Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2200results about How to "Good insulation performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aerogel heat insulation composite material and its preparing method

The heat insulating composite aerogel material consists of silica aerogel, titania as infrared opacifier and reinforcing fiber in the weight ratio of 1 to 0.1-0.7 to 0.7-3. Its preparation process includes compounding sol with silanolate, surface modifier, titanolate, alcohol solvent, acid catalyst and alkaline catalyst in certain proportion; soaking fiber felt or prefabricated fiber part in the sol; and supercritical fluid drying. The material of the present invention has high blocking effect on solid heat transfer, air heat transfer and infrared radiation heat transfer, excellent hydrophobicity, simple preparation process, low cost, mechanical strength over 2 MPa, and wide application range, and may be used in strict heat protection condition in aeronautics, astronautics, military and civil uses.

Owner:NAT UNIV OF DEFENSE TECH

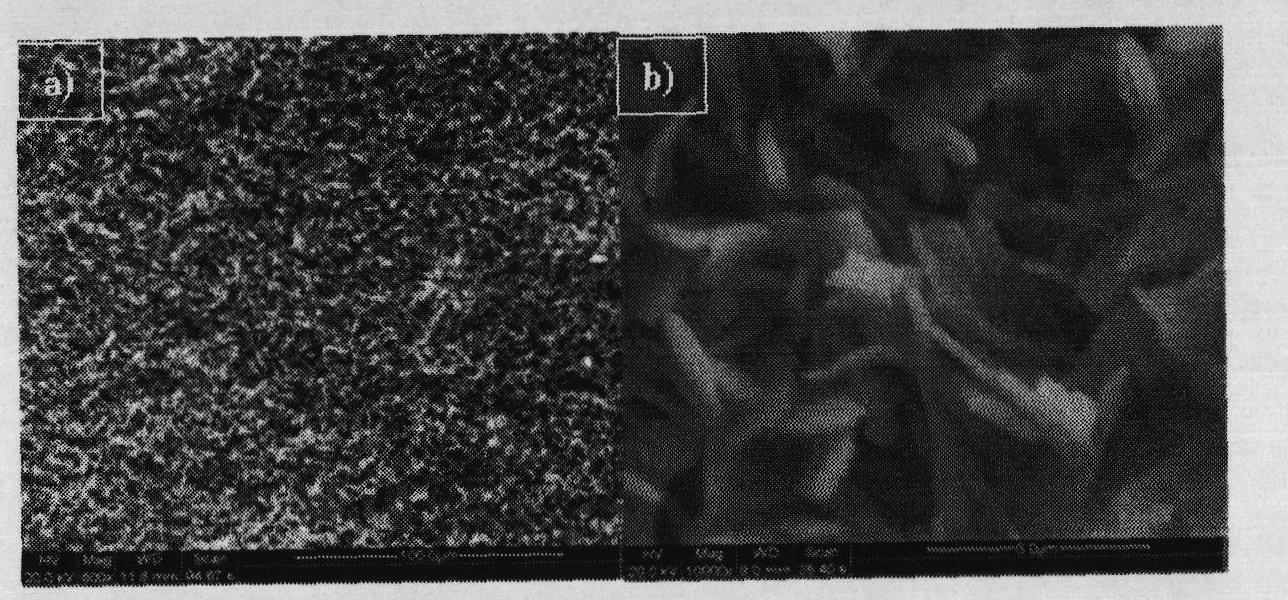

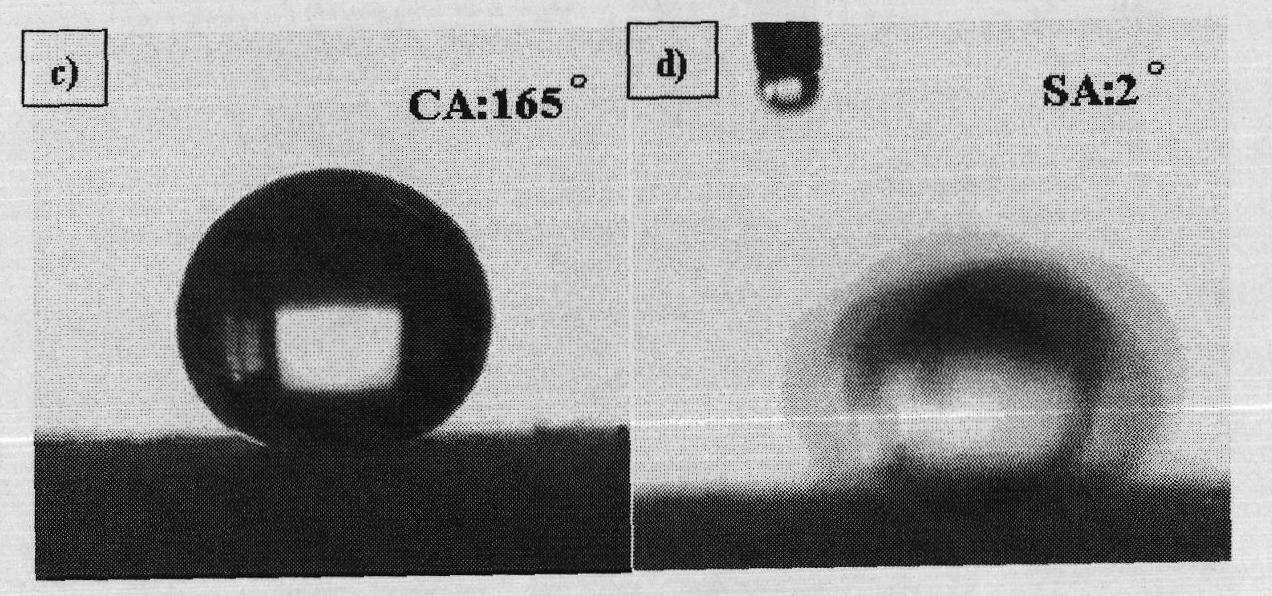

Super-hydrophobic polyurethane/ oxide nano particle hybrid coating material and preparation method thereof

ActiveCN101838496ALow costSimple equipment and preparation processPolyurea/polyurethane coatingsSurface energySelf-assembly

The invention relates to a super-hydrophobic polyurethane / oxide nano particle hybrid coating and a preparation method thereof. The super-hydrophobic coating is prepared by oxide nano particles, silane coupling agent and polyurethane which have wide material source and are easily obtained through a self-assembly method, and has the contact angle of 140-168 degrees and the rolling angle of 1-20 degrees as well as good visible light permeability. The invention solves the problems that the currently prepared transparent super-hydrophobic coating needs extremely low surface energy perfluorinated silane modification, has high production cost and complicated technique, and can not realize large-scale production. The method has simple technique, easily obtained raw material and low cost; and theprepared super-hydrophobic coating can be taken as a dustproof and antifogging protective coating of the surface of solids such as glass and the like, and a waterproof insulating layer used in a micro-electronic device, a sensor and the like.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

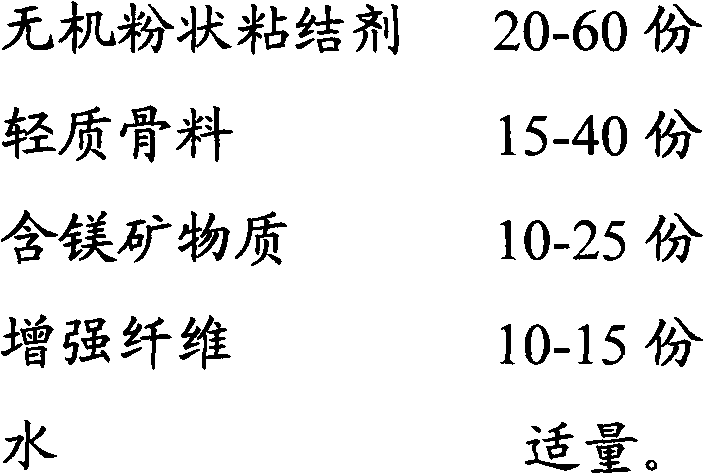

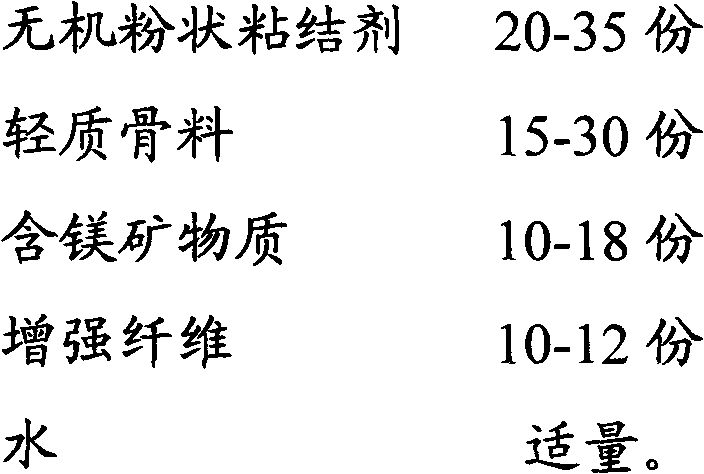

Thermal insulation and heat preservation slurry composition and thermal insulation and heat preservation plate containing the same

ActiveCN103086661AGood insulation performanceGood heat insulationClimate change adaptationHeat proofingThermal insulationMagnesium

The invention provides a thermal insulation and heat preservation slurry composition, which comprises the following components, by weight, 20-60 parts of an inorganic powder binder, 15-40 parts of a lightweight aggregate, 10-25 parts of a magnesium-containing mineral, 10-15 parts of reinforcing fibers, and a proper amount of water. The present invention further provides a thermal insulation and heat preservation plate containing the thermal insulation and heat preservation slurry composition, wherein the thermal insulation and heat preservation plate comprises one or more than two thermal insulation and heat preservation material layers, and thermal insulation and heat preservation slurry layers covered on both surfaces of the thermal insulation and heat preservation material layer. The thermal insulation and heat preservation plate has the following characteristics that: a thermal insulation and heat preservation performance is excellent; non-combustible property is provided, or combustion is not generated when the plate contacts open fire; the plate is mainly prepared from inorganic materials, such that characteristics of no toxic or harmful gas release and the like during use are provided; and the plate can be widely used in cold northern regions, and is the best alternative of polyphenylene plates, polyurethane plates and other materials.

Owner:深圳市爱思宝科技发展有限公司

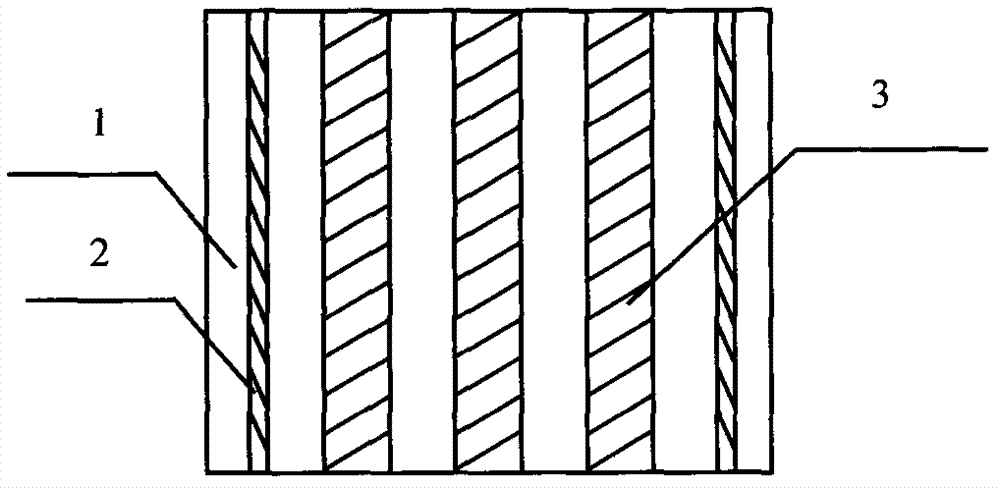

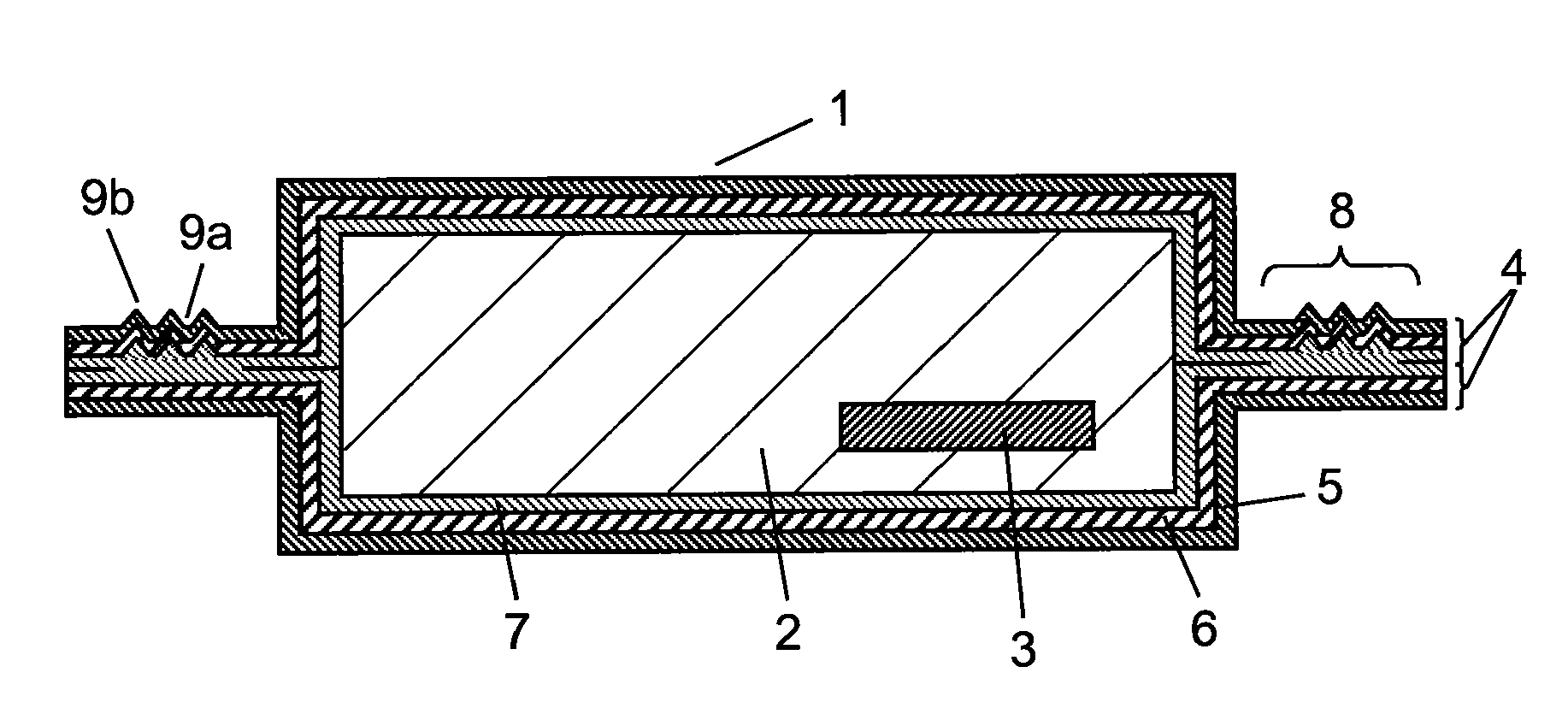

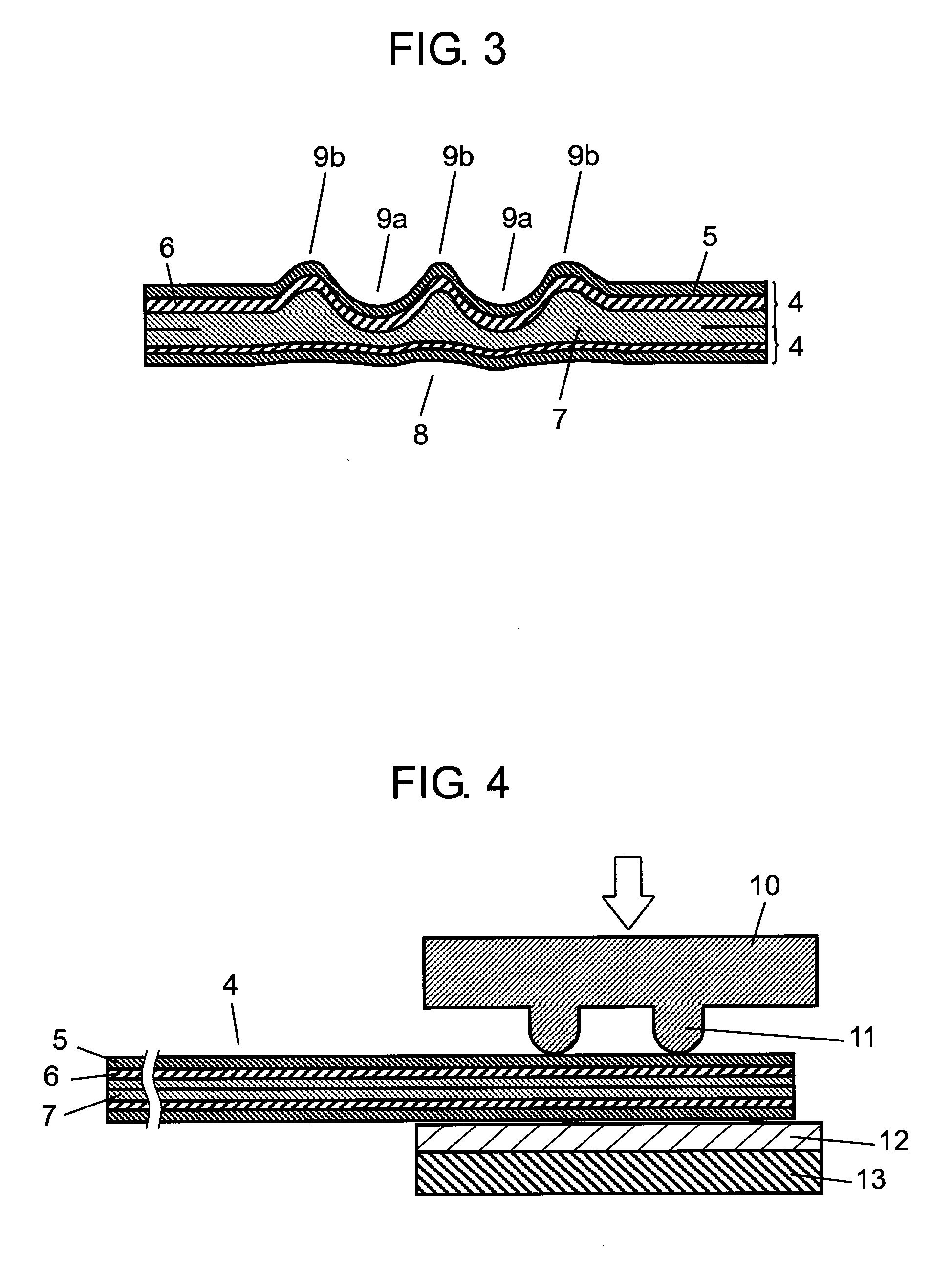

Vacuum heat insulation material and manufacturing method therefor

ActiveUS20110165367A1Avoid it happening againLimited amountThermal insulationClimate change adaptationThick wallEngineering

A plurality of thin-wall parts (9a) of a sealant layer (7) are formed in a portion continuously changed in the interval of one sealing part (8) and a gas barrier layer (6) of other laminate film (4). At the inner circumferential side between the adjacent thin-wall parts (9a) and the thin-wall part (9a) at the innermost circumferential side and at the outer circumferential side of the thin-wall part (9a) of the outermost circumferential side, a thick-wall part (9b) of the sealant layer (7) is formed. All of the opposing sealant layers (7) between the two adjacent thin-wall parts (9a) are mutually heated and fused, so that an excellent adiabatic performance is maintained for a long period.

Owner:PANASONIC CORP

High-temperature-resisting heat-insulation coating as well as preparation method and application thereof

ActiveCN103725074AEasy to use in constructionPlay the role of saving energy and reducing consumptionReflecting/signal paintsPetroleumEnergy consumption

The invention relates to the field of functional coatings and particularly relates to a high-temperature-resisting heat-insulation coating and a preparation method thereof. The high-temperature-resisting heat-insulation coating is composed of the following raw materials in percentage by mass: 10%-40% of high-reflection paint with a shell-core structure, 10%-40% of heat-insulation powder with the shell-core structure, 1%-5% of a toughening agent, 10%-50% of a high-temperature bonding agent, 1%-10% of a coating auxiliary agent, and the balance of water. The preparation method comprises the following steps: mixing, dispersing and grinding raw materials; carrying out homogenization to enable an average grain diameter to be 325-400 meshes; and filtering and packaging to obtain a finished product. The high-temperature-resisting heat-insulation coating can be applied to high-temperature fields of industrial furnaces, industrial boilers, high-temperature steam pipelines, petroleum cracking equipment, engine parts, high-temperature smelting, sintering furnaces and the like, and can be used under a higher temperature for long time; the energy consumption can be saved and the service life of the furnaces is prolonged.

Owner:武汉双虎涂料股份有限公司

Continuous fibre enhancement polyurethane foam material and manufacturing method thereof

A continuous fiber reinforce polyurethane foaming material and a relative production method relate to a polyurethane foaming material, wherein the continuous fiber reinforce polyurethane foaming material has strong rigidity, strength and shock resistance to produce foaming polyurethane material with reinforced glass fiber, which eliminates breaking and premixing with any component of polyurethane, is directly mixed and immersed with polyurethane mixture in an immerser and is foamed and shaped continuously, and contains A, B and C components. A comprises polyatomic alcohol, foaming agent, catalyst, foaming stabilizer, chain extender and adjuvant, B is polyisocyanate, C is fiber material. The preparation method comprises mixing the materials of A in A pot, the materials of B in B pot, immersing fiber via an immerser with the mixture discharged from a high-speed pouring head, feeding immersed material into a continuous foaming mold to be foamed and solidified, cooling, removing mould, taking off and cutting to obtain final product.

Owner:厦门高特高新材料有限公司

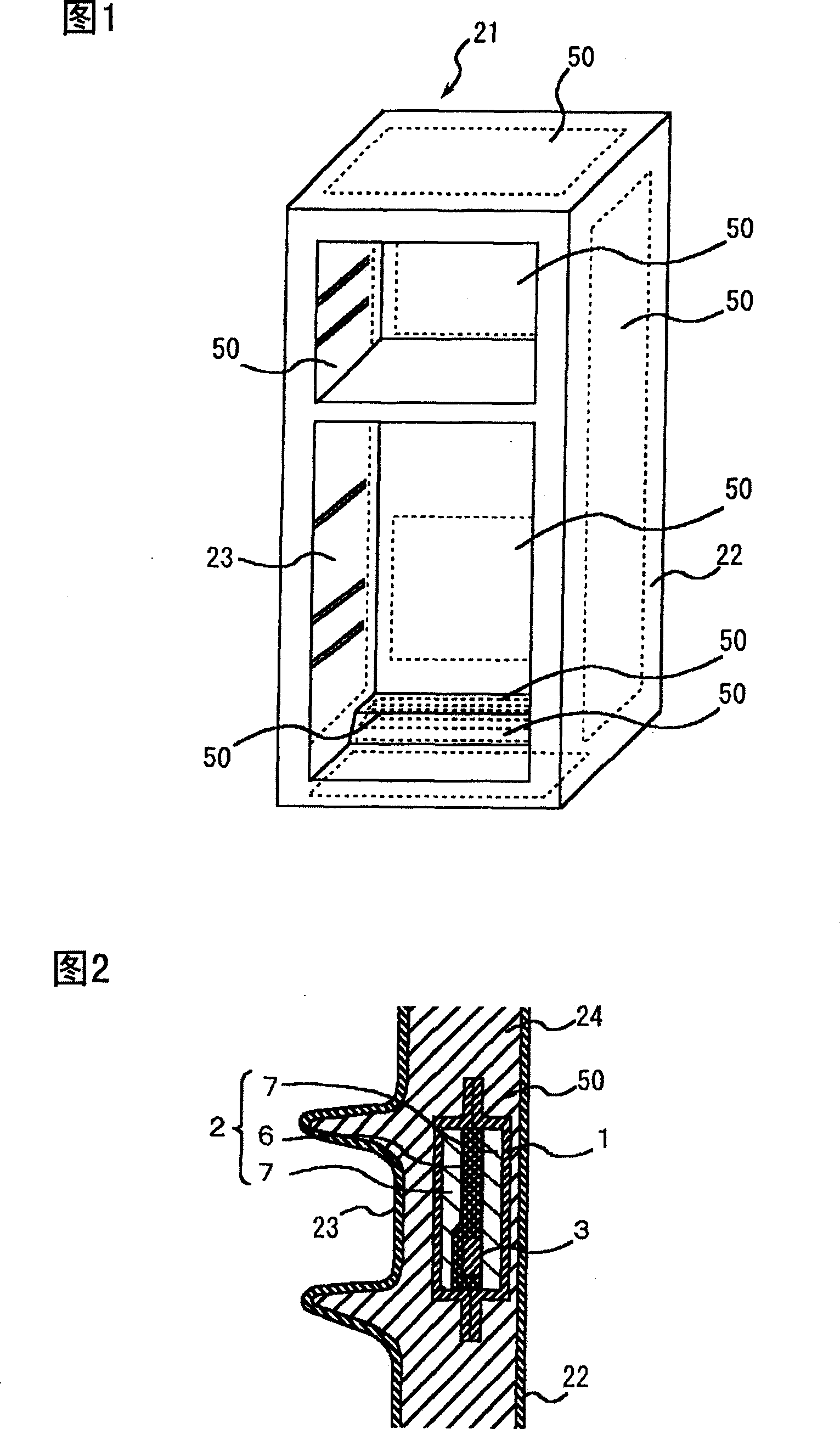

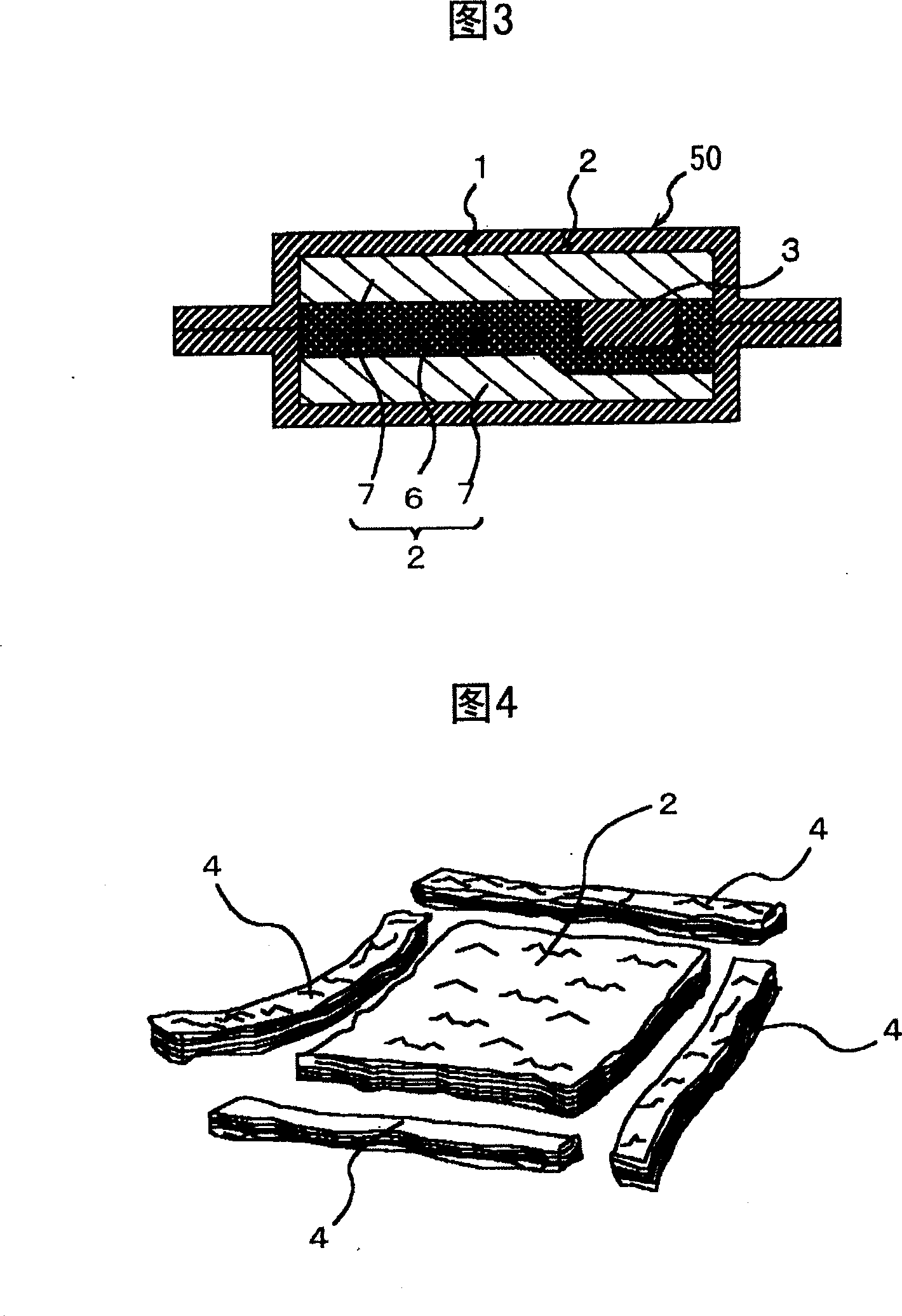

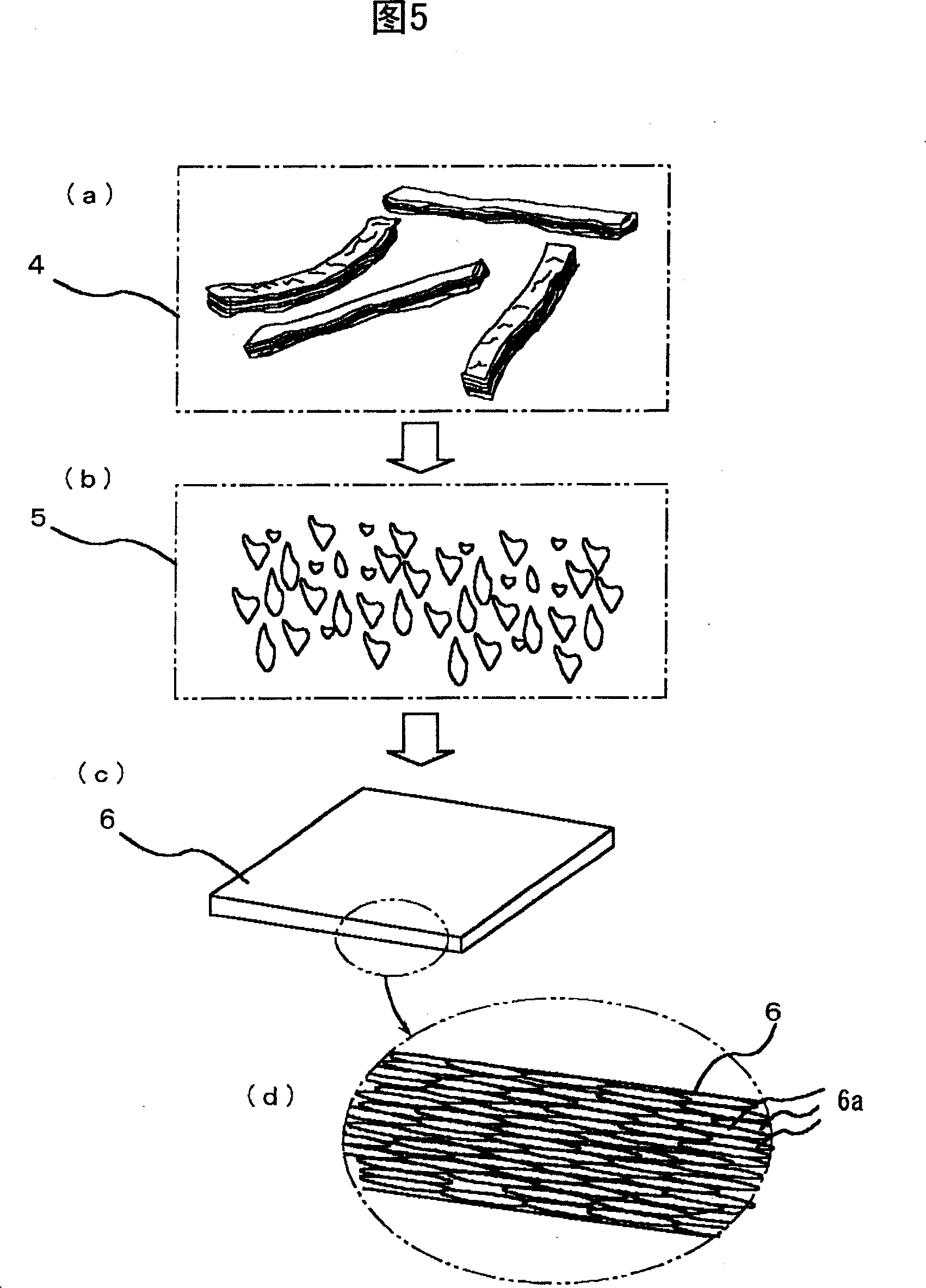

Refrigerator and vacuum thermal insulating material and producing method thereof

InactiveCN100359272CEfficient use ofGood insulation performanceThermal insulationLaminationFiberRefrigerated temperature

In the manufacturing method of the refrigerator in the invention, a new material inorganic fiber assembly 7 is produced in a sheet shape, and a waste material inorganic fiber assembly 6 is produced in a sheet shape using a waste core material formed of the inorganic fiber assembly. The new material inorganic fiber assembly 7 and the waste material inorganic fiber assembly 6 are laminated, and the laminated body is impregnated with a binding material and thermally pressed, thereby binding the laminated body via the binding material, compressing it to a predetermined thickness, and forming a core material 2. Then, the core material 2 is stored in a covering material 1 formed of gas barrier film and evacuated and sealed, thereby producing the vacuum heat insulating material 50. Then, the vacuum heat insulating material 50 is arranged between an outer box and an inner box, and then a foaming heat insulating material 24 is filled into a space between the outer box 22 and the inner box 23 to form a heat insulating body.

Owner:HITACHI APPLIANCES INC

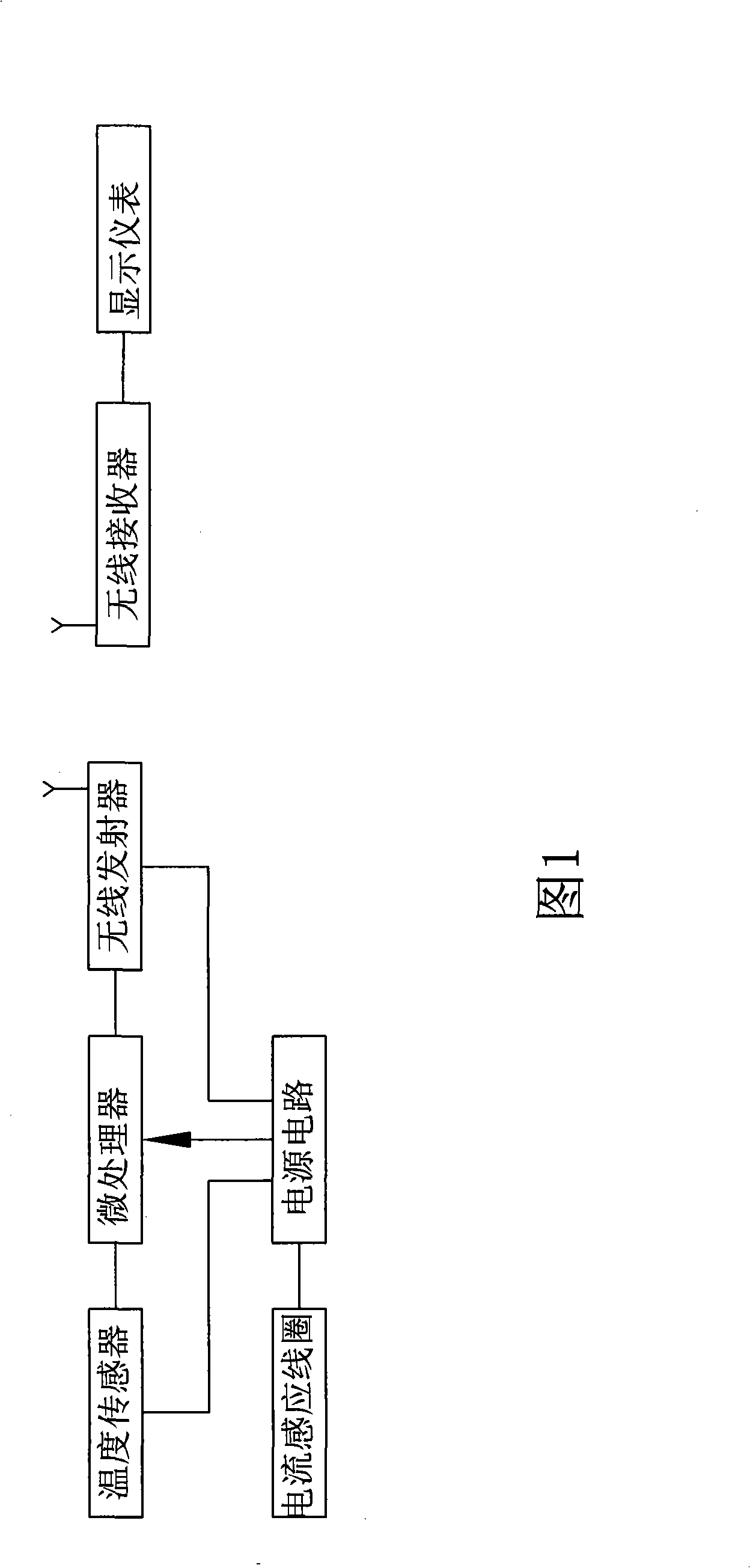

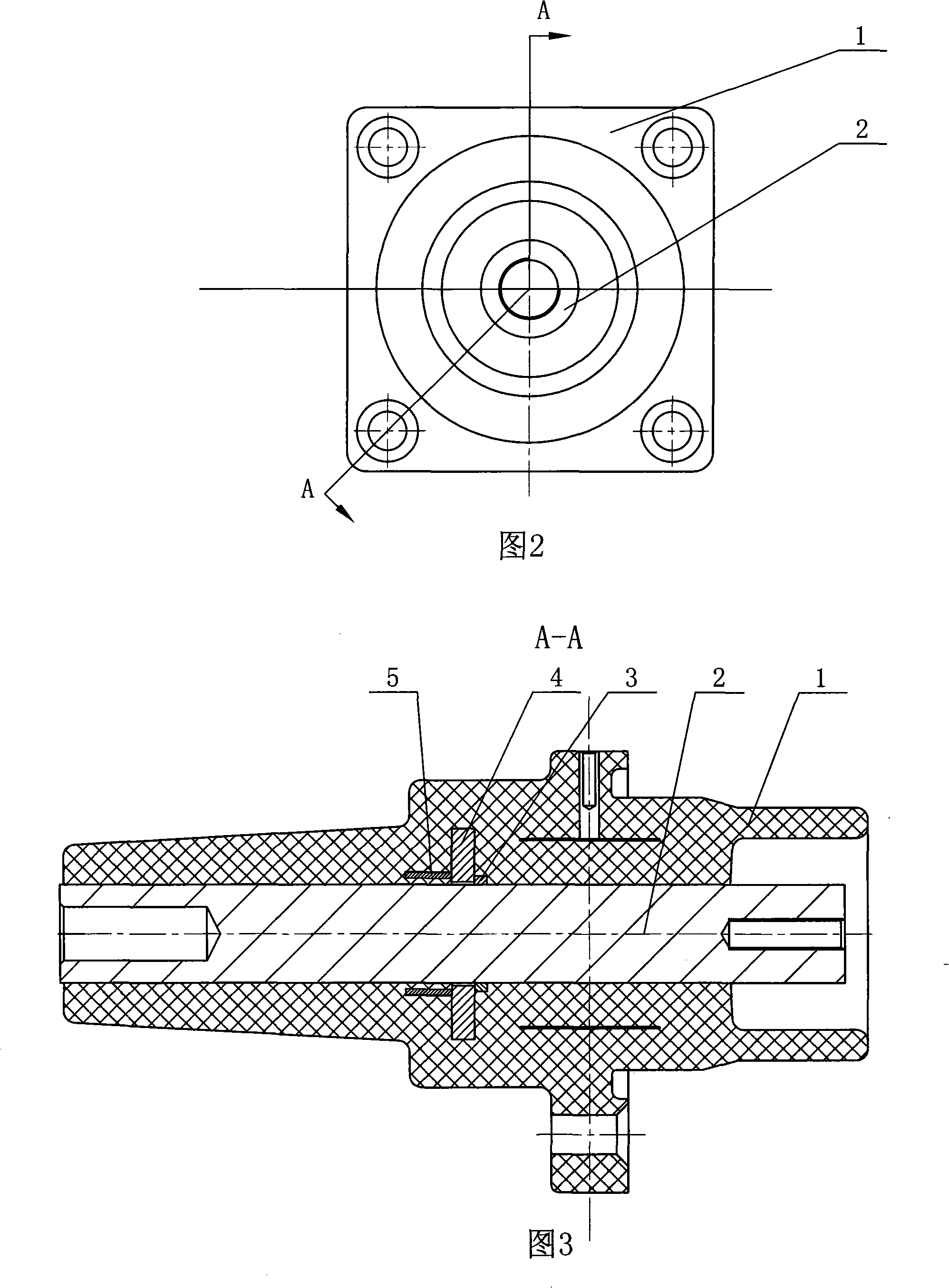

On-line temperature measurement method and device for cable joint of high-voltage plant

ActiveCN101319938AGood insulation performanceReduce volumeTransmission systemsThermometers using electric/magnetic elementsTemperature measurementPower circuits

The invention relates to an on-line temperature measuring method for the cable joints of a high voltage device; three temperature sensors are stuck on the surfaces of three metal conductive bodies; current induction coils are sheathed on the metal conductive bodies; a power circuit, microprocessors and wireless emitters are arranged on the metal conductive bodies and sealed in an insulator by circuit boards; the digital identifying codes of the three output ends of the measured cable joints are written in the microprocessors of each own; three metal conductive bodies sealed by insulating materials are respectively arranged at the three-phase output ends of the cable joints; each current induction coil after inducing that the currents are processed by the power circuit provides a working power for the temperature sensor, the microprocessor and the wireless emitter of each own; the microprocessors emit the monitored temperature signals and corresponding identifying codes by the wireless emitters; a wireless receiver receives the wireless electric signals of each circuit, demodulates the wireless electric signals into digital signals and transmits the digital signals to a display instrument; the display instrument receives and identifies three corresponding cable joints. The on-line temperature measuring method can instantly accurately monitor the temperature of the cable joints of the high voltage device on line.

Owner:常州帕斯菲克自动化技术股份有限公司

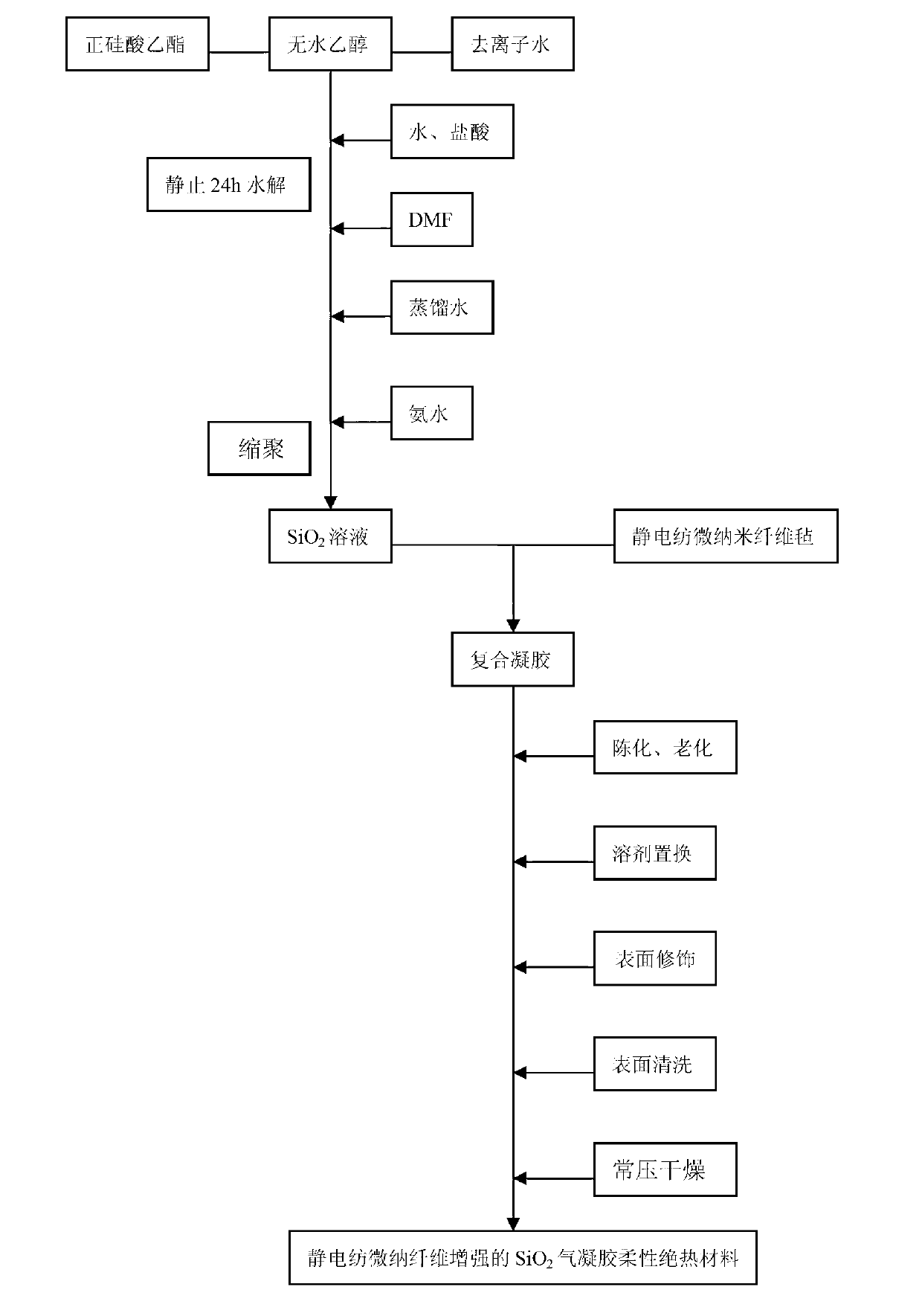

Electrospun micro-nanofiber reinforced aerogel flexible thermal insulation material and its preparation method

ActiveCN103102135AImprove thermal conductivityImprove heat transfer performanceMicro nanoPolymer science

Belonging to the field of heat preservation and thermal insulation materials, the invention puts forward an electrospun micro-nanofiber reinforced aerogel flexible thermal insulation material and its preparation method. The method takes electrospun micro-nanofiber as a reinforcement body, which is mixed with an SiO2 sol. A sol-gel process is employed to prepare an electrospun micro-nanofiber and aerogel composite thermal insulation material with a stable structure under normal temperature and pressure conditions. The method provided in the invention employs micro-nanoscale electrospun micro-nanofiber to reinforce the aerogel, so that the composite material can have better flexibility, interface bonding property and structural integrity. While the mechanical properties of the aerogel thermal insulation composite material are improved, the material also can maintain good thermal insulation performance.

Owner:吴会军

SiO2 enriched nano composite heat preserving and thermal insulating paste and preparing process thereof

The invention relates to SiO2 nano composite thermal insulation paste, which is characterized in that the form of the SiO2 nano composite thermal insulation paste is a paste mixture, and the dried paste mixture becomes micro pores, nano holes and a fiber structure compound. The paste comprises the following components by weight percentage: 20 to 50 percent of SiO2 nano aerogel, 0 to 30 percent of inorganic closed-hole micro-bead material, 7 to 15 percent of expanded pearlite, 0 to 1 percent of bentonite, 2 to 6 percent of penetrating agent, 10 to 20 percent of adhesive, 3 to 6 percent of calcium silicate fiber, 0 to 5 percent of magnesium aluminum silicate fiber, 0 to 5 percent of aluminum silicate fiber, 0 to 40 percent of water, 0.1 to 2 percent of flame retardant, and 3 to 7 percent of pigment. A preparation device is a vacuum intake and stirring device.

Owner:上海暄洋化工材料科技有限公司

Nano-pore SiO2 aerogel thermal insulation composite material and preparation method thereof

The invention discloses a nano-pore SiO2 aerogel heat-insulating composite material and a preparation method thereof. The nano-pore aerogel heat-insulating composite material comprises SiO2 aerogel, an infrared opacifier and reinforced fibers. The preparation method comprises: mixing silicasol and indium-tin oxide ITO nano alcohol slurry or nano composite alcohol slurry of ITO and TiO2 through supersonic wave action, mixing the mixture and the reinforced fibers, directly pouring the mixture into a die to form a wet gel complex, and performing supercutical fluid drying. The material has good heat transfer function and good obstructing function on solid heat conduction, air heat convection and infrared radiation heat conduction, simultaneously has good hydrophobicity, simple technique, low cost and wide application scope, has the mechanical strength reaching more than 1.2 MPa, and can be used in situations with higher heat protection requirement in the fields of avigation, spaceflight, military affairs and domestic use.

Owner:CHANGSHA XINGNA AEROGEL

Method for preparing foamed ceramic insulation board by waste glass ceramic wafer

The invention discloses a method for preparing a foamed ceramic insulation board by a waste glass ceramic wafer, belonging to the field of preparation technology of the foamed ceramic insulation board. The method comprises the steps of: washing the waste glass ceramic wafer with clear water, drying and grinding by ball milling to obtain waste glass ceramic powder with the fineness less than or equal to 100mu m; mixing the waste glass ceramic powder, pulverized fuel ash, furnace slag, coal gangue, ceramic tailings, foaming agent and modifying agent according to the mass ratio of (30-40):(10-15):(5-7):(10-18):(25-35):(1.8-2.2):(1.1-1.5); putting the mixture into a ball grinding mill, carrying out wet grinding and evenly mixing to form mixed slurry; drying by a pressure type spray granulation dryer and putting the dried product into a foaming refractory mould coated with aluminum oxide; heating to 1120-1150 DEG C in a heating furnace; and finally, annealing, cooling and cutting to obtain the foamed ceramic insulation board. The method is low in production cost and simple in technology, and can be used for continuously preparing the porous foamed ceramic insulation board with large size; and the product is good in performances.

Owner:ANSHENG SCI & TECH DEP

Ageing-resistant heat-insulation tarpaulin and production method thereof

InactiveCN101792975AImprove waterproof performanceGood insulation performanceHeating/cooling textile fabricsTextile treatment by pouringFiberPre treatment

The invention discloses an ageing-resistant heat-insulation tarpaulin. The tarpaulin is composed of a polymer cloth base and an ageing-resistant heat-insulation coating which is coated on the polymer cloth base in a casting mode. After aging is quickened for 236 hours by simulating natural manual work, the tensile strength of the tarpaulin is improved by at least 10%, the elongation at break thereof is improved by at least 5% than the elongation at break before aging, the ultraviolet reflectivity thereof is more than or equal to 80%, and the infrared obstruction rate thereof is more than or equal to 85%. The invention also discloses a preparation method thereof, comprising the following step: pretreating a heat-insulation material by utilizing a surface treating agent; and premixing the heat-insulation material with accessory ingredients such as vinyl type polymer, antioxidant and the like, then putting the heat-insulation material and the accessory ingredients into a double-screw extrusion casting coating machine to be fused, plasticized and extruded out to be casted and coated on the polymer fiber cloth base, and carrying out cooling shaping and reeling by utilizing a cooling roll to obtain the ageing-resistant heat-insulation tarpaulin. The tarpaulin product obtained by the invention has favourable water proofness, heat-insulating property and ageing-resistant property, wide application range, no pollution in the production process, small energy consumption, low cost and easy popularization and application.

Owner:SICHUAN UNIV

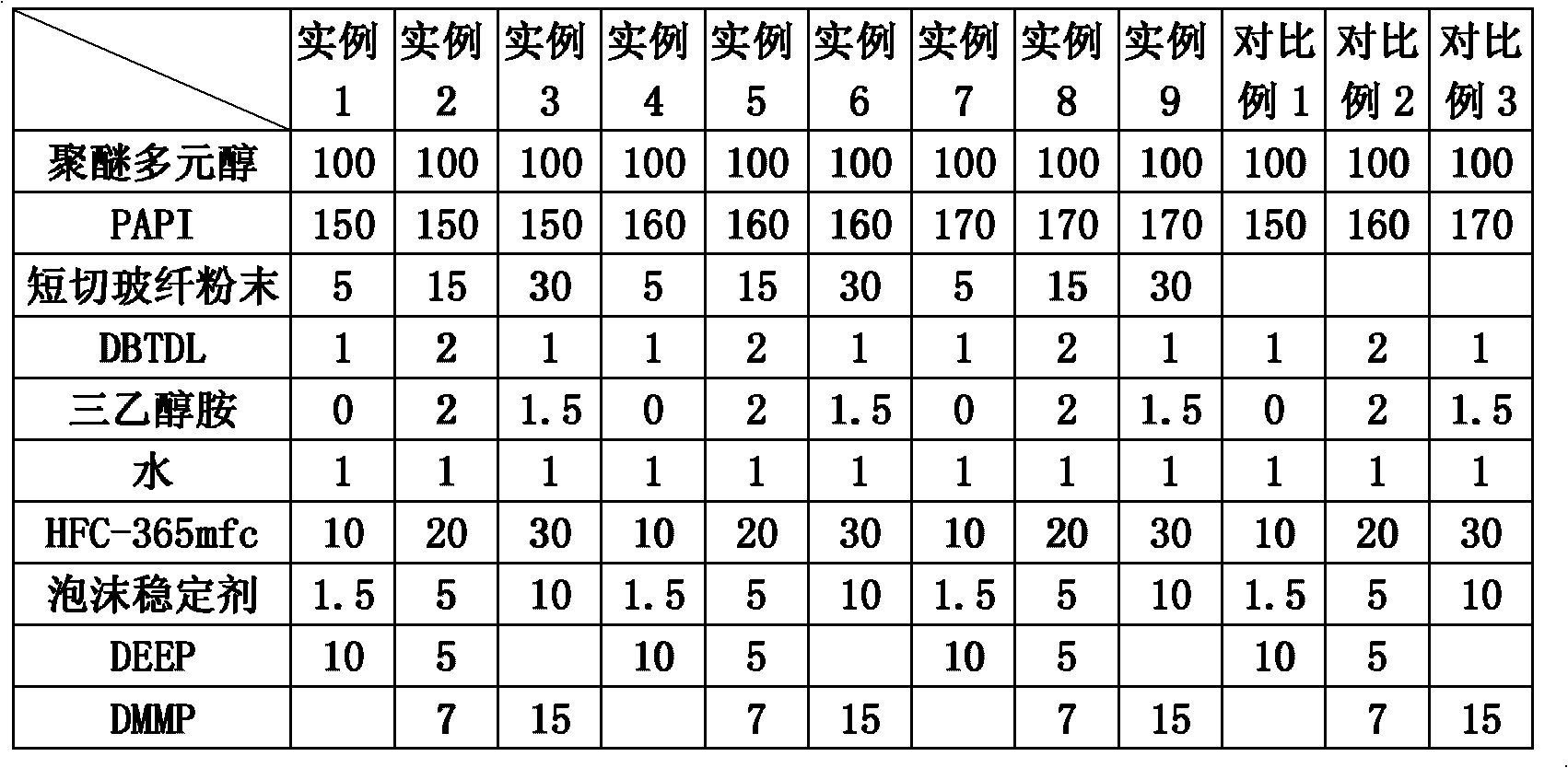

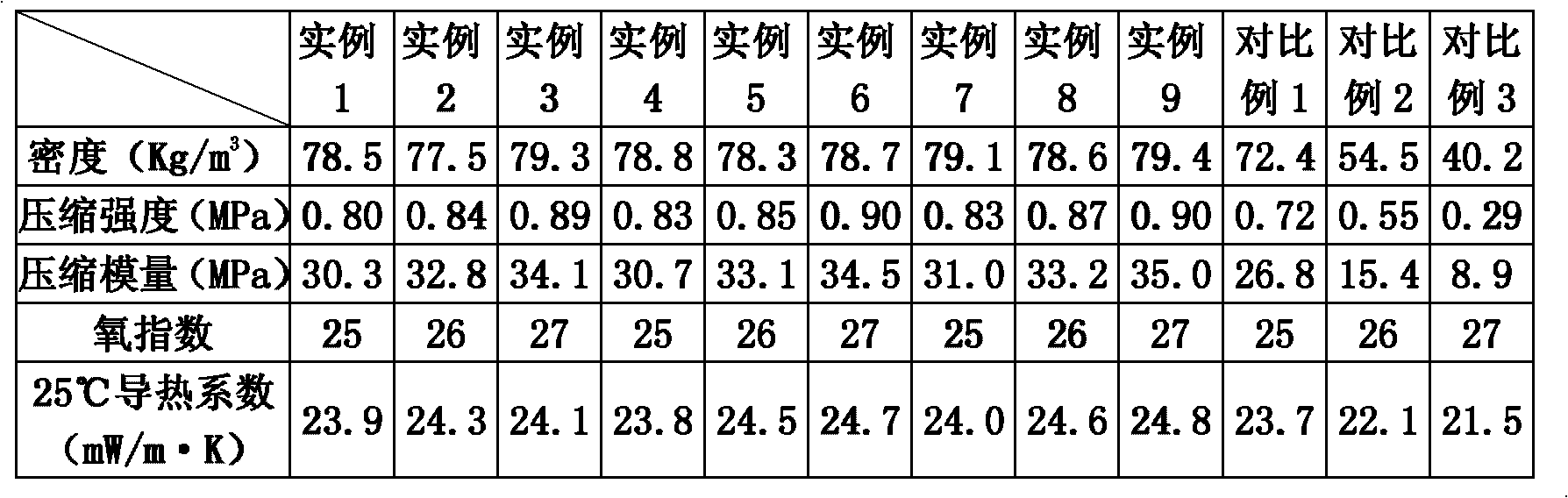

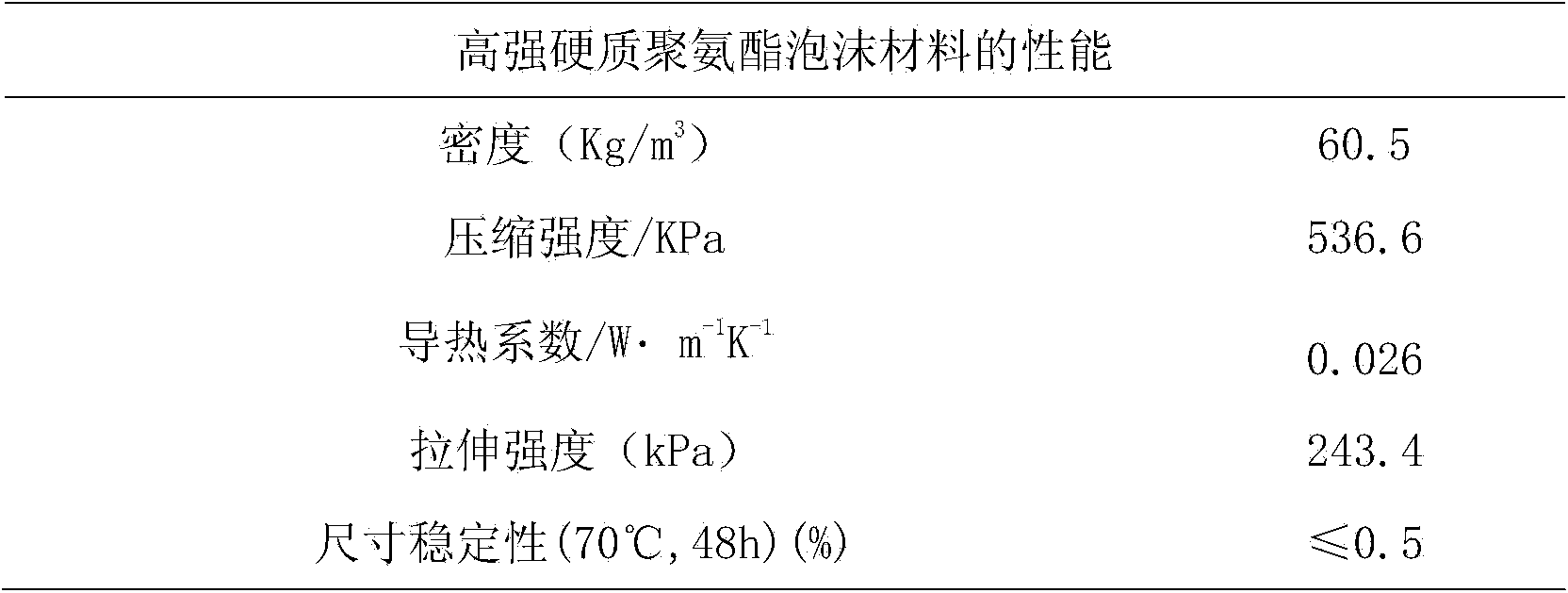

Hard polyurethane adiabatic heat-insulation foam material and preparation method thereof

The invention relates to a hard polyurethane adiabatic heat-insulation foam material and a preparation method thereof. The material contains the following components: polyether glycol, polymethylene polyphenyl isocyanate, chopped glass fiber powder, physical foaming agent, water, fire retardant, catalyst and foam stabilizer. The preparation method comprises that the surface of the chopped glass fiber powder is treated through silane coupling agent; and the polyether glycol, polymethylene polyphenyl isocyanate and the surface-treated chopped glass fiber powder are dried, mixing treatment and polymerization foaming treatment are sequentially conducted thereafter, curing treatment is conducted after a pouring mould blank is obtained and the mould is removed, and finally hard polyurethane foam is obtained. Since the invention adopts the third-generation zero-ozone-consumption latent-energy hydrofluorocarbon foaming agent and the halogen-free high-efficiency fire retardant, the foam material has the advantages of environmental protection, low density and excellent compression property and is suitable for use in the heat insulation field.

Owner:SHANGHAI JIAO TONG UNIV

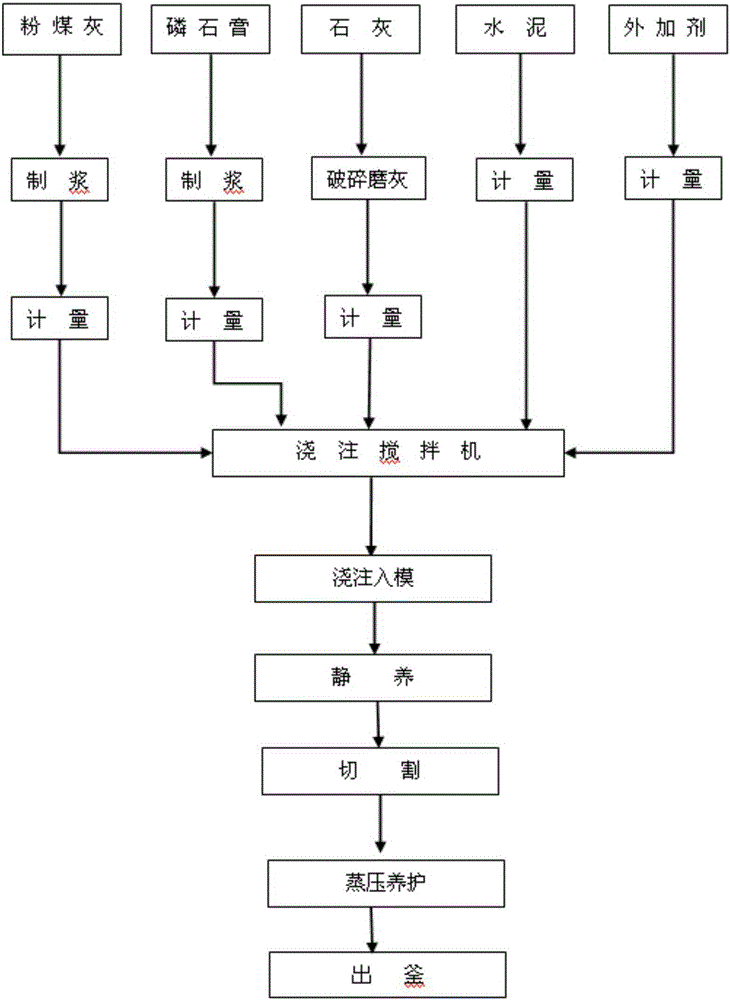

Production technology for autoclaved aerated concrete building block

InactiveCN105174833AReduce weightGood insulation performanceCeramic shaping apparatusGrinding millAluminium

The invention discloses a production technology for an autoclaved aerated concrete building block. The production technology is characterized in that the material formula comprises, by weight, 65% of fly ash, 15% of cement, 14% of lime, 5.5% of phosphogypsum and 0.5% of aluminum powder. The production technology comprises the following steps: firstly, slurries are prepared, namely, fly ash is ground by utilization of a ball grinding mill to prepare a fly ash slurry, phosphogypsum is added with water, then stirring is carried out for 1h, a phosphogypsum slurry is prepared, and then lime is crushed and ground to lime powder by utilization of the ball grinding mill; secondly, blending and stirring are carried out, namely, all the materials are sent to a casting mixer, the casting mixer is started, stirring is carried out and a concrete slurry is obtained; thirdly, casting and die entering are carried out, namely, all the concrete slurry in the casting mixer is placed in a die, and casting is carried out; fourthly, namely, a green body is thickened and condensed gradually; fifthly, cutting is carried out, namely, the shaped green body is cut according to a designed size; sixthly, autoclaved curing is carried out, namely, the cut green body is sent to an autoclaved curing kettle for autoclaved curing, and a finished product aerated concrete building block is obtained.

Owner:JIANGSU GOLDEN CUBE ENVIRONMENTAL TECH CO LTD

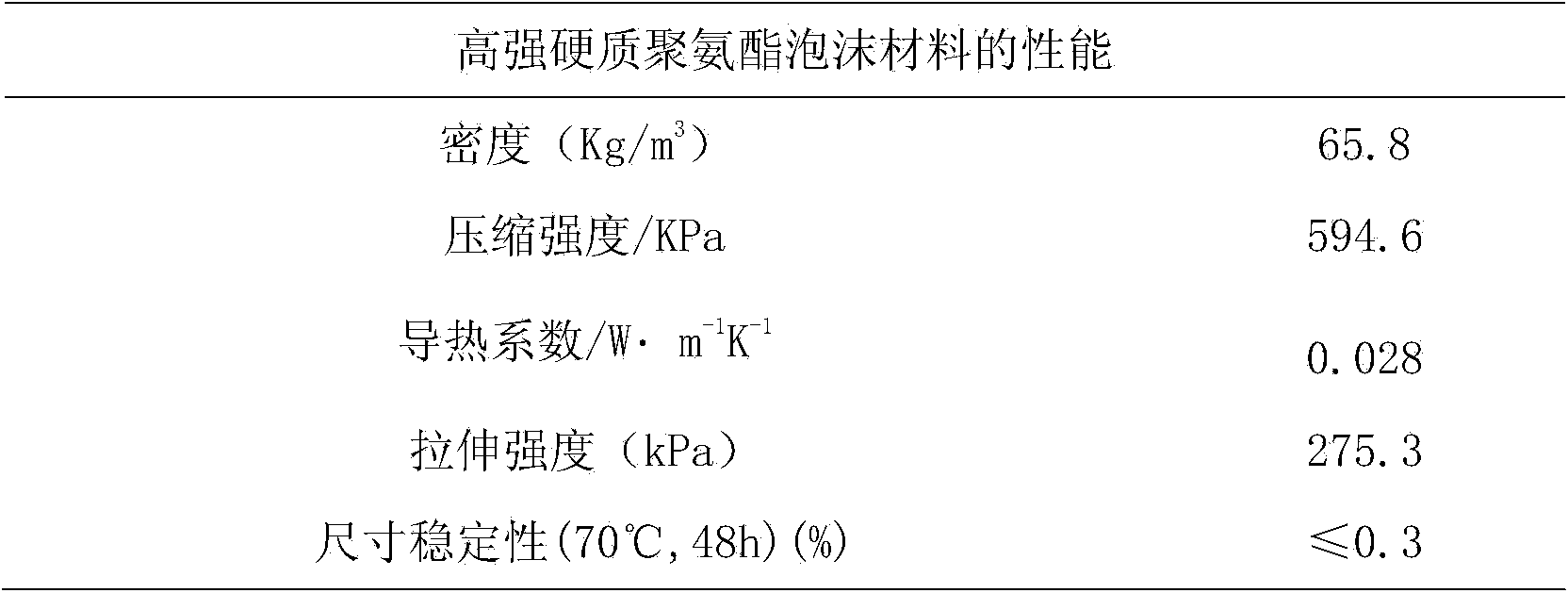

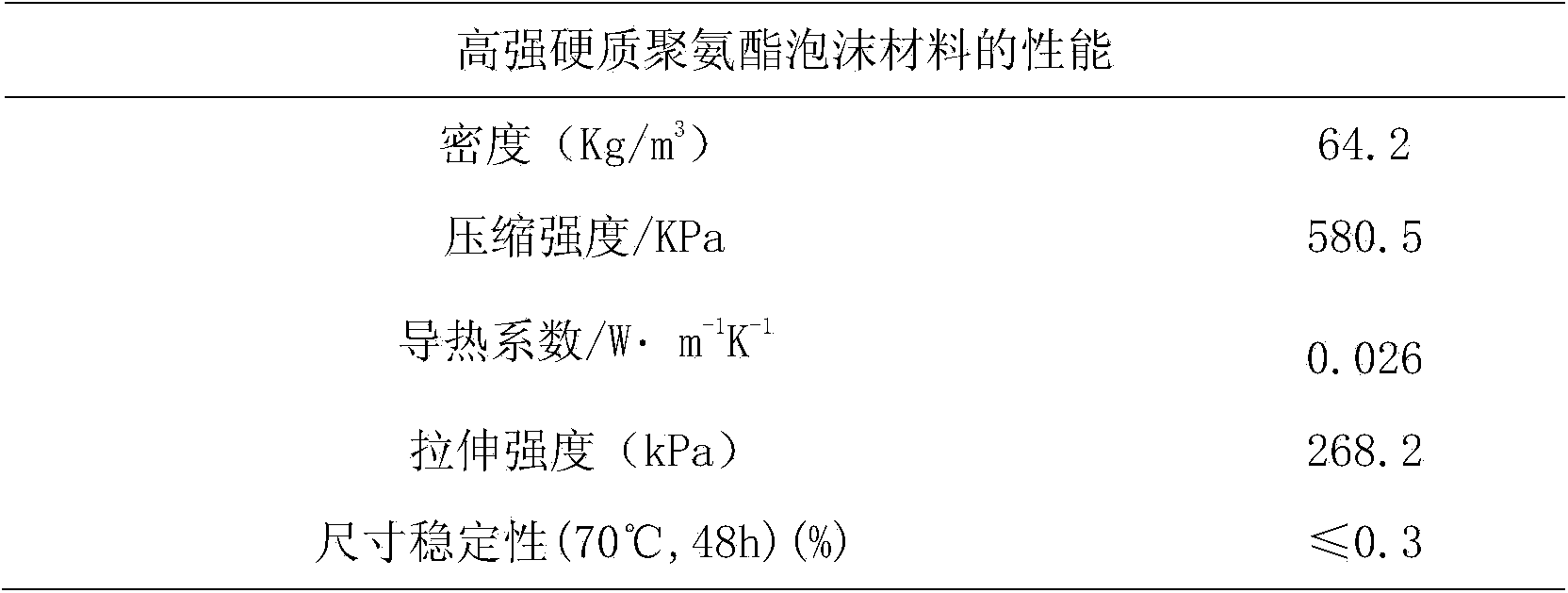

Hard polyurethane foam material and preparation method thereof

The invention discloses a hard polyurethane foam material. The hard polyurethane foam material comprises an A component and a B component, wherein the A component is polymethylene polyphenyl polyisocyanate, and the B component comprises a polyol, a foam stabilizer, a catalyst, a foaming agent, a chain extender, a cross-linking agent and a composite reinforcing material. The hard polyurethane foam material has characteristics of high strength, light weight, low heat conduction, good thermal insulation effects, good sound insulation, foam pores mainly being a closed-pore type, capability of bearing large load, good wear resistance, good corrosion resistance, good dimension stability, and the like, and is suitable for the fields of insulating materials, thermal insulation materials, thermal insulation materials of building walls, sandwich laminated plates, structural materials, sound insulation materials, aviation materials, spaceflight materials, road repairing, and the like. The hard polyurethane foam material can also be used as wood-imitation materials with high strength and high density, and is suitable for manufacturing various furniture, etc..

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD

Exterior wall waterproofing heat-insulating decorating integrated material and preparation method thereof

InactiveCN105694625AMeet various style requirements of high-end and high-end exterior finishesShort construction periodFireproof paintsAnti-corrosive paintsPolymer scienceSludge

The invention relates to an exterior wall waterproofing heat-insulating decorating integrated material and a preparation method thereof.The preparation method includes: using conventional resin like polyurea and polyurethane as raw materials, adding compound micropowder prepared from solid waste and sludge, and adding a mixed modifier and a thixotropic agent to prepare A-compound slurry; adding a promoter and a hardener, and performing spray coating, brush coating, roll coating and pouring methods to obtain the exterior wall waterproofing heat-insulating decorating integrated material.The material has the comprehensive advantages of good waterproof effect, high heat insulativity, high hardness, high hole closing rate, low density, good anti-seepage performance, high corrosion resistance, low linear expansion coefficient, high softening temperature, oxidization resistance, aging resistance, flame retardancy and firmness in binding with a substrate.When the material is used for building exterior walls, multiple times of leveling, waterproofing, heat insulating and decorating construction are not needed, on-site moisture-free operation and one-time forming can be realized, and the material is short in construction period, extremely low in cost and great in market prospect.

Owner:NANJING KAIBA ADVANCED MATERIALS CO LTD +1

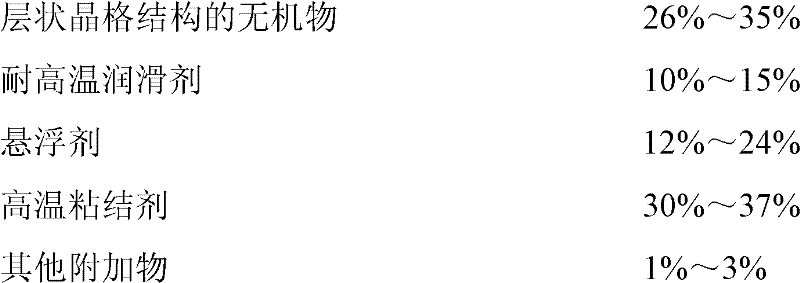

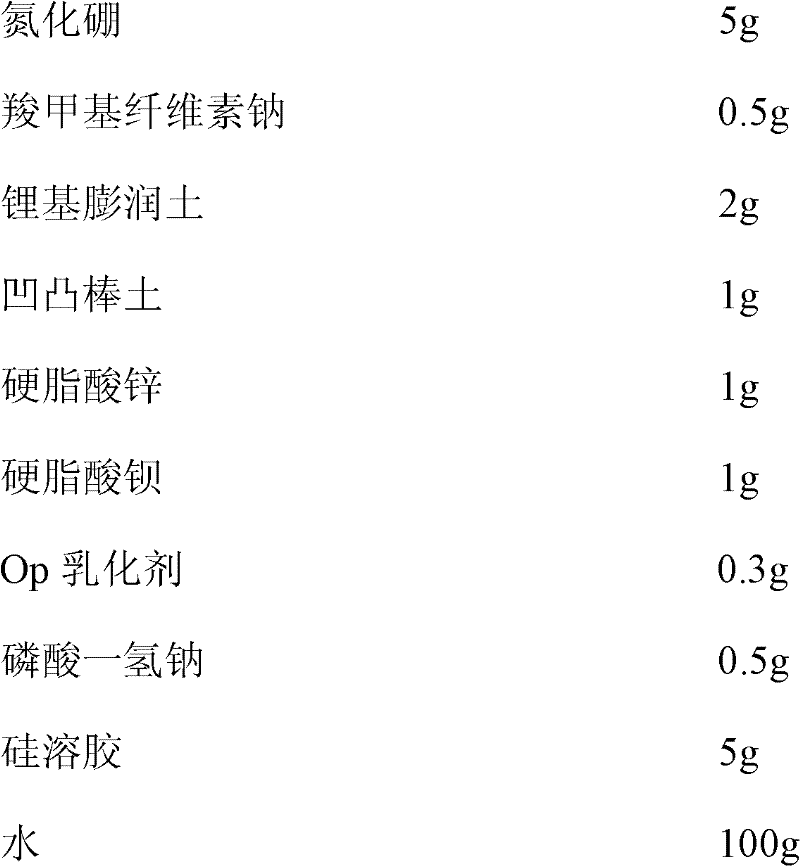

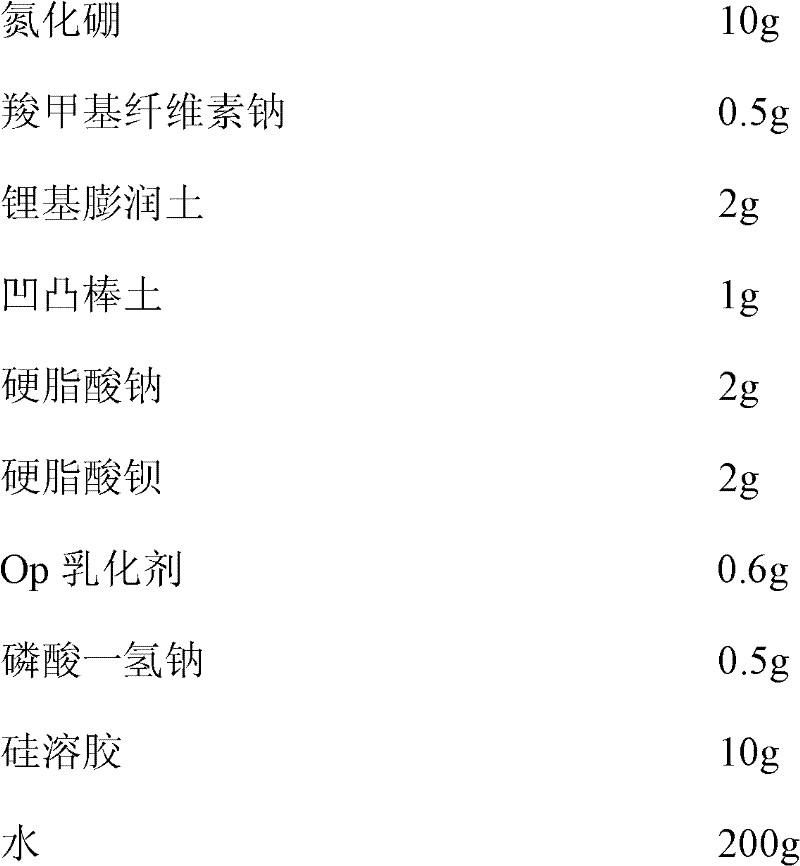

Non-graphite type lubricant for hot die forging of metal and preparation method of non-graphite type lubricant

The invention discloses a water-based non-graphite type lubricant, which is characterized by comprising the following ingredients in percentage by weight: 26%-35% of inorganic substance with layered lattice structures, 10%-15% of high-temperature-resistant lubricant, 12%-24% of suspending agent, 30%-47% of high-temperature adhesive and 1%-3% of adjuvant. The water-based non-graphite type lubricant is an environment-friendly lubricant for hot die forging, can replace a graphite type lubricant, and is especially suitable for the hot die forging of metal, in particular, for the hot die forging of large-sized aluminum pieces. The invention further discloses a preparation method of the water-based non-graphite type lubricant. The preparation method has the advantages of simple preparation process and excellent film-forming performance.

Owner:HUAZHONG UNIV OF SCI & TECH

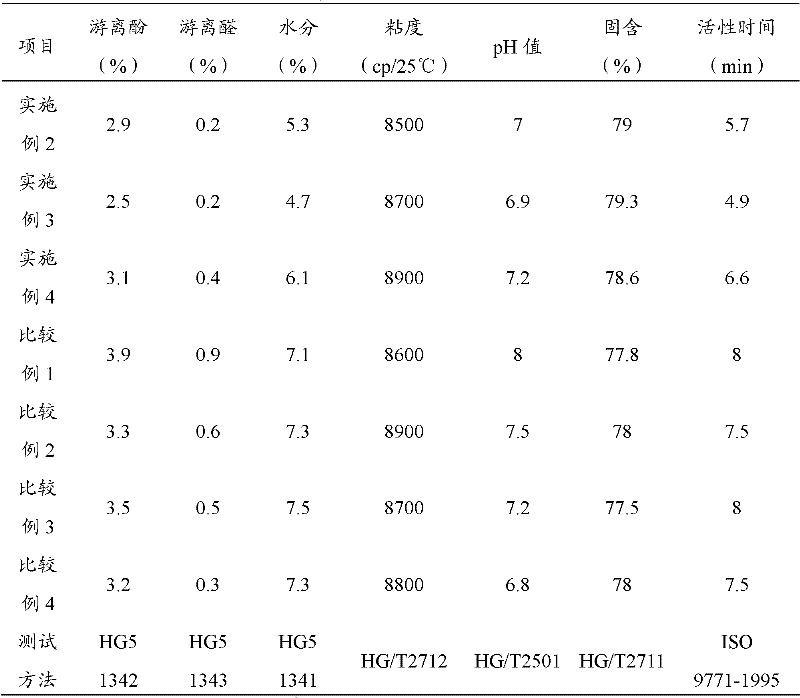

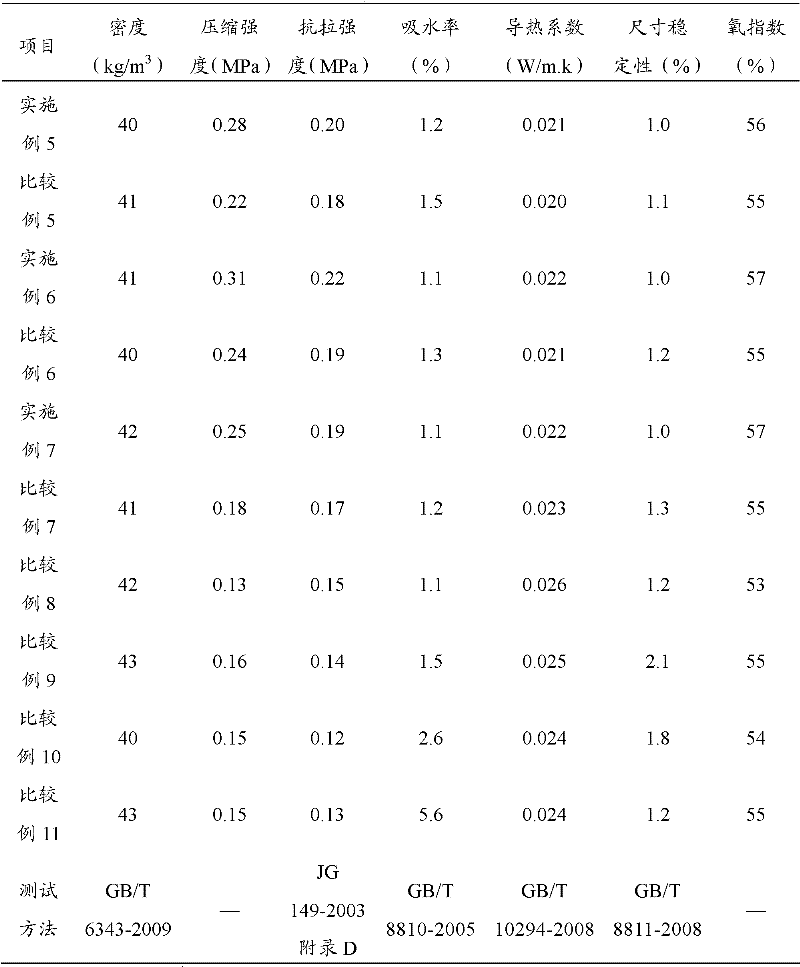

Method for preparing phenolic resin and phenolic resin foaming body

The invention provides a method for preparing phenolic resin, which comprises the following steps of: a) mixing molten phenol, a base catalyst and alkali lignin, and heating to the temperature of between 170 and 300DEG C for reflux reaction, wherein the alkali lignin is extracted from crops; and b) adding formaldehyde into reaction liquid obtained in the step a), and reducing temperature to 60-90DEG C for continuous reflux reaction to obtain the phenolic resin. The invention also provides a phenolic resin foaming body, which is obtained by foaming and curing a foamed phenolic resin mixture. Experiments prove that: the phenolic resin foaming body provided by the invention has the density of less than or equal to 50kg / m<3>, the compression strength of more than or equal to 0.18MPa, the tensile strength in the direction vertical to a panel of more than or equal to 0.11MPa, the water absorption of less than or equal to 3 percent, the coefficient of heat conductivity of less than or equal to 0.030W / (m.k), the dimensional stability of less than or equal to 1.5 percent and the combustion performance reaching grade B of GB8624-2006.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Aerogel heat insulation composite material containing nano semiconductor infrared light screening agent and preparation thereof

The invention discloses an aerogel thermal insulation composite material containing an infrared opacifier of nanometer semiconductor antimony tin oxide (ATO) or aluminum zinc oxide (AZO) and a method for preparing the same. The aerogel thermal insulation composite material comprises the components of SiO2 aerogel, the infrared opacifier which is nanometer ATO or nanometer AZO particles, and reinforcing fiber. Silicasol and ATO or AZO nanometer alcohol slurry can be mixed together through mechanical agitation or ultrasonic action, and the mixture flows to a fiber felt or fiber prefabricated part through a seepage process to form a wet gel complex to further perform supercritical fluid drying. The aerogel thermal insulation composite material has good thermal conductivity and good barrier effect on solid heat conduction, air heat convection and infrared radiation heat transfer, and has good hydrophobicity, simple process and low cost simultaneously; the mechanical strength of the material can reach 0.10 to 2 MPa; besides, the aerogel thermal insulation composite material has wide application range and can meet the applications in occasions with higher thermal protection requirements for aviation, aerospace, military and civil use.

Owner:CHANGSHA XINGNA AEROGEL

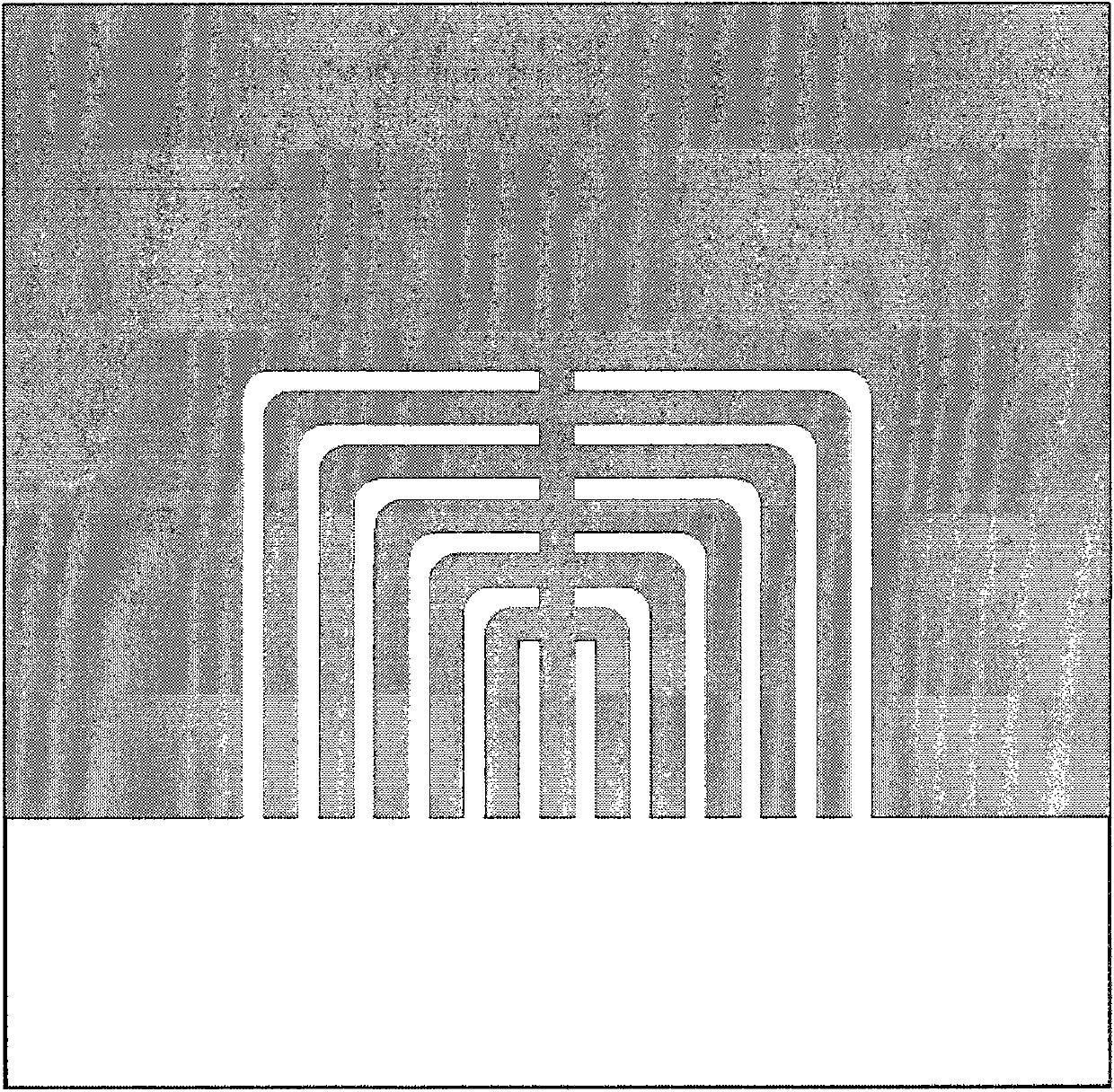

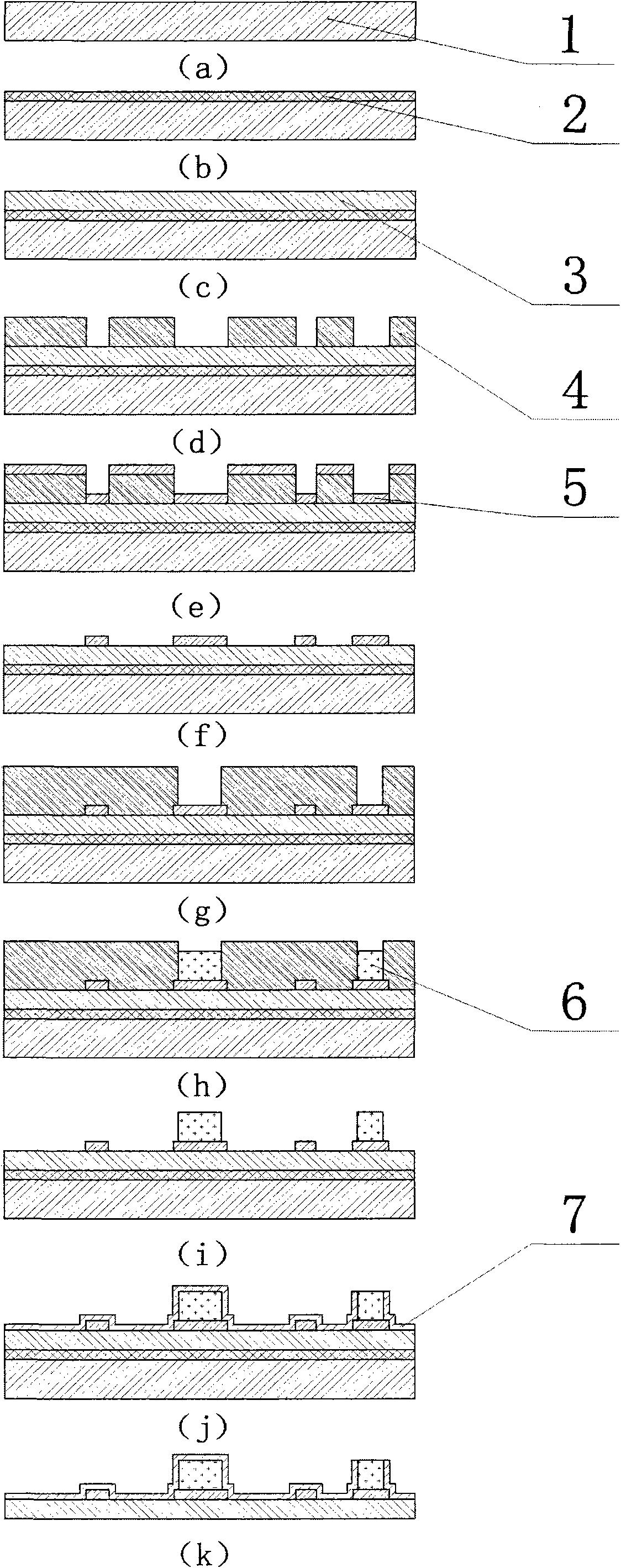

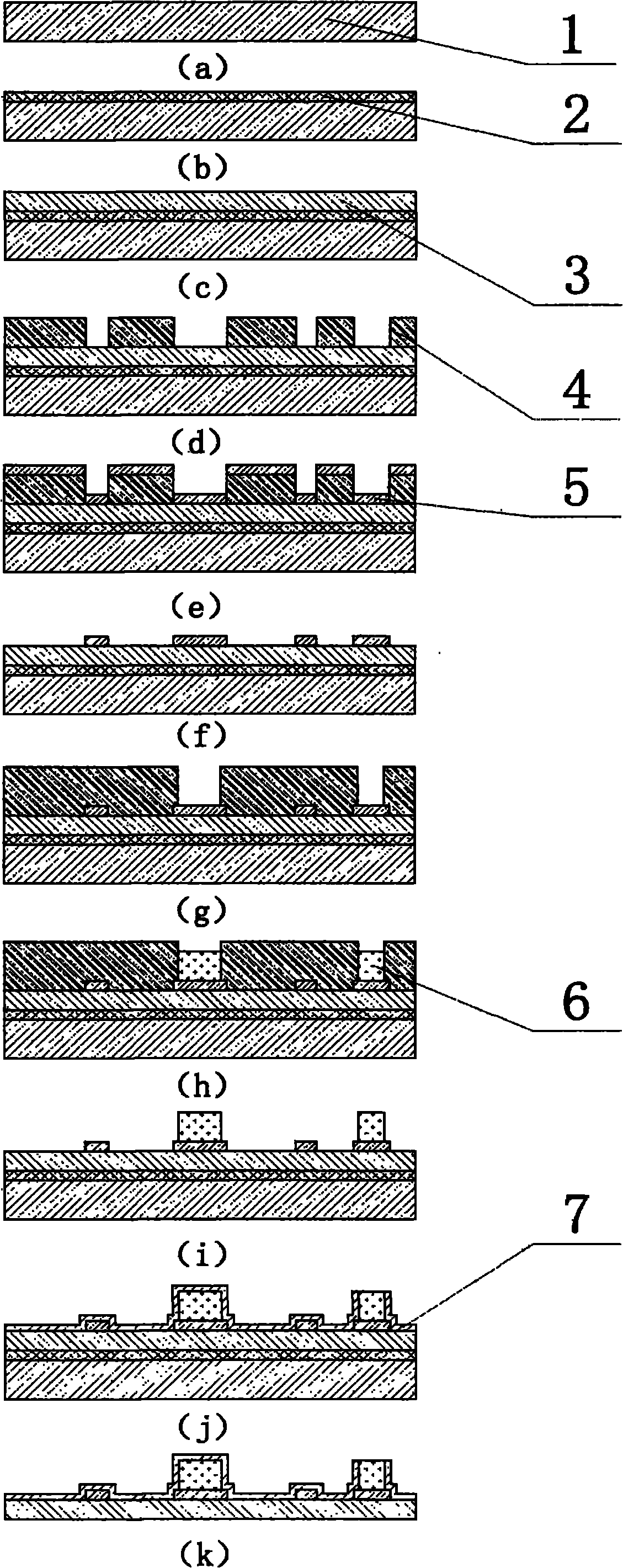

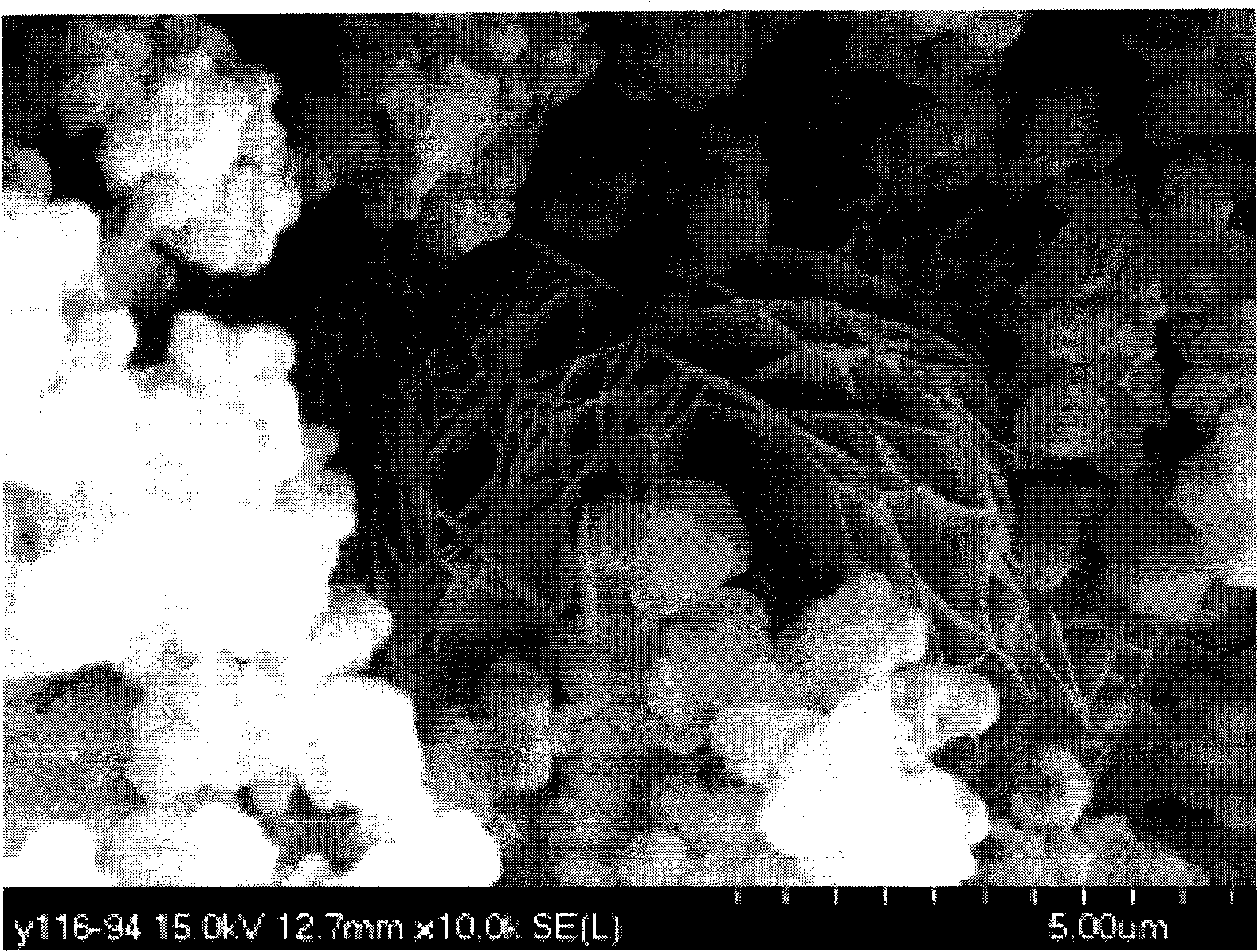

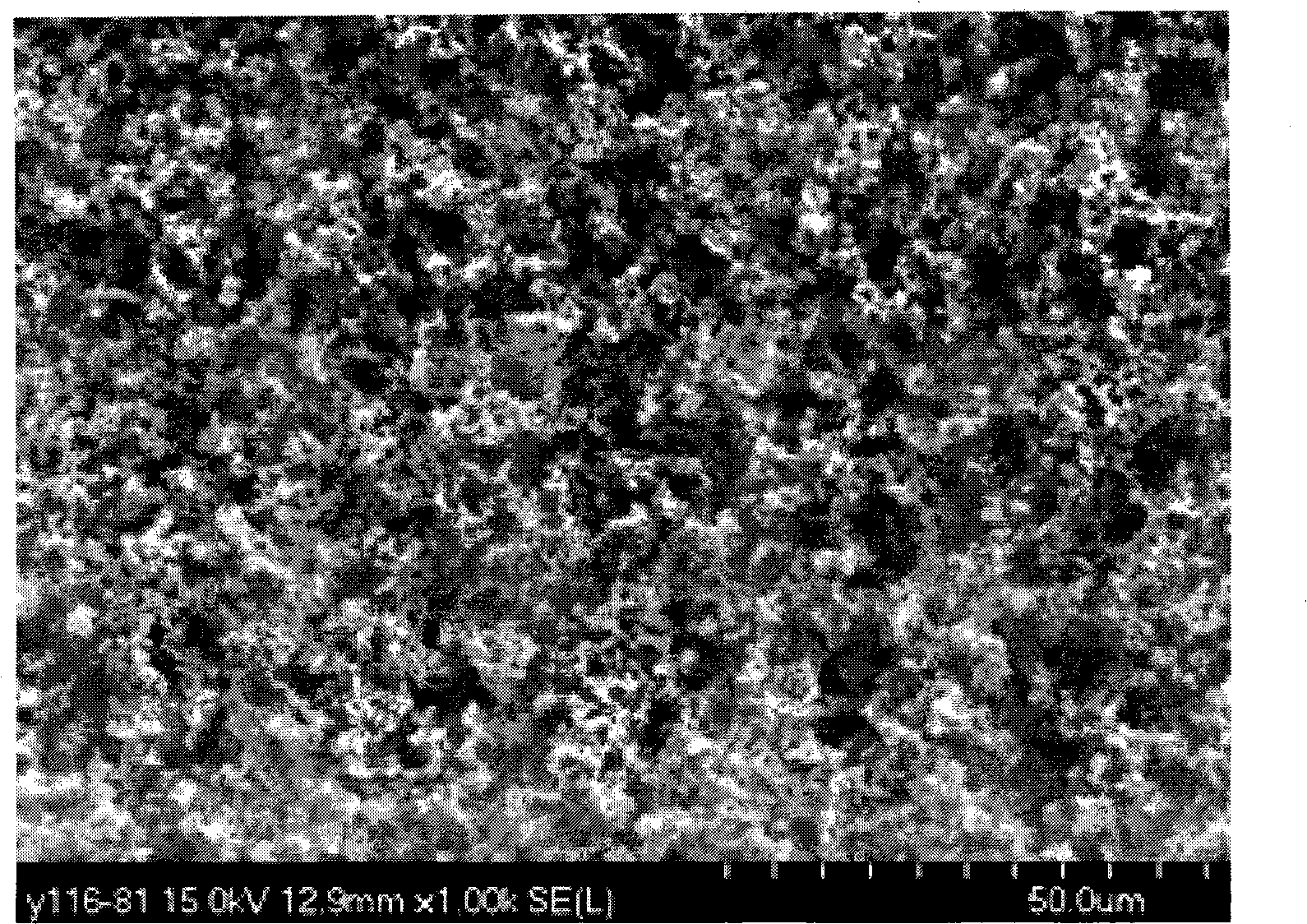

Manufacturing method of flexible heat-sensitive thin film resistor array

ActiveCN101950644AGood applicabilityGood insulation performanceNegative temperature coefficient thermistorsPositive temperature coefficient thermistorsPrepolymerSheet resistance

The invention discloses a manufacturing method of a flexible heat-sensitive thin film resistor array, which belongs to the field of micro-electromechanical systems (MEMS). The method comprises the following steps: firstly depositing a sacrificial layer on a silicon chip; spin-coating a PI prepolymer on the sacrificial layer, and forming a PI thin film by thermocuring; then spin-coating photoresist, carrying out lithographic patterning, and sputtering a required metal heat-sensitive thin film layer; adopting the stripping method to obtain a pattern of the heat-sensitive thin film layer; then spin-coating the photoresist, carrying out the lithographic patterning, and then electroplating for forming an electrical connection metal layer; removing the photoresist, and then carrying out heat treatment on heat-sensitive resistors; and finally depositing a parylene protective layer, removing the sacrificial layer and then obtaining the flexible thin film resistor array. The flexible heat-sensitive thin film resistor array has simple process, more reliable connectivity of the heat-sensitive resistors, and small interference of conductor resistance, and can greatly improve the measurement precision when being used as a sensing element of a sensor, and be applied in moist, underwater and other environments under the condition of ensuring the sensitivity of the sensor.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Fiber-reinforced flexible SiO2 aerogel heat-insulation material and preparation method thereof

The invention discloses a fiber-reinforced flexible SiO2 aerogel heat-insulation material and a preparation method thereof. Silicon-containing substances such as tetraethyl orthosilicate, tetramethoxysilane, sodium silicate and the like are used as precursors, a fiber felt pad is used as a reinforcing body, fiber / SiO2 composite wet gel is prepared with a sol-gel technology, and the fiber-reinforced flexible SiO2 aerogel heat-insulation material is finally prepared through aging and supercritical drying. The synthesis process is simplified, the preparation cycle is shortened, the cost for synthesis of the SiO2 aerogel composite material is effectively reduced, defects of poor mechanical strength, large brittleness and the like of pure aerogel are overcome, the prepared composite aerogel keeps the excellent performance of the aerogel, the flexibility of the material is obviously improved, the material is better in integrity, capable of being bent at will and very good in heat-insulation effect, the heat conductivity of the material can be decreased to 19 mW / mK, the application range of the aerogel is enlarged, and the material can be applied to actual engineering as an independent bulk composite material.

Owner:四川睿光科技有限责任公司

Ceramic aerogel and method for preparing the ceramic aerogel by gel injection moulding

ActiveCN101525248AGood high temperature resistanceGood insulation performanceClay processing apparatusCeramicwareSolid phasesThermal insulation

A ceramic aerogel and a method for preparing the ceramic aerogel by gel injection moulding belong to the field of porous materials. The invention solves the problem that the prior aerogel has easily broken and damaged air holes under the action of external force and low heat resistant temperature, and that the porous material prepared by prior gel injection moulding has bad heat-insulating property. The ceramic aerogel forms a three-dimensional skeleton structure by mutually jointing ceramic particles, porosity thereof is 50-90%, the aperture is micrometre-sized, and the most probable aperture can be below 3 microns. The ceramic aerogel is prepared by the gel injection moulding technology under the conditions of low solid phase content and no any foaming agent and pore forming agent. The product of the method has uniform aperture size distribution, heat resistance, thermal insulation and high intensity, is light, and can be used as heat-proof material of high-temperature structure. The heat-resistant temperature thereof is 1000-3000 DEG C and the compressive strength is 1-50 MPa. The method of the invention has a simple technology and short flow, can prepare finished pieces with complex shapes, and is suitable for large-scale industrial production.

Owner:HARBIN INST OF TECH

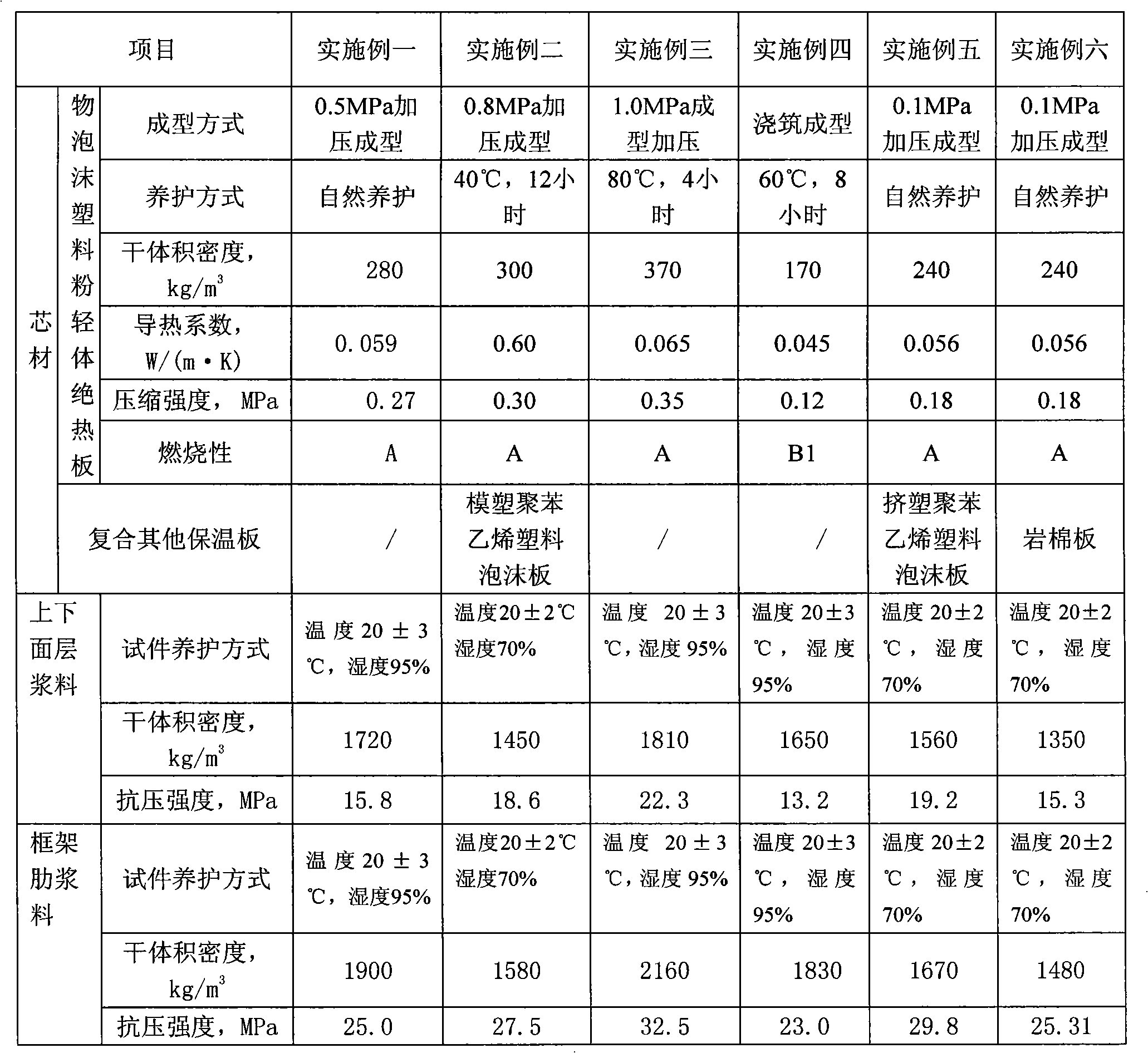

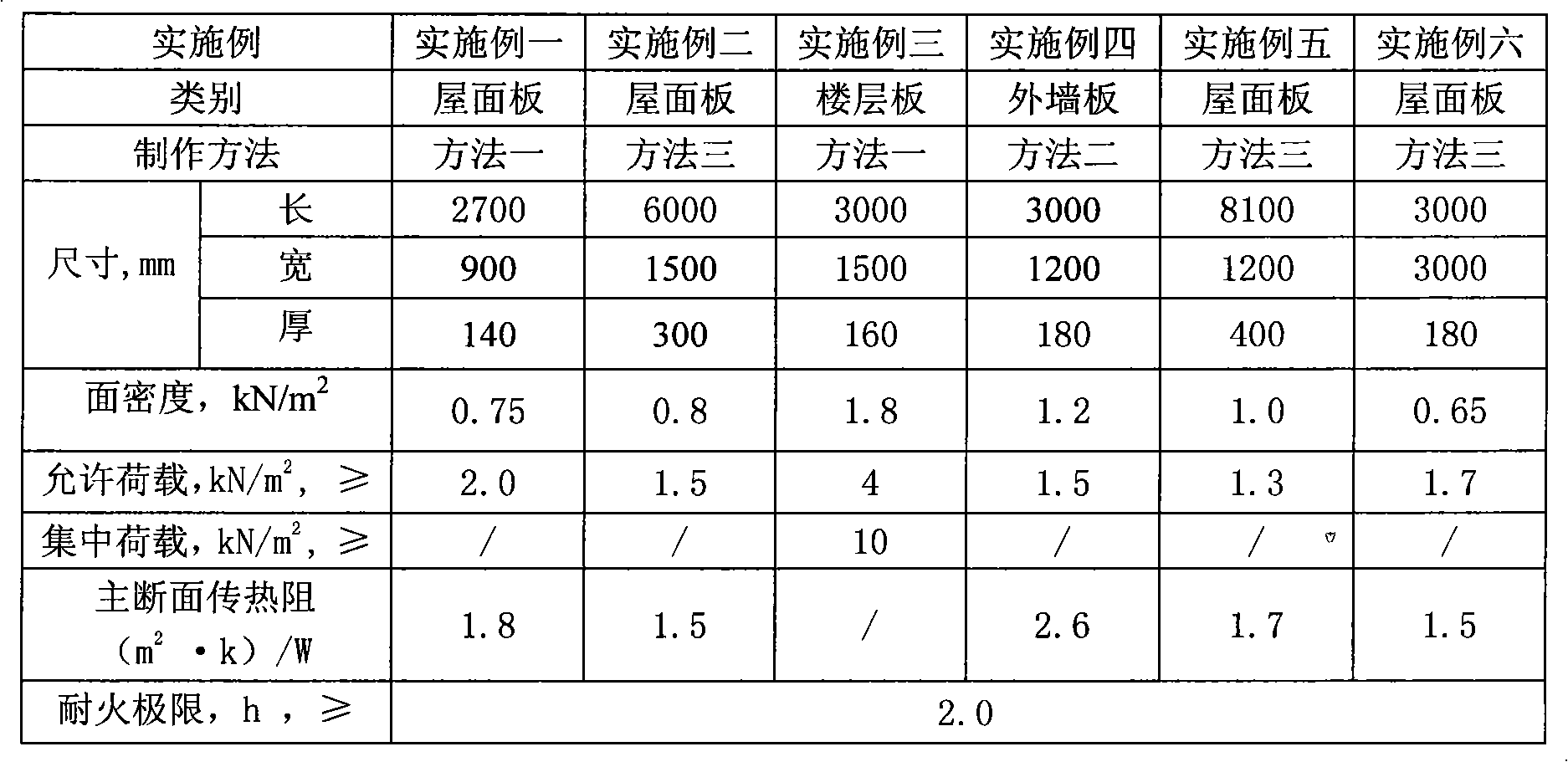

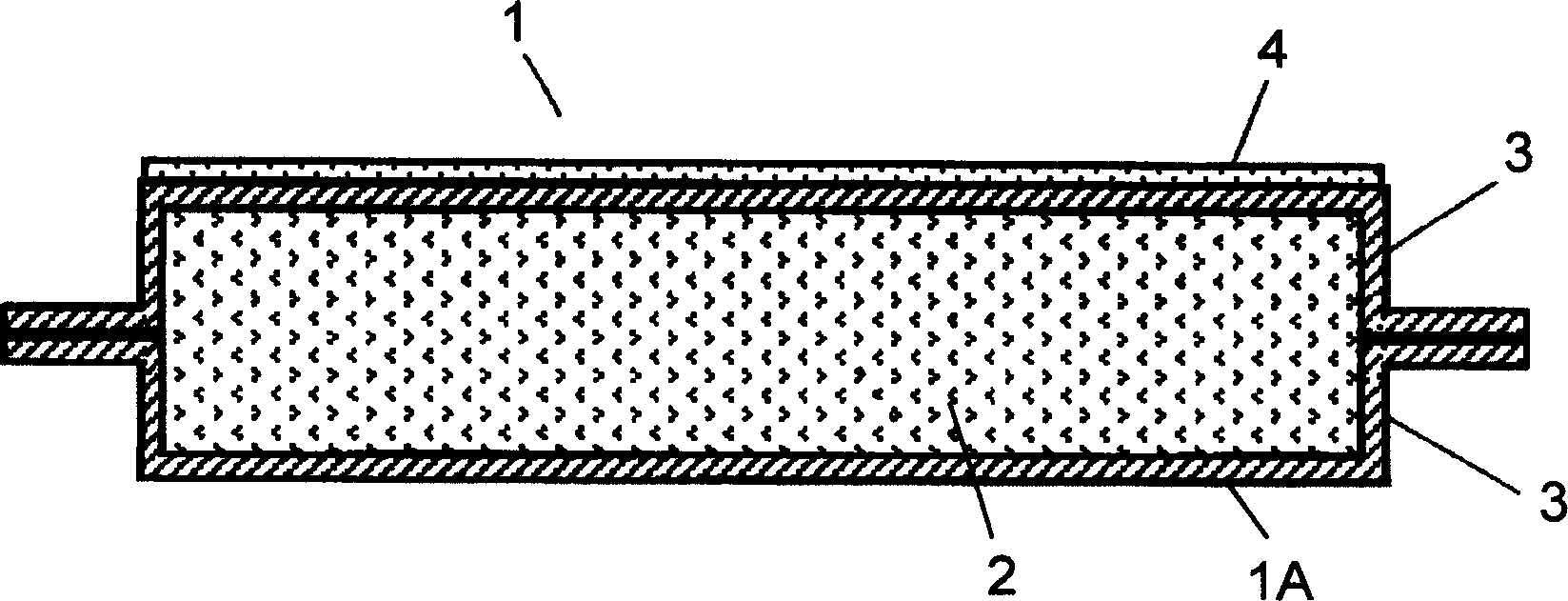

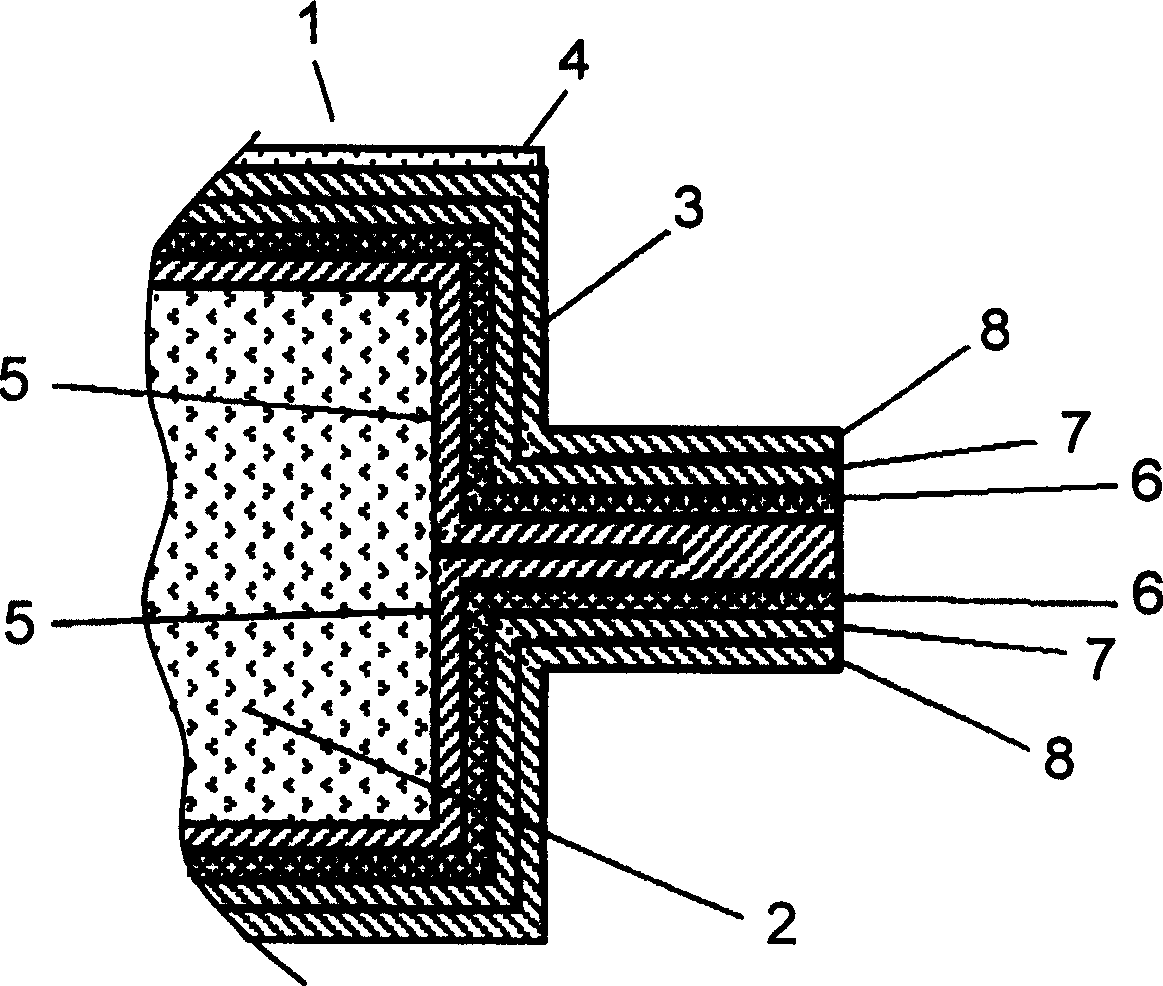

Environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard

ActiveCN101914977AStable chemical propertiesGood insulation performanceRoof covering using slabs/sheetsConstruction materialCrack resistancePolystyrene

The invention relates to an environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard, which comprises an upper surface layer, a lower surface layer and frame ribs. Insulating layers are arranged between the upper surface layer and the lower surface layer, and are cement polymer foamed plastic powder lightweight insulating plates or are formed by compounding the cement polymer foamed plastic powder lightweight insulating plates and any one of molded polystyrene foam plates, extruding-molded polystyrene foam plates and rock-wool slabs respectively; fiberglass alkaline-resistant mesh fabric is arranged in the upper surface layer and the lower surface layer; the frame ribs are fixedly connected to the lower surface layer; and an anticorrosion steel reinforcement frame is arranged in the frame ribs. In the environmentally-friendly, energy-saving and fireproofing lightweight roof panel, floor plate or wallboard of the invention, the lightweight insulating plates and lightweight surface layer mortar are manufactured by foamed plastic powder; the foamed plastic powder and heat-preservation foamed plastic form particles are applied to lightweight concrete; and materials for the upper and lower surface layers and the frame ribs are enhanced by two or more assorted fibers so as to fulfill the aims of lightweight, high strength, energy saving, sound insulation, fireproofing, crack resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

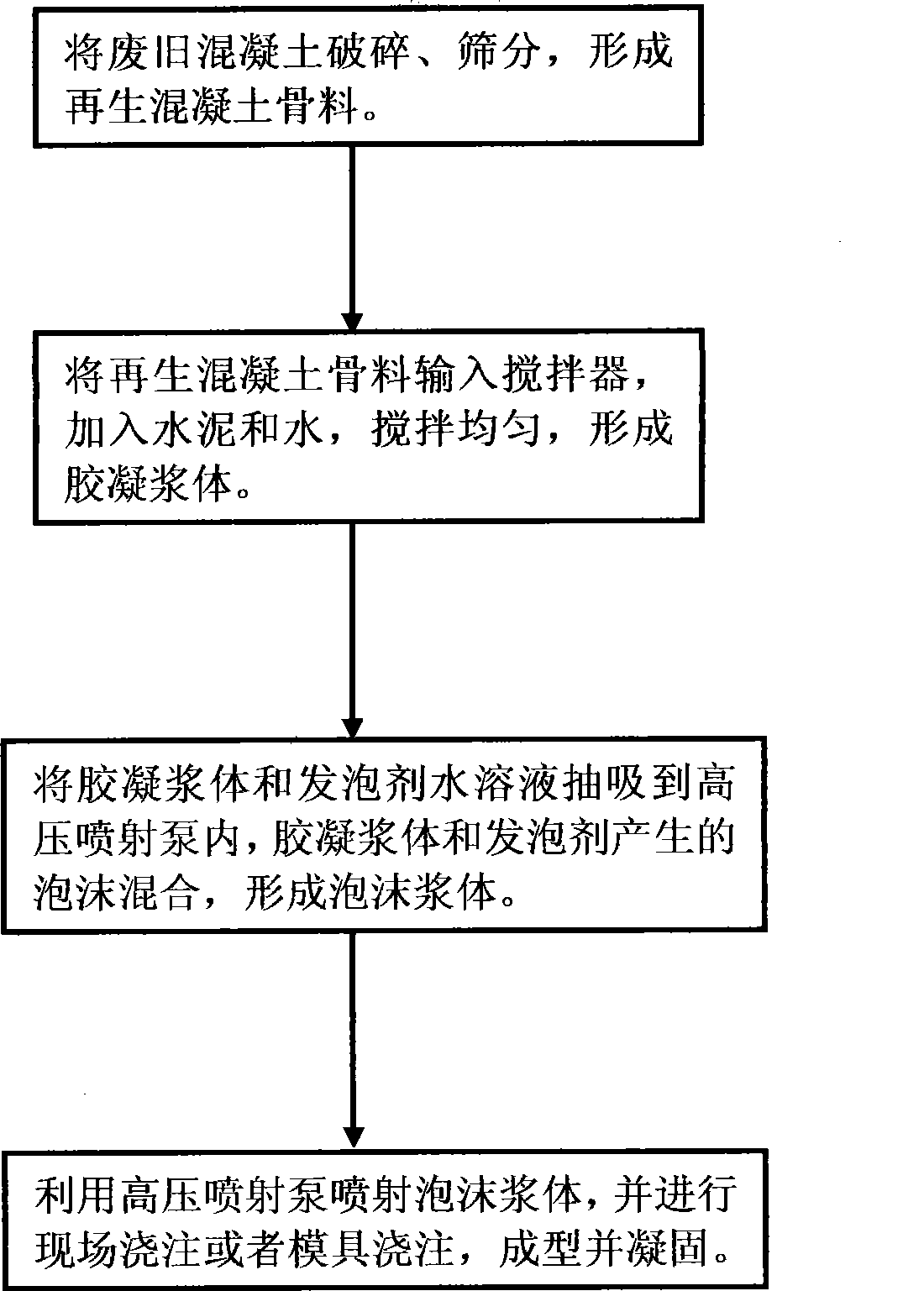

Foaming concrete made by waste and old concrete and production method thereof and use

InactiveCN101391902ASpeed up the solidificationGuaranteed continuitySolid waste managementCeramicwareUnderground pipelineSubgrade

The invention discloses light foaming concrete made by waste concrete, and the production method and application of the foaming concrete. The foaming concrete is formed by the mixing of regenerated foaming concrete aggregate formed after the smashing and screening of the waste concrete, jellous slurry formed by adding concrete, fly ash and water, and foam generated by a foaming agent. After on-spot injection, pouring or mould pouring, the foaming concrete can be used in a plurality of aspects in municipal infrastructure construction such as weak subgrade processing, high filling subgrade, road-widening subgrade, temporary subgrade, various underground pipeline foundation, narrow slot and small clearance space filling, road landslide emergency backfilling, building heat preservation, sound insulation walls and the like. The adoption of the waste concrete for making the foaming concrete has the advantages of utilizing the waste, being environment-friendly, saving energy and having low cost, and the like, and the produced foaming concrete has a plurality of good performances such as light weight, no lateral confinement compression resistance, self-compaction and vibro-free property, and the like.

Owner:BEIJING SIFANGRUGANG CONCRETE PROD

Vacuum heat insulating material and machine using the same vacuum heat insulation material

InactiveCN1576678AAvoid transmissionGood insulation performanceThermal insulationPipe protection by thermal insulationInfraredMaterials science

A radiation heat transfer suppressor for inhibiting heat transfer by infrared rays is provided on the external surface of the enveloping member of a vacuum heat insulator. In heat-blocking or keep warm using a vacuum heat insulator, a surface having a radiation heat transfer suppressor is faced to a high-temperature side. Thus, the vacuum heat insulator exhibits excellent heat-insulating performance in a temperature range of 150 DEG C or higher.

Owner:PANASONIC CORP

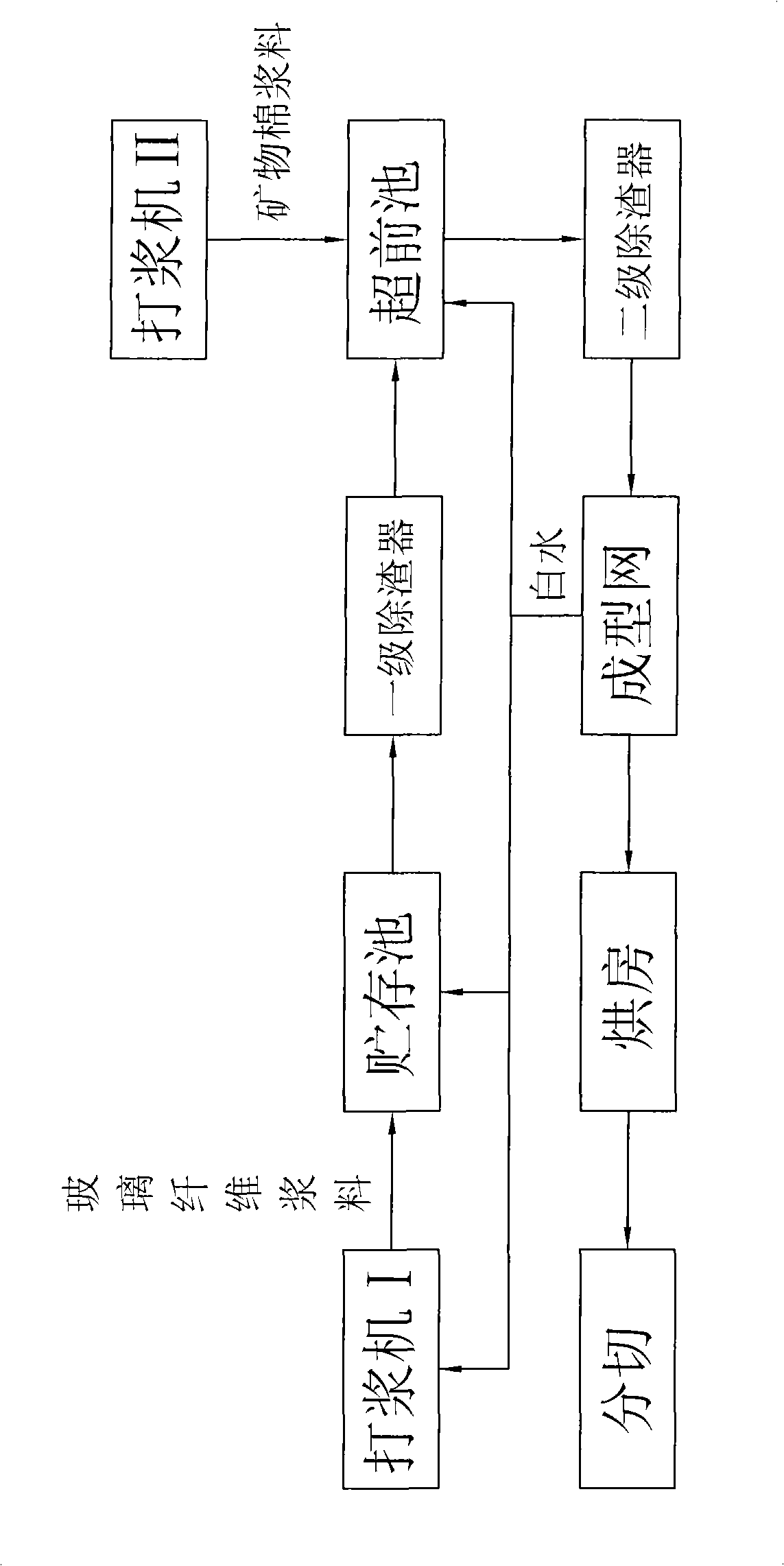

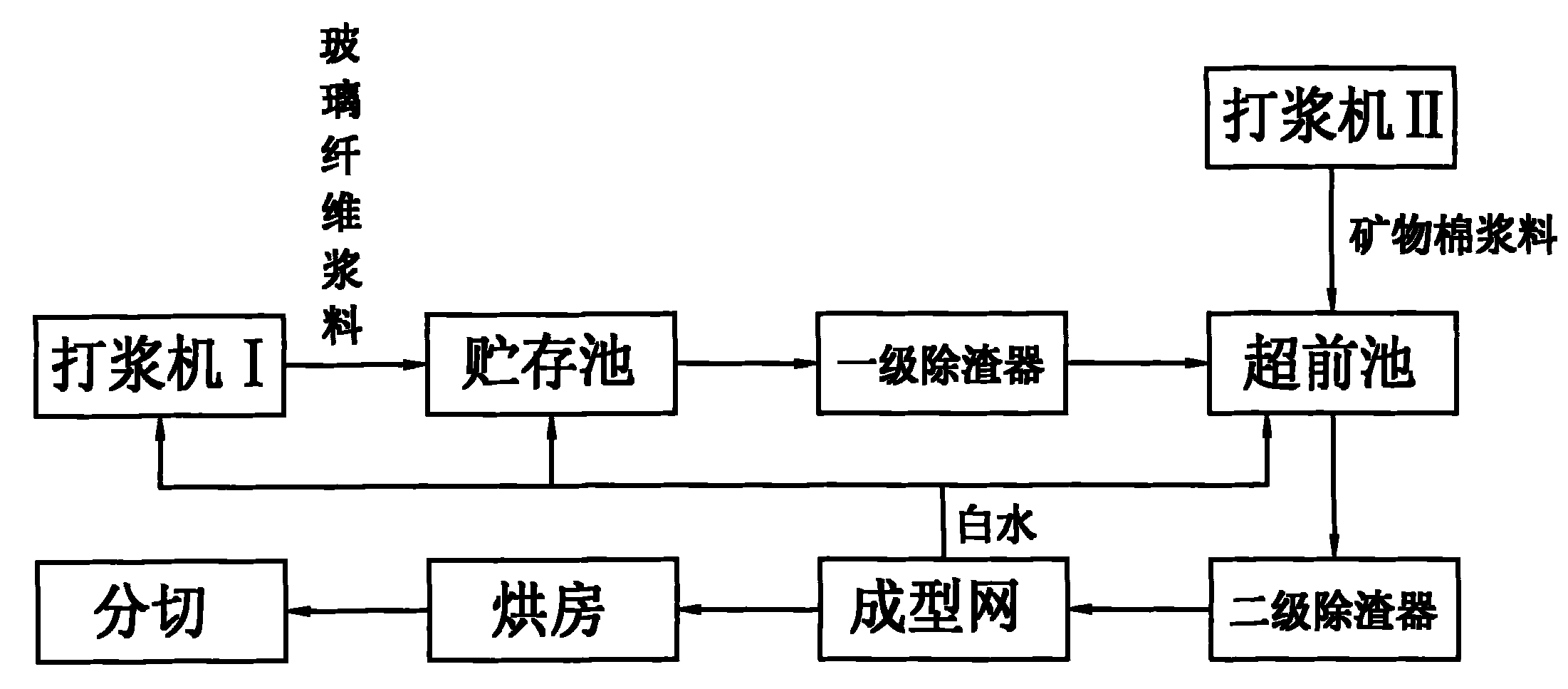

Vacuum insulated panel core material and manufacturing method thereof

ActiveCN101793340ALow manufacturing costImprove thermal insulationThermal insulationPipe protection by thermal insulationWater contentSlag

The invention discloses a vacuum insulated panel core material, which comprises the following raw materials in parts by weight: 48 parts of mineral wool, 45 parts of glass fiber wool 27-30 degree SR and 35 parts of glass fiber wool 18 degree SR. The diameter of the fiber of the mineral wool is 4-6 mum, the length is 1.0-4.0mm and the water content is 20 percent. The manufacturing method of the vacuum insulated panel core material comprises the following steps: pumping of glass fiber wool, pulping of mineral wool, dilution and slag removal, regulation of acidity, slag removal and making, drying and cutting. Since the mineral wool is used, the manufacturing cost of the core material is greatly reduced and the insulation performance is improved to certain extent when the vacuum insulated panel core material is compared with pure glass fiber wool core material and other conventional core material.

Owner:CHONGQING ZAISHENG TECH CORP

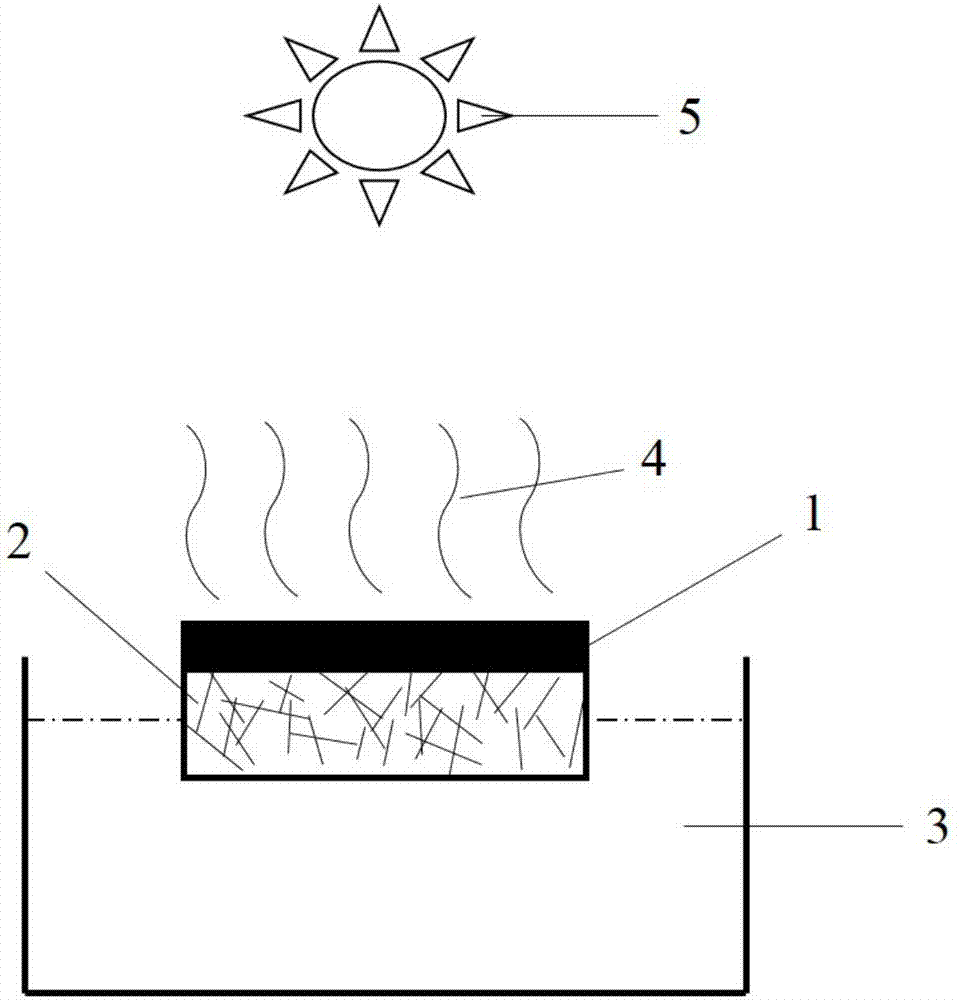

Functional nonwoven sea water desalination material and preparation method and application thereof

InactiveCN107338642AGood insulation performanceEasy to passGeneral water supply conservationSeawater treatmentWater desalinationThermal insulation

The invention discloses a functional nonwoven sea water desalination material and a preparation method and application thereof. The sea water desalination material uses non-woven as a basis material, and a carbon material loaded on the surface as a light absorber. The functional nonwoven sea water desalination material internally includes short staple which has a core absorption effect on sea water and provides a water transport corridor, and the pore structure of the material is beneficial to passing of water vapor. The sea water desalination material has a good thermal insulation performance to avoid the loss of solar energy, and as the light absorber, the material has a high utilization rate of solar energy so that the water vapor producing efficiency is high; the material is durable and convenient to transport, and the preparation method has low costs and a simple process.

Owner:JIANGNAN UNIV

Method for preparing micro expanded inorganic heat insulation mortar

ActiveCN102010166AWide variety of sourcesLow priceSolid waste managementCeramicwareMethyl celluloseEther

The invention discloses a method for preparing micro expanded inorganic heat insulation mortar. Materials such as common silicate cement, desulfuration ash, calcium carbonate powder, re-dispersible latex powder, hydroxypropyl methyl cellulose ether, wood fiber, polypropylene fiber, surfactant, foam stabilizer, water, vitrified micro bubbles and the like are adopted; and the mortar is obtained by adopting the steps of stirring, mixing, shaping, curing and the like. The method has the advantages of low cost, early micro expansion, low later linear shrinkage rate, fire resistance, durability and the like, is easy to construct, and achieves good effect of preparing the I-type building heat insulation mortar by using the III-class vitrified micro bubbles.

Owner:CHONGQING SIBEIKEN ENERGY SAVING TECH DEV +1

Nano-hole aerogel heat-insulating composite material and preparation method thereof

The invention discloses a nano-hole aerogel heat-insulating composite material and a preparation method thereof. The nano-hole aerogel heat-insulating composite material comprises SiO2 aerogel, ITO nano powder material or nano compound powder material of ITO and TiO2, and reinforced fiber felt or prefabricated body. Through action of ultrasonic wave, silicon gel and ITO nano alcohol slurry or nano compound alcohol slurry of ITO and TiO2 are mixed and then flow into the fiber felt or the prefabricated body through infiltration technology to form wet gel compound to be subjected to supercritical fluid drying. The material has good heat transfer and obstruction functions for solid heat transfer, air heat convection and far infrared radiation heat transfer, has good hydrophobic property at the same time, and has simple process and low cost; the mechanical strength can reach 0.10 to 2MP; and the material has wide application range, and can meet higher requirement of heat protection in navigation, spaceflight, military affairs and civilian use.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com