Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

849 results about "Shearing deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shearing deformation. noun. : detrusion or deformation by which a small rectangle is changed into a parallelogram and in which deformation is measured as the total angular change in radians at each corner.

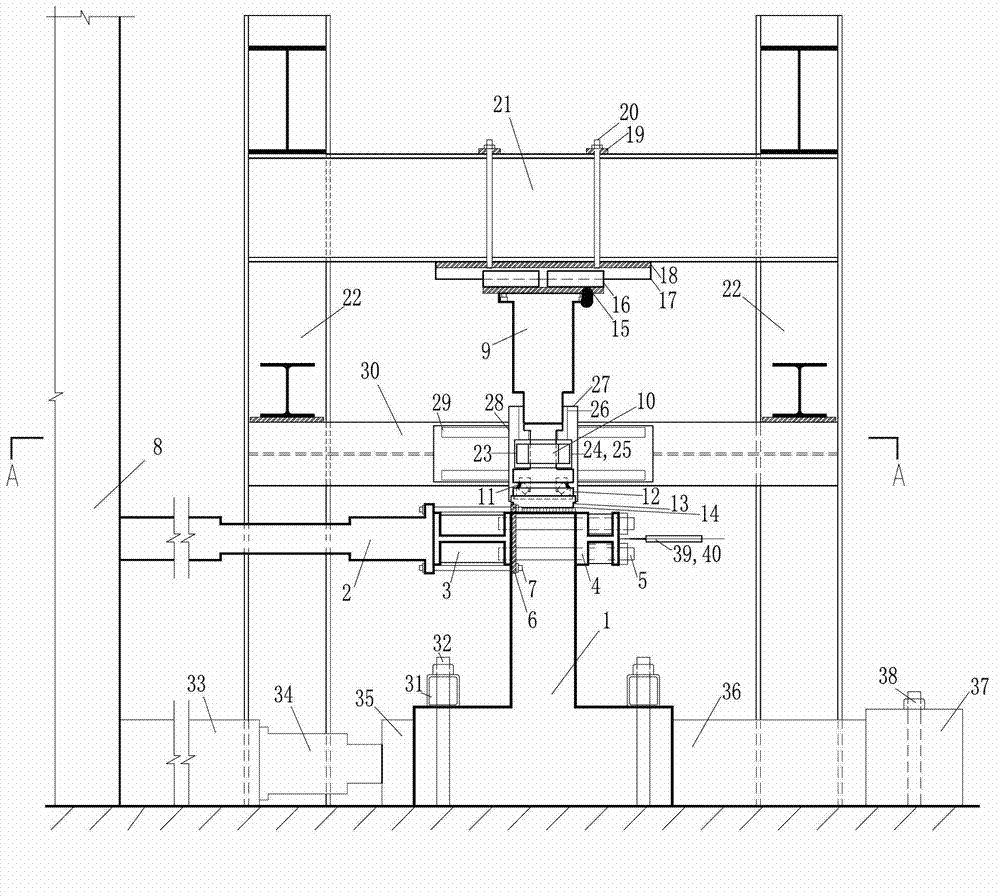

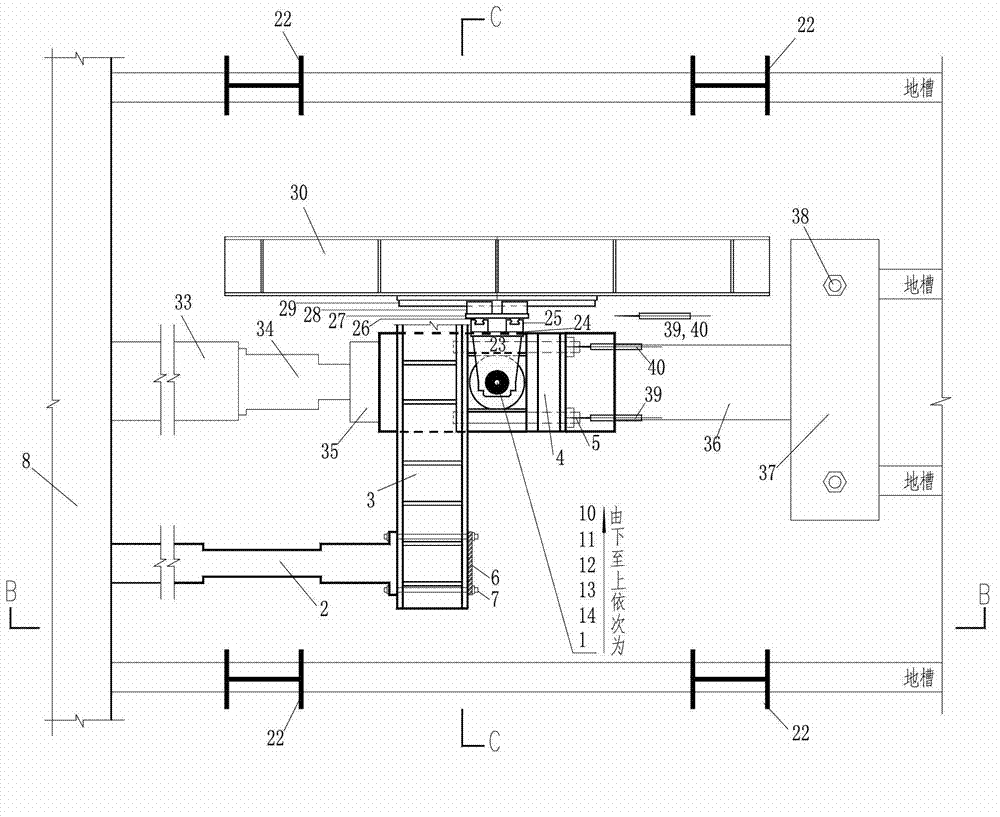

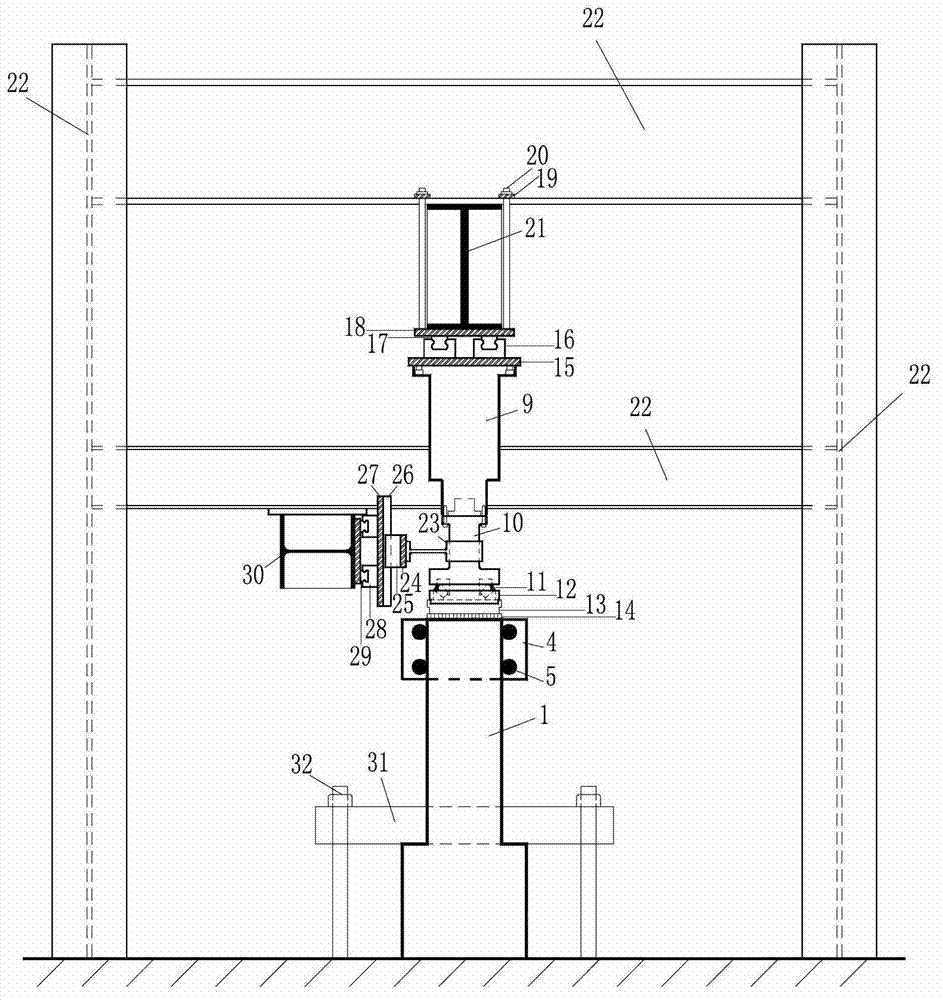

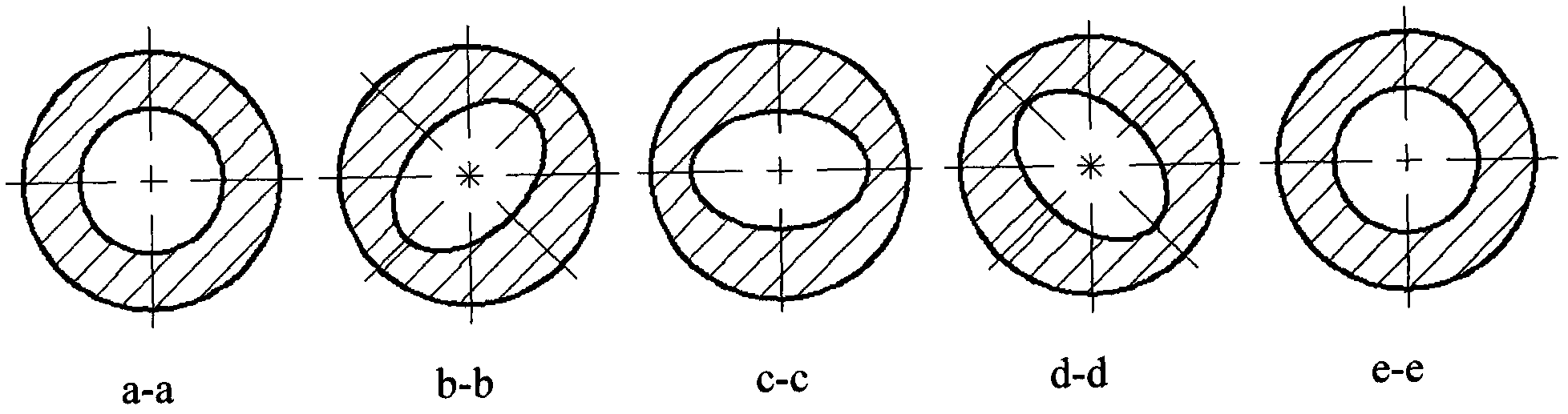

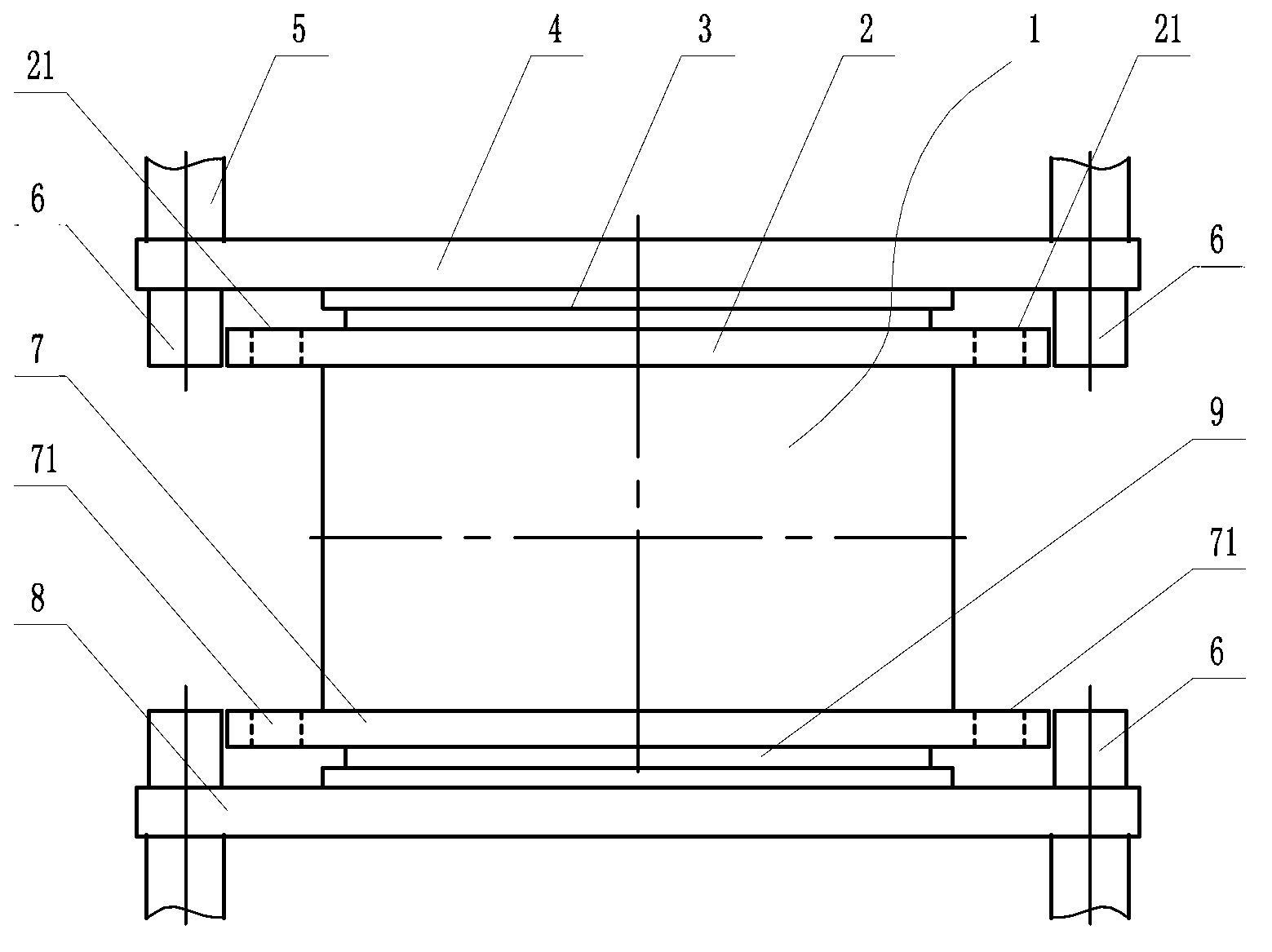

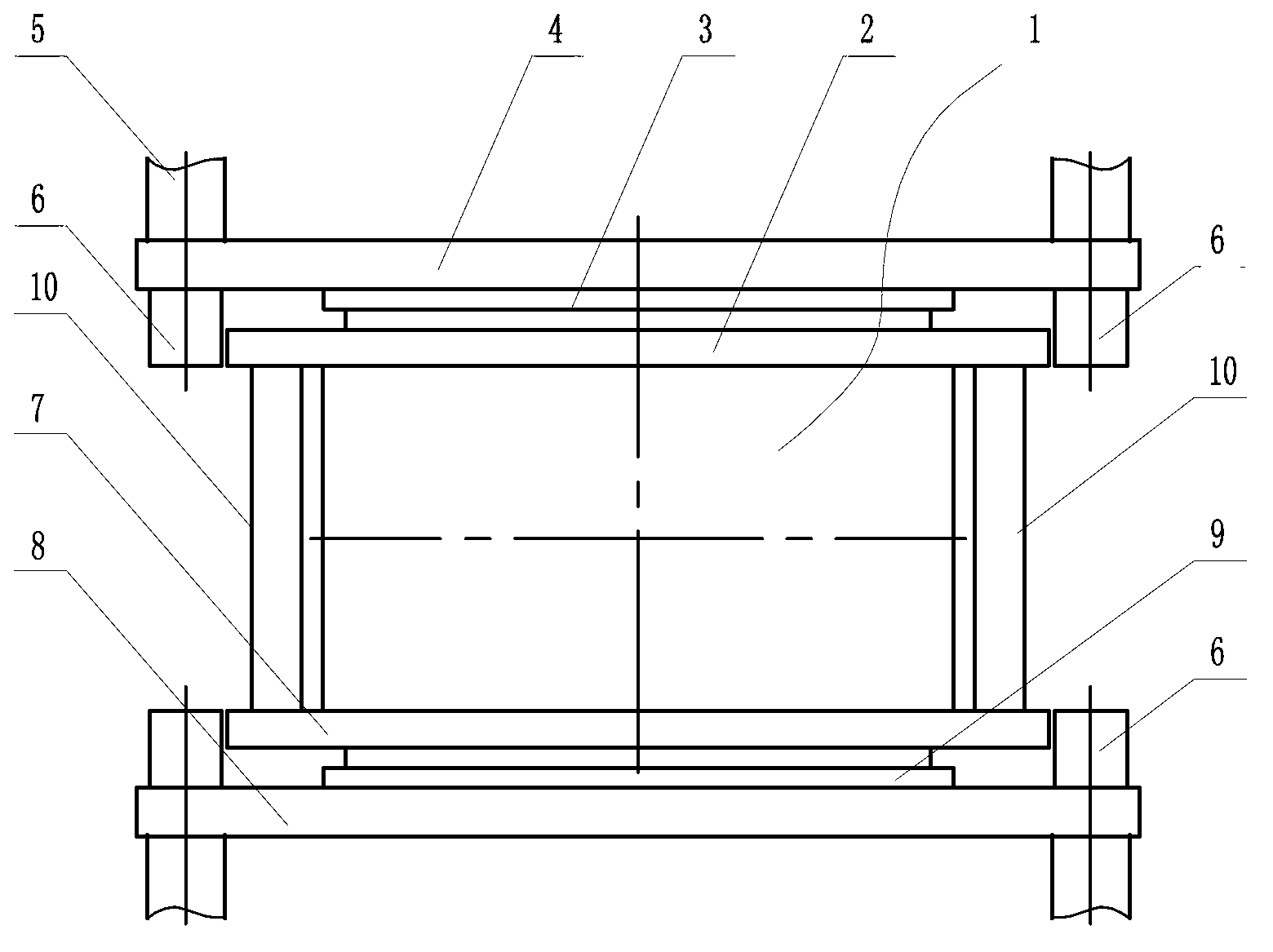

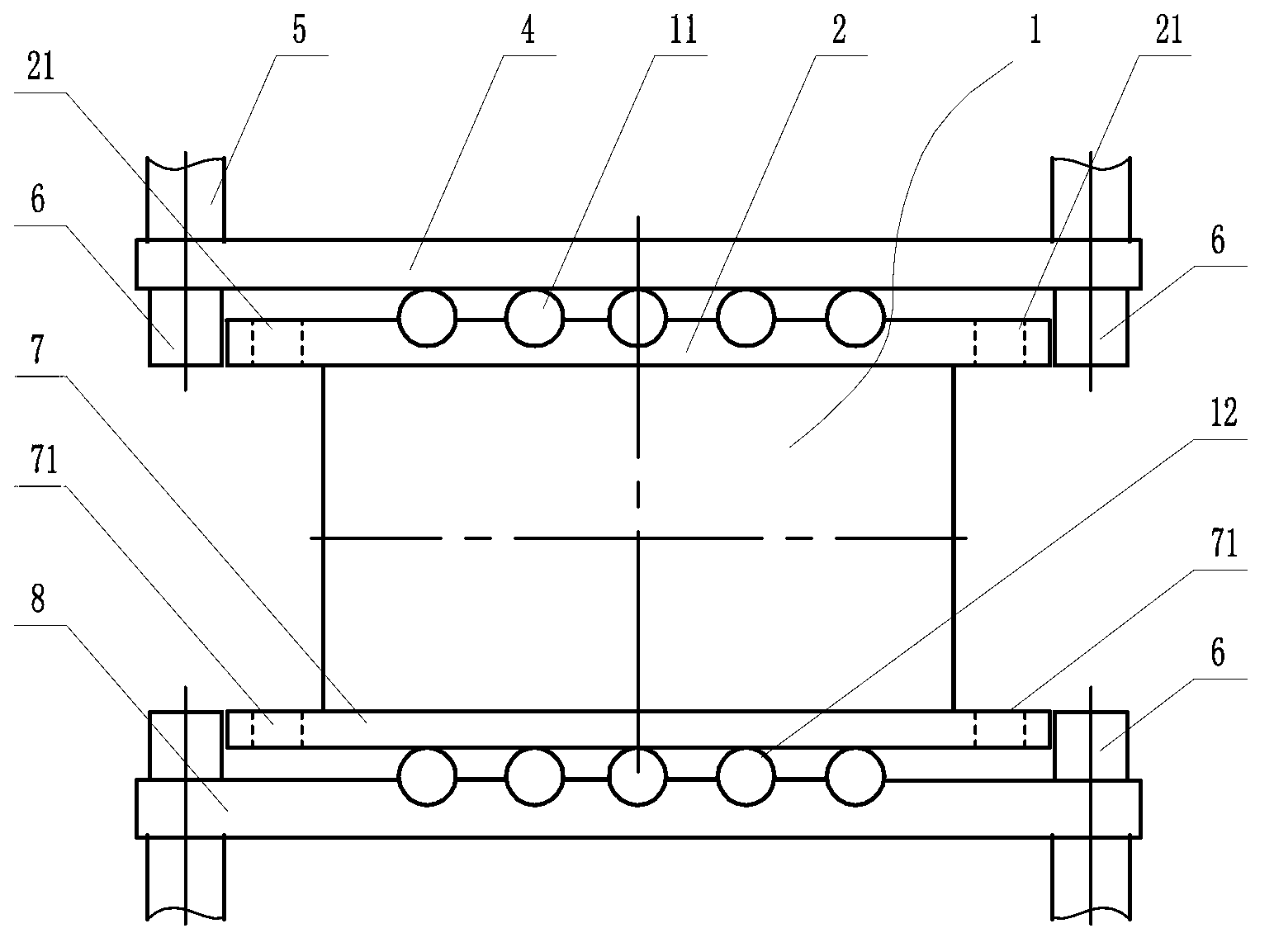

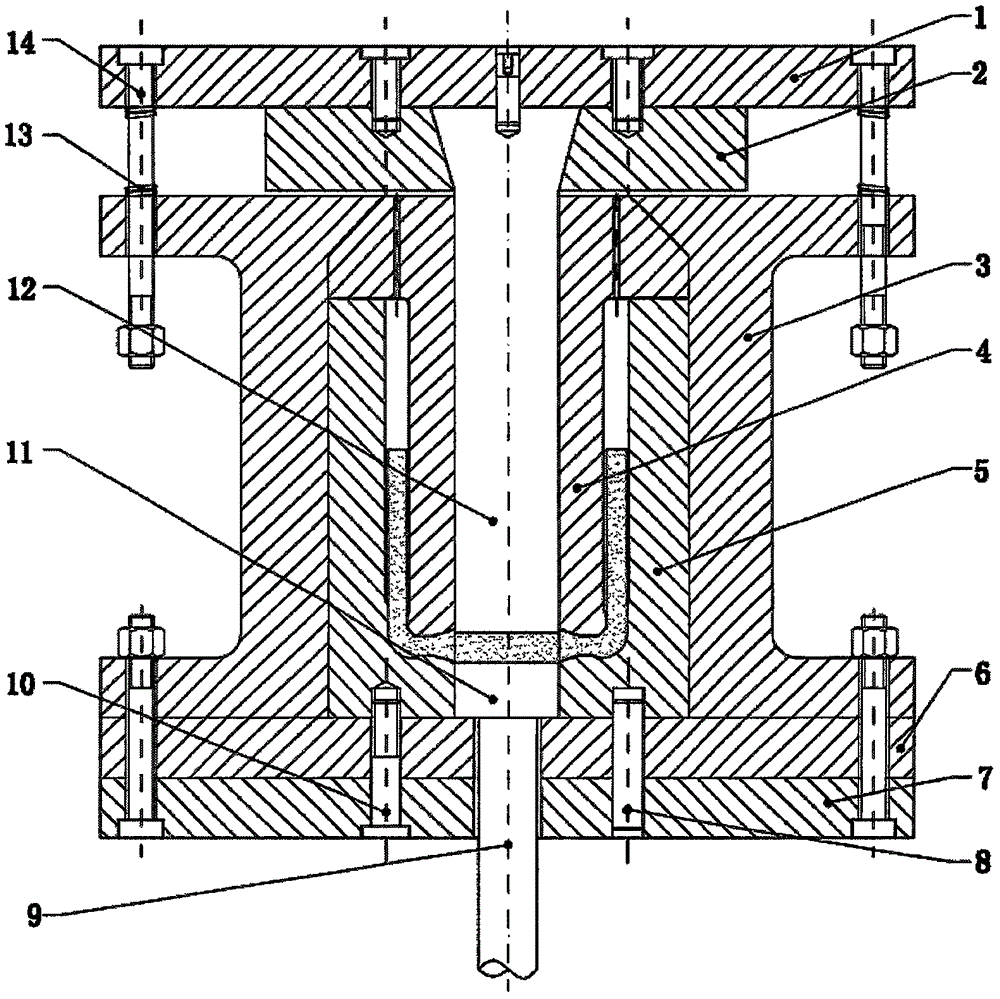

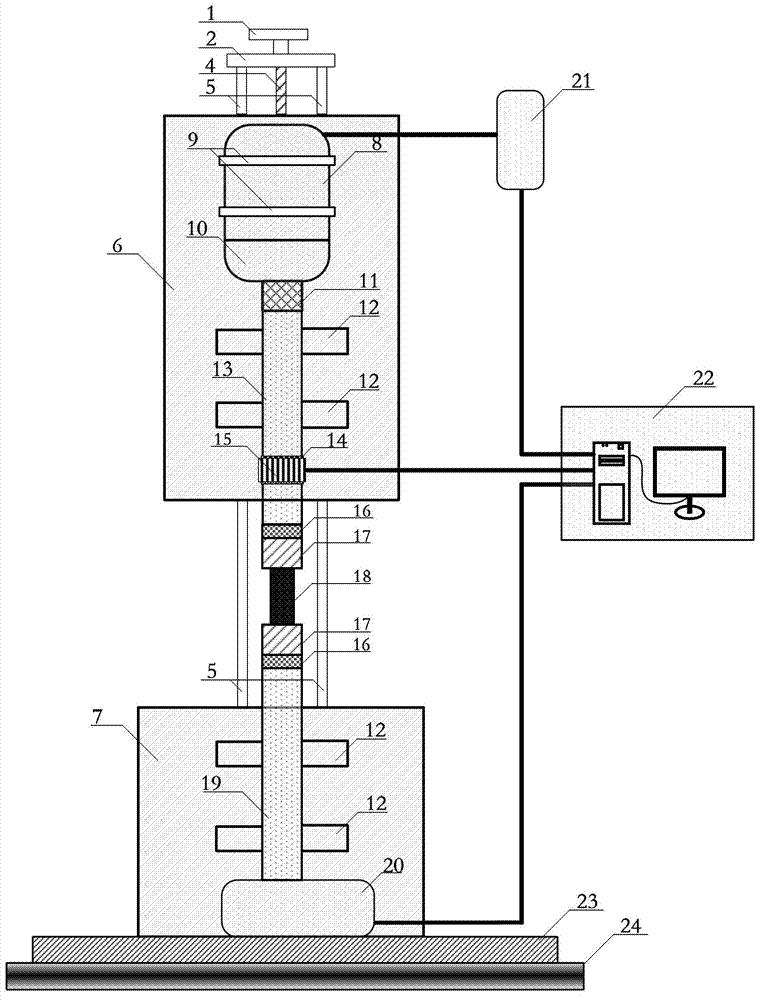

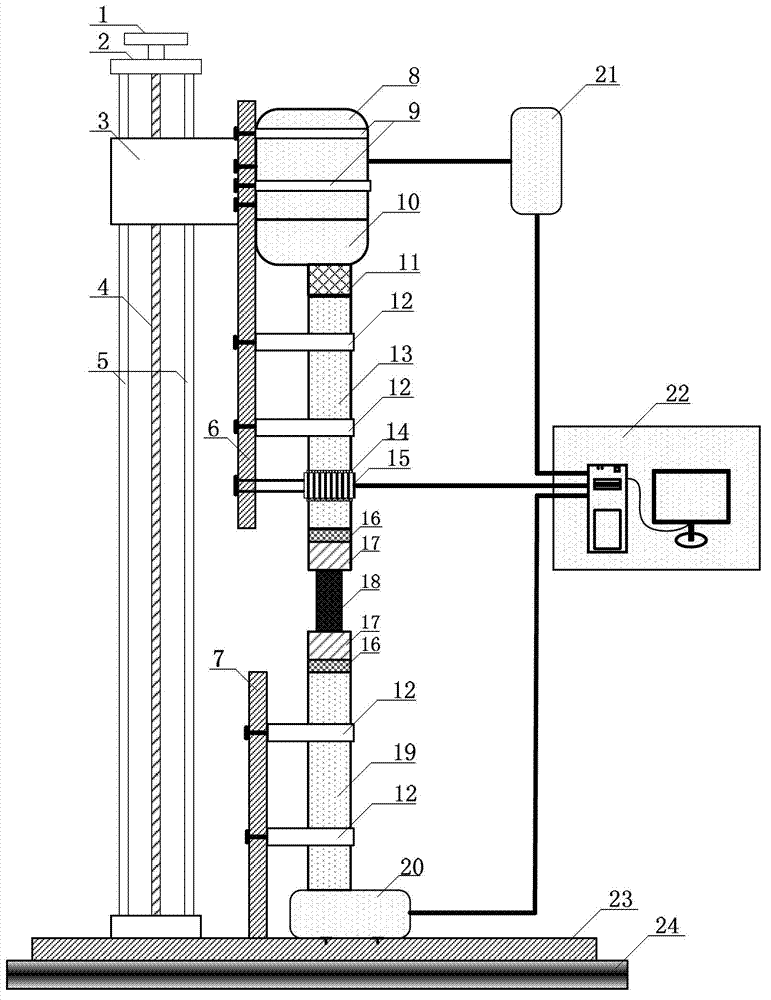

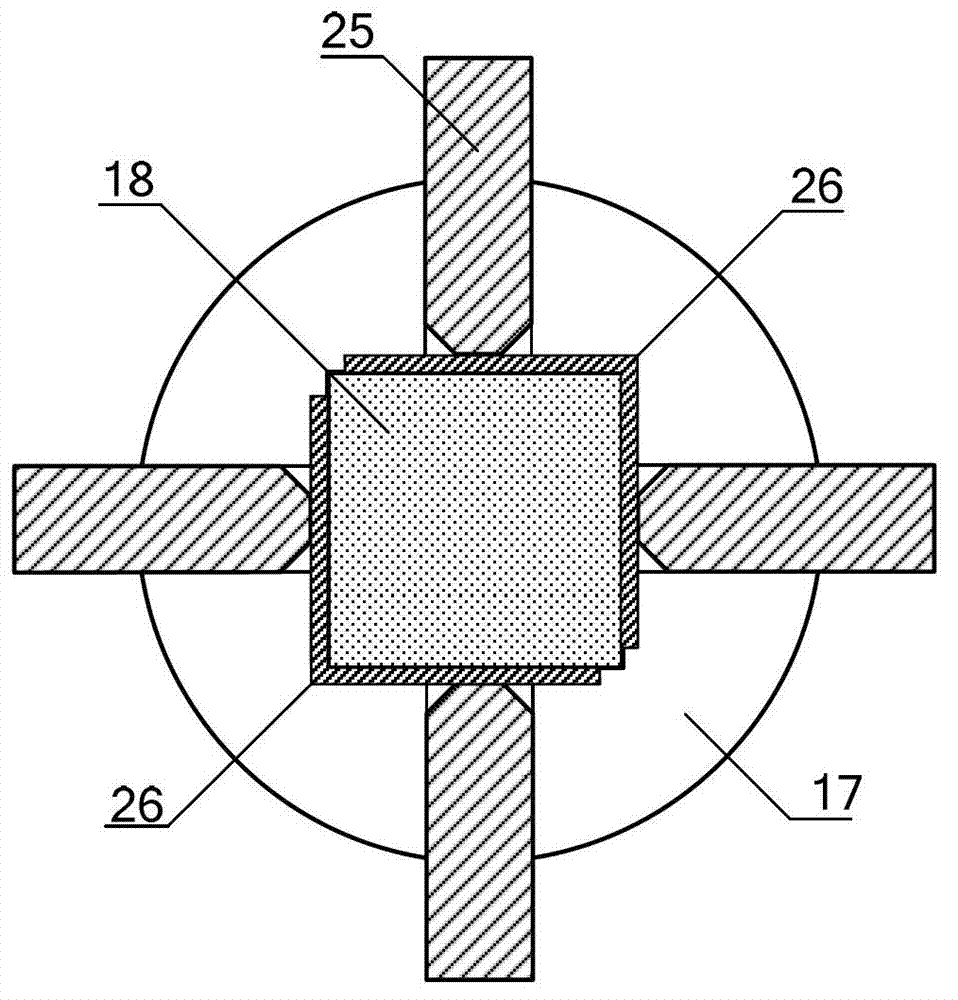

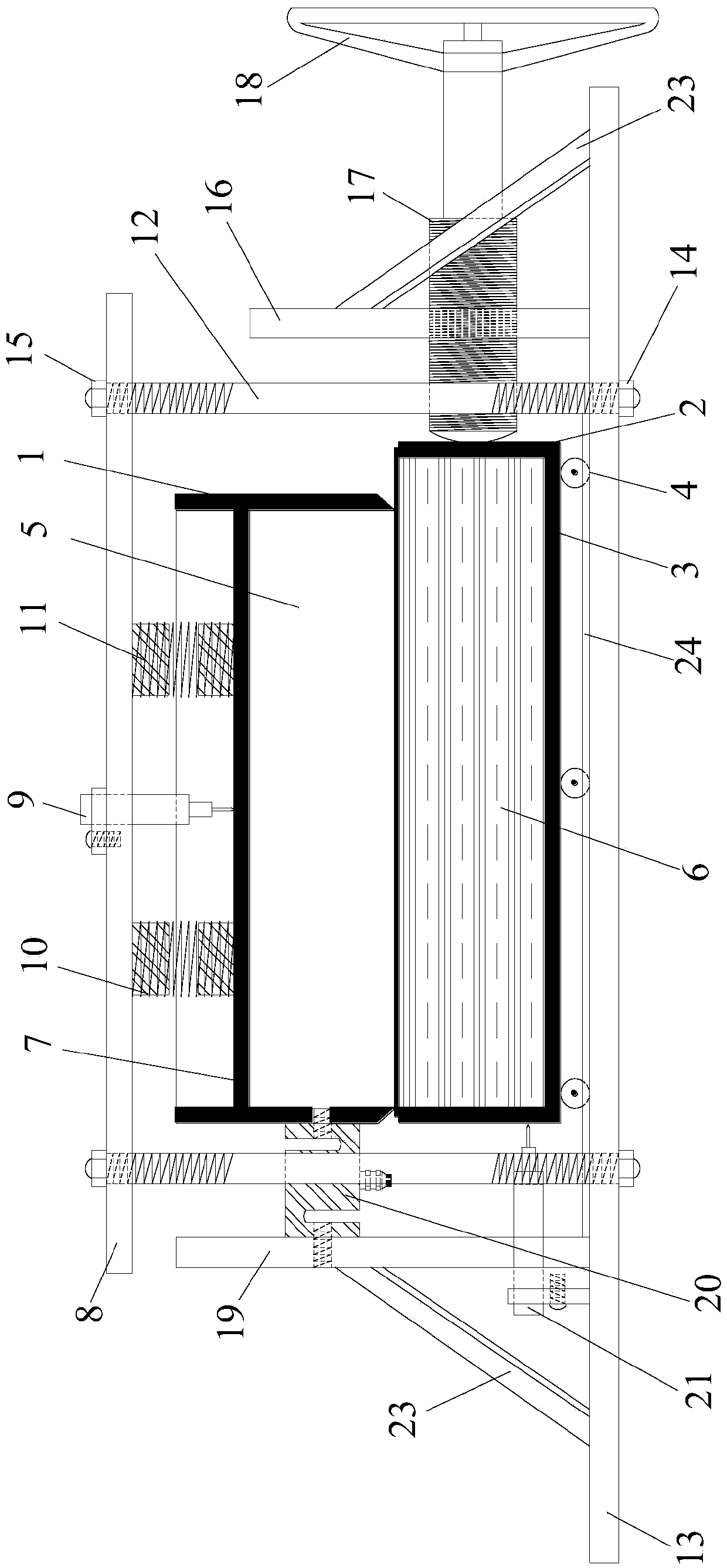

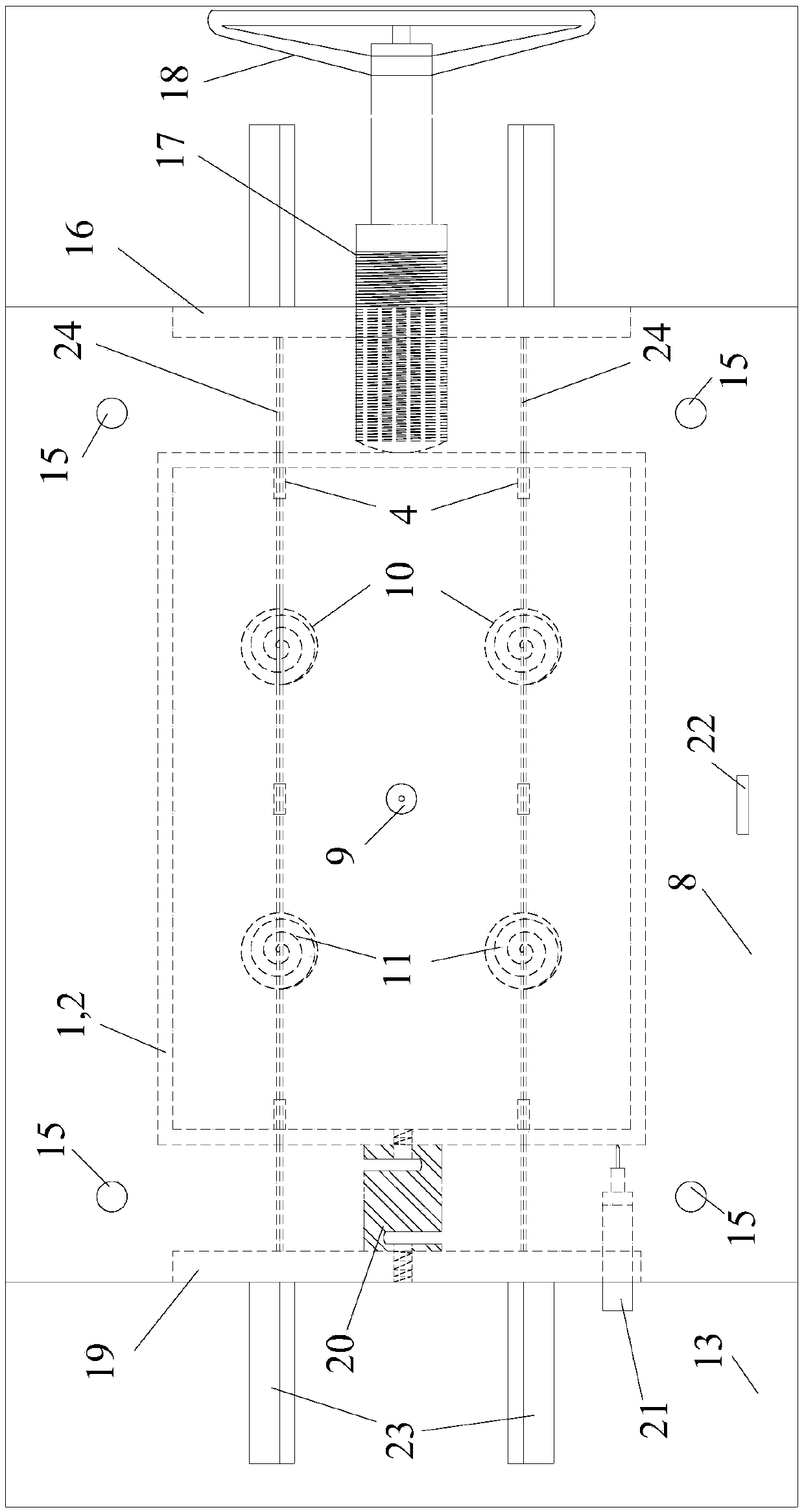

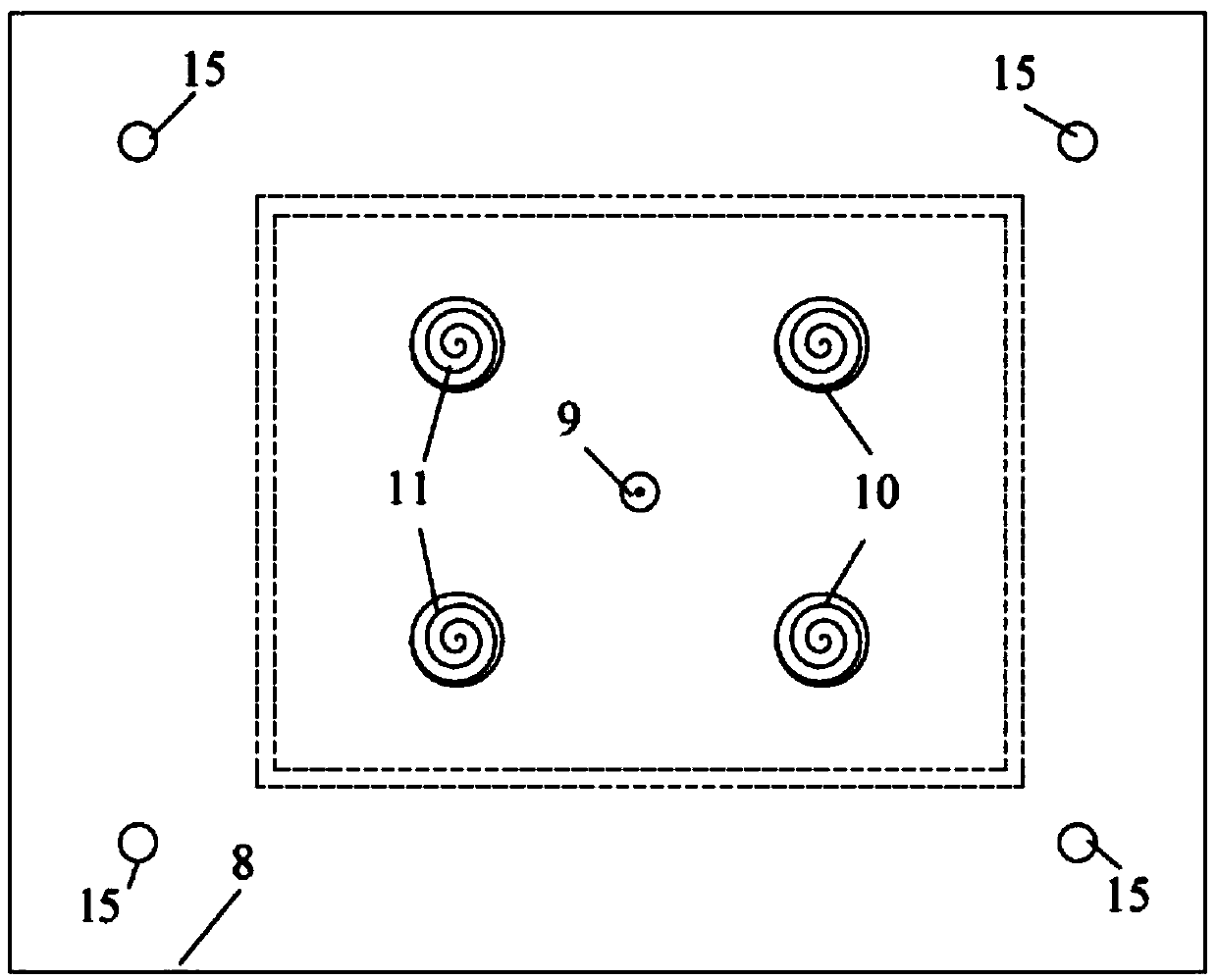

Component combined torsion experimental device and method

InactiveCN103115828AOvercome the disadvantages of inconsistent stress stateEasy to operateMaterial strength using steady torsional forcesEarthquake resistanceClassical mechanics

The invention discloses a component combined torsion experimental device comprising two counter-force frames which are fixed on a foundation terrace, a counter-force beam with two ends which are fixed at the upper ends of the counter-force frames and a counter-force wall fixed at the left side of the counter-force beam, wherein a component is fixed on the foundation terrace. The component combined torsion experimental device is characterized by further comprising a vertical force loading system for applying a vertical force to the component, a horizontal force loading system for applying a horizontal force to the component, a component top linear displacement guide system for meeting requirements of axial deformation, bending deformation and shearing deformation of the component, and a foundation displacement limiting system for fixing the position of the component. According to the experimental device and the method disclosed by the invention, the disadvantages of the existing similar experimental devices and methods are overcome; an experimental principle is scientific and an experimental process is simple to operate and control; the experimental device is convenient to assemble and can be used while being installed; and the experimental device can be circularly used and an experimental result meets a combined torsion performance of the structural component under the horizontal earthquake action, so as to provide experimental guarantees for disclosing a combined torsion mechanism and an anti-seismic property of the structural component.

Owner:TIANJIN YUANZHUO AUTOMATION EQUIP MFG CO LTD

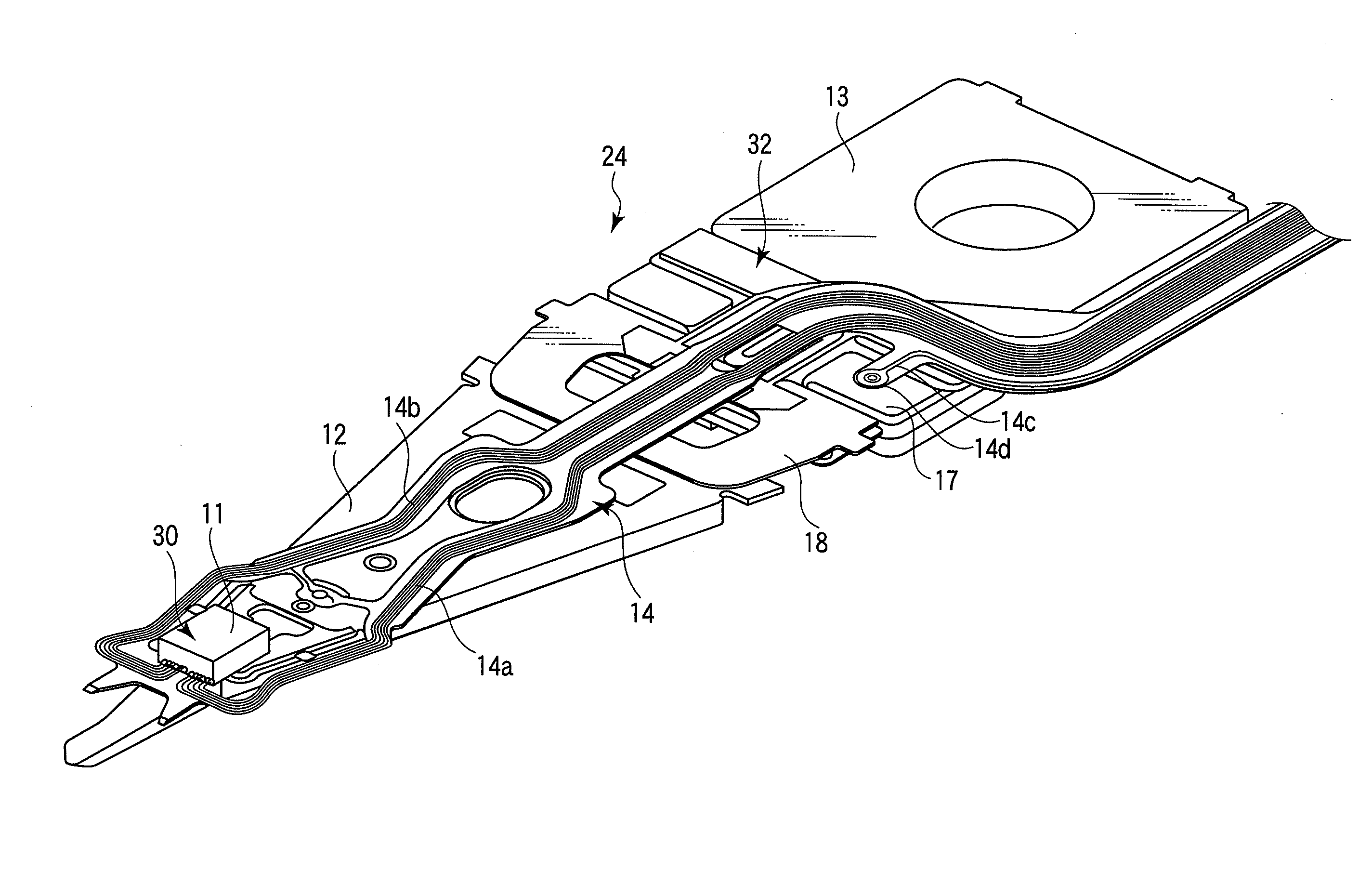

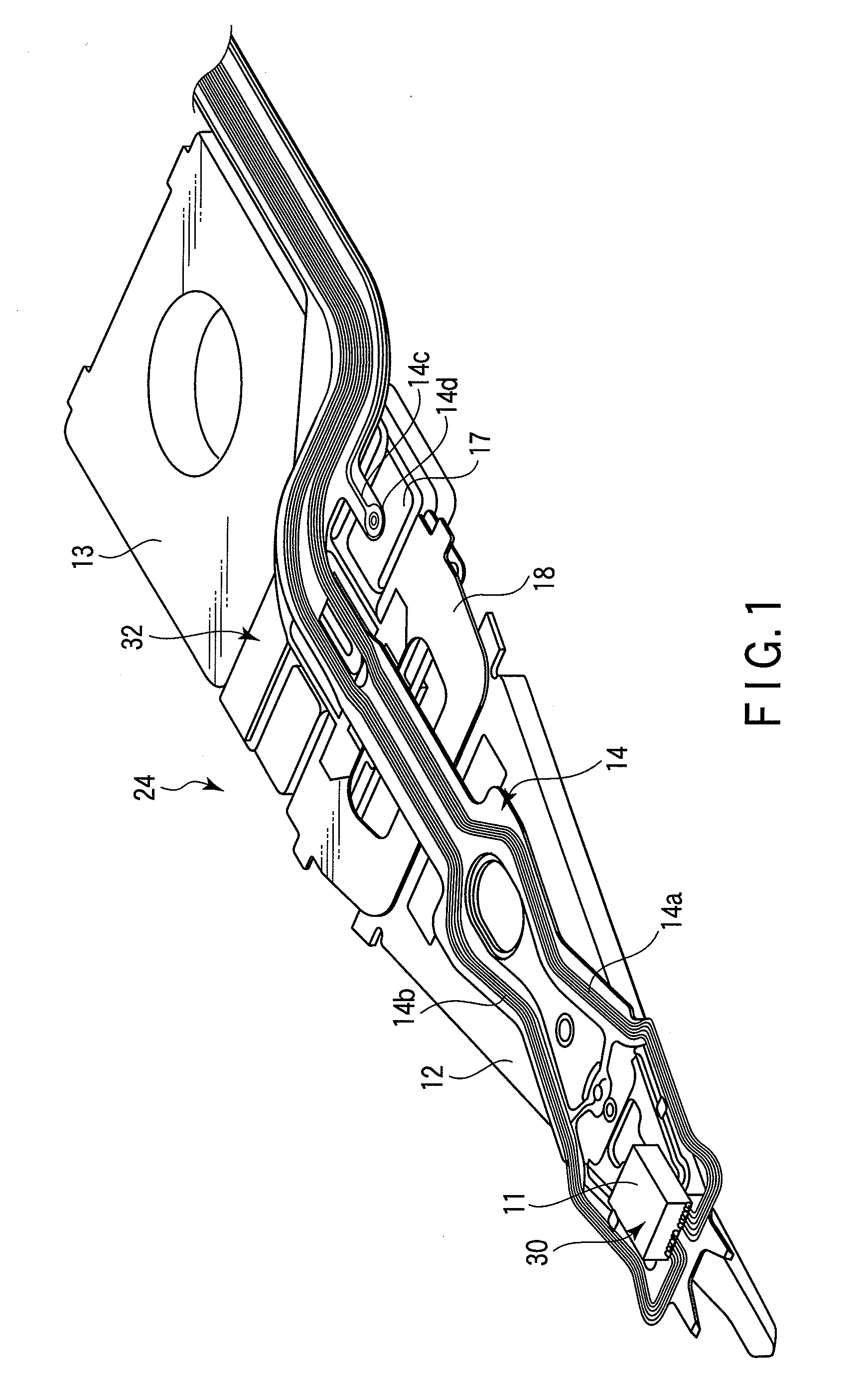

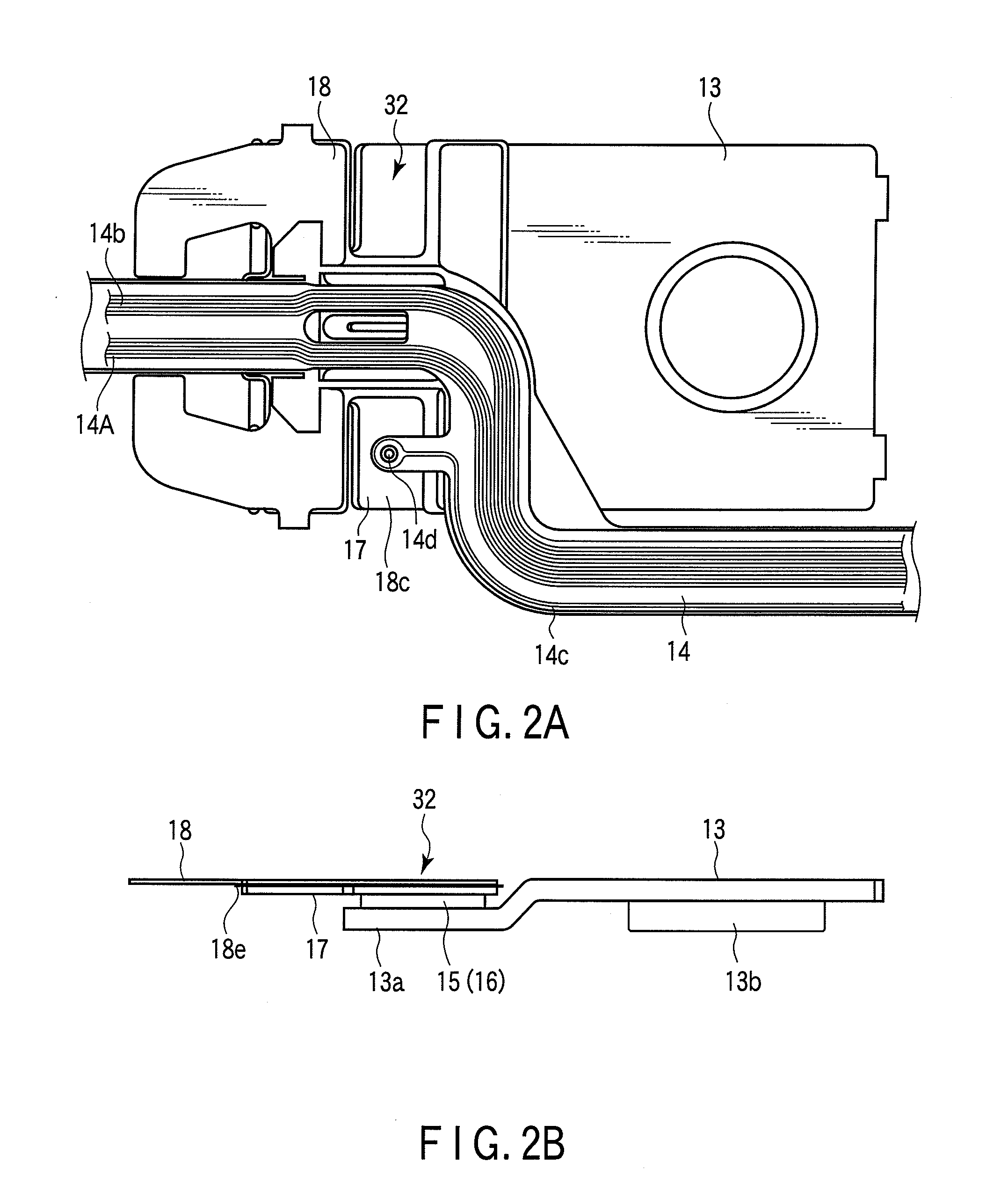

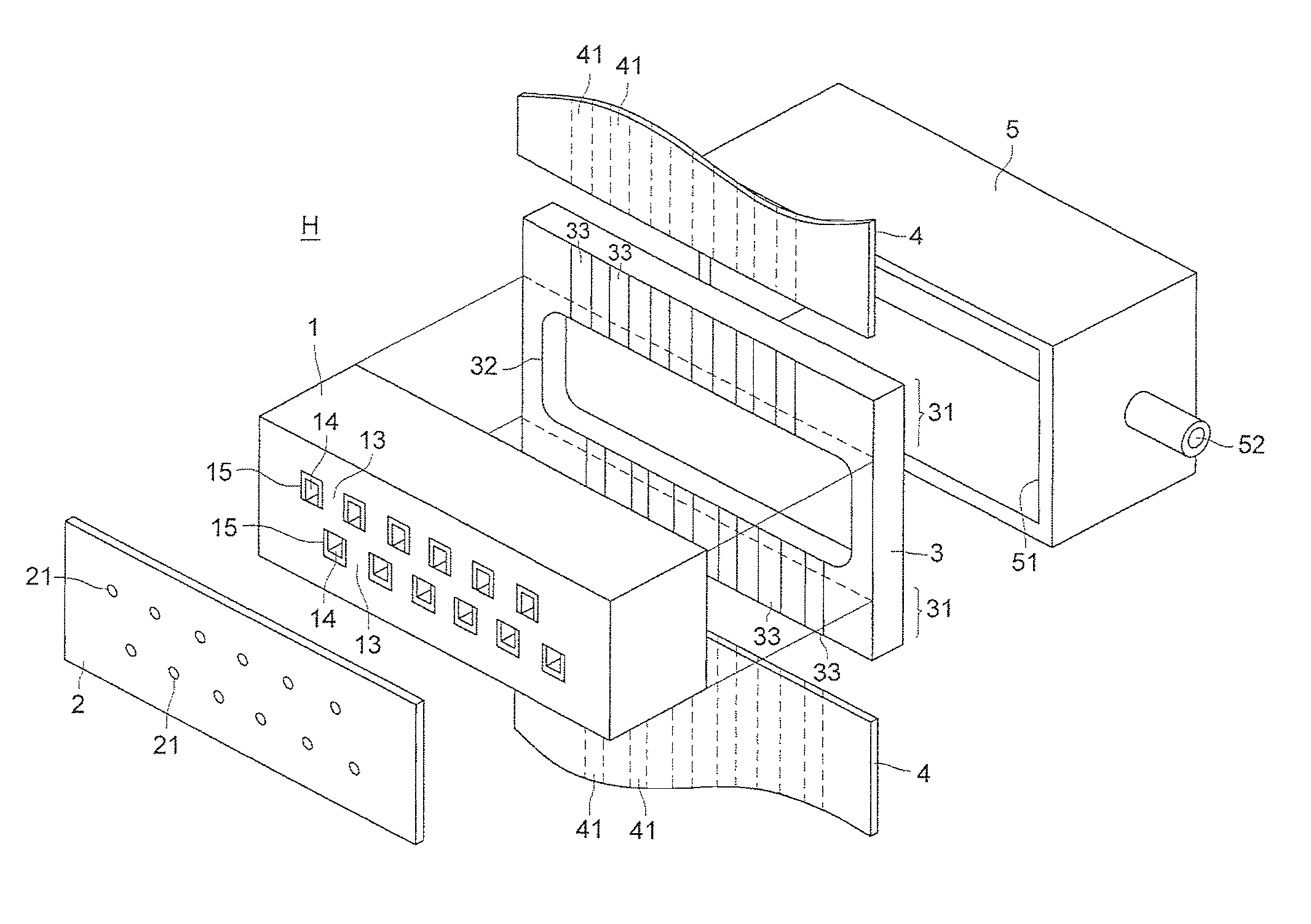

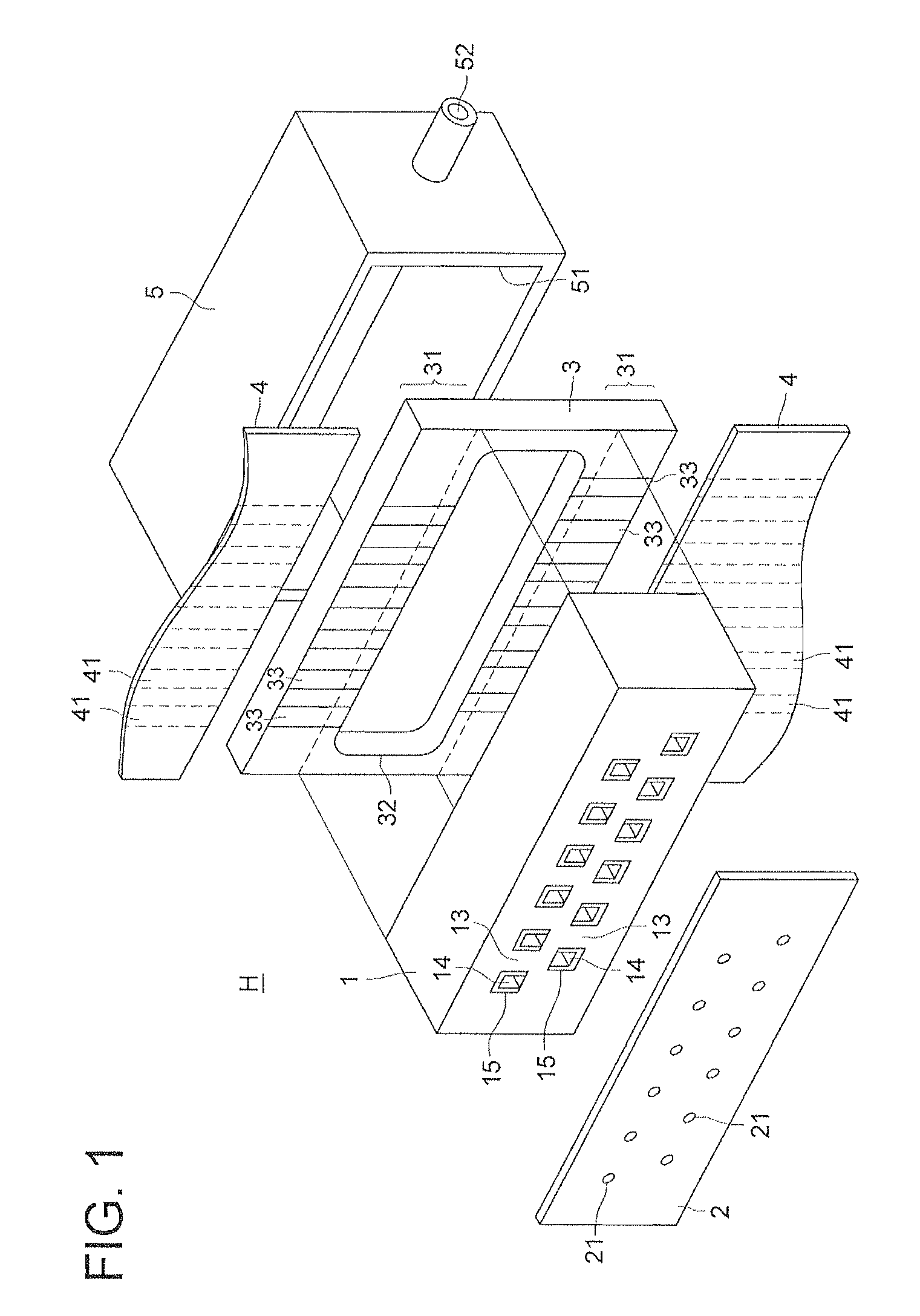

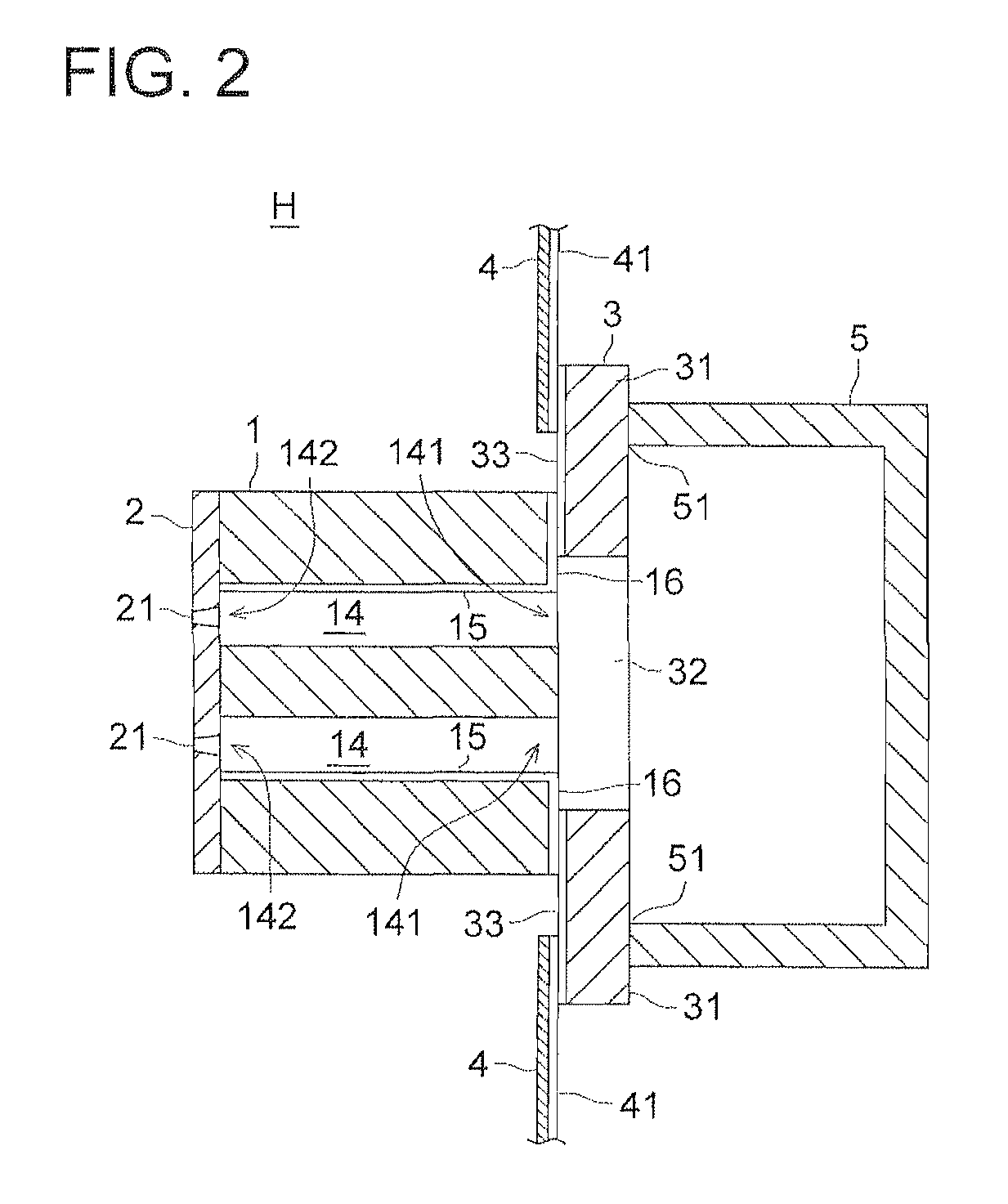

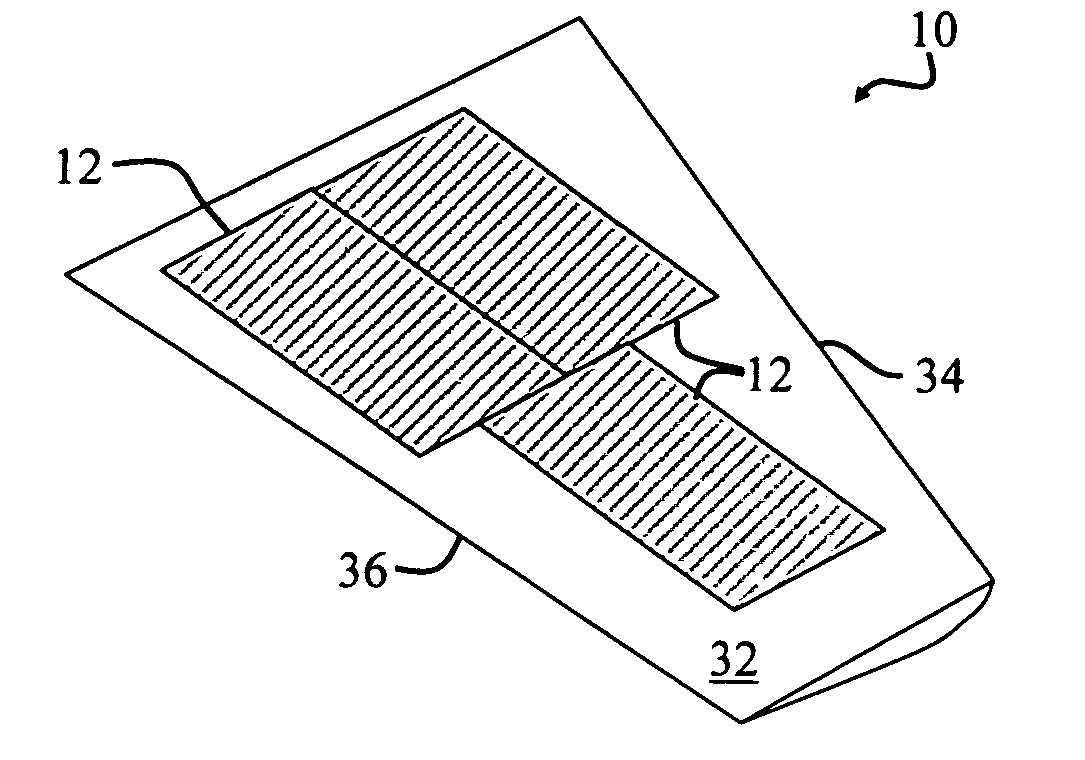

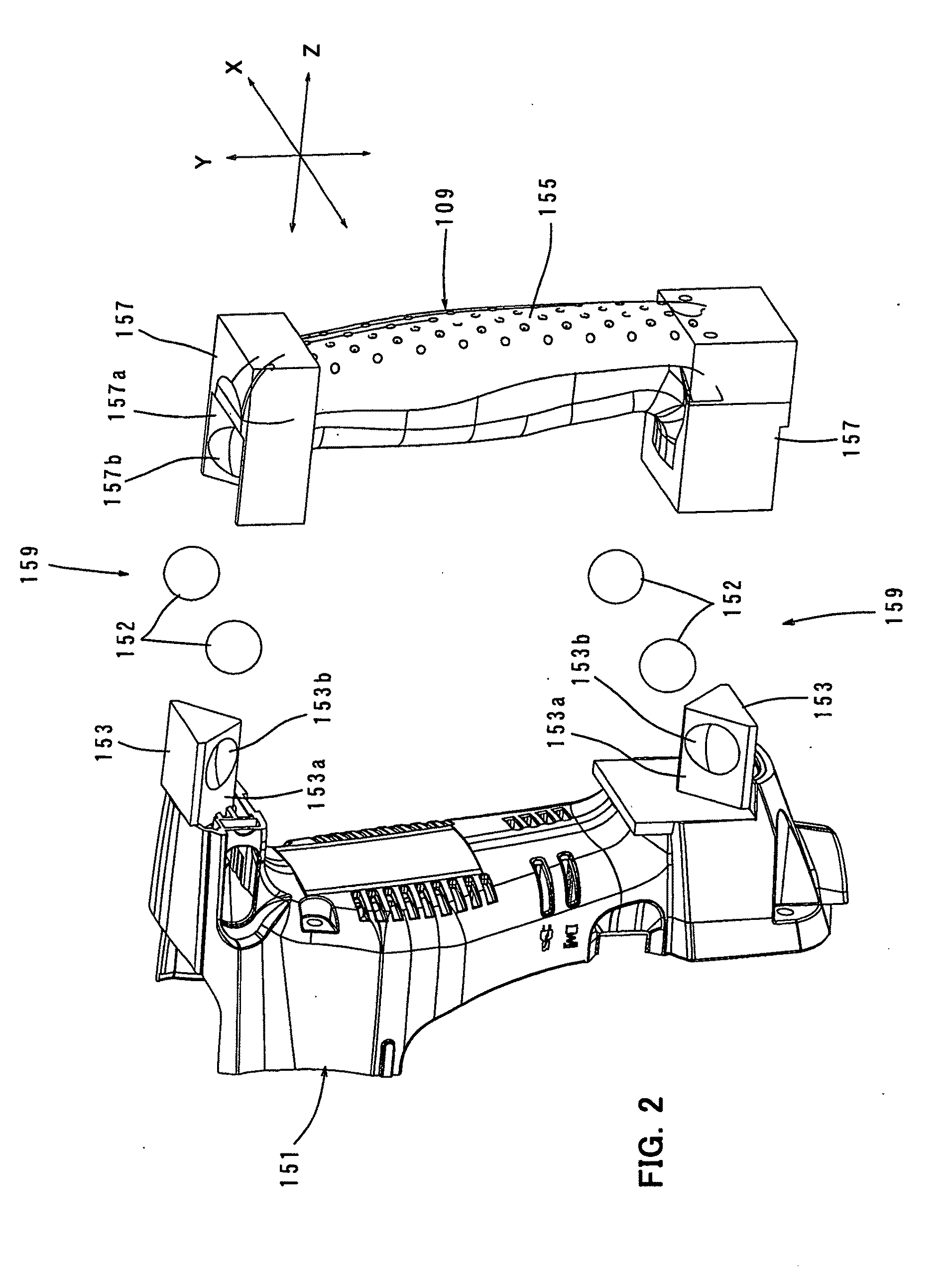

Head suspension assembly and magnetic disk drive

According to one embodiment, a head suspension assembly includes a load beam supporting a head, and a microactuator configured to swing the load beam. The microactuator includes two piezoelectric elements configured to undergo shear deformation when supplied with a voltage and juxtaposed in such a manner that respective shear deformations thereof are opposite in direction, a first electrode and a second electrode arranged so as to hold the piezoelectric elements therebetween, and a support plate joined to the first electrode with an insulating layer therebetween and joined to the load beam to support the load beam.

Owner:TOSHIBA STORAGE DEVICE CORP

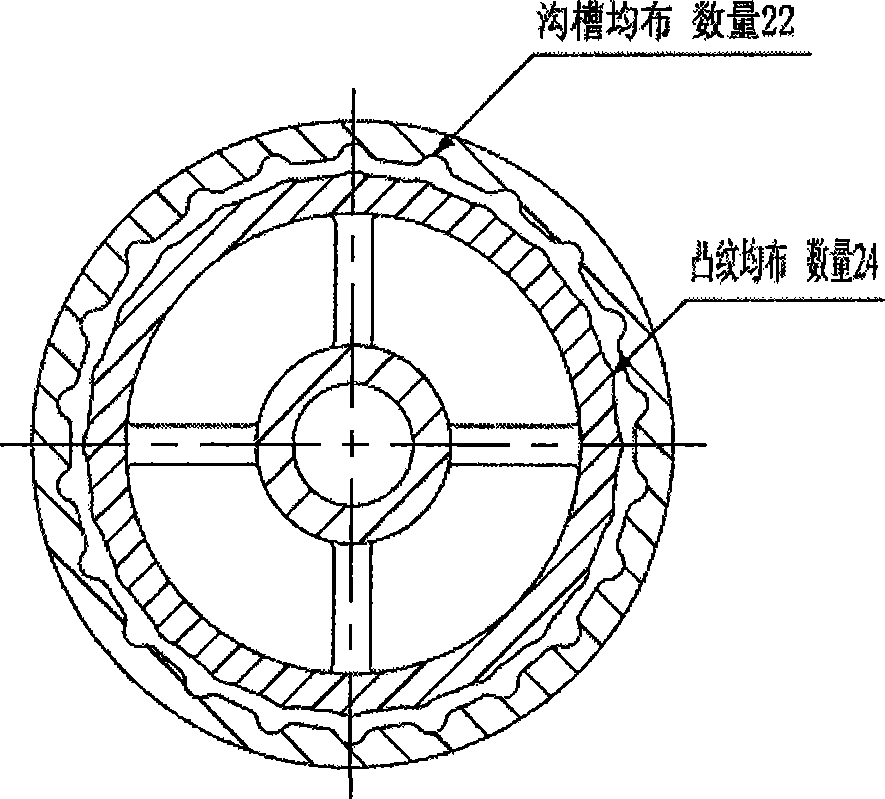

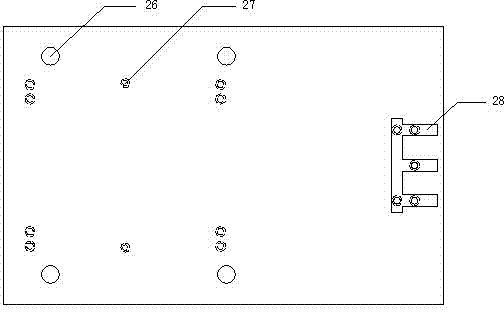

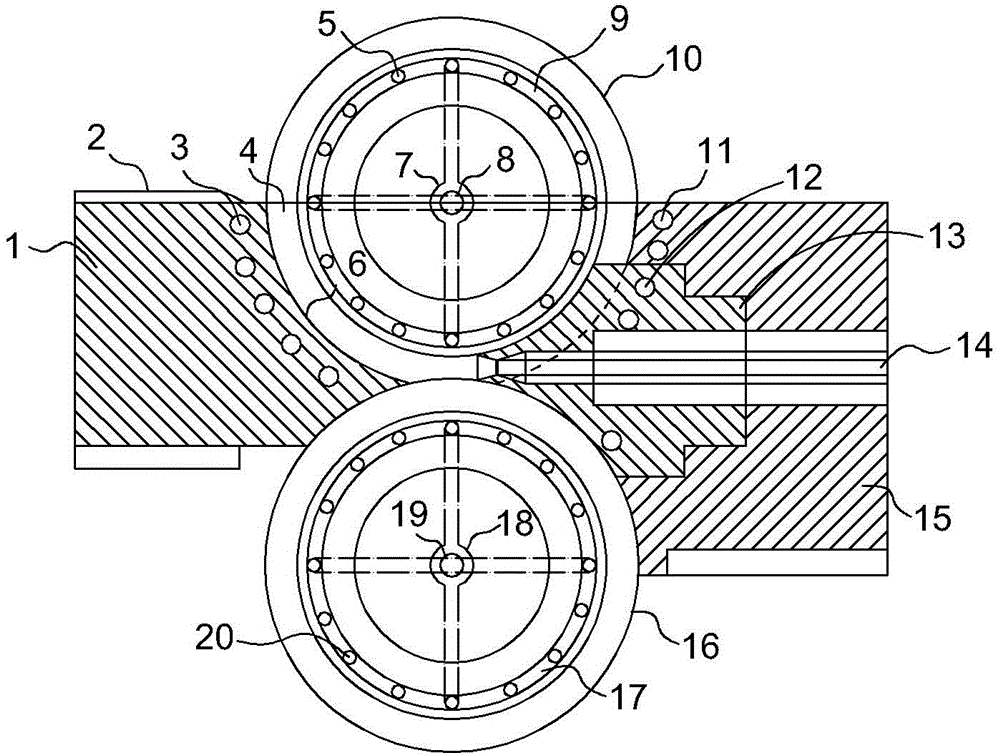

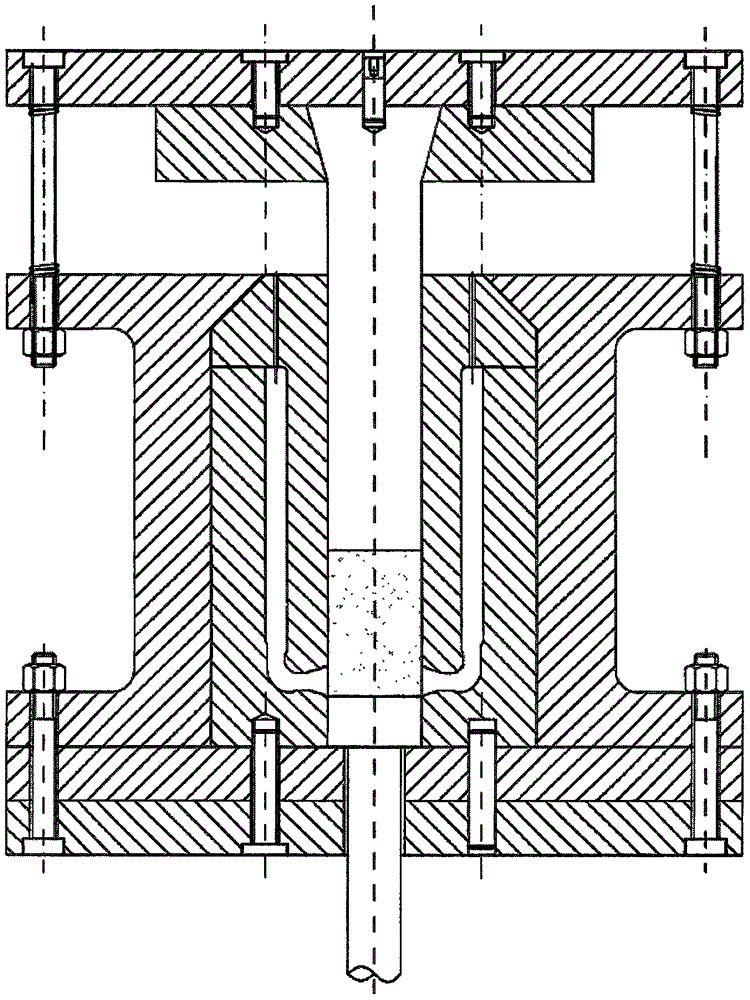

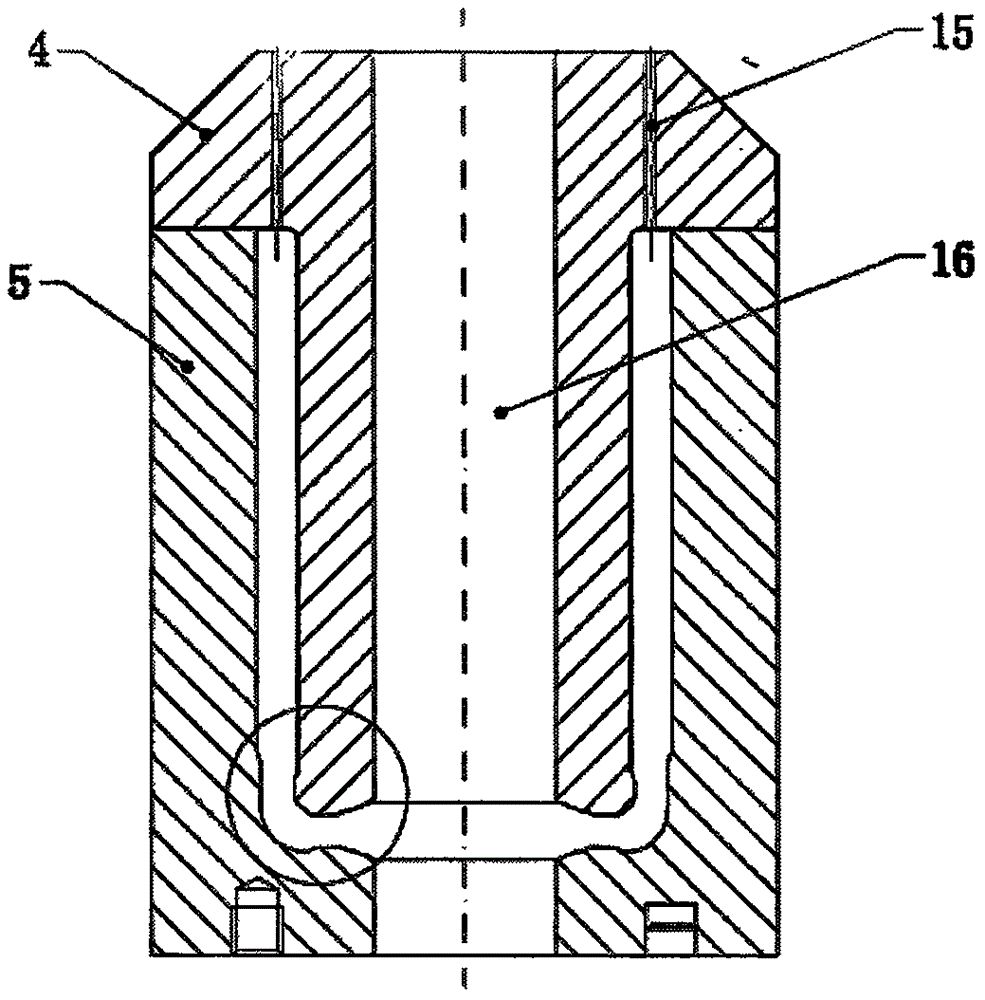

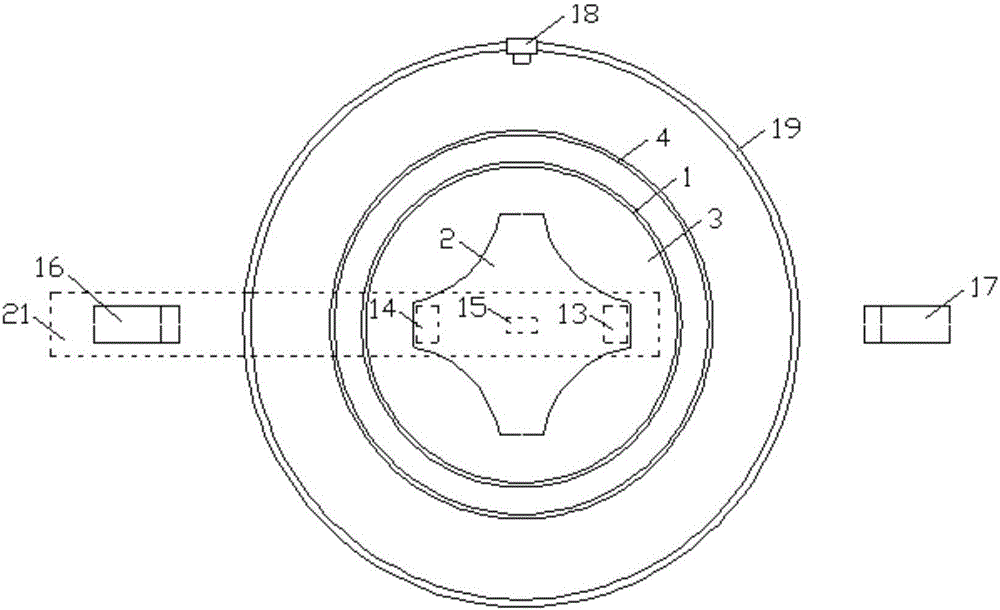

Suspension cone bucket type semi-solid metal slurry preparation and conveyor device

Disclosed is a suspending tapered bucket type semisolid metal slurry preparation and conveying apparatus, which belongs to the technique field semisolid metal machining. The apparatus comprises an adjustable speed motor 1, an elevating mechanism 2, an air pipe 3, a connecting device 4, a press-casting machine injection chamber 5, an air port 6, a transmission bevel gear 7, a mandrel 8, a coupling 9, an air pipe 10, a pony ladle 11, an inner tapered bucket 12, an outer tapered bucket 13, a heating and cooling element 14, a flanged disc 15 and the like. When in semisolid metal slurry preparation, according to the shearing deformation principle, the purpose of forming fine and even semisolid metal slurry can be achieved through the intense shearing function when the liquid state metal passes through gaps between the rotating inner tapered bucket and the outer tapered bucket which are inscribed with specific grooves, and the prepared semisolid metal slurry is conveyed to the press-casting machine injection chamber through the connecting device to realize the rheological die-casting molding. The invention has the advantages of: simple and compact equipment structure and light weight; high temperature control precision; convenient and reliable operation, and easy realization from semisolid metal slurry preparation, conveying to die-casting molding; and convenient maintenance and repair and industrialized continuous production.

Owner:UNIV OF SCI & TECH BEIJING

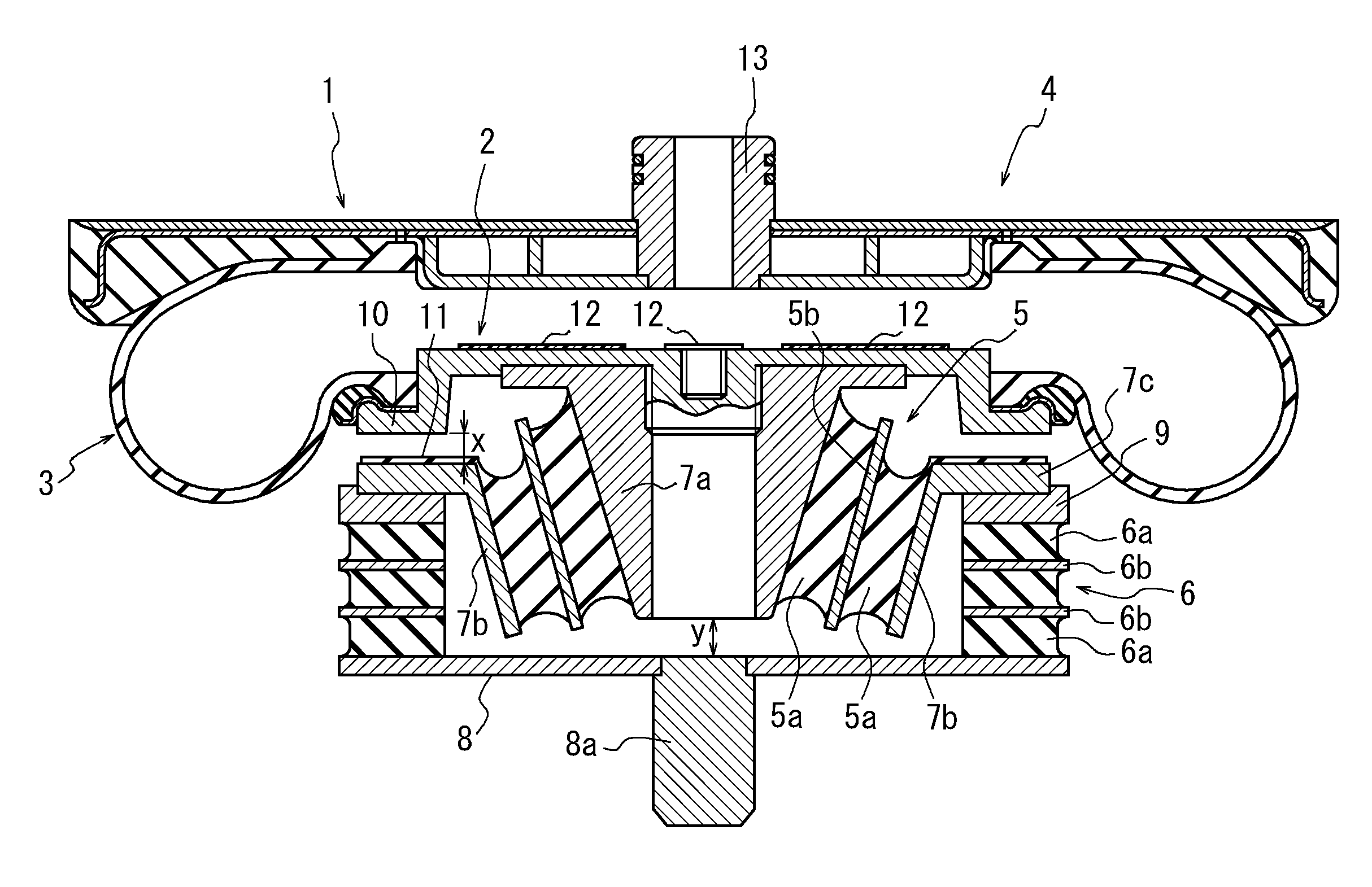

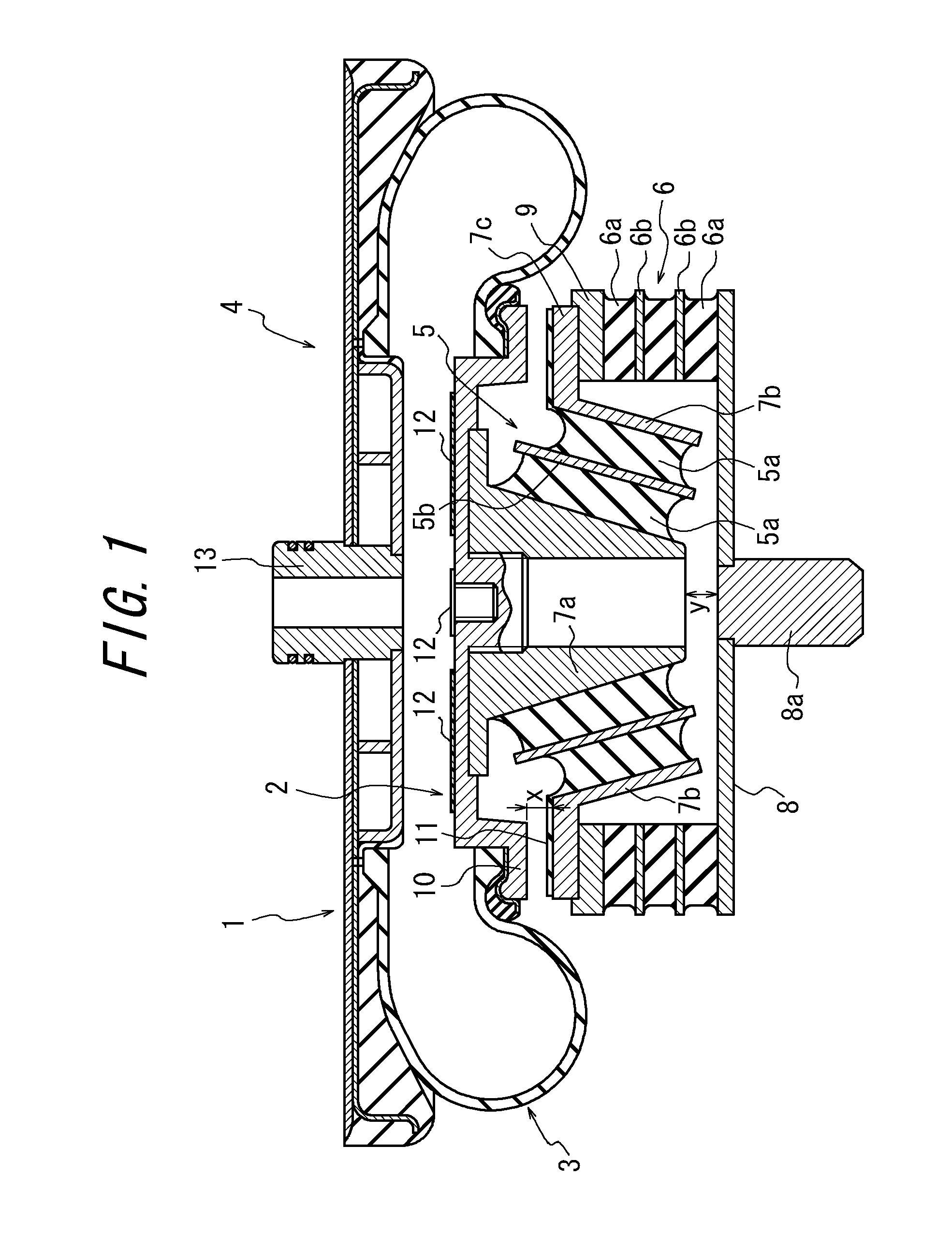

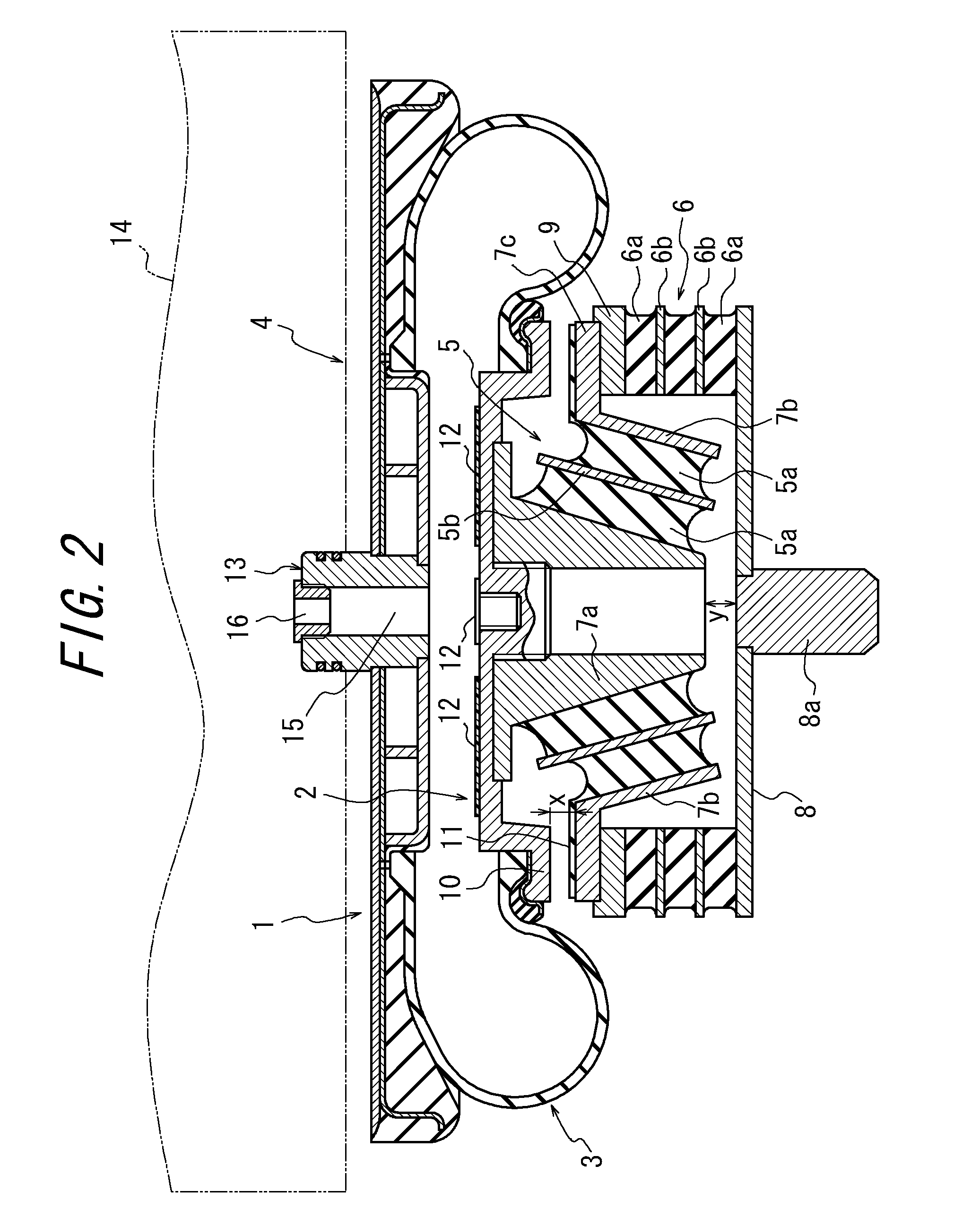

Air spring device

InactiveUS20110031662A1Stiff constantSimple structureNon-rotating vibration suppressionMultiple spring combinationsRubber materialAir spring

An air spring device includes an air spring (4) wherein gas is filled in an interior defined by an upper face plate (1), a lower face plate (2), as well as a cylindrical flexible diaphragm body (3) having opposite ends gas-tightly connected to the upper and lower face plates (1, 2), respectively. Between the lower face plate (2) and a lower supporting plate (8) spaced downward therefrom, a shear spring means (5) and a compression spring means (6) are series-connected, which are made mainly of rubber material. When a vertical load is applied to the air spring device, the shear spring means (5) and the compression spring means (6) are subjected mainly to shearing deformation and compressive deformation, respectively. The air spring device further includes an abutment member (10) allowing the compression spring means (6) to support the load in place of the shear spring means (5), after the deformation amount of the shear spring means (5) reaches a predetermined level.

Owner:BRIDGESTONE CORP

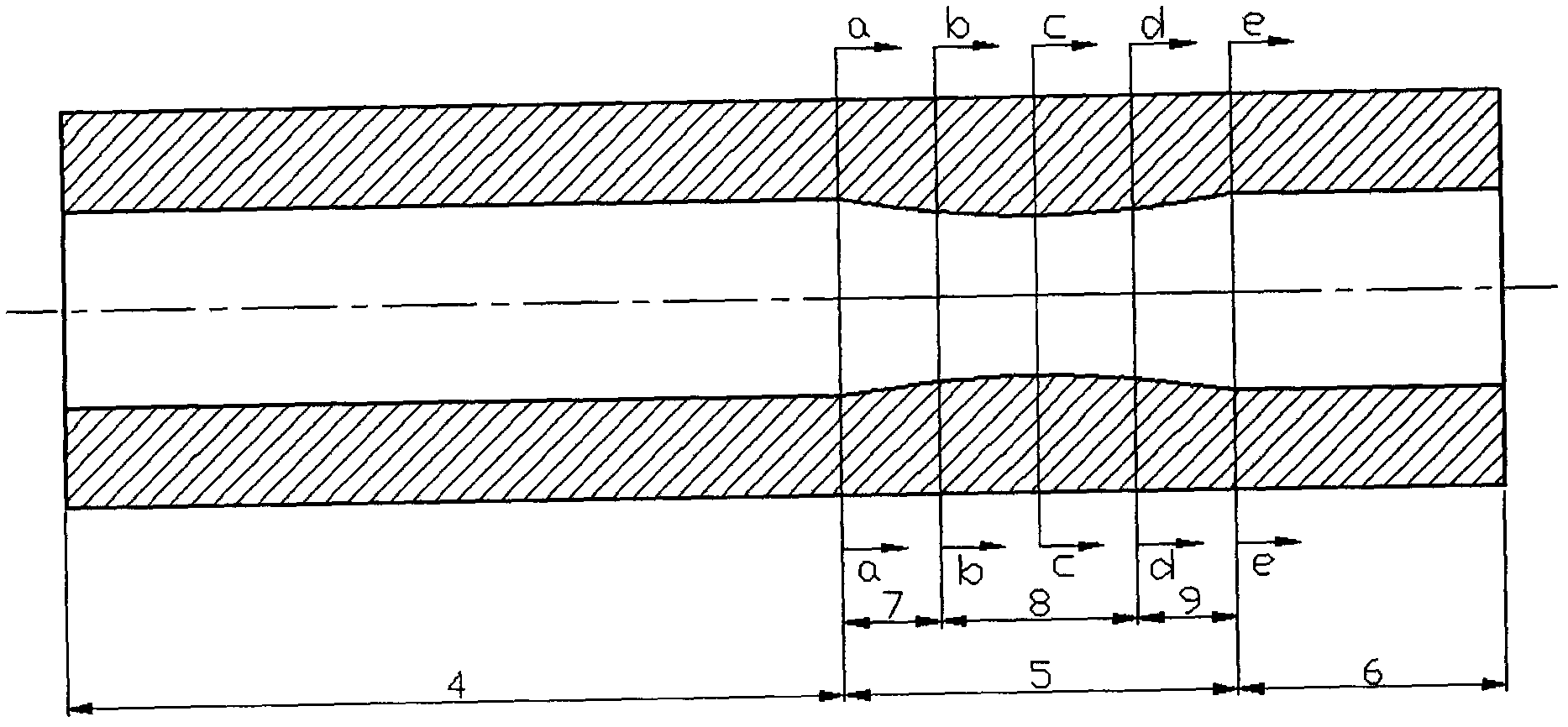

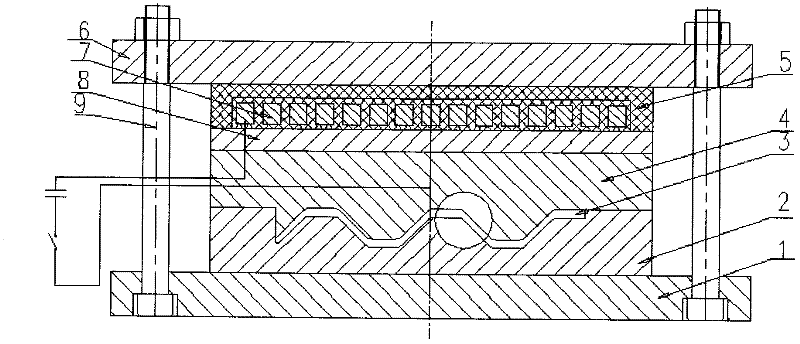

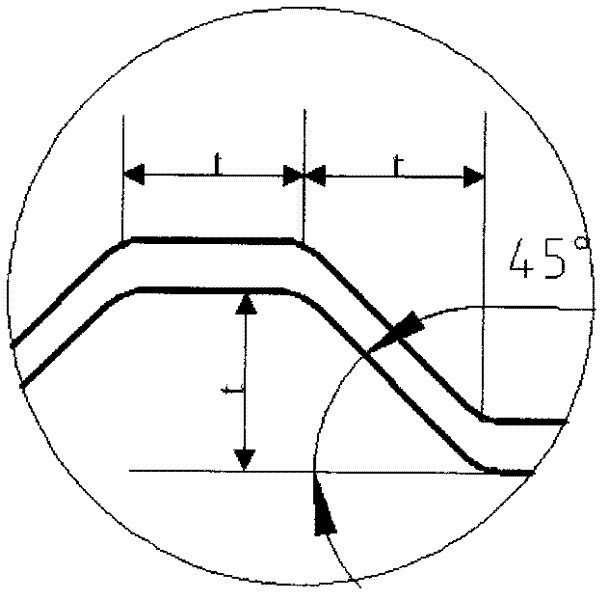

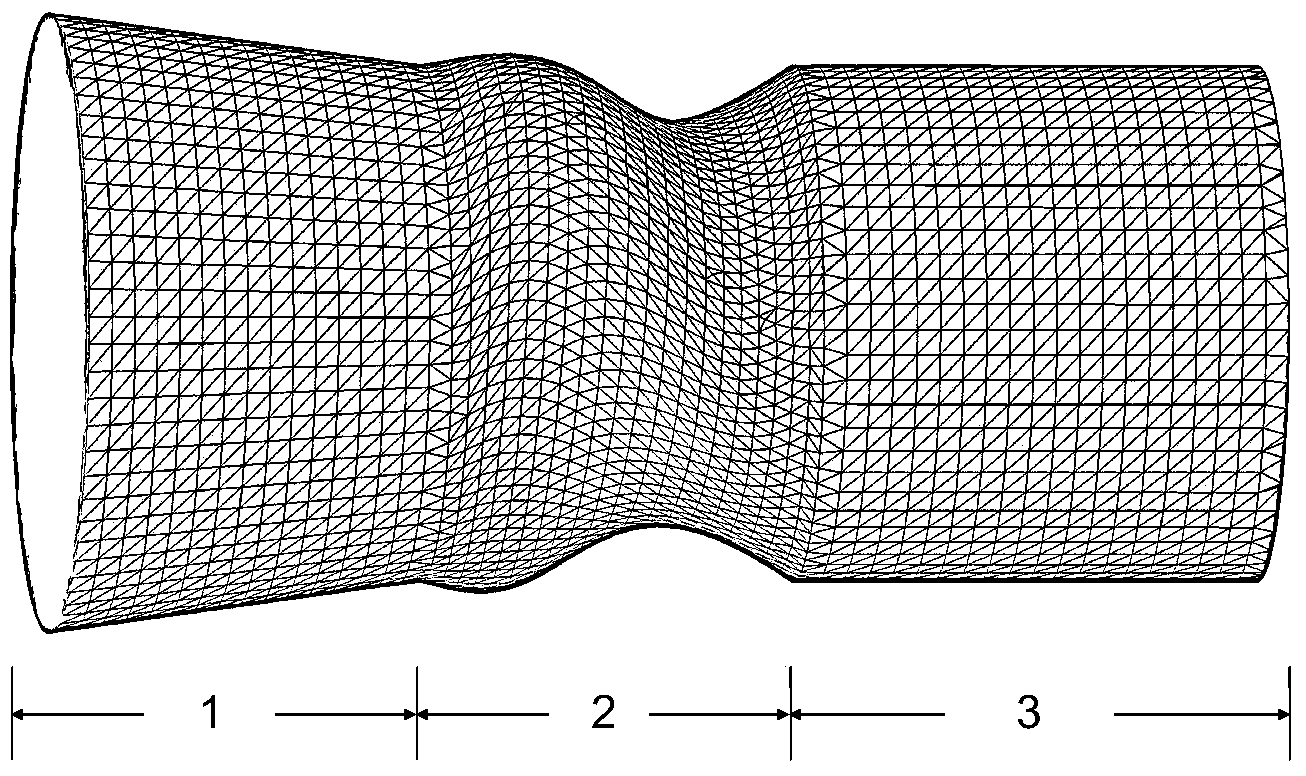

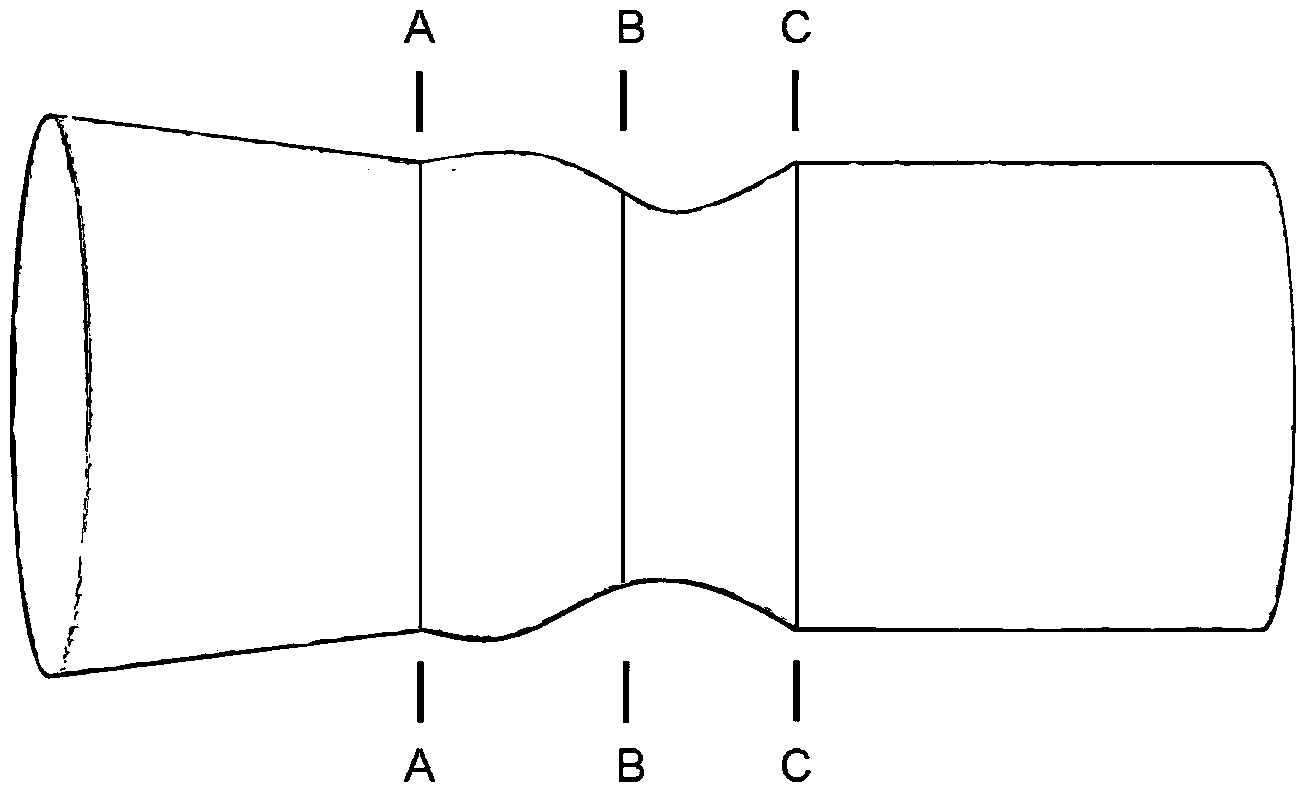

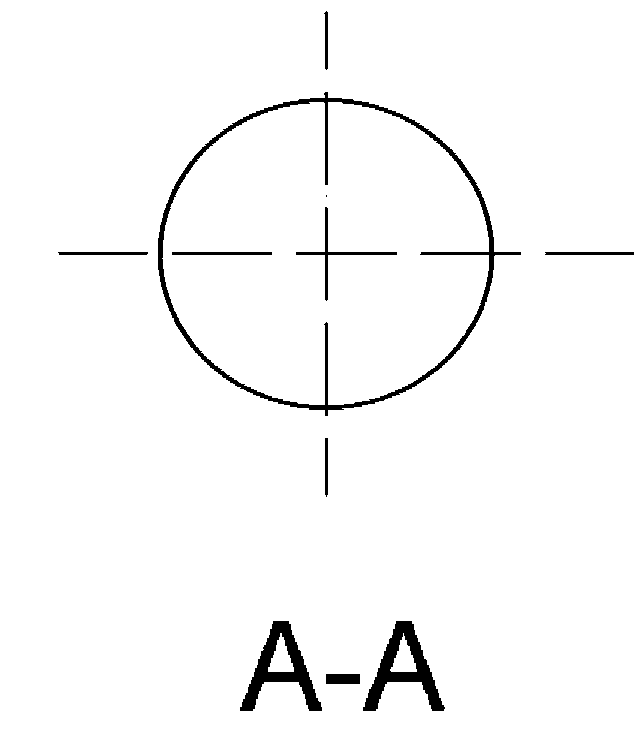

Equal-passage variable-cross-section extruding mold and extrusion forming method for pipes

InactiveCN102430609AImproved strain distributionIncrease stressExtrusion diesExtrusion mandrelsStress distributionShear stress

The invention relates to an equal-passage variable-cross-section extruding mold and an extrusion forming method for pipes. The equal-passage variable-cross-section extruding forming is adopted, so the extruding forming of the pipes is formed through the twisting shearing deformation and the upsetting deformation on the cross section, and the combination of various deformation modes in one extruding process is realized. The pipe walls are in a strong three-direction press stress state through being limited by die cavities and polyurethane foam filling agents, in the deformation stage of circle-ellipse-circle and ellipse twisting change, materials enter twisting shearing deformation zones of the metal transition regions, the material internal tissues generate rotation and shearing stress under the effect of the shearing stress, the orientation of the material tissue structure is caused, i.e. a new tissue structure is formed, and the material tissue structure under the same deformation degree is improved. The mold and the method have the advantages that deformation degree higher than that of the traditional forming process can be obtained, the strain distribution and the stress distribution inside the pipes are improved, residue casting tissues of the pipes can be favorably crushed, the forms and the distribution of inclusions are changed, and the internal tissue defects of the pipes are eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

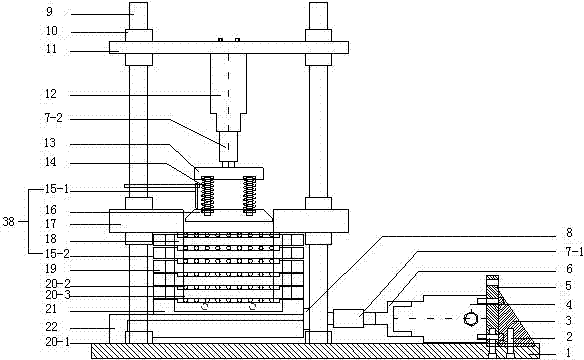

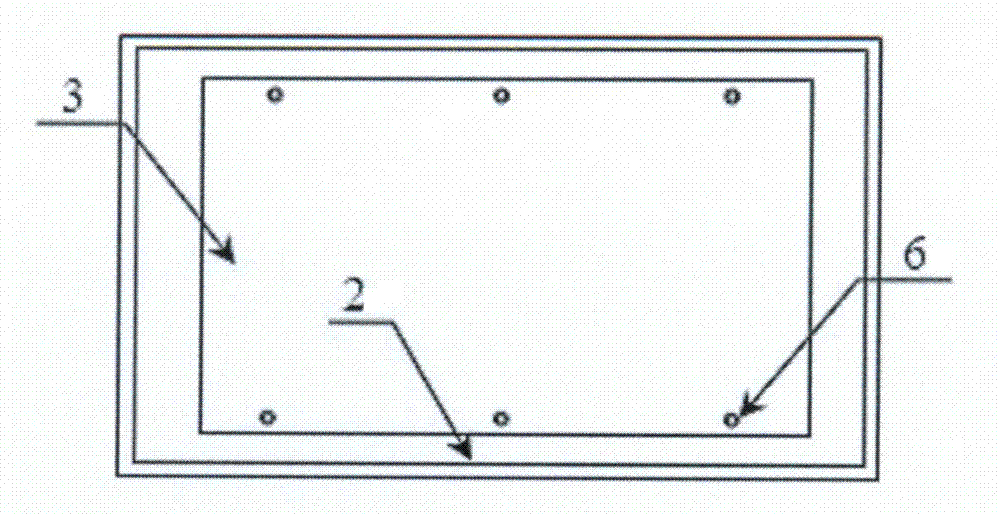

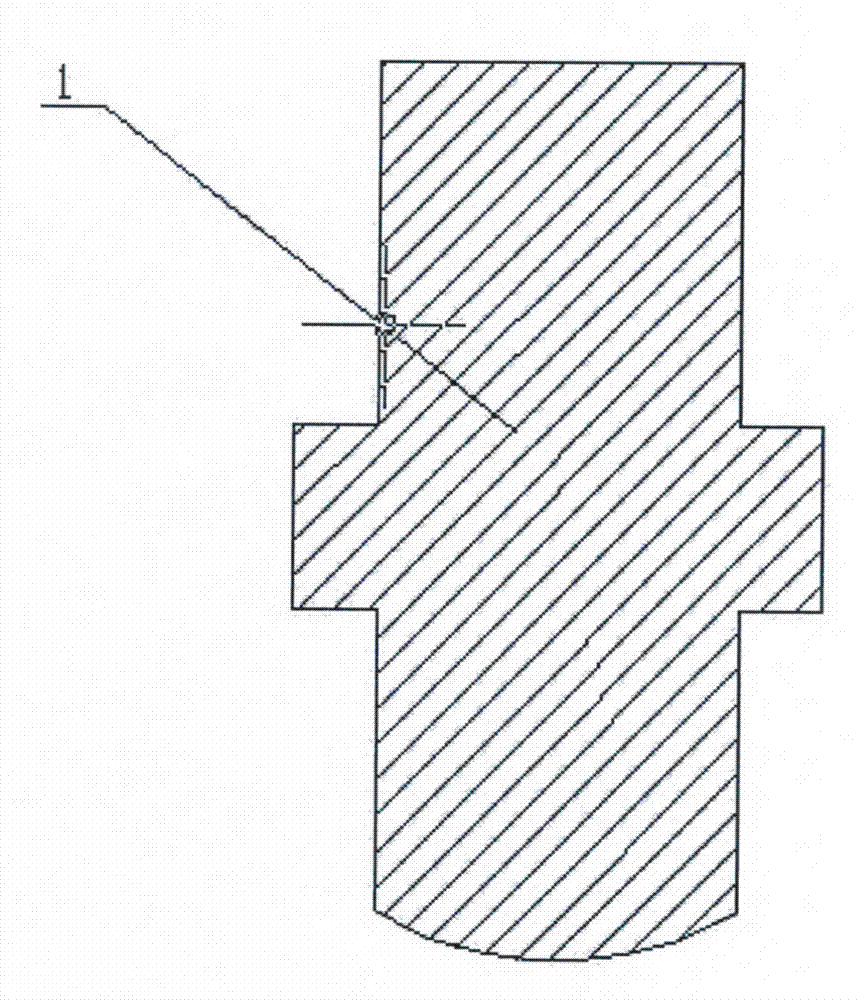

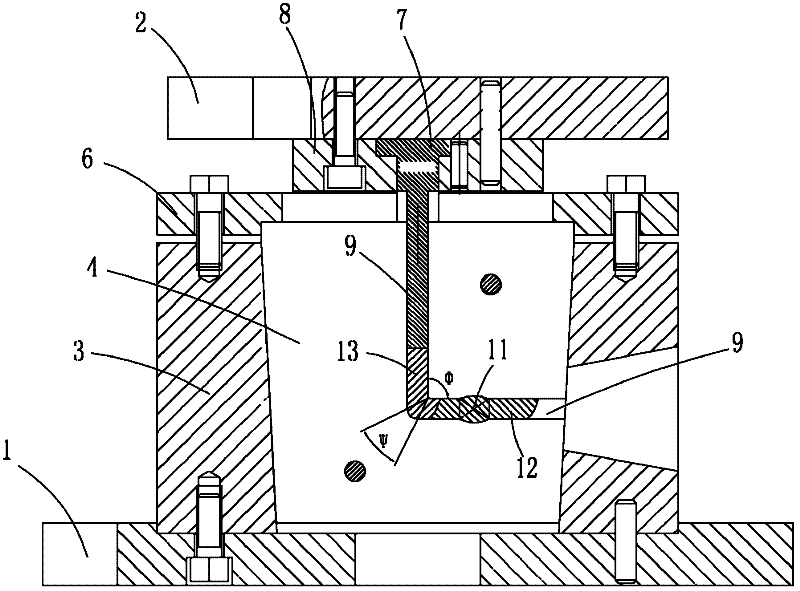

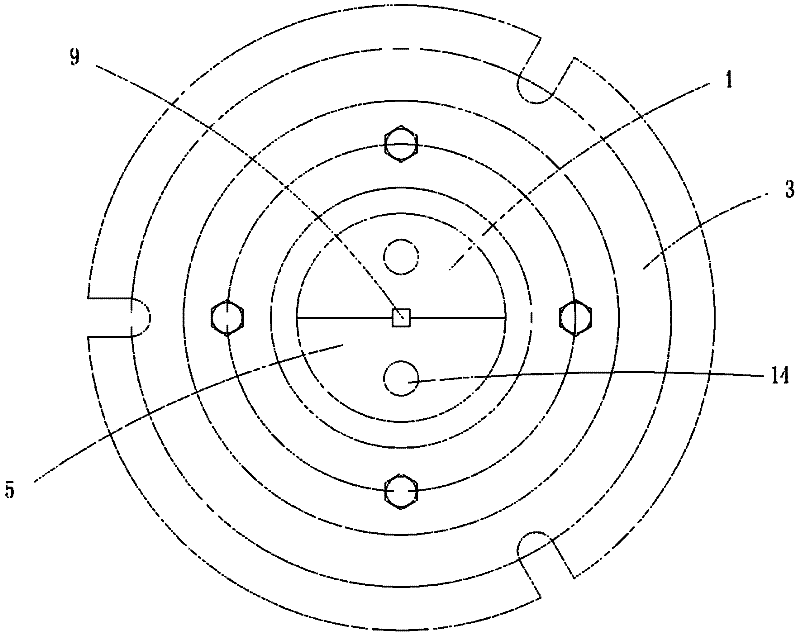

Movable plate stacking ring shearing apparatus capable of adapting to free shearing deformation

ActiveCN104849151ALess restraintReduce stress concentrationMaterial strength using steady shearing forcesShearing deformationTest equipment

The invention discloses a movable plate stacking ring shearing apparatus capable of adapting to free shearing deformation and belongs to the mechanical characteristic test equipment. The movable plate stacking ring shearing apparatus comprises a bracket, a lower shearing box, a stacking ring set shearing box, a vertical loading unit, a horizontal loading unit and a measuring unit, wherein the bracket consists of a bottom plate and a stand column; the lower shearing box and the stacking ring set shearing box are stacked between the bottom plate and the vertical loading unit in sequence; the vertical loading unit is fixed on the stand column; the horizontal loading unit is fixed on the bottom plate. According to the movable plate stacking ring shearing apparatus capable of adapting to free shearing deformation, a movable plate shearing frame capable of adapting to free shearing deformation can be used for performing a simple shear test and a direct shear test and also can be used for performing a pull-out test on geogrid, geotechnical cloth and the like. When the simple shear test is performed, the vertical loading unit can provide three normal boundary conditions of normal displacement, normal rigidity and normal stress, and the horizontal loading unit can be used for providing horizontal shearing force. The movable plate stacking ring shearing apparatus is delicate in design, convenient to operate, easy to assemble and disassemble, and capable of precisely performing research on shearing deformation characteristic between contact surfaces of geotechnical materials and structures.

Owner:WUHAN UNIV

Novel seismic mitigation and absorption support and changing method thereof

ActiveCN103215890AEasy to useReduce coefficient of frictionBuilding repairsBridge structural detailsFrictional coefficientClassical mechanics

The invention relates to a novel seismic mitigation and absorption support comprising a support body, an upper connection steel plate and a lower connection steel plate, wherein the upper connection steel plate and the lower connection steel plate are arranged at the upper / lower part of the support body, the support body is connected with the upper / lower connection steel plate through a sliding mechanism or a rolling mechanism in a sliding manner, the upper / lower side surface of the upper / lower connection steel plate is provided with a sleeve and an anchoring bolt, and the lower / upper side surface of the upper / lower connection steel plate is provided with a limiting stop block for limiting the horizontal sliding of the support body; and a connecting mechanism for mounting a pull rod is arranged on the circumferences of an upper steel plate and a lower steel plate of the support body. According to the novel seismic mitigation and absorption support disclosed by the invention, the friction coefficient of the support body and the upper / lower connection steel plate is small so that the removal and the change are easy; due to the limitation of the limiting stop block, the support body does not generate the horizontal sliding during regular use and does not interfere the shearing deformation of rubber in the support as well; and a change method of the support is simple, convenient and safe in operation, is not limited by the site condition, does not need to use large-scale jacking devices, has a short change periodand high efficiency and is low in cost.

Owner:柳州东方工程橡胶制品有限公司

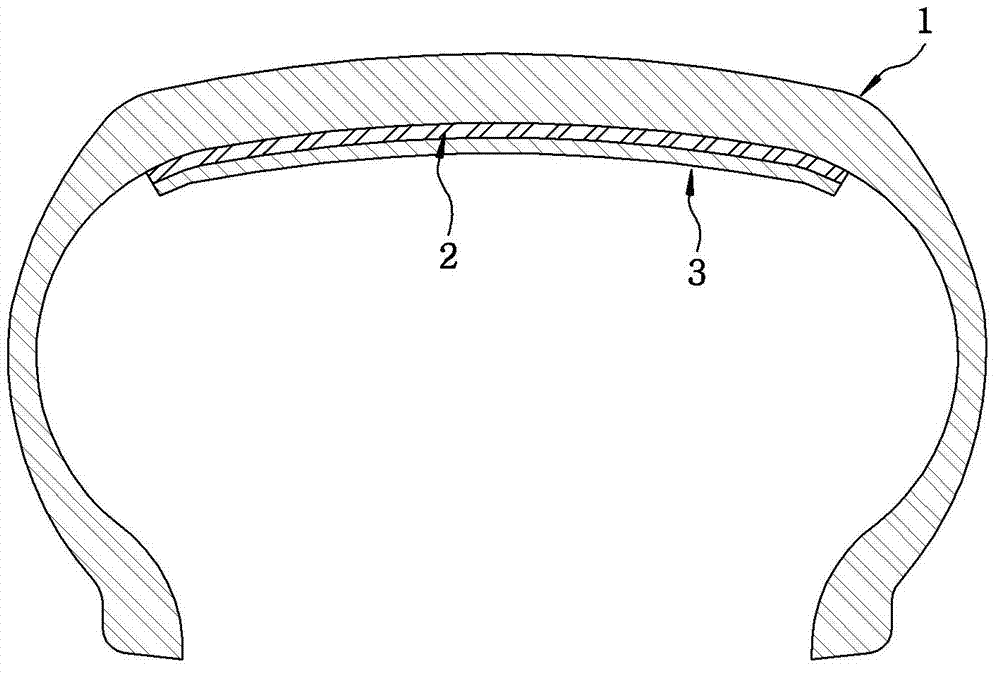

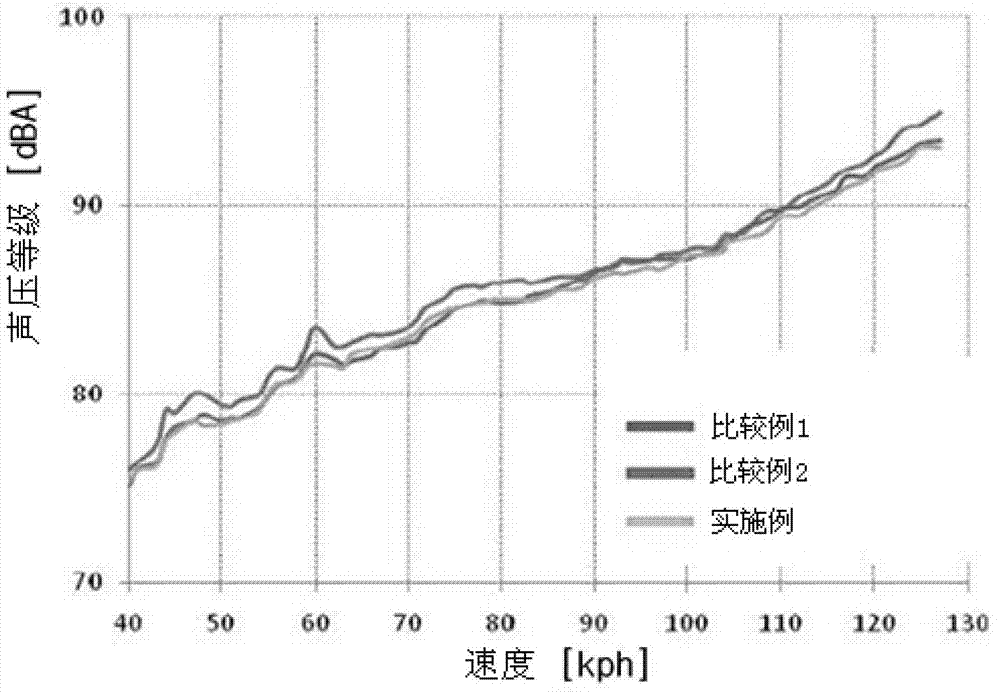

Pneumatic tire and method for manufacturing the same

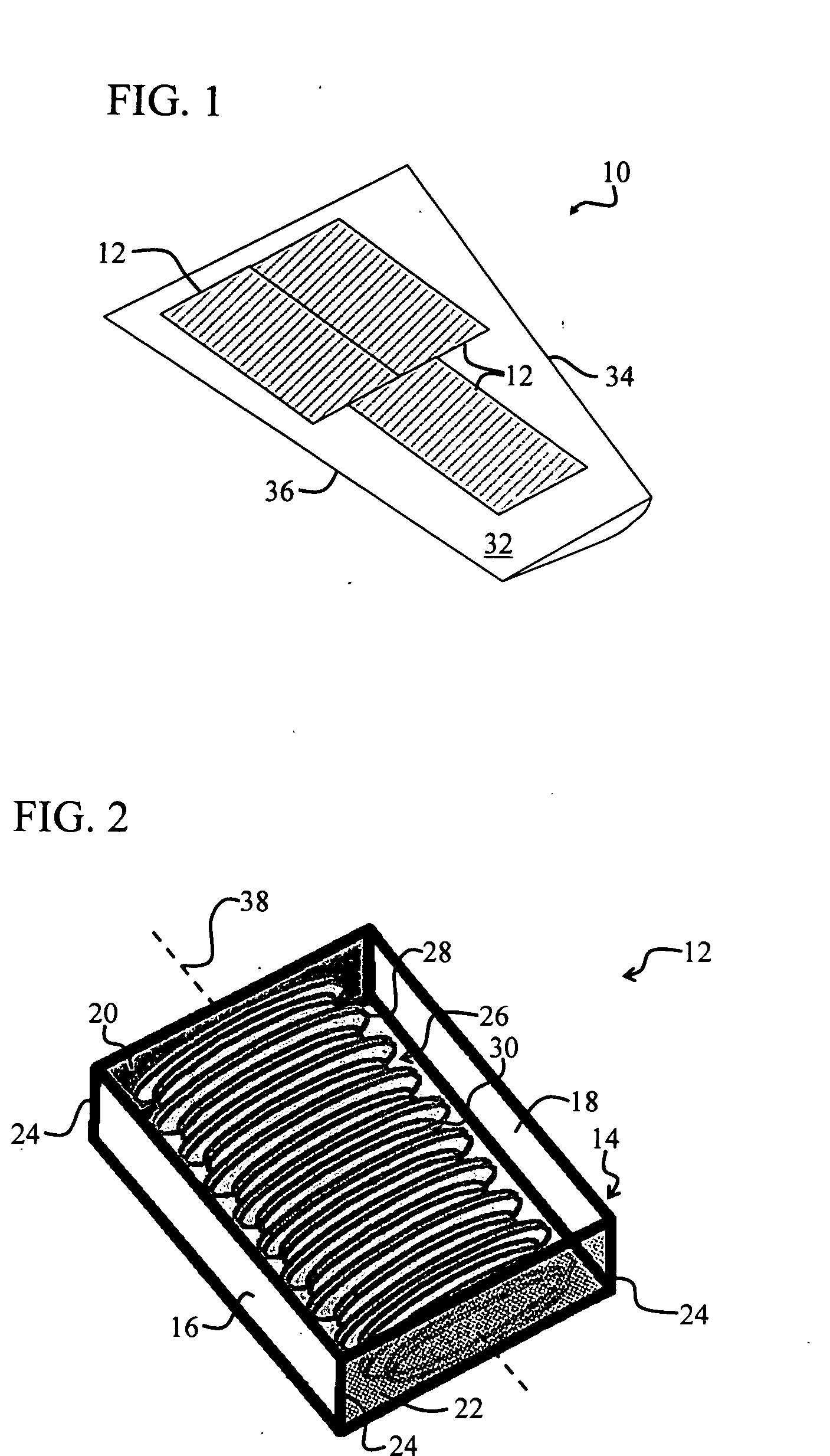

InactiveCN102950974AReduce noiseNo significant change in viscosityWithout separate inflatable insertsLaminationResonanceInternal noise

Pneumatic tire and a method for manufacturing the same, wherein the pneumatic tire includes a porous sound-absorbing material adhered via a sealant layer to the inside surface of an inner liner, wherein the sealant layer comprises 100 to 400 parts by weight of polyisobutylene, 10 to 100 parts by weight of an inorganic additive and 1 to 15 parts by weight of a vulcanizing agent, with respect to 100 parts by weight of a butyl rubber; the pneumatic tire can reduce internal noise by distributing noise energy, causing generation of resonance in the tire, or changing the generated frequency without a risk of shear deformation generated between the sound-absorbing material and the tire.

Owner:HANKOOK TIRE WORLDWIDE

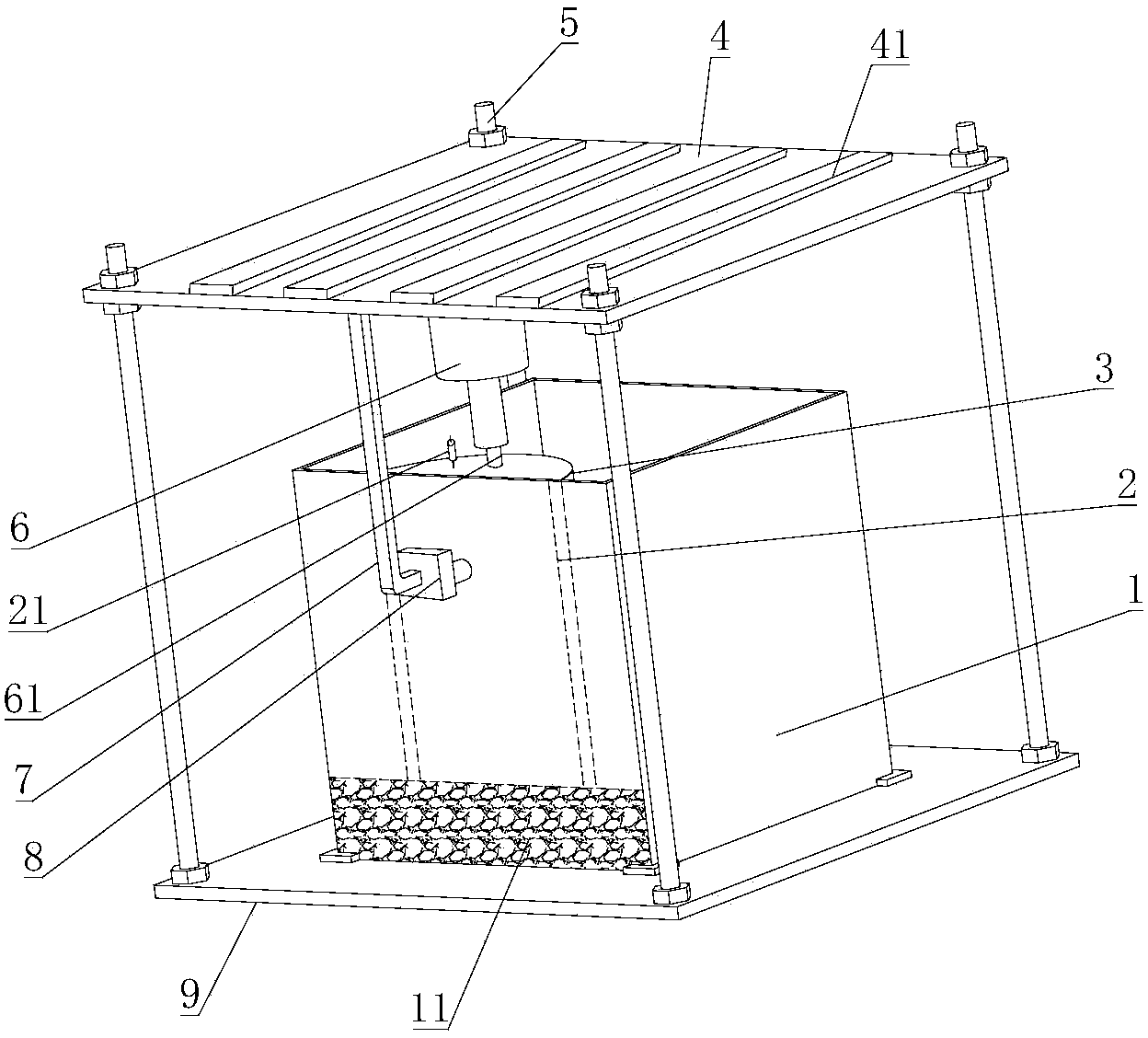

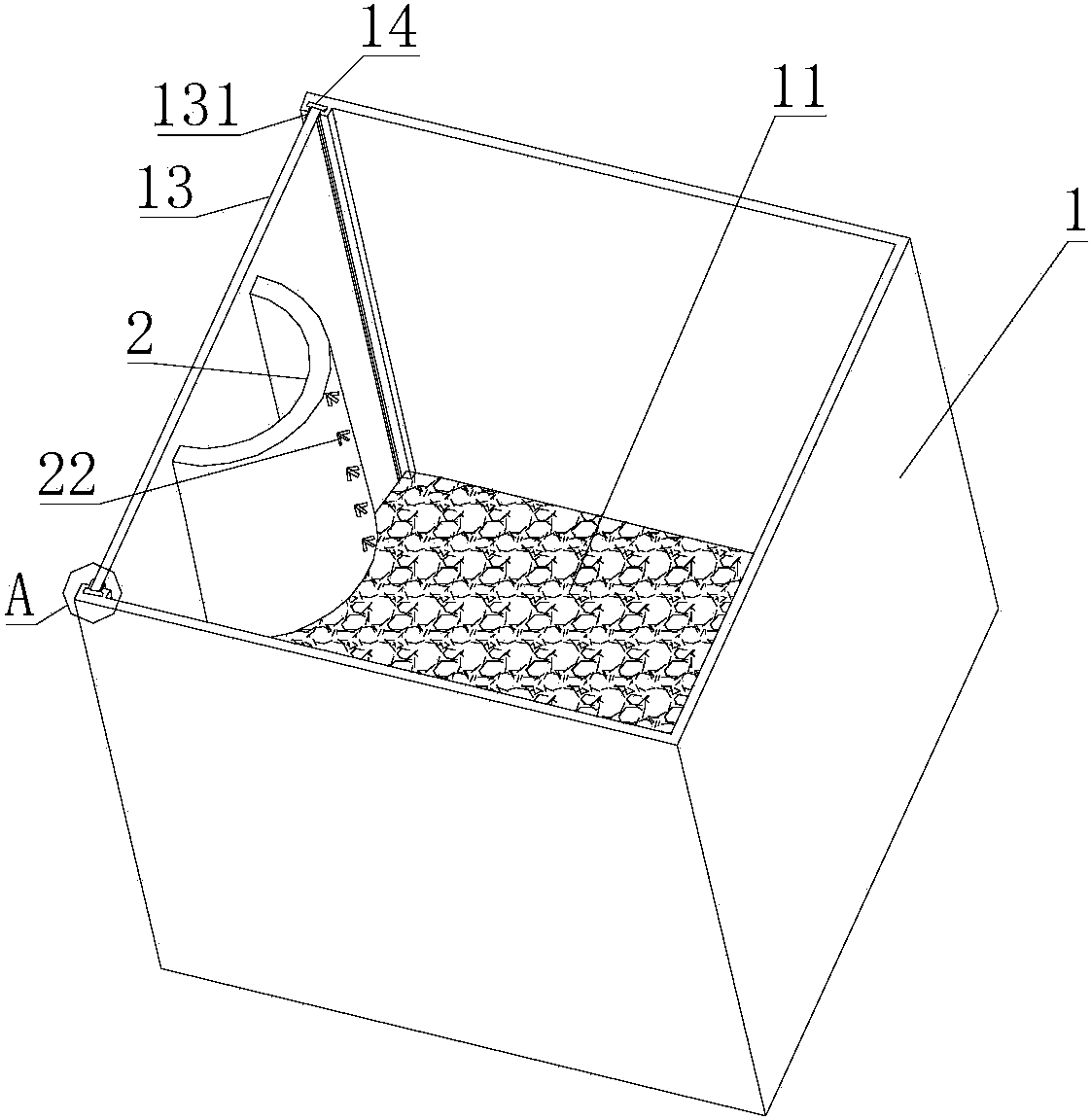

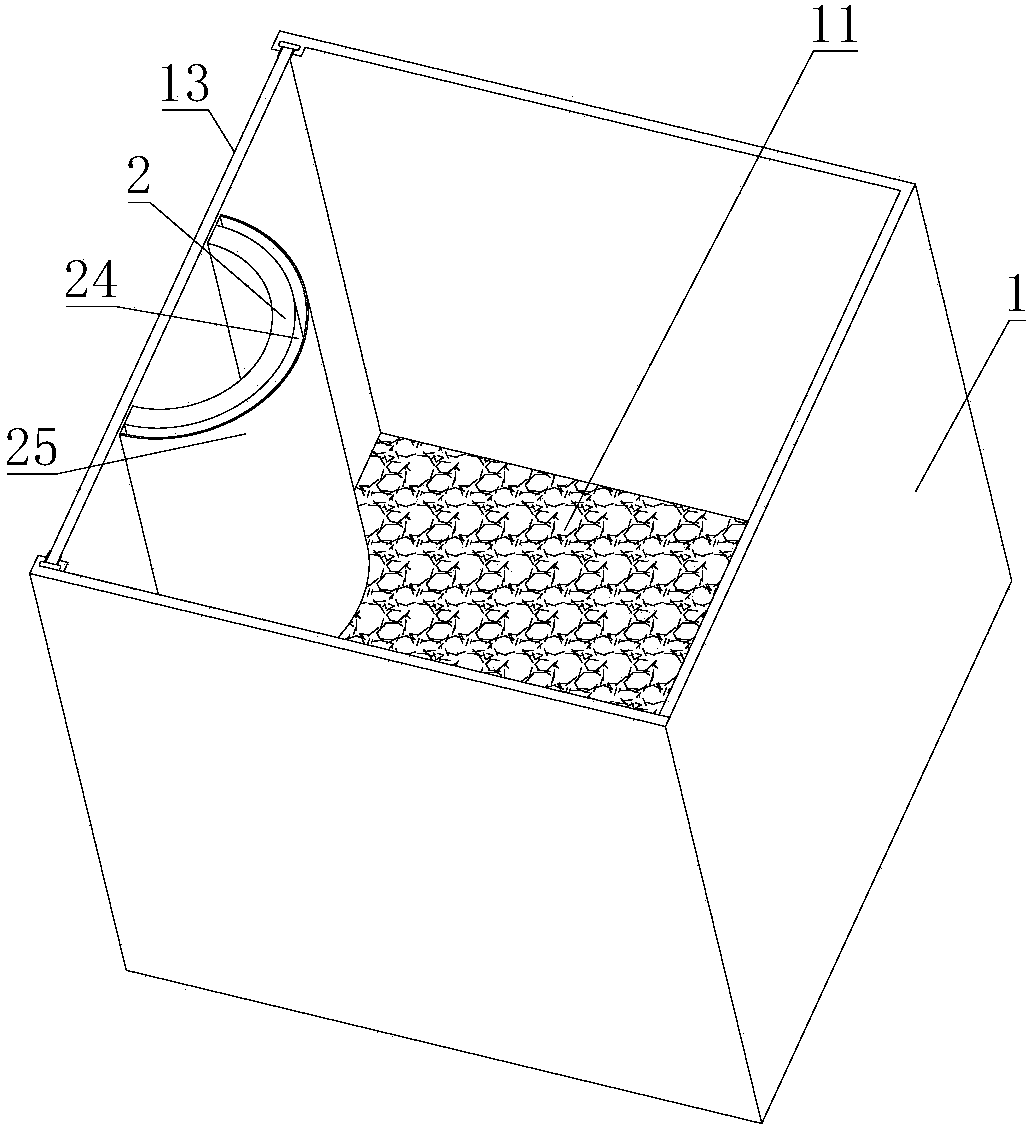

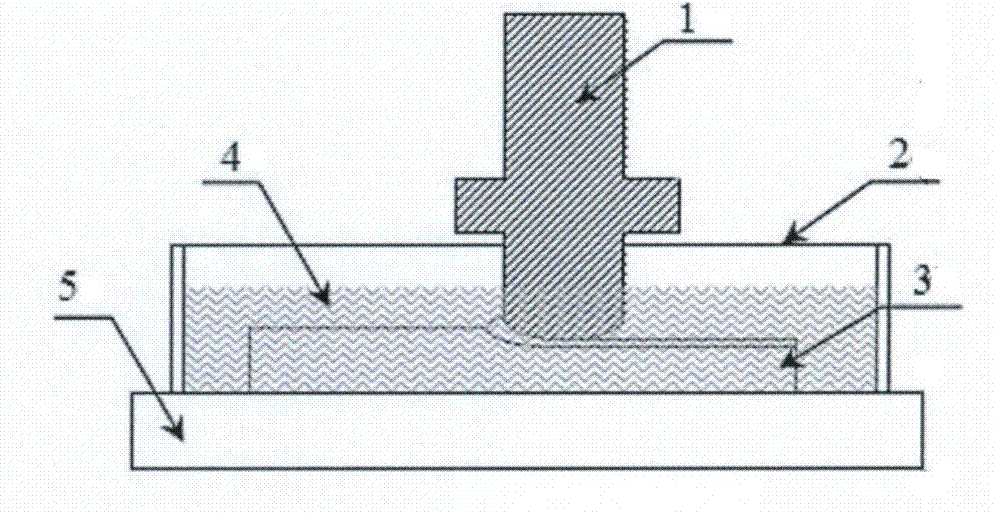

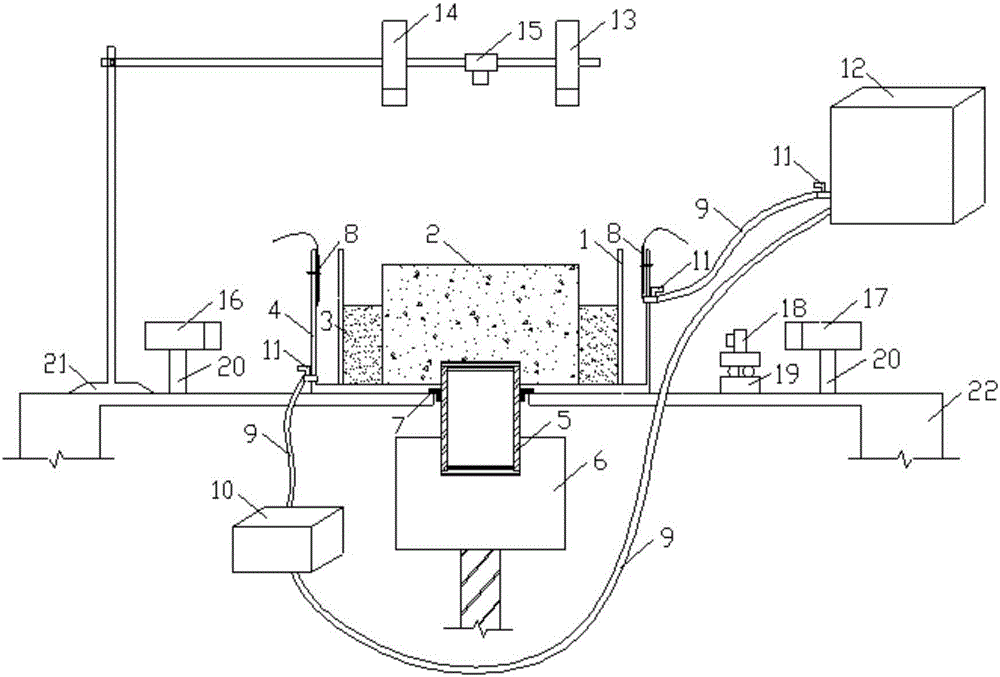

Testing device and method for observing shear deformation failure characteristics between tubular pile and grouting soil body

ActiveCN104374649AEasy to analyzeImprove the simulation effectMaterial strength using steady shearing forcesModel testingMonitoring system

The invention discloses a testing device for observing shear deformation failure characteristics between a tubular pile and a grouting soil body. The testing device comprises a fixing platform, a tubular pile model testing box, a loading mechanism and a monitoring system, wherein the fixing platform comprises a base plate, a top plate and a plurality of connecting screw rods; the tubular pile model testing box comprises a bottom wall, two side walls, a rear wall and a front wall, wherein the front wall is movably arranged between the side walls, and is made of colorless transparent organic glass; the monitoring system comprises a displacement sensor, a pressure sensor and a strain rosette group arranged on the outer surface of the tubular pile; the strain rosette group comprises a plurality of strain rosettes which are uniformly distributed along the central axis direction of the tubular pile, and are connected with an automatic recorder. According to the invention, a semi-circular pipe pile is adopted, so that the shear deformation failure characteristics between the tubular pile and the grouting soil body can be observed conveniently, and the shear resistant intensity between the tubular pile and the grouting soil body can be observed; a camera device is adopted for recording the video of the testing process; the visual testing enables the analysis to be relatively intuitive.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD +1

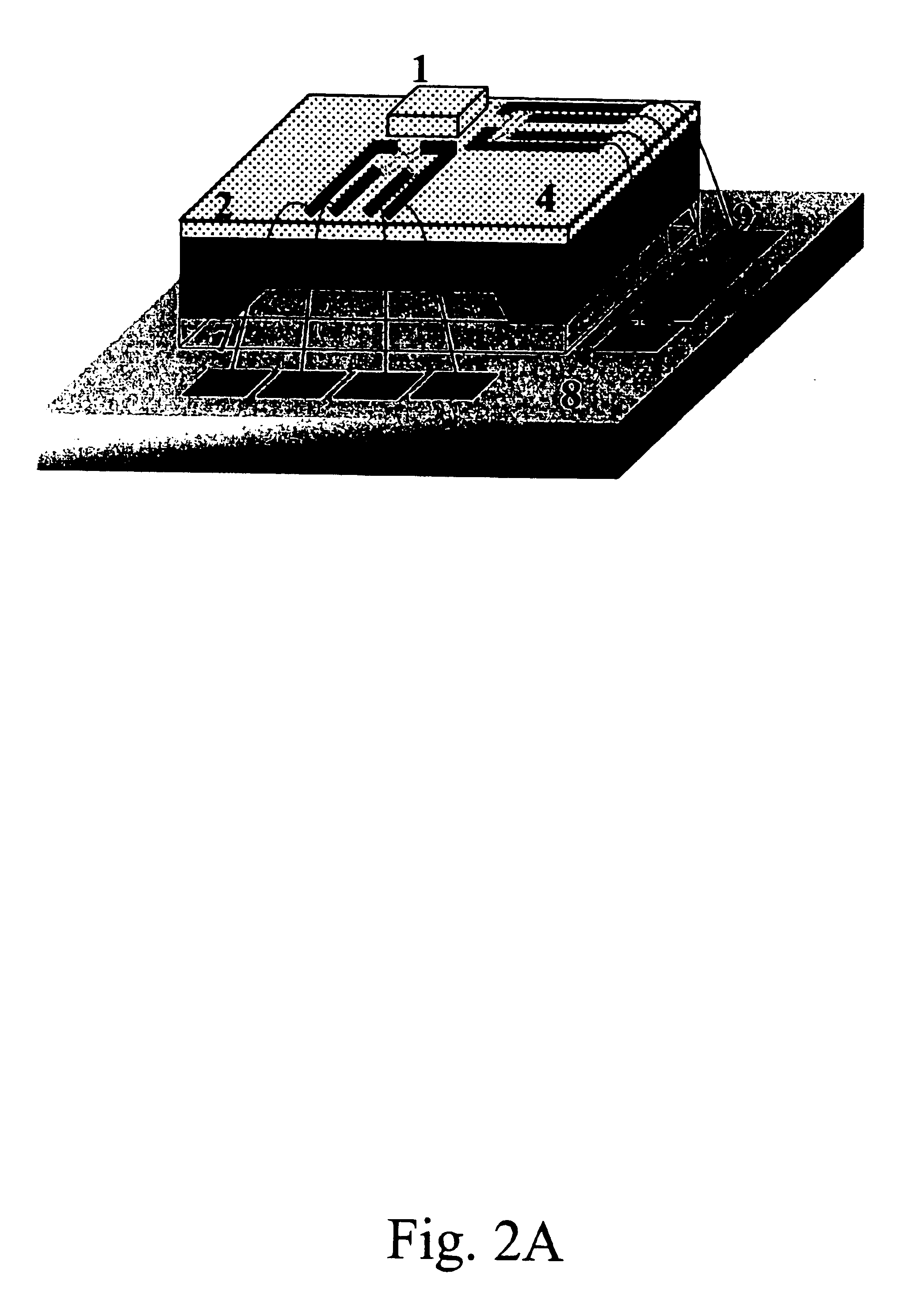

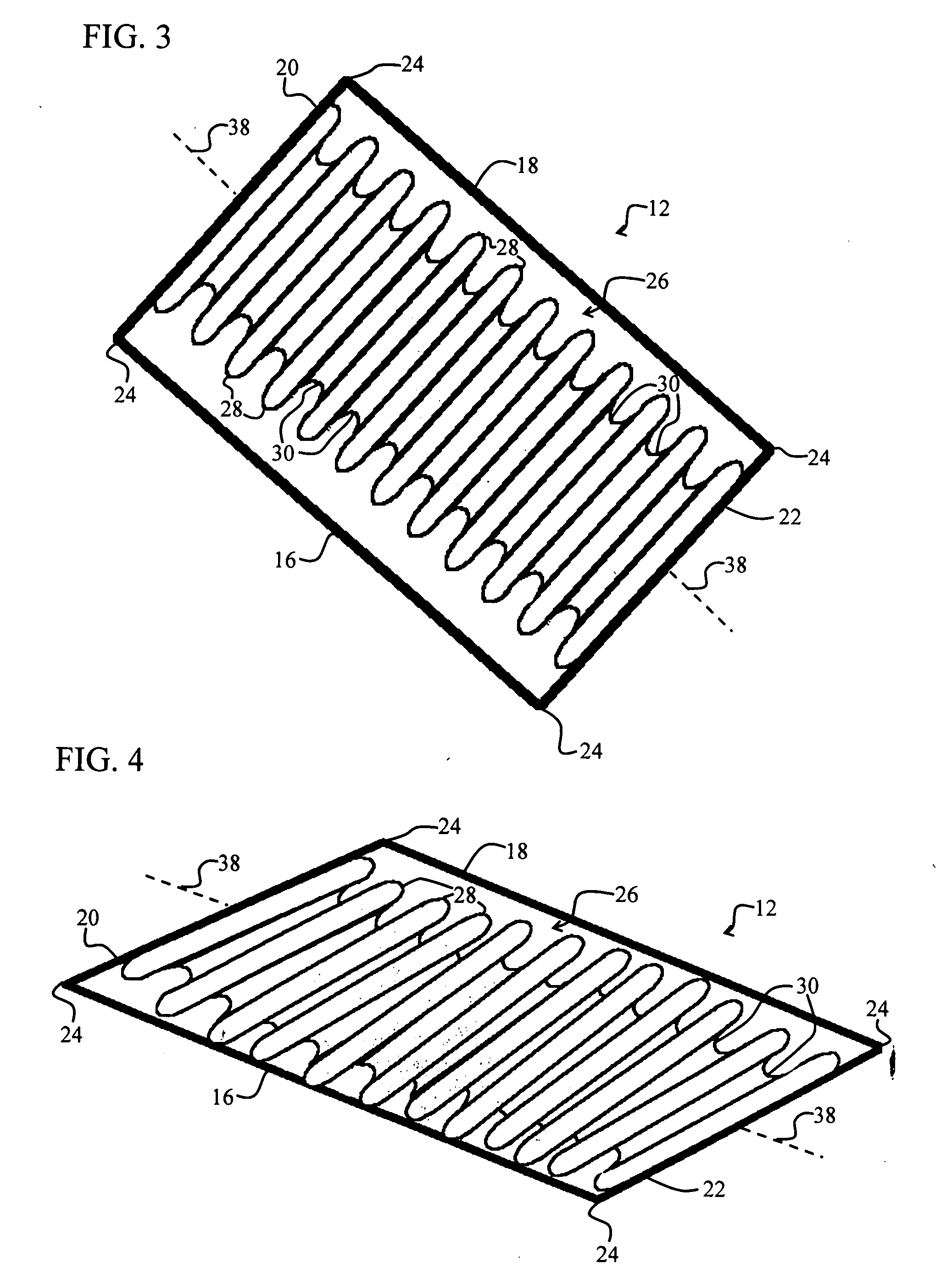

Contact type micro piezoresistive shear-stress sensor

InactiveUS6877385B2Using electrical meansForce measurement using piezo-resistive materialsEtchingEngineering

There is disclosed a semiconductor sensor for measuring the contact shear stress distribution between the socket of an above-knee (AK) prostheses and the soft tissue of an amputee's stump. The sensor is fabricated by the micro-electro-mechanical system (MEMS) technology, and its main sensing part is 2-X shaped with a flange structure. The sensor is prepared by anisotropic wet etching of bulk silicon in KOH solution and a square flange above the sensing diaphragm is formed through surface micromachining of deposited SiO2 thin film. This invention has the following characteristics: piezo-resistivity of the monolithic silicon will be utilized to convert shear deformation of the sensor into an electrical signal and a micro sensor which can measure the shear force vector acting on the sensing flange.

Owner:NAT SCI COUNCIL

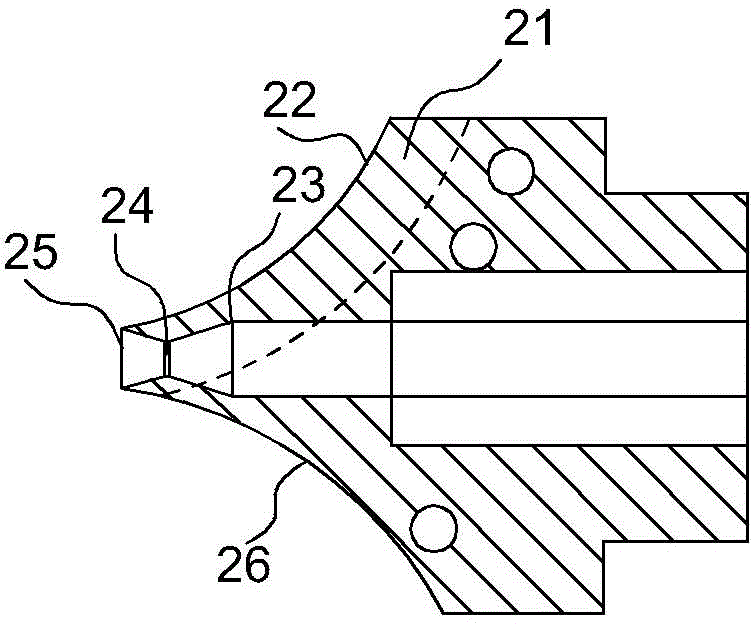

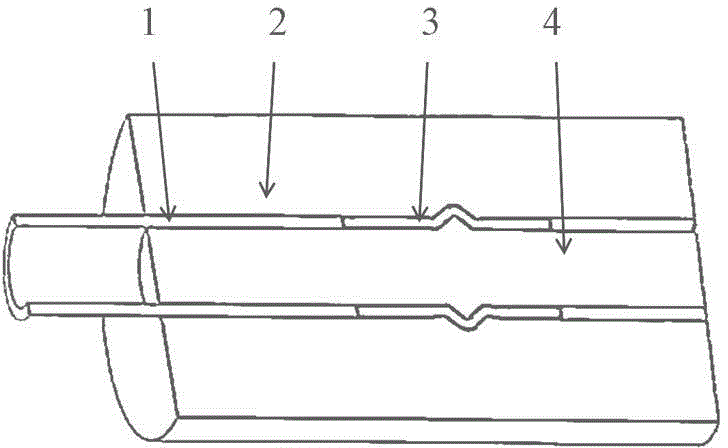

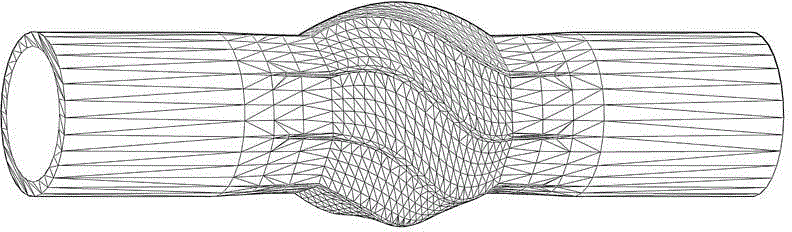

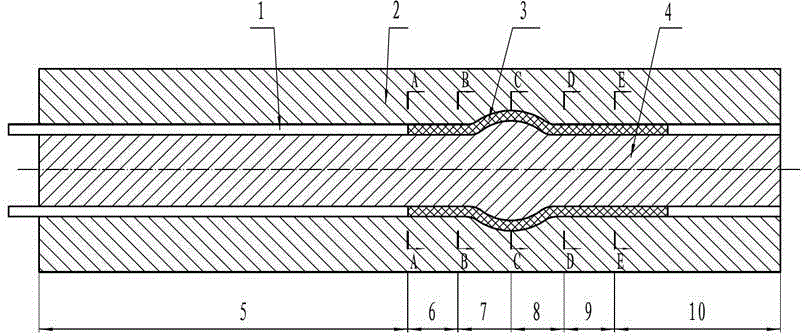

High-pressure shearing deformation method and device for tubular materials

ActiveCN102189706AThe principle is simpleEasy to processMetal-working apparatusEngine componentsAxial pressureHydrostatic pressure

The invention discloses a high-pressure shearing deformation method and device for tubular materials. The high-pressure shearing deformation method comprises the following steps of: firstly: selecting a workpiece to be machined, wherein the workpiece is tubular; respectively bounding the inner wall and the outer wall of the workpiece by adopting bonding objects; then directly applying the axial pressure to the end part of the workpiece so that the elastic deformation or tiny plastic deformation occurs in the workpiece; accumulating the hydrostatic pressure up to 1 to 15 GPa in the workpiece; afterwards, supplying a torque to one bounding object which is in contact with the outer wall or the inner wall of the workpiece so as to lead the bounding object to rotate around a central shaft of the workpiece; meanwhile, fixing the other bounding object, wherein under the action of the circumferential frictional force between the bounding objects and the inner wall and the outer wall of the workpiece, the interior of the workpiece rotates along materials with different radial thicknesses at different angular speeds, thereby realizing the circumferential shearing deformation of the workpiece. The high-pressure shearing deformation method has high technical feasibility and has no specific requirements for operation; and required equipment is simple and obtainable. Meanwhile, the high-pressure shearing deformation method is a new plasticity processing method which is realized by depending on the traditional extrusion equipment; and therefore, the functions of the traditional extrusion equipment are expanded.

Owner:NANJING UNIV OF SCI & TECH

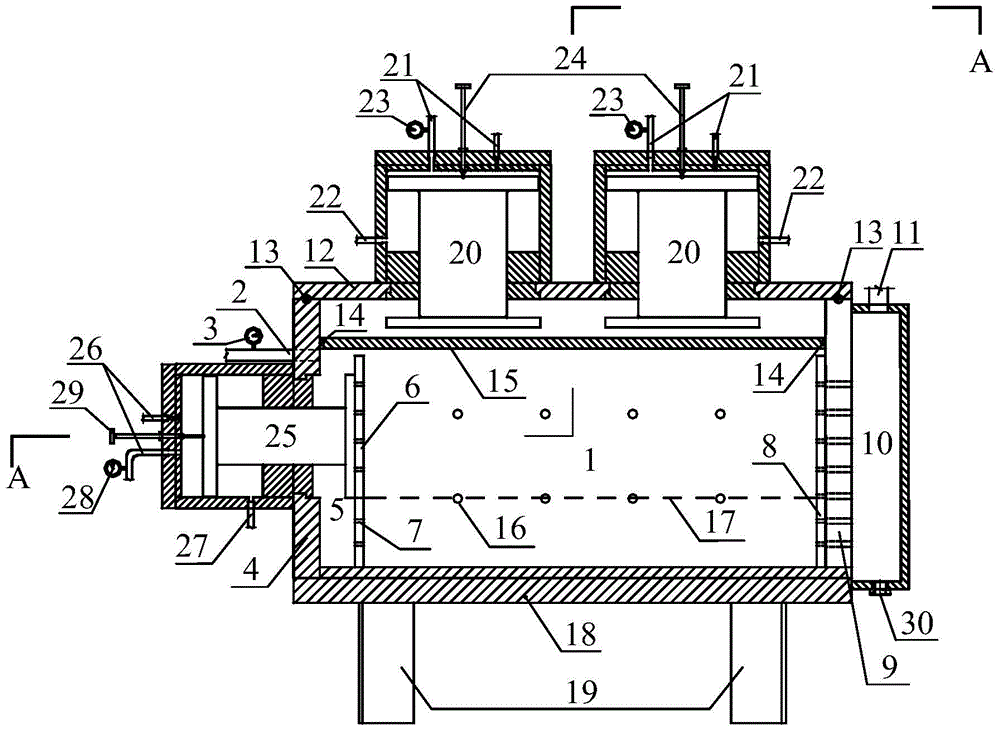

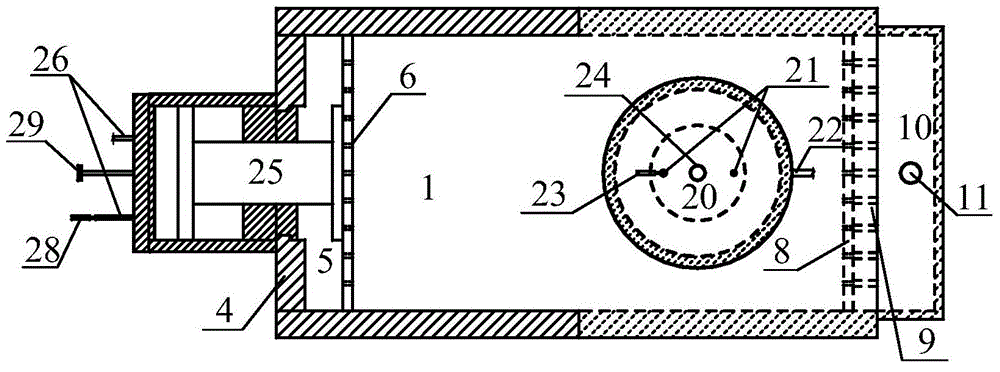

Horizontal permeameter suitable for soil horizontal contact surface shearing deformation

ActiveCN104897539AInto the uniformOutflow smoothlyPermeability/surface area analysisShearing deformationEngineering

The invention discloses a horizontal permeameter suitable for soil horizontal contact surface shearing deformation. The horizontal permeameter comprises a support, a test box arranged on the support, a sample chamber positioned in the test box, a vertical compression oil cylinder arranged on the top board of the test box, a transverse compression oil cylinder arranged on an outer side board of the test box, and an inlet water chamber and an outlet water chamber which are arranged at the two outer ends of the sample chamber along the piston action direction of the vertical compression oil cylinder, the inner side board at a water inlet end is formed by an upper transversely movable part and a lower fixed part, and a transverse compression oil cylinder piston acts on the transversely movable part. The horizontal permeameter can be used for researching the horizontal seepage characteristic and the horizontal contact surface wash destroy of a soil horizontal contact surface or a soil and structure horizontal contact surface under shearing deformation conditions.

Owner:SICHUAN UNIV

Inkjet head and method of manufacturing inkjet head

ActiveUS20070070125A1Easy to adjustEasy mechanical adjustmentPiezoelectric/electrostrictive device manufacture/assemblyElectrically conductive connectionsEngineeringShearing deformation

An inkjet head including: a head chip having; driving walls composed of piezoelectric element, wherein shear deformation is caused by applying voltage so as to jet ink, channels arranged alongside the driving walls alternatively to contain ink, outlet and inlet ports respectively provided on a front and rear surface of the head chip for each channel, driving electrodes formed on surfaces of the driving walls to apply voltage to the driving walls, and connection electrodes formed on the rear surface of the head chip to connect the driving electrodes electrically; a wiring substrate, wherein wiring electrodes are formed to apply voltage to the driving electrode through the connection electrode, bonded on the rear surface of the head chip to protrude from the head chip in a direction perpendicular to a direction of a channel array so that all the channels are exposed at the rear surface of the head chip.

Owner:KONICA MINOLTA INC

Non-ferrous metal continuous casting-rolling-extrusion integral processing forming device and method

InactiveCN104588430AShort processNo pollution in the processExtrusion diesShearing deformationZinc alloys

The invention discloses a non-ferrous metal continuous casting-rolling-extrusion integral processing forming device and method, belongs to the metallurgical technical field, and relates to the integral and continuous processing forming technology formed by integrating casting, rolling and extrusion processing methods into one. The device and the method can be applied in forming of aluminum alloys, magnesium alloys, zinc alloys, tin alloys, lead alloys and other materials, solve the problems of small plastic deformation and coarse grains in continuous casting and rolling, and also solve the problem that metals with lower plasticity are difficult to form because metal shear deformation is larger in continuous casting and extrusion. The device comprises a machine frame, a casting and extrusion boot, an extrusion forming device, a concave roller, a convex roller, a driving mechanism and a cooling system, and has the structural characteristics that the casting and extrusion boot and the extrusion forming device are respectively and fixedly arranged on the machine frame, the extrusion forming device is provided with an extrusion die, the concave roller and the convex roller driven by the driving mechanism are located between the casting and extrusion boot and the extrusion die, the concave roller is positioned at the upper side, the convex roller is positioned at the lower side, and the center connecting line is vertical to a horizontal surface.

Owner:NORTHEASTERN UNIV +1

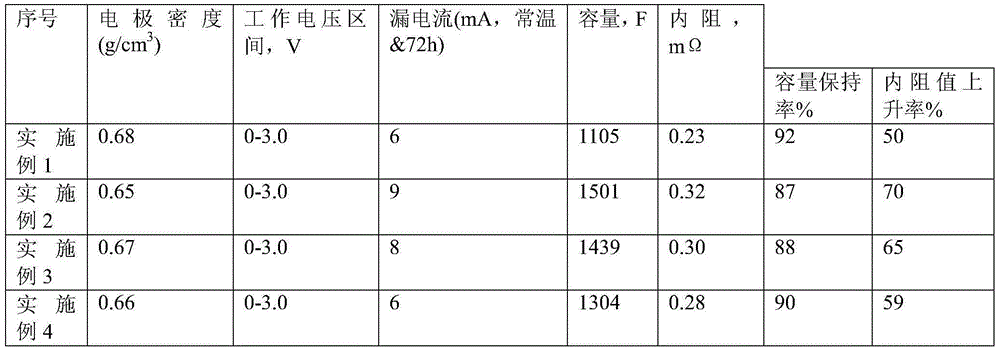

Electrode preparation technology of super capacitor

ActiveCN105225847AIncrease energy densityImprove cycle lifeHybrid/EDL manufactureCarbon filmConductive coating

The invention relates to an electrode preparation technology of a super capacitor. The preparation technology comprises the following steps: weighing raw materials including a conductive agent, binder polytetrafluoroethylene powder and active substance high specific surface area active carbon; carrying out dry-state powder uniform mixing on the power-state active carbon, the binder polytetrafluoroethylene powder and the conductive agent; carrying out heating under the effect of a super shearing machine, carrying out shearing deformation mixing, and obtaining a dry-state carbon film; spraying conductive resin to the surface of aluminum foil in advance, and forming a conductive coating; and pasting the dry-state carbon film evenly to the conductive coating, carrying out heat-curing, and finally obtaining a dry-method electrode. According to the invention, a high speed airflow mixing technology is adopted to realize uniform mixing among solid powder particles, and simultaneously by means of a deformation structure of PTFE under the high speed shearing condition, the mixing among the active substance, the conductive agent and the binder is realized, so that the electrode sheet high in density, uniform in surface and used for the high performance super capacitor is formed.

Owner:NINGBO CRRC NEW ENERGY TECH CO LTD

Differential-speed extrusion forming method of magnesium alloy high performance cup-shaped piece

ActiveCN106607468AIncrease the number of deformationsIncrease the amount of plastic deformationExtrusion diesChinese charactersHigh density

The invention provides a differential-speed extrusion forming method of a magnesium alloy high performance cup-shaped piece and relates to the technical field of metal and plastic machining and forming. A combined concave die is adopted and comprises a T-shaped upper concave die body and a U-shaped lower concave die body. The T-shaped upper concave die body is internally provided with a cylindrical cavity and installed on the U-shaped lower concave die body, and the section of a formed revolved cavity is shaped like a Chinese character 'shan'. Staggered 'ladder' type differential-speed extrusion steps are adopted for the bottom of the extrusion cavity shaped like the Chinese character 'shan'. Three stages of deformation are conducted, the first stage is the axial similar cylinder pier coarse deformation stage, the second stage is the radial extrusion large deformation stage, and the third stage is the corner extrusion and shearing deformation stage. The extrusion cavity shaped like the Chinese character 'shan' and the staggered 'ladder' type differential-speed extrusion steps at the cavity bottom are adopted for extruding the magnesium alloy high performance cup-shaped piece, the magnesium alloy material forming capacity is greatly improved, a high-density structure is obtained, great plastic deformation is obtained, the grain refining effect is remarkable, the effect of eliminating grain dual-mode distribution of the barrel wall of the cup-shaped piece is obvious, and the fabrication procedure of the high performance magnesium alloy cup-shaped piece is shortened.

Owner:ZHONGBEI UNIV

Electromagnetic force driven molded sheet forming method and equipment

InactiveCN102259132AImprove deformationUniform deformationShaping toolsHigh rateElectromagnetic interference

The invention discloses a method and equipment for forming a molded sheet material driven by electromagnetic force, which relates to the molding of a block plate-like ultra-fine grain material driven by electromagnetic force. Using electromagnetic force to drive the steel mold to achieve high-speed and severe deformation of the plate, thereby solving the problem that the effect of grain refinement is not obvious due to the limitation of material types and pressing passes when forming metal sheets based on conventional plastic deformation methods such as stamping forming. Its technology The feature is that the processed slab is put into the bending die for bending; the bent slab is leveled with the flattening die. Then, the slab is rotated 180° in the horizontal direction, so that the part of the sample that has not been sheared during the first two molding deformation processes enters the position of shear deformation, and then the bending is performed; Blanks are leveled. After 4 times of molding deformation, ultra-fine-grained slabs can be obtained without changing the dimensions of the slab. The invention effectively integrates the advantages of electromagnetic forming and molding deformation, and can prepare large-volume ultra-fine-grained plates of various metal materials.

Owner:HARBIN INST OF TECH

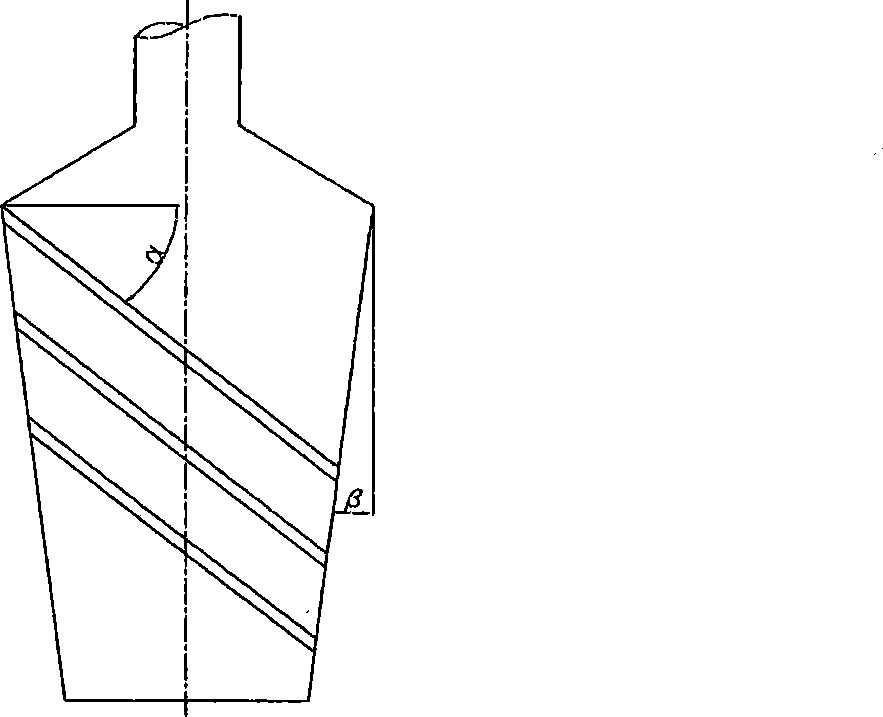

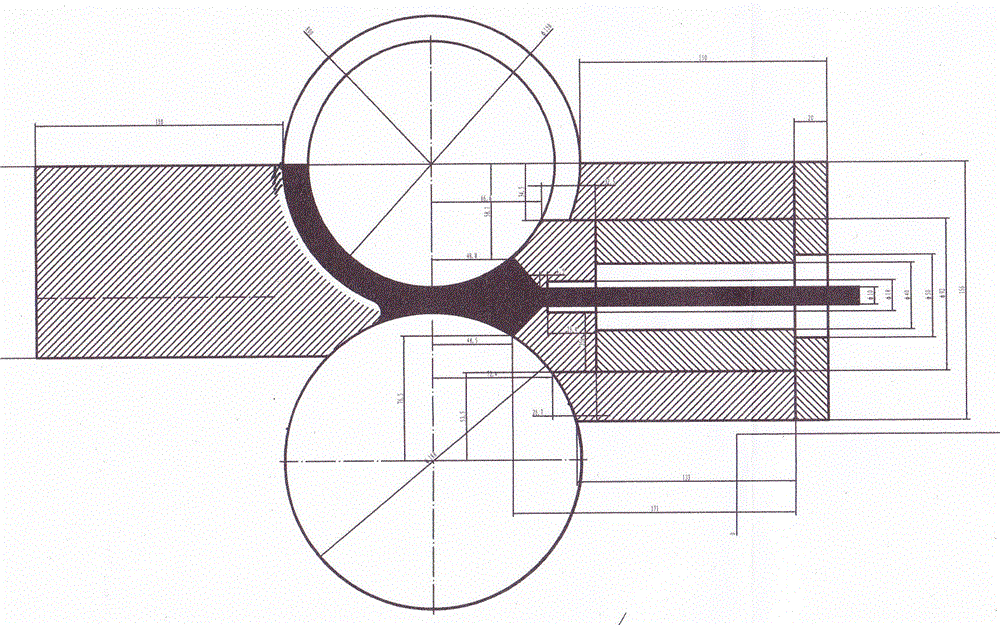

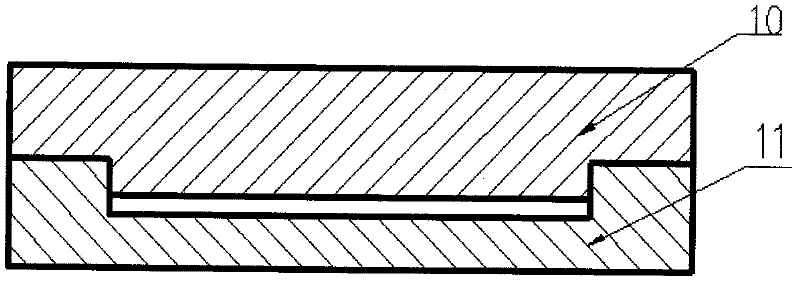

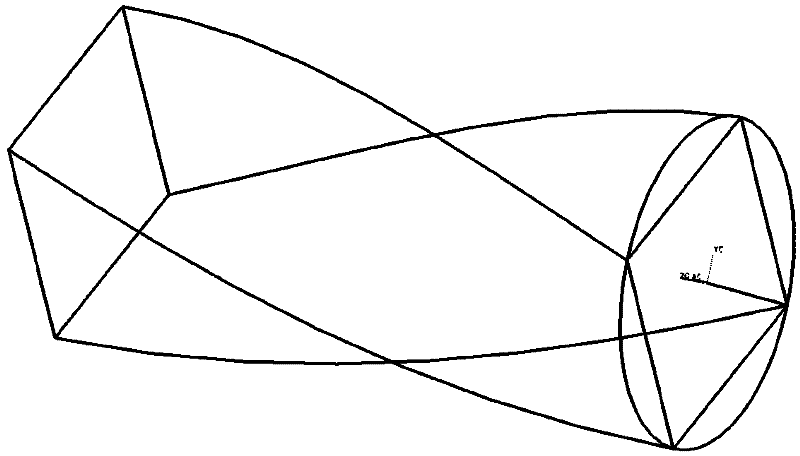

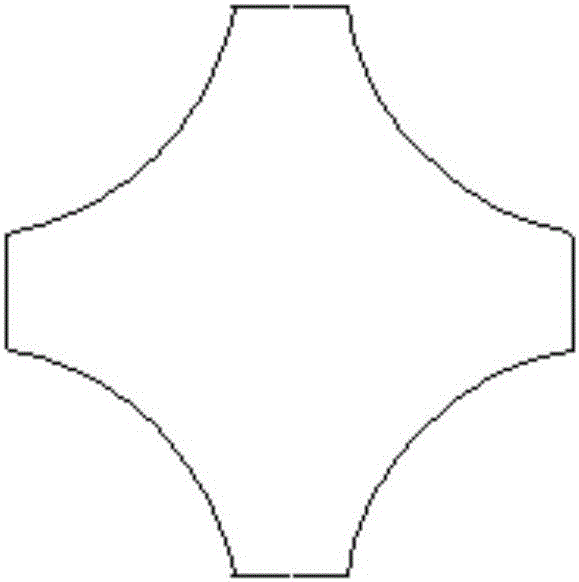

Equal channel forming die for thick-wall pipe and method of forming die for forming pipe

InactiveCN104307908AImproved strain distributionIncrease stressExtrusion diesDeformation effectShearing deformation

The invention relates to the technical field of forming pipes with thick walls (a ratio of pipe diameter to wall thickness is less than 20) of such metals as aluminum, copper and steel and round cross sections, and in particular discloses an equal channel forming die for a thick-wall pipe and a method of the equal channel forming die for forming the pipe. An equal channel corner variable-cross section twist extrusion forming technical scheme adopted by the invention is similar to combination of twist shear deformation and upsetting and drawing extrusion-bulging deformation on a cross section, thus realizing combination of multiple deformation modes in an extrusion process. The equal channel forming die disclosed by the invention has the advantages of good deformation effect, quick speed and high efficiency; and the equal channel forming die can overcome a shortcoming of a current process which is uneven in deformation, greatly improve stress-strain distribution and a deformation texture in the material, and simultaneously improve material performance.

Owner:TAIYUAN UNIV OF TECH

Rotary shear failure performance determination test device of asphalt mixture

InactiveCN103245571AReduce occupancyEasy to testMaterial strength using steady shearing forcesComputer control systemData information

The invention provides a rotary shear failure performance determination test device of an asphalt mixture and belongs to the technical field of mechanical property testing of the asphalt mixture. The rotary shear failure performance determination test device is composed of a testing platform, a loading system and a computer control system, wherein the loading system is used for carrying out rotary shearing loading on an asphalt mixture test piece according to a set shearing speed; the computer control system collects data information in real time; and a rotary shearing method is adopted to test a shear failure performance of the asphalt mixture. The rotary shear failure performance determination test device disclosed by the invention has the advantages that (1) a rotation torque acting on the test piece with an axially-symmetrical section only generates pure shearing deformation and a simple pure shearing stress state can be obtained, so as to be convenient for testing and controlling the maximum shearing stress and strain; (2) due to an axial symmetry property, the testing accuracy can be improved in theory; and (3) testing equipment and a testing process of rotary loading occupy a small testing space; and compared with pulling and pressing deformation, the rotary shearing deformation (angle displacement) can be infinitely great in theory and is basically not limited by the testing space, so that the rotary shear failure performance determination test device is particularly suitable for materials with great plastic failure deformation.

Owner:DALIAN UNIV OF TECH

Deformation-control system and method

A system for selectively controlling deformation. The system includes a first mechanism for resisting deformation about an axis of an accompanying fluid foil. A second mechanism, in communication with the first mechanism, enables deformation along the axis and / or at an angle to the axis. In more a specific embodiment, the axis is a lengthwise axis of the fluid foil, which is a transformable airfoil, and the system includes a bellows device that is approximately concentric with the axis. The bellows device is supported by first base structure at one end and a second base structure at another end. The deformation at an angle to the first axis includes shear deformation or bending deformation. The deformation along the axis includes extension or strain deformation. The deformation about the axis includes torsion deformation.

Owner:COWAN DAVID L +1

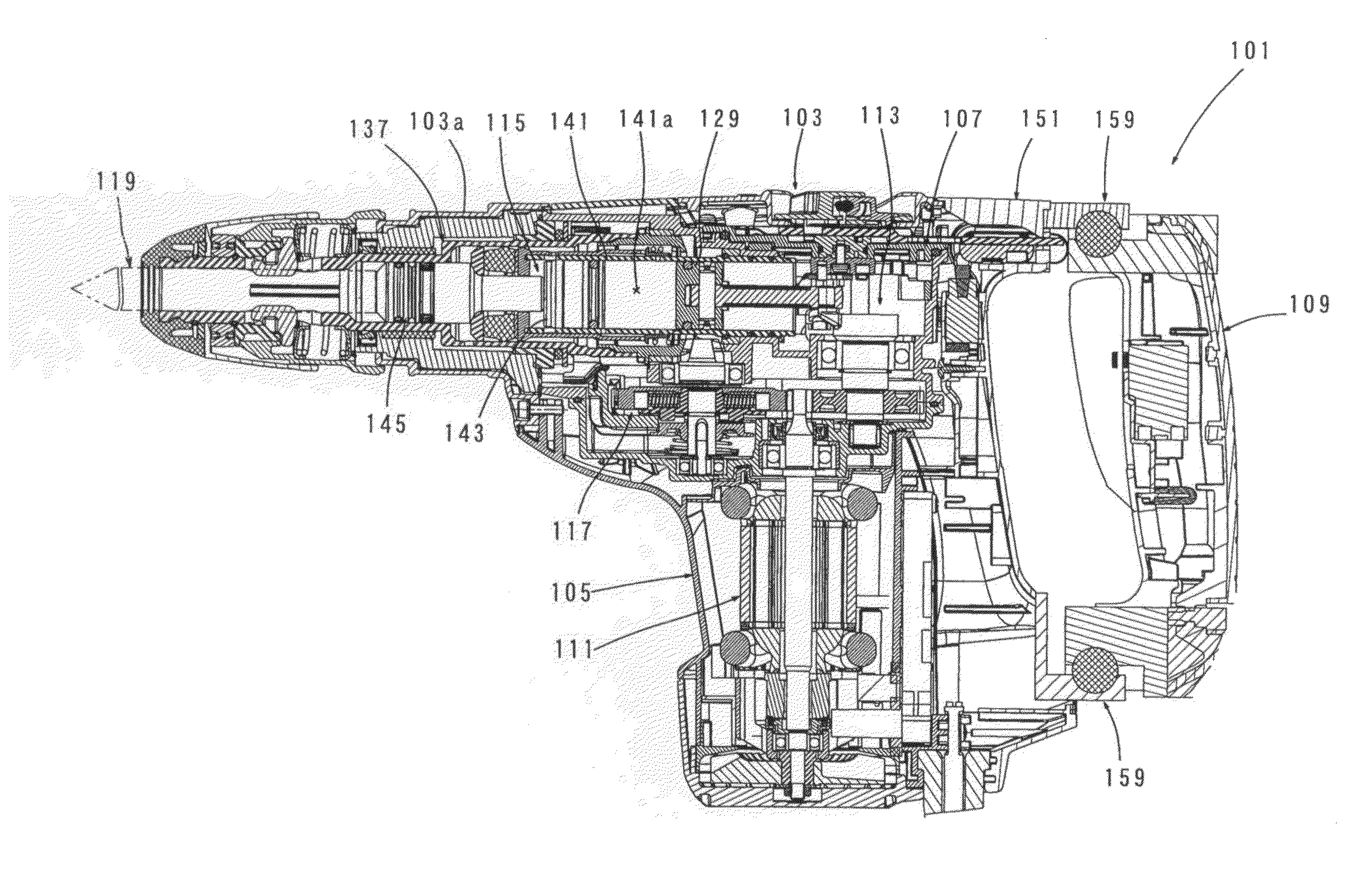

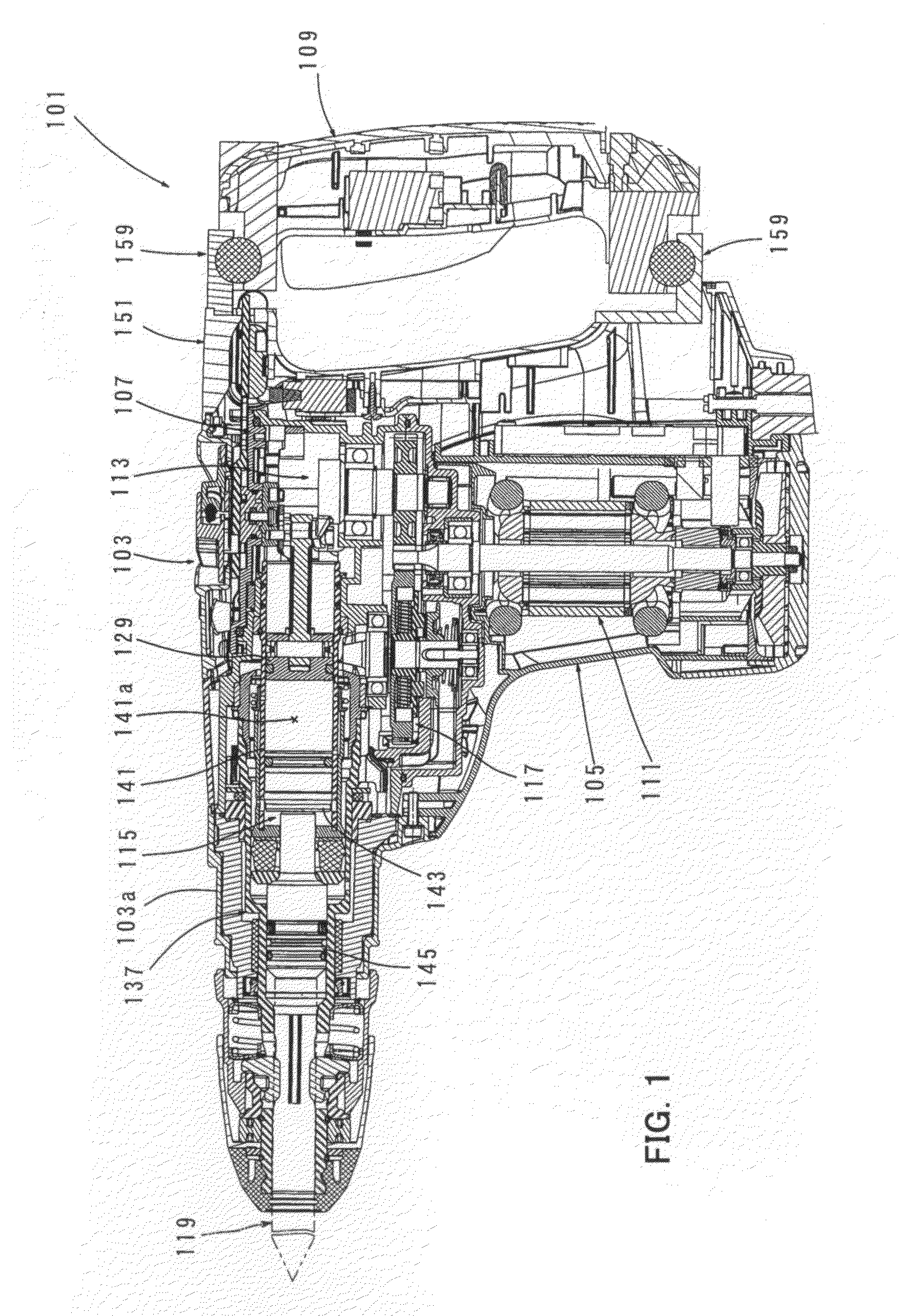

Hand-held power tool

InactiveUS20100206596A1Improve workabilityDifficult to operateMetal sawing devicesTravelling carriersHand heldEngineering

Improving vibration reduction of a handle in a hand-held power tool by performing a predetermined operation on a workpiece by linear movement of a tool bit in an axial direction. The power tool includes a power tool body, a handle and a vibration-proofing part. The vibration-proofing part includes an elastic element that is disposed between the power tool body and the handle and reduces transmission of vibration from the power tool body to the handle, and also includes a body-side receiving part and a handle-side receiving part which are opposed to each other so as to hold the elastic element. The vibration-proofing part is designed such that deformation of the elastic element is shearing deformation in each of the direction of a z-axis defined along the axial direction of the tool bit and the directions of a y-axis and an x-axis which intersect with the z-axis.

Owner:MAKITA CORP

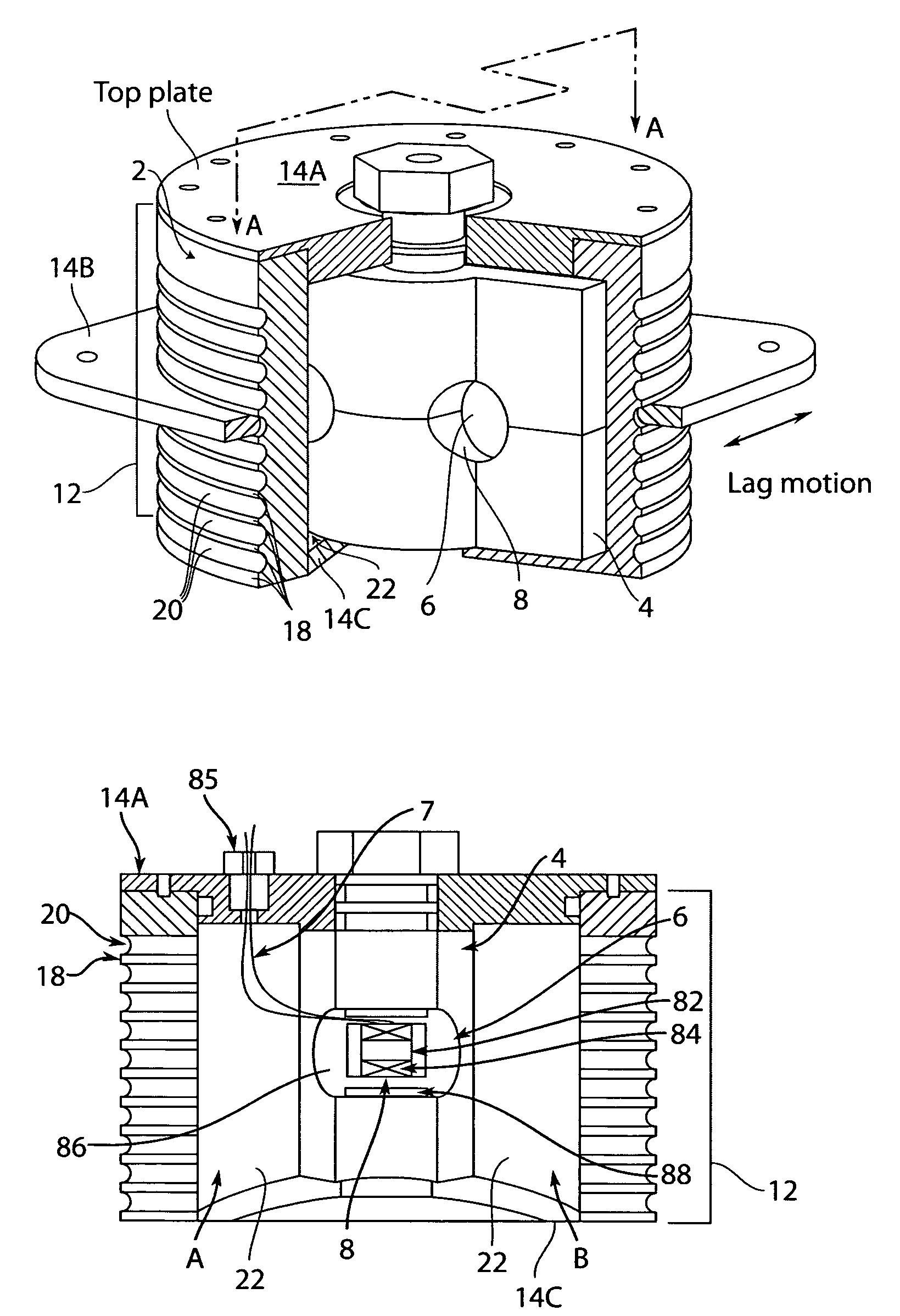

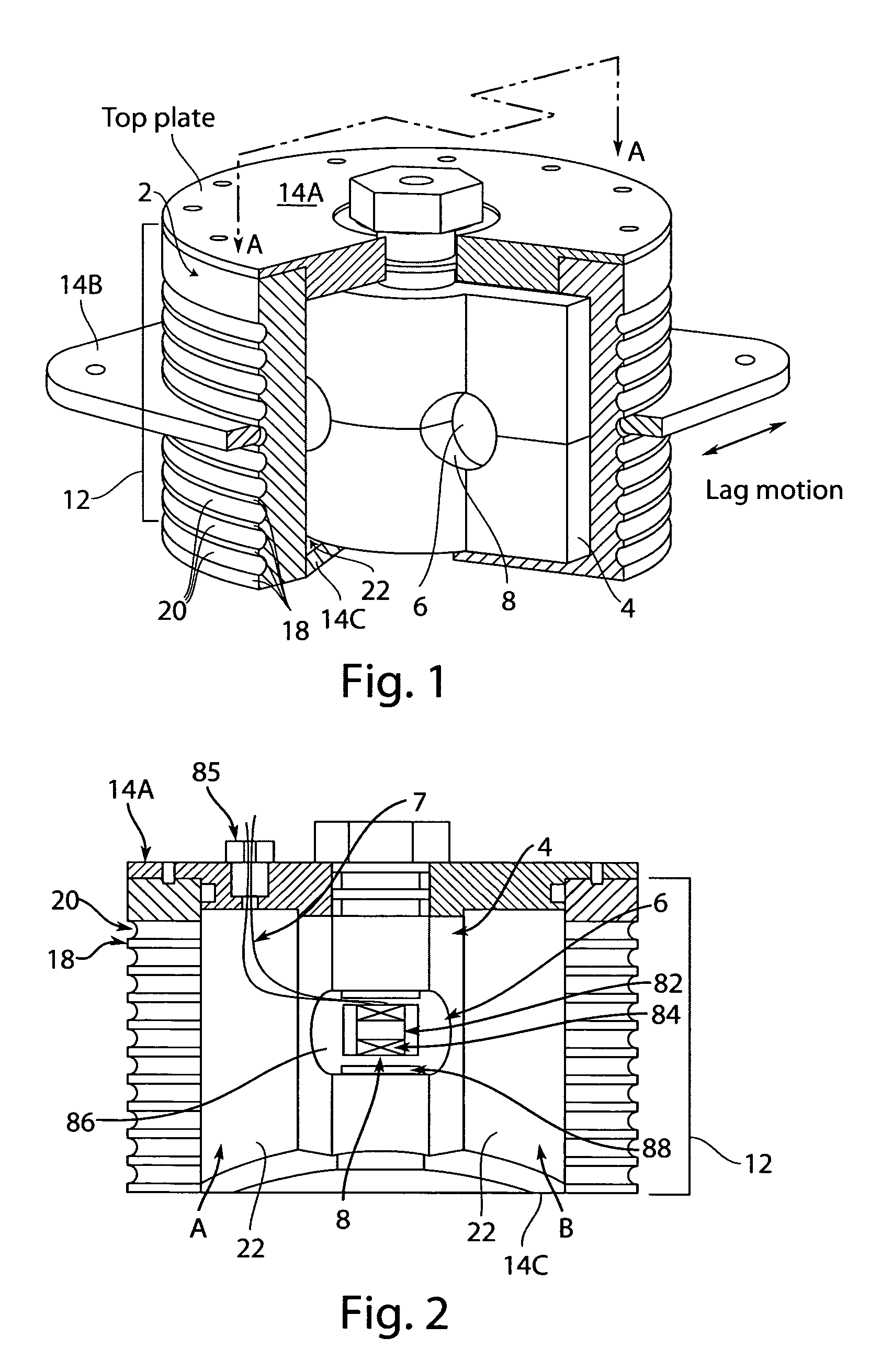

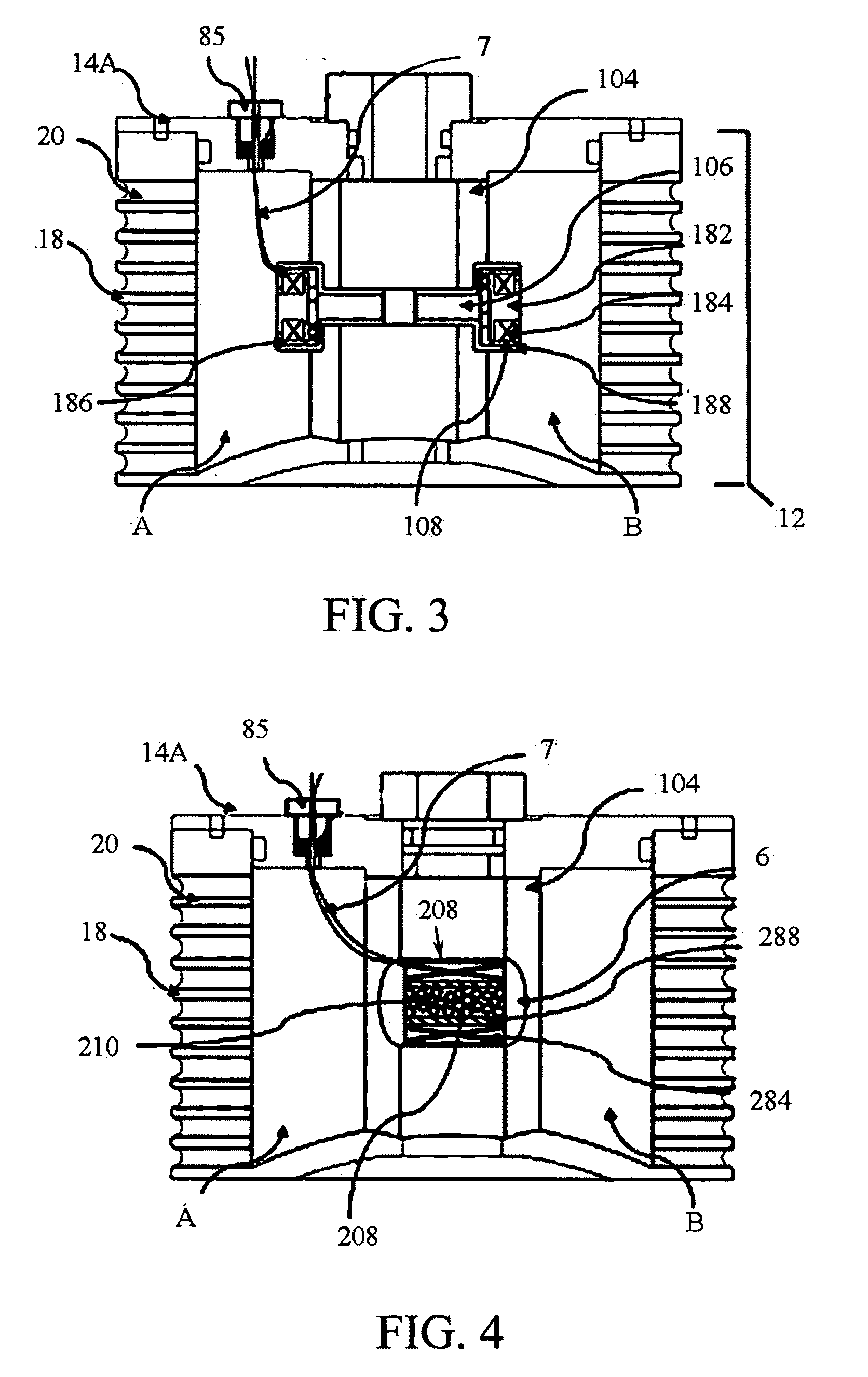

Magnetorheological fluid elastic lag damper for helicopter rotors

ActiveUS20090218443A1Adaptive dampingAdaptive stiffnessMachine framesAircraft stabilisationMagnetorheological fluidEngineering

A MagnetoRheolocial Fluid Elastic (MRFE) lag damper system for adaptive lead-lag damping of helicopter main rotors. Embodiments include snubber dampers especially for hingeless helicopter rotors, and concentric bearing dampers. The snubber lag dampers include a flexible snubber body defining a cavity, a flexible or rigid interior (e.g., center) wall subdividing the cavity, and a flow valve in the interior wall or external to the cavity. The flexible snubber body may comprise elastomeric materials and metal rings stacked together to create a sealed MR fluid cavity. The shear deformation of the snubber body induces MR fluid flow through the valve, controlled by a magnetic field in the valve. An MRFE concentric bearing damper is also disclosed, comprising a pair of concentric tubes with elastomeric material injected and cured in an annular gap between the two tubes, and an MR fluid reservoir with piston-mounted MR valve housed inside the innermost tube.

Owner:UNIV OF MARYLAND +1

Equal-channel extrusion mold for forming powder superalloy blank

InactiveCN103447341ASimple structureImprove general performanceExtrusion diesExtrusion mandrelsShear stressAlloy

The invention discloses an equal-channel extrusion mold for forming a powder superalloy blank, which is specifically used for improving the organizational characteristics of a powder superalloy blank. After a forging blank enters the mold, the round section of the forging blank is twisted to be elliptical and then to be round again, the deformation is combination of twisting and shearing deformation and extruding deformation, and thus the combination of multiple deformation modes in one-pass extruding process is realized. At the transitional section of deformation and twisting, due to the twisting deformation of the elliptical twisting surface, the blank rotates and is subjected to shearing strain under the action of shearing stress so as to realize shearing and crushing of crystal grains and further achieve the effect of refining the grains; simultaneously, since the blank is limited by a mold cavity, the intracrystalline deformation of the blank in the state of pressure stress is difficult, and thus the development of various original microscopic defects in a deformed body can be inhibited; since the refining effect of the grains in the extruding process is obvious, original grain boundaries are eliminated thoroughly, and the comprehensive mechanical property of the powder superalloy blank is obviously improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Process of direct powder rolling of blended titanium alloys, titanium matrix composites, and titanium aluminides

The present invention relates to the manufacture of fully dense strips, plates, sheets, and foils of titanium alloys, titanium metal matrix composites, titanium aluminides, and flat multilayer composites of said materials manufactured by direct rolling and sintering of blended powders. The resulting titanium alloy flat products are suitable in the aerospace, automotive, sporting goods, and other industries. The process includes the following steps: (a) providing a C.P. titanium matrix powder and at least one powder of alloying components such as elemental alloying powder, pre-alloyed master alloy powders, and / or hard reinforcing particles, (b) mechanical activation by attrition of all alloying components, whereby the particle size of attrited alloying powders is at least ten times smaller than the particle size of the matrix titanium powder, (c) blending titanium powder as a ductile matrix material with attrited alloying powders obtained in step (b), (d) cold direct powder rolling of the blend in a mill with horizontally-positioned rolls to achieve density of the rolled strip of 60±20% of the theoretical value, whereby diameters of rolls are different, so that the green strip is bent for the subsequent densification by a second horizontal re-rolling mill staying in line with the first powder rolling mill, and rotations of edging pair of rolls of at least one of the said mills differ in the rate by 5-15% to promote densification of the green strip by shear deformation, the diameter of the rolls of the direct powder rolling mill is 40-250 times larger than thickness of the rolled strip, (e) densification by cold re-rolling of the green strip in a horizontal rolling mill, whereby diameter of the rolls of the densification mill is 1.1-5 times larger than the diameter of rolls of the direct powder rolling mill to provide compressive action and avoid shearing action of the green strip and achieve density of the rolled strip in the range of 90±10%, (f) multiple cold re-rolling of the strip in vertically-positioned rolls at equal rotation rate of the edging rolls to achieve density of the green rolled strip about 100% of the theoretical value, and (g) sintering of near fully-dense green rolled strip in vacuum, or in protective atmosphere batch furnace, or in continuous belt furnace in protective atmosphere. Typical mechanical properties of fully-dense Ti-6Al-4V alloy strips manufactured by the process of the present invention are: tensile strength is 130-140 ksi (897-966 MPa), yield strength is 120-130 ksi (828-897 MPa), and elongation is over 10%.

Owner:ADMA PRODS

Method for preparing gradient nano-structure on surface of metal material

InactiveCN102816912AAdd Deformation DeformationImprove processing efficiencyNanotechnologyMetallic materialsEngineering

The invention relates to a method for preparing a gradient nano-structure on the surface of a metal material. According to the method, a processed plate workpiece is placed inside a cooling tank; a fixture is adopted to tightly press the workpiece; the lower end surface of a tool head is placed on the surface of the workpiece, and is pressed into the surface of the workpiece; a cooling medium is poured into the cooling tank, wherein the workpiece is submerged by the cooling medium; after a temperature of the workpiece reaches a temperature of the cooling medium, the tool head rotates at a certain speed while a work table horizontally moves at a certain speed to drive the workpiece to horizontally move at a certain speed so as to complete a shear deformation treatment by the high hardness end surface of the tool head during a high speed rotation process, wherein high strain rate and large strain are generated to the surface of the workpiece with the shear deformation treatment, and a plurality of deformation treatments are performed on the surface of the workpiece by using the high-speed shear deformation technology. Compared with the method in the prior art, the method of the present invention has advantages of high processing efficiency, low equipment loss, low manufacturing cost, simple process, strong applicability, and the like.

Owner:YANSHAN UNIV

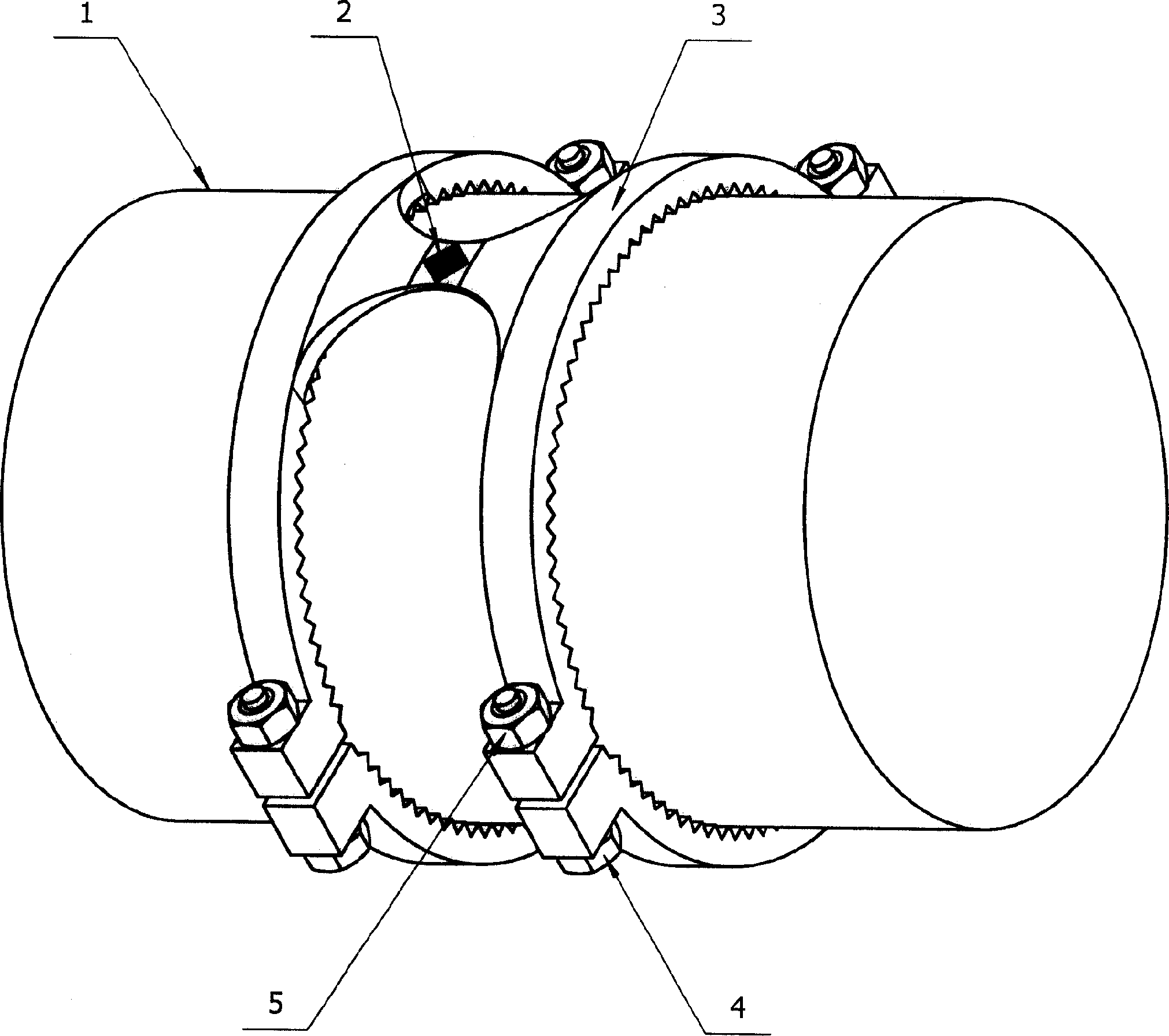

Clamp ring type torque sensor

InactiveCN1752725AEasy to detectAvoid insufficient clamping forceWork measurementTorque measurementElastomerDrive shaft

The present invention relates to a clamp ring type torque sensor for obtaining drive shaft torque. Said sensor adopts semi-ring design, and said sensor can be quickly clamp-mounted on the drive shaft only by utilizing holt and nut. When the torque is received by drive shaft, the shearing deformation which is directly proportional to the torque on the drive shaft can be transferred to the sensor elastic body on which a strain foil is stuck so as to obtain the torque signal of said drive shaft. Said invention also provides the design method of said sensor elastic body.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Large-scale soil interface shear test model and test method

ActiveCN105510153ASimple designRich sourcesPreparing sample for investigationMaterial strength using steady shearing forcesSource materialShearing deformation

Owner:CHINA UNIV OF MINING & TECH

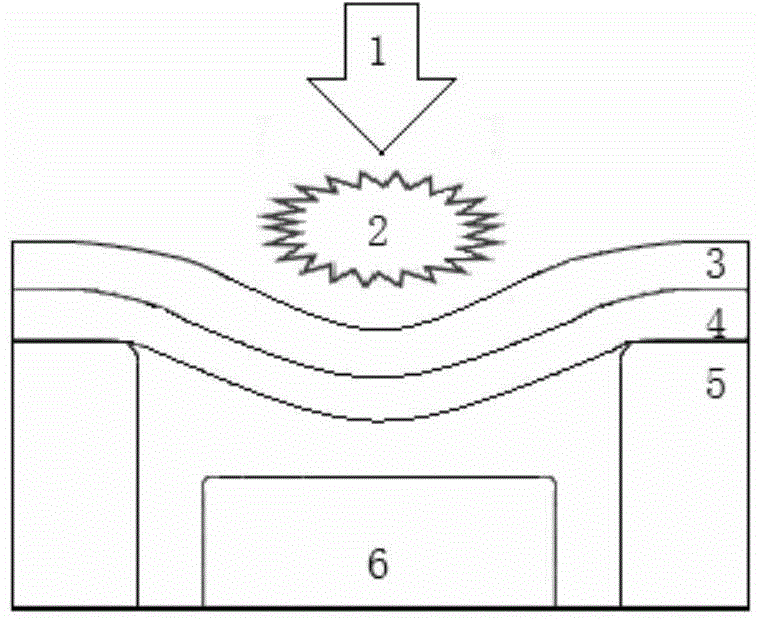

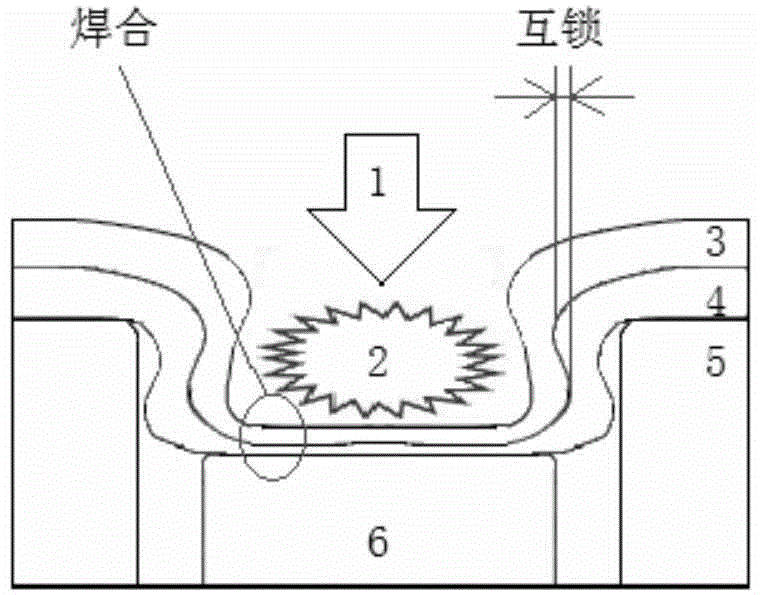

Pulse laser synchronous riveting and welding method and device of ultrathin plates

ActiveCN104816091ALow openness requirementsHigh strengthShaping toolsLaser beam welding apparatusEnergy absorptionShearing deformation

The invention relates to a pulse laser synchronous riveting and welding method and a device of ultrathin plates. An upper layer of plate and a lower layer of plate are stacked and positioned on a concave mold having mold holes; a bottom mold is arranged on the concave mold; a pulse laser beam is used for acting on the upper layer of plate or an energy absorbing layer coated on the surface of the upper layer of plate to form an explosive plasma; the lower layer of plate is collided by the upper layer of plate; the upper layer of plate and the lower layer of plate generate high-strain-rate plastic flow coupling; and under the restraint of the bottom mold, the upper layer of plate and the lower layer of plate are plasticized to form rivet button shapes so as to generate mechanical interlocking for riveting. In the plastic deformation process, the pressure stress exists on the contact interfaces of the upper layer of plate and the lower layer of plate, and the high-speed sliding and the shearing deformation are generated, so that the interfaces generate the melting and the atomic diffusion, and the upper layer of plate and the lower layer of plate are welded when colliding the bottom mold. The method and the device synchronously realize the riveting and the welding of the upper layer of plate and the lower layer of plate; and joints formed by the method and the device have higher connecting strength and fatigue resistance through the compounding effect characteristic of the mechanical bonding and the metallurgic bonding.

Owner:SHANDONG UNIV

Equal channel angular extruding, twisting and deforming mold for large plastic forming process

InactiveCN102513395AIncrease internal hydrostatic pressureHigh strengthExtrusion diesMetallic materialsShearing deformation

An equal channel angular extruding, twisting and deforming mold for large plastic forming process is disclosed. The mold is provided with a male mold (7) and a female mold, an inlet channel (8) and an outlet channel (9) communicated with a corner of the inlet channel (8) are arranged in the female mold; the inlet channel (8) and the outlet channel (9) have the same cross section; the male mold (7) and the inlet channel (8) are in clearance fit, wherein a section of spiral channel (10) composed of spiral slots and having the same cross section with the outlet channel (9) is arranged in the outlet channel (9). In the technical process of the invention, the corner formed by the inlet channel and the outlet channel provides strong shearing function for deformation, the spiral channel provides a large shearing deformation amount while increasing the inner hydrostatic pressure during the deformation of a workpiece, so that the effective strain is accumulated, the deformation evenness, and the room temperature strength and comprehensive mechanical property of deformed metal material are improved, the high-performance metal material is obtained, the processing cost of metal materials is reduced, and the yield is improved.

Owner:HEFEI UNIV OF TECH

Visual test device for damaged form of pile-soil contact surface of specially-shaped pile and use method

ActiveCN105716970AEasy to implementSimple structureMaterial strength using steady shearing forcesScale modelWater baths

The invention provides a visual test device for a damaged form of a pile-soil contact surface of a specially-shaped pile and a use method. The test device comprises a bearing platform, a model pile, a model tank, a water bath tank, a temperature control system, a laser source and a digital camera device, wherein the model pile is arranged as a full-scale specially-shaped pile and is arranged in the model tank; transparent soil is arranged on the periphery of the model pile; the model tank is arranged in the water bath tank; a rotating shaft hole is formed on the bottom of the model tank while a rotating shaft is arranged in the model tank; the rotating shaft is used for driving the model pile to generate vertical displacement or torsional displacement; the temperature control system is matched with the water bath tank and is used for adjusting the temperature of the pile-soil contact surface; and the laser source and the digital camera device are arranged on the upper side and side wall of the model tank. According to the visual test device provided by the invention, the visual observation for shear deformation of concave surface of the cross section of the specially-shaped pile can be realized; the shearing damage characteristics of different loading modes, different temperatures and different piles can be compared; the visual test device has significance in research on shearing of the contact surface of the full-scale model pile; the visual test device provided by the invention has the advantages of simple structure, convenience in operation, easiness in realization and lower cost.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com