Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

129results about How to "Good bonding performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of producing lithium iron phosphate with high compacted density and excellent adhesive property

InactiveCN101152961AGood winding performanceGood bonding performanceCell electrodesPhosphorus compoundsNitrogen atmosphereOxide

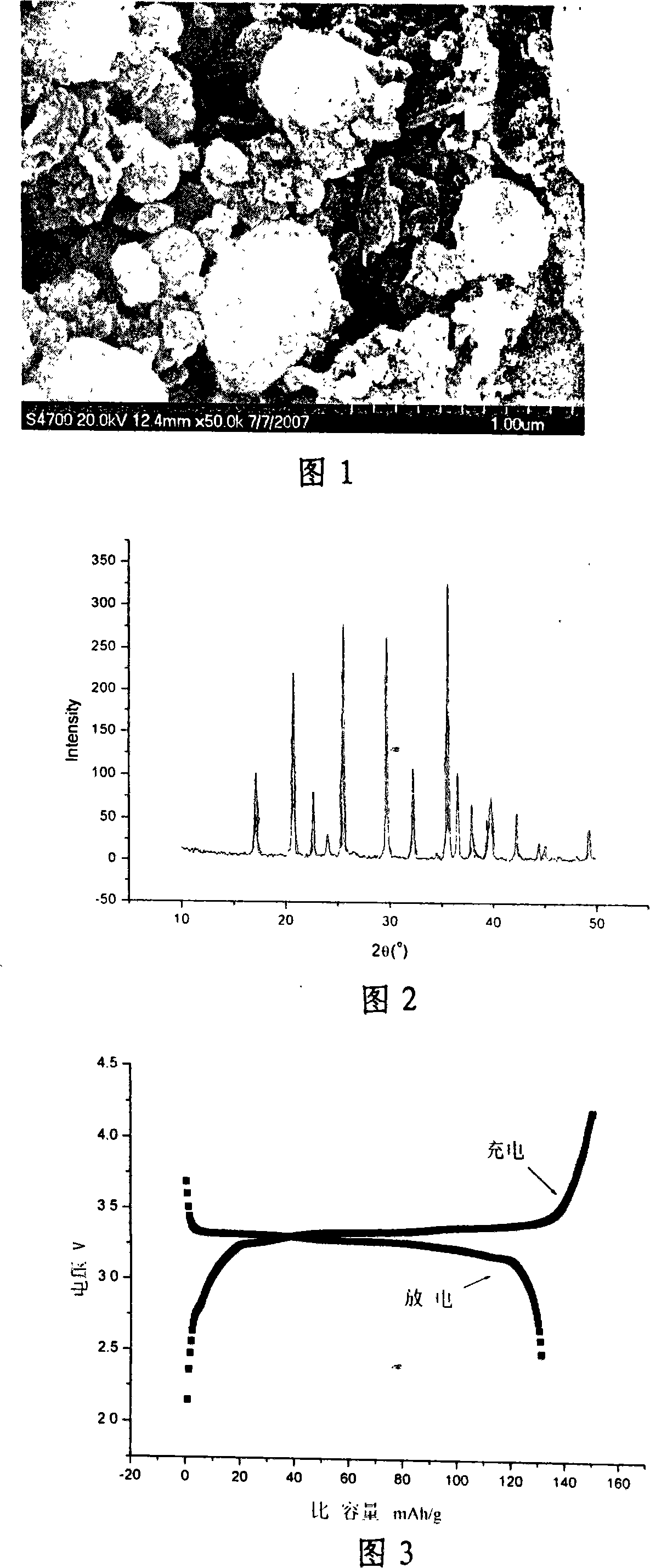

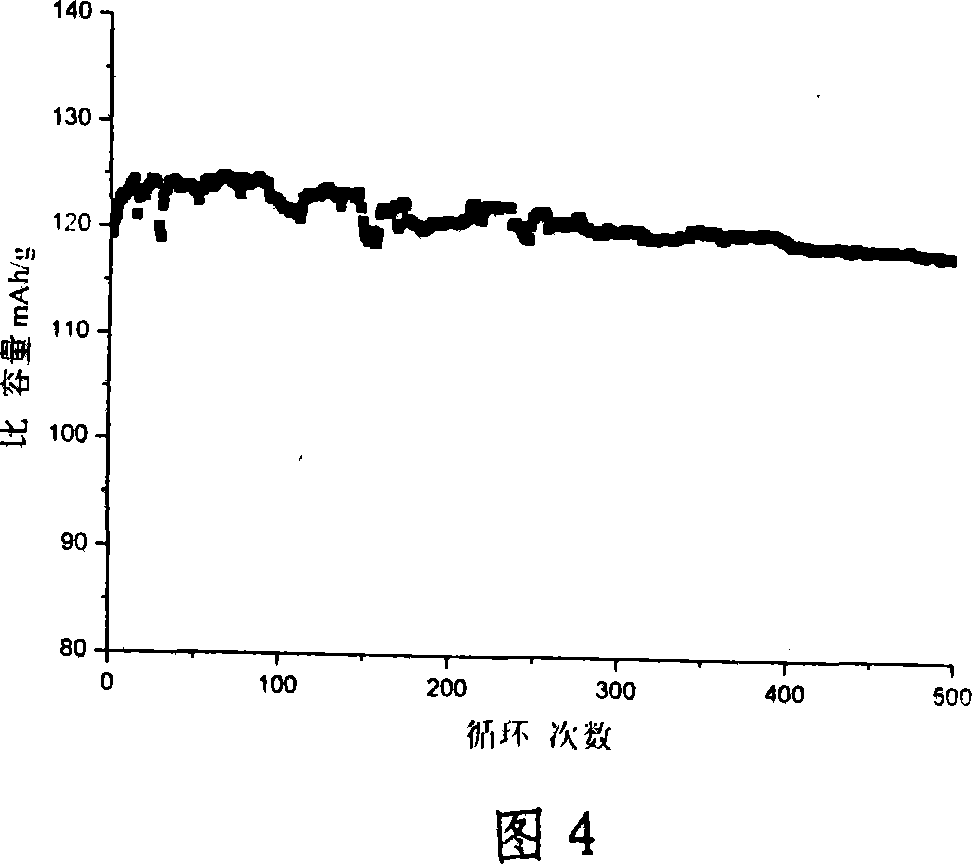

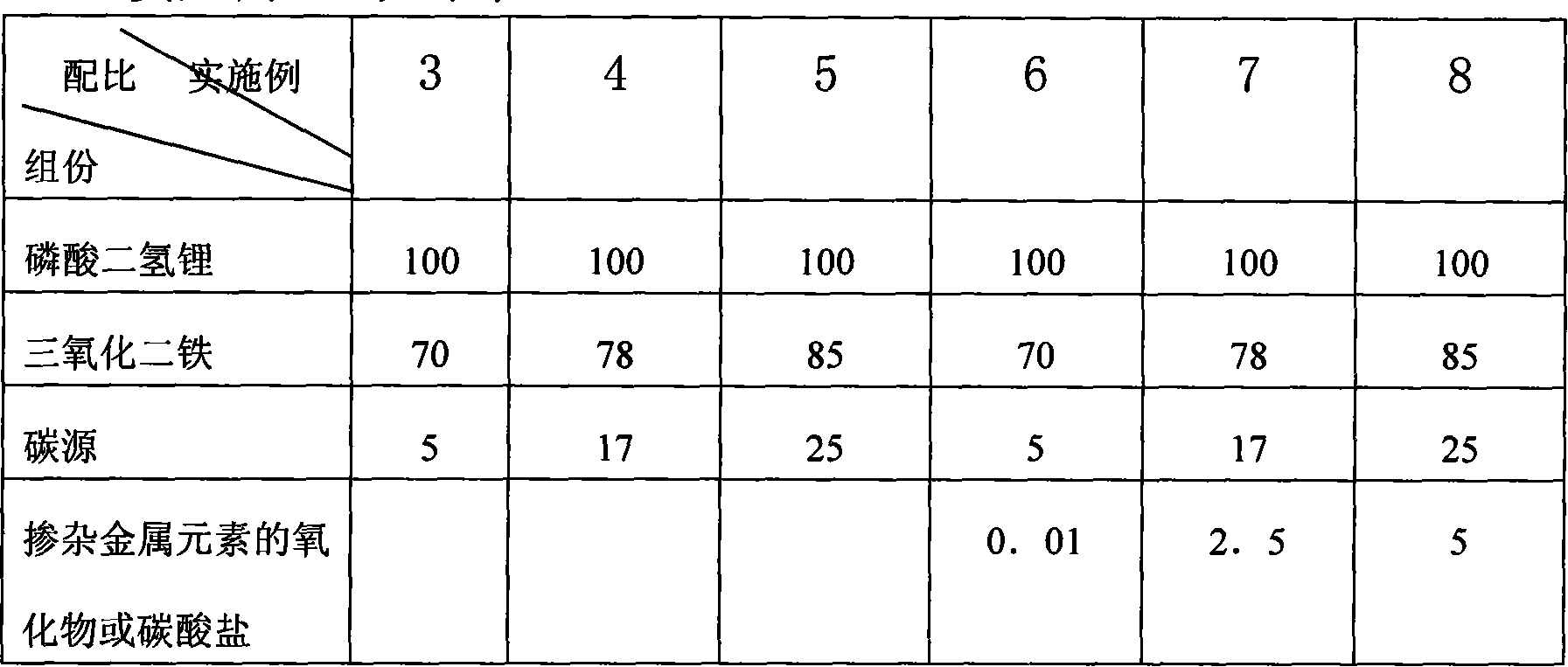

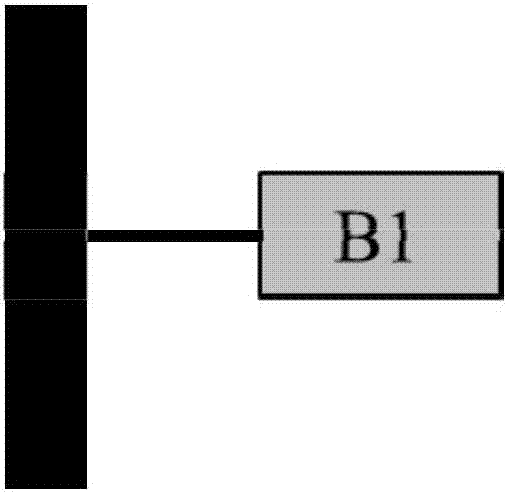

The present invention relates to a method preparing phosphate iron lithium with high compacted density and good cohesiveness. The technical points are as follows: firstly, ferric oxide, phosphate dihydrogen lithium, oxide or carbonate doping metal elements and carbon source are ball-milled evenly in an aqueous solution and are then sprayed and dried so that a spherical powder is obtained; the spherical powder is secondly mixed with carbon source; after ball-milling and in nitrogen atmosphere protection, the mixture is presintered for 4 hours to 48 hours in 300 DEG C to 400 DEG C; after breaking, the mixture is heat treated for 4 hours to 48 hours in a high temperature of 600 DEG C to 800 DEG C so the phosphate iron lithium with high compacted density and good cohesiveness is obtained. The present invention has the advantages that the phosphate iron lithium prepared by the present invention is good in cohesiveness when used as lithium ion battery anode, an anode plate is high in compacted density, softness and winding performance. The preparing method generates no harmful gas, costs little, is simple in process and especially suitable for large-scale industrial production.

Owner:天津科斯特汽车技术有限责任公司

Conductive adhesive for lithium ion batteries, preparation method thereof, electrode plate of lithium ion battery, preparation method thereof and lithium ion battery

ActiveCN107369835AGood electrical conductivityGood bonding performanceSecondary cellsNon-aqueous electrolyte accumulator electrodesPolyvinylidene fluorideSodium carboxymethylcellulose

The invention provides a conductive adhesive for lithium ion batteries. The conductive adhesive comprises graphene and a first adhesive grafted to the surface of the graphene, and the first adhesive comprises at least one of polyvinyl alcohol, sodium carboxymethylcellulose, polyethylene glycol, polylactic acid, polymethyl methacrylate, polystyrene, polyvinylidene fluoride, hexafluoropropylene polymer, styrene-butadiene rubber, sodium alga acid, starch, cyclodextrin and polysaccharide. The conductive adhesive for lithium ion batteries has good conductivity and adhesive property, and is of certain strength, so that the integral mechanical strength of the electrode plate can be strengthened; the conductive adhesive realizes that the adhesive is combined with a conductive agent, so that the content of active substances in the electrode plate can be increased, and the energy density of cells is further increased. The invention also provides a preparation method of the conductive adhesive, an electrode plate containing the conductive adhesive and the lithium ion battery.

Owner:HUAWEI TECH CO LTD

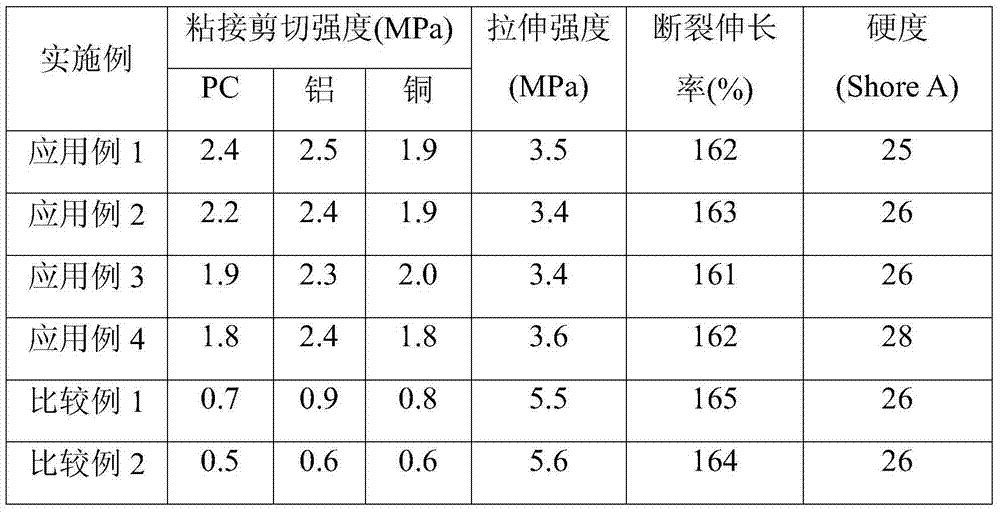

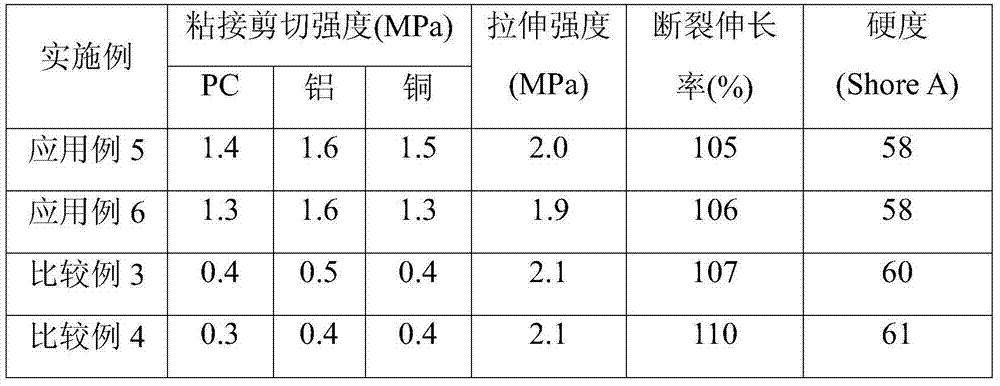

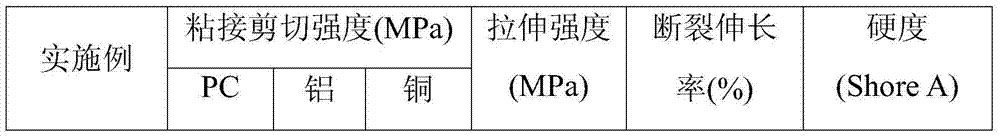

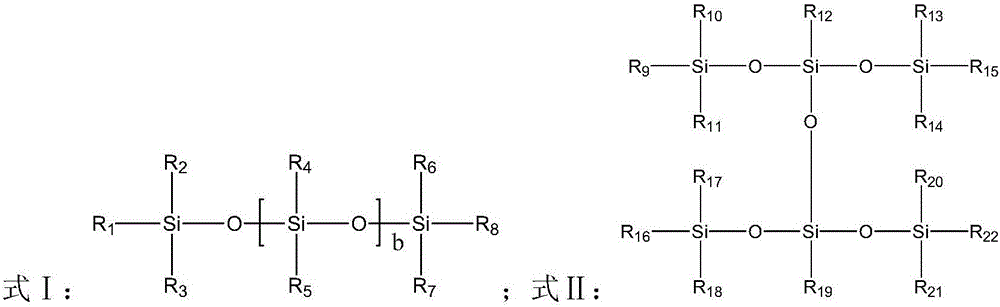

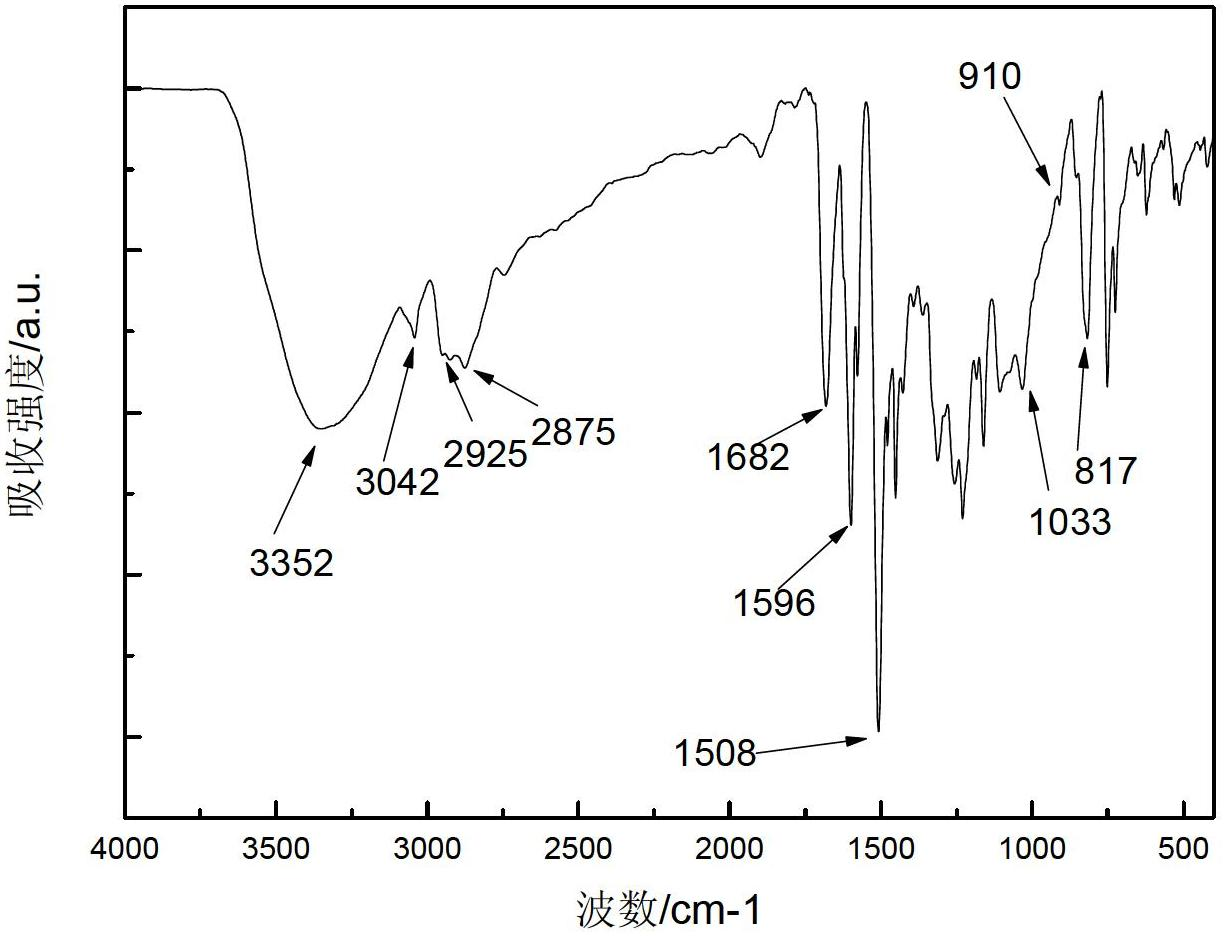

Addition type organic silicon rubber tackifier, preparation method and application thereof

ActiveCN104774333ARoom to improve designGood bonding performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolycarbonateChemistry

The invention discloses addition type organic silicon rubber tackifier capable of improving adhesion between addition type organic silicon rubber and base materials after the addition type organic silicon rubber is cured at moderate temperature, and a preparation method and application of the addition type organic silicon rubber tackifier. The tackifier is prepared through vinyl hydroxyl silicone oil, glycidyl ether alkoxy silane and titanate catalysts. The preparation method includes the following steps that the vinyl hydroxyl silicone oil and glycidyl ether alkoxy silane are mixed evenly at room temperature, added with phthalic ester in a stirring state and heated to 60-100 DEG C, and reacts for 1-6 hours, and the reaction mixture is obtained; the mixture is decompressed at 60-80 DEG C to remove low-boiling-point substances, keeps in a vacuum state, and is cooled to the room temperature, and the tackifier is obtained; the addition type organic silicon rubber tackifier is matched with auxiliaries to be applied to addition type silicon rubber. The tackifier is added into addition type organic silicon rubber so that the silicon rubber can have good adhesion with base materials especially polycarbonate after the silicon rubber is cured at moderate temperature.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

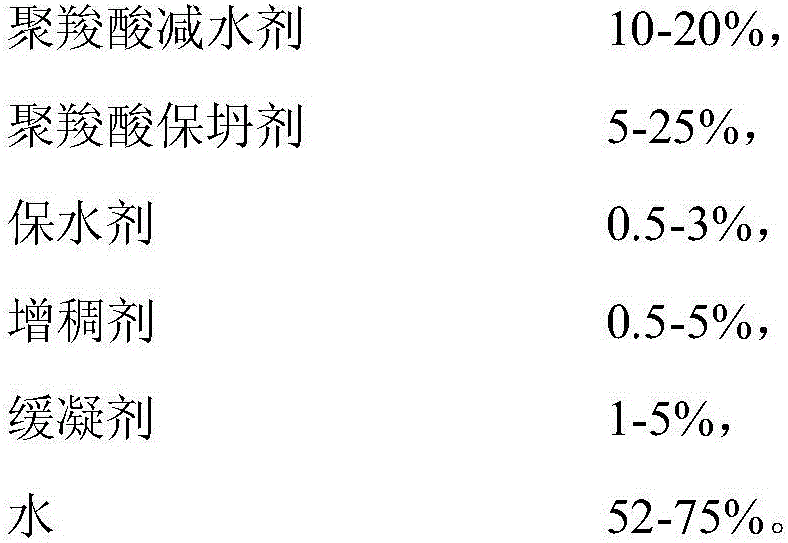

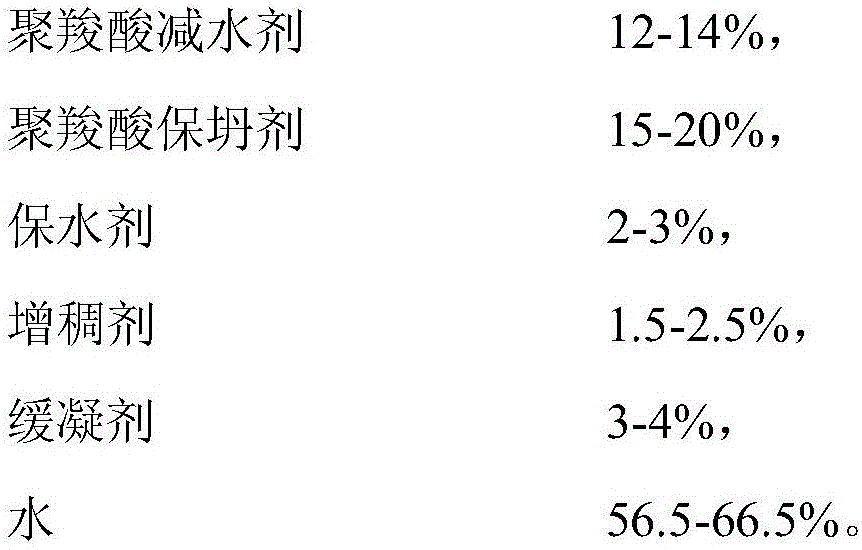

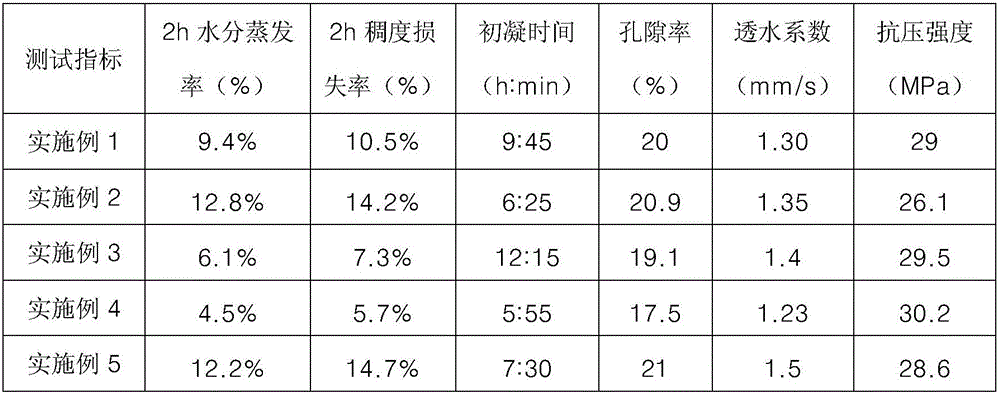

Pervious concrete special-purpose additive and use thereof

The invention discloses a pervious concrete special-purpose additive and a use thereof. The pervious concrete special-purpose additive comprises, by mass, 10-20% of a polycarboxylic acid water reducer, 5-25% of a polycarboxylic acid slump retaining agent, 0.5-3% of a water-retaining agent, 0.5-5% of a thickening agent, 1-5% of a delayed coagulant and 52-75% of water. A mass ratio of the additive to the gelling material in the pervious concrete is 1-2%. Ingredients of the pervious concrete special-purpose additive produce good synergism. The pervious concrete special-purpose additive guarantees water permeability, well keeps pervious concrete workability for 2h or more, improves strength after aging and realizes pervious concrete premixing production.

Owner:JIANGSU SOBUTE NEW MATERIALS

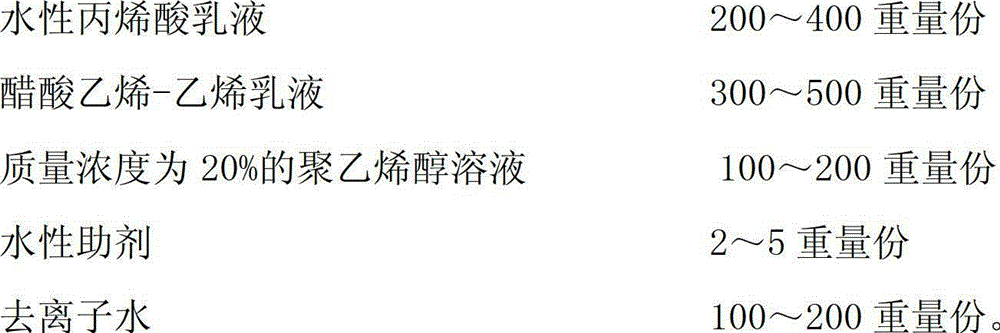

Water-based aluminium foil adhesive for cigarette packing and preparation method thereof

ActiveCN102977818AGood bonding performanceHigh peel strengthMonocarboxylic acid ester polymer adhesivesEster polymer adhesivesFunctional monomerAluminium foil

The invention discloses a water-based aluminium foil adhesive for cigarette packing and a preparation method thereof and belongs to the field of adhesive preparation. The adhesive is composed of water-based acrylic emulsion, vinyl acetate-ethylene copolymer emulsion, a polyvinyl alcohol solution, water-based additives and deionized water. The adhesive has the advantages that both the economy of the vinyl acetate-ethylene emulsion and the excellent adhesive property of the water-based acrylic emulsion are provided, so that the peel strength is high in and the risk that aluminium foil paper products are delaminated is avoided; meanwhile, the copolymerization is carried out by adopting soft monomer based acrylic monomers, so that the initial adhesive force is good; acrylic acid functional monomers are adopted, so that the emulsion stability is enhanced and the final peel strength of the emulsion is greatly increased; the water-based acrylic emulsion is introduced, so that the water resistance is obviously increased, the freezing resistance is better than that of general vinyl acetate-ethylene copolymer emulsion and the use cost is much lower than that of general water-based acrylic emulsion; and residual vinyl acetate monomers and formaldehyde are removed through vacuumizing, so that the requirements of water-based adhesives for the cigarette packing are completely satisfied.

Owner:NANTONG GAOMENG NEW MATERIAL

Isocyanate modified two-component silicon rubber adhesive and preparation method thereof

InactiveCN102010689AGood bonding performanceImprove body strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveMethyl silicone

The invention discloses an isocyanate modified two-component silicon rubber adhesive and a preparation method thereof. The adhesive comprises a component A and a component B which are prepared at the vacuum degree of more than -0.09MPa and the temperature of between 4 and 30 DEG C. A method for preparing the component A comprises the following steps of: (1) adding 100 weight parts of alpha, omega-dihydroxy polydimethylsiloxane, 0 to 500 weight parts of solid filler and 0 to 20 weight parts of pigment into a stirring kettle and fully stirring; (2) adding 0 to 5 weight parts of water and fully stirring; and (3) adding 0 to 50 weight parts of fumed silica in batches. A method for preparing the component B comprises the following steps of: (1) preparing an isocyanate modified silane coupling agent; (2) adding 10 to 50 weight parts of methyl silicone oil, 2 to 20 weight parts of cross-linking agent and 0 to 35 weight parts of solid filler which is dried and dehydrated at a high temperatureinto a reaction kettle and fully stirring; (3) adding 0 to 10 weight parts of silane coupling agent, 10 to 40 weight parts of isocyanate modified silane coupling agent and 0 to 3 weight parts of catalyst and fully stirring; and (4) adding 0 to 10 weight parts of fumed silica in batches and fully stirring.

Owner:TONSAN ADHESIVES INC

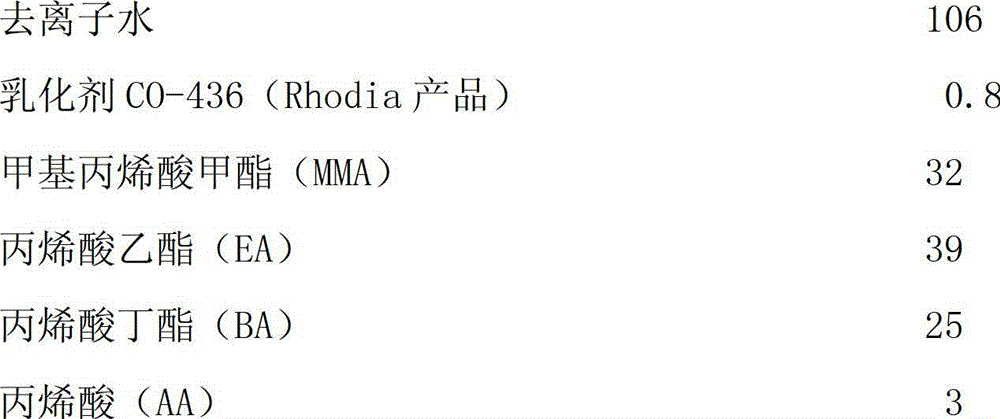

Molded metal-organic framework material and molding method thereof

InactiveCN107029670AGood bonding performanceHigh strengthOther chemical processesDispersed particle separationMetal-organic frameworkOrganic solvent

The invention discloses a molded metal-organic framework material and a molding method thereof. The molding method comprises the following steps: preparing a binder solution with a proper concentration to allow the binder solution to minimally block holes in a metal-organic framework material while maintaining good bonding performance; then uniformly mixing the binder solution with a suspension of the metal-organic framework material; placing a substrate membrane in the mixed solution obtained in the previous step to allow the surface of the substrate membrane to be uniformly adhered by a layer of the metal-organic framework material; and then soaking the substrate membrane uniformly adhered by the metal-organic framework material in an organic solvent to allow water molecules in the pore channels of the metal-organic framework material to be displaced out so as to reinforce the strength of the metal-organic framework material adhered on a substrate, wherein the molded metal-organic framework material with a large specific surface area and high mechanical strength is eventually obtained. Thus, the molding method provided by the invention overcomes the technical problems of complex molding process, a long molding period, severe conditions, high cost, severe loss of specific surface areas and the like in the prior art.

Owner:HUAZHONG UNIV OF SCI & TECH

Safe infusion apparatus and preparation method thereof

ActiveCN101537216AGood compatibilityGood bonding performanceInfusion devicesAssembly machinesDropping funnelPlasticizer

The invention provides a safe infusion apparatus and a preparation method thereof. The infusion apparatus comprises a dropping funnel and a perfusion tube; wherein, both the dropping funnel and the perfusion tube are made of polyurethane / polyvinyl chloride double-layer composite material; the inner surface layer of the dropping funnel made of the polyurethane / polyvinyl chloride double-layer composite material is a polyurethane layer, and the outer surface layer thereof is a polyvinyl chloride layer. The polyurethane / polyvinyl chloride double-layer composite material is prepared by a co-extrusion blow molding method, and the perfusion tube made of the polyurethane / polyvinyl chloride double-layer composite material is prepared by a co-extrusion method. The safe infusion apparatus can avoid the defect that the polyvinyl chloride perfusion tube absorbs micromolecules such as medicine, plasticizer and the like to pollute liquid medicine, and has the advantages of excellent mechanical property, easy bonding and assembling as well as low raw material cost.

Owner:SHANDONG WEIGAO GROUP MEDICAL POLYMER +1

Double-sided adhesive tape

InactiveCN102477264AGood bonding performanceImprove adhesionFilm/foil adhesivesEngineeringMechanical engineering

The invention provides a double-sided adhesive tape. The adhesive tape is characterized in that: the adhesive tape comprises a substrate layer, a first adhesion element layer and a second adhesion element layer. The substrate layer can be stretched and can provide the adhesive tape with enough stress forces, such that continuous integrity of the double-sided adhesive tape can be maintained when the adhesive tape is stretched and stripped. The first adhesion element layer has certain stretchability and adhesiveness, and is positioned on one side of the substrate layer for providing adhesive forces between the adhesive tape and a first material requiring adhesion. The second adhesion element layer has certain stretchability and adhesiveness, and is positioned on the other side of the substrate layer for providing adhesive forces between the adhesive tape and a second material requiring adhesion.

Owner:3M INNOVATIVE PROPERTIES CO

Protective coloring material used for concrete surfaces and preparation method thereof

The present invention relates to a protective coloring material used for concrete surfaces. The coloring material is composed of component A and component B, wherein the mass ratio of the component A and the component B is 1:2 to 1:4. The component A is composed of the following ingredients, by mass: 10-20 parts of water, 0.1-0.3 parts of cellulose, 4-8 parts of elastic latex, 5-10 parts of flexible latex, 0.3-0.7 parts of polyvinyl alcohol, 0.1-0.3 parts of anti-crack fiber 1, 0.3-0.8 parts of anti-crack fiber 2, 0.1-0.5 parts of a dispersant, and 0.1-0.2 parts of a preservative; and the component B is composed of the following ingredients, by mass:13-25cement parts of cement, 10-15 parts of coal ash, 20-25 parts of heavy calcium carbonate powder, 15-30 parts of sand, and0-0.2 parts of iron oxide black powder. The protective coloring material used for concrete surfaces of the present invention can has the effect of fair-faced concrete, and has super strong adhesion performance and weather resistance, so the protective coloring material can provided lasting protection to the concrete.

Owner:上海天补材料科技有限公司

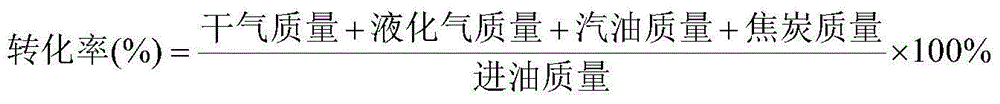

Catalytic cracking catalyst, preparation method thereof and application

ActiveCN105148985AGood bonding performanceLow coke selectivityCatalytic crackingMolecular sieve catalystsChemistryMolecular sieve

The invention discloses a catalytic cracking catalyst, a preparation method thereof and application. The catalytic cracking catalyst comprises cracking active components, clay and a binder, wherein the cracking active components include, by weight, a first Y-type molecular sieve 35-70%, a second Y-type molecular sieve 20-60% and a third Y-type molecular sieve 2-20%, and the binder is a modified alumina sol containing Cl and Si. The content of Al is 8-13 wt%, the content of Cl is 4-9 wt%, and the content of Si is 0.1-1 wt% based on the total weight of the modified alumina sol. The weight ratio of Al to Cl is 1.2-2.2:1, and the pH of the modified alumina sol is in a range of 2.2 to 5.2. The catalytic cracking catalyst has low coke selectivity and high catalytic cracking activity in heavy oil catalytic cracking process, and can obtain high yield of diesel oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

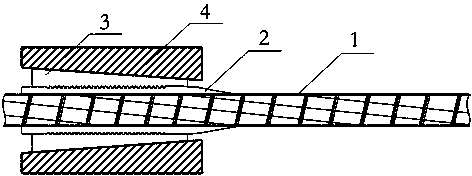

Anchoring method applicable to large-tonnage FRP inhaul cable

ActiveCN103669208AGood bonding performanceIncrease stress transferBridge structural detailsBuilding reinforcementsShearing deformationEngineering

The invention discloses an anchoring method applicable to a large-tonnage (larger than 50 tones) FRP inhaul cable. The FRP inhaul cable is anchored with a clamping piece type anchorage device, a protection transition layer with the length no smaller than the length of an anchoring area of the clamping piece type anchorage device is formed at the anchoring end of the FRP inhaul cable, the protection transition layer and the FRP inhaul cable are integrated, and the clamping piece type anchorage device is anchored to the protection transition layer. After the FRP inhaul cable and the protecting layer are pressed into a whole, while the shearing strength of the FRP inhaul cable and a protecting layer interface is increased, the phenomenon that the FRP inhaul cable weak in transverse strength makes direct contact with load transmitting mediums large in rigidity in the anchoring area can be avoided, a stressed buffering layer is formed, and the FRP inhaul cable can be indirectly protected. The anchoring method used for anchoring the FRP inhaul cable has the advantages of facilitating construction and being high in anchoring efficiency and the like, long-term performance of an anchoring system can be guaranteed, the method can also be used for tensile tests on the FRP inhaul cable, samples can be prepared easily and conveniently, and compared with an adhesive type anchoring method, test errors caused by overlarge shearing deformation of resin can be avoided.

Owner:SOUTHEAST UNIV +1

Porous thermal insulation filling material made of paper mill sludge and preparation method thereof

The invention discloses a porous thermal insulation filling material made of paper mill sludge and a preparation method thereof. Raw material paper mill sludge, cement, fly ash and gypsum are injected into a stirrer in proportion to be stirred evenly; a foaming agent is added into the stirrer, uniform mixing is performed to obtain mixed mortar; and the mixed mortar is contained in a storage chamber and undergoes rest curing foaming to obtain the semi-finished porous thermal insulation filling material; the semi-finished product is injected into a forming machine to be formed and granulated; the formed porous thermal insulation filling material undergoes natural curing, and a finished product is obtained. A mode of manufacturing the porous thermal insulation filling material made of the paper mill sludge is provided, the problem that existing paper mill sludge is stacked messily and pollutes the environment can be solved, and harmlessness, resource reutilization, economy and efficiency of the paper mill sludge can be guaranteed.

Owner:山东福航新能源环保股份有限公司

Solar cell light conversion packaging adhesive film and preparation method thereof

InactiveCN104388002AHigh light transmittanceGood bonding performanceNon-macromolecular adhesive additivesFilm/foil adhesivesTransmittanceAntioxidant

The invention discloses a solar cell light conversion packaging adhesive film and a preparation method thereof. The solar cell light conversion packaging adhesive film comprises the following components in parts by mass: 15-30 parts of epoxy resin, 1-3 parts of phthalic acid, 1-3 parts of zinc oxide, 1.8-6.6 parts of methacrylic acid, 2-5 parts of epoxidized fatty acid octyl ester, 3-6 parts of dioctyl phthalate, 5-15 parts of polyvinyl chloride, 1-4 parts of butyl epoxystearate, 1-3 parts of heat stabilizer, 1-5 parts of antioxidant, 1-3 parts of ultraviolet absorbent, 3-8 parts of inorganic filler and 0.5-1.5 parts of glass fiber. The packaging adhesive film is high in light transmittance as well as good in bonding property and ageing resistance.

Owner:WUXI SUNOCEAN

Solvent-free unfoamed polyurethane structured adhesive and preparation method thereof

InactiveCN106433546AEasy to operateGood bonding performanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesSolventPolyphenyl isocyanate

The invention relates to a solvent-free unfoamed polyurethane structured adhesive which contains a component A and a component B, wherein the mass ratio of the component A to the component B is 4:1; the component A contains the following raw materials in parts by mass: 30-45 parts of polyol, 50-47 parts of packing, 8-6 parts of a water removing agent, 4-2 parts of phthalic acid bi(2-ethylhexyl) ester, 3-0 parts of xylene formaldehyde resin, 4-0 parts of lyophobic gaseous silicon and 1-0 parts of an amino curing agent; and the component B contains the following raw material in part by mass: 100 parts of polymethylene polyphenyl isocyanate. The solvent-free unfoamed polyurethane structured adhesive provided by the invention is small in moisture influence, and is barely affected by ambient humidity, a foaming phenomenon in the gluing curing process can be avoided, and later reliability can be greatly improved.

Owner:YANTAI DARBOND TECH

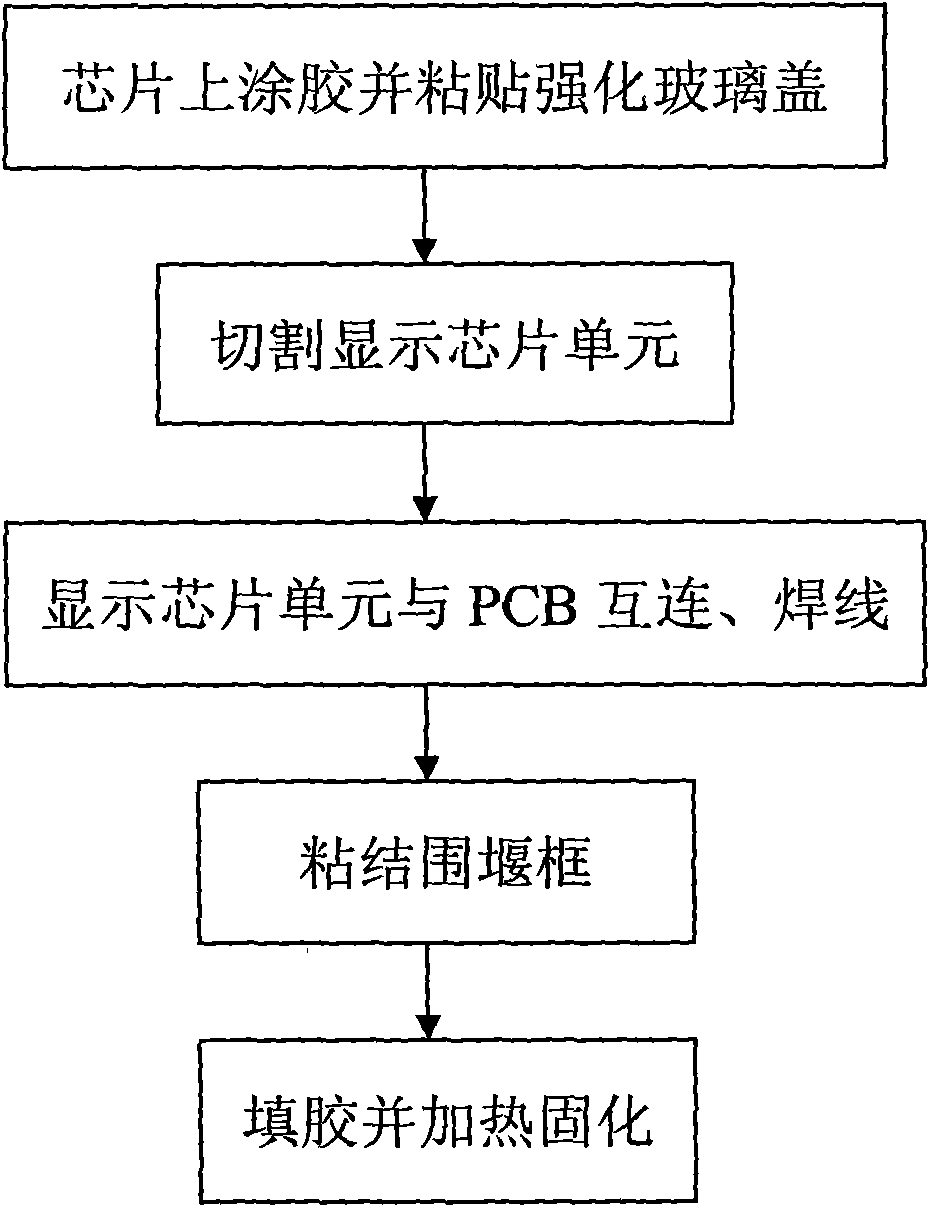

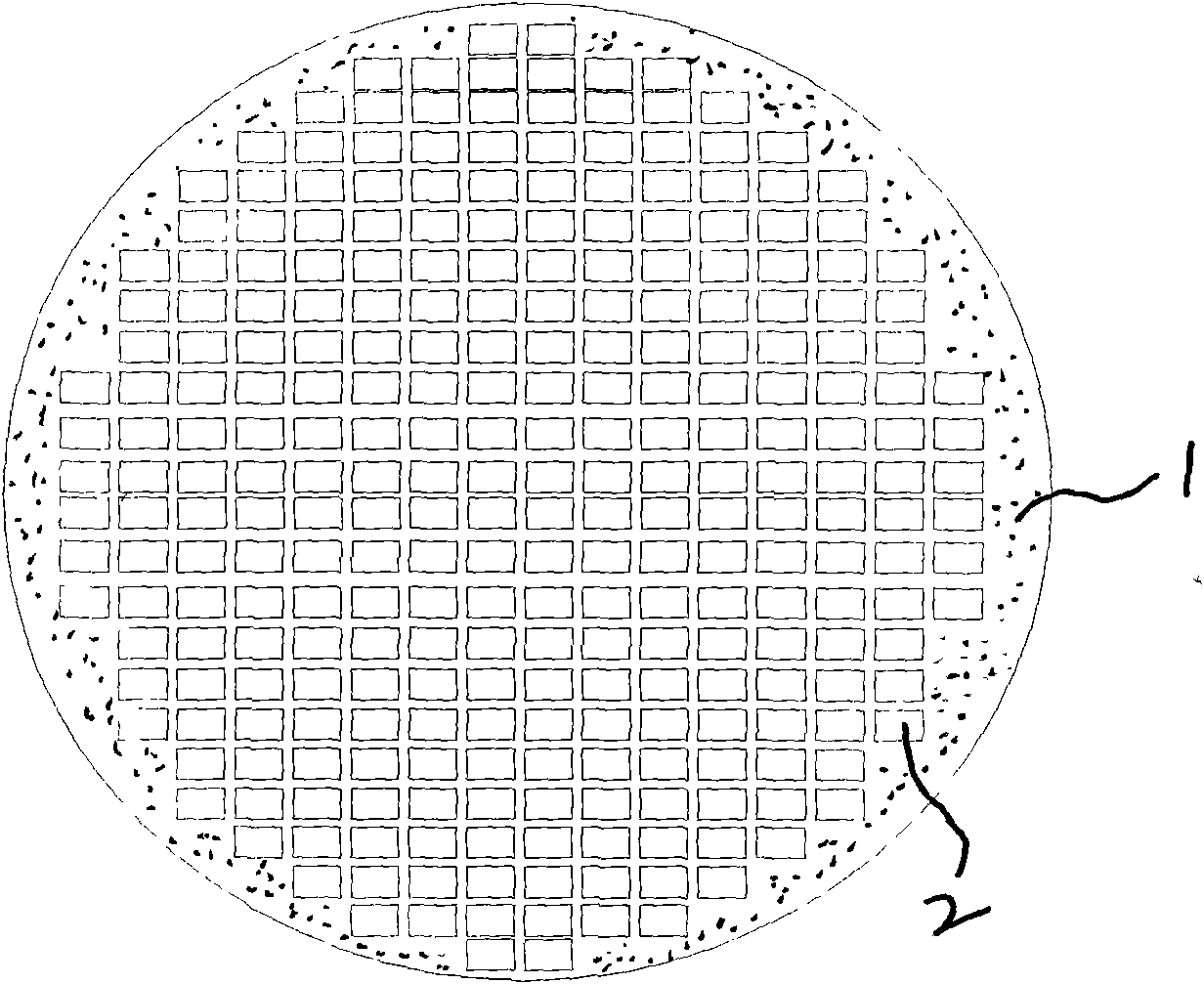

Quantity production packaging technique of minitype OLED display

ActiveCN101609872AGood bonding performanceGood wire strengthSolid-state devicesSemiconductor/solid-state device manufacturingSilicon chipOrganic electroluminescence

The invention relates to a packaging technique of an organic electro luminescent display, which is a quantity production packaging technique of a minitype OLED luminescent display. The invention specifically comprises the following techniques: step 1, vibrating thermocementing is carried out on a display chip of a silicon chip, and a square toughened glass upper cover is covered; step 2, the display chip covered by the toughened glass is cut into display chip units which are then cleaned; step 3, the display chip units are interconnected with a PCB and wires are welded; step 4, a cofferdam frame is bonded at the periphery of the welded wire; and step 5, the cofferdam frame is added with glue and then heated and cured. The packaging technique can improve the packaging strength of the display, has good thermal shock resistance, effectively reduces packaging cost and improves the packaging efficiency.

Owner:YUNNAN NORTH OLIGHTEK OPTO ELECTRONICS TECH

High-elasticity-recovery-rate silicone elastic sealant for hollow glass and preparation method of silicone elastic sealant

ActiveCN105950102AImprove strength and elasticityGood bonding performanceNon-macromolecular adhesive additivesOther chemical processesDibutyl tin dilaurateSilane coupling

The invention discloses a high-elasticity-recovery-rate silicone elastic sealant for hollow glass and a preparation method of the silicone elastic sealant. The silicone elastic sealant is mainly used for secondary sealing of the hollow glass. The silicone elastic sealant is characterized by containing a component A and a component B, wherein the mass ratio of A to B is (15-18):1. The preparation process comprises the following steps that alpha,omega-dyhydroxyl polydimethylsiloxane, inorganic filler and dimethicone are stirred to be uniform in a high-speed planetary stirring mechanism, and the component A is obtained; the component B is prepared from dimethicone, inorganic filler, an organosilicone cross-linking agent, a silane coupling agent, dibutyltin dilaurate and a titanium complex. In the using process, the component A and the component B are mixed to be uniform at room temperature according to the mass ratio. The silicone elastic sealant has good strength, elasticity and adhesion and excellent aging resistance, the elasticity recovery rate of the silicone elastic sealant is as high as 96%, and the service life of the hollow glass sealant can be greatly prolonged.

Owner:GUANGZHOU JOINTAS CHEM

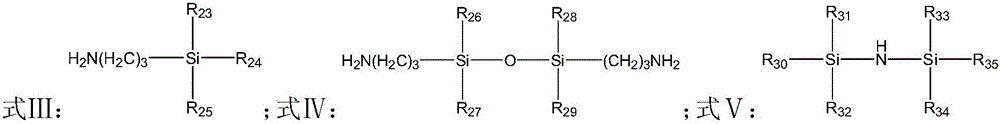

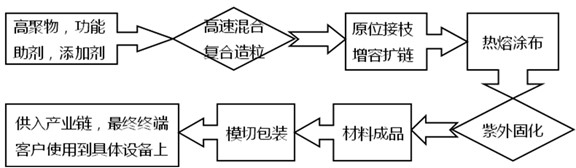

Acrylate hot melt adhesive composition and preparation method of hot melt adhesive by UV (ultraviolet) crosslinking

ActiveCN102660205AGood bonding performanceImprove heat resistanceFilm/foil adhesivesEster polymer adhesivesAntioxidantGrafting

The invention belongs to the technical field of a hot melt adhesive, and particularly relates to an acrylate hot melt adhesive composition and a preparation method of a hot melt adhesive by UV (ultraviolet) crosslinking. The composition of the acrylate hot melt adhesives comprises the following components based on weight content ratio: 9-90% of acrylate copolymer, 9-90% of copolyester and 0.1-1% of antioxidant. The preparation method of the hot melt adhesive by UV crosslinking comprises the following specific steps of: polymerizing at least one of acrylate monomer bodies; and adding the composition into a double-screw extruder to carry out high-speed mixing, in-situ grafting, compatibilization and chain extension, coating a base material by means of hot melting at the temperature of 130-160 DEG C, carrying out ultraviolet light crosslinking, and packing in a rolling way. The preparation method has the benefit effects that part of hot melt adhesive is crosslinked by means of UV crosslinking, so that the cohesive strength of the hot melt adhesive can be improved, and the glue-overflowing performance can be resistant, and the joint strength can be improved. Meanwhile, the hot melt adhesive provided by the invention is further added with copolyester with equivalent quantity besides the main body resin, and the higher wettability, cohesive strength and heat resistance, and good weather fastness can be obtained due to the introduction of the copolyester.

Owner:中新联科环境科技(安徽)有限公司

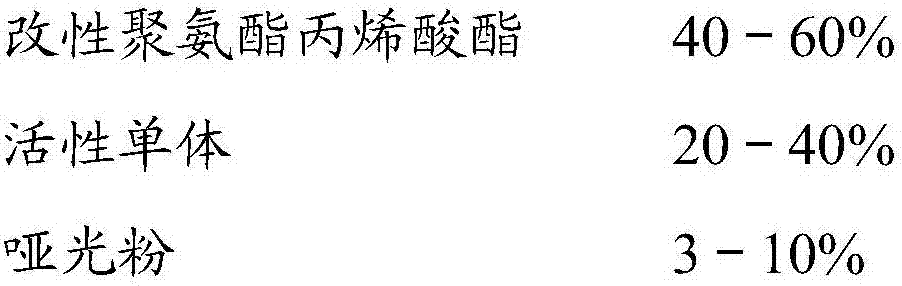

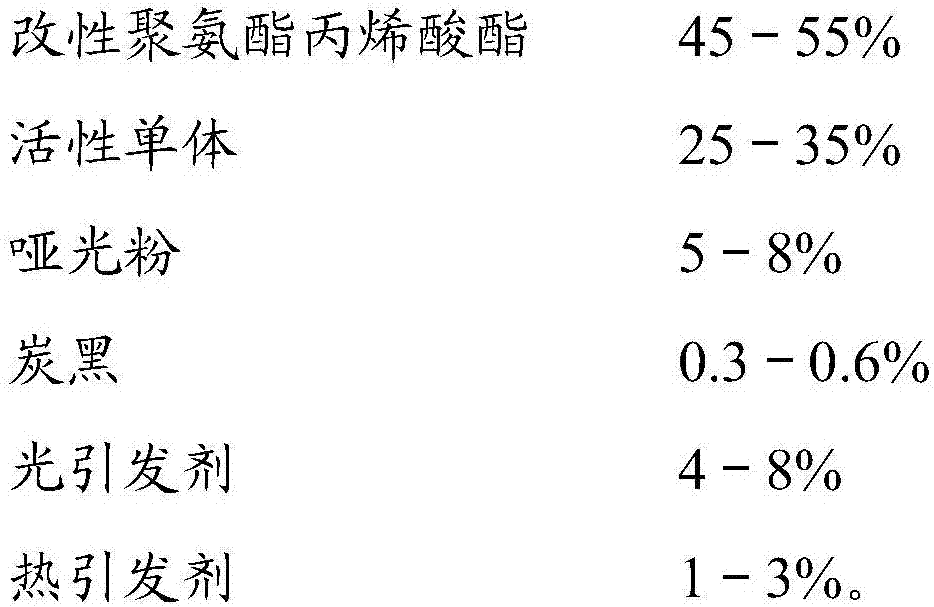

Ultraviolet-curing black adhesive and preparation method of same

ActiveCN107163901AGood bonding performanceImproved chemical resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPhotoinitiatorCarbon black

The invention relates to an ultraviolet-curing black adhesive and a preparation method of same. The UV-curing black adhesive is mainly prepared from the following raw materials: modified polyurethane acrylate, an active monomer, matt powder, carbon black, a photoinitiator and a thermo-initiator. The active monomer includes at least two selected from isobornyl acrylate, tetrahydrofuran acrylate, cyclic trimethylolpropane methylal acrylate, tricyclodecane dimethanol diacrylate, tri(2-hydroethyl)isocyanurate triacrylate. The modified polyurethane acrylate is mainly prepared from a mixture of polyether glycol and mercaptan, diisocyanate, hydroxyl-functionalized acrylate, a catalyst and a polymerization inhibitor. The diisocyanate is a composition composed of isophorone diisocyanate and toluene diisocyanate. The UV-curing black adhesive can satisfy the adhesion force demand of curing a thick coating, and is free of any undesirable phenomenon, such as oil dirt, for more than 300 h in a double-85 test.

Owner:广州日高新材料科技有限公司

Heat-insulating material

The invention discloses a heat-insulating material which comprises the following raw materials in parts by mass: 10-25 parts of volcanic ash and 75-90 parts of environment-friendly adhesive; and the environment-friendly adhesive is prepared by mixing 100 parts of water and 6-10 parts of polyvinyl alcohol. The heat conductivity coefficient of the heat-insulating material is only 0.036; the heat-insulating material has the advantages of favorable heat-insulating property, high acid / alkali corrosion resistance and high weather resistance; the volcanic ash raw material has abundant sources, so the cost is lower; and therefore the heat-insulating material disclosed by the invention can substitute the traditional heat-insulating material, and has unique advantages in the application field of architectural coating for industrial and mining enterprises.

Owner:珠海市联达环保科技有限公司

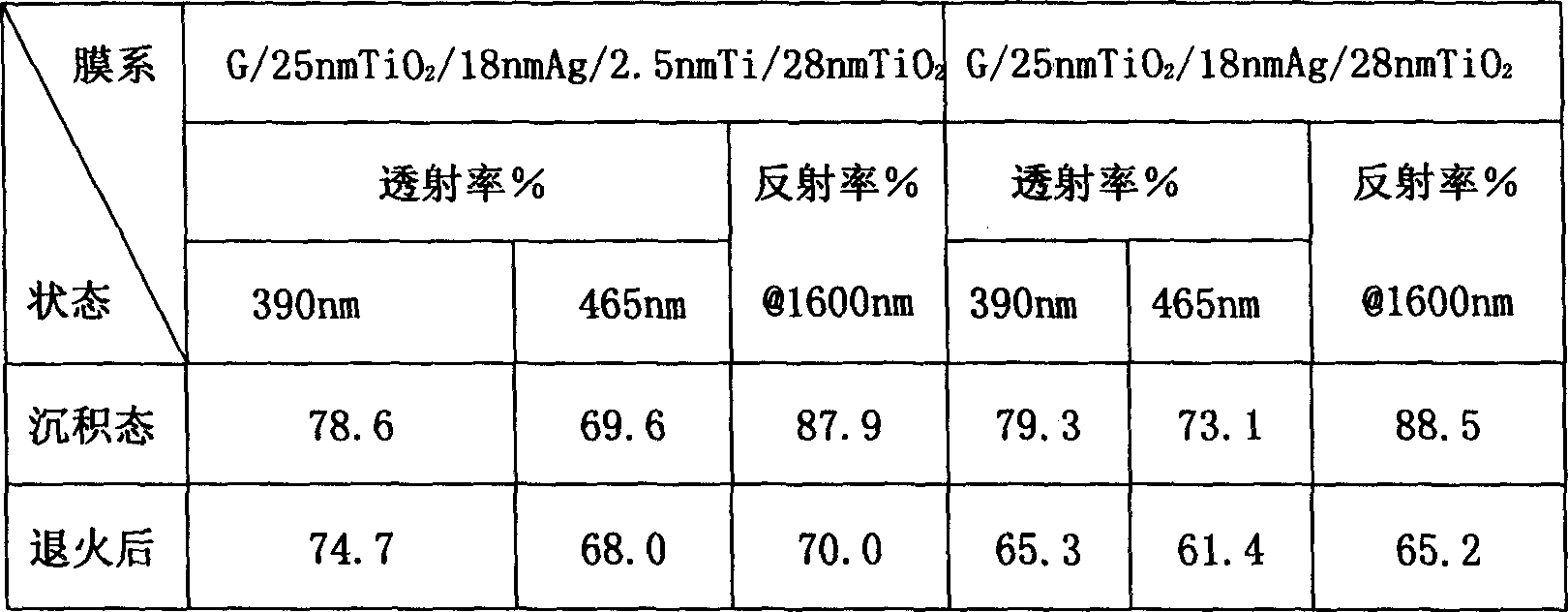

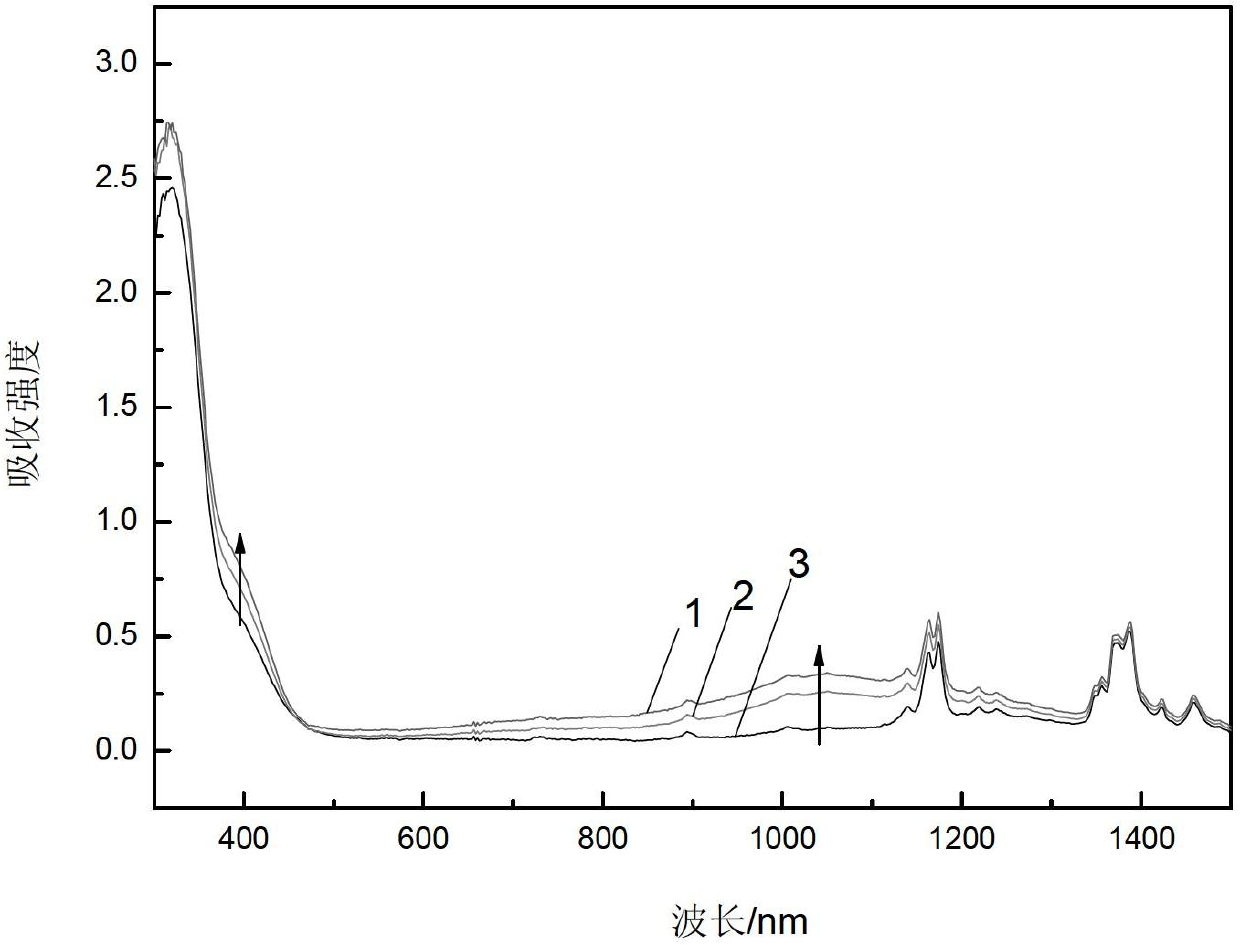

Method for improving Ag base composite transparent conductive film stability

InactiveCN1648693AGood optical performanceLittle effect on optical performanceOptical elementsDielectricTransparent conducting film

The present invention relates to method of raising stability of composite transparent conductive Ag-base film and belongs to the field of film material and film optics. In the sandwiched multilayer TiO2 / Ag / TiO2 film structure, one additional Ti layer of 2-3 nm thickness is coated between the metal Ag layer and the base dielectric TiO2 layer, and the Ti layer is used as the optimizing layer between the metal Ag layer and the base dielectric TiO2 layer and can raise the heat stability of the multilayer film structure while producing few influence on the optoelectronic performance of the multilayer film structure.

Owner:SHANGHAI JIAO TONG UNIV

Solvent-free polyurethane waterproof coating and preparation method thereof

InactiveCN107033769AGood bonding performanceStrong stabilityPolyurea/polyurethane coatingsSolventMethylene diphenyl diisocyanate

The invention discloses a solvent-free polyurethane waterproof coating and a preparation method thereof. The coating is prepared from the following raw materials in parts by weight: 30-50 parts of polyether polyol, 2-15 parts of a non-ionic emulsifier, 20-30 parts of methylene diphenyl diisocyanate, 4-12 parts of talcum powder, 10-20 parts of a liquid filling, 3-9 parts of acetyl tributyl citrate, 2-8 parts of a catalyst, 1-5 parts of pigments and fillers, 2-7 parts of a dispersing agent and 4-10 parts of a curing agent. The coating has a waterproofing effect; and by adding polyether into the raw materials, the viscosity index of the coating is increased, and the stability of the coating is strong.

Owner:温州月煌科技有限公司

Environment-friendly adhesion agent for coated abrasive tool product

ActiveCN103602296AGood bonding performanceGood water resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesActive agentAdhesive cement

The invention discloses an environment-friendly adhesion agent for a coated abrasive tool product. The environment-friendly adhesion agent for the coated abrasive tool product is obtained by adding a waterborne PUR dispersion into a substrate adhesion agent for mixing and then adding into a slurry tank for drying with the drying temperature of 65-75 DEG C; the substrate adhesion agent comprises the components by the weight percentage: 60-80% of waterborne polymer resin, 26-50% of a filler, 1.5-3% of a surface active agent, 6-8% of a pigment, and 11-20% of a diluent, wherein the sum of the content of the above components is 100%. The designed environment-friendly adhesion agent for the coated abrasive tool product can allows a paper base to have good adhesive performance with an abrasive material, and has relatively good water resistance, napping adhesive performance and grinding performance.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

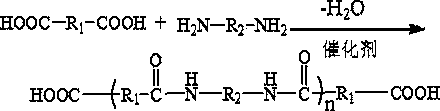

Primer for bonding silicon rubber to polyamide material and preparation method of primer

ActiveCN104559765AImprove adhesionGood bonding performancePolyamide coatingsPolyamideSilane coupling

The invention provides a primer for bonding silicon rubber to a polyamide material. The primer is prepared from 100 parts by weight of solvent, 0.05-5 parts by weight of polyamide oligomer, 0.05-5 parts by weight of silane coupling agent, 1-10 parts by weight of normal silicate ester, 1-10 parts by weight of high hydrogen-containing siloxane and 1-10 parts by weight of titanate; the structural formula of the polyamide oligomer is as shown in the specification, wherein R1 represents one or more of C0-C16 alkyls and -C6H4- benzene ring groups; R2 represents one or more of C0-C16 alkyls and -C6H4- benzene ring groups; and n is integral multiple of 1-20. The invention also provides a preparation method of the primer. The primer is used for bonding the addition-type silicon rubber and the PA material, and a good bonding effect can be achieved.

Owner:BYD CO LTD

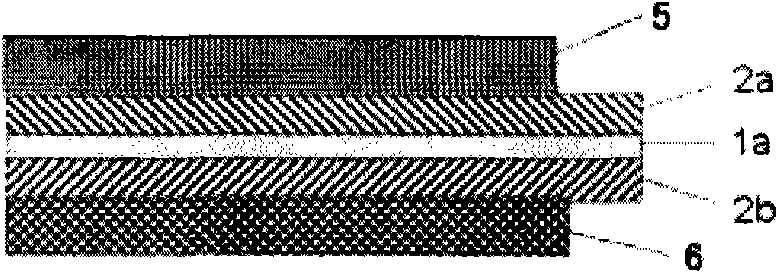

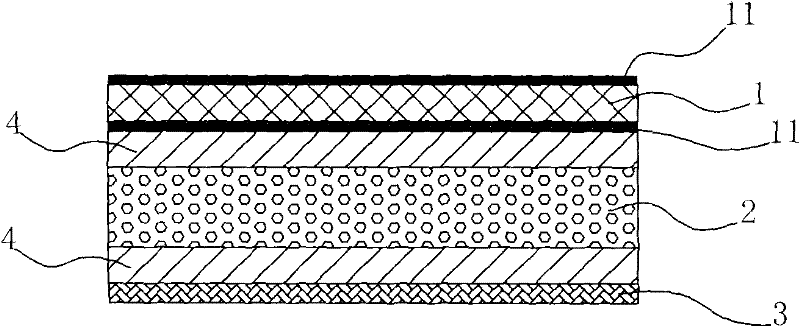

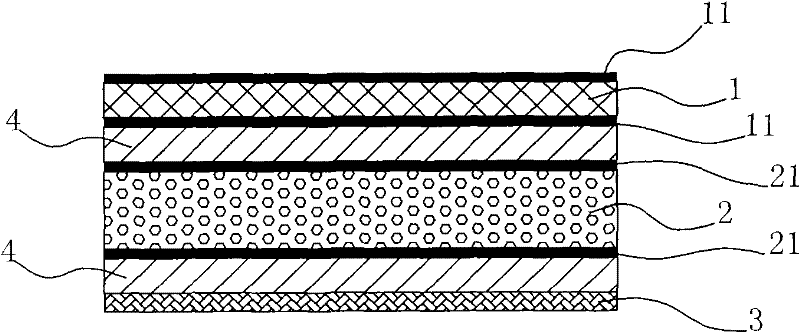

High-cohesiveness back film of solar cell and processing technology thereof

ActiveCN102529259AEasy to produceGood bonding performanceSynthetic resin layered productsPhotovoltaic energy generationPolyolefinAdhesive

The invention relates to a high-cohesiveness back film of a solar cell, which is characterized by comprising a fluororesin polymer layer, a base layer and a polyolefin bonding layer, wherein a high-polymer adhesive layer is arranged between the fluororesin polymer layer and the base layer, the high-polymer adhesive layer is arranged between the base layer and the polyolefin bonding layer, and fluorosilicone type formed film layers are arranged on the two sides of the fluororesin polymer layer. The polyolefin bonding layer is compounded onto the back film disclosed by the invention, and the two are made into an integrated structure so as to be conductive to bonding with other parts and enable the production of the solar cell to be simpler and more convenient.

Owner:JOLYWOOD SUZHOU SUNWATT

Degradable mulching product and its production process

InactiveCN101020766AGood bonding performanceGood film-forming performancePlant protective coveringsFertilizerNutrient

The degradable mulching product is prepared with 5000PPM activating ClO2 10-20 wt%, superfine ore powder 20-30 wt%, starch material 10-20 wt%, and honey locust gum powder or honey locust gum powder mixture 40-50 wt%. The degradable mulching can maintain temperature water and fertilizer of soil, raise plant seedling growth speed, etc. What is more important is that after the crop is harvested, the degradable mulching may decompose fast to kill bacteria and pests in soil and provide plant with nutrients without polluting soil and environment.

Owner:祝明福

Vegetable source pesticide suspension

InactiveCN1911048AHigh suspension rateGood bonding performanceBiocideAnimal repellantsPesticideSodium silicate

A suspension of vegetative insecticide for preventing and controlling tens agricultural pests is prepared from 11 raw materials including sodium modified attapulgite, tabacco leftover, red hot pepper, stemona root, garlic cloves, sodium silicate, sodium laury sulfate, etc through proportional mixing, stirring, grinding and packing.

Owner:蒋文兰

Cement-based sound insulation leveling adhesive material for overall sound insulation floor and preparation method thereof

The invention discloses a cement-based sound insulation leveling adhesive material for an overall sound insulation floor. The adhesive material is formed by dry mixing of the following raw materials by mass: 55%-70% of cement, 20%-30% of a vibration reduction and sound insulation component, 1%-5% of a sound absorption and insulation component, 0.3%-0.7% of a stress dispersion component, 5%-13% of a reinforcement component, 0.3%-0.9% of a tackifying assistant, 0.1%-0.5% of a water retention assistant, and 0.1%-0.2% of an anti-cracking assistant. The invention also relates to a preparation method of the cement-based sound insulation leveling adhesive material. The cement-based sound insulation leveling adhesive material provided by the invention has good bonding properties and deformation resistant ability, is used for making a sound insulation leveling layer of the overall sound insulation floor, can realize direct laying of a surface layer thereon according to the ordinary decoration practice, and can form good cementation both with the floor and the surface layer material, thus reaching the overall sound insulation effect.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD +1

Thermoplastic polyurethane composition with low viscosity and high adhesive strength and preparation method thereof

InactiveCN104311773AHigh bonding strengthGood bonding performancePolyureas/polyurethane adhesivesIsocyanatePolyester

The invention provides a thermoplastic polyurethane composition with low viscosity and high adhesive strength. The composition contains the aliphatic polyester glycol with weight-average molecular weight of 2000-6000 and diisocyanate, wherein the molar ratio of diisocyanate to aliphatic polyester glycol is 0.7-0.95. The polyurethane composition of the invention has melting point between 50-70 DEG C (DSC), high adhesive strength, especially good adhesive performance with nylon plastic material (PA66), and has realized the preparation of thermoplastic polyurethane with low melting point and high adhesive strength.

Owner:DONGGUAN JIXIN POLYMER SCI & TECH +1

Electrochromatic epoxy resin polymer and preparation method thereof

InactiveCN102675580AGood bonding performanceGood acid and alkali resistance and heat resistanceTenebresent compositionsAqueous sodium hydroxidePolymer thin films

The invention relates to an epoxy resin polymer and a preparation method thereof, particularly relates to an electrochromatic epoxy resin polymer and a preparation method thereof, and aims to solve the problem that existing polymer films are prone to shed in organic solution and difficult in detection of electrochromatic performance. The chemical formula of the epoxy resin polymer is shown as follows. The method includes: adding hydroxyl-contained monomer material A into epichlorohydrin, stirring at 60-80 DEG C while dripping aqueous sodium hydroxide solution into epichlorohydrin solution of the material A, and reacting for two to eight hours to obtain the electrochromatic epoxy resin polymer. The epoxy resin polymer is highly adhesive, highly resistant to acid, alkali and heat and high in mechanical performance, and has the electrochromatic performance of triphenylamine, the shear strength of the epoxy resin polymer is about 30MPa, and the maximum service temperature of the epoxy resin polymer is up to 120 DEG C. The electrochromatic epoxy resin polymer and the preparation method thereof are applicable to the field of electrochromism.

Owner:HEILONGJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com