Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4279 results about "Grinding mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

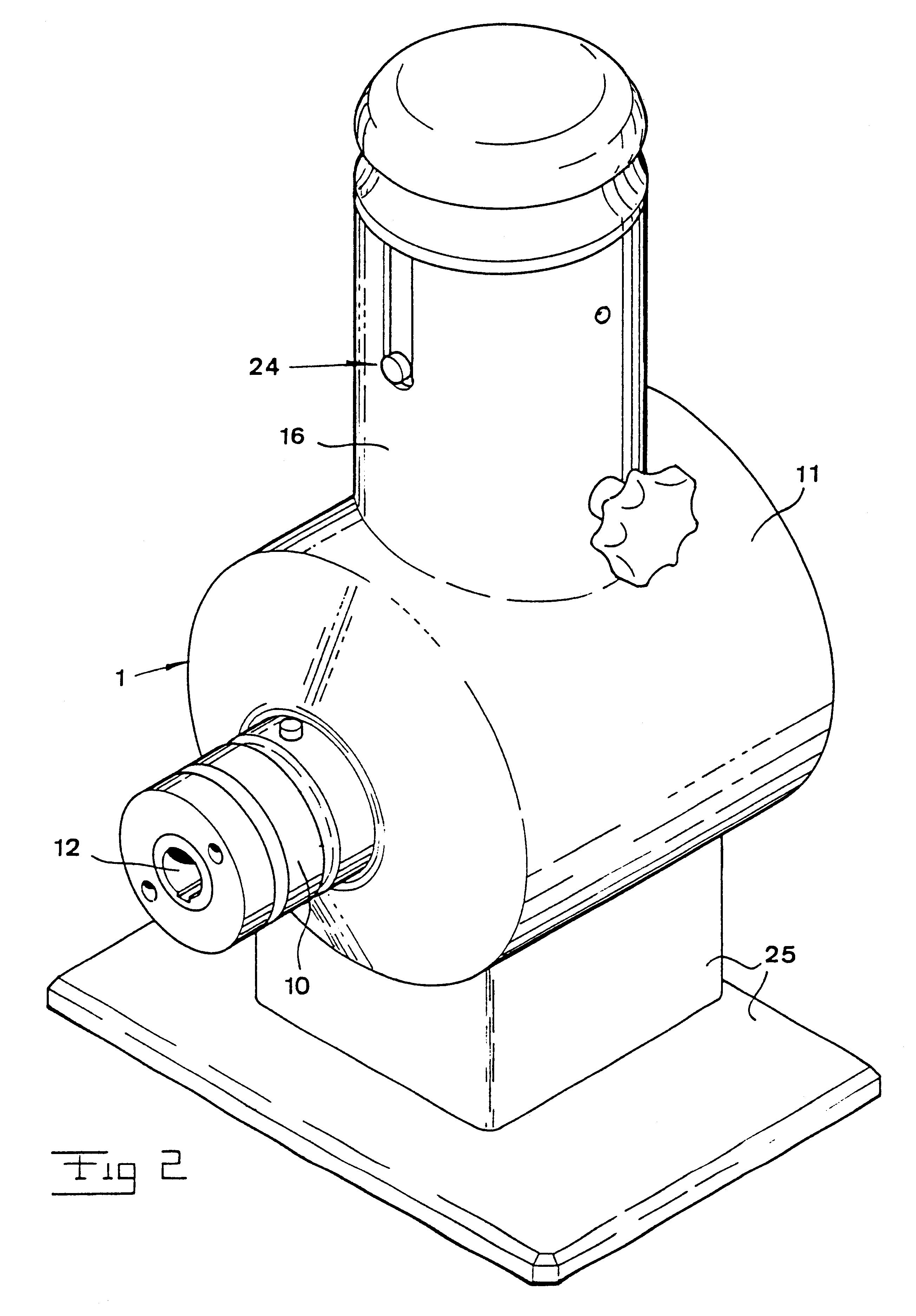

Small-scale mill and method thereof

A small-scale or micro media-mill and a method of milling materials or products, especially pharmaceutical products, use a dispersion containing attrition milling media and the product to be milled. The milling media can be polymeric, formed of polystyrene or cross-linked polystyrene, having a nominal diameter of no greater than 500 microns. Other sizes include 200 microns and 50 microns and a mixture of these sizes. The mill has a relatively small vessel having an opening, an agitator, a coupling and a motor. The agitator can have a rotor and a shaft extending therefrom. The rotor can be cylindrical or have other configurations, and can have tapered end surfaces. The coupling can close the vessel opening, or attaching the coupling to the motor can close the opening. The coupling has an opening through which the rotor shaft extends into the motor. A sealing mechanism, such as a mechanical or lip seals the shaft while permitting the rotor shaft to rotate. The vessel can contain one or more ports for circulating the dispersion, where milling can be made in batches or recirculated through the milling chamber. The media can be retained in the vessel or recirculated along with the process fluid. The rotor is dimensioned so that its outer periphery is spaced with a small gap from an inner surface of the vessel. The vessel also can have a way of cooling the dispersion.

Owner:ALKERMES PHARMA IRELAND LTD

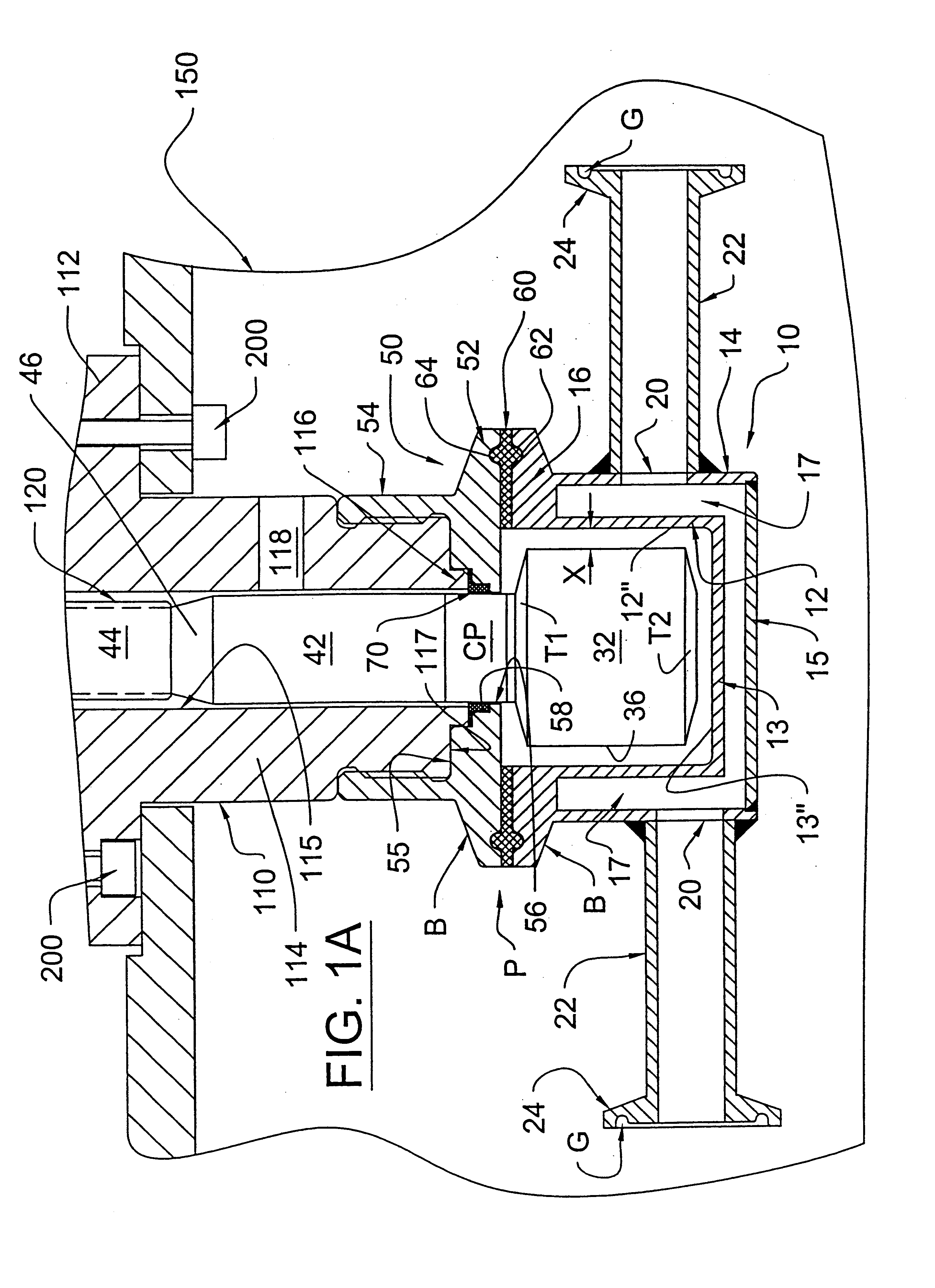

Wellbore milling methods

New wellbore milling systems and methods of their use have been developed, the milling system in one aspect including at least one mill, at least one stabilizing member connected to and above the at least one mill, and the at least one stabilizing member for maintaining position of the at least one mill for milling through the liner into the main wellbore. In certain aspects multiple spaced-apart stabilizers are used above a mill which, in one aspect, may include one or more reaming stabilizers. In one aspect the lowermost stabilizer is spaced-apart from a mill so that the stabilizer does not enter a bend portion of a liner to be milled until milling has commenced.

Owner:WEATHERFORDLAMB

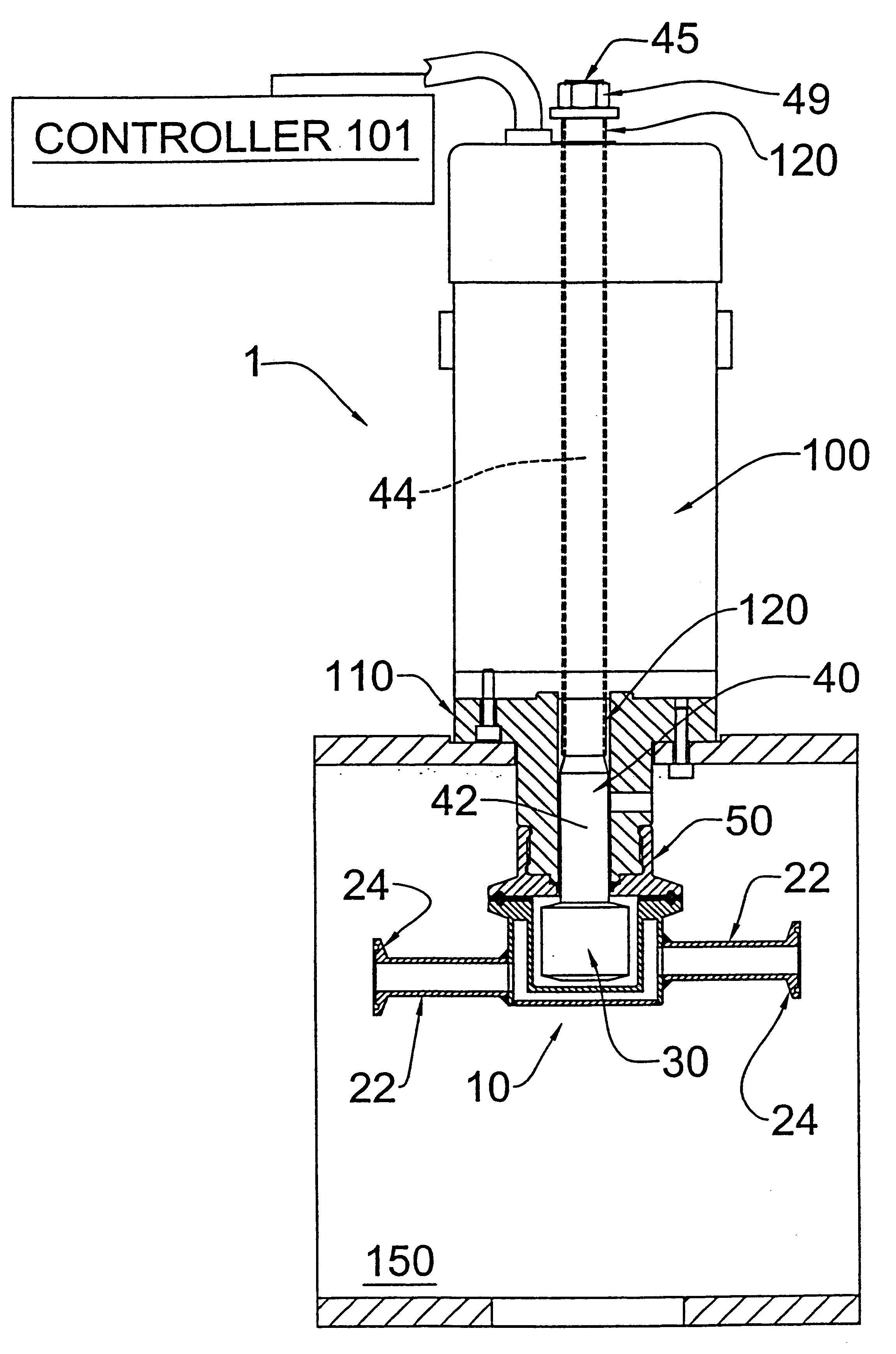

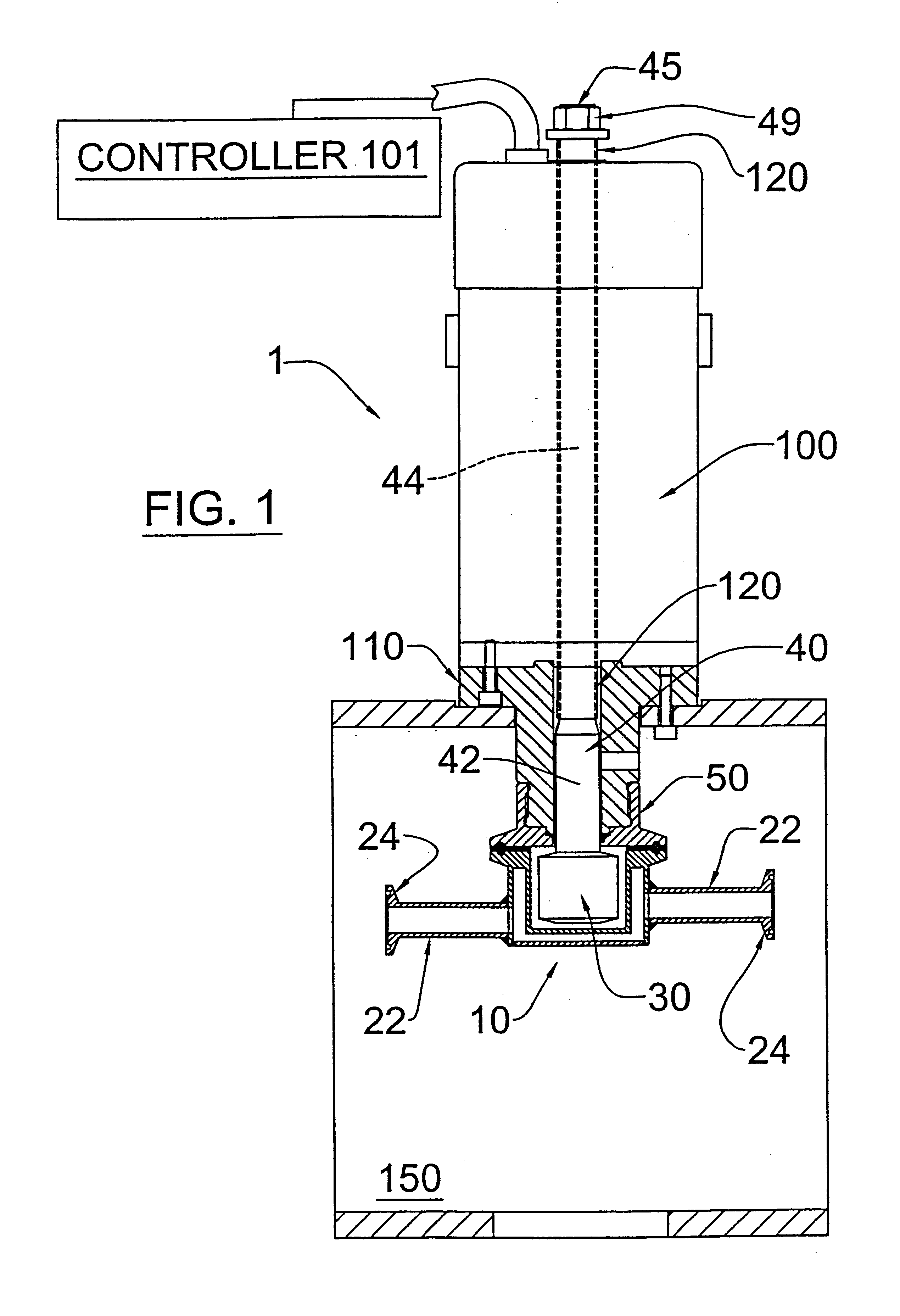

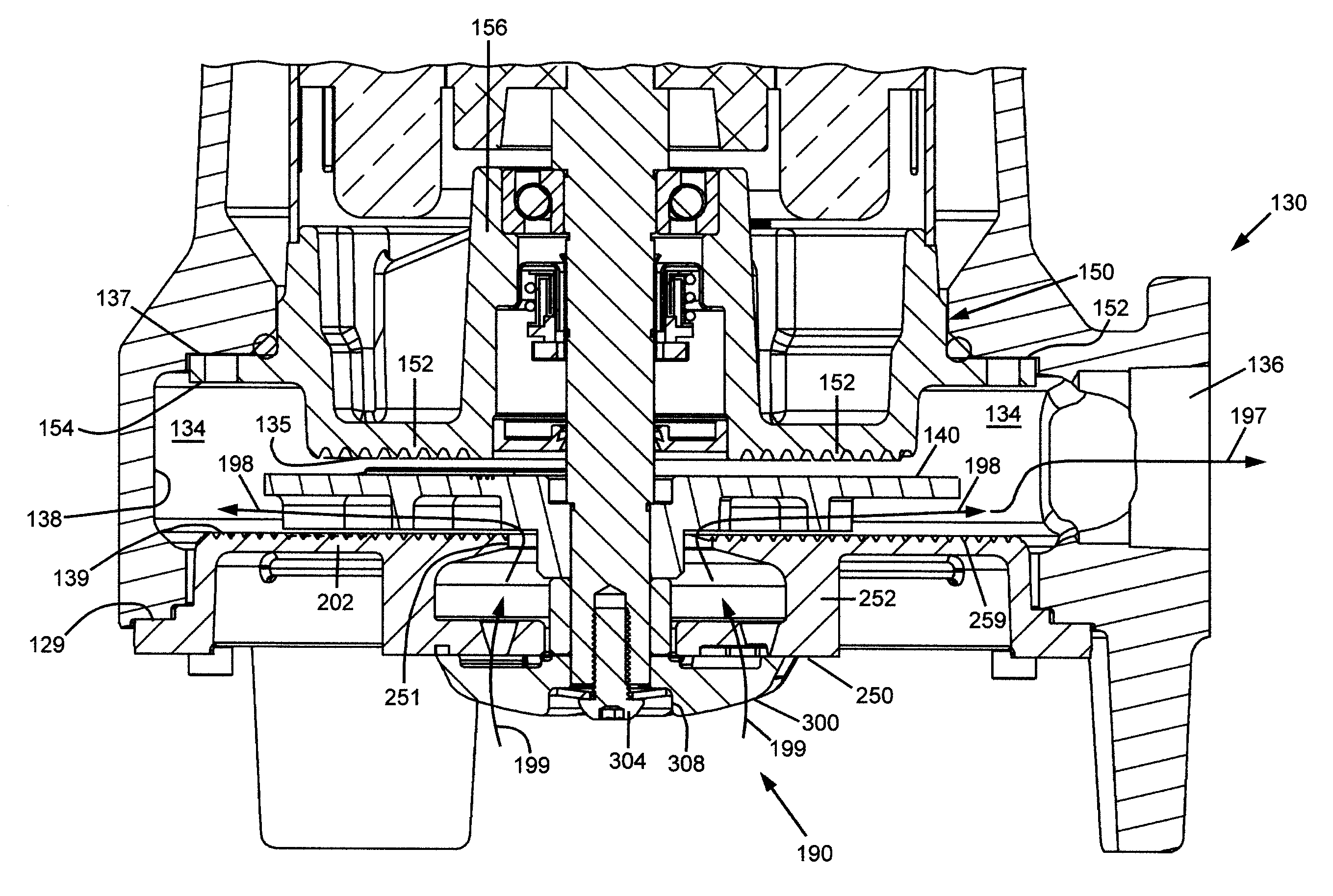

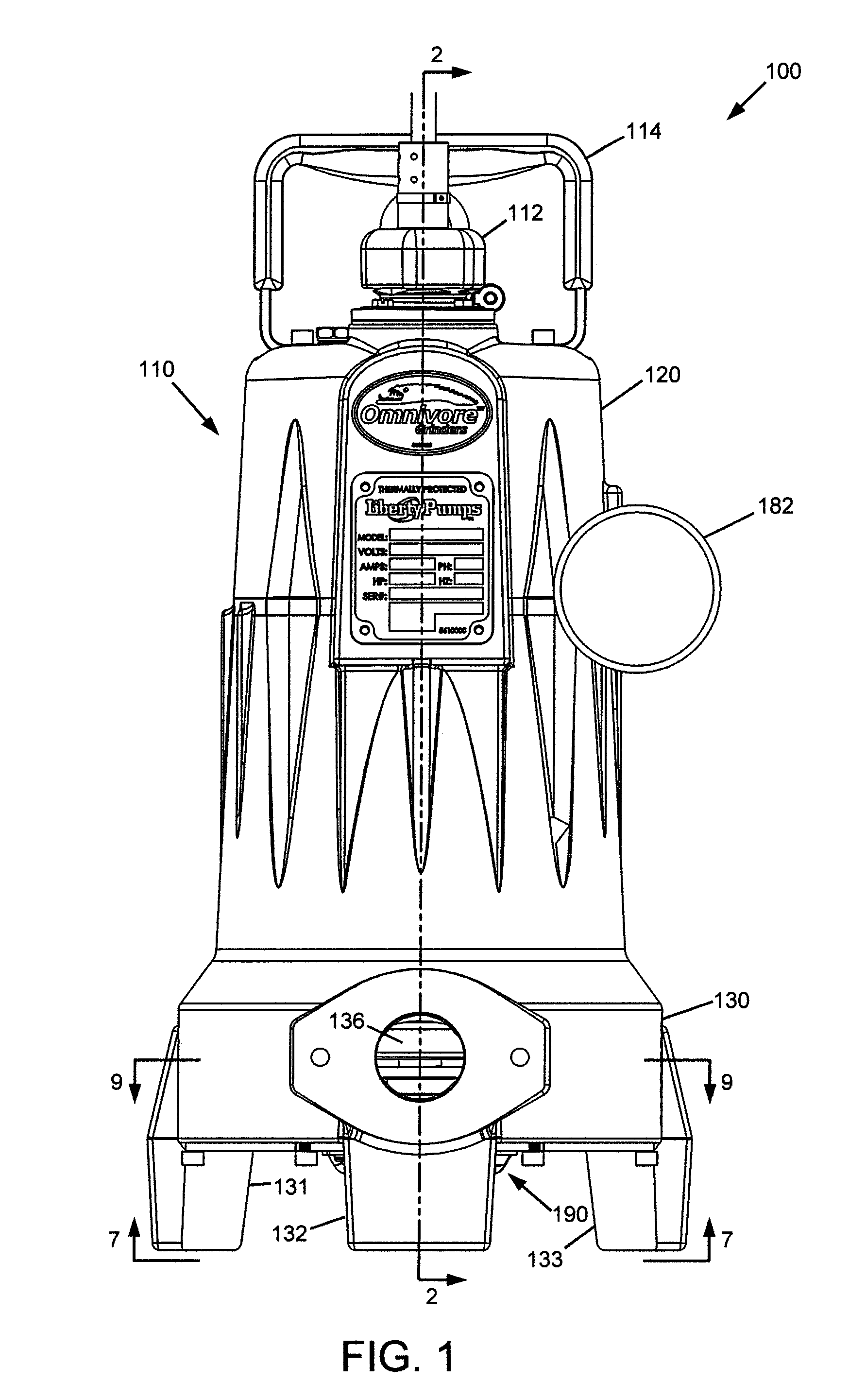

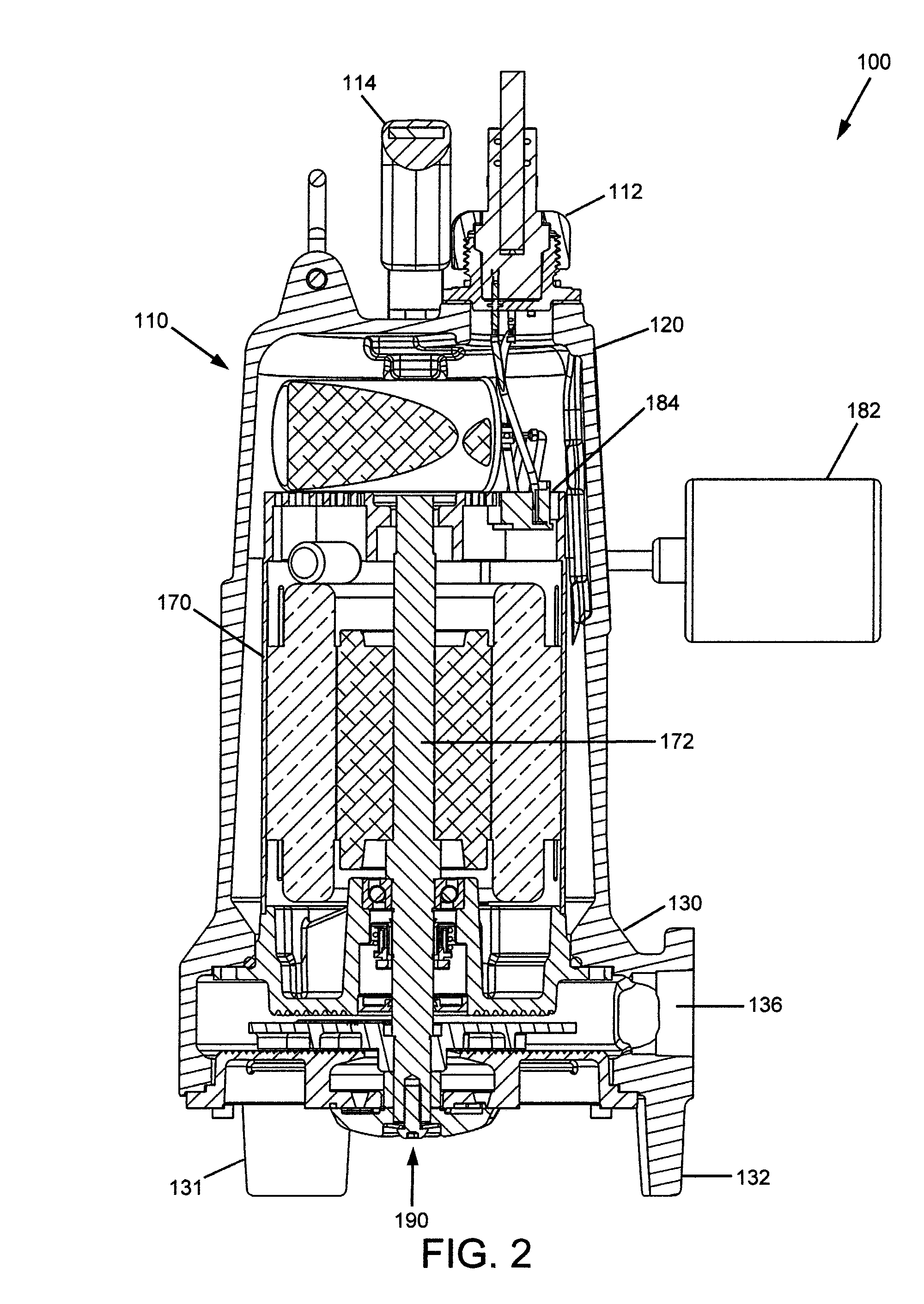

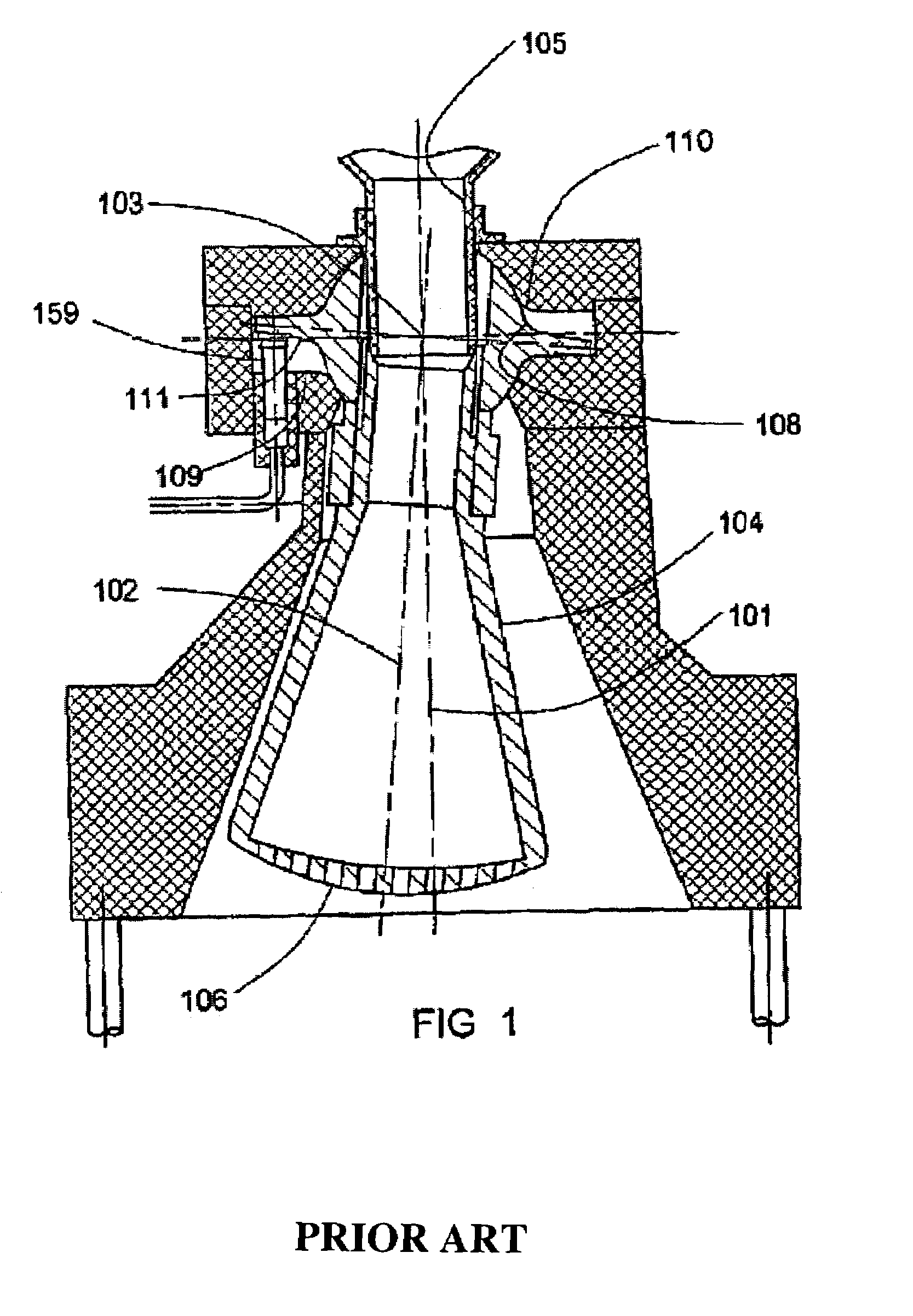

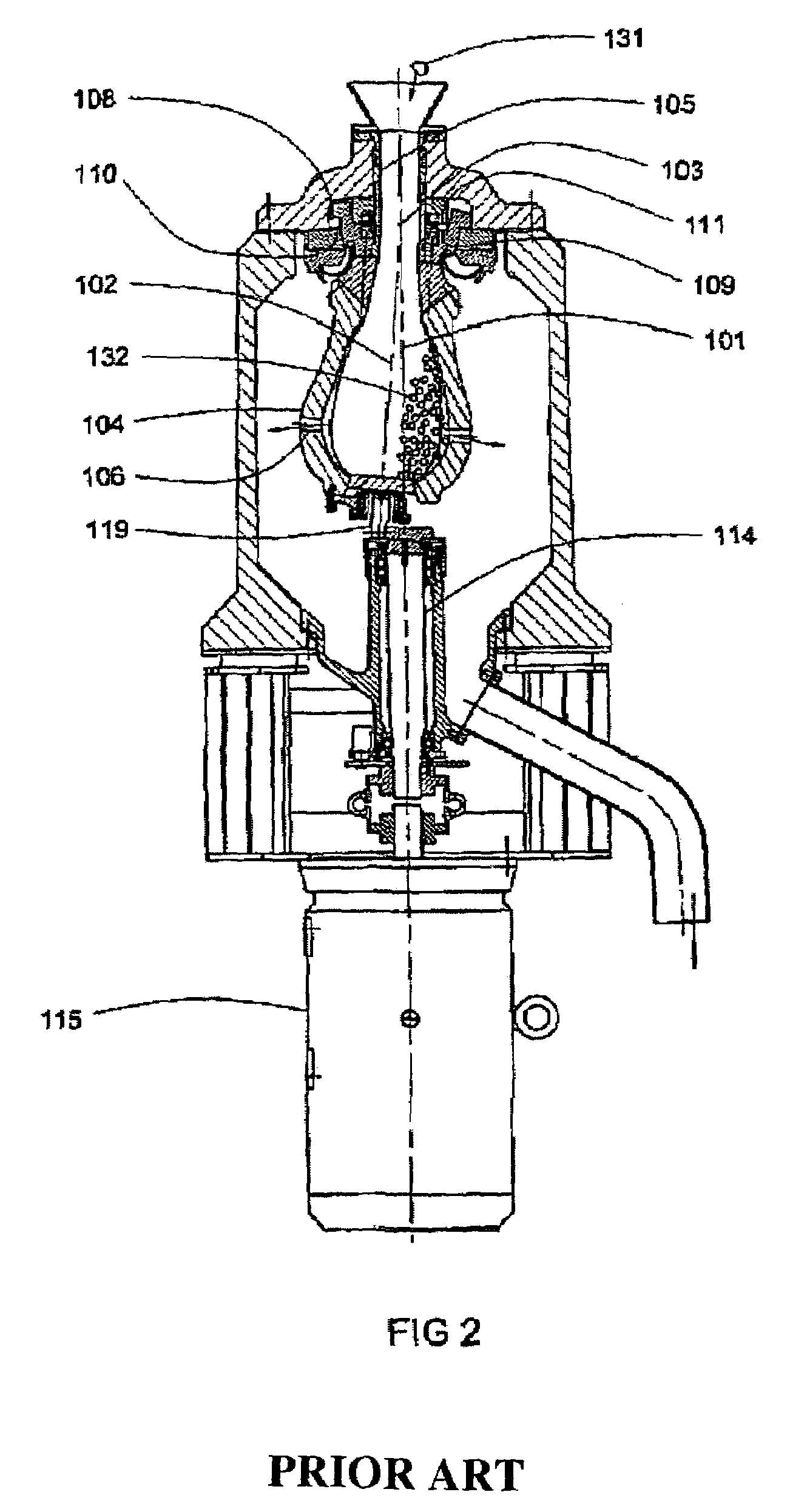

Cutter assembly for a grinder pump

A cutting assembly for a grinder pump comprised of a rotary cutter rotatable against an opposing plate cutter. The cutting edges of the plate cutter include a plurality of V-slice cutting teeth, which create bridging spaces to pinch material which is being sucked in to ports and begin cutting along the V-slice and then for cut material to pass through and onward into the volute of the pump. The rotary cutter has a ground edge with a rake angle which shears the gathered material in cooperation with the cutting edges of the plate cutter. A grinder pump including the cutter assembly is also disclosed.

Owner:LIBERTY PUMPS

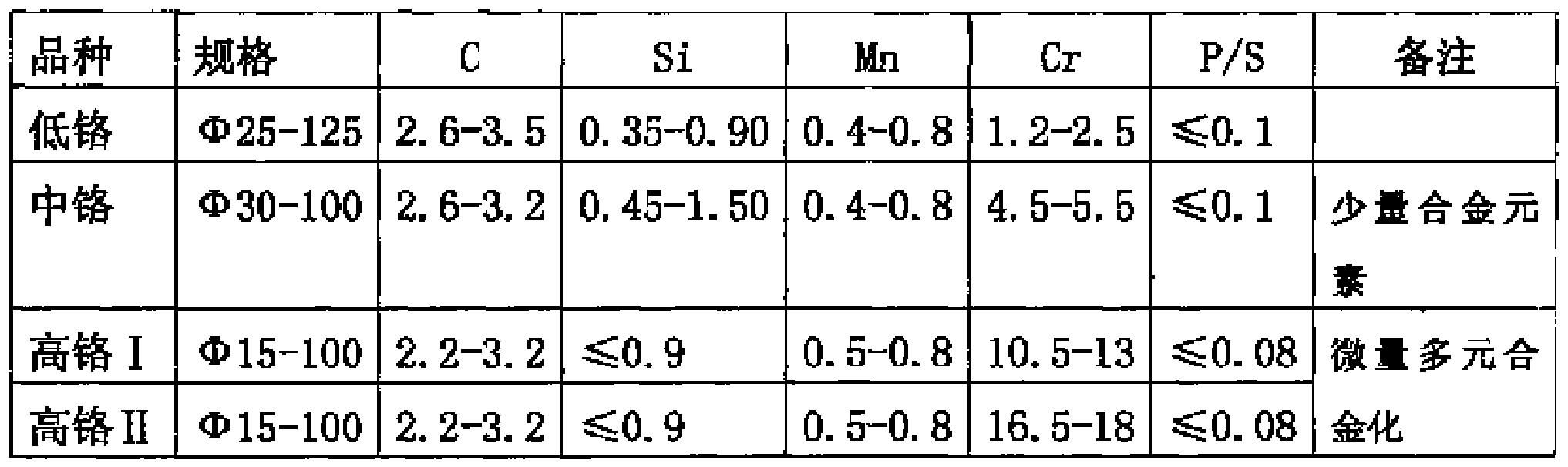

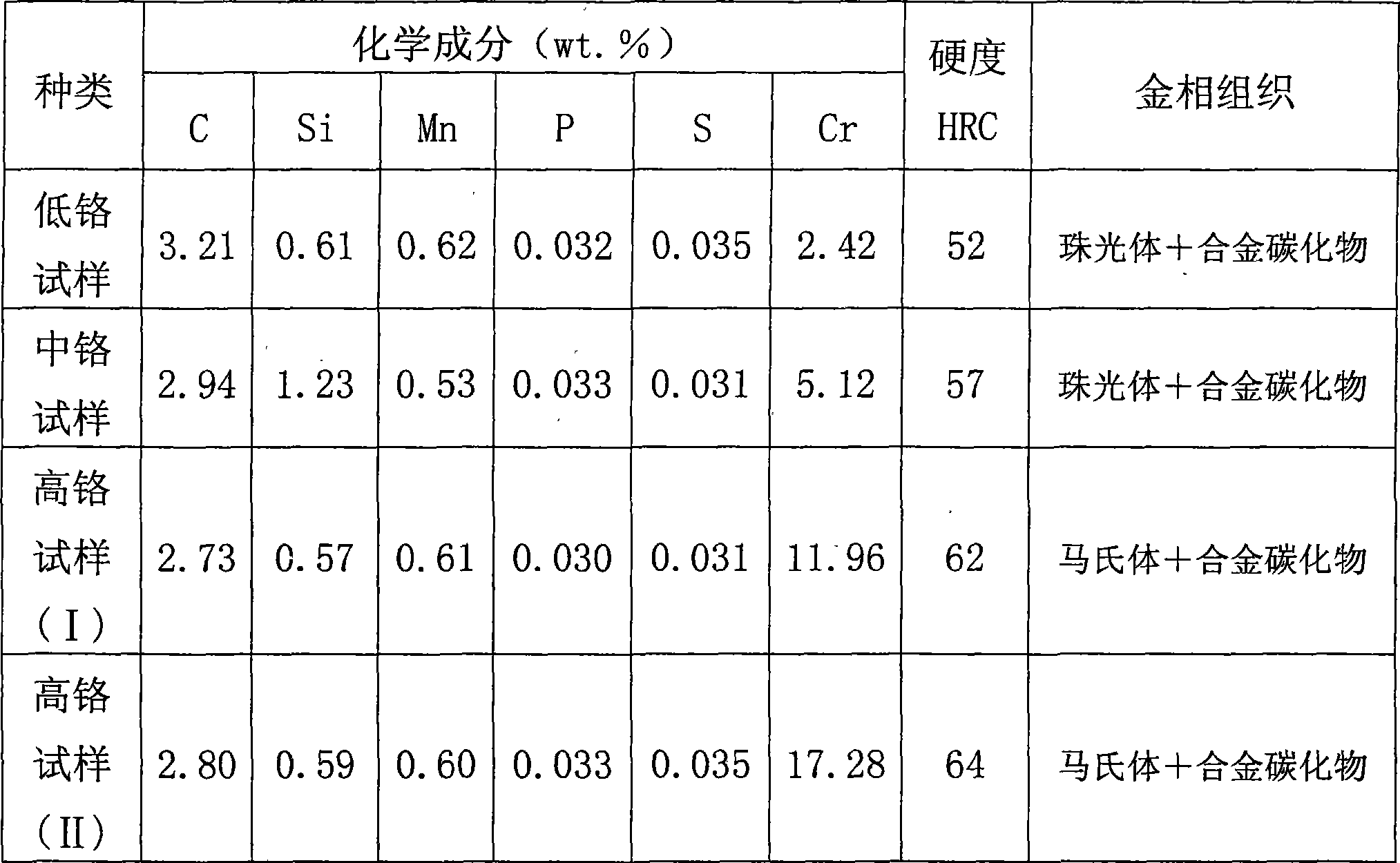

High chromium multielement alloy wear resisting ball and manufacturing method thereof

The invention discloses a high chromium multielement alloy wear resisting ball which comprises the chemical components by weight percentage as follows: 2.5-2.8% of C, 0.8-1.2% of Si, 1.2-1.4% of Mn, 12.5-14.0% of Cr, 0.4-0.6 of Mo, 0.7-1.0% of Ni, 0.8-1.2% of Cu, 0.05-0.1% of V, W smaller than or equal to 0.02, 0.03-0.05% of Ti, 0.02-0.04% of B, 0.03-0.04% of Nb, P smaller than or equal to 0.05%, S smaller than or equal to 0.05%, and the balance of Fe. According to the invention, wear resistance, high hardness, high tenacity and high impact resistance of the grinding ball are ensured by optimizing material formula to high chromium white iron, regulating the casting and melting process and combining a reasonable thermal processing method. Not only is production efficiency of a ball grinding mill improved, but also the production cost and energy consumption are further effectively reduced, the limited resources are saved, and extremely high economical value and social benefit are obtained.

Owner:MAANSHAN HENGDA WEAR RESISTANT MATERIALS

Jet Mill Producing Fine Silicon Powder

A method of jet milling silicon powder in which silicon pellets are fed into a jet mill producing a gas vortex in which the pellets are entrained and pulverized by collisions with each other or walls of the milling chamber. The chamber walls are advantageously formed of high-purity silicon as are other parts contacting the unground pellets or ground powder. The pellets and chamber parts may be formed of electronic grade silicon but polycrystalline silicon may be used for chamber parts. Additionally, the particle feed tube in which the particles are entrained in a gas flow and the vortex finder operating as the outlet at the center of the vortex may be formed of silicon. The milling and feed gas may be nitrogen supplied from a liquid-nitrogen tank lined with stainless steel. The feed pellets may be formed by chemical vapor deposition.

Owner:INTEGRATED PHOTOVOLTAICS

System for measuring wear in a grinding mill

The system for measuring wear in a grinding mill has at least one bolt passing through the shell and a wear plate. The bolt has an elongated oblong-shaped bolt head extending through the wear plate, flush with a surface of the wear plate. The bolt head is exposed to a same abrasion as the wear plate. The bolt has a groove there along and a plurality of wire loops embedded in that groove. Each wire loop extends to a distinct point along the bolt head, such as to form a ruler along the bolt head. A mobile transmitter-receiver is mounted to the stem of the bolt and is connected to the wire loops. The mobile transmitter-receiver has electronic circuitry therein for detecting broken loop conditions and for transmitting these conditions to a remote receiver where the conditions are related to degrees of wear on the wear plate.

Owner:SLATER DENNIS +1

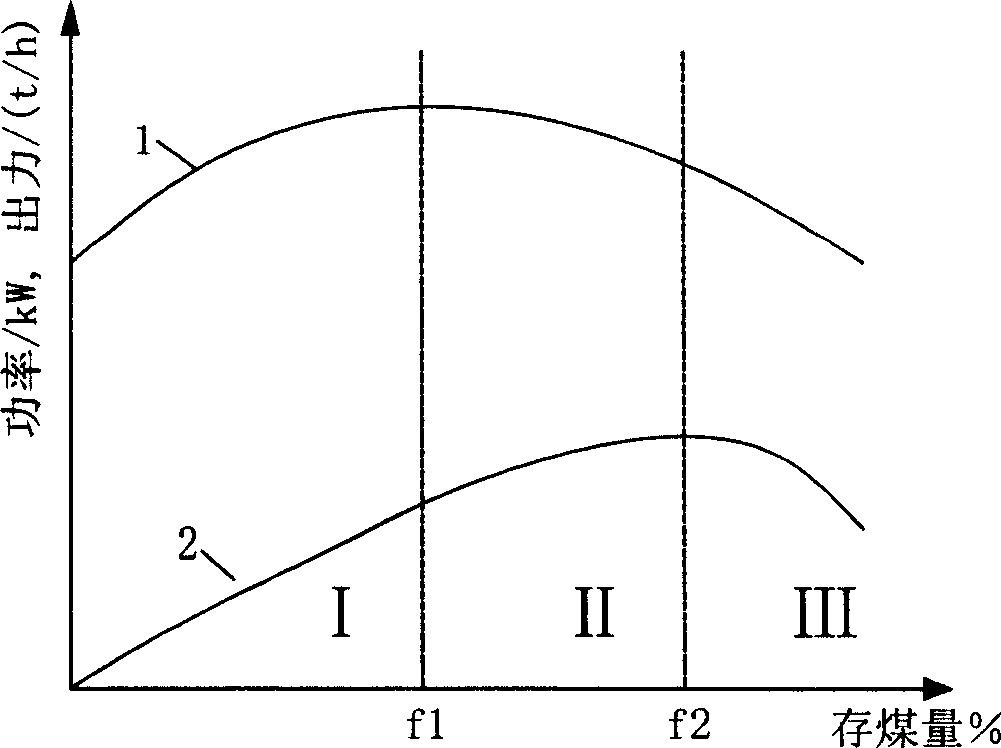

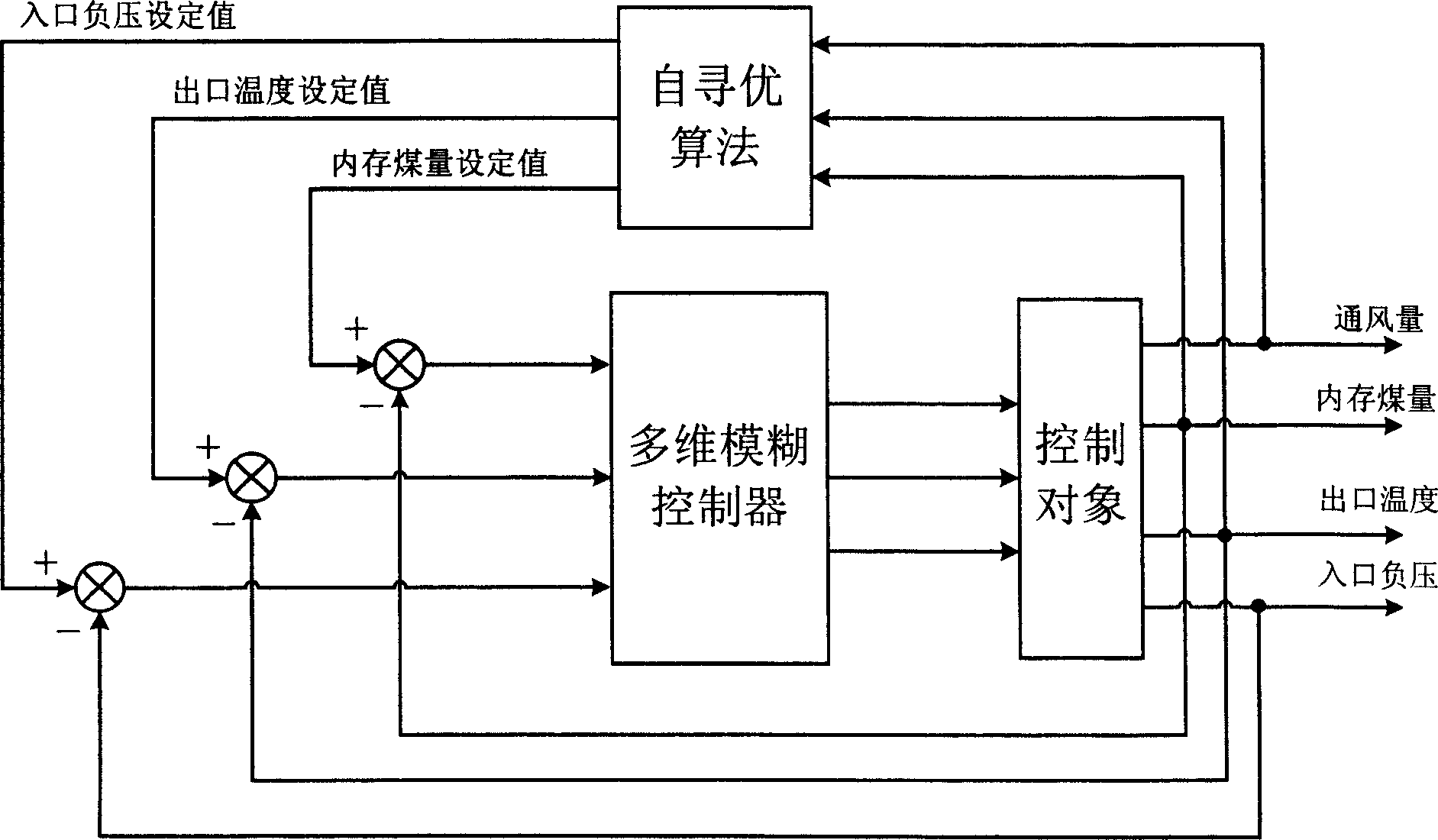

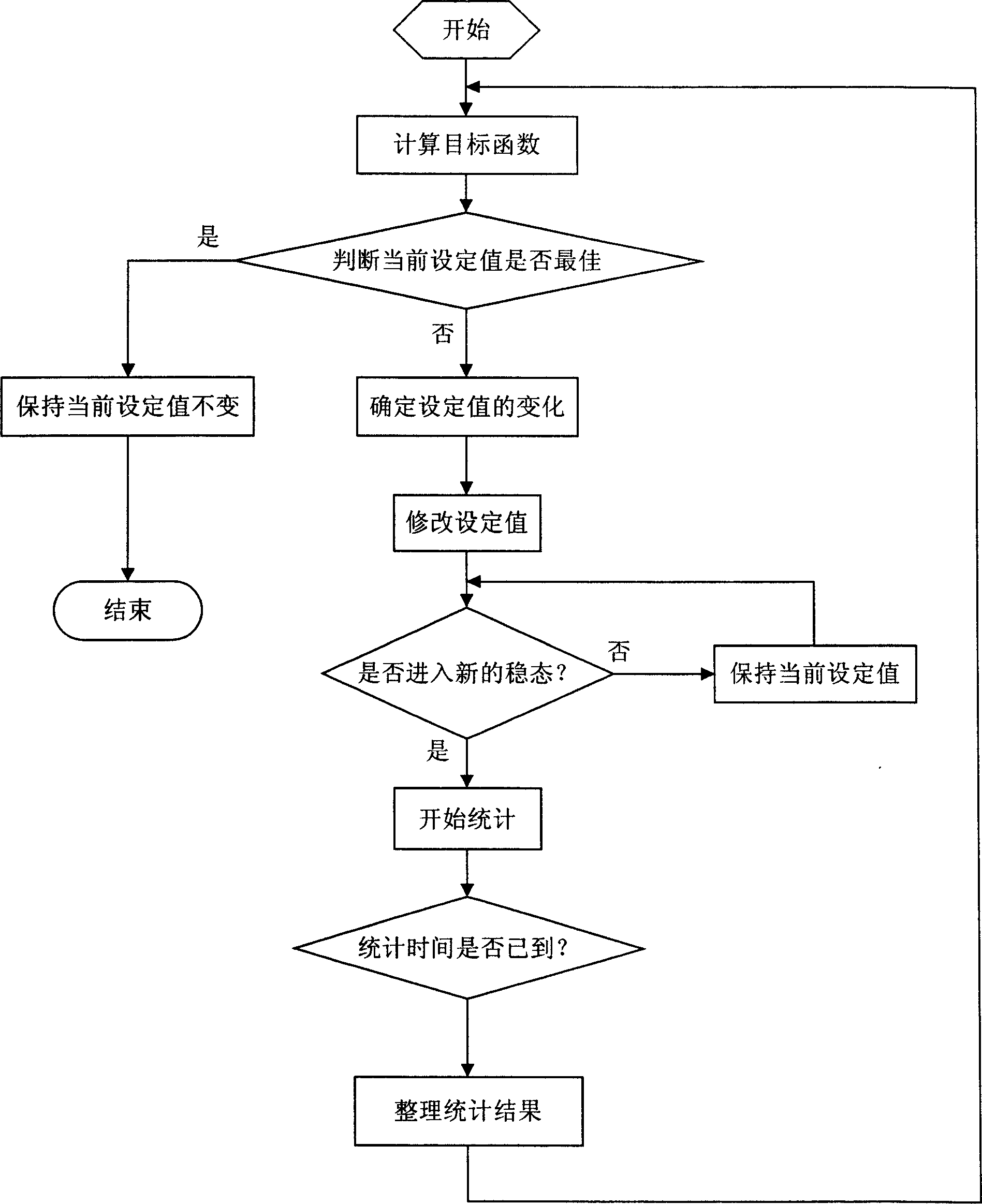

Powder-making system automatic control method for heat engine plant steel ball coal grinding mill

The automatic control method for steel ball coal mill in thermal power plant adopts a double-layer control structure, including an upper layer of self optimizing algorithm and a lower layer of multidimensional fuzzy control algorithm. The self optimizing algorithm finds out the optimal inside coal storage quantity inside the coal mill, the optimal outlet temperature of the coal mill and the optimal inlet negative pressure value of the coal mill as the controlling set values; and the multidimensional fuzzy control algorithm realizes the automatic regulation of the coal feed quantity, the hot air valve opening, and the recirculating air valve opening or the cold air valve opening, so as to ensure the safe and reliable running of the steel ball coal mill system in optimal mode.

Owner:XI AN JIAOTONG UNIV +1

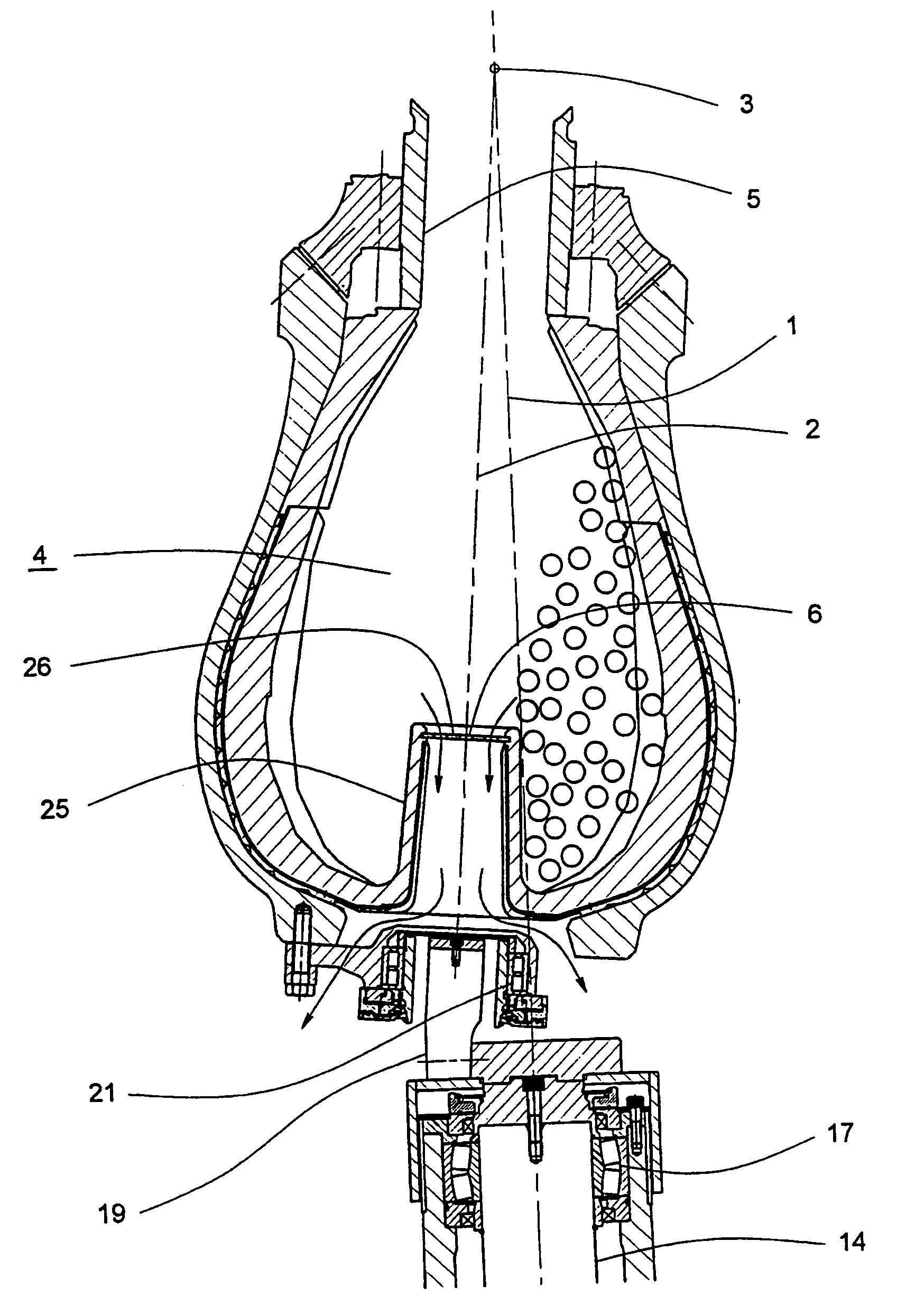

Centrifugal grinding mills

InactiveUS7070134B1Reduce shock pressureReduce abrasive wearGrain treatmentsNutationMaximum diameter

The present invention relates to a centrifugal grinding mill comprising a vertical axis of revolution (1), a nutating axis (2) intersecting axis (1) at a point of nutation symmetry (3), a grinding chamber (4) symmetrical about axis (2) connecting with feed passage (5) at its upper end and having discharge openings (6) of a screening element (26) located within a plane area aligned normal to, symmetrical with, and intersected by the axis (2), and adjacent the plane containing the maximum diameter of the grinding chamber (4).

Owner:F L SMIDTH & CO AS

High abrasion proof re-synthesizing cast iron grinding ball and production method thereof

InactiveCN101445889AHigh hardnessImprove toughnessEdge grinding machinesPolishing machinesIntermediate frequencyCarbide

The invention relates to a high abrasion proof resynthesizing cast iron grinding ball for a ball grinding mill and a preparation method thereof. The method reduces the content of carbon in material on the premise that carbide is formed in materials, thereby reducing the contents of chrome and molybdenum in the material and simultaneously controlling the content of other elements, so that the obtained material of the grinding ball has good overall mechanical property and service performance. Compared with a No. 45 steel forging ball, the abrasion proof property of the grinding ball is improved by 3 to 10 times, so that both the consumption of steel products and the recourses are saved. In the method, cast iron is melted and synthesized by using an intermediate frequency electric furnace and a large amount of scrap steel, steel scraps and other renewable resources are utilized, so that not only the quality of synthetic cast iron products is improved and the performance is stabler, but also the pollution to environment is reduced.

Owner:MAANSHAN YIFENG INDAL GROUP

Process for the preparation of self-glazed geopolymer tile from fly ash and blast furnace slag

InactiveUS20070221100A1Reduce energy consumptionLow production costSolid waste managementCeramic shaping apparatusSlagHigh energy

The present invention provides a process for the preparation of self glazed geopolymer tile using fly ash and granulated blast furnace slag. In the process of the present invention, the granulated blast furnace slag is fine grounded and / or mechanically activated in conventional grinding mills or high-energy mills. The fly ash, which is found in powder form and fine powder of granulated blast furnace slag, is thoroughly mixed to make a homogenous mixture. The alkaline solution is added into the mixture to initiate the geopolymerization. The ratio of water to powder is optimised to obtain a consistent paste to be used for vibration casting. During the casting, the consistent paste flows inside the mould and the particles settles at mirror finished surface of mould, giving rise to dense and smooth surface.

Owner:COUNCIL OF SCI & IND RES

Method for preparing foamed ceramic insulation board by waste glass ceramic wafer

The invention discloses a method for preparing a foamed ceramic insulation board by a waste glass ceramic wafer, belonging to the field of preparation technology of the foamed ceramic insulation board. The method comprises the steps of: washing the waste glass ceramic wafer with clear water, drying and grinding by ball milling to obtain waste glass ceramic powder with the fineness less than or equal to 100mu m; mixing the waste glass ceramic powder, pulverized fuel ash, furnace slag, coal gangue, ceramic tailings, foaming agent and modifying agent according to the mass ratio of (30-40):(10-15):(5-7):(10-18):(25-35):(1.8-2.2):(1.1-1.5); putting the mixture into a ball grinding mill, carrying out wet grinding and evenly mixing to form mixed slurry; drying by a pressure type spray granulation dryer and putting the dried product into a foaming refractory mould coated with aluminum oxide; heating to 1120-1150 DEG C in a heating furnace; and finally, annealing, cooling and cutting to obtain the foamed ceramic insulation board. The method is low in production cost and simple in technology, and can be used for continuously preparing the porous foamed ceramic insulation board with large size; and the product is good in performances.

Owner:ANSHENG SCI & TECH DEP

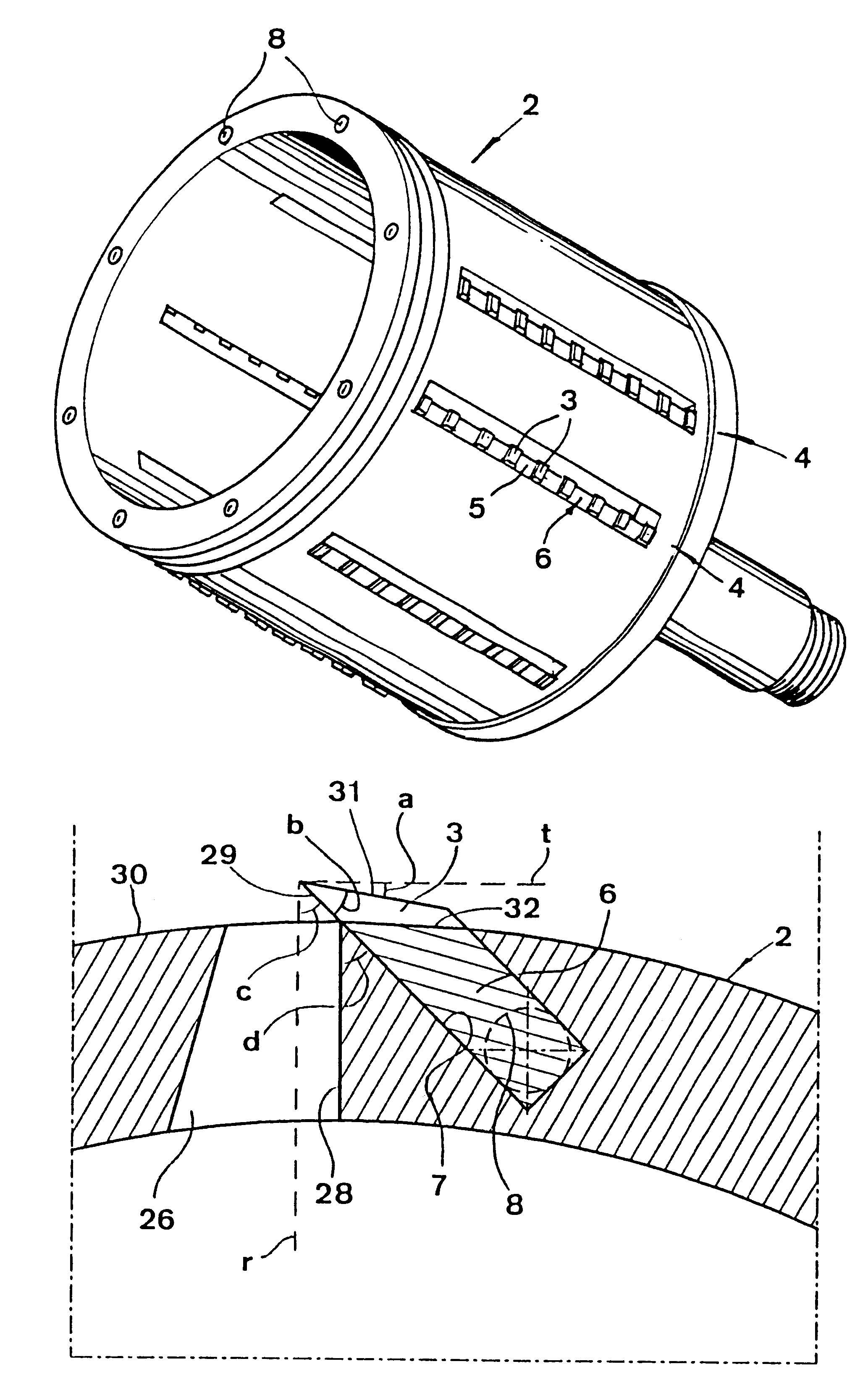

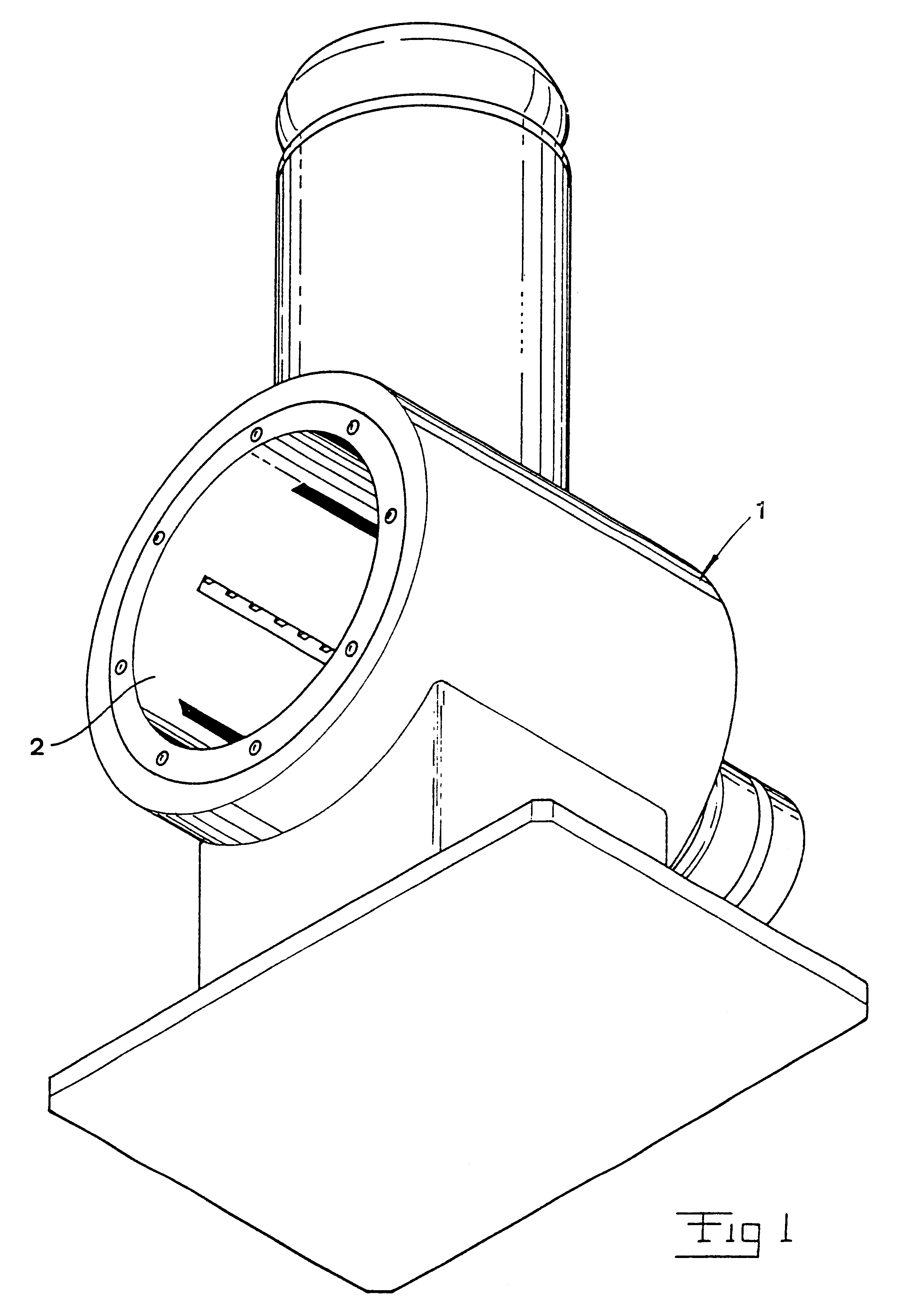

Mill, a method for producing bone transplantation material and use of a mill for such production

A mill comprises a casing having an opening for supply of material to be milled and a rotor rotatably supported in the casing and provided with cutting members (3) for disintegrating action on the material. The cutting members (3) are arranged in a plurality of sets (4a-d) distributed about the periphery of the rotor, and having an axial extent (arrow 33). At least two of the sets (4) have their cutting members (3) mutually displaced in axial direction.

Owner:HOVELIUS LENNART

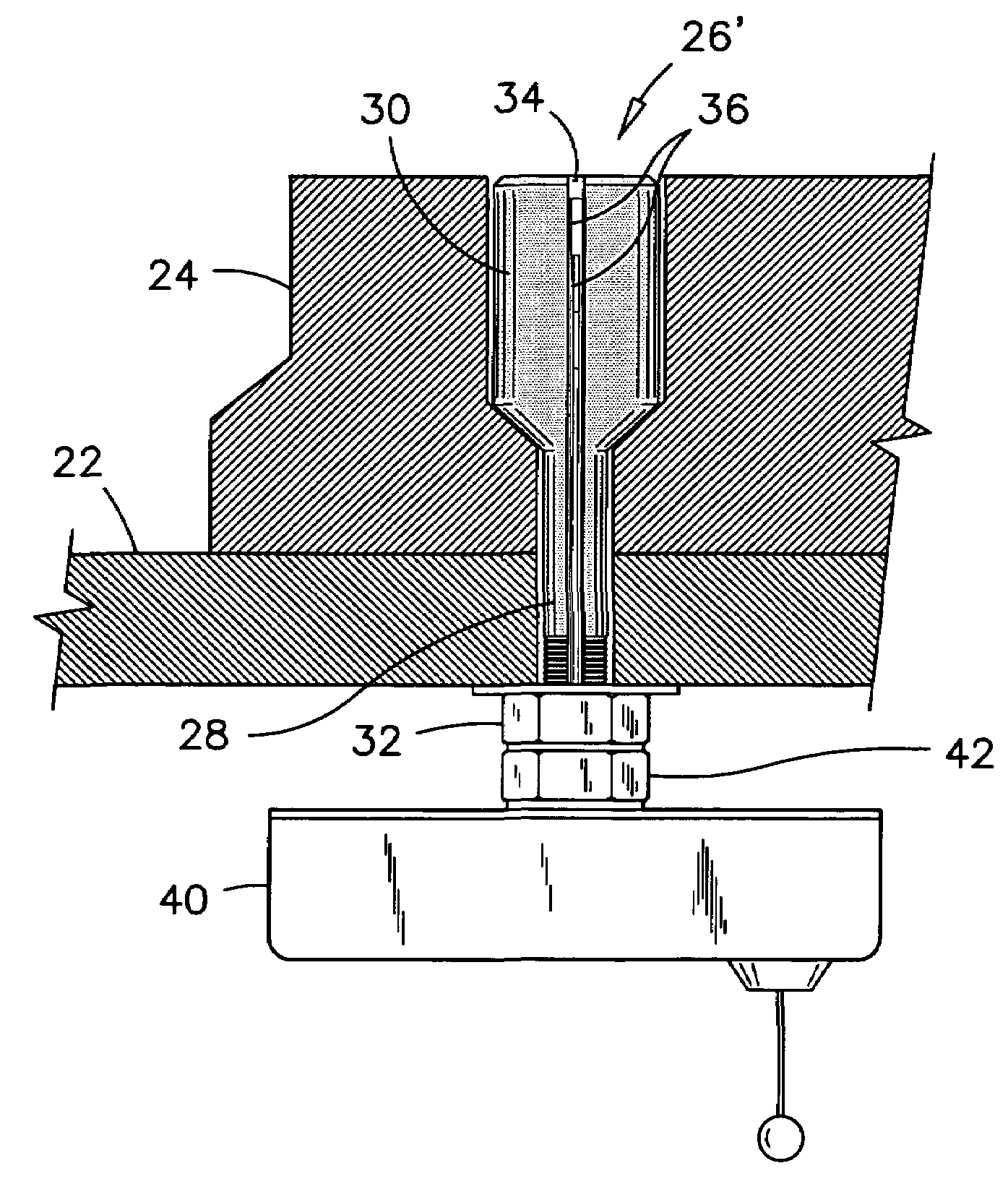

Method and device for sensing wear

A sensor for detecting erosion of a wear surface of a component, particularly a liner attached to the mill shell of a rotating grinding mill. The sensor comprises a conductive element embedded in the component, the conductive element comprising a first end positioned at a first distance from the wear surface, at least one conductive loop comprising a wear portion positioned at a second distance from the wear surface proximate to the first end and a circuit coupled to the at least one element for determining a continuity of the conductive loop.

Owner:MCGILL UNIV

Dryer/Grinder

A grinder / dryer having a plurality of beater blades carried on a rotating shaft in a cylindrical housing, including one or a plurality of grinding members on the cylindrical side wall. The grinding members are adjustably positioned at different locations within the cylinder. The grinding members may be provided in a variety of different combination of elevated ridges and / or valleys used to dry and classify materials.

Owner:SCOTT EQUIP

Method and device for sensing wear

A sensor for detecting erosion of a wear surface of a component, particularly a liner attached to the mill shell of a rotating grinding mill. The sensor comprises a conductive element embedded in the component, the conductive element comprising a first end positioned at a first distance from the wear surface, at least one conductive loop comprising a wear portion positioned at a second distance from the wear surface proximate to the first end and a circuit coupled to the at least one element for determining a continuity of the conductive

Owner:MCGILL UNIV

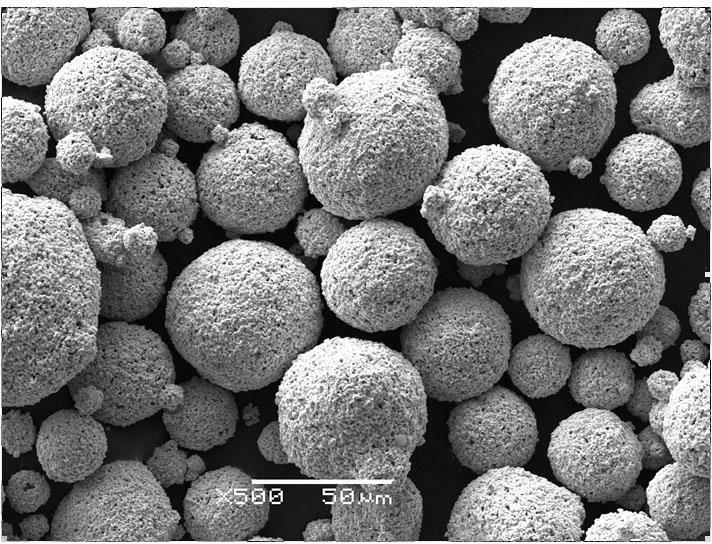

Method for producing spherical thermal-spraying powder

The invention discloses a method for producing spherical thermal-spraying powder. The method sequentially comprises the steps of: A, firstly, adding 55-95% of tungsten carbide powder, 5-33% of metal nickel powder or cobalt powder or iron powder, and 0-22% of chromium carbide powder into a ball grinding mill in terms of mass percentage, meanwhile, adding 15-35% of wet-grinding media and 2-5% of a forming agent in terms of the total mass of raw material powder, and performing wet grinding for 12-40h to obtain mixed slurry; B, centrifuging, atomizing and pelleting to obtain spherical mixed powder; C, placing the spherical mixed powder into a dewaxing and sintering integrated furnace, removing the forming agent, sintering for 20-70min in vacuum at the temperature of 800-1350 DEG C, cooling to below 50 DEG C and discharging out of the furnace; and D, crushing and sieving agglomerate materials obtained in the step C to obtain the spherical thermal-spraying powder. The method disclosed by the invention has wide applicability, and is not only suitable for producing the tungsten-carbide-based spherical thermal-spraying powder but also suitable for producing the thermal-spraying powder of other metal, nonmetal and mixtures of metal and nonmetal; and a production process is nonhazardous, the quality is stable and consistent, and the thermal-spraying powder smaller than 30 micrometers can be produced.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

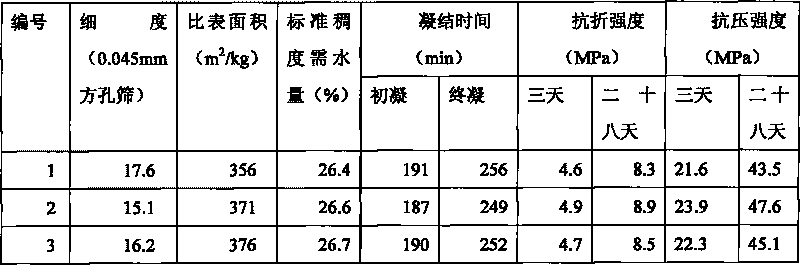

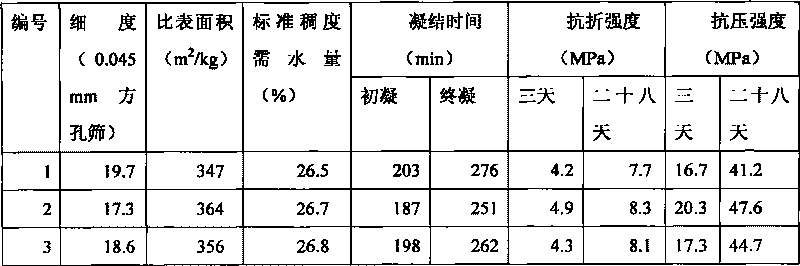

Composite cement grinding aid and preparation method thereof

The invention discloses a composite cement grinding aid and its preparation method. According to a formula, the composite cement grinding aid comprises: a grinding agent, a reinforcing agent, a surfactant, molasses, N, N-bis(2-hydroxyethyl)isopropanolamine and water. The composite cement grinding aid can enhance the fluidity of materials during grinding, effectively reduce overgrinding phenomenon of a mill, improve adhesion of the materials to a grinding body, a lining board, and a bin partition board as well as the self agglomeration phenomenon of the materials, thus increasing the machine-hour yield of the cement grinding mill by l0%-20%, enhancing the cement specific surface area to 20-40m<2> / Kg, reducing the sieve residue, optimizing cement particle gradation, promoting cement clinker hydration, and improving the cement mixture activity. The 3-day compressive strength is increased by 3-5MPa, and the 28-day compressive strength is increased by 4-8MPa. The clinker consumption is reduced by 6-10%. The cement production cost is effectively reduced, the cement security is improved, and the adaptability of cement and concrete admixtures are improved.

Owner:ZHEJIANG HUAJUN BUILDING MATERIAL

Testing method for content of coal seam methane sampled under negative-pressure environment

ActiveCN103776722AReduce lossesReduced sampling timeWithdrawing sample devicesMaterial weighingDesorptionBall mill

The invention provides a testing method for the content of a coal seam methane sampled under a negative-pressure environment. The testing method comprises the following steps: sampling, namely carrying out in-situ measurement on the methane desorption amount; recording the final in-situ desorption amount V2; determining a methane desorption principle of a coal sample under the negative-pressure environment; carrying out lost methane amount calculation, namely calculating the loss amount V1 according to the measured methane desorption principle of the coal sample under the negative-pressure environment; carrying out residual methane amount laboratory determination, namely heating the coal sample in a sealed state and degassing in vacuum; testing the first-time degassing amount V3; crushing the coal sample by a ball grinding mill and degassing to determine the second-time degassing amount V4; carrying out gas component analysis in the degassing process; and determining the content X of the coal seam methane according to the V1, the V2, the V3 and the V4, and the weight m of the coal sample. The testing method for the content of the coal seam methane sampled under the negative-pressure environment is simple and feasible and particularly has important theoretical values and actual meanings on the desorption amount and the desorption principle of methane under the negative-pressure environment when negative-pressure pumping-out type spot sampling is carried out; the accuracy and the reliability of testing data can be greatly improved and theoretical data are provided for the coal mine safety production.

Owner:HENAN POLYTECHNIC UNIV

Composite high-efficient liquid cement grinding aid

InactiveCN101693605AImprove durabilityReduce dosageCement productionCement grindingTriisopropanolamine

The invention belongs to the technical field of cement technology admixtures, and relates to a composite high-efficient liquid cement grinding aid which contains water solution with the following materials by weight percent: 10 to 20 percent of triethanolamine, 5 to 10 percent of glycol, 5 to 10 percent of tri-isopropanolamine, 5 to 10 percent of calcium lignosulphonate, 5 to 10 percent of molasses, and 5 to 10 percent of sodium silicate; and the water solution is subjected to magnetization treatment. The composite high-efficient liquid cement grinding aid has the following advantages: by the magnetization treatment, solid / liquid stable suspension durability is good, no separation or sediment phenomenon occurs after long-term storage, dosing amount is low, application range is wide, hourly output of a cement grinding mill can be improved by 15 to 20 percent, cement strength can be improved by 1 to 2MPa, 5 to 8 percent of clinker can be saved, and 5 to 8 percent of industrial residue can be additionally dosed.

Owner:山东天汇科技有限公司

Antibacterial anti-alga color master batch dedicated to fishing net and preparation method thereof

The invention discloses an antibacterial anti-alga color master batch dedicated to a fishing net and a preparation method thereof. The color master batch disclosed by the invention comprises the following raw materials in weight part: 35-75 parts of carrier resin, 10-48 parts of pigment, 10-20 parts of antibacterial agent, and 0.5-3 parts of compatilizer. The preparation method for the color master batch, disclosed by the invention, is realized through the following steps: adding the pigment, the antibacterial agent and a processing agent into a grinding miller as per the raw material ratio for grinding and refining, adding the carrier resin and the compatilizer together into a high-speed mixer for uniform mixing, and finally adding the mixed material into a double-screw extruder for mixing and extruding. According to the invention, the antibacterial agent is added into the color master batch dedicated to the fishing net, and the compatilizer is added to enhance the compatibility of the prescription components, so that the antibacterial anti-alga color master batch dedicated to the fishing net can be prepared; and moreover, the color master batch has antibacterial and anti-alga functions, is convenient to add and use, and has the advantages of low toxicity, high efficiency and long antifouling period.

Owner:CHONGQING AOCAI NEW MATERIAL CORP LTD

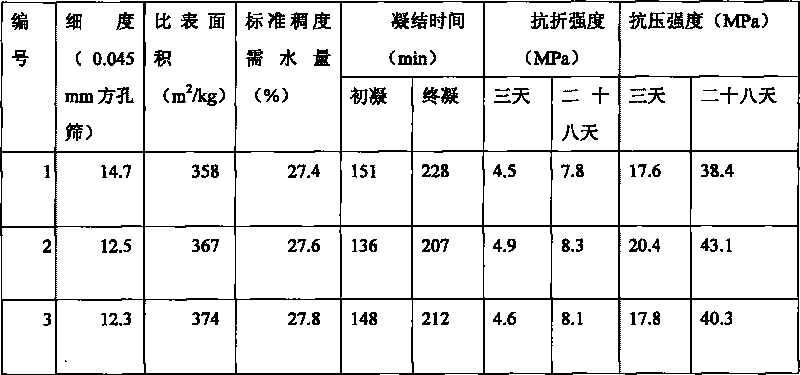

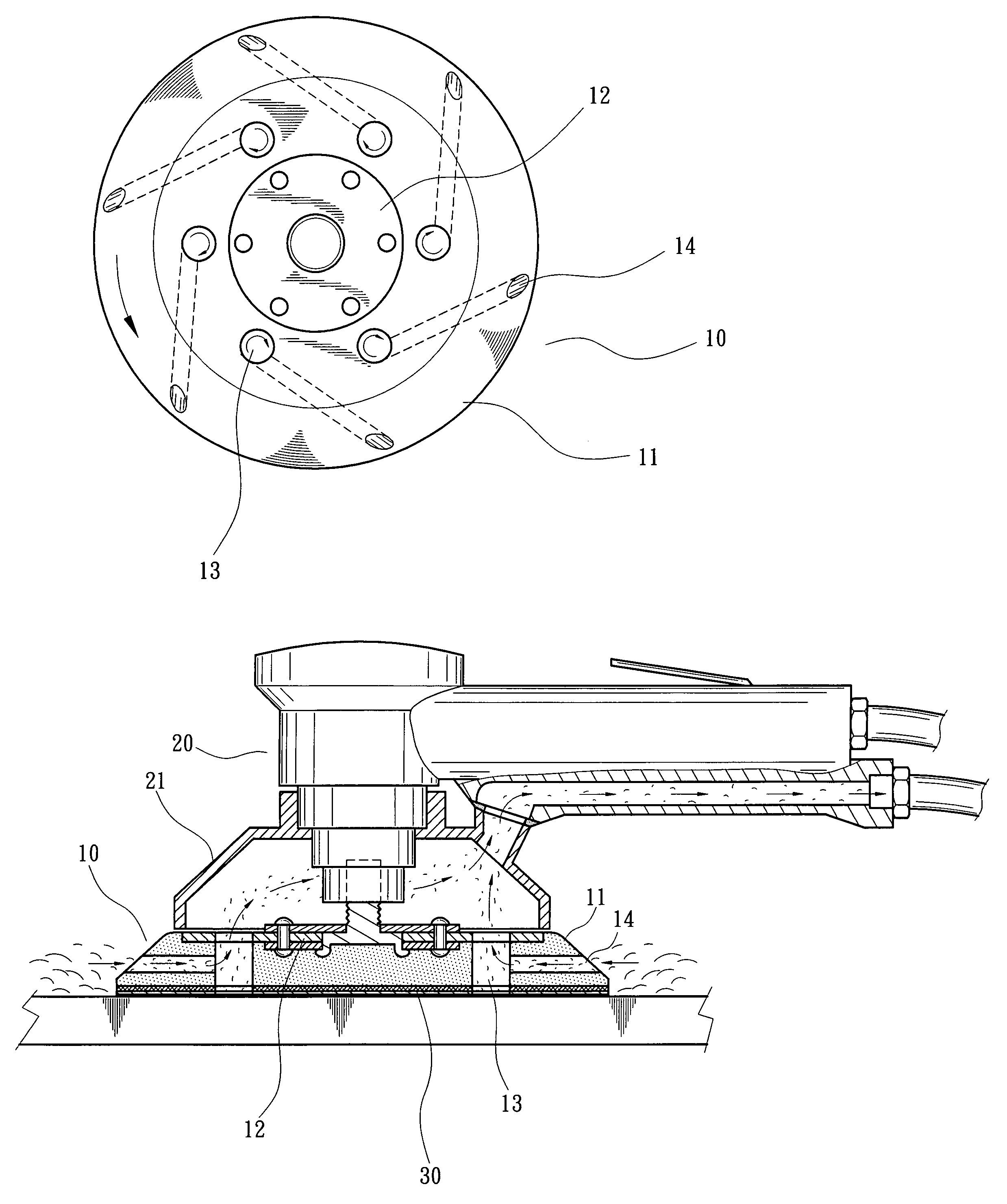

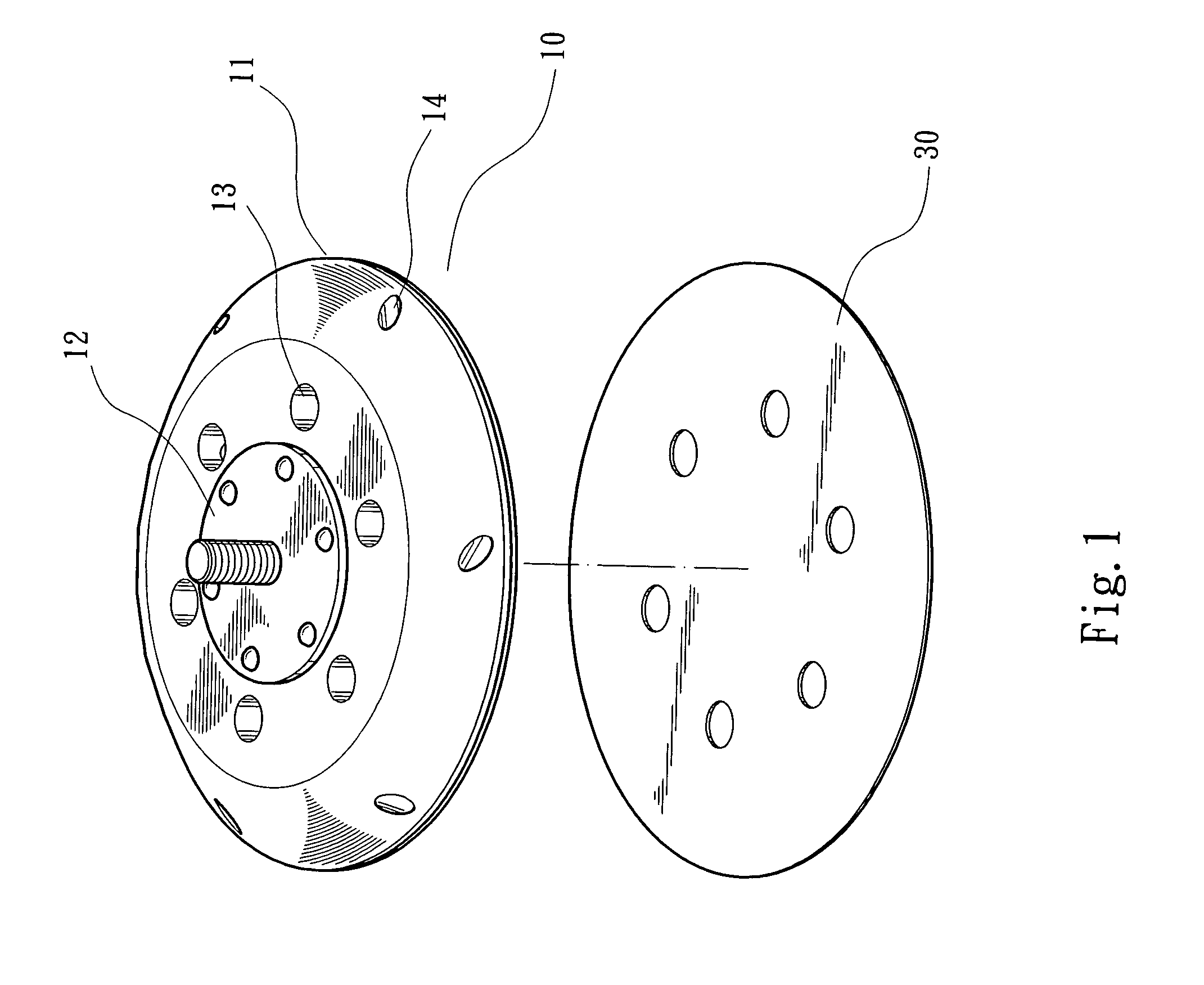

Grinding disc structure

InactiveUS7094138B2Revolution surface grinding machinesSupport wheelsEngineeringMechanical engineering

A grinding disc structure including an integrally formed main disc adapted to a dust-sucking cover body of a grinder. The main disc has multiple through holes nearly in parallel to an axis of the main disc. The main disc is further formed with multiple internal passages which are horizontally formed in the main disc corresponding to the through holes and nearly perpendicular to the axis of the main disc. The passages are tangential to the through holes. Two ends of each passage respectively communicate with the through hole and outer side around the main disc. The main disc has a complete bottom face to which a grinding layer can be fully adhered.

Owner:CHANG JEN PEN

Enhanced liquid cement grinding aid

InactiveCN102115316AIncrease late strengthImprove grinding efficiencySodium acetateSodium lignosulfonate

The invention relates to an enhanced liquid cement grinding aid capable of improving the grinding efficiency of a cement grinding mill and enhancing the strength of cement. The liquid cement grinding aid comprises the components with the weight percentages as follows: 10 to 20 percent of triethanolmine, 5 to 10 percent of triisopropanolamine, 3 to 5 percent of diethylene glycol, 2 to 5 percent of sodium formate, 2 to 5 percent of sodium acetate, 1 to 3 percent of sodium lignosulfonate, 10 to 20 percent of desugarized molasses, 5 to 10 percent of glycerin, and water.

Owner:山东国元新材料有限公司

Grinder

InactiveUS7604191B2The method is simple and convenientCoffee millsSpice millsEngineeringMechanical engineering

Owner:PAI

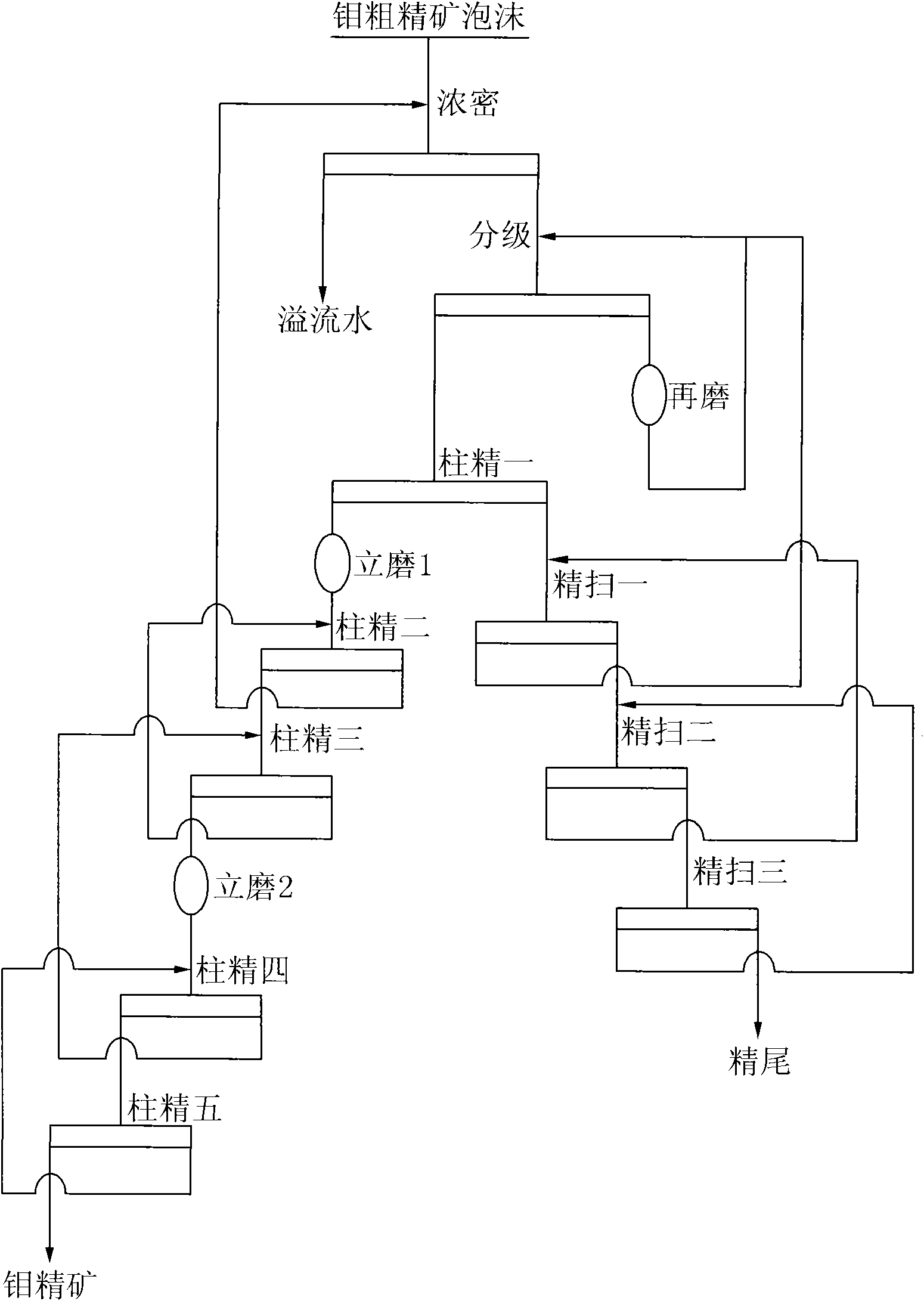

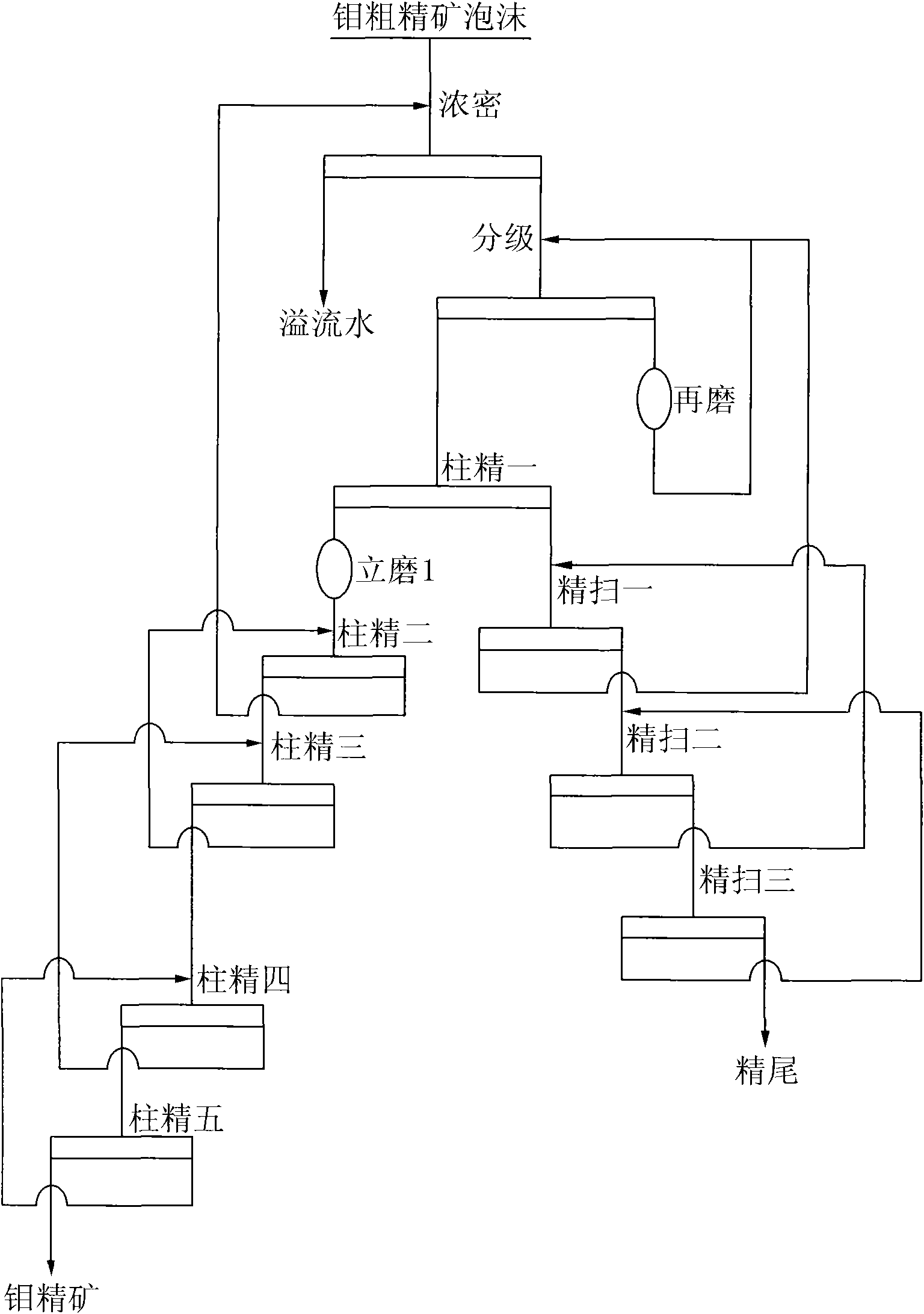

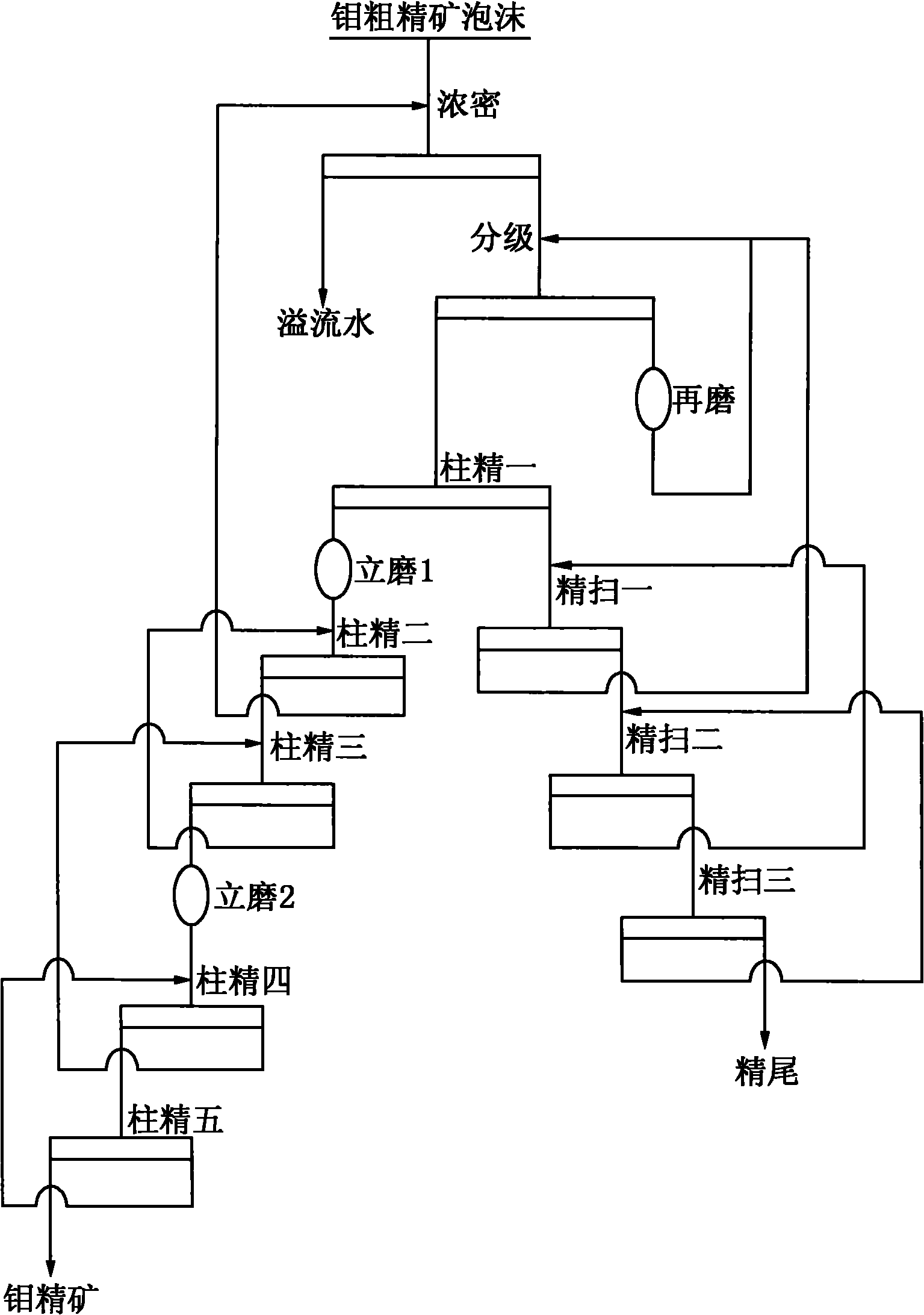

Production technology of high-grade molybdenum concentrate

ActiveCN101773871AReduce pollutionIncrease feed concentrationFlotationWet separationBall millReagent

The invention discloses a production technology of high-grade molybdenum concentrate, which comprises the following steps: rough molybdenum concentrate is obtained by roughing crude molybdenum ore, the rough molybdenum concentrate is concentrated and removed reagent through a thickener, underflow enters a hydraulic swirler to be graded previously, overflow after the grading enters a primary flotation column to be selected, the underflow after the grading enters a horizontal ball grinding mill to be reground, and after the regrinding, the ore discharge enters the hydraulic swirler to be regraded; selected concentrate from the primary flotation column is cleaned by a vertical ore mill to enter a secondary and a tertiary flotation columns to be selected, and the selected concentrate from thetertiary flotation column directly enters or enters a quartic or a quintic flotation columns to be selected after being cleaned by a second section of the vertical ore mill to obtain the high-grade molybdenum concentrate; the selected tailings from the primary flotation column is tertiary scavenged by a flotation machine, and the scavenged concentrate tailings from the tertiary scavenging enters the next procedure. The technology adopts the flotation columns and the flotation machine, so the flow is short, the agent system is simple, the adaptability of the crude ore is strong, and the molybdenum concentration ratio is high, the molybdenum concentrate has high grade, large yield and high recycling rate so as to provide excellent raw material to the following molybdenum chemical engineering and further processing.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Collision grinding type ultrafine smashing device

InactiveCN105833979ARealize one-time crushingImprove crushing efficiencyCocoaGrain treatmentsEngineeringCentrifugal force

The invention discloses a collision grinding type ultrafine smashing device. The device mainly comprises a feeding device, a collision device, a grinding device and a discharging device, wherein a feeding barrel body in the feeding device is matched with a material collecting disc; the material collecting disc is mounted on a main shaft through a key; discharge holes are formed in the edge of the material collecting disc; the main shaft rotates to drive the material collecting disc to rotate; material leakage pipes in the collision device are in threaded connection with the discharge holes of the material collecting disc; when materials are accelerated, the materials are thrown through a pipeline under the action of centrifugal force at a high speed to collide with collision pieces to be crushed; the grinding device comprises three levels of grinding mechanisms; the materials are sequentially fed into the first-level, the second-level and the third-level grinding mechanisms under the action of gravity; and grinding mechanisms comprise grinding discs and grinding blocks. According to the collision grinding type ultrafine smashing device, materials of which the particle size difference is relatively large can be smashed at a time, the condition that a pulverizer needs a sieving net is improved, the smashing efficiency and the smashing effect are improved, and the production efficiency for producing ultrafine powder can be improved.

Owner:TAIYUAN UNIV OF TECH

Apparatus for discharging material from a mill

A pulp lifter for installation in a grinding mill has a leading edge and a trailing edge with respect to rotation of the mill and comprises a first wall bounding an interior space and a second wall dividing the interior space into first and second sections. The first wall includes a leading edge wall formed with an inlet opening providing access to the second section and an inner edge wall formed with an outlet opening for discharge of slurry from the second section. The second wall includes a guide that extends substantially from an outer end of the leading edge wall to a trailing end of the inner edge wall, and the first section of the interior space is open at the trailing edge of the pulp lifter.

Owner:METSO OUTOTEC (FINLAND) OY

Preparation method of special low-density grinding ball for cement grinding mill

The invention relates to a preparation method of a special low-density grinding ball for a cement grinding mill. The preparation method comprises the steps of with bauxite, alumina powder and the like as main raw materials and chromium oxide, zirconium oxide, calcium oxide, magnesium oxide, ferric oxide, manganese oxide, titanium oxide, silicon dioxide and the like as modified raw materials, adding alumina sol, silica sol and metal salt into slurry at a grinding stage; molding by rolling, isostatic pressing or machine pressing to obtain a green body; and calcining after drying the green body to obtain the low-density grinding ball. By virtue of scientific proportion design, strict process control and unique calcining system, the special low-density grinding ball disclosed by the invention is low in cost, excellent in wear resistance, lower in power load as comparison with a high-density metal grinding body, suitable for substituting a metal grinding body in cement grinding, iron ore grinding and gold ore grinding and capable of reducing the electric consumption for grinding by 30-50%.

Owner:UNIV OF JINAN

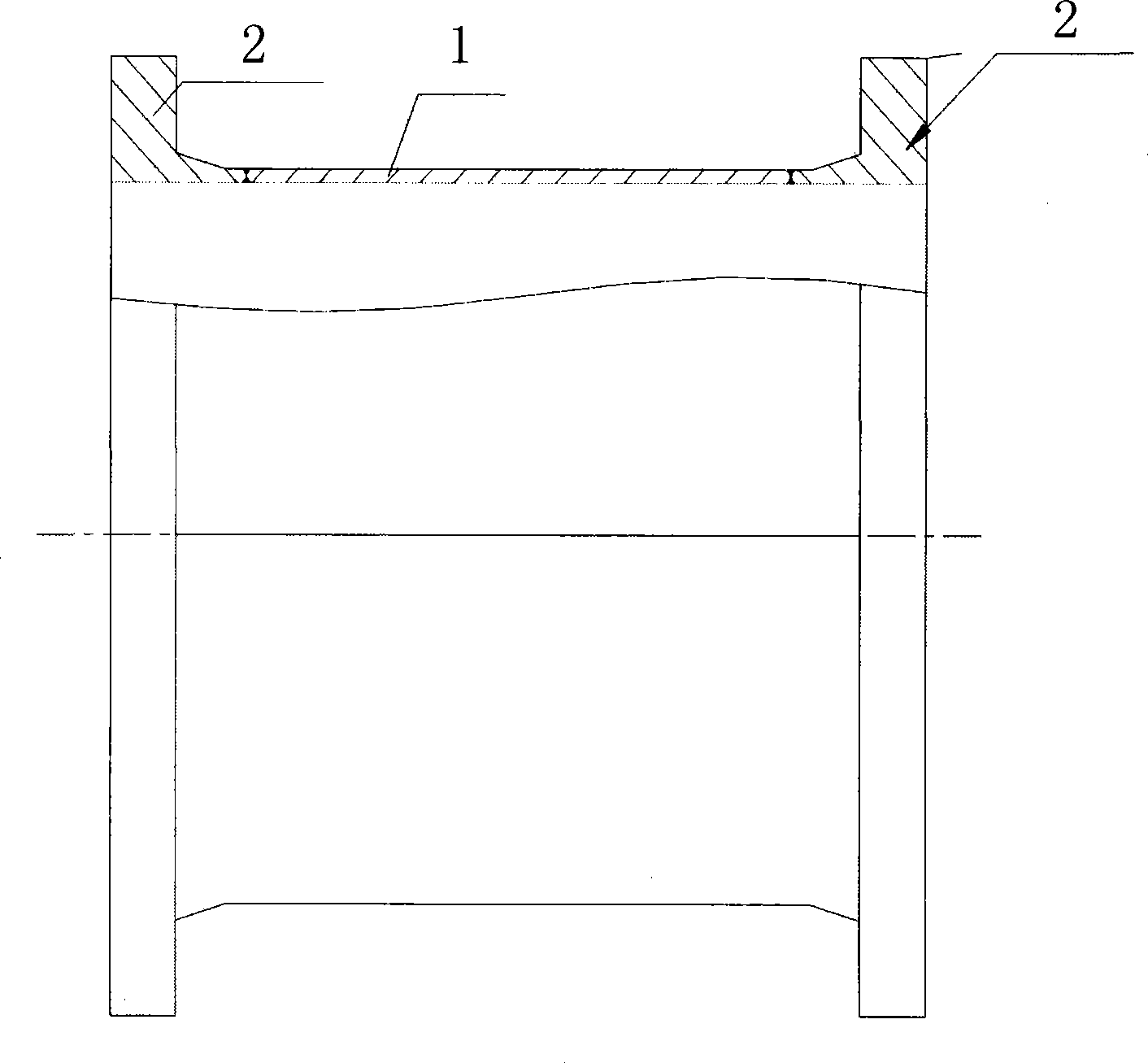

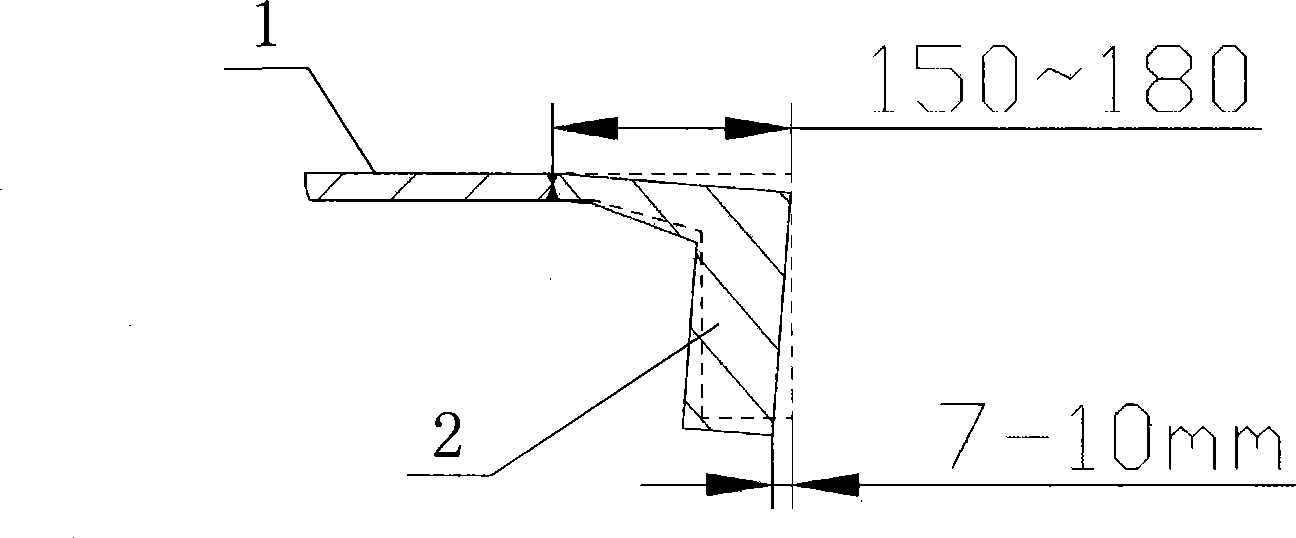

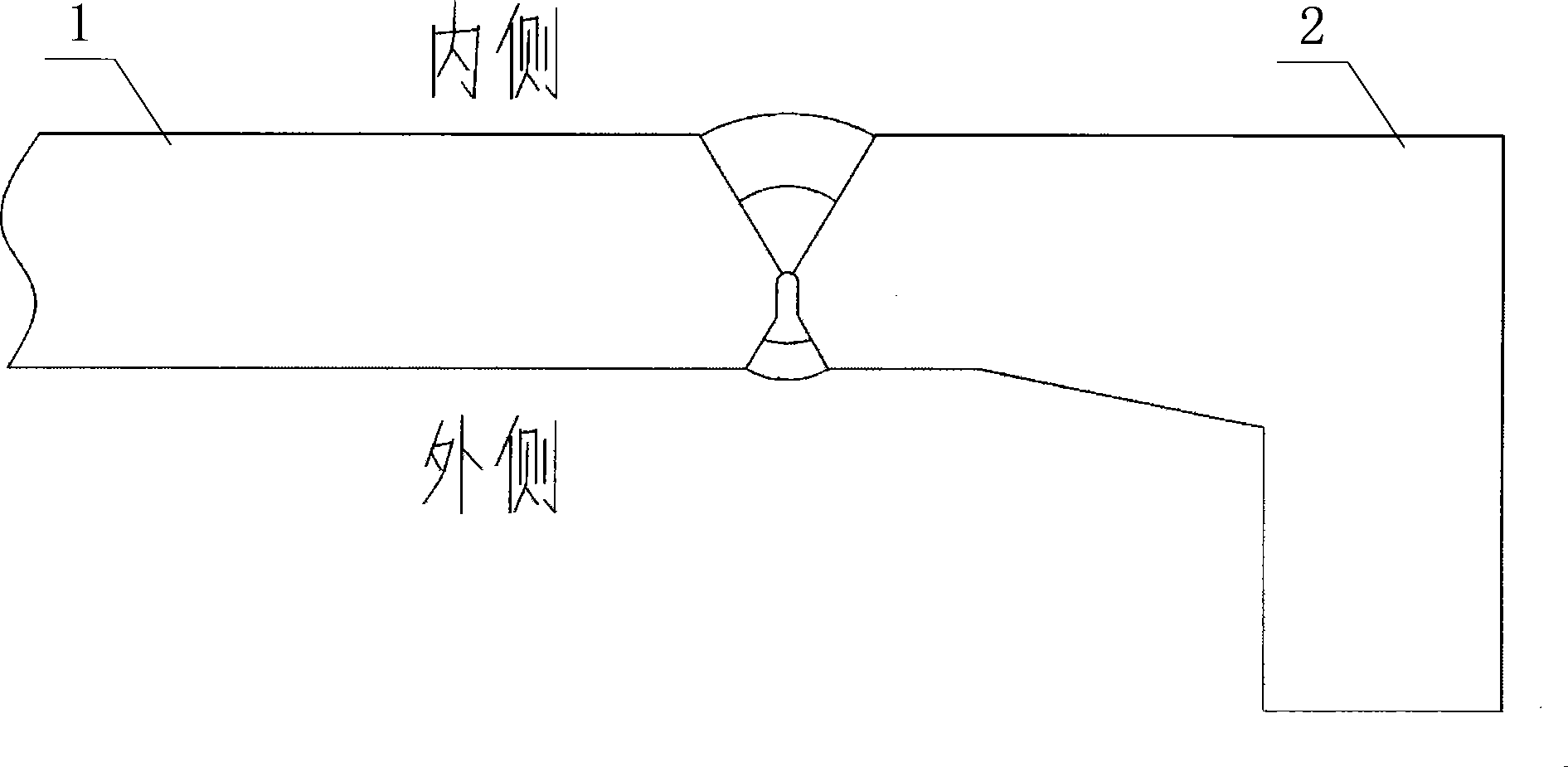

Control method of large-sized mining grinding mill end flange welding deformation

InactiveCN101412157AReduce welding distortionReduce workloadWelding/cutting auxillary devicesArc welding apparatusButt jointPart type

The invention provides a method for controlling welding deformation of an end flange of a large-sized mine mill, which comprises two contents: 1. the groove butt joint mode and welding mode before the end flange(2) and a barrel body(1) are welded are improved, the groove butt joint mode has three types which are small inner part and big outer part type, equal inner part and outer part type and big inner part and small outer part type respectively, and the welding mode correspondingly has three types; and 2. the correction is performed after welding, which has obvious effect, and the product quality is effectively ensured. By utilizing one welding stress to overcome the other welding stress, the welding stresses inside and outside the connecting part between the barrel body and the flange are balanced (i.e. the transverse shrinkages of the welding seams are the same); in the end, when the barrel body of the mill is subjected to relief annealing, the welding stresses inside and outside the barrel body of the mill are equally released, so that the method has the advantages of having little welding deformation, reducing the work load of correction after welding, improving the production efficiency, shortening the production cycle and lowering the production cost.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Chinese herbal medicine smashing and grinding machine

InactiveCN106964440AEvenly crushedImprove crushing efficiencyGrain treatmentsElectric machineryEngineering

The invention discloses a traditional Chinese medicine crushing and grinding machine, which comprises a base, a supporting foot, a grinding tank, a tank cover, a movable buckle, a crushing blade and a hammer; the top of the tank cover is fixedly connected with a casing, and the top of the casing is fixedly connected with a The top plate, the bottom of the top plate is provided with a crankshaft, the outer wall of the casing is fixedly connected with a second motor, the crankshaft is rotatably connected with a connecting rod, the bottom of the crankshaft is provided with a sliding plate, and the lower surface of the sliding plate is fixedly connected with the first motor, the first The shaft extension end of the motor is fixedly connected with a rotating shaft, the side wall of the rotating shaft is fixedly connected with a crushing blade, and the end of the rotating shaft is fixedly connected with a hammer, the crushing blade and the crushing blade are used to crush the Chinese medicinal materials, and the crushing blades are used to stir the Chinese medicinal materials; To a certain extent, the Chinese herbal medicine particles pass through the sieve hole and reach the bottom of the grinding tank, and the hammer head beats the Chinese herbal medicine up and down in the grinding tank while rotating, and crushes and grinds the Chinese herbal medicine; the invention can crush and grind the Chinese herbal medicine at the same time .

Owner:合肥红蔻健康管理有限公司

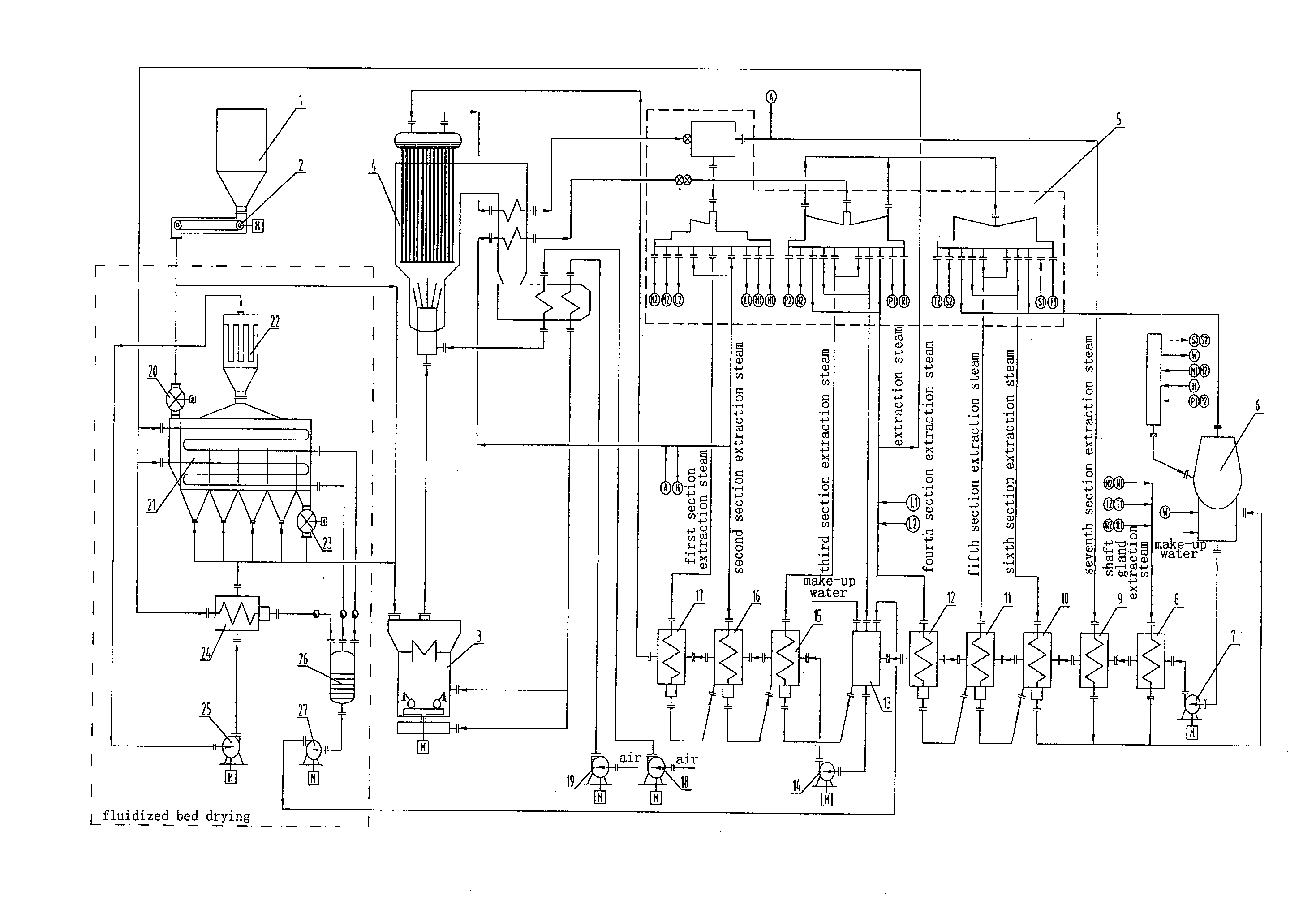

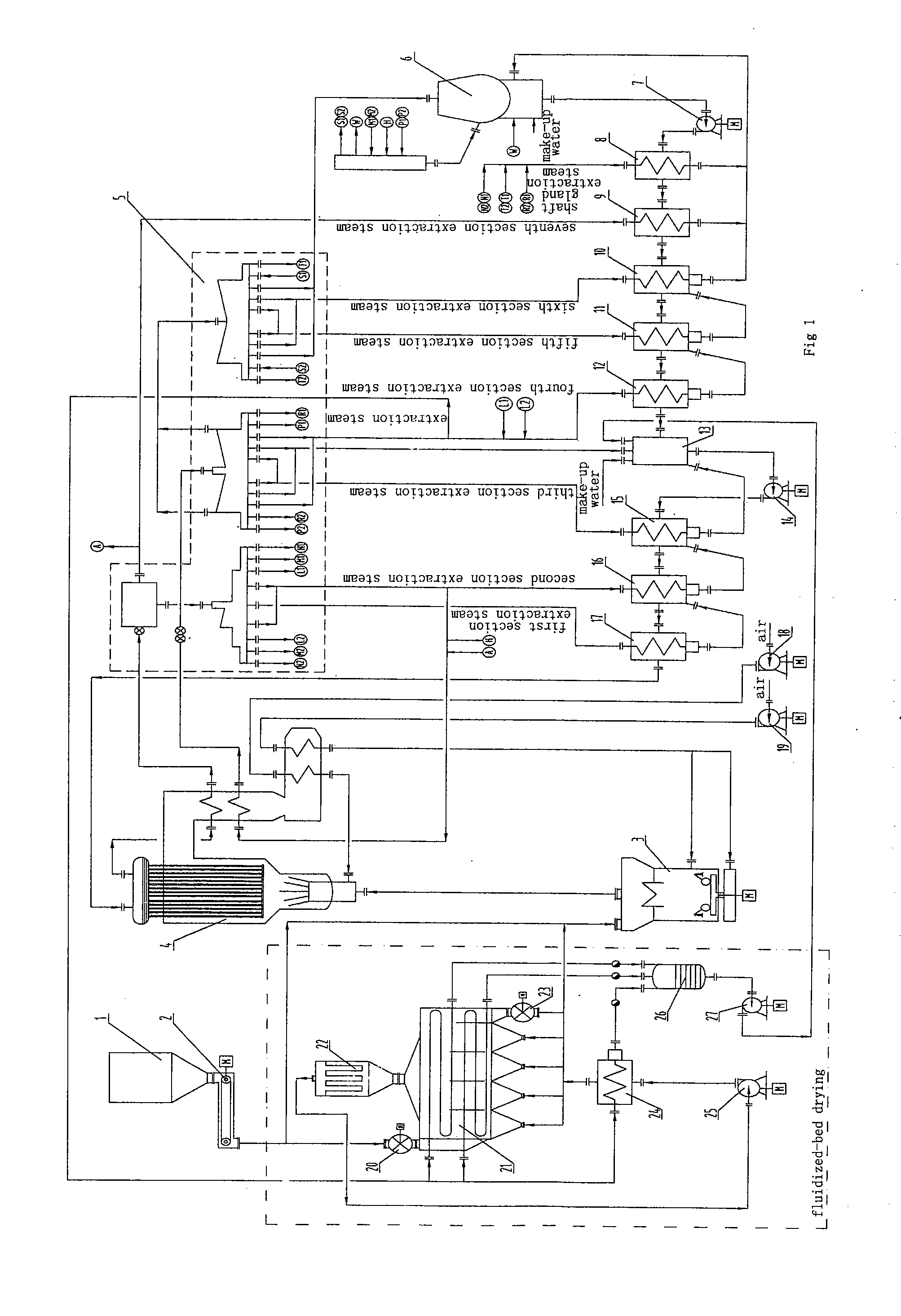

Process for reducing coal consumption in coal fired power plant with fluidized-bed drying

ActiveUS20110220744A1Reduce coal consumptionRemarkable effectFuel feeding arrangementsDrying solid materials with heatFluidized bed dryingProcess engineering

The present invention relates to a process for reducing coal consumption in coal fired plant with fluidized-bed drying, namely a fluidized-bed drying system is provided between a coal powder bunker as well as a weighing belt and a coal grinding mill of the prior coal fired boiler generating set, and superheated steam which has done partial work is extracted from an steam turbine and used as a drying medium, moisture contained in the coal powder is evaporated with sensible heat and latent heat of the superheated steam, water resulted from the condensation of the superheated steam is fed into a deaerator of the steam turbine via a condensate pump for recirculation. The present invention has advantages of reducing coal consumption and saving coal, recovering residual heat, reducing emission of carbon dioxide and adopting to the national industrial policy on energy saving and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com