Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2864results about "Spinning solutions preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Functional polymer nano composite material and preparation method and uses thereof

ActiveCN101161705AEvenly dispersedStable structureBiocideOther chemical processesEcological environmentPolymer solution

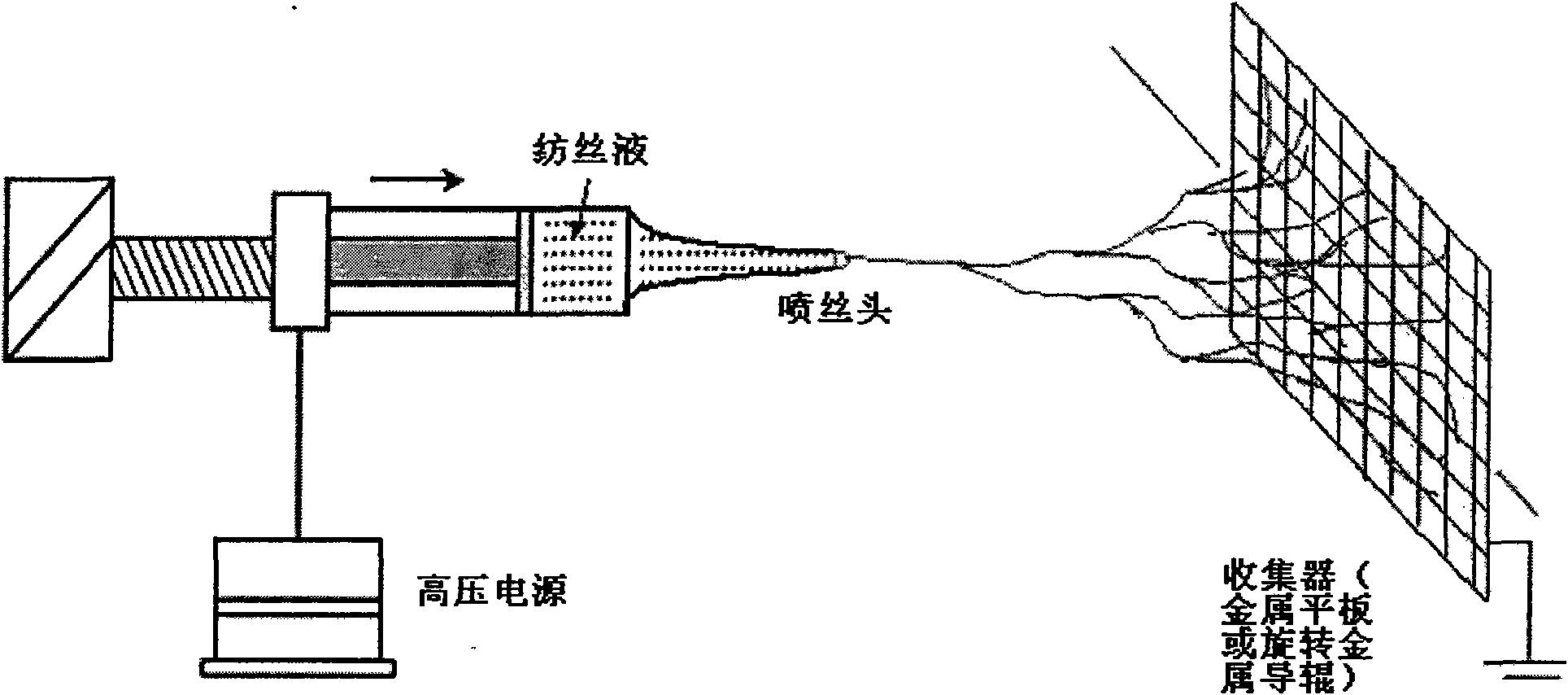

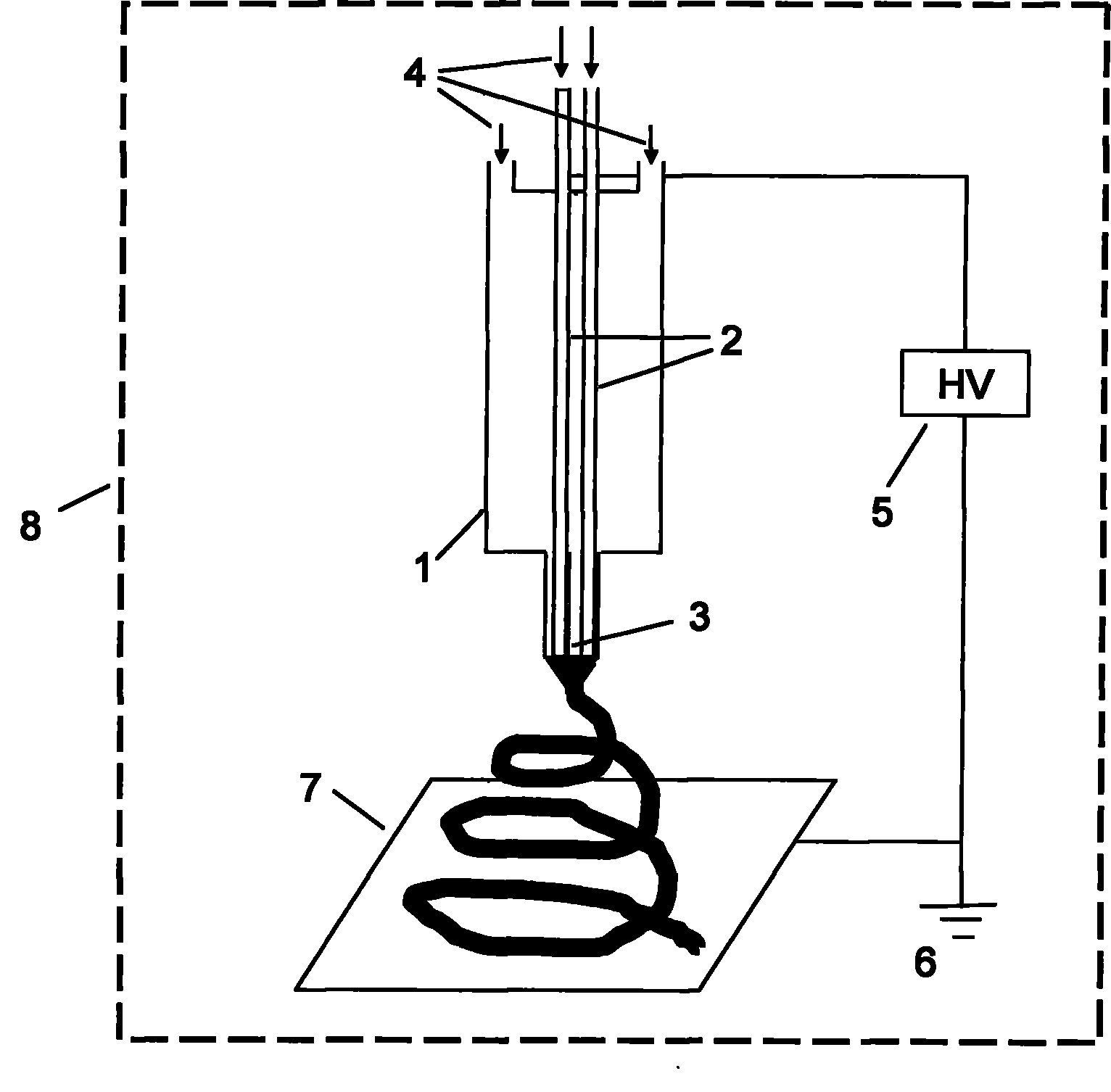

The present invention relates to a polymer nano-composite of the functional inorganic nano-particle with intermingle prepared by electrospinning method, and the use of the composite. The precursory sol of the functional inorganic nano-particle is prepared by the sol-gel method, and is mixed with the polymer solution to form spinning fluid, adding precursor of dopant if necessary, and then the mixed spinning fluid is sprayed on to the electric collecting board with the action of the electric field force by electrospinning method to obtain functional polymer nano-composite with intermingle. The equipment of the invention is simple, the operation is easy, the components, structure and characteristics of the composite is easy to control, the structure is stable, the inorganic nano-particle is dispersed uniformly. According to the difference of the functionality of the inorganic nano-particles, the composite can be used in conducting material, antistatic material, magnetic material, electrochromic material, photocatalysis and ecology environment material, antibiosis material and biomaterial.

Owner:INST OF CHEM CHINESE ACAD OF SCI

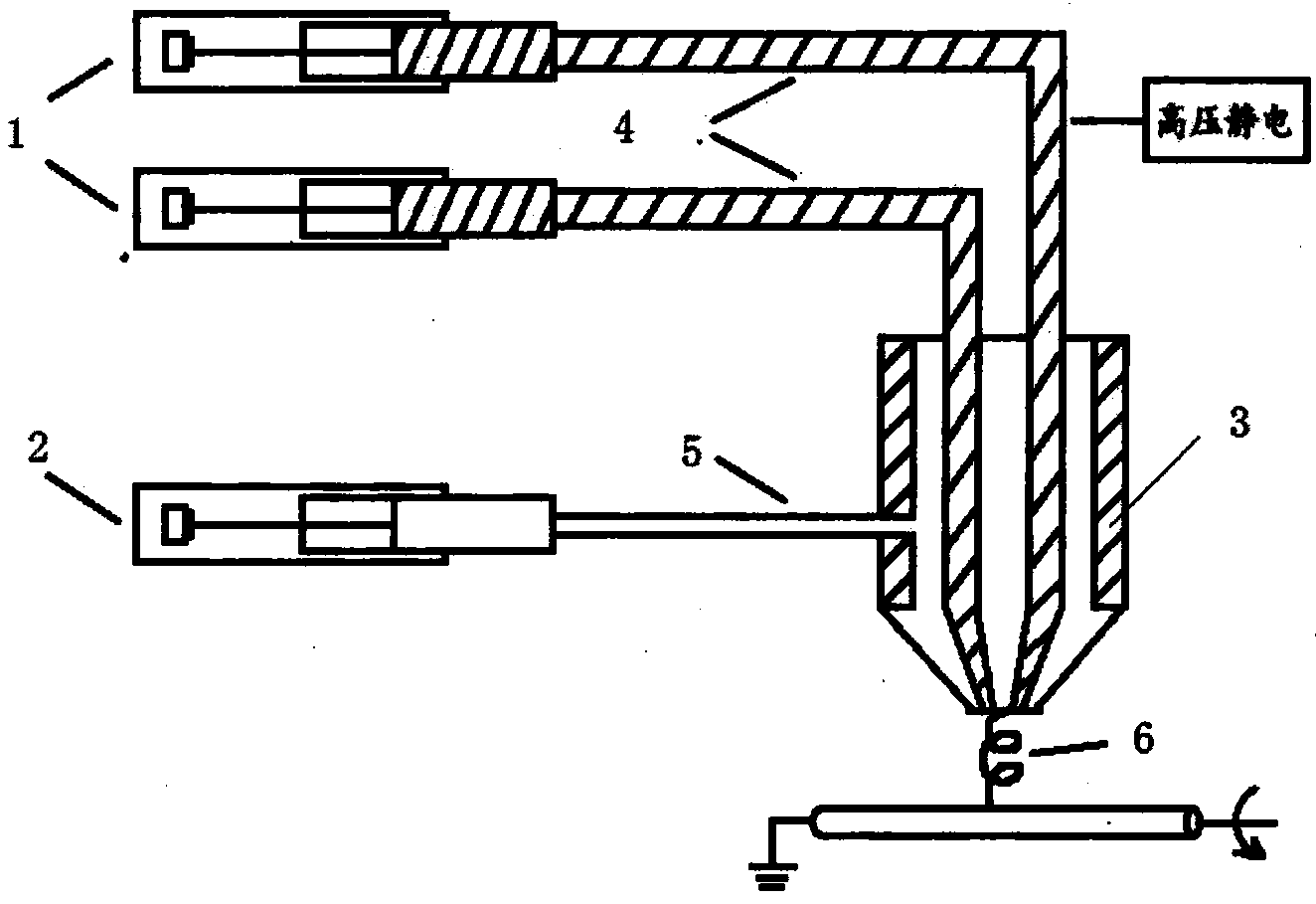

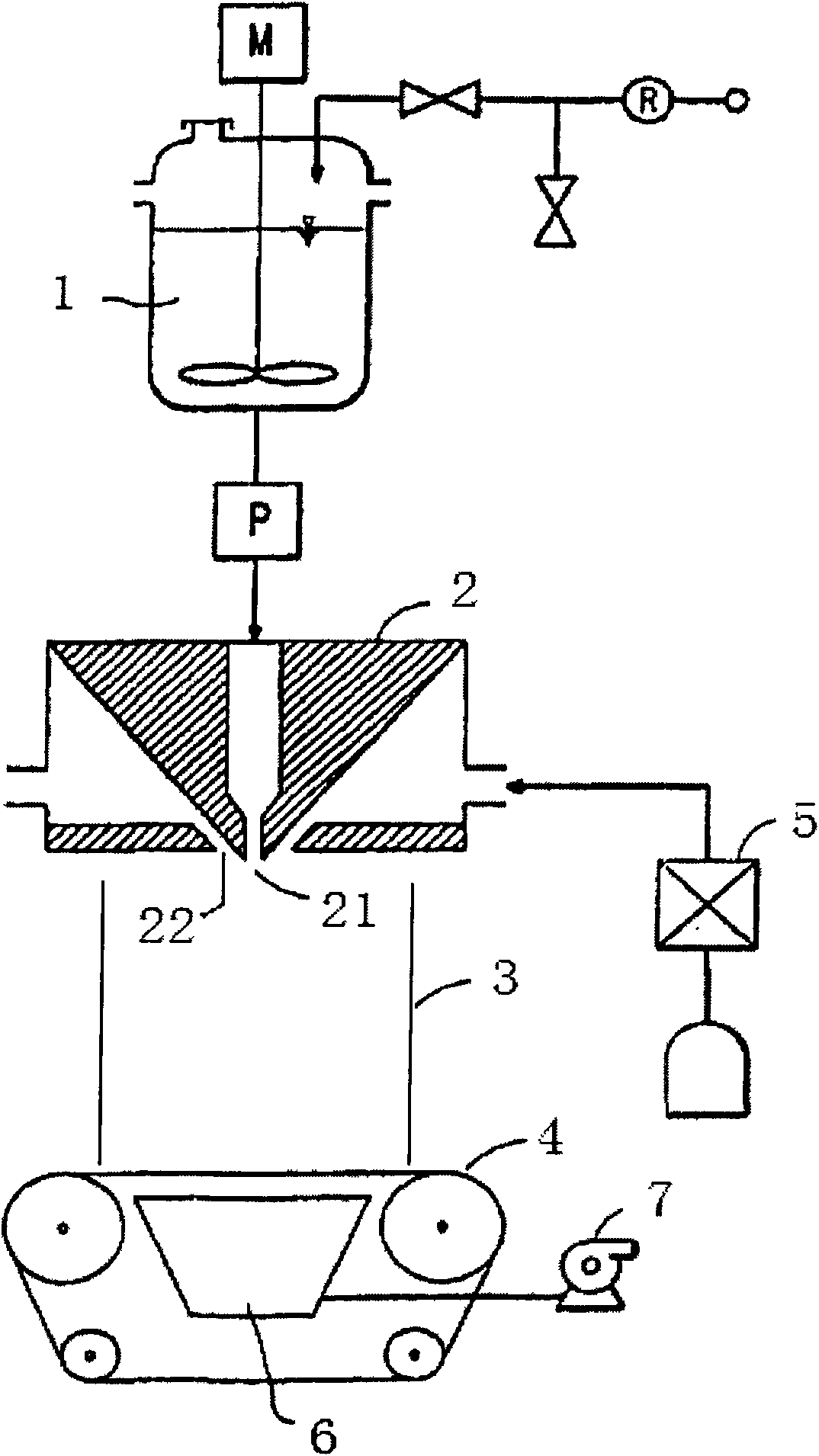

Method for producing shell-core structure medicament nano-fibre with coaxial electrostatic spinning technology

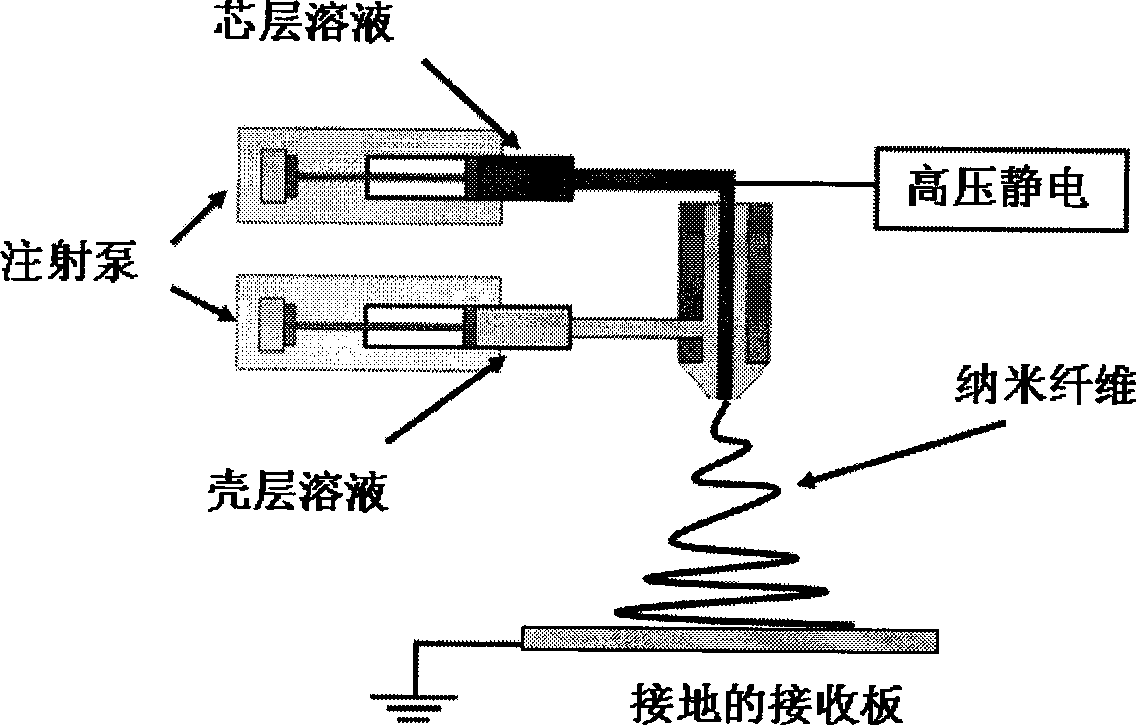

InactiveCN101509153AFix monotonic release behaviorMeet needsPharmaceutical delivery mechanismFilament/thread formingFiberDissolution

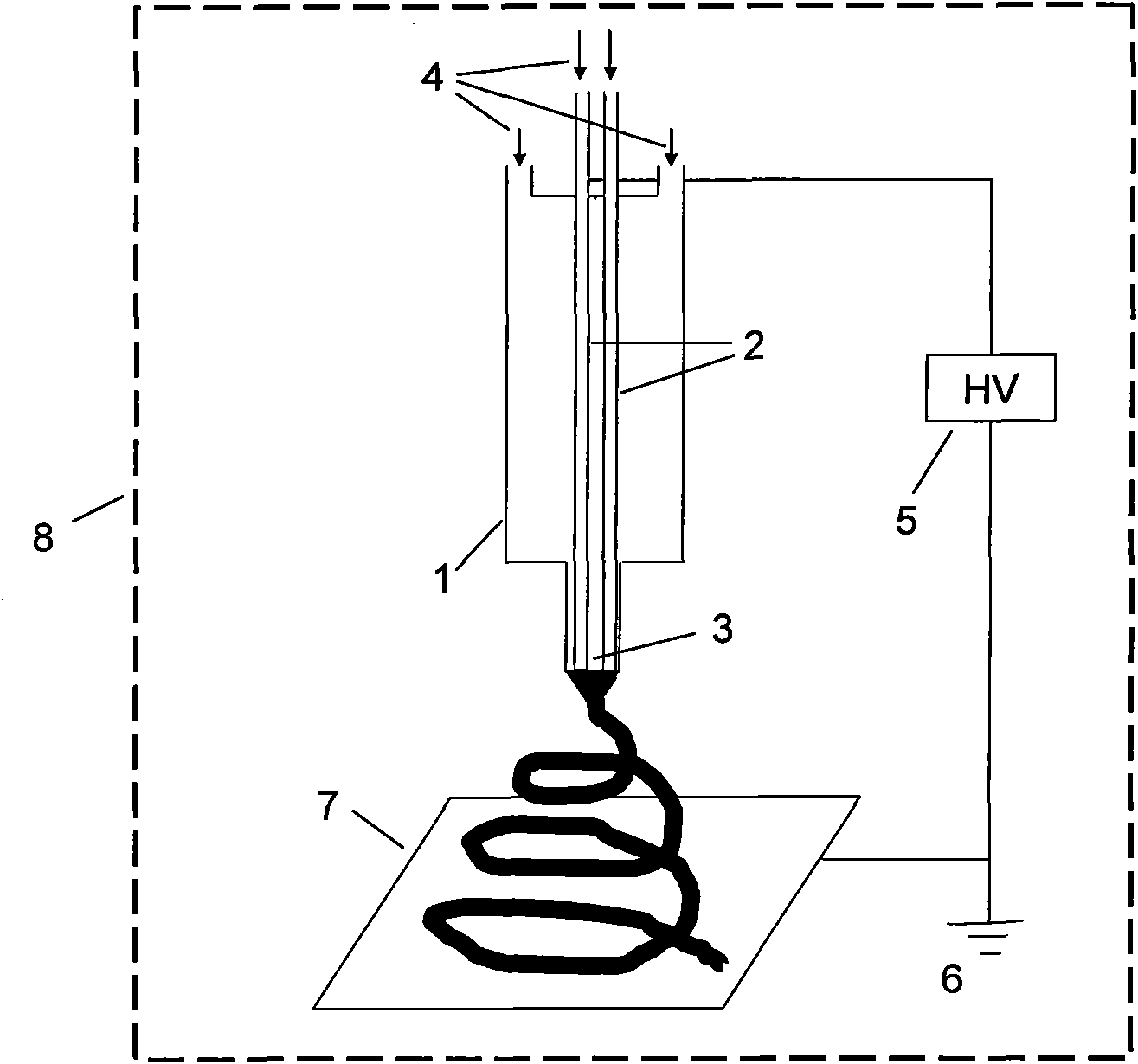

The invention relates to a method for preparing shell-core structured medicament nano fiber by coaxial electrostatic spinning technology, comprising: (1) dissolving high molecular polymer and medicament in mass proportion of 60-99.9:0.1-40 in organic solvent with high volatility, and stirring until complete dissolution to obtain shell solution; (2) dissolving one or more than one of natural polymer, medicament, and bioactive factor in the solvent, or dissolving the same in super pure water under aseptic condition to obtain core solution; and (3) carrying out coaxial electrostatic spinning, setting the spinning voltage at 15-25kv, the reception distance at 8-20cm, the spinning pushing speed at 0.1-1.5mL / h, and the spinning nozzle as 0.9mm, to obtain the shell-core structured medicament nano fiber. The preparation method is simple in operation, mild in reaction condition, low in cost and favorable for economic benefit; in preparing the shell-core structured medicament nano fiber, two or more than two medicaments can be simultaneously loaded and released, thus meeting requirements of tissue regeneration or patients.

Owner:DONGHUA UNIV

Preparation method of core-shell structured synthetic polymer-natural polymer composite fiber

InactiveCN102817105ASimple and fast operationMild reaction conditionsConjugated cellulose/protein artificial filamentsFilament/thread formingFiberPolymer science

The invention discloses a preparation method of a core-shell structured synthetic polymer-natural polymer composite fiber, and the method comprises the steps of: (1) selecting one or several of synthetic polymers to dissolve in a solvent, and conducting stirring until complete dissolution; (2) selecting a natural polymer to dissolve in a solvent, or adding a spinning assistant, and carrying out stirring until complete dissolution; and (3) taking the solution prepared in step (1) as an outer tube spinning solution, adopting the solution prepared in step (2) as an inner tube spinning solution, injecting them into the inner tube and the outer tube of a coaxial spinneret, and performing coaxial electrospinning at room temperature. The core-shell structured nano-fiber prepared by the invention selects the synthetic polymer as the shell layer, and can inhibit water molecules from penetrating the natural polymer as the core layer. The natural polymer as the core layer can more effectively encapsulate active substances to avoid inactivation of the active substances in the presence of an organic solvent, so that the core-shell structured composite fiber can play a good drug sustained release role in the drug carrier field, and an integral activity can be maintained.

Owner:SHANGHAI JIAO TONG UNIV +1

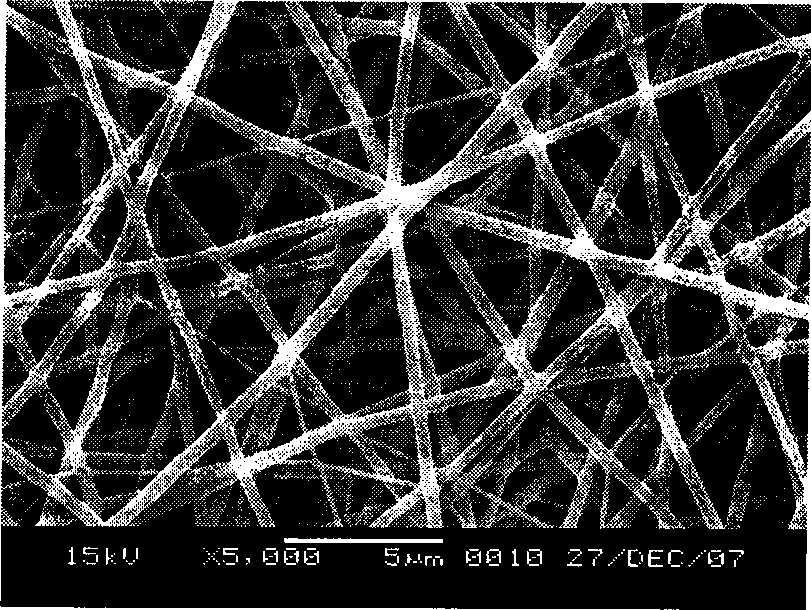

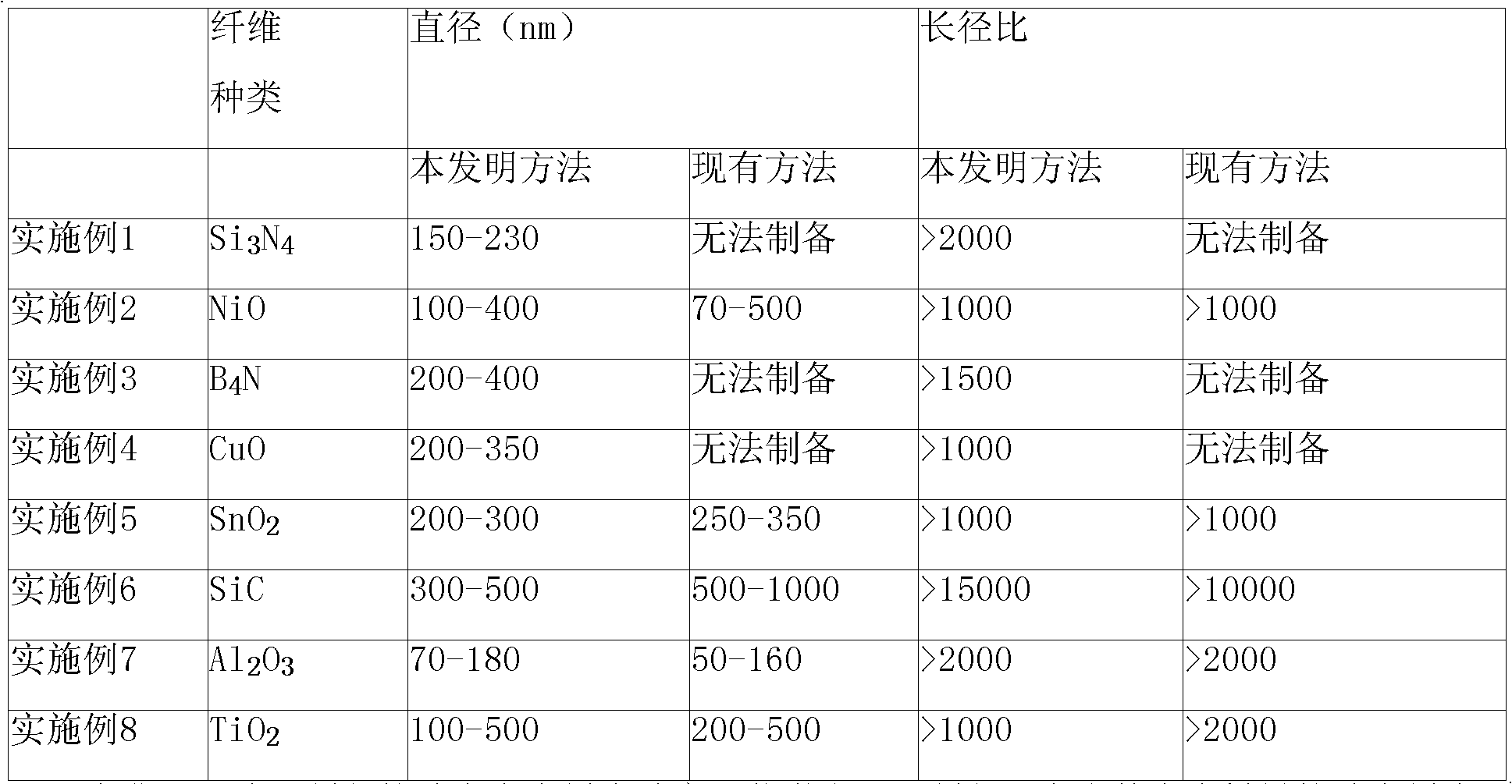

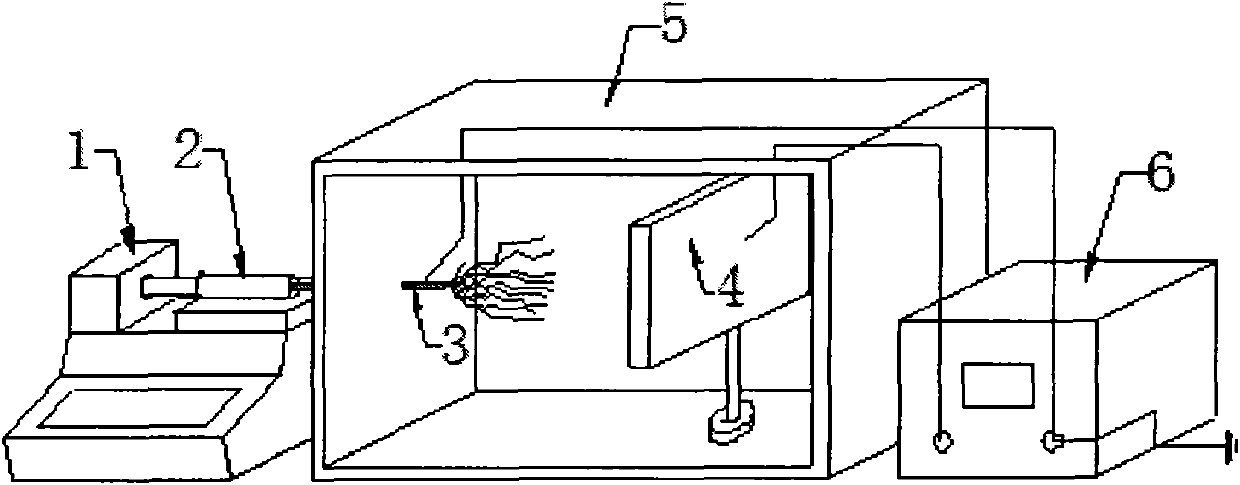

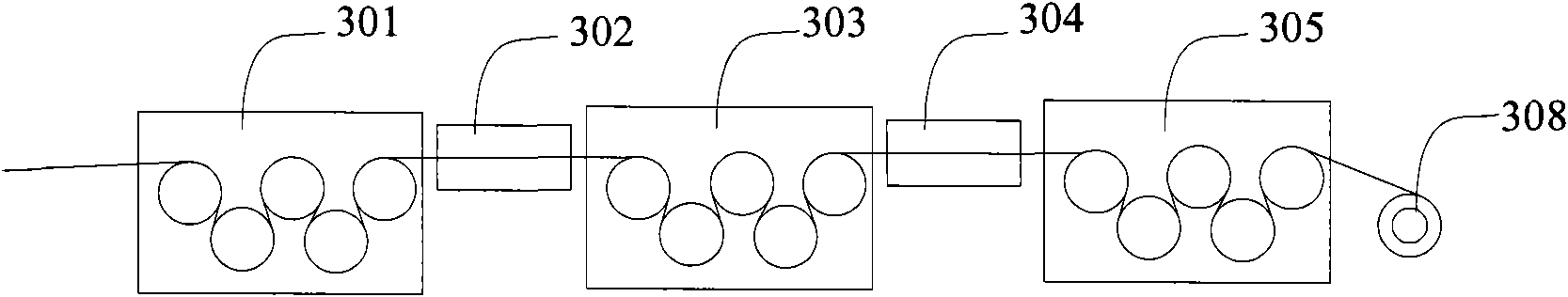

Method for preparing nano ceramic fibers

InactiveCN101880917AAverage diameter distributionHigh aspect ratioInorganic material artificial filamentsFilament/thread formingFiberWater baths

The invention discloses a method for preparing nano ceramic fibers, which is implemented by the following steps: 1, preparing 3 to 15 volume percent of 10 to 30 nanometer ceramic nanoparticles, 5 to 30 volume percent of spinnable high polymer, 0.5 to 5 volume percent of dispersant and the balance of solvent, wherein the total volume of the raw materials is 100 volume percent; 2, adding the spinnable high polymer into the solvent, heating the mixture in a water bath with magnetic stirring to obtain solution of spinnable high polymer; 3, adding the ceramic nanoparticles and the dispersant into the solution of spinnable high polymer obtained by the step 2, keeping the temperature of the mixture constant in a water bath, performing dispersion and ultrasonic dispersion, and performing swelling at a constant temperature to obtain ceramic nanoparticle / spinnable high polymer / solvent spinning solution; 4, controlling the electrostatic spinning process parameters of the spinning solution obtained by the step 3 to obtain nano fibers; and 5, sintering the nano fibers at 400 to 1,200 DEG C to obtain nano ceramic fibers.

Owner:XIAN UNIV OF TECH

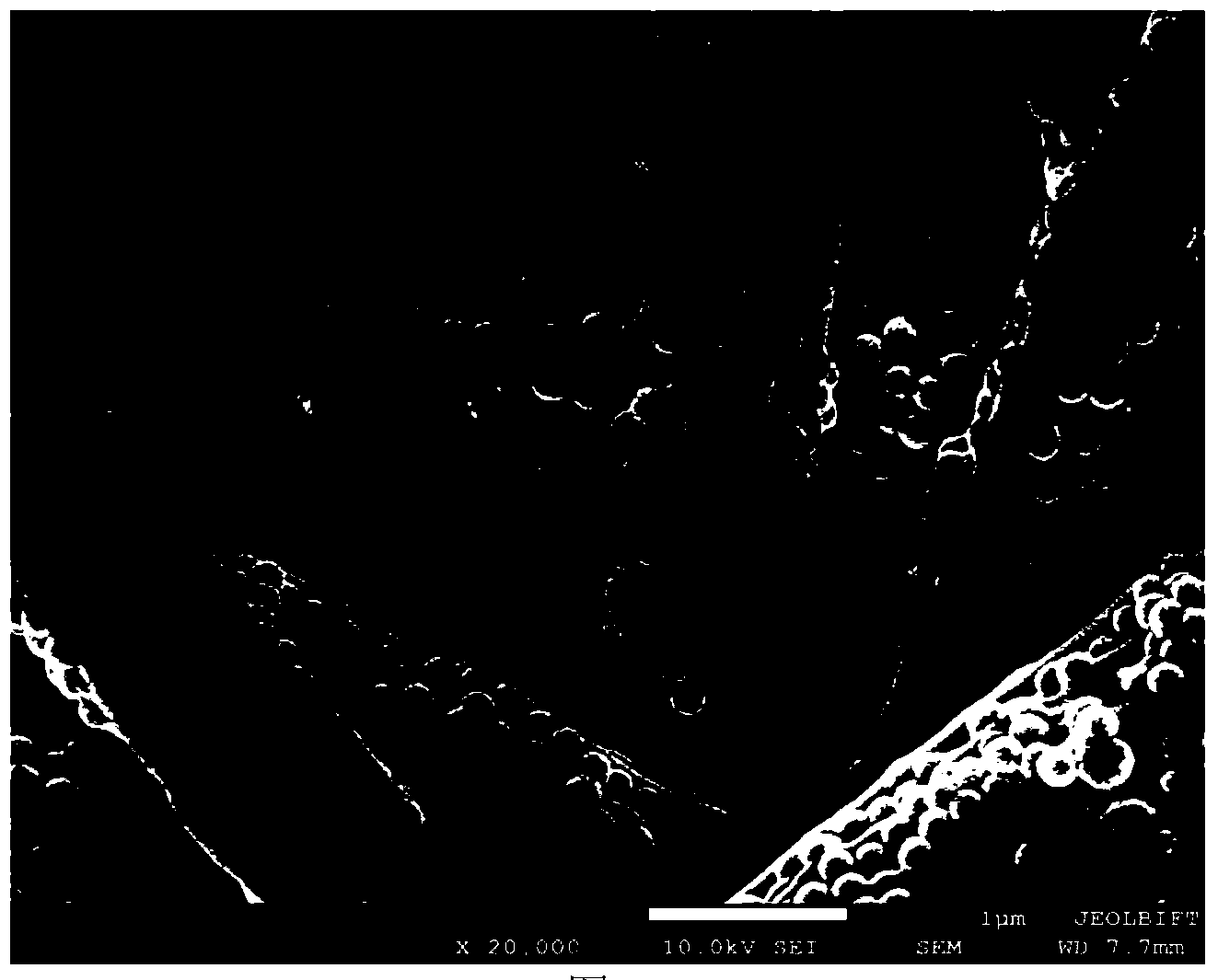

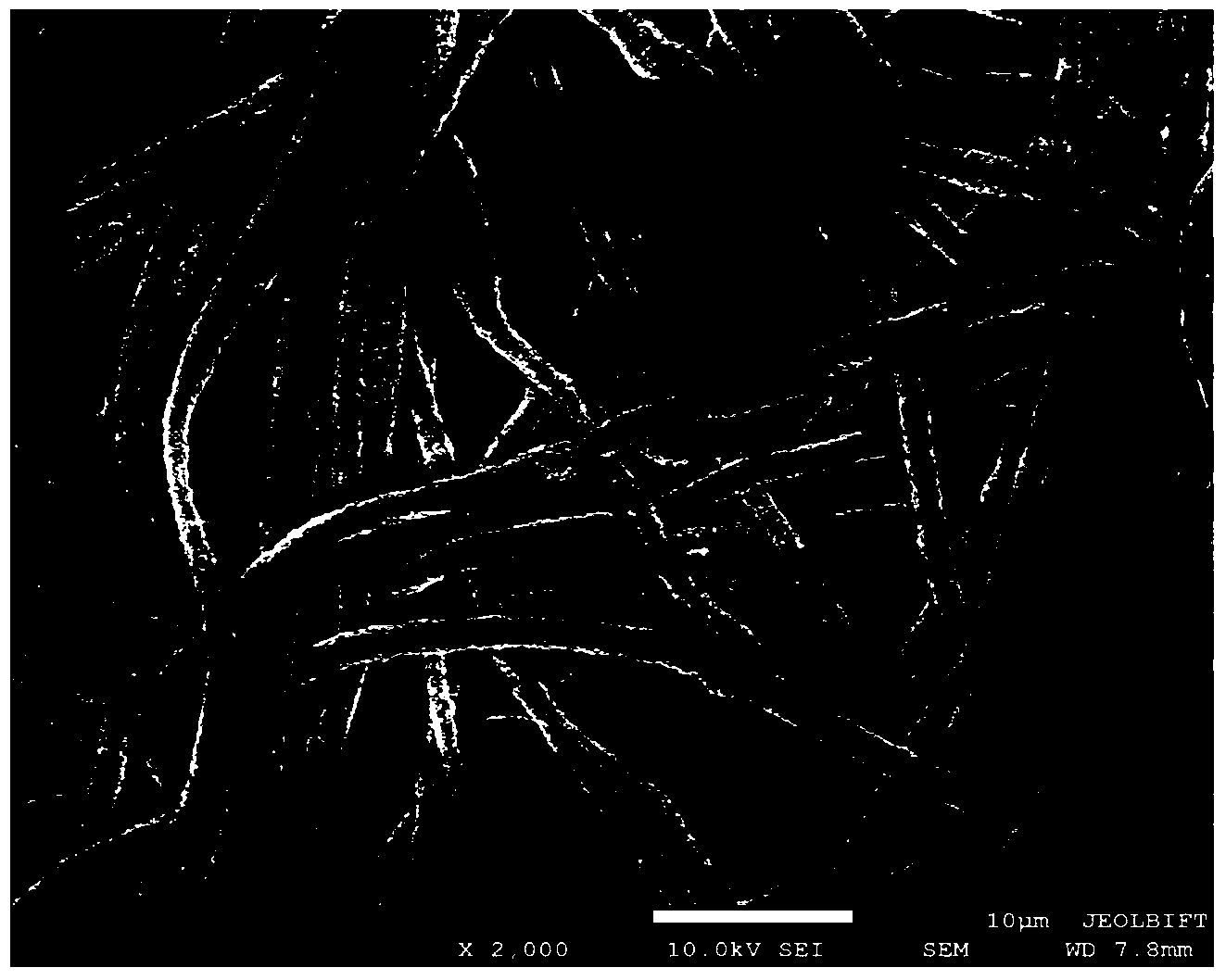

Lignin carbon nanofiber and preparation method thereof

ActiveCN101768799AImprove spinnabilityGuaranteed reliabilityFilament/thread formingFibre chemical featuresFiberCarbon fibers

The invention discloses a lignin carbon nanofiber and a preparation method thereof, belonging to the field of materials. The preparation method comprises 5 steps of lignin pretreatment, preparation of spinning solution, electrostatic spinning, pre-oxidation and carbonization. The preparation method is characterized in that the lignin pretreatment means that lignin with the relative molecular mass within 5,000 to 50,000 is selected, and then the treatment of removing carbohydrate and inorganic salt is respectively carried out on alkali lignin and acetic acid lignin (or formic acid lignin). The diameter of the obtained carbon nanofiber is within 50 to 300nm and the length is within 1 to 10mum. As the obtained lignin has good spinnability, the nanofiber can be spun and further processed into the carbon nanofiber without synthetic macromolecules. In addition, the method adopts simple electrospinning equipment for electrospinning, the diameter of a spinning nozzle is large, the blockage cannot easily occur, and the working reliability of the spinning equipment is ensured.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing polytetrafluoroethylene superfine fiber

InactiveCN101994161AEasy to prepareArtificial filament washing/dryingFilament/thread formingFiberElectrospinning

The invention discloses a method for preparing a polytetrafluoroethylene superfine fiber, comprising the following steps of: firstly dissolving polyvinyl alcohol into water to prepare a polyvinyl alcohol solution, then evenly mixing the polyvinyl alcohol solution with polytetrafluoroethylene concentrated dispersion to prepare a spinning solution; then making the spinning solution into a polytetrafluoroethylene / polyvinyl alcohol superfine fiber by adopting an electrostatic spinning method; and finally, carrying out polyvinyl alcohol removal aftertreatment on the prepared polytetrafluoroethylene / polyvinyl alcohol superfine fiber to obtain the polytetrafluoroethylene superfine fiber. The prepared polytetrafluoroethylene superfine fiber is white or dark brown, and the diameter of the fiber is 30-2000nm.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Viscose fiber with plant source anti-bacterial function and aromatic smell, and preparation method thereof

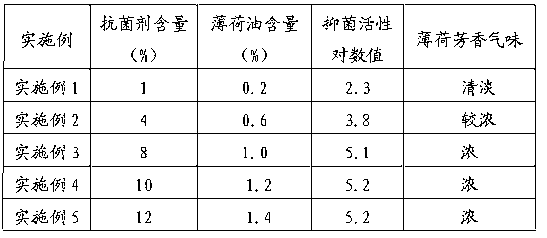

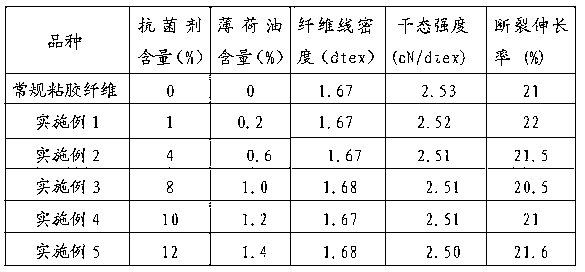

ActiveCN103225123ANo side effectsComfortable to takeArtificial thread manufacturing machinesArtificial filaments from viscoseSide effectMint extract

The invention discloses a viscose fiber with a plant source anti-bacterial function and aromatic smell. The viscose fiber is composed of a viscose spinning solution, an anti-bacterial agent and an aromatic agent, wherein the anti-bacterial agent is mixed powder of a mint extract and a isatis root extract, wherein the weight percentage of the mint extract accounts for 40%-80%; and the weight percentage of the isatis root extract accounts for 60%-20%; the aromatic agent is mint oil coated by microcapsules; the anti-bacterial agent accounts for 1%-8% of the mass of methyl cellulose in the viscose spinning solution; the mint oil accounts for 0.2%-1% of the mass of methyl cellulose in the viscose spinning solution; and the viscose fiber is prepared by adopting a wet spinning method by using the viscose spinning solution, the anti-bacterial agent and the aromatic agent. The plant source extracts and the plant source essential oil are used as the anti-bacterial agent and the aromatic agent; and the anti-bacterial agent and the aromatic agent are uniformly distributed in the fiber, so that the anti-bacterial function and the aromatic smell of the fiber are durable. Since the plant source extracts and the aromatic agent are natural substances extracted from the plants, so that the viscose fiber has no side effect to human body.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

High molecular weight poly(alpha-olefin) solutions and articles made therefrom

ActiveUS20070231572A1Improve productivityDry spinning methodsMonocomponent polyolefin artificial filamentPolymer scienceHigh molecular mass

Owner:HONEYWELL INT INC

Medical chitosan fibre and preparation method thereof

ActiveCN101250759AHigh molecular weightEnough aminoFilament manufactureArtificial filament washing/dryingAcetic acidBrute force

The invention relates to medical chitosan fiber in the textile processing field and a preparing method thereof, the method for preparing spinning fluid comprises the following steps: arranging the chitosan powder in glacial acetic acid water solution and slowly dissolving by stirring under the condition of controlling temperature and time, wherein the dissolution temperature is 10-30DEG C, the dissolution time is 10-48h, and the stirring speed is 60-180r / min, wherein the chitosan powder occupies 3%-10%, dissolvent glacial acetic acid occupies 1%-5% and the other is water in the spinning raw materials, the chitosan content is more than 99.9% in chitosan fiber, and the chitosan fiber has higher molecular weight, sufficient amido, steady fiber structure, and good antibacterial property, brute force and hygiene security property.

Owner:HISMER BIO TECH

Efficient oil and water separation composite fiber film and preparation method thereof

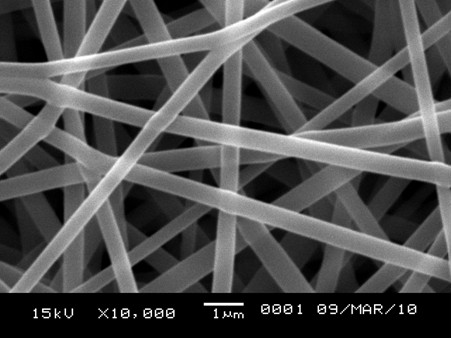

InactiveCN103866492ASelf-supportingRealize multiple reuseFilament/thread formingNon-woven fabricsFiberHydrophobic polymer

The invention discloses an efficiency oil and water separation composition fiber film and a preparation method thereof, and belongs to the field of functional nanometer fiber materials. Hydrophobic polymers such as polyurethane, polystyrene and polymethyl methacrylate or polycaprolactone are used as the main raw materials of the fiber film, the main raw materials are dissolved in an organic solvent to form a polymer solution, hydrophobic nanometer particles are added into the polymer solution in the preparation process, after the mixture is evenly mixed, electro-spinning is conducted on the mixed solution by means of the electrostatic spinning method, and then a fiber film material which is formed by micro-nanometer composite structures and is in the shape of non-woven fabric is obtained. The electro-spun fiber film of the micro-nanometer structure has super-hydrophobic / super-oleophylic property in the air and excellent oil adsorption performance, and the contact angle to oil is nearly zero. The efficient oil and water separation composite fiber film is simple in preparation method, low in energy consumption, high in efficiency, high in oil and water separation speed, and capable of being widely used in the fields such as oily water efficient purification.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Method for preparing drug sustained release nanofibers

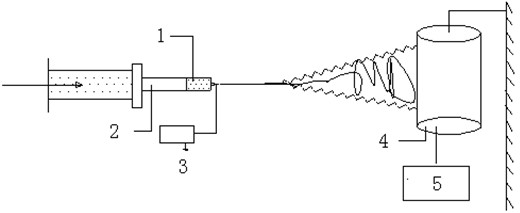

InactiveCN103966680AAdjustable structureControlled release rateArtificial thread manufacturing machinesFilament/thread formingFiberLiquid storage tank

The invention provides a method for preparing drug sustained release nanofibers. The method is characterized by including the specific steps that (1) drug-carried micro-spheres are arranged in an organic solvent to be evenly stirred and vibrated to obtain core layer spinning solutions; (2) degradable solutes and volatile solvents are evenly mixed to prepare surface-layer spinning solutions; (3) the surface-layer spinning solutions and the core layer spinning solutions are injected into a surface-layer liquid storage tank and a core layer liquid storage tank of a coaxial spinning jet respectively, coaxial electrostatic spinning is carried out at the room temperature, and the volatile solvents in the surface-layer spinning solutions volatilize to form through holes in the spinning process to obtain the drug sustained release nanofibers with the porous surface layer and the drug-carried micro-sphere wrapped core layer. By means of the method, the obvious multi-stage drug release system is achieved, and the drug-carried micro-spheres are released in the core layer firstly to enter a hole channel in the surface layer and finally enter damaged target components of the nanofibers to give play to drug effects. The method is simple in operation and gentle in reaction condition. A drug sustained release curve is well controlled, and the drug using efficiency is improved.

Owner:DONGHUA UNIV

Preparation method of fibrous membrane with super hydrophobic multi-stage nanometer structure

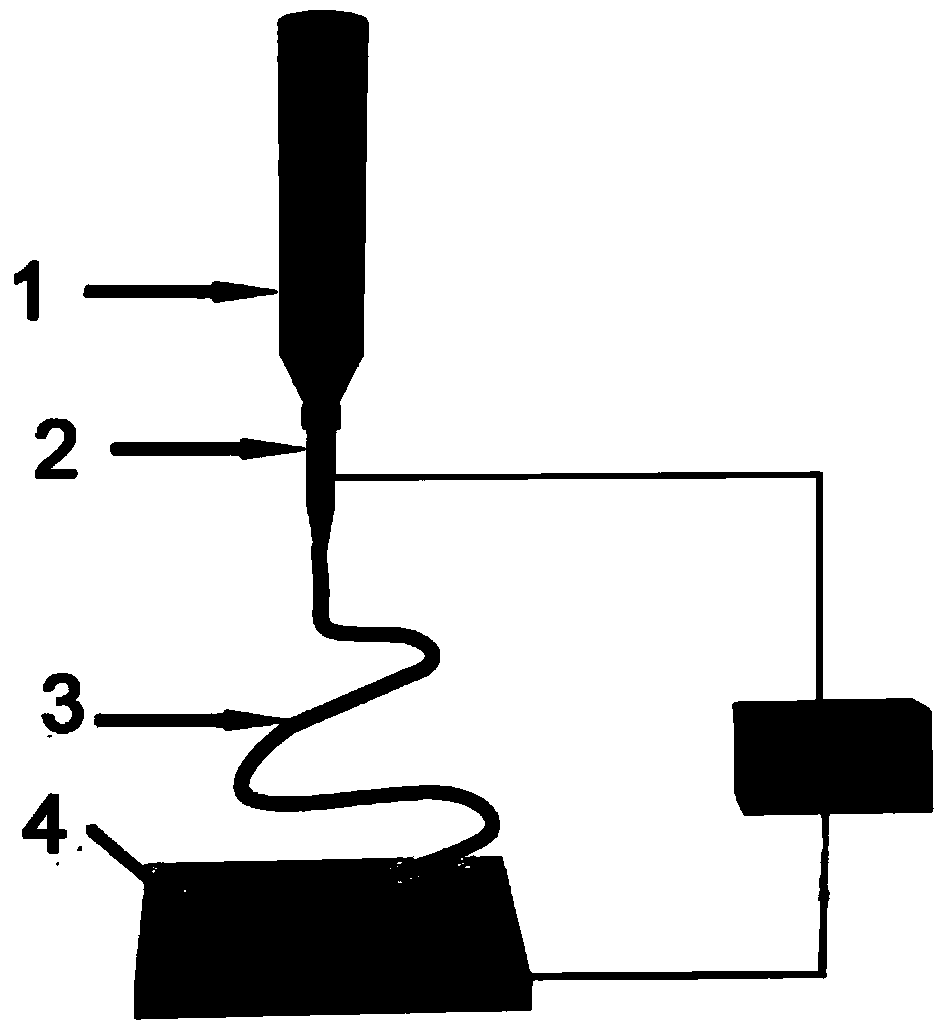

InactiveCN101928996AImprove hydrophobicitySimple processFilament/thread formingSpinning solutions preparationFiberHydrophobic polymer

The invention provides a preparation method of fibrous membrane with a super hydrophobic multi-stage nanometer structure, which is characterized by comprising the following specific steps: 1, at room temperature, adding hydrophobic polymer and hydrophobic inorganic nanoparticles into a sealed container filled with solvent, putting the sealed container on a magnetic stirrer to stir at the revolving speed of 10-200 rpm, and obtaining solution with even property; 2, at room temperature, inputting solution obtained in step 1 onto a spinning nozzle at constant flow velocity; connecting the spinning nozzle to a high voltage static generator to carry out electrostatic spinning; and receiving spun fiber by a receiver to obtain the fibrous membrane with super hydrophobic multi-stage nanometer structure. The invention can drastically improve the hydrophobic performance of the fibrous membrane.

Owner:DONGHUA UNIV

Multifunctional composite fiber and preparation method thereof

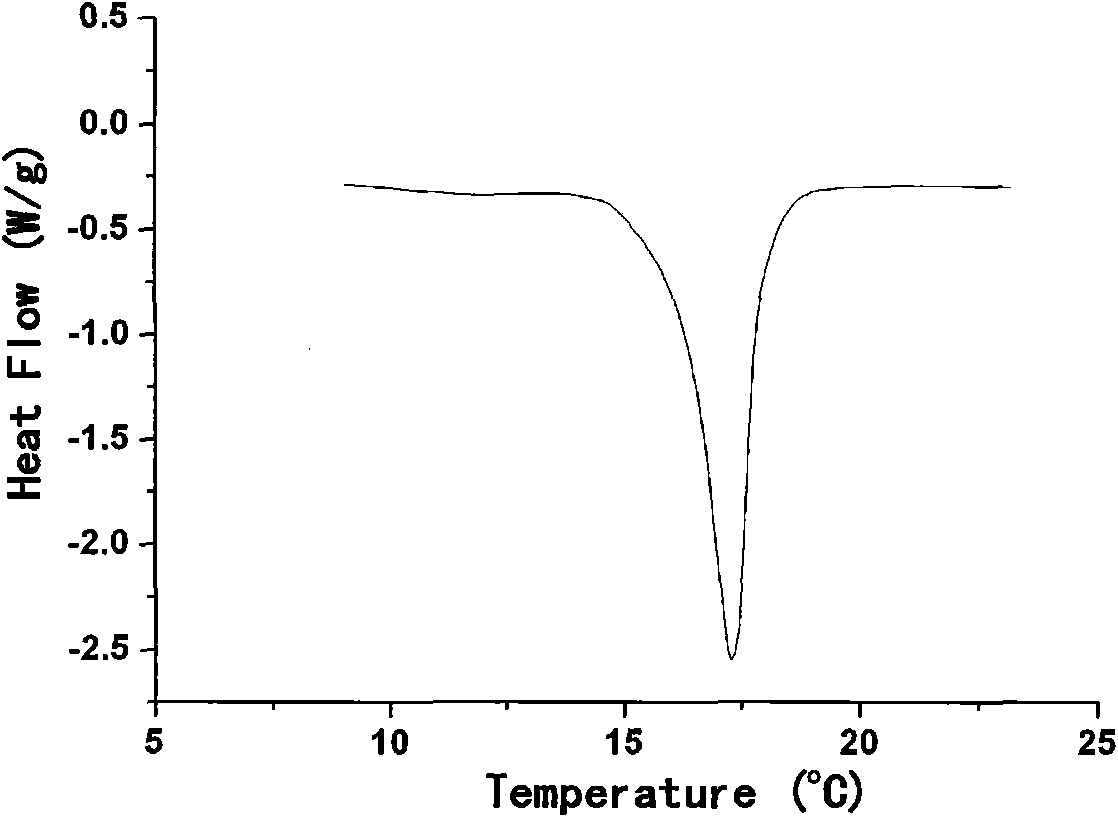

InactiveCN101845676AThe structure is convenient and controllableStable structureFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberThermochromism

The invention discloses multifunctional composite fiber and a preparation method thereof. The composite fiber has the properties of phase-change energy storage and thermochromism. The preparation method comprises the steps: preparing by a multi-fluid composite electrostatic spinning technology, adopting a phase-change energy storage material and a thermochromism material as two types of inner fluid, selecting proper outer fluid to form a multi-fluid composite jet flow, and obtaining micronano fiber shaped like non-woven fabrics under the function of high-pressure electrostatic force. The multifunctional composite fiber has the characteristics of stable structure, uniform dispersion and the like, and has the property of being capable of loading the phase-change energy storage material and the thermochromism material simultaneously. The composite material can be used for the fields of energy conservation of buildings, sensors, clothes, fabrics, energy storage materials and the like; and the multi-fluid composite electrostatic spinning technology adopted by the invention has simple device and easy operation.

Owner:BEIHANG UNIV

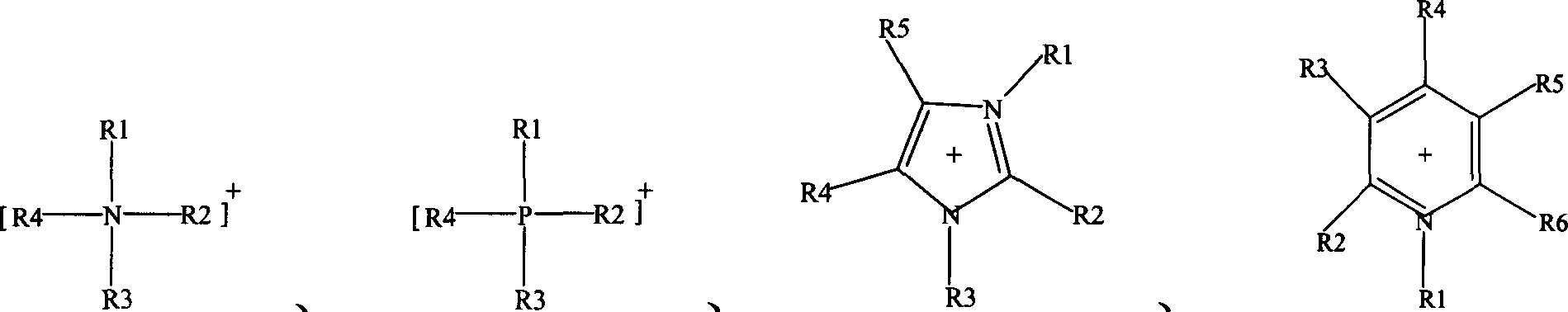

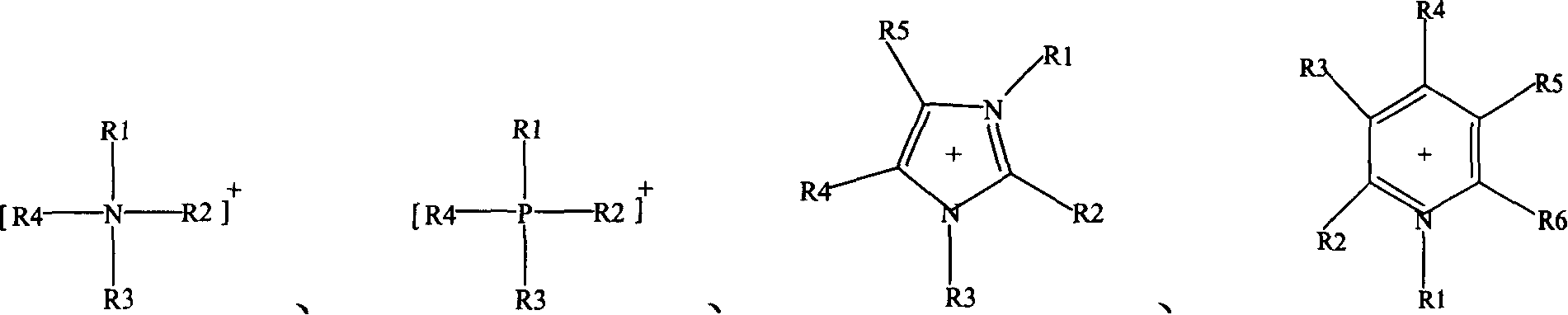

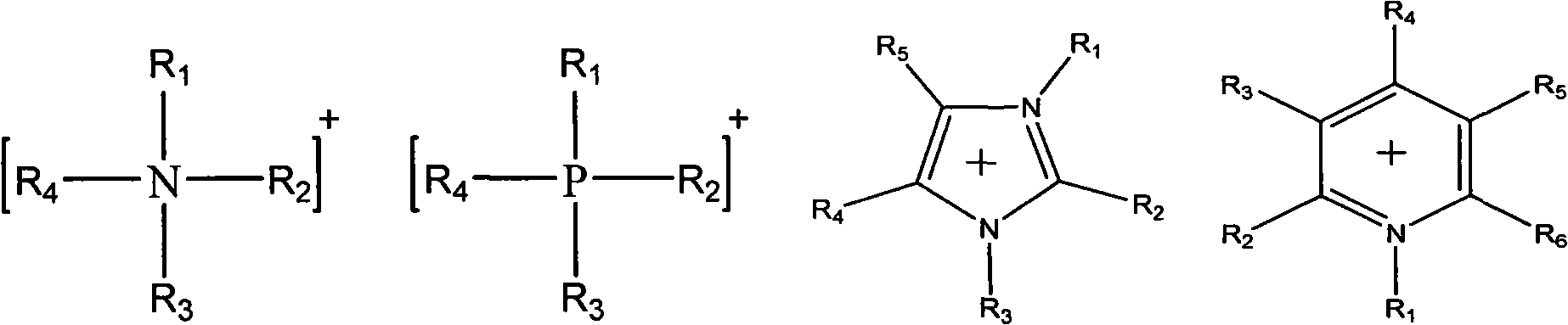

Method for preparing cellulose fiber using ion liquid as solvent

InactiveCN1851063ANon-volatileAvoid pollutionFilament/thread formingSpinning solutions preparationCellulose fiberSolvent

The invention discloses the method of producing the fibrin fiber by the ion liquid, the producing process includes the below steps: the crushed fibrin and the ion liquid are mixed evenly, the melting time keeps 1-100 hour under the temperature of 50-150 degree, the even steady filature original liquid is formed, the thickness of the filature original liquid is 5_35%; the filature original liquid is sifted and take off the doff to spin the silk, the freezing bath is composed of the water or the water and the ion, the thickness of the ion liquid in the freezing bath is 0-50%, the temperature is 0-90 degree. The conducing effect of the invention is showed below: the adopted solution is ion liquid which has the innocuity, volatility and the favor of protecting the condition and the health of the handling personnel; the melting point of the ion liquid has the wide range. so it is favor of controlling the temperature in the temperature range of the aggregation and the filature; the freezing reagent is composed of the water or the compound of the water and the ion liquid, it is the healthy solution and can protect the condition; the ion liquid has many merits such as the without volatility, the reclaiming easy, the falling of the cost, saving the resource and the energy and the improved producing efficiency.

Owner:DONGHUA UNIV

High-strength transparent cellulose material and preparation method thereof

ActiveCN101880410AGood mechanical propertiesImprove thermal stabilityMonocomponent cellulose artificial filamentSpinning solutions preparationSupercritical dryingCellulose

The invention discloses a transparent high-strength fiber material. The preparation method comprises the following steps that: cellulose is dissolved in NaOH-urea aqueous solution or LiOH-urea aqueous solution which is pre-cooled at low temperature to obtain a cellulose solution, and different thicknesses of cellulose hydrogels are prepared by the cellulose solution; water in the cellulose hydrogel is replaced into an organic solvent to obtain a cellulose organic gel; the cellulose hydrogel or the cellulose organic gel is subject to supercritical drying, ambient pressure drying or freeze drying to remove a liquid medium so as to obtain a cellulose aerogel; and the cellulose hydrogel, the organic gel or the aerogel are autoclaved at a temperature of 30-200 DEG C under the pressure of 10-160Mpa to obtain the high-strength transparent cellulose material. The cellulose material prepared by the invention has excellent mechanical properties, thermal stability and optical permeability.

Owner:WUHAN UNIV

Preparation method of high elasticity super hydrophobic high temperature nano silicon dioxide fibrous membrane

InactiveCN101603245AGood flexibilityBend freelyFilament/thread formingNon-woven fabricsElectrospinningSolvent

The invention provides a preparation method of high elasticity super hydrophobic high temperature silicon dioxide fibrous membrane. The invention is characterized in that the method includes the following steps: template polymer is stirred in solvent at 60 DEG C to obtain template solution with mass concentration of 5-30%; organic silicon or nano silicon dioxide are mixed with water and inorganic acid at normal temperature to obtain silicon source solution; the template solution and the silicon source solution are mixed to be uniform at normal temperature to obtain electro spun solution; the electro spun solution is subject to electrostatic spinning at normal temperature to obtain composite fibrous membrane; the compound fibrous membrane is placed into a muffle furnace to be forged, so as to obtain a nano silicon dioxide fibrous membrane; the nano silicon dioxide fibrous membrane is placed into organic silicon hydrocarbon compound solution to be soaked for 6-30h and then is dried in vacuum, thus obtaining the high elasticity super hydrophobic high temperature nano silicon dioxide fibrous membrane. The material is antifouling and self-cleaning under high temperature high pressure severe environment.

Owner:DONGHUA UNIV

Method for preparing polymeric nano-micro fiber non-woven fabric

ActiveCN102071542AOvercoming demandsUniversally applicableNon-woven fabricsDry spinning methodsFiberPolymer dissolution

The invention discloses a method for preparing a polymeric nano-micro fiber non-woven fabric. The method comprises the following steps of: firstly, dissolving at least one polymer in at least one solvent to prepare spinning solution; then supplying the spinning solution to a spinneret plate with a series of spinneret orifices so as to make the spinning solution extruded from the spinneret orifices of the spinneret plate to form a trickle of the spinning solution; secondly, stretching and refining the trickle of the spinning solution by utilizing at least one high-speed jet airflow, and accelerating the volatilization of the solvent to form nano-micro fiber; and finally, collecting the nano-micro fiber on a web curtain by utilizing high-speed airflow and suction airflow. The polymer is a fiber-forming polymer; the solvent can dissolve the fiber-forming polymer and has the volatility; a jet angle of the high-speed airflow is between 15 and 60 degrees, and the jet velocity is at least 50 times higher than extrusion speed of the trickle of the spinning solution; the mass concentration of the polymer in the spinning solution is between 2 and 50 percent; and the viscosity of the spinning solution at a spinning temperature is between 10 and 100, 000mP.s.

Owner:上海榕融新材料技术有限公司

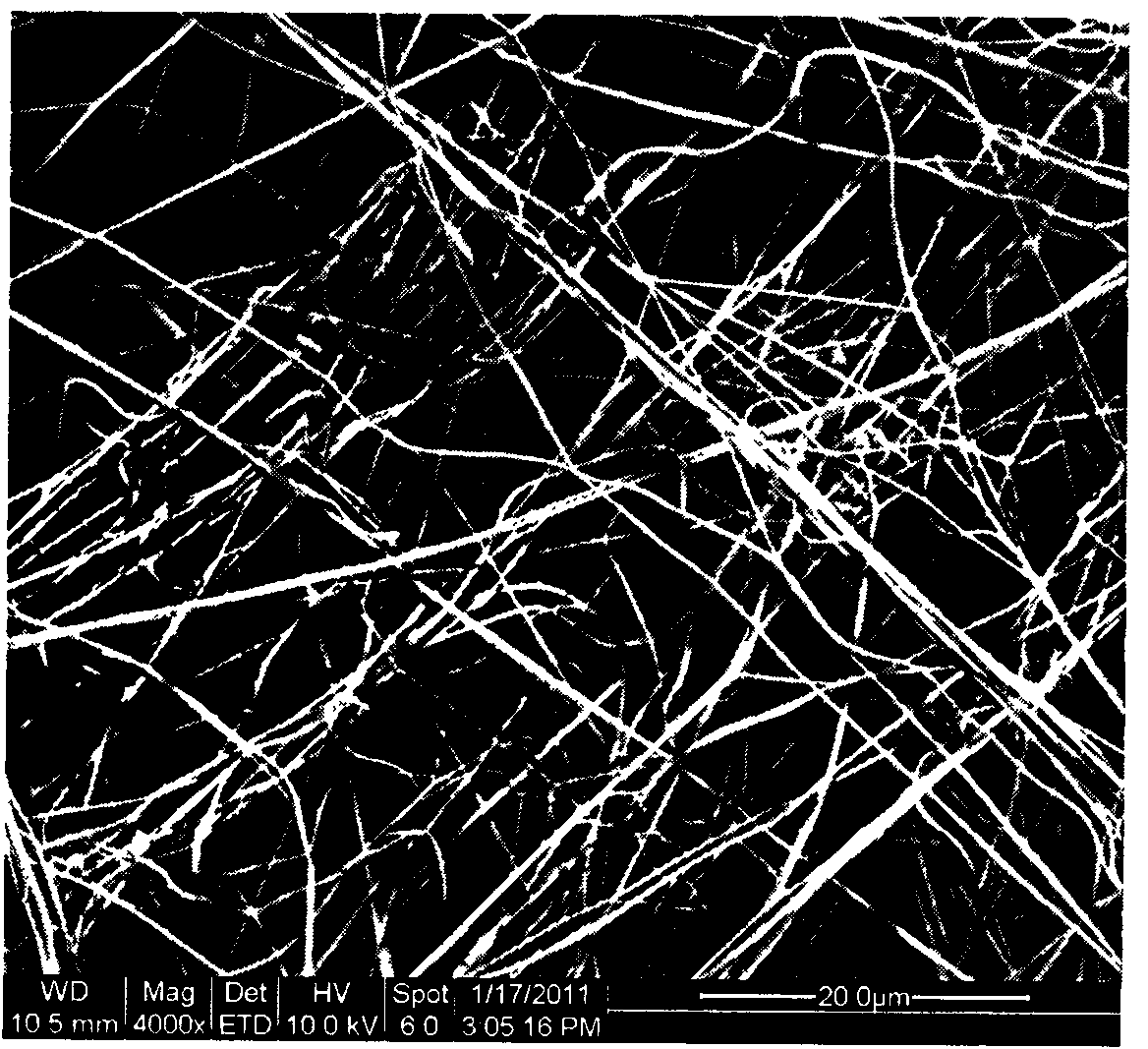

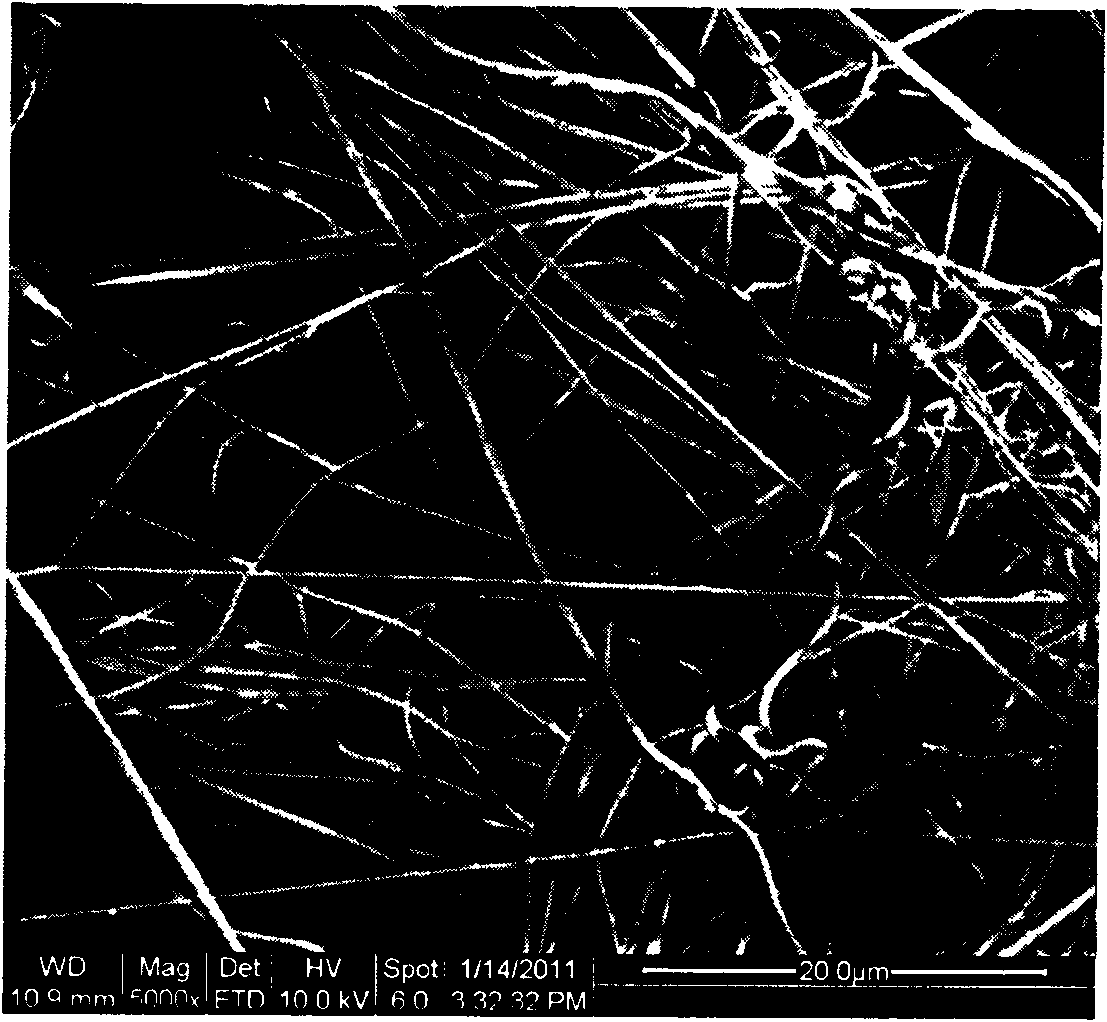

Preparation method of p-aramid nanofiber

ActiveCN105153413AReduce usageSimple processArtificial filament recoveryArtificial filament washing/dryingMicrometerNanofiber

The invention relates to a preparation method of p-aramid nanofiber, and belongs to the technical field of polymer new materials. The diameter of the prepared p-aramid nanofiber ranges from tens of nanometers to hundreds of nanometers, and the length of the prepared p-aramid nanofiber ranges from hundreds of nanometers to tens of micrometers. According to the preparation method, a certain amount of surface active agents are added in the PPTA low-temperature polymerization process, aggregation of PPTA molecules is controlled while PPTA molecule chains are lengthened, and the p-aramid nanofiber which is uniform in size and has the diameter capable of being regulated within the range between nanometer and submicron can be prepared under the auxiliary effect of other means (for example, precipitator and high-speed shearing and dispersing). The preparation method is short in production flow, devices are simple, batched and stable production can be achieved, and therefore the requirement for industrially producing the p-aramid nanofiber on a large scale is met; the preparation method has wide application prospects and can be used for preparing lithium-ion battery separators and high-performance composites.

Owner:SHANDONG JUFANG NEW MATERIAL CO LTD

Flame retardant cellulose fiber and preparation method thereof

InactiveCN101608348ASuitable for processingEasy to useFlame-proof filament manufactureMonocomponent cellulose artificial filamentMass ratioCellulose fiber

The invention discloses a flame retardant cellulose fiber and a preparation method thereof. The fiber has the components of fire retardant and cellulose which have the mass ratio of 10-25:100; wherein the fire retardant is novel phosphorus fire retardant having the average grain diameter being less than 1mum; the cellulose is wood pulp or cotton pulp having the polymerization degree of 400-1000 and alpha-cellulose content being more than or equal to 90%. According to the components with the mass ratio of the fiber, the preparation method of the fiber comprises the technique as follows: 1. preparation of flame retardant spinning solution as the following: according to the mass ratio, firstly adding the fire retardant into ionic liquid at the normal temperature, and leading the fire retardant to be uniformly dispersed in the ionic liquid under mechanical agitation; then adding the cellulose into the mixed ionic liquid to be fully dissolved with the dissolving temperature of 70-110 DEG C to prepare flame retardant spinning solution; ensuring the mass ratio between the cellulose and the ionic liquid to be 5-35:95-65: 2. preparation of the flame retardant cellulose fiber: preparing the flame retardant cellulose fiber according to the conventional spinning process flow.

Owner:TIANJIN POLYTECHNIC UNIV

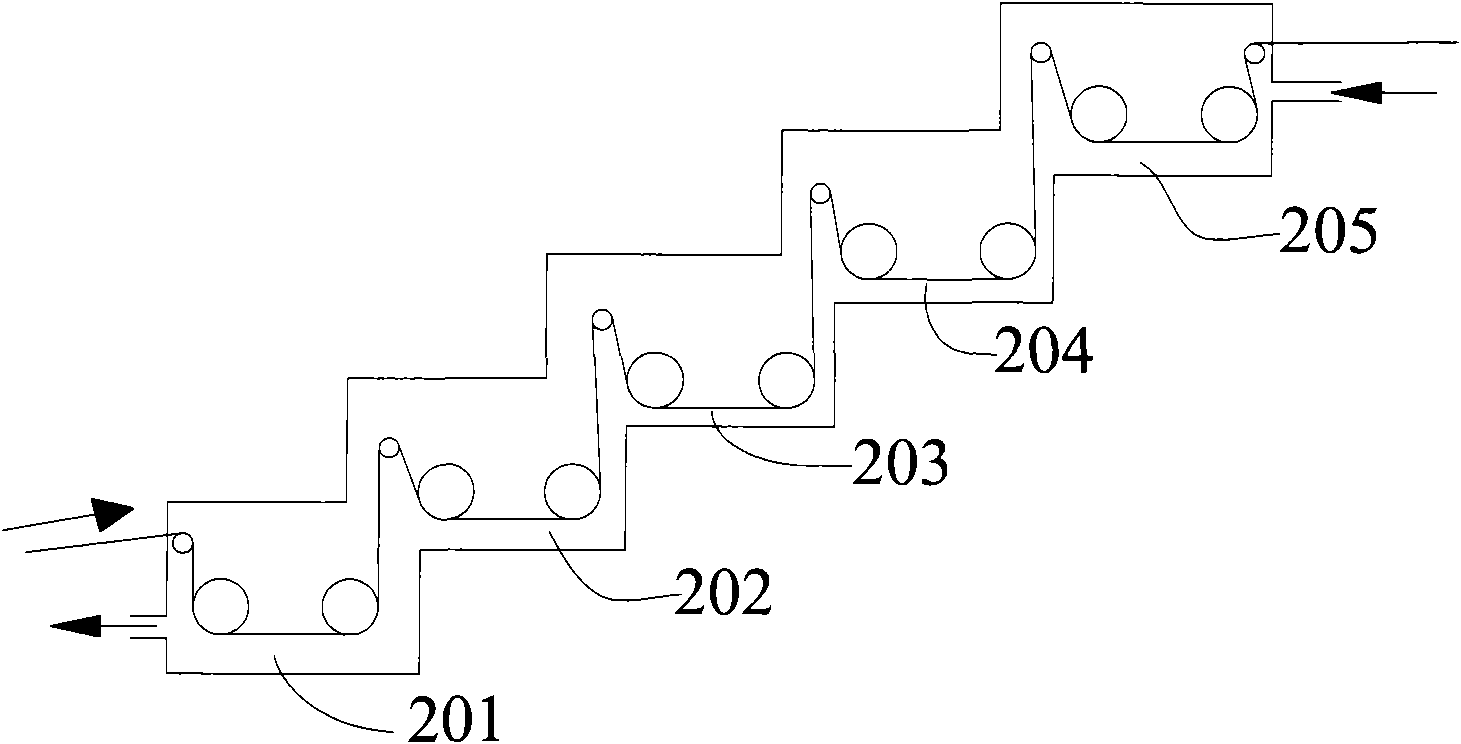

Preparation method of ultra-high molecular weight polyethylene fiber

InactiveCN101575742AImprove mechanical propertiesReduce internal stressArtificial filament washing/dryingWet spinning methodsFiberPolymer science

The invention relates to a preparation method of ultra-high molecular weight polyethylene fiber, which comprises the following steps: firstly, mixing ultra-high molecular weight polyethylene powder with solvent for swelling to obtain suspending liquid, and then extruding and dissolving the suspending liquid through a double screw extruder to obtain 4-25 percent of spinning solution, wherein the solvent is liquid hydrocarbon under room temperature; secondly, spraying and cooling the spinning solution to obtain gel filament; thirdly, applying 1-10 times of pretensioning to the gel filament, settling the pretensioned gel filament for 12-48h, extracting and drying the gel filament; fourthly, applying 4-130 times of heat drawing to the dried gel filament 70-160 DEG C to obtain the ultra-high molecular weight polyethylene fiber. After the gel filament is formed and pretentioned to a certain degree, the primary filament can be more uniform and has higher tension property , and the ultra-high molecular weight polyethylene fiber with excellent property can be prepared.

Owner:杨珍芬

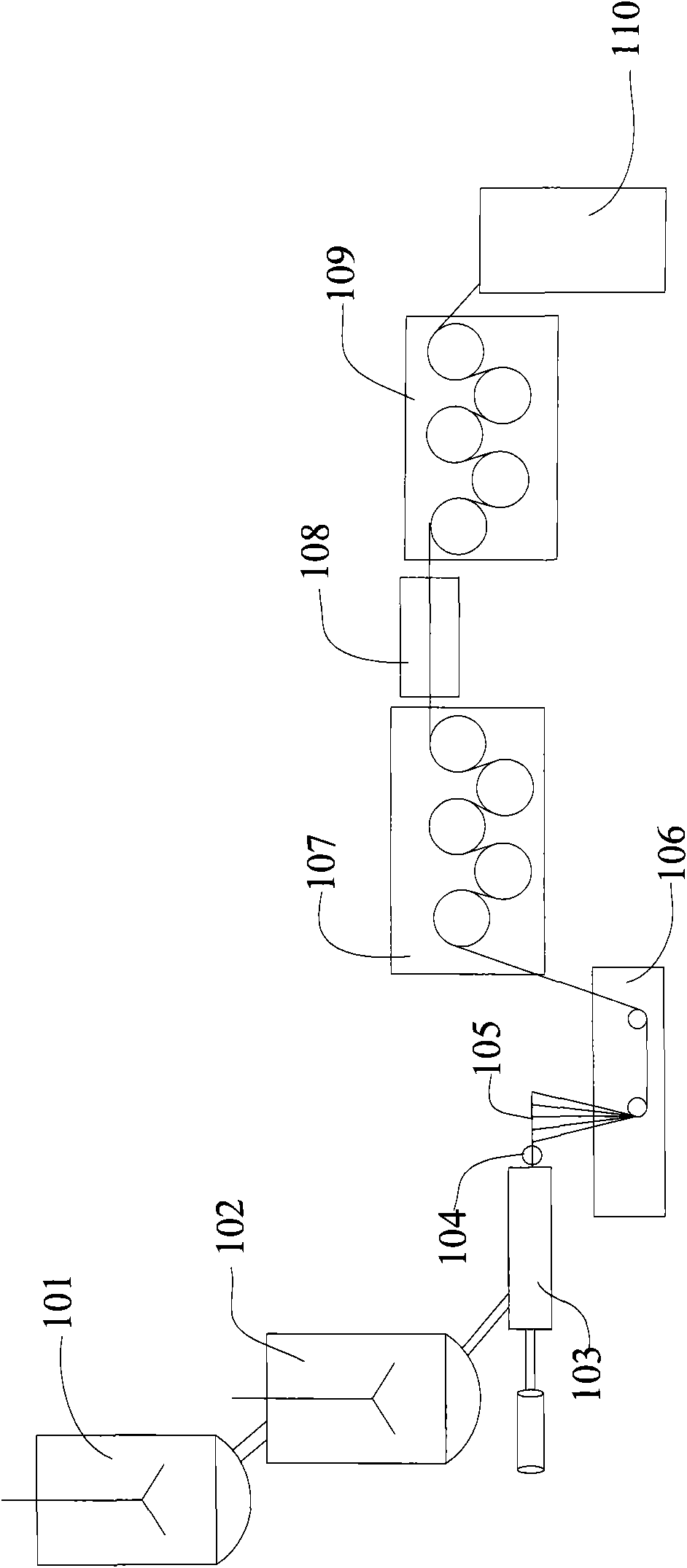

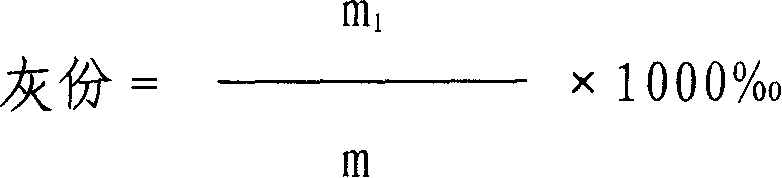

Method for preparing polyacrylonitrile-based carbon fiber protofilament

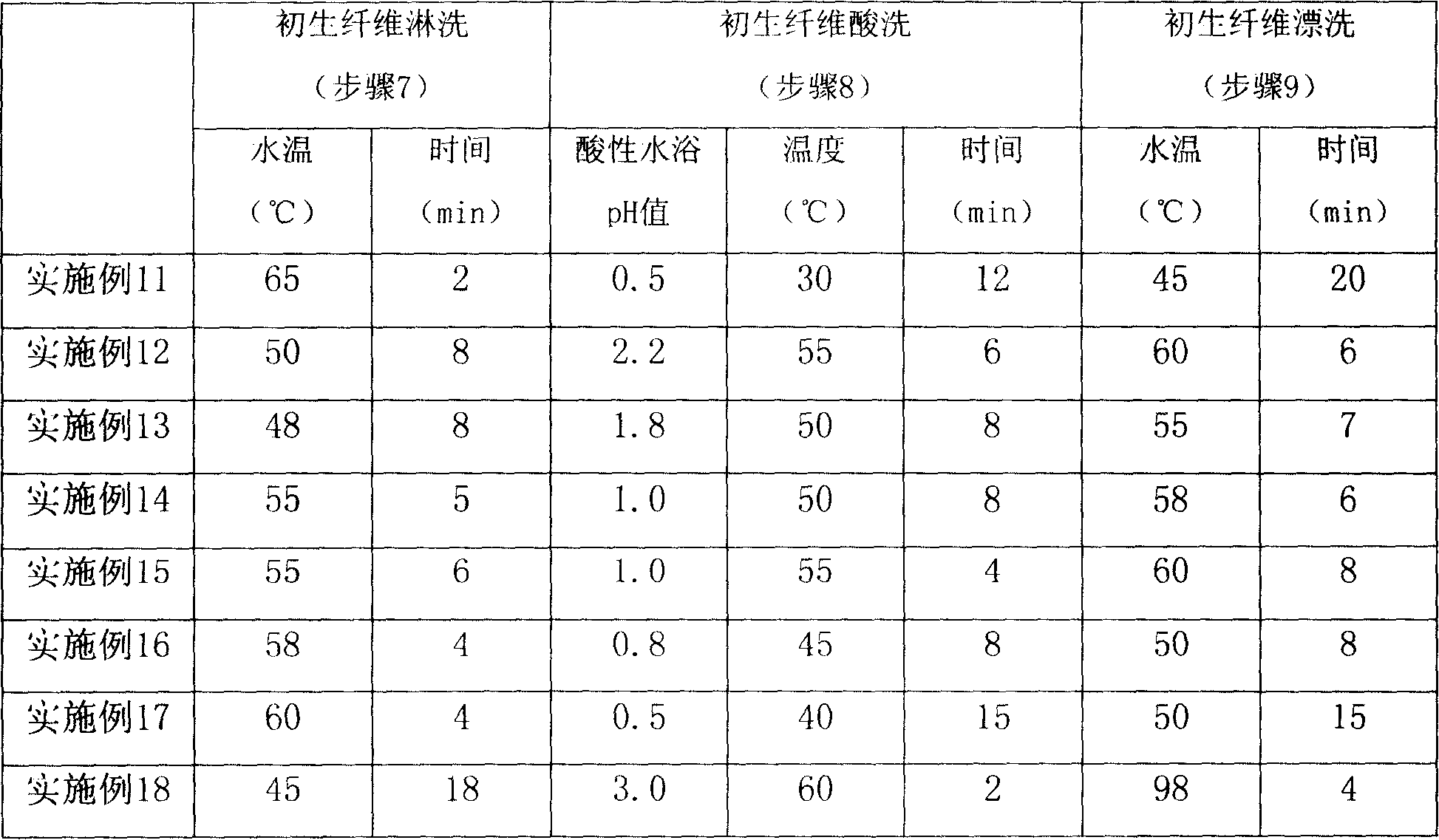

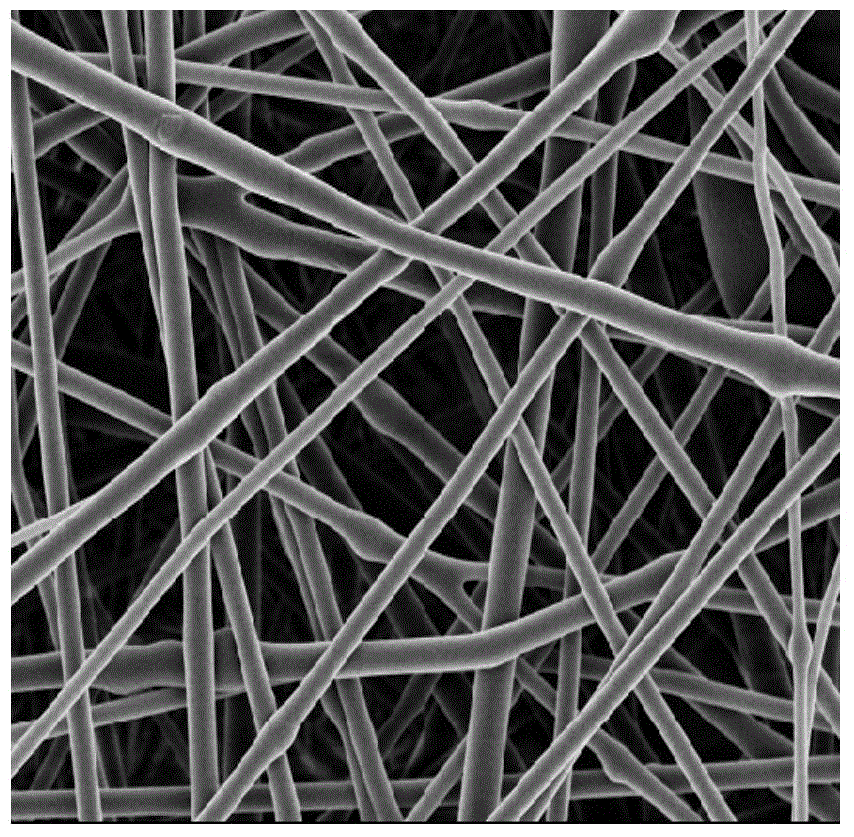

ActiveCN101165237AEfficient removalGood removal effectArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentPolymer scienceCarbon fibers

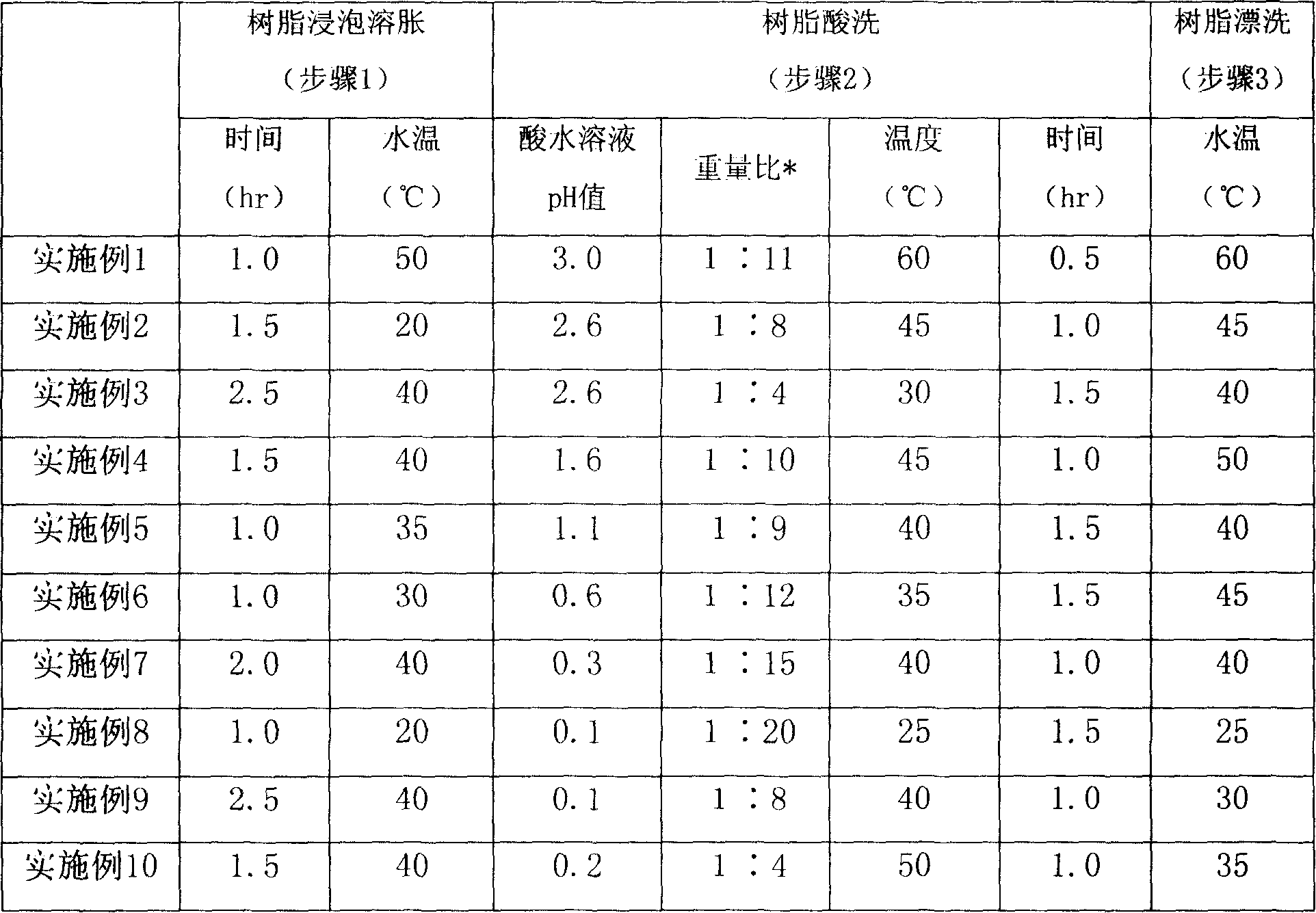

The process of preparing polyacrylonitrile fiber for carbon fiber includes the following steps: soaking resin in deionized water at 20-50 deg.c to swell for 1-2.5 hr; pickling in water solution of nitric acid or hydrochloric acid in pH 0.1-3.0 at 25-60 deg.c for 0.5-1.5 hr; rinsing with deionized water to neutral; dewatering and drying to water content lower than 3 %; dissolving in 35-58 wt% concentration NaSCN aqua to form spinning fluid in resin content of 8-16 wt%; debubbling and spinning to form initial fiber; washing with deionized water, acid aqua and hot water successively; drafting, oiling, drying, densifying, etc to produce polyacrylonitrile fiber for carbon fiber. The polyacrylonitrile fiber product has ash content not higher than 0.01% and alkali metal ion content not higher than 0.005%.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

Lithium hydrate and carbamide composition solvent for dissolving cellulous fiber and its use

InactiveCN1546556AHigh strengthWide range of usesMonocomponent cellulose artificial filamentSpinning solutions preparationAcid waterLithium hydroxide

The invention relates to a dissolvent for cellulose dissolution through freezing-unfreezing method or direct dissolution method, and process for preparing the regenerated cellulose fibers and films by utilizing the dissolvent, wherein the dissolvent is the water solution of lithium hydroxide and urea whose compositions are 3.0-7.0wt% of lithium hydroxide, 4.0-30.0.0wt% of urea, the rest is water. The water solution of lithium hydroxide and urea can directly dissolve cellulose through freezing-unfreezing method or by pre-cooling the dissolvent in advance to -10 deg. C - -4 deg. C. It can be used to obtain high dissolvability transparent concentrated cellulose solution. By using the concentrated cellulose solution and through 3-5wt% diluted acid water solution coagulation, regeneration, regenerated cellulose films and fibers can be prepared.

Owner:WUHAN UNIV

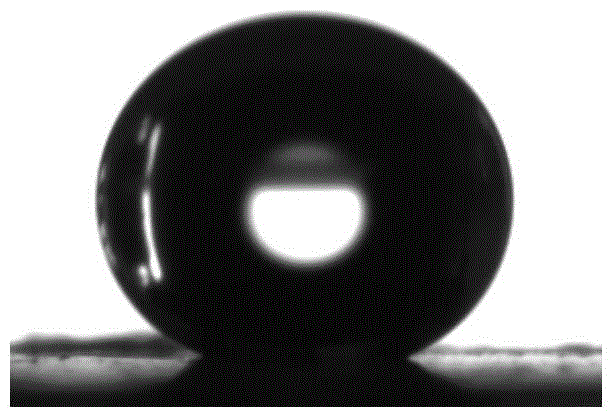

Hydrophobic film with self-cleaning function, preparation method thereof and application thereof

ActiveCN105002656AHigh porosityWith self-cleaning functionSemi-permeable membranesFilament/thread formingPorosityFiber

The invention relates to a hydrophobic film, and specifically relates to a hydrophobic film with a self-cleaning function, and a preparation method thereof and an application thereof. The hydrophobic film is a polymer nanofiber film prepared through an electrospinning fiber technique, the surface of the hydrophobic film is subjected to nanocrystallization modification to improve the surface hydrophobicity, and the contact angle between the hydrophobic film and water is 140-180 DEG. According to the invention, the electrospinning fiber technique and the surface nanocrystallization technique are combined, the preparation technology is simple, and the prepared hydrophobic film has the self-cleaning function and a high porosity factor, and can be applied to fields of air purifying filters, film distillation and oil-water separation and the like.

Owner:YANTAI LVSHUIFU MEMBRANE MATERIAL

Multifunctional aromatic type element fiber fabric protective clothing

ActiveCN103233287ASpinning solutions preparationArtifical filament manufactureAcute hyperglycaemiaSesamum orientale

The invention discloses multifunctional aromatic type element fiber fabric protective clothing. The multifunctional aromatic type element fiber fabric protective clothing comprises vitamin mineral substance nutrient element group, a free radical-scavenging anti-electromagnetic wave energy-accumulated heat-insulating material, natural antibiosis mite-proof traditional Chinese medicine fluid extract aroma nano microcapsule, and cotton, sesame, silk, wool, polypropylene fiber, nylon, acrylic fiber and a terylene viscose fiber spinning solution. The multifunctional aromatic type element fiber fabric protective clothing can entirely supplement and regulate the element balance of a human body, as well as the vitamin balance, release trace element negative ions, purify air, resist heavy metal elements and air, powerfully scavenge free radicals, enhance the immunity of the human body, and prevent electromagnetic wave pollution, is energy-accumulated, cold-proof and heat-insulating, as well as antimicrobial and mite-proof, can effectively prevent the infection of various pathogenic bacteria, influenza and skin pruritus, is anti-cancer, and resists hypertension, hyperlipidemia, hyperglycemia, cerebral thrombosis and the like, thus building the human body, and enabling the human body to emit natural and pleasant aroma.

Owner:中山巨邦科技集团有限公司

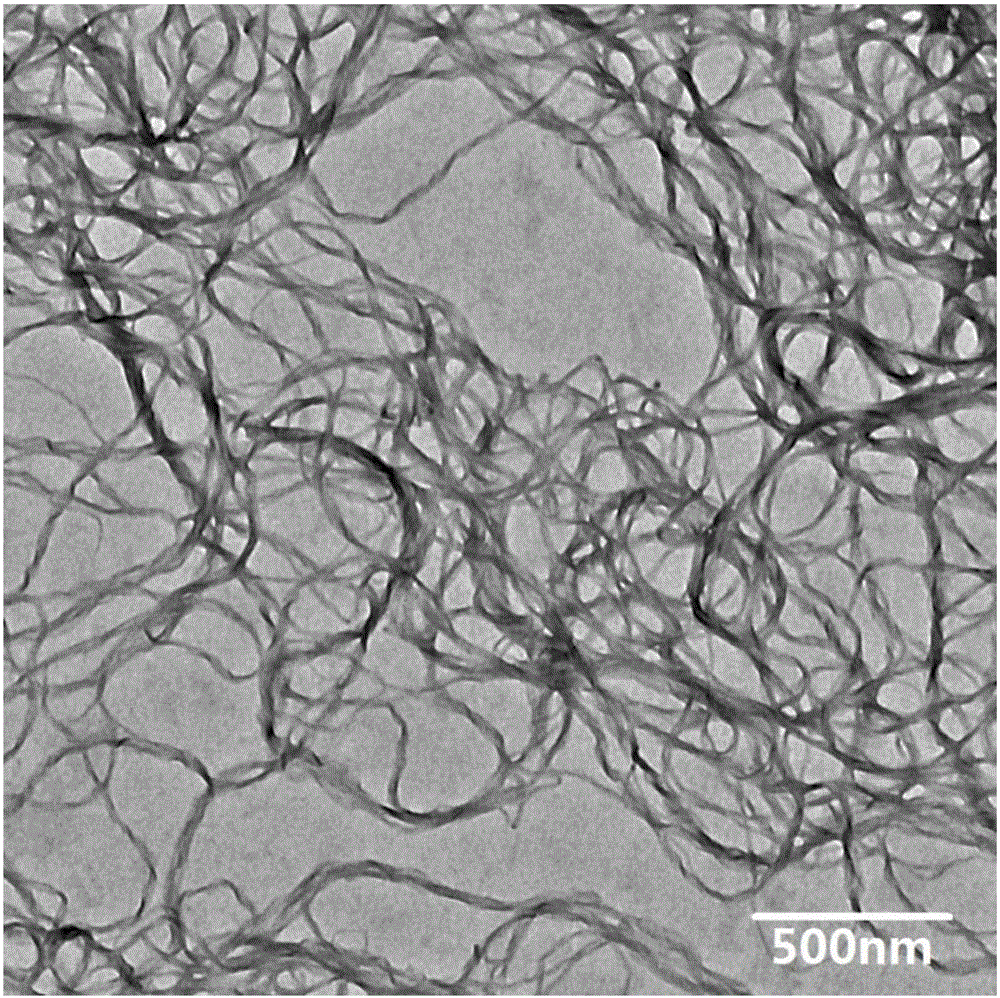

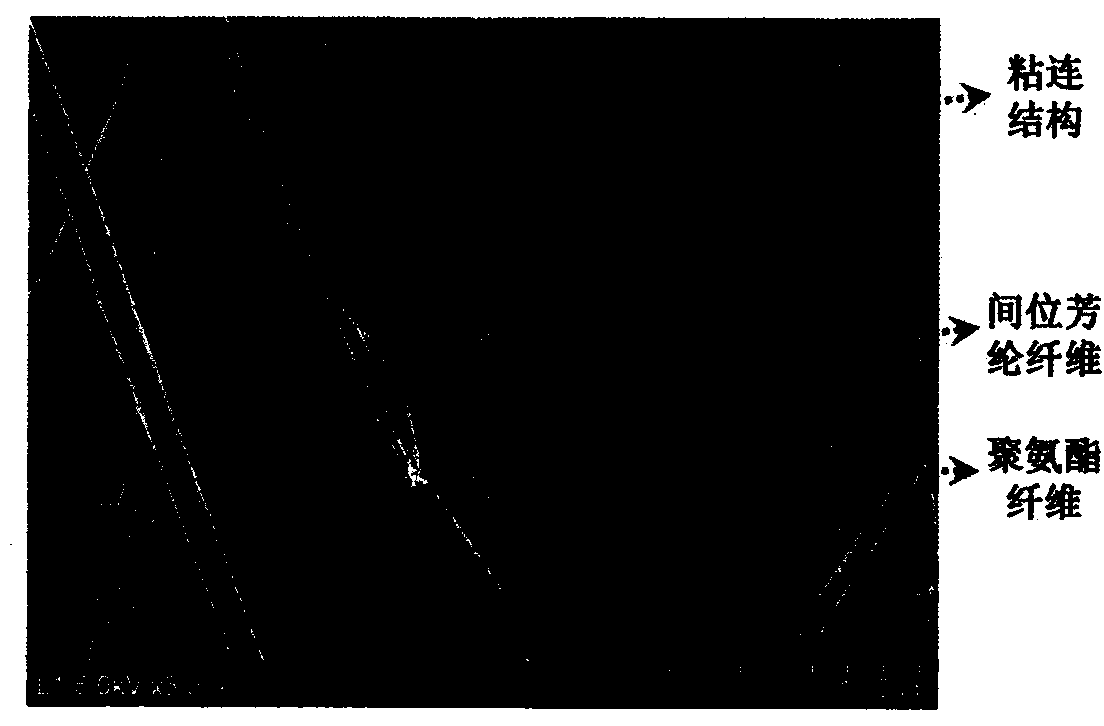

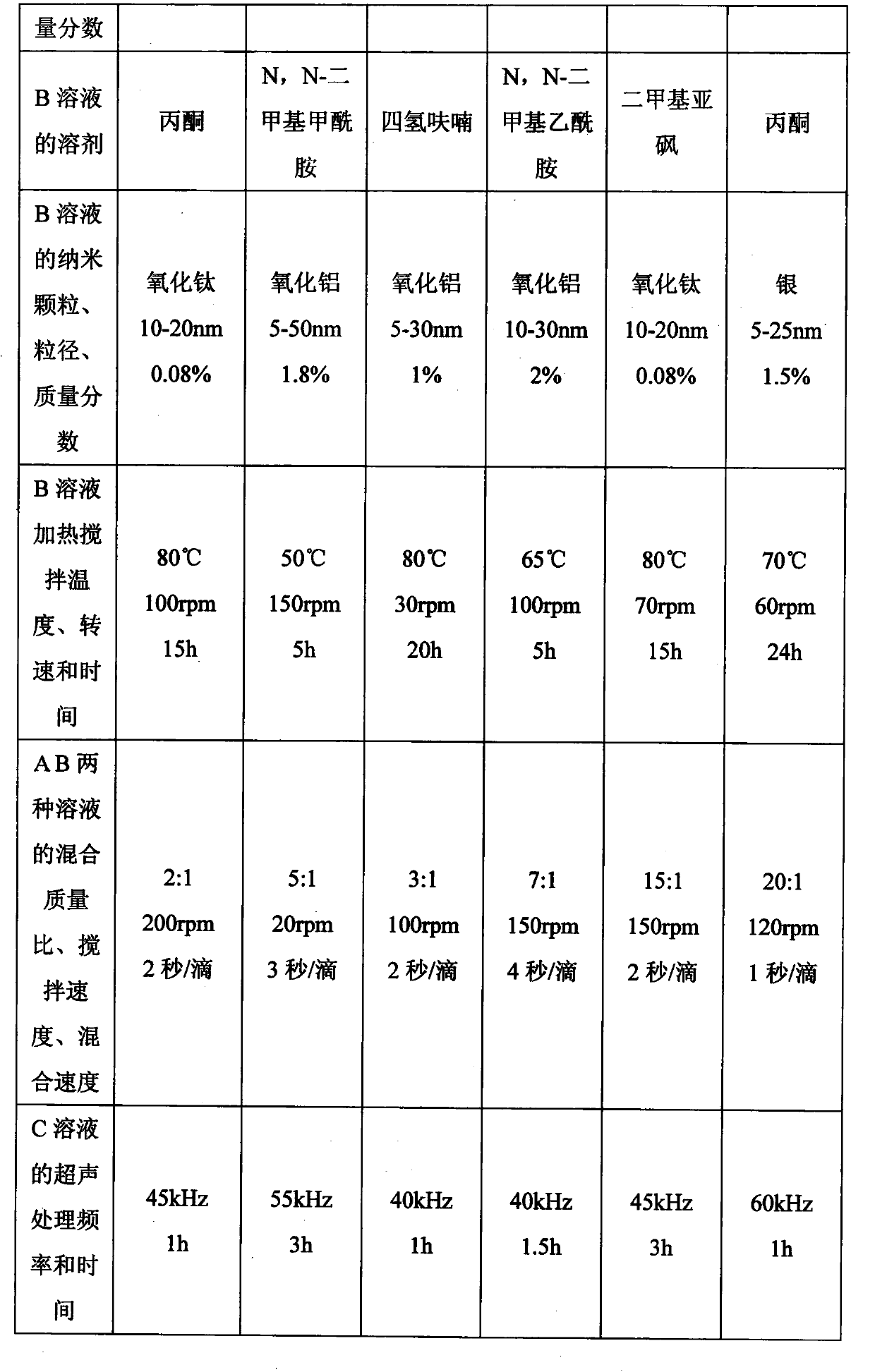

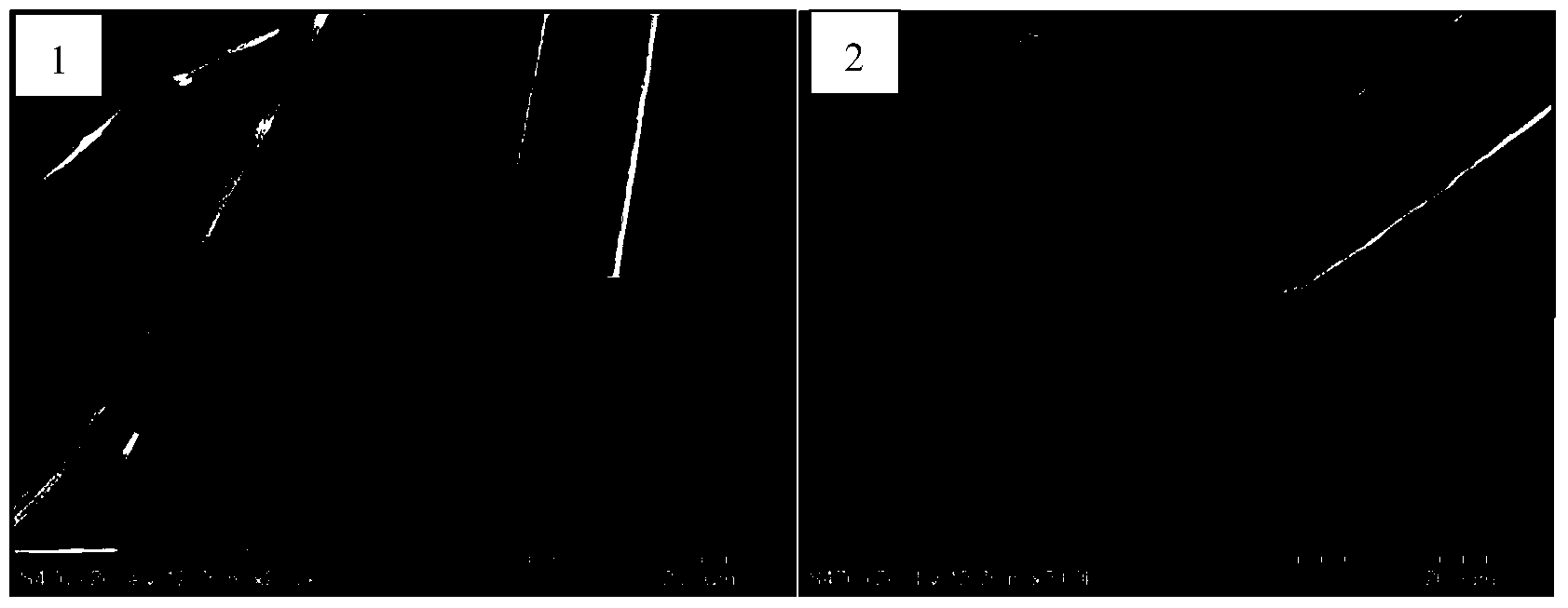

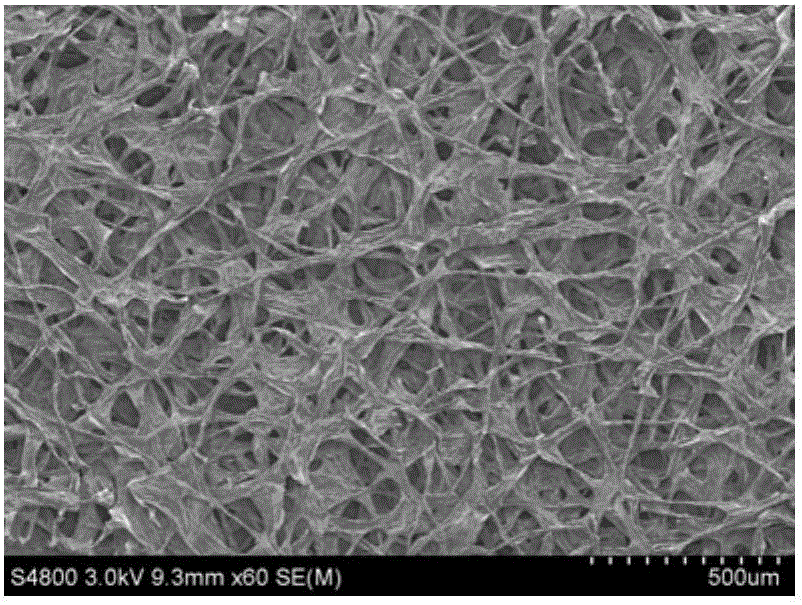

Preparation method for multi-component net-shaped nanofiber membrane

ActiveCN103806221AIncreased interaction surface areaImprove the degree of purificationFilament/thread formingNon-woven fabricsOrganic solventHalogen

The invention relates to a preparation method for a multi-component net-shaped nanofiber membrane. The preparation method includes the detailed steps that step1, mixing and beating are performed on meta-position aramid fibers, halogen salt and organic solvent by the mass ratio of 1:0.004-0.4:2.996-18.6, and a meta-position aramid fiber solution is prepared through mixing; step2, functionality high-molecular polymers and the solvent are mixed by the mass ratio of 1:5.4-98.99, then nano-particles are added, and heating and mixing are performed to prepare a functionality high-molecular solution, wherein the mass fraction of the nano-particles in the solution is 0.01-5%; step3, the meta-position aramid fiber solution obtained in the step1 and the functionality high-molecular solution obtained in the step2 are mixed by the mass ratio of 1:0.05-0.5 in a dripping mode, and then ultrasonic treatment is performed to obtain a spinning solution; step4, under the conditions of 20 DEG C-30 DEG C indoor temperature and 20-70% relative humidity, the spinning solution is used for electrostatic spinning, and finally the multi-component net-shaped nanofiber membrane with a 5nm-20nm net-shaped nanofiber diameter and reaches over 95% in net-shaped structure coverage rate is obtained. The preparation technology is simple and low in cost, tensile strength of material reaches 100MPa-2000MPa, and the functionality advantage is remarkable.

Owner:DONGHUA UNIV

Polyimide nanofiber membrane with surface coated with nano titanium dioxide and preparation method for polyimide nanofiber membrane

The invention discloses a polyimide nanofiber membrane with the surface coated with nano titanium dioxide and a preparation method for the polyimide nanofiber membrane. The preparation method comprises the steps of synthesizing polyamide acid through diamine and binary anhydride to prepare a nanofiber membrane by an electrospinning technology, and then immersing the nanofiber membrane into titanium dioxide sol with different concentrations or partially cyclizing a polyamide acid nano fiber membrane, immersing the cyclized polyamide acid nano fiber membrane into the titanium dioxide sol, drying and preparing the polyimide nanofiber membrane with the surface coated with the nano titanium dioxide through gradient heating thermal imidization. The polyimide nanofiber composite membrane provided through the preparation method disclosed by the invention is formed by coating the surface of a polyimide nanofiber with titanium dioxide particles or a titanium dioxide layer; the particle size of the titanium dioxide particles is 10-150nm, and the titanium dioxide layer is 10-200nm; the diameter of the polyimide nanofiber is 30-600nm; the composite membrane is 10-90 microns thick; due to the coating of the titanium dioxide nano layer, the surface wettability, the size stability and the heat resistance performance of the polyimide nanofiber membrane are improved; the implementation process is simple and is easy to processize; the polyimide nanofiber membrane has a good application prospect.

Owner:北京凯越嘉诚科技发展有限公司

Phase change composite spinning solution and its preparation and application

InactiveCN1493720AImprove spinnabilityIncrease the areaSpinning solutions preparationCelluloseParaffin wax

A composite phase-change spinning dope contains soluet and solvent. Said solute is composed of the phase change material chosen from polyol, polyolefin, polyether and paraffin wax hydrocarbon, and the fibre-forming high polymer chosen from cellulose and its delivatives, chitin and its derivatives, polyacrylonitrile, and polyvinyl alcohol. Said solvent is the mixture of DMSO, keton, organic, distilled water or DMF and acetone. It can be used to prepare the superfine phase-change fibres by electrostatic spinning. Said superfine phase-change fibres can be used to prepare multifunctional protecting clothes.

Owner:DONGHUA UNIV

Preparation method of titanium dioxide/active carbon composite nanofibrous membrane

InactiveCN102021676AAchieve mass productionImprove bindingWater/sewage treatment by irradiationOther chemical processesSpinningPhosphoric acid

The invention provides a preparation method of a titanium dioxide / active carbon composite nanofibrous membrane, characterized by comprising the following specific steps: dissolving polyacrylonitrile powder in N, N-dimethyl formamide; mixing titanium hydroxide gel with the polyacrylonitrile solution to obtain electrostatic spinning stock solution, and performing electrostatic spinning to get the composite nanofibrous membrane; placing the composite nanofibrous membrane in an electrically heated drying cabinet for being pre-oxidized; soaking the composite nanofibrous membrane in phosphoric acid or potassium hydroxide solution, washing the solution to be neutral by distilled water, and drying the composite nanofibrous membrane in the drying cabinet; and then, under nitrogen protection, heating up to 450-550 DEG C, and cooling to room temperature to get the titanium dioxide / active carbon composite nanofibrous membrane. The preparation method improves combination firmness between fibers and active ingredients of a photocatalyst, and also improves charge capacity of the fibers; the titanium dioxide / active carbon composite nanofibrous membrane is high in photo catalytic activity, good in absorption effect, reproducible and simple in a reproduction method, and can use sunlight, so that operations are easy and operation cost is low.

Owner:DONGHUA UNIV

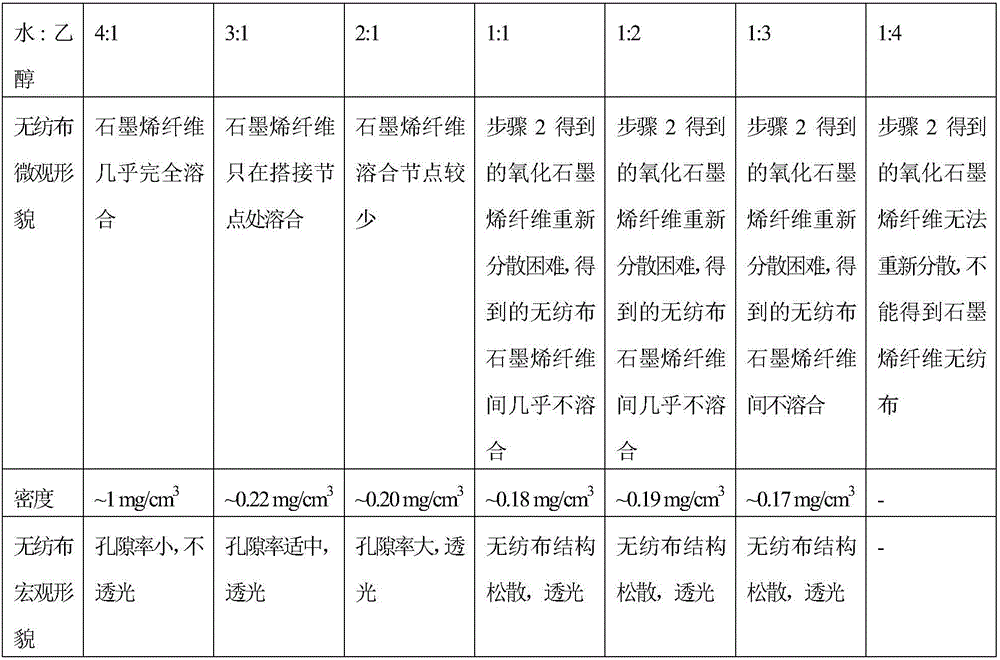

Graphene fiber non-woven fabric and preparation method thereof

ActiveCN106192201AGood electrical and thermal conductivitySimple methodNew-spun product collectionGrapheneElectricityPolymer science

The invention discloses a graphene fiber non-woven fabric and a preparation method thereof. The non-woven fabric is obtained by filtering and depositing a graphene short-fiber dispersion solution through a filter net and performing drying and reduction, so that the structural unit of the non-woven fabric is disorderly-stacked and bonded graphene short fiber, and fiber is overlapped to form a large number of holes through which liquid of gas can pass. The graphene fiber non-woven fabric has the good mechanical strength and tenacity, is completely composed of graphene fiber, does not contain high polymer materials as a skeleton or adhesives, the electricity and heat conducting performance of the reduced network structure overlapped by the graphene fiber is excellent, and the non-woven fabric can be used as a multifunctional high-performance fabric.

Owner:杭州德烯科技集团有限公司

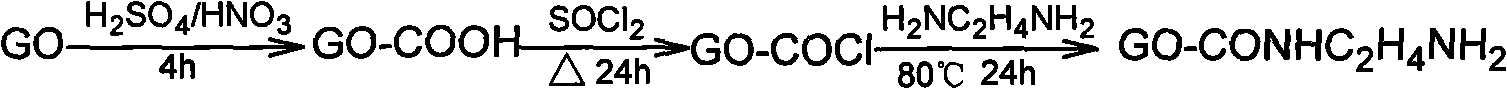

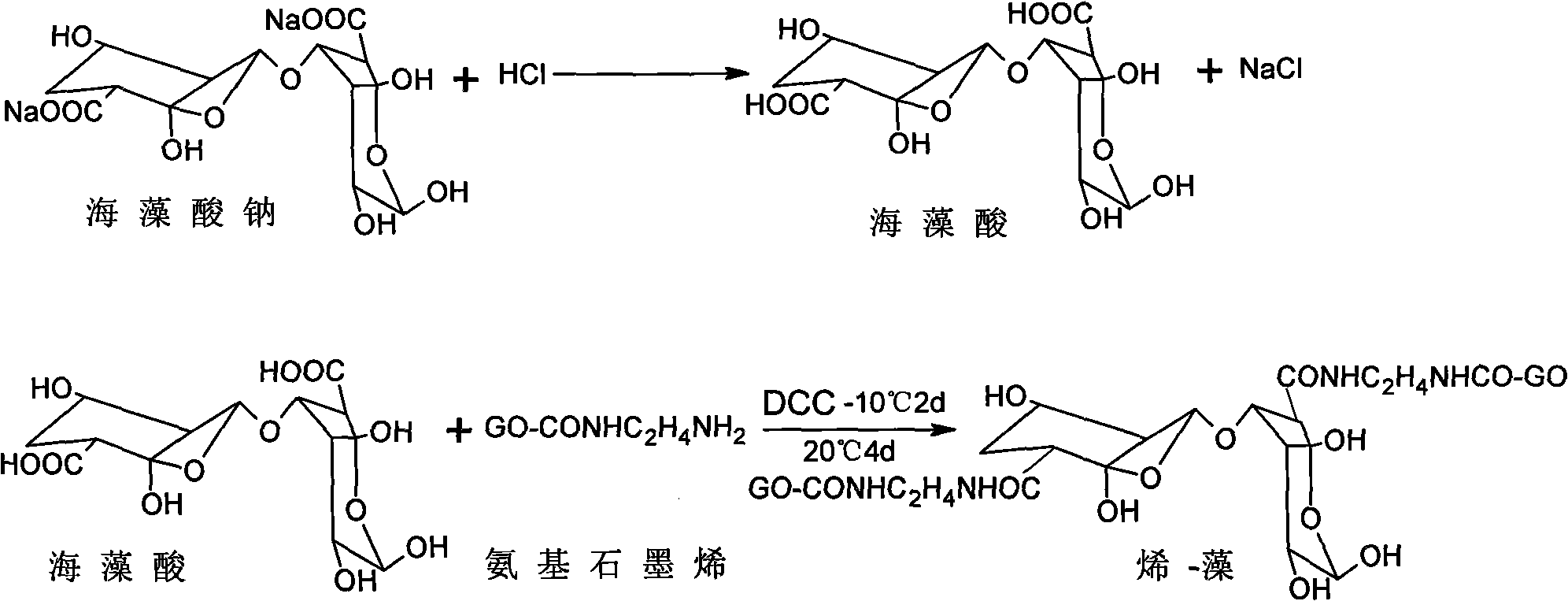

Method for preparing graphene functionalized alginate fibers

ActiveCN102181961AEffective orientationUniform and stable dispersionAlginate artificial filamentsWet spinning methodsFiberChemical reaction

The invention discloses a method for preparing graphene functionalized alginate fibers. The method comprises the following steps: firstly adding a defined amount of graphene to a sodium alginate solution to obtain a graphene / alginate spinning solution; or aminating the defined amount of graphene and then ensuring the aminated graphene to covalently bind with sodium alginate through a chemical reaction to obtain a graphene-alginate spinning solution; then ensuring the graphene / alginate spinning solution or the graphene-alginate spinning solution to respectively undergo a coagulation bath to obtain graphene / alginate as-spun fibers or graphene-alginate as-spun fibers; and then drawing, setting and oiling the graphene / alginate as-spun fibers or graphene-alginate as-spun fibers after ensuring the graphene / alginate as-spun fibers or graphene-alginate as-spun fibers to undergo a preheating bath and a drawing bath respectively to obtain graphene / alginate functionalized fibers or graphene-alginate functionalized fibers which are called graphene functionalized alginate fibers. The prepared graphene functionalized alginate fibers integrate the excellent performances of the graphene and the sodium alginate and have the excellent performances such as high tensile strength, good biocompatibility, antistatic performance, light weight, high elasticity, antibacterial performance and the like.

Owner:QINGDAO UNIV

Popular searches

Non-conductive material with dispersed conductive material Animal repellants Plant growth regulators Macromolecular non-active ingredients Conjugated synthetic polymer artificial filaments Prosthesis Artificial filament heat treatment Monocomponent halogenated hydrocarbon artificial filament Essential-oils/perfumes Stretch-spinning methods

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com