Preparation method of butyl acrylate

A technology of butyl acrylate and acrylic acid, which is applied in the field of preparation of organic compounds, can solve the problems of large reactor volume and low reaction rate, and achieve the effects of simplified separation process, fast reaction speed and reduced concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

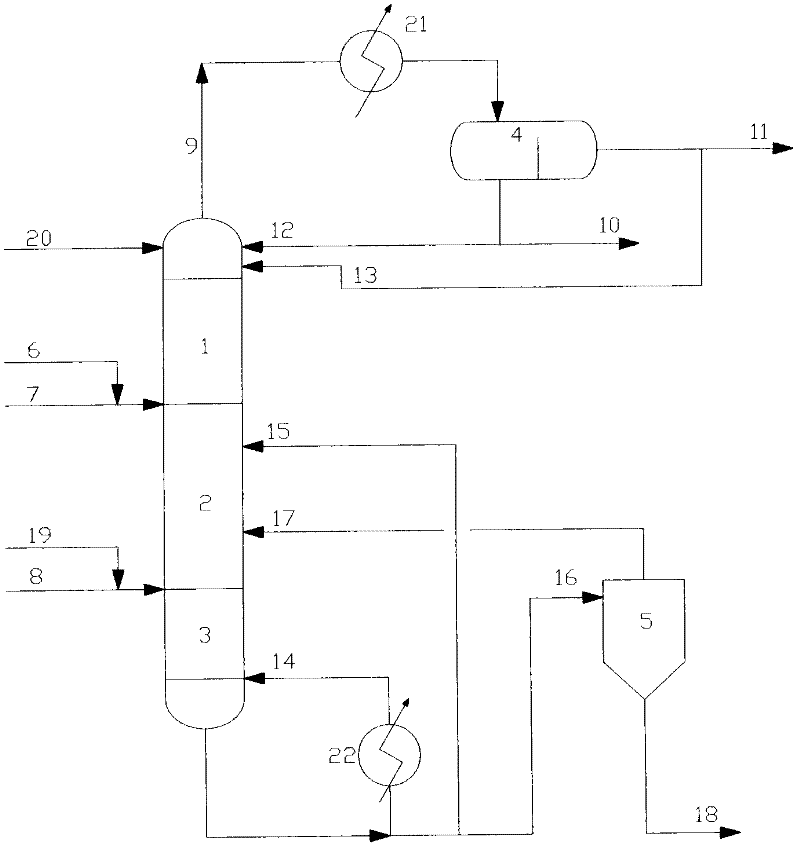

[0031] see figure 1 , which shows a schematic flow diagram of the principle of the rectification column system mentioned in the method of the present invention. 1 is the rectification section of the rectification tower, 2 is the reaction section, 3 is the stripping section, 4 is the condensate phase separation tank, 5 is the thin-film evaporator, 21 is the overhead condenser, and 22 is the tower kettle reboiler; The fresh AA is sent to the first plate of the reaction section by the pipeline 7, the fresh BuOH is sent to the bottom plate of the reaction section by the pipeline 8, and the supplemented fresh catalyst solution is sent to the first plate of the reaction section by the pipeline 6, and the polymerization inhibitor is passed through Pipeline 20 joins the first plate at the top of the tower; AA reacts with BuOH in the liquid layer on the plate of the reaction section, and the AEB and H produced simultaneously 2 O, BuOH distill out the liquid phase under the effect of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com