Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3187 results about "Acetic acid solution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acetic Acid Otic Solution, USP is a solution of acetic acid (2%), in a propylene glycol vehicle containing propylene glycol diacetate (3%), benzethonium chloride (0.02%), sodium acetate (0.015%), and citric acid. The empirical formula for acetic acid is CH3COOH, with a molecular weight of 60.05.

Preparation method of essence microcapsules

InactiveCN102039108AGood chemical stabilityHigh mechanical strengthEssential-oils/perfumesMicroballoon preparationTextile fiberEthylic acid

The invention discloses a preparation method of essence microcapsules. The preparation method comprises the following steps: (1) dissolving chitosan in acetum; (2) adding emulsifier and essence into the chitosan acetum for high-speed emulsification and dispersion to obtain the chitosan essence emulsion; (3) adding the mixed solution of sodium alginate and sodium tripolyphosphate dropwise into the chitosan essence emulsion; (4) adjusting the pH value of the system to 5-7 with NaOH solution to obtain the condensed essence microcapsules; and (5) adding cross-linking agent into the condensed essence microcapsule system to perform chemical cross-linking process on the condensed essence microcapsules to obtain the essence microcapsules. For the essence microcapsules prepared according to the method disclosed by the invention, as chemical cross-linking process is implemented on the walls of the capsules, the density of the capsule walls and the resistance to the solution alkalinity / acidity are improved, and the application stability of the essence microcapsules is increased; moreover, with small size, the capsules can easily permeate into textile fiber, and the water-washing resistance of the textile fiber is greatly improved.

Owner:广州市戴文高分子材料科技有限公司 +1

Low fat cocoa extract

InactiveUS20050031762A1Enhance cocoa flavorAdd flavorCosmetic preparationsDough treatmentAntioxidantCocoa Extract

The present invention relates to a low fat cocoa extract having a high level of cocoa flavors and cocoa flavor precursors, and a high level of antioxidants. It also relates to a cocoa flavor concentrate, an antioxidant concentrate, and a foodstuff containing them. It also relates to the use of in-vitro fermented beans as naturally fermented beans. The process used to obtain such extracts comprises the steps of placing cocoa seeds in acetic acid solution, heating the mixture, and concentrating the solids of the mixture after having removed the seeds.

Owner:NESTEC SA

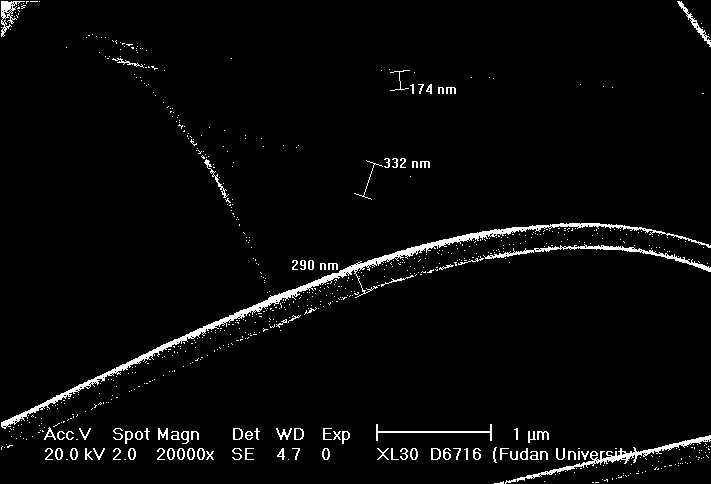

Nanometer ultrafine fibre film material of chitose and its preparation method

InactiveCN1569254ALarge liquid absorptionImprove cell affinityProsthesisPolyethylene oxideTissue repair

A nanometer superfine chitosan fibrous membrane material and its preparation process are disclosed. It belongs to tissue repair material technology. The film material with the diameter being 10 ª–mí½50ª–m, is made by chitosan with mass percent of 10-90% and polyvinyl alcohol or polyethylene oxide superfine fiber with diameter of 50nm -500nm The preparation process is: dissolving chitosan to acetic acid solution, adding PVA pr PEO into the solution, the mass ratio of chitosan with PVA / PEO being 10 / 90í½90 / 10, injecting the prepared 4%-8% spinning solution to the electrostatic spinning device for spinning to film material, therein, voltage being 5kVí½30kV, liquid inventory being 0.1mL / hí½0.5mL / h, receiving range being 5cmí½25cm. The advantages of the invention : large volume absorbing ability, favorable cell affinity, capable of degrading in vivo and promoting defect tissue repairing when the film material is utilized as artificial skin or artificial cartilage. In addition, the preparation process is simple.

Owner:TIANJIN UNIV

Method for preparing anti-pollution chitosan-nonwoven cloth composite porous filter membrane

InactiveCN101497002AImprove mechanical stabilityGood chemical stabilitySemi-permeable membranesWater bathsNonwoven fabric

The invention discloses a method for preparing an antipollution chitosan-nonwoven fabric composite porous filter membrane and belongs to the technical field of microfilter and ultrafilter composite membranes. The method is characterized in that the method adopts nonwoven fabric with nominal aperture of between 0.1 and 10 microns as a base membrane; a crosslinking agent is adopted to carry out pretreatment on the base membrane; 0.1 to 10 mass percent amylose is dissolved in an acetic acid solution; the crosslinking agent and a hole formation agent are added into the acetic acid solution; after the crosslinking reaction, a casting film liquid is obtained; at negative pressure, the casting film liquid is evenly coated on the surface and pores of the porous base membrane; and after treatment by a sodium hydroxide solution and a hot water bath, the antipollution chitosan-nonwoven fabric composite porous filter membrane is formed. The method has the advantages that the prepared composite membrane has good mechanical performance and chemical stability; and the surface of the membrane is levelled and smooth. The composite membrane has dual functions of hydrophile and antibiosis, can lighten adsorption of pollutants on the surface of the membrane, inhibit the growth and reproduction of thalli on the surface of the membrane, and keep the penetrating performance of the membrane and is widely applied to the water treatment process of various fields.

Owner:DALIAN UNIV OF TECH

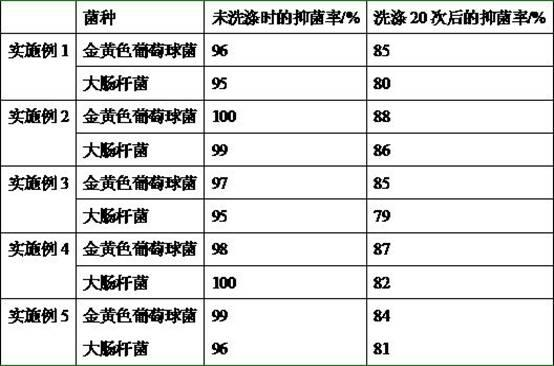

Traditional Chinese medicine inclusion compound with antibacterial effect and textile finishing method of traditional Chinese medicine inclusion compound

InactiveCN102605630AImprove the immunityOvercome the single defect of antibacterial effectFibre treatmentBiotechnologyCyclodextrin

The invention discloses a traditional Chinese medicine inclusion compound with an antibacterial effect and a textile finishing method of the traditional Chinese medicine inclusion compound. The traditional Chinese medicine inclusion compound is prepared from traditional Chinese medicine extract liquid with the total ingredient percentage being 100 percent and beta-cyclodextrin through a saturated water solution method, wherein the traditional Chinese medicine extract liquid comprises the following ingredients in percentage by mass: 25 percent to 60 percent of honeysuckle, 15 percent to 50 percent of folium Artemisiae argyi, 20 percent to 35 percent of liquorice and 5 percent to 15 percent of scutellaria baicalensis. The traditional Chinese medicine inclusion compound and cross linking agents are added into chitosan acetic acid solution to be prepared into antibacterial finishing liquid. A simple rolling baking process is adopted for carrying out antibacterial finishing on the cellulose fiber, the process is simple, the finished textile has the broad-spectrum antibacterial performance on common germs such as staphylococcus aureus, escherichia coli and the like, and in addition, the water washing resistance performance is good.

Owner:NANTONG JIAYUSI TEXTILE GROUP

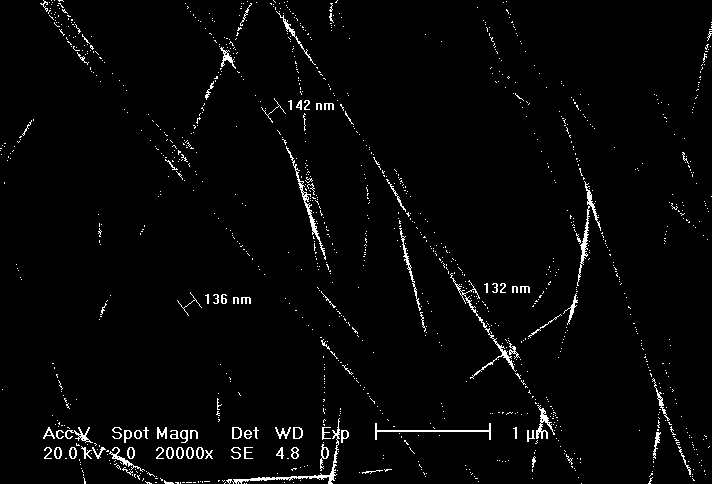

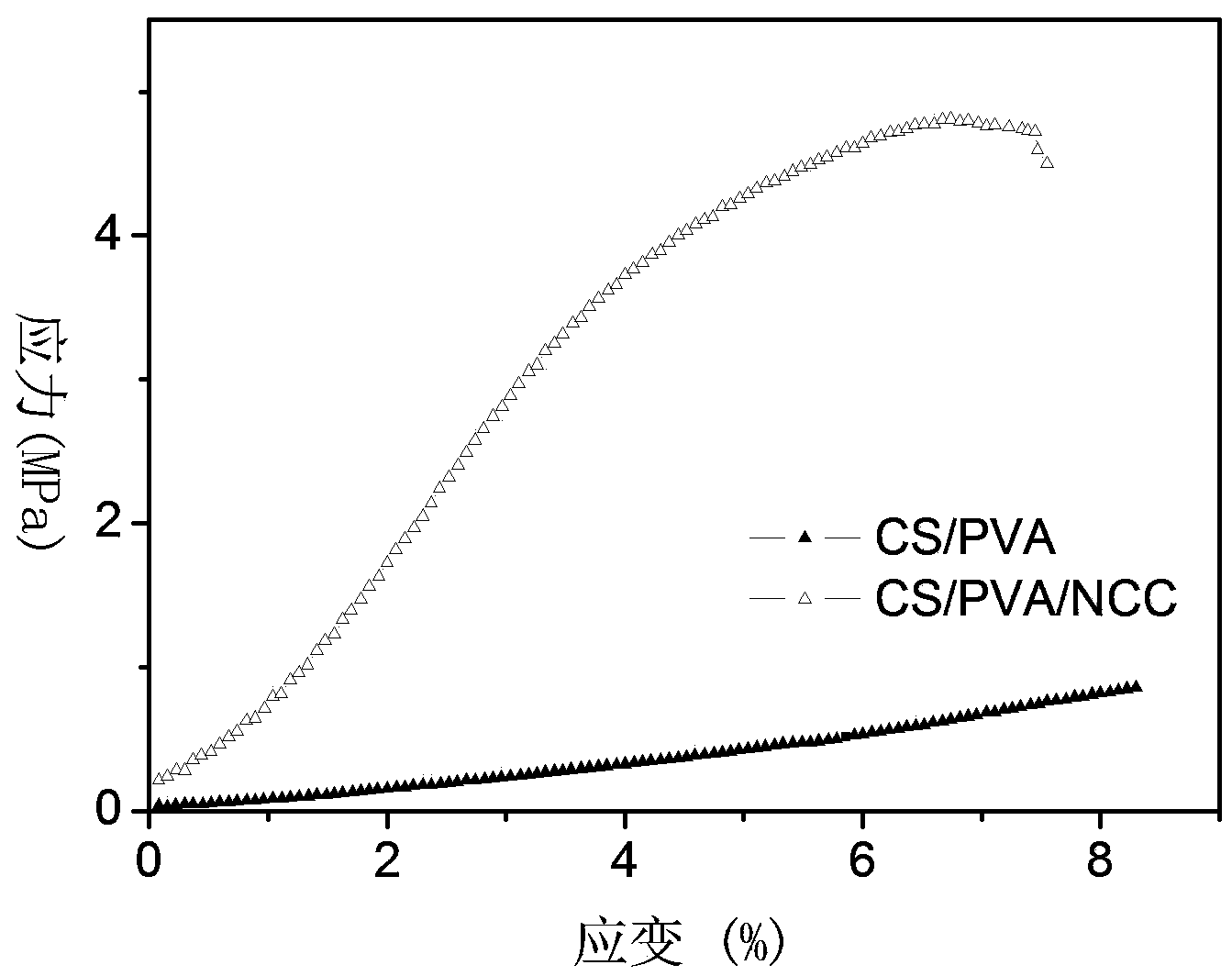

Method for preparing NCC/CS/PVA composite nano-membrane

ActiveCN103866487AAdjustable diameterLarger than surfaceNon-woven fabricsSpinning solutions preparationSpinningSilicic acid

The invention relates to a method for preparing an NCC / CS / PVA composite nanofiber membrane. NCC is rod-shaped particles, wherein the diameter of each particle ranges from 20 nm to 60 nm, and the particles are highly crystallized. The method comprises the steps that (1) an NCC / CS solution is prepared, wherein the concentration of the NCC, by weight, ranges from 0.09% to 0.21%; (2) an NCC / PVA solution is prepared, wherein the concentration of the NCC, by weight, ranges from 0.4% to 0.8%; (3) an acetic acid solution, tetraethyl orthosilicate, the NCC / CS solution obtained in the step (1) and processed through ultrasound, and the NCC / PVA solution obtained in the step (2) and processed through ultrasound are mixed to obtain a spinning solution, and the nanofiber membrane is obtained through the electrospinning technology, wherein the mass ratio of the acetic acid solution to the tetraethyl orthosilicate to the NCC / CS solution to the NCC / PVA solution is (2.5-3.5):(1.5-2.5):5:5; (4) the obtained nanofiber membrane is immersed in an alkaline solution for 2-6 hours at the normal temperature, and the membrane structure can be stable. The method for preparing the NCC / CS / PVA composite nanofiber membrane has the advantages that the nanofiber material preparation process is simple, the preparation process is environmentally friendly and free of pollution, nanofibers are excellent in mechanical performance, the surface of the nanofiber membrane is rich in modifiable functional groups, and the nanofiber membrane has a remarkable affinity effect on biomacromolecule.

Owner:TONGJI UNIV

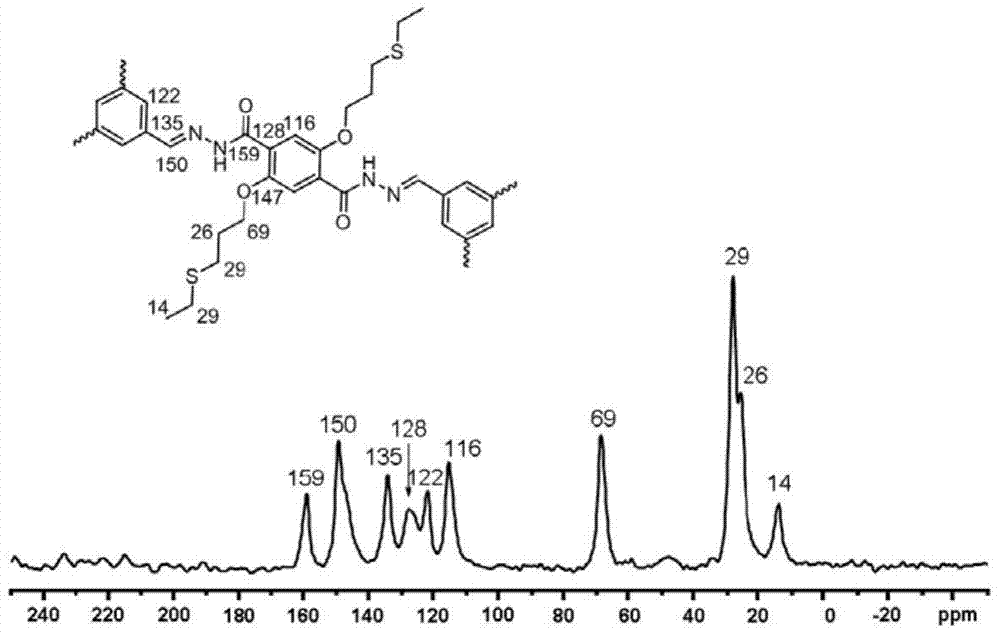

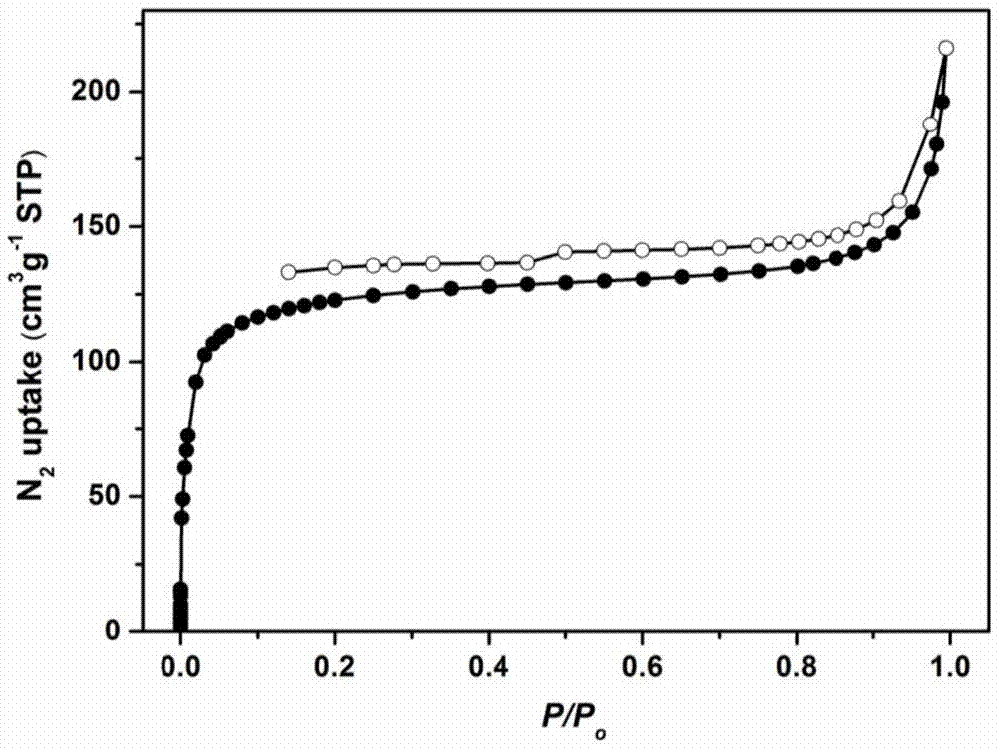

Sulfide functionalized covalent organic frame material and synthesis method thereof

ActiveCN103694469AHas a mesoporous structureHigh reaction yieldWater/sewage treatment by sorptionSynthesis methodsSolvent

The invention discloses a sulfide functionalized covalent organic frame material, The material has a structural unit shown in the specification, and is obtained by the following steps: adding 2,5-Bis(3-(ethylthio)propoxy)-terephthalohydrazide and benzenetricarboxaldehyde into a mixed solvent of 1,4-dioxane and mesitylene, adding an aqueous acetic acid solution into the above mixture and reacting at 120 DEG C for 1-3 days. The material has a mesoporous structure, has BET specific surface area of 470-480 m<2>?g<-1>, has good selective identification for mercury ions, and can be used for removal of the mercury ions.

Owner:LANZHOU UNIVERSITY

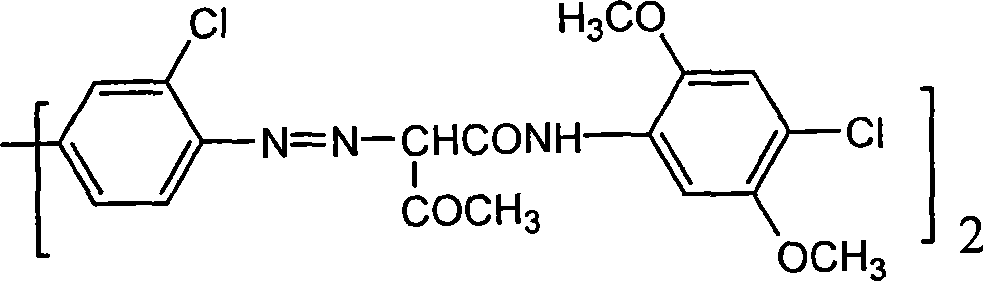

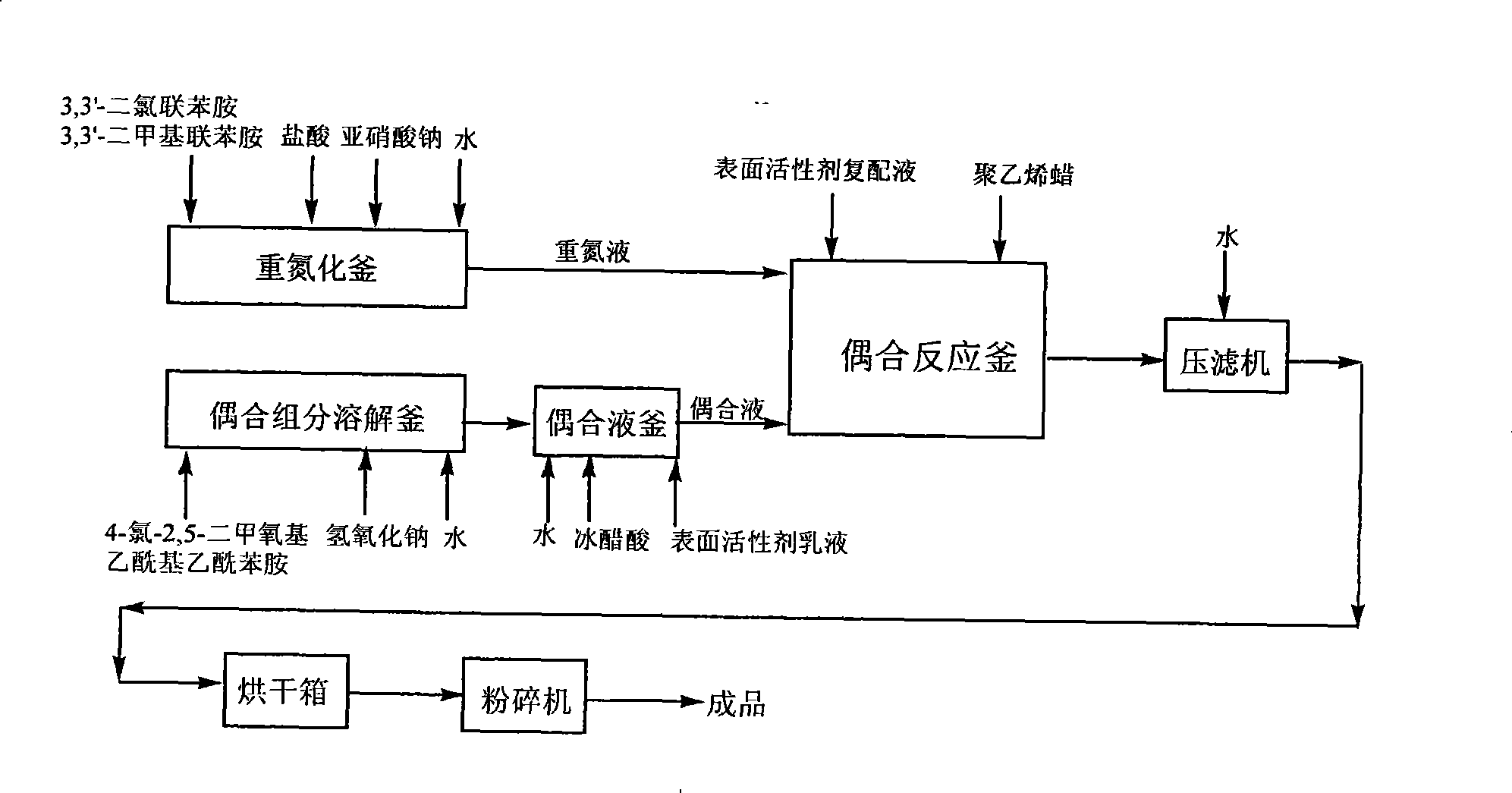

Method for preparing pigment yellow

The invention provides a method for preparing pigment yellow 83. The method comprises the following steps: 3, 3'-dichlorobenzidine, 3, 3'-dimethylbenzidine, hydrochloric acid and water are stirred, dissolved and added to sodium nitrite for diazotization, so as to obtain a diazonium solution; a sodium hydroxide solution containing 4-chlorine-2, 5-dimethoxy acetyl acetanilide is dripped into an acetic acid solution at the temperature between 20 and 40 DEG C, so as to prepare a coupling solution; the acetic acid solution contains an emulsion formed by well mixing anionic surfactant, nonionic surfactant, solvent and water; the diazonium solution is dripped into the coupling solution within 1 to 5 hours; the emulsion formed by compounding the anionic surfactant and non-polar hyper-dispersant is added to the coupling solution, reacts for 1 hour, and is heated to 90 to 100 DEG C; polyethylene wax is added in the mixture; and then the mixture, is insulated for 1 to 3 hours, pumped, filtered, washed, dried and ground, so as to obtain a finished product. The preparation method has the advantage of obtaining the pigment yellow 83 which is bright in color light, high in tinting strength, high in covering power and good in dispersibility.

Owner:宇虹颜料股份有限公司

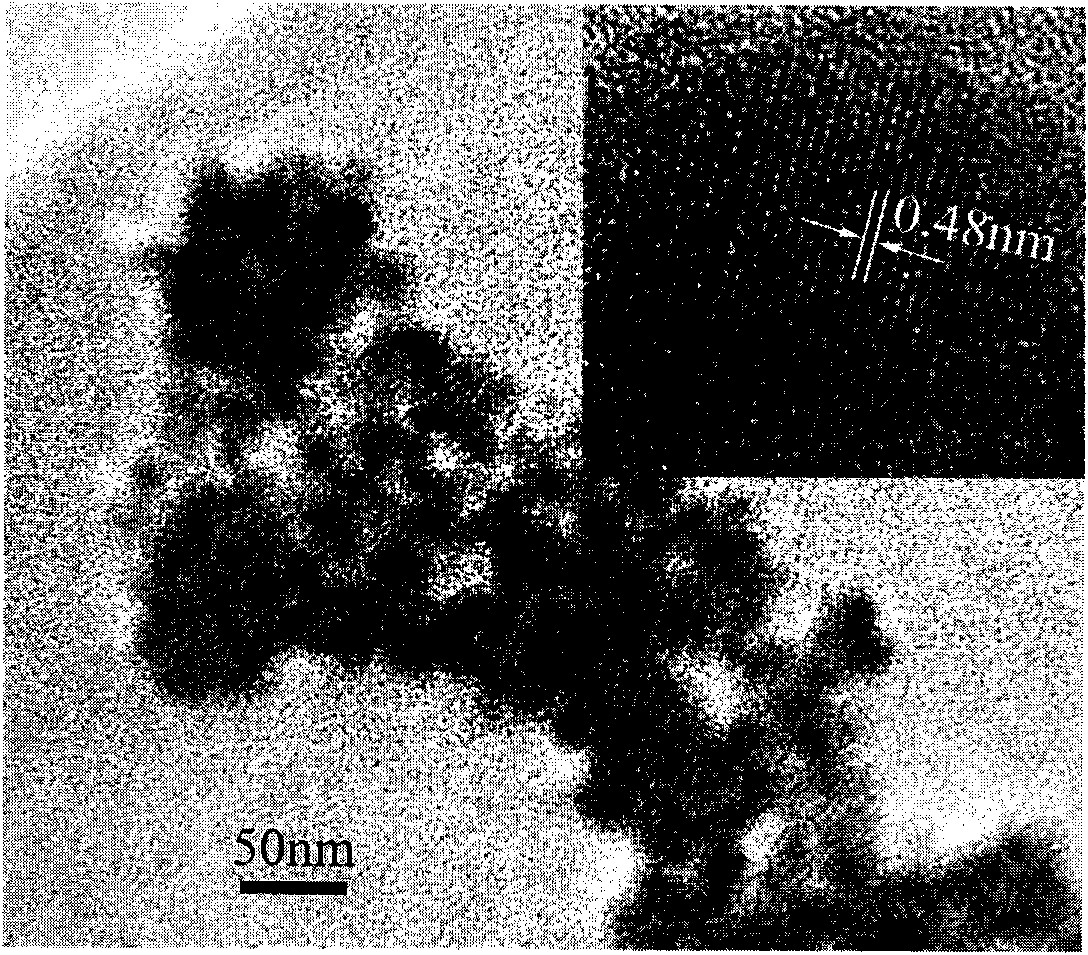

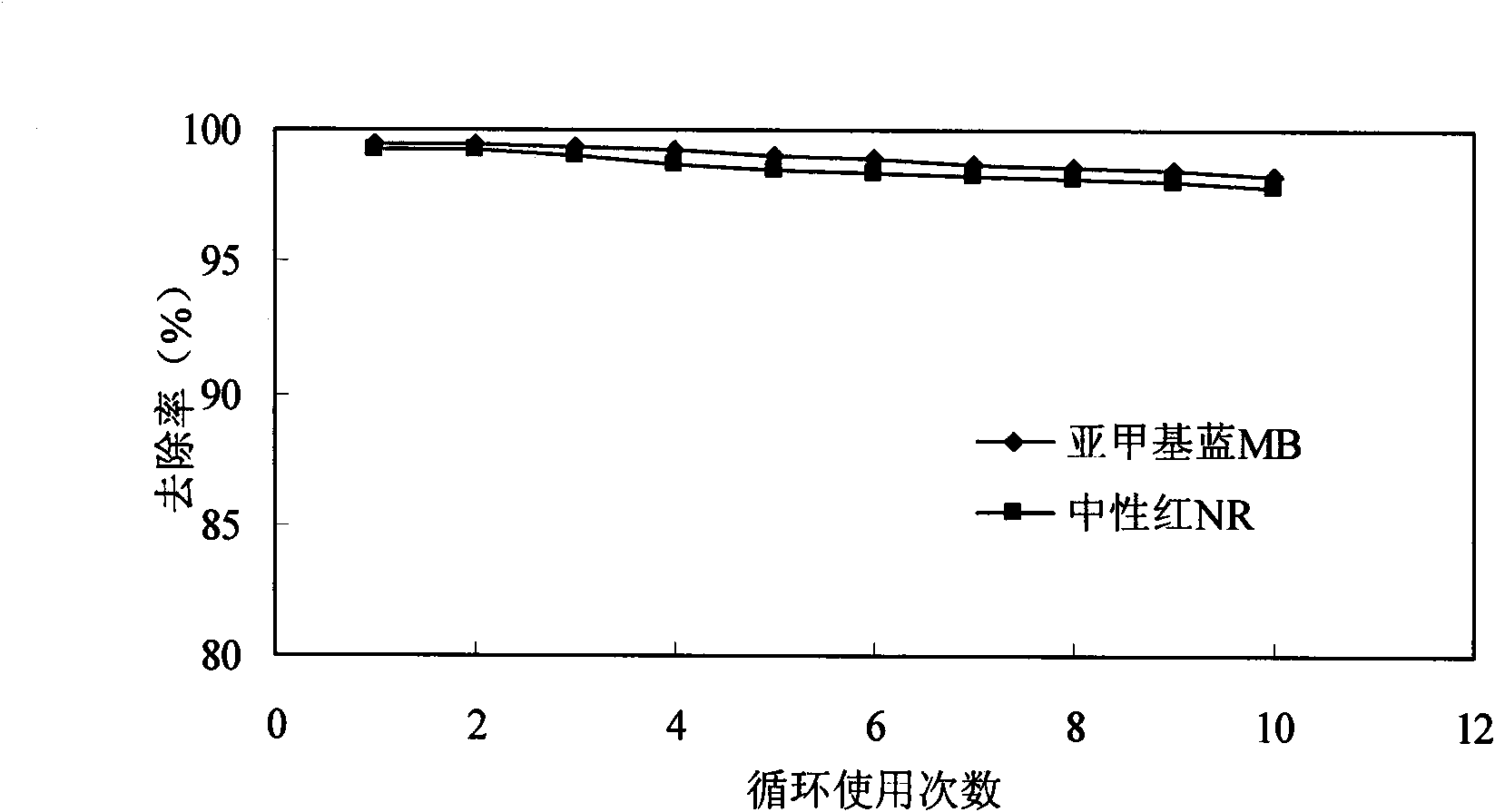

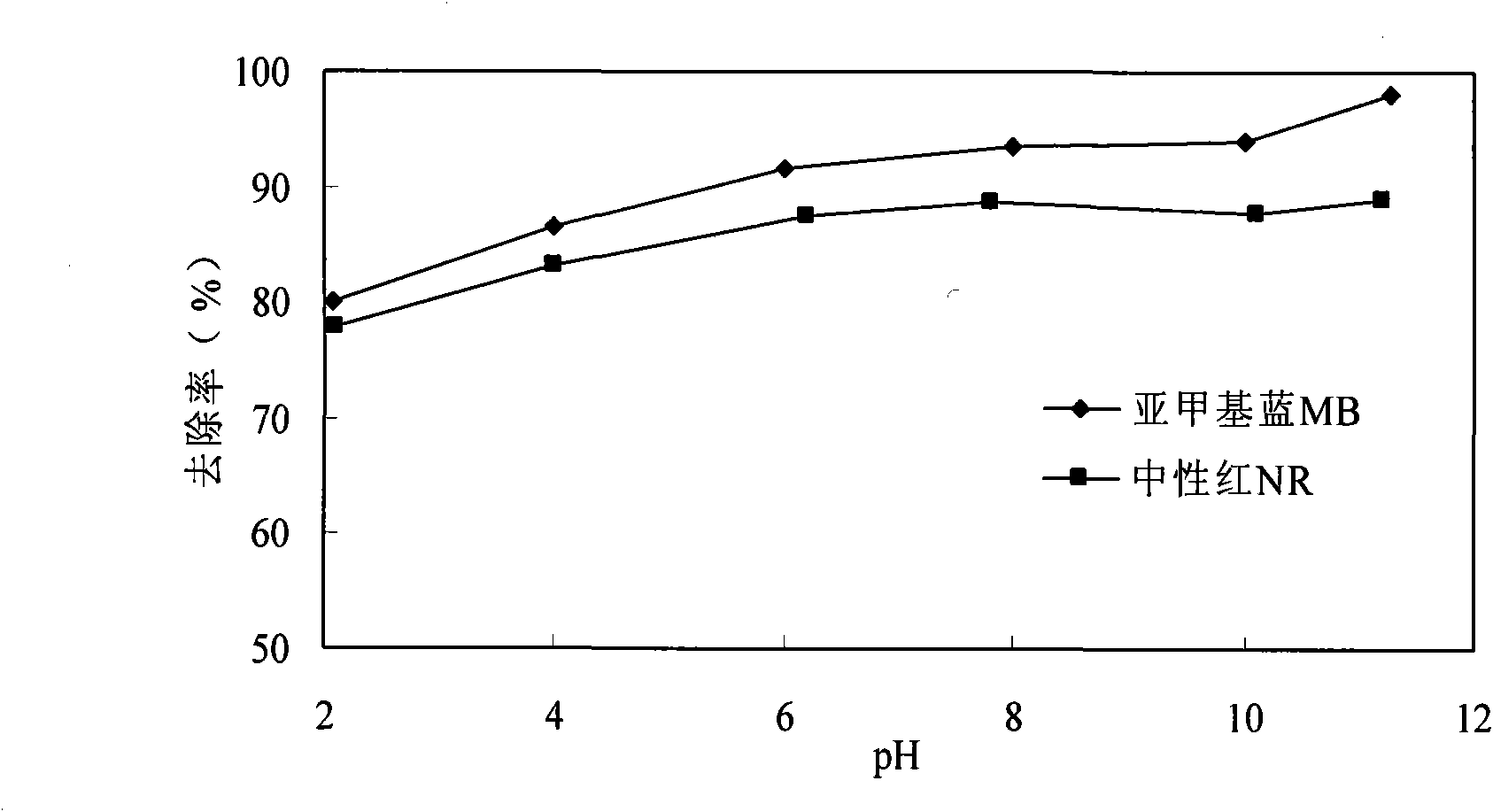

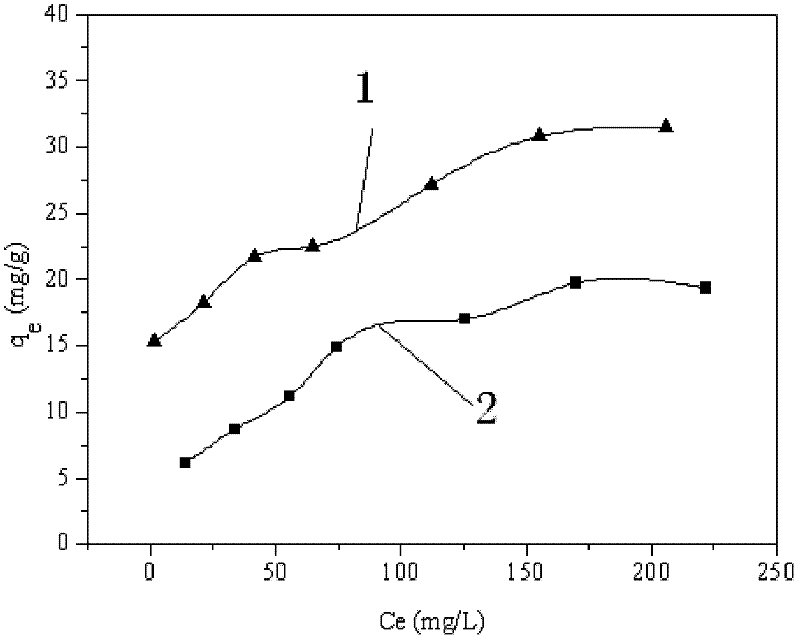

Method for removing organic cationic dyes from waste water by magnetic nano adsorption material

InactiveCN101670266AReduce internal diffusion resistanceImprove adsorption capacityOther chemical processesWater/sewage treatment by magnetic/electric fieldsDesorptionSorbent

The invention relates to preparation of a magnetic nano adsorbent and a method for removing organic cationic dyes from waste water by the same, and belongs to the technical field of wastewater treatment. The magnetic nano adsorbent uses Fe3O4 particles as a carrier, and coated humic acid as an active adsorbing component. The method comprises the following steps: adding mixed solution of ferric chloride and ferrous sulfate to alkaline humic acid solution, reacting under anaerobic, heating and stirring conditions, and obtaining the magnetic nano adsorbent after magnetic separation, washing, drying and grinding. The removal rate of methylene blue and neutral red reaches more than 95% by treating organic cationic dye wastewater with the magnetic nano adsorbent. The magnetic nano adsorbent after magnetic solid-liquid separation is regenerated by methanol-acetic acid solution, a desorption solvent recovers methanol and acetic acid by distillation for recycling use. The magnetic nano adsorbent has the advantages of nanoscale size, high active surface radicals, extremely high adsorption removal rate for cationic dyes, simple process, high efficiency and easy control.

Owner:BEIJING FORESTRY UNIVERSITY

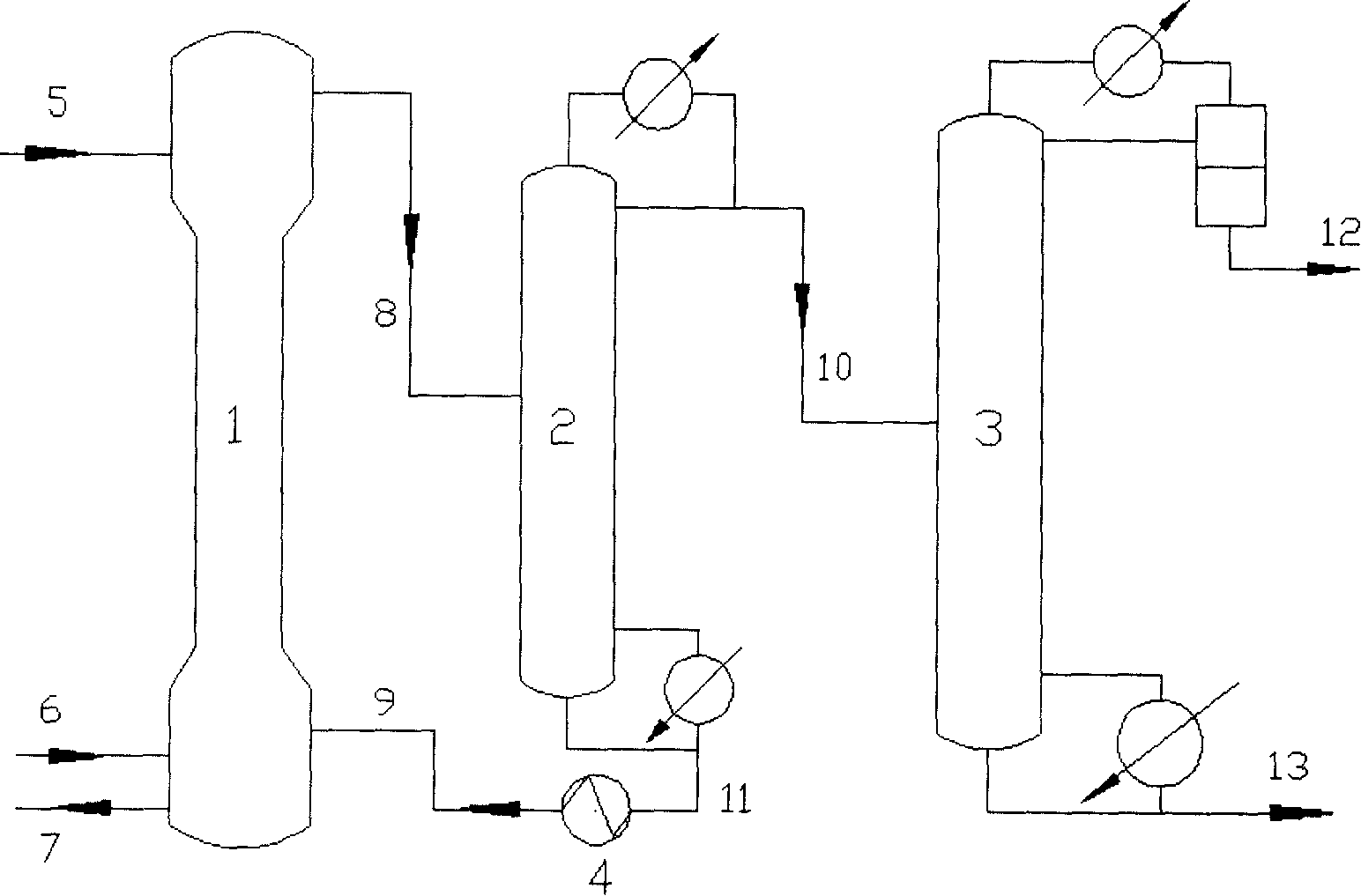

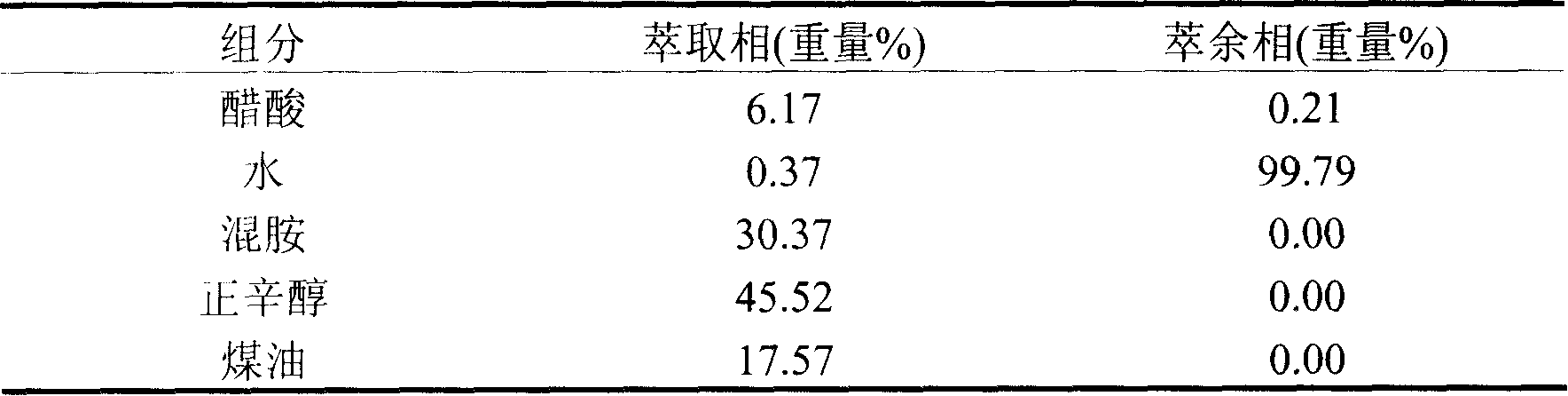

Method for recycling acetic acid in dilute acetic acid

ActiveCN101172941AImprove separation efficiencyIncreased acetic acid contentLiquid solutions solvent extractionCarboxylic compound separation/purificationBenzeneButyl acetate

The invention relates to a method for recycling acetic acid from diluted acetic acid, and aims at solving the problem that the recycling of acetic acid in the hydrolysis of furfural and methyl acetate as well as the Fischer-Tropsch combined production is difficult. The invention comprises the steps as follows: a) diluted acetic acid is extracted by a pulse filling extracting tower, the extractionphase containing extracting agent, the acetic acid and little water for the tower top is acquired, and the residual extraction phase of water containing micro acetic acid from the tower kettle is acquired; b) the extraction phase in an extracting agent recycling tower is conveyed; c) acetic acid 1 is fed into an azeotropic rectifying tower which utilizes one kind of benzene, cyclohexane, ethyl acetate, isopropyl acetate and butyl acetate as the extrainer, two-phase mixture of the extrainer and the water at a phase separator at the top of the tower is acquired, the water is extracted out from the tower top, and the retrainer returns into the tower. The utility model has the technical proposal of producing pure acetic acid at the tower top, solves the problems above, and adapts the industrial productions including recycling of acetic acid from wasted aldehyde water and extracting and refining acetic acid in the methyl acetate hydrolysis technique.

Owner:SHANGHAI RES INST OF PETROCHEMICAL TECH SINOPEC

Chitosan/carbon nanometer tube static spinning membrane preparation method

InactiveCN1730742AImprove solubilityGood film formingFilament/thread formingArtifical filament manufactureSolubilityPolyvinyl alcohol

The present invention is the preparation process of electrostatic spun chitosan / carbon nanotube film, and belongs to the field of antibiotic and antistatic material preparing technology. The preparation process includes the following steps: dissolving carbon nanotube in acid mixture to compound solution, heating the solution to boil, filtering, washing to weak acid and vacuum drying; dissolving chitosan inside glacial acetic acid solution to obtain yellowish glacial acetic acid solution of chitosan; mixing the carbon nanotube solution and the chitosan solution to obtain molecule level composite solution; mixing the molecule level composite solution with glacial acetic acid solution of PVA; and spinning. The preparation process is simple, and the obtained electrostatic spun chitosan / carbon nanotube material has high solubility, good filming performance, high conductivity, excellent antibiotic performance and excellent electromagnetic shielding performance.

Owner:TIANJIN UNIV

Acid soluble fish skin collagen and its preparing method

Owner:DALIAN POLYTECHNIC UNIVERSITY

Recycled concrete and preparation method thereof

InactiveCN111039624AReduce porosityCompact structureSolid waste managementEpoxyCompressive resistance

The invention relates to recycled concrete and a preparation method thereof, and belongs to the technical field of concrete. The recycled concrete comprises (by weight): 150-280 parts of cement, 90-130 parts of water, 800-950 parts of modified recycled coarse aggregate, 400-530 parts of fine aggregate, 40-85 parts of fly ash, 80-100 parts of mineral powder, 50-140 parts of zeolite powder, 30-60 parts of epoxy resin, 4-10 parts of a water reducing agent and 2-6 parts of an air entraining agent. The preparation method of the modified recycled coarse aggregate comprises the following steps: S1, crushing and screening waste concrete to obtain recycled coarse aggregate; S2, soaking the recycled coarse aggregate obtained in the step S1 in an acetic acid solution with the mass concentration of 2-7%, and airing; S3, stirring 80-110 parts of polyvinyl alcohol, 60-110 parts of silica fume, 40-80 parts of sodium silicate and 800-1,000 parts of water to obtain a modified liquid; and S4, soaking the recycled coarse aggregate obtained in the step S2 in the modified liquid obtained in the step S3, taking out the soaked recycled coarse aggregate, and baking the recycled coarse aggregate to obtainthe modified recycled coarse aggregate. The recycled concrete provided by the invention has a good compressive strength effect.

Owner:泸州临港思源混凝土有限公司

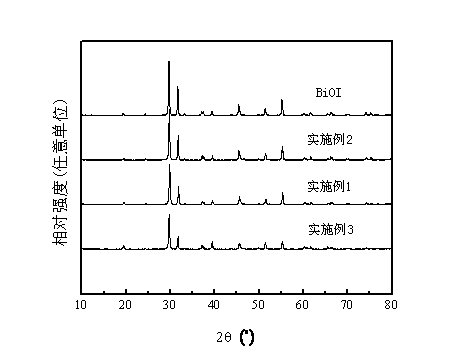

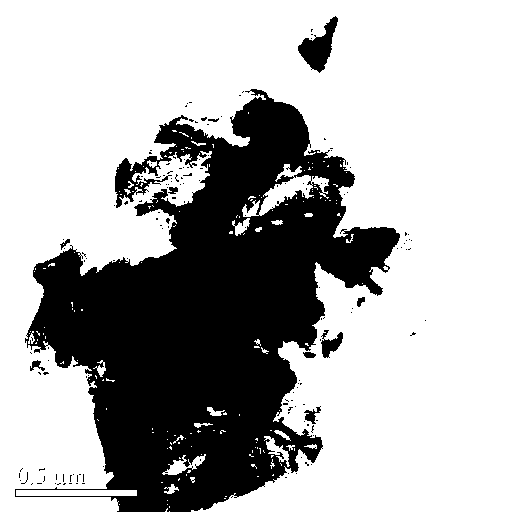

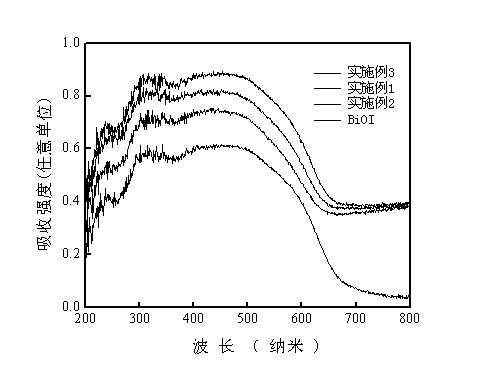

BiOI-graphene visible light catalyst and preparation method thereof

InactiveCN102698775ASimple preparation processThe preparation process is economical and environmentally friendlyPhysical/chemical process catalystsWater/sewage treatment by irradiationSolar photocatalysisPtru catalyst

The invention relates to a BiOI-graphene visible light catalyst and a preparation method thereof, belonging to the technical field of inorganic material synthesis and photocatalysis. BiOI and graphene are in the shape of a slice, and the graphene is 1.0%-3.0% by weight. The preparation method of the BiOI-graphene visible light catalyst comprises the following steps of: firstly ultrasonically dispersing graphite oxides into ethanol; then stirring, and adding a certain amount of sodium iodide or potassium iodide water solutions and bismuth nitrate glacial acetic acid solutions at the same time; transferring suspending liquid into a high-pressure reaction kettle with a polytetrafluoroethylene liner, and carrying out crystallization reaction at 120-150 DEG C for 6-12 hours; filtering, washing and drying obtain solid products so as to finally obtain the BiOI-graphene compound light catalyst. The preparation method has environment friendliness and simple process; and the prepared BiOI-graphene visible light catalyst has very high visible light catalytic activity and potential application value in a control technology decomposing organic pollutants by utilizing solar photocatalysis.

Owner:SHANGHAI UNIV

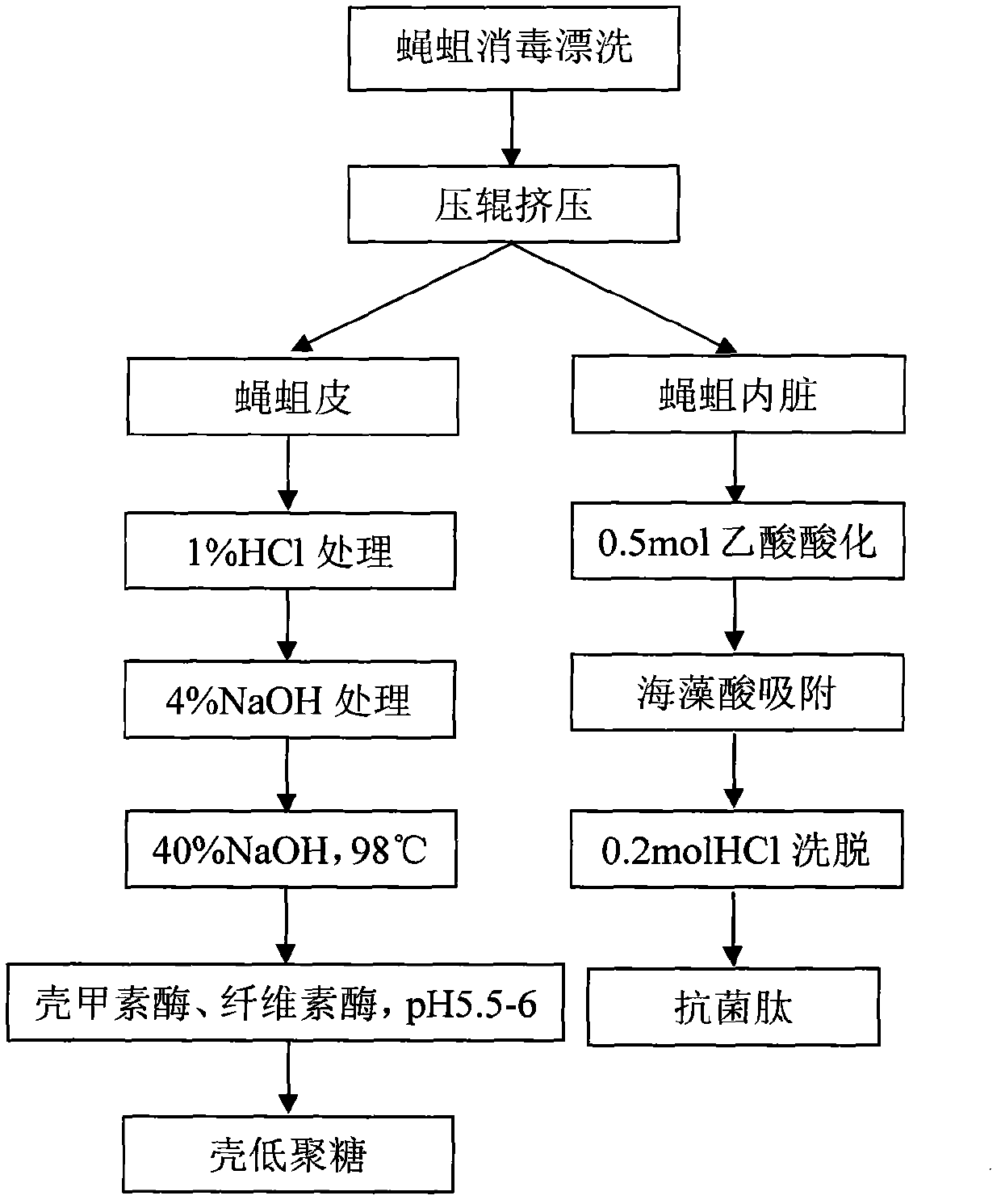

Method for extracting chitin and antibacterial peptide from fly larvae

InactiveCN102558387AReasonable technical routeReduce extraction costsPeptide preparation methodsWater bathsNatural product

The invention belongs to the field of product extraction technology and relates to a method for extracting chitin and antibacterial peptide from fly larvae. The method comprises the following steps of: firstly disinfecting and rinsing fresh fly larvae to be clean, then extruding the cleaned fly larvae to separate the fly larvae skin from visceral mass serous fluid; firstly soaking with hydrochloric acid solution, drying after washing, and then soaking with NaOH solution to remove protein; retaining residual liquid, drying after cleaning, adding the NaOH solution after crushing, carrying out water bath at the temperature of 98 DEG C, and heating for reaction; putting chitosan into acetic acid solution, stopping reaction after the chitosan is dissolved, filtering, cleaning, drying at the temperature of 50 DEG C, and obtaining the chitosan; and then adding acetic acid into the visceral mass serous fluid of the fly larvae, homogenizing, standing over the night at the temperature of 4 DEG C, filtering, adsorbing the filtrate with alginic acid, filtering, then eluting the antibacterial peptide adsorbed on the alginic acid with the hydrochloric acid solution, adjusting the pH value of the eluent to be 3.5, carrying out precipitation with NaCl, carrying out dialysis and desalting, drying and obtaining a crude antibacterial peptide product. The method has the advantages of reasonable technical route, low cost, high yield, large economic value, environmentally-friendly effect and effective utilization of the fly larvae resources for preparing natural product varieties.

Owner:QINGDAO ZHONGREN PHARMA

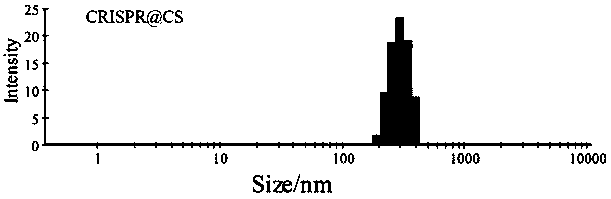

Preparation of CRISPR (clustered regularly interspaced short palindromic repeats)/Cas9 nano gene system and application of CRISPR/Cas9 nano gene system in transfection

InactiveCN107904261AEasy to operatePossess the function of transfection into cellsHydrolasesStable introduction of DNATransfer geneAcetic acid solution

The invention belongs to the technical field of biology and particularly relates to preparation and cell transfection application of a CS-based (chitosan-based) and CRISPR / Cas9 plasmid-constructed nano gene drug. The preparation comprises dissolving chitosan into acetic acid solution, dropwise adding the chitosan acetic acid solution into water, adding in CRISPR in mass proportion to the chitosan,encapsulating and carrying CRISPR / Cas9 with the chitosan to prepare a novel gene drug nano particle for good gene transfection effects or targeted exogenous gene introduction and further to achieve the effects of transferring gene drugs into cells. The novel nano compound of CRISPR@CS structured on the CS and the CRIPPR through an optimal feeding ratio can significantly improve the transfection efficiency of genes in cells to convey more genes into the cells to take effects, thereby being expected to being widely applied in the field of gene treatment through gene drug delivery.

Owner:FUZHOU UNIV

Gelatin-chitosan composite food packaging film and preparation method thereof

The invention relates to a gelatin-chitosan composite food packaging film. The gelatin-chitosan composite food packaging film is prepared by the following steps of: dissolving 0.5 to 6 grams of gelatin into 0.5 to 10 milliliters of distilled water to stir uniformly at the temperature of between 25 and 60 DEG C; dissolving 0.05 to 0.4 gram of chitosan into 10 to 40 milliliters of acetum at the concentration of 0.5 to 4 percent to stir uniformly at the temperature of between 20 and 30 DEG C; adding the prepared gelatin solution and the chitosan solution in a volume ratio of the gelatin solution to the chitosan solution of 1:9-6:4 to heat and stir for 5 to 25 minutes at the temperature of between 50 and 70 DEG C; adding 0.5 to 2.5 grams of glycerin and 0.05 to 0.5 gram of sorbitol sequentially into the mixture to continue to heat and stir for 5 to 25 minutes; ultrasonically oscillating the obtained solution for 15 to 60 minutes and then performing vacuum degassing for 0.5 to 2 hours; pouring the solution into a mould to form a film; drying the film and dip-coating the film with 0.5 to 5 percent edible oil solution; and then drying and cooling the film to obtain the gelatin-chitosan composite food packaging film.

Owner:FUZHOU UNIV

Method for preparing water soluble chitosan

InactiveCN1554267AHigh yieldLow costSugar derivativesSugar derivatives preparationAcetic anhydrideWater soluble chitosan

The process of preparing water soluble chitosan includes adding chitosan into 2-8 wt% concentration acetic acid aqua to compound acetic acid solution of chitosan of 2-10 wt% concentration, adding enzyme or oxidant to degrade chitosan to polymerization degree below 1000, cooling the solution to 0-10 deg.c, adding ethanol or methanol solution of acetic anhydride, stirring first at normal temperature for 2-24 hr and then at 20-40 deg.c for another 20-40 deg.c, adding alkali to regulate pH to over 8 under stirring, adding ethanol to deposit, centrifugation to obtain solid product, soaking in alcohol solution of KOH, centrifugation, alcohol washing, and drying to obtain water soluble chitosan of acetyl degree of 45-55%. The present invention has simple preparation process, and the product is used as material for tumor resisting and immunity raising medicine and health product and as additive for cosmetics and food.

Owner:孝感学院

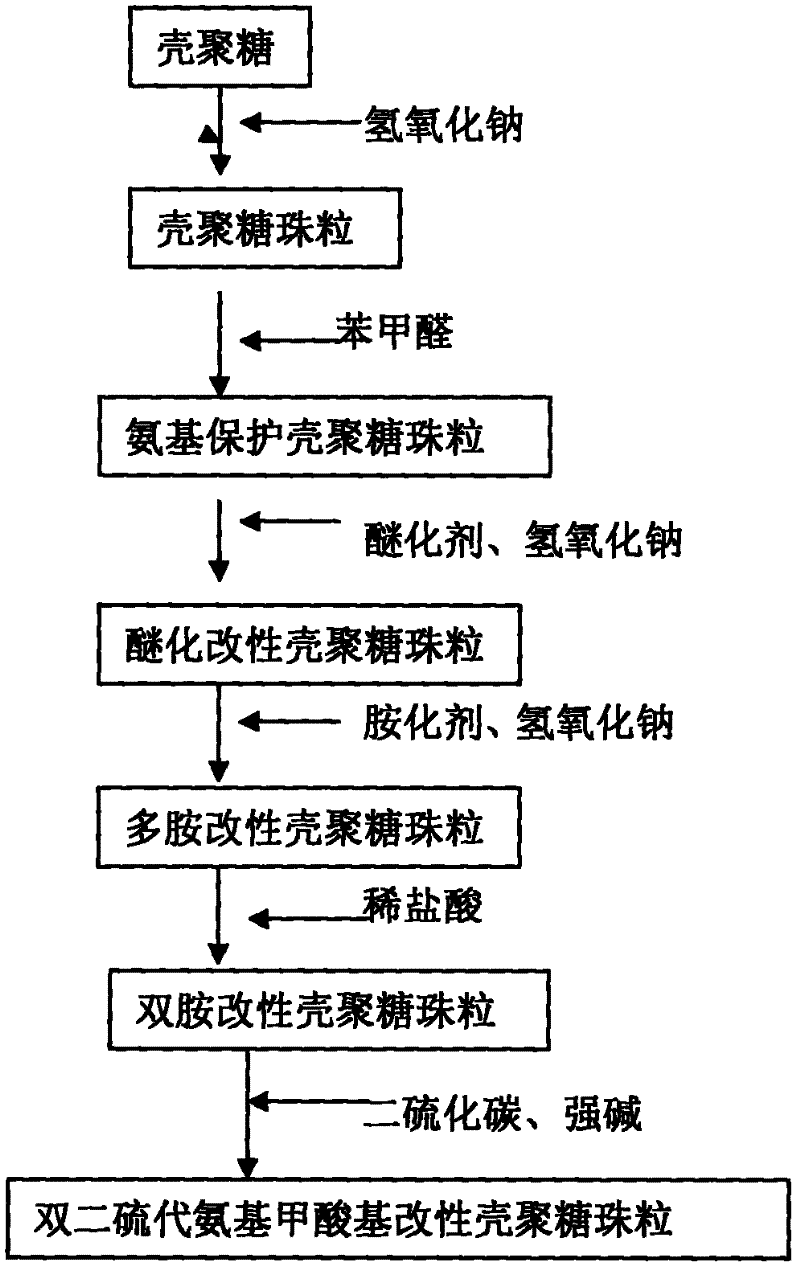

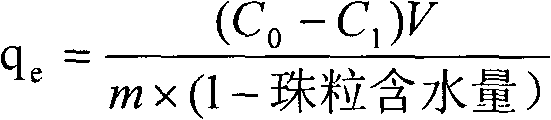

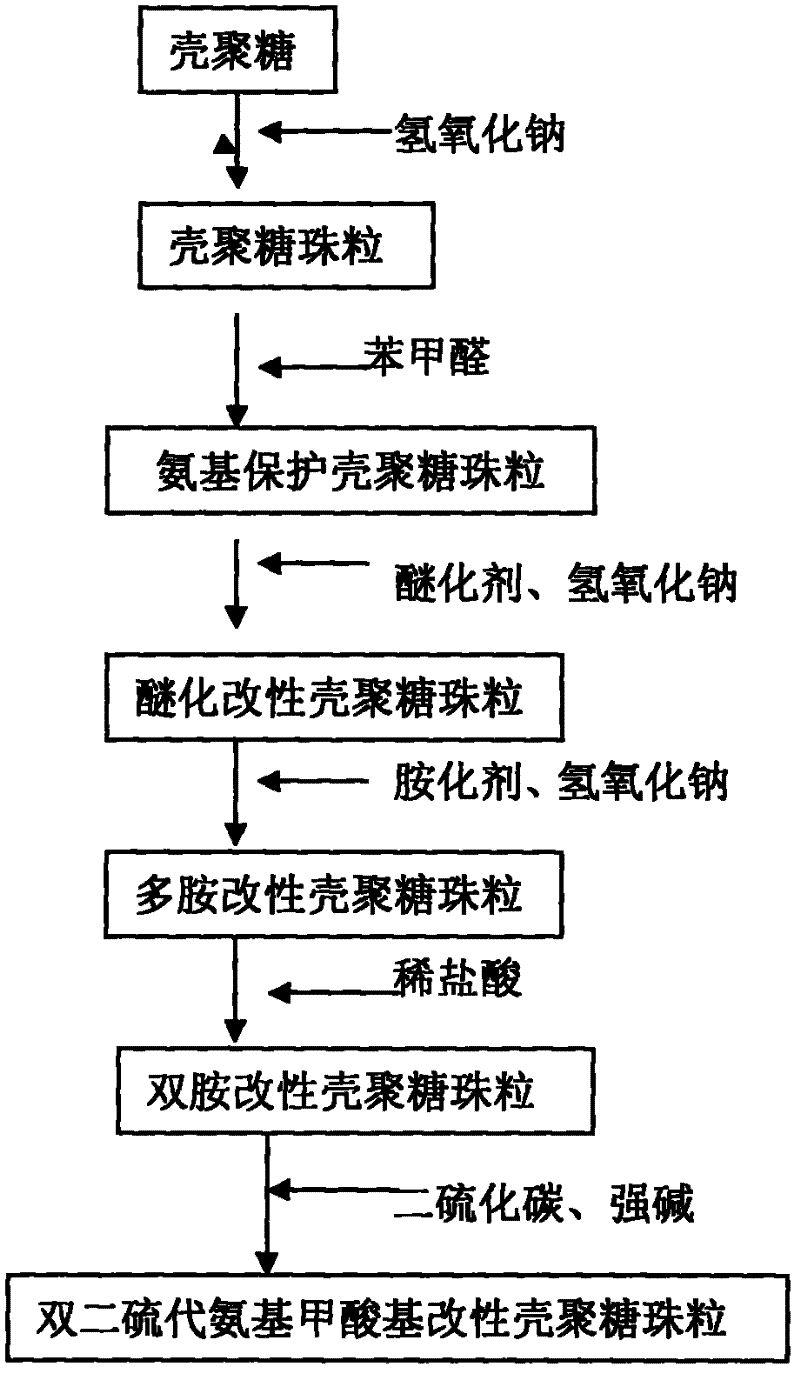

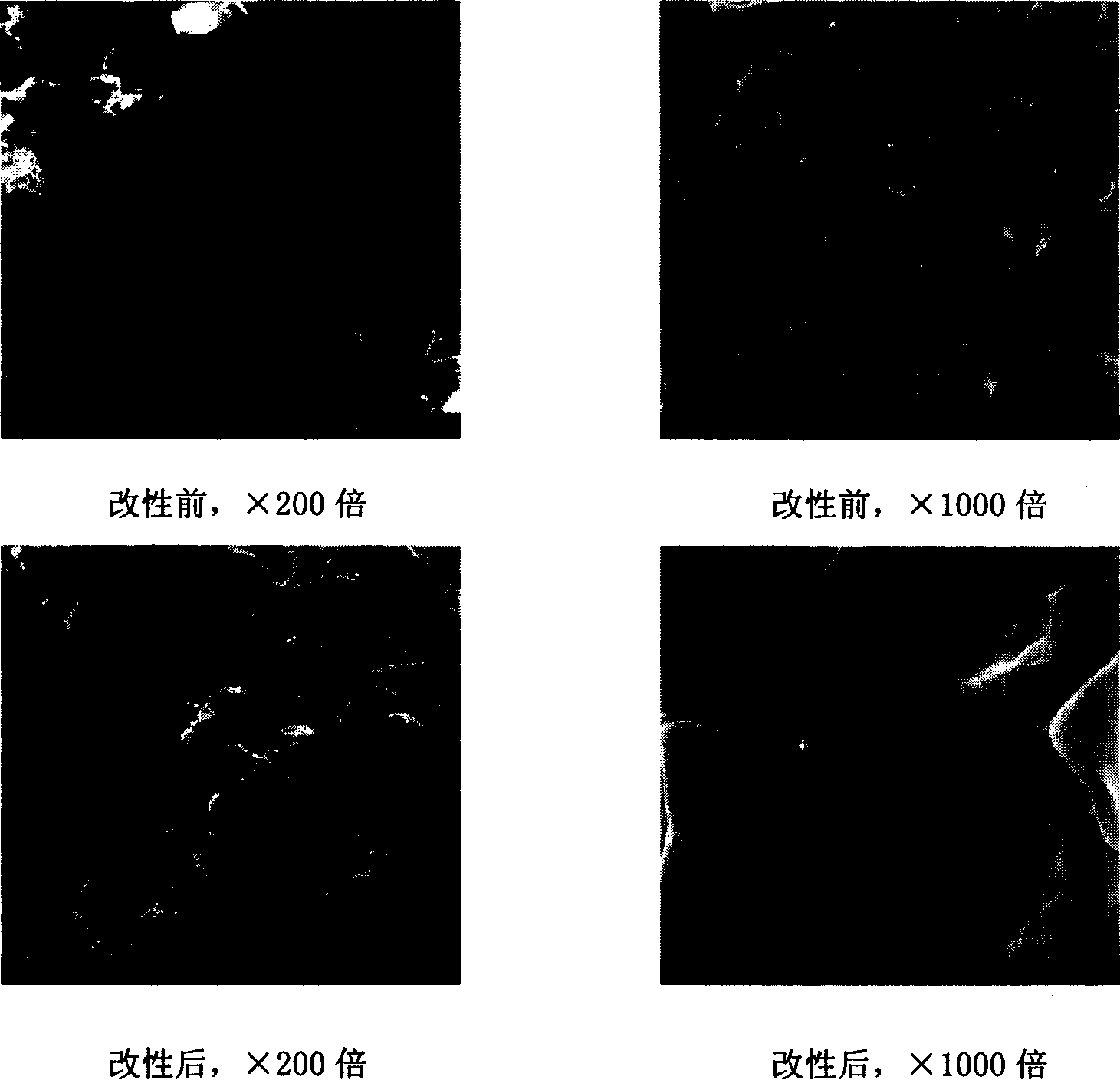

Method for preparing di-dithiocarbamate modified chitosan beads

InactiveCN102504312AGood dispersionLarge specific surface areaOther chemical processesWater/sewage treatment by sorptionBenzaldehydeMining industry

The invention relates to a method for preparing di-dithiocarbamate modified chitosan beads. The method comprises the following steps of: after dissolving 5 g of chitosan in an acetic acid solution at first, solidifying the chitosan in a sodium hydroxide solution to form chitosan beads with the diameter of 2-3 mm, wherein the solidifying time is 8-26 h; and, after carrying out Shiff alkali reaction, etherification, amination and elimination of benzaldehyde of the chitosan beads, grafting carbon disulfide under an alkaline condition to obtain di-dithiocarbamate modified chitosan. Compared with the original chitosan, the chitosan disclosed by the invention as a water treatment agent has stronger adsorption property and can be applied to treatment of heavy metal ions in wastewater, such as electroplating wastewater, battery wastewater, wastewater in mining industries and the like; the adsorption selectivity of the chitosan is increased; furthermore, the chitosan can be recycled for many times; and the purpose of rationally utilizing resources is achieved.

Owner:上海同纳环保科技有限公司

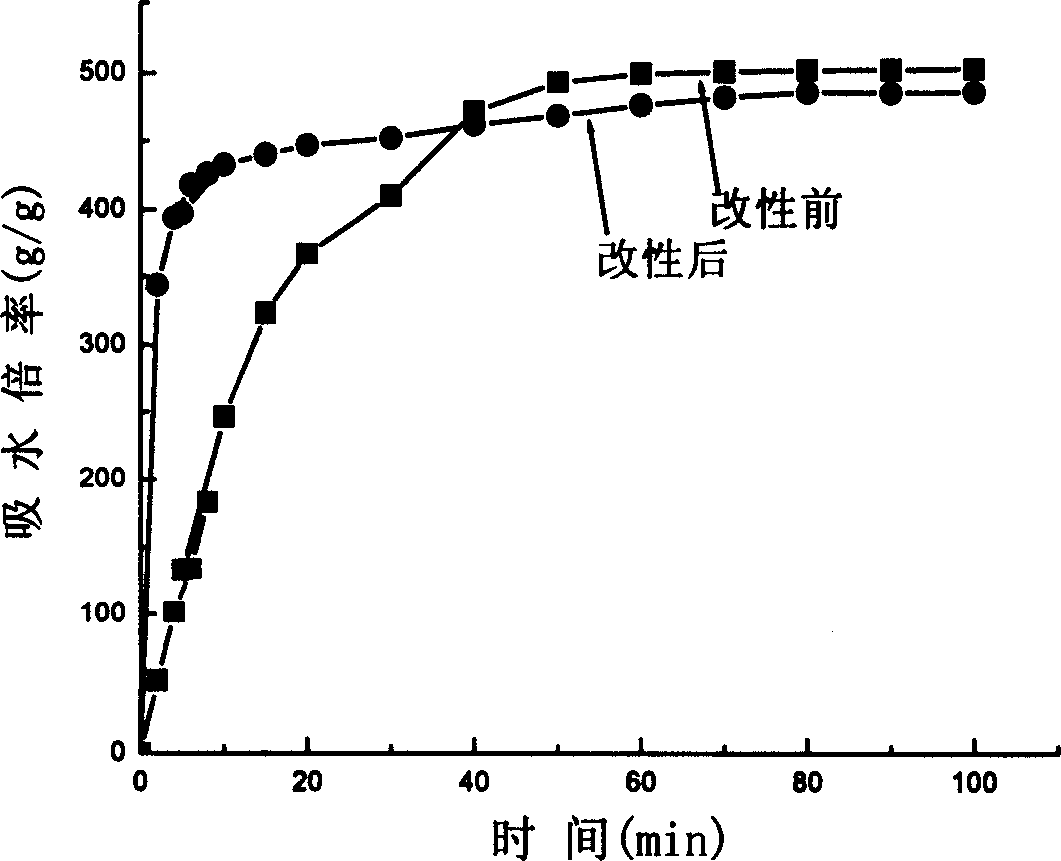

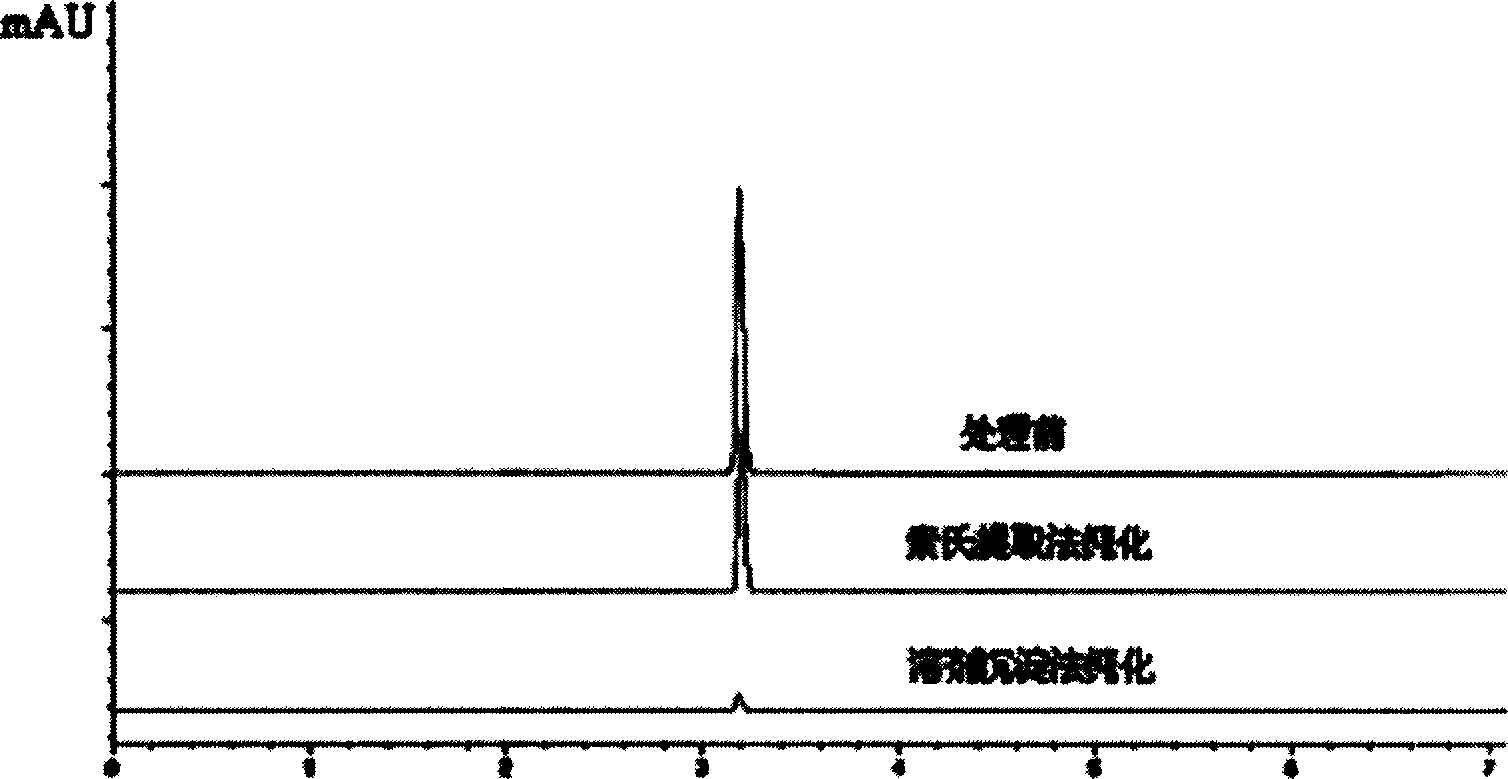

Process for preparing chitosan base macroporous high water absorptive resin

InactiveCN1616505AThe synthesis steps are simpleProcess conditions are easy to controlCross-linkPotassium persulfate

The present invention relates to the preparation process of chitosan base macroporous high water absorption resin. After chitosan is dissolved in dilute acetic acid solution, acrylic acid is made to graft on the molecular chain of chitosan under the initiation of ammonium or potassium persulfate and the product is cross-linked with cross-linking agent, so as to produce high water absorption chitosan grafted acrylic resin with distilled water absorption of 560-1210 g / g and physiological saline absorption of 76-125 g / g. The prepared resin is further modified via solvent deposition process to form macroporous structure to raise the water absorbing rate greatly. High efficiency liquid phase chromatographic test shows that the resin has greatly reduced acrylic acid monomer residue.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Preparation method of porous biological carbon heavy metal adsorbing material based on cotton straw

ActiveCN104941589AHigh porositySubtle structureOther chemical processesAlkali metal oxides/hydroxidesFiltrationSilanes

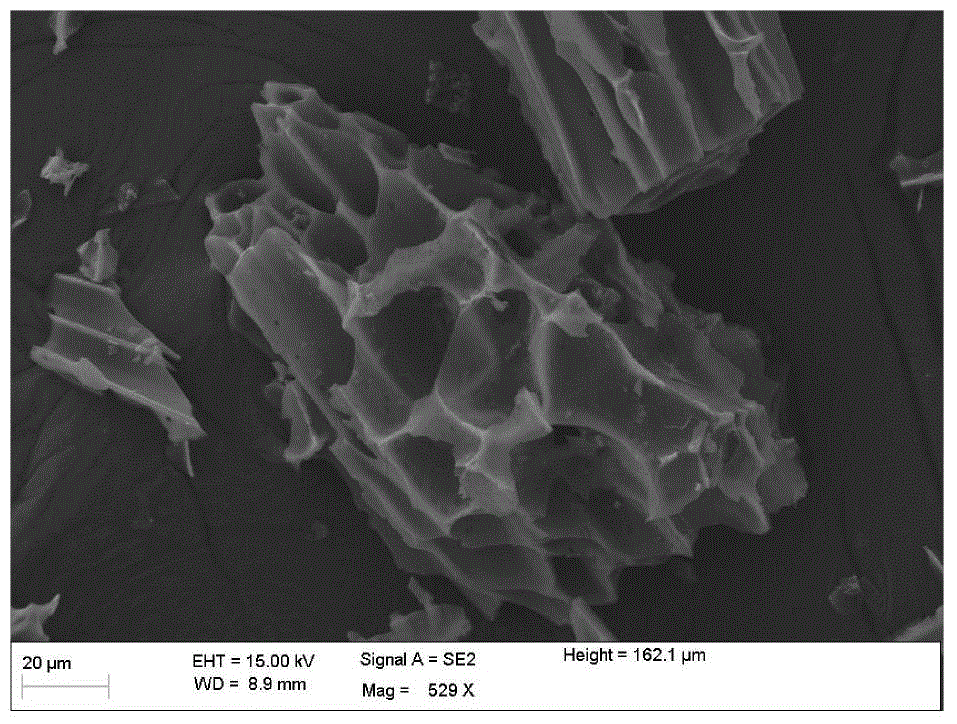

The invention discloses a preparation method of a porous biological carbon heavy metal adsorbing material based on cotton straw. The preparation method comprises the following steps: (1) adding the cotton straw into a ZnCl2 solution, carrying out stirring and impregnation for a certain time, and drying; (2) placing the dried cotton straw into an electric tube furnace for high-temperature calcination, grinding the calcined product into powder, adding the powder and ultrapure water into a hydrothermal reaction kettle, stirring till swelling is sufficient, heating for a reaction, and conducting centrifugal drying on the reaction product, so as to obtain a biological carbon material; (3) adjusting the pH of an ethanol aqueous solution with an acetic acid solution, adding 3-mercaptopropyl triethoxy silane into the ethanol aqueous solution, and carrying out oscillation to obtain a modified liquid; adding the biological carbon material into the modified liquid, carrying out oscillation and filtration, drying the obtained solid, washing the dried solid with an ethanol aqueous solution, and drying to obtain the biological carbon heavy metal adsorbing material. The preparation method is simple, and easy to operate; the biological carbon heavy metal adsorbing material prepared according to the method adopts a porous honeycomb-shaped structure, is large in specific surface area, high in heavy metal adsorbing property, and high in economic value and environment-friendly meaning.

Owner:WESTERN MINING CO LTD

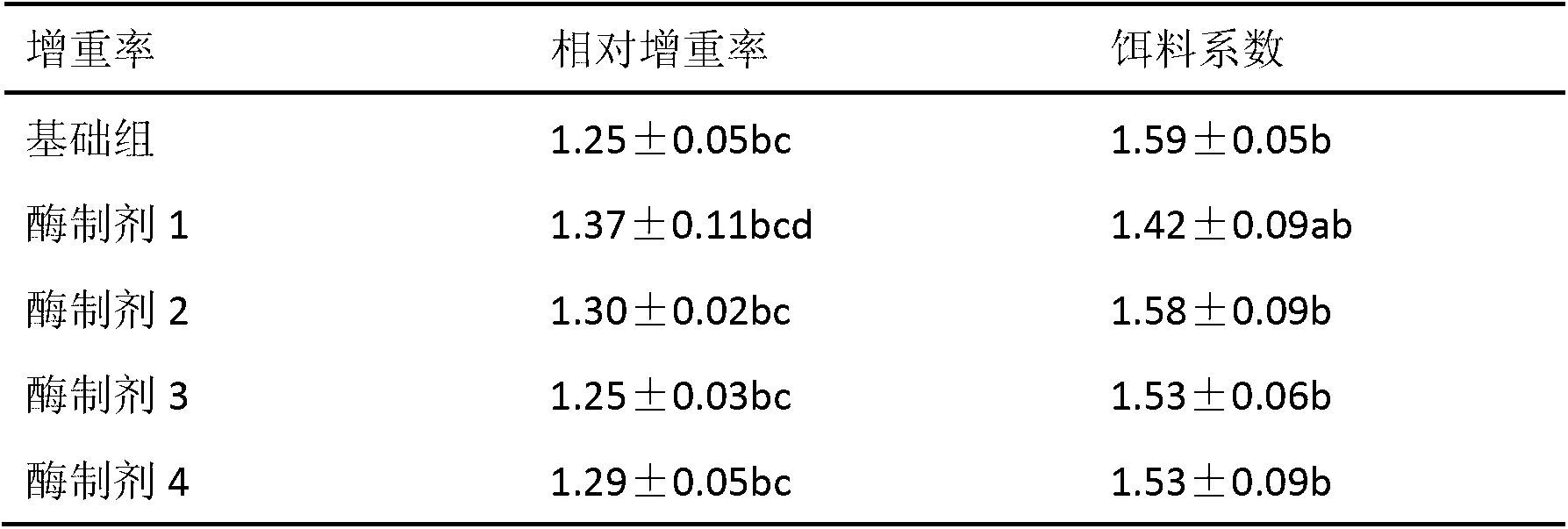

Production method of straw feed

InactiveCN102715350AImprove degradation efficiencyHigh in nutrientsFood processingAnimal feeding stuffFiberSolvent

The invention relates to a production method of straw feed, comprising the following steps: 1) smashing straw into particle materials; 2) carrying out ammoniation treatment on part of the straw particles with ammonia water or urea solution to obtain ammoniated straw; 3) adding plant lactic acid bacteria to the part of straw particle material for silage treatment so as to obtain silage straw; 4) adding water to uniformly mix the part of ammoniated straw with corncob particle, adding lactic acid or acetum to regulate the pH to 5-6, adding zymophyte solvent and uniformly mixing, and carrying out fermentation to obtain a straw degeneration enzyme strain; 5) uniformly mixing the ammoniated straw, the silage straw and the straw degeneration enzyme strain, adding a zymophyte solution, and carrying out fermentation to obtain a water-containing straw yeast; and 6) drying or pelleting the yeast to obtain the straw feed. The production method has the advantages that high-efficient fiber lignin degradation bacterium is adopted to produce the straw degeneration enzyme strain, and the degeneration efficiency and the nutrient content in feed are improved; equipment needed for material fermentation is simple, the operation is simple and convenient, and the cost for producing feed is lowered.

Owner:NANKAI UNIV

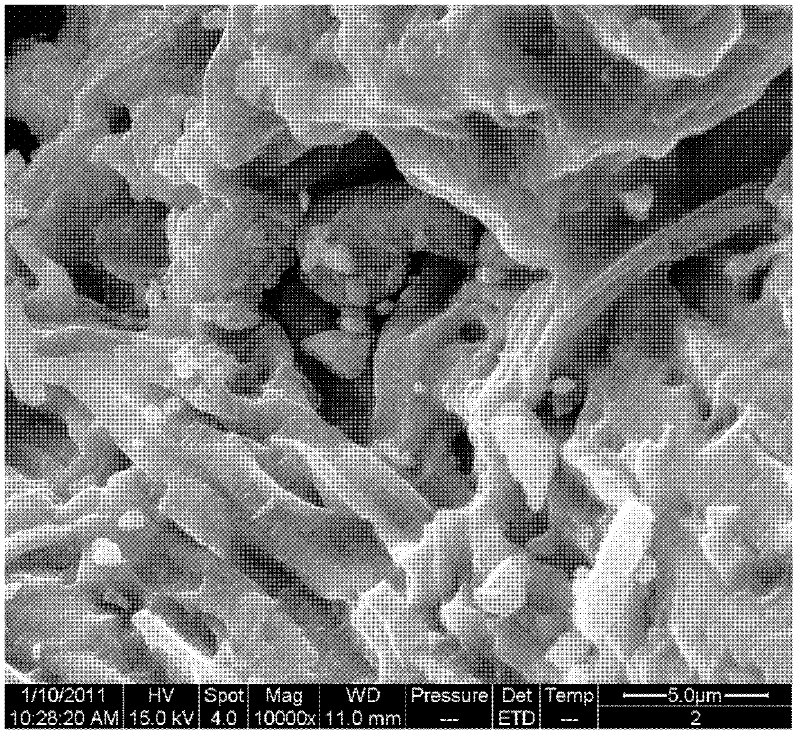

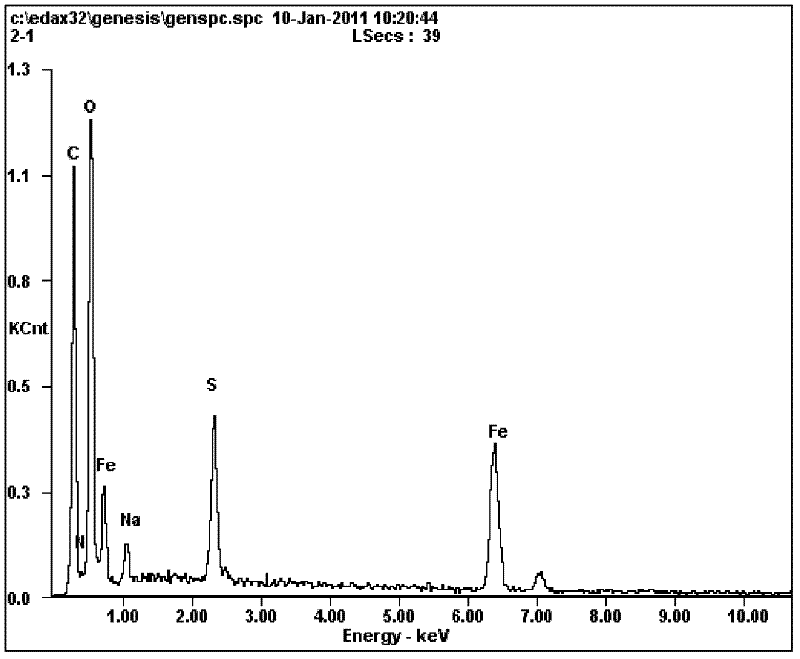

Preparation of sulfur-modified magnetic chitosan and method for treating heavy metal wastewater

InactiveCN102258980AHigh adsorption capacityEasy to prepareOther chemical processesWater contaminantsMaterials preparationVulcanization

The invention discloses a method for preparing sulfured magnetic chitosan and a method for treating waste water containing heavy metals by using the sulfured magnetic chitosan, which belong to the technical field of material preparation. The method for preparing the sulfured magnetic chitosan comprises: dispersing a ferrous salt and a ferric salt in acetic acid solution of chitosan in advance; dripping the mixed solution into alkaline solution by using an injector to form magnetic chitosan spheres; crosslinking the spheres by using glutaraldehyde to form crosslinked magnetic chitosan spheres;and drying under vacuum, grinding into powder and obtaining the sulfured magnetic chitosan. The prepared material is used for treating waste water containing heavy metals.

Owner:TSINGHUA UNIV

Method of extracting collagen and method of using collagen to prepare collagen protein

InactiveCN1903918ATake advantage ofRealize high value utilizationConnective tissue peptidesFreeze-dryingHydrolyzed collagen

The present invention discloses a method for extracting collagen and method for preparing collagen protein by using said collagen. Said method for extracting collagen includes the following steps: using Java tilapia skin as raw material, cutting said Java tilapia skin, adding n-hexane, defatting, using NaOH solution to remove heteroprotein, using acetic acid solution to extract collagen protein, concentrating and freeze-drying so as to obtain collagen. The method for preparing collagen protein by using extracted collagen includes the following steps: adding water to dissolve the collagen, then utilizing proteinase to make zymolysis, concentrating and spray-drying so as to obtain hydrolytic collagen protein.

Owner:SOUTH CHINA UNIV OF TECH

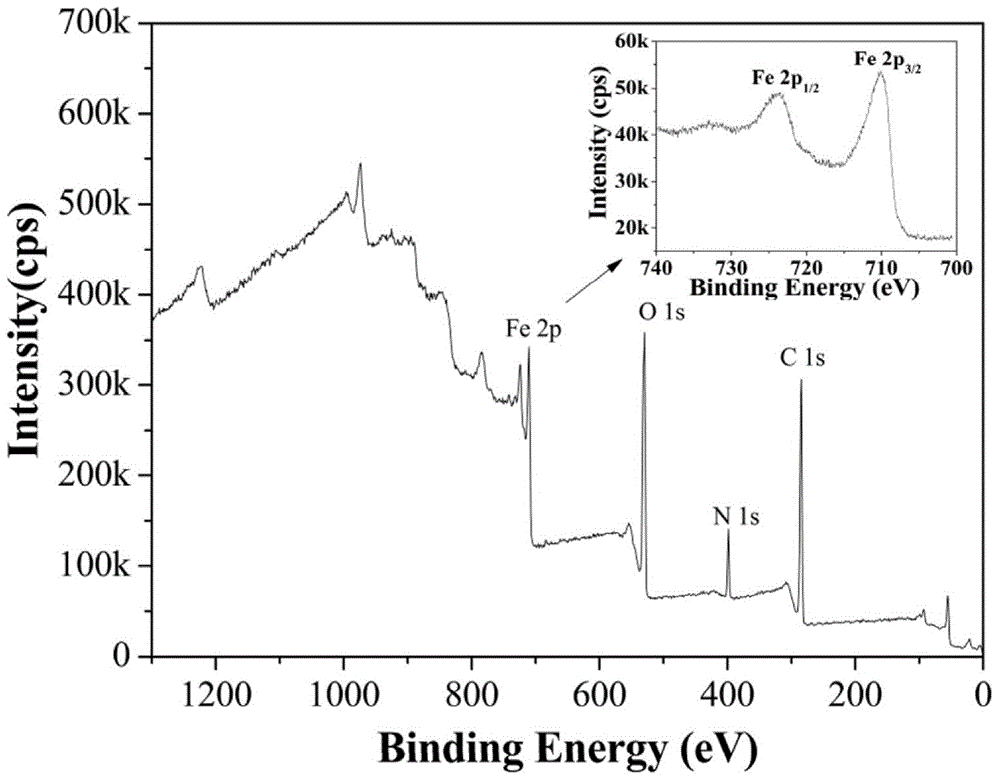

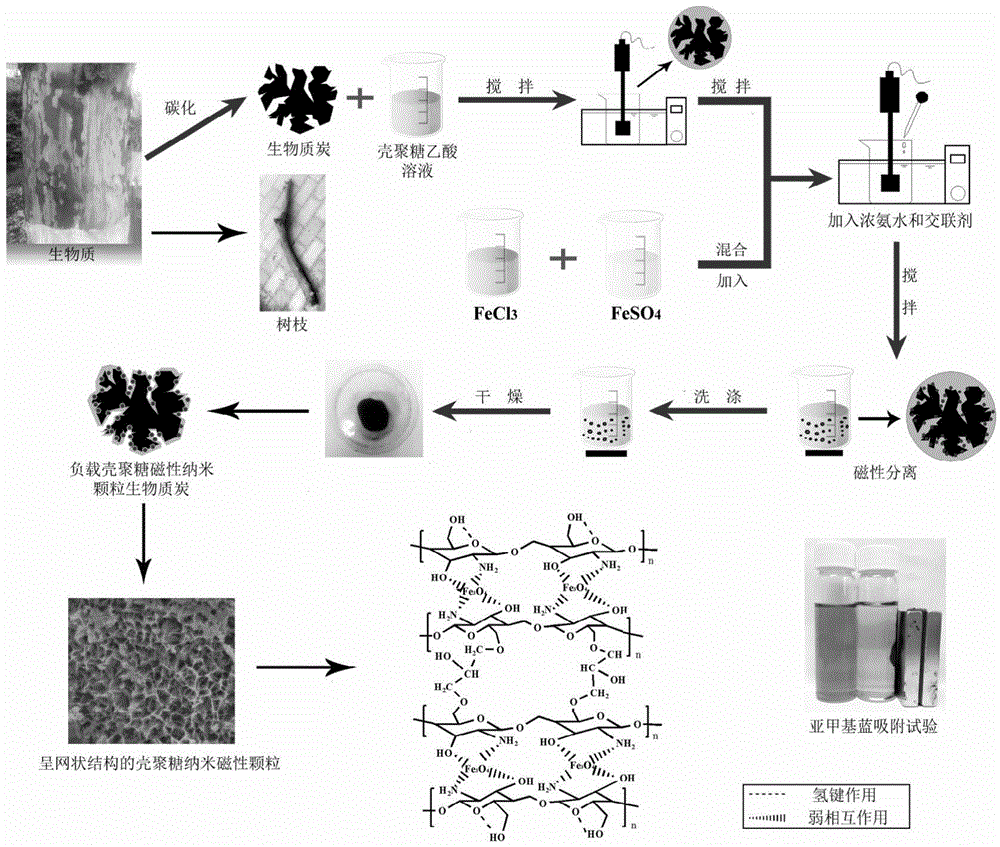

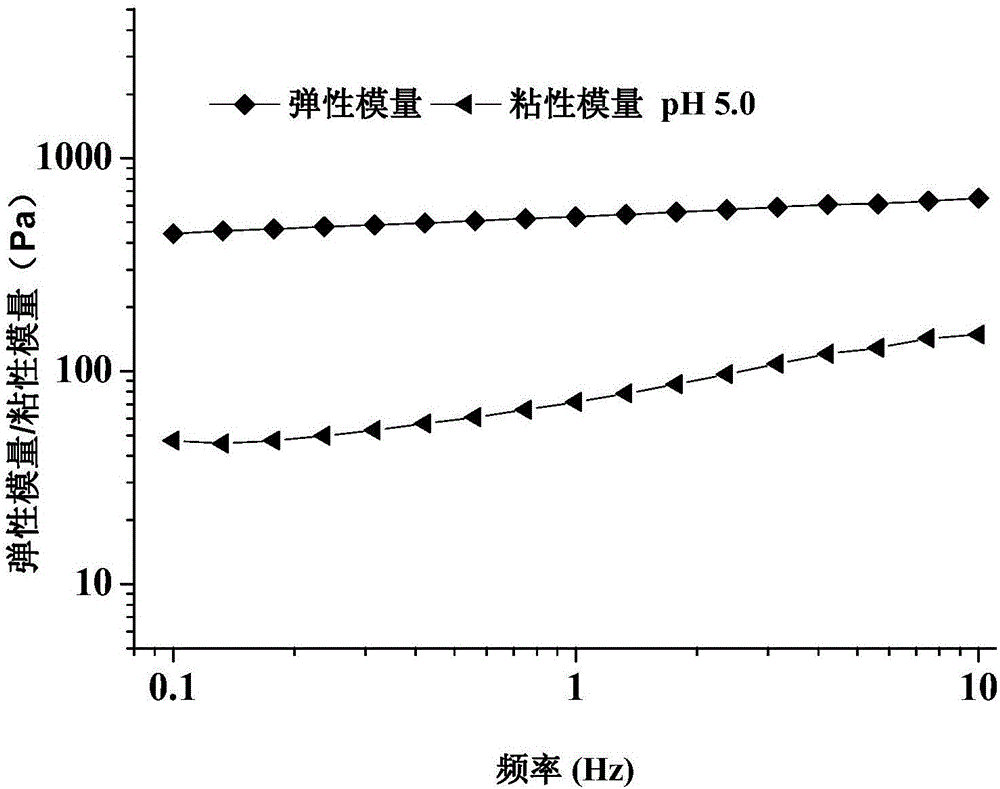

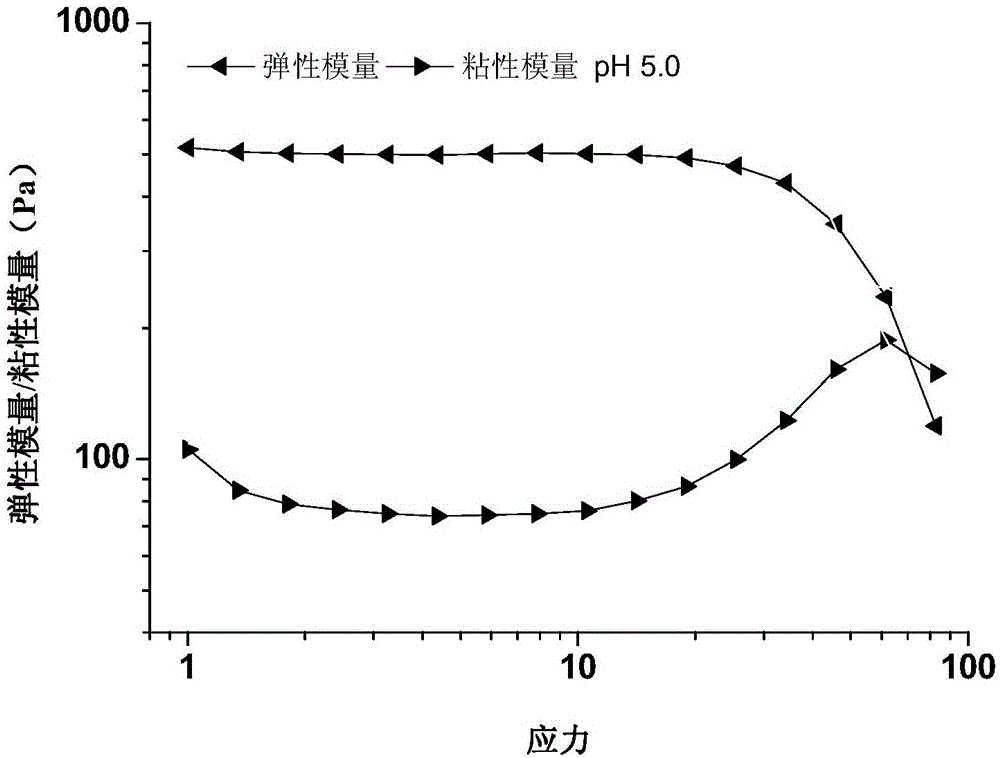

Preparation method for biomass charcoal adsorbent loaded with chitosan magnetic nanoparticles

InactiveCN104801280AImprove adsorption capacityEfficient removalOther chemical processesWater/sewage treatment by sorptionSorbentMagnetite Nanoparticles

The invention provides a preparation method for a biomass charcoal adsorbent loaded with chitosan magnetic nanoparticles. The preparation method comprises the following steps: preparing biomass charcoal, preparing a chitosan-acetic acid solution, preparing an iron solution and preparing biomass charcoal loaded with the chitosan magnetic nanoparticles. The invention further provides the biomass charcoal adsorbent loaded with the chitosan magnetic nanoparticles. According to the adsorbent, the biomass charcoal is used as a base material and the surface of the adsorbent is loaded with the chitosan magnetic nanoparticles. The adsorbent prepared through the preparation method can adsorb heavy metal, dye and partial anions, and has the advantages of high adsorption capacity, strong magnetism, stable property and high mechanical performance.

Owner:HOHAI UNIV

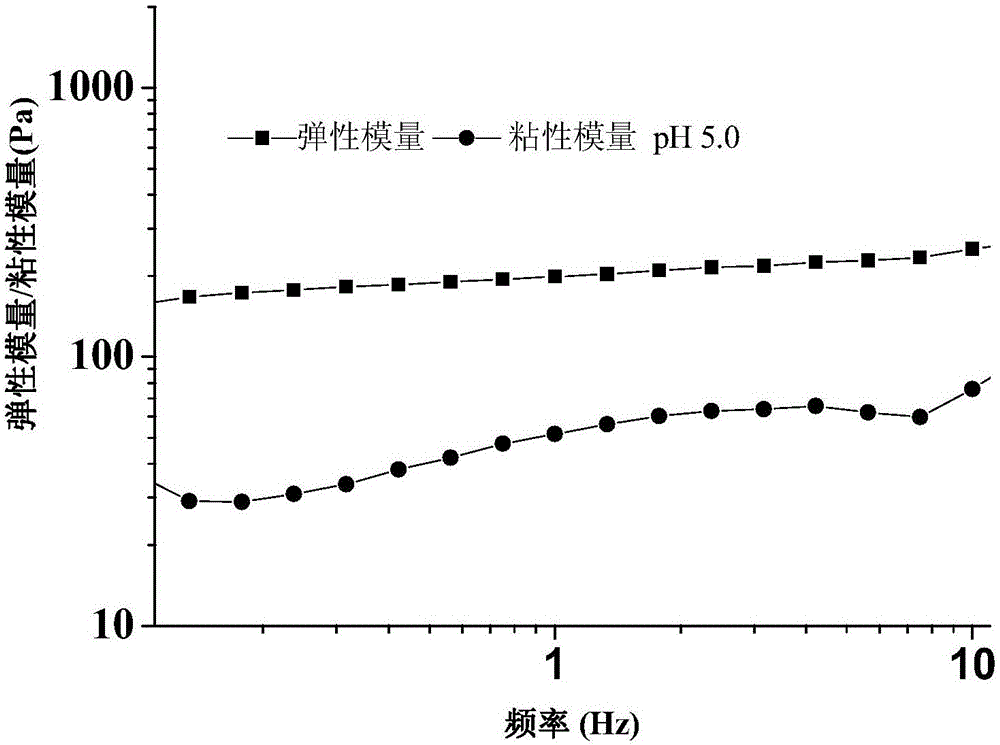

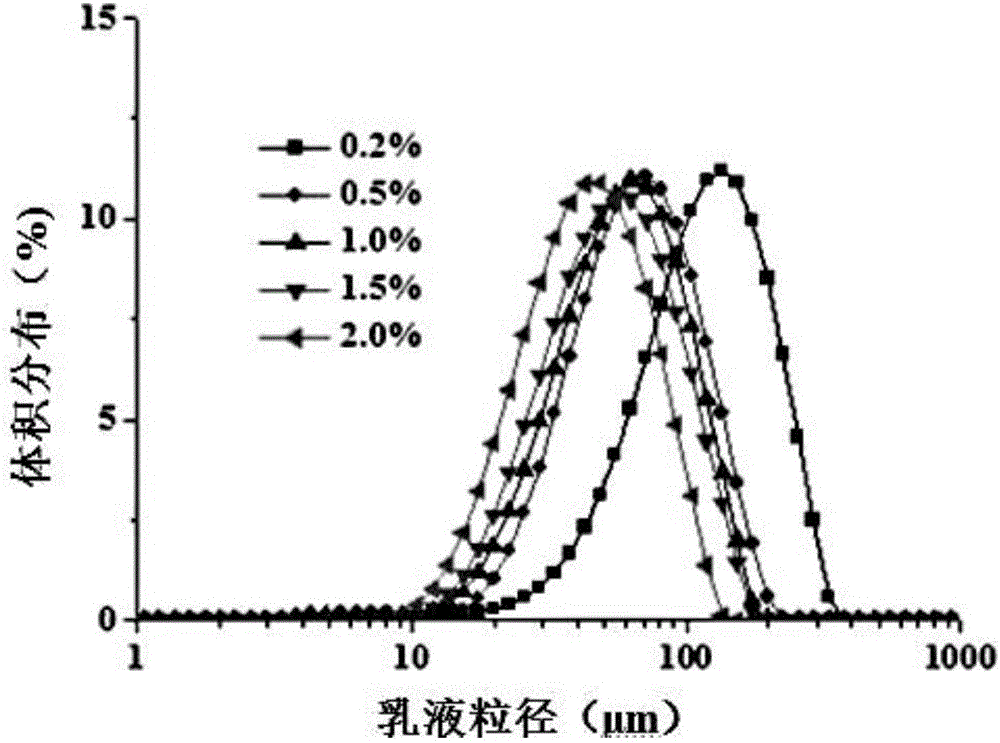

High internal phase gelatinous wheat gliadin Pickering emulsion and preparation method thereof

InactiveCN106578335AGelatinousImprove stabilityTransportation and packagingFood ingredientsAlcoholEvaporation

The present invention discloses a preparation method of a stable high internal phase gelatinous wheat gliadin Pickering emulsion. The preparation method comprises the following steps: (1) wheat gliadin is dissolved into an alcohol solution; (2) an chitosan acetic acid solution is prepared; (3) the obtained solution in the step (1) is poured into the chitosan acetic acid solution, homogenization is conducted, and the homogenized solution is subjected to rotary evaporation; (4) a pH value of the obtained solution in the step (3) is adjusted to be 4.0-6.0; and (5) the obtained solution in the step (4) is mixed with oil and the mixture is subjected to shear emulsification to obtain the stable high internal phase gelatinous wheat gliadin emulsion. The obtained wheat gliadin Pickering emulsion by the method is high in stability and good in viscoelasticity, and can be used for embedding a large amount of oil. The stable high internal phase gelatinous wheat gliadin Pickering emulsion is low in requirement for devices, and simple and easy to operate in the method, and has relatively good prospect in the application aspects of novel nutrient delivery carriers and food structure modification base materials.

Owner:SOUTH CHINA UNIV OF TECH

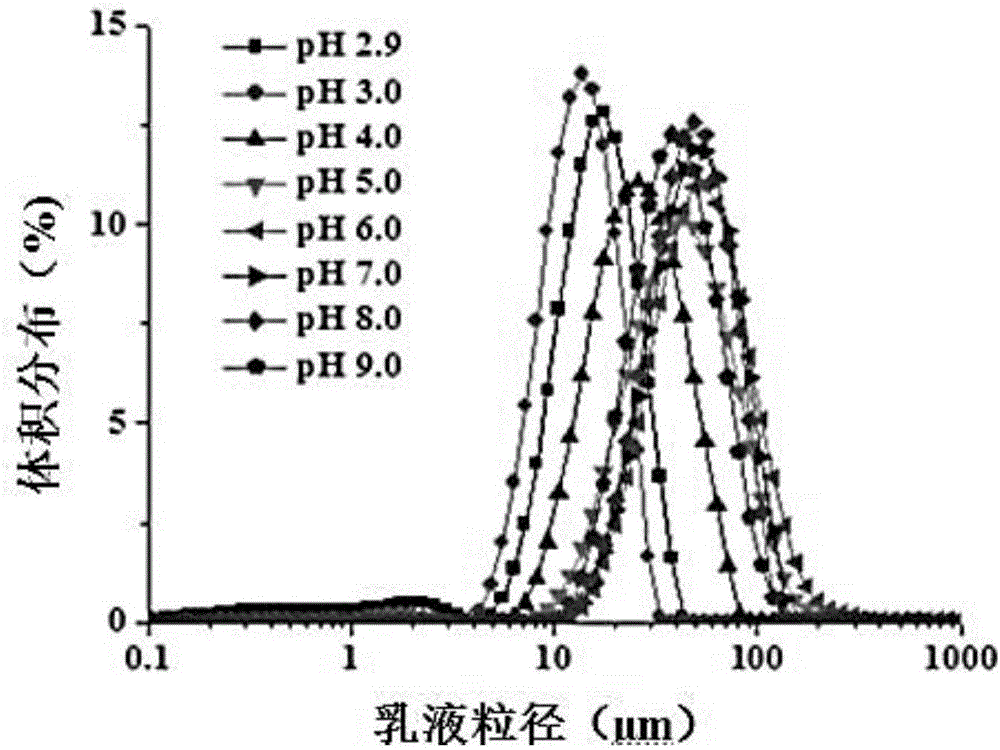

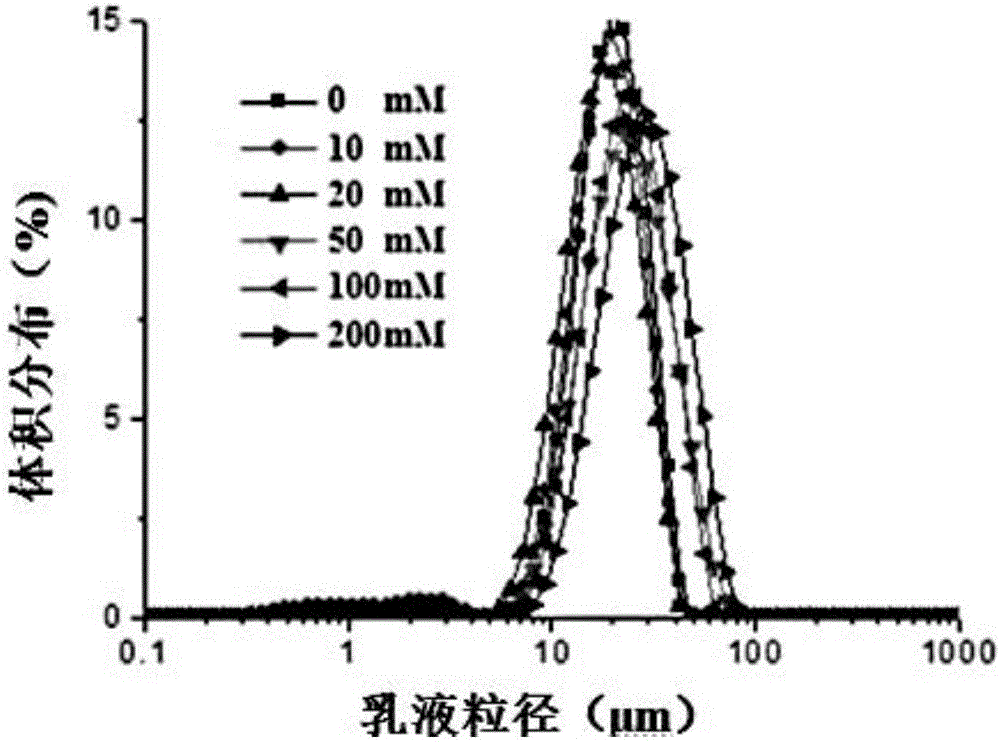

Preparation method of edible protein stable Pickering emulsion

InactiveCN105853358ANo side effectsNo harmEmulsion deliveryMacromolecular non-active ingredientsOrganic solventPickering emulsion

The invention discloses a preparation method of an edible protein stable Pickering emulsion. The method comprises the following steps: (1) adding chitosan into an acetic acid solution to be fully hydrated; (2) adding wheat gliadin into an ethanol solution to be fully dissolved; (3) adding the material obtained in the step (2) into the material obtained in the step (1), and carrying out shearing and homogenizing; (4) evaporating the material obtained in the step (3) until the mass concentration of wheat gliadin composite colloidal particles is 0.5-5%; (5) centrifuging the material obtained in the step (4), discarding precipitates, and taking supernatant liquid; and (6) adding corn oil into the material obtained in the step (5), and carrying out shearing and homogenizing to obtain a stable Pickering emulsion. The emulsion prepared by the preparation method does not contain any surfactant or organic solvent and can be used for conveying carrier loads and encapsulating biological active substances and especially fat-soluble biological active substances.

Owner:SOUTH CHINA UNIV OF TECH

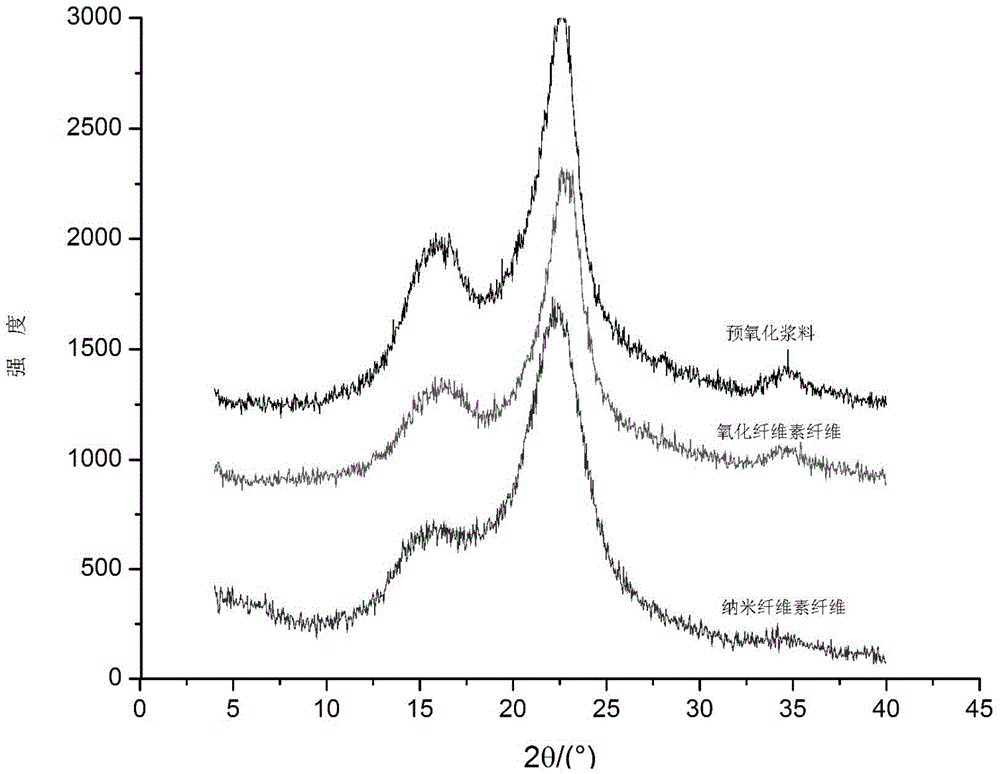

Nano-crystalline cellulose fiber high in carboxyl group content and preparation and application thereof

InactiveCN105463606AIncrease the total carboxyl contentGuaranteed crystallinityOther chemical processesArtificial filaments from cellulose derivativesPolymer scienceFreeze-drying

The invention belongs to the technical field of biomass nanometer materials and discloses a nano-crystalline cellulose fiber high in carboxyl group content and preparation and application thereof. A preparation method comprises the steps of preheating fiber slurry for 0.5-1.5h with sodium periodate at the temperature of 50-60 DEG C; adding a sodium chlorite solution and acetum into the slurry to be reacted for 1-3h at the temperature of 30-50 DEG C, adding TEMPO, NaClO2 and NaClO, and performing microwave heating to the temperature of 55-65 DEG C to enable the mixture to be reacted for 1-3h; performing ultrasonic dispersion and freeze drying to obtain the nano-crystalline cellulose fiber high in carboxyl group content. According to the nano-crystalline cellulose fiber, hydroxyl at the positions of C2 and C3 of cellulose is oxidized into a formyl group which is oxidized into carboxyl by sodium chlorite, hydroxyl at the position of C6 is selectively oxidized into carboxyl through a TEMPO neutral oxidation system, and accordingly the total carboxyl group content of the fiber is greatly increased, and obtained products can be used for advanced treatment of waste water at the middle section of paper making.

Owner:SOUTH CHINA UNIV OF TECH

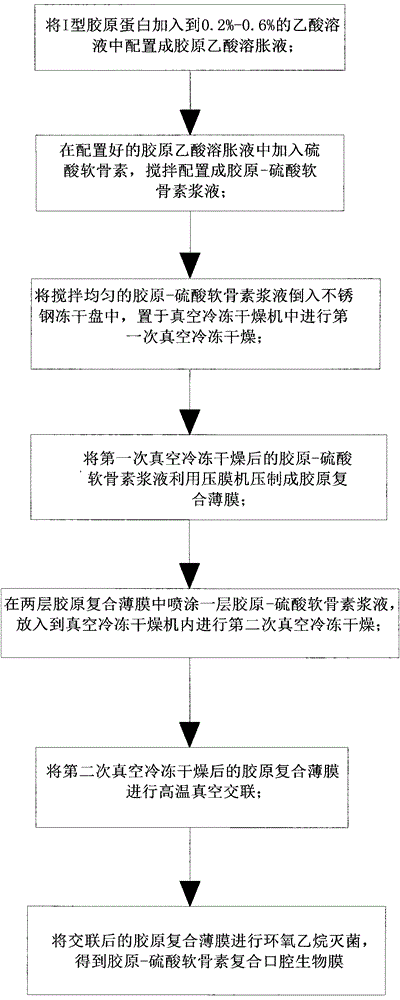

Preparation method of oral biofilm

The invention relates to a preparation method of an oral biofilm. The preparation method comprises the following steps: adding type I collagen protein into an acetic acid solution to prepare a collagen-acetic acid swelling solution; adding chondroitin sulfate and stirring to prepare a collagen-chondroitin sulfate serous fluid; carrying out vacuum freeze-drying; pressing to prepare a collagen composite film; spraying the collagen-chondroitin sulfate serous fluid between two layers of the collagen composite film, and carrying out vacuum freeze-drying; carrying out high temperature vacuum crosslinking; and sterilizing after crosslinking to obtain a collagen-chondroitin sulfate composite oral biofilm. The invention has the following beneficial effects: the oral biofilm prepared by the above method has good histocompatibility, suitable controllable degradability and absorbability, low antigenicity and good plasticity and mechanical property; the oral biofilm is used in oral operation; and the three-dimensional porous structure of the oral film provides a tissue engineering scaffold for repairing of wounded tissues, is beneficial to invasion of cells and differential growth and can induce reparative regeneration of defective tissues, and specific thickness of the biofilm can effectively prevent ingrowth of soft tissue.

Owner:TIANXINFU (BEIJING) MEDICAL APPLIANCE CO LTD

Microbial lysozyme microcapsule as well as preparation and application of microbial lysozyme microcapsule

InactiveCN103005168ARetain activityAddressing drug resistanceAnimal feeding stuffFreeze-dryingAquatic animal

The invention relates to the fields of microorganism preparations and aquaculture, and discloses a lysozyme microcapsule. The microbial lysozyme microcapsule is prepared by the following steps of: (1) dropping a mixing solution of sodium alginate and lysozyme into an acetic acid solution containing chitosan and calcium chloride, and stirring; (2) after dropping, curing for 0.5-4hours, and taking and washing a solid to obtain lysozyme / sodium alginate / chitosan beads; and (3) pre-freezing the lysozyme / sodium alginate / chitosan beads, and freeze-drying. The microcapsule disclosed by the invention is used for preparing fish feed, and is capable of reserving comparatively high activity of the microbial lysozyme after being extruded at the high temperature in the feed processing; in the process of conserving at normal temperature, the stability of the microbial lysozyme can be kept for more than half an year; and in feeding and breeding, the microbial lysozyme can bear the strong acid and digesting environment in the stomach of the aquatic animal, release in the intestinal tract and develop an effective growth-promoting healthcare effect.

Owner:SHANGHAI OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com