Pneumatic tire and method for manufacturing the same

A technology for pneumatic tires and a manufacturing method, which is applied to the reinforcement layers of pneumatic tires, special tires, tire parts, etc., to achieve the effects of noise reduction, strong adhesion, temperature stability, and excellent cushioning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 to Embodiment 3

[0072] The components in the following Table 1 were mixed to prepare a sealant-forming composition, and then coated on one surface of a porous sound-absorbing material (polyurethane foam) with a thickness of 8mm, and then carried out a cross-linking reaction at a high temperature of 170°C to form A layer of sealant with a thickness of 4mm. A release paper having the same area as the sealant layer was laminated on the formed sealant layer.

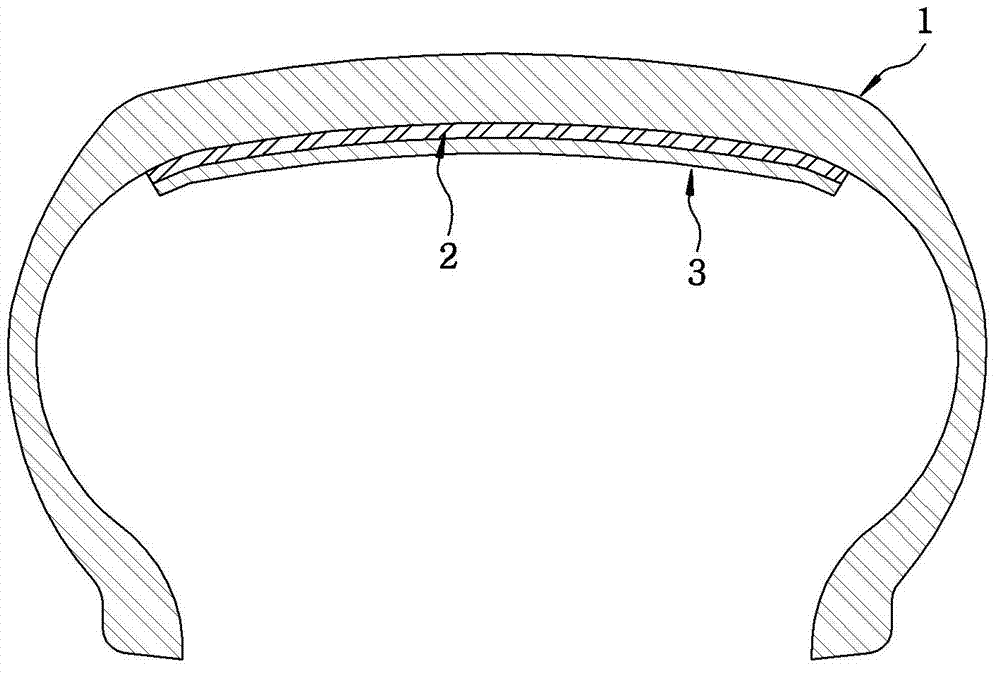

[0073] After peeling off the release paper from the sound-absorbing member for noise reduction prepared as described above, as figure 1 As shown, a sound-absorbing member for noise reduction was pasted so that the sealant layer faced the inner inner surface of the inner liner of a 235 / 45R17 tire (manufactured by Hankook Tire Co., Ltd.) to prepare a tire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com