Water-based clear topcoat with high solid content and preparation method thereof

A clear topcoat, water-based technology, used in biocide-containing paints, antifouling/underwater coatings, devices for coating liquids on surfaces, etc. and other problems, to achieve the effect of reducing the number of coating times, reducing the cost of coating, and excellent antibacterial and antifungal properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] This embodiment provides a high solid clear topcoat.

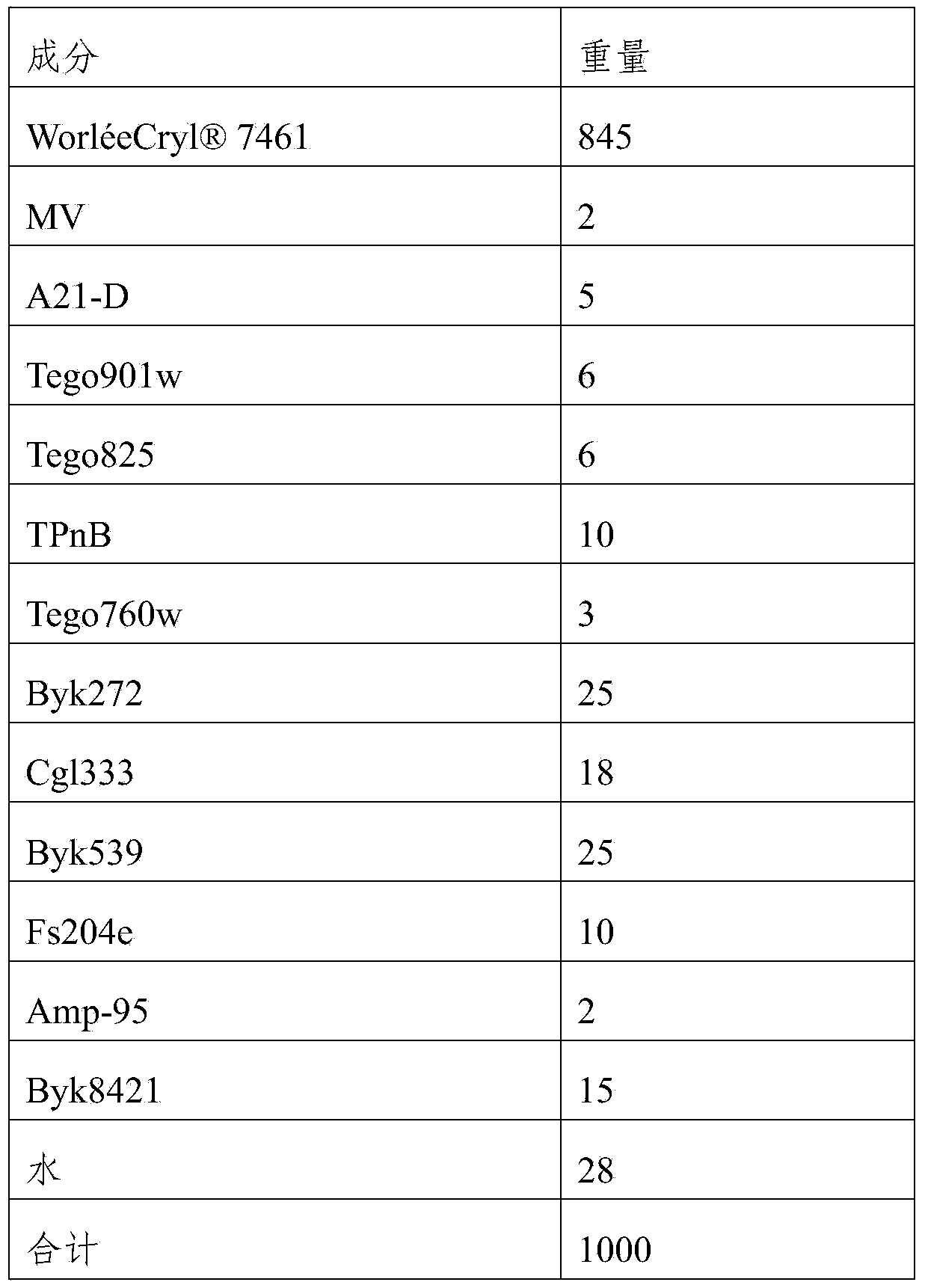

[0041] 1. Composition

[0042]

[0043] 2. Preparation method

[0044] 1) first put 7461 was weighed into the dispersing tank and started stirring to obtain mixture 1;

[0045] 2) Weigh the MV and A21d, and add the mixture 1 in the dispersion tank under stirring to obtain the mixture 2;

[0046] 3) Weigh tego901w, tego825, TPnB, and Tego760w into a clean container, mix well and add to the dispersion cylinder mixture 2 under stirring, then add Byk272, disperse at 1300 rpm for 15 minutes at high speed, and obtain mixture 3 ;

[0047] 4) Add Cgl333, Byk539, Fs204e and deionized water to mixture 3, and stir at a medium speed of 900 rpm for 10 minutes to obtain mixture 4;

[0048] 5) Add Amp-95, Byk8421 and the remaining deionized water to the mixture 4, and stir well to obtain a clear topcoat.

[0049] 3. Application: larch wood fence in villa garden: first, polish the larch wood fence that needs to be protect...

Embodiment 2

[0051] This embodiment provides a high solid clear topcoat. 1. Composition

[0052]

[0053] 2. Preparation method

[0054] 1) first put 7461 was weighed into the dispersing tank and started stirring to obtain mixture 1;

[0055] 2) Weigh Parmetol A28 and Preventol A14-D, and add them to the dispersion tank mixture 2 under stirring;

[0056] 3) Weigh BYK-028, BYK-024, PPH, and Tego715w into a clean container, mix well and add to the dispersion cylinder mixture 2 under stirring state, then add Acumist3105B, and disperse at 1200 rpm for 15 minutes at high speed , to obtain mixture 3;

[0057] 4) Add nanobyk3820, Emulsion32535, Surfynol104E and deionized water were stirred at a medium speed of 850 rpm for 10 minutes to obtain mixture 4;

[0058] 5) Add Amp-95, RHEOLATE299 and the remaining deionized water to mixture 4, stir well; send for inspection.

[0059] 3. Application:

[0060] Pure solid wood windows of catalpa wood: first, polish the pure solid wood window fr...

Embodiment 3

[0062] This embodiment provides a high solid clear topcoat.

[0063] 1. Composition

[0064]

[0065]

[0066] 2. Preparation method

[0067] 1) first put 7461 was weighed into the dispersing tank and started stirring to obtain mixture 1;

[0068] 2) Weigh Mv and Preventol A21-D, and add it into the dispersion tank mixture 1 under stirring to obtain mixture 2;

[0069] 3) Weigh Tego901w, Tego825, PPH, and Tego740w into a clean container, mix well and add to the dispersion cylinder mixture 2 under stirring, then add Byk272, disperse at 1400 rpm for 15 minutes at high speed, and obtain mixture 3 ;

[0070] 4) Add Cgl333, Byk539, Byk346 and deionized water to mixture 3, and stir at a medium speed of 950 rpm for 10 minutes to obtain mixture 4;

[0071] 5) Add Amp-95, Byk8421 and the remaining deionized water to mixture 4, and add TOLYTINT red3146, TOLYTINT yellow1016 and TOLYTINT black3147 for coloring, and stir evenly to obtain a clear topcoat.

[0072] 3. Applicatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com