Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

340results about How to "Overcoming demands" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

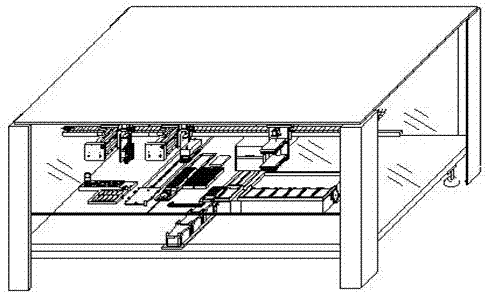

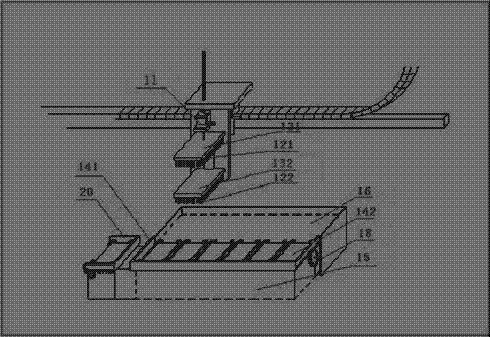

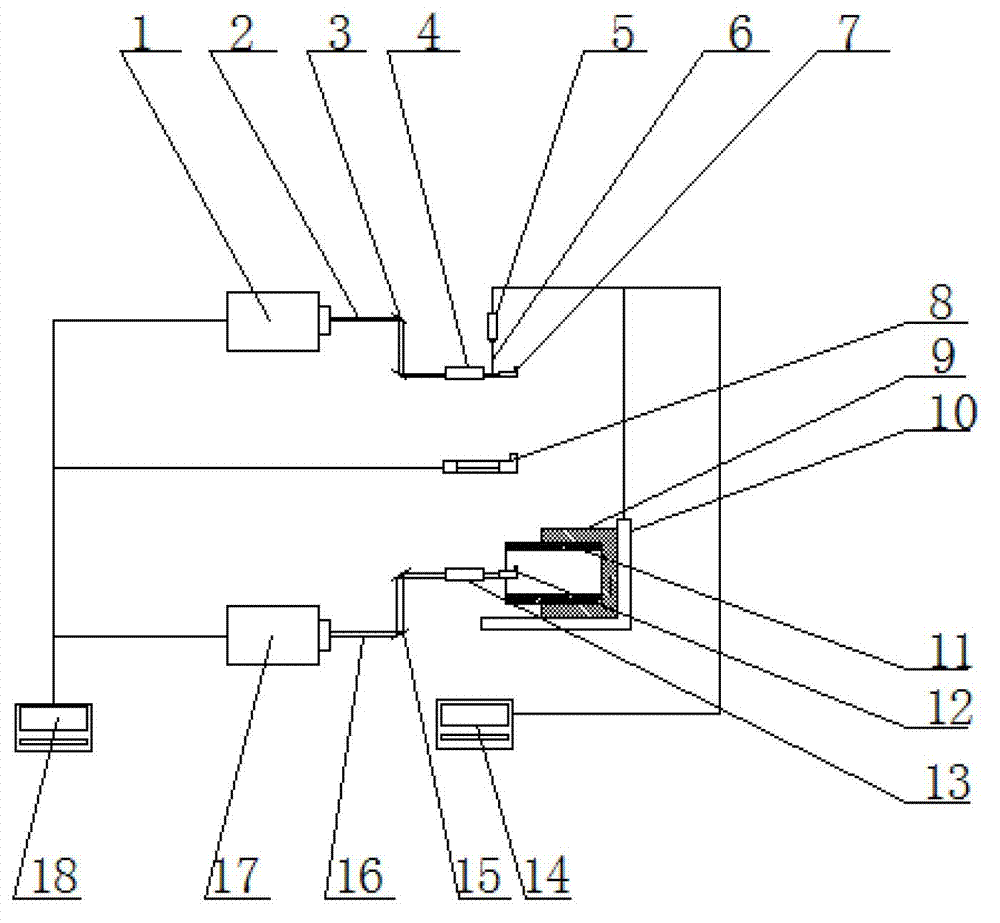

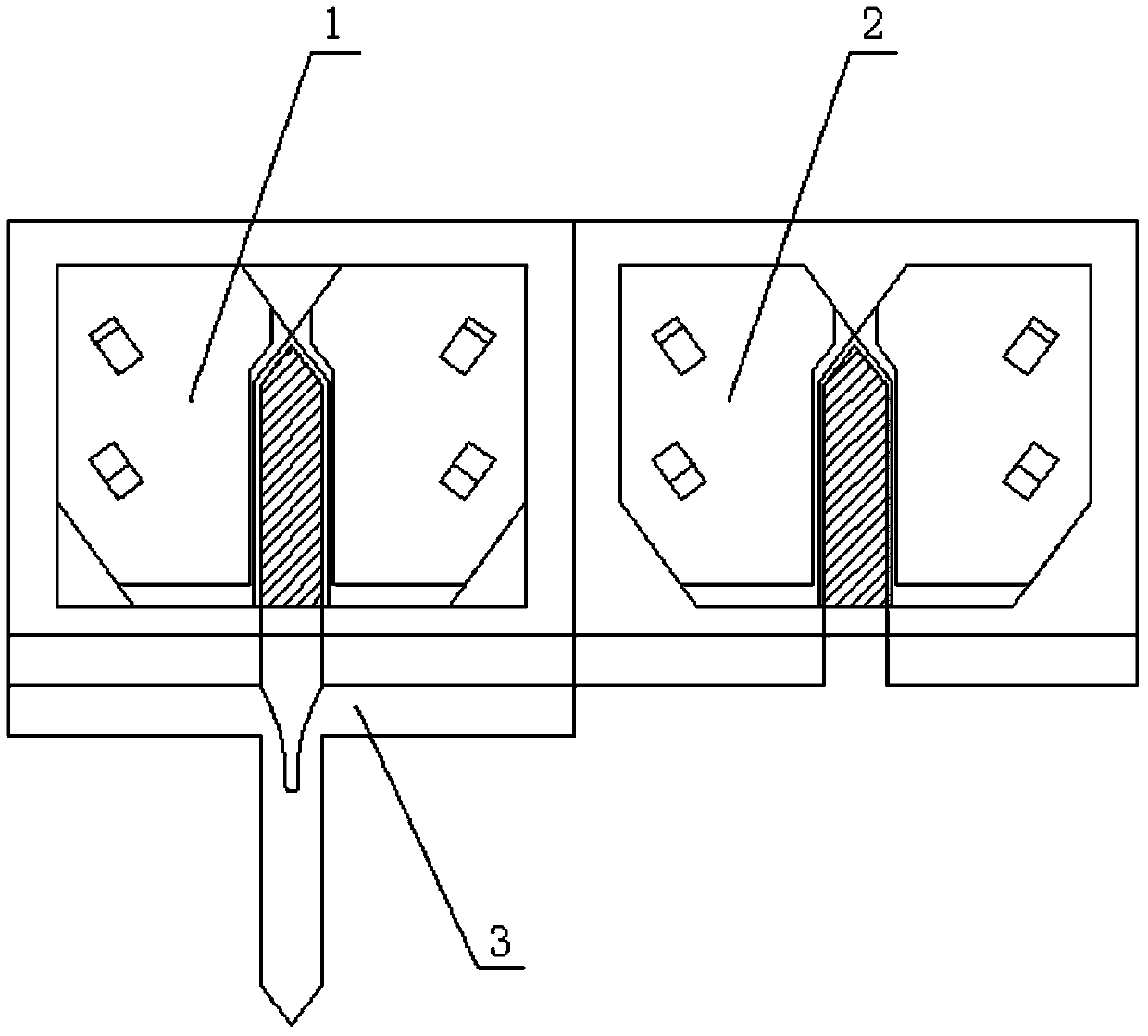

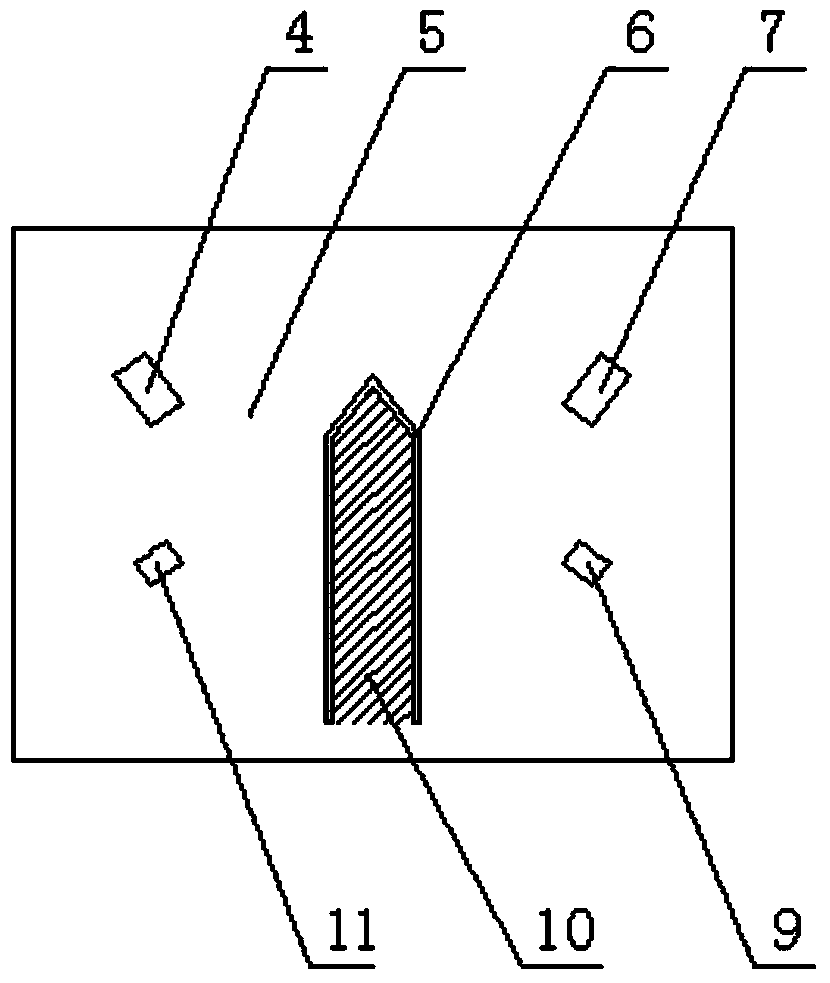

Automated instrument for nucleic acid extraction and mass spectrum sample application

ActiveCN102492603AAccurate extractionReduce infectionBioreactor/fermenter combinationsBiological substance pretreatmentsMagnetic beadMass analyzer

The invention discloses an automated instrument applied to nucleic acid extraction and continuous operation process of a mass spectrum sample application chip in biomass spectrometry analysis of a nucleic acid sample. The automated instrument comprises three main devices, namely, a nucleic acid extraction and purification device, a nucleic acid liquor relief distributing device and a mass spectrum chip sample application device, wherein nucleic acid in body fluid is extracted by using a magnetic bead method, a mechanical arm is utilized to complete a nucleic acid extraction action, the extracted nucleic acid is dispensed onto a sample board through a dispenser, a pipettor is used for transferring the sample board onto a chip sample application instrument, and the mass spectrum and relatedinformation of the nucleic acid are obtained through laser sampling of a mass spectrometer, so that the nucleic acid is analyzed rapidly, directly and continuously. The automated instrument is high-precision in controlling the volume of dispensed liquor, high-cleanliness in controlling the quality of the dispensed liquor and high-efficiency in meeting sample application requirements of large-batch samples; meanwhile, the samples are uniformly distributed under the control of a computer program, volume errors and possible foreign pollution caused by manual operation are avoided, and the speed and efficiency in sample application are increased at the same time.

Owner:BIOYONG TECH

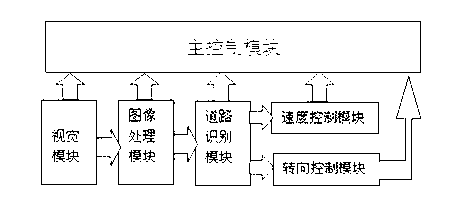

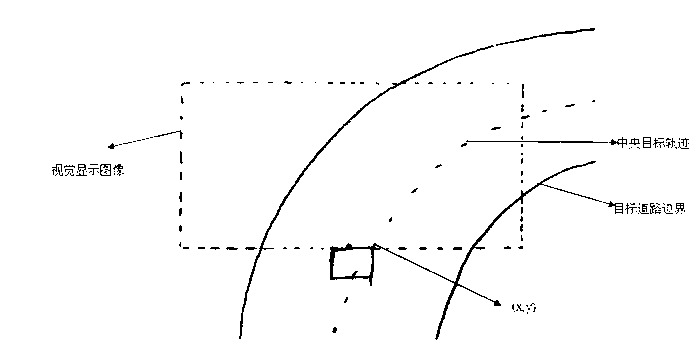

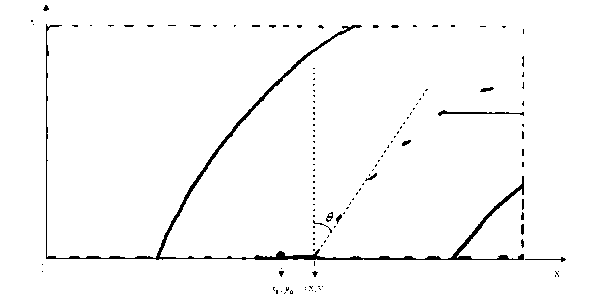

Photoelectricity-navigation-based unmanned road recognition system

InactiveCN103226354ARealize intelligent optimal controlSatisfy handlingCharacter and pattern recognitionPosition/course control in two dimensionsImaging processingControl system

The invention discloses a photoelectricity-navigation-based unmanned road recognition system which comprises a vision module, an image processing module, a road recognition module, a speed control module and a steering control module. Turning at a crossroad is mainly achieved through handling a road border, simulating a target trajectory at a track center and recognizing a turning sign. The multi-element PID steering control module and the speed control module realize constantly changing target trajectory when a vehicle rapidly tracks, and realize specified speed and the steering function through identifying color lumps marked by different colors. The intelligent optimized control system is different from a traditional tracking vehicle. The photoelectricity navigation vehicle can realize manless driving without peripheral support through identifying road borders (green belts, fences and the like) in reality and steering signs, thereby having a practical significance.

Owner:GUANGDONG UNIV OF TECH

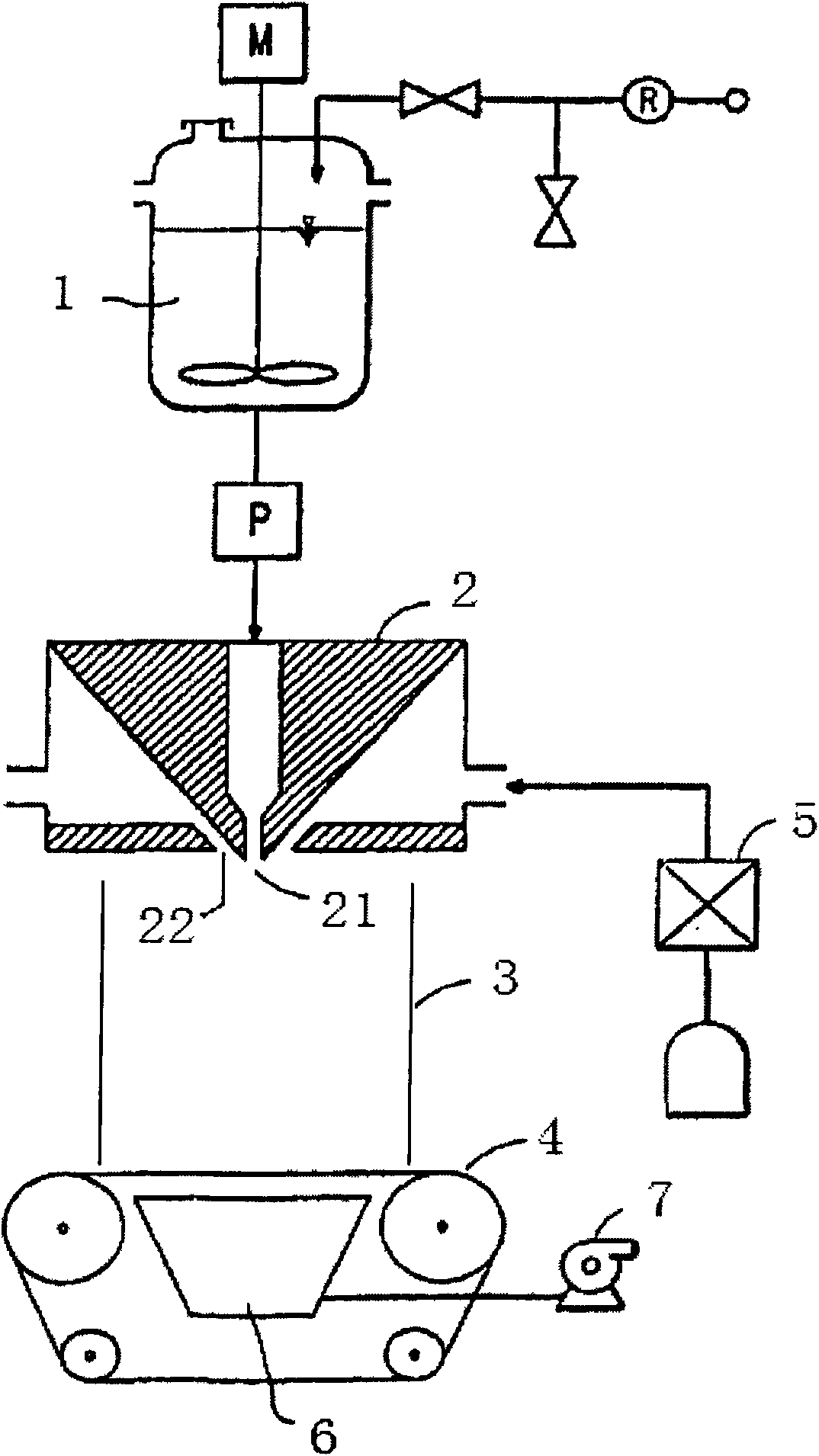

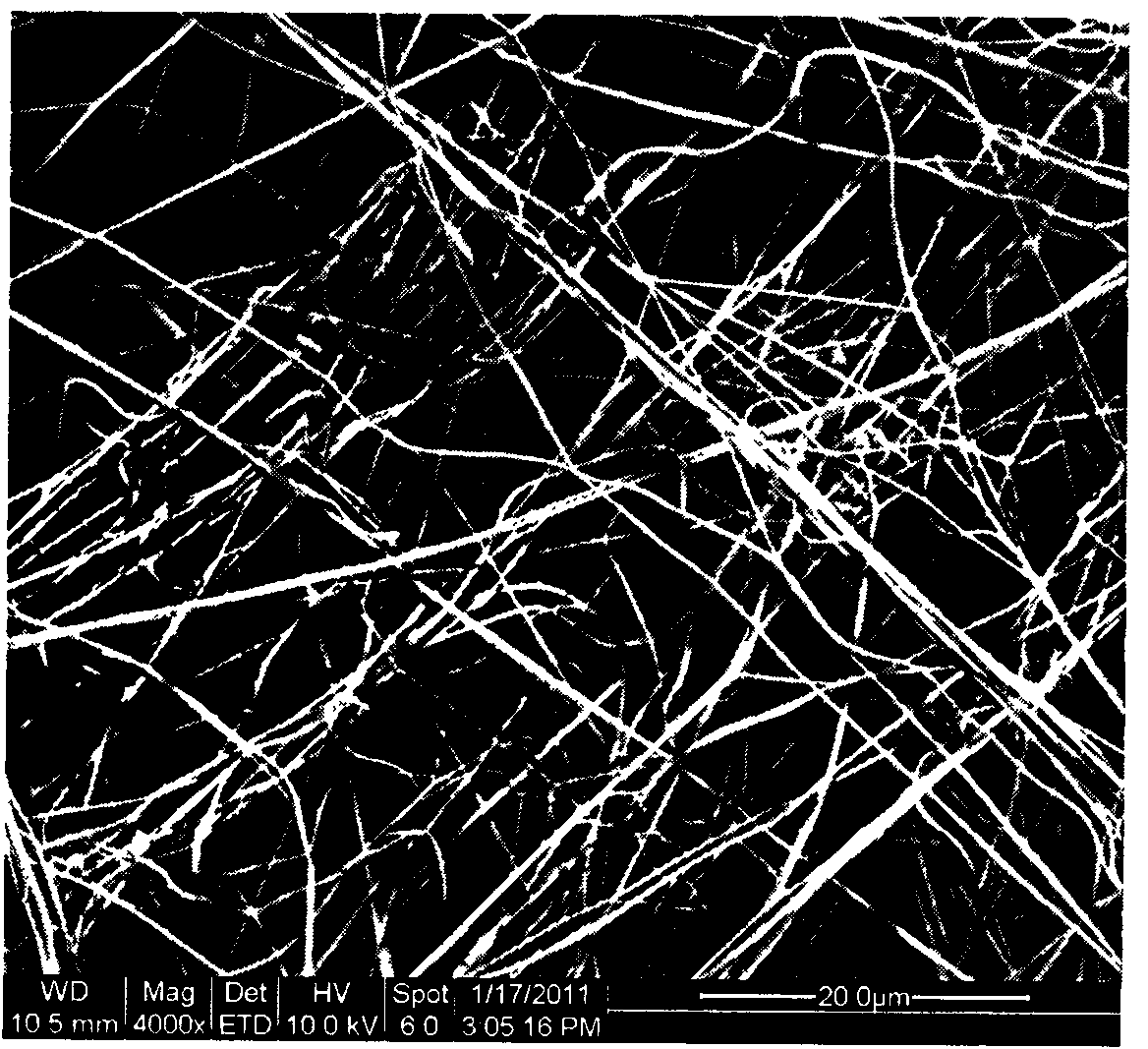

Method for preparing polymeric nano-micro fiber non-woven fabric

ActiveCN102071542AOvercoming demandsUniversally applicableNon-woven fabricsDry spinning methodsFiberPolymer dissolution

The invention discloses a method for preparing a polymeric nano-micro fiber non-woven fabric. The method comprises the following steps of: firstly, dissolving at least one polymer in at least one solvent to prepare spinning solution; then supplying the spinning solution to a spinneret plate with a series of spinneret orifices so as to make the spinning solution extruded from the spinneret orifices of the spinneret plate to form a trickle of the spinning solution; secondly, stretching and refining the trickle of the spinning solution by utilizing at least one high-speed jet airflow, and accelerating the volatilization of the solvent to form nano-micro fiber; and finally, collecting the nano-micro fiber on a web curtain by utilizing high-speed airflow and suction airflow. The polymer is a fiber-forming polymer; the solvent can dissolve the fiber-forming polymer and has the volatility; a jet angle of the high-speed airflow is between 15 and 60 degrees, and the jet velocity is at least 50 times higher than extrusion speed of the trickle of the spinning solution; the mass concentration of the polymer in the spinning solution is between 2 and 50 percent; and the viscosity of the spinning solution at a spinning temperature is between 10 and 100, 000mP.s.

Owner:上海榕融新材料技术有限公司

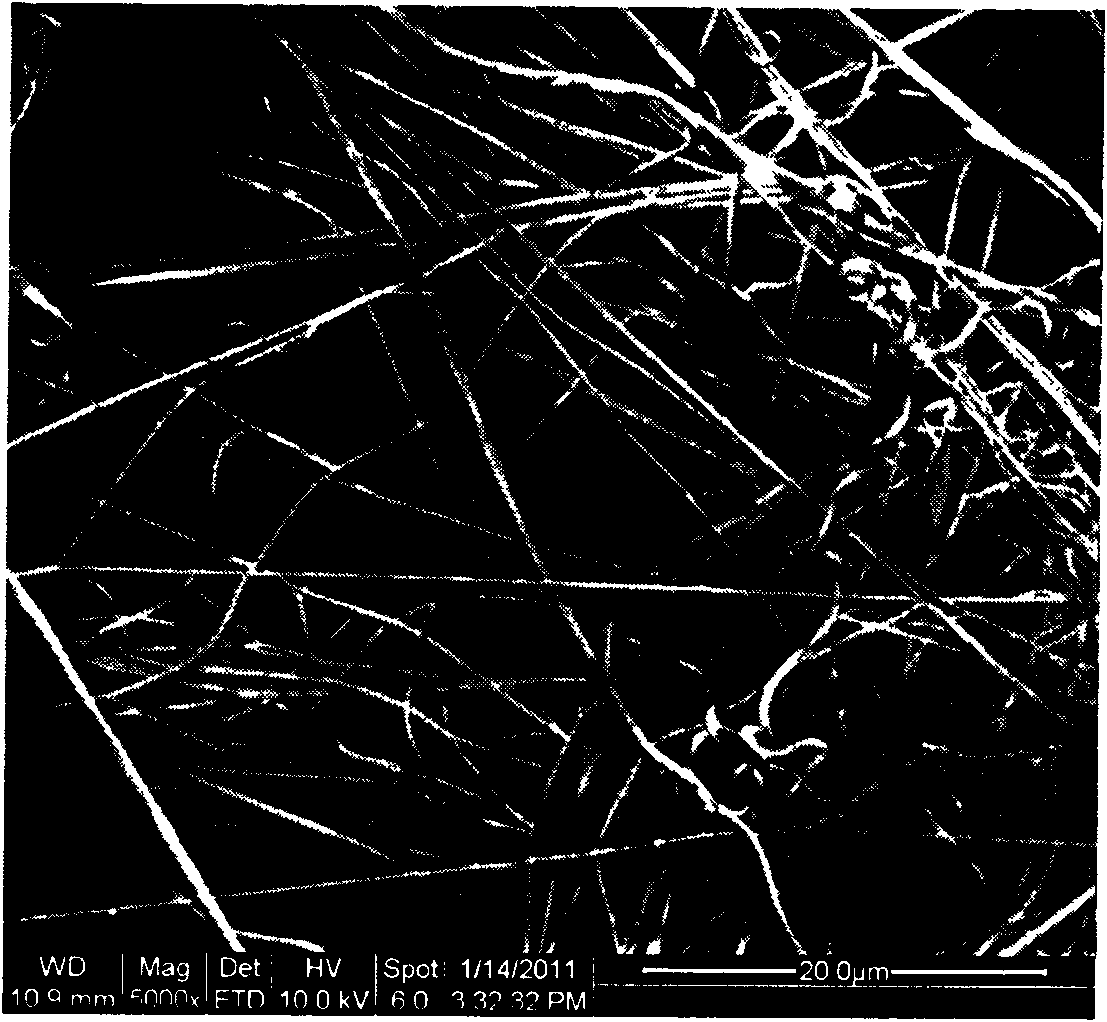

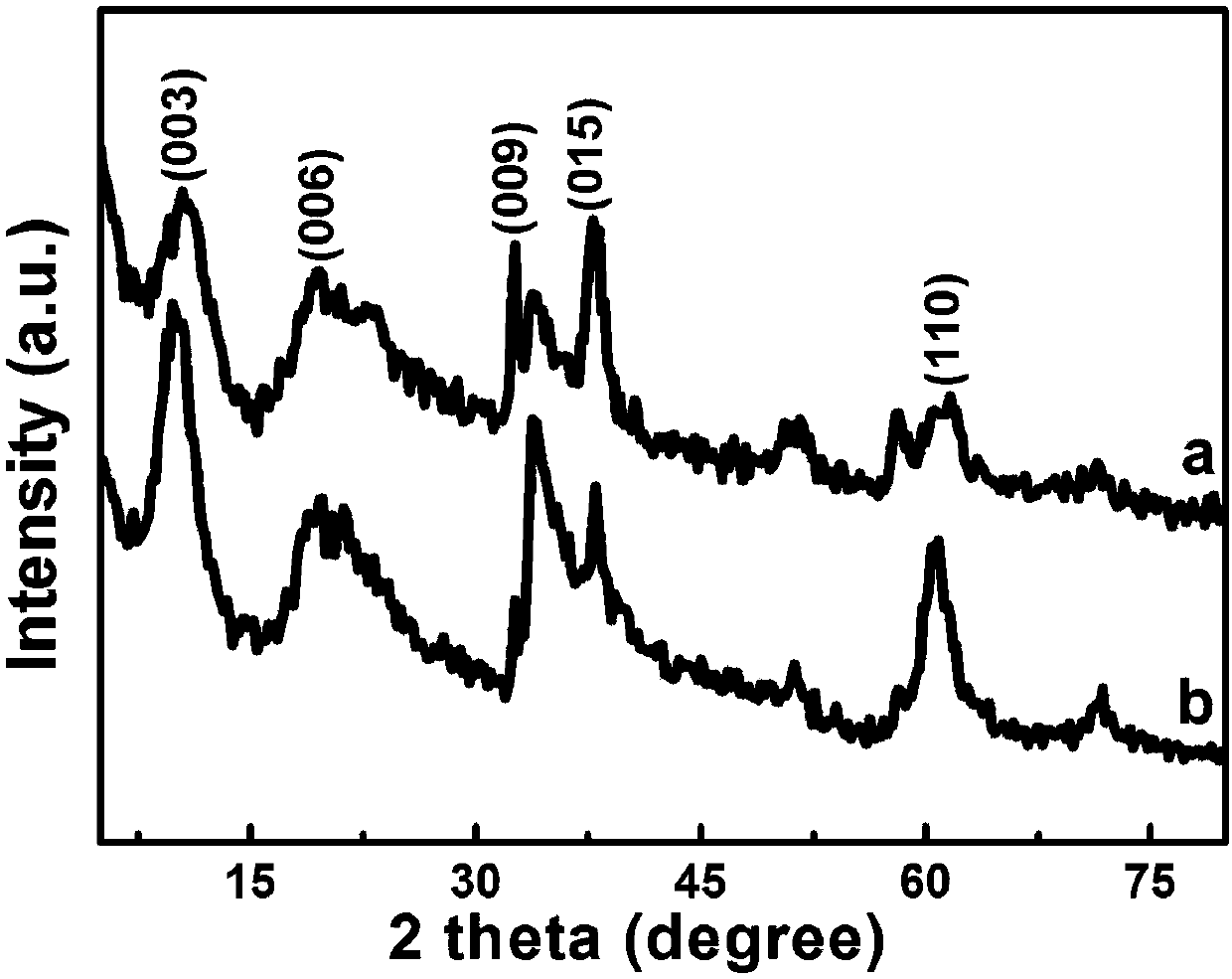

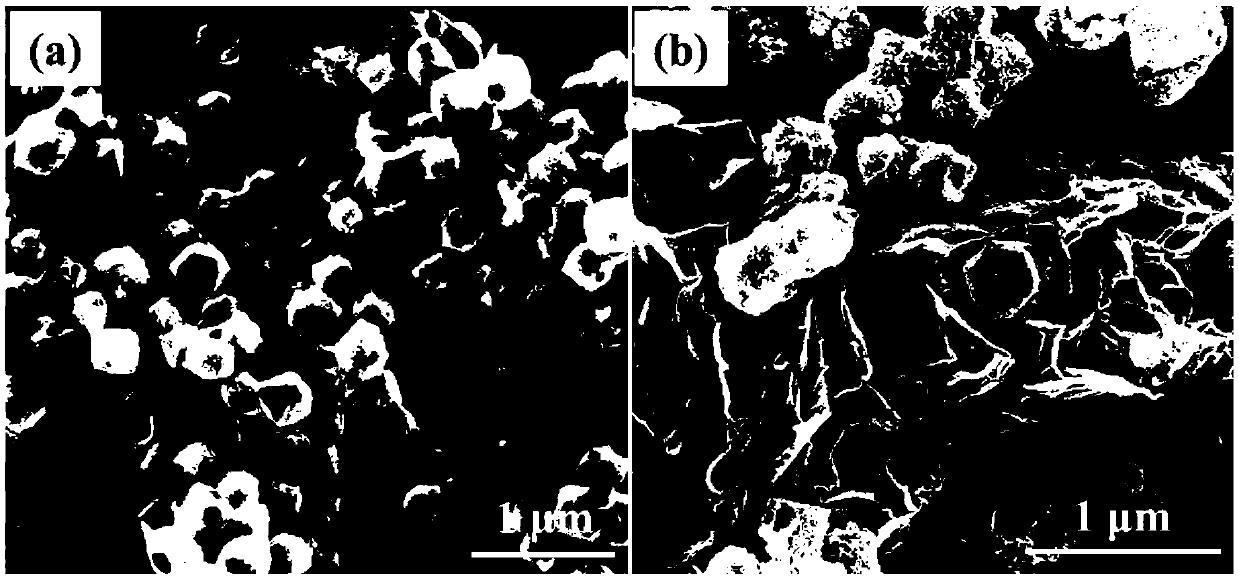

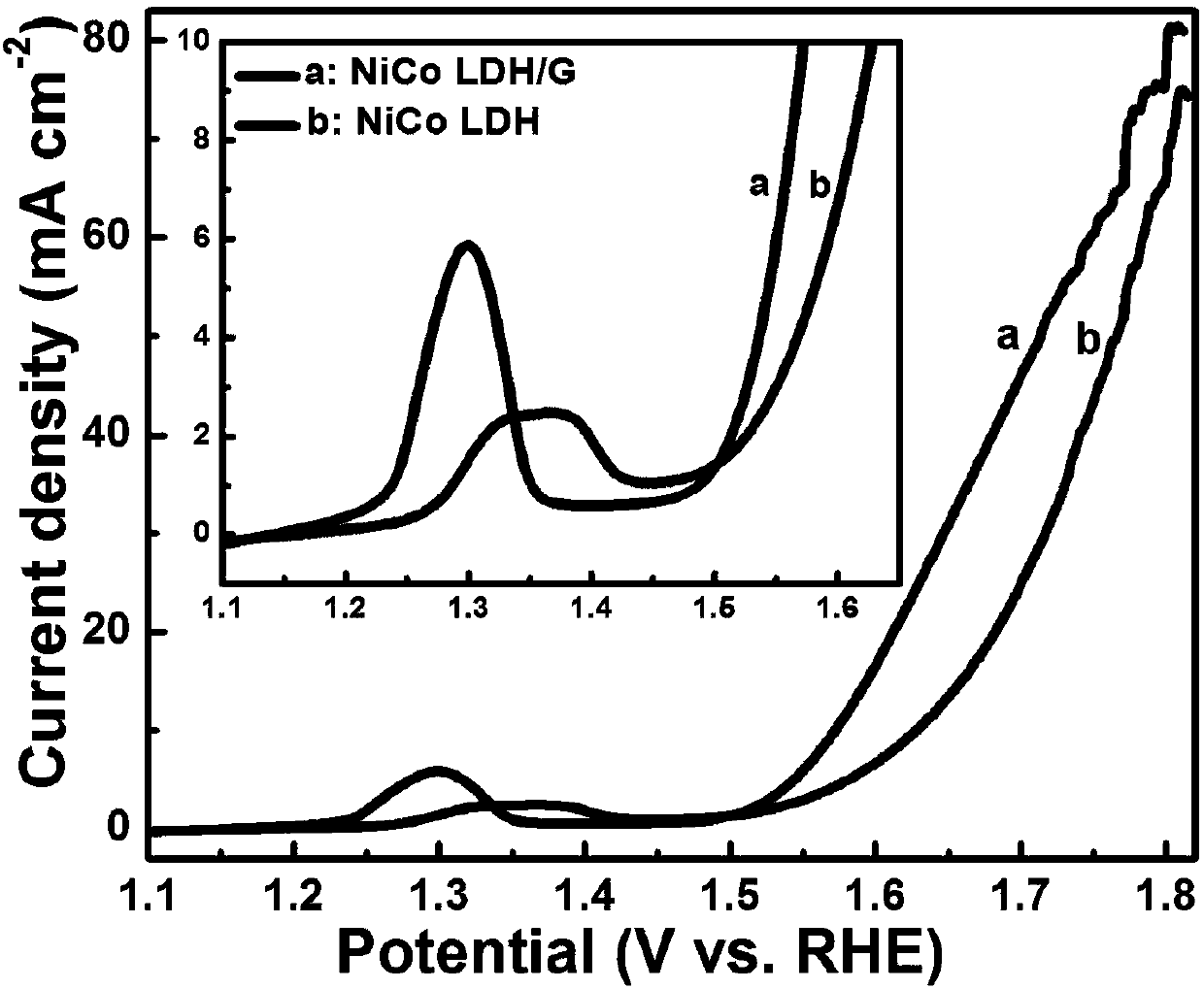

Preparation method of nickel-cobalt layered bimetallic hydroxide/graphene electrocatalyst

ActiveCN107824188ASimple processOvercoming demandsCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNickel saltSynthesis methods

The invention provides a preparation method of a nickel-cobalt layered bimetallic hydroxide / graphene electrocatalyst, which belongs to the technical field of electrocatalysts. The method disclosed bythe invention comprises the following steps: graphene and cobalt nitrate are uniformly dispersed in a methanol solvent by ultrasonic waves, so that an ultrasonic solution is obtained; the ultrasonic solution is added into a methanol solution of dimethylimidazole, is uniformly mixed and then is enabled to stand, and centrifuging, washing and drying are then carried out, so that a ZIF-67 / graphene composite material is obtained; the ZIF-67 / graphene composite material and nickel salt are mixed and dissolved in a solvent, refluxing is carried out for reaction, centrifugal separation is then carriedout, obtained precipitate is washed with absolute ethyl alcohol, and drying is carried out to obtain a NiCo LDH / G composite material with a nanoscale morphology. The method disclosed by the inventionovercomes the defects of high requirement on equipment, need for high temperature and high pressure and need for an expensive surfactant existing in conventional synthesis methods, and compared withthe prior art, the preparation method has the advantages of simple process, low cost, easy reaction process control and the like, and is suitable for industrial mass production.

Owner:GUANGXI NORMAL UNIV

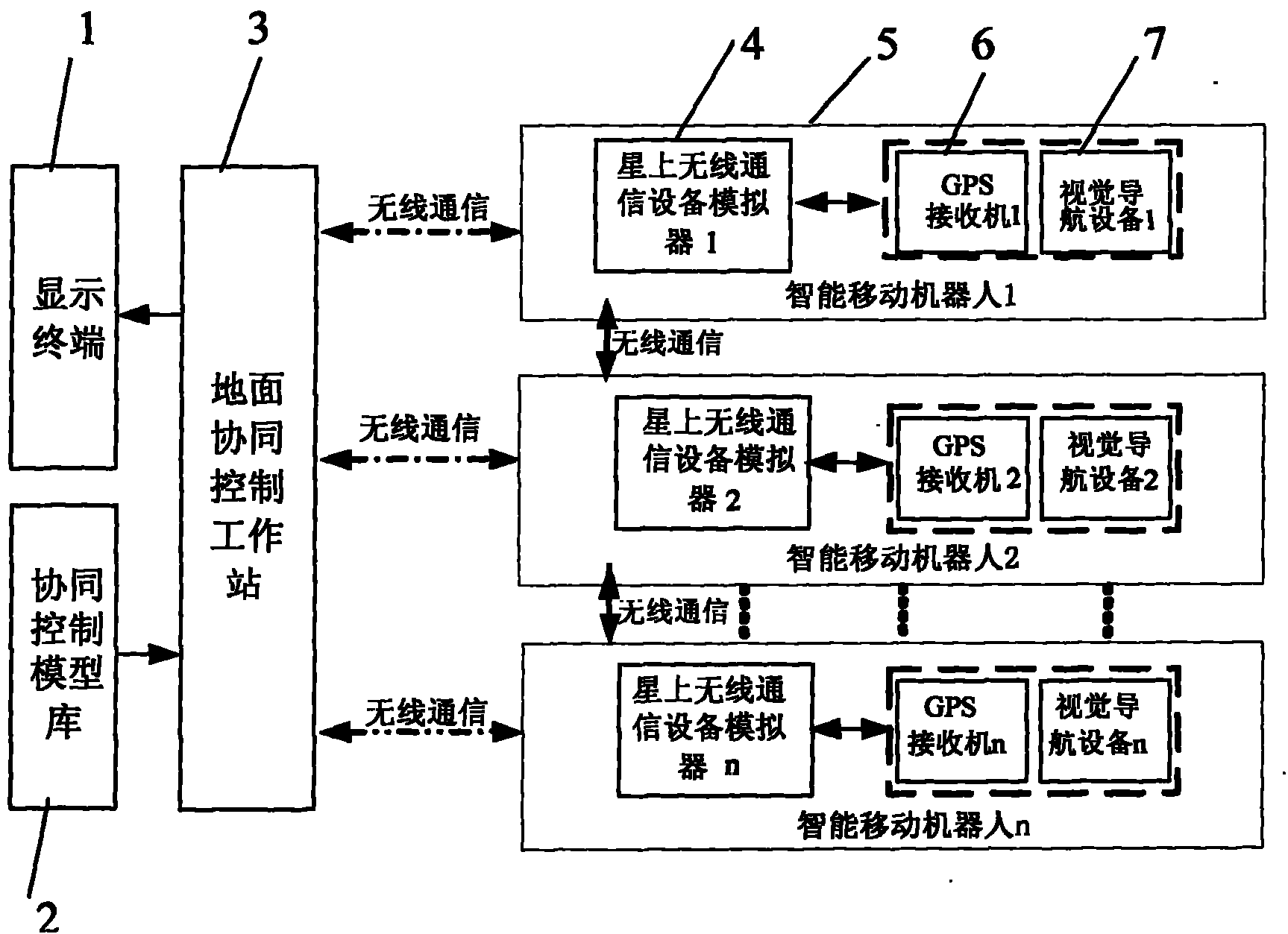

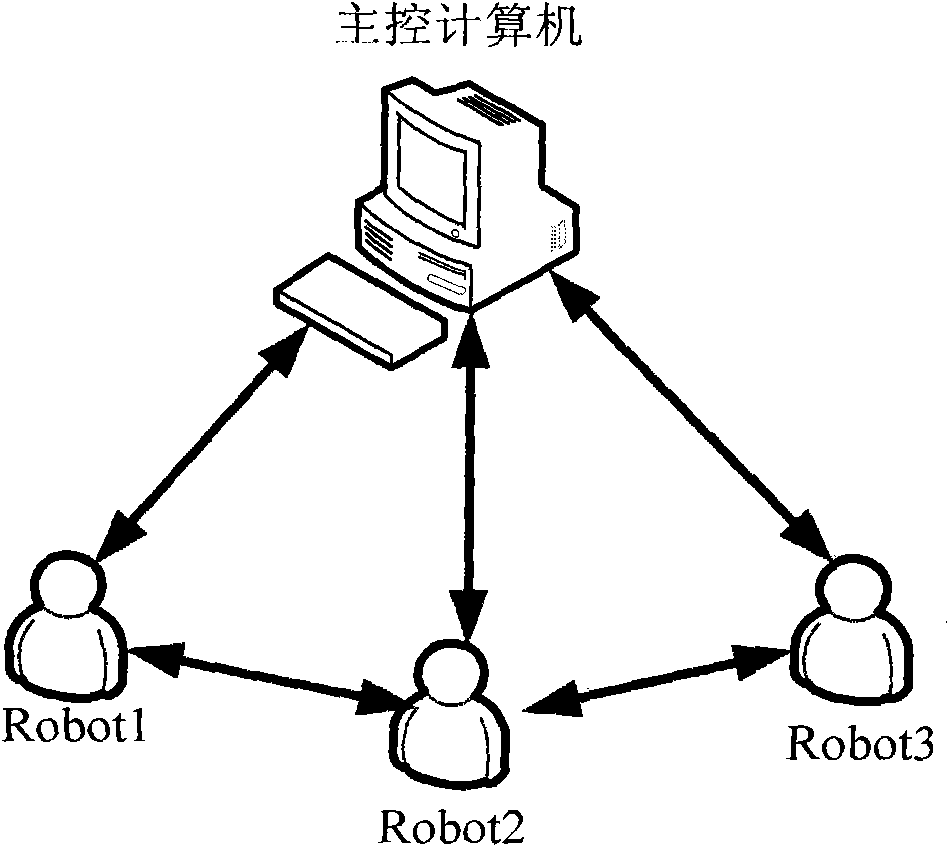

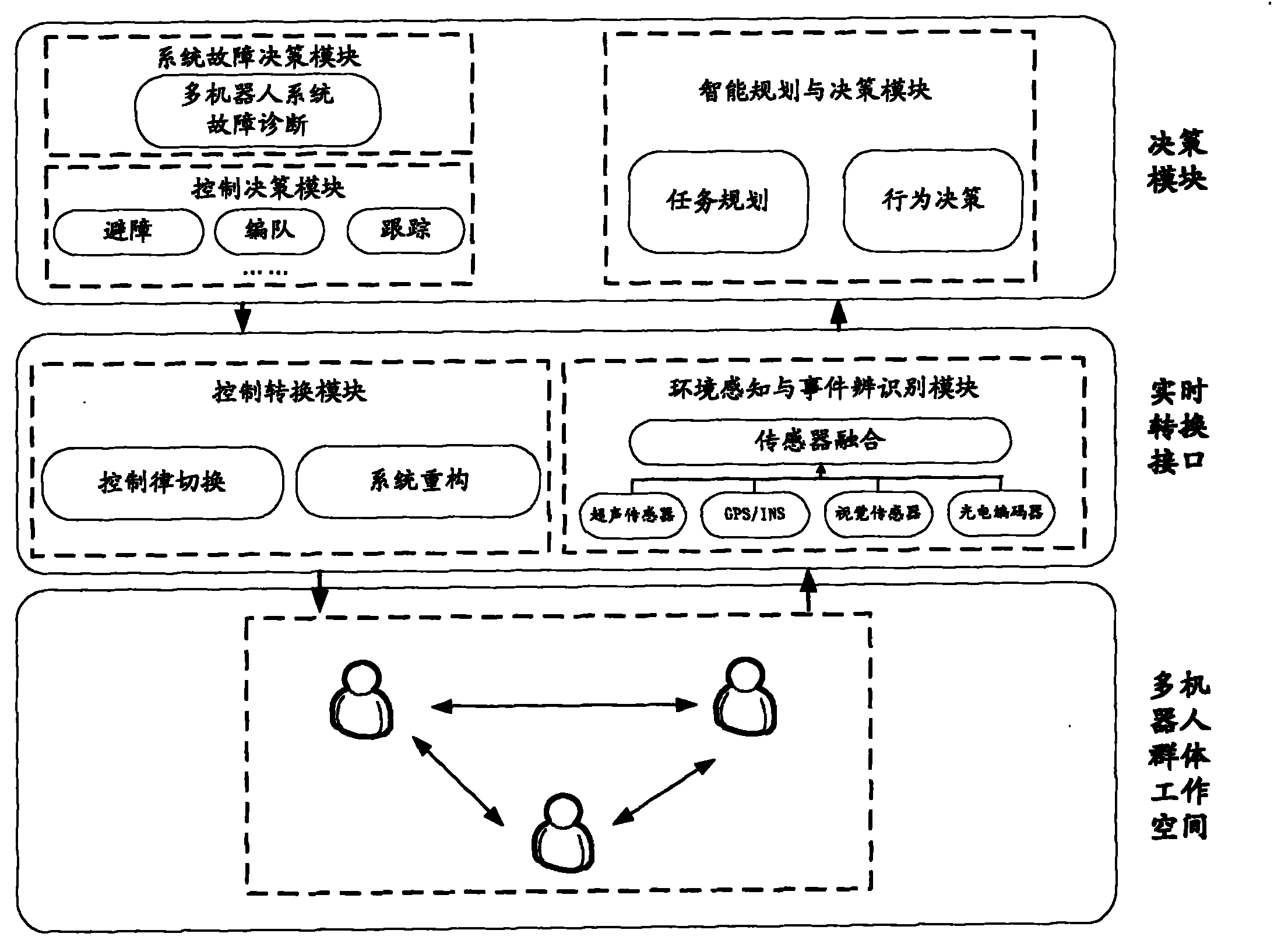

Multi-micronano detector networking joint demonstration verification system based on intelligent mobile robot

ActiveCN102122171AReduce data processing pressureReduce consumptionPosition/course control in two dimensionsTelecommunications linkCommunication link

The invention relates to a multi-micronano detector networking joint demonstration verification system based on an intelligent mobile robot, comprising a ground synergic control workstation, a synergic control model library, a satellite wireless communication equipment simulator, an intelligent mobile robot, a GPS (Global Positioning System) receiver, video navigation equipment and a display terminal, wherein the ground synergic control workstation controls the synergetic work and the formation transform and maintenance of the whole system; the synergic control model library provides a control algorithm and a control model for the ground synergic control workstation; the satellite wireless communication equipment simulator provides a communication link between satellites and the workstation; the intelligent mobile robot as a carrier of the GPS receiver and the satellite wireless communication equipment simulator is controlled by the control workstation to move and used for simulating the relative position change among the satellites; the GPS receiver and the video navigation equipment realize the relative navigation among the satellites; and the display terminal displays a networking joint verification result in real time. The invention can effectively decrease the test cost of a multi-micronano detector networking detection system, shortens a research and development period and has important engineering application values.

Owner:BEIHANG UNIV

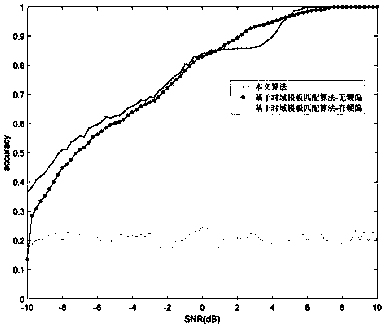

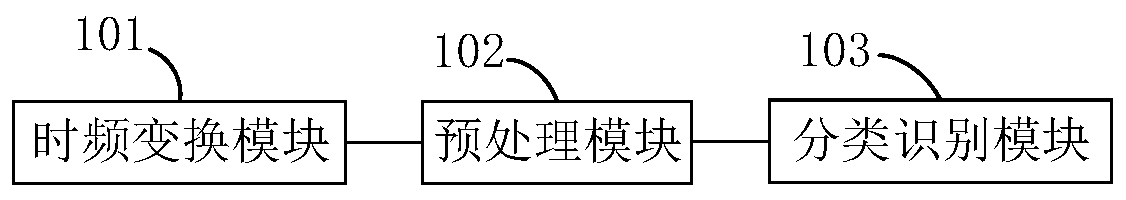

Communication protocol signal identification method based on depth residual network

ActiveCN109274621AAccurate identificationOvercoming demandsModulation type identificationSignal qualityFrequency spectrum

The invention belongs to the technical field of radio signal identification, in particular to a communication protocol signal identification method based on a depth residual network. The method comprises the following steps of: performing time-frequency analysis on a communication protocol signal in a sample library, and converting a time-frequency spectrum diagram of the signal into a gray-scaleimage; training The depth residual network model by gray-scale image. The trained depth residual network model is used to detect and identify the specific communication protocol signals trained in thetransmission process. As that depth residual network is applied to the field of communication signal identification, the invention overcomes the defect of high signal quality requirement and high prior information requirement of the traditional method, etc. At low SNR, multipath delay, When Doppler frequency offset and some features of signal are obscured by strong interference noise, Doppler frequency offset can still accurately identify the protocol type, and it does not depend on the prior information of received signal, so it can directly process the received IF signal, and has robust performance and high efficiency, which provides ideas for the subsequent research in this field, and has strong practical application value.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

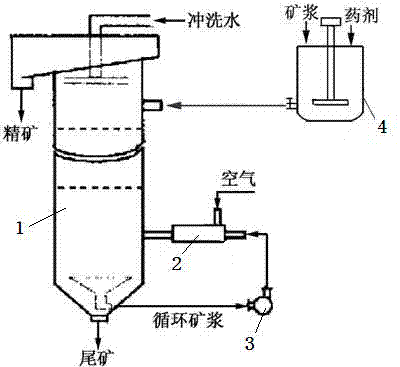

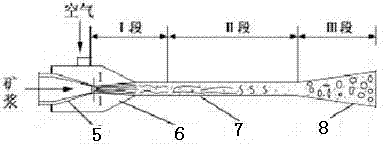

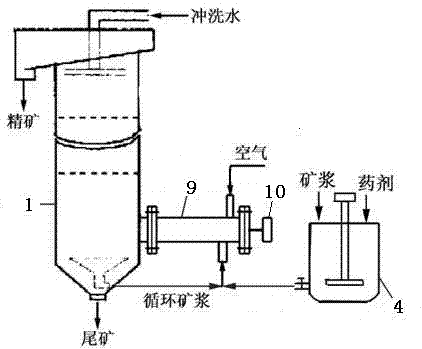

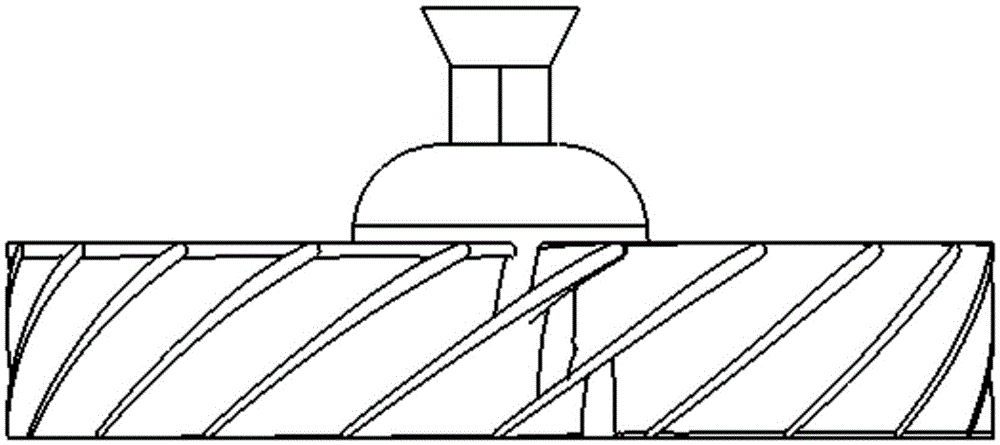

Novel flotation column and flotation method thereof

InactiveCN104841571AAchieve static flotation separationAvoid easy cloggingFlotationPulp and paper industryAir bubble

Owner:WUHAN INSTITUTE OF TECHNOLOGY

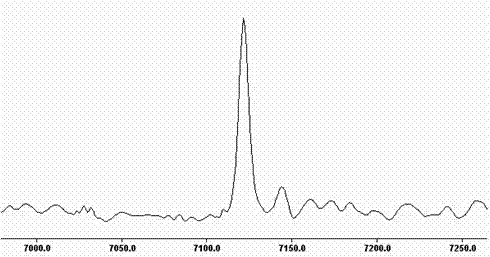

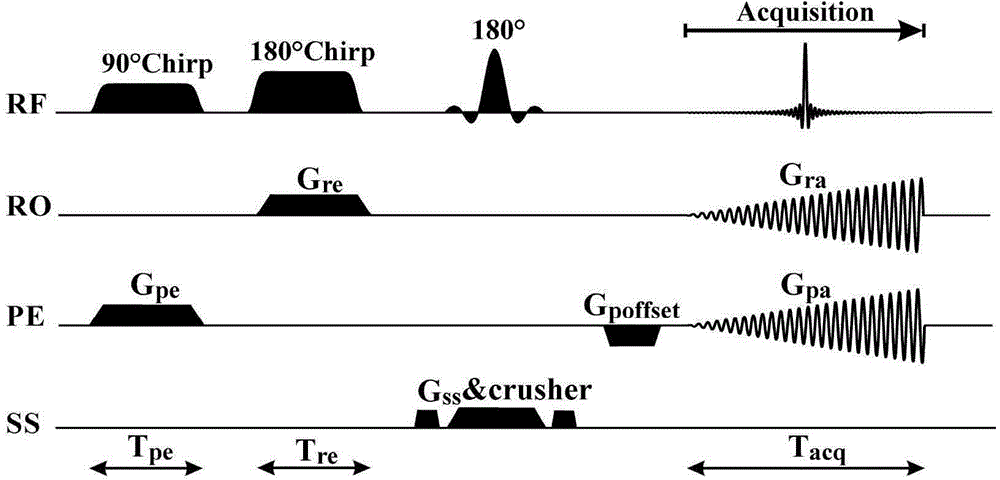

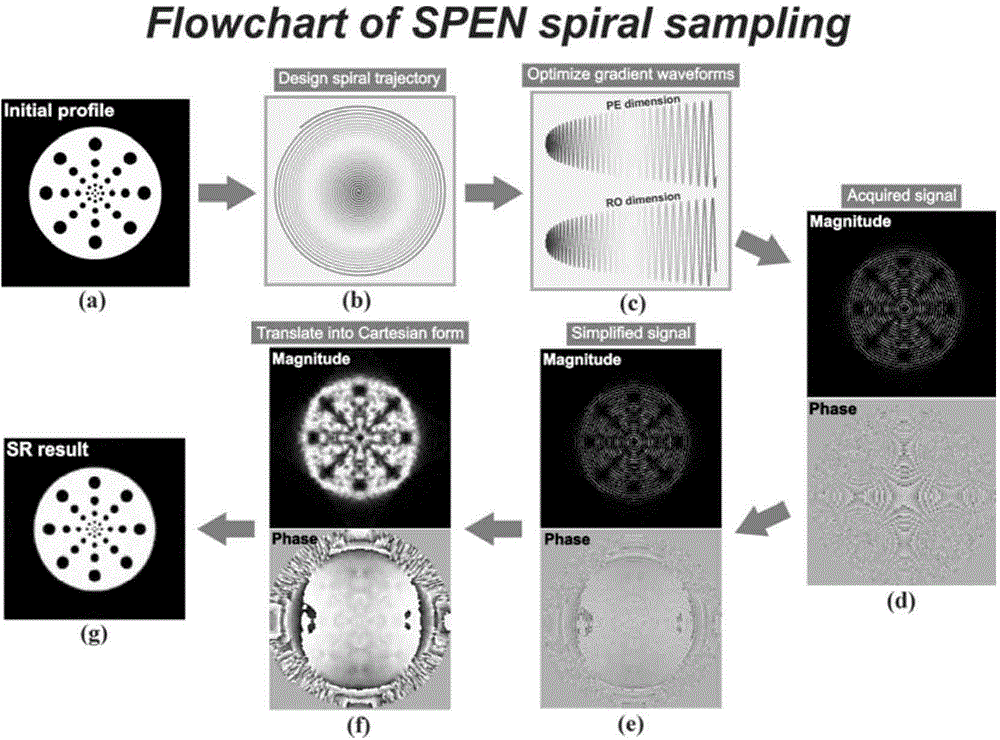

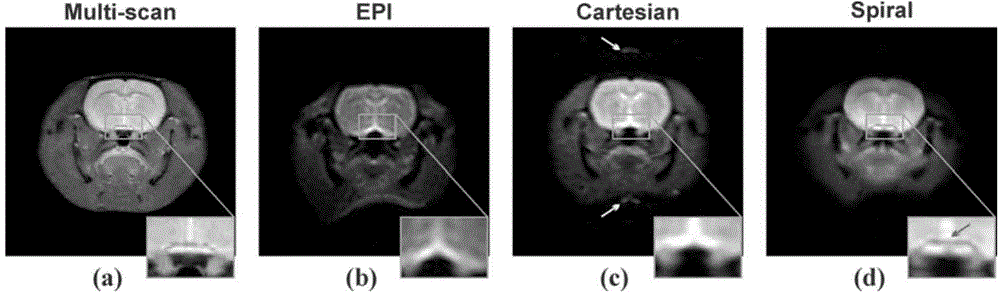

SPEN single-scanning magnetic resonance imaging spiral sampling and reconstructing method

ActiveCN104965184AHigh resolutionIncrease sampling densityMeasurements using NMR imaging systemsImaging qualityData acquisition

Provided is an SPEN (spatiotemporally-encoded) single-scanning magnetic resonance imaging spiral sampling and reconstructing method, relating to a magnetic resonance imaging method. 90 DEG linear scanning pulses and 180 DEG linear scanning pulses combine with corresponding SPEN gradients, and in a trigger period, protons in a space spin to obtain a quadratic phase relevant with a spatial position; in a sampling period, a spiral sampling gradient after optimization collets data, and obtains spatial domain magnetic resonance imaging data with T2*weighting in a superfast speed; and finally, spiral sampling data are reconstructed through a specific grid algorithm and a super-resolution reconstructing method based on compression perception, so as to obtain super-resolution high quality magnetic resonance images. The method greatly improves the image quality of SPEN single-scanning imaging, and provides a great imaging tool for the fields requiring superfast imaging.

Owner:XIAMEN UNIV

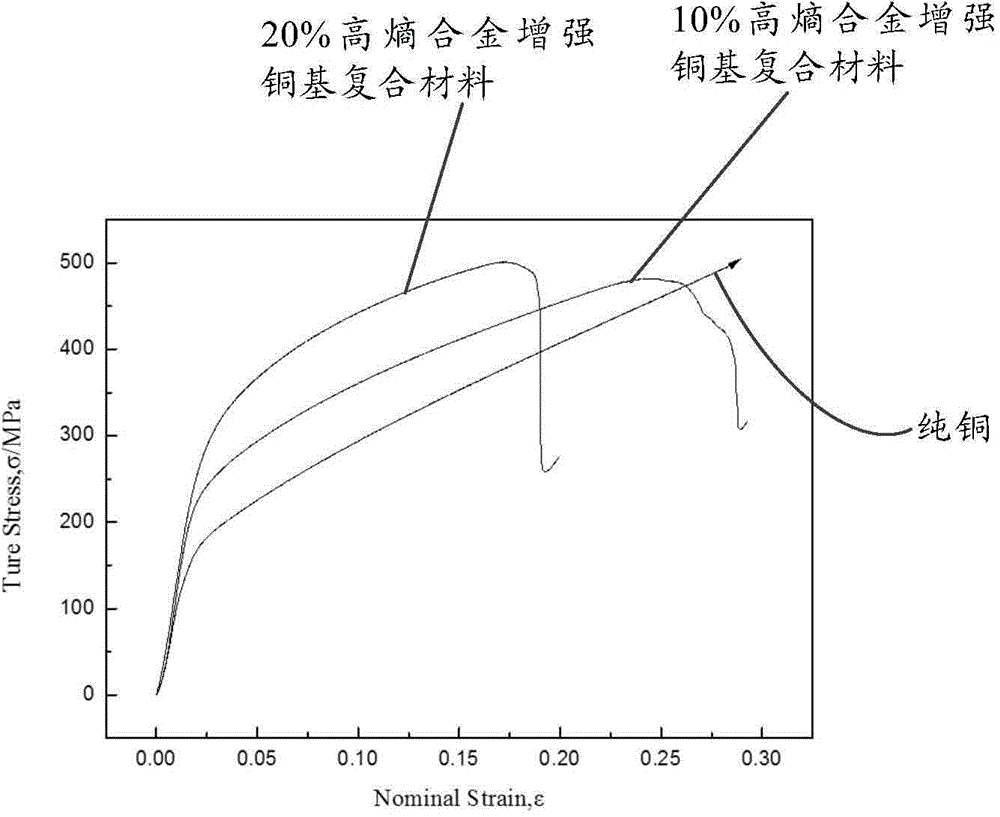

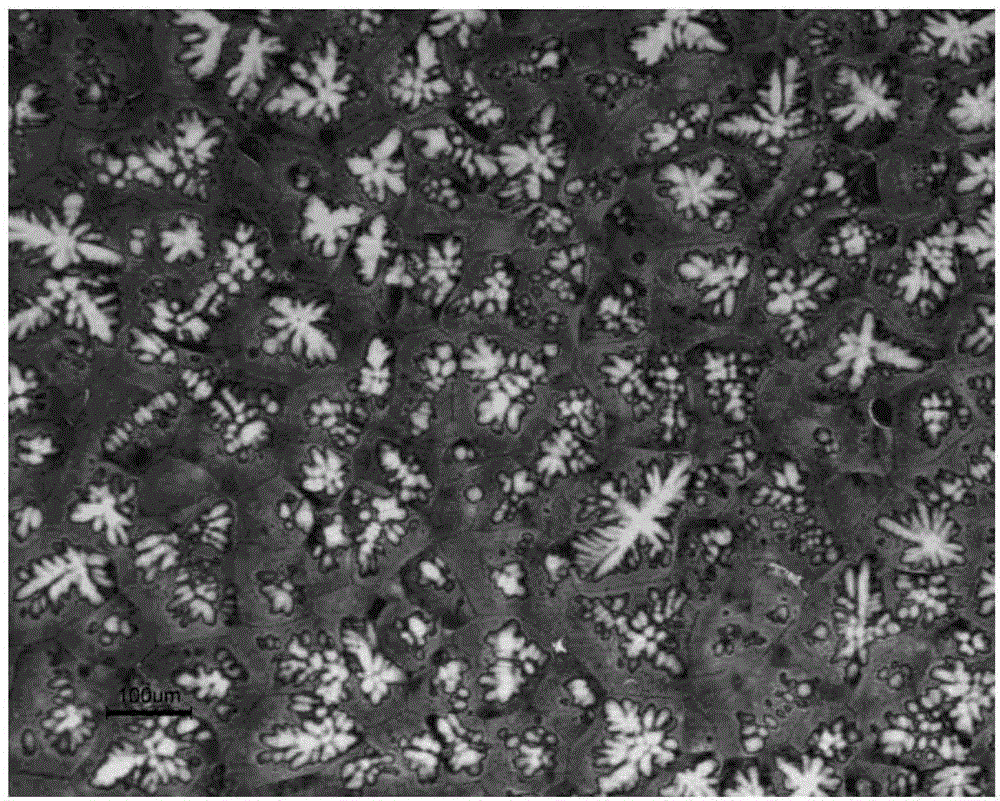

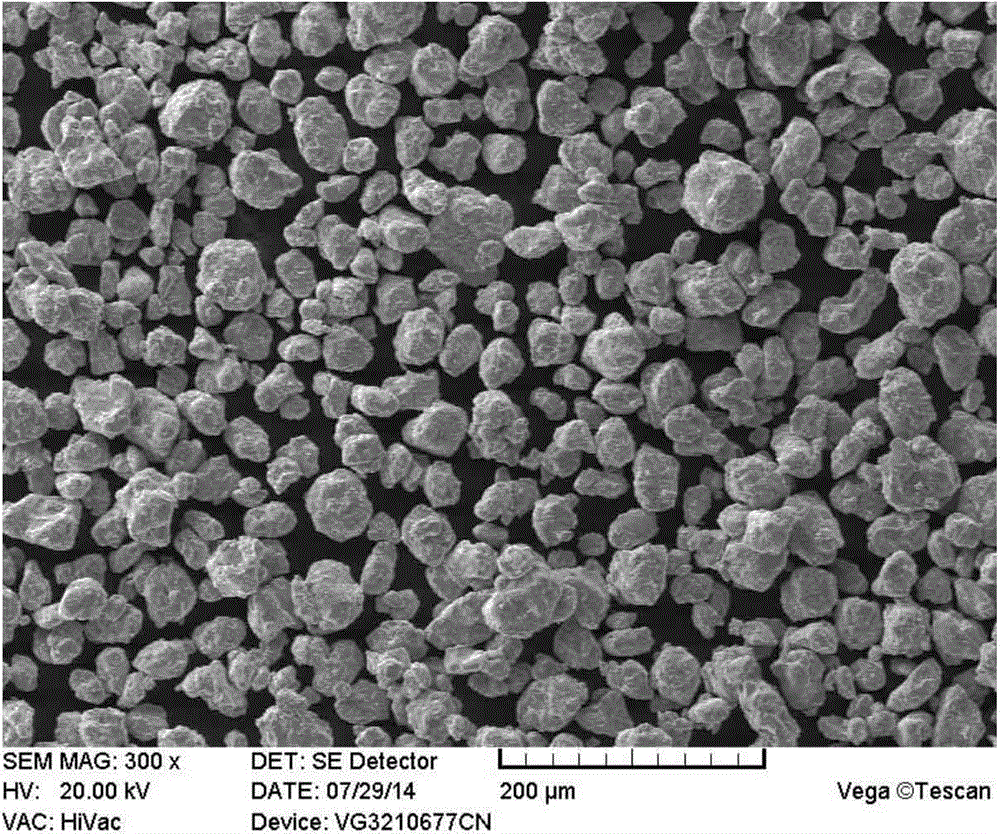

High-performance metal-matrix composite preparation method

The invention provides a high-performance metal-matrix composite preparation method. The method comprises steps: granular raw materials: Al, Fe, Cr, Co and Ni metal powder are acquired; under argon atmosphere protection, a high-entropy alloy powder body is prepared via a ball mill; a pure copper powder body and the high-entropy alloy powder body are weighed; the two are subjected to ball milling and mixing under the argon atmosphere protection, and composite powder is obtained; the composite powder is put in a cold pressing grinding tool, uniform pressurization is carried out, and after packing, a cold pressing green body is taken; the composite after cold pressing is put in a graphite grinding tool of an atmosphere protection sintering furnace, temperature rises to 800 DEG C, hot pressing is carried out and packing is carried out for one hour after temperature of the furnace is stable, and circulating nitrogen is provided during the whole process; and when the furnace is cooled to the room temperature, the copper-matrix composite is obtained. Compared with the prior art, by adopting the above preparation method, the high-entropy alloy and the metal matrix have good mutual dissolution and diffusion performance, the preparation process is simple, the high-entropy alloy has good hot stability, the composite has high density, the interface is good, and the mechanical performance is excellent.

Owner:XIAN TECHNOLOGICAL UNIV

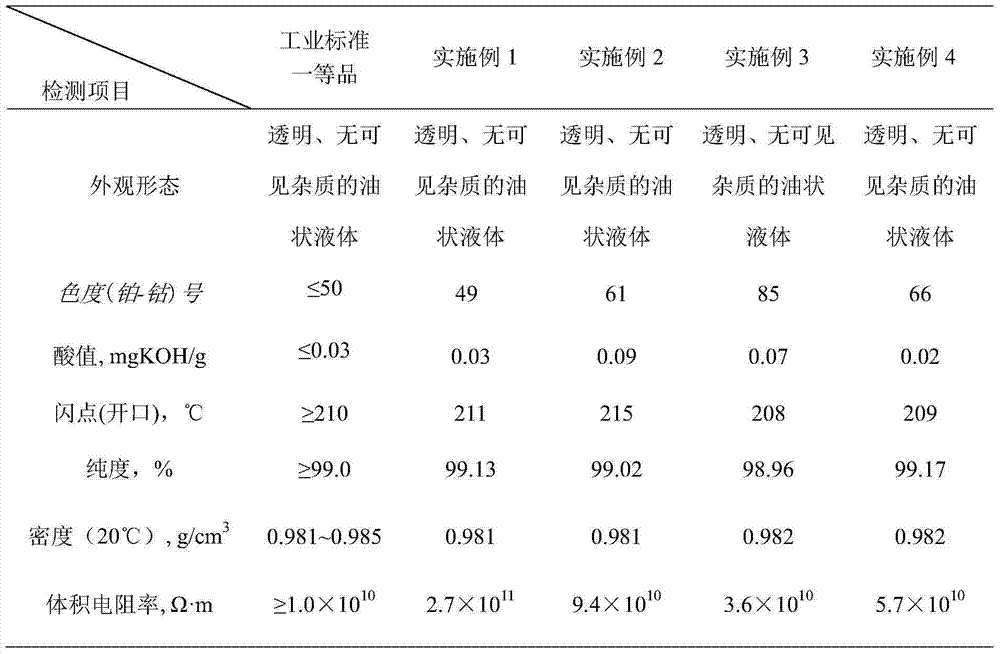

Method for preparing environment-friendly plasticizer by recycling waste resources

ActiveCN104496819AImprove qualityAvoid wastingOrganic compound preparationCarboxylic acid esters preparationFiltrationOctanol

The invention relates to a method for preparing an environment-friendly plasticizer by recycling waste resources. The method comprises the following steps of transferring alkali-reduction wastewater containing sodium terephthalate into an acid precipitation tank with a stirring device and adding sulfuric acid to further precipitate terephthalic acid (PTA) solids; carrying out plate-frame filtration on the mixed solution to obtain a crude PTA material; adding the recovered crude PTA material into an esterification reactor with an alcohol-water separation device, adding iso-octanol, heating and dehydrating, adding tetrabutyl titanate as a catalyst and carrying out esterification reaction; after water is no longer produced, stopping reaction and dealcoholizing to obtain a crude DOTP (Dioctyl Terephthalate) product; rectifying the prepared crude DOTP product in a packing-type rectifying tower to obtain a rectified product, adding the rectified product into a neutralization reaction kettle, adding sodium hydroxide lye, stirring and washing with alkali; standing, precipitating and discharging the aqueous solution in the lower layer, adding hot water, stirring and washing with water, standing, precipitating and discharging the moisture in the lower layer, carrying out temperature-raising dehydration, adding an inorganic filter aid and filtering to obtain the pure DOTP product. By the method, the recycling of the waste resources is achieved.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

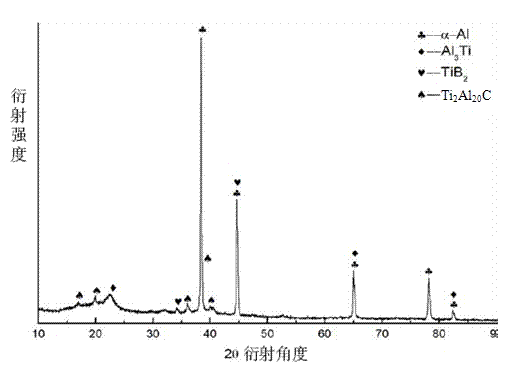

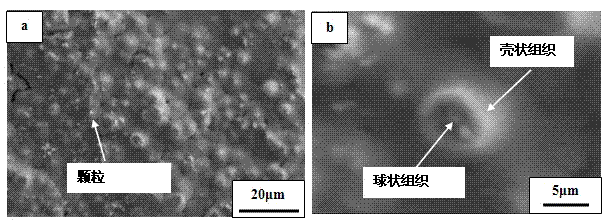

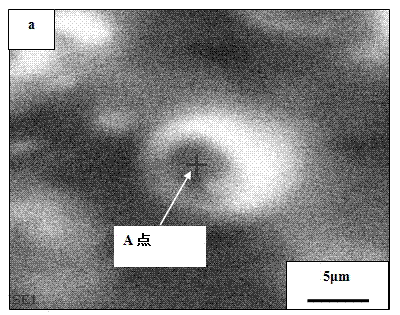

Preparation method of superfine crystal inoculating agent for aluminum alloy grain refinement

The invention provides a preparation method of a superfine crystal inoculating agent for aluminum alloy grain refinement and relates to aluminum-based alloy and is a method for preparing nano-crystalline Al-Ti-B-Re thin-strip intermediate alloy by a rapid solidification technology of metal, wherein the method comprises steps as follows: proportioning 5-5.4% of Ti, 1-1.04% of B, 1-1.2% of Ce, 0.05-0.2% of La and the balance of Al according to determined ingredients; weighing raw materials Al-5Ti-1B intermediate alloy and lanthanum cerium alloy to proportion the materials; melting in vacuum to obtain blocky Al-5Ti-1B-1Re intermediate alloy; carrying out rapid solidification to obtain the superfine crystal inoculating agent for the aluminum alloy grain refinement, wherein the superfine crystal inoculating agent is the nano-crystalline Al-5Ti-1B-1Re intermediate alloy. With the adoption of the method provided by the invention, adverse impact of needlelike TiAl3 on the matrix structure is eliminated, nucleating particles TiAl3 with thinner size and more dispersed distribution are obtained, and superfine nucleating particles are realized.

Owner:HEBEI UNIV OF TECH

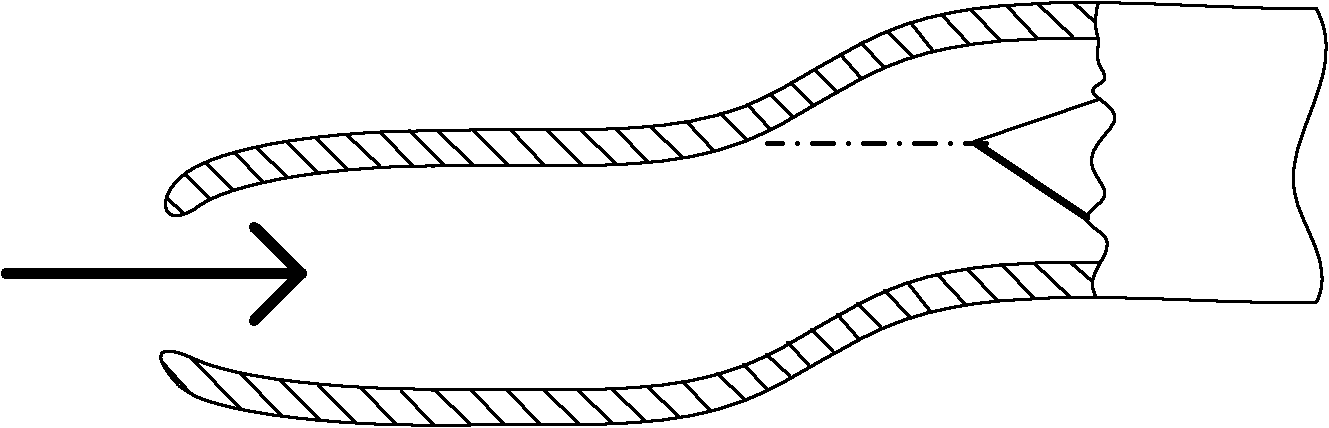

Shape memory polymer pipeline and use of shape memory polymer pipeline as aircraft engine intake

InactiveCN101922591AImprove performanceOvercoming demandsFlexible pipesTurbine/propulsion air intakesAirplaneAerodynamics

The invention relates to a shape memory polymer pipeline and use of the shape memory polymer pipeline as an aircraft engine intake, in particular to a shape memory polymer pipeline and use thereof, which solve the problem that a structure of the conventional aircraft engine intake cannot be deformed according to requirements, so air inflow cannot be regulated and the shape of the air intake cannot be changed to cause that the through capacity of the aircraft engine intake is discordant with the requirement of an engine to influence the aerodynamics performance of an air engine. The shape memory polymer pipeline is made of a shape memory composition material, and the shape memory composition material consists of 5 to 98 volume parts of shape memory polymer materials, 2 to 95 volume parts of reinforcement phase materials and 0 to 100 volume parts of resistance heating materials; and the shape memory polymer pipeline serving as the aircraft engine intake overcomes the defect that the structure of the conventional air intake cannot be deformed according to the requirements, and regulates the air inflow and changes the shape of the air intake, so that the through capacity of the air intake is in accordance with the requirement of the engine to improve the aerodynamics performance of aircrafts.

Owner:HARBIN INST OF TECH

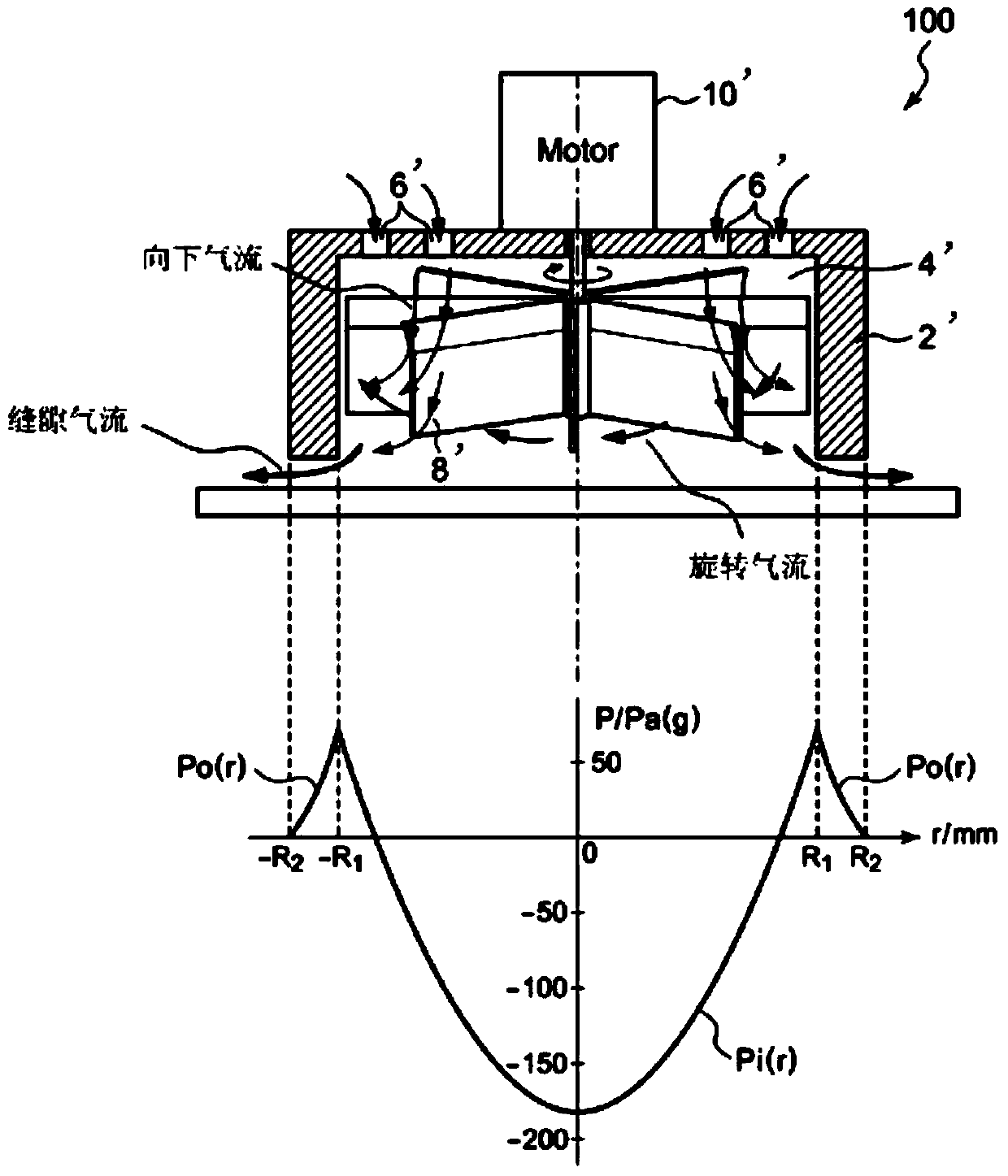

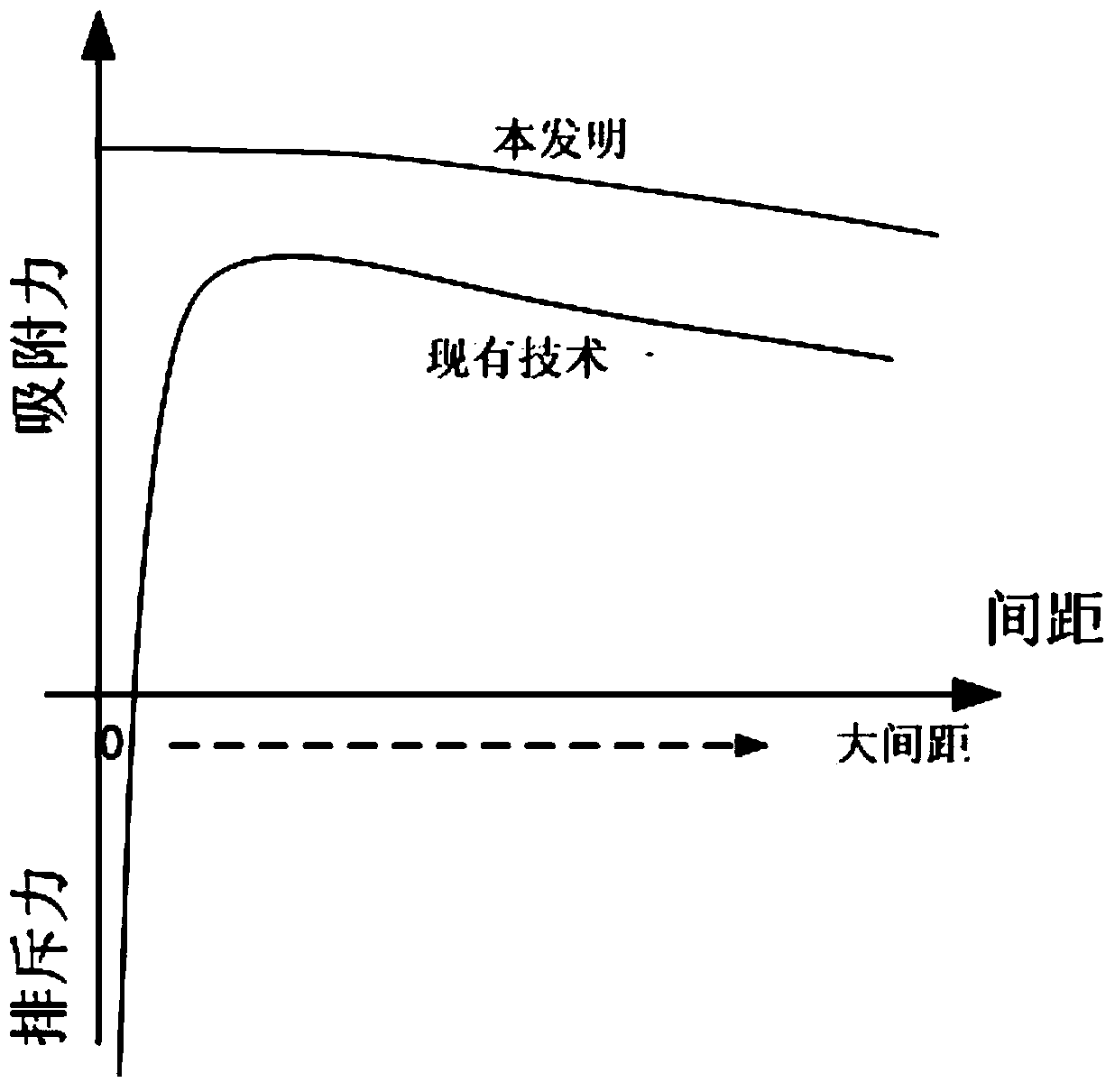

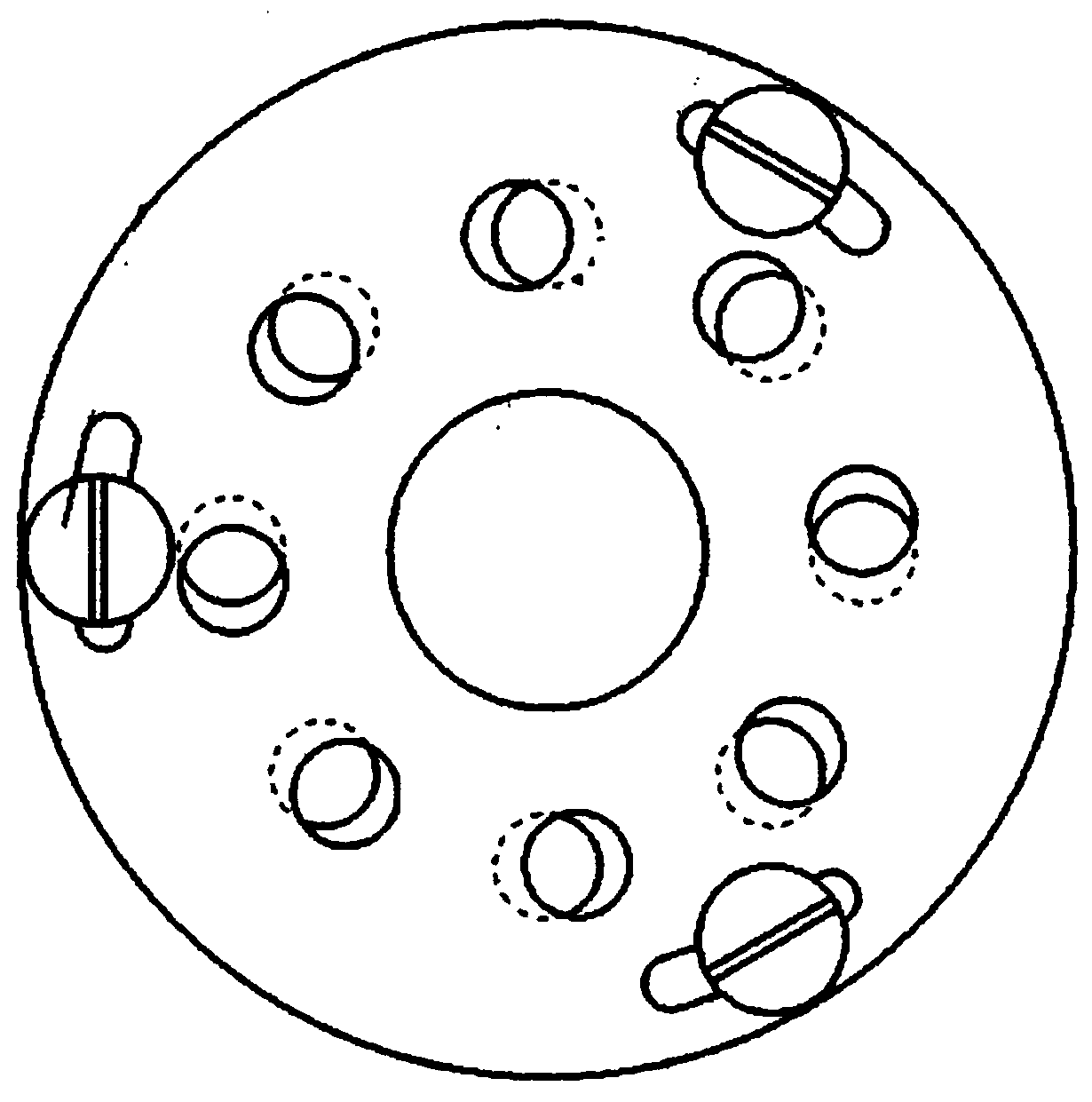

Object absorbing device

InactiveCN103496589AOvercoming demandsOvercome stabilityCharge manipulationConveyor partsSurface roughnessEngineering

The invention discloses an object absorbing device. The object absorbing device comprises a shell with the cross section being circular, a cavity with the cross section being circular is formed in the shell, and the cavity is provided with a closed end face and an opened end face. The opened end face forms an end face for absorbing an object, the closed end face is provided with a motor, and fan blades arranged inside the cavity are connected with an output shaft of the motor. The object absorbing device is characterized in that the closed end face is in an airtight state, and the fan blades are in linear distribution along the axis of the cavity. In the working process, the shell on the circumference of the opened end face can apply absorption force on the object under the condition that the shell makes contact with or does not make contact with the object. The object absorbing device can be widely applied to absorbing and grasping objects, is suitable for the objects with large surface roughness and can also be adaptive to the object tilting condition, and the advantage of being small in energy consumption is achieved as well.

Owner:ZHEJIANG UNIV

Hot and spicy sauce of preserved red peppers and preparation method thereof

InactiveCN101396113ASlightly spicySlightly spicy taste slightly spicy, not dry mouth after eatingFood preparationSesamumAdditive ingredient

The invention mainly relates to a table hot and spicy sauce and a preparation method thereof. The hot and spicy sauce, which is made from pickled pepper, is characterized by containing ingredients in terms of part by weight: pickled 18-20 parts of pickled pepper, 40-50 parts of edible oil, 6-7 parts of lobster sauce, 3.5-4.5 parts of black sesame seed, 3.2-8.8 parts of pignut, 4-4.5 parts of soybean, 7.2-8 parts of shallot, and 4.1-5 parts of sufu. The ingredients are prepared into the hot and spicy sauce, which has a slightly hot taste and does not cause people to have a parched mouth or tongue and excessive internal heat, thus being suitable for various people. Besides, the requirements of fresh-keeping and quality guarantying of the hot and spicy sauce can be satisfied without adding any additive, thus overcoming the defect that the fresh-keeping and quality guarantying can only be realized when the additive is added and facilitating eating and storage. The sauce is rich in nutrition, convenient to eat and store, and suitable for public taste; moreover, the sauce can not only used for mixing rice, steamed bread or cold dish, but also be widely used in restaurants, households and on journey.

Owner:邹春涛

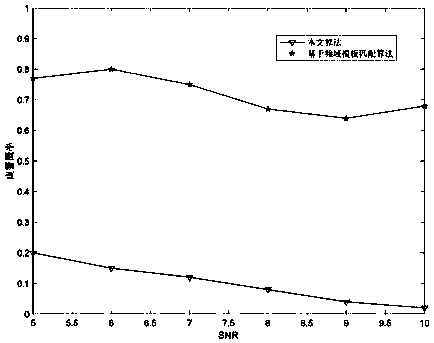

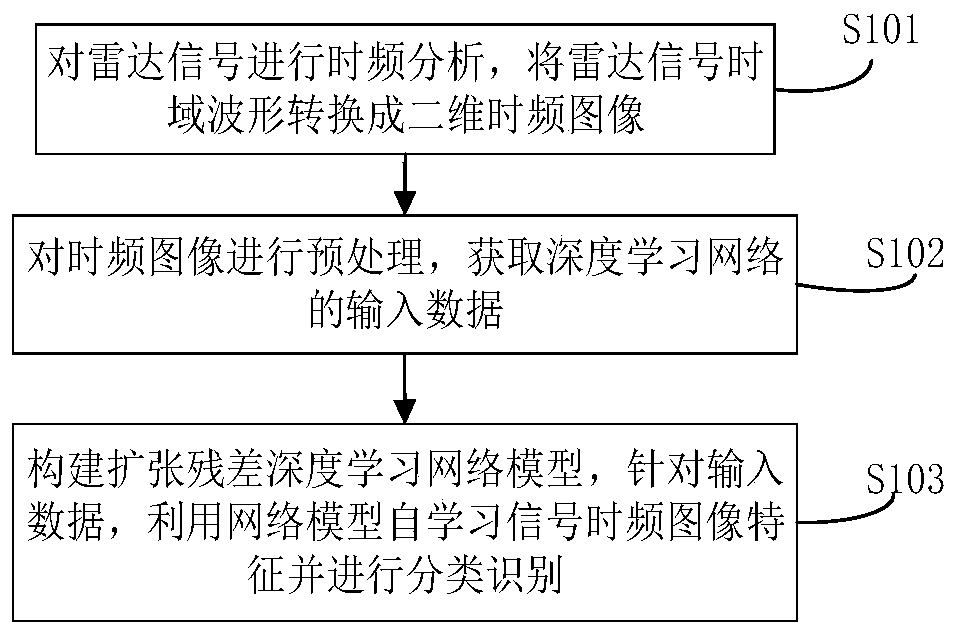

Radar radiation source identification method and device based on extended residual network

InactiveCN110147812AEasy to identifyWeak learning abilityWave based measurement systemsCharacter and pattern recognitionSignal-to-noise ratio (imaging)Time–frequency analysis

The invention belongs to the technical field of radar signal processing, and particularly relates to a radar radiation source identification method and device based on an extended residual network. The radar radiation source identification method comprises the steps: carrying out the time-frequency analysis of a radar signal, and converting the time domain waveform of the radar signal into a two-dimensional time-frequency image; preprocessing the time-frequency image to obtain input data of a deep learning network; and constructing an extended residual deep learning network model, and for input data, self-learning signal time-frequency image features by using the network model and carrying out classified identification. According to the radar radiation source identification method, the problems that a traditional method is sensitive to noise, low in extraction characteristic effectiveness and universality and the like are solved, and the excellent identification effect can still be kept for complex multi-class radar signals in the environment with the low signal-to-noise ratio; the radar radiation source identification method can solve the problems that a simple depth model is weakin learning ability, confusion time-frequency image similar signals and the like, and is good in confusion resistance, accurate in identification result and high in identification accuracy; and the radar radiation source identification method can be applied to radar radiation source identification of more types, and has very high adaptability and popularization.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

Industrial waste residue activating grinding aid

InactiveCN1451624APromotes hydration activityAchieve clinker effectOther chemical processesSolid waste disposalBiochemical engineeringElectric consumption

An activating grinding aid for industrial waste residues is prepared from catalyst (1-8 wt.%), activating agent (30-80 wt.%), setting regulator (0-20 wt.%), grinding aid (3-12 wt.%) and carrier (3-30wt.%). Its advantages are effective use of industrial waste residues, low electric consumption of grinder, and improve cement performance.

Owner:尹小林

Method and device for forming micro-texture in composite mode on inner surface of cylinder sleeve through laser

InactiveCN103111752AImprove mechanical propertiesImprove friction performanceLaser beam welding apparatusFriction reductionShock wave

The invention provides a method for forming micro-texture in a composite mode on the inner surface of a cylinder sleeve through laser. The method comprises the following steps: step (1), a femtosecond laser device is used for processing a needed microcosmic shape on the inner surface of the cylinder sleeve; and step (2), a nanosecond laser device is used for strengthening the area of the microcosmic shape processed in the step (1) through laser shock waves. Under the condition of dry friction, micro-concave surface texture can be used as a storage device for storing wear particles to reduce abrasive wear and furrows on the friction surface, and therefore the wear rate is lowered. The laser shock waves can eliminate residual tension after the micro-texture is formed on the inner surface of the cylinder sleeve, and therefore deep residual compressive stress is formed, grain refinement is enabled to be more uniform, the hardness, the abrasive resistance and the anti-fatigue performance of the cylinder sleeve are improved, and the service life of the cylinder sleeve is prolonged. The invention further provides a device for forming the micro-texture in the composite mode on the inner surface of the cylinder sleeve through the laser at the same time.

Owner:WENZHOU UNIVERSITY +1

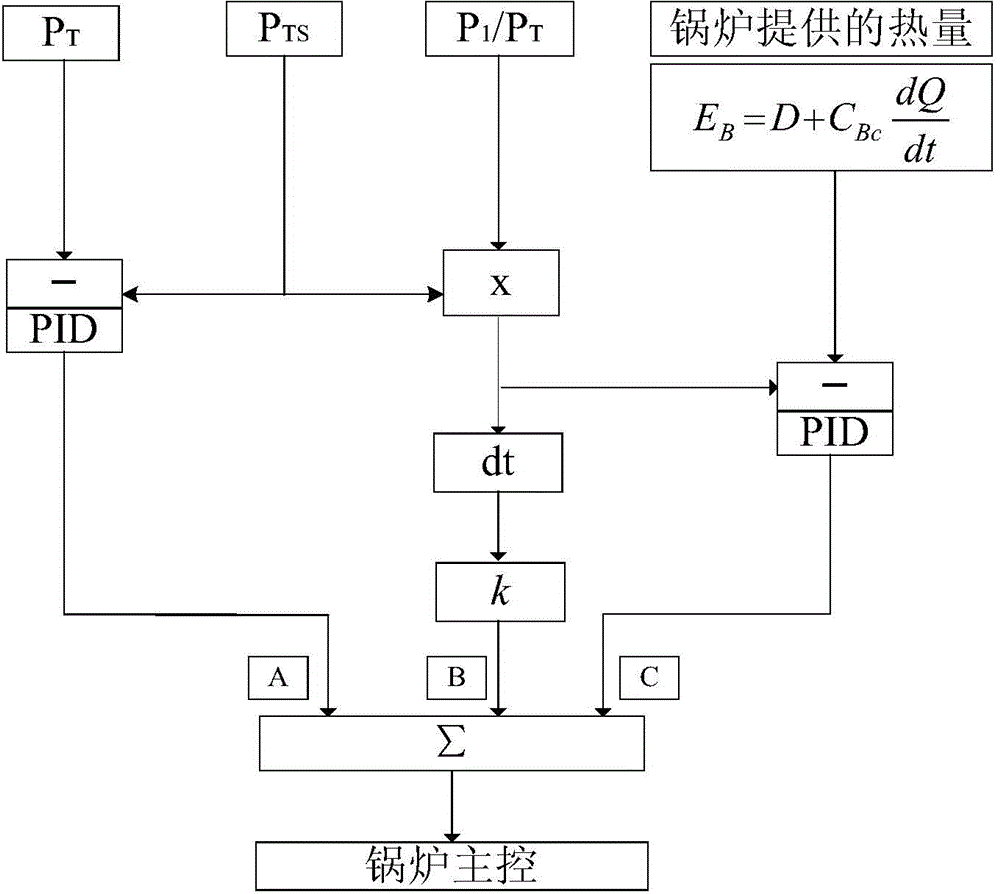

Energy balance-based control method of main steam pressure of supercritical CFB (circulating fluidized bed) boiler

ActiveCN104676574AOvercome stressOvercoming demandsFluidized bed combustionBoiler controlSteam pressureEnergy balanced

An energy balance-based control method of main steam pressure of a supercritical CFB (circulating fluidized bed) boiler includes the steps: S1, after a main steam pressure deviation signal P<T>-P<TS> of a unit is regulated by a PID (proportion integration differentiation) regulator, a signal A is output; S2: a steam turbine demanded heat signal is acquired through a steam turbine energy demand model; S3, a heat signal provided by boiler energy is acquired through an instant carbon mechanism model; S4, subtracting the steam turbine demanded heat signal E<R> by the heat signal E provided by boiler energy is performed, regulating is performed with the PID regulator, and a signal C is output; S5, after subjected to time differentiation, the steam turbine demanded heat signal E<R> is multiplied by a proportional gain k so as to obtain an output signal B, and a sum of the signals B, A and C is output to a boiler master controller; S6, coal feed is regulated according to master control output of a boiler so as to control the main steam pressure. The method has the advantages that regulating quality of the unit can be improved, stability of a main steam pressure control system of the supercritical CFB boiler is improved and ability to respond to load response of the unit is satisfied.

Owner:TSINGHUA UNIV

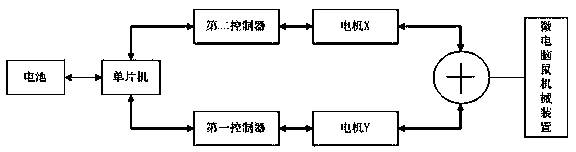

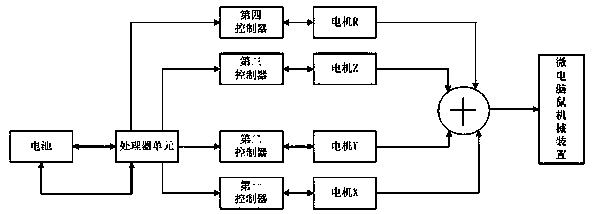

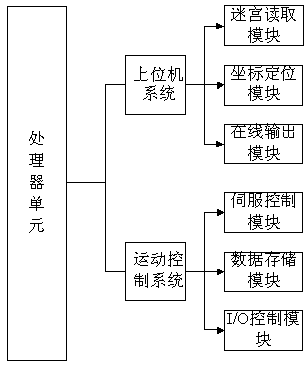

Dual-core four-wheeled top-speed microcomputer mouse-based diagonal sprint system

InactiveCN103529832AGuaranteed stabilityGuaranteed reliabilityProgramme controlComputer controlMicrocomputerElectric machine

The invention discloses a dual-core four-wheeled top-speed microcomputer mouse-based diagonal sprint system. A battery is electrically connected with a processor unit; the processor unit is electrically connected with a first controller, a second controller, a third controller and a fourth controller respectively; the first controller, the second controller, the third controller and the fourth controller are correspondingly and electrically connected with a motor X, a motor Y, a motor Z and a motor R respectively; the motor X, the motor Y, the motor Z and the motor R are connected with a microcomputer mouse mechanical device; the processor unit comprises an ARM 9 (Advanced RISC Machine) processor and an LM629 chip; the ARM 9 processor is electrically connected with the LM629 chip. According to the dual-core four-wheeled top-speed microcomputer mouse-based diagonal sprint system, the anti-interference capacity is greatly enhanced, meanwhile, the operation speed is improved, and the stability and the reliability of the dual-core four-wheeled top-speed microcomputer mouse-based diagonal sprint system are guaranteed.

Owner:SUZHOU INDAL PARK INSTITUE OF VOCATIONAL TECH

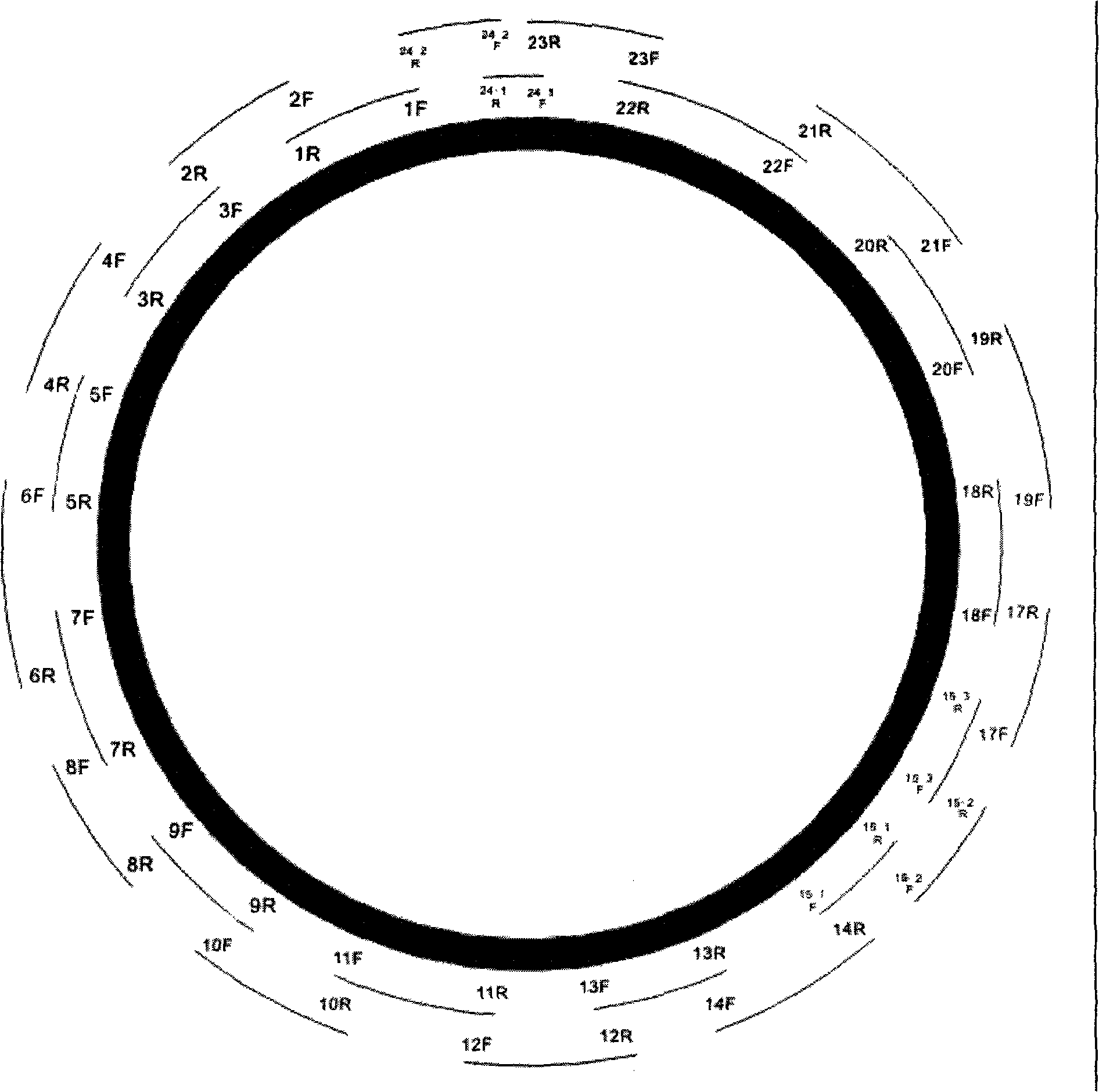

26-pair PCR primer for mitochondrion sequencing and parting method based on the primer

InactiveCN101270390AOvercoming demandsMicrobiological testing/measurementDNA/RNA fragmentationAgricultural scienceTyping methods

The invention relates to a detection method of nucleic acid, particularly discloses a whole base sequence typing of mitochondria and a determination method thereof, specifically 26 pairs of PCR primer for mitochondria sequencing and a typing method based on the primers. The 26 pairs of PCR primer which are adopted by the invention cover the total length of mitochondria genome, wherein, primer 15-1, 15-2, 15-3, 24-1 and 24-2 are designed renewedly based on Chinese population and has the pertinence of the typing of Chinese population. The amplified fragment which corresponds to the primer 24-1 is the minimum and equals to 420bp. The amplified fragment which corresponds to the primer 22 is the maximum and equals to 1162bp. The dimensions of all PCR fragments are moderate and favorable for PCR amplification. The 26 pairs of PCR primer of the invention is utilized in the laboratory of applicant for investigating the community information of Chinese nation, and the whole sequence information of Chinese population is submitted to GENEBANK databases. The result shows that the invention can be definitely applied in the field of individual recognitions, paternity testing and gene diagnosis of the field of forensic medicine, anthropology, genetics and disease.

Owner:XI AN JIAOTONG UNIV

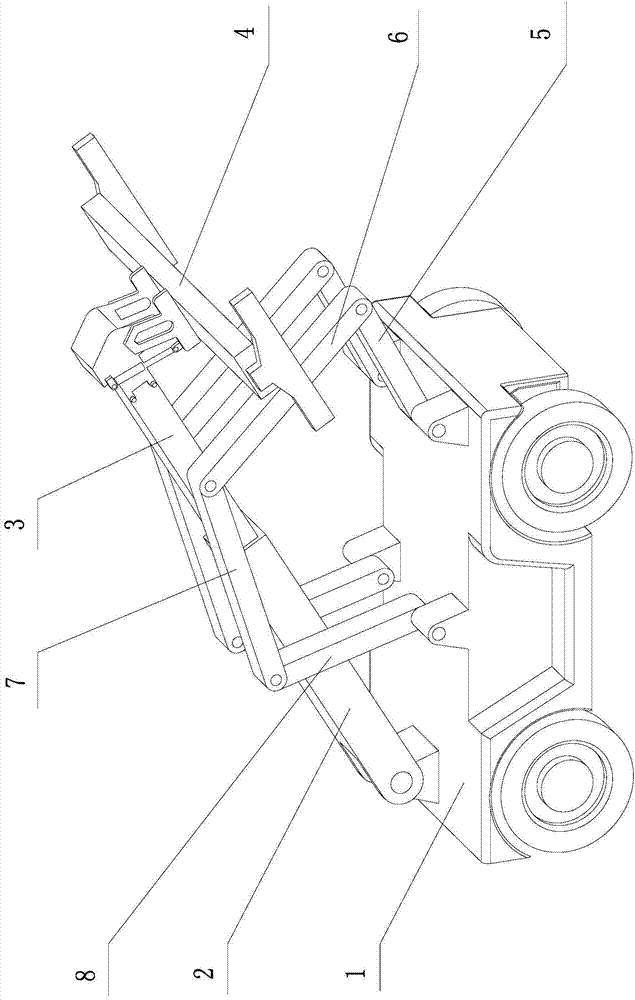

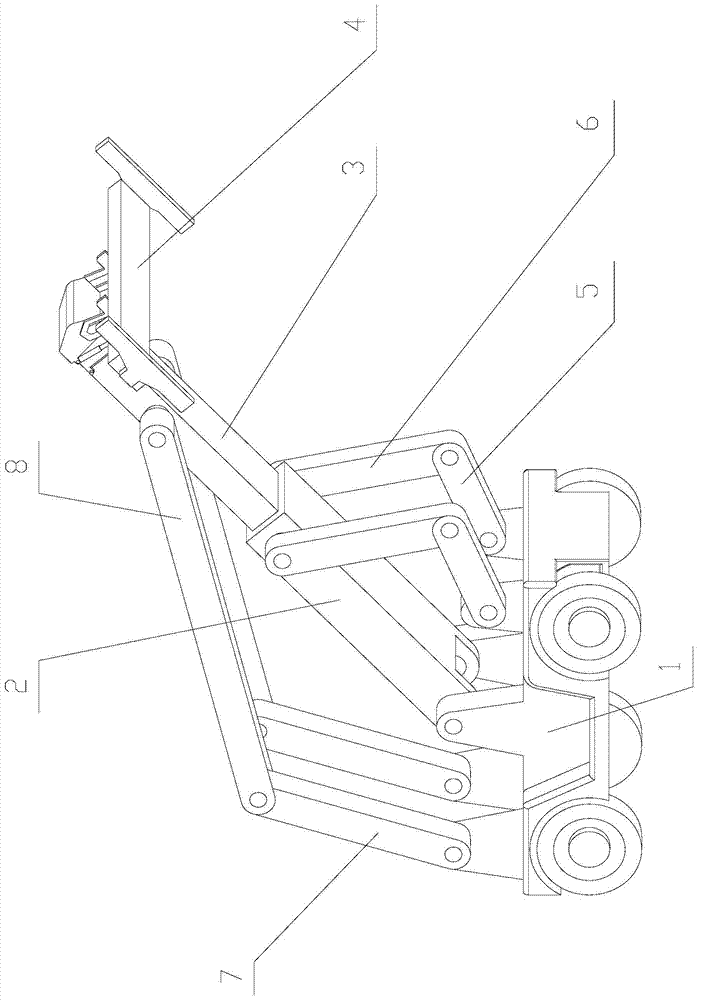

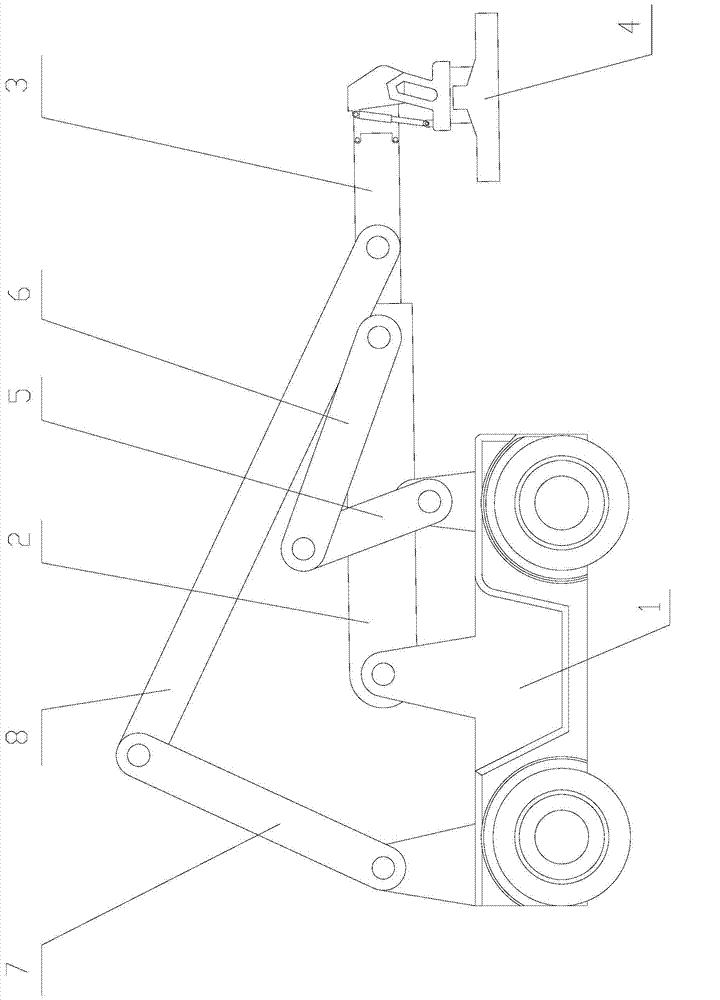

Plane two-degree-of-freedom seven-rod closed chain type reach stacker for containers

The invention relates to a plane two-degree-of-freedom seven-rod closed chain type reach stacker for containers. The plane two-degree-of-freedom seven-rod closed chain type reach stacker for the containers comprises a suspension arm and a suspension lifting and telescoping mechanism, wherein the suspension arm comprises a rotating arm and a telescopic arm; the rotating arm is hinged to the rear part of a frame; the telescopic arm is mounted on the rotating arm through a sliding pair; a clamping device is arranged at the front end of the suspension arm; the suspension arm lifting and telescoping mechanism comprises five-rod linkage mechanisms which are symmetrically arranged on the two sides of the suspension arm; each five-rod linkage mechanism comprises a front rocker, a front connecting rod, a rear connecting rod and a rear rocker; the front rockers and the rear rockers are hinged to the front part and the middle part of the frame respectively; the hinged points between the front connecting rods and the rear connecting rods are arranged on the telescopic arm. Ascending, telescoping and descending of the crane are realized under the drive of the five-rod linkage mechanisms. The plane two-degree-of-freedom seven-rod closed chain type reach stacker for the containers has the advantages of small movement inertia, flexible track output, high precision, high rigidity, excellent dynamic performance, high reliability and the like.

Owner:QINZHOU UNIV

System and method for eliminating long line transmission time delay of source synchronizing signal

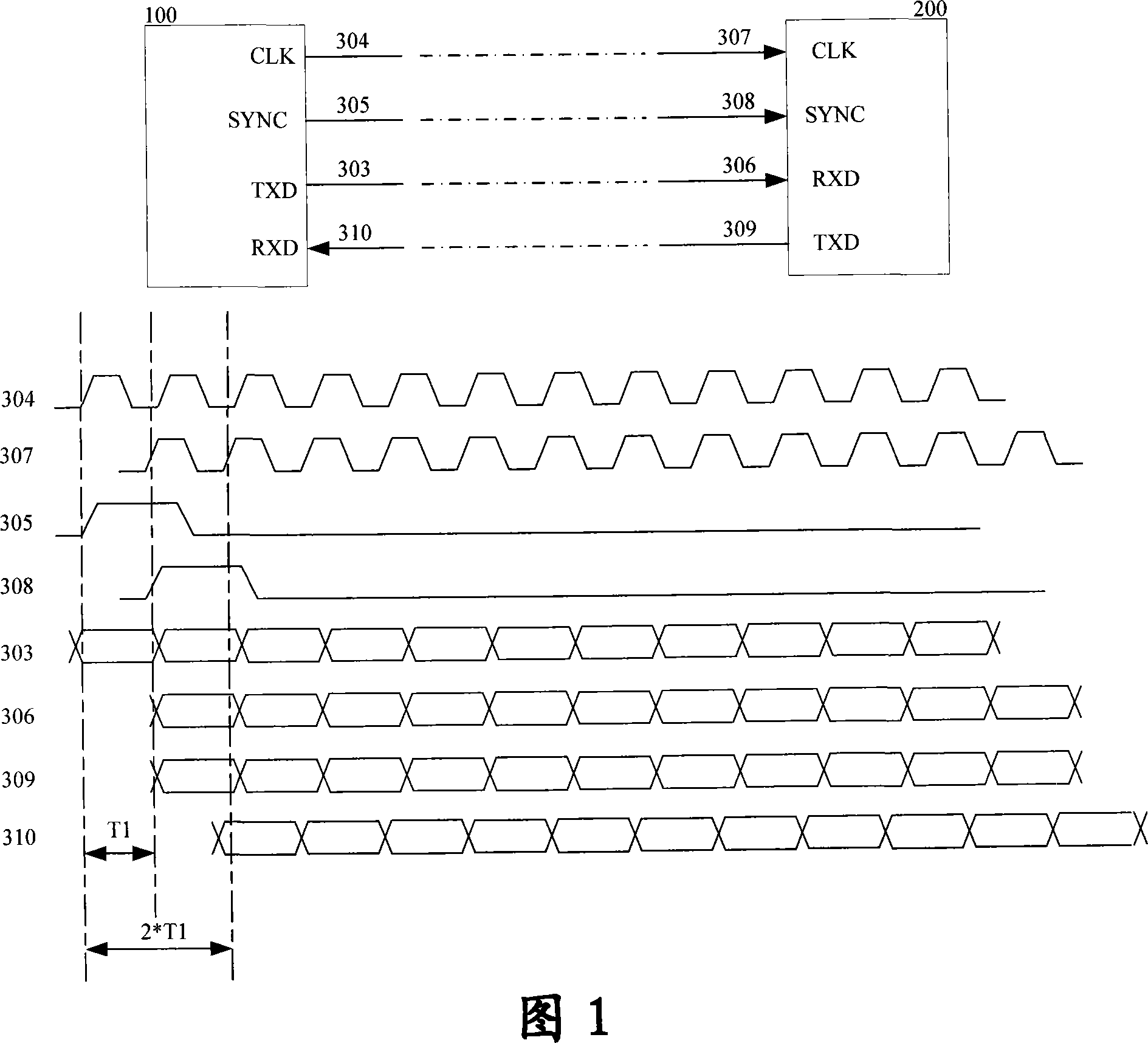

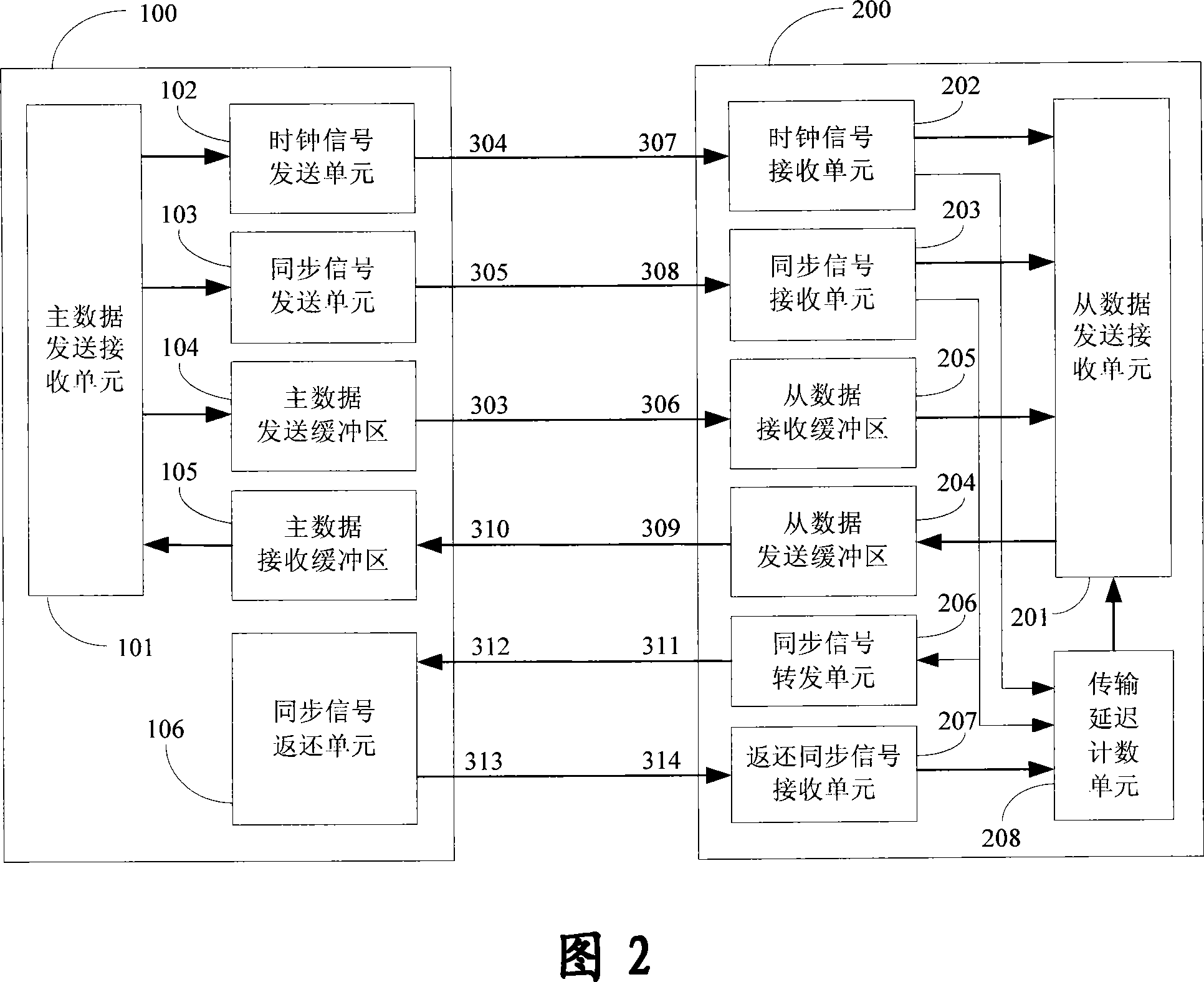

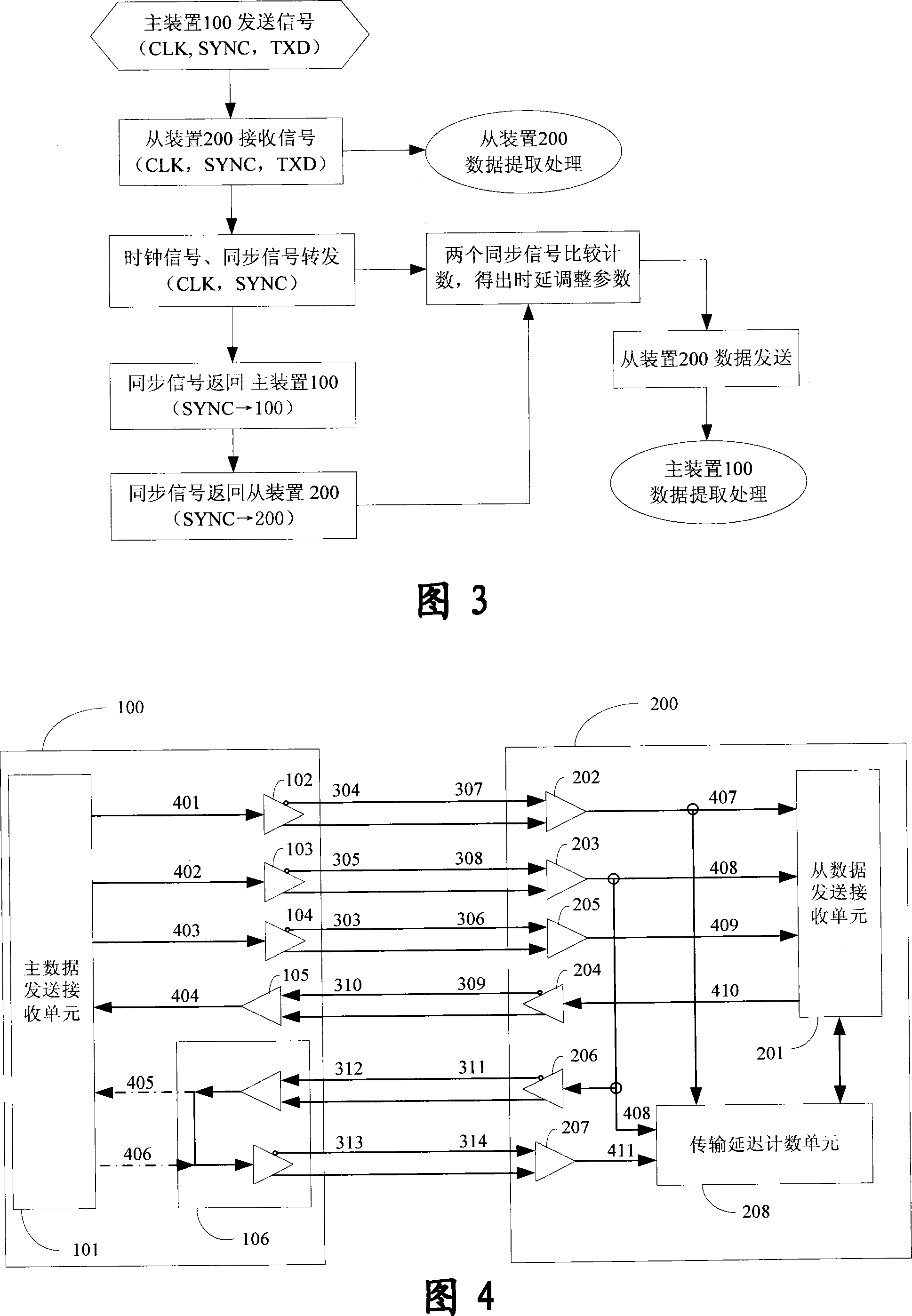

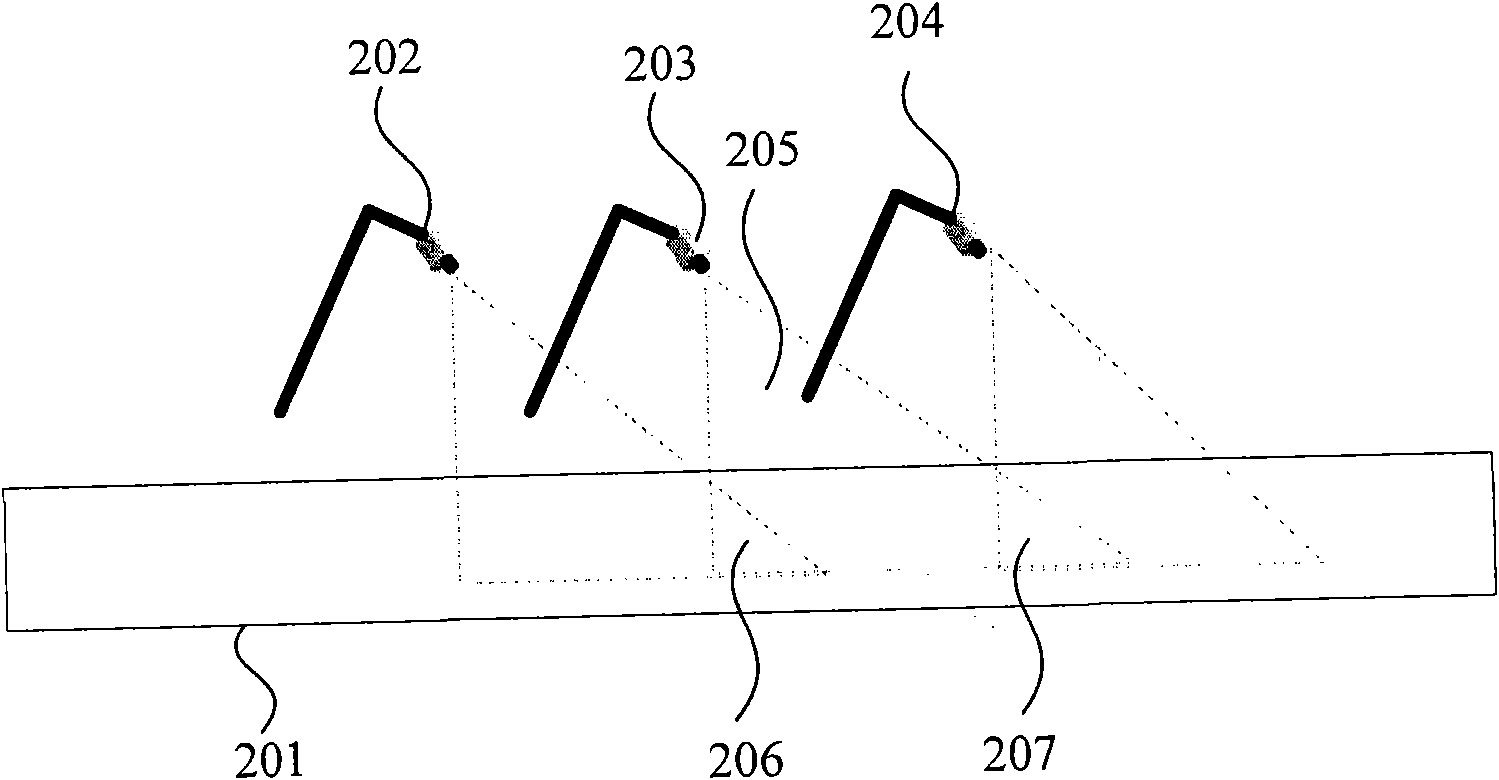

ActiveCN101136737AEliminate the effects of transmission delaysAvoid mistakesSynchronising arrangementTransmission time delayComputer science

Being related to master / slave devices, the method includes steps: (1) master device sends clock signal, synch signal, and data to slave device; (2) when receiving data, the slave device transmits the synch signal received at same time to the master device; after receiving the transmitted synch signal from the slave device, the master device returns the synch signal back to the slave device; (3) using the received clock signal, the slave device counts value of transmission delay (VTD) between the received synch signal and the returned synch signal; (4) using the received synch signal as reference and based on VTD, the slave device adjusts preact of time for sending data to the master device; (5) based on clock signal and synch signal, the master device extracts the received data. The invention prevents signal error from transmission delay of synch signal caused by long transmission line as well as overcomes too high demand on hardware and processing capabilities.

Owner:ZTE CORP

Device and method for acquiring traffic information

InactiveCN101540104AImprove collection qualityImprove real-time performanceDetection of traffic movementVisual field lossTraffic capacity

The invention discloses a device and a method for acquiring traffic information. A plurality of node devices for traffic information acquisition based on video are arranged on one side of a road one by one, and are used for acquiring the information of two-way traffic flow on the road. The adjacent node devices communicate with each other in a wireless mode so as to form a wireless sensor network. Visual fields of adjacent node devices have a covered overlap region used for providing the adjacent node devices with cooperation time and space. Through the traffic information synthesis of the adjacent node devices, a lowest-reaches node obtains the traffic information in a whole range. The node devices communicate through a Zigbee protocol, and the synthesis of overall information from the traffic information acquired by the node devices is realized through the cooperation of the adjacent node devices. The acquired traffic information comprises road flow rate, occupancy, average velocity and motion tracks of vehicles. The invention has the characteristics of flexible network structure, as well as the wide range and high real-time property of the acquired traffic information.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Integrally-formed shoulder tab mould

InactiveCN104005183ASolving technical problems with high operational requirementsWay to overcomeWork-feeding meansEngineering

An integrally-formed shoulder tab mould is formed by a base plate, a cover plate, a clamping plate and a fixing piece; one side of the base plate is hinged to the cover plate which comprises the same structure with the base plate and the cover plate and the base plate are in mirror symmetry; the base plate is formed by a base plate positioning plate, a base plate backing plate, a base plate cover plate, a left base plate clamping plate and a right base plate clamping plate; the base plate backing plate is composited between the base plate positioning plate and the base plate cover plate; a base plate seam through groove which is adaptive to a shoulder tab in shape is formed in the middle of the base plate positioning plate; a base plate cover plate through groove is formed at a base plate cover plate position which is corresponding to the base plate seam through groove; the left base plate clamping plate and the right base plate clamping plate are arranged in a base plate clamping plate through groove in an embedded mode, wherein the base plate clamping plate through groove is formed between the base plate positioning plate and the base plate cover plate. According to the integrally-formed shoulder tab mould, the base plate, the cover plate, the clamping plate and the fixing piece are matched with each other and accordingly the integral forming is achieved and the technical problems that the machining mode is complicated, the positioning is inconvenient, and the requirements for the operation level of workers are high in the process of shoulder tab manufacture are fundamentally solved.

Owner:TIANJIN SANDA CLOTHING

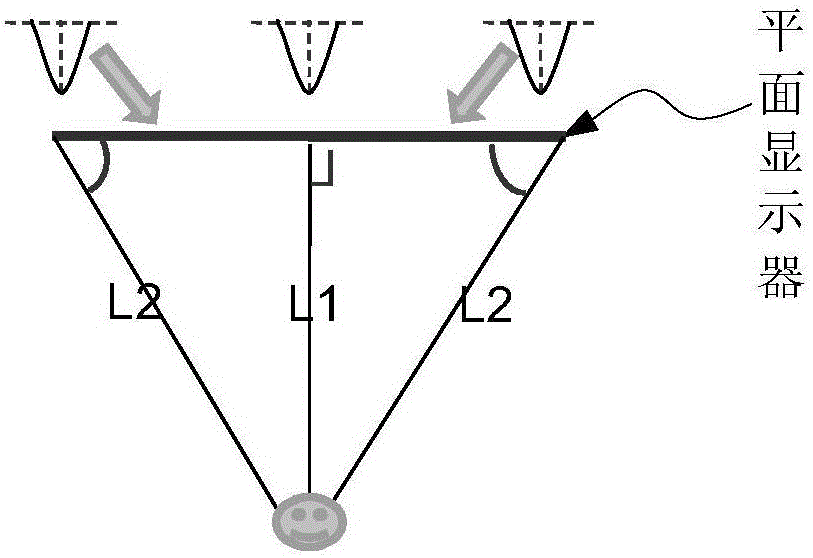

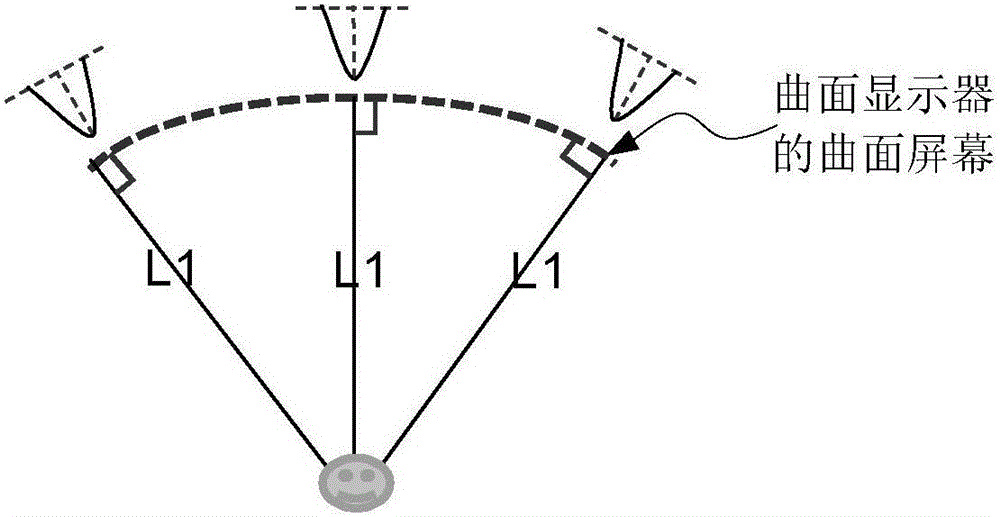

Display device

ActiveCN105700269AOvercoming demandsOvercome difficultyNon-linear opticsSurface displayDisplay device

The invention discloses a display device, and relates to the technical field of display. The display device is used for basically achieving the curved surface display effect on the premise of not conducting physical bending. The display device comprises a plane display panel and a liquid crystal lens located in the light-emitting direction of the display panel and used for converging light rays emitted by the display panel to a central face. The central face is a vertical central line perpendicular to the display panel and passing through the display panel.

Owner:BOE TECH GRP CO LTD +1

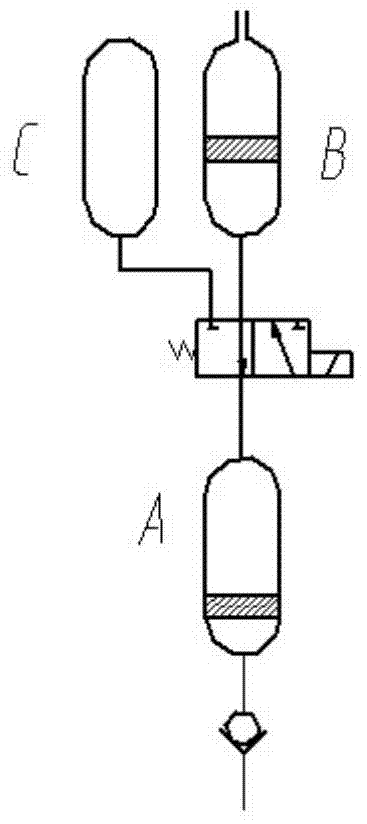

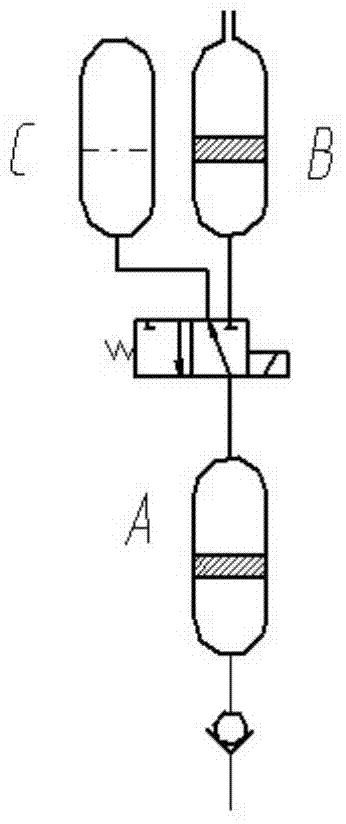

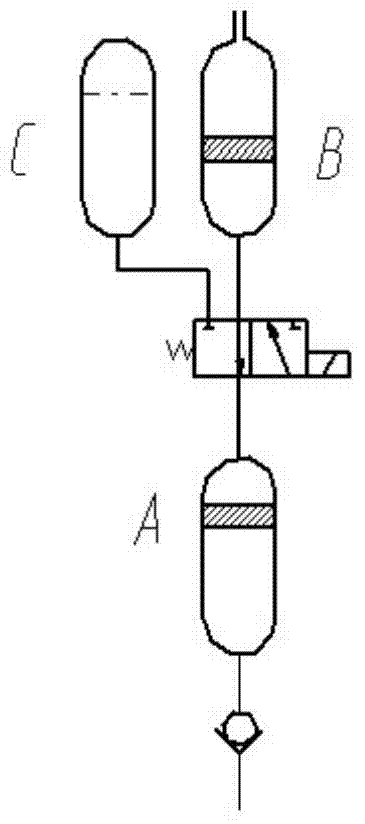

Two-position three-way electromagnetic reversing valve for deep-sea collection

ActiveCN103615570ANot affected by depthRelieve pressureOperating means/releasing devices for valvesMultiple way valvesEngineeringHigh pressure

A two-position three-way electromagnetic reversing valve for deep-sea collection comprises an end cap, a valve body, a left valve seat, a double-end conical valve core, a right valve seat, an electromagnet and the like. Openings A, B and C are formed in the valve body, the end cap, the valve body and the electromagnet are sequentially connected, the left valve seat, the double-end conical valve core and the right valve seat are sequentially disposed inside the valve body from left to right, a conical valve hole is arranged in each of the left valve seat and the right valve seat, an annular groove is formed in each lateral cylindrical face, multiple uniformly-distributed connecting holes are formed in each annular groove and communicated with the conical valve holes inside the respective valve seats, a connecting groove on the double-end conical valve core communicates a left-side inner cavity between the left valve seat and the double-end conical valve core with a right-side inner cavity between the double-end conical valve core and the right valve seat, the double-end conical valve core is connected with an armature pushing rod penetrating the right valve seat, horizontal moving of the double-end conical valve core is realized by controlling a coil to be powered on and off, the opening A and the opening B are externally connected with deep-sea high pressure, the opening A is externally connected with a water incoming one-way valve, and the opening C is communicated with low pressure.

Owner:BEIJING UNIV OF TECH

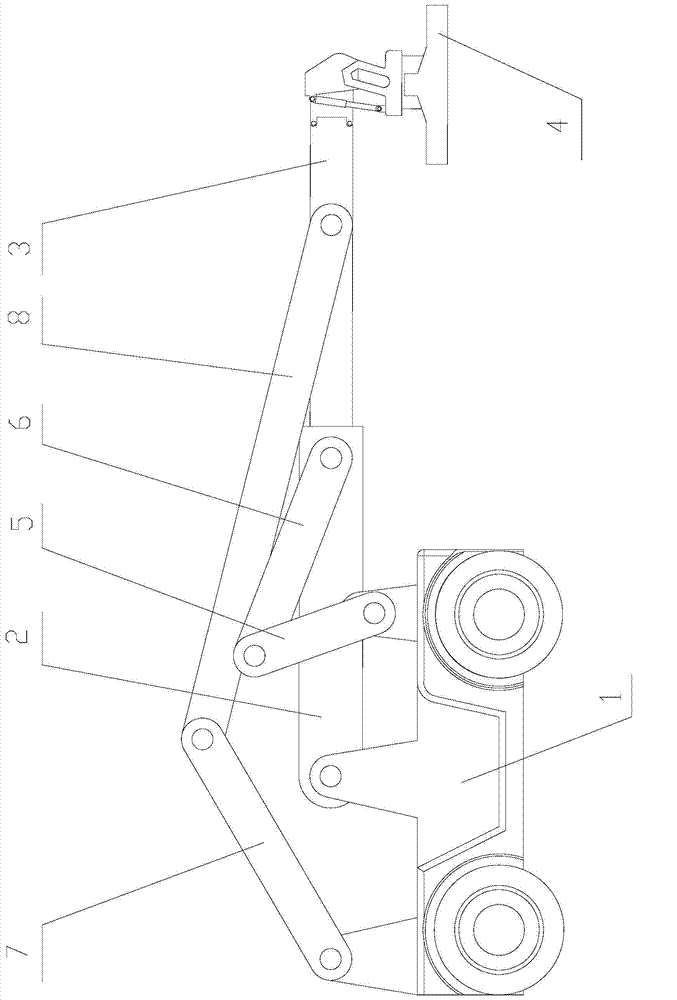

Plane two-degree-of-freedom seven-rod servo drive reach stacker for containers

The invention relates to a plane two-degree-of-freedom seven-rod servo drive reach stacker for containers. The plane two-degree-of-freedom seven-rod servo drive reach stacker for the containers comprises a suspension arm, a suspension arm lifting mechanism and a suspension arm telescoping mechanism, wherein the lower end of a rotating arm of the suspension arm is hinged to the middle of a frame; a telescopic arm of the suspension arm is mounted on the rotating arm in a sliding manner; the suspension arm lifting mechanism comprises a lifting rocker and a lifting connecting rod; the lower end of the lifting rocker is hinged to the front part of the frame; the upper end of the lifting connecting rod is hinged to the rotating arm; the lifting rocker is hinged to the other two ends of the lifting connecting rod; the suspension arm telescoping mechanism comprises a telescopic rocker and a telescopic connecting rod; the lower end of the telescopic rocker is hinged to the rear part of the frame; the front end of the telescopic connecting rod is hinged to the telescopic arm; the telescopic rocker is hinged to the other two ends of the telescopic connecting rod. The plane two-degree-of-freedom seven-rod servo drive reach stacker for the containers realizes clamping, lifting and carrying operation of the containers under the combined drive of the suspension arm lifting mechanism and the suspension arm telescopic mechanism, and has the advantages of small movement inertia, flexible track output, high precision and the like.

Owner:QINZHOU UNIV

Hot stamping bake toughening steel based on carbon partitioning principle and processing method thereof

ActiveCN104195455AImprove performanceLoose timing for allotment transfersHot stampingChemical composition

The invention relates to the field of metallurgical materials, also belongs to the field of advanced high-strength steel for cars and particularly provides hot stamping bake toughening steel based on a carbon partitioning principle and a processing method thereof. The hot stamping bake toughening steel comprises the following chemical components in percentage by mass: 0.2-0.5% of C, 0.25-1.5% of Mn, 0.2-0.6% of Cr, 0.2-1.0% of Mo, 0.1-0.8% of Ni, 0.2-1.2% of Si, 0.2-0.5% of Al, 0.002-0.004% of B, 0.02-0.03% of Ti, 0.5-1.5% of Cu, less than 0.01% of S and less than 0.01% of P. The processing method comprises the following steps: heating a steel plate until complete austenitizing, then immediately transferring onto a hot stamping apparatus, stamping, performing intra-mold pressure-maintained quenching, demolding, and cooling in air to room temperature, wherein the structure is martensite+unstable residual austenite; and performing baking treatment in a car body baking temperature range, and ensuring that carbon partitioning is performed to stabilize the residual austenite, thus finally obtaining a multiphase structure of the stable martensite and residual austenite, wherein the comprehensive property is consistent with that of traditional Q&P steel. According to the invention, on the basis of keeping the advantages of the Q&P steel, the disadvantages of the Q&P steel such as need of an independent isothermal partitioning apparatus and requirement for high transfer speed are overcome.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

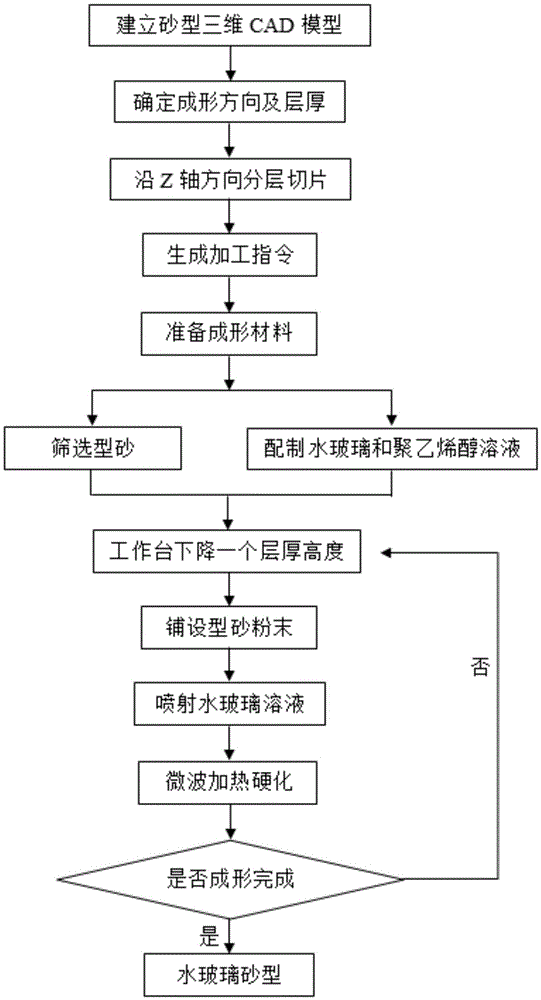

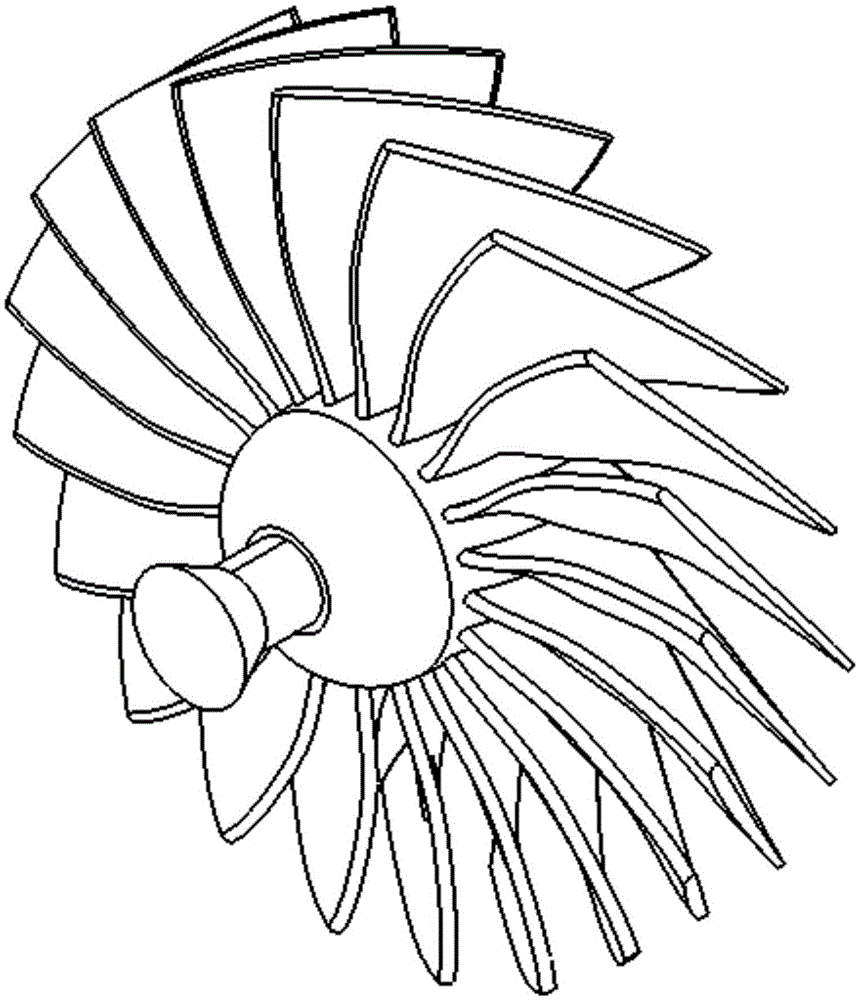

Rapid molding method of sodium silicate sand mould

ActiveCN105562623AFast bondingImprove liquidityAdditive manufacturing apparatusFoundry mouldsMicrowavePolyvinyl alcohol

The invention discloses a rapid molding method of a sodium silicate sand mould and belongs to the field of rapid casting. The rapid molding method comprises the following steps: (1), establishing a three-dimensional entity model of a sodium silicate sand mould to be molded, taking the Z axis as the molding direction, and setting molding layer thickness; (2), first, paving one layer of molding sand material, and then spraying an adhesive so as to form the current layer of outline pattern, wherein the adhesive is a mixed solution of sodium silicate and polyvinyl alcohol; (3), carrying out microwave heating on the current layer of outline pattern, and forming the current layer of sand mould outline; (4), stopping microwave heating, and lowering the work table for a height of one layer thickness along the Z axis; and (5), repeating steps (2-4) until the sodium silicate sand mould is molded. The method meets the high requirement of sodium silicate sand hardened through microwave heating on the mould, solves the problems that the surface of the sodium silicate sand mould becomes powdery due to overheating and easily absorbs moisture, and further overcomes the poor feasibility, difficult molding sand storage and difficult molding sand recycling defects of the existing micro-injection bonding sodium silicate sand rapid molding technology.

Owner:HUAZHONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com