Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

8175results about How to "Improve sound insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

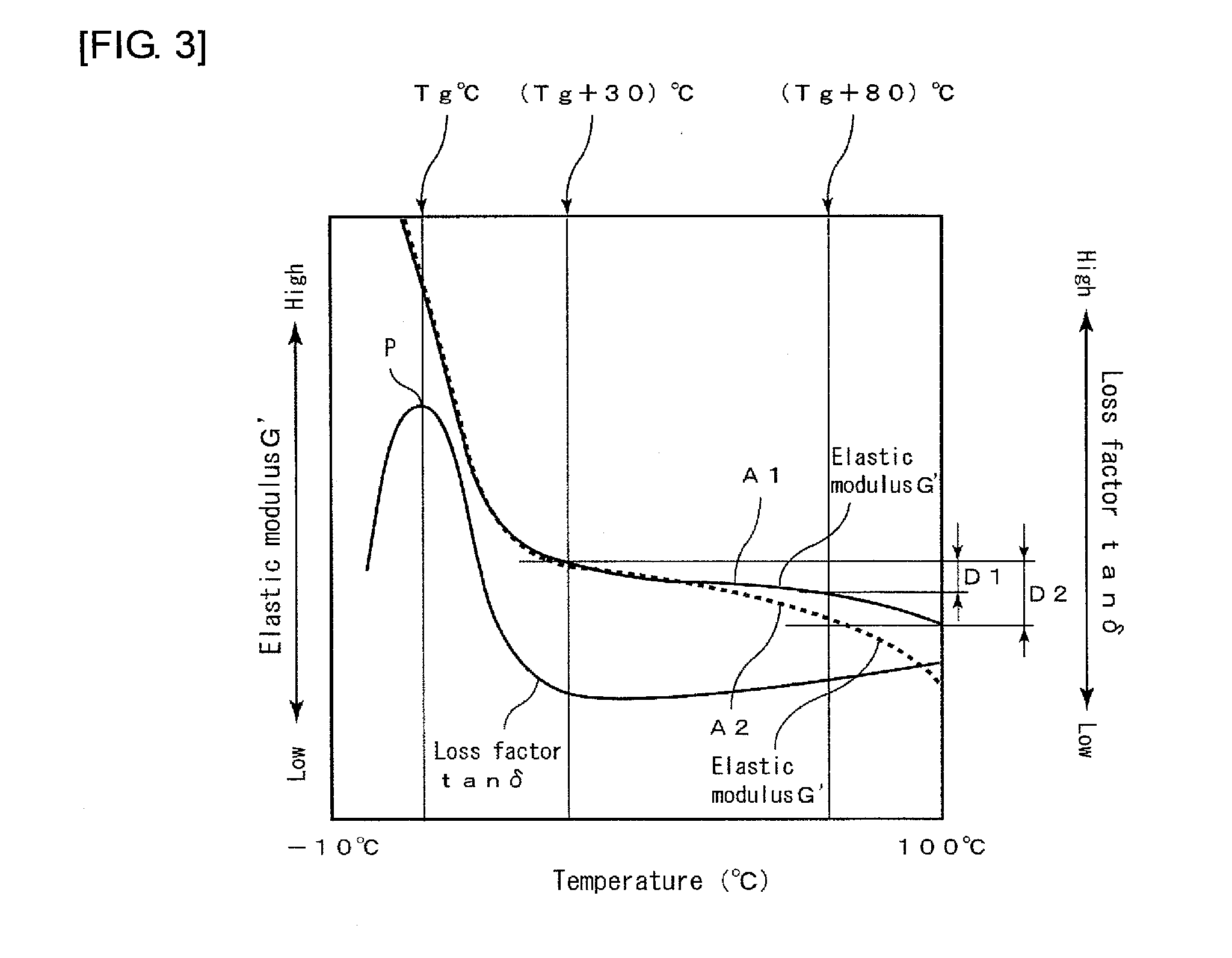

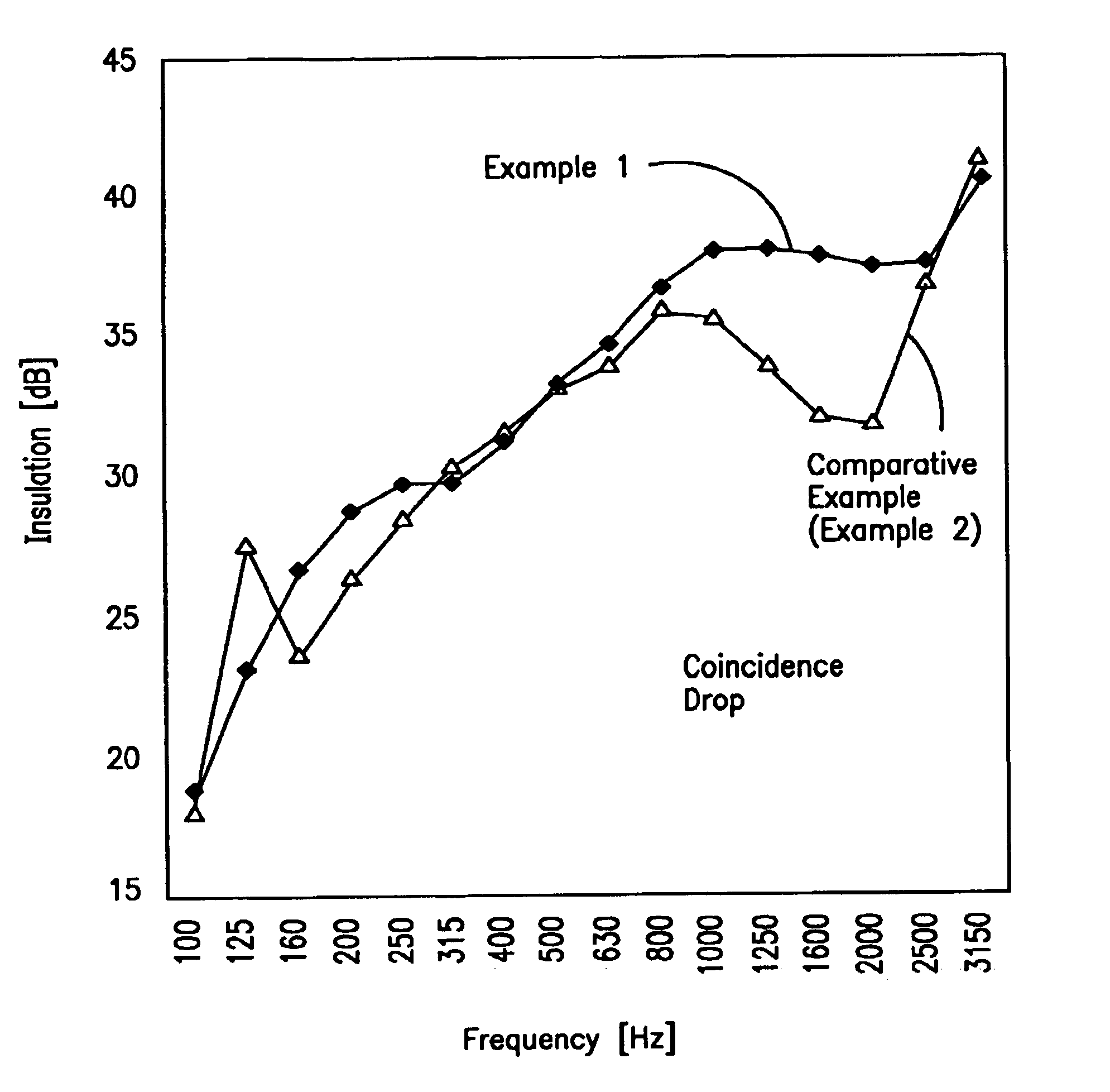

Interlayer film for laminated glass and laminated glass

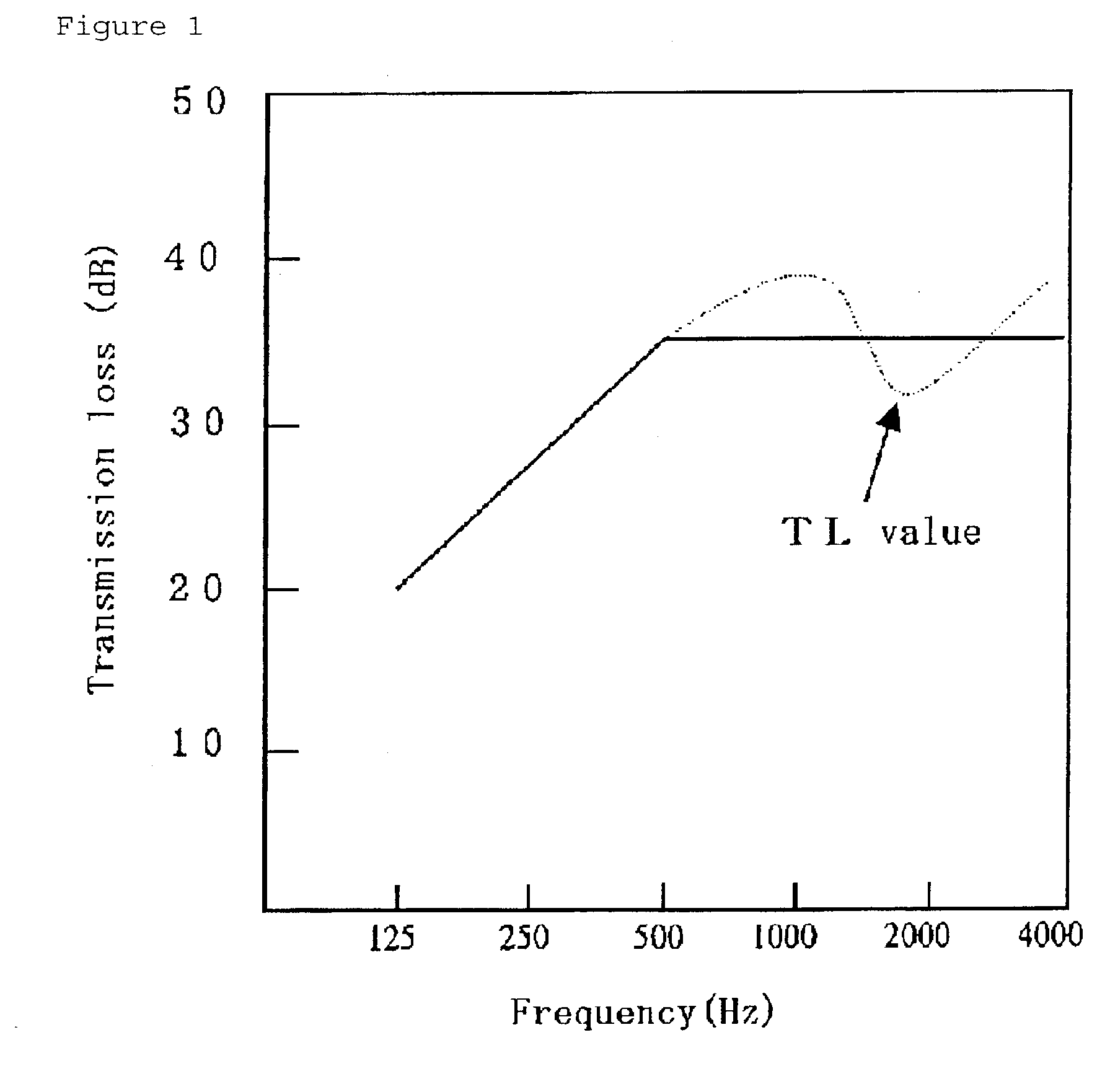

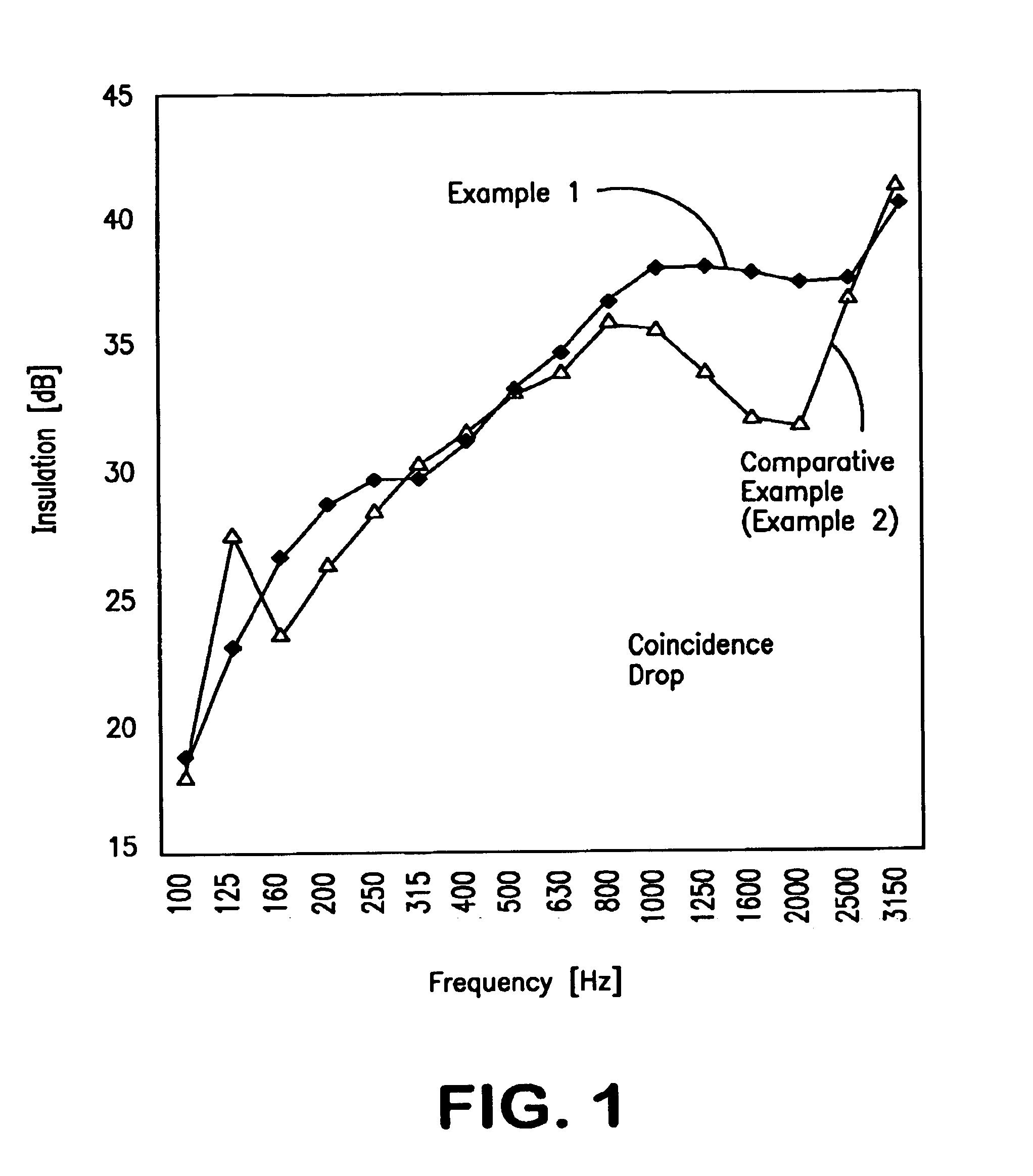

InactiveUS20030139520A1Improve adhesionHigh transparencyNon-fibrous pulp additionFibre treatmentChemistryUltrasound attenuation

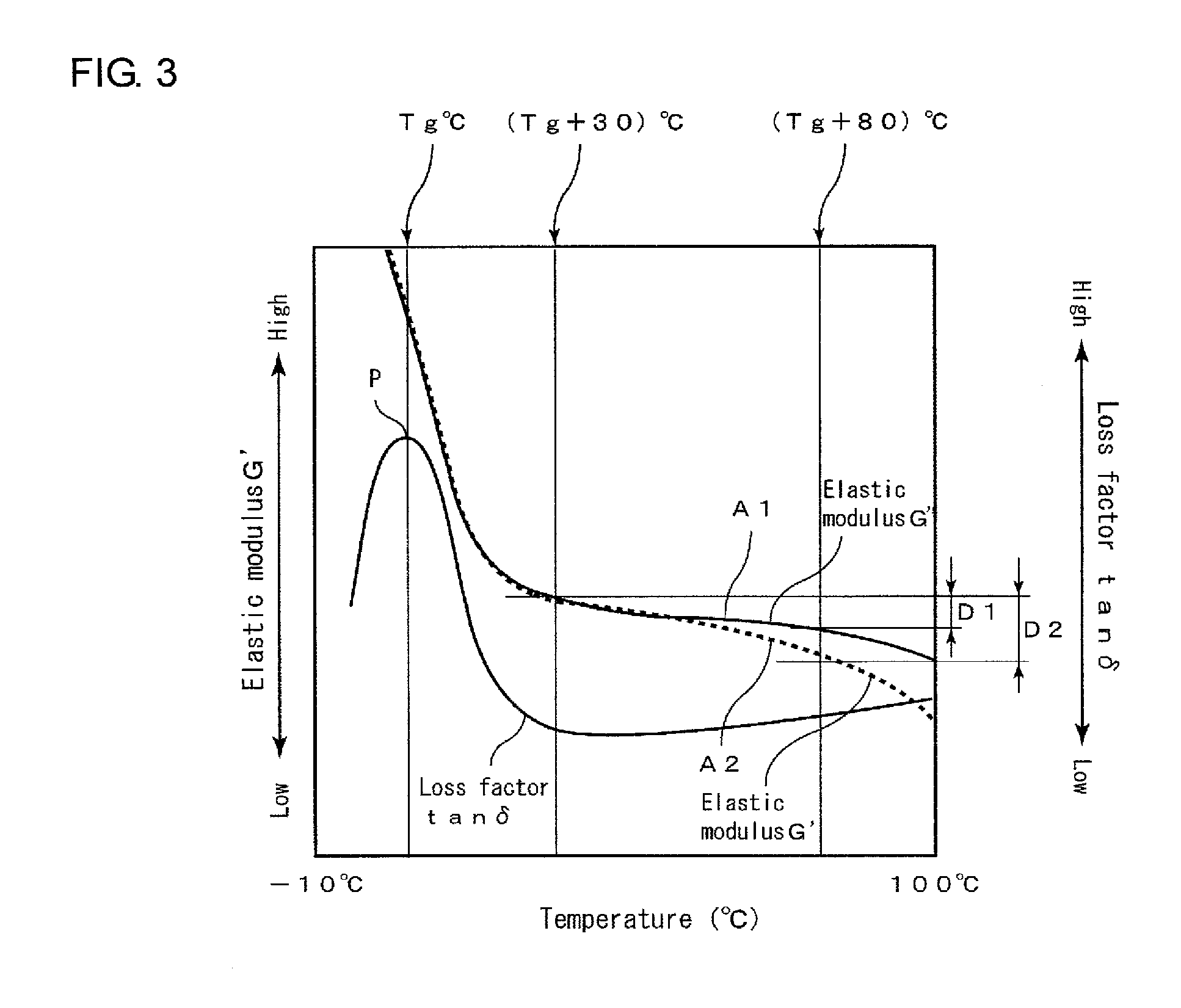

The invention provides an interlayer film for a laminated glass and a laminated glass, which are protected against a slump in TL value through attenuation of said coincidence effect and adapted to display an outstanding sound insulation performance over a broad temperature range. An interlayer film for a laminated glass comprising a plasticizer and a polyacetal resin, which is a blend of a polyacetal resin having an average polymerization degree of 1,000 to 3,000 and a polyacetal resin having an average polymerization degree of 3,000 to 5,000, and which has an acetalization degree of 60 to 85 mol % and an acetyl group content of 8 to 30 mol %. An interlayer film for a laminated glass which shows a temperature dependence of loss tangent in which the lowest-temperature side maximum of loss tangent appears at 30° C. or lower when examined for dynamic viscoelasticity.

Owner:SEKISUI CHEM CO LTD

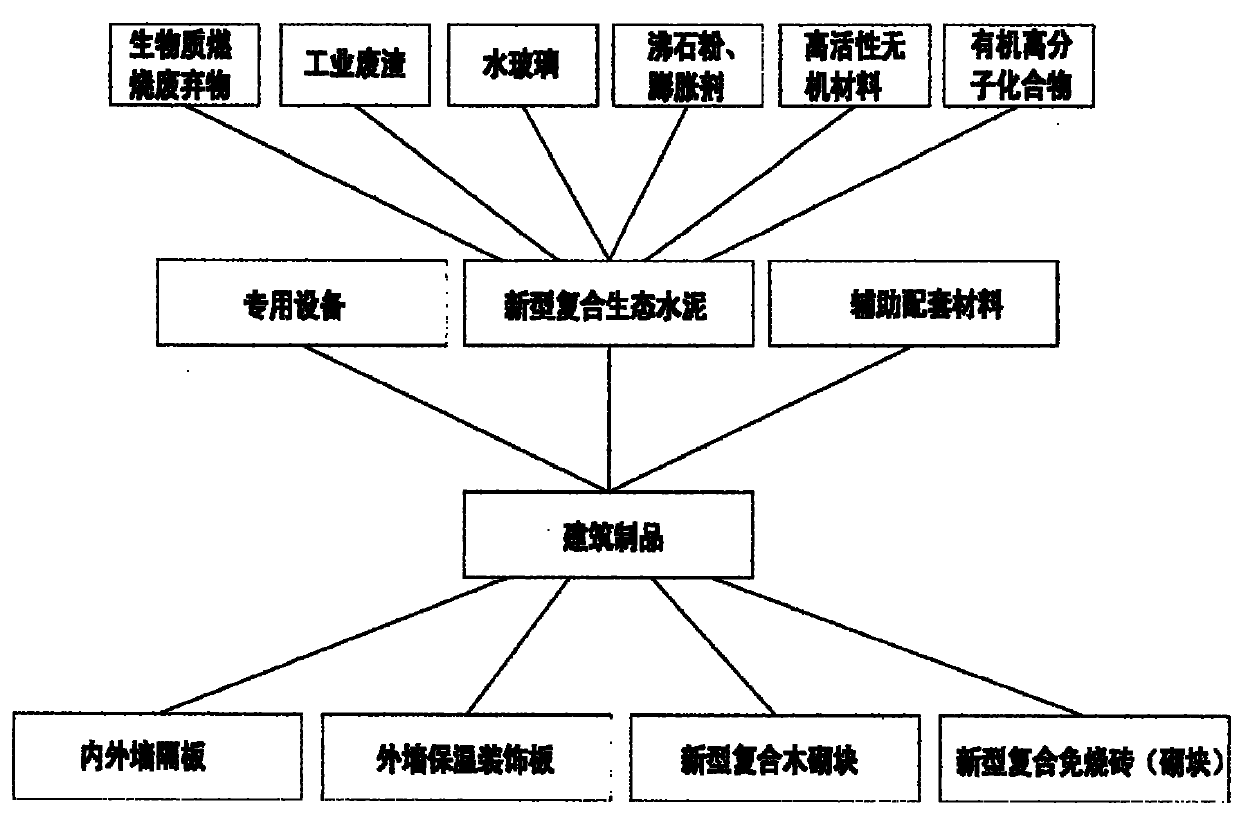

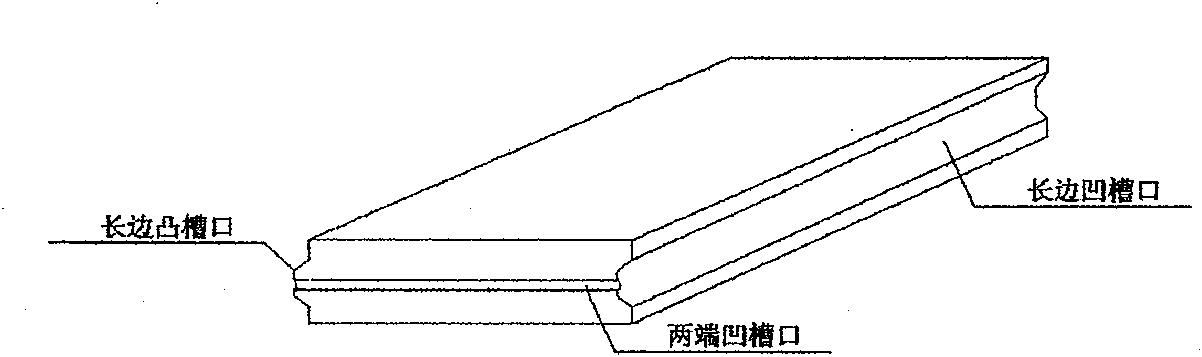

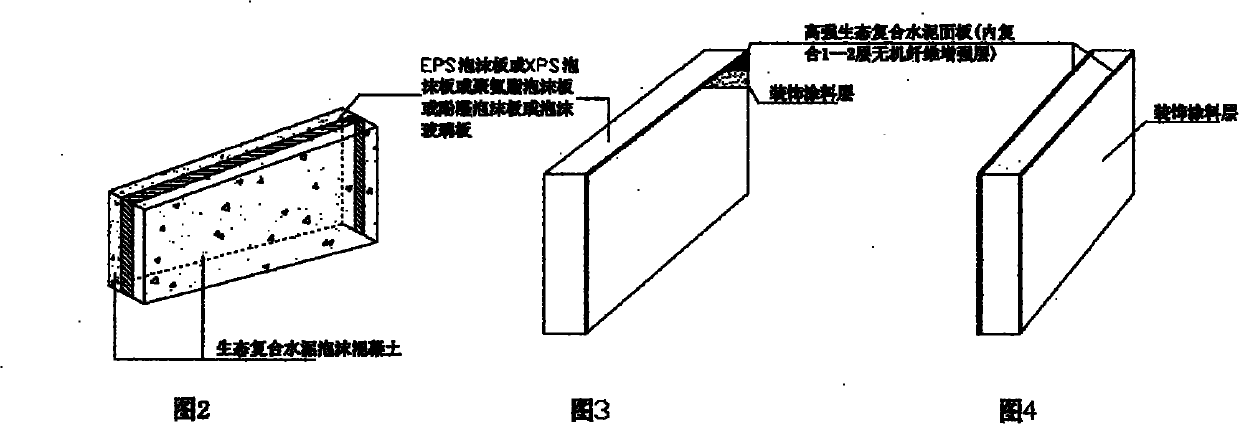

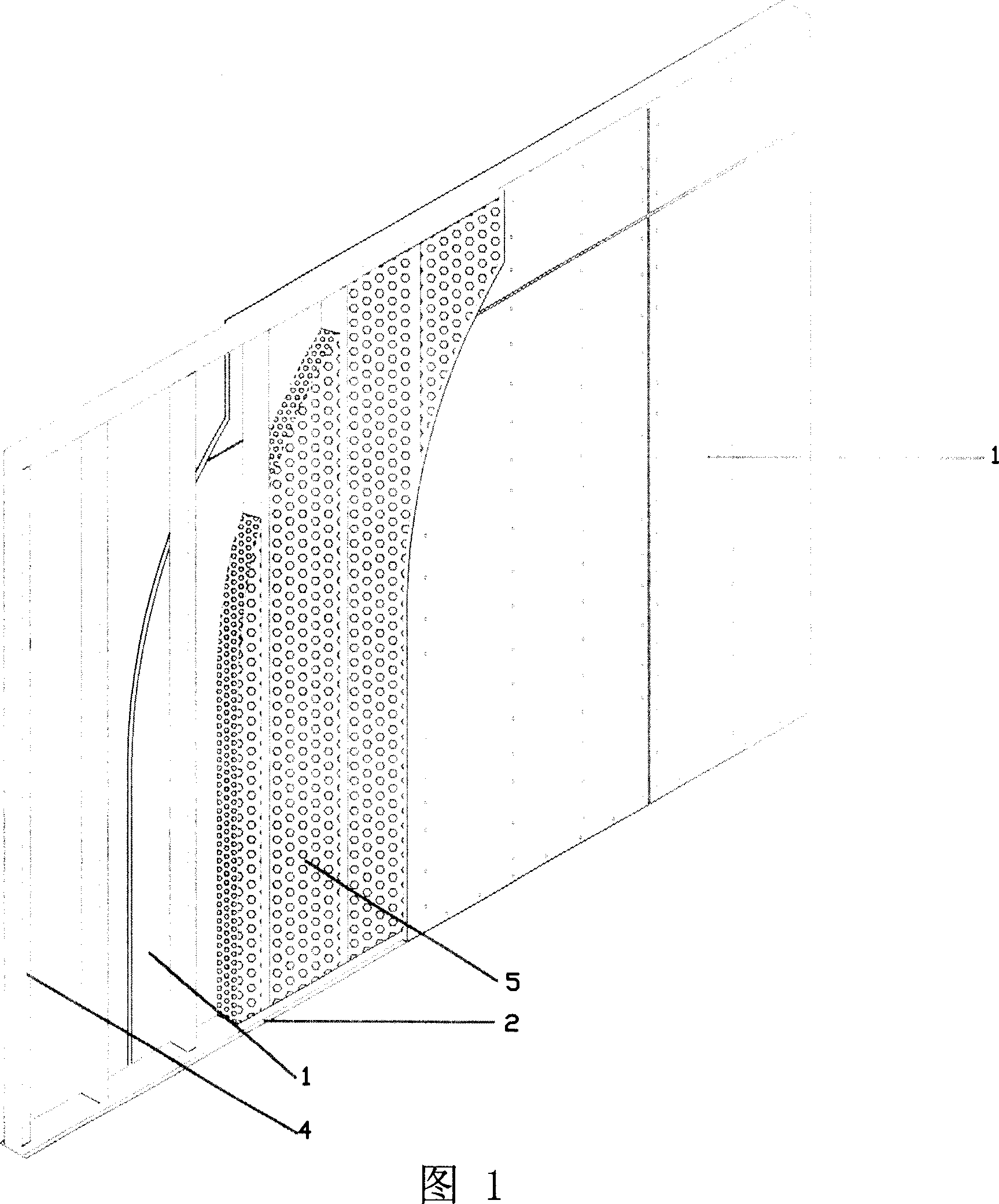

Novel composite ecological cement and product application thereof

InactiveCN101844883AWide range of applicationsHigh market demandSolid waste managementCeramicwareHigh intensityRenewable resource

The invention discloses composite ecological cement produced by using reproducible biomass combustion wastes, industrial residues and the like as main raw materials (the utilization ratio of the biomass combustion wastes and the industrial residues is over 80 percent). The novel gelling material namely the composite ecological cement is combined with other environment-friendly materials such as a paper honeycomb panel and the like to compound and manufacture a novel environment-friendly building product, such as a novel super-lightweight high-strength inner wall composite partition plate (having a dead weight of about 19 kilograms per square meter) special for novel high-rise and multi-layer frame constructions, a 65 percent self-heat preservation lightweight high-strength outer wall partition plate, an outer wall heat preservation and decoration integrative plate, a novel composite wood building block, a novel composite baking-free brick, novel bubble concrete and the like; and all the products are detected by a national level building material detection institution, reach a related product quality standard, are manufactured in factory by using specified machinery, are mounted and manufactured on site and are efficient and economical. The composite ecological cement uses various reproducible resources and various reclaimable wastes to the utmost extent, protects the environment, saves energy, reduces discharge and the overall comprehensive engineering manufacturing cost, and has important economic and social benefits.

Owner:汪超

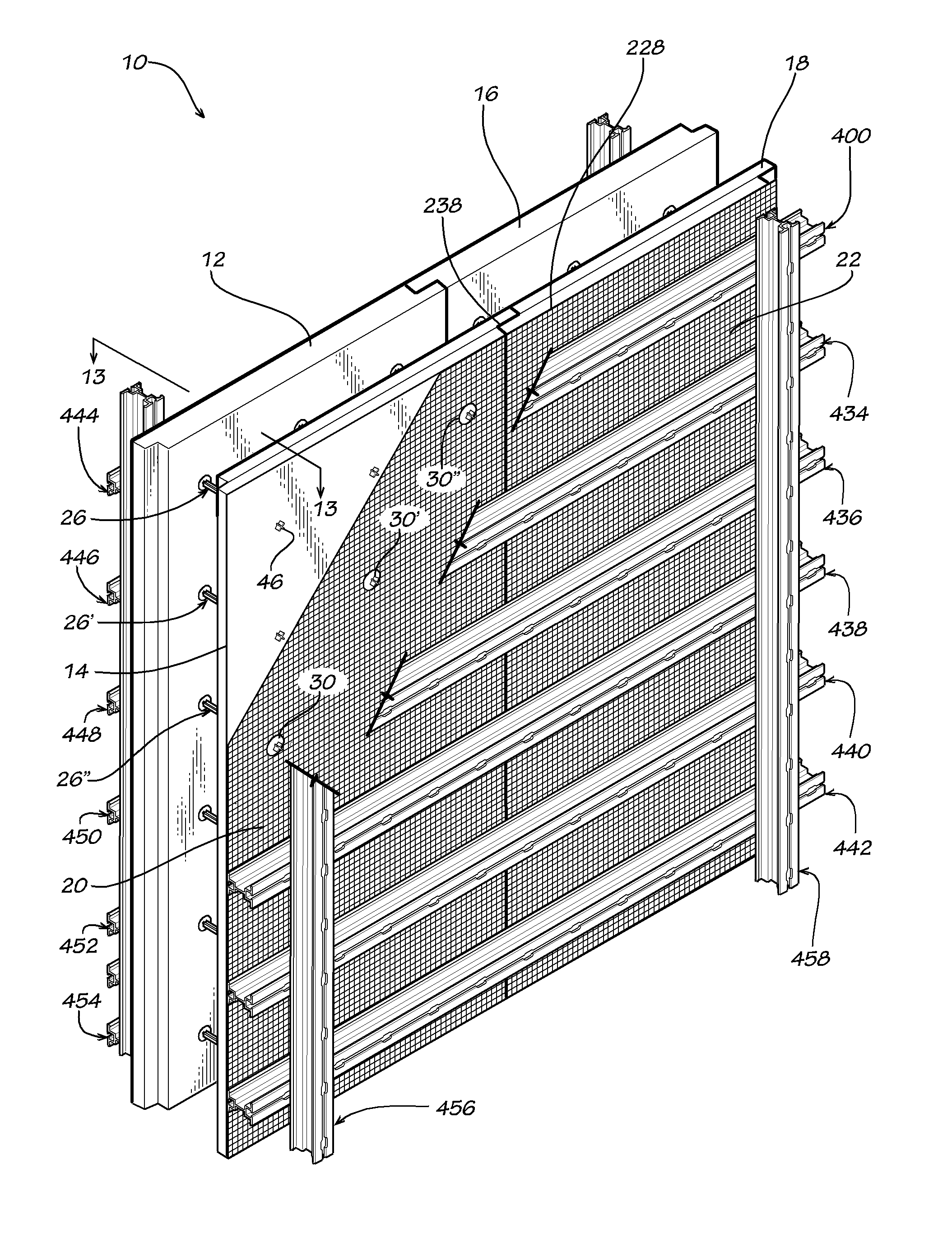

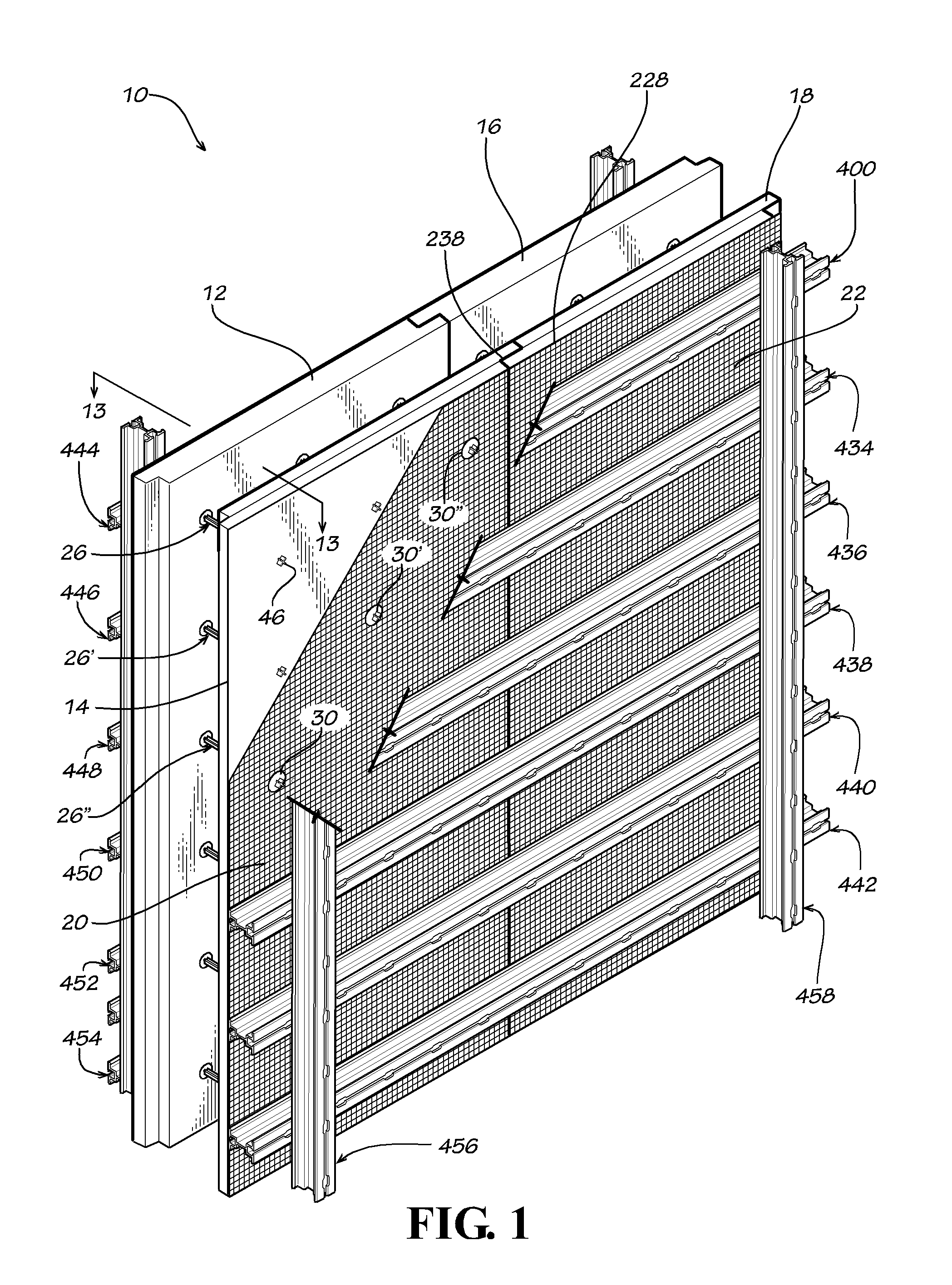

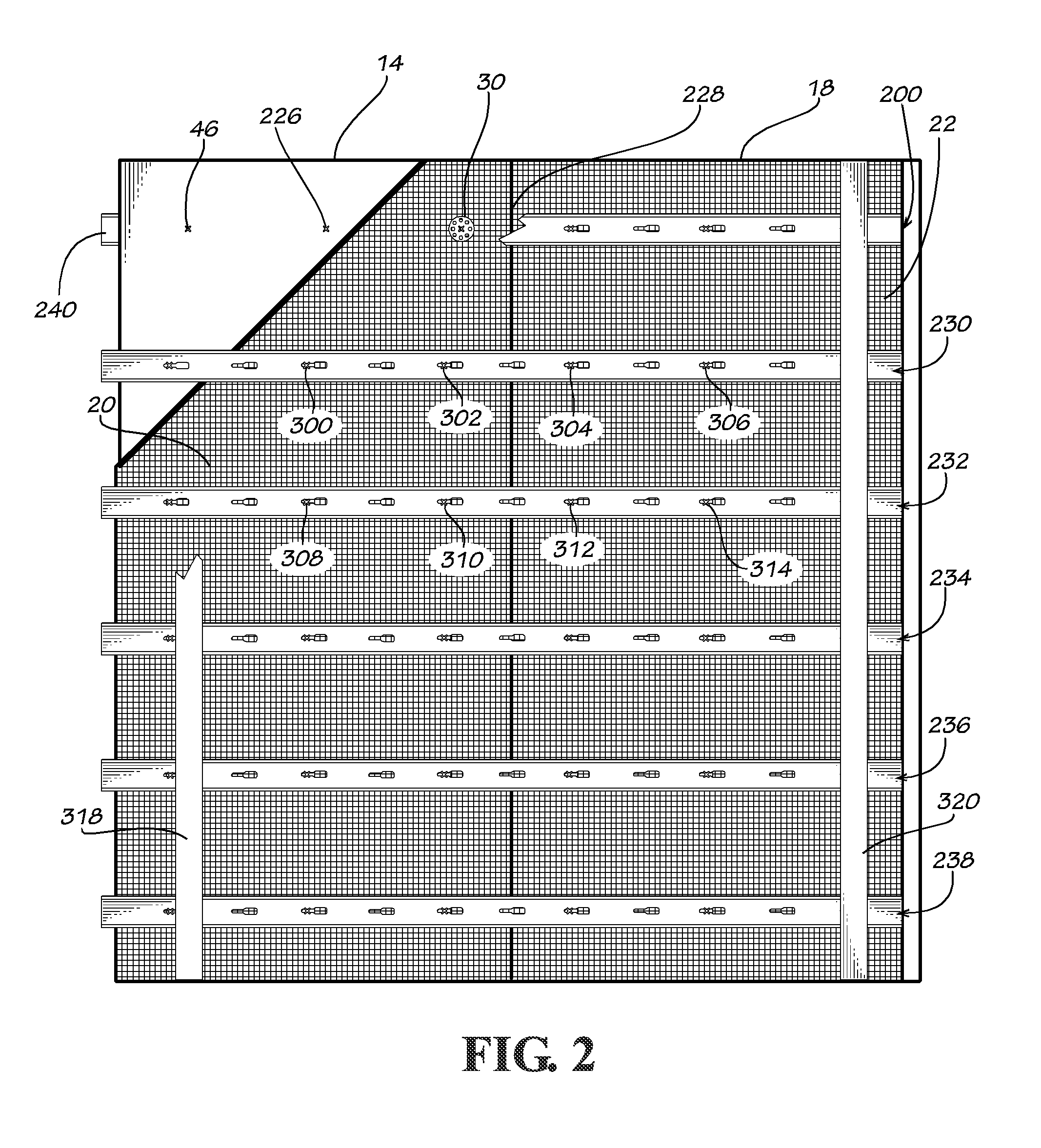

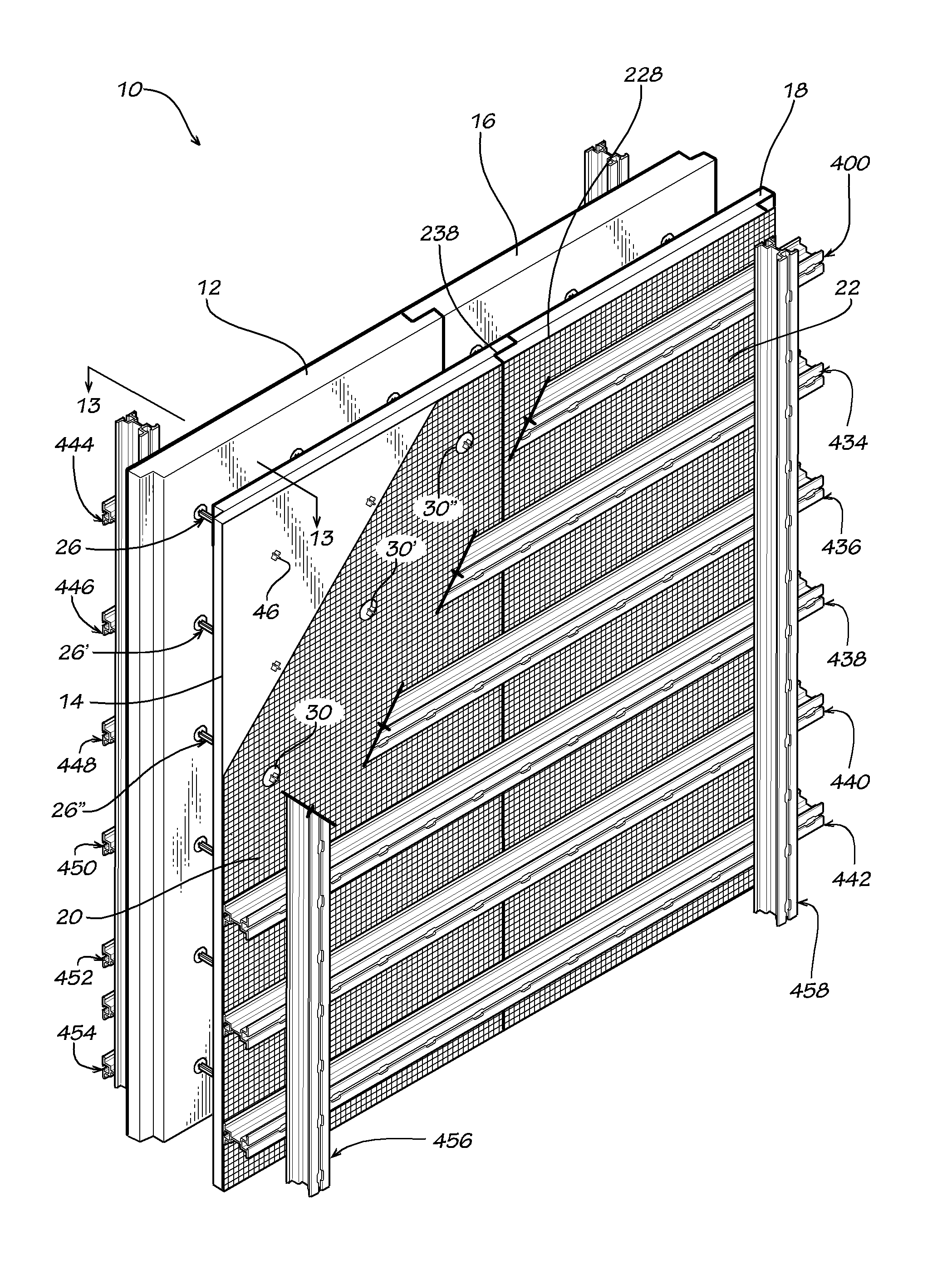

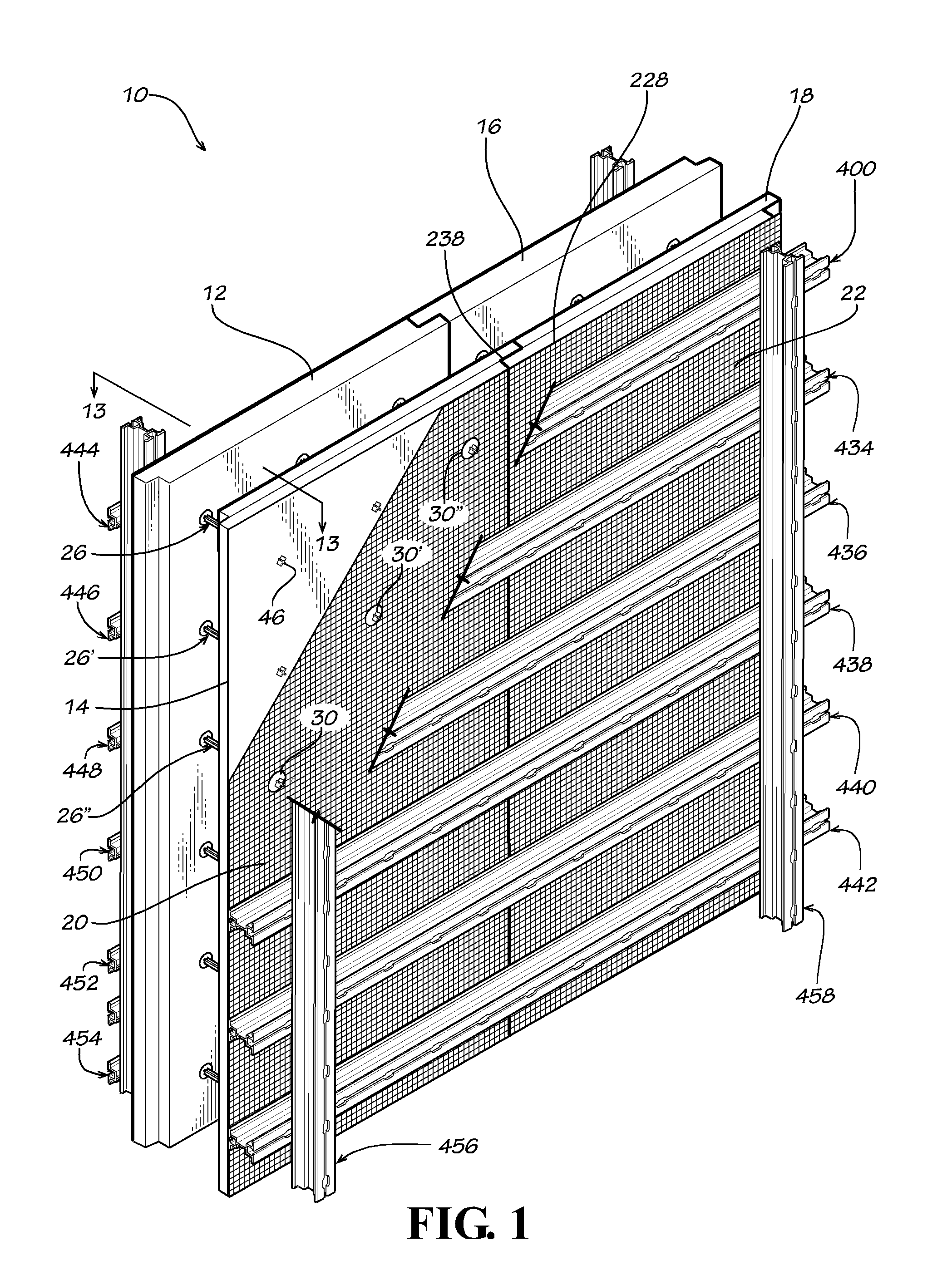

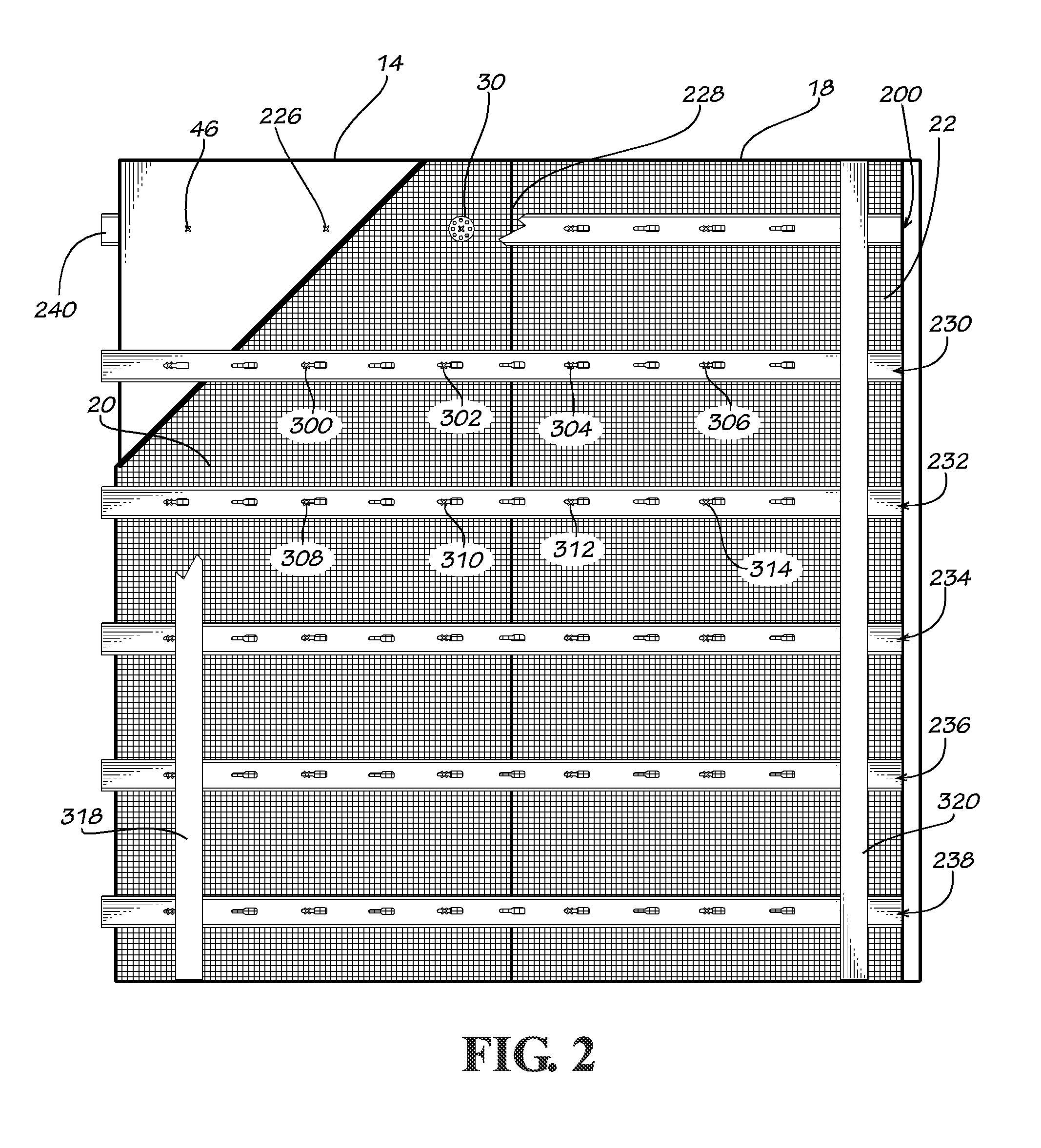

Insulated concrete form and method of using same

InactiveUS20130074432A1Retain heatEasy and inexpensive attachmentCeilingsConstruction materialInsulating concrete formFlange

Owner:CIUPERCA ROMEO ILARIAN

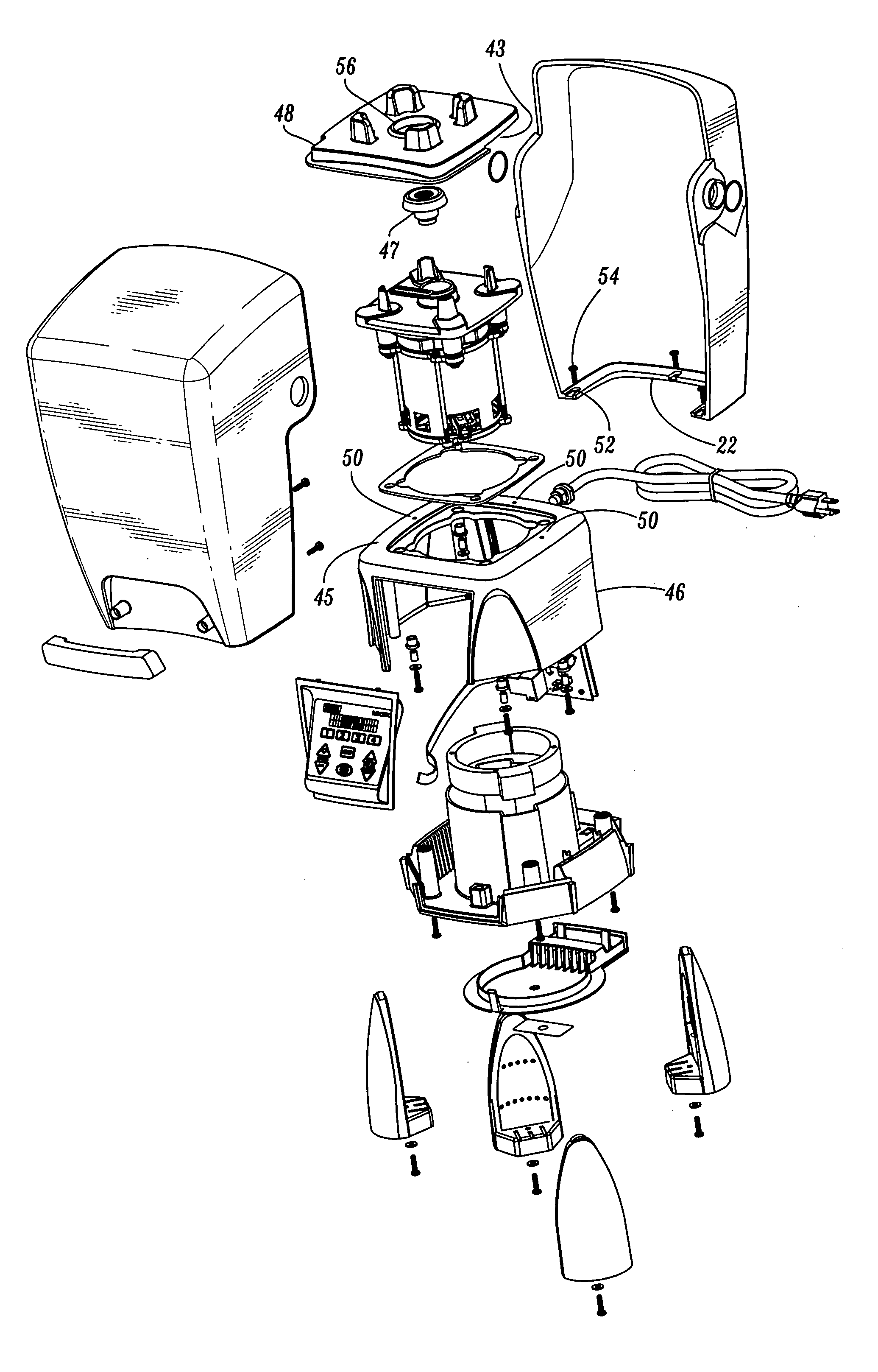

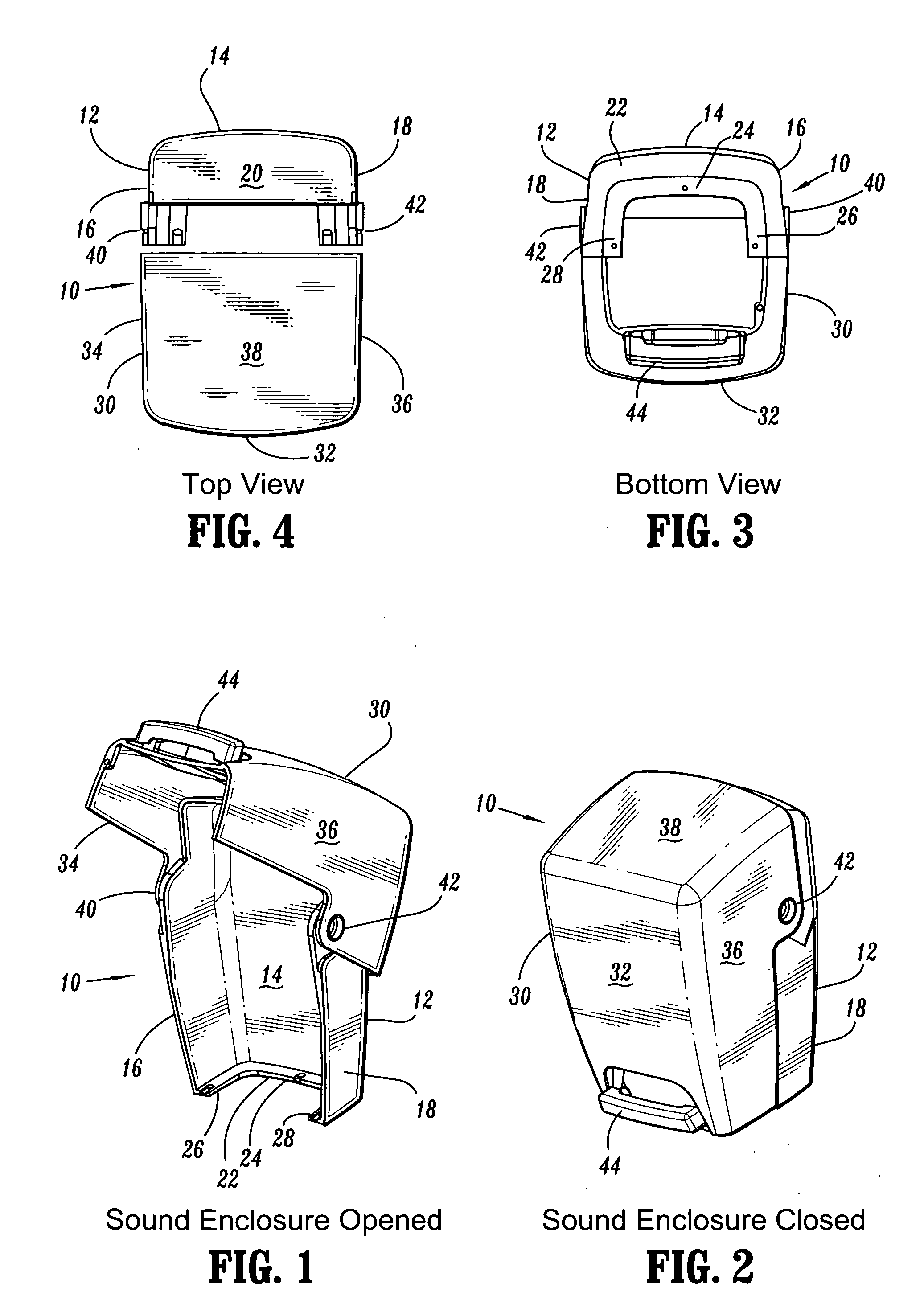

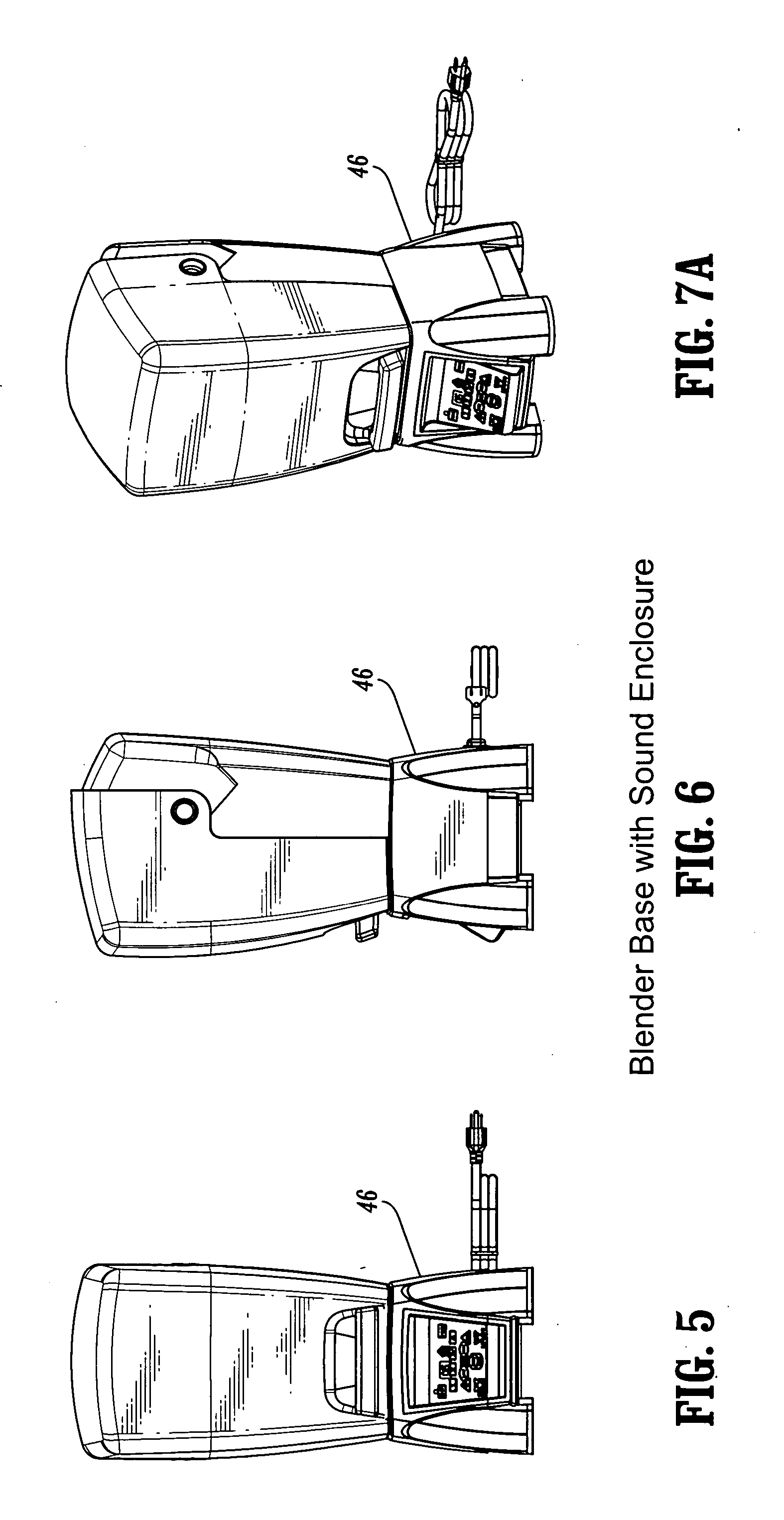

Blender and sound-dampening enclosure

InactiveUS20050152215A1Low external profileEasily attachRotary stirring mixersKitchen equipmentEngineeringControl logic

A blender has novel sound-dampening enclosure system that is selectively and conveniently attached to and detached from a blender, or retro-fitted to a blender, utilizing a bottom wall portion for engaging a blender jar base in a fixed manner. Another aspect of the blender includes a simplified control logic using a minimal number of input buttons and using user-prompts.

Owner:CONAIR CORP

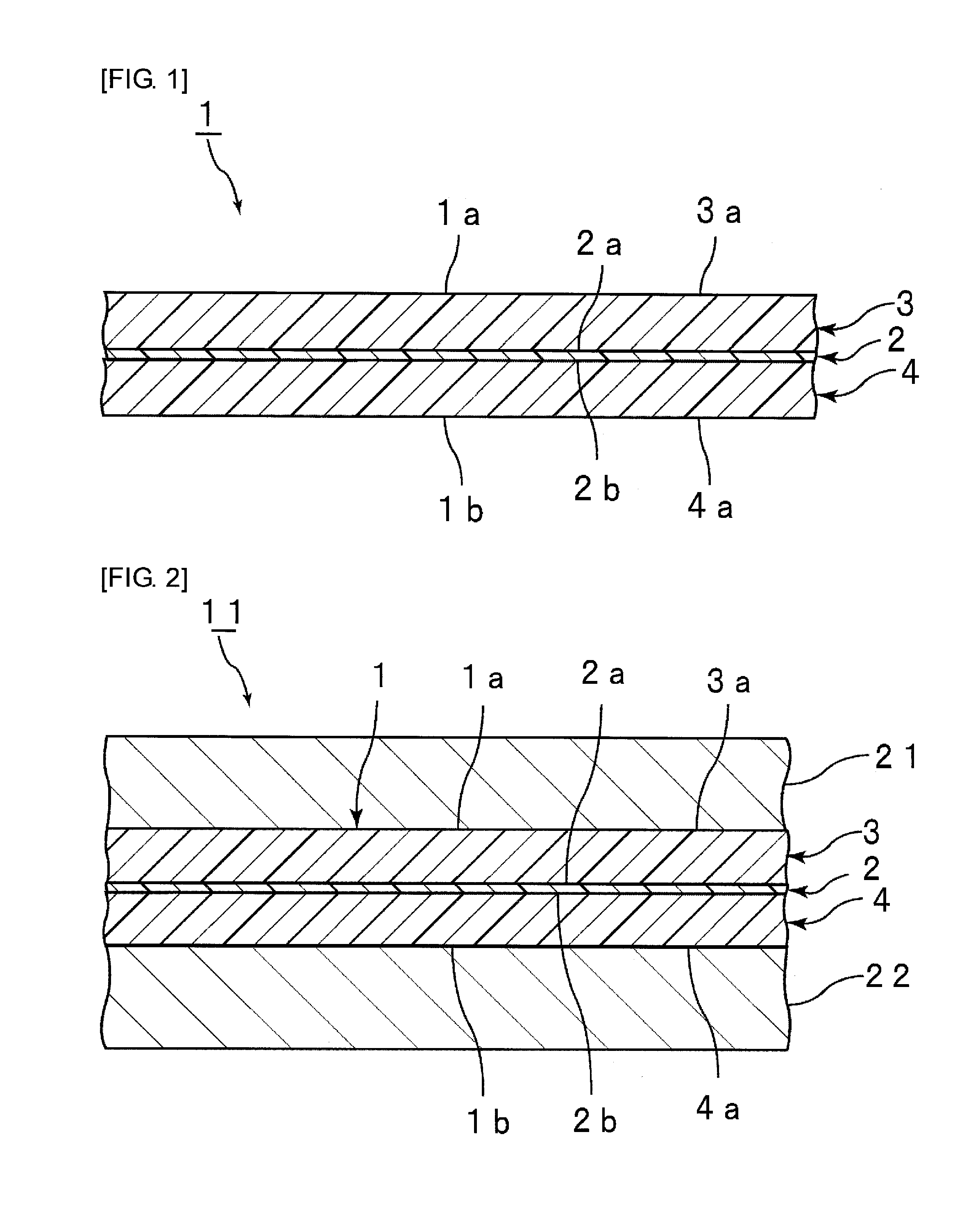

Intermediate film for laminated glass and laminated glass

InactiveUS20130183507A1Improve sound insulationAntiglare equipmentSynthetic resin layered productsPolyvinyl alcoholPlasticizer

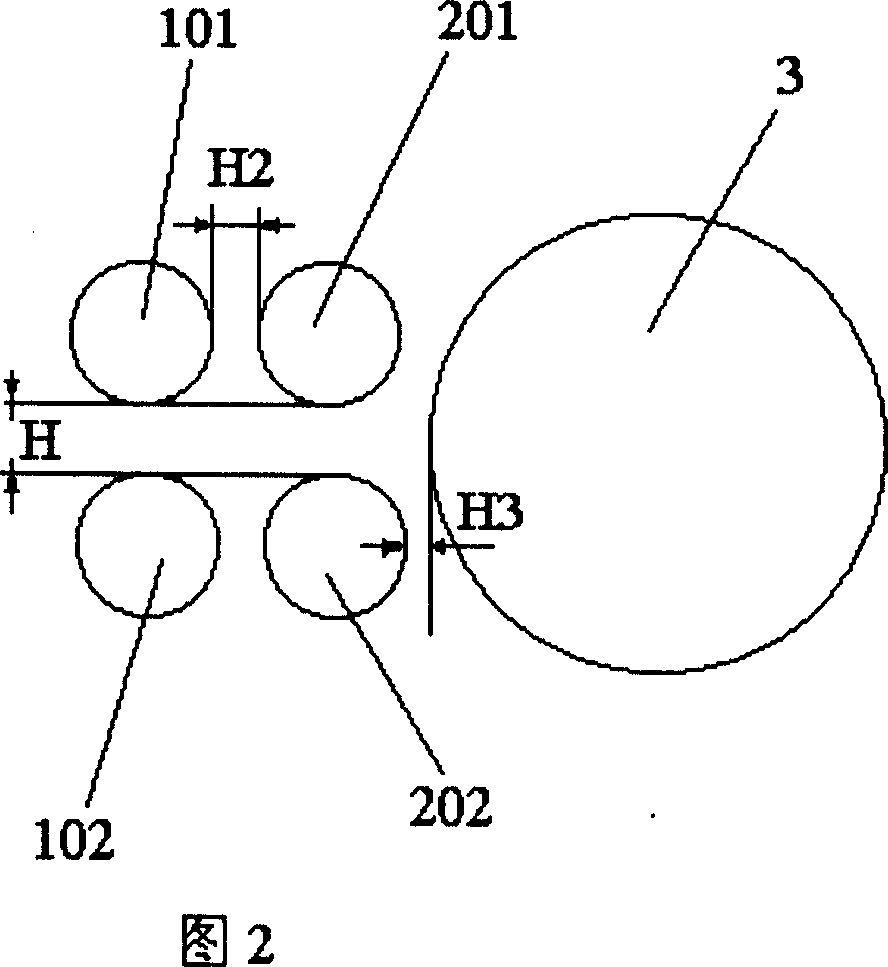

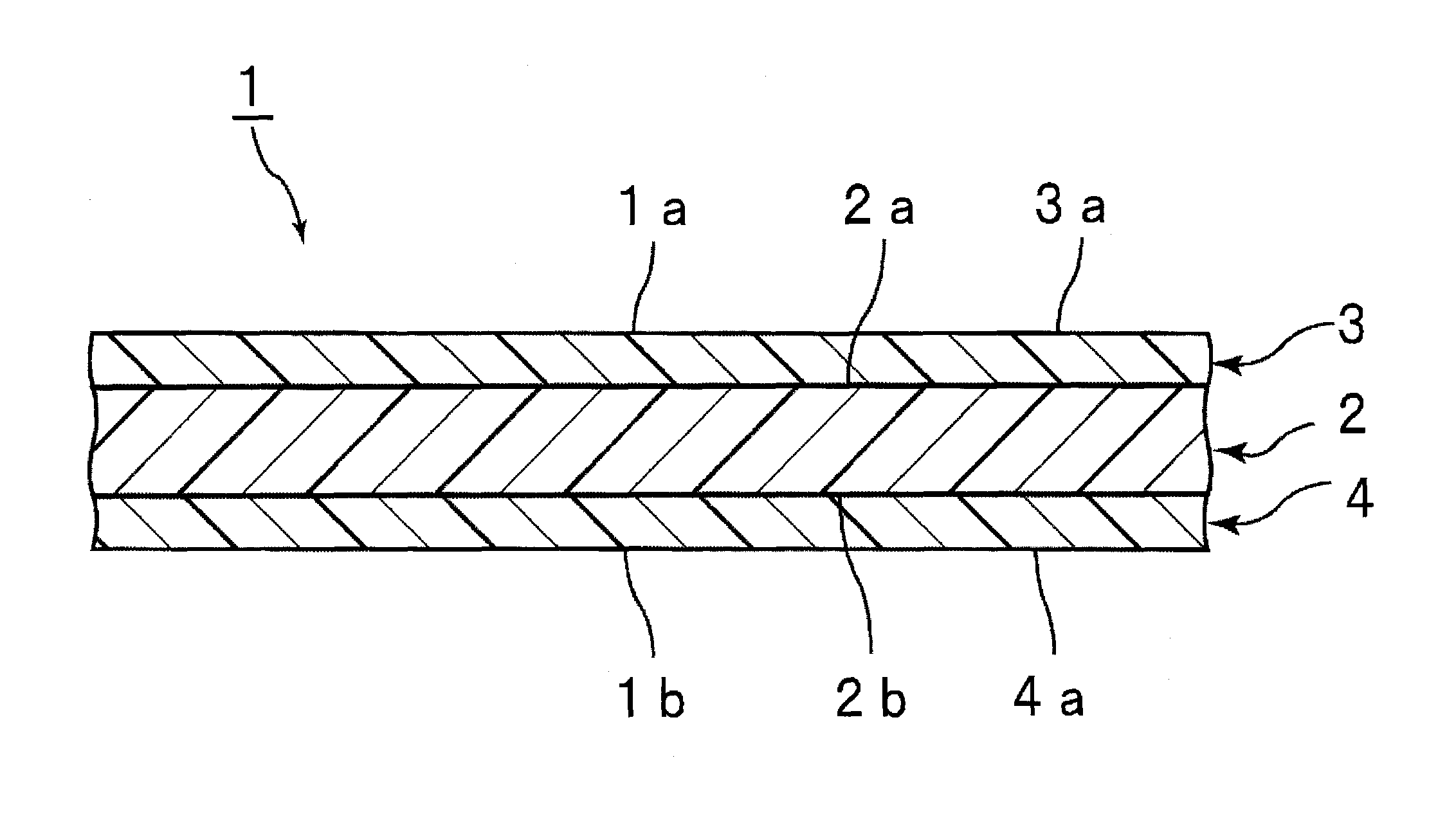

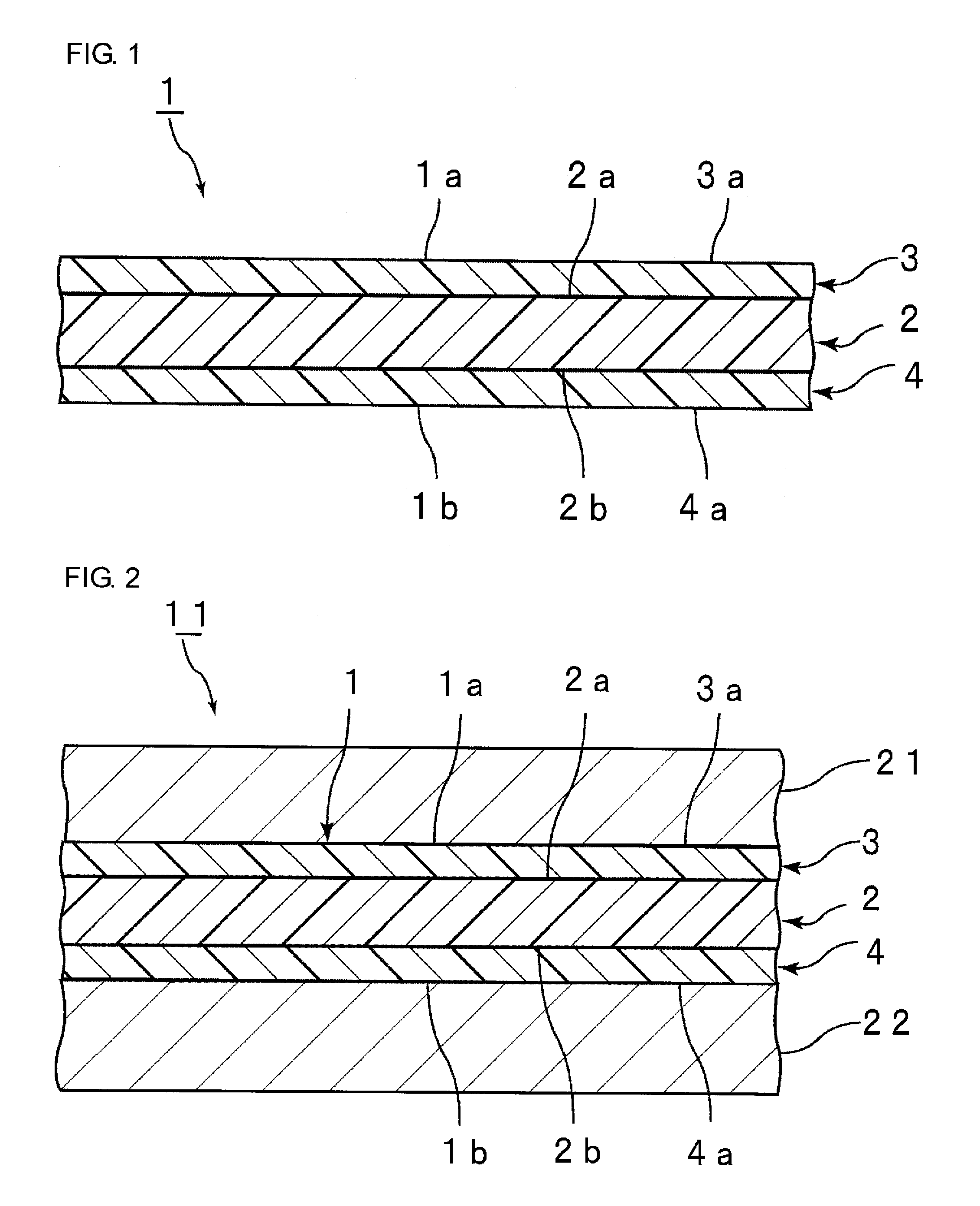

The present invention aims to provide an intermediate film for laminated glass which, in the case of being used for constituting a laminated glass, enables to improve the sound-insulating property in a high frequency range of the obtained laminated glass over a wide range of temperature. The intermediate film for laminated glass of the present invention 1 has a structure that a first layer 2, a second layer 3, and a third layer 4 are laminated in this order, each of the first, second, and third layers 2, 3, and 4 contains a polyvinyl acetal resin and a plasticizer, the hydroxy group content in the polyvinyl acetal resin contained in the first layer 2 is lower than each of the hydroxy group contents in the polyvinyl acetal resins contained in the second and third layers 3 and 4, and the ratio (T1 / (T2+T3)) of the thickness (T1) of the first layer 2 to the total thickness (T2+T3) of the second and third layers 3 and 4 is 0.14 or lower.

Owner:SEKISUI CHEM CO LTD

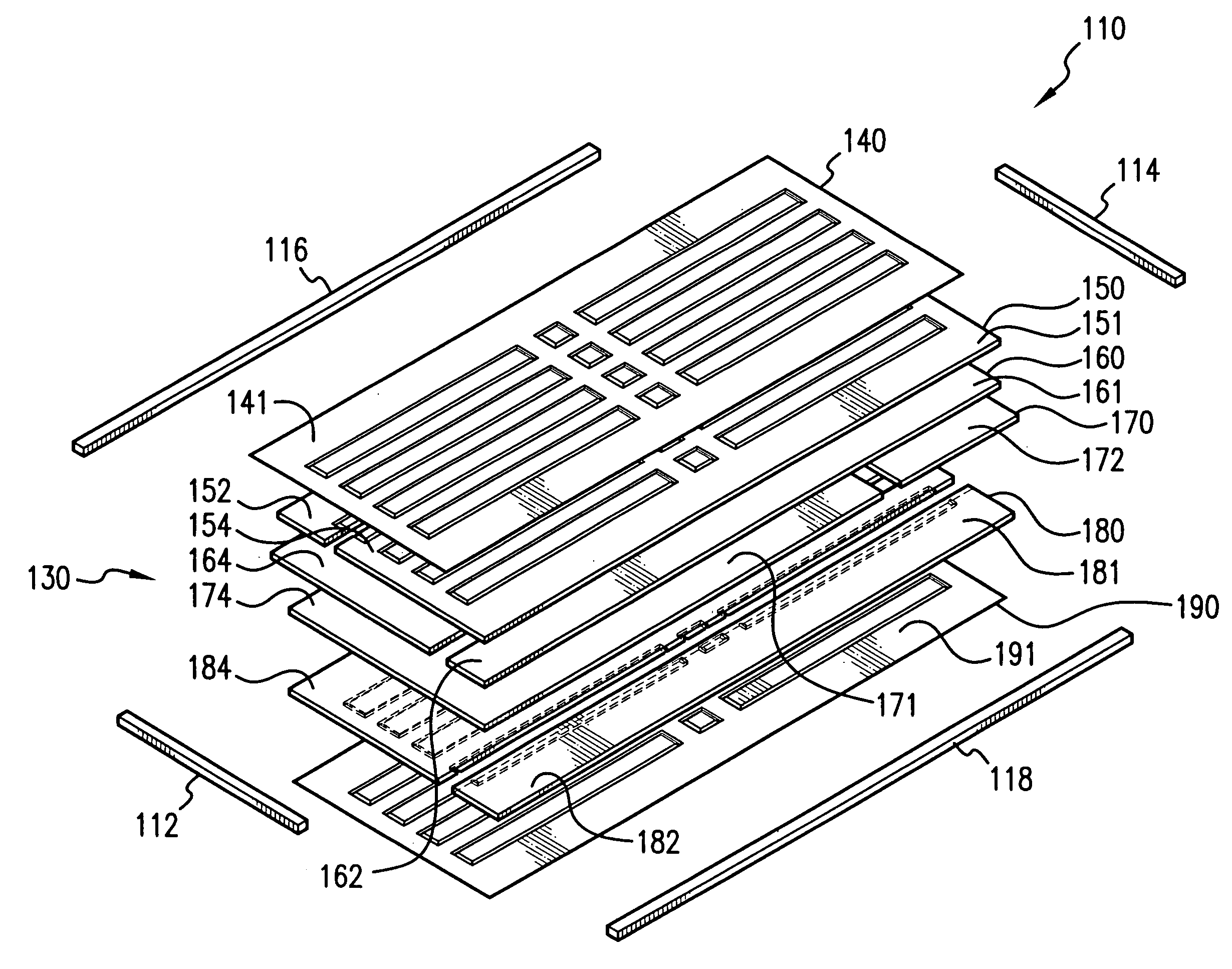

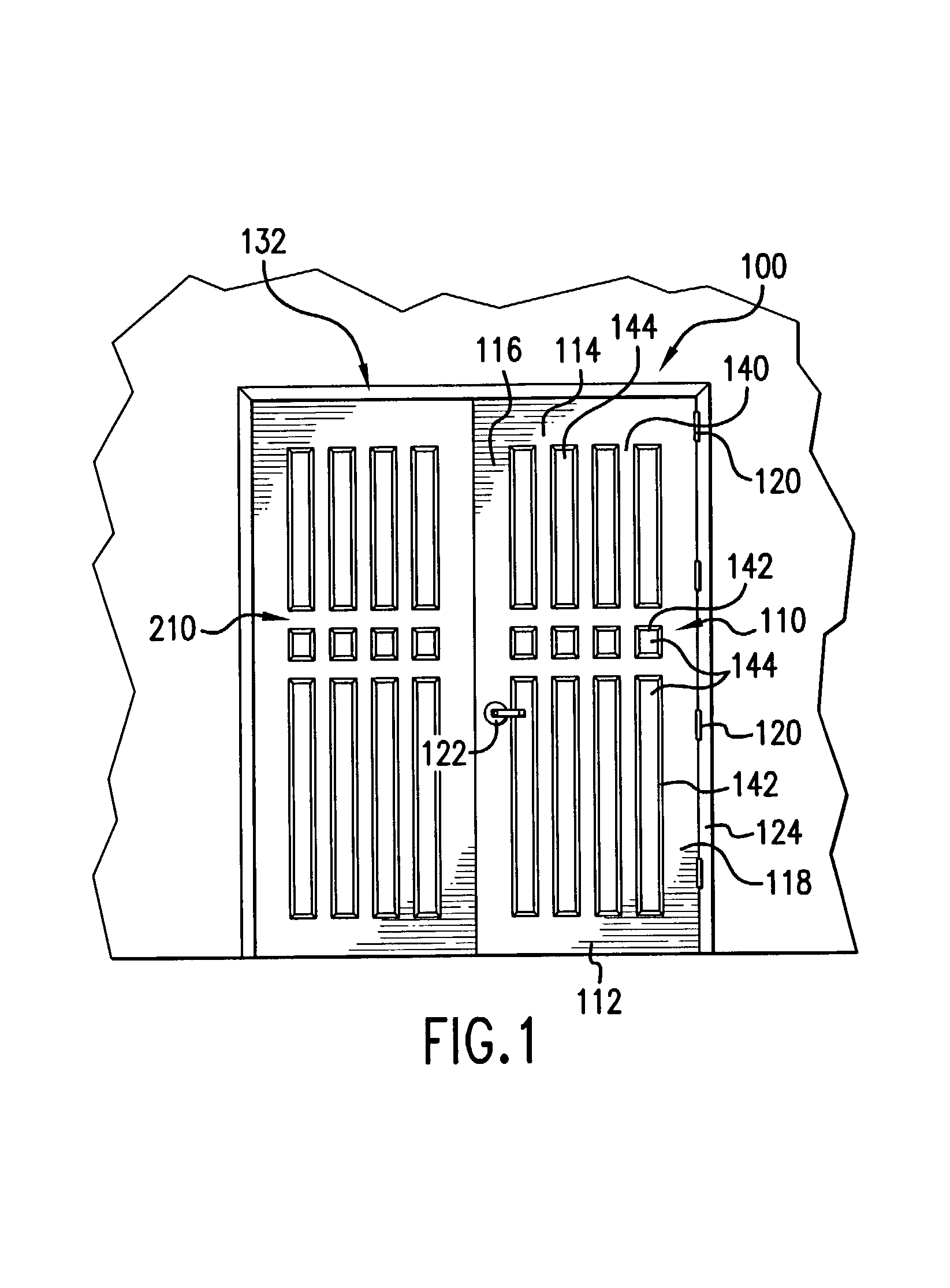

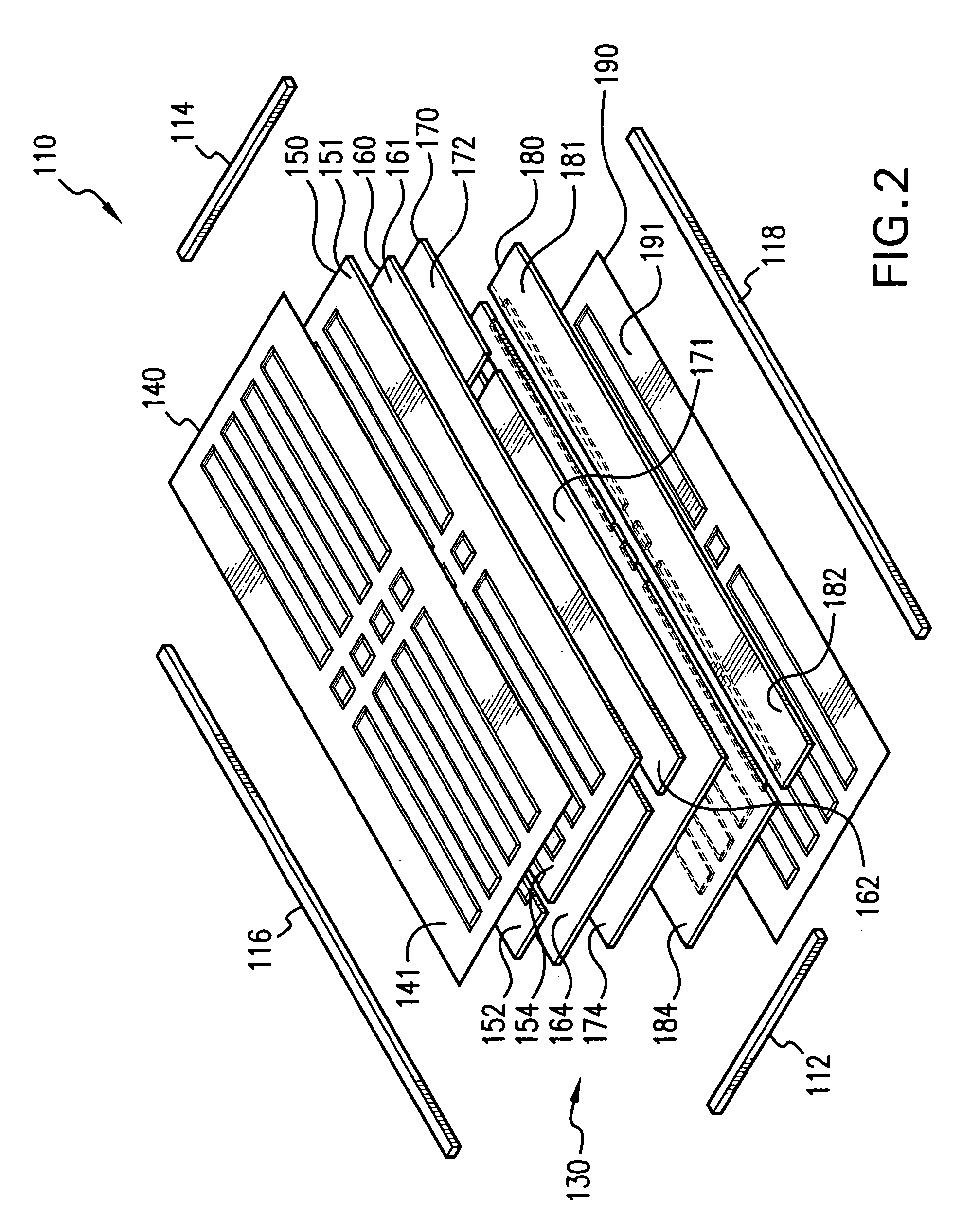

Multi-layered fire door and method for making the same

InactiveUS7185468B2Reduce complexityLow costFireproof doorsSynthetic resin layered productsPorous layerEngineering

A door has a core that includes a porous layer having a thickness and two opposing major surfaces. In one construction, the core also includes three fire-retardant layers, and two of the fire-retardant layers are separated by the porous layer. The porous layer and the fire-retardant layers are coupled together. Other constructions include one or more fire-retardant layers in balanced or unbalanced placement around the porous layer.

Owner:JELD-WEN

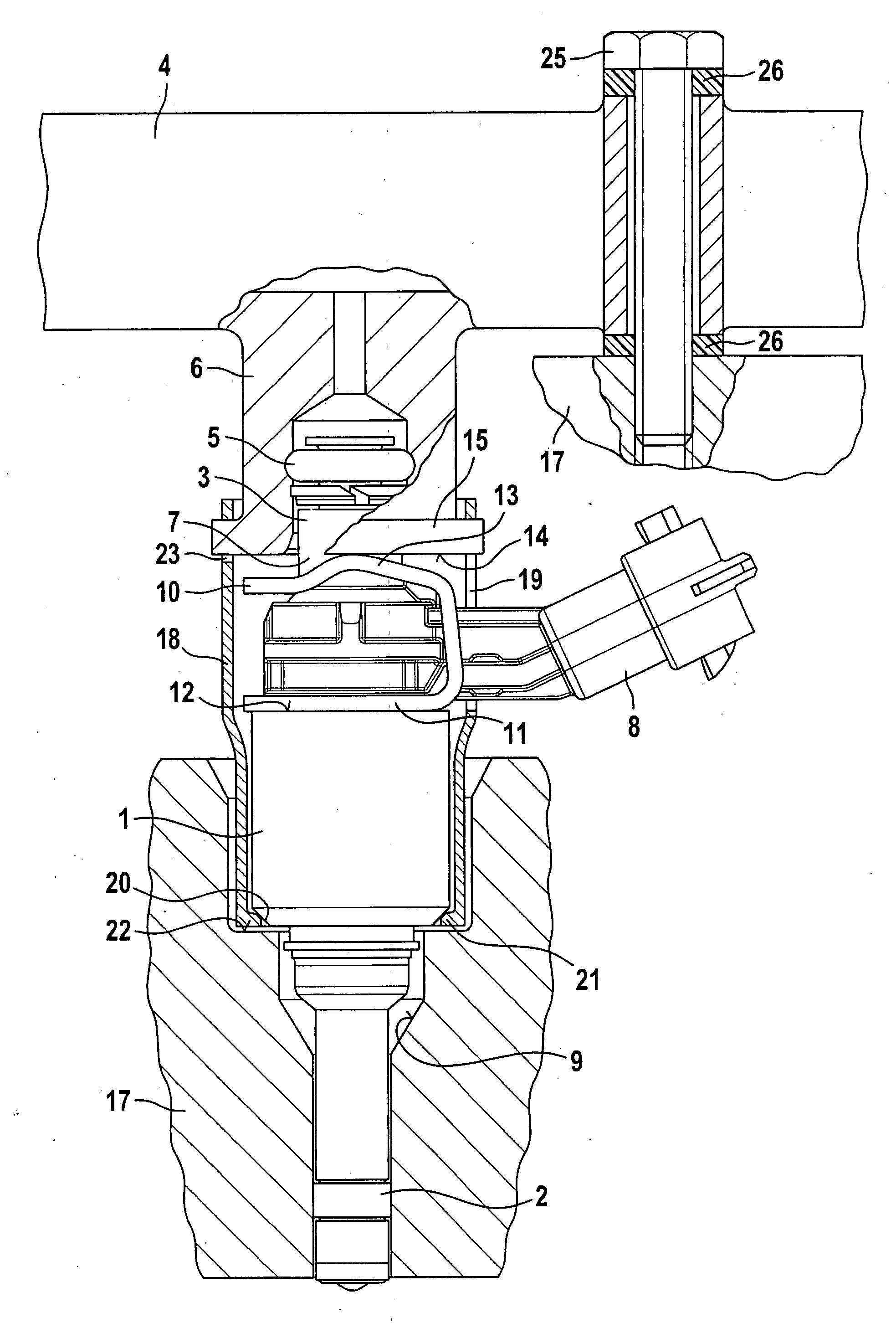

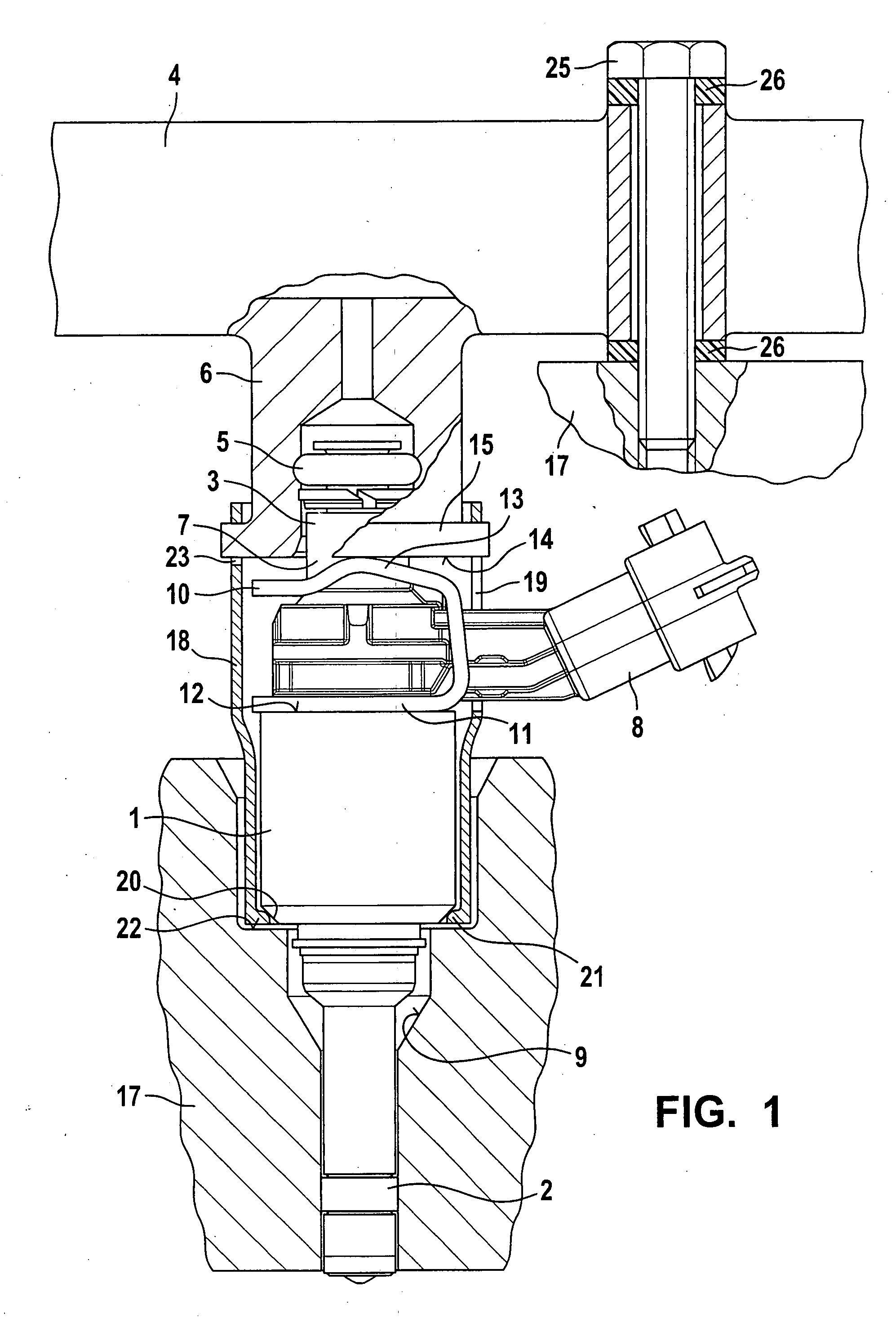

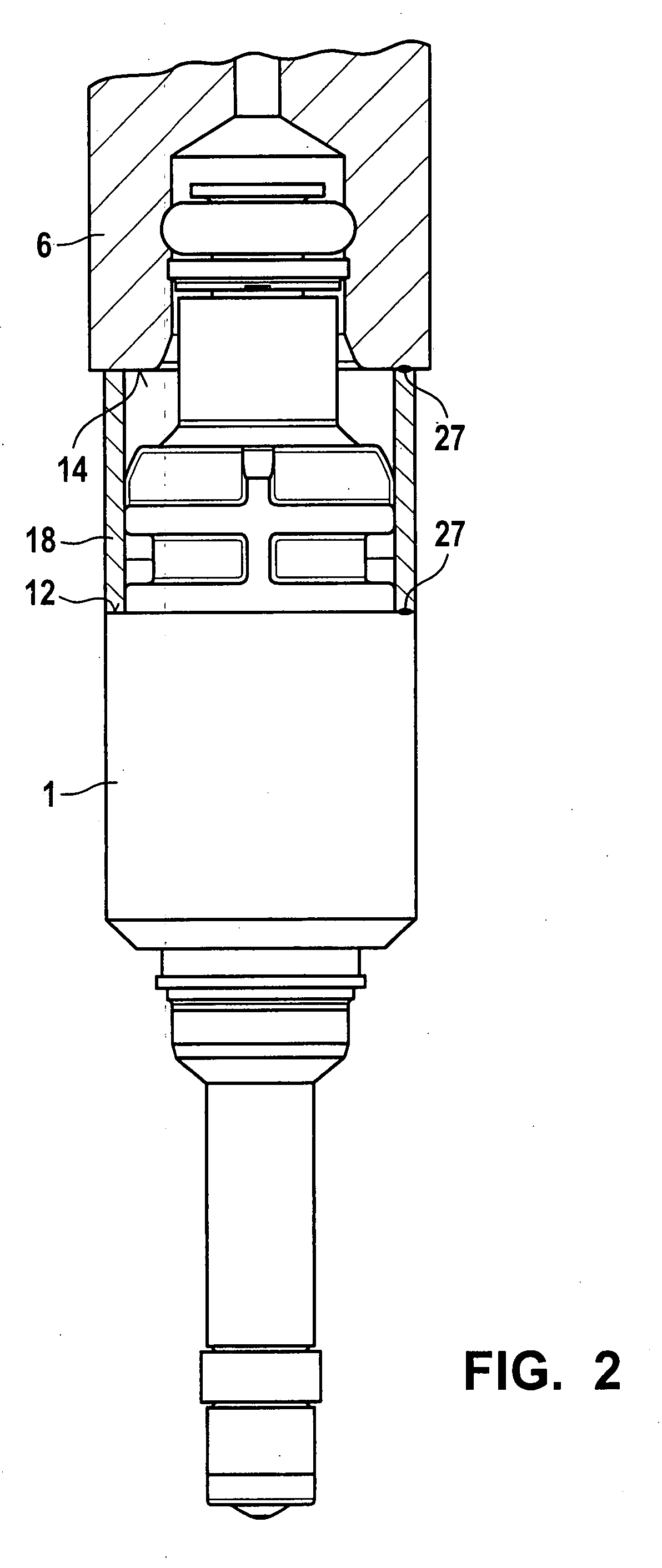

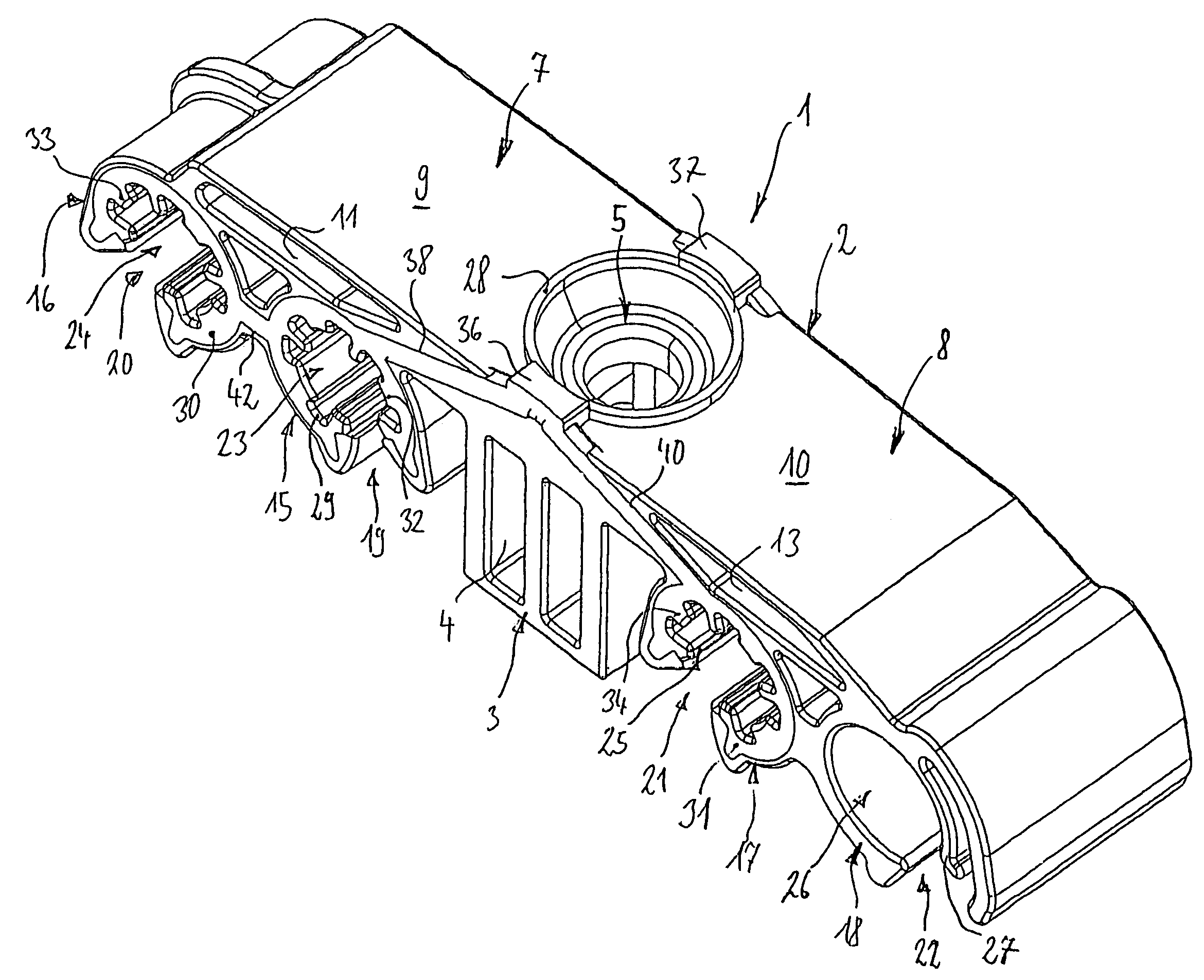

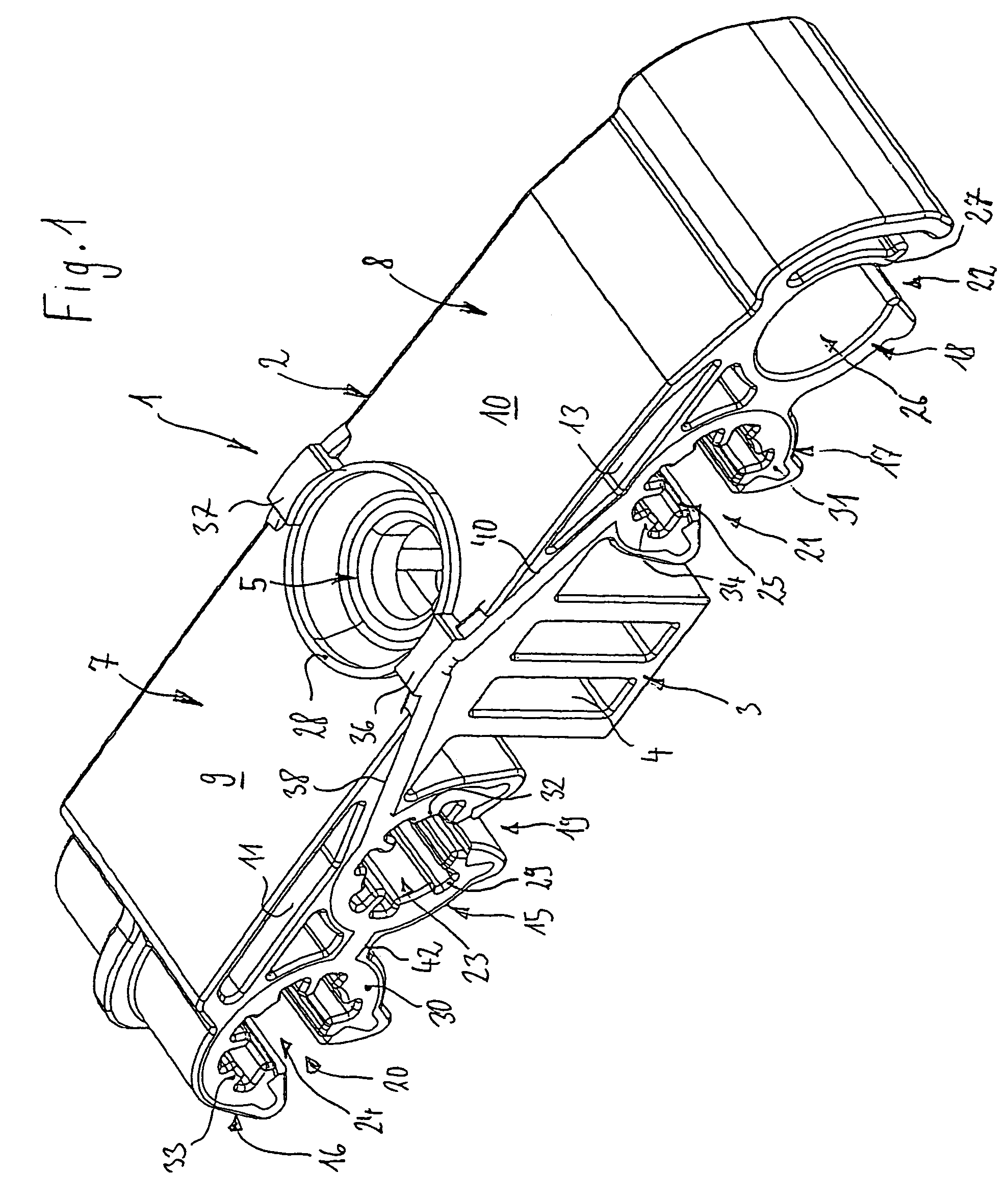

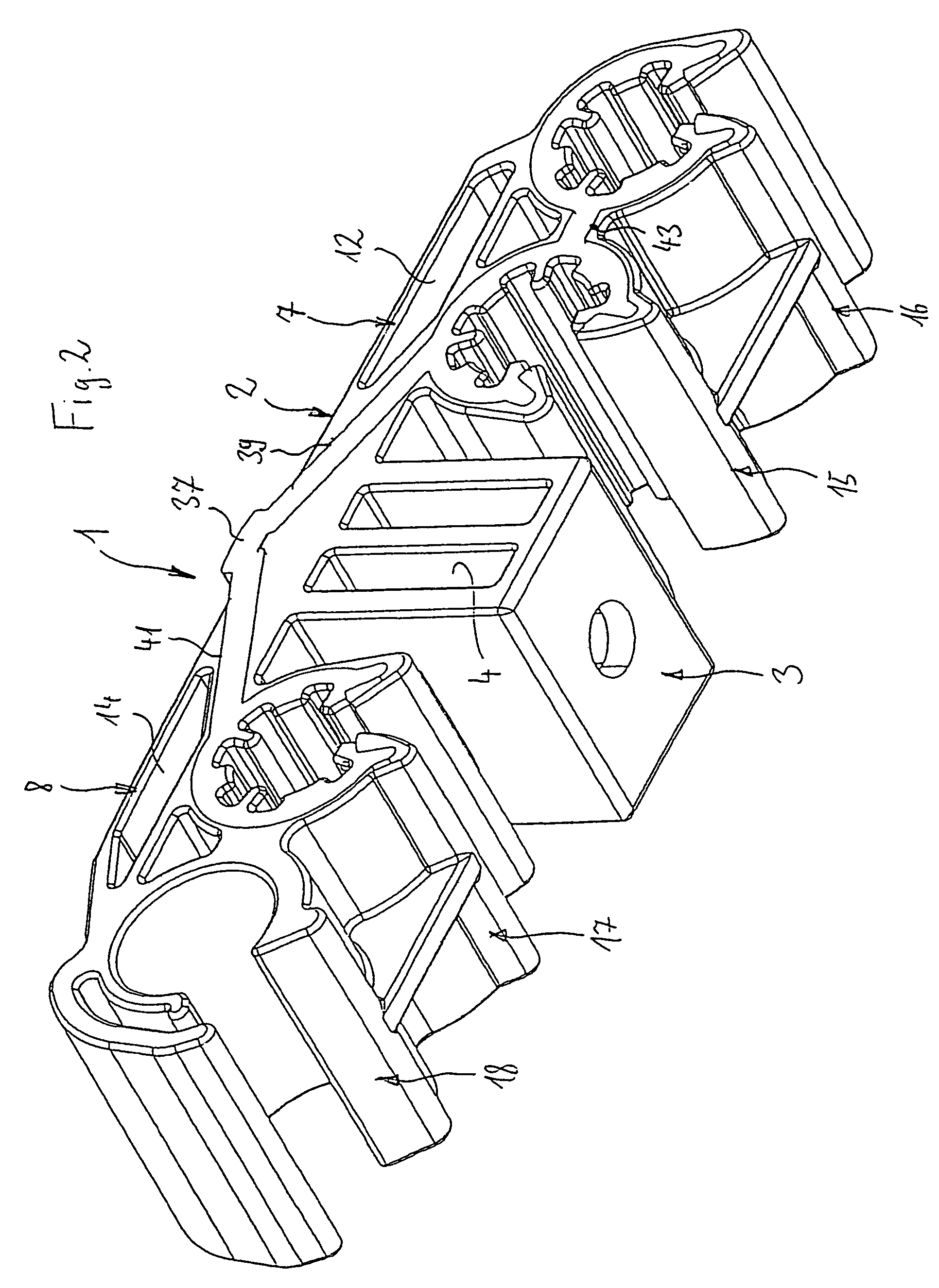

Fuel Injection Valve

InactiveUS20080302336A1Reduce sound transmissionReduce transmissionLow pressure fuel injectionMachines/enginesCombustionCylinder head

The fuel injection device provides a particularly effective sound-decoupling construction. The fuel injection device has at least one fuel injection valve, a receptacle bore for the fuel injection valve in a cylinder head, and a fuel distributor line having a fitting in which the fuel injection valve is placed in partially overlapping fashion. A connecting element is situated in the receptacle bore such that the fuel injection valve is held in the connecting element such that the fuel injection valve and the connecting element are held so that they do not contact any surfaces or walls of the receptacle bore of the cylinder head that do not run axially parallel to the fuel injection valve. For this purpose, the connecting element is attached immediately on the fitting of the fuel distributor line.The fuel injection valve is particularly well-suited for use in fuel injection systems of mixture-compressing externally ignited internal combustion engines.

Owner:ROBERT BOSCH GMBH

Super-light foam cement concrete and preparation method thereof

The invention discloses a super-light foam cement concrete and a preparation method thereof. The super-light foam cement concrete comprises the following raw materials by weight parts: 9-36 parts of dead burnt magnesium oxides, 9-32 parts of dihydric phosphates, 0.5-7 parts of adjustable solidification agents, 6-25 parts of light burnt magnesium oxides, 0.5-7 parts of sulfur-containing components, 1-25 parts of industrial slag powder, 1-20 parts of kieselguhrs, 0.3-3.9 parts of waterproof agents, 0.2-1.7 parts of foam stabilizing agents, 1.0-8.9 parts of foaming agents and 25-90 parts of water. The preparation method of the high-performance super-light foam cement concrete comprises the following steps of: metering raw materials; preparing the slurry containing the foam stabilizing agents; uniformly mixing the foaming agents; pouring and standing by; foaming and expanding; coagulating and curing; and naturally maintaining. The super-light foam cement concrete has the advantages of light weight, high strength, heat preservation and insulation, stable volume, low production cost, energy-saving property, no environmental pollution, and the like. The super-light foam cement concrete is simple in production process and is especially suitable for the heat-insulating material of external building wall, roof and floor.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

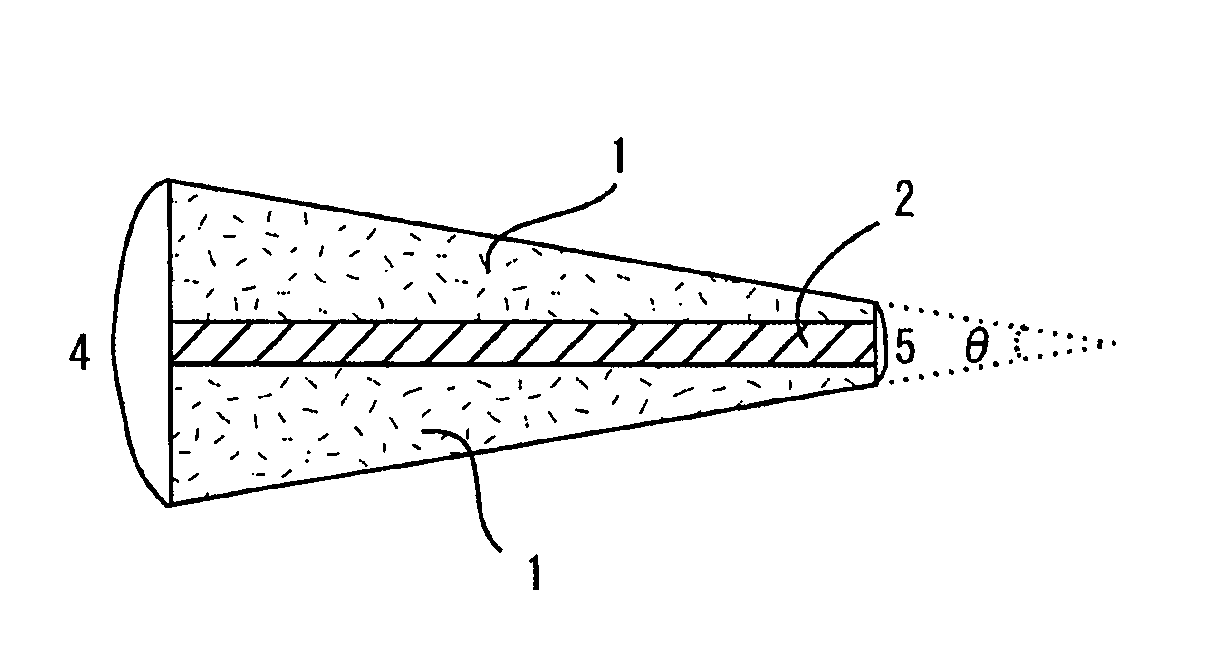

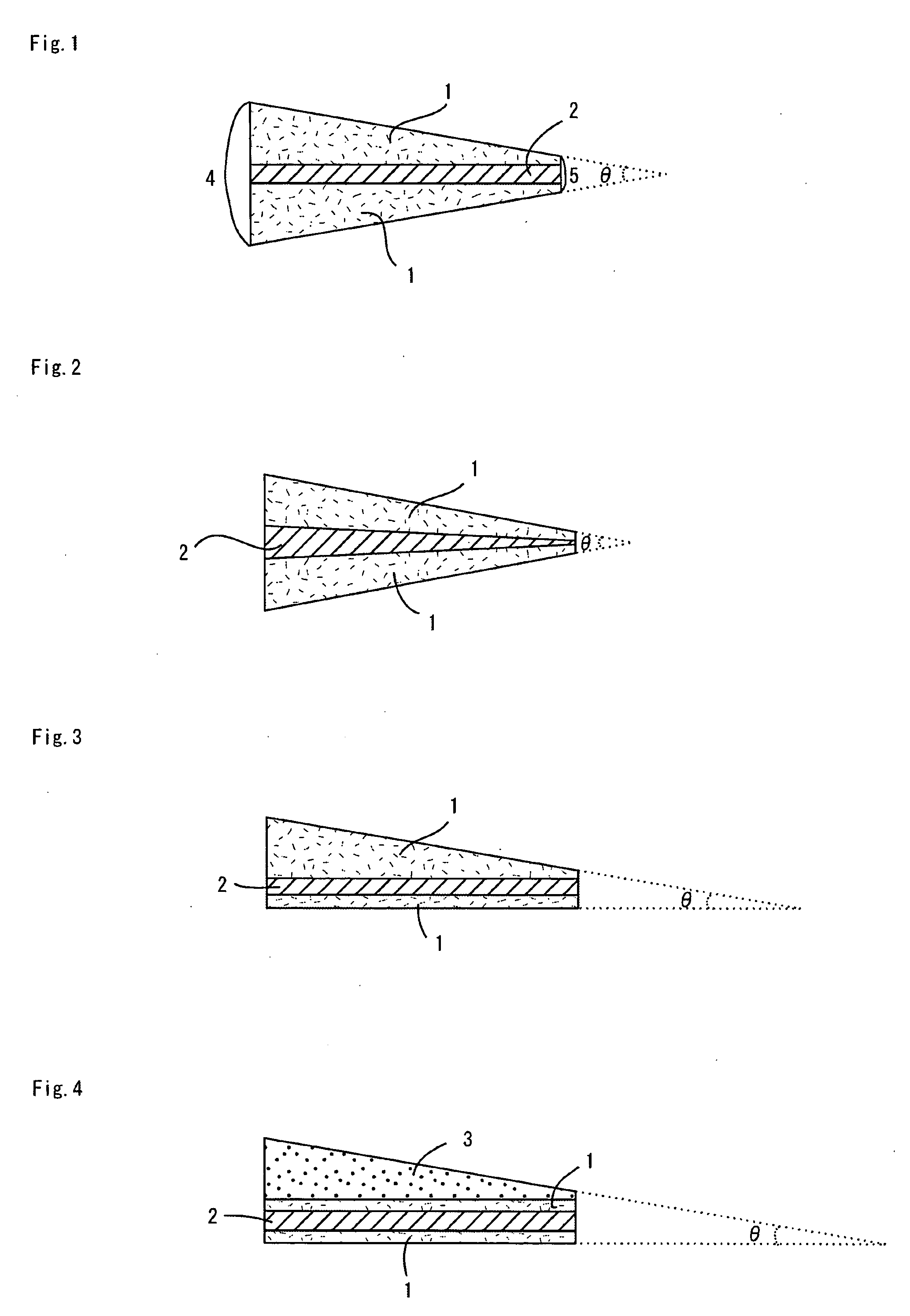

Interlayer Film for Laminated Glass and Laminated Glass

It is an object of the present invention to provide an interlayer film for a laminated glass excellent in a sound-insulating property, which is preferably usable for a head up display and the like wherein a driver can look at the front view and an instrument display simultaneously without requiring to look down, and to provide a laminated glass.The present invention is directed to interlayer film for a laminated glass, which comprises at least a pair of protection layers and a sound-insulating layer sandwiched between the pair of the protection layers, and which has a wedge shape as a cross-sectional shape, a wedge angle θ of 0.1 to 0.7 mrad, the maximum thickness of 2000 μm or thinner, and the minimum thickness of 400 μm or thicker, the minimum thickness of the sound-insulating layer being 20 μm or thicker.

Owner:SEKISUI CHEM CO LTD

Nano porous concrete taking thixotropic colloid as template agent and preparation method

InactiveCN105294141AHas a three-dimensional network microporous structureNo pollution in the processCeramicwareBrickThixotropy

The invention relates to porous concrete and a preparation method thereof, in particular to novel nano porous concrete which is prepared by taking thixotropic colloid as a template agent to form a uniform-water-phase three-dimensional network nano porous structure and adding cementing materials, fine aggregate, coarse aggregate, an admixture and an additive. The nano porous concrete has the characteristics of being light, high in strength and low in heat conductivity, can be prefabricated into bricks, building blocks, plates, and assembly type stairs, wallboards, balcony slabs and roof panel parts in a factory, can be also cast on a construction site, and further can be prepared into mortar, thereby having remarkable practical significance on promotion of development of housing industrialization and green building concrete material in our country.

Owner:浙江圣润纳米科技有限公司

Thermoplastic light-duty composite plate and preparing method thereof

The invention discloses a thermoplastic light compound plate and the manufacturing method, characterized in that it comprises acupuncture fiber carpet dipped in double faced foam of thermoplastic glue liquid and thermoplastic glue liquid layer coated on the surface, the density of compound plate is 0.35-0.90g / cm3, the weight of fiber scattered in bunchiness is 15-45% of acupuncture fiber carpet. The merit of invention is very remarkable. Special super long fiber and bunchiness fiber with certain proportion are maintained in the material so that the mechanical performance of material can be improved. In addition, the material is provided with foam structure, very good effect of heat and sound insulation. The invention is also provided with environmental protection and recovery.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

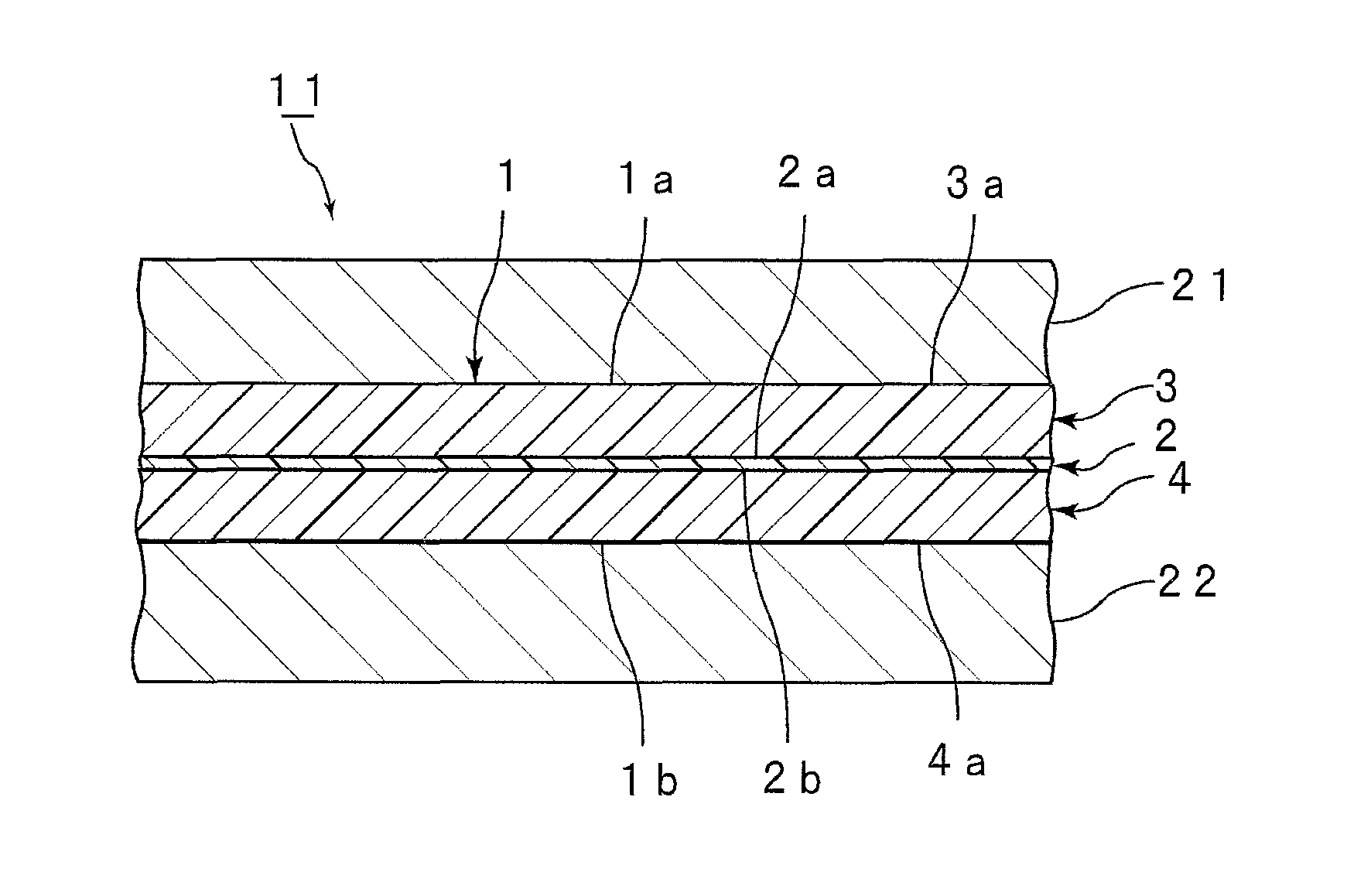

Laminated glass interlayer and laminated glass

ActiveUS8741439B2Improve sound insulationAntiglare equipmentSynthetic resin layered productsPlasticizerPolyvinyl alcohol

The present invention aims to provide an intermediate film for laminated glass which, in the case of being used for constituting a laminated glass, enables to improve the sound-insulating property of the obtained laminated glass, and a laminated glass. The intermediate film 1 for laminated glass of the present invention comprises a first layer 2 which contains a polyvinyl acetal resin and a plasticizer, and the polyvinyl acetal resin and the first plasticizer are a polyvinyl acetal resin and a first plasticizer which have a cloud point of 5° C. or lower when the cloud point is measured using a solution prepared by dissolving 8 parts by weight of the polyvinyl acetal resin in 100 parts by weight of the first plasticizer; and the laminated glass 11 of the present invention comprises first and second components for laminated glass, and the intermediate film 1 for laminated glass sandwiched between the first and second components for laminated glass.

Owner:SEKISUI CHEM CO LTD

Continuous fibre enhancement polyurethane foam material and manufacturing method thereof

A continuous fiber reinforce polyurethane foaming material and a relative production method relate to a polyurethane foaming material, wherein the continuous fiber reinforce polyurethane foaming material has strong rigidity, strength and shock resistance to produce foaming polyurethane material with reinforced glass fiber, which eliminates breaking and premixing with any component of polyurethane, is directly mixed and immersed with polyurethane mixture in an immerser and is foamed and shaped continuously, and contains A, B and C components. A comprises polyatomic alcohol, foaming agent, catalyst, foaming stabilizer, chain extender and adjuvant, B is polyisocyanate, C is fiber material. The preparation method comprises mixing the materials of A in A pot, the materials of B in B pot, immersing fiber via an immerser with the mixture discharged from a high-speed pouring head, feeding immersed material into a continuous foaming mold to be foamed and solidified, cooling, removing mould, taking off and cutting to obtain final product.

Owner:厦门高特高新材料有限公司

Insulated concrete form and method of using same

InactiveUS8756890B2Improve sound insulationImproved curing environmentCeilingsConstruction materialEngineeringInsulating concrete form

Owner:CIUPERCA ROMEO ILARIAN

Compound safety glass and PVB foil for the production thereof

InactiveUS6887577B1Easy to processImprove sound insulationPlastic/resin/waxes insulatorsSynthetic resin layered productsHydrogenPolyvinyl alcohol

Known intermediate foils for compound glasses with improved sound insulation consist of several layers or special materials which cannot be further processed in conventional plants. The aim of the present invention is to provide an intermediate foil for compound glasses with improved sound insulation, whereby said foil consists of one layer as far as possible and is based upon PVB. Said intermediate foil allows for an improved sound insulation of the compound glasses in room temperature and has essentially unchanged working properties, whereby said compound glasses are produced from the intermediate foil. To resolve the aim of the invention, an intermediate foil is provided which contains: 50 to 80 wt. % PVB (partially acetalised polyvinyl alcohol), 20 to 50 wt. % of a softener mixture containing 30 to 70 wt. %, calculated as a portion of the softener mixture, of one or more polyalkylene glycoles of the group consisting of polyalkylene glykoles of the general formula HO—(R—O)n-H with R=alkylene and n>5, block copolymers made of ethylene- and propylene glycole of the general formula HO—(CH2-CH2-O)n-(CH2-CH(CH3)-O)m-H with n>2, m>3 and (n+m)<25, derivatives of block copolymers made of ethylene- and propylene glycole of the general formula R1O—(CH2-CH2-O)n-(CH2-CH(CH3)-O)m-H or HO—(CH2-CH2-O)n-(CH2-CH(CH3)-O)m-R1 with n>2, m>3 and (n+m)<25 and R1 as the organic radical, derivatives of polyalkylene glycols of the general formula R1-O—(R2-O)n-H with R2=alkylene and n>2, wherein the hydrogen of one of the two terminal hydroxygroups of the polyalkylene glycol is replaced by an organic Rest R1, derivatives of polyalkylene glycols of the general formula R1-O—(R2-O)n-R3 with R2=alkylene and n>5, wherein the hydrogen of the two terminal hydroxygroups of the polyalkylene glycol is replaced by an organic Rest R1 or R3.

Owner:KURARAY EURO GMBH

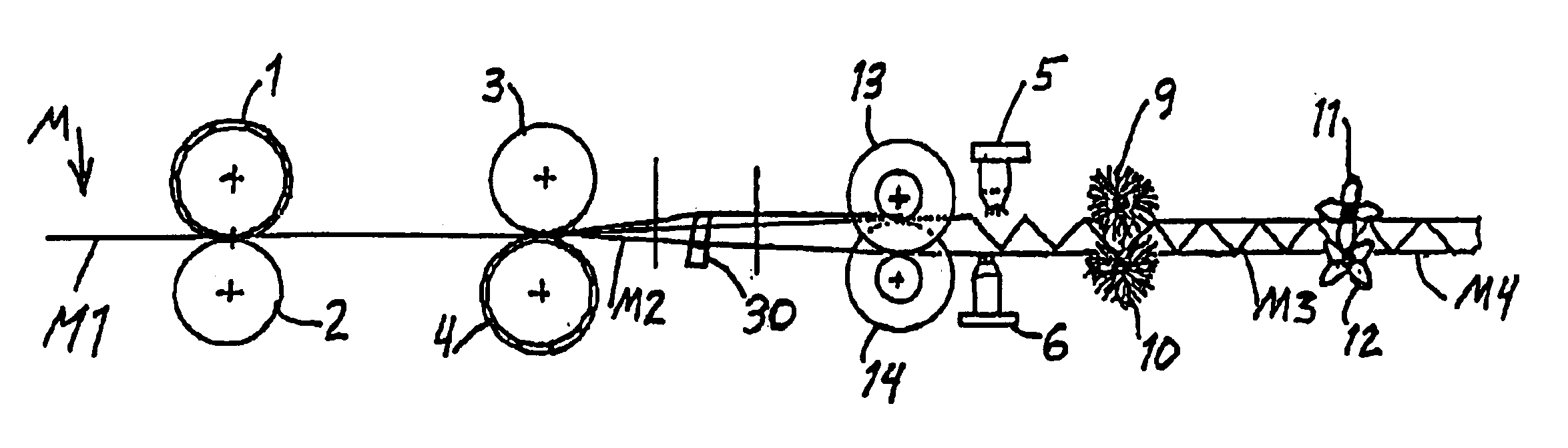

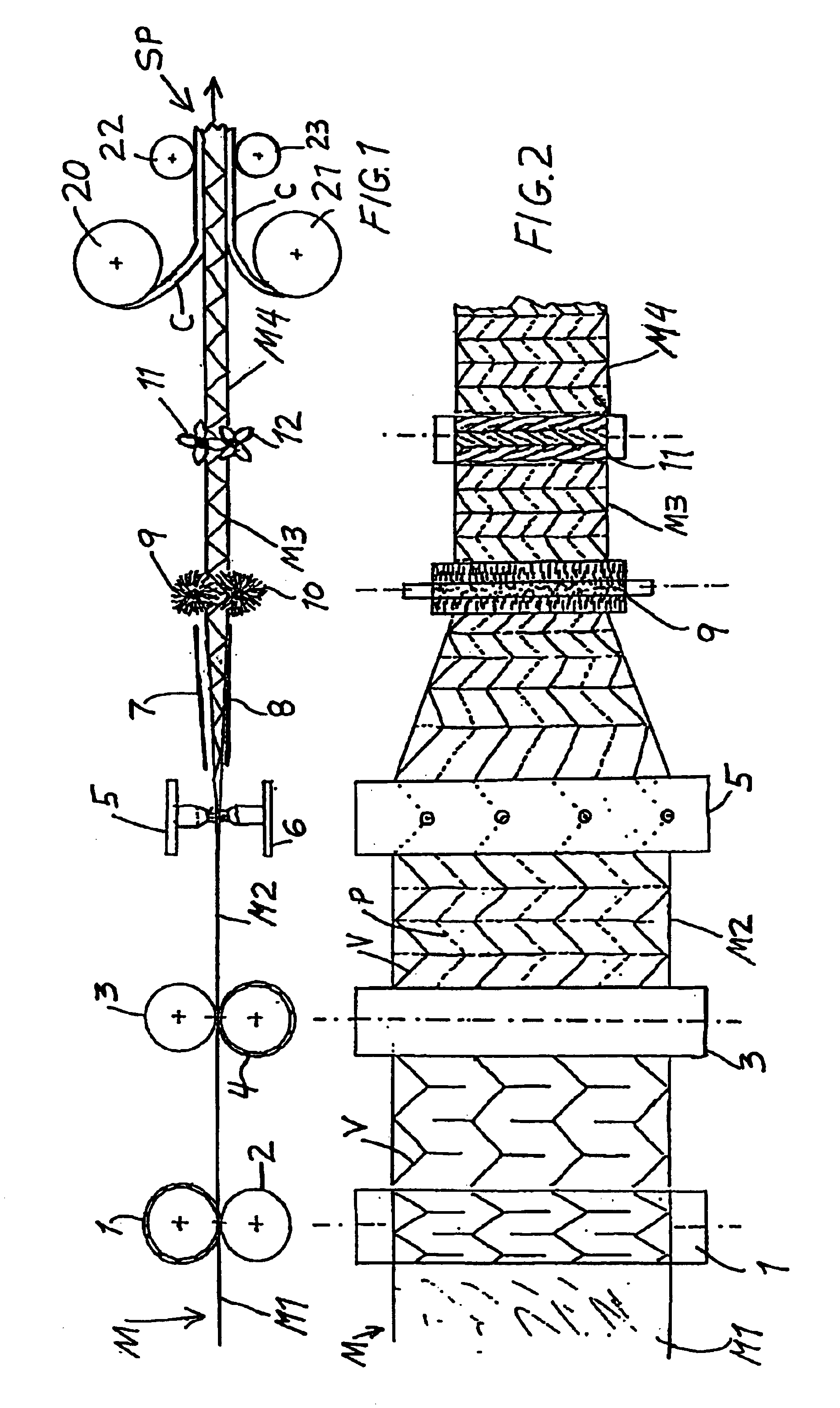

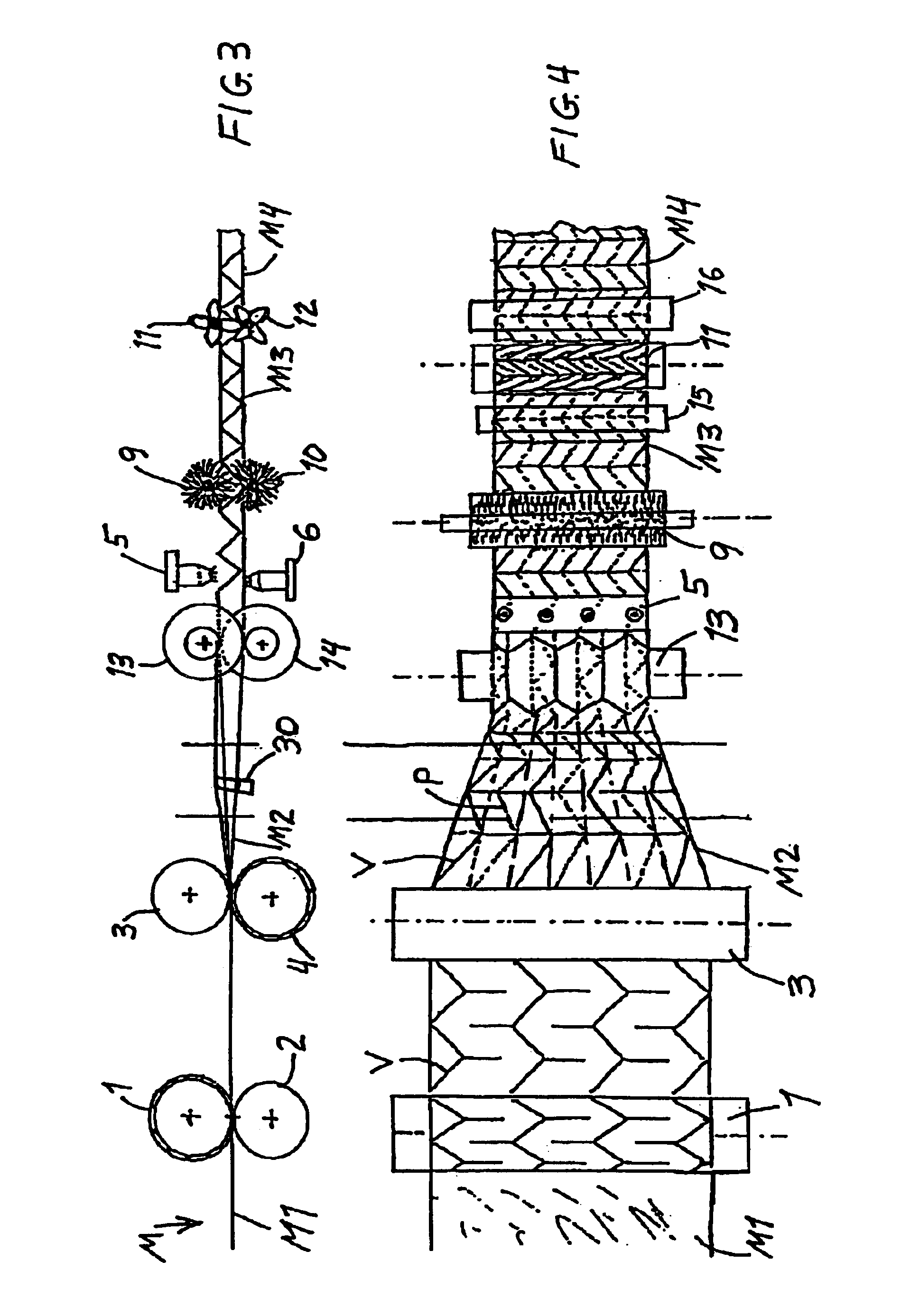

Method and apparatus for producing a composite structural panel with a folded material core

InactiveUS6913570B2Low densityIncrease stiffnessMechanical working/deformationPaper/cardboard articlesBristleEngineering

A folded core structure is produced by embossing fold lines into a flat planar material web, initiating folds along the fold lines on the upper and lower surfaces of the material web, proceeding with the formation of the folds along the fold lines to deform the material web from its two-dimensional starting configuration to a three-dimensional folded configuration, and post-processing the folded material web to stabilize or fix the folded configuration thereof. A composite structural panel is produced by bonding a cover layer onto at least one surface of the folded core structure. An apparatus preferably includes embossing or creasing rolls to form the fold lines in the material web, air nozzles or folding rolls to initiate the folding process, bristle brush rolls to complete the folding process, and further folding rolls to enhance and fix the folded configuration, optionally in connection with heating, cooling, applying a coating onto, or impregnating a resin or binder into the material web.

Owner:AIRBUS OPERATIONS GMBH

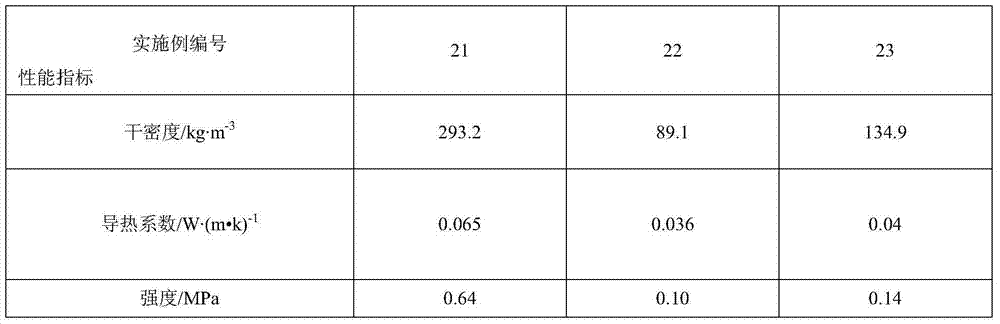

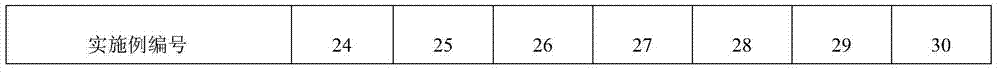

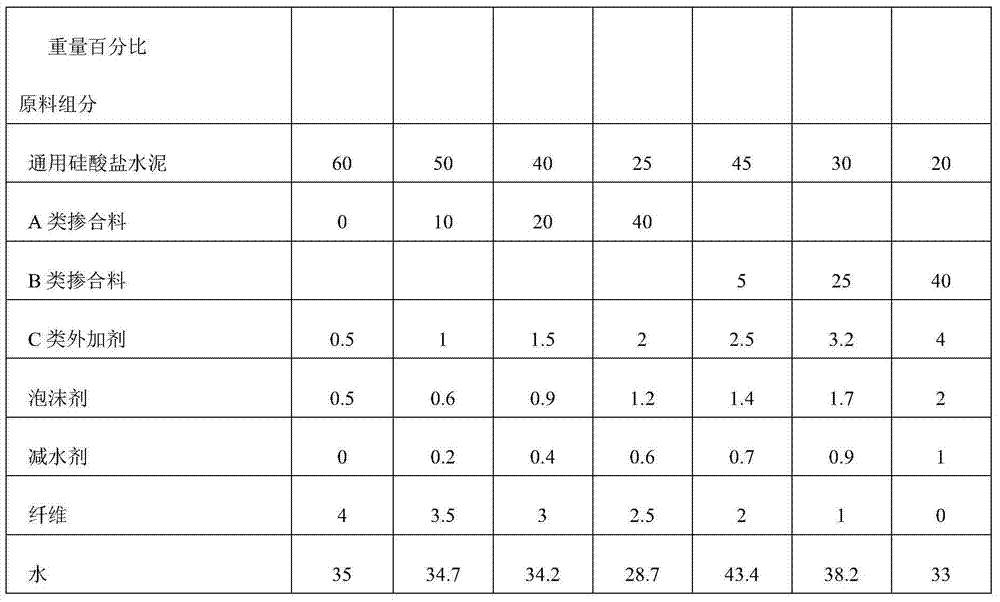

General purpose Portland cement based ultra-light physical foamed concrete

ActiveCN104774033AReduce raw material usageReduce resource consumptionCeramicwareCushionPortland cement

The invention discloses general purpose Portland cement based ultra-light physical foamed concrete which is characterized by being prepared by mixing, forming and maintaining the following components in percentage by weight: 20-70% of general purpose Portland cement, 0-40% of a type A admixture or / and 0-40% of a type B admixture, 0.5-4% of a type C additive, 0.3-2% of a foaming agent, 0-1% of a water reducing agent, 0-4% of fibers and 25-60% of water. The general purpose Portland cement based ultra-light physical foamed concrete disclosed by the invention has the characteristics of ultra-low dry density, low thermal conductivity, relatively high strength, wide raw material source, low cost, simple preparation process, easy maintenance process selection and the like, is suitable to serve as an earthquake-proof and energy-absorbing material, a lightweight cushion course and a catalyst carrier material in a thermal insulation project, a floor heating project and a back filling project, and is particularly suitable for a building exterior wall external thermal insulation system, a roof thermal insulation system, a composite thermal insulation wall body and a buffer energy absorbing system.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Gravel-shaped attapulgite fireproof ceramsite

The invention discloses a gravel-shaped attapulgite fireproof ceramsite. The key points of the technical scheme are as follows: the gravel-shaped attapulgite fireproof ceramsite is composed of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, granulated blast furnace slag powder, iron tailing powder, coal gangue powder, bauxite tailing powder and diatomite tailing powder. After ingredients of the gravel-shaped attapulgite fireproof ceramsite are mixed, granulated, baked, cooled, crushed and screened, the obtained product is packaged to obtain the gravel-shaped attapulgite fireproof ceramsite. The gravel-shaped attapulgite fireproof ceramsite is a grain with an irregular shape and the grain is internally provided with a plurality of small air holes; and the gravel-shaped attapulgite fireproof ceramsite is the fireproof ceramsite which has the advantages of light weight, strong compressive strength, low coefficient of heat conductivity, high refractoriness, stablechemical performance, and good corrosion resistance and heat-preservation and sound-proof effects. The gravel-shaped attapulgite fireproof ceramsite can be produced by comprehensively utilizing a plurality of types of the tailings, so that the gravel-shaped attapulgite fireproof ceramsite is good for improving the resource utilization rate, changing wastes to valuable things, and protecting the environment; and the gravel-shaped attapulgite fireproof ceramsite is applicable to producing fireproof ceramsite concrete and heat-preservation and sound-proof materials.

Owner:NANGTONG HAODI ANTICORROSION EQUIP

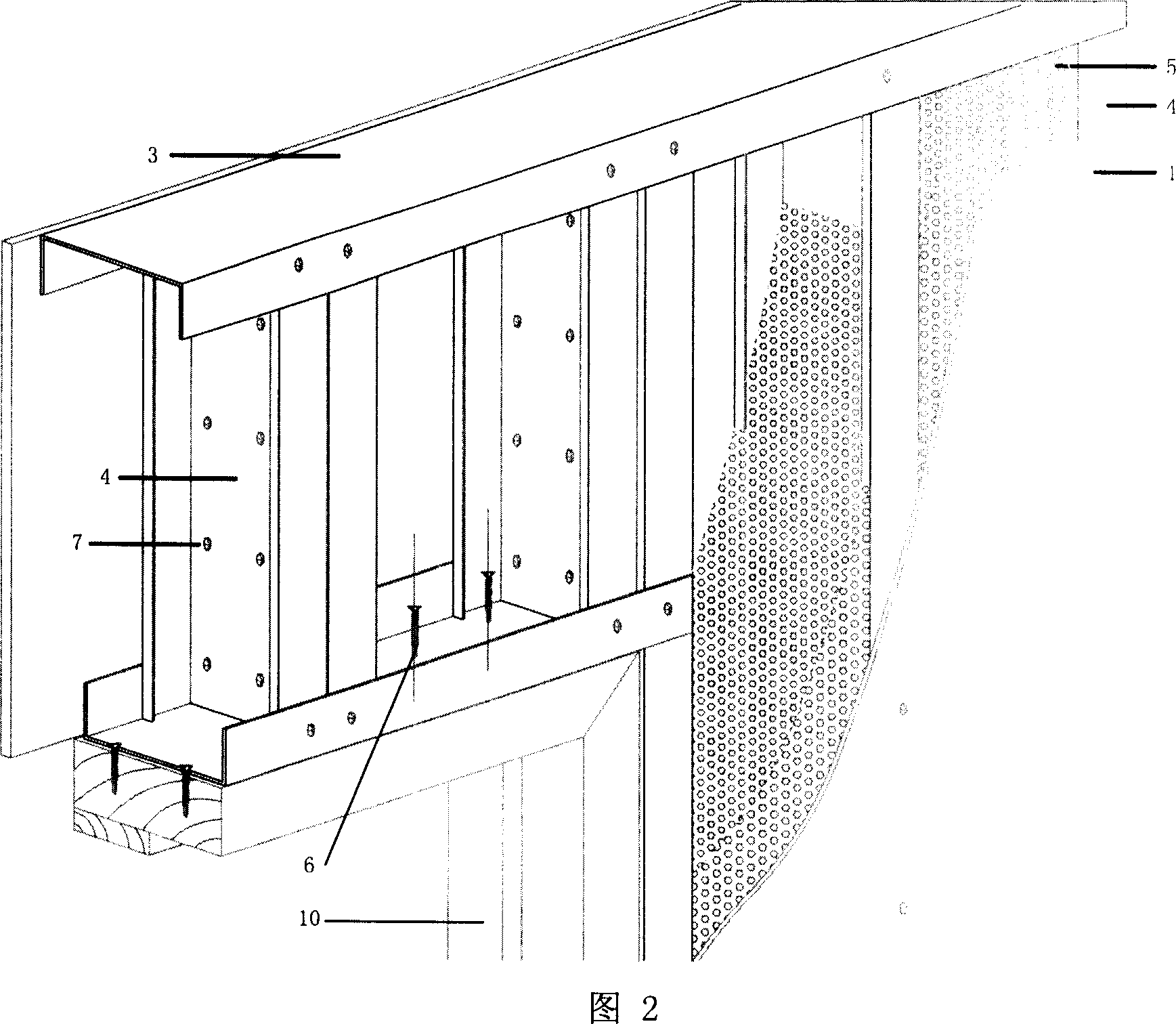

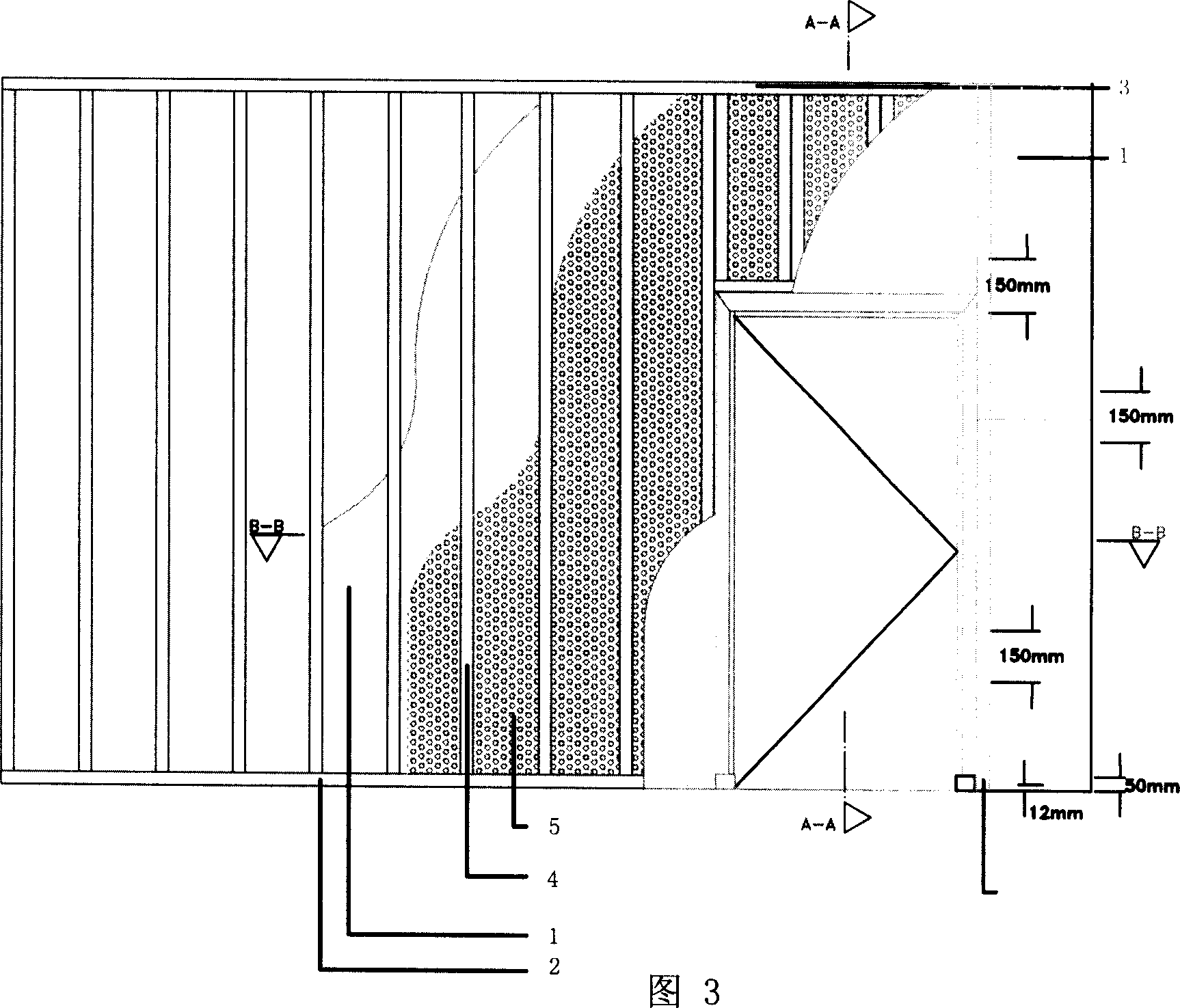

Fiver cement board grouting wall and construction method therefor

The invention discloses a lightweight nonbearing grouting wall and its construction method for inner walls of buildings, comprising a lightgage steel joist or C-shaped steel as a framework, two fiber cements covered on two sides, a hollow space within lightweight grouting materials by special equipment, and a skin layer decorated and dealt directly. The wall has a simple structure for easy construction and a light weight thereby reducing the cost of entire structure and improving the fireproof property up to 2.5 hours or more and the sound insulation property as 40dB, therefore the invention is an inner wall construction with higher utility and economic profit.

Owner:杨建平

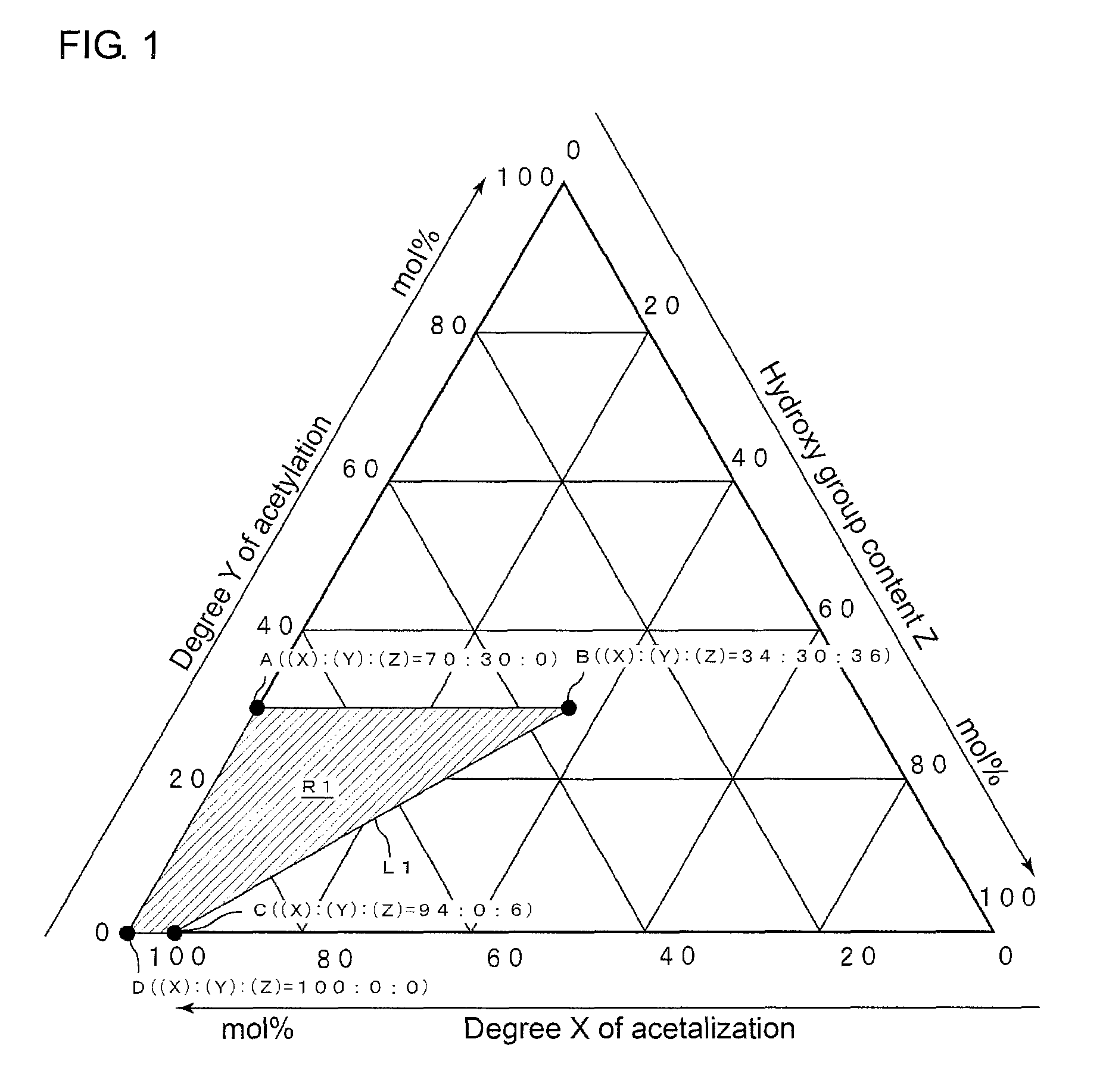

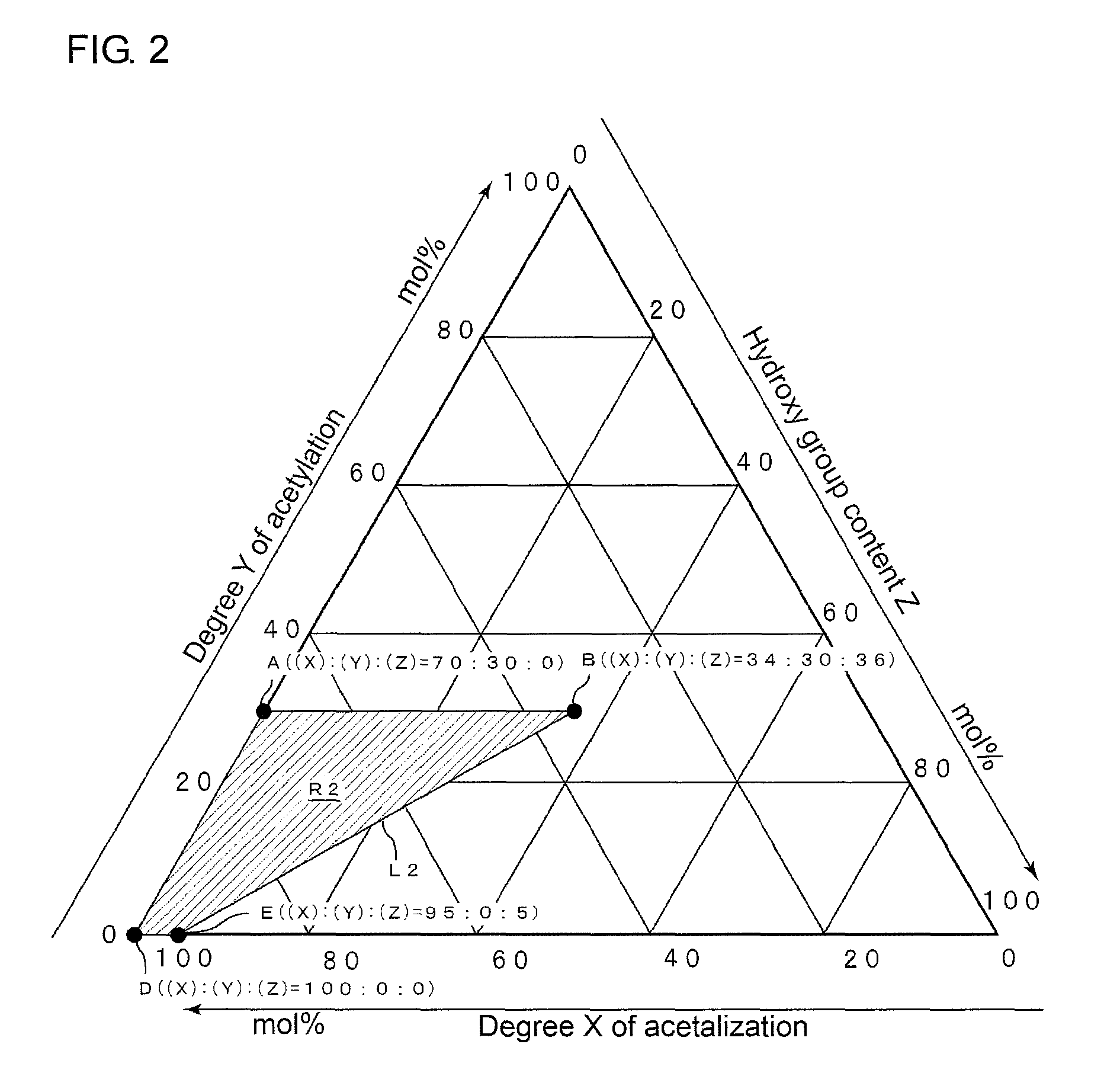

Laminated glass intermediate film and laminated glass

The present invention provides an intermediate film for laminated glass which can improve sound insulation. The intermediate film has a layered structure including at least two layers, comprising: a first layer containing a polyvinyl acetal resin and a plasticizer; and a second layer positioned on a first surface of the first layer. In a phase diagram of three values including a degree of acetalization, a degree of acetylation, and a hydroxyl group content of the polyvinyl acetal resin contained in the first layer, the values of the degree of acetalization, the degree of acetylation, and the hydroxyl group content each fall within a region surrounded by a line including four straight lines connecting first, second, third, and fourth coordinates, which respectively have a degree of acetalization:degree of acetylation:hydroxyl group content of 70 mol %:30 mol %:0 mol %, 34 mol %:30 mol %:36 mol %, 94 mol %:0 mol %:6 mol %, and 100 mol %:0 mol %:0 mol %.

Owner:SEKISUI CHEM CO LTD

Powder coating containing aerogel particles and preparing method thereof

InactiveCN101143981AImprove insulation performanceImprove sound insulationPolyurea/polyurethane coatingsPowdery paintsInsulation layerMixed materials

A powder coating containing aerogel particles and a method for preparing the same relates to a powder coating and a preparation method, which solves the problem that the existing heat insulating composite material containing aerogel is not suitable for making thinner heat insulation material and spraying insulation layer on the component surface, and the aqueous coating has high water content, long construction period and low heat insulation property. The coating of the invention is prepared by 5-80 percent of aerogel particles and 20-95 percent of powderedd resin by volume percentage, and the method includes the following steps: firstly, aerogel, resin and additive are mixed by volume percentage; secondly, the mixed materials are delivered into a melting-extruder melt and extrude; thirdly, the extrudate is pressed into thin sections; fourthly, the thin sections are ground into small pieces by roller machine; fifthly, the small pieces are conveyed into an air staged milling equipment to grind, so as to obtain the powder coating. The powder coating containing aerogel of the invention has advantages of environmental protection, clearness, economy, high efficiency, and good heat insulation property, sound insulation property and surface hydrophobicity.

Owner:HARBIN INST OF TECH

Retaining member

ActiveUS7267307B2Improve isolationSpring constantPipe supportsNon-rotating vibration suppressionEngineeringMechanical engineering

Owner:ITW AUTOMOTIVE PRODS

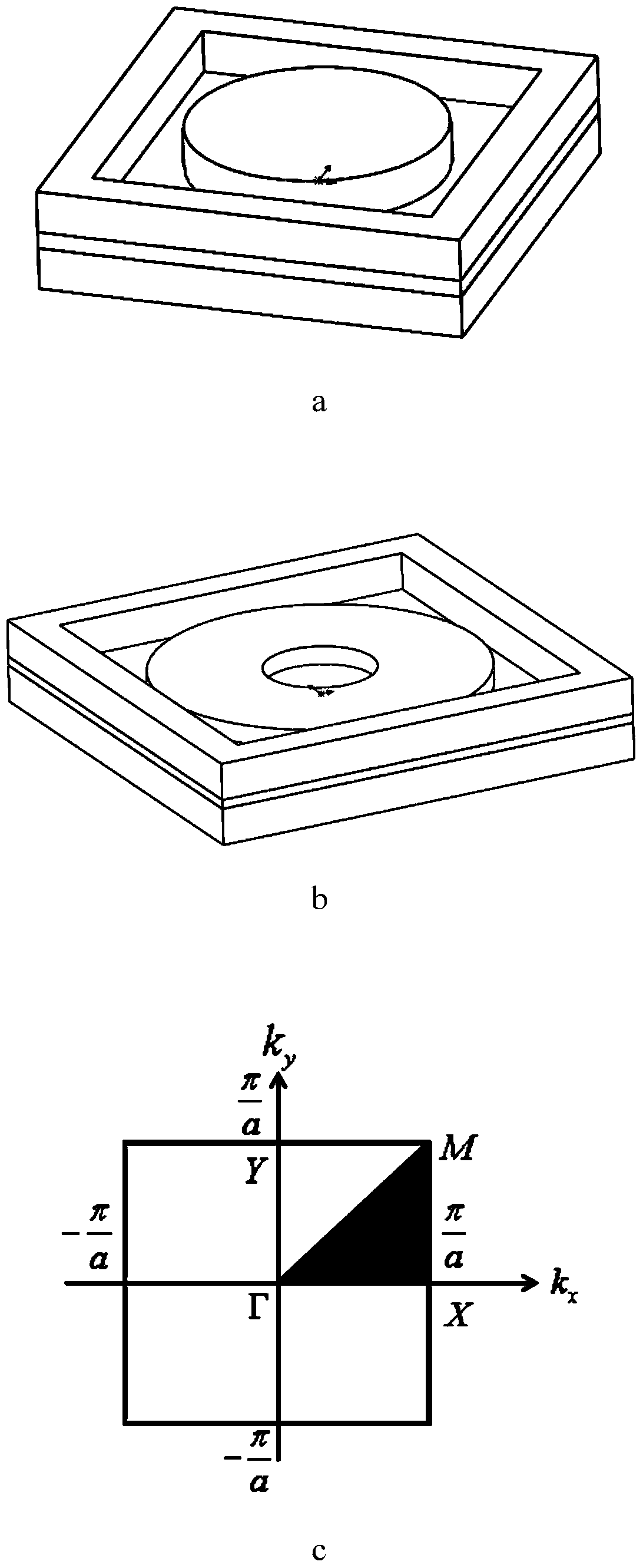

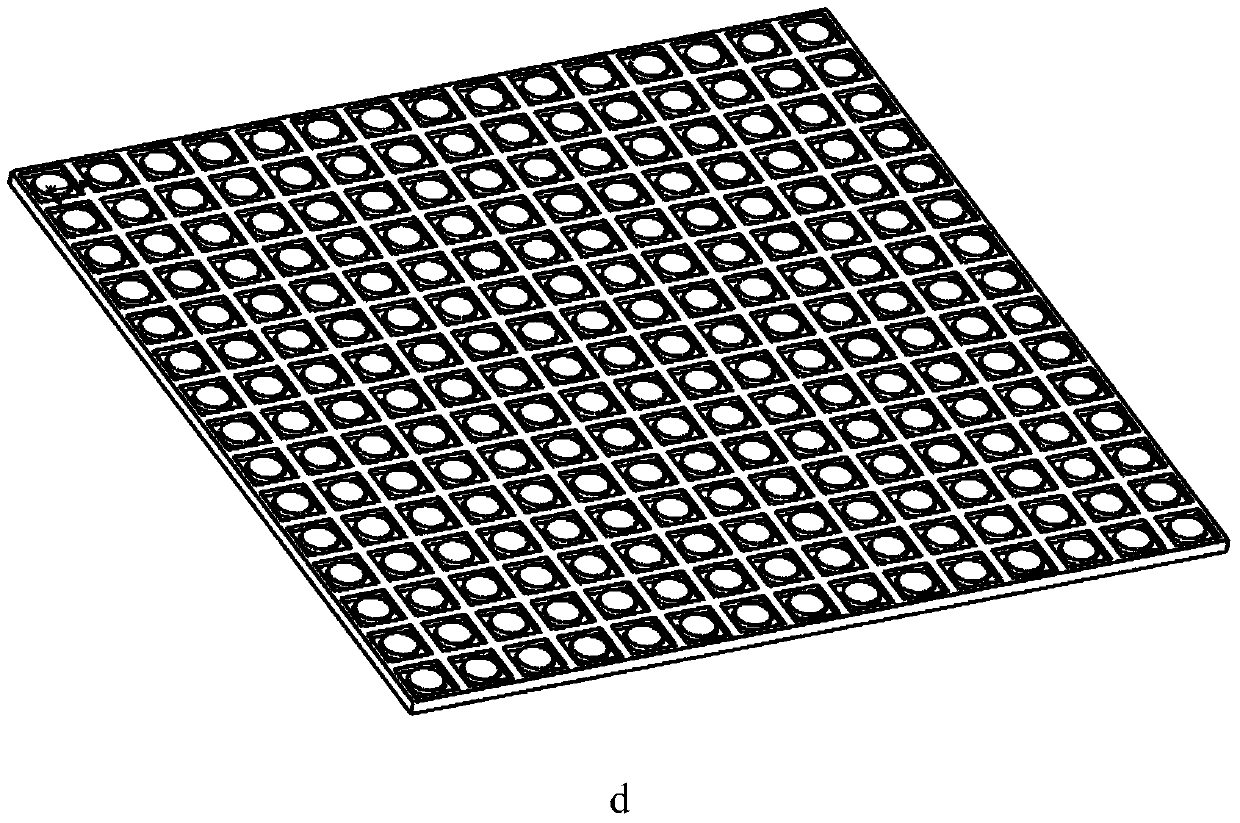

Elastic membrane-type low-frequency sound insulation metamaterial structure

InactiveCN103996395AMeet the requirements of low frequency sound insulationImprove sound insulationSound producing devicesLow noiseBroadband

The invention discloses an elastic membrane-type low-frequency sound insulation metamaterial structure which comprises two frames and a silicone rubber elastic membrane arranged between the two frames. A plurality of mass blocks are pasted on one side of the silicone rubber elastic membrane, and the mass blocks are separated with one another through the frames. The elastic membrane-type low-frequency sound insulation metamaterial structure solves the problems that a traditional sound insulation material is poor in low-frequency sound insulation performance, large in thickness, heavy in mass and the like and meets the five requirements of low-frequency sound insulation, wherein the five requirements include the low-frequency sound insulation requirement for noise below 500 Hz, the broadband requirement, the requirement for low structural thickness and low weight, and the requirement of easy design processing and low processing difficulty. The elastic membrane-type low-frequency sound insulation metamaterial structure has excellent low-frequency sound insulation performance, can effectively isolate low-frequency noise ranging from 200 Hz to 500 Hz, and can be applied to various carrying tools such as planes, automobiles, trains and ships and various types of building decoration. A brand new sound insulation solution is provided for creating low-noise working and living environments.

Owner:XI AN JIAOTONG UNIV

Unsteamed concrete air-filled insulating brick produced from building waste, and production method thereof

InactiveCN102617076AReduce encroachmentReduce pollutionSolid waste managementCeramicwareCelluloseBrick

The invention relates to an unsteamed concrete air-filled insulating brick produced from building waste, and a production method of the insulating brick. The insulating brick is prepared from the raw materials in parts by weight: 30-40 parts of cement, 20-30 parts of aggregate, 8-10 parts of CaO, 3-5 parts of CaSO4, 3-5 parts of carbamide, 3-5 parts of polyvinyl alcohol, 5-10 parts of cellulose hydroxypropyl methyl, 3-5 parts of calcium formate, 5-10 parts of foaming agent and 40-60 parts of external water, wherein cement contains one or more than two of common silicate, high-alumina cement, fly ash cement, alumina cement and aluminate cement; the aggregate is building waste with the particle size being less than or equal to 5mm; and the foaming agent contains one or more than two of aluminium powder, aluminium powder paste, hydrogen peroxide and sodium hydrogen carbonate. The unsteamedconcrete insulating brick is prepared by material preparing, mixing, injection molding and curing. Therefore, the land occupation and the living environmental pollution caused by the building waste can be effectively reduced, and the produced unsteamed concrete air-filled insulating brick has the advantages of good heat insulation effect, light weight, good sound insulation effect and high strength, and can be nailed and sawed; and the construction intensity can be reduced.

Owner:ANSHAN QUANYIJU ENVIRONMENTAL PROTECTION BUILDINGMATERIAL

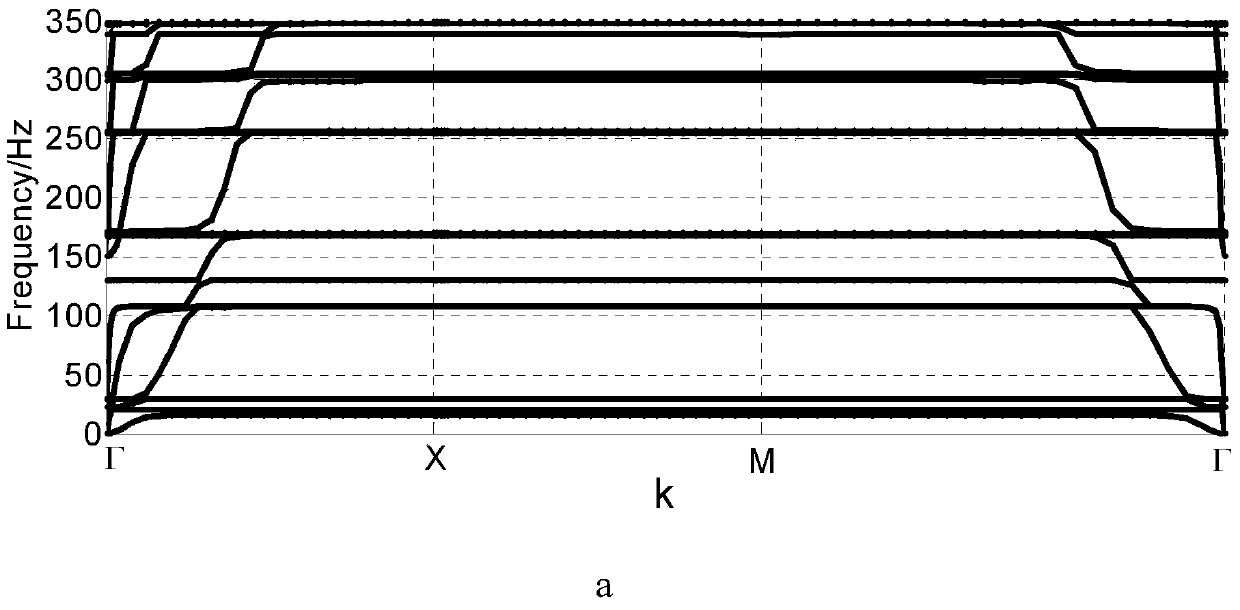

Functionally-graded cellular-concrete thermal-insulating material and preparation method thereof

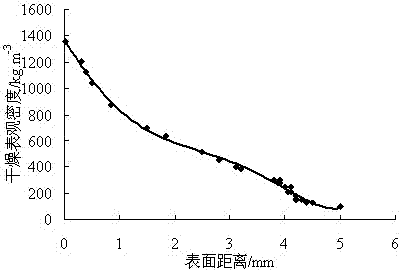

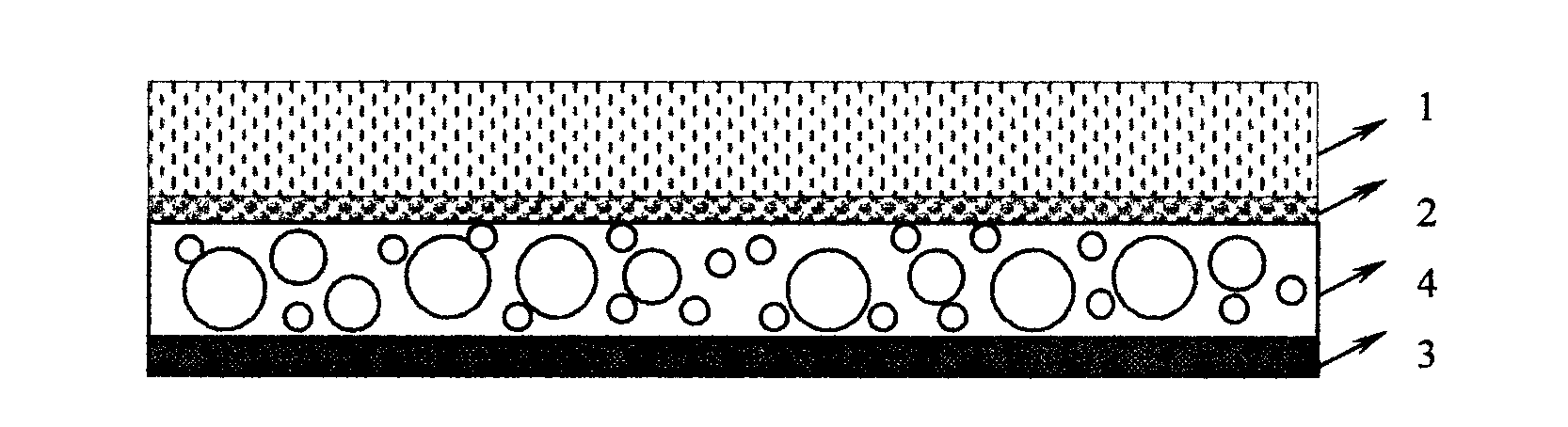

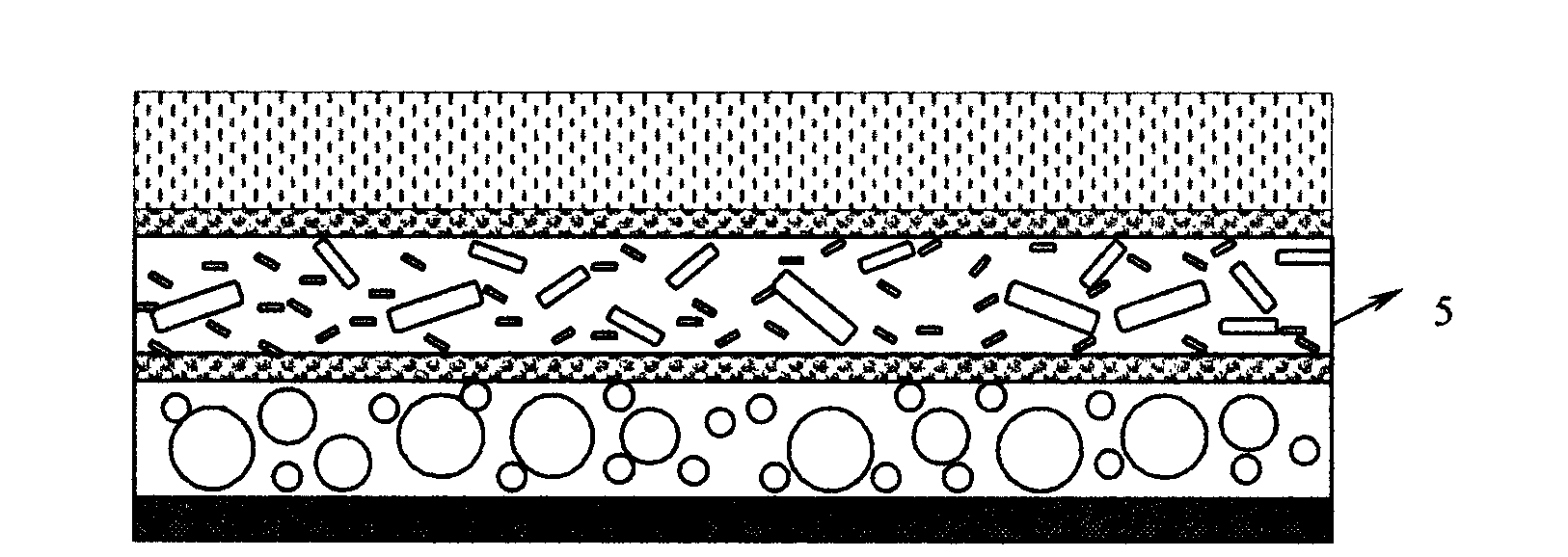

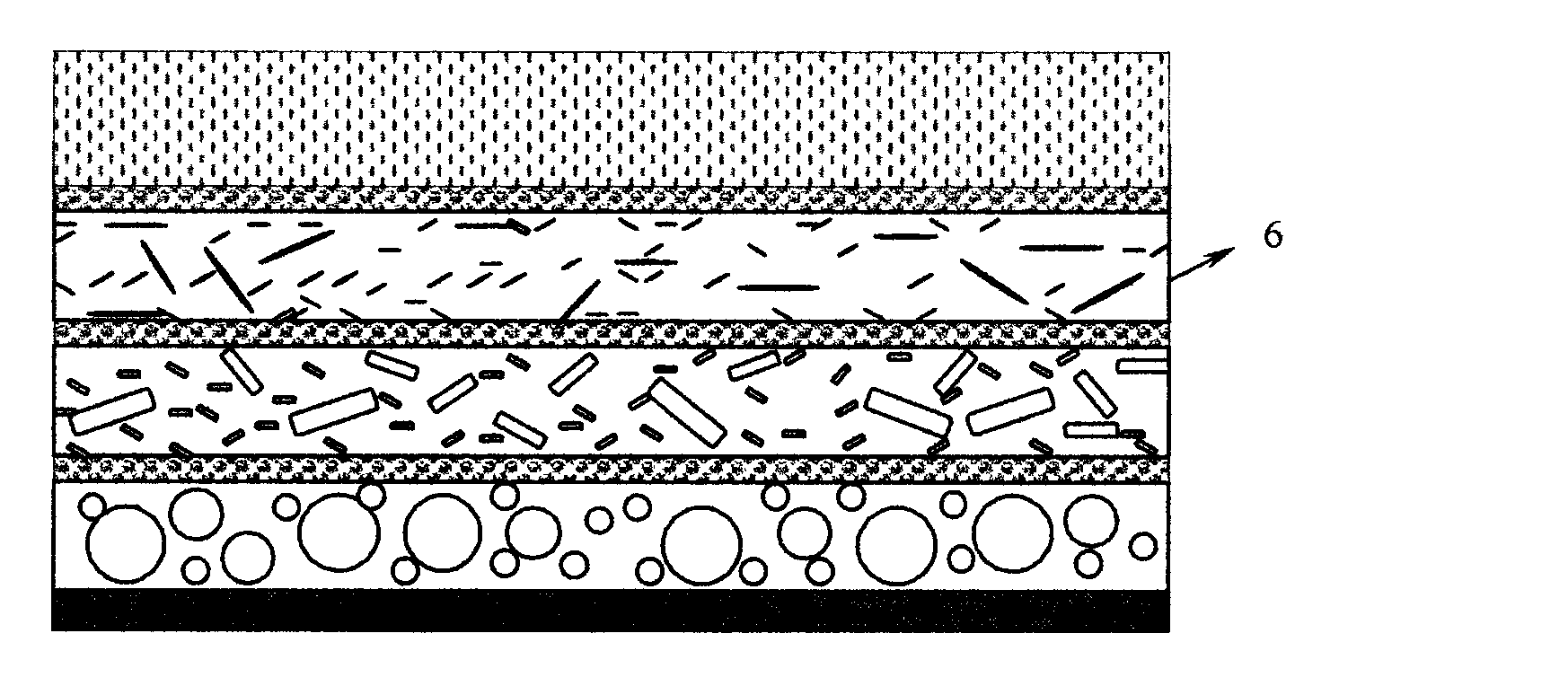

ActiveCN102561532AOvercoming the Interface Breaking DilemmaImprove bending strengthHeat proofingCeramicwareFoam concreteThermal insulation

The invention relates to a functionally-graded cellular-concrete thermal-insulating material and a preparation method thereof. The functionally-graded cellular-concrete thermal-insulating material comprises a cellular-concrete thermal-insulating core, a plurality of air holes are uniformly distributed in the thermal-insulating material, and the surface of the cellular-concrete thermal-insulating core is wrapped with a functionally-graded layer; in the air holes of the functionally-graded cellular-concrete thermal-insulating material, the air hole in the cellular-concrete thermal-insulating core has a maximum diameter, then, the diameters and porosities of the air holes from the cellular-concrete thermal-insulating core to the outside are in a continuous graded change in a descending order, the thickness of the functionally-graded layer is 0.1-20 mm, the porosities of the air holes are in a continuous graded change in a range of 1- 95%, and the diameters of the air holes are in a continuous graded change in a range of 0.1-8 mm. According to the invention, the interior of the material is porous and thermal-insulating, and the surface of the material is high in density and strength, the mechanical strength of the material is gradually improved from the inside to the outside, and the thermal conductivity factor of the material is gradually reduced front the outside to the inside, thereby achieving an effect of integrating light weight, high strength, thermal insulation and fire prevention.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Efficient sound insulation material and manufacturing method thereof

InactiveCN103903608AImprove heat and aging resistanceExcellent ozone resistanceSynthetic resin layered productsSound producing devicesInsulation layerFoaming agent

The invention relates to the field of products of sound insulation material, solves the problems in the prior art that the sound insulation material is poor in sound insulation effect, is incomprehensive in high and low frequency sound insulation, causes pollution and is easy to age, and provides an efficient sound insulation material and a manufacturing method thereof. The efficient sound insulation material includes a sound insulation layer, a sound absorption layer, and a bubble layer, wherein the bubble layer is located between the sound insulation layer and the sound absorption layer. The sound absorption layer is made of a sound insulation compound, and the sound insulation compound is prepared by raw materials of the following substances: a thermoplastic resin, inorganic fillers, and a foaming agent, wherein the inorganic fillers account for 15-80wt%, the foaming agent accounts for 5-15wt%, and the rest is the thermoplastic resin. In the efficient sound insulation material, the fillers with different particle diameters correspond to sound waves of different wave bands or frequencies, and thus consumption of sound energy of different frequencies is relatively comprehensive, and the sound insulation effect is good, so the sound insulation material is suitable for popularization and application.

Owner:浙江艾迪雅汽车部件新材料有限公司

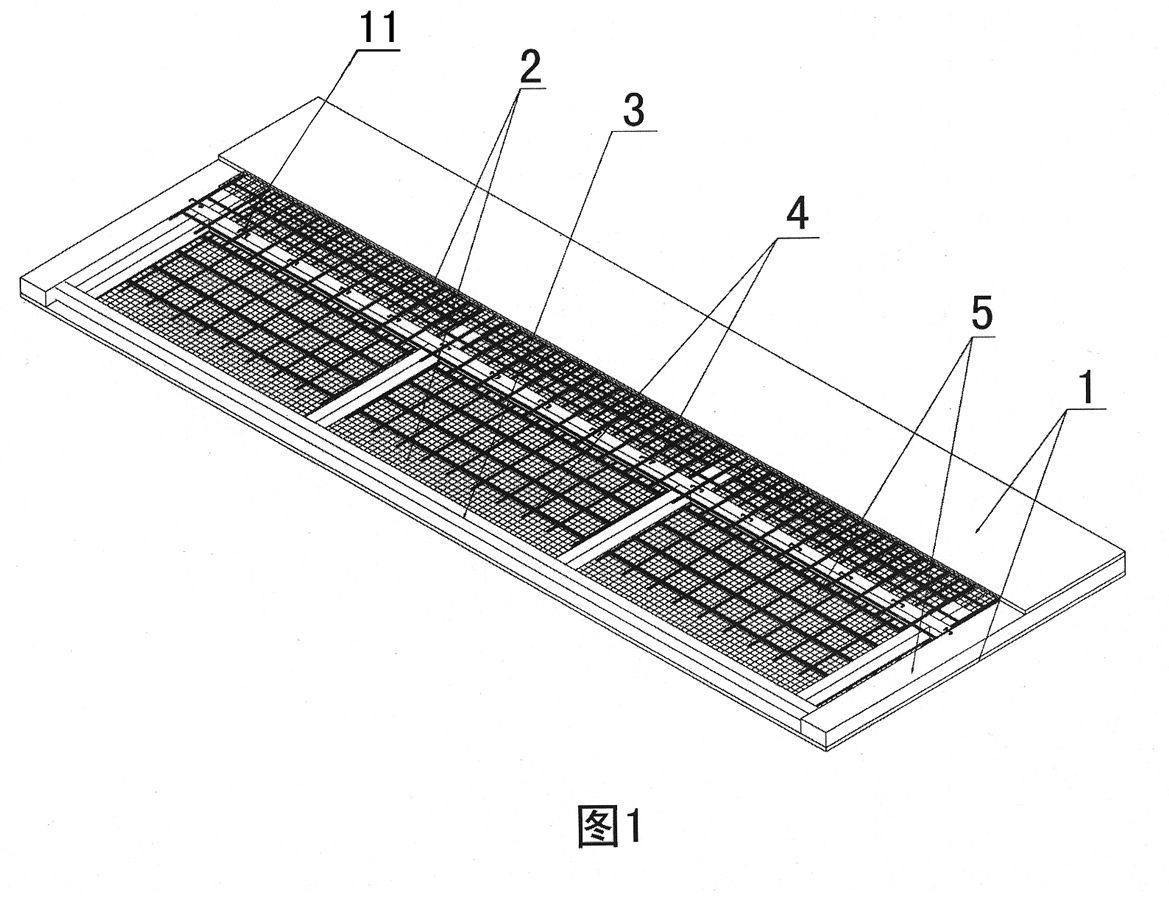

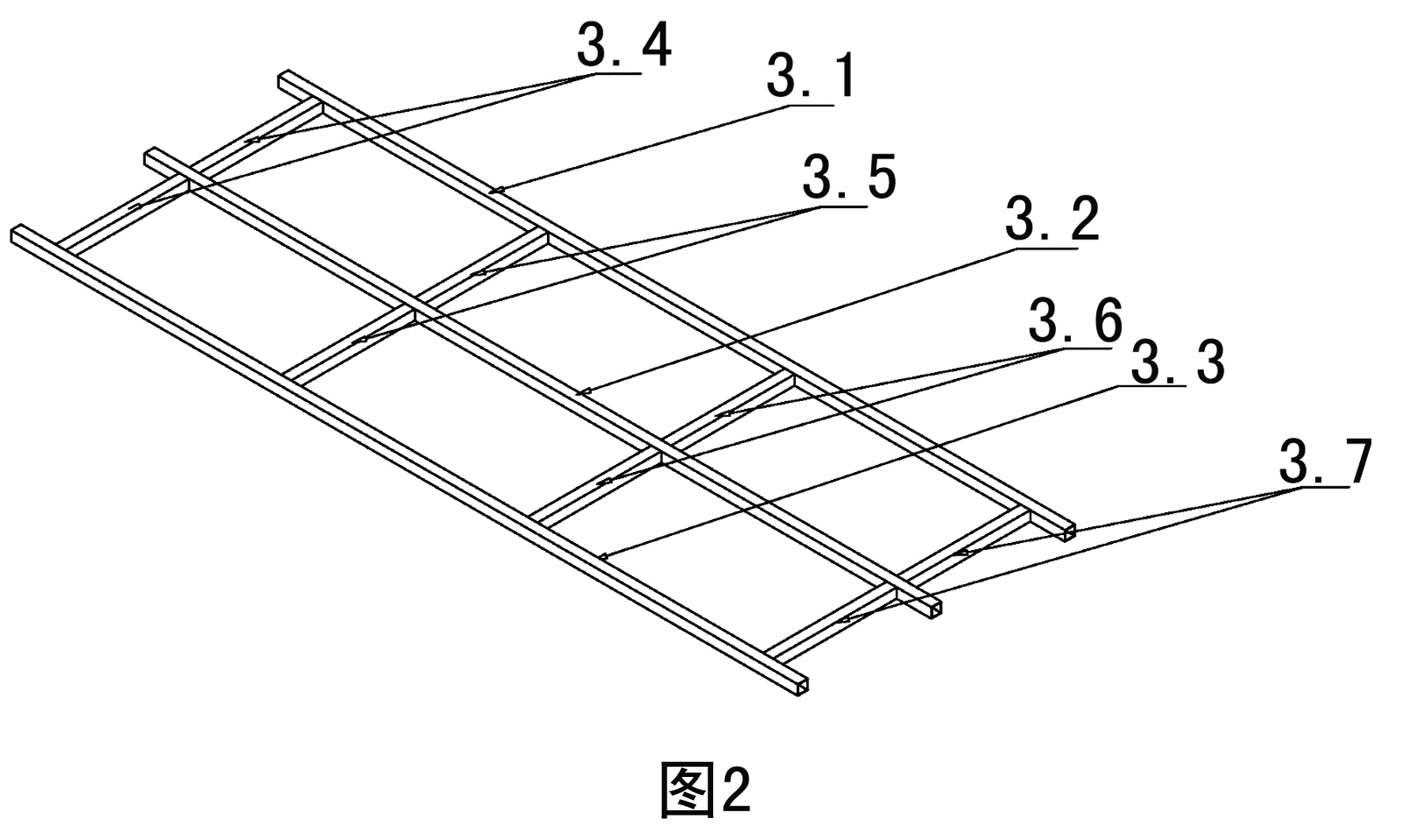

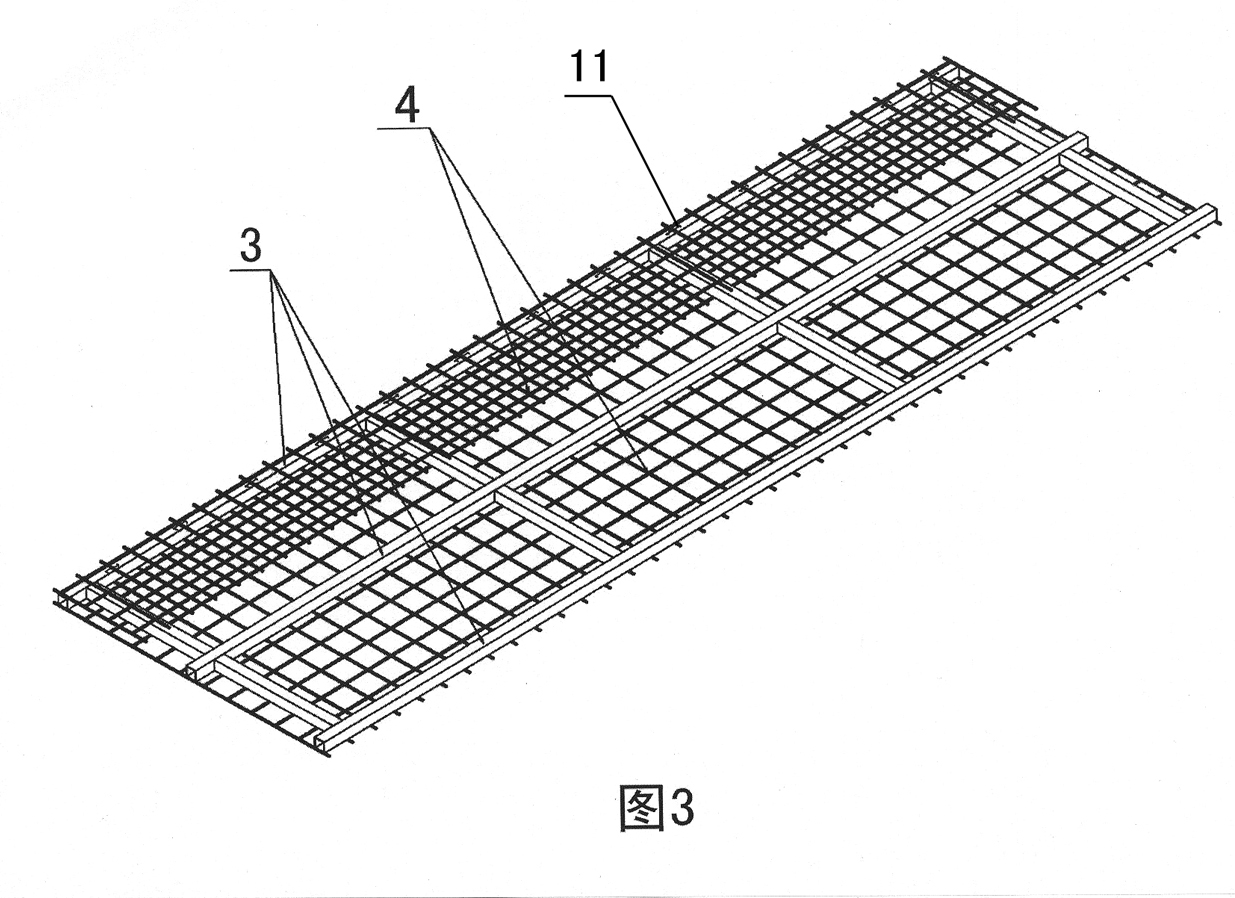

Built-in latticed steel frame exterior protected structural slab as well as building and production and construction method thereof

The invention discloses a built-in latticed steel frame exterior protected structural slab as well as a building and a production and construction method thereof. The built-in latticed steel frame exterior protected structural slab is of a solid core sandwich structure; the intermediate layer of the structural slab is a foamed cement filled layer; the two sides of the intermediate layer are combined with surface layers; the inner part of the foamed cement filled layer is provided with a built-in latticed steel frame; one side or two sides of the built-in latticed steel frame is or are covered with a steel wire mesh sheet or steel wire mesh sheets; the surface layer is a high-strength and anti-crack mortar strengthening surface layer internally doped with fiber silks and laid with fiber meshes; and a latticed steel frame net is formed by welding square steel tubes which are arranged vertically and horizontally at crossing intervals. The structural slab of the invention solves the problems that the existing building cover panel has low strength, is not convenient to be connected with a keel, is easy to fragment and has poor heat insulation property and the like, has the performances of energy conservation, environment protection, earthquake resistance, heat protection, heat preservation, heat insulation and sound insulation and the like, and can be widely applied in house buildings with lightweight-steel-construction wall bodies, floors and roofs.

Owner:筑巢(北京)科技有限公司

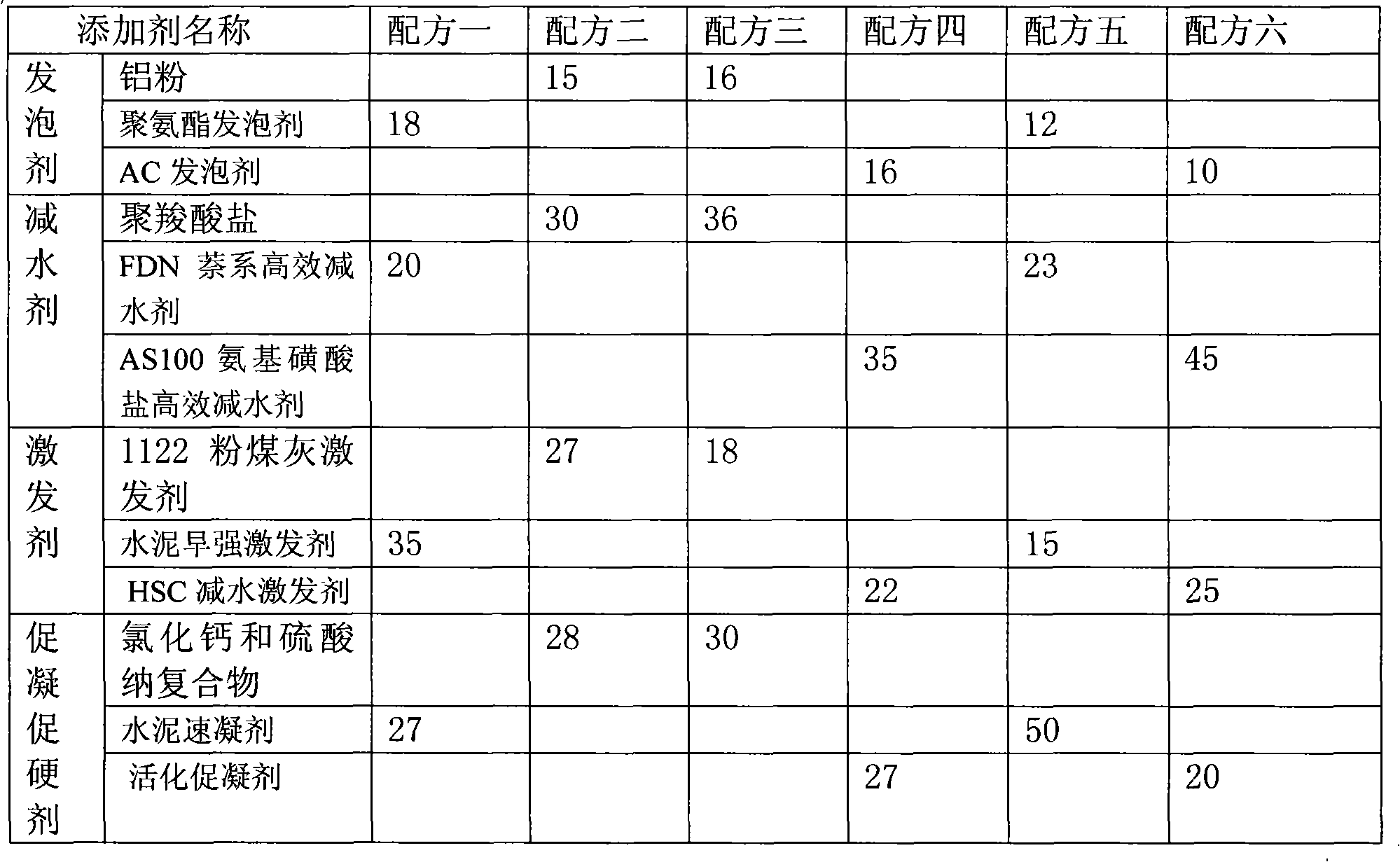

Haydite aerated concrete block and method for manufacturing same

InactiveCN101306934AImprove performanceIntegrity guaranteedSolid waste managementCeramic shaping plantsBrickSlag

The invention discloses a formula of a ceramic aggregate aerated concrete brick and a method for making the concrete brick. The compositions in portion by weight of the concrete brick are: 12 to 26 portions of cement, 26 to 46 portions of fly ash, 16 to 28 portions of ceramic aggregate, 2 to 6 portions of slag, 2 to 6 portions of cinder, 16 to 26 portions of water and 2 portions of addition agent, wherein the concrete matters in percentage by weight of the addition agent are: 10 to 18 percent of aluminum powder (a foaming agent), 20 to 45 percent of polycarboxylate (a water reducing agent), 15 to 35 percent of 1122 fly ash excitant and 20 to 50 percent of coagulant hardening accelerator in which calcium chloride and sodium sulfate compounds respectively occupies 50 percent. The concrete steps for making the ceramic aggregate aerated concrete brick are as follows: raw materials are weighed; the weighed raw materials are placed in a stirring machine to carry out stirring and mixing in advance; an addition agent is added in the stirring machine to carry out full stirring; a brick die is prepared, and stirred raw materials are cast in the brick die; initial set and forming are carried out; stripping is carried out; a water-proofing agent is sprinkled on a stripped brick; and natural curing is carried out. Moreover, the obtained brick has light dead weight, low density, high strength, low water absorption rate and excellent sound insulation performance and heat-shielding performance.

Owner:胡宗芳 +1

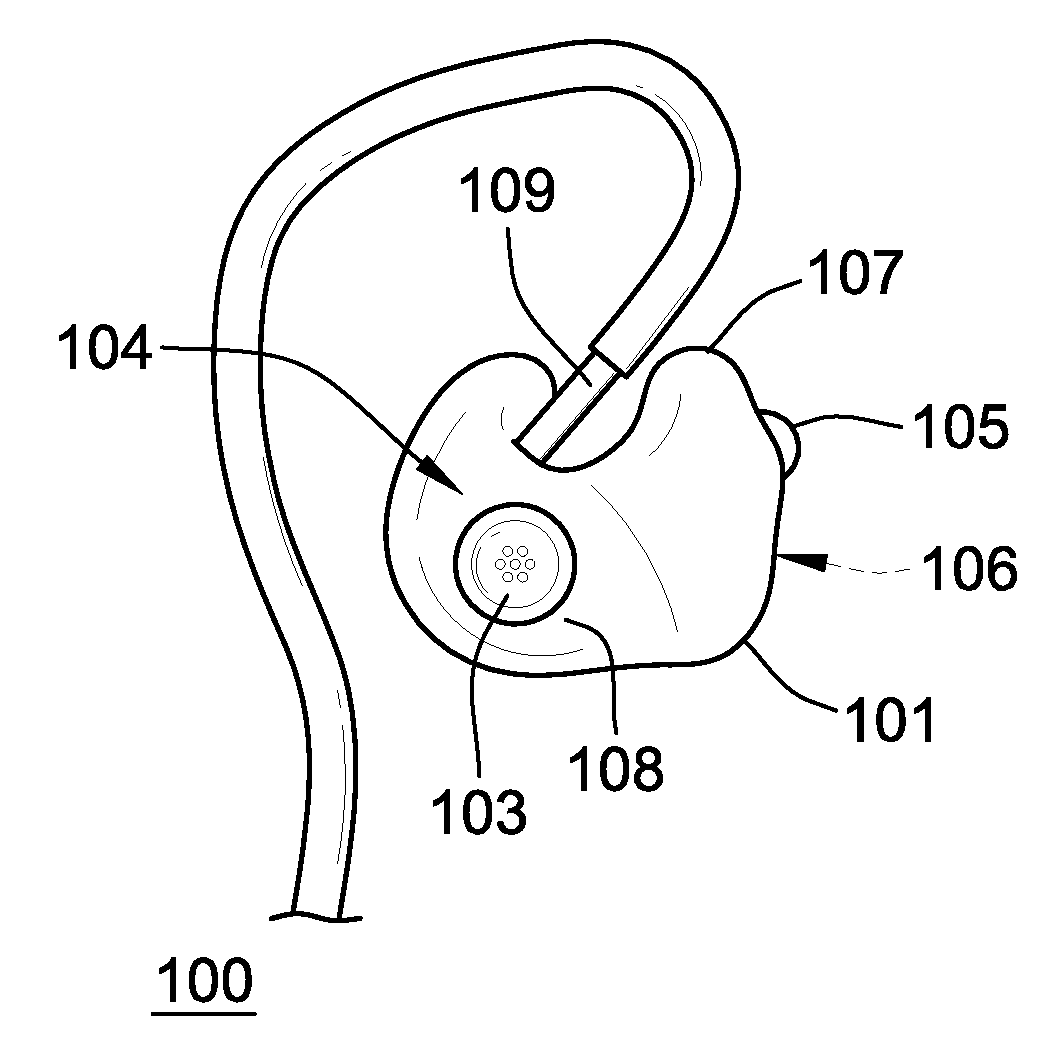

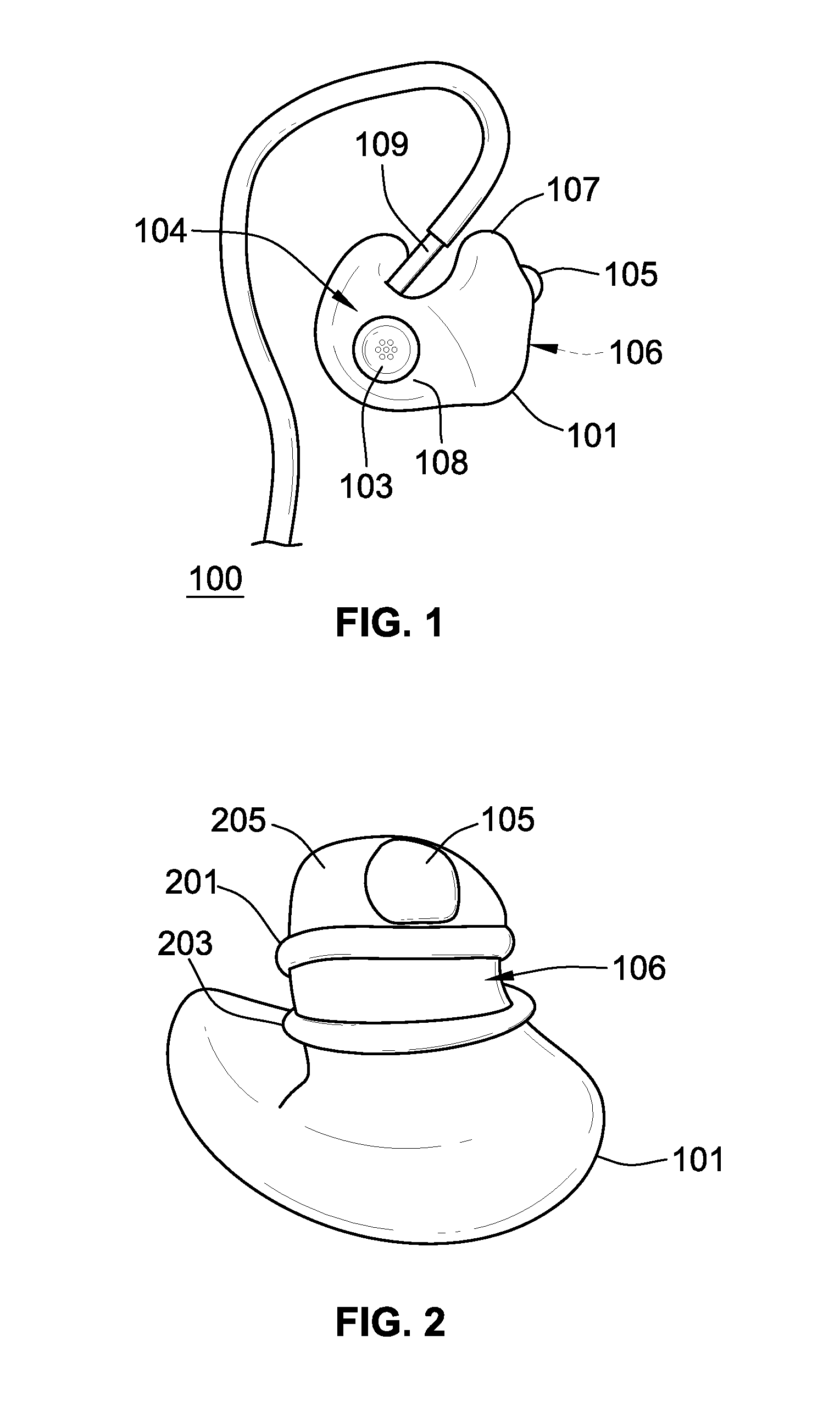

Custom in-ear headset

ActiveUS20110135120A1Improve sound insulationImprove sealingAdditive manufacturing apparatusStethoscopeLoudspeakerEar canal

A custom in-ear headset. The headset includes a housing having a proximate housing portion and a distant housing portion. The distant housing portion is shaped and sized to fit inside an ear canal of a user. The headset includes a miniature speaker that is acoustically coupled to a sound outlet in the distant portion of the housing for conveying sound pressure to an ear canal of the user. The headset further includes any one or more of: (a) a microphone with a sound inlet in the proximate housing portion, (b) a bone conduction microphone arranged in the distant housing portion, or (c) a microphone with a sound inlet in the distant housing portion. The headset further includes at least one ridge projecting from and circumscribing the distant housing portion.

Owner:INVISIO COMM

Concrete cement foaming insulation brick and manufacturing method thereof

The present invention discloses a concrete cement foaming insulation brick, taking a concrete perforated brick as a main body. The concrete perforated brick is injected with a cement foam material, so that the cement foam material and the concrete perforated brick are fully combined. By adjusting the formulation and improving the process, the present invention makes full use of industrial wastes such as fly ash and coal gangue, does not need autoclaved curing, and is small in investment and simple in process. The foaming brick produced by the present invention has excellent heat insulation and sound insulation properties, and is high in strength, good in impact resistance, low in moisture absorption, light in weight, compression resistant, good in weather resistance, environmental-friendly and energy-saving, and non-toxic. The brick has great market space and development prospects in the application field of building energy efficiency.

Owner:嵊州市万顺新型墙体材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com