Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

429 results about "Polyether polyurethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

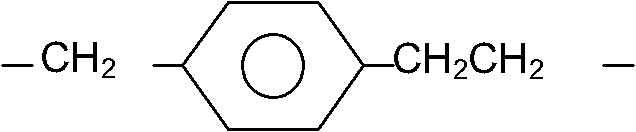

A “polyether polyurethane” is a polyurethane containing a polyether diol as its polymeric polyol component (a soft segment). For example, when a diisocyanate and a polyether diol are reacted with each other, urethane linkage-containing prepolymers having different molecular weights are obtained as shown below.

Lubricious coating

InactiveUS20050054774A1Reduce frictionPharmaceutical delivery mechanismCoatingsPolyether polyurethanePolymer chemistry

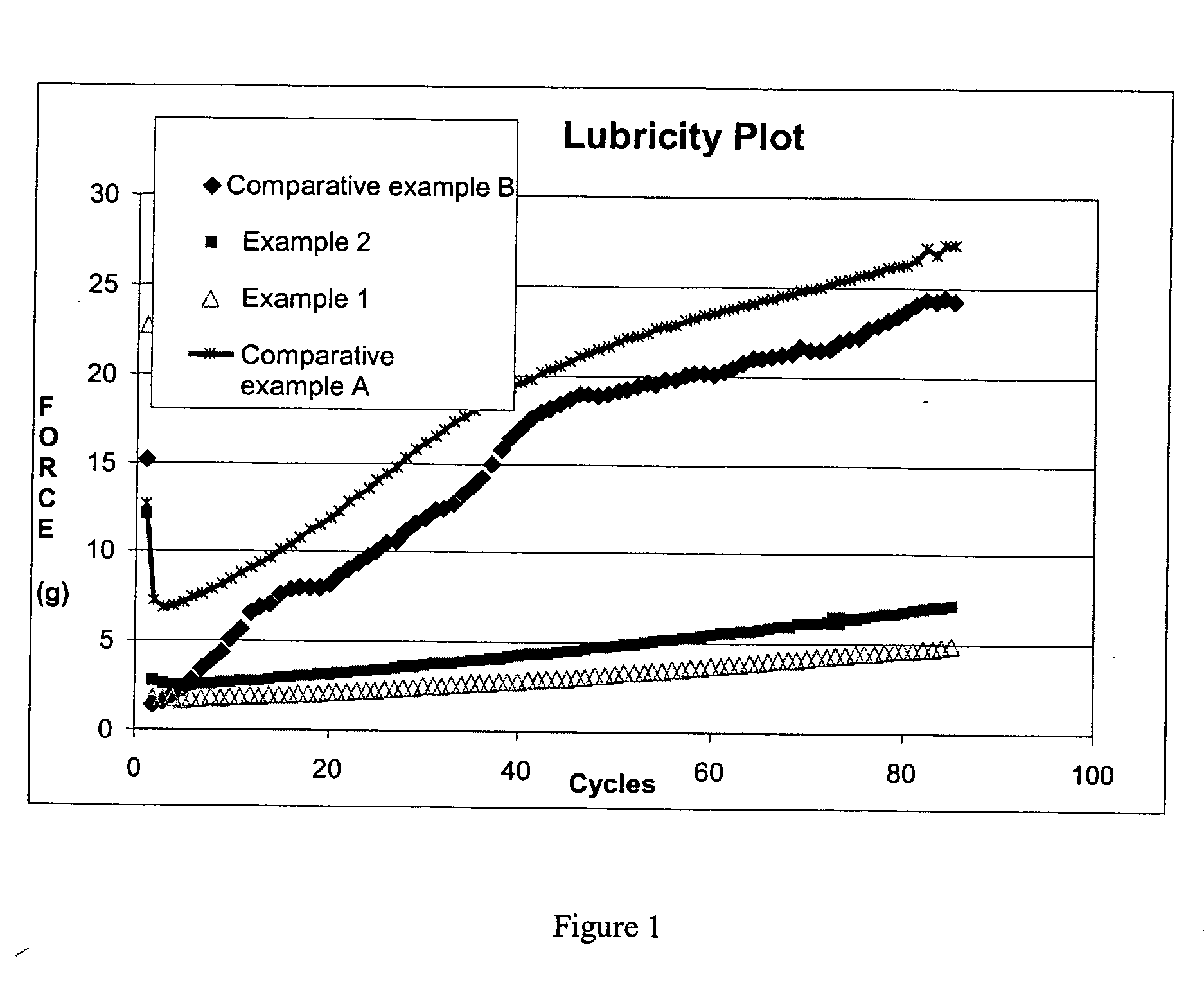

A lubricious coating including at least one ethylenically unsaturated resin and at least one hydrophilic aliphatic polyether polyurethane which does not crosslink with said ethylenically unsaturated resin, and to methods of making and using the same.

Owner:BOSTON SCI SCIMED INC

Absorbent structure with improved water-swellable material

This invention relates to improved absorbent structures containing improved water-swellable material that can significantly withstand deformation by an external pressure, thus showing improved liquid handling properties. In particular, this invention relates to absorbent structures comprising water-swellable material with an improved absorbent capacity / permeability balance. The water-swellable material is typically in the form of particles, which comprise a core of water-swellable polymer(s) and a shell of said elastomeric polymer(s), preferably selected polyetherpolyurethanes, whereby the water-swellable material is such that it can withstand deformation due to external pressure. The invention also relates to diapers, adult incontinence articles and sanitary napkins comprising said absorbent structure of the invention.

Owner:THE PROCTER & GAMBLE COMPANY

Absorbent structure with improved water-absorbing material

This invention relates to improved absorbent structures containing improved water-absorbing material having a specific coating of elastomeric, film-forming polymers and / or which are made by a specific coating process. Preferred are polyetherpolyurethane coatings. The invention also relates to diapers, adult incontinence articles and catamenial devices, such as sanitary napkins, comprising said absorbent structure of the invention.

Owner:THE PROCTER & GAMBNE CO

Enhanced polyurethane microcellular elastomer composite material and preparation method thereof

The invention discloses an enhanced polyurethane microcellular elastomer composite material and a preparation method thereof. The material is a reaction product of a polyol A component and a prepolymer B component, wherein the polyol A component is a mixture of 60-95 weight parts of polymer polyether polyol, 5-40 weight parts of polyether polyol I and auxiliaries; the prepolymer B component is a prepolymer prepared through the reaction of 35-70 weight parts of isocyanate and 30-50 weight parts of polyether polyol II; 0.1-7.5 weight parts of inorganic nanometer filler is added in the polyether polyol II; the NCO content of the prepolymer is 17-30wt.%. The preparation method the material is casting moulding process. The preparation method disclosed by the invention has the advantages that the material cost is reduced while the mechanical property of polyether polyurethane microcellular elastomers is increased at the same time; the application area of the material is greatly broadened. The material disclosed by the invention can be used for shoe parts, shoe sole materials, load-bearing tyres, automotive shock-absorbing buffering materials, bridge buffering shock-absorbing materials and the like.

Owner:重庆杰博科技有限公司

High performance nano polyurethane micropore elastomer composite material and preparation thereof

ActiveCN101486834AImprove mechanical propertiesHigh tensile strengthFoaming agentPolyether polyurethane

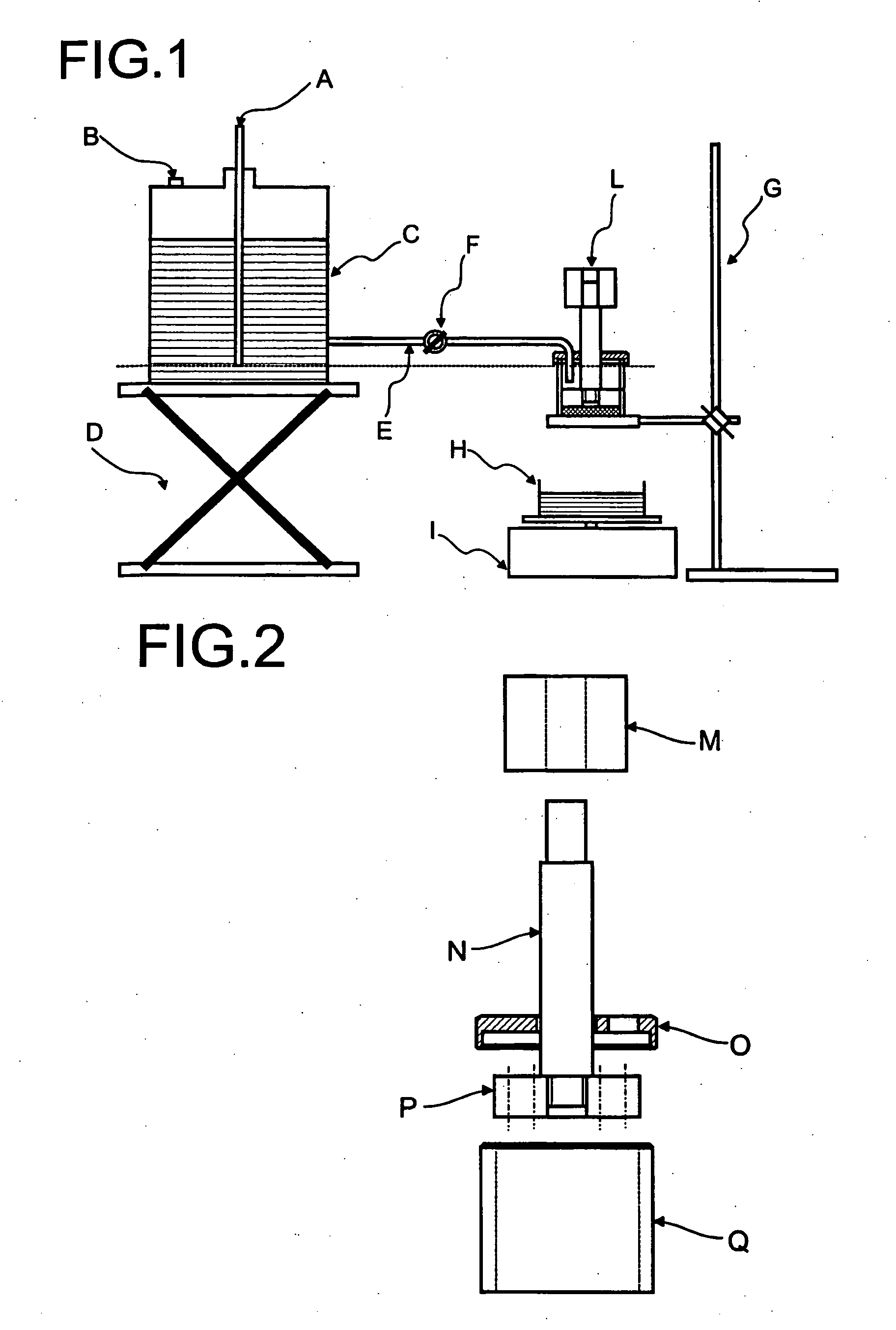

The invention discloses a high-performance nanometer polyurethane microcellular elastomer composite material and a preparation method thereof. Organic montmorillonite is added into polyether glycol I, heated and stirred, thus obtaining stably dispersed colloidal fluid; then polyether glycol II, an alcohols chain-extender, a foaming agent, a foam stabilizer and a catalyst are added, fully and evenly mixed, thus obtaining component A. B component is a performed polymer prepared by the reaction of the polyether glycol I, vulcabond or polyisocyanates at the temperature between 60 and 90 DEG C, with NCO percentage controlled between 17 and 26 percent by weight. The components A and B are mixed at high speed according to the weight mixture ratio that A:B equals to 0.5:1 to 3:1 by using a casting machine and at the temperature of 30-55 DEG C, and injected into a mould for injection moulding, consequently, the high-performance nanometer polyurethane microcellular elastomer composite material is obtained. With low cost, the invention improves a plurality of mechanical properties of a polyether polyurethane microcellular elastomer, such as the tensile strength, modulus and tear strength and the like, and broadens the application field of materials. The composite material can be used as shoe parts, bottom materials, bearing tires or shock absorption buffering materials, and the like. With a bi-component system and a casting moulding technology adopted simultaneously, the invention is simple and can be easily controlled, thus bringing convenience to production promotion.

Owner:ZHEJIANG HUAFON NEW MATERIALS CO LTD

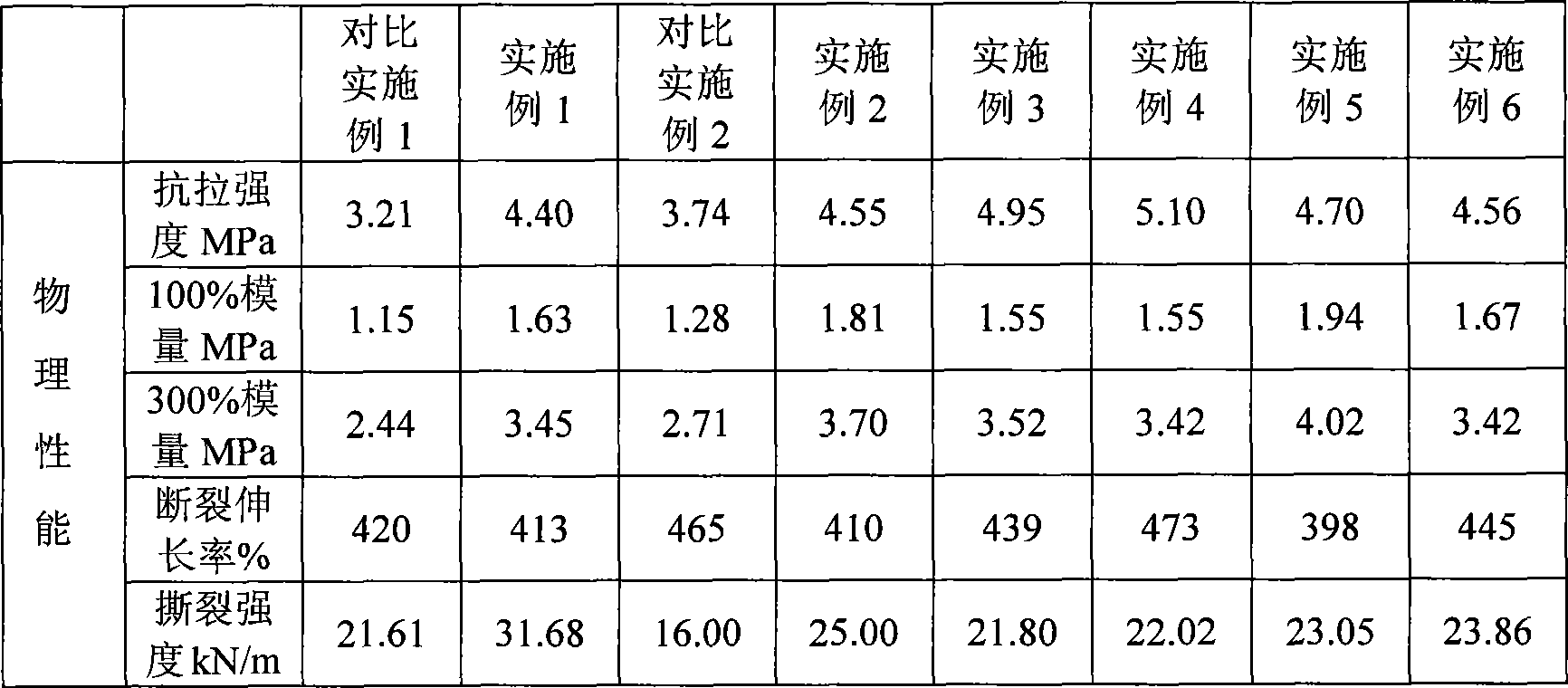

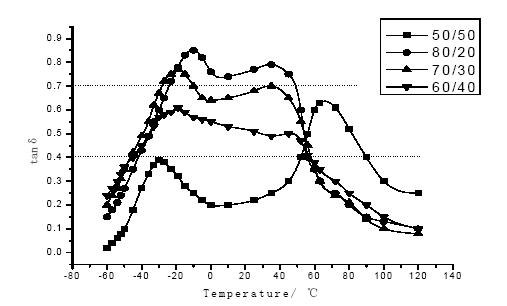

Method for preparing novel polyether-polyester polyurethane material

The invention belongs to the technical field of polyurethane materials and relates to a method for preparing novel a polyether-polyester polyurethane material, in particular to a method for preparing a polyether-polyester polyurethane material by a two-step process. The method is characterized by comprising the following steps of: preparing a polyether prepolymer and a polyester prepolymer respectively by using polyether polyhydric alcohol and polyester polyhydric alcohol and diisocyanate, mixing the two prepolymers according to a ratio, and crosslinking by using a chain extender to prepare novel polyether-polyester polyurethane. The polyether-polyester polyurethane material has the combined excellent performance of a polyether polyurethane material and a polyester polyurethane material, and has the wide-temperature range damping performance. The preparation method is simple and convenient and stable and mild in process and allows for controlling product performance, and can be used for large-scale industrial production. The polyether-polyester polyurethane material can be widely used as a damping material, an elastic material, a wearing resistant material, a sealing material, an anticorrosive material, a medical material, a sports material, a bonding material and the like.

Owner:TIELIN ERFAN RUBBER R & D CO LTD

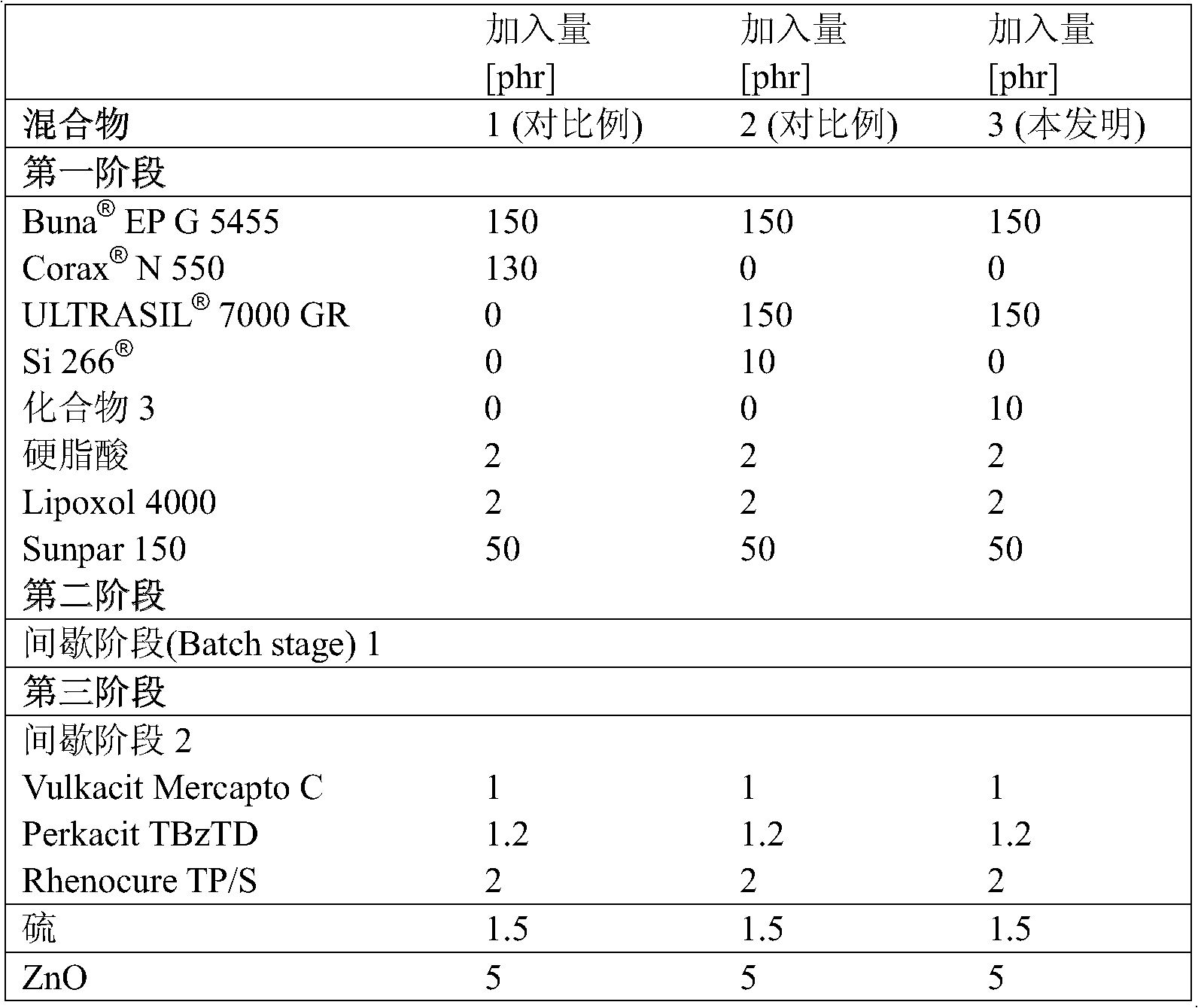

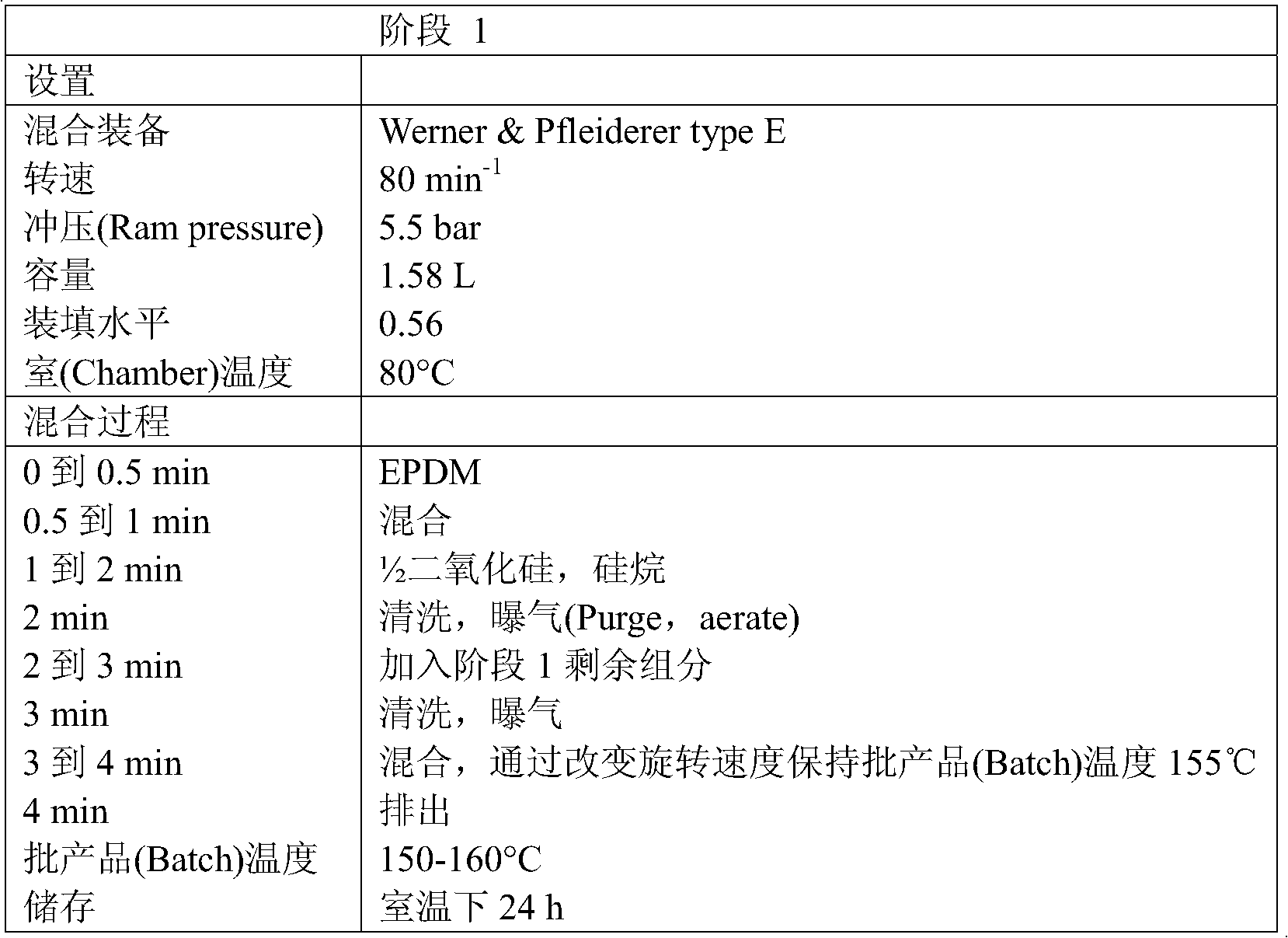

Rubber mixtures

ActiveCN102731915AHysteresis loss is smallImproved Dynamic BehaviorThin material handlingPolyesterPolymer science

A rubber mixture, comprising (A) at least one rubber selected from the group of ethylene-propylene-diene copolymer (EPDM), ethylene-propylene copolymer (EPM), chloroprene rubber (CR), chloropolyethylene (CM), chloro-isobutene-isoprene (chlorobutyl) rubber (CIIR), chlorosulfonyl polyethylene (CSM), etylene-vinyl acetate copolymer (EAM), alkyl acrylate copolymer (ACM), polyester polyurethan (AU), polyether polyurethane (EU), bromo-isobutene-isoprene (bromobutyl)rubber (BIIR), polychlorotrifluoroethylene (CFM), isobutene-isoprene rubber (butyl rubber, IIR), isobutene rubber (IM), polyisoprene (IR), thermoplastic polyester polyurethane (YAU), thermoplastic polyether polyurethane (YEU), silicone rubber with methyl groups on the polymer chain (MQ), hydrogenated acrylonitrile-butadiene rubber (HNBR), acrylonitrile-butadiene rubber (NBR) or carboxylated acrylonitrile-butadiene rubber (XNBR), (B) at least one oxidic filler, and (C) at least one silicon containing azodicarbamide of the general formula I (R 1 ) 3-a (R 2 ) a Si-R I -NH-C(O) -N=N-C (O)-NH-R I -Si(R 1 ) 3-a (R 2 ) a (I) . The rubber mixture is produced by mixing at least one rubber, at least one oxidic filler, and at least one silicon containing azodicarbamide of the general formula I. It may be used for moldings.

Owner:EVONIK OPERATIONS GMBH

Film-forming compositions for protecting animal skin

InactiveUS20050063926A1Simple compositionExtension of timeCosmetic preparationsPowder deliveryPolyether polyurethaneElastic Barrier

Improved film-forming skin protectant compositions are provided which are capable of forming a long-lasting elastic barrier film when applied to skin; the compositions have particular utility as barrier teat dips, for protecting cows against mastitis, especially during their susceptible non-lactating periods. The compositions include a film-forming component (preferably a mixture of polyether polyurethane and nitrocellulose) dispersed in a compatible carrier and further having a quantity of a tackifier resin incorporated therein in order to increase the time of adherence of the composition to skin, as compared with an otherwise identical composition without a tackifier resin. The compositions may also include a germicide (e.g., chlorhexidine diacetate), and a coloring dye.

Owner:DELAVAL HLDG AB

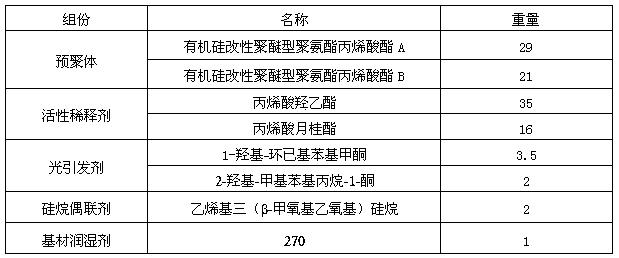

Ultraviolet-curing type optical resin adhesive and preparation method thereof

InactiveCN103436213ASuitable for industrial applicationsIncreased durabilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAlcoholUV curing

The invention discloses an ultraviolet-curing type optical resin adhesive. The ultraviolet-curing type optical resin adhesive consists of the following materials in parts by weight: 10-30 parts of tri-functionality polyether polyurethane acrylate which is prepared through the reaction of polyether trihydric alcohol, diisocyanate and hydroxyl acrylate, 5-40 parts of double-functionality polyether polyurethane acrylate which is prepared through the reaction of polyether glycol, diisocyanate and hydroxyl acrylate, 10-50 parts of plasticizers, 15-45 parts of acrylate reactive diluents, 1-5 parts of photoinitiators and 1-3 parts of silane coupling agents. The ultraviolet-curing type optical resin adhesive has the advantages of being simple and easily available, low in cost and suitable for industrial application and the like.

Owner:YANTAI DARBOND TECH

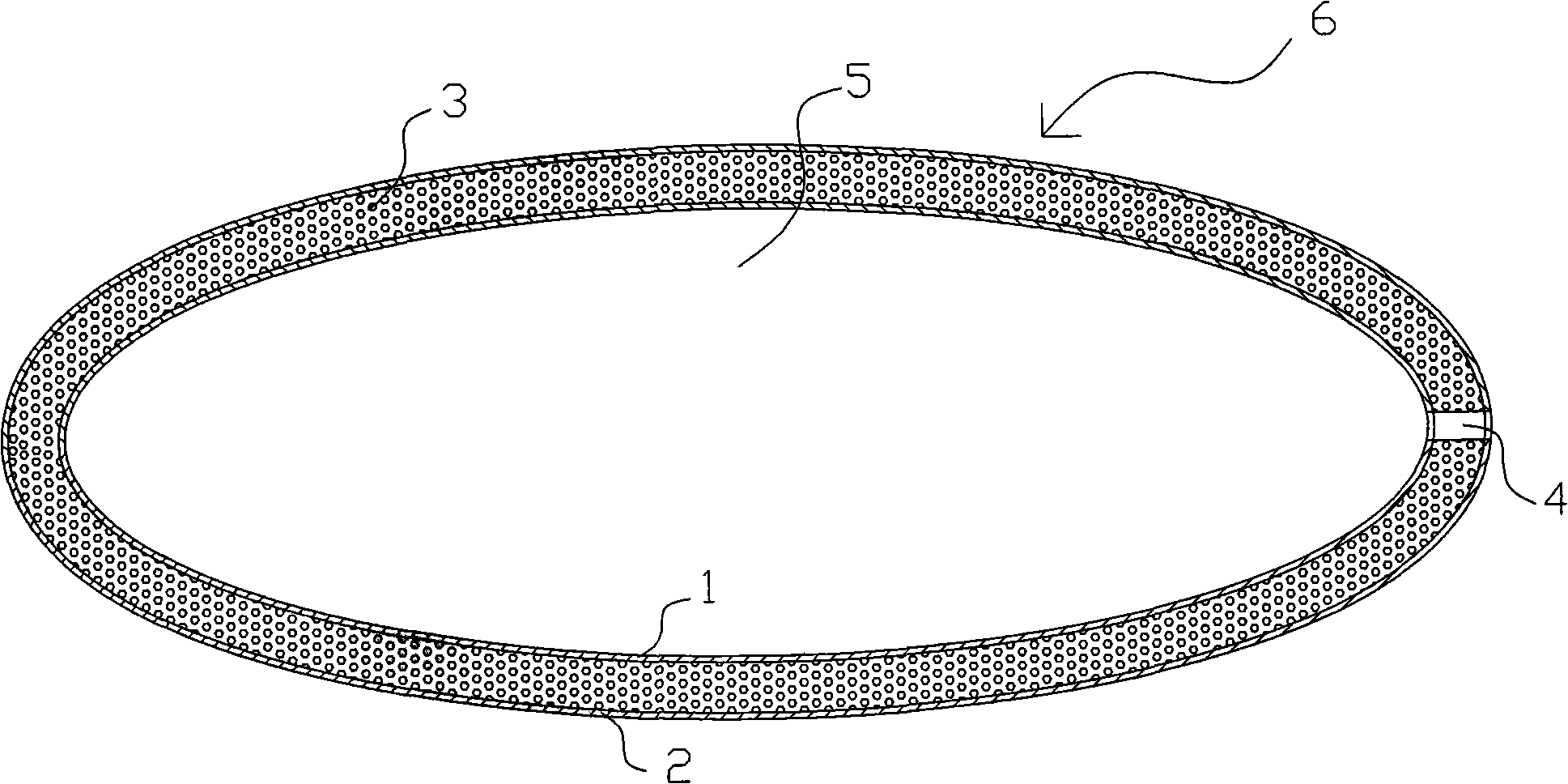

Novel bone surgery fixing system and method of use thereof and polyurethane applied therein

InactiveCN101279110ALearn about recoveryLow costSurgeryPlaster of paris bandagesPolyether polyurethaneMedicine

The invention provides a novel fixing system applied to orthopedic surgery. The novel fixing system comprises a cotton cavity with a dual-layer structure and an opening at one side and polymer foaming material; the polymer foaming material is filled in a sandwich layer of the cavity; the cotton cavity is provided with a zip or a nylon fastener belt to connect the cotton cavity; the cotton cavity closely covers and is attached to the part to be fixed. The invention also provides an application method of the system and polyether polyurethane used for the system.

Owner:上海优创医疗器械技术股份有限公司 +1

Process for making high simulation ultra-fine fabric leather based cloth

One high simulation superfine fiber leather base cloth production method, uses the double component altogether to mix spinning production law produce island superfine fiber, then makes the adhesive-bonded base cloth material, first contains soaks half polyether polyurethane resin or the polyester polyurethane resin, then blows in base cloth the surface spreads gathers the carbonic ether polyurethane resin or the entire polyether polyurethane resin, then carries on coagulation processing using the DMF solution after the polyurethane resin, then uses the lukewarm water completely to wash DMF, use toluene solution island superfine fiber's in 'sea' ingredient extract comes out, then carries on alkali decrement processing. This invention produce base cloth which has thickness direction from trapezoidal density distribution structure, the dermis feeling is strong, may further enhance the artificial leather product the scale.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

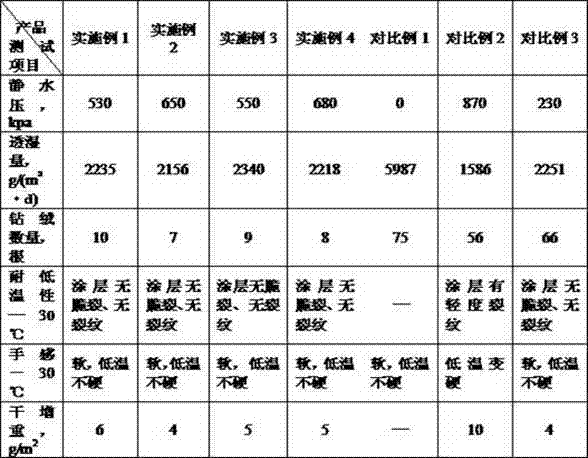

Down coat fabric treatment method for preventing down feather from escaping from needle holes

ActiveCN103614922ASolve the problem of drilling woolSolve the problem of drilling down, especially the problem of sewing needle hole drillingFibre typesPolymer scienceAdhesive

The invention discloses a down coat fabric treatment method for preventing down feather from escaping from needle holes. The down coat fabric treatment method is mainly technically characterized in that 100 parts by weight of a polyether polyurethane coating adhesive, 20-30 parts of a hydroxy terminated polydimethylsiloxane emulsion, 1-1.5 parts of an isocyanate cross-linking agent, 1.2-1.8 parts by weight of a cross-linking promoter, 3-5 parts of silicon dioxide extinction powder and 15 parts of butanone or toluene are mixed to prepare a coating adhesive, which is applied to a fabric by a floating knife coating machine, and the dry weight increase reaches 4-6 g / m<2>. The effect of preventing down feather from escaping from sewing needle holes is good, and the cold resistance, moisture permeability, washing fastness and flexibility of a fabric are ensured.

Owner:DANDONG UNIK TEXTILE

Antimicrobial foam and method of manufacture

An antimicrobial foam includes an open-cell foam in a foam matrix defining a plurality of interconnected bubbles therein. Silver nanoparticles are suspended within the foam matrix. The foam matrix may be made from polyether polyurethane, polyester polyurethane, polycarbonate, thermoplastic olefin, thermoplastic elastomer, and thermoplastic polyurethane. The silver nanoparticles may have an average size between about 5 and 100 nanometers. The silver nanoparticles may be incorporated into the foam matrix in a concentration of between about 0.01 weight-% and about 0.20 weight-%. A method of manufacture of the foam also is described.

Owner:INOAC USA INC

Polyether ester polyhydric alcohol and using method thereof

The invention belongs to the technical field of chemical synthesis, and in particular relates to polyether ester polyhydric alcohol and a using method thereof. Epoxypropane polyether polyhydric alcohol with the molecular weight of 400-1,000, diacid and small molecular dihydric alcohol are subjected to condensation under certain conditions to form the polyether ester polyhydric alcohol with the molecular weight of 1,000-2,000. The new polyether ester polyhydric alcohol prepared by the method contains ester keys and ether keys, is blocked by primary hydroxyl groups, and has high reaction activity. Polyurethane elastomer products synthesized by using the polyether ester polyhydric alcohol have the characteristic of excellent mechanical properties of polyester polyurethane products, and also have the characteristic of excellent hydrolysis resistance of polyether polyurethane products.

Owner:SHANDONG INOV POLYURETHANE

Lubricious coating

InactiveUS20070078388A1Reduce frictionSurgeryPharmaceutical delivery mechanismPolyether polyurethanePolymer chemistry

A lubricious coating including at least one ethylenically unsaturated resin and at least one hydrophilic aliphatic polyether polyurethane which does not crosslink with said ethylenically unsaturated resin, and to methods of making and using the same.

Owner:BOSTON SCI SCIMED INC

Heat resistant high moisture vapor transmission thermoplastic polyurethane

ActiveUS7202322B2Good moisture permeabilityMonocomponent polyurethanes artificial filamentSynthetic resin layered productsFiberPolyether polyurethane

A thermoplastic polyether polyurethane having high moisture vapor transmission, high melting point and static dissipative properties is disclosed. The thermoplastic polyether polyurethane is prepared by reacting a hydroxyl terminated polyether intermediate, an aromatic chain extender glycol, and a polyisocyanate. The polymers formed are useful for melt-spun fibers, fabric coatings for breathable garments, house wrap, roofing membranes, and other applications requiring high vapor transmission and high melting points.

Owner:NOVEON INC

Polyether polyurethane elastomer toughened polylactic acid alloy and preparation method thereof

The invention discloses a polyether polyurethane elastomer toughened polylactic acid alloy and a preparation method thereof. The alloy is prepared from the following raw materials in parts by mass: 70-95 parts of polylactic acid and 5-30 parts of polyether polyurethane elastomer. The alloy has the advantages of high toughness, high intensity, high modulus and the like, and the elongation at break and impact strength of the alloy are enhanced along with the increase in the dosage of the polyether polyurethane elastomer. The invention further discloses a preparation method of the alloy. The method comprises the following steps of: premixing the polylactic acid with the polyether polyurethane elastomer; and melting and blending in a double screw extruder at the temperature of 180-200 DEG C to obtain the polyether polyurethane elastomer toughened polylactic acid alloy. The preparation method is easy to operate and control and is suitable for industrial production.

Owner:ZHEJIANG UNIV

Room-temperature moisture cured one-component water-expansion polyurethane sealant

InactiveCN101885957AGood adhesionEasy constructionProductsNon-macromolecular adhesive additivesAdjuvantPolyether polyurethane

The invention discloses a room-temperature moisture cured one-component water-expansion polyurethane sealant which is paste and comprises the following raw materials in parts by weight: 30-50 parts of liquid polyether polyurethane prepolymer base material, 10-25 parts of plasticizer, 0.5-1 part of a coupling agent, 10-30 parts of super water absorbent resin, 10-30 parts of other fillers, 0.01-0.05 part of catalyst and 0.2-3 parts of adjuvant. The preparation method of the sealant comprises the following steps: 1. placing di-functionality polyether glycol and tri-functionality polyether glycol in a container according to a weight ratio, stirring and dehydrating by a vacuum pump, and then adding polyisocyanate and the catalyst under stirring to obtain the liquid polyether polyurethane prepolymer base material for later use; 2. adding the plasticizer and the coupling agent to the liquid polyether polyurethane prepolymer base material to obtain a mixture; and 3. adding the super water absorbent resin and other fillers to the mixture, then adding the catalyst and the adjuvant, evenly dispersing into paste, and then packing the paste into a packaging substance for sealing. The sealant of the invention has good adhesive property on a sealed surface, and the paste is cured under a moisture condition, thus achieving the purpose of avoiding leakage.

Owner:SHANDONG NORTH MODERN CHEM IND

Durable flame-retardant, water-repellent, waterproof and moisture permeable finishing method of polyester fabric

ActiveCN106049049AEffective Flame RetardancyDoes not affect flame retardancyFireproof paintsHeat resistant fibresPolyesterAdhesive

The invention relates to a durable flame-retardant, water-repellent, waterproof and moisture permeable finishing method of a polyester fabric. A flame-retardant and water-repellent finishing agent is prepared from 20-30 parts of cyclic phosphate flame retardants, 60-70 parts of water, 1-1.5 parts of isocyanate cross-linking agents, 3-5 parts of fluorocarbon copolymer waterproof agents and 2-5 parts of NaOH with 10% mass concentration. A bottom coating adhesive is prepared from 100 parts of polyether polyurethane polymer under-coating adhesives, 5-10 parts of methylbenzene, 5-10 parts of butanone, 2 parts of isocyanate cross-linking agents, 1 part of accelerant and 25-35 parts of organic phosphorus-nitrogen flame retardants. A surface coating adhesive is prepared from 100 parts of polyether polyurethane polymer top-coating adhesives and 35-45 parts of methylbenzene. The fabric is padded, calendered, under-coated and top-coated with water repellents to achieve finishing by the flame-retardant and water-repellent finishing agent, the bottom coating adhesive and the surface coating adhesive.

Owner:DANDONG UNIK TEXTILE

Slow-rebound polyether polyurethane sponge

The invention relates to polyurethane sponge, in particular to slow-rebound polyether polyurethane sponge, which comprises, by weight, 20-85 parts of first polyhydric alcohol, 10-90 parts of second polyhydric alcohol, 8-30 parts of MDI (diphenylmethane diisocyanate), foaming agent, catalyst, surface active agent, flame retardant and 0.2-0.8 part of silicon rubber toughening agent, wherein the first polyhydric alcohol refers to polymer of ethylene glycol and propylene glycol, the degree of functionality of the first polyhydric alcohol is 3, and the hydroxyl value of the first polyhydric alcohol is 45-99mgKOH / g; and the second polyhydric alcohol refers to copolymerized polyol of trimethylolpropane and epoxy butane, the EO (ethylene oxide) content of the second polyhydric alcohol is higher than 60%, and the hydroxyl value of the second polyhydric alcohol is 3-22mgKOH / g. The slow-rebound polyether polyurethane sponge is slow in rebound time, proper in hardness and less susceptible to temperature.

Owner:德清舒华泡沫座椅有限公司

Composition useful as an adhesive for installing vehicle windows

ActiveUS20080149257A1Rapid development of strengthGood anti-sag performanceAdhesive processesWindowsEndcappingPolyester

In one embodiment, the invention is an composition comprising: a) one or more isocyanate functional polyether polyurethane prepolymers; and b) one or more prepolymers of one or more polyisocyanates and one or more polyesters wherein the terminal groups on the polyester polyol polyurethane prepolymer are the residue of a monofunctional polyalkylene glycol (hereinafter capped polyester polyurethane prepolymer) or one or more polyester polyols which are capped with the residue of one or more monofunctional isocyanates (hereinafter isocyanate capped polyesters); wherein the composition is a low viscous paste at temperature of from about 40 to about 80° C. and is high viscous paste at a temperature of from about 40° C. or less. In a preferred embodiment the composition further comprises c) one or more catalysts for the reaction of isocyanate moieties with hydroxyl groups. In another embodiment the invention is a method of bonding two or more substrates together which comprise contacting the two or more substrates together with a composition according to this invention disposed along at least a portion of the area wherein the substrates are in contact wherein the composition is a low viscous paste. In a preferred embodiment the composition is heated to about 40° C. to about 80° C. and converted to a low viscous paste prior to contacting it with the one or more substrates.

Owner:DOW GLOBAL TECH LLC

Modified fluororubber sealing gasket used for engine and preparation method of modified fluororubber sealing gasket

The invention discloses a modified fluororubber sealing gasket used for an engine. The modified fluororubber sealing gasket comprises, by weight, 50-70 parts of maleic anhydride modified fluororubber, 20-30 parts of polyether urethane rubber, 10-20 parts of polypropylene, 5-15 parts of methyl vinyl silicone rubber, 1-3 parts of titanate coupling agents TMC-TTS, 0.8-1.6 parts of dicumyl peroxide, 1-3 parts of potassium peroxodisulfate, 1-3 parts of 2-thiol group benzimidazole, 5-8 parts of magnesium hydrate, 20-30 parts of polytetrafluoroethylene fiber, 5-10 parts of carbon fiber, 5-10 parts of ceramic fiber, 5-15 parts of white carbon black, 8-17 parts of talcum powder, 1-3 parts of anti-ageing agents, 1-3 parts of triphenyl phosphate, 1-3 parts of dibutyl phthalate, 1-2 parts of stearic acid, 0.5-1.5 parts of liquid paraffin and 1-3 parts of naphthenic oil. The invention further discloses a preparation method of the modified fluororubber sealing gasket. The product has good shock absorption performance and a good mechanical property, and the preparation method is simple.

Owner:ANHUI JINYANG FLUORINE CHEM

Composition useful as an adhesive for installing vehicle windows

ActiveUS7892395B2Rapid development of strengthGood anti-sag performanceWindowsOther chemical processesEndcappingPolyester

Owner:DOW GLOBAL TECH LLC

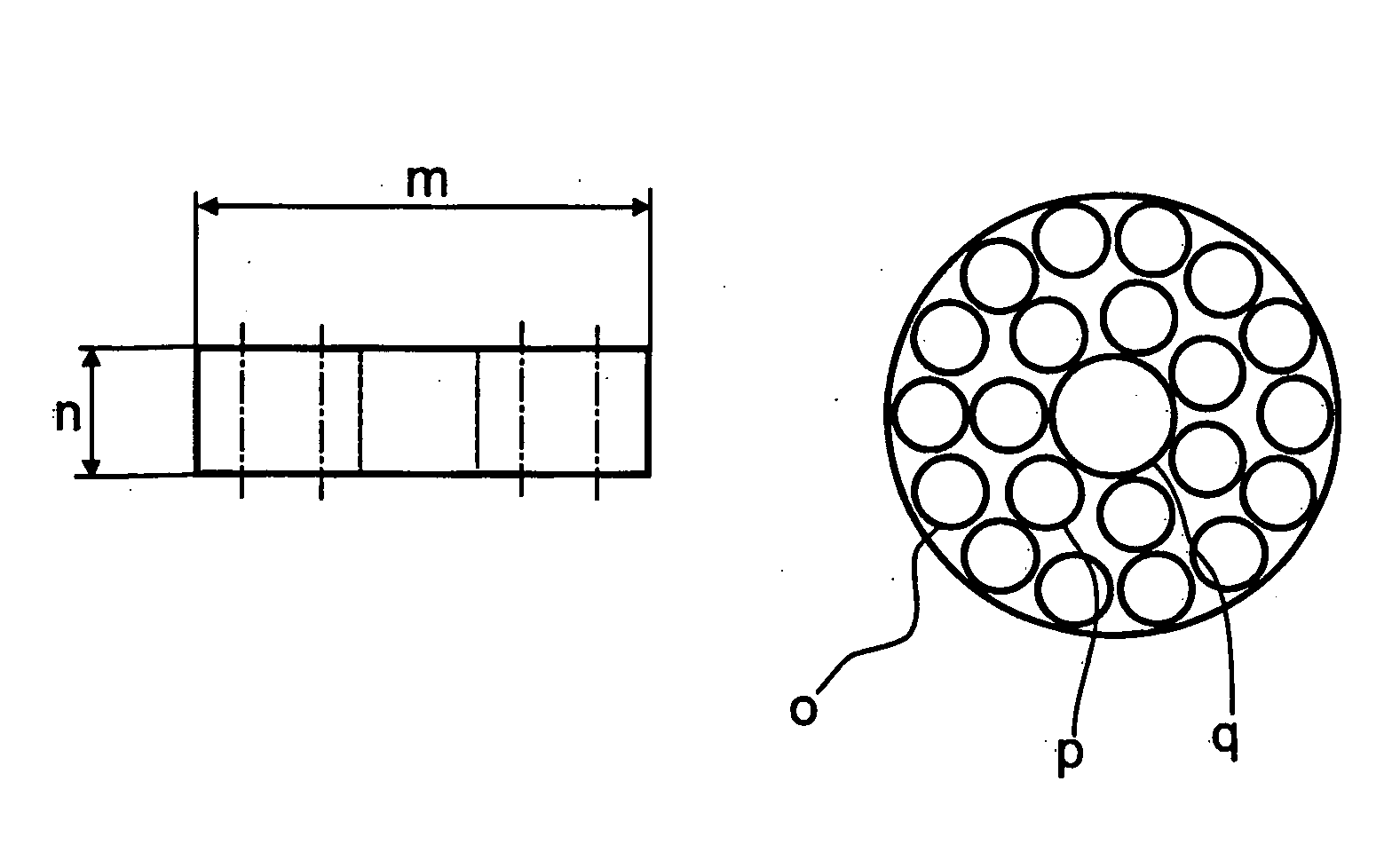

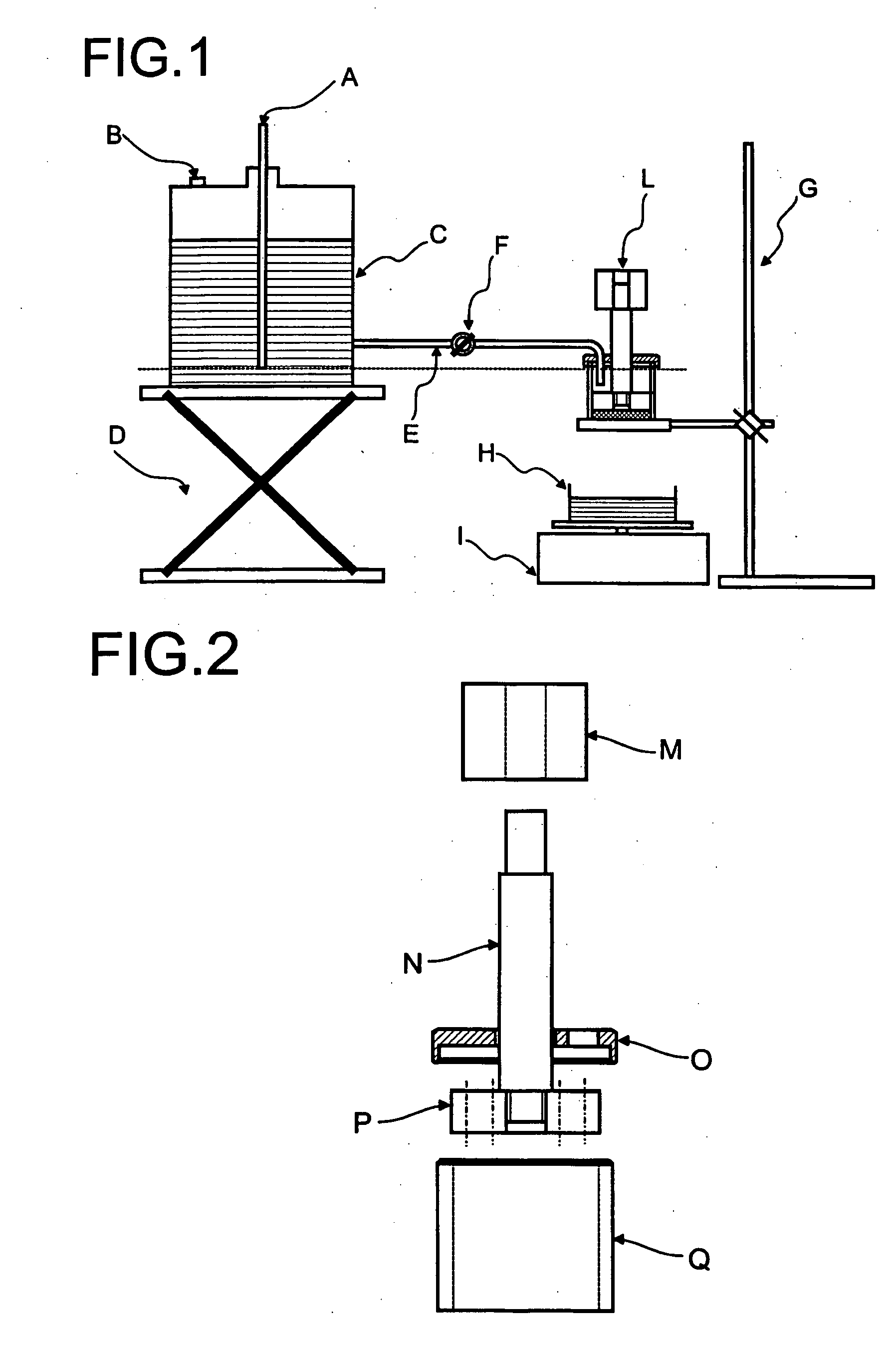

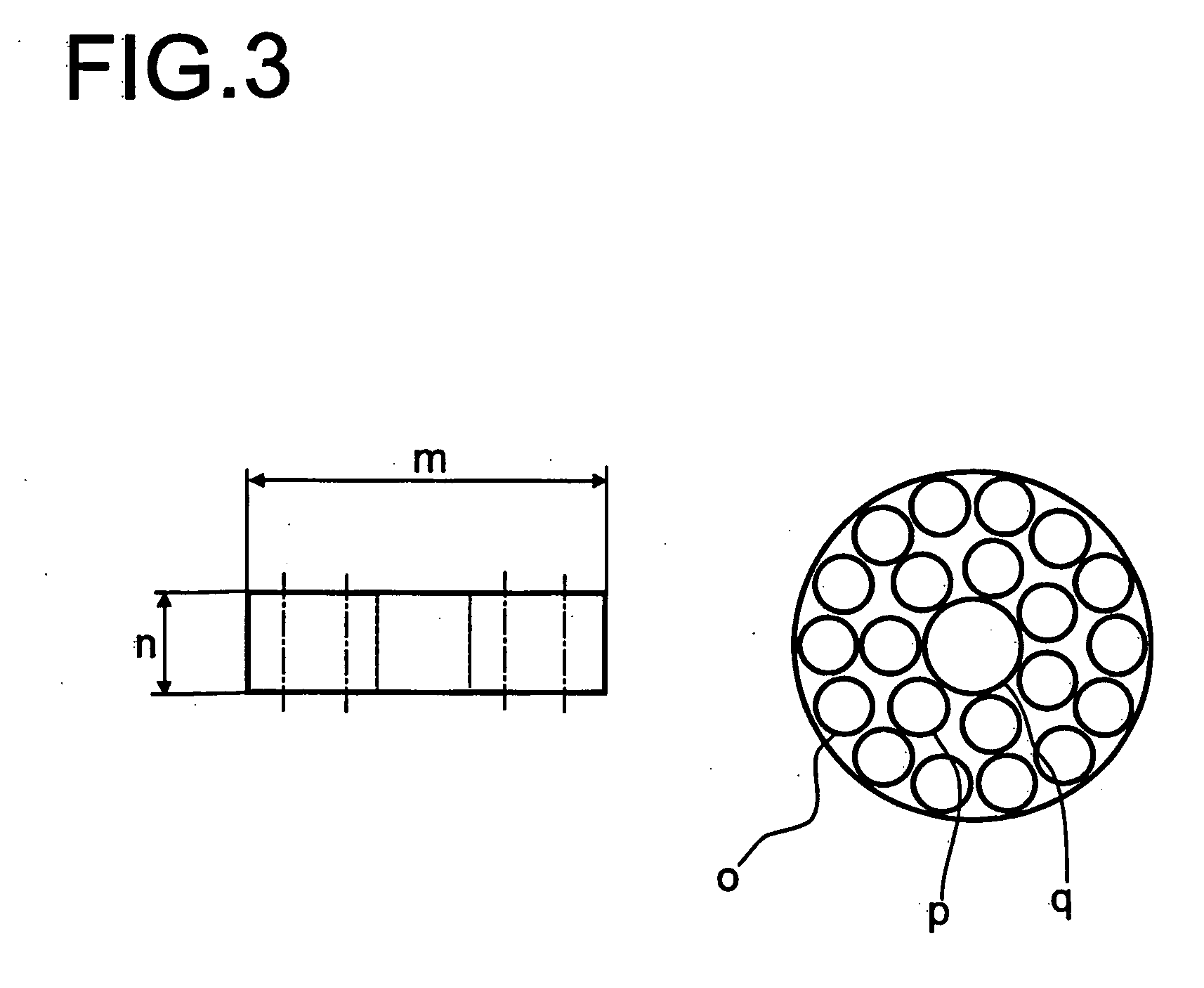

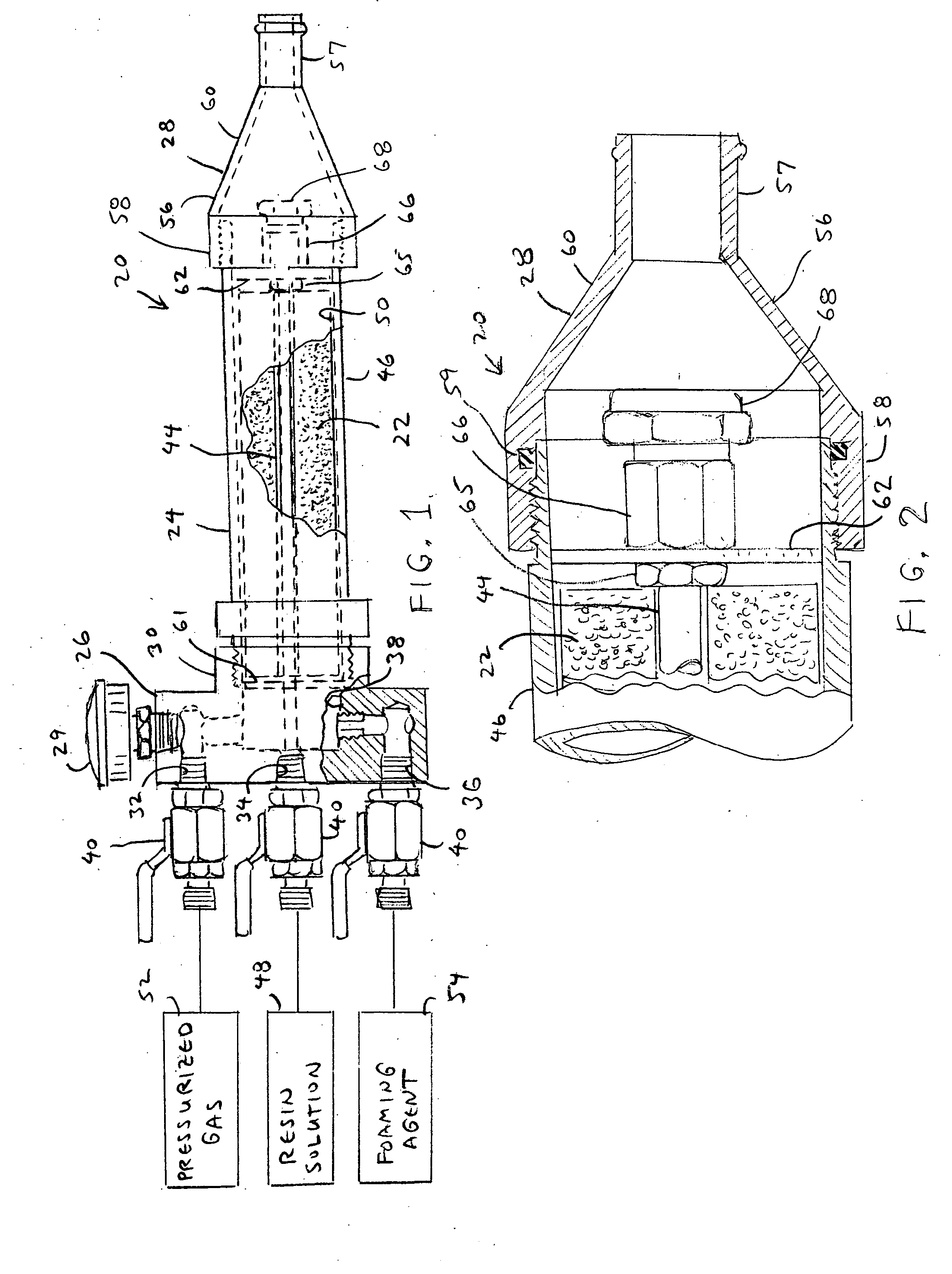

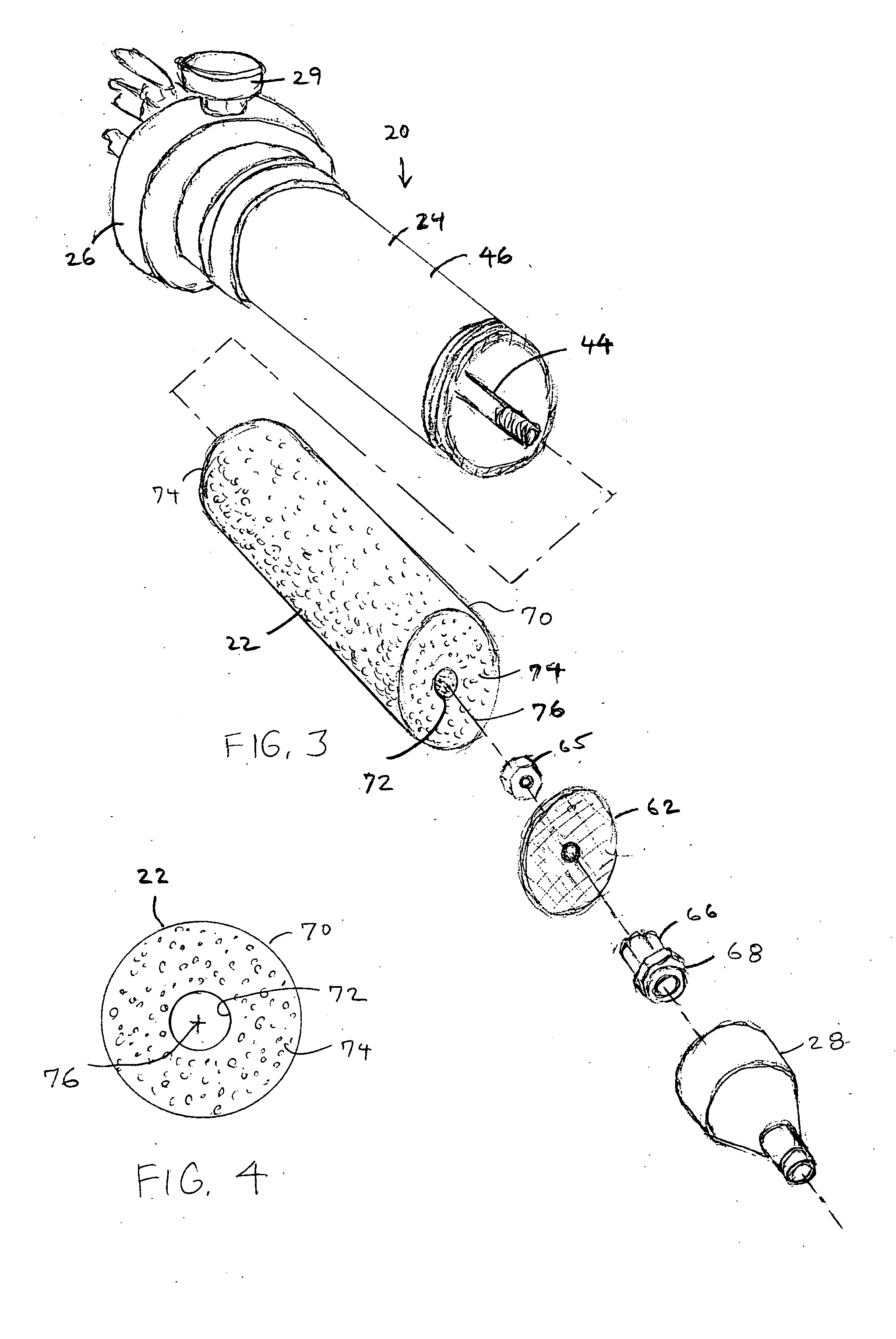

Cartridge foam insert for foam generating and injecting apparatus

InactiveUS20060293401A1Enhanced mixing processFlow mixersTransportation and packagingPolyether polyurethaneFilling materials

A filler material in the form of a cartridge insert is positionable within an apparatus for generating and injecting a foamed polymeric resin formed by the mixture of a plurality of foam-producing ingredients wherein the apparatus includes an elongate foaming chamber having an interior through which two mixable foam-producing ingredients are conducted. The filler material includes a body of polyurethane foam which is adapted to be accepted by and substantially fill the interior of the foaming chamber for enhancing the blend of the mixable foam-producing ingredients as the mixable foam-producing ingredients are conducted through the foaming chamber. Preferably, the polyurethane foam of the body is a polyether polyurethane foam, possesses an Indentation Force Deflection value which is at least as great as 30 pounds per 50 square inches (30 lbs / 50 in2) and possesses a density which is between within the range of between 1.0 lbs / ft3 and 5.0 lbs / ft3.

Owner:CORE FOAM

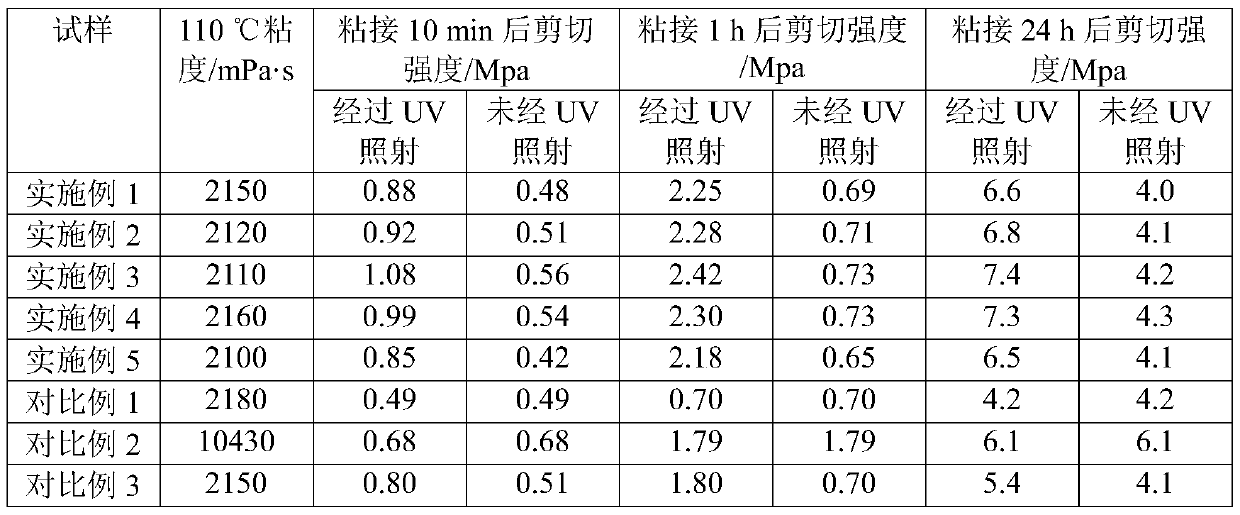

Low viscosity UV/moisture dual-curing polyurethane hot melt adhesive and preparation method thereof

ActiveCN109705794ALow viscosityStrong initial adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterAntioxidant

The invention relates to a low viscosity UV / moisture dual-curing polyurethane hot melt adhesive and a preparation method thereof, belonging to the technical field of photocuring adhesives. The low viscosity UV / moisture dual-curing polyurethane hot melt adhesive comprises the following components in parts by weight: 95-97 parts of UV / moisture dual-curing polyester polyether polyurethane, 1-3 partsof free radical photoinitiator, 0.25-2 parts of cationic photoinitiator, 0.25-1 part of photosensitizer, 0.06-0.35 part of polyurethane catalyst, 0.01-0.02 part of water reducing agent, and 0.05-0.2 part of antioxidant. The hot melt adhesive can be used for the bonding of opaque substrates. The viscosity of the adhesive at the sizing temperature 110 DEG C is in the range of 2000-2500 mPa.s, the viscosity is low, the construction is convenient, the initial viscosity is strong, the positioning is fast, the holding time is shortened, even the holding pressure is not needed. The hot melt adhesivedoes not contain small molecular active diluent and is environmentally friendly. The preparation process is simple, easy to operate and suitable for industrial production.

Owner:重庆中科力泰高分子材料有限公司

Heat Resistant High Moisture Vapor Transmission Thermoplastic Polyurethane

InactiveUS20070179255A1Good moisture permeabilityMonocomponent polyurethanes artificial filamentSynthetic resin layered productsFiberPolyether polyurethane

A thermoplastic polyether polyurethane having high moisture vapor transmission, high melting point and static dissipative properties is disclosed. The thermoplastic polyether polyurethane is prepared by reacting a hydroxyl terminated polyether intermediate, an aromatic chain extender glycol, and a polyisocyanate. The weight proportions of the reactants used to make the TPU satisfy the equation of (a)=wt. of hydroxyl terminated polyether intermediatewt. of polyisocyanate+wt. of aromatic chain extender=1.6±0.4The polymers formed are useful for melt-spun fibers, fabric coatings for breathable garments, house wrap, roofing membranes, and other applications requiring high vapor transmission and high melting points.

Owner:LUBRIZOL ADVANCED MATERIALS INC

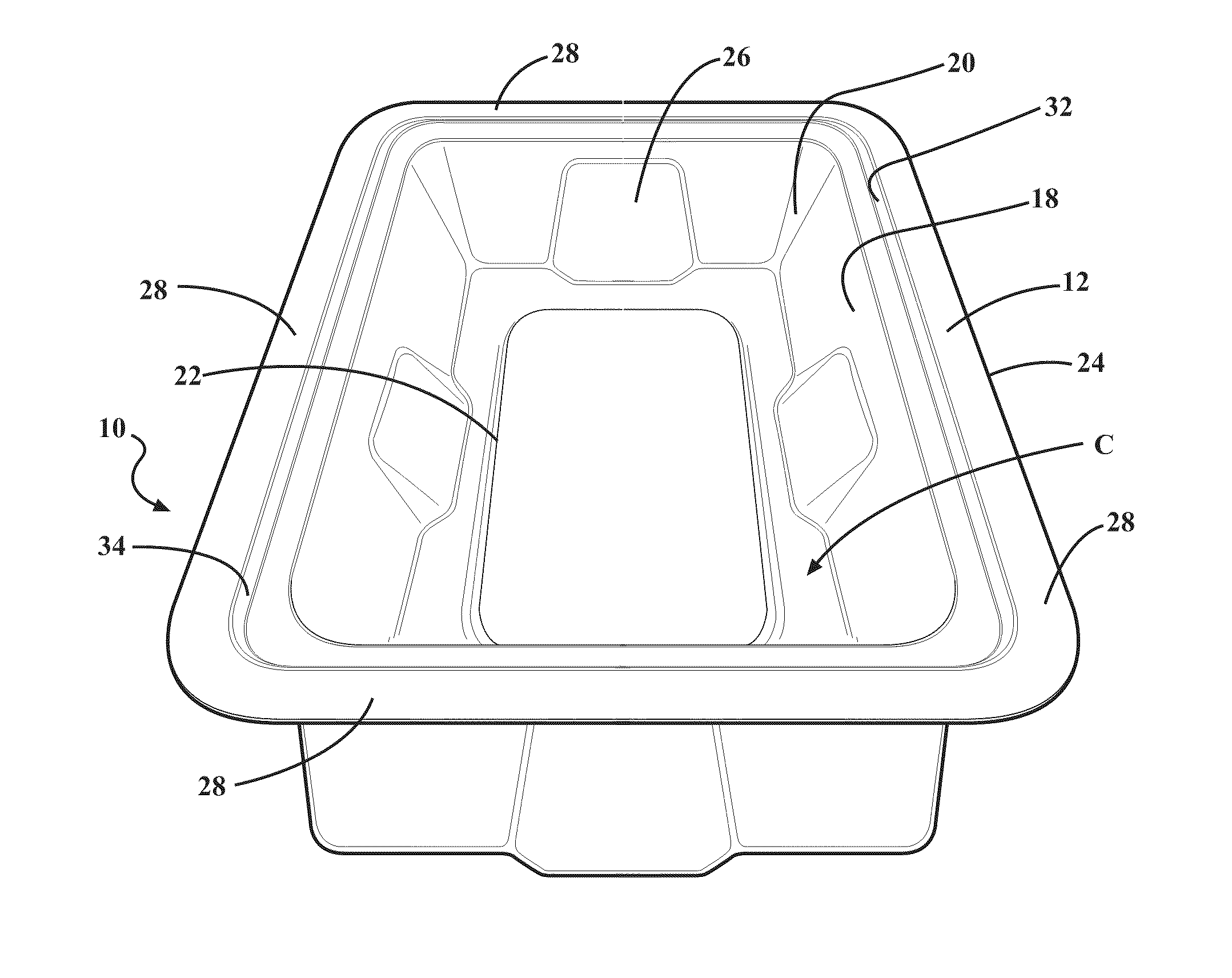

Composite for packaging a medical device and method of forming the same

ActiveUS9144464B2Increase resistanceReduce abrasion and generationFlexible coversWrappersPolyether polyurethaneEngineering

A composite for packaging a medical device has a first layer including an aromatic polyether polyurethane and a second layer. The first layer forms a base that has a plurality of walls extending therefrom to define a cavity for receiving the medical device. The second layer is disposed on the first layer opposite the cavity. The composite is formed from a method that includes the step of disposing the first layer on the second layer. The composite may also be included with a container to form a packaging system.

Owner:UFP TECHNOLOGIES

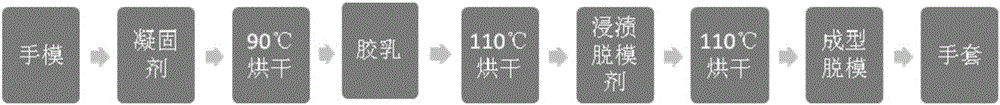

Waterborne polyurethane finishing agent for PVC (Polyvinyl Chloride) protective gloves and preparation method thereof

InactiveCN101845269AGood storage stabilityExtended service lifePolyurea/polyurethane coatingsPolyether polyurethaneEmulsion

The invention relates to a waterborne polyurethane finishing agent for PVC (Polyvinyl Chloride) protective gloves and a preparation method thereof, in particular to a waterborne polyurethane finishing agent for protective gloves and a preparation method thereof, belonging to polyurethane coating combinations. The waterborne polyurethane finishing agent is characterized in that firstly, mixed polyether glycol and aliphatic diisocyanate are used as raw materials to synthesize isocyanate-terminated perpolymer, wherein the mole ratio of a isocyanato group and a hydroxyl group is NCO:OH=2.0-3.2; secondly, dimethylopropionic acid DMPA is used as a hydrophilic chain extender, and the dosage of the DMPA is 3-6 percent of the weight of the perpolymer; thirdly, triethylamine is used as a branched chain extender, and the dosage of the triethylamine is 1-4 percent of the weight of the perpolymer; fourthly, a coupling agent is added in emulsion with the addition quantity of 2-5 percent of the weight of the perpolymer; and fifthly, the solid content of the emulsion is 25-30 percent. The invention provides the waterborne polyurethane finishing agent for the PVCprotective gloves, which has the advantages of favorable storage stability, strong adhesive force, strong elasticity, strong drawing force, long service life, comfortable wearing and free removal. and the preparation method thereof.

Owner:淄博永麒化工技术开发有限公司

Sports field poly(ethylene carbonate) polyurethane paving material and preparation method thereof

ActiveCN102093701AGood weather resistanceImprove scratch resistanceGround pavingsPerformance indexCarbonate

The invention discloses a sports field poly(ethylene carbonate) polyurethane paving material, which consists of a component A, a component B, black rubber particles and a catalyst. The component A comprises the following components in percentage by weight: 20 to 50 percent of diisocyanate, and 50 to 80 percent of poly(ethylene ether carbonate)diol. The component B comprises the following components in percentage by weight: 30 to 50 percent of poly(ethylene ether carbonate), 5 to 25 percent of processing aid, 30 to 70 percent of filler, 0.1 to 2 percent of pigment, 0.01 to 0.1 percent of ultraviolet absorber and 0.01 to 0.1 percent of inhibitor. The weight ratio of the component A to the component B is 1:(1-6), the content of black rubber particles is 10 to 40 percent based on the total weight of the components A and B, and the content of the catalyst is 0.05 to 1 percent based on the total weight of the components A and B. The invention discloses the preparation method of the paving material. The indexes of the paving material reach the performance indexes of polyether polyurethane paving materials. Compared with the polyether polyurethane paving materials, the paving material has higher weather resistance, scrape resistance, wear resistance and caking property, and is lower in cost, nontoxic and environmentally-friendly.

Owner:HUIZHOU DAYAWAN DAZHI FINE CHEM

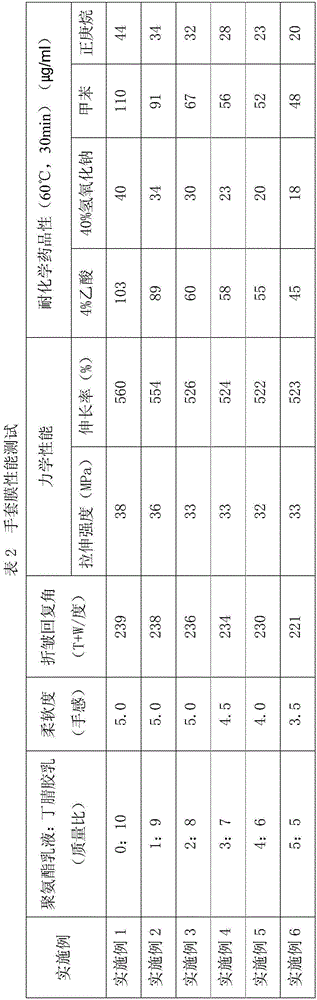

High-performance polyurethane-modified butyronitrile latex gloves and preparation method thereof

ActiveCN106084352AImprove the protective effectImprove performanceGlovesProtective garmentProduction lineLatex glove

The invention provides a pair of high-performance polyurethane-modified butyronitrile latex gloves and a preparation method thereof. According to the method, the chemical resistance of carboxyl butyronitrile latex can be enhanced by adopting a method of blending polyether urethane emulsion with butyronitrile latex. The butyronitrile gloves produced by adopting the impregnation forming technology of blended latex have the double characteristics of butyronitrile latex and polyurethane, as well as good chemical protection capability, and glove products can be produced on the existing butyronitrile latex glove production line.

Owner:中红普林(北京)医疗用品高新技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com