Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3852 results about "Transfer printing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transfer printing is a method of decorating pottery or other materials using an engraved copper or steel plate from which a monochrome print on paper is taken which is then transferred by pressing onto the ceramic piece. Pottery decorated using the technique is known as transferware or transfer ware.

Printing semiconductor elements by shear-assisted elastomeric stamp transfer

ActiveUS8506867B2Sacrificing printing yield and accuracyIncrease chanceConfectionerySolid-state devicesEngineeringVertical displacement

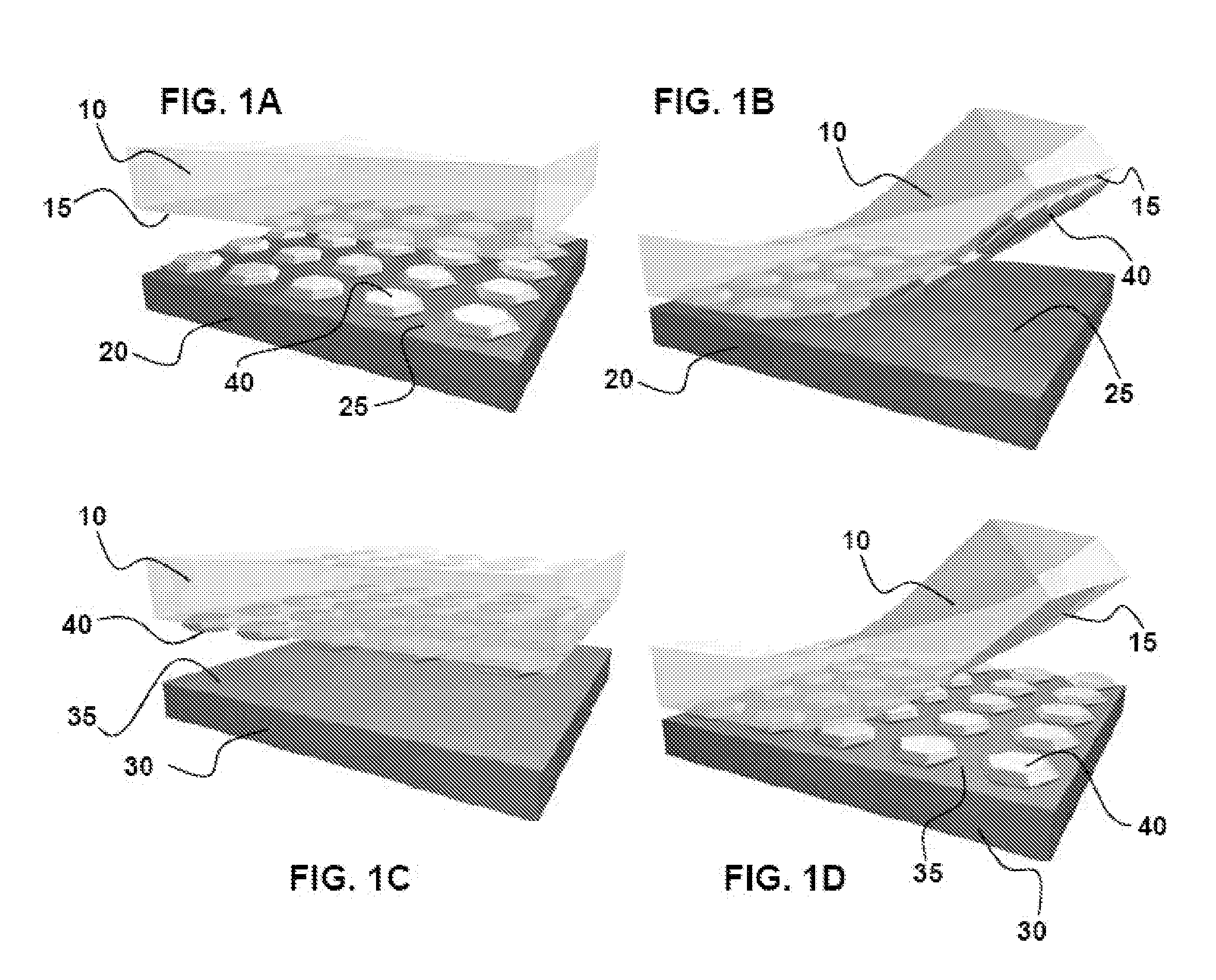

Provided are methods and devices for transfer printing of semiconductor elements to a receiving surface. In an aspect, the printing is by conformal contact between an elastomeric stamp inked with the semiconductor elements and a receiving surface, and during stamp removal, a shear offset is applied between the stamp and the receiving surface. The shear-offset printing process achieves high printing transfer yields with good placement accuracy. Process parameter selection during transfer printing, including time varying stamp-backing pressure application and vertical displacement, yields substantially constant delamination rates with attendant transfer printing improvement.

Owner:X DISPLAY CO TECH LTD

Pattern Transfer Printing by Kinetic Control of Adhesion to an Elastomeric Stamp

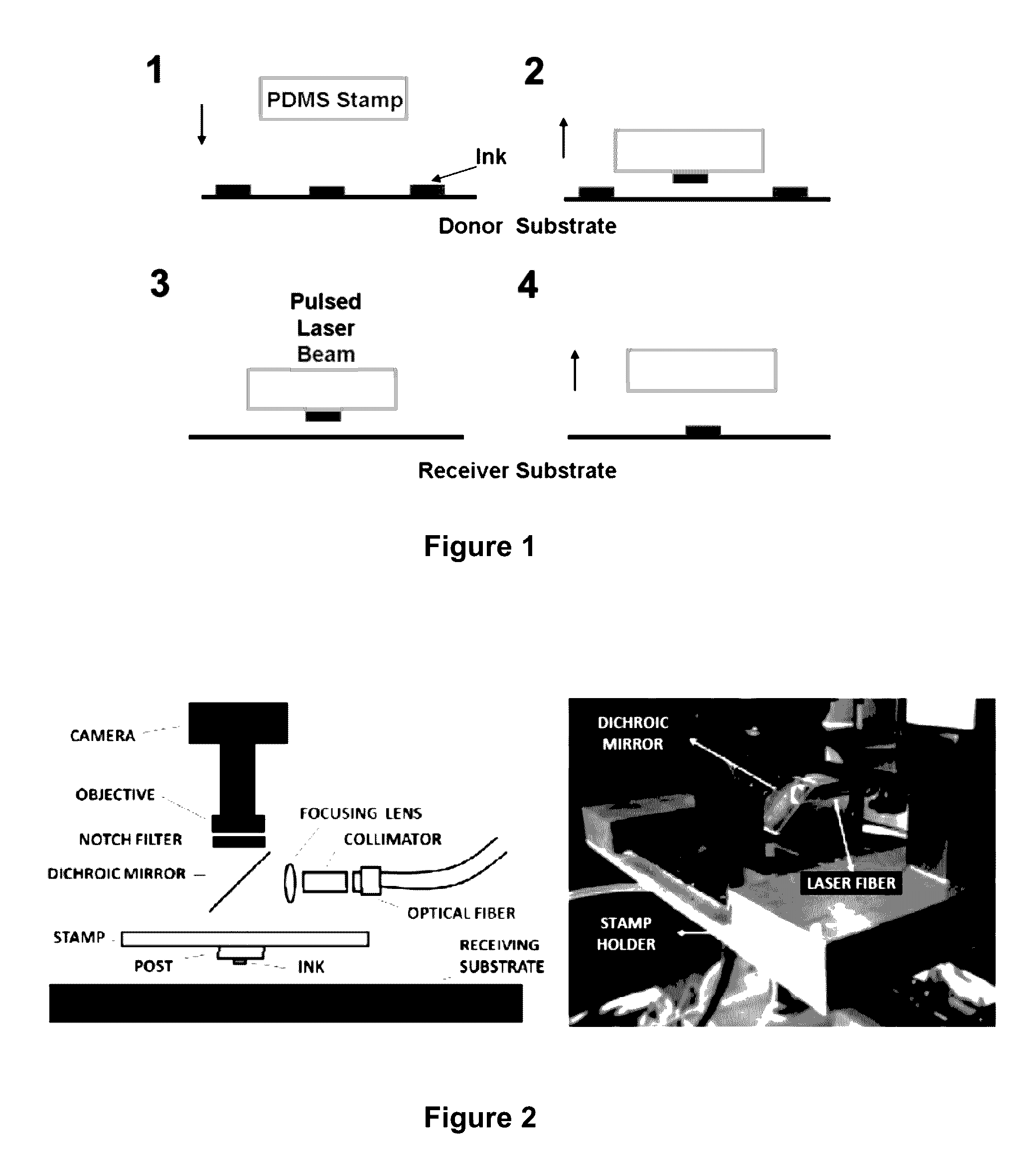

ActiveUS20090199960A1Keep the distanceEasy transferFinal product manufactureDecorative surface effectsSpatial OrientationsElastomer

The present invention provides methods, systems and system components for transferring, assembling and integrating features and arrays of features having selected nanosized and / or microsized physical dimensions, shapes and spatial orientations. Methods of the present invention utilize principles of ‘soft adhesion’ to guide the transfer, assembly and / or integration of features, such as printable semiconductor elements or other components of electronic devices. Methods of the present invention are useful for transferring features from a donor substrate to the transfer surface of an elastomeric transfer device and, optionally, from the transfer surface of an elastomeric transfer device to the receiving surface of a receiving substrate. The present methods and systems provide highly efficient, registered transfer of features and arrays of features, such as printable semiconductor element, in a concerted manner that maintains the relative spatial orientations of transferred features.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

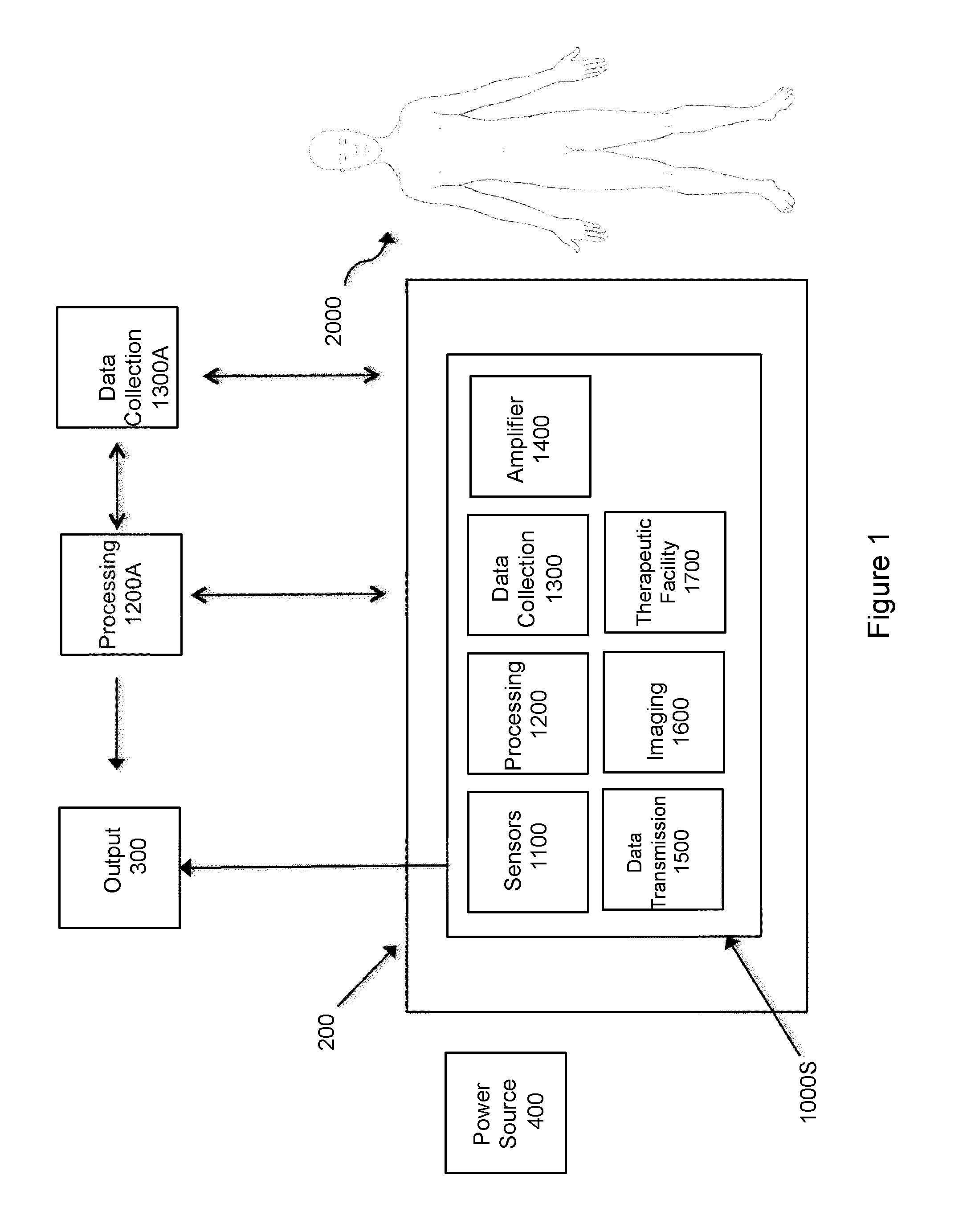

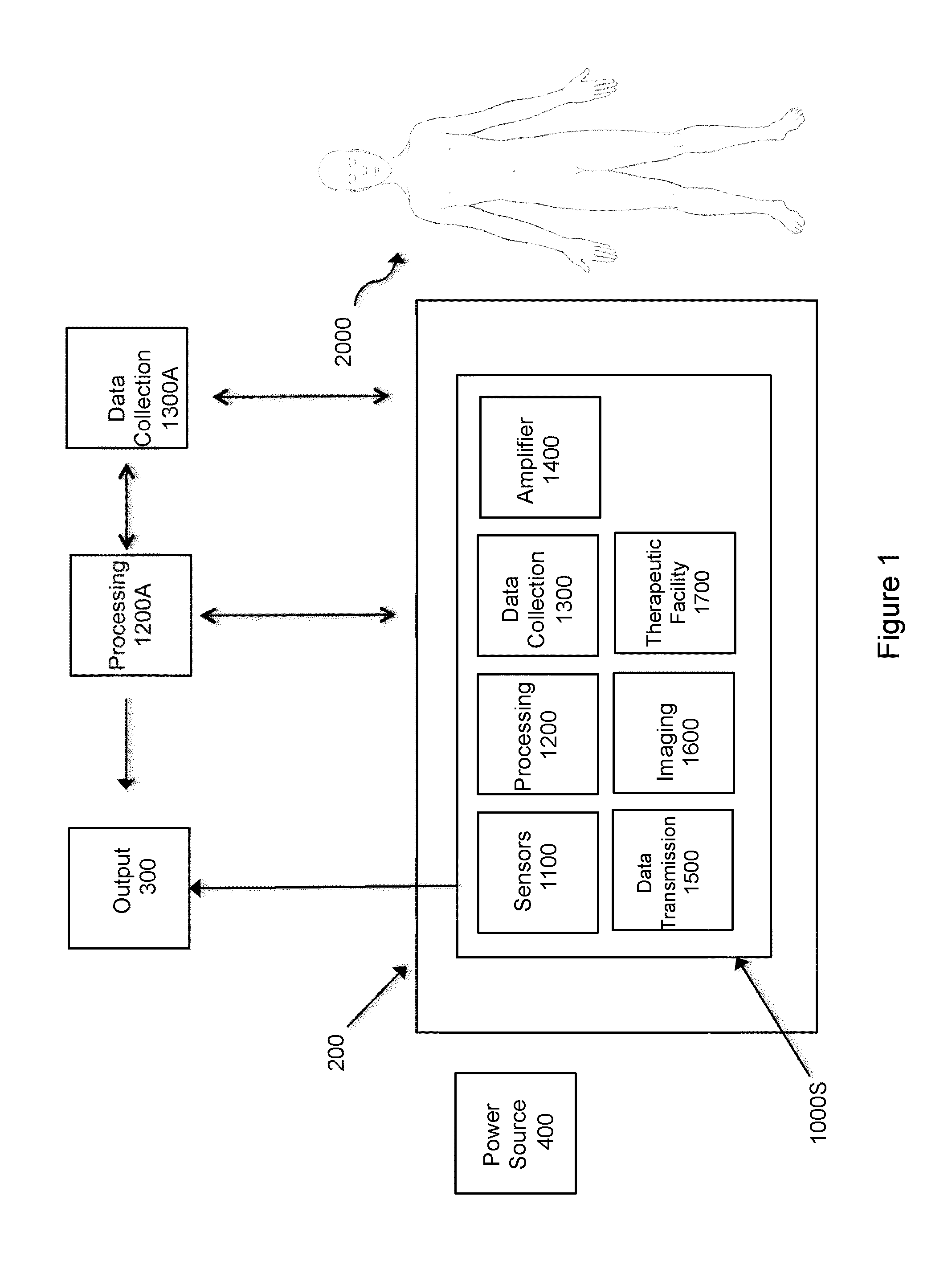

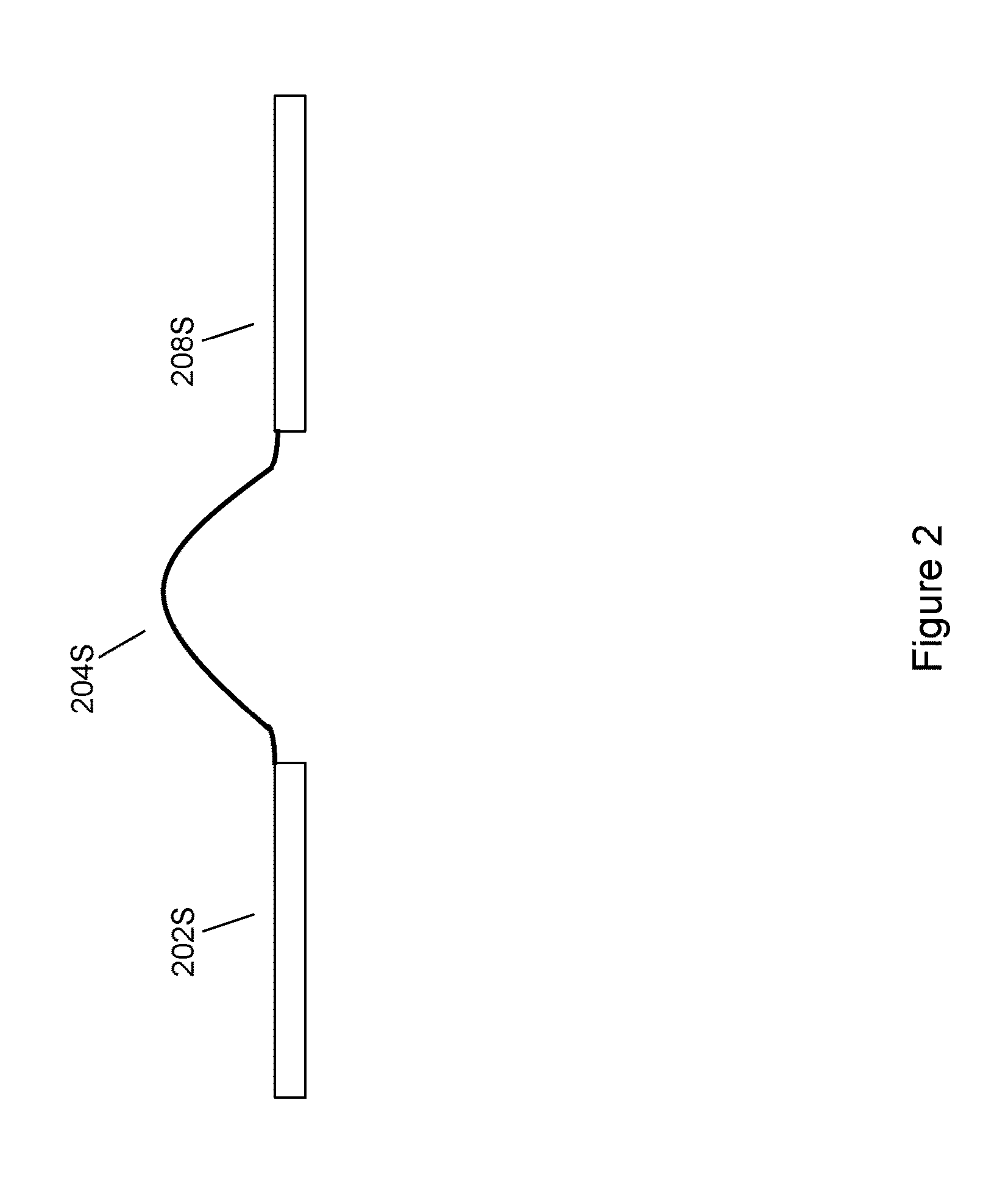

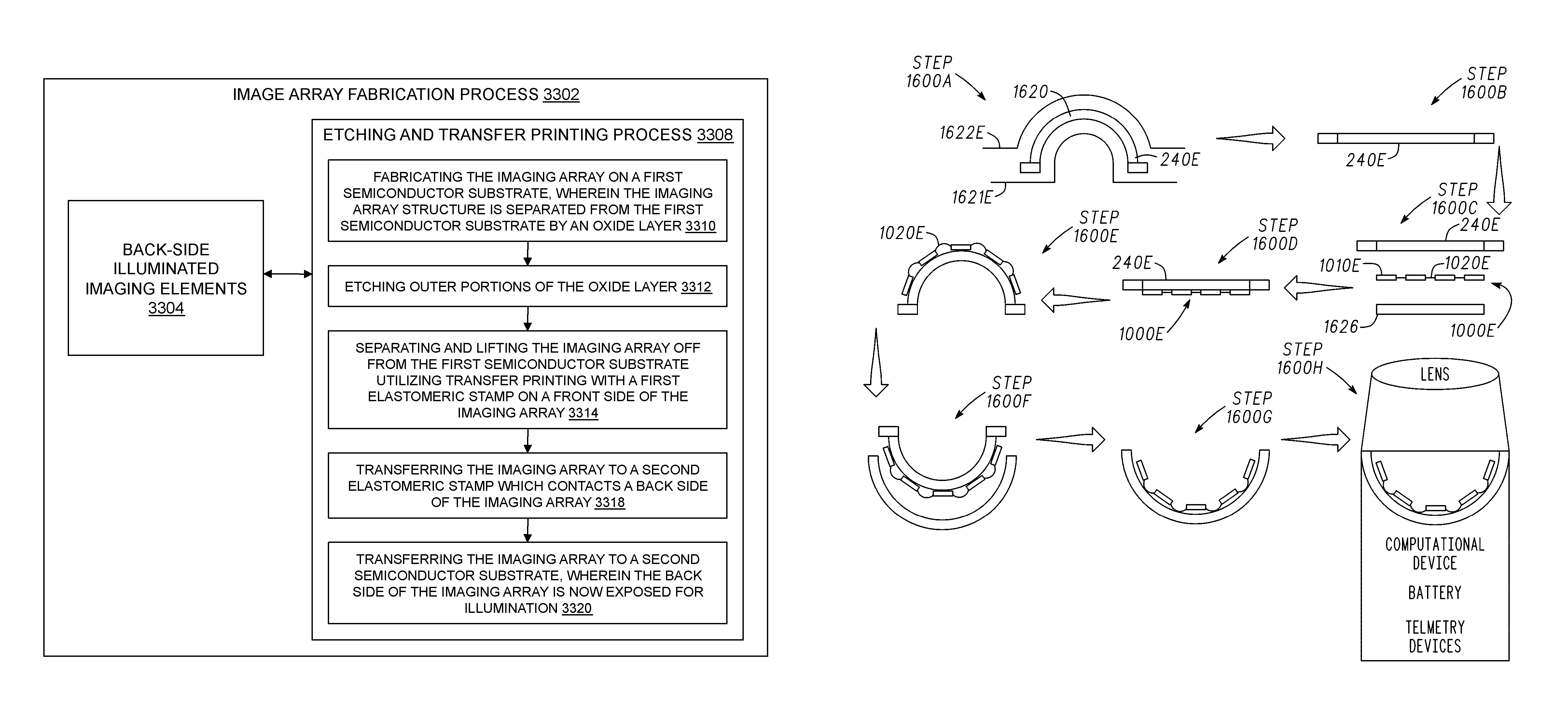

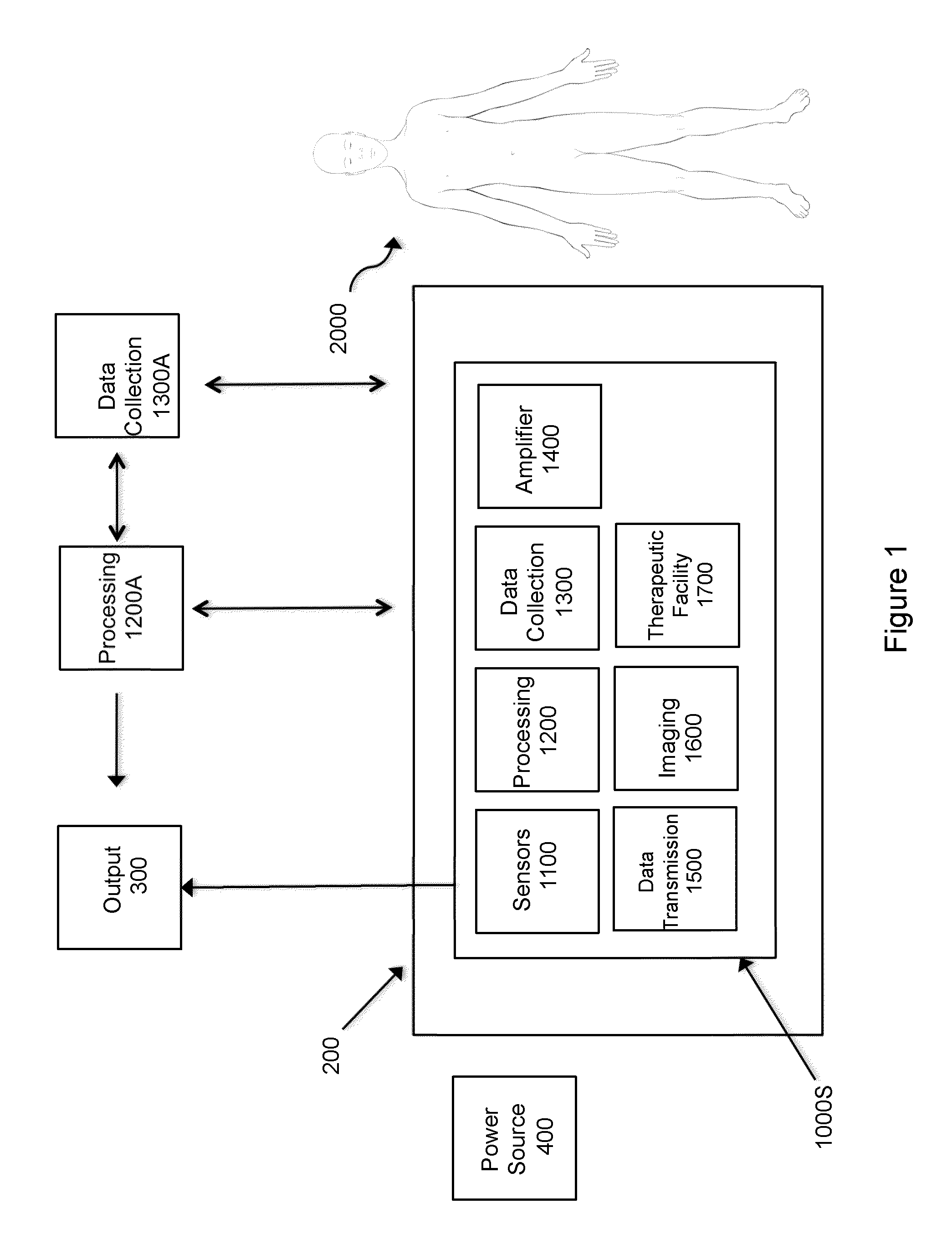

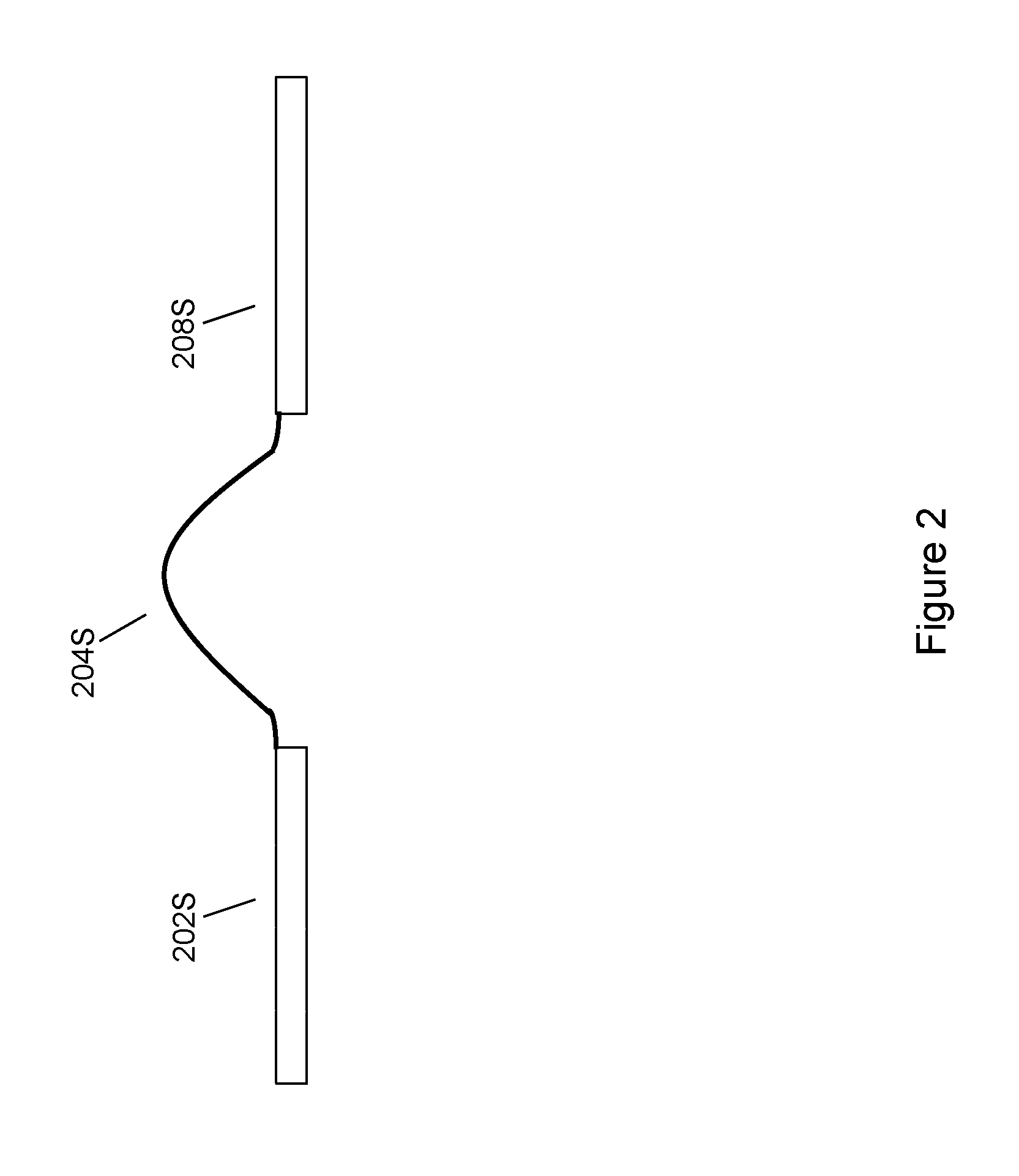

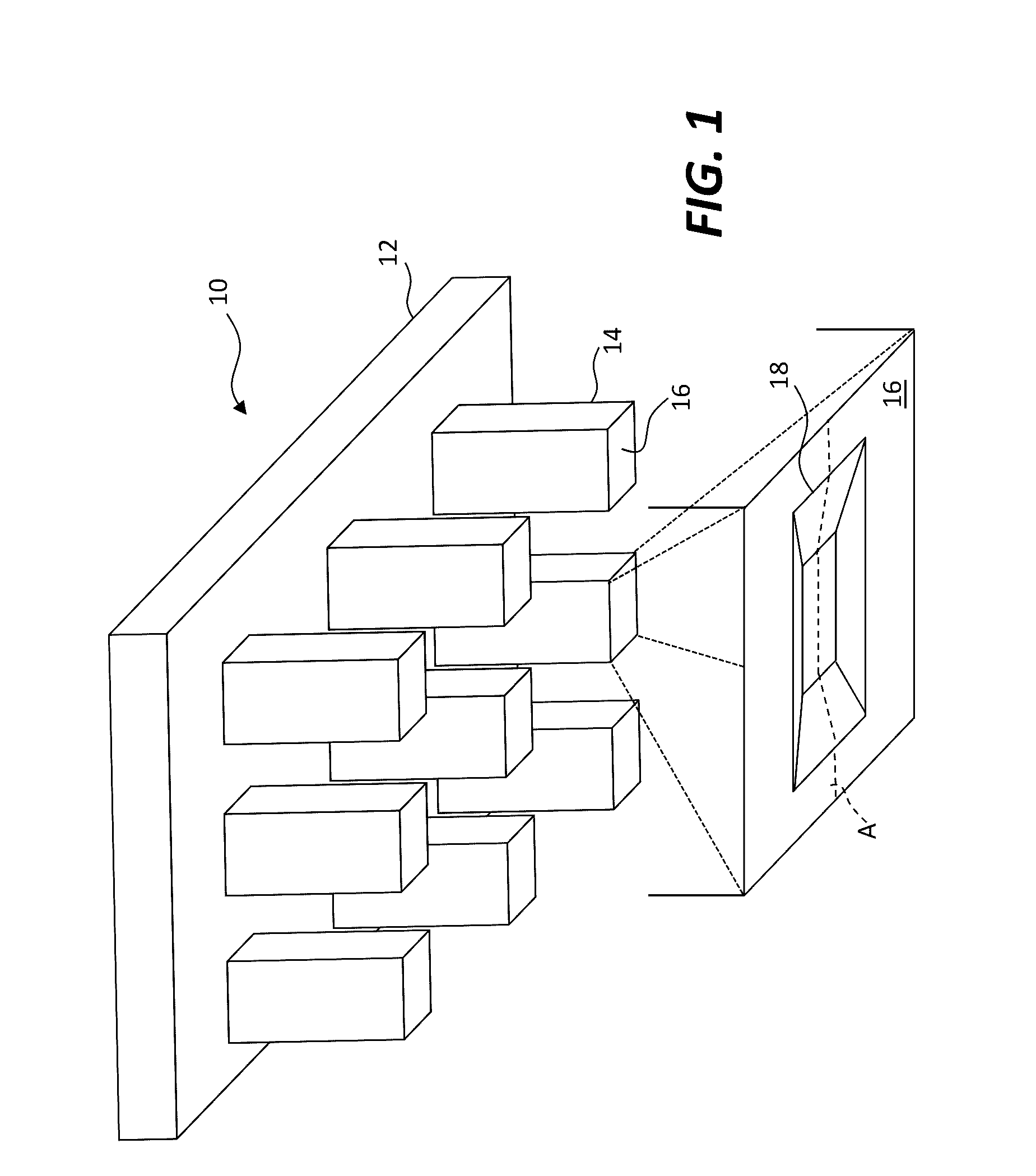

Methods and applications of non-planar imaging arrays

ActiveUS20100178722A1Low costLess reflection and diffraction defectCircuit bendability/stretchabilitySemiconductor/solid-state device detailsInterconnectionEngineering

System, devices and methods are presented that provide an imaging array fabrication process method, comprising fabricating an array of semiconductor imaging elements, interconnecting the elements with stretchable interconnections, and transfer printing the array with a pre-strained elastomeric stamp to a secondary non-planar surface.

Owner:MEDIDATA SOLUTIONS

Authentication method and system

InactiveUS7995196B1Improve the immunityPaper-money testing devicesCharacter and pattern recognitionComputer hardwareAuthentication

A method for authenticating an object, comprising determining a physical dispersion pattern of a set of elements, determining a physical characteristic of the set of elements which is distinct from a physical characteristic producible by a transfer printing technology, determining a digital code associated with the object defining the physical dispersion pattern, and authenticating the object by verifying a correspondence of the digital code with the physical dispersion pattern, and verifying the physical characteristic.

Owner:COPILOT VENTURES FUND III

Methods and applications of non-planar imaging arrays

ActiveUS20130316487A1Low costReduce reflectionSolid-state devicesAcoustic sensorsEngineeringInterconnection

System, devices and methods are presented that provide an imaging array fabrication process method, comprising fabricating an array of semiconductor imaging elements, interconnecting the elements with stretchable interconnections, and transfer printing the array with a pre-strained elastomeric stamp to a secondary non-planar surface.

Owner:MEDIDATA SOLUTIONS

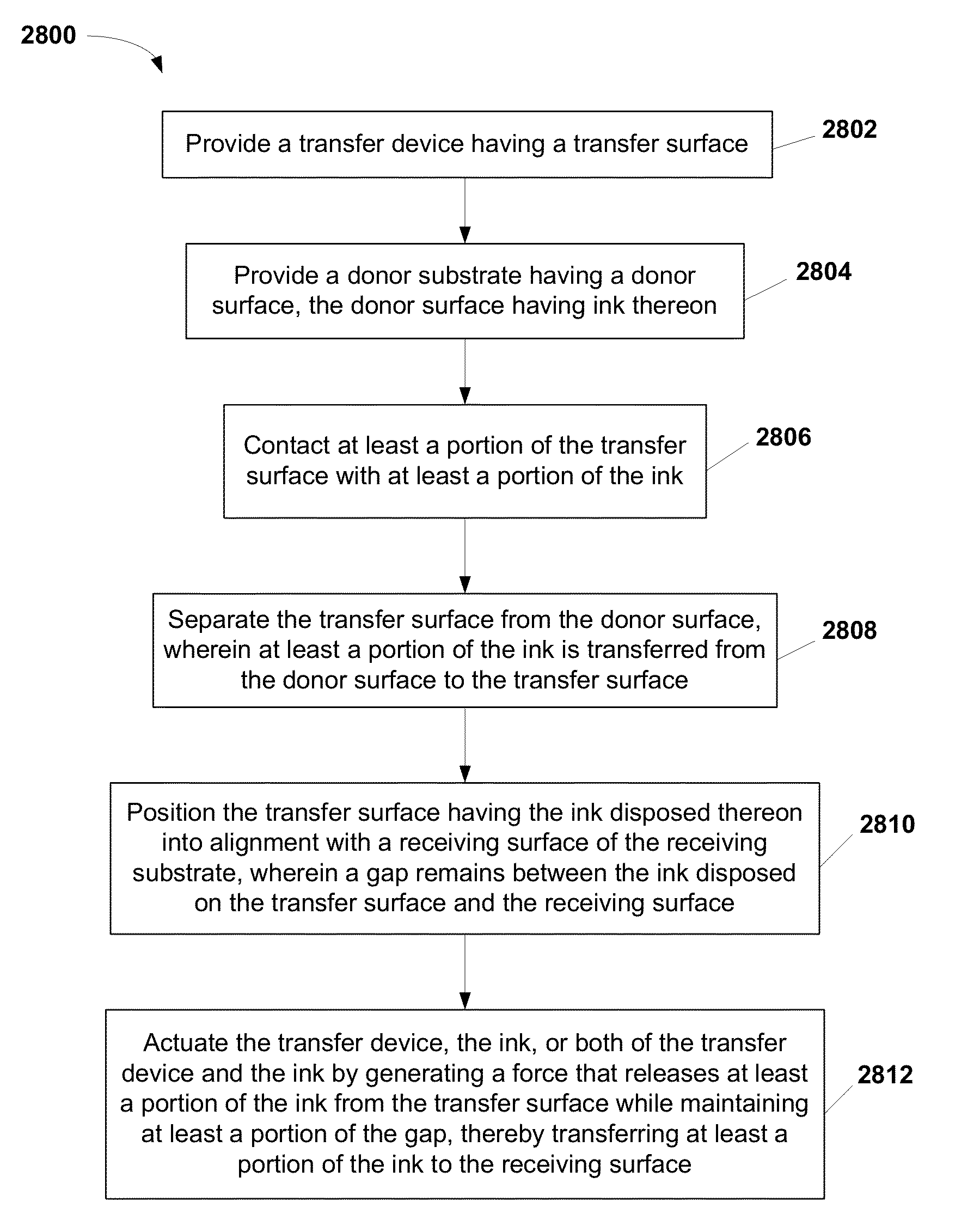

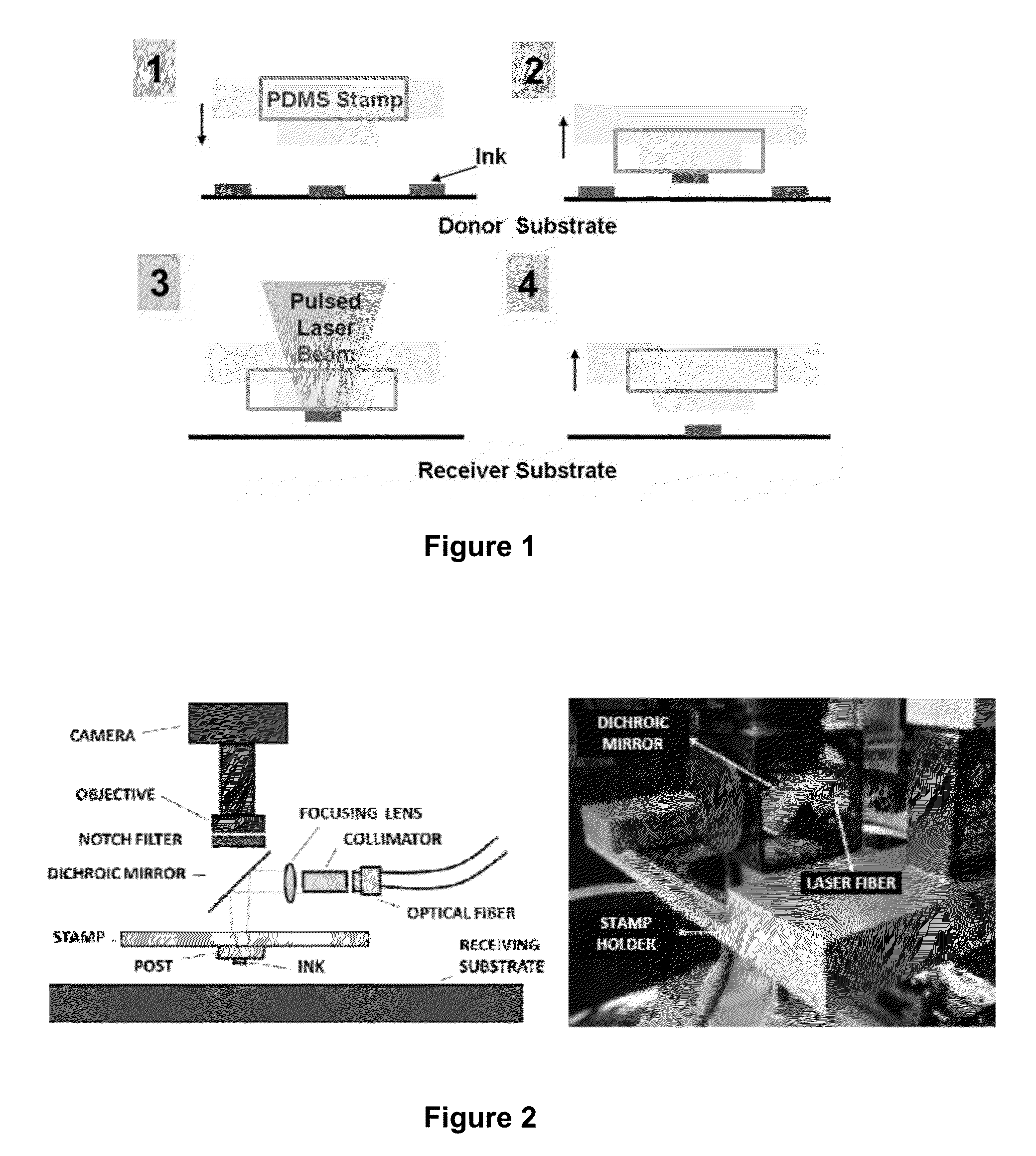

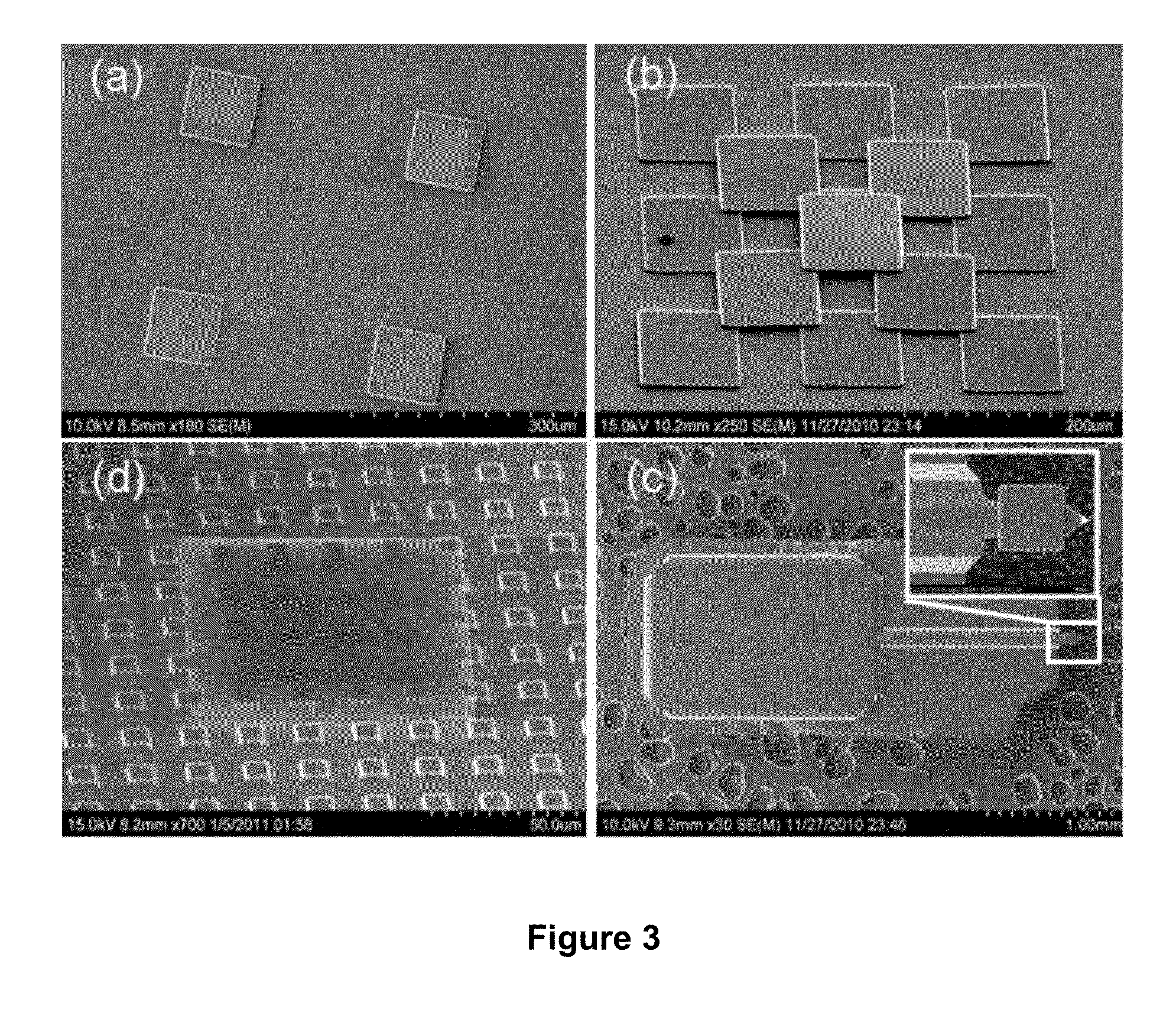

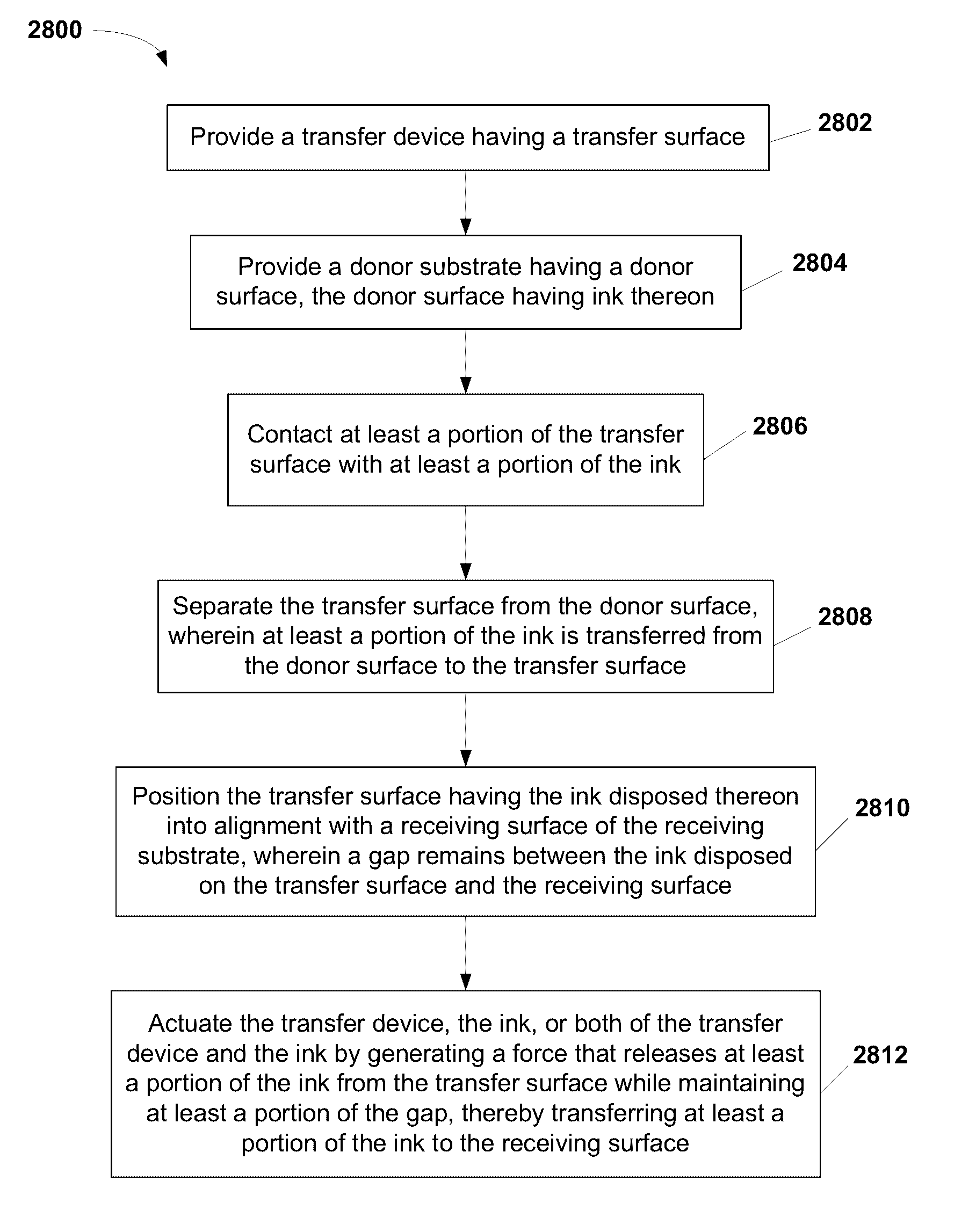

Non-contact transfer printing

ActiveUS20130036928A1Avoid damageNot to damageTransfer printingDuplicating/marking methodsNano-deviceLight-emitting diode

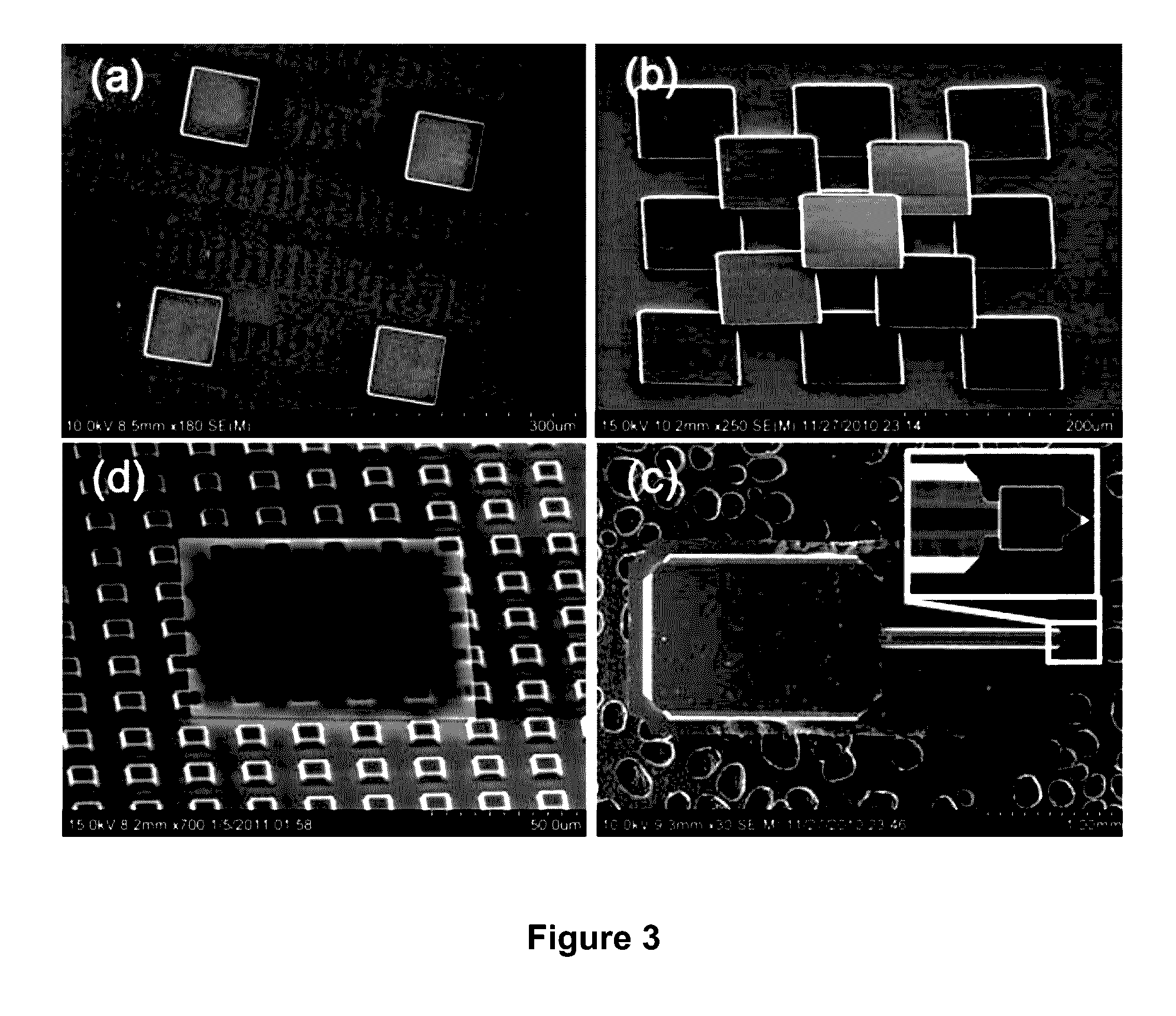

A transfer printing process that exploits the mismatch in mechanical or thermo-mechanical response at the interface of a printable micro- or nano-device and a transfer stamp to drive the release of the device from the stamp and its non-contact transfer to a receiving substrate are provided. The resulting facile, pick-and-place process is demonstrated with the assembling of 3-D microdevices and the printing of GAN light-emitting diodes onto silicon and glass substrates. High speed photography is used to provide experimental evidence of thermo-mechanically driven release.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

Non-contact transfer printing

ActiveUS9555644B2Avoid damageNot to damageTransfer printingDuplicating/marking methodsNano-deviceLight-emitting diode

A transfer printing process that exploits the mismatch in mechanical or thermo-mechanical response at the interface of a printable micro- or nano-device and a transfer stamp to drive the release of the device from the stamp and its non-contact transfer to a receiving substrate are provided. The resulting facile, pick-and-place process is demonstrated with the assembling of 3-D microdevices and the printing of GAN light-emitting diodes onto silicon and glass substrates. High speed photography is used to provide experimental evidence of thermo-mechanically driven release.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

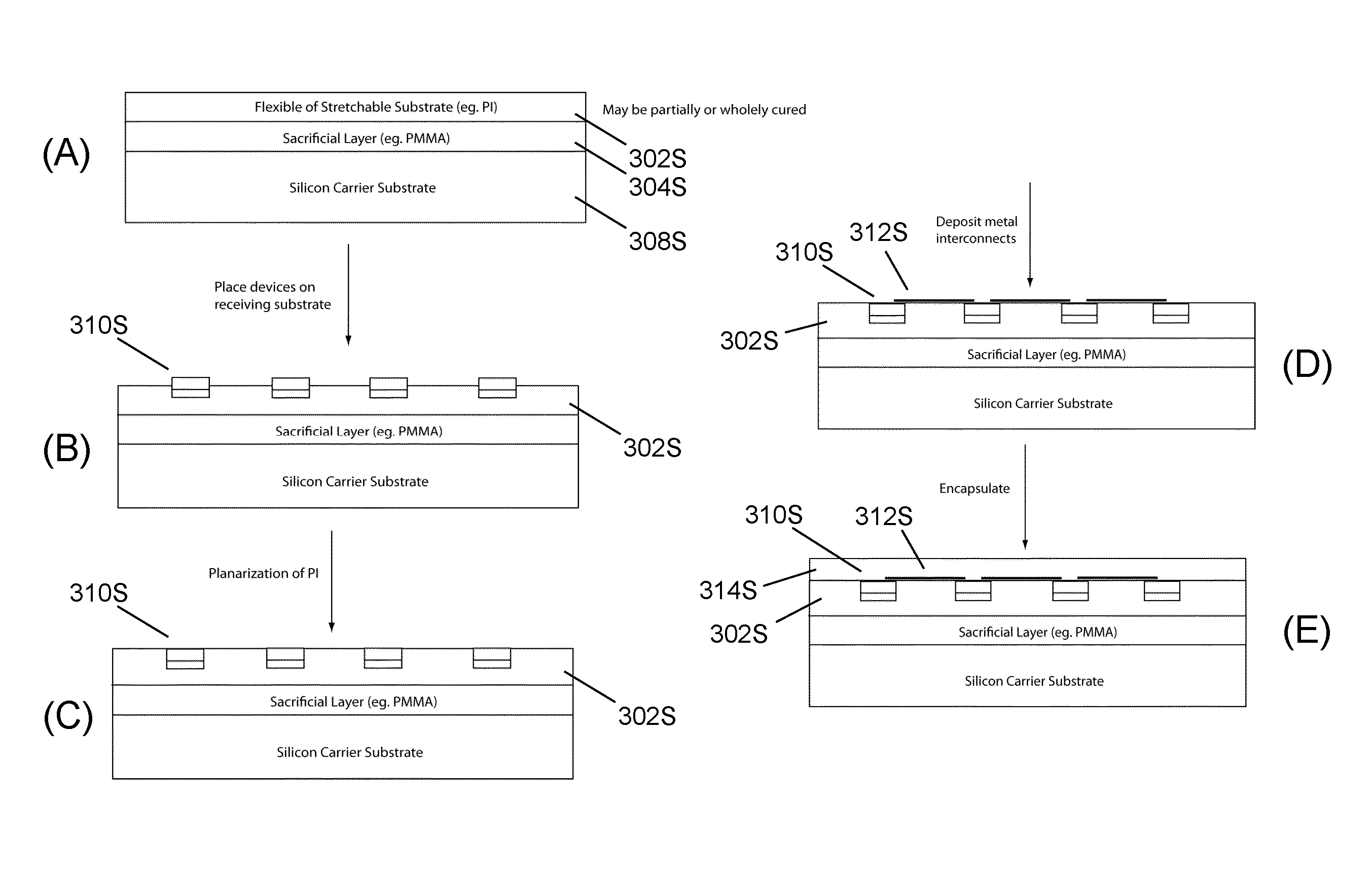

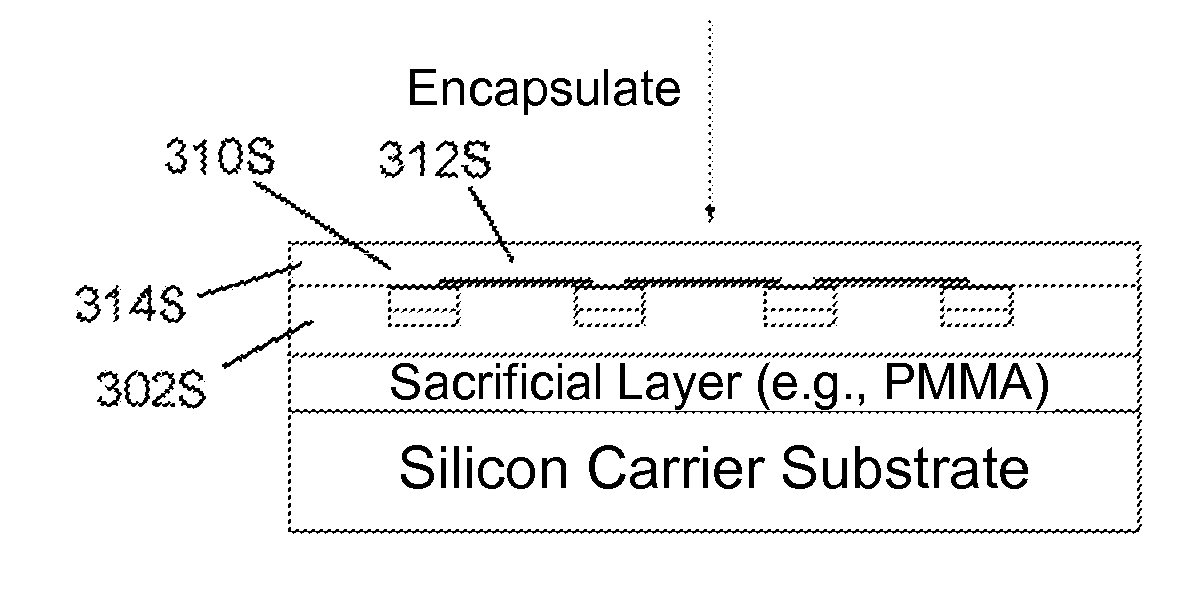

Printable inorganic semiconductor method

ActiveUS9368683B1Improve performanceReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorSemiconductor structure

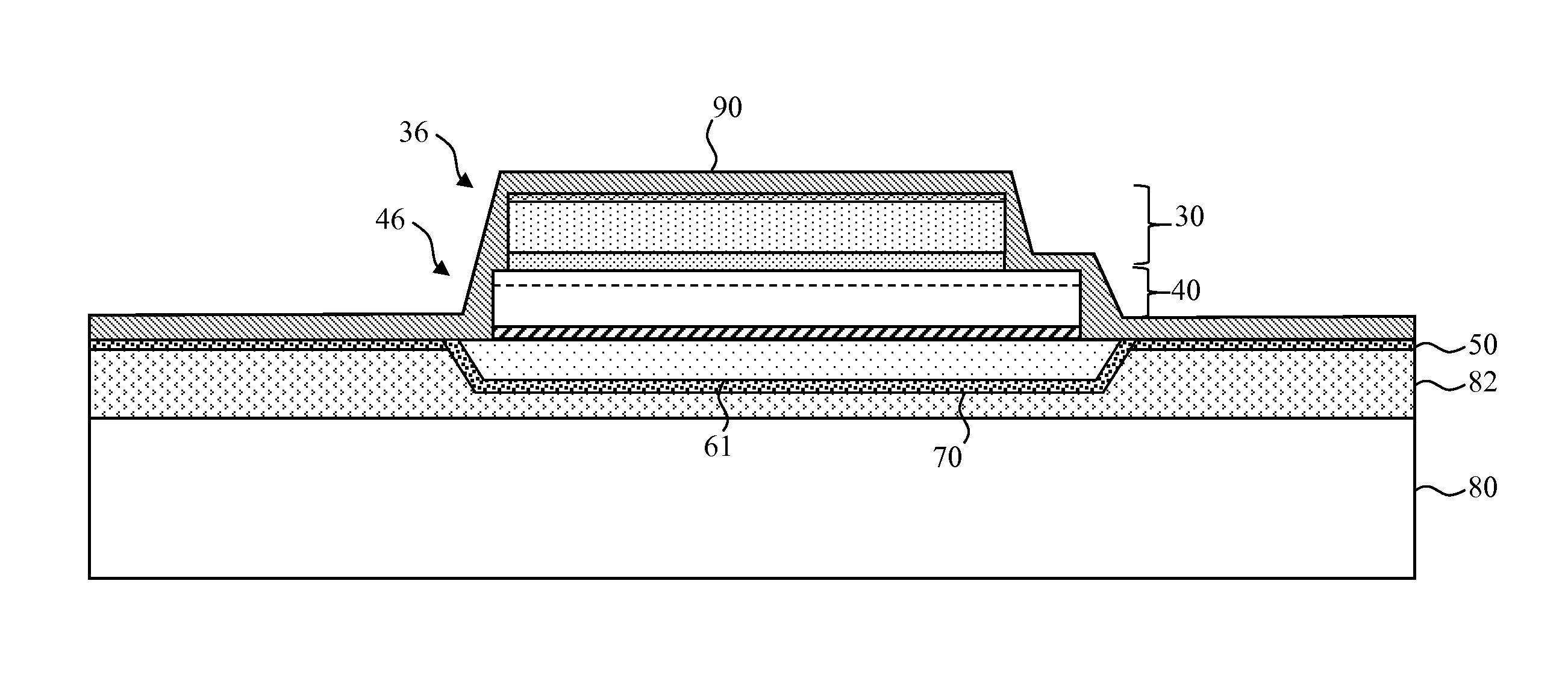

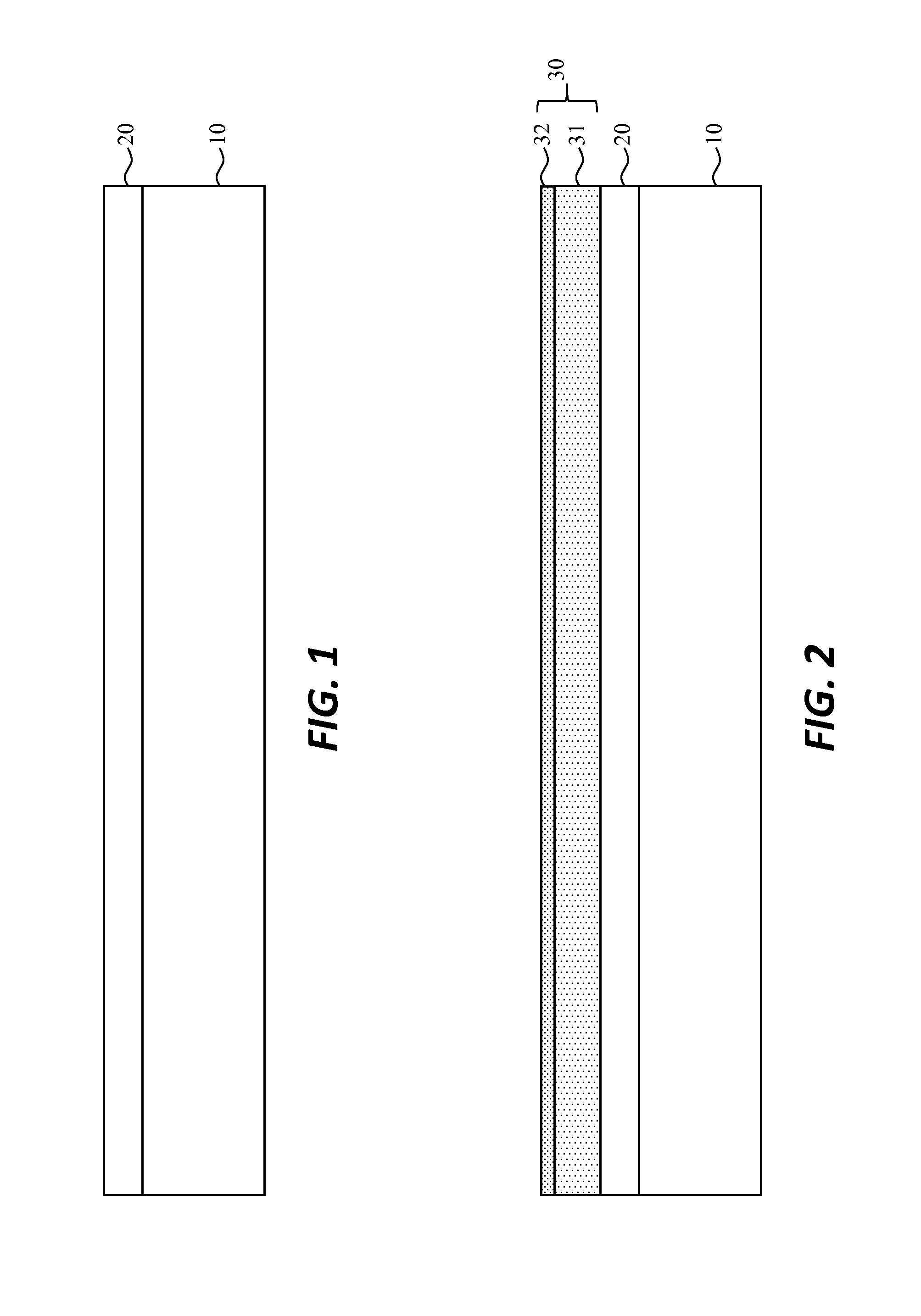

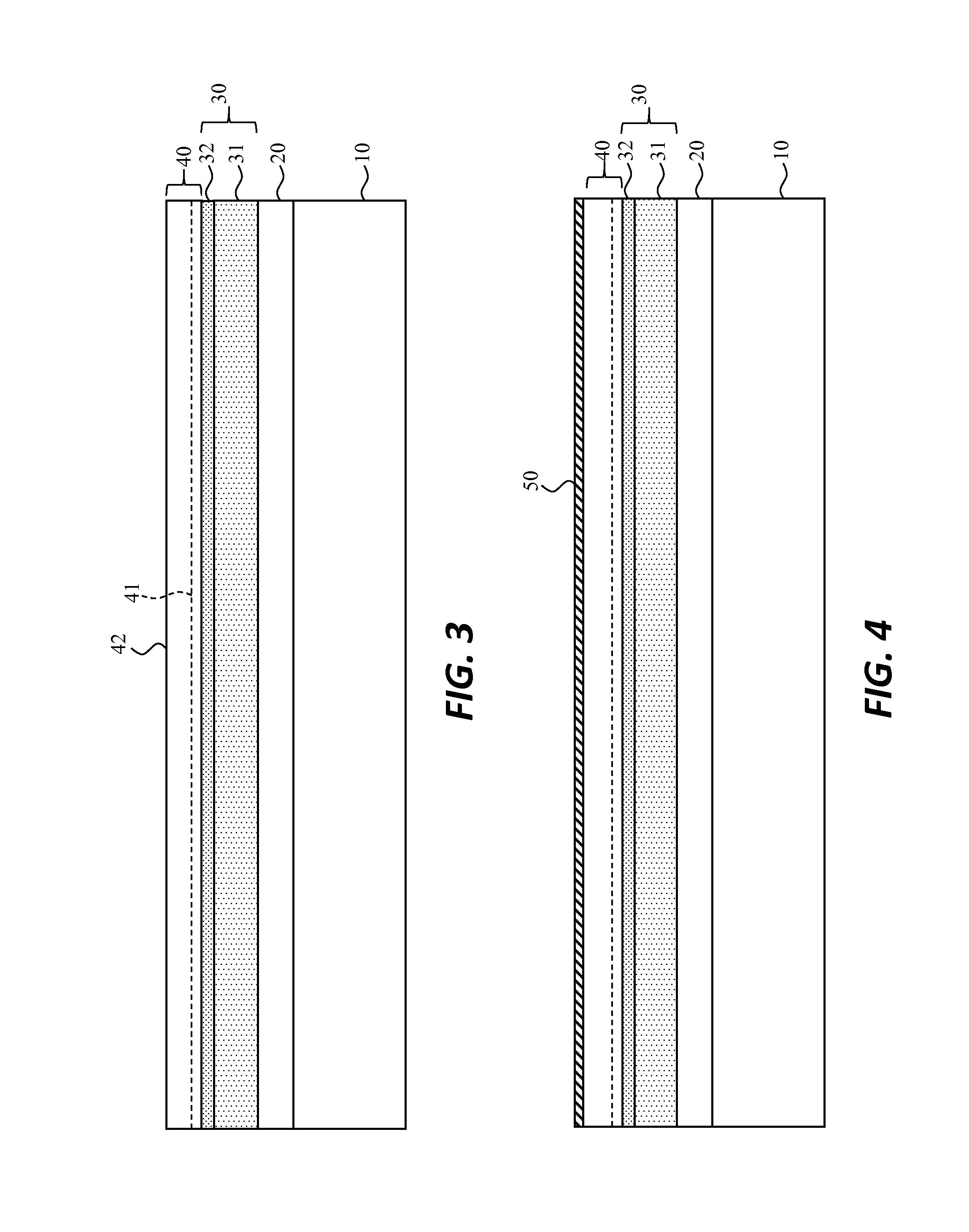

A method of making an inorganic semiconductor structure suitable for micro-transfer printing includes providing a growth substrate and forming one or more semiconductor layers on the growth substrate. A patterned release layer is formed on the conductor layer(s) and bonded to a handle substrate. The growth substrate is removed and the semiconductor layer(s) patterned to form a semiconductor mesa. A dielectric layer is formed and then patterned to expose first and second contacts and an entry portion of the release layer. A conductor layer is formed on the dielectric layer, the first contact, and the second contact and patterned to form a first conductor in electrical contact with the first contact and a second conductor in electrical contact with the second contact but electrically separate from the first conductor. At least a portion of the release layer is removed.

Owner:X DISPLAY CO TECH LTD

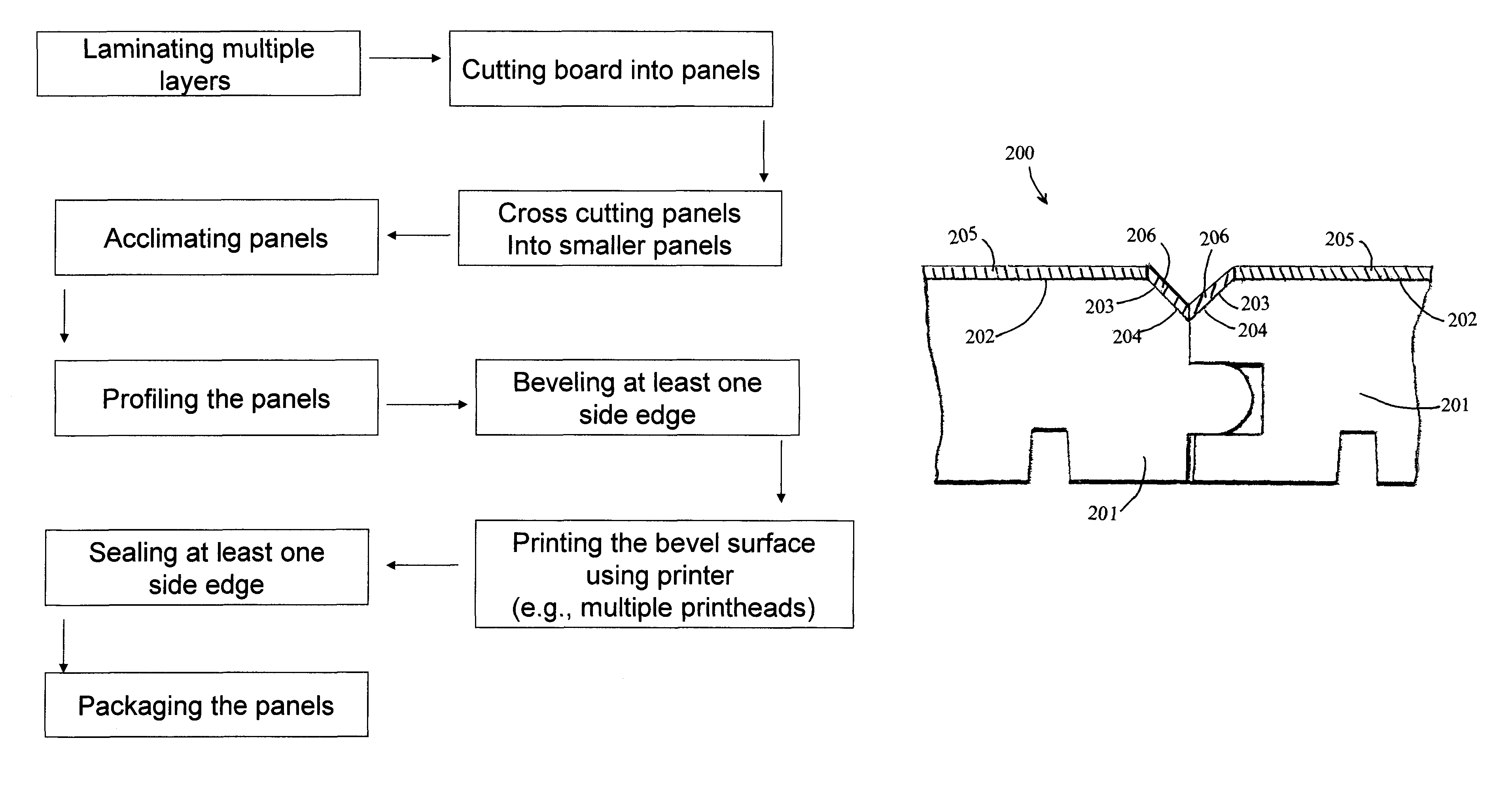

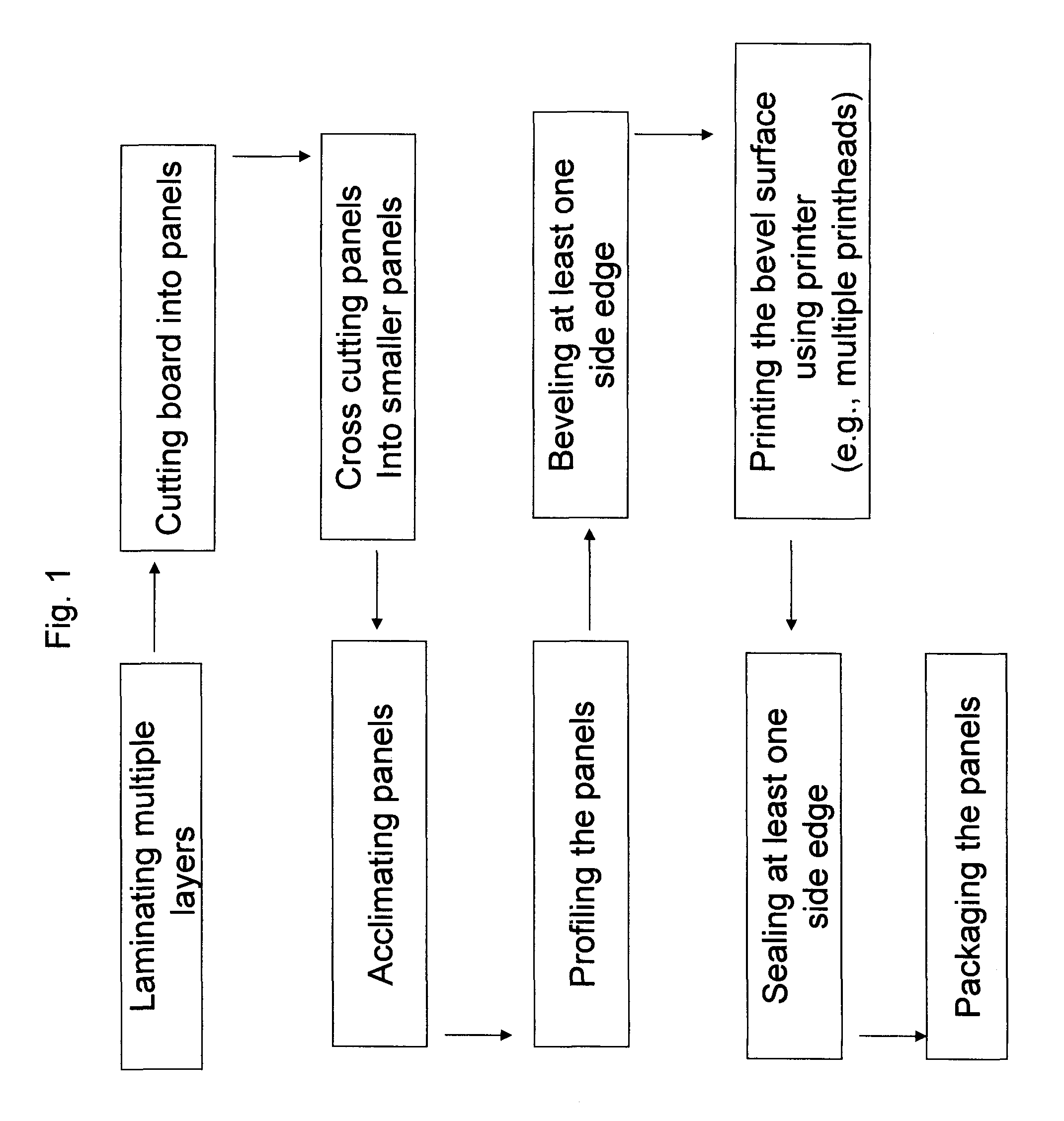

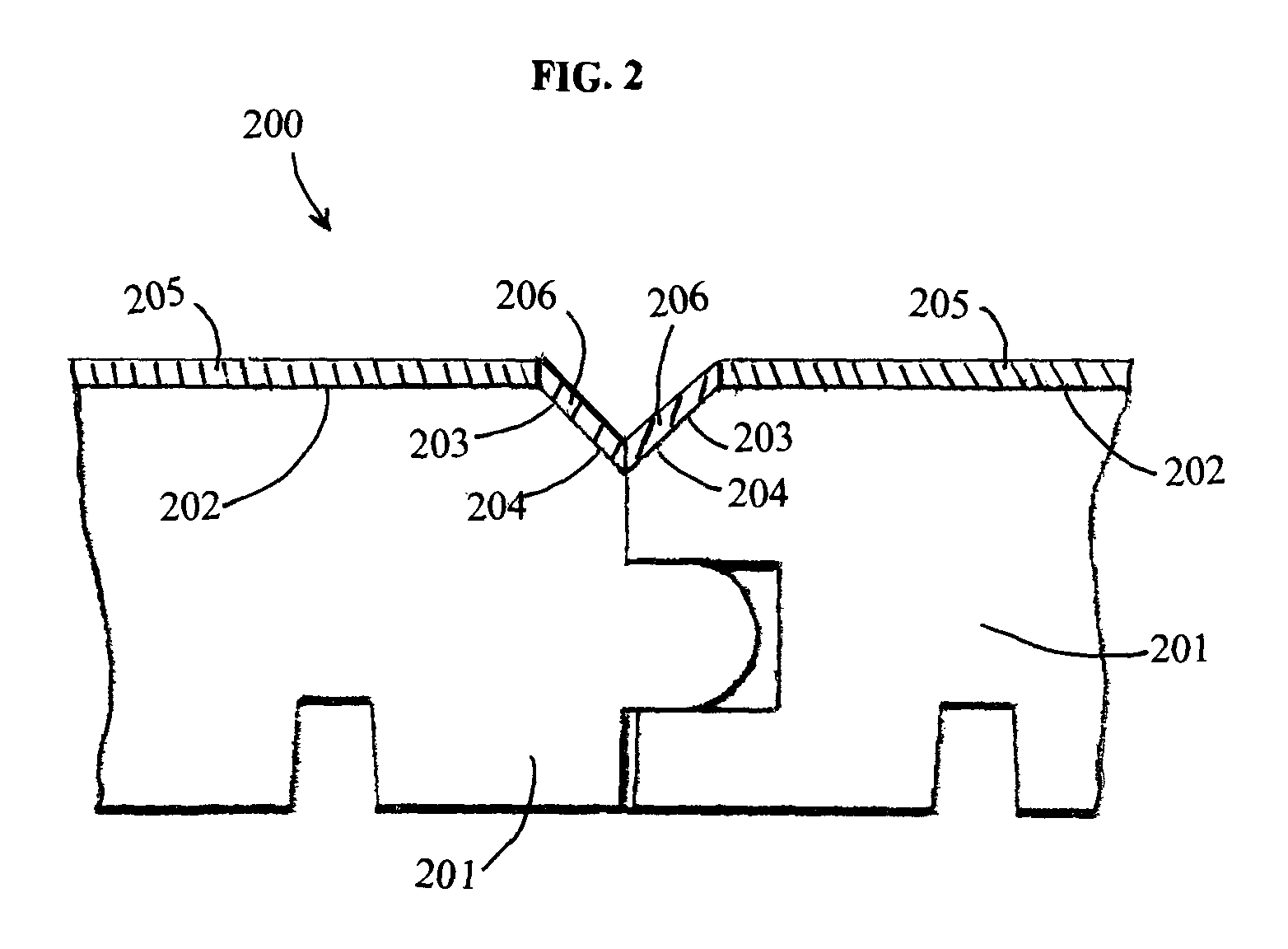

Methods and systems for decorating bevel and other surfaces of laminated floorings

ActiveUS20070283648A1Eliminate needEnhance the imageCovering/liningsWallsEngineeringDigital printing

Methods and systems for decorating at least one bevel surface or other surface of a laminated flooring are described. The bevel surface can be decorated by non-transfer printing such as digital printing. The digital printer can be an ink jet printer such as a piezoelectric drop-on-demand (DOD) printer that allows a color and pattern to be placed on the bevel surface that matches the print design (décor pattern or face design) of the laminated flooring. Other devices are provided such as a device that takes a picture of or scans an image of the print design, and modifies the taken picture or the scanned image so that the edge pattern thereof matches with an edge pattern of the print design.

Owner:FLOORING IND LTD

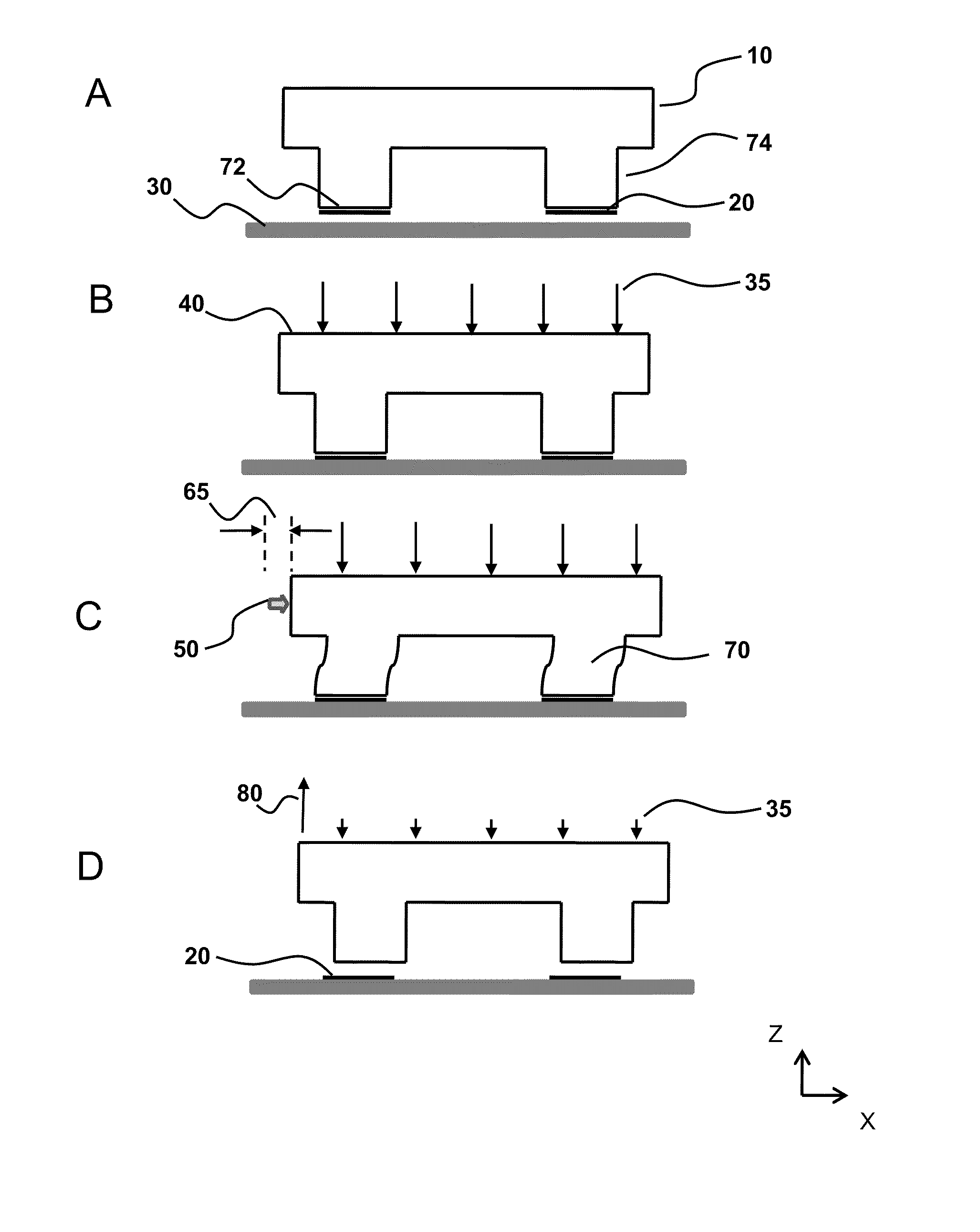

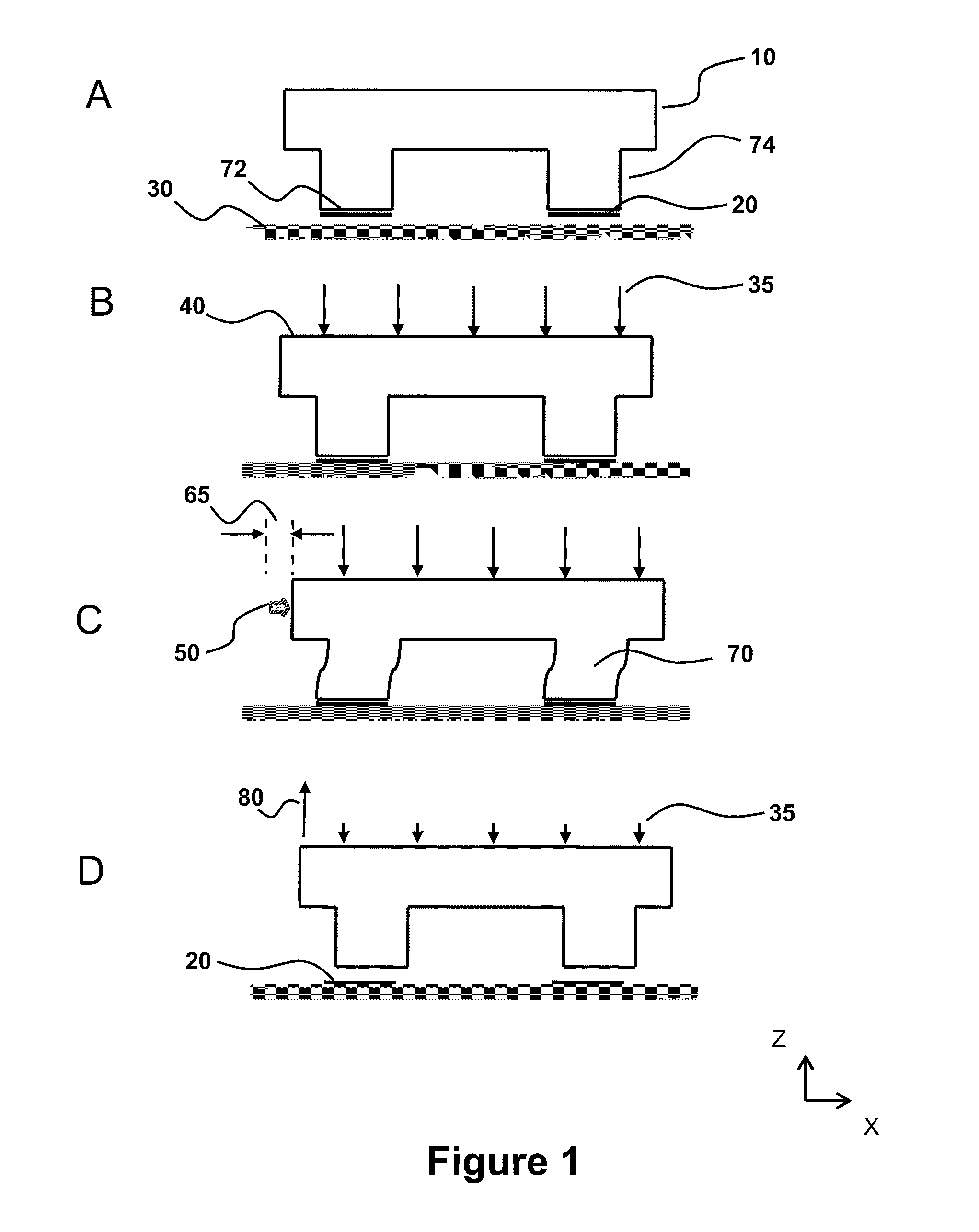

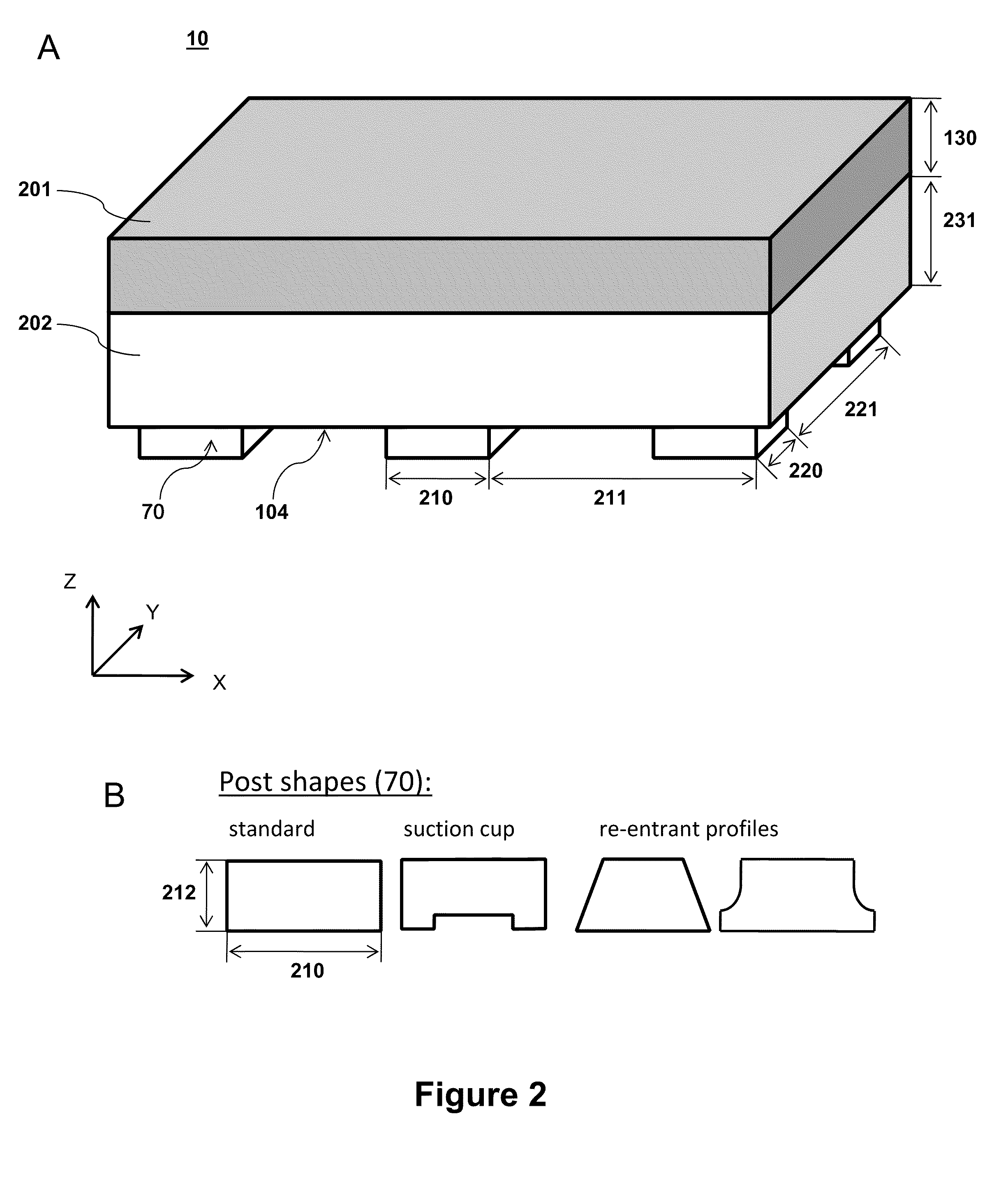

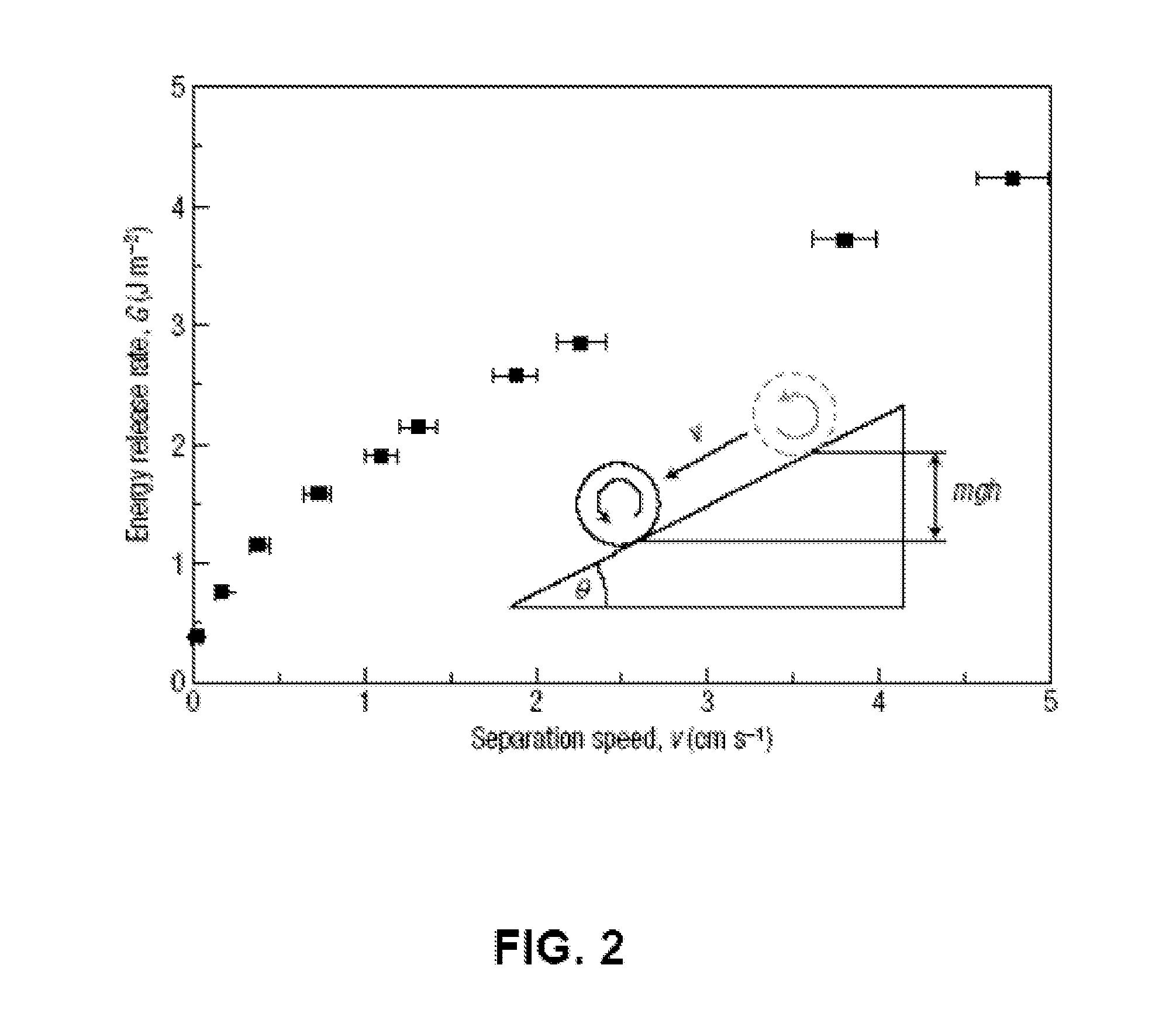

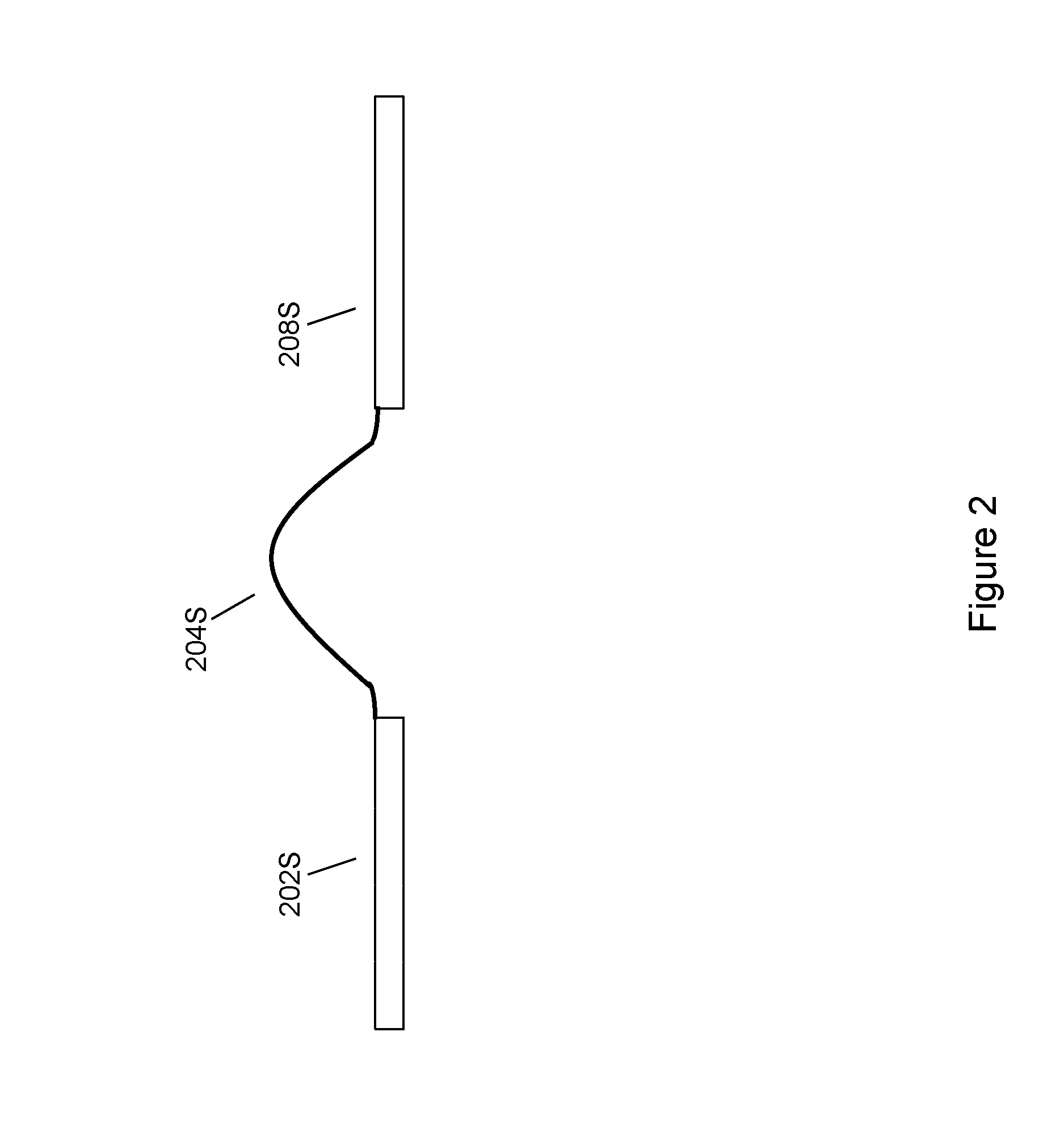

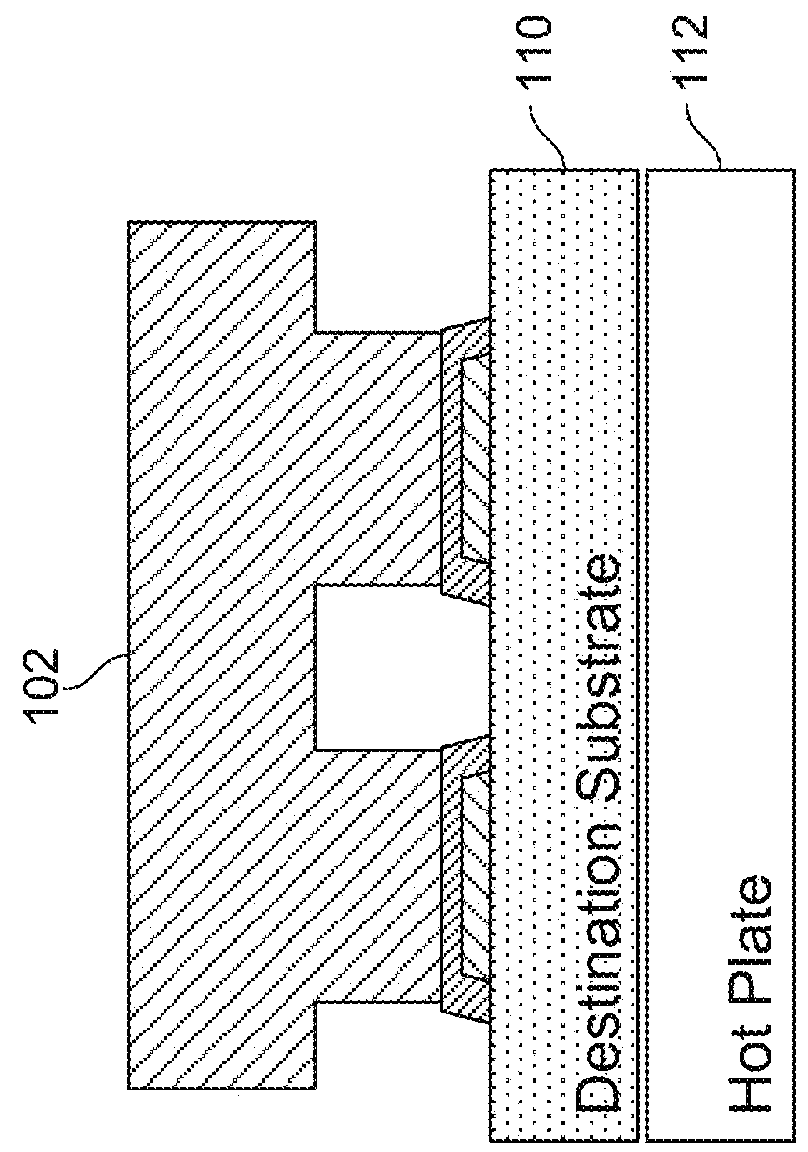

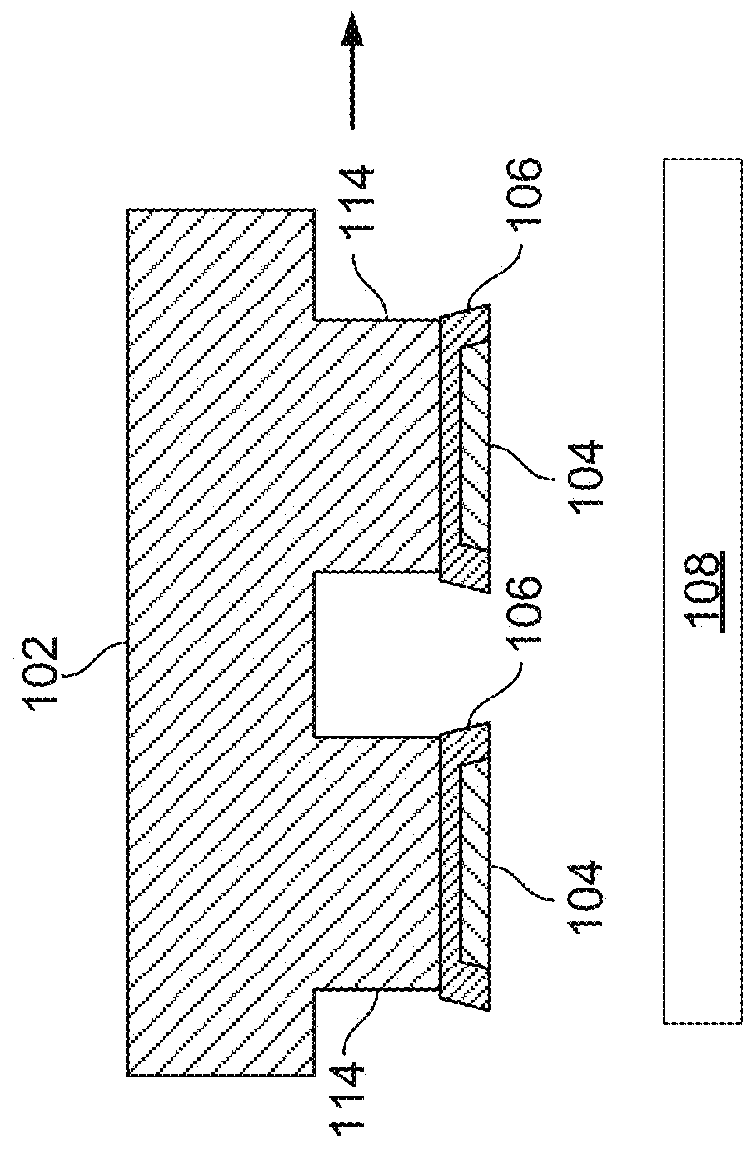

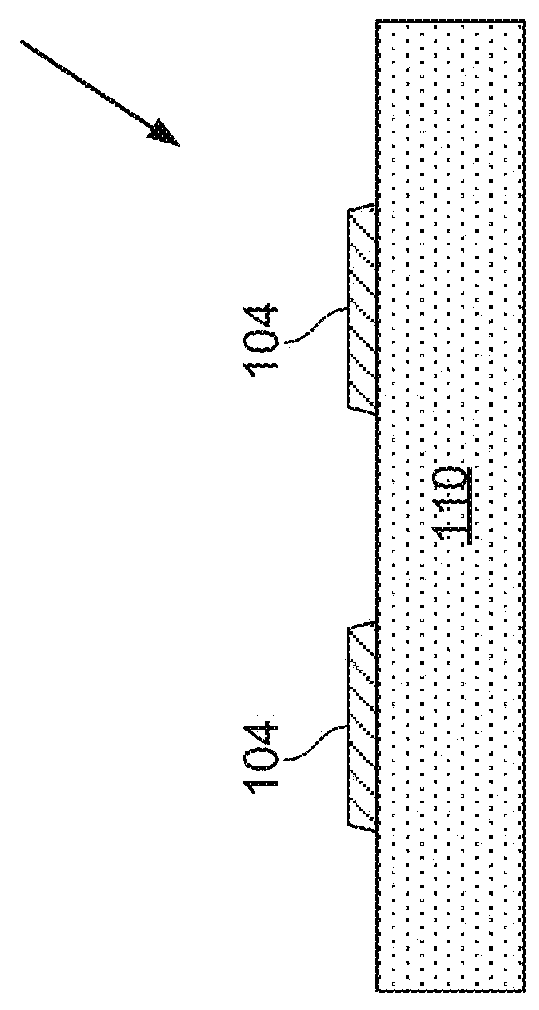

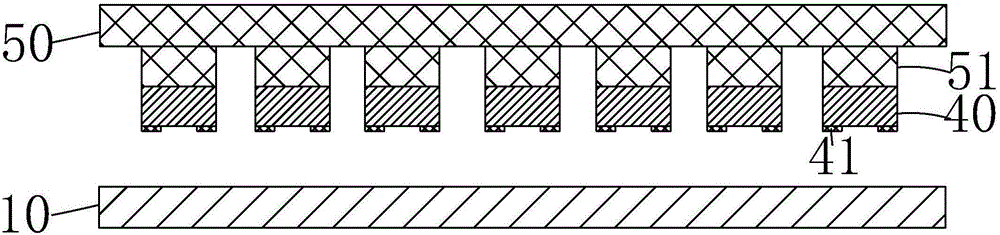

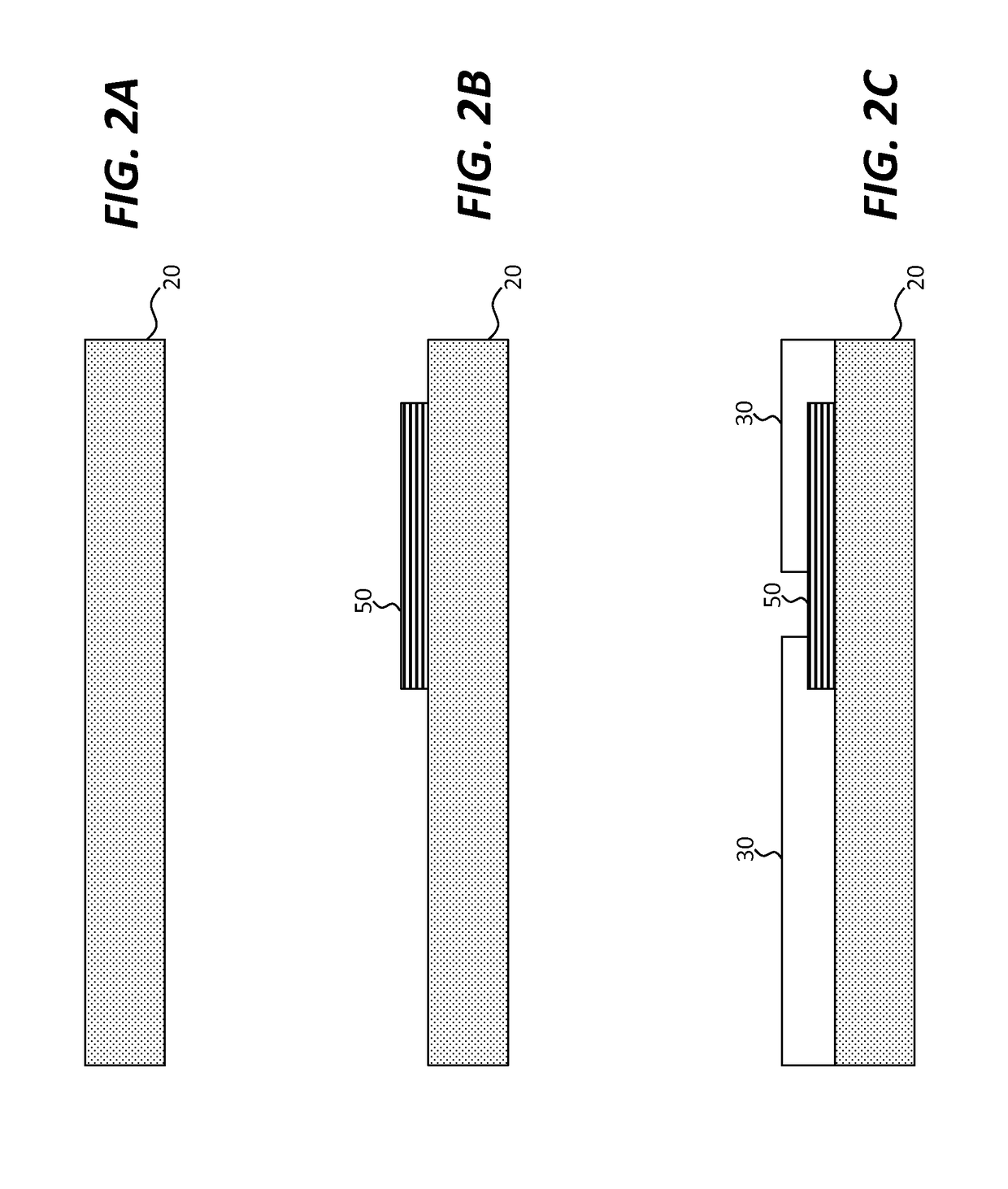

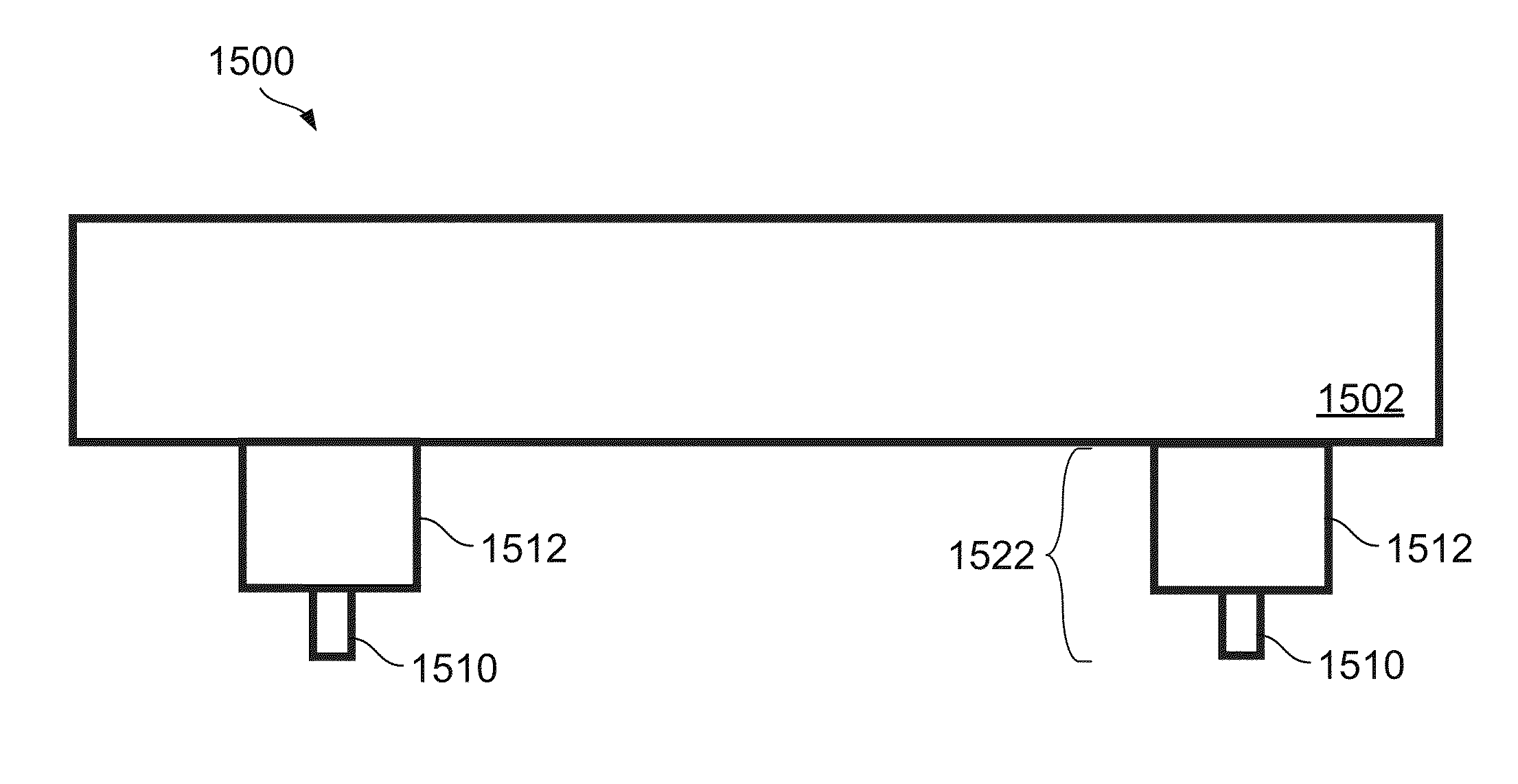

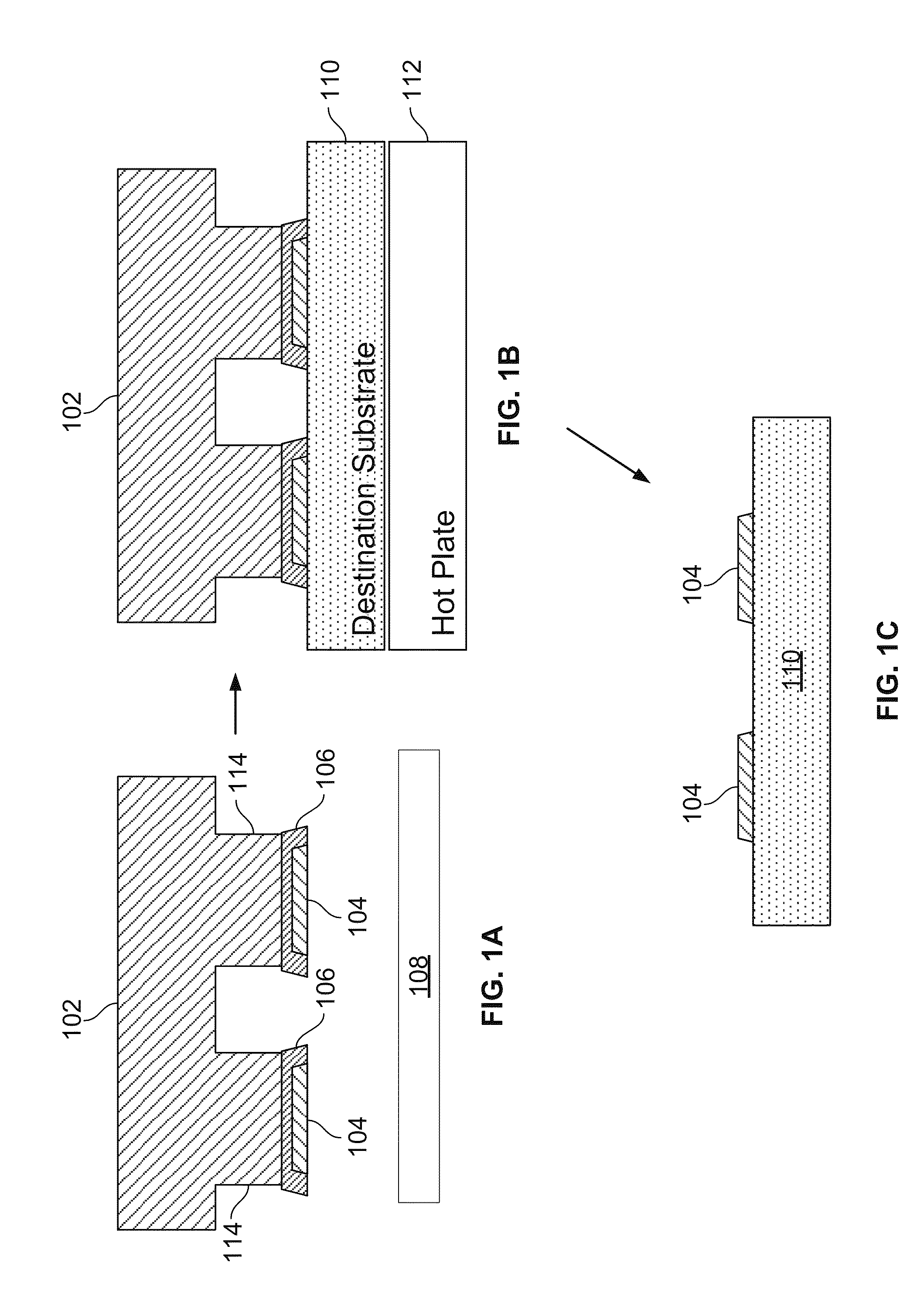

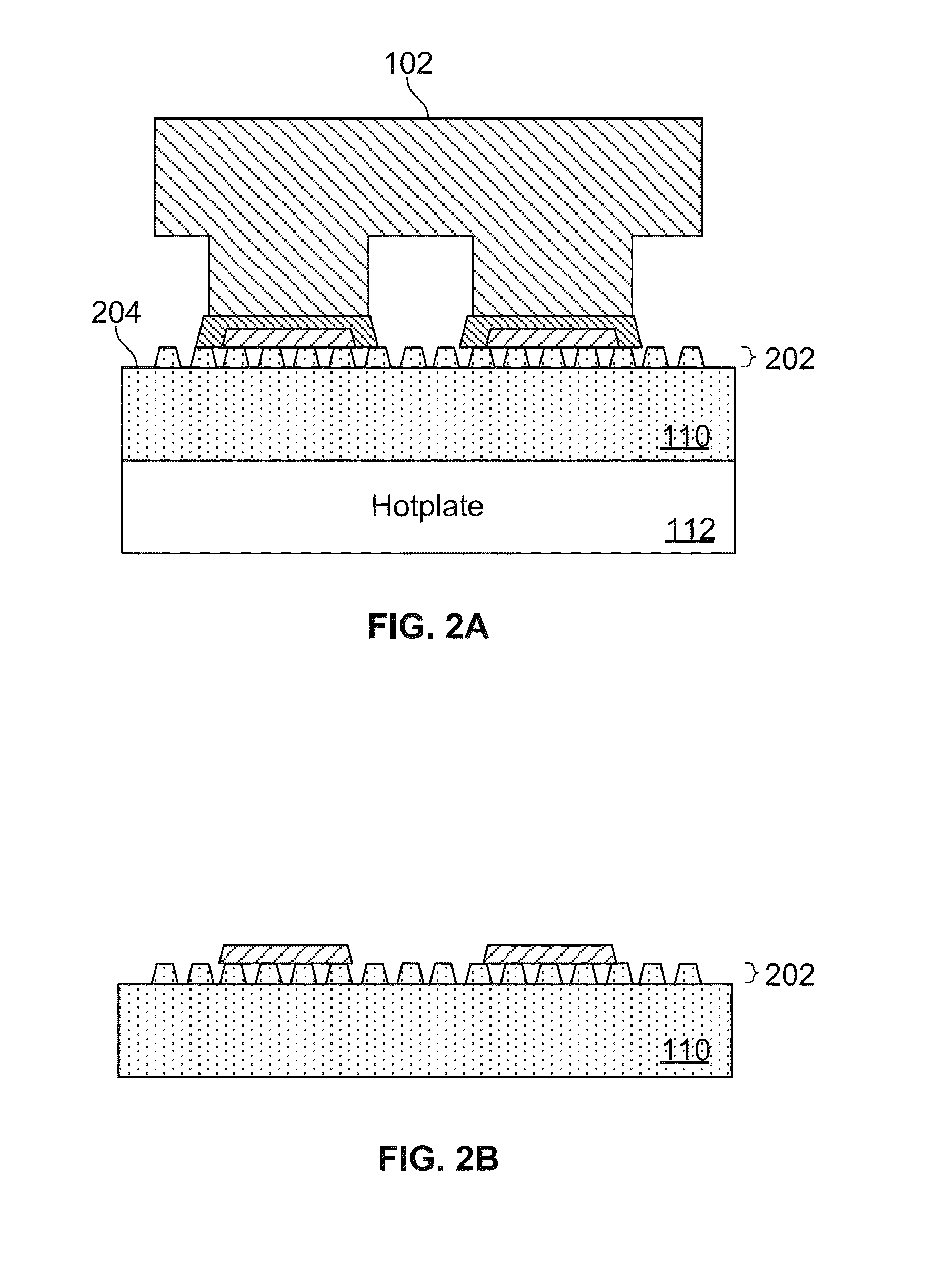

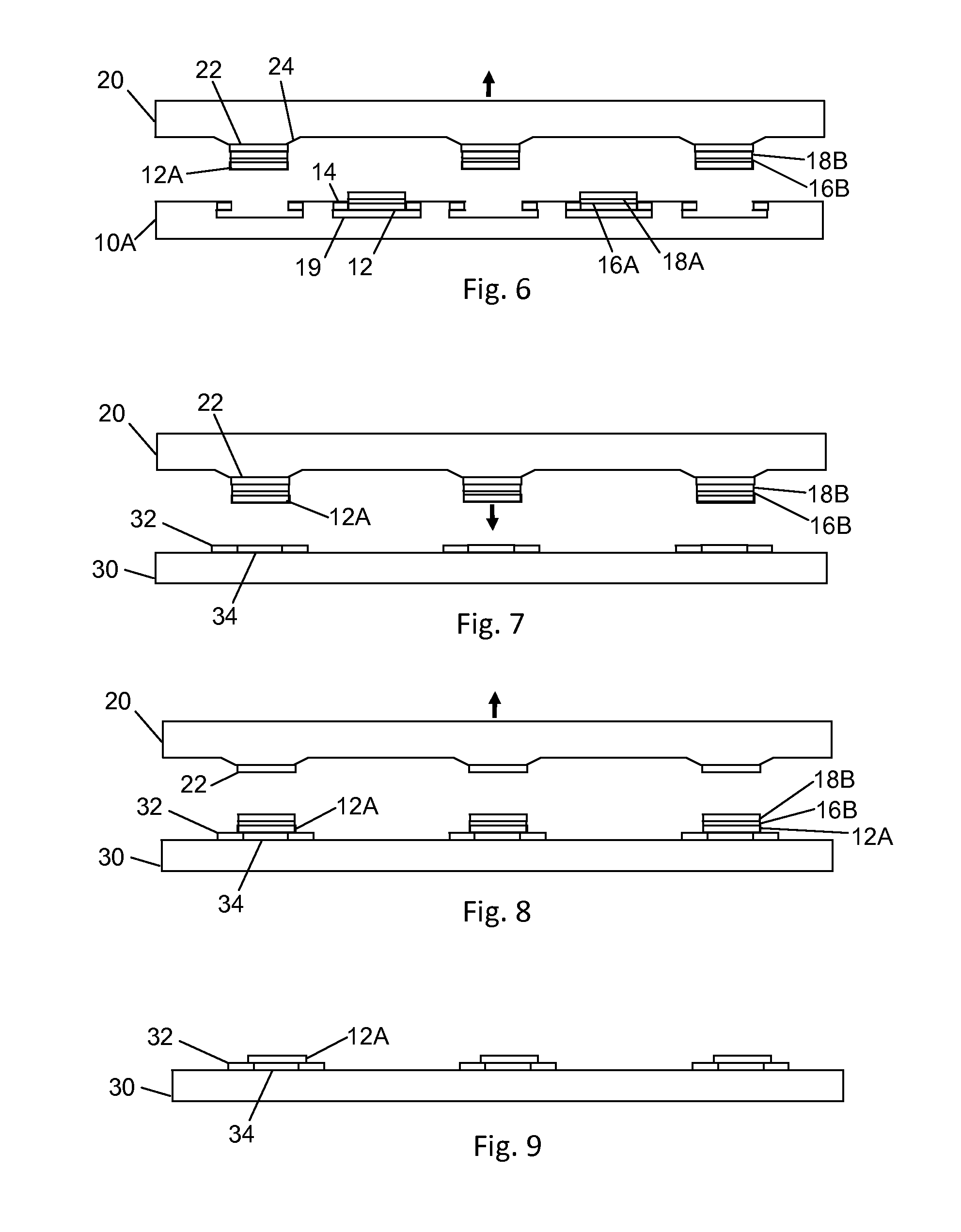

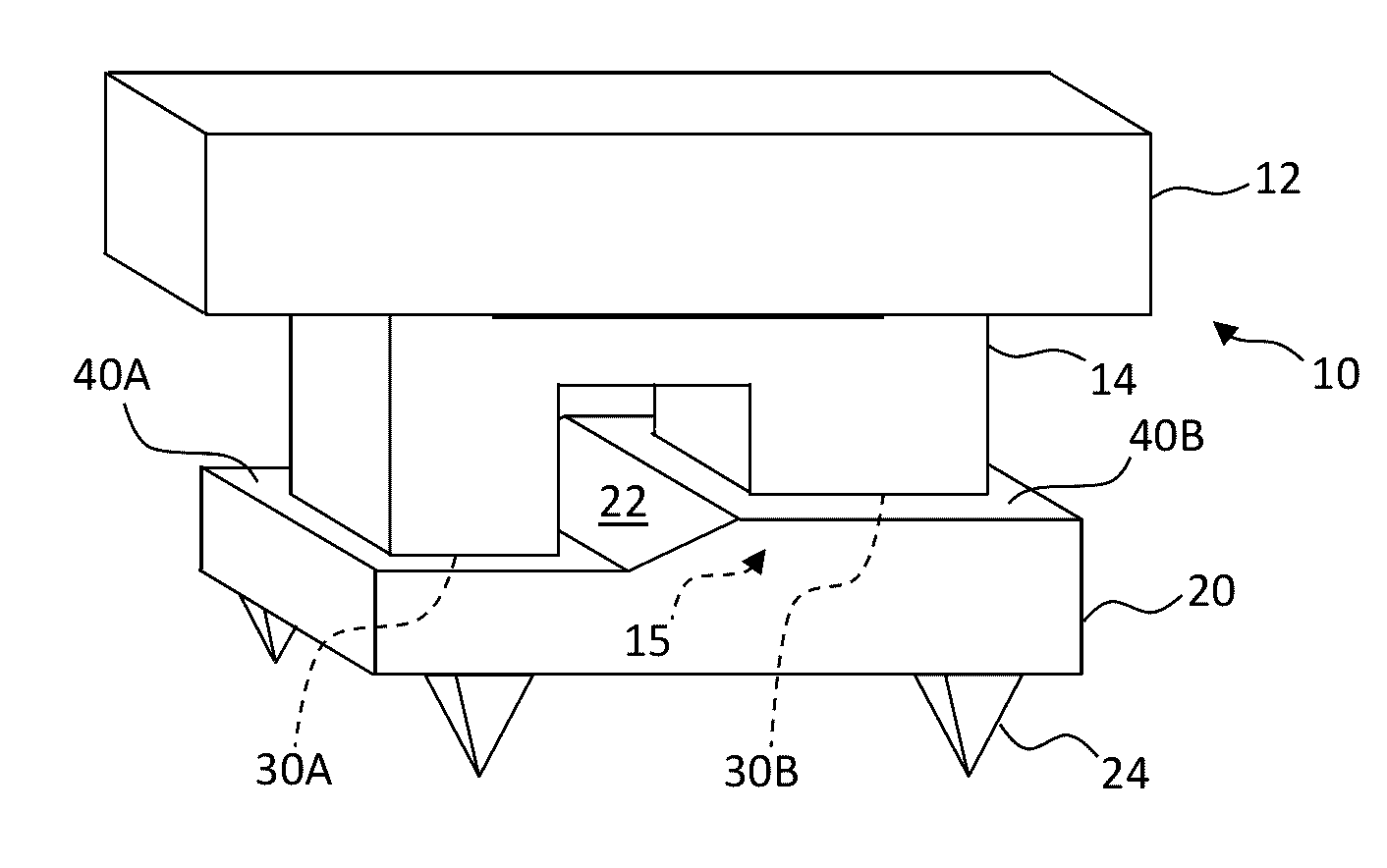

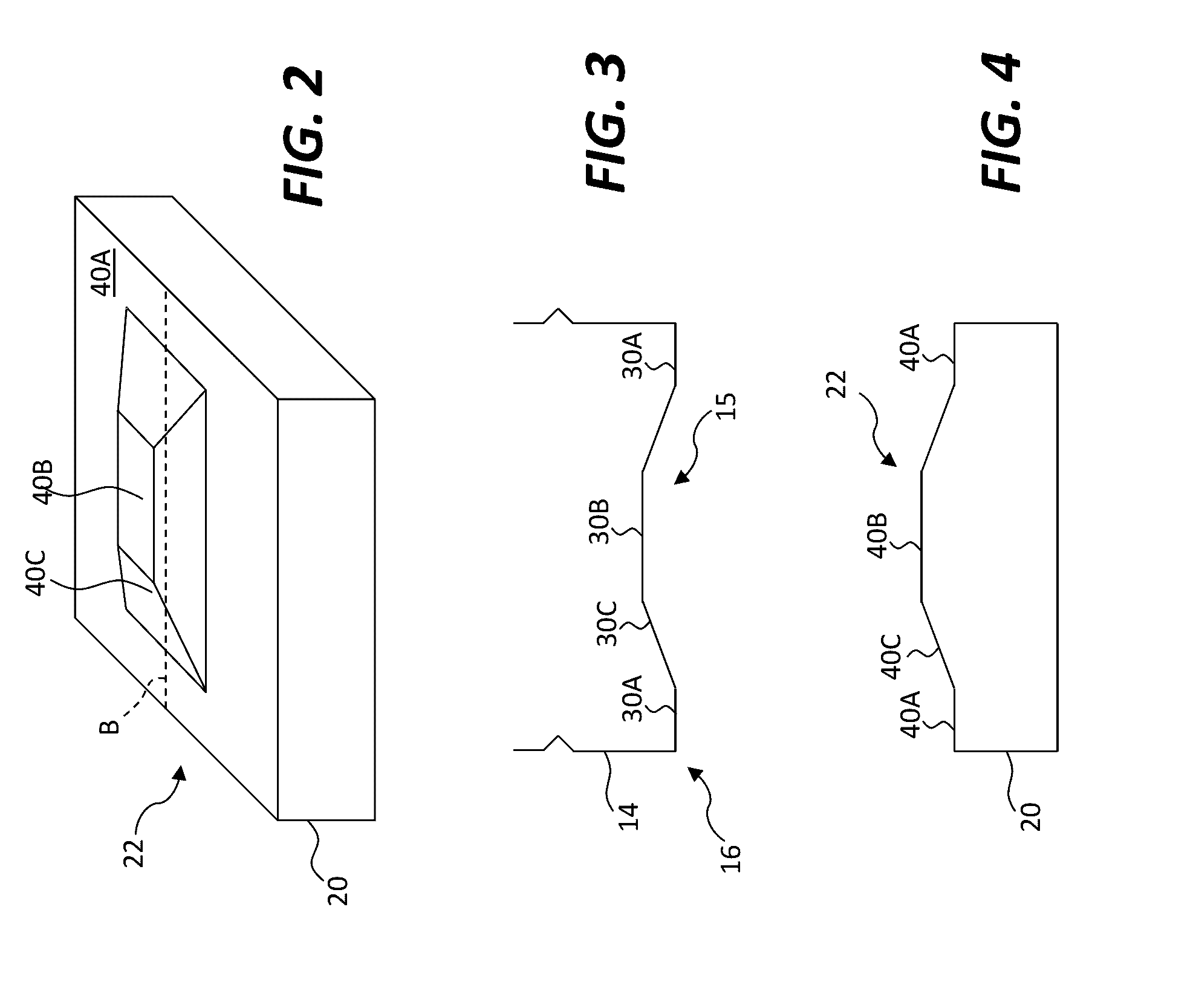

Apparatus and methods for micro-transfer-printing

ActiveUS9358775B2Increase heightImprove adhesionTransfer printingSemiconductor/solid-state device detailsSemiconductorSeparation system

In an aspect, a system and method for assembling a semiconductor device on a receiving surface of a destination substrate is disclosed. In another aspect, a system and method for assembling a semiconductor device on a destination substrate with topographic features is disclosed. In another aspect, a gravity-assisted separation system and method for printing semiconductor device is disclosed. In another aspect, various features of a transfer device for printing semiconductor devices are disclosed.

Owner:X DISPLAY CO TECH LTD

Methods and applications of non-planar imaging arrays

ActiveUS8372726B2Low costLess reflection and diffraction defectCircuit bendability/stretchabilitySemiconductor/solid-state device detailsInterconnectionEngineering

Owner:MEDIDATA SOLUTIONS

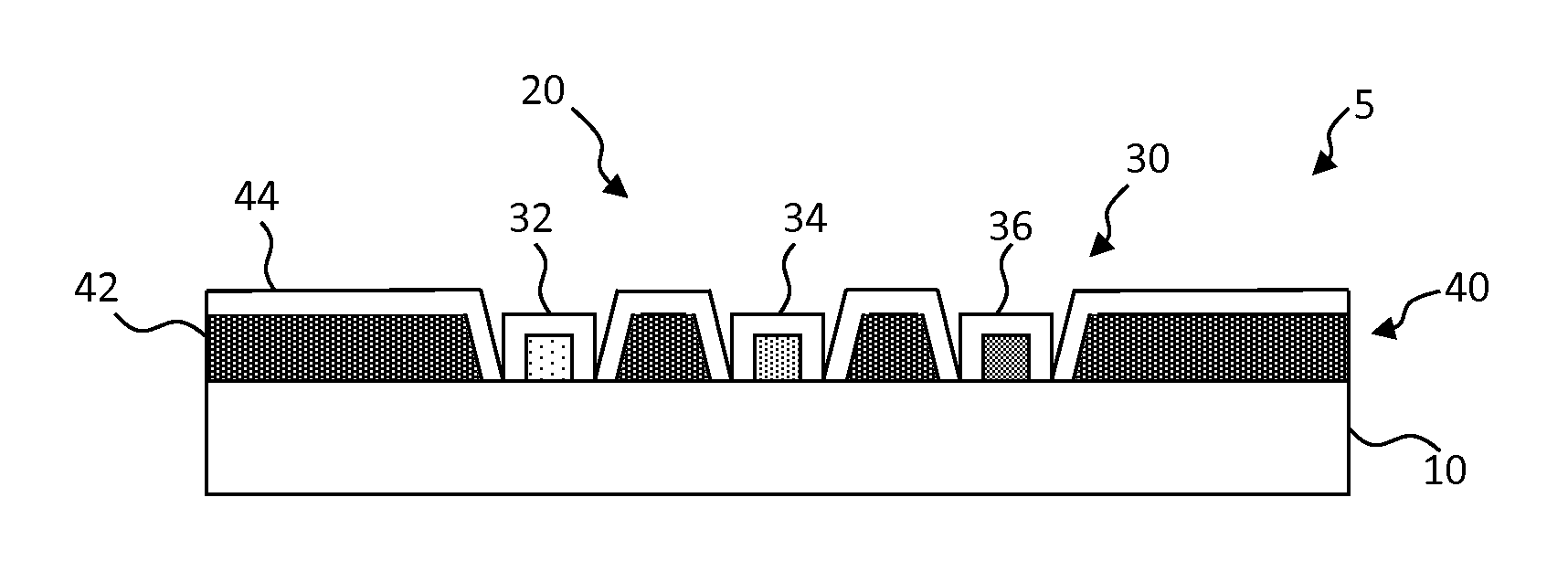

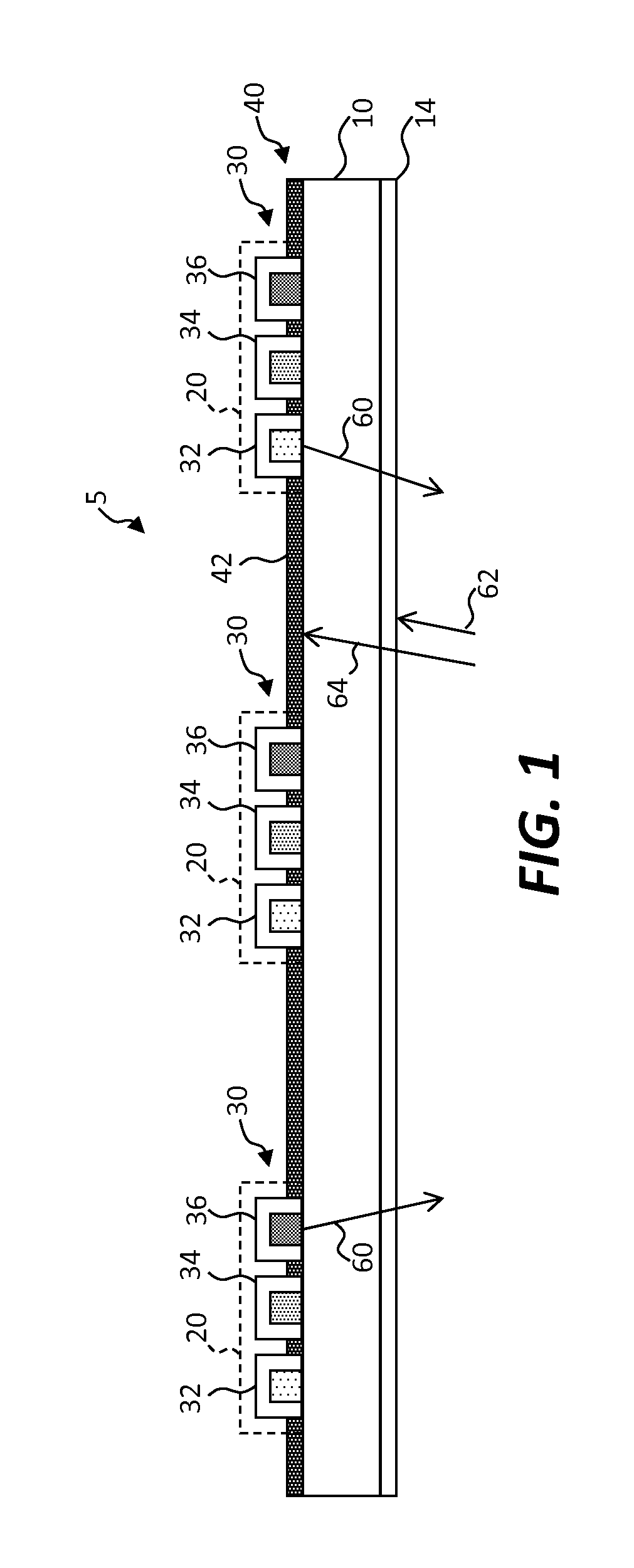

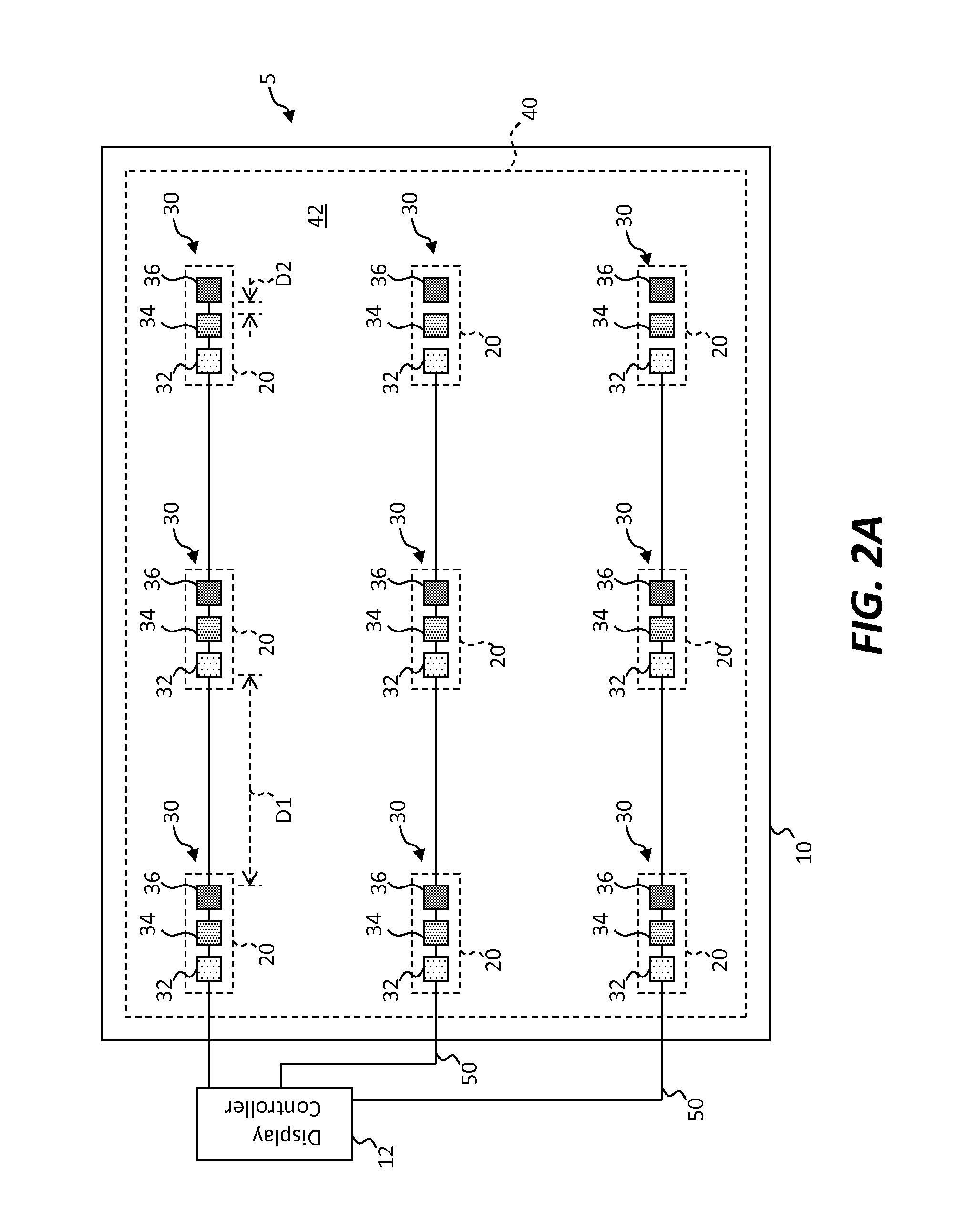

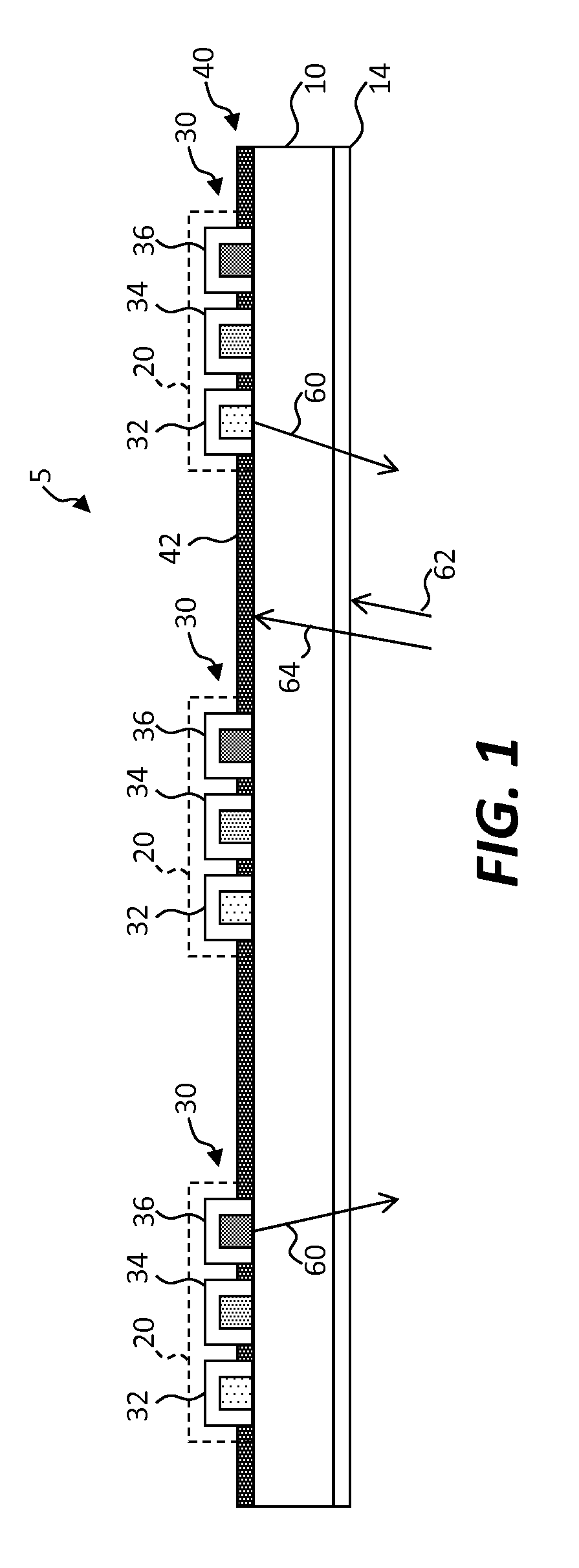

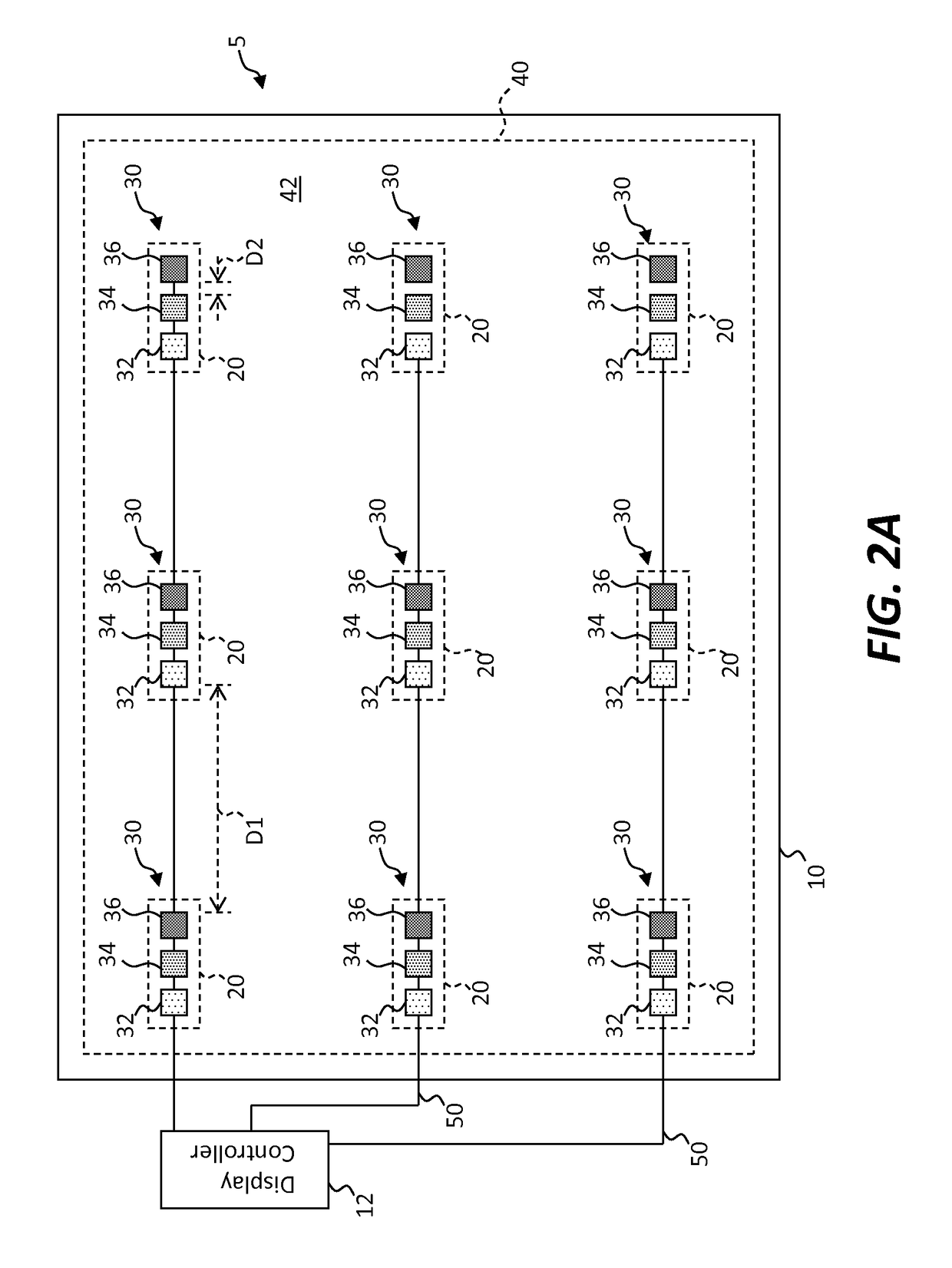

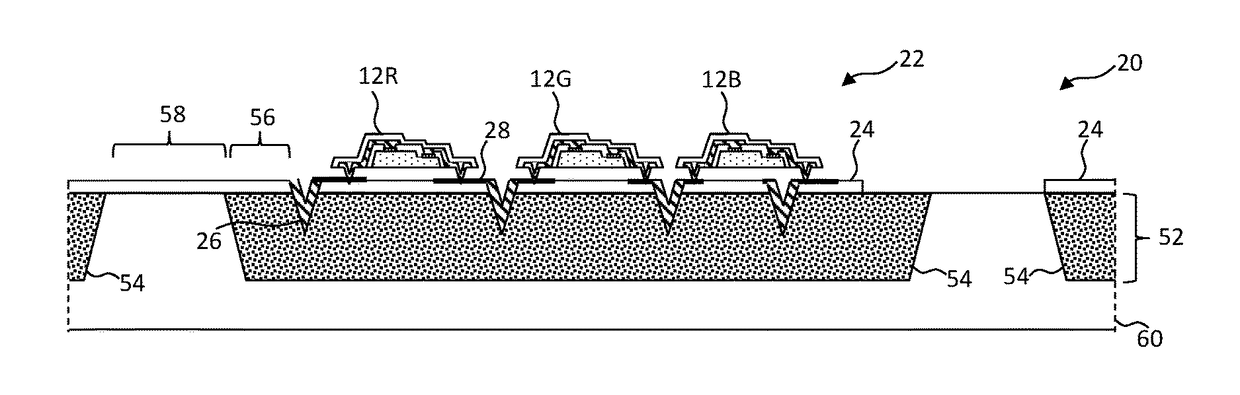

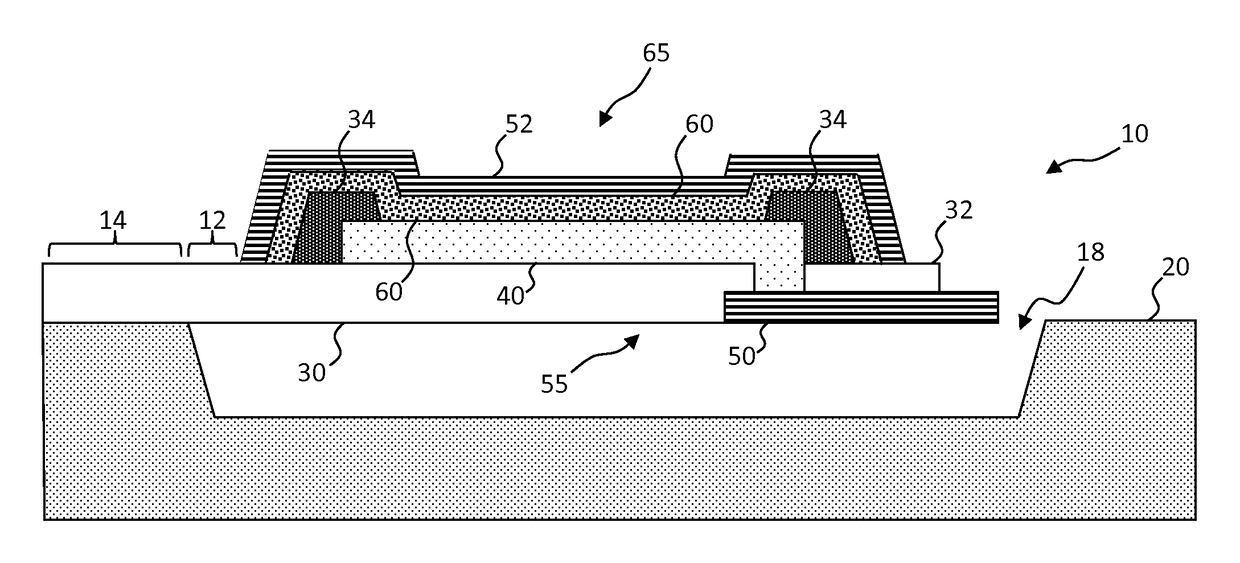

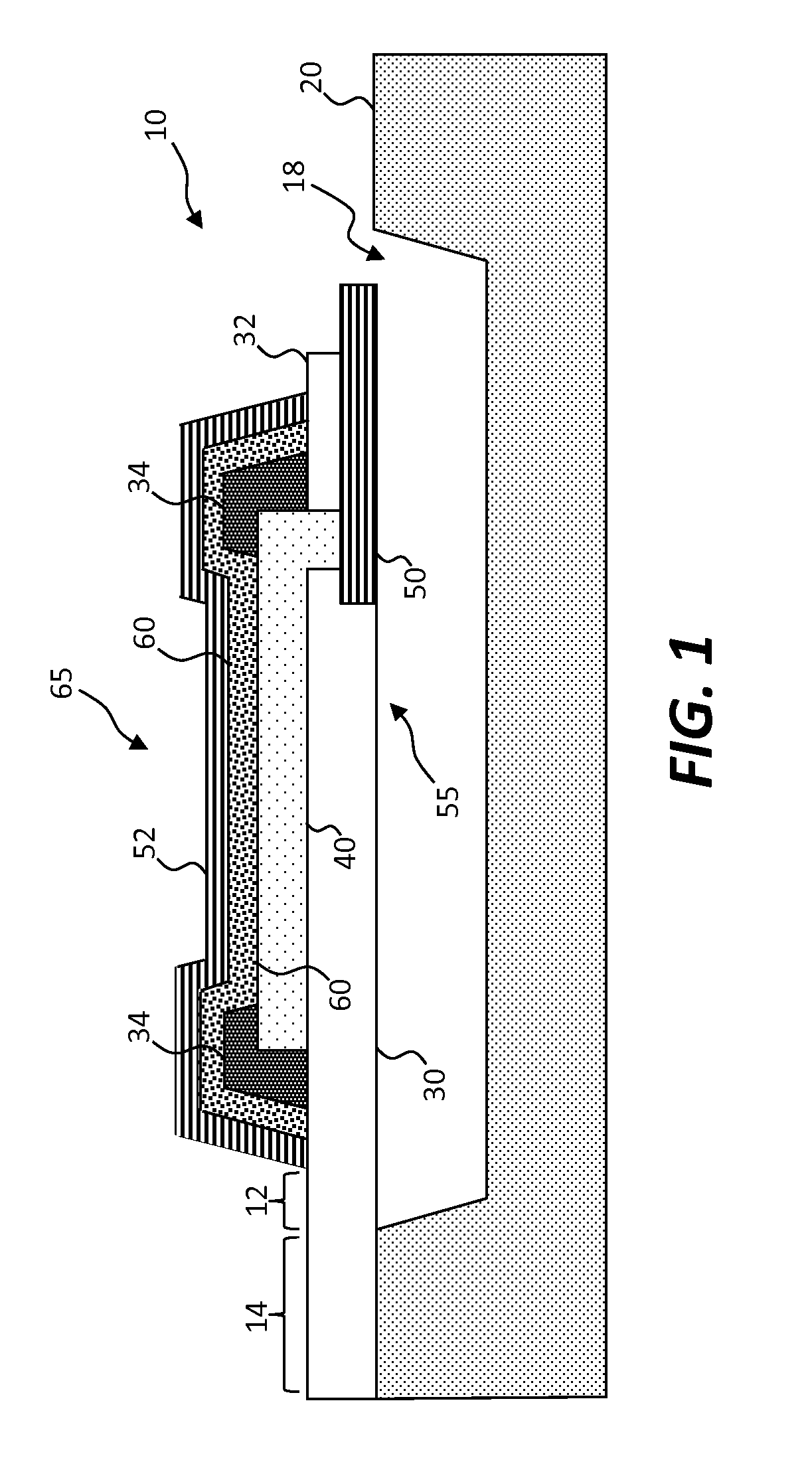

Inorganic-light-emitter display with integrated black matrix

ActiveUS20160351539A1Improve light output efficiencyImprove image qualitySolid-state devicesSemiconductor devicesParallaxManufacturing cost reduction

An inorganic-light-emitter display includes a display substrate and a plurality of spatially separated inorganic light emitters distributed on the display substrate in a light-emitter layer. A light-absorbing layer located on the display substrate in the light-emitter layer is in contact with the inorganic light emitters. Among other things, the disclosed technology provides improved angular image quality by avoiding parallax between the light emitters and the light-absorbing material, increased light-output efficiency by removing the light-absorbing material from the optical path, improved contrast by increasing the light-absorbing area of the display substrate, and a reduced manufacturing cost in a mechanically and environmentally robust structure using micro transfer printing.

Owner:X DISPLAY CO TECH LTD

Methods and systems for decorating bevel and other surfaces of laminated floorings

Methods and systems for decorating at least one bevel surface or other surface of a laminated flooring are described. The bevel surface can be decorated by non-transfer printing such as digital printing. The digital printer can be an ink jet printer such as a piezoelectric drop-on-demand (DOD) printer that allows a color and pattern to be placed on the bevel surface that matches the print design (décor pattern or face design) of the laminated flooring. Other devices are provided such as a device that takes a picture of or scans an image of the print design, and modifies the taken picture or the scanned image so that the edge pattern thereof matches with an edge pattern of the print design.

Owner:FLOORING IND LTD

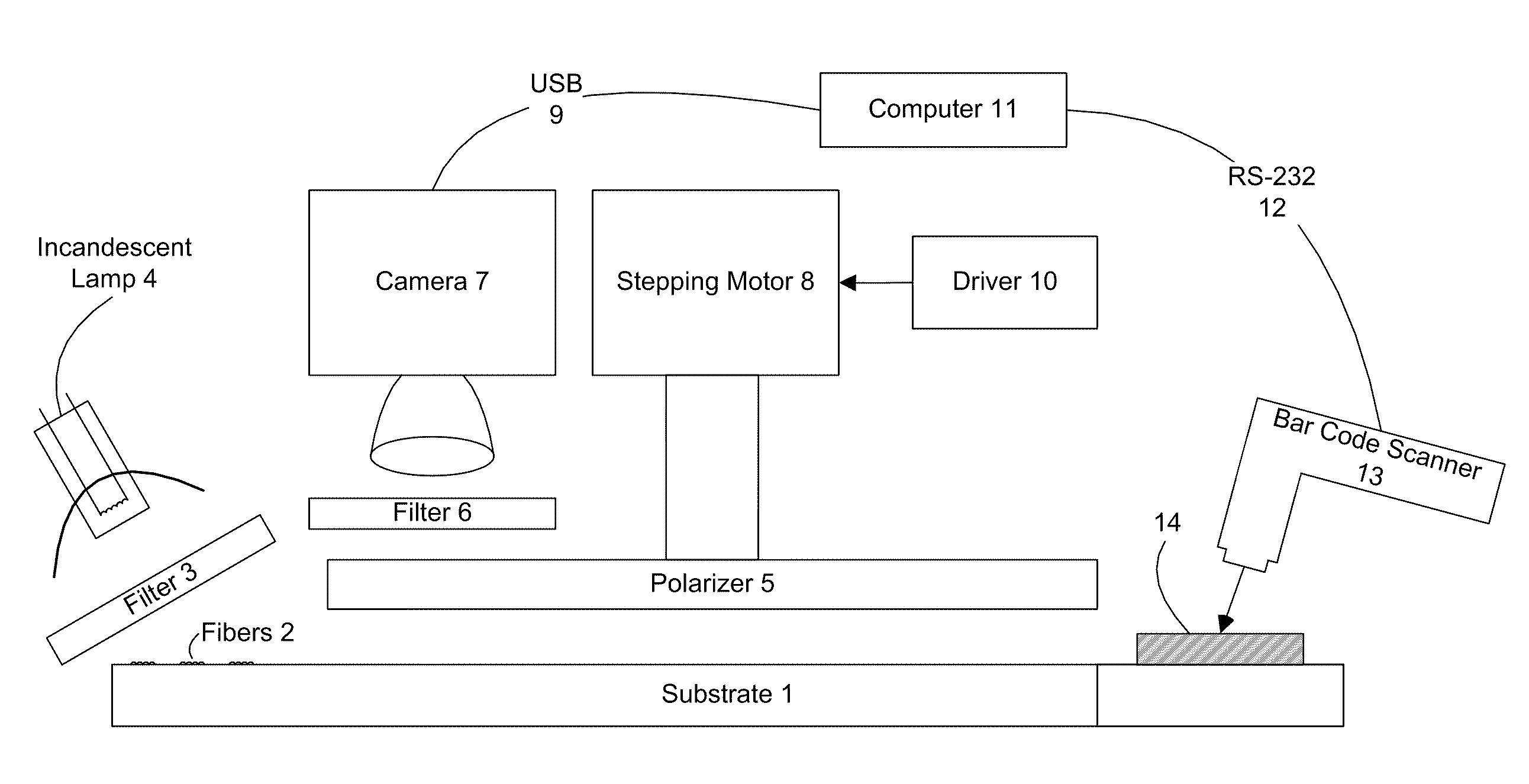

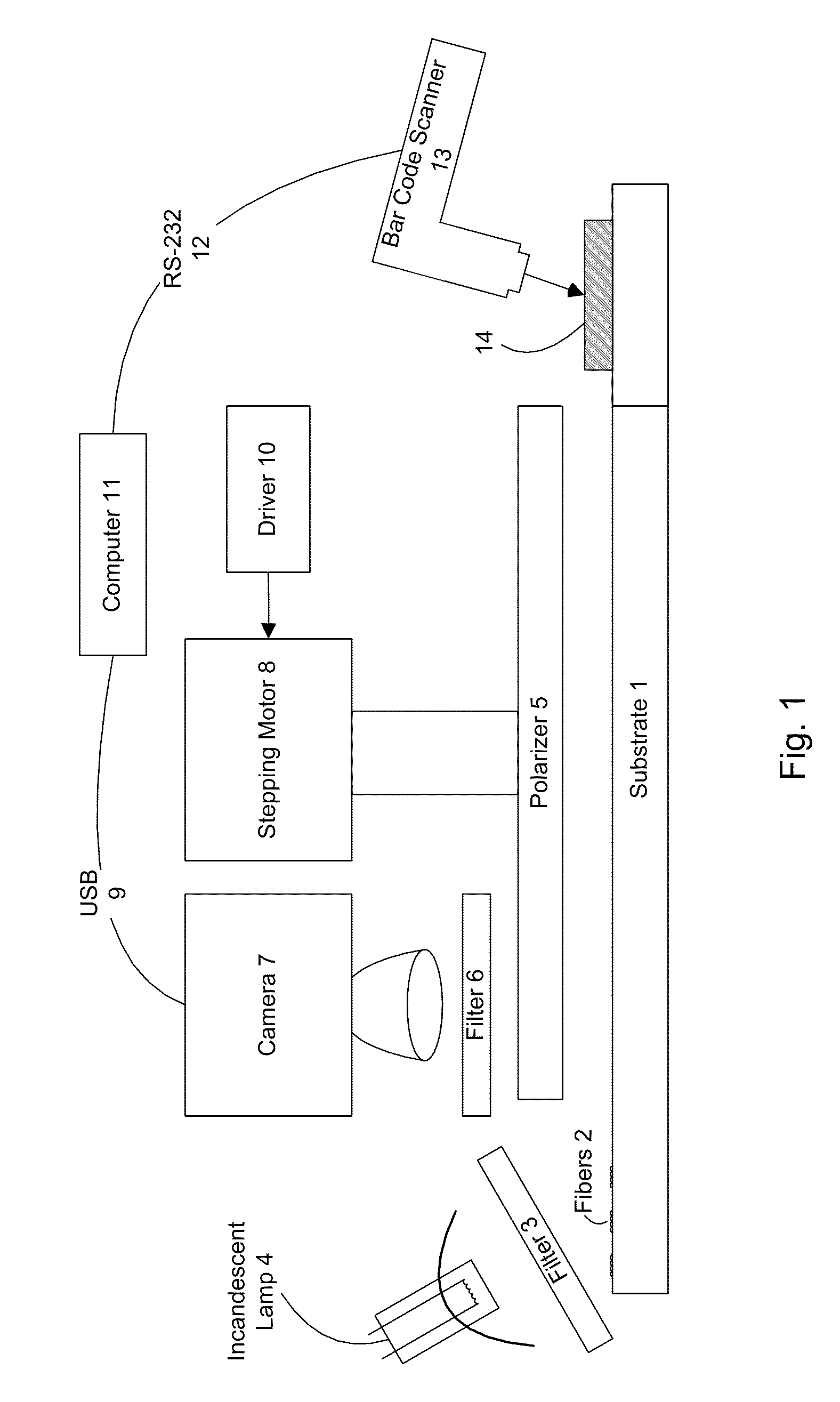

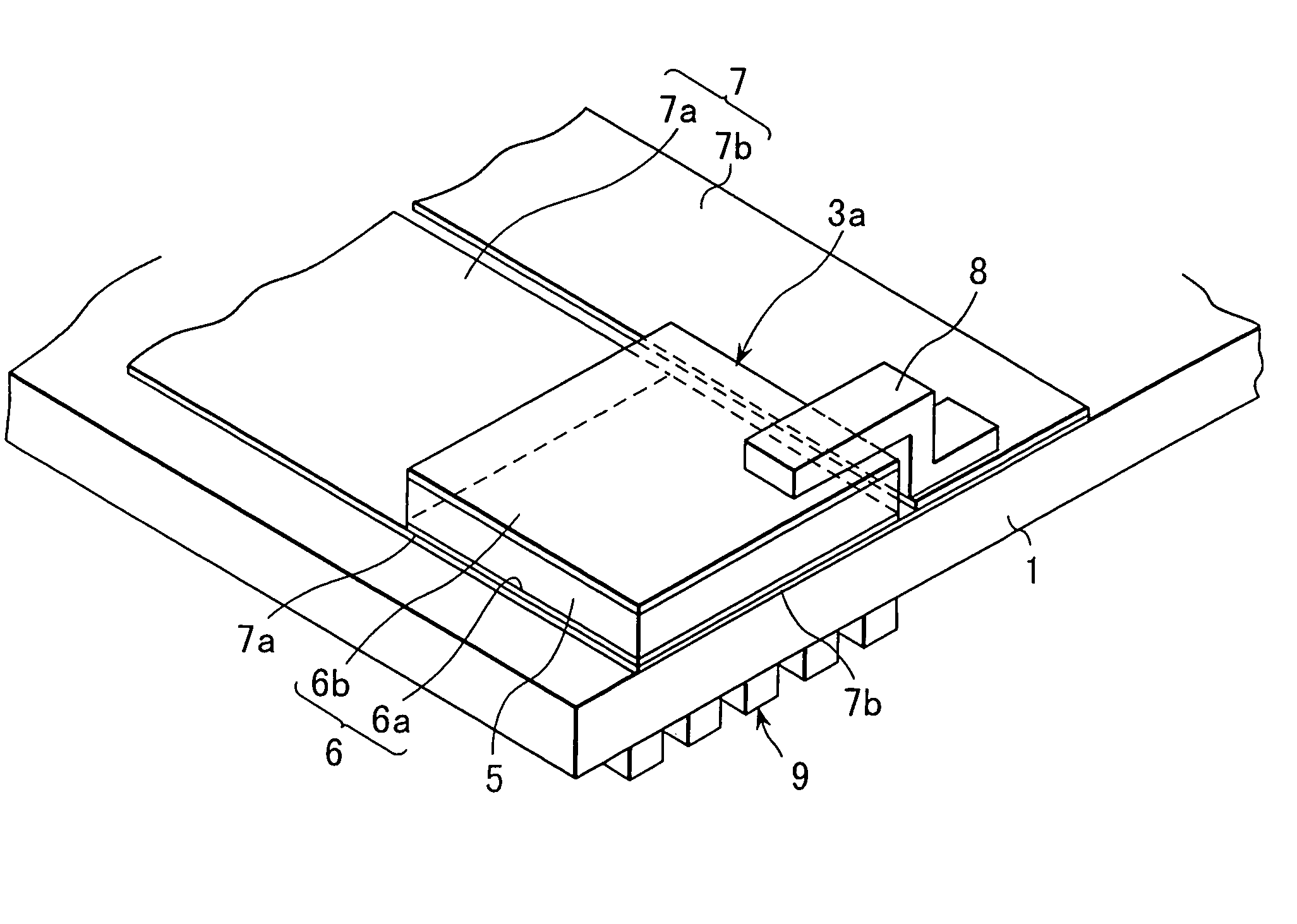

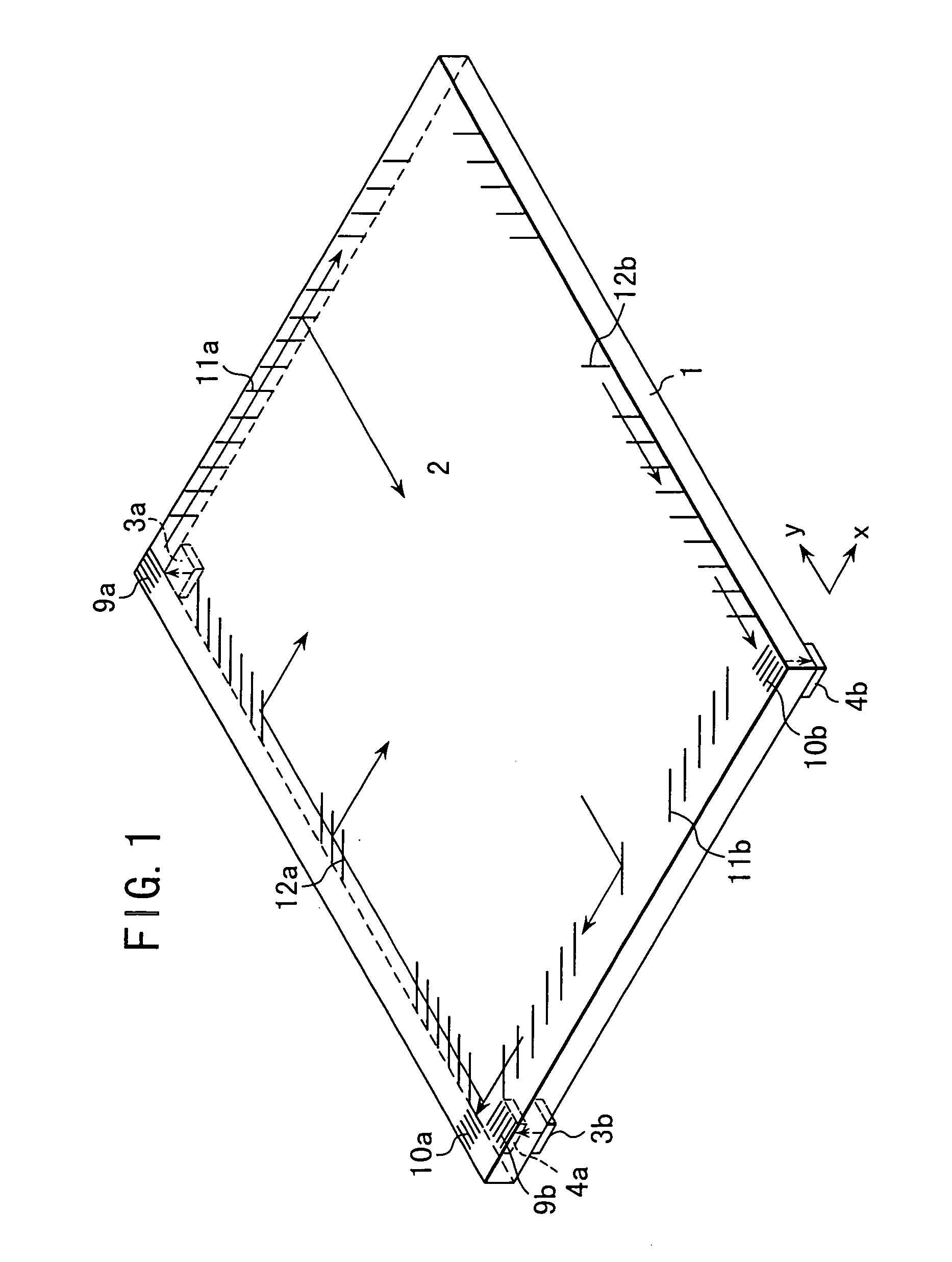

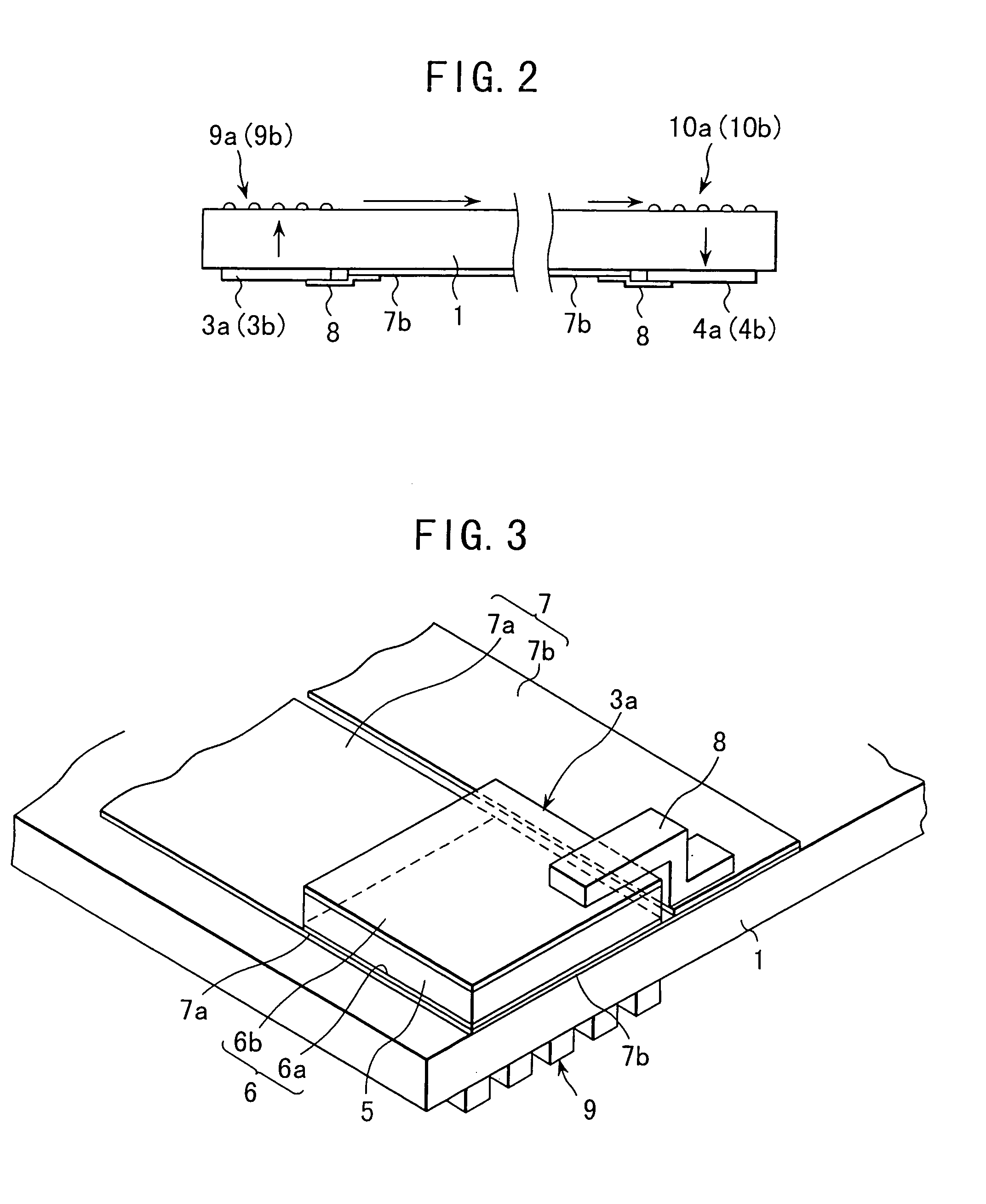

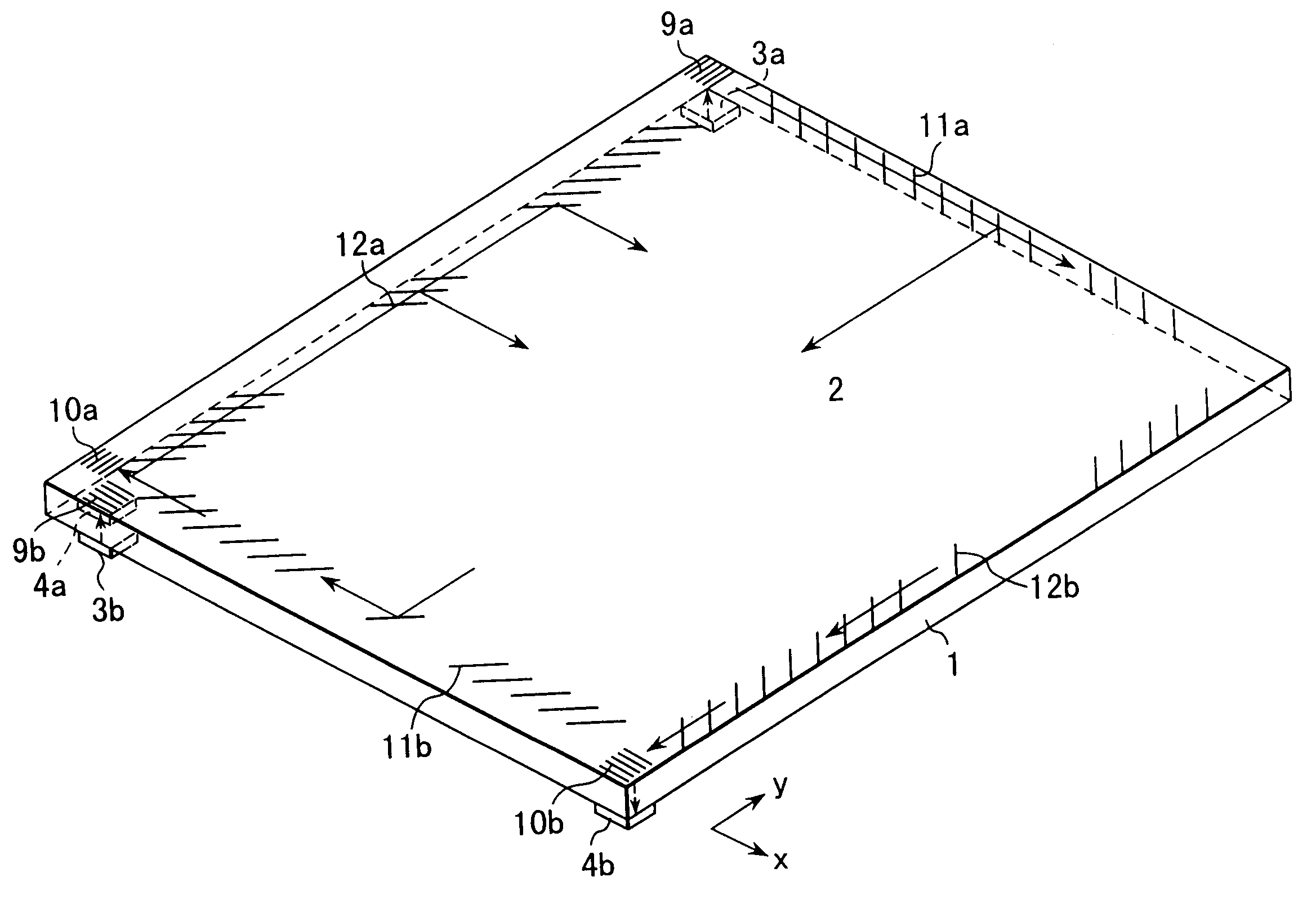

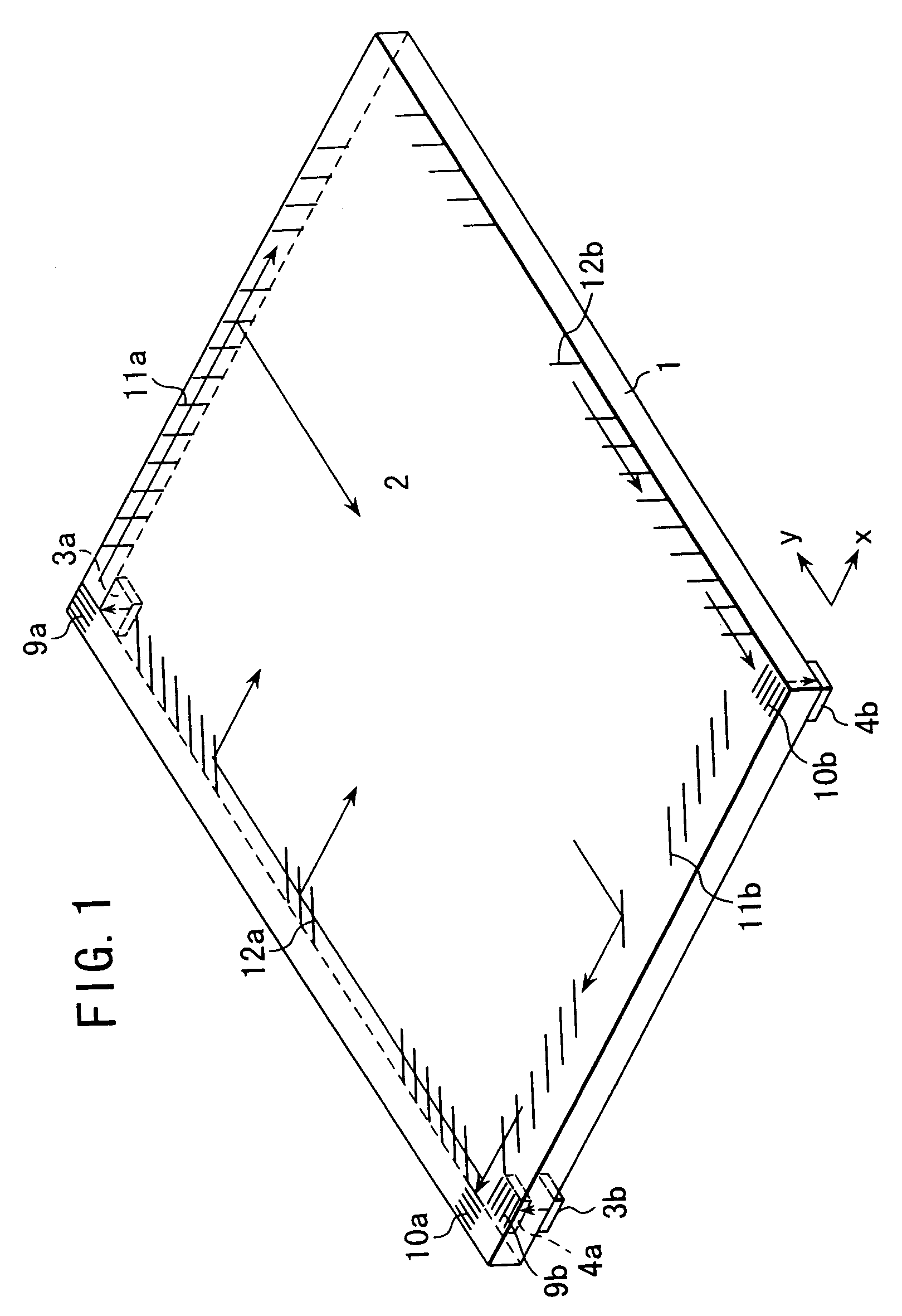

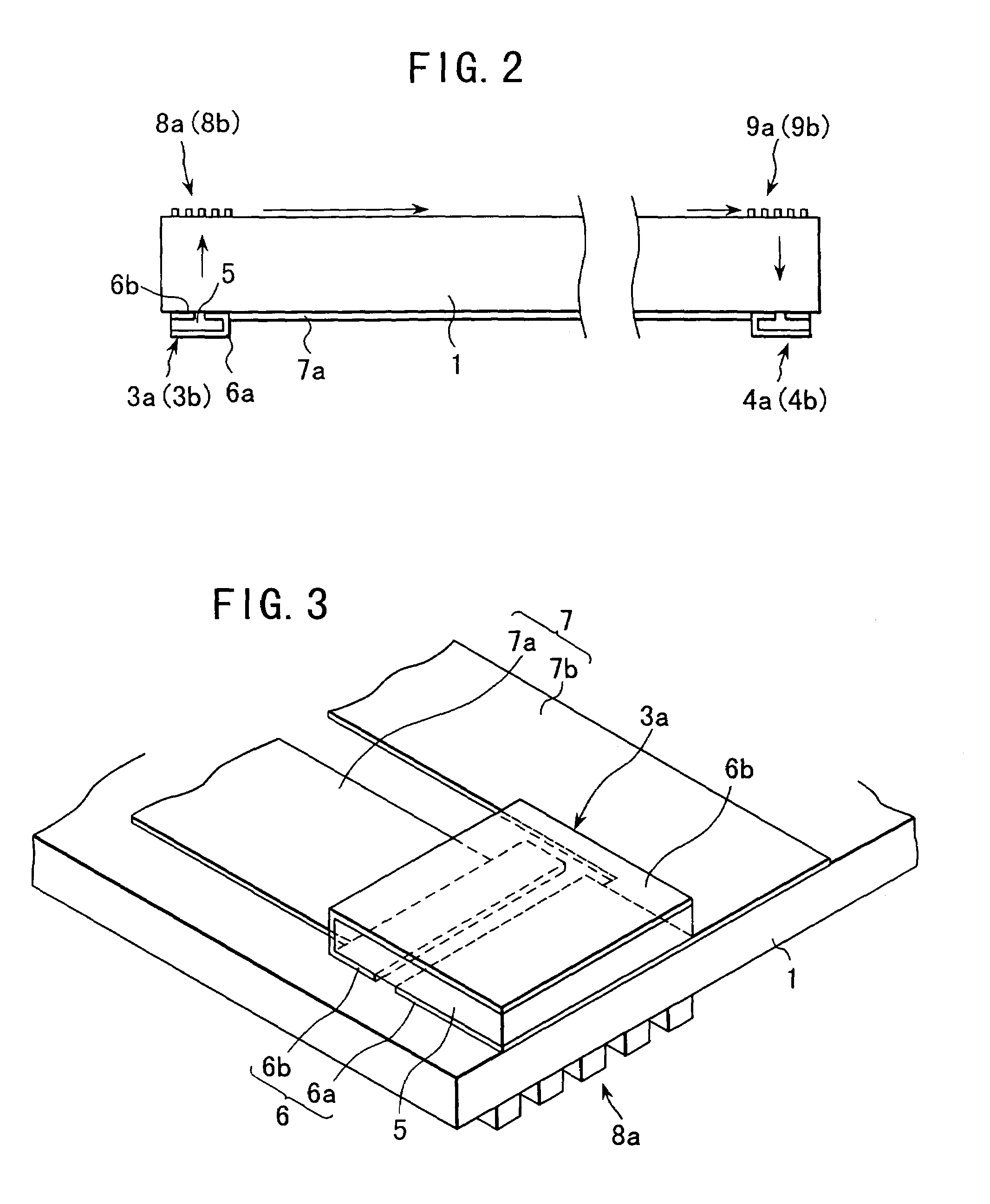

Acoustic contact detecting device

InactiveUS7193617B1Improve reliabilityEasy to manufacturePiezoelectric/electrostrictive transducersCathode-ray tube indicatorsConductive pasteSurface acoustic wave sensor

An object of the present invention is to provide a coordinate input device of touch-type capable of giving an electric signal to a transducer, even if a piezoelectric vibrator having electrodes on both surfaces thereof is employed.A device according to the present invention comprises: acoustic wave transducers (piezoelectric vibrators) 3a and 4a, each functioning for oscillating a bulk wave (a first wave) toward a top surface 2 of a substrate 1; a planar wiring 7 formed on a back surface of the substrate 1 by the method such as transfer printing with conductive paste, for supplying said piezoelectric vibrator with electric power; a connecting device 8 for connecting said planar wiring with an electrode of each of said acoustic wave transducers 3a and 4a; diffractive acoustic wave mode couplers 9a–10b, each functioning for converting said bulk wave into a surface acoustic wave (a second wave) and vice versa; and a means for detecting a scatter in the surface acoustic wave (the second wave) on the top surface of said substrate. Employing the combination of the planar wiring and the connecting device can resolve the problem of fragility associated with a cable wiring even in the piezoelectric vibrator having the electrodes on both surfaces thereof.

Owner:TOUCH PANEL SYST

Inorganic-light-emitter display with integrated black matrix

ActiveUS9818725B2Improve light output efficiencyImprove image qualitySolid-state devicesSemiconductor devicesParallaxImaging quality

An inorganic-light-emitter display includes a display substrate and a plurality of spatially separated inorganic light emitters distributed on the display substrate in a light-emitter layer. A light-absorbing layer located on the display substrate in the light-emitter layer is in contact with the inorganic light emitters. Among other things, the disclosed technology provides improved angular image quality by avoiding parallax between the light emitters and the light-absorbing material, increased light-output efficiency by removing the light-absorbing material from the optical path, improved contrast by increasing the light-absorbing area of the display substrate, and a reduced manufacturing cost in a mechanically and environmentally robust structure using micro transfer printing.

Owner:X DISPLAY CO TECH LTD

Acoustic touch sensor

InactiveUS7187369B1Smooth preparation processImprove reliabilityInput/output for user-computer interactionUsing subsonic/sonic/ultrasonic vibration meansConductive pasteSurface acoustic wave sensor

A coordinate input device of touch-type capable of giving an electric signal to a transducer, even if said transducer is disposed on a back surface of a substrate. The device contains acoustic wave transducers (piezoelectric vibrators), each functioning for oscillating a bulk wave (a first wave) toward a top surface of a substrate; a planar wiring formed on a back surface of the substrate by, e.g., transfer printing with conductive paste, for supplying the piezoelectric vibrator with electric power; diffractive acoustic wave mode couplers, each functioning for converting said bulk wave into a surface acoustic wave (a second wave) and vice versa; and a detector to detect scatter in the surface acoustic wave on the top surface of the substrate. Employing the planar wiring allows the wiring to be disposed even on the back surface of the substrate and also it may resolve the problem of fragility associated with a cable wiring.

Owner:TOUCH PANEL SYST

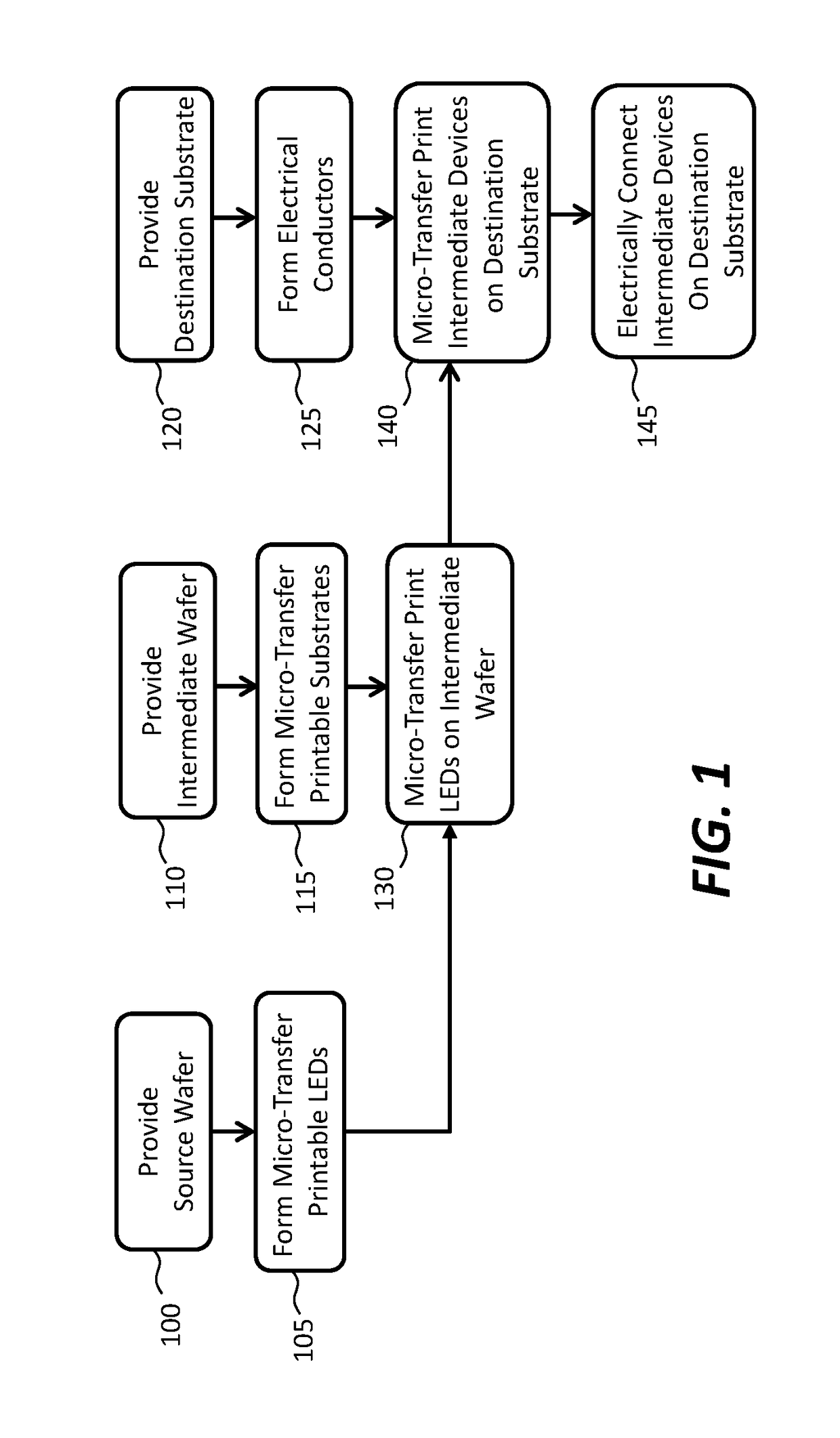

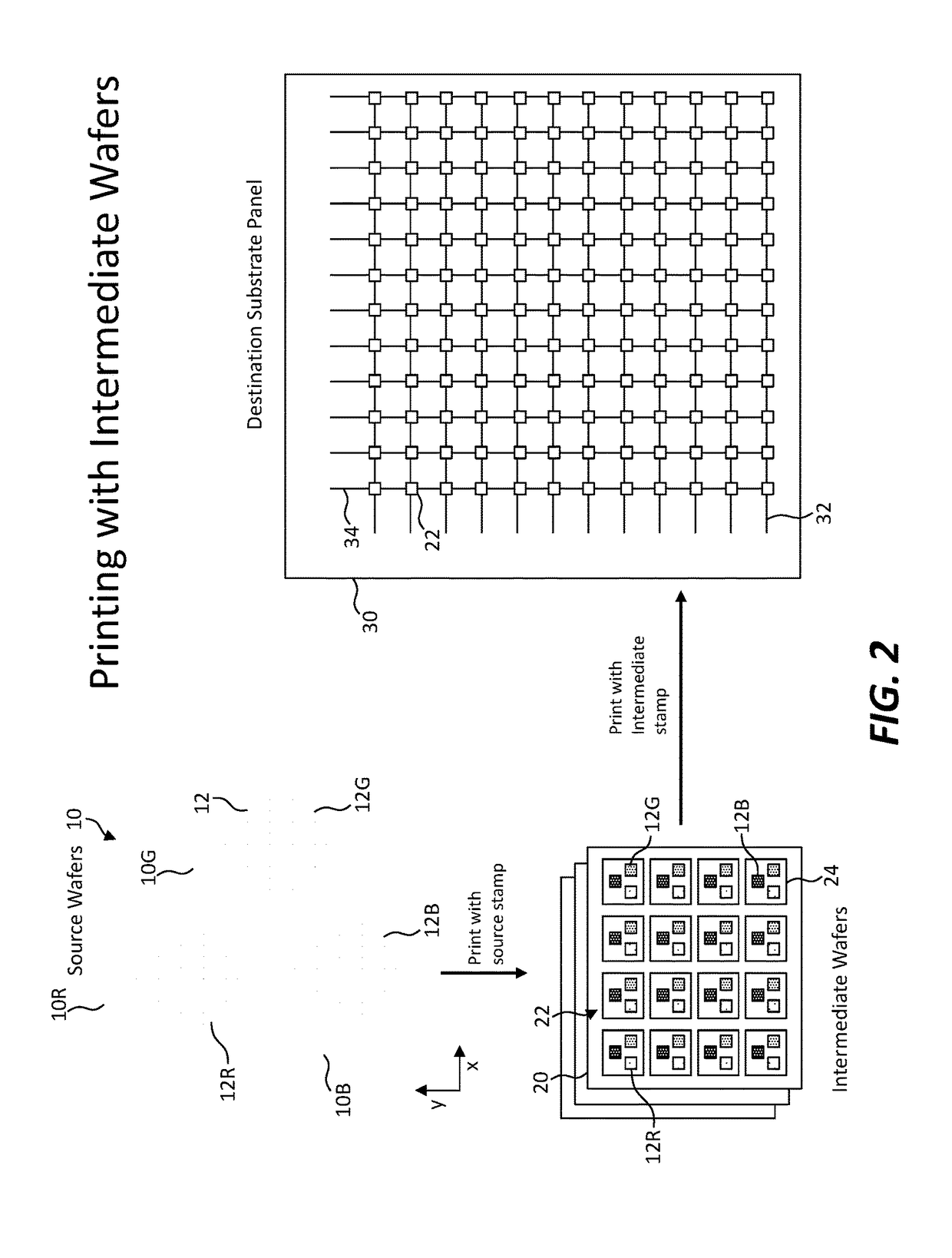

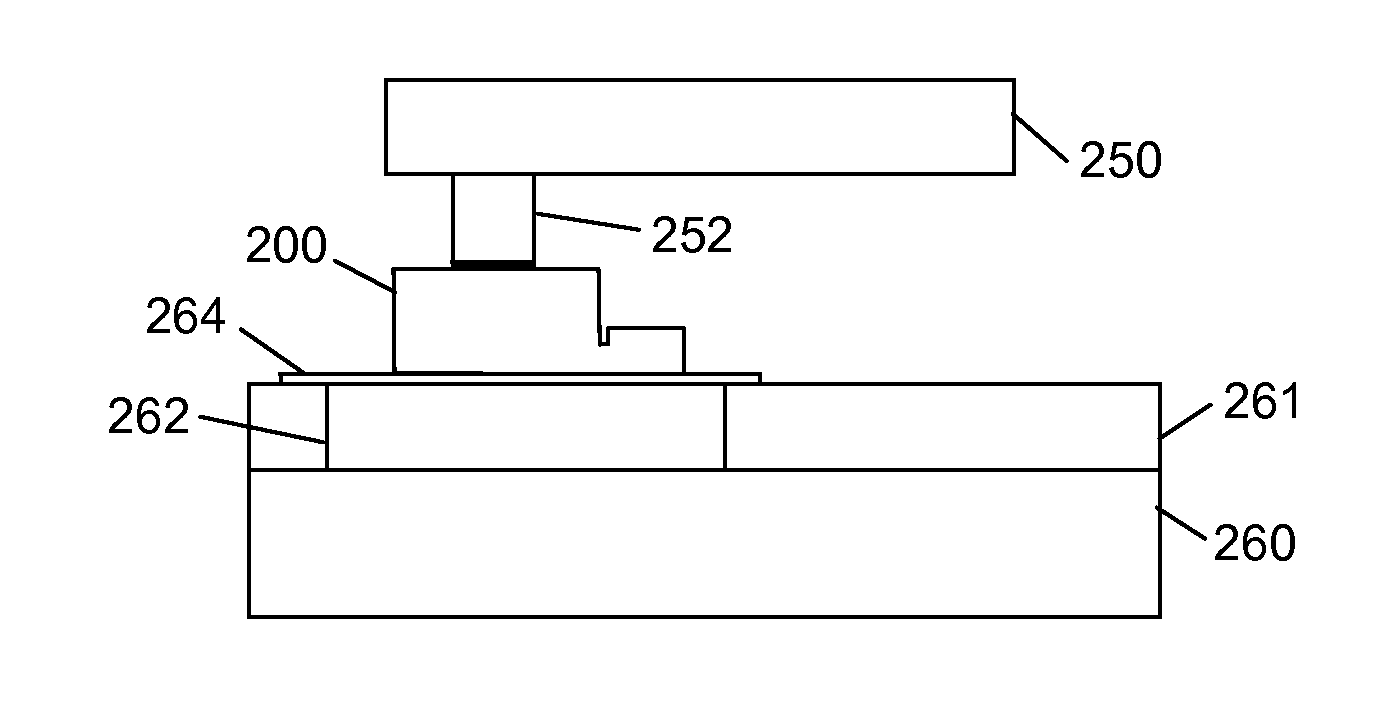

Efficiently micro-transfer printing micro-scale devices onto large-format substrates

ActiveUS20170250167A1Shorten manufacturing timeLow costSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringSpatial density

A method of making a micro-transfer printed system includes providing a source wafer having a plurality of micro-transfer printable source devices arranged at a source spatial density; providing an intermediate wafer having a plurality of micro-transfer printable intermediate supports arranged at an intermediate spatial density less than or equal to the source spatial density; providing a destination substrate; micro-transfer printing the source devices from the source wafer to the intermediate supports of the intermediate wafer with a source stamp having a plurality of posts at a source transfer density to make an intermediate device on each intermediate support; and micro-transfer printing the intermediate devices from the intermediate wafer to the destination substrate at a destination spatial density less than the source spatial density with an intermediate stamp having a plurality of posts at an intermediate transfer density less than the source transfer density.

Owner:X DISPLAY CO TECH LTD

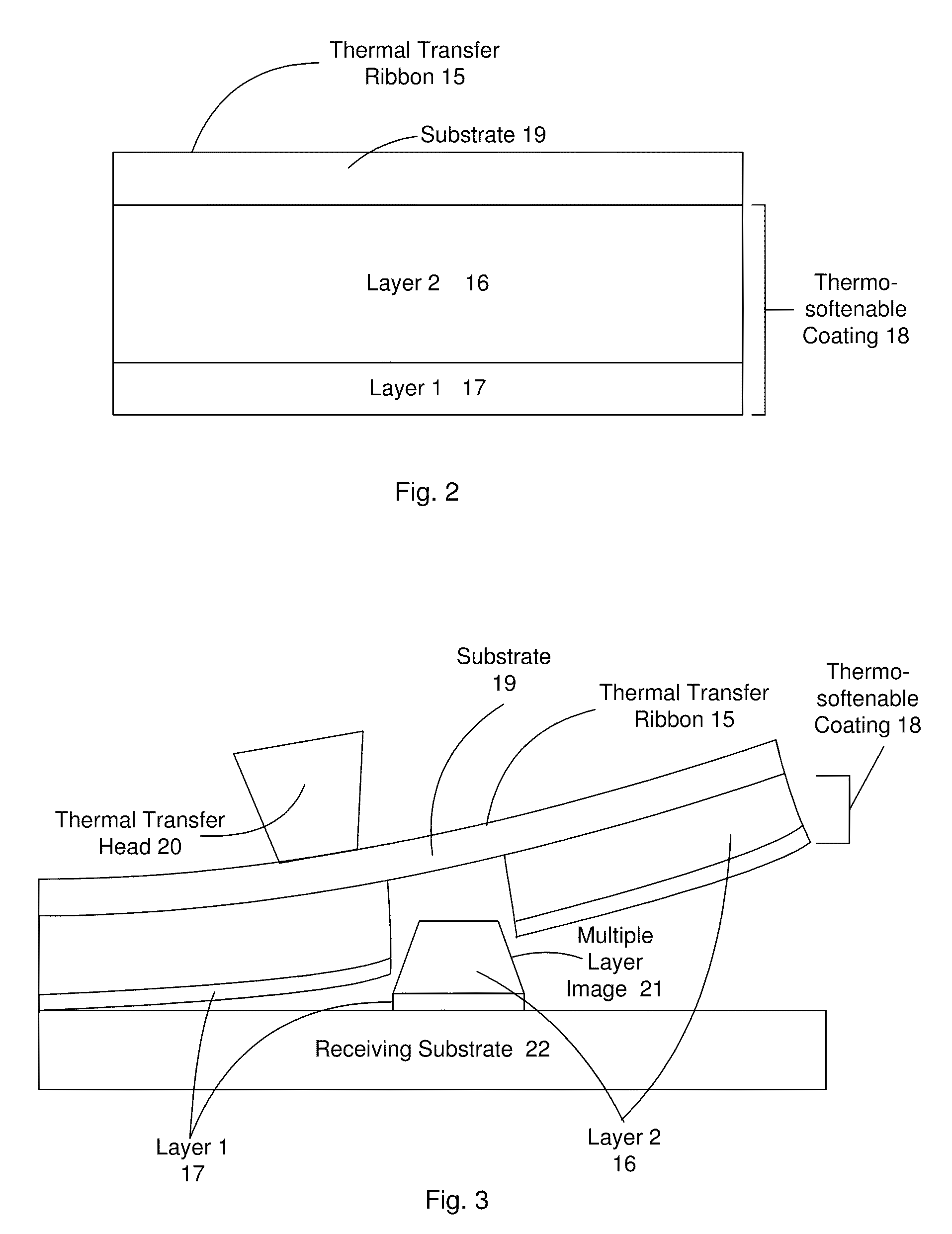

Wet method transfer printing method for natural fiber and polyamide fibre

InactiveCN101105006AHigh color yieldReduce consumptionTransfer printing processDyeing processPolyamidePrinting ink

The invention provides a wet-method transfer printing process of natural fiber and nylon, which mainly comprises the following steps: (1) selecting acidic printing ink or active printing ink; (2) printing: printing the surface of PET or BOPP film with the selected printing ink to obtain a transfer printed film; (3) transfer printing: treating natural fiber and nylon with a soaking liquid, subjecting the transfer printed film and printed fabric simultaneously to the compression by a rolling machine; and (4) oven-drying: oven-drying the fabric after the transfer printing is completed and baking to allow color fixation. The invention has the advantages of high transfer printing rate, high color yield of fabric, bright color, good color fastness, less pollution, reduced water consumption, simple process, high production efficiency, low cost, and success in non-paper transfer printing.

Owner:常州涵源新印花有限公司

Sublimation Printing Processes and Fabric Pretreatment Compositions for Ink Jet Printing onto Arbitrary Fabrics

InactiveUS20110169901A1Outstanding washfastness to repeated launderingImprove washing fastnessTransfer printing processDyeing processTextile fiberEngineering

An ink jet printing process for sublimation printing of arbitrary textile fiber substrates, wherein the fiber materials are pretreated with an aqueous coating composition, enabling ink jet printing of natural and regenerated cellulosic fibers and blends thereof with synthetic fibers, by direct sublimation or sublimation transfer printing, applying to said fibers a novel textile coating or fabric pretreatment composition, wherein said textile coating or fabric pretreatment comprises: an aqueous dispersion of fluoropolymer particles and a non-fluoropolymer binder.

Owner:ADVANCED COMM SOLUTIONS

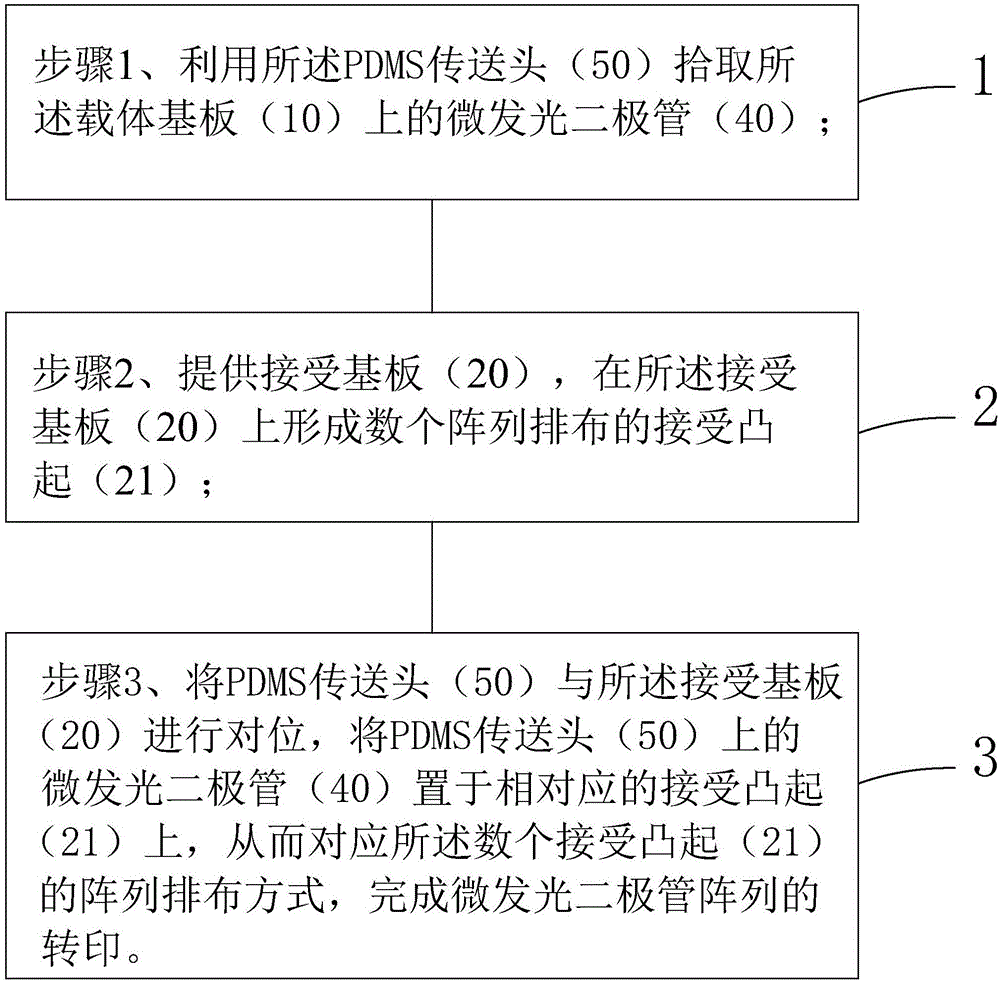

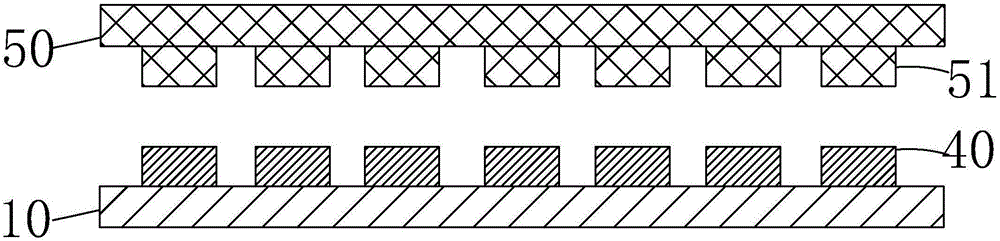

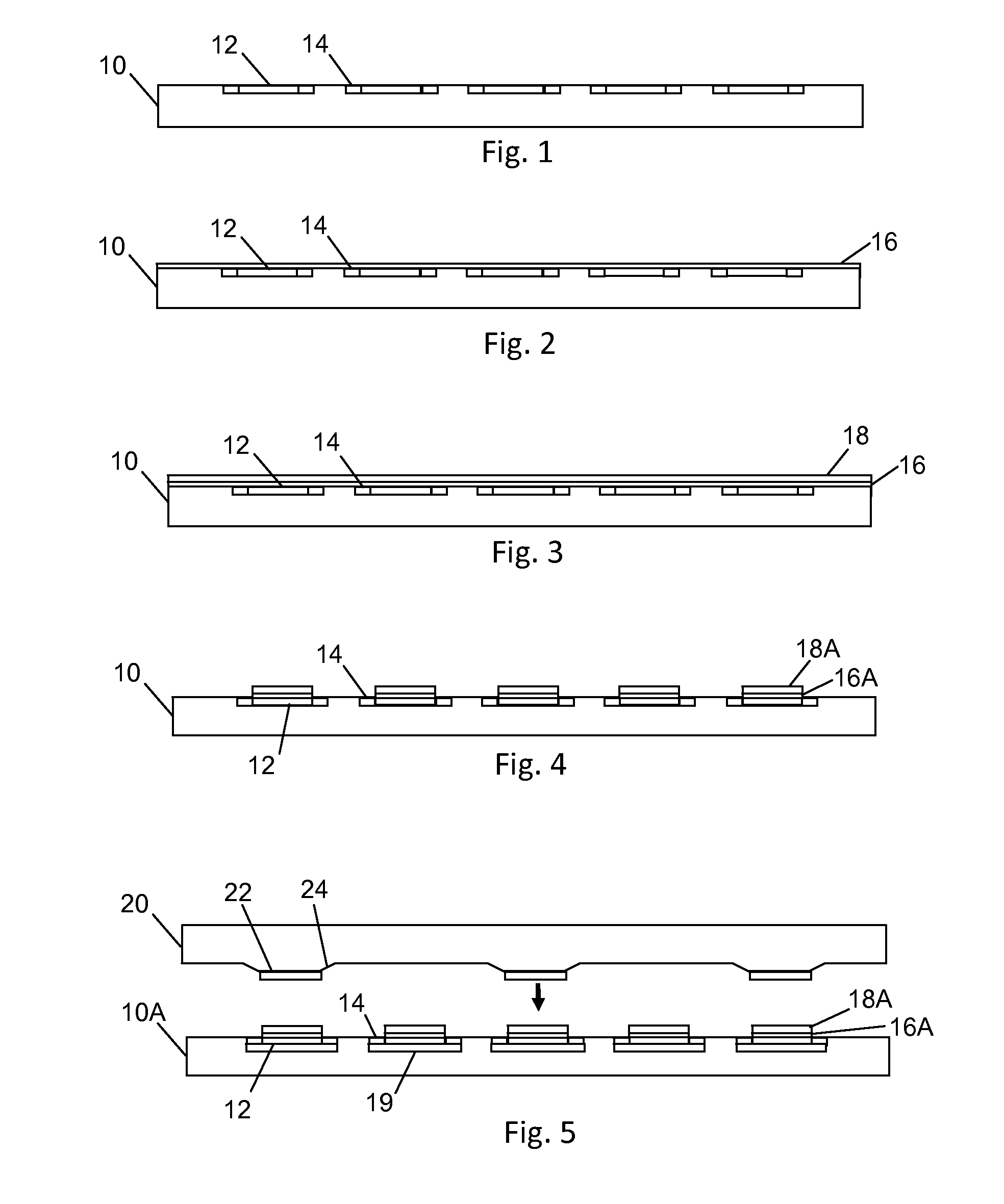

Micro light emitting diode array's transfer printing method

ActiveCN106058010ATransfer printingSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight-emitting diode

The invention provides a micro light emitting diode array's transfer printing method. A plurality of projections are arranged on a receiving substrate; micro light emitting diodes are placed on the corresponding projections on the receiving substrate; therefore, for the same transfer head, the change in the arraying manner of a plurality of projections on the receiving substrate make possible the transfer printing of micro light emitting diode arrays in different arraying manners on a receiving substrate.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Oleds for micro transfer printing

ActiveUS20170092863A1Solid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceLight-emitting diode

An organic light-emitting diode (OLED) structure includes an organic light-emitting diode having a first electrode, one or more layers of organic material disposed on at least a portion of the first electrode, and a second electrode disposed on at least a portion of the one or more layers of organic material. At least a portion of a tether extending from a periphery of the organic light-emitting diode. The organic light-emitting diodes can be printable organic light-emitting diode structures that are micro transfer printed over a display substrate to form a display.

Owner:X DISPLAY CO TECH LTD

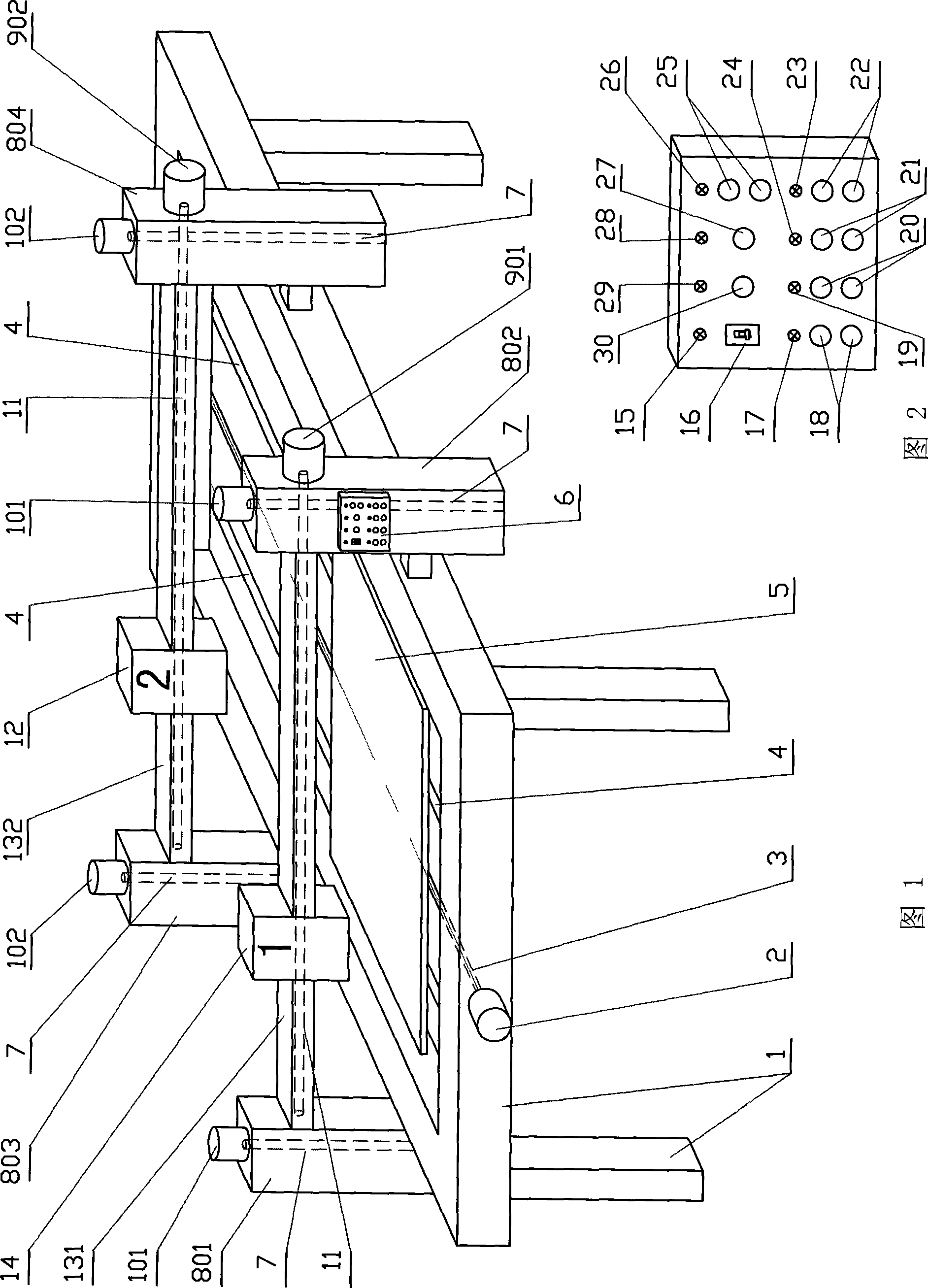

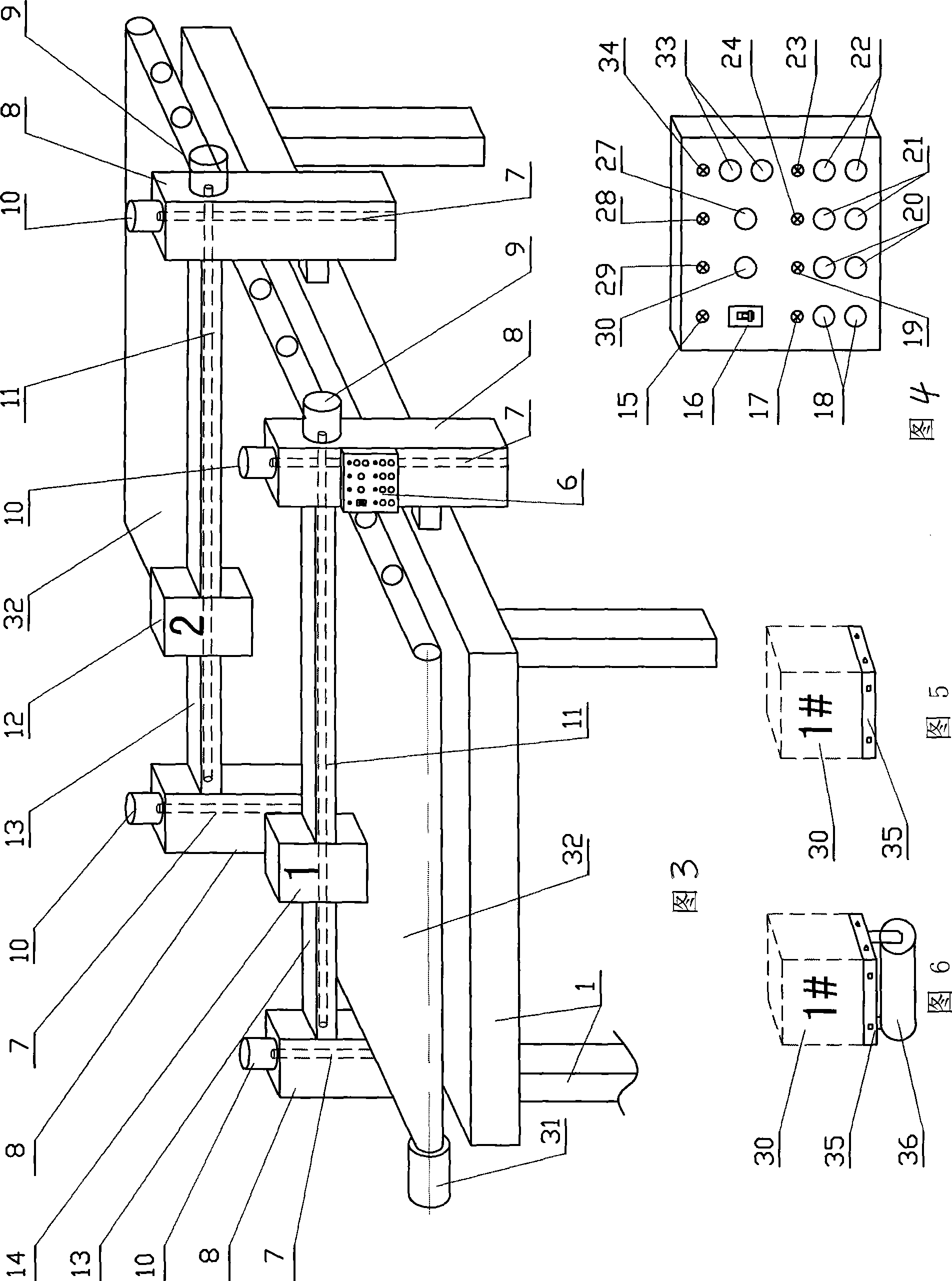

Color jet printing machine and jet printing method

InactiveCN101367296AImprove ergonomicsLow costTypewritersPower drive mechanismsScreen printingAdhesion force

The invention relates to a color jet printer and a jet printing method thereof. The color jet printer comprises a machine frame, an upright post, a horizontal beam, a jet printing worktable and an electric cabinet, wherein the structure of the jet printing worktable comprises a parallelly traveling worktable and a rotary conveyer belt; textile to be printed is tiled on the parallelly traveling worktable or the rotary conveyer belt; and pattern areas of the textile are sprayed with white bottom layers by a computer programmed NO. 1 inking box and white bottom areas are sprayed with colored patterns by a computer programmed NO. 2 inking box. By utilization of the prior computer programmed color jet printing technology to perform jet printing of patterns on the textile such as T-shirts and so on or planar carriers, the jet printing method improves the work efficiency, reduces the cost and strengthens the viewing effect compared with the prior printing method. The white bottom layers are printed on the pattern areas of the textile at first and then sprayed with patterns, thereby the jet printing method can improve the adhesion force of the patterns and the textile, guarantee that the patterns are not fallen off and strengthen the jet printing effect of the patterns. Moreover, the white bottom layers of the textile can be respectively printed by the jet printing technique, the hot transfer printing technique or the silk-screen printing technique.

Owner:徐中九

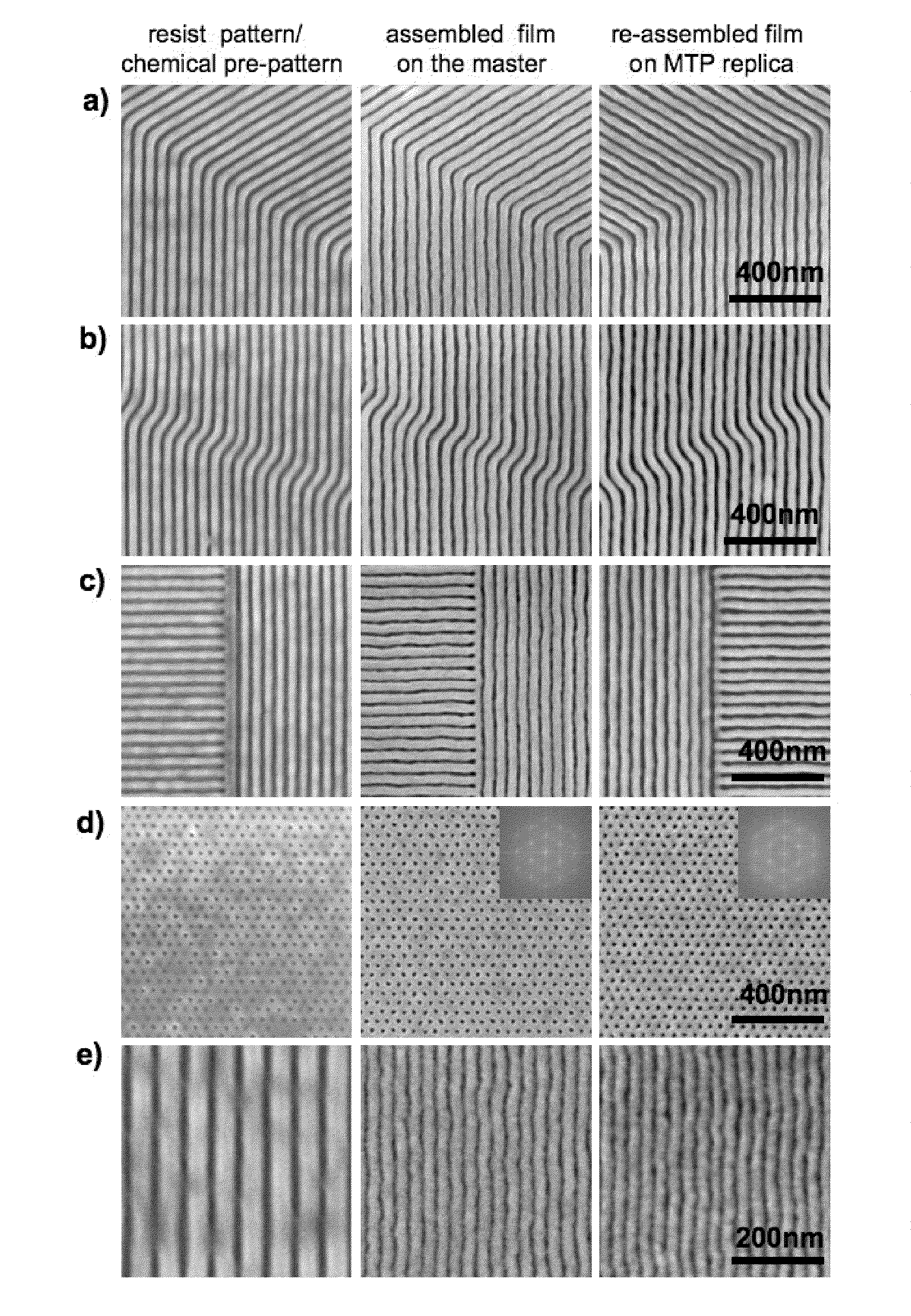

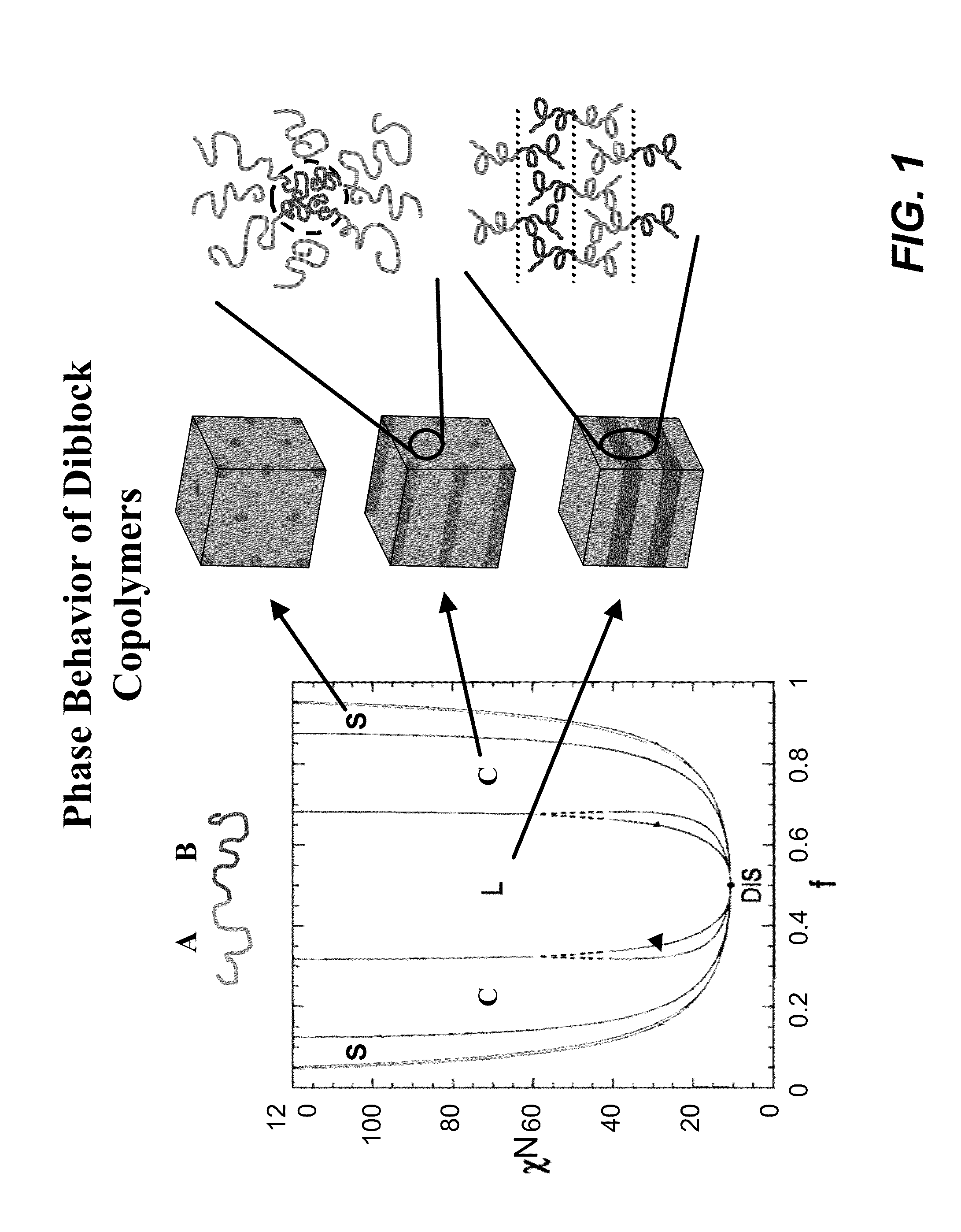

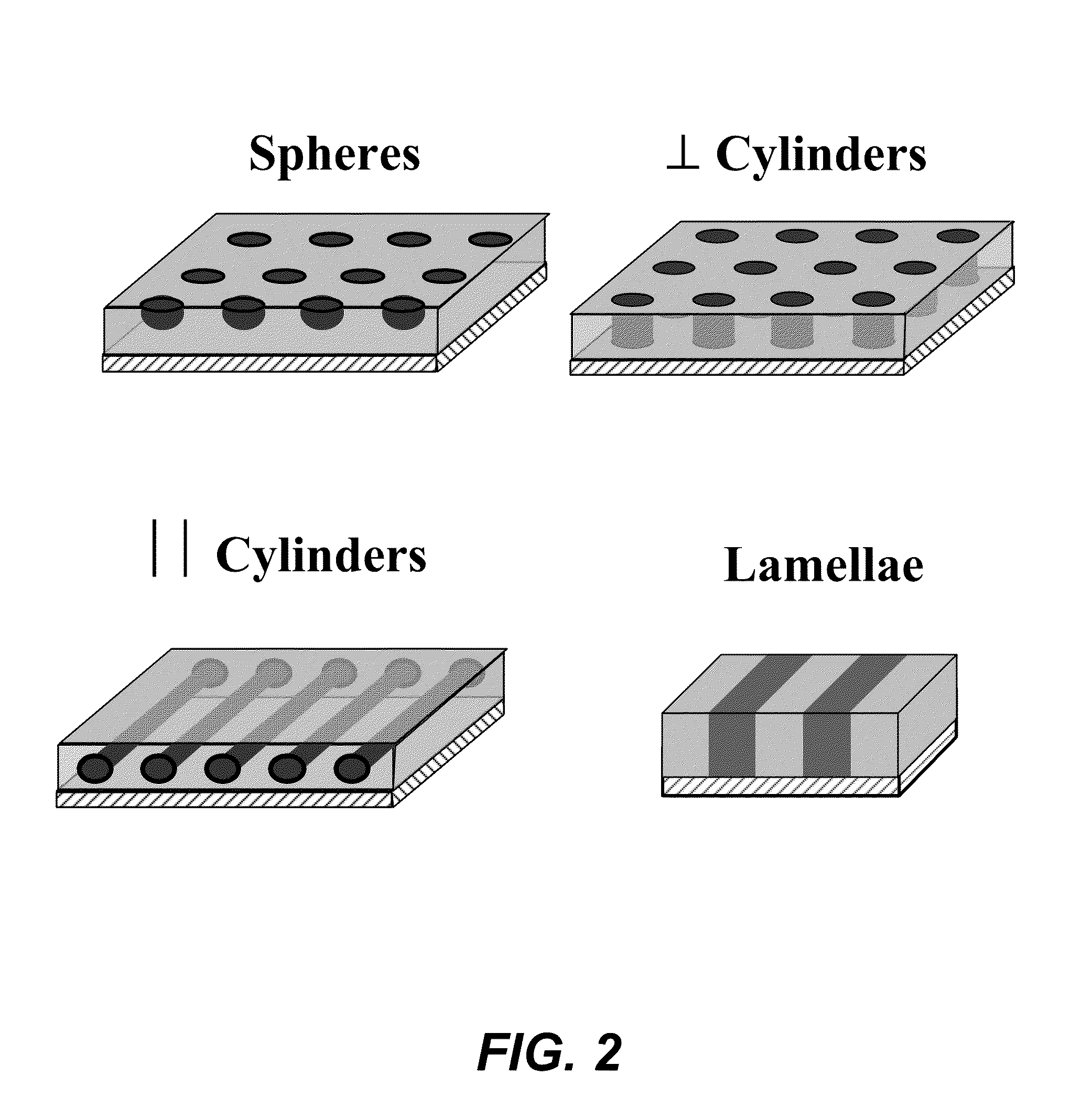

Molecular transfer printing using block copolymers

ActiveUS20090260750A1Technique is limitedMaterial nanotechnologyLamination ancillary operationsSelf-assemblyCopolymer

Methods of creating and transferring chemical patterns and physical patterns of deposited materials or molecules using block copolymers are provided. The methods involve providing block copolymer materials blended with one or more transfer molecules or inks. The differences in chemistry of the blocks of the copolymer that result in micro-phase separation (e.g., self-assembly into nanoscale domains) also allow inks to be sequestered into specific blocks. By designing the ink molecules to react, adsorb, or otherwise interact with a second substrate, inks are transferred to the second substrate in a pattern dictated by the pattern of block copolymer domains present at the surface of the block copolymer film.

Owner:WISCONSIN ALUMNI RES FOUND

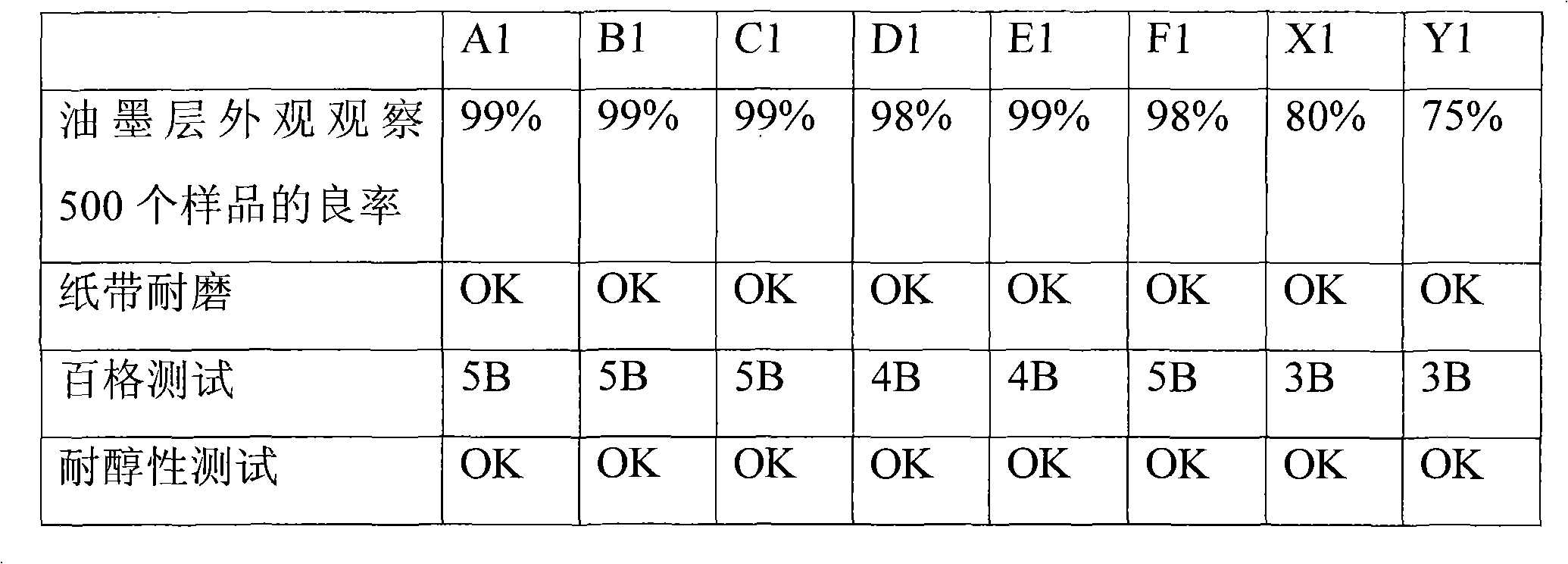

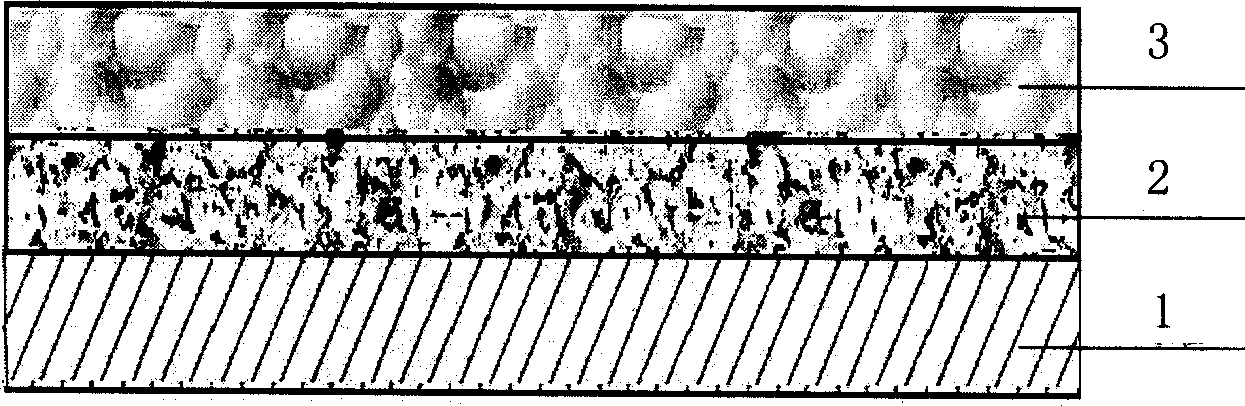

Transfer printing type ultraviolet light curing ink composition, preparation method thereof and mobile phone casing using ink composition

InactiveCN101993629AImprove adhesionClear patternInksTelephone set constructionsPolyesterAcrylic resin

The invention provides a transfer printing type ultraviolet light curing ink composition and a preparation method thereof. The ink composition comprises main body resin, a thinner, pigment and photoinitiators, and addition agents are included or not included, wherein the main body resin is polyester acrylate resin, modified acrylic resin, high-functionality-degree aliphatic urethane acrylate and hydroxy acrylic resin, the hydroxy acrylic resin is thermoplastic hydroxy acrylic resin, and the hydroxyl value content is between 45 and 70 mg KOH / g. The invention also provides a mobile phone casing using the ink composition, wherein the mobile phone casing sequentially comprises a substrate, a primer layer, a gloss oil layer and an ink pattern layer from bottom to top, and the ink pattern layer is obtained from the ink composition through transfer printing. When the transfer printing type ultraviolet light curing ink composition is adopted, the adhesive force between the ink layer and a contact layer can be enhanced, and in addition, when the surface of the contact layer is lower, the cured ink layer can effectively avoid the phenomenon of edge contraction.

Owner:BYD CO LTD

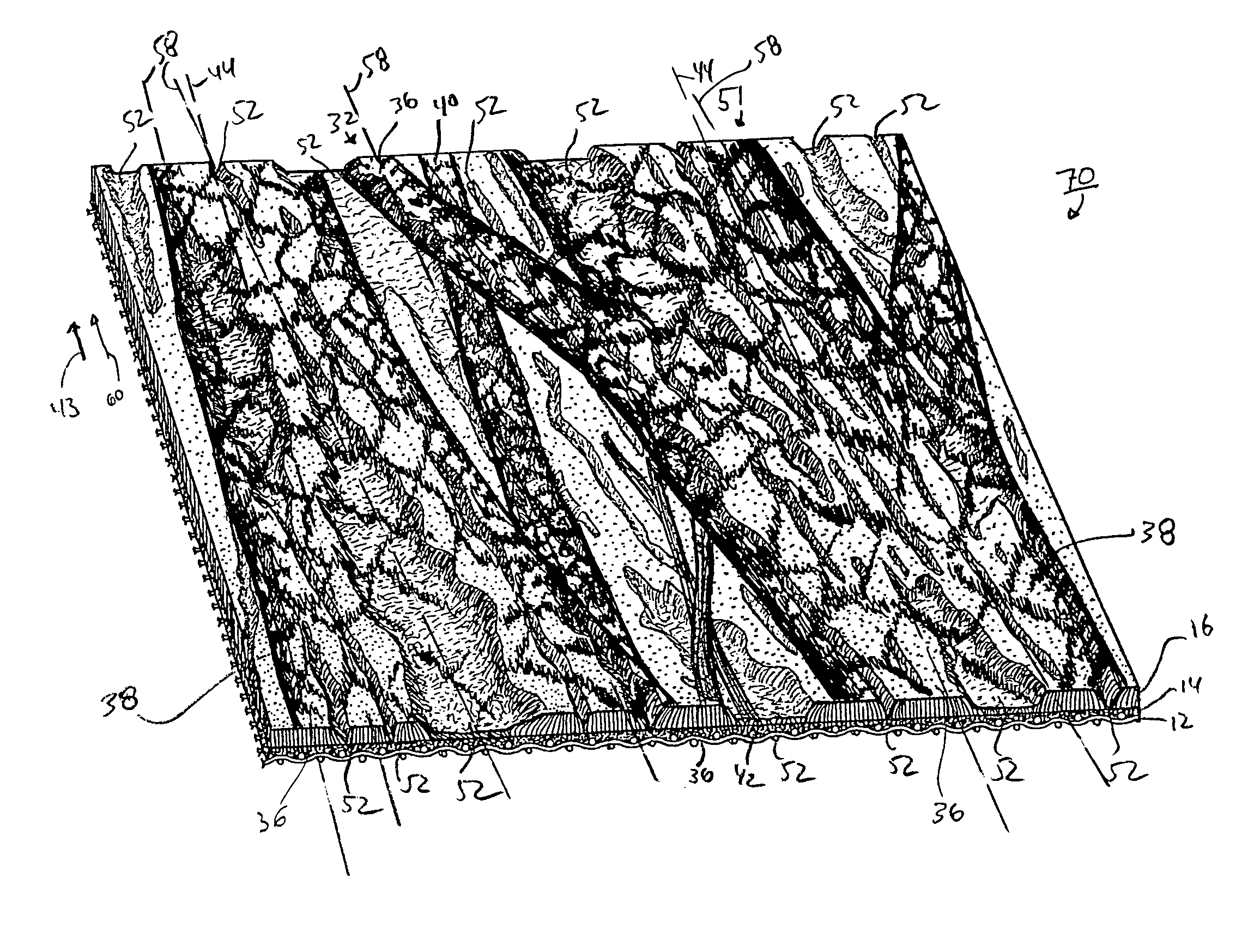

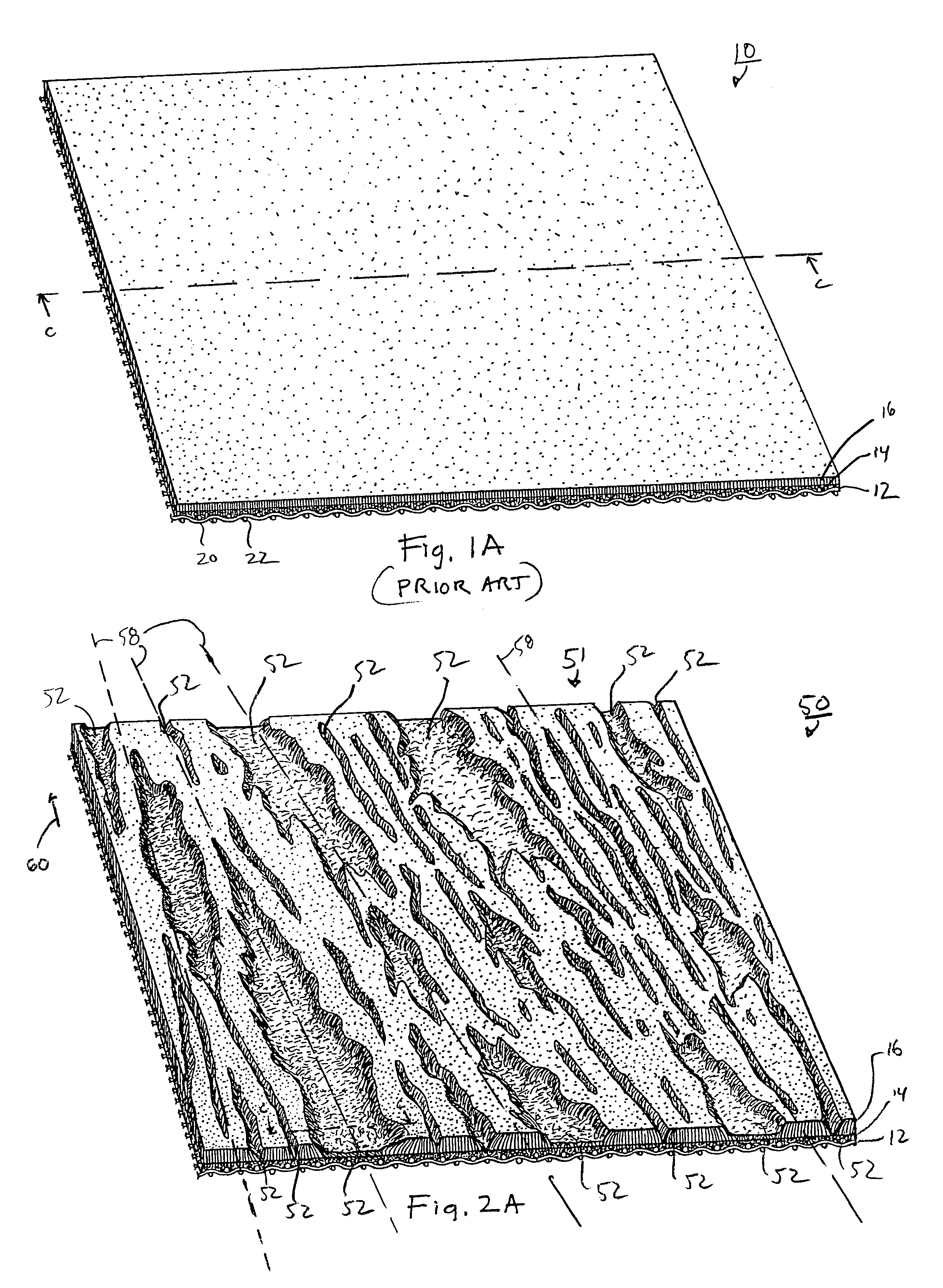

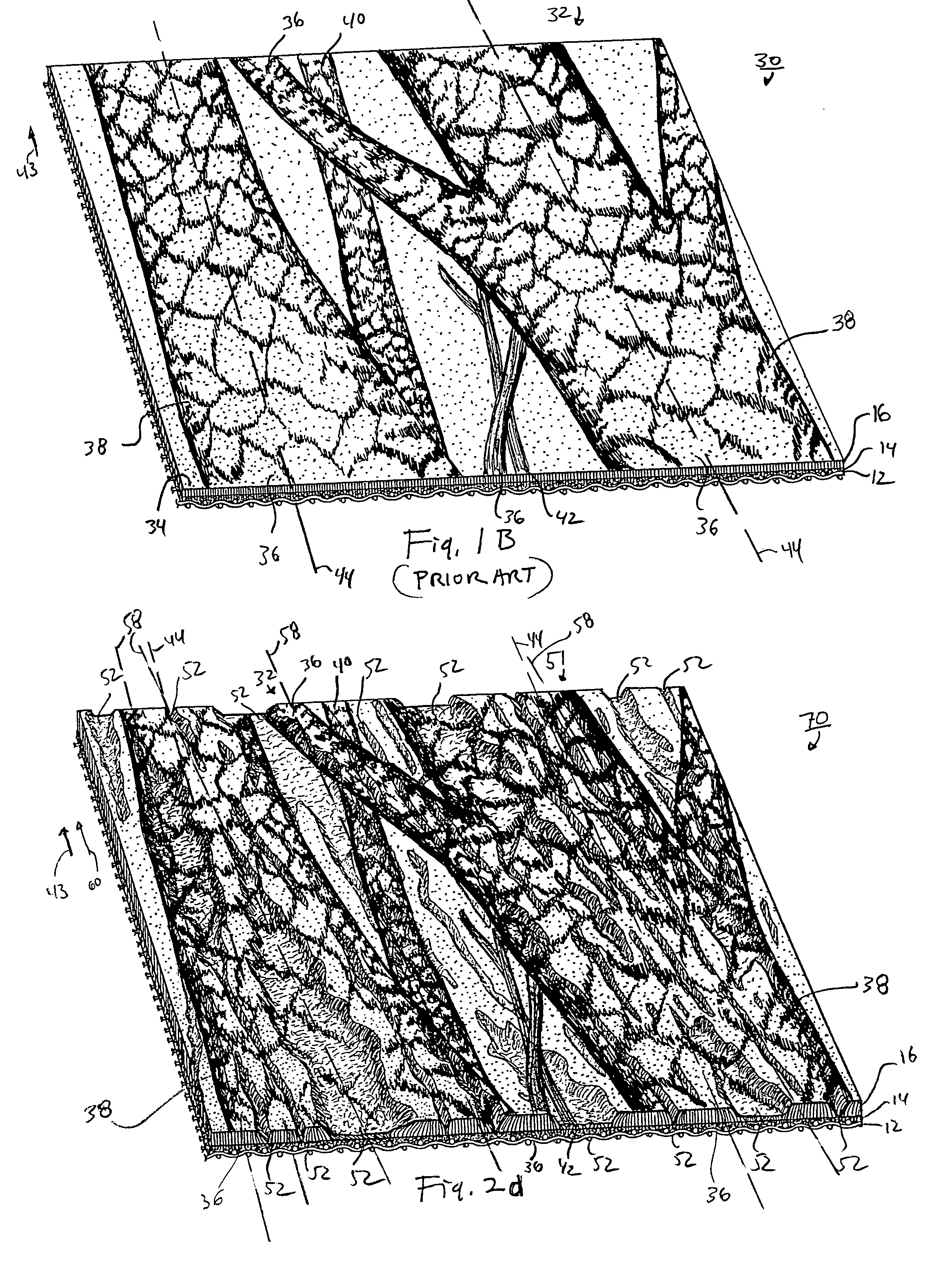

Realistically textured printed flocked fabrics and methods for making the fabrics

InactiveUS7229680B1Improve visual effectsDegree of reductionLiquid surface applicatorsLamination ancillary operationsEngineeringTransfer printing

The present invention is directed to unique flocked pile fabrics and methods for producing such fabrics. The fabrics provided according to one embodiment of the invention include an embossed pattern, characterized by a plurality of elongated depressions in the surface of the pile fabric, and a superimposed printed pattern, characterized by a scene or illustration including a plurality of visual features having elongated shapes. The inventive embossed, printed pile fabrics, having a superimposed embossed and printed pattern, advantageously superimpose the embossed pattern and the printed pattern upon the pile fabric so that the embossed pattern imparts a three-dimensional texture to the scene or illustration or pattern comprising the printed pattern. The texture provided by the embossed pattern can impart a visual effect to the scene or illustration which can render it more realistic than a similar scene or illustration printed upon a conventional unembossed pile fabric. In one embodiment, this unique texturing effect is accomplished by substantially aligning the longitudinal axes of the elongate features of the printed pattern and the elongate features of the embossed pattern. The pile fabric provided by the invention can be produced by utilizing a plurality of embossing and printing techniques. In one embodiment, the embossing technique comprises air embossing, and the printing technique comprises paper transfer printing utilizing a paper transfer sheet. The fabrics provided by the invention are especially useful as camouflage fabrics. Such fabrics typically include a printed scene or illustration representing a sylvan setting dominated by visual features such as trees, branches, bushes, leaves, flowers, berries, grass, rocks, moss, etc.

Owner:MICROFIBERS

Method for wet transfer printing digital color image onto fiber fabric of cellulose, and dedicated transfer paper

InactiveCN1727571AImprove breathabilityGood colorDuplicating/marking methodsTransfer printing processColor imageImage resolution

A method for transferring the digital color pattern onto cellulose fibre fabric includes such steps as printing said pattern on a transfer paper by ink-jet printer, wetting the position on said fabric, where the pattern is transferred, by the aqueous solution of sodium dicarbonate, coating a layer of transfer slurry, sticking the transfer paper to it, pressing until the transfer paper is wet, ironing by iron or plate-type thermotransfer machine, high-pressure steaming for 8-12 min, washing, and drying. Said transfer paper is composed of substrate paper, adhesive film and water-soluble resin layer.

Owner:熊平清

Apparatus and methods for micro-transfer-printing

InactiveUS20160020131A1Increase heightIncrease initial accelerationTransfer printingGripping headsSemiconductorSeparation system

In an aspect, a system and method for assembling a semiconductor device on a receiving surface of a destination substrate is disclosed. In another aspect, a system and method for assembling a semiconductor device on a destination substrate with topographic features is disclosed. In another aspect, a gravity-assisted separation system and method for printing semiconductor device is disclosed. In another aspect, various features of a transfer device for printing semiconductor devices are disclosed.

Owner:X DISPLAY CO TECH LTD

Method and magnetic transfer stamp for transferring semiconductor dice using magnetic transfer printing techniques

InactiveUS20110151588A1Solid-state devicesSemiconductor/solid-state device manufacturingMagnetic tension forceEngineering

Releasable semiconductor dice are deposited with a magnetic layer and held by magnetic forces to a magnetic or electromagnetic transfer stamp for the transfer of the dice from a host substrate directly or indirectly to a target substrate.

Owner:COOLEDGE LIGHTING

Production method of environment-friendly water-soluble gum electrochemical aluminothermic transfer printing film

InactiveCN101570090APromote environmental protectionThermographyInk transfer from master sheetPolyvinyl butyralAcrylic resin

The invention relates to a production method of an environment-friendly water-soluble gum electrochemical aluminothermic transfer printing film. The production method comprises the following steps: a PET film of 6 to 15 micron is adopted as a carrier film; the carrier film is sequentially provided with four coatings such as a releasing layer, a color layer, an aluminum layer and an adhesive layer; wherein the releasing layer, the color layer and the adhesive layer coat the coating materials on a PET basal membrane substrate by a smooth roll or an anilox roll in a forward coating mode or backward coating mode; the aluminum layer is spray-plated in a vacuum spray-plating mode; the invention adopts the environment-friendly material and the production technique to produce the aluminothermic transfer printing film product, and the key points are as follows: solvent based acrylic resin, ethylene-vinyl acetate resin, ketone resin and cellulosic resin hot melt adhesive are changed into cellulose acetate and products made by cellulose acetate; and vinyl cellulose, polyvinyl butyral and powdery silicon dioxide are synthesized by water and a mixed solvent in a mode of wetting and dispersing. The production method has the characteristics of having no solvent residue harmful to human body and being beneficial to environmental protection and the like.

Owner:莫国平

Stamp with structured posts

ActiveUS20170047306A1Great contact surface height variationLittle strengthTransfer printingSemiconductor/solid-state device detailsEngineeringSurface contour

A stamp for micro-transfer printing includes a body and one or more posts extending from the body. At least one of the posts has a non-planar surface contour on the distal end of the post having a size, shape, or size and shape that accommodates a non-planar contact surface of a micro-transfer printable device.

Owner:X DISPLAY CO TECH LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com