Fiver cement board grouting wall and construction method therefor

A technology of fiber cement board and construction method, applied in the direction of walls, solid waste management, building components, etc., can solve the problems of earthquake resistance, poor impact resistance, waterproof, fire prevention, poor sound insulation performance, low hanging force, etc., and achieve waterproof Good performance, simple waterproof construction, and the effect of reducing the cost of the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

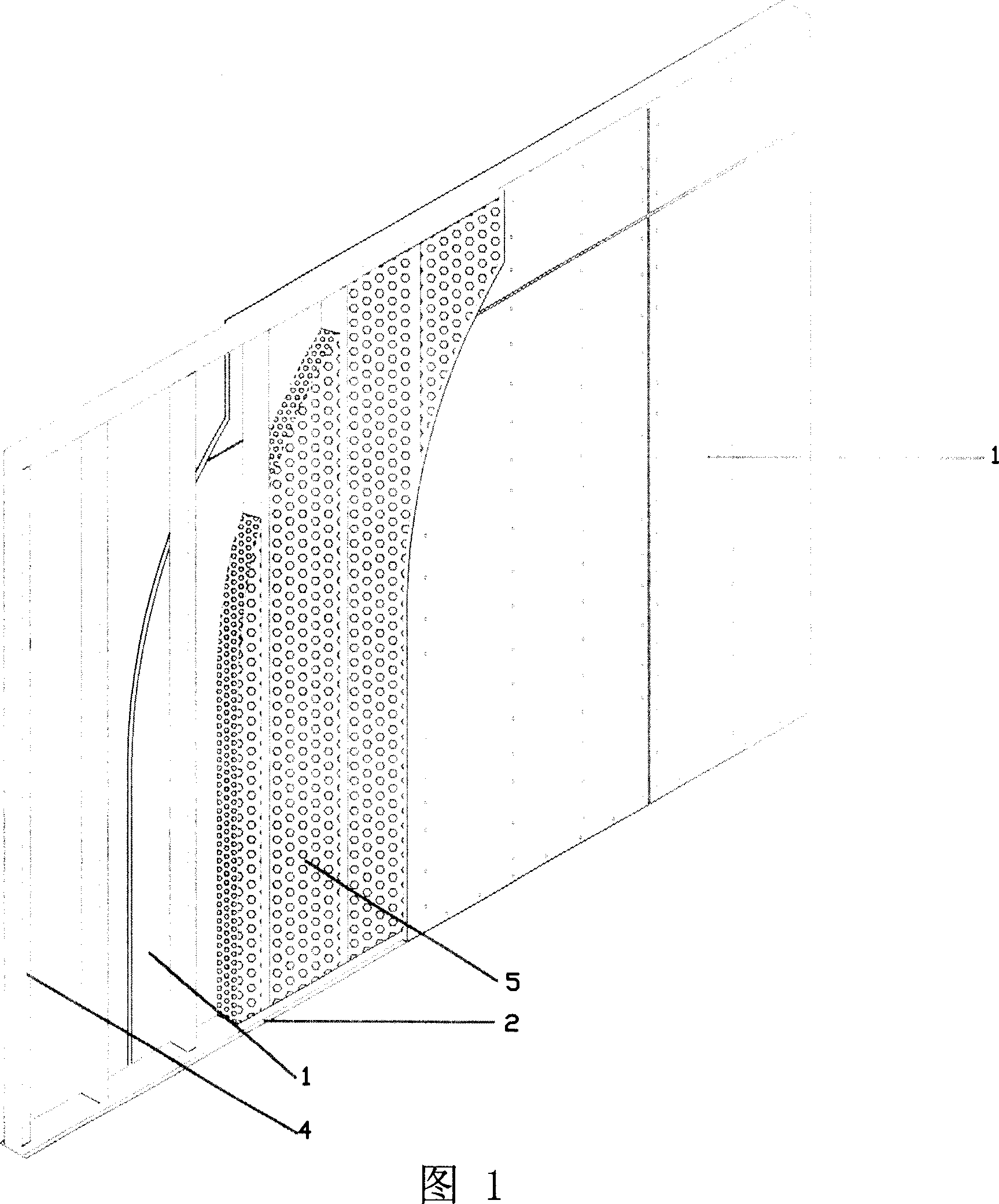

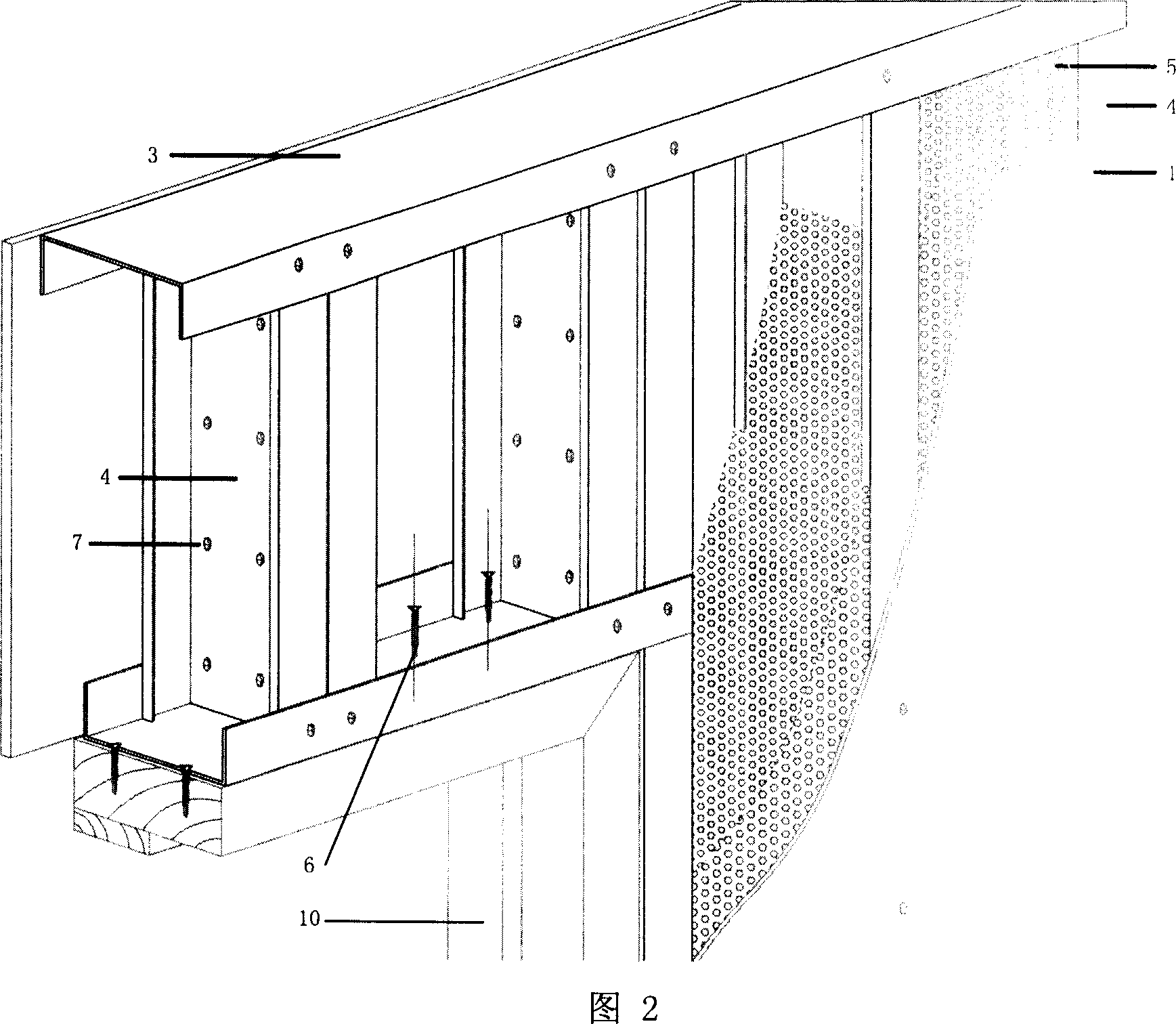

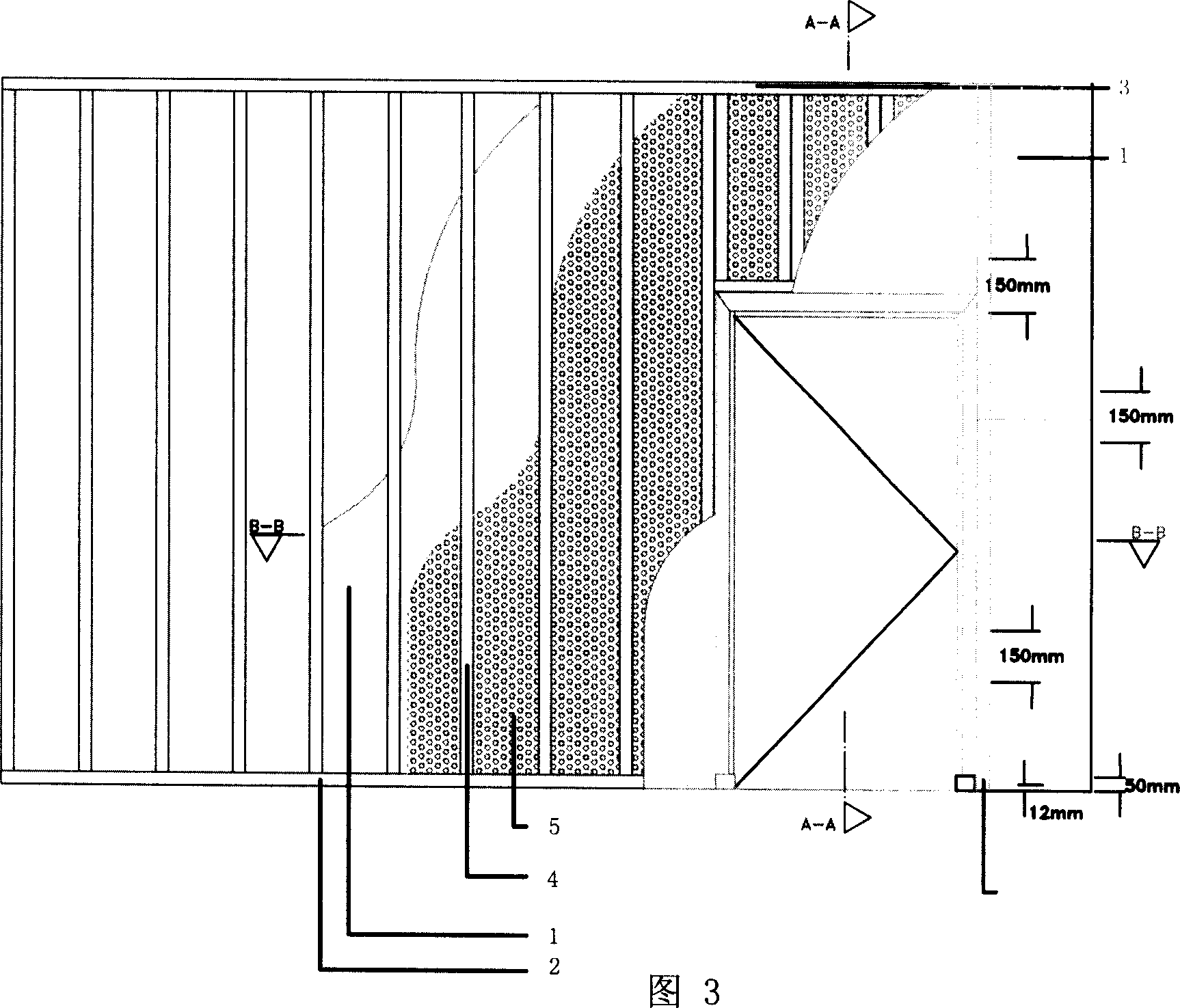

[0155] The specific construction specifications of the light grouting wall system structure (can be adjusted under different construction conditions): the total thickness is 87mm, the wall consists of 75 keels, and a single layer of 6mm thick 1200mm×2400mm BMW engineering board is installed on both sides, and lightweight grouting is poured in the middle of the keel material composition.

[0156] The light steel keel uses 75 wide light steel keels, and the spacing is generally 400mm according to the specific needs of the project. Cement fiberboard uses 6mm×1220mm×2440mm engineering board, board density: 1390kg / m 3 .

[0157] Screws Use self-tapping screws to fix the plate, and the screw spacing is less than 200mm.

[0158] Grouting material: cement, sand, EPS particles (Polystyrene), water;

[0159] The ratio reference: (specifically adjusted according to the actual situation on site)

[0160] Cement: 250kg

[0161] Sand: 350Kg

[0162] EPS particles: 650 liters

[0163]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com