Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

289results about How to "High color yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Digital reactive dye printing process for mulberry silk fabric

InactiveCN103451970AHigh color yieldIncrease color depthHeating/cooling textile fabricsDyeing processDigital printingUrea

The invention provides a digital reactive dye printing process for a mulberry silk fabric. The process comprises the following steps: carrying out textile sizing, drying, carrying out jet printing, steaming, washing by cold water, washing by hot water, washing by soap, washing by hot water, washing by cold water, and drying, wherein a sizing agent used in the textile sizing step comprises the following components in percentage by weight: 1%-3% of sodium sulfate powder, 0.5%-1% of sodium alginate, 3%-5% of urea, 0.5%-1.5% of sodium hydrogen carbonate, 1%-2% of modified starch, 5%-7% of electrolyte and the balance being water. By virtue of the process, the digital printing color yield of the mulberry silk fabric is increased, the inkjet printing color depth on a textile is increased, the color difference between a pattern on the textile and an electronic pattern is reduced, and the hand feel of the fabric is good.

Owner:SHIJIAZHUANG HEXI APPL TRADING

Method for preparing environment-friendly natural fiber printing paste

The invention discloses a method for preparing an environment-friendly natural fiber printing paste, comprising the following steps of: 1) selecting fine diatomaceous earth having a grain size less than or equal to 2 microns; 2) preparing raw printing paste, wherein the raw printing paste is composed of the following components in terms of weight: 6-13% organic printing paste material, 1-8% fine diatomaceous earth and 0.2-0.6% sodium hexametaphosphate, and rest being water; and 3) preparing the printing paste, wherein the printing paste is composed of the following components in terms of weight: 1-4% dye, 1-7% urea, 1-7% urea replacing agent, 1.5-2.5% sodium bicarbonate, 0.2-1% reserve salt S and 50% raw printing paste, and rest being water. The printing paste obtained through the method of the invention is capable of ensuring the printing quality and also capable of greatly reducing the content of organic matters in sewage discharged after printing, thereby reducing pollution.

Owner:ZHEJIANG SCI-TECH UNIV

Dyeing and finishing process for modail/polyester fibre blended fabric

The present invention relates to a dyeing and finishing process of model fibre and polyester fibre blended fabric, and its technological process includes the following steps: singeing, desizing, bleaching, NaOH causticizing treatment, setting, dyeing or printing and after-finishing, and the formula of treatment liquor for making causticizing treatment includes NaOH 40-50 g / L and penetrating agent 1-2 g / L, and the condition of NaOH causticizing treatment is as follows: padding causticizing treatment liquor at normal temperature, depositing for 30-40 min at normal temperature, fully washing with hot water with 80-90 deg.C to neutrality and drying. On the premise of no damaging fibre, as compared with the fabric which is not undergone the process of causticizing treatment the colour yield of said invented fabric can be raised by 20%-50%.

Owner:SHANGHAI SIMAITUO PRINTING DYEING

One bath super dark dyeing technology of polyester-cotton fabric disperse and reactive dyes

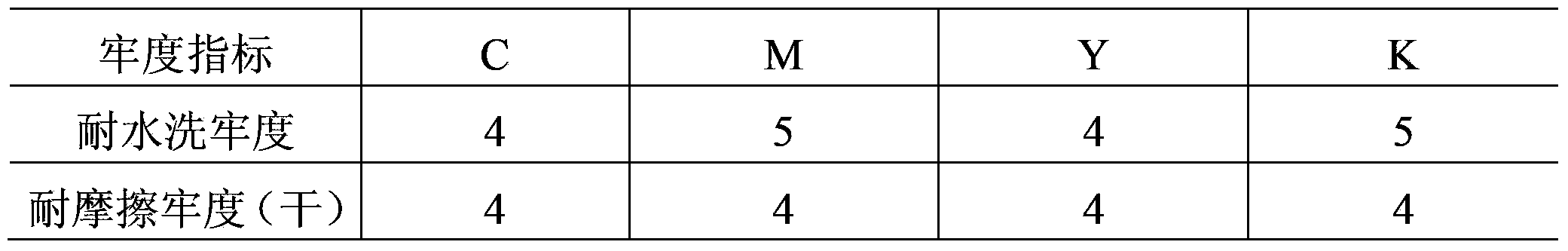

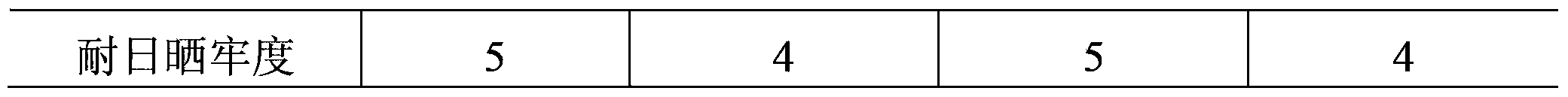

InactiveCN101392462AHigh color yieldGood color yieldDyeing processLiquid/gas/vapor textile treatmentReactive dyeColour fastness

The invention provides a super-dark dyeing technology by dispersing the polyester-cotton fabrics and one bath of the reactive dye, which belongs to a dyeing technology of the fabrics. The technology comprises the following steps: selecting the WW series disperse dyes and C series reactive dyes to soak the pure cotton fabrics into the dyeing solution for one time, then rolling with a squeezer for one time, then pre-baking and baking the cloth, then steaming in a steaming chamber, then washing with water after the steaming, then washing with soap after the water washing, then washing the cloth with water again and drying to finish the dyeing process. The disperse dyes and reactive dyes selected by the dyeing technology has high color yield and good color fastness and the loose color on the fabrics can be completely washed during the soap washing process, therefore, the loose color can not dye the surface of the fabrics, which basically solves the color transfer fastness and wet grinding fastness of the super-dark color. The design of the baking temperature is reasonable, which improves the color yield of the disperse dyes and the color fastness of the dye; the adopted one-bath dyeing process is simple in process flow and low in production cost and the amount of the sewage is few and the dyeing quality is stable.

Owner:HUAFANG

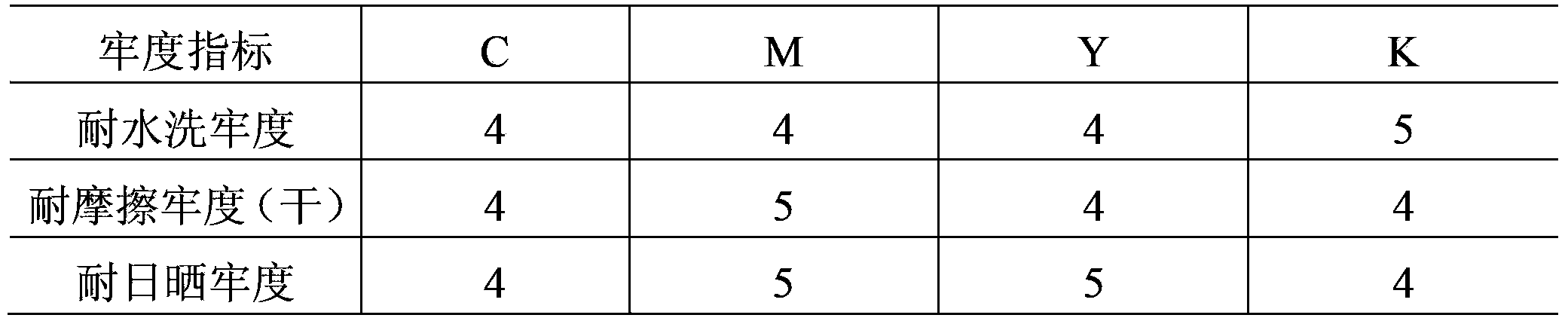

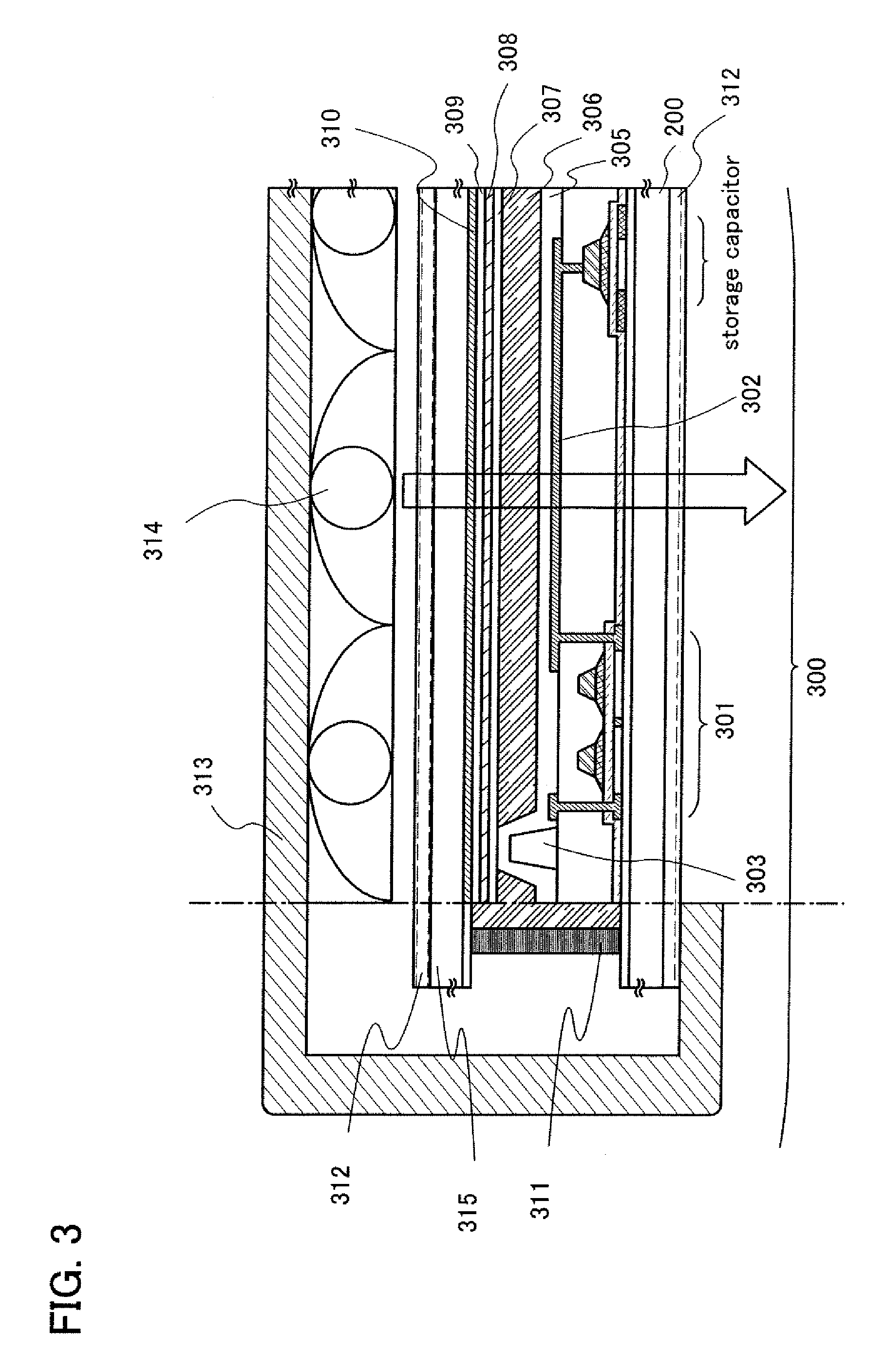

Light emitting device

InactiveUS6933520B2Inhibited DiffusionHigh color yieldElectroluminescent light sourcesSolid-state devicesHeat resistanceBoundary region

It is considered that in the fabricating steps of a TFT substrate, a color filter layer is prepared at the same alignment accuracy. However, since the heat resistance temperature is about 200° C., it could not withstand the process temperature of about 450° C. in the TFT. The pixel section is formed by arraying in a matrix shape a light emitting element in which an organic compound layer having the luminous property is formed between a pair of electrodes consisting of a translucent electrode and a non-translucent electrode and a TFT, the coloring layer of color filter provided corresponding to each pixel is provided in contact with the flat surface of the flattened insulating film composed of an inorganic or organic material between the light emitting element and the TFT, the boundary region of coloring layers adjacent each other is provided while overlapping with a gate signal line or data line for transmitting a signal to the TFT, and the translucent electrode is provided while overlapping with the layer inside of the coloring layer.

Owner:SEMICON ENERGY LAB CO LTD

Slurry disperse dye and preparation method and appliance

The invention discloses a slurry disperse dye and a preparation method and an appliance, wherein the slurry disperse dye comprises liquid disperse dyes, functional prepolymers and synthetic thickeners, the synthetic thickeners and functional additives are added into the slurry disperse dye to prepare trace printing paste, and can complete printings of polyester fabrics on a common rotary screen printing machine or a screen printing machine, then printed polyester fabrics are prepared through a heat-setting stenter in 180 DEG C-210 DEG C for 45-120s. The slurry disperse dye has the advantages of short printing process when being used for polyester fabric printings, is soft in fabric handing, does not need post process, saves a lot of water and energy consumption, nearly does not have discharge amount of waste water, uses common equipment as process equipment, and is a green printing process technology.

Owner:SUZHOU UNIV

Dyeing method for multilevel-color jean yarns

The invention relates to a dyeing method for multilevel-color jean yarns. The dyeing method comprises the following steps: carrying out modification treatment on yarns by adopting a cationic modifying agent; padding 1-2 paths of pigment printing paste on the treated yarns at a room temperature and drying; then carrying out continuous rolling and dyeing by indigo blue and sulfur dyestuff or overdyeing of the indigo blue and the sulfur dyestuff. The jean yarns produced by the dyeing method are bright in color and luster, good in color fastness, pure in colored light and low in room-temperature dyeing power consumption; the quantity of indigo blue dyeing grooves is reduced by priming a high-fastness pigment; a process flow is shortened, the pollution discharge is reduced and the production cost is reduced.

Owner:SHANDONG DAIYIN TEXTILE GROUP SHARE CO LTD

Anti-infrared military camouflage fabric and printing and dyeing process thereof

ActiveCN106049092AImprove friction resistanceImprove tensile strength at breakMercerising of indefinite length fabricsSingeingDisperse dyeColour fastness

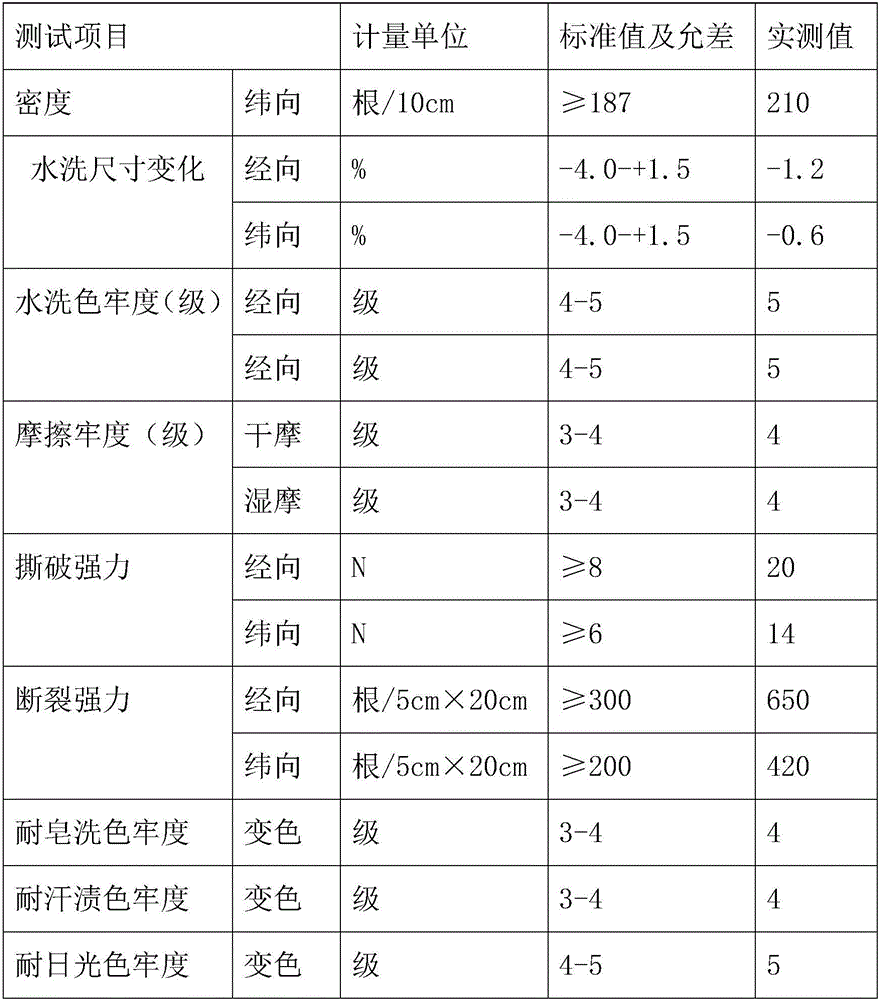

The invention discloses anti-infrared military camouflage fabric and a printing and dyeing process thereof. Warp and weft yarns of the camouflage fabric use cotton polyester blended yarns; the cotton polyester blended yarns are formed by blending 40 to 60 weight percent of cotton fiber, 30 to 50 weight percent of polyester fiber, 5 to 10 weight percent of polyamide fiber and 5 to 10 weight percent of spun silk fiber. The printing and dyeing process of the anti-infrared military camouflage fabric comprises the following steps of S1, a pretreatment process; S2, a dyeing process; S3, a printing process; S4, tentering sorting, wherein the dyeing process uses disperse bath process dyeing of reduced dye and disperse dye; the printing process uses printing of reduced dye and disperse dye in one paste. According to the anti-infrared military camouflage fabric and the printing and dyeing process of the anti-infrared military camouflage fabric, the fabric obtained through the printing and dyeing process has the advantages of good anti-infrared camouflage performance, high color fastness of all items, full color and luster and low cost.

Owner:ANHUI YAYUAN PRINTING & DYEING CO LTD

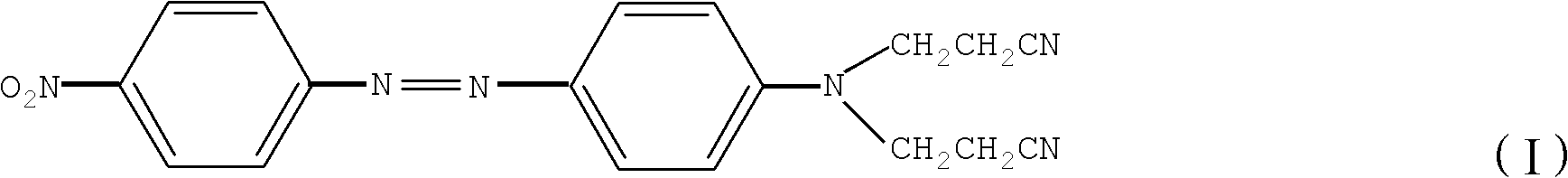

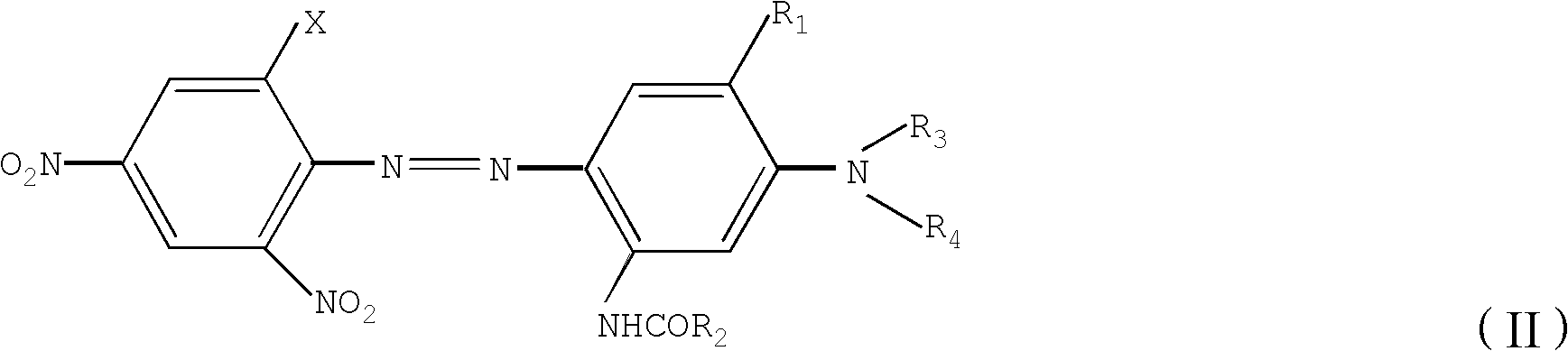

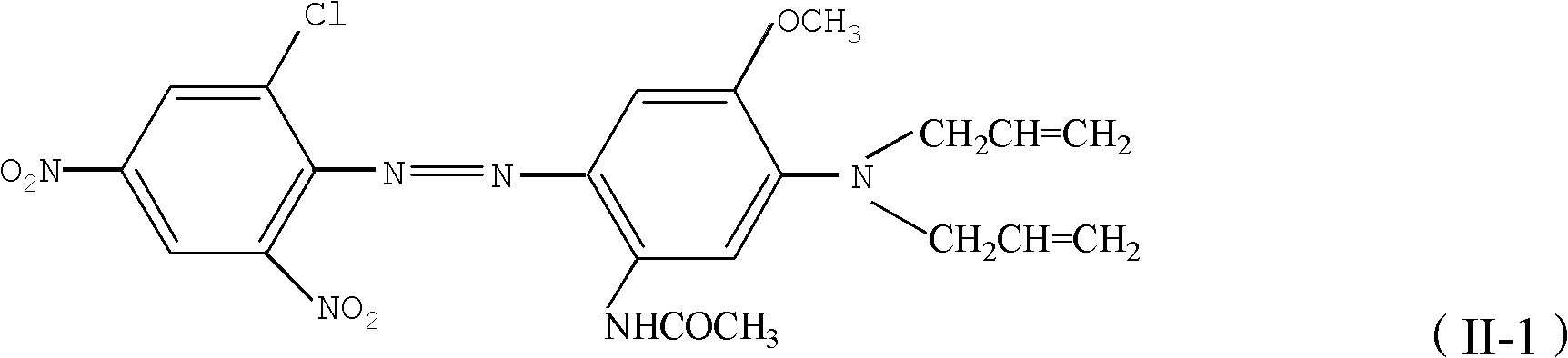

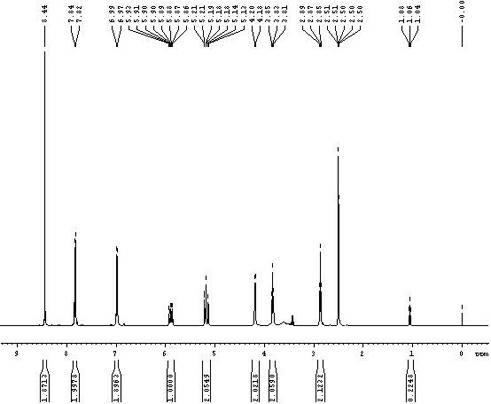

High-fastness black and blue disperse dye composite

ActiveCN102002259AImprove dye uptakeBright shadeOrganic dyesDyeing processDisperse dyePolymer science

The invention discloses a high-fastness black and blue disperse dye composite, which comprises the following components in percentage by weight: 7 to 42 percent of component A, 45 to 90 percent of component B and 3 to 13 percent of aids, wherein the component A is a compound shown by a formula (I), and the component B is one or more of compounds shown by a formula (II). The high-fastness black and blue disperse dye composite provided by the invention has excellent levelling property, beautiful and bright color light, strong deep dyeing property, high color yield and excellent fastness such as sublimation resistance fastness, washing resistance fastness, friction resistance fastness and the like, and particularly by the addition of the component A, the sublimation fastness of the black and blue disperse dye composite is improved obviously.

Owner:ZHEJIANG RUNTU

Method for dyeing cotton fabric with tea dye and finishing liquor used by method

InactiveCN103451963ARealize green environmental protectionHas antibacterial propertiesDyeing processVegetal fibresAcetic acid solutionClean water

The invention discloses a method for dyeing a cotton fabric with tea dye and finishing liquor used by the method. The method comprises the following process steps of (1) crushing tea leaves, and adding clean water to extract the tea dye; (2) preparing the finishing liquor from the following materials in parts by weight: 1-5 parts of chitosan powder, 20-25 parts of a glacial acetic acid solution with the concentration being 4%, and 1000 parts of water, namely firstly adding the glacial acetic acid solution with the concentration being 4% into the chitosan powder gradually, simultaneously stirring uniformly, adding water, and mixing uniformly to obtain the finishing liquor; (3) finishing the cotton fabric with the finishing liquor in an immersing and rolling method; and (4) dyeing the cotton fabric finished by the finishing liquor. The method disclosed by the invention has the advantages that not only can the dyeing depth and fastness of the dyed cotton fabric be improved, but also the antibacterial effect and the clean and environment-friendly effects can be achieved.

Owner:CHANGZHOU TEXTILE GARMENT INST

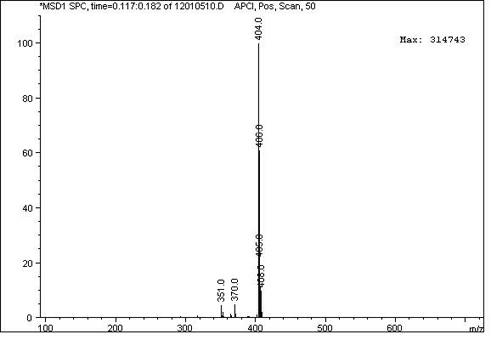

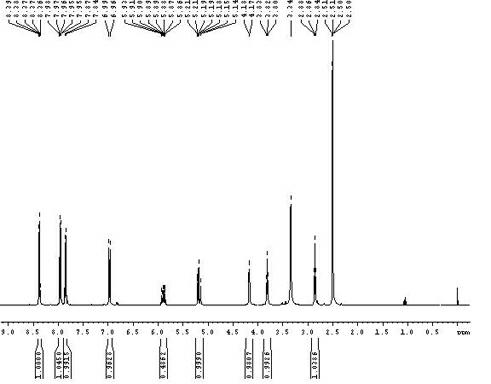

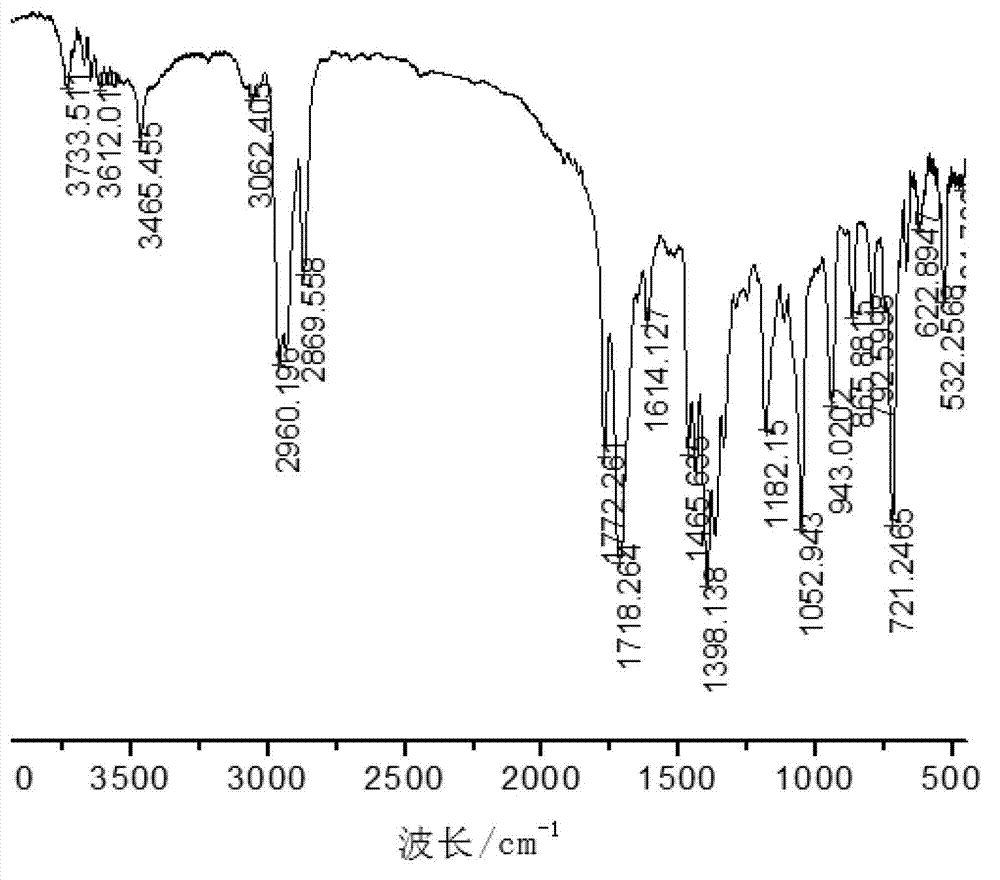

Middle-temperature type disperse dye compound and preparation method and application thereof

ActiveCN102604413ABright colorHigh color fixing rateMonoazo dyesDyeing processDisperse dyeHigh pressure

The invention discloses a middle-temperature type disperse dye compound and a preparation method and application thereof, relating to the technical field of a disperse dye. In order to solve the problem that the traditional middle-temperature types disperse dye is fewer in varieties, the invention provides the monoazo disperse dye compound and the preparation method and application thereof. The general formula of the middle-temperature type disperse dye compound is shown in (I); and the middle-temperature type disperse dye compound is used for dyeing polyester fibers, has the advantages of good dyeing effect at a high temperature and a high pressure, high fixation rate, low cost, high color yield, good fastness and simple production technology.

Owner:ZHEJIANG JIHUA GROUP +1

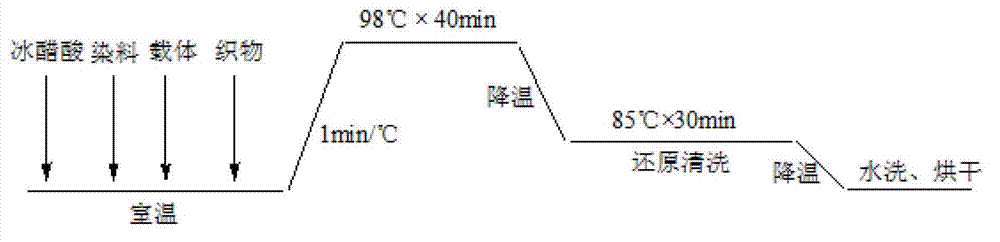

Polyester fiber dyeing carrier and preparation method thereof

The invention discloses a polyester fiber dyeing carrier and a preparation method thereof. The synthesis process of the carrier is simple, a dyeing accelerating effect is obtain by using environmental-friendly solvent to dye polyester fibers, and the production process is reduced because the solvent is not required to be recovered; the carrier is nontoxic, tasteless and biodegradable, colored spots are not caused during use and the fabric is odorless; and the carrier can also be used for normal-pressure low-temperature (95-110DEG C) dyeing of polyester fiber fabrics, the dyeing temperature of the polyester fiber fabrics is decreased, the color yield is high, the requirement on dyeing equipment is low and the large-scale production can be realized.

Owner:苏州联胜化学有限公司

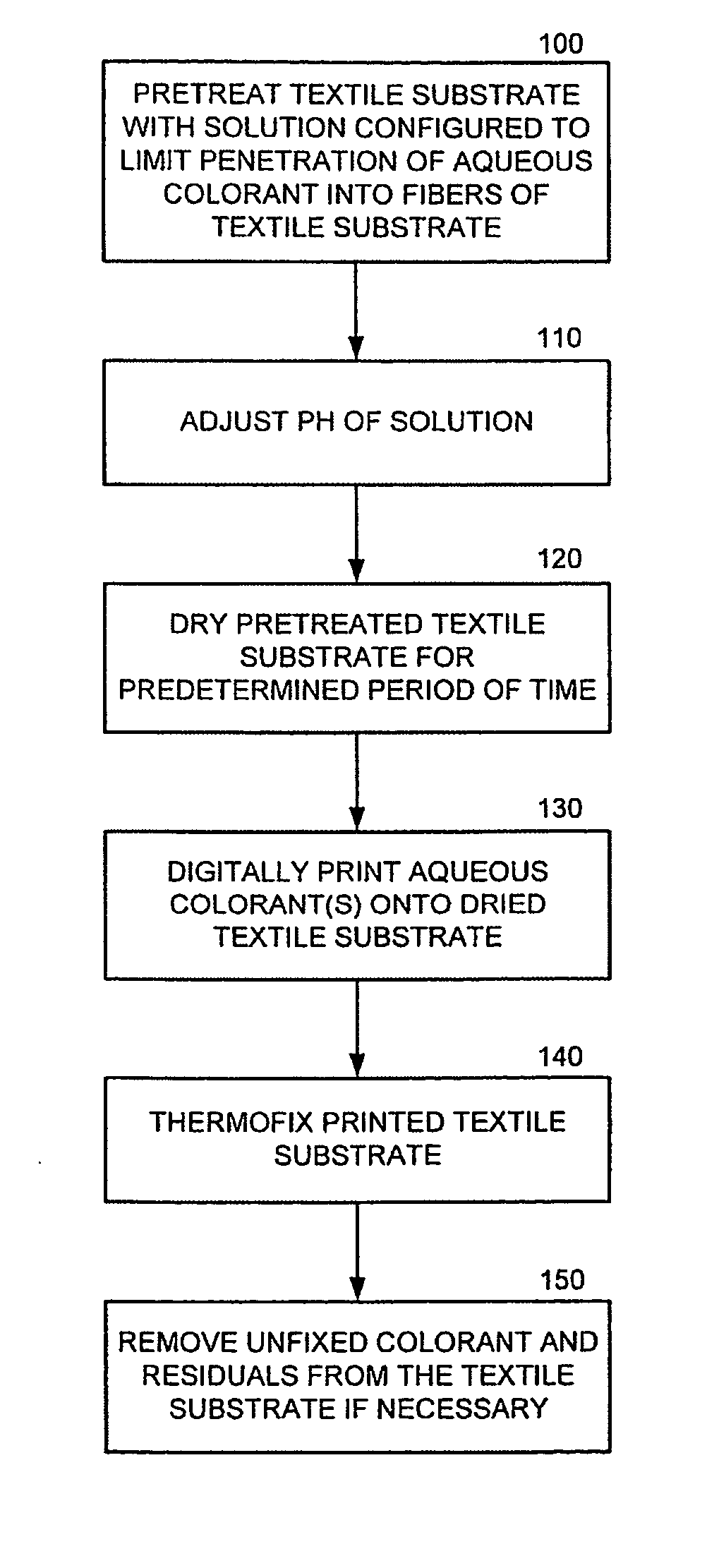

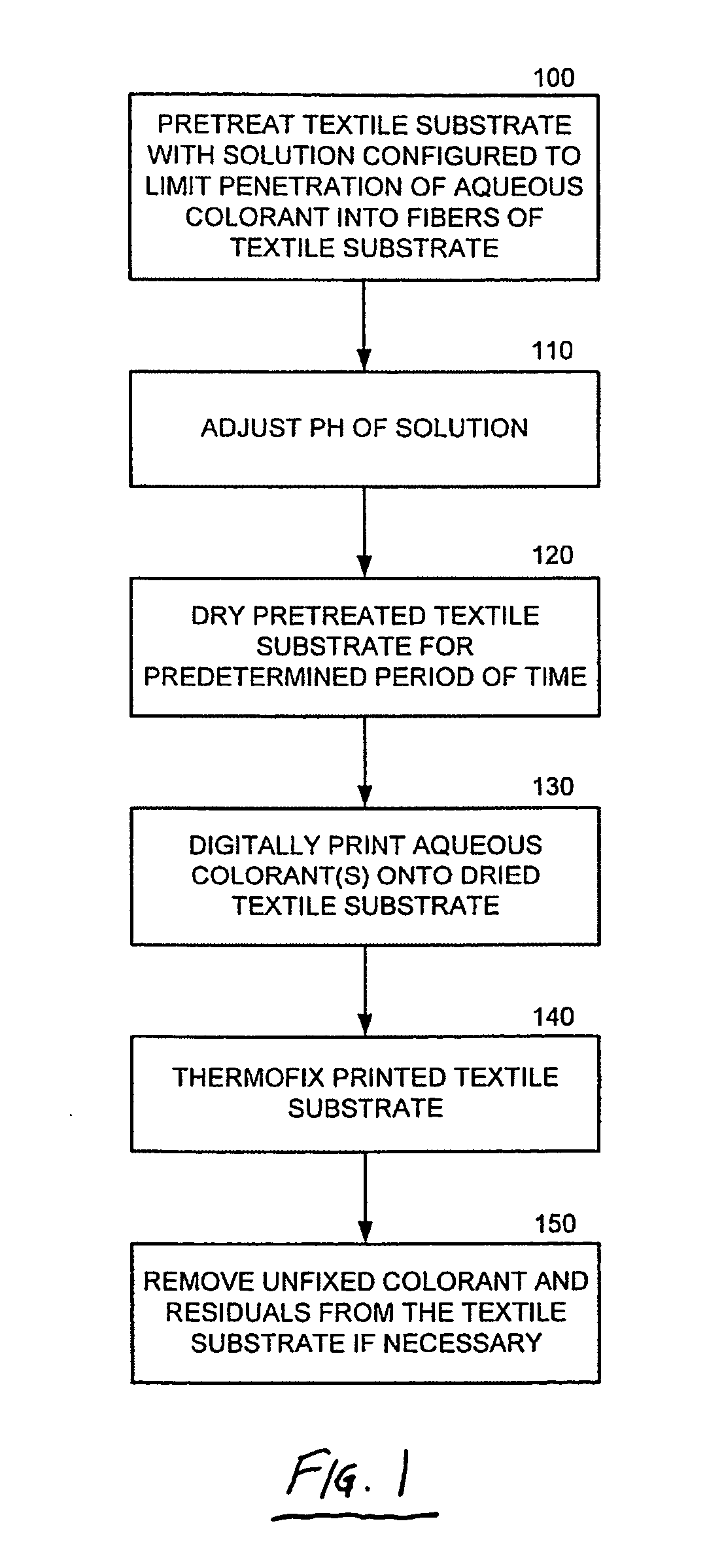

Direct digital printing methods for textiles

InactiveUS20060210719A1High color yieldLimited penetrationPretreated surfacesLiquid/solution decomposition chemical coatingFiberAmmonium compounds

A method of digitally printing textile substrates includes pretreating a textile substrate with a solution that is configured to limit penetration of aqueous colorant into fibers of the textile substrate, drying the pretreated textile substrate for a predetermined period of time, and digitally printing one or more aqueous colorants onto the dried textile substrate. The pretreatment solution comprises a polyamine with a quaternary ammonium compound attached to the polyamine backbone. The pretreatment solution may be applied onto one or both sides of a textile substrate.

Owner:PRECISION FABRICS GROUP

Heavy pure cotton fabric cold padding and stacking pretreatment method

ActiveCN103088645AExcellent desizingExcellent and refinedPhysical treatmentBiochemical fibre treatmentPretreatment methodTherapeutic effect

The invention discloses a heavy pure cotton fabric enzyme padding and stacking pretreatment process after normal pressure plasma treatment, and belongs to the technical field of dyeing and finishing pretreatment. The technological process comprises the following steps of: carrying out the normal pressure plasma treatment on the singed heavy pure cotton grey fabric; carrying out refining enzyme liquid padding on the fabric; then stacking at room temperature; then carrying out oxygen bleaching and low alkali mercerization; and finally sufficiently rinsing to complete the pretreatment process of the heavy pure cotton fabric. According to the method, the process has the characteristics of being good in treatment effect, little in fabrics strength damage, high in quality, soft in hand feeling, high in capillary effect and good in glossiness; the method provides a condition of high color yield for the subsequent dyeing and printing processing; the process operation is simple and high in controllability; the treated waste water, the pH value and the energy consumption of the process are far lower than the treated waste water, the pH value and the energy consumption of the traditional strong base scouring process; and the process is a clean production process meeting the environmental protection requirement, so that the sewage treatment burdens of enterprises are greatly reduced, the process is very high in social benefit and market prospect, and the process conditions are optimized.

Owner:浙江肯特科技股份有限公司

Process for dyeing poly (trimethylene terephthalate) carpet continuously

InactiveUS6836915B2Minimize the differenceAvoid frostFibre treatmentOrganic dyesPolyethylene terephthalateDry heat

In the process for continuously dyeing a poly(trimethylene terephthalate) bulked continuous filament yarn carpet an aqueous dyeing solution is applied to a continuously moving poly(trlmethylene terephthalate) bulked continuous filament yarn carpet at a temperature of 45° C. to 100° C., and then the poly(trimethylene terephthalate) bulked continuous filament yam carpet is steamed, rinsed and dried. Before applying the aqueous dyeing solution the carpet is heat-set at 120 to 150° C. The carpet is steamed with saturated steam at 102 to 150° C. for 5 to 10 mm. The aqueous dyeing solution does not include an anti-frosting agent. The process also advantageously includes heating the carpet with a dry heat of 140 to 300° C. for 30 to 60 sec after steaming the carpet and before rinsing it.

Owner:HYOSUNG CORP

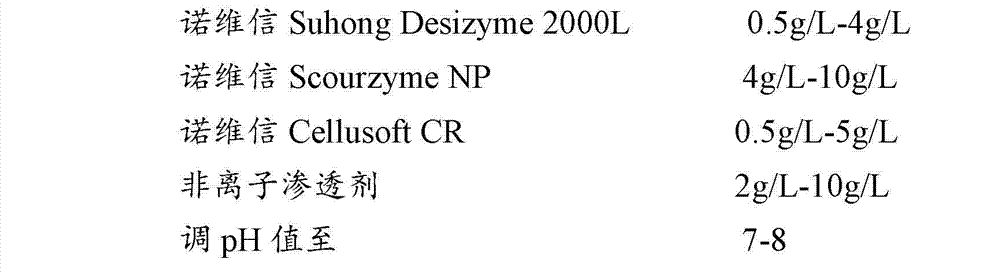

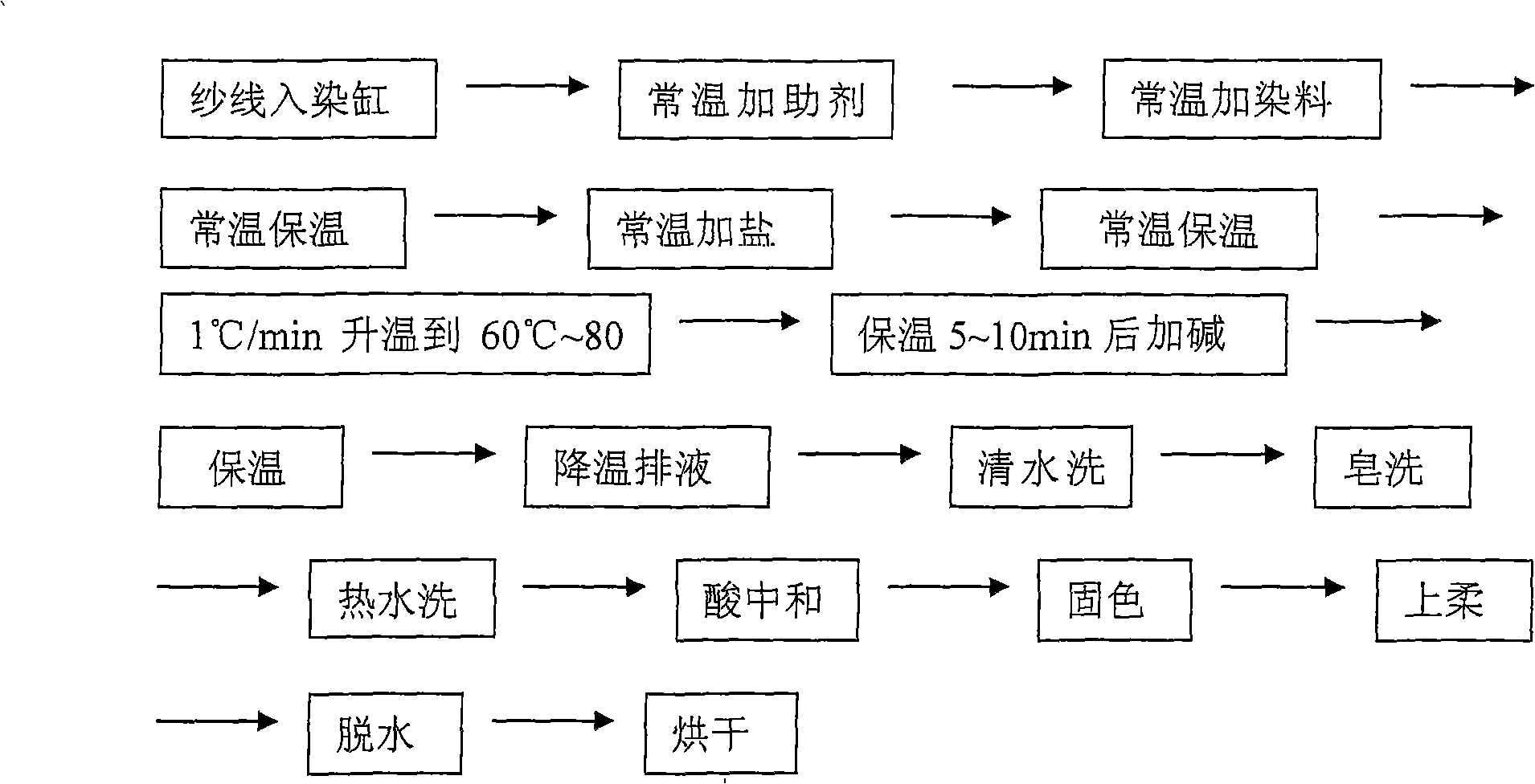

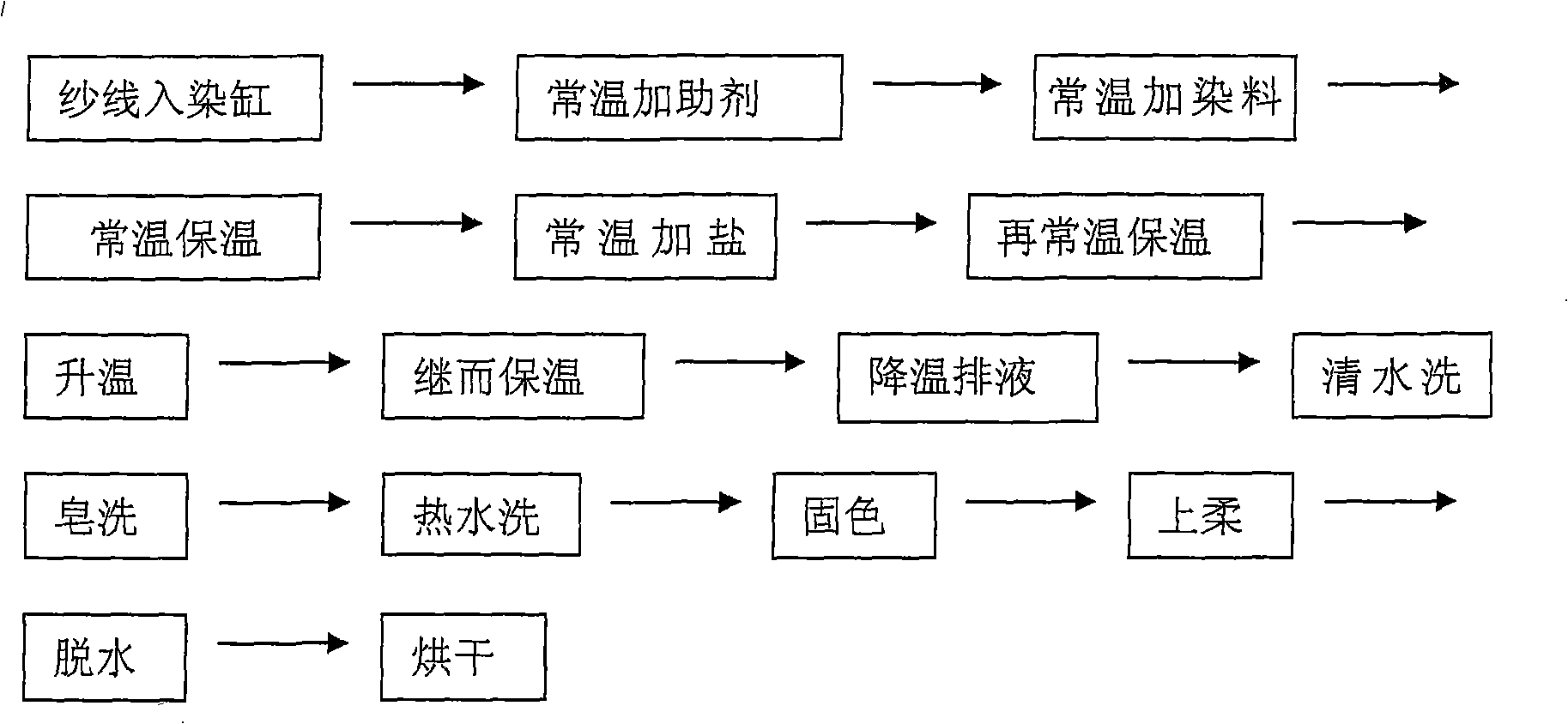

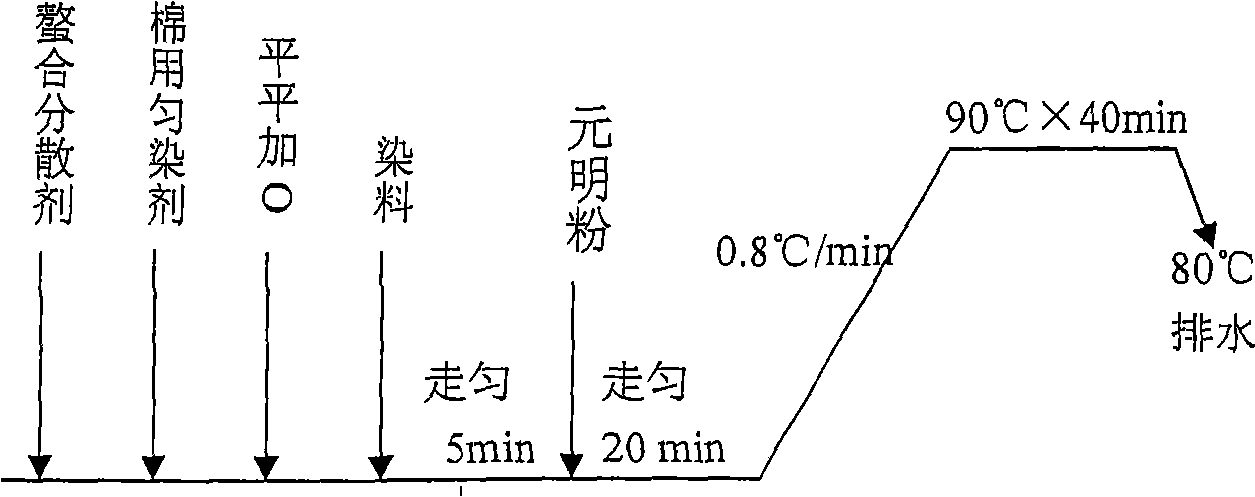

Dyeing process for spun silk

InactiveCN101289810ABe friendlyHigh color fastnessBeaming machinesDyeing processBreaking strengthColour fastness

The invention provides a process for dyeing spun silks, belonging to the weaving yarn dyeing technical field. The process comprises the following steps that: spun silk yarns which are ready to be dyed and undergo the pre-dyeing treatment are put in a dye vat, water is added in the dye vat, and the bath ratio is controlled; at the normal temperature, auxiliary agent and cotton-used reactive dyes are added in the dye vat; the dye vat is kept warmth at the normal temperature; at the normal temperature, salt is added in the dye vat; the dye vat is kept warmth at the normal temperature again; the dye vat is heated, and the temperature-rise speed is controlled; the dye vat is kept warmth; finally after sequential steps of temperature drop and liquid discharging, fresh water washing, soap washing, hot water washing, color fixation, upper flexibility, dewatering and drying, dyed spun silk yarns are obtained. The process has the advantages of improving the color fastness of dyed spun silk yarns by one or two levels, having good level-dyeing property, improving the color yield by 20 percent and improving the breaking strength by 5 to 10 percent; because alkali is not used for the color fixation, the process has the advantages of simple process, unnecessary following acid neutralization step, energy conservation and low dyeing cost; because alkalization and acid neutralization steps are not necessary, the process is environment friendly.

Owner:常熟市亨时特染织有限公司

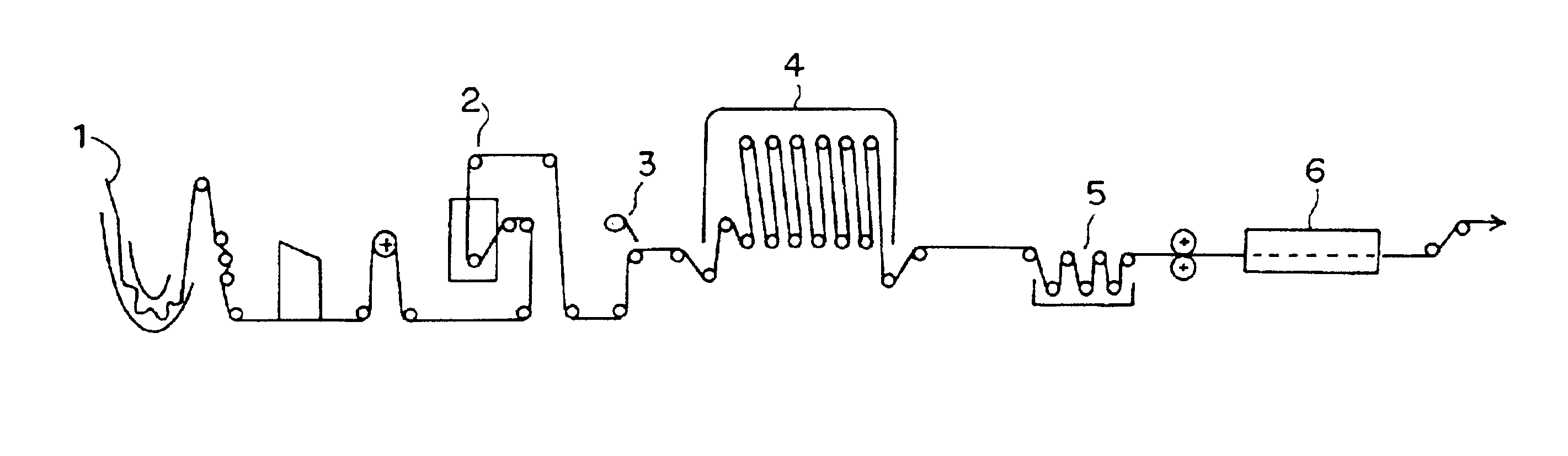

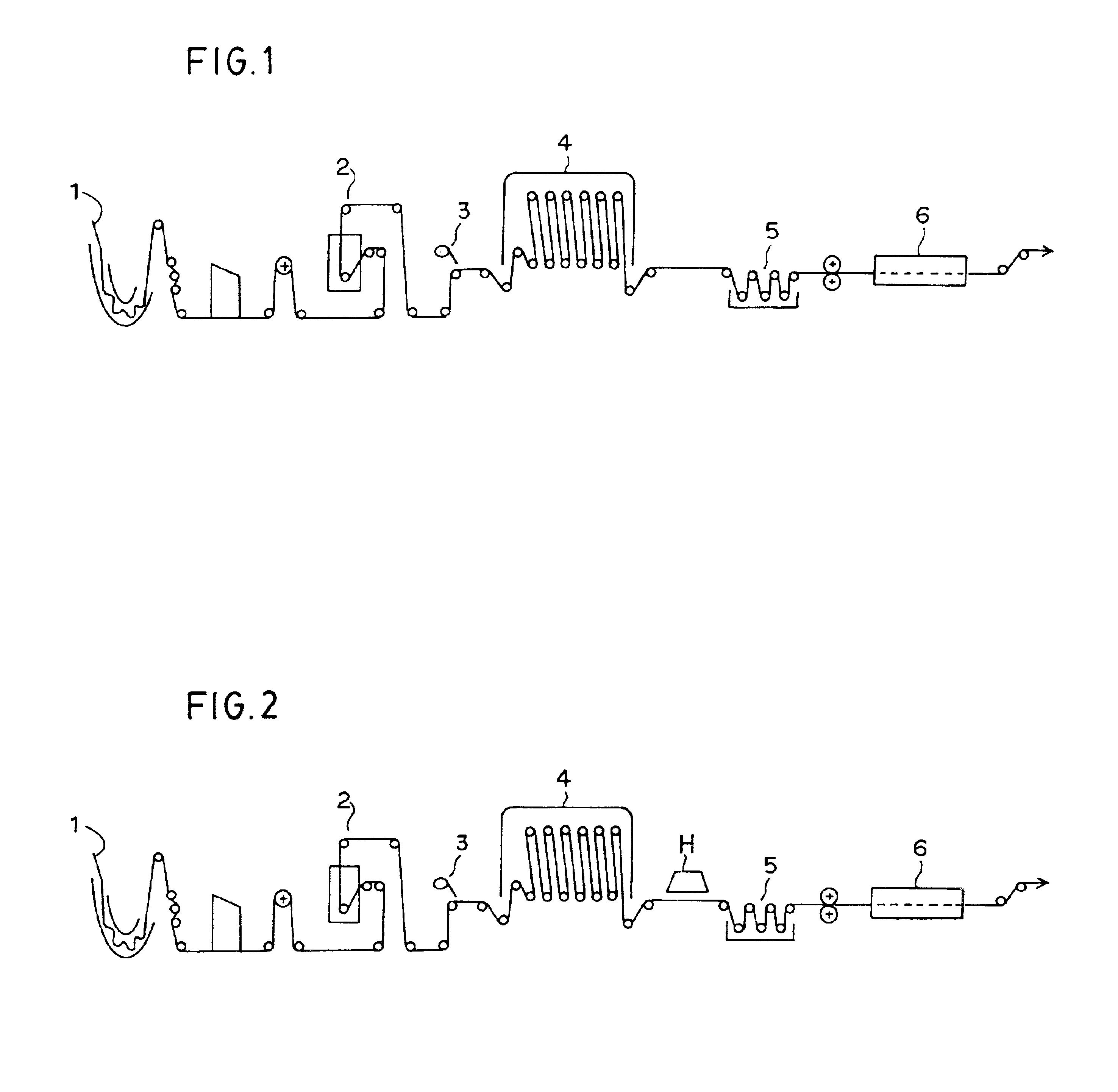

Continuous hot melting dyeing technology for polyester fiber fabric

InactiveCN103668829AReduce consumptionLow baking temperatureSucessive textile treatmentsDyeing processDisperse dyeHot melt

The invention aims at providing a continuous hot melting dyeing technology for a polyester fiber fabric. The traditional pad dyeing technology of carrying out rolling, drying and baking in sequence on the polyester fiber fabric is changed into the technology of carrying out steaming, rolling, drying and baking in sequence. Before padding, a polyester fiber is steamed through negative pressure saturation steam so that the expansion degree of the polyester fiber can be improved, the dyeing speed, the dye utilization ratio and the level dyeing degree of dyes can be improved, and the effects of shaping the polyester fiber and improving the quality of the fiber can be achieved. In the padding process, the dyeing speed and the dyeing uptake of disperse dyes are further improved by utilizing the function of a dyeing assistant, and the liquid rate and the level dyeing effect of two-immersing and two-rolling technology can be achieved by adopting the one-immersing and one-rolling technology. After pre-drying is carried out through high-frequency infrared rays, the temperature of the baking and drying is reduced to 180 DEG C to 190 DEG C from 210 DEG C to 220 DEG C by adopting the low-temperature dyeing technology. By means of the technology, dyeing and printing enterprises can greatly reduce energy consumption, and meanwhile, high quality dyed fabrics with the superior performance can be obtained.

Owner:YANCHENG INST OF IND TECH

Neutral low-temperature refining enzyme and use thereof in pretreatment of fabrics

ActiveCN102154230AReduce pollutionImprove water absorptionBiochemical fibre treatmentEnzymesPectinaseCellulose

The invention relates to a neutral low-temperature refining enzyme and use thereof in pretreatment of fabrics. The neutral low-temperature refining enzyme comprises 15 to 50 weight parts of neutral cellulose, 30 to 70 weight parts of pectinase, 10 to 30 weight parts of xylanase, 5 to 30 weight parts of lipase and 10 to 15 parts of laccase. When the neutral low-temperature refining enzyme is used, cotton seed hulls, pectic substances, waxiness and the like can be removed effectively, the water absorptivity, fiber strength and dyeing property of cotton fabrics can be improved, dye can be saved, process time can be reduced and the production efficiency can be improved. A green processing method which is low in carbon content, environment-friendly and energy-efficient can be realized actually in the fabric dyeing industry.

Owner:沧州夏盛酶生物技术有限公司

Trace amount of printing paste and preparation method and application thereof

ActiveCN105113284AReduce water consumptionReduce sewage dischargeDyeing processPrepolymerEnergy consumption

The invention discloses a trace amount of printing paste and a preparation method and application thereof. The printing paste is composed of liquid disperse dyes, a function prepolymer, a synthetic thickener, a functional addition agent and water. The trace amount of prepared printing paste can finish printing of a polyester fabric on a conventional rotary screen printing machine or a screen printing machine; high-temperature processing is performed through a tentering heat setting machine, the temperature is 180-210 DEG C, the time is 45-120 seconds, and a polyester printing fabric is prepared. The printing paste is used for printing and is characterized in that the printing process is short, the fabric is soft in touch, afttertreatment is not needed, plenty of water resources are saved, plenty of energy consumption is reduced, and there is almost no waste water emission. Processing devices are all conventional devices, and the preparation method is a green printing processing technology.

Owner:SUZHOU UNIV

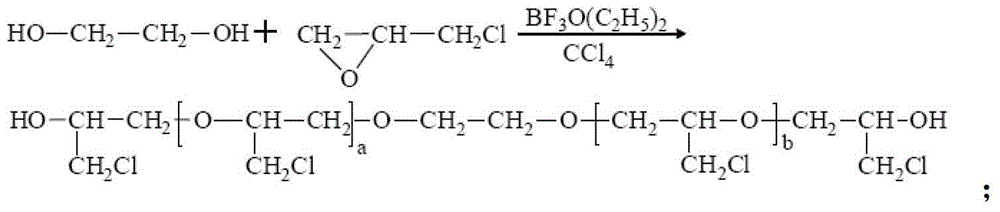

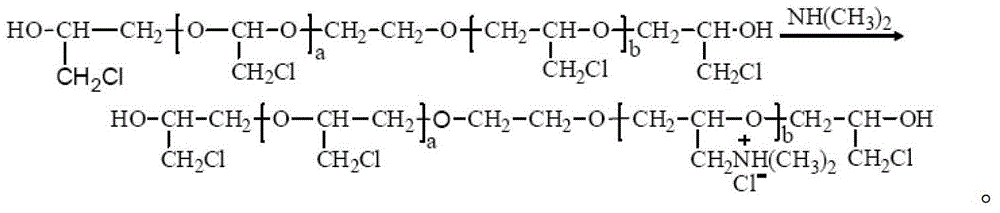

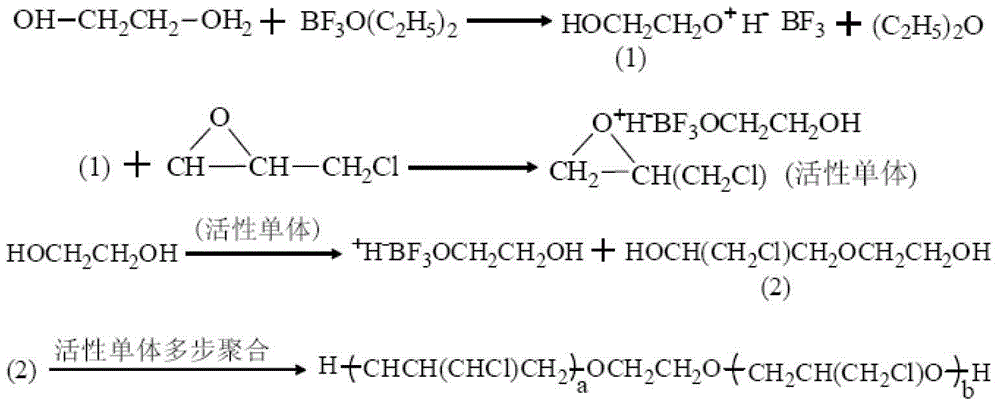

Preparation method and application off dyeing promoter

ActiveCN103333332AHigh color yieldUtilization rate and dyeing rate increaseDyeing processNatural fiberCellulose

The invention relates to a preparation method and application of a dyeing promoter. The invention aims to provide a method for preparing a promoter, which can carry out cation modification on natural fibers like cotton and silk, and provides a technology for modification of natural fibers by employing the above mentioned dyeing promoter. A technical scheme is as below: a preparation method of a polypichlorohydrin amide dyeing promoter is carried out according to the following steps: 1) synthesis of polypichlorohydrin; and 2) synthesis of the polypichlorohydrin amide dyeing promoter. The method for modification of natural fibers by employing the polypichlorohydrin amide dyeing promoter is carried out according to the following steps: preparing a modification liquid according to the scheme, and placing the modification liquid in a constant temperature water-bath pan for oscillation; and adding a natural cellulose fabric into the modification liquid, and taking out and washing the fabric; or preparing a modification liquid according to the scheme, and placing the modification liquid in a constant temperature water-bath pan for oscillation; and adding a natural silk fabric into the modification liquid, and taking out and washing the fabric.

Owner:HIGH FASHION CHINA CO LTD

Textile printing thickening agent and production process thereof

InactiveCN105735007AStrong structural viscosityGood dispersionDyeing processTextile printerOil phase

The invention discloses a textile printing thickening agent. The textile printing thickening agent is prepared by processing the following raw materials in parts by weight: 150-220 parts of acrylic acid, 20-60 parts of methacrylic acid, 50-80 parts of acrylamide, 1-10 parts of octadecyl acrylate, 0.01-0.5 part of N,N'-methylene-bisacrylamide, 120-250 parts of white oil or aviation kerosene, 15-50 parts of sorbitan monooleate, 0.2-2 parts of an initiator, 0.01-1 part of sodium hydrogensulfite, 10-50 parts of fatty alcohol polyoxyethylene ether, 5-50 parts of hydrophilic silicon oil and 200-500 parts of a sodium hydroxide solution. The thickening agent has good water holding performance, strong electrolyte resistance capability and high color yield. A production process comprises the following steps of: (1) neutralizing the acrylic acid and the methacrylic acid until the pH value is 5.2-6.5; (2) adding the acrylamide, the N,N'-methylene-bisacrylamide and the initiator to prepare a water phase; (3) mixing the white oil or the aviation kerosene, the sorbitan monooleate and the octadecyl acrylate to form an oil phase; and (4) adding the water phase into the oil phase and emulsifying, and adding sodium hydrogensulfite to carry out a polymerization reaction; and (5) adding the fatty alcohol polyoxyethylene ether and the hydrophilic silicon oil and mixing.

Owner:HEFEI JUHE RADIAL CHEM TECH

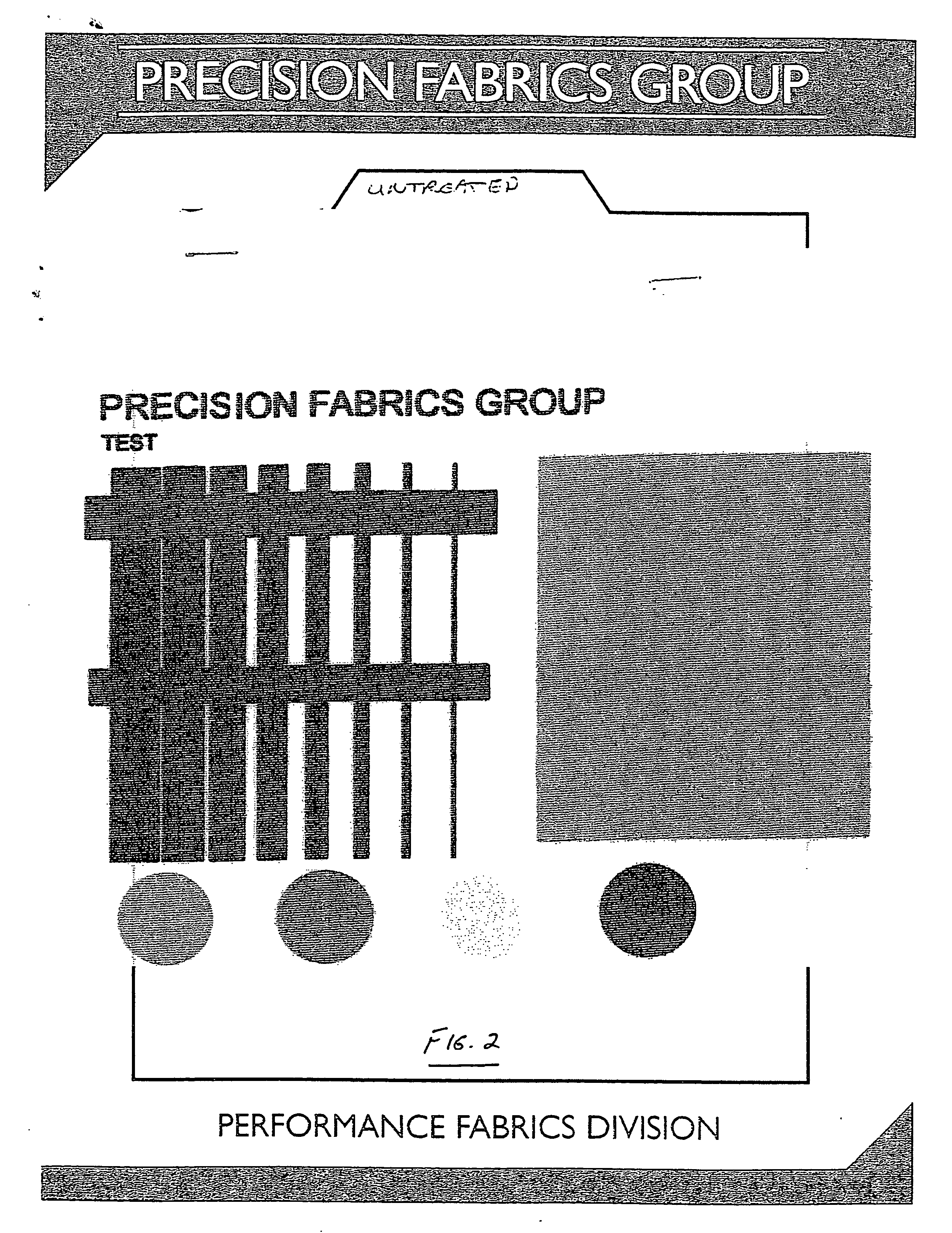

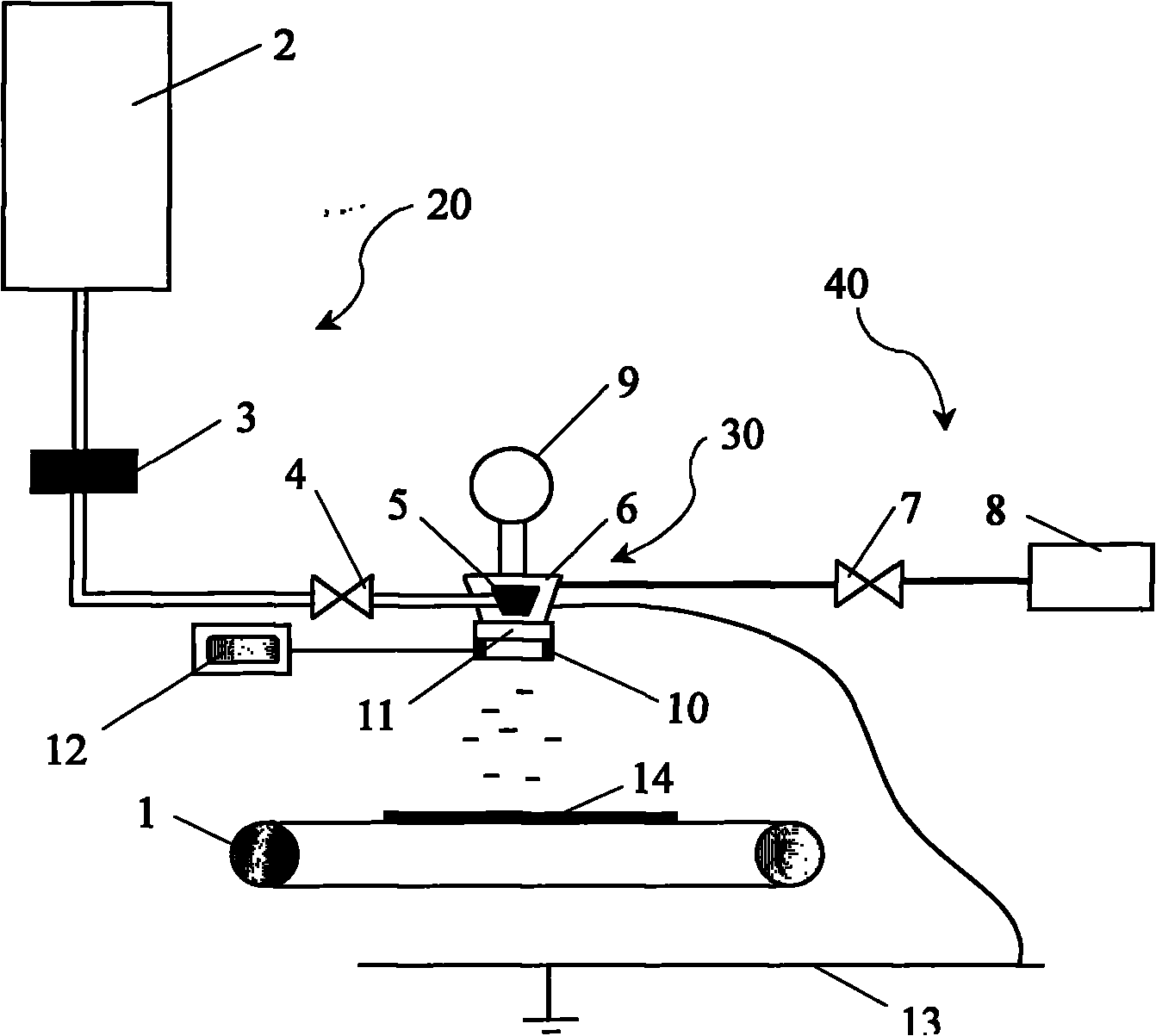

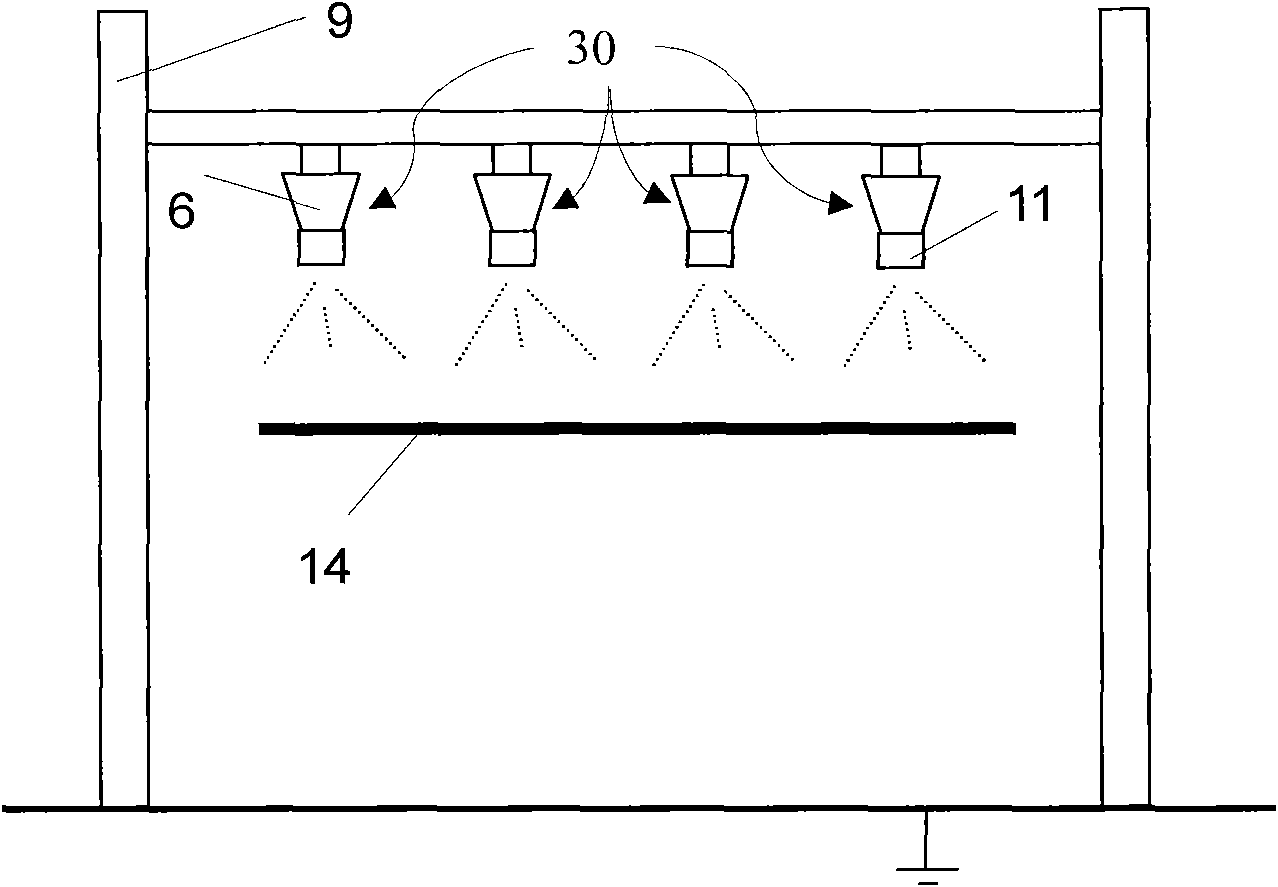

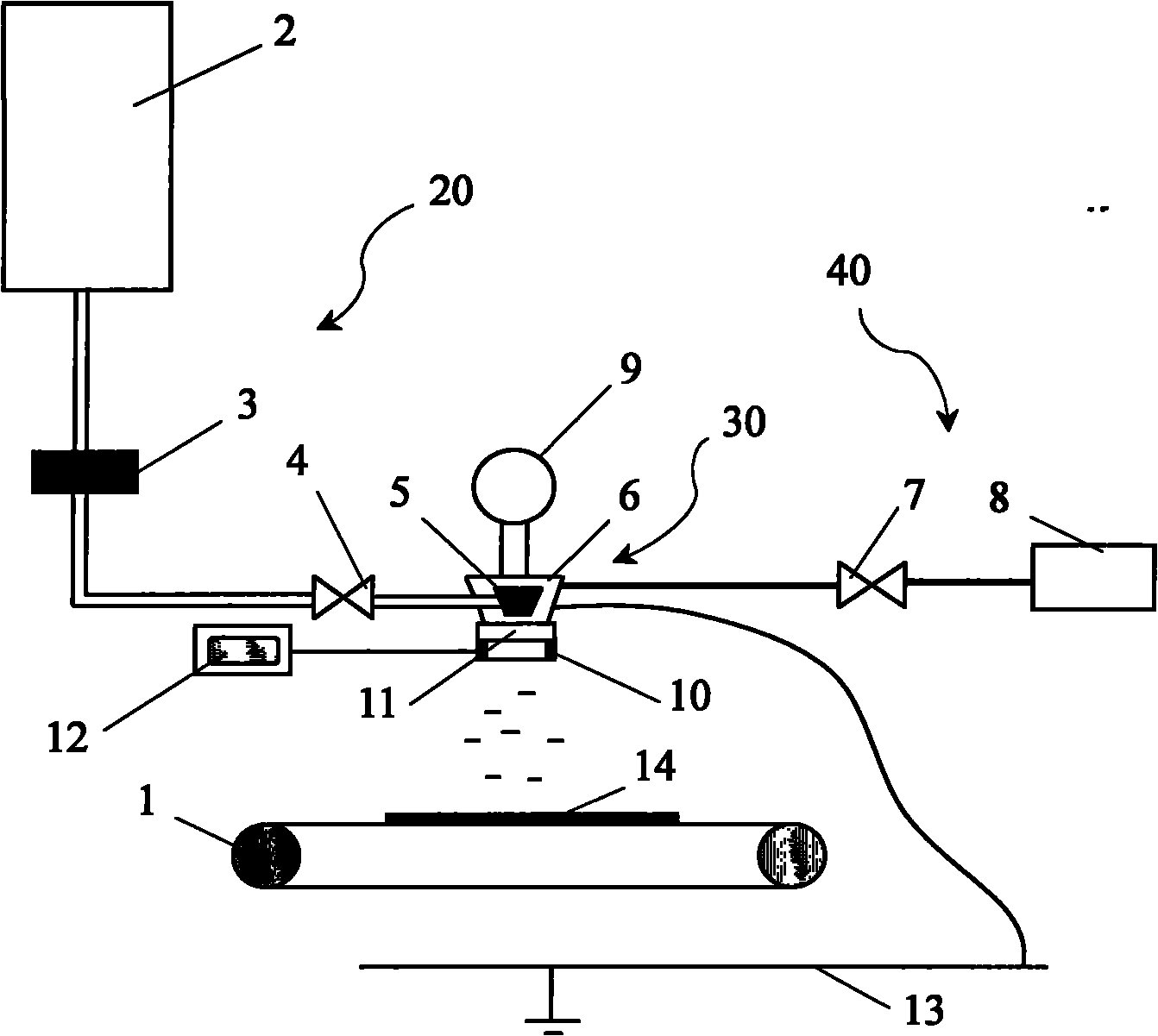

Spraying processing method and spraying machine for fabric dyeing and finishing

InactiveCN101974834ADyeing and finishing method realizationUniform depositionTextile treatment by spraying/projectingSpray discharge apparatusElectric forceCorona discharge

The invention relates to a spraying processing method and a spraying machine for fabric dyeing and finishing. The spraying processing method comprises the steps of: adopting an air-assisted electrostatic atomization way to crush a dyeing and finishing auxiliary into micron-sized droplets with static electricity and spraying the droplets with static electricity onto a fabric through the combined action of airflow, gravity and electric force so that the droplets form irregularly distributed microscale dyeing and finishing areas with certain gaps on the fabric to finish the dyeing and finishing process of the fabric. The spraying machine comprises a dyeing and finishing auxiliary conveying system, a fabric conveying device, a gantry and an electrostatic spraying dyeing and finishing device, wherein the electrostatic atomization dyeing and finishing device is a corona discharge atomization device conveyed by aerodynamic force and comprises a corona discharge chamber, an aerodynamic nozzleand an atomizer. The invention has the advantages of high efficiency, energy saving and environment protection and can greatly reduce water consumption.

Owner:JIANGSU UNIV +2

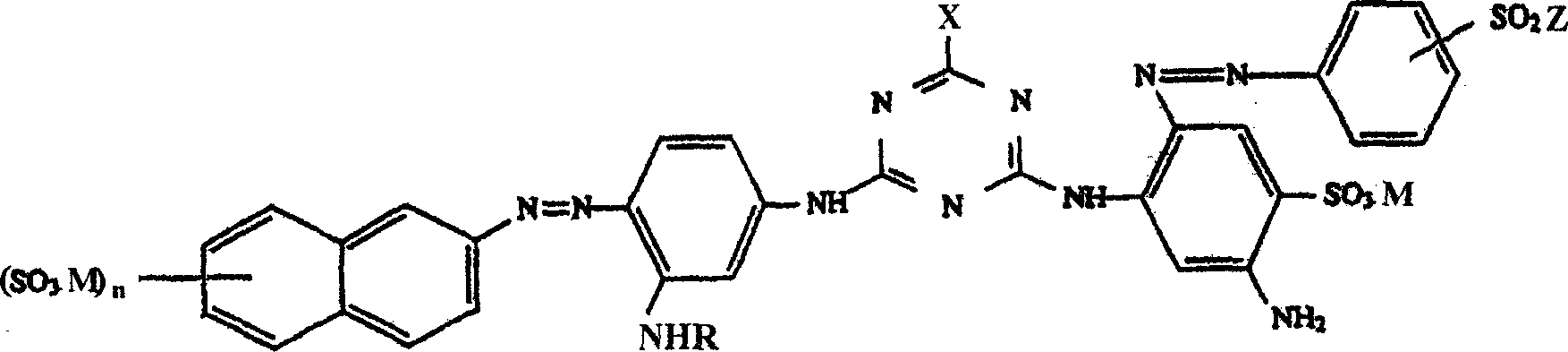

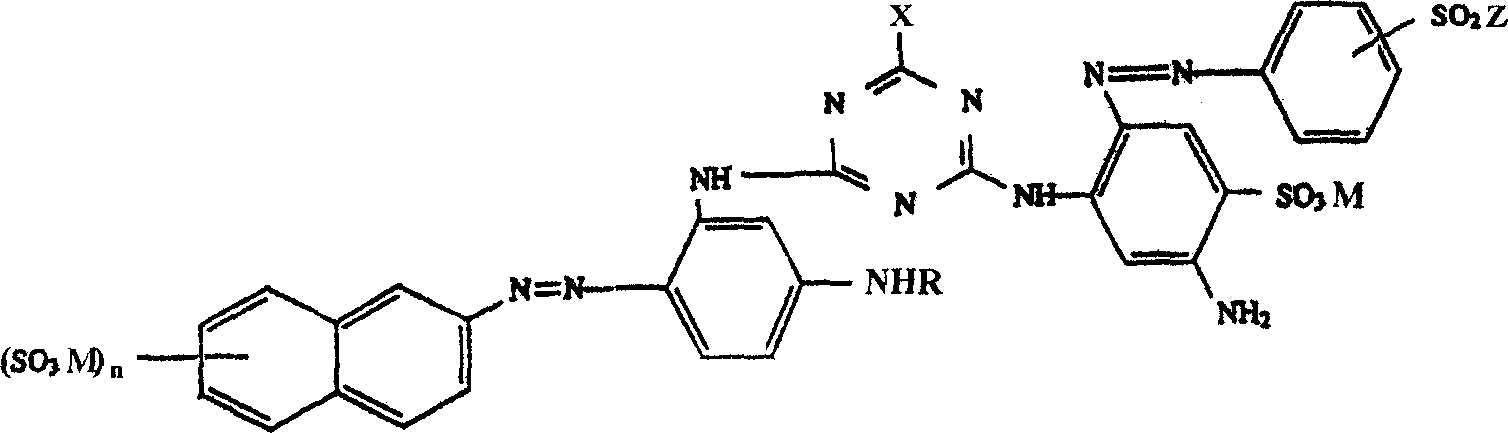

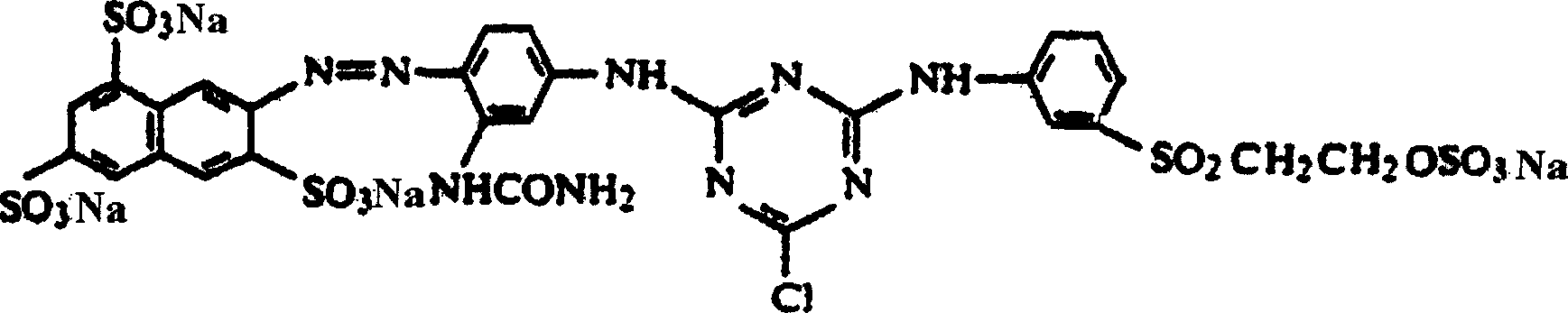

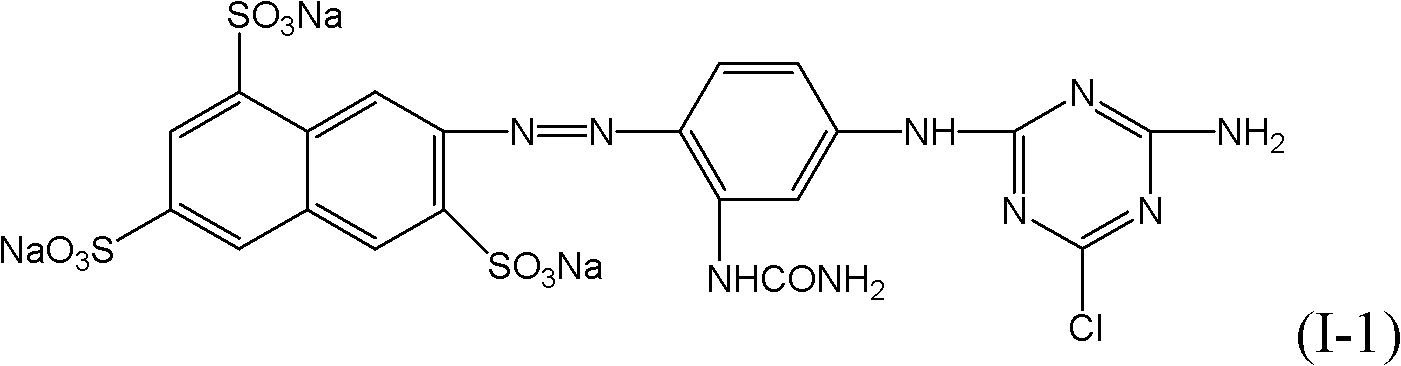

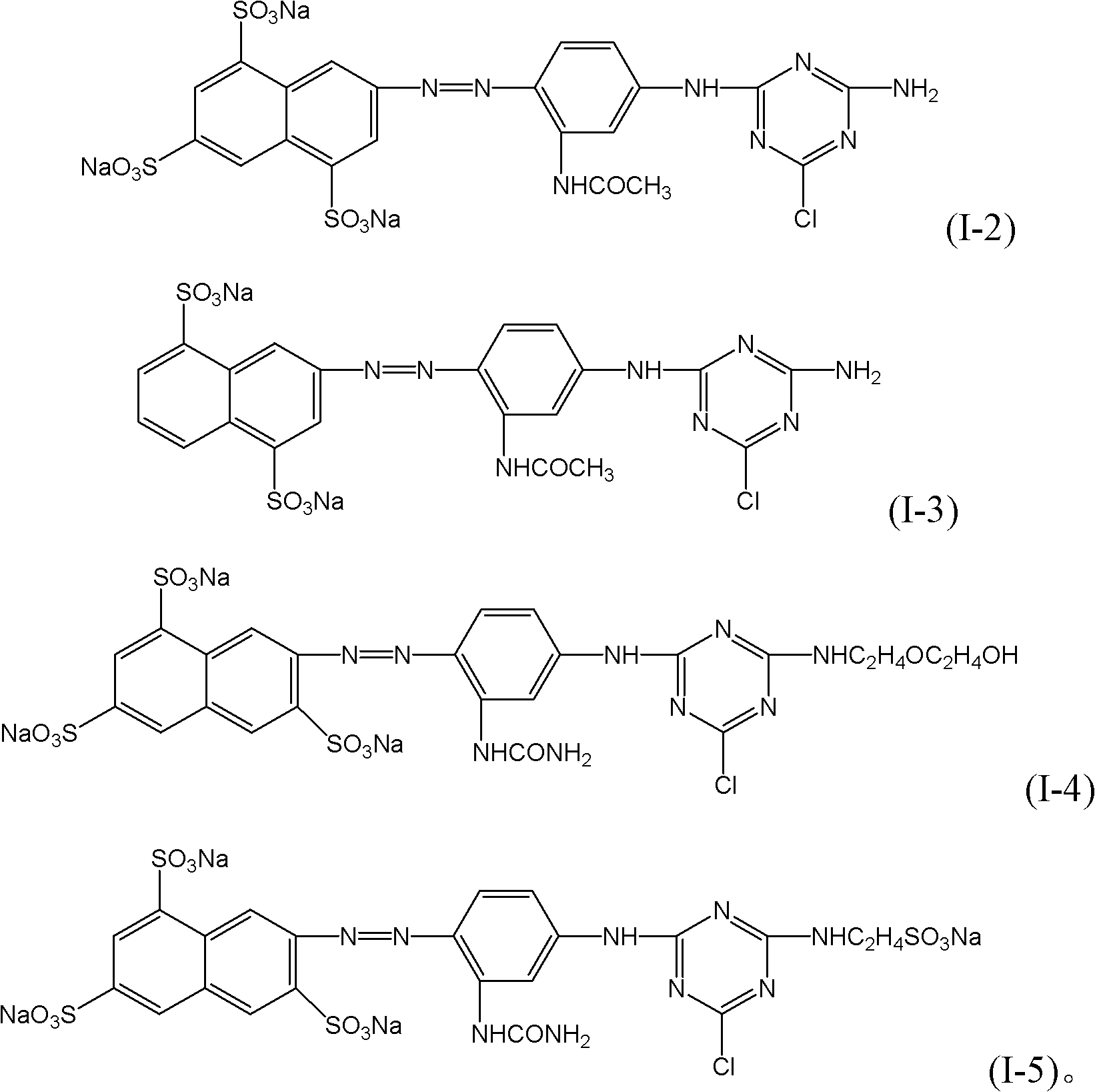

Yellow reactive dye composition and application thereof

A yellow active dye composite containing yellow active dye Iand yellow active dyeIIin proportion of 90-10:10-90 and its use are disclosed. In the general formula, M is selected from H or alkali metal; R is selected from -CONRaRb or -CORa, Ra and Rb are selected from H or C1-4 alkyl separately; X is halogen atom; n is 2 or 3; Z is -CH2CH2OSO3M or -CH=CH2. It has bright color, permeability, fastness, compatibility and dyeing degree.

Owner:ARGUS SHANGHAI TEXTILE CHEM

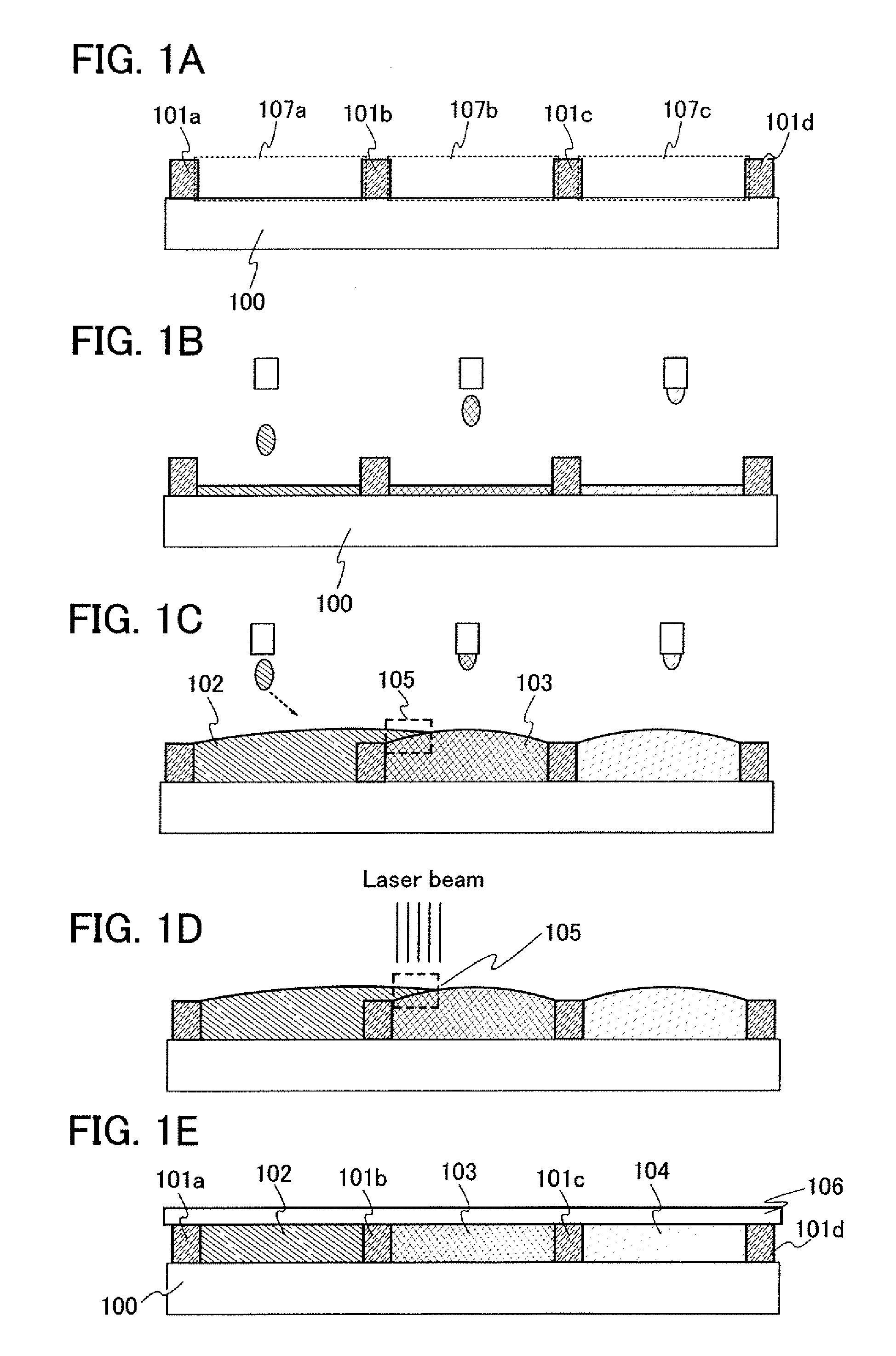

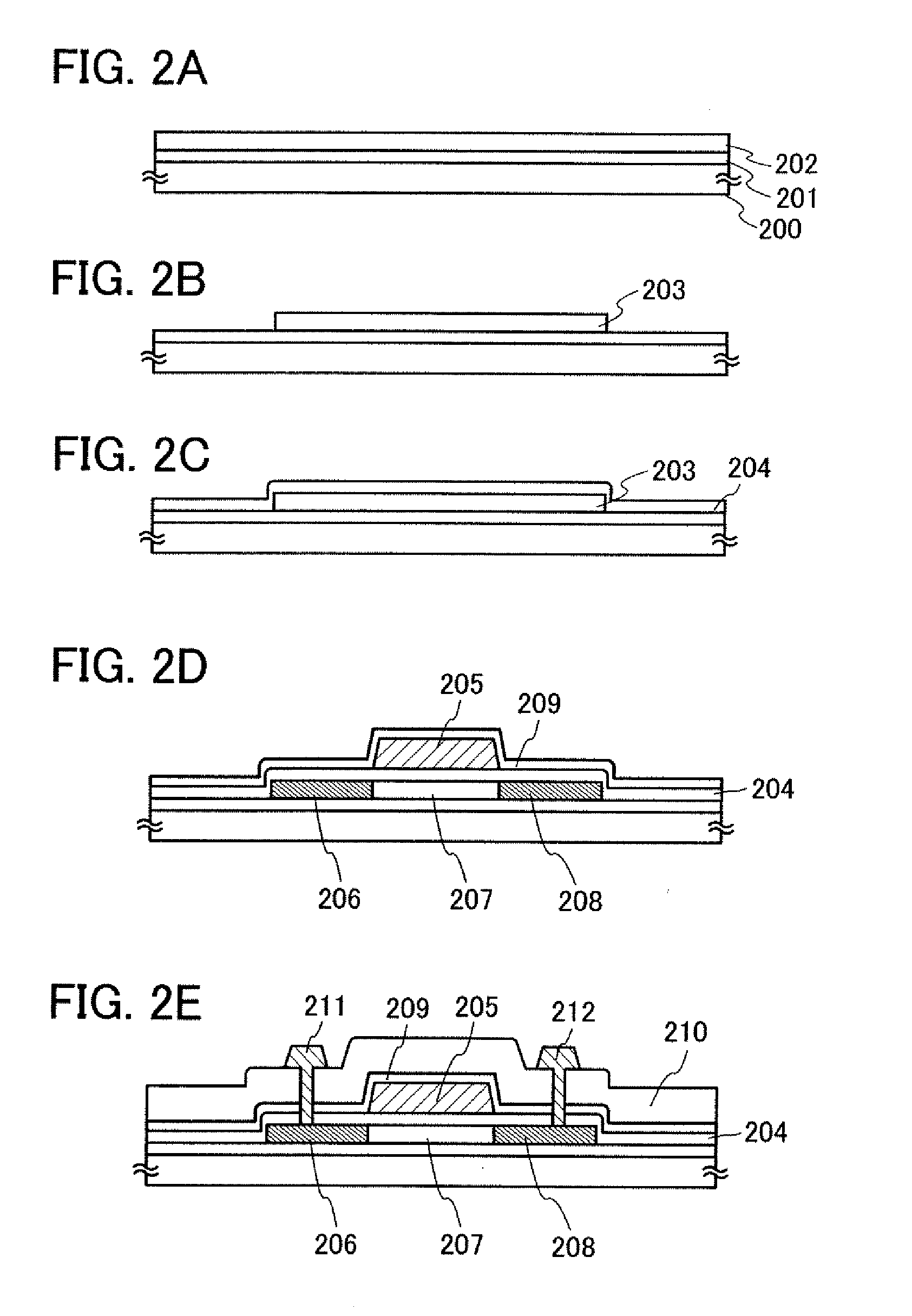

Color filter and manufacturing method thereof, and electronic appliance having the color filter

InactiveUS20080180629A1High color yieldIncrease productionRadiation applicationsOptical filtersPresent methodTransmittance

The present invention provides a method for manufacturing a color filter to facilitate the correction of the defect which is caused by the undesirable mixing of plural color filter materials with different color. Further, the present invention provides a color filter manufactured by the present method for manufacturing the color filter and also a semiconductor device using the color filter manufactured by the present method. In the manufacturing method of the present invention, the color-mixed portion which is undesirably formed during the production of the color-filter by using a plurality of color filter materials is irradiated with a laser beam which is different in transmissivity to each color filter material. This method allows the color filter material which is necessary to remain and the color filter material which is unnecessary to be selectively removed.

Owner:SEMICON ENERGY LAB CO LTD

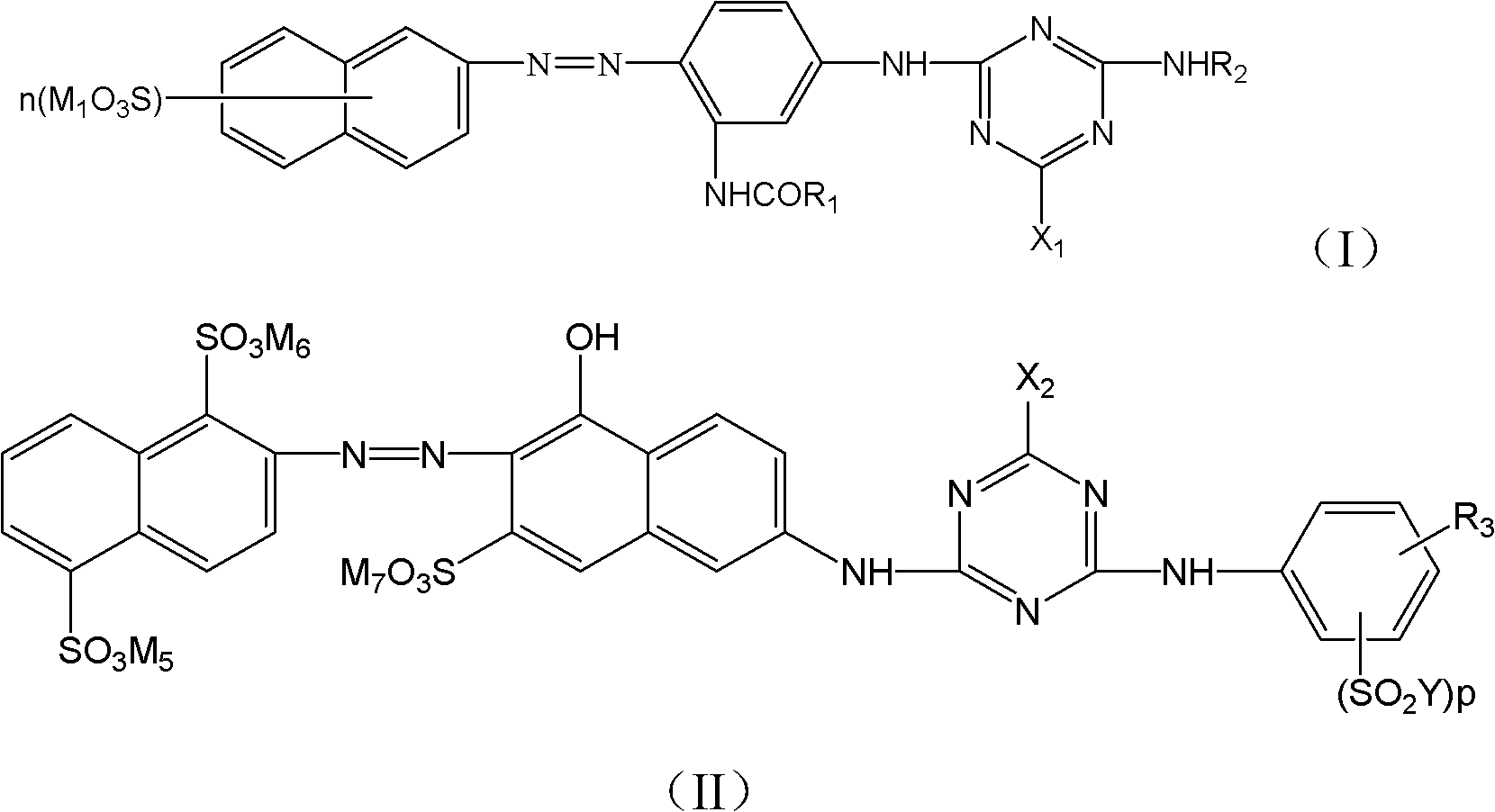

Active orange dye composition

The invention provides an active orange dye composition which mainly comprises one or a plurality of components A the structures of which are shown as a formula (I) and one or a plurality of components B the structures of which are shown as a formula (II). Based on the components A and the components B, the mass percent of the components A is 1 to 99 percent, and the mass percent of the components B is 1 to 99 percent; the active orange dye composition has high colour yield, high fixation rate and high enhancement property; and moreover, when the active orange dye composition is applied to cellulose fibre or a material containing the cellulose fibre for dyeing and printing, the active orange dye composition has good dyeing stability and bright colour, and various kinds of fastness, such as water washing resistance, friction resistance, perspiration resistance and colour fastness of chlorine water resistance, are excellent.

Owner:ZHEJIANG KEYONG CHEM CO LTD +1

Printed and embroidered seamless wall fabric and manufacturing method thereof

ActiveCN105804345ALow viscosityEvenly dispersedCovering/liningsDyeing processBiochemical engineeringMembranous layer

The invention belongs to the technical field of facing decoration materials and particularly relates to printed and embroidered seamless wall fabric and a manufacturing method thereof. The wall fabric comprises a cloth layer, a glue film layer and a raw paper layer or non-woven layer, wherein the glue film layer is located between the cloth layer and the raw paper layer; the surface, making contact with the glue film layer, of the cloth layer is a smooth surface, and the other surface of the cloth layer is provided with printed patterns; and embroidered patterns are arranged on the cloth layer, and the cloth layer is soaked or coated with a waterproof and mouldproof agent. The wall fabric is formed by conducting printing and embroidering on base cloth and then conducting shaping. The wall fabric manufactured through the manufacturing method has the advantages of being easy to stick, not prone to wrinkles, various in style and long in service life.

Owner:ZHEJIANG LIANXIANG EMBROIDERY CO LTD

Vegetable reactive dye printing paste and production method thereof

The invention relates to vegetable reactive dye printing paste comprising 80-90 percent of lightly-crosslinked ultra-high-viscosity high-substitution-value carboxymethyl starch, 3-6 percent of sodium polyacrylate, 5-9 percent of polyacrylamide, 1-2.5 percent of fatty alcohol polyethenoxy ether, 1-2.5 percent of solid lanthanon powders and the like. The vegetable reactive dye printing paste is produced according to the following process: the carboxymethyl starch prepared after secondary reaction is carried out the coarsely crushed, dried and finely crushed to be made into fine particle materials of granularity under 40 meshes; then the liquid material prepared from the sodium polyacrylate, the polyacrylamide, the fatty alcohol polyethenoxy ether and the like which are uniformly mixed is processed into solid materials by a high-speed centrifugation atomization drying device, and finally the carboxymethyl starch and other raw materials are added into a material mixer to be stirred and mixed uniformly according to the production formula of printing paste and enters into an automatic packaging machine to be packed into product. The printing paste has superior printing performance to sodium alginate, has simple processing technology and low cost and is the optimal substitute of the sodium alginate printing paste.

Owner:GANSU TIPTOP PLANT TECH CORP

Desert type anti-infrared camouflage fabric printing technology

The invention discloses a desert type anti-infrared camouflage fabric printing technology. The technological process comprises steps as follows: printing, baking, padding by a reduction liquid, rapid vat ageing, oxidizing, soaping, hot water washing, washing and drying. A high-temperature type disperse dye with good sublimation fastness and small cotton fiber staining and an anthraquinone indanthrene dye are adopted to perform one-paste printing with a double-phase method, a technology of thermosol and later reduction is adopted after drying, so that the color yield is increased, mutual staining is reduced, and dark and gloomy color and luster are avoided; the light transmittance of terylene is 100%, that is, the light reflectivity is zero, so that the colored light requirements are met by adjusting the use quantity of the disperse dye when the colored light approaches.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

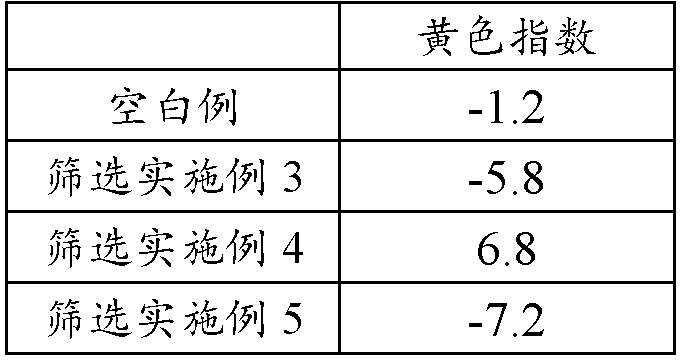

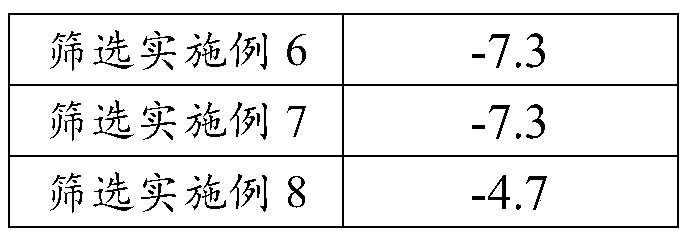

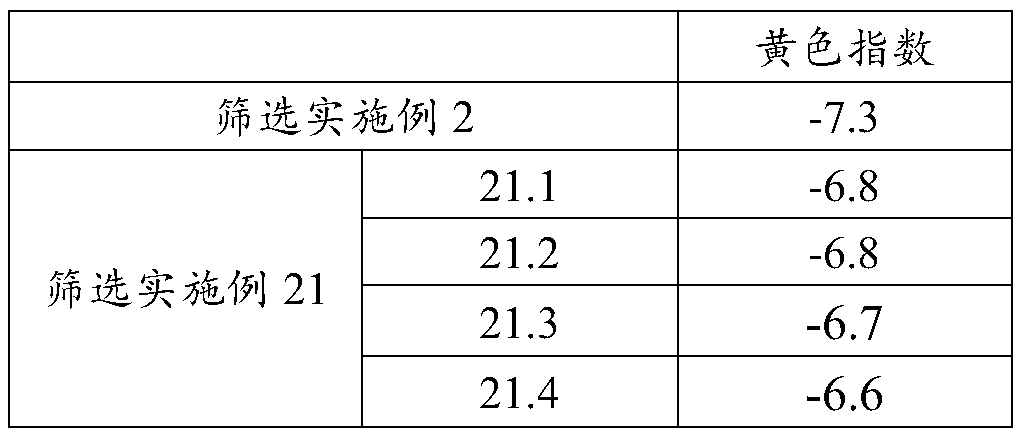

Preparation method of composite antioxidant for better improving yellowing of polymer caused by processing and long-term aging

InactiveCN110272563APrevents settling and agglomerationUniform pigment contentChemistryUltrasonic technology

The invention discloses a preparation method of a composite antioxidant for better improving yellowing of a polymer caused by processing and long-term aging. The composite antioxidant adopts a main antioxidant, an auxiliary antioxidant, a dispersant, an organic pigment, an inorganic pigment as main raw materials for preparation; and the method comprises the following steps: mixing the main antioxidant and the auxiliary antioxidant, performing melting to form a molten liquid, adding the dispersant, performing uniform mixing, performing ultrasonic treatment under ultrasonic waves, adding the organic pigment powder and the inorganic pigment powder, performing uniform dispersion, and finally performing extrusion granulation by using a twin-screw extruder to obtain the composite antioxidant particles. According to the method provided by the invention, the molten liquid of the main and auxiliary antioxidants is compounded with the pigments, the function of the dispersant and the ultrasonic technology are combined, so that the pigment powder is more uniformly dispersed into the molten liquid of the antioxidants, and the content of the pigments in a single composite antioxidant particle is uniform; and the composite antioxidant is compounded with the polymer, so that a color complementary effect of the pigments on coloring of the polymer is improved, and yellowing of the polymer caused by the processing and the long-term aging is effectively improved.

Owner:JIANGSU JIYI NEW MATERIAL CO LTD

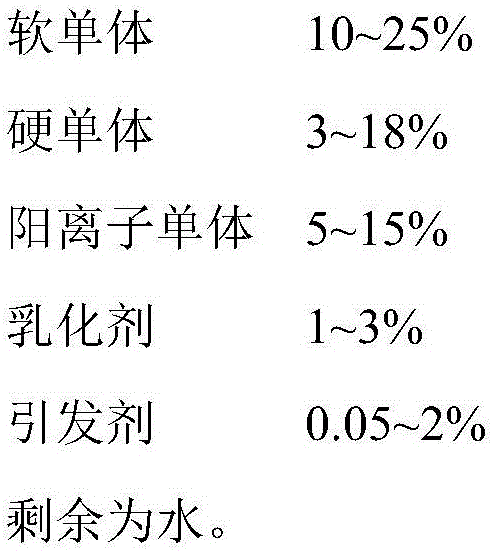

Cationic binder for denim paint dyeing

The invention relates to a cationic binder emulsion for denim paint dyeing. The binder emulsion is generated after a reaction of soft monomers, hard monomers, cationic monomers, crosslinking monomers, a compound emulsifier and an initiator. During preparation, a mixture of all the monomers and an initiator water solution are added into the emulsifier and distilled water for a reaction, cooling and filtering are conducted, and the cationic binder is prepared. The cationic binder is used for the denim yarn / fabric paint dyeing process or the paint overdyeing process, and during use, it is not needed to pretreat yarn / fabric or paint.

Owner:CHANGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com