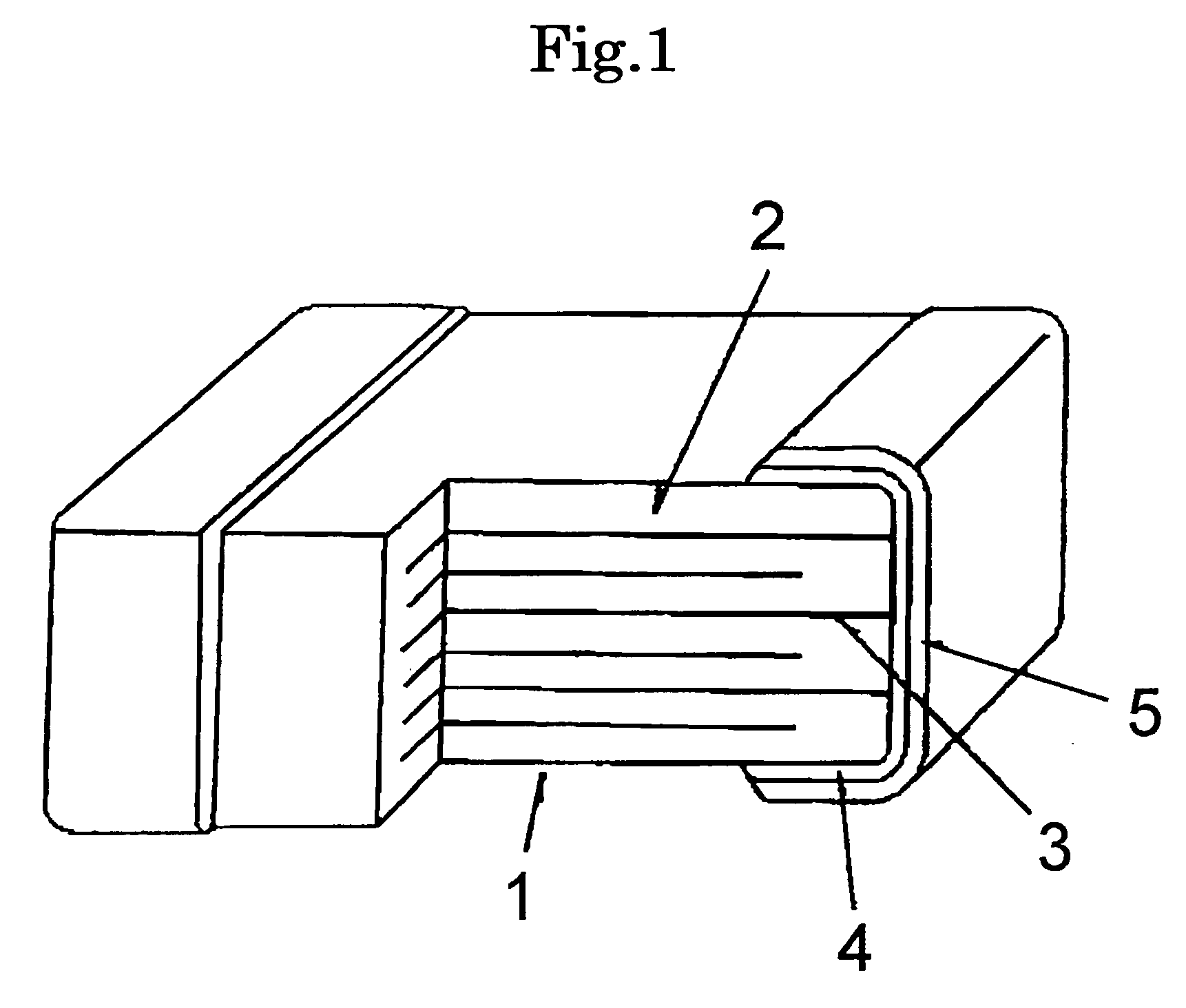

Electronic part with external electrode

ActiveUS20060044098A1High melting pointImprove adhesionFixed capacitor electrodesConductive materialConductive pasteBond properties

The present invention is intended to solve the problem of a conventional thermosetting conductive paste with respect to bonding-property between an internal electrode(s) and an external electrode(s) so as to provide a multilayer ceramic electronic part suitable for its mounting on a substrate and for its plating-treatment. The present invention relates to a multilayer ceramic electronic part, characterized in that it has an external electrode(s) formed from a thermosetting conductive paste comprising conductive particles having a high melting point, metal powder having a melting point of 300° C. or less and a resin(s).

Owner:NAMICS CORPORATION +1

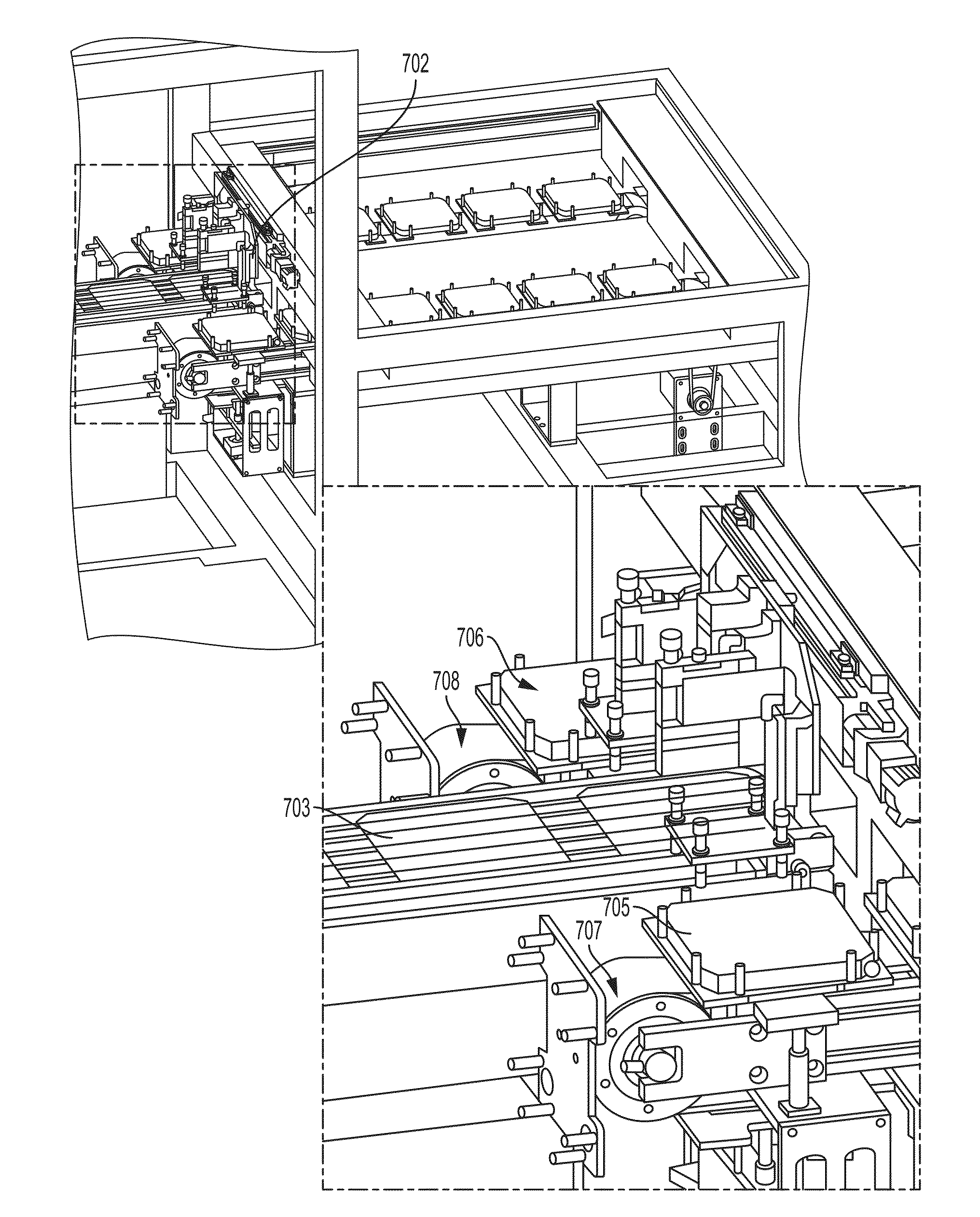

Systems, methods and apparatus for precision automation of manufacturing solar panels

Systems and methods for manufacturing solar panels are disclosed. Solar cells are placed on a conveyor that transports the cells from a start point to an end point. A laser scribing module scribes the cells at a predetermined depth. A paste dispensing module deposits a predetermined amount of conductive paste on the surface of the solar cells. A cleaving apparatus divides the cells into smaller strips. A shingling module creates a string of cells by overlapping the strips. A targeted annealing module cures the paste, and a layup module places the strings on a backsheet. A glass cover is then added to one side of the strings.

Owner:TESLA INC

Lead-free silver conductive paste used for positive electrode of solar battery and preparation technique thereof

InactiveCN101609850AStrong adhesionLower resistanceFinal product manufactureConductive materialConductive pasteSilver electrode

The invention provides a lead-free silver conductive paste used for positive electrode of solar battery and a preparation technique thereof. The paste comprises the following materials by weight percentage: 65 to 85 percent of silver powder, 2 to 8 percent of lead-free glass powder, 10 to 25 percent of organic carrier and 0.1 to 3 percent of additive. The paste adopts the lead-free glass powder of Si-B-Bi-Al-Ti-Zn-O series to replace the traditional lead-bearing glass powder; and the series glass powder has lower softening point, can lead the silver electrode to have good adhesive force after sintering, and ensures the silver electrode to be well contacted with a silicon substrate. In addition, zinc resinate is used as the additive in the invention, not only can well improve the printing performance of the paste, but also can improve the electrical property of the electrode.

Owner:CENT SOUTH UNIV

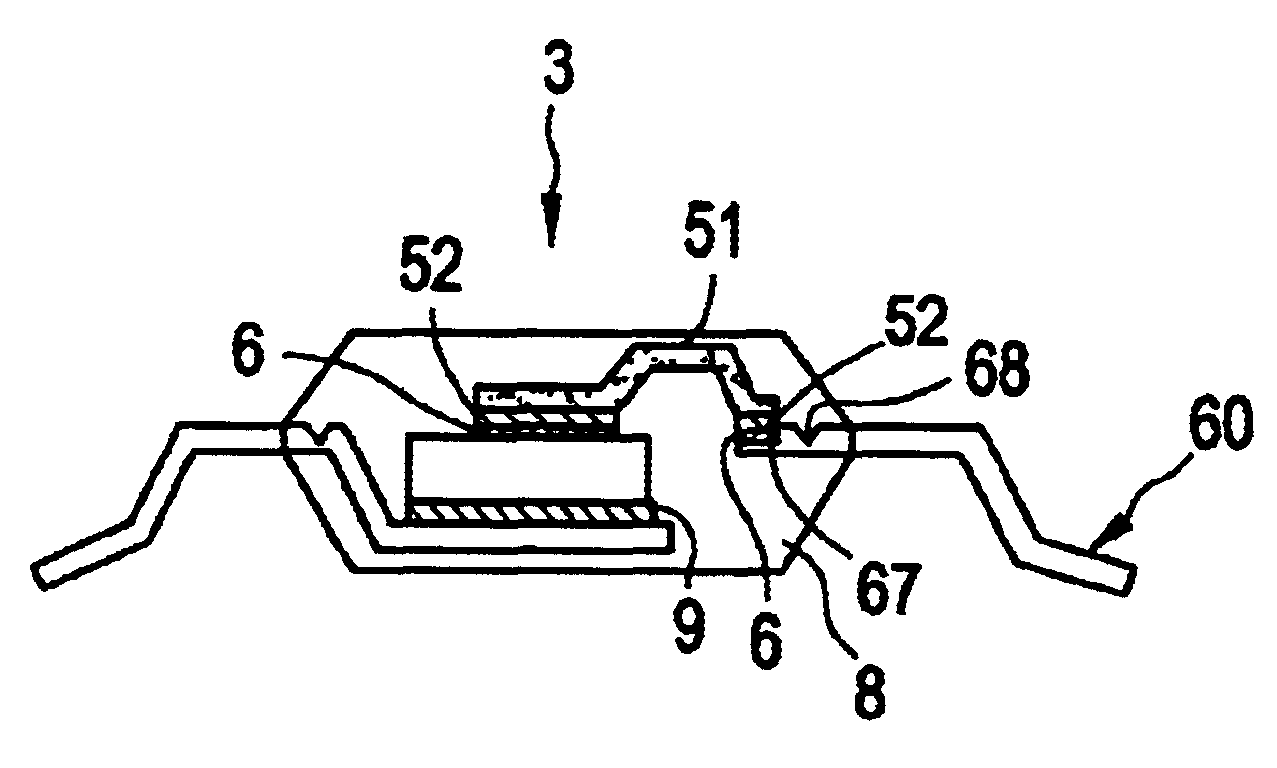

Acoustic touch sensor

InactiveUS7187369B1Smooth preparation processImprove reliabilityInput/output for user-computer interactionUsing subsonic/sonic/ultrasonic vibration meansConductive pasteSurface acoustic wave sensor

A coordinate input device of touch-type capable of giving an electric signal to a transducer, even if said transducer is disposed on a back surface of a substrate. The device contains acoustic wave transducers (piezoelectric vibrators), each functioning for oscillating a bulk wave (a first wave) toward a top surface of a substrate; a planar wiring formed on a back surface of the substrate by, e.g., transfer printing with conductive paste, for supplying the piezoelectric vibrator with electric power; diffractive acoustic wave mode couplers, each functioning for converting said bulk wave into a surface acoustic wave (a second wave) and vice versa; and a detector to detect scatter in the surface acoustic wave on the top surface of the substrate. Employing the planar wiring allows the wiring to be disposed even on the back surface of the substrate and also it may resolve the problem of fragility associated with a cable wiring.

Owner:TOUCH PANEL SYST

Method for making an integrated circuit substrate having embedded passive components

InactiveUS7334326B1Low incremental costIncremental costPrinted circuit assemblingElectrolytic capacitorsConductive pasteConductive materials

A method for making an integrated circuit substrate having embedded passive components provides a reduced cost and compact package for a die and one or more passive components. An insulating layer of the substrate is embossed or laser-ablated to generate apertures for insertion of a paste forming the body of the passive component. A resistive paste is used to form resistors and a dielectric paste is used for forming capacitors. A capacitor plate may be deposited at a bottom of the aperture by using a doped substrate material and activating only the bottom wall of the aperture, enabling plating of the bottom wall without depositing conductive material on the side walls of the aperture. Vias may be formed to the bottom plate by using a disjoint structure and conductive paste technology. Connection to the passive components may be made by conductive paste-filled channels forming conductive patterns on the substrate.

Owner:AMKOR TECH SINGAPORE HLDG PTE LTD

Coil component and electronic device

ActiveUS20060267719A1Prevent short-circuitingImprove installation strengthTransformers/inductances casingsTransformers/inductances coils/windings/connectionsConductive pasteElectronic equipment

A coil component comprises a core element having a mounting portion, a coil conductor placed on the core element, and at least two terminal electrodes which are placed in the mounting portion. The mounting portion has at least two terminal placement areas for placing the terminal electrodes respectively. A hollow portion opening to the mounting side face of the mounting portion is formed in an area between the at least two terminal placement areas in the mounting portion. When mounting the coil component on a circuit board, conductive paste is intervened between an area from the terminal electrodes placed in the mounting portion of the core element to the base exposed area of the mounting portion, and the electrode patterns on the circuit board.

Owner:TDK CORPARATION

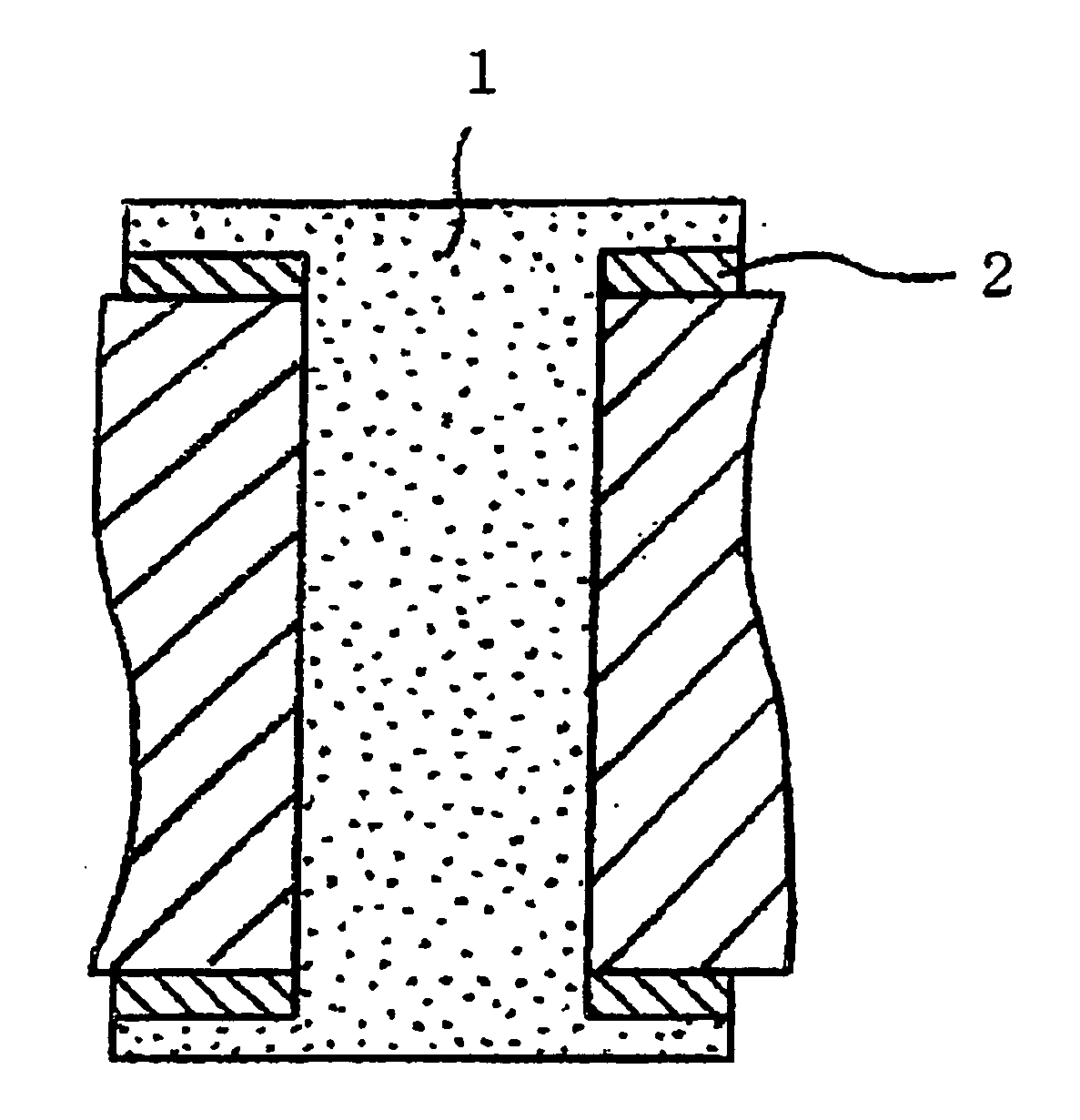

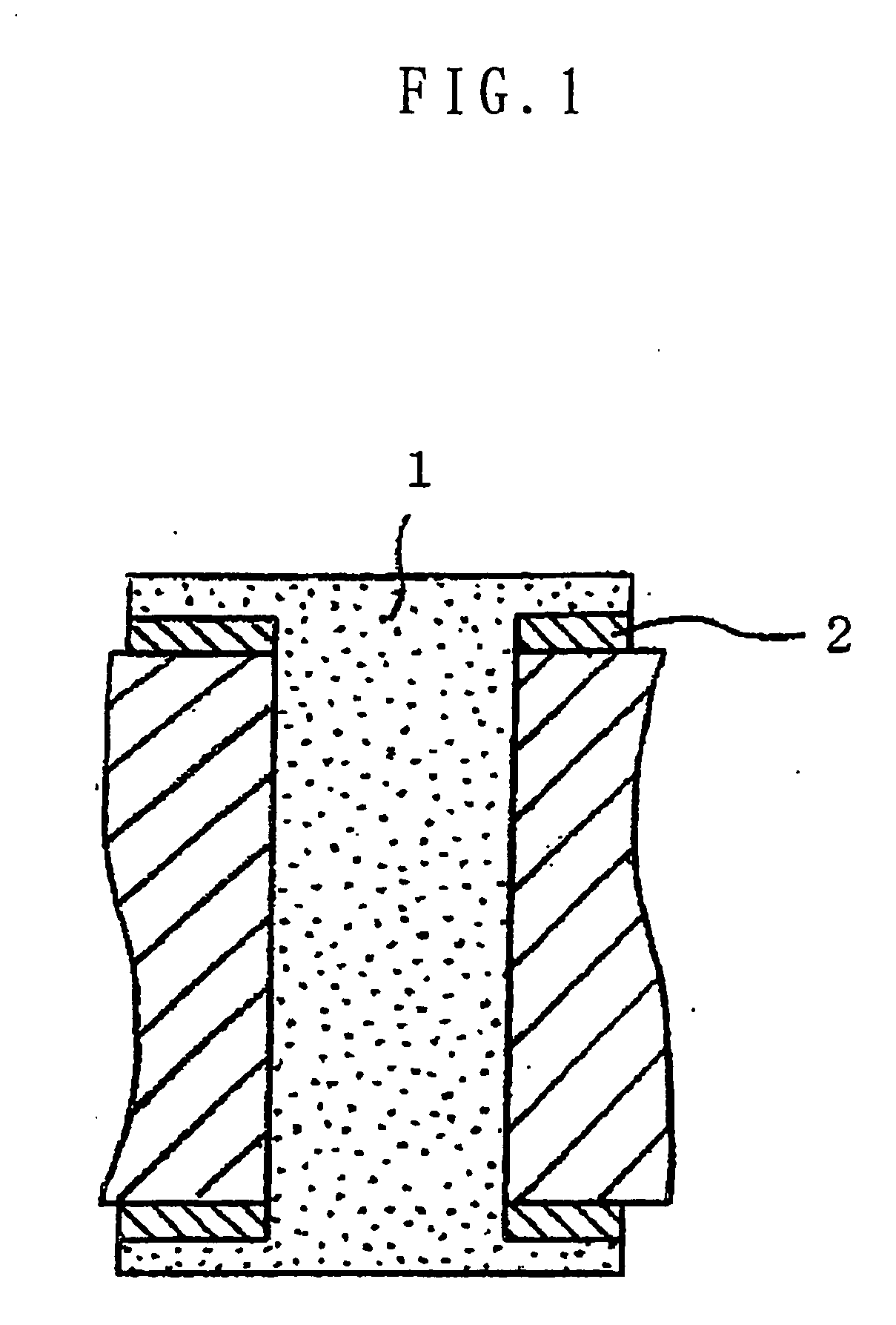

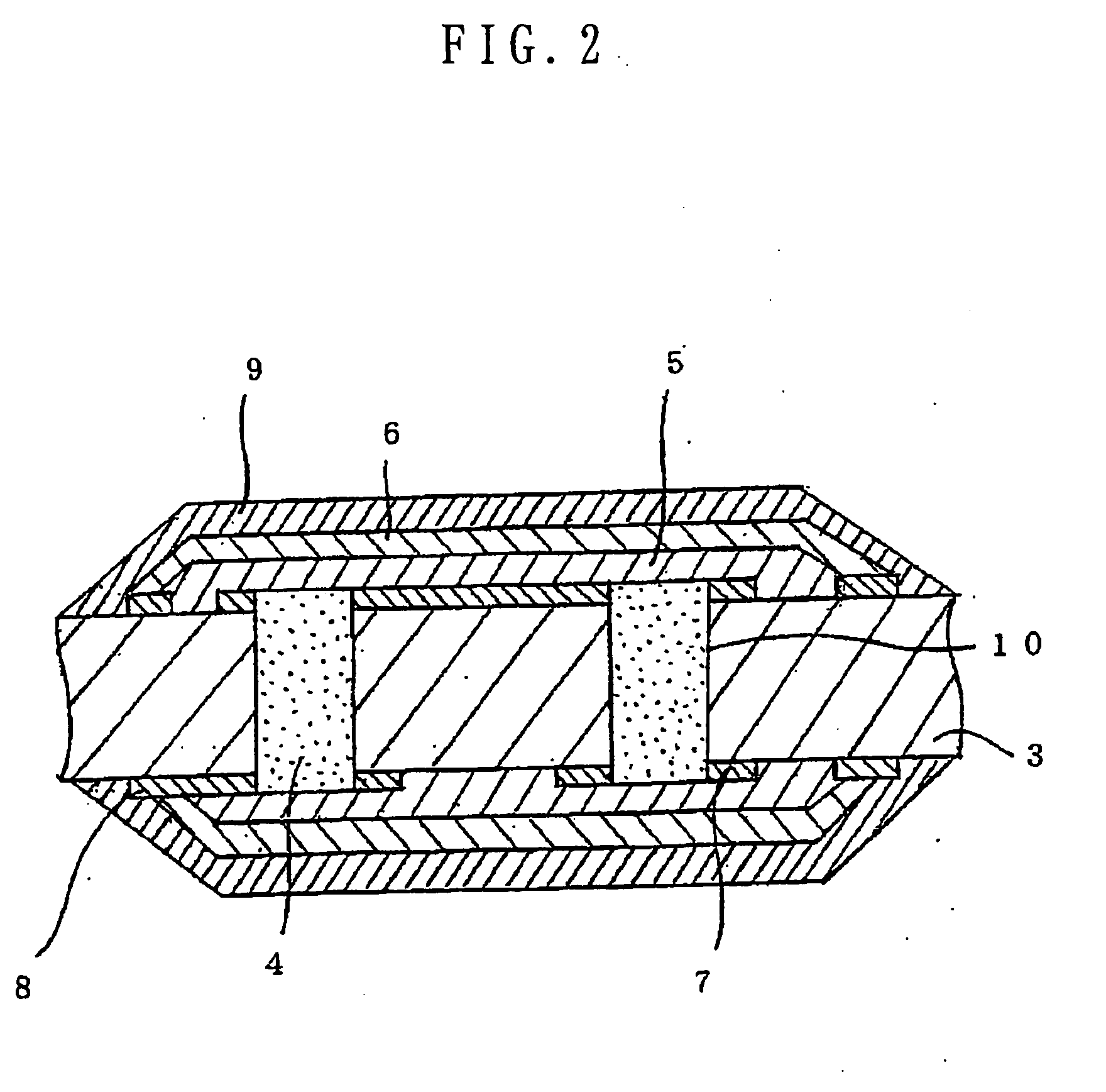

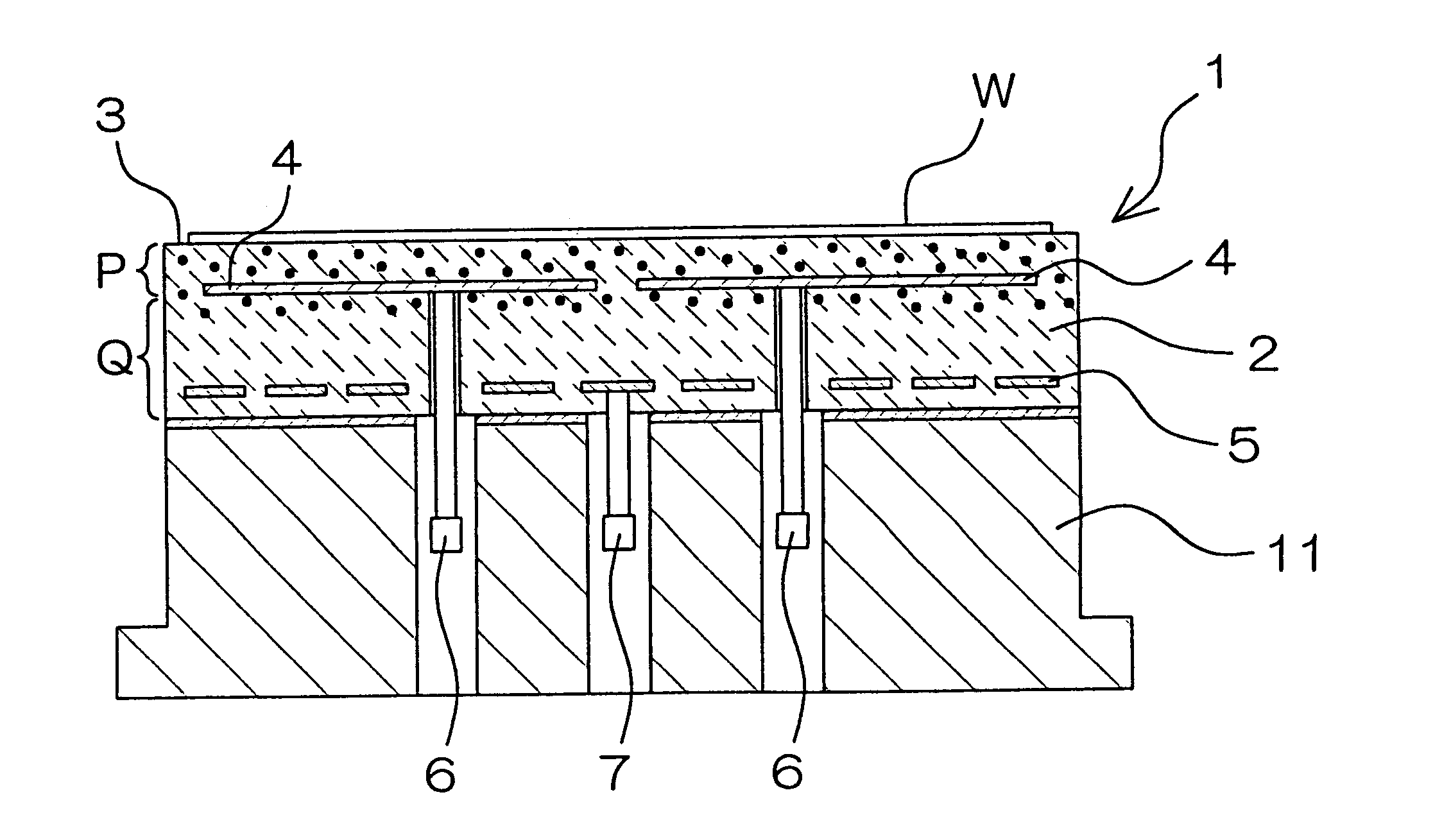

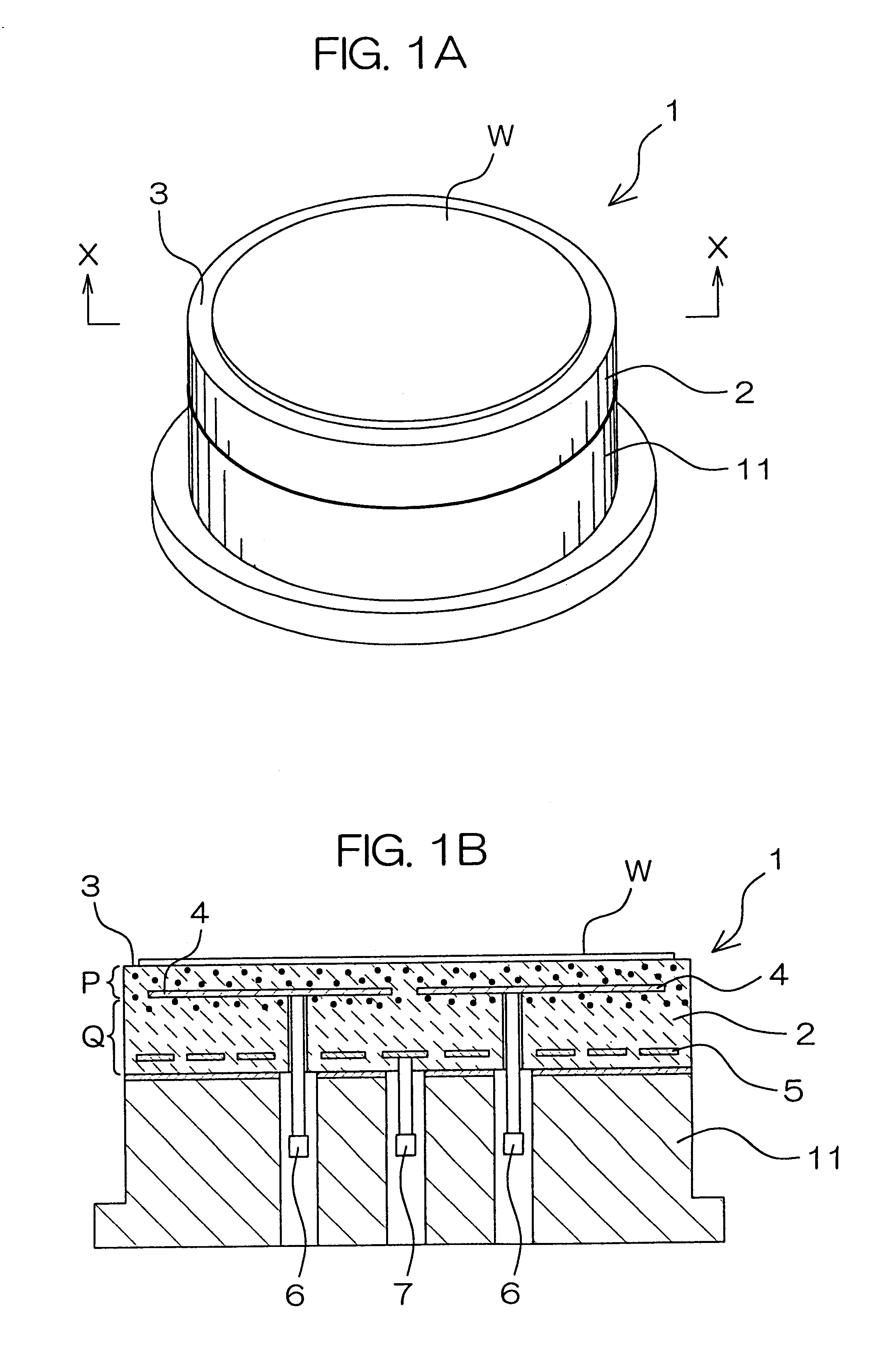

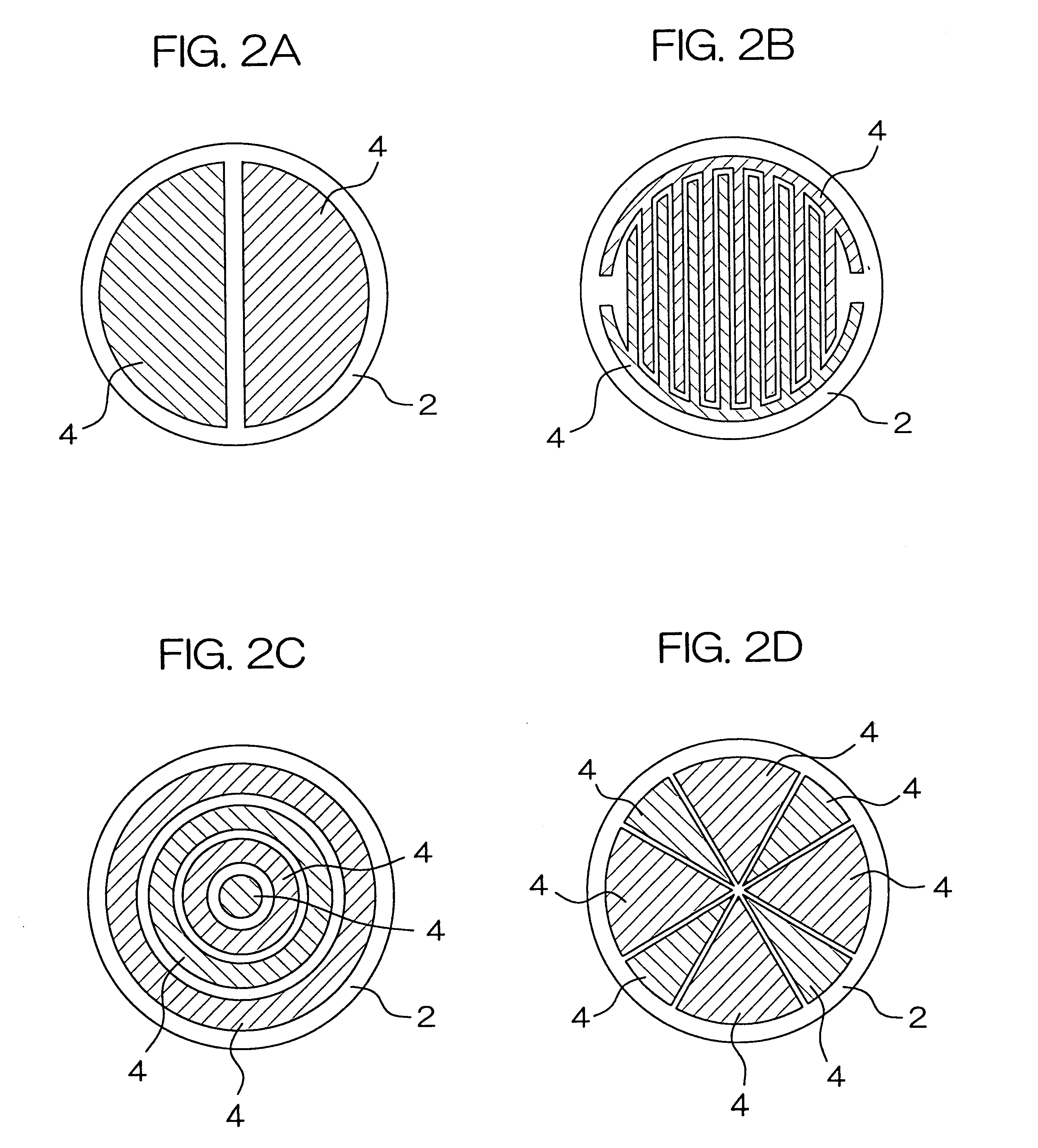

Electrostatic chuck and production method therefor

InactiveUS6215643B1Small resistivityImprove the forceSleeve/socket jointsSemiconductor/solid-state device manufacturingConductive pasteElectrostatic attraction

An electrostatic chuck according to the present invention exhibits a greater attractive force by virtue of the Johnson-Rahbeck effect, while ensuring satisfactory insulation in a ceramic portion present below an electrostatic attraction electrode thereof in a temperature range of 250 to 450° C. The electrostatic chuck is produced by superposing green sheets printed with a conductive paste and green sheets not printed with the conductive paste in a predetermined order with a binding liquid applied on the respective green sheets, heat- and press-bonding the superposed green sheets and firing the heat- and press-bonded green sheets. During the production, a conductive component of the electrostatic attraction electrode is diffused into the ceramic portion present between the electrode and an attractive surface of the chuck.

Owner:KYOCERA CORP

Semiconductor device with uneven metal plate to improve adhesion to molding compound

InactiveUS6849930B2Adhesive strengthImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesConductive pasteSemiconductor chip

The present invention provides a semiconductor device whose reliability is improved by improving the adhesion strength of a metal plate or connecting chip, said plurality of electrodes and a lead frame with a molding resin. Further, the semiconductor device of the present invention prevents flow out of a conductive joining material to be employed for joining a lead terminal and the metal plate other than the joining range of the metal plate and the lead terminal, and mounts the metal plate at high precision. In a semiconductor device (a plastic package) in which a source electrode of a semiconductor chip and source terminal of a lead frame are electrically connected by a copper plate and sealed by a resin, the surface of the copper plate is roughened to improve the adhesion strength to a molding resin. Further, a stepped part is formed in the source terminal to prevent a conductive paste from flowing out. The structure is so formed as to fit claw parts in the lead frame.

Owner:RENESAS ELECTRONICS CORP

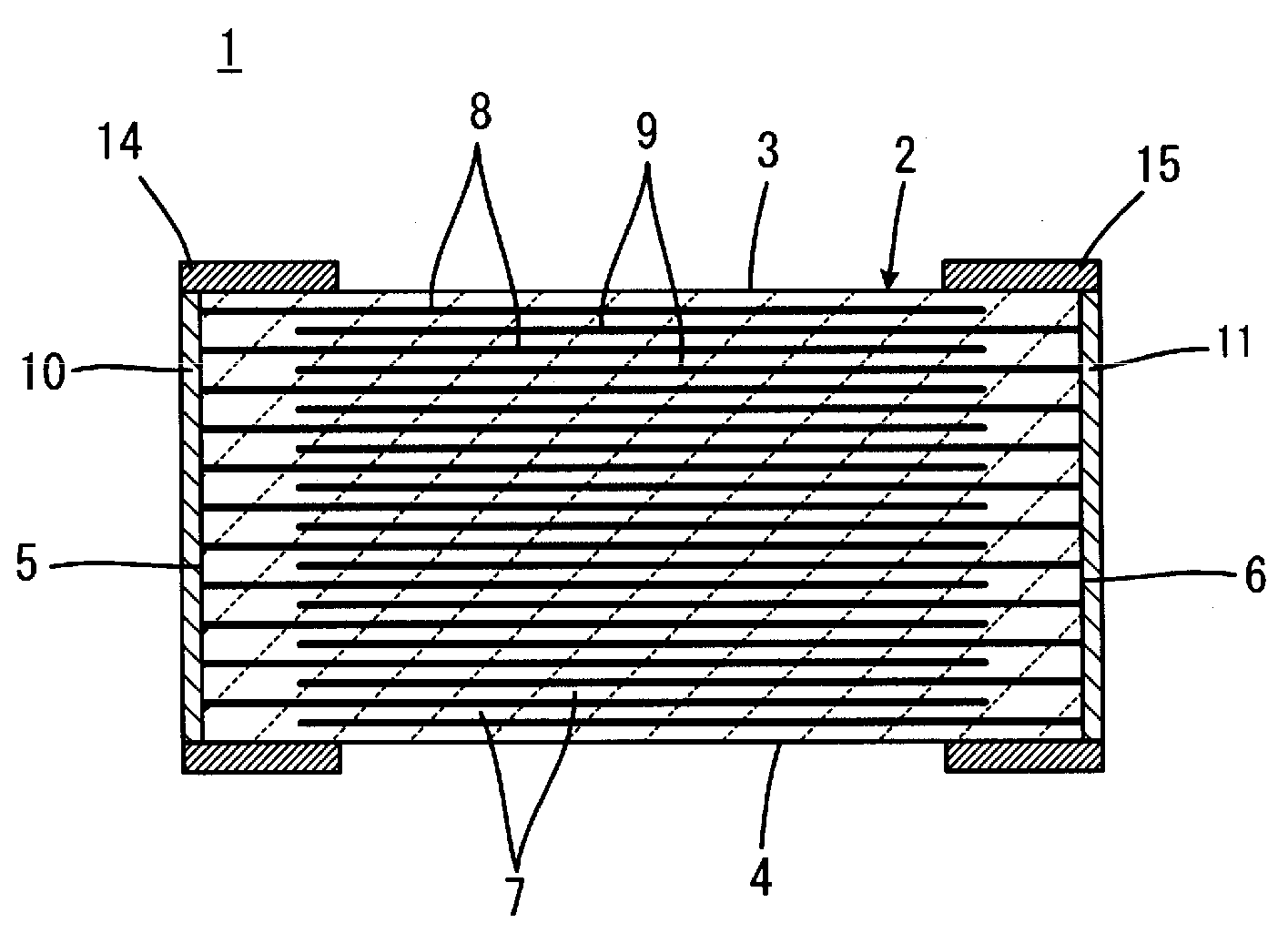

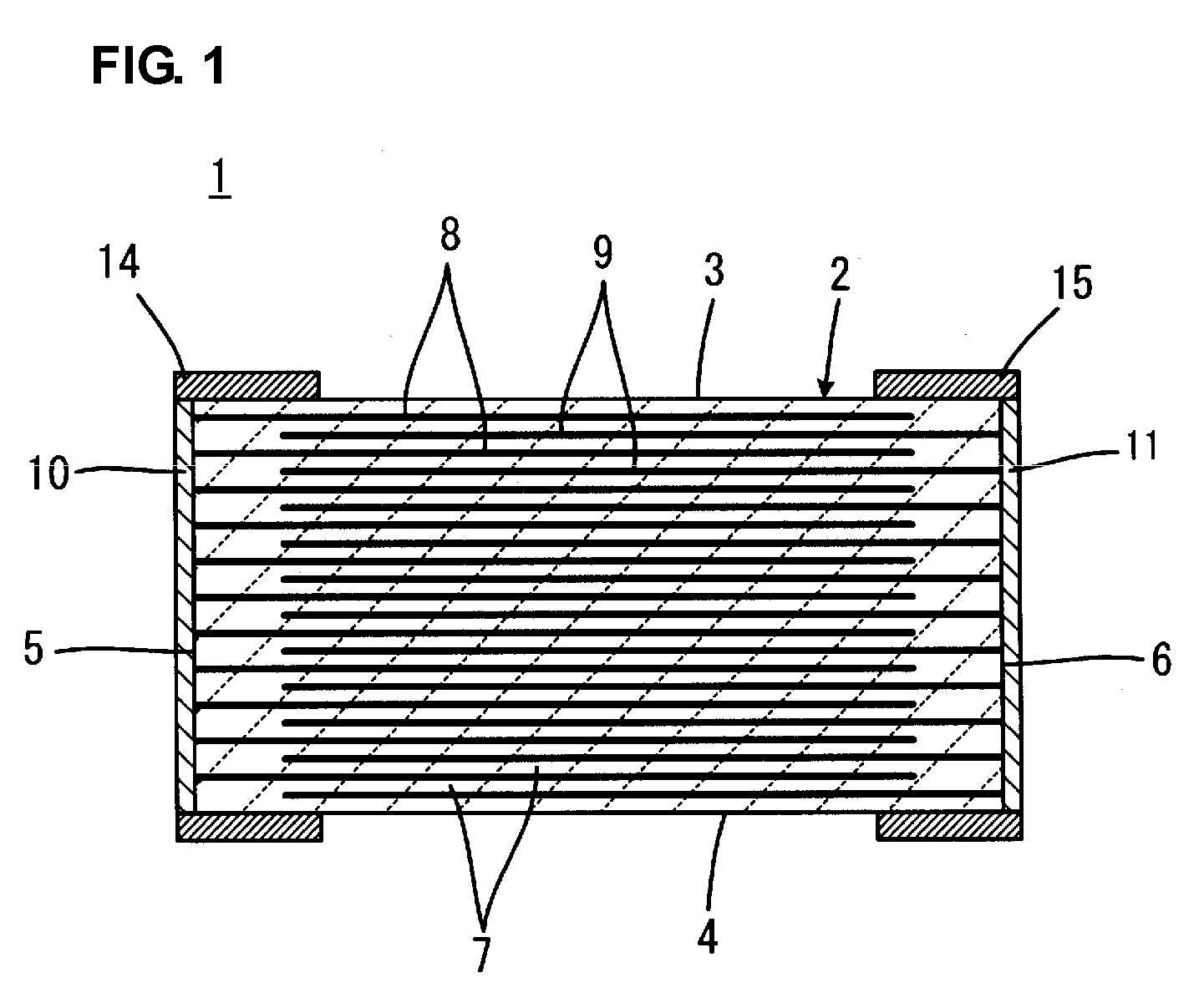

Multilayer electronic component and method for manufacturing multilayer electronic component

ActiveUS20080239617A1Large effective volumeImprove welding reliabilityStacked capacitorsFixed capacitor terminalsConductive pasteCeramic capacitor

A method for manufacturing a laminated ceramic capacitor includes a step of preparing a laminate which has a first principal surface, a second principal surface, a first end surface, a second end surface, a first side surface, and a second side surface and which includes insulating layers and internal electrodes having end portions exposed at the first or second end surface; a step of forming external electrodes on the first and second end surfaces such that plating deposits are formed on the exposed end portions of the internal electrodes so as to be connected to each other; and a step of forming thick end electrodes electrically connected to the external electrodes such that a conductive paste is applied onto edge portions of the first and second principal surfaces and first and second side surfaces of the laminate and then baked.

Owner:MURATA MFG CO LTD

Insulation sheet, multi-layer wiring substrate and production processes thereof

InactiveUS6855892B2Solid-state devicesElectrical connection printed elementsConductive pasteDislocation

An insulation sheet for use in producing a wiring substrate comprises, as via bole conductors, conductive paste filled in via holes formed through the insulation sheet, and a curing-starting temperature of the conductive paste is lower than a melting-starting temperature of the insulation sheet. A wiring substrate is produced by laminating such insulation sheets, that have conductive paste in via holes, and subjecting this laminate to thermo-compression bonding, wherein deformation of via holes and dislocation of the via holes, because of a molten insulation sheet, does not occur.

Owner:PANASONIC CORP

Conductive paste and grid electrode for silicon solar cells

InactiveUS20090211626A1Improve efficiencyReduce contentFinal product manufactureConductive materialConductive pasteGold particles

A conductive paste for grid electrodes in solar cells includes a conductive component, glass frit, and resin binder, wherein the conductive component is selected from the group consisting of (i) silver particles and metal particles selected from the group consisting of Pd, Ir, Pt, Ru, Ti, and Co, (ii) alloy particles comprising silver and metal selected from the group consisting of Pd, Ir, Pt, Ru, Ti, and Co, and (iii) silver particles and core-shell particles in which a metal selected from the group consisting of Pd, Ir, Pt, Ru, Ti, and Co is coated on the surface of silver or copper.

Owner:EI DU PONT DE NEMOURS & CO

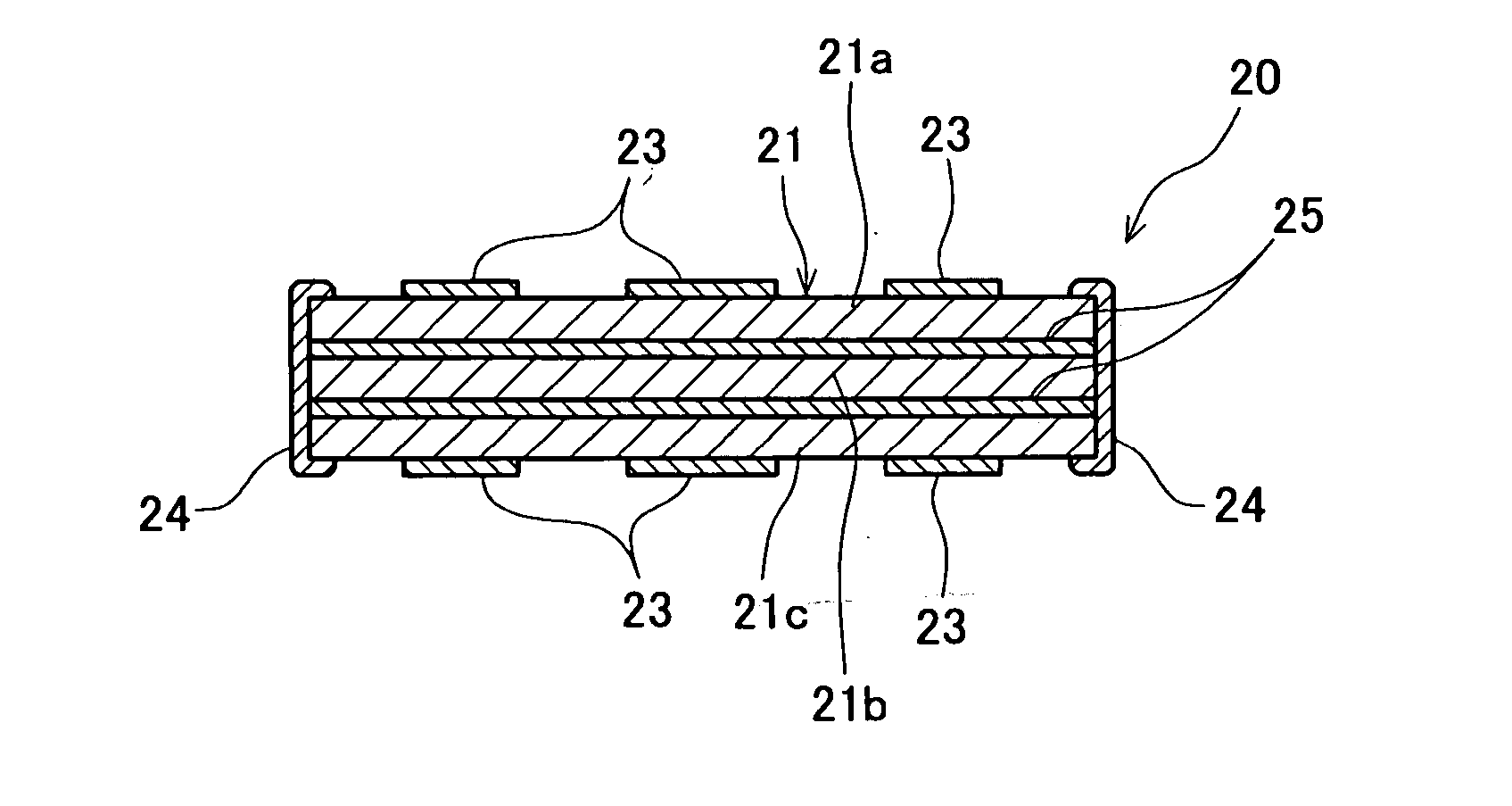

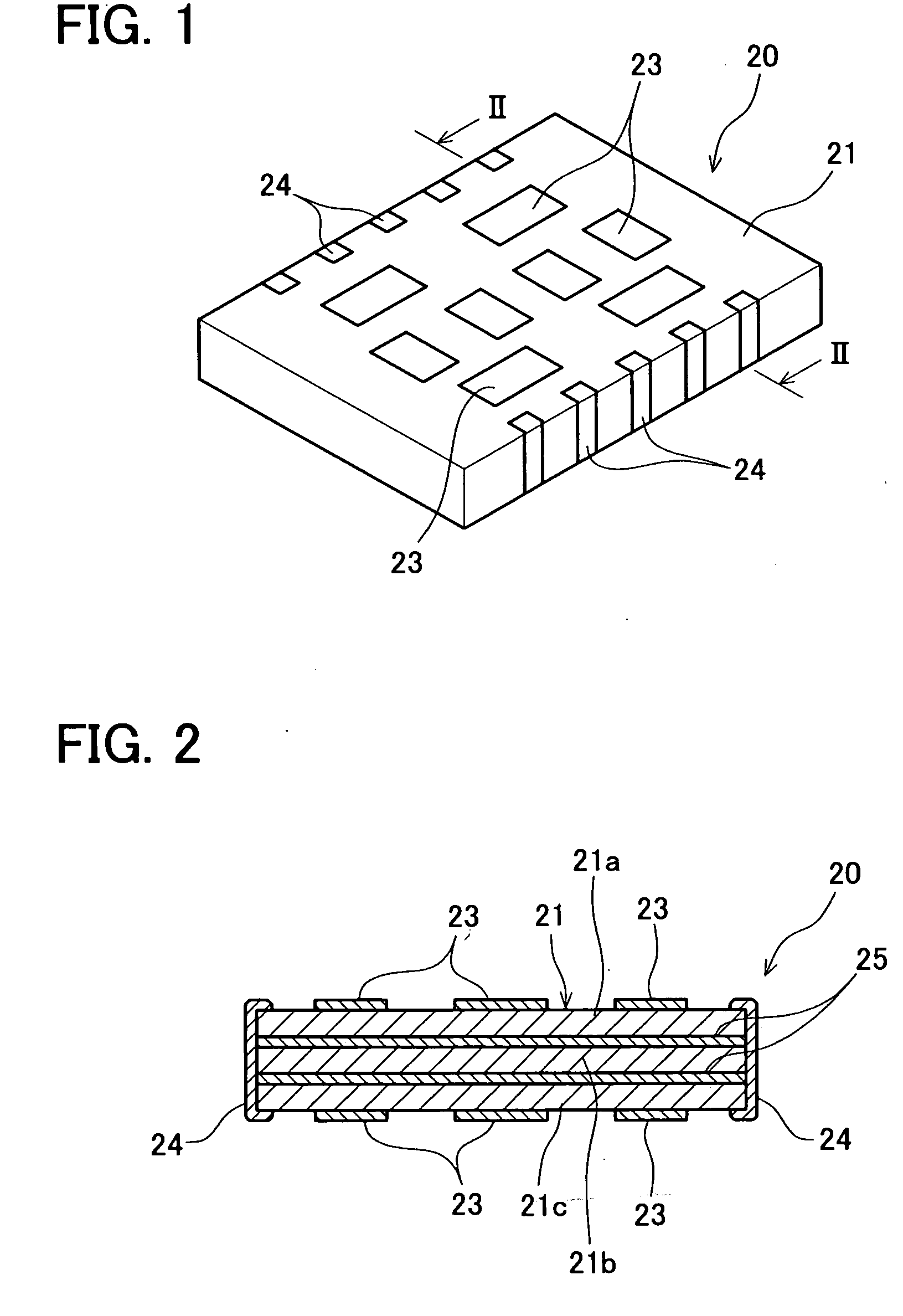

Ceramic electronic component and production method therefor

InactiveUS20040070915A1Quality improvementImprove electrical characteristicsLayered productsSemiconductor/solid-state device detailsOrganic compoundElectron

A ceramic electronic component (20) having surface conductor films (23) and side-surface conductor films (24) excellent in burning shrinkage, bonding strength, solder heat resistance, solder wettability and the like. A method of producing a ceramic electronic component which uses a conductive paste containing as a main component Ag-based metal powder, the surface of the metal powder being coated with an organic metal compound or a metal oxide having as a constituting element any one selected from a group consisting of Al, Zr, Ti, Y, Ca, Mg and Zn, to form conductor films (23, 24 25) on a ceramic base material (21). A side-surface conductor film-forming paste differs form a surface conductor film-forming paste in that (1) the former paste has a relatively small coating amount of the organic metal compound or metal oxide and / or (2) contains either at least one kind of inorganic oxide powder as an accessory composition or a comparatively high percentage of the inorganic oxide powder.

Owner:TDK CORPARATION +1

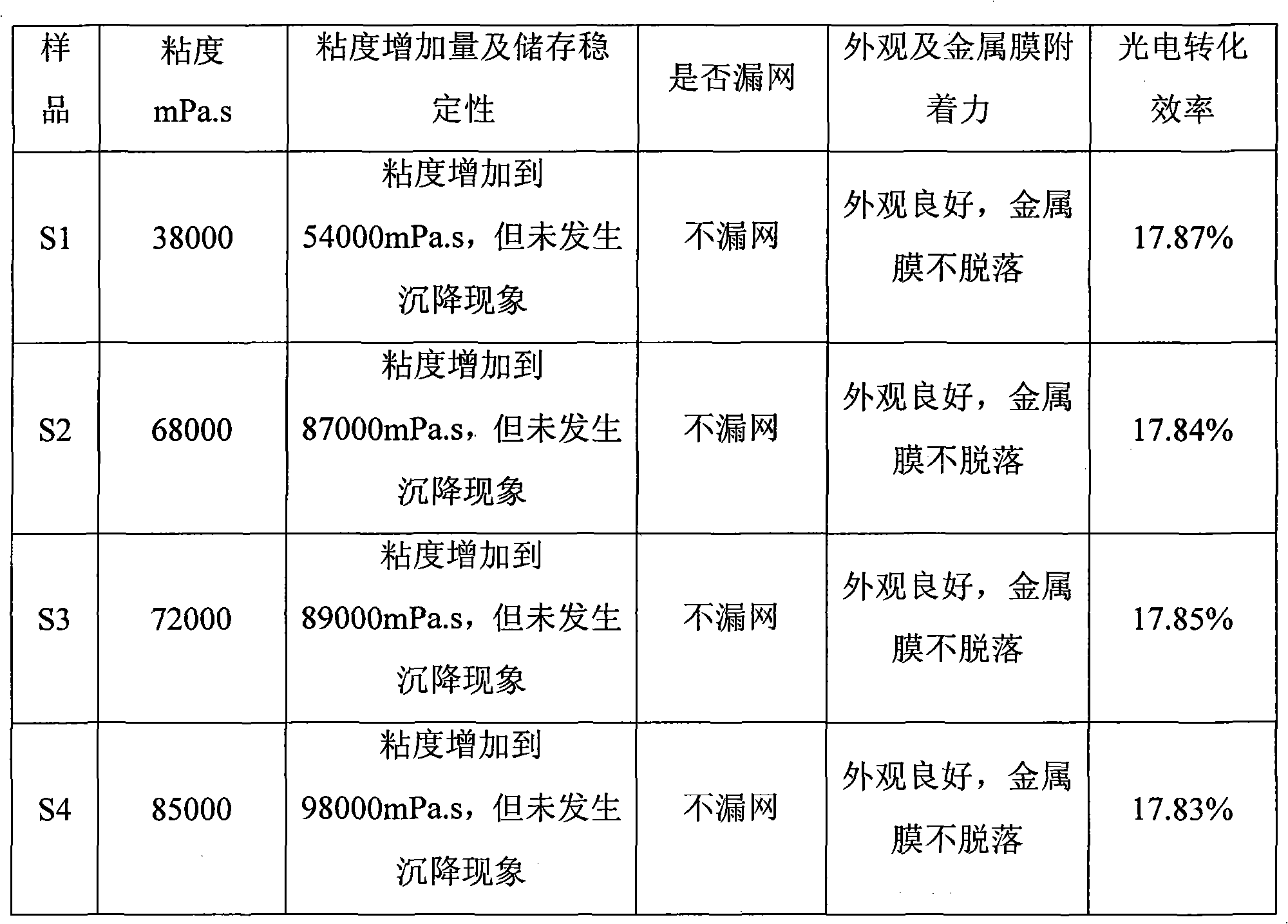

Conductive paste for solar cell and preparation method thereof

InactiveCN102034877AImprove performanceNo sedimentation and caking phenomenonConductive materialInksSilicon matrixSilicon solar cell

The invention provides a conductive paste for a solar cell, comprising the following components based on the total weight: 60-85 percent by weight of conductive metal powder, 0.5-10.0 percent by weight of inorganic binder, 10.0-30.0 percent by weight of water-borne binder and 0.05-5.0 percent by weight of additive, wherein the water-borne binder is a solution formed by dissolving a water-borne polymer into the water. The conductive paste for the solar cell, provided by the invention, has no organic solvent and pollution, is environment-friendly and has low cost of materials; the mesh leakage can be avoided when the conductive paste is stood in a screen mesh; the phenomena of settling and aggregation can be avoided after the conductive paste is stored for a long time; after being subjected to the silk-screen sintering, the conductive paste has firm adhesive force to a silicon matrix and excellent electrical performance; and the average photoelectric conversion efficiency of the produced monocrystal silicon solar cell is more than 17.80 percent.

Owner:BYD CO LTD

Method of producing circuit board

InactiveUS7458150B2Lower resistanceIncrease resistancePrinted circuit assemblingPhotomechanical apparatusConductive pasteOptoelectronics

A method of producing a circuit board includes a step of providing a conductive paste including metal nano-particles at an insulating substrate, and a step of sintering the conductive paste so as to form a circuit conductor. In the sintering step, the conductive paste is sintered in a low-oxygen condition including alcohol such that the metal nano-particles are sintered.

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com