Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3881 results about "Butyl rubber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

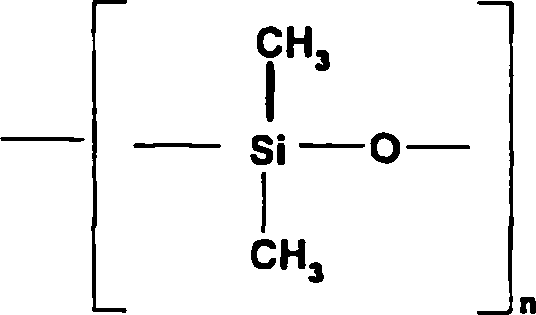

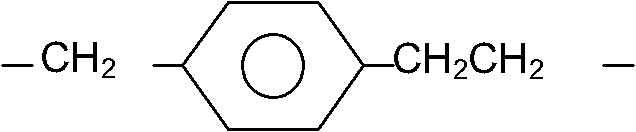

Butyl rubber, sometimes just called "butyl", is a synthetic rubber, a copolymer of isobutylene with isoprene. The abbreviation IIR stands for isobutylene isoprene rubber. Polyisobutylene, also known as "PIB" or polyisobutene, (C₄H₈)ₙ, is the homopolymer of isobutylene, or 2-methyl-1-propene, on which butyl rubber is based. Butyl rubber is produced by polymerization of about 98% of isobutylene with about 2% of isoprene. Structurally, polyisobutylene resembles polypropylene, but has two methyl groups substituted on every other carbon atom, rather than one. Polyisobutylene is a colorless to light yellow viscoelastic material. It is generally odorless and tasteless, though it may exhibit a slight characteristic odor.

Self-sealing pneumatic tire and preparation thereof

This invention relates to a pneumatic tire with puncture sealing property and a method for preparing such tire. Such tire is prepared by building an uncured butyl rubber-based layer, which contains a peroxide and a dispersion therein of a particulate precured rubber selected from pre resin-cured butyl rubber and / or pre sulfur-cured diene-based elastomer, into an uncured tire and between an innerliner layer and the tire carcass. Upon curing the prepared tire under conditions of elevated temperature, a major portion of the uncured butyl rubber composition is depolymerized to form a tacky material, which contains said dispersion therein of said particulate precured rubber, which has puncture sealant properties. Such layer of depolymerized butyl rubber and dispersed precured rubber particles may be collectively referred to as the sealant layer.

Owner:THE GOODYEAR TIRE & RUBBER CO

Method for clay exfoliation, compositions therefore, and modified rubber containing same

InactiveUS20060235128A1Reduce air permeabilityLow gas permeabilityPigmenting treatmentLayered productsPolymer scienceButyl rubber

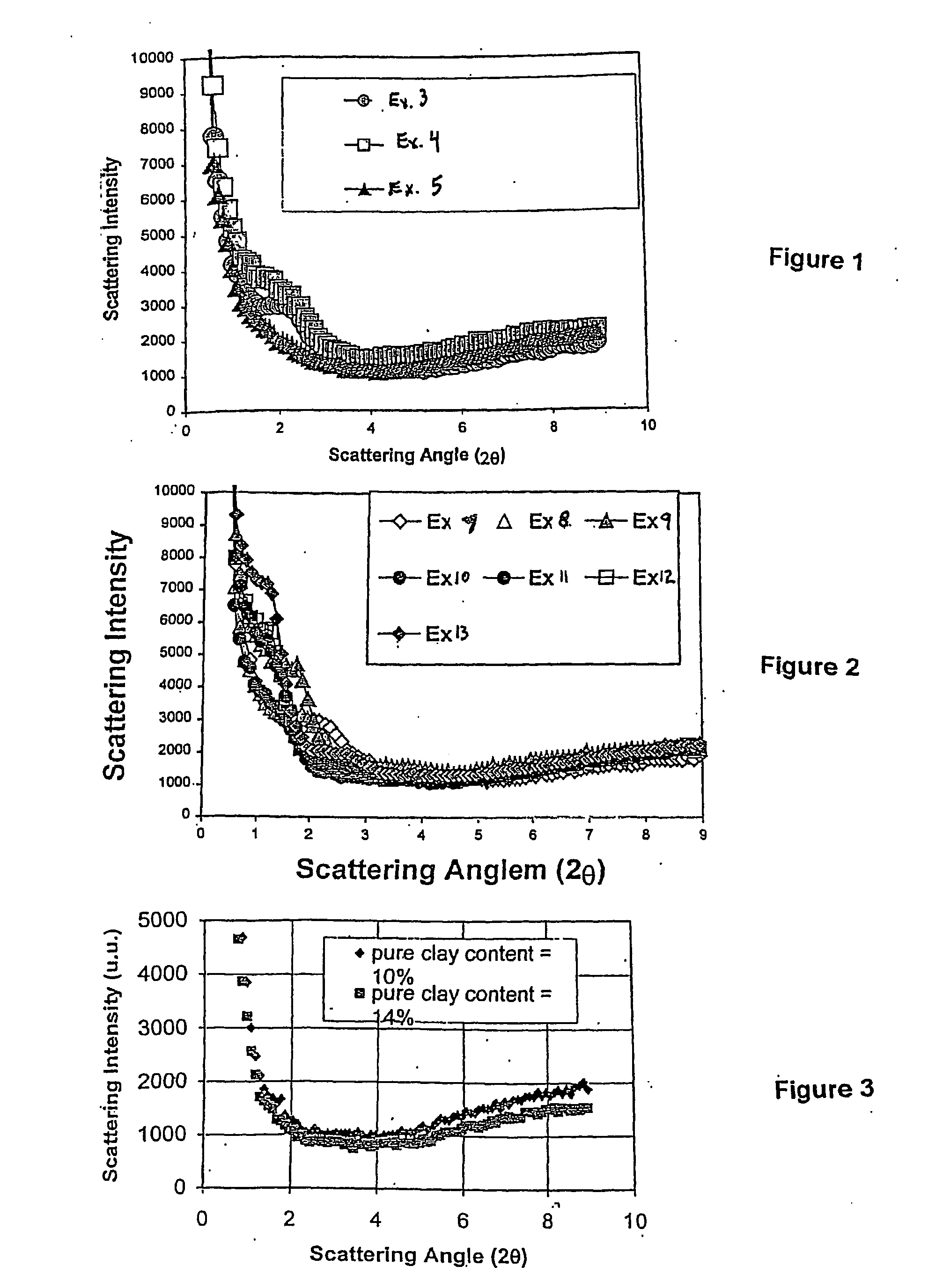

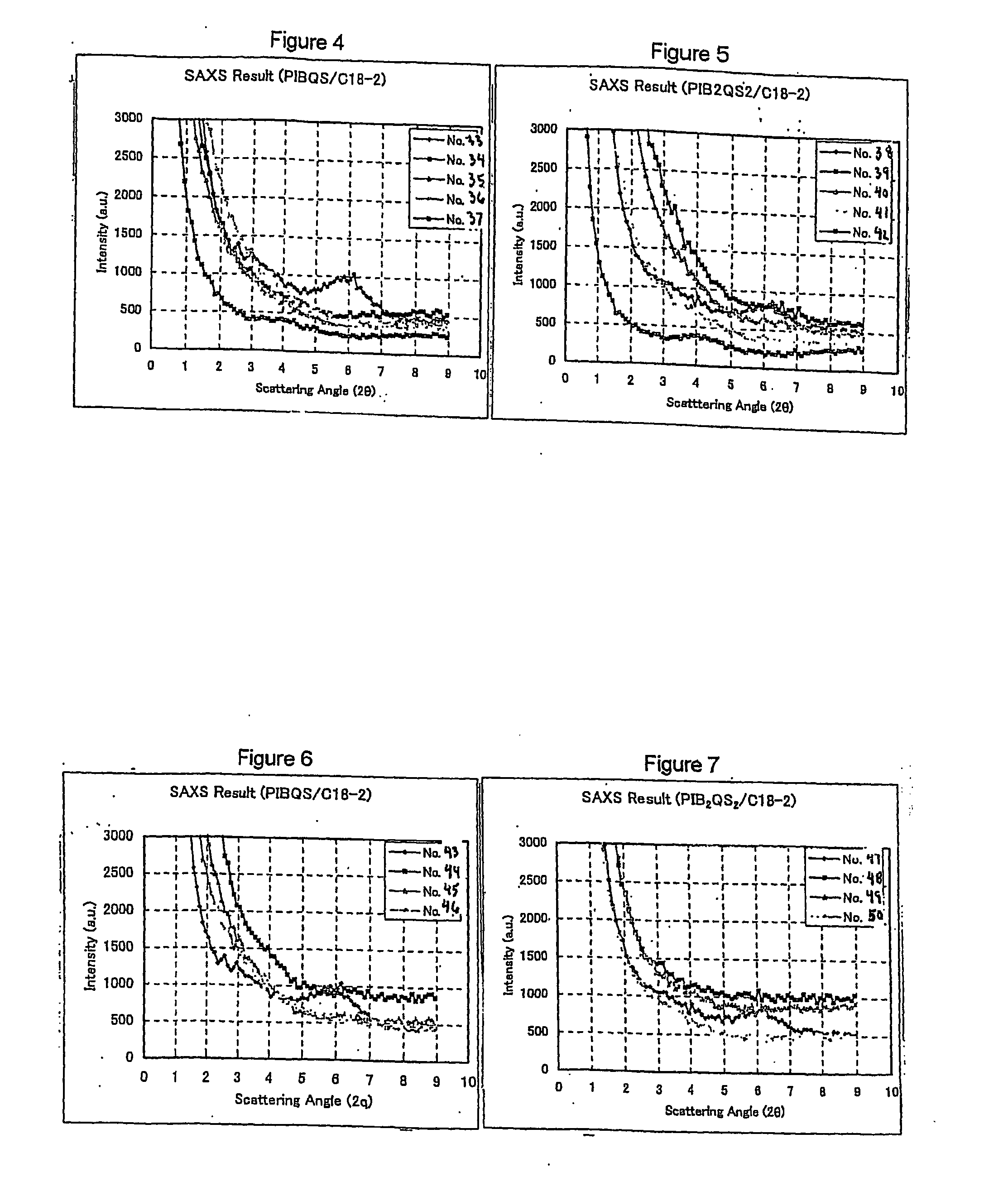

A polymer composition of low gas permeability. The composition includes an exfoliated organically-modified clay, butyl rubber, and a polymeric exfoliant. A method for producing the butyl composition by dry mixing the butyl rubber with the exfoliated clay is also provided.

Owner:BRIDGESTONE CORP

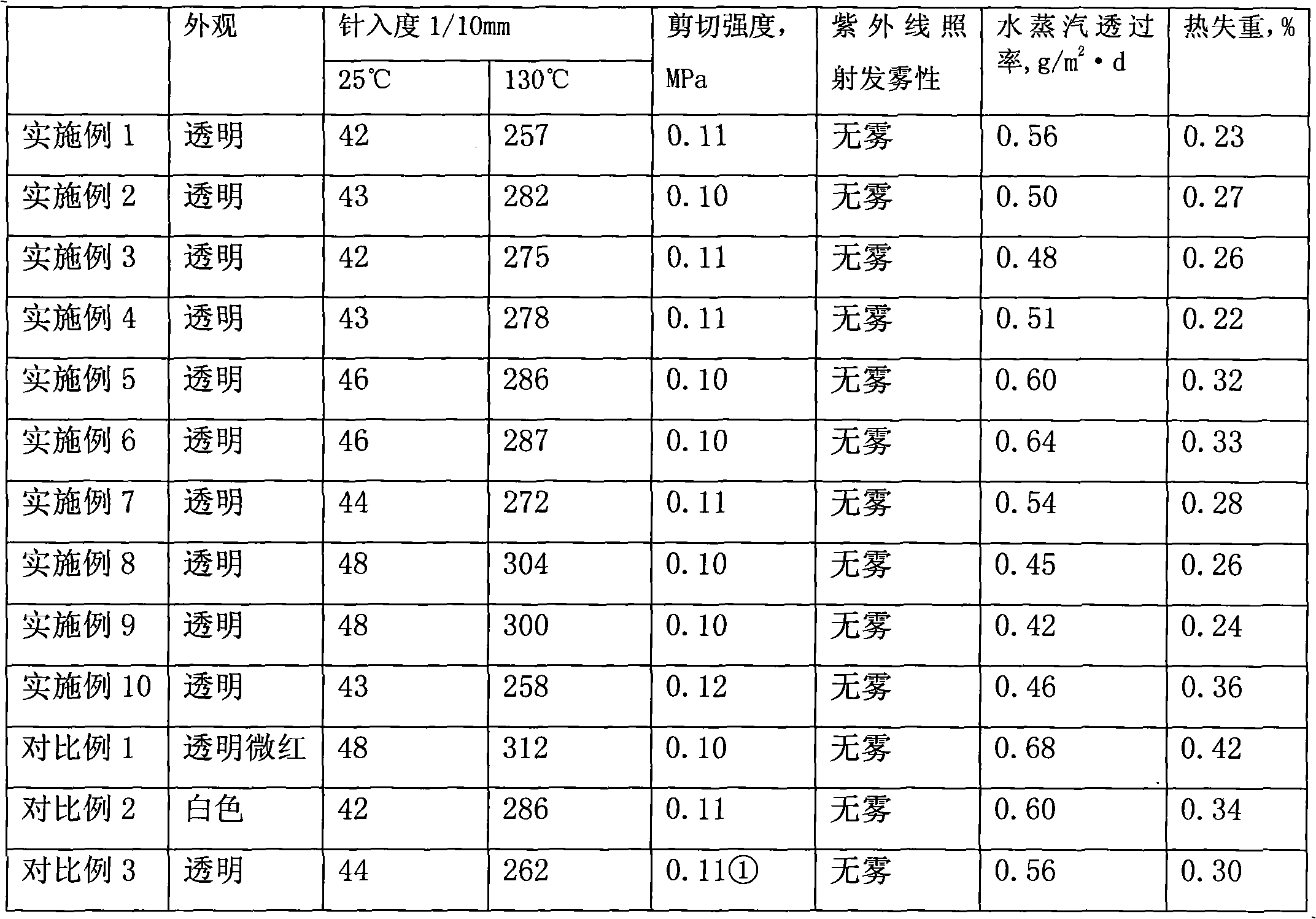

Transparent butyl hot-melt sealant and preparation method thereof

ActiveCN101805569AHigh strengthGood construction performanceNon-macromolecular adhesive additivesOther chemical processesSealantFumed silica

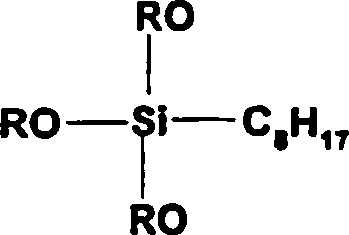

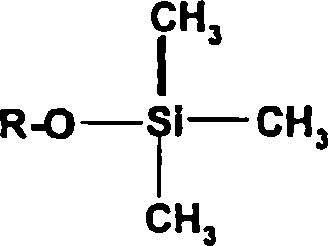

The invention relates to a transparent butyl hot-melt sealant, which is prepared with the following raw materials in parts by weight: 1-20 of butyl rubber, 10-80 of polyisobutylene, 5-30 of plasticizer, 3-10 of tackifier, 3-10 of softener, 0.1-5 of stabilizer, 5-30 of filler and 0.1-5 of adhesion promoting agent. The matching use of the butyl rubber and the polyisobutylene with different molecular weights facilitates the improvement of the strength and workability of the transparent butyl hot-melt sealant. The filler is selected from fumed silica or precipitated silica, which ensures the appearance transparency of the product. Due to the addition of the stabilizer and the strict control of the production process, the appearance transparency and the physical and chemical properties of the product are enhanced. The use of the active group substituted alkoxy silane as a coupling agent improves the adhesion of the product to glass, aluminum and other substrates.

Owner:ZHENGZHOU ZHONGYUAN SILANDE HIGH TECH CO LTD

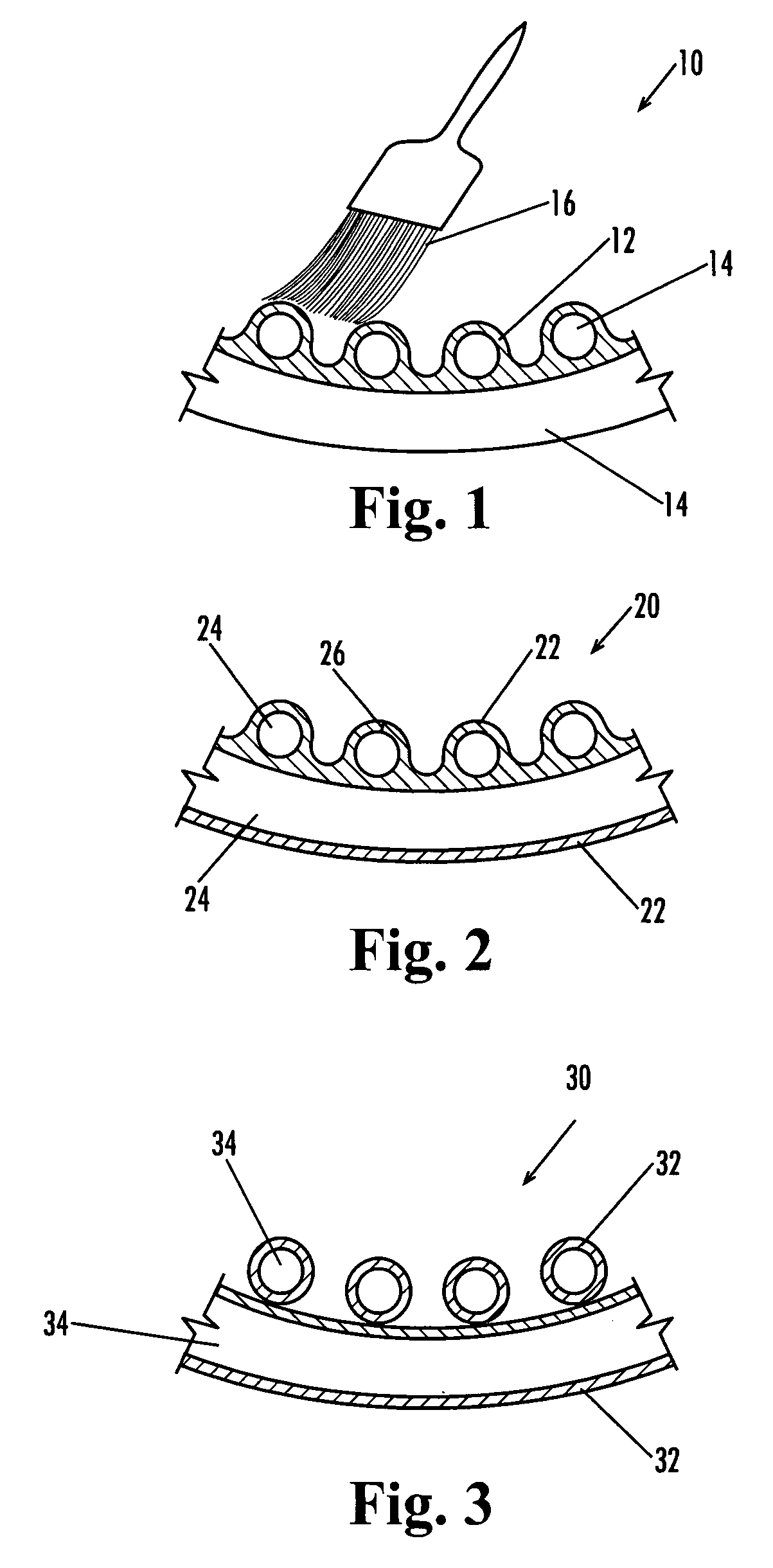

Pneumatic tire having built-in sealant layer and preparation thereof

This invention relates to a pneumatic tire having a built-in sealant layer and its preparation. The sealant layer precursor is a layer of a butyl rubber based composition which contains an organoperoxide. The butyl rubber of said precursor is a copolymer of isobutylene and isoprene containing from about 0.5 to about 5, alternately less than 1, mole percent isoprene. The precursor composition contains carbon black and / or coal dust and may contain a dispersion of liquid conjugated diene polymer (e.g. liquid cis 1,4-polyisoprene polymer), short fibers and / or hollow glass microspheres. A layer of the sealant precursor is built into the tire between a sulfur vulcanized halobutyl rubber innerliner and conjugated diene-based rubber of the tire carcass. The butyl rubber of the sealant precursor is partially depolymerized by the organoperoxide during the elevated temperature vulcanization of the tire to form the built-in sealant layer. In one aspect of the invention, said uncured butyl rubber sealant precursor layer composition has a storage modulus G′ (80° C.) in a range of about 100 to about 400 kPa and said partially depolymerized butyl rubber sealant layer composition has a storage modulus G′ (80° C.) in range of about 5 to about 50 kPa.

Owner:THE GOODYEAR TIRE & RUBBER CO

Cold resistant rubber

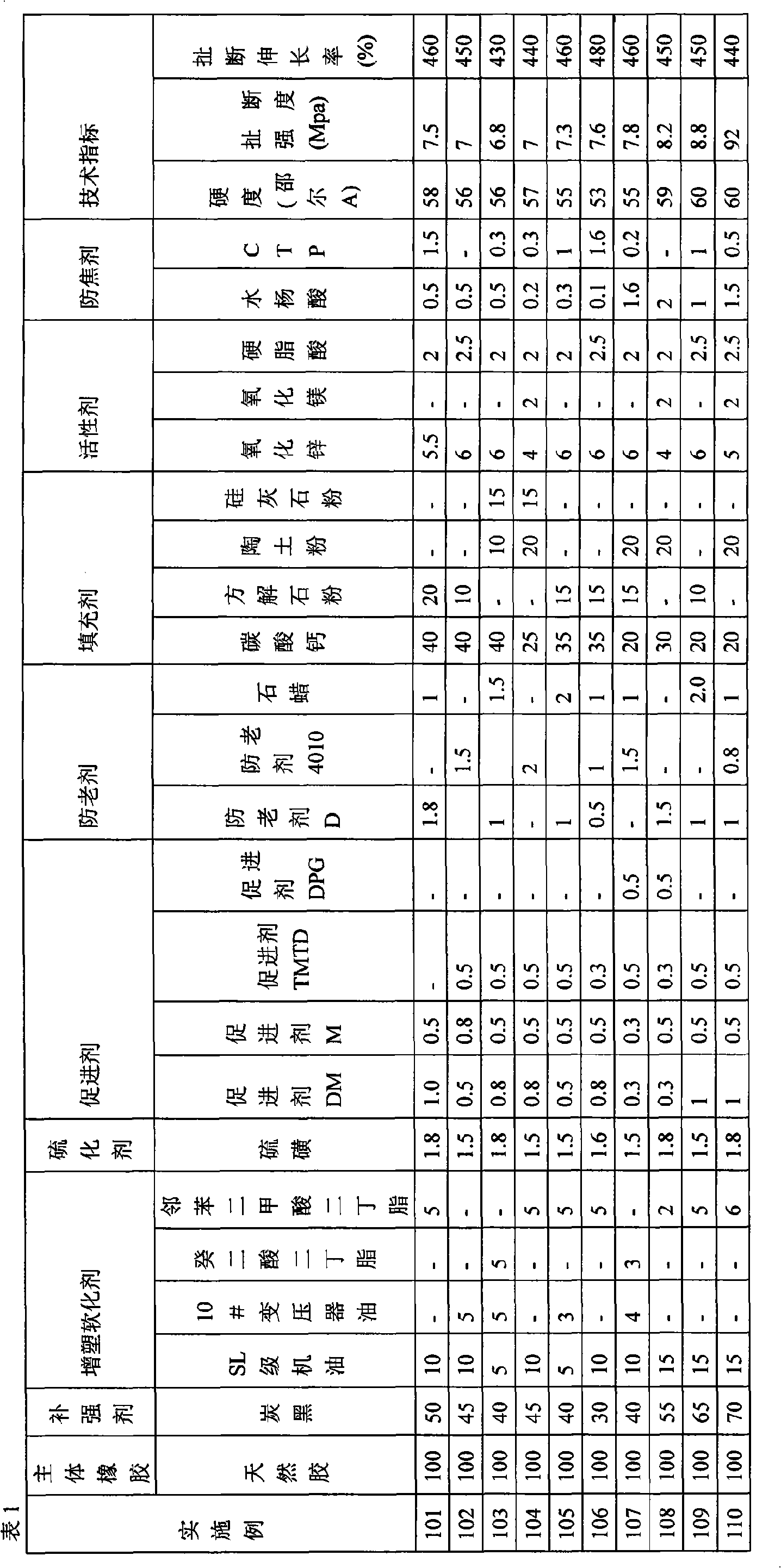

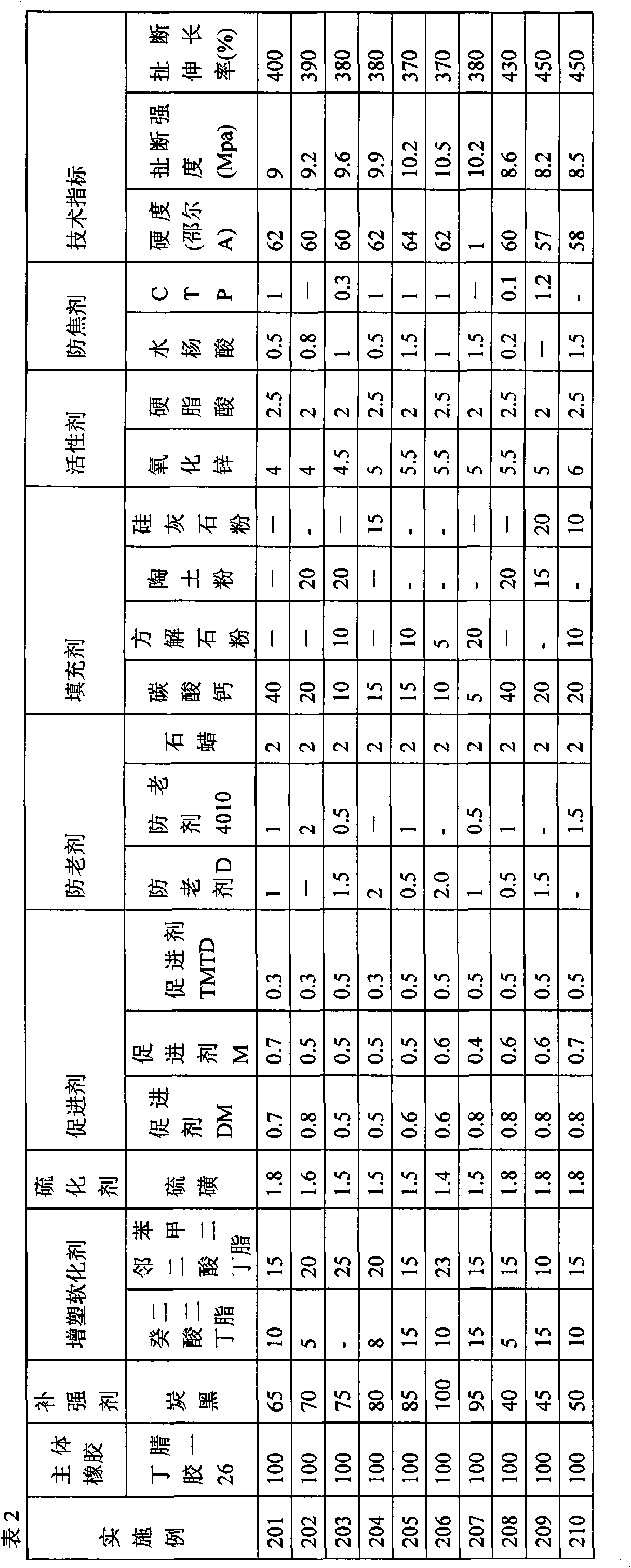

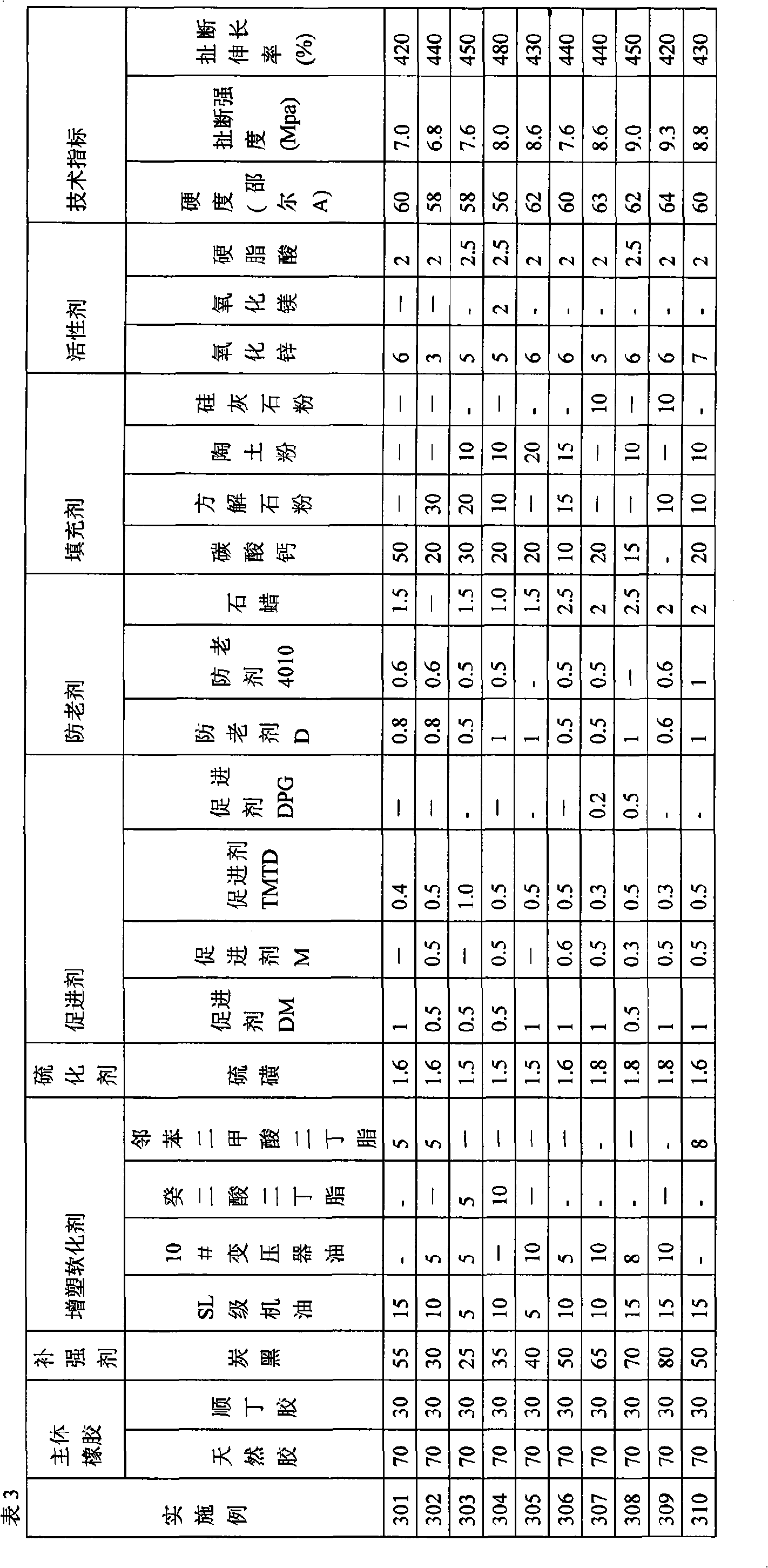

The invention aims at providing a low-temperature resistant rubber which can be used for a long time in low temperature and has almost the same tensile strength and elongation at break and the same hardness at low temperature as at normal temperature. The low-temperature resistant rubber contains main body rubber, strengthening agent, plasticization softener and curing ingredient, and the weight ratio of main body rubber : strengthening agent : plastifying softener : curing ingredient is 100:10-350:5-75:0.5-3; the main body rubber is natural gum, styrene-butadiene-rubber, cis-butadiene rubber, butyl rubber, ethylene propylene diene rubber, butadiene nitrile rubber or the combination of natural gum and cis-butadiene rubber; the strengthening agent is black carbon or white carbon; the plastifying softener is machine oil, transformer oil, dibutyl sebacate, dibutyl phthalate or silicon oil; the curing ingredient is 2,5-dimethyl curing ingredient or sulphur.

Owner:南京固柏橡塑制品有限公司

Hydrocolloid adhesive mass useful for medical purposes

The present invention relates to a novel hydrocolloid adhesive mass useful for medical purposes, characterized in that said hydrocolloid adhesive mass comprises:a) 0.2 to 5 parts by weight of an ethoxylated sorbitan fatty acid ester;b) 20 to 50 parts by weight of a hydrocolloid;c) 32 to 120 to parts by weight of an adhesive matrix made up of one or more polymers selected from poly(styrene / olefin / styrene) block copolymers, low-molecular polyisobutylenes and high-molecular polyisobutylenes, and one or more compounds selected from sticky resins, or tackifying resins, plasticizers, polybutenes, antioxidants, ethylene / vinyl acetate copolymers, butyl rubbers and ethylene / propylene block copolymers; andd) 0 to 15 parts by weight of an acrylate copolymer with a glass transition temperature below -20° C. It further relates to the use of this hydrocolloid adhesive mass for the production of dressings, especially for the treatment of superficial, deep, chronic or acute dermo-epidermal lesions, exudative wounds and bums.

Owner:LABORATOIRE URGO

Self-sealing pneumatic tire and preparation thereof

This invention relates to a pneumatic tire with puncture sealing property and a method for preparing such tire. Such tire is prepared by building an uncured butyl rubber-based layer, which contains a peroxide and a dispersion therein of a particulate precured rubber selected from pre resin-cured butyl rubber and / or pre sulfur-cured diene-based elastomer, into an uncured tire and between an innerliner layer and the tire carcass. Upon curing the prepared tire under conditions of elevated temperature, a major portion of the uncured butyl rubber composition is depolymerized to form a tacky material, which contains said dispersion therein of said particulate precured rubber, which has puncture sealant properties. Such layer of depolymerized butyl rubber and dispersed precured rubber particles may be collectively referred to as the sealant layer.

Owner:THE GOODYEAR TIRE & RUBBER CO

Split-stream process for making nanocomposites

ActiveUS7501460B1Adversely affect polymer propertyLess costlyPigmenting treatmentMaterial nanotechnologyElastomerMasterbatch

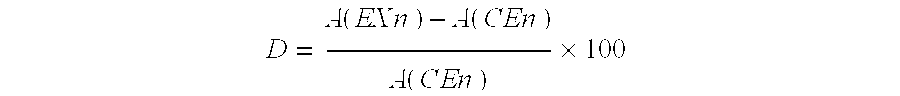

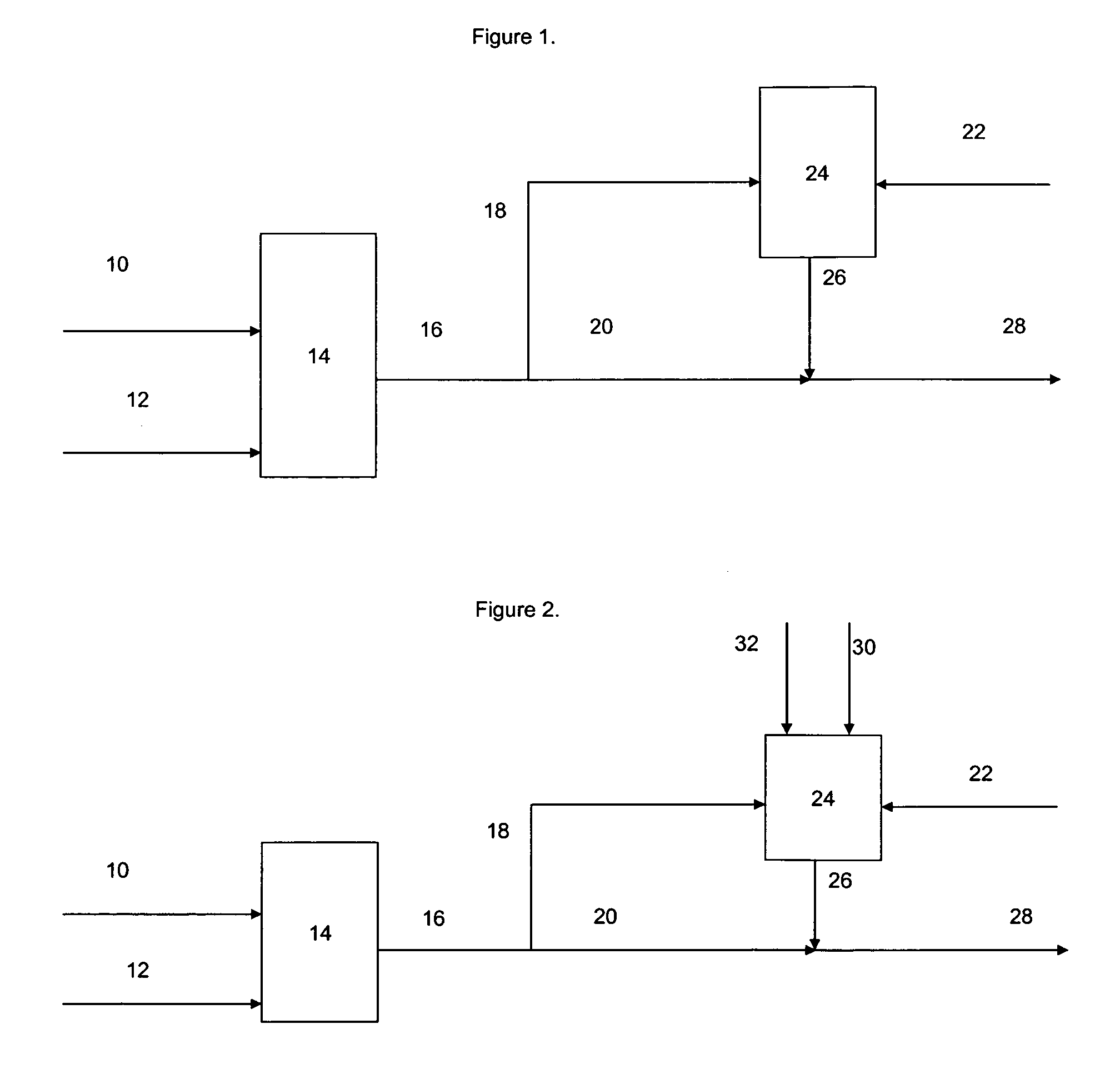

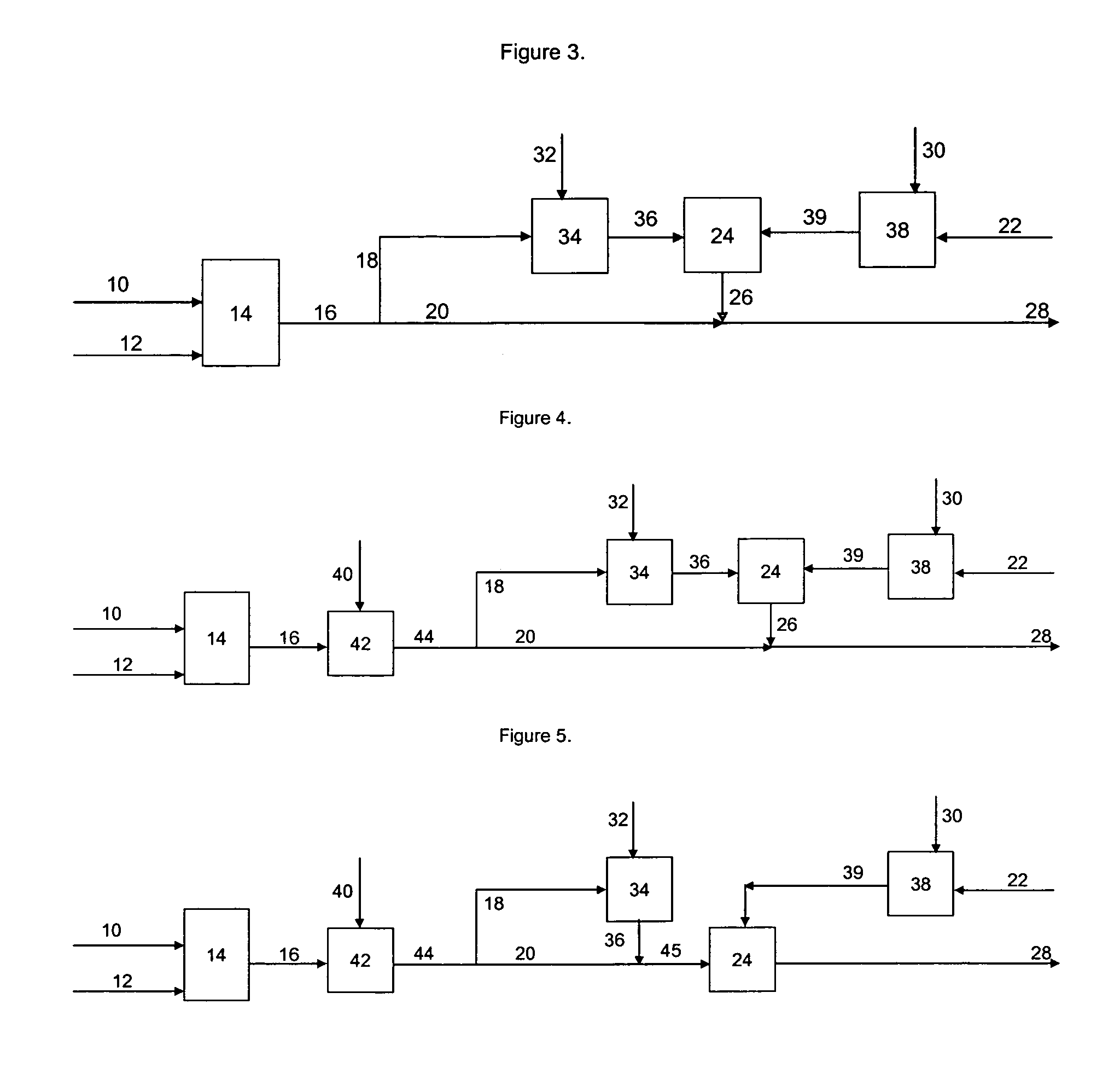

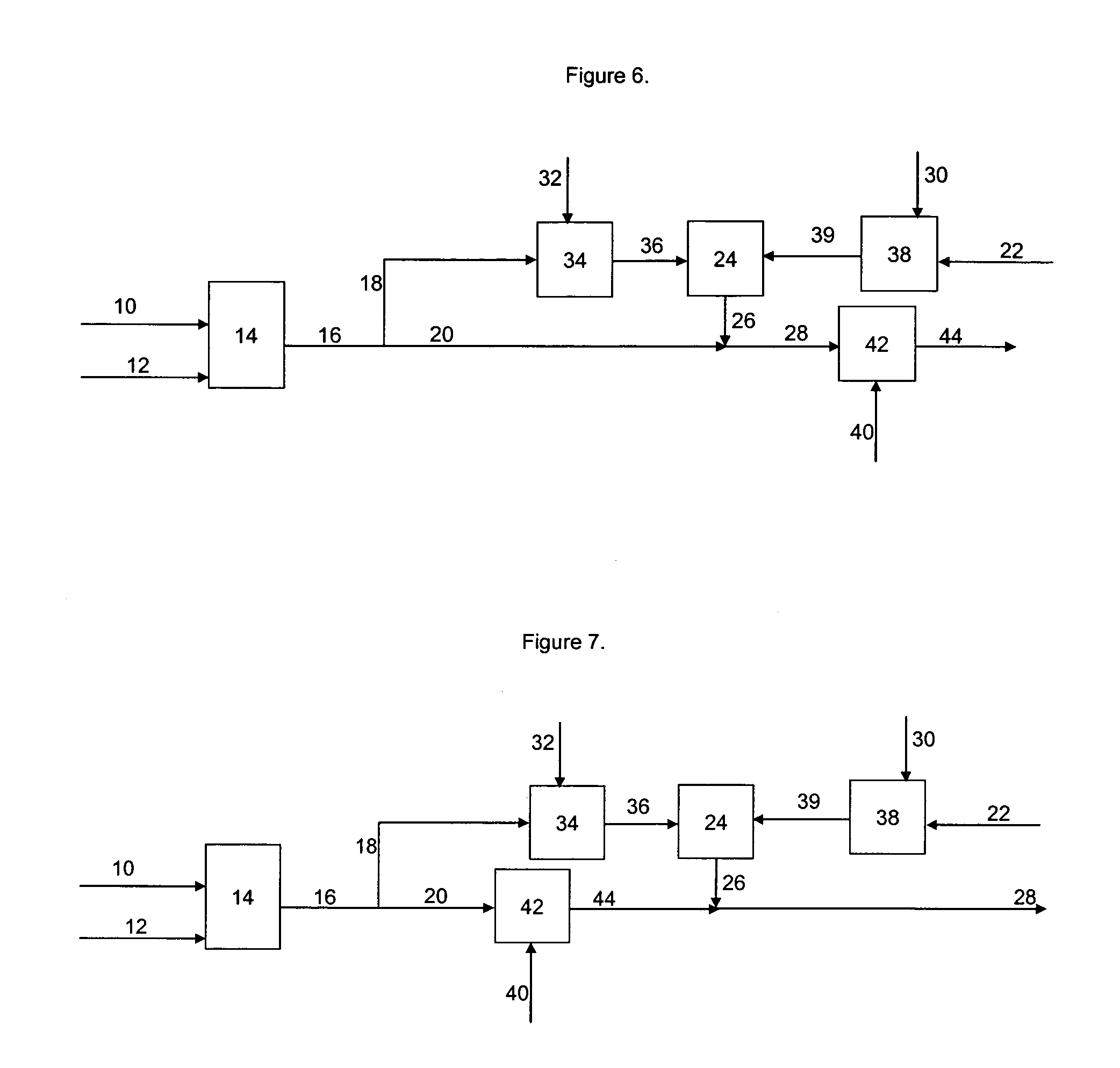

The present invention is a process to produce a nanocomposite of a elastomer and organic clay, e.g. an exfoliated clay, suitable for use as an air barrier. The process can include the steps of: (a) contacting a solution (10) of butyl rubber in an organic solvent with a halogen (12) to form a halogenated butyl rubber solution (16); (b) neutralizing the halogenated butyl rubber solution; (c) functionalizing at least a portion (18) of the halogenated butyl rubber; (d) mixing a dispersion (22) of clay with the functionalized butyl rubber (18) to form a masterbatch (26) comprising a polymer-clay nanocomposite; (e) combining the masterbatch (26) with the rest of the halogenated butyl rubber solution (20) to form a second mixture (28); (e) recovering the nanocomposite from the second mixture (28). The nanocomposite so formed has improved air barrier properties and is suitable for use as a tire innerliner or innertube.

Owner:EXXONMOBIL CHEM PAT INC

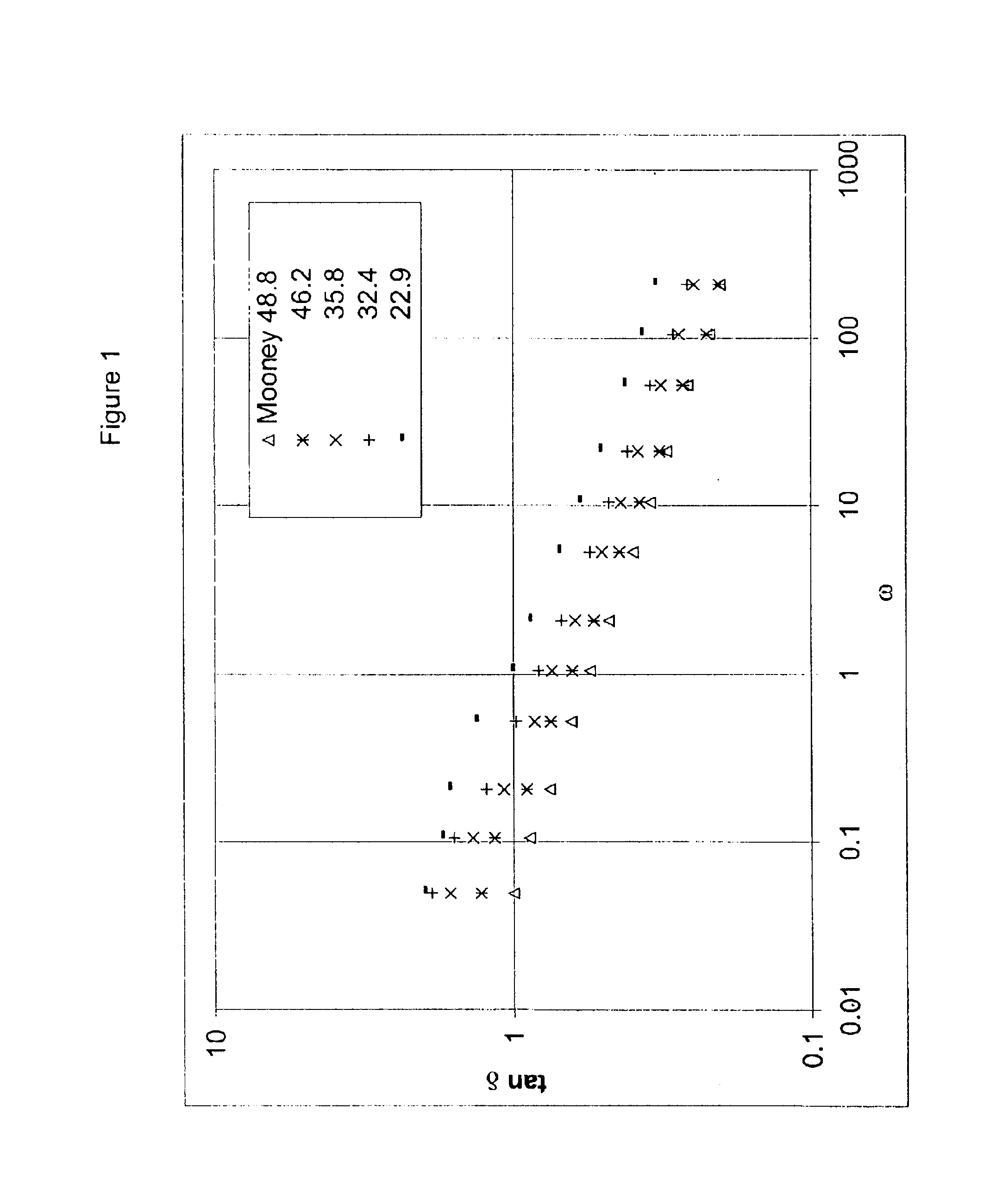

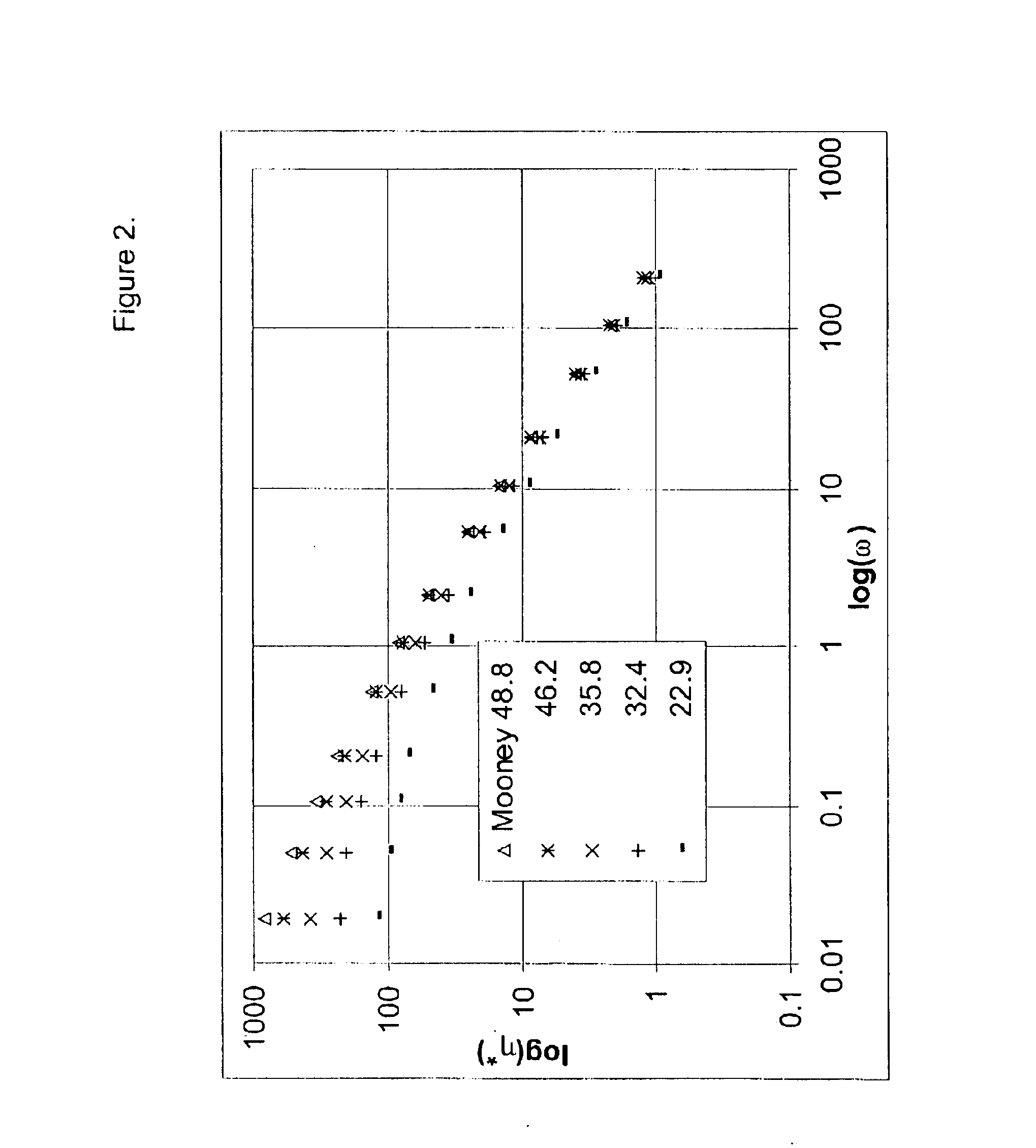

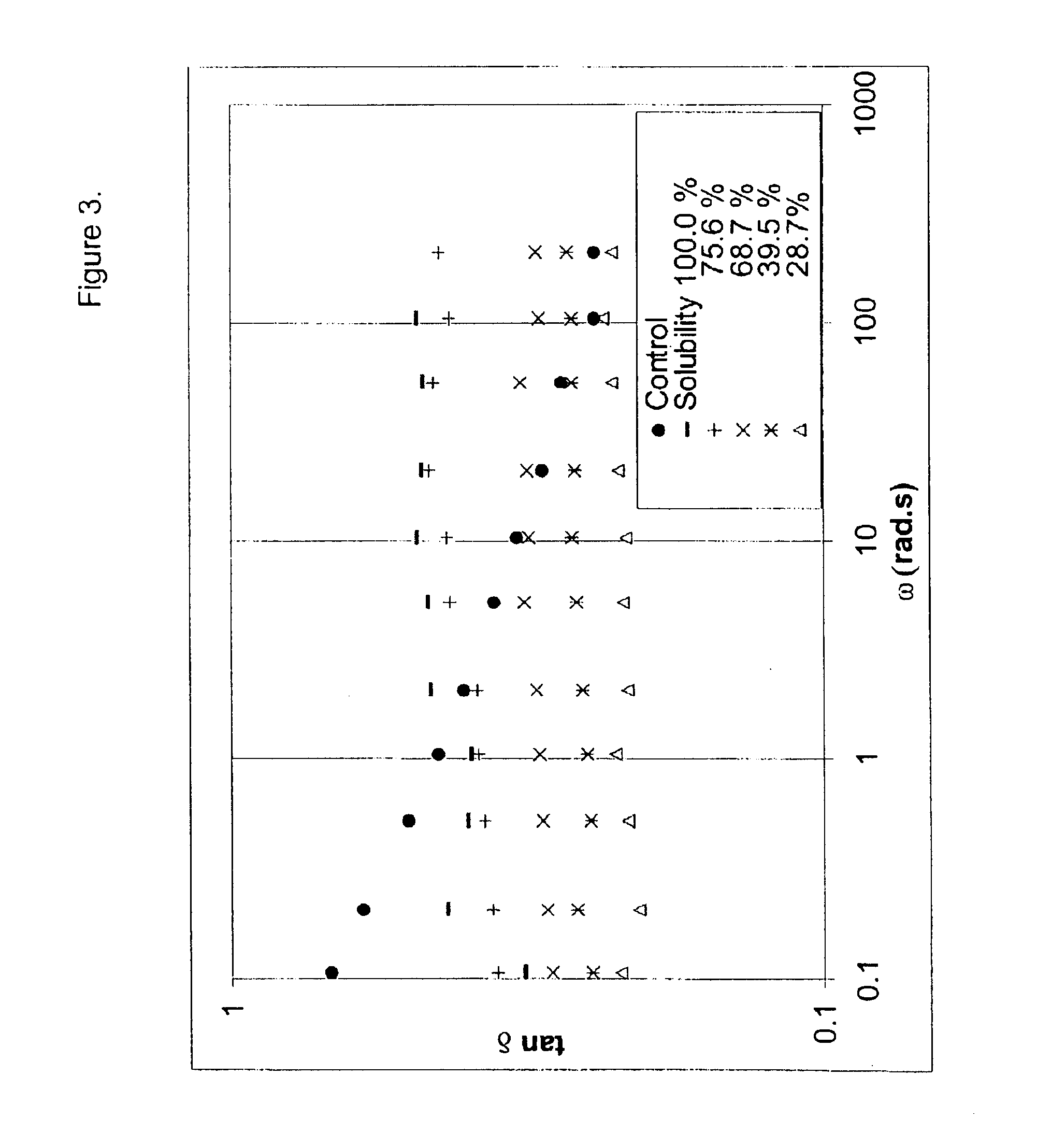

Processability butyl rubber and process for production thereof

A butyl polymer having improved processability is described, together with a process for production thereof. The butyl polymer derived from a reaction mixture which contains: (i) a monomer mixture comprising a C4 to C7 monoolefin monomer (preferably isobutylene) and a C4 to C14 multiolefin monomer (preferably isoprene); (ii) a multiolefin cross-linking agent (preferably divinyl benzene); and (iii) a chain transfer agent (preferably diisobutylene (2,2,4-trimethyl-1-pentene)). The subject butyl polymer has an improved balance of cold flow, filler dispersion, extrusion rate and die swell.

Owner:LANXESS LTD

Pneumatic tire with built-in colored sealant layer

InactiveUS20050113502A1Promoting aforesaid processingPromoting effectiveness of abilityOther chemical processesSpecial tyresEngineeringButyl rubber

The present invention relates to a pneumatic tire with a built-in sealant layer having a color other than black. The sealant layer is derived from a sealant precursor layer comprised of a butyl rubber, organoperoxide and silica together with a colorant. The butyl rubber-based precursor sealant layer is built into the tire to form a tire assembly and its butyl rubber component is depolymerized during a subsequent curing of the tire at an elevated temperature in a suitable mold to form the tire having the resultant built-in colored sealant layer. The sealant precursor composition may additionally contain clay and / or calcium carbonate.

Owner:FITZHARRIS WALL JENNIFER ELIZABETH +4

Pneumatic tire having built-in sealant layer and preparation thereof

ActiveUS20040159386A1Improve abilitiesImprove efficiencyOther chemical processesSpecial tyresFiberVulcanization

This invention relates to a pneumatic tire having a built-in sealant layer and its preparation. The sealant layer precursor is a layer of a butyl rubber based composition which contains an organoperoxide. The butyl rubber of said precursor is a copolymer of isobutylene and isoprene containing from about 0.5 to about 5, alternately less than 1, mole percent isoprene. The precursor composition contains carbon black and / or coal dust and may contain a dispersion of liquid conjugated diene polymer (e.g. liquid cis 1,4-polyisoprene polymer), short fibers and / or hollow glass microspheres. A layer of the sealant precursor is built into the tire between a sulfur vulcanized halobutyl rubber innerliner and conjugated diene-based rubber of the tire carcass. The butyl rubber of the sealant precursor is partially depolymerized by the organoperoxide during the elevated temperature vulcanization of the tire to form the built-in sealant layer. In one aspect of the invention, said uncured butyl rubber sealant precursor layer composition has a storage modulus G'(80° C.) in a range of about 100 to about 400 kPa and said partially depolymerized butyl rubber sealant layer composition has a storage modulus G' (80° C.) in range of about 5 to about 50 kPa.

Owner:THE GOODYEAR TIRE & RUBBER CO

Preparation method for airtight liner material and raw material formula of airtight liner material

The invention relates to airtight materials and provides a preparation method for an airtight liner material and a raw material formula of the airtight liner material. The raw material formula involves, by weight, 100 parts of branched polyethylene, 30-100 parts of carbon black, 2-10 parts of peroxide crosslinking agents, 1-10 parts of zinc oxide, 0.1-1 part of lubricants and 0.3-1 part of accelerants. The branched polyethylene serves as a principal raw material of the airtight liner material, and raw material cost is lower than that of butyl rubber; the glass-transition temperature is low, cold endurance is good, and the phenomenon of low-temperature hardening is unlikely to occur; no unsaturated double bonds exist in the molecular structure, and ageing-resistant performance is excellent; mobility is good, and the dispersion effect of filler is good; the airtight liner material has the same air tightness as the butyl rubber and is better than the butyl rubber in abrasive resistance and rebound resilience.

Owner:ZHEJIANG UNIV

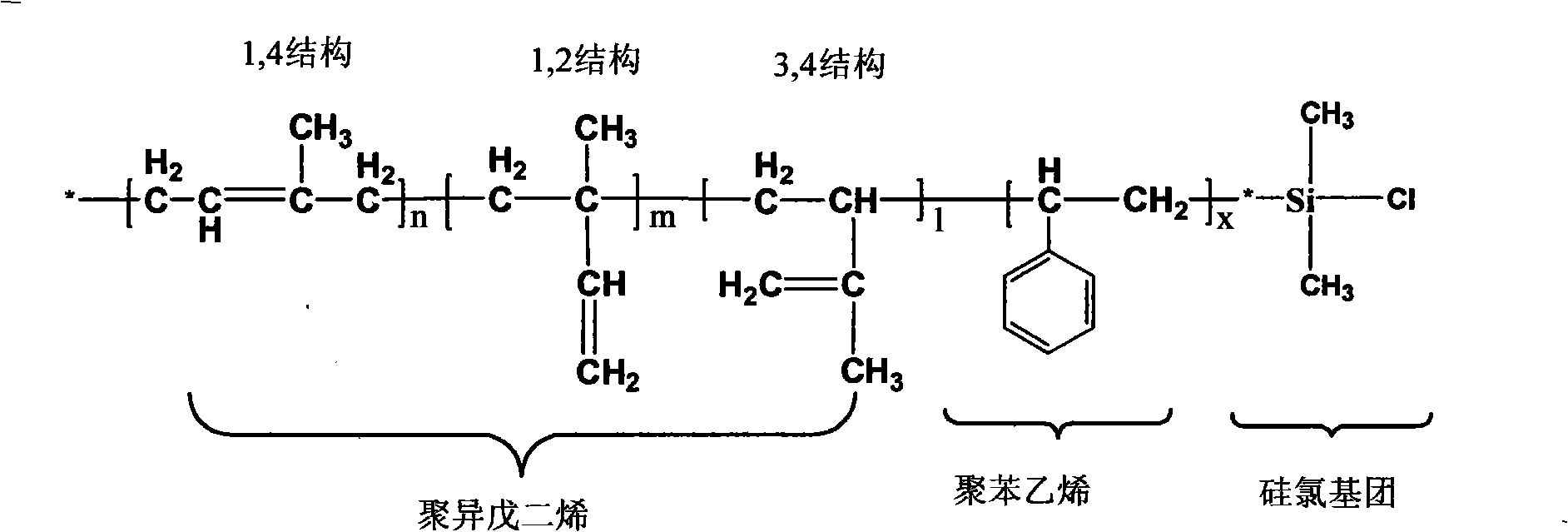

Preparation method of star branched polyisobutylene or butyl rubber

The invention relates to a preparation method of star-shaped branched polyisobutylene or butyl rubber, which uses polystyrene / isoprene block copolymers containing silicon chloride groups at the end or polystyrene / isoprene block copolymers containing silicon chloride groups at the end. As the initiator-grafting agent of cationic polymerization, the diene block copolymer directly participates in cationic polymerisation; through the initiation of cationic polymerisation by silicon chloride group, the star-branched polymer is prepared by participating in the grafting reaction through unsaturated bonds. Isobutylene and butyl rubber products; the advantages of the present invention are: the synthesized branched polymer exhibits different processing properties from the original linear branched polymer molecule in terms of colloidal strength and stress relaxation balance, and has excellent performance, involving thermoplastic elasticity body more.

Owner:CHINA PETROLEUM & CHEM CORP +1

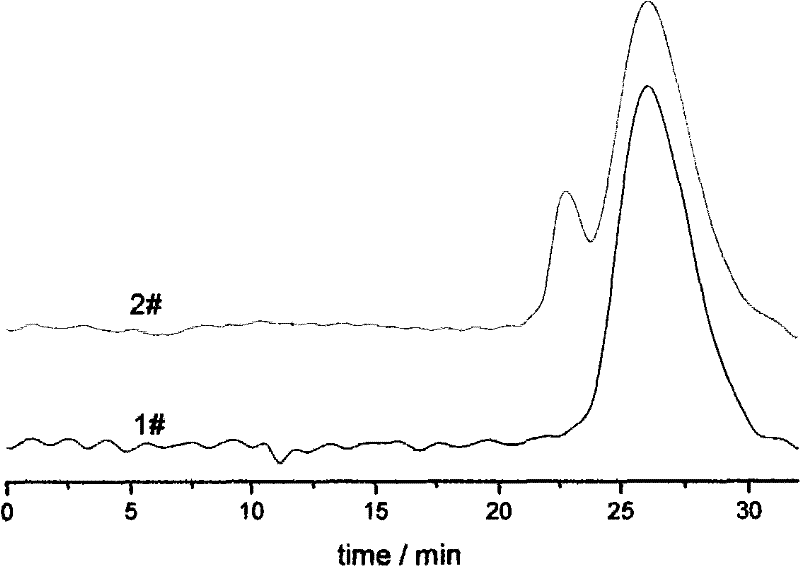

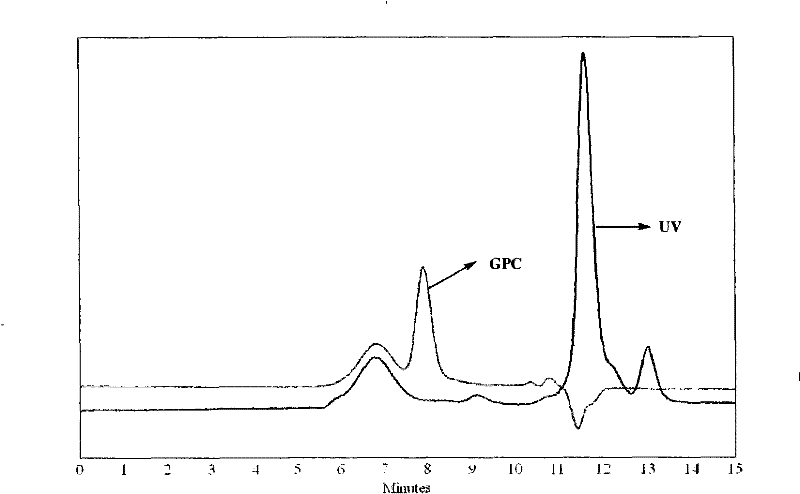

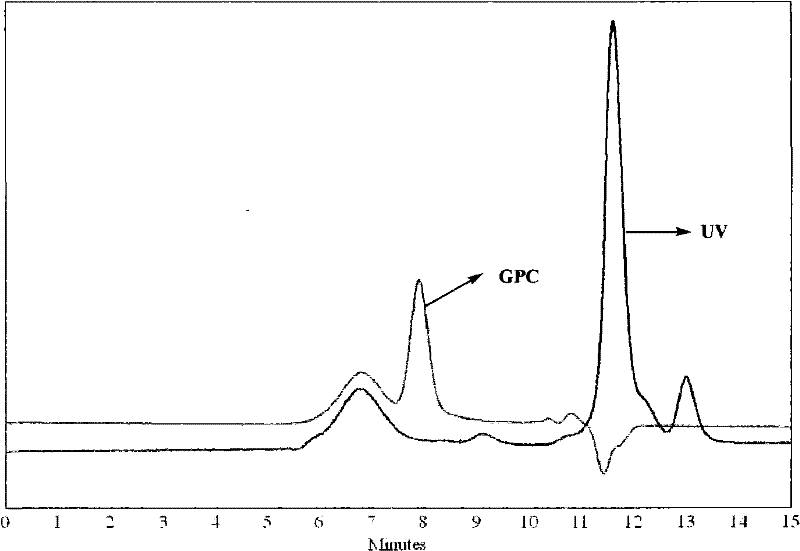

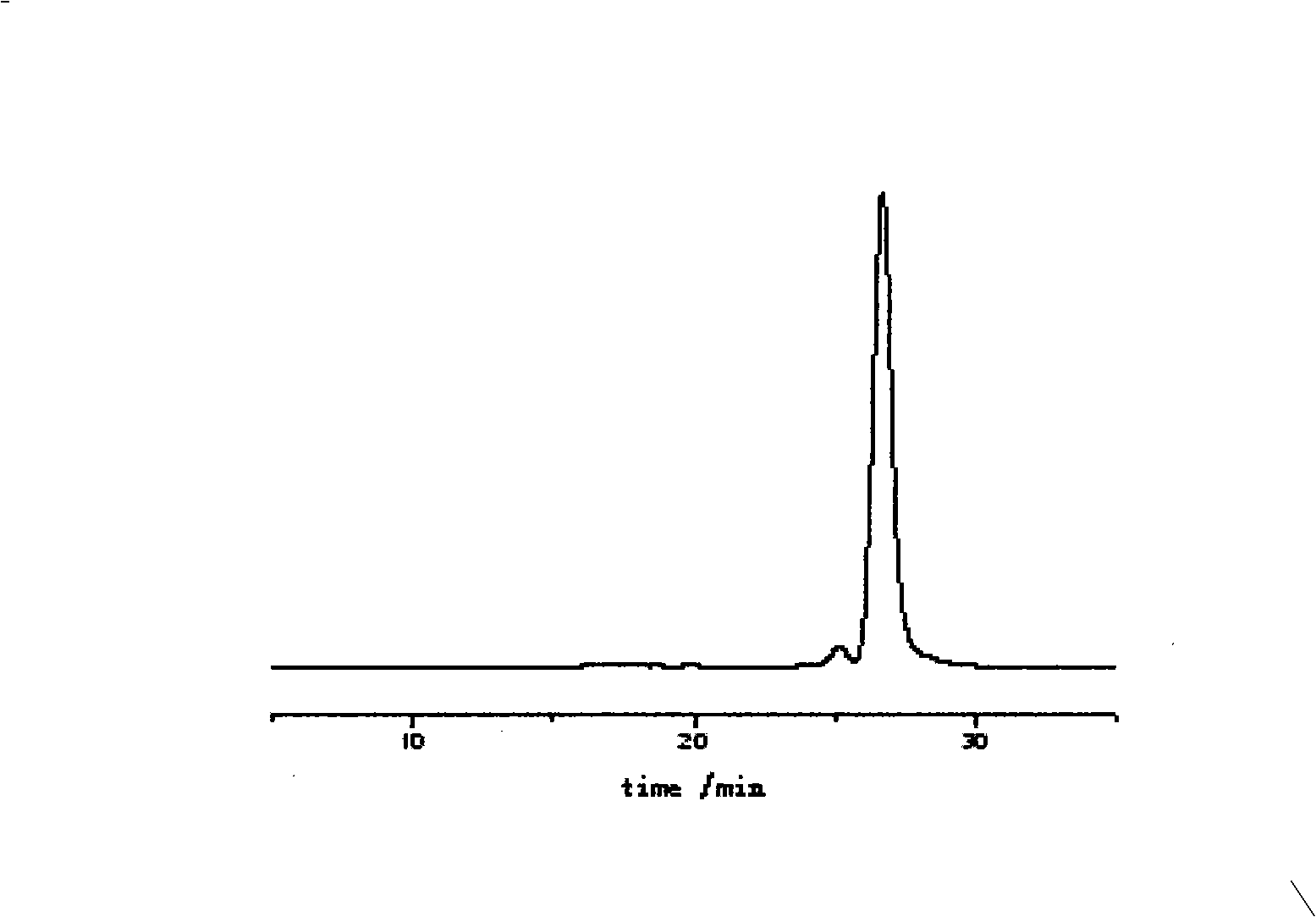

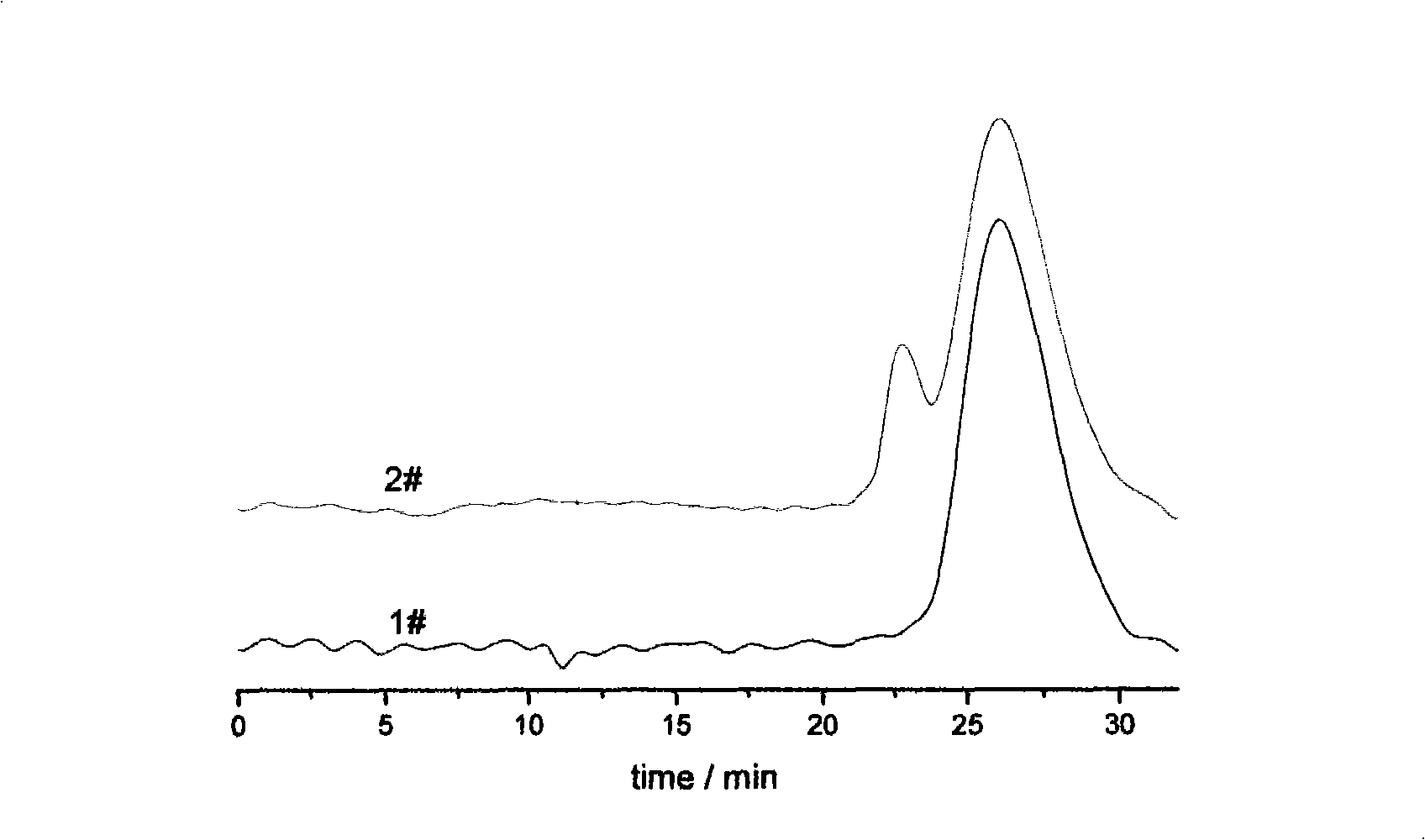

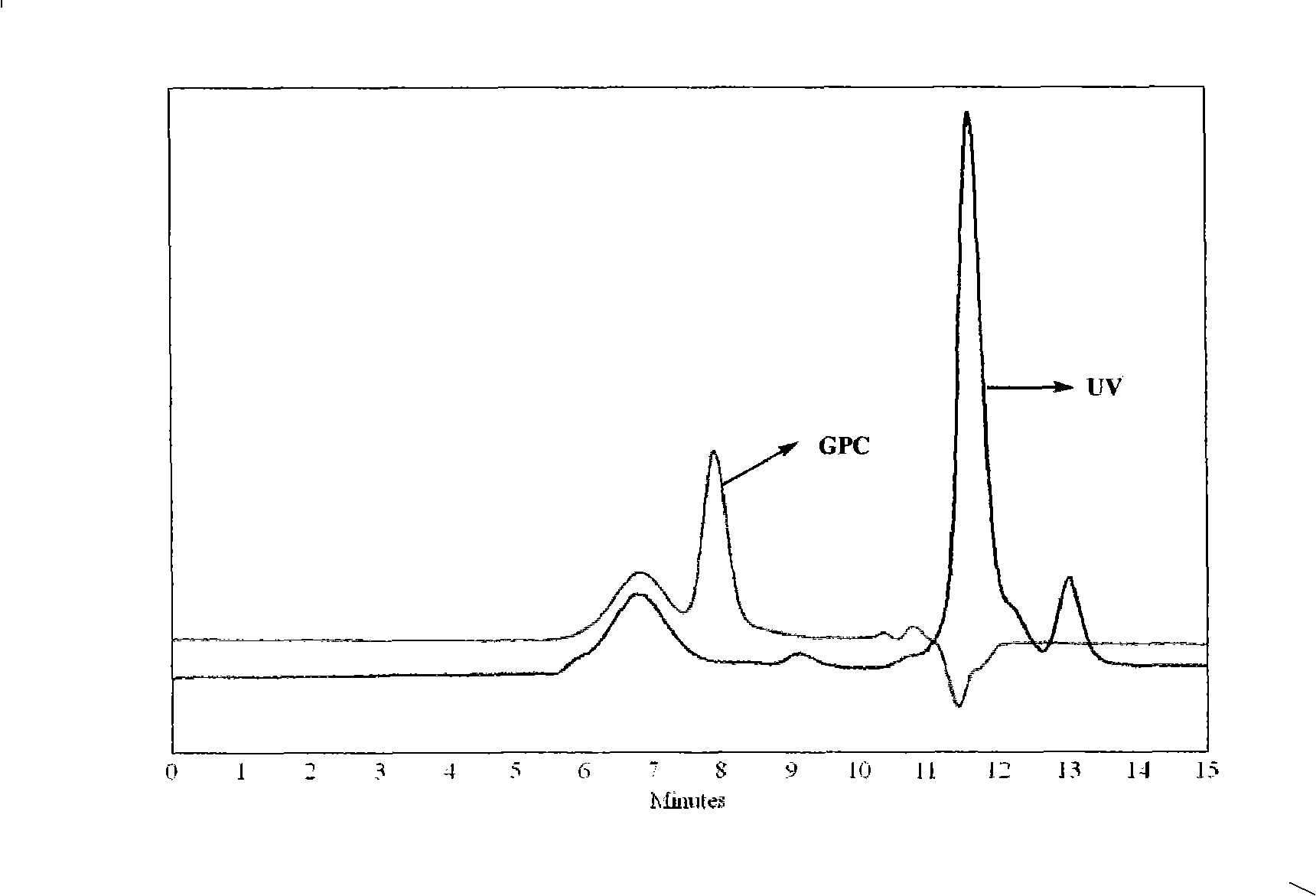

Initiation system for polymerization of star-branched polyisobutene or isobutene-diene rubber positive ion

The invention relates to an initiation system for preparing a star branching polyisobutylene or the polymerization of a butyl rubber cation. The invention is used for a macromolecule compound obtained by the cation polymerization reaction of carbon-carbon unsaturated bond. The novel initiation system consists of an initiation-grafting agent; a co-initiation agent and a nucleophile and is used for initiating an ethylene monomer to carry out homopolymerization, segment copolymerization, star polymerization and grafting copolymerization. The material used by the initiation system is a common chemical reagent which is cheap. The gel chromatography spectrogram of the obtained polymer is distributed in an obvious double-peak way. The performance of the products is excellent. The initiation system provides a beneficial condition to the industrialization of the cation polymerization technique for the activity of various olefin compounds.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Preparation of star-branched polyisobutene or isobutene-diene rubber

The invention relates to a preparation method of a star branching polyisobutene or a butyl rubber. The block multipolymer of polystyrene / isoprene with the tail end thereof containing a Si-Cl group or the block multipolymer of polystyrene / butadiene with the tail end containing a Si-Cl group is used as a grafting agent for the initiation of the cationic polymerization and directly participates in the cationic polymerization; the cationic polymerization initiated by the Si-Cl group is participated with a branching reaction for preparing the products of star branching polyisobutene and butyl rubber by a unsaturated link. The preparation method has the advantage that a composed branched chain polymer expresses different processing performances from the molecule of the original linear branched chain polymer on the aspects of tagma intensity and stress loosening balance. The performance is excellent; more thermoplastic elastomers are related.

Owner:CHINA PETROLEUM & CHEM CORP +1

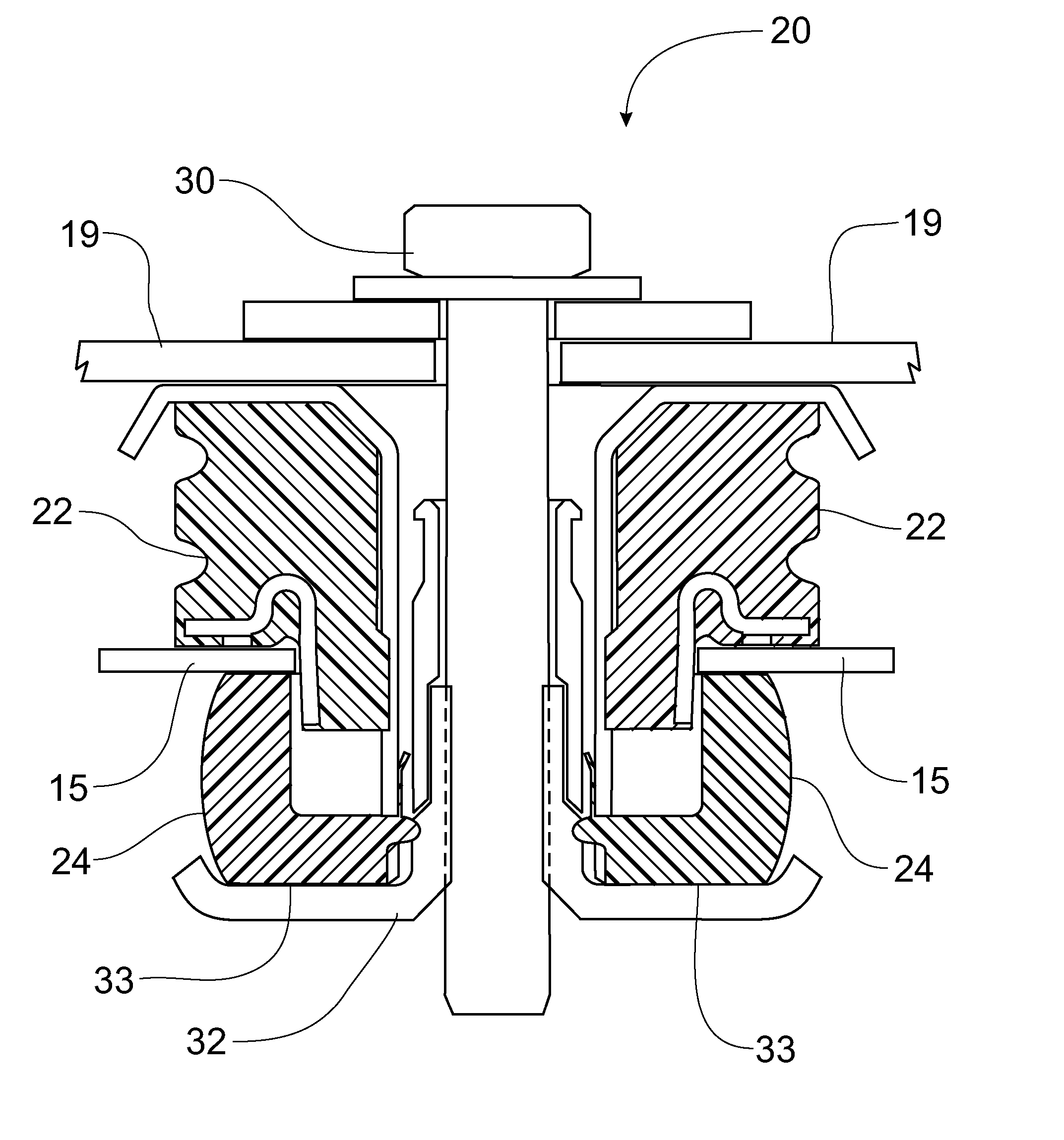

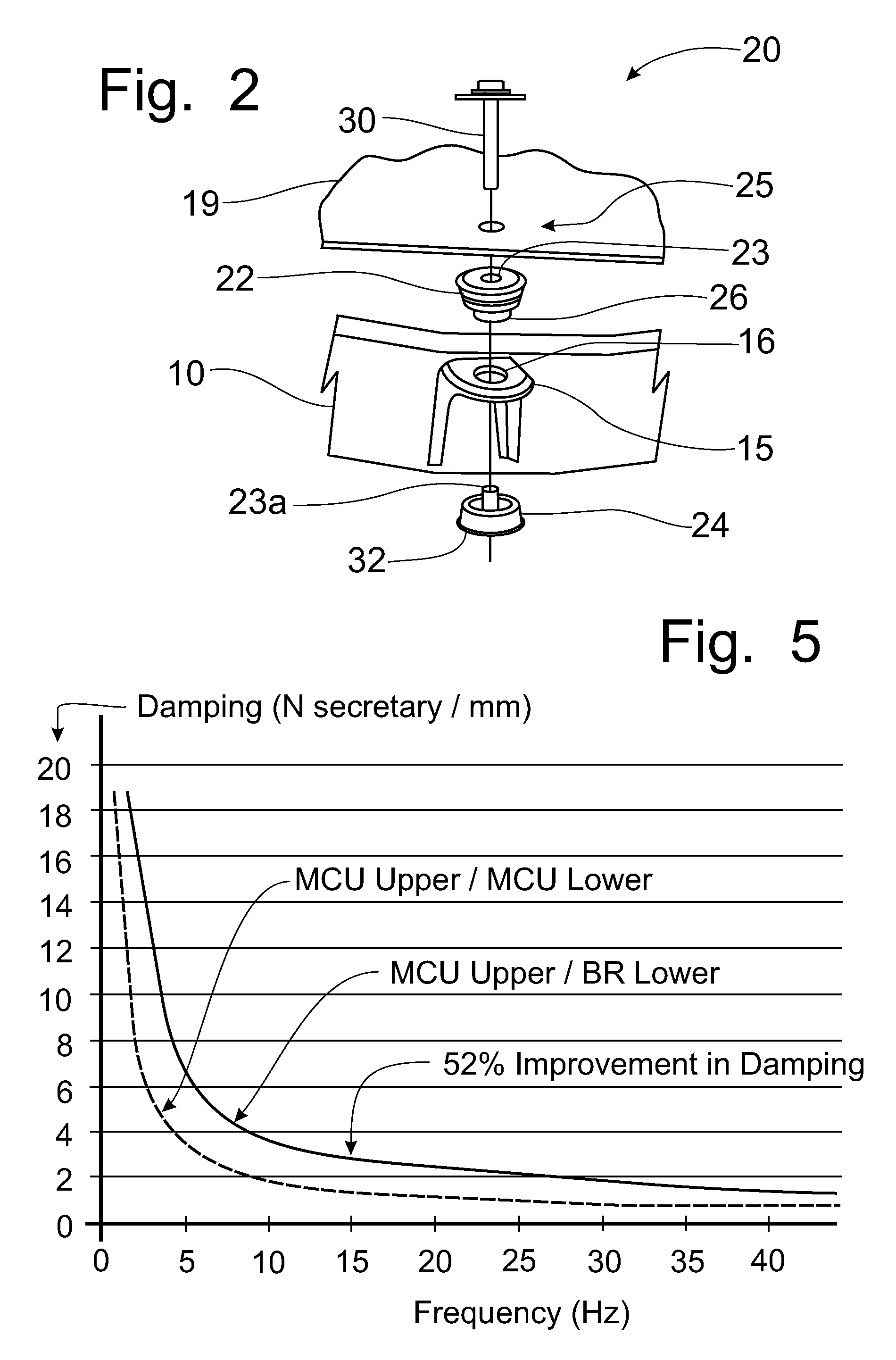

Hybrid material body mount for automotive vehicles

InactiveUS20050073166A1Easy to operateReduce transmissionVehicle body-frame connectionsMultiple spring combinationsHybrid materialButyl rubber

A hybrid body mount assembly is provided to mount automotive parts to a vehicle chassis. The body mount assembly is fabricated in a two-piece configuration with disparate elastomeric materials used for the upper and lower members. The hybrid material configuration both enhances noise transmission reduction and minimizes vehicle vibration. The upper body mount member is formed from micro cellular urethane to minimize noise transmission through the body mount assembly, while the lower mount member is fabricated from butyl rubber to minimize the transmission of vehicle vibrations. The hybrid material assembly achieves a 50% increase in damping without detrimentally affecting the transmission of noise.

Owner:FORD GLOBAL TECH LLC

Nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket and preparation method thereof

The invention discloses a nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket. Raw materials for the nanometer attapulgite-modified chlorosulfonated polyethylene rubber gasket comprise, by weight, 135 to 145 parts of chlorosulfonated polyethylene rubber CSM2305, 10 to 15 parts of butyl rubber CBK139, 10 to 15 parts of Lanxess 2470 EPDM rubber, 2 to 5 parts of phthalate, 3 to 5 parts of propanediol sebacate polyester, 2 to 5 parts of n-butyl methacrylate, 3 to 4 parts of zinc oxide, etc. The gasket provided by the invention has the advantages of good high temperature resistance, sealing performance and flame resistance, excellent resistance to corrosion, small changes in its volume and hardness when working in mediums like an acid, an alkali and oil for a long time, no adherency onto the surface of a metal, a small friction coefficient, good wear resistance, flexibility of bonding with a sealing surface, good resistance to weathering ageing and ozone ageing, durability, etc.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

Butyl rubber composition and method for producing butyl rubber adhesive tape by using same

InactiveCN101824288AHigh peel strengthLow viscosityNon-macromolecular adhesive additivesFilm/foil adhesivesPolymer scienceThermoplastic elastomer

The invention discloses a butyl rubber composition and a method for producing a butyl rubber adhesive tape by using the same. Based on the total weight of the composition, the butyl rubber composition comprises the following components: 15 to 40 percent of butyl rubber matrix, 5 to 12 percent of styrenic thermoplastic elastomer, 8 to 20 percent of plasticizer, 20 to 40 percent of tackifying resin, 0.2 to 2 percent of vulcanizing agent and 10 to 30 percent of inorganic filler. The method for producing the adhesive tape comprises the steps of extrusion molding and vulcanizing. The adhesive tape prepared by the butyl rubber composition has high peel strength and adhesiveness stability, and the process for producing the adhesive tape is simple and easy to control and is suitable for popularization and application.

Owner:中建材苏州防水研究院有限公司

Adhesive and sealant systems

Adhesive and sealant systems based on epoxy resins, polyurethane, silane-terminated polymers, silicones, unsaturated polyester resins, vinyl ester resins, acrylates, polyvinyl acetate, polyvinyl alcohol, polyvinyl ether, ethylene vinyl acetate, ethylene-acrylic acid copolymers, polyvinyl acetates, polystyrene, polyvinyl chloride, styrene-butadiene rubber, chloroprene rubber, nitrile rubber, butyl rubber, polysulfide, polyethylene, polypropylene, fluorinated hydrocarbons, polyamides, saturated polyesters and copolyesters, phenol-formaldehyde resins, cresol- / resorcinol-formaldehyde resins, urea-formaldehyde resins, melamine-formaldehyde resins, polyimides, polybenzimidazoles, polysulfones, which contain 1 wt.% to 15 wt.% of a compacted, hydrophobic pyrogenic silica.

Owner:DEGUSSA AG

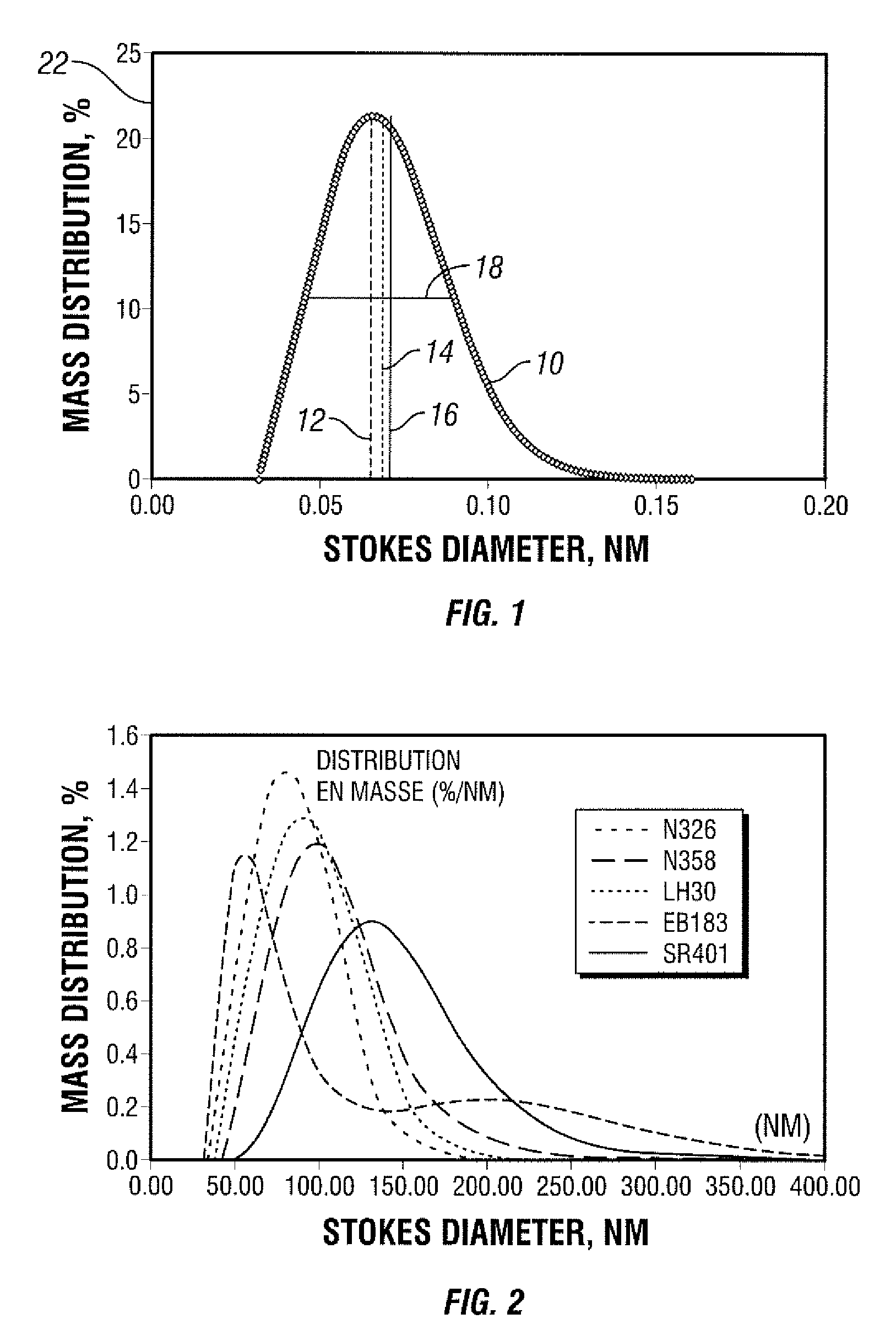

Elastomer compositions with carbon black

An elastomer composition includes an elastomer and a carbon black, wherein the carbon black is characterized as having a COAN of between about 90 and 150 ml / 100 g, a BET of between 50 and 69 m2 / g and a distribution index DI that is greater than 1.15, wherein the DI is a ratio of dw to dmode. In particular embodiments, the elastomer may be selected from one or more natural rubbers, one or more synthetic rubbers or combinations thereof For example, the one or more synthetic rubbers may be selected from styrene butadiene rubber, butadiene rubber, polyisoprene rubber, butyl rubber or combinations thereof. Products made from the elastomer composition include tires and other products, particularly tires that include a sidewall, a carcass, a carcass reinforcement, tread and / or an undertread comprising the elastomeric composition.

Owner:MICHELIN RECH & TECH SA +1

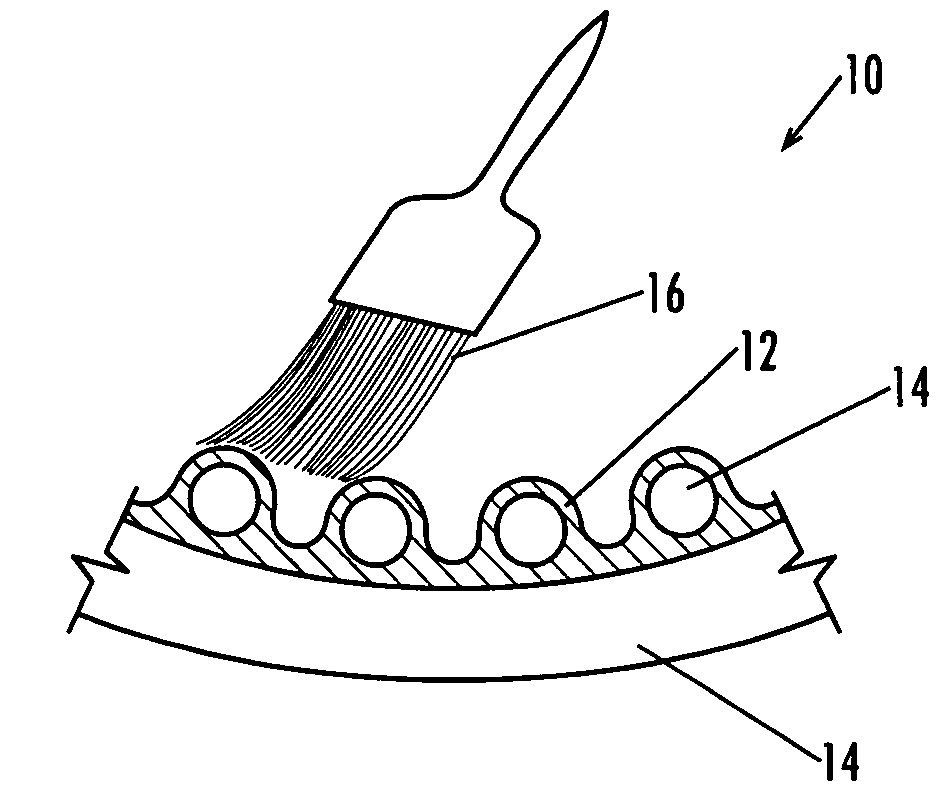

Lacrosse net

InactiveUS20080146385A1Improve adhesionImprove integrityThrow gamesCoatingsElastomerThermoplastic elastomer

A modified form of a lacrosse net provides increased adherence, integrity, and “give” as a result of a coating applied to the fibers. In one form, the fibers are manually coated by brushing them with a natural latex mixture followed by evaporation of the volatile components, which gives the coated fibers a tacky and energy absorbent nature. The soft nature of the coating may also aid in dissipating energy during impact with the ball, and this could contribute to the sense of increased “feel.” There are many natural and synthetic polymers that might be capable of delivering similar benefits, including conventional synthetic elastomers, e.g., butyl rubber. Thermoplastic elastomers are a growing field of interest in coating technologies, and with the appropriate tuning, they can be made with all of the same properties as the natural rubber coating. A brush-on method delivers the desired coating thickness and properties, but other methods, such as dip coating and spray coating, may increase feasibility for scaling-up the process. In one arrangement, the entire fiber is composed of a rubbery material. The resulting properties may not be exactly what is desired, however, because the underlying integrity of the nylon fiber would be absent, and this might result in netting with a “springy” feel.

Owner:LUNDBERG STEPHEN F

Dynamic vulcanization of non-nitrile rubbers in fluoroplastic polymers

Processable rubber compositions contain a cured elastomer dispersed in a matrix comprising a thermoplastic material. The cured elastomer is present at a level of greater than or equal to 35% by weight based on the total weight of cured elastomer and thermoplastic material. The thermoplastic material comprises a fluorine containing thermoplastic polymer, and the cured elastomer comprises a non-nitrile rubber selected from the group consisting of acrylic rubber, EPDM rubber, butyl rubber, silicone rubber, butadiene rubber, isoprene rubber, and natural rubber. Methods for preparing the compositions involve dynamic vulcanization of the elastomer and thermoplastic components.

Owner:FREUDENBERG NOK GEN PARTNERSHIP

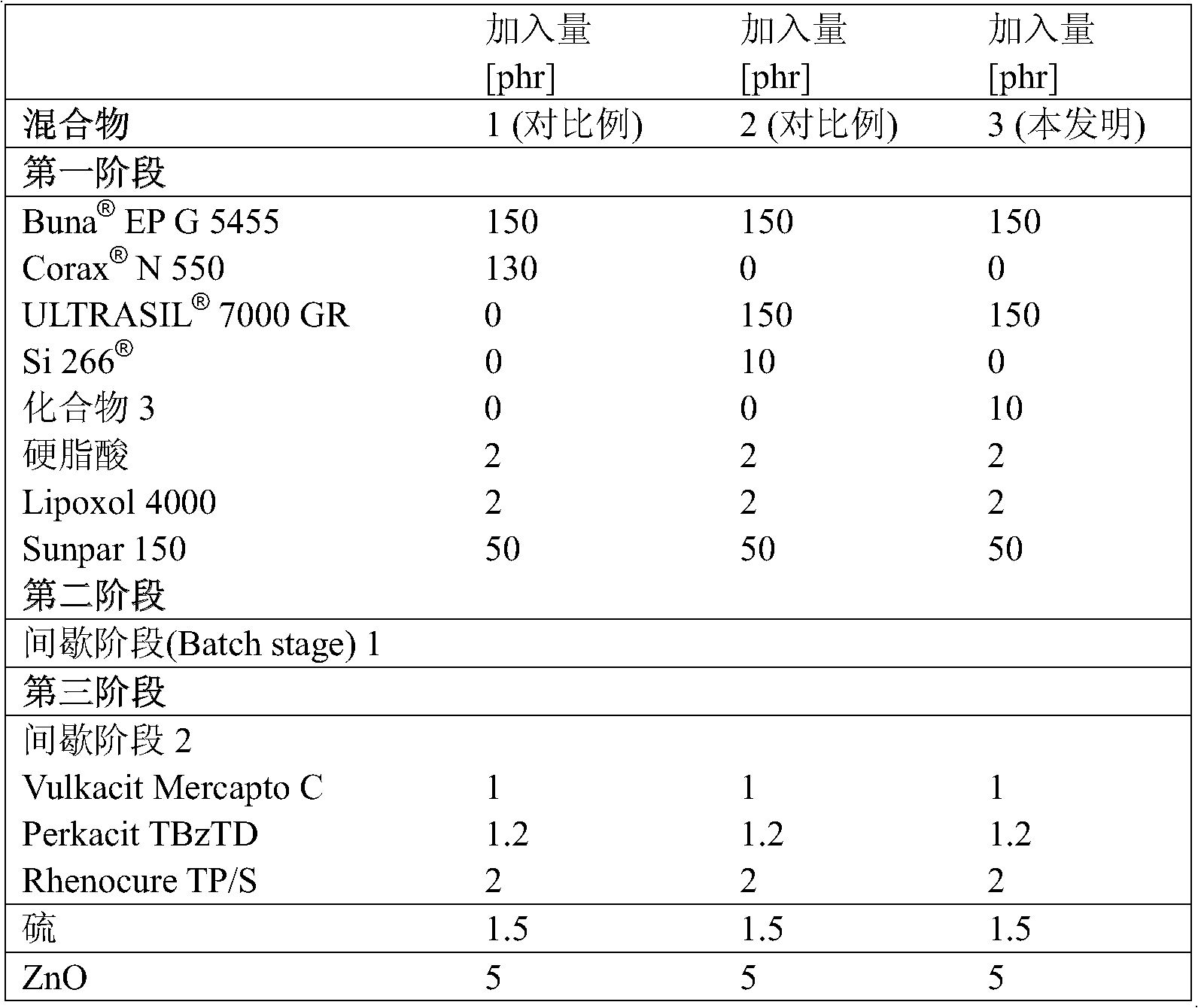

Rubber mixtures

ActiveCN102731915AHysteresis loss is smallImproved Dynamic BehaviorThin material handlingPolyesterPolymer science

A rubber mixture, comprising (A) at least one rubber selected from the group of ethylene-propylene-diene copolymer (EPDM), ethylene-propylene copolymer (EPM), chloroprene rubber (CR), chloropolyethylene (CM), chloro-isobutene-isoprene (chlorobutyl) rubber (CIIR), chlorosulfonyl polyethylene (CSM), etylene-vinyl acetate copolymer (EAM), alkyl acrylate copolymer (ACM), polyester polyurethan (AU), polyether polyurethane (EU), bromo-isobutene-isoprene (bromobutyl)rubber (BIIR), polychlorotrifluoroethylene (CFM), isobutene-isoprene rubber (butyl rubber, IIR), isobutene rubber (IM), polyisoprene (IR), thermoplastic polyester polyurethane (YAU), thermoplastic polyether polyurethane (YEU), silicone rubber with methyl groups on the polymer chain (MQ), hydrogenated acrylonitrile-butadiene rubber (HNBR), acrylonitrile-butadiene rubber (NBR) or carboxylated acrylonitrile-butadiene rubber (XNBR), (B) at least one oxidic filler, and (C) at least one silicon containing azodicarbamide of the general formula I (R 1 ) 3-a (R 2 ) a Si-R I -NH-C(O) -N=N-C (O)-NH-R I -Si(R 1 ) 3-a (R 2 ) a (I) . The rubber mixture is produced by mixing at least one rubber, at least one oxidic filler, and at least one silicon containing azodicarbamide of the general formula I. It may be used for moldings.

Owner:EVONIK OPERATIONS GMBH

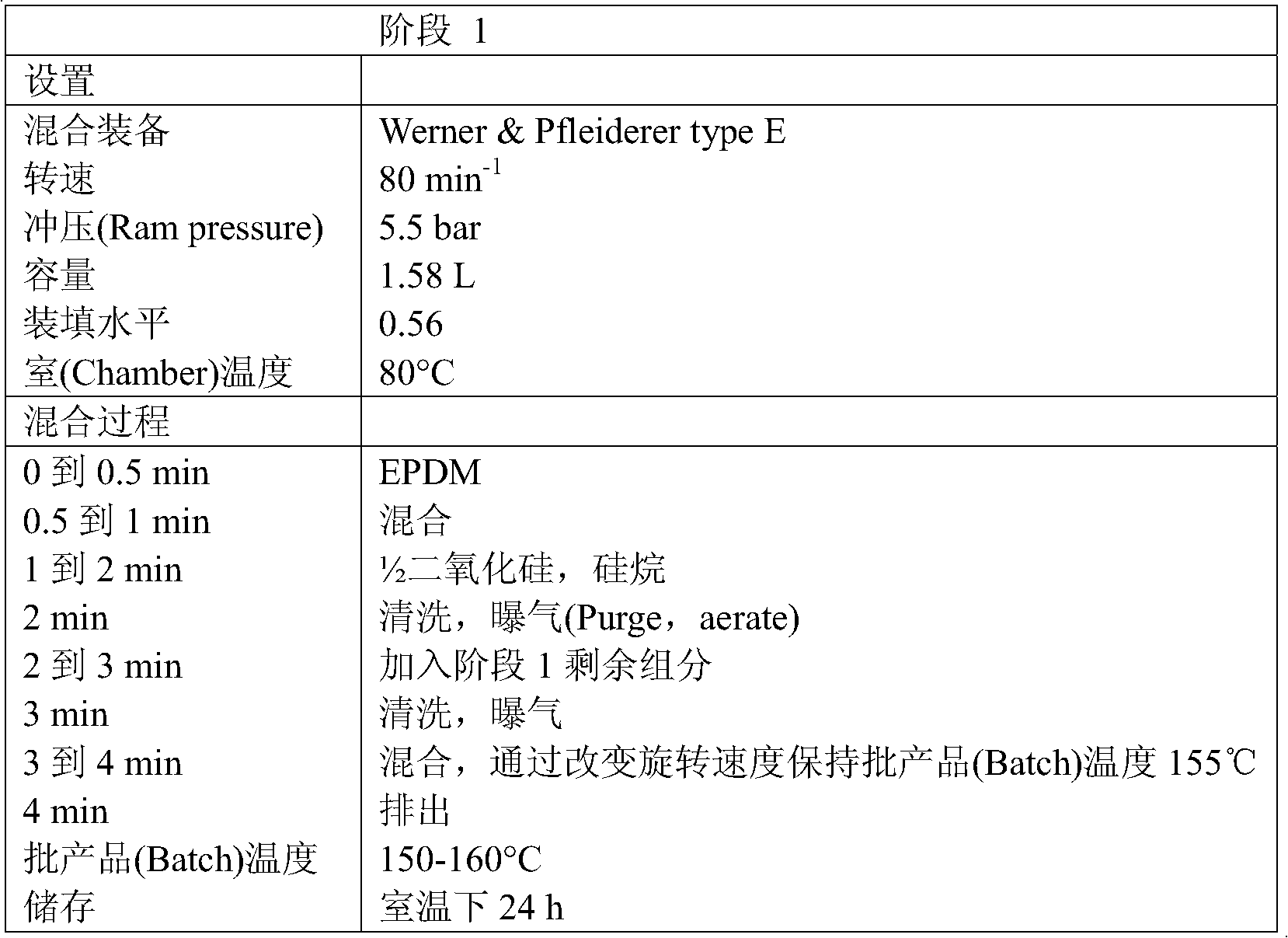

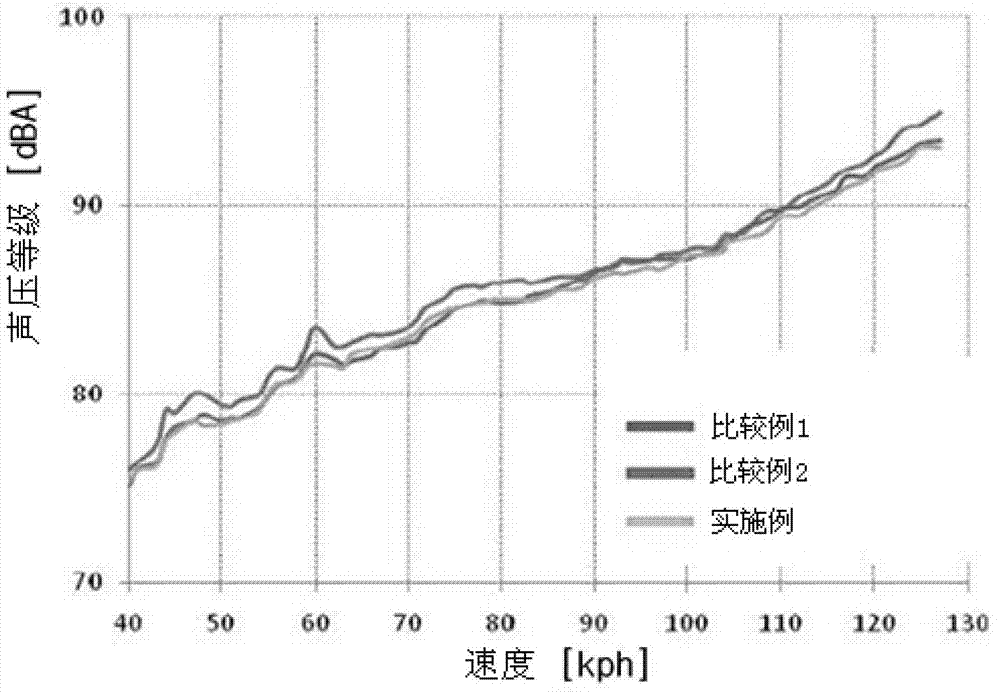

Pneumatic tire and method for manufacturing the same

InactiveCN102950974AReduce noiseNo significant change in viscosityWithout separate inflatable insertsLaminationResonanceInternal noise

Pneumatic tire and a method for manufacturing the same, wherein the pneumatic tire includes a porous sound-absorbing material adhered via a sealant layer to the inside surface of an inner liner, wherein the sealant layer comprises 100 to 400 parts by weight of polyisobutylene, 10 to 100 parts by weight of an inorganic additive and 1 to 15 parts by weight of a vulcanizing agent, with respect to 100 parts by weight of a butyl rubber; the pneumatic tire can reduce internal noise by distributing noise energy, causing generation of resonance in the tire, or changing the generated frequency without a risk of shear deformation generated between the sound-absorbing material and the tire.

Owner:HANKOOK TIRE WORLDWIDE

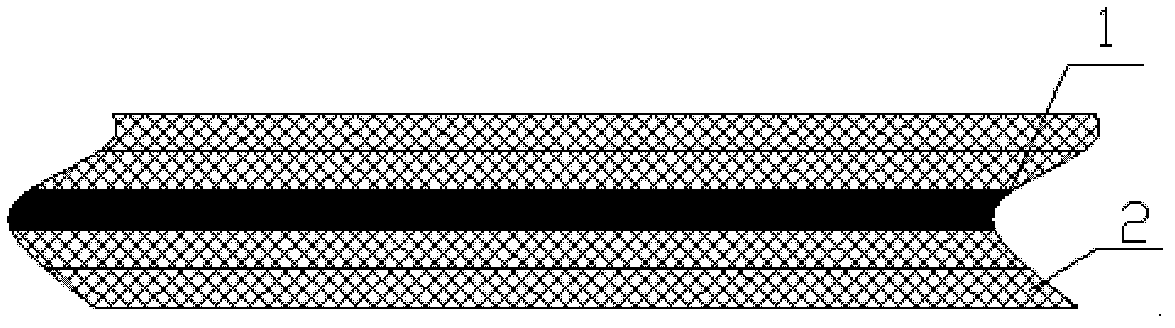

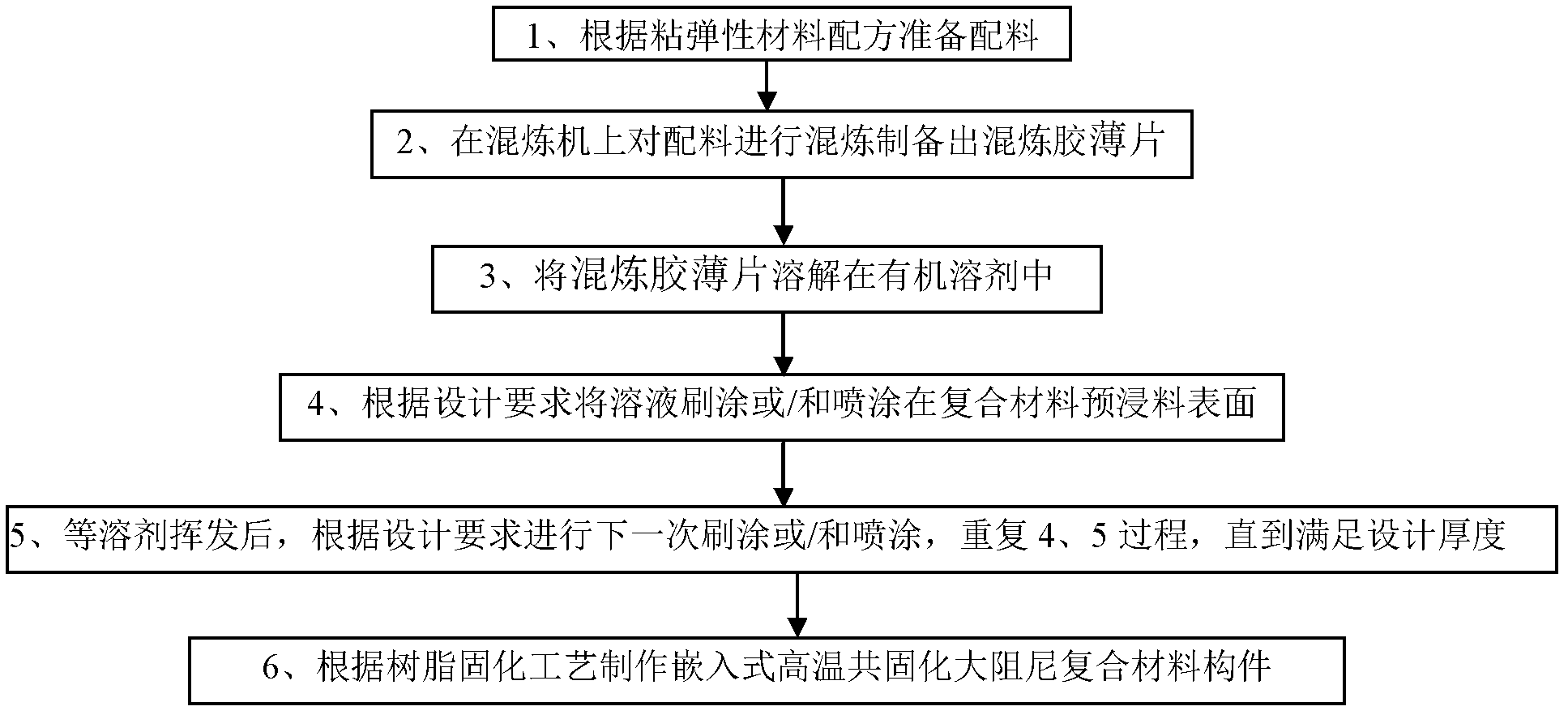

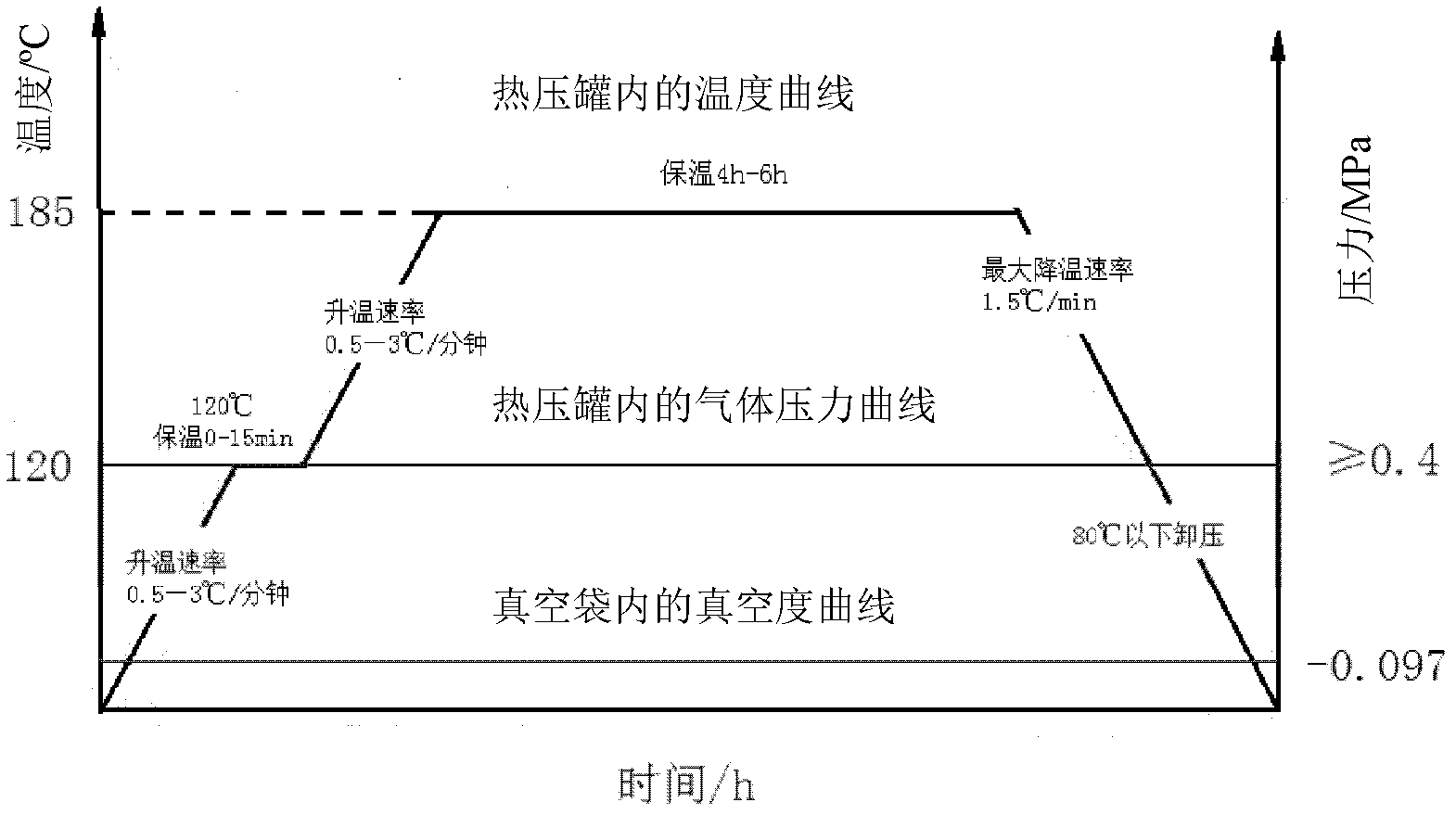

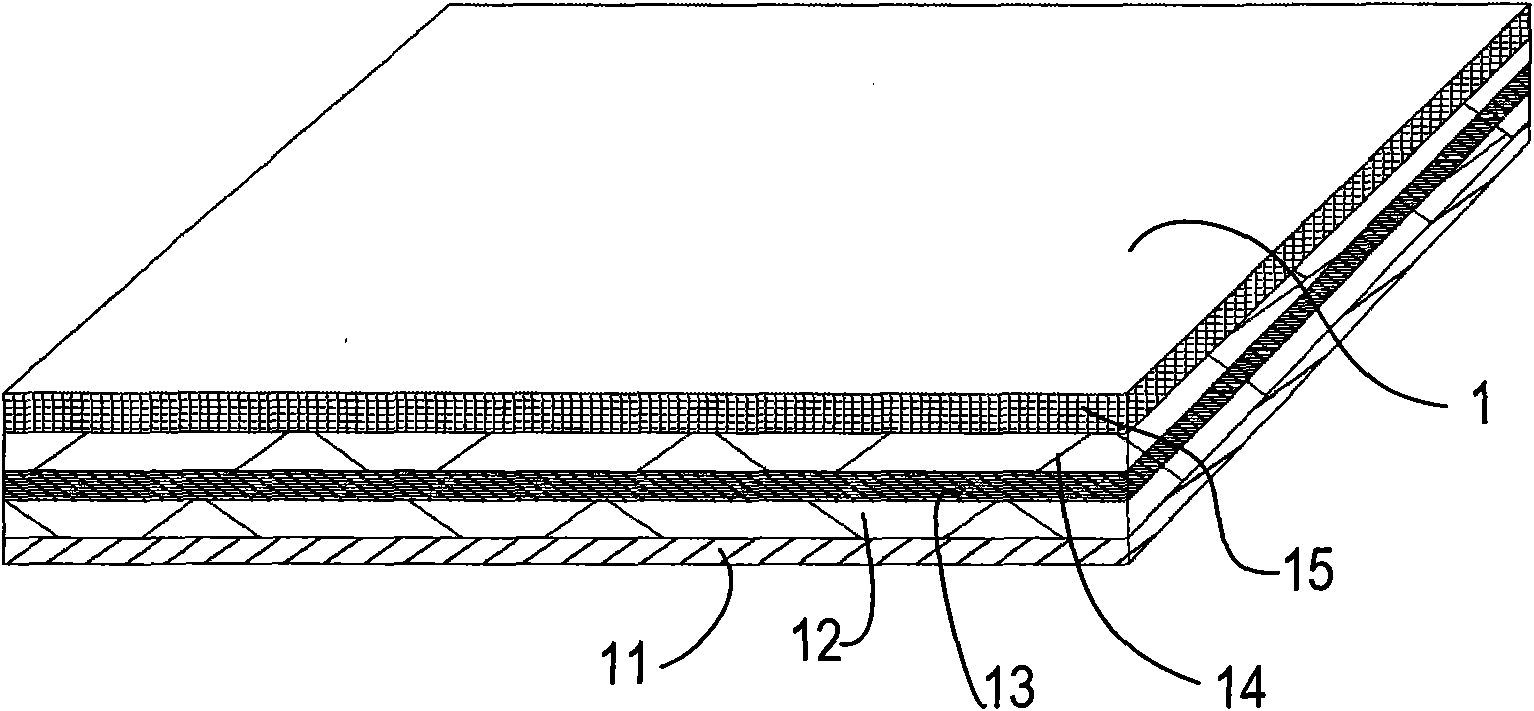

Embedded type high-temperature co-curing high-damping composite material and preparation process thereof

The invention discloses an embedded type high-temperature co-curing high-damping composite material. The embedded type high-temperature co-curing high-damping composite material comprises the following components in parts by weight: 92.5-93.5 parts of butyl rubber, 6.5-7.5 parts of chlorinated butyl rubber, 2.9-3.1 parts of chlorinated polyethylene, 3.9-4.1 parts of zinc oxide, 0.8-1 parts of stearic acid, 50-52 parts of carbon black and 5.9-6.1 parts of octyl phenolic resin. The invention also discloses a preparation method of the composite material. According to the method, the mixture of the butyl rubber and the chlorinated butyl rubber is taken as a main material, the mixture is dissolved in an organic solvent to be prepared into unvulcanized visco-elasticity damping material solution, the unvulcanized visco-elasticity damping material is brushed and coated on the prepreg surface of the composite material, by adopting a brush-coating method or / and spray-coating method, a damping layer is embedded in the structure of the composite material by being taken as a specific paving layer and then is processed into a damping-structure member of the embedded composite material by a co-curing process curve, and the damping-structure member of the embedded composite material has a wide application prospect in the high-tech fields such as high speed trains, aviation, aerospace and the like.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Anticorrosive viscoelastic body rubber belt and preparation method thereof

ActiveCN101935500AImprove adhesionUnique cold flow characteristicsNon-macromolecular adhesive additivesFilm/foil adhesivesCompound aWhole body

The invention relates to an anticorrosive viscoelastic body rubber belt, which comprises a protective film layer, a first viscoelastic body rubber belt, an enhanced network layer, a second viscoelastic body rubber layer and a release film layer arranged in turn, wherein the protective film layer is bonded with the first viscoelastic body rubber layer, the first viscoelastic body rubber layer is bonded with the enhanced network layer, and the enhanced network layer is bonded with the second viscoelastic body rubber layer to compound a whole body; and the release film layer is adhered to the second viscoelastic body rubber layer, wherein the viscoelastic body rubber is prepared from the following raw materials in percentage by weight: 3 to 10 percent of butyl rubber, 5 to 10 percent of highmolecular weight polyisobutylene, 25 to 35 percent of medium molecular weight polyisobutylene, 10 to 15 percent of low molecular weight polyisobutylene, 30 to 45 percent of inorganic enhanced powder,0.5 to 1.0 percent of antioxidant, 0.5 to 1.0 percent of anti-aging agent, and 0 to 1.0 percent of colorant. The viscoelastic body rubber belt has a self-healing function, is not brushed with a primer when used, and can be directly used for corrosion protection of irregular components. The invention also relates to a preparation method of the anticorrosive viscoelastic body rubber belt.

Owner:CYG CHANGTONG NEW MATERIAL

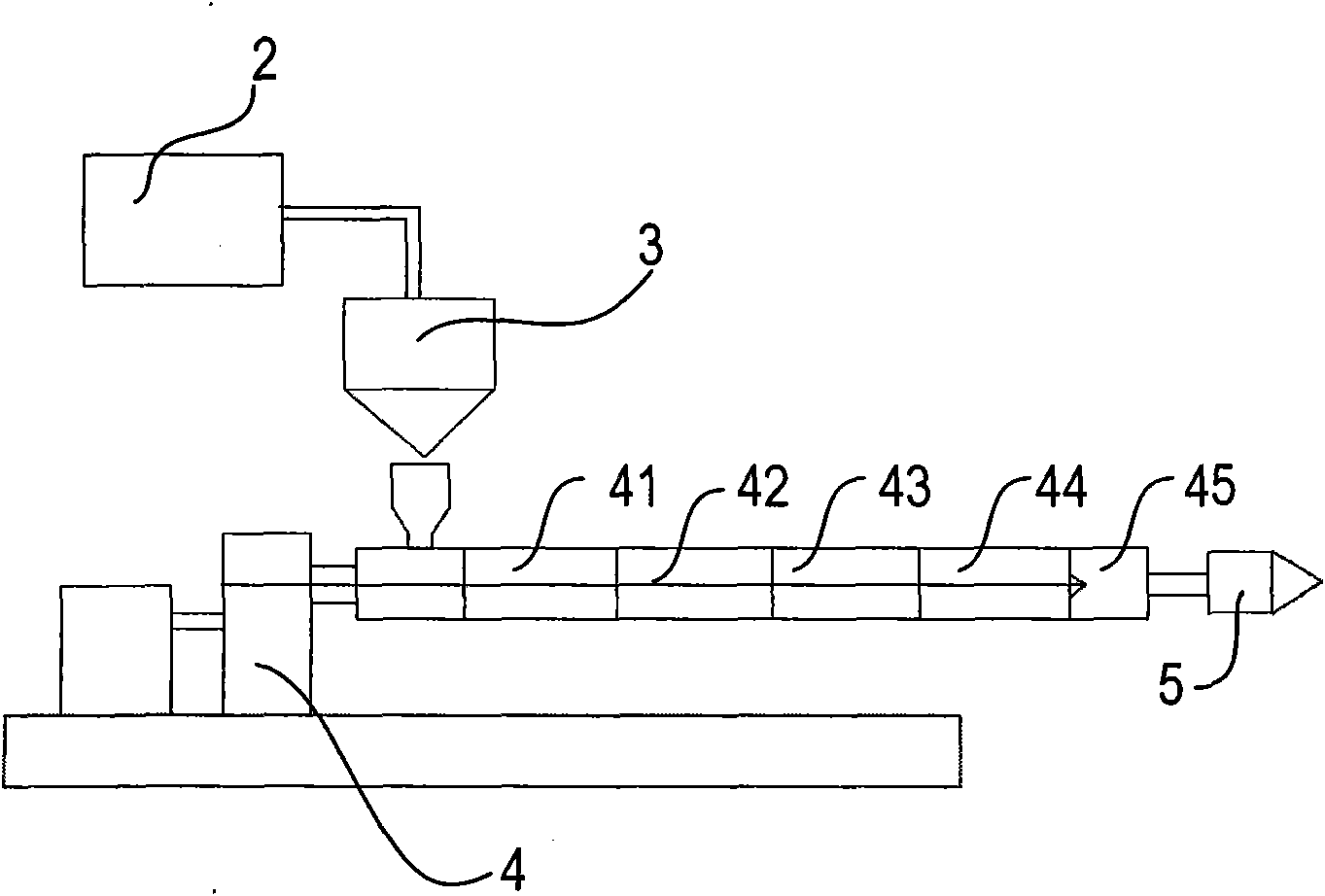

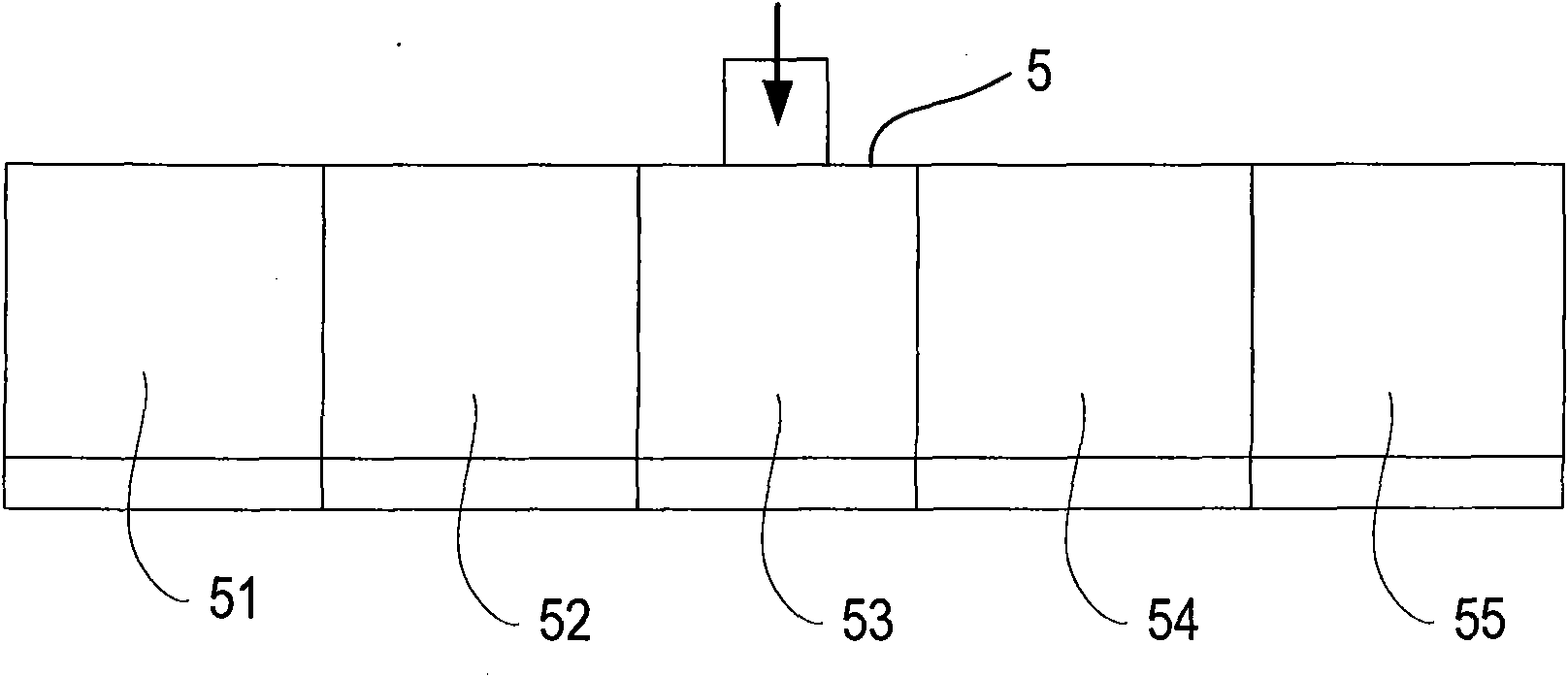

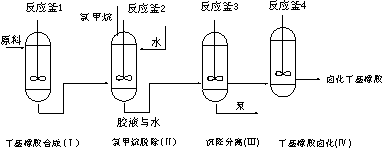

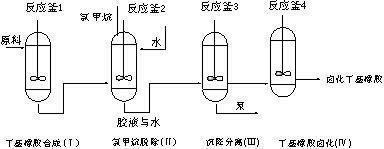

Technology for directly producing halogenated butyl rubber using butyl glue prepared by solution method

The invention discloses a technology for directly producing halogenated butyl rubber using butyl glue prepared by a solution method. The technology sequentially comprises the four steps as follows: (I), synthetizing butyl rubber; (II), removing methyl chloride; (III), settling for separation; and (IV), halogenating the butyl rubber. Halogenated butyl rubber is prepared through a halogenating reaction of solution method butyl rubber. In a mixed solvent of alkane and the methyl chloride, the solution method butyl rubber is prepared by copolymerising isobutylene and isoprene positive ions, halogenated butyl glue is prepared by removing the methyl chloride, settling for separation and halogenating the butyl glue at low temperature. The detailed technology can be consulted on the specification. The technology of the invention has the advantages that the butyl rubber not only forms additional crosslinking positions after being halogenated, but also increases double bond reactivity, increases the curing speed of the butyl rubber, improves the co-curing behavior with unsaturated rubber, and increases the adhesiveness and the cure efficiency of metal and the rubber, thereby avoiding solvent switching or rubber stock dissolving of a slurry process.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

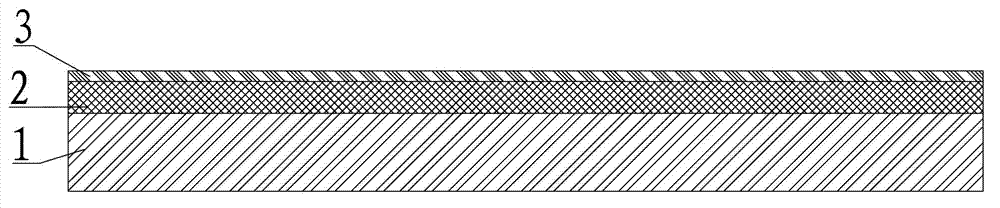

Macromolecule pre-laid waterproof coiled material

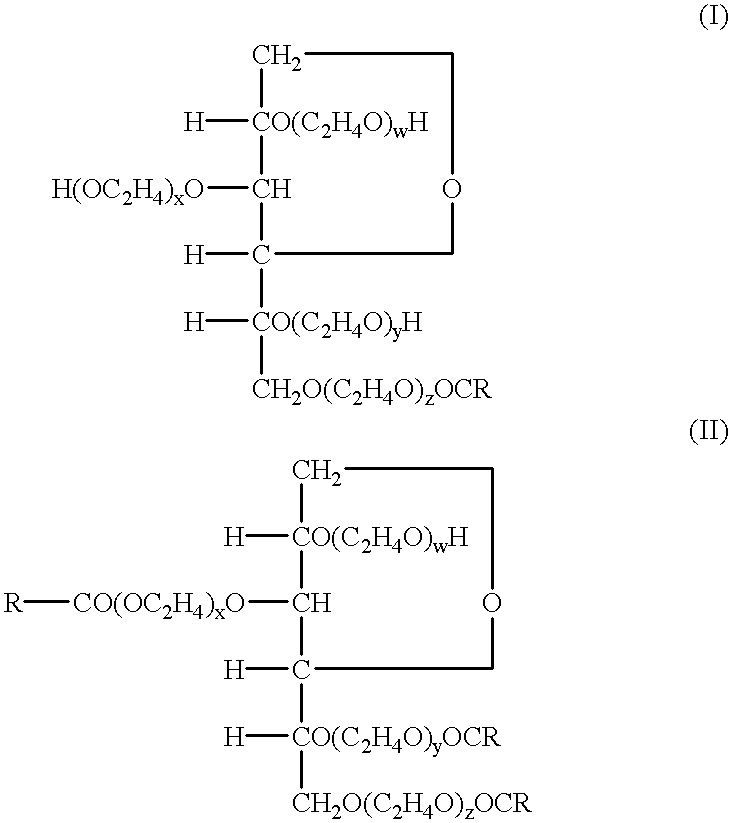

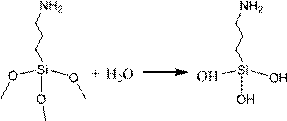

ActiveCN102774057AAvoid the disadvantages of poor high and low temperature resistanceImprove peel adhesion performanceSynthetic resin layered productsConjugated diene hydrocarbon adhesivesPolyethylene glycolCarboxylic acid

The invention relates to a macromolecule pre-laid waterproof coiled material which comprises a sheet-shaped macromolecule base material and a macromolecule adhesive layer formed on the macromolecule base material; and the macromolecule pre-laid waterproof coiled material is characterized by further comprising a protective layer coated on the macromolecule adhesive layer, wherein the macromolecule base material is high-density polyethylene, and polyethylene glycol terephthalate or ethylene-vinyl acetate copolymer; synthetic rubber is the main component of the macromolecule base material; and the material of the protective layer is silicon-containing unsaturated carboxylic acid modified butyl rubber which is prepared by the steps of grafting unsaturated carboxylic acid on butyl rubber molecule and then mixing with active silica. The macromolecule pre-laid waterproof coiled material has good high and low-temperature resistance and high adhesion peeling strength, and is easy to construct.

Owner:中建材苏州防水研究院有限公司 +1

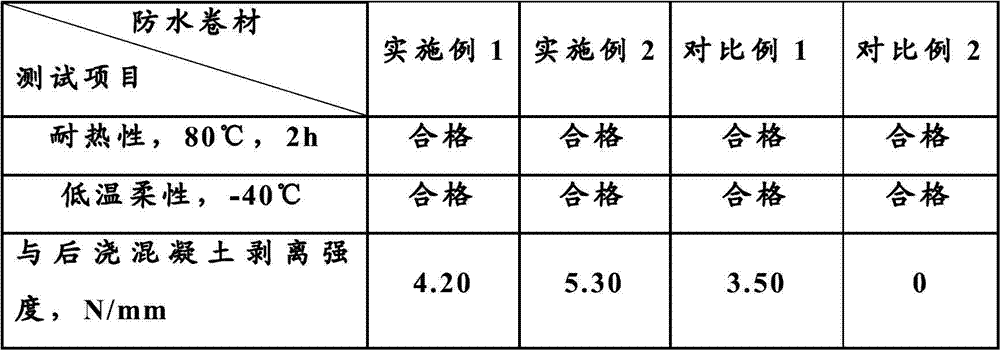

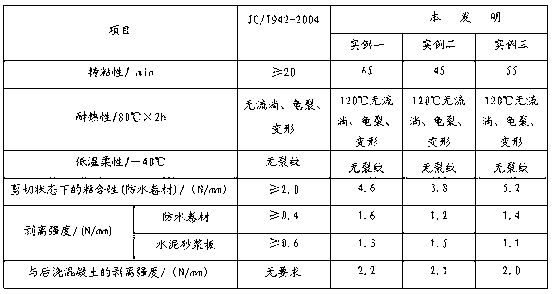

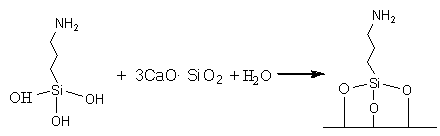

Reactive butyl rubber self-adhesive layer for waterproof roll and processing technology thereof

ActiveCN103102843ASelf-healingMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceAdhesive

The invention discloses a reactive butyl rubber self-adhesive layer for a waterproof roll and a processing technology thereof. The reactive butyl rubber self-adhesive layer comprises the following components in parts by weight: 20 parts of butyl rubber, 1.0-4.2 parts of ethylene vinyl acetate copolymer, 16.5-20.5 parts of tackifying resin, 18.4-24.0 parts of tackifier, 12-18 parts of carbon black, 9-14 parts of light calcium carbonate, 8.0 parts of functional aid, 1.8 parts of vulcanizing agent, 0.8 part of anti-aging agent and 0.5 part of coupling agent. The butyl rubber self-adhesive layer is prepared by mixing, kneading and extruding forming. Due to the mode, the invention provides a reactive butyl rubber self-adhesive layer for a waterproof roll and a processing technology thereof, the butyl rubber self-adhesive layer can be chemically reacted with cast-in-place concrete to form a whole, a permanent waterproof layer is formed and has the self-healing performance, the waterproof layer and various high polymer waterproof rolls can be compounded to form a functional waterproof material, and the reactive butyl rubber self-adhesive layer is suitable for various underground waterproof engineering.

Owner:常熟市三恒建材有限责任公司

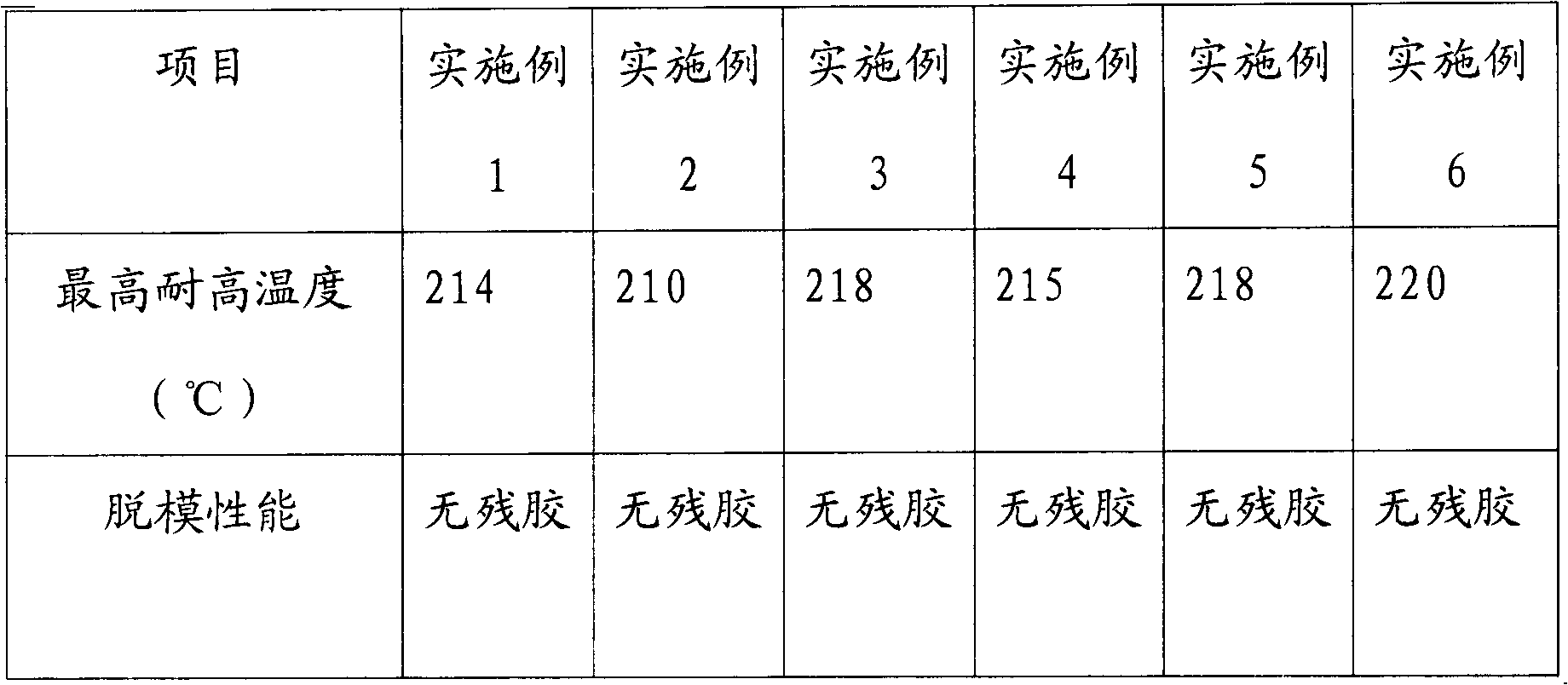

High temperature resistant vacuum bag sealing adhesive tape

The invention discloses a high temperature resistant vacuum bag sealing adhesive tape, which is characterized by adopting butyl rubber, chloroprene rubber, polyisobutene and nano calcium carbonate as main matrixes, then adding an auxiliary recessive high temperature vulcanizing agent, stirring and mixing, and extruding and molding, thus forming the high temperature resistant vacuum bag sealing adhesive tape. The high temperature resistant vacuum bag sealing adhesive tape is air-proof when vacuumizing is carried out, has no residual adhesive after demoulding and has good high temperature resistance, the highest resistant temperature of the sealing adhesive tape can reach 220DEG C.

Owner:科建高分子材料(上海)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com