Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

350results about How to "Good anti-sag performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

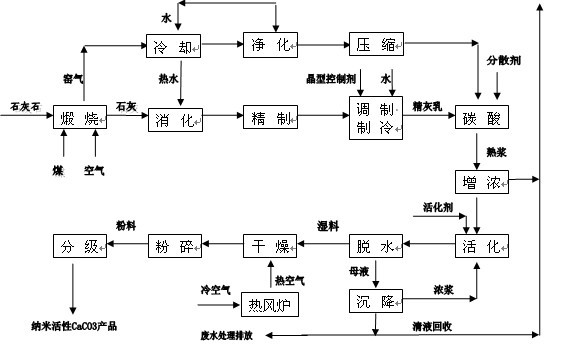

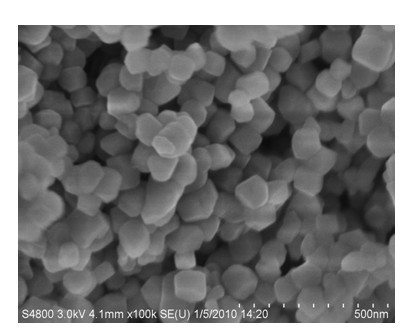

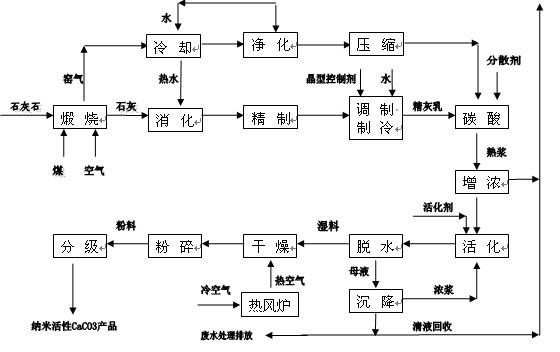

Preparation method of nano-calcium carbonate SCC-2 special for silicone sealant

InactiveCN102491397AProcessability can be optimizedEasy to processCalcium/strontium/barium carbonatesNanotechnologyDispersitySlurry

The invention discloses a preparation method of nano-calcium carbonate SCC-2 special for a silicone sealant, belonging to the technical field of inorganic chemical industry. According to an adopted technical scheme, the method comprises the following steps of: calcining limestone, crushing to obtain CaO; digesting, refining and aging the CaO in a hot state in the ratio of 1:4.8 of CaO to H2O; adding 1 percent of white granulated sugar crystal form control agent for undergoing a carbonation reaction to obtain CaCO3 slurry; performing activation surface treatment; and dehydrating, drying, crushing and degrading to obtain a nano-active CaCO3 product of 60-100 nanometers. The crystal form, size, regularity, oil absorption value and pH value of CaCO3 are controlled, so that 'hard aggregation' among particles is avoided from a surface modification production process, and the product has low oil absorption value and high bulk specific weight and has high dispersity in polymers.

Owner:广东嘉维化工实业有限公司

Novel high sealing property unsaturated polyester white primer, and preparation method thereof

The present invention discloses a novel high sealing property unsaturated polyester white primer, and a preparation method thereof. The unsaturated polyester white primer provided by the present invention comprises, by weight, 40-45% of unsaturated polyester PE resin, 0.2-0.3% of an antifoaming agent, 0.3-0.5% of a wetting dispersant, 0.2-0.3% of a polyacrylate leveling agent, 0.1-0.2% of an anti-green agent, 4-6% of organic bentonite pre-clotting slurry, 0.2-0.8% of fumed silica, 3-7% of zinc stearate, 3-9% of 1250 mesh pulvistalci, 7-11% of 800 mesh pulvistalci, 13-21% of ground calcium carbonate, 11-17% of rutile titanium dioxide, 2-5% of a nitrocellulose solution and 1-3% of n-butyl acetate. The unsaturated polyester PE primer provides especially good sealing property for the low density medium density fiberboard, wherein the low density medium density fiberboard is not subjected to a sealing treatment or is treated bad. In addition, the unsaturated polyester PE primer has characteristics of excellent caving resistance, excellent sagging resistance, short polishing time, good polishing property, strong interlayer adhesion, and can be applicable for the comprehensive primer solution schemes for different environments, various processes and plates.

Owner:恒昌涂料(惠阳)有限公司

Automobile water-based dual-component middle coating excellent in performance and preparation method thereof

The invention discloses an automobile water-based dual-component middle coating excellent in performance and a preparation method thereof. The water-based middle coating is composed of a component A and a component B. The component A is composed of hydroxy acrylic resin, powder syrup, auxiliaries and cosolvent, wherein powder syrup contains deionized water, amine neutralizer, auxiliaries, extender pigment and pigment. The component B is composed of a curing agent, auxiliaries and cosolvent. After being put in according to the formula of the powder syrup of the component A, materials are dispersed at a high speed for 15 min and then enter a grinding machine to be ground till the granularity is smaller than 30 micron, then powder syrup is obtained, and hydroxy acrylic resin, powder syrup, auxiliaries and cosolvent are evenly mixed to obtain the component A. The component A and the component B are mixed in certain proportion, viscosity is adjusted by adding deionized water, and a middle coating film is obtained through spraying construction. By means of the water-based middle coating, the water-based performance of the automobile middle coating is achieved, the VOC content is greatly decreased, and excellent comprehensive performance is achieved.

Owner:GUANGDONG YATU CHEM

Composition useful as an adhesive for installing vehicle windows

ActiveUS20080149257A1Rapid development of strengthGood anti-sag performanceAdhesive processesWindowsEndcappingPolyester

In one embodiment, the invention is an composition comprising: a) one or more isocyanate functional polyether polyurethane prepolymers; and b) one or more prepolymers of one or more polyisocyanates and one or more polyesters wherein the terminal groups on the polyester polyol polyurethane prepolymer are the residue of a monofunctional polyalkylene glycol (hereinafter capped polyester polyurethane prepolymer) or one or more polyester polyols which are capped with the residue of one or more monofunctional isocyanates (hereinafter isocyanate capped polyesters); wherein the composition is a low viscous paste at temperature of from about 40 to about 80° C. and is high viscous paste at a temperature of from about 40° C. or less. In a preferred embodiment the composition further comprises c) one or more catalysts for the reaction of isocyanate moieties with hydroxyl groups. In another embodiment the invention is a method of bonding two or more substrates together which comprise contacting the two or more substrates together with a composition according to this invention disposed along at least a portion of the area wherein the substrates are in contact wherein the composition is a low viscous paste. In a preferred embodiment the composition is heated to about 40° C. to about 80° C. and converted to a low viscous paste prior to contacting it with the one or more substrates.

Owner:DOW GLOBAL TECH LLC

Composition useful as an adhesive for installing vehicle windows

ActiveUS7892395B2Rapid development of strengthGood anti-sag performanceWindowsOther chemical processesEndcappingPolyester

Owner:DOW GLOBAL TECH LLC

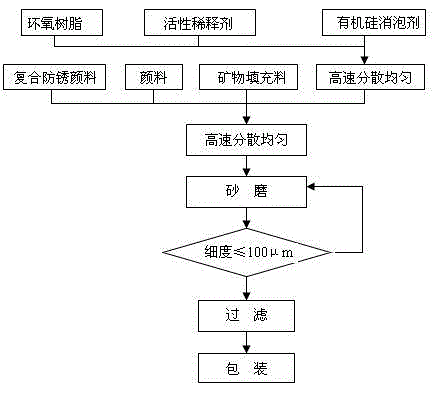

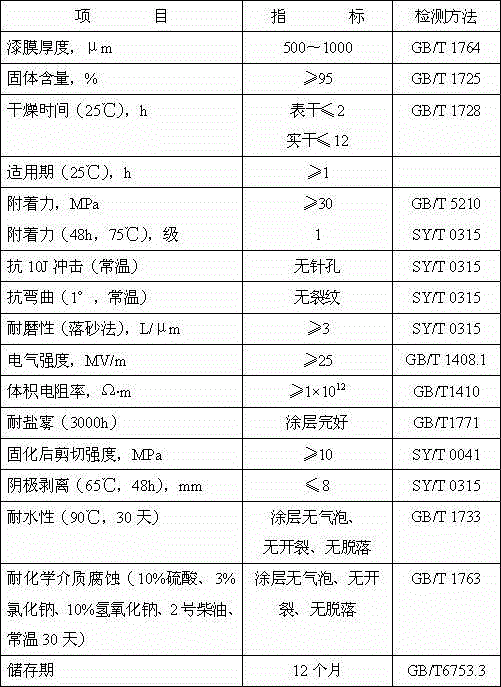

Solvent-free epoxy weight anticorrosion paint used for coated joints of steel buried pipeline

ActiveCN102719171AModerate viscosityEasy constructionAnti-corrosive paintsEpoxy resin coatingsSolvent freePolyamide

The invention introduces a solvent-free epoxy weight anticorrosion paint used for coated joints of a steel buried pipeline, which comprises a component A and a component B; wherein the mass percentage of each raw material in the component A comprises: 30-45% of epoxy resin, 5-15% of glycidyl ether active diluent, 0.05%-1% of silicone defoamer, 20-35% of compound anti-rust pigment, 3-10% of other pigments, 5-15% of barium sulfate mineral filler, 10-20% of other mineral fillers and 0.3-1.5% of polyamide wax; the mass part of each raw material in the component B comprises: 10-25 parts of polyamide curing agent, 5-15 parts of Mannich base and 0.5%-2 parts of curing accelerator; and the mass ratio of the component A to the component B is 100 to 15-35. The paint provided by the present invention has the advantages of pure epoxy, environmental friendly performance and saved resource due to solvent-free property; and is capable of raising the anti-corrosive property, chemical resistance property and insulating property; and is capable of raising the toughness resistance, wear resistance and impact resistance of the coating by employing the mineral fillers.

Owner:XIAMEN SUNRUI SHIP COATING

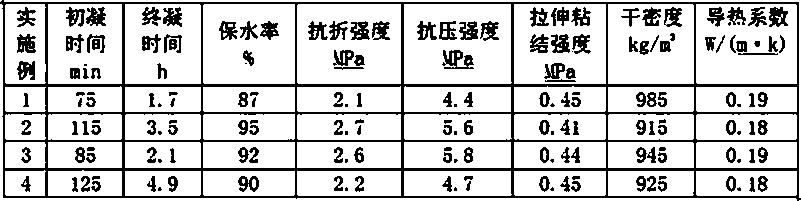

Desulfurized-gypsum-base lightweight spraying gypsum mortar

Disclosed desulfurized-gypsum-base lightweight spraying gypsum mortar is composed of the following compositions in parts by weight: 50-65 parts of desulfurized gypsum, 20-30 parts of building sand, 3-5 parts of vitrified microsphere, 10-20 parts of stone powder, 0.1-0.5 part of a retarder, 0.1-0.3 part of cellulose ether, 0.02-0.04 part of an air-entraining agent, and 0.05-0.1 part of starch ether. The desulfurized-gypsum-base lightweight spraying gypsum mortar employs mechanical spraying for construction, possesses the dry density less than 1000 Kg / m<3>, the heat-conduction coefficient of 0.20 W / (m*K) and the compressive strength lager than 4.0 MPa, and possesses the characteristics of being light in weight, low in heat-conduction coefficient, high in strength and suitable for mechanical spraying construction, and the like.

Owner:JIANGSU NIGAO SCI & TECH +1

Polyethylene compositions, methods of making the same, and articles prepared therefrom

ActiveUS8344068B2Good long-term durabilityGood anti-sag performanceRigid pipesThin material handlingElutionViscosity

The invention is related to compositions suitable for the fabrication of pipes, and other articles, with excellent performance properties. The invention provides a composition, comprising a blend, wherein said blend comprises a high molecular weight ethylene-based interpolymer and a low molecular weight ethylene-based interpolymer, and the high molecular weight ethylene-based interpolymer is a heterogeneously branched linear or a homogeneously branched linear ethylene-based interpolymer, and has a density from 0.922 g / cc to 0.929 g / cc, and a high load melt index (I21) from 0.2 g / 10 min to 1.0 g / 10 min, and the low molecular weight ethylene-based interpolymer is heterogeneously branched linear or a homogeneously branched linear ethylene-based interpolymer, and has a density from 0.940 g / cc to 0.955 g / cc, and a melt index (I2) from 6 g / 10 min to 50 g / 10 min. The blend has a single peak in an ATREF profile eluting above 30° C., and has a coefficient of viscosity average molecular weight (CM?) less than −0.0032 in the log(calculated Mv) versus elution temperature, said CMv calculated in the range of elution temperatures from 70° C. to 90° C. The Mv is the viscosity average molecular weight.

Owner:DOW GLOBAL TECH LLC

Surface-treated calcium carbonate, method for production thereof and resin composition comprising said calcium carbonate

InactiveCN1692076AImprove adhesionHigh impact strengthCalcium/strontium/barium carbonatesOther chemical processesCalcium hydroxideSlurry

A surface-treated calcium carbonate, characterized in that it comprises calcium carbonate surface-treated with an organic agent for surface treatment, and has respective specific ranges of values for a BET specific surface area (Sw), a weight reduction by heat per unit specific surface area (As), an average pore diameter (Dxp) at which an increase in mercury penetration takes a maximum value in a specific range of pore diameter distribution by the mercury porosimetry, and an amount of the average pore diameter [a maximum value of the increase in mercury penetration (Dyp) / an average pore diameter (Dxp)] and a method for producing the calcium carbonate which comprises adding a complex-forming material to a calcium hydroxide slurry, followed by blowing a carbon dioxide gas, to synthesize calcium carbonate, adjusting a calcium carbonate concentration, followed by aging, and treating the surface of the product with an organic agent for surface treatment. The surface-treated calcium carbonate is useful especially for a resin and can be used for producing a resin composition having improved adhesion to an article to be attached and forming a tough coating film.

Owner:MARUO CALCIUM COMPANY

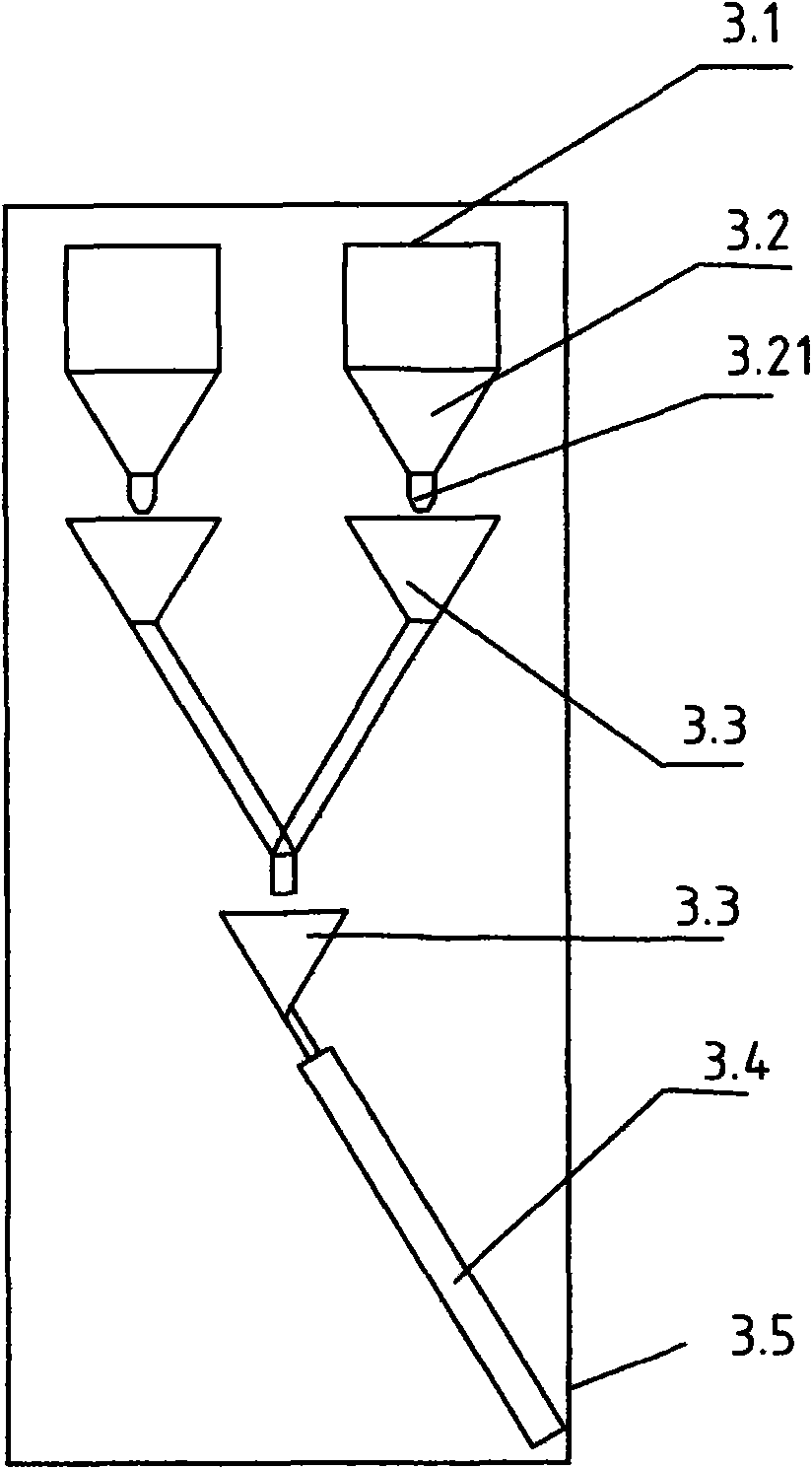

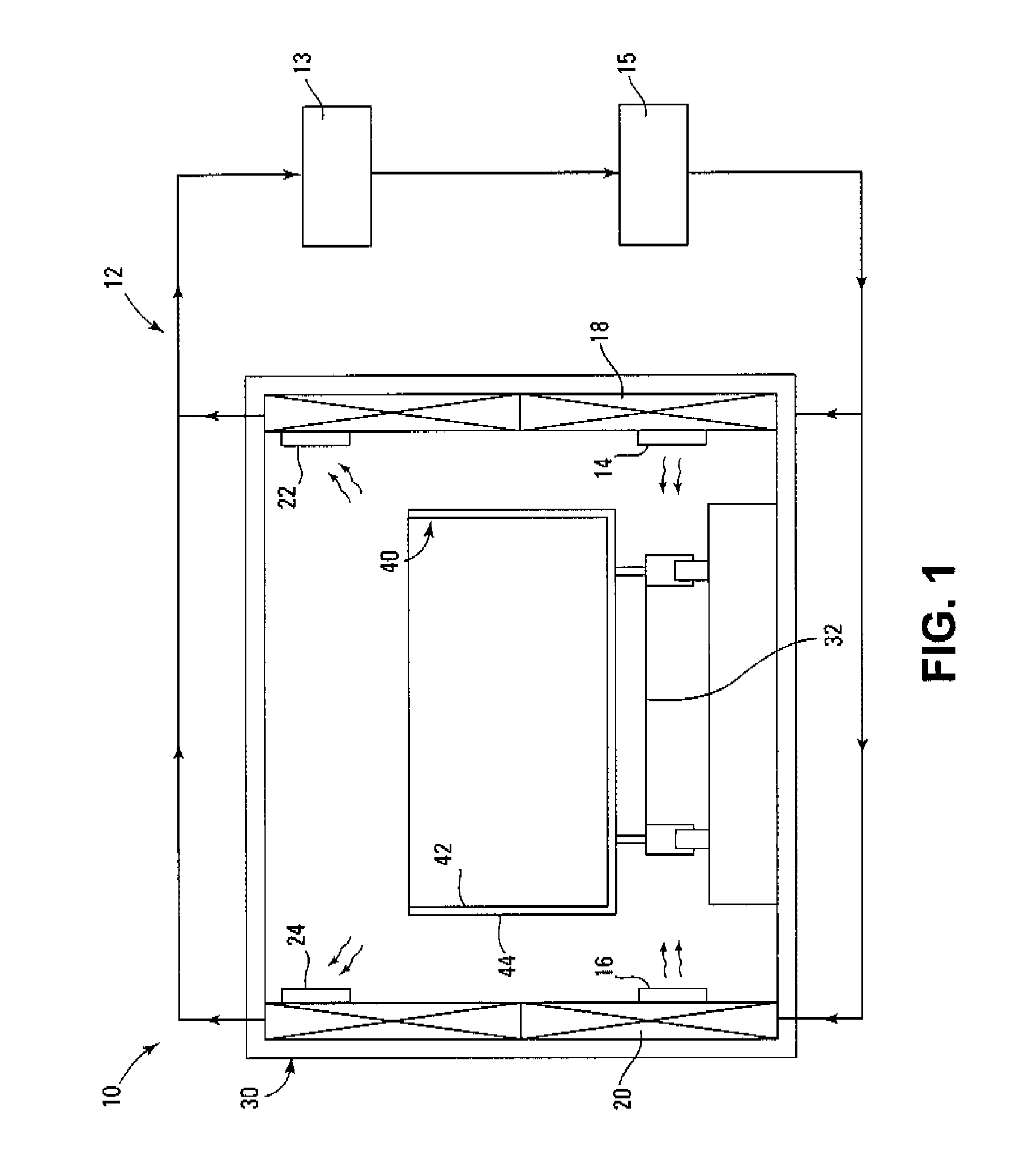

Process for producing arc quartz crucible by vacuum plus coating, equipment, product thereof

InactiveCN101570391AEasy to controlHigh strengthBy pulling from meltGlass shaping apparatusState of artSpray coating

The invention relates to the crucible manufacturing field and is a process for producing an arc quartz crucible by vacuum plus coating, equipment, products thereof. The invention solves the problems that the crucible manufacturing process in the prior art can not solve the operating requirements of long time, high temperature, and high purity of the quartz crucible, a uniform high purity quartz layer can not be formed in the vacuum state by uniform spraying, the layered spraying can not be accurately and timely carried out, and the like; therefore the process and the equipment for producing the arc quartz crucible by vacuum plus coating are provided; the quartz sand is poured into a vacuum mould to shape a prebuilt shape which is put into a founded chamber; a vacuum pump is started and the temperature is controlled, and then the melting and preheating begin; by controlling two hoppers of a double-hopper charging machine, the high-purity quartz sand is sprayed into the quartz crucible in the process of melting, and then mixing spraying coating is sprayed; the vacuum pump is closed during keeping the temperature. The quartz crucible produced by the process and the equipment of the invention has strong non-deformability of long time and exhaustion resistance in high temperature and can be used for long time.

Owner:余姚市启明石英有限公司

Anti-doodle anti-contamination bottom-universal aqueous woodenware white paint and preparation method thereof

InactiveCN108485421AImprove stain resistanceGood chemical resistanceAntifouling/underwater paintsPaints with biocidesSolventContamination

The invention relates to the technical field of paint, and concretely discloses anti-doodle anti-contamination bottom-universal aqueous woodenware white paint and a preparation method thereof. The aqueous woodenware white paint comprises the following components by mass percentage: 40-50% of an aqueous acrylic acid emulsion, 8-12% of an aqueous polyurethane dispersion, 0.3-0.5% of a base materialwetting agent, 0.4-0.6% of an antifoaming agent, 13-18% of deionized water, 1-3% of an environmental protection solvent, 3-5% of a wax emulsion, 1-2% of a thickening agent, 0.3-0.5% of a levelling agent, 0.5-0.8% of an anti-doodling auxiliary agent, 0.5-1% of an organosilicon surface auxiliary agent, 0.5-1% of a dispersant, and 18-20% of titanium dioxide. The aqueous woodenware white paint has high hardness, and excellent contamination resistance and doodle resistance, and a paint film has the advantages of fast drying speed, high glossiness, excellent chemical resistance, and artificial agingresistance.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

Environmentally Friendly Colorant Compositions and Latex Paints/Coatings

ActiveUS20110112223A1Good anti-sag performanceModerate and good sag resistanceLiquid surface applicatorsTransportation and packagingAlkylphenolSolvent

The invention relates to colorant compositions, and aqueous latex paints or other water-borne coatings made from them, which have a mitigated environmental impact. Levels of solvents, additives and impurities comprising volatile non-aqueous constituents, alkylphenol ethoxylates (and derivatives thereof), crystalline silica, and / or formaldehyde are decreased relative to those typical of preceding generations of colorants and tinted aqueous latex paints and other water-borne coatings. On the other hand, paint-performance as indicated by any of Stormer viscosity stabilization, rheological profile flow / leveling and sag resistance, water sensitivity and color transfer resistance is comparable to a paint in which the aforementioned solvents, additives and impurities are still present.

Owner:BENJAMIN MOORE & CO

Method for producing potassium-contd. metal tungsten bars

A technology for manufacturing the K-contained tungsten strips by powder metallurgy includes such steps as preparing K doped tungsten powder, reducing one or two times, acid washing, die pressing, pre-sintering, vertical smelting and indirect sintering. Its advantages are high strength, purity and rate of qualified products, and high uniformity of crystal grains and K element.

Owner:ZIGONG CEMENTED CARBIDE CORP

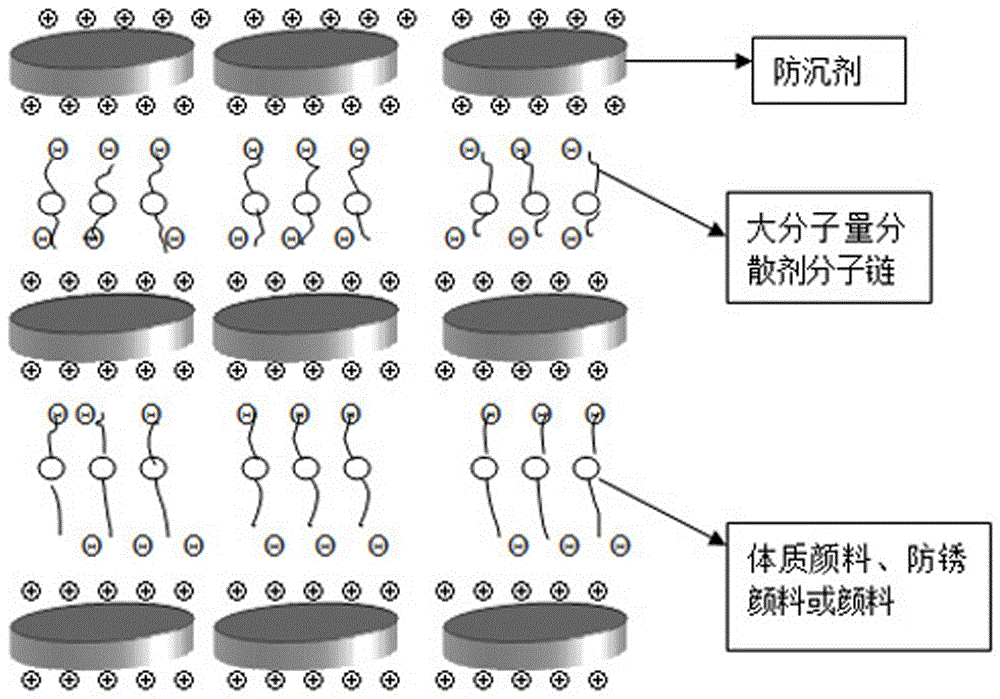

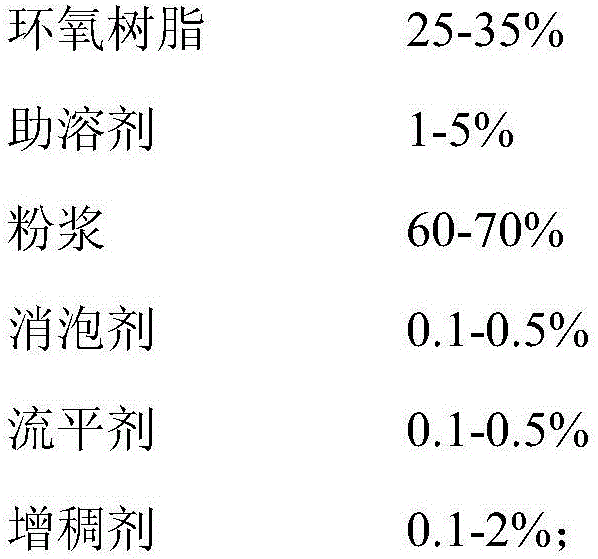

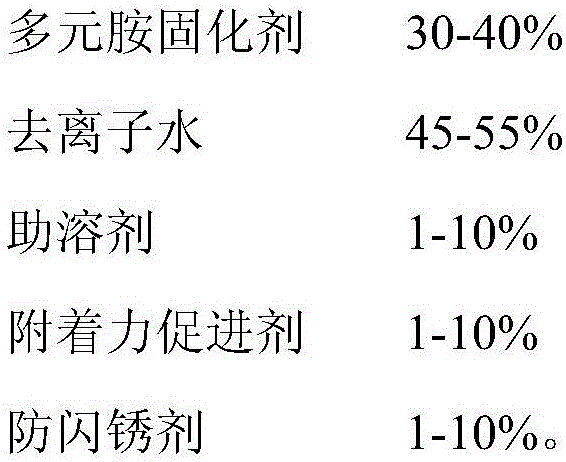

Automobile water-based two-component epoxy primer with excellent performance and preparation method thereof

The invention discloses an automobile water-based two-component epoxy primer with excellent performance and a preparation method thereof. The water-based epoxy primer involved in the invention is composed of a component A and a component B. The component A is composed of epoxy resin, a cosolvent, powder slurry and assistants, wherein the powder slurry includes deionized water, additives, extender pigment, anti-rust pigment and pigment. The component B contains a polyamine curing agent, deionized water, a cosolvent and assistants. The preparation method includes: conducting charging according to the powder slurry formula of the component A, then performing high speed dispersion for 15min, then bringing the materials into a sand mill to conduct grinding to fineness of less than 30 micrometers to obtain the powder slurry, mixing epoxy resin, the cosolvent, the powder slurry and the assistants evenly to obtain the component A, mixing the component A with the components B in certain proportion, adding deionized water to adjust viscosity, and carrying out spray coating to obtain an epoxy primer film. The water-based epoxy primer provided by the invention not only realizes aquation of automobile epoxy primer and great reduction of the VOC content, but also has excellent comprehensive performance.

Owner:GUANGDONG YATU CHEM

High-performance high-solid general modified epoxy antirust paint and preparation method thereof

ActiveCN102363690AHas acid and alkali resistanceNo acid and alkali resistanceAnti-corrosive paintsEpoxy resin coatingsLife ProlongationSlurry

The invention discloses a general modified epoxy antirust paint with high performances and high solids and a preparation method thereof. The paint comprises a component A and a component B, wherein the component A comprises 10-20 parts of an E44 epoxy resin, 10-20 parts of an NPPN-631 epoxy resin, 5-15 parts of a terpene resin, 4-18 parts of a cumarone resin, 0.1-1.0 parts of a BYK antifoaming agent, 0.1-1.0 part of an HX leveling agent, 0.1-1.5 parts of a rheological assistant, 5-20 parts of active silica, 10-20 parts of a mixed solvent and 10-30 parts of a pigment-filler; and the component B comprises 10-40 parts of cardanol modified amine and 0.5-3 parts of a modified silane coupling agent. The antirust paint of the invention has the advantages of compact coating, low viscosity, good compatibility and fast curing of a curing agent, high tough strength and strong adhesion of the coating, coating number reduction during the thick slurry curing, construction efficiency improvement, construction cost reduction, and anticorrosion life prolongation.

Owner:XIAMEN SUNRUI SHIP COATING

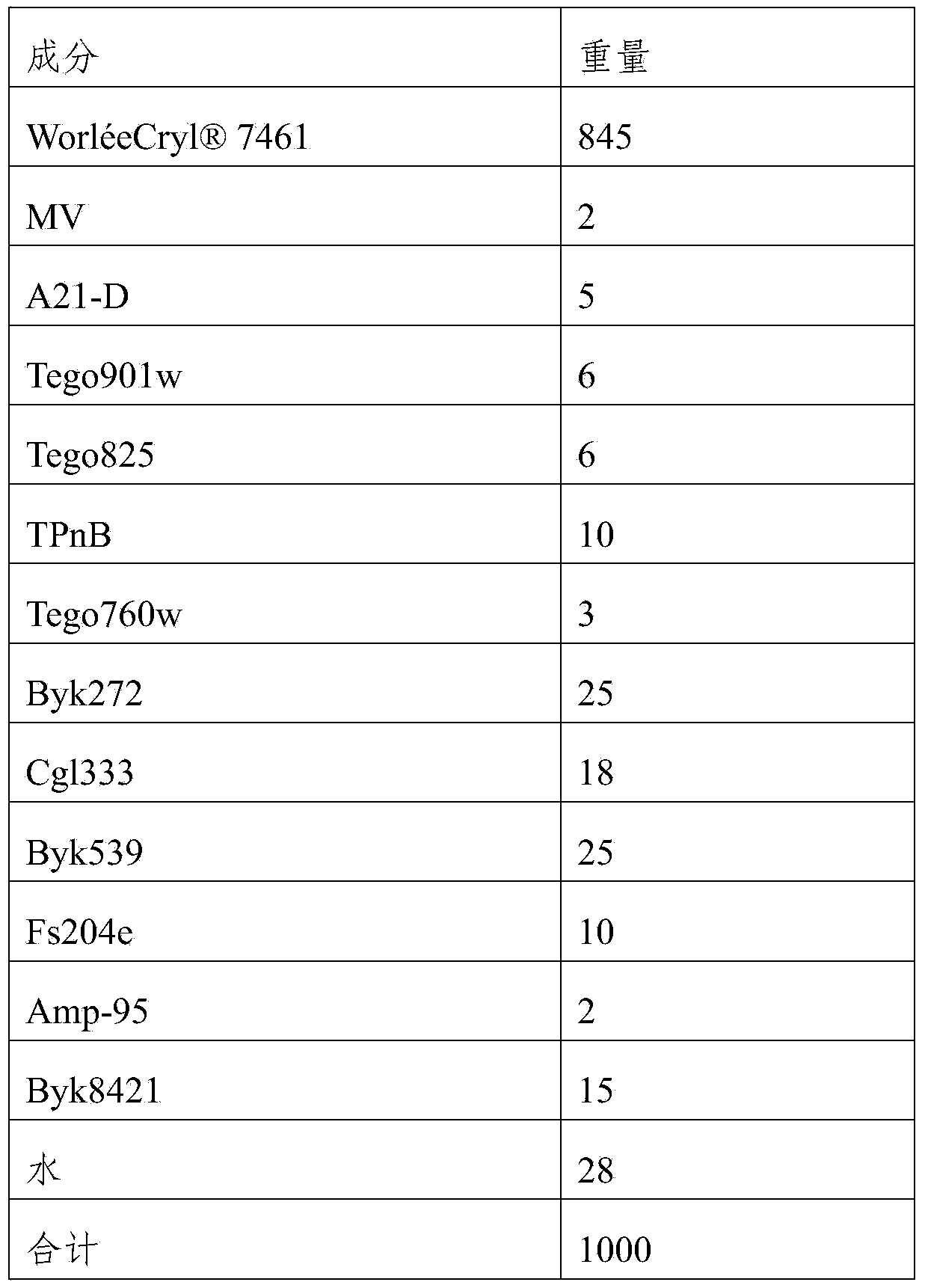

Water-based clear topcoat with high solid content and preparation method thereof

ActiveCN103881495AReduce contentImprove protectionLiquid surface applicatorsAntifouling/underwater paintsWaxPreservative

The invention relates to a water-based clear topcoat with high solid content, which is prepared from the following components in parts by weight: 750-900 parts of water-based resin, 1-4 parts of bactericide, 3-8 parts of dry film preservatives, 5-25 parts of coalescing agents, 5-15 parts of defoamer, 5-20 parts of base material wetting agents, 2-5 parts of pH adjuster, 10-35 parts of anti-sagging agents, 10-40 parts of extinction wax additives, 15-50 parts of special wax additives, 3-15 parts of dispersants, 15-35 parts of complex aging resistant additives, 0-100 parts of resin-type water-based coloring materials, and 0-60 parts of water. The product with high sold content is applicable to coating and protection on wood platforms, wood doors and windows, fences, leisure tables and chairs and other wood structures manufactured and formed outdoors. The water-based clear topcoat with high solid content is simple in preparation method, easy to operate, free of harm to an operator, and applicable to industrial popularization and application.

Owner:濮阳展辰新材料有限公司

Automobile wear-resistant paint and preparation method thereof

ActiveCN104119737AGood anti-sag performanceImprove flame retardant performanceCoatingsWear resistantPlasticizer

The invention discloses an automobile wear-resistant paint and a preparation method thereof. The preparation method comprises the following steps: adding 100 parts by weight of PVC and 115 to 125 parts by weight of plasticizer into a reactor, evenly mixing; adding 1 to 6 parts by weight of silane coupling agent and 0.001 to 0.01 part of azodiisobutyronitrile into the reactor, increasing the stirring speed to evenly stir the mixture; adding 0.3 to 0.8 part by weight of organic fluorine surfactant and 2 to 8 parts of tackifier into the reactor, fully stirring until the added materials are evenly mixed; adding 250 to 300 parts of inorganic powder, increasing the stirring speed; and vacuumizing to remove the gas after the inorganic powder is evenly dispersed so as to obtain the automobile wear-resistant paint. The automobile wear-resistant paint has the excellent flame retardant performance, anticorrosion performance, and electric insulation performance, and high mechanical strength of polyvinyl chloride resin paint, and also has a very good anti-dropping and anti-sagging performance at the same time.

Owner:GUANGDONG TGPM AUTOMOTIVE IND GRP

Modified paint

A modified coating consists of acrylate 6-60wt%, water 10-60wt%, aggregate 12-50wt%, wetting disperser 0.01-5wt%, thickener 0.2-10wt%, film forming agent 0.1-10wt%, anti-bubbling agent 0.07-1.7wt%, anti-shrinking leveling agent 0.1-10wt%, fungicidal bactericide 0.02-4wt%, pH regulator 0.01-5wt%, propanediol 0.1-5wt%, pigment and dye. Particle diameter of mixed components is 0.1-1 nanometer. The process is carried out by proportioning the components. Its advantages include simple, non-toxic, good anti-aging and pollution preventive performances, and better air permeability.

Owner:闫俊杰 +1

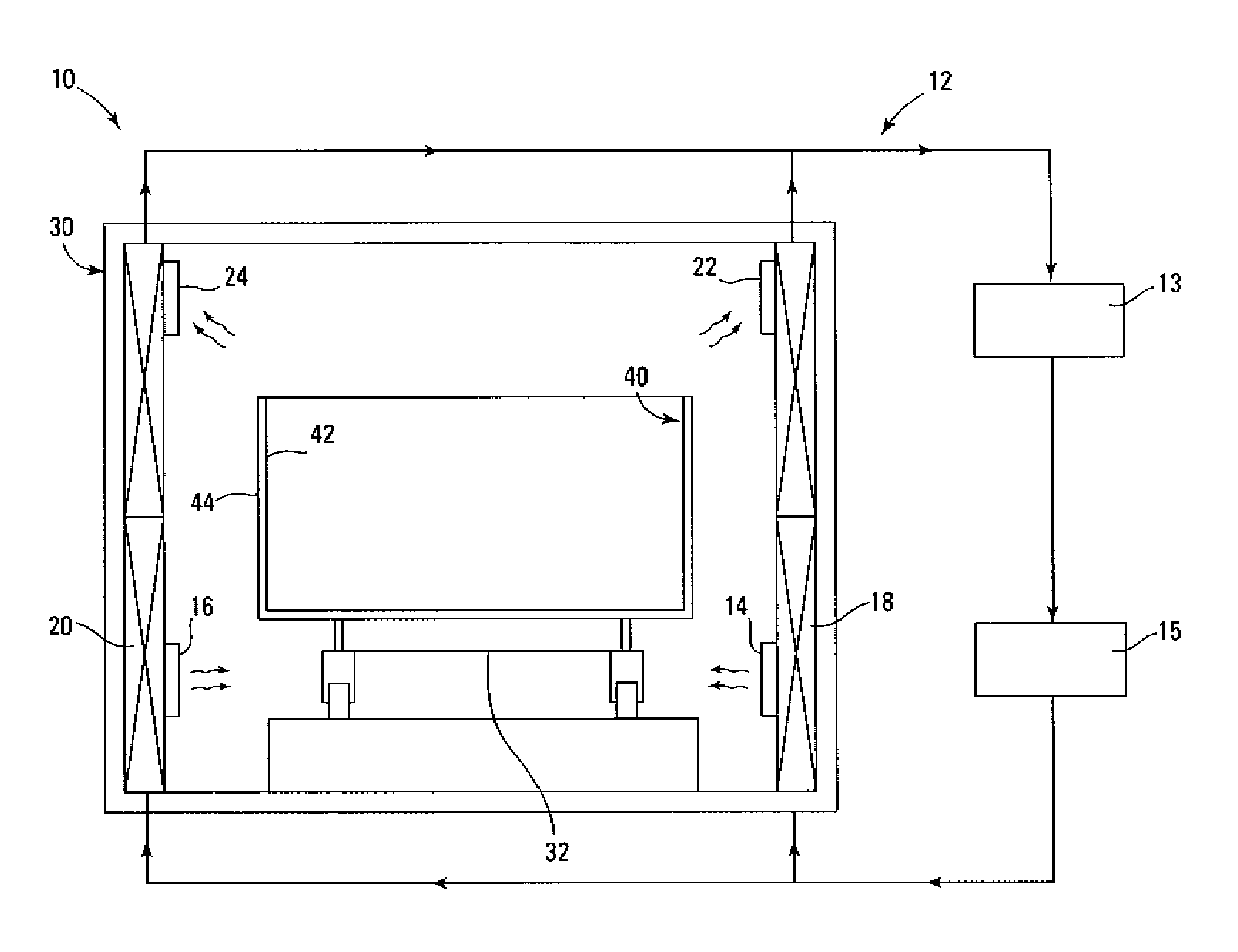

Water-based coating compositions and systems with improved sag resistance and related methods

InactiveUS20130105473A1High viscosityExtended drying timeSpraying apparatusDrying gas arrangementsWater basedCoating system

The present invention provides a water-based coating and / or coating system that can be used to form sag resistant wet layers or coatings on a wide range of substrates. The coating system is particularly effective for protecting metal-containing substrates, such as intermodal cargo containers, against corrosion. As an overview, the present invention provides water-based compositions suitable to form primer coats on substrates. Desirably, the primer incorporates a high level of one or more CAS agents for excellent sag resistance while drying in a broad range of relative humidity environments. Alternatively, modifications can be made to control temperature and humidity during spray application and drying as a way to increase sag resistance of the coating.

Owner:VALSPAR SOURCING INC

Solvent-free epoxy glass flake paint and manufacturing method

ActiveCN102260451AImprove adhesionImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsSolventCarbon black

The invention discloses a solvent-free epoxy glass flake coating and a preparation method. The coating is used for splash zones of offshore platform jackets to improve the anticorrosion capacity of steel pipes and prolong the service life of the steel pipes. The preparation method comprises the following steps of: adding a reactive diluent 660A into an epoxy resin, adding an organic bentonite rheological aid 881-B, an EP 2440 adhesion promotion resin, silicone oil, carbon black, titanium white and aluminum trippolyhosphate, mixing uniformly, grinding, adding glass flakes, and stirring uniformly to form solution A; forming solution B by using an epoxy curing agent H633; and mixing the solution A and the solution B to obtain the solvent-free epoxy glass flake coating during use. Solvents are not volatilized in the curing process, the coating is slightly shrunk, and the solvent-free epoxy glass flake coating has a compact structure and high permeability resistance; moreover, the solvent-free epoxy glass flake coating has extremely strong cohesive force and good anticorrosion performance.

Owner:BC P INC CHINA NAT PETROLEUM CORP +2

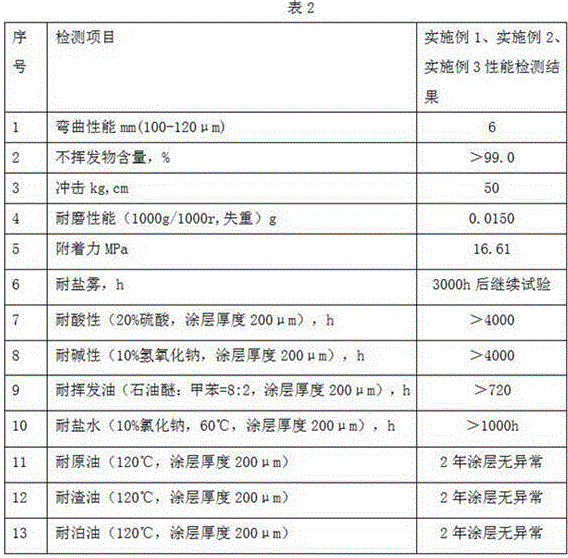

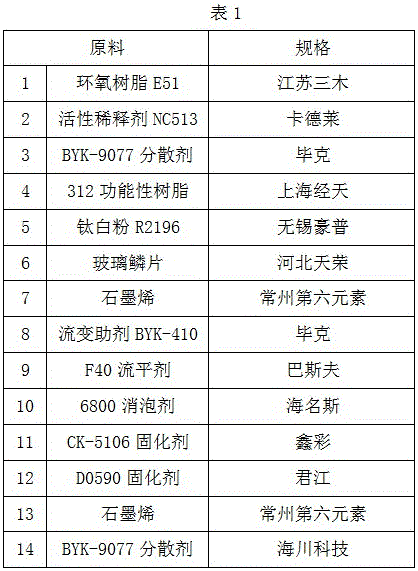

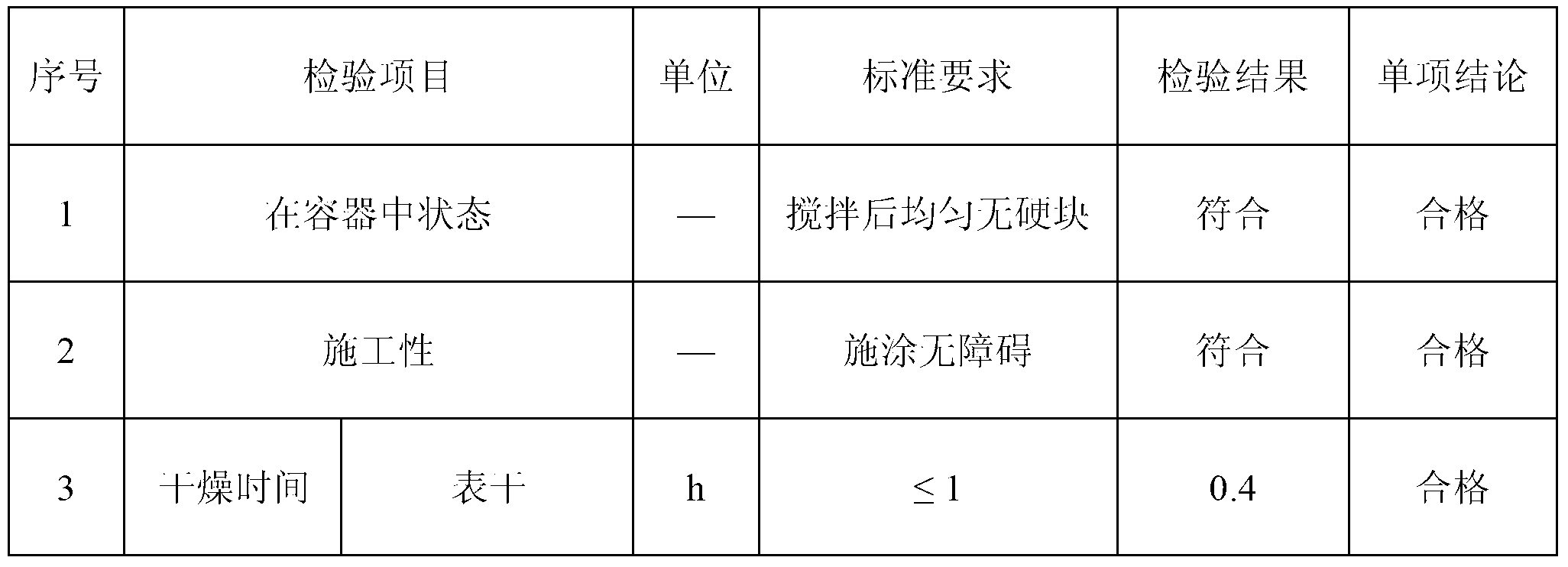

Low-viscosity solvent-free epoxy graphene glass-flake coating and preparation method thereof

ActiveCN106243922AEnsure structural dispersion stabilityGuaranteed flexibilityAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

The invention discloses a low-viscosity solvent-free epoxy graphene glass-flake coating and a preparation method thereof, and aims to solve the problems that the conventional solvent-free epoxy graphene glass-flake coating has a high requirement on a construction thickness, is not ideal in corrosion resistance, needs to apply heating spraying and has a large number of coating working procedures. The coating consists of two components specifically as follows: the component I is prepared from the following raw materials in percentage by mass: 37 to 40 percent of epoxy resin E51, 2 to 4 percent of an active diluents NC513, 0.2 to 0.6 percent of a dispersing agent BYK-9077, 15 to 23 percent of functional resin 312, 14 to 15 percent of titanium dioxide R2196, 20 to 25 percent of glass flakes, 0.2 to 0.3 percent of graphene, 0.2 to 0.5 percent of a rheological agent BYK-410, 0.2 to 0.4 percent of a leveling agent F40 and 0.2 to 0.6 percent of a defoaming agent 6800; the component II is prepared from the following raw materials in percentage by mass: 75 to 94 percent of a curing agent CK-5106, 5.6 to 24.2 percent of a curing agent D0590, 0.2 to 1.5 percent of graphene and 0.2 to 1.0 percent of the dispersing agent BYK-9077. The coating can be directly used for coating by a conventional construction process without being heated, and the construction is rapid, simple and convenient.

Owner:西北永新涂料有限公司

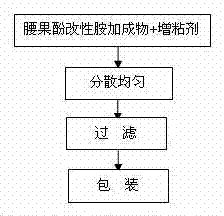

Air-drying automobile-used water-based finishing coat and water-based intermediate coat, as well as preparation method and use methods thereof

ActiveCN104804636ASmall molecular weightUniform particle size distributionPolyurea/polyurethane coatingsWater basedAcrylic resin

The invention discloses air-drying automobile-used water-based finishing coat and water-based intermediate coat, as well as preparation method and use methods thereof. The air-drying automobile-used water-based finishing coat and water-based intermediate coat mainly comprise water-based castor oil modified alkyd resin, water-based acrylic resin, a silicon modified dual-crosslinking water-based polyurethane curing agent, and other additives. The preparation methods comprise the following steps: preparing main coat with castor oil modified alkyd resin, water-based acrylic resin and the additives; providing curing agents and water. The use methods comprise the steps of mixing main coat, the curing agents and water in a weight proportion. The air-drying automobile-used water-based finishing coat and water-based intermediate coat can be dried directly in a natural environment, and have the advantages that defects of curtaining, flower formation, drifting and the like are avoided in spraying on a large-area vertical surface; the rigidity, fullness and weatherability are high.

Owner:肇庆千江水漆有限公司

Tile cement mortars using water retention agents

InactiveCN1946652ALess quantityCorrection time improvedPropellersSolid waste managementEtherCement mortar

A mixture composition of a cellulose ether made from raw cotton linters and at least one additive is used in a cement extrusion mortar composition wherein the amount of the cellulose ether in the cement extrusion mortar composition is significantly reduced. When this cement extrusion mortar composition is mixed with a sufficient amount of water and extruded to form an object with comparable or lower crack formation, the plastification and / or extrusion properties of the resulting wet mortar are improved or comparable as compared to when using conventional similar cellulose ethers.

Owner:HERCULES INC

Emulsion composition for vibration damping material

InactiveUS20110060066A1Increase dampingInhibit swellingAbsorbent padsBaby linensEmulsionHigh humidity

The present invention provides an emulsion composition for a vibration damper, which has heating and drying properties high enough to form an excellent coating film which can exhibit excellent damping without swelling during drying by heating, and an emulsion composition for a vibration damper, which can exhibit basic performances demanded in vibration dampers, in particular, markedly superior anti-sagging even under the condition of high humidity or a thick film where the coating film may sag in conventional technologies, and thus can be useful in vibration dampers of various structures. The emulsion composition for a vibration damper includes an emulsion obtainable by emulsion polymerization of monomer components, the emulsion composition containing 0.5 to 20% by mass of a film-forming agent with a weight average molecular weight of 100 to 20000 in 100% by mass of the emulsion composition.

Owner:NIPPON SHOKUBAI CO LTD

Epoxy resin system for wind blade hand lay-up repair and preparation method thereof

The invention discloses an epoxy resin system for wind blade hand lay-up repair and a preparation method thereof. The epoxy resin system is formed by mixing of a resin part and a curing agent part that are prepared respectively and are in a weight ratio of 100:28-32. Specifically, the resin part is formed by mixing 85-95 parts by weight of one of or a mixture of bisphenol A epoxy resin and bisphenol F epoxy resin, and 5-15 parts by weight of a diluents; and the curing agent part is prepared by modification of, by weight, 40-70 parts of fatty amine, 0-30 parts of alicyclic amine, 0-10 parts of aromatic amine, 0-35 parts of an assistant, and 5-15 parts of an epoxy compound. The epoxy resin system for wind blade hand lay-up repair provided by the invention is accord with the medium viscosity requirement of hand lay-up molding, and has the characteristics of good sagging resistance, low operating environment requirement, and excellent fiber material infiltration. After curing, the product has excellent toughness, mechanical properties, heat resistance, water resistance and other comprehensive performance, and can meet the requirements of hand lay-up molding epoxy resin used for wind blade matched repair.

Owner:EPOXY BASE ELECTRONICS MATERIAL

Anti-sinking PU extra-clear primer and preparation method thereof

ActiveCN103305113AGood anti-sag performanceHigh transparencyPolyurea/polyurethane coatingsMethyl carbonateSlurry

The invention provides an anti-sinking PU extra-clear primer which is prepared by mixing an anti-sinking PU polyurethane primer, a PU anti-sinking curing agent and a PU anti-sinking diluent, wherein the anti-sinking PU polyurethane primer is prepared from soybean oil alkyd resin, a dispersant, an antifoaming agent, anti-settling slurry, pigment and filler, nitrocotton liquid, a leveling agent, a dryer and the like in addition with an environment-friendly solvent; the PU anti-sinking curing agent is prepared from n-butyl acetate, isocyanate tripolymer and isocyanate heteropolymer; and the PU anti-sinking diluent is prepared from the solvents such as n-butyl acetate, propylene glycol monomethyl ether acetate, dimethyl carbonate and the like. The anti-sinking PU polyurethane primer, the PU anti-sinking curing agent and the PU anti-sinking diluent are sufficiently and uniformly mixed to prepare the anti-sinking PU extra-clear primer which has excellent anti-sinking property and extra high transparency and is easy to polish; and the shortcomings of slow drying, poor anti-sinking property, common adhesion, low transparency, common polishing property and the like of the commercially available products are overcome.

Owner:广东花王涂料有限公司

High-performance lightweight composite mortar

The invention relates to the field of building materials, in particular to high-performance lightweight composite mortar, which is characterized by comprising the following substances in part by weight: 250 to 350 parts of cement, 120 to 200 parts of reinforcing material, 160 to 200 parts of composite heat insulation aggregate, 0.5 to 2.0 parts of short fibers, 0.2 to 1.5 parts of water repellent, 0.5 to 2.0 parts of thickening agent, 5 to 10 parts of re-dispersible powder and 300 to 400 parts of furnace slag sand. Compared with the prior art, the high-performance lightweight composite mortar can effectively save the use of materials such as cement and the like, meanwhile has good performance of water holding, cracking resistance, water prevention, fire prevention and the like and good adhesive force and flow resistance, avoids hollowing and cracking, meets various performance requirements of a rendering layer, and has the remarkable advantages of energy conservation, environmental protection, simple construction, high strength, low cost, good product quality and the like.

Owner:山东隆济时节能科技股份有限公司

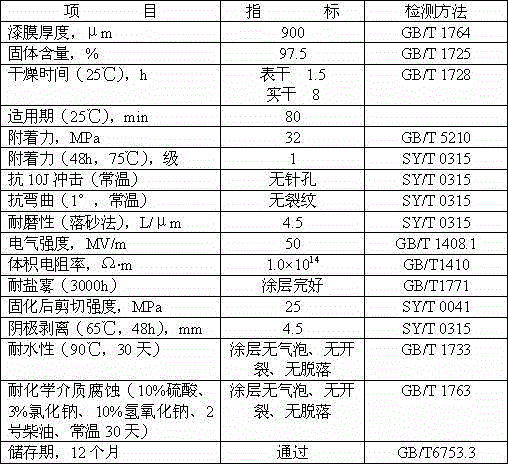

Solvent-free epoxy heavy anti-corrosion paint extruded and coated to inner wall of crude oil gathering pipeline

InactiveCN109181477AGood chemical resistanceAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent free

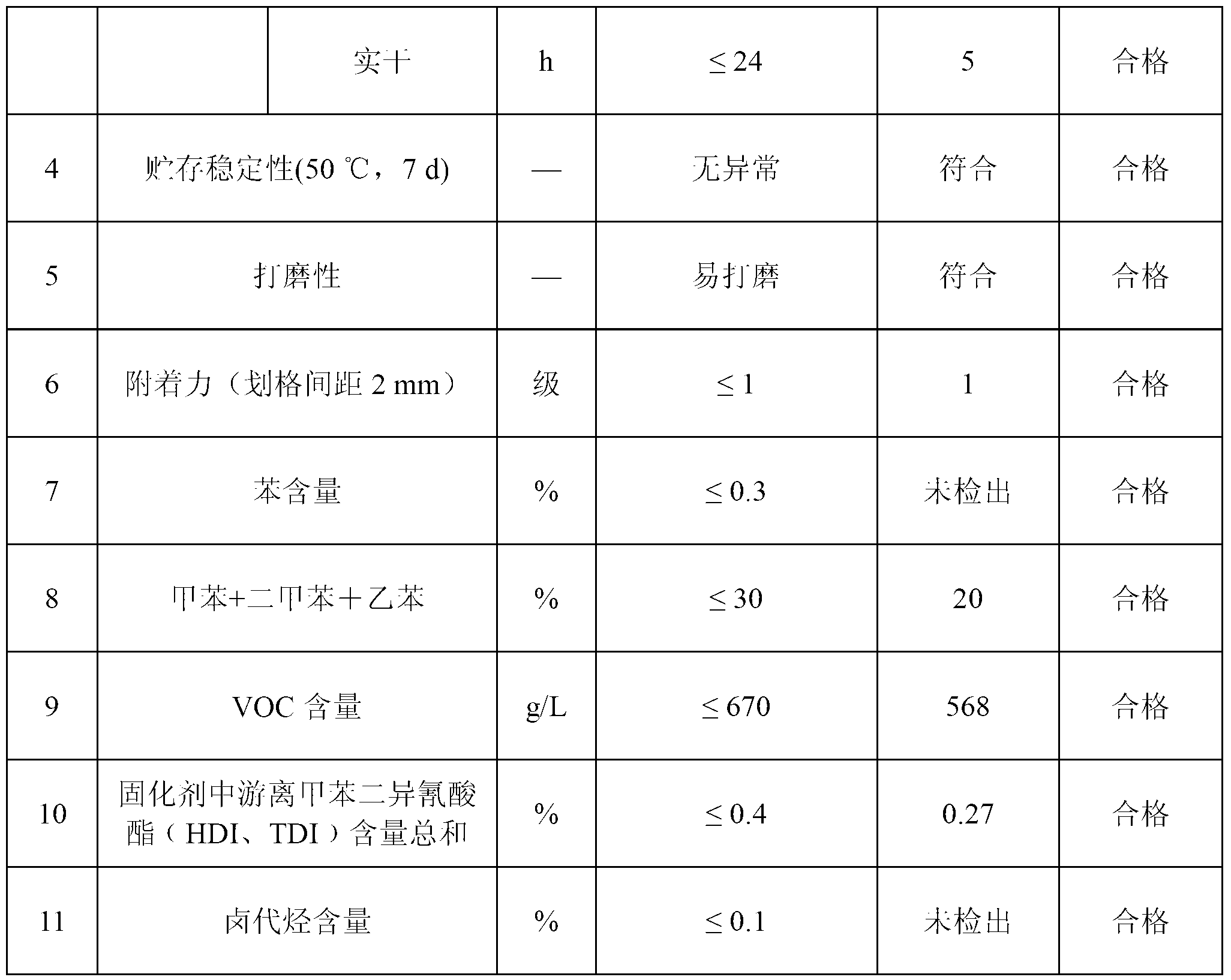

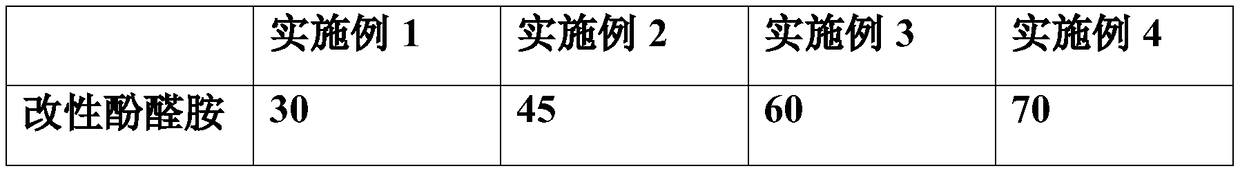

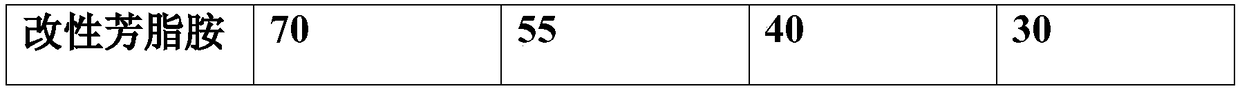

The invention discloses a solvent-free epoxy heavy anti-corrosion paint which is extruded and coated to the inner wall of a crude oil gathering pipeline. The paint comprises a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 10-25 parts of E-51 epoxy resin, 12-30 parts of F-51 epoxy resin, 10-15 parts of titanium dioxide, 1-2 parts of phthalocyanine green, 1-2 parts of organic yellow, 1.5-3 parts of a thixotropic agent, 0.3-0.5 part of a wetting dispersant, 5-8 parts of inert liquid resin, 3-5 parts of an active diluting agent, 3-5 parts of a hyperbranched toughening agent, 15-20 parts of precipitated barium sulfate, 8-15 parts of anti-rust pigment, 0.3-0.5 part of a defoaming agent, 0.2-0.4 part of a flatting agent; the component B is prepared from 30-70 parts of modified phenolic amine curing agent and 70-30 parts of modified aromatic amine curing agent; and the mass ratio of the component A to the component B is(5-7):1. The solvent-free epoxy heavy anti-corrosion paint is applicable to gathering pipeline extruding and coating processes, the pipeline inner wall coating has excellent corrosion resistance and physical performance, the coating process can be reduced, the construction time can be saved, and the work efficiency can be improved.

Owner:石家庄市油漆厂

PU (polyurethane) high-fullness anti-sinking luster white finish paint

ActiveCN102964975AHigh fullnessGood anti-sag performancePolyurea/polyurethane coatingsPolyester coatingsSolventChemistry

The invention relates to a PU (polyurethane) high-fullness anti-sinking luster white finish paint which is composed of a component A, a component B and a component C, wherein the component A is prepared from saturated polyester resin, synthetic fatty acid resin, acrylic resin, PU high-grade luster white finish slurry, dispersant, leveling agent, defoaming agent, environment-friendly solvent and the like; the component B is prepared from n-butyl acetate and curing agent; and the component C is prepared from n-butyl acetate, methylbenzene and the like. The detection and trial prove that the polyurethane white finish paint provided by the invention has the advantages of excellent yellowing resistance, strong coating adhesive force, high hardness, wear and scratch resistance, high heat resistance, favorable constructability, favorable leveling property, high fullness and excellent anti-sinking capacity; and the environment-friendly property conforms to the index in GB18581.

Owner:四川巴德士新材料有限公司

Latent-curing conductive paste and method of forming electrode on substrate thereby

ActiveCN103000253AShape stableAvoid deformationNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive pasteLow temperature curing

The invention relates to latent-curing conductive paste and a method of forming an electrode on a substrate thereby. The latent-curing conductive paste comprises low-melting-point thermoplastic polymer, conductive particle, glass powder, curing reaction agent, curing catalyst and auxiliaries. The low-melting-point thermoplastic polymer is solid or jelly at room temperature, melts into liquid at 35-85 DEG C, and starts curing reaction with the curing reaction agent under the action of the curing catalyst in the temperature range of from 85 DEG C to 160 DEG C. To form the electrode on the substrate by the latent-curing conductive paste, post-printing low-temperature curing is needed. Compared with the prior art, the latent-curing conductive paste is well resistant to medium temperature after printing and curing, so that environmental temperature sensitivity of the conventional hot-melt conductive paste after printing is effectively overcome and printed pattern can be well kept. The latent-curing conductive paste is especially suitable for solar cells.

Owner:JIANGSU RUIDE NEW ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com