Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

230results about How to "Reduce painting cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature resistant economical electrostatic powder coating for electric room heater and preparation method thereof

InactiveCN101565587AImprove heat resistanceAvoid harmFireproof paintsPowdery paintsMetallurgyHigh pressure

The invention discloses a high temperature resistant economical electrostatic powder coating for an electric room heater and a preparation method thereof. The formulation of the powder coating comprises the following compositions in percentage by weight: 53 to 57 percent of thermosetting resin, 3 to 7 percent of curing agent, 1 to 30 percent of pigment, 5 to 34 percent of filler and 2 to 5 percent of auxiliary agent. The powder coating is produced by adopting the method of premixing, melt extrusion and mixing, tabletting, cooling and crushing, fine grinding and classification, sieving and separation, and product, wherein the average particle size of the powder coating is between 25 and 30 mu m, and the thickness requirement between 50 and 60 mu m of an economic coating is met. The powder coating is suitable for coating by a high voltage electrostatic powder coating method and simultaneously is suitable for coating by a frictional electrostatic powder coating method.

Owner:杨彬

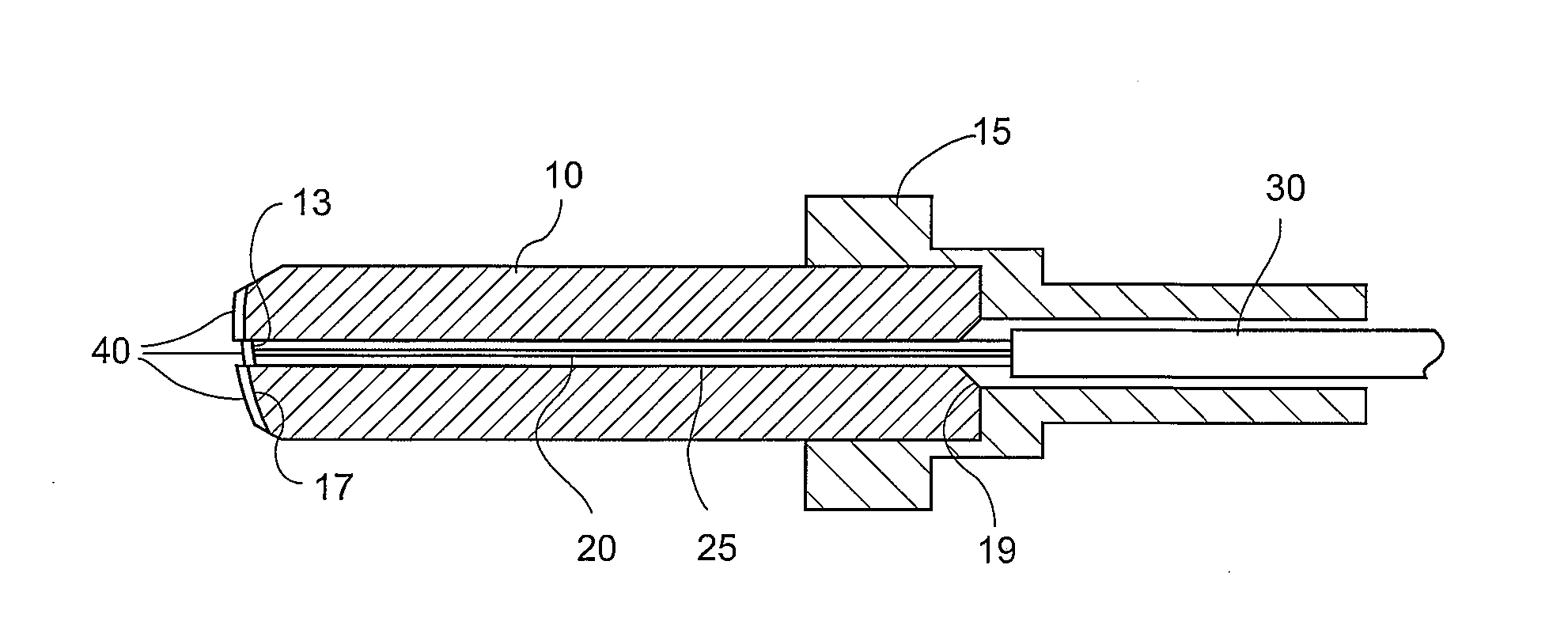

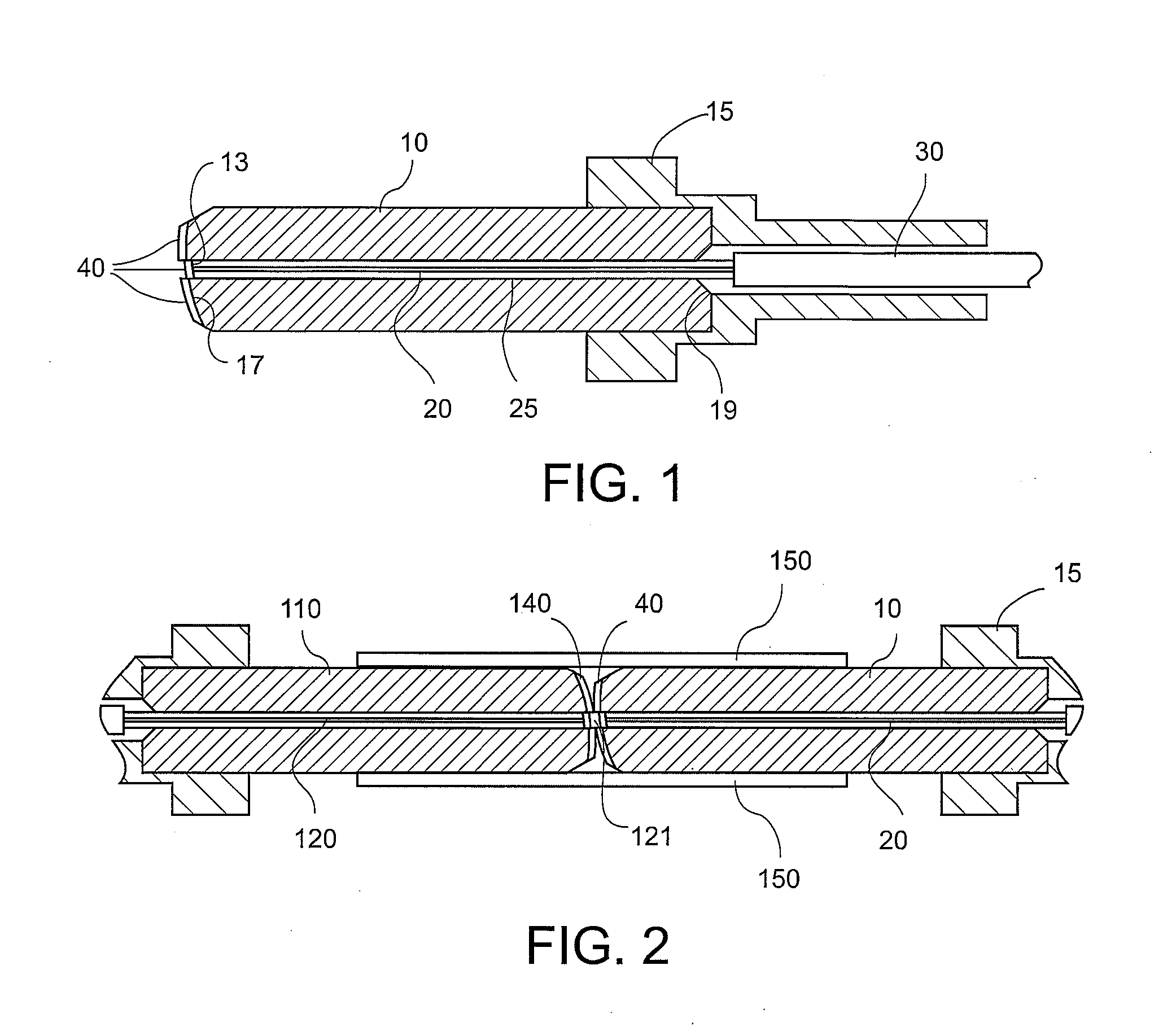

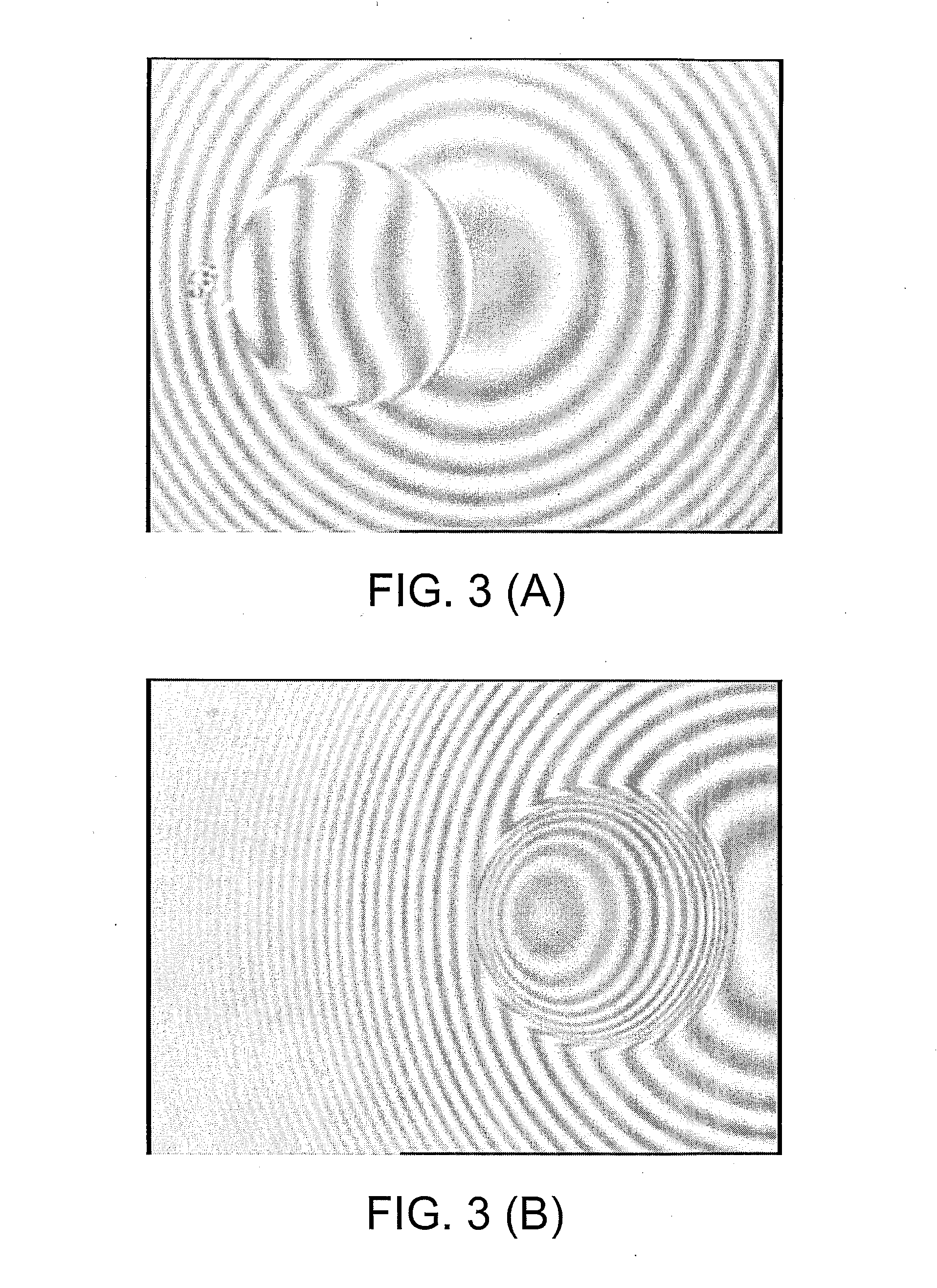

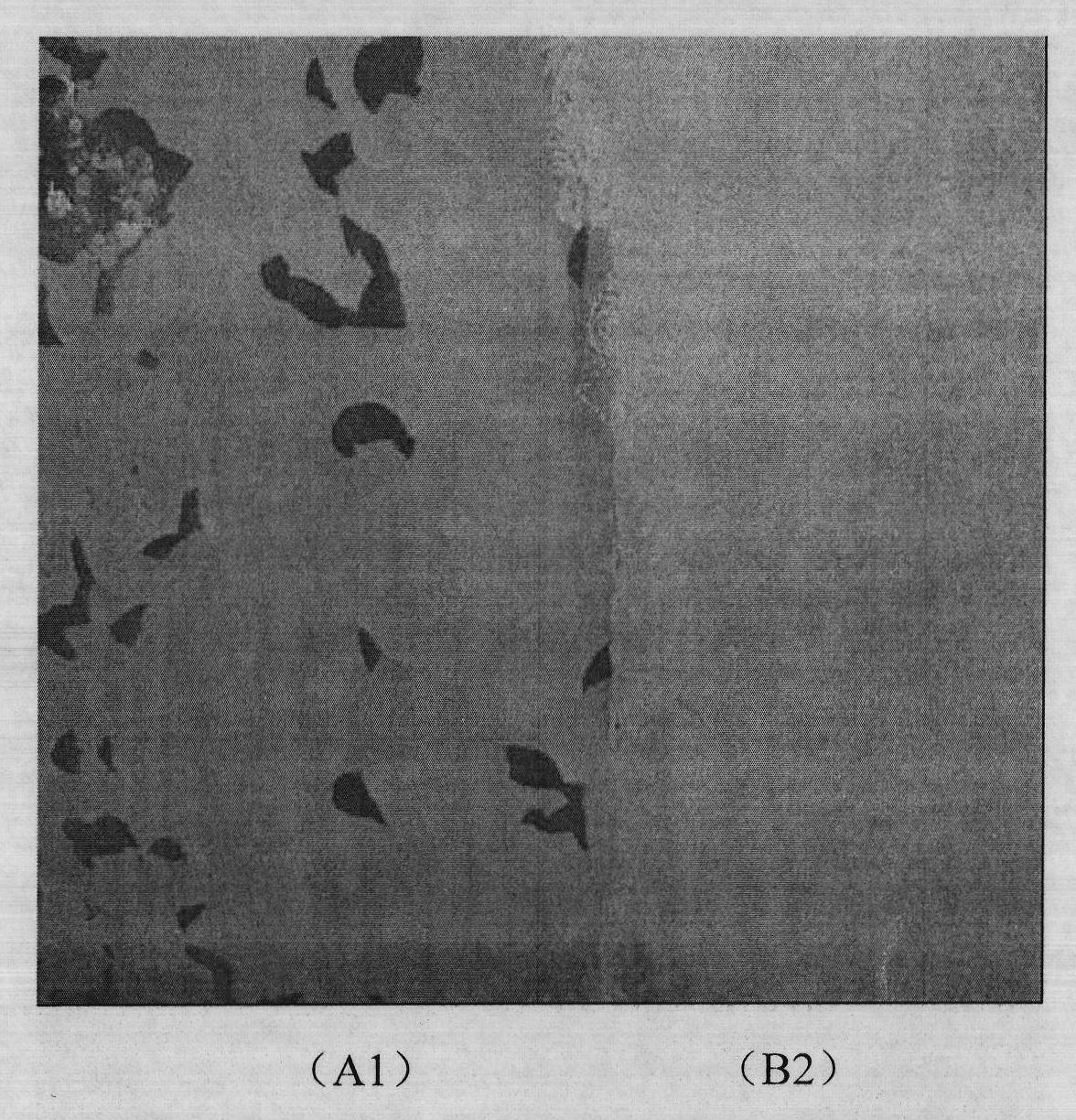

Non-contact optical fiber connector component

InactiveUS20130163930A1Eliminate transmission lossEnhanced couplingCoupling light guidesMetal working apparatusFiberEngineering

An optical fiber connector component that is useful for joining and connecting fiber cables, particularly in the field. A joinder component includes a fiber ferrule coaxially housing a short section of optical fiber with a rearward flanged sleeve that allows the fiber to extend through it. Rearwardly the flanged sleeve extends into a connector body where a fusion splice of the fiber section to the main fiber cable is hidden. Forwardly, the fiber facet and ferrule have anti-reflection coatings and are configured so that the fiber has an output facet recessed slightly relative to the forward polished end surface of the ferrule so that when two ferrule end surfaces are brought together in an adapter, respective fiber facets are slightly spaced apart thereby avoiding wear on fiber facets due to physical contact, yet having good optical communication.

Owner:ARRAYED FIBEROPTICS CORP

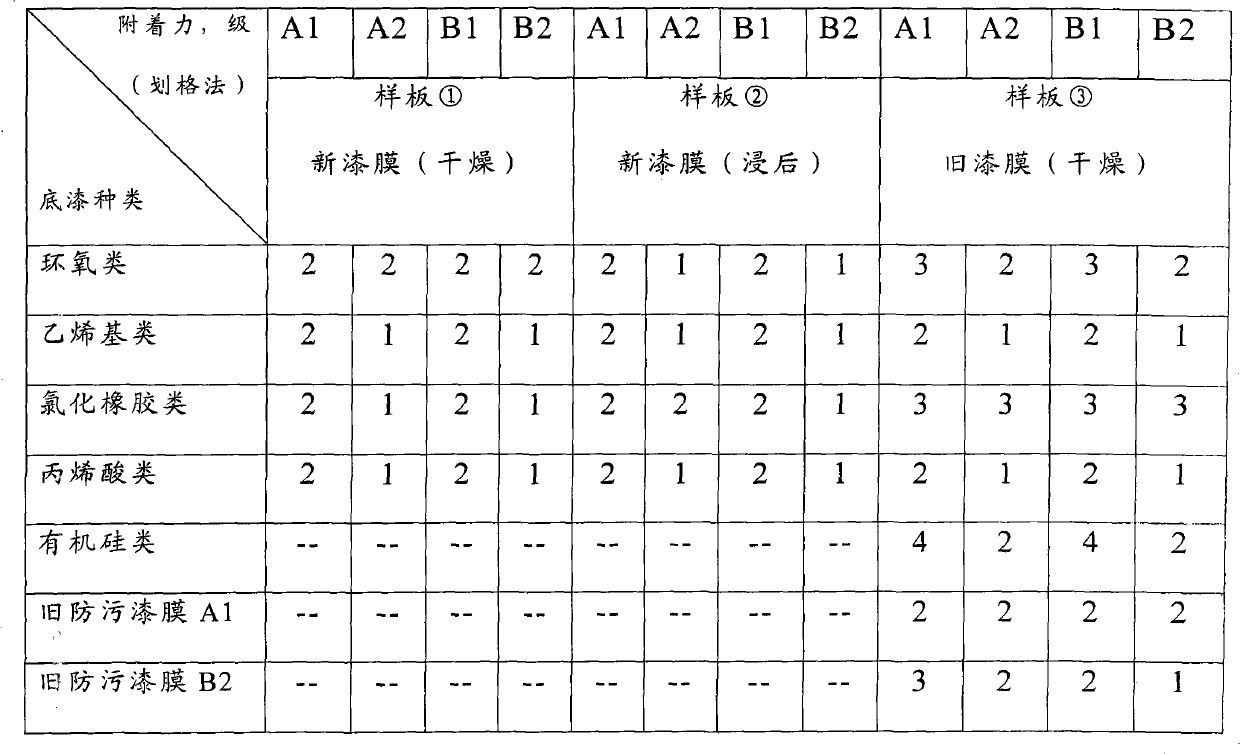

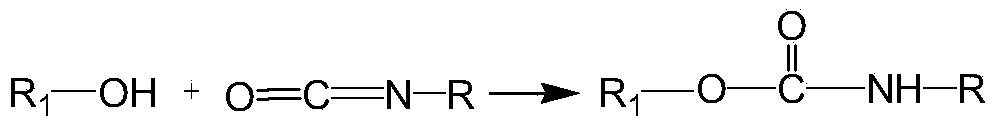

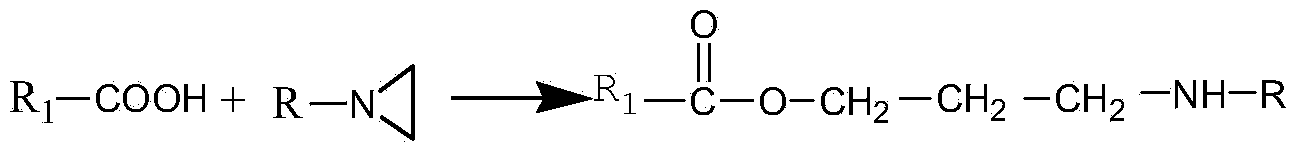

Anti-fouling coating material with excellent compatibility and use thereof

InactiveCN102558989AGood compatibilityImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesAcrylic resinSolvent

The invention relates to the field of anti-fouling coating materials, in particular to an anti-fouling coating material with excellent compatibility. The anti-fouling coating material with excellent compatibility contains liquid bisphenol A epoxy resin, polished acrylic resin, at least two thermoplastic resins for a coating film-forming material, at least two antifouling agents, at least two pigments and fillers, at least two solvents and at least two additives. With the adoption of the anti-fouling coating material with excellent compatibility, the excellent compatibility between a new / old anti-corrosion coating layer and an old antifouling coating layer can be provided, a connecting layer cannot be a coating layer necessary to be coated any more, the processes of coating are reduced, and excellent attachment and antifouling performances are shown after the long-term application of the anti-fouling coating material.

Owner:MARINE CHEM RES INST

Waterborne residual rust antirust coating and preparation method thereof

ActiveCN103897510AExcellent physical and chemical anti-rustFunction increaseAnti-corrosive paintsEpoxy resin coatingsAcrylic resinMechanical equipment

The invention discloses a waterborne residual rust antirust coating and a preparation method thereof. The waterborne residual rust antirust coating is prepared from styrene-acrylic emulsion, water soluble epoxy resin, water soluble acrylic resin, iron oxide red, graphene, zinc oxide, barium sulphate, transforming agents, a transformation accelerator, a levelling agent, a defoaming agent, a dispersing agent, a thickening agent and water. The waterborne residual rust antirust coating contains no organic solvent, is environment-friendly and pollution-free, has the characteristic that bottom and surface are combined and has an excellent physical and chemical antirust and rust transforming function, is applicable to rust protection of the surface of steel with rust, a hard oxidation skin layer or an oil paint film and is also applicable to rust protection of the surface of rust-free steel, the preparation method is simple, construction is easy, two transforming agents are complexed in the waterborne residual rust antirust coating, so that a binding force between the waterborne residual rust antirust coating and rust is increased, the waterborne residual rust antirust coating can be directly brushed and coated on the surface of rusty steel and is applicable to multiple construction ways such as spraying, brushing and showering, the coating cost is low, and the rust protection requirements of urban road facilities, bridges, oil and gas pipelines, engineering mechanical equipment, ships and the like can be met.

Owner:重庆南方漆业有限公司

Aqueous two-component wood varnish and application thereof

The invention discloses an aqueous two-component wood varnish and application thereof. The aqueous two-component wood varnish mainly comprises a main agent and a curing agent. The main agent comprises the following components in percentage by mass: 60-80% of emulsion containing hydroxyl polymer, large than 0 and less than or equal to 6% of polycarbodiimide cross-linking agent. The curing agent mainly comprises the following component in percentage by mass: 80-85% of water dispersible polyisocyanate. By adopting double cross-linking, a varnish film with sensory effect and final performance better than that of a one-component aqueous self-crosslinking paint and an ordinary two-component aqueous paint is obtained; the varnish has the advantages of quick varnish film drying speed, quick performance improving speed, excellent varnish film performance and small dosage of aqueous isocyanate. The aqueous two-component aqueous varnish can be used as surface paint in match with the one-component priming paint which is excellent in initial water resisting property and quick in hardness improvement, thereby achieving the coating effect and performance of the conventional two-component aqueous paint at lower cost.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

Double-component polyurethane coating and production method and construction method

InactiveCN101457120AShorten the coating production cycleHigh fullnessPretreated surfacesPolyurea/polyurethane coatingsLacquerPolyurethane coating

The present invention discloses a bicomponent polyurethane paint and preparation method and execution method thereof, wherein the bicomponent polyurethane paint includes primer, primer fluidifying agent and bicomponent polyurethane PU varnish lacquer that matched with the primer. The bicomponent polyurethane PU paint can be used on HIPS plastic rubber case with complicated structure, and can improve productivity effect and save energy sources, have appearance with high lustrousness and high fullness; the preparation method provides simple producing process and the execution method provides convenient painting.

Owner:DONGGUAN JIAZHUOCHENG CHEM TECH

Protective Coating of Silver

ActiveUS20090004386A1Avoid tarnishingThin coatingJewelleryChemical vapor deposition coatingAtomic layer depositionFilm-coated tablet

In the method, silver is protected against tarnishing using an Atomic Layer Deposition method. In the Atomic Layer Deposition method, a thin film coating is formed 5 on the surface of silver by depositing successive molecule layers of the coating material. For example aluminium oxide (Al 2O3) or zirconium oxide may be used as the coating material.

Owner:BENEQ OY

Metal corrosion resistant coating and its manufacturing process

InactiveCN1789360AGood weather resistanceAccelerated corrosionAnti-corrosive paintsBituminous coatingsViscosityMetal

The invention discloses long-acting metal anticorrosive paint used in metal member and equipment and preparing method, which is made by stirring and grinding coal tar pitch, organic polymolecularity resin, antirusting agent and auxiliary agent and then adding curing agent after adjusting viscosity. The metal anticorrosive paint possesses good weatherability and corrosion resistance, and can be used in metal member, metal member, building, underground engineering, ship and other preservative engineering.

Owner:刘赞成

Method of forming a sugarless coating on chewing gum

InactiveUS20050008747A1Cost reductionReduce painting costChewing gumAnimal housingChemistryChewing gum

A method of forming a sugarless coating on chewing gum cores comprises: providing chewing gum cores; providing a coating syrup comprising one or more sugarless sweeteners; providing a dusting mix comprising about 20% to about 60% of a bulk sweetener selected from the group consisting of malitol, hydrogenated isomaltulose, lactitol, sorbitol and mixtures thereof and about 40% to about 80% filler; and applying a plurality of layers of the coating syrup and a plurality of layers of the dusting mix to the chewing gum cores to form a sugarless coating on the gum cores.

Owner:WM WRIGLEY JR CO

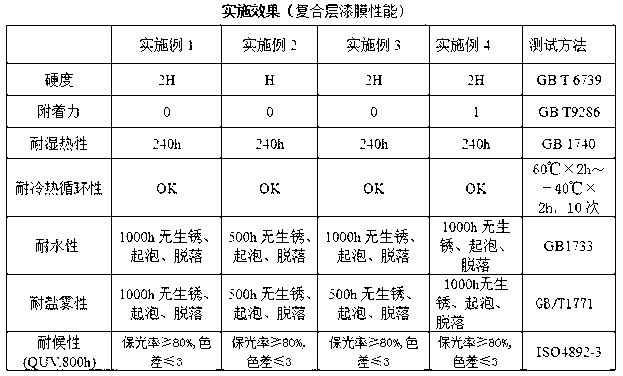

High-gloss cathodic electrophoretic paint and preparation method thereof

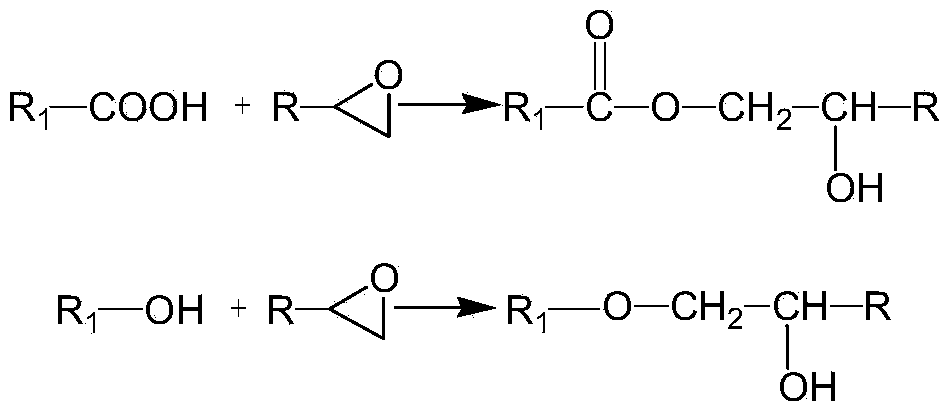

ActiveCN101851456AHigh glossThe ratio is scientific and reasonablePaints for electrolytic applicationsEpoxy resin coatingsEpoxyEmulsion

The invention relates to high-gloss cathodic electrophoretic paint and a preparation method thereof. The paint comprises emulsion and a color paste; the mass percent of the emulsion is 36 to 40 percent; and the mass percent of the color paste is 5 to 6 percent. The formula of the emulsion takes the mass percent as the unit and comprises 20 to 60 percent of amine modified epoxy resin, 5 to 20 percent of isocyanate sealing element, 30 to 60 percent of deionized water, 0.3 to 0.6 percent of emulsifying agent and 0.3 to 0.6 percent of formic acid. The color paste comprises 10 to 40 percent of quaternary ammonium salt dispersion resin, 35 to 45 percent of deionized water, 5 to 8 percent of dibutyl tin oxide, 10 to 20 percent of kaolin, 5 to 15 percent of carbon black and 2 to 5 percent of emulsifying agent. The method comprises the following step of: after mixing the color paste, the emulsion and the deionized water according to the proportion of 1:7:11, carrying out electrophoresis coating for 3 to 4min at the construction voltage of 200V after curing for 48 to 50h at the temperature of 28 to 30 DEG C. The invention has scientific and reasonable mixture ratio, high gloss of a coated film, good decoration property, high safety and environmental protection.

Owner:湖南伟邦汽车涂料有限公司

Coating process applying water-based paint to metal parts of construction machinery

InactiveCN102974520AMeet the use requirementsGood lookingAnti-corrosive paintsPolyurea/polyurethane coatingsProcess engineeringMechanic - metal

The invention discloses a coating process applying water-based paint to metal parts of construction machinery. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the metal parts of the construction machinery. The coating process applying the water-based paint to the metal parts of the construction machinery enables the water-based paint to be correctly used for the coating of the metal parts of the construction machinery, not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

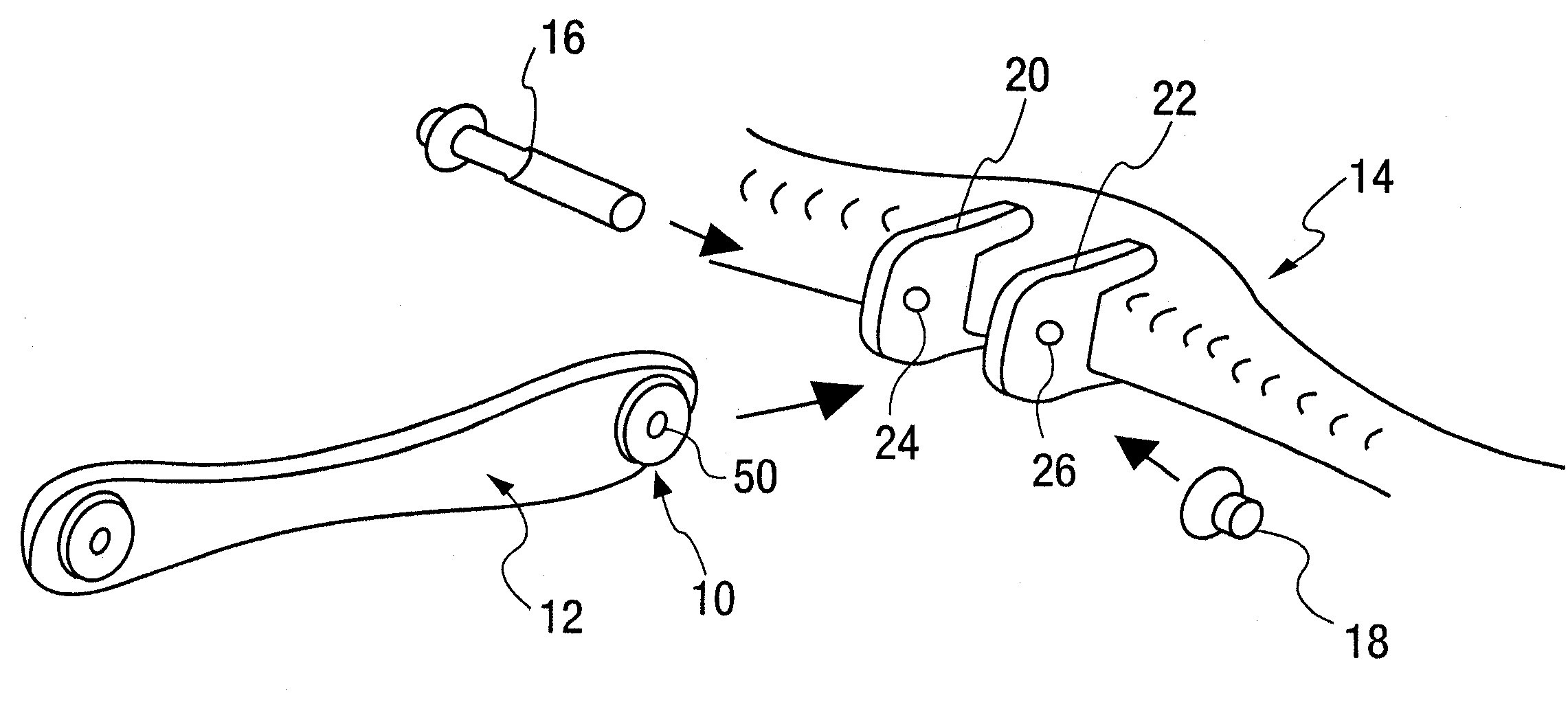

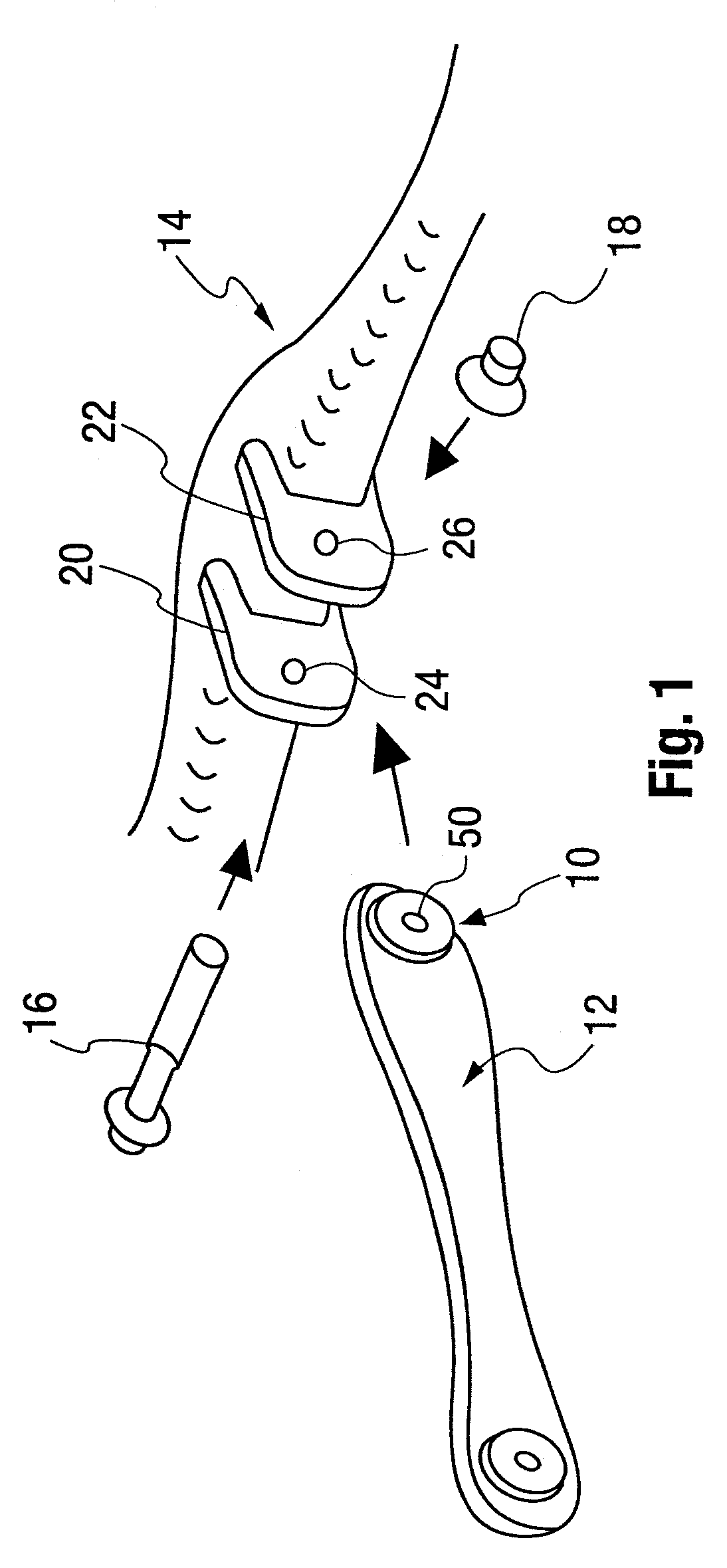

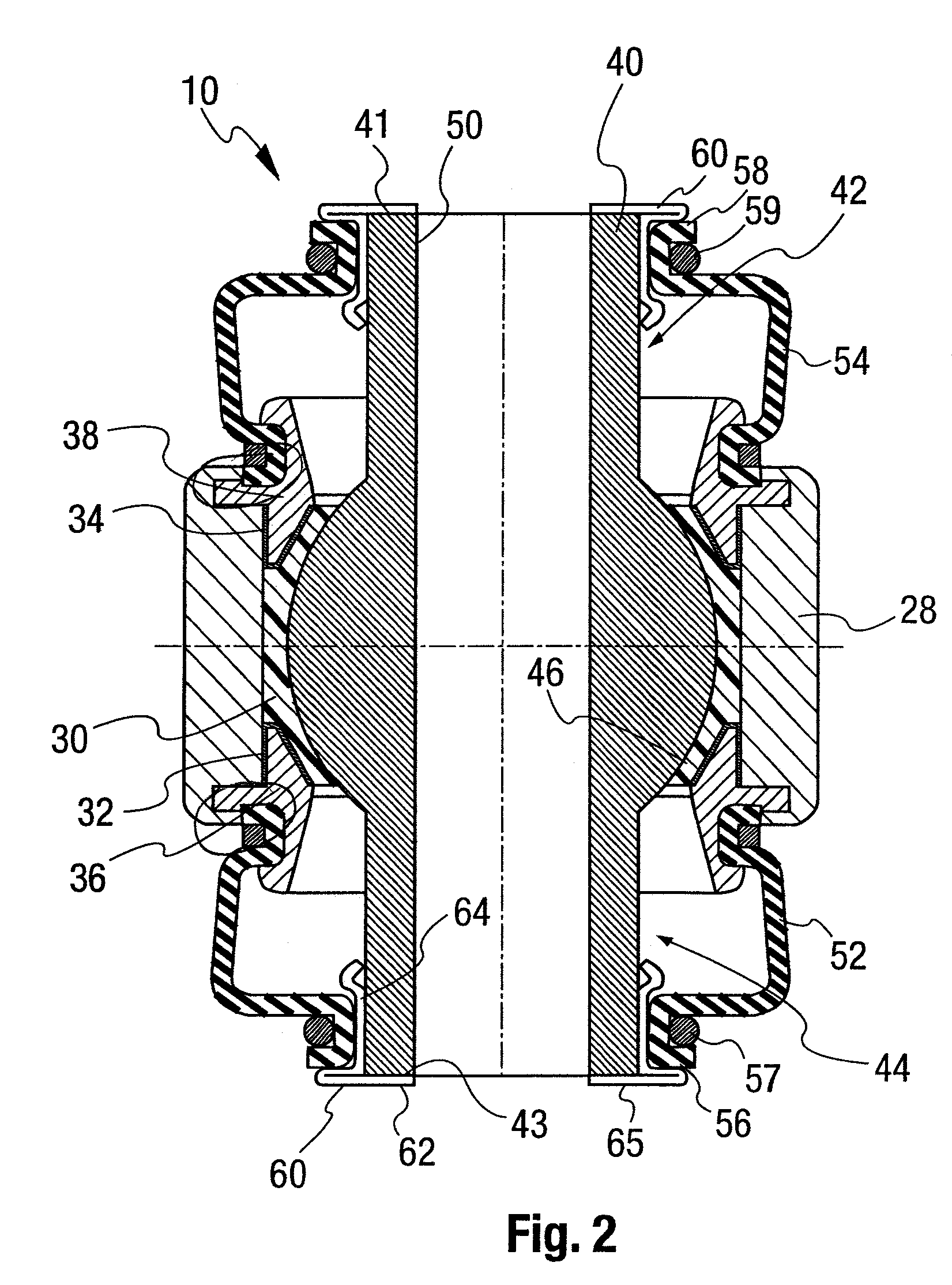

Cross axis ball and socket joint with sealing ring for cross axis sleeve ends

InactiveUS7438493B2Simple designRugged in constructionEngine sealsPipeline expansion-compensationTransverse axisBearing surface

A ball joint, is provided in the form of a cross axis joint with a housing, a bearing shell in the housing and a ball sleeve. The ball sleeve includes a ball portion with a bearing surface cooperating with the bearing shell and a first pivot pin and a second pivot pin extending from said ball portion in an axial direction. The ball sleeve has an inner surface defining a through hole (50) for receipt of a connection bolt. The first pivot pin has a first end with a first outer surface (42) and a first annular end face (41) and the second pivot pin has a second end with a second outer surface (44) and a second annular end face (43). Sealing rings (60, 60′, 60″, 90, 95) are provided, each having a first axially extending portion extending along the first outer surface and having a sealing area outer surface defining a bellows seal seat (64, 98) and a radially extending portion extending along the end face. Each bellows seal (52, 54) is connected to the housing at one end and connected to said bellows seal seat (64, 98) at another end.

Owner:ZF FRIEDRICHSHAFEN AG

Coating process applying water-based paint to cast iron parts

InactiveCN102974518AMeet the use requirementsGood lookingPretreated surfacesAnti-corrosive paintsCast ironCoating

The invention discloses a coating process applying water-based paint to cast iron parts. The coating process is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the cast iron parts of machinery. The coating process applying the water-based paint to the cast iron parts enables the water-based paint to be correctly used the coating of the cast iron parts of the machinery, and not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and the physical and chemical performance of the coating process, and prolongs service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

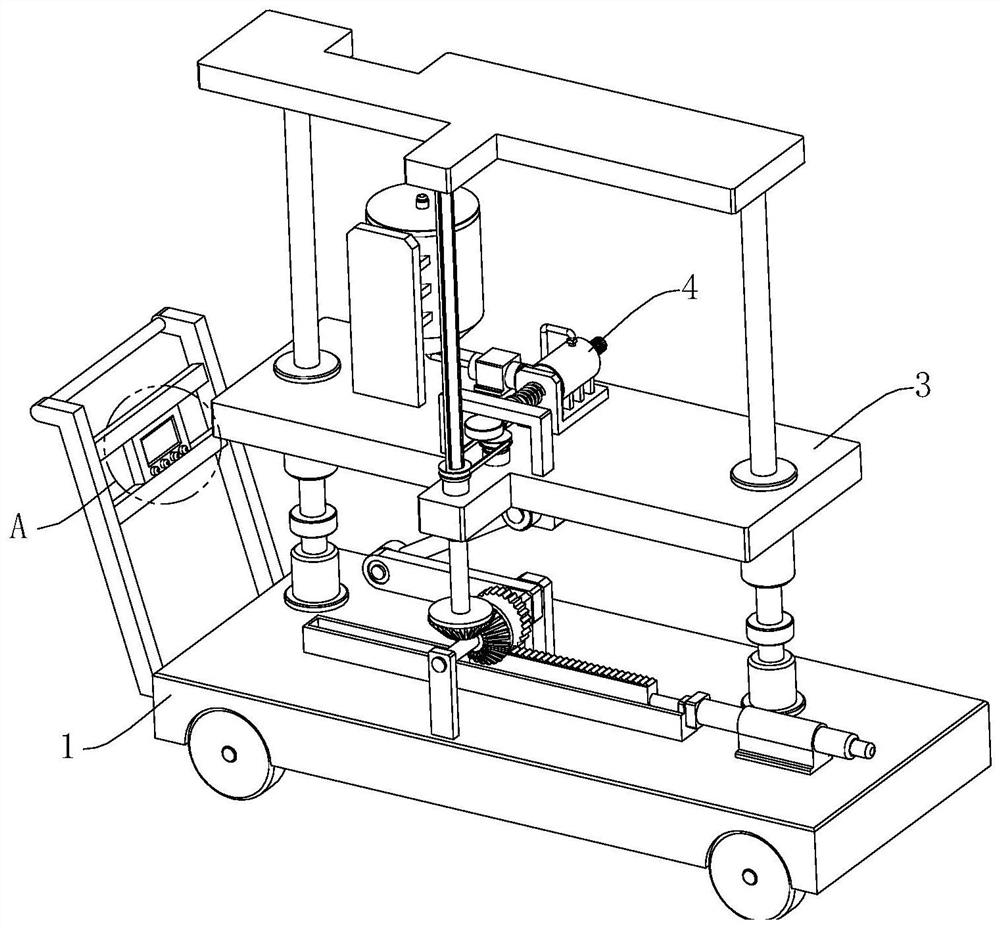

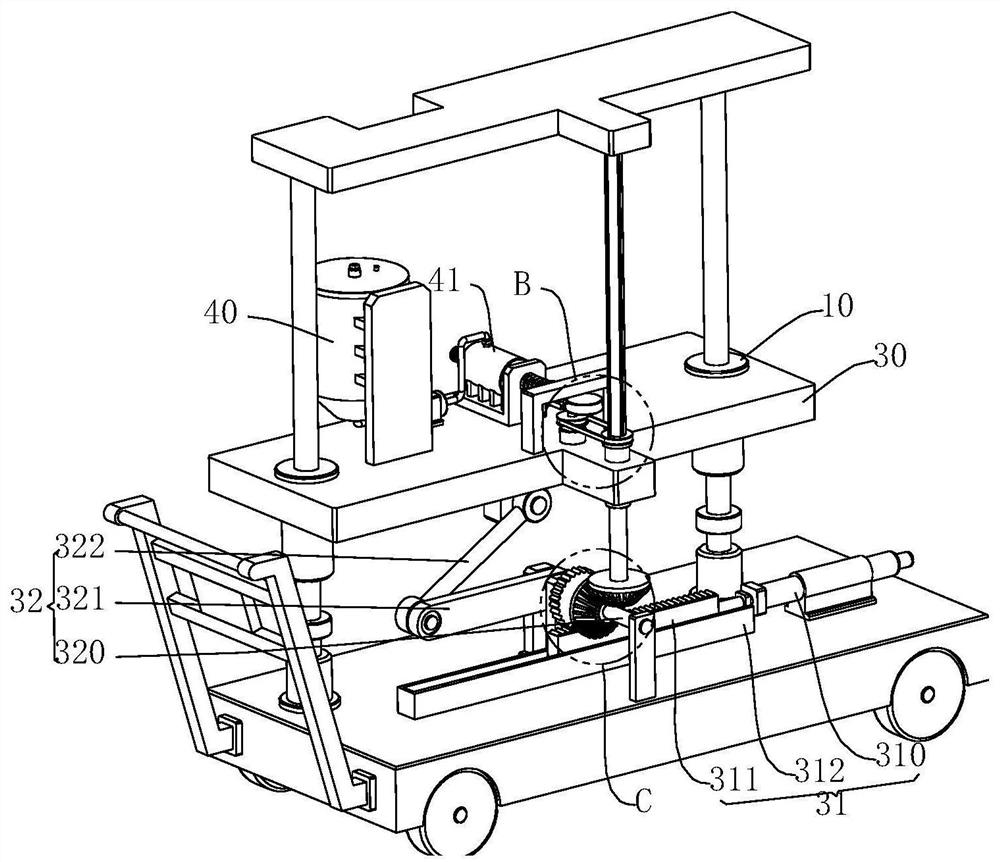

Painting device and method with lifting and spraying-adaptive for indoor decoration

ActiveCN111841927ASpray evenlyAvoid wastingBuilding constructionsLiquid spraying apparatusStructural engineeringAerosolization

The invention relates to the field of decoration devices, in particular to a painting device and method with lifting and spraying-adaptive for indoor decoration. The device comprises a platform cart,and further comprises a controller, a lifting mechanism and a spraying mechanism, wherein the lifting mechanism is arranged at the top of the platform cart to support lifting of the spraying mechanism; the lifting mechanism comprises a lifting plate, a pushing assembly and a jacking assembly; the spraying mechanism is arranged at the top of the lifting plate for painting the indoor wall surface; and the spraying mechanism comprises a storage barrel, a material receiving pipe, an atomizing nozzle, an extrusion assembly and a conveying assembly, wherein the pushing assembly and the conveying assembly are electrically connected with the controller. According to the painting device and method with lifting and spraying-adaptive for the indoor decoration, the wall surface can be synchronously sprayed when the atomizing nozzle rises, so that the power consumption is small, and in the lifting interval, spraying is in an on-off state, and waste of paint materials is effectively avoided; and meanwhile, when the air temperature is low, the anti-curing function is achieved, and thus the paint spraying efficiency is improved.

Owner:银丰工程有限公司

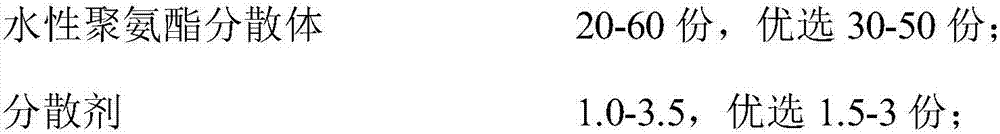

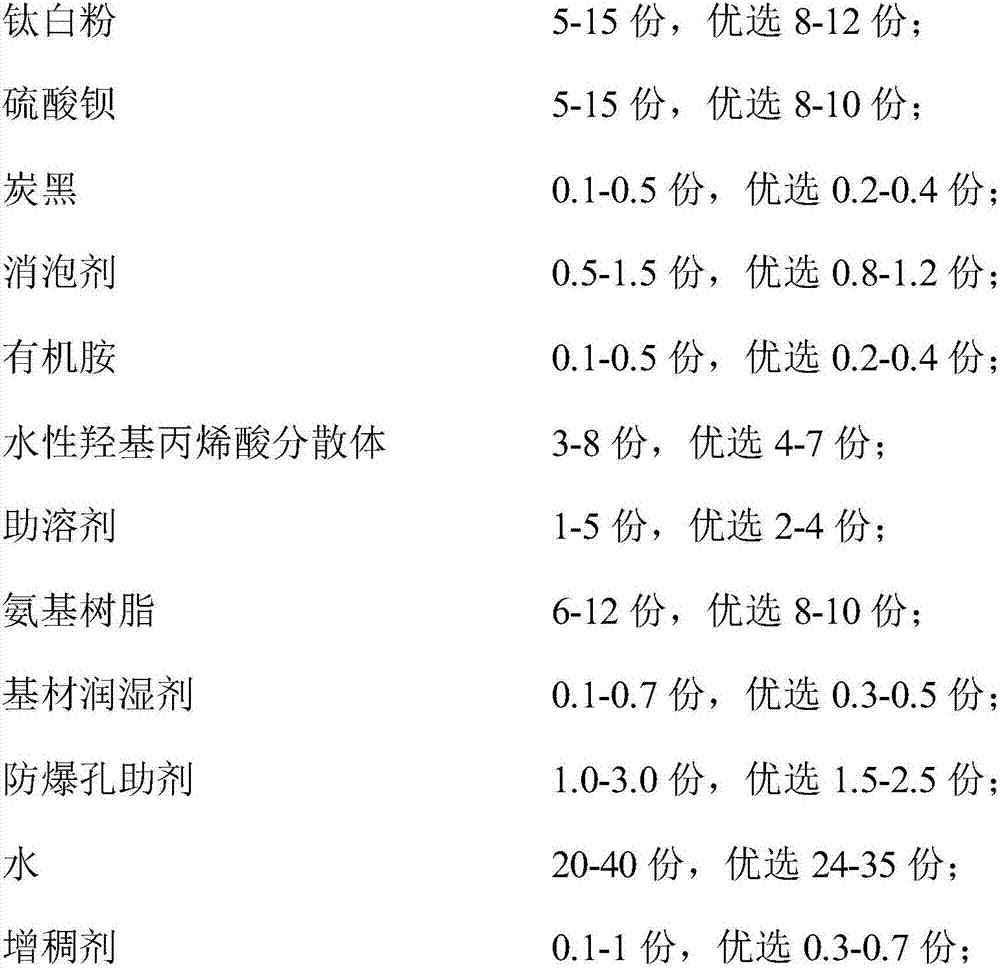

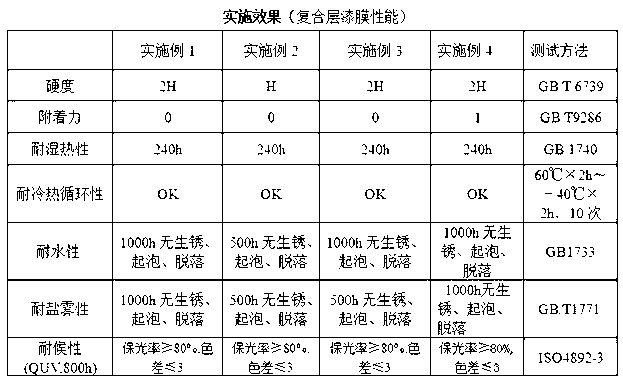

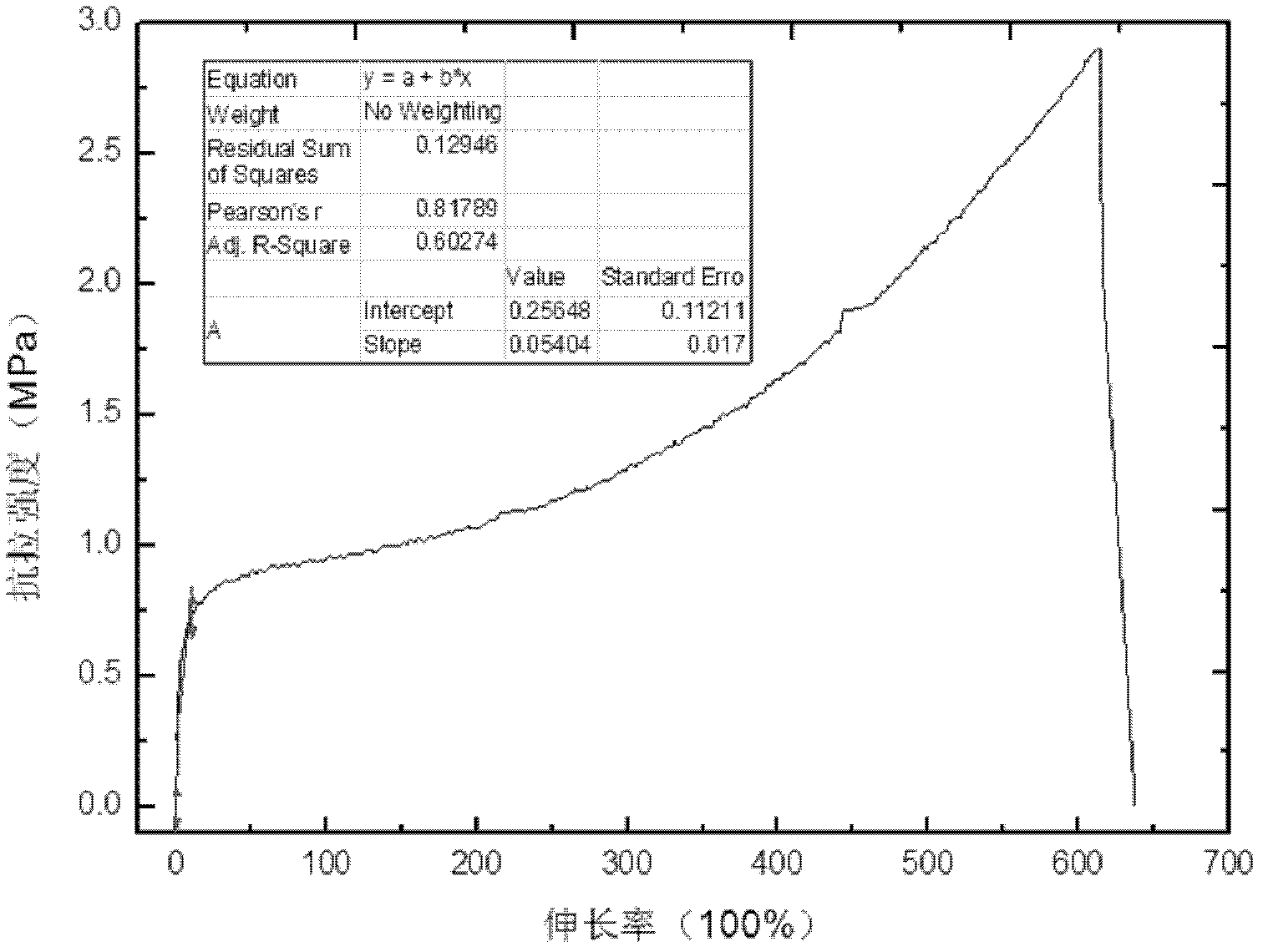

A waterborne automobile coating composition and a preparing method and applications thereof

InactiveCN107099238AImprove stone impact resistanceIncreased chemical resistancePolyurea/polyurethane coatingsPolyesterCooking & baking

A waterborne automobile coating composition is provided. The composition is prepared from, by weight, 20-60 parts of a waterborne polyurethane dispersoid, 1.0-3.5 parts of a dispersing agent, 5-15 parts of titanium dioxide, 5-15 parts of precipitated barium sulfate, 0.1-0.5 part of carbon black, 0.5-1.5 parts of a defoamer, 3-8 parts of a waterborne hydroxy acrylic acid dispersoid, 0.1-0.5 part of an organic amine, 6-12 parts of amino resin, 0.1-1 part of a substrate wetting agent, 1-3 parts of an explosion-proof auxiliary agent, 1-5 parts of a cosolvent, 20-40 parts of deionized water and 0.1-1 part of a thickening agent. The waterborne polyurethane dispersoid is a compound of a polycarbonate-type waterborne polyurethane dispersoid having hydroxy groups and a polyester-type waterborne polyurethane dispersoid preferably. The coating composition has excellent resistance to rock crash, and can meet requirements on an automobile coating process including three times of coating and one time of baking, namely a 3C1B process, in the field of environment protection.

Owner:WANHUA CHEM GRP CO LTD

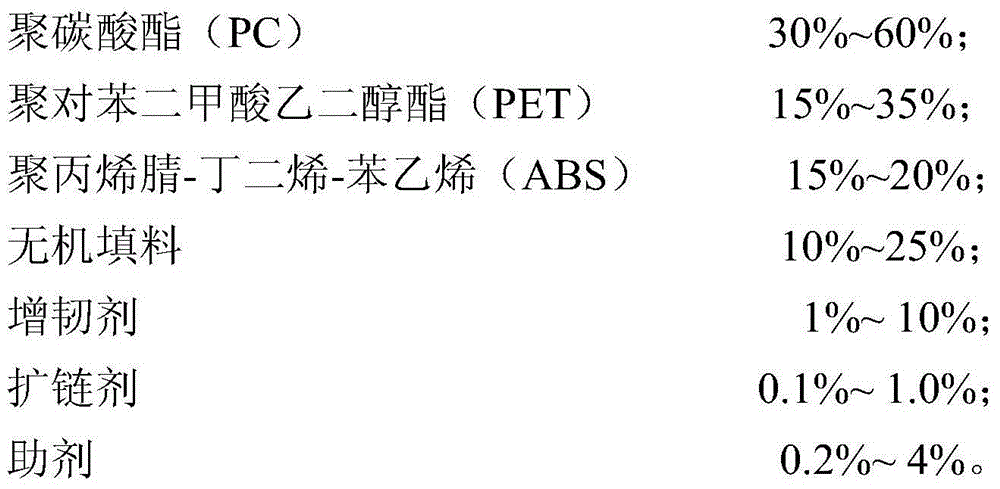

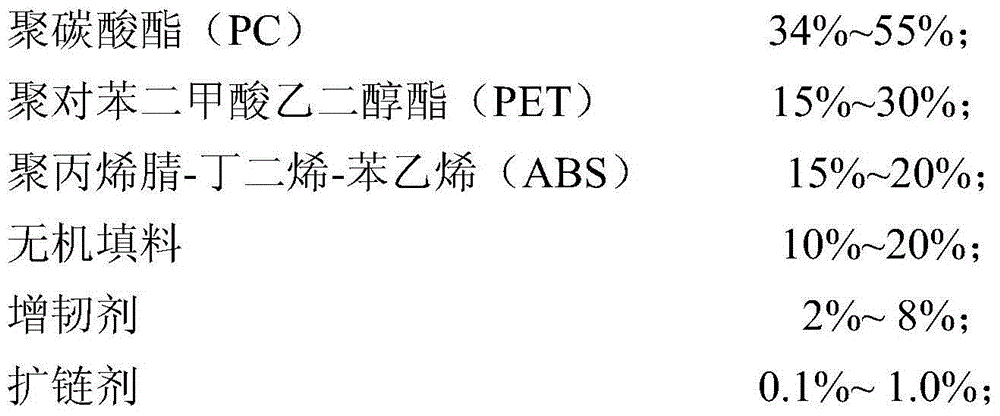

PC/PET (polycarbonate/polyethylene terephthalate) alloy material and preparation method thereof

ActiveCN104559110AImprove toughnessTo achieve the perfect effectPolyethylene terephthalate glycolAlloy

Owner:CGN JUNER NEW MATERIALS +1

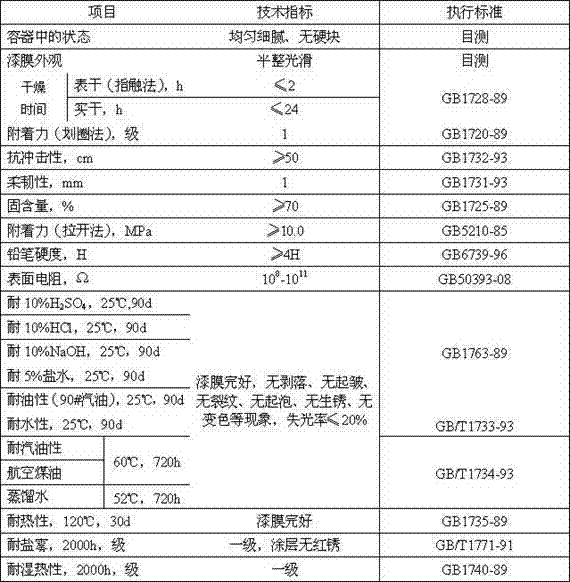

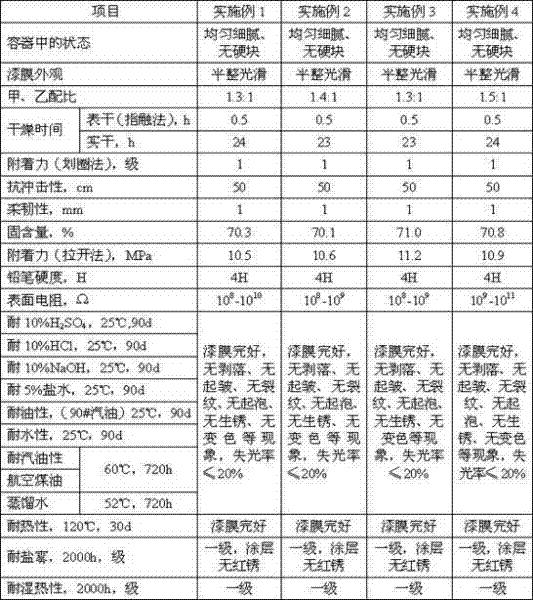

High-solid-content superhigh-corrosion-resistant water-based epoxy static conductive paint and preparation method thereof

ActiveCN102533061ALow water absorptionLow viscosityAnti-corrosive paintsEpoxy resin coatingsWater basedEpoxy

The invention discloses a high-solid-content superhigh-corrosion-resistant water-based epoxy static conductive paint and a preparation method thereof. The high-solid-content superhigh-corrosion-resistant water-based epoxy static conductive paint comprises a component A and a component B, wherein the component A comprises deionized water, wetting dispersant, a foam inhibitor, a flash corrosion inhibitor, a water-based epoxy curing agent, a film-forming cosolvent, conductive mica powder, a corrosion inhibitor, a defoaming agent, a flatting agent and a thickening agent; and the component B comprises modified epoxy resin, a conductive additive, an anti-settling agent, an amphoteric dispersant, an amphoteric defoaming agent, a diluents and a filler. The high-solid-content superhigh-corrosion-resistant water-based epoxy static conductive paint is smooth and hard in paint film, high in compactness, excellent in physical and mechanical properties such as adhesive power, high in heat resistance and water resistance, superhigh in corrosion resistance, and stable in conductivity; the painting requirement can be met by forming a film at one step; the paint is low in cost and strong in market competitiveness; and the deionized water serves as a solvent, so the paint is non-toxic, harmless, safe and environment-friendly.

Owner:洛阳双瑞防腐工程技术有限公司

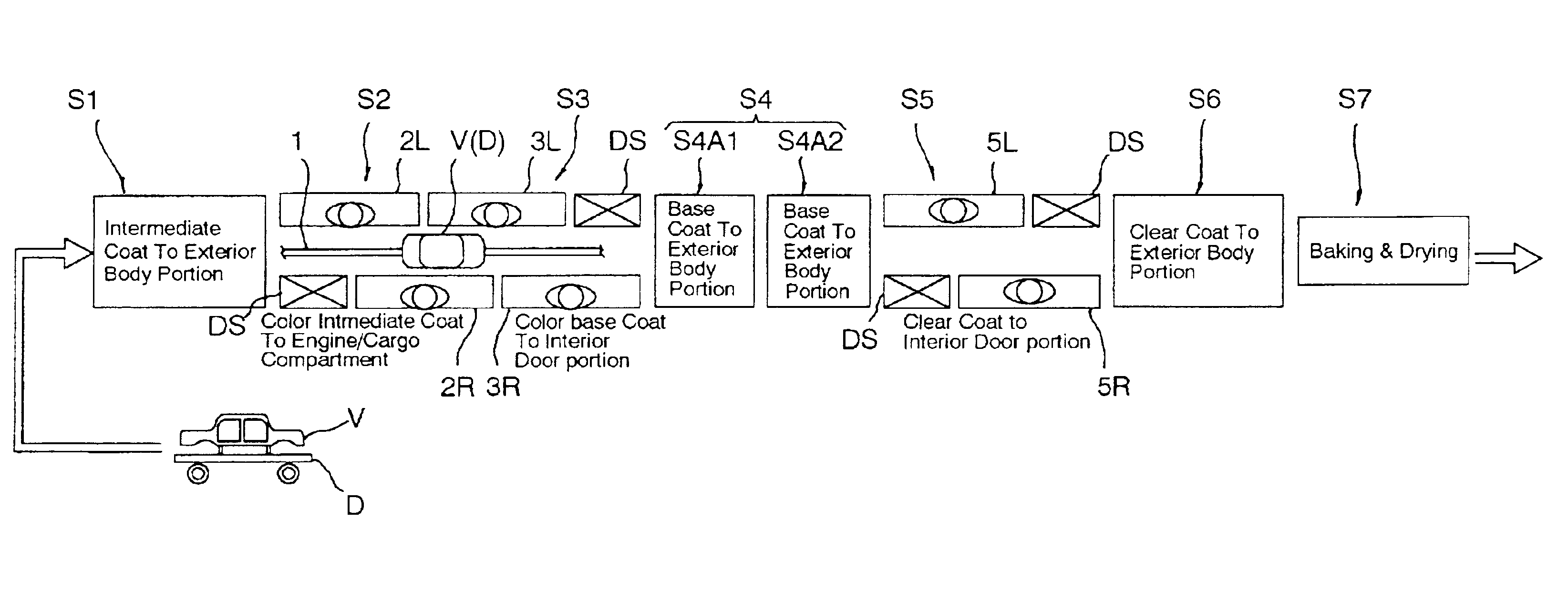

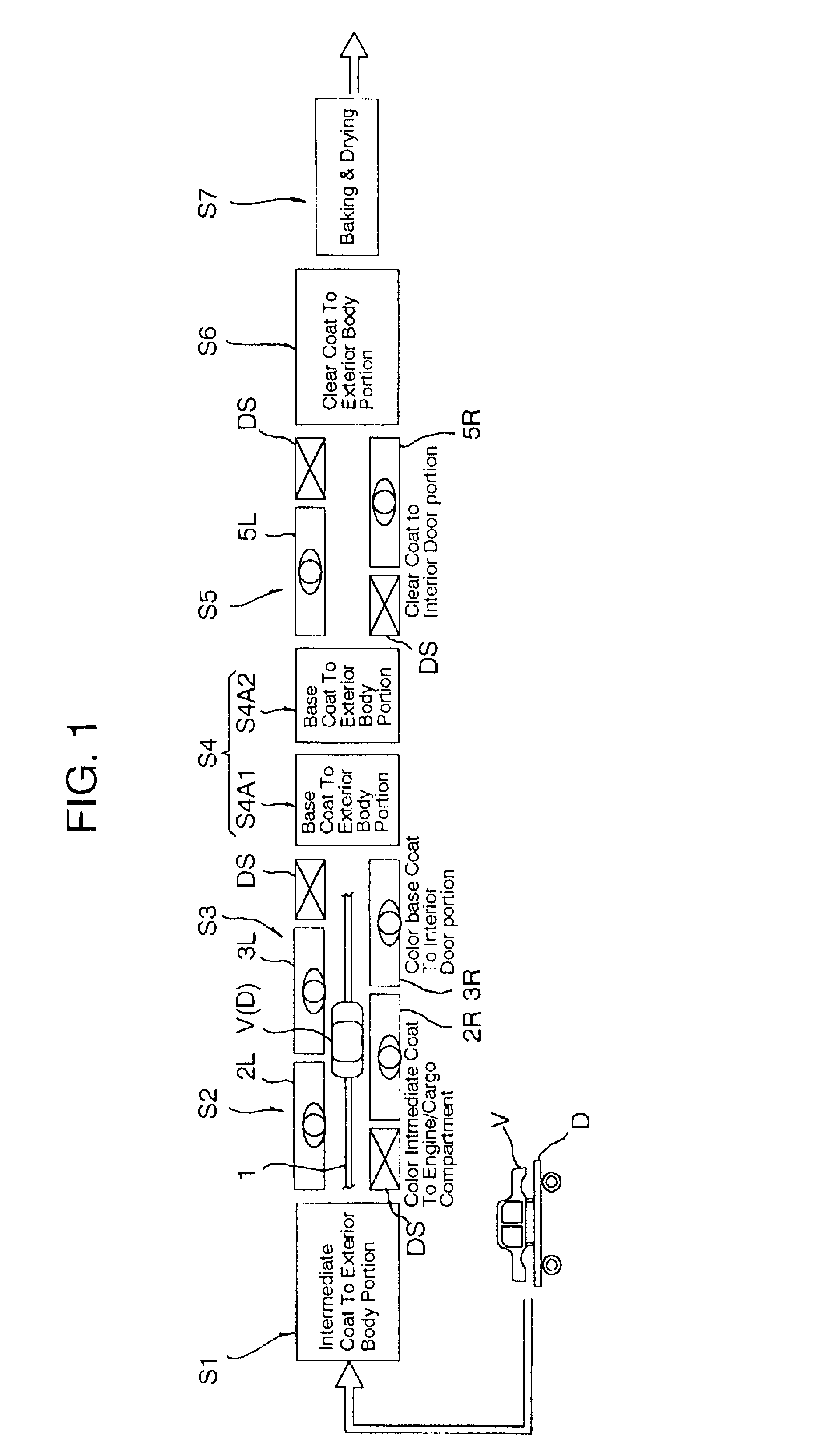

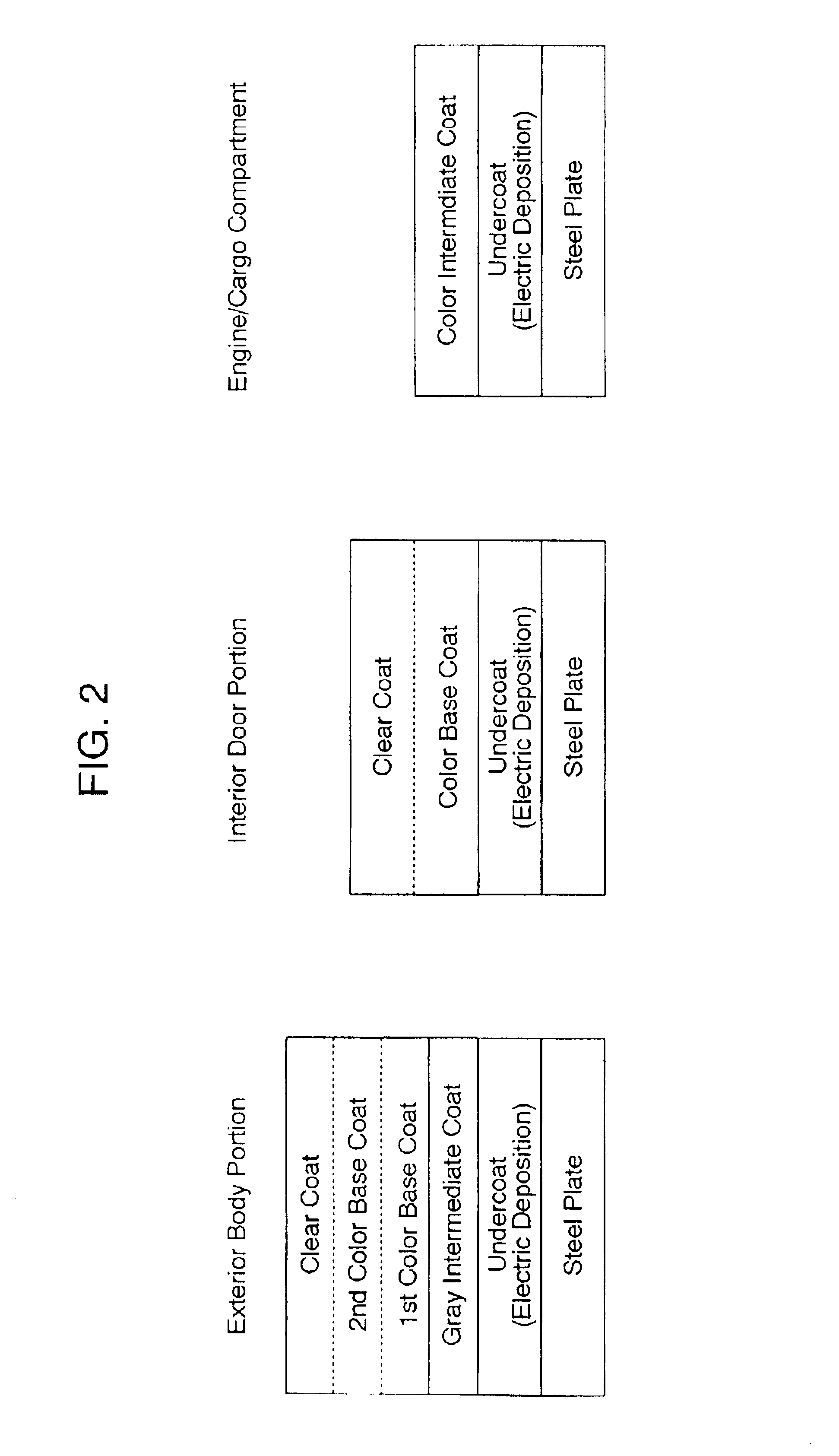

Process for painting vehicle body

InactiveUS6777032B2Cost advantageImprove design flexibilitySpraying apparatusPretreated surfacesEngineering

Painting a vehicle body comprising an exterior body portion, engine and cargo compartments and an interior door portion all of which are applied with an undercoat is completed by applying a gray intermediate coat to the exterior body portion, an intermediate coat to the engine and / or cargo compartments, a base coat comprising a single color base coat or a color base coat and a bright base coat to the interior door portion, a base coat comprising either a single color base coat or a color base coat and a bright base coat to the exterior body portion, a clear coat to the interior door portion and a clear coat to the exterior body portion in this order, each of the applications of coat being performed while coat layers formed preceding the each application of coat remain wet, and then baking and drying the coat layers all together.

Owner:MAZDA MOTOR CORP

Technique method of coating powder on hot-rolled plate no-cavity vehicle parts

InactiveCN101391250ALess investmentReduce energy consumptionPretreated surfacesCoatingsPeeningWeld seam

Disclosed is a technological method of powder coating of non-cavity automobile parts of hot rolled plates, comprising the process steps: 1. surface oil removing of rolled plate parts; 2. blow drying of water; 3. shot (or sand) blasting or throwing; 4. blowing-off of shot or sand; 5. electrostatic powder coating; 6. powder coating solidification; and 7. cooling. The invention brings forward a novel process for immediately implementing the powder coating to the hot rolled plate automobile parts with non-cavity structures after using an air supply to clean the surface of a workpiece after the rust removing through shot (sand) blasting, aiming at the characteristics of the surface state after the shot (sand) blasting of the hot rolled plate automobile parts and the adoption of powder coating, and reasonably controls the thickness of powder coating according to the anticorrosion quality requirements and the surface roughness of the coated workpiece, thereby simplifying the pre-painting surface treatment process, reducing the coating equipment investment, energy consumption and discharge of waste water and waste residues, meanwhile solving the problem that poor conductivity at the welding seams of the parts influences the coating quality.

Owner:CHINA FIRST AUTOMOBILE

Coating process applying water-based paint to metal parts of engineering machinery

InactiveCN102974522AMeet the use requirementsGood lookingAnti-corrosive paintsPolyurea/polyurethane coatingsMetallurgyEngineering

The invention discloses a coating process applying water-based paint to metal parts of engineering machinery. The coating process applying the water-based paint to the metal parts of the engineering machinery is characterized in that water-based anti-corrosion priming paint and waterborne polyurethane texture finish paint are combined and used on base materials of the metal parts of the engineering machinery. The coating process applying the water-based paint to the metal parts of the engineering machinery enables the water-based paint to be correctly used for the coating of the metal parts of the engineering machinery, and not only solves harm and potential safety hazards brought about by a traditional coating process to a forklift, but also improves the protecting performance and physical and chemical performance coating process, and prolongs the service life of the forklift.

Owner:GUANGZHOU QINGTIAN INDAL +1

Method and apparatus for airfoil electroplating, and airfoil

InactiveUS20060275624A1Reduce variationReduce plate thicknessCell componentsCurrent insulating devicesElectroplatingAerospace engineering

A chemically-nonreactive, electrically-nonconductive shield having a recess generally corresponding to the shape of an airfoil portion to be positioned therein. The shield is submerged in an electroplating solution in a plating tank. The recess in the shield is sized to provide a predetermined, closely-spaced apart clearance between walls of the recess and the adjacent airfoil portion sufficient to reduce the flow rate of an electrolyte present in the electroplating solution between walls of the recess and the adjacent airfoil portion. The clearance permits control of the amount of electroplating that is deposited on the portion of the airfoil that is positioned in the recess in relation to portions of the airfoil not positioned in the recess.

Owner:GENERAL ELECTRIC CO

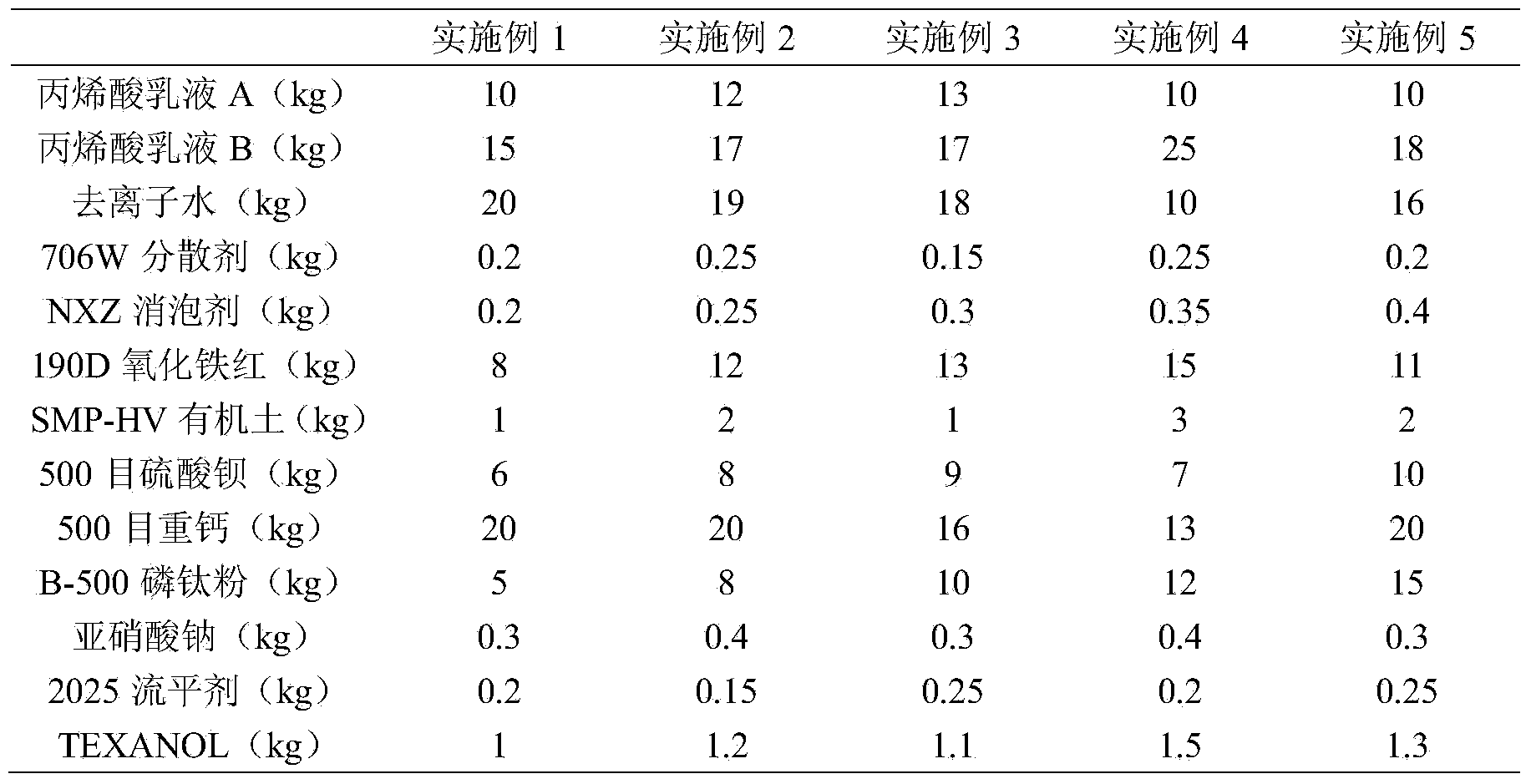

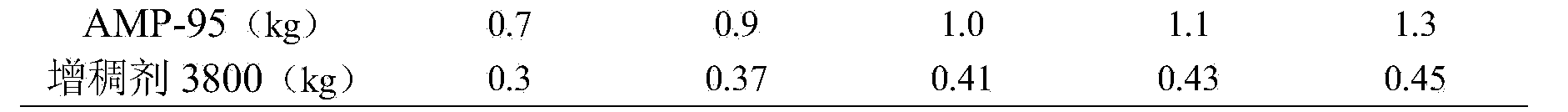

Water-based antirust paint for steel structure as well as production method thereof

The invention provides a water-based antirust paint for a steel structure. The water-based antirust paint comprises the following components in parts by weight: 25-35 parts of an acrylic emulsion, 3-15 parts of pigment, 5-15 parts of an antirust agent, 15-25 parts of filler, 0.15-0.25 part of a flatting agent, 0.15-0.25 part of a dispersant, 0.2-0.4 part of a defoamer, 1.0-1.5 parts of a film-forming agent, 0.3-0.4 part of an anti-flash rust agent, 10-20 parts of deionized water, 0.7-1.3 parts of a neutralizer and 0.3-0.45 part of a thickener. The water-based antirust paint provided by the invention is fast in drying speed: 5-10 minutes for surface dry and within 6 hours for hard dry, so that the coating production efficiency is enhanced. When a product is coated, the paint is just diluted by tap water, so that the coating cost is lowered. The VOC (Volatile Organic Compounds) content is not greater than 85, so that damage to human body during coating is reduced. The salt spray resistance property of the paint can reach over 500 hours, and the corrosion resistance of the paint is strong.

Owner:JIANGSU HUAXIA PAINT MAKING

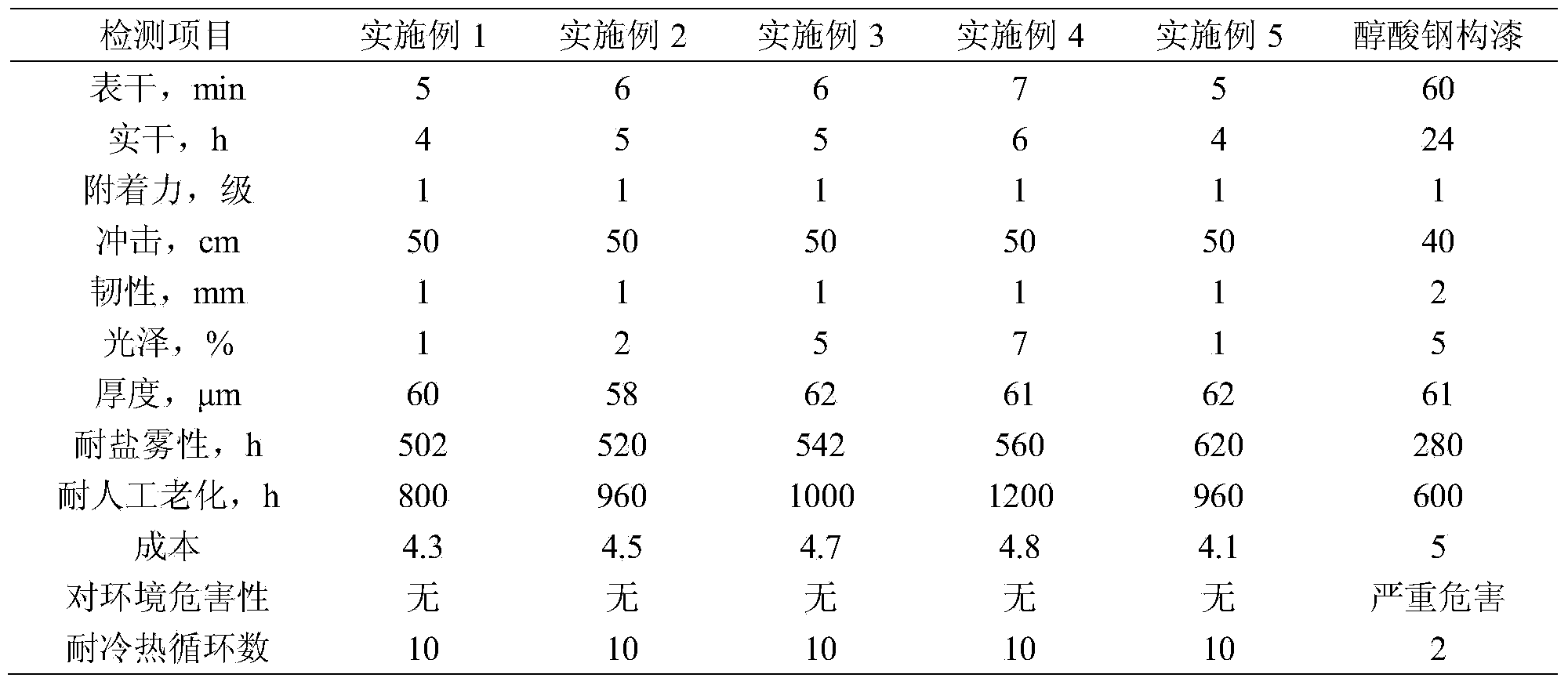

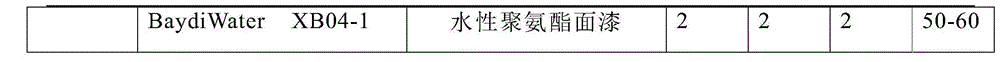

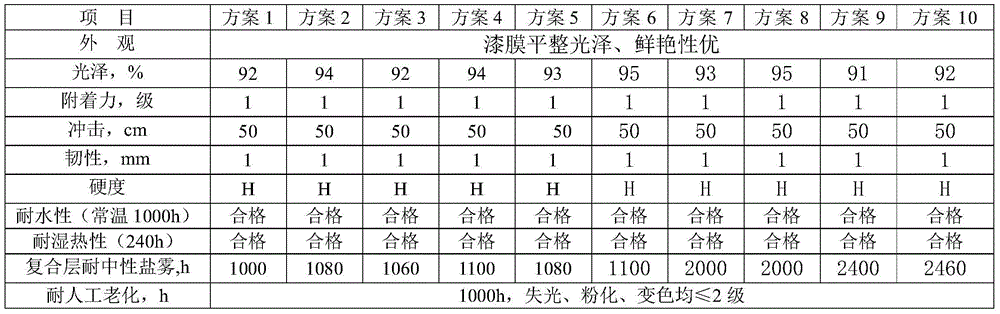

Coating of water-based paint applied to engineering machinery product

InactiveCN104449233ASolve various requirements of environmental protectionImprove performanceLiquid surface applicatorsPolyurea/polyurethane coatingsEpoxyWater based

The invention provides coating of a water-based paint applied to an engineering machinery product; coating of the water-based paint provided by the invention comprises primers, intermediate paints and finishing paints; the primers comprise single-component primers and double-component primers; the single-component primers comprise a water-based epoxy ester primer, a water-based acrylic acid primer, a water-based polyurethane primer, a water-based inorganic silicate primer and a water-based inorganic zinc-enriched primer (single component); the double-component primers comprise a water-based epoxy primer, a water-based epoxy zinc-enriched primer, a water-based polyurethane acrylate primer and a water-based inorganic zinc-enriched primer; all the intermediate paints are double-component intermediate paints comprising a water-based epoxy mica iron intermediate paint and a water-based polyurethane acrylate intermediate paint; the finishing paints comprise single-component finishing paints and double-component finishing paints; the single-component finishing paints comprise a water-based acrylic acid finishing paint and a water-based polyurethane finishing paint; and the double-component finishing paints comprise a water-based polyurethane acrylate finishing paint. According to the invention, various environment-friendly requirements of the novel environment-friendly method to coating products are solved; simultaneously, the comprehensive properties of engineering machinery required by adopting the traditional oily coating are also optimized; and the coating cost is greatly reduced.

Owner:成都拜迪新材料有限公司

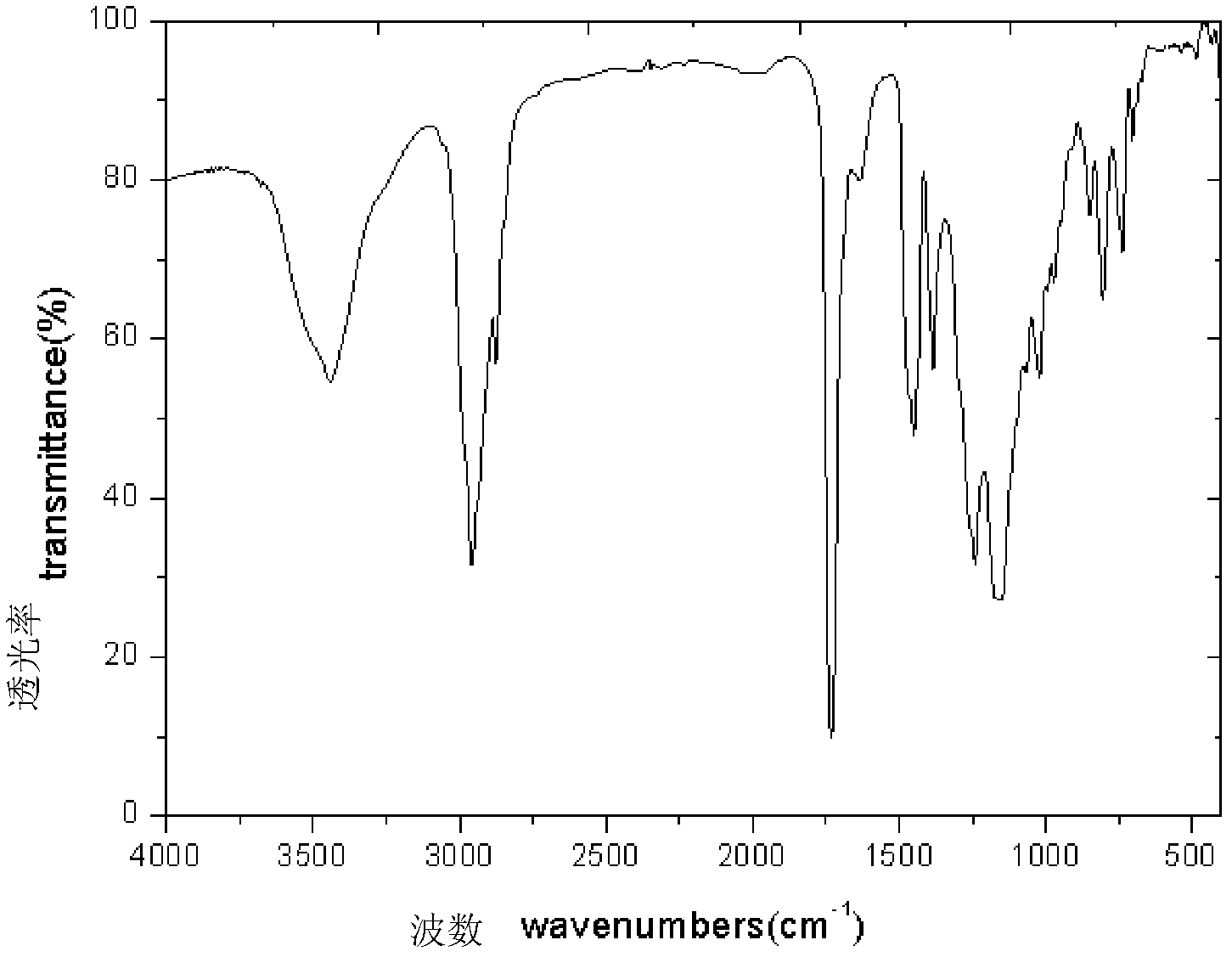

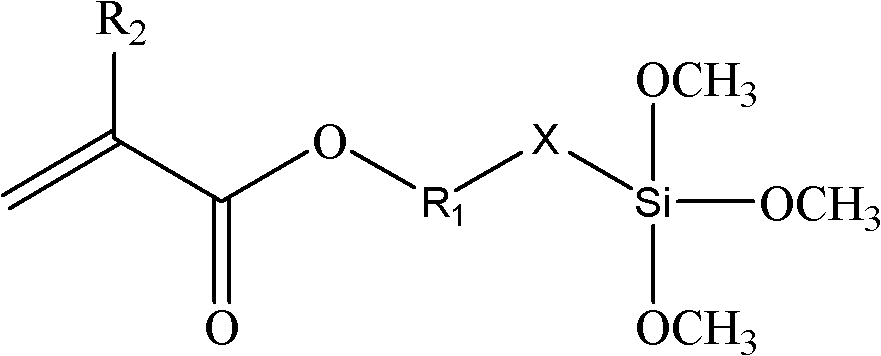

Preparation method of low-surface energy fluorinated polysiloxane modified acrylic acid anti-fouling resin and product

ActiveCN102432739AReduce dosageLow VOC contentAntifouling/underwater paintsPaints with biocidesFunctional monomer(Hydroxyethyl)methacrylate

The invention discloses a preparation method of a low-surface energy fluorinated polysiloxane modified acrylic acid anti-fouling resin. The preparation method comprises the following steps of: counted by weight percentage, adding 5-30 percent of first mixed solution containing butyl acetate and dimethyl benzene and 5-30 percent of silicone soil as solvents into a flask; preparing a second mixed solution containing an acrylate monomer and an acrylic ester functional monomer and enabling an initiator to be dissolved in the second mixed solution, wherein the second mixed solution consists of 20-50 percent of methyl methacrylate, 10-20 percent of butyl acrylate, 3-20 percent of mixed solution of fluorine (methyl)-containing acrylic ester monomer and silicon-containing (methyl) acrylic ester monomer, 3-10 percent of hydroxyethyl methacrylate and 0.5-5 percent of initiator; raising the temperature of the solvent to be 60-100DEG C; slowly dropping the second mixed solution in which the initiator is dissolved into the solvent and stirring at constant speed; and after dropping, enabling the solvent to be maintained at the constant temperature for 2-20 hours and obtaining the low-surface energy fluorinated polysiloxane modified acrylic acid anti-fouling resin. The invention also provides the resin prepared by adopting the method.

Owner:上海华晖新材料科技宿迁有限公司

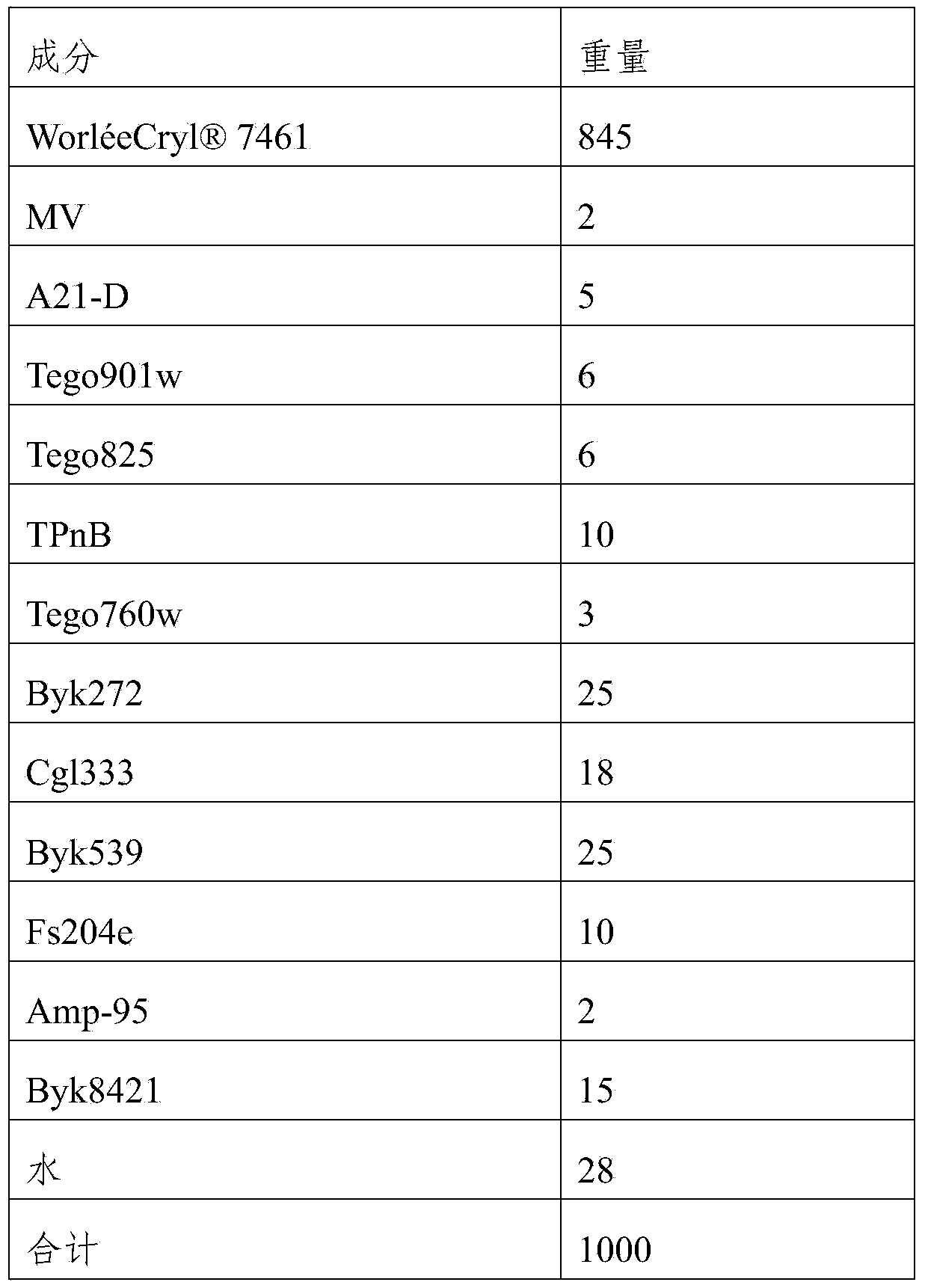

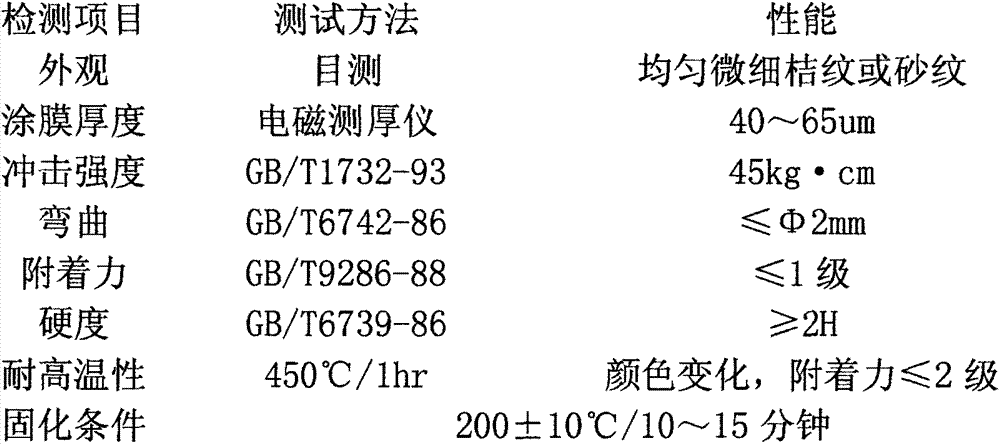

Water-based clear topcoat with high solid content and preparation method thereof

ActiveCN103881495AReduce contentImprove protectionLiquid surface applicatorsAntifouling/underwater paintsWaxPreservative

The invention relates to a water-based clear topcoat with high solid content, which is prepared from the following components in parts by weight: 750-900 parts of water-based resin, 1-4 parts of bactericide, 3-8 parts of dry film preservatives, 5-25 parts of coalescing agents, 5-15 parts of defoamer, 5-20 parts of base material wetting agents, 2-5 parts of pH adjuster, 10-35 parts of anti-sagging agents, 10-40 parts of extinction wax additives, 15-50 parts of special wax additives, 3-15 parts of dispersants, 15-35 parts of complex aging resistant additives, 0-100 parts of resin-type water-based coloring materials, and 0-60 parts of water. The product with high sold content is applicable to coating and protection on wood platforms, wood doors and windows, fences, leisure tables and chairs and other wood structures manufactured and formed outdoors. The water-based clear topcoat with high solid content is simple in preparation method, easy to operate, free of harm to an operator, and applicable to industrial popularization and application.

Owner:濮阳展辰新材料有限公司

High temperature resisting powder paint and preparation method thereof

The invention discloses a high temperature resisting powder paint and a preparation method thereof. The high temperature resisting powder paint comprises the components in percentage by weight as follows: 40-55% of modified organic silicon resin, 2-3% of curing agent, 40-48% of high temperature filler, 1-2% of assistant and 0.5-3% of high temperature pigment. The method mainly comprises the following steps of: modifying the organic silicon resin; mixing; and extruding and forming. The curing temperature of a conventional high temperature resisting powder paint is reduced, and the problems that conventional high temperature resisting powder paint is easy to bubble and poor in adhesive force and the like are solved, so that the coating yield is greatly improved and the coating cost is greatly lowered.

Owner:TAISHAN GUANG AN LIN CHEM CO LTD

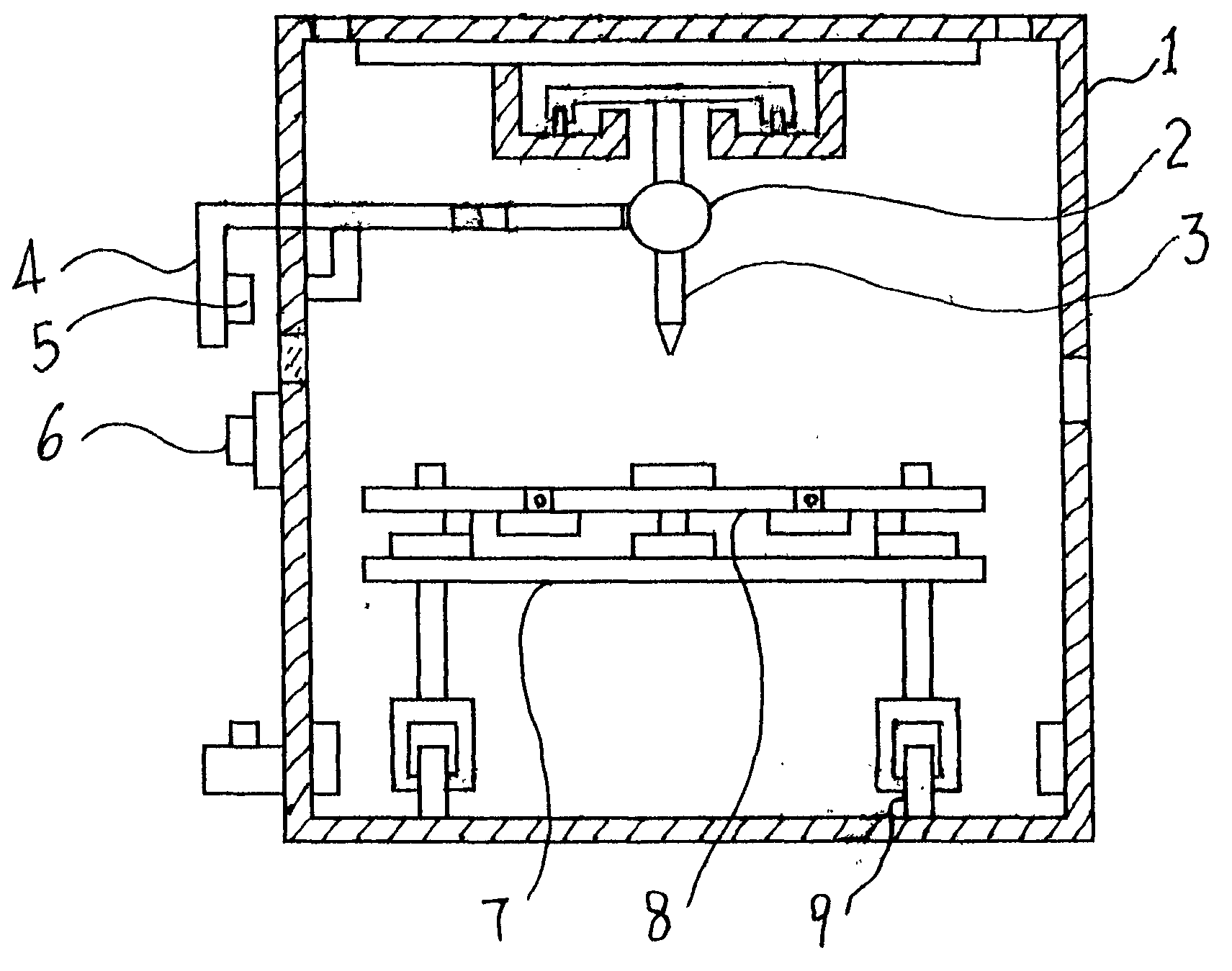

Environment-friendly, safe and efficient paint spraying device

InactiveCN103567105AImprove paint qualityReduce painting costsLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses an environment-friendly, safe and efficient paint spraying device to overcome deficiencies that the work efficiency is affected and the like due to the poor operation environment of prior paint spraying devices. A paint spraying mechanism comprises an operation mechanism capable of displacing and rotating the paint spraying mechanism. The operation mechanism comprises a paint spraying switch and an operation handle which stretches out of a paint spraying case and is capable of controlling the rotation of the paint spraying mechanism. A shelf capable of holding an object to be sprayed is arranged in the paint spraying case and comprises moving rollers. A supporting plate is arranged in the shelf and is composed of a rotation mechanism, a lifting mechanism and a supporting plate folding mechanism. The paint spraying case comprises a controller for controlling the displacement rotation of the paint spraying mechanism and the shelf. The device is used for environment-friendly, safe and efficient paint spraying of furniture and other objects, and paint spraying workers can operate the paint spraying mechanism to spray paint through the operation handle or the controller on the outside of the case and perform appearance judgment, so that the work efficiency is improved by 10%, and the paint spray efficiency is improved by 15%.

Owner:会同县康奇瑞竹木有限公司

Elastic emulsion paint and method for preparing same

InactiveCN101338163AImprove hydrophobicityImprove stain resistanceEmulsion paintsEmulsionWeather resistance

The invention discloses an elastic emulsion paint which is prepared from raw materials of deionized water, adipic dihydrazide, hydroxyethylcellulose, propanediol, 215 titanium dioxide, wollastonite powder, kaolin, 800 coarse whiting, waterborne fluorocarbon resin, styrene-acrylic emulsion, elastic emulsion, and the like in dispersive mixing way. With good expansion rate, the elastic emulsion of the invention can be painted in brushing, rolling and spraying way, is provided with breakthrough in stain resistance and hydrophobic property and has the advantages of waterproof and breathable performance, strong anti-pollution performance, alkali and acid resistance and lasting weather resistance.

Owner:山西天时涂料装饰有限公司

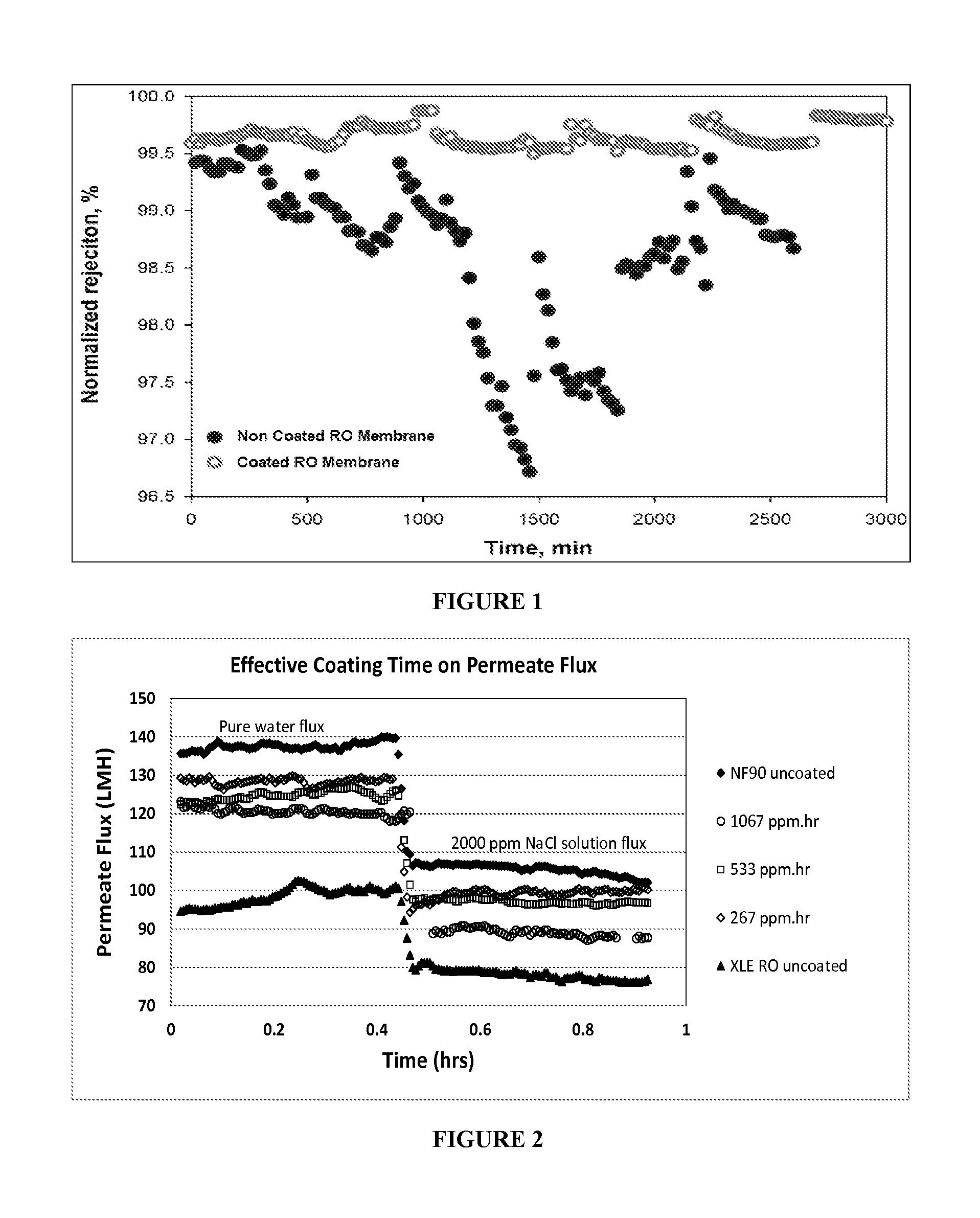

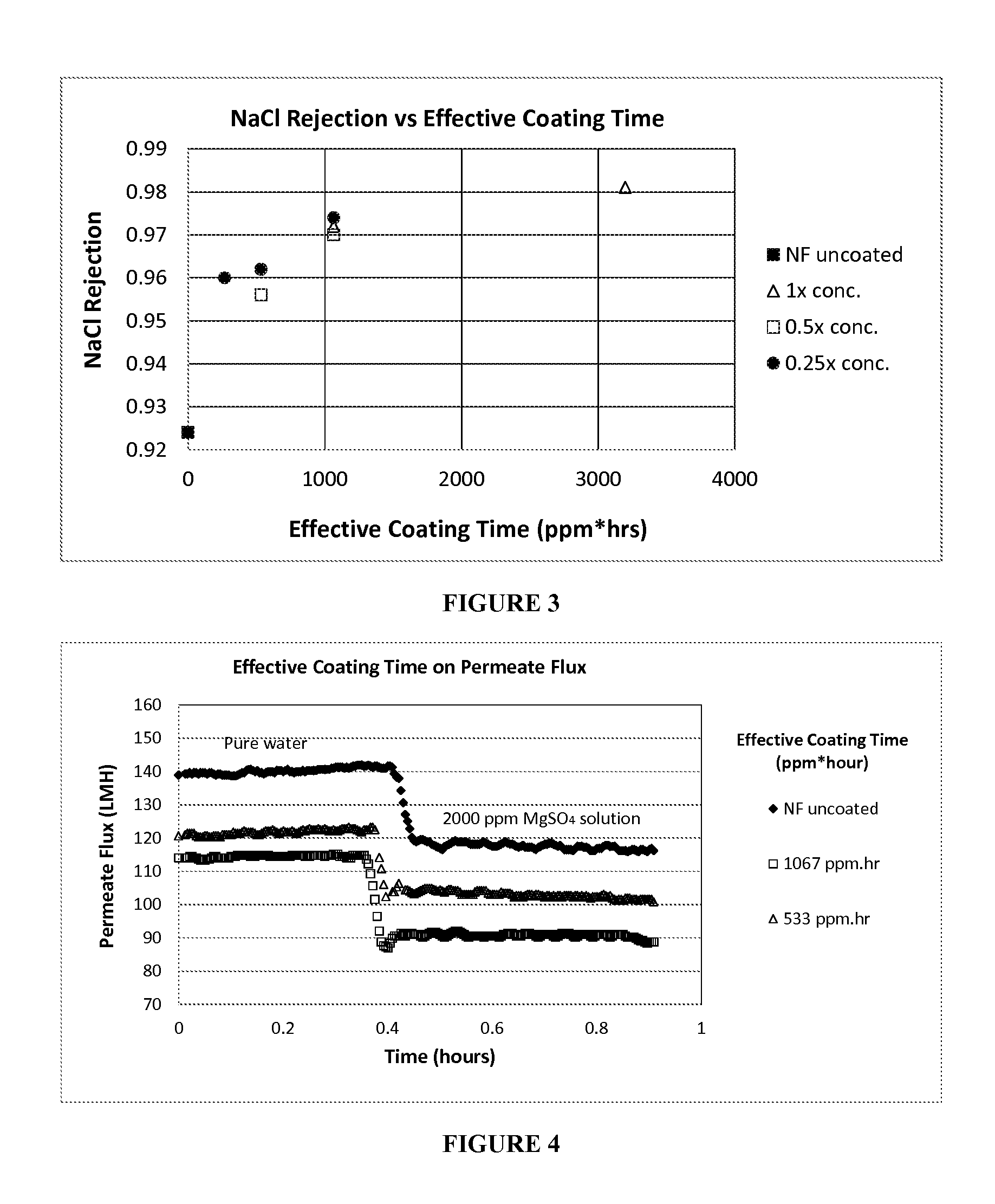

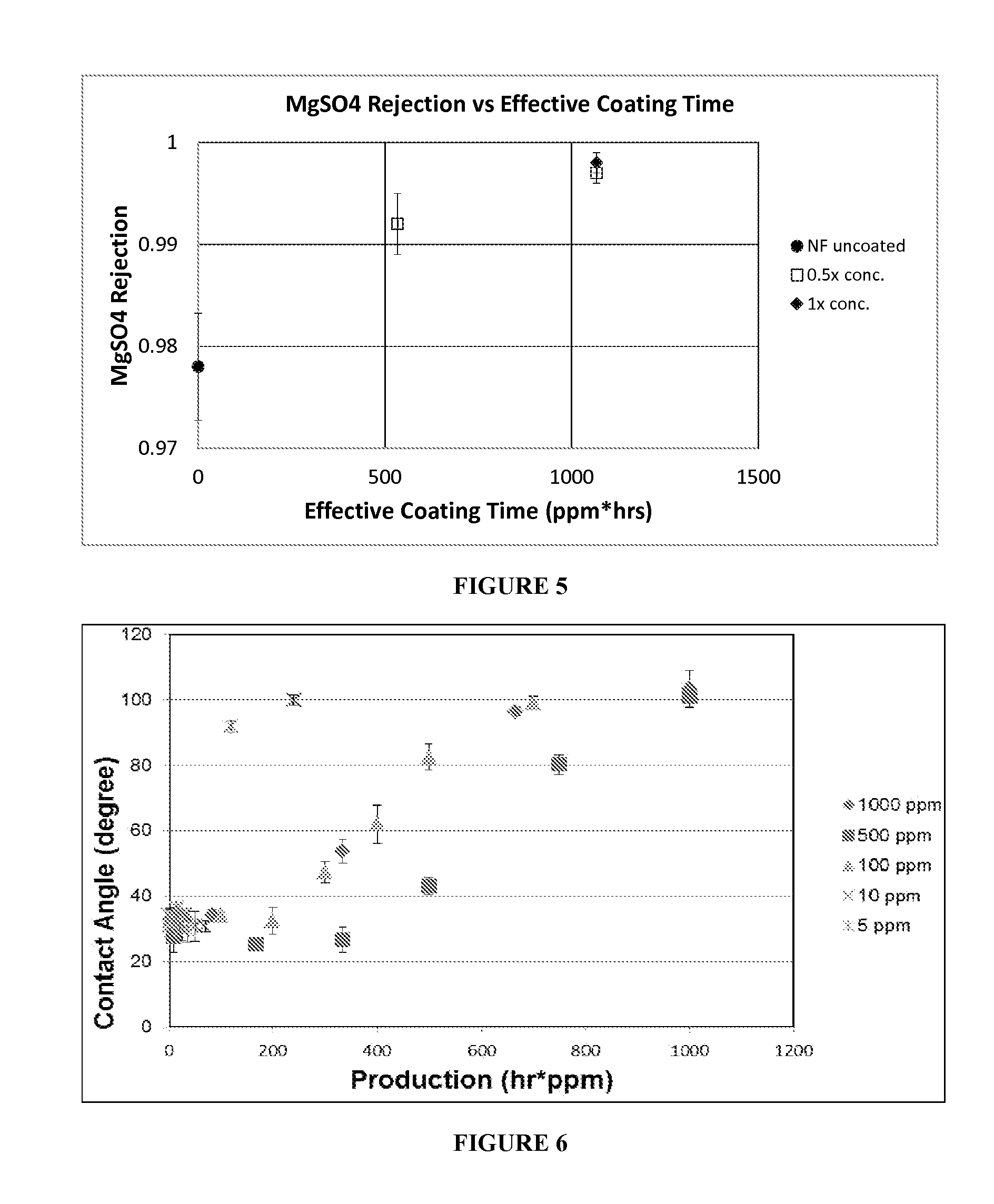

Membranes with polydopamine coatings

ActiveUS20140054221A1Strengthen membraneImprove the immunitySemi-permeable membranesPretreated surfacesHydroquinone CompoundPolymer

A membrane with rejection properties for mono and divalent-salts, BOD and COD good resistance to cleaning chemicals and maintaining high permeability for water. A polymeric coating prepared from polydopamine or hydroquinone or catechol or mixtures thereof, is deposited. In another embodiment, coating process steps and conditions are taught to achieve thickness control to tune the rejection properties of the membranes.

Owner:SURPLUS MANAGEMENT INC

Plastic part coating process of electric vehicle

ActiveCN104070001AImprove coating qualityReduce painting processPretreated surfacesCoatingsElectric vehicleMechanical engineering

The invention provides a plastic part coating process of an electric vehicle and relates to the technical field of coating processes. The plastic part coating process of the electric vehicle comprises the steps of firstly cleaning oil stains and dust on the surface of a plastic part, enabling the surface of the plastic part to be smooth through sanding and polishing so as to facilitate coating of a coating layer; then performing first-time primer spraying and second-time primer spraying, supplementing red plaster on the plastic part and then performing plaster scraping and drying; performing first-time polishing, then performing drying treatment, part installation and finish spraying after polishing is finished and finally performing soaking treatment. A traditional coating mode is changed, twice primer spraying is adopted, a refrigerating fluid soaking working procedure is performed, the product coating layer quality is improved, coating working procedures are decreased, the coating cost is reduced, and the plastic part coating process has very good actual application significance.

Owner:安徽省宏宝莱机车科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com