Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

16970results about "Cocoa" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

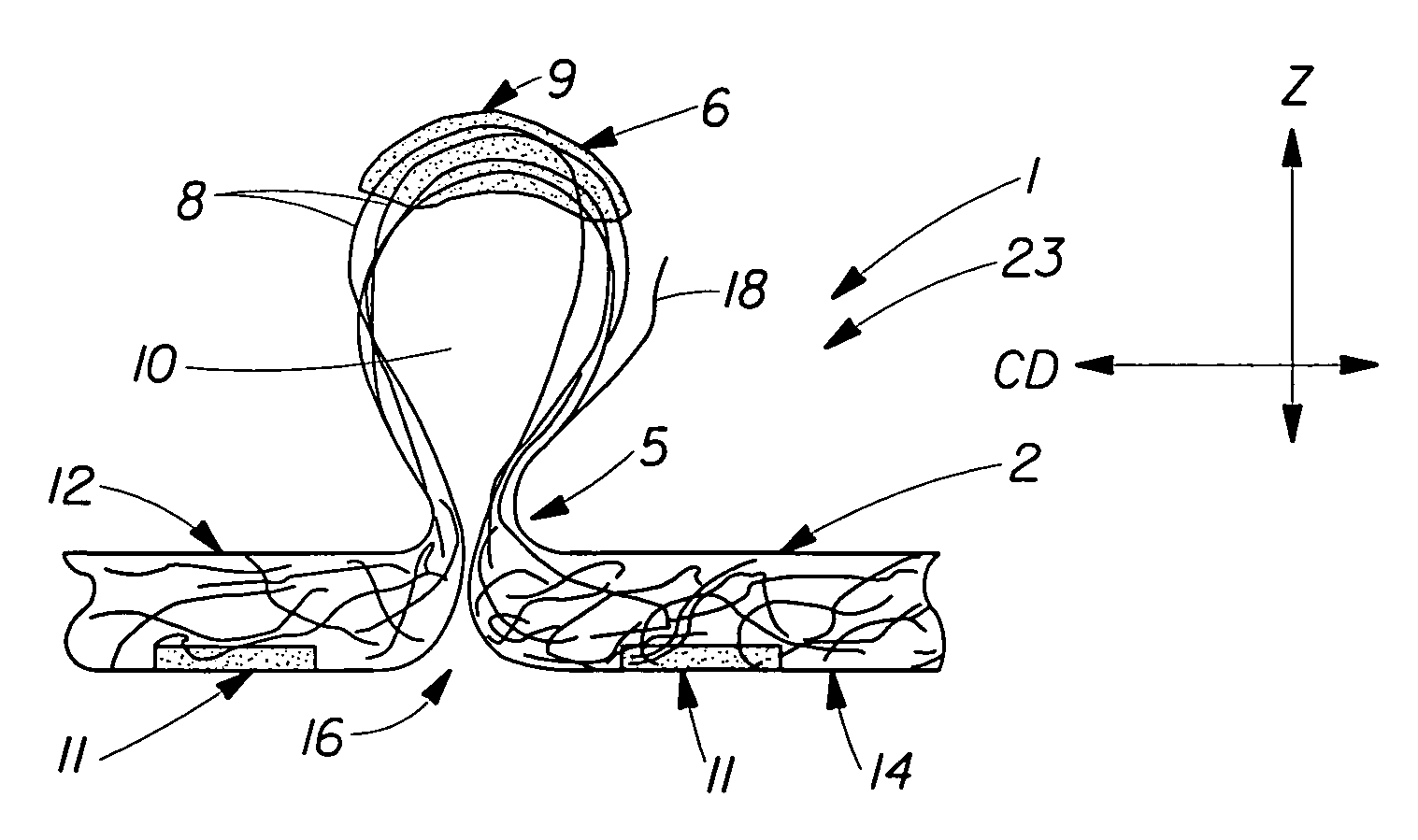

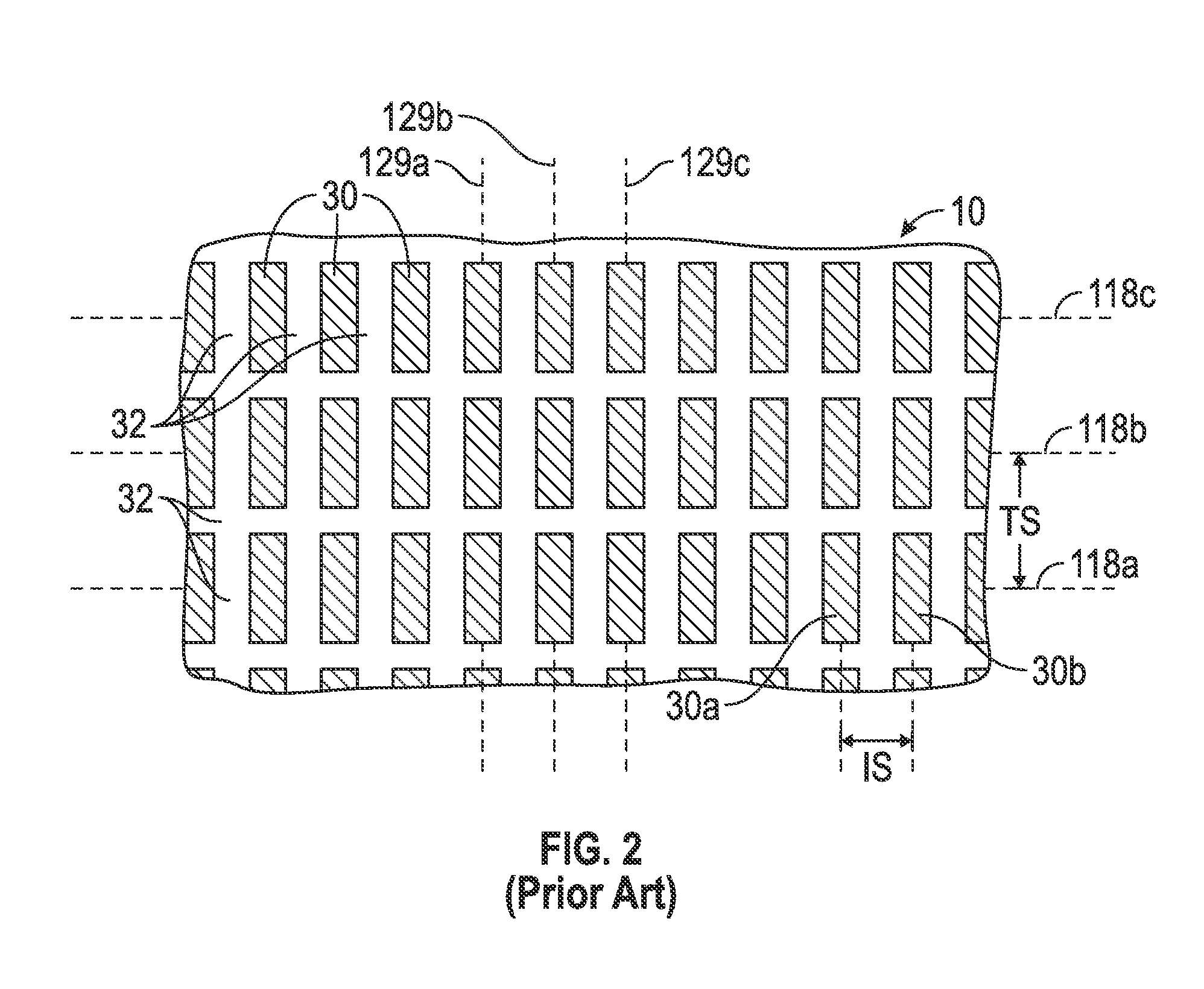

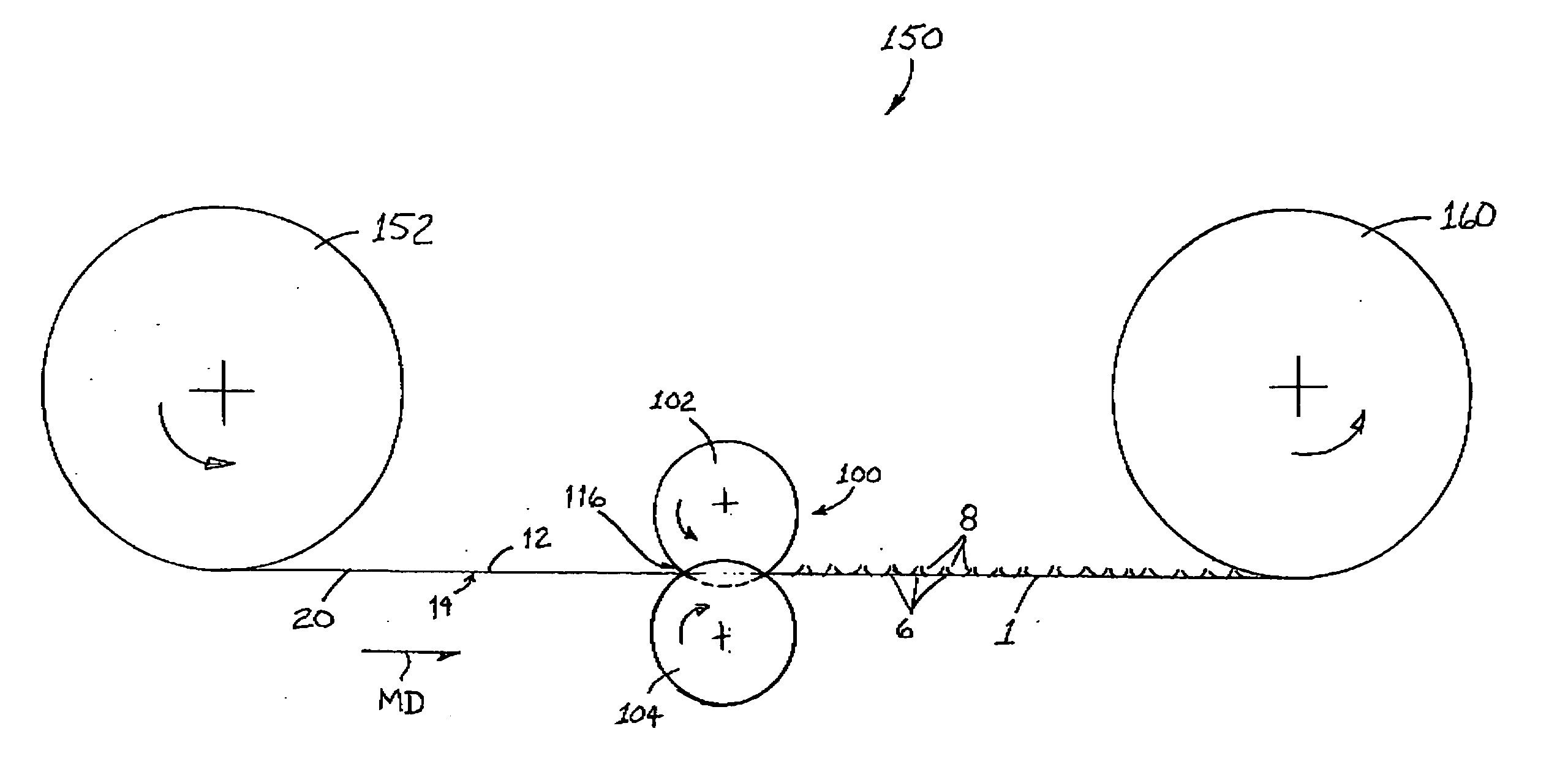

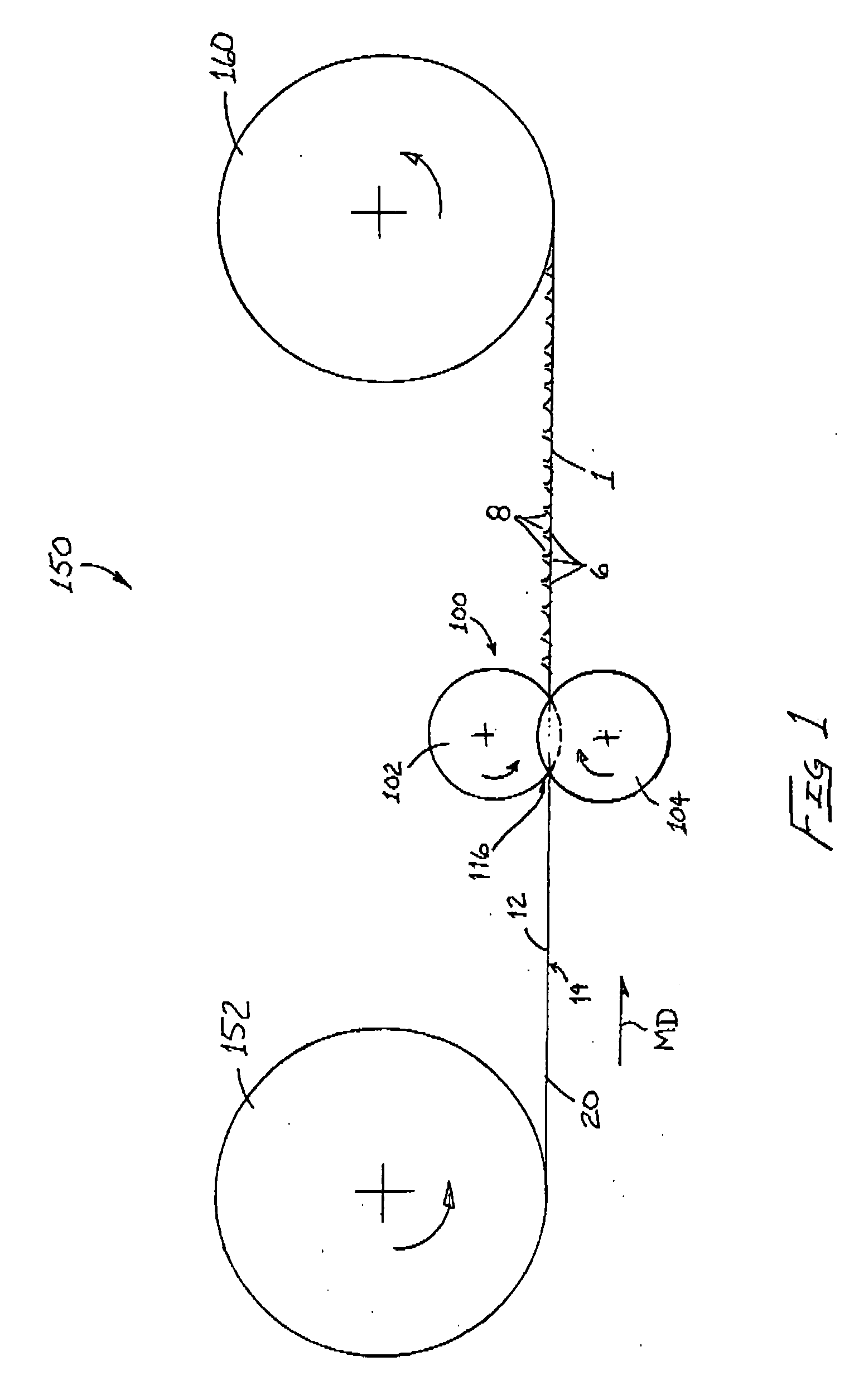

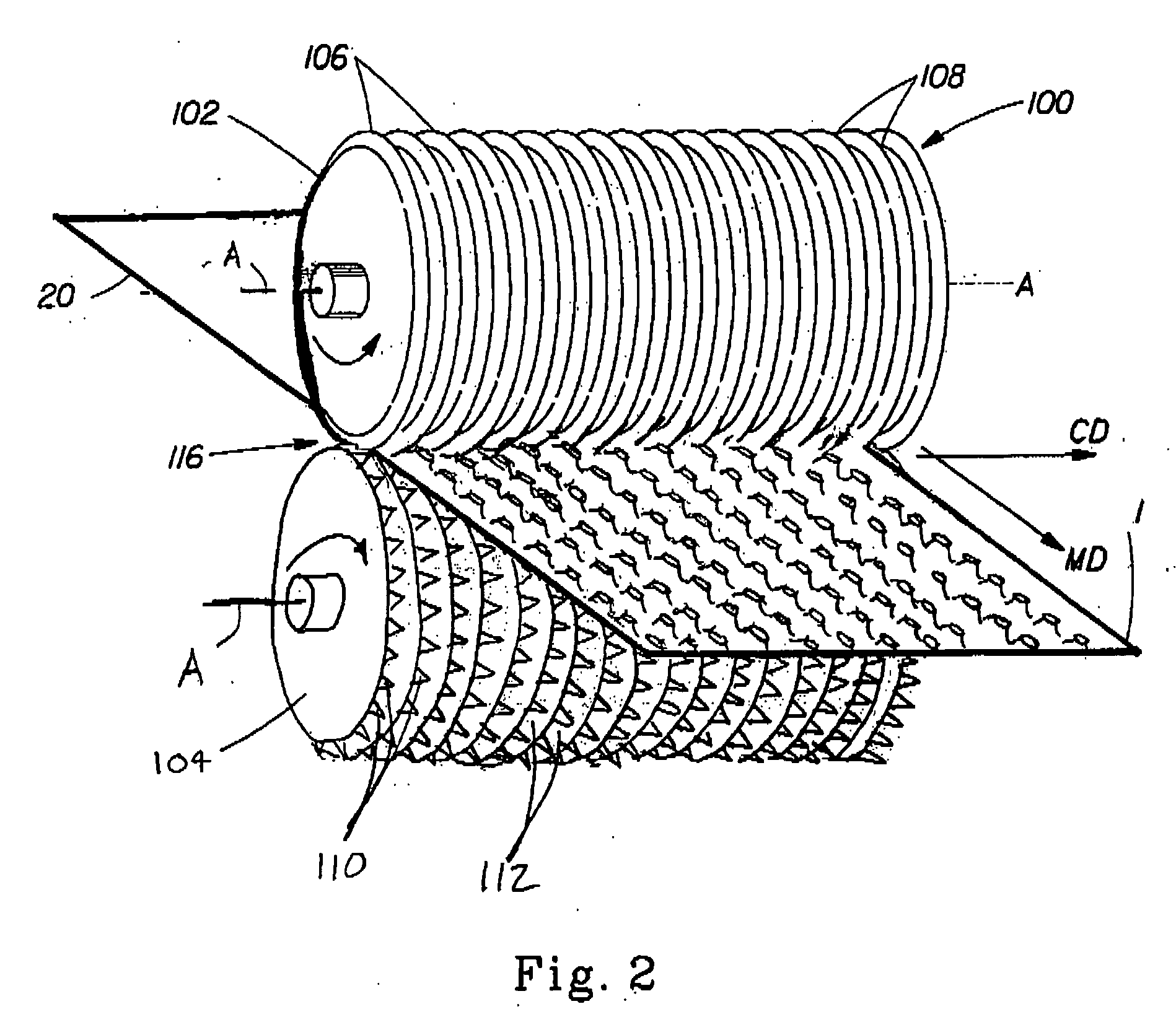

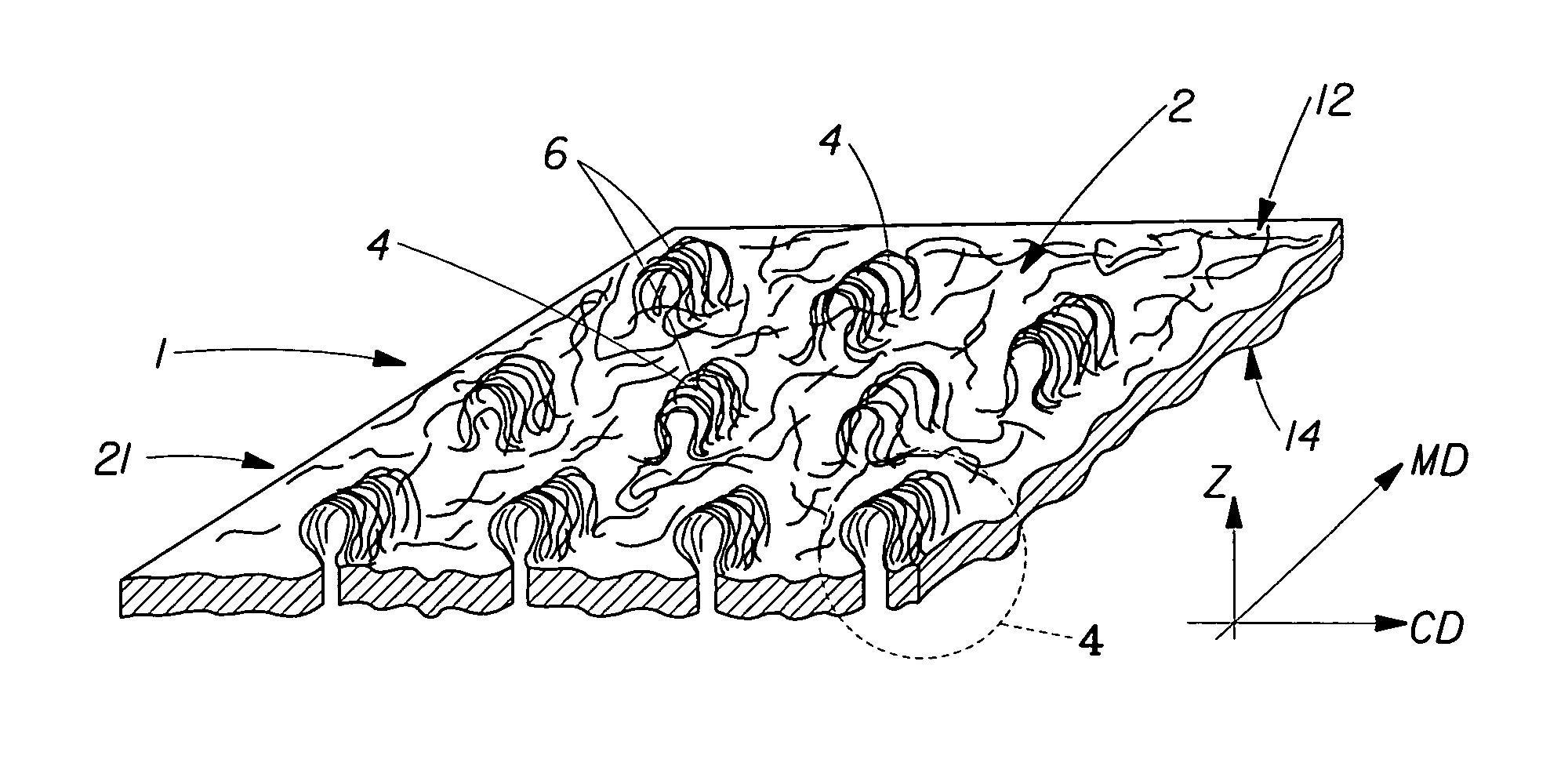

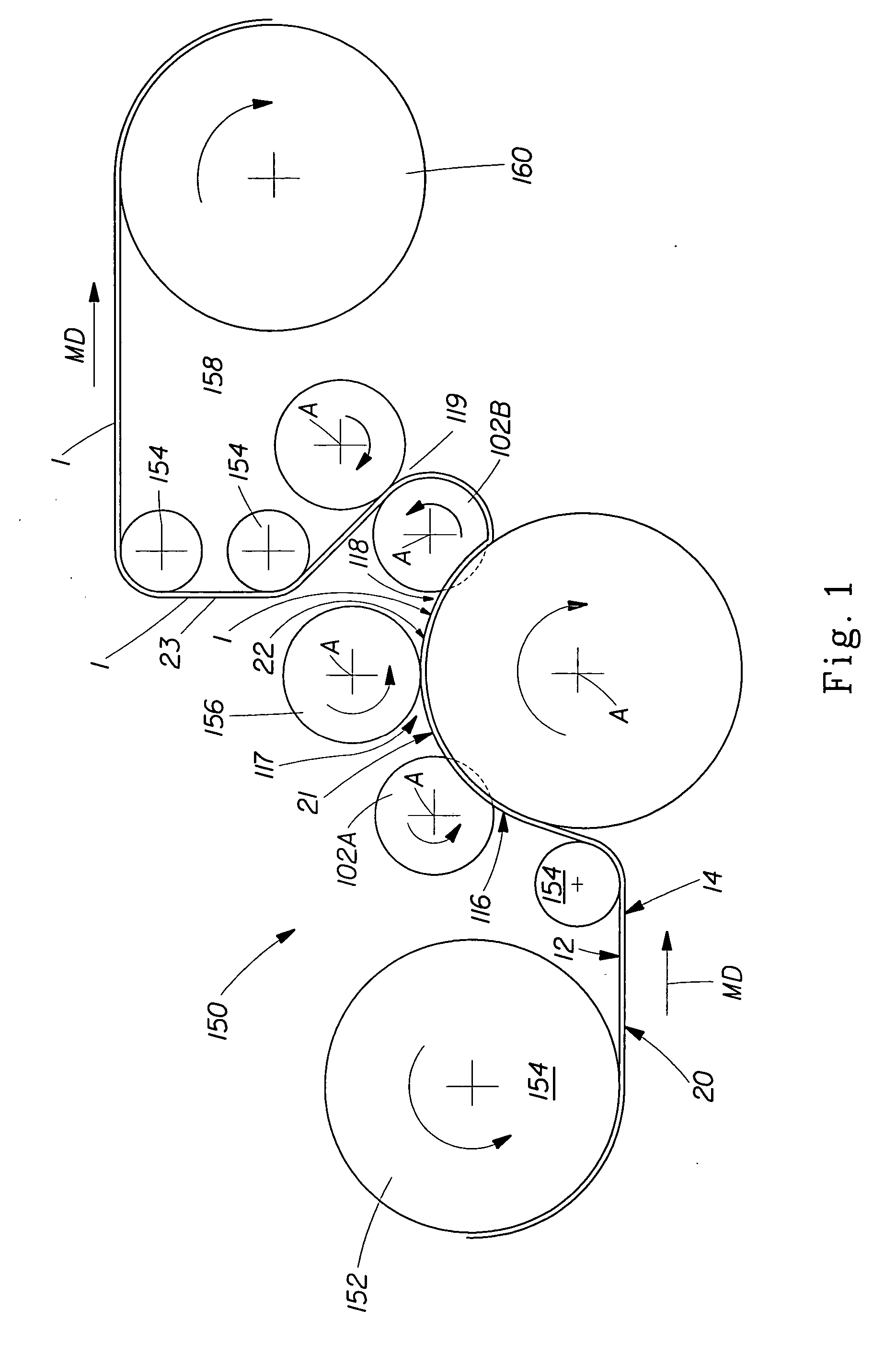

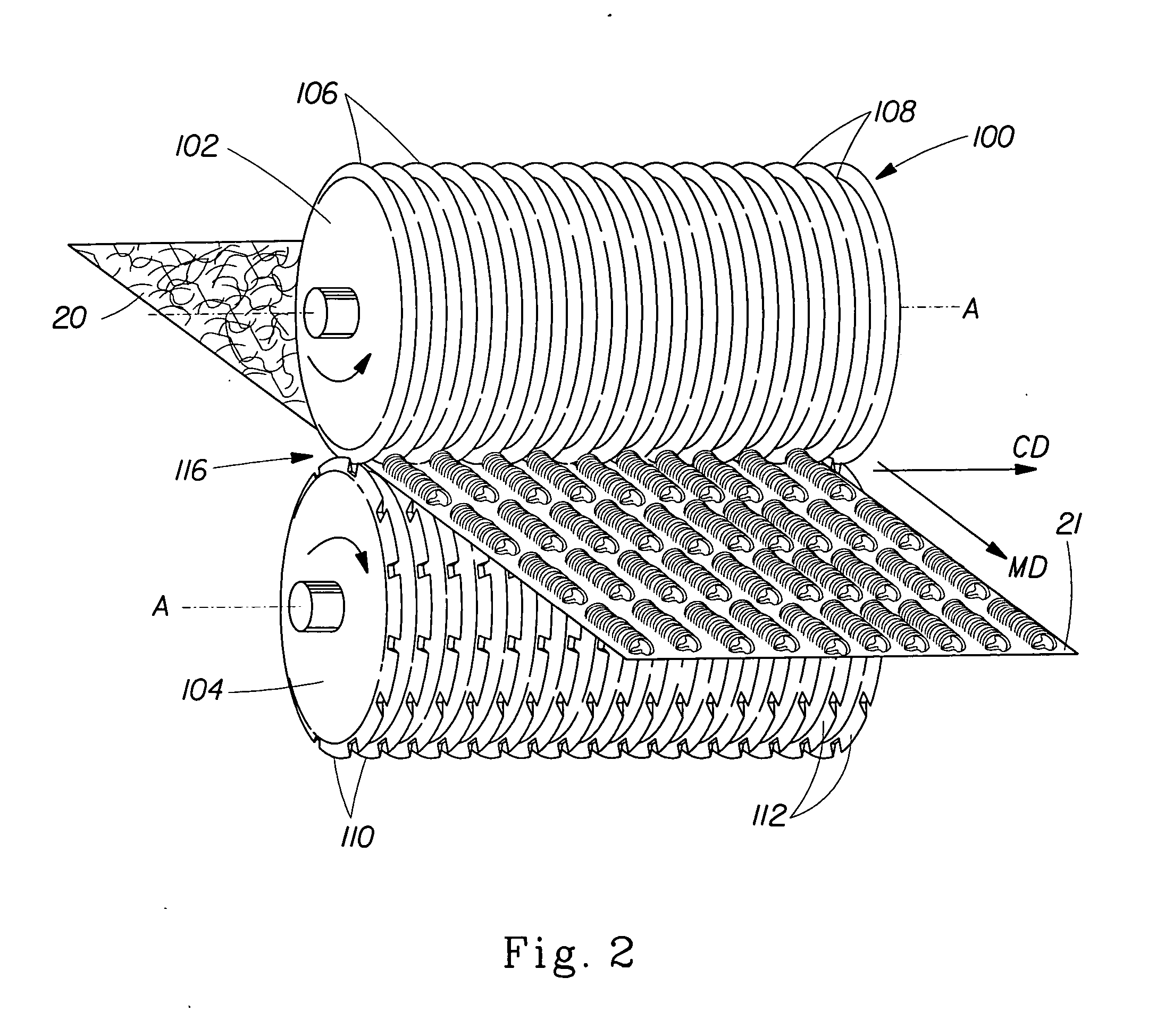

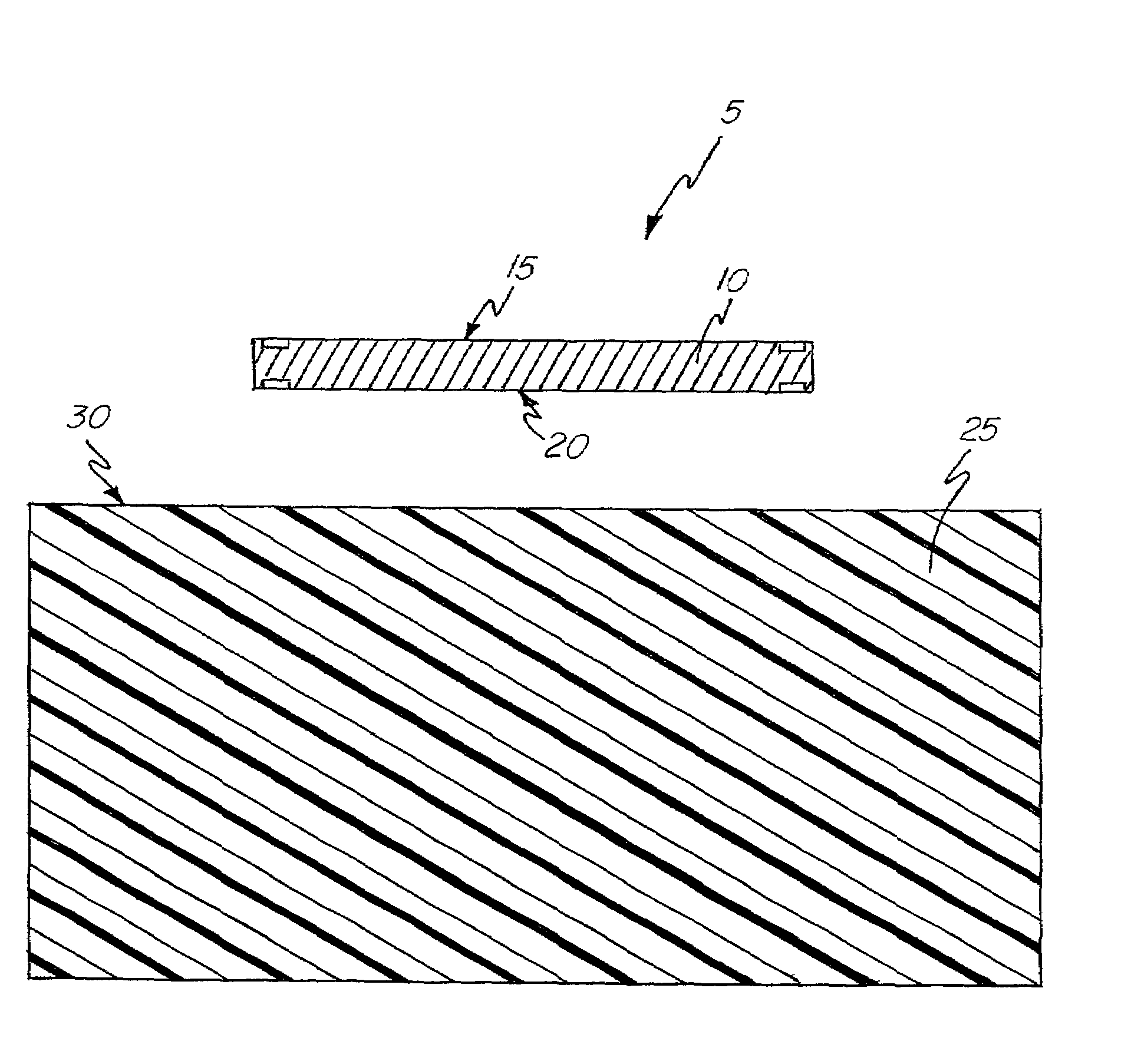

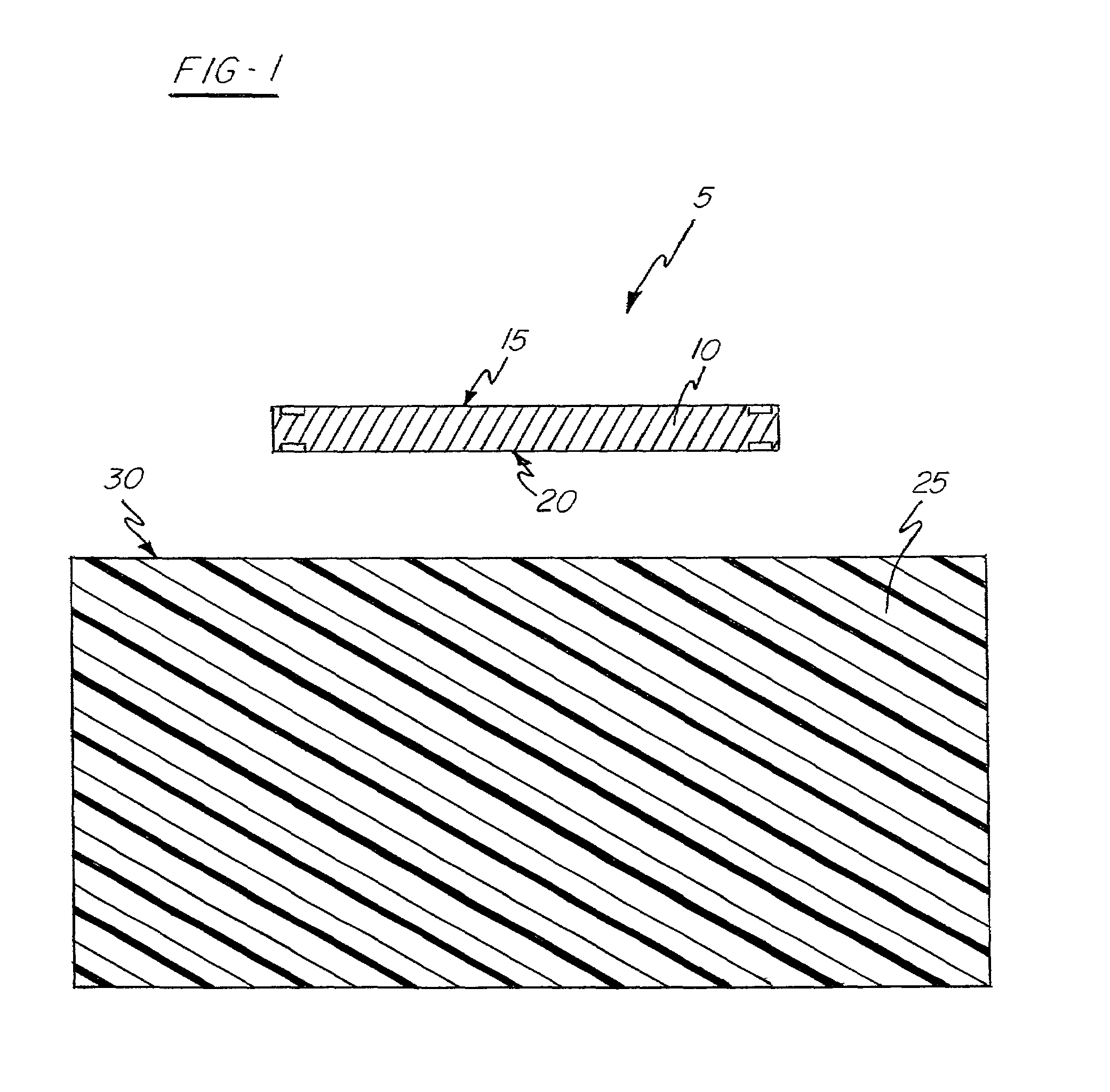

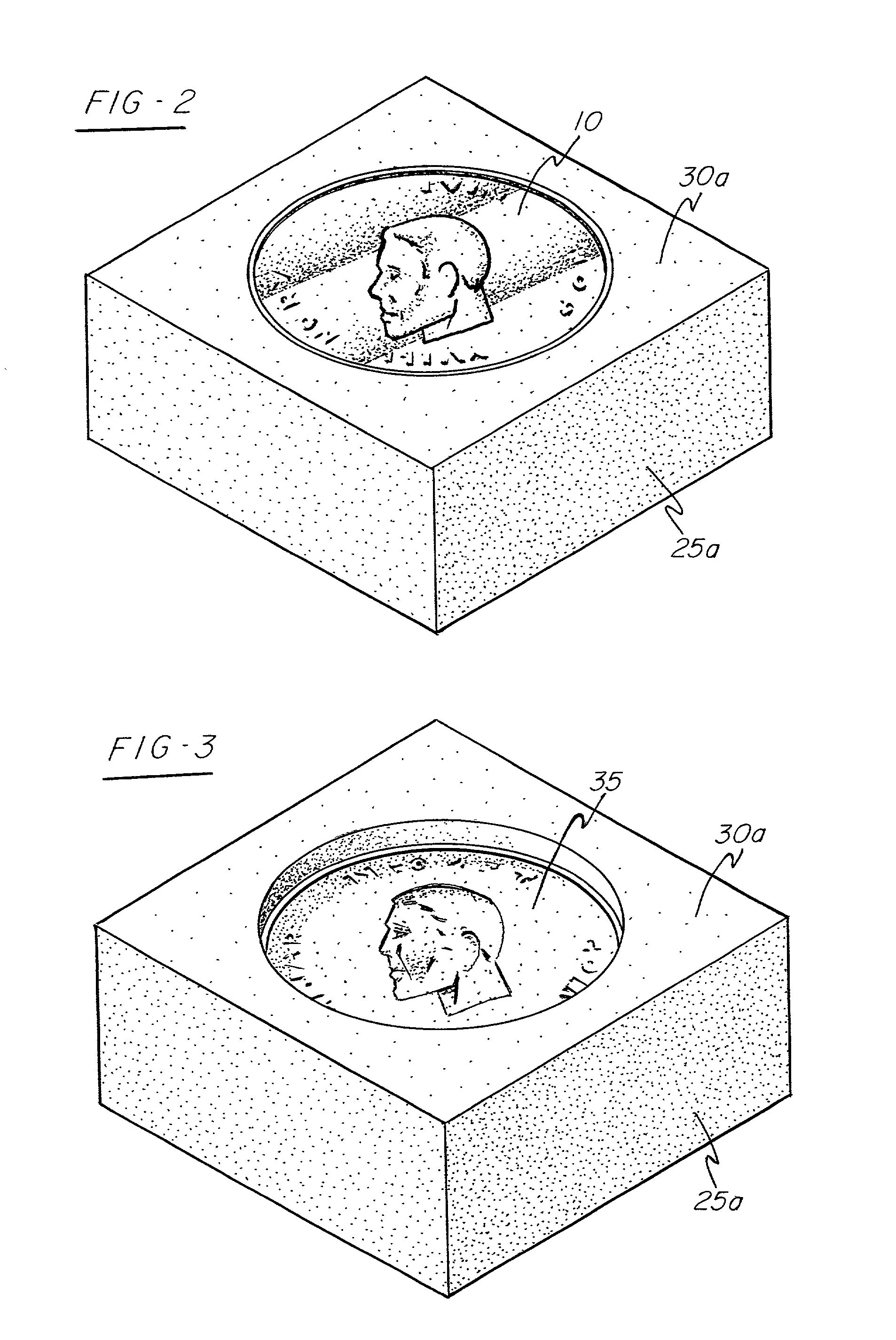

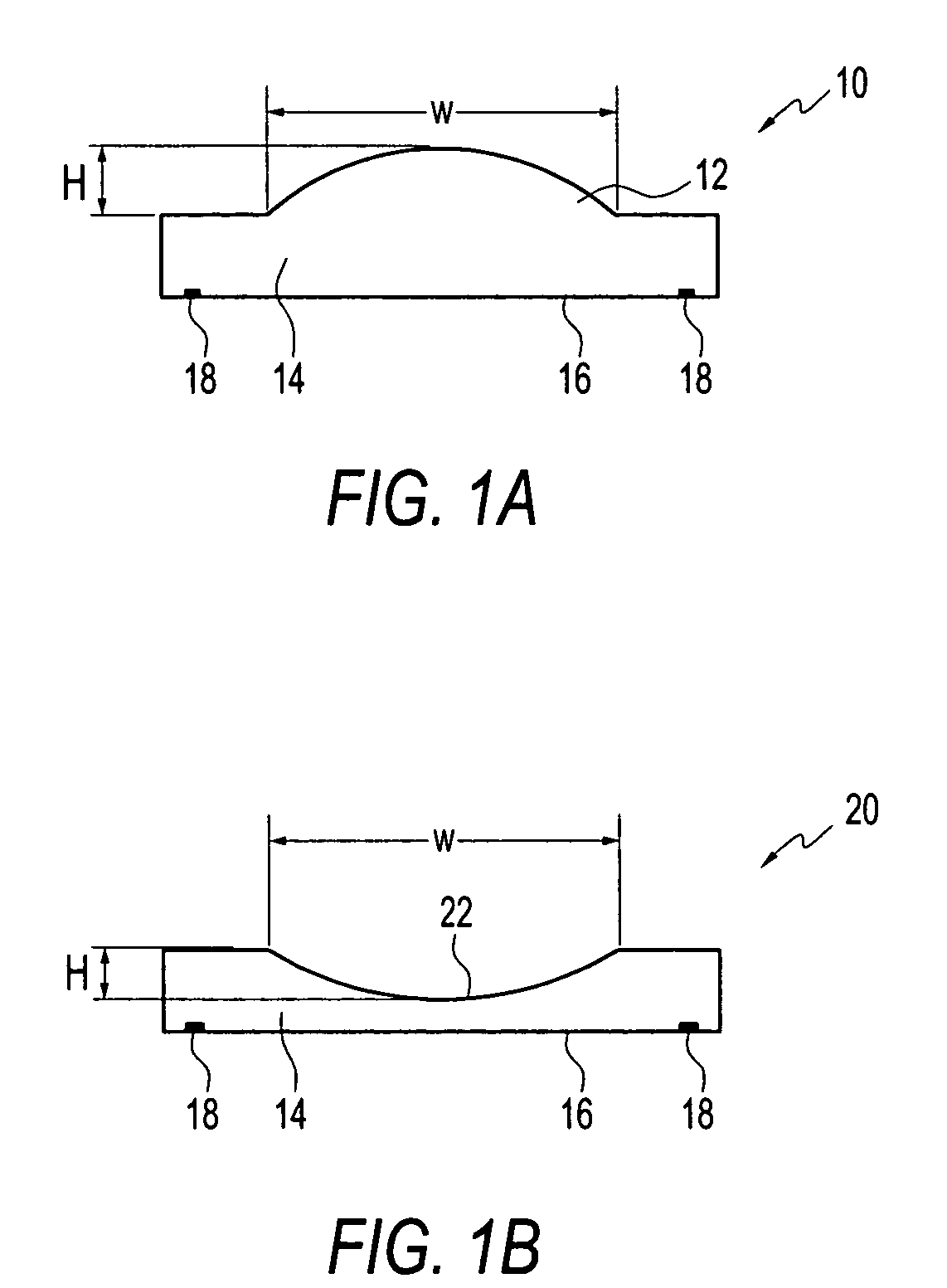

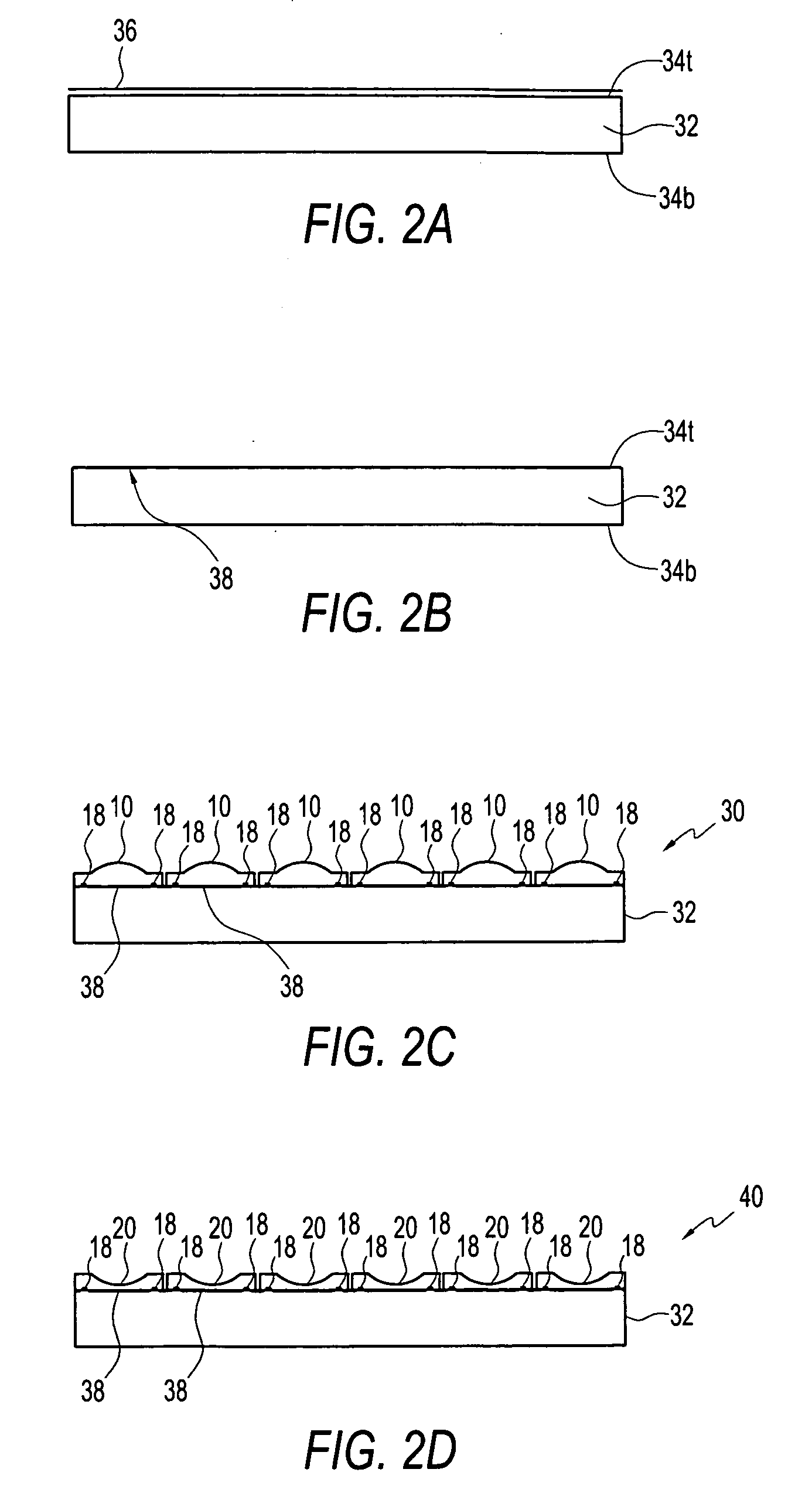

Tufted fibrous web

A fibrous web having a first surface and a second surface. The fibrous web has a first region and at least one discrete second region, the second region being a discontinuity on the second surface and being a tuft comprising a plurality of tufted fibers extending from the first surface. The tufted fibers define a distal portion, the distal portion comprising portions of the tufted fibers being bonded together. Bonding can be thermal melt-bonding. In another embodiment the second surface of the web can have non-intersecting or substantially continuous bonded regions, which also can be thermal melt-bonding.

Owner:PROCTER & GAMBLE CO

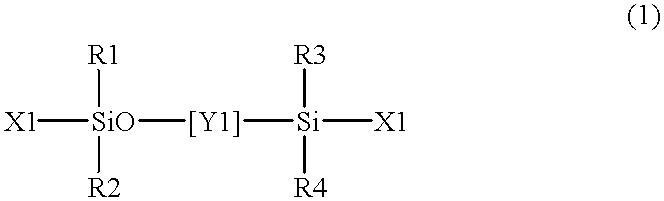

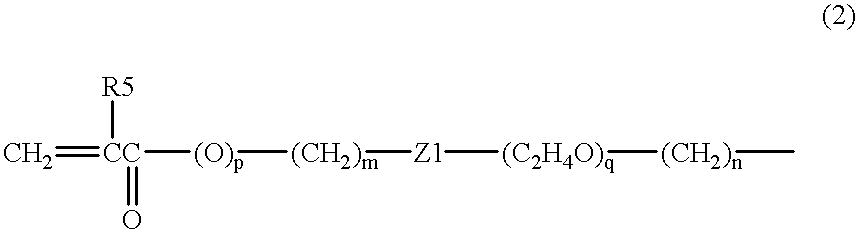

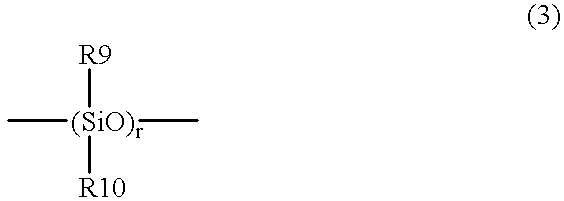

Long wearable soft contact lens

The present invention relates to a soft contact lens, and provides a contact lens which shows small and stable contact angle to water at its surface in water as well as in air, little deposition in wearing, high oxygen permeability, no adhesion of lens to a cornea and superior extended-wearing characteristics. The present invention provides a hydrogel soft contact lens which has contact angle at a lens surface in a range of 10-50° by the captive bubble method in water and 30-90° by the sessile drop method in air, oxygen permeability of not less than 30 and water content of not less than 5%, and also a hydrogel soft contact lens consisting of a polymer comprising a hydrophilic siloxanyl monomer shown by a specified general formula.

Owner:COOPERVISION INT LTD

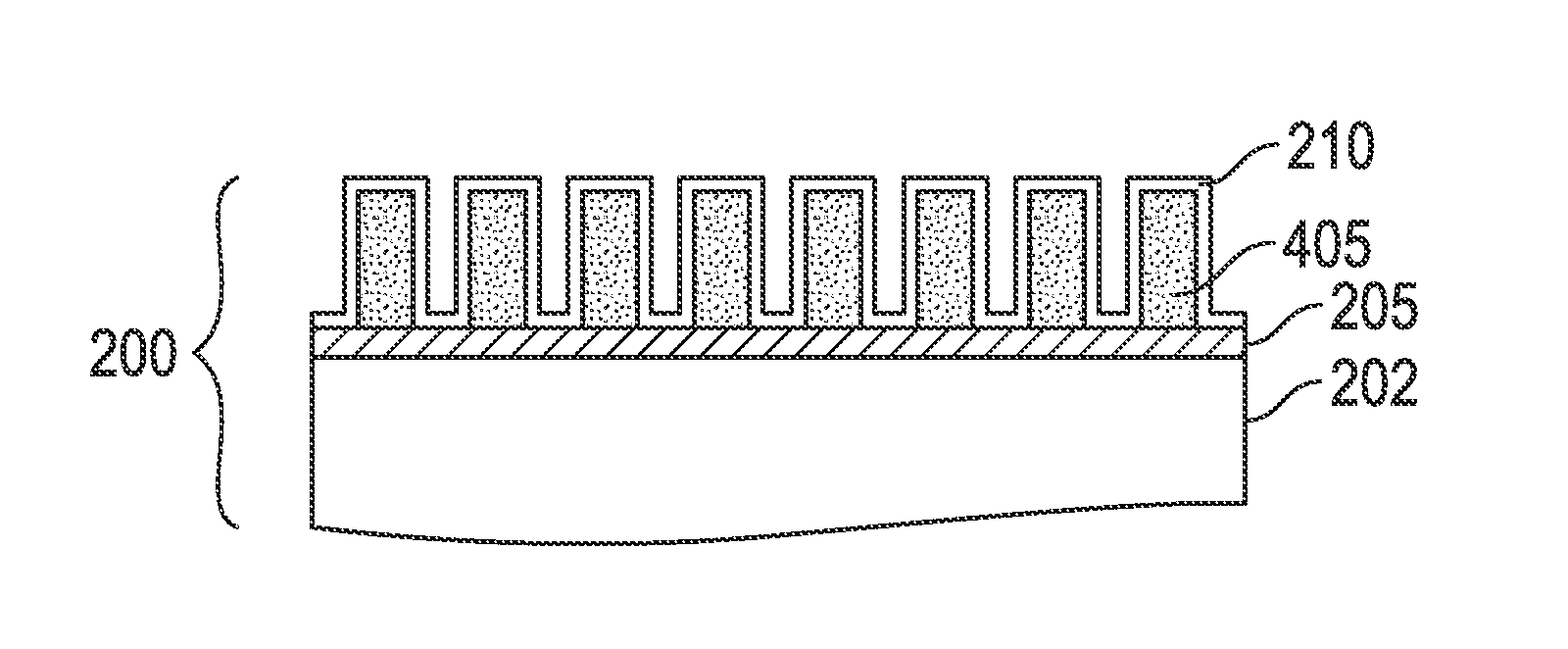

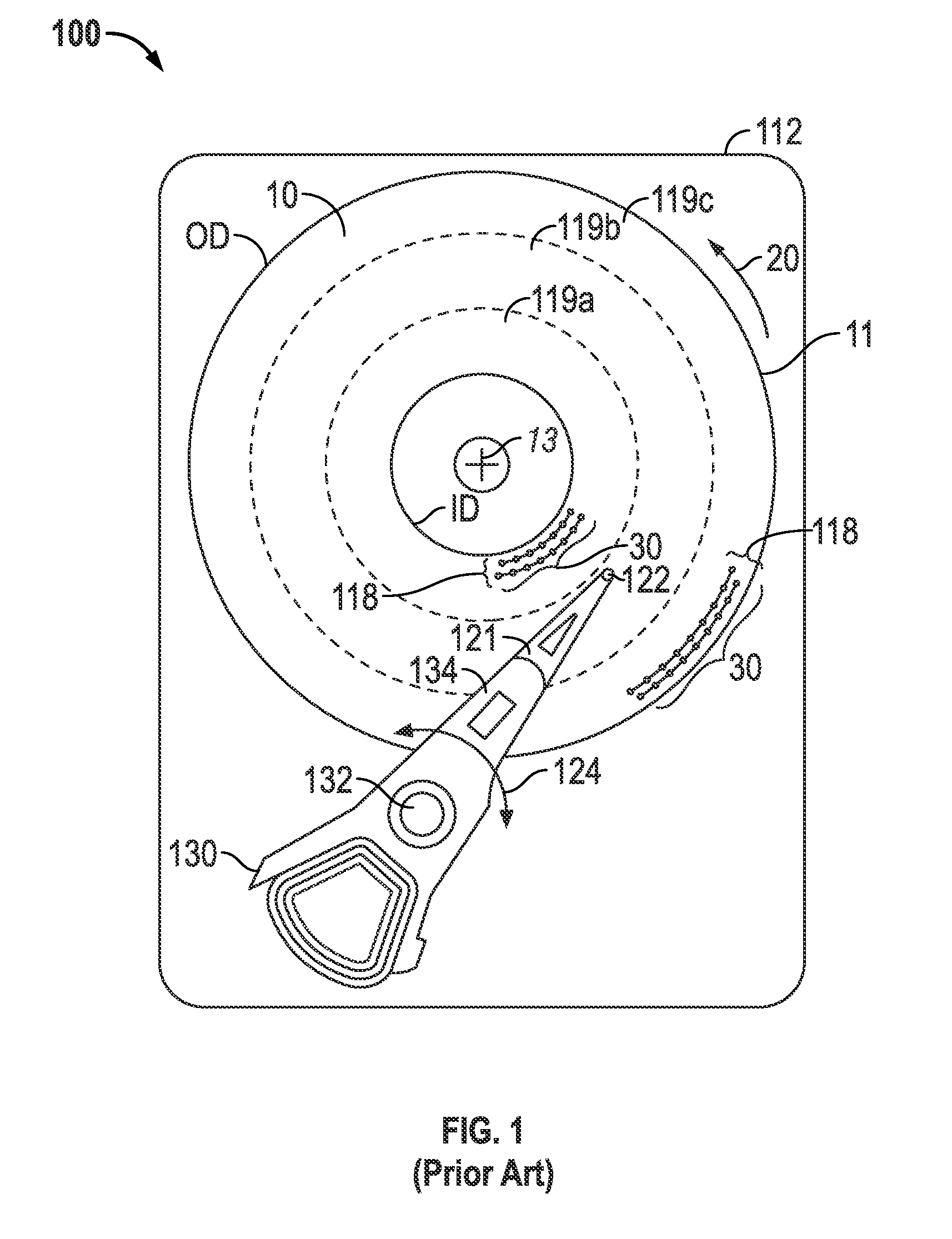

Imprint mold and method for making using sidewall spacer line doubling

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

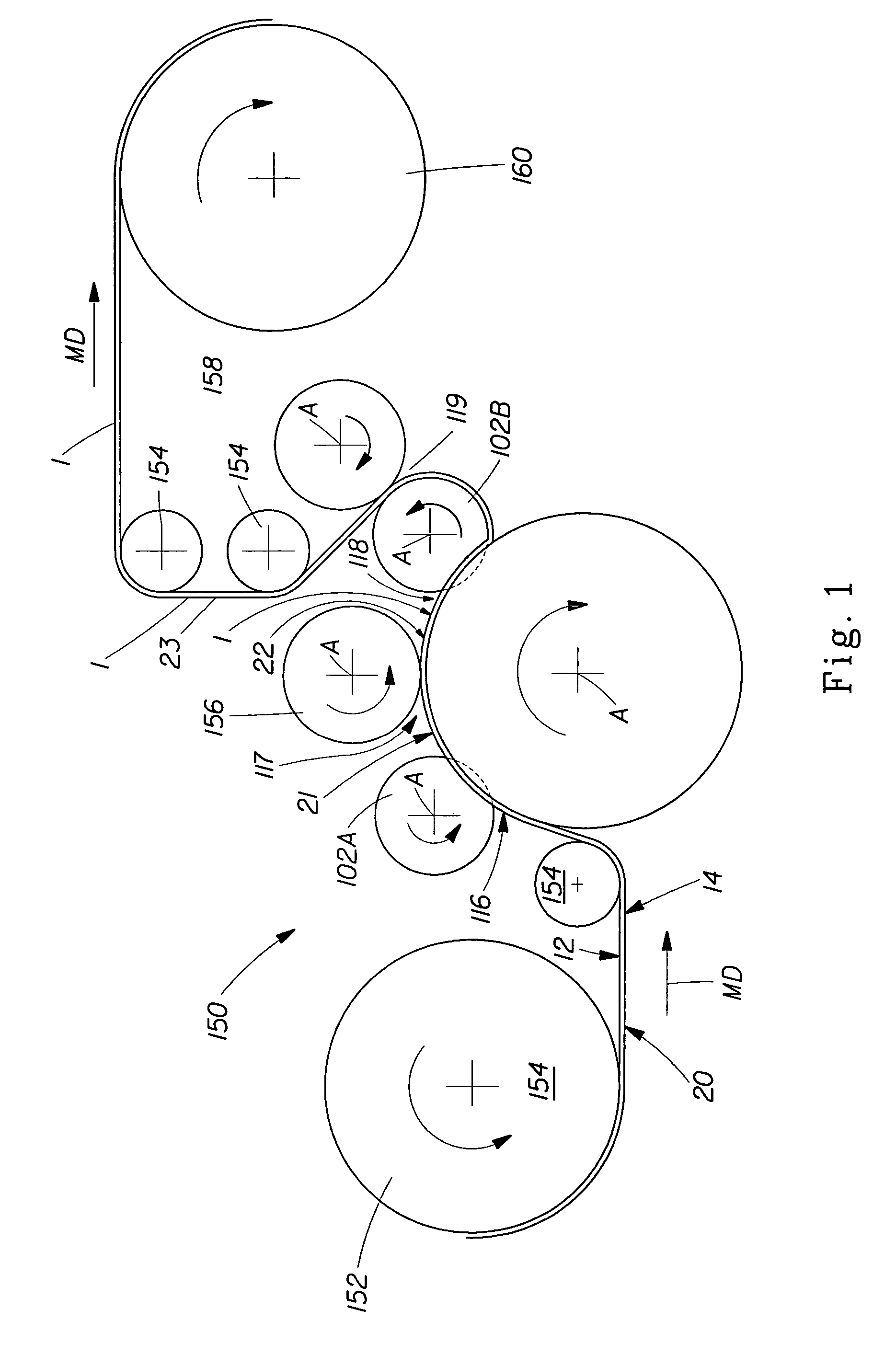

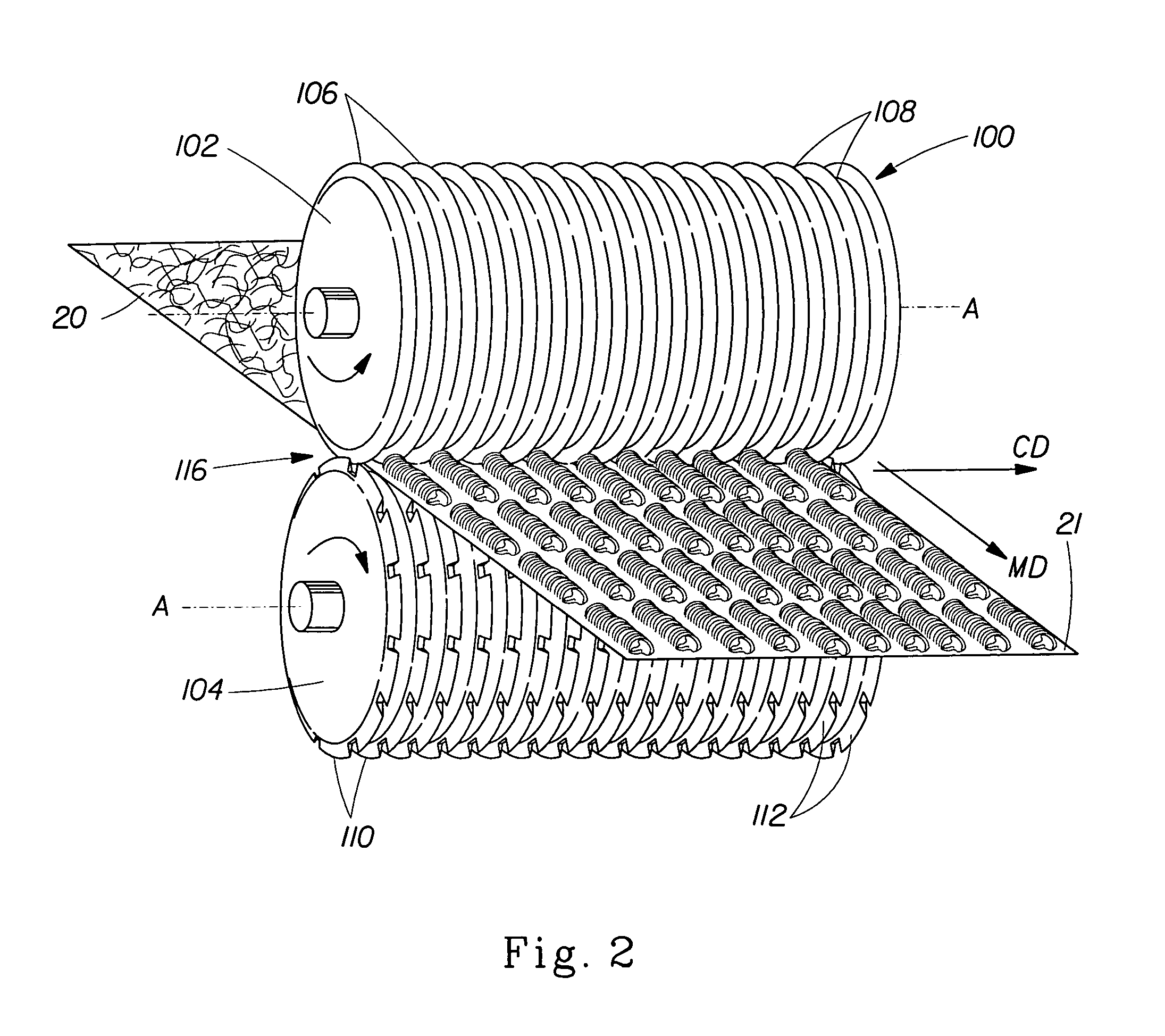

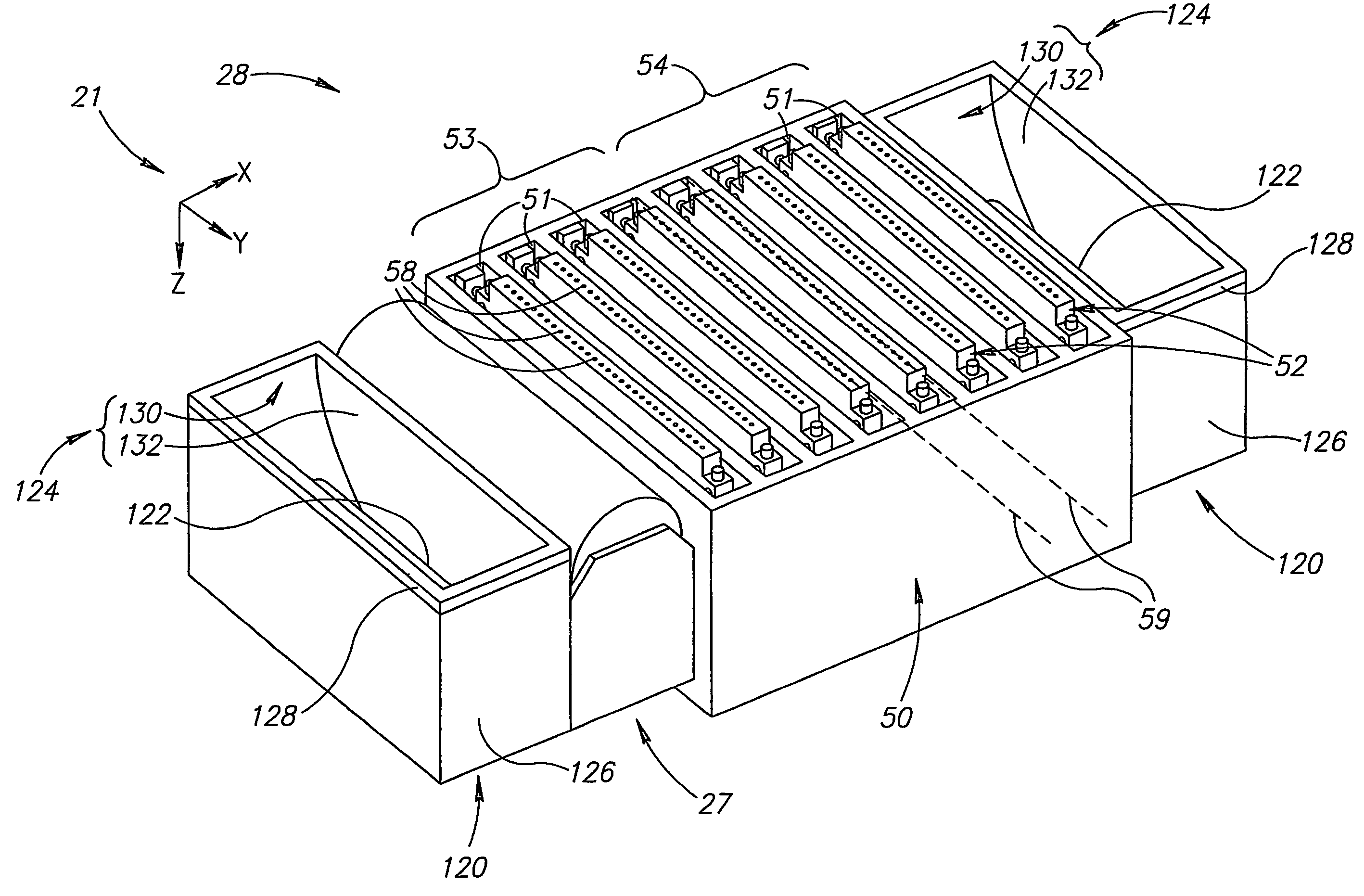

Method and apparatus for making an apertured web

Owner:THE PROCTER & GAMBLE COMPANY

Taste-improving composition and application of the same

The present invention provides a method for improving the taste of sweeteners, and a method for improving the taste of edible products containing sweeteners. The present invention can be worked by using sclareolide and 2-acetylpyrrole in combination with a sweetener. By using the method of the present invention, an astringent taste, bitter taste or aftertastes such as lingering taste originating especially in high-intensity sweeteners can be reduced, so that edible products with an improved taste can be provided.

Owner:SAN EI GEN F F I

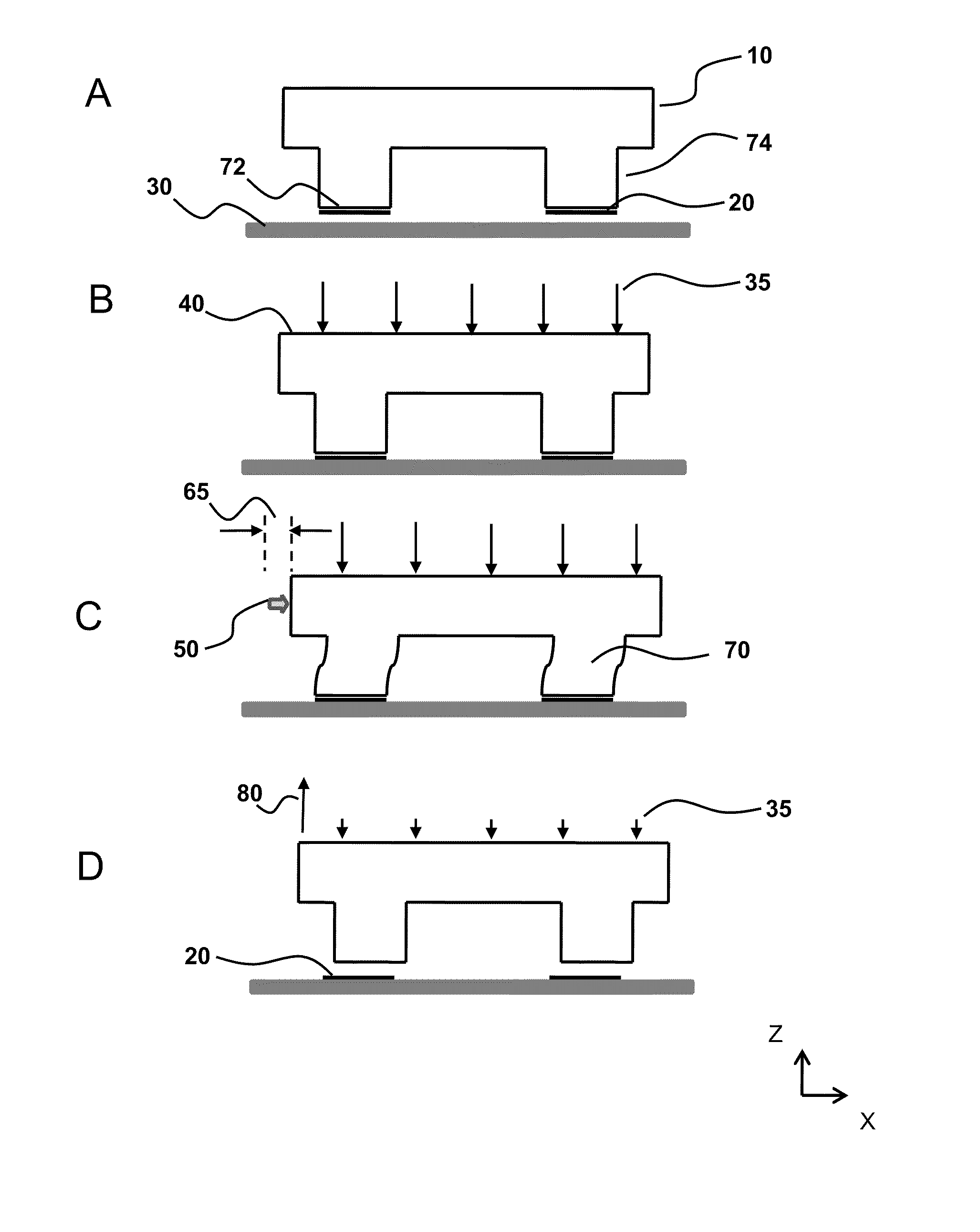

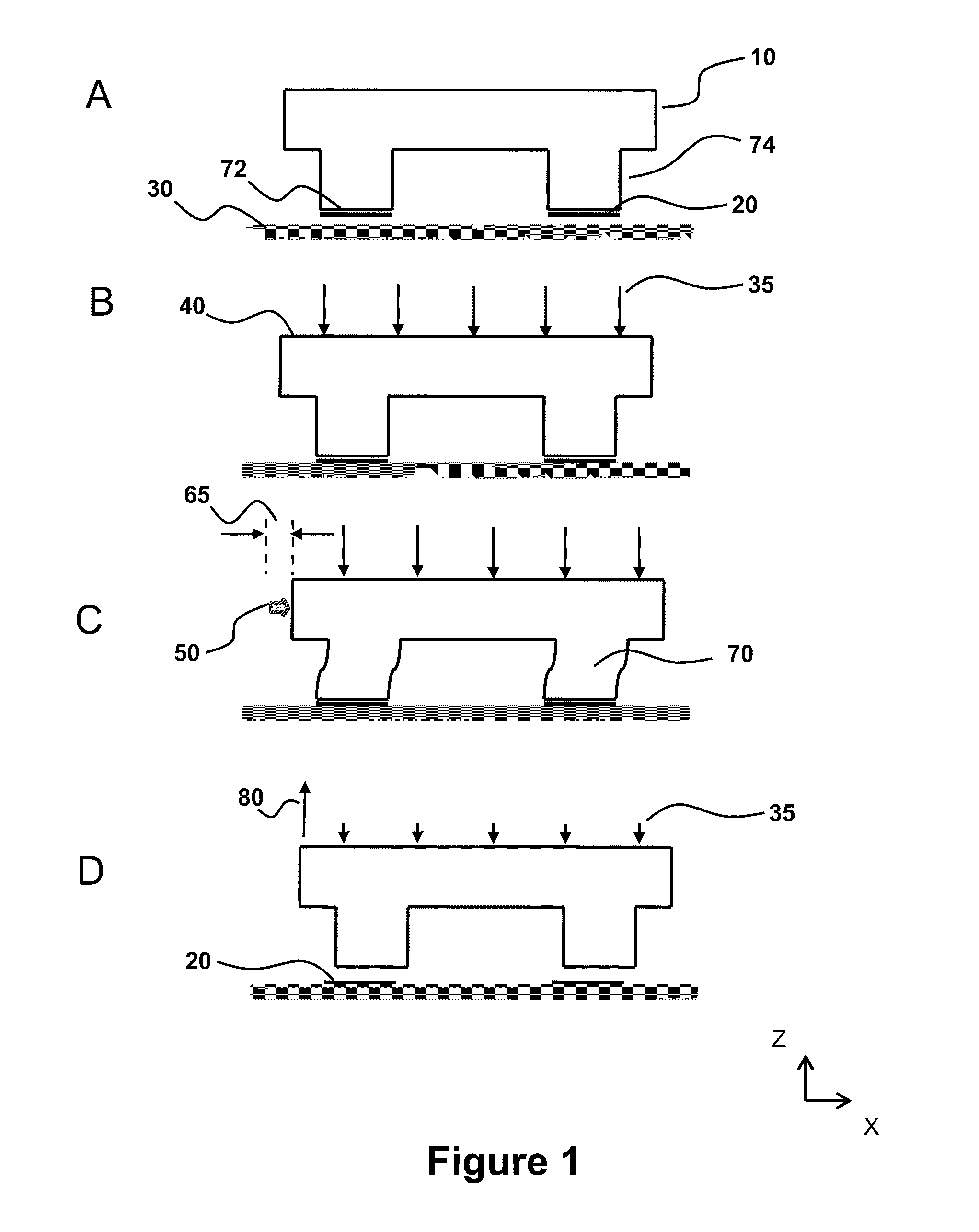

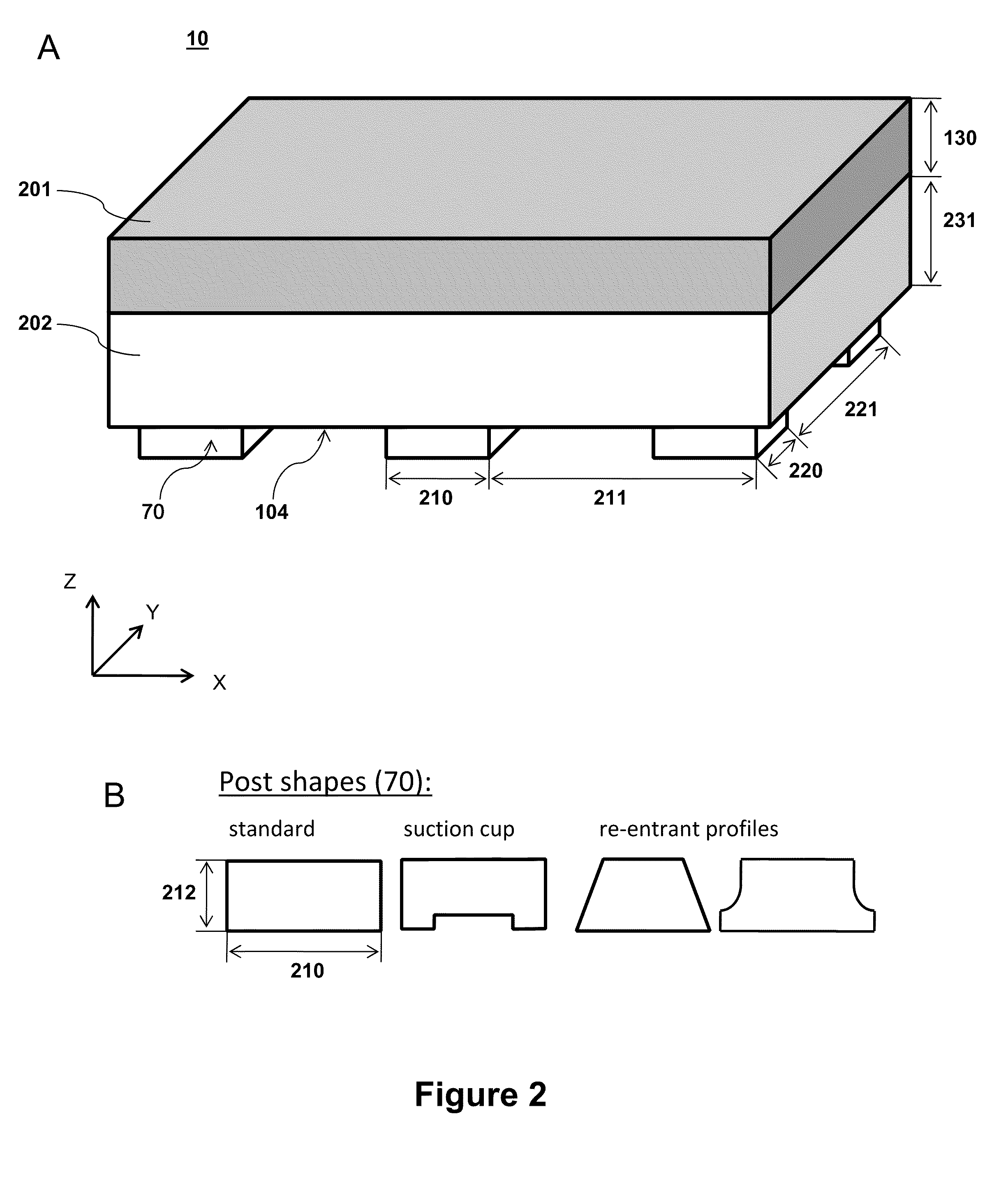

Printing semiconductor elements by shear-assisted elastomeric stamp transfer

ActiveUS8506867B2Sacrificing printing yield and accuracyIncrease chanceConfectionerySolid-state devicesEngineeringVertical displacement

Provided are methods and devices for transfer printing of semiconductor elements to a receiving surface. In an aspect, the printing is by conformal contact between an elastomeric stamp inked with the semiconductor elements and a receiving surface, and during stamp removal, a shear offset is applied between the stamp and the receiving surface. The shear-offset printing process achieves high printing transfer yields with good placement accuracy. Process parameter selection during transfer printing, including time varying stamp-backing pressure application and vertical displacement, yields substantially constant delamination rates with attendant transfer printing improvement.

Owner:X DISPLAY CO TECH LTD

Tufted fibrous web

A fibrous web having a first surface and a second surface. The fibrous web has a first region and at least one discrete second region, the second region being a discontinuity on the second surface and being a tuft comprising a plurality of tufted fibers extending from the first surface. The tufted fibers define a distal portion, the distal portion comprising portions of the tufted fibers being bonded together. Bonding can be thermal melt-bonding. In another embodiment the second surface of the web can have non-intersecting or substantially continuous bonded regions, which also can be thermal melt-bonding.

Owner:THE PROCTER & GAMBLE COMPANY

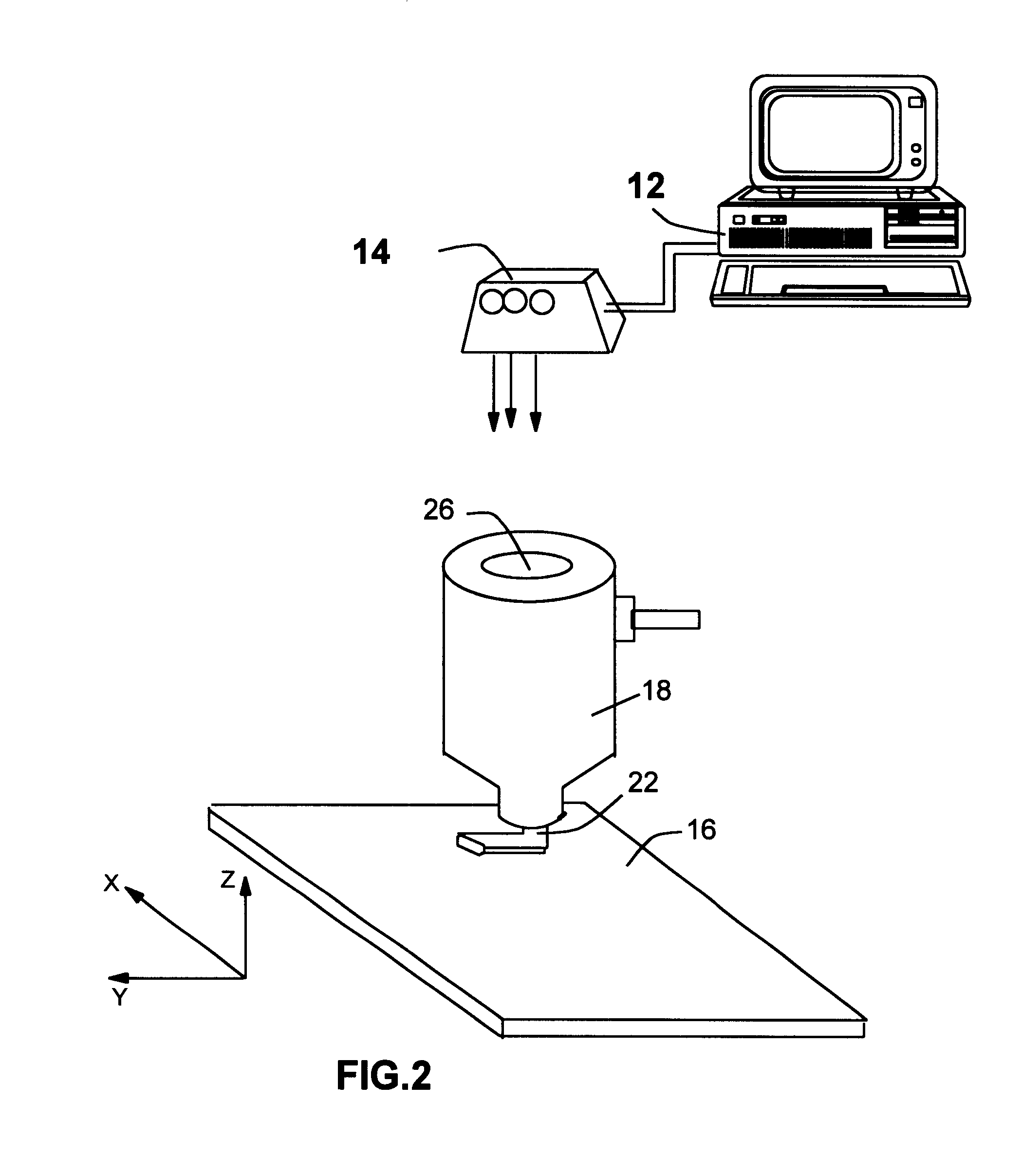

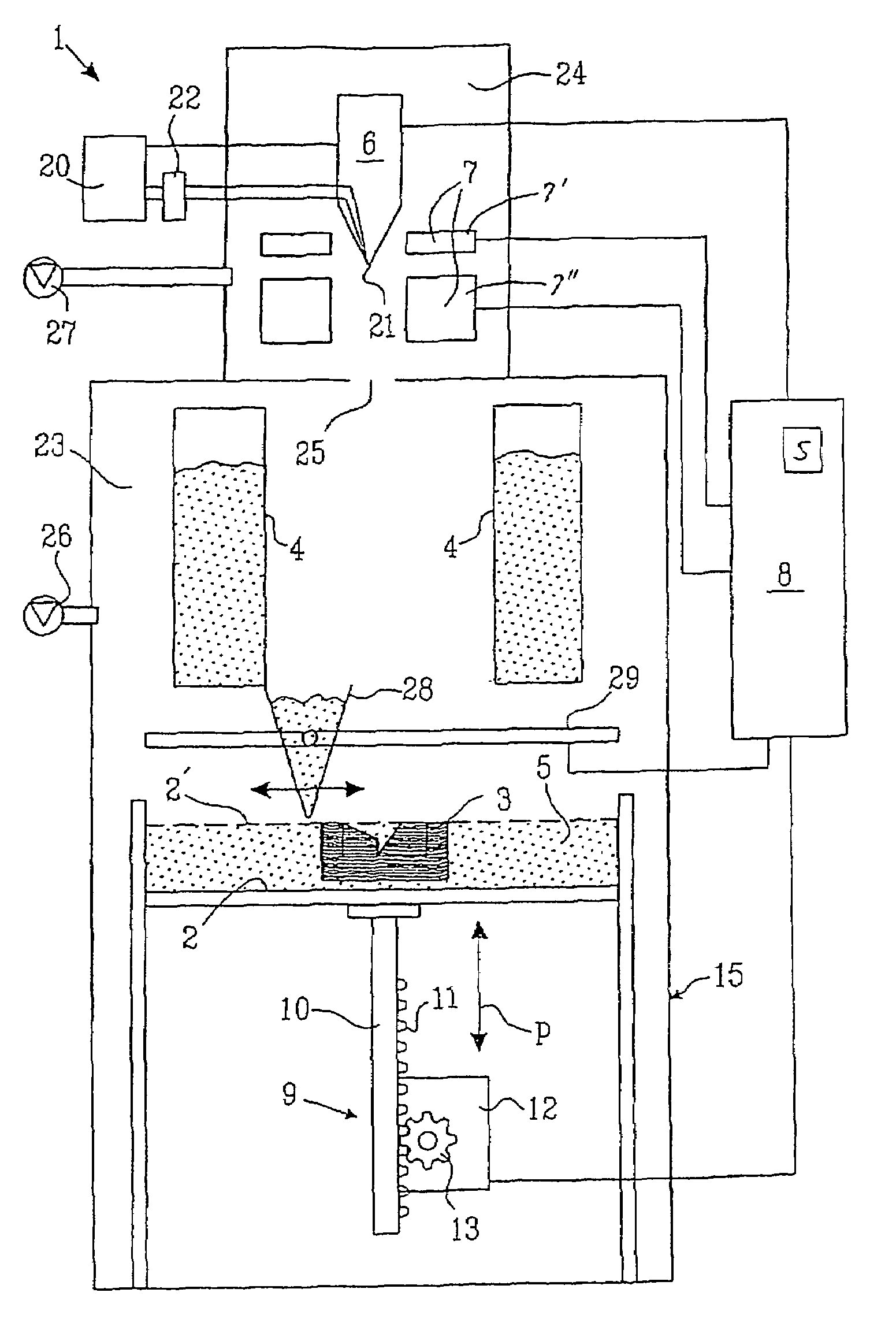

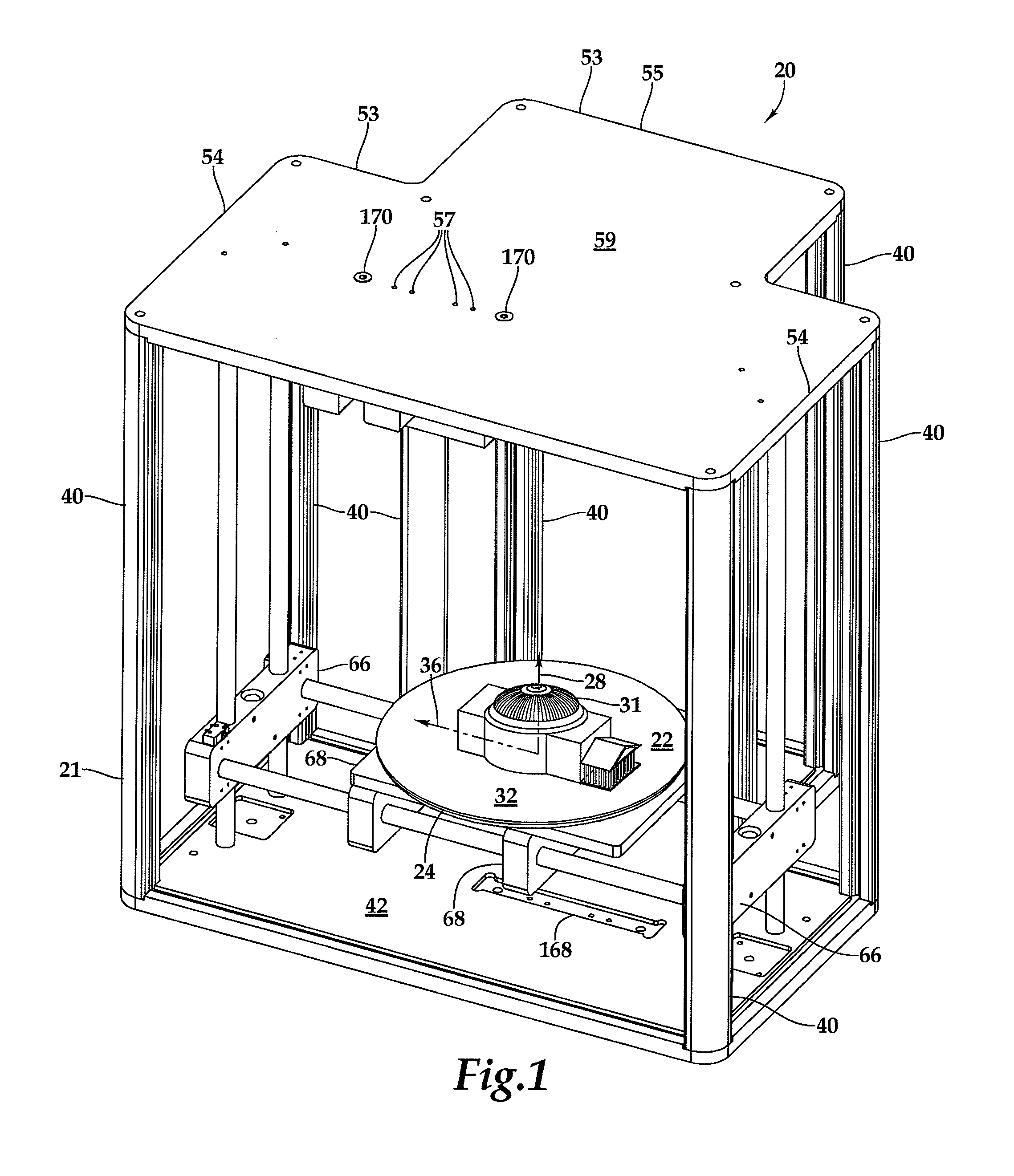

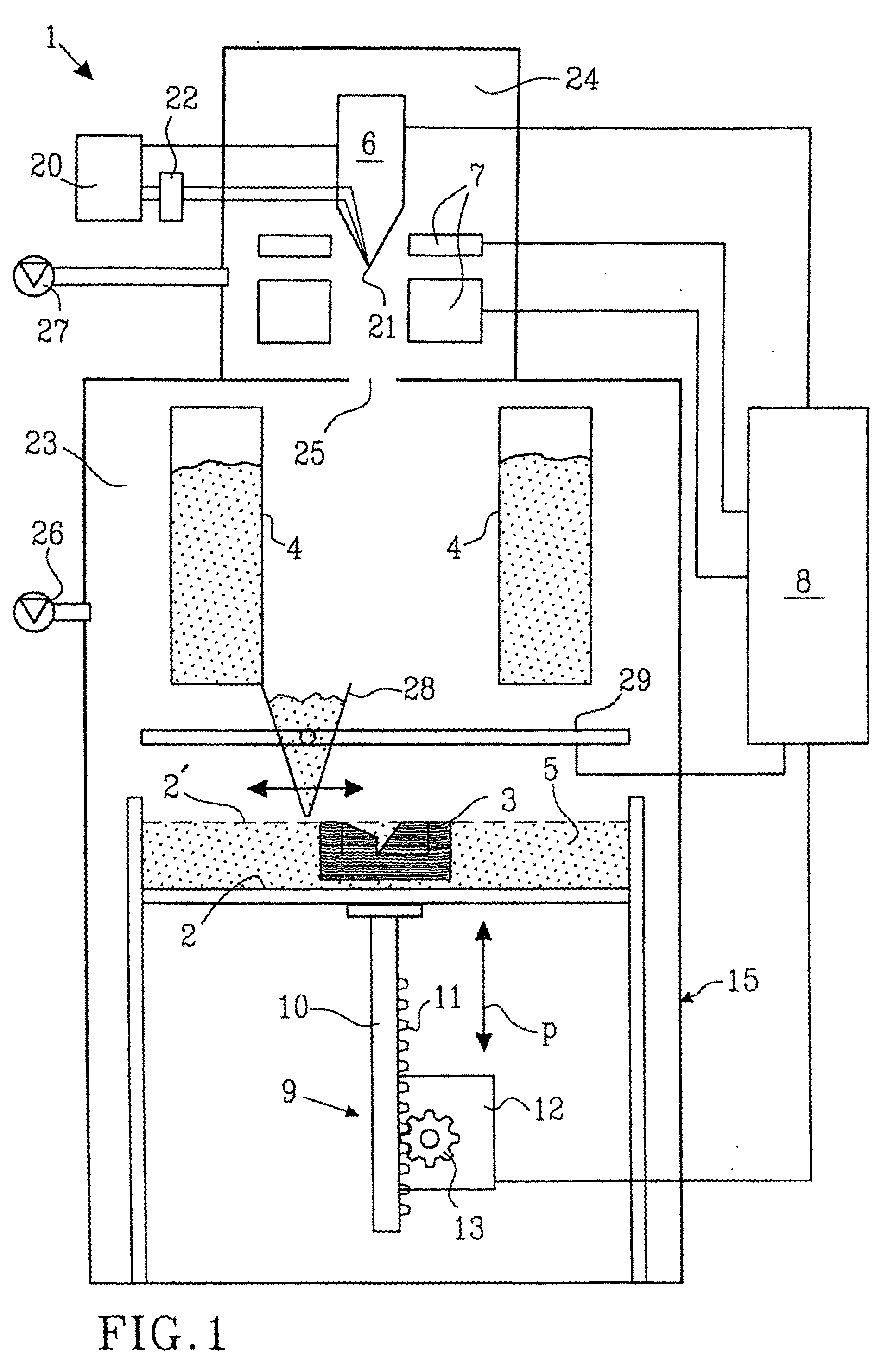

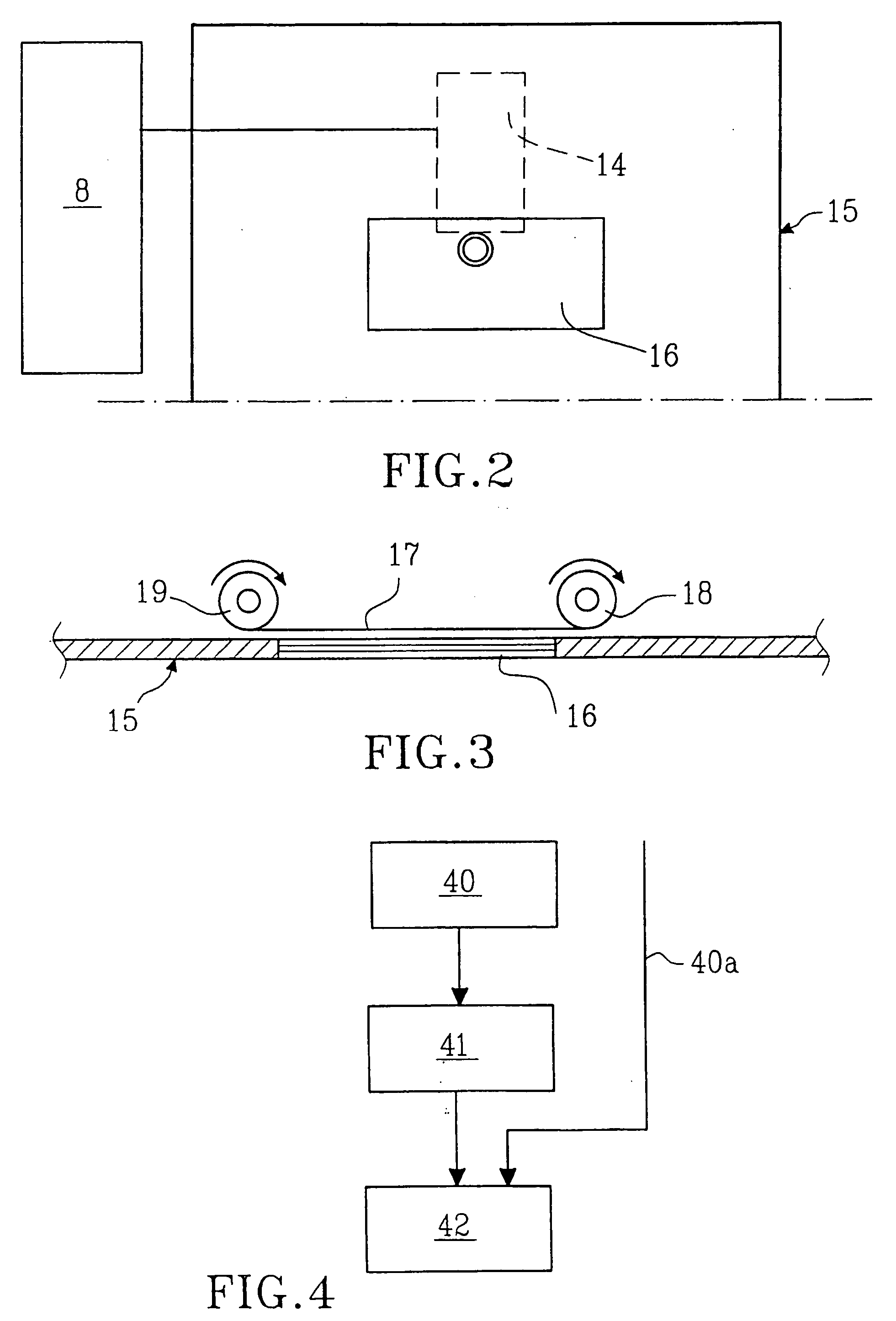

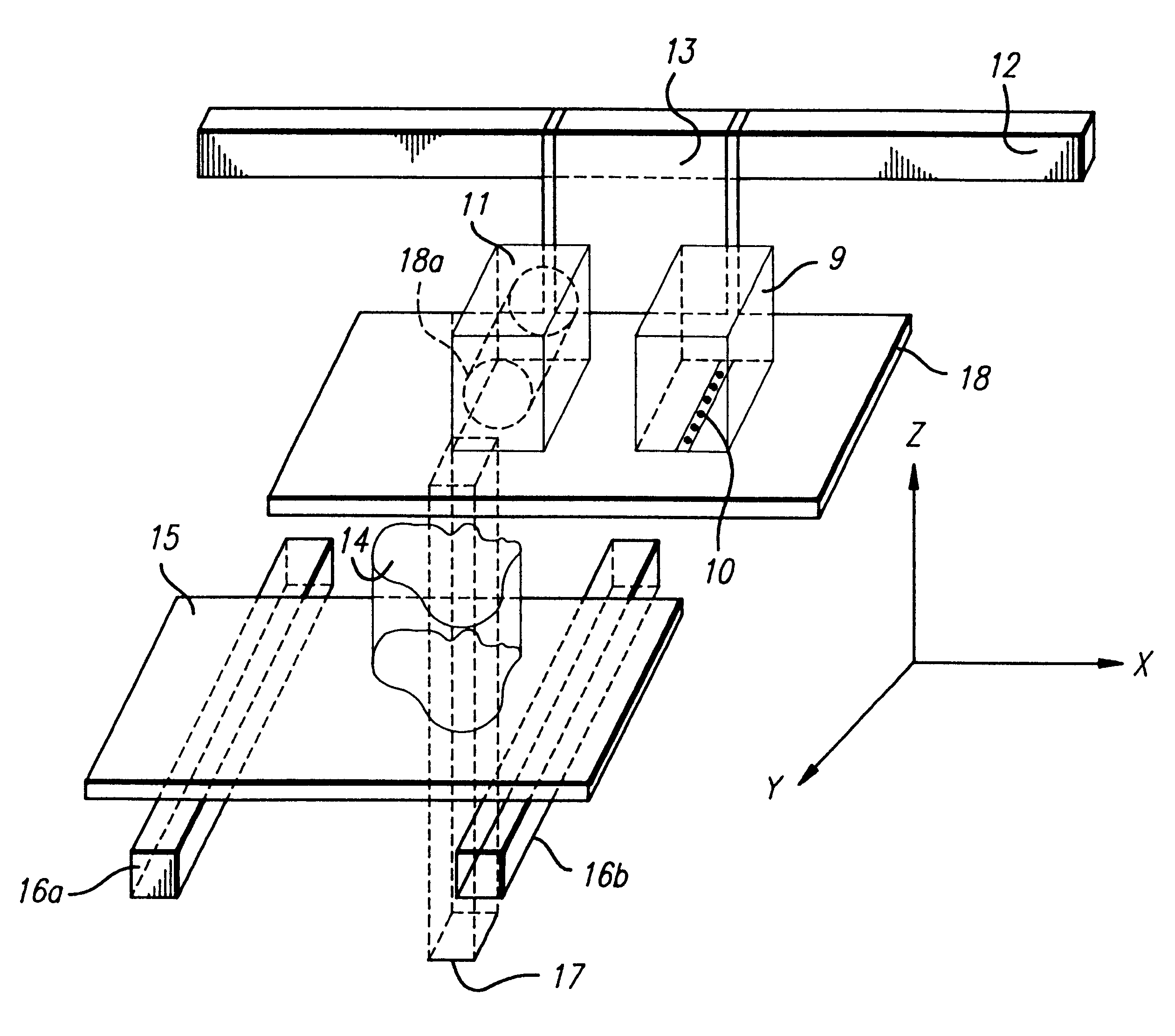

Rapid prototyping apparatus

ActiveUS7500846B2Improve operating characteristicsRapid productionConfectionerySweetmeatsThin layerEngineering

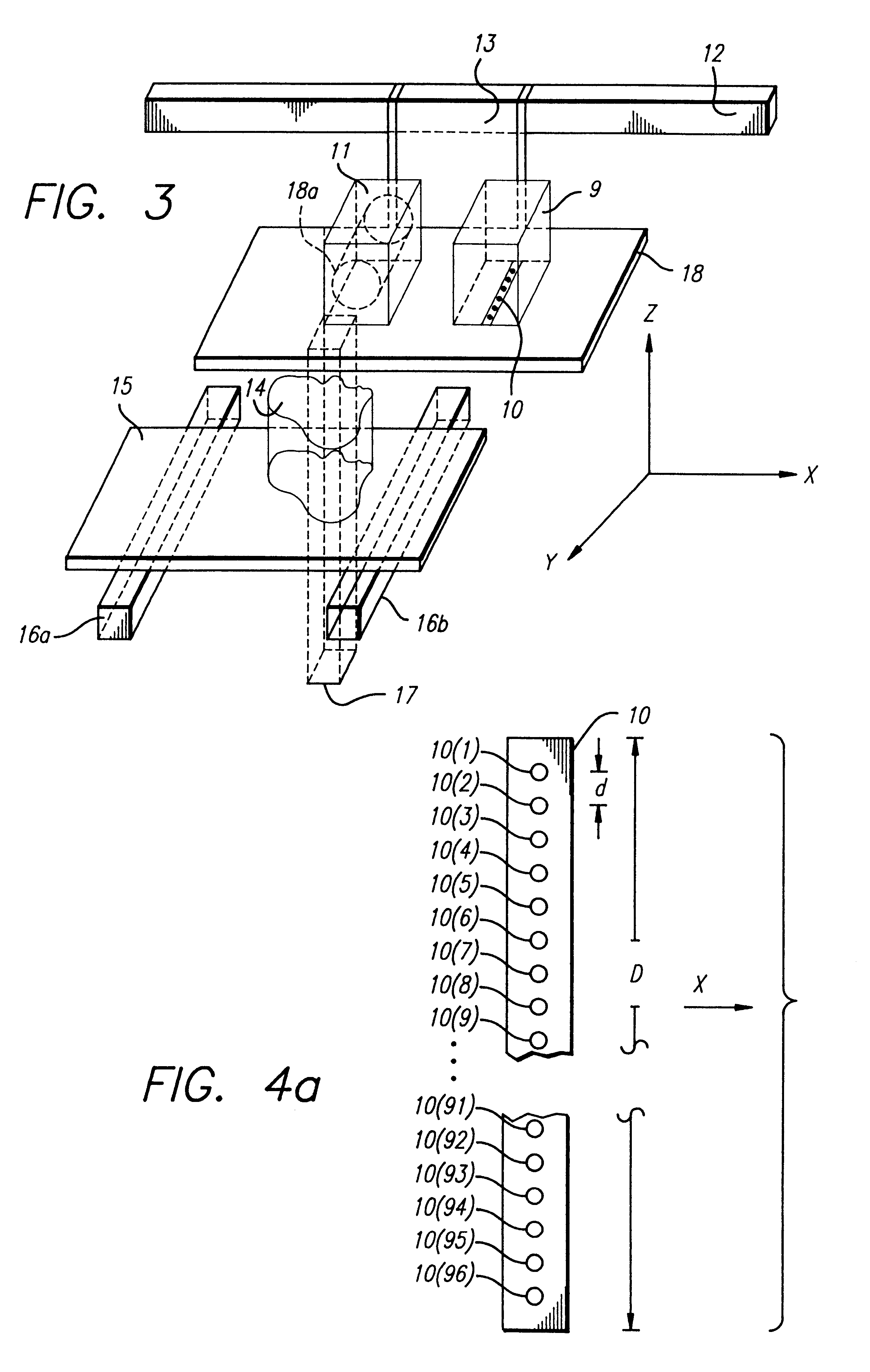

Apparatus for producing an object by sequentially forming thin layers of a construction material one on top of the other responsive to data defining the object, the apparatus comprising: a plurality of printing heads each having a surface formed with a plurality of output orifices and controllable to dispense the construction material through each orifice independently of the other orifices; a shuttle to which the printing heads are mounted; a support surface; and a controller adapted to control the shuttle to move back and forth over the support surface and as the shuttle moves to control the printing heads to dispense the construction material through each of their respective orifices responsive to the data to form a first layer on the support surface and thereafter, sequentially the other layers; wherein each printing head is dismountable from the shuttle and replaceable independently of the other printing heads.

Owner:OBJET GEOMETRIES

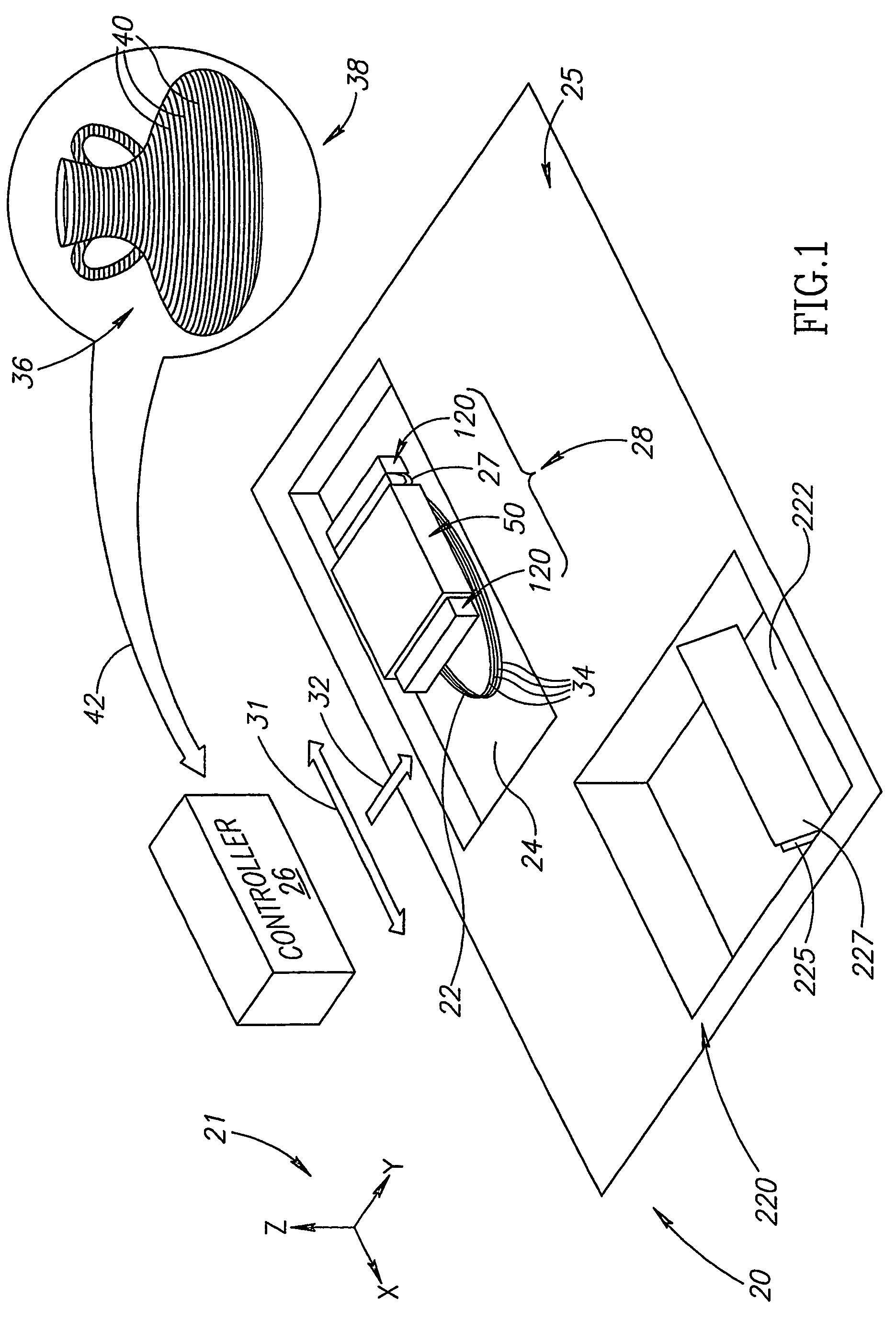

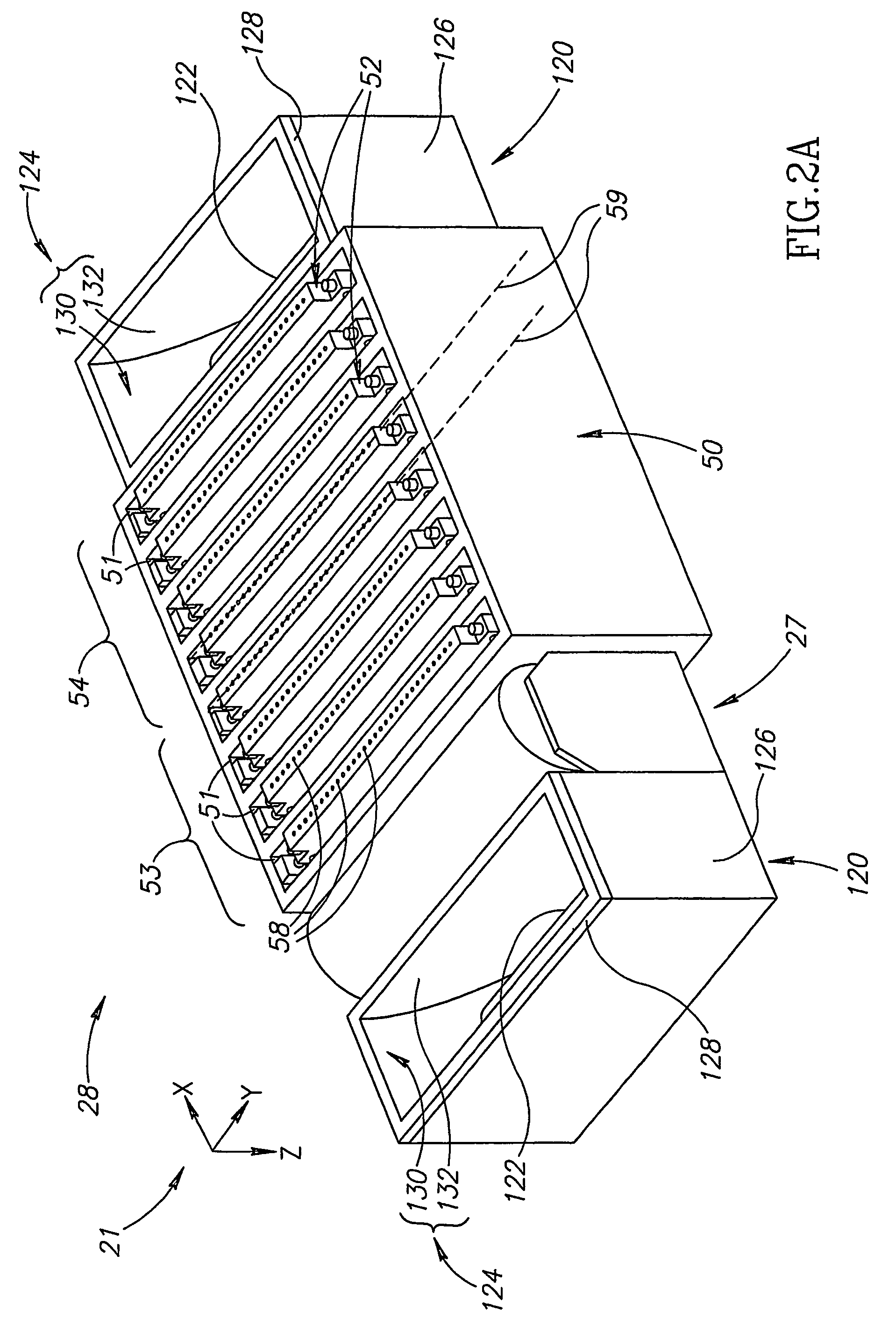

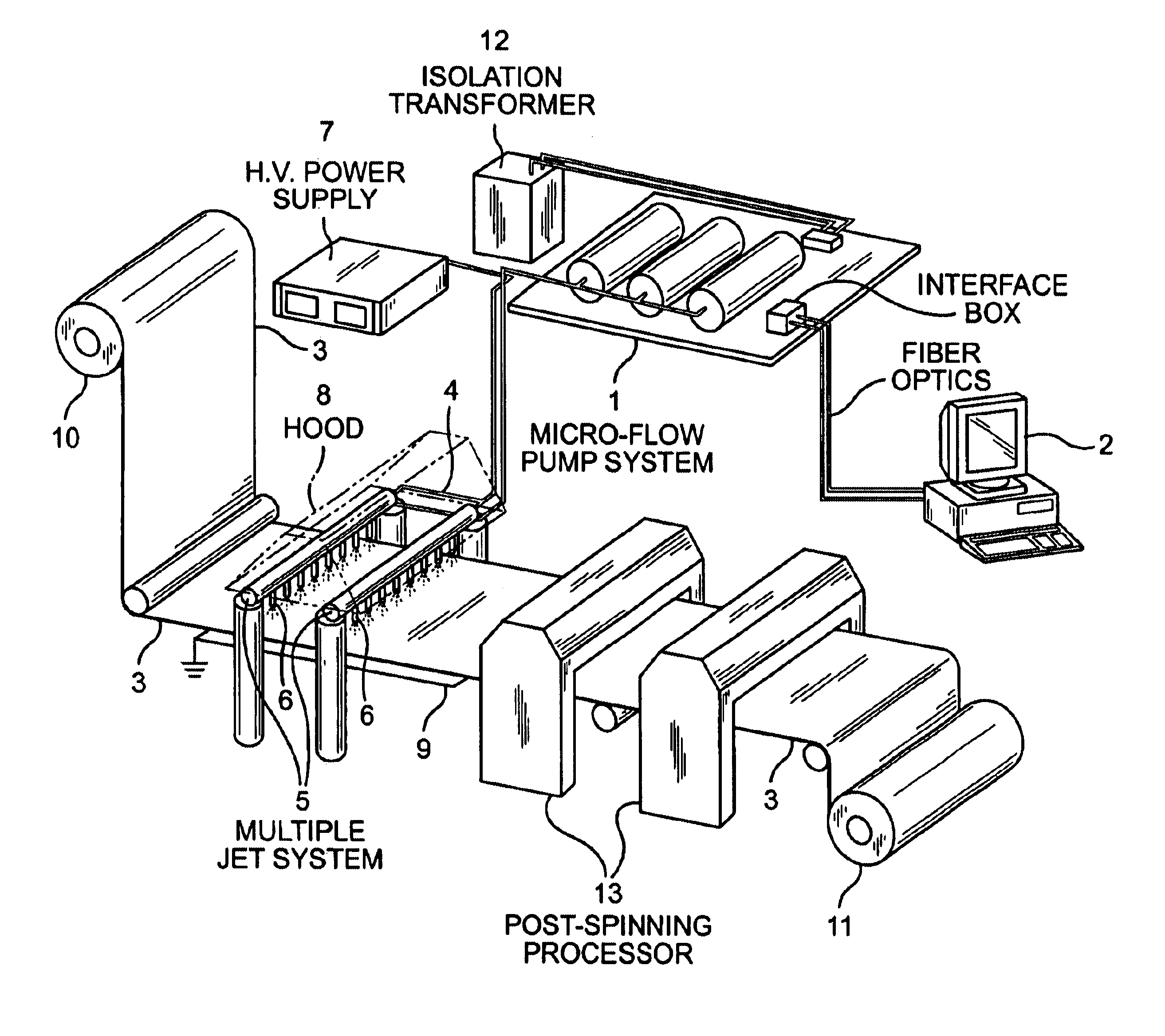

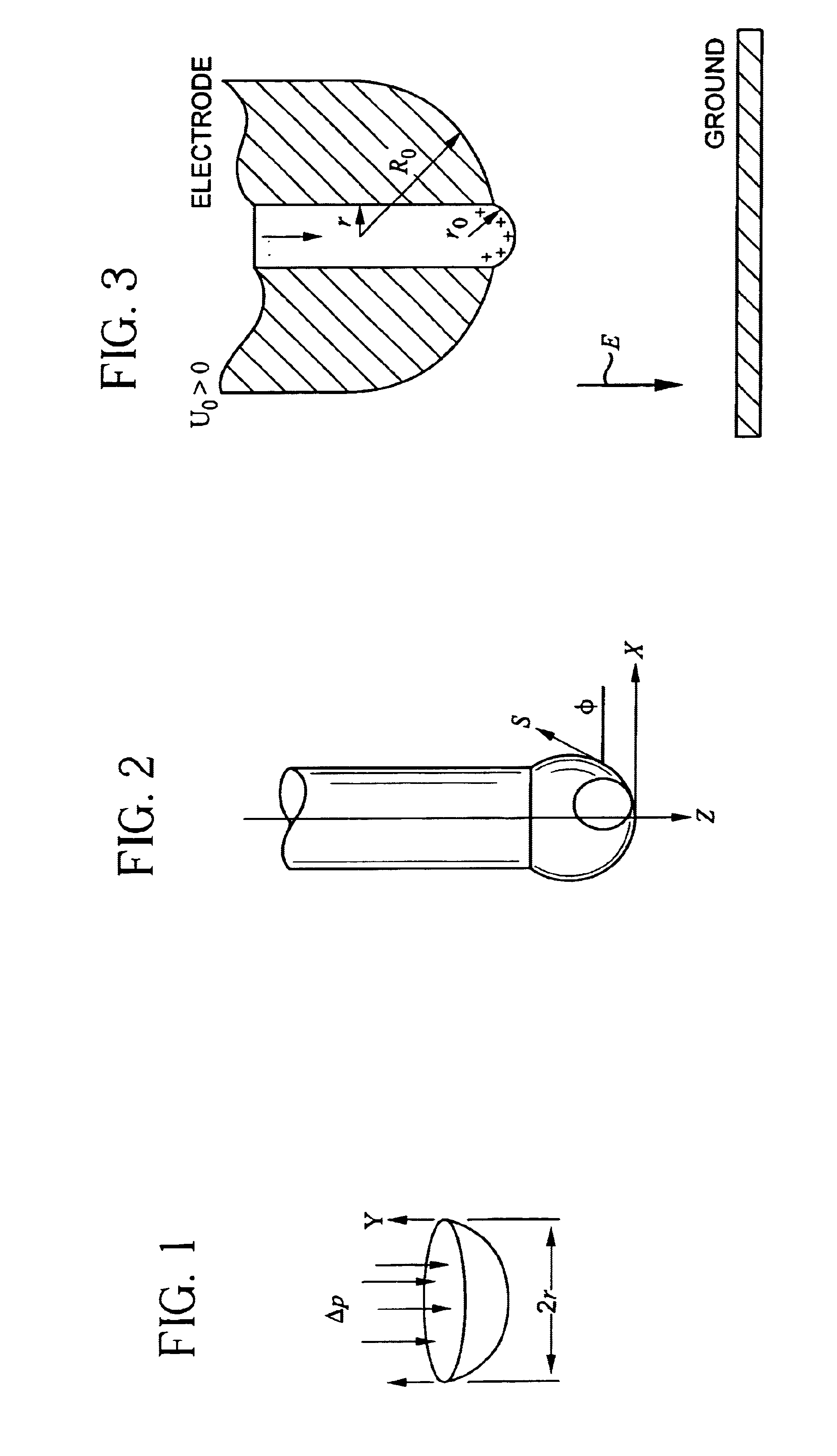

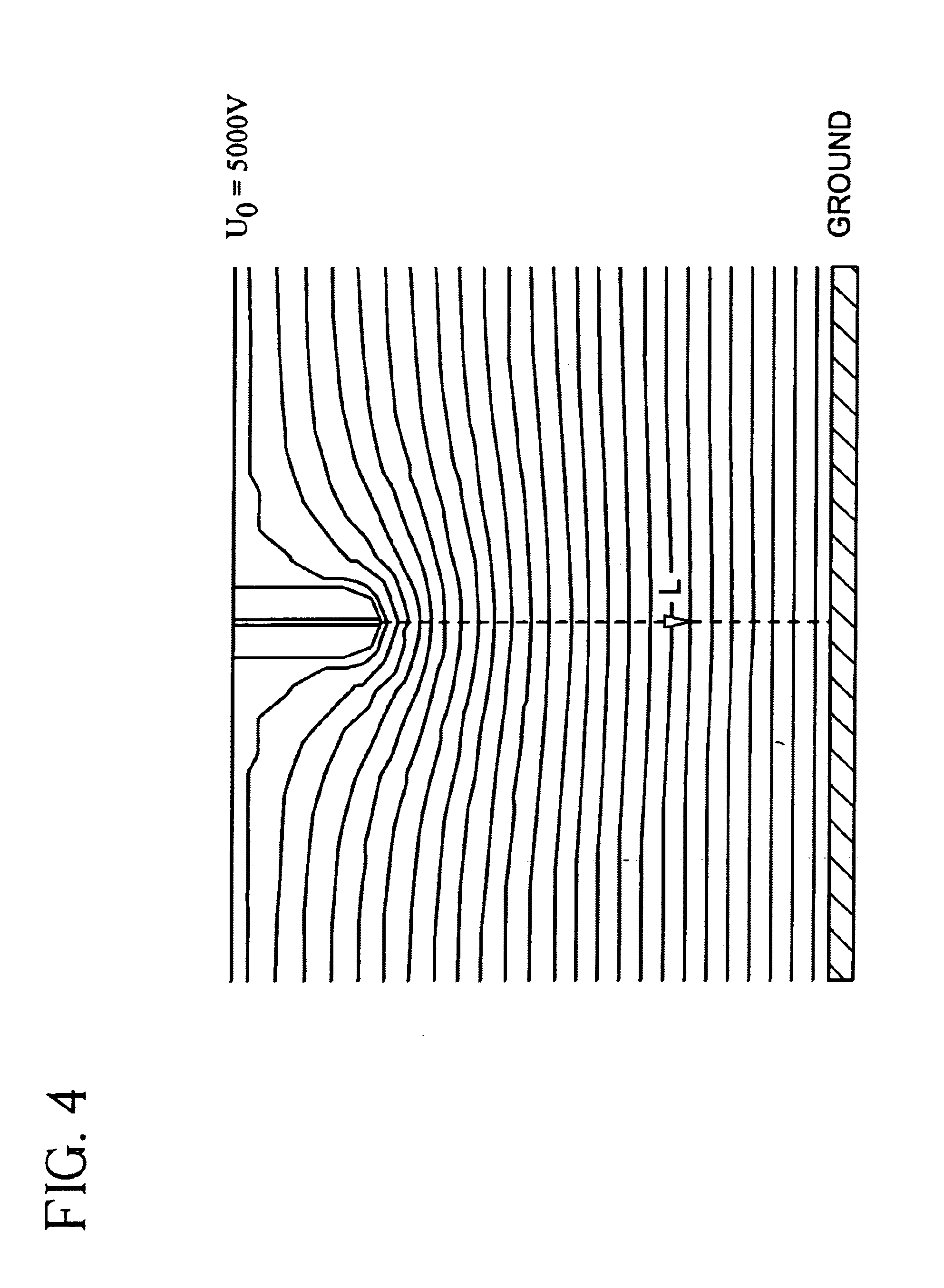

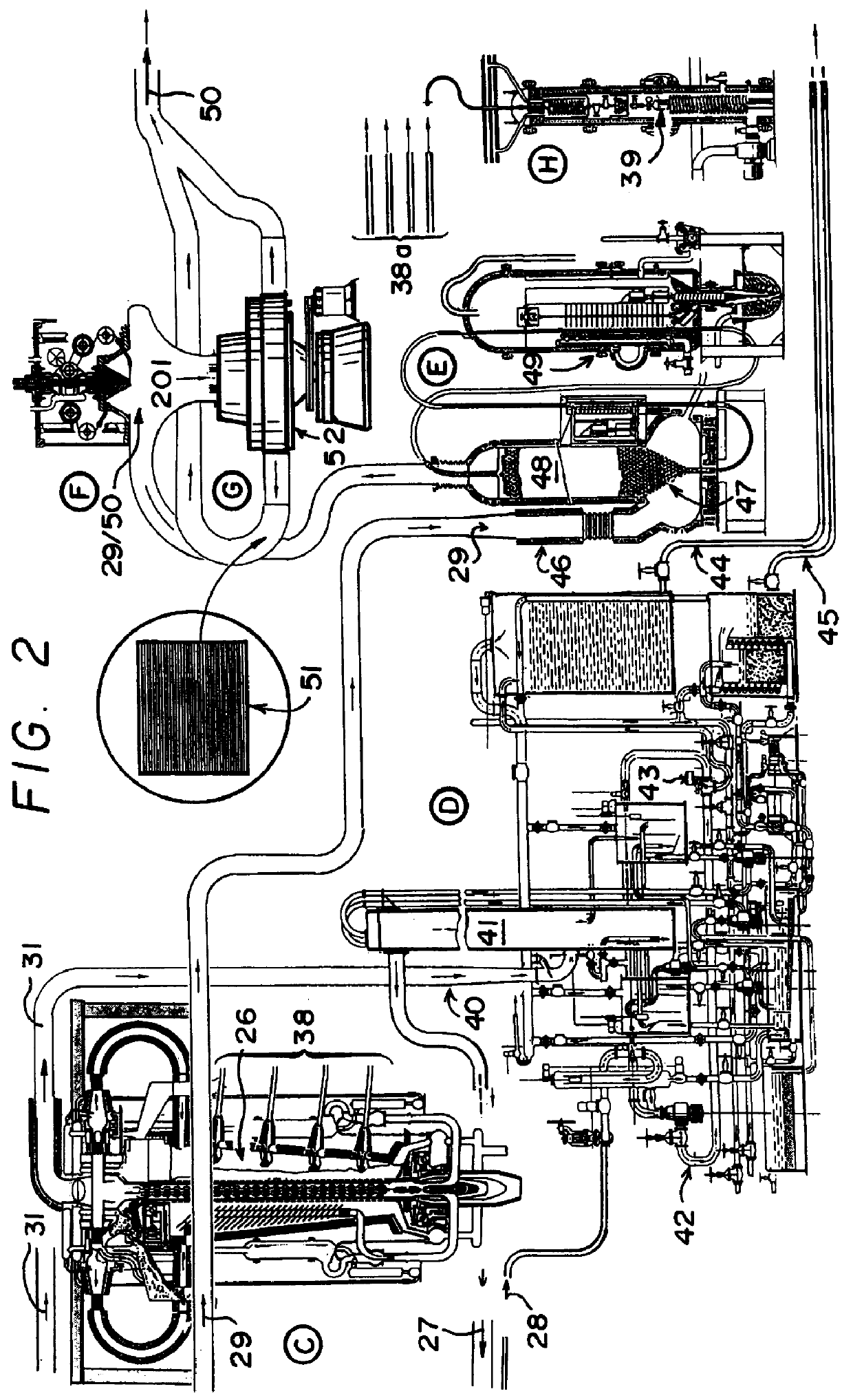

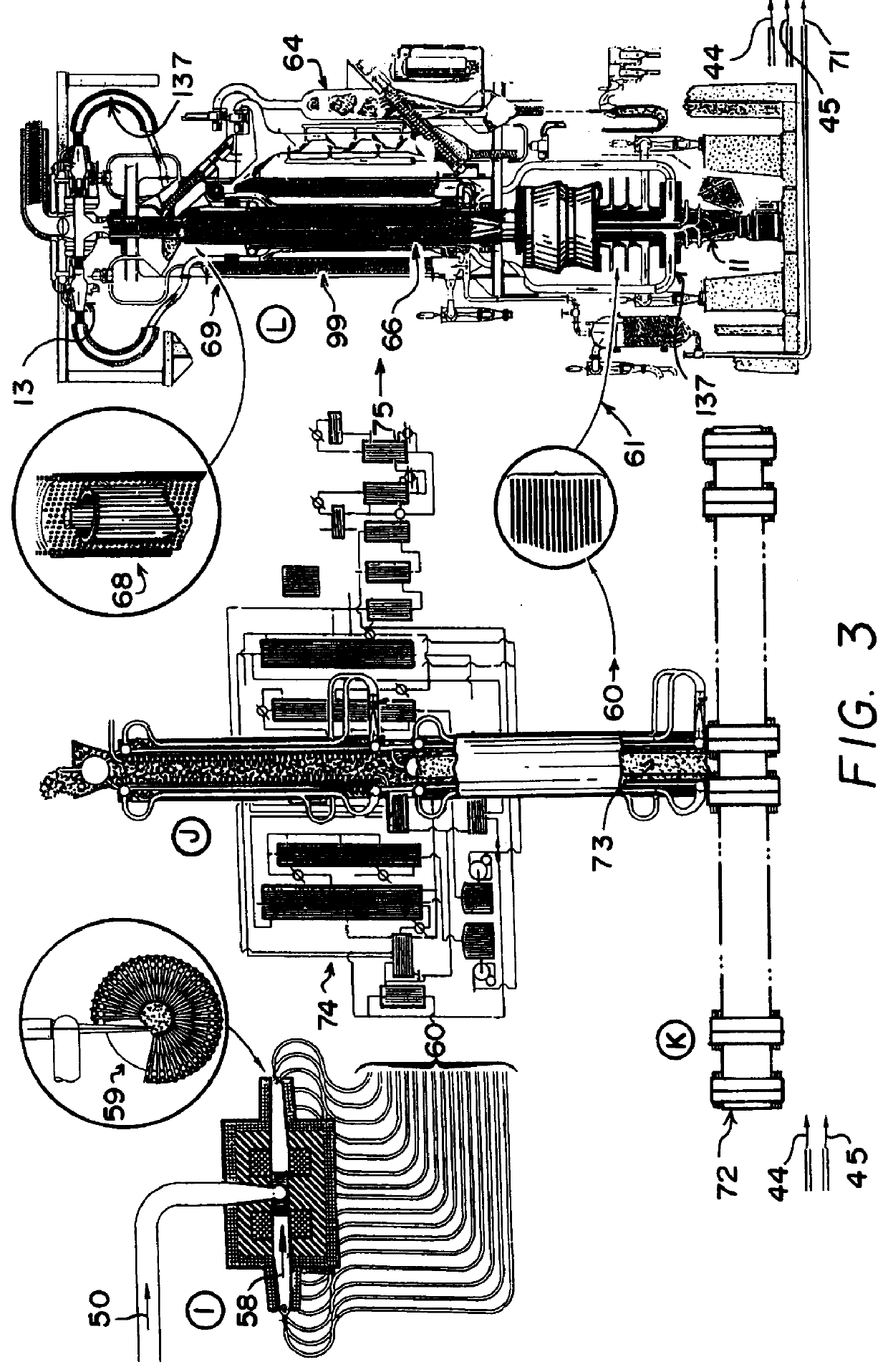

Apparatus and methods for electrospinning polymeric fibers and membranes

InactiveUS6713011B2Easy to controlLarge specific surface areaElectric discharge heatingConfectioneryFiberElectrospinning

An apparatus and method for electrospinning polymer fibers and membranes. The method includes electrospinning a polymer fiber from a conducting fluid in the presence of a first electric field established between a conducting fluid introduction device and a ground source and modifying the first electric field with a second electric field to form a jet stream of the conducting fluid. The method also includes electrically controlling the flow characteristics of the jet stream, forming a plurality of electrospinning jet streams and independently controlling the flow characteristics of at least one of the jet streams. The apparatus for electrospinning includes a conducting fluid introduction device containing a plurality of electrospinning spinnerets, a ground member positioned adjacent to the spinnerets, a support member disposed between the spinnerets and the ground member and movable to receive fibers formed from the conducting fluid, and a component for controlling the flow characteristics of conducting fluid from at least one spinneret independently from another spinneret.

Owner:RES FOUND THE

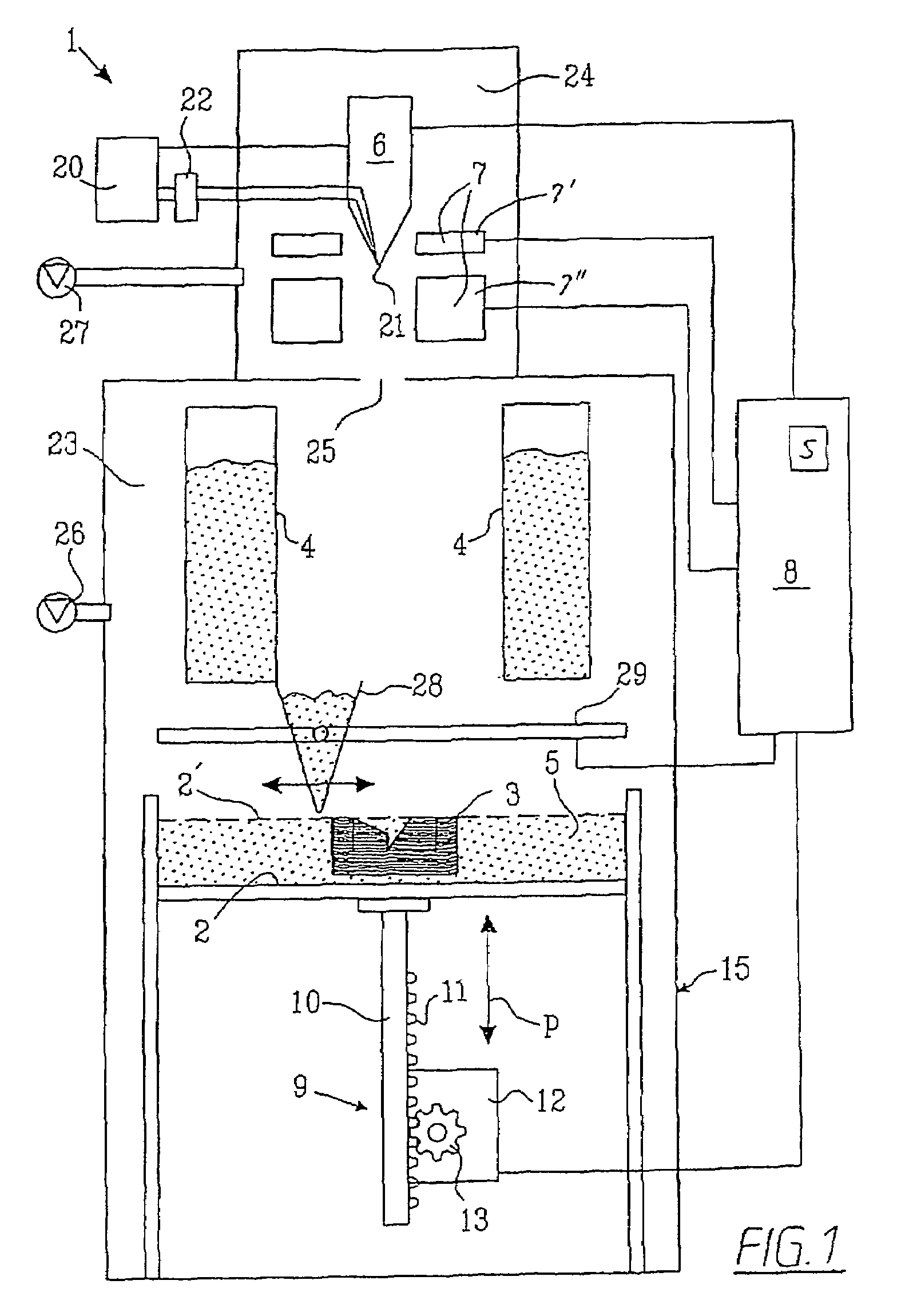

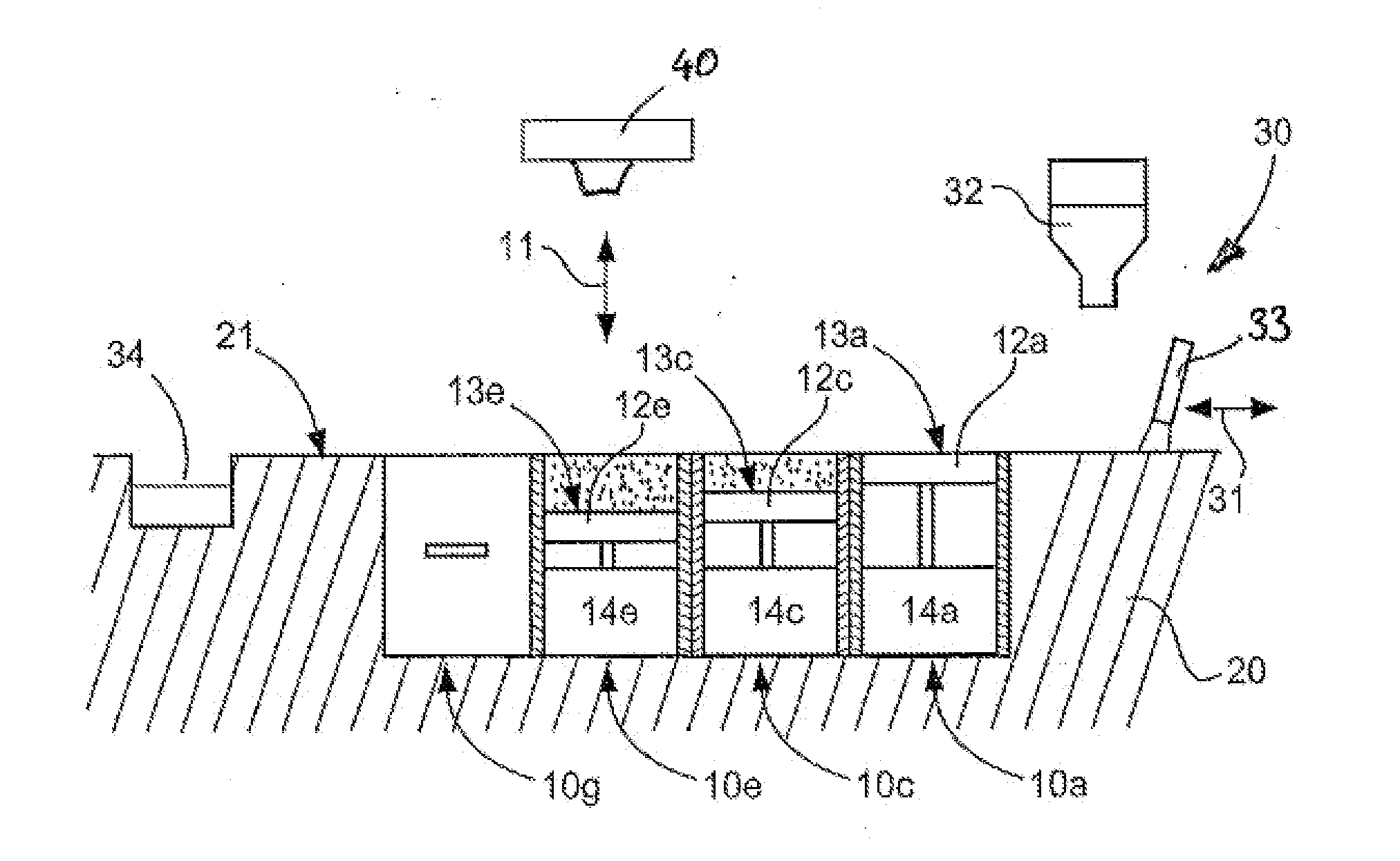

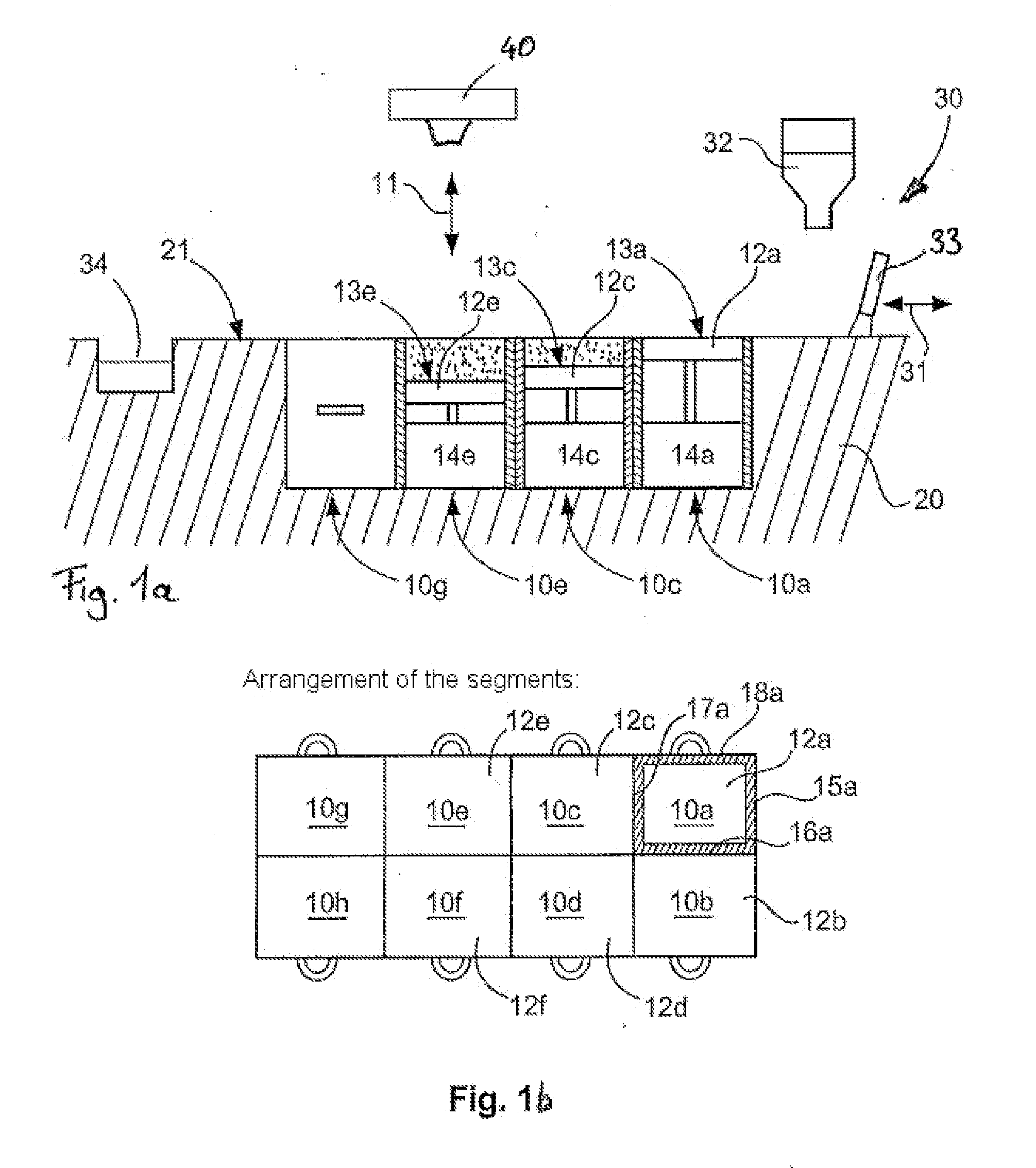

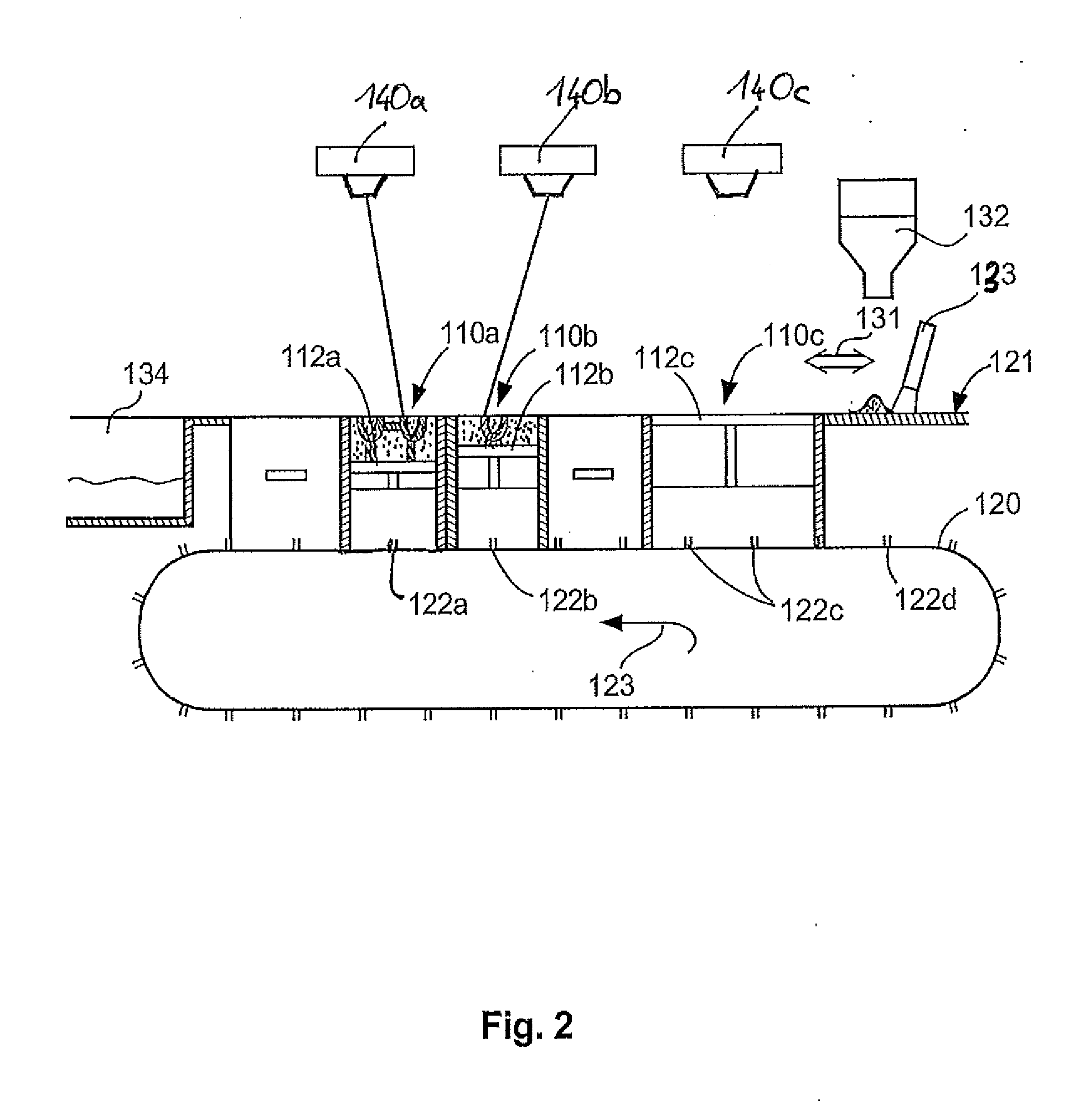

Methods and systems for the manufacture of layered three-dimensional forms

ActiveUS20050017394A1Lower potentialEasy to controlConfectionerySweetmeatsParticulatesBiological activation

New methods and systems for manufacturing a three-dimensional form, comprising steps of providing a plurality of particulates; contacting the particulates with an activation agent; contacting particulates having the activation agent with a binder material that is activatable by the activation agent; at least partially hardening the binder for forming a layer of the three-dimensional form; and repeating these steps to form the remainder of the three-dimensional form. Following sequential application of all required layers and binder material to make the form, the unbound particles are appropriately removed (and optionally re-used), to result in the desired three-dimensional form. The invention also contemplates a novel method for preparing a form, where unbound particulates free of binder material are re-claimed.

Owner:EXONE

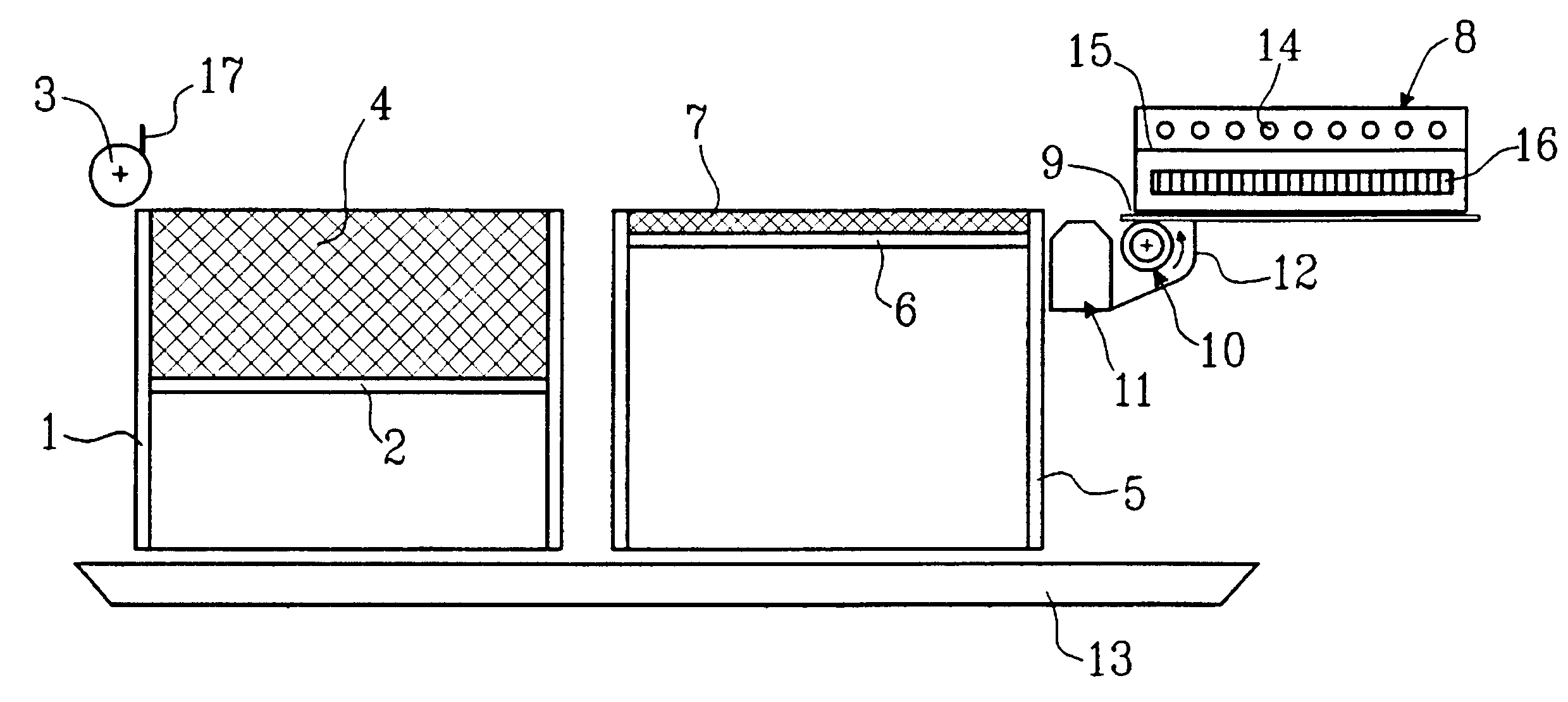

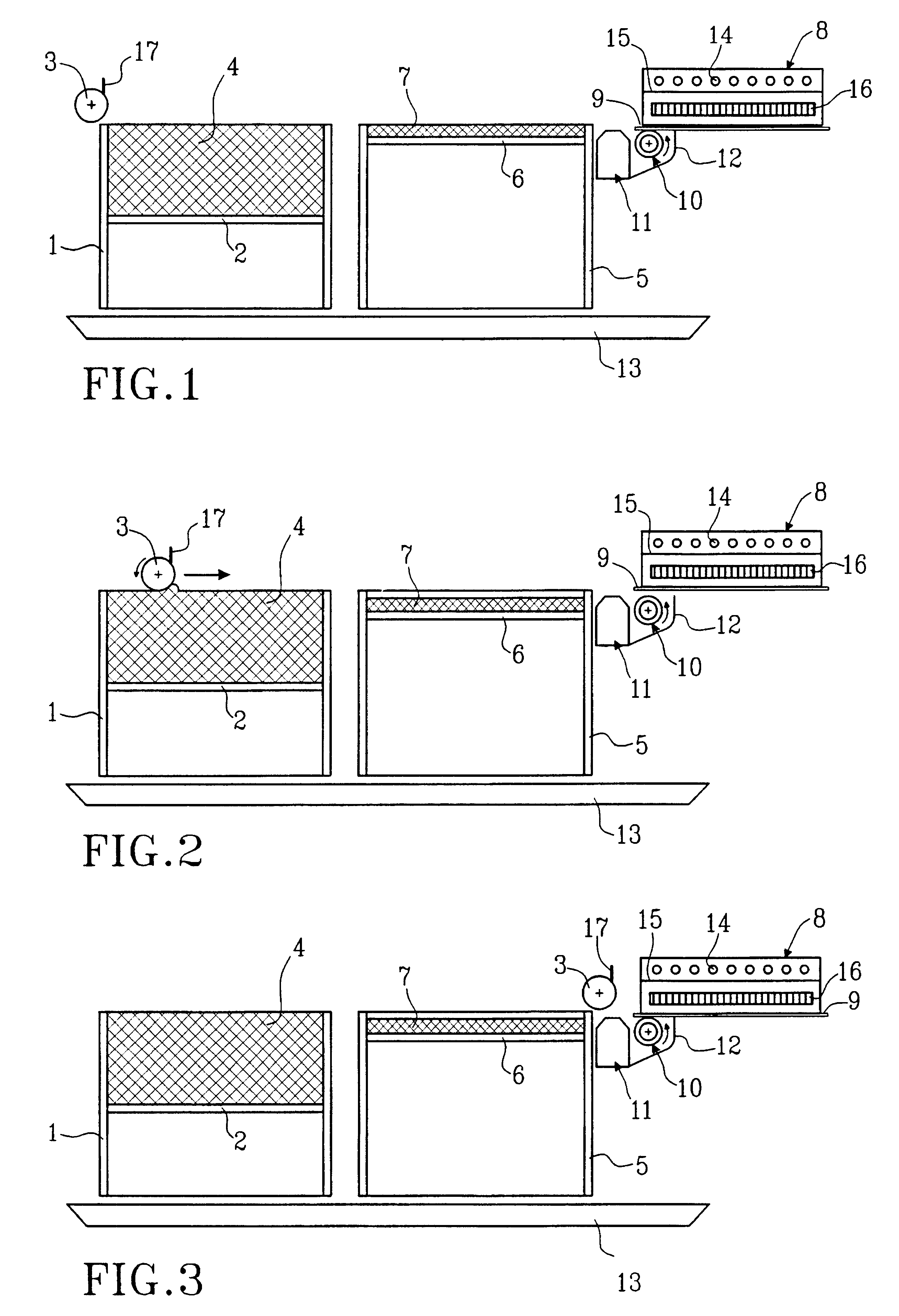

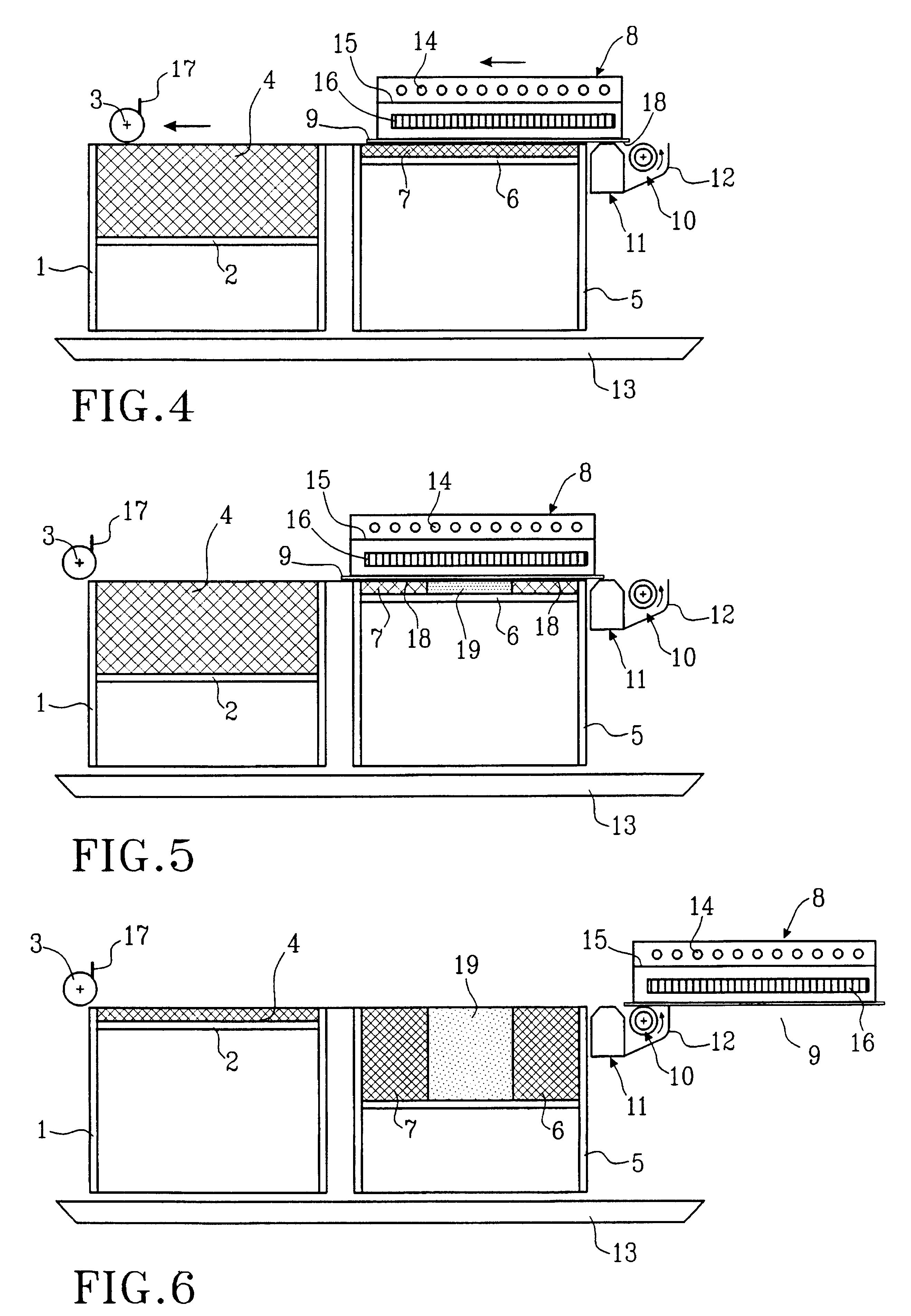

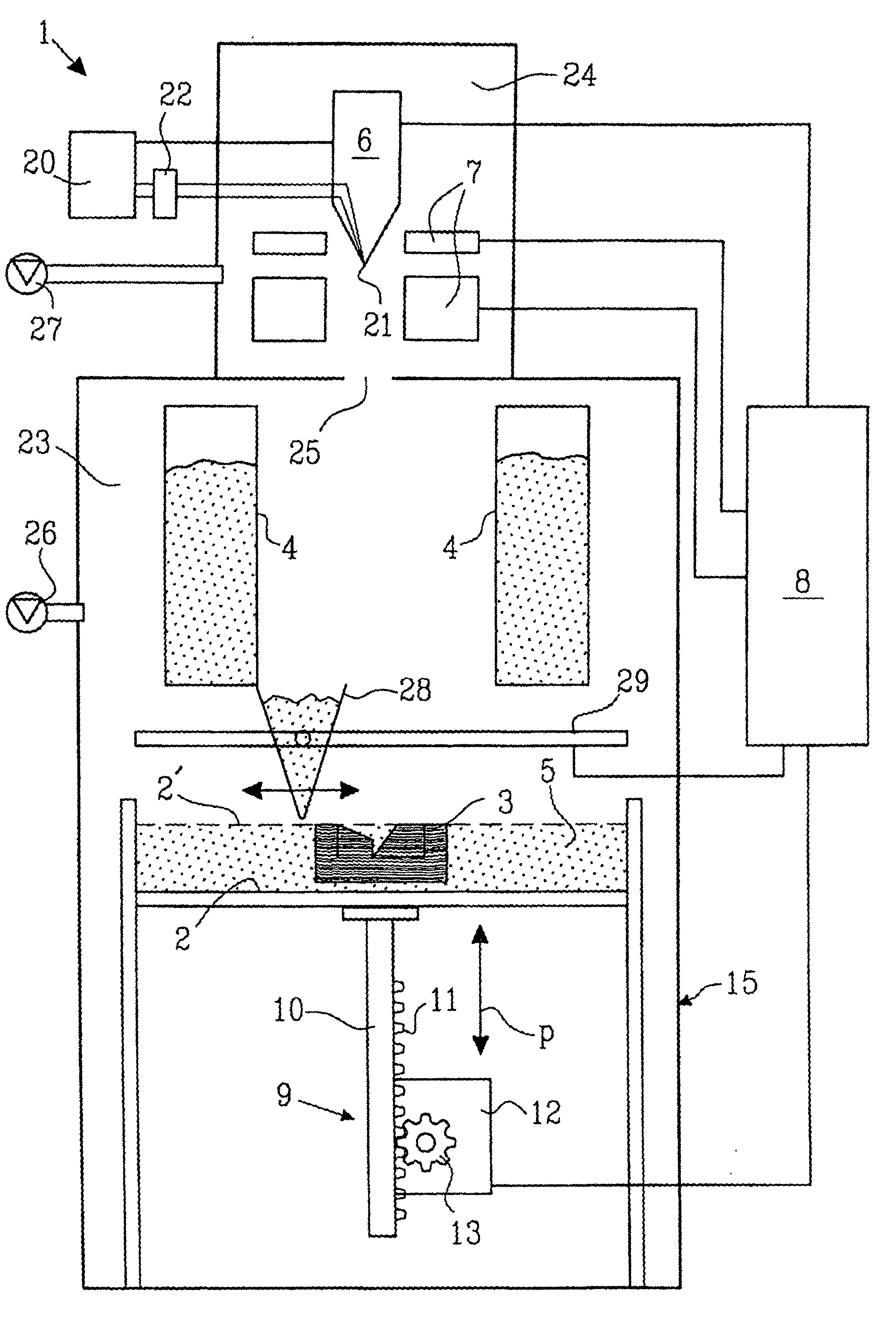

Method and device for manufacturing three-dimensional bodies

A method for producing three-dimensional bodies of a large number of mutually connected layers of a particle-shaped material such as a powder, and where the information of the appearance of each layer is achieved from a computer's CAD-unit or similar. An essentially even particle layer (7) of building material is applied on a support base (6) and on a masking device (9) is arranged a masking pattern in accordance with the information from the CAD-unit, which masking device is led over said particle layer and close to it. A radiation producer (8) is arranged or is led over the masking device (9), whereby the particles which are not covered by the masking pattern are exposed for radiation and thereby are attached to each other. The masking pattern is removed from the masking device and new sequences in accordance with the above are carried through until the three-dimensional body (19) is produced.

Owner:SPEED PART RP

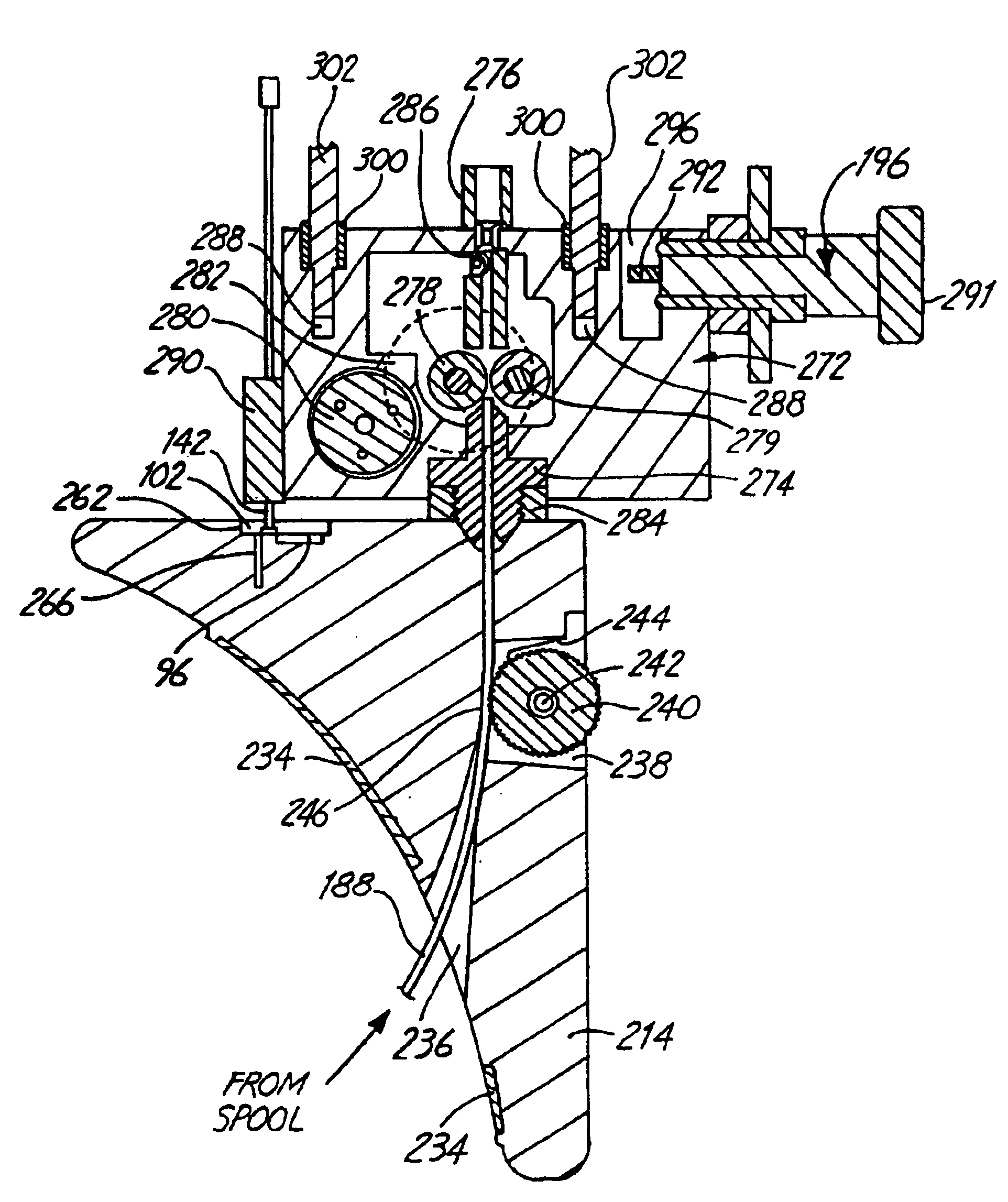

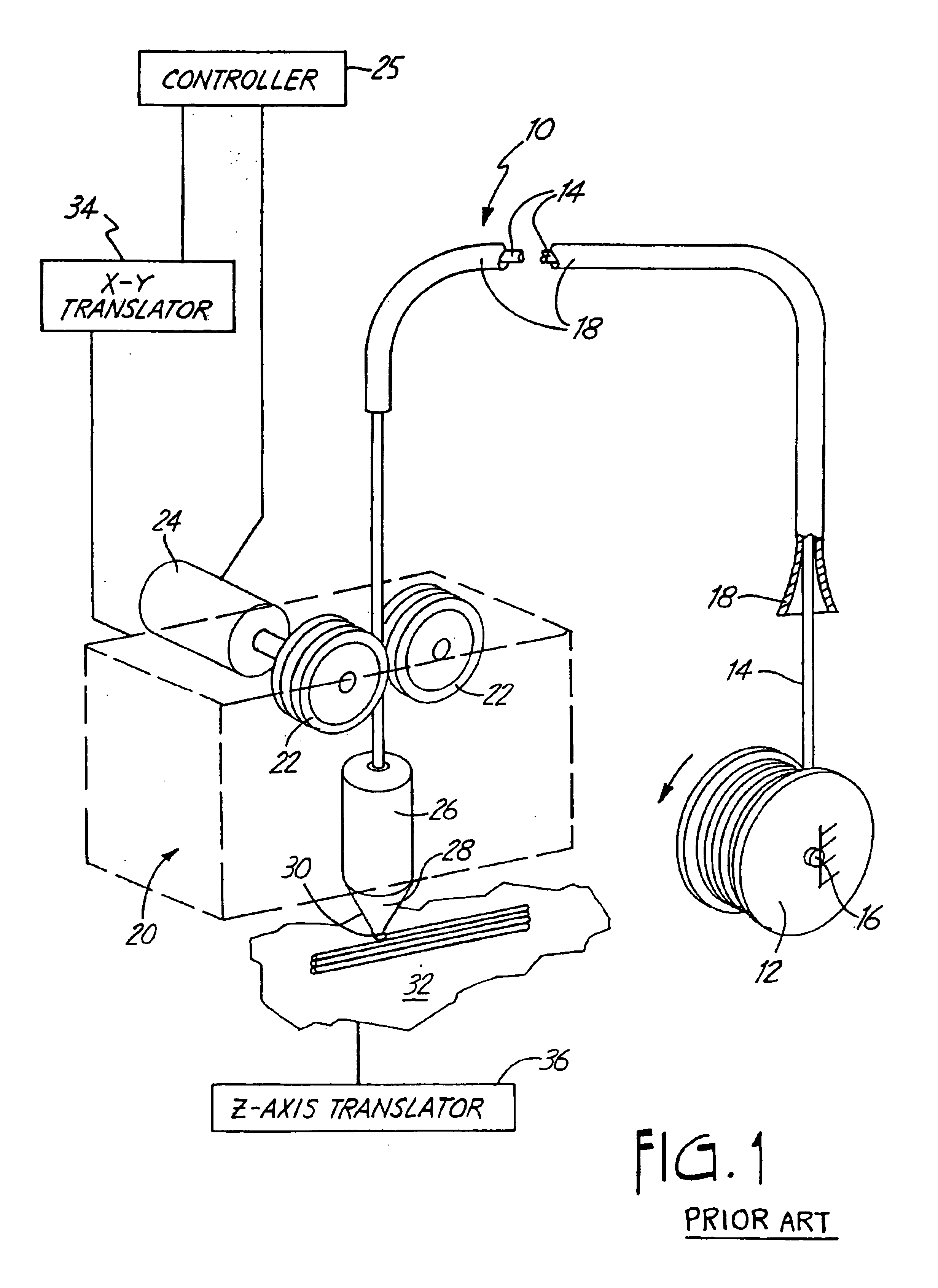

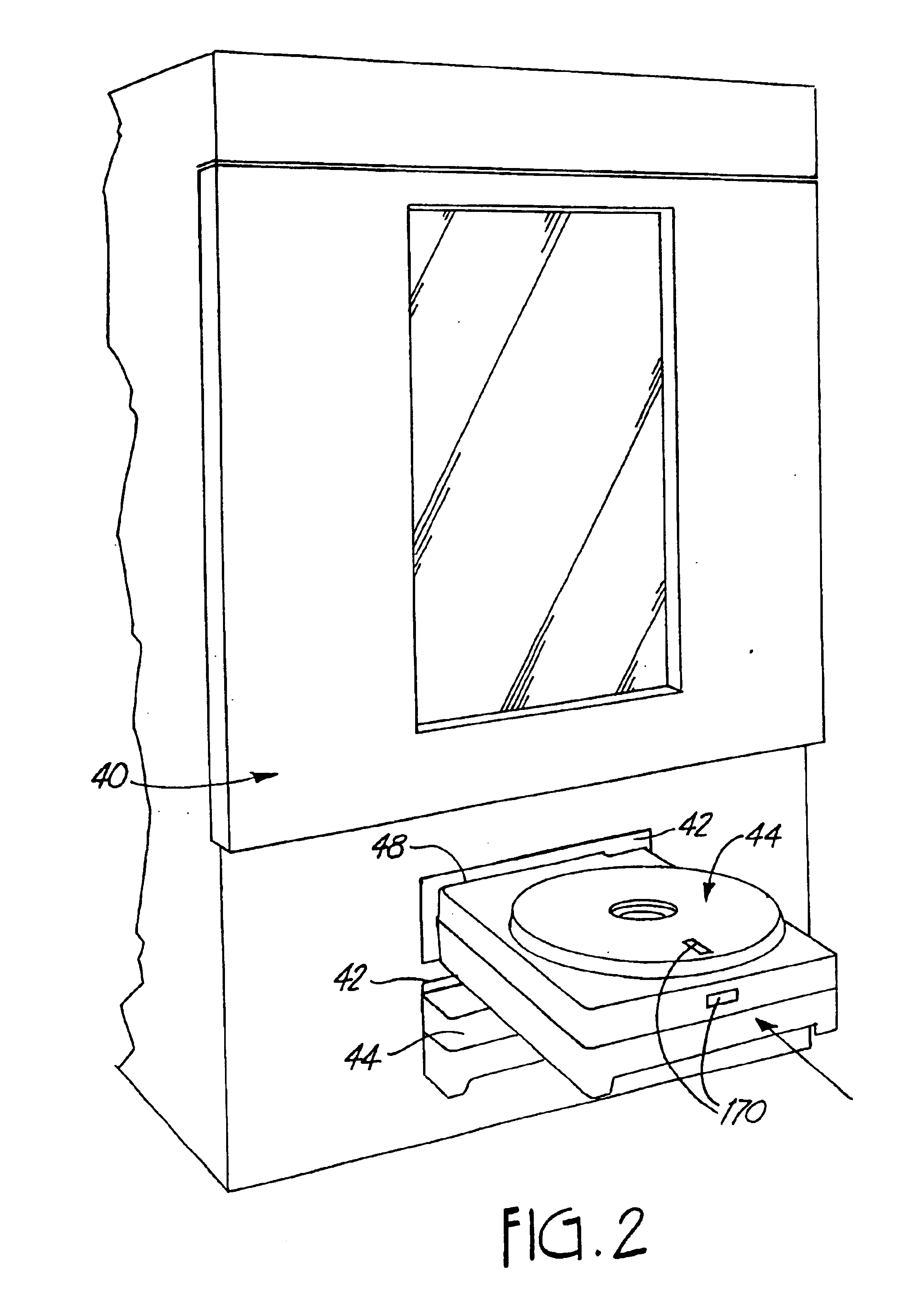

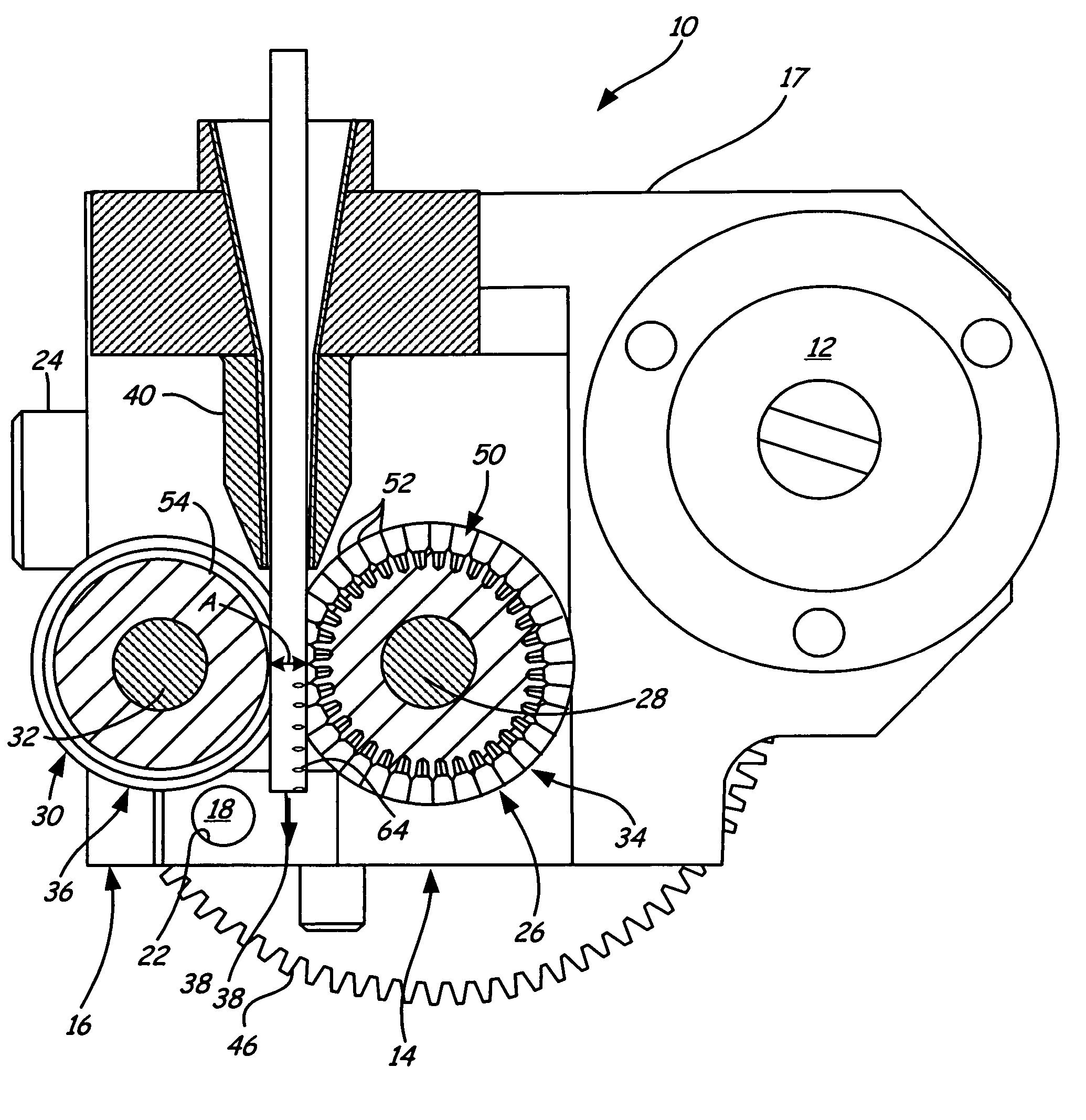

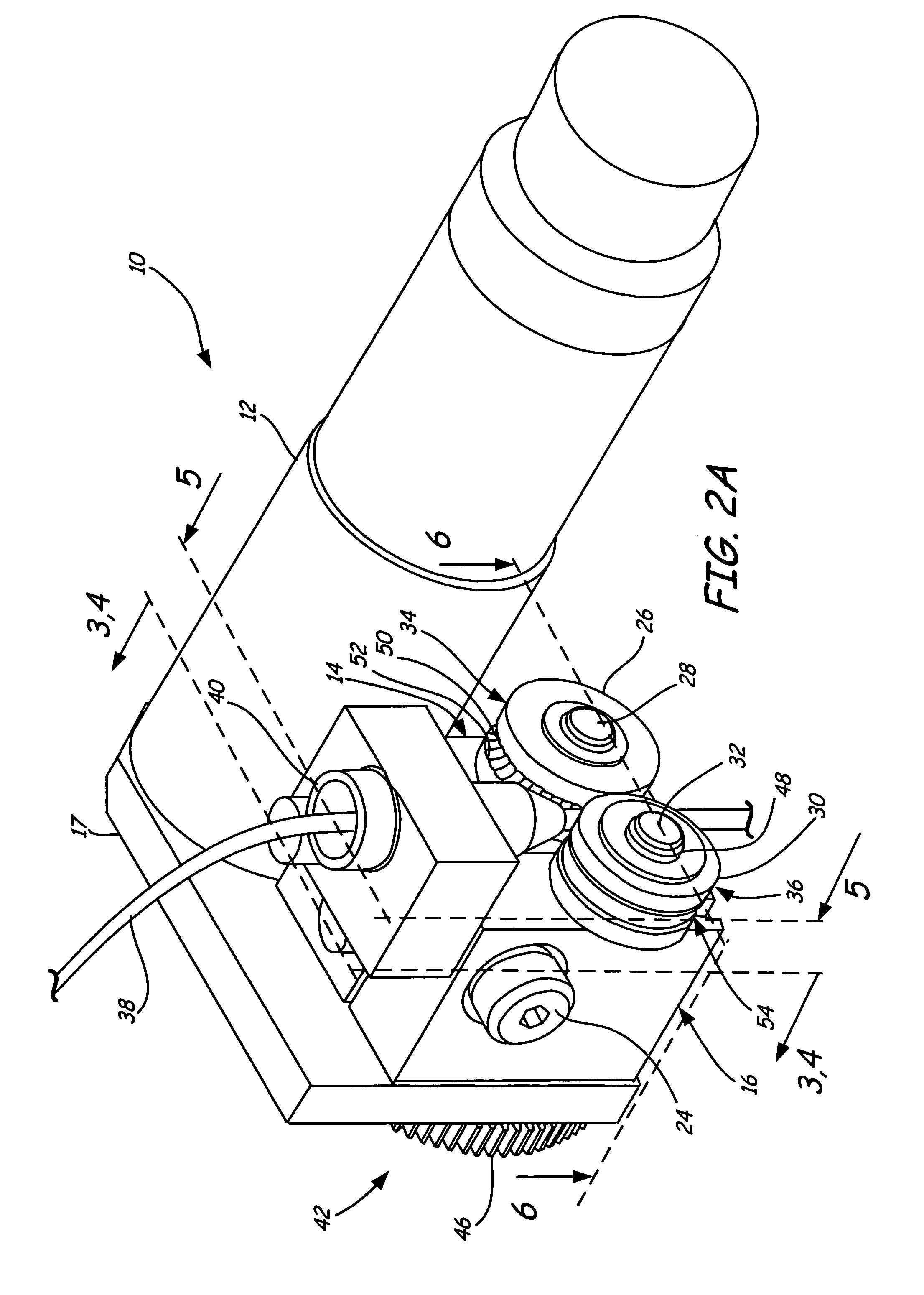

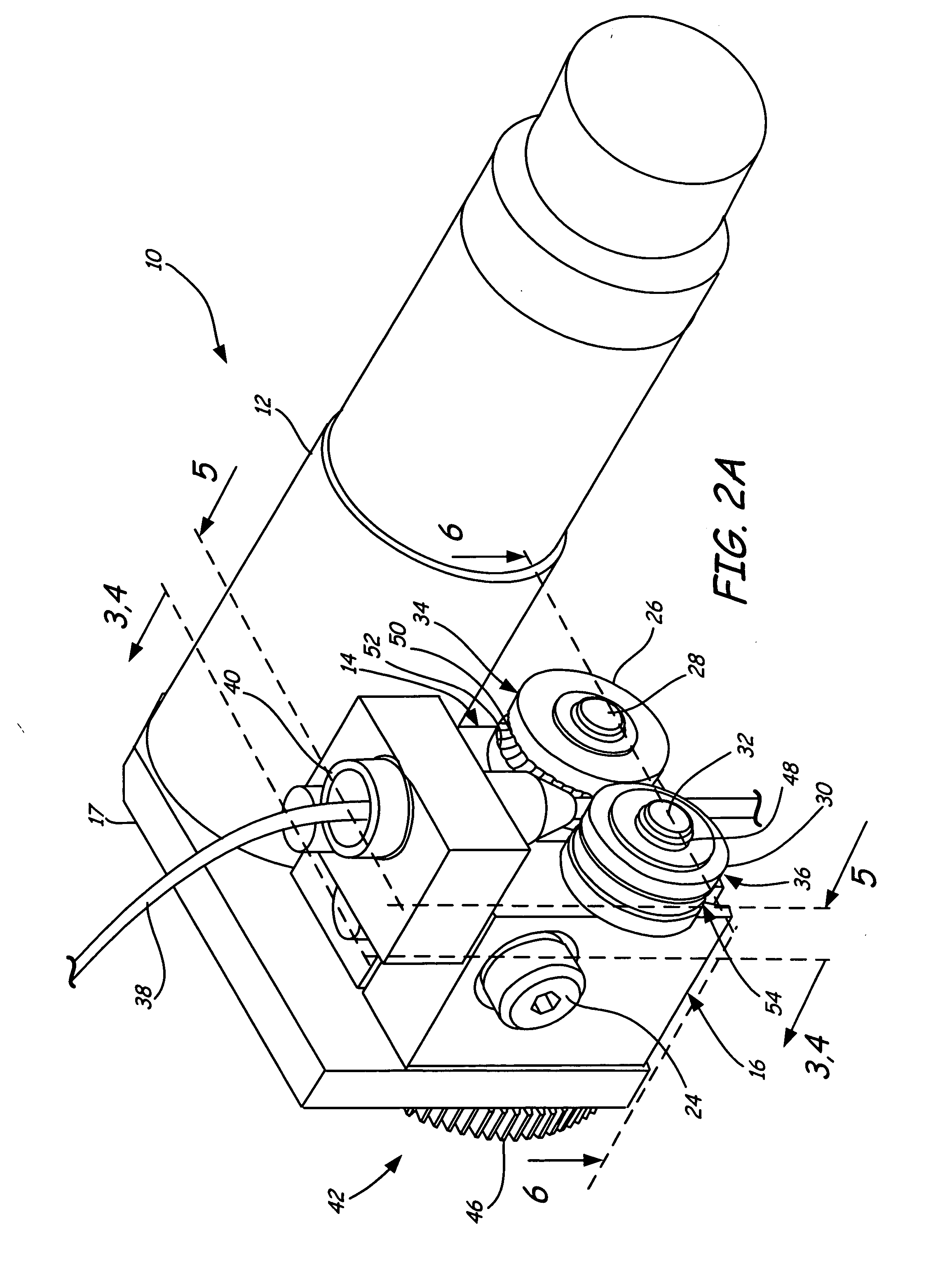

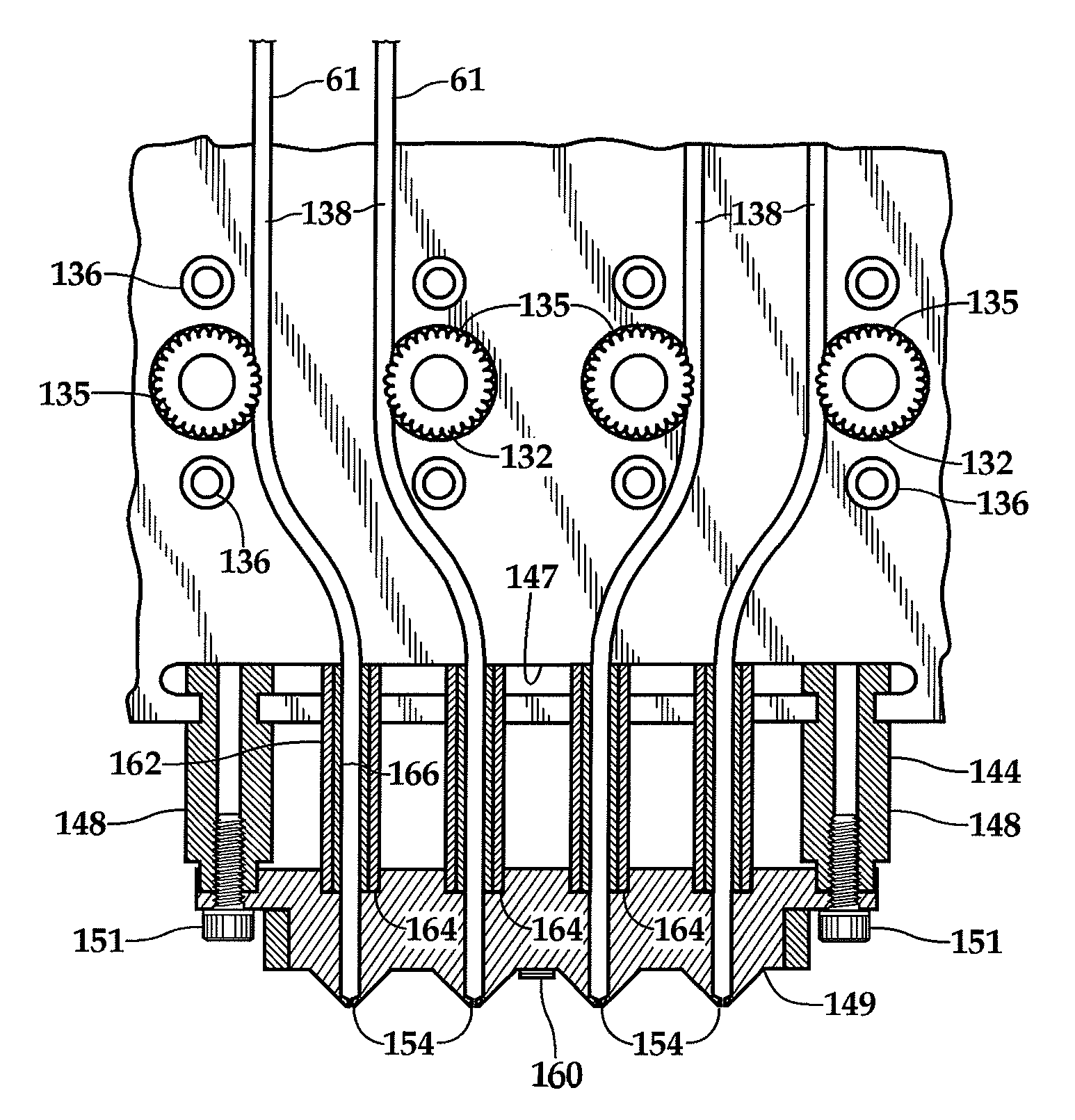

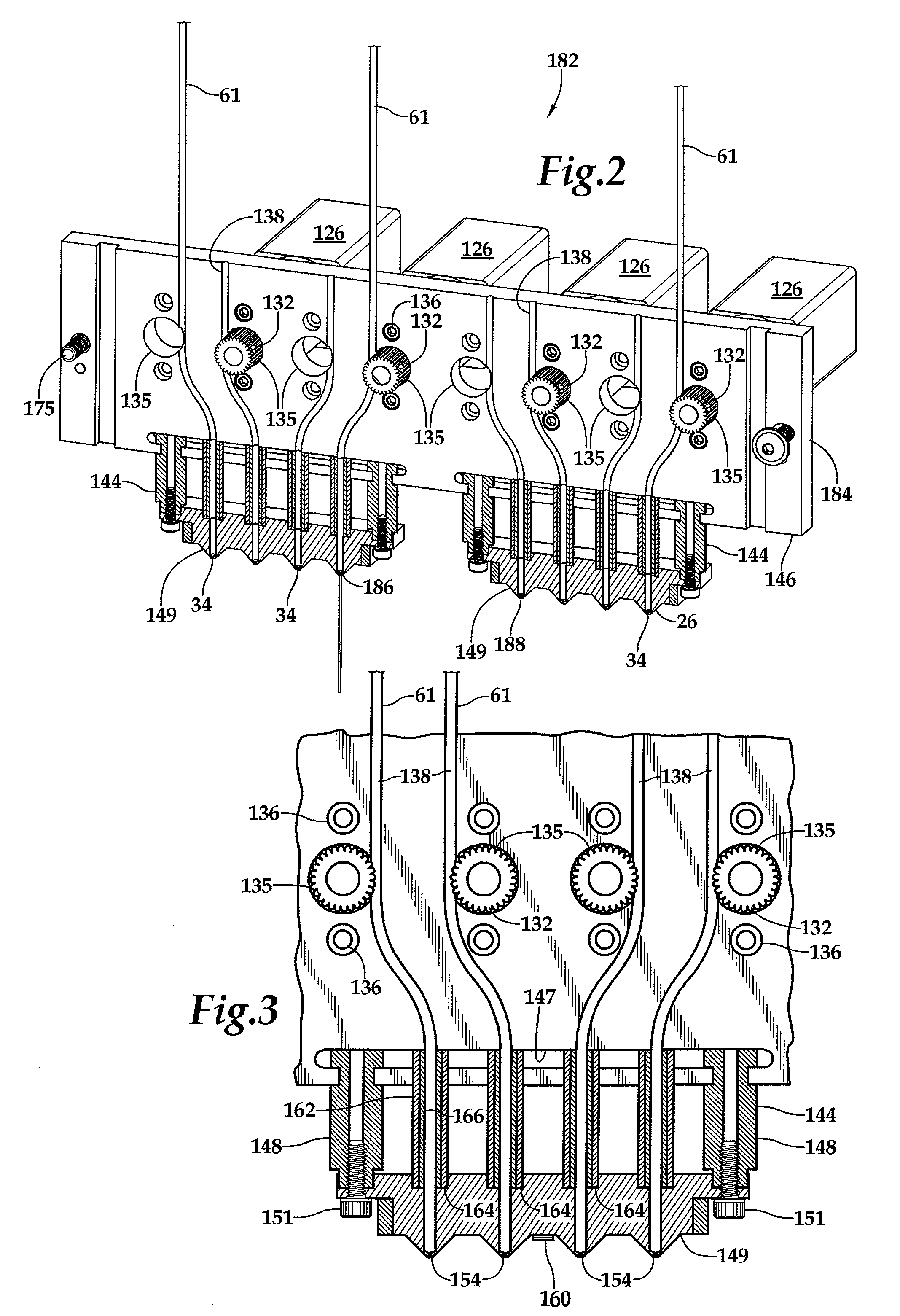

Filament loading system in an extrusion apparatus

InactiveUS6923634B2Protect environmentEasy loadingConfectionerySweetmeatsDrive wheelDimensional modeling

An apparatus which extrudes flowable material from a liquifier includes a system for loading filament supplied in a cassette. The cassette is loaded into a loading bay of the apparatus. A strand of filament from the cassette is engaged and advanced along a path to the liquifier using a drive wheel or roller pair. A conduit having an entrance in the loading bay guides the filament as it is advanced. The filament loading system of the present invention provides a convenient manner of loading and unloading filament in a three-dimensional modeling machine, and can be implemented in a manner that protects the filament from environmental moisture.

Owner:STRATSYS INC

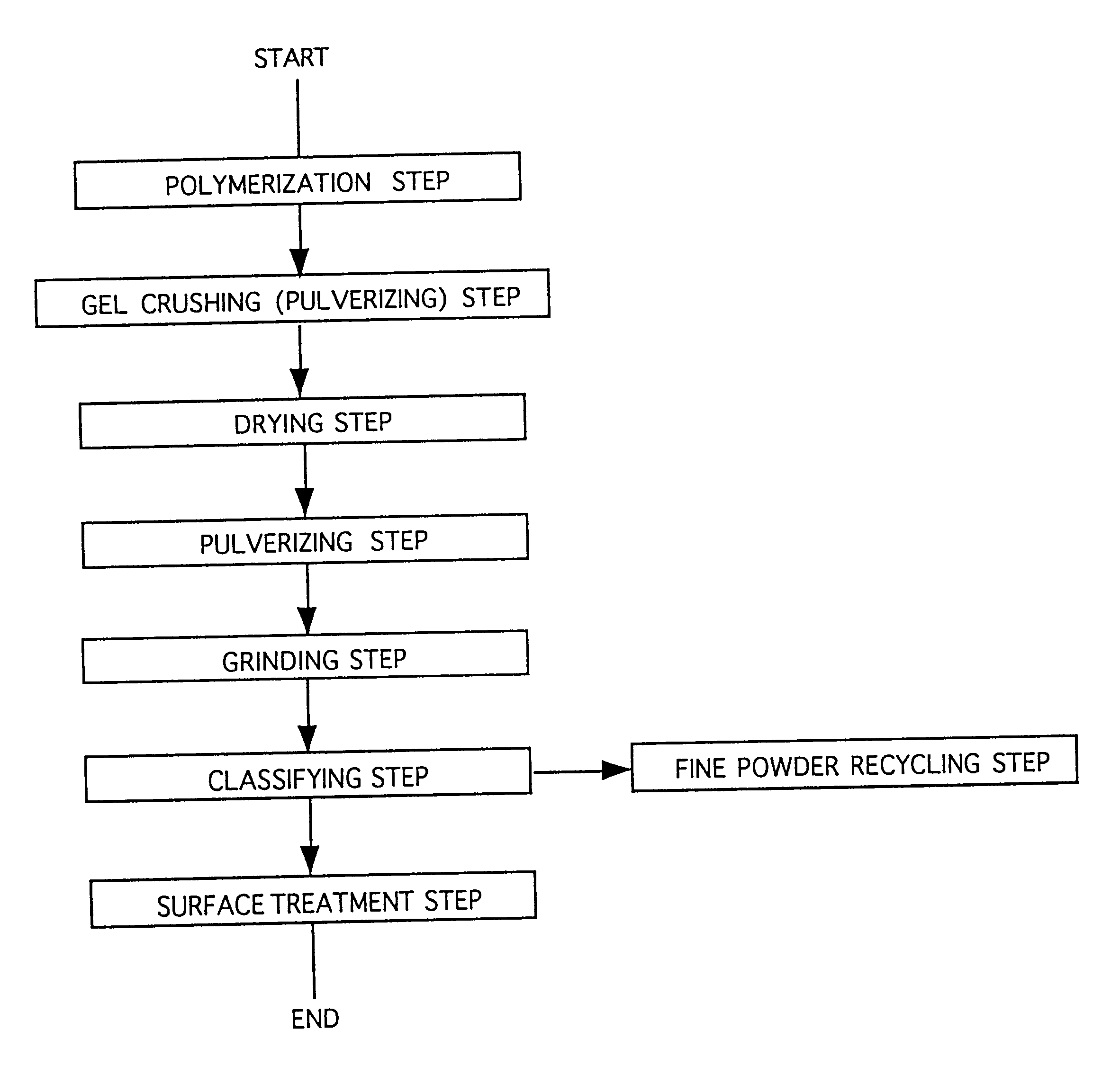

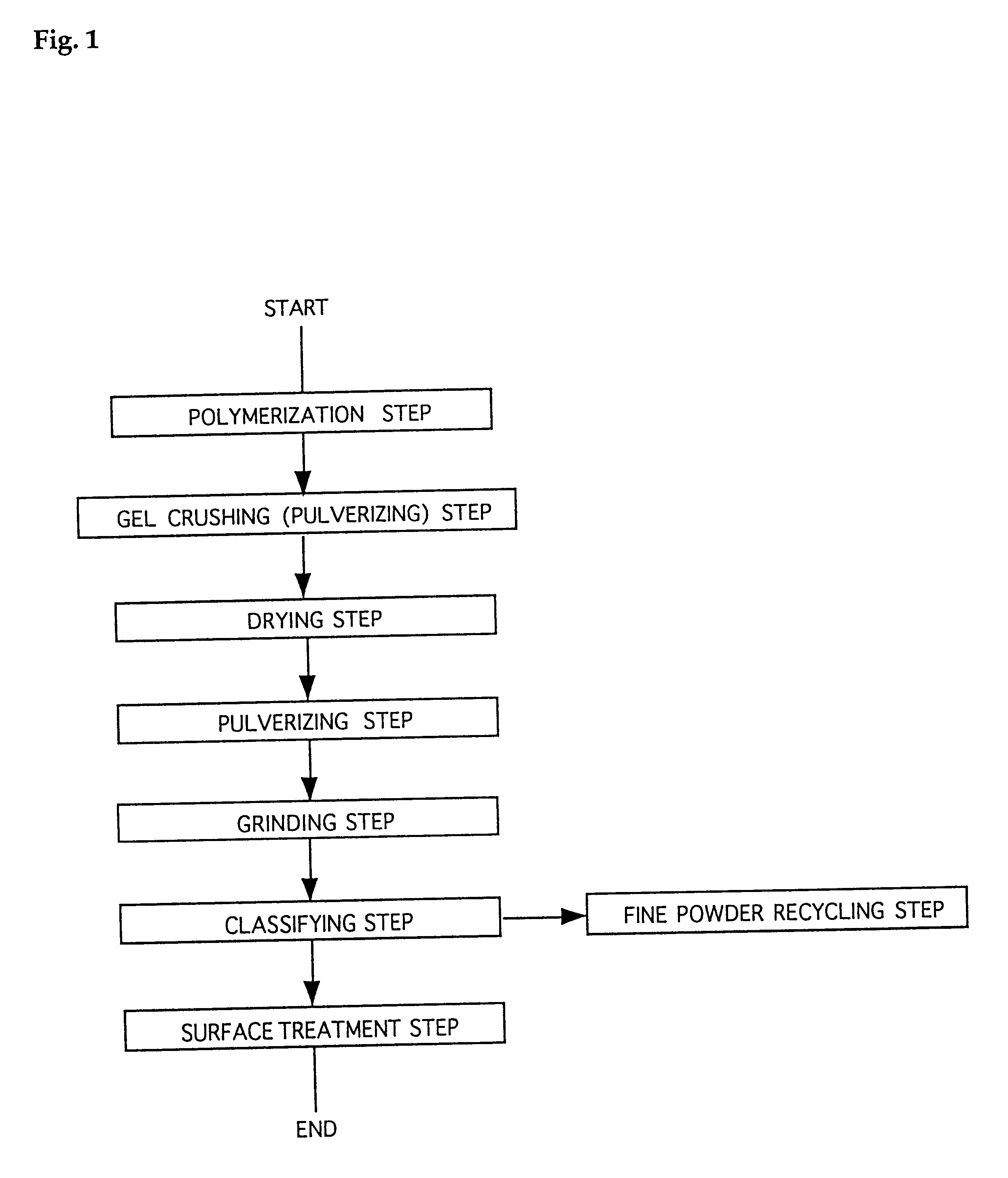

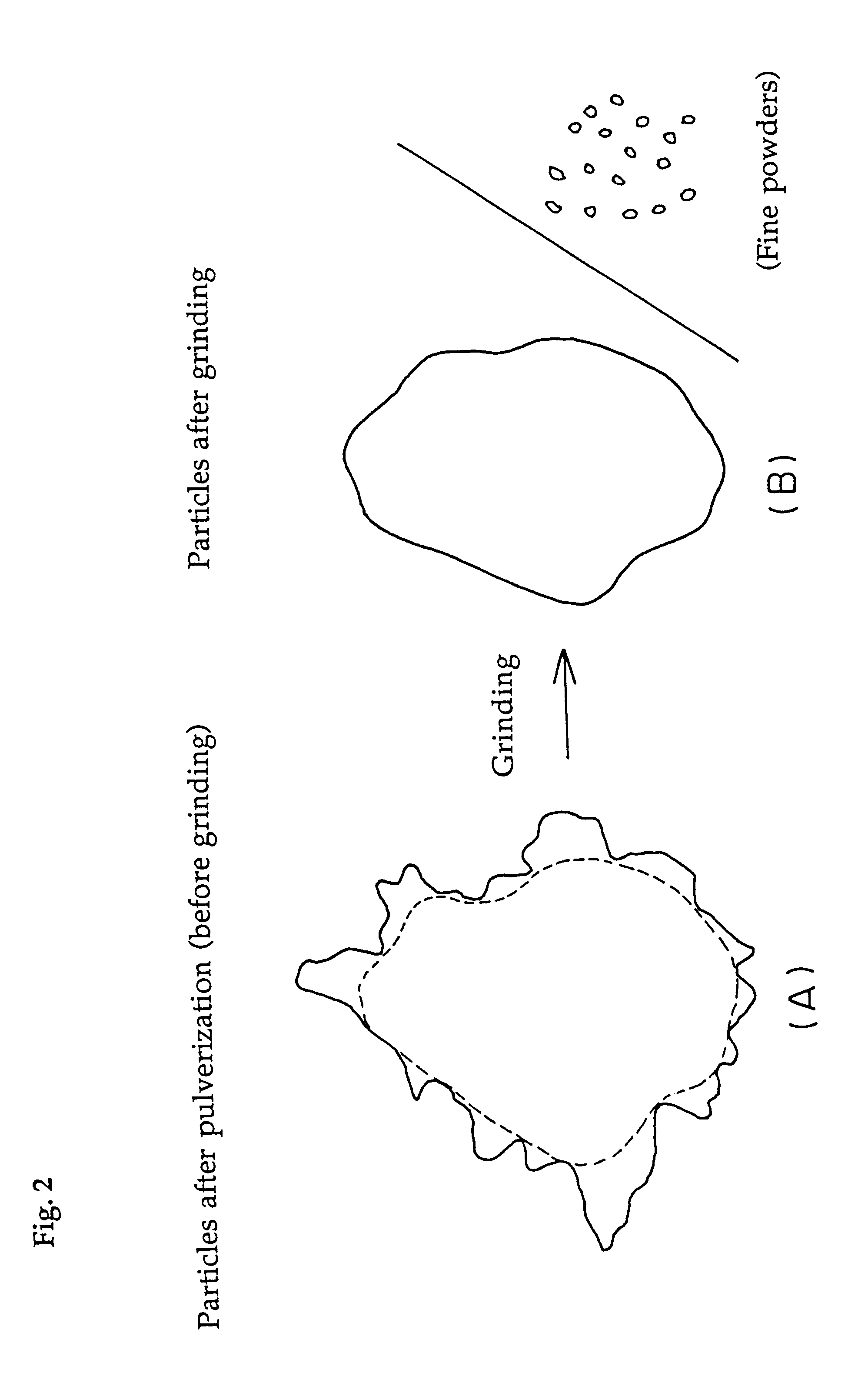

Water-absorbent resin powder and its production process and use

The present invention provides a water-absorbent resin powder and its production process and use, wherein the water-absorbent resin powder has high liquid permeability and high water absorbency. The production process for a water-absorbent resin powder, according to the present invention, comprises the step of obtaining water-absorbent crosslinked polymer particles by an aqueous solution polymerization step, and grinding the resultant crosslinked polymer particles until the bulk density thereof increases to not lower than 0.72 (g / ml). The water-absorbent resin powder is characterized by being arbitrarily pulverized and having a bulk density of not lower than 0.74 (g / ml) and a water absorption capacity of not lower than 20 (g / g) for 0.9 weight % physiological saline under a load of 0.7 psi (4.83 kPa). In addition, the absorbent structure comprises the above water-absorbent resin powder and a fibrous material. The absorbent article comprises an absorbent layer including the above absorbent structure.

Owner:NIPPON SHOKUBAI CO LTD

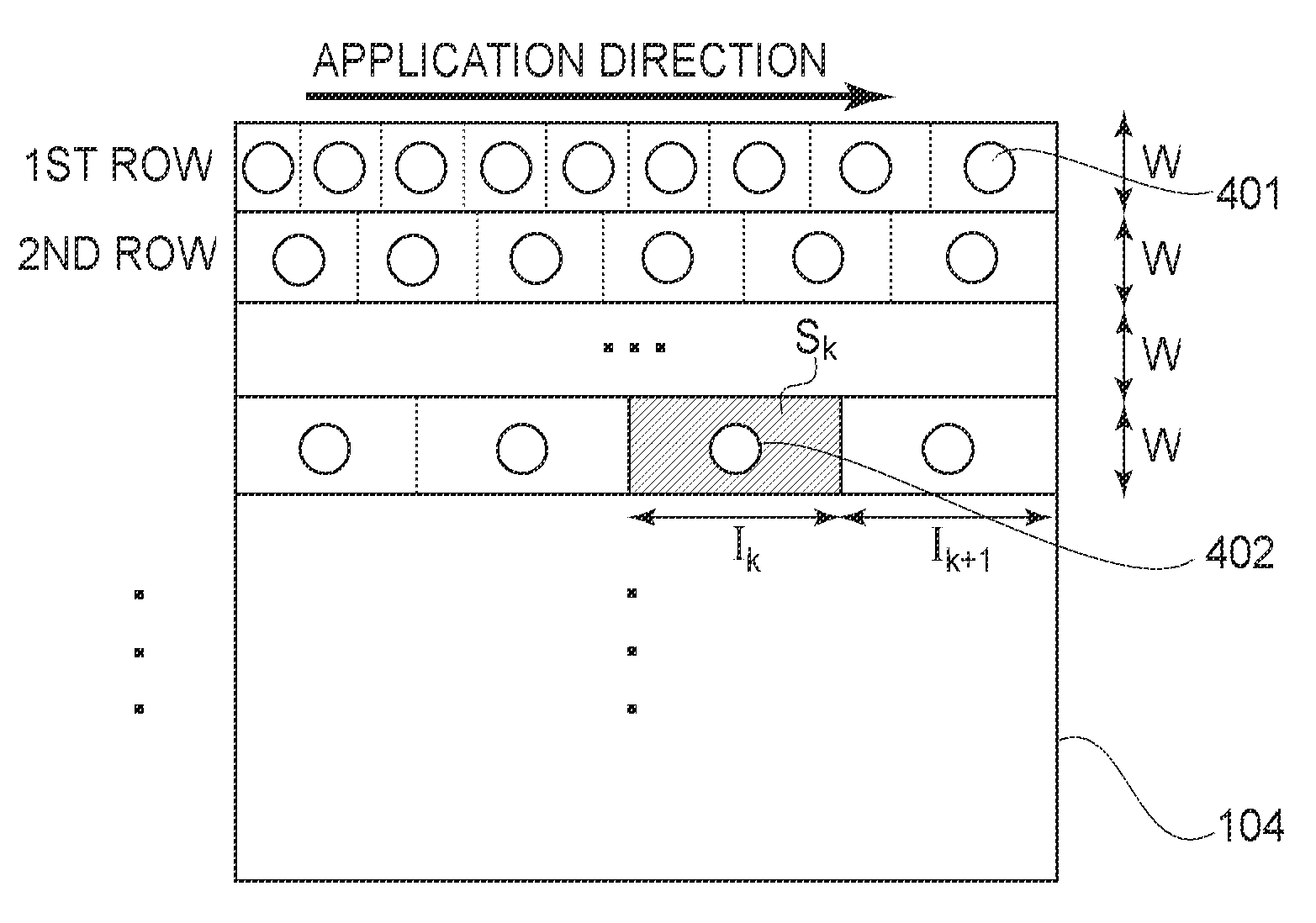

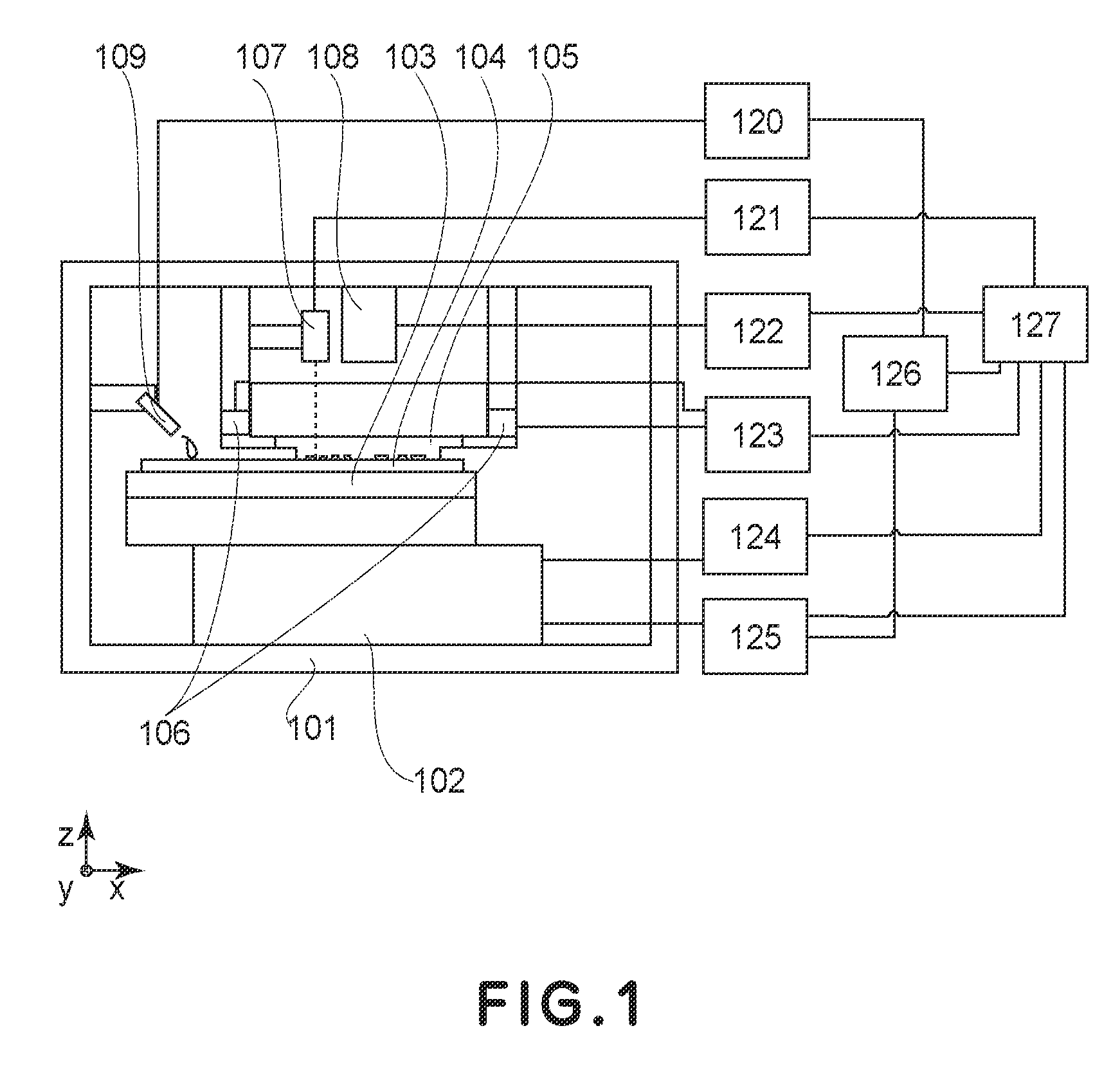

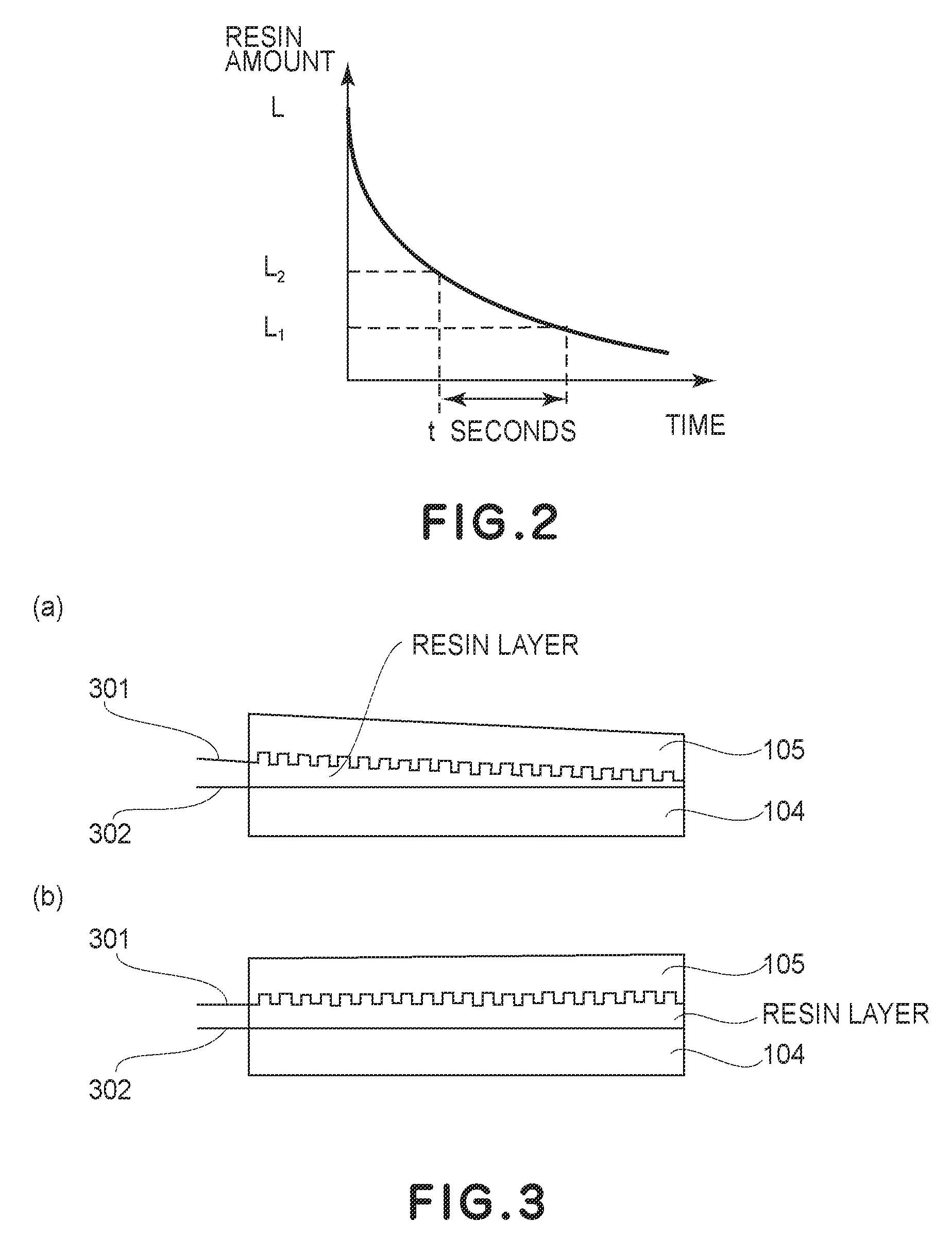

Pattern forming method and pattern forming apparatus

Owner:CANON KK

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

Rapid prototyping system with controlled material feedstock

A deposition modeling system incorporates a drive mechanism to feed a strand of filament to create a model. The drive mechanism comprises a pivot block that is rotatably connected to a fixed block and a motor that rotates a drive shaft. A drive roller is connected to the drive shaft and an idler roller is connected to an idler axle that extends from the pivot block in a substantially perpendicular direction to the direction of rotation of the pivot block with respect to the fixed block and in a substantially parallel direction to the drive shaft.

Owner:STRATSYS INC

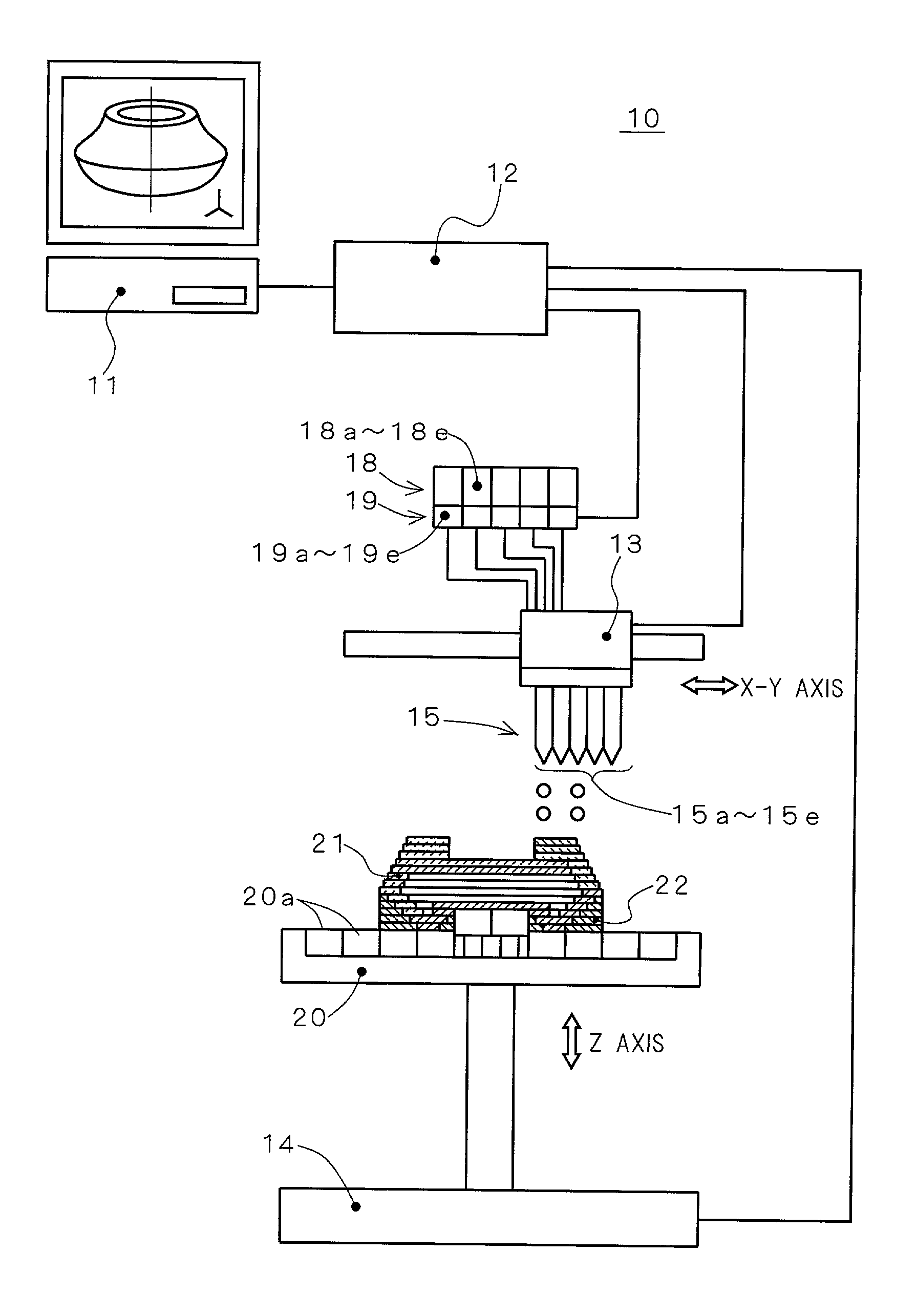

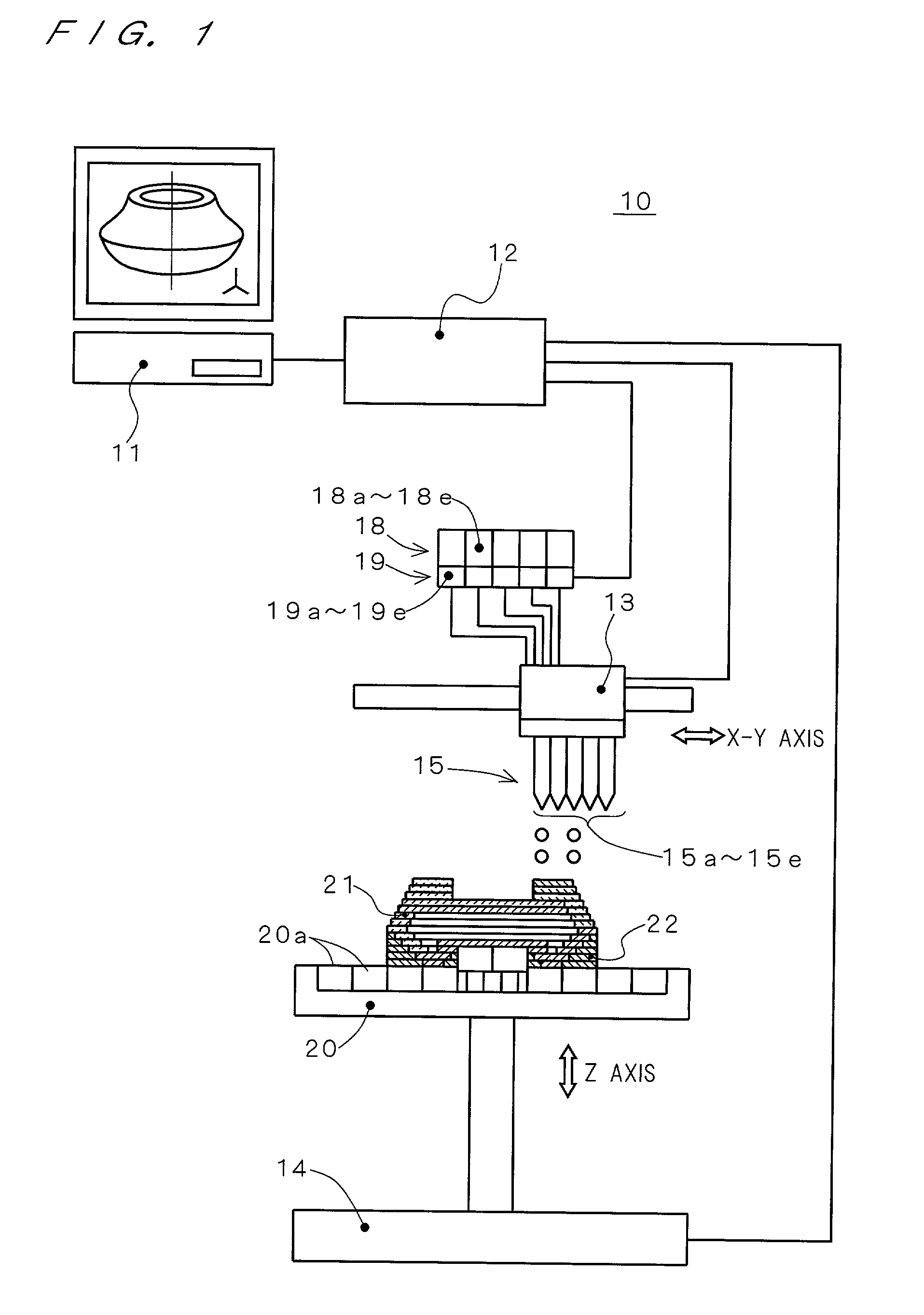

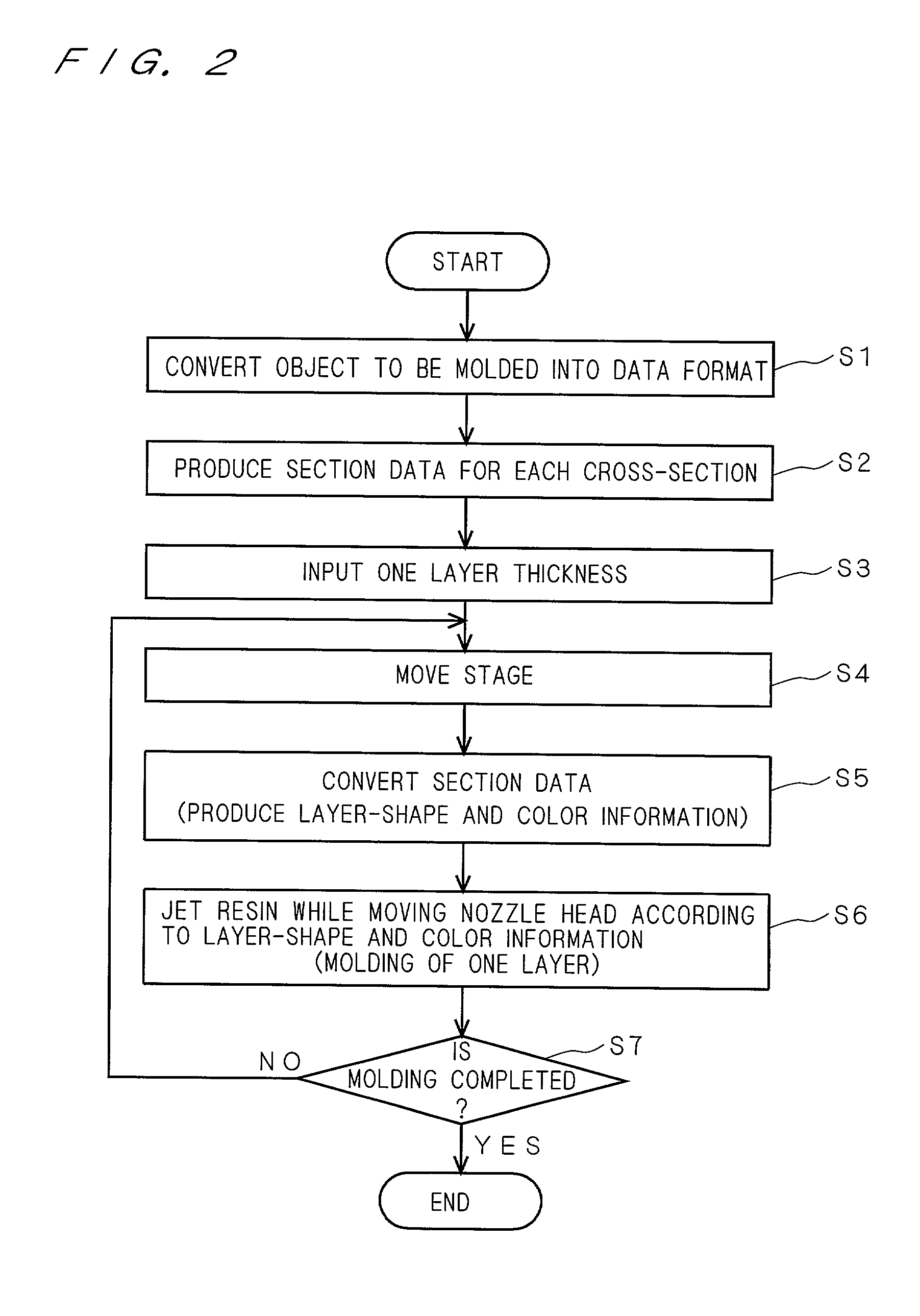

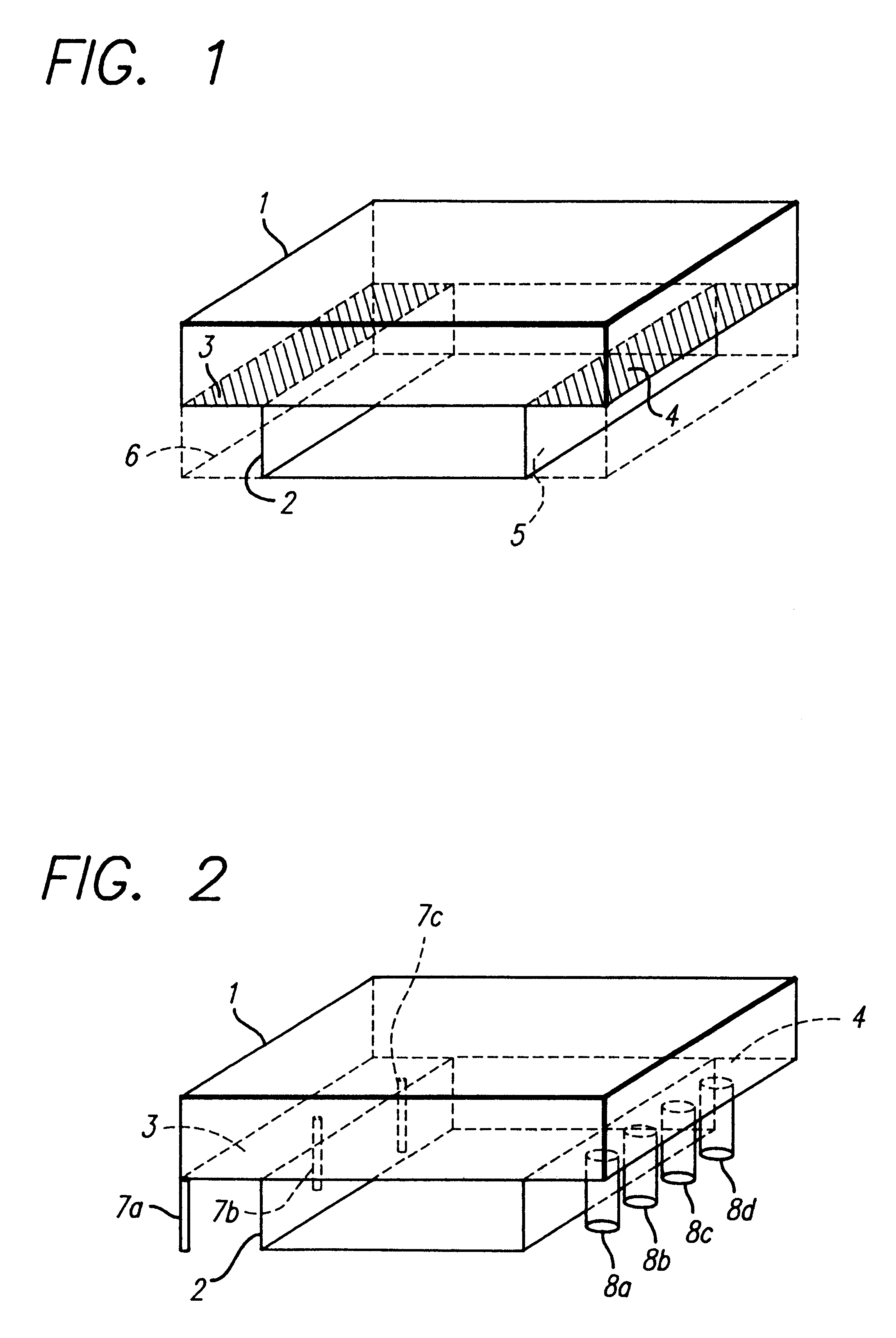

Three-dimensional object molding apparatus and method

InactiveUS20020167101A1Facilitate short-time low-cost moldingShort-time low-cost coloringConfectioneryPattern printingShell moldingColor intensity

In a 3D object molding apparatus (10), a tank (18d) holds an uncolored or white resin as a first material for use in interior molding, and tanks (18a to 18c) hold colored resins as second materials for use in surface molding. These resin materials are jetted from injection nozzles (15a to 15d) in the direction of a stage (20). A drive control unit (12) serving as control means moves a nozzle head (15) in the XY plane and controls jets of resin materials from the injection nozzles (15a to 15d). In the interior molding of a 3D molded product (21), at least the first material is jetted, while in the surface molding, at least the second materials are jetted. The injection nozzles (15a to 15c) are coloring nozzles to jet colored resins in molding color portions of the 3D molded product, and the injection nozzle (15d) is a molding nozzle to jet an uncolored molding resin in molding the other portions. The apparatus 10 provided with the coloring nozzles to jet predetermined coloring agents such as colored resins can jet coloring agents from the coloring nozzles in molding the 3D molded product, thereby achieving coloring of the 3D molded product in the molding process. Further, the use of a white resin allows representation of blight colors that are not available only with three colors (Y, M, C), thereby permitting reproduction of the color intensity and gradations in the coloring of the 3D molded product (21) in the molding process.

Owner:MINOLTA CO LTD

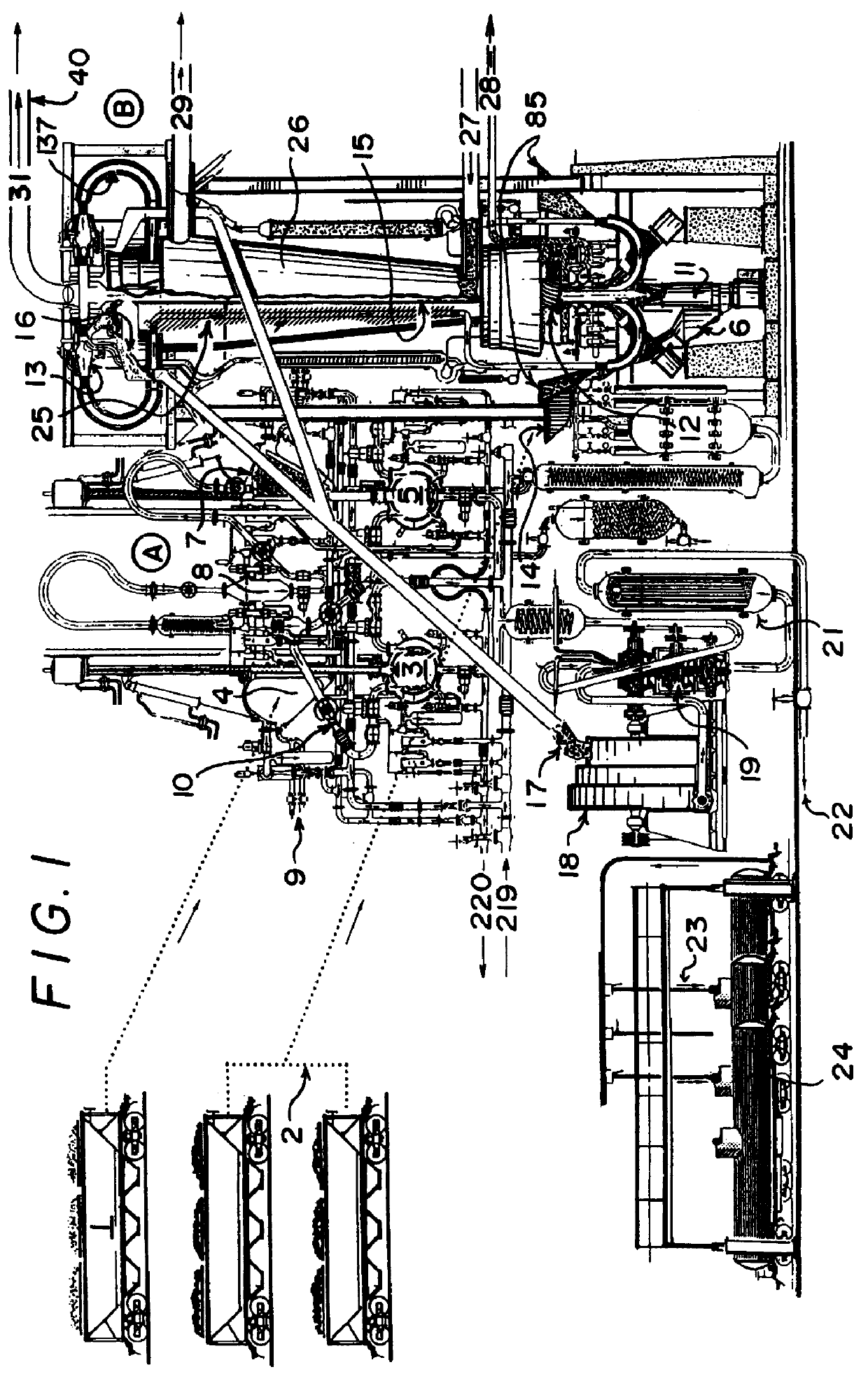

Apparatus for converting coal to hydrocarbons

InactiveUS6013158ALess producedLow costCombustible gas coke oven heatingDirect heating destructive distillationParticulatesSuspended particles

An apparatus for forming liquid hydrocarbons from solid coal. The coal is pulverized to provide a particulate coal feed, which is then extruded to provide a hollow tube of compressed coal supported inside of a support tube. A clay feed is extruded to provide a hollow tube of compressed clay supported inside of the coal tube and a combustible fuel is burned inside of the clay tube. The temperature of combustion is sufficient to fire the extruded clay and pyrolyze the extruded coal to produce hydrocarbon gases and coal char. The support tube has holes for releasing the hydrocarbon gases, which contain suspended particles formed during combustion. The suspended particles are removed from the hydrocarbon gases to provide clean gases, which are passed through an ionizing chamber to ionize at least a portion thereof. The ionized gases are then passed through a magnetic field to separate them from each other according to their molecular weight. Selected portions of at least some of the separated gases are mixed, and the mixed gases are cooled to provide at least one liquid hydrocarbon product of predetermined composition. Portions of the separated gases may also be mixed with the coal char and other input streams, such as waste plastics, and further treated to provide other hydrocarbon products.

Owner:WOOTTEN WILLIAM A

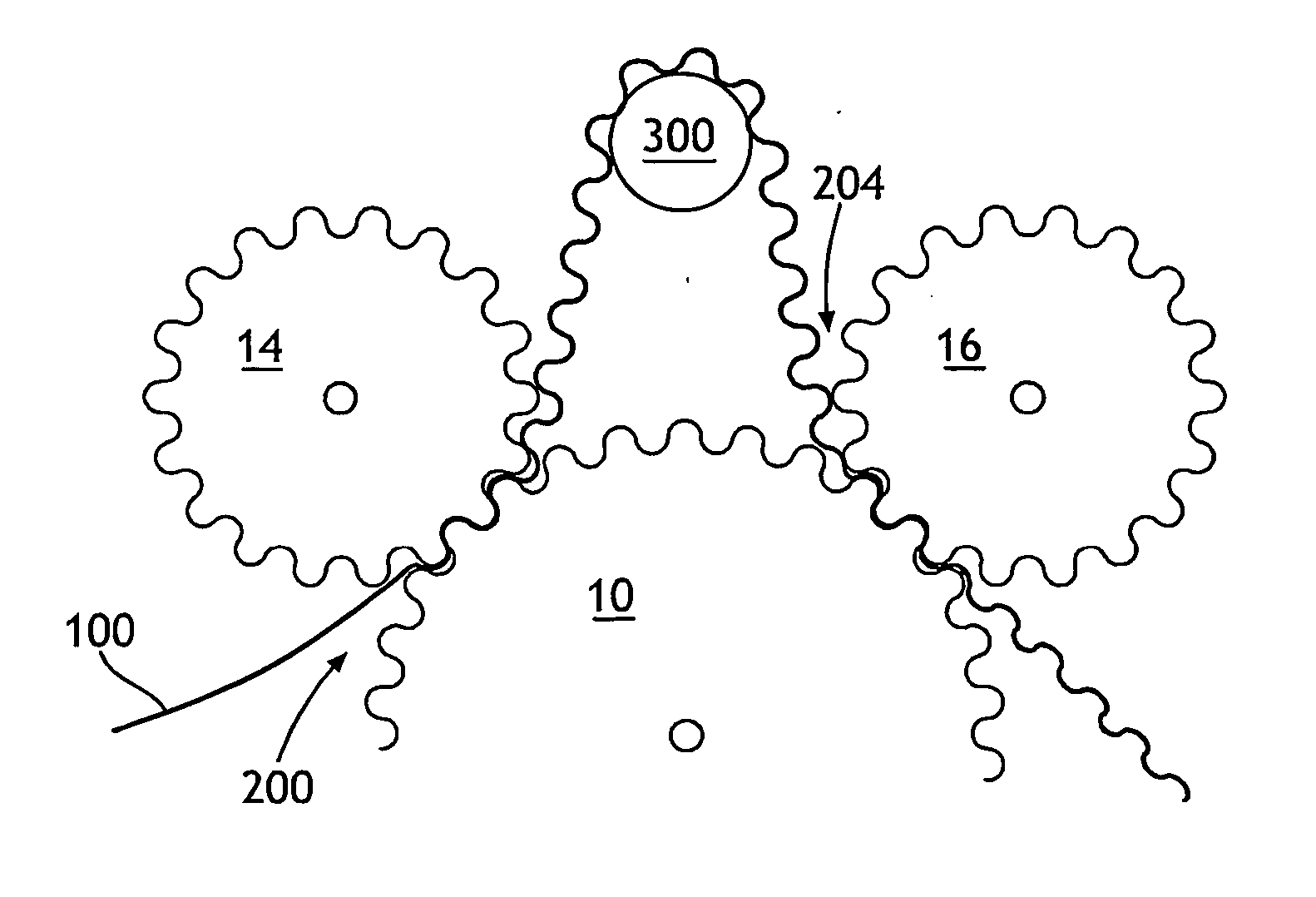

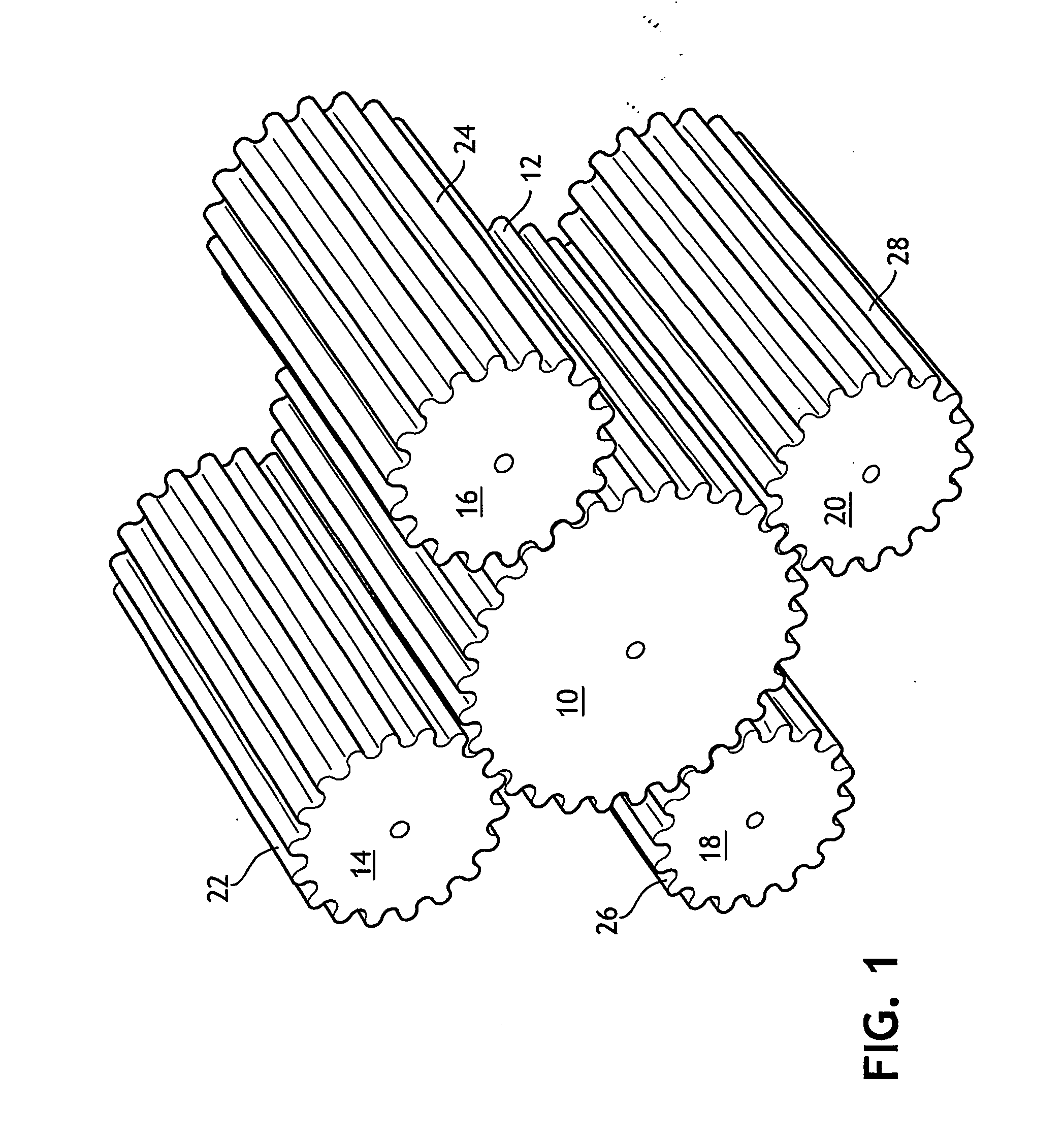

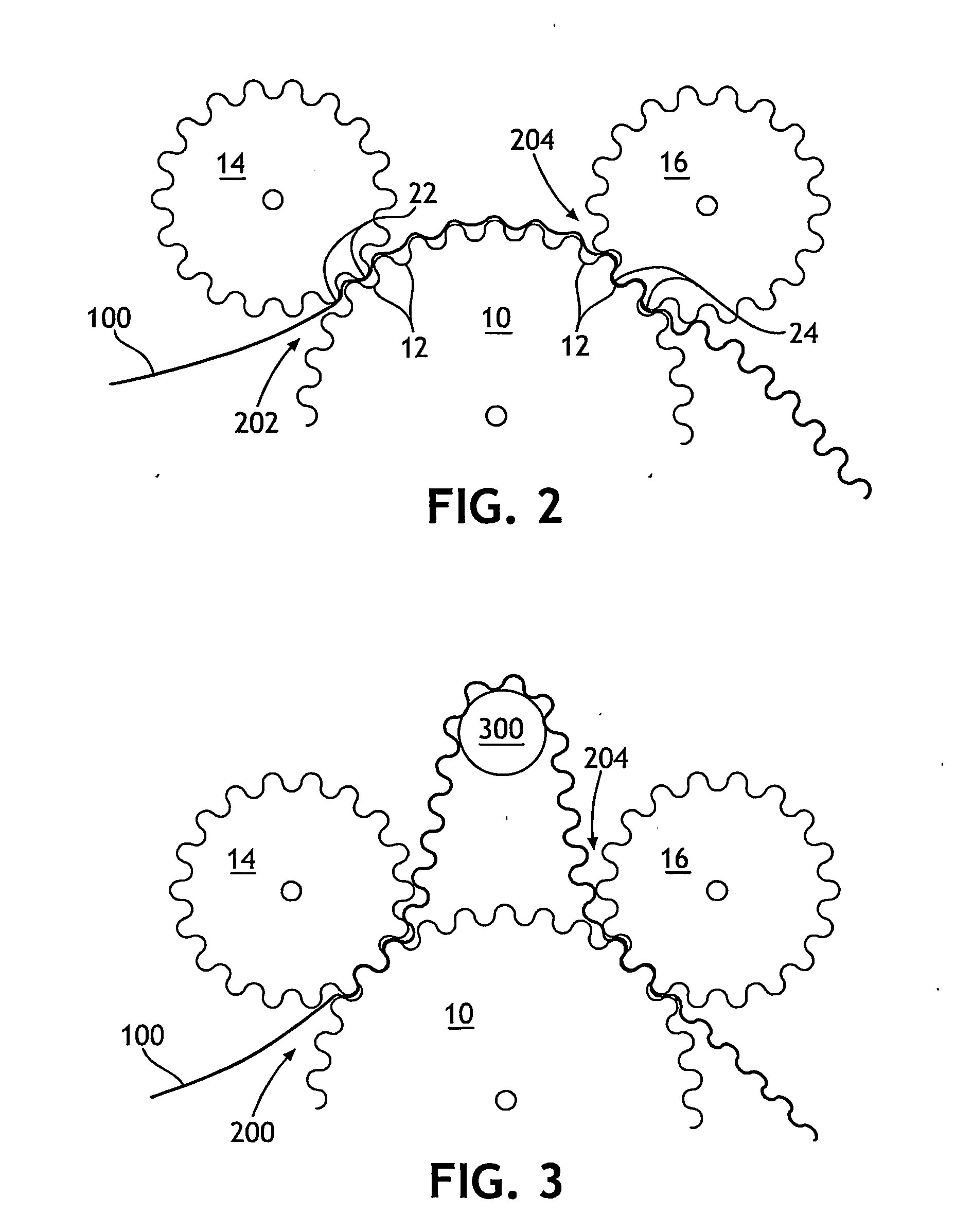

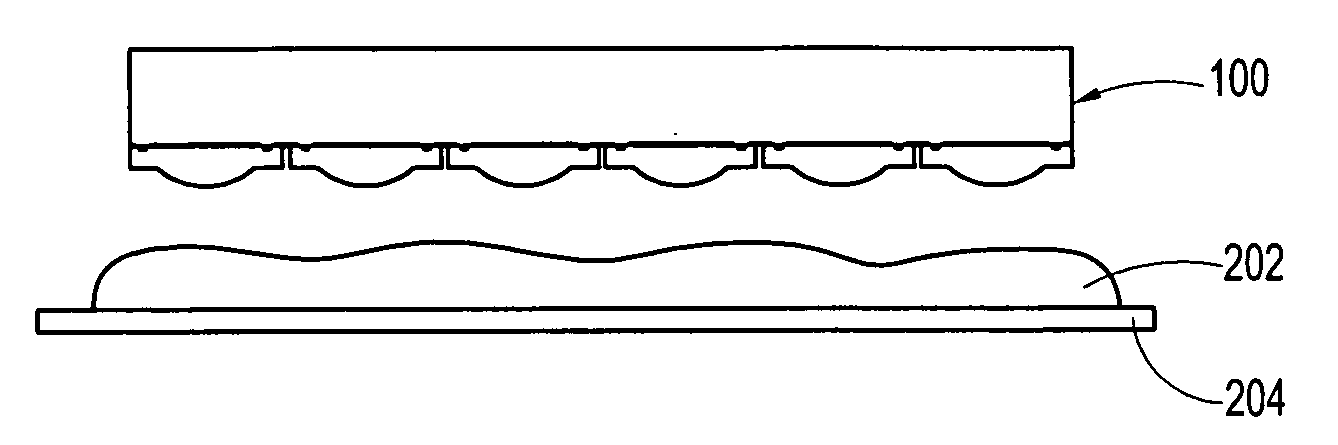

Device and process for treating flexible web by stretching between intermeshing forming surfaces

InactiveUS20060151914A1Increase flexibilityWidely vary degree of stretchDough-sheeters/rolling-machines/rolling-pinsConfectioneryPersonal Care ProductBiomedical engineering

A series of nips (200, 202, 204, 412, 414) formed by intermeshing grooves (22, 24, 26, 28) provides for a higher degree of stretch, particularly for lightweight webs (100) by stretching in stages in multiple grooved nips. The ability to adjust the degree of stretch at each nip can provide a high degree and variability of stretch with reduced web damage compared to a single step application of the same stretch. Improvements to the manufacture of lightweight components of personal care products such as diaper backing components are obtained.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Structural and optical applications for shape memory polymers (SMP)

InactiveUS6986855B1Easy to processReduce handling costsDischarging arrangementMouldsVisual inspectionUltraviolet

The methods of manufacturing molds from shape memory materials and molds made thereby, in accordance with the present invention, provide numerous advantages for molding castable composite parts. The initial mold cost is low enough to accommodate economical production of as few as a single part incorporating high surface definition and intricate three dimensional detail. The preferred methods and molds made thereby are transparent, thereby, curing of the corresponding part by ultra-violet and infra-red light is made possible, as well as, visual inspection during injection and curing of the given resin. Removal of the cured part from within the mold is simplified.

Owner:SPINTECH LLC

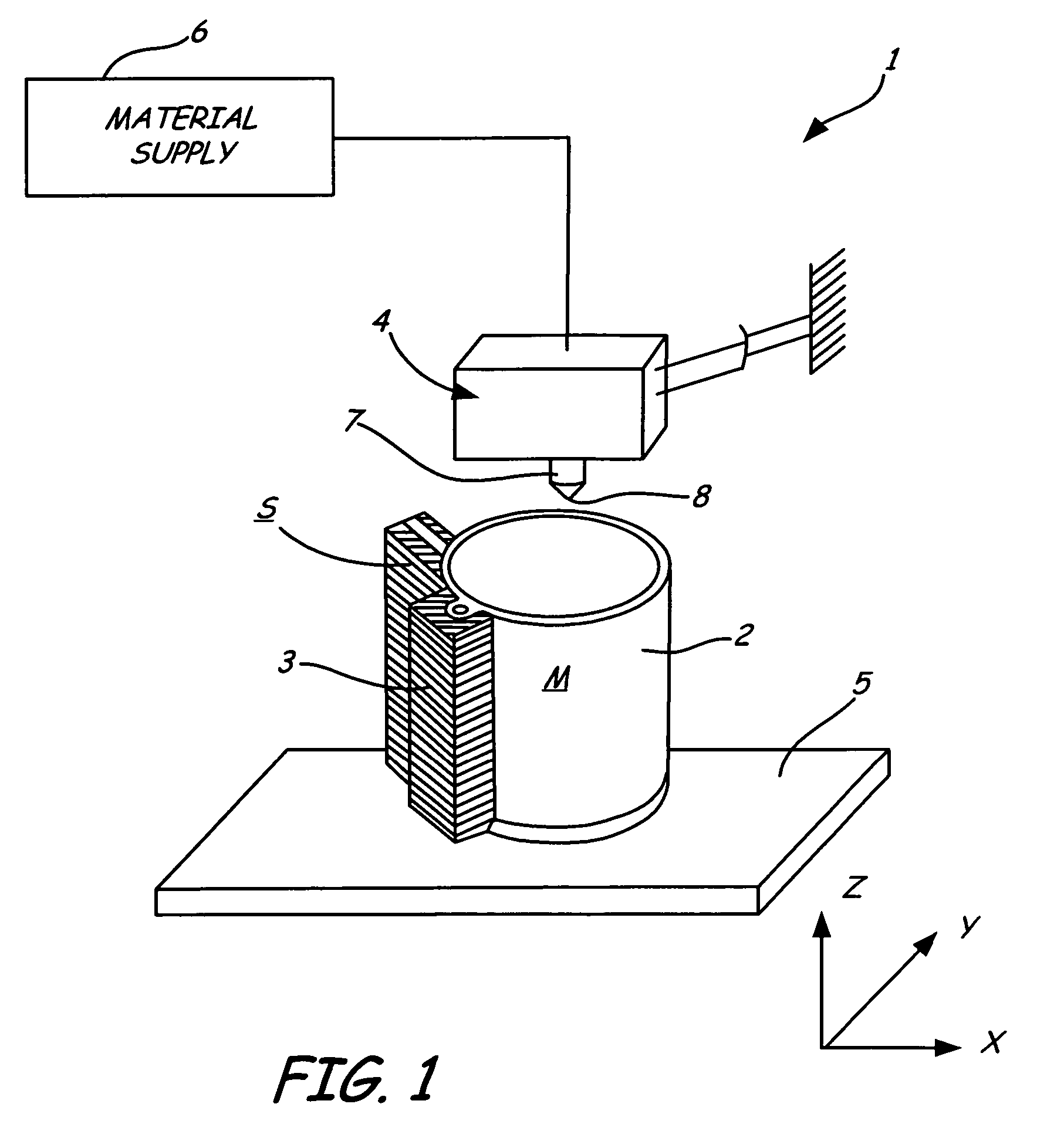

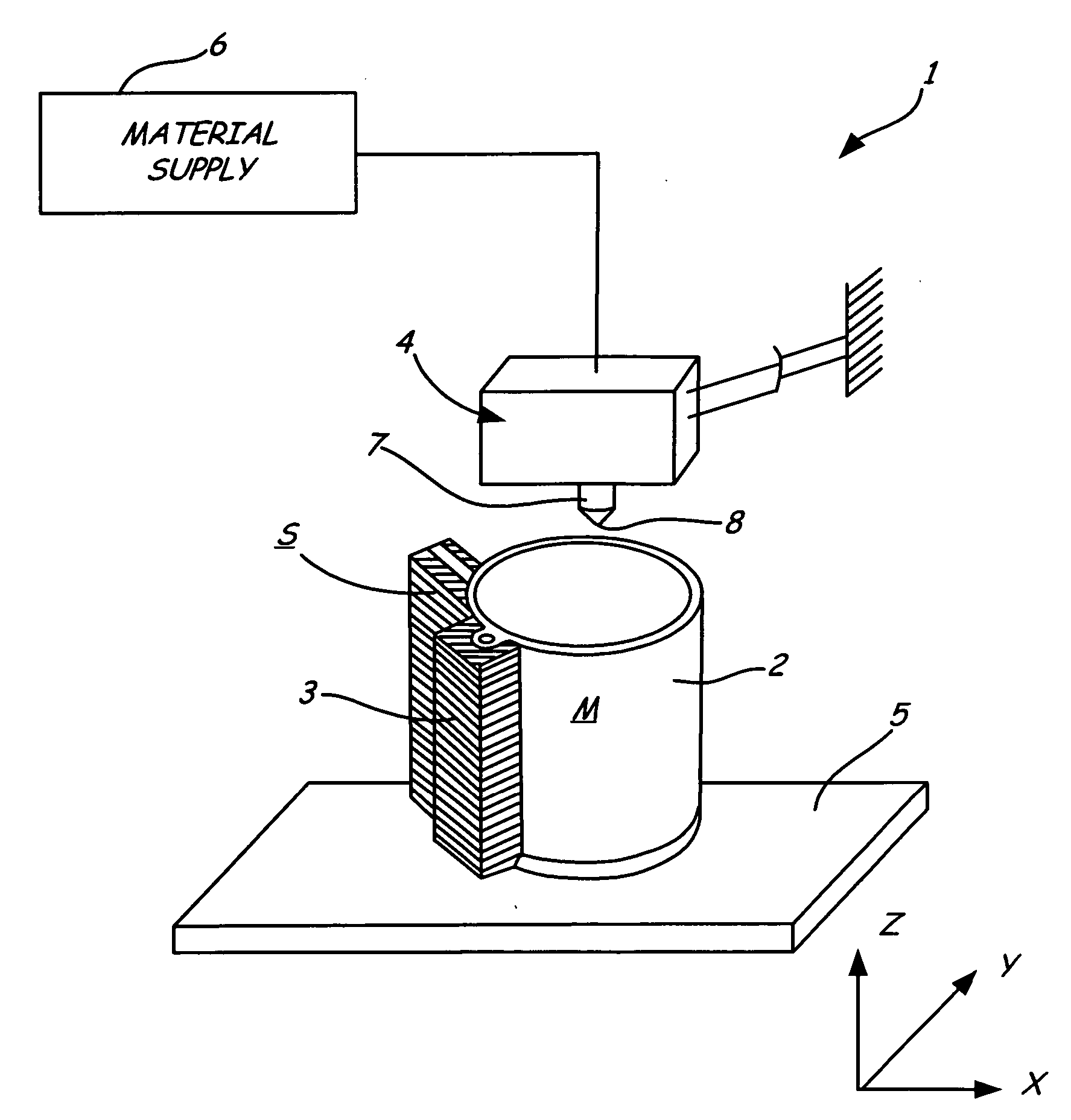

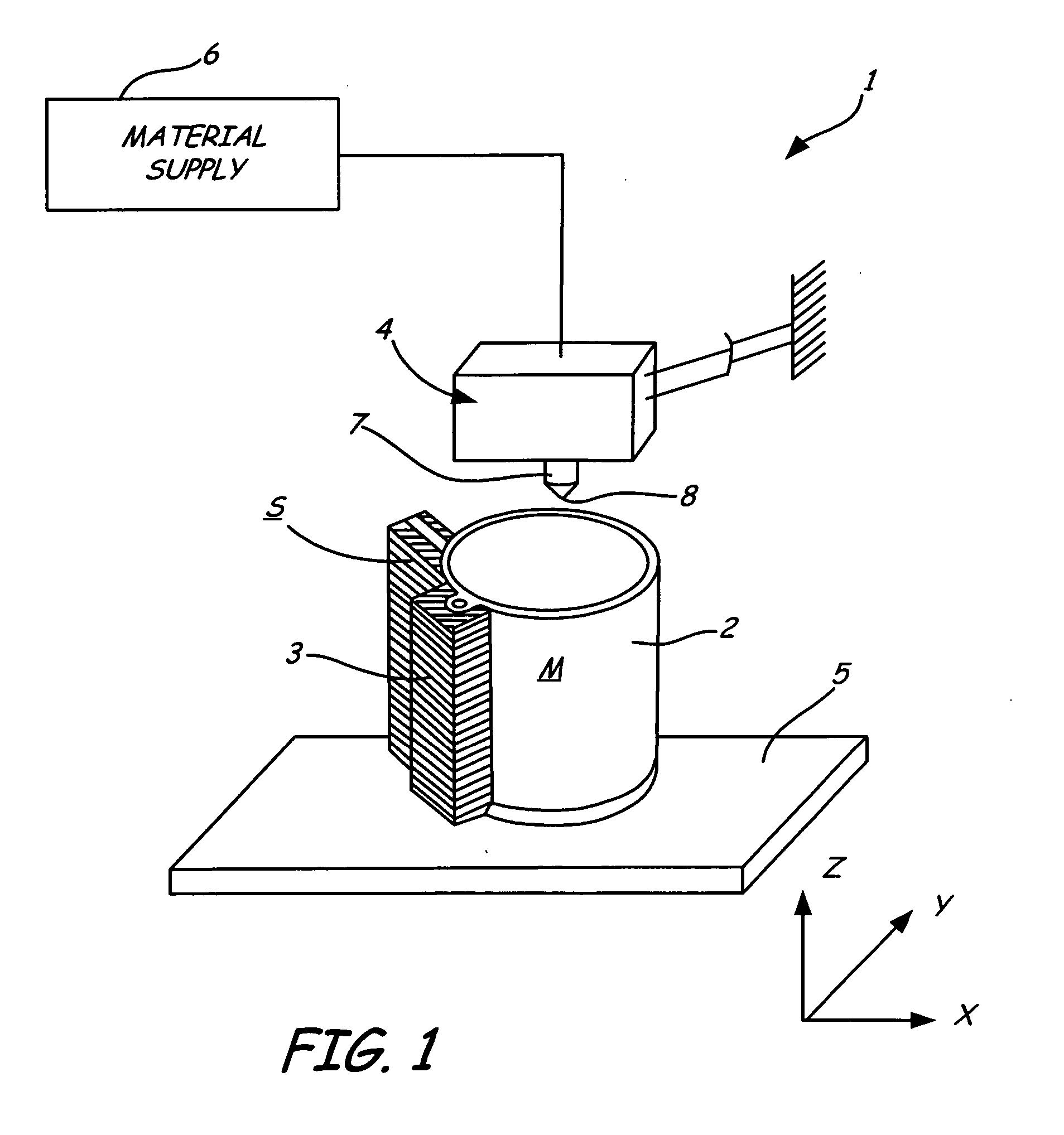

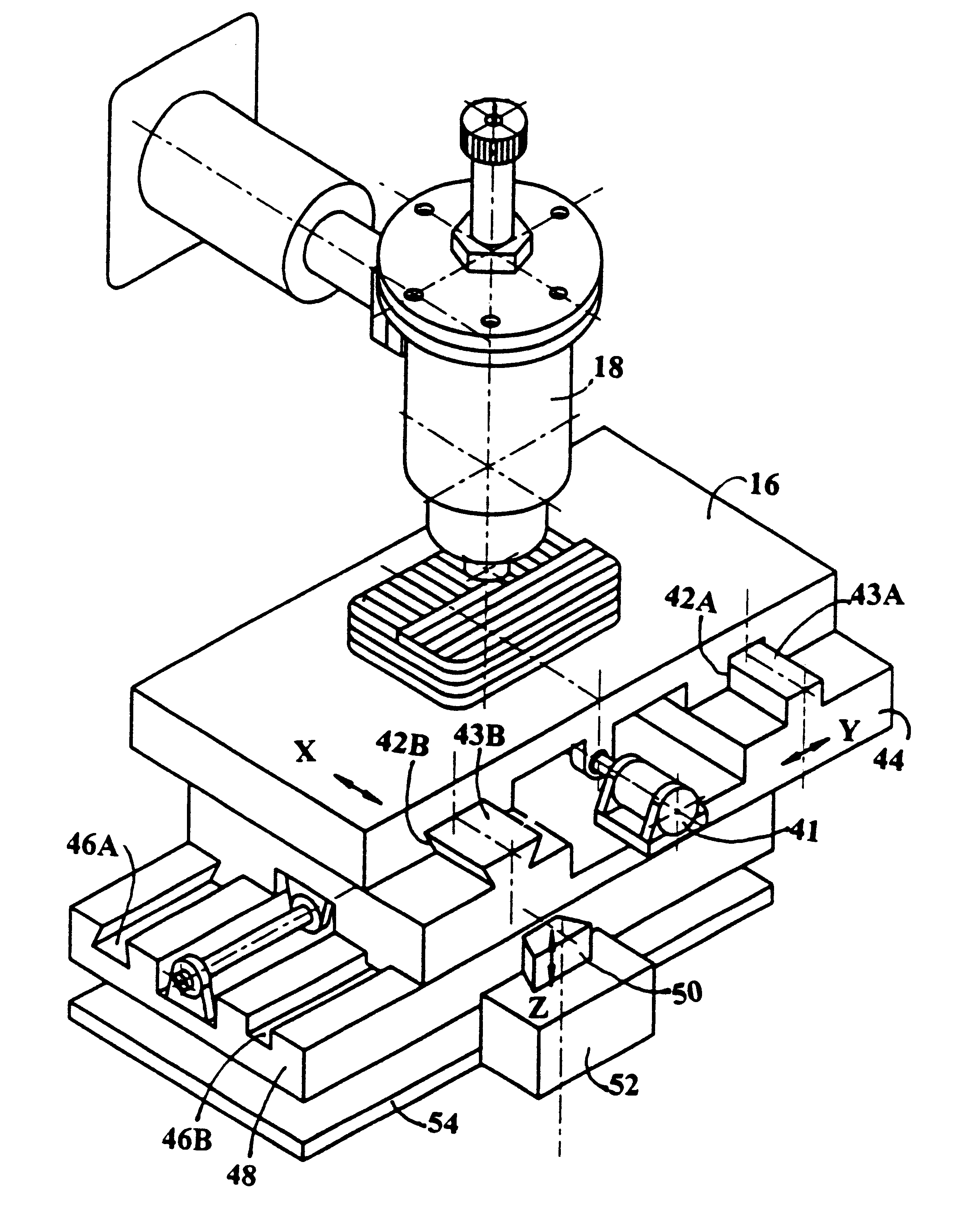

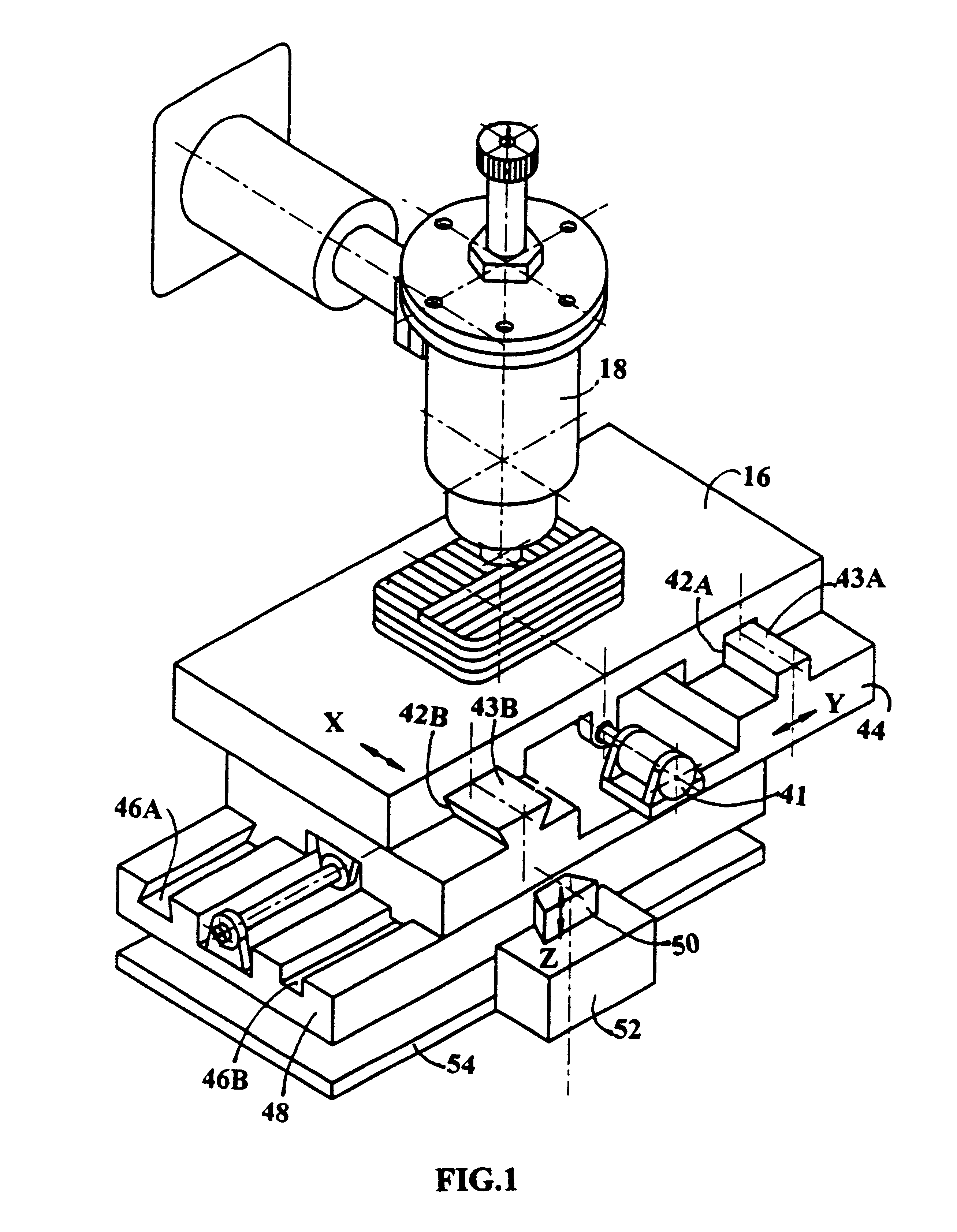

Rapid prototyping and fabrication method for 3-D food objects

InactiveUS6280785B1Versatile and Realistic Rapid PrototypingRapid productionLayered productsConfectioneryFree formControl signal

A freeform fabrication method for making a three-dimensional food object from a design created on a computer, including: (a) providing a support member by which the object is supported while being constructed; (b) operating a material dispensing head for dispensing a continuous or intermittent strand of food composition in a fluent state; this food composition including a liquid ingredient and a primary body-building food material and the dispensed food composition having a rigidity and strength sufficient for permitting the food composition to be built up layer by layer into a three-dimensional shape in a non-solid state; and (c) operating control devices for generating control signals in response to coordinates of the object design and controlling the position of the dispensing head relative to the support member in response to the control signals to control dispensing of the food composition to construct a 3-D shape of this object. The method optionally includes an additional step of applying a heat treatment to the 3-D shape after this 3-D shape is constructed. This method can be used to form an intricate shape of a cake mix, which is then baked in an oven. It can also be used to form a custom-designed decorative shape on the top surface of a pre-made cake.

Owner:NANOTEK INSTR GRP LLC

Lens master devices, lens structures, imaging devices, and methods and apparatuses of making the same

Owner:MICRON TECH INC

Arrangement and method for producing a three-dimensional product

Arrangement for producing a three-dimensional product, which arrangement comprises a work table on which said three-dimensional product is to be built up, a powder dispenser which is arranged so as to distribute a thin layer of powder on the work table for forming a powder bed, a radiation gun for delivering energy to the powder, fusing together of the powder then taking place, means for guiding the beam emitted by the radiation gun over said powder bed for forming a cross section of said three-dimensional product by fusing together parts of said powder bed, and a control computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build up the three-dimensional product, where the control computer is intended to control said means for guiding the radiation gun over the powder bed according to an operating scheme forming a cross section of said three-dimensional body, said three-dimensional product being formed by successive fusing together of successively formed cross sections from by the powder dispenser, and method for producing three-dimensional product using such an arrangement.

Owner:ARCAM AB

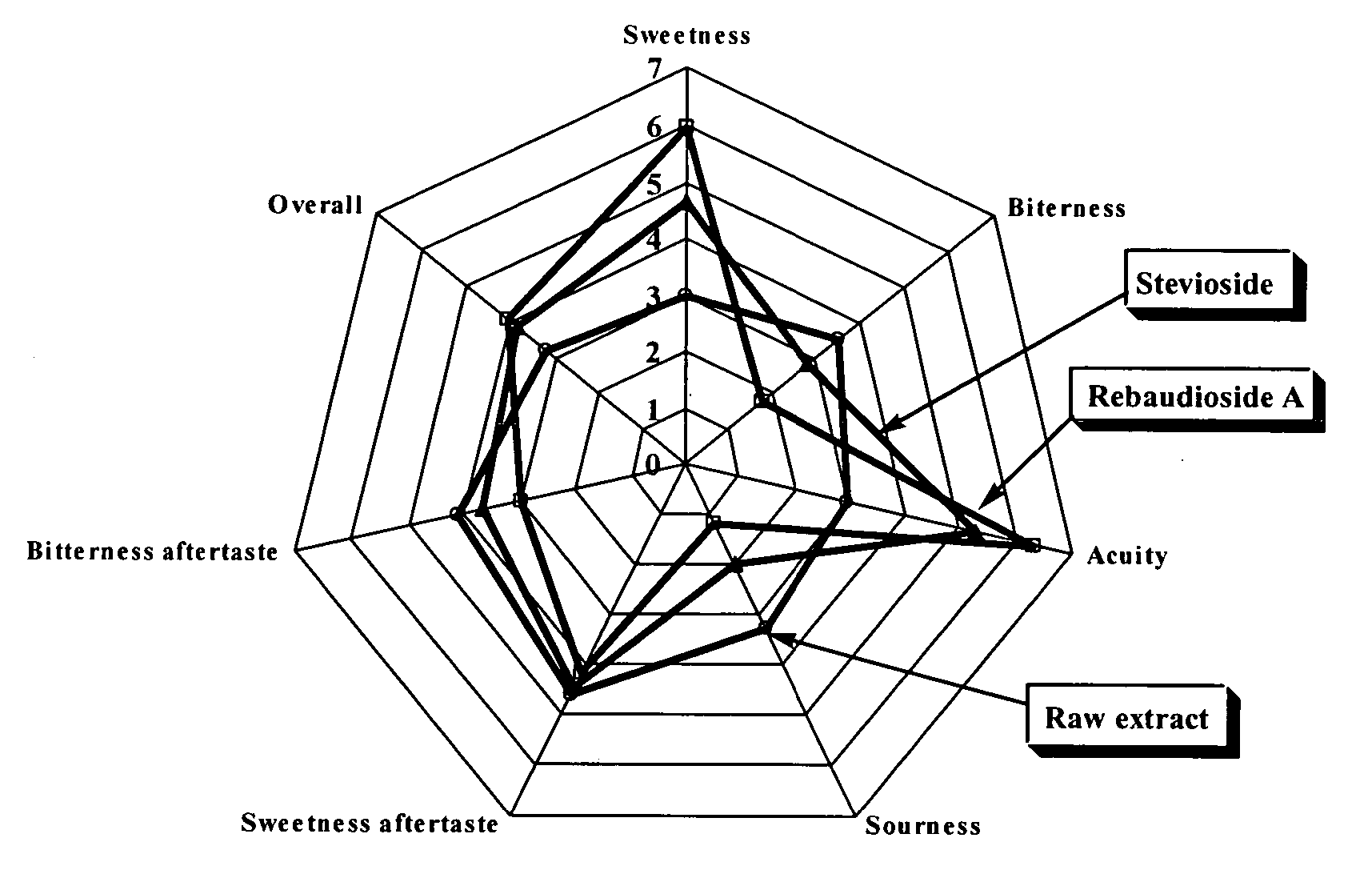

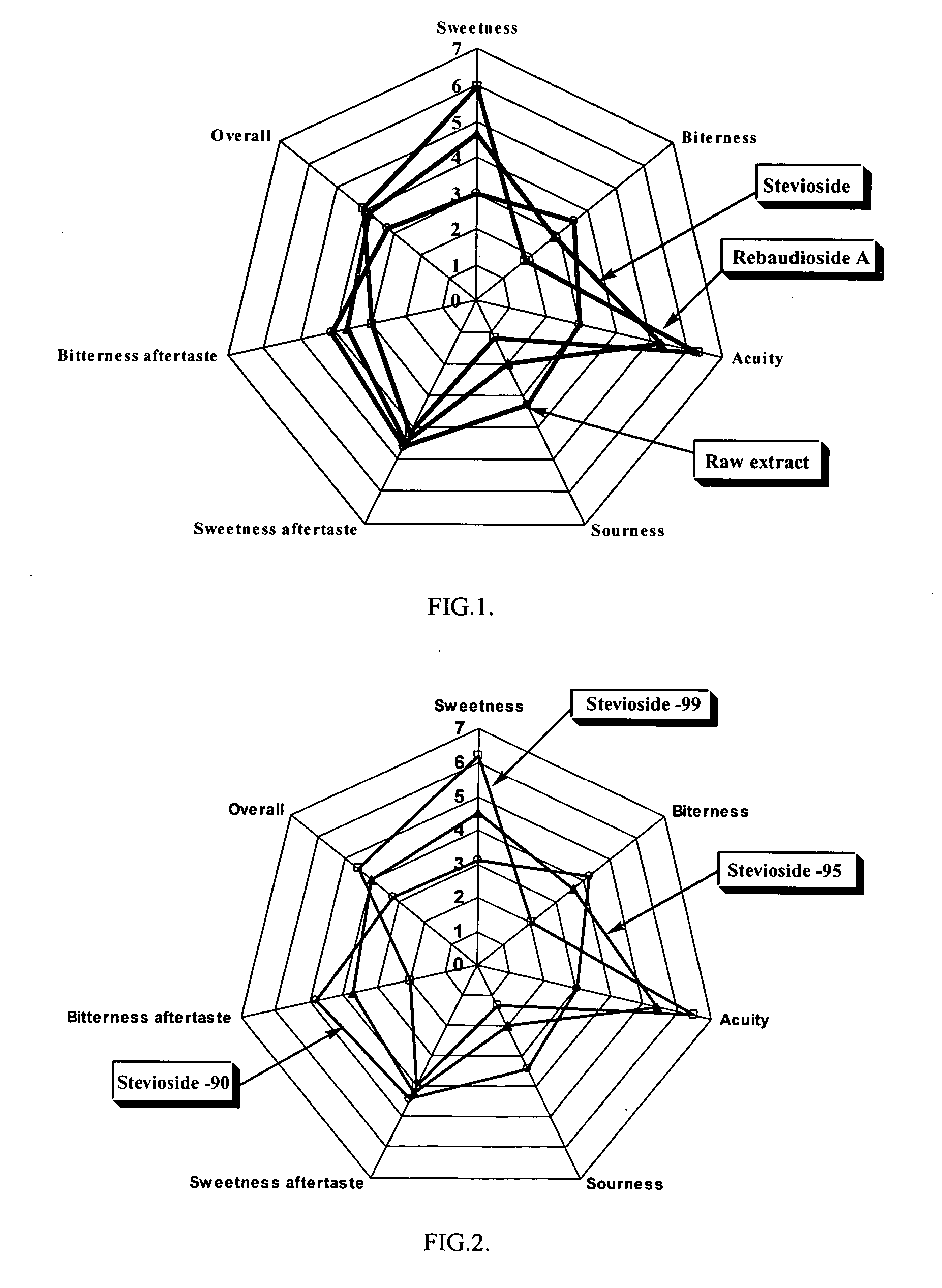

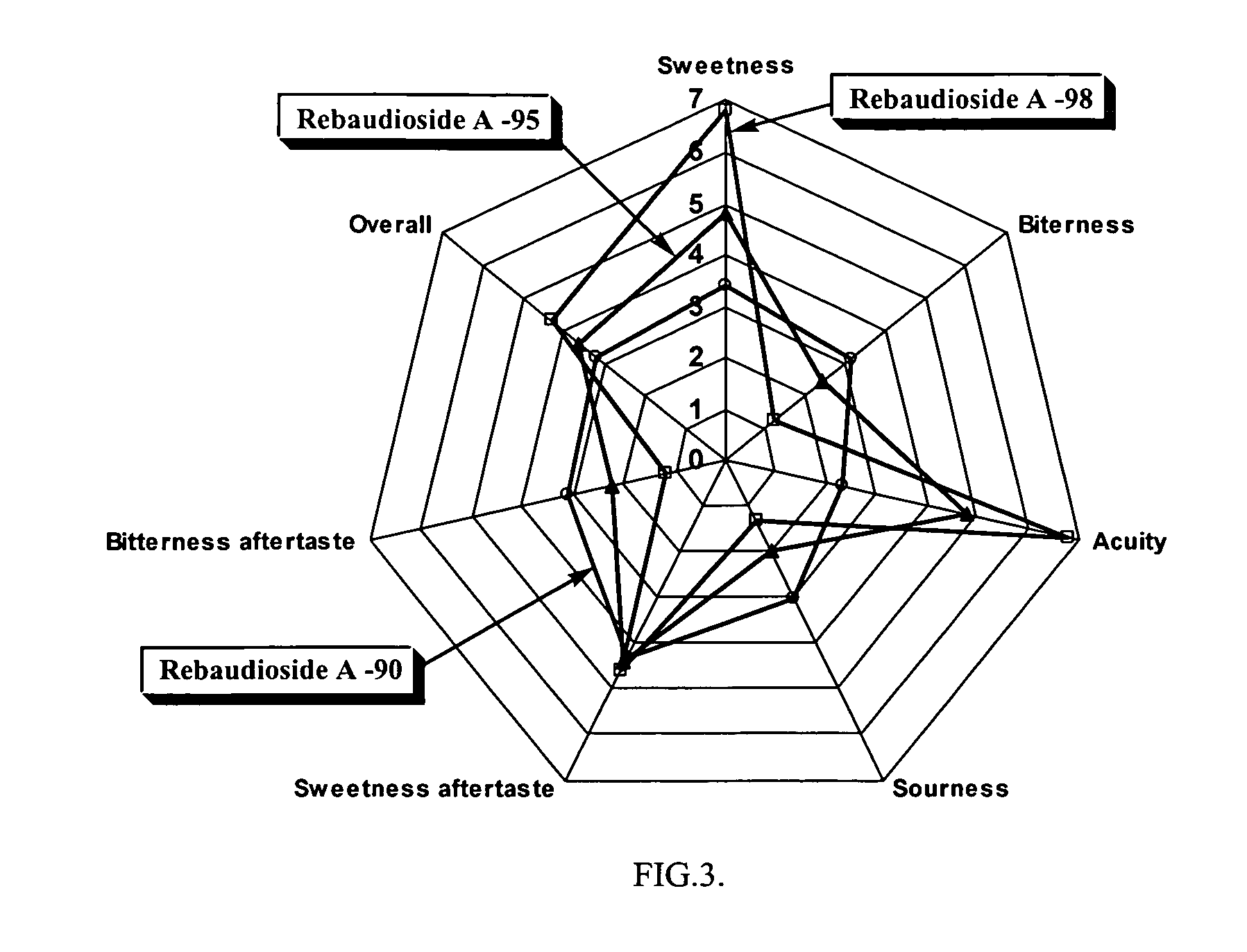

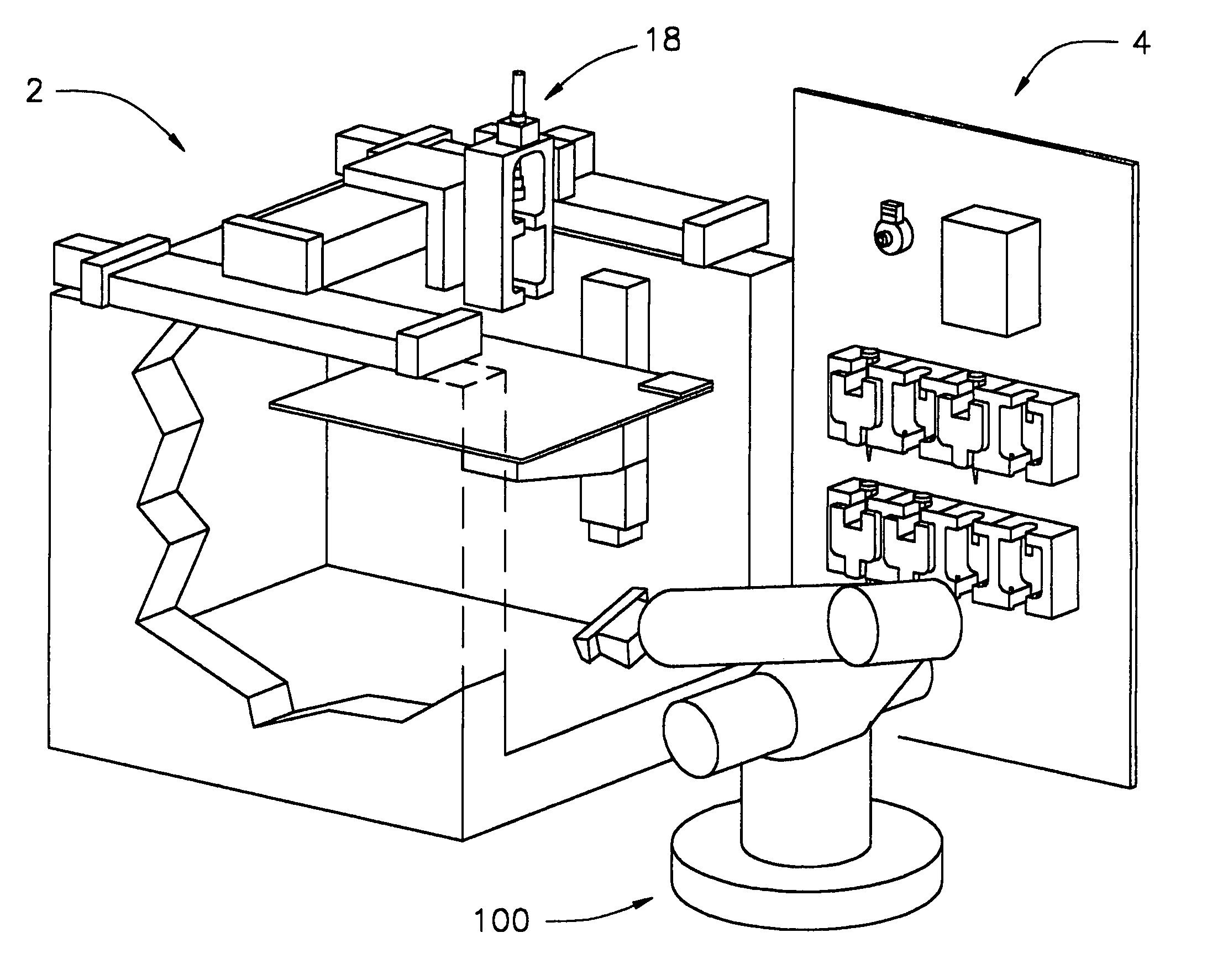

Process for manufacturing a sweetner and use thereof

Highly purified Stevioside and Rebaudioside A were prepared from sweet glycoside extracts obtained from Stevia rebaudiana Bertoni leaves. The resulting sweeteners are suitable as non-calorie, non-cariogenic, non-bitter, non-lingering sweeteners, which may be advantageously applied in foods, beverages, and milk products.

Owner:PURECIRCLE SDN BHD

Effervescent green tea extract formulation

InactiveUS6299925B1Fast absorptionMaintain good propertiesAntibacterial agentsPre-extraction tea treatmentNatural productAdditive ingredient

A solid state water soluble formulation in granular or tablet form is provided. The formulation is a natural products formulation containing a green tea plant extract in combination with other ingredients which create an effervescent liquid composition upon dispensing the formulation in a liquid. The liquid form of administration, as well as the effervescent properties of the dissolved formulation increase bioavailability of the advantageous components of the green tea plants such as Polyphenols, by increasing absorption speed and amount in the human body. The formulation may include additional components such as, other plant extracts, vitamins, ionic minerals, and other substances purported to be of a health benefit.

Owner:XEL HERBACEUTICALS INC

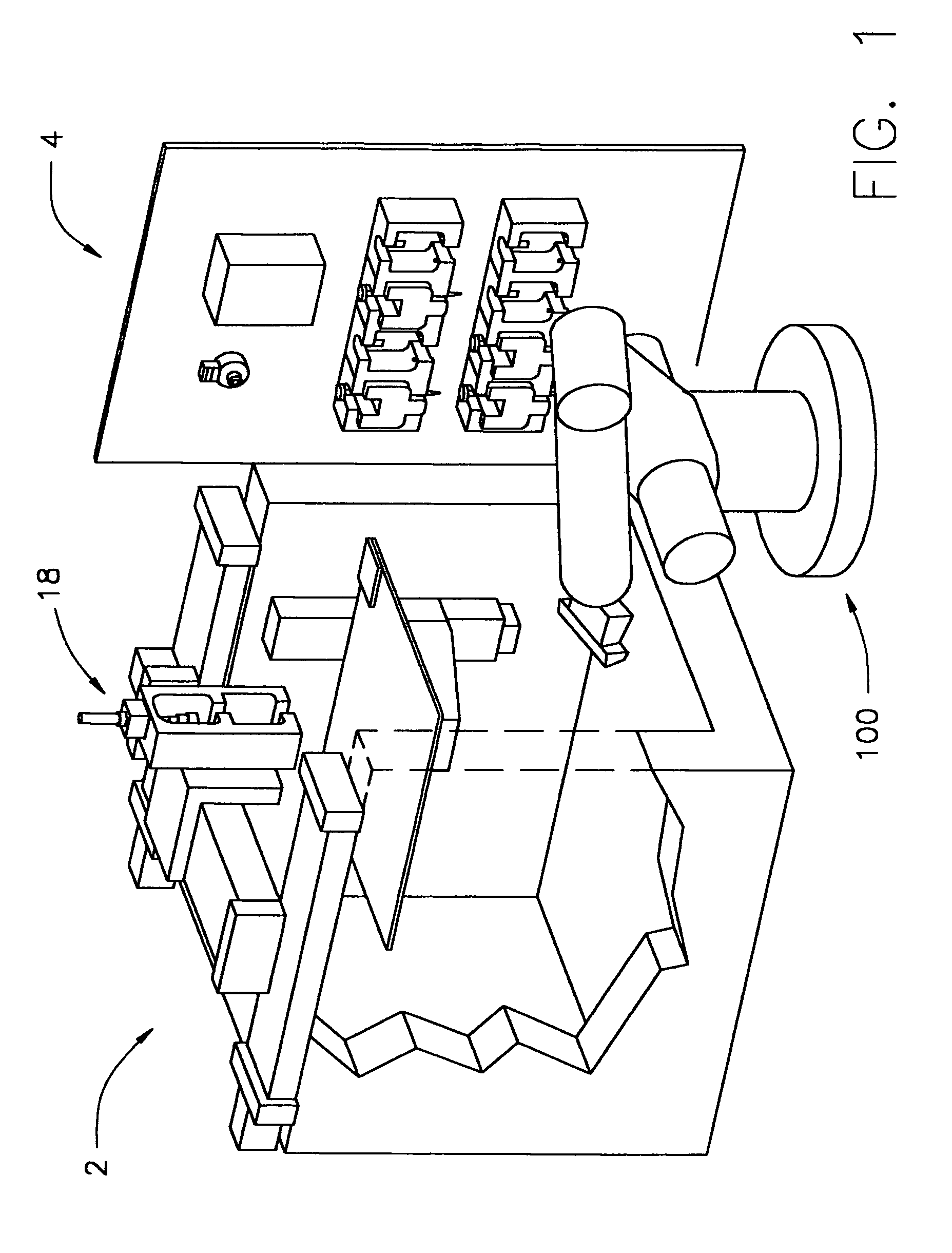

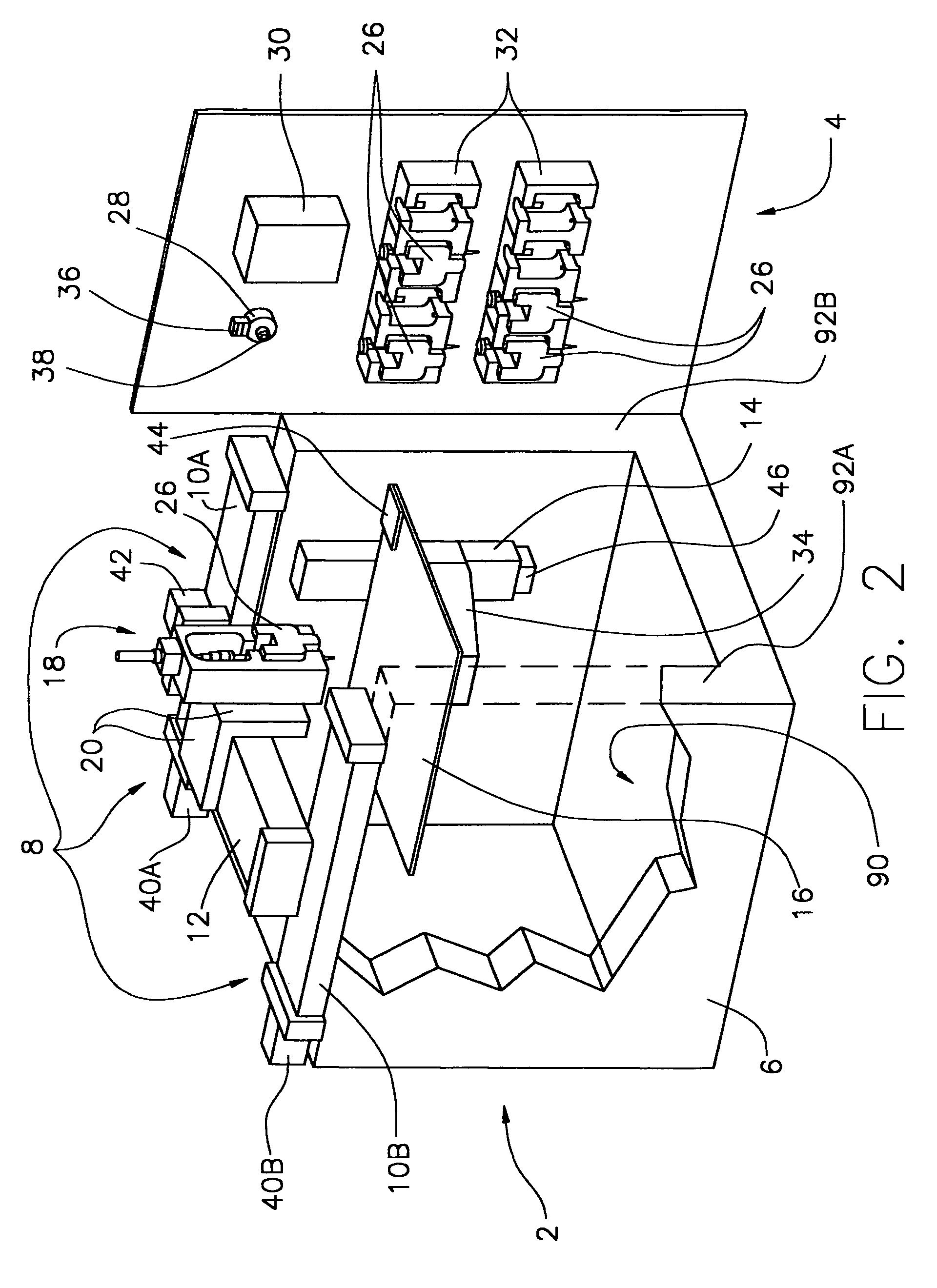

Modular fabrication systems and methods

ActiveUS7625198B2Improve throughputAdapt to a wide rangeLiquid surface applicatorsConfectioneryEngineeringSystem controller

The present invention relates to an article fabrication system having a plurality of material deposition tools containing one or more materials useful in fabricating the article, and a material deposition device having a tool interface for receiving one of the material deposition tools. A system controller is operably connected to the material deposition device to control operation of the material deposition device. Also disclosed is a method of fabricating an article using the system of the invention and a method of fabricating a living three-dimensional structure.

Owner:CORNELL RES FOUNDATION INC

Device for the generative manufacturing of three-dimensional components

ActiveUS20130108726A1Efficient and cost-effective operationEfficiently formedManufacturing platforms/substratesConfectioneryEngineeringMonochrome

The invention relates to a device for producing products having individual geometries, comprising a substrate carrier device, a material application device for applying material, preferably above the substrate carrier device, which material application device can be moved relative to the substrate carrier device, and a control device which is coupled to the material application device for signaling. According to the invention, the material application device is coupled to an input interface for signaling and for selection of a first or a second application mode, the control device and the application device being designed such as to produce, in the first application mode, a three-dimensional product on the surface of a substrate plate by way of an additive production method, said substrate plate being connected to the substrate carrier device. According to the additive production method, a curable material is applied in consecutive layers, one or more predetermined regions are selectively cured after or during each application of a layer, the predetermined regions being bonded to one or more regions of the underlying layer. The predetermined region(s) is / are predetermined by a cross-section geometry of the product in the respective layer and is / are stored in the control device, and the curable material is applied in a plurality of consecutive layers to produce the three-dimensional product. The control device and the application device are further designed such that in the second mode of application one or more colors are applied to predetermined regions of a print substrate material connected to the substrate carrier device to produce a monochrome or polychrome print.

Owner:BEGO MEDICAL

3D printer and printhead unit with multiple filaments

InactiveUS8827684B1Reduce complexityIncrease speedConfectionerySweetmeatsFused filament fabricationMetal filament

A fused filament fabrication printer has a fixed extrusion module having multiple printheads having print tips. The fixed arrangement of the printing heads allows the close spacing of multiple print tips in a printhead unit, and the simple routing of multiple plastic or metal filaments to the individual printing heads. The closely spaced print tips in the printhead unit share common components. An exemplary printhead unit has four printing heads which share a common heating block and heating block temperature sensor. The heating block incorporates a group of four print tips evenly spaced along a line. Each printing head has a separate filament which is controlled and driven by its own stepper motor through the heating block to one of the print tips. Printing of a part is by control of individual stepper motors which drive filaments through the heating block and through one of the printing tips.

Owner:RADIANT FABTION

Device and arrangement for producing a three-dimensional object

InactiveUS20040026807A1Reduced form requirementsSmall sizeConfectioneryWood working apparatusThin layerRunning time

A device for manufacturing a three-dimensional product, which device comprises a work table on which said three-dimensional product is to be built, a powder dispenser which is arranged to lay down a thin layer of powder on the work table for the formation of a powder bed, a ray gun for giving off energy to the powder whereby fusion of the powder takes place, members for controlling of the beam released by the ray gun across said powder bed for the formation of a cross section of said three-dimensional product through fusion of parts of said powder bed, and a controlling computer in which information about successive cross sections of the three-dimensional product is stored, which cross sections build the three-dimensional product, the controlling computer intended to control said members for guiding the ray gun across the powder bed according to a running schedule forming a cross section of said three-dimensional body, whereby said three-dimensional product is formed by successive fusion of successively formed cross sections from powder layers successively laid down by the powder dispenser.

Owner:ARCAM AB

Selective deposition modeling method and apparatus for forming three-dimensional objects and supports

InactiveUS6270335B2Less distortionReduce the risk of bridgingAdditive manufacturing apparatusConfectioneryEngineeringSelective deposition

Owner:3D SYST INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com