Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

468results about How to "Evenly crushed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

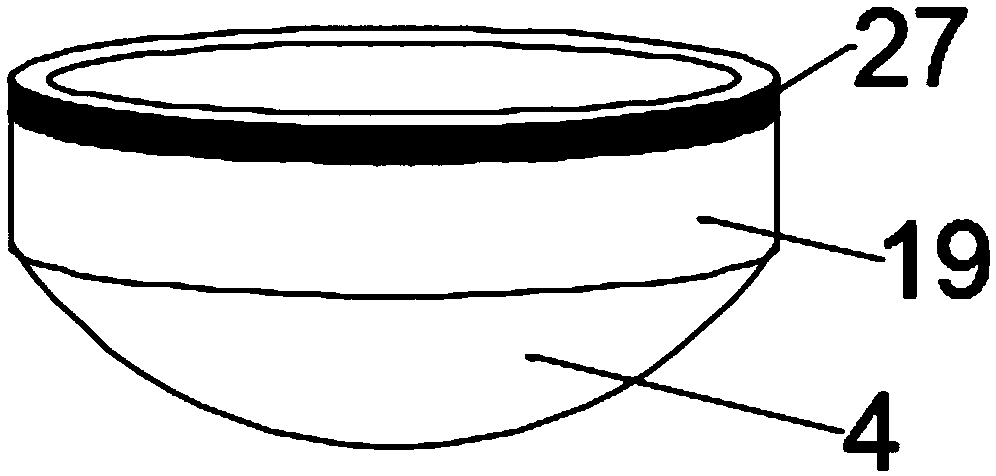

Preparation method of soybean milk

ActiveCN104798890AIncrease concentrationNot easy to agglomerateBeverage vesselsMilk substitutesWater vaporDry bean

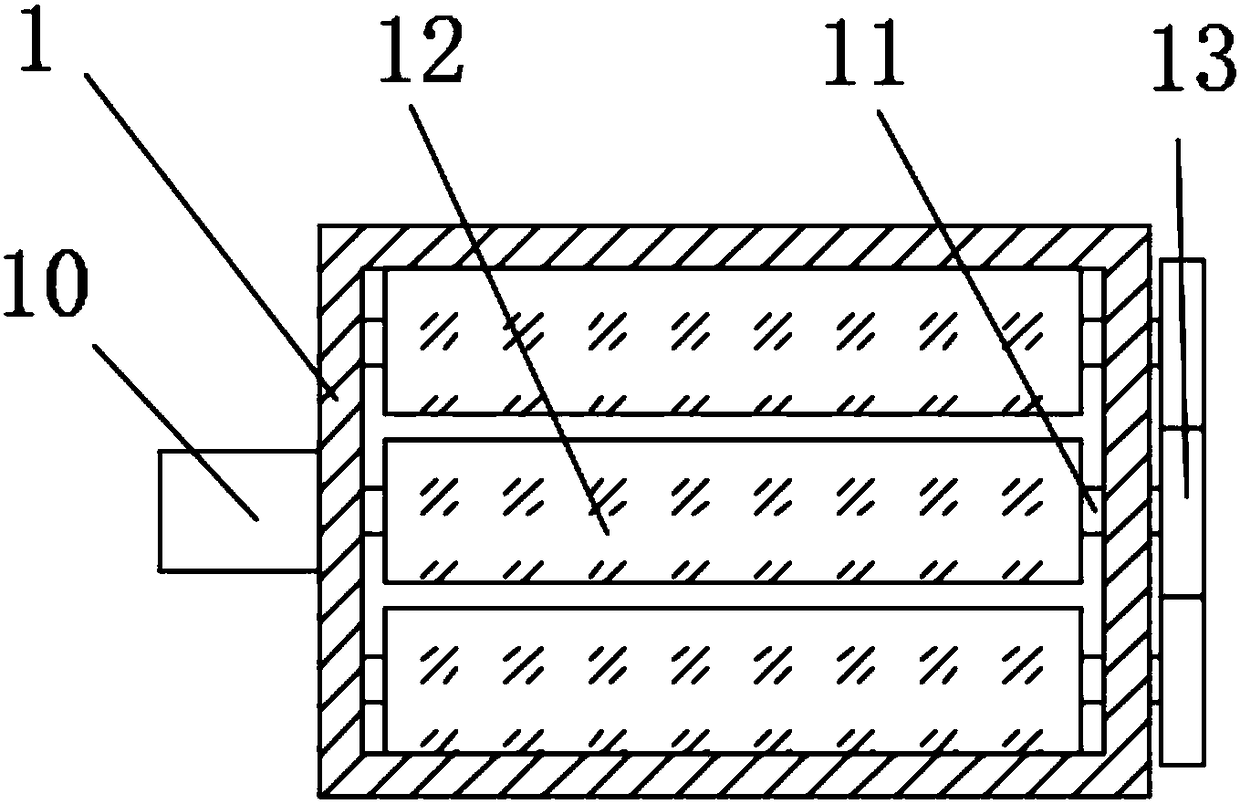

The invention relates to a preparation method of soybean milk. The preparation method at least comprises the following stages: (a), flour preparation stage: providing a crushing container, a heating element for heating the crushing container and a crushing device, directly heating the crushing container through the heating element, so as to ensure that the temperature of the crushing container is increased to 70-90 DEG C, adding dried beans into the crushing container, crushing the dried beans into bean flour through the crushing device, and ensuring that lipase and beany flavor of the bean flour are removed in the crushing container at ambient temperature; (b), preparation and boiling stage: adding water to the bean flour, so as to prepare the bean flour into pulp, and heating and boiling the pulp till the pulp is well cooked. By adopting the air temperature inside the crushing device, crushing, lipase removal and beany flavor removal are performed at the same time, protein can keep invariant, beany flavor can be effectively removed, and crushing the beans into bean flour firstly can greatly enhance the crushing fineness, so that the soybean milk concentration can be effectively enhanced. In addition, water vapor can be evaporated during crushing of the beans in the high-temperature environment, the bean flour is not easy to agglomerate, and the crushing effect is good.

Owner:JOYOUNG CO LTD

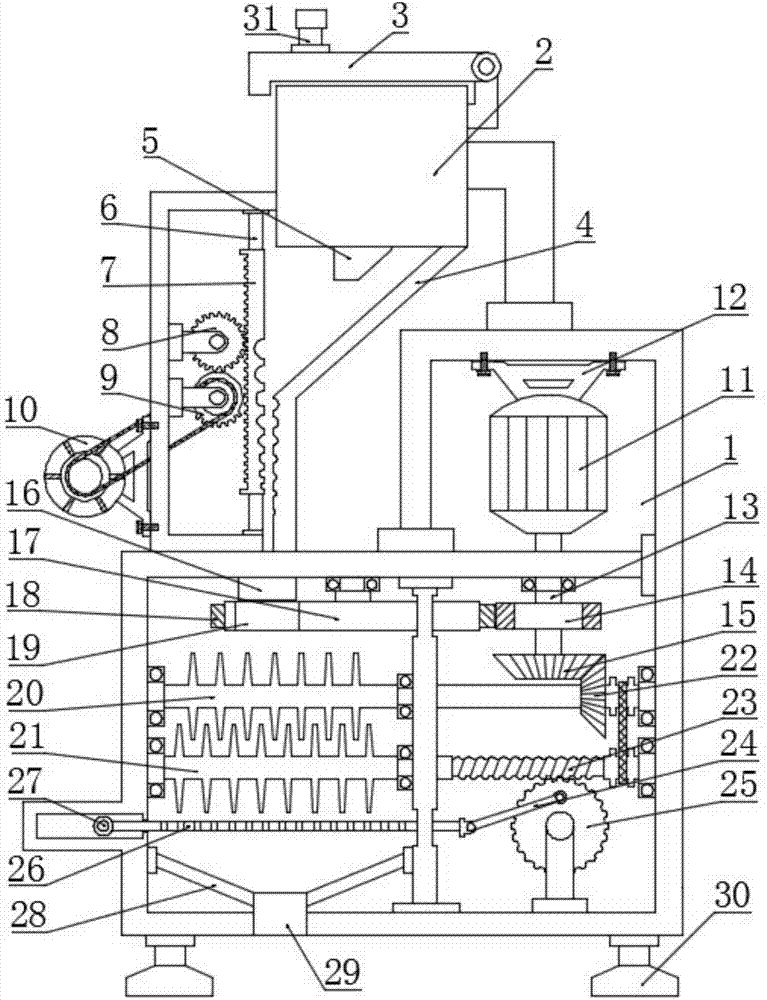

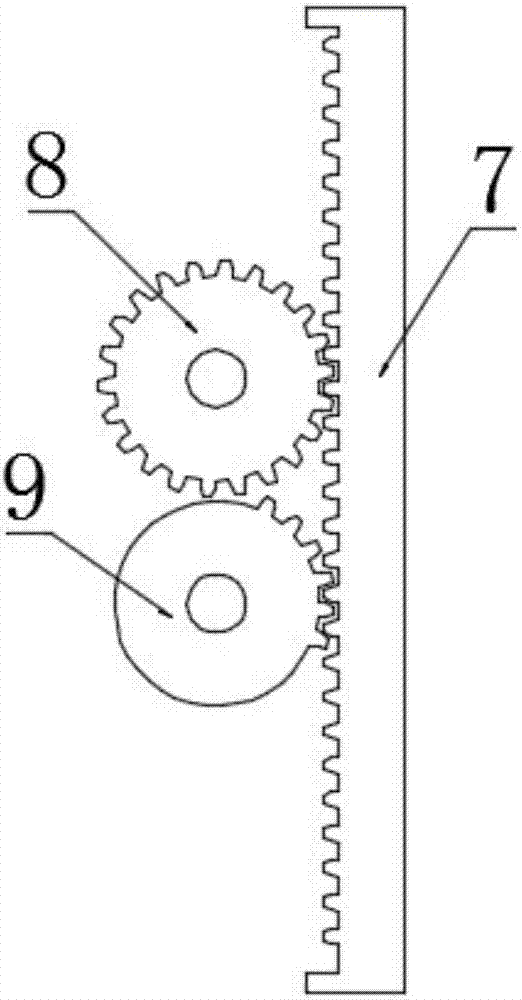

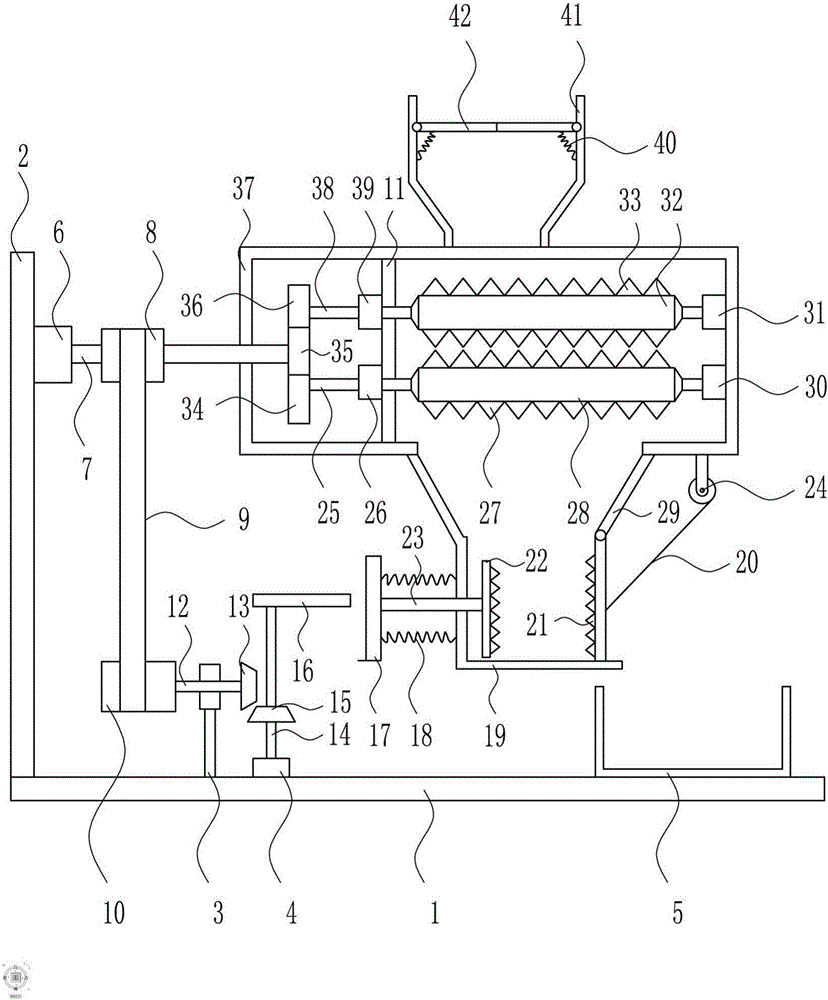

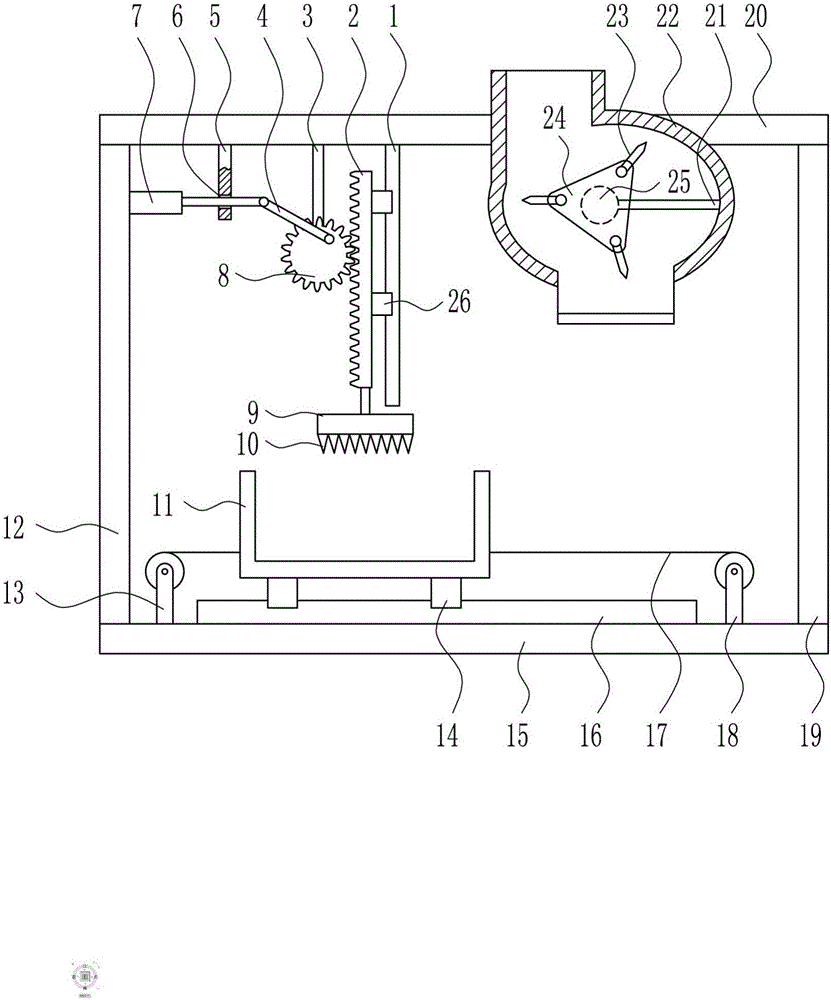

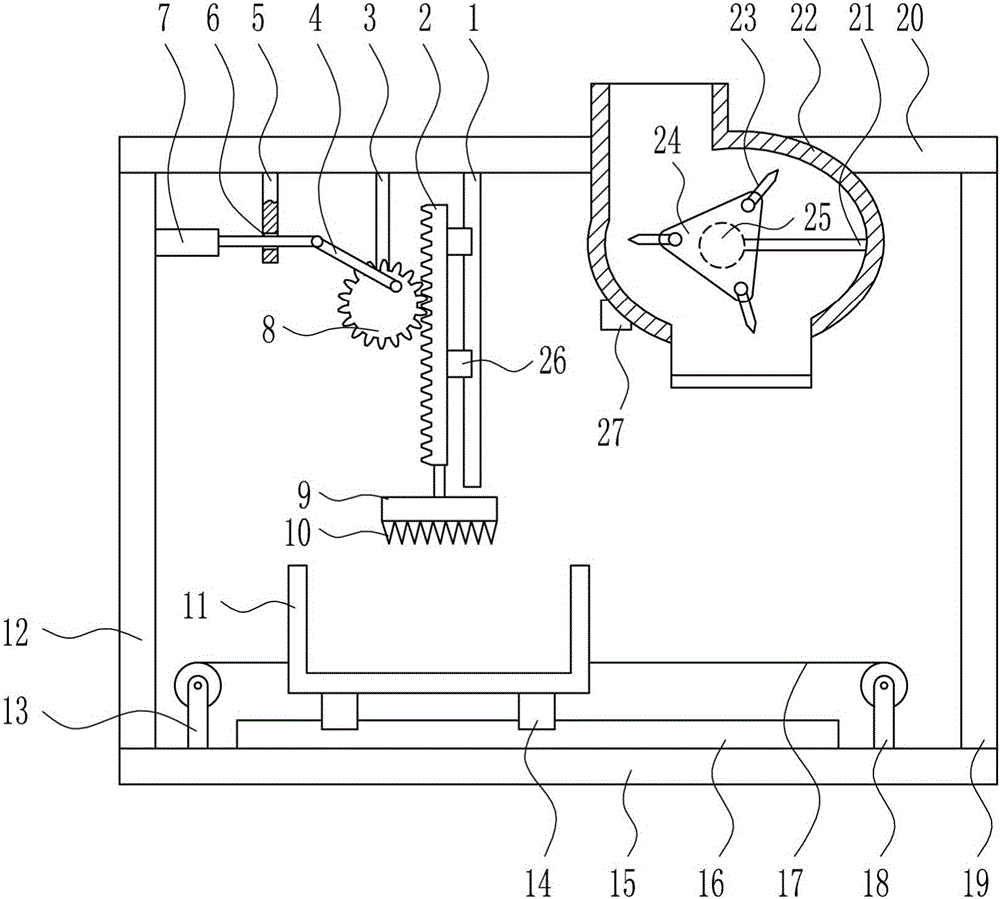

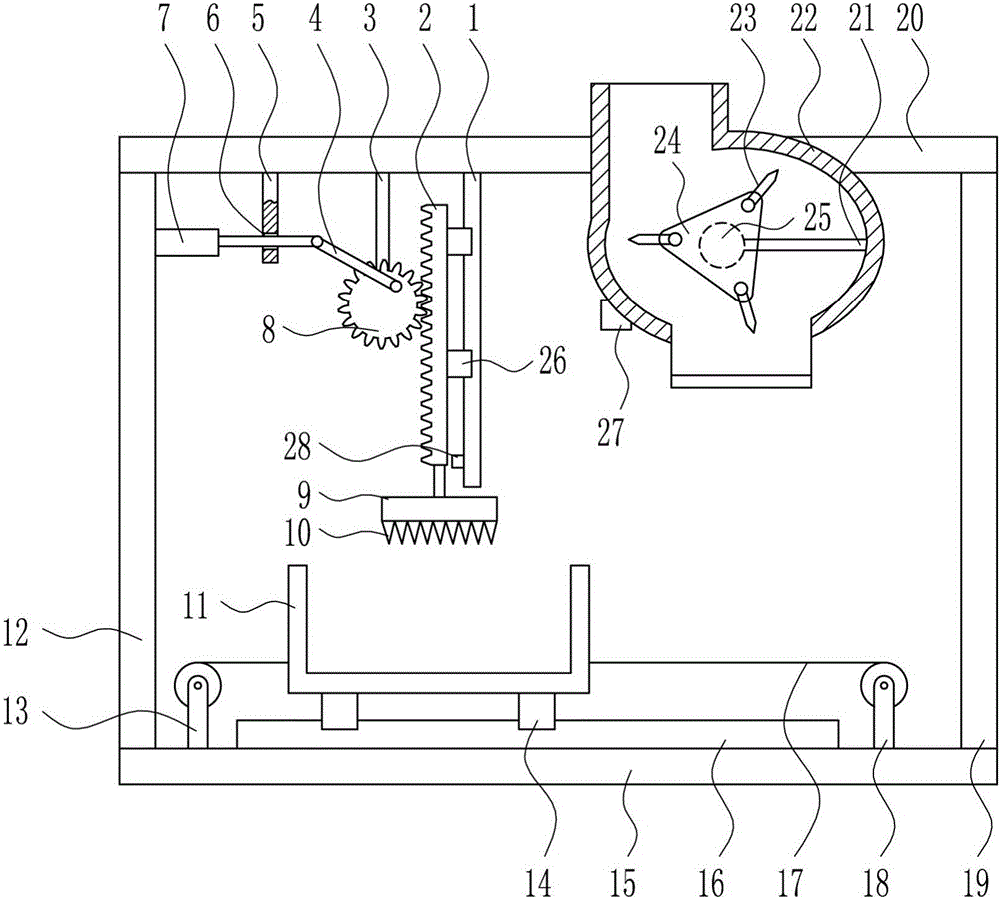

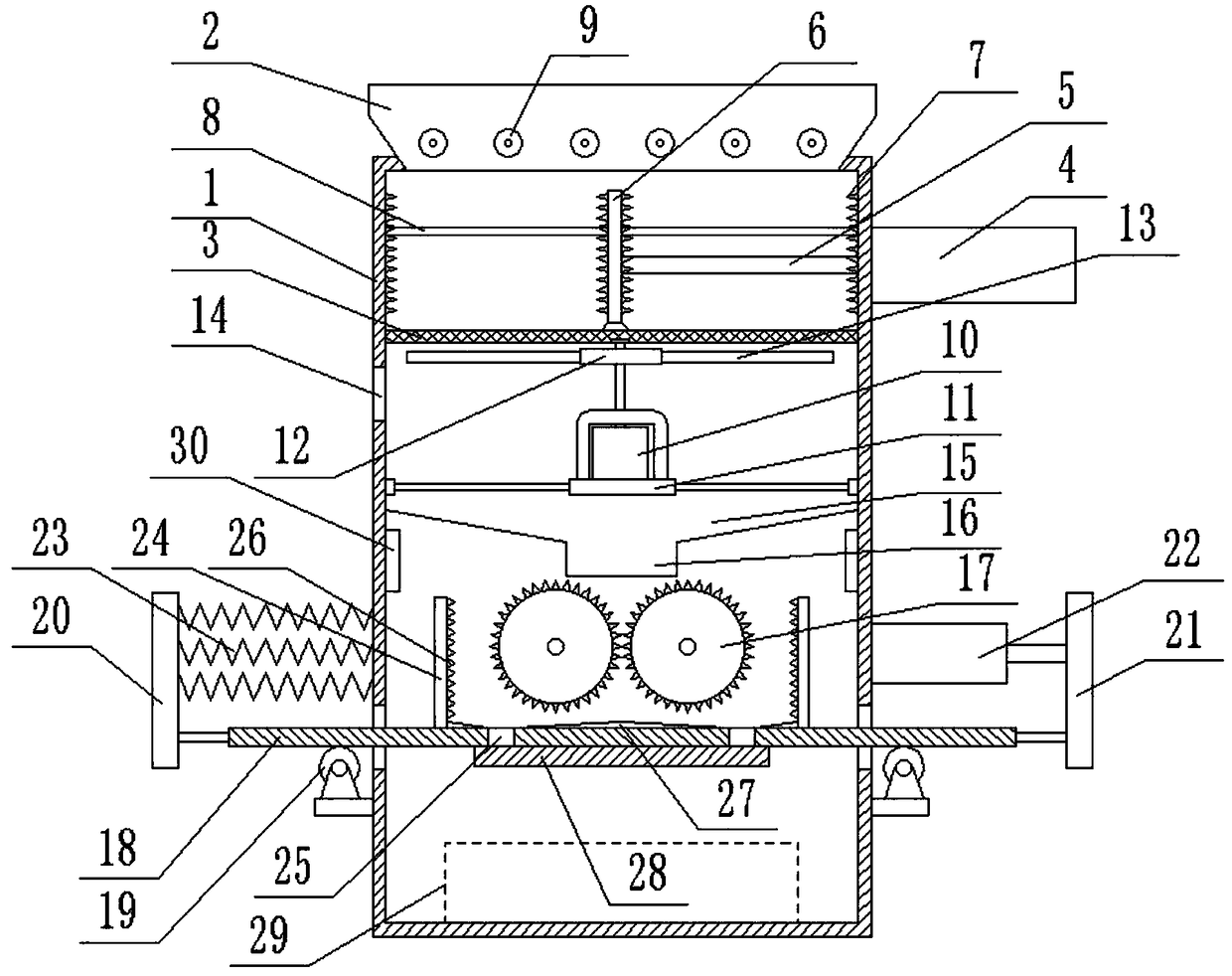

Efficient feed smashing device

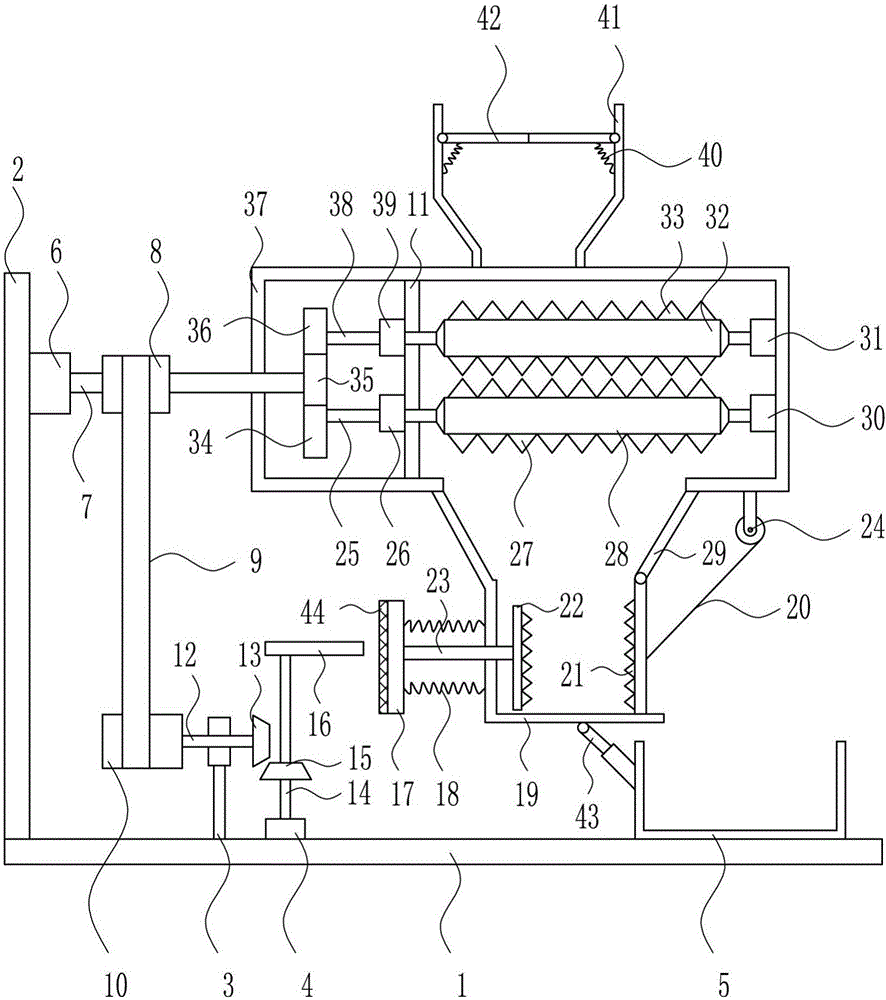

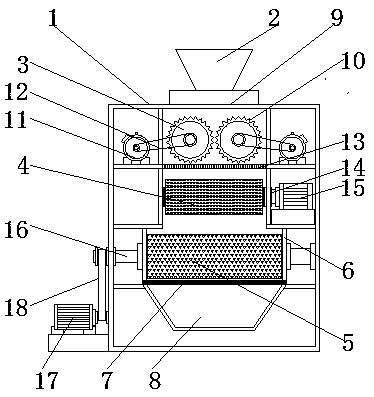

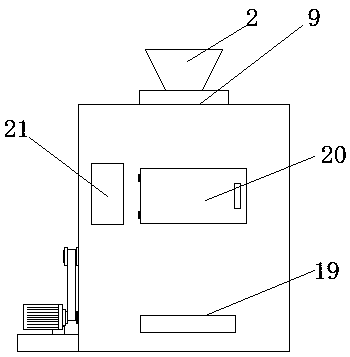

The invention discloses an efficient feed smashing device. A fixed plate is fixedly connected to the left side of the upper end of a device body, a movable tooth plate externally sleeves the fixed plate, the left end of the movable tooth plate is in engaged connection to a free gear, and the movable tooth plate is in intermittent engaged to an incomplete gear; the incomplete gear is in intermittent engaged to the free gear; a first bevel gear is arranged at the lower end of a transmission gear, and is fixedly connected to the lower end of a driving shaft, a second bevel gear is fixedly connected to a first smashing roller, and the right end of the first smashing roller is in belt transmission to a driving worm; the lower end of the driving worm is in engaged connection to a worm wheel, the edge of the worm wheel is hinged to a connecting rod, and the end portion of the connecting rod is hinged to a sieve plate. By means of a matching action of the free gear, the incomplete gear and the movable tooth plate, the movable tooth plate reciprocates up and down to grind the feed movably, and the ground feed is then secondarily smashed by the first smashing roller and the second smashing roller and the smashed feed is finally vibrated in a reciprocating manner to fall off on the sieve plate. The device is simple and applicable in structure, the feed smashing quality and efficiency are improved greatly, and the labor force is saved.

Owner:常园争

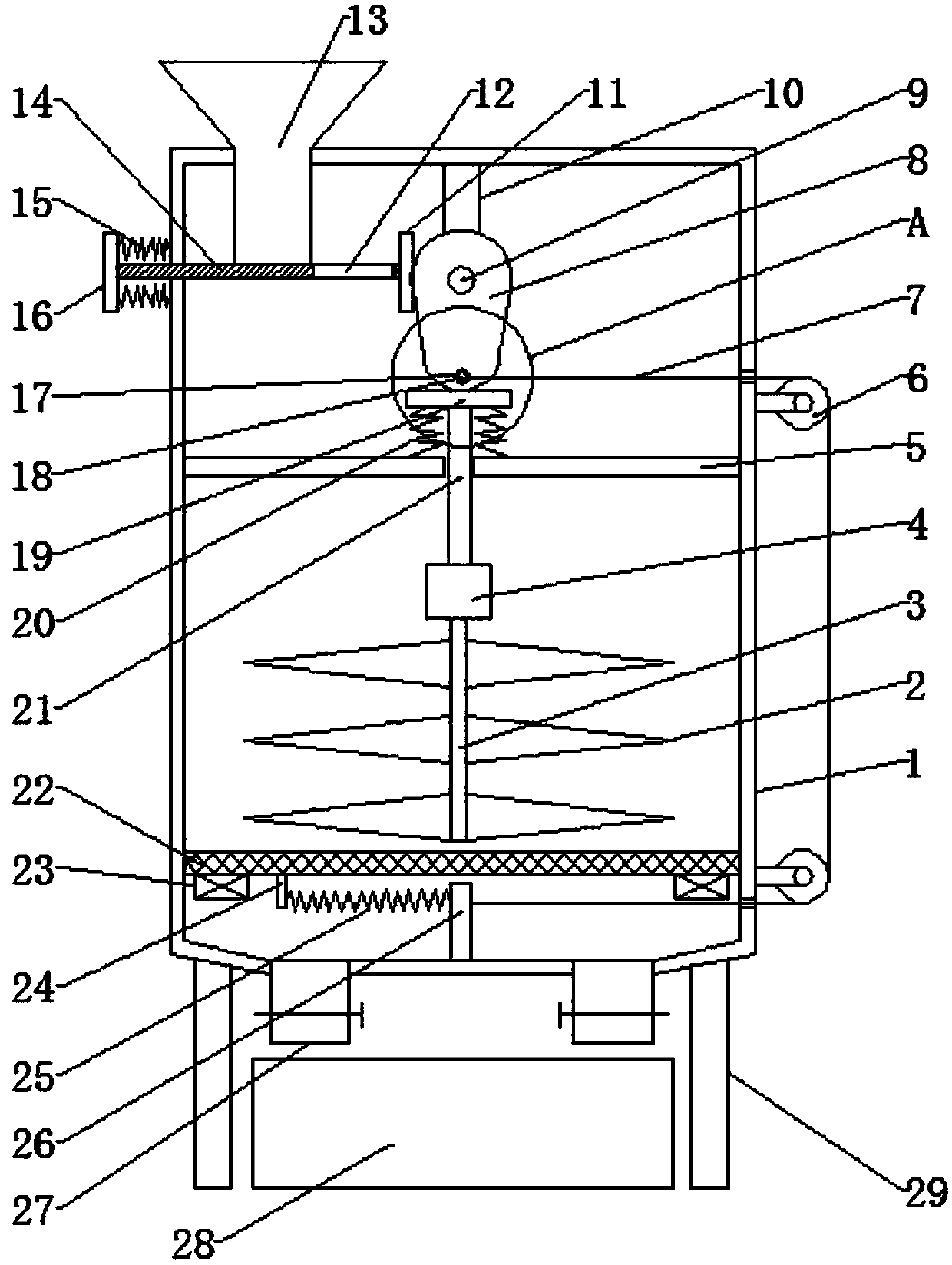

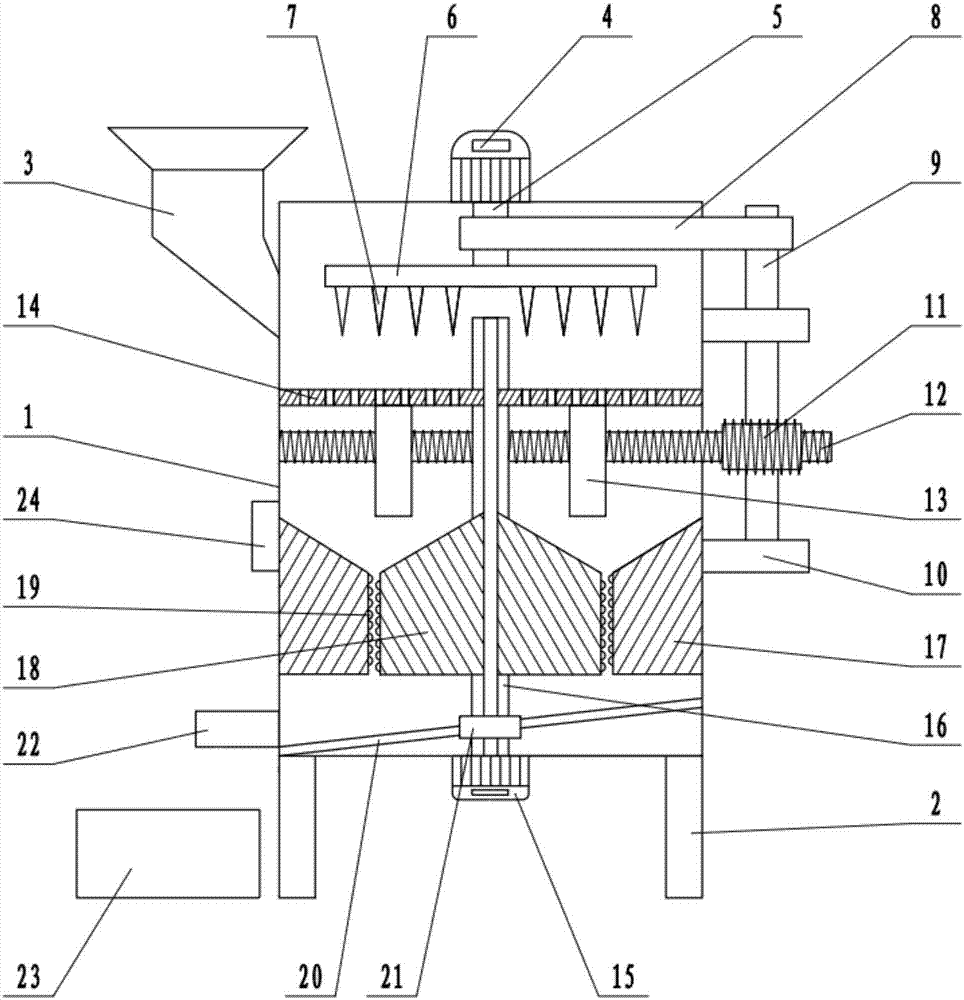

Animal husbandry feed efficient crushing apparatus

The present invention discloses an animal husbandry feed efficient crushing apparatus, which comprises a box, a collecting frame, a material inlet hopper, a material blocking plate, a first fixing plate, a first spring, a second fixing plate, a cam, a first motor, a third fixing plate, a support rod, a second motor, a rotation shaft, a crushing cutter blade, a second spring, a sieve mesh, a pushing plate, a third spring, a pulling rope, a bush and a pin shaft. According to the present invention, by arranging the cam, the material blocking plate and the first spring, the intermittent and uniform material feeding is achieved by matching the components, and the incomplete and insufficient crushing caused by the excessive material feeding at one time is avoided; by arranging the second spring,the second motor and the rotation shaft, the crushing cutter blade is driven to rotate and continuously move up and down by matching the components, such that the crushing is complete, uniform and rapid, and the working efficiency is improved; and by arranging the pushing plate, the third spring and the pulling rope, the blocking plate continuously pushes the feed to the material outlets at bothsides by matching the components, such that the material discharging is convenient, and the clogging is avoided.

Owner:罗娟

Environment-friendly smashing and recovering device for waste electronic products

The invention discloses an environment-friendly smashing and recovering device for waste electronic products. The environment-friendly smashing and recovering device comprises a barrel, a screen, a crank, a second motor, a shaft bushing, a connection rod, a movable rod, a smashing plate, a ring-shaped baffle, a tank, a first motor, a threaded rod, a first sleeve, a connection rod, a pressing plate, an air outlet pipe, an air inlet pipe, a rotating sleeve, a third motor, a first gear and a second gear. Through arrangement of the second motor, the crank, the connection rod, the movable rod, thesmashing plate and the ring-shaped baffle, intermittent discharging is achieved, sufficient and uniform smashing is ensured, and the smashing efficiency is improved; through arrangement of the third motor, the first gear, the second gear and the rotating sleeve, rotating smashing is carried out, fertilizer can be ground, the smashing speed is further increased, and the smashing efficiency is improved; and through arrangement of the first motor, the threaded rod, the connection rod and the pressing plate, smashed electronic products are automatically compressed, then a door is opened, the compressed products are pushed out, and discharging and collection are facilitated.

Owner:童拓

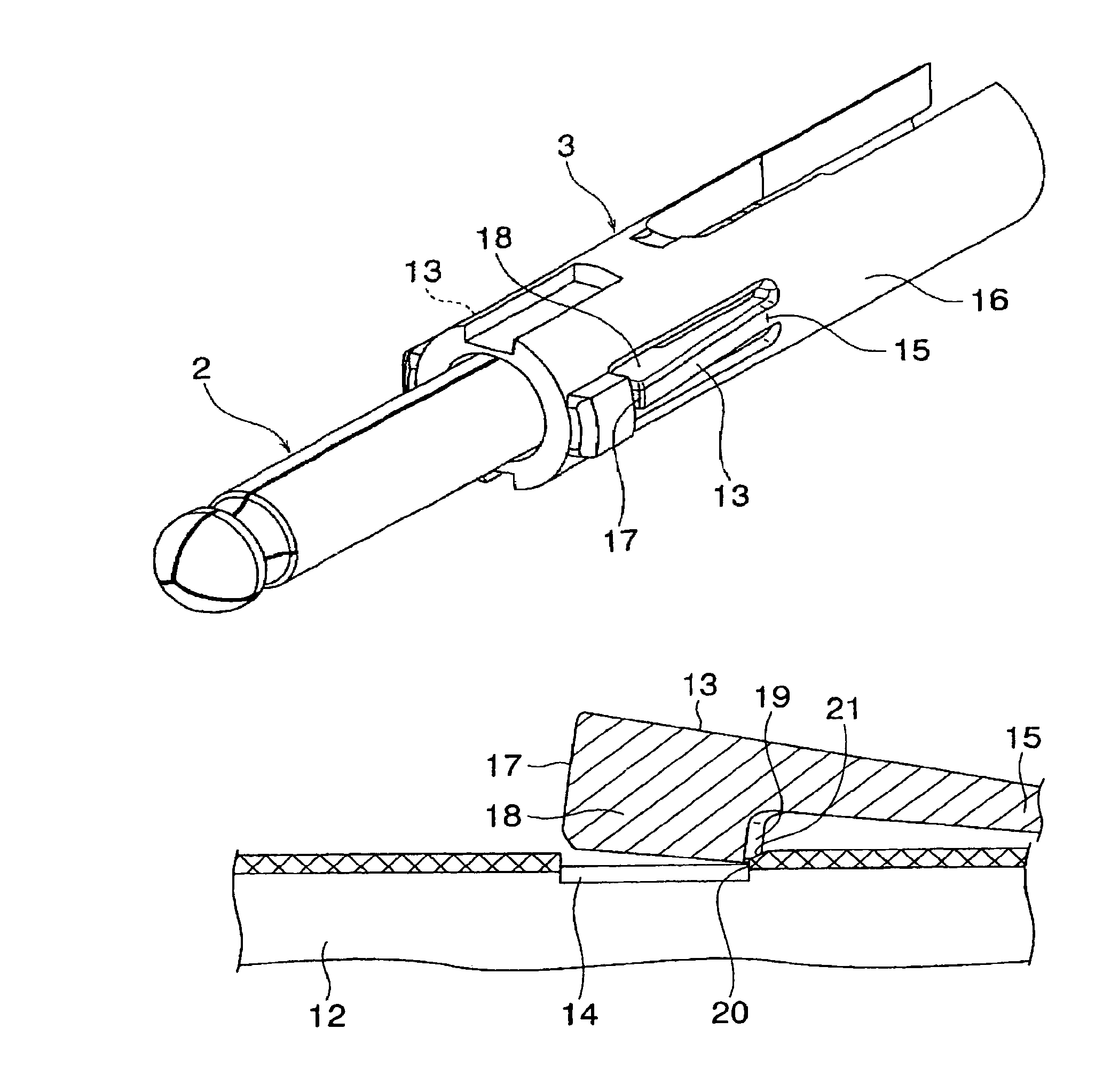

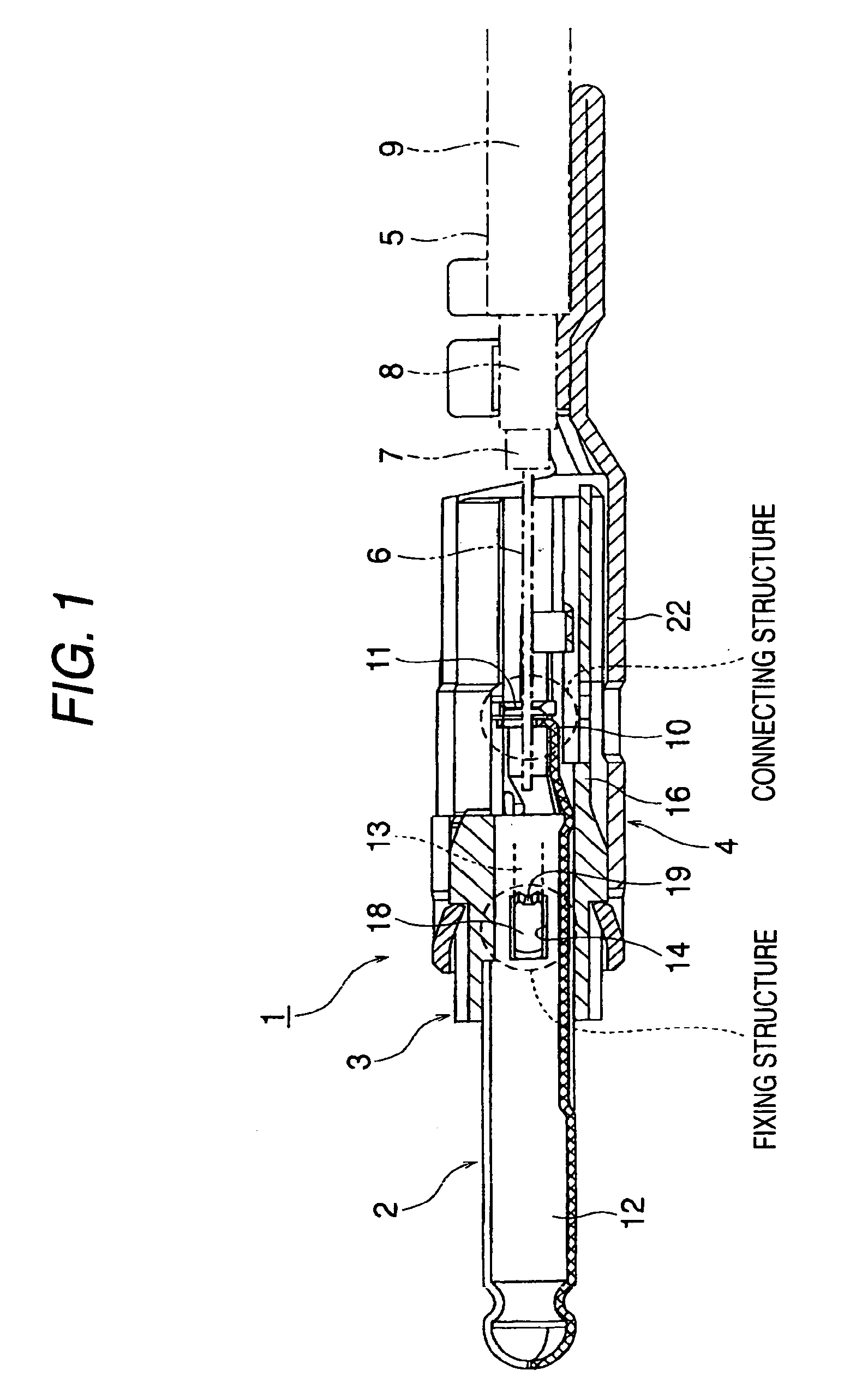

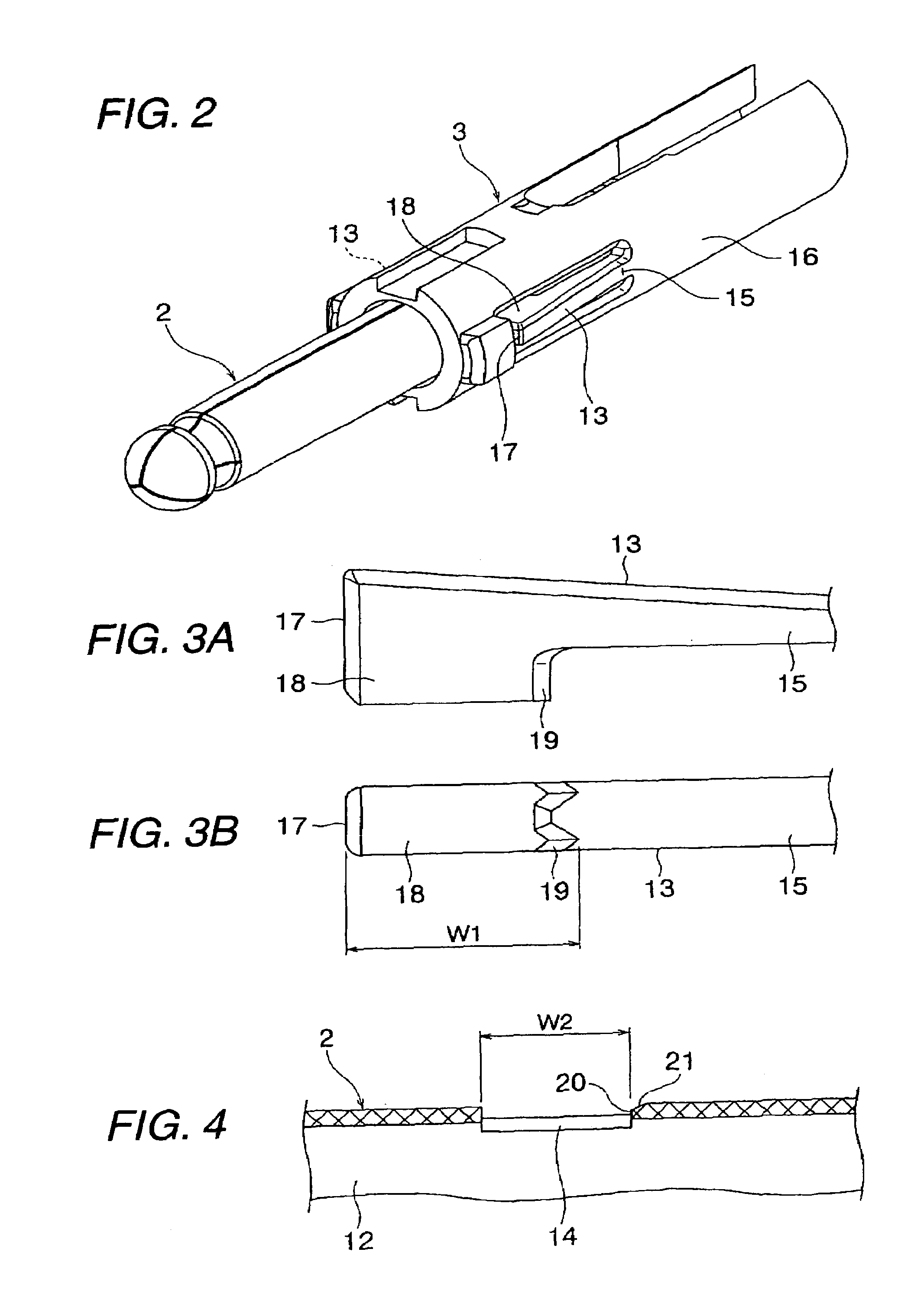

Connector having an improved locking structure

ActiveUS7226320B2Improve connection reliabilityImprove productivitySubstation/switching arrangement detailsTwo pole connectionsEngineeringCantilever

A connector includes an electrically conductive plug provided with a retaining hole, and an insulating housing that has a retaining member shaped in a cantilever beam. The retaining member has a retaining claw portion. The retaining claw portion has a projecting portion formed at a proximal end side of the retaining member. The projecting portion is crashed by an edge portion of the retaining hole when the retaining claw portion is engaged with the retaining hole.

Owner:YAZAKI CORP

Feed crushing and grinding equipment for animal husbandry

The invention discloses feed crushing and grinding equipment for animal husbandry, relates to the technical field of animal husbandry. The feed crushing and grinding equipment aims to solve the problem that an existing device is single in crushing mode. The feed crushing and grinding equipment comprises a box body, a first motor, a rotating shaft, crushing blades, a first screen, a grinding rollerand a second screen; an inner cavity of the box body is provided with the first screen and the second screen at intervals from top to bottom; crushing plates are arranged at the positions, located onthe two sides of the upper portion of the first screen, in the box body; first driving mechanism are arranged at the positions, located at the crushing plates, of the two outer walls of the box body;a movable block sleeves the outer side of a threaded rod; the grinding roller is arranged at the bottom of the movable block; and a brush strip is arranged at the top of the movable block. The feed crushing and grinding equipment has the advantages that the crushing plates and the driving mechanisms are arranged, so that a feed is pushed to the crushing blades, and therefore the crushing efficiency is improved, and crushing is more sufficient and uniform; and a forward and reverse rotation motor, the threaded rod, the movable block, the grinding roller and the brush strip are arranged, so that the feed on the second screen is further ground, meanwhile, meshes of the first screen are prevented from being blocked, and therefore the screening efficiency is improved.

Owner:吕桂英

Preparation method for coarse grain rice noodles

ActiveCN103271292AConserve waterReduce manufacturing costFood preparationEnergy consumptionWater content

The invention discloses a preparation method for coarse grain rice noodles. The preparation method comprises the following steps of (1) mixing raw materials of rice and coarse grains according 55-75% by weight of the rice and 25-45% by weight of the coarse grains; (2) adding water to adjust water content in powder so as to make the powder accounts for 35-45% of a total weight of rice pulp, adding a quality improver with an amount of 0.3% of the total weight of the rice pulp, stirring and mixing uniformly to form powder base, performing early steam by passing through steam to make the gelatinization degree of the powder base reach 70-80%; (3) putting the powder base into a rice machine to extrude noodles, re-steaming for 8-12 minutes, cutting the re-steamed rice noodles into sections; and (4) sending the cut rice noodles into a drying oven, drying the rice noodles, controlling the water content within 11-13 wt%, and cooling the dried rice noodles to obtain the coarse grain rice noodles. The preparation method can increase preparation efficiency of the rice noodles and at the same time, reduces water consumption and energy consumption in the preparation process.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

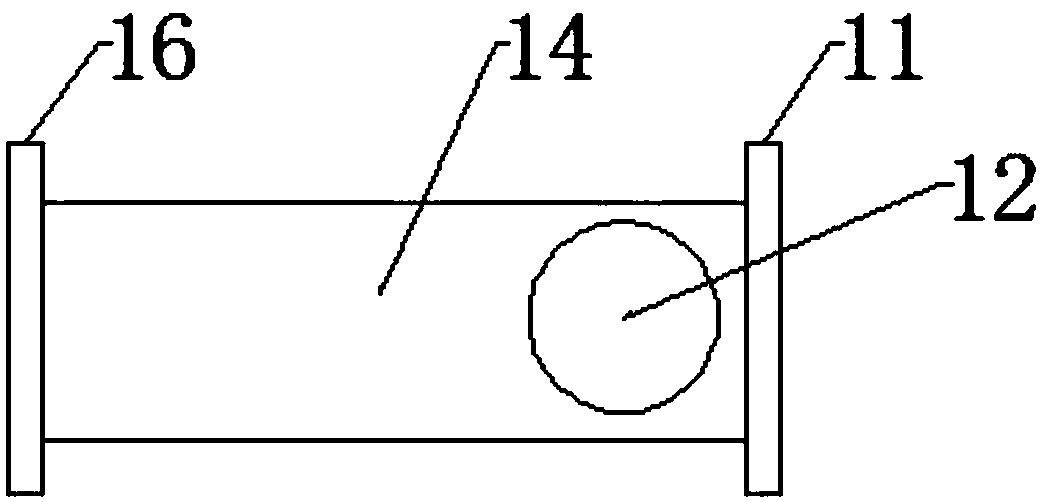

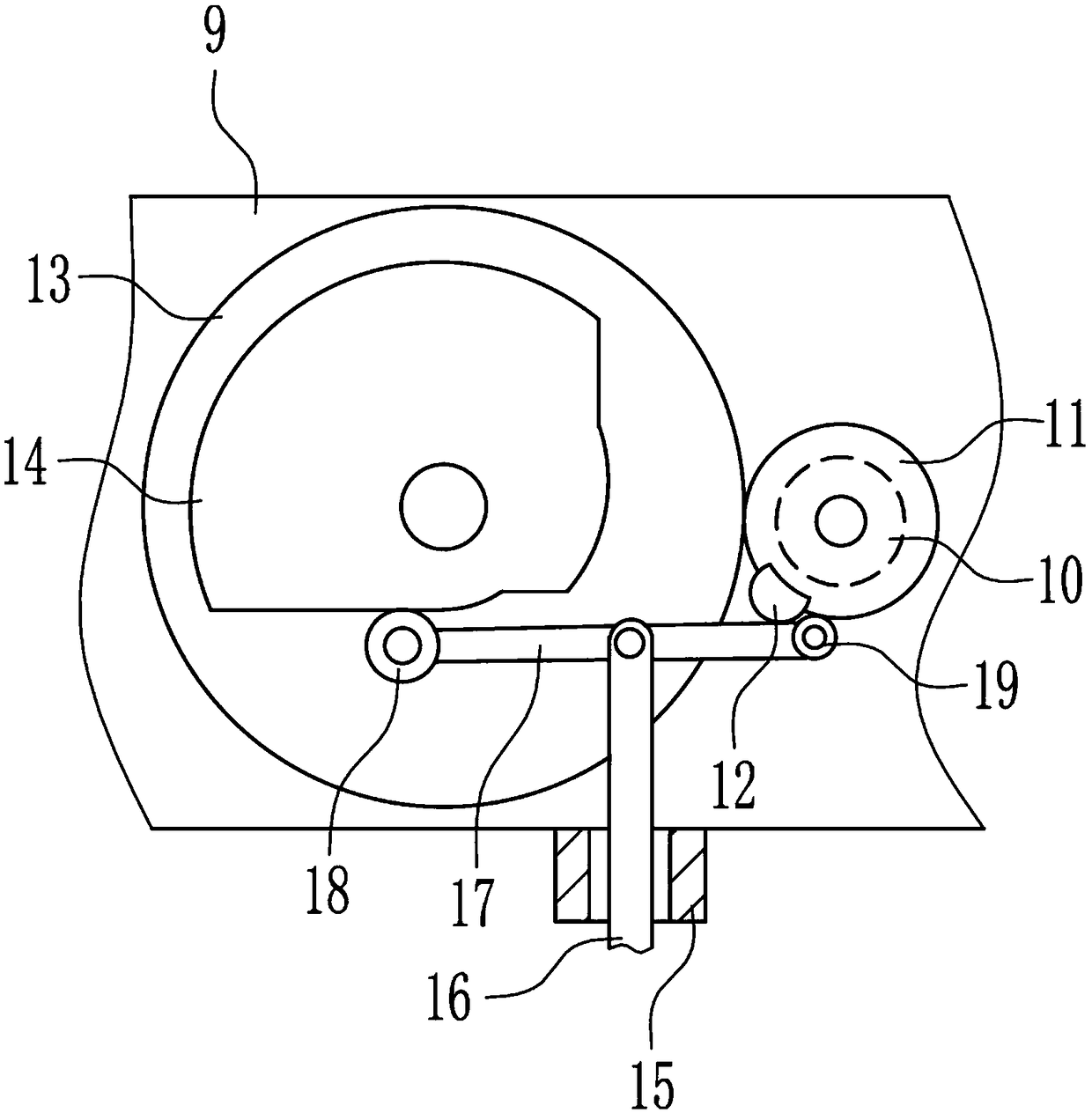

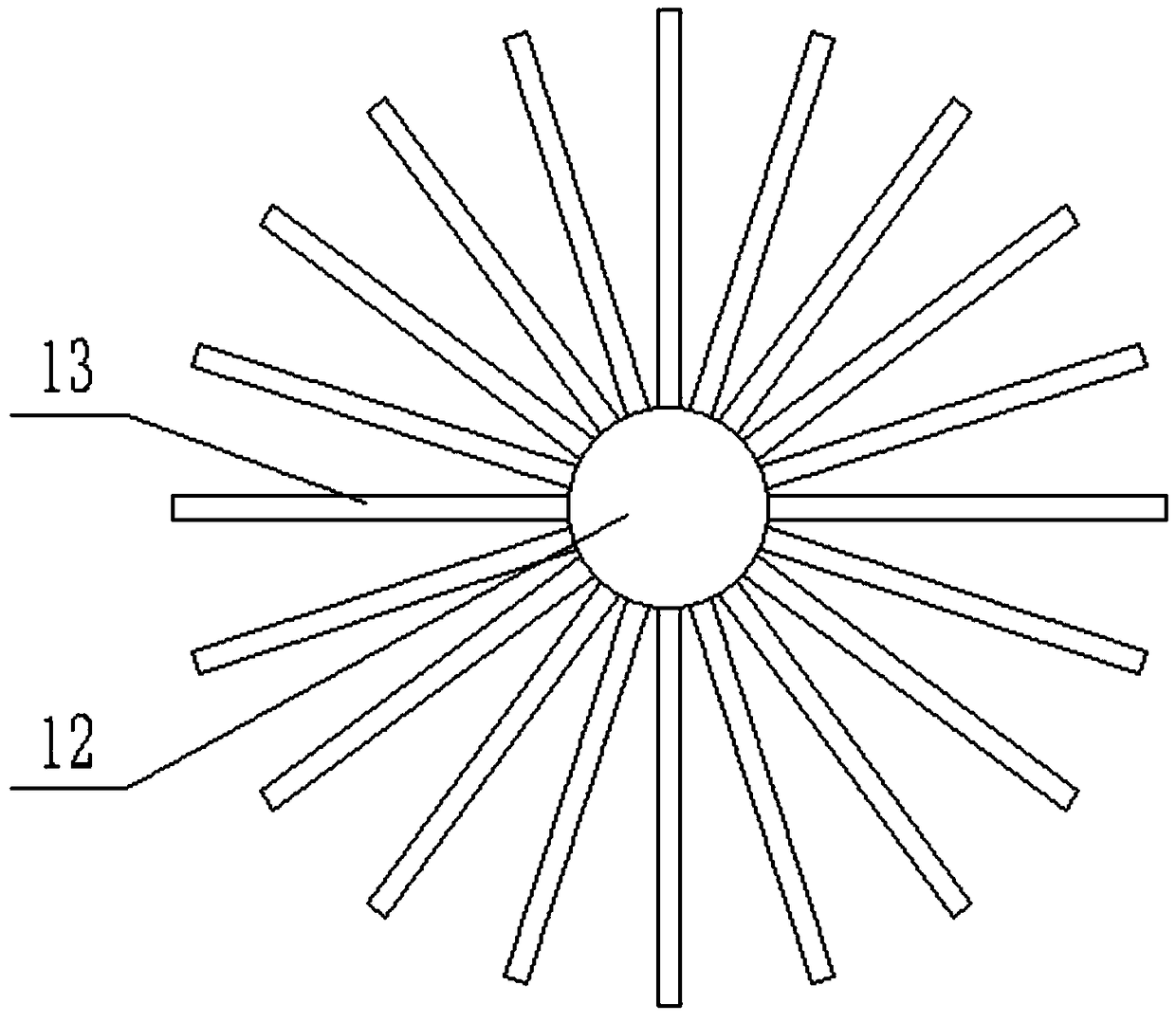

Pasture smashing device for animal husbandry

The invention relates to an animal husbandry smashing device, in particular to a pasture smashing device for animal husbandry. The pasture smashing device for animal husbandry is complete and uniform in smashing and simple in structure. In order to achieve the technical aim, the pasture smashing device for animal husbandry comprises a bottom plate, a left frame, a guide sleeve, a first bearing seat, a collecting frame, a motor, a first rotary shaft, a small belt wheel, a flat belt, a large belt wheel, an installing plate, a second rotary shaft, a first bevel gear, a third rotary shaft, a second bevel gear and the like. A smashing box is arranged over the bottom plate. The effects of being complete and uniform in smashing and simple in structure are achieved, the manufacturing cost is low, the structure is reasonable, and maintenance and repair are easy; use is convenient, investment of manpower and material resources is reduced, and cost is reduced.

Owner:邵鹏程

Construction waste recovering and powdering device

The invention discloses a construction waste recovering and powdering device. The construction waste recovering and powdering device comprises a machine frame outer shell, a hopper, a crushing roller,a permanent magnetic iron core, a grinding roller, a grinding barrel, filtering holes and a powder collection tank. The hopper is arranged on the upper portion of the machine frame outer shell. The crushing roller is arranged at the upper end of the interior of the machine frame outer shell. A first filtering screen is arranged at the bottom of the crushing roller and fixedly connected with the machine frame outer shell through nuts. The permanent magnetic iron core is arranged under the first filtering screen. The novel construction waste recovering and powdering device is provided with a crushing roller, construction waste is evenly crushed, the permanent magnetic iron core is arranged under the crushing roller and can be driven by rotation of a magnet motor to adsorb various metal irondoped in the construction waste, garbage and iron are separated, and the iron is recycled, resources are saved; and the construction waste recovering and powdering device is provided with the grinding roller, construction waste is further ground into powder, and the construction waste is recycled.

Owner:南京极佳物联网科技有限公司

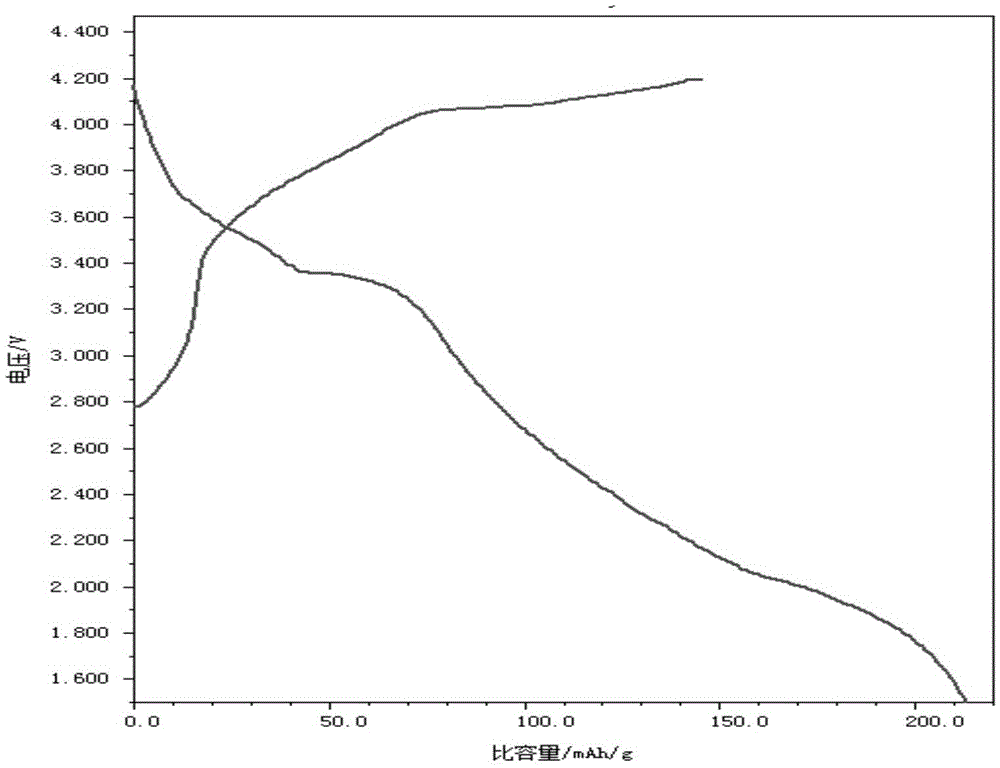

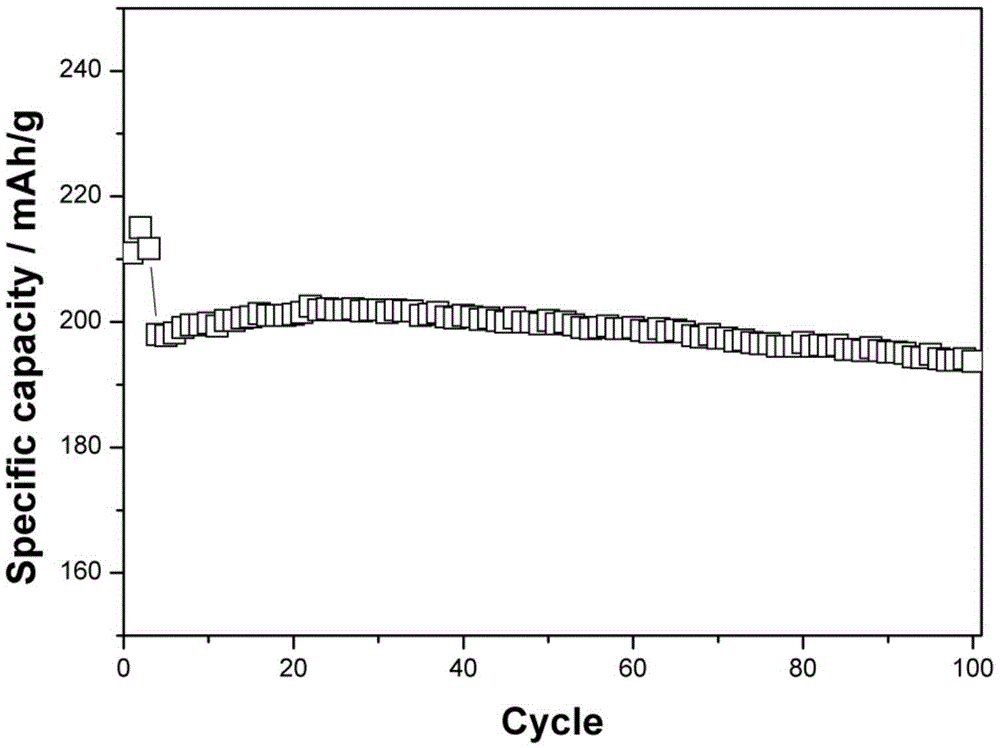

Method for preparing multielement positive pole material for sodium-ion batteries

InactiveCN105576229AEvenly crushedWell mixedCell electrodesSecondary cellsTunnel kilnSodium-ion battery

The invention relates to a method for preparing a multielement positive pole material for sodium-ion batteries and belongs to the technical field of lithium-ion batteries. The method for preparing the multielement positive pole material for the sodium-ion batteries comprises the following steps: (1) weighing a nickel source compound, a ferrum source compound, a manganese source compound and a lithium source compound according to the atomic ratio of x, y and z in a chemical formula, i.e., Na(0.67)Ni(x)Fe(y)Mn(1-x-y-z)O(2) of a predetermined synthesized product, and carrying out preliminary mixing on the raw materials, wherein each of x, y and z is not smaller than 0.01 and is smaller than 1; (2) feeding the preliminary-mixed raw materials to an airtight gas tank by using high-speed gas flow, and subjecting the raw materials to mutual collision and mutual friction inside the airtight gas tank, so as to obtain a crushed, mixed and activated precursor; (3) placing the precursor, which is crushed and activated by the high-speed gas flow, into a high-temperature tunnel kiln, heating the precursor to the temperature of 875 DEG C to 950 DEG C in an air or oxygen atmosphere, carrying out heat preservation for 15 hours to 20 hours, and carrying out cooling, thereby preparing a powder product of the multielement positive pole material Na(0.67)Ni(x)Fe(y)Mn(1-x-y-z)O(2). The method has the advantages that the process is simple, the cost is low, the production efficiency is high, the uniformity of the product is good, the electrochemical properties are excellent, and the like.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

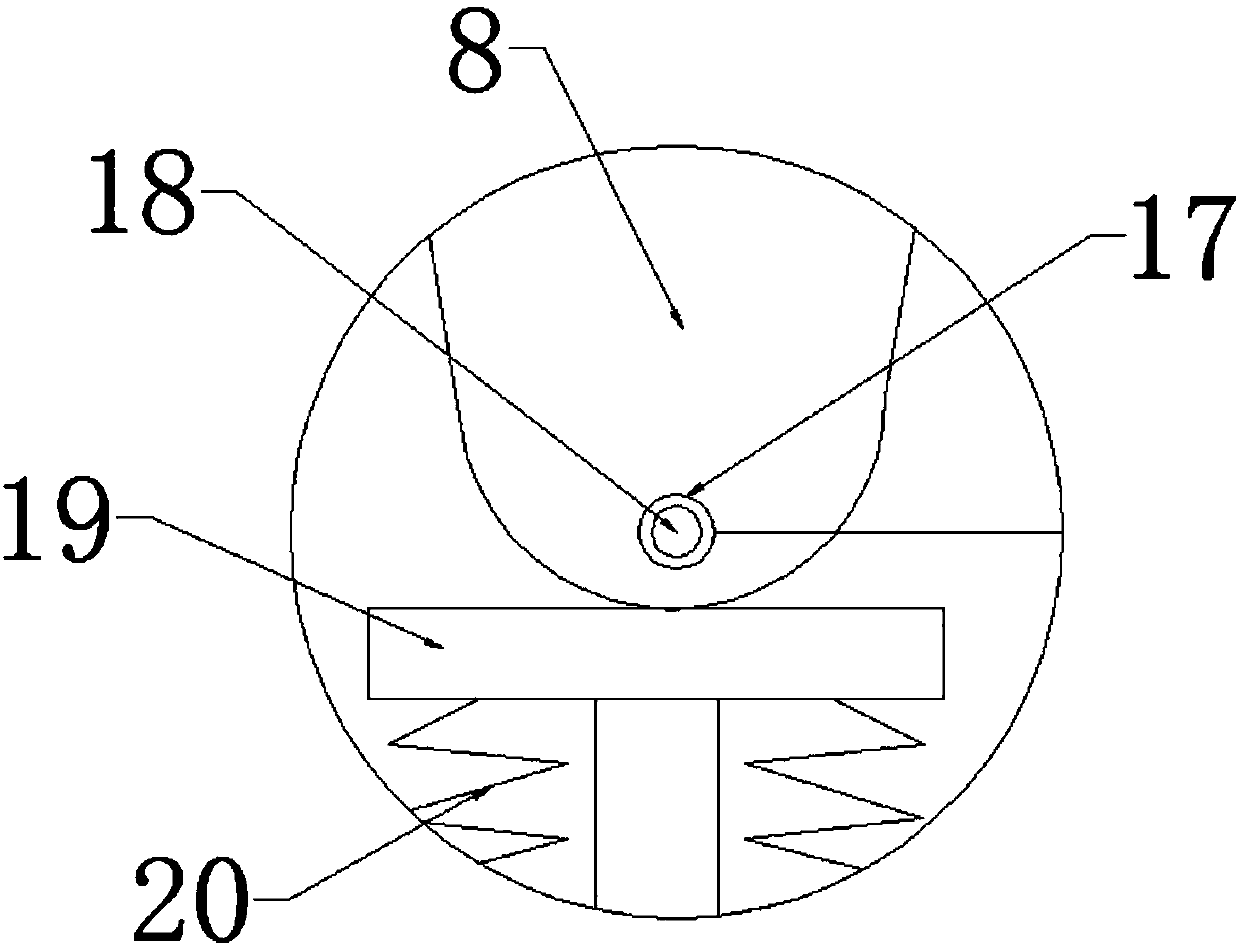

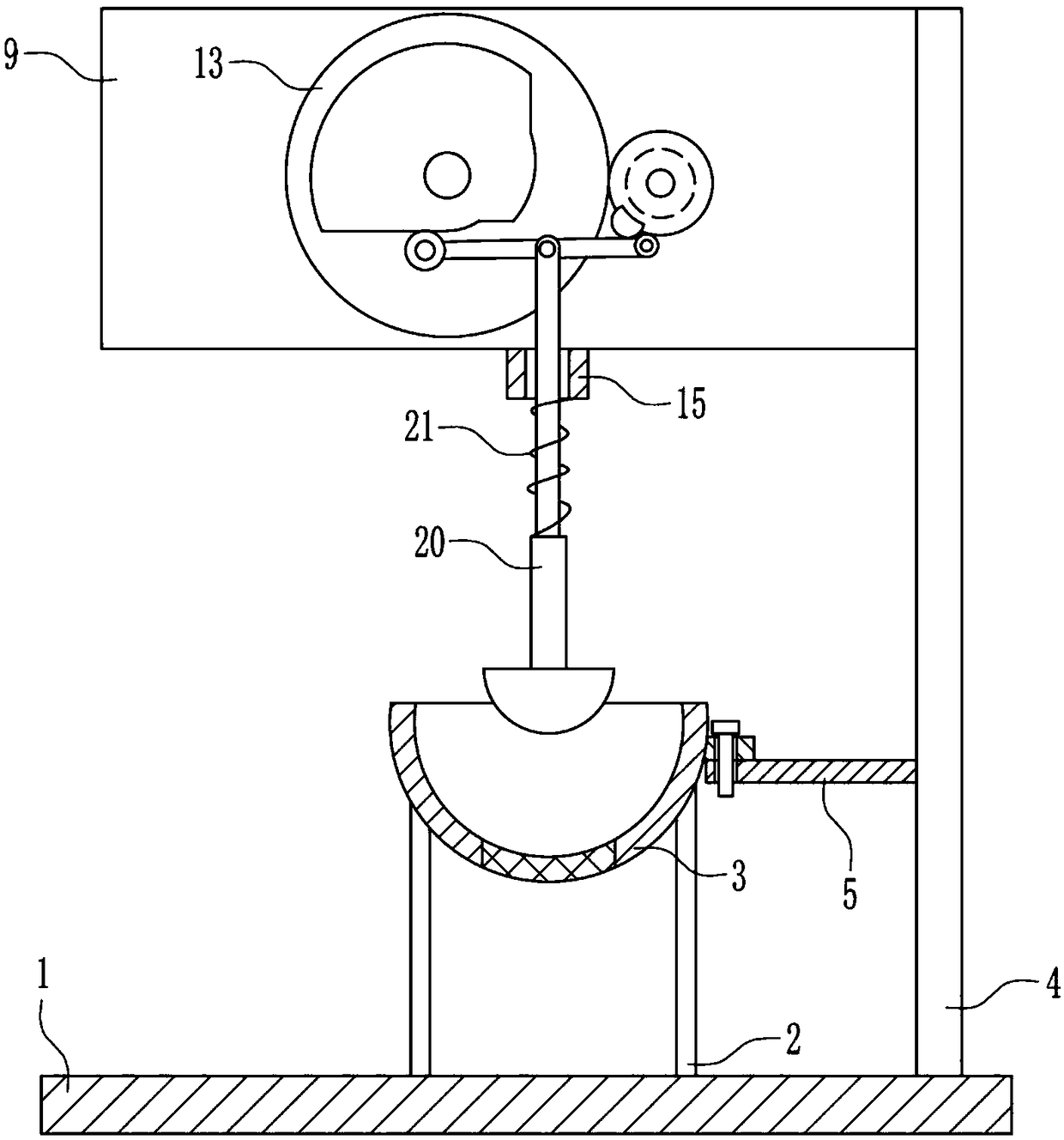

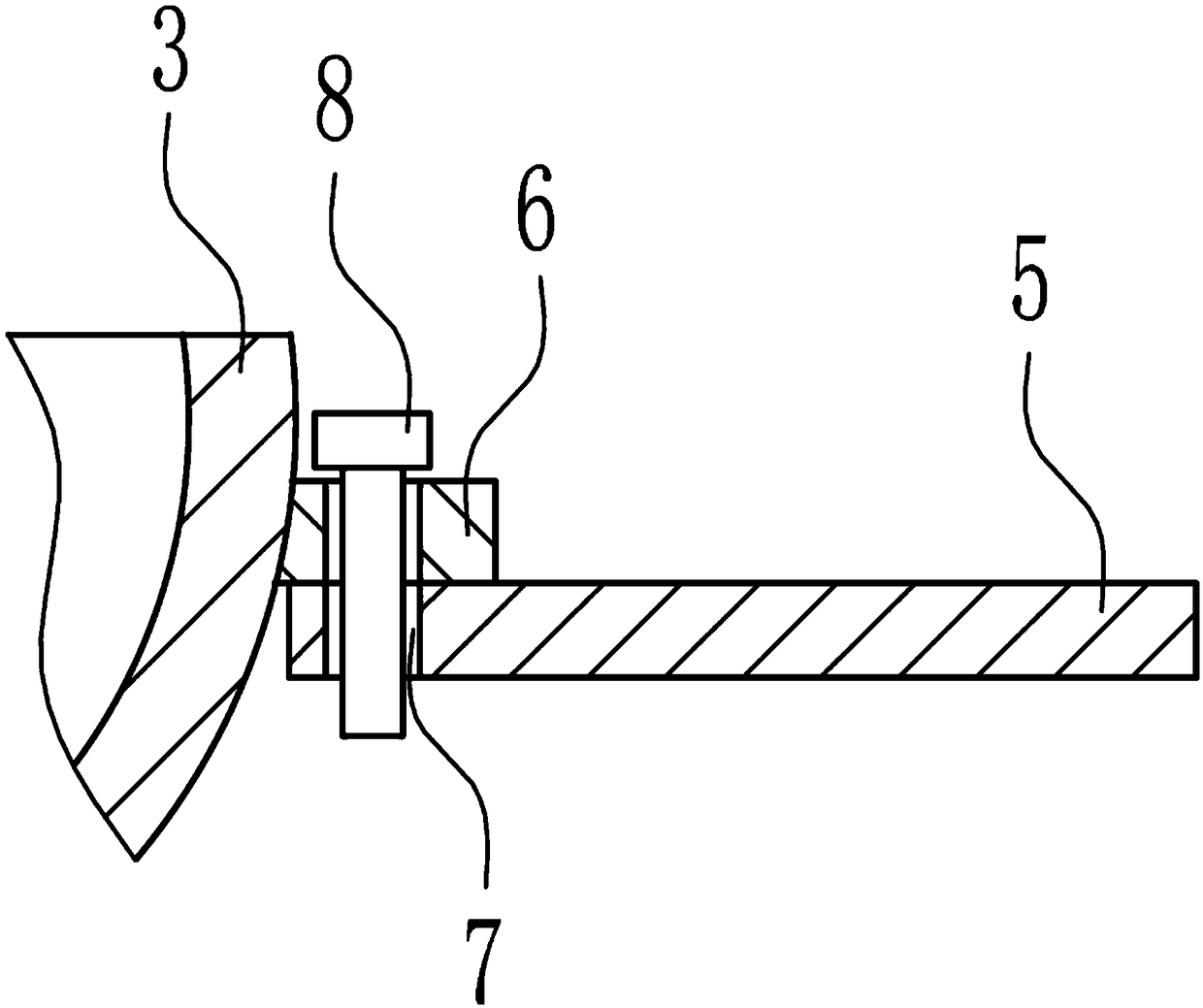

Medical granular tablet crushing device

The invention relates to a crushing device, in particular to a medical granular tablet crushing device. Technically, the invention aims to provide a medical granular tablet crushing device characterized by uniform tablet crushing and faster grinding speed. According to a technical scheme, the medical granular tablet crushing device includes a base plate, support rods, a crushing frame, a support plate, a connecting plate, etc. Two support rods are disposed at the top of the base plate, the crushing frame is connected to the tops of the two support rods, the bottom of the crushing frame is netty, a connecting block is connected to the right side upper part of the crushing frame, the support plate is connected to the right side of the base plate top, and the connecting plate is connected tothe left side lower part of the support plate. According to the invention, reverse rotation of a motor can drive a crushing plate to move up and down so as to crush granular tablets, therefore manualcrushing of granular tablets is unnecessary, and reverse rotation of the motor also enables a knock block to knock the crushing frame continuously, and the crushed granular tablet powder can better fall into a container, thus reaching the effects of uniform crushing of tablets and fast grinding speed.

Owner:沈水秀

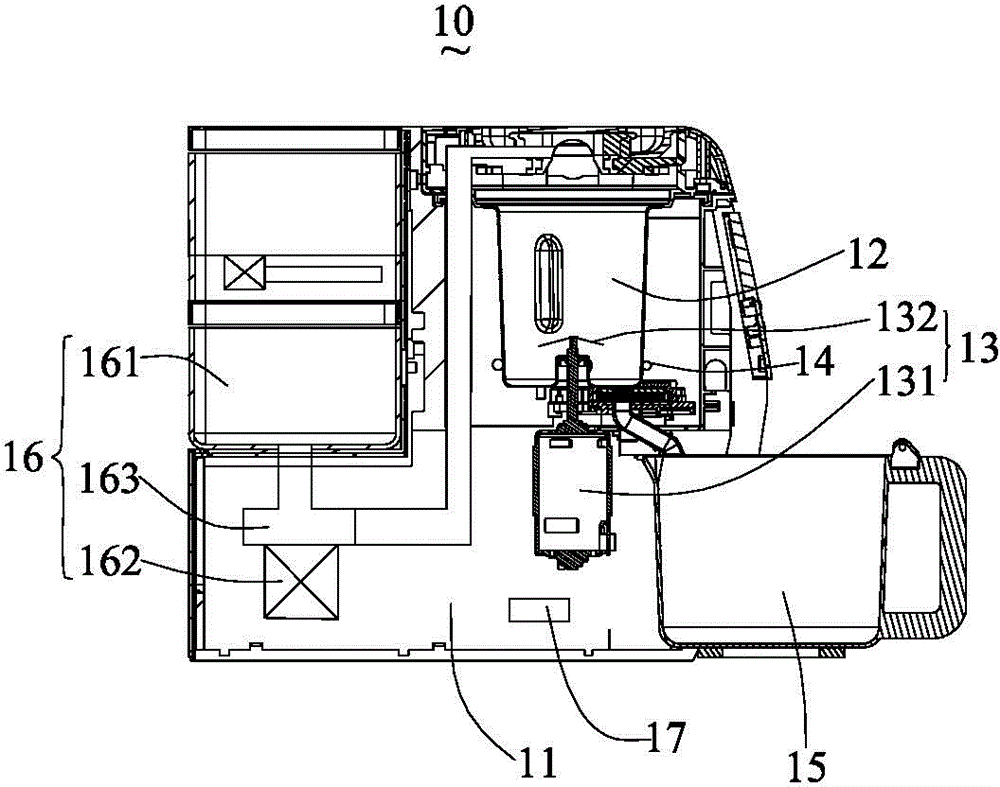

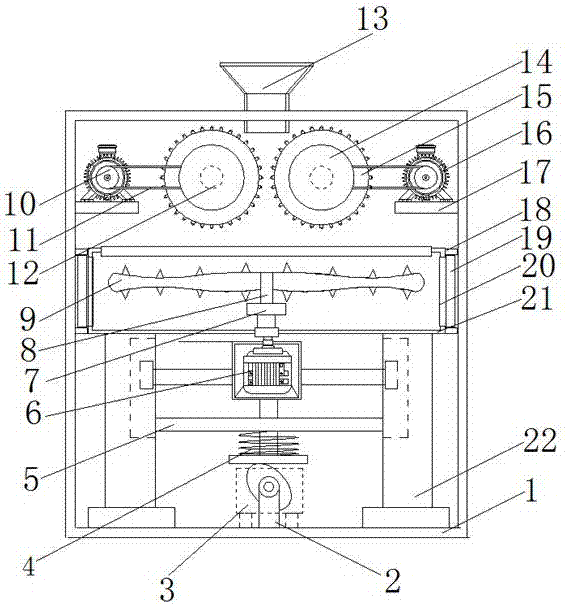

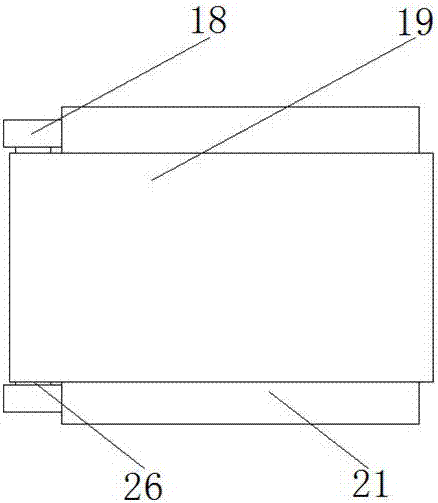

Pork processing device used for production of meat products

InactiveCN107593859AEasy to processEnter at a constant speedMeat mixing apparatusMeat processing devicesBiochemical engineering

The present invention discloses a pork processing device used for a production of meat products. The pork processing device comprises a base seat, a box body, a stirring chamber and a crushing chamber. Walking wheels are arranged on a bottom part of the base seat, the box body is arranged on the base seat, a sliding chute is arranged on the base seat in the box body, a material taking groove is arranged on the sliding chute via sliding blocks, a second supporting plate is arranged in the box body at an upper side of the material taking groove, the stirring chamber is arranged on the second supporting plate, a first material discharge funnel extending to the material taking groove is arranged on a bottom part of the second supporting plate of an output end of the stirring chamber, and a servo motor is mounted on the second supporting plate at one side of the stirring chamber. The processing device is more comprehensive in a processing of pork. During a stirring in the stirring chamber,working staff can conduct a throwing of seasoning materials at the same time according to an amount of the pork and an amount of water in the stirring chamber. The processing device realizes the stirring and at the same time conducts a blending of the pork, avoids the blending by the working staff in a material discharge of the pork, and is strong in practicality and worthy of promotion and use.

Owner:江苏裕邦食品有限公司

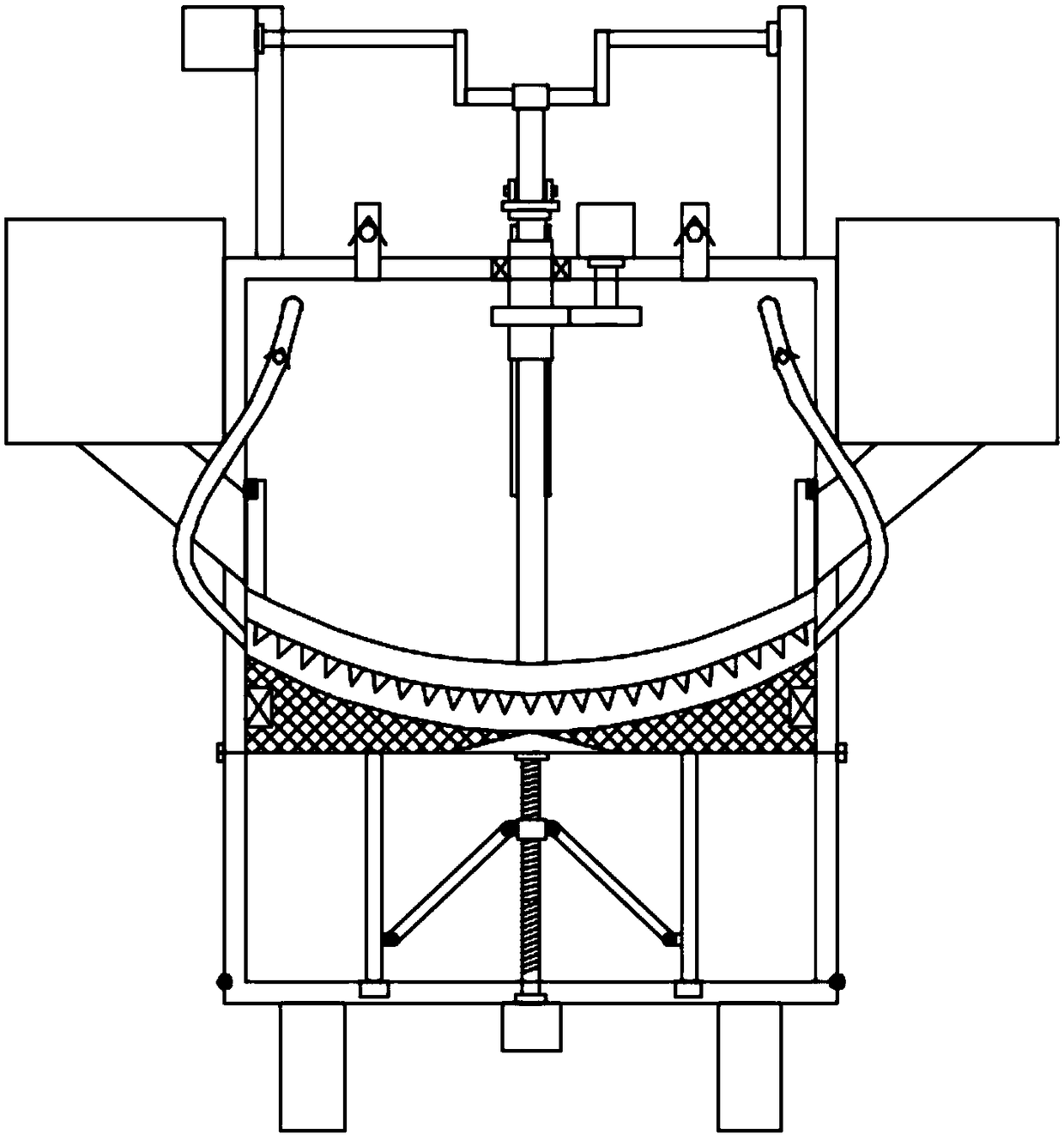

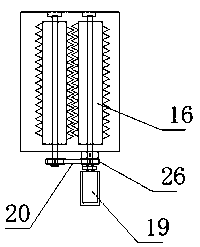

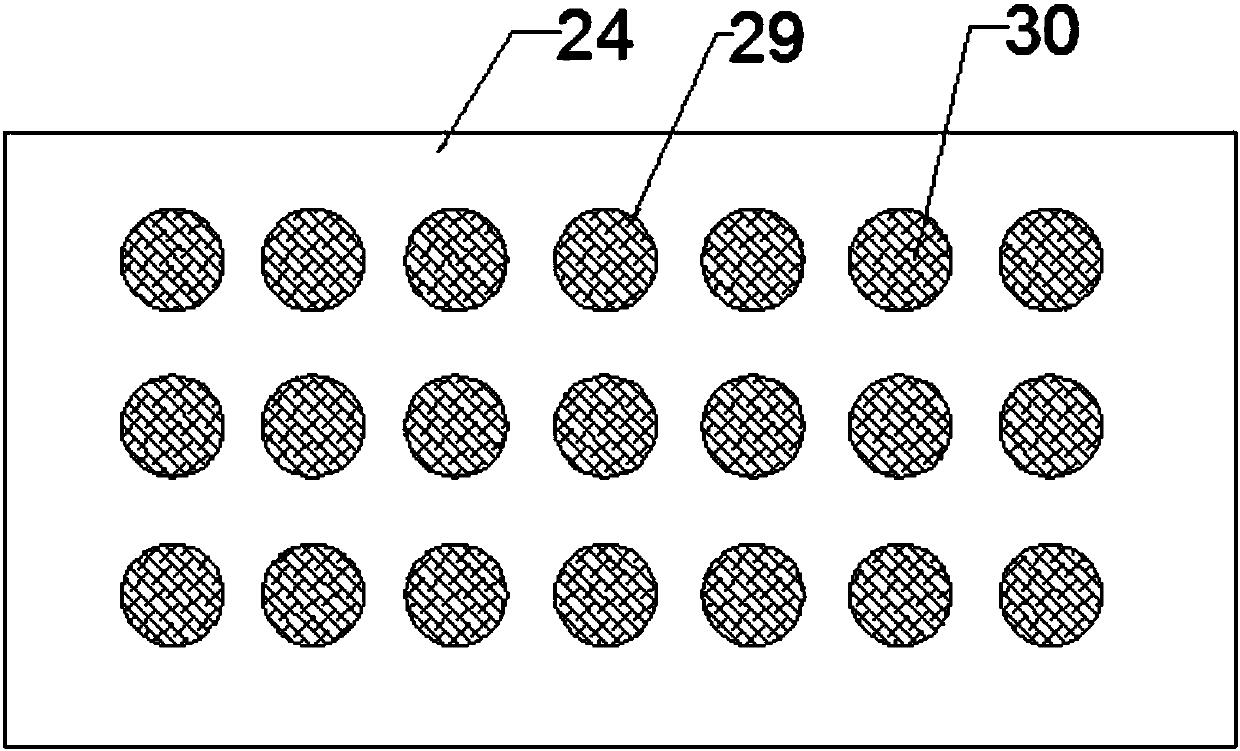

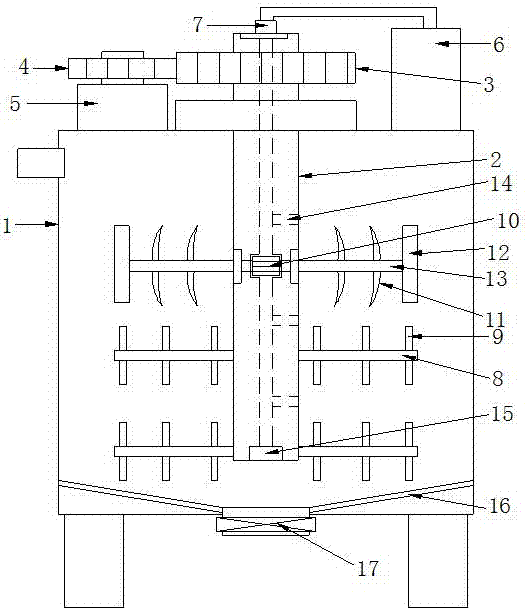

Bio-organic fertilizer raw material crushing equipment with good crushing effect

InactiveCN108704707AEvenly crushedSmash thoroughlyRotary stirring mixersTransportation and packagingCouplingEngineering

The invention discloses a bio-organic fertilizer raw material crushing equipment with a good crushing effect. The bio-organic fertilizer raw material crushing equipment is characterized in that a first motor is fixedly arranged on one side of a stirring cavity through a motor assembly base; the output end of the motor is connected with a stirring shaft I through a coupling; the stirring shaft I islocated in the stirring cavity; stirring blades are fixedly arranged on the stirring shaft I; the other side of the stirring cavity is fixedly provided with a ventilation fan; a ventilation pipelineis connected to the ventilation fan; the ventilation pipeline at the input end of the ventilation fan is located in the stirring cavity; the part, which is located in the stirring cavity, of the ventilation pipeline is fixedly provided with a sponge block; the ventilation pipeline at the output end of the ventilation fan is located out of the stirring cavity; a material outlet of a primary crushing cavity faces right to a material inlet of a secondary crushing cavity; a third motor is fixedly arranged on the outer part of the secondary crushing cavity; the output end of the third motor is connected with a stirring shaft II through a coupling; the stirring coupling II is located in the secondary crushing cavity; and a thread reamer is arranged on the stirring shaft.

Owner:王玉玲

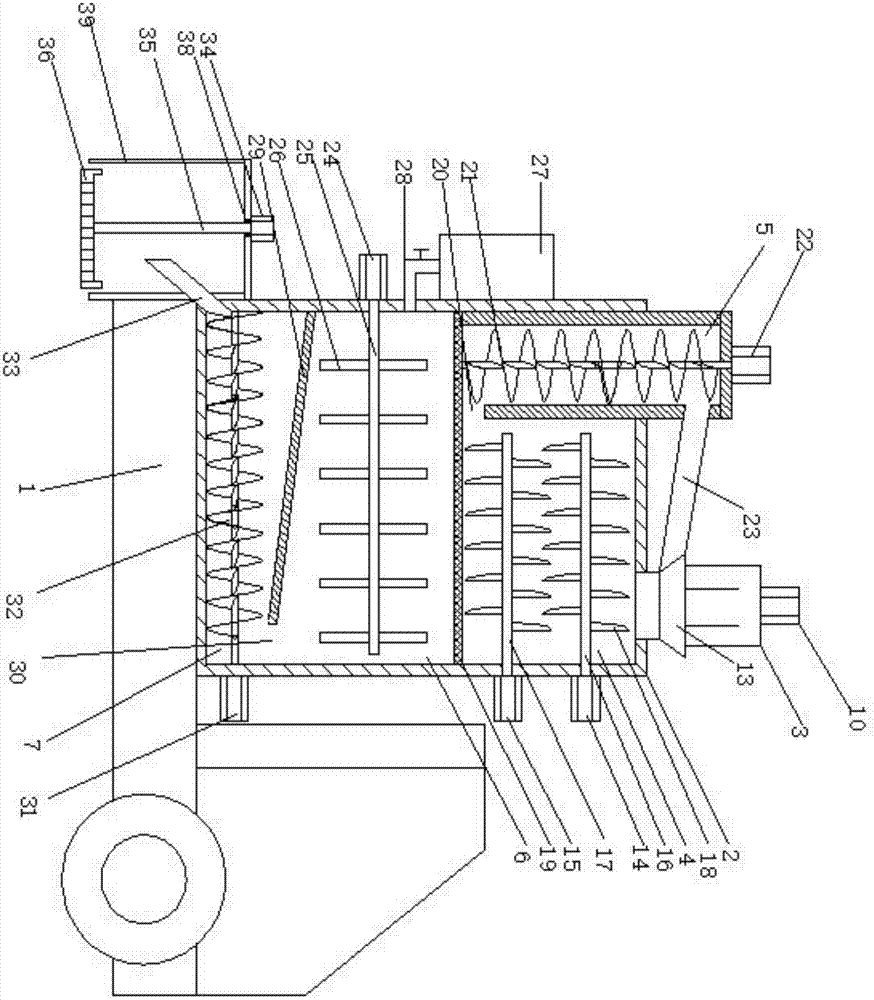

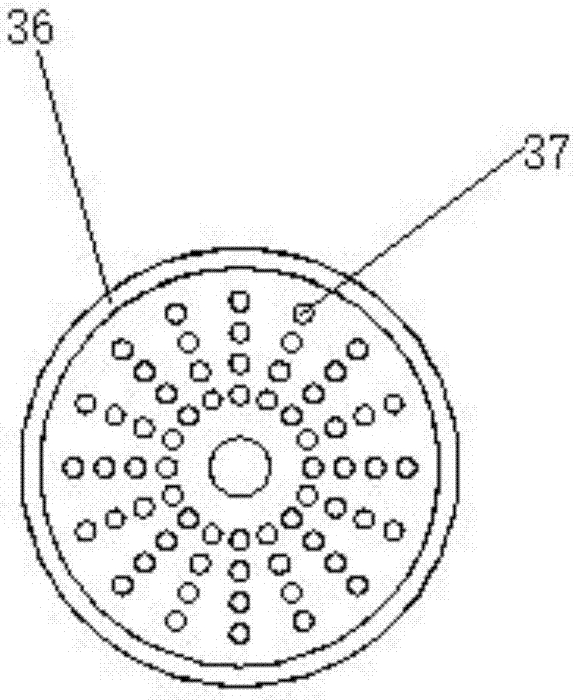

Harvester provided with protective ladder and lifting type lower header capable of smashing straw and preventing smashed straw from splashing

The invention discloses a harvester provided with a protective ladder and a lifting type lower header capable of smashing straw and preventing the smashed straw from splashing. The harvester comprises the lower header and the protective ladder, and the lower header is hinged to a front axle of the harvester. The lower header comprises a lower header main frame, a lower cutting mechanism, a straw smashing mechanism, a transmission mechanism and a lower header lifting mechanism. Blocking angle iron is further fixedly connected with the rear portion of a shield of the lower header main frame. The lower header lifting mechanism comprises a lower header lifting oil cylinder, a lower header lifting oil cylinder upper base and a lower header lifting oil cylinder lower base. The harvester provided with the protective ladder and the lifting type lower header capable of smashing straw and preventing the smashed straw from splashing can cut and smash straw left after grain harvesting, and the feed quantity of the harvester is reduced. Cutting stubbles are short and flat so that tillage can be convenient. The straw cutting and smashing efficiency is high, smashing is uniform, and the smashed straw cannot splash. The lower header can ascend and descend so as to control the height of the cutting stubbles and avoid obstacles to protect equipment safety. The arranged protective ladder makes people climb safely and conveniently, and can also be used as a safety guardrail.

Owner:纪小坤

Flexible display screen and manufacturing method thereof

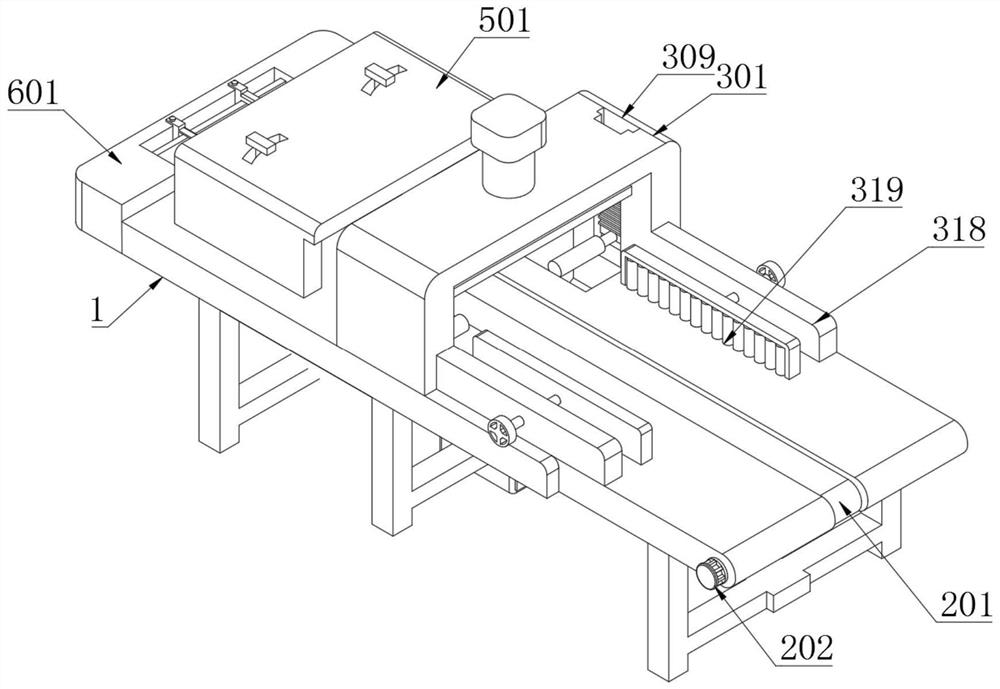

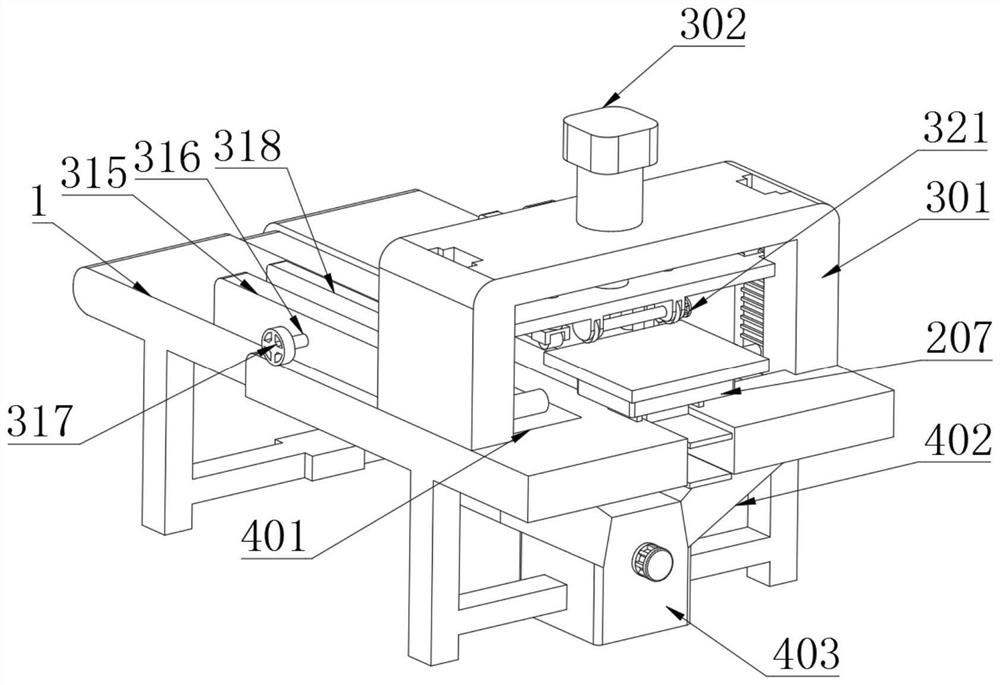

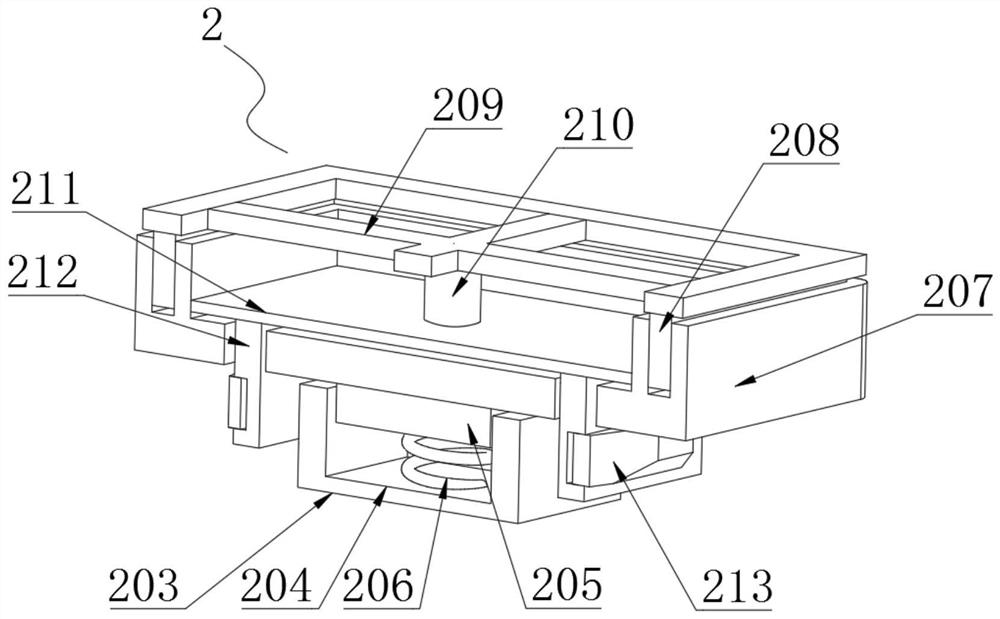

ActiveCN111882991AScientific and reasonable structureEasy to useEdge grinding machinesGrinding carriagesElectric machineryDrive motor

The invention discloses a flexible display screen and a manufacturing method thereof. The middle of the top end of a machine base is fixedly connected with a positioning cutting mechanism, the other side of the top end of the machine base is fixedly connected with a power conversion and grinding mechanism, and the middle of the machine base is rotationally connected with an adsorption fixing and moving mechanism; The adsorption fixing and moving mechanism comprises a conveying belt, a driving motor, a mounting base, an embedding groove, a movable plate, a supporting spring, a suction cup and arubber plate. The flexible display screen is scientific and reasonable in structure and safe and convenient to use, the adsorption fixing and moving mechanism is arranged, glass is adsorbed and fixedthrough the suction cups, the stability of the glass is improved, loss caused by falling of glass in moving machining process is avoided. The movable plug plate is driven to slide in the suction cupthrough cooperation of the rubber plate and the connecting rod in the glass adsorption process, and meanwhile the movable plug plate extrudes air pressure in the suction cup due to the fact that the movable plug plate is attached to the interior of the suction cup.

Owner:SHENZHEN RUGIN ELECTRONICS

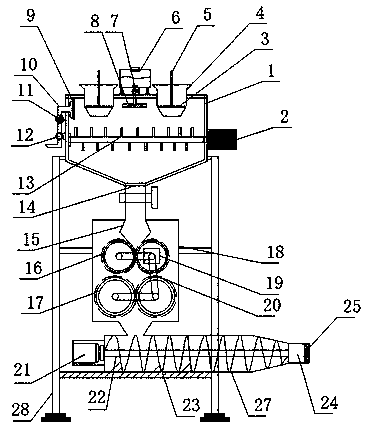

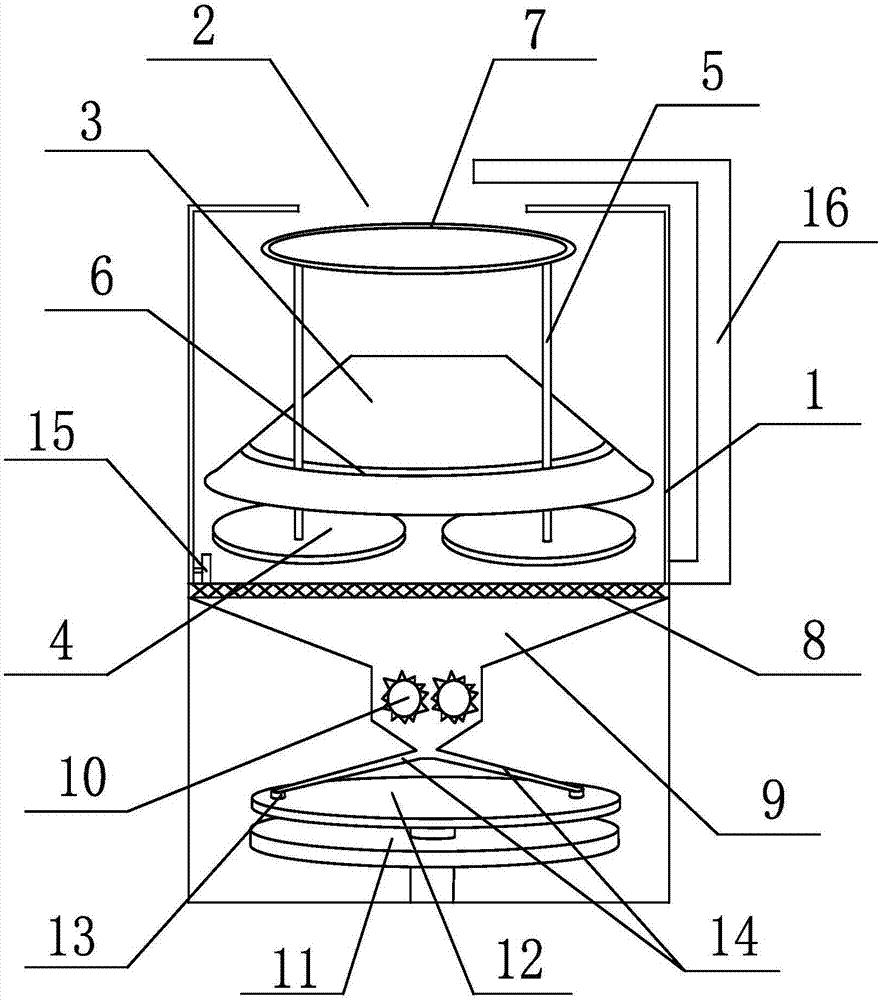

Efficient pulverizer used for preparation of traditional Chinese medicine decoction pieces

The invention discloses a high-efficiency pulverizer for preparing Chinese herbal decoction pieces, which comprises a pulverizer body, a feeding port is arranged above the pulverizer body, a conical barrel-shaped feeding cover is provided below the feeding port, and a feeding table is provided below There are a plurality of disc-shaped cutters, the upper surface of the cutters is connected with a driving rod, and a circular through-slot is opened on the side of the material passing cover, and the driving rod passes through the through-slot and the upper end is connected to a circular driving rod. On the track, there is a screen under the cutter, a funnel-shaped gathering hopper under the screen, a crushing roller at the bottom opening of the gathering hopper, and a grinding base and a grinding disc under the gathering hopper. The high-efficiency pulverizer of the present invention can process the size of Chinese medicinal materials step by step through multiple processes, and can efficiently and quickly cut, pulverize and grind Chinese medicinal materials, avoiding the damage of the crushing device caused by directly crushing raw materials, and at the same time After crushing, the seamless connection of grinding is realized, which greatly improves the processing efficiency of Chinese herbal medicines and saves time and cost.

Owner:谭证书

Efficient shredding device for discarded shoe soles for shoe industry

The invention relates to a sole shredding device, in particular to an efficient shredding device for discarded shoe soles for the shoe industry. To solve the technical problem, the efficient shredding device for the discarded shoe soles for the shoe industry is provided, wherein the efficient shredding device is high in shredding speed, uniform in shredding and simple in structure. The efficient shredding device for the discarded shoe soles for the shoe industry comprises a first sliding rail, a rack, a first supporting rod, a first connecting rod, a guide plate, an electric push rod, a gear, a pressing block, shredding teeth, a shredding frame, a left frame, a first electric winding wheel, a first sliding block, a bottom plate, a second sliding rail, a pull wire, a second electric winding wheel, a right frame, a top plate, a second connecting rod, a feeding hopper, cutters, a disc-shaped cam, a motor and a second sliding block. By means of the efficient shredding device, the effects that the shredding speed is high, shredding is uniform, and the structure is simple are achieved, the efficient shredding device plays an important role in achieving the good shredding effect, the working efficiency is improved as well, and the safety is high.

Owner:临沂港控能源有限公司

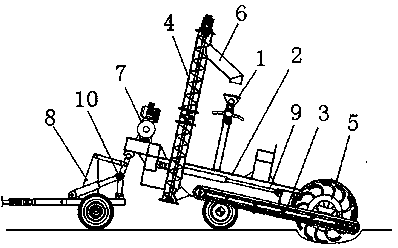

Straw-smashing-and-even-field-returning integrated device

InactiveCN107046961AEvenly crushedAccelerated rapid decompositionCentrifugal wheel fertilisersCuttersDecompositionNitrogen

The invention discloses an integrated device for crushing straw and evenly returning it to the field. An integrated device for crushing straw and returning it evenly to the field includes a vehicle seat, and the vehicle seat is provided with a processing box and a feeding tower. , the inside of the processing compartment is provided with a crushing chamber, a feeding chamber, a mixing chamber and a discharge chamber, the rear side of the vehicle seat is equipped with a material rack, and the front side of the crushing chamber is respectively equipped with a first crushing motor and a The second pulverizing motor, the rear ends of the first pulverizing motor and the second pulverizing motor are respectively connected with the first pulverizing shaft and the second pulverizing shaft, and the first pulverizing shaft and the second pulverizing shaft are alternately installed with Several cutting blades; the beneficial effect of the new invention is the integrated operation of collecting and transporting materials, crushing, stirring and mixing, and spreading materials; after the straw is crushed, nitrogen fertilizer is added and fully mixed with it, so as to accelerate the rapid decomposition of straw and ensure the seedling stage of crops Double the power of vigorous growth.

Owner:刘志坚

Traditional Chinese medicine smashing and grinding device

The invention discloses a crushing and grinding device for traditional Chinese medicine, which comprises a shell, a pillar, a feed port, a crushing blade, a discharge port and a collection box; a crushing motor is fixedly connected to the upper surface of the shell, and a rotating shaft is installed at the shaft end of the crushing motor. The lower end of the rotating shaft is fixedly connected with a cutter head, and the outer wall on the right side of the casing is provided with a transmission shaft, which is connected with the middle part of the rotating shaft through a transmission mechanism; The middle part is set with a worm wheel, and the worm is set with a cam, and the cutter head and the sieve plate rotate at the same time, so that the traditional Chinese medicine is crushed more uniformly and the crushing efficiency is improved; during the process of Chinese medicine crushing, the sieve plate vibrates up and down to make the traditional Chinese medicine mix more evenly , to further improve the crushing effect; after the traditional Chinese medicine is crushed to a certain size, it passes through the sieve hole on the sieve plate and falls between the outer grinding cylinder and the inner grinding cylinder to grind the Chinese medicine particles. Improve processing efficiency.

Owner:张大化

Medlar powder preparing method

InactiveCN108325648AGood crushing effectImprove crushing efficiencySievingScreeningPulverizerThrough transmission

The invention discloses a medlar powder preparing method. Medlar is taken, a traditional Chinese medicine pulverizing machine for adjusting the particle diameter is used for conducting pulverizing, and the traditional Chinese medicine pulverizing machine for adjusting the particle diameter comprises a shell, a feeding port, pulverizing motors, pulverizing shafts, pulverizing blades and a collecting groove. The pulverizing motors are fixedly connected to the left side and the right side of the shell correspondingly. The pulverizing shafts are arranged on the left side and the right side of thefeeding port correspondingly. The lower ends of the pulverizing shafts penetrate the top of the shell and stretch into the shell. The pulverizing shafts are rotationally connected with the top of theshell. The shaft stretching ends of the pulverizing motors are connected with the pulverizing shafts through transmission mechanisms. An upper sieve plate is arranged below the pulverizing shafts andfixedly connected with the inner wall of the shell. A lower sieve plate is arranged below the upper sieve plate. In the pulverizing process, stirring vanes are used for stirring the medlar, and traditional Chinese medicines are pulverized more evenly; through adjustment of the lower sieve plate, sieve holes in the upper sieve plate and sieve holes in the lower sieve plate are staggered, the size of medlar particles penetrating the upper sieve plate and the lower sieve plate can be conveniently adjusted, and different machining requirements of people are met.

Owner:苏州高新区鼎正精密机电有限公司

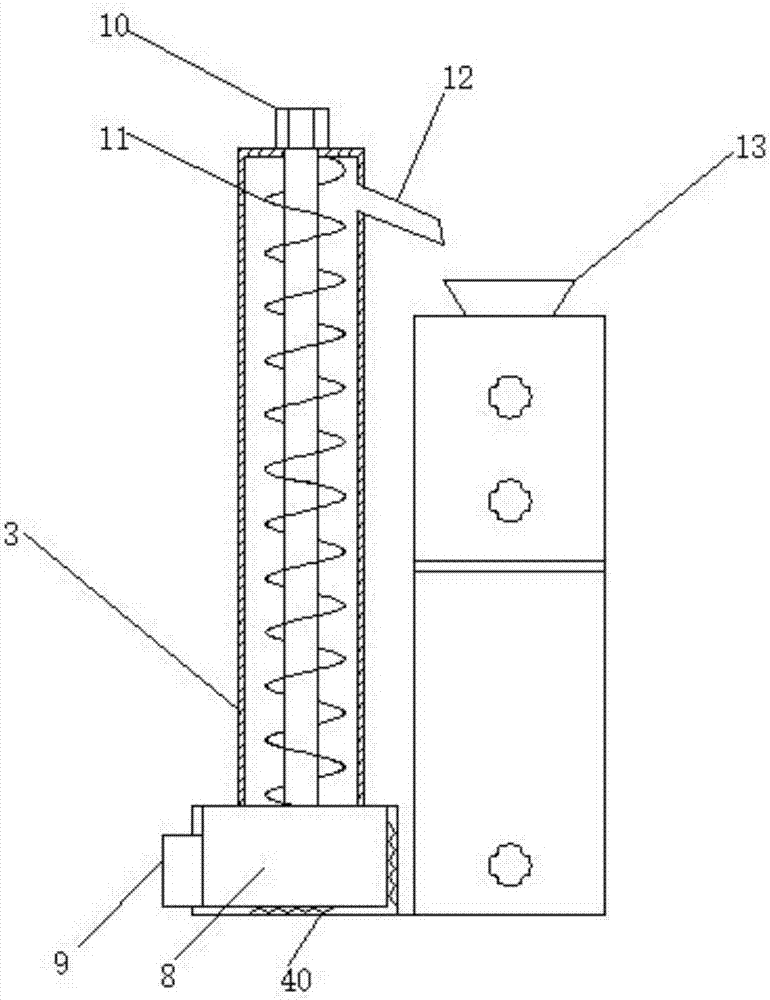

Soil raising fire extinguisher and fire extinguishing method

The invention discloses a soil raising fire extinguisher and a fire extinguishing method. The soil raising fire extinguisher comprises a soil raising device, a soil sampling device and a conveying device, which are arranged on a vehicle frame, wherein the soil sampling device is a rotary tillage type operating machine, and is at least provided with a soil sampling cutting head; the soil sampling cutting head rotates at low speed to crush soil on the ground, and the sampled crushed soil is conveyed to a fire extinguishing soil inlet of a screw conveyor arranged on the vehicle frame through a chain conveyor of the conveying device by the soil sampling cutting head; the screw conveyor is vertically arranged on the vehicle frame; the fire extinguishing soil is conveyed to an inlet of the soil raising device after being further crushed through the screw conveyor; the soil raising device is also arranged on the vehicle frame; the fire extinguishing soil is ejected for fire extinguishing operation through the soil raising device. According to the soil raising fire extinguisher and the fire extinguishing method, the fire extinguishing soil can be uniformly crushed by twice pulverization and twice conveyance, is spirally conveyed to a part above a soil ejection gun, and is ejected by utilizing high-pressure airflow, so that soil ejection fire extinguishing effects can be effectively improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

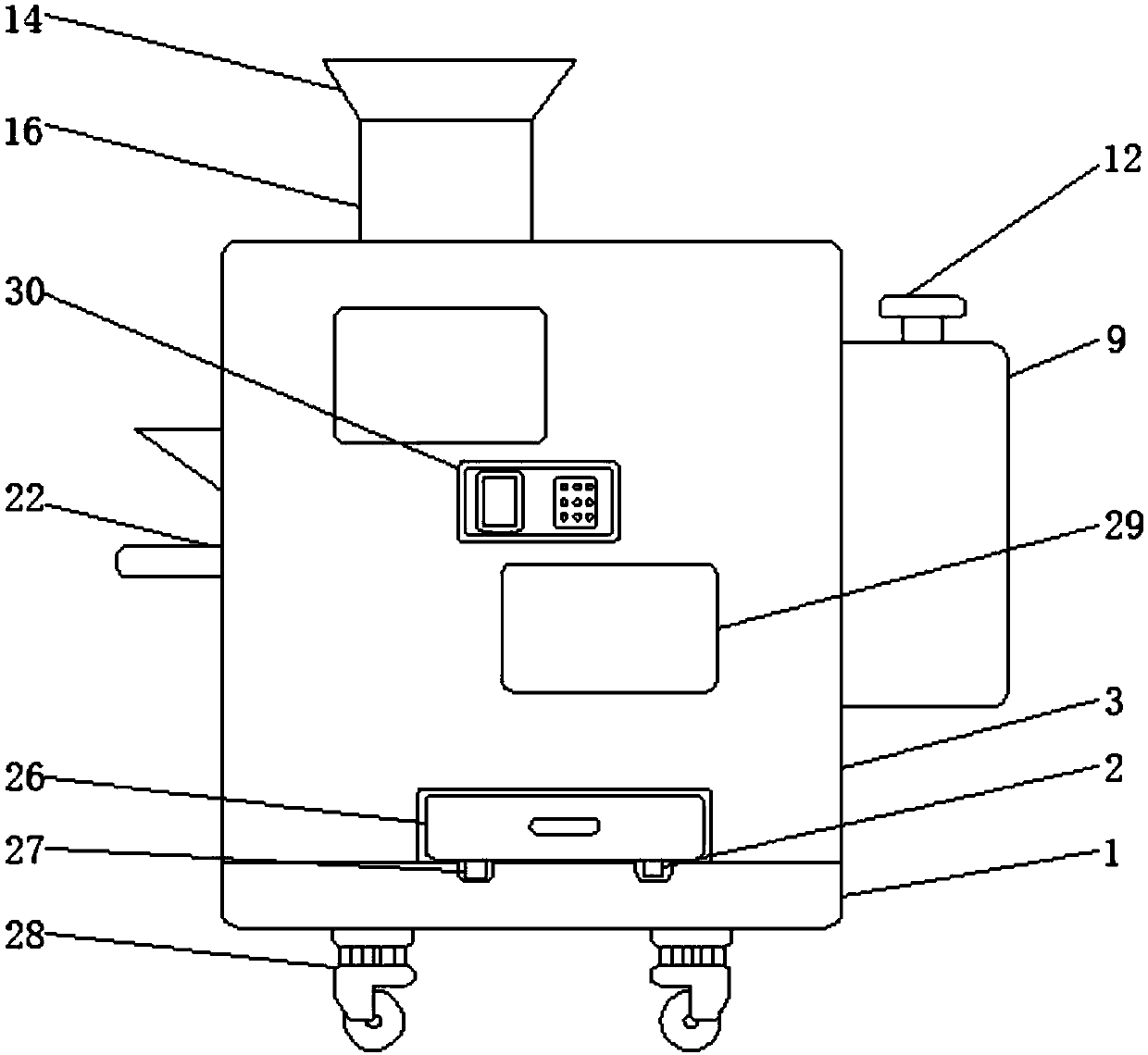

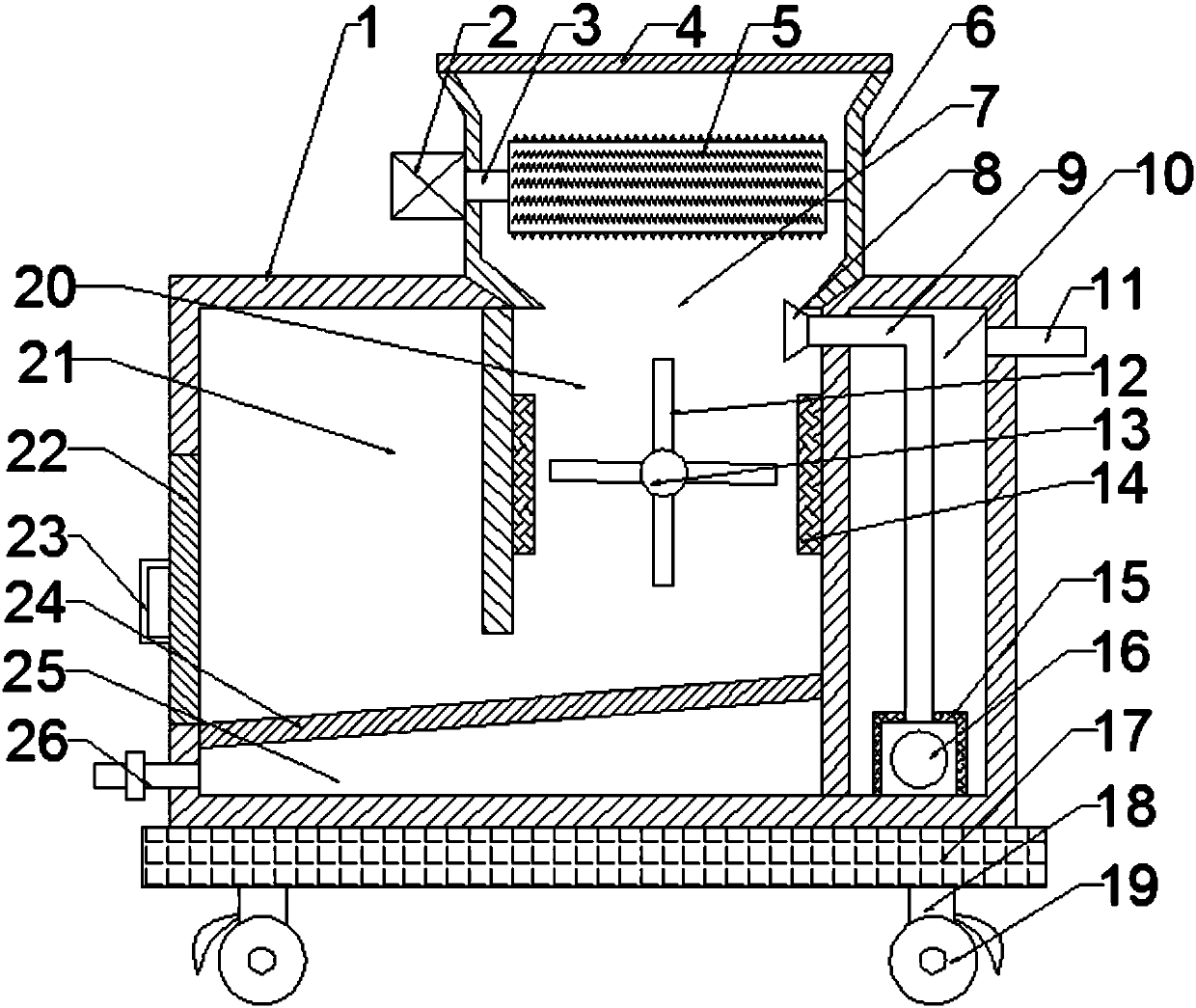

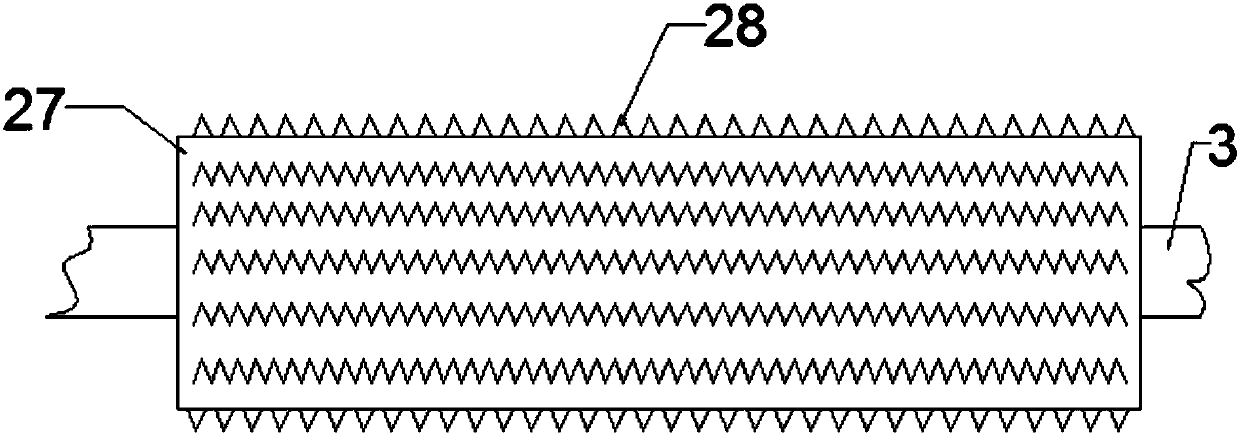

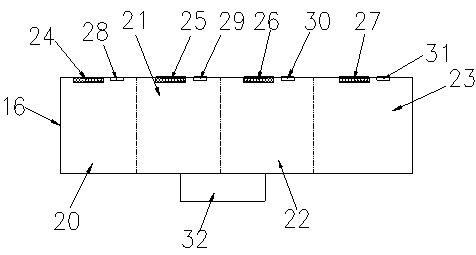

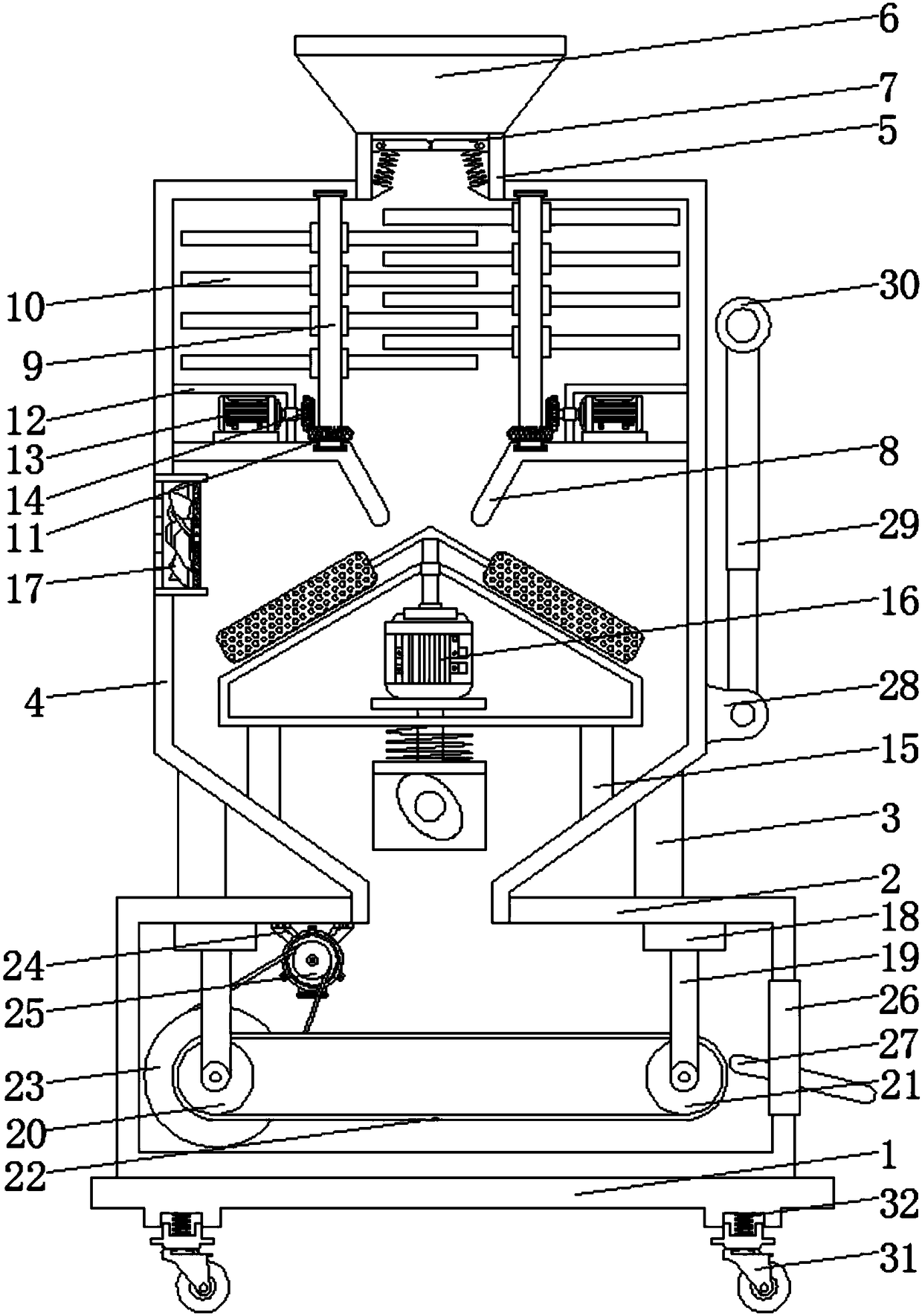

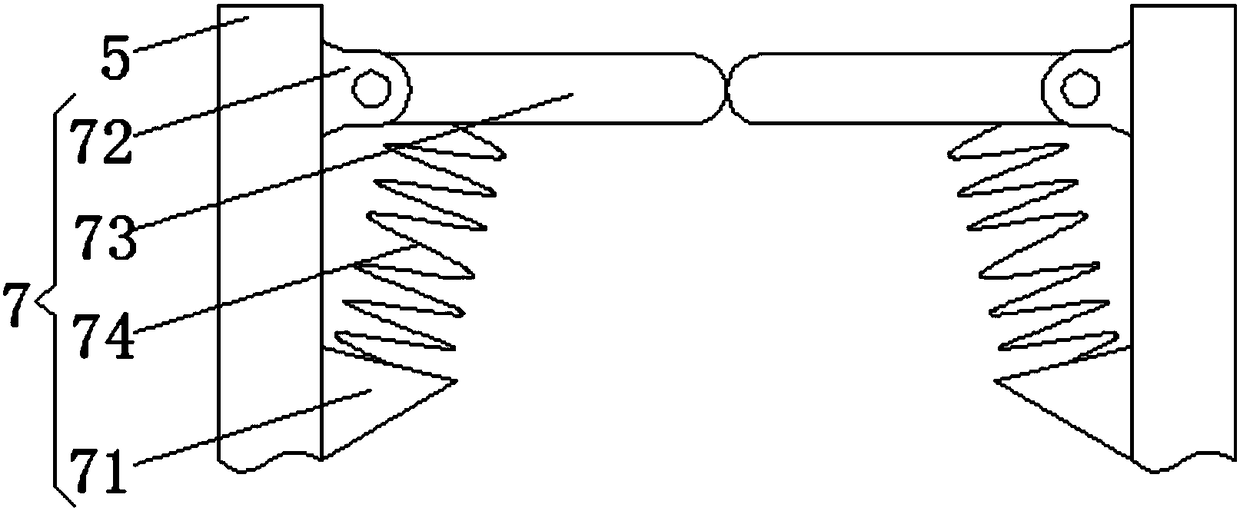

Medical waste treatment device convenient to move

The invention discloses a mobile medical waste disposal device, which belongs to the field of medical technology and comprises a housing; the housing is fixedly arranged on the upper end of a base, and the bottom of the base is provided with rollers through a bracket; the top of the housing is provided with a feeding Shell; the inside of the shell is provided with a disinfectant solution room, a disinfection room, a garbage storage room and a waste water room; the feed shell is fixed on the top of the shell, and the feed shell is provided with a motor, a crushing shaft, a cover plate and crushing device; the cover plate is arranged on the top of the feeding casing through a hinge; the motor is fixedly arranged on the left side of the feeding casing, and the output shaft of the motor is connected to the crushing shaft; the invention can completely crush medical waste , and then carry out disinfection and sterilization treatment, so as to effectively avoid secondary pollution, and make the medical waste evenly sterilized, thereby effectively solving the problem of incomplete disinfection of medical waste.

Owner:ZHENGZHOU RENHONG PHARMA CO LTD

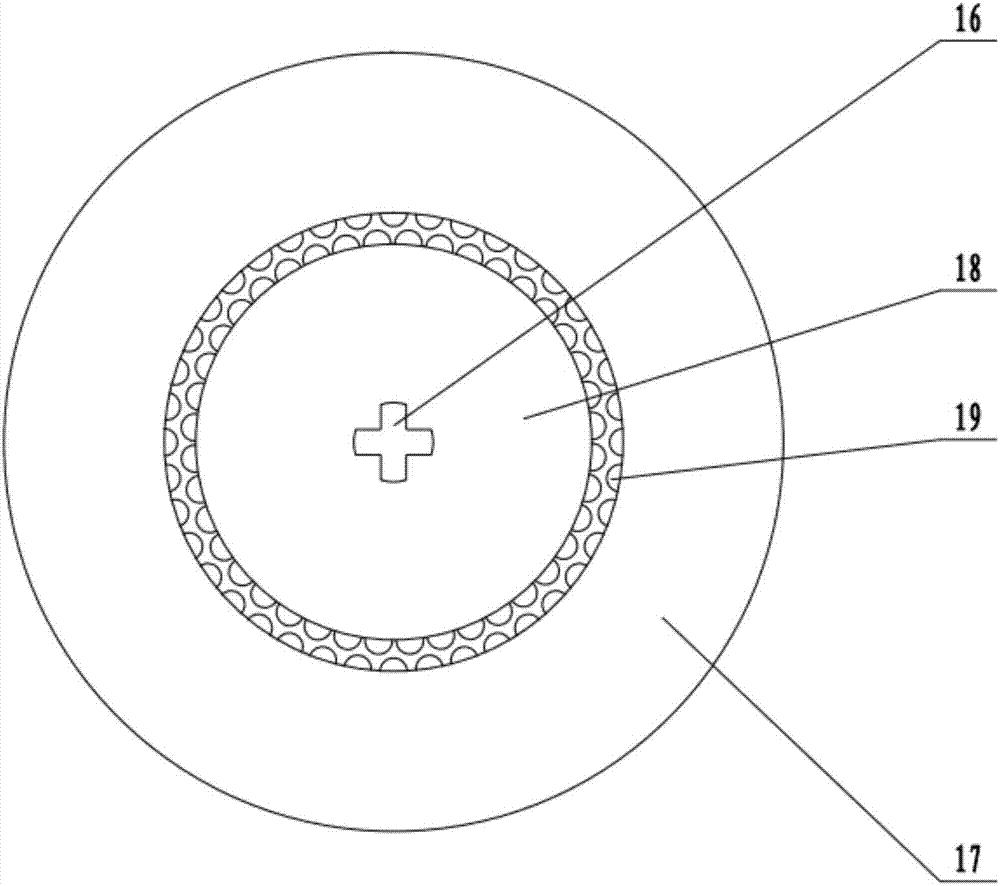

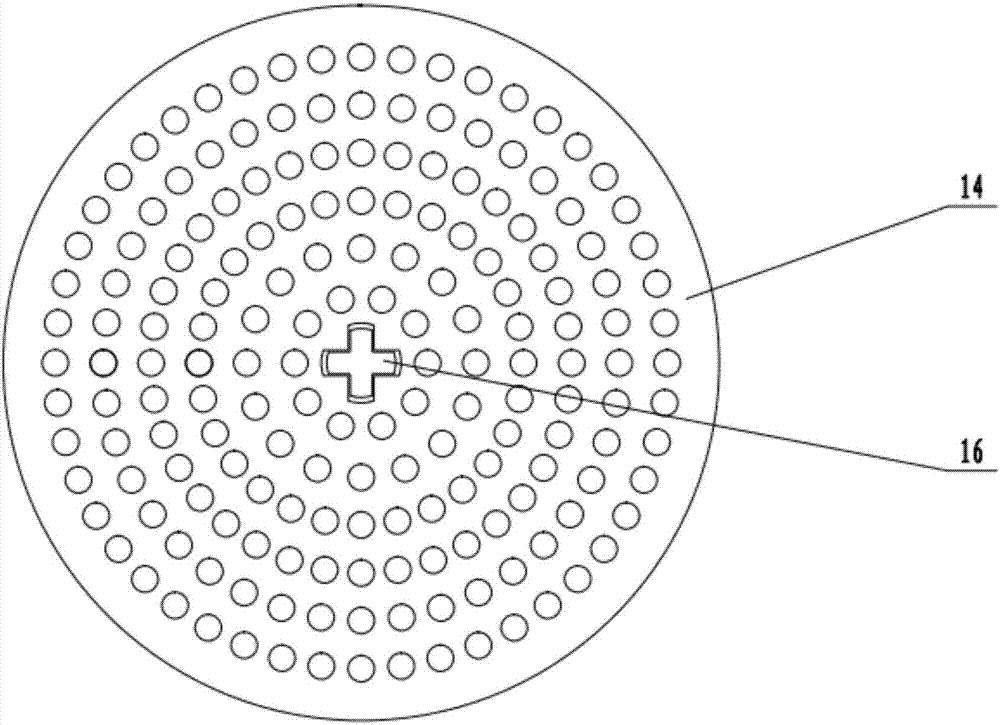

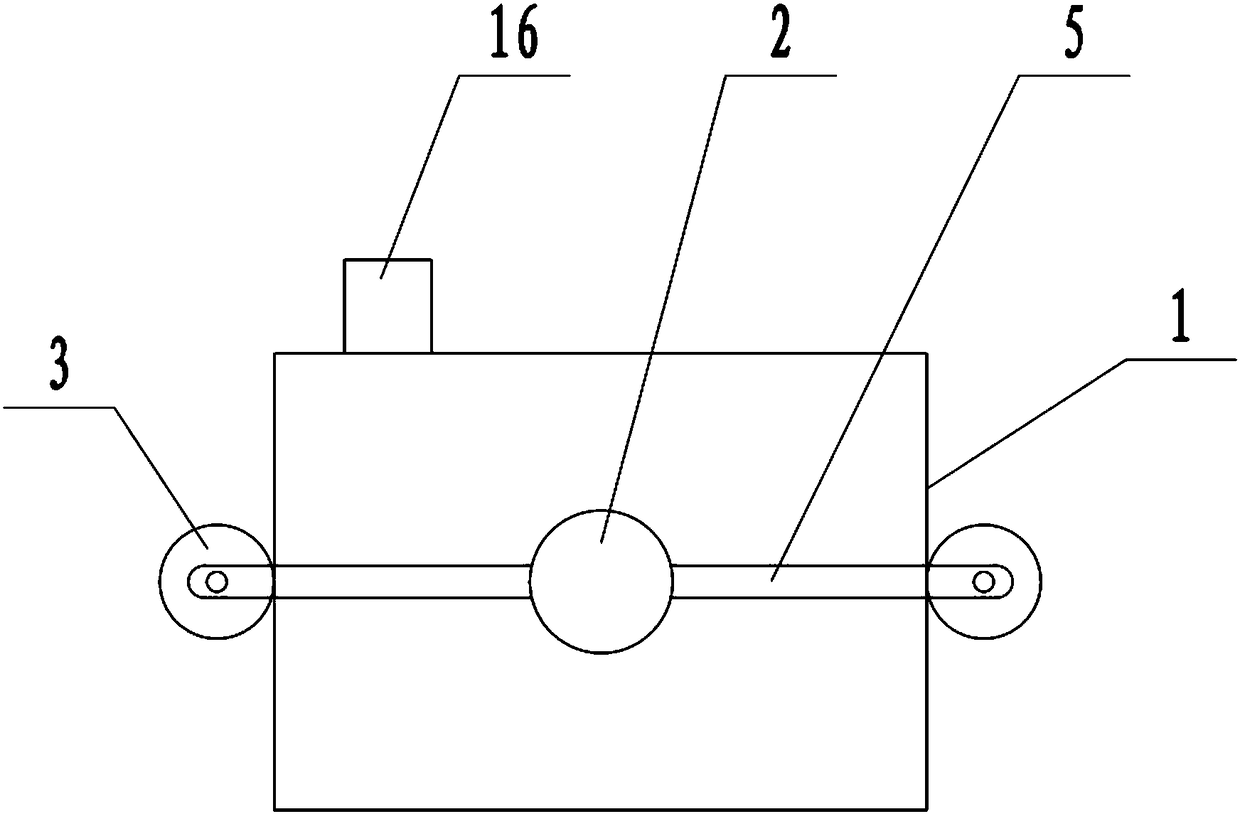

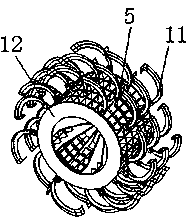

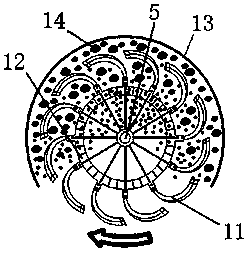

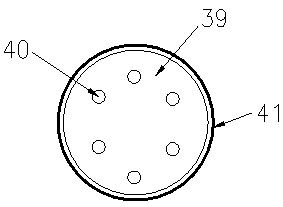

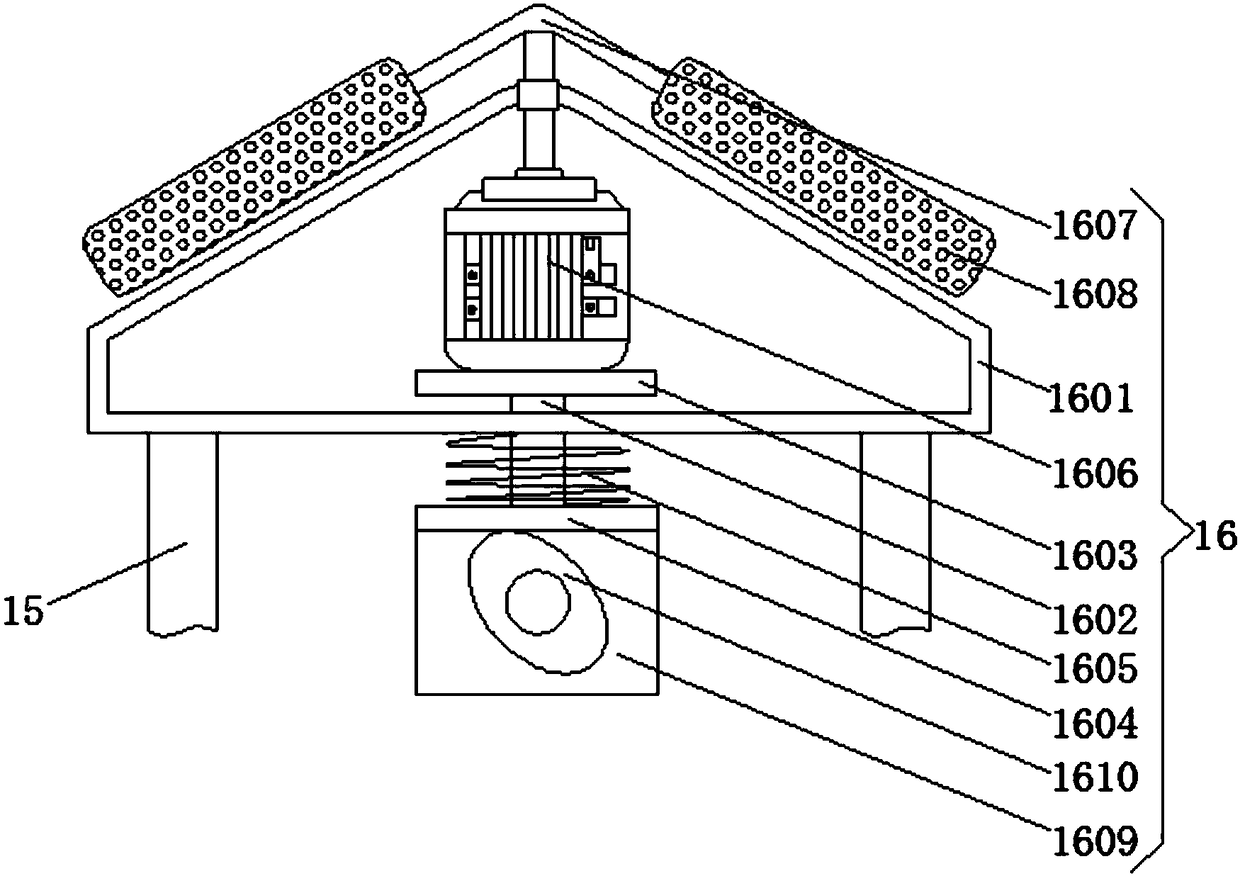

High-efficiency mushroom wood pulverizer

PendingCN107051643AAvoid damageAvoid enteringGrain treatmentsElectric machinePulp and paper industry

The invention discloses a high-efficiency mushroom wood pulverizer and relates to the technical field of edible mushroom breeding. The high-efficiency mushroom wood pulverizer comprises an outer frame. Supporting columns are fixedly connected to the two sides of the bottom of the inner wall of the outer frame, a cross plate is fixedly connected between the opposite sides of the two supporting columns, and the top ends of the supporting columns are fixedly connected with a pulverizing box. A first motor is fixedly connected to the position, located between the two supporting columns, of the bottom of the inner wall of the outer frame, and a movable device is fixedly connected to an output shaft of the first motor. The high-efficiency mushroom wood pulverizer achieves the purpose of improving the pulverizing efficiency, it is avoided that wood directly enters the pulverizing box, the pulverizing efficiency is greatly improved, the mushroom wood is more radically pulverized, and damage, caused by the fact that the wood directly enters the pulverizer, to the pulverizer is avoided; and pulverizing heads are driven by the movable device to move, the pulverizing effect is more uniform while the pulverizing efficiency is improved, and the use effect of the pulverized mushroom wood is improved.

Owner:江苏福利达农业科技有限公司

Graphite smashing device in lithium battery

InactiveCN108554595ARealize automatic feedingSimple structureSievingScreeningWorking environmentEngineering

The invention discloses a graphite smashing device in a lithium battery. The smashing device comprises a smashing shell body, a first electromotor, a rotary shaft, smashing blades, a hairbrush, a sieve plate, sieve holes, a rubber column, a spring, a vibration motor, a second electromotor, a rotary shaft, a pulverizing cylinder, a gear, a storing shell body, a feeding pipe, a feeding shell body, ascrew rod, a third electromotor and a discharging shell body. The graphite smashing device in the lithium battery is simple in structure and novel in design, achieves automatic feeding of graphite, can conveniently break bigger graphite blocks, avoids that graphite particles splash during the breaking process, ensures the surrounding working environment quality, screens the broken graphite through the sieve holes in the surface of the sieve plate to conveniently break the graphite, during the use process, further smashes the collected graphite after screening, ensures uniform smashing for thegraphite, reduces the smashing time of the graphite, improves the smashing efficiency of the graphite, and stores the graphite smashed uniformly, the smashed graphite can be conveniently taken out, and the device is applicable to use and popularization.

Owner:JIANGSU OLITER ENERGY TECH

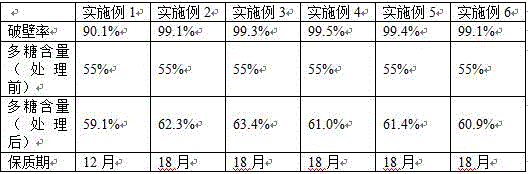

Preparation method of directly orally-taken traditional Chinese medicinal decoction dendrobium powder

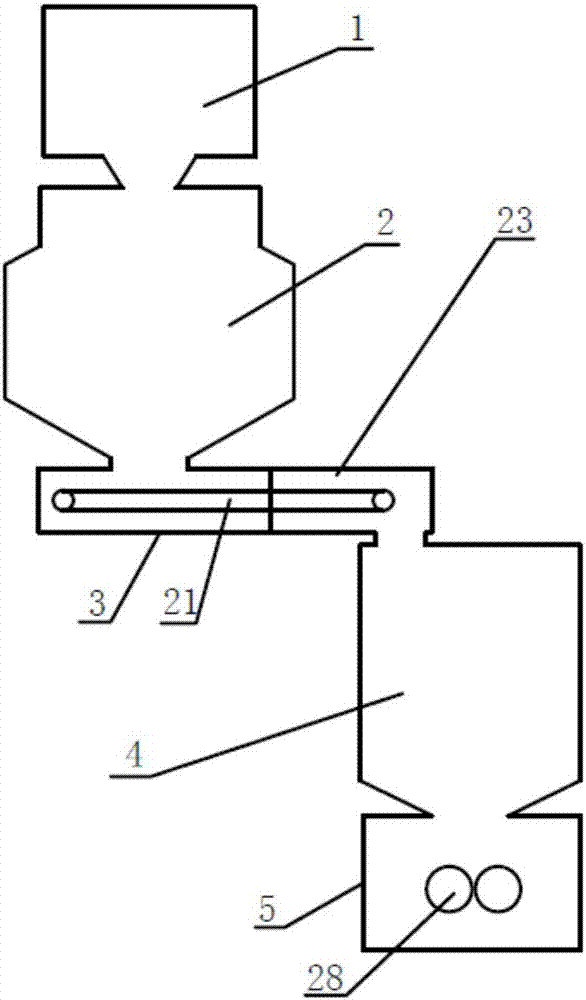

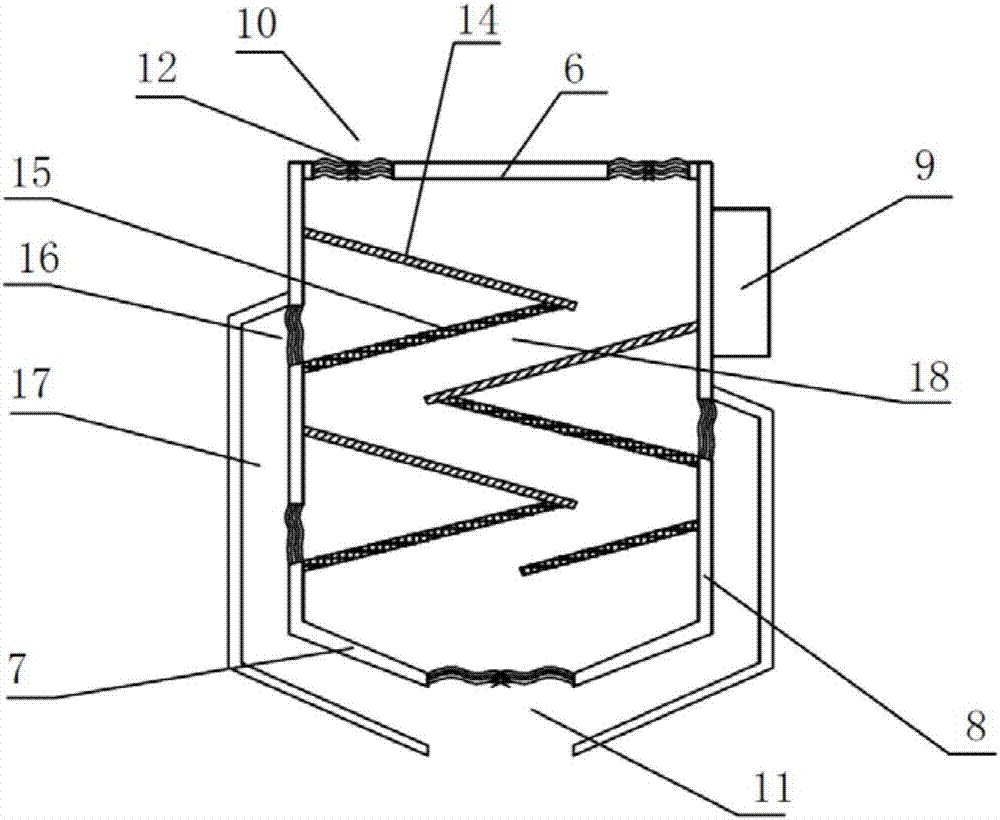

The invention relates to the technical field of traditional Chinese medicinal material processing, in particular to a preparation method of directly orally-taken traditional Chinese medicinal decoction dendrobium powder. The preparation method comprises the following steps: (1) sterilizing: putting dendrobium into ozone water for performing ozone sterilization; (2) crushing: crushing the dendrobium by a wet crushing method to obtain a dendrobium slurry; (3) filtering: performing vacuum suction filtration on the dendrobium slurry by using a filter screen to obtain a filtrate slurry; (4) concentrating: performing vacuum reduced pressure concentration on the filtrate slurry to obtain a concentrated slurry; (5) drying: performing vacuum freeze drying on the concentrated slurry to obtain the dendrobium powder. A finished product prepared by the preparation method is extremely fine powder which is 100% broken, and has good water solubility; the sterilizing effect is good; active components are basically not destroyed; the finished product is high in active component polysaccharide content, low in moisture content, sterile and long in shelf life.

Owner:昆明斛之梦制药有限公司

Microwave ore processing method and device

The invention relates to a microwave ore processing method. The microwave ore processing method includes the following steps that large block ore is crushed into small block ore in size suitable for subsequent treatment steps; the small block ore is led in a primary microwave heating oven to be subjected to primary microwave heating; the heated ore is subjected to water cooling; water on the surface of the ore subjected to water cooling is removed in a blowing manner; the ore is fed into a secondary microwave heating oven to be subjected to the secondary heating; and the heated ore is fed into a smashing box to be smashed. According to the ore processing method, a two-stage crushing device is arranged, the primarily crushed ore blocks are subjected to microwave heating and cold water sprinkling to make hot expansion and cold shrinkage deformation generated in the ore, and smashing is easier and more uniform because of automatic breaking in the ore.

Owner:青岛科锐思新材料科技有限公司

Stone multi-stage smashing device for ore mining

ActiveCN108686740AAvoid equipment overloadEnsure safe and stable useMagnetic separationGrain treatmentsDrive motorEngineering

The invention discloses a stone multi-stage smashing device for ore mining. The stone multi-stage smashing device for ore mining comprises a shell, a filler opening, a screen, a drive motor and smashing rollers. Multiple limiting rollers are horizontally distributed in the filler opening. The horizontal screen is fixed to the upper portion in the shell. A vertical extrusion plate is arranged abovethe screen, and multiple horizontal magnetic bars are fixed to the circumference of a rotary disc. The two cooperated smashing rollers are arranged under a discharge pipe, a horizontal moving plate horizontally penetrating out of the two sides of the shell through openings is arranged below the smashing rollers, and vertical pushing plates are fixed to the portions, located on the outer sides ofthe two smashing rollers, of the horizontal moving plate. Stones entering the device are preliminarily smashed through the extrusion plate moving left and right, the stones which cannot fall are continuously smashed, and complete smashing is guaranteed; and through the rotating magnetic bars, iron is removed out of the stones, it is guaranteed that following fine treatment of the stones is safer,and damage to equipment is reduced.

Owner:溆浦县广正石业有限公司

Efficient transverse and longitudinal pulverizer

ActiveCN106914322AImprove crushing efficiencyShorten the timeGrain treatmentsAgricultural engineeringDrive motor

The invention discloses an efficient transverse and longitudinal pulverizer, which relates to the technical field of mechanical devices. The upper end of a longitudinal main shaft is provided with a main gear, the main gear is meshed with a drive gear, the drive gear is mounted on the rotary shaft of a drive motor, a vent hole is arranged in the longitudinal main shaft, the upper end of the vent hole is provided with a connection nozzle, the connection nozzle is connected to an air outlet of a high pressure pump by an air pipe, the side surface and the bottom of the vent hole are respectively provided with a plurality of side air nozzles and a bottom air nozzle, the middle of the vent hole is provided with a mounting groove, an air wheel is mounted in the mounting groove, a transverse rotary shaft on two ends of the air wheel is connected in the longitudinal main shaft in a penetrating manner through a bearing block and extends out of the longitudinal main shaft, the outer surface of the transverse rotary shaft is provided with a plurality of pulverizing blades, and the tail end of the transverse rotary shaft is provided with a material poke rod. The efficient transverse and longitudinal pulverizer can conveniently realize transverse and longitudinal rotary pulverizing, and is high in pulverizing efficiency, saves time and can pulverize uniformly.

Owner:上海孚加新材料科技有限公司

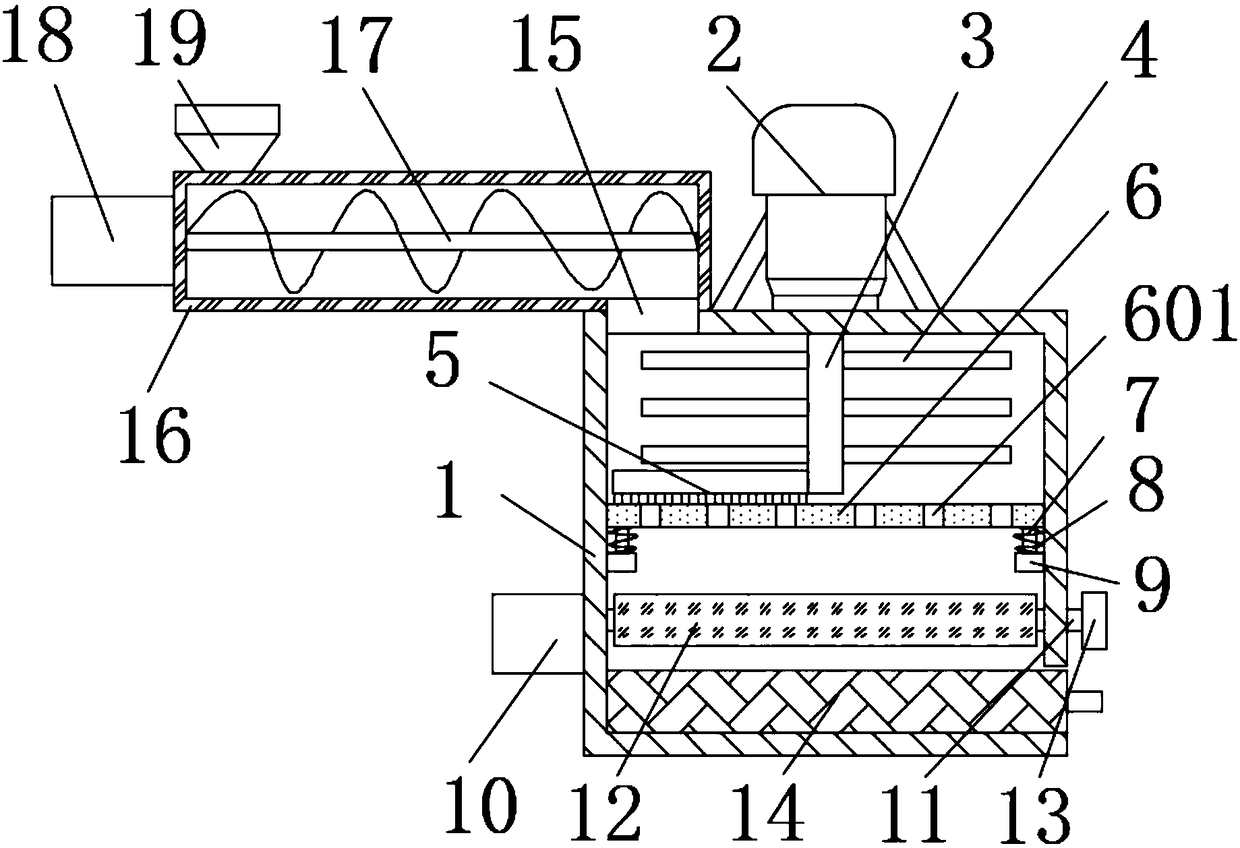

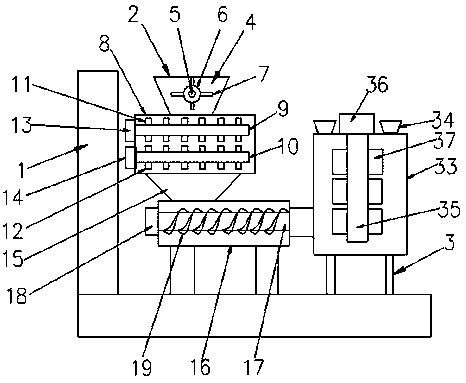

Efficient feed processing device and method

InactiveCN110063512AImprove processing efficiencyImprove processing qualityFeeding-stuffTransportation and packagingUv disinfectionEngineering

The invention discloses an efficient feed processing device and method. The device includes an L-shaped bracket, a crushing mechanism, an extrusion mechanism and a mixing mechanism are installed on the L-shaped bracket, a storage bin is installed on the upper portion of the crushing mechanism, the extrusion mechanism is installed on the lower portion of the crushing mechanism, the crushing mechanism is communicated with the extrusion mechanism, the stirring mechanism is installed on one side of the extrusion mechanism, and a recycling box is installed on the lower portion of the stirring mechanism. To-be-processed raw materials are mixed in the storage bin and then fed in the crushing mechanism for uniform crushing, the crushed materials are heated and extruded in the extrusion mechanism,and the extruded materials enter the stirring mechanism and then are mixed and stirred with an additive and finally discharged into the recycling box for ultraviolet disinfection. The structural design is novel, crushing, extrusion, stirring and disinfection of feed can be achieved, the feed processing efficiency and quality can be improved, and the labor intensity of workers is reduced.

Owner:王春梅

Waste and old plastic pulverizing and grinding device

The invention discloses a waste and old plastic pulverizing and grinding device. The device comprises a supporting bottom plate. The top of the supporting bottom plate is fixedly connected to a conveying box. The top of the conveying box is fixedly connected to a pulverizing box through symmetric first supporting legs. The center of the bottom of the pulverizing box is communicated with the top ofthe conveying box. The center of the top of the pulverizing box is communicated with a feeding channel. The top of the feeding channel is communicated with a waste feeding hopper. The two sides of the inner wall of the feeding channel are fixedly connected to symmetric anti-pinch splash-proof devices. The middles of the two sides of the inner wall of the pulverizing box are fixedly connected to symmetric supporting material falling plates. The invention relates to the technical field of plastic processing machinery and equipment. The waste and old plastic pulverizing and grinding device solves the problem that the existing plastic pulverizing device has high energy consumption and poor pulverizing effects and produces secondary pollution, realizes uniform and thorough plastic pulverizing,effectively improves the plastic recovery efficiency and protects the environment.

Owner:湖州南浔博逸金属材料经营部

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com