Two-position three-way electromagnetic reversing valve for deep-sea collection

An electromagnetic reversing valve, two-position three-way technology, applied to multi-way valves, lift valves, valve details, etc., can solve problems such as reversing valves not working properly, to overcome seawater corrosion resistance, pressure reduction, and deep sea Effects of High Pressure Environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

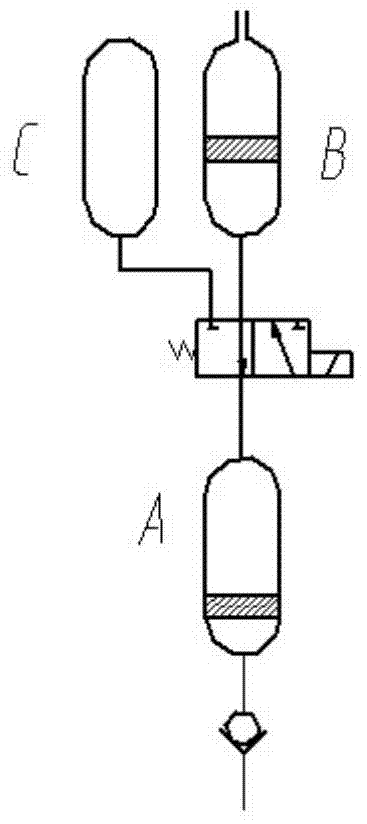

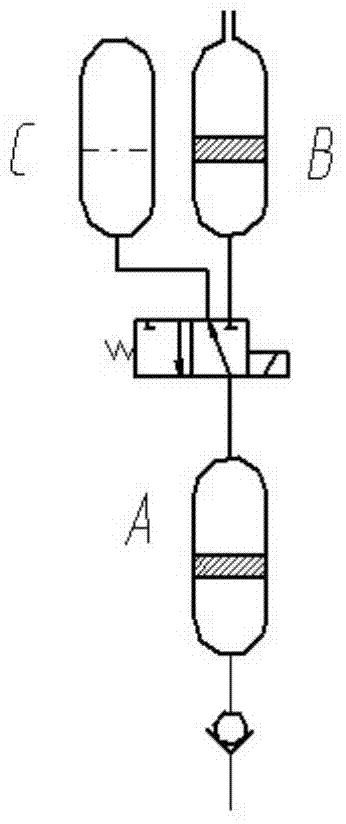

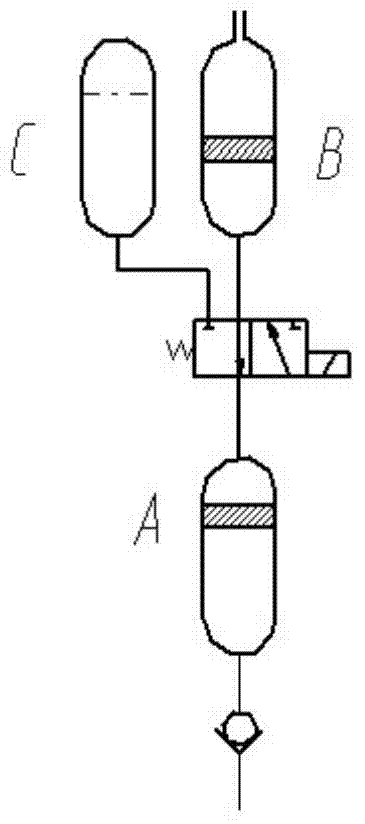

[0020] Figure 1 to Figure 4 As shown, an embodiment of the present invention includes: end cover 1, valve body 2, left valve seat 3, double-ended poppet valve core 4, right valve seat 5, electromagnet 6, baffle plate 7, return spring 8, can Adjust spring seat 9, armature push rod 10, bobbin 11, coil 12, electromagnet housing 13, etc. The spool is a double-ended cone valve structure with a tapered shape. Back-moving spring 8 is positioned by the inner hole of baffle plate 7 and adjustable spring seat 9. When installing, first pass the right connecting rod of the double-ended poppet valve core 4 through the inner hole of the right valve seat 5, and after the armature push rod 10 of the electromagnet 6 is sealed by the gray ring, it is connected with the double-ended poppet valve. The connecting rod on the right side of the core 4 is tightly connected by threads, the A port communicates with the collection bottle with a one-way valve at the end, the collection bottle communica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com