Water-based antirust paint for steel structure as well as production method thereof

A water-based, anti-rust paint technology, applied in the field of paint, can solve the problems of oil-based alkyd anti-rust paint smelly, harmful to painters, and high cost, so as to improve painting production efficiency, reduce painting costs, and improve anti-corrosion performance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Acrylic emulsion A (MC-105 Beijing Dongfang Yakeli Chemical)

[0016] Acrylic emulsion B (BS-104 Xinzhongyuan emulsion)

[0017] Iron Oxide Red (190D Henan Xinxiang Iron Oxide Factory)

[0018] Antirust agent (B-500 Changzhou Zhongpu Technology Co., Ltd.)

[0019] Barium sulfate (500 mesh precipitated barium sulfate, Shandong Zibo Yongbin Ore Factory)

[0020] Heavy calcium (500 mesh heavy calcium carbonate)

[0021] Organic bentonite (SMP-HV Zhejiang Fenghong Material Co., Ltd.)

[0022] Dispersant (706W Tego)

[0023] Defoamer (NXZ Germany BASF former Corning)

[0024] Coalescing agent (TEXANOL American Eastman)

[0025] Leveling agent (2025 France Godis)

[0026] Anti-flash rust agent (sodium nitrite chemical supermarket store)

[0027] Thickener (3800 French Godis)

[0028] Neutralizer (AMP-95 American Dow)

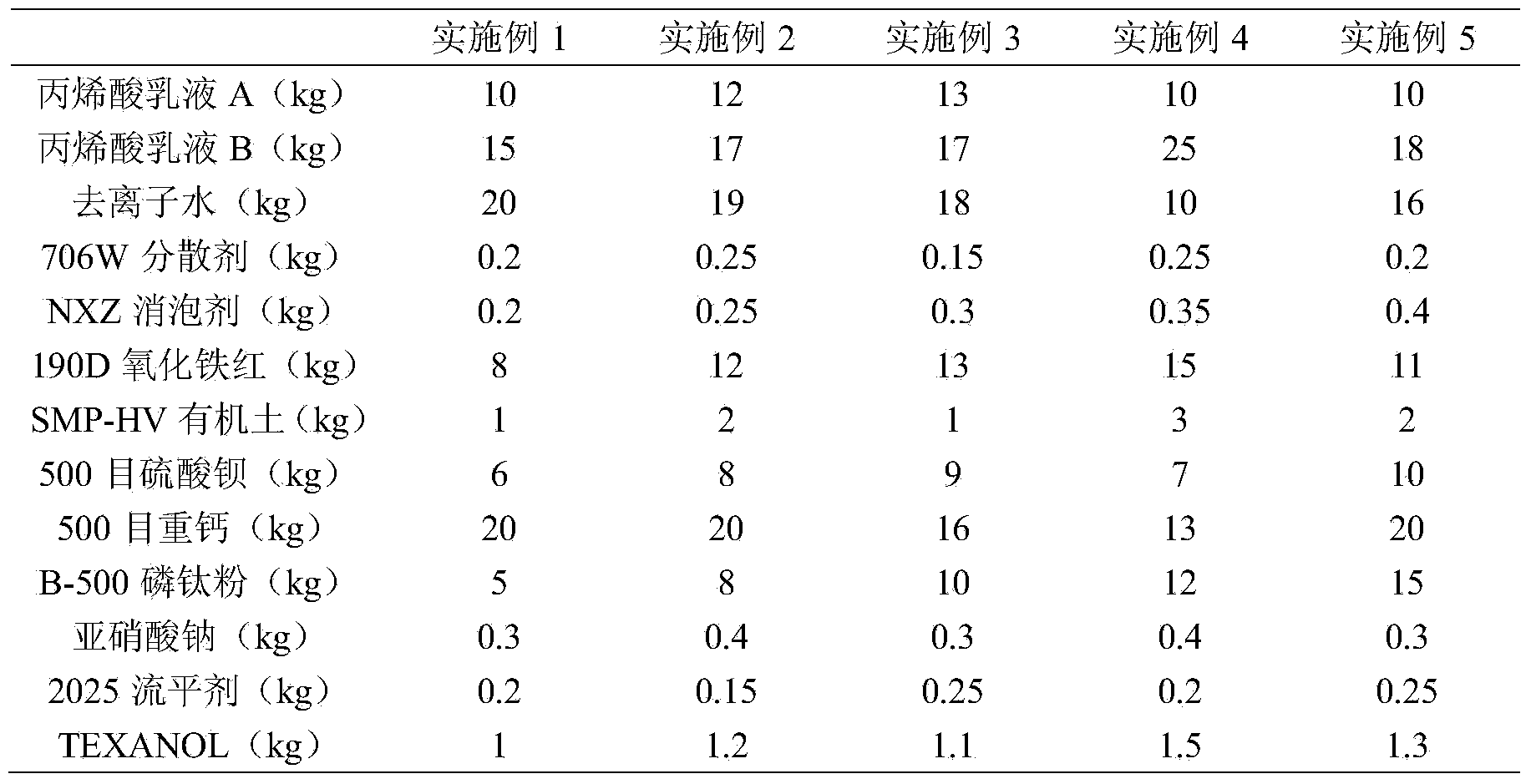

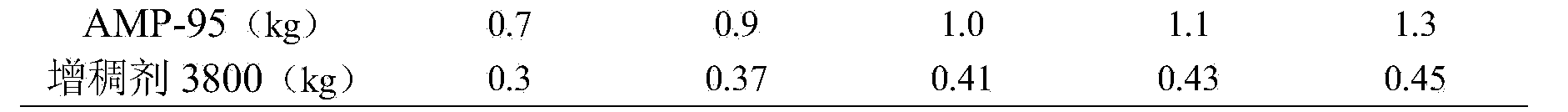

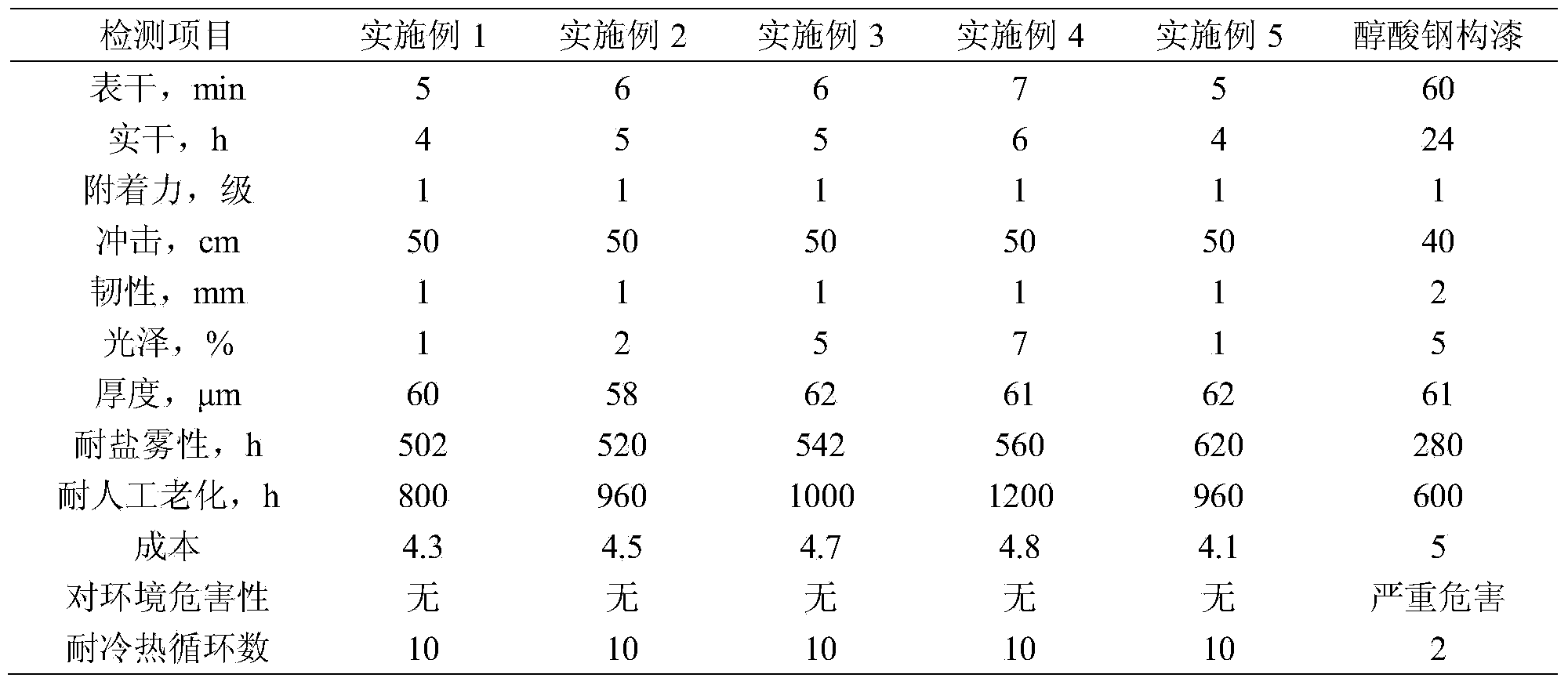

[0029] The formula of water-based antirust paint for steel structure of embodiment 1 to 5 is as follows:

[0030]

[0031]

[0032] Preparatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com