Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5118 results about "Butyl acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Butyl acrylate is a chemical used in manufacturing.

Smooth, flexible powder coatings

The present invention, a powder composition for making powder coatings comprising one or more than one curable polymer or resin and an agglomerate of a core-shell polymer, wherein the agglomerate of a core-shell polymer has an average particle size of from 5 to 190 microns, preferably from 10 to 127 microns. The powders in accordance with the present invention provide a cured powder coating that is flexible, smooth, and which may be applied in a thickness of only from 0.3 to 8 mils. In a preferred embodiment of making a powder in accordance with the present invention, the agglomerate is cryoground to form a reduced agglomerate prior to adding it into a powder as a post-blend or a powder-forming mixture as a preblend. The preferred core-shell polymer for use in accordance with the present invention comprises an acrylic impact modifier having a poly(methyl methacrylate) shell and a poly(butyl acrylate) core. Further, the preferred curable polymer or resin powder is an epoxy resin, wherein the powder composition is a low temperature curing one component powder composition which cures at from 107 to 149 degrees C.

Owner:ROHM & HAAS CO

Foamable interpolymer resin particles containing limonene as a blowing aid

ActiveUS20040152795A1Lower Level RequirementsImprove acceleration performanceFoundry mouldsFoundry coresPolyolefinFoaming agent

Interpolymer resin particles comprised of 20% to 80% by weight polyolefin, e.g. polyethylene and 80% to 20% by weight of an in situ polymerized vinyl aromatic resin, e.g. polystyrene or poly(styrene-butyl acrylate) and forming an interpenetrating network of polyolefin and vinyl aromatic resin particles. The interpolymer particles are impregnated with a volatile hydrocarbon blowing agent, and limonene, e.g. d-limonene, ranging from about 0.1 to about 5 parts, preferably 0.1 to 1 part by weight, based on 100 parts by weight of the interpolymer particles, for improved expandability and a pleasant fragrance.

Owner:BVPV STYRENICS LLC

Nano titanium dioxide/ acrylate composite emulsion and preparation method thereof

InactiveCN102516477AAvoid reunionStable structureCoatingsGraft polymer adhesivesPtru catalystPolymer chemistry

The invention discloses nano titanium dioxide / acrylate composite emulsion and a preparation method thereof. The method comprises the following steps of: hydrolyzing butyl titanate to generate nano titanium dioxide sol in absolute ethanol by using hydrochloric acid as a catalyst, adding a vinyl-containing silane coupling agent for modifying the sol, performing centrifugal washing, drying and grinding on the obtained product to obtain nano titanium dioxide, and thus obtaining the nano titanium dioxide / acrylate composite emulsion by using acrylate monomers of methyl methacrylate, butyl acrylate and the like as reaction monomers and adopting a method combining in-situ emulsion polymerization and seed emulsion polymerization. The nano titanium dioxide / acrylate composite emulsion prepared by the method has good storage stability and is stable in a polymerization reaction process; and a film formed by the composite emulsion has good hardness, impact strength and heat resistance.

Owner:SOUTH CHINA UNIV OF TECH

Foamable interpolymer resin particles containing limonene as a blowing aid

ActiveUS6908949B2Improve acceleration performanceLower Level RequirementsFoundry mouldsFoundry coresPolyolefinFoaming agent

Interpolymer resin particles comprised of 20% to 80% by weight polyolefin, e.g. polyethylene and 80% to 20% by weight of an in situ polymerized vinyl aromatic resin, e.g. polystyrene or poly(styrene-butyl acrylate) and forming an interpenetrating network of polyolefin and vinyl aromatic resin particles. The interpolymer particles are impregnated with a volatile hydrocarbon blowing agent, and limonene, e.g. d-limonene, ranging from about 0.1 to about 5 parts, preferably 0.1 to 1 part by weight, based on 100 parts by weight of the interpolymer particles, for improved expandability and a pleasant fragrance.

Owner:BVPV STYRENICS LLC

Wet-rub resistant styrene-acrylic emulsion and preparation thereof

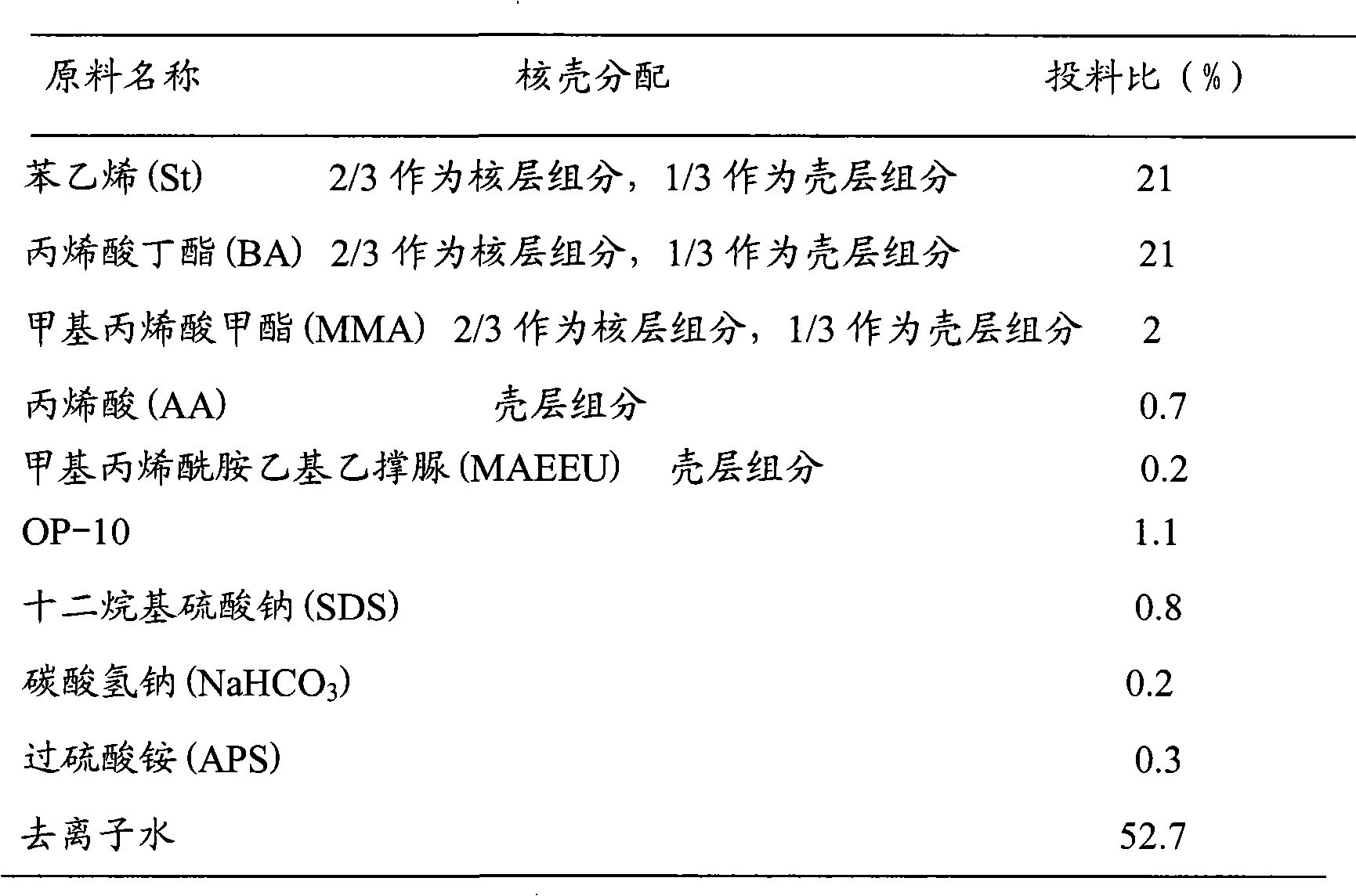

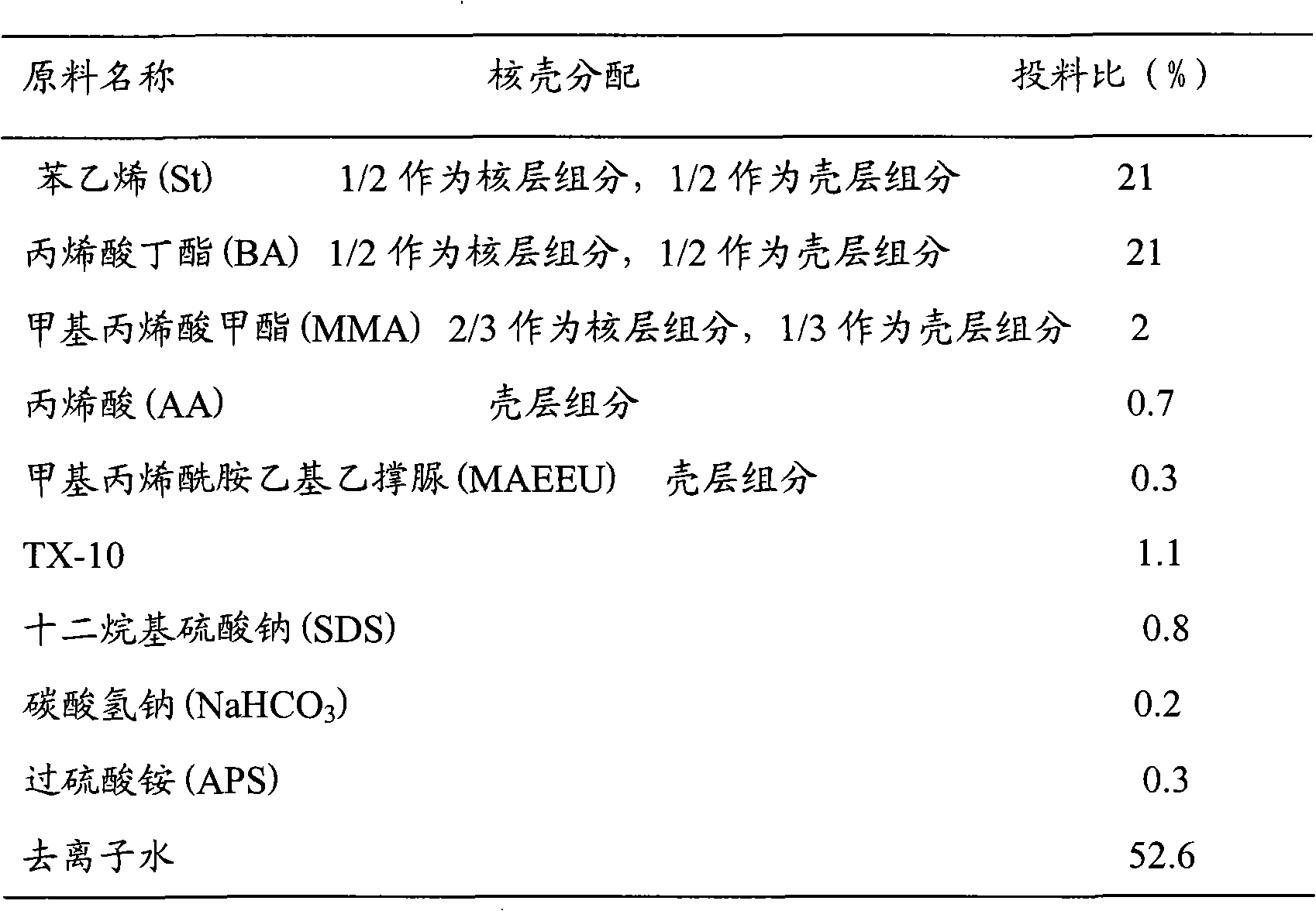

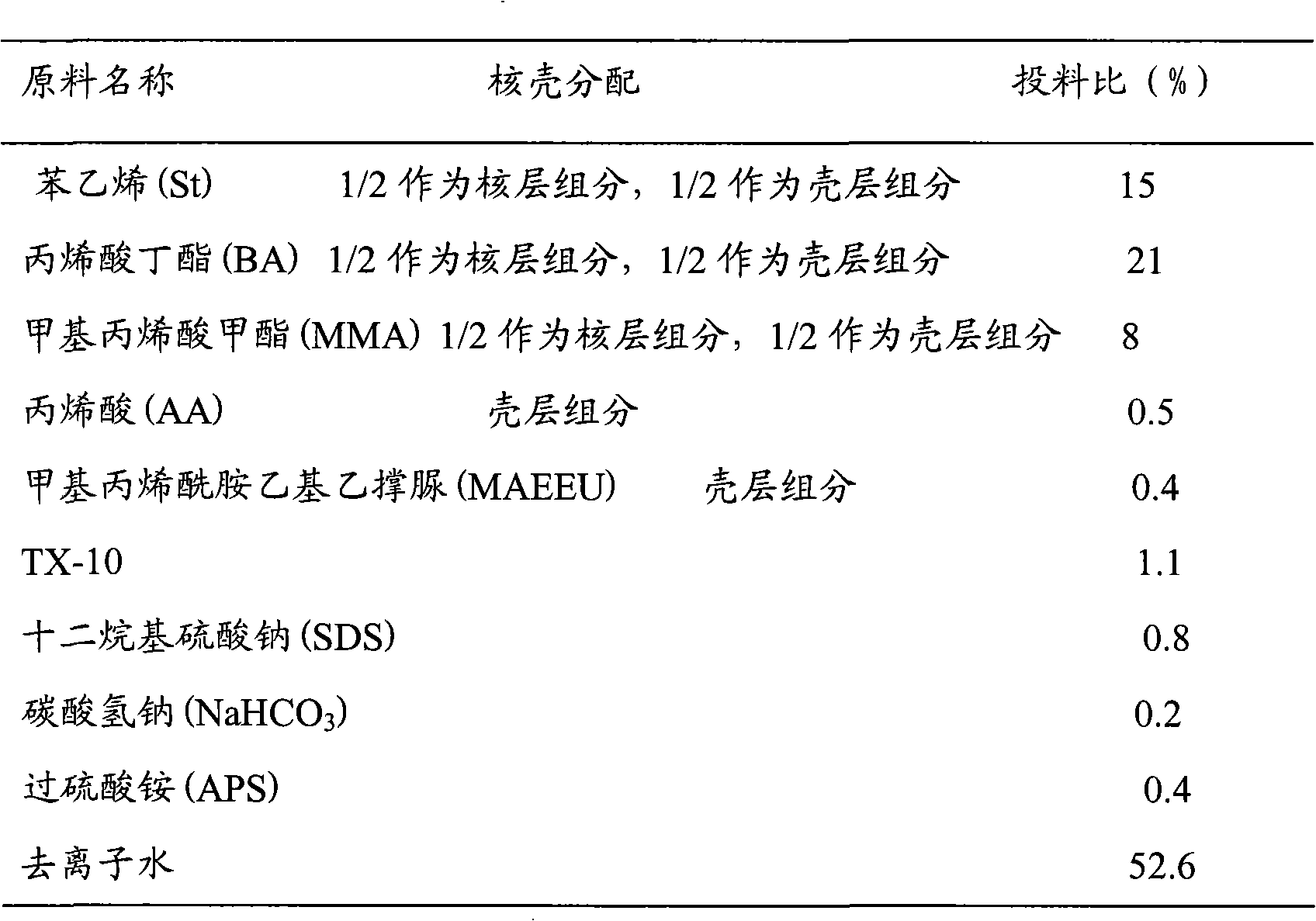

The invention discloses a wet-rub resistant styrene-acrylic emulsion and the preparation method. The existing styrene-acrylic emulsion still can not reach the requirements under the conditions with high wet-rub resistance. The invention is takes styrene, butyl acrylate, methyl methacrylate and acrylic acid as the polymeric monomer of the system, the functional monomers containing ureido as the modified monomer of the system, compound emulsifiers as the emulsifier of the system, and thermal decomposition initiators as the initiator of the system, so as to prepare and obtain the wet-rub resistant styrene-acrylic emulsion through core-shell polymerization. The invention adopts the core-shell polymerization technology to enable the functional monomer components to be mainly distributed in the shell layers by controlling the dropping rate, so as to achieve the purpose of modifying the styrene-acrylic emulsion. The styrene-acrylic emulsion obtained through such a method has better wet-rub resistant performance and can be used as the base material of interior and exterior wall coatings, which has good prospects for development.

Owner:传化智联股份有限公司

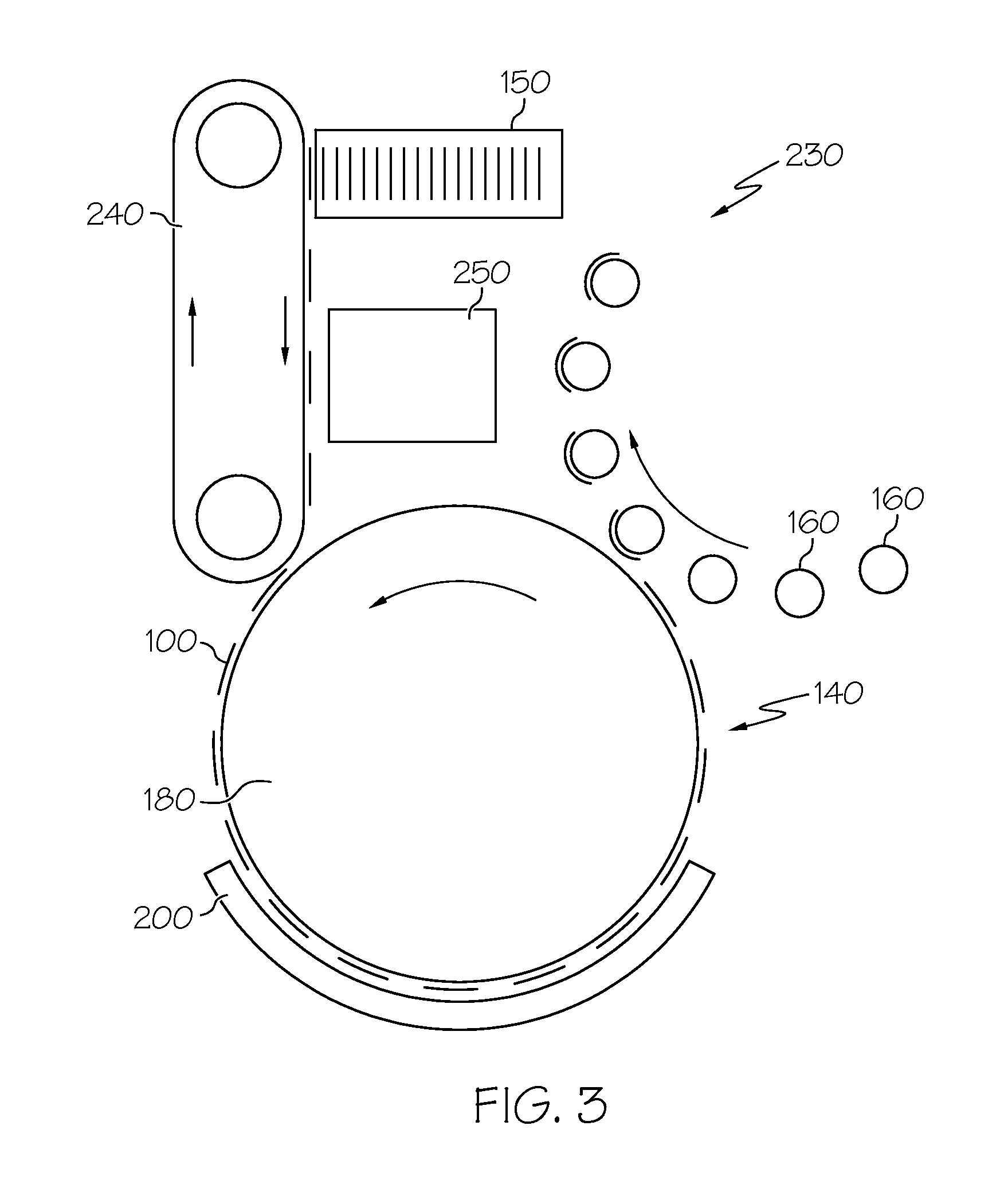

Linerless labels and activatable adhesives, systems, machines and methods therefor

InactiveUS20130133532A1Improve securityEasy to operateStampsRecord information storagePlasticizerAdhesive

A system is disclosed for printing, activating and applying a flow of linerless activatable labels to a flow of items to be labeled. An activatable adhesive is formulated to readily absorb energy from a given radiation source, an activatable adhesive linerless label incorporates such the activatable adhesive. Related methods and uses are described. The activatable adhesive includes a plasticizer, a tackifier, and an adhesive base polymer that includes butyl acrylate, styrene, methyl methacrylate, methacrylic acid, and acrylic acid.

Owner:AVERY DENNISON CORP

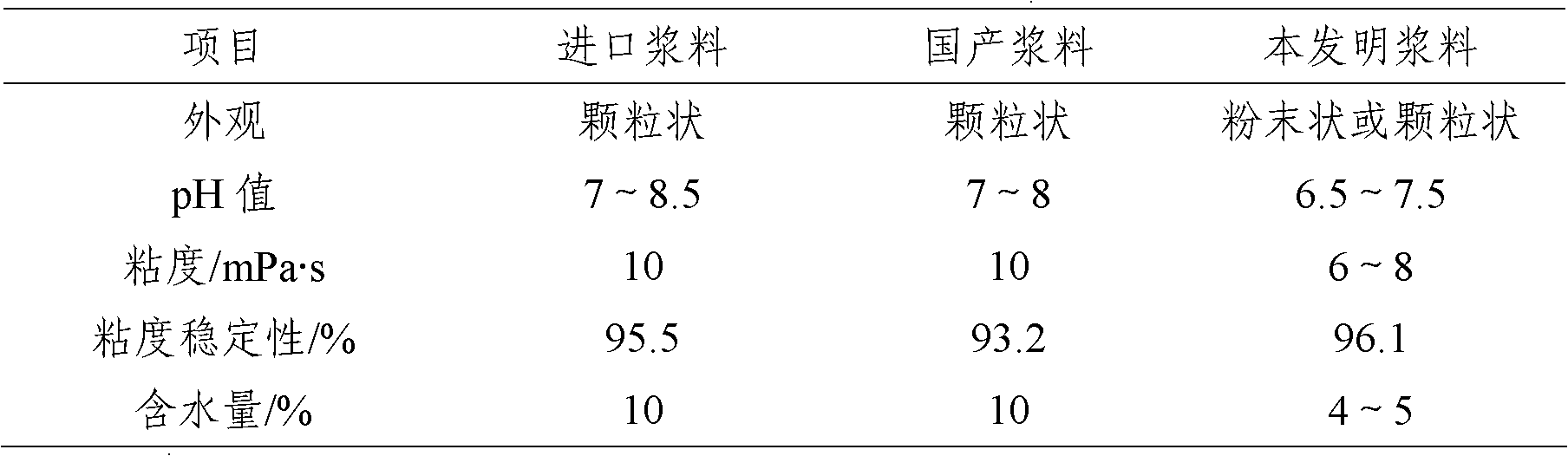

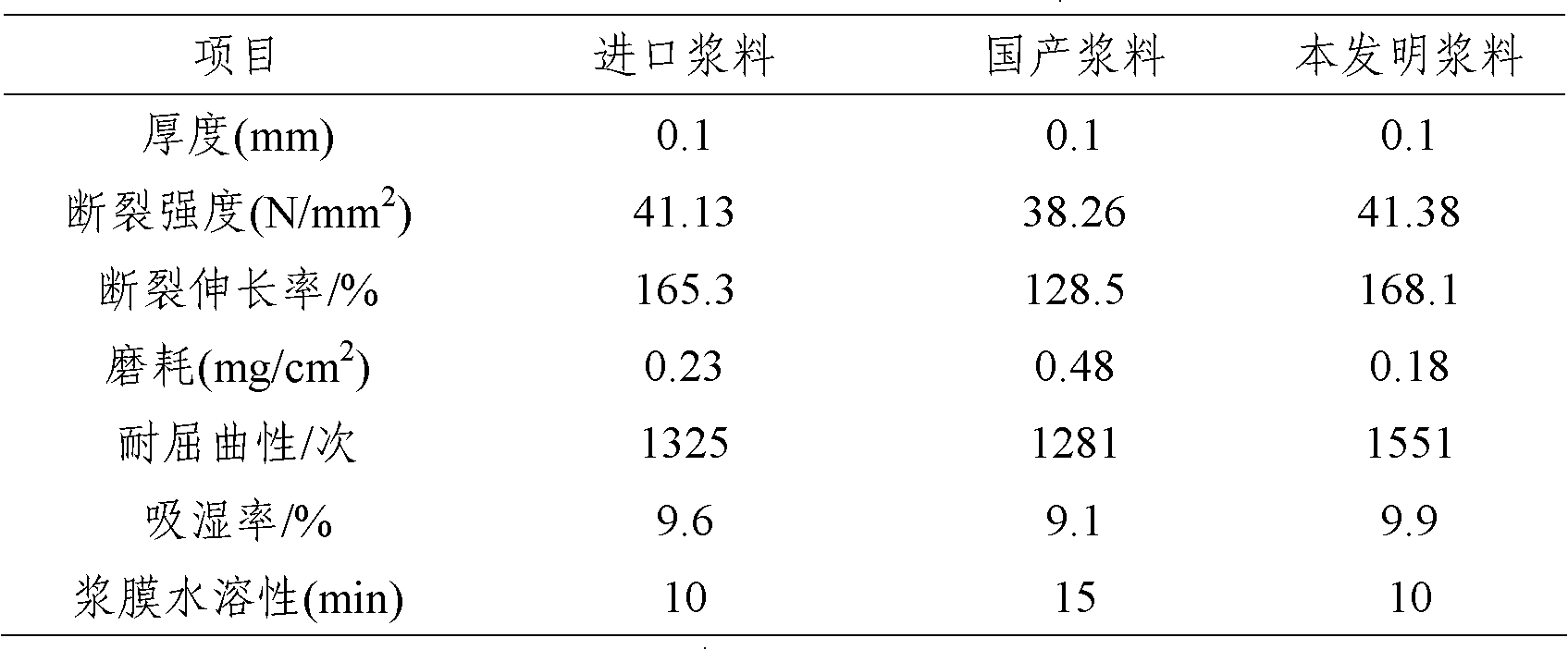

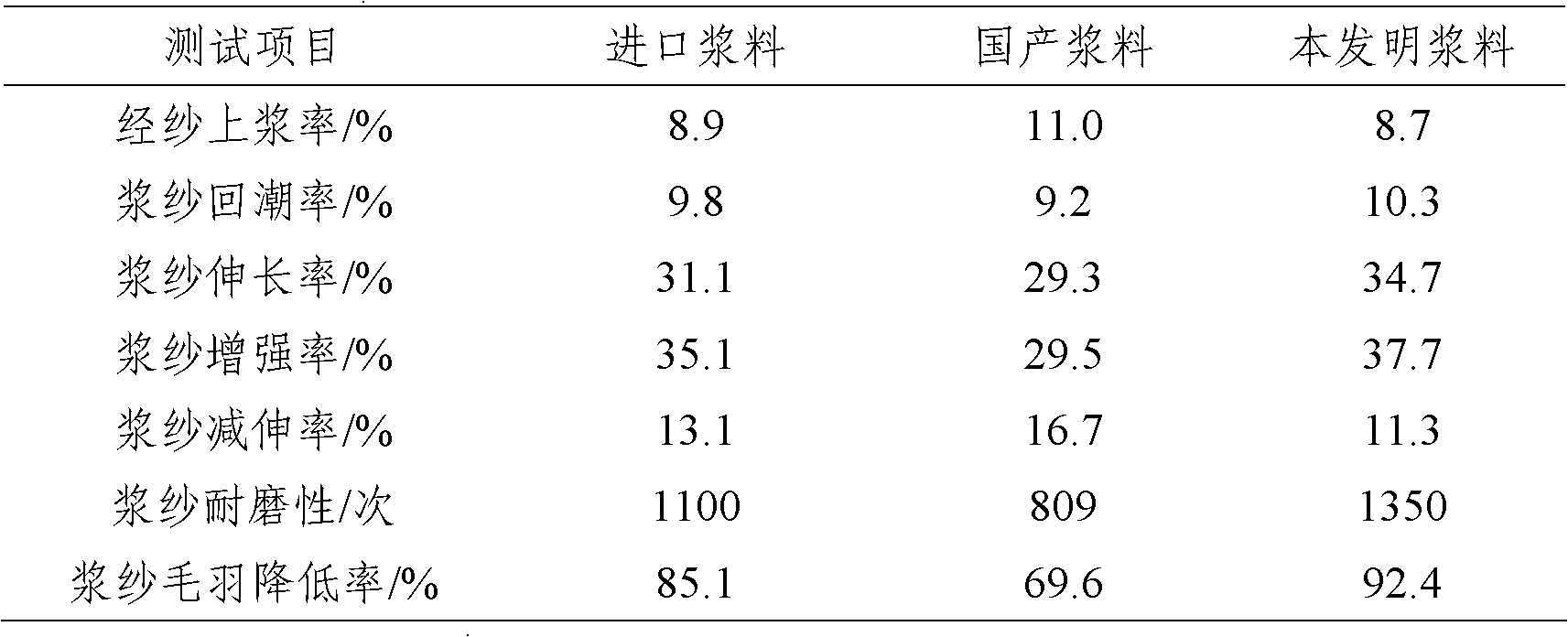

Textile size combination

The invention provides a textile size combination which is prepared by mixing solid acrylate with nano SiO2 compound modified starch in proportion, wherein the solid acrylate is prepared by the following steps: mixing acrylonitrile, methyl acrylate, butyl acrylate, methyl methacrylate, acroleic acid, methacrylic acid with acrylamide in proportion, and enabling the mixed solvent to be subject to internal polymerization under the action of compound initiator and chain transfer agent, neutralizing with sodium hydroxide and drying; and the nano SiO2 compound modified starch is prepared by the following steps: sequentially acidifying, crosslinking and oxidizing starch, introducing surface-modified nano-level SiO2 and carrying out ultrasonic dispersion. The size can obviously improve the warp sizing performance and improve the weaving efficiency, can be completely replace PVA and imported sizes in the same amount or partial amount, and is widely used for the warp sizing of purified cotton, terylens, novel fibers and mixed yarns of various counts.

Owner:HUBEI DAYA BIOLOGICAL TECH CO LTD

Aqueous acrylic acid-modified alkyd resin and preparation method thereof

ActiveCN103554379AImprove water resistanceImprove aging resistanceCoatingsBenzoic acidPolymer science

The invention discloses aqueous acrylic acid-modified alkyd resin and a preparation method thereof. Basic alkyd resin of the aqueous acrylic acid-modified alkyd resin is prepared from an unsaturated fatty acid, benzoic acid, trimethylolpropane, pentaerythritol, maleic anhydride, isophthalic acid, ethylene glycol monobutyl ether and butanol. The aqueous acrylic acid-modified alkyd resin is prepared by adding styrene, methyl methacrylate, butyl acrylate, acrylic acid, a silane coupling agent, benzoyl peroxide, tert-butyl hydroperoxide, ethylene glycol monobutyl ether and a mixing neutralizer into the basic alkyd resin. According to the aqueous acrylic acid-modified alkyd resin and the preparation method thereof, the advantages of alkyd resin and acrylic resin are integrated, and a product has high gloss retention, color retention and weather resistance; a production process is simple, the raw materials are readily available, and the production cost is low; a paint production process is simple, water is used as a diluting agent, and safety and convenience in construction are ensured.

Owner:西北永新涂料有限公司

Method for synthesizing carboxyl butadiene-styrene latex used for cement group water-proofing material

ActiveCN101139413AAvoid pollutionReduce energy consumptionAntifouling/underwater paintsPaints with biocidesSodium bicarbonateEthylenediamine

This invention relates to a synthesis method for carboxylated styrene-butadiene latex used in the cement-based waterproof coating. The preparation method involves 30 to 50 shares of butadiene or isoprene isoprene, 30 to 55 shares of styrene, 0.1 to 5 shares of methyl acrylate , 1 to 5 shares of itaconic acid, 1 to 8 shares of n-butyl acrylate butyl acrylate, 1.2 to 2.8 hares of emulsifier, 0.3 to 1.2 hares of initiator potassium supersulphate, 0.2 to 0.8 shares of molecular weight regulator, 0.01 to 0.5 shares of pH buffer sodium bicarbonate, 0.01 to 5 shares of electrolyte, 0.01 or 5 shares of chelating agent ethylenediamine tetraacetic acid or endrate disodium and 100 to 150 shares of soft water for polymerization. The electrolyte is the combination of potassium phosphate and disodium hydrogen phosphate, with the ratio of 3 to 2: 1; in the polymerization reaction, monomer and a variety of agents are added with intermission. And reaction temperature control adopts the two-step laddered control. When the conversion rate reaches 99.0 percent, the mixture experiences the vacuum degassing treatment. The latex produced by the present invention is of good compatibility with the additives as the paint during the paint preparation. The prepared paint is of excellent fluidity, water retention and machinery stability under the high-cut condition. The improved mortar has the advantages of good permeability, high bond strength and so on.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-solid low-viscosity hydroxy acrylic resin and preparation process thereof

The invention discloses a high-solid low-viscosity hydroxy acrylic resin and a preparation method thereof. The hydroxy acrylic resin comprises the following raw materials in part by mass: 25 to 35 parts of solvent, 0.2 to 2 parts of acrylic acid, 7 to 16 parts of methyl methacrylate, 15 to 35 parts of styrene, 3 to 10.5 parts of butyl methacrylate or butyl acrylate, 12 to 23 parts of hydroxy-containing acrylic monomer and 1.5 to 8 parts of initiator. During preparation, the product is obtained by pressurized reaction. The solid of the hydroxy acrylic resin can reach 65 to 75 percent, and the viscosity is only 1,00 to 2,500mps. The solvent used in the process is cheap, the expensive solvent with high boiling point is not needed, the preparation process is simple, and the production cost is low.

Owner:JIANGMEN PAINT FACTORY

Silicone modified acrylic ester emulsion and preparation method thereof

The invention discloses a silicone modified acrylic ester emulsion and a preparation method thereof. The emulsion is prepared from the following raw materials in parts by weight: 6.5-9 parts of acrylic ester mixed monomers, 1-3.5 parts of an organosilicone monomer, 0.4-0.6 part of an emulsifier, 0.2-0.3 part of an initiating agent, 0.01-0.03 part of a pH conditioning agent, 28-32 parts of deionized water, wherein the acrylic ester mixed monomers are methyl methacrylate and butyl acrylate with the mass ratio of (5.5-6.5):(3.5-4.5); the organosilicone monomer is gamma- 3-[Tris(trimethylsiloxy)silyl]propyl methacrylate. According to the emulsion, the reactive emulsifier is adopted for polymerization reaction, the prepared emulsion is stable, and the latex film of the emulsion has lower surface energy and better water resistance, and can be used as the main film forming matter of a metal anti-corrosion coating.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

Automobile metal sparkling paint and preparation method thereof

ActiveCN101077954ANo condensationImprove stabilityLiquid surface applicatorsCoatingsFiberWater dispersible

The water-thinned flash paint consists of water dispersible acrylic resin, deionized water, water-thinned curing cross-linking agent, water dispersible aluminum powder, dispersant, carboxymethyl butyl acetate resin fiber and water thinned assistant. The water dispersible acrylic resin is prepared with monomer mixture of methyl methacrylate, styrene, butyl acrylate, methacrylic acid, ethoxy methacrylate and acetyl acetoxy methacrylate, and through free radical polymerization. The water-thinned flash paint has regularly arranged water dispersible aluminum powder, and can form paint film with high flash number, great adhesion of metal grain, high water tolerance, etc.

Owner:GUANGDONG YATU CHEM +1

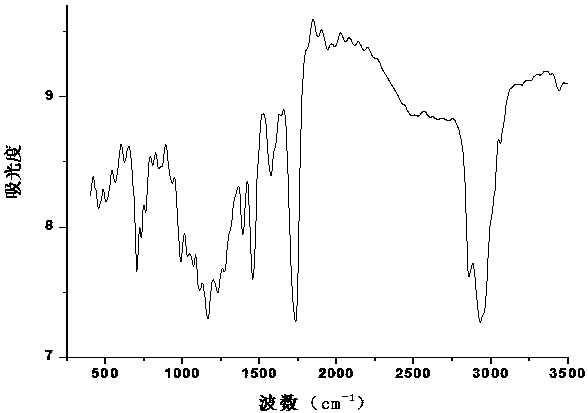

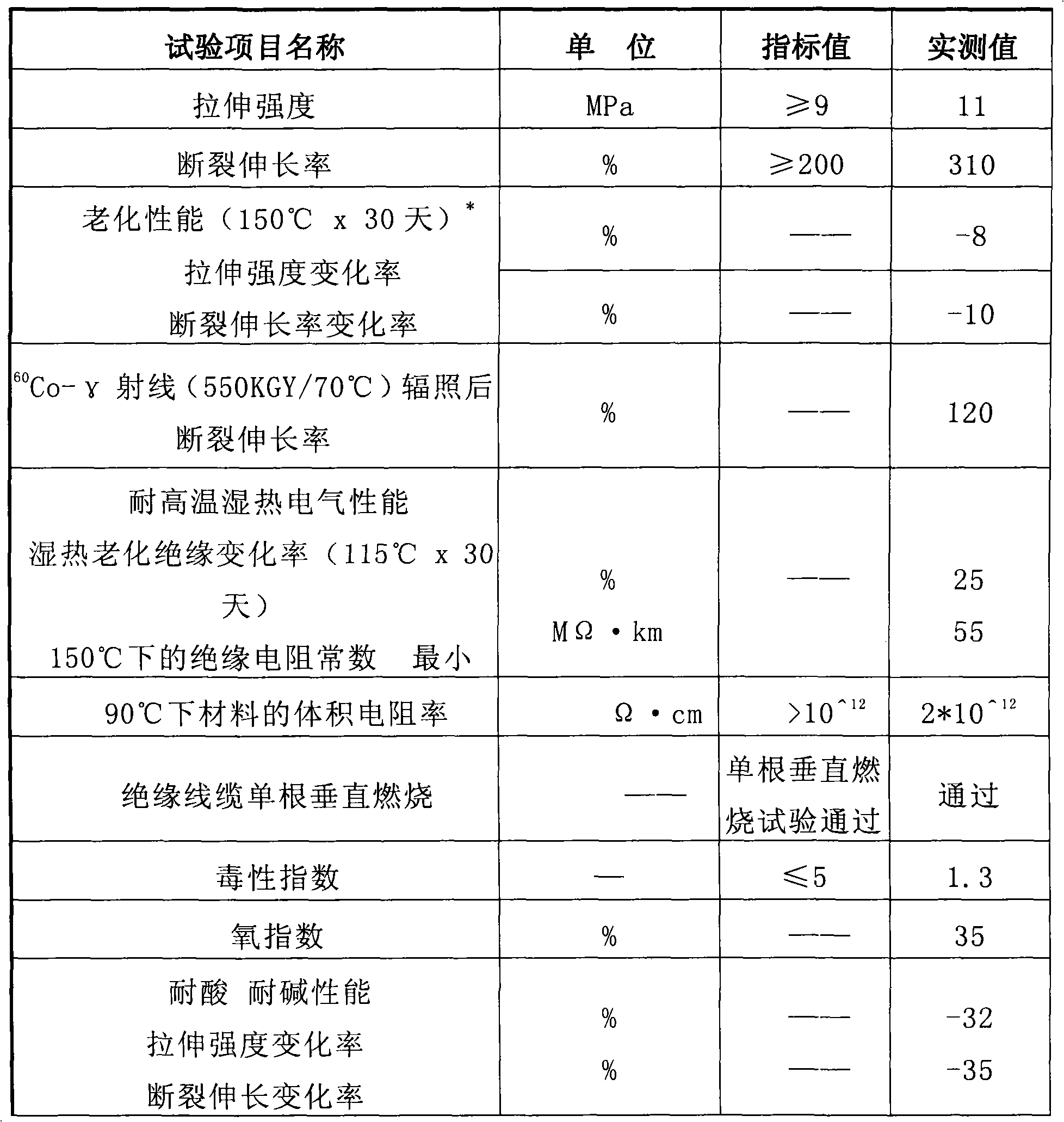

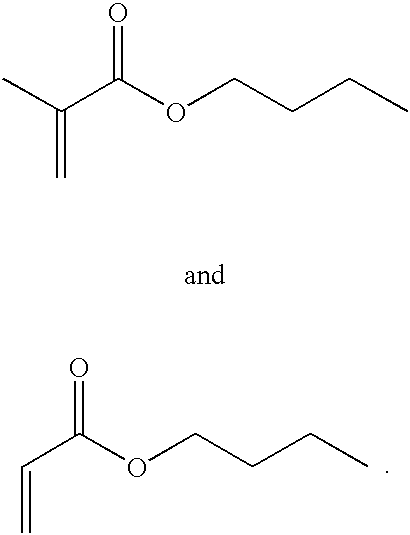

Irradiation-crosslinked low-smoke halogen-free inflaming retarding insulation material for nuclear power station cable and preparation method thereof

ActiveCN102108148AFulfil requirementsExcellent long-term heat aging resistancePlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneCross-link

The invention provides an irradiation-crosslinked low-smoke halogen-free inflaming retarding insulation material for a nuclear power station cable. The insulation material comprises the following components in parts by weight: 100 parts of basic resin (A), 2-5 parts of antioxidant (B), 3-10 parts of irradiation-resisting agent (C), 110-170 parts of fire retardant (D), 2-10 parts of compatilizer (E), 0.1-0.8 part of anticopper agent (F), 0.2-2 parts of lubricant (G) and 2-10 parts of cross-linking sensitizing agent (H), wherein the basic resin (A) comprises a combination of polyethylene-octeneelastomer (POE) ethylene-butyl acrylate (EBA) and linear very low density polyethylene (VLDPE), and the weight ratio of the POE to the EBA to the VLDPE is (10-20):(65-80):(10-20).

Owner:上海至正新材料有限公司

Water-based acrylic emulsion dispersants utilized as grind resins for pigments and method of preparing the same

The present invention is directed to a water-based acrylic emulsion dispersant to be used as a grind resin to incorporate inorganic pigment into a pigment dispersion for a coating composition. The acrylic emulsion dispersant is the reaction product of butyl methacrylate, butyl acrylate, styrene, methyl ether polyethylene glycol methacrylate, polyethylene glycol methacrylate, and polyphosphoric acid. The present invention is also directed to a method of preparing the acrylic emulsion dispersant. In this method, the butyl methacrylate, butyl acrylate, and styrene are combined with water to establish a first reaction blend. Similarly, the methyl ether polyethylene glycol methacrylate and the polyethylene glycol methacrylate are combined with water to establish a second reaction blend. Next, the first and second reaction blends are polymerized to form an intermediate emulsion polymer containing a hydroxyl group from the functionality of the polyethylene glycol methacrylate. Finally, the hydroxyl group from the polyethylene glycol methacrylate is reacted with polyphosphoric acid to form the acrylic emulsion dispersant which is utilized for efficient wetting and grinding of the pigment.

Owner:BASF CORP

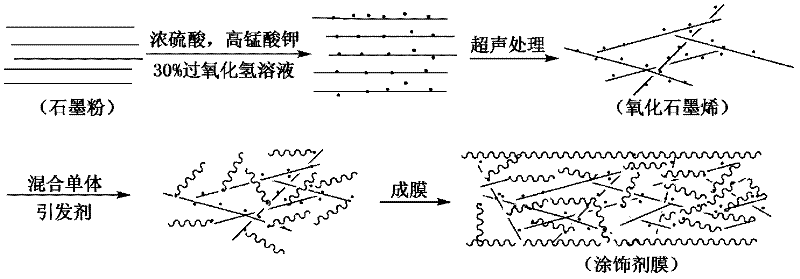

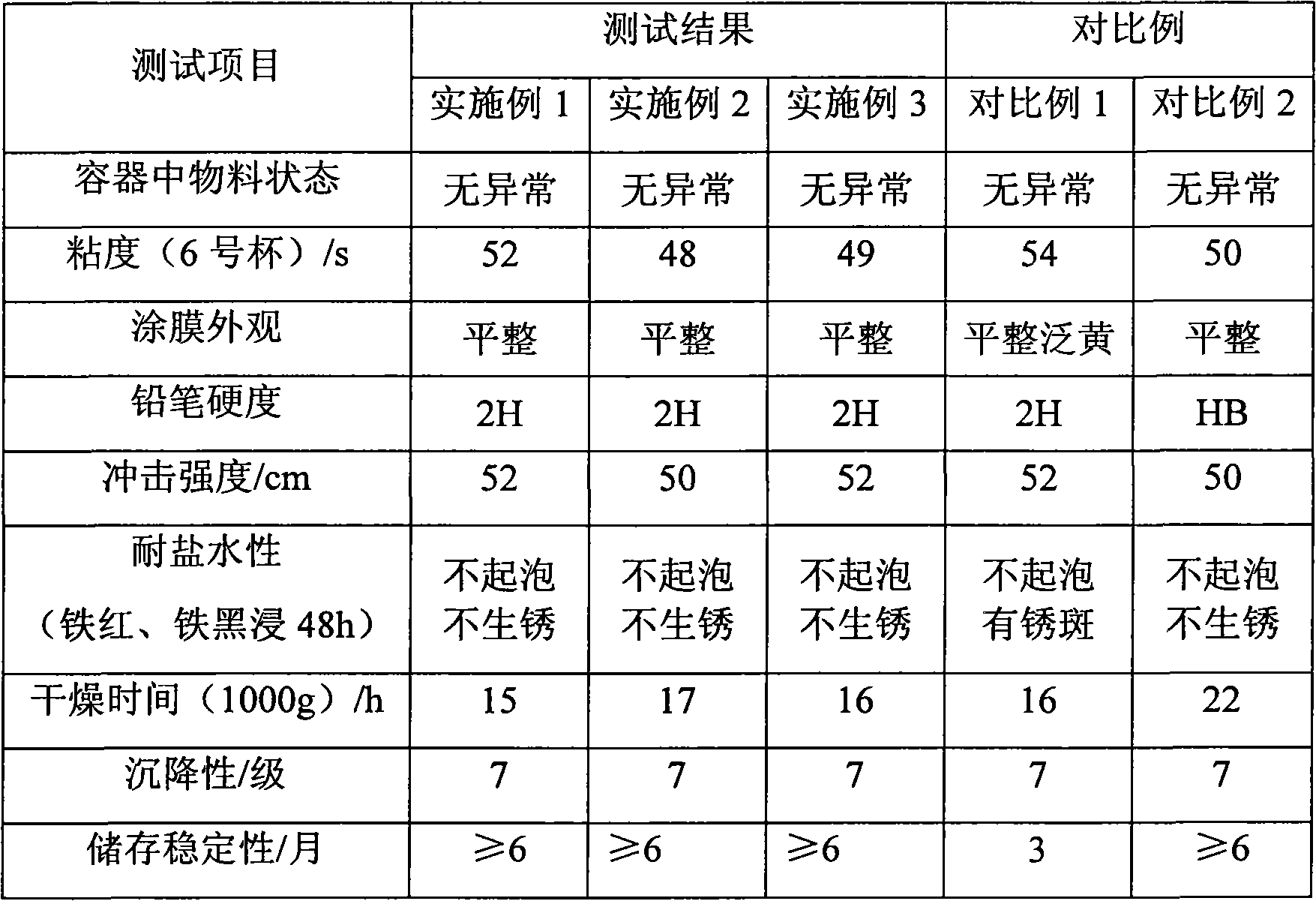

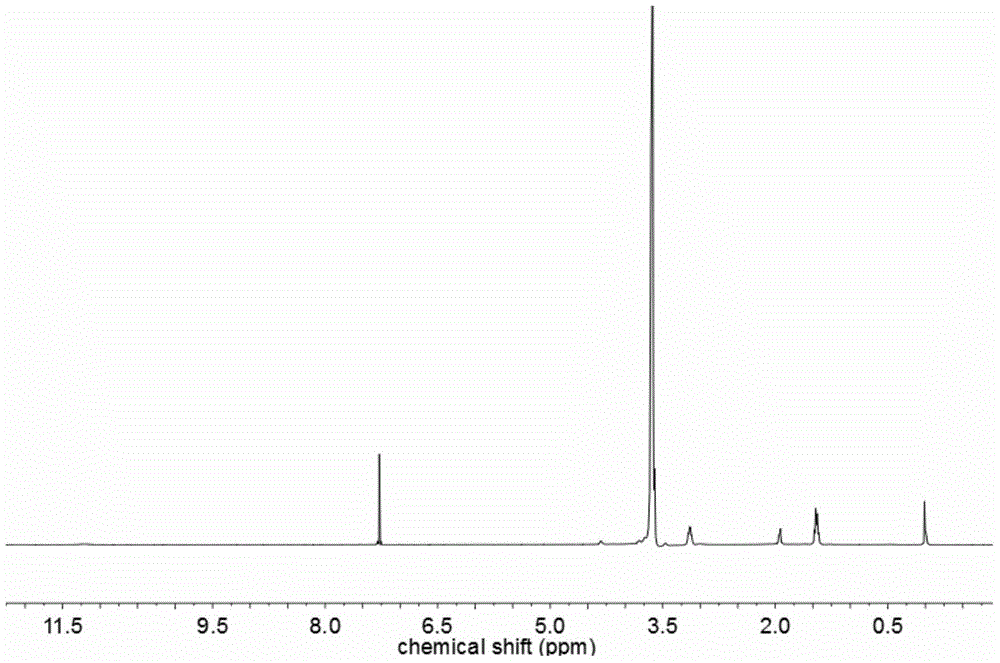

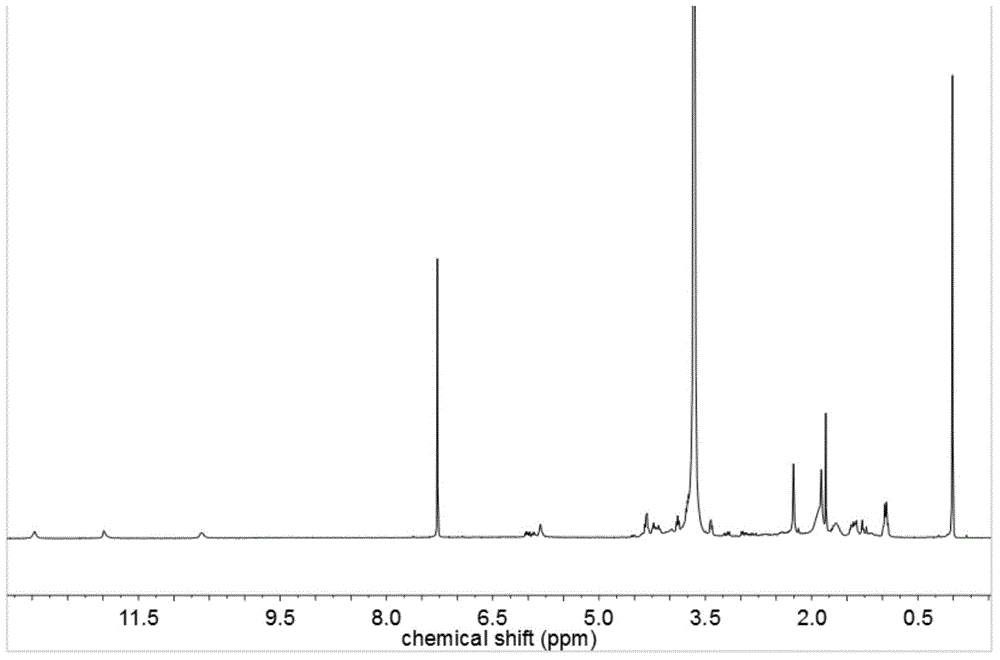

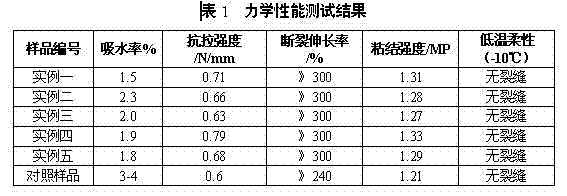

Preparation method of acrylic resin/graphene oxide nanometer composite leather finishing agent

The invention relates to a preparation method for an acrylic resin / graphene oxide nanometer composite leather finishing agent. In the preparation method, a nanometer graphene oxide suspension liquid is formed through peeling and dispersing; and then the acrylic resin / graphene oxide nanometer composite acrylic resin finishing agent is prepared through in-situ polymerization. The preparation methodcomprises the following specific steps: carrying out oxidization and ultrasonic stripping on natural graphite powder to prepare graphene oxide; adding graphene oxide to a mixed monomer of methyl acrylate, ethyl acrylate, butyl acrylate, acrylic acid and hydroxyethyl acrylate under the action of ultrasonic waves; and carrying out in-situ free radical copolymerization reaction under the action of an initiator ammonium persulfate to obtain the acrylic resin / graphene oxide nanometer composite leather finishing agent. The preparation method has the characteristics that the acrylic resin / graphene oxide nanometer composite leather finishing agent with excellent film-forming hand feel, strength and anti-static performances and no heat bonding and cold brittleness defects is prepared by using the specific laminated structure and performance of graphene oxide.

Owner:JIANGSU BESCON PHARMA

Water-borne epoxy ester modified alkyd resin emulsion and preparation method thereof

InactiveCN101942063AStrong adhesionImprove performanceDyeing processCoatingsEnvironmental resistanceEpoxy

The invention provides water-borne epoxy ester modified alkyd resin emulsion and a preparation method thereof. The method comprises the following steps: allowing unsaturated fatty oil, polyalcohol, epoxy resin and the like to carry out alcoholysis reaction by using triphenylphosphine and an alcoholysis catalyst; adding polyacid for esterification; dropwise adding crylic acid monomers such as methacrylic acid, phenylethylene, butyl acrylate and the like and a silane coupling agent for copolymerization under initiation of benzoyl peroxide; adding amine to the obtained copolymer for neutralizing to form salt; and dispersing with water to obtain the high-performance water-borne epoxy ester modified alkyd resin emulsion. The emulsion maintains self-drying property, flexibility and other excellent properties of alkyd resin, has excellent adhesive property of the epoxy resin as well as excellent adhesion force, excellent physical and mechanical properties and strong water resistance, strong salt fog resistance, strong acid and alkali resistance and other properties; and the emulsion has the advantages of possessing good stability and being nontoxic and harmless, thus meeting the environmental friendly requirement.

Owner:SOUTH CHINA UNIV OF TECH

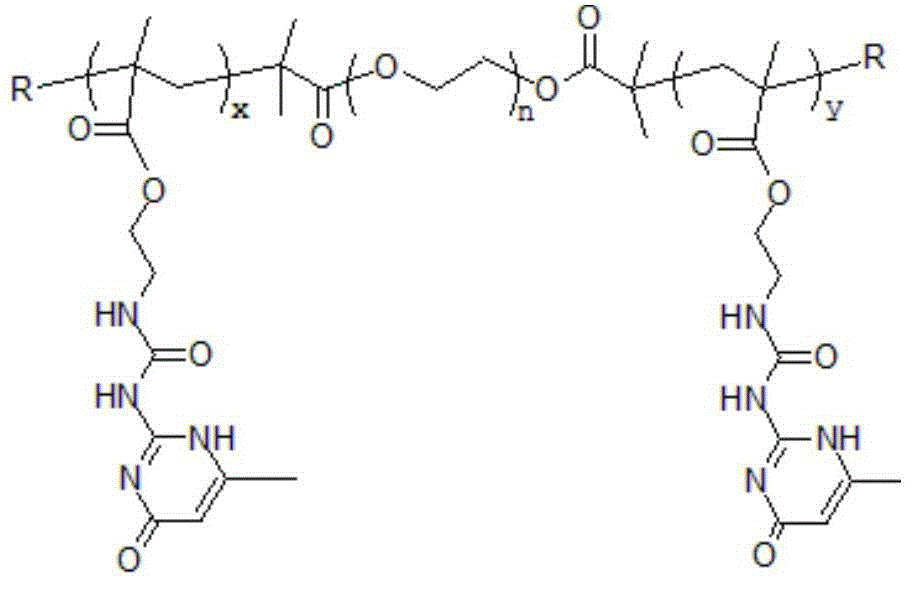

Hydrogel with self-repairing function and preparation method of hydrogel

ActiveCN104892871AImprove hydrophilicityIncrease the number ofOrganic chemistryMethacrylatePolymer science

The invention discloses hydrogel with a self-repairing function and a preparation method of the hydrogel. The hydrogel is a hydrophobic unit-UPy (ureido pyrimidinone)-PEG (polyethylene glycol)-UPy-hydrophobic unit polymer. According to the preparation method, firstly, an intermediate Br-PEG-Br and a quadruple hydrogen bonding unit intermediate UPyMA are synthesized and then are copolymerized with hydrophobic units such as butyl acrylate, styrene, methacrylate containing 3-10 carbon and the like, and a target polymer is obtained. The hydrogel has high water-retaining property, varieties of hydrogel with better performance can be prepared by adjusting the proportion of hydrophilic and hydrophobic chain segments in the polymer or changing the variety of a hydrophobic monomer, and the application range is enlarged.

Owner:XIAMEN UNIV

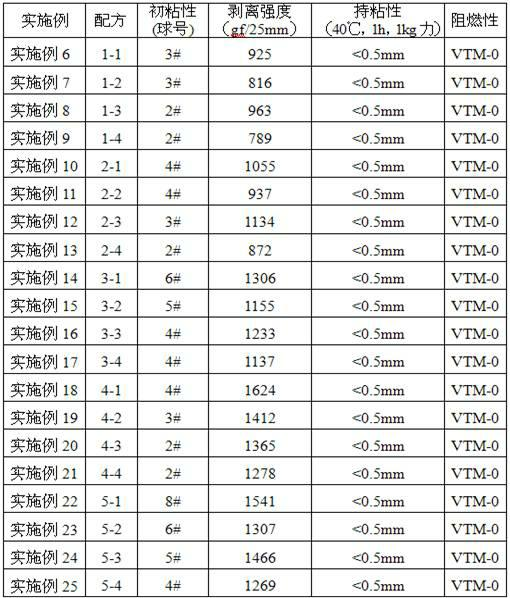

Preparation method for halogen-free flame retardant polyester labeled paper

ActiveCN102518003AImprove flame retardant performanceImprove stabilityStampsNon-fibrous pulp additionMethacrylatePolyester

The invention discloses a preparation method for halogen-free flame retardant polyester labeled paper. The method is characterized in that the method comprises the following steps: adopting butyl acrylate, ethylhexyl acrylate, acrylic acid, hydroxyethyl acrylate, ethyl methacrylate, a phosphorus-containing flame retardant monomer, a solvent, an initiator, and the like as raw materials to prepare a phosphorus-containing flame retardant acrylic acid pre-polymerization resin; preparing a phosphorus-containing flame retardant acrylic acid pressure sensitive adhesive; uniformly coating the phosphorus-containing flame retardant acrylic acid pressure sensitive adhesive on a halogen-free flame retardant polyester thin film; compounding the polyacrylate pressure sensitive adhesive-coated halogen-free flame retardant polyester thin film and a polyester release film; and carrying out ripening to prepare the halogen-free flame retardant polyester label product. With the present invention, the flame retardant and pressure sensitive adhesion property, the appearance and the environmental protection quality of the whole label product can be effectively improved, and the halogen-free flame retardant polyester labeled paper can meet the performance requirement of VTM-0 grade flame retardation.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Cable semiconductive shield compositions

InactiveUS20020032258A1Special tyresPower cables with screens/conductive layersAliphatic unsaturated hydrocarbonGram

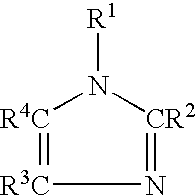

A composition comprising: (a) one or more copolymers selected from the group consisting of (I) a copolymer of ethylene and vinyl acetate containing about 10 to about 50 percent by weight vinyl acetate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes; (II) a copolymer of ethylene and ethyl acrylate containing about 10 to about 50 percent by weight ethyl acrylate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes; and (III) a copolymer of ethylene and butyl acrylate containing about 10 to about 50 percent by weight butyl acrylate and having a melt mass flow rate of about 1 to about 100 grams per 10 minutes, and based upon 100 parts by weight of component (a): (b) about 55 to about 200 parts by weight of a linear copolymer of ethylene and an alpha-olefin having 3 to 12 carbon atoms, the copolymer having a melt mass flow rate of about 0.1 to about 30 grams per 10 minutes and a density of 0.870 to 0.944 gram per cubic centimeter; (c) about 5 to about 50 parts by weight of polypropylene having a melt mass flow rate of about 0.5 to about 30 grams per 10 minutes and a density of 0.900 to 0.920 gram per cubic centimeter; (d) about 2 to about 50 parts by weight of an organopolysiloxane having the following formula: R1xR2ySiO(4-a-b) / 2 wherein R1 is an aliphatic unsaturated hydrocarbon group; R2 is an unsubstituted or substituted monovalent hydrocarbon group excluding aliphatic unsaturated hydrocarbon groups; x is equal to or greater than 0 but less than 1; y is greater than 0.5 but less than 3; x+y is greater than 1 but less than 3; a is greater than 0 but equal to or less than 1; and b is equal to or greater than 0.5 but equal to or less than 3; (e) about 10 to about 350 parts by weight of carbon black; and (f) optionally, up to about 2 parts by weight of an organic peroxide.

Owner:NIPPON YUNIKAA

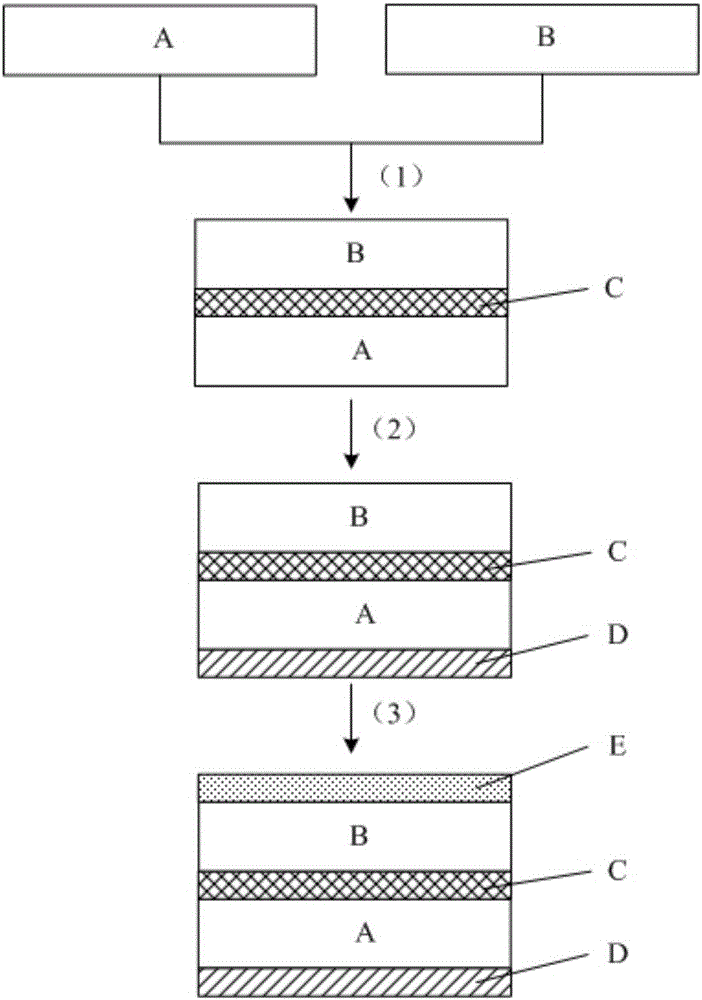

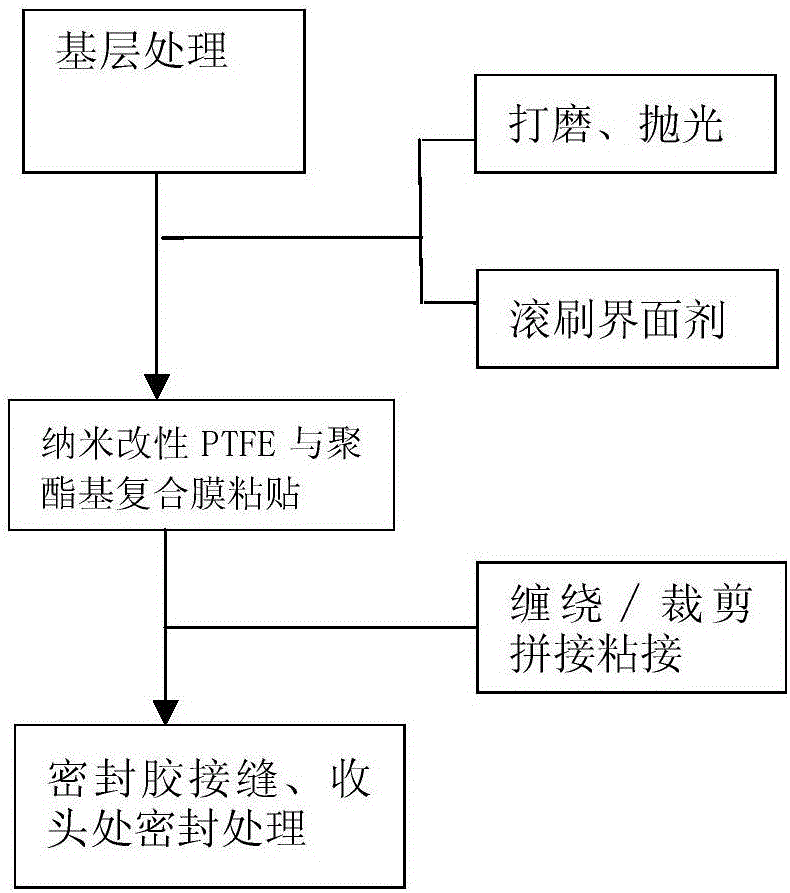

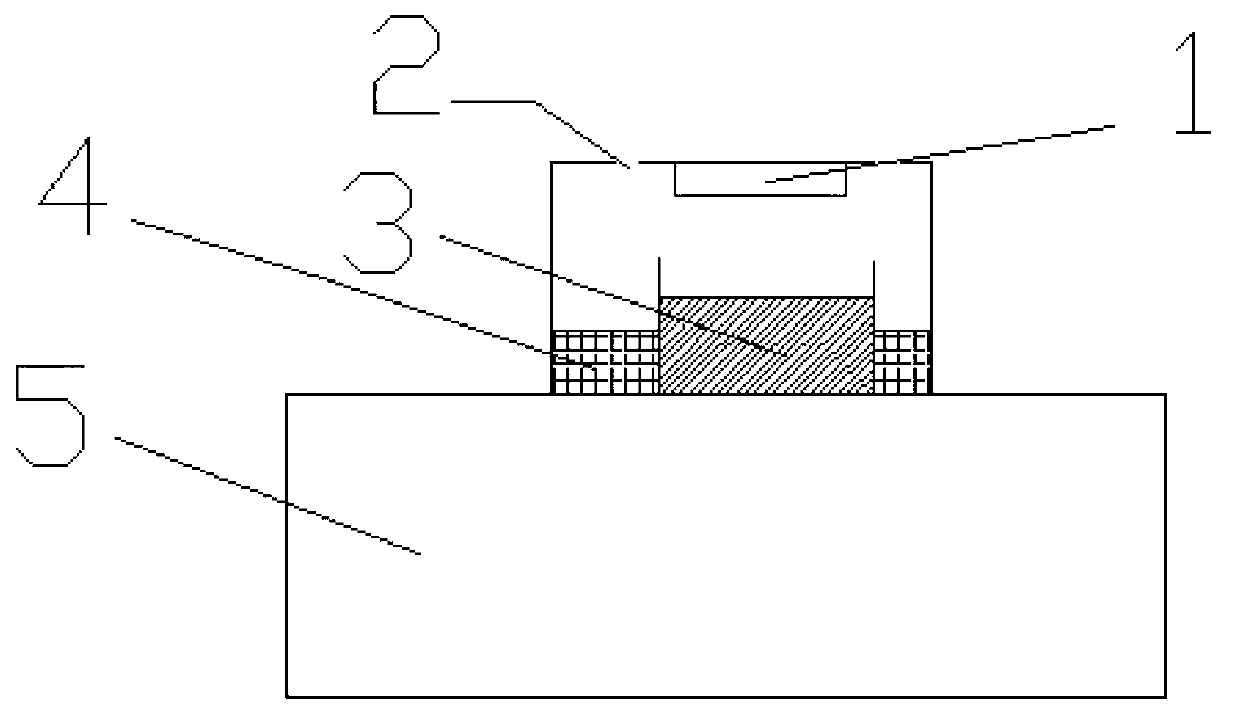

Preparation method and application of nano-modified PTFE and polyester-based composite film for preventing fan blades from icing

ActiveCN106313811ASolving non-adhesive technical problemsConvenient engineering constructionSynthetic resin layered productsLaminationPolyesterComposite film

The invention provides a preparation method and application of a nano-modified PTFE and polyester-based composite film for preventing fan blades from icing. The method includes the steps of PTFE film modification, lamination complexing and photo-crosslinked adhesive application. A modifier is prepared from antimony-doped tin oxide nano-crystals, nano-titanium dioxide, nano-silicon carbide, an organic fluorine waterproofing agent and pentaerythritol tri-(3-aziridinyl)-propionate; in lamination complexing, a bonding complexing agent is prepared from 3-isocyanatomethyl-3,5,5-trimethylcyclohexyl isocyanate, vinyl acetate, ethyl carbamate, alpha-linolenic acid, (2)ethoxylated bisphenol A dimethacrylate, trimethylolpropane triacrylate and benzoyl peroxide; a photo-crosslinked adhesive is prepared from a poly[butyl acrylate-glycidyl methacrylate-n-butoxy methacrylamide]copolymer, vinyl acetate, butyl acrylate, an acrylate derivative, a photoinitiator and dimethylformamide. The method and the composite film solve the non-adhesion problem that a PTFE film can not be pasted on the surfaces of fan blades with an adhesive directly.

Owner:NANJING HAOHUI HI TECH CO LTD

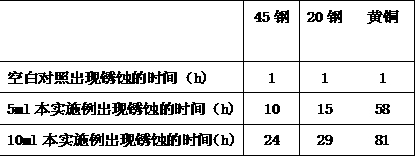

Metal rust-preventive oil comprising butyl acrylate

ActiveCN103214886AGood gas phase anti-rust effectExcellent contact rust resistanceAnti-corrosive paintsMeth-Composite film

The invention discloses metal rust-preventive oil comprising butyl acrylate. The oil is prepared from the raw materials of: No.120 solvent oil, paraffin, methyl diethanolamine, epoxy octyl stearate, magnesium naphthenate, a silane coupling agent KH560, a silane coupling agent A171, microcrystalline wax, aluminum stearate, magnesium lanolin soap, monoethanolamine, barium petroleum sulfonate, sodium lauryl sulfate, trioctyl trimellitate, benzotriazole, 2-aminoethyl heptadecenyl imidazoline, zinc stearate, an antioxidant BHT, an antioxidant 1010, dipropylene glycol, phytic acid, butyl acrylate, modified nano-grade dolomite powder, a composite film-forming material, and ferrocene. The rust-preventive oil provided by the invention has excellent contact rust resistance and good gas-phase rust resistance. The rust-preventive oil provided by the invention provides good gas-phase rust resistance and contact rust resistance for steel and brass.

Owner:SHANTOU HONGSHENG BOLT IND CO LTD

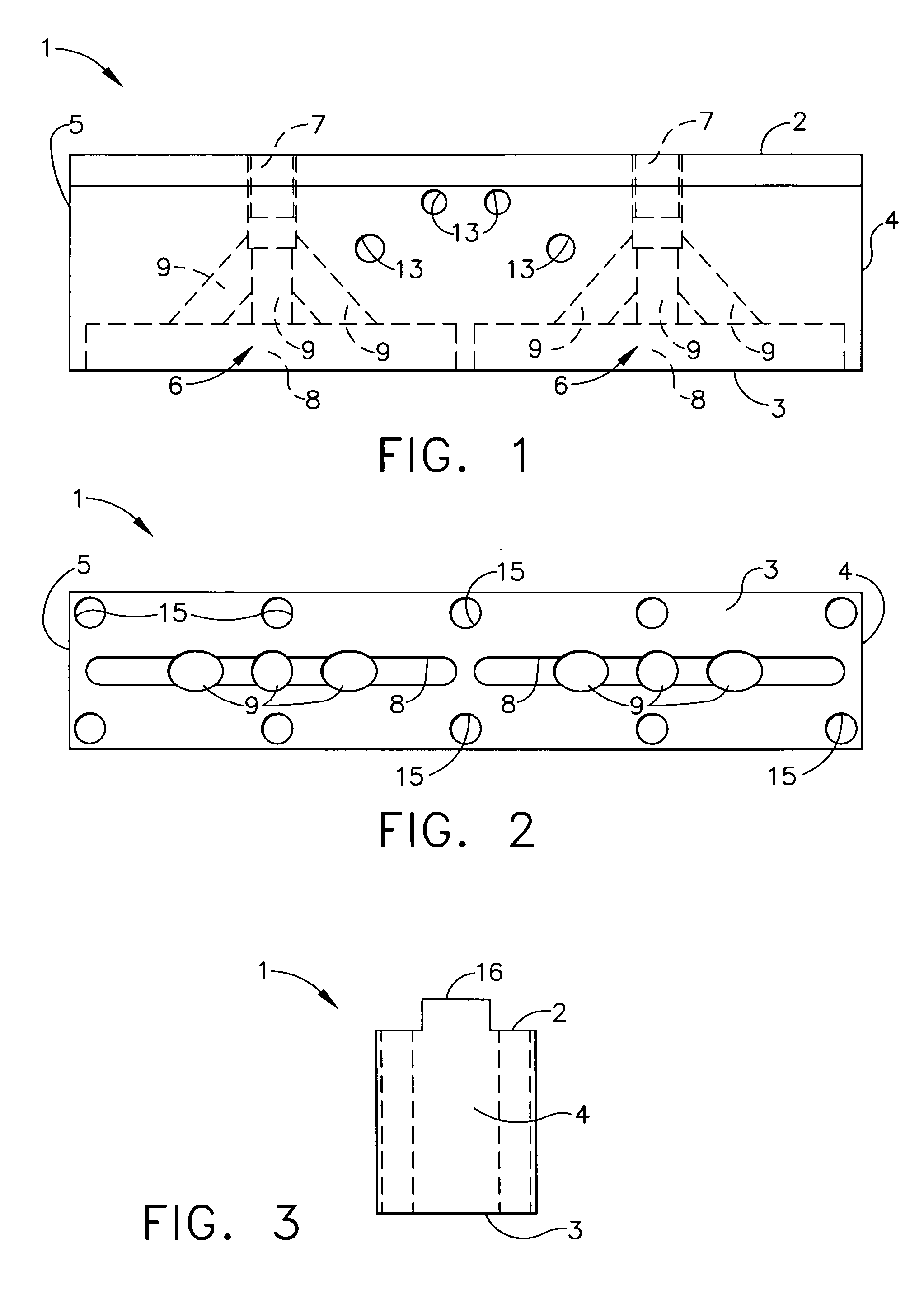

Applicator head for applying fluid material to substrate

InactiveUS20050189442A1Improve sound insulationGood curative effectMovable spraying apparatusSpray nozzlesControl mannerAcrylonitrile

An applicator head for connection to a robotic device, and useful for applying a fluid material to a substrate. The applicator head comprises: (a) a body portion; (b) at least one material delivery system comprising an inlet, a fluid delivery cavity, and two or more passageways connecting the inlet to the fluid delivery cavity; and (c) a nozzle plate attached to the bottom surface of the body portion, and having a plurality of openings communicating with the fluid delivery cavity. In one embodiment, the applicator head comprises a nozzle inserted in each of the plurality of openings in the nozzle plate, with each nozzle adapted to apply a bead of a fluid material to a substrate, with the beads spaced less than about 2 mm apart. Also disclosed is a sound-damping composition comprising: (a) n-butyl acrylate-acrylonitrile-styrene copolymer; (b) at least about 0.5% by weight of a low-density glass bead filler; (c) at least one additional filler; and (d) at least one rheological modifier; and having a density of from about 1 to about 2 g / cc. Methods for applying the sound-damping composition by extruding it onto a substrate and baking it to exhaust water in a controlled manner, and methods for increasing the sound-damping efficacy of an aqueous polymeric composition, are also disclosed.

Owner:EFTEC NORTH AMERICA

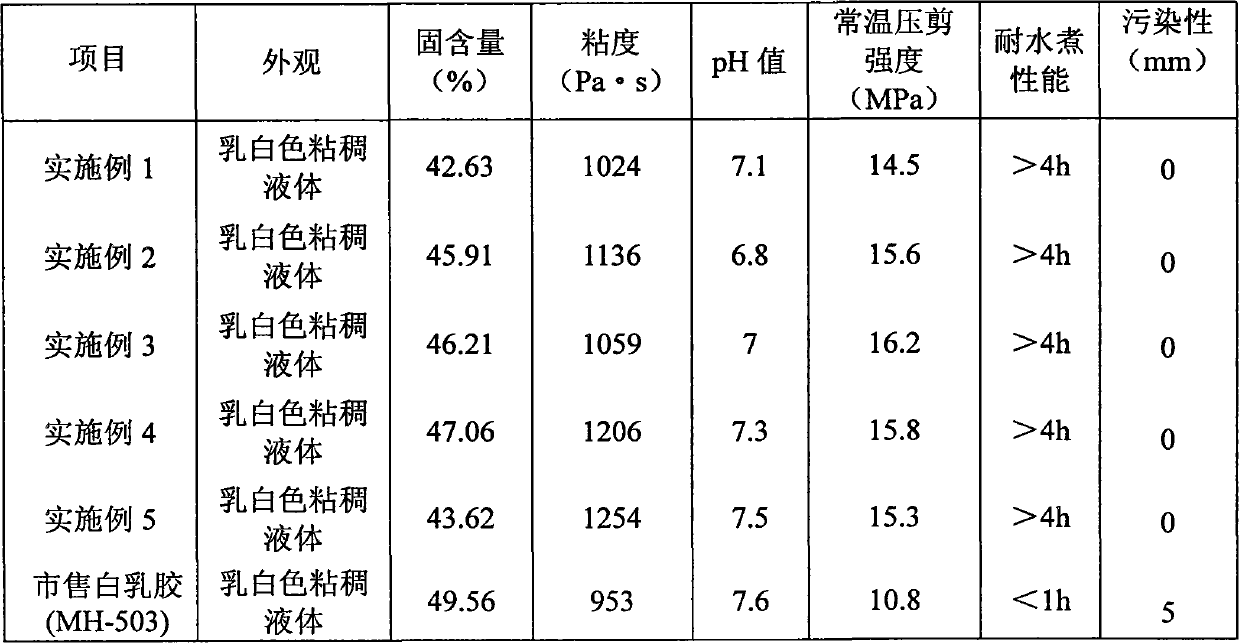

Modified white latex

InactiveCN103923581AHigh viscosityHigh bonding strengthMonocarboxylic acid ester polymer adhesivesRoom temperatureCarvacryl acetate

The invention discloses a modified white latex which comprises the following components in parts by weight: 10 parts of vinyl acetate, 0.7 part of acrylic acid, and 1.5 pars of butyl acrylate; the amount of an initiator is 0.3% of the sum of the amounts of acrylic acid and butyl acrylate, and the amount of an emulsifier is 2%-3% of the sum of the amounts of acrylic acid and butyl acrylate. The white latex after modification has high viscosity, can form a film at room temperature, has the advantages of relatively good bonding strength, relatively good water resistance and the like, and has relatively great market popularization value.

Owner:上海吉妮乳胶厂

Stress/Thermal Cracking Resistant Cable Sheath Material

InactiveUS20100101822A1Improve the immunityPlastic/resin/waxes insulatorsInsulated cablesCrazingEthyl acetate

A composition useful as a wire or cable insulation or sheathing layer, the composition comprising (i) an inorganic flame retardant, e.g., aluminum trihydroxide (ATH), (ii) ethylene ethyl acetate (EEA) or ethylene butyl acrylate (EBA), (iii) a homogeneous polyethylene, (iv) an ethylenic resin modified with an organo-functional group, e.g., maleic anhydride (MAH) grafted polyethylene, (v) a silicone polymer, and optionally, (vi) a smoke suppressant. The insulation or sheathing layer comprising the composition of this invention exhibits good resistance to stress and / or thermal cracking.

Owner:DOW GLOBAL TECH LLC

High-stripping-resistance acrylate pressure-sensitive adhesive and preparation method thereof

InactiveCN105315926AMeet different needsIncrease stickinessEster polymer adhesivesFunctional monomerButyl acrylate

The invention discloses a high-stripping-resistance acrylate pressure-sensitive adhesive and a preparation method thereof. The high-stripping-resistance acrylate pressure-sensitive adhesive is prepared from, by weight, 20%-30% of 2-ethylhexyl acrylate, 5%-15% of butyl acrylate, 4%-15% of vinyl acetate, 0.5%-3% of functional monomers, 30%-50% of solvent, 0.05%-0.15% of initiator and 10%-20% of tackifying resin. According to the high-stripping-resistance acrylate pressure-sensitive adhesive and the preparation method thereof, a certain amount of the tackifying resin is added, the reasonable coating process and curing condition are made, and an acrylate pressure-sensitive adhesive product which has high stripping resistance and good persistent adhesivity is prepared. The high-stripping-resistance acrylate pressure-sensitive adhesive has the advantages of being high in stripping strength, good in high-temperature persistent adhesivity and high in stability.

Owner:西安航天三沃化学有限公司

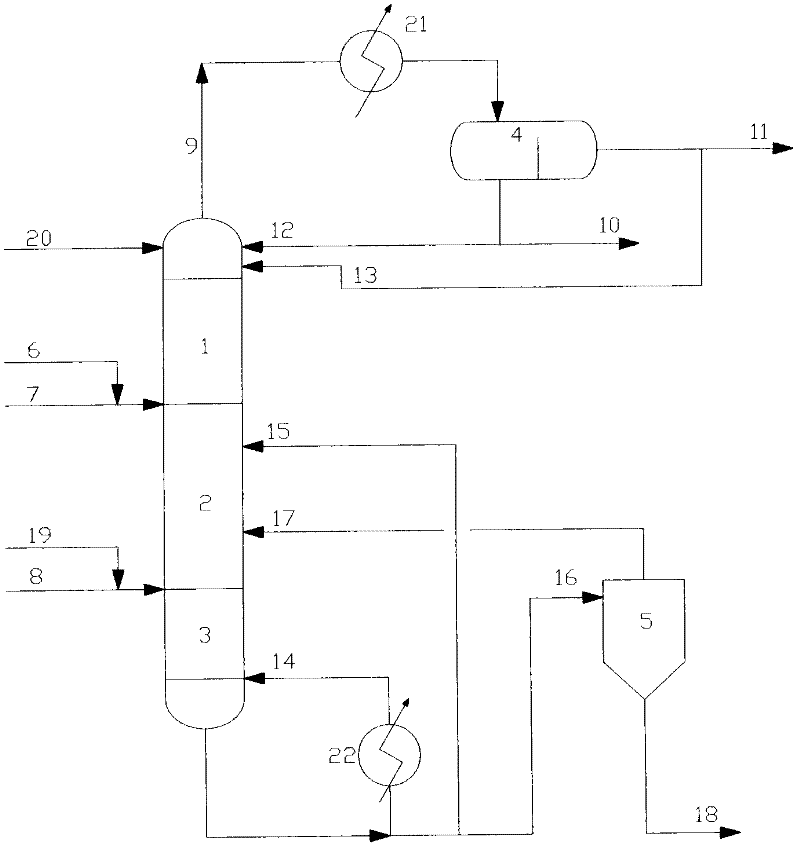

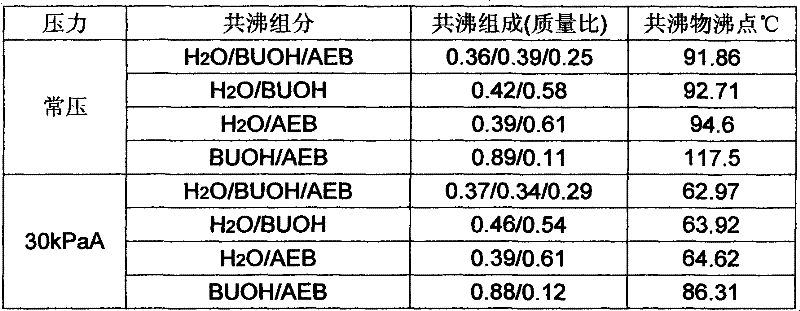

Preparation method of butyl acrylate

ActiveCN102249913AReduce concentrationQuick responseOrganic compound preparationCarboxylic acid esters preparationOrganic chemistryRaw material

The invention relates to a preparation method of butyl acrylate, which is characterized in that the synthesis of butyl acrylate is completed in a reaction rectifying tower, the separation of products and raw materials is completed through azeotropic rectification, and heavy components generated by the reaction in a stripping section and the tower are resolved into the raw materials and the products so as to finally obtain a butyl-acrylate-enriched organic phase having an acrylic acid content of 4ppm at the tower top.

Owner:SHANGHAI HUAYI NEW MATERIAL

Preparation method of polyacrylate emulsion containing silicon, fluorine and phosphate group

The invention relates to a preparation method of polyacrylate emulsion containing silicon, fluorine and a phosphate group. The polyacrylate emulsion is widely applied in the fields of leather, paper and architectural decoration and finishing paint due to excellent caking property, film-forming property and mechanical properties. According to the preparation method provided by the invention, butyl acrylate, methyl methacrylate, styrene, hydroxypropyl methacrylate, vinyl triethoxy silane, phosphate functional monomer and dedecafluoroheptyl methacrylate are taken as polymerization monomers, lauryl sodium sulphate and fatty alcohol-polyoxyethylene ether are taken as emulsifiers, peroxysulphate is taken as an initiator, and a pre-emulsification seeded emulsion polymerization process is adopted for preparing the polyacrylate emulsion. According to the polyacrylate emulsion obtained by adopting the preparation method provided by the invention, fluorine, silicon and the phosphate group are introduced into a molecular structure, flame retardance, low temperature resistance, corrosion resistance, water resistance, anti-scouring property, mechanical properties and adhesiveness with materials such as metal and cement of a polymer emulsion film are obviously improved, and the obtained polyacrylate emulsion can be applied to leather, textile, metal antirust paints and decorative finish paints for an internal wall and an external wall of a building material and has good development prospect.

Owner:南京紫鸿生物科技有限公司 +1

Inorganic nano particle modified composite waterproof emulsion and preparation method thereof

The invention provides inorganic nano particle modified composite waterproof emulsion and a preparation method thereof and belongs to the technical field of preparation of an exterior wall water-based paint. The composite waterproof emulsion comprises the following components in percentage by mass: 2 to 3 percent of acrylic acid, 15 to 20 percent of methyl methacrylate, 12 to 16 percent of butyl acrylate, 1 to 3 percent of other monomers, 2.4 to 4.8 percent of modified nano particle mixture, 1.5 to 3 percent of complex emulsifying agent, 0.4 to 0.8 percent of initiator, 2.4 to 4.8 percent of organic silicone monomer, a right amount of pH regulator, 45 to 55 percent of deionized water and 0.3 to 0.7 percent of buffering agent. In the invention, the addition speed, the addition ratio and the stirring speed of nano particles are strictly controlled. Compared with emulsion which is not modified, the prepared emulsion provided by the invention has the advantage that the waterproofness, themechanical strength, the self-cleaning property and the aging resistance of the emulsion are improved.

Owner:CHINA MCC17 GRP

Single-component polyvinylacetate binding agent and preparation method thereof

InactiveCN101906278AImprove water resistanceImprove heat resistanceMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesChemical industryPolyvinyl alcohol

The invention discloses a single-component polyvinylacetate binding agent and a preparation method thereof. The single-component polyvinylacetate binding agent comprises the following raw materials in percentage by weight: 48 to 52 percent of deionized water, 3 to 5 percent of polyvinyl alcohol, 25 to 40 percent of polyvinylacetate, 5 to 10 percent of butyl acrylate, 2 to 3 percent of hydroxyethyl acrylate, 1 to 3 percent of methyl acrylic acid, 10 to 15 percent of organic silicon, 2 to 3 percent of composite emulsifier, 0.1 to 0.9 percent of initiator, 0.1 to 0.3 percent of pH regulator and 5 to 10 percent of plasticizer. The binding agent of the invention is modified waterproof and high temperature-resistant white latex prepared by acrylic ester and organic silicon modification with polyvinyl alcohol as protective colloid and polyvinylacetate as a base stock. All technical indexes of the binding agent are beyond standards of chemical industry, the waterproof performance and high temperature resistance of the binding agent are high, the production process of the binding agent is simple, the cost of the binding agent is low, and thus, the binding agent is a safe and environmentally-friendly product.

Owner:SOUTH CHINA UNIV OF TECH

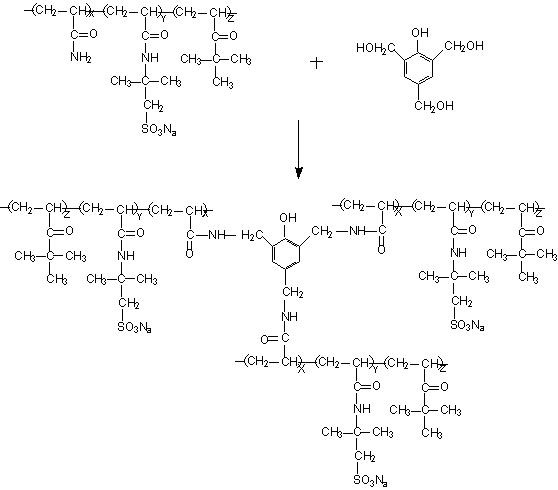

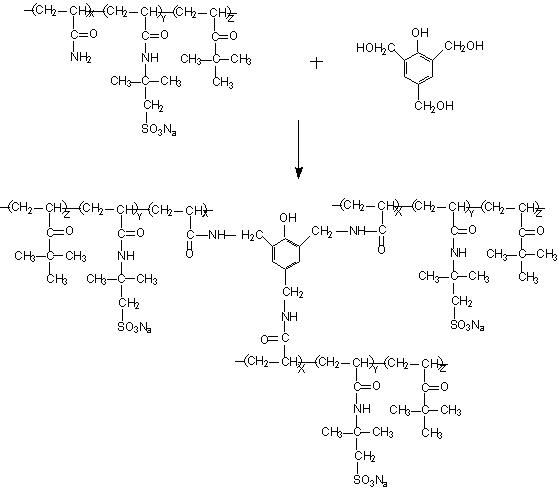

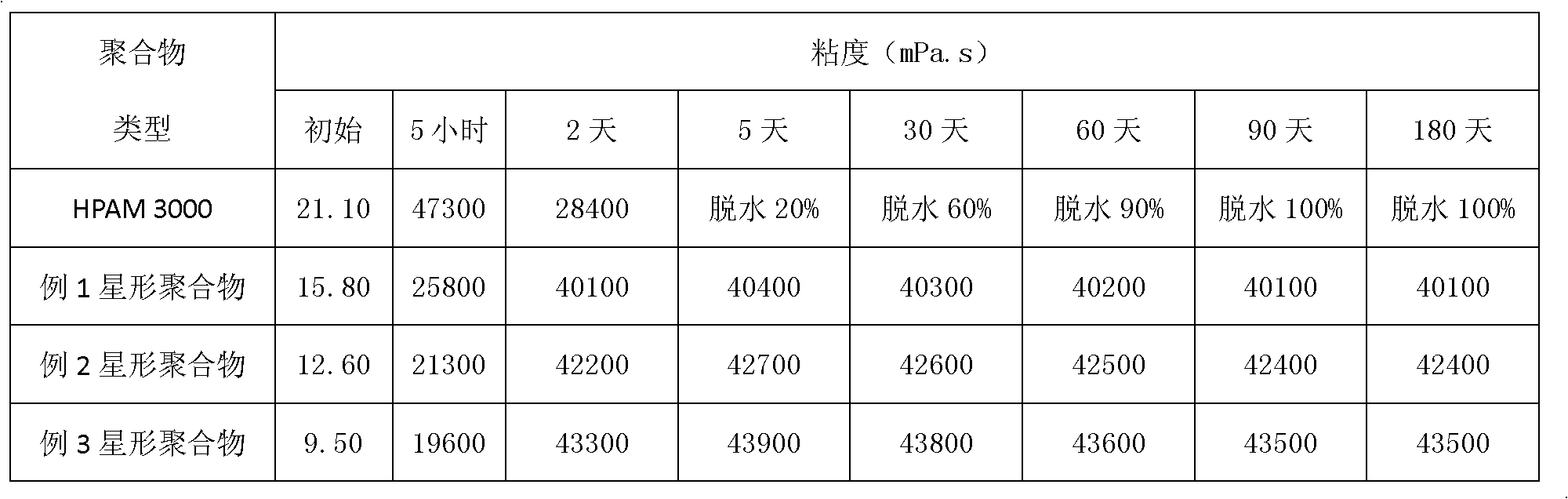

Preparation method of star polymer

ActiveCN102093505AHigh molecular weightLower the polymerization initiation temperaturePolymer scienceMeth-

The invention discloses a preparation method of a star polymer, belonging to the technical field of petroleum extraction. The method adopts a redox initiation system, and carries out water solution radical copolymerization on three water-soluble monomers, including tert-butyl acrylate, 2-acrylamido-2-methylpropane sulfonic acid and acrylamide. The redox initiation system comprises trihydroxymethyl phenol, persulfate, hydrogen peroxide, urea, sodium formaldehyde bisulfite, azoisobutyronitrile, chain transfer agent and surfactant. The molecular weight of the star polymer prepared by the method is 8-15 million; the star polymer is water-soluble; the content of the residual monomers in the product is less than or equal to 0.1 wt%; and the star polymer and a crosslinking system, which is composed of water-soluble phenolic resin and polyethylene imine, can form a movable gel system for carrying out deep profile control on a high-temperature high-salt oil reservoir of which the salinity is 117000 mg / L and the temperature is 140 DEG C.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com